Volume 3 | Issue 1

September - October 2020

TO

FAÇADE DESIGNING AND MATERIAL SELECTION FOR FIRE-SAFE BUILDINGS

Discussion on the methods of façade designing and the best façade materials to make the buildings fire-safe

Volume 3 | Issue 1

September - October 2020

TO

Discussion on the methods of façade designing and the best façade materials to make the buildings fire-safe

Sustainable solutions for every building.

To g e ther wi t h o ur n e t w ork o f partners, a rchi t ec t s , s pecifier s an d in v e s t ors , Schüco d e li v ers t ail o r e d pr o duct s fo r n e w b uil d s and r e n ovat i o ns, de signe d t o m e e t in d ivi d u a l u s er n e e d s in all clim a te z o nes . E v e r y one in v ol v ed is s up po r te d with a co mp reh e nsi v e rang e of se rv ic e s a t e v e ry s t ag e of t h e c o n s tructi o n proces s W ind o w s , door s a n d f açad e s o lu t ions fro m Schüc o m e e t the highest requir e ments i n terms of design, comfort and security, whilst simultaneously reducing CO2 www.schueco.ae

Fires in buildings have always been one of the key concerns issues for architects, builders, and realestate developers in the Middle East. Many people die in fire accidents in buildings and it also causes property losses. The authorities and government bodies have also been taking this issue seriously and are also taking steps to encourage the use of fireproof façade products, and to adopt the best design practices to make the buildings fire-safe. Many new fire safety codes have already been introduced to prevent the fire spread in the buildings.

The updated safety policy is part of their wider action to ensure façades are adequately fireproofed to prevent future accidents. Buildings are replacing the façades and cladding materials with new solutions in order to comply with the UAE’s updated Fire and Life Safety Codes.

This edition’s cover story is presenting the experts’ opinions on the right choice of materials for firesafe buildings and the key design techniques to prevent fire spreads. Apart from this, there are other technical articles related to façade designing and façade materials, interviews of a well-known architect, and an industry expert, case studies showcasing the design practices for a residential and industrial project.

We are delighted to announce that we have taken an initiative to build the world’s first virtual platform for the façade and fenestration segment. Named as “WFM Community”, the platform will connect architects, builders, contractors, developers, façade engineers, and fabricators. The registration is free for architects, builders, consultants, developers, and engineers for a limited period. Click the link to register yourself: https://community.wfmmedia.com/community/#/login.

You can write to us to share your feedback and suggestions at editorial@wfmmedia.com. You can also suggest some article topics that you would like to read, we will try to bring the articles on those topics for you.

Team WFM

9

29

43

The Influences of Material Selection in interior Façade Design within Healthcare Facilities

Mohanad Abobakr, Facade Engineer - Healthcare Projects

Façade – More than Just Aesthetics

Cover Story

Façade Designing and Material Selection for Fire-Safe Buildings

Face to Face

Interview with Tariq Khayyat, Co-Founder, Tariq Khayyat Design Partners (tkdp)

Industry Speaks

Interview with Mark Leigh, Sales Director - Dubai, Tremco illbruck LLC

Case Study: Façade Design and Cladding

Project Watch: The Tube House, Dubai Desert Conservation Reserve

Avinash Kumar, Associate Partner, Godwin Austen Johnson 38

Discussion on the methods of façade designing and the best façade materials to make the buildings fire-safe 48

Ahmed M. Aglan, and Haridas Narvekar - Design Architects, Dorsch Holding GmbH - Abu Dhabi

Fawaz Hashim, Senior Engineer - Fire & Building Products, Al Futtaim Element Materials Technology Front Cover courtesy: Buro Happold Back Cover courtesy: Tremco illbruck

About the Author:

Mohanad Abobakr

Facade Engineer - Healthcare

Mohanad Abobakr is a Healthcare Architect and specialist in Healthcare Façade Design. He holds a master’s degree in international façade design and construction from Ostwestfalen-Lippe University. He is award winner of Building HEALTHY building(s) competition, Germany in 2017.

The author can be reached at abobakr.m@outlook.com

The world is racing to discover a vaccine for COVID-19 to save mankind. Under the current circumstances, social distancing has become an integrated practice in our lifestyle. Globally, the emphasis is placed on a better hygienic atmosphere for both healthcare and non-healthcare buildings.

Healthcare systems have been overwhelmed by a high rate of hospitalisation and quarantine measures. In fact, there has been a shift in building design perspective particularly related to healthcare facilities. This necessitates reshaping the architecture and interior spaces to accommodate the new requirements dictated by the evolved regulations and standards post the pandemic. The pandemic has highlighted the importance of refining healthcare frameworks and proposing innovative tools to accommodate the rapid increase in patients. Therefore, it has become obvious that countries worldwide have to expand, upgrade, and retrofit existing healthcare facilities with an appropriate selection of façades and building design materials, such as cladding, flooring, and ceiling.

Healthcare-acquired infections (HAIs), caused by the transmission of pathogens from infected patients to other patients, visitors, and healthcare personnel have gained much attention. HAIs

can extend hospitalisation stays and exert a tremendous economic burden on patients and healthcare systems. Within healthcare facilities, environmental contamination is often identified as a major contributor to the transfer of pathogenic HAI. Research has shown that HAIs are linked to the presence of patients, visitors, and medical personnel in the hospital environment.

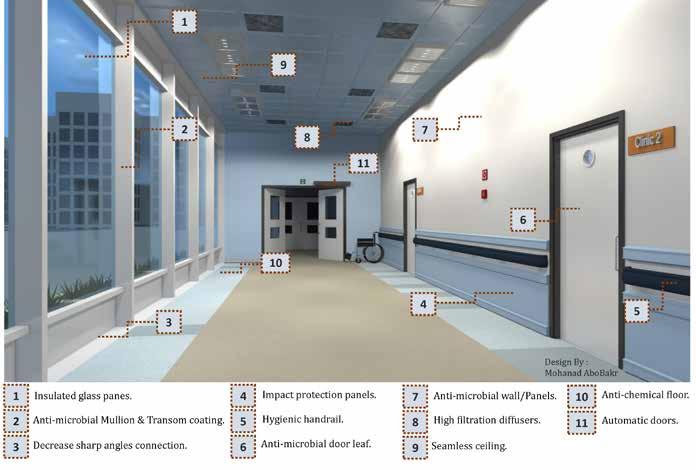

Recently, the building biology term has been considered an essential element in façade design for both interior and exterior designed systems. Building biology: “the study of the holistic relationship between humans and their living and work environments”. It is committed to human health, environmental sustainability, and preventive building measures and focuses on a humane and ecological way of building that strives to strike a balance between humans, the built environment, and nature” [1]. Therefore, façade materials selection and building design are of paramount importance in maintaining a better-built environment through facilitating hygienic performance. The integrated approach of façade design is concerned with building physics, architecture appearance, and aesthetic as well as the hygienic performance of material selection as shown in Figure 1. However, it is important to highlight that the design parameters of the façade

might vary between the exterior and interior systems. Whereas the exterior system parameters depend on microclimate and building physics, the interior system is perceived as a functional unit. For instance, external walls affect its structure and physical properties whereas the interior wall meets the requirements of materials function and durability.

Ultimately, the exterior system performance entails several parameters such as heating, ventilation, air conditioning, and indoor air quality, amongst other parameters. The hygienic material selection for the internal system plays a pivotal role in controlling the acquired infection in hospitals. While the building physics design parameters could contribute to contamination prevention, appropriate material selection continues to have a pronounced effect on the health environment quality and infection prevention.

Appropriate building material selection is essential in fulfilling the hygienic requirements of healthcare buildings. “Materials and finishes need to be robust and easy to maintain, as well as attractive. Well-selected, fit-for-purpose furnishings will complement a clear approach to design” [2]. Therefore, such selection should be made by certified healthcare architects to ensure performance adherence to international standards as shown in Figure 2. Inappropriate material selection could lead to the performance deviation of the entire building systems.

Healthcare experts opt for extensive disinfection of contact surfaces, equipment, and facilities which are fundamental in microbial prevention. Not doing so, can risk the spread of pathogens

such as staphylococcus, aureus, and salmonella as they can survive on different surfaces for periods ranging from several hours to days and form a biofilm [3]. Bioaerosols have a natural tendency to adhere to surfaces by means of several mechanisms and may adopt their strategies for attachment according to the nature of surfaces. Therefore, the most important parameters that should be taken into consideration when selecting the healthcare finishing materials are like the following:

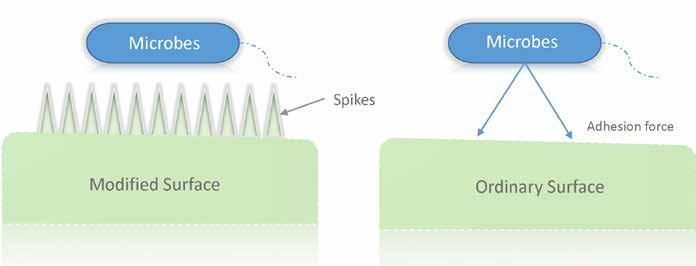

• Topography of surfaces.

