Nuveen Infrastructure (formerly Glennmont Partners), one of the world’s largest fund managers investing in clean energy, and Exus Renewables, the independent renewables asset management and development firm, have agreed to co-develop c.800MW of battery storage projects in southern Italy, with each company co-developing a portfolio of c.400MW of projects.

The deal will see Nuveen Infrastructure and Exus commence a series of standalone battery energy storage system (BESS) projects across the Puglia region of Italy.

These will constitute four projects each for both Nuveen Infrastructure and Exus, each with a total capacity of c.100MW.

800MW Italian battery storage project agreed APRIL

The developer for all projects will be an Italian developer specialising in battery storage systems. Construction on the first projects in the portfolio is planned to begin in Q4 2026.

Francesco Cacciabue, Global Head of Clean Energy Investments at Nuveen Infrastructure, commented: “As Italy continues its renewable energy transition, battery technology stands to play a hugely important role

AMIENS & CHP

47 km-long heating network now connects to19,000 homes in the Franch city. Here, Ameins Energy provides CHP services for all the citizens.

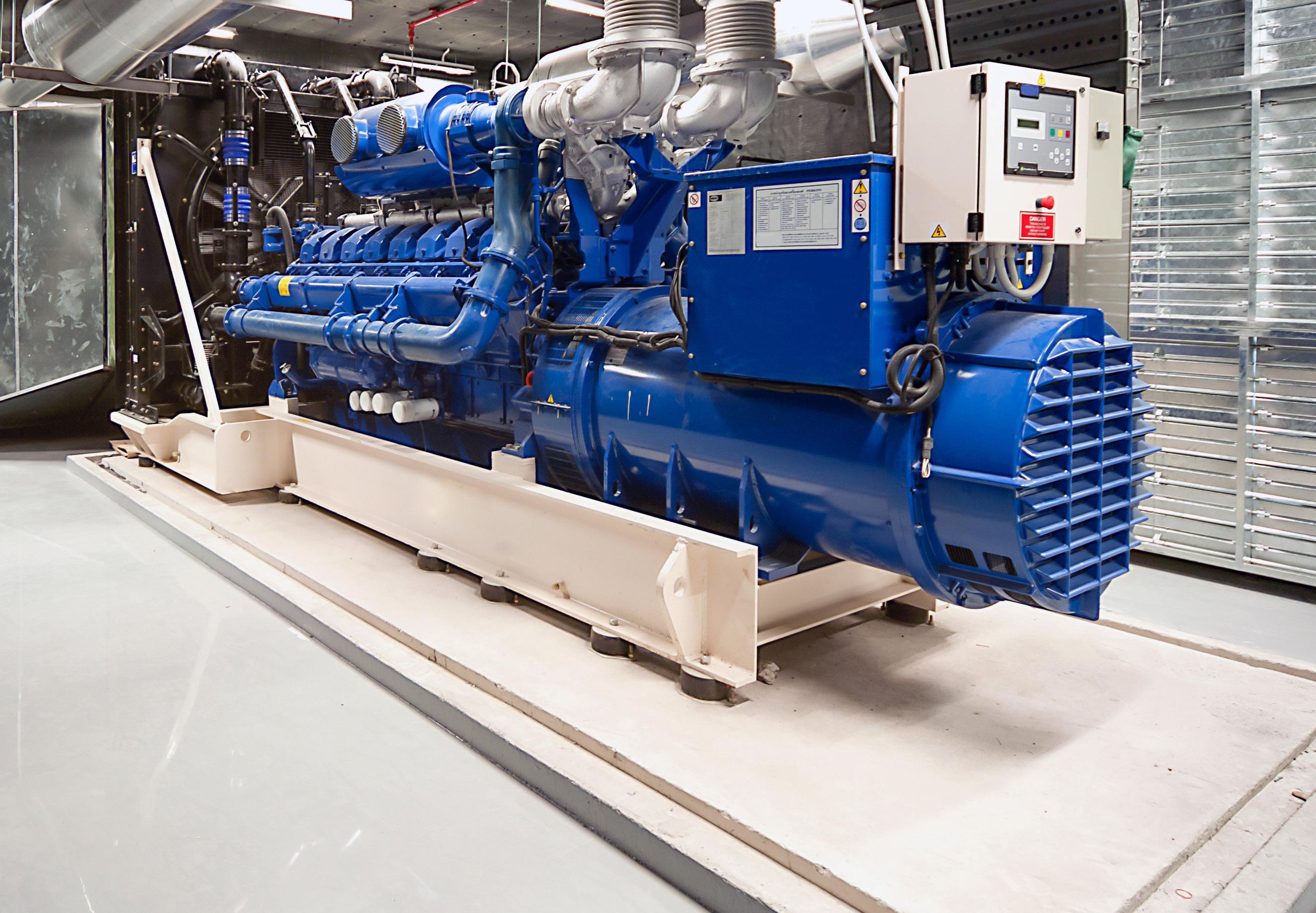

CHP FOR DYNEX SITE

A Combined Heat and Power (CHP) solution has now become part of its key manufacturing sustainability thanks to MWM.

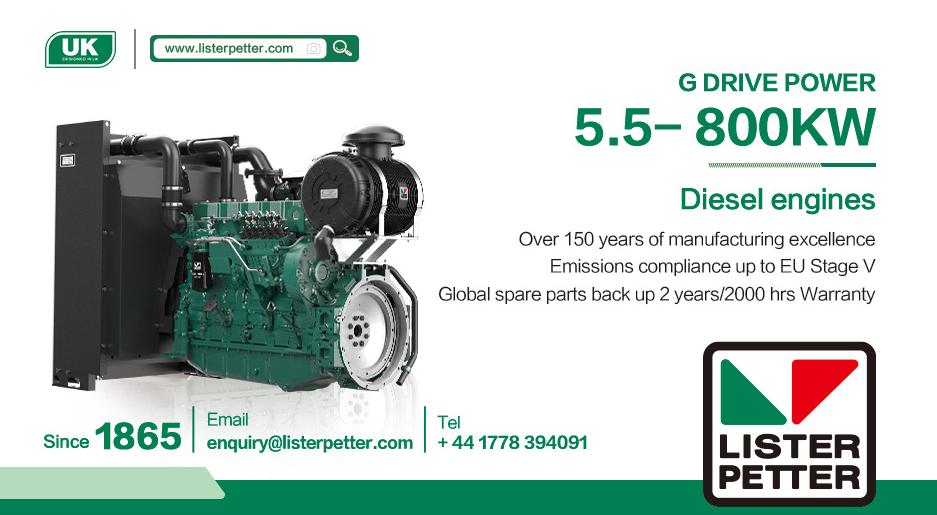

NETHERLANDS DATA CENTRE BUYS DIESEL GENSETS KONINKLIJKE

VAN TWIST of Dordrecht has installed three diesel T2800 generator sets.

in supporting established clean energy generators, through its ability to manage intermittency issues and associated price fluctuations.

“The quality of existing battery storage technologies means they are now capable of fulfilling this role, and they will be a critical enabler as Italy and Europe look to meet their clean energy targets.

“As a result, we’re pleased to be working with our Italian

developer on this project and are confident this new portfolio will provide strong returns to investors, while also supporting more traditional renewables projects in the region.”

Page 14 Page 18 Page 20

1 EURO POWER NEWS APRIL 2024

all-round talent. www.mwm.net/gas-engine-TCG-3020 CES20001_Anzeigen_MWM_TCG3020_235x55mm_EN__RZ1_0_mg.indd 1 09.09.22 11:44

with hydrogen.

TCG 3016, TCG 3020

TCG

www.mwm.net/25H2-Kits MWM 25H2-Kit CES20001_Anzeigen_MWM_25H2-Kit_3erRange_95x145mm_EN_1_0_RZ_sm.indd 1 05.03.24 14:28

2024

The

Operation

New variants of the

and

2032 series enable natural gas operation with hydrogen admixture of up to 25 vol.%. Retrofit solutions for existing plants are also available.

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director:

Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager:

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

MWM, EUROPGEN, Perkins, Ansaldo Energia, Edina, GE Vernova, Stamford, Doosan Skoda, ABB, MEGSA, Volvo Penta, INNIO, MUT, ROLLSROYCE, Siemens Energy, KOHLER Power, De Van Twist, ENEL Green Power, HIMOINSA, Hispanio Acoustica, HiAcoustic, Electra Molins, Genesal Energy, Cummins inc, AUGA Group AB, Arken Jenerator, Mecc Alte, SICES, HITZINGER, ENERIA, EVA ELEKTROMEKANIK, FIAMM, Linz Electric, Ultragreens, HELLUKABEL.

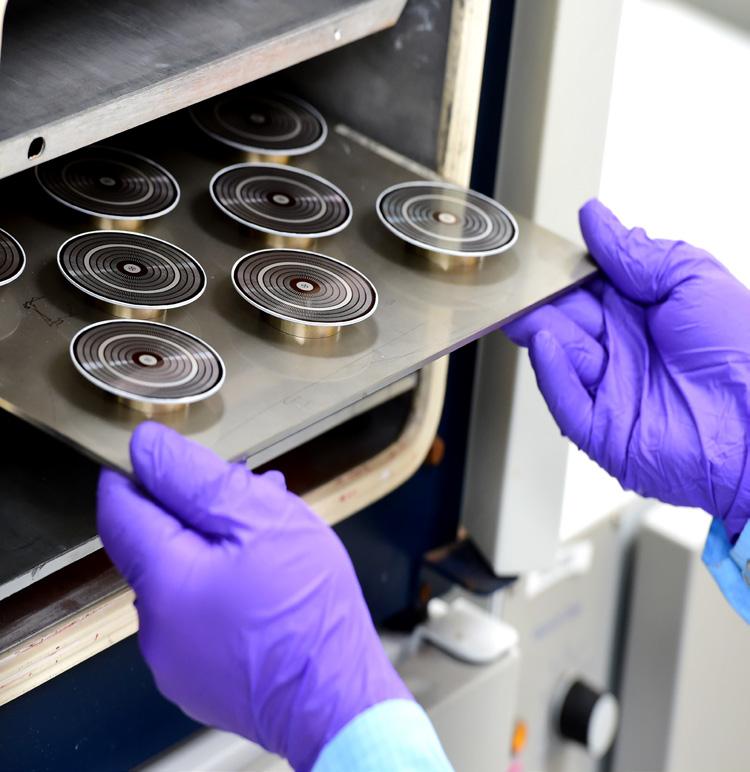

Europe’s PV markets threatened by imports from China

An influx of relatively inexpensive Chinese solar panels is apparently forcing local manufacturers in Europe out of the market.

Europe’s ambitious plans to expand green energy generation with “Made in EU” solar panels face a distinctly cloudy future as the continent faces a massive glut of the devices.

Across Europe solar panels are said to be accumulating in warehouses because of a manufacturing struggle in China, where hard competition has driven the world’s biggest panel-makers to expand production far faster than they can be installed.

The supply surplus has caused solar panel prices to halve. The EU recently pledged to triple its solar power capacity to 672 gigawatts by 2030. This is roughly equivalent to 200 large nuclear power stations. But this has caused a crisis.

The EU’s “Green Deal Industrial Plan” means almost tripling its solar power generation capacity over the next seven years. In fact, 40% of the panels being installed were supposed to be made by European manufacturers.

However, the influx of Chinese alternatives means that instead of tooling up, manufacturers are pulling out of the market or becoming insolvent. Last year 97% of the solar panels installed across Europe came from China.

EXPLOSION AT HYDROELECTRIC PLANT IN ITALY

April 10th, 2024: At least three people were killed after a fire and explosion occurred underground at the hydroelectric power plant owned by Enel Green Power, part of Enel Group, in Bargi, about 80 km (50 miles) from Bologna, Italy. Five other workers were injured and four are missing.

“The rescuers’ hope is always to find people alive. The scenario we see does not make us believe much in these hypotheses, but I repeat that we are also accustomed to miracles,” fire brigade’s spokesperson, Luca Cari said, as EPN went to press.

Cari said that the situation was very difficult, due to the water rising quickly inside the power plant, which was built underground on one of the banks of Lake Suviana.

The rescuers had been working mainly with divers, but details on the potential causes and the dynamics of the accident are still unclear. The power plant had apparently been undergoing efficiency works, which Enel Green Power entrusted in 2022 to three primary companies, Siemens Energy, ABB and Voith, Enel’s subsidiary said in a statement.

“From what has been reconstructed, the testing of the first generation group had already been completed in the past days and, at the time the accident occurred, the testing of the second group was underway,” Enel Green Power said.

The CEO of Enel Green Power, Salvatore Bernabei, went immediately to the site on Tuesday, the company said, adding it would fully collaborate with the relevant authorities to ascertain the facts. The power station has a capacity of 300 megawatt, part of Enel Group’s 13,000 MW of total hydroelectric capacity in Italy. Enel Green Power has established an immediate fund of two million euros in order to allow the people impacted and their families to meet near-term, urgent needs.

