ARCHITECTURAL HARDWARE & BEYOND

Experts’

INDUSTRY SPEAKS

Experts’

When we think about architecture, our minds often gravitate toward the visual impact of a building—the design, the materials, the interplay of space and light. However, beneath these striking elements lies a critical layer that is often overlooked: architectural hardware. These components, though small in size, are fundamental to the safety, functionality, and longevity of any structure.

In recent years, the architectural hardware industry has undergone a remarkable transformation. Advances in technology and a heightened focus on design trends have led to innovations that not only enhance the aesthetic appeal of buildings but also prioritize safety and compliance with rigorous building codes. From fire-resistant materials to smart locking systems, the evolution of hardware is redefining what is possible in modern architecture.

This issue of our magazine delves into the ever-important world of architectural hardware. Our cover story features insights from industry experts in the Middle East, who discuss the latest technological advancements and the importance of adhering to specifications and standards in hardware selection and installation. Their perspectives offer a glimpse into the future of the industry, where innovation and compliance go hand in hand.

Architectural hardware encompasses a wide range of products—from door handles and locks to hinges and closers. Each piece, though often unnoticed, plays a crucial role in ensuring that buildings are safe, secure, and functional. As architects and builders, it is essential to stay informed about the latest products and best practices to ensure that every element of a project meets the highest standards of quality and performance.

In addition to our cover story, this edition brings you the latest industry news in our Buzz section, keeping you updated on emerging trends and developments. We also feature a compelling Faceto-Face interview with a prominent architect, offering valuable insights into the role of hardware in contemporary design. Furthermore, our expert contributors provide in-depth articles on façade and fenestration, exploring how hardware is integral to the performance and aesthetics of these critical building elements.

As we continue to explore the evolving landscape of architectural hardware, we invite you to engage with the content in this edition and reflect on how these essential components influence the success of your projects. Your feedback is important to us, and we encourage you to share your thoughts and suggestions at editorial@wfmmedia.com.

We hope this issue provides you with inspiration and knowledge as you navigate the complexities of architectural design and construction.

08

20

32

42

Façade Fire Safety: How to Prevent Fire Spread on the Exterior of Your Building

Ali Al Mudhei

Green Façades: A Cool Solution for Urban Heat?

Daniel Dendra, Owner, anotherArchitect

Kinetic Façades: The Future of Dynamic Architecture

Victor Georges Gemayel, Senior Architect, Nesma & Partners

Comprehensive

Mohammad Salameh

04

12

“Technology has Drastically Influenced Modern Architectural Hardware, with the Introduction & Integration of Smart Access Control Systems Changing the Way Many Buildings Operate”

Daniel May, Director, Consort Architectural Hardware

“The Future of Architectural Hardware will be Characterised by Smart Technology, Minimalist Design, Sustainability, Durability, Customisation, Integration with Building Systems, and Multi-Functionality”

Tabish Khan, Sales Director - MEA, EuroArt

“The Future of Architectural Hardware is Set to Combine Innovative Technology, Sustainable Practices, and a Focus on Security & User Experience”

Gilbert Nicolas, Architectural Consultant, Dormakaba

“The Integration of Smart Technology has Led to Hardware that Offers Enhanced Security, Automation, and Convenience for Users”

Karam Hamadeh, Managing Director, TPS

28

the Author

Ali Al Mudhei is a distinguished architect with a master’s degree in architectural engineering and over two decades of specialised experience in building safety, with a particular focus on building and fire codes. Throughout his career, he has been a key consultant on several mega projects, providing expert guidance on the implementation and compliance of building and fire codes. He is the author of the book, “Implementation of Building Codes,” which examines the critical factors impacting the adoption of the Saudi Building Code. In addition to his consulting work, Ali has significantly contributed to the development of fire safety standards at both national and international levels. He served as the vice chairman of the Saudi Fire Code Technical Committee. His expertise is further recognised through his current appointment as a member of the International Building Code Development Committee for the 2024-2026 update cycle. he is actively involved in advancing global building safety.

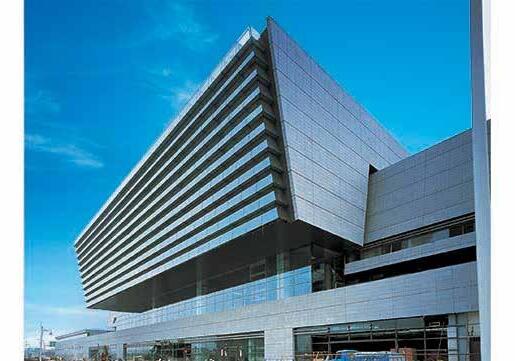

The building façade is one of the main contributing elements to the spread of fire between floors. Fire spread through the exterior façade can be deadly and lead to significant property damage and business interruptions. Fire on the exterior of the building is becoming increasingly challenging for firefighting operations, building code enforcement professionals, and building safety experts due to advancements in cladding materials that often incorporate combustible materials, including plastics.

In the past decade, there has been an increase in fires that propagate rapidly through the exterior of buildings due to the use of substandard exterior cladding. This has led to deaths, injuries, property damage, and business continuity issues. The most

unfortunate example is the deadly fire incident at Grenfell Tower in the UK in 2017, which resulted in the deaths of more than 70 people and injured many more. The fire spread through the exterior Aluminum Composite Material (ACM) cladding system, engulfing the entire building. Another example is the Address Hotel fire in Dubai in 2015, where the fire spread through the exterior ACM cladding system and destroyed the entire façade. Additionally, a fire broke out in the TAM building in Baku, Azerbaijan in 2015, starting at the ground level and spreading through combustible exterior materials, resulting in the deaths of 15 people.

The main question is why fire spreads so quickly through the exterior façade of a building.

The rapid spread is due to the use of combustible materials and a phenomenon known as the “chimney effect” or stack effect. In this effect, air movement in the vertical cavity behind the exterior cladding is driven by differences in pressure and temperature, causing hot air to rise rapidly.

Metal Composite Materials (MCM) are widely used in exterior cladding systems due to their aesthetic appeal, durability, and insulation properties. These materials consist of multiple layers that provide both functional and decorative benefits. The construction components of MCM cladding systems include the following key elements:

1. Core Material: The core is the central layer sandwiched between the outer metal skins. It can be made from various materials, including polyethylene, mineralfilled cores, or fire-retardant materials. The choice of core material significantly impacts the panel’s fire resistance, structural integrity, and overall performance.

2. Metal Skins: The outer layers of MCM panels are typically composed of aluminum, but other metals such as zinc, copper, or stainless steel can also be used. These metal skins provide the primary weather barrier and give the cladding its visual characteristics. They are coated with protective finishes, such as PVDF (polyvinylidene fluoride), to enhance durability, color retention, and resistance to environmental factors.

3. Adhesive Layers: Adhesive layers bond the core material to the metal skins, ensuring the structural stability of the panel. High-quality adhesives are crucial for maintaining the panel’s integrity under various environmental conditions, such as temperature fluctuations and moisture exposure.

4. Protective Coatings: The metal skins are often coated with protective layers to improve resistance to corrosion, UV radiation, and other environmental elements. These coatings can also include selfcleaning properties, enhancing the appearance of the cladding.

5. Subframe and Support System: The subframe, often made of aluminum or galvanised

steel, provides the structural support for the MCM panels. It includes brackets, rails, and fixings that attach the panels to the building’s façade. The design of the subframe ensures proper alignment, ventilation, and load distribution.

6. Sealants and Gaskets: Sealants and gaskets are used to seal joints and seams between panels, preventing water

infiltration and ensuring a weather-tight installation. They also accommodate thermal expansion and contraction, maintaining the integrity of the cladding system over time.

7. Insulation and Vapor Barriers: Insulation materials can be incorporated behind the MCM panels to enhance thermal performance. Vapor barriers are also used to prevent moisture penetration into the building’s structure, reducing the risk of condensation and mold growth.

International Building Code Requirements for the MCM

Building Codes and regulations around the world have evaluated the use of MCM and other combustible exterior finishing materials, such as Plastic Veneer, Exterior Insulation Finishing Systems (EIFS), and Insulation.

While there might be different approaches to regulating the use of

these materials from one country to the other or in different model codes, the Intranational Code Council (ICC) Codes and standards are one of the leading references globally.

The International Building Code (IBC), which is one of the ICC codes, has specific fire performance requirements for Metal Composite Materials (MCM) used in building construction. These requirements are designed to ensure that MCM does not contribute to the spread of fire. Following are the main areas where the IBC focuses:

MCM used in exterior walls must comply with the fire propagation

performance criteria of NFPA 285, which is known as the “Full-Scale Test”. These standards tests the ability of wall assemblies to resist fire spread when exposed to a fire involving combustible materials. Passing the NFPA 285 test is crucial, especially for high-rise buildings or another chimney effect as discussed earlier can be present.

The IBC requires MCM to meet specific surface burning characteristics when tested by ASTM E84 “Test Methods for Surface Burning Characteristics of Building Materials”, or as know “Tunnel test”. This test measures the flame spread index and a smoke-developed index of

material surfaces. According to IBC, the MCM must achieve a flame spread index of 25 and a smoke development index of 450, to ensure the material surface will not support fire spread.

Thermal Barrier: The MCM must be separated from the interior of the building by a 12 mm (1/2 inch) gypsum Board or by the equivalent material to ensure it won’t ignite within the building or catch fire due to high temperature from within the building. A thermal Barrier might not be required if the MCM passes the NFPA-286 “test or is used on architectural trims and balconies.

The IBC requirements for MCM are also based on the height of the building, the percentage of the face covered by the MCM, the combustibility class of the MCM, the separation of the MCM panels, provision of sprinkler systems and the separation of the exterior faced from other buildings and properties. More strict requirements are applied to taller buildings or those with a higher percentage of wall coverage.

In conclusion, architects should pay more attention to the design and specification of exterior wall cladding. The use of MCM shall be limited to a height of 22 m only and shall pass both tests NFPA -285 and ASTEM-E-84. The cavity behind the MCM system shall be also considered carefully, in terms of the combustibility of the insulation, opening protection, and ignition sources. In addition, the areas covered by the MCM shall be limited and separated effectively from each other to eliminate the possibility of vertical spread.

Daniel Dendra Owner, anotherArchitect

About the Author

Daniel Dendra’s path has led him through Zaha Hadid Architects, A.M.O, OMA, and under the visionary Rem Koolhaas in Rotterdam. Founded anOtherArchitect in Berlin to meld sustainability with groundbreaking design in architecture, interior, and landscape. Their work, like the Blütenviertel in Caputh, is where vision meets action. He champions a sustainable future, evident in initiatives like OpenSimSim and FutureCityLab. As a visiting professor across Europe, he inspires the next wave of architects to think beyond today.

This summer has been nothing short of bizarre. One day it is sweltering hot, and the next, we’re drenched in unexpected downpours. Extreme weather events are becoming more frequent, making it clear that climate change is no longer a distant threat; it is here, and it is reshaping our daily lives. Walking through Berlin’s streets recently, I stumbled upon a historic building whose lower floors were completely covered in ivy. The vibrant green contrasted beautifully with the old stone, turning the façade into a living, breathing wall of nature. This site got me thinking: how do

these green façades impact their surroundings and could they be a solution to our urban climate challenges?

Starting with the basics, plants on building façades provide natural insulation. Imagine the ivy on that Berlin building as a green blanket, shielding it from the summer sun. By absorbing sunlight and reducing heat penetration, these green façades can lower indoor temperatures, cutting down the need for air conditioning. This not

only saves on energy bills but also reduces our carbon footprint.

Now, let’s picture Berlin with more green façades. Studies have shown that plants can help cool the air through evapotranspiration, where water is absorbed by roots and then released as water vapor through leaves. This cooling effect can mitigate the urban heat island effect (UHIE), where urban areas are hotter than their rural surroundings due to human activities and infrastructure.

However, let’s be realistic with our numbers. Research indicates that a 10% increase in green spaces can reduce urban temperatures by up to 1°C. Extrapolating from this, if 25% of Berlin’s building façades were greened, we might expect a reduction of around 1-2°C. Increasing this to 50% could result in a reduction of approximately 2-3°C. While exact numbers can vary, the trend is clear: more green equals cooler cities.

But the benefits don’t stop there. Plants are natural air purifiers. The ivy on our Berlin building is hard at work absorbing pollutants and releasing oxygen. This means cleaner air and a healthier environment for city dwellers.

But let’s not get carried away with the green façade hype. There are significant challenges and potential downsides that need to be addressed.

Of course, it is not all sunshine and roses—or should I say ivy? One

downside is pest management. Plants, especially climbers like ivy, can become cozy homes for insects and other critters. This could be a minor nuisance or a significant problem, depending on your tolerance for urban wildlife.

Example: While Bosco Verticale in Milan is a great success, some green buildings have faced unexpected issues. The Eden Project in Cornwall, UK, had to deal with an invasion of aphids in their Mediterranean Biome. The bugs thrived in the lush environment, causing damage to the plants. It was a significant challenge to manage the infestation without resorting to chemical pesticides, which would harm the ecosystem.

And then there’s the maintenance. Keeping these green façades lush and healthy requires regular care— think of it as giving your building a weekly spa treatment. Plus, if not properly managed, these plants can damage the building’s structure. Proper planning and the right plant choices are crucial here.

Example: The green wall at the CaixaForum in Madrid is another example. This stunning vertical garden requires meticulous care, including irrigation, pruning, and pest control to keep it thriving and prevent damage to the building structure.

Let’s face it: greening façades is not a cheap or simple solution. The initial costs of installing a green façade can be high, and the ongoing maintenance adds to the expense. For many cities and building owners, this could be a significant barrier.

Let’s not forget, a garden needs a gardener. Or in this case, every building would need someone to tend to its green façade. Imagine a brigade of urban gardeners, perhaps a mix of enthusiastic volunteers and dedicated professionals. This could even become a fantastic community project. Picture elderly residents sharing their gardening wisdom with younger generations, teaching them about plants, sustainability, and the joys of getting their hands dirty. It is a winwin: healthy buildings and vibrant community interaction.

The urban heat island effect (UHIE) is a real headache for city planners. But greening façades could be our aspirin. If Berlin could green 50% of its façades, we might see a reduction in peak summer temperatures by up to 2-3°C. This cooling effect not only makes cities more livable but also reduces the strain on our power grids.

Berlin, with its temperate climate, is a perfect candidate for greening

façades. Let’s crunch some numbers: if 25% of Berlin’s buildings were greened, we could see a temperature drop of about 1-2°C in the summer. At 50% coverage, this could increase to around 2-3°C. This would drastically reduce the urban heat island effect and make summers much more bearable.

Now, let’s hop over to Athens, where the climate is hotter and drier—a cooling-dominant environment. In Athens, greening façades could save significant energy costs on air conditioning. Studies suggest that green façades can reduce a building’s cooling

energy demand by up to 30%. If 25% of Athens’ buildings had green façades, energy savings could be substantial, potentially reducing air conditioning costs by up to 15-20%. Combine this with greywater recycling from household systems like washing machines and showers, and you have a sustainable, water-efficient cooling system that also reduces utility bills.

Example: The Stavros Niarchos Foundation Cultural Center in Athens incorporates green roofs and façades, using local plant species that require minimal water. This reduces the need for

air conditioning and showcases how combining green architecture with water recycling can lead to substantial energy savings.

Dubai is a different beast altogether. The extreme heat and arid climate make greening façades a real challenge. But where there’s a will, there’s a way. Implementing green façades in Dubai would require high-tech but low-cost solutions - think innovative irrigation systems and drought-resistant plant species. It is a tough nut to crack, but it is not impossible with clever design and resource management.

Example: The Green Planet building in Dubai, primarily an indoor vertical rainforest, demonstrates the feasibility of maintaining large green installations in an arid environment through advanced irrigation and climate control systems.