• Anti-adhesive surface.

• Place of use.

In the medical environments, the “high touch” surfaces such as walls, door handle, and worktops are subjected to retain soil and/or micro-organisms which will impact on the cross infection control [4]. Therefore, the topography of the surface can influence the ration of growing micro-organisms and bacteria by the nano/micrometer design features of the surfaces. Modifying the Nano-structure feature of the materials can suppress microbes’ attachment in the way of increasing the spikes and reduce the flatness cross-area of microbe’s adherent on surfaces as shown in Figure 3.

In principle, surface smoothness plays a critical role in decreasing the microbe’s colonisation on surfaces, where the higher roughness, the greater the contact area resulting in a higher fouling rate. This depends on the protein feature comparing to the surface roughness. However, decreasing the forming of a microbe’s biofilm by using smooth surfaces can lead to the inactive state of microbes on surfaces without removing them. Enhancing the surface smoothness contributes further to microbial prevention [4]

Forming a biofilm of bacteria appears when adsorption of proteins on the material surfaces is initiated.

Anti-adhesive features can lead to the following:

• Blocking of the transmission paths.

• Reduction of the adhesion force between microbes and solid surfaces before biofilmforming.

• Allowance of easy removal from the surfaces.

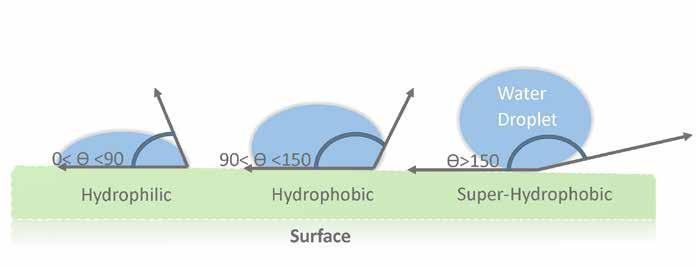

However, this mechanism can reduce the number of microbes’ attachment on surfaces and convert them to an inactive state without removing them. Therefore, hydrophobic (water-repellency) and super-hydrophobic surfaces which are characterised by water contact angle greater

than 90º have shown the reduction of colonyforming units (CFU) up to 80% of Staphylococcus aureus bacteria in some Nano-structured superhydrophobic surfaces such as (Silane coated polyacrylic acid) or Teflon coating as shown in Figure 4 [4]. In general, the greater molecules adhesion force of surfaces than the cohesion force of microbe’s attachment represents in anti-adhesive surfaces. Therefore, considering this parameter of the exterior or interior material selection of façade design can improve the hygienic quality and assist to reduce acquired infection.

Within healthcare facilities, whether the use of surface materials is for exterior or interior purposes, there are a variety of factors to select proper materials. However, their performance to microbe’s growth varies as per the place of use and stain types. It is important to realise that cladding selection can be application-sensitive as what could be optimal for the operating room may not necessarily be appropriate for patient rooms use. In addition, each material can be active against a range of specific strains of microbes. For example, Titanium Oxide (TiO2) Nano-particles have a high ability to prevent Gram-positive/ negative bacteria growth by induced their toxicity by visible light or ultraviolet. This position is to be an optimal selection in the presence of abundant light. On the other hand, Zinc oxide (ZnO) prevents the growth rate of various microorganisms such as MSSA (Methicillin-Resistant Staphylococcus). However, ZnO is known as UV blocking material, in which such a feature will be optimal to utilise as glass or fabric coating [5] .

The proliferate of epidemics and the need for a hygienic atmosphere has been intensified by the recent COVID-19 pandemic, which has placed more emphasis on reshaping all aspects of design that have been taken for granted for a long time. Therefore, refining the material selection and placing appropriate emphasis on the key and underlying parameters of such selection will prove invaluable to the integrated performance of buildings.

References:

[1] Walter de Gruyter GmbH, Building biology, Criteria and architectural design, 2018, Retrieved from http://ebookcentral. proquest.com.

[2] Mike Kagioglou & Patricia Tzortzopoulos, Improving Healthcare through Built Environment Infrastructure, 2010.

[3] Patrizia Losito, Pierina Visciano*, Marisa Genualdo & et al. Evaluation of hygienic conditions of food contact surfaces in retail outlets: Six years of monitoring. 77 (2017) 67-71.

[4] C. Adlhart, J. Verran, N.F. Azevedo & et al. Surface modifications for antimicrobial effects in the healthcare setting: a critical overview. 99 (2018) 239-249.

[5] M. Abobakr, Design study of different façades for various zones of hospitals and rehabilitation resorts, 2017.

Fawaz Hashim Senior Engineer – Fire & Building Products, Al Futtaim Element Materials Technology

About the Author:

Fawaz Hashim graduated as a mechanical engineer in 2012 and currently leads the technical team at Al Futtaim Element Materials Technology, Dubai. The company is under the Element Materials Technology group that delivers a comprehensive range of testing, inspection, and certification services to the global aerospace, transportation, fire, oil & gas and infrastructure sectors. Apart from being an associate member of the Institution of Fire Engineers from the UK, Fawaz is an active participant with ASTM’s E05 committees on fire and also participates at the European Group of Organisations for Fire Testing, Inspection and Certification (EGOLF).

The buildings we live and work in should provide user comfort, reduce energy consumption, and act as a safe haven for us and our loved ones. When there is too much focus on a building’s aesthetics, we tend to ignore the technology that is available today, which allows us to harness energy for our daily needs. A simple example of this is the integration of solar cells into curtain walls or façade systems. Although retrofitting an existing building with photovoltaic cells (PV Cells) would be time-consuming and costly, integrating PV cells into the façade of a new building would be much easier and should be considered at the design stage.

With so many technologies that can be implemented, we could innovate to the point of calling a façade a smart façade if it uses natural, renewable energy sources such as solar radiation, airflow, and geothermal energy. This could meet the building’s energy needs with respect to heating, cooling, ventilation, and lighting. However, all such designs must go through a

series of evaluation processes to ensure their performance parameters are not compromised while making them user friendly, energy-saving, and sustainable.

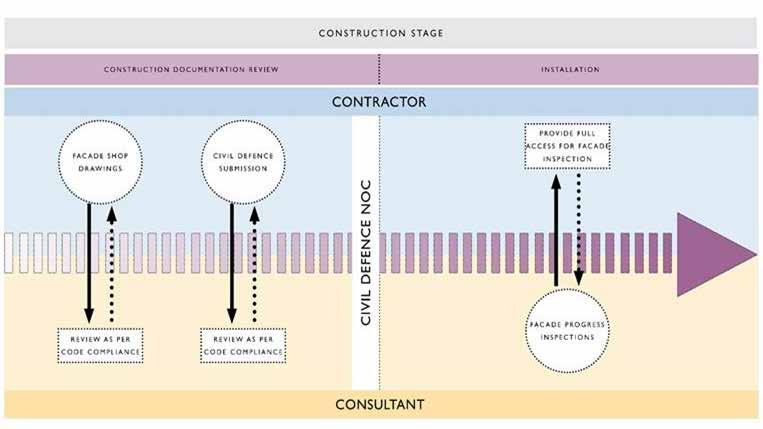

The process of selecting and finalising a complying system involves multiple steps, including extensive research and design of the mock-up; evaluation of the design against performance parameters; approvals; and then finally, the execution of the approved design of the project.

A building’s design often focuses on its external appearance and ‘wow factor.’ But to ensure the design complies with all other factors that make it safe and environmentally friendly, the design ideas should be based on tested evidence. Rather than only prioritising the aesthetics of the building, it is important to look at other demands on the building envelope: it has to protect against rain, weather, fire, and burglary, while simultaneously regulating light and ventilation, and providing solar protection, and minimising the effects of cold and heat.

Designing a building without considering these factors would be difficult for the project consultant and the manufacturer to run the materials or systems through bespoke tests, which evaluate their performance to resist the effects of naturally occurring physical phenomena. The project consultant/manufacturer, in conjunction with the testing laboratory, would sketch the mock-up for the system that would most closely imitate the system design as per project conditions. A design that just closely resembles the one on the project would only give an assumptive number to the performance of the overall system at the site. As such, the mock-up design would need extensive study about the build-up of the façade; materials used; variations in the build-up throughout the façade system; and different architectural details that are projecting away from the façade, which could probably act adversely when it comes to the performance of the façade on site.