Enel has stated that the dam basin remains intact and that the plant was not operational at the time. There was no disruption to the electricity supply. The company has evacuated the Bargi site and is working with emergency services.

The blast took place during maintenance at the decades-old Bergi facility. Regional fire chief Francesco Notaro said that part of the nine-storey underground structure had collapsed, igniting a fire and causing flooding up to depths of 60m.

PowerEx Live 2024 - THURSDAY 12th DECEMBER, Location: LONDON, UK

PowerEx Live 2024 at London’s Park Plaza Hotel, will be held on Thursday 12th December, 2024.

PowerEx Live 2024 aims to offer the perfect networking opportunities for international professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at GEN-SET, CHP & ENERGY LIVE the top of their respective fields you can be sure to glean some valuable insights into the industry. The conferences are held alongside premier display space in a world class venue. This event has become a priority for all those in the power and energy markets. The conferences will run parallel with prime exhibitor space available in adjoining rooms. Do not miss this opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

The Power Hub Learning Zone

With the Biden administration pouring hundreds of billions of dollars of subsidies into clean energy under the auspices of the US Inflation Reduction Act, and amid growing Sinoscepticism in Europe, some EU officials are making the case for an industrial resurgence of PV at home. Raphaël Glucksmann, a European parliament member, said: “Thirty years of deregulation and free-trade policy in Europe has ironically led to the triumphs of the Chinese Communist party. “

Camugnano town mayor Marco Masinara has publicly suggested that a turbine defect might have caused the explosion.

PowerEx Live 2024 will again feature a special Power Hub Learning Zone. The training experience will cover four subjects presented by different companies & speakers . The object is to teach, inspire and educate students, young people and fellow industry professionals about the importance of equipment familiarisation and other key aspects of the training experience within industry. This highlight of the UK’s Power & Energy calendar for 2024 is being held at . London’s iconic South Bank hotel, the Park Plaza, Westminster Bridge, London.

2 APRIL 2024 EURO POWER NEWS NEWS NEWS www.powermediagroup.co.uk

EPN DIARY

**************** EURO POWER NEWS Published by: Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK Tel: +44 (0)1403 888019 Fax: +44 (0)1403 220751 powermediagroup.co.uk © Worldwide Independent Power (ISSN 1468-7100). Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to Euro Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

LABORATORY BUYS GENSET

TWO 1,400 KVA GENSETS SUPPLIED FOR DATA CENTRE

ELECTRA MOLINS has supplied 2 x 1,400 kVA diesel generators fitted with Baudouin engines and Mecc Alte alternators.

The company has installed these two gensets equipped with bidirectional non-zero crossing switching systems CON-5012, exclusive from Electra Molins, into a new room DC1 at a newlydeveloped data centre in Spain.

The genset is supplied with quality certification ISO 9001 and is compliant with EC mark which includes the following directives:

• 2006/42/CE Machinery safety.

• 2014/30/UE Electromagnetic compatibility.

• 2014/35/UE electrical equipment designed for use within certain voltage limits

• 2000/14/EC Sound Power level. Noise emissions outdoor equipment. (amended by 2005/88/EC)

• EN 12100, EN 13857, EN 60204

The genset has been designed & manufactured to supply the following:

- Prime Power (PRP):

According to ISO 8528-1:2018, Prime power is the maximum power which a generating set is capable of delivering continuously whilst supplying a variable electrical load when operated for an unlimited number of hours per year under the agreed operating conditions with the maintenance intervals and procedures being carried out as prescribed by the manufacturer. The permissible average power output (Ppp) over 24 h of operation shall not exceed 70 % of the PRP.

- Emergency Standby Power (ESP): According to ISO 8528-1:2018, Emergency standby power is the maximum power available during a variable electrical power sequence, under the stated operating conditions, for which a generating set is capable of delivering in the event of a utility power outage or under test conditions for up to 200 h of operation per year with the maintenance intervals and procedures being carried out as prescribed by the manufacturers. The permissible average power output over 24 h of operation shall not exceed 70 % of the ESP

- Continuous Power (COP): According to Standard ISO 8528-1:2018, this is the maximum power available for continuous loads for unlimited running hours a year between the maintenance times recommended by the manufacturer under the environmental conditions established by the same.

- Data Center Power (DCP): The manufacturer declares an acceptable average daily and annual load factor of 100%. Overload margin: +10%. Operating hours per year: Unlimited

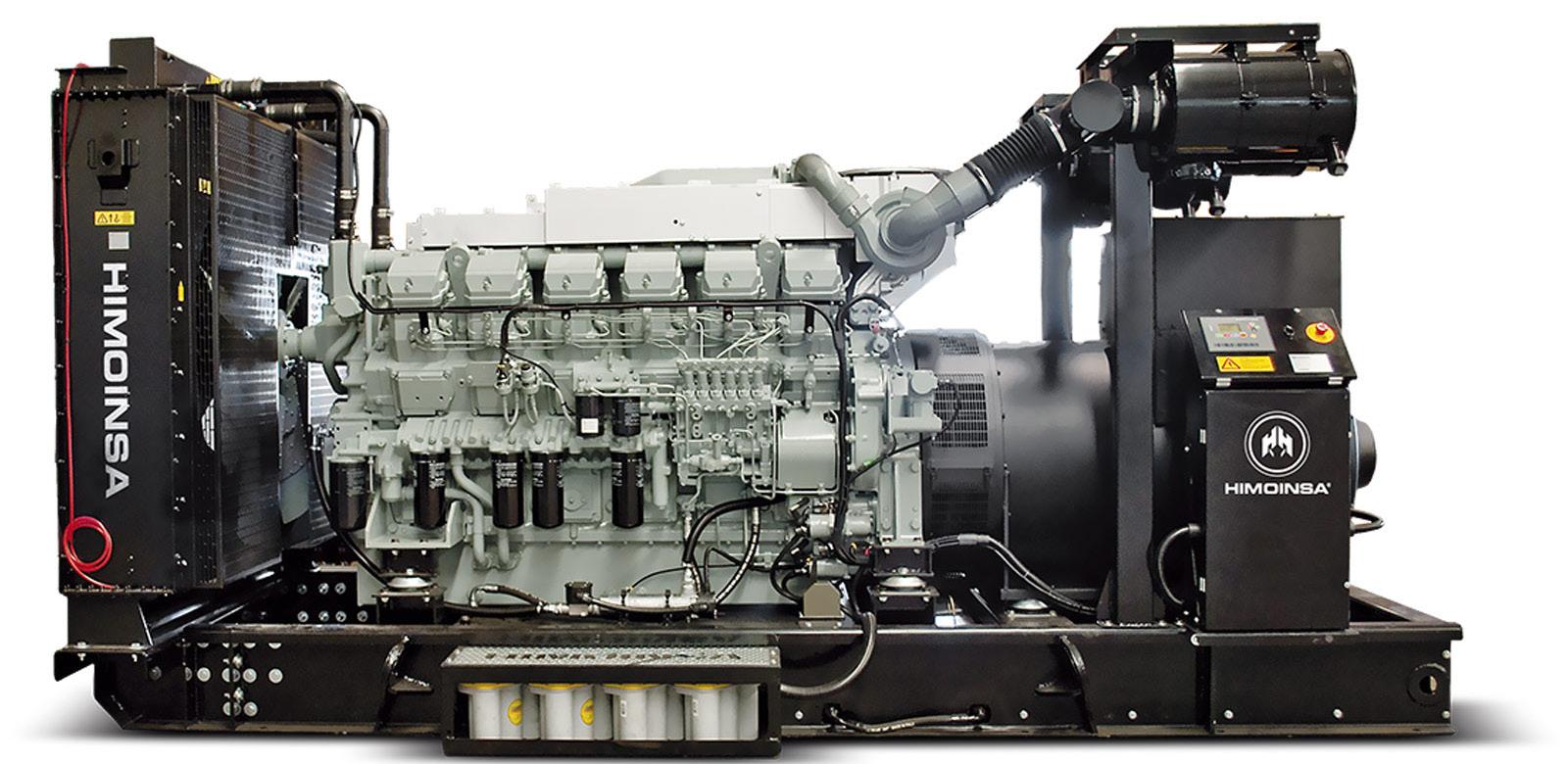

HIMOINSA acquires new company

HIMOINSA recently acquired Hispano Acústica, a company specialising in industrial soundproofing solutions. The result of this strategic merger is HiAcoustic, with the aim of strengthening the company’s position in the international acoustic engineering market.

Hispano Acústica is a benchmark company in the acoustic engineering solutions sector with an outstanding track record in the design of industrial soundproofing systems and its acquisition represents a significant step forward for HIMOINSA. From now on, the company will be known in the market as HiAcoustic in order to strengthen its position both in Europe and worldwide, offering innovative and competitive soundproofing systems that include everything from acoustic booths and screens to enclosures and absorbent treatments for both generator sets and installation rooms.

HIMOINSA reports that it remains committed to transversal growth in the power generation sector by incorporating proven know-how, industrial capacity and engineering teams, in this case in the field of acoustics, into its business group in order to offer its clients a complete solution.

With 40 years of experience in the power generation sector and the support of the Yanmar group of companies since 2015, HIMOINSA is consolidating its growth in the power generation sector. Its aim is to ensure that its Power Solutions, business unit can offer 360º solutions for mission-critical projects, including innovative acoustic solutions.

“The synergies we share with HiAcoustic are a key factor in driving our strategic growth plan, and will also allow HiAcoustic to expand internationally,” explains Francisco Gracia, President and CEO of HIMOINSA. The company continues to focus on transversal growth and the integration of different engineering, technology and innovation capabilities in order to provide our clients with a complete solution. “This acquisition certainly reaffirms our commitment to the design, production and commercialisation of innovative solutions for the market.”

The Low Voltage Electrotechnical Regulations in force in Spain ITC-BT-40 4.2 for no break load transfers, establishes a series of technical requirements which are met by the company’s switching systems.

Some requirements affect the control equipment CON-5012: No break load transfers may only take place for generating sets of an output of more than 100 kVA; Only one no break load transfer switch system can be installed between mains and genset. To make easier the load transfer switchboard construction, ELECTRA MOLINS provides the wiring diagram appropriate to each installation.

The client has also chosen ELECTRA MOLINS to provide maintenance through a contract with periodic reviews and 24/365 customer service - this is a necessary step for an installation with these critical characteristics, reports the company.

The EMB-1400 kVA genset from

ELECTRA MOLINS features an AUT-MP15 control panel and a BAUDOUIN 12M33G1400/5 4-stroke engine and a MECC-ALTE ECO43 2L4 alternator.

The stated outputs correspond to the maximum continuous power with variable load according to ISO-85281, in atmospheric conditions of 40ºC and 1000 m of altitude.

The generating set can operate at higher temperatures and altitudes with the application of power correcting factors.

The prime power output admits a 10% overload in limited time peaks, maximum one hour every 12 hours. However, in order to extend the engines life, it is advised that the average active power charges (kW), either continuous or discontinuous, connected to the generating set during any 24 hours working period, should not exceed:

* 70% PRP power, in main service.

*80% LTP power, in standby service on mains failure.

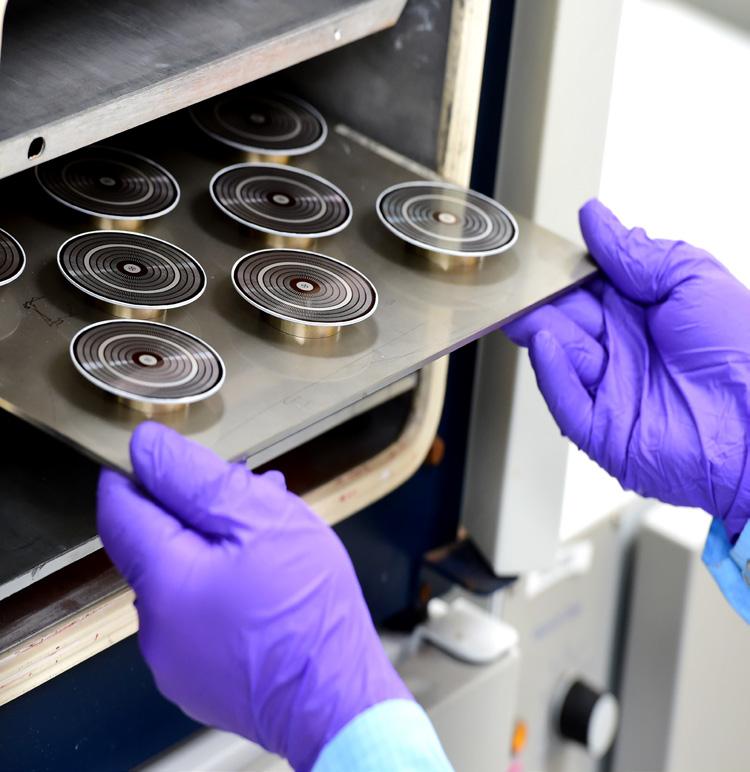

ITALY-BASED MANUFACTURER SUPPLIES CATALYTIC CONVERTERS

Green Power is an Italy-based company offering a quality range of advanced gensets. Its new catalytic converter generators offer low emission generators with a CO reduction of 85%, HC reduction 70%, Metal support, Quick installation, Minimum maintenance and Zero cost management. Thanks to the technology the sets achieve a reduction of particulate (PM) > of 97%, VERT certificate, Scheduled maintenance which is applicable on all types of generators, independently from

the power of the engine. The SCR system developments mean a reduction NOx 80% using the UREA TECHNIQUE. This can be installed on all engines, says Green Power, with minimum maintenance

EURO POWER NEWS APRIL 2024 3 NEWS NEWS

HIMOINSA has announced the delivery and installation of a Himoinsa HTW 1260 T5 generator set in a 16-ton container with reinforced soundproofing, integrated 500 kw load bank, on a slab - a project achieved with its partner ATM Levage and supplied to a laboratory equipment supplier based in France.

