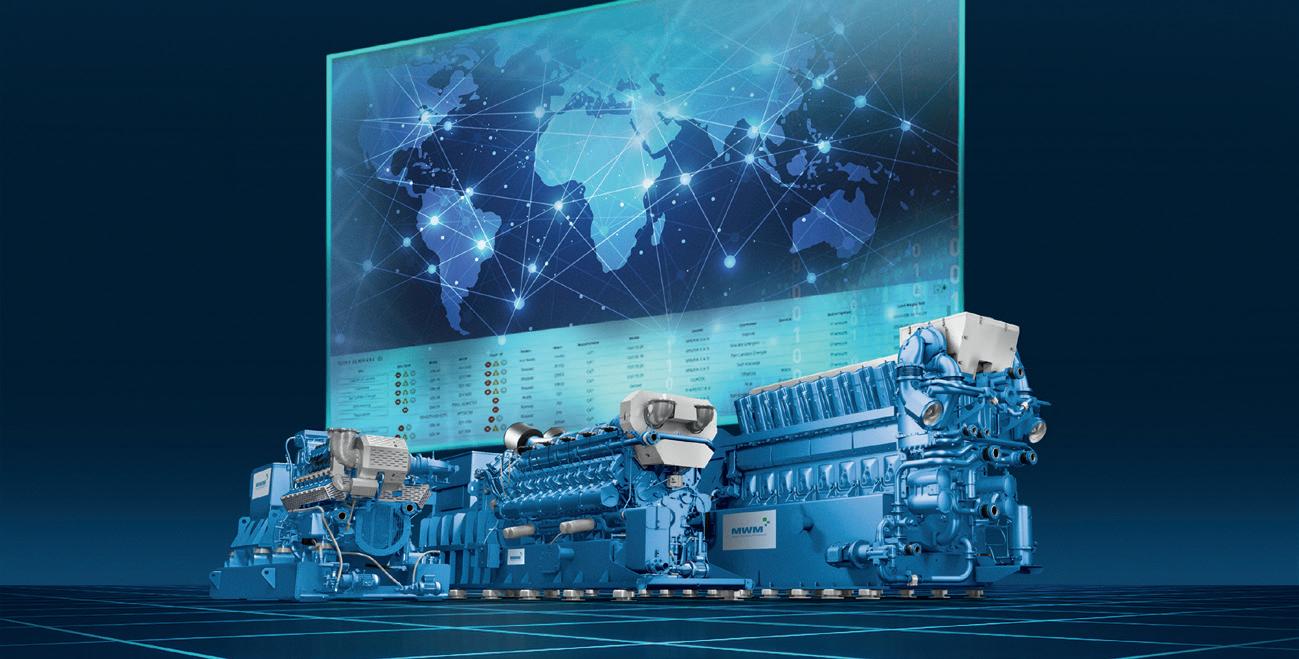

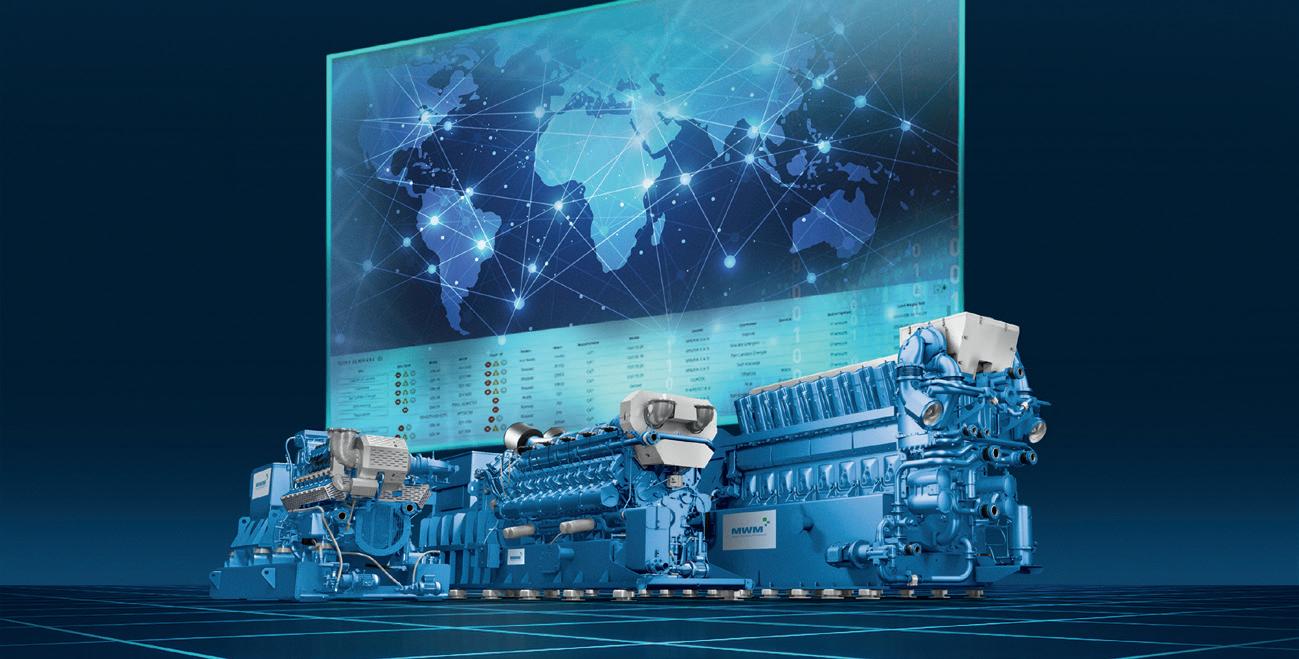

More transparency, more value.

With MWM Remote Asset Monitoring. Remote Asset Monitoring (RAM) is the new digital application from MWM that enables you to continuously monitor your plant. The system displays the status of your MWM fleet in a wellstructured, transparent manner, allowing you to act with foresight and more effectively.

www.mwm.net/ram

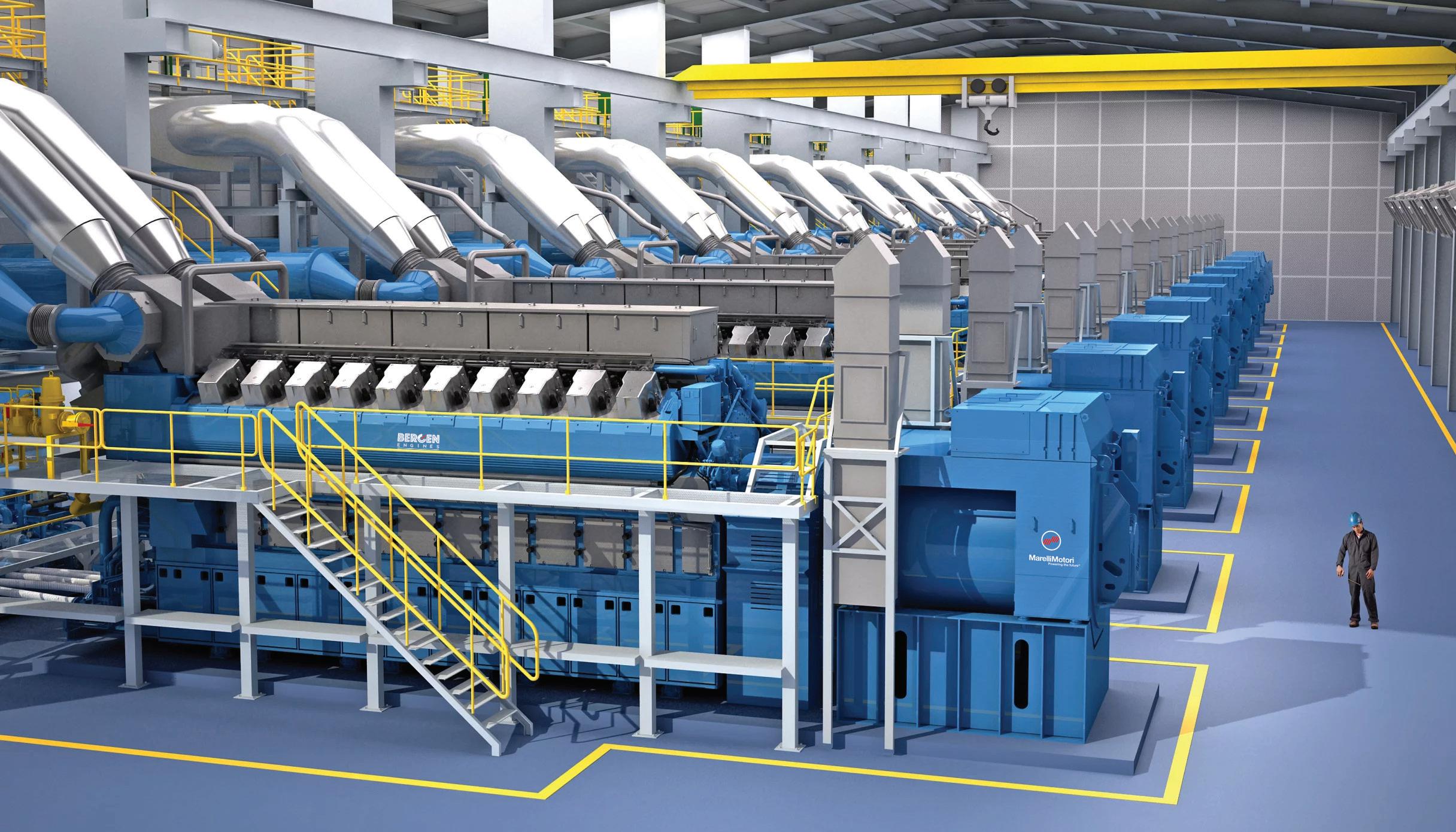

GAS-FIRED ALFHAUSEN PROJECT

MWM is behind an innovative gas-fired cogeneration project being rolled out in Alfhausen in Germany.

Page 14

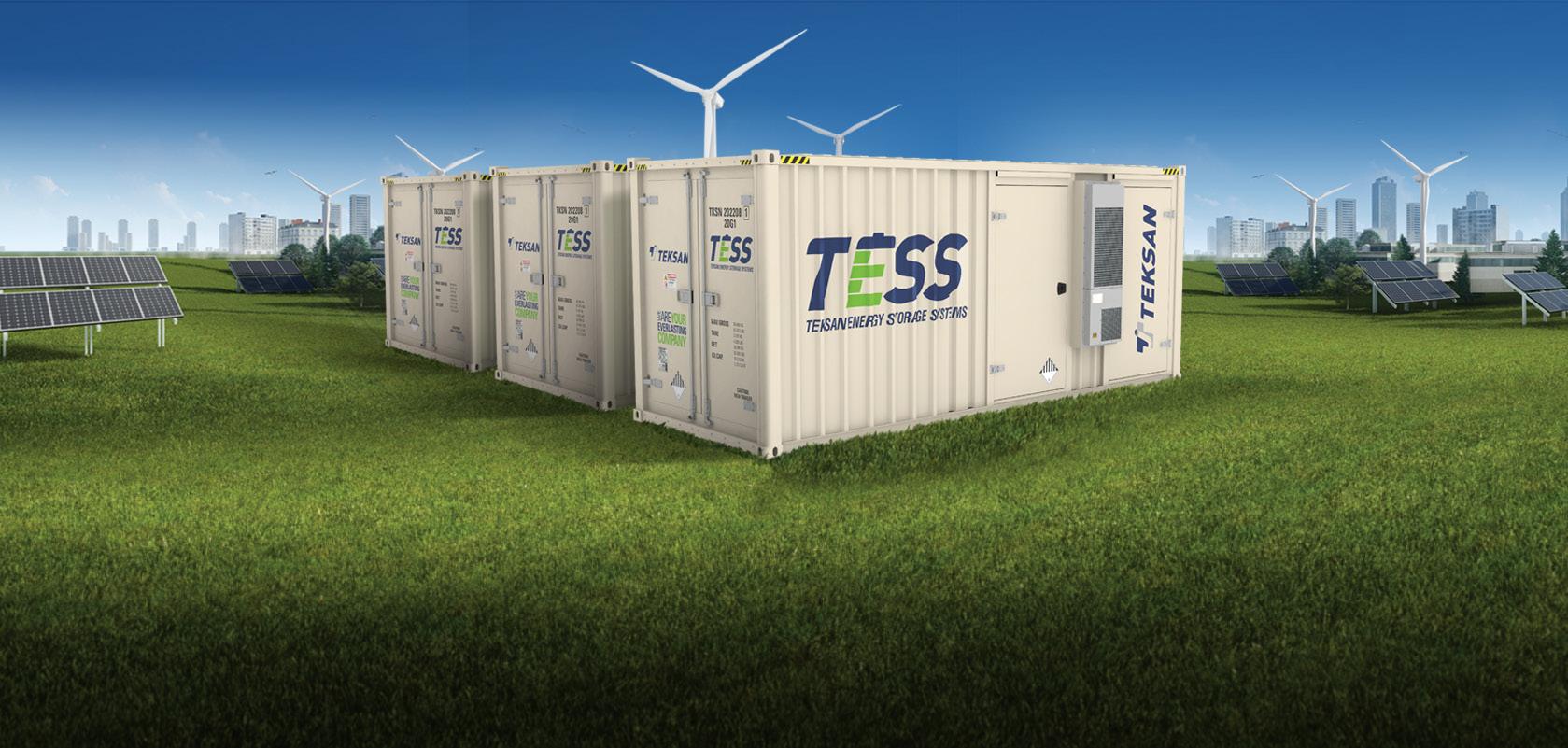

BESS SYSTEM FOR THE NETHERLANDS

Zwart Techniek Battery is supplying an a 1 MW/2 MWh BESS to BE Fresh Produce BV of the Netherlands.