Often, a simple component, such as the sealing gasket (e.g. EPDM), is ignored or given the least importance. And unsurprisingly, it would be this single component that would play an important role in the overall performance of the system. On another note, over the usage of any component,

and expecting it to add to the positive curve of some of the performance parameters, would lead to failure of the system on some other performance parameters. For instance, the same EPDM gasket, which was neglected, could be overused on a system to protect the façade design from allowing water or air leakage. And the same overused EPDM would create a huge impact in terms of the façade’s fire performance or its reaction to fire. Hence a design that would create a balance among all the required performance parameters should be the main goal of the team designing the mock-up.

A mock-up should comply with a few important factors:

• The designed mock-up should replicate the worst-performing design of the overall system, based on the project.

• It should aim to accommodate all components in the build-up of the system as a present on the project.

• It should also be fabricated/installed using the same material as would be used on the project. Any grade, alloy number, material finish, etc. should match the material to be used on the mock-up as well.

A well-designed mock-up system would most closely resemble the performance parameters of the system.

Once the mock-up design has been finalised, the next task is to evaluate the mock-up for various parameters of potential naturally occurring, physical phenomena. There are several laboratories around the globe that are well-equipped with the infrastructure to conduct such physical tests. The Al Futtaim Element Materials Technology Dubai LLC (AFE) has the capacity to accommodate several standards and bespoke designed cladding systems to evaluate their performance to fire and non-fire testing methods.

AFE can support the evaluation of the façade system with accredited tests, such as:

• Air permeability

• Static and dynamic water penetration

• Wind resistance

• Seismic activity evaluation

• Thermal cycling and condensation analysis

• Impact resistance

• Forced entry resistance

• Evaluation of fire propagation characteristics of exterior wall assemblies based on NFPA 285 and BS 8414.

AFE also has three fire test rigs, of which two are for BS 8414 part 2 and one is for BS 8414 part 1. All three rigs are accredited for the current 2020

version of the standards by UKAS. The BS 8414 rigs are capable of accommodating cladding systems with larger cavity sizes, allowing customers to test the most onerous conditions of their system, which provides them with a wider range of compliance through certification or assessment of the system. The laboratory’s recent addition to the fire propagation testing scope is the NFPA 285. It is accredited by IAS to conduct fire tests of façade systems to NFPA 285 as of September 2020.

Apart from the testing of the system, one other important factor that many consider irrelevant is the dismantling of the system after the test. AFE promotes the option of the controlled dismantling of the system post-testing. This procedure will give additional information to the end-user of the system, or someone who is due to further evaluate the system to investigate the reasons for failures. Or in the best case, evaluating the reasons the system performed really well. This is a best practice that will allow the industry to learn and improve from mistakes, and to observe and implement these learnings for future projects.

A system that cleared the evaluation phase would have undergone several trial tests to various performance parameters. This is when the manufacturer/project consultant would find out the number of variations they have to make to their initial design in order to conform to the design that has cleared the evaluation phase, and has met the performance criteria required in the standard(s).

This brings into light the importance of evaluating a façade system prior to initiating the fabrication, or even in the worst case, installation of the system on-site. We see a lot of projects where the façade material/system is selected for a project without a proper evaluation of the system to the performance parameters and instead look at the product qualification and certifications. What they miss out here is a quantified answer to how these products would behave when assembled into a system. How would the system behave in the presence of non-material aspects in the system? And without this vital information, proceeding with the fabrication or installation

of the system on-site could invite a variety of problems that would cost the project time and money.

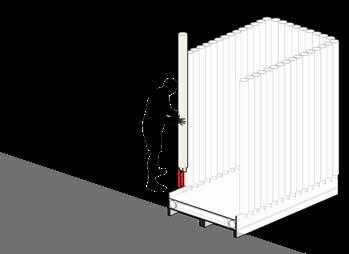

Now that the system is evaluated and is proven to clear all intended performance parameters, the ball is with the installers of the cladding system. Despite the efforts taken by several teams to design the mock-up and evaluate its performance, the installation or execution of the system on-site plays an important role in ensuring the desired outcome is achieved. To ensure there is no miscommunication between the input given to the installers and the outcome we receive, there must be proper training and practical educational sessions provided for them to be aware of the critical aspects of the façade system. Education is one of the key factors of success.

Façade designs and materials have improvised in the past years to meet the fire safety regulations in the Middle East. The façade materials should be appropriately tested and fire stopping is also very important to ensure the safety of the buildings. Specifying the correct product is vital but the quality of the installation of the product is vital too to protect. The safety of life is a vital aspect that should be considered during the design and material selection section of buildings. A fire-safe façade does not propagate fire but it also prevents or not allows the fire and heat to travel from one area to another.

This cover story focusing on the major reasons behind fires in buildings in the Middle East, the façade material selection and design approach for a fire-safe building, the importance of compartmentation and fire stop, etc.

Over the past decade, the desire for taller buildings has increased dramatically around the world, particularly in the GCC region where the real estate developers compete to recognise their buildings among the tallest, if not the world’s tallest. This was the reason why local fire authorities have been regularly revising the applicable fire codes, in order to enforce stricter requirements related to the design, manufacture, and installation of façade systems, says Dr. Ayoub Nasr, Principal Engineer, Ramboll

When combustible materials are used for façade cladding and/or insulation, there is undoubtedly a risk that a fire can spread rapidly from floor to floor if it comes into contact with these materials. This would delay or completely rule out the possibilities for a safe evacuation, which could lead to death, injury, and loss of business confidence. Therefore, increasing the level of understanding of the mechanisms governing the vertical spread of fire across façades as well as the acceptable testing methods and fire stopping solutions is nowadays a key task for all fire experts, façade engineers, and contractors in order to achieve the required authority approvals, but most importantly to achieve a safe and operationally efficient building.

As a result, the risk of vertical spread of fire around the building façade should never be underestimated!

Abdullah Faza, Senior Fire and Life Safety Consultant, AESG believes that there are three main fire safety aspects that should be considered at the various stages of the façade design:

• Fire rating requirement on the façade and the exterior wall systems: This aspect should be determined at the early design stage (concept) which will rely on the separation distance to the adjacent building or plot limit. Table 1.3 on page 59 of UAE Fire & Life Safety Code, 2018 defines the fire rating requirements of exterior walls based on horizontal separations. In most of the cases (based on the occupancy type) 6m separation distance and more to the adjacent building will not require fire rated exterior walls.

Boundary situated such that a and b can compy with regulations

This aspect will have a direct impact on façade and exterior cladding materials, whether noncombustible or fire-rated materials are required.

• Location of fire stopping systems at the façade and exterior wall systems: this exercise should be carried out during the Concept and Schematic design stages to identify the required locations of:

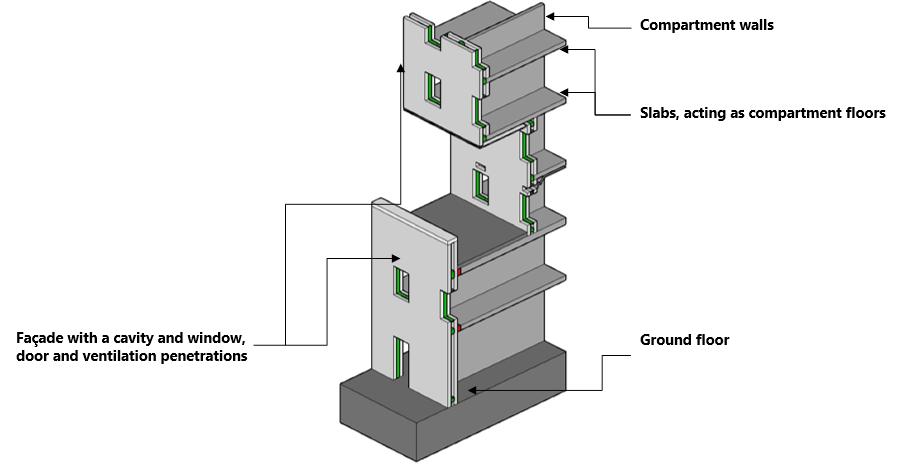

o Horizontal fire barriers: following the requirements of UAE Fire & Life Safety Code, 2018, Section 4.5.4.1, page 142, cavity fire barriers shall be incorporated horizontally on every floor.

o Vertical fire barriers: following the requirements of UAE Fire & Life Safety Code, 2018, Section 4.5.4.2, page 142, cavity fire barriers shall be incorporated at every floor vertically to restrict flame within continuous cavities or where cavities bridge the perimeter fire-stopping.

o Perimeter fire barrier: following the requirements of UAE Fire & Life Safety Code, 2018, Section 3.2.4, page 128 The perimeter barrier shall be intended to restrict the interior vertical passage of flame and hot gases from

one floor to another at the location where the floor intersects the inside of an exterior curtain wall.