Greening façades is not just a sustainable solution; it is a golden design opportunity for architects. Imagine transforming urban landscapes with vertical gardens that cool buildings, clean the air, and create beautiful, living structures. It is a low-tech, costeffective approach with highimpact results.

So next time you walk past a building covered in ivy, like the one in Berlin, remember: it is not just a pretty face. It is a powerful tool in the fight against urban heat and a testament to the potential of sustainable design. Let’s embrace the green revolution and make our cities cooler, cleaner, and more beautiful.

Victor Georges Gemayel Senior Architect, Nesma & Partners

About the Author

Victor Georges Gemayel is a Lebanese distinguished architect based in Riyadh, Saudi Arabia. With over nine years of experience in the Saudi construction industry, he specialises in façade engineering, agile project management, and risk management. He is presently involved in The Avenues Riyadh Project, managing the building envelope package for what is projected to be one of the largest malls in the MENA region. Victor holds a Master’s degree in Architecture and is certified in Façade Engineering and Negotiation. He is an alumnus of INSEAD’s Management Acceleration Program. Victor’s linguistic versatility complements his professional expertise in Arabic, English, and French. Beyond his professional and educational credentials, Victor is deeply committed to community service. He volunteers with health, elder care, and child welfare organisations. His long-standing involvement with the Scouts has further instilled strong leadership and community values in him.

Introduction

Kinetic façades represent a groundbreaking evolution in architectural design, merging aesthetics with functionality. These dynamic building exteriors can change in response to environmental conditions, enhancing energy efficiency and creating visually stunning structures. This article explores the concept, benefits, and future potential of kinetic façades, highlighting how they are revolutionising the field of architecture.

A kinetic façade is a type of building envelope that features movable elements. Unlike traditional static façades, kinetic façades are designed to respond dynamically to various stimuli, such as sunlight, temperature, wind, or human

interaction. The movement can be mechanical, hydraulic, or based on smart materials that react to environmental changes.

The idea behind kinetic façades is to create a responsive building

skin that can adapt to optimise indoor comfort, reduce energy consumption, and enhance the building’s aesthetic appeal. This adaptability makes kinetic façades particularly useful in climates with varying weather conditions

or in buildings aiming for high sustainability standards.

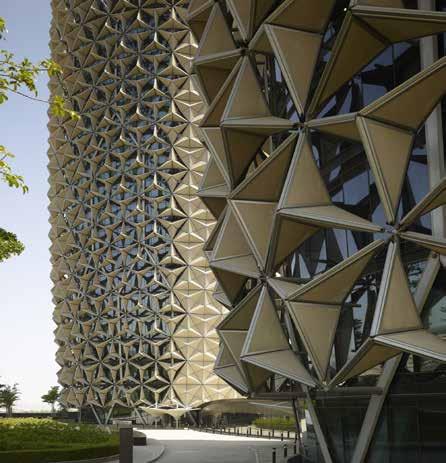

The world-renowned Al Bahar Towers in Abu Dhabi, designed by Aedas Architects, feature a responsive façade inspired by the traditional Islamic “Mashrabiya” shading device. The façade, completed in June 2012, uses a parametric design to adjust to sunlight, reducing solar gain and glare by over 50%. The system operates as a curtain wall with fiberglass-coated triangles that move according to the sun’s position, closing in the evening. This innovative design not only

enhances indoor comfort but also reduces the need for air conditioning, allowing the use of more naturally tinted glass for better views. The project was awarded the 2012 Tall Building Innovation Award for its sustainable engineering and cultural sensitivity.

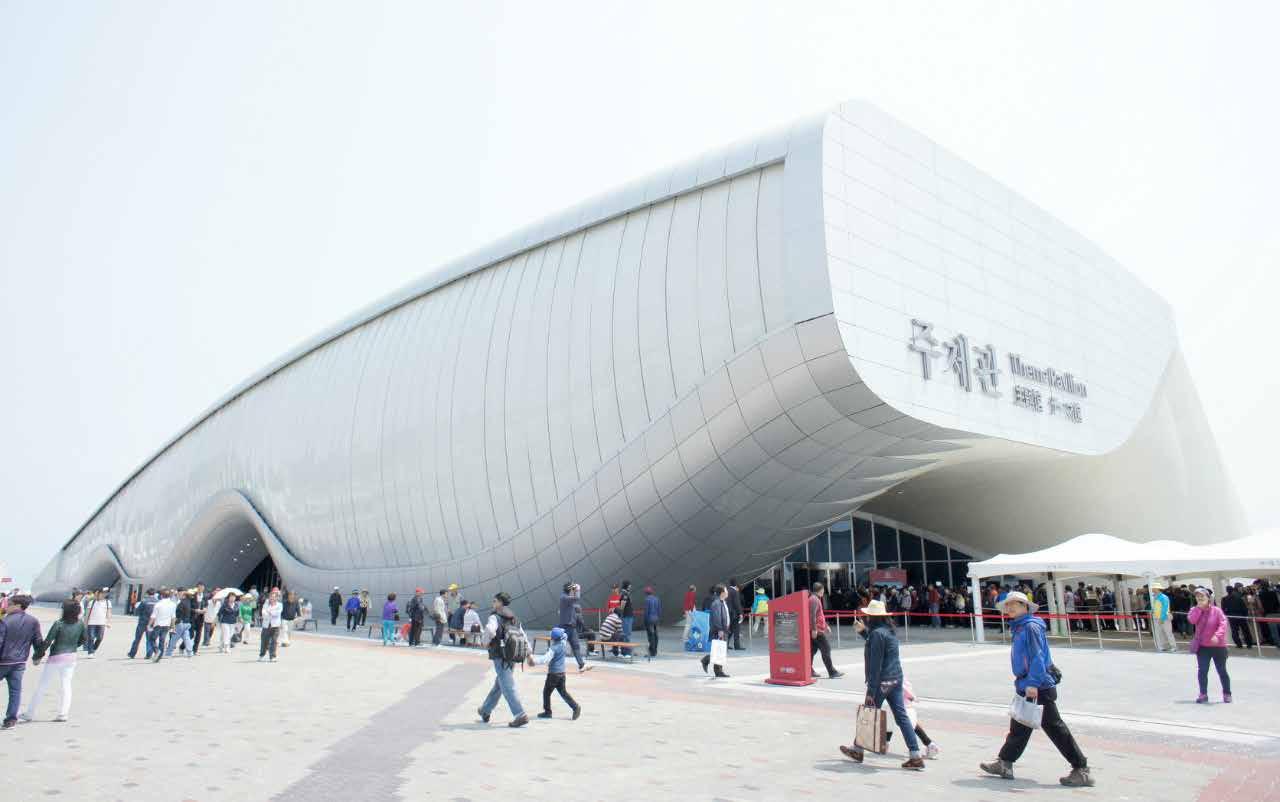

The Thematic Pavilion for EXPO 2012 in Yeosu, South Korea, designed by Austrian architect Soma, opened to much anticipation. This unique building, known for its fish-like characteristics, features a cuttingedge kinetic façade made of glass fiber-reinforced polymers (GFRP) that can morph into various animated patterns. Selected as the first prize winner in an open international competition in 2009, the pavilion’s design was inspired by biological movement mechanisms and developed in collaboration with Knippers Helbig Advanced Engineering. The pavilion’s concept reflects the dual nature of the ocean,

with continuous surfaces twisting from vertical to horizontal, defining interior spaces and creating a dynamic exterior. The kinetic media façade, which faces the Expo’s entrance, becomes particularly eyecatching after sunset.

The Kiefer Technic Showroom, designed by Ernst Giselbrecht + Partner, is an office building and exhibition space featuring a dynamic façade that adapts to outdoor conditions to optimise

the internal climate. The façade, made of aluminum posts and transoms with electronic perforated aluminum shutters, changes throughout the day, allowing users to personalise their spaces. The building’s shell includes solid brick walls, reinforced concrete ceilings and floors, and steel-encased concrete columns. This dynamic design regulates the building’s internal environment, presenting it as a constantly evolving sculpture.

One of the primary benefits of kinetic façades is their ability to enhance a building’s energy efficiency. By adjusting to control sunlight and shade, kinetic façades can reduce the need for artificial lighting and air conditioning. This dynamic control over the building’s thermal environment can lead to

significant energy savings, making kinetic façades an attractive option for sustainable architecture.

Kinetic façades offer a unique aesthetic dimension to buildings. The movement of façade elements can create patterns, shadows, and reflections that change throughout the day, adding a dynamic visual element to the building’s exterior. This can make the building a landmark and a piece of public art, attracting attention and interest.

Kinetic façades can adapt to various environmental conditions, providing optimal comfort for building occupants. For instance, during hot weather, the façade can provide maximum shading while allowing more sunlight to enter the building in cooler conditions. This adaptability makes kinetic façades suitable for various climates and applications.

Kinetic façades offer flexibility in allowing architects to choose from a wide range of glass types that align with their design concepts and creativity, including tinted, clear, and low-iron glass. The dynamic shading devices incorporated in kinetic façades can respond to varying sunlight and weather conditions, providing effective solar protection and maintaining comfortable indoor environments. This feature enables the use of highly transparent glass, which typically allows more light and heat to pass through, without compromising occupant comfort or the building’s energy efficiency.

Interactive kinetic façades offer an engaging user experience, allowing individuals to interact with the building’s exterior. This interaction can be educational, artistic, or simply entertaining, adding a layer of engagement that static façades cannot offer.

While kinetic façades offer numerous benefits, they also present challenges that need to be considered:

The design and implementation of kinetic façades are more complex and expensive than traditional façades. The mechanical systems, smart materials, and control technologies required can significantly increase the building’s initial cost. However, long-term energy savings and maintenance benefits may offset these costs.

Kinetic façades involve moving parts, which can be prone to wear and tear. Regular maintenance is essential to ensure the façade’s continued functionality and longevity. The materials’ durability, especially in harsh weather conditions, is also a critical consideration.

While kinetic façades can reduce energy consumption for heating, cooling, and lighting, the systems themselves require energy to operate. Designers must balance the energy savings from improved

building performance with the energy consumed by the kinetic systems.

The future of kinetic façades looks promising, with advances in technology and materials driving innovation. As smart materials become more affordable and reliable, we expect to see more kinetic façades incorporating these technologies. Additionally, AI and machine learning advancements could lead to façades that autonomously respond to environmental conditions and occupant preferences, optimising energy use and comfort without human intervention.

Kinetic façades also align with the growing emphasis on sustainable and adaptive architecture. As the demand for green buildings increases, kinetic façades offer a way to achieve energy efficiency and reduce environmental impact. Moreover, as cities become more crowded and buildings taller, the ability to create visually striking and adaptable façades will become increasingly valuable.

Kinetic façades represent a significant leap forward in architectural design, blending aesthetics, functionality, and sustainability. While they come with challenges, the benefits of improved energy efficiency, adaptability, and aesthetic appeal make them an exciting area of innovation. As technology advances and the demand for sustainable buildings grows, kinetic façades will likely become a more common and integral part of modern architecture.

24 - 26 September 2024. Landmark Centre, Lagos

big5constructnigeria com

MOHAMMAD SALAMEH

About the Author

Mohammad Salameh is a distinguished mechanical engineer with over 11 years of experience in the doors and architectural hardware industry. He holds certifications as an Electrified Hardware Consultant (EHC), Door and Hardware Consultant (DHC), and Certified Door and Hardware Technician (DHT), from the Door and Hardware Institute (DHI) in Washington, USA. Salameh has contributed to over 100 projects across various sectors, including education, security, petrochemical, and healthcare. His expertise in specification writing ensures that all projects meet the highest standards of quality, safety, and security. Known for his meticulous analysis and tailored solutions, Salameh collaborates closely with architects, builders, and clients to deliver customized hardware solutions that enhance structural integrity and occupant protection.

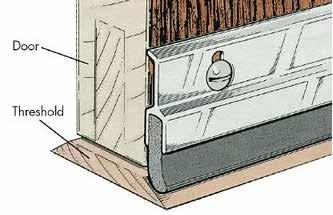

Properly hanging a door is crucial for its functionality, longevity, and compliance with industry standards. Here are the primary types of hinges:

• Mortise Hinges: Mortise hinges are recessed into the door and frame, offering a seamless and secure fit. They are preferred in both residential and commercial settings for their durability and compliance with ANSI/BHMA standards.

• Pivot Hinges: Pivot hinges support doors from the top and bottom, minimizing stress on the frame and allowing smooth operation. These hinges are essential for heavy doors and are compliant with DHI’s recommended practices.

• Floor Closers: Integrated into the floor, these closers provide robust support and control for heavy-duty applications. Floor closers must comply with ANSI/BHMA standards for performance and durability.

Ensuring door security involves selecting the appropriate locking mechanisms and exit devices that meet safety standards:

• Mortise Locksets: These locks are installed within a mortised pocket in the door, providing enhanced security and strength. Mortise locksets must meet ANSI/BHMA A156.13 standards for high-security applications.

• Panic Devices: Essential for emergency egress, panic devices ensure quick and safe exit during emergencies. These devices, typically used in buildings where a high number of people congregate, feature a horizontal push bar that, when pressed, unlocks the door. They must comply with NFPA 101: Life Safety Code and ANSI/BHMA A156.3 standards.

• Fire Exit Hardware: Fire exit devices are designed to function under fire conditions, allowing safe evacuation and containing fire and smoke. Unlike panic

devices, fire exit hardware often includes additional features like fire-resistance ratings and automatic relocking mechanisms. Compliance with NFPA 80: Standard for Fire Doors and Other Opening Protectives is mandatory.

Door closers are vital for controlling door movement, ensuring they close securely and comply with safety regulations:

• Surface-Mounted Closers: These are the most common type of door closers, visible on the door surface and easy to install. They must comply with ANSI/ BHMA A156.4 standards for performance and reliability.

• Concealed Closers: Installed within the door or frame, these closers provide a clean aesthetic while maintaining functionality. Compliance with ANSI/BHMA standards is required.

• Floor Closers: Embedded in the floor, these are ideal for heavy

• doors, offering superior control and durability. They must adhere to ANSI/BHMA A156.4 standards.

Protecting doors from damage and wear ensures their longevity and maintains their appearance:

• Mop Plates: Installed at the bottom of doors, mop plates protect against cleaning tools and moisture. They should meet ANSI/BHMA A156.6 standards.

• Kick Plates: These plates shield the lower part of the door from impact damage and are crucial in high-traffic areas. Compliance with ANSI/BHMA A156.6 standards is essential.

• Armor Plates: Covering larger sections of the door, armor plates provide extensive protection, especially in commercial settings. They must adhere to ANSI/BHMA standards.

• Edge Guards: These guards protect door edges from chipping and

wear, particularly in environments with frequent contact with carts and equipment. They should meet ANSI/BHMA standards.

Effective sealing prevents drafts, noise, and moisture infiltration, enhancing comfort and energy efficiency. Different types of sealing systems include:

• Adhesive Seals: These seals are easy to install, adhering directly to the door or frame. They provide a simple yet effective barrier against drafts and sound. Compliance with ANSI/BHMA A156.22 standards ensures performance.

• Surface-Mounted Seals: Mounted on the door surface, these seals are more robust and durable than adhesive seals. They offer enhanced protection against elements and are suitable for high-traffic areas. They must adhere to ANSI/ BHMA A156.22 standards.

• Bottom Sweeps: Attached to the bottom of the door, bottom sweeps are crucial for sealing gaps between the door and the floor. Types of bottom sweeps include:

• Surface-Mounted Sweeps: Easily attached to the door bottom, they provide an effective barrier against drafts and pests. Compliance with ANSI/BHMA standards is necessary.

• Semi-Mortised Sweeps: Partially recessed into the door bottom, semi-mortised sweeps offer a more integrated look while maintaining functionality. They must adhere to ANSI/BHMA standards.

• Automatic Sweeps: These sweeps are designed to automatically lower and seal the gap when the door is closed, retracting when the door is open. They provide an excellent balance of aesthetics and performance, complying with ANSI/BHMA standards.

