www.wfm.co.in

www.wfmmedia.com Volume 5 | Issue 1 | ` 150 September - October 2018

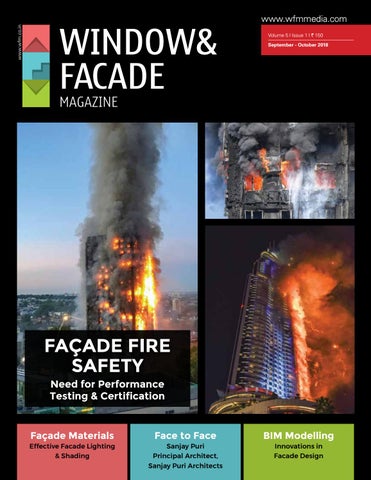

FAร ADE FIRE SAFETY Need for Performance Testing & Certification

Faรงade Materials

Effective Facade Lighting & Shading

Face to Face

Sanjay Puri Principal Architect, Sanjay Puri Architects

BIM Modelling Innovations in Facade Design