However, the above three applications might not be the case in all façade designs. In general, the location of fire barriers shall consider the location and quantity of openings at the exterior wall systems, mechanism of fire spread, ignition sources, cavity size, different exterior wall types, and combustibility of the exterior wall materials. The professional Fire Consultant should have sufficient knowledge in façade and exterior wall design and materials, which will help him/her to carry out flame and smoke risk assessment to identify the location of fire barrier systems. The risk assessment should consider all the possible fire scenarios “in and within” the façade and exterior wall systems.

• Fire characteristics of the façade and exterior wall materials: this exercise can be carried out in advanced or final design stages to determine the following key material’s characteristics from a fire safety perspective:

o Fire rating: Duration for which a passive fire

protection system can withstand a standard fire-resistant test. Testing example: AEST E119

o Combustibility: How fast material will burn, typically classified in Class A, B, C, D, E, F. Testing example: EN 13501-1

o Flame / Smoke spread index: Measurement of surface flame spread and smoke density. Testing example: ASTM E84

o Self-Ignition Temperature: The value of the lowest ambient air temperature that will cause the ignition of the material (flash ignition temperature). Testing example: ASTM D1929

o Fire propagation: Determine the fire propagation characteristics of exterior wall assemblies and panels. Testing example: NFPA 285 / BS 8414 or similar large-scale test.

Abhishek Chhabra, Business Development Manager, Thomas Bell-Wright International Consultants says, façade designing is the key starting point of

ensuring fire safety. Incorrect comprehension of reaction to fire properties can lead to accidents ready to happen! Further and equally critical is to ensure correct materials reach the site using certification and listing. Validated designs are installed correctly using qualified inspectors.

Faza explains, windows and doors at the façade and exterior wall elevations form a key mean of flame, heat, and smoke spread from the building to the exterior walls and cavities. In many cases, they will have a direct interface with cavities (air gaps) behind the exterior wall panels (window for example) and the exterior surface of the panels (balcony for example). This direct interface can lead to a rapid-fire spread from building interior to the exterior wall systems, just like what happened with Grenfell Tower in London.

Cavity fire barriers are the most efficient control measure to minimise the risk of flame, heat,

and smoke spread at fenestration (exterior wall openings). They shall be located around the openings to restrict any spread of flame, heat, and smoke from an apartment fire, for example to the air cavity which will avoid fire spread from apartment to another. The location of those barriers shall consider the air gap size, design interface between openings and exterior walls, and the internal building compartmentation (separation between apartments for example). I highly recommend the need to adopt a party wall separation design approach of Approved Document B (British Standard).

With almost every international and local fire code nowadays requires adjacent buildings to be located at a sufficient distance from each other, a large building fire is likely to occur when a fire breaks out within the building itself, either from the inside of the building or from the outside immediately next to the external wall cladding, notes Dr. Dr. Nasr. In both cases, the installation of combustible façade materials consists of the main cause for a fire to spread over multiple floors, thereby increasing its severity while reducing the response and egress time for higher floors of the building.

Other factors include human errors that cause

active and passive fire protection systems to fail during fire emergencies, from simple-but-serious actions like switching off the fire protection systems to more complex errors such as adopting faulty engineering practices during design development, installing cheap but incompatible systems, or disregarding the regular testing and maintenance works which are required to sustain the long-term functionality of these systems.

I believe that avoiding a large fire to occur in a building is a long journey starting at the early design stage through adopting the correct engineering practices, that continues during construction through achieving a proper installation of the tested and listed façade and fire stopping systems, to finally ensure the regular inspection and maintenance works are well managed by the facility manager after the building is occupied.

Faza says, the causes of building fires in the Middle East vary from occupancy to another. However, by focusing on façade fires in the Middle East, aluminium composite panel got the highest record of causing rapid fire spread at the building exterior due to the combustible and flammable used cores (specially for buildings designed before 2013). The lack of fire safety design requirements at that time (before 2013) created a knowledge gap of how to design a safe façade and exterior wall cladding systems.

Nowadays, Fire & Life Safety codes have been updated with specific sections about how to design the building’s façade and exterior walls to be safe. He adds, “I highly encourage designers and engineers to consult the right fire engineers / consultants in helping them achieve the functional requirements of the code and not only comply with the code requirements because it might not be sufficient but to go above and beyond in the measures taken to make buildings safe”.

According to Chhabra, the common causes for fire accidents in the buildings are: designs using the incorrect materials, lack of validation of designs using large scale mock-up tests, missing out and not using certification and listing evidence to inspect that certified materials have reached the site or some other, and use un-qualified inspectors to validate the installation.

Despite the fact that all new high-rise buildings are equipped (or must be) with an

automatic sprinkler system with a proper fire compartmentation should be maintained throughout the building spaces and between adjacent floors, an internal building fire can still occur which has the potential to spread to the external façade, remarks Dr. Nasr.

A ventilation-controlled fire represents the scenario in which a fire burning in a room grows enough to break the window glazing, permitting hot gases to flow out the top portion of the opening. After the temperature of the fire has increased enough and the exterior façade is exposed to sufficient heat fluxes, the window of the story above the room of origin could fail, resulting in the spread of the fire to the upper floor. This is what is usually referred to in fire engineering books as the “leap-frog effect”. From a fire dynamic perspective, flames emitting from an exterior window can extend higher than 5 m above the top of the window.

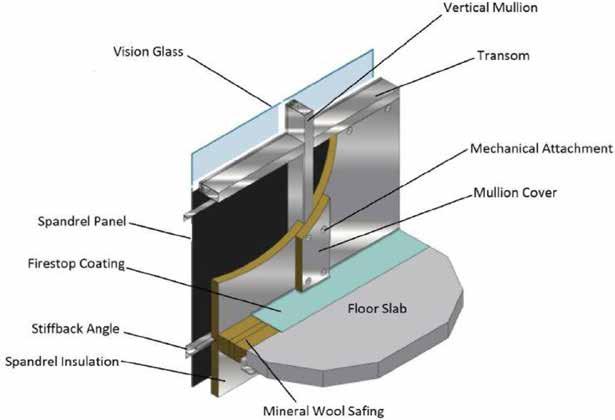

He adds, to prevent a leap-frog effect to occur, a good practice that has been largely adopted lately in the Middle East is to separate the exterior openings in adjacent floors by using insulated spandrel panels of 915 mm in thickness or similar

assemblies that have a fire-resistance rating of at least 1-hour. Alternatively, flame barriers that extend horizontally at least 760 mm beyond the exterior wall can also be proposed to restrict the vertical fire spread through the façade. Let’s not forget to mention other protection means such as installing window sprinklers on the inside of an exterior window which could also limit the spread of fire from inside the building to the outside.

The lack of passive and active control measures might lead to internal fire to spread to the external façade. Some of the passive fire protection failures can be related to the absence, poor, or damage of fire stopping/cavity barrier systems at the external wall systems along with the provision of combustible/flammable materials such as insulation, membranes, sealants, baker rod, etc. On the other hand, the provision of a sprinkler system as an active fire protection measure will minimise the fire spread risk by extinguishing the fire (inside the building) at a very early stage and controlling the temperature at a certain level (low temperature), says Faza.

A compliance design approach with Fire & Life Safety Code requirements can be considered as an adequate protection measure. However, a risk assessment, design approach is highly recommended when it comes to façade and exterior wall design. It will identify any hazard and risk within the façade and exterior walls, which will provide a clearer path to the fire engineer / consultant in proposing passive measures, active measures, or a combination of both, he adds.

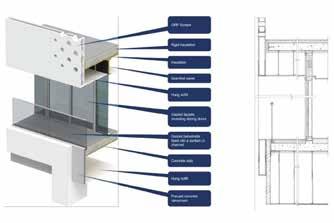

Both fire stops and smoke stop systems are used to fill the continuous gap at the interface junction between the façade and concrete slab edge. These systems aim to keep fire, smoke, and noxious gases to a restricted area/ floor by dividing a building into fire resisting compartments. Hence, these systems play a crucial role in minimising fire damage and limiting casualties, opines Dr. Nasr.

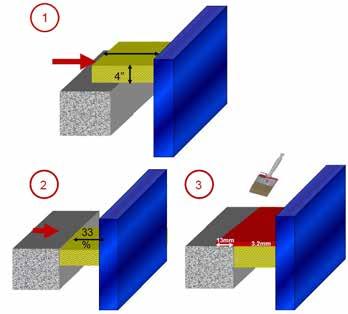

Fire stops usually consist of fire-rated compressed insulation materials, such as mineral wool insulation, having a thickness of a minimum of 100 mm. The fire stop shall be a minimum of 33% greater than the gap width and compressed into place (reference: Hilti installation guide).

Smoke stops consist of water-based coatings/ sprays with smoke sealing property which is applied on top of fire stop insulation to prevent the passage of smoke between fire compartments. The thickness of smoke, stop sealants usually varies between 1-3 mm. The smoke seal should have the flexibility to allow all anticipated movements in the wall system and should remain intact.

