Trust in a passive fire protection manufacturer whose products and systems are underpinned by clear and accessible evidence of performance from rigorous testing. Collaborating in 250+ large-scale system tests and investing in its own fire testing capabilities.

As a practitioner of best practice, we go beyond testing, advocating independent certification even though it’s not always mandatory - but because it is the right thing to do.

Are you ready to Go Beyond?

GEALAN doesn’t just give windows a trend-setting in uPVC window systems. And on top of that, we develop innovative customers real added value. We form the framework for the world of windows.

More

Handle operated multi-point lock for sliding doors

Large choice from Edge, Horizon or Sobinox handle range

Modular: expandable to a multi-point lock with extensions

Vent weights up to 300 kg

Durability: up to 50.000 cycles

Cylinder operated two-point lock for sliding doors

Aesthetical solution for architectural applications

Burglar resistant: SKG*** certified

Vent weights up to 400 kg

Durability: up to 50.000 cycles

Powerful, handle operated, modular lift-slide system

Available in two versions:

standard with locking pins and premium with hooks

Vent weights up to 440 kg

Durability: 20.000 cycles

14

18

22

Façades: The Interactive Element that Elevates Buildings

AR. HARSH POTE & AR. GAURAV SANGHAVI, Pentaspace Design Studio, Mumbai

Façade Design - an Important Element for Leveraging the Real Estate Values

AR. MITESH GADA, Senior General Manager, Design, Brookfield Properties

Harmony in Design: Mitigating Urban Light Pollution through Thoughtful Building Glass Façades and Fenestrations

TANYA KAUR BEDI, Researcher, Indian Institute of Technology, Kharagpur

27 How Enabling Information Transparency Can Improve the Value Recovery of Façades

ADARSH RAINA, Director, Head of Façade Engineering UK, Ramboll; RHEA ISHANI

Graduate Engineer, Façade Engineering UK, amboll

32 Façade Materials and Installation Technologies for Better Acoustics

NISHANTH H.H., Director – Operations & Design, Aedium Design, Bengaluru

38 Understanding the Variations in Test Regimes for Compartmentation & Spandrel Protection Systems in Curtain Walls

DONEL DIPPI, Head of Technical and Compliance, Siderise Middle East, India, and Asia Pacific, Siderise

43 The Critical Role of Fire-Safe Cladding Materials in Fire-Safe Building Façade

UPENDRA WALINJKAR, Founder & Principal Consultant, Aluvision Façade Solutions

48 Explore The Surging Exterior Cladding Market in India

ASHOK KR BHAIYA, Owner and CMD, Aludecor Lamination Pvt. Ltd.

52 Future of Cladding: Innovation and Trends in the Cladding Industry

S antosh G , Global Chairperson - Global Council for the Promotion of International Trade, Director - Global Alliance for Green Building and Infrastructure

68 Cutting-Edge Cladding Solutions Smart & Environmentally Responsible Choices

96 Face to Face

Interview - AR. SRIRAM RAMAKRISHNAN, Principal Architect – FHD India, Bengaluru

104 Industry Speaks

Interview - MALVINDER SINGH ROOPRAI, M.E (Structures), BU Head (AIS Division) Kuraray India Pvt. Ltd.

110 Tensile Architecture PSG College of Architecture, Coimbatore

ARUN MADAPPALLATH, General Manager - South Asia, Serge Ferrari India Pvt Ltd

Cover Image: Credit – FHD India, Bengaluru

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications Printed and published at Thomson Press India Ltd, B-315., Name of the Editor-Ms. Renu Rajaram”

We are excited and happy to inform you that soon we will be launching all-new, cutting-edge website for WFM Media, ushering an advanced digital dimension to our magazine. Stay tuned to tons of information on products and technology related to Façade and Fenestration… A lot of hard work and dollops of passion have gone in to this new initiative and we are sure that our readers will enjoy and benefit from it!

This 56th edition (March-April) is dedicated to a mix of different stories put together for our discerning readers. The article by Ar. Nishanth, Director – Operations & Design, Aedium is on an interesting subject - Façade materials and installation technologies for better acoustics. Experts from Ramboll explain the influence of information transparency in improving the value recovery of façades. There are many other informative articles including the one by Donel Dippi, Head of Technical & Compliance at Siderise and by Upendra Walinjkar of Aluvision Façade Solutions.

Cladding material for exterior façades is usually a non-structural material, which protects the wall against moisture, sun, and wind, while adding to beauty. There’s huge focus in the industry right now on cradle-to-cradle products and systems that are better for the environment, making designers respond to this trend. With carbon restrictions lurking in the near future and increased push towards iconic and innovative buildings, architects and developers find it challenging in choosing cladding materials and systems while complying with budgetary restrictions and tight construction schedules.

How can architects, developers and contractors create buildings alike that achieve improved aesthetics, and optimum performance within budgetary provisions? One solution which strikes the perfect balance is high performance cladding. When design teams select an effective cladding solution, the building realizes a number of high performance benefits including easier maintenance, effective waterproofing, constructability, durability, excellent thermal and acoustic insulation alongside superb performance. We spoke to a number of experts in the construction sector on the subject and the newest in cladding technology and materials. In this exciting edition of Window & Façade, we present interesting views of these experts and their experience in the articles on Cladding Solutions.

WFM team takes pleasure in presenting this issue to our readers and we are sure that it will inspire you to infuse new materials and trends in your projects. We want our readers to analyse contents of this magazine, comment on what appeals and send feedback on the same. Hope you will find this issue informative and thoughtful and enjoy reading it.

Buildings possess the charm to speak to their environment. Their surroundings include other buildings, people, the street, and the place as a whole. Amid the repetitive faces seen in the surrounding structures, a building with a distinct façade catches the eye. It then starts a dialogue between the occupants, the passersby, the rest of the buildings, and the street, and becomes a landmark in itself.

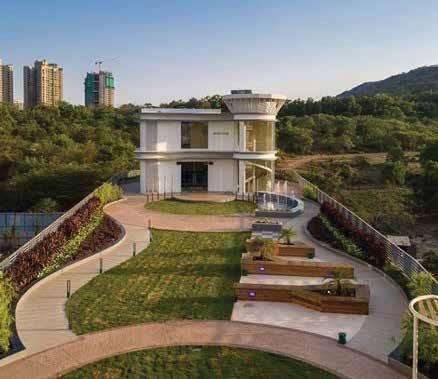

Pentaspace Design Studio, an architecture and design firm in Mumbai, creates distinct façade designs that become landmarks in the town. Gaurav Sanghavi and Harsh Pote, Partners, speak of a few of their projects that define Pentaspace’s distinct signature.

Nestled in the heart of the city lies a stunning architectural masterpiece that captures the essence of the surroundings and creates discourse. Rainforest, a residential complex

located in the Marol area of Mumbai, is situated amidst the lush rainforest trees that offer stunning views of Powai Lake and Aarey Colony. Pentaspace has taken inspiration from nature itself to create a replica of its surrounding landscape that blends seamlessly with its environment

and provides an oasis of calm amidst the hustle-bustle of the city.

The earthy tones used in the façades, landscape elements, and drop-off canopies beautifully reflect the natural beauty of the rainforest. The dropoff areas have been designed as tree canopies, making visitors feel as though they are entering a forest. “We translated the foliage as a design feature and made it an integral part of the design where the architectural language reflects the natural surroundings. More than an acre of land was landscaped on Mother Earth with the theme of the Amazon rainforest,” says Gaurav.

The site of the complex was heavily contoured and the area was covered with dense rainforest trees that had to be retained. The architects had to achieve a balance between retaining the most number of trees on the site and providing a wide vista for the eleven residential towers, so, the buildings were planned in a staggered manner to adapt to the topography.

Capturing the essence of the Amazon rainforest, the complex’s design is aesthetically pleasing and offers residents a unique living experience that is both tranquil and luxurious.

The Chambers building in Andheri is a marvel of architecture that stands tall and proud in the bustling Chakala commercial area. Its unique form has earned it the title of the ‘Jewel of the suburban business

district’. The diamond-shaped building reaches angularly for the sky, a result of several challenges faced during the design process.

One of the biggest challenges faced by the architects was the oddshaped, curvilinear plot on which the building was to be constructed. Other challenges included the ongoing Metro rail construction along the adjoining road, modifications in municipal

and construction rules, and height restrictions.

The site’s unusual shape posed significant difficulties for the designers, who had to come up with innovative solutions to make the most of the available space. They decided to turn the building elevation diagonally north-west at a 45-degree angle, which opened it up to the busy highway and the surrounding cityscape.

The building, which catches the eye during the day, stands in its full glory in the dark hours as well. The striking LED strip around the edges of the diamond glows brightly in the night sky, making it a shining landmark for the surrounding area and giving a unique identity to the region.

The residential project Aroha in Borivali is a perfect example of how architecture and design can be inspired by the rich cultural heritage of a place. The design of the building is inspired by the nearby Kanheri Caves, which have been recognized as a UNESCO World Heritage Site. Pentaspace has integrated aspects of Buddhism into the design, creating a space that is not only aesthetically pleasing but also evocative of the historical significance of the area.

As inhabitants enter, they are greeted by lobbies adorned with carvings depicting the story of Buddha, directly reproduced from the Kanheri Caves. The history and significance of the area are carried into every aspect of the design. These carvings also help to create a sense of continuity between the past and present, reminding visitors of the rich cultural heritage that surrounds them.

Natural stones are used for wall cladding and flooring, which adds to the aesthetic appeal of the building. The long drop-off canopy with cutouts is a unique feature that allows natural light to penetrate through the entire space and emulate Buddha’s teachings. The flooring on the podium level and the landscape area are made of stamped concrete that resembles a cave floor.

“The caves narrate a story, and Aroha has been designed in a way to create a microenvironment for its inhabitants amidst

the concrete jungle by amalgamating the cave architecture features into modern architecture, to inculcate a sense of awareness and curiosity of the heritage grandeur present in the vicinity,” says Harsh.

Rainforest, Chambers, and Aroha show the ways in which buildings become the representation of the locality. The frontage of a building is a crucial element of its architecture; it sets the tone for what is inside and gives passersby a glimpse of what to expect. Pentaspace Design Studio has made this part a focus of their style that leaves an impression on the minds of visitors as well as the whole city.

Pentaspace Design Studio, Mumbai

A 15-year-old full-service design consultancy, Pentaspace works on real estate projects in the residential, commercial, institutional, and hospitality sectors. Over the years, they have expanded their portfolio from a single building in Mumbai to nearly 1.5 crore square feet of real estate development. Pentaspace is one of the fastest-growing architectural firms in the country today. In Mumbai, Pentaspace is currently working in a multitude of pockets broadly categorized into two diverse portfolios – Premium High-Ticket and Standard High-Volume. Venturing beyond Mumbai, Pentaspace is tapping into other regions like Nagpur, Chennai and Hyderabad doing 15,00,000 to 20,00,000 square feet of projects.

The firm is headed by Gaurav Sanghavi, Harsh Pote, Pragya Sanghavi, and Bhakti Pote.

It is often said that “Looks do Matter” and this is very true when it comes to the building facades too.

The word ‘façade’ originates from the Italian word “facciata” and it means the exterior or the faces of a building. The façade on any building has 2 main functions. Firstly they act as a barrier or skin that separates the interior face from the external environment and secondly, they create an image of the building. And hence façade design is a very important aspect of a building. Building façade or the skins plays a pivotal role in architecture. They determine the aesthetic appearance of a building, and its relationship with the surrounding context, and they are the interface between the built and human dimensions of our cities. They often dynamically mediate between the indoor and outdoor environments.

With the changing times architecture and façade design have also changed and people are becoming more and more conscious about the environment

they stay and work. Be it their houses/ apartments/workspaces or business premises everything matters to all from children to the youth, to the adults and the old generation.

There is a sense of ownership one carries for their houses and workspaces and the building facades play a crucial role in this. Buildings today are no longer considered boxes or just functional spaces as it is here where people interact, grow, create memories, and live their lives.

The building façade, be it for a residential apartment or a commercial building, is the calling card of the project as it is the most iconic, one of the most aesthetic and recognisable elements which help create an identity of the building. With more and more globalization, a lot of focus has been seen on ESG and Sustainability by various companies, stakeholders & governing bodies. There is a lot of focus on IGBC, USGBC, LEED, WELL, and EDGE certifications of the building where façade design becomes a very crucial element of the building design.

Broadly the façade design should be addressed with the following characteristics.

Adding a Character to a Building:

The building façade could be a derivative of the local architecture, create a new identity of its own or be a result of a climate-responsive design.

Natural Ventilation:

If intelligently designed and executed façade could also help natural ventilation to the buildings and help reduce the ventilation cost and improve the wellbeing of the users. E.g. The Jali’s used in the traditional buildings in Jaipur like Hawa Mahal and the modern-day version of the same can be seen in the PAM centre in Malaysia.

Act as a barrier against the external environment:

The interiors of the building are protected from the rain/sun/wind. There are buildings which have smart façades where the façade as a whole or some elements such as fins and shades move or rotate basis the change in local climate during different times.

Energy Efficiency:

Today when we speak highly of ESG, Human Well-being, and Sustainability, the façade design plays a very important role here. The façade, apart from being aesthetic, also has to address the issue

of energy efficiency. A good climatic responsive façade can help reduce the solar heat gain and reduce cooling requirements thus reducing the HVAC cost in terms of the CAPEX and OPEX. A lot of research has been done on this including biophilic design, Vertical greens, glass selection and other façade elements like sunshades, fins, canopies, and multi-level terraces to increase the energy efficiency of the buildings.

A good climatic responsive and successfully implemented façade has a deep impact on the occupants of the building. Carefully designed façade which allows light and natural ventilation through various design elements such

as louvers, courtyards, terraces, shading devices and automated façade systems that help regulation of the air and light movement through the structure and have a positive impact on the occupants. It impacts their mental well-being and physical well-being too. This in turn results in better productivity and results.

While façades are often referred as to the skins, they add an aesthetic appeal to the buildings. Interesting facades with distinctive features, a splash of colours, layers and elements add a lot of visual appeal and appreciation to the building. Buildings with unique features often become local or global landmarks for the way they have been designed and add a lot of value to the structure itself and the neighbourhood too at times.

Facades which are carefully designed can also influence the life and valuations of the buildings. The use of innovative materials, shading devices, unique systems, sustainable designs and a pop of colours is what brings structures to life and shall help extend the life and value of the building. The extended life and value in terms translates to higher yields for the people associated with the buildings whether they are the developers, the owners, or the occupants.

Today when we see such buildings around us, they bring a sense of pride

to the developers, consultants, and contractors associated with building these structures, the companies (including local as well as Global MNCs) who buy/lease these and the end user who actually use it on a day-to-

day basis. There are various examples where we see that buildings which have aesthetically pleasing façade easily demand more rents or selling prices with their competitors which are similar in nature. E.g. The World Towers by Lodha developers in Mumbai.

1. Invest in High-Quality Materials:

Be it a residential or a commercial building, the use of durable and longlasting materials adds life to it. The use of high-quality materials brings a sense of luxury to the buildings. Modern-day buildings use modern technology and materials to create an amazing façade.

E.g. The Guggenheim Museum, Bilbao.

2. Colour, Texture, Pattern:

Adding a splash of colours, certain textures and patterns can make the façade very interesting and create an ever-lasting memory for developers and the occupants of the building. A unified and aesthetically beautiful facade can be achieved by selecting a colour scheme that compliments the architectural design and the surrounding area. Contrarily, the texture gives the exterior depth and intrigue. E.g.: IMI International Management Institute – Kolkata, India & Brandhorst Museum – Munich, Germany.

3. Interesting façade elements:

Various façade elements such as curved walls, fins, and colours can bring drama to the building façade and enhance the building design. e.g. Kuggen Building –Gothenburg, Sweden.

With rapid globalization, the Gen X and Gen Y who are well travelled and who have the world at their fingertips their choices of homes, workplaces and other spaces of interaction are largely and deeply driven by the pointers mentioned above. They should not be referred to “as spoiled for choices” but for “wise decisions” they make. And to conclude “LOOKS DO MATTER”. Kuggen Building – Gothenburg, Sweden

Senior General Manager, Design, Brookfield Properties

Mitesh Gada is an architect and interior designer based out of Mumbai and is associated with Brookfield Properties as a Senior General Manager, Design.

With an overall experience of 20+ years, he has diverse experience in architecture, interiors, master planning, retail design and execution. Graduated from the prestigious Rizvi College of Architecture, Mumbai Mitesh started his career as a Junior designer with Access Architects Mumbai. He worked on projects for developers like Mahindra Lifescapes, Shaopoorji Pallonji, Naman Group and others. Further, he has successfully anchored the design management for Lodha Developers on their prestigious projects like The World Towers, and Lodha Seamond.

Later he worked with Runwal Developers on their project a 115-acre integrated development at Dombivli He then moved to a bigger role at Godrej Funds a private equity arm of The Godrej Group as the Lead for the Mumbai and Pune regions for their upcoming Commercial developments.

He owes this knowledge and leadership qualities with his enriching associations with international and national consultants such as Pei Cobb Freed & Partners New York, LERA New York, Armani Casa Italy, Nikken Sekkei Japan, Kohn Pederson Fox London, Hirsch Bedner Associates Singapore and others.

The increase of artificial light at night, contributing to the phenomenon of light pollution, is an escalating concern amid global urban development. Numerous cities now boast a luminous sky visible from considerable distances, showcasing the foremost manifestation of light pollution, characterized by excessive or misdirected artificial light. Light pollution poses significant threats to human health, impacting various physiological and psychological aspects. Exposure to artificial light during the night disrupts circadian rhythms, leading to sleep disturbances and insomnia. The suppression of melatonin production, particularly by blue light emitted from electronic devices and outdoor lighting, contributes to an increased risk of certain health issues, including cancer. Moreover, prolonged exposure to bright artificial light is associated with heightened stress and anxiety levels, potentially

leading to mental health disorders such as depression. The impact extends to ocular health, causing discomfort, eyestrain, and potential vision problems. As a researcher, it is crucial to explore

the specific mechanisms through which light pollution influences human health, citing relevant studies and proposing mitigation strategies. Additionally, acknowledging the indirect effects on wildlife and ecosystems can provide a comprehensive understanding of the broader implications of light pollution. Recent urban development trends have ushered in a surge of artificial light at night, primarily for amenity or security lighting purposes. This surge has substantially transformed the nocturnal landscape & luminosity of urban areas. Light pollution has transcended local boundaries to become a worldwide issue, progressively diminishing the ability to observe stars and instigating a range of environmental and energy challenges. Its components include glare, heightened unnecessary illumination, temporary lighting, and unforeseen fluctuations in lighting levels.

Diverse sources such as streetlights, fishing boats, buildings, vehicle headlights, and even lights on undersea research vessels collectively contribute to the creation of a domical sky glow, among which reflective building Façades and light through fenestrations are major contributors in urban areas. Additionally, Artificial Light at Night (ALAN) has also been linked to energy wastage, urban heat islands, and, air pollution, further emphasizing the intricate web of consequences associated with excessive night-time illumination. The use of glass in Façade and fenestration design has become increasingly popular in modern architecture due to its aesthetic appeal and functionality. However, the extensive use of glass poses challenges in terms of light management, particularly in urban environments where artificial lighting is prevalent. These contribute to light pollution through various mechanisms, buildings with glass Façades often use exterior lighting for illumination or decoration, which can add to light pollution if not properly controlled or directed; the transparency of glass allows internal lighting to be visible from the exterior, contributing to glare. Glass surfaces can reflect artificial light, amplifying its intensity and contributing to light pollution in surrounding areas. Architects, urban planners, and lighting designers can collaboratively address

and reduce light pollution, specifically in the context of building Façades and fenestrations, through the following strategies:

• Minimizing Decorative Lighting: Controlling and regulating the use of decorative exterior lighting in architectural structures as a means to diminish light pollution can be helpful.

• Directional Lighting Design: Opt for selective and directional lighting that minimizes upward or outward light spillage. Use fixtures with shields or hoods to direct light where it is needed.

• Smart Fenestration Planning: Integrating smart fenestration systems that control the amount of natural and artificial light entering buildings based on time and environmental conditions. Utilizing window films or coatings that reduce glare and limit light reflection into the surrounding environment.

• Selective Glazing: The use of selective glazing materials can help control the amount of light transmitted through windows while reducing reflectance.

• Low-E Coatings: Low-emissivity (Low-E) coatings can be applied to glass surfaces to reduce both heat gain and reflectance, thereby

improving energy efficiency and visual comfort.

• External Shading Devices: External shading devices, such as louvres or overhangs, can be incorporated into Façade design to reduce direct night light penetration and minimize glare for occupants indoors.

• Building Materials: Choose building materials with low reflectance to reduce the scattering of light, and contribute to a darker urban environment during the night.

• Adaptive Lighting Control: Implement advanced lighting control technologies such as dimmers, timers, and motion sensors to regulate artificial lighting levels. Adaptive lighting systems that adjust intensity and colour temperature according to the time of day, occupancy or specific activities.

The impact of building glass Façades and fenestration design on urban environments extends beyond aesthetics, profoundly influencing light pollution levels and reflectance properties. By employing thoughtful design strategies, architects and urban planners can mitigate light pollution, enhance urban sustainability, and create more liveable cities. Balancing the aesthetic appeal of glass Façades with the need to optimize reflectance is essential for sustainable urban development in the 21st century. The design of building glass Façades and fenestrations significantly influences the quality of urban environments, particularly concerning light pollution and reflectance. Innovative design strategies and technologies empower architects and urban planners to address these issues while crafting sustainable and visually appealing spaces. However, effective light management necessitates a multidisciplinary approach that considers both environmental and human factors. Ongoing research and collaboration are essential to tackle such challenges. The contribution of building Façades to light pollution at night is a significant concern in urban

environments. Exploring strategies to mitigate the adverse effects of illuminated Façades on light pollution is crucial for promoting sustainable urban lighting practices.

References:

1. Hatori, M., Gronfier, C., Van Gelder, R.N. et al. The global rise of potential health hazards caused by a blue light-induced circadian disruption in modern aging societies. npj Aging Mech Dis 3, 9 (2017). https:// doi.org/10.1038/s41514-017-00102

2. Shariff, N N M & Hamidi, Zety & Faid, Muhamad Syazwan. The Risk of Light Pollution on Sustainability. ASM Science Journal. 12. 134 (2019).

3. Bedi, T.K., Puntambekar, K. & Singh, S. Light pollution in India: appraisal of artificial night sky brightness of cities. Environ Dev Sustain 23, 18582–18597 (2021). https://doi.org/10.1007/ s10668-021-01384-2

4. Bedi, T.K., Puntambekar, K. & Singh, S. Assessment of Light Pollution in Indian Scenario: A Case of Bangalore. J. Inst. Eng. India Ser. A 102, 657–672 (2021). https://doi.org/10.1007/ s40030-021-00530-3

TANYA

KAUR BEDI

Researcher, Indian Institute of Technology, Kharagpur

Tanya Kaur Bedi has an extensive academic background in architecture and environmental planning, culminating in a PhD from the Indian Institute of Technology (IIT), Kharagpur. Tanya has achieved notable accolades throughout her professional journey, including being a Gold Medallist from NIT Bhopal and receiving the CSIR and SERB Grants from Government of India. She specializes in devising solutions for challenges such as declining indoor air quality and light pollution, with a focus on the health and well-being of building occupants. She has effectively disseminated her research findings as a published author in reputable journals and by presenting her work internationally in the United States, China, Portugal, and others. Through these, Tanya has contributed to the global discourse on built-environment issues.

The building industry is materialintensive and has a significant impact on the economy and the environment. It is responsible for approximately 40% of the total waste generated across the European Union (Boorsma et al., 2019). Additionally, façades can account for up to 40% of a building’s total carbon emissions.

The building industry can be regarded as dynamic and highly fragmented in nature. There are many stakeholders involved right from the inception to the End-ofLife (EoL) of the building. The concept of Circular Economy (CE) is heavily debated and interpreted differently by numerous

stakeholders. This suggests that while the concept of Circular Economy (CE) is wellestablished in theory, it lacks a transparent framework which can be translated into practice.

The core idea of CE can be simply translated into three fundamental strategies towards the cycling of resources.

l Slowing resource loops: extending the service life of a product through the application of strategies such as reuse, recycle and remanufacture.

l Closing resource loops: recycling bridges the loop between post-use and production leading to a circular flow of resources.

l Resource efficiency: narrowing resource flows with a goal of using fewer resources per product.

In the contemporary discourse, digital technology is increasingly recognised as a pivotal force fostering the seamless exchange of information among stakeholders throughout the value chain, serving as catalysts for the adoption of circular business models. The enhanced transparency and improved quality of information can boost decision-making processes to improve the value recovery of façade (building) components. Ultimately the implementation of circular strategies hinges on effective management of

resources, highlighting the integral role of digital technology in shaping sustainable practices.

Several digital innovations have emerged to support circular strategies in the built environment namely, material passports (MPs), Building Information Modelling (BIM). This has sparked the initiation of numerous funded projects such as BAMB and Platforms such as Madaster. They are leading the way in developing, testing, and promoting the use of material passports while also emphasising Reversible Building Design. The former will offer data regarding manufacturing processes, packaging, handling, and warranties, guiding manufacturers in implementing appropriate strategies at the end of the product’s lifecycle. Meanwhile, the latter will assist in disassembling and reusing building components. Additionally, Blockchain technologies, the Internet of Things (IoT), and Façade as a Service (FaaS) are other enabling technologies that have the potential to streamline the transfer of information among stakeholders.

Despite our awareness of viable solutions that could propel us to achieving a circular economy, the question persists: What are the current challenges and how does this shape our current design process? To answer the posed question, the following iterative concepts are explored: (1) Challenges with existing buildings (2) Lack of product data is one of the biggest inhibitors (3) Material passports and their role in implementing circular economy (4) Our Current design process must address these challenges in our new designs.

General challenges related to conducting technical assessments on the existing façade systems include:

l Limited or no information available on the original façade manufacturer

l Limited as-built information

l Most of the façade components have reached their End of Life (EoL)

l Challenges in coordination between

various stakeholders of the value chain to disassemble the existing façade.

Challenges associated with the reuse of façade components include:

l Reduced strength

l Limited as-built information

l Potential non-compliance with current regulations

l Uncertain strategy to procure warranties due to varied approaches to residual service life (e.g., glass, perimeter seals, gaskets, etc).

Some of these challenges can be overcome by testing, validations, and or modelling to establish the baseline performance. However, these processes are often time-consuming and reliant on assumptions derived from limited existing information, thereby introducing uncertainty and commercial risk.

As mentioned in the previous section, lack of product data is a key obstacle

to reuse, repair and remanufacture the product. Notably, one significant difference between building products and general consumer products is the short ownership period compared to the product’s service life.

Consequently, original manufacturers lose control over the building products post-installation, with repairs typically handled by third parties who lack manufacturer status. This results in a knowledge gap, leaving manufacturers unaware of product drawbacks. At the product’s End of Life (EoL), a third party steps in to recover residual value, yet pertinent information such as packaging instructions, disassembly procedures, and maintenance documentation is often absent.

This communication gap poses challenges for disassembly and recovery, rendering repair and reuse unfavourable options. The industry’s initial step toward resolution involves integrating material passports into Building Information Modelling (BIM)

models, thereby transforming existing buildings as material banks.

As defined by (Bokkinga,2018), “a Material passport (MPs) is a digital database with valuable information on materials,

elements and components present in the building”. Its range is classified into different levels namely materials, components, products and systems that are present in the building.

The concept of Material passport is increasingly being recognised as a crucial component within the construction industry as an integrated information system which will bridge the gap between physical materials and digital databases. They contain information on lifecycle management that can be used to recover a product at its EoL thereby reducing waste generation, pollution, and decreased landfill. This quality makes them crucial in steering the construction industry towards a circular value chain.

The advanced tracking features of MPs provide immediate information on location and material properties highlighting the risks associated and promoting sustainable recovery. While the potential of MPs is established in academic literature, there is a gap in realising its application. The selection of a suitable MP is vital due to the complex supply chain comprised of numerous stakeholders with variable data needs. One of the compelling options is the integration of MP with automatic identification systems such as Radio Frequency Identification

(RFID) which provides an efficient method for managing the flow of materials and information. Façade system designers namely Schueco have already integrated this technology into their products, and a notable transformation is anticipated as these technologies become commonplace.

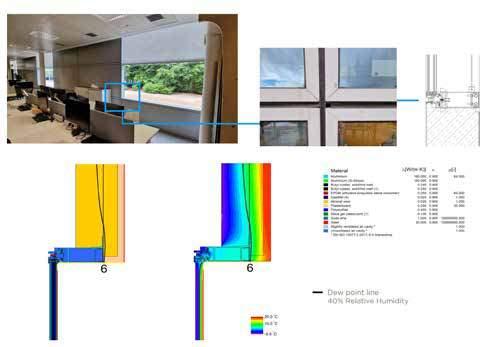

A notable disparity exists and we acknowledge this gap and are actively leading efforts to promote sustainable transformations across projects. Our façade design process fosters collaboration among diverse engineering disciplines, with project inputs and outputs mutually influencing each other—an aspect we are particularly mindful of.

It is crucial to bridge this gap and endeavour to narrow it as much as possible. To facilitate collaboration, several digital tools are developed which enable rapid and accurate assessments of various façade systems, generating essential data crucial for informed decision-making. These initiatives are guided by sustainable design principles and lay the groundwork for the future development of material passports.

ADARSH RAINA Director, Head of Façade Engineering UK, Ramboll

Adarsh, Head of Façade and Façade Access Engineering in the UK, is dedicated to crafting sustainable and innovative façade solutions. With extensive expertise in façade engineering, he excels in technical, aesthetic, and performance aspects of diverse façade systems. Adarsh remains abreast of industry trends and technologies, leveraging his experience on complex, multi-disciplinary projects across sectors like Aviation, rail, hotels, and more. His portfolio spans India, UK, Middle East, and France, showcasing his global perspective and versatile skill set.

RHEA ISHANI Graduate Engineer, Façade Engineering UK, Ramboll

Rhea, a graduate Façade Engineer with an architectural background, completed her studies at (Bouwkunde) Delft University of Technology, specializing in Building Technology. Her thesis centered on circular economy and remanufacturing of end-of-life façade products. Engaged in diverse residential and commercial projects, her focus is on crafting innovative solutions for an environmentally conscious and resilient built environment. Passionate about sustainability, she aims to contribute positively through her work

“Experience the best of both wor ld’s with us”

Discover the future of window a u t o m a t i o n w i t h o u r e l e c t r i c opening drives. Say goodbye to the hassle of manual window operation, making daily life more comfortable.

These drives ensure effortless ventilation, and in emergencies, they serve as essential smoke a n d h e a t e x t r a c t i o n o p e n i n g s during fires, providing an extra layer of safety. Make your space

s m a r t e r a n d s a f e r w i t h o u r cutting-edge window automation s o l u t i o n s , w h e r e c o n v e n i e n c e meets security.

In the fast-paced urban landscapes of today, where the rhythm of city life reverberates, the necessity for peaceful and tranquil architectural spaces has become increasingly apparent. Acoustic comfort, often overlooked yet crucial for both wellbeing and productivity, stands as a fundamental consideration in contemporary architectural design. The façade, serving as the intermediary between the external environment and the interior sanctuary, holds significant sway in shaping the acoustic ambience within structures.

This article embarks on a journey into the intriguing realm of façade materials and installation techniques, exploring their role in optimizing acoustic comfort in modern constructions. From conventional materials with enhanced

mass characteristics to cutting-edge sound-absorption technologies, this piece will delve into the myriad of options available to architects, designers, and builders aiming to craft spaces that blend harmoniously with their auditory surroundings as well as their visual aesthetics.

The importance of acoustics in architectural design cannot be overstated. Unwanted noise stemming from traffic, construction activities, or other sources can disrupt concentration, impede communication, and adversely affect overall well-being. Moreover, internally generated noise, such as that from HVAC systems or human activities, exacerbates the issue. Consequently, addressing acoustic challenges is imperative in creating environments conducive to productivity, relaxation, and a sense of serenity.

Façade materials play a pivotal role in mitigating noise infiltration from external sources. By opting for materials with superior sound insulation properties, architects can establish a barrier between the interior and exterior environments, thereby minimizing the impact of external noise on occupants. Furthermore, innovative materials like acoustic insulation panels or perforated metal panels offer targeted solutions for managing reverberation and echo within enclosed spaces, thereby enhancing acoustic comfort.

Installation technologies also wield significant influence in optimizing acoustic performance. Techniques such as decoupling, which isolates building elements to reduce sound transmission, and active noise control systems, which utilize advanced technology

to counteract ambient noise, present effective means of enhancing acoustic comfort in buildings. Proper sealing and weather stripping of a building ensures components ensure airtightness, further mitigating the ingress of external noise.

By embracing the latest advancements in acoustic design, architects and designers can fashion spaces that not only captivate the eye but also provide solace to the soul, offering a refuge of tranquillity amidst the urban commotion.

Before delving into the specifics of façade materials and installation techniques, it is imperative to comprehend the fundamental principles governing acoustics within buildings. Such comprehension is essential for crafting spaces that prioritize comfort and productivity. Acoustics in buildings pertain to the behaviour of sound waves within enclosed spaces, influenced by diverse factors such as architectural layout, material selection, and activities conducted within.

External sources of noise, including traffic, construction, and urban development, pose significant challenges to indoor environments. These noises can permeate buildings through windows, walls, and doors, disrupting concentration, communication, and overall comfort. Additionally, factors such as proximity to highways or industrial zones can exacerbate noise levels, impacting the quality of life for occupants.

Internally generated noise, encompassing HVAC systems, mechanical equipment, and human activities, further contributes to the acoustic dynamics within buildings. Inadequately insulated walls, floors, and ceilings can facilitate noise reverberation and echo, creating discomfort and distraction for occupants. Moreover, open-plan layouts, while fostering collaboration, can also lead to elevated noise levels if not properly managed.

Architectural design assumes a crucial role in mitigating the impact of both external and internal noise sources. Strategic placement of rooms, corridors, and building elements can minimize noise transmission and optimize sound quality within different areas of a building. Additionally, the selection of appropriate materials endowed with sound-absorbing properties is vital for controlling reverberation and enhancing acoustics.

Materials such as acoustic insulation panels, mass-loaded vinyl, and doubleglazed windows are commonly employed to ameliorate sound insulation and reduce noise transmission. These materials absorb sound waves, preventing them from bouncing off surfaces and causing

reverberation. Green façades, integrating vegetation on building exteriors, can also function as natural sound barriers, thereby further enhancing acoustic comfort.

Advanced installation technologies, such as decoupling systems and active noise control, offer additional tools for managing acoustic dynamics in buildings. Decoupling techniques entail isolating building elements to minimize sound transmission between them, while active noise control systems utilize sensors and speakers to detect and counteract ambient noise in real time.

In conclusion, comprehending acoustic dynamics in buildings is crucial for creating environments that promote wellbeing and productivity. By addressing

external and internal noise sources through architectural design, material selection, and advanced installation technologies, architects and designers can optimize acoustic comfort within buildings. Ultimately, a holistic approach that considers the unique characteristics and requirements of each space is pivotal in achieving optimal acoustics and enhancing the overall quality of life for occupants.

1. Mass-Enhancing Materials: Dense materials like concrete, brick, and stone possess inherent mass that effectively absorbs and dissipates sound energy. When integrated into façade construction, these materials serve as robust barriers against external noise intrusion, shielding indoor environments from unwanted sound. Incorporating massenhancing materials into façade assemblies significantly enhances sound insulation properties, fostering tranquillity and acoustic clarity within buildings.

2. Acoustic Insulation Panels: Engineered to absorb sound energy, acoustic insulation panels offer

tailored solutions for controlling noise levels within buildings. Comprising of materials such as fibreglass, mineral wool, and foam, these panels mitigate reverberation and echo, thereby enhancing acoustic comfort and clarity. By integrating them into façade assemblies, architects and designers can achieve remarkable improvements in acoustic performance, creating serene indoor environments conducive to concentration and relaxation.

3. Double-glazing Systems: Windows, often perceived as weak points in building envelopes, can be fortified against sound infiltration through double or triple-glazing systems. These systems feature multiple layers of glass separated by air or gas-filled gaps, providing enhanced acoustic insulation. Laminated glass with an acoustic interlayer further augments sound attenuation, ensuring tranquillity within indoor spaces while facilitating visual connectivity with the external environment.

4. Perforated Metal Panels: Blending functionality with aesthetics, perforated metal panels offer an elegant solution for acoustic optimization. By strategically

incorporating perforations of varying sizes and patterns, these panels scatter and absorb sound waves, mitigating reverberation and controlling noise levels. Customizable in design and highly effective in performance, they constitute an integral component of acoustically superior façades, enhancing both visual appeal and auditory comfort.

5. Green Façades: Nature, with its innate tranquillity, holds immense potential for mitigating noise pollution. Green façades, adorned with lush vegetation, serve as natural sound absorbers, reducing noise levels within buildings. Beyond their acoustic benefits, they contribute to environmental sustainability, thermal regulation, and aesthetic enhancement, fostering a harmonious integration of built and natural environments.

Decoupling Systems: Decoupling methods rely on isolating structural elements to minimize the transmission of sound vibrations. Utilizing resilient mounts, floating floors, and suspended ceilings, these systems effectively prevent the spread of structural noise, thereby enhancing overall acoustic performance. By reducing direct contact between building components, decoupling systems create tranquil indoor environments conducive to concentration and relaxation.

Maintaining airtightness is crucial for combating both air infiltration and sound transmission. Various weatherstripping materials, such as silicone seals, rubber gaskets, and acoustic caulks, are employed to create impermeable seals, safeguarding indoor spaces against external noise intrusion. Proper sealing of building envelope components ensures clarity and comfort in acoustics, thereby enhancing the overall quality of indoor environments.

Soundproofing Membranes: Applied to structural elements like walls and floors,

soundproofing membranes offer a robust defence against airborne noise. These flexible membranes dampen vibrations and impede sound transmission, thereby reinforcing sound attenuation within the building envelope. By improving the acoustical integrity of building assemblies, soundproofing membranes contribute to creating tranquil and harmonious indoor environments.

Active Noise Control Systems: Leveraging advanced technology, active noise control (ANC) systems provide real-time mitigation of unwanted noise. Employing microphones and speakers to detect and counteract ambient noise, ANC systems offer tailored solutions for enhancing acoustic comfort and fostering serene indoor environments. Whether in open-plan offices or residential dwellings, ANC systems provide versatile solutions for creating tranquil and harmonious indoor environments.

In summary, achieving optimal acoustic performance in buildings necessitates a holistic approach that integrates both façade materials and installation technologies. By leveraging soundabsorbing materials, double-glazing systems, green façades, and innovative installation methodologies, architects and designers can create spaces that prioritize tranquillity, productivity, and well-being. Enhancing acoustic comfort not only enhances the occupant experience but also reflects a commitment to creating sustainable, user-centric architectural environments.

As the demand for acoustically superior buildings continues to grow, embracing the latest advancements in façade materials and installation technologies becomes paramount in shaping the future of architectural design.

Director – Operations & Design

Aedium Design, Bengaluru

With 20 years of professional experience, Nishanth H.H. is a design leader who has contributed to top design practices in India. His expertise lies in spearheading the design, management, and delivery of a diverse portfolio of projects, including large-scale commercial, residential and mixed-use developments.

Nishanth plays an integral role in every stage of project development, ensuring that each design meets the highest standards of quality and innovation. His passion for design excellence drives him to continuously push boundaries and set new standards.

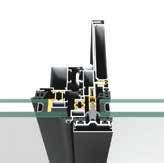

CCurtain walls have been shaping the visual identity of modern buildings since the late 19th century, especially for sky-high multi-occupancy structures. However, design and safety standards have evolved - and so have the passive fire protection measures employed to safeguard the lives of those using these buildings.

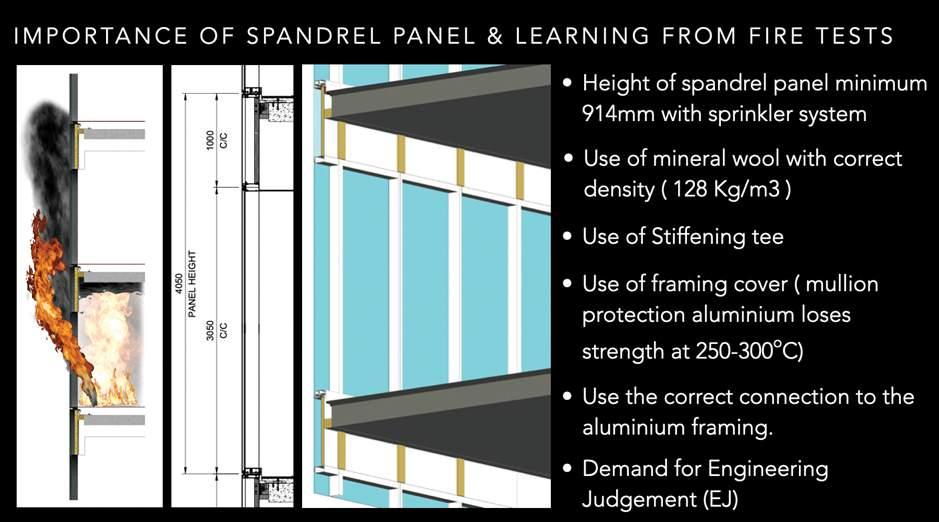

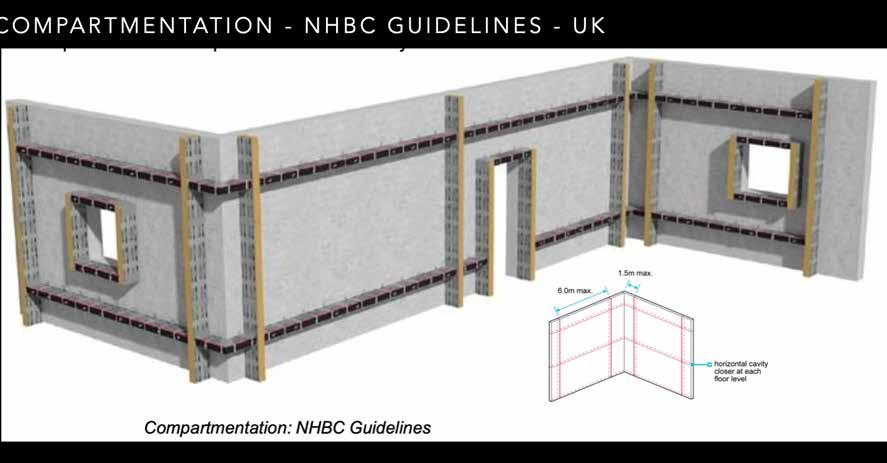

To protect these properties effectively in a fire, it is vital to ensure that compartmentation between the floor slab and the façade—an area referred to as the spandrel zone— is robust. However, there are many different passive fire protection products on the market that have been tested to different standards or combinations thereof. It is important that designers, specifiers, and fire engineers appreciate the variances in the scope of these tests for a more

holistic understanding of the firestopping measures installed within the spandrel zone and to ensure the highest levels of fire safety are achieved.

To prevent fire spread through the movement joint, there must be a continuation of fire resistance of the compartment floor right up to the façade using perimeter firestopping measures. Many codes and regulations around the world make provision for this, demanding the use of slab-edge fire seals that have had their fire resistance certified to different product test standards. However, the test paths to compliance offered can vary hugely in scope, and the types of curtain walling systems they can apply to.

For example, in the UK, the legacy path is to use BS 476-20: 1987 - Fire tests on

building materials and structures. Method for determination of the fire resistance of elements of construction (general principles). This is a small-scale, static test that requires a specimen to be installed between two concrete lintels within a furnace and subjected to defined heating and pressure conditions. Whilst BS 476-20 can provide a basic understanding of a product’s standalone performance, the test is designed to be generalised and therefore cannot give a clear indication of a perimeter fire seal’s ability to resist fire in its intended application. EN 1366-4 - Fire resistance tests for service installations - Part 4: Linear joint seals is a test method similar to that of BS 476-20. However, in 2021 it was amended to exclude curtain walling perimeter seals from its scope.

As anyone who works in fire safety knows, it is often not the performance of

individual products that determine how fire will spread, but the combination of all the materials, elements and how they have been assembled. Whilst perimeter firestops are highly effective at inhibiting fire and smoke spread, compartmentation is reliant on them being able to maintain their fit between the floor slab and façade. This is why many regions look toward standards that offer a much more holistic perspective of the perimeter firestop’s performance in a spandrel construction rather than its performance as a standalone product.

This is particularly important when we consider that most curtain wall systems comprise non-fire rated aluminium framing and non-fire-resistant vision glazing. These are sometimes referred to as ‘Type A’ systems. With a melting point of approximately 660°C, aluminium loses its strength around 350°C. This can result in the framing structure distorting and gaps forming at the wall / slab edge intersection, impacting the perimeter fire barrier. Not only can this open multiple paths for fire, smoke, heat, and gasses to spread upwards internally, but the increased ventilation can also fuel the fire, enabling it to grow in size and ferocity.

To reduce this risk, a high density stone wool fireboard that shields the spandrel panel and the mullions within the spandrel zone can be used alongside the perimeter firestop. This can help to prolong the stability of the assembly, allowing the firestop to fully perform its compartmentation function whilst reducing the chance of the fire breaking through the spandrel panel itself. This approach is common practice in jurisdictions such as the United Arab Emirates and Australia and can be assessed by both European (EN) and American (ASTM) test standards.

EN 1364-4: 2014 – Fire resistance tests for non-load bearing elements (Curtain walling – part configuration) is widely referenced in building codes and regulations in many countries across Europe— including the UK— Middle East and Asia Pacific. It is also the recommended test standard for curtain wall perimeter barriers in the Association for Specialist Fire Protection’s (ASFP) Advisory

Note 7, with CWCT having announced that it proposes updating Technical Note 98 to recommend the test too.

As a ‘part configuration’ test, it looks at the spandrel assembly of a curtain wall system, comprising the mullions, transoms, and infill and spandrel panels. This makes it far more representative of a perimeter firestop in its end use application. It also allows for multidirectional movement which would occur in the event of a fire as different building elements heat up and deform.

It tests individual parts of the assembly such as the perimeter seal or the anchoring attaching the curtain walling to the

floor slab, or systems with fire resistance requirements only to the spandrel zone. There are specific configurations of the test that can be chosen depending on the primary element that needs to be assessed. In very simplified terms, Configuration 5 is used to assess the ability of the perimeter fire seal to contain the fire inside the compartment, under the stress of temperatures and pressures that lead to in-test deflection of the façade and floor slab. Meanwhile, Configuration 2 tests the upstand and downstand with the perimeter seal and anchoring, or a combination of and is often used by façade manufacturers as it incorporates flaming on both the inside and outside of the

façade; this configuration would be used by curtain wall system manufacturers for specific data on the façade.

Additionally, to validate the durability of the perimeter firestop, EN 1364-4 also includes provision for long-term façade movement by referring to the European Technical Approval Guidelines 026-3, which is now superseded by European Assessment Document (EAD) 350141-001106. This requires that the perimeter seal is subjected to a minimum of 500 cycles between the minimum and maximum joint width, to simulate in-service wind sway, seismic activity and thermal load at a rate designated by the test applicant 24 hours before fire exposure.

It is important to note that this test and its configurations focuses on the performance of materials and elements just within the spandrel. EN 1364-3: 2014 - Fire resistance tests for non-load bearing elements (Curtain walling – full configuration, complete assembly) on the other hand offers a full configuration test to evaluate the performance of the complete curtain wall assembly and includes any transoms

and mullions, infill panels and the spandrel zone. However, it is only applicable to ‘Type B’ fire-rated systems, which are rare.

Another common test standard for perimeter edge fire seals used in USA, UAE, and parts of Asia Pacific (using the international code council’s (ICC) International Building Code (IBC) that takes into consideration the performance of the spandrel) is ASTM E2307, Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using IntermediateScale, Multi-story Test Apparatus.

This measures “the performance of the perimeter fire barrier and its ability to maintain a seal to prevent fire spread during the deflection and deformation of the exterior wall assembly and floor assembly during the fire test.” It uses intermediate scale multi-storey apparatus to better replicate a fully developed curtain wall fire. The perimeter joint and perimeter firestop are exposed to fire from both inside the test room and outside to simulate the room where the fire started, as the fire plume exits the room of fire origin

through a window opening and attempts to leapfrog to the next floor. Like EN 13644, it also includes provisions for pre-cycling, or ‘cold’ movement before the test begins, covering thermal load, wind sway, seismic movement, and all these combined.

Alongside this perimeter firestop test, there is also now a relatively new standard that looks more specifically at assessing the spandrel assembly’s resistance to fire spread and the leapfrog risk. Unlike the aforementioned test standards, ASTM E2874 Standard Test Method for Determining the Fire Test Response Characteristics of a Building Spandrel-Panel Assembly Due to External Spread of Fire Using Intermediate-Scale, Multistory Test Apparatus has been designed to emulate a fire scenario at post-flashover stage inside a compartment. It analyses the ability of the spandrel assembly to prevent fire from spreading over the façade exterior to a room’s interior on the floor above the compartment of origin. The test specimen includes the exterior wall spandrel panel assembly, fasteners, structural supports, and any glazed openings. When applied in conjunction with ASTM E2307, this can provide a uniquely rounded view

Smoke Ventilation is an integral part of a buildings design for fire safety, without it you compromise the life safety of occupants.

The most common cause of death for fire-related fatalities is asphyxiation by smoke, which is trapped within the environment.

For over 40 years, SE Controls has been developing innovative control systems that automatically open vents in the early stages of a fire to facilitate the extraction of smoke, keeping escape routes and the perimeters of facade clear for the fire service to enter the building and allowing occupants to escape safely.

SE Controls is the trusted global expert in fire safety, facade engineering and product manufacturing, providing bespoke project specific smoke ventilation and controls by partnering with our clients from early stages of the project to system installation, commissioning and testing.

Contact us today for technical tailor made solutions for your facade ventilation needs, as every building is different.

of how both the perimeter firestop and spandrel insulation can achieve complete compartmentation, preventing fire from spreading floor to floor both internally through the curtain wall system and externally up its surface.

The Indian standard, IS 18190: 2023 - Fire Resistance of Perimeter Fire Barrier Joint System released in June 2023 by the Bureau of Indian Standards (BIS) references ASTM E2307, as well as UL 2079 – Tests for Fire Resistance of Building Joint Systems specifically for assessing air leakage of the fire test assembly, the resulting L-rating is an important factor when considering the ability of a passive fire protection measure to provide an effective smoke seal. Additionally, IS 18190: 2023 mandates adherence to the ISO 834-1 time-

temperature curve for evaluating the perimeter fire barrier joint system, which is the same time-temperature curve followed by EN 1363-1 and subsequently used within testing to EN 1364-4.

Curtain wall systems present several unique challenges when it comes to ensuring passive fire safety. Choosing curtain wall perimeter firestops that have had their performance verified with testing that is reflective of their end use in the ‘asbuilt’ condition, such as the EN or ASTM standards, can not only enable compliance in many jurisdictions but also encourage best practice and, where possible, help to go beyond regulatory requirements to deliver enhanced spandrel protection, contributing to safer curtain walled buildings around the world.

Head of Technical and Compliance for Siderise Middle East, India, and Asia Pacific

Donel Dippi, Head of Technical and Compliance for Siderise Middle East, India, and Asia Pacific, is an experienced stakeholder-focused Technical Engineer who specialises in passive fire protection and acoustic solutions for the façades of buildings.

With a deep understanding of testing, certification, compliance, and regulatory codes, he helps architects, façade consultants, contractors, developers, and fire and rescue services navigate the complexities of fire safety in both the new construction and retrofitting of buildings, whilst giving guidance on where there is scope for improving performance levels.

Donel is an advocate of best practice in testing, design, installation inspection, and auditing and firmly believes that this principle should guide all our actions. He takes great pride in encouraging developing countries to avoid repeating the mistakes of others by adopting standards and practices that promote safer buildings to allow their people to live, work, learn, play, and worship with peace of mind – “doing the right thing today is one step closer to protecting the people of tomorrow”.

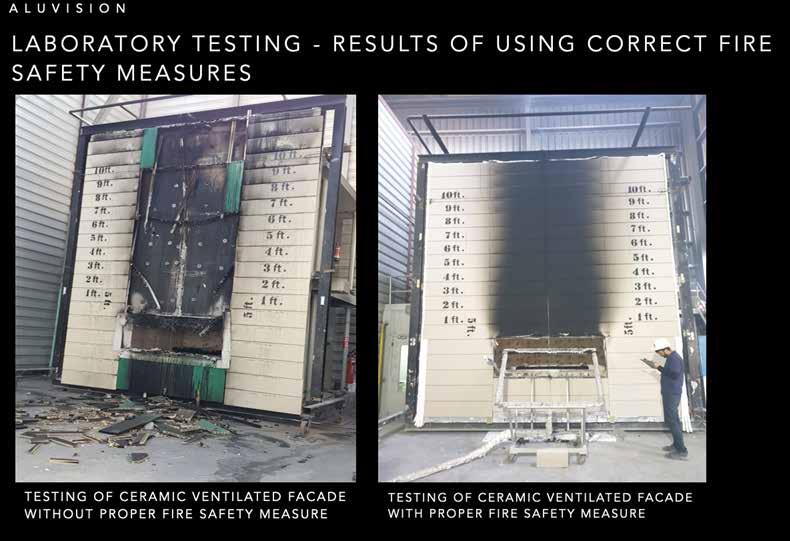

In the realm of architectural design and building construction, the façade of a building is more than just its outward appearance; it plays a pivotal role in ensuring the structure’s safety, particularly against fires. As we’ve seen in numerous incidents around the globe, the choice of cladding materials can be the difference between a minor incident and a catastrophic tragedy. This guide, penned from the perspective of a façade consultant, seeks to shed light on the importance of fire-safe cladding materials, explore the key elements of façade fire safety, and navigate through the complexities of testing standards and certification processes.

1. LEARNING FROM PAST INCIDENTS:

Let’s examine some significant fire

incidents of the past that have taught us important lessons about fire safety concerning building façades. If we go back a few decades, we can see some horrifying façade fire accidents that have impacted the entire world. In order to understand the importance of fire-safe façades, it is essential to study case studies of a few major façade fire accidents worldwide and their impact on local and global regulations.

1.1.1. The Grenfell Tower fire that occurred in June 2017 led to a global call for a review and reform of building and fire safety regulations. The Hackitt Report recommended a complete overhaul

of the regulatory system to ensure higher safety standards. Following this report, changes were made, including a ban on combustible cladding and the introduction of the Building Safety Bill. The ongoing public inquiry aims to uncover the circumstances leading to the tragedy and ensure that lessons are learned. The tragedy has resulted in increased scrutiny of building practices, fire safety measures, and the role of government and industry in ensuring safety. It has also raised public awareness about fire safety and prompted countries worldwide to reevaluate their building and fire safety regulations.

1.1.2. The Address Downtown Dubai fire that occurred on New Year’s Eve in 2015 led to significant improvements

in building and fire safety regulations in Dubai and the UAE. The incident highlighted the vulnerabilities of certain building materials, leading to revisions in fire safety codes, a ban on combustible cladding, increased compliance and enforcement, and greater awareness and training. These changes also influenced international standards on building fire safety, showcasing a model of proactive and responsive regulatory reform in the face of disaster.

1.1.3. The Torch Tower, located in Dubai, UAE, is one of the world’s tallest residential towers. Unfortunately, it has experienced two significant fires in February 2015 and August 2017. The exterior cladding material contributed to the rapid spread of flames in both incidents. Although there were no fatalities, the fires caused extensive property damage and displacement of residents. As a result, the safety concerns around cladding materials were brought to the forefront, and fire safety inspections and regulations were intensified in Dubai.

1.1.4. The Lacrosse Building in Melbourne, Australia, faced a fire incident in November 2014 caused by a discarded cigarette on a balcony. The fire quickly

spread through the building’s aluminium composite cladding. Fortunately, no fatalities were reported, but the incident caused significant damage and revealed the potential fire hazards associated with certain types of cladding. The Lacrosse fire initiated a comprehensive review of building codes in Australia, with a particular emphasis on the use of combustible cladding in high-rise buildings.

