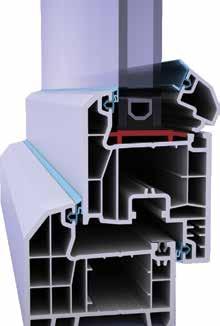

Lingel - Panzer - Glazing 14 mm

Recommended for P6B as per EN356

LPG 18

Lingel - Panzer - Glazing 18 mm

Recommended for P7B as per EN356

LPG-X

Upgrade your existing Lingel security glazing to LPG performance

LINGEL SAFE BOX hardware

to upgrade your existing Lingel window Recommended for RC2 and RC3 as per EN1627-30

LINGEL SAFE BOX hardware

for your new state of art

Lingel - security - window recommended for RC2 & RC3 as per EN 1627-30 LSB 1 LSB 2

Lingel Provides Masterpiece Windows Where Every Component Is Merged To Perfection

5monsoons S�llwater-�ght, S�llrollssmooth

PatentedJapanesetechnology

Water�ghtto350Pa

Factorytestedfor30,000 openings&closings

YKK AP|BhorukaExtrusionsPrivateLimited

Bangalore [Branch Office]

No.1001& 1002,“A” Wing, 10Floor Mittal Tower, M. G.Road,Bangalore 560001, Karnataka

Tel: +91-80-4256-0000

www.bhorukaextrusions.com

Mumbai[BranchOffice]

No.B-39, 41,42, 43,Solaris-1, Saki ViharRoad, Andheri East,Mumbai400072, Maharashtra

Tel: +91-22-415-2040

Mysore [Factory] No.1 KRS Road, Metagalli, Mysore570016, Karnataka, Tel: +91-821-428-6100

ykkiwin1@bhorukaextrusions.com

Volume 7 | Issue 1

November - December 2020

PUBLISHED BY

F & F Media and Publications

C-55, Okhla Industrial Area, Phase - 1, New Delhi-110 020

T: +91-11-40623356

CO-FOUNDERS

Syed Ahad Ahmed Amit Malhotra

TECHNICAL PANEL

Mahesh Arumugam Director Meinhardt Façade Consultants KR Suresh

Regional Director Axis Façade Consulting

EDITORIAL

Renu Rajaram renu@wfmmedia.com +91 9312864830

Shefali Bisht editorial@wfmmedia.com

DESIGN & CONCEPT BY Prashant Kumar

MARKETING & OPERATIONS

Kapil Girotra kapil@wfmmedia.com +91 9560925255

SUBSCRIPTION & CIRCULATION Kapil Girotra support@wfmmedia.com +91 9560925255

Mukesh Kumar mukesh@wfmmedia.com +91 9560088995

RNI: DELENG/2014/57870

10 Exterior Wall Flammability: Fire Safety & Façade Designs

Santosh Revankar, GM, Designs, Salarpuria Sattva Group

16 Why is Fire Safety Such a Big Deal in High-Rise Buildings?

P Jothi Ramalingam, Director, Winwall Technology India Pvt. Ltd.

22 Catastrophic Exterior Wall Fires in Highrise Buildings

Dwayne Sloan, Technical Director - Building & Life Safety

Technologies, UL LLC

28 Fire Testing for Façades

Abhishek Chhabra, Market Development Manager, Thomas BellWright International Consultants

36 Fire Safety and Façade Design

Prameena Karunairaj, Principal Engineer – Sustainability, WSP

42 Fire Rating of Glass Façades - A Review of Applicability & Codal recommendations

Jatin Shah, National Director, MD & Chairman, Colliers International; S. Mridul Naidu, Sr. Manager, Planning and Developments, Colliers International

50 Face to Face

Ar. J.P. Agrawal, Principal Architect, Agrawal & Agrawal Architects

58 Cover Story

Façade Fire Mitigation - The Need for a Comprehensive Approach

74 Interviews:

• Ar. Anand sharma, Founder & Partner, Design Forum International; Kirti Arora, Project Engineer, Axis Facade Consulting Pvt Ltd

• Ar. Sanjiv De, Principal Architect, One. By. Design

86 Industry Speaks

Shankho Chowdhury, President, Decoratives Division, CenturyPly

92 Project Watch

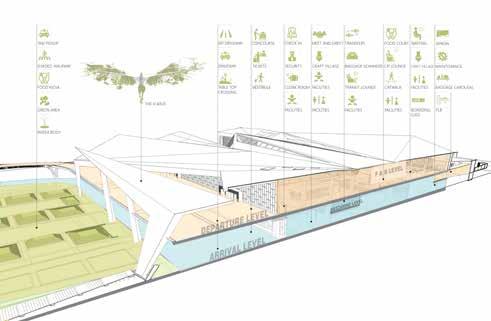

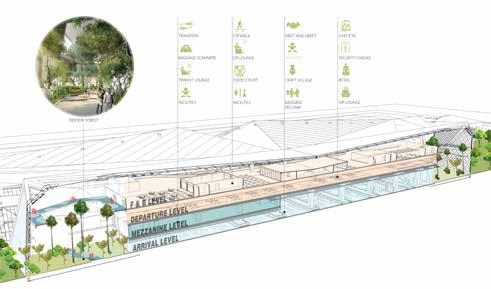

• Karle Town Centre Masterplan, Bengaluru by UNStudio

• Pioneer Urban Square, Gurugram by Urban Architecture Works (UAW)

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

As the world and industries are struggling under the grip of the deadly pandemic, this question still remains unanswered. How will the pandemic affect the upcoming market opportunities? Covid created various operational and financial challenges for Indian businesses. During the lockdown, approximately 71.31% of the businesses dealt with reduced cash flows, and the manufacturing sector being the worst hit. Additionally, delay and cancellation of projects have also been a major cause of concern, We wish that vaccines will bring hope for a return to normal by summer 2021.

This edition is a special one on Fire Safety. There are many highrise buildings in Indian metros, and those of more than 40 levels are understood as ultra-high-rise buildings. There are concerns about fire safety in those ultra-high-rise buildings. Recent building fires in Mumbai and Delhi, even in tier-2 cities like Surat and Ahmedabad, raises concern.

Basically, building fire safety codes deal with accidental fires. High rise buildings are very susceptible to fire. New architectural features, such as using so many glass constructions, might give additional problems. Cracking and falling of glass panels due to the explosion or failure of the fittings for fixing the glass panels would give a higher air intake rate to sustain combustion. As a result, higher heat release rates would be emitted to cause severe damages. This edition of the magazine covers many important topics including fire safety provisions in highrise buildings, fire safe façade and fenestration design, impact of structural elements on fire, mitigation of fire spread using various active and passive means, use of non-combustible materials, etc.

We will keep posting our scheduled events, which are curated by experts in the fields of fenestrations and facades. Please do watch these insightful discussions on our platform WFM Community.

As we crawl towards the end of the year, we hope and wish that the year 2021 will bring more certain times for all our readers. We wish all the negativity and difficulties also end with this year and 2021 brings success and desired results for all of you. May the new year come in mellow and warm, filled with good vibes.

Renu Rajaram renu@wfm.co.in

Façade is one of the most fire susceptible elements of building design

Façade is one of the most susceptible elements of building design. The majority of the population, being ignorant about the performance of the material, often fail to understand the veracity that the façade design plays, especially in controlling or propagating

the spread of fire. With more emphasis on aesthetics, energy efficiency, cost factor, etc., fire safety has always been kept under the radar. However, keeping in view the present market trends, this has gone beyond just the aesthetic part and plays a more prominent role in light conveyance, acoustics

execution, and effectiveness.

The scenario has become more complex with the unstoppable mushrooming of high-rise buildings which pose a greater fire hazard. Though there are numerous fire safety-related codes and standards, in India these are scarcely followed. When it comes to façades, it is mostly influenced

by the pure considerations of alluring appearance and pricing, and is yet to hit the nail on the head in terms of fire safety norms and testing methods.

There is a lack of awareness about the characteristics of façade materials, such as combustibility, smoke release, toxicity, ignitability, etc. that contribute to massive fire proliferation. Therefore, an active involvement of industry experts from design to construction can be of significance in deciding the appropriate material for the façade along with their correct usage. It is much more than just the precaution and more about unanimous acceptance of the fact that any potential fire hazards can only be combatted when façade systems, materials and testing are given due importance. Here, the focus should be on

the holistic approach towards analyzing the performance of façade materials, aspects of façade design for fire safety, fire testing of façade materials along with the importance of compartmentalisation and much more.

There are primarily two methods to plan a building façade for fire safety. One is to detect and act (active fire protection) using detectors, annunciators, sprinklers, etc. While the second method is to contain and restrict fire in a given location (passive fire protection). Here, reaction and resistance to fire properties are utilised to contain or create a compartment, which helps

in minimising damage and also in evacuation to save lives. There are plenty of important elements in architecture and façade which are key components, and these should be designed keeping in mind the aesthetical part of it as well as other safety measures to endure any adverse situation; both natural or man-made.

Cladding and façade play the most prominent role in fire safety because these are the main reasons for fire spread. Correct selection of material and system design are the two key elements that form the basis of fire safety of a façade system. Engineers planning firesafe cladding framework need to know the fire properties of the material being utilised and their key response to fire like ignitability, combustibility, fire spread, and responses of droplets and smoke.

This essential information is utilised to plan a framework and the net fire properties when the given materials are contiguous to one another. Façade must not propagate fire and also not let the fire or heat travel from one area to another, or should not disintegrate in the presence of fire for a reasonable amount of time.

The enactment expected out of most building materials from a fire safety standpoint is its resistance to fire and not the combustibility alone. The resistance time the material provides is calculated towards the dissolution of the material, the rate of fire spread, and the essential escape time it gives the occupants before it is out of control. It should be able to bear a minimum of 30 minutes to two hours of fire resistance, depending on the distance from the source of fire or required resistance.

Petrochemical-based materials like aluminium composite panels, PU foam metal panels, insulations, etc. can propagate fire. The façade material can be further classified based on certain lab assessments as ‘A’ class and ‘B’ class and their subclasses. ‘A’ class, being the highest amongst the non-combustible fire safe materials, comes a bit costly making it hard to afford for large-scale project formats. However, where the fireproof enclosure is absolutely essential, the specifications should be prerequisite to adhere to ‘A’ class. Keeping in view the objective of maximum fire resistance, all materials used in the construction has to be fire safe and not the façade. Additionally, as mentioned earlier, the structure must be able to retain its integrity for a minimum of 30 minutes, as

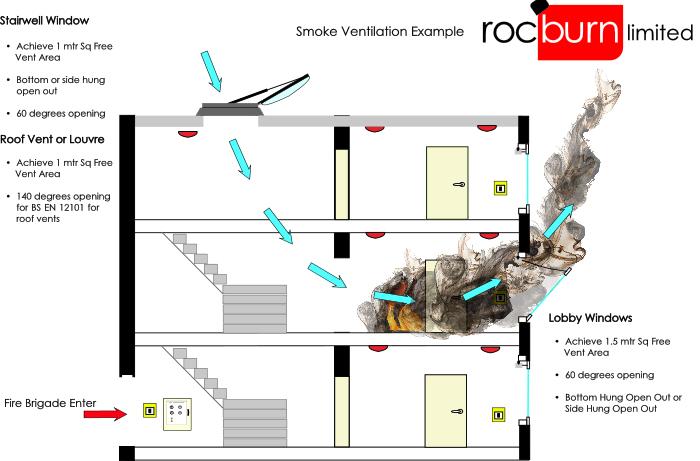

per the NFPA 285 code for fire resistance of façades. Moreover, smoke vents are an important part of the facades, which primarily include aluminium, glass, sealant, gaskets along with the hardware, and the automation kit might also be vulnerable to fire. Therefore, these also should be tested basis global standards like the EN 12101 Part 2 and CE marked which ensures the holistic performance of the vent and not just the builtup hardware. In this scenario, the entire vent is placed in a fire test chamber as high as 300°C, where post 5 minutes, the vent is expected to open fully within 60 seconds and remain open for a minimum period specified. Only thereafter this can be passed into the system testing. Considering the various vulnerable points while planning a fire safety system, it is always advisable to test one or more large scale fire mock-ups, to validate the effectiveness of the system design, planned to be implemented at the site.

Material selection and system design being the two key elements, it is necessary to identify the accurate cladding and façade material to mitigate the fire hazards as much as possible. These materials also contribute to choosing the accurate cladding framework, which is fundamental while assessing the environmental effect of the structure in future settings. A couple of different elements that should be considered as fundamental for the framework ought to be – their inner and outside conditions, toughness, nearby setting, arranging prerequisites, openness, buildability, appearance,

accessibility, support necessities just as the auxiliary necessities.

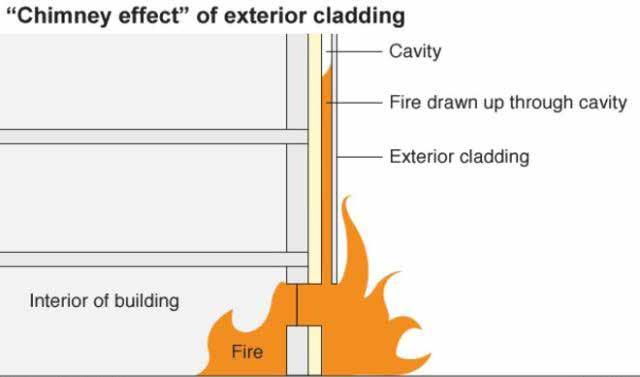

Structural wall elements play an instrumental role between the wall and cladding. If due to the lack of effective planning, there is a gap in the structure then in case of a fire, this might draw the hot air up, elevate fire, and spread to the head of cladding. Amongst preferable materials, brick has magnificent fire resistance along with fibre concrete/steel weatherboards. In addition, aluminium and reconstituted timber items have great resistance as well, where the timber weatherboards and pressed wood sheets can also act as a shield to fire. Fire will be spread by the cladding if the centre is fire-prone. External wall systems frameworks comprise of essentially three thingsoutside cladding with air cavity behind, persistent protection (CI), and water/climate resistive hindrances (WRB). Here, the combustibility of each one of these segments can severely impact the fire execution of the entire lot. The final segment is the climate/water-resistive obstruction (WRB) introduced over the outside sheathing. It is utilized to forestall dampness harm to the structure and assists in keeping up the comfort level inside the structures by controlling relative moistness. In terms of cladding as well, it is advised not to advance with any combustible element as it might heighten the fire risk status through ACPs along with highly flammable polymer core.

Few precautions are advisable while building the façade to control fire spreading which

can be done through applying fire stops and smoke seal. There is little point in having a fire evaluated segment if the division is intended to compartmentalize the fire does exclude fire stopping. On the off chance that if space isn't accurately fixed, it can prompt the fire spreading, smoke, and poisonous gases getting away. Time is the key substance with regards to hindering the spread of fire and fire-stopping when introduced close by other aloof assurances. In this situation, firewalls can repress the spread of fire for as long as four hours, permitting individuals to leave the structure and the fire administrations to show up. Depending upon the sort of fire anticipation technique required, the scope of fire-stopping should be utilized at its best. The essential part of this passive fire protection is a fire stopper, which is why it is so important that it is installed by trained professionals.

In India, there are innumerable fire safety-related codes and

standards which are hardly followed. In terms of facades as well, the primary importance is always given to the pure considerations of alluring appearance and pricing.

In building structure, fire safety is dependent on the choice of each and every material that is identified and applied in construction. Facade design needs to be done in a manner that it does not allow the fire to spread from one compartment to another. Its design has a contradictory impact on buildings, as these can be significant in case of regular usage, but at the same time can also be hazardous and unsafe if combustible materials are being used. We can say that the materials used can be due to ignorance or value engineering (VE) options as the façade cost is considered at the end of the project. Therefore, it is always important to step back, review and then move forward while designing a façade and focus on the fire preparedness it can offer, in order to achieve a safe and holistic experience.

SANTOSH REVANKAR GM, Designs, Salarpuria Sattva Group

Santosh Revankar has been with the company Salarpuria Sattva Group for over 13 years, heading architectural design development. With 25 years of experience in architecture and construction, his expertise includes architectural design development of commercial, IT, retail and residential projects. Revankar has worked with international architects and consultants from U.K, Hong Kong, Canada and Singapore on various projects. He has played an active role in Salarpuria Sattva’s flagship projects like Knowledge City and Knowledge Park in Hyderabad, also is a part of other ongoing Commercial/ IT developments, on the ground, as well as on the drawing board. Besides, he also takes care of structural and MEP service-related integration, of the overall project and in resolving design/ site related issues.

Reena Mukerjee looked up in horror at the smoke billowing from the 27th floor of the building which houses her office her own Architectural firm ‘Reema Athreya and Boon’, located on the top floor of this 39 storied glass clad high-rise. The fire was raging and as she watched some of the glass panels shattered and the flames leapfrogged towards the floor above. The high winds were helping the fire burn even more vigorously and it looked like very soon the entire structure above the 27th floor will be fully gutted soon. Only divine intervention can help. She prayed fervently with all her heart. “OH God! please do something. Please bring the fire to douse itself. Please

save all those people who are stuck in the building and fighting for their lives”. Will her prayers be answered? It all depends.

This is a familiar scenario which plays out many times a year across India and any of us could be that Reena Mukerjee. Our colleagues, our family members or even we ourselves could be stuck in a similar situation. Unfortunately, there is no one on earth who can give you a guarantee that the building which houses your office or home can be made absolutely fire proof but if the architect, consultant and developer of such superlative high rise buildings decide to keep fire safety as a priority then they can definitely make the building extremely safe against fire accidents.

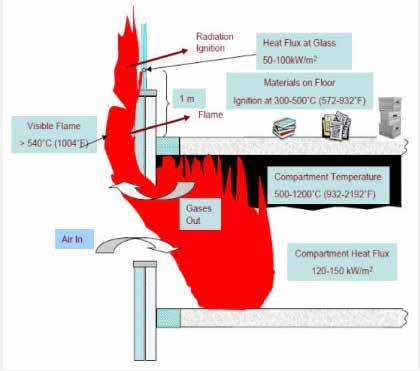

Fire safety and fire engineering is a vast and highly technical subject which is yet to become popular in India despite its criticality. When we speak about fire safety, we need to understand that this entire subject can be classified into two kinds of testing to classify the products.

1. Resistance to fire which studies those properties of materials or their assemblies that prevents or retards the spread of excessive heat, hot gasses or the flames across different compartments in the building during a fire. The classification for resistance to fire will be as follows: E30 to E120 where E denotes the ability of the product or system to have integrity to

prevent the spread of flames and smoke/gasses and 30, 60, 90,120 denoting the number of minutes the product or system successfully stops this.

(The NBC specifies E120 and EI 20 as the bare minimum requirement for doors and partitions used in the escape corridors and refuge areas).

EW 30 to EW 120 where EW denotes the ability of the product to not just stop the spread of fire and smoke but also ensure that the radiation passing through the glass and frame of the system is always below 15KW per Sq m per hour. This is the minimum radiant heat required to have spontaneous combustion happening on the non-fire side during a fire. As such, most

specifications worldwide fall in this category.

EI 30 to EI 120 where EI denotes the not just the fire resistant properties but also the insulation properties of the system thus ensuring that the maximum temperature on the non-fire side never exceeds 1850C.

2. Reaction to classifies materials on the basis of how they behave during a fire to withstand fire exposure. This can be broadly classified for the following characteristics

Flammability from A1, A2 to F where A is non-flammable and F is unfit to be tested since it is highly combustible.

Smoke index from S0 to S3 where 0 means low smoke and 3 is heavy smoking if the

product is on fire

Burning droplets from d0 to d2 where 0 means no burning droplets are produced during fire and 3 being high number of burning droplets falling down which can create secondary fires.

Based on these characteristics there are two kinds of agencies who certify the products to be used in buildings.

1. ISO17025 accredited independent laboratories who can test the products for either resistance or reaction to fire and issue test certificates classifying them according to the relevant standards.

2. International certifying bodies that use the data generated during the testing either in their own laboratories or

Two important parameters that define the performance of fire safe façade materials are their combustibility and smoke production

in third party accredited laboratories and then classify the products either according to international standards or their own (UL). These certifying also audit the manufacturing process of the manufacturers and undertake to do random tests on samples to ensure that the product sold is as per the tested specification. There are several reputed such agencies worldwide and UL, INTERTEK, FM GLOBAL, EXOVA are a few well-known brands.

The most important aspect to be kept in mind is that when a system gets tested and certified the certification holds good only if all the components which were used in the original test is used fully while the system is manufactured in the factory. Even if any one component is replaced, then the validity of the test report will become void.

Once again there are two kinds of products which go into a building which focus on fire safety.

1. Passive fire products or systems are those which are built into a building

to prevent the spread of fire and smoke from one zone to another within the building for the specified period, by virtue of its physical properties, as mentioned in the local specifications. These products need no manual or other intervention to start working in the event of a fire. Examples of passive products are fire doors, fire rated partitions, Penetration seals, Ablative paints, in tumescent collars or tapes etc.,

2. Active fire products or systems which focus on containment and extinguishing of the fire in the building. These require human or automated intervention to get the system working in the event of a fire. Examples of active fire systems are fire extinguishers, smoke extraction systems, smoke alarms and detectors, etc.

Once tested products and systems are used in the building the risk of fire incurring and spreading reduces drastically. The chart attached below gives the details

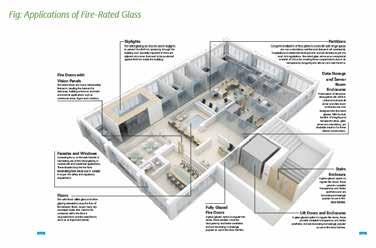

of most commonly used passive products in buildings for fire safety and their relevant testing specifications.

Fire safety is a vast subject which has gained immense interest in India in the recent past. However, in most advanced countries this is a very critical subject which is dealt by professionals with the utmost seriousness it deserves. The objective of the fire specialist would be to make the building as fire resistant as possible by ensuring that only tested and certified products are used in the project. No doubt such tested and certified products would be more expensive, but then that is the price one needs to pay to keep human life safe in these buildings.

Fire happens in a building mostly as an accident and sometimes as a result of arson. Irrespective of the causes let us stick to how its impact on the people who occupy that building and the building itself can be minimised. The focus for the fire consultant would be to design the building in such a way that even if there is an outbreak of fire it is confined to a limited zone or compartment for as long as it’s necessary. This gives adequate time to the occupants to evacuate safely out of the building, without panicking, while the active systems get triggered on to douse the fire. At the same time, this will also allow the fire rescue teams to access the hot zone without any hindrance.

When it comes to façades there are only three critical areas which need to be taken into consideration to make the façade resist the fire from spreading.

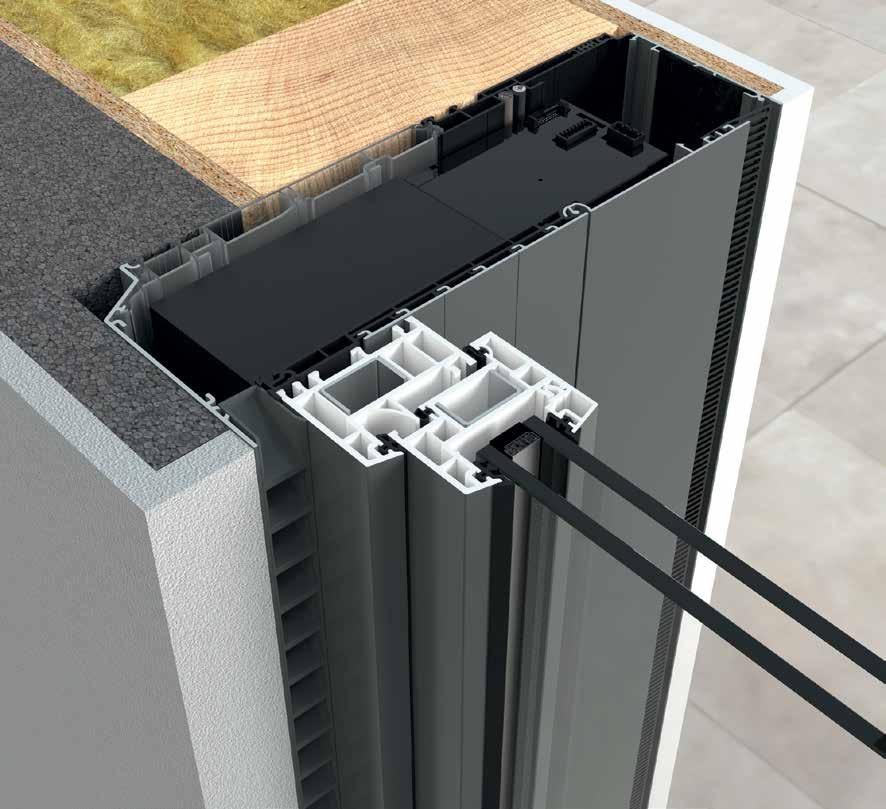

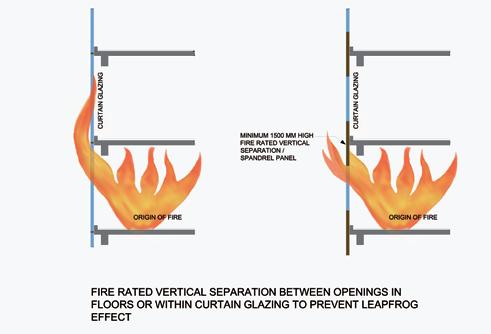

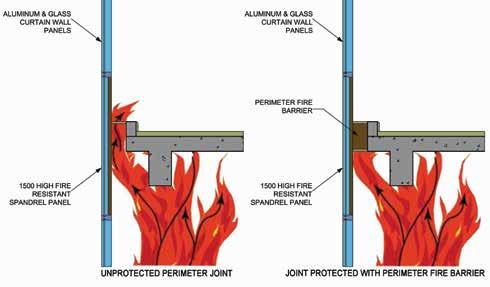

1. The gap between the curtain wall glazing system and the floor slab is one of the most critical zones which need to be adequately protected in the event of fire to prevent the

“chimney effect” spreading the smoke and fire to the floors above. A well designed smoke seal or fire barrier which uses a certified system is something which the consultant should never compromise on, come what may.

2. The height of the spandrel panel must be designed for a minimum of 950 mm and the

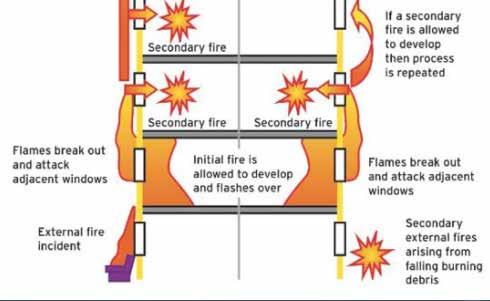

material used in the spandrel panel must be fire rated for a minimum B2 classification to prevent a “leapfrogging effect” i.e. the fire jumping from one floor to a higher floor after the glass panel in the curtain wall explodes with the intense heat.

3. A well designed water sprinkler system within 600 mm from the glass façade inside the building to ensure that the glass temperature stays low thus preventing the glass from shattering.

A well designed curtain wall has no inflammable components and can never aid or abet the spread of fire. The hundreds of fire accidents which continue to occur worldwide give the fire professionals enough clues about why the fires occurred and what could have been done to prevent it and even if it was not preventable how to minimise the losses. It is important that every professional working on the design and execution of high rise project keep fire safety in mind while designing. Fire can be accident but the consequential damage from that fire need not be left to chance. With all the information on fire safety freely available on the net

no one can take umbrage under the excuse that they did not have adequate inputs while designing the project.

Even within the building care must be taken to minimise the use of inflammable products made of wood or polymers and make the building more resistant to fire. Certified passive products must be used wherever necessary in the HVAC ducts, cable trays and pipes as they travel through the building from one compartment or one floor to another. These passive fire products get to work in the event of a fire and prevent the smoke and fire from spreading through the HVAC ducts and the space above the false ceiling. As we all know smoke kills more people in the event of a fire than fire itself and therefore every fire safety system must also consider the risk of smoke spread along with fire.

All the doors facing the escape corridors must be fire rated to keep these zones free of smoke and fire for at least 120 minutes. This will allow the occupants to reach safe zones without panicking. The fire-rated doors and partitions must be tested and certified as a complete system and not

assembled by the supplier with test certificates from individual component manufacturers. Such a product has no one agency giving the guarantee and in the event of a fire there will be a lot of finger pointing going round to take the blame when the system fails.

Damage to life and property can avoided or at least minimised if a proper fire safety design is built into a high rise project. Then even if there is a fire no one needs to panic as there is a built-in system to ensure that the occupants reach a safe zone without any loss or injury.

Coming back to the Reema Mukerjee story, she remembered clearly the focus she and her team had put in while designing the fire safety systems for this project and she believed that these systems will ensure that this fire does not go out of control. Half an hour later she got a call from her partner telling her that she along with all her team members are safe and the fire services have reached the spot and doused the fire. Under these circumstances, the fire code book that she had referred was a life saver like any other holy book she had read.

P JOTHI RAMALINGAM Director

Winwall Technology India Pvt Ltd

P. Jothi Ramalingam is a management graduate who is associated with the architectural aluminium industry for the last 25 years. Since 1990 he has specialised in setting up and running and aluminium anodizing plant and a fully conveyorised powder coating plant to surface finish aluminium extrusions to International Standards. In 2012 he entered into a joint venture with Winwall Technology Pte Ltd, Singapore to set up a performance testing laboratory in Chennai to cater to the ever growing demand of the façade and fenestration industry. Winwall Technology India Private Limited is based in Chennai and in its seven years of existence conducted performance tests for over 245 projects across India and Sri Lanka in its laboratory and half a dozen on site tests for projects in India.

Horrific fires involving the exterior walls of high-rise buildings have fueled debate over how to best mitigate rapid-fire progression on building exteriors. These fires represent a global challenge that begs for a solution.

Recent exterior

wall fires involving high-rise buildings have fueled discussion and debate over how to mitigate rapid- fire progression on

exterior wall that are clad with various construction materials.

To better understand the exterior wall flammability issue and move towards solutions, this article will:

• Discuss the factors that influence building construction related to these types of fires

Grenfell Tower, London - The building's exterior construction was the cause for the fire spreading so quickly

• Provide an understanding of certain fire tests that are sometimes misconstrued as suitable for the evaluation of exterior walls

• Examine the importance of selecting tests for specific regions, codes, and regulations.

The article will also cover UL’s thirdparty certification approach that can be used to identify exterior wall assemblies that have successfully complied with required test methods. This information can hopefully be useful in preventing future exterior wall fires of these types.

In October 2019, the longawaited Grenfell Tower Inquiry Phase 1 Report was released. The Grenfell Tower inquiry is a public investigation independently examining the circumstances surrounding the fire at Grenfell Tower that occurred on June 14, 2017. According to the inquiry report, a fire broke out on the fourth floor of the 24-story housing flat in North Kensington, London, and spread to the building exterior. It quickly raced up the building exterior, ultimately resulting in 72 deaths. The report can be viewed at https://www.grenfelltowerinquiry. org.uk/phase-1-report.

There are several factors influencing exterior wall construction today. First, due to the fast pace of today’s construction and the need for less costly, easier to install designs, new materials are constantly being introduced into the marketplace. The combination of new and existing products creates an expansive list of exterior wall components options for designers and builders. The material combinations and their means of installation must be evaluated

appropriately to determine whether they are suitable for use as a complete assembly. Fire testing has demonstrated that the testing individual materials does not always result in a reliable determination of fire performance once multiple materials are combined into an exterior wall system. It is only through fire testing of the complete wall assembly that an accurate assessment of fire performances can be made.

Another challenge is the growing attention to building envelope performance such as thermal performance, air leakage, permeability, water infiltration, etc. In some areas, this is even driven by local codes and regulations. The result is insulation products with higher thermal properties and increased use of air barriers and vapor barriers. Consequently, these new wall constructions also require testing and evaluation for their conformance to the appropriate exterior wall fire requirements as a complete unit.

Another building construction factor is the increased use of exterior veneer materials that are aesthetically pleasing, but lack evidence of compliance with codes or regulations for fire safety. Around the globe, especially since the Grenfell tragedy, there has been a strong focus on the challenges associated with nonfire-retardant metal composite panel construction, which is versatile and aesthetically pleasing, but does not always perform well when subjected to certain exterior wall fire tests.

Many building professionals, fire protection experts and design

professionals are aware that taking a holistic approach to fire protection within buildings is ideal. This includes choosing materials that have been assessed for their reaction-to-fire properties (to slow the spread of fire), and considering detection and alarm, fire suppression and compartmentalization. However, there is not always a clear understanding of which fire tests or protection approaches should be used for exterior wall fires.

For example, there have been discussions in some areas about relaxing requirements for exterior wall testing if the interior of the building is protected by sprinklers. For an exterior wall fire originating external to the building, it should be understood that the interior sprinkler system is not designed to protect the building’s exterior surface, so significant fire and smoke damage could still occur to the structure.

Another misconception is that the large-scale fire test conducted in accordance with UL 263 Standard for Fire Tests of Building Construction and Materials (ASTM E 119) which is used to establish hourly fire resistance ratings should be challenging enough to examine fire growth for an exterior wall assembly. This test method is useful for evaluating building assemblies for limiting the spread of flame between building compartments (utilising walls and/or horizontal assemblies) or protecting structural steel members such as beams and columns. However, it is not intended to evaluate fire progression extending to the outside of an exterior wall assembly, which was an important

factor in the Grenfell Tower and other recent high-rise fires, such as:

Monte Carlo Hotel, Las Vegas

Nevada - 2008

Mermoz Tower, France - 2012

Lacrosse Building, Melbourne

Australia - 2014

Torch Tower, Dubai UAE – 2015

Address Downtown Hotel, Dubai UAE - 2015

Grenfell Tower, London England - 2017

Torch Tower, Dubai UAE – 2017

Tests such as the NFPA 285 multi-story apparatus fire test are specifically designed to evaluate the ability of an exterior wall system to prevent an interior contents fire to leapfrog up the outside of an exterior wall system.

In recognition of the importance of establishing the most representative test, there are various standards groups around the world focusing on exterior wall test methodologies. The

Test Method Country

NFPA 2851 US, UAE

BS 8414-12 UK, UAE

ISO 13875-23 International

AS 51134 Australia

JSA JIS A13105 Japan

LEPIR II6 France

SP Fire 1057 Sweden / Denmark

CAN/ULC S1348 Canada

FM 48809 International

Table 1 – Exterior Wall Test Methods

Fire Source10

Gas burner; up to 40 kW/m2 @ 1 m height above the opening

Wood crib; Approximately 75 kW/m2 @ 1 m height above the opening

Propane; 55 kW/m2 @ 0.6 m height above the opening

Based on ISO 13875-2 or BS-8414-1

Based on ISO 13875-2

600 kg wood crib

60 liters of heptane

Gas burner; 45 kW/m2 @ 0.5 m height above the window

340 kg wood crib; no opening

good news is that the issue of flammability of exterior walls is being addressed seriously, and many jurisdictions are updating or creating new codes and performance standards. The challenge is that there are several different methods being implemented in different countries and regions that may not have the exact same scope or deliver the same outcomes. It is important to understand the methods used to qualify a product or system to ensure it is suitable for use in exterior wall construction.

Many of these prominent fullscale exterior wall fire test methods are already embedded into codes and regulations. For example, the International Building Code (IBC) and NFPA 5000 make reference to NFPA 285 for buildings of Types I, II, III and IV over 40 feet in height and buildings employing foamed plastics in the exterior wall. Table 1 lists some of the test methods and the countries where they are typically enforced. This is not intended to be a comprehensive list, asthere are other methods under development.

Historically, the acceptance of wall systems utilising noncombustible materials involved a fairly complex review of building code requirements, test reports covering individual components, engineering analysis and manufacturer’s installation instructions. With the increased demand and availability of combustible insulation products, combustible water barriers and façade veneers coupled with the occurrence of several catastrophic exterior wall fires on high-rise buildings, fire prevention requires a robust fire testing and certification program for wall assembly systems is to determine that installed systems comply with the most current model codes and standards.

The Grenfell Inquiry Phase 1 Report states, “The widespread use of combustible rainscreen cladding panels and insulation on the exterior of buildings and the introduction of new kinds of building materials in external walls may have increased the risk of similar fires, but improvements in the regulations relating to fire safety and the requirements for testing and certification of materials, which will be a particular focus of attention in Phase 2, should be capable of mitigating that risk in the future.”