The glass itself does not support combustion, hence it is very common to see standard nonfire rated glass panels and windows installed at building envelopes in the Middle East. This practice should be acceptable as long as the building can maintain a minimum horizontal separation from the adjacent buildings and the plotline, says Dr. Nasr. On the other hand, and despite the high cost associated with the use of fire-rated glass, architects tend to propose fire-rated glazing systems for interior design applications, such as to achieve the required fire separation between different occupancy groups, enclose lift and escalator lobbies, etc. The advantage of using a fire-rated glazing system is that it allows to maintain a sense of transparency and openness throughout the building, and at the same time to satisfy the authority requirements for fire compartmentation.

Faza explains that the fire stops are a continuous barrier/membrane with a minimum of 1-hour fire rating that subdivides the building spaces to restrict the spread and movement of fire. Whereas smoke stops are a continuous barrier/membrane that subdivides the building spaces to restrict the spread and movement of smoke. It can be noticed that the key difference between them is that fire stops are fire rated membranes, but smoke stops are not, which qualify fire stops to work as smoke stops as well as its main purpose of fire stopping.

NFPA 5000 requires smoke and fire barriers to be continuous from an outside wall to an outside wall, from a floor to a floor, or from a smoke/fire barrier to a smoke/fire barrier, or a combination thereof.

The provision of competent passive fire protection measures represented by fire stopping systems will help in preventing a fire spread in buildings. Fire stopping provisions should cover all the firestop classifications following UAE Fire & Life Safety Code, 2018, Section 3, page 126:

• Through-penetration firestop system:

a. Penetrations through fire-resistancerated floor, including both empty openings and openings containing penetrants.

b. Penetrations through fire-resistancerated wall assemblies including both empty openings and openings containing penetrants.

c. The penetrants include, but are not limited to, mechanical, electrical, piping, structural, and communication devices.

d. Testing examples: ASTM E 814, UL 1479, EN 1366-3, FM 4990

• Membrane-penetration firestop system:

a. Membrane penetrations in fire-resistancerated wall assemblies where items penetrate one side of the barrier.

b. Testing examples: ASTM E119, E 814, UL 263, UL 1479, BS EN 1366-3, BS EN 13664, FM 4990.

It also requires them to be continuous through all concealed spaces, such as those found above a ceiling, including interstitial spaces.

According to Dr. Nasr, there are some basic steps to take that will help to reduce the chances of a façade fire occurring:

• Avoid façade materials that belong to the flammable class.

• Maintain a minimum height, distance between windows on exterior walls in order to prevent the possibility of a fire spread from one floor to another

• Fire resistive joint systems:

a. Any gap, joint, or opening (whether static or dynamic) between two fire-rated barriers, including where the top of a wall meets a floor, wall edge to wall edge configurations, floor edge to floor edge configurations, floor edge to wall configurations.

b. Testing examples: ASTM E1966, UL 2079, FM 4990, BS EN 1366-4.

• Perimeter fire barrier system:

a. Any gap, joint, or opening, whether static or dynamic, between a fire-rated floor assembly and a non-rated exterior wall assembly.

b. The perimeter barrier shall be intended to restrict the interior vertical passage of flame and hot gases from one floor to another at the location where the floor intersects the inside of an exterior curtain wall.

c. Testing examples: ASTME 2307, BS EN 1364-3, BS EN 1364-4

It has to be noted that all of the above should be tested and certified by approved laboratories and certification bodies, designed by certified fire engineers, installed by approved firestopping installed and finally certified and inspected by fire stopping specialists.

Abdullah

Faza, Senior Fire and Life Safety Consultant, AESG

The glass itself does not support combustion, hence it is very common to see standard non-fire rated glass panels and windows installed at building envelopes

• Cavity fire barriers shall be incorporated into the façade design at every floor, horizontally and vertically

• Protecting the building perimeter also requires the extension of the fire-rated floor to the exterior wall surface; apply fire/smoke stop systems where necessary to fill the gap between the façade and concrete slab edge

• Ensure regular inspection and maintenance of perimeter fire barriers and fire protection systems

• Increase fire safety awareness among the building occupants and enforce certain FM rules such as restricting cooking and BBQ activities in balconies etc.

Faza believes that the main purpose of fire

separation/compartmentation is to restrict the spread of flame, heat, and smoke from one area to another. The restriction will provide certain insulation and integrity period depends on the building Fire & Life Safety Strategy (1 hour, 2 hours, etc.). The provision of such fire spread measures will enhance the protection of building structural elements such as beams, columns, bearings, floors, etc., by keeping them away from direct exposure to flame and heat. This will eventually buy more time for the building to reach the catastrophic fire stage, which can be demonstrated by longer Available Safe Egress Time (AEST). It is very important to understand the relationship between Available Safe Egress Time (AEST) and Required Safe Egress Time (REST) in adopting a performance-based design approach.

Fire-safe buildings are gaining more popularity and have changed the scenario of the building

and real estate industry around the world. Several façade materials that ensures the safety of the building during the fire incidents have become the most demanding materials of today’s time.

The improved designing and installation methods have been introduced in order to ensure the firesafe buildings or to prevent the fire spread if the building catches fire.

Chris Chennell Regional Discipline Leader (Specialist Consulting), Buro Happold

What are the impacts of façade design on the fire safety of buildings?

There are quite a few impacts, such as falling debris and fire spread between buildings. However, the most significant impact on building fire safety in the façade design is the potential to breach compartmentation within the building. All buildings are divided into defined compartments. These compartments are separated by construction that can achieve a level of fire resistance. The purpose of doing so is to restrict the spread of fire and contain heat & smoke to the area where the fire originated.

Curtain wall systems, or other types of insulated façade designs, have the potential to offer a path for fire spread between compartments. If this occurs the façade design can breach the fireresistant separation resulting in a much larger fire than assumed within the design of a building’s fire strategy. The consequences being people could become trapped, attending fire crews could be prevented from accessing the fire, and, the building could collapse whilst either of these two eventualities are in process.

The most infamous case study would be the Grenfell Tower disaster: the insulation installed over the existing building was a pathway for fire to spread floor to floor. This residential building had been designed to compartmentalise each floor – meaning the fire strategy, design has assumed a fire could be contained in the floor of fire origin (actually, the apartment of fire origin). As such, the means of escape design had assumed a ‘defend in place’ strategy – as the fire-resistant floor and walls were designed to limit the spread of heat & smoke. When the compartmentation was compromised, as the fire spread floor to floor via the façade, the alarm strategy, stair smoke clearance, and exit capacity were all in turn compromised.

What is the role of the fenestration design in firesafe buildings?

The orientation of openings within a façade offers a potential path for the fire spread, as described above. Where a window, louvre, grill, door, etc. is not adequately fire stopped, a fire can spread via the fenestration into the façade system. A large number of existing façade systems installed in the last 20 years contain combustible insulation or panels due to the thermal benefits to the performance of the building. Ignition of this material can cause fire spread, as well as adds to the fire load contained in the external walls of the building.

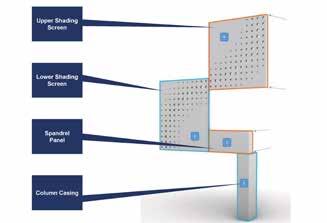

Fire stopping is an essential element within the passive fire protection of the building. The intent of such protection in the design of a façade system is to continue the compartmentation (the walls or floors) out to the building exterior. Spandrel panels are a good example, as are cavity barriers. Often these are not considered during the design, or, inadequately installed during construction.

Likewise, the testing of façade systems often negates the inclusion of fenestration. The NFPA 285 test only considers an exemplar window opening. So, when a façade system is tested the results do not account for the risk of spread into the cavity via various window orientations, doors, louvre, etc. Where this occurs in the Middle East, it is common

practice to adopt an engineering judgement – an approval pathway that is being questioned around the world due to the unquantifiable fire risk.

Can you identify some of the potential remediation methods that can be adopted within façade design which could lower the fire risk?

There are a number of measures that can be adopted within existing façade systems to improve fire safety. All assessments undertaken by professionals should be consulted with the wider stakeholder party to ensure all considerations are accounted for. Here is an example – we were appointed to assess an existing building before a client made a purchase. Panel cores and insulation samples were taken for testing in the lab. These identified that the material installed was combustible, and, the desktop review and inspection demonstrated that inadequate fire-stopping and cavity barriers were installed to match the floor by floor compartmentation strategy. Whether the design was inadequate, or the installation was at fault, was not clear as the building was more than 10 years old hence lacked installation reports, documentation, or construction photos.