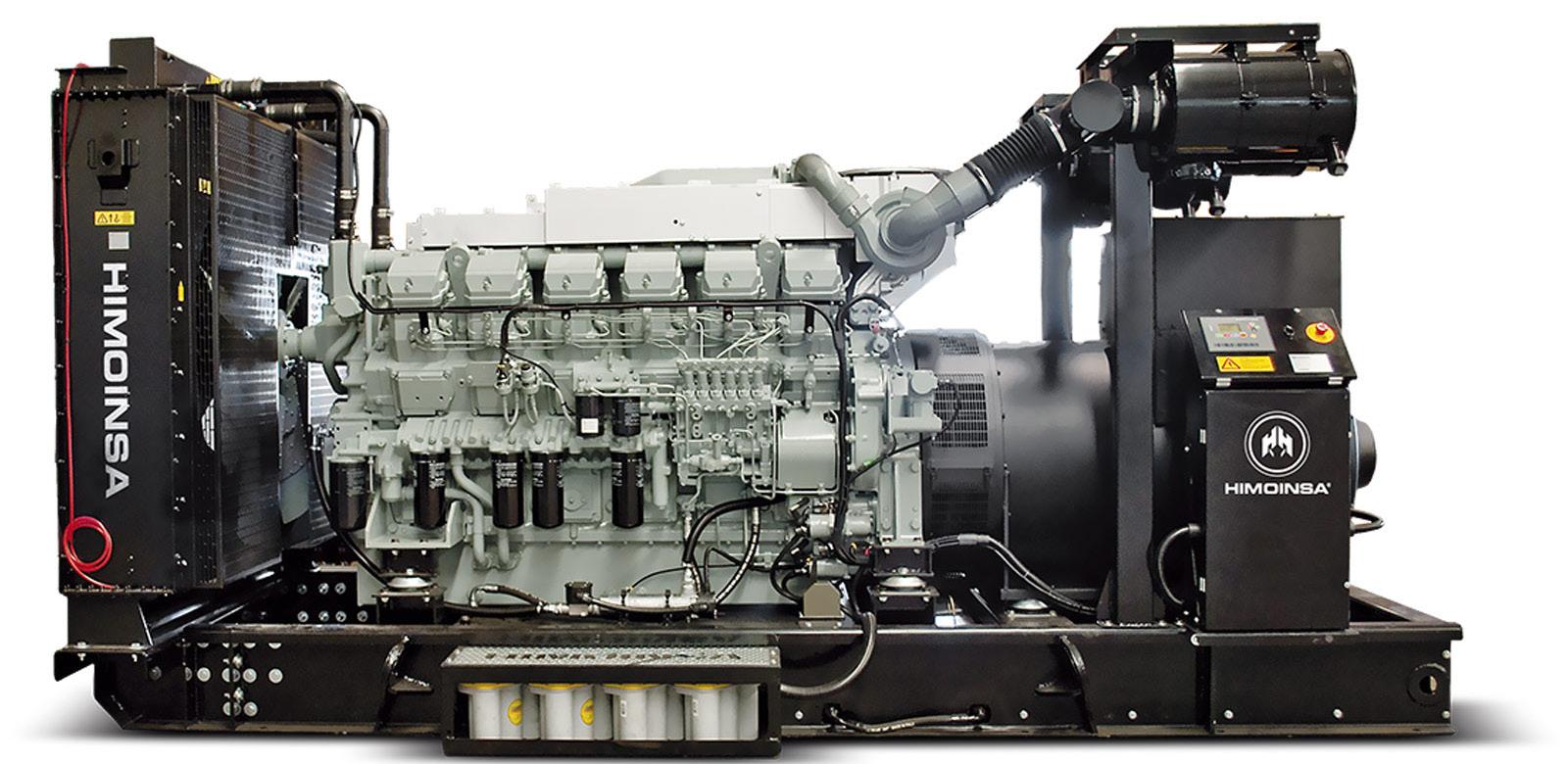

DIESEL GENSETS FOR A DATA CENTRE BASED IN NORWAY

Adata centre in Norway needed six reliable generator sets and turned to Genesal Energy for the required cutting-edge engineering and experienced personnel. Six generator sets were needed to power the emergency network belonging to this key data centre. The six generator sets were specially designed to withstand Norway’s low temperatures.

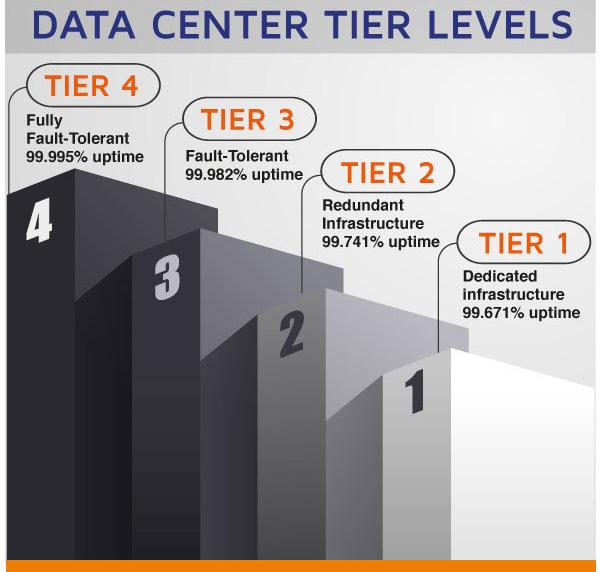

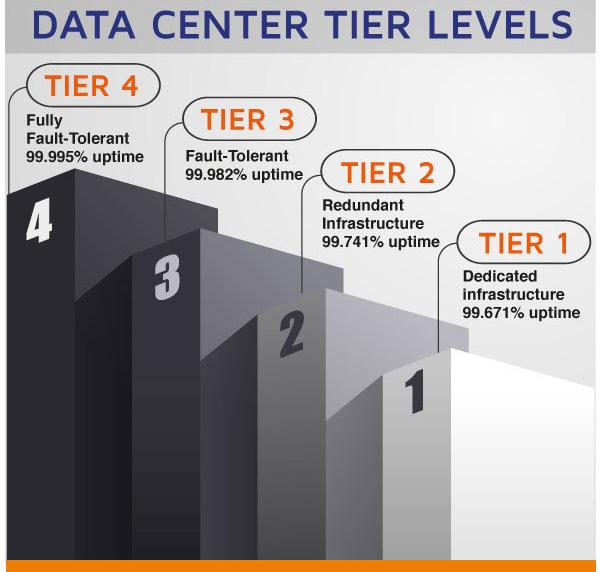

The customer asked for 11MW of backup power for the data centre, designed according to TIER III criteria. A data centre with TIER III means it has multiple paths for power and cooling, and redundant systems which allow the staff to work on the setup without taking it offline. This tier has an expected uptime of 99.982% per year.

A TIER III data centre is a concurrently maintainable facility with multiple distribution paths for power and cooling. Unlike TIER I and II data centres, a TIER III facility does not require a total shutdown during maintenance or equipment replacement.

A TIER III facility requires all the components present in a TIER II data centre, but these facilities must also have N+1 availability:

“N” refers to the necessary capacity to support the full IT load. +1” stands for an extra component for backup purposes. N+1 redundancy ensures an additional component starts operating if the primary element runs into a failure or the staff removes the part for planned maintenance.

Tier III data centres also require a backup solution which can keep operations running in case of a local or region-wide power outage. The facility must ensure equipment can continue to operate for at least 72 hours following an outage. TIER III setups are said to offer a significant jump in availability when compared to lower ratings. ata Centres or Data Processing Centres (DPCs) are facilities which house complex and modern IT equipment, from computers to storage or network systems, where any electrical failure can lead to a catastrophe due to the large amount of information managed in the facility which is put at risk. For this reason, it is imperative that the electrical supply in these facilities is continuous and uninterrupted.

In terms of system availability, Uptime Institute created the TIER rating system to assess data centre infrastructure. The classification starts at DPC TIER I used for small businesses, up to TIER IV, used in large corporations.

At the TIER III data centre site in Norway, heat recovery was achieved by means of a heat exchanger system in the engine, explains Genesal Energy.

Six 2250-2500 kVA soundproofed generator sets were supplied in a 40-foot long HC container ready to work in permanent parallel with the grid.

Two gensets were designed with the power output on the right-hand side and four sets, symmetrical to the first two, with the power output on the left-hand side, which facilitated the installation of the power cabling, reports the company.

Genesal Energy is a business group based in Northern Spain devoted to the distributed energy sector with a firm commitment to innovation, specialisation and sustainability.

It takes pride in its strong R&D department and designs, manufactures, and services top-quality generator sets and internationalisation is key to its business strategy.

Around 70% of its production is exported. It has subsidiaries in Mexico and Peru and sells its products to more than 30 countries.

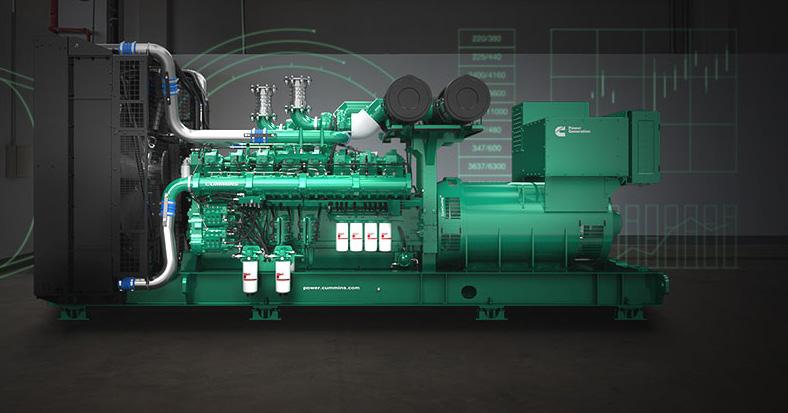

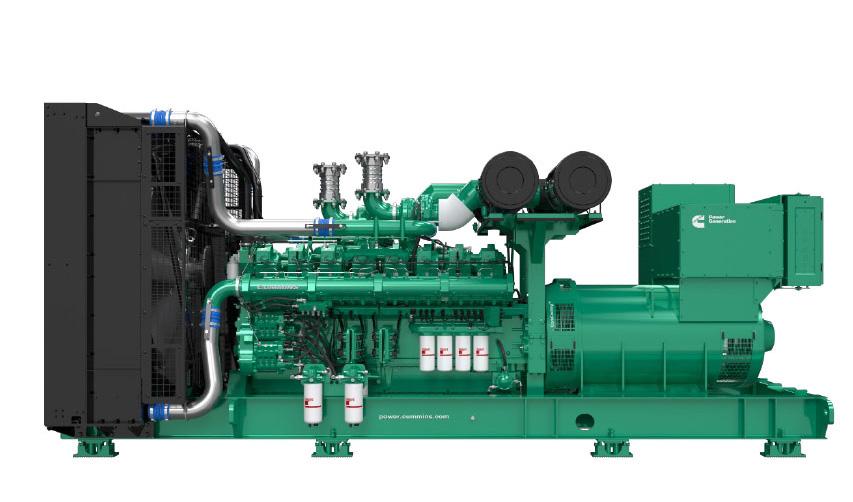

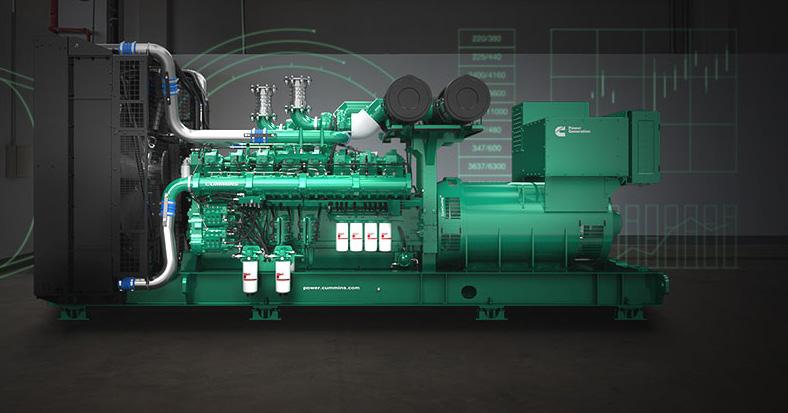

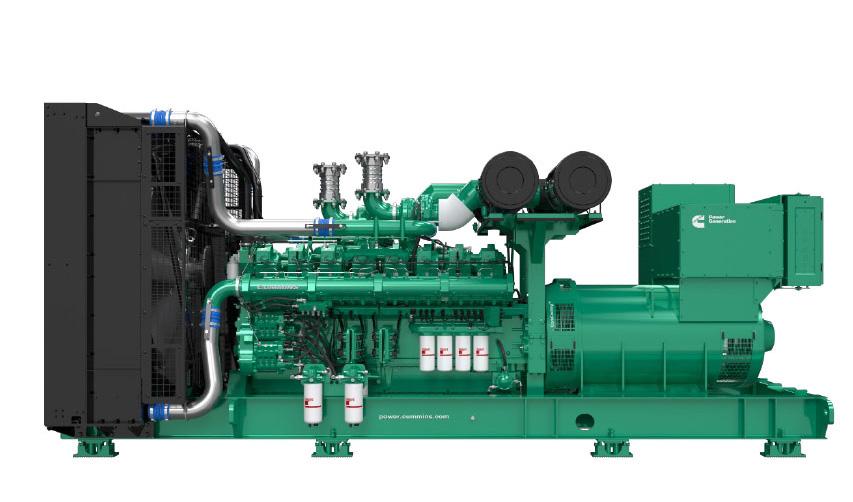

EUROPE GETS NEW RANGE OF 1750-2000KW GENERATOR

Cummins Inc. has introduced two new generator sets to the award-winning CentumTM Series, C1750D6E and C2000D6E.

These two generator sets have been designed to offer a complete spectrum of power to meet global demands for more efficient and sustainable power.

The generator sets are powered by the brand new QSK50 engine. This engine delivers superior power efficiency in a smaller footprint and offers a more compact design for ease of installation, service and maintenance.

With a power range of 17502000kW, the new Centum Series models produce market leading power density with a displacement of just 50 liters.

These new models boast reliable power at reduced emissions, all without sacrificing performance.

Key benefits for C1750D6E and C2000D6E include:

•QSK50 engine and STAMFORD® S-Range alternators deliver superior power efficiency

•Compact design,

offering ease of installation, service and maintenance

•Robust transient performance and high altitude/ambient performance

•Integration with Cummins

Integrated Power System products including generator set controls, transfer switches, system controls and switch gear, microgrid controls and digital solutions,

LITHUANIA BEGINS SUPPLYING BIOMETHANE

The AUGA group, AB and its subsidiaries is well-known for developing sustainable agricultural technologies and solutions. The company has begun supplying biomethane gas through a natural gas system operated by the gas transmission system operator Amber Grid, AB.

Produced in Lithuania, the gas will be sold on the German market, which the company said operates the most developed biomethane infrastructure in Europe.

The project capacities of three biogas power plants will allow for the generation of 61,000 megawatt hours of gas per year. The group of companies has agreed a deal to supply biomethane gas to Tube

Green, UAB.Biomethane gas is currently being transported into the natural gas system using the company’s gas intake point. This is a relatively new development: biomethane gas has been supplied to the natural gas system via a remote intake point not directly connected to the gas production facility only since the end of 2023, reports the company.

“Although we have been able to start producing biomethane gas for some time, laws of the Republic of Lithuania did not envisage the supply of such gas through an intake point separate from the production facili-ty,” explains Kęstutis Juščius, the current chairman of the Board of AUGA.

4 APRIL 2024 EURO POWER NEWS NEWS NEWS

Cummins CENTUM

HYDROGEN

Enabling your transition to a green future

We're ready for H2. Get ready, too!

At INNIO* Group, we are continuously innovating flexible, scalable, and resilient energy solutions to help you generate and manage energy efficiently and sustainably.

Our Jenbacher* engine technology is an investment in the future. It can be converted to run on traditional gas-hydrogen mixtures and up to 100% hydrogen when it becomes more readily available. Installing our “Ready for H2”**-designed power plant now will enable you to convert it to 100% hydrogen operation later, delivering a sustainable energy solution that works for you today and accelerates a greener tomorrow!

Let us support your transition journey. jenbacher.com

* & indicates a trademark.

** In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

Jenbacher is part of the INNIO Group

ENERGY SOLUTIONS. EVERYWHERE, EVERY TIME. World Hydrogen Forum May 21 - 22, 2024 Booth: B82

CONTROLLERS BUSINESS ACQUIRED BY ITALY-BASED ALTERNATOR GIANTA ‘TRANSFORMATIVE’ MOVE

In a strategic expansion of global capacity, Mecc Alte has acquired SICES’ controllers business worldwide. Effective from Thursday 7 March, all SICES controller design, manufacturing and logistics resources now form part of Mecc Alte’s expanded global SMARTECH™ offer to genset designers and manufacturers.

Commenting on the takeover, Mario Roberto Carraro, President and CEO of Mecc Alte, said: “In the heart of the energy transition and the decentralisation of power, we have embarked on a transformative journey, transitioning from a focus on single industrial alternators to embracing genset controls and components that together help create next-generation power solutions. This strategic shift is both a response to industry trends and a proactive commitment to shaping a sustainable future for energy.”

The move follows a sustained period of co-operation between the two businesses, with SICES controllers incorporated into Mecc Alte products since 2021. Mecc Alte sees the acquisition as an essential response to a changing energy landscape.

“Genset controls are a pivotal solution as power generation becomes decentralised with the rapid expansion of renewable sources of energy. These sophisticated control systems provide not only efficiency in power generation but also the intelligence to adapt to varying energy demands. By integrating advanced technologies such as these and future controllers, and linking them to Mecc Alte’s highly successful range of products, we aim to empower our clients with the ability to optimise power generation and contribute to a more sustainable energy grid,” said the head of Mecc Alte’s SMARTECH™ division Miles Revell.

As one of the world’s leading manufacturers of alternators, Mecc Alte is well-positioned to expand its reach. The SICES acquisition builds on other advanced capabilities, such as advanced rotating electrical machines, advanced power generation systems, and LV industrial alternators with specialised custom products such as liquid cooled PMG machines. The range also includes MV and HV alternators and many unique multipole solutions optimised specifically for their given solution.

“This acquisition, in line with our company’s transition within the wider energy landscape enables us to transfer our knowledge and expertise gained across multiple energy sectors to new and exciting markets,” said Jonathan Stokes Mecc Alte’s Group Marketing Director. “Market evolution means traditional singular systems are being replaced by mixed and complex multi-dimensional systems where the integration of digital technology is essential. As we continue to navigate the complexities of the energy transition, we stand proud as pioneers in the journey towards a decentralised, responsible, and more sustainable energy landscape.”

Laura Curioni, SICES CEO, said: “We’re delighted that Mecc Alte will be able to continue to develop and expand the controllers technology that we created while we focus on other key aspects of our business. Through our previous partnership, it’s clear that Mecc Alte has a very clear grasp of both the technology and its strategic potential.”

Mecc Alte’s SMARTECH™ will continue to be designed and developed in its Italian plants, with production also expected to start in the company’s Indian facilities. Mecc Alte’s global supply chain will provide support to customers worldwide, incorporating previous SICES distributors where needed.

660 KVA GENSET FOR POLAND HIGHRISE

ENERIA has supplied a company belonging to the Cavatina Group S.A with a DE660 GC generator set and a steel enclosure. The generator was installed on the roof of a 62-metre-high highrise building in the Quorum complex –an investment consisting of five buildings which together comprise over 91,000 m2 of offices, over 300 apartments, as well as 7,000 m2 of terraces and green spaces. Producing reliable power 660 kVA at 50 Hz, the DE660 GC generator set is powered by C15 diesel engine designed to ISO 8528-5 transient response requirements. ENERIA CAT not only delivered the generator, it also prepared the design documentation and the design of accompanying installations - fuel, electricity and exhaust gases. The Quorum complex is an investment that is expected to have a significant impact on the development of Wrocław.

ADVANCED GENSETS FOR THE ERMADEN COAL MINE

Arken Jenerator has supplied independent power systems for the Ermaden Coal Mine Project recently completed in Zonguldak, a key port on the Black Sea in the Western Karadeniz region of Turkey.

The project consists of two container-type Baudouin 1925 kVA generator groups. A special control panel has been produced to link three synchronous generator groups. Two units have been completed in the first stage of the project. Project generators are 400V each but this voltage is increased to 15.8 kV via two 1650 kVA step-up transformers and synchronisation is achieved at 15.8 kV. There are two asynchronous mains in the system. Alongside this, step-up transformers, neutral resistors and medium voltage breakers have been supplied by

Arken. The system features a cylindrical 12-ton main fuel tank. Automatic fuel filling and monitoring systems are also used in the project, reports the company.

Around 300 kilometres of anthracite coal mines lie under Turkey’s northern province of Zonguldak, dubbed as the “TwoStorey City,” where thousands of miners work to bring “black diamonds” to the surface and provide a vital energy boost for the Turkish economy.

Arken Jenerator was established in Istanbul Arnavutköy in 2012 with 100% Turkish capital with the partnership of Alaattin Birkan Yuksel, Yahya Kemal Teryaki ve Recep Asirok.

The company has since grown to become a leader in the field of generator production, sales and aftersales technical services.

Arken Jenerator has a factory facility with up to 14,000 m2 of area to produce generators from 5 kV to 2500 kVA. The site has the capacity to manufacture 5,000+ diesel generators per year and uses the most advanced tools in all its processes from supplier selection to manufacturing, and involving product development .

UPS POWER CONTROL & CLEAN POWER FOR INDUSTRIAL SYSTEMS

Dynamic UPS Systems from HITZINGER are used to achieve a constant, uninterruptible power supply of high quality.

U POWER is now available in the variants HPCON (HITZINGER Power Conditioning) and NBDD (No-Break Dynamic Diesel).

U POWER HPCON UPS systems made by HITZINGER have been specially developed for unstable networks, reports the company. They ensure a filtered, clean and reliable power supply. The U POWER HPCON systems provide clean power to critical loads with time-limited bypass capability. By providing reliable mains stabilization and mains filtering of harmonics, voltage spikes, voltage sags and frequency errors, HITZINGER Power Conditioning (HPCON) UPS systems deliver guaranteed power.

Technical highlights include:

-Network stabilization and filtering of harmonics, voltage peaks, voltage drops and frequency errors.

-U POWER systems work with voltages of up to 11 kV, which offers advantages such as fewer losses and higher reliability due to the minimization of components, including the elimination of “step-up” transformers.

-Preventive system protection to increase the service life, system monitoring, winding temperature monitoring, vibration monitoring, …

-Reduced downtimes / maintenance intervals through automatic relubrication devices, with the advantage of a completely contactless excitation device (“brushless design”) of the generator, further strengthened and special tropical coatings.

EURO POWER NEWS APRIL 2024 7 NEWS NEWS

ROMANIA’S VERTICAL FARMING RELIES ON TOP QUALITY POWER CABLES

Vertical farming - the cultivation of food in multi-storey greenhouses - is considered one of the most exciting trends in food production. A pioneer in this field is the Romanian start-up Ultragreens. In their highly automated indoor farms, the company relies on top-quality and thoroughly tested solutions from HELUKABEL for the reliable transmission of power, signals, and data.

The Romanian start-up company Ultragreens is committed to growing food in closer proximity to points of sale.

Ultragreen’s plants grow under precisely calibrated LED light and without soil in so-called hydroponics, where they are supplied with all the necessary nutrients through special substrates. Irrigation, ventilation, temperature and many other factors are precisely regulated by computer systems and continuously monitored with comprehensive sensor technology.

For the cabling, the company has relied on HELUKABEL since the very beginning: The electrical connection technology specialist supplies the connection, control and data cables required for the operation of the vertical greenhouses. Tried and tested solutions such as the JZ-500 and JZ-600 cable types, the H07V-K single cores or the TRONIC-CY data cable are applied.

“For us, quality was the most important criterion when selecting our suppliers,” reports Cristian Tudor, co-founder and CEO of Ultragreens. “HELUKABEL was recommended to us by one of our technical service partners - and met our high expectations.” The HELUKABEL Romania team, led by Managing Director Ionut Nica, thoroughly examined the application and selected the optimal solutions for the special operating environment. “Importantly, the cables used must be resistant to moisture, and they must also be sufficiently bendable to allow for a flexible installation even in tight spaces,” explains Nica.

