The perfect window. It is what you get when the world’s largest uPVC profile manufacturer joins forces with India’s largest. For the past 90 years, we’ve obsessed over our engineering and paid attention to the slightest detail. So, every window we make is perfect, and lasts for generations.

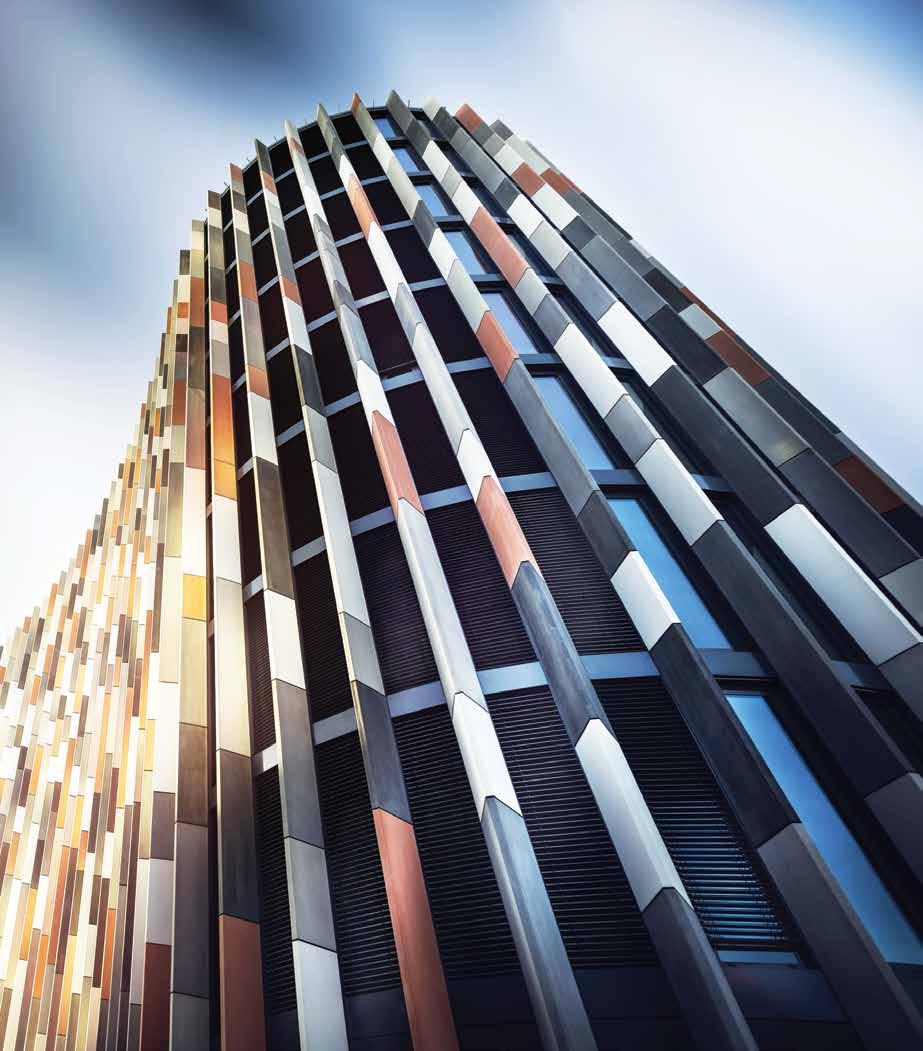

Siderise has been serving the curtain wall façade market for over 30-years with highperformance passive fire compartmentation solutions backed by an unrivalled support service from design and engineering, to build and beyond.

Protecting iconic buildings across the globe, our range of thirdparty certified perimeter fire and smoke seal systems are tested to the most stringent standards, where protection of the spandrel is needed to extend the fireresistance rating of the floor to the façade. In application, this allows our unique stone wool Lamella firestop to maintain its full performance and buy more time – valuable time.

Our Integrity. Your Designs. Safer Façades.

Discover more at siderise.com

Or get in touch today:

Siderise India

T: +91 998 700 4611

E: siderisein@siderise.com

Specifications

Recommended End Use

Interpon

Interpon

"Qualicoat Class 1 AAMA 2603"

Interior

Residential

Interpon

"Qualicoat Class 2 AAMA 2604"

High-end

Sublimation

Sublimation

Interpon

Volume 9 | Issue 2

March - April 2023

Ar. Subrata Ray, Senior Team Lead, Studio Lotus

21 Innovative Glass and Glazing Solutions

Rounaq. K. Choudhari, Founder and Managing Director, Micasa Luxuries

24 Energy-Efficient Glass Façades

Ar. Shweta kaw, Principal, Studio, Meraki

29 What Makes Glass a Class Apart

Anand Santhanam, Chief Sales & Marketing Officer, Saint-Gobain India –Glass Business

35 Improving the Consistency and Quality of the Processed Glass Used in the Construction Industry

Jothi Ramalingam Ponnusamy, Director, Winwall Technology India Pvt. Ltd.

40 Performance and Performance Testing of Glazing System on Building Façades

Reji Bhami, Director- Eminent International, Testing Centre, Dubai, United Arab Emirates, Hyderabad, India

44 The Importance of Properly Installed Passive Fire Protection

Sreenivas Narayanan, Technical and Compliance Director, India, the Middle East & Asia Pacific, Siderise Insulation Limited

50 What Lies Behind the Façade

Ar. Akhila Pillai & Ar. Baghya Venkataramani, Architects, Cannon Design

59 Façade Lighting Designs: Trends and Technologies

Manish Kumar, Director, Principal Façade Consultant, TDS Coetus Pvt. Ltd.

61 Digital Technology and its Relevance in Design

Sneha Gurjar, Director, CEM Engineers

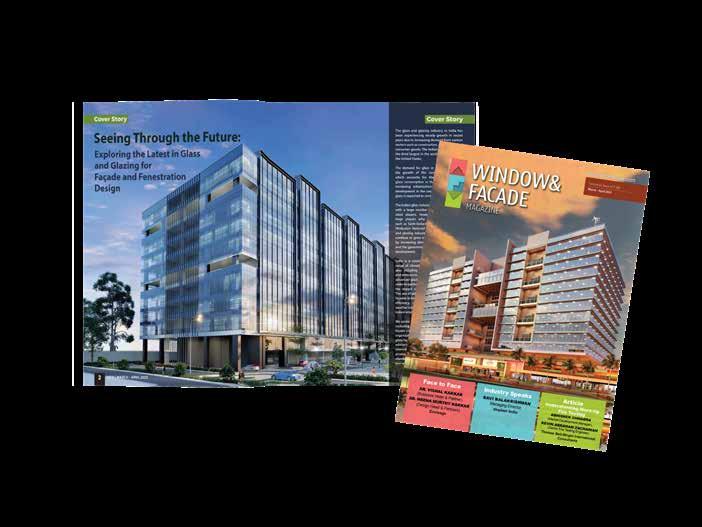

74 Cover Story

Seeing Through the Future: Exploring the Latest in Glass, and Glazing for Façade and Fenestration Design

104 Face to Face

Interview with Pramod Jain, Founder, Creative Architects and Interiors (CAI), Chennai

112 Industry Speaks

Interview with Piyush Srivastava., Country Head, Hydro BS India Pvt. Ltd.

125 Amity University, Kolkata

Ar. Saurabh Gupta & Ar. Akanksha Gupta, Partners, Vijay Gupta Architects

Cover Image: IT Park – Pune by Ar. Vivek Bhole, Vivek Bhole Architects Pvt Ltd

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications Printed and published at Thomson Press India Ltd., B-315, Name of the Editor-Ms. Renu Rajaram”

According to a report by Transparency Market Research, the Indian glass market was valued at USD 4.7 billion in 2018 and is projected to reach USD 11.1 billion by 2027, growing at a CAGR of 9.7% during the forecast period. This growth is driven by the increasing demand for glass in the construction sector, particularly for use in façades, windows, and doors.

Glass has become a popular choice for façades in the Indian real estate market due to its aesthetic appeal, functionality, and energy efficiency. According to a report by JLL, glass façades are estimated to account for 25-30% of the total building envelope market in India, with demand being particularly high in commercial and high-end residential projects.

The percentage of glass used in a building depends on the building’s design and function. For example, a building that is designed to maximise natural light and views will require more glass than a building that prioritizes energy efficiency or privacy. Similarly, a building located in a hot and sunny region of India may require more glass with advanced glazing technologies to reduce solar heat gain and improve energy efficiency.

WFM Media approached many experts to understand their views on various aspects pertaining to the latest in glass and glazing, including efficient designing and installing efficient façades, advanced glazing technologies, selection of apt glass, advanced glass façades using insulated glass units (IGUs), electrochromic glass, etc., and double-glazed windows, which can help improve the thermal performance of glass façades, reducing energy consumption and carbon footprint.

This edition is a culmination of diverse ideas, thoughts, and skills of experts including glass manufacturers, architects, façade consultants, civil engineers, and specialists from those organizations working on testing of glass and glass façades, ensuring safety and security.

Till now, we have published 50 editions of Window and Façade Magazine. It was an exhilarating yet excruciating journey for all of us, to learn quite a lot on the job and to get fully entrenched in the world of buildings. We have set out to present the best, the latest, and the most relevant information to you, and to create a platform to share knowledge on technologies, materials, etc.

Should you wish to address the industry in the next edition, feel free to contact me for a more tailored discussion at your earliest convenience. This is WFM Media, the World’s one and only magazine exclusively for the façades and fenestration industry.

certainly influenced the choice of glass for façade design.

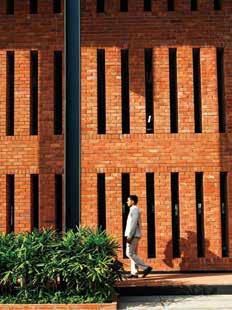

However, there are several factors that determine good façade design apart from the visual and aesthetic impact of a building and the occupant experience within. For one, we must recognise from the outset that glass as a material is not suited to India’s climate. This means that to cut down glare, heat ingress, and regulate ventilation, screens or fins need to be added to the primary envelope of glass which can become a costly exercise if not done correctly.

Façade design also contributes to a building’s overall environmental impacts and the construction industry’s contribution to global carbon emissions—nearly 40%. It contributes to a building’s performance and its carbon footprint because it is the primary threshold that regulates external environmental conditions. Thus, a sustainable approach to façade

There is a general trend in façade design currently to opt for glass as a primary material, in a sense aping the west. Glass façades are easy to install, maintain and lend a modern, elegant look to a building. Further, in the wake of the pandemic, people are

looking for spaces that offer flexibility of use and a connection to nature. The design of such spaces attempts to merge the inside and the outside through sliding-folding doors and windows, among other features. This sense of porosity and permeability has

The design for Max House, an office

incorporates several design features to reduce its environmental impact

Incorporating an optimal wall-window ratio should be a pre-requisite in order to reduce heat gains and losses through the facade

design involves developing the building envelope strategically. Requisite analyses and calculations should be carried out by studying the impact of light, heat, and wind on the building’s massing and orientation to determine an optimal design that does not adversely impact a building’s energy performance.

For example, our design for Max House, an office building for Max Estates in New Delhi, incorporates several design features to reduce its environmental impact. The façade, composed of hollow brick masonry, insulated spandrel panels, and Double Glazed Units (DGU)s, is engineered to cut out glare and reduce the heat gains and losses through the building envelope, lowering operating costs.

While glass as a façade material is indispensable, it should be used judiciously. In our projects, we’ve often worked with a 70:30/60:40 wall-window ratio to create a well-designed façade system for commercial edifices. The wall-window ratio, in fact, gives us a lot of room for play with 60–70% of the building’s exterior—with materials, patterns, and textures, which lends aesthetic character to the building.

Incorporating an optimal window ratio is one of the prerequisites that help us evaluate the performance of a façade.

The façade design system should be able to strike a balance between aesthetics, cost, energy consumption, and occupant well-being. For instance, every window at Max House is operable and can be controlled by occupants to let in the natural breeze and light as per the requirements. We came to such a model through our research and analyses, aided by modern energy modelling tools, which helped us in achieving the most appropriate façade design.

As is evident, façade engineering is a fundamental aspect of the overall building design and is something we incorporate at Studio Lotus from the concept stage itself. Our processes are highly collaborative; the discussions and insights with our consultants and engineers surrounding façade design— or any other aspect for that matter—hold paramount importance. As an industry, we should explore more possibilities in making the use of glass more sustainable, but that hasn’t happened due to blindly following trends. Often, the façade becomes an afterthought in the design process. It should ideally be conceptualised and developed from the very beginning of the project. We can improve the energy performance of our buildings substantially if a researchoriented strategy is adopted and utilised from the word go.

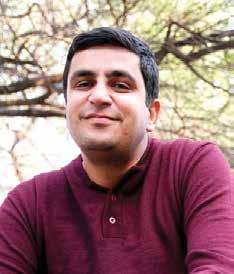

Subrata has over 15 years of domain experience in designing and executing of architectural projects. A graduate from Dr D Y Patil College of Architecture, Pune, he brings the expertise of handling national and international large-scale projects, including townships, master planning, high-rise, residential, commercial, workspace, retail, museum and preengineered buildings.

Associated with Arcop Associates Pvt Ltd for over 6 years, Subrata has practiced architecture in Mumbai, Pune, Bangalore and Delhi as a design consultant and completed the design and execution of several projects. He is a recipient of the ‘Excellence in Architecture Design’ award from the Indian Institute of Architects.

At Studio Lotus, Subrata heads a large number of projects where he adds value with his diversified technical knowledge and detailing capability. His key interest is architectural design, sustainability and urban architecture. Contact: subrata@ studiolotus.in

Clear glass has become increasingly popular as a glazing substance recently, especially for windows. Although glass is tough and lets a lot of sunlight into buildings, it offers little to no resistance to the passage of heat. Glass that has been sandblasted, frosted, or etched is the glazing material of choice for the majority of builders. Budget restrictions often force people to forgo such an extravagant choice, which is where alternative glazing materials come into play. Alternative glazing materials come in a variety of forms, and the new generation of materials offers customers windows with better performance and efficiency. While the market is quickly embracing this new breed of glazing materials, research into more effective technologies continues.

As more builders and designers become aware of the need to use energy-efficient materials, a variety of glazing materials have emerged. There is no one glazing type that works for all uses. Alternative materials with various functions are widely accessible

and include polycarbonate (PC), polyethylene (PE), acrylic, fiberglass and PVC. Additionally, due to the orientation of the windows and the regional climate, clients might believe that a home requires the use of two different types of glazing. Let’s examine each of these substances individually and learn more about them.

With many more alternate glazing materials already in the category, researchers are still busy developing new kinds of windows called “smart windows” or chromogenic or optical switching windows which will enable windows to adjust their transmittance vis-à-vis the temperature (thermochromic) or light (photochromic) fluctuations or in response to small electrical currents (electrochromic). With a host of options available for glazing besides glass, the future definitely looks brighter and lighter! One such project successfully executed is Bagmane Rio - world’s largest electrochromic glass project.

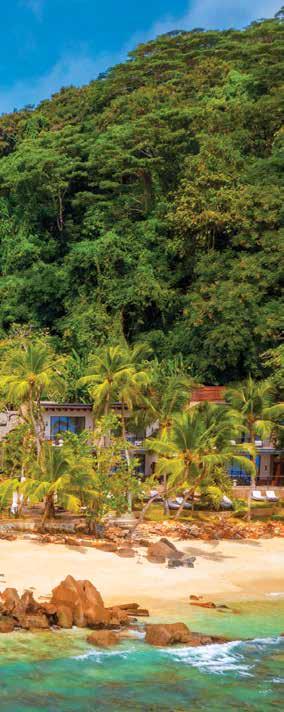

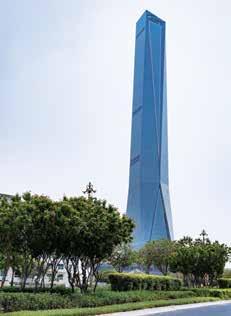

Let’s look at some of the prestigious projects in the world in which Glass is used efficiently and effectively:

Currently, we are in the process of executing the prestigious tower for Samudhura Group, the Samudhura Capitol, which is a 1.4 million sq ft of commercial space. We are also doing Taurus 4- Amazon Office for Bagmane Group in Bengaluru. Delhi International Airport, The Park- Lodha, Embassy Tech Zone, Pune, and Wipor SEZ are some of the interesting projects.

So, in my opinion, innovation and sustainability are perhaps the most preferred word in the world of architecture lately. In light of climate change and the growing population, a larger group of consumers have limited resources, resulting in developers and architects looking for innovative facade developers.

If I have to note down a few points for façade innovation, I would say the façade needs to be not only visually appealing on the exteriors of a building but also driven with highend technology and performance when it comes to functionality. Taking the example of Rio-Business Park, the

facade is not just visibly entreating but also caters to high-end performance and functionality with the innovation of dynamic glass and smart façades. All in all, I believe, the innovation of smart facades is a trend in this industry as we lead travel towards the future.

“All fenestrations in the future will have a minimum carbon footprint”.

Modern, durable fenestration has been demonstrated effective. Future fenestration will all be processed and/or made with a minimum carbon footprint. Use of renewable energy, minimal or no waste of raw materials, a life cycle that is comparable to that of the entire building envelope, fully recyclable materials, and contributions to energy and CO2 reduction are the necessary steps for the same. Additionally, they should be cost-effective, safe to use, offer traditional or contemporary designs, and operate ergonomically, particularly for the aging population. Any of the known fenestration materials will have a difficult time meeting these required characteristics. The industry hasn’t yet discovered the “ideal” frame substance that meets every requirement.

The real application will always determine the best or most appropriate fenestration solution in terms of frame material and glass. It is crucial to be aware of some innate material flaws. By altering design parameters to capitalise on the strengths of their chosen material combination, architects and fenestration designers can effectively overcome those.

The building skin can control heat transfer, provide natural ventilation, improve occupant well-being, and establish visible and physical connections between inside and out, as opposed to acting as a static enclosure.

A façade that is ecologically responsive, self-cleaning, information sensitive, and communicative would be a component of advanced façade technology. Consequently, architects and fenestration designers will select the substance.

The most recent development in the façade business is energy harvesting façades, which use solar panels installed on the façades to collect more energy. However, this could lead to poor lighting conditions inside the building.

Automated frame production lines must have high volume, a narrow product range, and superb production planning. The majority of fabricators have been discouraged from making the significant step change due to the necessary factory area, the high investment level, and the sporadic, unpredictable order intake. The choice of cutting/machining centers, flatbed multi-head welders, and corner cleaner combinations as the initial stages of automation is not unexpected, but the automation technology ends when the sashes are combined with the outer frames or when the frames require factory glazing. However, by using

straightforward techniques like adding positioning and drill jigs, employing specialised hardware tables, upright glazing frames, transport and storage racks, etc., every operation in fabrication can be made more efficient. Even though they are occasionally neglected, those comparatively small investments are easy to forget.

We have successfully completed various large projects of which the façades have been publically appreciated. A few examples are, Kohinoor Square Mumbai - 1,00,000 sqm of façade area, World One - 85,000 sqm of façade, IndiaBulls Blu - 80,000 sqm of the façade, Antilia Residence in Mumbai, Bagmane Goldstone in Bangalore, THE 42 in Kolkata, Oberoi 360 in Mumbai, JW Marriot in Kolkata, Mondeal Heights in Ahmedabad, The Capital BKC in Mumbai, Wipro IT Sez in Bangalore and many more projects across the country.

ROUNAQ. K . CHOUDHARI

Founder and Managing Director, Micasa Luxuries

Rounaq Choudhari is a successful entrepreneur as the Director at Glass Wall System India Pvt Ltd, Founder and Managing Director for Waterways Ceramica, and MICASA Luxuries. After obtaining his Master’s degree from the University of Bath (UK) and gaining hands-on experience from the bottom up, he branched out on his own and became a Director at Glass Wall System. Rounaq is at the forefront of the façade industry and is an innovator at the age of 24 and has successfully managed and completed various projects. He is always striving to set up a trend in futuristic technology within the building façade industry. He has been successful in executing the world’s largest smart glass project - Bagmane Rio, and other prestigious interior projects like Antilia Residence, Piramal Gulilta, Godrej House, Four Seasons Hotel, Taj Hospitality, Mumbai Airports, and many more.

(https://www.architecture.org/learn/resources/buildings-of-chicago/building/crown-hall/

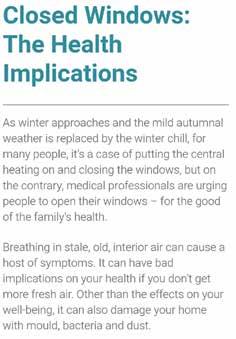

Energy-conserving and efficient glass façades and fenestrations are essential for creating sustainable and energy-efficient buildings. Glass is a popular choice for building façades because it allows natural light to enter the building while providing thermal insulation. However, without proper design and technology, glass façades can also contribute to heat loss and gain, resulting in increased energy consumption.

The benefits of an energy-efficient glass façade include improved energy efficiency, reduced reliance on artificial lighting, and increased occupant comfort. However, they can also be more expensive than traditional building envelopes and may require additional maintenance and cleaning due to their large surface area.

Here are some ways to make glass façades and fenestrations energy-efficient: 1. Massing & orientation: Orienting and developing geometry and massing of the building to respond to solar positions. The orientation of the glass in relation to the sun can also impact energy efficiency.

facing south can gain more heat in the winter, while windows facing east and west can gain more heat in the summer.

2. High-performance glass: Using high-performance glass with low emissivity coatings, multiple layers, and special gas fills between the layers can significantly reduce heat loss and gain. This helps to maintain a comfortable indoor temperature and reduces the need for heating and cooling. These coatings are thin, transparent layers of metal or metallic oxide that are applied to the glass surface. They work by reflecting heat back into the atmosphere, reducing the amount of heat that enters inside the building skin through the glass. This can significantly reduce energy consumption and heating costs.

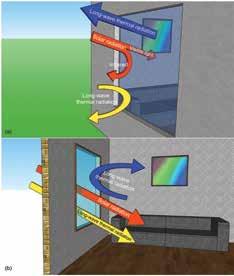

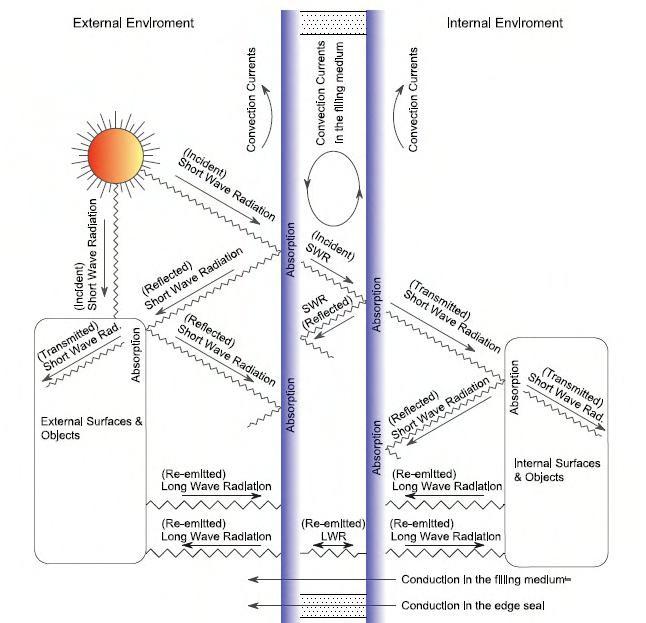

3. Double skin façades. Almost a self-explanatory name for façade systems consisting of two layers, usually glass, wherein air flows through the intermediate cavity. This space (which can vary from 20 cm to a few meters) acts as insulation

against extreme temperatures, winds, and sound, improving the building’s thermal efficiency for both high and low temperatures. Perhaps one of the most famous examples of double-skin façades is Foster+Partners’ 30 St Mary Ax Building, “The Gherkin.” The airflow through the intermediate cavity can occur naturally or be mechanically driven, and the two glass layers may include sun protection devices. While the concept of doubleskin façades is not new, there is a growing tendency for architects and engineers to use them. Particularly in skyscraper design, they are favored for their transparent façade, thermal and auditory comfort, reduced air conditioning costs, and elimination of the need for window-specific technologies.

4. Insulated glass, also known as double glazing or insulated glazing, is a type of window or door glass that consists of two or more glass panes separated by a layer of air or gas, such as argon or krypton. The glass panes are usually held together with a spacer bar and

SR Crown Hall- Mies Van Der Rohe (https://www.architecture.org/learn/resources/buildings-of-chicago/building/crown-hall/)

sealant. The primary purpose of insulated glass is to improve energy efficiency by reducing the transfer of heat through windows and doors. The trapped air or gas layer between the glass panes acts as an insulator, reducing heat loss or gain through the glass. Insulated glass also offers additional benefits, such as noise reduction, improved safety, and reduced condensation. It is commonly used in residential and commercial buildings and can be found in a variety of window and door styles, such as double-hung windows, sliding doors, and patio doors.

5. Solar shading: Incorporating solar shading devices like louvers, shades, or screens can reduce the amount of direct sunlight that enters the building, thereby reducing solar heat gain. This can help to reduce the need for air conditioning and lower energy consumption.

6. Window-to-wall ratio of the WWR can have a significant impact on the performance of glass in a building. A higher WWR can result in increased solar heat gain, greater potential for glare and overheating, more heat loss through windows, and increased noise levels. Therefore, it is essential to consider the WWR carefully when designing a building and selecting glass for the windows.

7. Vacuum insulated glass: This technology involves sealing two panes of glass together with a vacuum between them, which eliminates heat transfer through convection and conduction. This can provide even greater insulation and energy savings than traditional double or triple-glazed windows.

8. Electrochromic glass: Also known as smart glass or switchable glass, is a type of glass that can change its opacity or transparency in

response to an electrical signal. This is achieved through the use of thin films or coatings of electrochromic materials, which are typically made up of metal oxides. When an electrical current is applied to the electrochromic material, ions are transported from one layer to another, causing a change in the material’s color and/or opacity. This change can be reversed by applying a voltage of opposite polarity, allowing the glass to switch back and forth between transparent and opaque states. This technology can be used to control the amount of sunlight and glare that enters a building, reducing the need for heating and cooling.

9. Photovoltaic glass: Photovoltaic glass, also known as solar glass or PV glass, is a type of glass that is designed to generate electricity from the sun’s energy. It is made by embedding photovoltaic cells, which are typically made of silicon, into the glass. When sunlight hits the PV cells embedded in the glass, it is converted into electrical energy, which can be used to power a range of devices, such as lights, appliances, and even entire buildings. This technology is often used in building façades and windows, as it allows buildings to generate their energy and reduce their reliance on the grid. In addition to generating electricity, photovoltaic glass can also help to regulate the temperature inside buildings by reducing heat gain and glare. This can help to improve energy efficiency and create a more comfortable living or working environment. Overall, photovoltaic glass is an innovative technology that has the potential to transform the way we generate and use energy, and it is likely to play an increasingly important role in the sustainable buildings of the future.

10. Spectrally selective glass: Spectrally selective glass is designed to allow visible light to pass through while blocking heat-producing

Double skin curtainwall was at Cambridge Public Library (https://www.architecture.org/learn/resources/buildings-of-chicago/building/crown-hall/)

1. infrared radiation. This type of glass is useful in sunny climates where heat gain is a significant issue.

Conclusion:

The energy we consume is limited and precious, hence we all need to try and build it in an energy-optimised way. This requires greater communication and cooperation between the product groups. The aim is to reduce the need for primary energy for the operation of a building to a minimum – ideally even to zero. This

means that the energy consumption for ventilation, lighting and cooling must be reduced through smart glass façades that react actively and automatically to their environment. Resource-saving, energyefficient façade solutions, therefore start with intelligent and interdisciplinary planning and design. Smart façade systems represent a particularly promising technology for new buildings and the energy-efficient renovation of buildings. Energy saving with intelligent façades already is the future.

AR. SHWETA KAW

Principal, Studio Meraki

Shweta Kaw is an architect with 15 plus years of experience in the industry including a successful role as a Sustainable Design Consultant in Singapore after completing her post-graduation (M.Sc. in Building Performance & Sustainability) from the prestigious National University of Singapore. Currently, she is heading Studio Meraki. The Studio’s practice is diverse and ranges from architecture, green building design, interior & furniture design as well as graphics. As the name suggests, they intend to aim for building happy and healthy spaces for man to dwell in its habitat and nurture for him an improved sense of well-being by paying attention to psychological & physiological comfort and hence garnering lesser distress levels in our society.

The use of glass in building design has become increasingly popular over the years for the unparalleled benefits it offers. Today, architects and designers consider glass as the go-to material, not only for the aesthetics it delivers but also for the performance it assures. It is the only material that blends the exteriors with the interiors, seamlessly bringing the outdoors inside. In this article, we will look at the ways and means by which glass adds value to any building, be it commercial or residential.

Glass can be used to create a range of visual effects in building design. When it comes to facades, unlike other building materials, glass scores high on aesthetics by adding colour and character to a building’s façade. As a façade cladding material, glass provides an unobstructed

view of the surrounding environment, while tinted, frosted or textured glass can offer privacy and add value in terms of visual interest for interior decor. Talking about interiors, coloured or lacquered glass is one of the most popular new-age trends to take over living and working spaces. It is well-suited for a variety of applications, from table tops to kitchen countertops, from pillars to partitions, and so on.

Glass has the rare ability to magnify spaces; in fact, the use of mirrors is an age-old trick to create a sense of space when there is scope for none. Interior designers look beyond the functional value of mirrors, to use them as a décor element across the home. Mirrors have transitioned from normal to highdefinition to tinted to LED, making them an indispensable aspect of design and décor.

When designing a building using glass as an aesthetic element, it’s important to work with experienced professionals who understand the intricacies of glass design and installation. Architects, engineers, and glass manufacturers are actively collaborating to create edifices that are both visually stunning and functional.

Glass can positively impact the energy efficiency of a building. The use of energy-efficient glass in windows and facades can enhance natural daylighting even while cutting down the incoming heat, thus reducing the need for artificial lighting & cooling. This results in lesser energy costs that otherwise go towards additional lighting and air-conditioning. India being a tropical country with excessive light and heat, the solar performance of glass is critical in building design. When made into double-glazed

Bringing a sense of space, expansively or triple-glazed units, energy-efficient glass can provide improved solar performance.

The glass used in building design must be able to withstand external impact. Toughened or laminated glass can provide improved impact resistance and is a common choice for high-traffic areas. Toughened glass is significantly stronger than normal glass and is breakresistant. In the rare event of breakage, it

breaks into small, blunt pieces, causing no harm. Laminated glass comprises two or more pieces of glass with a PVB (Poly Vinyl Butyral) interlayer. In case of breakage, this interlayer holds the glass in place so that shards are not strewn around and cause injury. It is ideal as a vandal-proof glass. Fire is another risk that must be factored in. Today, glass can be made fire-resistant and aids at multiple levels. In case of a fire breaking out in a building, the fire-resistant glass acts as a barrier by compartmentalising fire and

preventing the spread of fire and smoke. A passive protector, a fire-resistant glass, given its transparency, helps detect a fire early and facilitates quick action during emergencies. Today, there are also other enhanced variants of safety glass that help protect against attacks, bullets, and blasts.

Sustainability is a key consideration in modern building design. One must keep in mind the entire life cycle of a building material when evaluating its sustainability, and the use of glass in buildings has been known to play a significant role in achieving sustainable outcomes. Glass is infinitely recyclable which makes it capable of being used repeatedly without losing its quality. It is non-toxic, has a long lifespan and requires minimal maintenance. Glass is not only recyclable, but it is also made sustainably, with very efficient use of resources. Being a lighter material, it is the perfect choice for designing lean and sustainable buildings, the way forward for the future of architecture.

Did you know, glass also has an integral positive impact on various aspects of comfort that occupants experience, such as solar, visual, acoustic, and indoor air quality comfort

• Solar and Thermal Comfort: Solar comfort is an important factor while choosing glass, particularly for tropical climates. In a tropical country like India, where there is excessive solar heat, a solar control glass helps cut down on solar heat gain keeping the spaces less hot. This adds to savings on air-conditioning expenses. For cold climates, a low-E glass helps insulate the interiors from heat loss, enabling warm spaces during cold days and saving on heating expenses.

• Visual Comfort: Natural light is an important aspect of building design, and given its transparency, glass can provide ample natural light. Studies have time and again proven that good natural lighting and outdoor views from private spaces enhance the productivity of the occupants. One can choose from a wide range of

GEALAN doesn’t just give windows a frame with our profiles, we’re genuinely trend-setting in uPVC window systems. And on top of that, we develop innovative solutions that offer all our partners and customers real added value. In our new GEALAN campaign, we show that the right frame holds the world together.

We form the framework for the world of windows. We design and manufacture the most innovative profile systems, surfaces and digital solutions for windows and doors.

• glass options according to the light transmission metrics that are needed for a space.

• Acoustic Comfort: Glass is the most preferred material to cut down external noise. The use of glass in acoustic partitions, insulated windows, etc. can considerably make the space sound-proof without hindering the views. Particularly, acoustic glass panels add to the sleekness of a design compared to other traditional and bulkier acoustic materials.

• Indoor Air Quality Comfort: Indoor air quality is critical to occupant health and comfort. Glass is not prone to developing fungus or molds and does not create any odour. Lacquered Glass has nil Volatile Organic Compounds (VOCs) unlike many other painted surfaces and adds to the breathability of the spaces.

• Cognitive Comfort: Studies have shown that glass-enclosed spaces improve the cognitive abilities of occupants. People with access to outdoor views, and naturally welllit and ventilated environments, demonstrate enhanced productivity

as well as respond better to crises, than those in claustrophobic surroundings.

There was a time when glass connoted just doors and windows. Today, glass has the most wide-ranging applications that have become indispensable to modern living and working spaces. Glass TV units, partitions, cubicles, mirror art, flooring, ceilings, and furniture such as table-tops, tea poys, side tables, etc. are integral to every living room. In the bedroom, glass applications include wardrobe shutters, headboards, wall cladding and pillars. Being an easy-to-clean and hygienic material, it is widely used in the kitchen as countertops, splashbacks and shutters. Shower cubicles and LED mirrors are the faces of contemporary washrooms. In tune with a dynamic generation, there is the dynamic smart glass that can tint automatically on demand and switchable glass that can switch from transparent to translucent states.

Indeed, glass is the ideal material for endusers and designers alike, for the sheer benefits it offers – be it from the usage point of view or the design perspective.

What’s more, the use of glass in building design can provide a high ROI by reducing energy costs, increasing property value, and improving occupant comfort, by being a durable and long-lasting material.

With its diverse uses made possible as a versatile material, glass remains the most preferred choice when it comes to blending aesthetics and performance. Having stood the test of time with its evolving applications, glass will only bring a plethora of possibilities in the years to come.

In this case study, we look at the design of a magnificent 6000 sqft penthouse in Chennai. The clever use of glass and mirrors have added depth to this space, which has the blend of a neo-classical and contemporary aesthetic. The versatility of glass is evident in the ceiling design, the home-temple space, and the use of mirrors in the passage, among others. This gives the space an elegant and open vibe and serves as the perfect testimonial of a modern home. Let us have a detailed look

Bringing form and function, flawlessly

at how glass has been thoughtfully used throughout this home.

Glass and mirrors give a spatial quality to the area by increasing the depth & brightness and effortlessly doubling up the space. In the ceiling of the dining area, glass assumes the shape of a wave, while on the walls – it has been used as tiles. Instead of a wall or wooden partition to cover the back side of the home temple, the idea of a fluted glass with a frame gives a sense of continuity that spills into the living room.

Glass being a versatile material, has been used across the home in different ways. Solar control glass for windows helps cut down the heat and humidity of Chennai while bringing ample daylight and giving unobstructed panoramic views of the ocean. There is a narrow passage that flows from one wing to another but to make it look wider, an antique-shaped window with a mirror was added. To make the long wall seem more spacious, mirrors with tiled patterns were incorporated. On entering the passage, a huge curved structural glazing brings the outdoor views seamlessly inside.

In the living space, a prominent column has been cladded with veneer and a brown-tinted mirror, that is subtle and adds elegance to the ambiance. Tinted glass has been interestingly used in the kitchen to make the cabinets transparent, yet not too visible. In the washrooms, LED mirrors have been used to ensure clean and clear images, while doubling up as a piece of art.

Glass blends easily with the interior elements provided it is combined with the correct textures, materials and shades. If used in the right manner, it can open up a world of infinite possibilities.

References:

Helmy P. Rethinking The Future. https:// www.re-thinkingthefuture.com/casestudies/a8480-jacobs-medical-Centre-bycannondesign/

Vitro Architectural Glass. Glass Helps Provide Patients with a Natural, Soothing Environment. Architect Magazine https:// www.architectmagazine.com/design/ buildings/glass-helps-provide-patientswith-a-natural-soothing-environment

Chief Sales & Marketing Officer, Saint-Gobain India – Glass Business

Anand Santhanam brings over 22 years of experience and expertise as a wellseasoned sales, marketing and business development professional. He has a successful track record of working in diverse sectors like construction and building materials, automotive, durables and electronics. Anand’s skill sets in marketing management, sales, channel management, consumer insight generation and leadership management have been instrumental in shaping his career graph. Over the years, Anand has held key positions in his various stints across some of India’s best-known companies including Carrier Aircon, ONIDA (MIRC Electronics), Philips India Ltd, Tractors & Farm Equipment (TAFE), Massey Fergusson Tractors, etc.

Anand holds a Bachelor’s degree in Engineering (Instrumentation and Control) from the University of Madras and a Master’s degree in Management Studies (Marketing) from the University of Mumbai. He is an active member of the CII Marketing Forum.

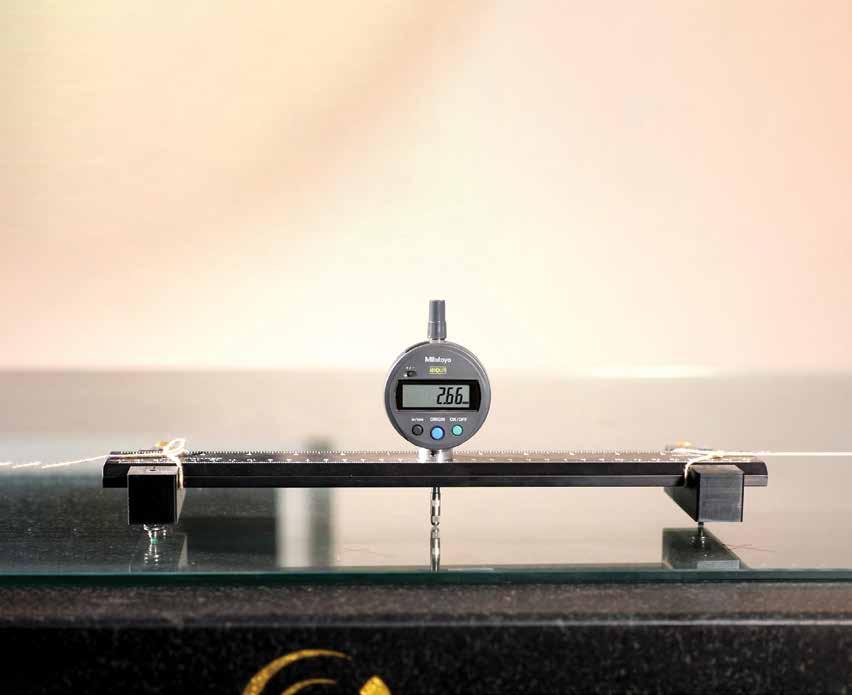

Glass is an essential part of the construction industry and is extensively used in facades, windows, doors and handrailing apart from its use in special furniture, interior partitions and skylights. As a matter of safety all the glass used in construction must be further processed, depending on its application, to increase its energy efficiency, structural strength, impact strength and breaking patterns. The need to ensure consistent performance of the different kinds of processes has been highlighted under Section 8 of the National Building Code 2016 under Glass and Glazing.

Float glass in India is manufactured by large well-established companies that have set up sophisticated facilities

to produce products of international quality. However, all the glass produced by these float glass producers are not processed in-house by these manufacturers themselves and a large part of that processing is done by glass multiple glass processors located across India, most of whom are in the MSME sector.

In order to improve the safety of buildings the Govt of India had issued a Gazette notification on March 20th, 2020, making it mandatory for all safety glass panels (toughened and laminated) which are used in buildings to carry the ISI mark. This essentially means that all the glass processors within India who supply glass panels to the construction industry must get

their process audited and certified by the Bureau of India Standards (BIS) and the performance of the glass processed in their respective plants must comply with IS 2353 (Part 1) specifications. Furthermore, every panel of safety glass supplied to the construction industry must carry the ISI mark to confirm its quality. This directive will come into effect from 1st April 2023.

Therefore, all glass processors in India who wish to sell processed safety glass to the construction industry must submit a specified number of samples as per the norms set by BIS in the thinnest and thickest wall thickness being processed to a BISrecognised laboratory for testing. If their products comply with the requirements set down by IS 2553 (Part 1) then they

would have to submit their test report to the BIS and get the formal approval to use the ISI mark on each panel of glass being delivered to their customers.

This move by the Government will help go a long way in ensuring consistency in the quality of safety glass being used in the buildings. With rapid urbanisation and the increase in the number of highrise buildings used for commercial or residential purposes, the focus has shifted to the safety of the large number of people using the building or moving around these buildings.

The glass processing industry will now have to move quickly to comply with the requirements set by the IS 2553 and get their facilities approved by the BIS to be eligible to service the needs of the fastgrowing building construction industry.

Presently, processed glass panels delivered by the glass processor to the aluminium contractor get directly into the glazing process and once the silicone is cured the aluminium panel

is shipped to the site for installation. Most aluminium contractors presume that the quality of glass panels received at their factory complies with the required specifications. The quality of the processed glass is checked only if there is a major quality issue, which comes to the notice of the consultant or the project engineers. By the time this comes to light, the panels have already

been installed and it’s too late to do any kind of rectification.

Glass processors can now take advantage of the services offered by performance testing laboratories recognised by the BIS for glass testing to test their product samples and use the test report generated to get their process certified by the BIS.

IS 2553 (Part 1): 2018 is a standard specification released by the Bureau of Indian Standards (BIS) that outlines the requirements for architectural safety glass in buildings. The standard lays out the specifications for the quality, strength, and performance of safety glass used in architectural applications. The specification divides safety glass into two main categories: laminated safety glass and toughened safety glass. Laminated safety glass consists of two or more glass layers bonded together with a polymer interlayer, while tempered safety glass is produced by heating and cooling a single glass layer rapidly to increase its strength.

IS 2553 (Part 1): 2018 specifies the thickness and mechanical properties of both types of safety glass. It also outlines the test methods that must be used to assess the performance of safety glass, including dimensional and visual tests such as thickness, dimensions, squareness, determination of defects, resistance to impact, boil and bake, fracture and adhesion tests, surface compression, mechanical strength – four-point bending test, humidity test.

Overall, IS 2553 (Part 1): 2018 plays a crucial role in ensuring the safety and reliability of architectural safety glass, which is an essential component of modern building design.

Façade consultants too can make the testing of processed glass panels being delivered to the aluminium contractors, on a random basis, a part of their tender specifications to ensure the consistency of the quality of the processed glass installed at the sites.

This notification of the BIS will go a long way in raising the level of quality of safety glass being used in the

construction industry and the BIS plans to extend the same norms for insulated glass panels too in the near future. With glass being the preferred medium to clad the entire façade of the modern high-rise buildings being developed all across our country the need for more stringent quality control measures need to be put into place to ensure the safety of the occupants and the general public.

Jothi Ramalingam is the Director of Winwall Technology India Pvt Ltd. He has been associated with the architectural aluminium industry since 1990 as an anodising and powder coating specialist. He is presently a member of the Doors, Windows, and Shutters Sectional Committee, CED 11, which is responsible for creating the Indian Standards for design, fabrication, testing and installation of doors, windows and shutters.

Under his stewardship, Winwall India has been Accredited by NABL as the first laboratory in India to set up an NFPA 285 facility to test the fire propagation characteristics of exterior wall assemblies containing combustible components, becoming India’s first accredited testing facility for processed glass and to conduct cyclic testing of hardware used in the window and door industry. Winwall is an ISO 17025, NABL Accredited façade performance testing laboratory based in Chennai which is also accredited to test processed glass as per the specifications laid down by IS 2553 (Part 1) and is also recognised by the BIS for glass testing. It is the first and only private laboratory in India to have this accreditation.

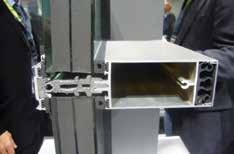

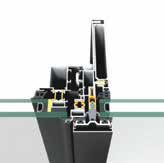

The façade is a non-structural, exterior cladding system that is typically made of lightweight materials such as glass, aluminium, or composite panels. It is used to enclose a building’s exterior, providing a protective barrier against the elements while allowing natural light to enter the building.

These are typically designed as a series of individual panels that are connected to the building’s structural frame. The panels are supported by brackets or anchors that are attached to the building’s structural elements, such as concrete slabs or steel beams.

The façade of a building is often the most important aspect from a design standpoint, as it sets the tone for the building. From an engineering perspective, it is crucial due to its impact on energy efficiency. Given the criticality, it is strongly advised that a prototype

of this foundation is tested at the initial stage to validate the design.

The ideal time to perform the testing on the prototype would be once the

design is finalised and the materials are selected and approved. Performance prototype testing can help identify any issues with the façade system before it is installed in the building. This allows for necessary modifications or improvements to be made early in the process, reducing the risk of costly remedial work later on.

It can help verify the effectiveness of the design and installation of the façade system, ensuring that it meets the intended performance requirements and is installed correctly.

The Prototype testing is in line with the building codes, construction standards, and industry guidelines to ensure the safety and performance of building façades. Compliance with these requirements can help prevent costly remedial work and potential legal issues. Upon testing and validation of the design, there is a 90% guarantee that the façade will withstand calamities with regard to air, water, wind and building movements, etc.

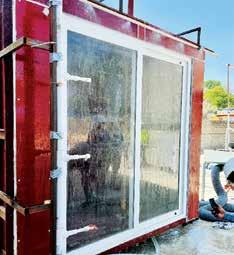

• A dynamic water penetration test is one of the important tests that should be performed as part of prototype testing. And this can be conducted only in the laboratory. The testing consists of a portable wind generator and installing a spray rack system at the exterior of the specimen. It combines volumes of water with high buffeting winds delivered by an aeroplane engine or another similar wind generator.

• The wind produced shall be adjusted to equivalent static pressure. Water is sprayed with an array of nozzles and simultaneously the required wind speed is produced by a wind generator. During the test, the façade is observed for any signs of water penetration or leakage. The water that penetrates the façade is collected on the inside of the façade system to measure the amount of water that enters the building envelope. This test is typically performed for a specified duration [approx. 15 minutes] and is intended to test if the façade can withstand the effects of a heavy rainstorm.

• Next is the Thermal Cycling Test (Weathering Tests) which is performed to determine the resistance of exposure to alternating extremes of high and low temperatures. This again can be conducted only at the laboratory.

• The target parameters for the high and low temperature phases are the air temperatures defined as per the standard [Per standard AAMA 501.5 - High temperature is up to 82oC and low temperature is -18oC]. The number and duration of the cycles can vary depending on the specific requirements of the test and the expected conditions that the façade system will be subjected to in its actual use.

• The façade sample is monitored for any signs of damage or deterioration, such as cracking, delamination, or loss of adhesion etc.

• In addition to the pressure tight test chamber a sealed test chamber

plus air-conditioning equipment is required to regulate the temperatures in order to carry out the thermal cycling sequence.

• Constant temperature conditions are maintained inside the corresponding interior of the prototype, while the exterior of the prototype is subject to changing temperatures according to the defined test cycle.

• Another important test would be the ‘Building Movement Test’. This test provides a performance evaluation of the façade when subjected to the specified displacements (horizontal/ vertical); for example, an earthquake. Furthermore, it is intended to analyse the seismic safety of architectural glass components within a façade. Testing is done at three cycles where a single cycle is defined as a full displacement in both directions and back. Each cycle is completed in about 2 minutes. After the tests, all the areas are inspected in detail and observed for any disengagement, metal distortion, sealant or glazing failures.

• Building movement testing for façade prototype samples is an important part of the quality control process for building envelopes.

The results of the testing can help to ensure the safety and performance of the building façade system, and can help prevent costly and time-consuming remedial work on the completed building façade.

Next an onsite testing (Chamber Testing + Site Hose Testing) during construction stage will help in assessing the quality of workmanship.

These tests are typically performed by an independent testing agency, and the results are used to verify that the installed façade system meets the required performance standards.

During onsite testing, we can perform air infiltration and water penetration along with structural load testing. The onsite structural load test validates the behaviours of bolts tensile and shear performance along with the mullion and transom deflection in real site conditions.

In order to perform air infiltration, static water penetration and structural performance test onsite, a test chamber is to be built inside the building attached to the test specimen.

A required test pressure will be supplied inside the test chamber by a centrifugal blower.

• The air leakage will be measured with equipment such as orifice plates, differential pressure transmitters, etc. It is really important to record the ambient temperature, relative humidity, and barometric pressure.

• For the onsite water penetration test, a Spray Rack System shall be kept at the required distance [The minimum required water flow rate is 3.4 L/min.m2 as per ASTM E1105 standards]. The flow rate of the spray

• rack depends on the total count of the nozzles used for the test [Each nozzle produces 1/3 US gallon of water per minute].

• In order to perform the structural performance test on site and measure the mullion and transom deflection, a device that can measure the deflection must be installed inside the test chamber. These deflection gauges will be fixed near two successive anchorages on a typical mullion, transom and midway between anchorages.

• For the mullion and the transom, the distance between the outermost transducers will be measured and recorded. The design load will be applied to the test chamber as per the standard requirements and procedure.

So, the question would be why do we test in a lab when we can do the air, water and structural test at site and ensure that the workmanship was properly done?

Due to site conditions, there is a limitation in performing all the testing at site such as building movements testing [including live and dead load testing], dynamic water penetration testing, thermal cycling testing, etc. which gets covered in the lab test.

In a nutshell, by performing both tests, results can be compared and risk at the site can be reduced.

Both lab tests and site tests are not interchangeable. They need to be considered independently.

If tests are not conducted on a façade system, it can potentially result in a number of issues or problems that could have been avoided if the proper testing had been performed. These problems could range from minor aesthetic issues to more serious safety concerns.

REJI BHAMI

Director- Eminent International Testing Centre, Dubai, United Arab Emirates, Hyderabad, India

Over 18 years of experience in façade testing in the Middle East, India and other Asian Countries.

• In case of any excessive air or water leakage, the hot air travels inside and damages the materials which in turn leads to interior damage which doubles the cost for contractors.

• Structural failure will have government as well as legal consequences.

• Seismic activities can lead to glass breakage and system failure.

The expense to perform these tests are lower compared to the cost that would be incurred in case of damage. So, to be on the safer side, it is advised to do the tests prior and guarantee the safety of the building.

For every building, the project (building structure, interface, testing performed, etc.) in its entirety is different. The assessment of the capability of the contractor and the design applied to the new system is key.

Reji has handled several iconic projects such as Dubai International Airport [UAE], Hamad International AirportDoha (Qatar), Riyad Metro Stations (KSA), Nirlon Knowledge Park- Mumbai [India], St. Regis Hotel- Amman (Jordan), French Avenue Project (Lebanon), Cairo Festival City (Egypt), Crescent Tower - Baku (Azerbaijan), Future Museum Dubai (UAE), etc.

He has obtained training from BSRIA (UK) as well as ATTMA for air tightness testing. Reji has completed several air tightness tests in the Middle as part of the LEED certification programme as well as Dubai Green Building Regulations and façade ESTIDAMA requirements.

When constructing any type of façade for any purpose, protecting it with the right passive fire protection solutions is crucial. However, even the most robust and carefully considered fire safety specification can underperform if not installed correctly, undermining the overarching fire safety strategy and increasing the risk to life and property.

Passive fire protection is built into the building envelope and works by containing the spread of fire, heat, and smoke by creating areas of manageable risk— known as compartments— using fire-resistant materials and gap-filling measures. This limits the movement of

Discover how to match esthetics with functionality. With its zip blinds, RENSON® has developed the first exter nal sun screen in the world that was truly wind-tight

• Upto 12 degree reduction in indoor temperature

• Upto 35% reduction in Air conditioning tonnage tonnage

• 10 0 % retractable, motorize d, BMS controlled

• Wind -tight up to 130 k m/h thanks to ingenious zip system

• For glas s sur faces up to 22 m² (width up to 6 m and height up to 6 m)

• N o glare inside, no disturbing reflection in television or computer scre ens

• Inse ct- pro of in close d p osition

• Available in Mosquito mesh fabric as well

Kendre Makarand | Area Sales Manager India Mob: +91 98 22 912 403 india@renson eu www.renson.eu

flames and smoke, protecting escape routes and reducing the risk of fireinduced structural damage which could result in collapse.

Whilst these solutions do not need any input from the building owners or operators, they must be installed correctly to work as intended. Failure to do so could result in gaps in the compartment. This could be caused by inadequate fire-stopping around penetrations such as pipes or gaps, or openings forming between fire-resistant elements such as between the floor slab and the wall construction. These breaches could then provide an easy path for flames, heat, and smoke to spread up and around the building in the event of a fire.

Additionally, passive fire protection solutions that are not installed in line with their manufacturer’s recommendations may not achieve the project’s fire safety design requirement. This is because the installation will not be reflective of the way the products have been designed to work and tested to demonstrate how they would perform. Issues could include the use of incorrect fixings, installing products in the wrong orientation or without the right level of compression, and using them alongside other passive fire protection solutions in untested ways. This could result in a solution which underperforms, reducing the time it will resist fire spread from one compartment to another.

With mitigating the risk of human error in mind, using products that have been

Some firestopping systems are designed with ease of installation in mind - form, fit and function

engineered to be installed quickly and easily can assist in meeting a project’s design intent. This can not only help to ensure a safer project but can help to reduce additional costs and lost time associated with remedial works.

For example, the vertical fibre orientation of dry-fix Lamella fire-stopping products, coupled with clear instructions on the foil facings, can help guide the installer in the correct direction in which to install.

Add it with listing requirements for thirdparty certified tested systems, some curtain wall fire-stopping products carry standardized compression percentages of 10, 12, or 20% for voids of varying sizes, which can simplify the calculation for the installer onsite. This differs from two-part, wet-fix fire-stopping solutions, where the compression requirement for the insulation ‘safing’ component can jump anywhere from 25% to 33% and 55% depending on the listing requirement, and if different safing products from different manufacturers are used interchangeably, the passive fire safety of a project can be compromised.

Factory-engineered one-part solutions not only reduce complications commonly associated with traditional safing material such as: calculating compression; cutting to different dimensions; having to install different sized sections in multiple layers before the wet-apply smoke seal is applied; and dealing with challenges presented by curved and inclined facades, but their dry-fix application also makes it easier to judge the bracket location and distance and ensure tight jointing.

Another key benefit of dry-fix firestopping products is that there is no need for destructive inspection to sign off their installation, with visual inspections being sufficient.

Where required or desired, some manufacturers can also provide these inspections to verify whether their firestopping and cavity barrier products and systems have been correctly installed. This can be invaluable, particularly on large and complex buildings where there may be many different considerations.

Whilst some projects may need or prefer an in-person inspection, some manufacturers also offer inspection apps to streamline this process for contractors working onsite as well as for façade consultants wanting to check the progress and quality of the installation. Typically, only suitable for standard systems, they can allow users to capture images as each area/element is installed and update the data input fields using their smartphone or tablet. The app then immediately turns this into a comprehensive report which can be reviewed offsite by a technical team to ensure the installation meets recommendations and quickly identify if any areas need remedial actions.

Of course, making sure installers are equipped with all the necessary knowledge to deliver an effective installation is important. Working with manufacturers who provide practical onsite training that includes everything from ‘toolbox talks’ to ensure installation instructions and method statements are understood, to delivering practical training and benchmark installations, can provide installers with invaluable insight into potential practical challenges, allowing them to be addressed before the install has progressed.

Moreover, unless a specialist façade contractor with dedicated firestop and cavity barrier installers has been appointed, the individuals installing the safing measures can change from project to project, or even at different stages of a single project. Therefore, having access to manufacturer training throughout the project, and not just at the start, can help to ensure continual adherence to the fire safety strategy.

For this training and onsite support to be effective, early engagement with the product manufacturer is crucial. This is especially true for ambitious, complex designs that need a tailored installation approach, or where there are deviations from the original drawings due to unforeseen challenges or changes in conditions onsite. Additionally, manufacturers can often feedback to design teams so they can learn to help improve the practicality of future designs, ensuring continuous improvement and collaboration.

Installation is crucial to the effectiveness of passive fire protection solutions. Therefore, it is vital installers on all kinds of projects feel confident and competent to deliver accuracy on site. Engaging with manufacturers as early as possible in the process can provide the support necessary to ensure products are handled and fitted in line with recommendations and that they will perform as expected in the unfortunate event of a fire.

(For more information, please email: siderisein@siderise.com or visit www. siderise.com

SREENIVAS NARAYANAN

Technical and Compliance Director , India, the Middle East & Asia Pacific, Siderise Insulation Limited

Sreenivas is the Technical and Compliance Director for India, the Middle East, and Asia Pacific at Siderise Group. He is an avid advocate of advancing fire safety to build safe buildings by getting it right the first time around. Siderise has 50 years of experience in the passive fire protection industry and three fundamental principles underpin their activity: Insight, Ingenuity, and Integrity. Siderise is the only passive fire protection products manufacturer offering a complete factory-engineered solution for spandrel protection comprising perimeter fire seals and perimeter fire barriers. They place technical, accredited and third-party-certified product performance at the very heart of their passive fire protection solutions. Siderise believes that if buildings are to be designed and built with integrity, optimising fire safety in façades and curtain wall structures should start at the concept and design stages.

There is an eternal debate when it comes to the nature of the design process regarding what drives it–whether it’s art or building sciences. The genesis of a concept could be anything–a single spark or an idea that is iterated, developed with the use of tools and knowledge from various trades, and eventually translated into the final form.

A study on ‘Exploration of Aesthetics in Façade Design’ funded by The Dutch Research Council, drove home the underlying parameters that govern our design decisions and preferences.

A statement from the study that most designers would resonate with is a subconscious desire for the complexity of form and the overall character of the façade, despite a strong inclination for simplicity when it comes to the details. This could be achieved through the

medium of design principles such as composition, the play of solids and voids, materiality and more.

The façade is the first thing the user notices when approaching a building and the designer is charged with making it as unobtrusive or as striking

as the requirements and the context calls for. Many of the city skylines across the world are defined by unique silhouettes or characteristic façades. Therefore, designers not only have the onus of meeting project goals and creating a suitable environment for the users, but also have a responsibility for placemaking and identity creation in the urban environment.

The fundamental objective of every project is to enhance the user’s wellbeing and experience. With the plethora of materials, tools, and construction technologies available within our easy reach, we are also becoming increasingly conscious of the impact of our design decisions on the environment and the planet. This brings energy design and performance of the building into greater focus—with designers employing an entire gamut of measures ranging from

passive strategies to designing kinetic façade components for shading and glare reduction.

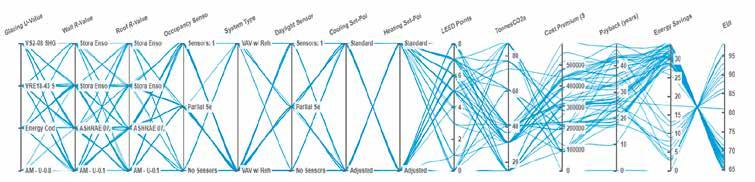

In recent times, we are realising the benefits of treating design, simulation, and fabrication as symbiotic processes. Parametric workflows allow us to rapidly create and evaluate iterative options, with feedback loops created between various parameters such as energy performance, daylighting, shading requirements, material optimisation and structural stability. BIM processes utilized in combination with computational tools, help bridge the gap between design and execution as in the case of the Resnick Sustainability Centre for Caltech.

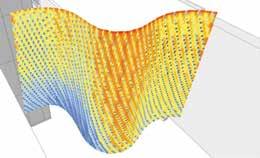

Different tools were used to generate a detailed environmental analysis including a sun path study to understand the solar exposure on different planes of the façade, and a radiation study to understand the thermal comfort of perimeter spaces within the building that have exposure to strong solar loads. The optimisation of the external

fin system and sizing of the mechanical systems has been achieved through a series of thermal comfort studies as shown below.

The interoperability between the key softwares–Rhino and Revit–was leveraged to achieve this façade design. Moreover, there is a conscious shift to involve the contractors early in the design process, where various collaborative building delivery models such as designbuild, design-assist are employed using

the same 3D model for fabrication. This facilitates a seamless transition without information loss across various stages of the project, from concept to construction.

A challenge that we routinely encounter when it comes to getting on board with the data-driven design movement is the lack of conviction and fear of change. A leap of faith into the future would see us embracing computational design and the concept of ‘curation’ and not merely ‘creation’.

When it comes to the design & execution of façades, it is important to resolve every joint and every detail to ensure stability, longevity, and performance. With the advent of technology and relative ease in the production of drawings, one needs to be mindful when it comes to the art of detailing, storytelling & conveying the design intent. The addition to the Kline Center at Dickinson College in Carlisle, Pennsylvania, illustrates the importance of efficient detail resolution amidst design complexity.

An elegant and purposeful sunshade/ veil strikes a delicate balance between

providing views to the exterior while shading the glazed façades. The veil that extends across a majority of three façades could potentially have been heavy and imposing. However, the way it is designed and detailed makes it graceful and unobtrusive. It comprises of keyhole-shaped aluminum hollow extrusions, providing a clean method of attachment, and a stiffer profile to address the requisite span and deepen the shading cut-off as the sun moves across the sky. The angled aluminum blade at the corner of this veil (Fig 7.17.3) is a unique detail and gives the viewer the expression of a crisp edge.

Architectural exposed structural steel with Kynar finish was used throughout the project. The articulated joints of the exposed steel Y-columns and structural tree-shaped columns for the canopy were the results of an extensive design exploration process by the project team.

An ideal façade is ultimately a synchronised symphony, brought to life by the amalgamation of the aforementioned aspects and much more. The following case studies from CannonDesign illustrate several such successful outcomes.

CJ Blossom Park in Suwon, South Korea, designed for one of Korea’s largest companies, consolidated the corporation’s previously disparate pharmaceutical, biotechnology, and food products businesses into a single location. The building’s architecture, which was designed by the Yazdani Studio of CannonDesign, is inspired by CJ’s brand identity—defined by a threepetal blossom. These are represented by three elliptical towers of differing heights,

engagement with fluid circulation and natural light.

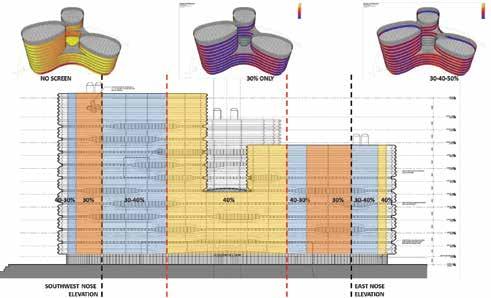

An outer-pleated perforated screen wraps around the entire complex and shades the floor-to-ceiling semi-unitized glazing, providing an even distribution of light deep into the building. By carefully coordinating pleat folds and screen densities with building orientation and program elements, this secondary skin enabled the team to place full-height glazing around the entire perimeter of the building without negatively impacting thermal performance. With a wealth of diffused daylight, the circulation was placed at the perimeter, separated by a glass wall from the laboratories at the centre within each tower. In this way, there is visual connectivity between different disciplines within the building, and the laboratories benefit from panoramic views and natural light.

each housing one of CJ’s divisions. The towers rise around a central atrium that cultivates interconnectivity and

A complete approach to daylighting was achieved with the provision of glarecontrolled exterior and daylighting sensors in addition to the large central atrium. Flexibility, efficiency, and comfort are afforded throughout each floor by a chilled beam system for temperature controls. A detailed solar study led to the optimisation of the perforations to control the incident solar radiation around the building. Perforations range from 30% to 50% at 2-3% intervals based on the

orientation to reduce solar heat gain where needed while still maintaining high levels of natural daylight. This enables the building to save energy, reducing the output of carbon dioxide and other greenhouse gases, ultimately helping to reduce the carbon footprint of the building.

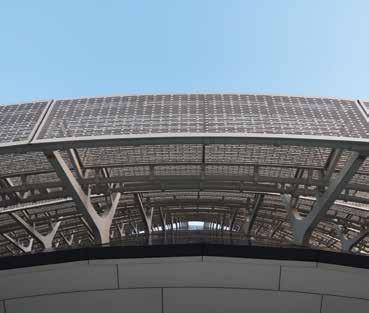

The design of this sophisticated doubleskin facade with the perforated screen wall came with the challenge of its maintenance. Working in tandem with the façade maintenance vendor, the team designed a

Building Maintenance Unit (BMU) system where the automated façade access system runs along tracks on the roof with the carriage dropping from telescoping arms within the space between the veil and the exterior glazing. With over 14,000 panels and well over 1,000 unique panel types, the complex veil form with varying densities presented a challenge to the design, fabrication, and installation efforts. Once the form was resolved, emphasis was placed on detailing and alignments, enhancing the fluidity, and tying together the discrete elements.

• Project: CJ Blossom Park

• Location: Suwon, South Korea

• Client: CJ Cheiljedang Corporation

• Architect: Yazdani Studio of CannonDesign

• General contractor/ construction manager: CJ E&C

• Other Consultants: Iljin, Thronton Tomassetti, ARUP

• Executive Architect and Engineers: Heerim Architects & Planners

• Materials used for façade & fenestration: Unitised glazed aluminum curtain wall without vertical mullions between the floor and the ceiling, folded perforated painted aluminum plate panels on a steel frame and outriggers, and pointsupported glass on glass fins.

• Commencement Date: 2010

• Completion Date: 2015

Case Study - 2

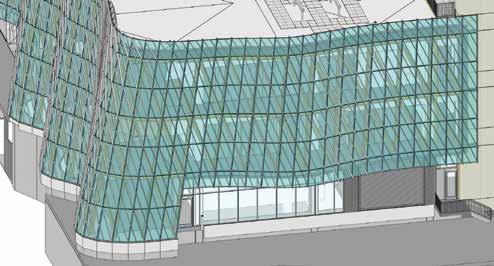

This 10-storey hospital functions as three medical specialty centres— housing inpatient services for high-risk obstetrics and neonatal care, cancer care and advanced surgical care. The building’s overall curvilinear form was driven by the design of the patient units in conjunction with advanced modelling to capitalise on views, maximise daylight, minimise solar gain and glare.

The geometry creates a continuous flowing curve of the exterior—a dynamic form with beautiful proportions that changes as one passes around the building’s perimeter. Elevated gardens and terraces are integrated into the exterior, bringing nature up to the patient floor level. In addition, the façade is further articulated by a series of horizontal and vertical projections, which serve as shading devices. The interplay of these projections along with the varying floor plates breaks down the building mass, making it less intimidating.

With the intent of creating a homogeneous envelope while still achieving screening, thermal performance and daylighting where required, a white ceramic frit pattern was extensively used on the unitised glazing system. To disguise the spandrel areas, the frit pattern is denser, and gradually transitions into the ultra-clear glass at the eyeline. This gradation in the glazing translucency is a defining quality of the entire façade and invokes a sense of serenity.

Maximising views of nature was a critical design consideration since this has been shown to improve the healing process. The floor-to-ceiling vision glazing is a low iron, low-E, solar control glass providing panoramic views of adjacent hills and oceans. The low iron attribute imparts a higher level of clarity and transparency to the glazing, so as not to add a green tint to the pure white ceramic frit. The insulating glazing units have a laminated outside lite with the frit on the exterior and the Low-E coating on the back of the laminated lite within the airspace.

The laminated layer allowed for the frit and the Low-E coating to be located on separate pieces of glass, which improved the procurement and fabrication process. This careful attention to detail, fabrication and execution resulted in this remarkable high-performance façade.

• Project: Jacobs Medical Centre

• Location: San Diego, United States

• Client: UC San Diego Health

• Architect: Yazdani Studio of CannonDesign

• Other Consultants: KPFF Consulting Engineers, Burkett & Wong Engineers, EXP, Pamela Burton & Company

• Materials Used for Façade & Fenestration: Custom Curtain wall by Enclos with glazing by Vitro® and Cristacurva

• General Contractor: Kitchell

• Commencement Date: 2012

• Completion Date: 2016

Credits:

• Prieto. A(2021). What Makes a Façade Beautiful?

https://www.researchgate.net/ publication/352903041_What_Makes_a_ Facade_Beautiful_Architects%27_ Perspectives_on_the_Main_Aspects_ That_Inform_Aesthetic_Preferences_in_ Facade_Design

• Helmy P. Rethinking The Future. https://www.re-thinkingthefuture.com/ case-studies/a8480-jacobs-medicalCentre-by-cannondesign/

• Vitro Architectural Glass. Glass Helps Provide Patients with a Natural, Soothing Environment. Architect Magazine

https://www.architectmagazine.com/ design/buildings/glass-helps-providepatients-with-a-natural-soothingenvironment

AR. AKHILA PILLAI & AR. BAGHYA VENKATARAMANI

Architects, Cannon Design

Akhila Pillai & Baghya Venkataramani are avid design and technology enthusiasts, working with the Mumbai office of CannonDesign. CannonDesign is a global integrated design solutions firm focused on helping people continuously flourish through the ‘Living-Centered Design’ approach. This article is a culmination of a series of interviews with Joe O’Neill, John Reed, Demosthenis Simatos, and Natasha Luthra, leaders from CannonDesign, supplemented with research and perspectives from the authors.