With this information, we undertook a full buildingwide holistic fire risk assessment of the means of egress, active fire systems, passive protection, and, the Civil Defence access facilities. We were able to show that a firestop every second floor (assuming a fire across two floors as a worst-case) would be sufficient to enable people to escape and attending fire crews to tackle a fire. However, when

we consulted with the insurer, they advised they had only ever considered a fire on one floor as the worst case. Meaning, whilst life safety and firefighter safety could be accounted for, the property protection measures needed to be more stringent, and required fire stopping at every floor.

A remediation study should be undertaken by competent professionals in collaboration with the entire stakeholder body. Where deficiencies in knowledge are identified these should be engaged before a decision on the best course of action is agreed upon. Typically, the choice of remediation measures can be categorised into short, medium, or long term;

• Short term covers the introduction of temporary detection ahead of system overhaul, full building inspections, management of evacuation strategies, and, the removal of transient fuel load and ignition sources.

• Medium-term can include testing and maintenance of existing systems (sprinklers, smoke control, door openers), increasing fire detection coverage, and improved occupant training.

• Long term typically involves a planning application, relocating occupants, and significant rectification works such as fire stopping, enhanced sprinkler coverage, capping balcony, gas mains, and ultimately a full or partial replacement of the

system with a tested, compliant façade (that poses a lower fire risk).

What scenarios could cause an internal building fire to spread to the external façade and other parts of the building? What protection measures are in place to control fire?

The most common measure to prevent the spread of fire in a building is sprinkler protection. In the 2014’s LaCrosse fire in Melbourne, the fire spread from level 6 to level 21 via the façade. Whilst the façade system failed to prevent fire spread, the sprinkler system worked beyond expectation – up to 24 heads operated in system design for only 4 heads to activate at one time. As such, the fire did not spread into the building, and all of the 100 evacuees survived.

Around much of the world, legislation has now changed in the aftermath of the Grenfell disaster, to mandate that sprinklers be installed in new build high rise residential buildings over a given height (typically where external access is not possible by attending fire crews). Whilst sprinklers in high-rise buildings are a common design aspect the risk of people being trapped is addressed by further lowering the height at which this is mandated.

It can be challenging to retrospectively install sprinklers in an existing building due to the infrastructure demand, sprinklers can be fed from

the mains or potable water in some jurisdictions meaning this can be a potential rectification measure to lower the fire risk.

What are the various aspects of façades which could prevent the spread of fire in the building? Fundamental to the design of a façade system is the continuation of the building compartmentation. Where a compartment wall/floor meets the façade system a fire stop should be included to ensure there is not a path of the unseen fire to spread into an adjoining compartment.

This can be particularly challenging where the façade design does not align with the compartmentation –in such instances a bespoke fire stopping, or fire barrier, the solution can be considered. However, it is recommended these undergo project specific testing.

Where ventilated cavities exist in a building as part of the wider façade design strategy, a cavity is inherently created which links multiple floors together, circumnavigating compartmentation. This has become an ever more common arrangement, and the need to close the cavity in the event of a fire is of concern. To address this aspect of design, cavity barriers are provided with an intumescent seal. The intumescent seal is a strip that expands when subject to heat, and closes off the cavity, helping to restrict smoke and fire spread through

the cavity when fully closed, but allowing ventilation day-to-day.

Could you please tell us about the difference between fire stops and smoke stops?

There are three mechanisms that a fire-resistant system can achieve: integrity (resistance to the passage of smoke), insulation (resistance to the passage of heat), and stability (resistance to structural failure). Depending on the purpose of the compartment design, the wall/floor may only need to resist the passage of smoke. When this is the case a smoke stop is required. Where a wall/floor is required to resist the passage of heat & smoke a fire stop is required. Always consult your Fire Engineer when specifying the necessary passive protection measures!

How important is the use of fire rated glass?

Glazing that has been designed to resist the passage of fire (insulation & integrity) is typically used where a window is required in a fire-resistance-rated partition or wall or floor. Such an approach can offer the benefits of natural light, but comes with challenges in terms of costs and the limitations of height & width.

Other options are sprinkler protected toughened glazing, or, ensuring that the compartmentation strategy within a building is designed such that open

connection between areas can be achieved without the need for fire-resistant separation. A good Fire Engineer should be able to deliver on this.

Where fire-rated glazing is required it can offer either resistance to the passage of smoke, or, smoke & heat. The former is often achieved by toughened glazing where a suitable analysis is undertaken. All good manufacturers and suppliers will be able to advise on when and where such products need to be specified – as well as the fire engineer.

Of course, fire-resistant construction could be required in a façade where the building is close to an adjoining building or the build plotline. Again, this can include fire-rated glazing, however, there are real benefits in engaging a Fire Engineer to assess the necessary protection measures to enable design flexibility and minimise production costs.

What are passive and active fire safety protection methods?

Passive systems are those typically applied to the primary structure (the elements holding up the building) and the secondary structures (all other elements, including the façade). Compartment walls and floors are considered primary elements, whilst the fenestration, for example, would be

considered secondary. Discussed above are the benefits and role of compartmentation, including fire stopping and cavity barriers.

Active systems, on the other hand, include sprinklers, smoke control, hydrants, hose reels, etc. Hence active systems can be used in the protection of glazing (window wetting sprinklers), but predominately passive systems are utilised in façade and fenestration protection.

What can be done to prevent fire spread in buildings? Please suggest some steps. Fire spread via the façade occurs for a number of reasons. If we consider case studies, numerous scenarios have occurred during construction. The challenge is: whilst the finished installation may be adequately protected, exposed insulation or unsealed panel systems can offer a route for ignition to occur. This was the cause of the 2015 fire in Binagadi, Baku, and, the 2010 fire in Jing’an District, Shanghai. A competent contractor who understands

the need for dynamic risk assessments, permits to work, and, hot work permits will be able to advise on how this can be mitigated.

Likewise, façade fires in occupied buildings have occurred where either the design has not provided with the necessary fire protection (fire stops, cavity barriers, combustible insulation), the contractor has installed hazardous systems (100% PE cores, combustible insulation, timber framing, polystyrene panels), or, the operation of the building contradicts the assumptions made in the design (fire pits or barbeques on balconies, cars parked against façade panels). The disconnection between the design and the construction is well known within building engineering, and within fire engineering this is further exacerbated by the disconnection between the design and the operation. Measures are being taken to resolve this around the globe – success is typically driven by legislation as the capital gained from paying for safety is hard to be quantified when a construction budget is being drafted.

“Façade Technologies are One of the Main Driving Forces of the Progress of the Architectural Industry”

Tariq Khayyat Co-Founder, Tariq Khayyat Design Partners (tkdp)

About the Author:

Tariq Khayyat is an architect, designer and university lecturer with over 15 years of experience in delivering international projects across all stages, from inception to completion. He founded Tariq Khayyat Design Partners (tkdp) in 2018. Tariq is responsible for the overall design direction and business strategy of the firm, overseeing all R&D aspects from market analysis to technological advancement. Prior to establishing tkdp, Tariq worked as project director and designer at Zaha Hadid Architects in London. He co-designed and led a number of ZHA’s seminal projects, including Bee’ah HQ in Sharjah, UAE, and the Meixihu International Culture & Arts in Changsha, China and King Abdullah II Performing Art Centre.

Here are the excerpts from his recent interview with Window & Façade Magazine…

Tell us about your design approach. tkdp was established in 2018 as a bespoke design-led practice providing architectural and design solutions to clients and communities. Driven by the ambition to achieve excellence, exclusivity, and the highest level of quality. tkdp solid experience pushes the studio to keep developing architectural solutions that stand out, add a significant value to the built environment, benefitting clients and communities at large.

tkdp’s ethos is based on continuous research and innovative methods to introduce architectural and design solutions that ultimately respond to the ever-evolving market needs and contemporary lifestyle.

What are the milestones you have achieved to date?

As a young practice, we were thrilled to win our first international design competition 6 months after we established the studio. The competition was for a 1 million sqm master plan in Shenzhen, we were competing against giants in the industry such as Zaha Hadid Architects and others, the client picked our scheme due to our implacable approach to address his vision, his business model and introduce a landmark at the same time.

Our second key milestone as well was landing our first project in the beautiful Dubai, a mixed-use building with retail and high-end apartments, the design proposed by our office will add a new milestone to the real-estate concept in the UAE and we were blessed to work with a visionary client A.R.M holding on this unique project which will ground break on March 2021.

What inspired you to become an architect? It started when I was a kid, I used to visit my father at his office (he is an architect) and watch the team how they work, how they produce drawings, how they produce physical models, I was astonished by the process, the details and how sketches are transferred into buildings. I used to be in my dad’s car driving while he is pointing to his projects, it gave me a feel that the architects legacy and contribution to the community is tangible and can live for generations.

