Saipem and Siemens Energy have co-signed a Memorandum of Understanding for the joint development of a cuttingedge technology solution in the offshore energy sector.

At the heart of the deal lies a radical new concept - a 500 MW high-voltage alternating current (HVAC) floating electrical substation designed for use primarily in offshore wind farm applications.

A spokesman for the company commented: “This kind of substation is intended for potential installation in deep water areas.

“It offers severaladvantages, such as a lightersubstructure, plus an easier and asset-light installation in challenging conditions, and lower decommissioning costs.”

The new design has been based on a proven semisubmersible substructure, which has been developed to operate in the most extreme environments with enhanced stability, and can be scaled up as required.

Essentially modular, it can be adapted to fabrication and assembly infrastructures worldwide. The floating substation could also represent a tangible solution for reducing the levelised cost of energy of floating wind

BLOOM ENERGY MEETS FERRARI

A 1MW solid oxide fuel cell (SOFC) power system has just been supplied to one of Italy’s most prestigious vehicle manufacturers.

MAJORCA‘S WASTE TREATMENT

An MWM TCG 2020 V12 gas genset is now producing energy from the island’s 730,000 tonnes of waste.

ISTANBUL HOTEL CHAIN INVESTS IN GENSETS

AKSA supplied two 1400 kVA sets for a large hotel chain which is located in Zeytinburnu.

farms in European waters. Saipem’s expertise in the engineering of complex and sustainable offshore infrastructures, including floating solutions, will be combined with Siemens Energy’s broad transmission portfolio to develop a cutting-edge, standardised and scalable technology, reports the company.

Fabrizio Botta, CCO of Saipem, explains: “The new concept will be an enabler to enhance offshore

wind developments in deeper waters by lowering the overall infrastructure investment. This agreement further confirms Saipem’s ambition to strengthen its leadership role in the offshore wind market.”

State-of-the-art components and the TPEM (Total Plant & Energy Management) control ensure maximum reliability and availability. A secure IT infrastructure and smart data analysis enable ongoing plant optimization and cost savings.

Welcome to the future – with MWM Digital Power.

www.mwm.net/en-3016

TCG 3016 Robust. Efficient. Digital. CES20001_Anzeigen_MWM_TCG3016_95x145mm_EN_RZ_1_0_mg.indd 1 09.09.22 11:24

Page 15 Page 21 Page 23 The all-round talent. www.mwm.net/gas-engine-TCG-3020 CES20001_Anzeigen_MWM_TCG3020_235x55mm_EN__RZ1_0_mg.indd 1 09.09.22 11:44

New: 500 MW high-voltage alternating current (HVAC) floating substation concept AUTUMN 2022 1EURO POWER NEWS AUTUMN 2022

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale

richard@wipmagazines.com

Managing Editor: Aidan Turnbull

aidan@wipmagazines.com

Accounts Manager: Alison Williams

accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu

Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko

power@wipmagazines.com

Contributors

Bloom Energy, MARGEN, Kohler, Boudouin, MWM, RollsRoyce SMR, AKSA, Bergen Engines, Libeherr, Thomassen, Atlas Copco, EUROPGEN, Loop Energy, BASF, ENLIT, IBT Europe GmbH, Capstone, Hitachi Energy, Shell, RWE, Air Liquide, Siemens, Deutz AG, Black & Veatch, ENERGEN, BlackRock, KARPOWERSHIP, Fluence, ANDRITZ|, Mercury Renewables, Urban Electric Power, Eirgrid, ENI, Ansaldo Energia, Doosan Skoda, Energy Dome, ABB

BASF LUDWIGSHAFEN, GERMANY, WILL BE THE SITE OF GIANT HEAT PUMP PROJECT

An industrial-scale heat pump is being built at the BASF site in Ludwigshafen, Germany by BASF and MAN Energy Solutions.

Both companies are now conducting a feasibility study for the planned heat pump in an effort to reduce emissions and natural gas consumption.

The planned large-scale heat pump will enable production of steam using electricity from renewable energy, tapping waste heat from the cooling water system at BASF as a source of thermal energy.

The residual heat in the water will be processed using compression to produce steam that will be fed into the site’s steam network.

By integrating the planned heat pump into the site’s production infrastructure, up to 150 metric tons of steam can be produced per hour, equivalent to a thermal output of 120MW.

The project could reduce CO2 emissions at the site by up to 390,000 metric tons per year. At the same time, it would make the cooling water system more efficient and less dependent on climate and weather conditions.

Fuel cells for Netherlands Innovahub

DIARY

NEWS

Media International

Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

1468-7100).

Dr. Martin Brudermüller, chairman of the board of executive directors of BASF SE said in a statement: “In the medium term, we want to reduce our CO2 emissions by 25% by 2030. The use of technologies such as large heat pumps, which already exist and can be scaled up to industrial size, brings us a lot closer to this goal.”

Loop Energy has sold a 30kW proton exchange membrane (PEM) fuel cell system to Hylife Innovations, a Netherland-based developer of sustainable power solutions. Loop’s S300 fuel cell system will be integrated into Hylife’s Innovahub, which powers residential districts by using green hydrogen to power residential buildings in the Netherlands.

The sale was facilitated by Loop Energy channel partner Aliant Battery, an Italian developer of lithium batteries.

Hylife’s solution aims to combine battery technology and a hydrogen fuel cell system to generate electricity for “Green Residential Hub” applications within neighborhoods.

Aliant Battery and Loop Energy will lead the engineering of the two technologies to provide a high-efficiency hydrogen electric generator. Aliant Battery was added as a qualified ecosystem partner in Loop Energy’s Total Customer Care program in May 2021.

Loop Energy’s partnership with Aliant Battery previously resulted in the sale of an S300 fuel cell system to emfeld Gmbh to develop generators for film sets in December 2021.

Loop Energy President & CEO, Ben Nyland said: “We were excited to open a new facility in the UK recently, where both the private and public sector is quickly growing around decarbonizing commercial vehicles. We were also pleased to see the UK government’s recent commitment to the hydrogen sector, with the Business Secretary’s pledge to unlock £9bn investment needed to make hydrogen a cornerstone of the UK’s greener future,”

“Our investment commitment for the UK market is strategic to serve both UK and the rest of Europe. We expect to service a truck and bus market size upwards of US $15 billion over the next 2 to 3 years, and our UK facility is established as the localised support centre for these vehicles.

“Our investments to the UK will grow in lock-step with the growth of our local OEM customers, and our investment strategy will align with the timing and volume of our ecosystem partners as the industry ramps up supply to this market. We also believe that the UK’s strong pool of manufacturing and design talent will help take Loop to the next level in its growth story.”

ENLIT 2022 EUROPE 29TH NOVEMBER - 1ST DECEMBER, 2022

Frankfurt. Germany: Enlit Europe Conference & Exhibition brings together OEMs, third-party service providers with plant owners and operators in a forum where knowledge and operating experiences can be shared and best practices showcased, alongside exhibits of relevant hardware and digital technologies for operation, overhaul and servicing.

ENLIT 2022 looks at Power generation maintenance

• Modernisation • Plant Operations • Process Control • Purchasing & Procurement

• Upgrades • Conventional Generation - coal, natural gas, fuel oil • Thermal & Cogeneration - solar thermal, waste to energy, combined cycle • Renewable Generation - hydrogen, wind, solar, geothermal, biomass.

“Enlit Europe is an opportunity to come back to do networking, new business and meeting in person with customers and providers,” reports the company.

Worthing Road, Horsham, West Sussex RH12 1SL,

Heat pumps like the one proposed by BASF will play a major role in industrial processes and district heating in Europe’s largest economy in the future.

Amidst continuing uncertainty surrounding fossil fuel energy supplies and the growing need to decarbonize industry, largescale heat pumps, powered by renewable electricity, will increasingly be employed to deliver ecological and efficient solutions to many of the nations of western Europe.

Loop Energy has said that its latest cell system can deliver better fuel economy than a diesel engine at current price levels. Daimler and and Volvo are two companies which are investing heavily in hydrogen fuel cells as they weigh much less than batteries. Hydrogen fuel cells run hydrogen through a catalyst which produces energy and heat and the only emission from these cells is water.

Until recently, hydrogen fuel cells have faced two challenges for broad adoption: they have so far been less efficient than diesel and fuelling infrastructure in Europe is virtually non-existent.