Page 15

LIDL-SPAIN BUYS NEW GENSET ELECTRA

The MOLINS Group has supplied a 2,250 kVA genset with Baudouin engine & Mecc Alte alternator

Page 18

The New Children’s Hospital (NCH) project in Dublin, Ireland, comprises a main hospital on the shared campus at St James’s and two paediatric Outpatient and Urgent Care Centres CHI at Connolly, Blanchardstown, and CHI at Tallaght.

The NCH Project will have a significant impact on 25% of the population and is a Government priority, it is the most significant capital investment project in the healthcare system ever undertaken in Ireland.

Anglo Nordic - part of the Flowmax Group of companies - has partnered with Inpro Research & Development to supply and install gas oil pumping technology for the NCH’s prime/standby gensets.

Anglo Nordic installed two different fuel supply systems for the burners and the gensets, both controlled by a master PLC.

The whole installation has two main storage tanks. Both the burner ring pipeline and the genset ring pipeline suck fuel from these two main storage units.

The burner’s supply installation comprises a double pump unit and five burners., plus inlet stablisers. The genset’s supply

The

New Children’s Hospital (NCH) Project in Dublin features new genset tech

installation is composed of a double-pump unit and five generators with their corresponding daily tanks , safety devices and their return single pump units. The master control will be redundant with two separate PLC programmed to control the installation. There will be two different communication lines for each PLC, one via Modbus and the other via TCP IP as well: there will be four redundancy communication channels.

The NCH project provides a key hospital at St James’s campus, delivering the best care and treatments for Ireland’s sickest children and young people. It will play play a central role in the provision of acute paediatric healthcare services across Ireland.

We designed and built your genset –and we know it like no other.

Entrust the service to the one who knows best: the manufacturer. www.mwm.net/en/services

CES22027-Anzeigen_MWM_Service_V1_95x145mm_EN_1_0_RZ_sm.indd 1 08.03.23 09:23

CES20001_Anzeigen_MWM_RAM_235x55mm_EN_1_0_RZ_sm.indd 1 07.03.23 10:13

MARCH 2023 1 EURO POWER NEWS MARCH 2023

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager:

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

Kohler, Boudouin, MWM, Rolls-Royce SMR, AKSA, Zwart Techniek, Electra Molins, Danfoss, NIDEC, Leroy-Somer, Bergen Engines, EUROPGEN, Anglo Nordic, Inpro Research & Development, E-world Conference & Exhibition, Vaisala, AFC Energy, Mace Dragados, Rolls-Royce MTU, Volvo Penta, COELMO, JDPS, FPT Industrial, Manitou, easyLi, Webuild, All-Generating, YANMAR, Alfen, SemperPower, GeoPura, Redcentric PLC, NKT, Prysmian, 4 D Data Centres

EURO POWER NEWS

Published by: Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to Euro Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

H-POWER TOWER TRIALS USING A HYDROGEN FUEL CELL ON EUROPEAN CONSTRUCTION SITES

AFC Energy, a leading provider of hydrogen power generation technologies, is pleased to announce details of the latest in a series of field trials of the H-Power Tower on European construction sites.

Mace Dragados Joint Venture, the construction team building HS2’s new Euston station in the UK, is primarily trialling the hydrogen fuel cell to charge a fully electric JCB telehandler.

It is also being used to charge lighting towers and a water pump on site. The H-Power Tower is an entirely emission free solution, reducing noise and capacity requirements from mains power.

This is the latest in a series of construction deployments for AFC Energy’s H-Power Tower and also follows the recent successful field trial in Spain of the Company’s first prototype Methanol Fuel Tower.

Charging electric construction machinery with zero-emission solutions at point of use provides a real step forward in decarbonising the activities of construction activities where mains supply is not possible.

HS2, Europe’s largest construction project, has continually challenged its contractors to find new, innovative methods of construction and power supply that will result in lower emissions, be greener, and more environmentally- friendly. This is just one of the many ways HS2 is reducing carbon emissions and air pollution typically projected in construction and accelerating HS2 sites to be diesel-free by 2029.

BIOGAS IS A KEY POWER SOURCE FOR THE EU

Around 75% of the biogas currently produced in the EU is used as a source of local heat and power generation, with almost 20% of biogas being converted to biomethane, explains Antti Heikkila of VAISALA.

Antti Heikkilä is an Industry expert and Product Manager at VAISALA, where he has been in charge of bringing Vaisala’s groundbreaking and sustainable innovations for biogas measurement to market.

Countries around the world are urgently seeking alternatives to fossil fuels in order to lower greenhouse gas (GHG) emissions and thereby limit global warming. One of the ways in which this can be achieved is by replacing natural gas with biomethane, but this can only be a viable solution if it is environmentally and financially sustainable. To achieve this goal, it is necessary to monitor biogas production continuously so that the process can be optimized. Vaisala has developed monitors that are capable of measuring methane, carbondioxide and humidity in-line.

Formed over a timespan of millions of years when layers of organic matter decompose deep underground at high temperature and pressure, natural gas consists of methane and small amounts of other gaseous hydrocarbons. Natural gas is therefore a fossil fuel, and its combustion is responsible for a significant portion of global greenhouse gas emissions. For example, according to the USEPA, emissions from natural gas consumption represented 79% of the direct fossil fuel CO2 emissions from the (USA) residential and commercial sectors in 2020.

Biogas represents an important green alternative, but only if it is economically viable and able to compete with alternative forms of renewable energy. In-line monitoring of biogas production and the upgrading process to biomethane enable significant production efficiency improvements; making biomethane an economically and environmentally viable alternative to fossil fuels.

Around 75% of the biogas currently produced in the EU is used as a source of local heat and power generation, with almost 20% of biogas being converted to biomethane. According to the European Commission’s RePowerEU scheme, biomethane production is projected to increase tenfold by 2030 and to grow even more rapidly up to 2050. Today, the production cost of biomethane has been estimated to be around 80 euros/MWh, but the European Biogas Association expects this to fall to 55 euros/MWh in the future. These increases in both production and efficiency can only be achieved with the latest technology in process control instrumentation.

Biogas also offers an opportunity for a more circular economy. This is because the feedstock for anaerobic digestion (AD) can include waste products such as food, crop residues, animal manure, and wastewater sludge, and the digestate from AD.

EPN DIARY

E-WORLD ENERGY & WATER

May 23rd-25th 2023.

Essen, Germany

E-world energy & water is the meeting point for the European energy industry. Exhibitors from all over the world present sustainable technologies and intelligent services for the energy future. Approximately one fifth of the exhibiting companies are based abroad. The majority of international exhibitors come from countries of the European Union. An exhibition spokesman comments: “Optimal trade fair preparation, sustainable networking and extensive knowledge exchange: we can offer this to the E-world Community - it represents the ideal digital component to the presence trade fair. The online platform is available to you free of charge all year round. Find out industry news even faster and maintain your network around E-world even better.”

What the show is about: Exhibitors from various sectors of the energy industry will be at at E-world: about half of them work in the field of energy services, followed by information technology, energy trading and energy supply. Further topics are mobility, energy efficiency, marketing and sales, transport and grids as well as storage.

More information: www.e-world-essen.com

2 MARCH 2023 EURO POWER NEWS NEWS NEWS www.powermediagroup.co.uk

****************

ENERGY PACKS WILL STABILISE GERMANY’S ENERGY GRID

Rolls-Royce has delivered six of a total of eight mtu EnergyPacks to Vispiron, the southern German provider of sustainable mobility and energy solutions. The battery storage systems have largely been commissioned in solar parks in Bavaria and Thuringia in Germany and are used for so-called intraday trading – the short-term purchase and sale of electricity delivered on the same day.

Intraday trading is particularly important for absorbing unpredictable changes in electricity production and demand caused by the volatile feed-in of renewable energy sources such as solar and wind. “With regard to increasingly volatile electricity markets, battery storage can be used to profitably market storage capacity while having a stabilizing effect on our power grids,” said Florian Schönberger, CTO of Vispiron Energy GmbH & Co. KG.

One of the decisive factors for Vispiron to co-operate with the Rolls-Royce Power Systems was that the mtu EnergyPacks are fully integrable, modular systems, which are available with power ratings from 60 kVA to 2000 kVA and storage capacities from 70 kWh to 2200 kWh.

When connected to the public grid, the MTU EnergyPack helps reduce demand charges and increase self-consumption of existing onsite generation to mitigate rising energy costs. Community The MTU EnergyPack increases the self-sufficiency of urban areas with local power generation, and provides reliable backup power in the event of grid failure.

The scalable, all-in-one EnergyPack is a perfect fit for the changing energy environment, enabling existing power systems to adapt to current trends, and creating a host of possibilities when combined with renewable energy sources – aimed at creating sustainable energy systems that are in tune with the times and ready for the future.

The mtu EnergyPack can take care of frequency regulation, manage grid congestion and allow the avoidance of significant investment in grid infrastructure, for example to enable a scale-up of electric vehicle charging. It will also make solar and wind power more reliable and instantly switchable, while enabling gas or diesel power plants to operate more efficiently when combined with the mtu EnergyPack.

Facilities with onsite generation such as solar arrays or combined heat and power (CHP) plants can increase their own-use consumption by adding an mtu EnergyPack to take advantage of time-of-day electricity tariffs by shifting their power draws. If needed, backup power capability can also be provided. Remote industrial operations currently running on diesel power with no grid connections can reduce their fuel consumption and meet legal or company environmental standards more easily by integrating renewable sources with an mtu EnergyPack. When connected to the public grid, the mtu EnergyPack helps reduce power draw charges and increase own-use consumption of existing onsite generation to mitigate rising energy costs.

The mtu EnergyPack increases the self-sufficiency of urban areas with local power generation, and provides reliable backup power in the event of grid failure. In areas unconnected to the public grid, adding an mtu EnergyPack to a local microgrid ensures high quality power supplies and allows the integration of renewable energies to reduce carbon footprint and save fuel.

Where a grid connection is not reliable, the mtu EnergyPack increases security and quality of supply for public facilities. Stability of existing power plants can be improved by spinning reserve from the mtu EnergyPack, and solar arrays can be built in to reduce fuel consumption. If grid-connected, own-use of solar power can be increased to lower the amount of power drawn from the grid. The mtu EnergyPack is available in different sizes and different housings.

The enclosed QS system and the containerized QM and QL systems are as tough as they come and have been custom-designed for harsh environments and challenging logistics. Offering superb protection from dust, insects, humidity and heat – both inside and out.

The interiors of the containerised housings are divided into sections – some with outside air contact and some without – to keep the sensitive electrics and batteries protected from any pollution. Batteries and battery management system.

The mtu EnergPack integrates 0.5C/1C/2C rated high-quality cells from leading manufacturers. The battery system consists of vertical racks, scalable in number to meet the required energy capacities. Each rack contains several battery modules and one battery management system (BMS) to monitor and control the battery modules. The BMS units connect the racks to a DC power switch, allowing each rack to be disconnected from the inverter as required.