Could you please talk about your projects featuring very innovative and different kinds of façade and fenestration designs? Since the core of our projects is based in the

region, we always focus on proposing solutions tailored to the environment, the cities characters, and needs. In our design philosophy, we believe that all projects components are developed

we always focus on proposing solutions tailored to the environment, the cities characters, and needs

together, you can’t think of the volume/ massing without thinking of structure, landscape, lighting, and most importantly the envelop, we start developing the envelope principles, the concept from day one along with the façade specialists to ensure a coherent process. Quite often the envelope concept plays a major role in the form-finding process. Research is a big part of our studio philosophy and we always carry on extensive studies along with the specialists to propose innovative yet viable solutions.

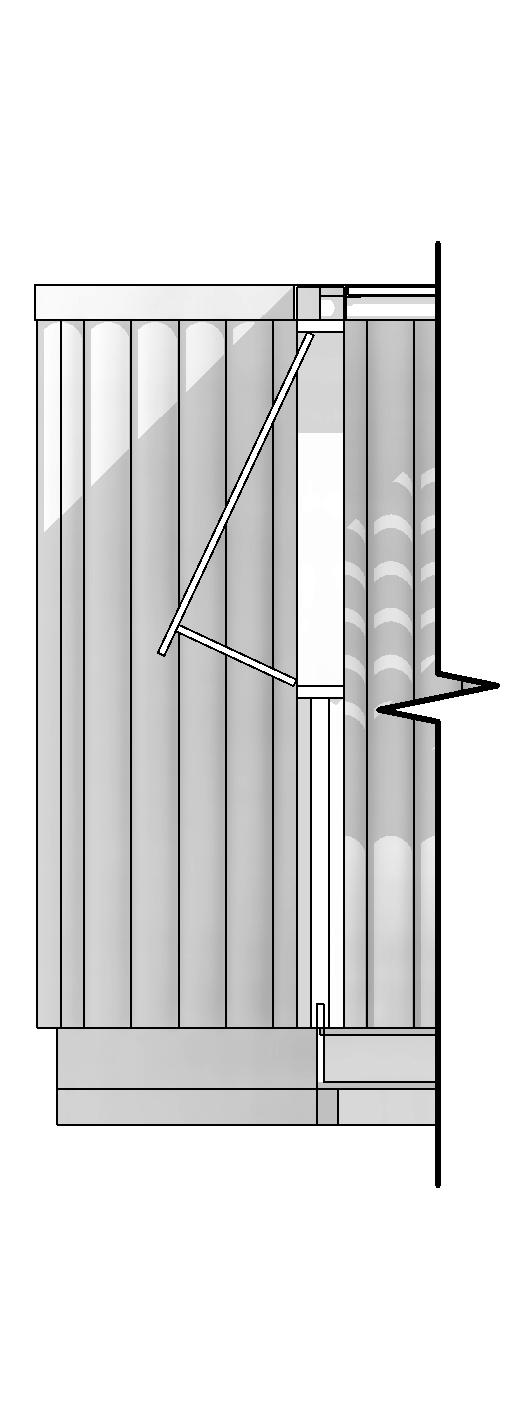

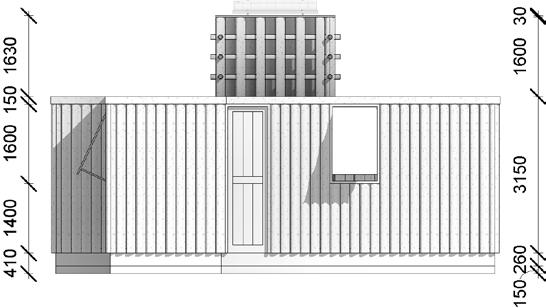

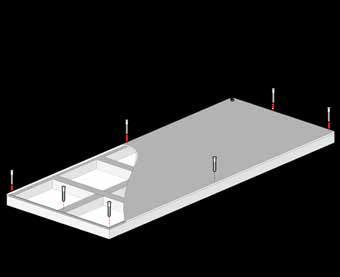

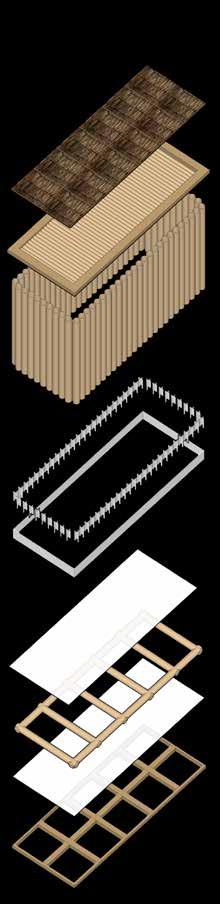

We pay extra effort and focus on our projects in the GCC, the climate challenges force us to explore options out of the box to achieve design excellence and human comfort. Our recent project is a mixed-use development in Dubai, the client brief was clear about achieving a high-level product which stands out within the market offers, the client also pushed us to

ensure innovative environmental solutions to provide comfort to tenants and residents, this gave our office a great push to explore along with our façade consultant (Drees and Sommer on this project) to come with practical solutions of multi-layer façade that which achieves aesthetic, privacy and environmental comfort. We created an additional “external perforated curtain” out of GRC providing calculated shades and natural light to the indoor spaces with full privacy to the tenants. The exact position, proportion, and perforations percentage have been extensively studies whilst maintaining the core of the design aesthetic.

How do you go about choosing the material of the façade and cladding?

Selecting the material is an early step that we start while we are exploring the initial form-finding and envelop design, it is important to explore all

façade material options early so we direct and focus or initial design studies. The importance of exploring all potential material from the initial design steps is important when the project is going through budget constraints (which is the common case) this allows us to focus our research on locally available material which can provide us with the design quality we envision.

According to you, where is the architectural segment is heading in the Middle East?

I believe that there is a huge demand towards communities driven projects, scale, the layout is not the key factor anymore, and it is the experience the buildings are providing to the end-users and communities. I think that the new social pattern not only in the region but worldwide pushes architects to tailor all their designs to serve the public, buildings cannot be designed to serve the end-user, each building is a puzzle within the big

Selecting the material is an early step that we start while we are exploring the initial form-finding and envelop design

picture of the cities, therefore thinking of the community is a key for the success of architecture in the region.

What are the major challenges in the architectural segment in the Middle East?

Architecture in the Middle East is facing a serious challenge to reach the global progress the industry achieved. We believe that the main challenge is to realise the importance of understanding how essential to look at this industry as a fully integrated process, the architects in the region need to start accepting further collaboration with other building specialists, comprehensive early research between all disciplines is crucial to take architecture to the level where it achieved elsewhere in the world.

What opportunities do you see for the architects in the region?

Assuming opportunities will be very difficult if architects do not change their approach on how they deal with projects, clients, I believe what architects mainly miss is a union, a society or a club, whatever you want to call it, a place which protects their rights, which will boost their confidence in their important role in the society.

The architects’ role in building safety is very important. Fire safety is one such aspect. How do you go about choosing the fire safety materials for building envelopes?

There are a few key factors;

• Limitation of the use of petroleum-based material

• More strict measures related to fire rating, and testing of new systems

• Increasing the spandrel zone within a fully glazed wall to a minimum 1m

What are your views on the future façade and fenestration technologies as well as materials?

I always believe that the façade technologies are one of the main driving forces of the progress of the architectural industry overall, architects alongside engineers and specialists should

collaborate in a much elaborative way. This cannot be achieved without establishing groups of think tanks which include; architects, engineers, and environmental experts.

What is your advice for young and upcoming architects?

My main advice to young architects is to have full dedication, architecture is one of the unique professions which require a high level of physical and emotional attachment to succeeding. It is a full-time job and young architects should have their goal and vision from the early days. My second piece of advice is to develop significantly their digital skills. The competition amongst young architects is extremely strong and the only way to stand out is by sharpening your digital skills. Design is a talent, you improve, but you can’t control how far it goes, however, the digital skills can be endlessly developed which will be a powerful tool in their career progression.

Mixed use is a 20,000 sq.m. project providing a platform for new F&B concepts and innovative retail experiences, as well as housing the client’s HQ offices.

It is located in one of the city’s most sought-after locations, and it will re-activate a much-loved area for the local community to populate and enjoy.

Mixed use project aims to redefine the mixeduse building typology by blurring the boundaries between the different sections of the site while also establishing a continuous relation between the interior spaces and the surrounding plaza, without compromising privacy and tranquillity.

Location of the project: Jumeirah, Dubai

Facade material: GRC, GRP, Glazing

Client: A.R.M Holding

Completion date: 2022

The envelope design is based on a multi-layer system to enhance the thermal and social performance of the building; an external “Perforated GRC curtain” has been integrated within the project envelope to provide maximum thermal comfort to the indoor spaces. The perforations percentage, size has been calculated along with the specialists to maximise natural daylight yet provide thermal comfort. The perforated curtain has another social role of providing complete privacy for tenants where they can enjoy the outdoor views without being seen.

