The perfect window. It is what you get when the world’s largest uPVC profile manufacturer joins forces with India’s largest. For the past 90 years, we’ve obsessed over our engineering and paid attention to the slightest detail. So, every window we make is perfect, and lasts for generations.

Easy and quick fixing

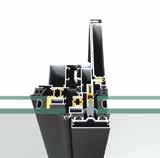

Setting the tone for design and modernity in the world of aluminium windows. Supra7 combines modern design with the most refined finishes, for a uniform and trendy aesthetic for every room of the building. It is available in a great variety of mechanisms with the Asia, Kora, Prima and Aria aesthetic lines.

Universal application: compatible with 7 mm square pin.

Minimal and modern design

No base equals simple and elegant design.

Versatile

Available for side-hung, tilt-and-turn windows, as well as terrace doors and apex version for outward openings.

Vast range of finishes

Infinite finishes for infinite creativity. AntigermTM treatment also available.

Volume 7 | Issue 5

September - October 2021

PUBLISHED BY

F & F Media and Publications

C-55, Okhla Industrial Area, Phase - 1, New Delhi-110 020

T: +91-11-40623356

FOUNDERS

Amit Malhotra TECHNICAL PANEL

Mahesh Arumugam Director

Meinhardt Façade Consultants

KR Suresh

Regional Director Axis Façade Consulting

EDITORIAL

Renu Rajaram renu@wfmmedia.com +91 9312864830

Shefali Bisht

editorial@wfmmedia.com

DESIGN & CONCEPT BY Prashant Kumar

MARKETING & OPERATIONS

Kapil Girotra kapil@wfmmedia.com +91 9560925255

SUBSCRIPTION & CIRCULATION

Devagya Behl support@wfmmedia.com +91 9871151112

Mukesh Kumar mukesh@wfmmedia.com +91 9560088995

RNI: DELENG/2014/57870

12 Dynamic Glass – Offering Solutions for Daylighting Design Challenges

Eloïse Sok-Paupardin, Occupant Experience and Sustainability Lead, Saint-Gobain SageGlass

16 Latest Technologies & Trends in Façade Design & Installation

Atharva Moroney, Founder, Alucomét

21 Evolution of Modern Façades Towards Sustainability

Akhil Chacko, Manager - Fire and Façade Testing, Winwall

Technology India Private Limited

26 Sustainability with Context of Indian Homes

Priyanka Arjun, Founder & Principal Architect, Priyanka Arjun and Associates (PAA), Udaipur

32 Role of Firestops in Ensuring Fire Safety of Modern Façade Buildings

Aravind Chakravarthy V, Head - Codes & Approvals, Business Unit –Fire Protection, Hilti (India) Pvt Ltd

38 Evaluating the Field Performance of Windows and Curtain Walls of Large Buildings

Monalisa Das, Project engineer, Built Environment, UL

47 Expert Speaks

Interview with Mahesh Ramanujam, President and CEO, U.S. Green Building Council (USGBC)

56 Cover Story

Architectural Hardware for Façades & Fenestrations - Trends, Testing, Standards & Selection Criteria

76 Face to Face

Interview with Ar. Sanjay Gulati, Principal & Managing Director, Gensler - Bangalore & Mumbai

86 Industry Speaks

Interview with Ajay Tenany, Managing Director, SIEGENIA India

Cover Image, Courtesy: Gensler, Bengaluru; Project: Shanghai Tower - Shanghai, China; Photo Credit - Connie Zhou

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www. wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications Printed and published at Thomson Press India Ltd., B-315, Okhla Industrial Area Phase 1, New Delhi. Name of the Editor-Ms. Renu Rajaram”

Dear Patrons,

I am super delighted to write to all of you this time…

Welcome to our new world 2.0 where in pretty much loads of elements of our daily lives have changed and are ever-evolving from 100% Work @ Office to 100% Work From Home (WFH) to now back to this Hybrid Work from Home and Office Environment. Importance of Life and Value of Life seems to be the element all must have evolved with…

We have managed to remain afloat thanks to all our advertisers, contributing authors and professionals who believed in our growth story over the past 8+ plus years and have welcomed this print edition after a gap of 18 months, and their commitment means a lot for us! We shall continue to present the latest developments in the facade and fenestration, and construction sector, and with loads of new initiatives to come @ wfmmedia.com

As much as our partners and customers, I give 500 % plus marks to our wonderful, honest, sincere and committed team here @ WFM, right from Renu Rajaram (Global Editor in Chief), Kapil Girotra (Head - Global Sales), Shefali Bisht (Middle East Relations and Editor), Prashant Kumar (Head Design), Tarun Bajaj (Lead Web and SEO), Prem Kumar (Creative Head), Devagya Behl and Vincy Sangi (Customer Support Stalwarts), Amreen Fatima (Head - Culture and People @ Team McCoy) and other support members from the team mccoymart.com for their support. For me, being an entrepreneur, building successful and committed teams is all I have achieved in life and will continue to do so…

Within December 2021, we will be launching the World’s First-Ever EdTech Platform of Learning and Up Skilling for the Facade & Fenestration Industry called edu.wfmmedia.com. Log in to find out more.

With this message, we are all in deep gratitude of our industry, our contributors without whom this content would be meaningless and God Almighty for building our courage on every step to keep going on and continuing despite all challenges

Thank You all Once Again

Yours Truly

Amit Malhotra Founder - WFM and Leader - McCoy Group

Natural light is crucial to the health and well-being of building occupants. However, it can also be a source of glare and visual discomfort.

Daylight glare in our buildings can be caused by different sources:

• Direct view of the sun or the sky when it’s very bright through windows

• Sunlight reflected from windows onto neighbouring buildings, the ground (e.g. snow) or water

• Reflections of daylight on screens (e.g. computers, projector screens, notice boards) or other work surfaces. They cause a decrease in contrast between the visual task and the immediate surroundings, a phenomenon also known as “veiling glare”.

• Reflections of daylight on any shiny or reflective surface in the space directly facing the observer’s eye

• Major contrast between direct or indirect light sources (e.g. illuminated surfaces) and adjacent surfaces

Although the risks of glare are well known in theory, those

are often either overlooked in project planning or handled in an unsuitable way. Project teams may fail to consider the negative effects on the health and well-being of building occupants.

When we are exposed to glare, the effects are of two types. We can experience instant effects: it alters our visual acuity and we are no longer able to see the details of the visual task we are performing. We then need a little time to recuperate our full visual capacity — ranging from a few seconds to a few minutes, depending on the person — and carry on with the activity that was interrupted. We could also still be able to continue with our tasks, but in disruptive or uncomfortable conditions, which requires additional effort on our visual system. Such intense and prolonged strain on our visual system causes visual fatigue.

In work environments, if not well managed, glare can lead to a decrease of 15 % to 21 % in productivity. Besides, one can also expect decreased satisfaction and motivation as an increase in absenteeism, which comes at an extra cost for the company. In schools, poorly managed light influx can create reflections on tables, projector screens or desks, making it difficult for students to read, write and learn. In terms of medium- to long-term effects, visual fatigue and the migraines caused by glare can directly affect

students’ ability to learn and teachers’ performance, as well as their mental state. In residential care homes and services for elderly people in healthcare facilities, it is also crucial to limit the risk of glare as much as possible for safety and wellbeing, as human visual functions deteriorate with age, for example people have an increased sensitivity to light and a weaker resistance to glare etc.

As we have just seen, poor glare management can have negative repercussions on employees’ performance at work, students’ learning in school, the safety and well-being of the most vulnerable in care facilities — and on people’s health more broadly. The risk of glare must hence be treated with the same seriousness as the risk of overheating, poor air and sound quality.

That being said, holistic solutions should be found to ensure that access to natural light and views to the outdoors are not compromised. While the role of daylight on circadian well-being and health is well recognised, numerous studies have also demonstrated the psychological and physiological benefits of external views. Views to nature have been shown

to particularly support stress reduction as well as cognitive performances. Furthermore, the Covid-19 pandemic has strengthened the importance of windows and windows’ views, as those are our primary way to connect with the outside world in buildings. A well-thought-out concept combined with smart solar protection solutions like dynamic glazing now allow us to efficiently manage glare while keeping continuous daylight and views.