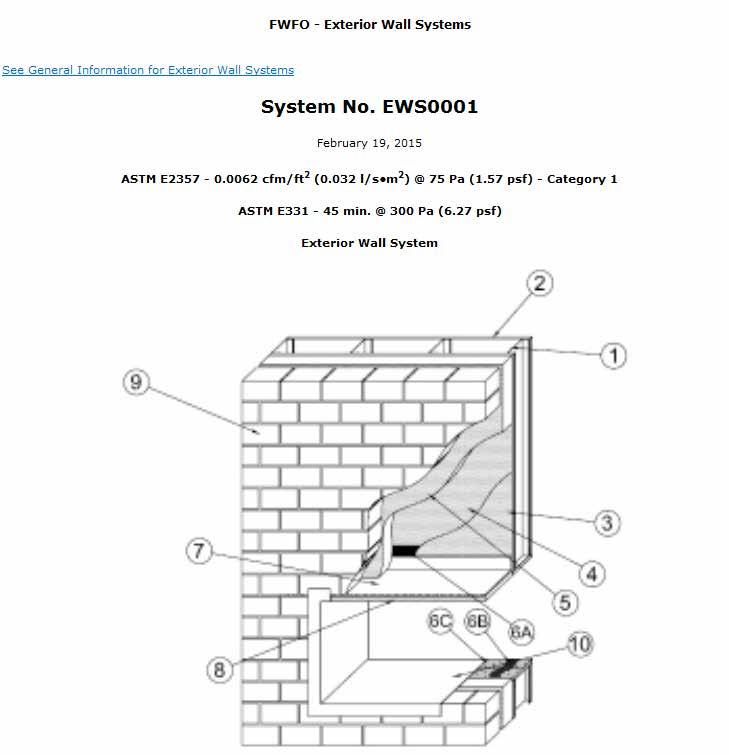

UL developed a certification approach to simplify the review process and ensure compliance with NFPA 285 by providing a public database that illustrates

complete wall system designs and details how individual components are evaluated as part of a system. This approach meets the immediate needs of manufacturers, architects, specifiers and code officials by providing an available, no cost, accessible and up-todate method of determining compliance with a code. The illustrated designs within the UL certification reflect the precise details of a compliant assembly and are readily available to architects, fire safety experts and code authorities.

For an exterior wall system to receive NFPA 285 certification from UL, it must be tested using the specific construction details provided in a manufacturer’s

instructions. If a system is in compliance, a drawing of the exterior wall system and description of critical construction components are documented in the UL certification information. Critical components used in the tested system are specifically identified and will also bear the UL Mark. All certified wall systems and components are now published in the Product iQ online database in the categories Exterior Wall Systems (FWFO) and Exterior Wall System Components (FWFX). Examples of wall system components available through Product iQ include, but are not limited to, various types of insulation products (including foamed plastic), water resistive barriers, air resistive barriers, laminates, sheathing and composite panels.

References

UL recently partnered with International Association of Firefighters (IAFF) to develop a new demonstration and training video. The video will help educate the fire service on the fire behavior associated with these types of fire events and provide them with a better understanding of the test method NFPA 285. This video can be viewed at IAFF - UL Video Exterior Walls.

There is continuing global focus on the challenges associated with rapid fire spread on exterior walls. As UL strives to better understand the impacting factors, and the appropriate tests and certification approaches that can be used to evaluate these assemblies, we can move to offering solutions that will raise the level of fire safety for all.

(© 2020 UL LLC. Reprinted with permission)

1. NFPA 285. Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies. NFPA, 2019

2. BS 8414-1. Fire performance of external cladding systems-Part 1: Test methods for non-loadbearing external cladding systems applied to the face of a building. BSI 2015

3. ISO 13785-2. Reaction-to-fire tests for façades –Part 2: Large-scale test. ISO, 2002

4. AS 5113. Fire propagation testing and classification of external walls of buildings, 2016

5. JSA JIS A1310. Test method for fire propagation over building facades, 2019

6. LEPIR II Test. Large-scale Fire Performance testing of construction systems for façade CECMI (French committee for the evaluation and the classification of products and elements of construction as regards to fire hazard – under the French Ministry of Internal Affairs directives), 2013

7. SP FIRE 105. Issue 5. Large scale testing of facade systems. SP Boras Sweden, 1994

8. CAN/ULC-S134. Standard Method of Fire Test of Exterior Wall Assemblies. Underwriters Laboratories of Canada, 2013

9. FM 4880, Class 1 Fire Rating of Insulated Wall or Wall and Roof/ Ceiling Panels, Interior Finish Materials or Coatings, and Exterior Wall Systems FM Approvals, 2010

10. White, N. and Delichatsios, M. Fire Hazards of Exterior Wall Assemblies Containing Combustible Components. Quincy, MA. The Fire Protection Research Foundation, 2014

DWAYNE SLOAN

Technical Director -

Building & Life Safety Technologies, UL LLC

Dwayne Sloan is the Technical Director for UL’s Building and Life Safety Technologies division. Dwayne provides technical oversight of certification and testing activities for exterior wall systems among many other product areas. He serves on several international, UL, NFPA, and ASTM committees, including the NFPA Fire Test Committee responsible for NFPA 285. During his 32 years at UL, he has worked in and managed, a variety of UL’s fireprotection areas, with 17 years as the Reaction to Fire Principal Engineer. He is the current Chair of UL’s Fire Council and is a UL Corporate Fellow.

For more information regarding this topic contact Dwayne Sloan at Dwayne.E.Sloan@ ul.com or visit UL.com/ exteriorwalls.

The façade of a building is an architectural feature with functionality. Along with the function of keeping the weather and environment out, it also fulfils an important need of a building, that is to differentiate itself from others. It is rare to find a façade designer/contractor wanting to create a building envelope exactly like another one. And if it is being re-created; you can never find the exact same combination of materials and workmanship!

This need to differentiate combined with driver of ‘the economies of scale’ challenges the architects, engineers and businesses in almost every tall building which is susceptible to a façade fire. The challenge is to minimise the cost and time to build it and ensure it complies with all the expectations of performance. Let us dig deeper to view the understanding that has developed so far to ensure fire safe façades and why so many people around the world continue to get it wrong.

A key source to fulfilment is

when our expectations are met. Expectations of what a building (or a product we buy) looks like or performs like. These expectations are based on parameters claimed and defined. All the products we use or see around us are assumed to be exactly the same on several parameters. Mobile phones to cars; chocolates to burgers; glass to gaskets; insulation to brackets. looks, taste, performance: so many parameters!

Now, bringing about repeatability is not always a straightforward process. With constantly changing supply chains of raw materials and changing people dynamics, quality professionals struggle to implement processes that ensure repeatability. As the focus on achieving fire safety increases, it is important to know and understand how this repeatability is realised. And most specifically, understand how repeatability of performance is achieved when creating ‘building envelopes’ which need to be unique in the way the look every time. What are the evolving tools and procedures to realise this repeatability?

The vagaries of the weather

endured by a building creates the need for the inside of a building to be separated from the outside. Heat/cold, wind, water, sound and the list can go on. Varying levels of performance about the ability of a building envelope to effectively separate the ‘outside’ and the ‘inside’ have been acceptable around the world. But with fire risks creeping into the equation, matters related to ‘repeatability of fire safety’ have become very important. Performance levels once linked with ‘comfort’, ‘energy efficiency’ have paled against ‘life safety’, ‘property protection’ and even ‘brand value’. So how do we design and implement a building envelope that will not end up in a fire accident? Here are the key steps used to create a solution that can demonstrate repeat performance on fire safety.

The key for repeatability of any designed system is to ensure that the building blocks can demonstrate repeatability of performance. Image 1 shows the pillars of ensuring Fire Safety is designed and implement accurately.

In countries around the world, the tools of surveillance are always visibly stricter for matters related to safety of human life. You will notice that “medical devices” and “structural integrity of buildings” will get more importance as compared to “furniture performance” or “weather insulation in a building”.

Image 2 describes a common process for enabling a higher degree of ‘quality assurance’, that is certification and listing. Here an

independent third party (different from buyer/ first party and seller/ second party) is independently involved in a contract to assess and assurance the claimed performance of products being bought or sold (buyer/seller).

There are International Standards of ISO 17025 (general requirements for the competence of testing and calibration laboratories), ISO 17065 (conformity assessment, requirements for bodies certifying products, processes and services)

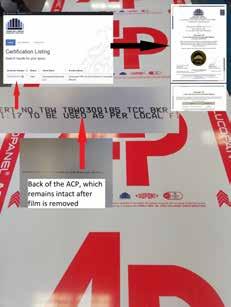

among others have been published and guide on bringing forth parity to the processes followed by these third-party certification bodies. Key common outcomes of these independent certifications and listings are a unique marking or a mark with a traceability code or a number which is carried by all the products assured by a given certification body and a public domain website directory where details are ‘listed’ to enable buyers to distinguish and verify the certified products. Image 3 shows an example.

This is critical step where the knowledge and experience of façade specialists (designers, contractors, suppliers) should be correctly used to ensure the designed systems can withstand the possible scenarios that could cause a fire incident.

Façades used in buildings today have taken over many functions which were originally performed by thick load-bearing walls half a century ago. Ranging from weather-tightness to preventing

initiation of fire or growth of fire within or on the exterior surface. And of course, the designs need to ensure the fire should neither ‘move-into’ a building or ‘moveout-of’ the building (on to the façade). To understand how this is prevented, let us start with commonly misunderstood terminology.

Often detailed using the word compartmentalisation: Fire resistance is the ability of a designed product or a system (like a wall or a door) to ensure that the fire if initiated is compartmentalised or contained within a small area and does not spread rapidly outside this containment zone. Often the time between the initiation of a fire (dropping a burning matchstick or a cigarette stub as an example) to the time when major combustible items like sofa or mattress, etc. are burning (creating a temperature of over 1000 °C and pressures of

more than 10 Pascal) can be less than 5 minutes (flashover time). So, if you are in a room which is fire rated, then the walls, doors, ducts/ dampers, windows, etc are verified for being able to contain the fire within the room (for a given duration of 1/2/3 hours).

Materials like Aluminium Composite Panels/ACP (4-6 mm) which are made using less than 1 mm of aluminium (whose melting point ranges from 300 to 600 degrees) can never be ‘fire rated’. This is a common misconception. A wall assembly could carry an ACP and the wall system could be fire rated, but a ACP alone does not stand a chance to contain a flashover fire.

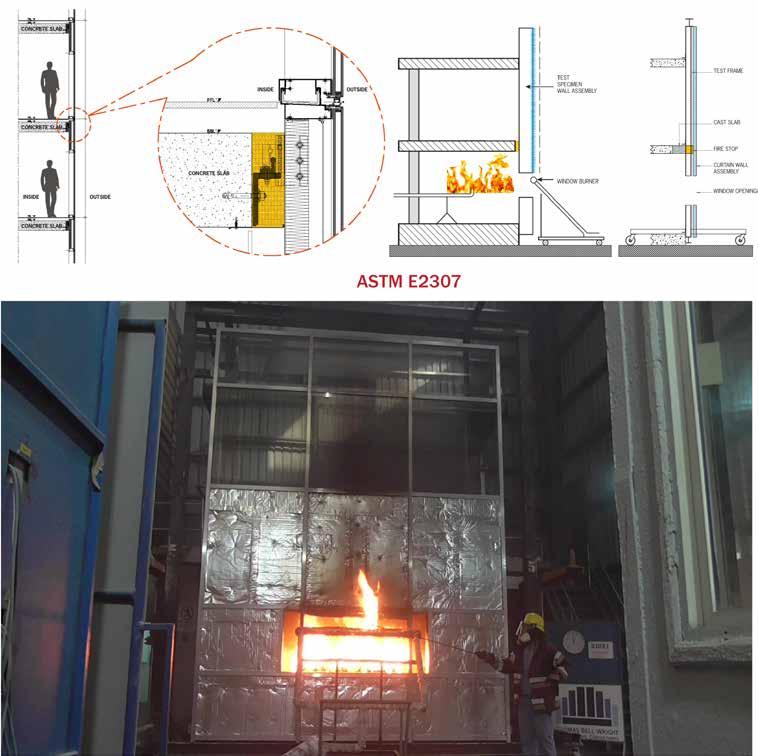

Though usually known to be created using walls, ceilings, etc., in the context of a building envelope there are a few other sections where this becomes important. See Image 4 to view the section between the façade and the slab of a floor which requires such a

containment. This containment is brought about using “perimeter fire barrier” which also needs to allow for building movement. The “perimeter fire barrier” ensures that the fire does not move from the compartment of a room on a given floor to another floor. Also see image 7 to see how they get tested.

How any given material will behave when the environment around it can create a fire or is creating a fire can be defined in many ways. Knowing exactly how building materials behave on these parameters become very helpful for façade designers when considering their use to design a building envelope system.

Ignitability is the ability of a material to be ignited (catch fire). Quantified using test methods like ASTM D 1929 (determining ignition temperature of plastics) or BS EN ISO 11925-2(ignitability by direct flame) or EN ISO 1182 (non-combustibility test).

The chemical composition of a material dictates amount of latent energy the material has. Quantified using parameters like Calorific Value and Heat Release Ratio using test methods like BS EN ISO 1716 (gross heat of combustion/calorific value).

Spread of flame, smoke and other behaviour depends on the composition and distribution of potentially flammable ingredients of a material. This is often quantified using tests like the ASTM E84 (surface burning characteristics of building materials), BS EN 13823 (single burning item) and many others.

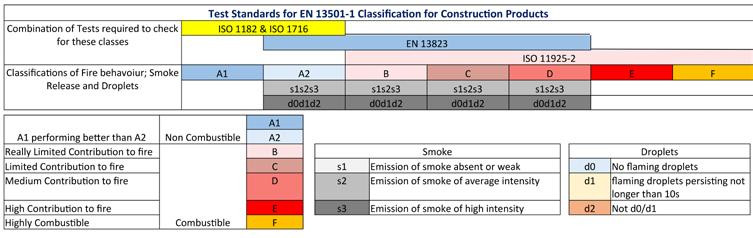

The European Classification Standard EN 13501-1 (fire classification of construction products and building elements. Classification using data from

reaction to fire tests) summarises the reaction to fire behaviour very well. Look at Image 5 for more. It is a common mistake to confuse the reaction to fire properties like low Ignitability and call it ‘fire rated’.

Often there are several dozen different materials used to design and bring about a façade. It is also very common that there are large number sectional drawings detailing façades design details for buildings. For certain highrise constructions, the number of these drawings could go into hundreds or even more. This is the critical point for the fire safety of a building façade. Using the understanding of ‘reaction to fire’ properties of materials to be used designers and contractors have the last chance to screen specific sections where higher risk of fire exists. Incorrect combinations of material, thickness, spacing and even the air-gaps can lead to weak-spots capable to creating an un-controllable fire.

To validate the design and material selection, fire propagation tests are conducted. Here an assembly of a building envelope is mocked up with all materials, components, gaps replicated to

represent the worst-case scenario of a given building. Some projects call for several such tests as there would be several potential weakspots. Several different tests methods are used in the world to validate if the fire can grow or move across the building envelope in any direction. Fires can move across materials, in-between airgaps and often in a chain-reaction mode where reaction to fire of one material instigates the reaction to fire of an adjacent material.

While most of these tests validate aspects of fire propagation, some tests also evaluate the fire resistance of the elements of a building envelope system that are needed to contain the spread of fire from one compartment to another (like floor to floor).

Image 6 shows the Intermediate Scale Multi-Storey Test Apparatus (ISMA) which is used to validate the fire propagation of vertical façades using the NFPA 285 (standard fire test method for evaluation of fire

propagation characteristics of exterior - Non-load-bearing wall) test and Image 7 shows the same apparatus being used to conduct the ASTM E2307 (standard test method for determining fire resistance of perimeter fire barrier

systems using intermediate-scale, multi-story test apparatus) test to validate the ‘fire resistance properties of perimeter fire barriers’ using a mock-up test. Image 8 shows the fire propagation test from the United Kingdom, the BS

8414 (intended to give an indication of fire spread across or within an external cladding system) test.

ASSURANCE OF INSTALLATION

Building façades often comprise of repetitive designed elements

that go up floor on floor. For tall buildings, a small error simply magnifies. Specialist inspectors are called to verify comprehensive details of façades. They are capable not only to read and understand drawings but also, they are able to verify the supplied materials to have evidence of certification and listing (described in Image 3). These installation inspections are extremely critical and hence the need to hire specialist inspectors who are objective and experienced. International standards like ISO 17020 (specifies requirements for the competence of bodies performing inspection and for the impartiality and consistency of their inspection activities) and ISO 17024 (contains principles and requirements for a body certifying persons against specific

requirements, and includes the development and maintenance of a certification scheme for persons) are used to define the minimum requirements of inspection agencies and inspectors in technical specifications. These standards help bring about the parity between different agencies and inspectors who are being relied for assurance of installation and fire safety.

So, the three pillars described in the sections above and summarised in Image 1 are key to ensuring the fire safety of a façade implementation. Projects where any one of the three getting less importance can nullify the money and time spent on the other pillars.

ABHISHEK CHHABRA

Market Development Manager, Thomas Bell-Wright International Consultants

Abhishek joined Thomas Bell-Wright International Consultants in 2013 and has been the driving force behind the expansion of the fire compliance activities into new markets. An engineer with a postgraduate diploma in finance, Abhishek brings with him valuable experience from other, larger TIC (Testing, Inspection & Certification) companies. He has been advocating the need for compliance to standards for improved safety and quality across industries for most of the last 18 years. Along with helping certification bodies expand their horizons of business for over a decade, he has been writing articles and presenting at various forums about mandatory and voluntary quality and safety compliance activities. He also owns and drives a blog called Gurus of Testing, Inspection and Certification (www.tic. guru) aimed at expanding the understanding of conformity.

Design for fire safety is still in a nascent stage in India. There is now a growing demand for ‘fire-rated materials’ among the decision-makers in the Indian construction industry, particularly pertaining to the façade. The recent spate of fire accidents both on a national and international level has fueled the discussion further. Many of these mishaps were preventable if only a few basic principles of firesafe design were included in the façade design. This article aims to

shed some light on some of the key aspects of fire safety in façade design.

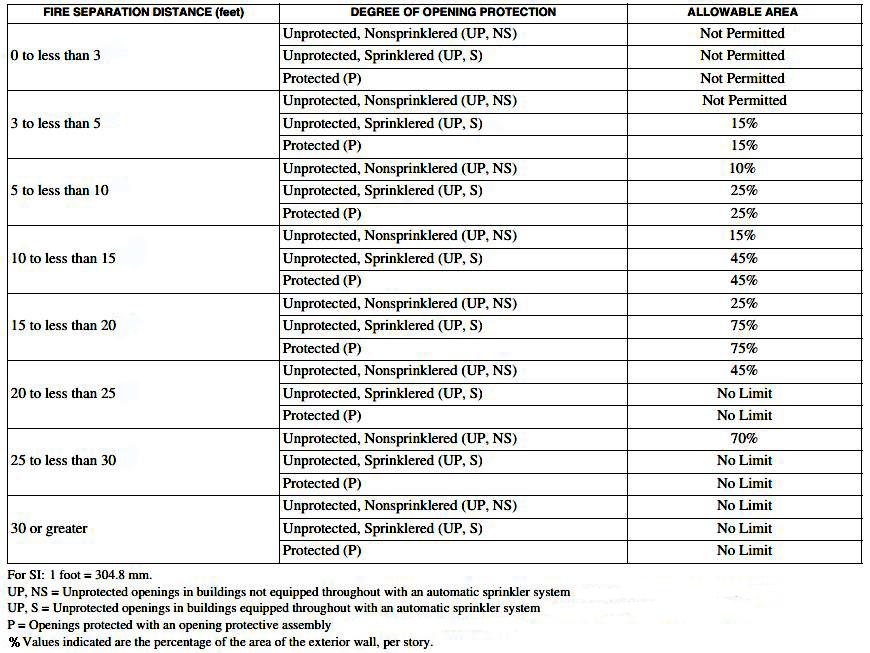

There are many well-known standards and testing methodologies which are followed across the world when it comes to fire safety in façade design. Some of the notable ones are as follows:

• National Building Code (NBC 2016) of India: NBC provides guidelines for

glazing selection in buildings. Excerpts from Part 4 – Clause 3.4.10.2 of NBC pertaining to glass selection can be summarised as below:

1. For fully sprinkler enabled buildings with fire separation of 9 m or more, tempered glass in a noncombustible assembly shall be used

2. For buildings which are not sprinkler enabled, 60240 minutes fire rated glass is recommended for the external façade.

• EN13501-1:

This European standard provides classification of building materials in terms of their reaction to fire. Materials are classified in terms of Class A1, A2, B, C, D, E and F ranging from non-combustible to most combustible. In addition to this, the standard also classifies material in terms of ‘flaming droplets and particles’ during the first 10 minutes of exposure denoted by ‘d’ and ‘smoke propagation’ during the first 10 minutes of exposure in terms of ‘s’.

Consider, for example, a hypothetical cladding material of Class A2 s3 d2. The fire performance of the material can be understood as follows:

Flaming

A2 Non-combustible

S3 Produces substantial smoke

D2 Produces quite a lot of flaming droplets and particles

It can be seen that even when a material is non-combustible, it can perform badly in the event of fire if it causes high levels of smoke or produces lot of flaming droplets.

All the three parameters listed above are to be seen together to select the right cladding material in terms of fireresistant properties.

• BS8414:

This is a British Standard which provides technical specifications explaining the fire performance of external cladding systems.

• BS 476:

BS 476 is a British standard that provides information on fire tests to be carried out on building materials and structures. It has 2 parts: Part 6 and Part 7.

BS 476 EN 13501

Noncombustible

Limited combustibility

Class A1

Class A2

Class 0 Class B

Class 1 Class C

Class 2 Class D

The classification of materials in terms of BS 476 can be juxtaposed on the classification of materials in terms of EN 13501 to arrive at equivalent classification of materials as shown below:

• NFPA 285:

This a standard fire test method for evaluation of fire propagation characteristics of exterior wall assemblies containing combustible components provided by the National Fire Protection Association (NFPA).

Two parts of BS 476 What it explains Part

Tests fire propagation in terms of actual contribution of component assembly to the fire growth Part

Tests surface spread of flame in terms of spread and extent of flame across the material surface

There are many well-known standards and testing methodologies which are followed across the world (Image courtesy - www.fmglobal.com/)

One of the common misconceptions in understanding the fire behavior of the façade materials is encapsulated by the following statement: ‘I need a material with 2-hours fire rating’. While this is a perfectly fine thing to ask for when discussing glass partitions, it is not how the fire performance of a cladding material is defined. Although glazing and cladding together form the elemental units of façade design, their performance parameters vary.

• Glazing:

Typically, tempered glass has better performance against fire than annealed glass. Tempered glass can withstand double the temperature threshold that annealed glass can withstand. Also, even when tempered glass breaks or shatters, it breaks into many small pieces which are relatively less harmful than annealed glass which breaks into large shards with sharp edges. However, there are glasses specifically meant for fire protection also. These are generally used in places where compartmentalisation of spaces is required. These are called fire-resistant glasses and they fall into 3 categories as follows:

Integrity (E):

This is the most basic type of fire-resistant glass and as the name suggests, this type of glass provides integrity to the partition. It prevents flame and hot gases from reaching the non-fire side for some time.

Radiation control (EW):

In addition to preventing flame and hot gases, the EW

type of fire-resistant glass also prevents heat reaching the non-fire side to some extent. It allows people to pass through on the non-fire side for a certain specified amount of time.

Insulation (EI):

The EI category provides the highest level fire-rating since it also helps maintain the temperature of the nonexposed side at reasonable levels for a specified period of time. This is in addition to preventing passage of flame and hot gases. These are available in many performance ratings such as 30 minutes, 60 minutes and 90 minutes fire rating. Nevertheless, for façade applications, generally tempered glass is suggested along with other fire-safe design features.

• Cladding:

The common method of classification adopted for cladding materials is based on the European Standard EN – 13501 – 1. As shown in the table below, cladding materials are classified in to the following 5 types based on their flammability:

Class A1:

These cladding materials have the highest performance in terms of fire protection. They are non-combustible and are made up of totally inorganic materials such as concrete, stone, fired clay and ceramics. One of the disadvantages of these panels is the dead load which makes them a potential danger in the event of falling from heights.

Class A2:

Cladding materials belonging

to this class are also noncombustible but they are generally composite materials such as some types of high pressure laminates (HPL), aluminium composite panels (ACP) with mineral core and a few types of plasterboards. These are lighter in weight compared to A1 category but come with a price and the options available in India are limited.

Class B:

Combustible materials which make very limited contribution to fire are grouped under Class B category. There is a plethora of options available in this category in Indian market. Most of the aluminium composite panels (ACP) and high pressure laminates (HPL) available in India fall under this category. These panels when used with non-

combustible insulation offer superior fire performance to buildings.

Class C and Class D:

Class C and Class D make limited to medium contribution to fire respectively and are combustible. In general,

these 2 categories are also not preferred in façade design due to their risky nature. Composite panels made of organic materials without fire retardants generally fall under this category.

Class E and Class F: These 2 classes of materials

Example of fire test acc. to ITB procedure.https://www.degruyter.com/ view/journals/eng/8/1/article-p147.xml

easily catch fire and are not considered in façade design.

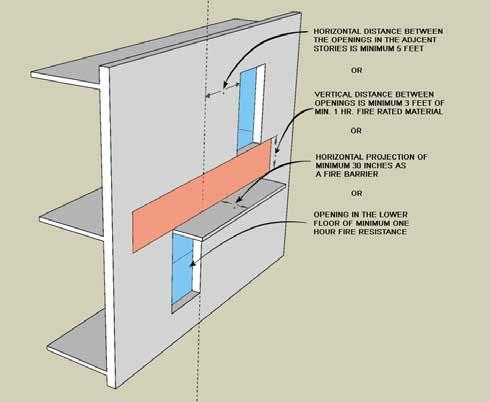

Method of installation adopted is as important as selecting the right material as per the above specifications. There are various cladding methods adopted in India ranging from wet cladding to dry cladding. Generally dry cladding methodologies involve fixing the cladding panels to a structural frame fixed to the building. This results in a cavity between the building and the cladding material. Fire breaks need to be provided to prevent the chimney effect in order to deter the fire from spreading from one floor to another vertically and from one room to another horizontally. In addition, the provision of a minimum 10% of total openable vision glazing is required to mitigate the effect of smoke built-up in the event of fire.

After the Grenfell accident, there has been a lot of discussion about fire safety of cladding materials. Incidentally, the cladding material that was used in the Grenfell tower during the infamous fire accident of 2017 was ACM panel with an unmodified polyethylene (PE) core. The Ministry of Housing, Communities & Local Government (MHCLG), UK, commissioned testing the behavior of non-ACM (Aluminium Composite Material) cladding materials. The Expert Panel that undertook this study made a few recommendations1 and the points related to cladding materials are summarised below: • ACM panels with unmodified PE filler pose significant fire hazard on residential buildings at any height and should be removed.

• ACM panels with fireretardant PE filler when used with rigid polymeric foam insulation presents significant fire hazard for residential buildings over 18 m or buildings at any height where residents need significant assistance to evacuate and these systems should be remediated.

• HPL systems with panels of Class C s3 d2 or Class D s3 d2 does not meet the functional requirements of the UK building regulations and are to be remediated.

• HPL systems with panels of any class with combustible insulation on residential buildings over 18 m or buildings at any height where residents need significant assistance

References

to evacuate should be remediated.

A system is only as strong as its weakest element. This applies to fire safety of buildings as well. Fire safety in design starts with the selection of right materials. But testing the system and adopting right installation methods are also important in achieving fire safety at a holistic level. It is understood that the aforementioned materials and installation practices come with a cost. Only when there is a conscious effort from building designers, builders, operators and end users, can fire safety become an integral part of design and fire tragedies like the Grenfell incident can be prevented in the future.

PRAMEENA KARUNAIRAJ

Principal Engineer – Sustainability, WSP

[1] https://assets.publishing.service.gov.uk/government/uploads/ system/uploads/attachment_data/file/869532/Building_safety_ advice_for_building_owners_including_fire_doors_January_2020. pdf

Prameena Karunairaj is a sustainability and façade professional, with over 10 years’ experience in the façade industry ranging from glass to cladding materials. She has been associated with big names in the industry such as Saint-Gobain, Infosys and FunderMax. She has worked on hundreds of projects, both Indian and international and provided consultancy in areas of sustainable material selection, green ratings, passive architectural techniques and so on. Currently, she is with WSP, a world leader in engineering consultancy services. She can be reached at prameena88@ gmail.com.

The façade is a derivative of the French word, ’façade’ which means "frontage" or "face”. In architecture, the façade of a building is one of the most critical aspects from an aesthetic standpoint as it becomes the identity of the building, just like the face of a human being.

Their façades recognise the most iconic buildings of the world.

Fully glazed façades have become the industry standard when it comes to commercial office space design. They enable natural lighting for larger floor plates compared with RCC and

brick façades and impart an iconic perspective to the building. Developers can extract higher rentals for fully glazed buildings as compared to buildings with conventional façades.

While consultants and designers focus remains towards aesthetics, sustainability, newage materials and cost, the aspects of fire safety often get ignored.

This article attempts to identify the fire risks associated with glass façades, their application concerning codes, and commercially available options to minimise the fire risks.

The spread of fire pertaining to glass façades:

1. Poke through effect: Spread of fire from external fire to internal areas of a building.

2. Chimney effect: Spread of fire and smoke through the gap between glazing and the slab.

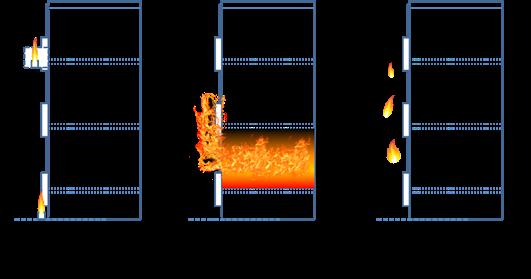

3. LeapFrog effect: Spread of fire from internal areas to upper floors through external façade.

Apart from the above, debris falling on a passer-by’s is also identified as a major risk during fire incidents. Before delving into the solutions for providing firerated façades, it is essential to be aware of the code requirements for the provision of fire-rated glass façades.

Previous versions of NBC were more suited for RCC buildings with brick and mortar façade with minimum openings. Masonry and RCC walls are by default 2-hour fire-rated. Hence, they comply automatically with fenestration fire rating criteria. This is not the case with glazing and other cladding materials, which are not fire-rated by default.

In India, awareness of the dangers of fire in buildings is prevalent. There are strict fire prevention and firefighting norms followed by every local fire force department regarding the design and implementation of suppression and detection system. With the widespread adaption of fully glazed façades, particularly in high-rise commercial buildings, there was a gap observed in codes in terms of fire rating of the façade. Fire rating for glazed façades had remained fairly non-critical from the regulations perspective even though there are codes and tests as per NFPA and BS standards.

NBC 2016 has tried to bridge the gap by providing guidelines on the following aspects: 1) Design and construction of glazing for buildings

2) Building elements where fire-rated glass needs to be provided

3) Details about fire-rated glazing assemblies, components, and requirements for testing

The code has listed out several norms for fire safety of façades in high-rise buildings. Table 1 shows the tabulation of the relevant clauses and articles which dictate fire safety of glasses and building fenestration: also non-flammable.

Based on the study of the clauses above and the codes, the following key points are brought out:

1. For buildings with a distance greater than 9m from adjacent buildings, normal tempered glass or above, is acceptable as a fenestration material, provided the same is installed in a non-flammable assembly. Care should be taken that the PVB coatings, sealants, etc. are

2. Mandatory use of fire-resistant glass is restricted to usage in areas or elevations which require a specific fire rating. These would include, but not be limited to:

a. Building elevations with a distance less than 9m from an adjacent building

b. Refuge balcony

c. Fire escape corridor

d. Staircase area if one or more elevations are with glazing

1 4

3.4.10.2 a

2 4 3.4.10.2 b

For fully sprinklered buildings having fire separation of 9 m or more, tempered glass in a non-combustible assembly, with the ability to hold the glass in place, shall be provided. It shall be ensured that sprinklers are located within 600 mm of the glass façade providing full coverage to the glass. If the fire separation (distance from the adjacent building) is less than 9 m, then table 1 for the fire rating of the external wall is applicable.

All gaps between floor-slabs and façade assembly shall be sealed at all levels by approved fire-resistant sealant material of equal fire rating as that of the floor slab to prevent fire and smoke propagation from one floor to another.

3 4 3.4.10.2 c

4 6 – Sec 8 6.4.2.1

Openable panels shall be provided on each floor and shall be spaced not more than 10 m apart measured along the external wall from centre-to-centre of the access openings. Such openings shall be operable at a height between 1.2 m and 1.5 m from the floor, and shall be in the form of openable panels (fire access panels) of size not less than 1 000mm × 1 000mm opening outwards. Such panels shall be suitably distributed on each floor based on occupant concentration. These shall not be limited to cubicle areas and shall be also located in common areas/corridors to facilitate access by the building occupants and fire personnel for smoke exhaust in times of distress.

Glazing system shall be so constructed, treated, or combined with other materials to reduce the loss of life or property during an event of a fire, in comparison with an ordinary sheet or flat glass thereby preventing the passage of flame, hot gases, and smoke.

Following glasses are permitted as fire resistant glasses in glazing systems:

1) Wired glass (Permitted for non-accessible windows and vision panels)

5 6 – Sec 8 6.4.2.2

2) Annealed fire-resistant glass (AFG)

3) Tempered fire-resistant glass (TFG)

4) Intumescent laminated fire-resistant glass (LFG)

5) Double glazed fire-resistant glass (DFG)

6 6- Sec 8 6.4.2.2.5

It should be noted that the use of any fire-rated glass has to be installed in a tested system. The fire-rated glass alone cannot provide the desired fire resistance since the fire resistance of a partition or a door assembly or any glazed building element is a function of the glass, frames, hardware, gaskets, and fixings which forms the glazed system

Operations: SALAMANDER WINDOW & DOOR SYSTEMS PRIVATE LIMITED Gat No. 147, Shed No. 03, Village: Chakan-Mahalunge, Tal: Khed, Dist: Pune - 410 501, India info.india@sip.de

3. NBC acts as a guideline; however, the local fire authority is the final authority on fire norms to be followed. It is recommended that the consultants design the building to meet the more stringent requirements. (Local or NBC)

4. Providing openable panels is mandatory as per the codes. The code remains silent on the provision of fixed breakable panels instead of openable access panels.

5. Performance glasses with laminates are generally not fire-rated-rated. The PVB coating provided is not resistant to fire. Hence the use of the same should be restricted to the outer lite of glass. In fire-rated glass façades, the entire system should be performance tested and certified to be labelled as a fire-rated system. In the case of fire-rated DGU, where the outer lite is not fire-rated (performance glass for Green Building requirements), the entire system with all its constituents should be tested and certified as fire-rated.

6. The code further specifies each type of glass's maximum width and size along with support conditions in elaborate tables.

Below are the mitigation measures adopted to address the 3 types of fire spread on glazed façades:

1. Poke through effect: This is applicable for buildings with fire separation of less than 9 m. The only way to mitigate the fire spread through external fires is by using firerated glazing on the external façade. Some local authorities also insist on a row of sprinklers on the external parapet of the building to deluge the building façade with water and prevent

the propagation of the external fire into the building. This also helps prevent inflammation of Façade components like glazing, sealants, coatings, etc. Also, internal compartmentation by tenants as per NBC recommendations is important to contain the fire spread within one compartment.

2. Chimney effect:

The codes have specified the use of fire-rated sealant at the gap between the curtain wall and slab to mitigate the chimney effect.

Vertical or horizontal, all façades will have gaps at interface junctions and this is where the smoke and fire stop needs to be used. It acts as the barrier for fire or smoke to

As laid out in NBC part 4, the gap between the glazing and the slab should be sealed with a material having equal fire rating as the slab (Source – Side rise Smoke Seal Catalogue)

travel from one compartment to the other adjacent or vertical compartment.

As laid out in NBC part 4, the gap between the glazing and the slab should be sealed with a material having equal fire rating as the slab. Typical assembly is explained below: It is important to ensure the integrity of the system wherein the tenants extend their flooring to the façade mullion. To achieve this, additional stiffeners may have to be provided. Alternatively, RCC upstands may be provided above the system to ensure that the tenants do not extend their flooring till the glazing line.

Following points are proposed in the codes to mitigate the leapfrog spread of fire (Floor to floor fire spread from external face)

a) Use of row of sprinklers 600 mm from glazing – This prevents spread of fire in the area adjacent to the glazing

and therefore prevents the spread to upper floors.

b) Provision of openable fire –This allows smoke to escape away from the building and prevents build-up heat adjacent to the glazing.

New norms specified in the latest edition of NBC are a start and should be followed in all projects irrespective of commercial or residential. The provisions should find a mention in the Fire NOCs which are issued by local authorities. At present, there is a lot of ambiguity concerning the provision of codes and requirements of local authorities, where certain clauses of the code are ignored.

Different countries have different regulations and tests for façades and there are a large number of different tests used for verification and classification of façade systems, ranging from small-scale tests to full-scale tests and fire spread simulation using advanced models.

The following aspects should be considered by consultants while designing the Façade and material selection for Fire safety.

• Fire rating of the façade material and other cladding elements

• Provision of openable panels

• Façade treatment for refuge terraces

• Secondary protection measures for glazing like sprinklers, etc

• Fire sealing of the gap between glazing and structural slab edge