Located at the northern gateway of Luohu District in Shenzhen, at the heart of China’s “Silicon Valley”, the 1,300,000 sq.m. Shenzhen Luohu Master Plan responds to the city’s need for new social and resettlement housing, offices, hospitality structures, retail spaces, and public facilities.

The project brief, and the overall programme, are the result of a 10-year effort spent in market studies, trend assessments, and consultations with the local community. Over the past two years, a number of proposals and ideas fitting the client’s vision as well as the government regulations and the funding strategies, have been shortlisted.

Fact File

Project Name: Shenzhen Luohu Master Plan

Location of the project: Shenzhen, China

Facade material: Curtain wall, GRP, perforated aluminium

Client: MSUN

Completion date: 2027

Project type: Master plan (residential, hotels, retail, offices)

Following the final, closed, competition in September 2019 against a global architecture powerhouse based in London, tkdp presented their proposal to the client’s board as well as to the government representatives and were awarded the project, signing the agreement for the next phase.

“We have a Full

of

Mark Leigh Sales Director, Dubai Tremco illbruck LLC

Mark Leigh is the Sales Director for Tremco illbruck LLC in Dubai and has been with Tremco for more than 27 years. He was previously head of flooring and waterproofing sales for the UK and Ireland and was leading a team of Technical Sales Professionals specialising in commercial flooring, sub and superstructure waterproofing, and liquid coatings. In 2014, he was transferred to the Asia Pacific region where he was mainly responsible for the sales of the illbruck range of sealing, bonding, and PU foam insulation products. In the Middle East, Mark leads a team of dedicated Sales and Technical Specialists from the Dubai Headquarters, focussing on high-performance construction solutions in the windows, facades & structures, waterproofing, and fire protection markets.

In a conversation with Window & Façade Magazine, Leigh talked about Tremco’s product range, their fire safety solutions for buildings, the market of fire safety materials in the Middle East, etc. Here are the excerpts…

Please brief us about your journey in Tremco. I joined Tremco in 1993 as a Sales Representative for the North of England and Scotland. I became the National Sales Manager of the UK & Ireland Flooring business from 1998. In 2014, I became the Export Sales Manager responsible for all sales in the Asia Pacific. In 2018, I moved to Dubai as Sales Director for the Middle East where I am responsible for the business in all of the GCC countries as well as Egypt.

Tell us about your product offerings? What benefits do they offer?

Tremco offers a comprehensive range of construction solutions, particularly in the sealing and bonding segments. We have been one of the market leaders in structural and in-plant glazing for more than 30 years in the Middle East and we are very proud to have been part of this amazing construction journey. Tremco brands are globally trusted and recognised for providing highperformance and long lasting solutions that offer our clients true investment value. We are able to

point out a huge number of iconic buildings where our products have provided complete protection for more than 25 years. Our key brands include Nullifire, Flowcrete, illbruck, Vandex, Willseal, Dryvit, Nudura & Euclid. It is fair to say that Tremco can provide sealing and waterproofing solutions to all six sides of the building envelope.

Name some of the major projects in which your products have been used?

Our projects have been used in many projects in the Middle East. Some of the projects are Al Khaleej Centre Dubai, Radisson SAS Hotel (Jumeirah Beach), Sheikh Marwan Tower, Sky Tower, British Bank of Middle East, Enoc House, Olaya Commercial Centre (Riyadh, Saudi Arabia), National Bank of Dubai, Dubai Creek Tower, Bahrain City Centre, etc.

Could you please tell us about your manufacturing facility and capacity?

Most of our manufacturing is currently outside the region, but we are currently reviewing our

options in the Middle East also. For example, our firestopping products are manufactured in the UK and North America, and our tapes and foams are manufactured in Germany. Our adhesives and sealants are manufactured in various plants across the world with our PU foams manufactured in The Netherlands. Capacity is never an issue!!

What do you see as the main challenges faced by your industry?

I think, delayed and non-payments are the major issues. Companies need money to pay employees and suppliers and long delays can seriously jeopardise the viability of a business. PostCOVID, I expect businesses to be more discerning in choosing who to do business with. Also, I

think that there may be a temptation to choose low price over long term solutions which in my opinion should be avoided. One of my favourite quotes of all time is: “The bitterness of poor quality remains long after the sweetness of low prices are forgotten.” ~Benjamin Franklin.

The Corona pandemic has affected all the businesses. How are you coping with this situation?

So far we have been fortunate. We have shown growth year on year and we have continued to invest in new personnel to meet our needs and growth expectations. I also cannot let this pass without saying how much my engaged and dedicated team has contributed to help mitigate the effects of the pandemic. Again, we are fortunate to have such a team.

Could you please brief us about Passive Fire Protection?

Passive fire protection (PFP) is a crucial element in providing structural fire protection and fire safety in a building. Passive Fire Protection contains and isolates fires or slows the spread in one location which is called compartmentation. The compartmentation is between each apartment and floors. The benefit of passive fire protection is that it does not require an external source of energy to initiate when there is a fire, as it is activated when in contact with fire. It is not only used to save lives, but also to reduce the risk of damage to the property which can also be devastating. The vital asset of PFP is that it provides time for evacuation of the building and to enable the emergency services to control the spread of fire.

What are your offered solutions for fire safety?

Tremco CPG UK provides a complete solution for fire protection. We have a full range of fire protection for structural and penetration fire stopping. The Nullifire and Tremstop brand of Tremco CPG has a complete range of products for virtually all penetrations and joint seals; from acrylic sealants to batts and intumescent collars. Nullifire and the Tremstop (UL approved range) products are designed to provide solutions for numerous site situations which we believe differentiates us from many of our competitors. We continuously carry out

extensive testing on our key products including Nullifire FB750 Intubatts which helps to provide superior results and provide our clients with complete peace of mind. We at Tremco CPG, understand the market requirements and seek to continually improve our solutions with regular testing to provide innovative solutions for our customers. The Nullifire brand is tested to both EN standard and UL-EU standards which can meet the requirements of most consultants and specifiers.

How is the market for fire safety materials for buildings?

In the UAE market, fire safety naturally plays a critical role in a building. High standards of quality and service are crucial for the safety of the building occupants and assure the longevity of the building structure. There are different levels of legislation to control the safety aspect of the building. It starts with obtaining approval from the Local Authority (Civil Defence) by issuing proof of international standard testing and accreditation. After the Civil Defence approval, the product quality is inspected by DCL (Dubai Municipality) this is carried by factory audit for ISO standard and tested locally to make sure the right quantity of product is used on site. The application is subsequently carried out by the local authority (Civil Defence) approved contractor.

In some cases, a 3rd party inspector is appointed (CFPS Certified Fire Protection Specialist) to inspect the installation of the fire protection to ensure the right product is used in the right place and complies with the specification. It is essential that our products have complied with all requirements and this has an approach and commitment to excellence has enabled us to grow rapidly in this sector during the past 10 years.

When I was travelling around the world, I noticed some of the poor window installation techniques, even in Japan, where I experienced heavy condensation running down the inside of my hotel windows!! In this region, the challenge generally is to keep our buildings cool whilst reducing energy consumption and this can only work by addressing the whole

window system including the perimeter sealing. Tremco has developed a range of ‘intelligent membranes’ which are water and airtight, but vapour breathable to prevent excessive build-up of moisture inside the building and reduce the loss of cool air. Vandex was the first crystalline waterproofing solution designed for water tanks and has numerous accreditations with respect to potable water etc. We also offer a range of liquid roofing systems which can be used to repair or renew existing roofs and a range of window, façade, and floor renovation systems which are designed to save time and money and provide the consultant with sustainable and aesthetically pleasing solutions. Tremco solutions are often designed to last for the life of a building, often negating the need for damaging and disruptive regular replacement due to the use of inferior quality materials.

What are the major opportunities for your business in the Middle East?

We believe that we can support environmental initiatives by providing energy-saving and sustainable solutions in our chosen sectors. We also expect legislation to drive the need for greener and safer buildings and we are well placed to offer proven systems that meet both UL and BS EN standards. We can also supply Construction solutions to meet the demands of both new-build and renovation projects.

What are your goals and plans for the next 4-5 years?

We plan to capitalise on the opportunities across the region. The UAE remains a key strategic region and our beachhead because our company has been based here for many years. We believe that the country has the capabilities to recover more quickly than other economies and we want to be a major part of the recovery both in new build and renovation projects. In addition, we intend to invest in Saudi Arabia as we expect more and more people will visit and enjoy the breathtaking natural beauty, history, and cultural landmarks of the Kingdom.

We will continue to invest in our people and our products and fully utilize our significant global resources to continue and accelerate our growth. We feel privileged to be able to work in this region and we aim to be a significant contributor to this community for the foreseeable future.

Avinash Kumar Associate Partner, Godwin Austen Johnson

About the Author: