Volume 3 | Issue 5

July - August 2021

DIGITISATION IN BUILDING ENVELOPE INDUSTRY

From Concept to Completion Experts’ views on BIM and Parametric Design in Façades

INDUSTRY SPEAKS

Volume 3 | Issue 5

July - August 2021

From Concept to Completion Experts’ views on BIM and Parametric Design in Façades

INDUSTRY SPEAKS

Sustainable solutions for every building.

To g e ther wi t h o ur n e t w ork o f partners, a rchi t ec t s , s pecifier s an d in v e s t ors , Schüco d e li v ers t ail o r e d pr o duct s fo r n e w b uil d s and r e n ovat i o ns, de signe d t o m e e t in d ivi d u a l u s er n e e d s in all clim a te z o nes . E v e r y one in v ol v ed is s up po r te d with a co mp reh e nsi v e rang e of se rv ic e s a t e v e ry s t ag e of t h e c o n s tructi o n proces s W ind o w s , door s a n d f açad e s o lu t ions fro m Schüc o m e e t the highest requir e ments i n terms of design, comfort and security, whilst simultaneously reducing CO2 www.schueco.ae

Dear Readers,

We all will agree that Building Information Modeling or BIM is one of the most important technologies that are revoltionising the architectural and construction industry.

As the use of customised building façade systems grows in modern buildings, it is critical to use an integrated design process to help with issue solving and design decisions. The combination of BIM and parametric performance analysis tools create a one-of-a-kind design approach with the potential to improve built-environment sustainability and façade fabrication efficiency.

Building Information Modeling is extremely beneficial to architects. The way architects approach building design has drastically changed as a result of this enhanced the modeling software. Architects utilise Building Information Modeling (BIM) to help enhance quality and speed up design processes with integrated workflows for concept design, modelling, multidiscipline collaboration, and so on.

Building information modeling has advanced significantly in terms of architecture and building envelope in recent years. It allows to quickly advance and analyse variables in a concept design, as well as coordinate disciplines during the detailed design phase.

During both the early building design stage and the later construction stage, digital innovation and computational tools have revolutionised the traditional approach to architectural façade design.

From thermal envelope performance modelling to parametric architectural façade design with BIM tools, from parametric design of the solar façade to digital fabrication of the physical prototype with 3D printing, the approach explores numerous potential and possibilities.

In this edition’s cover story, we have featured the industry experts’ views on the benefits of this technology, its limitations, latest technological advancements, its future, and how it has transformed the architectural industry. There are other informative articles and interviews featured in this edition which you can’t miss reading.

Enjoy reading!! Send your feedback and suggestions to editorial@wfmmedia.com. Keep supporting us.

9

20

47

Façades and Acoustics – Key Considerations

BIM and Façades

Chito Reyes, Senior Project Architect-BIM, RSP Architects Planners & Engineers (Pte) Ltd

BIM Design Process and its Capabilities

Mathieu Meur, Director, DP Façade

4

Jon Lee, Associate - Head of Acoustics (MENA), Cundall 16

Digitisation in Building Envelope Industry: From Concept to Completion Experts’ views on BIM and Parametric Design in Façades

Industry Speaks

Interview with Rizwanulla Khan, Executive President, Emirates Glass LLC

Face to Face

Interview with Sophie Campbell, Architecture Co-Studio and Projects Director, Gensler 35

https://edu.wfmmedia.com/

About the Author:

Jon Lee

Associate - Head of Acoustics MENA, Cundall

Jon Lee is a Chartered Engineer and honours degree graduate in the field of acoustics. His extensive experience in acoustic consultancy is supported with business development, project management and commercial acumen. He has held a committee seat and is a corporate member of the UK Institute of Acoustics (IOA). Jon’s international consultancy experience includes environmental acoustics projects of various scales from small, planning-related residential assessments to major power and infrastructure developments. His background in building acoustics includes a significant design portfolio of development types including residential-led mixed-use projects, schools, healthcare and office buildings, shopping centres and cinemas. Jon also has led a wide range of specialist acoustics projects such as theatres, broadcast radio and TV studios, large scale tunnel ventilation systems, renewable energy installations, rollercoasters, family entertainment venues and more.

A façade of a building defines its visual identity, allows light in, provides a fire barrier to protect occupants and addresses thermal requirements. It also shapes and responds to the external noise environment around the building and controls the intrusion of environmental noise (“noise pollution”) into spaces within.

Noise pollution is now known as a global public health concern. In 1995, the World Health Organization (WHO) declared, “… these effects [of noise] have a detrimental infuence on wellbeing and perceived quality of life”. Among other issues, noise pollution has been scientifically linked with sleep disturbance, hearing functionality, increased blood pressure and heart disease. In Europe, this has been translated into a societal cost estimated to be 40 billion Euros annually. Closer to home, in 2019, Dubai residents filed more than 2,500 noise complaints to the municipality.

The world is also getting noisier. The UN predicts that, by 2050, two-thirds of people will live in cities. India is projected to have another 416 million urban dwellers than it does now, with China adding 255 million and Nigeria 189 million. And as cities swell,

there are signs we are finding it harder to cope with the noise. For example, the UK government’s most recent National Noise Attitude Survey found “… a strongly statistically significant increase” in the proportion of respondents who reported being disturbed by road traffic, neighbours, aircraft and construction. The COVID-19 pandemic has also shown us that human population mobility directly and significantly affects environmental noise levels.

Legislation and guidance differs between countries, however most align with each other in terms of controlling noise intrusion to suitable levels to avoid adverse health effects. The following is a guide on factors to consider in façade design to effectively control environmental noise intrusion into buildings.

Implementing measures to reduce noise pollution in a completed building can prove costly, with requirements for secondary glazing systems built within the constraints of the existing façade system, or even entirely separate to it, taking up valuable floor space, effectively reducing the market value of the building (affecting gross internal area and aesthetics).

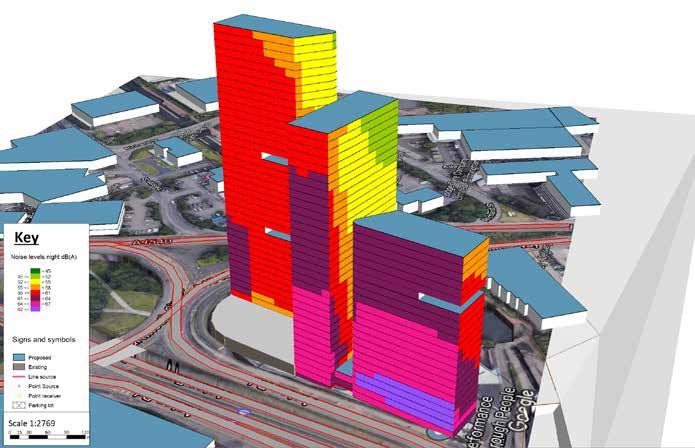

The most effective way to deal with environmental noise is at the start of a project, by appointing a suitably qualified acoustic consultant who will undertake an assessment of the proposed building location and massing by either measuring or predicting noise levels [Figure 1] (or a combination of both) that will be incident on the building’s façade. The results of this assessment can then be used to inform the architect’s early design in terms of site location, building orientation, positioning of noise-sensitive rooms within the development, optimising internal layouts (such as using productivity mapping [Figure 2]), designing in building elements that offer acoustic screening and efficient glazing configurations. Fundamentally, an early noise study can even help dictate site suitability.

Typically, the part of a façade system offering the least noise reduction is the glazing. However, where potential noise issues are present, the building façade should be assessed holistically by a suitably qualified acoustics consultant. Considerations include the glass configuration; acoustic losses from framing details, mullions and transoms; ventilation openings and other acoustically weak façade constructions such as certain types of cladding systems.

There are several other factors to consider which are often overlooked, such as:

• Glazing performance is not just STC or Rw

Sound Transmission Class (STC) is a laboratory measured value originally developed to evaluate speech attenuation and is commonly used in the US. The Weighted Sound Reduction Index, or Rw, is also a laboratory measured value, commonly used in the rest of the world and also limited to certain frequencies. Consequently, neither of the above may completely consider exterior noise sources that are generated at lower frequencies (i.e. below 100 to 125 Hz). A fuller frequency evaluation is therefore required to determine appropriate façade constructions.

The OITC measurement was developed in 1990 and was intended to evaluate attenuation due to typical exterior noises such as buses, construction, and sirens. The OITC rating emphasizes low-frequency noise in the evaluation more than the STC rating since the ambient environment has more of these sound sources compared to speech.

Rw + Ctr is Rw with the addition of a low frequency sound correction factor Ctr (always a negative number). Rw + Ctr is used because of the increase in low frequency sound sources such as traffic or aircraft noise.

• Double glazing is not always better at reducing noise than single glazing

Often thermal performance requirements govern

the use of double glazing over single, however consider the following table in relation to the sound insulation of different constructions.

Typical glazing systems have small airspaces resulting in resonances in the range of 150 to 190 Hz, which is more noticeable to people, relevant to speech privacy, and included in the evaluation in Table 1. As an example, 13 mm monolithic glass has a rating of STC 34 (entry B in Table 1), while a 25-mm Insulated Glass Unit (IGU) consisting of 6 mm glass, 13 mm airspace, and 6 mm glass (entry D in Figure 1) will result in STC 33 for the same area of glass. It is also important to note the effect of a larger airspace between glazing panes by comparing entries D and E in Figure 1.

Each glass thickness has a weakness in a particular frequency (resonant, or natural, frequency) which results in a ‘coincidence dip’ in performance. Using two (or three) panes of glass in a casement that have the same thickness can compound this weakness, leaving noticeable loss in performance at certain frequencies. One project our engineers worked on was to investigate noise problems in a building fitted with triple glazing next to a busy railway track. The window casement was found to be three panes of 6 mm glass, separated by 4 mm each; the coincidence dip of 6 mm glazing is around 2 kHz, which coincides with the squeal of brakes of the trains, resulting in bedrooms

where most external noise was cut out, except for the brake squeal which appeared amplified, resulting in residents not being able to sleep.

Laminated glass can improve acoustical separation by allowing for an impedance change in the material (the mass-spring-mass principle). When sounds or vibrations experience changes in density, part of the noise is reflected back in the direction it originated. Thus, by including a thin layer of polyvinyl butyral (PVB) or ethylene-vinyl acetate between two thin layers of glass, the change in density between the glass and the lamination layer causes the reflection of some of the sound energy. A piece of 13 mm plate glass (entry B in Figure 1) provides acoustical separation of STC 34, while a piece of 13.8 mm laminated glass (entry C in Figure 1) offers acoustical separation of STC 38.

It should also be noted that glazing performance (for the same glazing configuration) changes depending on pane / panel size, getting worse as the pane gets larger.

• External noise levels can increase with building height?

There is a common misconception that buildings are quieter on upper levels. Generally, in urban areas, the higher up, distance attenuation is cancelled out by increased angle of view, exposure to other noise sources (including rooftop plant on podium levels and other lower building roofs) and the Canyon Effect (where sound bounces off adjacent buildings). Cundall have been involved in several projects where measurement data has backed this up.

• Connection of the façade to the building interior

D 25 mm IGU (6 mm glass / 13 mm airspace / 6 mm glass)

E 102 mm IGU (6 mm glass / 90 mm airspace / 6 mm glass)

(est.)

Curtain walls and floor-to-floor detailing are important. It is not just noise coming in that has to be considered with the façade, but connections of the façade to the building structure, usually via mullions and transoms, is an acoustical weak point. A robust partition or floor specification can be severely compromised if there is a weak point in the façade connection. In tall buildings it is necessary also to allow for movement of the façade to account for wind loading and other environmental factors – careful design is required to ensure that this movement does not compromise sound insulation performance of walls and floors (similar to deflection at partition heads).

Various studies have been undertaken on the shape of façades and façade elements on noise pollution,

both inside the buildings and on the street. A 2019 study on the effect of façade shape and acoustic cladding on reduction of leisure noise levels in a street canyon summarises the following regarding balcony shapes:

• Balconies slightly shield the façade from noise in the street.

• Increased balcony depth reduces sound pressure level (SPL) on the pertaining façade up to 1 dB.

• Sound absorbing balconies and loggias reduce the SPL over the façade up to 6.5 dB.

• An entirely sound absorbing façade reduces SPL on the façade itself up to 9.5 dB.

• A sound absorbing street paving achieves 1 dB in noise reduction over the façade.

A study in 2015 also concluded the following:

“Different building shapes can lead to variations of up to 9 dBA as for road traffic sound pressure levelsforpedestrians.Building-façadedesigncan reduce the average value along a window with 8.5 dBA. Geometric configuration of the street can increase the positive effect of low barriers and reduce 11 dBA in pedestrian exposure.”

All components of the building allow the façade to properly expand and contract. Without providing slip connections and avoiding rigid connections between the façade and interior components such as the acoustical ceiling grid, pops and creaks occur as the two components heat up differently and attempt to expand.

Aeroacoustic noise is unwanted sound generated when turbulent air passes over an object, stimulating audible frequencies. Recently, aeroacoustic noise has become a subject of concern for buildings, where façade elements such as screens and shading devices may create wind induced noise. Façade elements of concern are typically perforated screens which provide shade and privacy while allowing natural ventilation and preserving views to the outdoors. However, other elements such as tightly spaced louvers, brise soleil and even vanity tower elements can also be problematic (just Google “Beetham Tower noise”).

So, façade design is not simple. Every design decision has an impact on multiple factors that need careful consideration by relevant experts.

Chito Reyes Senior Project Architect-BIM, RSP Architects Planners & Engineers (Pte) Ltd

About the Author:

Chito Reyes has over 15 years of experience in architectural design, production, design coordination, and BIM implementation in hospitality, commercial, residential, institutional and mixed use sectors. Currently he is handling all BIM implementation and delivery in the firm and managing a team of interior designers, engineers, and all stake holders involve on the project.

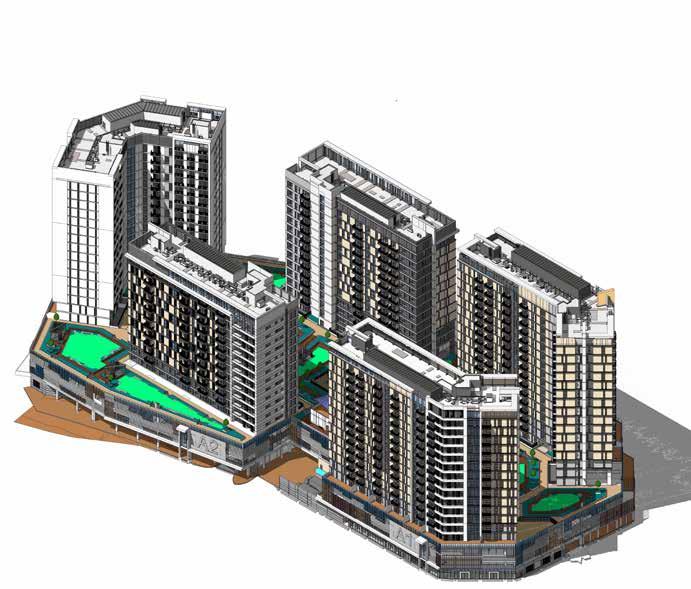

The emergence of CAD technology transformed manual drawings into electronic drawings which helps to cut the production time and cost of each design company around the world. Since we are already entered a new age, the Implementation of BIM has started around the world. Even here in the UAE, the government started mandating everyone to adapt to this so-called BIM. Building Information Modelling (BIM) is a process of managing the use of digital 3D models, the main purpose is to facilitate collaboration during the design process. A BIM model contains all the information necessary to define the project design. The use of BIM has already shown benefits in design, construction, and facility management, reducing the cost, schedules, and better quality.