TÜRKİYE SUPPLIES NEW ADVANCED AIR INSULATED SWITCHGEAR

The advanced Air Insulated Switchgear from EVA ELEKTROMEKANIK is (EVA MMMH) a medium voltage switching element used in the secondary distribution system of electricity at levels of 12 kV, 24 kV, and 36 kV and according to the customer various demands. EVA Air Insulated Switchgear is very suitable for the use in the monoblock concrete substations, prefabricated concrete substations, metallic substations, and special type buildings. Due to its modular structure, EVA Air Insulated Switchgears can be installed and commissioned with ease and fast manner. In air insulated switchgear, the busbar outputs are insulated by air, while, the electrical switching and breaking operations are performed in either SF6 gas or vacuum environment which by that a maximum safe operation can be achieved. EVA Air Insulated Switchgears stand out with their metal compartment structure (PM), Loss of Service Continuity class (LSC2B), internal arc classification structure (AFL), and the insulation medium which could be either SF6 gas or vacuum for circuit breakers and SF6 gas for disconnectors.

NEW ALTERNATORS AVAILABLE ACROSS EUROPE

LINZ ELECTRIC has developed three new types of alternators for the power generation sector, for both stationary and mobile gen-sets for industrial applications, construction, telecom, oil & gas and marine and power take-offs (PTOs. New alternators will also power specific loads such as in lighting towers.

These include:

•A wide range of two- and four-pole synchronous brushless alternators with different types of voltage regulation and provided with auxiliary winding.

•The Alumen series, originally intended for lighting towers, is a family of single-phase, fourpole brushless alternators with an auxiliary winding to regulate the voltage loaded onto highly insulated capacitors to protect from high ignition voltage. The Alumen alternators are available in four models with power rating from 4.2 to 10 kVA in the 60-Hz variant.

•The Compatto series of four-pole, brushless, compact alternators with exciter and automatic voltage regulation (AVR) used for continuous service applications such as gen-sets and other industrial applications, and in harsh ambient conditions such as dusty, humid and saline environments and high temperatures. This series covers from 7 to 30 kVA for 60 Hz and is

especially appreciated in the U.S. for marine applications.

•The Phase9 directcurrent (DC), lowvoltage alternator series is composed of synchronous brushless alternators with ninephase windings that ensure a very stable voltage after conversion to DC (residual ripple below 1%).

This makes these alternators ideal with hybrid systems using batteries for various applications and for recharging systems of batteries of any kind.

The new range of alternators reflects an increased emphasis on the electronics that are needed to manage more complex systems in various market sectors.

One example is the development of the HVR-BMS automatic voltage regulator range, which makes it possible to manage the AVR directly from the battery in hybrid systems. Sandro Alberghini, president of Linz Electric’s U.S. subsidiary comments: “Linz Electric is one of the alternator manufacturers using more aluminium components in its products.

The use of aluminium has a very high initial manufacturing cost related to the casting dies, but results in a very efficient and cost-effective product for the end user. Such investments have been possible thanks to the financial solidity of the Pedrollo Group.”

Linz Electric is also further expanding its manufacturing plant at the Italian headquarters with the addition of a new production hall dedicated to winding operations, which will allow it to further increase production capability and serve customers with tflexibility and care.

NEW ECO FORCE AFB TR 540 BATTERY MODEL AVAILABLE

The new TR 540 battery model from the FIAMM ecoFORCE range with maintenance-free AFB technology is now available in Europe.

The ecoFORCE AFB (Advanced Flooded Battery) is an evolution of conventional lead batteries and is said to be the best solution for vehicles and power systems equipped with Start&Stop system which require a higher energy support than that offered by conventional SLI batteries. In this case, the battery is characterised by twice the strength of a traditional battery: during traffic jams or at red

lights ecoFORCE AFB provides energy to all electrical components when the engine is turned off and reliably guarantees the car’s start as soon as the clutch is engaged. This technology supports those applications where a high charge and discharge acceptance, a good starting performance, and longer cycle life are required.

8 APRIL 2024 EURO POWER NEWS NEWS NEWS

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime across the whole product lifecycle, so you can be sure of reliable power generation, regardless of the operational conditions. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

FINLAND’S LARGEST HOSPITAL HAS UPGRADED ITS ELECTRICAL SYSTEMS

Acomprehensive power distribution solution has upgraded and improved security, safety and sustainability for the tech-savvy Hospital District of Helsinki and Uusimaa (HUS) at their Meilahti Hospital Area. A project involving complete protection relay and circuit breaker retrofits has reduced the risk of mission critical downtime in an industry where 24/7 power output essential. The new intelligent asset and energy management solution now optimises maintenance with real-time condition and temperature monitoring.

Finland’s largest hospital area has future-proofed its life saving power supply thanks to a modernization program with electrification partner ABB. The Meilahti Hospital Area in Helsinki, which is operated by HUS, upgraded its electrical system to maximize uptime, eliminate the use of SF6, a potent greenhouse gas, in the medium-voltage (MV) switchgear, extend the life of electrical equipment and optimize hospital operations.

The Meilahti Hospital Area uses the same amount of electricity a year as a small town, and delivers healthcare to more than half a million patients annually, so having a reliable and safe power supply is critical to providing a dependable service where lives are at stake.

Jari-Pekka Korhonen, Operations Manager for HUS Kiinteistöt Oy, the organization that manages real estate services for HUS, said: “What matters most is that in our hospitals, the healthcare professionals can perform surgeries and treat patients safely – and that the power supply won’t cause any problems for them. We’re well-prepared to face any problems with the power distribution. This is all down to the reliable, high-quality products and solutions ABB provides.”

The upgrades included a turnkey MV circuit breaker retrofit, where SF6-insulated models have been replaced with next generation VD4 vacuum circuit breakers. These new devices clear potentially harmful short-circuit faults in tens of milliseconds, thereby preventing severe damage to the hospital’s electrical infrastructure and minimizing the risk of downtime.

What’s more, thanks to ABB’s full-circle end of life service, the old SF6 breakers and gases were disposed of safely and sustainably, eliminating the risk of severe environmental impact and adhering to strict national laws.

The ageing relays in the switchgear were also replaced with ABB’s Relion® protection relays from the 615 series, REF615. These protection relays offer extensive protection and control functionality to ensure uninterrupted power supply. In this project, a solution was implemented where reliable and fast arc fault protection is now ensured with ABB’s REA 101 modules. The protection is based on optical arc flash detection with fiber-optic light sensors, tripping at arc faults in milliseconds.

Sixten Holm, Business Development Manager at ABB in Finland, said: “For service providers such as HUS, one of the greatest opportunities for improving reliability and reducing carbon and costs is by modernizing outdated components, rather than replacing the entire switchgear. Replacing aging circuit breakers and protection relays can also be done quickly with minimal downtime.”

This timely and essential overhaul has given HUS a technologically-driven and environmentally friendly solution that improves reliability, security and safety. But to reduce operating costs in the long term, it needed to be supplemented by an intelligent system that could optimize the hospital group’s maintenance activities.

ABB Ability™ Energy and Asset Manager was installed to facilitate remote monitoring and provide HUS personnel real-time information on the condition of equipment, such as temperatures, with alarms from devices alerting them instantly by text message. This level of predictive maintenance ensures early warnings of any potential failures, providing crucial information to act upon to avoid unplanned downtime.

In addition, specific condition monitoring for the MV switchgear is now available, which allows HUS to carry out maintenance when necessary. ABB’s SWICOM diagnostics system reports the mechanical and electrical health status of the equipment in real-time.

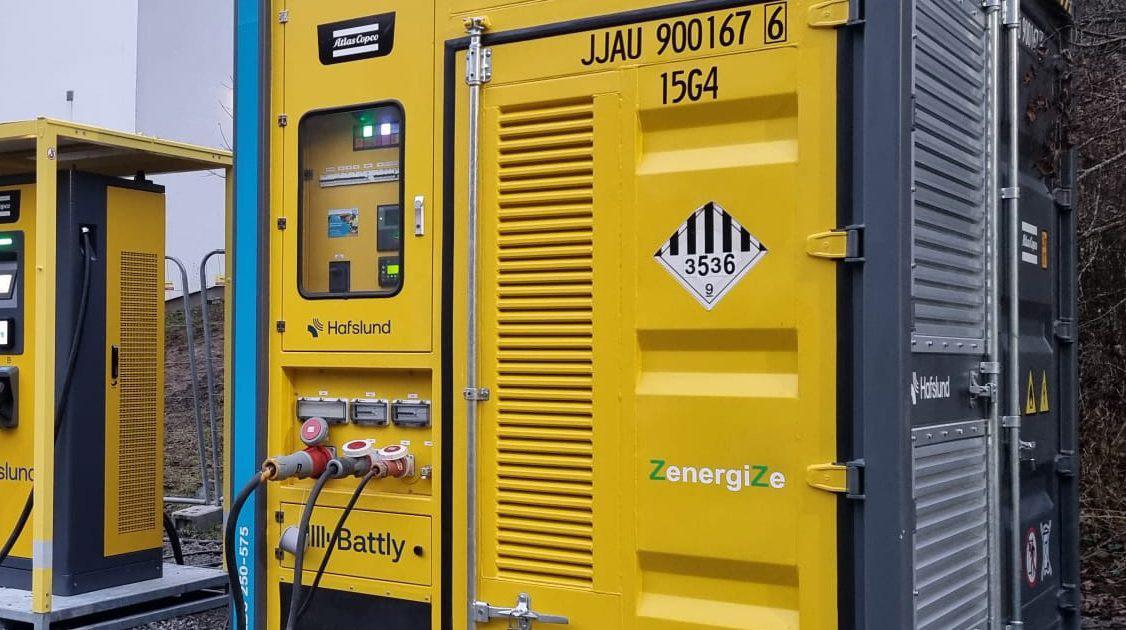

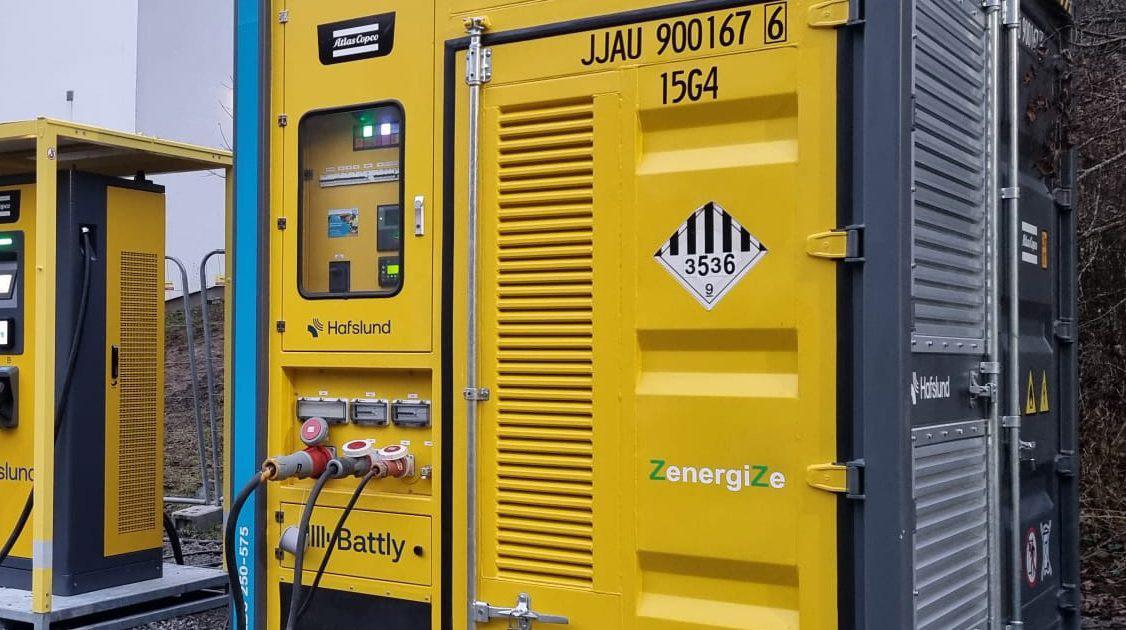

CONSTRUCTION SITE IN OSLO, NORWAY, DEPLOYED AN EMISSION-FREE ENERGY STORAGE SYSTEM

An Atlas Copco ZBC energy storage system provided emission-free running on a construction site in Oslo, Norway. In 2023 Atlas Copco’s ZBC 250575 energy storage system provided the necessary energy to reline 2,400 meters of pipeline at a residential neighbourhood in Kruttverkveien, in the greater Oslo area. The power grid available on site would not have been enough to cover the load profile of the worksite, which comprises the daily use of two electric excavators, among other machinery. To make up for that deficit and comply with environmental regulations, instead of relying on more traditional dieseldriven alternatives, a battery-based energy storage system manages the energy input provided by the grid and a hydrogen fuel cell, making sure the load demand is covered. The construction sector alone is responsible for over 10% of global greenhouse gas emissions. When considering CO2 emissions from energy use, the industry accounts for a staggering 38% of global

emissions. In Norway, the goal is to lead the world in decarbonizing the construction industry. While construction in Oslo accounts for 7% of the city’s total emissions, it still has a significant impact on local air and noise pollution.