The above case studies are enough to understand that a building’s façade and its materials plays a pivotal role in fire safety. Fire-safe cladding materials are not just important; they are essential for the safety and integrity of any building. These materials are designed to resist ignition, limit the spread of flames, and ensure that in the event of a fire, the structure can withstand the heat long enough for occupants to evacuate safely and for emergency services to respond. The right cladding materials can significantly reduce the risk of fire spreading from one part of a building to another, a crucial consideration in high-rise structures where evacuation can be challenging.

As a responsible façade consultant, we believe. These materials are not a luxury but a necessity, as they provide essential protection in emergency situations, ensuring that safety is not compromised for aesthetic appeal.

3.1.Fire-Resistant Materials: The selection of fire-resistant materials for façades is critical. Materials that are noncombustible or have high fire-resistance ratings are preferred to reduce the intensity of flames and slow the spread of fire.

3.2.Design and Construction: The architectural design must incorporate fire safety measures such as fire breaks or barriers to prevent the spread of fire across the façade. The quality of construction techniques used also plays a significant role in ensuring that these design features function as intended.

3.3. Compliance with Building Codes and Standards: It is mandatory for buildings to adhere to local, national, and international fire safety codes and standards. These regulations specify

requirements for materials, design, and features such as fire escapes and sprinkler systems.

3.4. Fire Safety Systems: Active fire protection systems, including sprinklers and drenchers designed specifically for façades, can be critical in controlling a fire. Detection systems can provide early warning and facilitate a faster response.

3.5.Inspection and Maintenance:

Regular inspection and maintenance of the façade and its fire safety components ensure that all parts of the system are in good working order. This includes checking for potential combustible materials accumulation and ensuring that fire safety systems are operational.

3.6. Innovation and Technology:

Advancements in materials science and building technology, such as smart sensors and fire-resistant coatings, offer

new ways to enhance façade fire safety. Continuous research and development are essential for improving fire safety measures.

3.7. Education and Awareness: It is necessary to educate building owners, managers, and occupants about fire safety practices. This includes the specific risks associated with façades and the measures in place to mitigate these risks.

The journey to ensuring fire safety in façades is rigorous, with cladding materials undergoing extensive testing to meet international safety standards. These standards, such as the British Standard (BS) 8414, the International Building Code (IBC), and the European Standard (EN) 13501, serve as benchmarks for material performance in fire situations. Through a series of

controlled tests, materials are evaluated for their combustibility, flame spread, and heat release rates, ensuring they meet the stringent requirements to be fire-safe. This meticulous process ensures that only materials that can truly withstand the challenges of fire are utilized in building façades. We have local codes like NBC 2016 & IS181902023, which adhere to ASTM E2307.

Despite the availability of fire-safe materials and the knowledge of their importance, the construction industry faces several challenges in implementing fire-safe façades. These include

5.1. Cost considerations and architectural limitations become challenges for a few projects.

5.2. A lack of awareness or understanding

of fire safety standards among stakeholders.

5.3. Retrofitting Older Buildings: Updating the façades of existing buildings to meet modern fire safety standards can be challenging and costly.

5.4. Balancing Aesthetics and Safety: Architects and designers must find ways to integrate fire safety features without compromising the building’s aesthetic appeal.

5.5. Global Variation in Regulations: Differences in fire safety regulations across jurisdictions can

Historical fire incidents have profoundly influenced the development of regulations governing façade fire safety. The Grenfell Tower tragedy in London and the Torch Tower fire in Dubai are stark reminders of the consequences of neglecting façade fire safety. These and other incidents have led to tighter regulations, more rigorous testing protocols, and a greater emphasis on

the use of non-combustible materials in façade construction.

Past fire incidents offer invaluable lessons for the construction industry. They highlight the critical importance of adhering to fire safety regulations, the need for regular inspections and maintenance of façade systems, and the potential risks associated with certain materials. These insights inform current practices and drive the ongoing evolution of fire safety standards.

Education and knowledge sharing are vital for advancing façade fire safety. Architects, builders, and façade consultants must stay informed about the latest materials, technologies, and fire safety strategies. Seminars, workshops, and conferences provide platforms for professionals to share experiences, discuss challenges, and explore new solutions. Such events contribute to a collective understanding and approach to enhancing fire safety in building design.

Upendra Walinjkar, Founder & Principal Consultant of Aluvision Façade Solutions (AFS), is working in the curtain wall industry for more than 22 years. He has worked in engineering and designing of prestigious projects all over the world, covering the UK, Canada, Singapore, Kenya, Philippines, UAE & Qatar. Notable projects such as FORTE D1 D2, Boulevard Towers, Pearl Diving pool, and the entrance canopy of TELUS Garden Canada, among others, have enabled him to transform design ideas and visions into reality. AFS is an independent Façade Engineering Consultancy, offering a wide range of professional services predominantly dealing in design, engineering & consulting for the specialised field of façades. Their expertise and experience in designing bespoke systems for local and international markets have made them masters of their skills. They provide optimised solutions for their clients’ projects, ensuring their buildings look stunning for years.

In the realm of architecture and design, the façade of a building serves as its defining feature, reflecting both its aesthetic appeal and functional integrity. At the heart of this captivating tale lies the enigmatic world of exterior cladding materials.

Exterior cladding materials play a pivotal role by:

1. Offering protection from harsh weather, pollution, rains and winds.

2. Saving energy by maintaining an optimal temperature.

3. Provide protection to people and the building from fire hazards.

The demand for exterior cladding materials in India has shown consistent growth in recent years. From natural materials like stone and wood to the advent of modern innovations such as metal alloys and composite materials, the evolution of cladding materials is a journey through time.

The exterior cladding and façades use a number of metal alloys and composite materials, including but not limited to:

l Aluminium: Made out of 100% recyclable aluminium, Aludecor has introduced ACPs with fine finishes like wood, stone, and glass, to provide the perfect blend of style and durability.

l Zinc: Using Zinc’s beautiful natural colour and with premium shades,

Aludecor has created ZCPs and Zinc Solid Panels which provide longevity and lend flawless strength to modern and classical architecture.

With its latest collaboration, Aludecor has tied up with Nedzink to create architectural innovations and the latest Zinc façade designs.

l Copper: Introduced in India for the first time by Aludecor, take cladding dreams to a superior level with Copper Composite Panels. CCPs are natural, and robust, with ease of fabrication and costeffectiveness that Aludecor products are known for.

l Honeycomb: Aludecor’s latest offering, Honeycomb Panels, are in high demand for its exceptional strength-to-weight ratio, ideal for applications where both durability and reduced weight are crucial, such as in aerospace, construction etc. Honeycomb Panels can be made using different metals like Aluminium, Zinc, Copper and Stainless Steel.

Widely used in Europe, Honeycomb Panels are still in their infancy within the Indian market, currently holding a modest 1% share of the market. Experts anticipate their market share to grow substantially, potentially reaching up to 5% of the overall Indian cladding market soon.

Recent industry reports estimate the current valuation of India’s exterior wall cladding/covering material market to range between `15,000-20,000 crores

(approximately USD 2-3 billion) in 2022. Indian façades and cladding market can be segmented into:

Material-wise:

l Glass façades (40-50% market share)

l Aluminum façades (20-30% market share)

l Stone façades (10-20% market share)

l Ceramic façades (5-10% market share)

l Others (5-10% market share)

Application-wise:

l Commercial buildings (60-70% market share)

l Residential buildings (20-30% market share)

l Industrial buildings (5-10% market share)

l Institutional buildings (5-10% market share)

India’s exterior wall cladding materials market is forecasted to provide a

projected growth rate of over 10-12% CAGR during the period of 2022-2027, propelled by heightened construction endeavours spanning various sectors. The surge in demand for cladding options is driven by:

l Increasing demand for sustainable buildings: The Indian government’s goal of achieving net-zero carbon emissions by 2050 is expected to drive the demand for sustainable and energyefficient buildings, which will in turn drive the demand for advanced façades and cladding materials.

l Growing urbanisation: The rapid urbanisation of Indian cities is expected to lead to an increase in the demand for high-rise buildings, which will require advanced façade design and cladding materials.