By adhering to DHI and NFPA standards, architects and builders can ensure that doors are functional and secure and compliant with industry regulations, providing safety, durability, and efficiency.

This expanded article now provides more detailed information about the differences between panic devices and fire exit hardware and a comprehensive explanation of various sealing systems and bottom sweeps.

Electrified door hardware integrates advanced technology to enhance security and functionality. Key components include:

These locks use electrical power to control locking and unlocking. They come in two types:

• Fail-Safe (Power-To-Lock): In the event of a power failure, the door unlocks, ensuring safe egress. This is commonly used in applications where safe exit is paramount, such as in stairwells and exit doors.

• Fail-Secure (Power-To-Unlock): In the event of a power failure, the door remains locked,

maintaining security. This is suitable for securing sensitive areas like data centers or financial institutions.

• Electric Strikes: Installed in the door frame, electric strikes allow doors to be unlocked remotely by releasing the latch. They are often used in conjunction with access control systems and must comply with ANSI/BHMA A156.31 standards. Features include:

• Field Selectable Voltage: Allows the strike to be compatible with various power supply configurations.

• Integrated Monitoring: Provides feedback on door status, enhancing security and monitoring capabilities.

These devices offer a range of functionalities to control egress and secure doors:

• Electrical Latch Retraction: Allows the latch to retract electronically, enabling smooth push/pull operation. This feature is often used in high-traffic areas and integrates with access control systems.

• Electrified Dogging: Keeps the latch retracted, enabling the door to operate freely until reset.

This function is useful in facilities where doors need to remain open during business hours and lock automatically after hours.

• Alarmed Exit Devices: Sound an alarm if the door is used without authorization, providing an audible deterrent against unauthorized exits.

• Delayed Egress Exit Devices: Delay opening for a predetermined time (usually 15 seconds) to deter unauthorized exit while complying with NFPA 101. These are often used in retail and healthcare facilities to prevent theft or unauthorized departure.

• Electrified Trim: Electrically controls the handle or lever to lock/unlock doors. This is commonly used in conjunction with access control systems to provide secure, keyless entry.

• Request to Exit (REX): Sensors or switches that signal the access control system when someone exits, ensuring security and monitoring. Common REX devices include motion sensors, push buttons, and touchless exit devices.

• Low Energy Operators: Designed for doors that open and close at a slower pace, these operators are typically used in facilities to comply with ADA (Americans with Disabilities Act) standards. They aid those with mobility impairments by allowing the door to open with minimal force or by activating a switch.

• Full Energy Operators: These operators are designed for high-traffic areas where doors need to open and close quickly. They are commonly used in commercial settings such as airports, shopping centers, and office buildings. Full energy operators must comply with ANSI/BHMA A156.10 standards, which cover power-operated pedestrian doors.

• Power Assist Operators: These operators reduce the effort required to open a door manually. They provide a mechanical advantage, making it easier for individuals to open heavy doors. Power assist operators are often used in healthcare facilities and other environments where ease of use is essential.

• Remote Lock/Unlock: Allows doors to be controlled remotely via access control systems, enhancing security and convenience.

• Integration with Fire Alarm Systems: Ensures doors unlock automatically in the event of a fire, complying with NFPA 72 standards.

Automatic door operators provide ease of access and improve the functionality of doors in various settings. Types of automatic operators include:

• Battery Backup: Ensures that electrified door hardware remains operational during power outages.

• Sliding Door Operators: Used for automatic sliding doors, these operators are common in retail environments and hospitals. Sliding door operators must comply with ANSI/BHMA A156.27 standards, ensuring safety and reliability.

• Swing Door Operators: These operators are used for swinging doors, providing automated opening and closing functions. They are suitable for both single and double door configurations. Compliance with ANSI/BHMA A156.19 standards is essential for safety and performance.

Energy-efficient door hardwareincluding door closers, locks, panic devices, and sealing systems— plays a crucial role in advancing building energy conservation. These components ensure doors close securely and operate effectively, significantly minimizing energy loss. Properly designed and maintained door hardware is essential for preserving the integrity of a building’s thermal envelope, which, in turn, reduces the load on heating, ventilation, and air conditioning (HVAC) systems. Given that HVAC systems are major energy consumers in commercial environments, optimizing door hardware is integral to enhancing overall energy efficiency.

Energy efficiency refers to a system’s or component’s ability to perform its functions while minimizing energy consumption. By reducing energy waste, we lower carbon emissions and decrease energy costs. Doors, often overlooked, can be significant

sources of energy loss and inefficiency in buildings. Gaps around the door frame, poor insulation, and inadequate sealing can lead to air leakage, allowing conditioned air to escape and unconditioned air to enter. This creates unnecessary energy demands and discomfort for occupants.

Choosing the right door handles can enhance energy efficiency. Opting for handles made from materials with low thermal conductivity, such as insulating materials or those incorporating thermal breaks, can help prevent heat transfer. This ensures that the handle does not become excessively hot or cold, thereby contributing to a comfortable indoor environment.

A properly installed and functioning door lock is crucial not only for security and peace of mind but also for energy efficiency. A poorly fitted or malfunctioning lock can create gaps between the door and

frame, leading to air leakage. An automatic door lock system can ensure that the door is securely closed, thus minimizing energy loss and maintaining the desired indoor temperature.

Door closers are mechanisms designed to ensure that doors close automatically after use, eliminating the risk of leaving the door open. They play a critical role in energy efficiency by preventing doors from being unintentionally left ajar. An automatic door closer ensures that the door is tightly and promptly closed after each use, effectively preventing air leakage and minimizing energy waste.

Door seals are essential for enhancing energy efficiency by preventing air leakage and reducing energy waste. They act as a barrier, sealing the gaps between the door and the frame, which effectively reduces drafts and prevents the exchange of conditioned air with the outside environment. By ensuring a tight seal, door seals help maintain the desired indoor temperature, thereby reducing the workload on heating and cooling systems and resulting in significant energy savings. A gap as small as 1/8 inch under your door can lead to heat loss and higher energy bills, similar to having a 3-inch hole drilled into the side of your home. Additionally, if the gap is large enough, it may even invite bugs and critters into your home.

To check if your threshold or bottom door weather stripping is functioning properly, hold a burning candle or incense stick next to the bottom of the door on a windy day. If the flame or smoke diverts, it indicates that the wind is getting through and action is needed.

Adjustable door thresholds require periodic adjustments and may need replacement weather-stripping every couple of years. Adjusting them involves a bit of trial and error; make very small movements towards the bottom of the door and be patient.

Weather-stripping along the sides and top of the door should also be checked using the candle method and replaced if necessary. There are various styles and types of weatherstripping, so it’s important to find an exact replacement type suitable for your door. Door sweeps, which mount at the bottom edge of the door, provide a seal when the door closes and typically cost under $20. A door shoe is another type of weather-stripping made of rubber, mounted on the underside of the door

Using energy-efficient door hardware offers numerous advantages for buildings and occupants alike. Key benefits include:

• Energy Savings and Cost Reduction: Improved door hardware, such as energyefficient handles, locks, and closers, can lead to substantial

energy savings. These components reduce heating and cooling loads by minimizing air leakage and preventing energy waste. Consequently, energy consumption decreases, leading to lower utility bills and long-term cost savings.

• Enhanced Comfort: Energyefficient door hardware helps maintain a comfortable indoor environment. By preventing drafts and air leakage, occupants can enjoy a consistent temperature free from cold spots or sudden temperature changes. Additionally, wellsealed doors contribute to noise reduction, enhancing overall comfort within a building.

• Indoor Air Quality: When doors are adequately sealed with energy-efficient hardware, they act as a barrier against outdoor pollutants, allergens, and dust. This helps maintain better indoor air quality, creating a healthier living or working environment.

• Reduced Environmental Impact: By promoting energy efficiency in buildings, we can reduce our carbon footprint and contribute to a sustainable future. Energyefficient door hardware helps lower energy consumption,

thereby decreasing greenhouse gas emissions associated with energy generation. This represents a small yet impactful step toward mitigating climate change.

When selecting door hardware, it is essential to look for products that have undergone testing and received certification for energy efficiency. These ratings ensure that the hardware meets rigorous performance standards and actively contributes to energy savings. By choosing certified door hardware, you can be confident that it has been evaluated for its ability to reduce energy loss and improve overall efficiency. These certifications validate that the hardware has undergone thorough testing and meets specific criteria for energy conservation, allowing you to make informed decisions that align with your goals of reducing energy consumption and promoting sustainability.

Exploring the latest advancements in energy-efficient door hardware can reveal a range of exciting possibilities. For example, some door closers now incorporate cuttingedge smart technology that goes beyond traditional mechanisms. These intelligent closers are equipped with sensors that detect foot traffic and adjust the closing speed accordingly. By dynamically adapting to the flow of people, they effectively reduce unnecessary air exchange, limiting energy loss while maintaining convenience and accessibility. Additionally, features such as adjustable closing force and adjustable latching speed allow for customization of the door’s operation, ensuring a balance between secure closure and controlled energy consumption.

Moreover, the shift towards sustainability has compelled manufacturers to adopt eco-friendly practices, ensuring that the hardware is not only durable but also produced with minimal environmental impact. This story also explores the critical importance of proper installation, as it directly influences the performance and lifespan of the hardware, underscoring the need for meticulous planning and execution.

One of the most vulnerable aspects of building design is the façade. Because the majority of the populace is unaware of the material’s performance, they frequently misunderstand the importance of façade design, particularly in limiting or spreading fire spread. Fire safety has traditionally been overlooked in favour of beauty, energy efficiency, cost, and other factors. However, in light of current market trends, this has progressed beyond only the aesthetic aspect and now plays a larger role in light conveyance, acoustical execution, and efficacy.

With the ever-increasing complexity of building designs, the architectural hardware industry faces numerous challenges, from maintaining safety and regulatory compliance to meeting the evolving demands of architects and end-users. As we look towards the future, the experts provide a glimpse into how architectural hardware is expected to evolve, focusing on design, functionality, and the integration of cutting-edge technologies that promise to transform the built environment.

It is about the universal understanding of the reality that any possible fire threats can only be mitigated when façade systems, materials, and testing are given the attention they deserve. The emphasis should be on a comprehensive approach to examining the performance of façade materials, components of façade design for fire safety, fire testing of façade materials, compartmentalization, and much more.

The opinions and ideas of subject-matter experts are featured in this cover story. We sought to collect their thoughts on things like façade fire safety, laws and regulations, appropriate materials, the best approach to build a fire-safe façade, and so on. In the rapidly evolving world of architecture, the role of architectural hardware has grown beyond mere functionality, emerging as a crucial element that marries aesthetic appeal with practical necessity. As façades and fenestrations continue to dominate contemporary architectural designs, the selection of appropriate hardware becomes pivotal in defining not just the look, but also the longevity and efficiency of a building. This cover story delves deep into the intricacies of architectural hardware, offering insights from industry experts on the primary criteria that guide the selection of these essential components.

The architectural hardware landscape is continuously shaped by emerging trends, technological advancements, and the growing demand for sustainable solutions. As modern aesthetics demand sleek and innovative designs, manufacturers are challenged to produce hardware that not only complements the architectural vision but also meets stringent performance standards. This has led to the integration of smart technology, which is revolutionizing the functionality and user experience of architectural hardware, making buildings more intelligent and responsive.

This cover story delves into the intricacies of architectural hardware, guided by expert opinions on the primary criteria for hardware selection, the latest trends shaping the industry, and the impact of modern aesthetics on hardware design. We explore how technological innovations, such as smart technology, are revolutionizing the functionality and user experience of hardware, making buildings more intelligent and responsive. Additionally, we examine the shift towards sustainable practices and the critical role of proper installation in ensuring hardware performance and durability.

As we navigate through the evolving landscape of architectural hardware, our experts shed light on the current challenges faced by the industry and offer predictions on how hardware design and functionality will continue to evolve. Read this cover story to discover the answers to these pressing questions and gain a comprehensive understanding of how architectural hardware is shaping the future of modern buildings.

“Technology

DANIEL MAY Director, Consort Architectural Hardware

• What are the primary selection criteria for architectural hardware used in façades and fenestrations?

Modern architectural hardware projects require a blend of durability, functionality, and aesthetics. More than ever before, products must be able to withstand a multitude of environmental factors whilst offering users

reliable operation and possessing enough aesthetic appeal to enhance building design. To ensure hardware can fulfill performance and regulatory requirements, specification teams must consider material quality, safety certifications, and energy performance. This information is often made accessible by reliable manufacturers.

• What are the current trends in architectural hardware that are gaining popularity?

Minimalist designs with sleek, unobtrusive profiles are increasingly coveted and there is an ongoing need for enhanced security and automation with integrated smart technology. The industry is appropriately shifting focus to sustainability too, with the environmental

performance of construction products being placed under the spotlight. In response, many conscious manufacturers are using recycled materials and adopting eco-friendly processes.

• Can you discuss any recent trends in hardware design that cater to modern architectural aesthetics?

Clean lines, smooth finishes, and concealed fittings. These features help to maintain the sleek look of contemporary building design, with popular finishes including brushed metals and matte black. Slim profiles and colour-matching options also allow hardware to seamlessly blend with various materials and architectural styles.

• What are the latest sustainable practices being adopted by hardware manufacturers?

Conscious hardware manufacturers are adopting a number of sustainable practices, such as utilising recycled materials, implementing energy-efficient production technologies, and using eco-friendly coatings with low volatile organic compounds (VOCs). In reviewing the full life cycle of products, many are actively assessing the responsible sourcing of raw materials and are striving to minimise waste

streams with streamlined manufacturing processes and comprehensive recycling schemes.

• How does proper installation impact the performance and lifespan of hardware?

Accurate installation is crucial to the long-term success of projects, as it ensures optimal performance, safety, and the longevity of the hardware. When hardware is appropriately installed, it minimises wear and tear, prevents failures, and upholds the building’s structural integrity. In any case, hardware should be installed by qualified professionals and must follow manufacturer guidelines, to ensure performance and compliance are not put at risk.

• How has technology influenced the design and functionality of modern architectural hardware?

Technology has drastically influenced modern architectural hardware, with the introduction and integration of smart access control systems changing the way many buildings operate. The development of advanced materials with superior properties continues to change the landscape still, with the use of precision manufacturing techniques such as CNC and 3D printing paving the way to more secure, durable, and energyefficient hardware solutions.

• Can you discuss the integration of smart technology into architectural hardware and its benefits?

The integration of smart technology into architectural hardware offers numerous benefits, from enhanced security through smart locks and surveillance systems to the increased convenience associated with remote

access control. In relation to building management, smart hardware can collect data to inform teams of maintenance schedules as well as provide greater accessibility for individuals with disabilities. Decision makers can also positively impact the energy management of their buildings with automated windows and shading systems, for example.

• What are the key considerations for ensuring architectural hardware meets safety and regulatory standards?

The safety of our built environment is critical and with architectural hardware playing such an important role to fire safety and security, it must meet rigorous testing standards and relevant local and international building codes. Quality assurance tests ensure the use of materials meets or exceeds the minimum industry standards for strength, durability, and fire resistance and decisionmakers must take note of product information during the specification stages of a project. In application, door hardware needs to be fitted by qualified professionals and regular inspections to be conducted to ensure standards are maintained throughout a product’s lifecycle.

• What are the current challenges faced by the architectural hardware industry?

The architectural hardware environment is always changing, and the industry must keep pace with rapid technological advancements and supply chain disruptions. Safety and building code regulations have seen a period of progression also and the industry must adapt to the evolving standards across different regions to maintain competitiveness in a crowded market. Finally, from a design point of view, architectural hardware must balance performance with sustainability and cost considerations.

• How do you foresee the future of architectural hardware evolving in terms of design and functionality?

The future of architectural hardware is encouraging. We are likely to see a more streamlined integration of smart technology alongside an emphasis on sustainability, with eco-friendly materials and processes more widely adopted. Customisation will become more prevalent too, with advancements in security features and aesthetic design continuing to evolve - helping manufacturers to align with users' demands and contemporary architectural trends.

“The Future of Architectural Hardware will be Characterised by Smart Technology, Minimalist Design, Sustainability, Durability, Customisation, Integration with Building Systems, and Multi-Functionality”

TABISH KHAN Sales Director - MEA, EuroArt

• What are the criteria for the selection of architectural hardware for facades & fenestrations?

When selecting architectural hardware for façades and fenestrations, the focus is on balancing aesthetics with

structural integrity. The façade, as the building's exterior, requires visually appealing hardware that complements the building's overall character while considering local climatic conditions. Each project demands unique hardware solutions.

• Key criteria for selecting architectural hardware include:

• Performance and Durability: Ensuring reliable operation and long-term resilience.

• Visual Appeal: Enhancing the building's aesthetics.

• Project Specifics: Considering location, type, budget, security needs, occupancy, and client preferences.

Trends toward transparent buildings with minimal visible hardware push manufacturers to create products that are high-performing, durable, and visually pleasing. Quality is crucial, as poor fittings compromise both functionality and appearance.

Project location, type (residential, commercial, industrial), product finish, location of the door, budget, general climatic conditions, security level, access control requirements, occupancy, and local stock availability are important factors in the selection of hardware. By considering these criteria, architects and designers can select hardware that not only meets the functional requirements but also enhances the visual appeal and character of the building.

• Can you discuss any recent trends in hardware design that cater to modern architectural aesthetics?

The hardware industry continues to evolve, and several key concepts are gaining traction in the industry. This model not only enhances functionality but also highlights the combination of aesthetics with modern architecture.

Current trends in hardware include:

• Finishes: The industry is moving away from standard finishes of Satin SS, black, satin brass, etc. The interior designers and developers are experimenting with bold finishes like gunmetal, dark umber, fused nickel bronze, brushed bronze, etc.

• Digital Door Locks: In the GCC market, door locks are gaining popularity because they incorporate digital technology to meet the growing demand for home automation and the demand for keyless entry systems. These locks offer superior security, including biometric authentication and remote access, making them an essential part of the modern smart home. The system has completely replaced the door hardware.

• Integrated Lock Levers: Integrated lock levers are revolutionising traditional door hardware by incorporating locking functions directly into the lever handle, eliminating the need for a separate escutcheon. These minimalist lever handles can also accommodate matching veneers and stones, seamlessly blending with the door finish and enhancing the overall aesthetic appeal.

• Pocket Sliding Fittings with Service Tracks: Pocket sliding fittings have historically been avoided due to high maintenance requirements and the potential need for wall modifications during servicing. However, the advent of dualtrack technology has addressed these concerns. This system allows for the installation of a fixed track during construction, while an internal serviceable track can be easily removed for repairs or adjustments without disrupting the wall structure.

• Invisible Frames & Door Fittings: Invisible door fittings are designed to create a sleek, seamless appearance by minimising gaps between the door and frame to just 2-3mm. These doors are mounted with concealed hinges and door closers, ensuring smooth operation while maintaining a discreet profile. The use of metal frames and camouflaged designs allows these doors to blend seamlessly with wall finishes, achieving a modern, minimalist look.

In summary, the latest trends in architectural hardware reflect a shift towards integrating advanced technology, enhancing aesthetics, and improving functionality.

• What are the latest sustainable practices being adopted by hardware manufacturers?

‘Longevity is sustainability’ – extended cycle testing ensures the product is fit for many years of operation & does not need replacement throughout the lifetime of the building. Accordingly, companies are designing hardware products with durability and recyclability in mind, facilitating easier disassembly and recycling at the end of the product's life. This cradle-to-cradle approach helps reduce landfill waste and supports a circular economy.

Furthermore, companies are showing their commitment to sustainability by participating in carbon offset programs like planting trees and using renewable energy sources, such as solar or wind power, to reduce their environmental footprint further. Use of plastic is being avoided & recyclable packaging is being considered in the packaging of material. These efforts collectively contribute to a more sustainable hardware industry.

• How does proper installation impact the performance and lifespan of hardware?

Proper installation ensures that the hardware is securely fitted and aligned, preventing issues such as

misalignment, loosening, or undue stress on parts. For instance, in door hardware like hinges and locks, improper installation can lead to misalignment, causing the door to sag or not close properly, which can accelerate wear and necessitate early replacement.

Moreover, correct installation includes following manufacturer guidelines and using the appropriate tools and materials. This adherence to specifications ensures that the hardware can handle the expected loads and stresses, maintaining its structural integrity over time. In short, proper installation not only optimises the immediate functionality of hardware but also significantly contributes to its longevity and durability, protecting the investment and reducing long-term maintenance costs.

Annual inspections of fire-rated assemblies & exit doors should be conducted and enforced to ensure door openings are properly adjusted and maintained for usability and safety.

• How has technology influenced the design and functionality of modern architectural hardware?

• Smart Technology: Integration of keyless entry systems, automated doors, and sensor-activated hardware for improved security and convenience.

• Energy Efficiency: Development of low-energyconsuming door closers and window hardware that optimise natural lighting and ventilation. Smart digital locks are also being furnished with rechargeable lithium-ion batteries.

• 3D Modelling: The use of 3D software helps factories to experiment with designs more creatively. Even the use of 3D printers facilitates to manufacture the visualised designs in ABS plastic through rapid prototyping with stereolithography machines. This is the first step we do for custom handles so that actual geometry & dimensions can be reviewed.

Overall, these technological innovations provide functional, durable, and aesthetically pleasing solutions for architectural hardware.

• Can you discuss the integration of smart technology into architectural hardware and its benefits?

The integration of smart technology into architectural hardware is transforming the way we interact

with buildings and spaces. Smart architectural hardware, such as automated door locks, touchless access systems, and intelligent lighting, enhances convenience, security, and energy efficiency. These innovations allow for seamless control and monitoring via smartphones or other devices, making building management more accessible and efficient.

One of the key benefits of smart technology in architectural hardware is enhanced security. Features like biometric access, remote monitoring, and automated locking systems ensure higher levels of protection against unauthorised access.

• What are the key considerations for ensuring architectural hardware meets safety and regulatory standards?

Ensuring architectural hardware meets safety and regulatory standards is crucial for the integrity and functionality of a building. Doors act as barriers to the spread of smoke and fire. Ironmongery on doors is an important component to ensure the effectiveness of the operation of the barrier. Selfclosing mechanisms, positive latching intumescent packs behind mechanical items on timber doors to limit the spread of fire, and seals to prevent the spread of smoke. There are third-party certification bodies that test the products on doors and guidelines issued

by international bodies to ensure conformity to the guidelines.

In the selection of hardware, safety and security are interchangeable which creates some confusion in the selection process. It is important to note that security is of utmost importance and many times a balance must be made between safety and security.

• What are the current challenges faced by the architectural hardware industry?

Construction methods have been constantly evolving and with that, all trades are also expected to keep pace. Safety, security, climate change, sustainability, price, and finishes are given a lot of credence along with aesthetics and traditional forms of operating doors and windows.

The hardware industry has been keeping abreast of all these challenges with constant improvements being made. Hardware specification for doors and windows is now a very specialised subject and we have multiple educational qualifications to train aspiring professionals on the nuances of specification. GAI and AHC for European and American norms respectively have more than three years of courses to get a professional certification that helps them aid consultants and contractors on the specification, installation, and compliance to various statutes that exist.

• How do you foresee the future of architectural hardware evolving in terms of design and functionality?

Design trends will shift towards minimalism, with hardware becoming more concealed and integrated to maintain a sleek, modern look. Sustainability will play a crucial role, with ecofriendly materials and energy-efficient designs gaining prominence.

The future of architectural hardware will be characterised by smart technology, minimalist design, sustainability, durability, customisation, integration with building systems, and multifunctionality. These trends will not only enhance the functionality and aesthetics of buildings but also contribute to more efficient, secure, and environmentally friendly architectural solutions.

“The

to

and a

GILBERT NICOLAS Architectural Consultant, Dormakaba

• What are the primary selection criteria for architectural hardware used in façades and fenestrations?

First and foremost, the hardware must work properly, doing its intended functions effectively and reliably. This involves ensuring that doors and windows function properly and perform their

intended objectives. Functionality, durability, safety, and aesthetics are only a few of the essential requirements. As security needs rise, access control is another issue that must be handled. Another crucial consideration is accessibility. Not to mention the increasing importance of sustainability. For exampleFitted hardware increases the insulation of the building envelope and reduces its carbon impact. The hardware, particularly those for doors and windows, must increase the building's energy efficiency and overall environmental performance. A comprehensive evaluation is essential to ensure that the hardware not only works correctly but also enhances the building’s overall design and environmental performance.

• What are the current trends in architectural hardware that are gaining popularity?

Current trends in architectural hardware are all about blending technology, design, and sustainability. Smart and connected hardware, like biometric locks and automated door systems, are becoming more common, making buildings safer and more convenient. Minimalist designs are also popular, providing a sleek, modern look that fits well with today's architectural styles.

Sustainability is a big focus, with more eco-friendly materials and energy-efficient options being used to reduce environmental impact. Enhanced security features, such as advanced locks and stronger materials, are crucial for keeping buildings safe. Customization is on the rise, allowing for hardware that perfectly fits the specific needs and style of each project. Integration with building management systems is another trend, offering better control and monitoring of building functions.

• Can you discuss any recent trends in hardware design that cater to modern architectural aesthetics?

When it comes to current hardware design trends for modern architecture, the objective is to combine functionality with sleek design since it complements the minimalist style and allows for more natural light through larger glass panels. Furthermore, minimalist aesthetics with concealed hardware are popular. Designers favor hidden hinges, locks, and handles, which provide clean, smooth surfaces with no interruptions. It's all about the seamless appearance.

• What are the latest sustainable practices being adopted by hardware manufacturers?

Hardware manufacturers are rapidly adopting sustainable techniques to lessen their environmental impact and meet the growing demand for eco-friendly products. They’re getting creative with some impressive strategies. For example, they use recycled metals and eco-friendly materials to reduce waste and promote a circular economy. Factories are becoming more energy-

efficient, often powered by renewable sources like solar and wind. Many companies are committed to carbon neutrality, using smart technologies to streamline processes and shrink their carbon footprint. By offering repairable and recyclable items, they ensure less waste and more sustainable choices for everyone. It’s all about blending innovation with responsibility. How does proper installation impact the performance and lifespan of hardware?

• How does proper installation impact the performance and lifespan of hardware?

Proper installation is essential for making sure hardware works well and lasts a long time. When hardware is installed correctly, it functions smoothly and safely. For example, well-aligned hinges, correctly set closers, and properly fitted locks all work better and last longer.

If hardware isn’t installed properly, it can become misaligned or face extra strain, which leads to quicker wear and possible breakdowns. For instance, a misaligned

door closer can cause uneven pressure, which wears out both the hardware and the door faster.

Proper installation also ensures that the hardware meets building codes and safety standards, which helps it perform as expected and keeps the building safe.

In short, installing hardware correctly helps it work better, last longer, and keep everything safe and reliable.

• How has technology influenced the design and functionality of modern architectural hardware?

Technology has greatly influenced the design and usefulness of modern architectural hardware, resulting in developments that improve both aesthetics and performance. Smart technology integration is critical; for example, smart locks and access control systems now include biometric identification and smartphone connectivity, which improves security and convenience. Automated hardware, such as motorized doors and windows, may be operated remotely or programmed to respond to environmental conditions, increasing energy efficiency and user comfort.

• Can you discuss the integration of smart technology into architectural hardware and its benefits?

Smart technology is about creating better settings for everyone in every important site, not only high-tech gadgets.

The way we connect and manage buildings fundamentally. For instance, to enable entry without the need for traditional keys, smart locks use biometrics, keypads, or smartphone applications. Particularly in

places where security is a big concern, this greatly improves convenience and safety.

The accessibility and safety of these smart technologies are enhanced. In addition to making life easier for everyone, including those with disabilities, touchless controls and automatic doors also help to stop the spread of disease. An environment that is safer, more efficient, and easier to utilize is the ultimate result.

• What are the key considerations for ensuring architectural hardware meets safety and regulatory standards?

To make sure architectural hardware is safe and meets all the necessary standards, there are a few key things to keep in mind. First, it’s important to follow local codes and regulations related to safety, accessibility, and structural integrity. Using high-quality, durable materials is also crucial, as they need to withstand wear and environmental conditions.

Look for hardware that has been tested and certified by trusted organizations to ensure it meets safety standards. Proper installation by skilled professionals is essential, and regular maintenance checks help keep everything in good shape.

Last but not least, consider the needs of all users when designing hardware and incorporate features like sturdy locks and suitable for ADA-compliant features to ensure safety and accessibility.

• What are the current challenges faced by the architectural hardware industry?

A lack of awareness about the specifics of door hardware can lead to failing to meet important regulations and

standards. Door hardware isn't just about installing basic components like hinges, closers, and locks; it's about ensuring that every piece serves its intended purpose within the design of the building. The hardware needs to align with the overall design goals and operational needs of the space.

To ensure that all aspects of the door hardware are compliant with relevant standards and regulations, consultants and contractors must seek expert guidance. Experts can provide valuable insights into the correct selection, installation, and maintenance of hardware to ensure it meets safety, accessibility, and performance standards. Proper consultation helps avoid costly mistakes and ensures that the final setup not only works efficiently but also adheres to legal and safety requirements.

• How do you foresee the future of architectural hardware evolving in terms of design and functionality?

The future of architectural hardware is set to combine innovative technology, sustainable practices, and a focus on security and user experience. This will lead to more efficient, smart, and aesthetically pleasing environments.

Innovative technology will play a crucial role, with smart locks, biometric recognition, and automated systems becoming standard. These advancements will offer enhanced security and convenience, while IoT-enabled devices will provide real-time monitoring and control, boosting building efficiency and safety.

Sustainability will remain a key focus as the industry strives to reduce environmental impact. The use of eco-friendly materials, energy-efficient solutions, and sustainable manufacturing processes will become more prevalent.

High-security requirements will be upheld by more convenient and adaptable wireless and keyless solutions, such as electronic keypads and mobile app-based controls.

User experience will see significant improvements with designs focused on accessibility. Touchless controls, automated doors, and easy-to-use interfaces will enhance convenience, making buildings more inclusive. Customization options will ensure hardware aligns with the aesthetic and functional needs of each project.

“The Integration of Smart Technology has Led to Hardware that Offers

KARAM HAMADEH Managing Director, TPS

• What are the primary selection criteria for architectural hardware used in façades and fenestrations?

When selecting architectural hardware for façades and fenestrations, durability is essential since products need to withstand various environmental conditions. We also focus on aesthetics because we believe hardware should complement the overall design of a building. Functionality is another crucial aspect - our hardware

needs to be easy to use and highly reliable. Of course, safety and compliance with industry standards are always top priorities. We also consider how well the hardware integrates with other building systems and the overall cost-effectiveness.

• What are the current trends in architectural hardware that are gaining popularity?

We are noticing a growing trend towards minimalist and sleek designs. High-performance materials like stainless steel and aluminum are in demand because they offer both durability and a modern look. Smart technology is another big trend. More architects and builders are looking for hardware that provides advanced security features and automation. Sustainability is also becoming increasingly important, with a preference for products made from recycled materials and produced using ecofriendly processes.

• Can you discuss any recent trends in hardware design that cater to modern architectural aesthetics?

Modern architectural aesthetics often emphasise minimalism, which is reflected in our hardware designs at Allegion. Concealed hardware is particularly popular because it maintains a sleek, uninterrupted look. We are also seeing a rise in customisable finishes and colors, allowing architects to tailor hardware to their specific design themes. Our goal is to blend functionality with form seamlessly.

• What are the latest sustainable practices being adopted by hardware manufacturers?