The new cell system essentially addresses the first of those challenges, says Hylife.

Enlit is a constantly growing, inclusive and end-to-end forum which addresses every aspect of the energy agenda. A community that for 365days a year collaborates and innovates to solve the most pressing issues in energy.

www.enlit-europe.com/ exhibit/power-generation

2 AUTUMN 2022 EURO POWER NEWS NEWS NEWS www.powermediagroup.co.uk

EPN

**************** EURO POWER

Published by: Power

Group Ltd, The

© Worldwide Independent Power (ISSN

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to Euro Power News, Power Media International Group Ltd 30

UK.

Don’t miss PowerEx Live

8th December, 2022, London

C1000S microturbine for the Breuil-Cervinia ski resort, Italy

The municipality of Cervinia – the location of Italy’s most renowned Breuil-Cervinia ski resort –required a reliable electrical supply.

Following consultations, Europe GmbH. Energetica S.p.A. commissioned a Capstone microturbine to provide a reliable solution for generating electricity and steam for the Breuil-Cervinia district heating plant.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run parallel with prime exhibitor space available in adjoining rooms. Take your products to your customers with the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

GREAT SPEAKERS LINED UP SO FAR:

-Ian Bitterlin - DATA CENTRES – Emergency standby generators for applications

-Ian Bitterlin - ENERGY STORAGE – Tech for large scale applications ie. Batteries

-Dr Michaela Kendall - UK Fuel Cells & Hydrogen Technology Supply Chains

-Romain Mocaer - 2023-2024 Diesel & Gas Generator market Outlook

-John D. Kerr - NOISE – Reciprocating Engines Noise

-Keith Maclean - Sustainable Critical Power systems

-Bernard Gospel - Red Diesel – Changes to rebated fuels

-Dave Andrews - CHP and Cogeneration markets

-Ian Wassman/Hassaan Minhas - G99 Protection and G99 Generator compliance

-Richard Payne - EMISSIONS – The Application of Emissions Legislation

-Dave Philips - STAGE V Compliance & Considerations

-Mike Benzies/Nathaniel Fuller - The challenges relating to stored fuels in critical standby applications. Are existing OFTEC regulations really suitable for our industry?

-Professor Mark Barrett - Role of engines and turbines in wind and solar droughts - 100% zero carbon energy for the UK - Cost and feasibility?

-Professor Mark Barrett - Energy modeling of UKs optimum energy supply system under various scenarios

-Richard Lowes/David Cebon - Wake up to the hype around green hydrogen for heating – where might it realistically have an application – engine power generation in wind and solar droughts?

-Dave McGrath - On-demand low-pressure hydrogen gas perfect feed gas for engines and Fuel Cells.

-Andy Erlam - Direct air capture of CO2 for methanol engine and turbine fuel – the way forward?

-Richard Hanson-Graville - HP with DH, CHP and heat pumps, running the BEIS SRBI project to deliver open control systems for renewables including a number of field trials from domestic installs through to heat networks.

-Colin Mallett - Renewables and flexibility markets

-Gordon Taylor - District Heating for Most of the UK; Far Better than Hydrogen

-Brendon Uys - How to install heat pumps correctly, so they work properly and have a good winter and seasonal COP

-Dr Andrew Cripps - Heat Networks: recent progress and their future potential as part of decarbonising heat and the role of engines chp in the transition

-Dr. Bill Bordass - Beyond space heating and cooling PowerEx Live 2022 is organised by the Power Media International Group Ltd. This event continues to attract leading companies and key power speakers, along with exhibitors from the Critical Power sector. These include: Generator Power, Bergen Engines UK, Wernick Power, Cummins Generator Technologies, Clarke Energy, Aksa, Crestchic, Durr Universal, HMS Industrial Networks, Industrial Power Systems, IPU Group, Leroy Somer|NIDEC, Mecc Alte, BGG UK, Scania, MHM Group, Volvo, YorPower, Edina, Eminox and many more. Companies who have recently reserved exhibition slots include: AKSA, Scania, Lister Petter Engine Co., MEMS, Edina and Teksan, reports the organiser.

Register for free: attendees have the chance to learn from energy experts within several key fields: Gen-Sets, CHP, District Energy, Engines, Emissions, Rental, Hydrogen, Distributed Energy, Fuels, Grid Codes, Data Centres, Batteries, Energy Storage, Fuels, Noise Reduction, Genset Statistics and Industry Consultants.

The AMPS Awards for Excellence’ (black tie) event is being held in the evening at the same location.

PowerEx Live has won a solid reputation at a quality networking and industry event held at a Covid-secure venue in the heart of London, with excellent rail, tube and road links. The choice of exhibitor stands is allocated on a ‘first-come-first-serve’ basis, so please contact us ASAP and prepare for the highlight of the UK’s Power & Energy calendar for 2022.

EVENT SPONSORED BY: AMPS, Institution of Power Engineers, Baudouin, Crestchic, Greenox and Reich.

More information: www.powerexlive.co.uk

The IBT and Energetica project partnership developed because of IBT’s ability to provide a unique solution which utilised a Capstone microturbine instead of a classic piston engine, says Dario Alberto Babuin, Supply Chain Manager for IBT Europe GmbH. “Mountain communities unfortunately cannot yet rely on a stable electricity supply from the grid. For this reason, a dual mode C1000S standalone system was selected,” says Babuin.

The C1000S dual mode high pressure natural gas microturbine now enables a continuity of electrical energy and heat service for the area’s population in the event of a temporary malfunction of the national grid.

IBT was able to install the solution at 2,000 meters above sea level.

“Having very few scheduled maintenances visits is important during winter time because the site is difficult to access because of snow,” explains Babuin. Very low atmospheric emissions are another benefit.

The onsite thermal demand for

superheated water at 105°C (221°F) can be produced with speciallydesigned heat recovery modules, says the installer.

At the boiler output, the fumes are subsequently introduced into the atmosphere while the hot water is fed into the distribution network to the connected users.

“The C1000S is part of the Capstone range of clean and green turbines, which are scalable from 30kW to 30MW and can operate on a variety of gaseous or liquid fuels. Capstone turbines are the ideal solution for today’s distributed generation needs,” says a spokesman for the manufacturer.

Today Capstone is one of the world’s leading developer and manufacturer of clean and green microturbine power generation systems, with over 9,000 installations globally, including many within the Fortune 500 top global companies.

Its portfolio features the world’s only microturbine-powered Uninterruptible Power Source (UPS) solution which delivers reliability and performance critical facilities require.

Major order from TenneT and TransnetBW to supply a new power transmission solution

Hitachi Energy has won a major order from TenneT and TransnetBW, two of Germany’s four transmission system operators. This will involve supplying a transmission solution for the SuedLink DC4 high-voltage direct current (HVDC) interconnection between the north and south of the country. Using Hitachi Energy’s HVDC Light® technology, SuedLink DC4 will transfer up to 2,000 megawatts of emission-free electricity, enough to power 5 million

German households. Hitachi Energy will supply an HVDC Light converter station at each end of SuedLink DC4 to convert AC power from the transmitting grid to DC for delivery through the link, and back to AC for transfer to the receiving grid.

The contract includes three cable section stations to speed up fault detection in the link. Hitachi Energy has recently won or completed orders for solutions which integrate large-scale renewables like the converter stations for NordLink.

Held at the prestigious Park Plaza, Westminster Bridge, London, UK, on Thursday, December 8th 2022, PowerEx Live 2022 aims to offer the perfect networking opportunities for professionals across the Genset, CHP, Data Centre and Consultancy industry sectors. With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this One-Day event becomes a priority for all those in the power and energy markets.

Held at the prestigious Park Plaza, Westminster Bridge, London, UK, on Thursday, December 8th 2022, PowerEx Live 2022 aims to offer the perfect networking opportunities for professionals across the Genset, CHP, Data Centre and Consultancy industry sectors. With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this One-Day event becomes a priority for all those in the power and energy markets.

EURO POWER NEWS AUTUMN 2022 3 NEWS NEWS

-

Shell has committed to building the Holland Hydrogen I, which it said will be Europe’s largest renewable hydrogen once in operation in 2025 in the Netherlands.

The 200MW electrolyser will be constructed on the Tweede Maasvlakte in the port of Rotterdam and will produce up to 60,000 kilograms of renewable hydrogen per day.