To address this, Oslo has set a target for all municipal construction sites to be zero-emission by 2025, and for all construction work, public or private, to be zero-emission by 2030. Six of Norway’s largest cities have also committed to the same goals. Thanks to Norway’s electricity grid, which is made up from 98% renewable energy, mostly from hydropower, the country is an ideal testing ground for emission-free sites. While Oslo has taken the lead, it has been quickly followed

GENSET-GIANT ABSORBS ONE OF SPAIN’S KEY GENSET MAKERS

AKSA Power Generation Europe

B.V. has becomes the majority shareholder of Dagartech

- Both organizations will continue operating under their respective brands, generating synergies that will allow them to further grow in the power generation sector.

- The acquisition is part of AKSA Power Generation’s global growth strategy, demonstrating its commitment to providing reliable and sustainable solutions.

AKSA Power Generation and Dagartech announced today the majority acquisition of shares of the Spanish company by the Aksa Power Generation Europe B.V. This acquisition is a part of Aksa Power Generation’s global growth strategy. The transaction aims to

expand the capacity and volume to offer global power generation market high-quality, customized energy solutions and at the same time, commit to develop reliable and sustainable high-value-added solutions.

An alliance for mutual growth

Although both organizations will continue to operate under their respective brands and carry out their business projects independently, they see this milestone as an opportunity for mutual growth and the creation of synergies.

10 APRIL 2024 EURO POWER NEWS NEWS NEWS

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

HYDROGEN GENERATION PLANT IN GAMPERN, UPPER AUSTRIA, IS COMMISSIONING NEW ENGINE TECHNOLOGY

In 2023 RAG Austria AG (RAG) selected INNIO Group’s (INNIO) Jenbacher innovative hydrogen engine technology to power its hydrogen cogeneration plant in Gampern, Upper Austria.

The combined heat and power plant (CHP) has just commissioned the world’s first 100% hydrogen storage facility in a porous underground reservoir – RAG’s “Underground Sun Storage”; here, up to 4.2 gigawatt hours of electricity produced in summer can be kept ready for winter in the form of green hydrogen.

Commissioning of the highly efficient, flexible Jenbacher hydrogen CHP plant in the 1 MW rangecurrently taking place. In winter, electricity can then be generated on-demand from the green energy reserves, and the waste heat can be used for heating purposes. In this trailblazing project, INNIO and RAG are augmenting the entire value chain, focusing on seamless coordination between the generation, conversion, storage, and – most notably – supply of green energy.

“Our hydrogen technology is foundational for energy security in the age of volatile renewables. We are already helping businesses and communities around the world to become carbon-neutral,” says Dr. Olaf Berlien, President and CEO of INNIO Group. “Hydrogen-ready decentralized energy solutions, ideally in the form of highly efficient CHP plants, make our energy supply future-proof.”

“In Gampern, Upper Austria, we are demonstrating what can and must be done to manage the energy transition by securing a reliable supply of green energy throughout the year,” explains Markus Mitteregger, CEO of RAG Austria AG. He goes on to say that “The hydrogen cogeneration plant is a key building block for the entire hydrogen ramp-up, because flexible, quick-start CHP plants can not only generate electricity as needed, but also produce the heat that is so important in winter. This significantly improves efficiency while also facilitating the heating transition.”

INNIO Group is a leading energy solution and service provider that empowers industries and communities to make sustainable energy work today. With its product brands Jenbacher and Waukesha and its digital platform myPlant, INNIO offers innovative solutions for the power generation and compression segments that help industries and communities generate and manage energy sustainably while navigating the fast-changing landscape of traditional and green energy sources. INNIO is individual in scope, but global in scale. INNIO enables its customers to manage the energy transition along the energy value chain wherever they are in their transition journey.

SAHARA DUST AFFECTS GERMANY’S SOLAR POWER LEVELS

Dust carried by winds from the Sahara Desert in northern Africa to central Europe have reduced solar power output in Germany during the week of the 2024 Easter holidays, sources report. The power output of solar panels was significantly lowered, especially in the southern state of Baden-Wurttemberg. Its effects have been noted all across the Mediterranean region. Grid operator TransnetBW had predicted a peak solar PV output of 3500 MW for 30th March 2024, buthe dust cloud cut maximum output to 1600 MW. To make up any shortfalls in the grid operators switched the load to alternative power plants. Ssuch load management in the grid means that prices can temporarily spike, and lead to an increase in costs to consumers via their grid fees.

The meteorological phenomenon of Saharan dust in central Europe occurs up to 15 times per year and usually leads to dust particles accumulating at an altitude of about 2,000 metres. However, the volume and density of dust on this occasion was significant enough to cause aerosols fall to ground level, which may have resulted from higher-than-usual air temperatures above the Mediterranean.

£250M INVESTMENT ENABLES BATTERY/PV EXPANSION

Copenhagen Infrastructure Partners, through its flagship fund CI V, has signed an agreement to acquire a majority share in Elgin Energy, and will, together with Elgin’s retained management team, invest £250 million in the company, enabling it to deliver and expand on its existing 15 GW solar PV and battery portfolio.

The investment will combine CIP’s industrial approach for procurement and construction with Elgin’s development portfolio to enable Elgin to become an independent power producer (IPP) and expand its team and pipeline in existing and new markets, with the aim of developing it into a fully integrated and full-service solar and storage company. Elgin has already delivered close to 2GW of ready-to-build solar PV

and storage projects and, in recent years, the company was successful on over 30 projects in the UK and Ireland government–backed auctions.

Elgin’s current project pipeline of 15GW is supported by development activities in the UK, Irish, and Australian markets, covering standalone solar, solar co-located with battery storage, and stand-alone battery storage.

“Elgin is a perfect fit for CIP’s investment strategy given its strong leadership and culture, market leading development expertise, high quality pipeline of scale and significant growth potential in markets with attractive fundamentals. We are well placed to support Elgin in transforming into an IPP with our expertise,” commented Nischal Agarwal, partner in the CIP Flagship investment team.

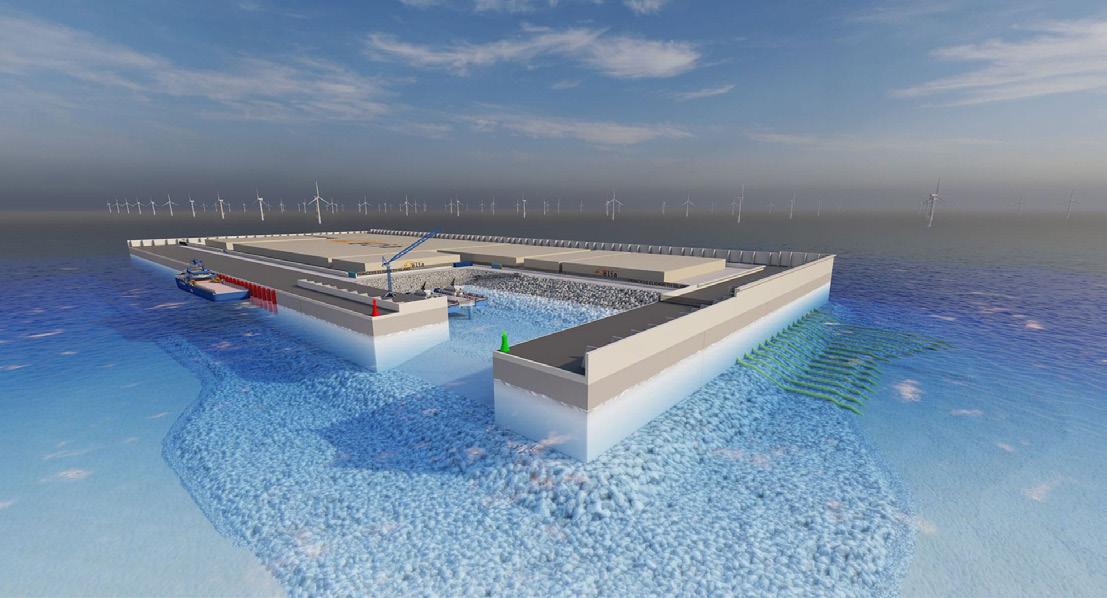

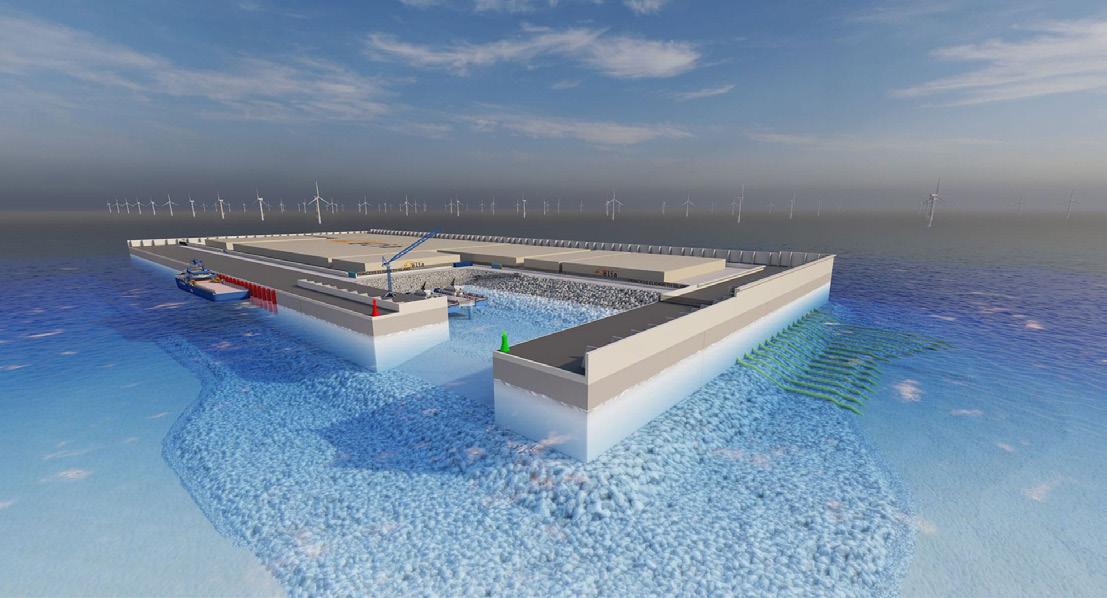

‘ENERGY ISLAND’ BEING BUILT IN THE NORTH SEA

Offshore construction work on Princess Elisabeth Island, the world’s first energy island, is expected to start soon in the Belgian sector of the North Sea. Cardinal buoys have been deployed to demarcate an exclusion zone within which only vessels working on the energy island will be allowed, according to a Notice to Mariners issued on 26th March, 2024.

Jan De Nul and DEME, the two companies which won the tender to build the energy island have already begun construction. Once completed in August 2026 the site become the world’s first artificial energy island.

The site is being developed 45 km off the Belgian coast, within the Princess Elisabeth offshore wind farm zone, and will cover approximately five hectares above water. The area that holding the electrical infrastructure will be built across six hectares. The first segments to be built will be concrete caissons filled with sand, to form the contours of the island.

In June 2023, a similar environmental permit was granted for the construction of the caissons at Verbrugge Zeeland Terminals at Bijleveldhaven, a location in the North Sea Port.

12 APRIL 2024 EURO POWER NEWS

NEWS

Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

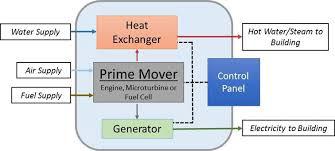

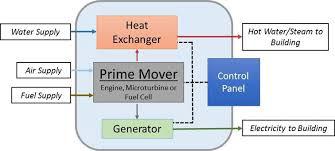

THE CITY OF AMIENS, FRANCE DEPENDS ON CHP SYSTEM

Meeting the heating and domestic hot water needs in Amiens, France, is the responsibility of the Amiens Energies, a public service entity established for the distribution and production of district heating for the entire city. The 47 km-long heating network now connects to19,000 homes in the conurbation.

The Amiens CHP system has been developed from two existing gas-fired heating networks and looks set to deliver an annual reduction of 28 000 tons CO2 from the heating of buildings. Amiens Energies had opublicly announced that it wanted to extend and interconnect its heating network by adding new production units. Amiens Energies pensures that the distributed heat meets the heating and hot water needs of the buildings in the area.

This project is supported by EU funding - ‘Le réseau - de chaleur Amiens Energies’ harnesses renewable energy from five different sources to deliver heat to about a third of Amien’s housing stock.

The designers of the CHP system sought to engineer a large interconnected northsouth heat network to supply a large number of local buildings and the work began with the establishment of three turnkey CHP plants, The plants are CTM 1 & 2, Porte de Flandres (1 x 624) and Coliseum (1 x 416).

The Enedis network.depends upon CHP units from Clarke Energy which produce electrical power for the system. Working with an average

effective pressure (MEP) of 25.06 bar, means that around 4.6 MW per engine is generated over 720 hours per year.