The façade or exterior envelope of a building is the element that makes the internal space habitable, it acts as a skin allowing beneficial elements of the external climate whilst providing a barrier to the less desirable elements.

Façade or envelope design will start with the architect. The architect will design the façade according to his imagination intent, and character he/she wants on the building, and at the same time meet the energy efficiency required. During the design process, the architect will work with several specialists that will be involved in the design process like a structural engineer- who will provide support and connection on the façade, a façade engineer – who will work on the constructability of the façade design, an interior designer- who will check how the interior design will talk to the exterior envelope, lighting specialist- who will design and light up the façade, and a sustainability specialist- who will work with the architect to achieve the energy efficiency criteria required. Later on, contractors, suppliers, etc. will join the team during the construction stage.

Since there is a lot of specialist and designers are involved in one single element, Building Information Modelling can allow for greater, more effective communication of quantities and details of a building between designers and specialist

involve during design and construction stage. The information is shared on a Common Data Environment (CDE) which every individual will have access to in real-time, which everyone can work together efficiently and effectively.

As I said the façade design will start with the architect. He can check and visualise the design by using BIM. There is a lot of BIM software in the market currently, every software can do conceptual massing, which I can say the 1st workflow in BIM.

Conceptual mass is a 3D mass modeling and generally performed by architects and its main purpose is to create 3D models of the required shape of the building. By using this 3D modeling process, users create a base of any shape based on the architect’s imagination and intent. Once the architect is done, he/she can develop further by

Once the BIM model is created, it is very easy to extract other information like a Plans, Sections, Elevations, etc for the purpose of Presentation or Coordination.

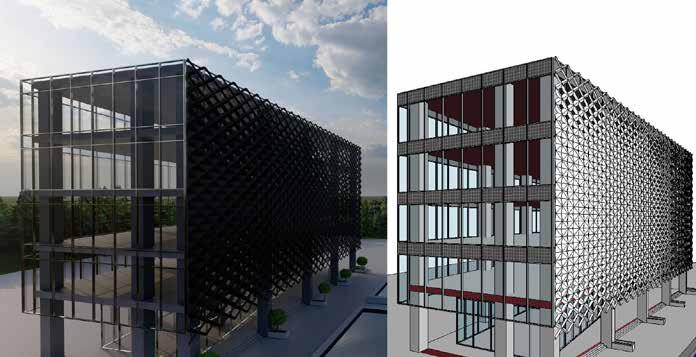

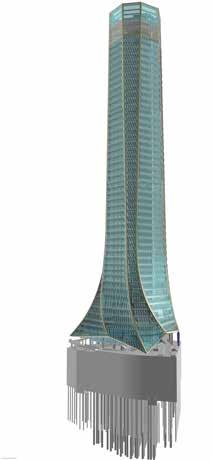

Project: EAIG Headquarters, Abudhabi UAE.

Client: Emirates Advance Investment Group

adding floors, roof, and exterior envelope/façade. The Sustainability specialist can start working with the architect and use the same conceptual mass to perform initial energy analysis.

BIM parametric design changes all the façade system and changes the façade panel shape, this helps the designer to explore more design option and schemes as he like. The Information is linked via the system in a digital parametric structured model so that when a change is made, components are updated automatically in line with specified parameters. Parametric is a process that is not only focused on an individual result, such as with traditional CAD design but rather describes the method of design. This process can be used to describe and automatically derive many different design variants. By this method, façade’s design will be easy and less time-consuming.

A simple workflow starting from left by creating a mass in desired shape. Once the shape is established, you can start providing the basic elements of the building, like floors, roof, and the building enveloped (middle). Then once the basic building elements are in place you can start playing the materiality and configuration of the envelope (right)

According to Richard Mcpartland of NBS, the common data environment (CDE) is a central repository where construction project information is housed. The contents of the CDE are not limited to assets created in a ‘BIM environment’ and it will therefore include documentation, graphical model, and non-graphical assets. In using a single source of information collaboration between project members should be enhanced, mistakes reduced and duplication avoided.

The CDE is set up before the project starts. This platform will be used by all trades involved in the project. The goal is to improve the creation, sharing, and issuing of information that underpins the delivery of your project. The idea of collaboration to drive improved results and efficiencies is at the heart of implementing a Building Information Modelling (BIM) approach on construction projects. The advantages are the following;

• Shared information should result in coordinated data which will, in turn, reduce both time and cost on your project.

• People involved on the project can generate the documents/ views they need using different combinations of the central assets, confident that they are using the latest assets (as are others).

• Spatial coordination is inherent in the idea of using a centralised model.

• Production information should be right the first time assuming that contributors adhere to processes for sharing information.

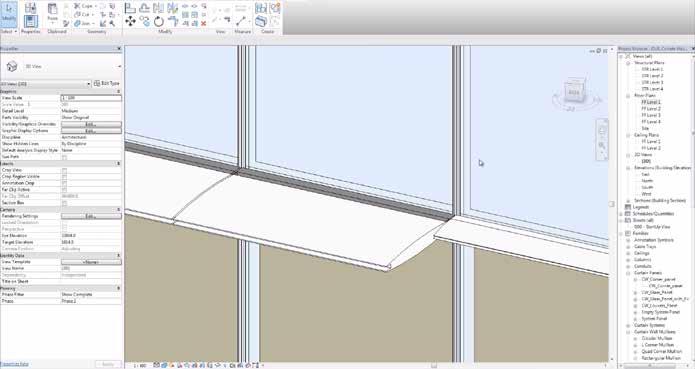

Clash detection is one of the critical parts of the BIM Modeling process. Depending on the scale of the project, one single project may consist of different models, like architecture, structure, MEP, and façade models which each trades will create an independent model. For this process, you need to provide a federated model, meaning a single model which contains all specific models as mentioned. Through clash detection via Building Information Modelling, you can already speed up the coordination by identifying all clashes between

trades and provide the necessary solution during the design stage. The clash detection process identifies where the independent models clash with each other- finding where elements from one model overlap the elements of models from other architect-engineering design disciplines. Clash detection ensures every aspect works handin-hand and nothing is incompatible. Unlike the traditional way, most of the time these issues are resolved during the construction already since it was not required and mandated during the design stage.

Using advanced-stage computer-aided 3D modeling, the instances of last-minute hurdles due to inconsistencies in different models are

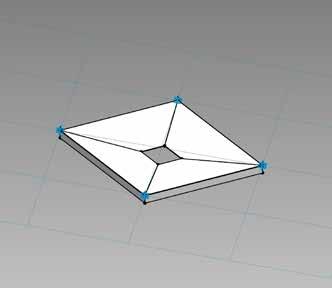

Image 5 :A snap shot of façade treatment panel creation, where the façade panel shaped is created and parametric controls are added to customised the configuration of the panel anytime

eliminated. As all the things are taken care of during the design stage itself, clash detection saves valuable time, effort, and money throughout the entire BIM execution plan during a construction project.

4D BIM is an extra dimension of information that contains a schedule. Based on the 3D BIM information, designers and project managers can use this information and create an accurate program on how the project will start and end during the construction stage. The project program which has been made by the project manager can be inserted on the 3D BIM model and create the 4D BIM or what we call the construction sequencing. This is like an animation that will show all components that will be build based on the program by using the 3D BIM models. This animation will show and help project managers, architects, engineers, and even clients to foresee how the construction will be and also help identify any issues along the way during construction.

In façade, since this component will be somewhere in the middle of the program, everyone will have the ability to see how the façade components will be fabricated, delivered, and installed during construction.

5D BIM is another extra dimension in BIM, personally, this is one of the most important

integrals in BIM modeling, because it is related to cost. The BIM model is composed of different elements, like walls, ceilings, floors, curtain wall systems, columns, etc. Each of these elements and systems contains metadata inside of it which is important to suppliers.

Metadata is information added to each element. Dimensions, finishes, fire rating, etc., depends on the element and system you have on the model are the information inserted on each element or object. These are critical information used in quantification and cost scheduling. In façade, you can generate the number of panels on each type used in the model. In this way, you can easily provide a quantification estimate as accurately as possible.

Due to VDC implementation, data can be reused and captured from conceptual design to prefabrication and apply the data to the entire construction process from ideation design to modular construction. BIM technology is a foundation for the implementation of VDC. BIM is correlated with the façade design field.

Centralised façade panels that are fabricated and assembled at the factory site, the builders working in the construction site have a good flair of façade panels for different façades design, floor heights, and types. After the BIM façade design model is completed, the material components that are fabricated and assembled such as unit panels, keel frames, etc. are given a unique numeric code for data planning, then the façade model is assembled, and data is extracted to material list. The material list has a unique number given to components.

Fabrication and placement of material in design panels are according to numbers and units assembled in the unit template.

With the BIM process and technology involved, façade designers are successfully implementing a 3D model which assists them in showcasing building data, components, material fabrication process, cost of materials and improves the communication flow among other disciplines.

A snap shot of

Adapting to BIM can be difficult at 1st, especially for the firms that are starting to set up and invest in this process. Some companies are only required to do so because the project they undertaken required

so, we should not look at it this way, but to look at how this BIM process will help and benefit us in the long run, not only in our company but also in the client and the construction industry.

Image 6B : Depending on the requirement and design, the facade panel was made to control the size of the opening, In this process, you can start playing the design by using this advantage - as shown on the image the facade if fading from right to left

About the Author:

Mathieu Meur Director, DP Façade

Mathieu Meur provides the strategic and technical leadership for DP Façade, the specialist façade consultancy arm within the DP Architects Group of companies. He was heavily involved in the construction of the Changi Airport Terminal 1 Upgrading, Resorts World at Sentosa, Grand Hyatt Gurgaon and The Dubai Mall, amongst hundreds of other projects on 5 continents. Through his training as a multi-disciplinary engineer and subsequent years of experience, he has developed extensive knowledge of all types of building envelope systems in terms of design, engineering and related codes of practice.

I have not always been a proponent of BIM, far from it. For a long time, and until a few years back, I thought that BIM was just an unnecessary complication, with limited added value as far as façade design and engineering are concerned. Without diving into it further, it seemed from the outside that BIM was simply a more complex method for documenting the façade design compared with simpler and more traditional approaches. Indeed, we had spent the better part of two decades designing façades first using hand-drawn sketches and manual computations, then subsequently using CAD applications for the production of drawings, along with finite element analysis software to speed up computations. Feeling comfortable with this state of play, I was for a while reluctant to explore alternative approaches to design documentation. After all, this method of work had proved effective in the delivery of projects for many years and seemed to work well, with no apparent flaw or gap in the process. On the other hand, BIM seemed to me, on the face of it, to be ill-adapted to the workflow of façade design. At the time, I was under the impression that BIM was best suited for detecting clashes between architectural, structural, mechanical and electrical

components in the building, and not much else, a mere glorified 3-D CAD program.

Through a fortuitous change in circumstances, I found myself forced to dig deeper and to investigate the BIM design process and its capabilities. Several years back now, DP Architects made a commitment to adopt BIM for designing and documenting all projects, and this mandate applied to all specialist companies within the group, including our engineering, landscape/arboricultural, lighting, ID and façade teams. I would be lying if I said that the transition happened seamlessly and painlessly. Instead, it required investing time and effort in training the teams, as well as financial investment into new software and upgraded hardware solutions. All business leaders would easily agree that once such a commitment is made, it must be in full, lest return on the investment is not realised.

In for a penny, in for a pound, we decided to make the most of this shift in our internal design processes. We first ensured that the team was fully conversant with the software. Fortunately, our group has in place an in-house Academy in charge of continuous professional development,

With BIM, changing the geometry of a component instantly updates all detail drawings as well

and which had developed several courses for bringing our teams up to speed with the BIM design process. For companies without such a training arm, a plethora of courses are available in many countries to help make the transition to BIM smoother.

Next, we considered what would be the most appropriate method for leveraging the power of BIM in our everyday workflow. Rather than doing what we have done before using 2-D CAD but with a 3-D software this time, we set about to develop our own families of façade systems ranging from curtain walls to cladding to louvres and many more. From the outset, these families were all designed to be parametric in nature, which means that once the geometry of the façade is set in terms of floor-to-floor height and horizontal modulation, the size of the framing members as well as the thickness of the various elements is automatically computed and adjusted through formulas built into the definition of the families. So if changes are made at any stage in the design process the shape of the members can be tweaked on-the-fly, without the need to make changes to individual drawings. Incidentally, this approach ensures that details drawn on plans, elevations and sections are always coordinated between each other and

there is no longer a risk of mismatch. Also, the whole design process is sped up since there is no need to customise sections or systems manually for each project. Instead, the customisation is built into the definition of the families. It is even possible to automate the structural analysis of the system through bilateral communication between the BIM and FEA programs.

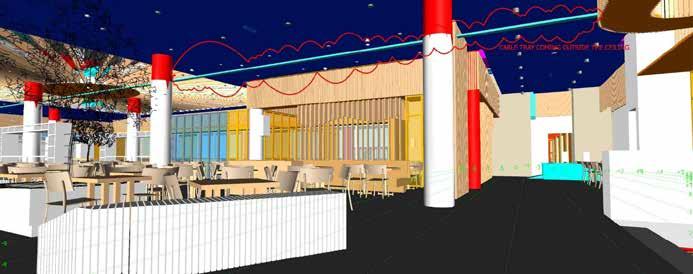

Not content with these achievements, we set about to explore all the ways to exploit the power of BIM models. One of the capabilities that we have developed is the ability to produce rapid, high-end rendering of building envelopes, along with fly-throughs and navigable models. This allows the various parties involved in the design process including the architect, the client and others to carefully consider the aesthetics of the façade elements, the façade systems, the material choices, the colour palette and many other parameters through visualisation. To push things further, we wanted to address one of the common problems encountered in the design process of building façades. When it comes to visual mock-ups, whenever changes are required, a lot of time, effort and money is spent in refining design elements before interested parties sign off on the design. We have thus created a parallel design stream consisting in first building an

interactive virtual mock-up (iVMU in short), which can be viewed either on a computer screen, or better still using VR googles, and which can be modified while it is being reviewed. Everything from glass colour, materials, finishes and other aspects can all be changed in real-time until everyone is satisfied with the appearance of the façade. Only then does a physical visual mock-up get built. The net result of this approach is that the approval process is cut short tremendously.

Having gone through this whole process over the past five years or so, besides extolling the virtues of BIM, I would like to share some lessons learned.

One of the interesting things that I have noticed time and time again, is that while a lot of people talk about it, not many actually understand intimately how BIM works, and how to make the best use of it. One of the most misunderstood aspects has to be the LOD (level of detail). Many articles have been written on this, and I do not need to cover the topic extensively here. Suffice to say that it is essential to set expectations right from the beginning of the project, and even better, before finalising one’s appointment on a project. In particular, the right LOD should be done by the correct party and at the proper stage of a project. For instance, it makes little sense for the façade consultant to build the model up to LOD 100 or LOD 200, which would be tantamount to becoming the drafter for the architect. This is inefficient for both the disciplines and brings no added value. Instead, once the architect has built the model up to a sufficient level of detail, then it makes sense for the façade consultant to take over and push this up to LOD 300 or greater, since doing so requires a relatively deep understanding of the functioning of the façade systems.

Other than the scope of work, it is essential to develop a BIM-specific workflow. Some of the team members who felt more comfortable with other software initially preferred to start the documentation process in 2-D CAD or sometimes using SketchUp, Rhino or other programs. While it seems at first that this can result in faster progress, our experience has shown that it ultimately takes more time to convert this initial model to BIM, and that we need to start from scratch when moving to BIM. This meant that BIM was considered as just an additional layer of documentation on top of the traditional one, and thus taking more time and money to prepare. Through the development of a complete BIM workflow from start to finish, this impression was reversed. This not only

Using iVMU (interactive virtual mockup), one can make instantaneous changes to the appearance of the façade

resulted in time savings, but the attitude towards BIM changed fundamentally. Instead of being viewed as something that just took more effort to produce, it was seen as a method for ensuring quality and consistency of the project documentation.

Another important lesson learnt is that to fully reap the rewards from the BIM documentation process, one needs to first invest time and effort in building a model in the correct manner, using the right processes. As a simple example, one can directly extract the façade quantities to generate a bill-of-quantities from the BIM model, without having to measure the façade dimensions one by one in the traditional manner. However, if the model was not built correctly, and this is particularly true for buildings with complex geometries, then quantity take-off from the model can become a real nightmare, requiring long hours to fix or amend the model.

The famous quote attributed to Greek philosopher Heraclitus “change is the only constant in life” sums it all up. Ultimately, the design of modern building envelopes, more than in the past, requires intimate collaboration between various disciplines that did not even traditionally need to work together previously, or in some cases did not even exist in the first place. On projects requiring intense inter-disciplinary coordination, the advantages of a proper BIM documentation process become immediately clear. Besides allowing faster and deeper coordination across various disciplines, when properly implemented, BIM opens the door to faster workflow, and simplifies or automates a number of tasks. The question seems to no longer be whether BIM will become the default method for documenting building projects, but rather when it will become the norm.

The architect's never-ending artistic pursuit and the continued emergence of urban complexes and super high-rise buildings give façade design technology plenty of room to play a role in design, manufacturing, and installation, and the advent of BIM brings good opportunities for the development of façade design. BIM technology has become the unavoidable choice for the building envelope industry's development.

A façade component in BIM-parametric design is not only a virtual geometric component, but it also has additional geometric qualities, such as component material, thermal performance, cost, purchasing information, weight, installation number, and so on.

We have interviewed a few of the industry experts and presented their views in this cover story. In this cover story, we will look at how BIM is used in façade design, evaluate its benefits and drawbacks, and forecast the technological advancements that BIM will bring to the entire process of façade design, fabrication, and installation.

Building Information Modelling (BIM) is the use of a shared digital representation of a built asset to facilitate design, construction and operation processes to form a reliable basis for decisions as per the ISO-19650 Part 1 definition. BIM is about more discipline and not more work, providing the correct information at the correct time, doing the work once, doing it right and enabling those downstream to use the information effectively and efficiently saving time and costs with less waste being created, says Juan Tena Florez, Regional Digital Design Manager, KEO

BIM has supported the building and façade design industry into better collaboration, coordination and communication across the life cycle of any asset, providing asset owners with better management and visibility of their supply chain as well. It has also helped with complex or large scale projects where traditional methods would be more costly, less efficient and subject to more errors and rework, which will cause more waste being created.

Ahmed AbouAlfa, Digital Business Strategy & Transformation Specialist, AECO Industry says, nowadays we are witnessing a revolution in façade design. The complex, deconstructed, high tech and a lot more façades are the outcome of BIM implementation within the projects.

Abdulmajid Karanouh, Head - Interdisciplinary Design & Innovation, Drees & Sommer explains, BIM has provided the platform for project teams to work in a single virtual environment and has therefore improved their ability to coordinate their disciplines and scopes in a more visual and transparent way. The issue with most BIM platforms however is that they are still too heavy and rigid to act as reliable design tools that enable design teams to explore multiple options early on with the required level of agility and flexibility. BIM therefore remains more of a coordination and information production tool than a design tool. That being said, most BIM platforms used architects have a long way to go before they become reliable for engineering and construction. Normally engineers and contractors re-build their own models using their own specialised technical digital tools like SolidWorks, Inventor and Tekla for engineering analysis and fabrication, as the latter tools are rarely if ever used by architects.

According to Juan, processes (Building Information Modeling) are implemented to ensure the support of the different stakeholders to speak the same language and tools (parametric authoring tools) are implemented to facilitate the design iteration during conceptualisation mainly. There are different objectives and goals to achieve its implementation accordingly. BIM is implemented by setting a set of standards, procedures and workflows to enable coordination, communication and collaboration by all parties involved throughout the life cycle of the asset. Parametric design is implemented based on tools (software) and people (skills) which enable the possibilities to iterate through several options quickly and effectively providing real time feedback on its outputs.

BIM is increasingly adding to design process starting from the initiation up to the handover process. By adding BIM factors along with parametric design aspects, the implementation of design became smoother, easier and lesser in discrepancies and issues, believes AbouAlfa.

The implementation of BIM and parametric modelling in the design process very much depend on the nature of the design teamstarting with the architect of course - and the nature of the building design itself and its level of complexity, opines Abdulmajd.

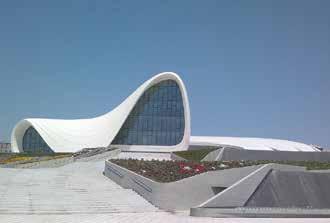

He suggests that some practices like Zaha Hadid Architects need to do a lot of early ‘freeform’ design exploration and therefore prefer using tools like Rhino-Grasshopper and Maya as they offer the ability to manipulate geometry parametrically with a lot of easy while maintaining relatively lightweight and easy to handle models. This then followed by a very intense design post-rationalisation exercises, starting with the architectural team, then the engineering team, and finally the contracting team, using BIM and other more technical digital tools as mentioned earlier. Technical parametric and BIM tools with more engineering design and construction features like SolidWorks and Inventor make it possible to technically simulate,

analyze, evaluate, optimise, and develop and extract construction/fabrication information for very complex designs indeed.

Other practices that produce more predefined and subsequently more prerationalised designs may perhaps have a clearer idea early on of what the design should be like. Therefore, their approach to parametric modelling and BIM may be more focused on coordination and information production as opposed to design exploration and geometric manipulation.

Many design practices nowadays aspire for more creative and geometrically challenging designs, and therefore it is important to have the right mix of parametric modelling and BIM tools, and to better understand the requirements for both parametric design and BIM modelling.

Juan explains, BIM is about the process, standards and use of a shared digital representation of a built asset to facilitate design, construction and operation processes to form a reliable basis for decisions, and

therefore the requirements are the definition of standards, methods and procedures to be met by all stakeholders during the asset life cycle.

Parametric design requires tools which can generate 3D models with the possibility to easily iterate through several options quickly and effectively providing real time feedback on its outputs in order to make decisions easily.

According to my humble point of AbouAlfa, we cannot compare BIM with parametric design,

but we can say that, parametric design can be implemented within a BIM framework.

He further explains, parametric design is a process using some kinds of tools with addition of some factors and parameters to achieve a consistent type of façade, building or a model which depends on a single element that can be fit within any type of design or space. On the other hand, BIM is a framework in which we are building and managing our projects virtually before the actual execution on site.

Abdulmajid describes that the basic concept of parametric design and modelling – whether the design team adopts a pre-rationalised or postrationalised approach to the building design – is to break down the building design into a series of interlinked adjustable parameters (floor to floor height, slab thickness, wall thickness, window/ door size etc.). These parameters are often based on a variety of architectural geometric ‘algorithmic’ design rules, and potentially quantitative and qualitative performance and construction rules are used that enable the design modification and optimisation of the building in a parametric and automated fashion. Parametric design will therefore ‘force’ designers to pre-rationalise their design and the relationship between various building elements early on offer clearer guidelines for the design development and construction stages. Too much pre-rationalisation however too early into the process can over-constrain the design making

it either too difficult to modify without resulting in a lot of aborted work. Therefore, the design rules and associated parameters should be gradually built-up as the design develops.

He adds, the basic concept of Building Information Modelling on the other hand - as the name suggests - is to create a digital model in a virtual environment with all the information needed to simulate the whole lifecycle of the building, including the design geometry, materials quantities and specs, cost rates, and phasing and construction sequence among others. Parametric modelling is increasingly becoming an integral part of BIM in order to offer the ability to modify the building design while automating the process of updating al embedded information in the model. Therefore, plug-ins like Dynamo have been created in order to offer a higher degree of parametric design and geometric manipulation for BIM platforms like Revit. Like parametric design however, the information embedded into BIM models should be gradually built-up as the design develops in order to avoid the model becoming too heavy, rigid, and difficult to modify and handle without ending up with a lot of aborted work.

Therefore, the requirements for both parametric modelling and BIM in terms of selection of software and skills vary depending on the design practice’s approach to design and the level of complexity of the building design itself. The combination of both parametric design and BIM modelling can offer a powerful design, construction and operation simulation platform than can save a lot of time and money during the design development and construction stages, and can also offer major savings during the operation stage of the building, if used in a balanced way.

One of the latest and more promising advancement is generative design. We can define generative design as a collaborative design process between people and technology. During this workflow, the user defines the design parameters and the hardware produces design studies (alternatives), evaluates them against quantifiable goals set by the user, improves the studies by using results from previous ones and feedback from the user, and ranks the results based on how well they achieve the user’s original objectives, Juan Explains.

He adds, using generative design we could set for example, as objective to maximise the number

of typical curtain wall panels, or to optimise the curtain wall shades orientation, or to minimise the energy consumption based on certain constraints, the use cases are endless and the limit is the level of optimisation required. Other use cases, for using visual programing, which is the engine behind the generative design, is to randomise the position of curtain wall panels or to position a different panel type based on an attractor point. All of these different cases could be used as well for analysis and to make informed decisions despite being randomised.

According to AbouAlfa, off-site construction is the most used process in the past two years, in which BIM and parametric design are being used intensively.

Augmented reality and virtual reality are gradually gaining popularity where both the project team and the client are able to ‘walk through’ to explore the various design elements and browse related information of the BIM model and walk through it as if they are physically ‘inside’ the model. This will offer major advantages from a design coordination and construction standpoint, and will also offer a better way for both designers and clients to ‘feel’ and experience the design in a more realistic way, says Abdulmajid.

Abdulmajid strongly believes that it is very important for both parametric designers and BIM operators to understand the principles of algorithmic rules-based design and the objectives behind it, while at the same time it is important for parametric designers to also understand the capabilities and limitations of BIM to avoid over utlising it (too early into the process) or under utilise it (use it for information production only)

• By research, development, supply & apply:

• We need to identify gaps and do our researches.

• Develop a feasible solution that solution providers can work on it

• Solution providers will work to supply the needed solution as mentioned above

• Apply the solution within the BIM environment.

• Additionally, we need to differentiate between reflection of the design using a parametric tools and the parametric design, what we are using right now is a parametric tool that can help us achieving the needed sketched design.

Ahmed AbouAlfa, Digital Business Strategy & Transformation Specialist, AECO Industry

and therefore miss the opportunity to maximise the benefits and advantages of this technology.

Juan believes, in regards to BIM, there are no limitations as such, but there are definitions about its different maturity levels or stages from 1 to 3. Stage 2 maturity is also identified as “BIM according to the ISO 19650 series”. Stage 3 will be the evolution of BIM in the future to enhance collaboration even more, once the status of certain technologies and processes will allow for it.

In regards to parametric design, the current tools are quite advanced and there is good progress and developments in the use of Artificial Intelligence and Machine Learning engines to improve the outcomes and results of the user of parametric design.

AbouAlfa says, “I think in the present time we don’t have much limitations except of integration between different platforms and software, additionally, regulations and mandates that need to be rolled-out by governments and clients”.

Juan explains, the advantages that the BIM process and tools bring to asset owners,

architects, engineers, project managers and constructors are extensive, they can explore and analyse the planned asset internally and externally before one sod of earth is turned. Master plans, infrastructure, buildings and landscape assets and the drawings produced to materialise its ideas, can be sometimes difficult to read, analyse and understand to make the appropriate decisions during the lifecycle of the asset.

3D visualisation, including virtual reality and augmented reality, of a project, allows users to see the project in a more natural environment, regardless of the professional background. Clash detection and 3D coordination bring greater quality and more effective collaboration during design and construction. Linking projects to the construction programs provides an ability to virtually see the projects construction, past, present and future.

All of these outcomes and others not mentioned combined, provide a better environment for all project stakeholders which encourages more in-depth collaboration, communication and information exchange to achieve an informed decision-making process.

High-tech façade that implies different techniques starting from energy modeling, cost savings, parametric façade as well as coordination with slab edges and building different elements is one of the major of BIM, believes AbouAlfa.

Some of the projects we can find in the Middle East are unique and challenging at the same time, in terms of the complexity of their geometry or scale. Using advanced BIM authoring tools, as well as visual programing tools, like Dynamo or Grasshopper, the development of this complex or large-scale façade and curtain walls geometries is simplified and can be achieved in less time, effort and with more consistency and quality, notes Juan.

That is achieved due to the nature of working not only with geometry but with data as well, which will drive the creation of parametric elements that can be easily updated and provide a quick interaction during the design process. We cannot, therefore, think of being able to be efficient and responsive, without using BIM authoring tools to achieve better and more sustainable curtain wall systems throughout the project lifecycle and as the outcome.

“Due to the tangible importance that had been noticed since BIM was used, with no doubts, I

can say that more than 70% of consultants are implementing BIM using different procedures, tools and requirements”, quotes AbouAlfa.

Similarly to any other stakeholder involved in the project lifecycle, façade engineering is one of the building components which needs coordination with other parties like architects for space planning and code compliance, or structural engineers to coordinate the loads and location of elements, or MEP engineers to arrange openings or other features required to ensure correct compliance with MEP equipment location and ventilation needs, or with sustainability in order to ensure that the energy consumption and other standards requirements are met, elucidates Juan.

“Given all of the above stakeholders involved, it is critical to communicate and coordinate effectively. BIM processes ensure that the coordination is effective and there is a communication exchange workflow using a common data environment, which will be the single source of truth for all the data exchanged”.

The 3D coordination of the design is enhanced as teams work collaboratively using a shared model which is checked and approved by other task teams involved so that the Façade model can be developed referencing other disciplines models. As new iterations of the shared models are produced, a federated model is created in order to aggregate all the 3D models into a combined model and to perform a clash detection to automatically detect elements clashing with each other based on a set of rules agreed and defined.

He adds, BIM authoring tools are live information database. Information on quantities can be utilised for evaluating the embodied carbon within the proposed components. Different concepts can be compared to an early design stage. Populated BIM libraries, with suppliers’ information, can be used to evaluate overall buildings’ materials environmental aspects, rather than on component by component basis. BIM libraries can also be used for reducing construction waste, by evaluating which systems could be manufactured off-site within a controlled environment.

Facilitate the way of how façade is designed, make it easier to design more fancy and complicated façades, and saved lot of time, cost efforts during the EPC process of façades, notes AbouAlfa.

Juan opines that in every project, there are multiple iterations throughout the design process in order to achieve the desired outcome and to provide different design options to the asset owner. BIM authoring tools can assist to make that workflow more efficient, faster and providing more insights to evaluate them accordingly. Based on the understanding of working on a 3D parametric model which can be accessed simultaneously by multiple users, it can be created several options within minutes without losing any of the options designed and

with the ability to compare and analyse them to make informed decisions.

Given that the production of the drawings is extracted from the 3D model developed, any changes or updates done in the geometry or information attached to the elements, the drawings will automatically update the contents providing consistency and quality assurance to the information produced, as well as an increased speed of production and elimination of abortive work.

AbouAlfa remarks, all clients are always seeking to cut and add, cut costs and time and add more

in quality and value by implementing BIM and Parametric design, customer demands can be easily fulfilled.

“In the AEC industry, we are all committed to improve and optimise the environmental conditions, design, reduction of waste, undertaking carbon accounting and supporting operations, among others. BIM tools can be used as a live platform where teams are working in parallel to optimise the design and provide time and cost benefits to any project, regardless of their scale or complexity”, says Juan.

BIM tools allow us to quickly implement design changes to be assessed against various environmental parameters to achieve your sustainability goals and reporting requirements. Commercial software in thermal energy simulation, energy consumption assessment, assessment of environmental conditions and computational fluid dynamics are commonly used as part of the design development process.

He adds, “You will discover intuitive, outcomedriven insight into energy and environmental optimisation, from design to operation with the BIM parametric modelling capabilities,

which can be used for the examination of various concepts of the design, modelled faster and more efficient. Real-time feedback can be visualised and interacted with key performance indicators, factors, and ranges to help make better design decisions”.

Using daylighting analysis, we can simulate, calculate, and visualise key daylighting metrics, like daylight autonomy and annual sunlight exposure. Also, we could analyse the total building heating and cooling load calculations.

With the advancement of building industry technologies and people's persistent quest for sustainable structures, BIM has become a hotly debated and investigated topic in the construction business. BIM has inspired significant changes in the construction and building business. Thanks to its benefits of visualisation, coordination, simulation, optimization, and drawing production - BIM has played a huge role in the construction of many complex projects in the Middle East.

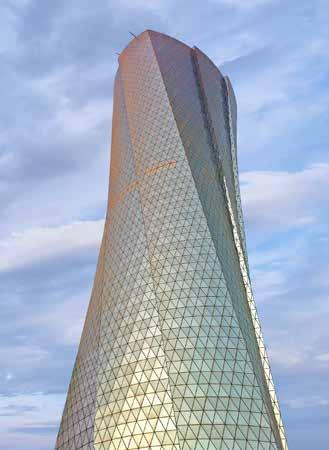

Turning Torso

Craig Garrett BSc MIED IEng Projects Manager & BIM Strategist, Joseph Engineering ServicesDubai

How BIM has influenced building and façade design?

BIM is a massively disruptive force that is transforming every aspect of the construction industry. But it is not Building Information Modelling (BIM) per say, but rather digital engineering and delivery and the way we approach the efficient information management on a project that is changing.

This current revolution is long overdue as many traditional design and construction approaches have not changed in hundreds of years. What has changed is the adoption, workflows and processes created to fully utilise 3D technologies, which have allowed the design team and especially architects, to imagine and create more complex forms than ever before.

The façade as the outer face or skin of any building is what is most visible to the outside world and often a building is better known for its striking façade more than anything else. In addition, the look, feel and geometry of the façade often then drives the entire concept for the building’s interior spaces.

Very fortunately in my 35-year career where the last 10 plus years have been in the Middle East, I have had the opportunity to work on many projects with exceptionally complex and iconic façades that have challenged every aspect of digital engineering design and construction.

How Building Information Modelling (BIM) and parametric are implemented procedures into the design process?

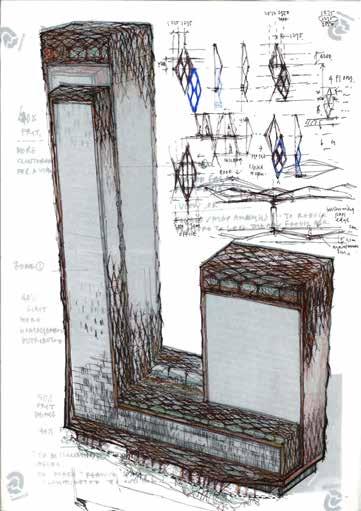

It is important that architects and the design team generally can convey their vision or design intent to all necessary project stakeholders. Traditionally, this would have been done using presentations or sketches or references to real world items or natural elements.

But in this now digital world this is best achieved using a variety of geometric and parametric modelling tools which allow the creation of a digital representation of the physical and functional building shape, form or surface that will define the façade.

This streamlines the process of design and communicates complicated information accurately to everyone involved, allowing the joint work of architects, clients, builders, engineers etc. to occur within a single intelligent and shared process, making it a critical workflow to increases efficiency and cross-discipline integration.

While inherently parametric, the common approach of utilising BIM is mainly through labor-intensive modeling. The usability of BIM throughout the design process is strengthened, by improving the integration of parametric driven parameters which automate the modelling workflow reducing time and therefore cost.

Efficient reuse of data or information in various forms across all disciplines is at the heart of what digital engineering is all about, not so much “Building Information Modelling” but rather “Better Information Management”, ensuring efficient reuse of project data.

What are the requirements and differences in BIM and Parametric procedures?

Here it is best to consider we have two separate approaches or two differing communities. The difference between these approaches is emphasised when focusing on the semantic meaning of created objects.

Parametric design is almost exclusively oriented towards creating geometry. While this geometry is more and more tied to external analysis tools, to evaluate different performance criteria such as day-light availability or energy consumption, the process is inherently focusing on modeling. As such, the resulting geometry contains little information and is not so different from geometry created in traditional CAD systems: points, curves and surfaces placed on layers.

Fueled by the requirement for iterations, optioneering and prototyping, parametric design has allowed engineers and designers to rethink their approach in numerous ways and introduce new and daring approaches which might otherwise have been dismissed.

At the other side of the specter, BIM relies on a pre-defined semantic structure. All entities have

a clear meaning and function. The culmination of the BIM structure is the Industry Foundation Classes (IFC), which describe all possible and foreseeable building elements in over 800 entities, 350 property sets and over 100 data types.

Whether the structural steel members of a façade or curved roof or the setting out of a ceiling with lighting fixtures or fire detection items, each relies on the rules and definitions of the products being used and the structured profile that they follow.

What are the latest advancements and trends? Personally, I find it almost impossible to keep up with technological change in current times, what I will say is that developments that allow complex calculations or data manipulation to be achieved through a more user-friendly interface are number one in my book.

I am of course referring to the visual programming environments that have taken over many of our design processes in recent years. These are easy to learn as they provide many built-in objects that are organised in a flowchart type nature.

Basically, a typical text-based programming language means the programmer must think like a computer, while a visual programming language lets the programmer describe the process in terms that make sense to humans.

This form of coding has opened a world of possibilities not just in terms of simplicity of use but also in terms of building complex operations by combining pre structured modules, many of which are now available as they are being shared freely online.

How to bridge the gaps between parametric design and BIM?

“Parametricism” is a term being used for a new global style of design that covers all industries and disciplines and implies that all elements are parametrically malleable with the right computational design tools and manufacturing methods.

Basically, that any item can be transformed from its initial state, through a computational process bound by constraints and into a future state.

These skills however do not come naturally and therefore traditional roles and responsibilities are changing. Whether through education, upskilling or development, new roles are now emerging for computational experts, parametric modelers, data analysts, visual programmers, data miners and the like.

However, don’t for a minute think this wave is affecting the whole industry. In my experience many organisations, especially in the Middle East, are still struggling to come to terms with the basic concept of 3D BIM, never mind digital or computational engineering.

So, what you are left with is a huge gap, growing by the day, between the international tier 1 organisations who are actively adopting parametric thinking and pushing the industry capability forward and those smaller tier 2 or 3 organisations further down the food chain who are trying desperately to continue for as long as possible in 2D CAD, just like they have always done.

While parametric design can process thousands of iterations in minutes, removing tedious trudge work to find the optimum solution, it is still a human decision that ultimately will make the final choice.

What are the limitations of BIM/parametric design?

Arguably the only limitation is your imagination. However, there is a very steep learning curve involved (like any other skill) parametric design requires hundreds of hours of practice, patience, and perseverance. While the traditional style of designing usually focuses on the 2D plan first, parametric design focuses on extensive data collection & validation and the setting up of relationships between parameters. Plus, all this needs to be setup at the beginning of the project.

Additionally, since this method of design heavily relies on the data we provide during the design phase, extensive research and data collection is usually done first. Anything and everything, from site location to available materials, will contribute key data to the process.

Unfortunately, parametric design is not always the one to steal the show. It requires a large amount of investment of time at the start – where various relationships and algorithms are defined. This does not sit well with some organisations with limited resources, on tight budgets or schedules.

If the end product is a production-ready model, then the idea is feasible, but for small companies, where the end product is only a 2D Drawing and a visualisation of the finished product, the entire scheme might not work out cost effective. In this case the traditional design might still be the best choice.

What are the benefits with respect to implementing BIM and parametric processes for façades?

The advantage of any computational process is of course the ease with which you can accommodate change. Once the initial formula or program is configured, usually with a set of baseline settings, then any further change is just a simple adjustment to the inputs and re-run.

Façades are often simple geometric shapes or patterns repeated to appear complex. Therefore, a parametric process using a geometric pattern can be generated with ease.

Combine this with the fact that most parametric design programming tools accommodate seamless integration with other traditional software such as, environmental analysis, building physics, structural simulation and clash test, etc. then this solves the need for multiple copies of the data on

separate platforms as all the data is linked and interoperable.

The final step is that with every adjustment you make to your parametric design the 3D model automatically creates the optimised solution and then updates the extracted drawings, BOQ, and schedules. Now you really have a solution that is replaced CAD with CODE.

Having worked with and for several consultants and façade manufacturers I have experienced these processes firsthand. This has allowed me an insight into the complexities of façade systems and their installation both traditional and bespoke.

However, it is wise to remember that the world of design inside a computer, where your 3D model can be measured to the millimeter, is far removed from a construction site where a build-up in structural steel fabrication tolerances can make a vast difference to the actual final position of the façade panels.

Why BIM appears to be fundamental in the current architectural design? How can architects use BIM to streamline complex façade designs? The use of BIM or parametric design is normally associated with complex shapes and curved geometry. But parametric definitions can be used for material and manufacturing optimisation or simply to produce better and faster impressions or iterations when designing traditional rectangular glazing solutions.

Parametric design for façade is the application of computational strategies to the design process.

While designers traditionally rely on experience and intuition to solve complex design problems, the computational design aims to enhance that process by encoding design decisions using computer power and language. The result is a graphic representation of the steps required to achieve the end designs.

An external architectural façade is one of the most expressive, inspiring, and complex aspects of building design. It is the outermost skin with a multitude of roles from visual character to weatherproof barrier. Today, the façade, interior skin or cladding can be a complex as the building itself and balances the aesthetics, visual character, structural stability, solar gain, daylight, visibility, thermal comfort, and zoning together in one component.

How has BIM changed the façade modeling? Any project with a BIM requirement means that design reviews focusing on fully coordinated 3D models now feature the façade like any other discipline.

The total façade envelope can be around two meters in section. This is from outer skin, through weatherproof paneling and insulation to primary and secondary structural steel and then to interior mounting and final finish of the internal skin.

This extensive zone in many cases also needs to accommodate MEP services. Therefore, creating a complex space that needs to be modelled, coordinated, and understood fully. Add to this mix a façade that maybe curving in multiple geometric plains, and you can see that 3D modelling is not just a good idea, it is absolutely essential.

I have seen façades represented on a drawing as a single line, because the external shape and form was considered all that was important. But once you fully understand the complex mounting and adjustment that must be anchored to the primary steel, you realise that “the devil is in the detail”, as they say.

As an industry we now refer to the “Level of Detail (LOD)” of our 3D models. But in my opinion the façade system has always been a difficult one to define. While I have explained why we should model a façade due to understanding the complexity, the reality of a fully modelled solution with every fixing, adjustment detail and seal, would of course create a model that most normal users could not even open. Here a commonsense approach to what is modelled and what is not must be adopted.

How 3D parametric modelling and automation can help meet customer demands?

“The customer is always right”, or so the saying goes. Often the vision for the constructed asset originates from the client in some form or another, the challenge then for the architect is to realise that vision with a solution that meets the aesthetic, creative and functional demands, while allowing the engineers to then create a design that can be manufactured and constructed.

The parametric process then allowing for accelerated crunching of design ideas and efficient options to find the optimum solution, therefore providing additional time to be spent on the artistic touch provided by the human expert input.

Fast and efficient optimisation is a real game changer. Whether reducing structural steel sizes used, or onsite fabrication time reduction, or standardisation of façade panel types and dimensions or automatic development for space planning. Each utilising a lot of data but capable of substantial material and time savings.

Being able to then visualise these savings in a plain language format is then critical. Several applications are now available to allow a client or customer to manipulate data in such a way so that they can themselves “play around with” the controlling parameters to adjust the solution as they see fit.

This real time interactive ability takes customer configuration to the next level.

How technology can be used to reduce costs, reduce defects, and improve designs?

Becoming efficient at any process by adopting whatever means possible, means that you can effectively complete that process in less time. Saving time in real terms means saving money, and that is the main driver behind almost everything.

The technology itself, whether software or otherwise is merely an enabler, it simply replaces

the use of a paper and pencil. Let’s remember, we humans can do whatever a computer does, it is just that they can usually do it faster and with less errors. The takeaway being, we save time.

With tried and tested effective processes and workflows in place, then deploying technology to do the work is usually a success.

The question of “improving design” in my opinion comes from what we have learned from our past experiences. The construction industry generally is not great at lessons learned or sharing valuable experience for the benefit of everyone.

Being better at managing information intelligently provides the tools to allow us to make better informed decisions and that knowledge then leads to better outcomes.

Some parametric processes can now even learn from previous iterations therefore understanding what is good and bad, and this then influences future solutions created.

In final summary smart solutions developed by the use of smart technology, in the hands of suitably smart people is a force to be reconned with and will shape the design and construction industry going forward.

“An entrepreneur who wants to build a sustainable company in the glass industry must formulate a bolder and more explicit strategy”

Rizwanulla Khan Executive President, Emirates Glass LLC

Rizwanulla Khan is the Executive President of Emirates Glass LLC, Saudi American Glass and LumiGlass Industries. He joined the company in September 20, 2005 as Senior Vice President – Manufacturing & Operations at Glass LLC. Since assuming the Executive President position for three glass subsidiaries on December 23, 2013, he has been responsible for the Company’s overall vision, strategy and financial objectives. In his current role, he is a key architect of the Company’s long-term strategic plan, which is focused on increasing geographic penetration in the global and regional glass industry and delivering sustainable, long-term, profitable growth. He is strategically-focused and results-oriented leader with unparalleled enthusiasm, passion and energy. Prior to joining Emirates Glass LLC, he had 18-year career at Zamil Glass Industries where he led the production and operations team from 1987-2002.

In a conversation with Window & Façade Magazine, Rizwanulla Khan talked about Emirates Glass’ journey and its plans. He also discussed about the glass industry and the opportunities in the region. Excerpts…

Please brief our readers about the journey of Emirates Glass in the Middle East?

Emirates Glass was established in 1997 by Khalid Bin Kalban to become the leading provider of energy efficient architectural glass in the Middle East. Since its inception the company has been an integral part of Dubai’s growth and evolution, having supplied glazing and expertise for many of the most iconic buildings across the city. However, Emirates Glass has also expanded its international presence and we are proud to have supplied our solutions to GCC countries such as Saudi Arabia, Oman and Kuwait, but also to Azerbaijan, Turkey, India, Sri Lanka, Pakistan, Bangladesh, East and South Africa and even Canada.

Together with 80 different coatings, from hard and solar control coatings to low-emissivity single and double silver coatings across the entire colour spectrum, Emirates Glass can offer a wide range

of glass products with more than 400 different combinations to meet even the most challenging requirements we receive from consultants and architects in terms of performance and aesthetics. Other than that Emirates Glass produces a wide array of double or triple glazed insulating glass units, safety, bullet-resistant and otherwise laminated glass - or a combination of any of the above. Some more special products include glazing units with captured or suspended aesthetical or performance enhancing elements

such as honeycomb diffusers, metal and synthetic meshes or mashrabiya inserts to reflect our local heritage and ability to integrate traditional elements in modern and contemporary architecture.