The renewable power for the electrolyzer will come from the offshore wind farm Hollandse Kust (noord), which is partly owned by Shell. The renewable hydrogen produced will supply the Shell Energy and Chemicals Park Rotterdam, by way of the HyTransPort pipeline, where it will replace some of the grey hydrogen usage in the refinery, Shell has announced.

Hydrogen has a diverse range of applications and can be deployed in a wide range of industries. It can be produced in a number of ways. One method includes using electrolysis, with an electric current splitting water into oxygen and hydrogen.

If the electricity used in this process comes from a renewable source such as wind or solar then some call it “green” or “renewable” hydrogen.

Shell confirms that the electrolyzer in the Netherlands would use renewable power from the Hollandse Kust (noord) offshore wind farm, a 759 MW project set to be operational in 2023. Shell is a part-owner of the wind farm.

The idea is that this renewable hydrogen “will replace some of the grey hydrogen” — which is produced using fossil fuels — used at the site. “This will partially decarbonise the facility’s production of energy products like petrol and diesel and jet fuel,” Shell said.

In a statement, Anna Mascolo, Executive Vice President for emerging energy solutions at Shell, said renewable hydrogen would “play a pivotal role in the energy system of the future and this project is an important step in helping hydrogen fulfil that potential.”

Shell says it remains a major producer of oil and gas and has faced legal action related to its net-zero plans. Shell’s ambitions to build a renewable hydrogen plant in the Netherlands represent the latest attempt by multinational firms to lay down a marker in the sector.

In June 2022 another oil and gas supermajor, BP, said it had agreed to take a 40.5% equity stake in the Asian Renewable Energy Hub, a vast project planned for Australia.

At the time, BP said it would become the operator of the development, adding that it had “the potential to be one of the largest renewables and green hydrogen hubs in the world.”

Similarly, Siemens Energy and Air Liquide have announced plans to set up a joint venture focused on the production of “industrial scale renewable hydrogen electrolyzers in Europe.”

Ground-mounted power plant in Guadalajara under construction

RWE is still expanding its solar business in Spain. Last year it started construction of two solar farms in the province of Guadalajara, and the company is now building a ground-mounted photovoltaic plant with a planned capacity of 10 MW in the south west of Spain.

Early construction works for the solar farm Las Vaguadas in the province of Badajoz have already begun, says RWE.

The installation of around 20, 000 solar panels has already begun in an area of about 21 hectares.

RWE is currently constructing the solar farms Casa Valdes and Puerta del Sol in Guadalajara, each with a capacity of 44 MWac.

For all three solar projects, RWE is using bifacial high-performance modules.

The advantage is that the bifacial cells are embedded in a doublesided glass module so solar radiation can be absorbed from both the front and the back of the module, which helps to increase production.

Once all three solar farms are completed they provide enough green electricity to supply the equivalent of 68,000 Spanish homes.

RWE already operates onshore wind

farms with a total capacity of more than 440 MW in Spain. It is also involved in a floating wind project.

DemoSATH, which is planned to be launched and commissioned in late 2022.

Robert Navarro, President and CEO, RWE Renewables Iberia:“We are happy to contribute to the energy transition in Spain with our three new solar farms under construction.

In total we will install more than 210,000 solar modules. Once completed, these projects will make a substantial contribution to reach the local climate targets and will add around 100-megawatt solar capacity to our already strong renewables footprint in Spain.”

RWE has gained considerable experience in Spain and already operates onshore wind farms with a total capacity of more than 440 MW in the country.

The company is also involved in a PV plant in the Spanish province of Toledo and in the solar thermal power station Andasol

3. Furthermore RWE’s groundmounted solar farm Alarcos went into operation in 2020. This solar farm has a capacity of 45 MWac and is located south of the city of Ciudad Real, in the Autonomous Community of Castilla-La Mancha.

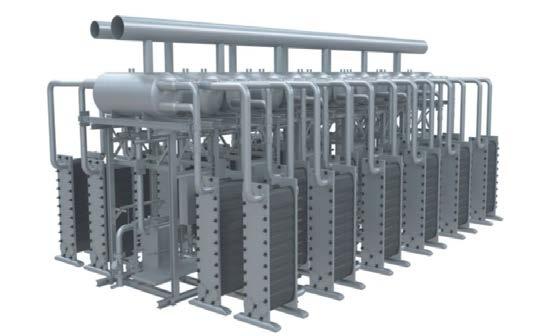

Berlin will be the base for European electrolyser deal

A joint-venture between AIR LIQUIDE and Siemens Energy–and subject to approval by the relevant authorities – marks a major boost in the scale-up of electrolyser production in the region and for its hydrogen economy in general.

The JV will be headquartered in Berlin, where also a multigigawatt facility for the production of electrolysis modules is being established.

This facility, in which production is expected to begin in the second half of 2023 with a ramp-up to an annual capacity of 3GW by 2025, will supply stacks to both groups for their respective customers and to serve what is anticipated as a

rapidly growing market. Siemens Energy and other companies have committed to a ten-fold scale-up in electrolyser production in Europe –from approximately 1.75GW/year currently to 17.5GW/year – by 2025. The companies utilise proton exchange membrane (PEM) electrolysis technology, which they say features a high degree of efficiency and is ideally suited to harvest volatile renewable energy.

Europe’s ‘largest’ renewable hydrogen plant - Hydrogen 1 - will be key to powering an existing Dutch refinery reports Shell

4 AUTUMN 2022 EURO POWER NEWS NEWS NEWS

GAS

Since 2012, PowerLink group has launched GXE, GRS series PowerLink gas gensets, powered by PowerLink, are equipped with cost-effective engine and high-quality spare parts, covering power range from 10kw to 350kw with open type, soundproof type, mini container type and container type for your selection. Our units are distributed in Europe, South America, Russia, Southeast Asia, the Middle East and other countries. They are providing continuous and stable power on the project sites, bringing excellent benefits to owners and investors.

GENERATOR SET GXE, GRS Series PowerLink Engine 10KW-350KW

www.powerlinkenergy.com | Tel: +44(0)1977 689100

TOTAL CONTROL FROM EVERY PERSPECTIVE

Anyone who knows gensets, knows that Mecc Alte is unrivalled for our knowledge and expertise worldwide. From alternators and controllers to an integrated generator system, we are the Power from Within. From prime power to standby power, data centre, renewables, telecoms and more, Mecc Alte delivers complete intelligent systems with digital AVR to identify fuel efficiencies and every component working perfectly together. All backed up by the support and unbiased advice you only get from the world’s leading independent alternator specialists. Take 360° control. Talk to Mecc Alte.

The world’s largest independent producer of alternators 1 – 5,000kVA

FOR FURTHER INFORMATION VISIT WWW.MECCALTE.COM

Engine manufacturer Deutz AG and RheinEnergie AG, a Cologne, Germany-based regional energy supplier, are trialling a power generation system incorporating a Deutz hydrogen engine. The flagship project, which teams two Cologne-based companies whose heritage goes back to the 19th century, got under way on June 20 when the first H2 gen-set went into operation at RheinEnergie’s cogeneration plant in the Niehl district of Cologne.

The combination of a Deutz TCG 7.8 H2 hydrogen engine and a generator will deliver electric power of up to 170 kVA during the initial six-month test phase. The electricity will be fed directly into Cologne’s power grid. In a second step, the genset’s waste heat is to be utilized. The solution being piloted by Deutz and RheinEnergie has huge potential for the local, carbon-neutral supply of energy in urban centres, Deutz said.

“We are a utility company for a major city and specialize in concepts for neighborhoods and districts,” said Dr. Dieter Steinkamp, CEO of RheinEnergie. “An engine like this can help to provide electricity and heating locally. When combined with heat accumulators, heat pumps, solar installations, and electricity storage, this technology makes it possible to supply entire neighborhoods on a climate-neutral basis.” Deutz said the joint pilot project marks an important step on its journey to volume production of the TCG 7.8 H2, which is scheduled to start in 2024. With an output of around 200 kW, the hydrogen engine is suitable for all off-highway applications, the company said.

“The pilot project to generate carbon-neutral energy shows that high tech and the city of Cologne are a great match,” says Michael Wellenzohn, member of the Deutz board of management responsible for sales, marketing, and service. “We have found a strong partner in RheinEnergie and are very excited to put the TCG 7.8 H2 through its paces in the real world in our pioneering project.”

Dr. Markus Müller, member of the Deutz board of management with responsibility for research & development, said, “We are already seeing a lot of interest in our H2 engines from customers across all application areas and we are already planning further pilot applications.”

Together, Deutz and RheinEnergie invested €1.3 million in the pilot project to supply electricity on a climate-neutral basis. A reliable and local energy supply without greenhouse gas emissions necessitates expansion of the H2 infrastructure and requires sufficient green hydrogen to be made available at affordable market prices. The partners said they believe that the onus is now on politicians, as the European Green Deal will not succeed without regulatory support.

Ireland to build first hydrogen generator

830kVA diesel genset with Doosan engine for Romania

ENERGEN has supplied and commissioned an 830 kVA diesel generator with Doosan engine for a client in Romania.

A spokesman comments: “As the first step of our production, another Doosan engine is now on the stage with a Crompton alternator. This is also destined for residential project in Bucharest. When finished this will provide 830 kVA in power.”

Backup generators are an important resource for any residential zone where power could be lost to power elevators, heating, lighting or cooling systems. The growth in charging points for Electric Vehicles has also underlined the issue of being grid-dependent, especially in Romania.

ENERGEN describes itself as ‘a reliable partner which provides people with uninterrupted power solutions by improving energy

services, designing and installing high quality generators designed to exceed customer expectations.”

ENERGEN specialises in the design, manufacture and selling of power generators, offering clients technical consulting, training, installation and maintenance services.

A company spokesman comments: “Thanks to our vast genset experience, we can offer efficient solutions even in the most difficult conditions for large projects such as construction, telecommunications, data centres, hotels, residential buildings and supermarkets.”

ENERGEN says it can offer high quality power generators, approved with international quality certifications and equipped with the best engines in the world and with reliable, quality alternators providing high performance.

Zaporizhzhia Power Plant has gensets with diesel for 10 days

A back-up power line to Ukraine’s Zaporizhzhya Nuclear Power Plant (ZNPP) was restored this month, providing the plant with the external electricity it needs for reactor cooling and other essential safety functions, the International Atomic Energy Agency (IAEA) has confirmed.

The Zaporizhzhia Power Station in southeastern Ukraine is the largest nuclear power plant in Europe and among the 10 largest facilities in the world.

Even with all the reactors in shutdown, power is still required for reactor cooling and other systems needed to maintain safety.

“Despite this damage, plant operators and engineers have been able to restore one of the reserve power lines, in very challenging circumstances, to provide the ZNPP with badly-needed external electricity,” Director General Grossi said.

Afirst-of-a-kind

green hydrogen generation project located on the border of Counties Mayo and Sligo, in Ireland has been announced. To provide consultancy and development expertise for project Firlough, Mercury has contracted Black & Veatch.

The development will be among Ireland’s earliest co-located onshore wind farm and hydrogen electrolysis plants. A 75 MW wind farm will power an electrolyser plant generating green hydrogen. Black & Veatch’s initial role in the project has been the feasibility studies needed to cover all aspects of the hydrogen development.

“The abundance of renewable energy potential in Ireland means green hydrogen should play a significant role in regional and national cross-sector decarbonisation. Projects like Firlough put Mercury at the vanguard of delivering Ireland’s hydrogen economy,” commented Tim Bills-Everett of Mercury. “Our business model is to combine local knowledge with international best practice in renewable energy development. For Firlough we also need proven hydrogen expertise.”

Black & Veatch’s involvement will cover decisions concerning which combination of electrolyser technology, and its size, as well as hydrogen storage and transport options best meets Mercury’s business goals for the project.

Once the optimal configuration is identified, Black & Veatch will develop an outline design for the facility that is sympathetic to the local surroundings; and support engagement with the local community, as well as work to ensure the plant’s safe operation.

The ZNPP also has 20 emergency diesel generators available with supplies for at least 10 days of operation.

Although the Enerhodar thermal power station remains down, the now restored power line provides the ZNPP with power from the Ukrainian grid transported through the station’s switchyard.

Director General Rafael Mariano Grossi welcomed the latest developments regarding the ZNPP’s power status – which were also confirmed by Ukraine – but he stressed that the situation at the plant remained precarious after weeks of shelling in the area which damaged vital power infrastructure.

“However, I remain gravely concerned about the situation at the plant, which remains in danger as long as any shelling continues. To address this serious situation, consultations have begun on the urgent need to establish a nuclear safety and security protection zone at the Zaporizhzhya plant.”

All-German power generation system incorporating a Deutz hydrogen engine is being trialled at a cogeneration plant in Cologne

EURO POWER NEWS AUTUMN 2022 7 NEWS NEWS

Floating powerplants could be the answer to energy shortfall

Greece is in embarking on one of Europe’s most ambitious energy projects by linking up its electricity grid with Egypt’s. An underwater cable will carry 3,000 MW of electricity - enough to power up to 450,000 households - and will run from northern Egypt directly to Attica in Greece.

The project is being undertaken by the Copelouzos Group, whose management met this month with the Egyptian leaders to speed up the process.

As oil and gas prices surge, Europe is facing a looming energy crisis. Russia was the largest supplier of oil and gas to the bloc in 2021 providing around 40 per cent of its total energy needs. But, after the invasion of Ukraine and the imposition of sanctions, energy prices have surged leaving some nations unsure of their supplies this winter. “By bringing 3,000 MW of clean energy to Europe via Greece, we are helping Europe wean itself off Russia’s fossil fuels and natural gas,” says Ioannis Karydas, the CEO of Copelouzos Group.

He reports: “The green energy we will transport will be much cheaper than today’s energy prices. You understand that this will help both Greek and European consumers.”

The ‘GREGY interconnection’ is set to cost €3.5 billion – it has been deemed a Project of Common Interest (PCI) by the European Union. This means it is identified as a key priority for interconnecting the European Union’s energy system infrastructure.

It will carry clean electricity produced in Egypt and other African countries through underwater cables via wind and solar parks. The total length of the project is an incredible 1373km and it will transfer electricity produced in Egypt and other African countries via solar or wind parks.

“Approximately one third of the electricity that will come from Egypt will be consumed in Greece, and mainly in Greek industries, another third will be exported to neighboring European countries and one third will be used in Greece, for the production of green hydrogen. The majority of this hydrogen will also be exported to neighboring European countries”, added Ioannis Karydas.

Egypt has completed interconnections with Libya, Sudan and Saudi Arabia and aspires to become a major energy hub for SE Europe too. The “GREGY interconnection” is expected to be fully operational by 2029. Russia is likely to lose billions of dollars in business as result of the ‘proposed energy switch’.

Energy woes could mean less beer about

The Belgian brewer of Delirium Tremens beer is facing a real risk of halting production for the first time in more than a century as Europe’s energy crisis creates unexpected ripple effects in energy supplies across the region.

From German tomatoes to Swedish bread, Russia’s squeeze on gas supplies is starting to hit sectors well beyond power stations and energy-intensive industries. The spillover on food and drink supplies will likely intensify as temperatures drop and households require additional electricity supplies and heating, forcing businesses and consumers into tough decisions. The price of diesel fuel for generator sets is predicted to rise as well.

Brewery Huyghe, located in the Belgian village of Melle, has considered shutting production because of a 13-fold surge in the price of liquid carbon-dioxide, which it uses to make beers bubbly. Higher energy bills are also putting pressure on its finances.

Alain De Laet, owner of the family-run company, said his CO2 inventories could run out this week and force a stoppage for the first time since 1906, unless deliveries from a temporary supplier come through. “I will believe it when I get it in the brewery,” he said.

The European Union is trying to stem the crisis caused by Russia’s gas cuts, which last year supplied about 40% of the bloc’s demand for the fuel. Commission President Ursula von der Leyen will propose a mandatory target to cut power use - a step toward rationing - along with measures to funnel energycompany profits back to the pockets of struggling consumers. For the past two decades gas has been the fuel which has driven much of Europe’s industry and provided the bulk of its power station fuels as the use of coal and oil has been phased out.

Germany is at risk of ‘catastrophic’ power shortages as result of the Russia’s embargo on gas and oil supplies.

According to an internal report by Germany’s civil protection agency, prolonged power shortages would disrupt the supply of vital goods in the country.

Accordingly, the government has taken steps to lease floating power plants from KARPOWERSHIP, a company based in Turkey.

As the owner, operator and builder of the world’s only Powership fleet, Karpowership uses these floating power plants to generate electricity and supply countries around the world. The company has 5,000 MW installed capacity and another 3500 MW is under construction or in the pipeline.

When asked about what the company is doing to advance LNG’s

role in the energy transition, Mehmet Katmer, Business Development Director, Karpowership, commented on his company’s global LNG-topower projects:

“We have spent many years pioneering the combination of robust LNG-power plants with ships capable of deploying anywhere in the world within accelerated timeframes,” explained Katmer.

“More recently, with our joint venture KARMOL, we’ve been building Floating Regasification and Storage Units which are specifically designed to work with our Powerships.”

KARMOL is a partnership with Japanese shipping giant Mitsui OSK Lines. Recent projects undertaken by KARMOL include a series of vessel conversions – turning LNG carriers into FSRUs, reports the company.

Europe could spiral into a severe recession caused by energy crisis inflation

Europe could spiral into a severe recession as the shortage in energy supplies is set to spike inflation even higher and weigh heavily on Europe’s GDP, energy analysts BlackRock have suggested.

“The energy crunch will drive a recession in Europe, as we’ve argued since March. The crisis has worsened since then as Russia has halted gas supplies,” BlackRock analysts warned, pointing to the indefinite cutoff of flows from Russia’s Nord Stream 1 pipeline.

Eurozone inflation reached 9.1% in August 2022, causing the European Central Bank to issue its first-ever 75-point rate hike to control prices. This level of monetary tightening threatens to squash Europe’s economic activity, which is already under pressure from the energy crisis.

Energy spending currently accounts for 11.7% of the EU’s GDP, compared to just 5.3% in the US.

“The European Central Bank isn’t acknowledging how it will crush activity further by trying to fight high

inflation, in our view. We think the ECB will wake up to this sooner than markets expect – but not before it inevitably faces a severe recession,” BlackRock’s tream has commented.

Experts are also expecting the worst of the energy crisis to hit Europe this winter 2022, as heating & power demands will put more pressure on the supply shortage and send prices even higher.

Although the EU has built up gas reserves to more than 80% of capacity, the 27-country bloc is still struggling to ration supplies ahead of winter, and some European nations have never relied on reserves alone. through the winter without additional gas flows.

‘Green energy’ boost to be provided by a cable link between Egypt and Europe’s electricity grid

8 AUTUMN 2022 EURO POWER NEWS NEWS NEWS

Google has chosen to purchase a 2.75MW battery system from Fluence to replace some diesel capacity at its data centre based in St. Ghislain, Belgium . The move will not only reduce emissions but will also support the local electricity grid. The battery will be connected to the grid by Centrica, and will employ Centrica’s FlexPond software to store and discharge energy, so it can support the data centre during potential power cuts and blackouts, and also provide energy to the grid on a short term basis to improve grid stability.

In January 2021 Google first announced its plans to replace some diesel backup capacity at St. Ghislain. The announcement represents a step towards Google’s committment to use entirely carbon-free energy by 2030.

The installation will rely on Fluene’s Gridstack batteries, a system based on modules called Fluence Cubes which use LFP (lithium iron phosphate) batteries made by Contemporary Amperex Technology Co., Limited (CATL). The batteries can store 5.5MWh of energy, up to half of which is available to the grid as needed.

LFP depend on lithium-ion battery chemistry which offers lower power density than Li-ion battery chemistries such as nickel manganese cobalt (NMC) and nickel cobalt aluminum (NCA), but offers a better duty cycle and safety record, while using less toxic raw materials, says the company..

Fluence’s Gridstack energy storage products are already being used with the Killala Community Wind Farm in County Mayo in Ireland.

Once fully operational, the technology will help increase system stability in the Irish electricity grid, as Greencoat Renewables will use the system to participate in energy flexibility markets. The project is the first investment in energy storage technologies by Greencoat Renewables and the first of any company managed by Greencoat Capital. It highlights the fund’s commitment to support the deployment of technologies that accelerate the transition to a low-carbon future. With some of the best wind energy resources in the world, Ireland is said to be perfectly positioned to secure an affordable, reliable, and low-carbon energy supply through increasing renewable generation.

Battery-based energy storage technology is key to enabling the integration of renewables, by offering a cost-effective and fast-todeploy source of flexibility and capacity.

Greencoat Renewables chose Fluence as its partner based on a successful track record in deploying complex batterybased energy storage systems with high configurability, and industry-leading reliability and safety standards. This is Fluence’s third project involving battery-based energy storage co-located with wind farms in Ireland.

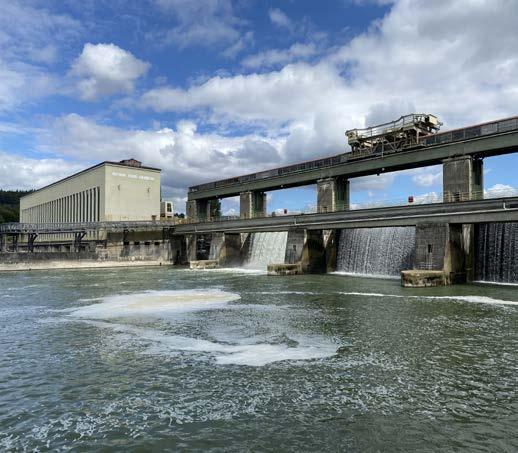

Four Kaplan turbines will be upgraded at Rhine powerplant

Kraftwerk Rburg-Schwörstadt AG has commissioned ANDRITZ to upgrade four Kaplan turbines at the 120MW Ryburg-Schwörstadt hydropower plant on the Rhine River in Switzerland.

The run-of-river plant was commissioned in 1930, and ANDRITZ installed two of those original units.

With annual average energy production of about 760GWh, Ryburg-Schwörstadt contributes toward a sustainable and emissionfree future.

The work will be performed by the ANDRITZ location in Kriens, Switzerland, as the contractor responsible for overall project management, logistics and transport, engineering, erection and commissioning.

Model testing and runner design will be carried out at the ANDRITZ location in Tampere, Finland, and manufacture of the new Kaplan runners and factory overhaul of the large turbine components will be conducted at the ANDRITZ manufacturing facility in Ravensburg, Germany.

ANDRITZ currently offers a broad portfolio of plants, equipment, systems, services and digital solutions for the pulp and paper,

metals, hydro and separation industries. ANDRITZ Hydro supplies electromechanical equipment and services for hydropower plants.

The aim of the upgrade project is to ensure the service life and operating safety until the end of the concession, as well as to make environmental improvements by installing oil-free bearing systems on wicket gates and oil-free hubs for the new runners.

The new license for the project was granted in February 2010. The units will be renovated one after the other between 2023 and 2027.

The ANDRITZ scope of supply and services for the hydro-mechanical overhaul of the four Kaplan turbines, including hydraulic turbine governors, comprises design, engineering, manufacture of new parts, factory overhaul, transport, erection, testing and commissioning.

Hydro Turbine Generator Sets market up by 4.5% by 2028

Following the ongoing effects of the COVID-19 pandemic, the global Hydro Turbine Generator Sets market size is estimated to be worth US$ 3,614 million in 2022.

The market is also predicted to reach a readjusted size of US$ 4,709.1 million by 2028 with a CAGR of 4.5% up to 2028, says a new research report. The study, entitled the ‘Global Hydro Turbine Generator Sets Market (20222028)’ by Stats Market Research , is described as ‘deep analysis of the historical and current status of the market/industries’.

The technical study categorises the global hydro turbine generator set market by Segment, Player, Type,

Application, Marketing Channel, and Region. It also tracks the latest market dynamics, such as driving factors, restraining factors, and industry news like mergers, acquisitions, and investments.

The Hydro Turbine Generator Sets Market Research Report provides market size (value and volume), market share, growth rate by types, applications, and combines both qualitative and quantitative methods.

Fluence Cubes will be used to store 5.5MWh of power at a data centre based at St,Ghislaine in Belgium - a move said to improve grid stability

10 AUTUMN 2022 EURO POWER NEWS NEWS NEWS

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

Companies announce joint plans to develop projects based on innovative technological solutions for electricity storage

Power curbs in Ireland close down data centre projects

The technologies, which are being studied and have already undergone Eni’s technology validation pro-cess, will be implemented at a number of industrial sites of Eni and its subsidiaries in Italy, exploiting the potential of existing power generation and consumption systems.

Electricity storage is essential to over-come the structural limitations of renewables in terms of predictability and intermittency, says the company, and is consequently necessary to promote their development.

“Renewable energy sources, such as wind and photovoltaic, are indispensable solutions for the success of the energy transition and Eni is devoting a great deal of effort and resources to grow rapidly in those areas and help overcome their structural and economic limitations due to their intermittency of production,” said Giuseppe Ricci, Eni’s Energy Evolution chief operating officer.

“This agreement is part of our approach to the transition based on technological leadership, the know-how of our people and the ability to transform and evolve our industrial sites. These are fundamental elements to successfully tackle the significant challenges of decarbonisation.”

Francesco Giunti, CEO and Chairman of Enipower comments: “The initiative with Ansaldo Energia fits perfectly into the growth plans for Enipower as a provider of grid services, which are increasingly necessary - as the growth of renewables and the electrification of end-use consumption continues - to guarantee the stability of the national grid.”

“Being chosen by Eni, a group we have worked with for many years, to cement a concrete commitment to support the energy transition is a great source of pride and satisfaction for us all,” concludes Giuseppe Marino, CEO of Ansaldo Energia.

Daniela Gentile, CEO of Ansaldo Green Tech had the last word: “The technological solution underpinning the agreement - an alternative to lithium-ion batteries - is rooted in a strong European supply chain and guarantees a safe, long-lasting energy storage service, overcoming obstacles related to disposal and avoiding problems related to critical supply issues.”

Green hydrogen plant for Mayo/Sligo

Mercury Renewables has announced a first-of-a-kind green hydrogen generation plant on the border of Counties Mayo and Sligo, Ireland. Here, Mercury is developing one of Ireland’s first co-located onshore wind farms and hydrogen electrolysis plants.

A 75-megawatt wind farm will power an electrolyser plant generating green hydrogen. Black & Veatch’s initial role in the project has been the feasibility studies to provide data on all aspects of the hydrogen development.

Black & Veatch’s early involvement has been to help Mercury understand which combination of electrolyser technology and size, as well as hydrogen storage and transport options – and water supply alternatives – best meets its business goals for the project. This is achieved through developing multiple scenario studies and conceptual site layouts.

Once the optimal configuration is identified, Black & Veatch will develop an outline design for the facility that is sympathetic to the local surroundings; and support engagement with the local community, as well as work to ensure the plant’s safe operation.

Mercury Renewables has been developing renewable energy projects in Ireland since 2009. At Firlough, as with other projects, the company will endeavour to provide localised economic growth; using, where possible, local people, equipment and services.

To support decarbonisation initiatives, and the use of hydrogen as a part of decarbonisation strategies, Black & Veatch in 2021 joined the Hydrogen Council and was appointed advisor to the US Department of Commerce’s Renewable Energy and Energy Efficiency Advisory Committee.

Previously set to be a a major data centre hub, regional planning proposals have been largely cancelled due to electricity curbs in Ireland.

As of last month Ireland’s state electricity grid authority - EirGrid - has cancelled plans for up to 30 potential data centres, to conserve electricity.

In November 2021 Ireland’s Commission for the Regulation of Utilities (CRU) recommended curbs on data centr ebuilding until 2028, as Ireland was unable to build renewable capacity fast enough to meet other needs, including a commitment to decarbonize the grid. Ireland had previously pledged that 80% of the country’s electricity must come from renewable sources by 2030.

The Irish inward investment agency, IDA Ireland CEO Martin

Shanahan has confirmed that new data centres “are unlikely to happen in Dublin and the East Coast, at this point.”

EirGrid has previouslu warned that data centres across the nation already use more than 10% of the country’s electricity supply, and this could grow to 30% by 2030. Not only would this make it impossible to decarbonize the grid, it would cause “rolling blackouts,” said EirGrid.

Eamon Ryan, minister for the environment, climate, and communications told the media that Ireland is currently in a ‘’very tight situation’ regarding the power supply, and Eirgrid is ‘’absolutely right’’ not to take new applications from data centres. ‘

The Minister told the media: ’We haven’t taken a new application for a new data centre going back almost two years to July 2020,’’

Eijsden in The Netherlands invests in BESS systems

Urban Electric Power has made its first delivery of rechargeable alkaline batteries to Europe, and has achieved a place in an Amazon Web Services clean energy startup program.

UEP, whose batteries made their first appearance in data centres at the University of California San Diego’s Supercomputer Center in early 2022, has supplied a 20 kilowatt-hour (kWh) battery energy storage system (BESS) to the zinc oxide factory in Eijsden, Netherlands belonging to its part ner EverZinc.

The batteries have been in stalled by Belgian energy services company Enersol.

“This is our first European installation, and one of several high-profile installations we’ll be announcing in the coming months,” comments Sanjoy Baner jee, who developed the rechargeable alkaline batteries at City College of New York. “Supporting solar pow er is one of many applications for which our products are cleaner, safer, and more affordable than other available

technologies.”

Urban Electric Power offers aa powerful rechargeable alkaline battery which the market needs as ‘incumbent battery solutions are falling short to meet the needs of changing energy infrastructure’.

UEP was created with federal and state research funds from the City University of New York Energy Institute. The Urban Electric Power battery is said to use earth-abundant materials from existing supply chains mined within ally nations, ensuring safe supply. Urban Electric Power says it envisions a future with clean renewable energy and safe battery technology.

Italian energy company Eni and Ansaldo Energia have joint plans to develop projects based on innovative technological solutions for electricity storage as an alternative to electrochemical batteries.

12 AUTUMN 2022 EURO POWER NEWS NEWS NEWS

OEM SUPPLY OF – CANOPIES – BASES – FUEL TANKS – FRAMES – SILENCERS – CROSS MEMBERS FOR GENERATING SETS, PUMP SETS AND POWER PACKS. Sound Proof Systems is specialized in standard Flat-Pack canopies and custom products for OEM’s around the world. THE PLEASURE OF SILENCE www.soundproofsystems.com Sound Proof Systems B.V., Engelenburgstraat 45, 7391 AM TWELLO, The Netherlands T. (+31) 571-27 69 00, F. (+31) 571-27 68 00, info@soundproofsystems.com AVAILABLE FROM STOCK QUALITY FLAT-PACK CUSTOM PRODUCTS Also enclosures and tank frames for telecom applications. Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

Doosan Škoda Power has delivered a 270MW steam turbine for the Metsä Group’s bioproduct mill in Kemi, Finland.

The Kemi bioproduct mill produces 1.5 million tonnes of softwood and hardwood pulp per year, as well as other bioproducts. The new mill will produce 2.0TWh of renewable electricity every year, equivalent to about 2.5% of Finland’s total electricity production.

The mill will have an electricity self-sufficiency rate of 250%, will operate without using any fossil fuels will supply surplus electricity to the national grid. Doosan Škoda Power will also deliver a generator, condenser, and rest of the accessories for the steam turbine as part of the contract, The turbine itself has a tailor-made condensing turbine section solution and is equipped with two steam bleed connections of different pressure levels. The turbine is equipped with two steam bleed connections of different pressure levels and a condensing turbine section. The turbine generator, to be installed in connection with the recovery boiler, is a central part of the high energy efficiency of the new mill. It would generate electricity fully from renewable fuels.

Jindřich Závodný, project manager at Doosan Škoda Power, told Euro Power News: “The engineering, procurement and manufacturing phase of the project has been a challenge due to the previous COVID-19 restrictions, which caused significant delays together with increase in the raw material costs.

“Despite all these challenges and thanks to the extraordinary effort, our team managed to deliver in full as per the client requirements.Heavy lifts have currently been carried out on the construction site, mechanical assembly continues, and commissioning will follow. We are staying focused to keeping up the good work.“

The bioproduct mill would operate without using any fossil fuels. Its self-sufficiency in electrical energy would be 250 percent, and the surplus bioelectricity would be supplied to the national grid. When completed the bioproduct mill is projected to increase the share of renewable energy in Finland by more than two percentage points. This would further strengthen Metsä Group’s position as a major electricity producer relying on renewable Finnish fuels.

The Kemi bioproduct mill will ultimately produce some 1.5 million tonnes of softwood and hardwood pulp per year, as well as many other bioproducts. The investment will secure the existing 250 jobs in the Kemi current mill.

Through its direct value chain, the bioproduct mill would employ a total of around 2,500 people in Finland, which would be 1,500 people more than the current level.

Sardinia, Italy: a new CO2 battery facility launched

Energy Dome, a provider of utility-scale long-duration energy storage, has successfully launched its first CO2 Battery facility in Sardinia, Italy.

The final de-risking of the CO2 Battery technology and entrance into the commercial scaling phase makes it the first commercial longduration energy storage technology on the market, the company states. It is now said to be providing a reliable alternative to fossil fuels for dispatchable baseload power globally.

Energy Dome began its operations in February 2020 and has progressed from a concept to full testing at multi-megawatt scale in just over two years.

This successful launch is in part due to the unique nature of the company’s technology, which integrates known components in a novel industrial process based on a thermodynamic process that efficiently stores energy by manipulating CO2 under different state conditions in a closed thermodynamic transformation.

The initial phase of operations confirmed the performance of the CO2 Battery and its capability of storing energy for a long duration, all while maintaining highly competitive

round-trip efficiency, without degradation or site dependency. The demonstration project also used off-the-shelf equipment available from a globally-established supply chain – meaning the technology can be quickly deployed at rless than half the cost of similar-sized lithium-ion battery storage facilities.

The CO2 Battery is a long duration and large scale energy storage system based on a thermodynamic process that efficiently stores energy by manipulating CO2 under different state conditions in a closed thermodynamic transformation.

The CO2 Battery can operate in charging mode (absorbing power from the grid) and discharging mode (returning power to the grid).

When operating in charging mode the CO2 is withdrawn from an atmospheric gasholder, the Dome, and compressed into an interrefrigerated compressor. The heat generated from the compression is stored into two Thermal Energy Storage Systems (TES).

The CO2 is then condensed and stored under pressure at ambient temperature in the CO2 liquid vessels. When the system is operating in discharging mode, the liquid CO2 is evaporated and heated by recovering heat from the TES.

Switchgear panels to be tested in Brno, Czech Republic

An innovative Climatic Test Chamber in Brno, Czech Republic, will be used to test all ABB energized indoor MV switchgear panels, to ensure they keep the power on 24/7 in the harshest of operating environments.

ABB has invested €700,000 to create the state-of-the-art test facility, which is the first of its type in Europe. The chamber will simulate harsh climatic site conditions, from lows of minus 50 °C to temperature highs of up to 80 °C as well as pollution conditions. It will also test for 0-100% humidity and water condensation, all of which can cause switchgear to age faster.

The enhanced testing, which can take from four to eight weeks to complete for each component, will take ABB’s switchgear beyond current standards, to comply with the new (IEC/TS 62271-304 from Class 1 to Class 4) regulation. It will improve the quality and reliability of ABB’s energised MV indoor switchgear solutions when

Doosan Škoda Power has delivered a 270MW steam turbine to the Metsä Group’s bioproduct mill in Kemi, Finland - installation follows shortly

14 AUTUMN 2022 EURO POWER NEWS NEWS NEWS

Ferrari Italy has been supplied with new fuel cells

A1MW solid oxide fuel cell (SOFC) power system supplied by California’s Bloom Energy is central to a new project with Ferrari.

The deal with Ferrari – a signature brand in the luxury and automotive sectors for 75 years – marks Bloom’s entry into the European Union and Italian markets. It is the first step toward potentially larger projects between the two companies, Bloom Energy has said.

“Ferrari is a legendary trailblazer in the luxury automotive industry, and Bloom Energy commends its commitment to leading in both operational excellence and carbon neutrality across their entire value chain by 2030,” comments KR Sridhar, founder, chairman and CEO, Bloom Energy.

“By collaborating, we’re showcasing how energy-intensive industries such as manufacturing can be decarbonized through clean, reliable energy,” he says.

“Ferrari, like Bloom Energy, has a commitment to uniqueness, innovation, technology leadership and continuous learning that makes them the ideal partner for Bloom’s entry into the European manufacturing landscape, where energy resilience is more crucial than ever. Bloom Energy’s fuel cell platform is a best-in-class solution for a best-in-class luxury automaker.”

Conserving energy

The Bloom Energy servers were installed at Ferrari in May 2022 and are expected to be

commissioned and go fully online shortly. When operating at peak efficiencies, they will initially provide 5% of the energy needed at Ferrari’s Maranello headquarters and manufacturing center.

The Bloom Energy Servers are expected to cut gas requirements by around 20% from the combined heat and power (CHP) system now in use at Ferrari, while also reducing emissions.

This will enable Ferrari to bolster energy conservation amid record-high energy prices, while simultaneously reducing greenhouse gas emissions and improving local air quality, with virtually zero harmful air pollutant emissions, such as sulphur-oxides, nitrogen-oxides and particulate matter.

The new fuel flxible energy platform

Bloom Energy’s fuel-flexible platform also equips Ferrari to lead the race in Italy’s emerging hydrogen economy. According to Italy’s Ministry of Economic Development, the country plans to cover one-fifth of its overall energy demand from hydrogen by 2050.

Along with its fuel cell products, Bloom Energy is also using its solid oxide technology to develop electrolyzers for producing hydrogen from lowand zero-carbon sources.

Earlier in 2022 the company and LSB Industries, a North American producer of industrial and agricultural chemicals, announced a plan to install a 10 MW solid oxide electrolyzer at LSB’s

“ The 10 MW solid oxide electrolyzer installation will contribute to making LSB’s Pryor facility the largest green ammonia production site, Bloom Energy said. ThyssenKrupp will co-develop the multiphase project, developing an initial engineering design to convert a small portion of existing conventional gray ammonia capacity at LSB’s Pryor facility into green ammonia.”

Pryor, Okla., facility.

The project is expected to generate green hydrogen which will contribute to the synthesis of approximately 13,000 metric tons of zero-carbon ammonia per year.

The 10MW solid oxide electrolyzer installation will contribute to making LSB’s Pryor facility the largest green ammonia production site, Bloom Energy said.

ThyssenKrupp will co-develop the multi-phase project, developing an initial engineering design to convert a small portion of existing conventional gray ammonia capacity at LSB’s Pryor facility into green ammonia.

Bloom Energy will then install, operate and maintain the 10 MW electrolyzer, targeting hydrogen production to begin in 2023.

Green ammonia refers to ammonia, which has been produced through a process that is 100% renewable and carbon-free.

One way of making Green Ammonia is by using the hydrogen from water electrolysis and nitrogen separated from air. These two elements are then fed into the Haber process. In the process, nitrogen and hydrogen react together in high pressure and temperature to produce Ammonia.

Currently, ammonia making is not a green process. It is mostly now made from methane in an apporoach called the Steam Methane Reforming (SMR) process. Around 90% of carbon-dioxide is produced from SMR process.

Around 80% of Ammonia produced in the world is used in agriculture as fertilizer.

The ammonia in the fertilizers releases nitrogen, which is an essential nutrient for the growth of crops. Green ammonia is an energy vector which is a vital part of the hydrogen revolution. The ammonia produced from green hydrogen can be considered green ammonia and its combustion does not generate CO2.

www.bloomenergy.com

Italian automotive icon Ferrari is driving toward carbon neutrality in manufacturing at its headquarters in Maranello, Italy, by 2030. This initiative is being accelerated by a 1MW solid oxide fuel cell (SOFC).

EURO POWER NEWS AUTUMN 2022 15 GENSETS

NRMM - extension of the Commission’s Empowerment under Regulation (EU)

2016/1628 on Non-Road

Mobile Machinery

The EU Commission has published the Regulation (EU) 2022/992 of the European Parliament and of the Council of 8th June 2022 amending Regulation (EU), reports Europgen 2016/1628.

Regulation (EU) 2016/1628 limited all empowerments of the Commission to adopt delegated acts to a period of five years which expired on 6th October 2021.

As there is a need to constantly update elements of the type-approval acts to technical progress or to introduce other amendments in line with the empowerments, the Regulation amends the Regulation (EU) 2016/1628 to provide for an empowerment of another five years.

The Commission shall draw up a report in respect of the delegation of power not later than 6th January 2026 and nine months before the end of each following five-year period. The delegation of power shall be tacitly extended for periods of five years, unless the European Parliament or the Council opposes such extension not later than three months before the end of each period.’

The regulation (EU) 2022/992 is available on the Europgen website.

OUTDOOR NOISE DIRECTIVE (OND) REVISION – 2000/14/EC

On 21st July, the Commission has published an initiative about Noise emitted by equipment for use outdoors (updated measurement methods). This initiative will make it possible to bring the methods for measuring airborne noise emitted

by equipment for use outdoors (equipment for cleaning, construction, gardening, waste collection, recycling, generating power, etc.) in line with technical progress.

The initiative is also available on the Europgen website.

In connection with this initiative and during the OND Commission Expert Group meeting held end of June, the EU COM presented the final draft of the Delegated Regulation to amend the Annex III of the OND (2000/14/EC).

EUROPGEN sent the Commission a position paper with its comments. This position paper is also available on our website.

UPDATE OF THE BLUE GUIDE

On 29th June, the Commission published the updated version of the ‘Blue Guide on the implementation of the product rules 2022’. The Guide is meant for a better understanding of EU product rules and facilitation of their uniform application across sectors throughout the Single Market.

The Blue Guide is a non-binding instrument and it was published in 2000. It has been subsequently updated twice, in 2014 and 2016. The current revision is a substantial update and takes into account developments that have come up since 2016.

The 2022 Blue Guide includes changes to address new regulations, perceived challenges of new technologies and new marketing structures (online sales). It also signals important reinterpretation of some fundamental principles of European law. Products stakeholders will need to consider whether changes in the 2022 Blue Guide have an effect on their products and procedures.

The main changes are: placing on the market, right to repair, components and spare parts, repairs and modifications, software, CE marking, Declaration of Conformity (DoC), new Market Surveillance Regulation and Brexit. What has not changed: Instructions and safety information and labelling (name and address of economic operators).

BREXIT - UKCA

In June 2022, the UK Department for Business, Energy & Industrial Strategy published an updated guidance on UKCA marking. The guidance provides information on the following topics (nonexhaustive):

•Placing goods on the market in Great Britain

•Circulation of goods on the market

•UKCA labelling easement

•Components

•Prototypes and testing

•Leasing and hiring

•Economic operator responsibilities.

This guidance is intended to apply to goods which require UKCA marking. The guidance was updated following an announcement on proposed measures to make UKCA compliance easier for businesses.

More information: Government to make it simpler for businesses to apply new product safety markings - GOV.UK (www. gov.uk)

The updated guidance is available on our website.

16 AUTUMN 2022 EURO POWER NEWS EUROPGEN

CEN & CENELEC Annual Report 2021

A new edition of the CEN & CENELEC Annual Report for 2021 is available. This document provides an overview of the diverse standardization activities that the CEN and CENELEC community implemented over the course of 2021, a challenging but successful year. The Report is available on the Europgen website.

Ongoing revisions

The generating sets are mainly concerned by the ISO 8528 series. The following parts are under revision and arrives at the last steps:

•ISO/DIS 8528-5: Test methods – published on 29th June 2022.

•ISO/FDIS 8528-10: Measurement of airborne noise by the enveloping surface method – the last step FDIS consultation (last step before publication) started on 5 July (2 months ballot). Publication Target date: October 2022.

•ISO/FDIS 8528-12: Emergency power supply to safety services. The FDIS ballot is ongoing.

MEETINGS & EVENTS

Next meetings

•EUROPGEN Executive and Technical Committees meetings, Paris, 23rd September 2022

•EC Expert’s Group on Machinery meeting, Brussels, 10th November 2022

How is Europgen organised?

EUROPGEN has the following bodies:

•The General Assembly

•The Executive Committee

•The President

•The Secretary General

•The Treasurer

•Working Groups

The affairs and policies of the Association are directed by the Executive Committee. Key decisions will be made by consensus.

*President Antonio Leitao;

* Secretary General Jean-Michel Geiller

*Accounts Director Philippe Jan;

*Accounts Administrator Maryline Sivilla;

*Communication Manager Romain Mocaër

EUROPGEN is working in close cooperation with many partners in Europe to achieve its targets. The Legislative partners include the European Commission and the European Council | Council

EUROPEAN SISTER ASSOCIATIONS

Agricultural machinery | CEMA – European agricultural machinery

Material handling | FEM – European federation of materials handling Garden equipment | EGMF – European garden machinery federation

Engines | EUROMOT – European association of combustion engine manufacturers

Municipal Equipment | EUnited Municipal Equipment – European Association of Municipal Equipment Manufacturers

Construction Equipment | CECE –Committee for European Construction Equipment

Engineering industries | Orgalim – European engineering industries association

NATIONAL ASSOCIATIONS (members)

France | GIGREL – Groupement des Industries du Groupe Electrogène Italy | ANIE – Federazione Nazionale Imprese Elettrotecniche ed Elettroniche UK | AMPS – The Association of Manufacturers and suppliers of Power Systems and ancillary equipment

New EUROPGEN Position Paper on the European Commission Third Draft of amended Annex III of directive 2000/14/EC (OND-22-3-3) - 15th July 2022

EUROPGEN comprises of National Associations as well as direct company members representing approximately 75 generating set manufacturers around Europe. Technical specialists within EUROPGEN has been continuously monitoring progress on the development of the noise emission in the environment by equipment for use outdoors Directive (OND). Comment No. 1 (on Annex III OND-22-3-3,

“ In June 2022, the UK Department for Business, Energy & Industrial Strategy published an updated guidance on UKCA marking. The guidance provides information on the following topics (non-exhaustive):

•Placing goods on the UK market

•Circulation of goods on the market

•UKCA labelling easement

and testing

•Leasing and hiring

•Economic operator responsibilities. This guidance is intended to apply to goods which require UKCA marking. The guidance was updated following an announcement.”

This sentence in the scope can lead to misinterpretation about which standard shall be applied:

“If a product specific standard in Part B gives the possibility to use other general standards for the determination of sound power level different than EN ISO 3744, e.g EN ISO 3746, ISO 9614, etc, manufacturers shall use EN ISO 3744 as indicated in Part A.”

EUROPGEN’s proposition to improve the sentence is as follows:

If a product specific standard in Part B gives the possibility to use noise test codes based on other general standards than EN ISO 3744, e.g EN ISO 3746, ISO 9614, etc., manufacturers shall exclusively use the parts of the product specific standard that are based on the EN ISO 3744.

The specification of the test method, as it is written, is subject to interpretation: “EN ISO 8528-10:2022. However, the determination of the A-weighted sound power level shall be carried out using EN ISO 3744:2010 and not EN ISO 3746:2010.”

This can be understood that for the determination of the A-weighted sound power level, the EN ISO 3744:2010 shall be applied instead of EN ISO 8528-10:2022. In EN ISO 8528-10:2022, clause 5.2.1, it is clearly defined that “For sound power level measurements, the grade 2 method is based on ISO 3744:2010”.

Moreover, the name of the method is specified in clause A.9.1: “The method of sound power level measurement according to this document, grade 2, is designated as follows: Sound power level measurement ISO 8528-10 grade 2.” Position Paper

So, in the Annex III, it should be written as follows: EN ISO 8528-10:2022. The noise test code “sound power level measurement ISO 8528-10 grade 2” shall be applied.

Due to all the questions raised with the current Draft, EUROPGEN requests another round of review before the final document.

EURO POWER NEWS AUTUMN 2022 17 EUROPGEN

•Components •Prototypes

3,300 kVA diesel gensets supplied to a German plant

AMargen spokesman commented: “The two units at the pharmaceutical plant perform an emergency function, in the event of a power failure, by operating in parallel power.

“In addition, a sophisticated system for synchronising and managing the plant allows parallel return on eight different grids forming a medium voltage ring to guarantee high reliability for factory. MARGEN was chosen for this project because of its extensive expertise and ability to provide complex systems.”

Margen is well-known for its G70 and G80 series of automatic control panels which were designed where the number of I/O, logic, calculations and functions require high power. They suit applications where the generator set is not the only device to manage, but management is also necessary for all the processes accompanying the systems connected to it.

The G80 series can be used in emergency systems connected to the network and standalone production.

However, its most suitable application is on parallel systems. Thanks to the synchroniser and built-in load sharing it can be used in production plants with multiple generator sets parallel to one another and parallel to one or more networks, cogeneration with control and management of the heating production system and, if required, cooling (trigeneration).