Dynamic glazing enables to

control the amount of daylight and solar heat entering a space, over a large range varying between 60 % and 1 % in visible light transmission and 0.40 to 0.03 in g-value. The modulation of light and heat can be controlled automatically or manually to dynamically adapt to the external climatic conditions and occupants needs.

Not only can dynamic glass help to reduce the energy loads significantly, but it also enables to optimise the indoor daylight levels while preventing the risks of glare without the use of blinds

or shades. Since the glass remains transparent in any of the tint states, the view and the connection to the outdoors is always preserved, providing occupants an enhanced experience.

Furthermore, dynamic glass is suitable for a variety of buildings, from offices and schools to healthcare environments, restaurants and airports. Dynamic glass also allows designers to design with glass to achieve more daylight, maintain exterior views, and meet their aesthetic goals without energy or comfort penalty.

In the case of façades using single large panes to span most or all of the floor to ceiling height, dynamic glass with in-pane zoning characteristic is essential in order to effectively co-optimise glare control, daylight quality and energy performance. Indeed, in many cases tinting the whole façade is unnecessary to block the source of heat and glare. With the ability to have several tint zones within a single pane of glass, glare can be managed through fully tinting one area of the glass, while allowing sufficient qualitative daylight to enter the building by leaving the remaining areas in intermediate and clear states. Recently, dynamic glazing

offering a gradual in-pane tint transition from fully clear to fully tinted is available on the market, for an improved targeted solar and glare control. This new and unique dynamic glass solution provides precise glare and daylight control and a smooth visual aesthetic through a natural, seamless inpane tint transition.

In summary, dynamic glass offers a unique answer to solve the daylighting design challenge, i.e. achieving high energy performance, daylight harvesting and views, without compromising occupant thermal and visual comfort. Therefore, it changes the way buildings are designed and greatly supports the transition to more sustainable and healthier buildings.

Occupant Experience and Sustainability Lead, Saint-Gobain SageGlass

Eloïse Sok-Paupardin is the Occupant Experience and Sustainability Lead at SaintGobain SageGlass. She holds a Double-Degree in the Engineering field from Ecole Centrale (France) and Tsinghua University (China). She provides scientific guidance and acts as a trusted advisor, and coordinates strategic research projects with internal multidisciplinary teams and external academic institutes. Her career growth has always been driven by her passion for science, her desire for continuous learning, and her fascination for sustainable architecture. Today, Eloise aspires to enhance public awareness on the impact of the indoor built environment on well-being and health, and share knowledge on best practices and innovative sustainable building solutions.

India is growing vertically upwards, specifically in metro cities. Now, we all as colleagues into construction industry are concerned about the MEP services, and the main structure (whether it be steel, concrete or composite) - but believe me, only an iota of people is thinking of the façade during the planning stage and this is really ALARMING to me.

But the fact is that a façade is the first barrier that has to perform for all the weather cycles, leakages (air & water), withstand dead load, wind load (positive & negative), wind pressures during its entire life cycle, also stand up to the acoustical and thermal performance, and all the above incorporated within the architectural intent and aesthetics.

Fabricators have always kept themselves updated regarding current trends, and futuristic products needed for the betterment of projects. Nevertheless, new products bring in new ideologies and new installation techniques required for executing the same into reality, they are geared up for it.

I have been into the industry for almost 8 years, and have always been a keen observer and a fan of my own dad, and I strongly believe that he played an instrumental role in letting people in the central

part of India know façades as a concept.

The industry has been ever evolving and is graduating towards a performance based design demand wherein now a day we see tenders and specifications asking for a U-value based system, which is actually very good.

This process of evolution in itself is a compliment to the evolving industry when it comes to the respect with the latest designs. As in previous times, we just used to speak of the U-value of the glass and nothing else. And now, we are

discussing the performance of the complete assembly as a whole, consisting of the aluminium system, glass, gasket, sealant and other accessories.

This brings us to talk and discuss about thermally broken system, providing us with the following benefits:

• Pressure equalised,

• Thermally broken,

• Multiple lines for total weatherproof,

• Upto 30% energy savings,

• Maintaining indoor air quality,

• Energy reduction,

• CO2 emission reduction,

• Environmentally friendly,

• Energy efficient and durable,

• Increased durability and lighter weight,

• Less volatile, lower emission materials.

Apart from the regular façades, we also look forward to the new concept of Thermal Break Profiles getting popular in India.

Many of the fabricators offer a complete gamut of services when it comes to façade engineering & installation technology. They are also capable to take up challenges and accomplish complex design in a well stipulated timeline.

OF THE NEW MATERIALS THAT WE HAVE COME ACROSS ARE AS FOLLOWS:

• UHPC - Ultra-High Performance Concrete (Under R&D),

• High Pressure LaminatesExternal Grade,

• Metal Composites,

• Ceramics/Porcelain Tiles,

• Sandwich Panels,

• Glass Fiber Reinforced Panels.

• Materials that have evolved and are known to us as team:

• 3rd-generation metal coatings,

• Optimised glass coatings,

• LOW/No VOC paints and coatings,

• Self-cleaning surfaces,

• Non-bleeding silicones,

• 2nd generation glass interlayer.

Double Skin Systems: The double-skin façade is a system of a building consisting of two skins placed in such a way that air flows in the intermediate cavity. The ventilation of the cavity can be natural, fan-supported, or mechanical. Apart from the type of ventilation inside the cavity, the

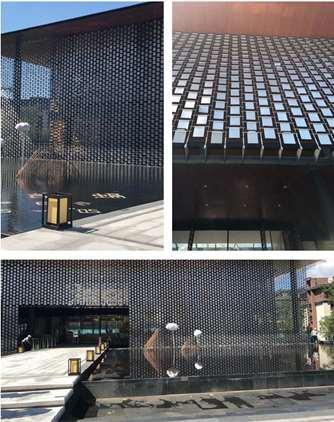

origin and destination of the air can differ depending mostly on climatic conditions, the use, the location, the occupational hours of the building, and the HVAC strategy. The glass skins can be single or double glazing units with a distance from 20 cm up to 2 meters. Often, for protection and heat extraction reasons during the cooling period, solar shading devices are placed inside the cavity. For the cladding needs, the future can be seen coming in the form of 1. Metal mesh, 2. Aluminium mesh and 3. Aluminium perforated cladding.

1. Metal Mesh and its Advantages:

Expanded metal is a form of metal stock made by shearing a metal plate in a press, so that the metal stretches, leaving diamondshaped voids surrounded by interlinked bars of the metal. The most common method of manufacture is to simultaneously slit and stretch the material with one motion. Expanded metal is often used for architectural details and finds use in security applications such as in the walls of a sensitive compartmented information facility because of

its heavier grades, it is difficult to breach without heavy cutting equipment or explosives. The material used is recyclable and the colour is not just a simple coating but it is designed to offer special aesthetic effects making any project more valuable. Besides having the ability of all the colours of the RAL shade, customised and unique colours are being offered with innovative effects and the powder coating applied is highly resistant and nontoxic.

2. Aluminium Mesh and its Advantages:

a. Light and cost efficient: It is a great advantage that expanded metal is not assembled nor welded, but always made in one piece. Hence no metal is lost in the expansion process and thus, the expanded metal is a cost effective alternative to other products. As there are no strained joints or welds, expanded metal is stronger and is ideal for forming, pressing and cutting. Due to the expansion, the weight per meter is less than that of the original sheet. Also, due to the expansion a much bigger open area is possible to be covered as compared to other similar products.

b. Greater strength: The threedimensional shape of the meshes is another advantage since the areas where the meshes meet are strong and enable the material to stand a far heavier point load than similar products or a flat sheet. Applications of expanded metal and aluminium mesh can be seen in the following places: Walkways, footbridges, footsteps, safety fences, reinforcing of

Confidence Tower (residential area) double skin façade comprising of wooden finish screen system, brass cladding on the 2nd skin and Laminam exterior wall tile cladding and Technal make double height sliding window systems on the interior skin

concrete as well as for shielding in buildings as architectural construction, etc.

3. Aluminium Perforated Cladding:

As far as perforations are concerned it can be depending upon the aesthetic look as desired by the architect and functionality of the same as conceived by the façade consultant regarding its opening size, percentage visibility and various other factors associated with it.

This too is currently being used extensively in various projects as part of double-skin façades and in fact, we are ourselves using perforation cladding as an alternative to the other two mesh claddings briefly summarised

above in one of our on-going projects in Nagpur called the Confidence Tower. We have tried to cover the design part in a short description in the project highlights along with this article.

Also, as far as the installation part is to be discussed, apart from inspecting our installed façade we also request the auditors to inspect the civil work for plum and line-level.

We as fabricators minutely consider the manufacturing tolerance, construction tolerance, fabrication tolerance and then finally installation tolerance for a smoother execution of all our projects.

All this with just a common thought to build an iconic, leakproof, sustaining marvel.

ATHARVA MORONEY Founder, ALUCOMÉT

ABOUT THE AUTHOR:

Atharva Moroney believes in the principle of ‘Form-meetsfunction’. To him, façades are more than just the exterior walls of a building. Having pursued his BSc - IT, he decided to take up his passion and made a mark in the system, contrary to his field of study. The advantages of starting young have clearly outnumbered the roadblocks. - partnering with clients on small projects in Tier 2 cities to becoming the maiden independent contractor for façade work of the reach-1 stations of Maha Metro Rail Corp. His team of passionate experts have grown from strength to strength, ensuring a balance between robustness, function, aesthetics & cost. His constant endeavour is to keep pushing boundaries and be the partner of choice for his clients and bring the benefits of purposeful design to Central India.

After the great Chicago fire in 1871, there was a rapid improvement in build construction and selection of building materials for construction. From 1883, when William LeBaron Jenney was able to design a 10-story building for home insurance building, his achievement paved the way for Chicago School. From there,

together architects and engineers developed modern skyscrapers for that era. Understanding and mastering in glass mass productions and engineering of smarter design, fabrication and erections of glazed curtain walls have led us to many façades wonders today we see all around the globe.

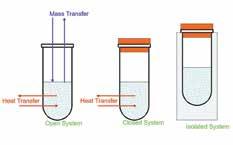

Ideally, to make any system most efficient in the context of heat transfer the system has to control the modes of heat transfer by

1. Making the system opaque to reduce the heat transfer by radiation.

2. Reducing the mass transfer through the system to reduce heat transfer by convection.

3. Insulating the system to reduce the heat transfer by convection and conduction. When following all the above criteria, the system thermodynamically becomes an isolated system, “like a thermal flask”, and which is impossible in the case of façades or building envelopes. Keeping the above ideal points in mind the most modern building envelopes are designed. Without compromising on the major purpose of a building envelope that is to keep a building

in a human comfort zone and aesthetics, technology excels today in modern building technology. This was made economically and efficiently possible after the revolution of the modern façade industry.

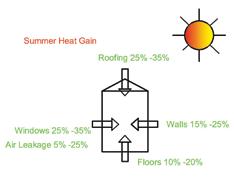

Most modern façade systems consist of glass and as this is not an opaque body, so sunlight enters the building. The radiation from the sun in the form of light passes into the glazing façade building and heats up everything the walls, plants, floors etc. Now the unused energy is in the form of infrared radiation, which cannot travel through the glass and gets trapped in the building, and eventually, the temperature rises high. The absorbed heat also convects into the building from the inside face of the system.

When the glazing system which can just allow enough light to

light up the building and unused light is reflected back or blocked then the façade becomes more sustainable. Today smart glasses which are able to adjust opacity are invented which may revolutionise tomorrow’s façade glazing units as even very cold countries fear high temperatures during summers.

High-performance glazing can contribute to optimising energy efficiency and enhance light penetration, this has low U- value, low shading coefficient and has high visual light transmittance.

When there is an increase in temperature above the human comfort zone in the building, engineers come up with many solutions, that is to reduce the U-value and the solar heat gain coefficient (SHGC) of the envelope and to introduce an air-cooling system into the building. In the case of a glass building, the tinting and metallic coating are processed on glazing, to get better performance. Here the light is allowed to travel from inside of the building to outside, and light is partially or completely restricted from sun or light source travelling outside of the façade to inside. This technology has revolutionised façade engineering, and today most of the glazing façades are optimally tinned / coated. Another analysis for choosing the right glass depends on building orientation analysis, sun path analysis, site shadow analysis, solar exposure analysis and daylight analysis.

The buildings are usually

made totally opaque using ACP, tile or any composite material constructions. This has very good insulation properties, and very low heat transfer properties. Using an electric light system is more efficient as this don’t heat up the building thus providing very high efficiency to HVAC systems.

The above structure located in Saadiyat Island, Abu Dhabi, UAE is an example of an opaque façade system. The outer skin of the skylight façade is constructed of individual tiles, which can reflect sunlight, this also has insulation layers, where the heat transfer has been restricted to a minimum. The skylight glazing façade used here is also made opaque. This construction has transparent façades around the building vertically installed, where there is no direct incident rays of sun falls. The advantage is very high as there is enough light in the building, for extra light, electric lights are used.

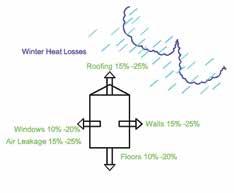

When there is an air cooling & heating system in the building, the building envelope should be thermodynamically a closed system, where there is no mass transfer taking place. When there is a large temperature difference between inside and outside of the building, especially in heat dominant regions and

cold dominant regions, that can create a pressure difference, and cause the building like a “leaking balloon”. For an efficient façade system that has air cooling & heating systems, it is necessary to have very low air leakage.

When we have fenestrations in the façade system then prevention of complete air leakage is impossible, but we could get it to an optimum level.

We use air infiltration/ exfiltration tests to determine the air leakage through any given façade system. It is very important to have it done practically, with an international standard because even if it's calculated theoretically, the actual values may change due to many variables which we may not consider during theoretical calculations. A system with large air leakage will literally vaporise money, energy and contribute heavily to global warming. At this point of time, when it's very late when we speak on global warming and rise in temperature,

with red alerts on, every apartment, buildings, offices, residential houses, small or large which uses cooling systems, the air leakage test should be conducted. In large buildings, air curtains, revolving doors are used to reduce air leakage.

When the façades are insulated, that could control a large amount of heat loss through convection and conduction. Most of the efficient façades with glazing uses double glazed units or more in which gas is filled between each glass which serve this purpose and also give an improved acoustic performance. For curtain walls used in heat and cold dominant regions, thermal breaks have a great role to insulate a building façade. In non-glazed façades, other insulations with very low heat transfer rates like foam insulation, rockwool, etc are used. The outer envelope can be composite materials of aluminium, glass fibre or cement boards. This can drastically

increase the thermal efficiency and acoustics of buildings. When those combinations are used, the risk of fire also shares a part of the problem.

When a building is called with a high sustainable index, we still

have room for improvement. When technology develops, construction industry could adopt more sustainable ideas into it.

When solar panel glazing façades are used in suitable locations to convert the impact radiation to electricity, and use electric lights to light up the building and to air-condition the building, then that is the most sustainable way in the context of building efficiency any building could get.

Once the synonym of brittleness was glass, we have engineered that to replace our building envelope. This is the high time we have to discover and invent more sustainable ideas in all aspects of engineering and also in our dayto-day life, and this should be incorporated into the educational system for our safe future. I see the silver lining when I know that engineering technology grows better and smarter every day, and that makes me optimistic towards a bright sustainable future.

Manager - Fire and Façade Testing, Winwall Technology India Private Limited

Akhil Chacko is presently working as the Manager – Fire and Façade Testing, Winwall Technology India Private Limited. He has over 8 years of experience as a third-party testing engineer and has been part of façade performance testing for more than 600 projects across the globe.

Akhil started his career as a façade testing engineer at AL Futtaim Exova, Dubai UAE.

He is currently working on introducing fire testings as per NFPA285, ASTM E 2307 and BS8414 for Winwall India, for Indian and global markets.

Asustainable home in India should allow the Indian way of living in the current scenario. It should provide comfortable living conditions of yesteryears haveli's, yet look contemporary. We used to have bungalows with lush green envelopes, where an old fan was sufficient to gauze summer heat. Try designing a space where air conditioning is not a year-round necessity.

The planning principles of inducing desirable microclimates can be combined with modern construction techniques to create smarter homes. Rather than blindly following what is happening in the world, we should see our environment and social needs as a parameter to design living units.

Few techniques that we are trying to revive include stone and lime construction. These buildings withstand time and climate beautifully. They are breathable, living surfaces that combine to make a responsive space.