All rack BMS are connected to the mtu EnergyPack’s control cabinet via a master BMS.The inverter operates bidirectionally, converting AC from the grid into DC for charging the batteries, and vice versa. It supports both grid-supporting and gridforming modes.

The transformer is the interface to the upstream power grid. Its task is to transform the voltage to the level required by the inverter or grid.

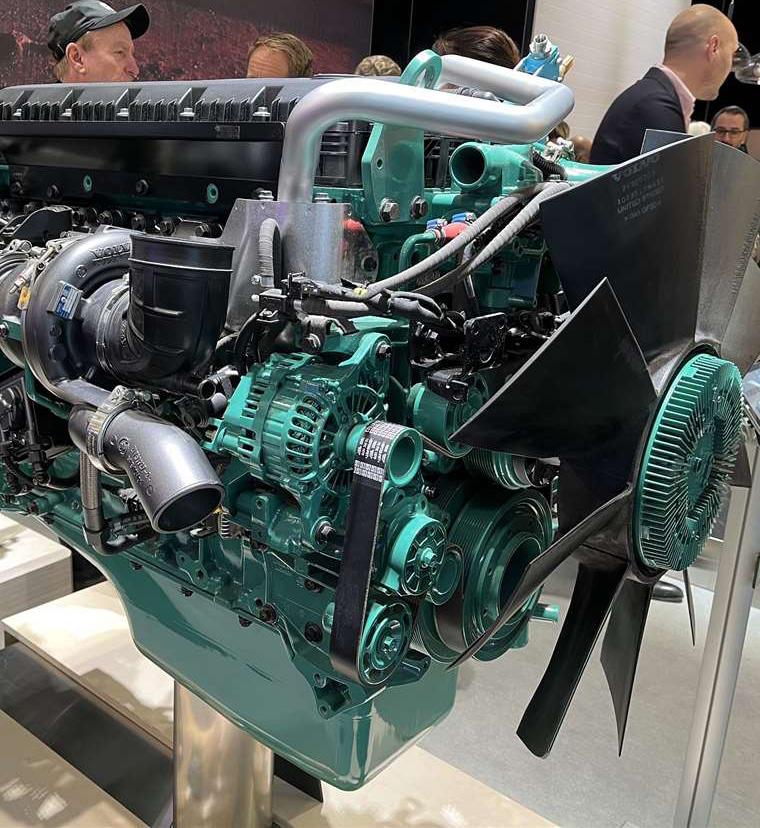

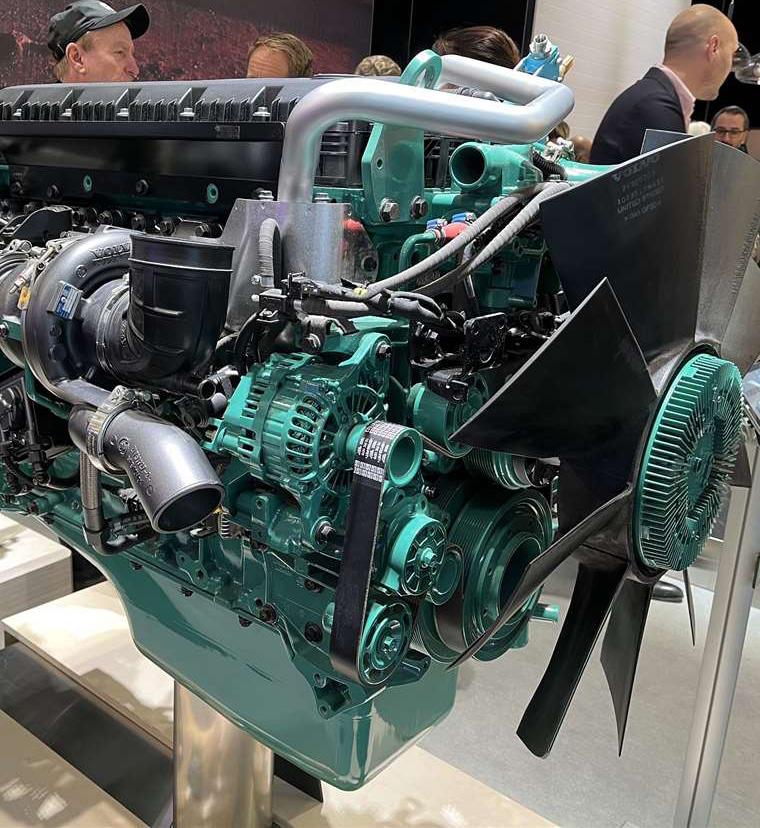

Dual-fuel engine using hydrogen as renewable fuel

Volvo Penta has developed a dual-fuel engine using hydrogen as a renewable fuel source.

A technology is based on the existing D8, an inline six-cylinder, 7.7 L diesel engine. According to Volvo Penta, the dual-fuel configuration reduces CO2 emissions as much as 80%.

The 8 L variable-speed, Stage V engine operates much like the conventional D8 – delivering the same power and torque curve –while using hydrogen as the primary fuel rather than diesel.

The engine has also been designed to run on traditional diesel. Anders Wernersson, product manager for the dual-fuel hydrogen engine, explains: “The technology is relatively simple and can be installed with minimal disruption.”

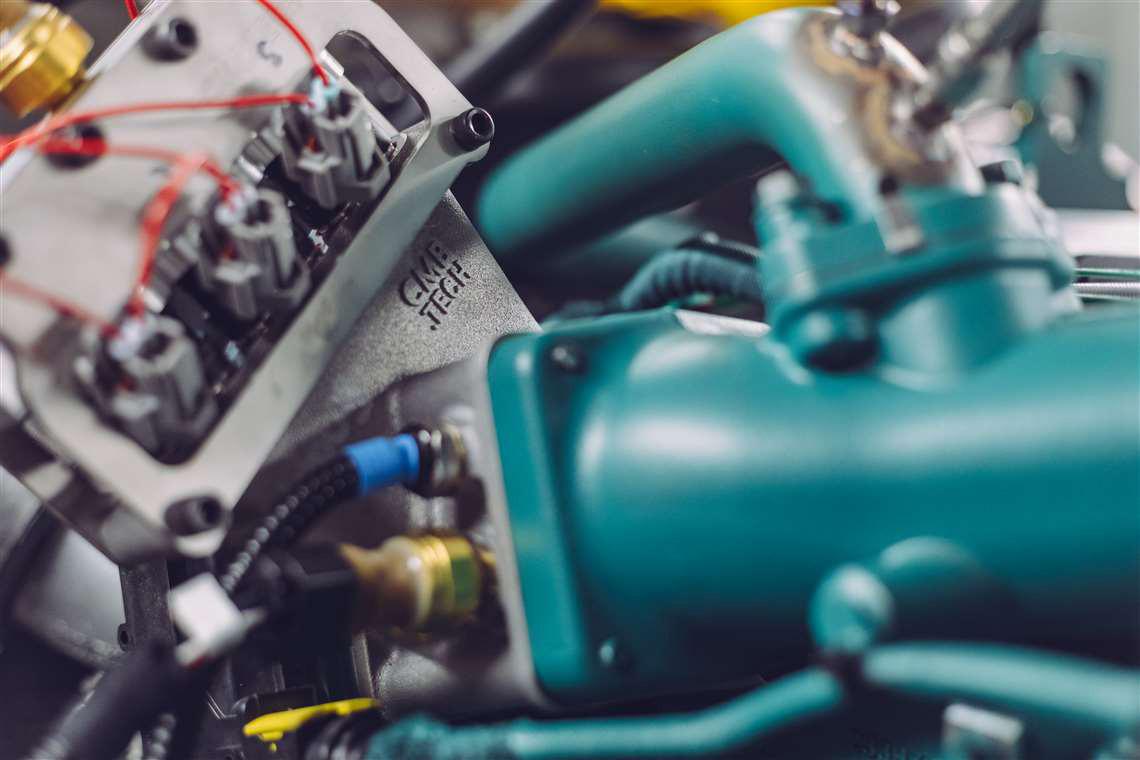

The dual-fuel engine is the result of a partnership with CMB.Tech to work on prototype dual-fuel hydrogenpowered project.

CMB.Tech provides and trials the hydrogen add-on kit and tank system which works in conjunction with the Volvo Penta D8 engine and software.

Anders outlines the programme:

“Collaboration and partnerships are essential to facilitate the transformation towards more sustainable power solutions.

“This close partnership approach is a cornerstone of Volvo Penta’s longterm decarbonisation and business strategy.”

The development engines are being run in test cells to optimise the hydrogen-diesel injection strategy, with plans for the first engines to be potentially working in gensets in Europe in 2023 as part of a market pilot project. Small-scale production is expected to follow.

New 500kVA genset for logistics plant in Poland

A genset installation involving a FDTC137W 500 kVA COELMO genset has been carried out by COLEMO for a corporate operation located in Kielce, Poland.

The generating set, powered by an FPT engine, now provides backup power for a logistics plant and features a parallel control panel and soundproof canopy.

COELMO generating sets are designed and produced for professional applications covering a range from 3 to 4000 kVA. These robust and reliable generating sets can be personalised and have

accessories which allow them to easily adapt to the different industry sectors. They are considered to be the ideal choice for demanding users, says the manufacturer.

The 500kVA genset has been supplied with a COELMO® Manual Control Panel which features a unique command system, designed to avoid potential breakdowns caused by of lack of oil and high engine temperature. The set is zinc plated steel painted in epoxy powder with a minimum protection grade of IP30 (on request they can be supplied separately) and is fully protected from vibration.

EURO POWER NEWS MARCH 2023 3 NEWS NEWS

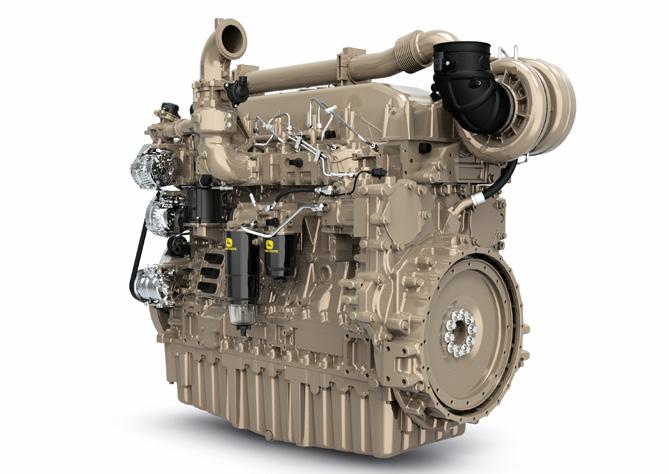

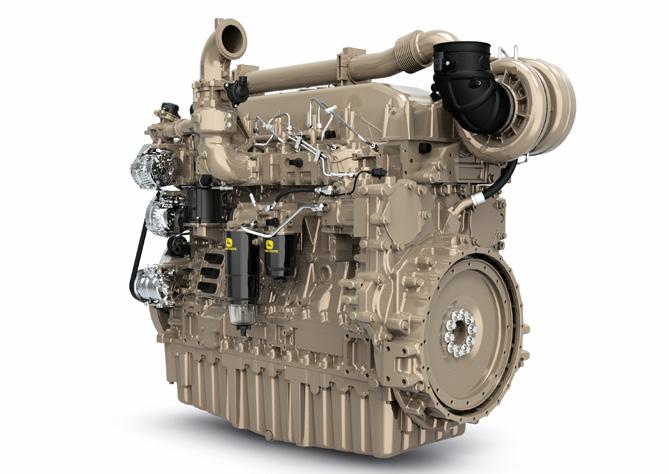

the Next Generation engines - the JD4, JD14 and JD18

Meet

OEMs in Europe face increasing demands for improved emissions performance, fuel economy, and equipment productivity, power solutions providers like John Deere Power Systems (JDPS) are investing in future-forward technologies that will give OEMs and their customers a competitive edge in the off-highway market as they work to meet productivity and sustainability goals.

Leveraging the best technologies of John Deere in new ways to meet both market and customer demands, JDPS is delivering new levels of reliability, durability, flexibility, and serviceability with its Next Generation Engines. When developing its Next Generation Engine lineup, JDPS consulted leading equipment manufacturers to learn more about which engine improvements were at the top of their lists.

The result? An expanded engine power range that can easily integrate into a wide array of heavy-duty applications — and the opportunity to offer engines that don’t require extra fluids like diesel exhaust fluid.

The Next Generation Engine lineup includes the JD4, JD14, and JD18. With this extended power range, OEMs can put John Deere power and performance into their entire line of equipment, from 36 to 677 kW (48 to 908 hp).

New to the John Deere engine lineup, the JD4 provides up to 116 kW (156 hp) of power. It features a rear gear train that provides customers with low noise and higher PTO power. The engine also has an extended single turbo range and provides 670 Nm (494 lb-ft) of maximum torque for improved highload capacity and productivity.

The JD4 offers a more reliable diesel exhaust fluid (DEF) delivery system. The engine also features extended fluid service intervals of 750 hours, reducing maintenance costs for customers. Hydraulic lash adjusters eliminate valve lash maintenance.

The JD4 engine offers up to two auxiliary drive pads, providing three times more available auxiliary power. This additional power allows flexibility and enables off-boarding for electrification and hybrid applications.

The JD4 will be compatible with EU Stage IIIA – Stage V emissions levels through common interfaces. The engine is low-NOx ready with planned external cooled exhaust gas recirculation (EGR) and a single overhead cam shaft valve train. The JD4 engine is also compliant with US EPA Final Tier 4 and EU Stage V with no EGR.

The JD14 industrial engine is the culmination of more than 15 years of developing and refining effective engine design while keeping up with evolving emissions regulations. Having met the emissions regulations in both the EU and North America, JDPS focused its resources on refining and optimizing these systems.

The JD14 features a reduced footprint for more space and offers more power in a smaller package, which allows it to meet the needs for a wide array of heavy-duty applications. The featured hydraulic lash adjusters provide longer engine life while eliminating valve lash maintenance. An advanced control system analyzes sensor data to keep operators working without interruption. Prognostic capabilities are also built into the engine to help users identify potential problems and schedule service prior to downtime.

The in-line integrated Emissions Control system of the JD14 offers 90 degrees of optionality. It can be mounted horizontally or vertically, allowing the industrial engine to be compatible with more machines in customers’ fleets while reducing connection points and optimizing thermal management. Building on the rugged design of the JD14 engine, the JD18 was designed with ease of service and repair in mind. The JD18 extends Deere’s rated power range to 522 – 677 kW (700 – 908 hp). The engine features a rear gear train, which produces excellent direct power and options up to two rear aux drives for a total of 902 Nm (665 lb-ft) max torque providing quiet operation.

The JD18 features new combustion technology which allows John Deere to offer an engine in the 522 – 677 kW (700 – 908 hp) power range without aftertreatment. Without the need for DEF, users have one less fluid to manage. The high-pressure common-rail fuel system allows the engine to deliver optimized fluid consumption. The Diamond Like Coating (DLC) improves bio-Diesel compatibility and system robustness, reports the company.

The new combustion technology offers a simplified air system with fixed and wastegate turbos, allowing the engine to meet emissions requirements without applying aftertreatment. This feature provides a simplified engine integration and package size.

New Smart Hybrid Hub originates in Switzerland

The Smart Hybrid Hub powered by FPT Industrial is a completely new project for environmentallyfriendly power generation.

The unit is composed of FPT’s F28 gas engine and a 37-kWh battery pack. FPT Industrial took charge of overall development of the Smart Hybrid Hub and the project was led by the Innovation Team located in the company’s R&D centre in Arbon, Switzerland.

Andrea Ercolino, head of Power Generation Product Marketing at FPT Industrial,comments: “The FPT genset features the new FPT F28 variable-speed gas engine. This variable-speed engine allows us to calibrate the engine according to the actual load and have it operate within its best efficiency point.

“Furthermore, the load profile in power generation is never flat. Instead of over-dimensioning the internal combustion engine to cover peak loads and have it run at very low efficiency with low loads, we can increase the engine speed and add the batteries to help cover these peaks, or use the batteries with no engine running when loads are really low.”

Ercolino explains: “The unit is powered by the F28 engine in its gas-fuelled version utilizing

biomethane that can be produced from the anaerobic digestion of agricultural waste and cattle slurry or from capturing its fugitive methane. So, the net CO2 emissions balance is zero.”

Ercolino reports that the 37-kWh battery pack is a high-voltage system (capable of working from 350 V to 700 V) produced in collaboration with Potenza and Microvast.

“This is the same battery pack that will be integrated in the new e-Daily van by Iveco. The batteries are produced in the new battery plant in Turin, Italy, officially inaugurated mid-October 2022.

The use of a high-voltage battery pack derived from on-road applications has the advantage of reducing currents inside the system and allowing for an easier integration in a power generation unit that has to be housed under a canopy or within a container,” says Ercolino.

As for the system control unit, the hardware is supplied by Woodward, including the gas engine control unit. The algorithm that is the basis of the Hybrid Control Management system was developed by FPT Industrial’s Innovation Team and is based on a study of the engine’s load curves for the optimum integration.

Buy-out for lithium-ion battery company from Poitiers, France

Manitou Group has announced the acquisition of an 82% stake in easyLi, a specialist in the design and production of lithium-ion batteries.

Founded in 2011, France-based easyLi manufactures and maintains lithium-ion battery systems for electric mobility and stationary energy storage solutions. It has 25 employees and is based in the Poitiers, Futuroscope business district. The deal provides the group with an energy transition advantage and will expand its capabilties in R&D in the production and reconditioning of batteries.

Michel Denis, president and CEO of the Group, explained: “easyLi’s expertise adds substantial value to

our organisation. By internalising this expertise, we are going to be able to study machine-battery interactions in depth and thus continue to reduce total cost of ownership for our users. This operation is in keeping with our research and development plan to accelerate our energy transition.” François Barsacq, founder and CEO of easyLi, added: “We are proud to be joining Manitou Group. It is a fantastic opportunity.”

4 MARCH 2023 EURO POWER NEWS NEWS NEWS

POWER YOUR BUSINESS

With efficient energy and economics

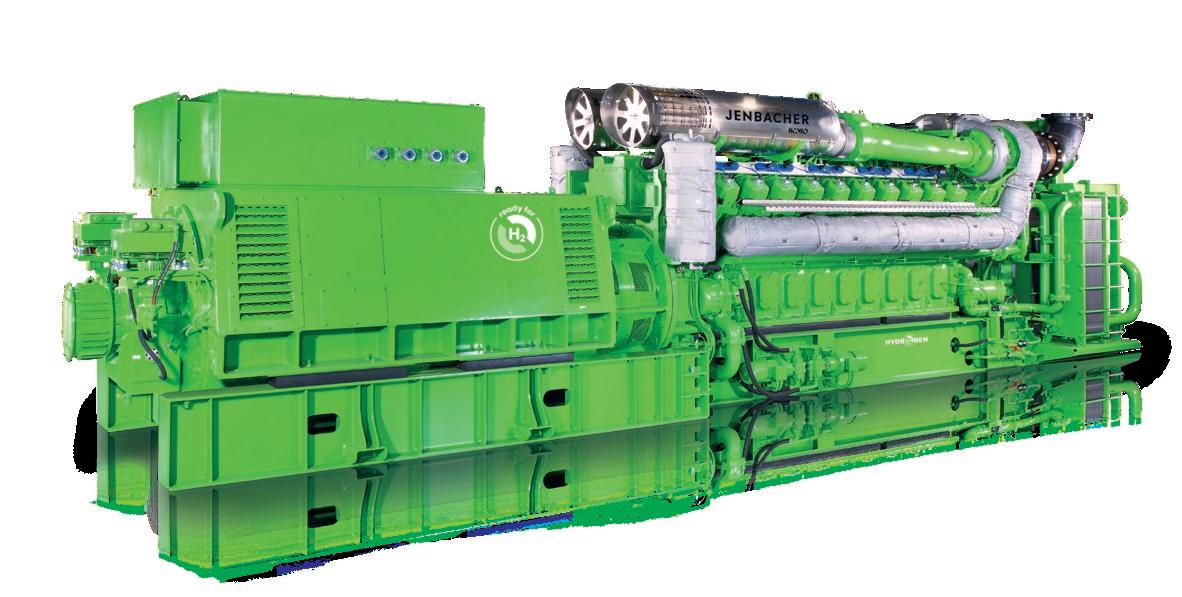

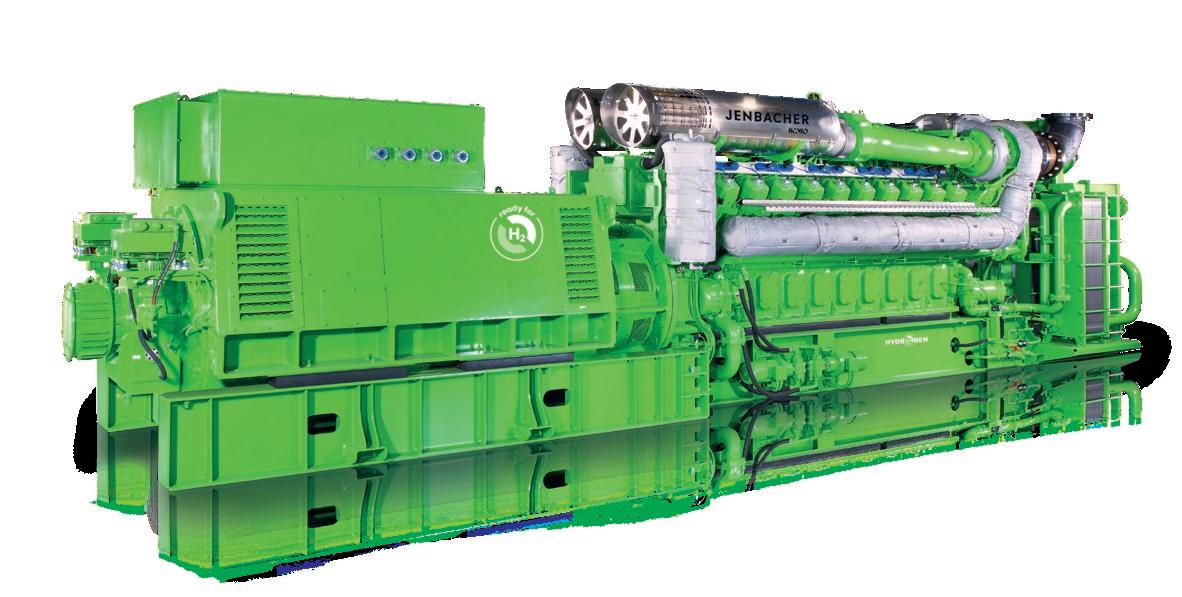

INNIO* is among the world’s leaders in CHP and CCHP solutions.

Power your business with INNIO’s flexible and innovative Jenbacher* CHP and CCHP energy systems, which deliver power, heat and/or cooling for your local site. With up to 95 % total efficiency, cogeneration can reduce your energy consumption and CO2 emissions by more than 30 % compared to the separate generation of power and heat for significantly lower energy costs. Combined with heat storage, you can operate your asset flexibly. INNIO’s CHP and CCHP systems run on a wide range of gases with the option of converting to CO2-free H2** operation once that fuel is more readily available.

Let us support your transition journey. innio.com

* Indicates a trademark.

** Optional scope on demand.

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME.

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

TheDanube Suspension Bridge Project involves two enormous cables: 18,000 intertwined steel wires, a total weight of 6,775 tons and a cumulative length of about 38,000 kilometres, or 23,612 miles (just a bit less than the circumference of the earth). All this to support the weight of the Brăila Bridge, the second-longest suspension bridge in Continental Europe.

The construction site is located in Romania, where a joint venture led by Webuild Group is on the job completing a highly complex work that will significantly improve area’s mobility, allowing the 7,000 vehicles that cross the great river on ferries every day to make the leap in two minutes. Right now, it takes them 45 minutes. Construction work on the largest suspension bridge to span the Danube River and connect two regions of Romania began in 2018.

The massive project, stretching almost 2 km, represents an important step forward in connecting the regions. Romania-based All Generating and genset manufacturer Himoinsa [part of the YANMAR Group] have supplied 15 gensets providing more than 8 MW of power for construction of this major road linking Braila and Tulcea Counties and forming part of the Buzau-Constantia highway. The gensets have powered the extraction pumps used to lay the bridge pillars and anchorages and the welding equipment used to secure all the metal parts of the bridge framework.

During the first phase of the project, more than 4 MW of portable power was required to operate the water extraction pumps located both on the anchorages and on the central pillars of the bridge, one of which has been erected on an artificial island in the Danube. To extract water from the first anchorage, a 1 MW containerized genset was installed; in the second anchorage, three gensets providing a total power supply of 1.5 MW were deployed. Both anchorages measure 40m in diameter and are 23m deep.

During the second phase, model HFW 600 T5 gensets mounted on slow-speed, four-axle trailers were supplied, generating almost 4 MW of power and running at least 20 hours per day for a minimum of three months. One of the requirements of the project was that the controller could monitor the generators via GSM for geolocation purposes and for parallel synchronization, if necessary. Attached to the gensets is a switchboard that connects the numerous welding equipment used during the construction of this infrastructure.

According to Catalin Stanciulescu, general manager at All Generating, “Our end customer has been very positive about the compact size of our generator sets with high-capacity tank we installed to increase the running time of the equipment and reduce the need for refuelling, thus reducing the risk of contaminating the river. Another positive factor was the chassis which we designed to retain any possible spillage of liquids inside the canopy itself. The performance and responsiveness of the equipment, Himoinsa and All Generating’s know-how, as well as the quality of the generator sets are the reasons why our equipment was chosen for this project.”

Europe’s largest battery storage system to go online soon

Alfen, an energy solutions specialist at the heart of Europe’s energy transition to limit climate change, and SemperPower, a leading player in the development of independent large-scale energy storage projects in The Netherlands, have launched Project Pollux. Pollux represents the largest battery energy storage system in terms of energy capacity ever built in the Netherlands. Located in Vlissingen, the storage system featuring Alfen’s ‘TheBattery Elements’ system will solve two of the energy transition’s biggest challenges: an unbalanced grid and the unpredictability of renewable energy sources.

Europe’s energy transition from fossil-based power to zero carbon is accelerating every day, and it brings new challenges to the energy grid such as matching supply and demand and accommodating power peaks.

So far, it has always been managed by gas and coal plants, but since Europe is focused on closing all fossil fuel plants, the continent faces a new challenge. Flexible energy storage is one

of the most promising solutions to tackle this challenge. With large-scale battery energy storage systems like Project Pollux, it becomes possible to store renewable energy at times of abundance and release it again when the market demands it.

“Alfen is excited to be part of SemperPower’s continued growth to help it contribute to Europe’s energy transition,” said Michelle Lesh, Chief Commercial Officer for Alfen.

“Supporting grid challenges caused by increased intermittency from renewables and continued load growth is critical to Europe’s energy transition’s long-term success. Battery energy storage systems like Project Pollux play a crucial role in making our grid future-proof and effectively manage demands on the grid.”

Alfen’s TheBattery Elements energy storage systems are said to be tailor-made for different markets and applications will guarantee performance, flexibility, modularity and longevity. SemperPower will develop & operate the large-scale energy storage system, and Alfen will manage design, supply, civil works, installation and testing.

£36 million investment boost to scale up off-grid hydrogen

A £36 million investment boost have been given to GeoPura to scale up its off-grid hydrogen power generation technology.

The funding round was led by GM Ventures and Barclays Sustainable Impact Capital, with participation from SWEN CP and Siemens Energy Ventures.

The investors will also act as strategic partners for GeoPura moving forward.

GeoPura offers an alternative to traditional diesel generators with its hydrogen power unit (HPU) technology used for temporary, supplementary, off-grid and backup power.

The company generates hydrogen and transports the fuel to customers for use in its HPUs – customers simply rent the units and pay for the fuel used. This latest investment will

enable mass manufacturing of HPUs and will increase the production of green hydrogen to fuel the units.

GeoPura chief executive Andrew Cunningham commnts: “The investment allows us to build on our installed base of HPUs and hydrogen production infrastructure to stimulate the green hydrogen economy.and then expand the use of clean fuels.”

EURO POWER NEWS MARCH 2023 7 NEWS NEWS

Romania is home to the second-longest suspension bridge in Europe: 15 gensets have been supplied to the construction team involved in the project

constraints and driving energy

in Europe’s data centres

65GW of offshore wind energy to be installed by 2030

Theneed for data centres has accelerated rapidly in line with new demands, but providing power for them isn’t always easy. Despite the rollout of the UK government’s support package, there are still challenges for data centre operators looking to make changes to cut costs and improve energy efficiency, explains Steve Wright, Chief

Operating

Officer at 4D Data Centres, part of Redcentric plc.

Data centres need electricity to run their infrastructure and keep their environment at optimally cooled temperatures. In 2010, data centres used 1% of the world’s energy and sites are still using around this amount with minimal increase today. The expectations for data centres are increasing and with growing pressure on the power grid, it’s getting harder to deliver efficiencies.

The high rise of data capacity is becoming a global issue due to a hunger for instant-data processing as data centres are kept running 24/7. The world’s population is becoming more IT literate, which has led to households consuming huge amounts of data. Online streaming services such as Netflix and Spotify require the support of a data centre, so the demand for additional facilities to combat this growth is unsurprising.

To keep up with market trends, there’s an increased demand in finding new sites to build and operate data centres, but also to make better use of space for existing facilities. They are important to the digitalisation of society and establishment of a smart energy system, yet have implications for energy demand and greenhouse gas emissions in the UK.

Research shown to the National Grid reveals that the UK has the largest data centre capacity in Europe, with London being the continent’s data centre hub. This is largely due to the size of the city’s financial centre and its size and reach of its fibre capacity. But more recently, London has started to see data centre developments running into physical limitations.

EU countries such as Ireland and the Netherlands have now begun to review their energy consumption in response to an increase in power shortages and grid constraints. One example is the EirGrid group, which manages and operates the transmission grid of electricity across Ireland. It has halted a proposed plan for 30 new data centres last year, after restrictions to build such facilities were put in place until 2028.

Amazon and Microsoft have reportedly scrapped their own plans to build data centres in Ireland due to the risk of overwhelming the national power grid. Google and Equinix have showcased their awareness of the implications of emissions, by pledging to make their data centres carbon neutral via the Climate Neutral Data Centre Pact.

Operators and trade associations in the EU who have signed this pact have committed to make Europe carbon neutral by 2050. Actions include meeting a high standard of energy efficiency and water conservation, matching their electricity supply through the purchase of clean energy and the reuse, repair and recycle of servers and electrical equipment.

The UK has also enhanced its Energy Savings Opportunity Scheme (ESOS) with increased expectations on qualifying organisations. The mandatory legislative requirement is for all large organisations operating in the country and ensures major energy users are documenting and reporting on a clear list of opportunities available to reduce their energy usage. Administered by the Environment Agency, it requires businesses to carry out a comprehensive evaluation of energy usage across buildings, transport and industrial operations.

Norway’s government is working on plans to become ‘the world’s most sustainable data centre nation’. The country’s data centre industry already contributes 2,000 jobs and this figure could grow to 11,000 by 2025. Between 2019 and 2020, more than 2.6 billion Norwegian Krone (£226 million) has been invested, resulting in 19 new data centres.

Data centre operators want to have a facility with a low Power Usage Effectiveness (PUE), but currently there is no one silver bullet.

Well-established technology developments such as adiabatic, evaporative and liquid cooling are a number of techniques used to reduce energy consumption. Switching from traditional methods to racklevel, direct to chip cooling also delivers significant advantages such as reduced energy, space and downtime, as well as increased processing capacity. It is believed liquid’s heat-carrying capacity can be up to 3,500 times greater than traditional air cooling methods. While it’s regarded as almost impossible to achieve a 1.0 PUE rating, the average ratio for a data centre in 2020 was around 1.58. By adopting and implementing tactics like those mentioned above, it will ensure operators are doing their part in boosting their own sustainability credentials.

Final thoughts

Data centres consume a staggering amount of energy to maintain their operations on a 24/7 basis. In some cases, the world’s biggest facilities use more energy than an entire country. Operators are having to adapt their business decisions and think more critically about how sites can stay energy efficient and still comply with ongoing regulations.

The fact Amazon and Microsoft are not planning to invest further in Ireland shows that even the world’s biggest companies are constantly analysing their decisions.

The next couple of years will likely see energy price levels increase even further, so operators need to be prepared to make changes to their working environment if further constraints come into force.

NKT and Prysmian will install five 525 kV XLPE HVDC cable connections for Dutch 2 GW projects to be completed between 2028 and 2030.

In the Esbjerg Declaration in May 2022 at the North Sea Energy Summit, Germany, the Netherlands, Denmark, and Belgium agreed to jointly install at least 65 GW of offshore wind energy by 2030. Transmission system operator TenneT will account for almost twothirds of this with 40 GW, 20 GW in each of the German and Dutch North Seas.

Recent geopolitical developments have underlined the need to invest in electricity transmission, to ensure energy security by accelerating the energy transition.

TenneT’s innovative 2GW programme plays a crucial role in managing the energy transition

from offshore and ‘will help Europe become the world’s first climateneutral continent’. This new standard combines TenneT’s expertise in offshore grid connections with a unique transnational approach that could provide a blueprint for future offshore grid connection systems and enables faster deployment.

The awarding of the world’s first 525 kV XLPE HVDC offshore cable connections systems for five Dutch 2 GW projects is the next step in realising the new 2 GW standard.

In due course TenneT will announce the partners for the Framework agreements for suppliers for the projects and partners for the Framework agreement for cable connections of other 2 GW projects. NKT will handle the cable connections for IJmuiden Ver Beta, IJmuiden Ver Gamma and Nederwiek 2.

Belgium and Germany collaborate on upgrading their joint energy infrastructures

Belgium and Germany have agreed to link their hydrogen networks, to double gas flow into Germany, and to explore the possibility of a second high voltage electricity interconnector for cross-border flows.

The announcement was made following the first Belgian-German Energy Summit last month.

Both countries have agreed to further develop hydrogen infrastructure between Belgium and Germany, with the clear goal of connecting it by 2028; The nations will also facilitate a major increase in the flow of liquefied natural gas (LNG) from Belgium to Germany, with the goal of doubling transit. They will also examine the possibilities offered by carbon capture and storage;

Both have pledged that they will Intensify co-operation on offshore energy in the North Sea and focus on joint hybrid and cross-border offshore projects;

Also on the cards is a second highvoltage interconnector for crossborder electricity flows;

Germany and Belgium have cooperated on energy matters for some years – the first interconnector went into operation at the end of 2020 – but the Russian invasion of of Ukraine and the acceleration of the energy transition have affected this.

LNG from Belgium, alongside that of Norway and the Netherlands, has helped make up for reduced gas flows via Germany’s Nord Stream 1, contributing significantly to the country’s energy security.

Until recently, Germany had no infrastructure to enable the importation of LNG. However, since the war in Ukraine energy co-operation between Belgium and Germany has more important.

8 MARCH 2023 EURO POWER NEWS NEWS NEWS

Power

efficiencies

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime across the whole product lifecycle, so you can be sure of reliable power generation, regardless of the operational conditions. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

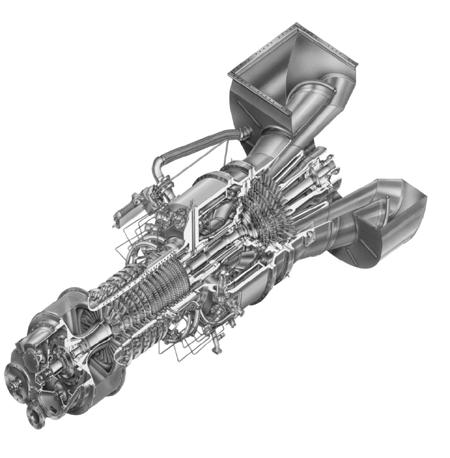

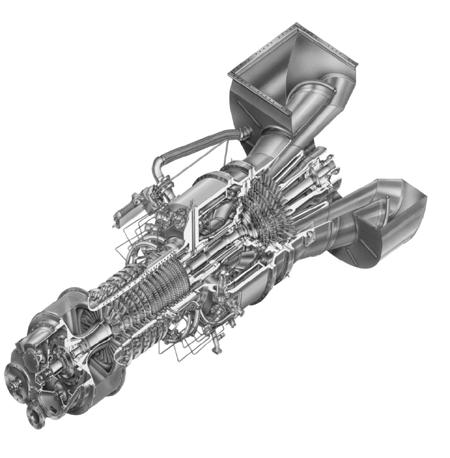

Test success: low emissions Titan 139

SoLoNOx Solar gas turbine with a blend of hydrogen and natural gas

New hydrogen-fuelled internal combustion engine for gensets

A finished prototype of a hydrogen internal combustion engine has been developed by Hyundai Doosan Infracore (HDI).

HDI is banking on its new hydrogen engine being a success in Europe.

It is based on an 11 L engine which produces 402 hp (300 kW) and a maximum torque of 1254 lb. ft. (1700 Nm) at 2000 rpm.

The new H2 engine will meet EPA Tier 4, EU Stage 5 and Euro 7 emissions regulations and with CO2 emissions below 1 g/kWh it should be classified as zero emissions in the EU.

The new hydrogen engines could be approved for use in off-road applications such as gensets by 2024, and the company reports that full-scale mass production is likely to be planned for 2025.

Kim Joong-soo, head of the HDI’s Engine Department, commented:“Hydrogen internal combustion engines will be used in mid-to-large-sized commercial vehicles such as trucks, buses and construction equipment and mid-tolarge-sized power generators.

strict carbon emission regulations.” Hydrogen-fuelled engines are said to be 25 to 30% more economical than fuel cells or battery packs when component price and maintenance costs are considered, HDI said. With engines such as these the exhaust gas primarily includes water vapour. This is the main reason why hydrogen combustion engines are being preferred.

The thermal efficiency of these H2 engines (around 45%) is much higher than petrol (25-30%) and diesel engines (30-38%).

Engines which adhere to strict emission laws generally offer negligible NOx emissions.

HDI says it plans to leverage its existing engine technology and facilities to reduce costs and accelerate commercialisation of its new H2 engines.

GRTgaz Deutschland, Open Grid Europe (OGE) and Solar Turbines have jointly tested a low emissions Titan 130 SoLoNOx Solar gas turbine with a blend of hydrogen and natural gas driving a natural gas compressor in Germany - and have been pleased by the results.

The Titan 130 SoLoNOx was tested with blends of up to 25% hydrogen at a compressor station on the MEGAL gas pipeline system in Waidhaus, Bavaria. These gas turbines are usually powered by natural gas taken from the pipeline system.

OGE owns 51% of the MEGAL pipeline system. The balance is held by GRTgaz Deutschland. The system transports natural gas from the Czech/German border to the German-French border.

Nicolas Delaporte, managing director of GRTgaz Deutschland, explains: “This test is a good example of how companies working collaboratively across national borders can tackle and solve important issues in the energy industry. In the spirit of international partnership, I am convinced that we will continue to write MEGAL’s success story.”

Preparations for the project began in 2021 when a mobile blending plant the size of a 40-foot ISO shipping container and a temporary hydrogen supply were set up for the tests. The entire configuration was acceptance tested by an independent expert in accordance with the rules and regulations applicable to public energy supply and approved for operation.

Using only green hydrogen, the gas turbine was extensively tested with various H2 blending rates under different loads. Emissions and turbine performance were measured, demonstrating the turbine’s ability to operate with the same available power while meeting the required emission levels. The demonstration, which lasted for more than six weeks, operated on the H2 blend for more than 200 hours. The ability of the gas turbine to safely start on the fuel blend was also demonstrated.

Thomas Hüwener, a member of OGE’s board of management, put the results into context: “The project shows the desire and ability to expand and realize the hydrogen economy. But to do this, we now need the right legal and regulatory framework to accelerate Germany’s hydrogen economy supported by a strong financing model.”

GRTgaz Deutschland

operates a network of about 1,200 kilometres of pipeline that transports gas through southern Germany. Its network links the gas infrastructure of the Federal Republic with the networks of a parent company in France and those of the Czech Republic and Austria.

In this way, the company feels it makes a decisive contribution to the security of supply in Germany and also in Europe.

OGE is a major European gas transmission network, with about 12,000 kilometres of gas transmission pipelines operating throughout the regions of Germany.

” We will put in the utmost effort to realize carbon neutrality in response to the eco-friendly market by developing green hydrogen-related technologies in line with increasingly

Launch of EU and Swiss-funded FLEX4H2 project

A consortium of nine partners led by Ansaldo Energia, and jointly funded by the EU Horizon Europe Research and Innovation Framework is changing the energy landscape in Europe.

A programme established under the Clean Hydrogen Partnership and the Swiss Federal Department of Economic Affairs, Education and Research, State Secretariat for Education, Research and Innovation (SERI), the ‘FLEX4H2’ project –Flexibility for Hydrogen – aims at ‘moving technological frontiers for low-emission combustion of hydrogen beyond the latest state-ofthe-art’ technology.

FLEX4H2 has an overall budget of approximately € 8.7 million, and will

run for four years, between January 2023 and December 2026, reports the consortium.

FLEX4H2’s goal is to support European ambitious climate targets towards shifting away from the use of fossil fuels. In this context, utilisation of hydrogen offers a unique chance to decarbonise the power generation sector reliably, independently from weather or seasonal conditions.

10 MARCH 2023 EURO POWER NEWS NEWS NEWS

EXHIBITION & CONFERENCE

27-28 JUNE 2023

SANDTON CONVENTION CENTRE, JOHANNESBURG

Headline

Sponsor:

Supporting Organisation:

To find out more and register visit: www.datacentres-africa.com

Investment. Infrastructure. Services. Solutions

Power at Europe’s largest nuclear plant has been lost after Russia launched missiles across Ukraine on March 9th, 2023. The attacks hit cities from Kharkiv in the north to Odesa in the south and Zhytomyr in the west.

Ukraine media reports that Russia has fired 81 missiles in what is the biggest strike in weeks.

Nuclear energy operator Energoatom said a strike at the Zaporizhzhia plant meant the “last link” between the facility and the Ukrainian power system was cut off. For the sixth time since it was taken over by Russia a year ago, the facility is now operating on diesel generators, which only have enough supplies to last until March 20th, 2023, says the authorities, before poqwer goes out.

The director general of the International Atomic Energy Agency (IAEA) called for a commitment to protecting the safety of the plant, saying he was “astonished by the complacency” surrounding the successive strikes since the invasion began.

“Each time we are rolling a dice. And if we allow this to continue time after time then one day our luck will run out,” Rafael Grossi said.

Russian officials in the Moscow-controlled part of Ukraine’s Zaporizhzhia region said the halt in electricity supplies to the power station from Ukrainian-held territory was “a provocation”.

Ukrainian President Volodymyr Zelensky said energy systems were being restored and all services were working after the “massive” rocket attack struck critical infrastructure and residential buildings. In Kyiv much of the city has been left without electricity, with four in 10 people without power.

Since the New Year 2023 Russian forces have adopted a strategy pf attacking Ukrainian power facilities, fuel storage depots and water works. Ukraine’s national power company, Ukrenergo, says damage to electricity installations is so great that 50% of demand cannot be met. The war has cost the country around $US100 billion in national infrastructure damage.

Between 20,000 and 30,000 Russian troops have been killed or wounded in the battle for the Ukrainian city of Bakhmut alone since it began last summer, Western officials say. The figures cannot be verified independently.

Gerlos 1 says yes to 6-nozzle turbine

The Gerlos 1 power plant is a pumped storage facility in the Ziller Valley in Tyrol which has been trialling the first horizontal, six-nozzle Pelton turbine . Early results suggest the power plant has been running successfully for over four months now, and is ‘setting new benchmarks’. First commissioned in 1949, Gerlos has an annual output of 326 GWh, allowing it to supply renewable energy to more than 70,000 four-person households. The trial operation of the Pelton turbine, which is especially suited to plants with high heads, used a design where the water is directed by forming free jets at very high velocity from one or several nozzles to the Pelton runner. Until now, Pelton turbines with more than three nozzles have always been designed with a vertical shaft. The main reason for this was that it allowed higher efficiency than a horizontal arrangement. Voith Hydro has now successfully eliminated this drawback, as demonstrated in the Gerlos 1 power plant, where for the first time, an efficiency level comparable to that of the vertical configuration has been achieved. The plant’s existing four vertical Pelton turbines were successfully replaced by one six-nozzle horizontal Pelton wheel. In addition to this application, the technology is of particular interest for upgrades of existing hydropower plants where single- or doublenozzle horizontal units are already installed. This is because the turbine can be replaced without major structural works, which significantly reduces civil costs and installation times. At the same time, there is enormous potential for increasing efficiency, says Voith. The associated potential reduction in the number of turbines is also said to lower future maintenance costs. The new development requires less excavation and is more compact with a smaller footprint than conventional solutions.

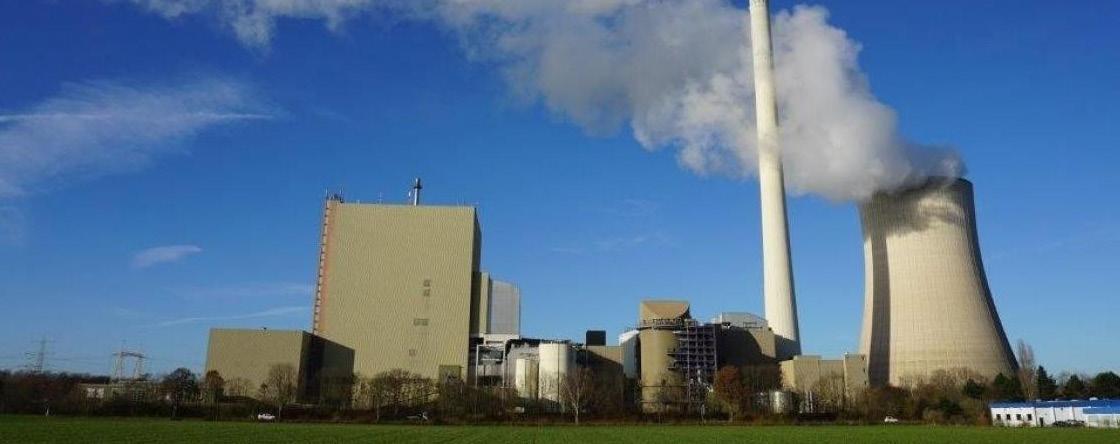

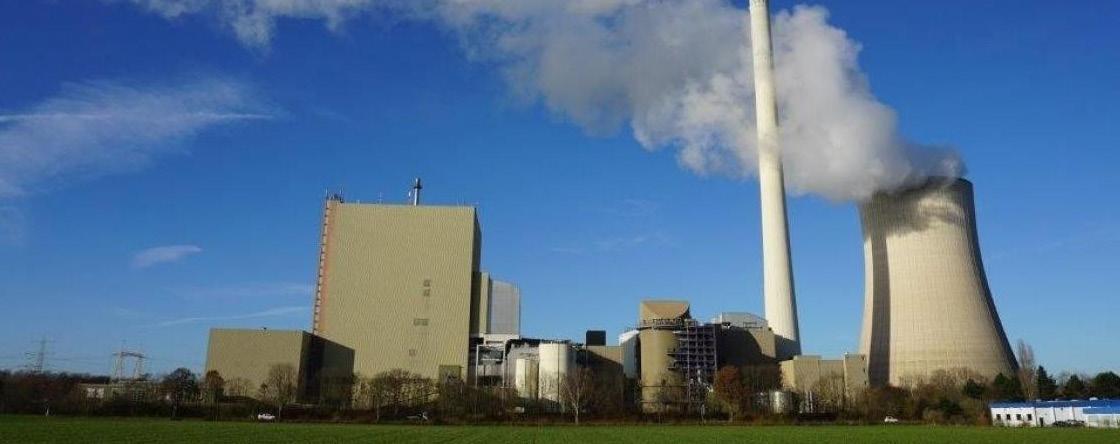

Uniper extends operation of Heyden 4 and Staudinger 5

The market operation of the Heyden 4 and Staudinger 5 hard coal-fired power plants in Germany are being extended by Uniper effective until 31st March 2024 at the latest.

The measure is being taken as part of the German government’s Substitute Power Plant Provision Act to secure the energy supply in the coming winters. This law pursues the goal of using as little gas as possible for power generation and replacing it with other energy sources.

The 875 MW Heyden 4 power plant in Petershagen near Minden had already ceased commercial operation after an award in the first tender to reduce coal-fired power generation, but returned to the market in August from the grid reserve on the basis of the EKBG and the associated first ordinance. This first ordinance only allowed a

return to the market until 30 April 2023. Now this term has been extended and continued operation is allowed until 31 March 2024.

The 510 MW Staudinger 5 hard coal-fired power plant near Hanau would have had to cease commercial operation on 21 May 2023 but instead of being used only in the grid reserve from 22 May, it is now going to remain on the market, also on the basis of the EKBG. Both power plants will be used commercially to support the security of energy supply in Germany. Uniper is currently preparing for the continued operation of the 345 MW Scholven B hard coal-fired power plant in Gelsenkirchen beyond June 2023. With Heyden 4, Scholven C, Irsching 3 (415 MW) and Staudinger 5 in operation Uniper will have brought around 2150 MW of capacity back into the German market.

German electrolyser company wins major Multicore order

Enapter AG with its business partner YEST, received an order from South Korea for the delivery of two AEM Multicore electrolysers with a total capacity of 2 MW.

These will be installed in a 12.5 MW hydrogen pilot project on Jeju Island.

The demonstration project is supported by the South Korean Ministry of Industry and Trade (Motie) with more than US$43.3 million in investment.

Among the five companies selected for the project, Enapter AG is the only technology supplier from Europe. The systems supplied are expected to produce more than 1,000 tonnes of green hydrogen per year. Installation of the two electrolysers in what is a pioneering project for South Korea will be carried out by YEST, which has been supporting Enapter as an integration partner since 2021

With the AEM Multicore, Enapter has developed what it believes is a cost-efficient alternative to traditional systems. This electrolyser can supply around 450 kg of green hydrogen per day, and

by using several units in parallel, production can be expanded on an industrial scale.

Enapter AG regards itself as the technology leader in innovative Anion Exchange Membrane (AEM) electrolysis, which can be used to produce green hydrogen.

The technology enables the construction of efficient, cost-effective and standardised electrolysers and stacks that can be scaled up to larger units according to the principle of modularity. Its products depend on state-of-theart Energy Management System software to ensure easy operation, control & monitoring and high compatibility.

12 MARCH 2023 EURO POWER NEWS NEWS NEWS

Missile strike at the Zaporizhzhia plant meant the ‘last link’ between the facility and the Ukrainian power system has been cut off since March 9th

Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

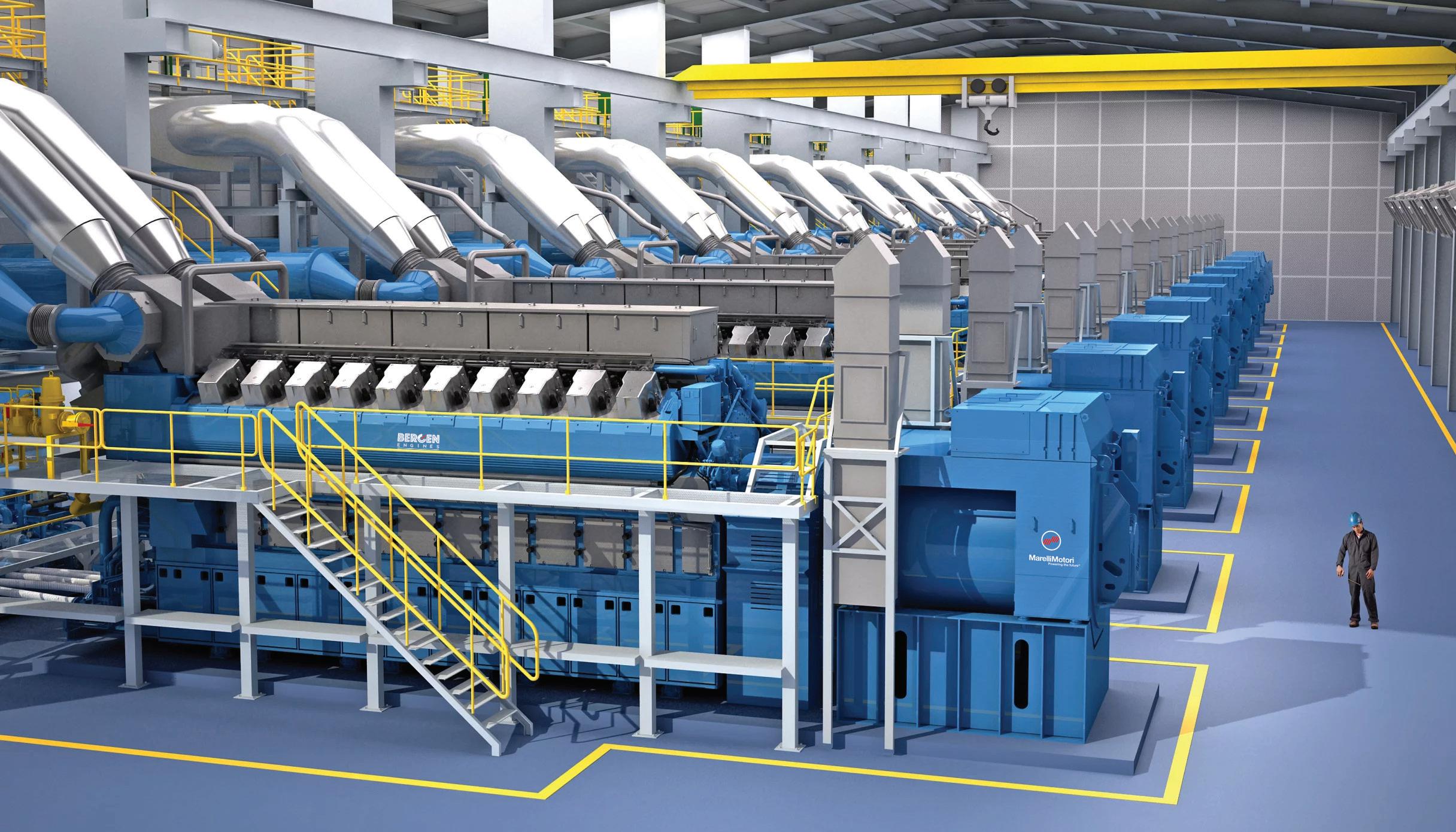

COGENERATION

INNOVATIVE ENERGY PROJECT FOR GERMANY

The 19-km district heat network is being set up by Rasche & Weßler GmbH. The development started in 2021 and will be ready for operation by the end of 2023.

The two TCG 3020 V20 gas gensets were delivered by Caterpillar Energy Solutions in Mannheim, Germany. Since a TCG 3020 V20 gas genset delivers an electrical output of 2,300 kW, the cogeneration power plant has a total output of 4.6 MW.

The project in Alfhausen in Germany’s Osnabrück Land region demonstrates how it will be possible to implement smart, flexible heat supply in the future.

Two containerised cogeneration power plants, each of which is powered by an MWM TCG 3020 V20 gas genset, form the core of the project.

The Alfhausen cogeneration power plant is the first of three biomethane district heat projects to be rolled out in the Osnabrück region. Even before the go-live, the Alfhausen cogeneration power plant won an award as a lighthouse project for outstanding climate protection projects as part of the overall “Green Village” concept.

MWM gas gensets now form the core of the Alfhausen District Heat Network.

Since the autumn of 2022 the new Alfhausen cogeneration power plant has been producing heat and power for the local population. The plant is based in Alfhausen’s new industrial zone “Am Waller Esch” located opposite the local transformer station.

The plant makes it possible to feed the power produced by the MWM gas gensets through combined heat and power (CHP) generation directly into the public power grid. The heat generated by the engines will be transported to the connected homes in Alfhausen through a pipeline network.

The district heat network in Alfhausen was established by Rasche & Weßler GmbH, a local company specialising in energy management and automation technology.

The concept is based on the use of biomethane as a regenerative energy source and fuel for the MWM gas gensets.

Biomethane, which is produced by treating biogas, is a renewable energy source which is capable of replacing natural gas, a fossil energy source.

The gas comes from the natural gas network of Westnetz GmbH in Osnabrück. Additionally, biogas from various biogas plants in Germany is fed into the natural gas network at another location.

In this way, the natural gas becomes ‘eco-gas’, which is used as fuel for the gas genset. Apart from the new plant, the industrial zone also hosts a hot water storage tank with a capacity of approximately 2,500 m3.

The water will be heated using the exhaust heat of the two MWM gas gensets and be transported to the individual homes through the district heat network. In the event of a cogeneration power plant outage or unexpected cold spells, the storage facility can be used as an additional buffer in order to continue to supply Alfhausen with heat for several days.

“From the outset, we knew that we were going to deploy MWM gas engines,” says Ralf Wessler, Managing Partner at Rasche & Weßler GmbH. “We are familiar with the technology, and we know that the large engines from Mannheim are very reliable and powerful. Another important criterion is the quick and comprehensive service provided by MWM, which guarantees high plant availability.”

From the start, the sustainable, trendsetting supply concept in Alfhausen has been attracting a lot of attention. In recent months, the demand for district heat network connections underwent a sharp increase. Up to 1,000 homes can be supplied through the district heat network. Thanks to the co-operation with Glasfaser Nordwest, it was possible to implement the district heat network without redundant construction measures. The result: a climate-friendly infrastructure.

CHP flagship project with pioneer function

The overall ‘Green Village’ concept with the Alfhausen energy plant, which won an award in the ‘Klima Kommunal 2022’ contest, is the first of three CHP generation projects implemented in the vicinity of Osnabrück. In Fürstenau, 25 km from Alfhausen, an identical district heat plant is being built and is set to go live in 2023. Another 9-MW biomethane plant is being planned just a few miles from the Alfhausen plant.

www.mwm.net

14 MARCH 2023 EURO POWER NEWS

An innovative energy project is currently being rolled out in Alfhausen in Germany’s Osnabrück Land region, reports MWM. The project demonstrates how it will be possible to implement smart, flexible heat supply in the future in Europe.

“The Alfhausen cogeneration power plant is the first of three biomethane district heat projects to be rolled out in the Osnabrück region. Even

before the go-live, the Alfhausen cogeneration power plant won an award as a lighthouse project for outstanding climate protection projects as part of the overall ‘Green Village’.”

1 MW/2 MWH BESS FOR NETHERLANDS SUPPLIER

States, Australia, the UK, Japan, China, and many other countries.

What is a BESS and how does tt work?

A

n energy Storage Solution (BESS) is being supplied to BE Fresh Produce BV of the Netherlands by Zwart Techniek Battery.

BE Fresh is a full-service supplier of topquality fruit and vegetables to chefs, importers, wholesalers and food & beverage managers in hotels and restaurants all over the world.

Zwart is committed to supplying, installing and commissioning a 1 MW/2 MWh BESS next to the office and warehouse of Be Fresh in De Lier.

A company spokesman comments: “Our Power Management System (PMS) integrates all the assets, including 500 kWp solar PV and energy management system of Samax B.V., who will provide the energy management on the different energy flex markets.”

“Our hybrid off-grid plants power communities and businesses in developing countries. A combination of solar power and diesel generators (sometimes combined with battery storage) ensures that electricity is generated in the most energy-efficient and economical way.

“This can be done for an Angolan village of 200 homes, a power station in Kenya or a region in Burundi that needs electricity to keep the local fruit and vegetable harvest cool and prepare it for sale. We have already installed over 100 power systems in Africa, driving local businesses and connecting these communities to the world.”

With over 7,000 projects in more than 50 countries in the field of emergency power and off-grid solutions, Zwart has an outstanding track

record, throughout Europe, Africa and the Middle East.

According to Zwart, Europe’s the biggest data centres and financial institutions i- as well as major airports and mobile networks - rely on Zwart expertise and technology.

Its 100 in-house trained professionals are qualified to design, engineer, realise and maintain integrated and complete systems for emergency power supply and have been doing so for over 90 years, reports the company.

“We set the bar high for ourselves and demand the same from our partners and suppliers; we work exclusively with premium quality products and service providers, we assemble the systems at our own 6,000-square metre site in Ijmuiden and subject them to a rigorous testing and inspection program before releasing them. Our customers also receive the same high level of attention through training and knowledge sharing our training centre equipped with a state-of-theart simulator.”

Offering a wide range of power and storage capacities, a battery energy storage system (BESS).can vary from small-sized household devices to large-scale systems used for utilities and industrial applications.

In 2020, over 31,000 and 100,000 battery energy storage systems were installed by Australian and German households respectively. Nowadays, large-scale BESSs have been operating all over the world, including the United

A BESS is an energy storage system (ESS) which captures energy from different sources, accumulates this energy, and stores it in rechargeable batteries for later use. Should the need arise, the electrochemical energy is discharged from the battery and supplied to homes, electric vehicles, industrial and commercial facilities.

A BESS is a compound system comprising hardware components along with low-level and high-level software. The main BESS parts include:

-A battery system. It contains individual- battery cells that convert chemical energy into electrical energy. The cells are arranged in modules that, in their turn, form battery packs.

-A battery management system (BMS).

A BMS ensures the safety of the battery system. It monitors the condition of battery cells, measures their parameters and states, such as state-of-charge (SOC) and state-of-health (SOH), and protects batteries from fires and other hazards.

-An inverter or a power conversion system (PCS). This converts direct current (DC) produced by batteries into alternating current (AC) supplied to facilities. Battery energy storage systems have bi-directional inverters which allow for both charging and discharging.

- An energy management system (EMS). This is responsible for monitoring and control of the energy flow within a battery storage system. An EMS coordinates the work of a BMS, a PCS, and other components of a BESS. By collecting and analyzing energy data, an EMS can efficiently manage the power resources of the system.

www.zwarttechniek.com

EURO POWER NEWS MARCH 2023 15 GENSETS

Zwart Techniek Battery is supplying an Energy Storage Solution (BESS) to BE Fresh Produce BV of the Netherlands. BE Fresh is a full-service supplier of topquality fruit and vegetables to chefs & importers.

“ Our Power Management System (PMS) integrates all the assets, including 500 kWp solar PV and energy management system of Samax B.V., who will provide the energy management on the different energy flex markets. Our hybrid offgrid plants power communities and businesses in developing countries, using a combination of solar power and diesel generators.”

NEW MACHINERY PRODUCT REGULATION PROPOSAL (MPR) –STATE OF PLAY

economic and environmental matters related to all types of batteries.

By January 25th, 2023, the COREPER meeting of the Council officially approved the provisional deal for the Regulation on Machinery Products.

After this point the text was referred to the Parliament for approval by the IMCO Committee on the 1st of March, 2023. The plenary vote is expected to be scheduled for April or May 2023.

In the meantime, the Commission is working on further verification by the lawyer linguists. Once the text is adopted by the Plenary and all the verifications are finalised, the text will be cited in the Official Journal of the EU, possibly in May 2023.

It can reasonably be expected that the application date will be effective as of end of 2026. Next steps: Although some changes may still be introduced in the verification process these are likely to be editorial in nature.

ELECTROMAGNETIC COMPATIBILITYEVALUATION OF THE EU RULES

The Electromagnetic Compatibility Directive (EMCD) was the subject of a public consultation between October 2020 and January 2021. The summary of that consultation was published on 12th January, 2023.

The report looked at the Effectiveness, Efficiency, Relevance , Coherence and Added

value of the Directive in its current form and the headline statements are that the directive does not need to be revised, and that some stakeholders would benefit from a more precise definition of ‘fixed installation’ in the guidance notes.

The EMCD remains highly relevant because of the new electronic equipment constantly placed on the EU market, and it was recognized that selfcertification significantly contributes to keeping conformity assessments costs low and allows flexibility to economic operators.

However, it was noted that there are still too many products reaching the market (especially ordered online from third countries) in the EU that do not comply with the EMCD’s essential requirements.

GREEN DEAL: EU AGREES NEW LAW ON MORE SUSTAINABLE AND CIRCULAR BATTERIES TO SUPPORT EU’S ENERGY TRANSITION AND COMPETITIVE INDUSTRY

On December 9th, 2022, a provisional political agreement was reached between the European Parliament and the Council aiming to make all batteries placed on the EU market more sustainable, circular and safe. The agreement builds on the Commission’s proposal from December 2020 and addresses the social,

For the first time the legislation will regulate the entire life cycle of a battery – from production to reuse and recycling – and ensure that they are safe, sustainable and competitive.

The ‘final’ text of the EU Batteries Regulation agreed between the European Commission, Parliament and Council has been published.

Whilst it’s possible there could still be minor changes, it is expected that this text will be substantively the same as the final published legislation.

ELECTRICITY MARKET DESIGN: COMMISSION LAUNCHES CONSULTATION ON REFORM TO SUPPORT A CLEAN AND AFFORDABLE ENERGY TRANSITION

On January 23rd, 2023, the European Commission launched a public consultation on the reform of the European Union’s electricity market design to better protect consumers from excessive price volatility, support their access to secure energy from clean sources, and make the market more resilient.

The reform of the electricity market design was announced by President von der Leyen in her annual State of the Union Speech last year and has been called for by the European Council.

The consultation launched today will support the Commission’s work on a legislative proposal which we aim to deliver in the first quarter of this year.

Commissioner for Energy, Kadri Simson, said: “The EU’s electricity market has served us well for over 20 years. But the unprecedented energy crisis we are facing shows that we need to make the electricity market design fit for the future, allowing it to deliver the benefits of affordable clean energy to everyone.”

16 MARCH 2023 EURO POWER NEWS EUROPGEN

On January 17th, 2023, the Council Working Party Technical Harmonisation referred the provisional deal on the Machinery Regulation for approval by the Council, reports EUROPGEN.

Kadri Simson concluded: “I look forward to the contributions from a wide variety of stakeholders, which will help guide our legislative proposal this year.”

The current system has delivered an efficient, well-integrated market for many years, allowing the EU to reap the economic benefits of a single energy market, ensuring security of supply and spurring the decarbonisation process. However, the system has also demonstrated some shortcomings. In the current crisis of high and volatile electricity prices, the economic burden has been pushed on to final consumers. Reform is therefore needed to better shield households and businesses from high energy prices, to increase resilience, and to accelerate the transition set out in the European Green Deal and REPowerEU Plan.

STANDARDISATION: FIRST MEETING OF THE HIGH-LEVEL FORUM PICKS OUT STRATEGIC STANDARDISATION NEEDS TO SUPPORT THE DIGITAL AND GREEN TRANSITION

On January 20th, 2023, the European Commission held a first meeting of the new High-Level Forum on European Standardisation, which will help set priorities, advise on standardisation needs and contribute to the EU’s role as a global standard-setter.

The Forum was chaired by Commissioner for Internal Market, Thierry Breton. During the meeting, members discussed several focus areas – such as clean tech, raw materials and quantum, as well as education and skills

in standardisation – on which dedicated work streams will be set up. Executives from EU companies and SMEs, civil society organisations, academia, European standardisation organisations and Member States sit on the Forum. The Commission will shortly open a continuous open call for nominations for another 10 seats.

Standards are an essential foundation of the Single Market, helping to ensure interoperability of products and services, improve their safety and enhance competition and innovation. They also play a crucial role in delivering the EU’s green, digital and resilience ambitions by helping companies accelerate market roll-out of clean and digital technologies and allowing them to access international markets.

The Commission announced the creation of the High-Level Forum as a part of the EU Strategy on Standardisation in 2022 to align standardisation actions with European policy priorities, industrial innovation and investment activities as well as to address other actions foreseen under the Strategy.

ECHA - NINE SUBSTANCES ADDED TO EU REACH SVHC CANDIDATE LIST, REPORTS EUROPGEN

On January 17, ECHA announced the addition of 9 substances to the EU REACH SVHC Candidate List. The Candidate List of substances of very high concern now contains 233 entries for chemicals that can harm people or the environment.

The inclusion of substances in the Candidate List brings immediate obligations for concerned companies using the substances in their products above the stated threshold. Companies are responsible for managing the risks of these chemicals and must also give their customers and consumers information to use them safely.

ECHA’s Member State Committee confirmed the addition of these substances to the Candidate List. The Candidate List now has 233 entries – some are groups of chemicals so the overall number of impacted chemicals is higher.

These substances may be placed on the Authorisation List in the future. If a substance is on that list, its use will be prohibited unless companies apply for authorisation and the European Commission authorises them to continue its use.

Consequences

of the Candidate

List: Under REACH, companies have legal obligations when their substance is included – either on its own, in mixtures or in articles – in the Candidate List. Suppliers of articles containing a Candidate List substance above a concentration of 0.1 % (weight by weight) have to give their customers and consumers information to be able to use them safely. Consumers have the right to ask suppliers whether the products they buy contain substances of very high concern.

ERA HAS RELEASED ITS 2022 MARKET REPORT

ERA sees a return to growth across all European rental markets, followed by a slow down in 2022 and 2023.

The European Rental Association (ERA) has now released its 2022 Market Report.

The European rental market experienced strong growth of 7.9% in 2021, with a total rental turnover of more than EUR 24.6 billion in the 15 countries covered by the Market Report. There was growth across all markets, with the UK, Germany and France retaining the largest share of the European rental market, comprising about 60% of the total market size.

The market slowed down to 4.1% growth in 2022, in nominal terms, as soaring energy prices, inflation and high interest rates dampen the outlook for businesses and households. In volume, this could represent a decrease from 2021, with differences among countries depending on the level and impact of inflation. However, the market is projected to remain strong through to mid-2023.

In the longer term, the European rental market will benefit from the economic uncertainty as rental will replace demand for machinery due to increasing price pressures and constant changes in technology and regulations.

The leading source of intelligence on the European equipment rental market was developed in collaboration with IHS Markit, now a part of S&P Global. The ERA Market Report is a leading source of market intelligence on the European equipment rental market and the only Europe-wide industry benchmark.

It contains detailed market information for the years 2019 to 2024 and key indicators, including rental turnover, fleet value and investments. europgen.eu

EURO POWER NEWS MARCH 2023 17 EUROPGEN

“ A provisional political agreement has been reached between the European Parliament and the Council aiming to make all batteries placed on the EU market more sustainable, circular and safe. The agreement builds on the Commission’s proposal from December 2020 and addresses the social, economic and environmental matters related to all types of batteries.

For the first time the legislation will regulate the entire life cycle of a battery – from production to reuse and recycling –and ensure that the products are safe, sustainable and competitive.”

2,250KVA DIESEL GENSET FOR A LIDL SITE

diesel generator with Baudouin engine and Mecc Alte alternator to a new logistics platform owned by Lidl in Spain, reports Euro Power News.

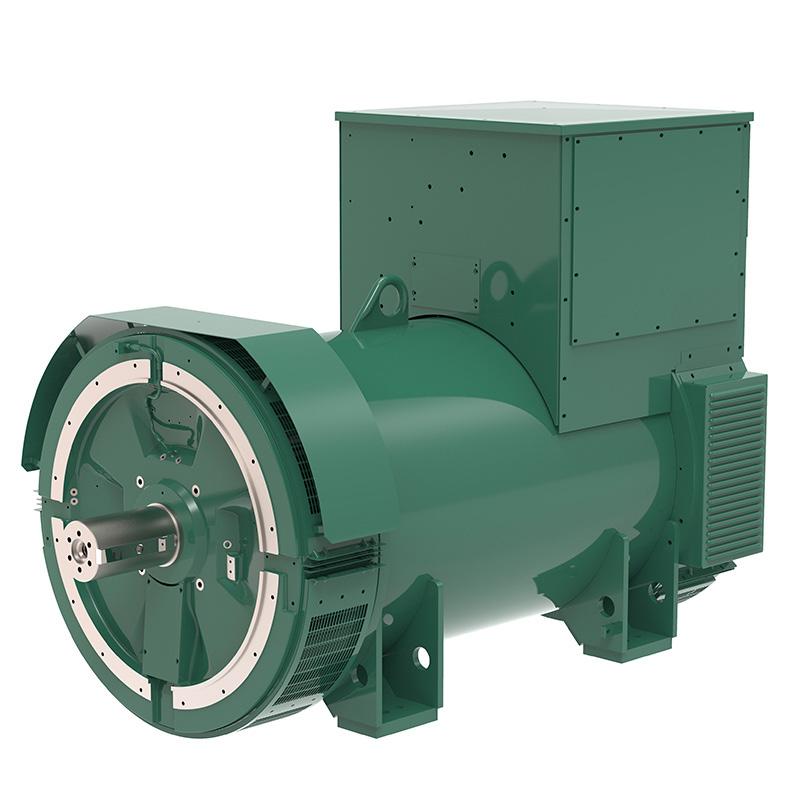

Akey retail management site owned and operated by Lidl in Spain now has a backup power source provided by a 2,550 kVA genset which features a Baudouin 20M33 series engine, a Mecc Alte ECO46 alternator and a closed-loop switching MP15 series (Electra Molins).

The installations have been carried out by the Elecnor Group. The task of installing the genset also involved the installation of the silencers, chimneys and the connection of the Schneider Electric Canalis with an ABB circuit breaker.