Since the commissioning of the plant in 2018, the two CTM engines have each produced 116 GW and each has been operating for 13,000 OpH. Two INNIO Jenbacher engines: JMS 624 GS N.L and BMEP : 25.06 bar are fed by natural gas and provide an installed capacity of Elect. power: 9.2 MW. Thermal power : 8.6 MW. The Amiens Energies heating network project creates huge environmental benefits. With this kind of partnership between public and private companies, Amiens Energies was given a a strong opportunity to contribute to the energy transition. By using local and recuperation energy sourcing, this innovative project is improving the purchasing power, local employment and sustainability of the local economy.

The two existing heating networks based in the north and south of the city are being connected, overhauled and extended through this project. The new network can run on five renewable energy sources: geothermal based on groundwater; biomass; biogas; and two different

“ The CHP units produce electrical power which is fed into the Enedis network. Working with the average effective pressure (MEP) of 25.06 bar, means that around 4.6 MW per engine is generated over 720 hours.”

heat recovery systems.

The two old networks date back to the 1970s and provided heating for 5 300 homes.

Through its sustainable development policy, the city wants to connect more houses to the heating network while evolving towards a renewable energy mix of more than 60 %.

The new network is capable of delivering 196 984 MWh of energy (hot and cold), including 125 077 MWh from the renewable energy sources.

The project has improved the city’s air quality as emissions savings from operating the network are equivalent to the annual emissions of 13,500 cars. In addition, about 120 jobs were created. To help deliver its 60 % renewable energy mix, six 15 MW heat pumps were installed, capable of pumping 8.5 million m3 of wastewater.

Meanwhile, the network’s 8 MW biomass boiler house runs on sustainably sourced wood chips (60 %) and pallet shreds (40 %). A monitoring and diagnostic system based on digital technologies has been installed, which allows engineers to assess the network in real time.

Power plants which generate energy for the network either produce zero emissions or are equipped with technologies to limit the output of nitrogen dioxide, dust and sulphur dioxide. In addition, the heating network’s optimised energy mix allows subscribers to get the best price for their energy at any given time. Plus, open data is published which helps users understand and control their energy consumption.

www.rezomee.fr

14 APRIL 2024 EURO POWER NEWS CHP

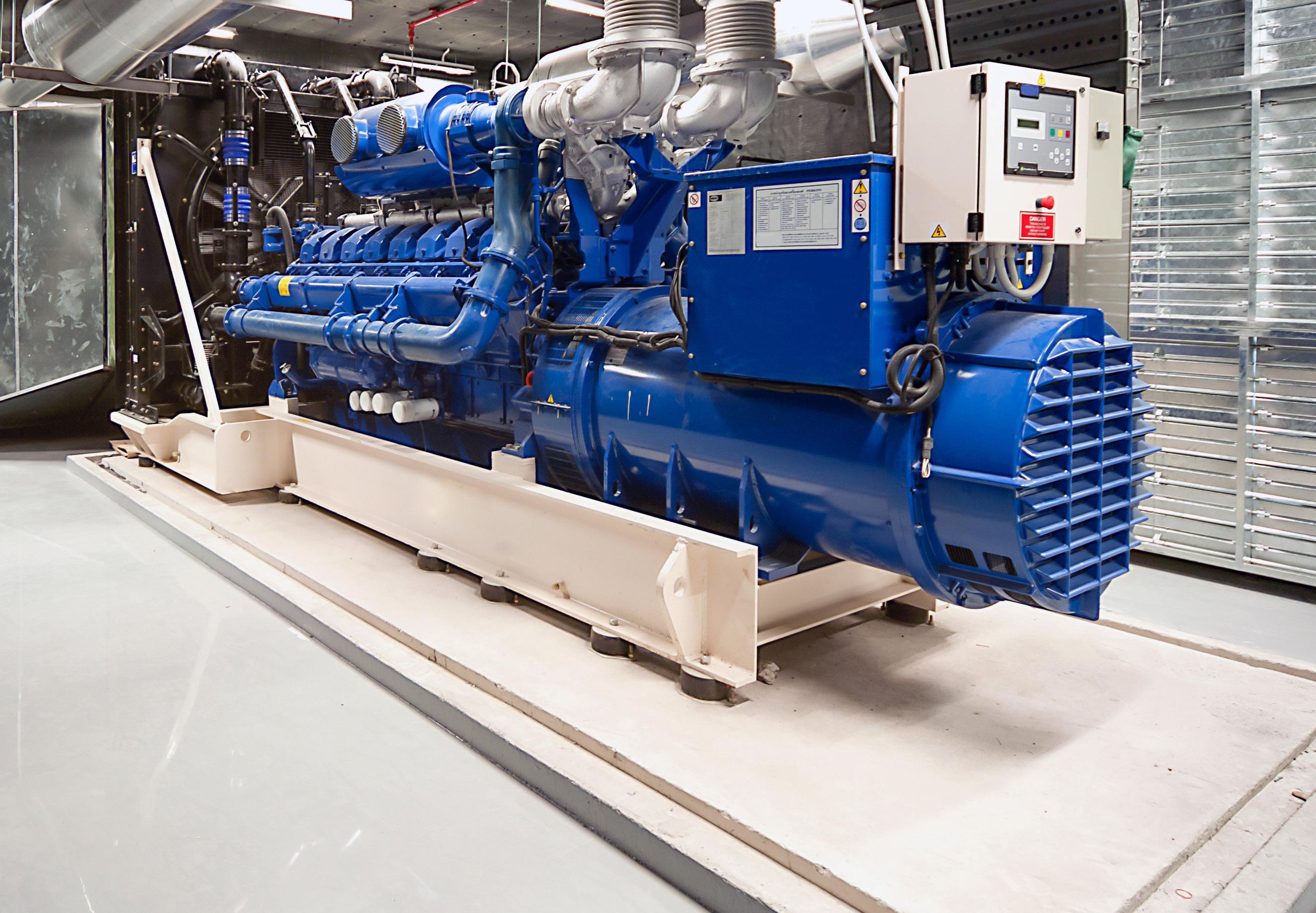

4000 DS2750 GENERATOR SETS FOR THE EUROPEAN COMMISSION GENSETS

Rolls-Royce/mtu has announced the successful completion of Factory Acceptance Tests at Ruhstorf in Bavaria for two mtu 20V 4000 DS2750 generator sets, destined for the Jean Monnet 2 building, the future office complex for the European Commission in Luxembourg City. This is a massive project that will house around 3,600 officials, reports EPN.

In a deal brokered by the mtu local partner Energolux, two 2500 kVA gensets will provide emergency power to all security-related facilities within the Jean Monnet 2 building, the future office complex for the European Commission in Luxembourg City. building.

The installation process will also involve the technical systems required for generator operation.

The successful tests are carried out to guarantee their reliability and performance in critical scenarios. Ergolux reports a ‘satisfied customer’ and is said to ‘be proud to be part of building the infrastructure which will ultimately support the core activities of the European Commission.

The Jean Monnet 2 building (also known as JMO2) is a future office complex for the European Commission under construction on Boulevard Konrad Adenauer in the European district of the Luxembourg City quarter of Kirchberg, Luxembourg. The complex is to be composed of a welcome pavilion and two office buildings to be completed in two phases respectively; an 8 storey 180 metre (m) long block and a 24-storey tower, connected at the basement and second storey levels.

The first phase was expected to be completed by late February 2023, and the second phase by late February 2024. This timetable has been pushed back due to the global COVID-19 pandemic.

The first Jean Monnet building, opened in 1975,

was demolished between 2016 and 2019, after exceeding its lifespan, and following the discovery of airborne traces of asbestos.

The construction site combines some of the plot of the previous building with an adjacent former open air car park.

Upon completion, the Jean Monnet 2 building will enable the European Commission to consolidate the majority of its Luxembourgbased staff on one site.

Like its predecessor, the building’s namesake is European Union (EU) founding father Jean Monnet.

The building has been designed to meet class “A” energy performance requirements and BREEAM’s “excellent” level certification.

The design includes, amongst other energy efficiency features, triple-glazed windows, radiant ceiling panels, offices designed to optimise the use of natural light, an all LED artificial lighting installation, and roof-mounted photovoltaic panels.

The building will be connected to Kirchberg’s existing district heating system via two heat exchanges.

The site will occupy the Kirchberg’s European district. To the building’s southwest, along Boulevard Konrad Adenauer is the seat of the Court of Justice of the European Union, and to its south, across rue Antoine de Saint-Exupéry is the IAK building, currently occupied by the European Investment Bank. Further to the south are located the seat of the European Court of

“ As well as having two mtu 20V 4000 DS2750 generator sets providing backup power, the Jean Monnet 2 building has been designed to meet class “A” energy performance requirements and BREEAM’s “excellent” level certification. Its design other energy efficiency features including heat exchangers.”

Auditors, and the Konrad Adenauer building, housing the European Parliament’s secretariat.

Diesel generator sets

The mtu 20V4000 DS2750 diesel generator sets are said to offer benefits such as low fuel consumption, optimised system integration, high reliability, high availability of power and long maintenance intervals.

The gensets are designed and manufactured in facilitiers certified to standards ISO 2008:9001 and ISO 2004:14001

Each generator set complies with ISO 8528 and meets NEMA MG1, BS5000, ISO, DIN EN and IEC standards as well as NFPA 110.

Power ratings are as follows: System ratings: 2660 kVA - 2910 kVA - accepts rated load in one step per NFPA 110.

Each generator set complies with G3 according to ISO 8528-5. Each genset exceeds load steps according to ISO 8528-5

Performance assurance certification (PAC): each engine-generator set is tested to ISO 8528-5 for transient response and offers 85% load factor. Each genset is fuel consumption optimised and comes with a 4-pole three-phase synchronous generator (brushless,self-excited, self-regulating, self-ventilated and comes with a digital voltage regulator.

There is an anti-condensation heater and one design feature is a stator winding Y-connected, accessible neutral (brought out) IP23 protection, and insulation class H, utilization acc. to H.

Radio suppressionto EN55011, group 1, cl. B, short circuit . capability 3xIn for 10 seconds. Winding and bearing RTDs (without monitoring), Excitation by AREP, Mounting of CT´s: 2core CT´s, Winding pitch: 2/3 winding, Voltage setpoint adjustment ± 10%. Each genset features a cooling system which includes a jacket water pump, Thermostat(s), Water charge air cooling, a mechanical radiator, electricallydriven front-end cooler and a jacket water heater.

www.mtu-solutions.com

www.rolls-royce.com

EURO POWER NEWS APRIL 2024 15

NETWORK CODE FOR GRID CONNECTION

There is an ACER recommendation to amend the network code on requirements for the grid connection of generators (NC RfG) - however a certain number of issues have been highlighted which will hamper the level-playing field between different manufacturers and technologies. These issues are further explained below and relate to definitions, response time and lack of consideration of mCHP issues with FRT requirements.

EUGINE and EUROMOT welcome the ACER Recommendation to review the network code on requirements for grid connection of generators (NC RfG), which carries significant improvements when it comes to harmonising the grid connection requirements at EU level and making them future-proof.

As associations representing engine power plant manufacturers at European level, we would nevertheless like to highlight a certain number of issues that will hamper the level-playing field between different manufacturers and technologies. These issues are further explained below and relate to:

a. An unclear definition of “synchronous power generating module” (SPGM)

b. Lack of consideration of different responsetimes to LFSM-O events

c. Lack of consideration of mCHP issues with FRT requirements.

Our recommendations

1. Further clarifying the definition of “synchronous power-generating module”

2. Considering trade-offs in response-times to LFSM-O events

3. Considering trade-offs between the NC RfG and the Gas Safety Regulation.

Further clarifying the definition of “synchronous power-generating module”

With the existing text proposed by ACER in Article 2(9) and Whereas (11), the definition of a ‘synchronous power generating module’ and its determination of significance in the case of a synchronous machine that can be operated independently from others is left ambiguous.

According to ACER, it is to be left to the relevant system operator to determine how a synchronous machine that can be operated independently from others should be assessed. From experience, this ambiguity leads to different interpretations of the current text in different Member States, which, in turn, results in a market barrier where the same synchronous power generating unit cannot be sold into identical applications in different Member States because of different interpretations of the requirements.

Therefore, manufacturers face a challenging landscape and are required to fulfil different classifications of requirements across Member States for the same power generating unit.

For the sake of clarity, and to avoid different national interpretations and different technical requirements imposed upon a unit of the same size in different Member States, we recommend clarifying the case of a synchronous machine that can be operated independently from others (as suggested below).

Considering trade-offs in responsetimes to LFSM-O events

Article 13(3)(g) sets requirements for Limited Frequency Sensitive Mode –Overfrequency (LFSM-O) response time where a rapid decrease in active power, 45% of maximum power within 8 seconds, is defined for synchronous power generating modules.

The basis for this requirement is an Implementation Guideline Document (IGD) published by ENTSO-E in 2018, which was not approved with the consensus of manufacturers.

Although this requirement may be technically possible, such operation could potentially lead to other technical, safety and emission requirements not being fulfilled. This issue has been recognised byseveral Member States, which have adopted different values and, when not explicitly stated, have permitted units to operate within their capabilities.