Most sustainable techniques are taught to us in schools, like the size of windows in different directions, or the length of sunshades. All we have to do is to use the knowledge wisely. The checklists from IGBC are a great help in checking all parameters. Although currently there is no standard rating system, we have

used the pointers extensively.

To obtain an ecologically highperformance building, multiple variables should be taken into consideration - thermal insulation, daylighting, solar shading, glare acoustics, and indoor air quality.

Another element that we use in all homes is a courtyard or skylight.

Suggestions for sustainable planning-

They bring light to dark corners and aid in natural ventilation. Currently, we are working on using geothermal energy and solar energy to create homes that can function off-grid. Seems like these buildings are the future of smart homes, where the occupant can live carbon neutral.

• Every space should be naturally lit, but glare-free

• Cross-ventilation to allow breeze

• Water-coolers for larger areas, to reduce energy consumption. This allows for fresh air, as spaces do not have to be air-locked

• Composite-wall system for better insulation, finishing and longevity

• Go local

• Efficient space planning

• Use natural resources, solar energy, bio-digester tanks

• Live as our parents did, prudent and wise. They saved resources for us, it is our responsibility to leave this planet well for future generations

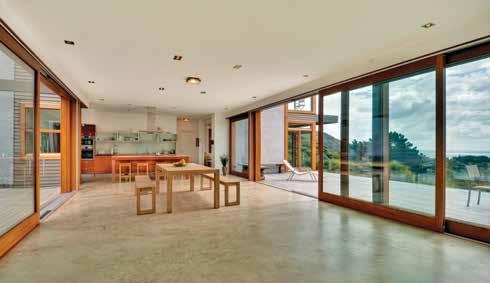

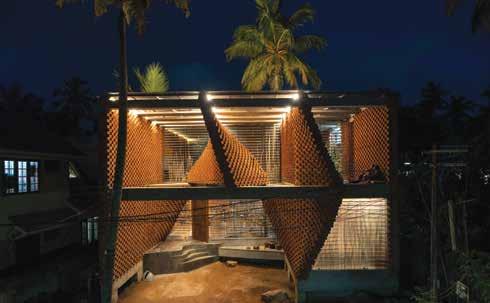

The bungalow is located at the foothills of Aravali mountains, overlooking Goverdhan Sagar Lake. The scenic surroundings demanded the country look. The clients approached us with a picture of their ‘dream home’ in their hands and the urgency to complete it.

Demands were clear; we went on to work it out.

This story began with a quest to create the perfect dream home at the foothills of Aravali Hills with a scenic Lake view.

Owing to the hot and dry climate of Rajasthan, choosing a central courtyard to plan things around was a good start. The aim was to get thermal comfort in either of the seasons without using mechanical means to achieve a sustainable space in terms of energy consumption. The house should stay cool during summers and warm during winters.

Spatially, internal spaces merge into one another on both floors. External terraces abutting each room create private space for the individuals. The house is seamless in planning and the decor is uniform Rajasthani style. The matrix of private and semi-private spaces is created in a way that volume and scale strike a balance, resulting in each space complimenting the other. The flavour of Rajasthan in motifs and colour is reflected in the details

In this project, the built system highlights using a composite wall system; showcasing the amalgamation of design and technology in the contemporary realm. We undertook this challenge and it worked.

The exterior aggrandize the beauty of the surroundings, whilst internal planning follows passive climate control and function. The central courtyard suits the hot and dry climate of Rajasthan and allows light, ventilation and communication with the upper floor. Exterior has composite stone wall proving as good insulator, solar power and bio-digester tank makes it a sustainable abode.

The approach of designing a double skin façade prevents thermal energy loss in buildings. An efficient approach included handling thermal energy waste/ loss efficiently, use of solar power, reduction in consumption of

power for heating and cooling, good façade sound insulation, and protection against pollution.

Conventional framed structure is modified to have a stone and brick composite wall. This facilitates thermal insulation from the exterior and integration of electrical services in interiors. Design is such that RCC beams and columns are enveloped in stone on the outside and brick on the inside. Special details are made for door and window openings. Several samples were made for various joints and corners to ascertain proper stone masonry. This works two ways, ensuring aesthetics and climate control. The exterior wall is 6 inches thick stone from Chittor, and every stone was manually cut by local craftsmen on site.

This stone is a great insulator and resistant to the effects of rain and weather. There is no

need for painting, coating, or any maintenance. Since the time, it has been long proven that incorporation of local materials within the built results in a green or sustainable building. Even the smallest pieces of stone were used in building the gabion wall for a boundary. Local materials help in easier handling for local craftsmen reducing the execution time while benefitting structurally and aesthetically.

The outside provides a fitting foreground to this splendid house. A variety of plants, cactuses and vegetables grow there. The vines and trees are yet to grow and add to the landscape. Upon entry, the front lawn, flanked by a gabion wall is a social space where bonfires are done and barbeque aroma floats. It is made with minimum metal and similar colour stones are fixed in.

Smaller openings are given towards western and southern façades, reducing heat gain and glare, whilst big picture windows are provided in

Project: Residence 58

Location: Udaipur, Rajasthan

Client: Mr. GS Jhala

Principal Architect: Ar. Priyanka Arjun

Design Team: Priyanka Arjun, Shaunak Singh, Rida Rafi, Shailesh Rawal

Civil Contractor: Mr. Narayan Singh

Structural Consultant: Mr. BP Joshi

Façade Engineering: Shingles - Kitmart, Fabrication - Mr. BP Joshi

Brand/Product Details: Tiles - Bikaner Tiles; Plywood - Green Ply; Marble - Nijarna White Marble, Indian Onyx Marble

Fenestration - Veka

Build Area: 7270 Sq ft

Site Area: 5400 Sq ft

Year of Commencement:

January 2016

Year of Completion: September 2018

Project Cost: 1 CR. Photography: Raghu Raj Singh

the north direction. The dining area has a big picture window touching the ceiling, no beam there too. Big picture windows on the north side accentuate the life to the next level, as more natural light washes the floors and ceilings. Everywhere one sees, there is something to gaze upon. Spatially, all spaces open to the central courtyard, which has natural light through the day and stars can be seen through at night. The house is seamless in planning and uniform culturally rich decor is done. The matrix of private and semi-private spaces is created in a way that volume and scale strike a balance, resulting in each space complimenting the other. The central courtyard is an integral part of all residences as it gives a central void space, the shunya, with light entering from the top. This also creates vertical airflow in hot and dry regions. Small openings are kept at the top for venting out hot air. This is a sustainable home with style and contribution to the environment. In the client’s own words, they are enjoying the home very much and it is exactly as they wanted it to be! There is no need for artificial light till sunset. During summers, they rarely use air-conditioners and winters are comfortable. It’s peaceful, serene with retreat vibes yet connected with the hustle around.

PRIYANKA ARJUN

Founder & Principal Architect, Priyanka Arjun and Associates (PAA), Udaipur

Priyanka Arjun is the founder of Priyanka Arjun and Associates (PAA), Udaipur. She has over 15 years of work experience in India and abroad. The Times of India has awarded her with the prestigious ‘Woman of Substance’ award for her work as a noted architect. PAA’s core strength lies in taking up bold ideas and deriving spaces around them. All the projects by PAA are unique and innovative. PAA strongly believes in working out the best solutions suited to individual projects. The work spectrum ranging from huge eco-resorts to small terrariums. PAA has always incorporated sustainable initiatives into its projects. This includes making vernacular stone-lime buildings, a tradition of Udaipur city. Currently, they are working on IGBC and GRIHA rated Green Buildings.

Afaçade is the exterior wall or face of a building and glazed exterior wall assemblies, commonly referred to as curtain

walls, have become a dominant feature in modern architecture.

Façade is one of the most important elements of a building since it acts as the primary barrier against external weather elements

such as sun, rain, wind, snow, etc. The exterior walls are generally assembled by securing individual glass or composite panels to an arrangement of aluminium mullions and transoms. A shift from the traditional look of buildings which were being built of blocks and bricks in the past, glazed façade creates a sense of modernism. Alongside the eloquent display of technology, this modernisation has also witnessed several fire incidents.

Typically, the paths for the fire to spread to adjacent floor levels at the building perimeter are as below:

a) Through Void: Spreading within the building through the void space created between the edge of the floor and an exterior curtain wall.

b) Through Cavity: Spreading through a void or cavity within the exterior curtain wall. In this situation, the fire would spread by a path within the concealed space of the exterior wall.

c)Leap-frogging: Spreading to the exterior and then impinging on an opening in an upper level. This path is generally referred to as “leapfrogging”.

Amongst the various paths mentioned above, the spreading of fire within the building through the void space created between the edge of the floor and an exterior curtain wall through

‘Chimney effect’ is quite a frequent phenomenon observed in many of the fire incidents and it can be mitigated through appropriate design, installation, maintenance and Inspection of perimeter fire barrier systems.

It’s important to recognise that the width of the horizontal gap between the slab edge and the curtain wall can vary drastically, especially considering construction tolerances in concrete buildings. Furthermore, when it is coupled with normal building deflection tolerances, creates a dilemma for builders, designers, consultants, and architects – how to provide a fire barrier that can move and flex while maintaining a seal against fire and smoke. This is when the building codes and the relevant standards play a vital role by providing guidance on the need and the importance of protecting the void between the fire-rated floor and an exterior wall in order to effectively mitigate the risk of fire and smoke propagation from one floor to other.

For buildings featuring glass façade assembly NBC 2016, clause 3.4.10.2 b) recommends that all gaps between floor-slabs and façade assembly shall be sealed at all levels by approved fire-resistant sealant material of equal fire rating as that of the floor slab to prevent fire and smoke propagation from one floor to another. Similarly, IBC 2015, Section 715.4 states that the void created between the slab edge and the curtain wall must be sealed with an approved system tested per ASTM E2307 that remains securely in place for the time period equal to the fire-resistance rating of the floor assembly. Furthermore, NFPA 101, 2018 clause 8.3.5.4.1 mentions that the Voids created between the fire-resistance rated floor assembly and the exterior curtain wall shall be protected with a perimeter joint system that is designed and tested in accordance with ASTM E2307, Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-Scale, Multistory Apparatus.

In general, any void between the fire-rated floor and an exterior wall must be protected using a perimeter fire containment system that has been tested in accordance with ASTM E 2307 standard that provides an ‘F-rating’ that is equal or greater than the fire-resistance rating of the floor. The ASTM E2307 test is titled the ‘Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-Scale, Multistory Test Apparatus’.

The basic configuration of the test furnace and test sample in ASTM E

2307 includes a two-story building with the test room in the first floor fully engaged in a post-flashover fire condition. The fire is provided using two burners, one internal burner placed inside the structure and one external burner placed outside the structure, providing a flame plume up along the side of the building. An exterior curtain wall is then installed on one side of the structure. The void between the curtain wall and the edge of the floor slab is then protected with materials that are intended to prevent the passage of flames through the void.

To be considered a dynamic perimeter joint protection, both expansion/ contraction and shear movements must be cyclic tested. The cyclic movement demonstrates the perimeter joint protection’s ability to move in expansion/contraction responding to environmental forces (wind, thermal, and seismic) and to move in shear in reacting to live loads while maintaining a seal between the floor assembly and exterior wall assembly and resisting fatigue and degradation. The cyclic rate, magnitude, and duration of movement can also affect the performance of the perimeter joint protection when subjected to standardised fire exposure and ASTM E2307 provides test conditions for these variables.

When field conditions differ from the original design or unanticipated construction hindrances are encountered, Engineering Judgments (EJ’s) are typically made that recommend alternative methods to ensure the performance of the firestop system is not compromised. Generally, these conditions or hindrances cannot be easily or

cost-effectively redesigned so alternative protection schemes must be implemented to maintain the system’s integrity. Since these recommendations are to be based upon identical designs as those which were fire tested, it is important that they be developed using sound engineering principles and has to be provided by the trained and qualified personnel based on the recommendations prescribed in IFC guidelines.

In order to choose the right system, it is important to know the basic details of the application such as the is the makeup of the exterior wall - spandrel glass, aluminium panel etc., hourly rating, joint width, static or dynamic joint etc.

The right system selection for the perimeter firestop system can be done by accessing third-party certification laboratory listing directories. One of the examples is the Intertek certification directory. The Intertek directory follows a specific nomenclature to identify the different firestop systems listed based on which right system can be chosen to suit the specific needs of the project.

A firestop system must be properly installed to be effective and hence it needs to be installed by a trained and qualified installer. Since the perimeter fire barrier system is a ‘Listed’ system, it must be installed in accordance with their listing and the manufacturer’s installation instructions. Typically, firestop manufacturers will have their own programs and qualification criteria for installers wherein they educate and train them on the trade-specific installation methodologies.

W.r.t Inspections, NBC 2016 requires fire safety audit to be conducted at least once in two years. Code users may want to be aware of the ASTM E 2393 standard, Standard Practice for On-Site Inspection of Installed Fire-resistive Joint Systems and Perimeter Fire Barriers. Typical points that are considered for inspection of perimeter fire barrier system include the following aspects:

• Is the rating of the perimeter fire barrier system equal or greater than the floor it is adjacent to?

• Is the EOS joint system tested and listed by an accredited lab?

• Is EJ made available in case of non-availability of the tested system exactly matching the actual site condition

• Does the field installation follow the listing w.r.t width of the gap between floor edge and curtain wall, curtain wall spandrel insulation (type, thickness, density, etc.), safing insulation (type, depth, % of compression) etc

For speciality Firestop contractors and special inspection agencies conducting speciality firestop inspections, the ULULC qualified contractor, FM 4991 approved and IAS AC 291 programs are credible 3rd-party accreditation programs.

Per IFC 2015, clause 703.1, Maintenance - The required fireresistance rating of fire-resistancerated construction, including, but not limited to, walls, firestops, shaft enclosures, partitions, smoke barriers, floors, fire-resistive coatings and sprayed fire-resistant materials applied to structural members and fire-resistant joint systems, shall be maintained.

For speciality firestop system, appropriate 'documentation' is an integral part of the installation

Such elements shall be visually inspected by the owner annually and properly repaired, restored, or replaced where damaged, altered, breached or penetrated. Records of inspections and repairs shall be maintained.

Use of tested and listed perimeter firestop system is required by the ‘Building and Life safety codes’ in order to contain fire and smoke in place of its origin and absence of such system in buildings may turn simple fire incident into a catastrophic inferno. It is important to have the right ‘Firestop System’ designed and installed by trained and qualified personnel. Furthermore, the national and international building codes also mandates proper documentation and periodic inspection of ‘Firestop systems. Adherence to code requirements ensure safety and peace of mind for the builders, contractors, architects, inspectors,

occupants. In addition, it helps the fire fighters to carry out firefighting and rescue operations thereby enable to save lives and protect assets.

ARAVIND CHAKRAVARTHY V Head - Codes & Approvals, Business Unit – Fire Protection, Hilti (India) Pvt Ltd

Aravind Chakravarthy V is a Polymer Engineer having 14.5 years of experience in the field of product safety certification, inspection, testing and training as per UL, ASTM, ISO & IEC standards for materials used in electro-technical equipment and the built environment. In his previous stint with UL India Pvt. Ltd, he was leading the techno-commercial activities in developing the testing and certification business for wire and cable, performance materials and had conducted ‘fire and life safety’ inspections for various types of buildings including hotels, hospitals, malls, commercial complexes and educational institutions in India and Middle East region. He is currently working as Head - Codes and Approvals for Fire Protection Division in Hilti (India) Pvt. Ltd.

The most common and costly problems associated with the inservice performance of vertical building envelopes of large buildings can be attributed to excessive air leakage and water intrusion. Windows and curtain walls in particular — as well as their interfaces with adjacent wall constructions — are critical elements in the performance of the vertical building envelope. Improved standards and design principles have contributed to significant overall improvements in the performance of window and curtain wall systems, including resistance to water penetration, air leakage, wind load or condensation. However, the reality is that many recently constructed buildings still experience problems with the inservice performance of installed windows and curtain walls. Typically, these problems result from poor fabrication or installation or lack of adequate quality control.

This article discusses evaluating the field performance of windows and curtain walls for large buildings during the early stages of construction to validate asbuilt designs and during later construction stages as a quality control measure. Through several practical examples, we’ll illustrate how large-scale field testing can be used to assess building envelope

performance in large buildings. Our objective is to help increase awareness among members of the building community regarding the benefits and limitations of field testing when evaluating the performance of the large vertical building envelope.

Windows and metal and glass curtain walls can constitute from 50% to 100% of the exterior cladding of large buildings in modern construction projects. An important architectural feature, these building elements represent a significant portion of the overall cost of a construction or renovation project and play an essential role in the vertical building envelope’s performance. Windows and curtain walls must be airtight and watertight, prevent condensation from occurring on interior surfaces and resist wind load and other exterior forces acting on the building envelope. Therefore, an evaluation is an essential part of minimising the risk of undesirable and costly problems during a building’s expected service life.

Any form of water infiltration or excessive air leakage to the interior of a building would be considered unacceptable to any building owner or occupant. Accordingly, having an appropriate level of resistance to water penetration

and air leakage are two of the primary performance criteria for any window and curtain wall system. However, these are not the only performance criteria that must be considered. Other factors include thermal performance, condensation resistance and wind load resistance.

The primary performance requirements that must be

considered during the design phase of each project include the following critical factors:

Wind load resistance: Specified design pressures, typically established by the project structural engineer, are based on the building’s exposure classification, height, type and configuration. Window and curtain wall components must be designed to resist deflection and failure at the design pressure.

Resistance to water penetration:

Performance requirements for resistance to water penetration vary depending on the building’s height, geographic location and exposure classification. In

the U.S., ratings for resistance to water penetration are typically established as a function of the design wind pressure. In Canada, requirements for resistance to water penetration are determined by the driven rain wind pressure metric, a unique measure of the climatic condition that has been established in more than 640 cities across Canada, based on their geographic location and the building’s installation height.

Air leakage resistance: Air leakage resistance performance requirements are often established by the National Building Code (NBC) applicable in India or any other local building and energy codes and will vary from fixed and operable sections.

Condensation resistance:

Condensation resistance performance requirements depend on the building’s geographic location and anticipated climate conditions as well as the interior hygrothermal design conditions and type of building occupancy. Ultimately, performance requirements will be established for each project on a case-by-case basis, depending on building height and geographic location, exterior and interior design parameters and the type of building occupancy.

The following is a list of the principal industry standards commonly used to establish the laboratory performance criteria for windows and curtain walls.

• AAMA/WDMA/CSA 101/I.S.2/ A440: NAFS – North American fenestration standard/ specification for windows, doors and skylights

• CSA A440S1: Canadian supplement to AAMA/WDMA/ CSA 101/I.S.2/A440, NAFS –North American fenestration standard/specification for windows, doors and skylights

• AAMA 501-05: Methods of tests for exterior walls

• NFRC 102: Procedure for measuring the steady-state thermal transmittance of fenestration systems

• AAMA 1503: Voluntary test method for thermal transmittance and condensation resistance of windows, doors and glazed wall sections

• CAN/CSA A440.2: Energy performance of windows and other fenestration products

The following is a list of the principal industry standards commonly used to establish the field performance criteria for installed windows and curtain walls in North America:

• AAMA 502-12: Voluntary specification for field testing of newly installed fenestration products

• AAMA 503-14: Voluntary specification for field testing of newly installed storefronts, curtain walls and sloped glazing systems

• CAN/CSA-A440.4-07 (Appendix E): Field testing of window and door installations

Field Performance Evaluation

Given the ever-growing complexity and variety of modern building envelopes, evaluating the performance of installed windows and curtain walls in the preconstruction and construction phases is essential to avoid undesirable and costly problems during the building’s service life. In most projects of any significance, the performance of the window and curtain wall systems intended to form part of the building envelope are evaluated in an accredited testing laboratory prior to construction. However, it is equally important that the installed products’ field performance is evaluated during

different phases of construction as a quality control measure. Site conditions, variations in the manufacturing process, or the quality and experience of the field installation team are all factors that can impact the performance of the installed products or systems.

When considering field testing, identify test areas that represent the most common elements of the building envelope. Due to budgetary and scheduling constraints, field testing is typically limited to three to six test areas. Therefore, obtaining the most representative sampling depends on the careful selection of the areas to be tested.

Test areas should be selected based on the complexity of any given detail or condition as well as the frequency at which a given detail or condition is repeated throughout the project. Further, in order for field testing to provide results that are representative of the entire installation, it must always include the interface between the window and/or curtain wall and the adjacent wall assembly. This interface is often the most critical element of any installation and may not have been validated by any form of laboratory testing conducted before construction has begun.

The specified test area for metal and glass curtain walls must incorporate all essential components to thoroughly represent anticipated conditions. This means that a given test area should include at least three glass bays in width to incorporate a central bay as well as all of the junction details. In the case of a unitised curtain wall system, a vertical module joint should also be included in the test area. The test area height should include at

MONALISA DAS

Project Engineer, Built Environment, UL

least one expansion or stack joint, at least one spandrel section and one vision section. Typically, the height of the area should be at least one full floor-story high. Finally, if the curtain wall is installed adjacent to another type of assembly, the interface detail between the two types of assemblies should also be included in the test area.

Today, major building projects require specialised attention to the quality and integrity of windows and curtain wall structures and

components at all stages of construction. The testing of these critical building elements to evaluate their performance under a range of anticipated exposure scenarios is essential. Such testing will help ensure the safety and comfort of building occupants and reduce the potential for premature repairs and renovations that can adversely impact a building’s return to investors and shareholders.

“This article is a reproduction of a white paper published by UL, based on an article originally authored by Mario Gonçalves and Robert Jutras”

Monalisa is a Project Engineer for UL’s Built Environment division. Her passion, enthusiasm, and dedication to work towards fire safety fulfil the purpose of her work life. She is currently working for testing, inspection, and certification of fire resistance, containment and suppression products as per international standards. Her role in UL also includes assisting first responders and all public safety stakeholders in their work to reduce fire risks, strengthen protections, understand fire science and bring innovative fire protection equipment to market. She is an expert in understanding construction and engineering best practices related to fire protection, detection, and alarm systems. She is part of UL’s glass façade fire testing research project in collaboration with IIT, Gandhinagar. Contact Monalisa Das at Monalisa.Das@ul.com for more details.

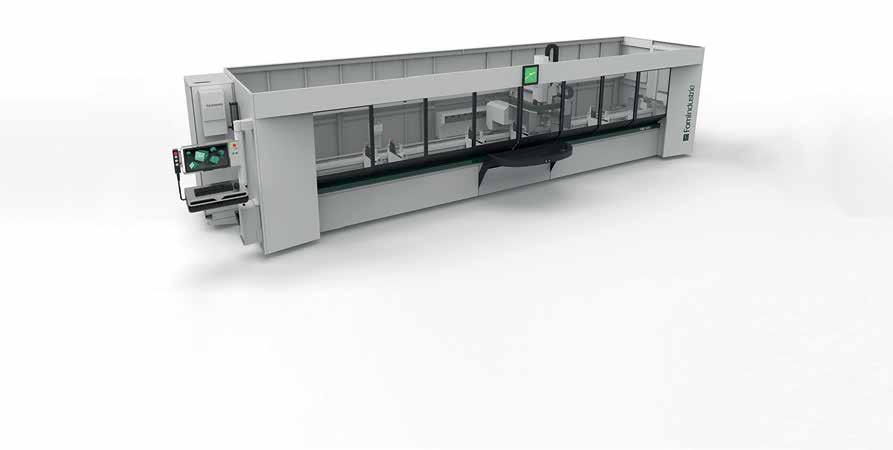

Keshav Babu. M is an engineer by profession with a management degree. He was earlier associated with World’s largest metrology and machine tools company from Japan and is presently associated with FOMINDUSTRIE - Italy as Director for more than a decade. He is leading a team of professionals and serving the façade and fenestration segment with FOMINDUSTRIE.

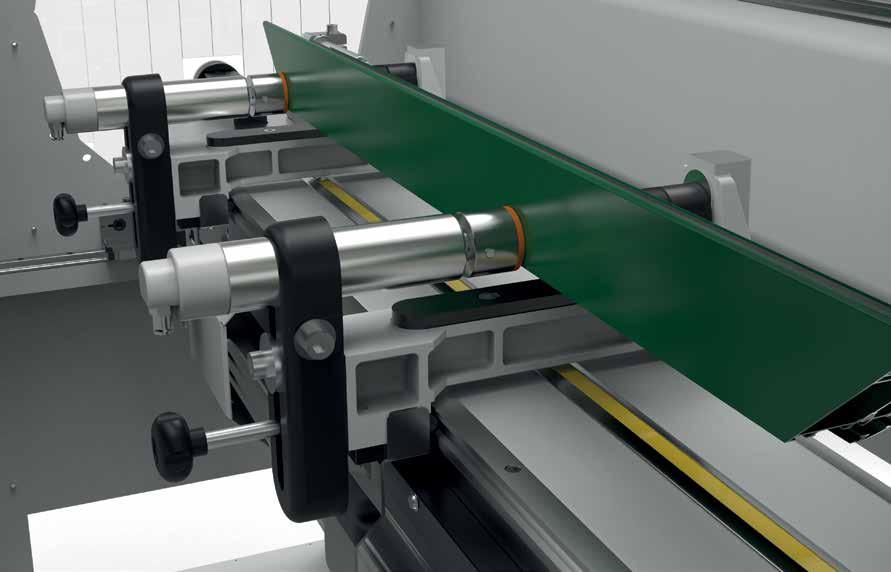

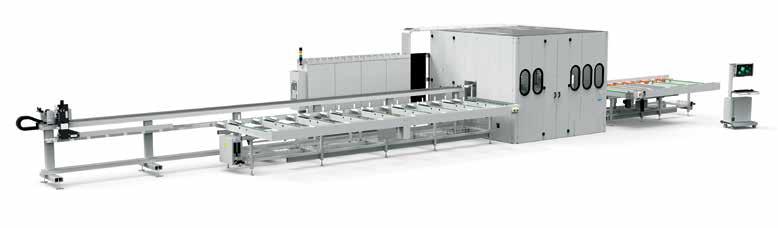

Can you brief us about your journey in India?

FOMINDUSTRIE - Italy, started selling machines in India way back from 2005 onwards through Hydro Building system, and in 2009 opened its subsidiary as FOM Aluminium machines Pvt Ltd. We have our operations HO located in Bangalore, with wear housing of machines and spare parts to support our customers.

Today We are proud of having installed 50+ CNC machining centres, 2500+ machines and approximately 400+ happy customers located across India. Apart from this, FOM has installed two state-of-the-art 12 spindle machining centres, which are unique and first-of-their-kind in India. We are enjoying serving customers of all segments from corporate to small and mediumsize fabricators. We are happy to say 60% of our business is thru repeated buyers, and this speaks all.

How do you differentiate FOM from other suppliers? Firstly, thanks to our machines,

we follow excellent design philosophy, wherein, all the machines, roll out of our factory are contemporary with the latest innovation. We constantly upgrade our machines and incorporate the latest technology into our machines. We are also supplying machines to many major system companies across Europe and the USA as OEM, which is very unique with FOM. Many system companies work very closely with FOM for feasibility study while developing their systems, and our machines are capable of handling all possible variants of the systems in present and future. FOM has an excellent inhouse manufacturing capability, limiting the outsourcing of components, helping FOM to achieve quality components in every stage.

We have factory trained engineers in place across India, our engineers and managers are located in Mumbai, Pune, Hyderabad, Bangalore and Delhi. This will help us to maintain a

large number of customers at ease. We stock the required spare parts at Bangalore HO to support customers on time and every time, we maintain stock of machines helping customers to plan better, reducing the delivery time for machines.

How do you support customers to choose the right machine?

FOMINDIA being a subsidiary of Italy, we have a perfectly integrated front office and technical office with Italy, and we have a team of experienced technical staff in India, trained at factories in Italy to understand the machines better, and their applications in all respect. Our advantage is we keep the TOTAL COST OF OWNERSHIP in mind while selecting the right machines, so that cost of maintaining/ handling machines will be minimal in long term. We study the requirement and customers’ expectations, and offer a best-suited solution, without compromising the purpose of the customer.

We educate our customers regarding the selection of machines to suit their purpose

and budget so that customers feel comfortable to start the factory with many inputs from us. We always insist our customers on first choosing the right supplier/ partner, and follow their suggestion to choose the right machine and solution, instead of negotiating with many suppliers. We always advise customers to hire qualified and experienced engineers on the shop floor for better utility of technology used in machines.

Brief us on your observation on machine maintenance and usage in India

We observe both extremes, wherein machines are monitored and managed professionally, and in some cases, machines are used till they cry for servicing. We always suggest customers to approach the seller, for proper timely servicing

and right spare parts for better performance and longer life of machines, instead of approaching local freelancers and unauthorised service persons, wherein they will compromise on spares to be used and spoil the machines, which will be very expensive to the customer at a later date. We offer an annual maintenance contract at a reasonable price, to upkeep the better health of installed machines. We also provide a checklist on periodic maintenance, so that customers can follow and maintain the optimal health of the machine.

How do you see India in the next few years ahead?

As free India turns 75 years, it is going to be an interesting journey ahead for all of us in the building and construction segment. India being a young democratic country

compared to the west, wherein shelter /housing is being addressed slowly and gaining good pace now, and the real estate market is also very young and emerging, giving good hopes to all of us in this segment, I hope this will continue till at least next three decades to reach an optimum level and to change to next orbit.

Tell us about your new launch / release of machines?

We have launched new generation machining centres with lots of innovation and with patented technologies, FMC 470-4Axis CNC, FMC 340 4 Axis CNC and FMC 120 3 Axis CNC, which have gained popularity in Europe and USA, all machines are with Industry 4 readiness, keeping future revolution in manufacturing engineering.

For more details, contact: FOM Aluminium Machines Pvt. Ltd.

# 96, 3rd Phase, Peenya Industrial Estate, Bangalore 560058, India

Mobile: 9008489134

Tel: 080-42111136/37

Fax: 080-28391775

Email: kbabu@fomindustrie.in

Website: www.fomindustrie.in

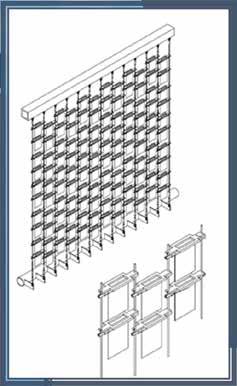

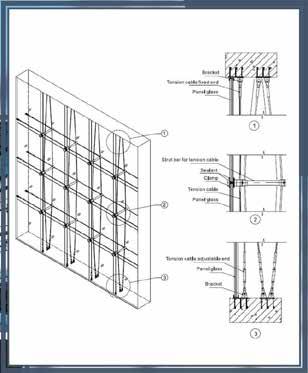

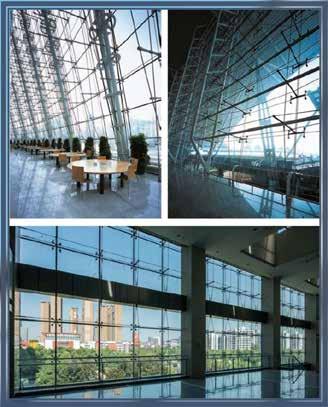

• Patented curtain wall system

• Long spans

• Elimination of horizontals

• High transparency

• Complex geometries

• Versatility

• Superior thermal performance

• Jumbo glass sizes

• System material options: aluminum, glass, & timber

“The LEED Plaque has Become the Symbol of Green Building Leadership”

As President and CEO of USGBC, GBCI and Arc, Mahesh leads millions of green builders in transforming green building standards to ensure public health, equity, and environmental sustainability in communities across the country.

Driven by his belief in a brighter future, Ramanujam is an experienced and enthusiastic thought leader, paving the way for better buildings, communities, and cities. Known for his optimism and out-of-the-box innovation, Mahesh couples an extensive background in technology

MAHESH RAMANUJAM President and CEO, U.S. Green Building Council (USGBC)

with his goal of democratising sustainable living to ensure an

equitable future where public health and a strong economy are complementary, not competitive.

Through USGBC, Mahesh was at the helm of the LEED certification program, setting the gold standard for green building credentials. Always looking ahead, Mahesh now focuses on advising investments to mitigate climate change, with a passion for the built environment.

In his interview with WFM Media, Mahesh Ramanujam talks about his role as President and CEO of the U.S. Green Building Council USGBc’s role in ratings and certification of buildings, and much more.

Tell us about USGBC and its role in the ratings and certification of buildings.

For more than 25 years, the U.S. Green Building Council has been dedicated to building an awareness of the impact buildings have on the environment and human health. With the evolution of LEED and the incredible support of our partners, we have established an entire community of sustainability leaders around a common cause: better buildings equal better lives.

Over the last two decades, the LEED plaque has become the symbol of green building leadership. Today, people know that if they are in a LEED-certified building, they are using less energy and water, avoiding waste, saving on maintenance costs, improving indoor air quality, offering comfort to their occupants and creating less environmental burden on their community. With 110,000 registered and certified LEED commercial projects and nearly 2 million+ registered and certified residential units, LEED is reducing carbon emissions, fighting climate change, and improving people’s quality of life across 182 countries and territories around the world. In fact, the business case for LEED is so powerful, we have expanded from a single building approach to one that addresses sustainability of entire cities and communities, as well. This is change on a grander scale.

Could you please tell us about the different certifications administered by GBCI? Is it different from those of USGBC? Can you explain the fundamental difference between LEED Standards for India by IGBC and those by USGBC?

GBCI was founded in 2008, to drive the implementation of the LEED rating system and, as evidenced by the statistics, LEED has become the most widely used green

building program in the world.

In our most recent update, LEED v4.1, we have raised our energy reference standard and added a carbon metric for new and existing buildings. We have also made improvements to the renewable energy credit and updated the materials credits to address embodied carbon through Whole Building Life Cycle Assessments and tools like Environmental Product Disclosures. And, importantly, LEED

v4.1 is the first true performance standard for green buildings. Leaders lead with LEED because it is the only rating system in the world that seamlessly connects buildings to communities to cities through its focus on performance.

In addition to the continuous improvements and forwardthinking additions we’ve made to LEED, a few years ago, we began thinking about how to expand on that extraordinary legacy by administering complementary rating systems. GBCI now has a suite of nearly 10 certification programs and 15 professional credentials that cover nearly every facet of the sustainability industry. We have SITES for sustainable landscapes, RELi for resilient design, and PEER for smarter and more reliable power systems, to name a few. While LEED is still at the heart of everything we do, we want to equip our community with the best in class market tools for leading their transformation efforts across all areas of the built environment.

In terms of environmental sustainability, how exactly are USGBC recommendations and standards effective?

LEED has transformed traditional

building design and construction practices. LEED buildings save more energy, water, and waste than traditional construction which is evidenced by the thousands of case studies that demonstrate their environmental, economic, and social benefits. Research has shown that what people want most are ways of having a better day-to-day experience – they want cleaner air, less waste, lower energy, and water use. People now recognise the impact these factors have on their quality of life, which is why LEED buildings have higher rental and property premiums and occupant satisfaction. Even nonLEED buildings draw inspiration from LEED strategies, such as daylighting, enhanced indoor air quality, biophilic design, etc.

LEED provides an effective tool to minimise the environmental burden of urbanisation and population growth. In the last two decades, rapid urbanisation has elevated more than 1 billion people out of extreme poverty. In the absence of LEED and USGBC’s efforts, that progress would have come at a very significant impact on the environment. We can balance growth with environmental burden while also inspiring a new generation of leaders to innovate on this progress and help us tackle the single largest existential crisis of our lifetime: climate change.

Where does India stand today, and how much further do we have to go to either create or convert buildings so that they comply with LEED principles?

India is the third largest region for LEED outside of the US and thanks to the hard work of our GBCI India team on the ground, we have established strong partnerships which helps to accelerate awareness and adoption. But we can do more.

India is hurting. Sadly, the pandemic has brought to light

the inextricable link between the environment, human health, and the economy. Climate disasters caused more internal displacement than war in 2020, and India had 929,000 disaster driven internally displaced people last year alone — making it second only to Afghanistan, which had over a million. That, on top of a public health crisis that shut down the global economy and overwhelmed an already burdened health care system.

As we emerge from this pandemic, we can no longer treat public health, climate change, economic recovery, and growth as single-issue topics. We must recognise the intersectionality of these issues to emerge stronger in a complicated, post-pandemic world. The primary message we need to convey is that buildings are part of the solution. By prioritising sustainable, healthy, equitable, and resilient design into everything we do, I am confident we can tackle climate change and lift people out of extreme poverty. LEED can not only play a role but deliver on this important outcome for millions of Indians.

Tell us about your role as President and CEO of the U.S. Green Building Council?

As President and CEO of USGBC and GBCI, I have the great privilege of leading an incredible community, dedicated to creating market solutions that address the harmful impacts that the building industry impose on our environment, our health, and the global economy.

Over the years, I’ve travelled to nearly every state in the U.S. and many countries around the world to see the impact of our work and how we can all work together to build a better future. It is so energising for me to connect with people and hear stories about how green buildings have made a personal impact on them and their communities. Whether it’s a story about rebuilding a town after a devastating flood, or reducing energy costs in a school to fund a teacher’s salary, or building a resilient energy grid so that a hospital can continue to provide emergency services in a blackoutreflecting on all of these incredible stories inspires me.

And I know that it is the most

vulnerable among us that feel the gravest impacts of climate change so there isn’t a day that goes by where I don’t consider that in my decision-making. We must continue raising the bar on the industry – pushing the richest and most ambitious to reach for the stars, but we must also provide solutions for the most vulnerable among us – we cannot do one without the other.

What drove you to select a career in sustainability?

Growing up in Chennai, “sustainability” wasn’t a buzzword

in my family, it was a simple fact of life. With an income equivalent to about 50USD/month, my parents somehow managed to pay for my education entirely and support my brother and me. I feel extremely fortunate to be where I am today. At the same time, I know there were others less fortunate than me. There were children in my neighbourhood who went to school just for the free meal provided, and many of them lived in rags. It’s a sad state when starvation leads to education. I am dedicated to working towards improving the quality of life for all.

I believe a higher living standard is what every person on the planet deserves and leading a long and healthy life shouldn’t be a privilege but a basic right for everyone, regardless of their circumstance.

Please tell us briefly about your professional journey and milestone achievements? Also tell us about a few of your sustainable projects, which are considered milestones

My professional journey began in technology, after graduating from Annamalai University with a degree in Computer Engineering, I led a succession of groundbreaking business transformation programs for both IBM and Lenovo. When I started at USGBC, I led the technology department, before becoming COO, and later succeeding our founder and CEO, Rick Fedrizzi. I saw USGBC as an opportunity to pay it forward and utilise my successes in the global market transformation to achieve a higher living standard for all.

Over the years our team has reached some incredible milestones, delivering market solutions that affect the lives of billions of people around the world. Some of those achievements include the launch of LEED v4 and v4.1, the development of the LEED for cities and communities rating systems, the launch of the Arc platform, the Living Standard campaign, the introduction of LEED Zero certification, USGBC’s Four Pillars strategy which includes our the All-In for Equity program, the LEED Safety First Pilot credits released in response to COVID-19, the Healthy People in Healthy Places Equals a Healthy Economy strategy, the launch of USGBC Live and numerous Greenbuild events.

I have also had the great pleasure of visiting some iconic LEED buildings, such as Taipei 101 in Taiwan, the Salesforce Tower, in CA, USA and the Olympic House in Lausanne, Switzerland to name a

few. And I look forward to visiting many more in the future!

The façade industry has seen a dramatic rise in the use of many innovative materials for the façade and cladding. According to you what are the key factors to consider while choosing the materials for façades?

There is a lot of literature and knowledge about the various factors that influence the materials for façades which has significantly helped to advance the green building agenda. From my point of view, I strongly recommend prioritising making sure materials are sustainable and healthy. That is why we made materials a primary focus of LEED v4 and v4.1, calling attention to tools like Whole Building Life Cycle Assessment and Environmental Product Disclosures, to weigh options for building design and materials selection with lower carbon impact. We also established a Better Materials platform to help project teams and manufacturers prioritise sustainable material selection. By prioritising the “embodied carbon” of materials – how they are extracted, manufactured, distributed, used and recycled – we can encourage

better material use in the market and accelerate our vision for a sustainable, healthy, equitable and resilient future.

In your opinion, what is the greenest type of façade?

Sustainability depends on a variety of factors like local climate, material access and building type. The greenest type of façades is one that takes a holistic and integrated approach to prioritise multiple attributes, such as whole building life cycle assessment, environmental product disclosures durability, and “embodied carbon”.