If the amendment to Article 13(3)(g) proposed by ACER becomes a legal requirement, it will effectively exclude some products/technologies from the market. In our experience, the exemption clause (“If the response time is greater than stated above, the power-generating facility owner shall justify the delay, providing technical evidence to the relevant TSO”) will result in lengthy and uncertain negotiations around exemptions and will not be sufficient to prevent some technologies being excluded from markets. With this in mind, we recommend stating LFSM-O

16 APRIL 2024 EURO POWER NEWS EUROPGEN

response time “shall be as fast as technically feasible” and removing the stated response times for SPGMs and PPMs.

Considering trade-offs between the NC RfG and the gas safety regulation

Micro-Combined Heat and Power (mCHP) appliances with a capacity of ≤50kW include different technologies such as engines and fuel cells. These technologies need to comply both with the network code on requirements for generators and the Gas Appliance Regulation (EU) 2016/426 (GAR).

The GAR provisions include mandatory safety measures that are incompatible with the request to meet fault-ride-through (FRT) capabilities in the amendments to NC RfG proposed by ACER.

Specifically, in an under-voltage event, the power supply to the gas safety system ceases. In this situation, the gas safety system must shut-down the appliance –which is the opposite of the FRT requirement that requires the gas appliance to ride through that under-voltage fault.

With this in mind, we recommend applying Fault Ride Through (FRT) capabilities to Type A generators only when not in contradiction with other technical and safety requirements.

Three more regulations involving CE markings

The UK Department for Business and Trade (DBT) have announced a further pragmatic approach to improving product regulation in GB, to reduce barriers to trade and support businesses to invest and grow.

Please note that this does not apply in Northern Ireland.

Last summer (2023), DBT announced the intention to indefinitely recognise current EU requirements, including CE marking, for the 18 product regulations under the UK department’s remit.

Following feedback from industry, the UK government is now expanding the scope of continued CE recognition to include three more regulations.

To provide legal certainty to industry, the UK government intends to legislate for

this indefinite CE recognition this Spring (2024). Later in the year, UK government also intends to introduce greater labelling flexibility, including the voluntary option for manufacturers to use digital labelling.

Along with the 18 DBT regulations, the three further regulations now included are:

· Ecodesign for Energy-Related Products Regulations 2010

· The Explosives Regulations 2014

· The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012 (‘The RoHS Regulations’) – in most circumstance

*New laws to introduce digital labelling for businesses and reduce regulation costs –GOV.UK (www.gov.uk)

New president of CECE

As of January 1st 2024, Jose Antonio Nieto of Putzmeister Iberica and ANMOPYC became the new President of CECE.

After serving as Vice-President for the past two years, he is now taking over this leadership role for 2024 and 2025.

Jose Antonio Nieto is CEO of Putzmeister Iberica, a member company of the Spanish industry association ANMOPYC.

His professional career in construction machinery began in aftersales service, joining Putzmeister as Head of Service in 1999 and progressing to Technical Director and COO.

He has been in his current position as CEO since 2007. In addition to leading the Spanish subsidiary of the Putzmeister Group, he has been responsible for growing the underground business unit for tunnelling and mining within the group.

After the 2008 crisis he had to turnaround the Spanish affiliate business from local construction machinery sales to international own underground product sales.

Nowadays Putzmeister has an underground business unit serving the tunnelling and mining customers all over the world.

CECE is the recognized organization representing and promoting the European construction equipment and related industries, co-ordinating the views of National Associations and their members by influencing European/National Institutions.

Article 13(3)(g) sets requirements for Limited Frequency Sensitive Mode – Overfrequency (LFSM-O) response time where a rapid decrease in active power, 45% of maximum power within 8 seconds, is defined for synchronous power generating modules.

“ Micro-Combined Heat and Power (mCHP) appliances with a capacity of ≤50kW include different technologies such as engines and fuel cells. These technologies need to comply both with the network code on requirements for generators and the Gas Appliance Regulation (EU) 2016/426 (GAR).

The GAR provisions include mandatory safety measures that are incompatible with the request to meet fault-ride-through (FRT) capabilities in the amendments to NC RfG proposed by ACER. Specifically, in an under-voltage event, the power supply to the gas safety system ceases.

EUGINE is the voice of Europe’s engine power plant industry. Our members are the leading European manufacturers of engine power plants and their key components.

Engine power plants are a flexible, efficient, reliable and sustainable technology, helping to ensure security of electricity supply and providing (renewable) electricity and heat.

EUROMOT is the voice of the key manufacturers of internal combustion engines and alternative powertrains installed in industrial non-road mobile machinery, marine and stationary applications that are operating in Europe and worldwide. Our mission is to drive smart regulation and sustainable innovation.

EUROPGEN represents the voice of the power generation industry in Europe (generating sets,BESS, fuel cells) and brings together Europe’s most prominent corporate companies and trade associations in order to form a powerful and unified voice. By bringing together

EUROPGEN members from all parts of the energy market, we strengthen bonds, promote cross-border trade and help deliver a stronger EU industry

EURO POWER NEWS APRIL 2024 17 EUROPGEN

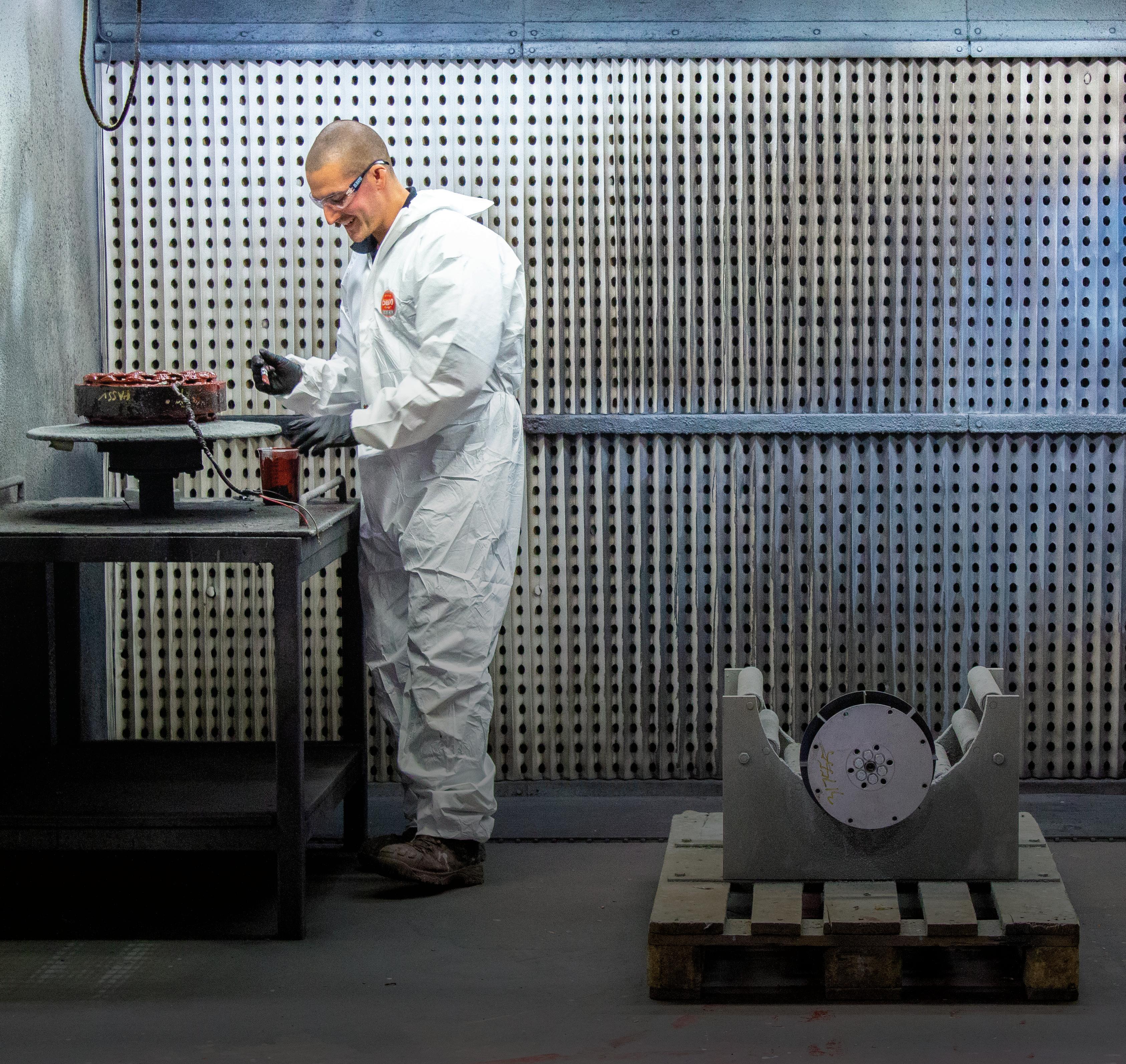

CHP POWERS A SEMICONDUCTOR MANUFACTURING SITE

Dynex, a world-leading designer and manufacturer of high-power semiconductors and assemblies, is now benefitting from an Edina-installed and maintained Combined Heat and Power (CHP) solution as part of its sustainability measures.

Edina, a distributed energy solutions provider, was contracted to design, engineer, install, commission, and maintain the 1.56MW electrical output Combined Heat and Power (CHP) plant at Dynex Semiconductors’ Lincoln manufacturing facility.

Key benefits:

-Combined Heat and Power (CHP) plant provides electricity on-site thus reducing grid imports

-CHP plant protects Dynex Semiconductor from volatile energy market

-CHP generates 75% of the sites hot water demand for heating

-Hydrogen-ready asset

Edina, a distributed energy solutions provider, was contracted to design, engineer, install, commission, and maintain the 1.56MW electrical output Combined Heat and Power (CHP) plant at Dynex Semiconductors’ Lincoln manufacturing facility.

The move to accelerate on-site generation CHP was driven by the volatile energy market and the need to manage rising energy costs, reduce carbon emissions, and improve energy-efficiency measures at the site by replacing old inefficient gas boilers.

Dynex is one of the world’s leading manufacturers in the design, development and production of High-Power Semiconductor modules and Power Assemblies used within industrial, traction, renewable and power grid, electric vehicles, fusion energy, and hydrogen electrolysis applications.

The CHP plant, powered by a single MWM TCG 2020 V16 gas genset, produces the site’s electrical requirement, thus offsetting grid imported power.

The heat from the electrical generation process is captured and utilised on-site to provide 75% of the hot water demand for temperature and humidity control within the manufacturing areas. In doing so, CHP provision reduces the boiler house demand for hot water generation and energy costs on-site.

Improving Energy Efficiency

Combined Heat and Power (CHP) is the cogeneration of electricity and heat from a single fuel source.

CHP forms part of Dynex’s sustainability and low-carbon measures to improve energy efficiency and reduce its carbon and water

“ Working with Dynex we were able to deliver a support solution to reduce their dependency on the grid, allowing them to take control of their energy requirements and support their long-term sustainable measures.”

- Adam Bloom, Head of Sales, Edina

footprint. The CHP plant offers highefficiency energy utilisation of 95%.

Because electricity and heat are produced and used onsite, Dynex will avoid transmission and distribution losses – typically around 7.5% that occur in transporting electricity from the grid.

Further sustainability measures include 200kW roof-mounted solar PV, which generates an average of 42,952kWh/ year, site-wide LED lighting rollout, and improvements in waste recycling.

These are just some of the measures enacted as part of Dynex’s commitment to the UK Government’s Climate Change Agreement (CCA) which sets energy reduction targets for the semiconductor industry.

As principal contractor, Edina designed and engineered the CHP engine within an acoustically treated weatherproof enclosure for ease of installation and ongoing asset-care access.

Edina delivered, installed, and commissioned the Dynex CHP plant on time and within budget and is maintaining the plant over a 15-year life cycle.

According to the latest 2022 plant availability performance data, the Dynex CHP is averaging a strong hourly availability at over 98% set against a 92.5% industry standard benchmark.

As the authorised official distributor for MWM gas gensets, Dynex are benefitting from Edina’s in-market support leveraging its local field services engineers, 24/7 remote plant monitoring and conditioning, and access to genuine MWM parts to ensure the CHP plant remains operational and downtimes are at a minimum.

Working with Dynex and their incumbent mechanical team, Edina were challenged with dovetailing the programme for civil works, CHP installation and commissioning, with Dynex’s own extensive programme to overhaul the full heating and power networks within the site.

From civil works design and installation to lifting operations and final operational testing, both Dynex and Edina worked in synergy to ensure minimum impact to ongoing operations.

A further testament to both teams that the project delivery took place during the COVID Pandemic and the unique challenges this posed.

www.mwm.net

18 APRIL 2024 EURO POWER NEWS

GAS GENSETS

Start today at power.fgwilson.com

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

focus on connecting companies and people www.ukgsa.uk Find out why we will be Your No.1 Association: