The rapid technological growth that has altered today’s wire and cable manufacturing landscape calls for new measures of understanding and implementation. Share your expertise at INTERWIRE 25 in one of the following areas:

•AI and Industry 4.0

•Material Advancements

•Market Trends & Economic Factors

•Safety & Standards Compliance

•Sustainability & Environmental Impact

•Product Development

•Production Efficiency

•Quality Management

•System Security

•Workforce Training

•Professional Development

Submit your abstract here: bit.ly/WAIabstracts

Accepted authors receive one year WAI membership & conference registration.

ABSTRACTS DUE: OCTOBER 3, 2024

NOTICE OF ACCEPTANCE: NOVEMBER 7, 2024

MANUSCRIPTS DUE: FEBRUARY 13, 2025

Conference: May 13 - 15, 2025

Georgia World Congress Center Atlanta • Georgia • USA

It may feel like this topic has been presented over and over, and that Industry 4.0, even with AI, largely remains the bastion of larger manufacturers. But change can and does happen, and it may be that the staid wire and cable industry is inching to a more advanced state ... whether it wants to or not. This feature explores some of the big picture.

A recent report from Deloitte, AI Adoption in Manufacturing, spells out the role of Artificial Intelligence (AI) in dealing with the staggering amount of data that is created. It also shows that a closer look may find some statistics to be misleading. Below is an example from the report.

First, that a lot of data are created is not going to surprise any reader, but that manufacturing leads all sectors in its creation might. Just how much? Manufacturing is estimated to generate about 1,812 petabytes (PB) of data every year, more than communications, finance, retail and several other industries. To take in just how big that is, one petabyte equals 1,024 terabytes. If a factory has a thousand sensors that send signals every 10 seconds, that creates 360,000 entries per hour, more than a million in a single day. While it is great to create data, it needs to be useful, and that’s where AI comes in. Some experts have tagged 2019 as the date when AI began to be used in a meaningful way. Many algorithms have been created since then that help manufacturers further automation, smart operations and cut costs; predict market trends and schedule production to control inventory; and increase product quality and yield. That backdrop is reflected in Deloitte’s manufacturing survey that found that 93% of the surveyed companies

“believe that AI will be a pivotal technology to drive growth and innovation in manufacturing.” In terms of AI adoption, the report notes that China was an early leader, declaring in 2017 that it was part of its national policy. Also, the country has provided substantial funding. By 2025, it predicts that 63% of China’s manufacturing sector will have adopted AI. However, those statistics alone may not reflect the actual results.

The Deloitte survey found that among surveyed Chinese manufacturers, only 9% thought their projects reached 80% to 100% of the goals. The majority, 33%, rated results at 60% to 79%, 28% reported 40%-59%, 17% reported 20% -39%, and 13% reported less than 20%.

Possible limitations can stem from infrastructure, with 45% of surveyed companies saying that their operations were not at a point where they could proceed. (Going back to China, the report found that while lots of data were collected, much of it was not key information.) Another problem was not having the necessary staff, software and hardware resources as well as the inherent challenges of large, complex projects that can be beyond AI, albeit from the support for it or the ability to define the goals.

For the full report, go to www.deloitte.com.

TE Connectivity decided to focus on the intersection of AI, sustainability and innovation in its 2024 Industrial Technology Index, an annual survey of engineers/executives in a broad range of industries that are shaping (and shaped by) technology trends. Below is an excerpt. To see the full report, go to www.te.com/techindex.

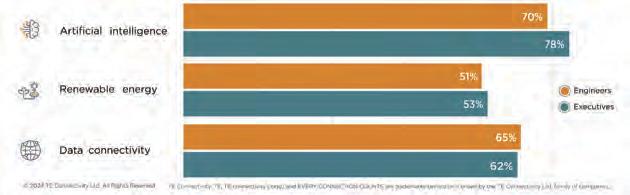

Even though it is still an emerging technology, AI has quickly become a focus for technology organizations. Our survey found that 70% of engineers and 78% of executives named AI as one of their top investment priorities over the next three years, scoring higher than other technologies such as renewable energy and data connectivity.

To maximize the impact of these investments, organizations must develop a clear strategy for AI integration. Successful strategies will include alignment between engineers and executives on roles and responsibilities in AI implementation, as well as targeted training and upskilling programs to develop in-house AI skills.

Organizations that follow this strategic approach are more likely to reap the benefits of AI in their innovation efforts. Those that struggle to build alignment between engineers and executives or fail to invest in the needed training could fall behind their peers.

business operations within three years. That short deployment window makes it essential to accelerate AI adoption to gain a competitive advantage. Likewise, more than 75% of engineers believe AI expertise will be a must-have skillset for continued success in their careers.

However, these convictions raise important questions about who will lead AI implementation within an organization, and how engineers will develop the skills needed to master this innovative technology. Executives largely see AI implementation as a technical question, with 74% saying that engineers should drive AI integration within their organizations. However, engineers are concerned about how AI will change expectations for their role, and they want more strategic direction and training to implement their organization’s goals. Most engineers (68%) say they wish that organization leadership would lay out a clearer plan for integrating AI.

More than 80% of both groups say they are optimistic about their ability to integrate AI into their organizations. Engineers and executives also agree that accelerating AI adoption will improve their innovation abilities by delivering important benefits, such as increased efficiency and productivity, improved data analysis, and enhanced decision-making capabilities.

However, we see differing levels of optimism depending on age and geographic location. Globally, 84% of younger engineers (Gen Z and Millennial) are optimistic about AI integration at their organizations, vs. 74% of Gen X and Baby Boomer engineers.

Among the specific countries we surveyed, engineers and executives in China are the most confident about the integration of AI into their organizations (90% are highly confident vs. 70% globally). Yet Chinese engineers are also more likely to be worried that AI could replace their jobs (45% of Chinese engineers vs. 26% of all engineers).

On the other end of the spectrum, only 57% of German engineers and executives are very confident in their ability to integrate AI. Respondents in Japan and the U.S. also ranked their confidence in their abilities lower than the global average of 70%.

More than 80% of executives believe that AI will be a critical component of

A lack of alignment on expectations and responsibilities could make it difficult for an organization to achieve its AI goals and, as a consequence, reduce the competitive advantage they expect to gain.

“When introducing any new technology into an organization, sometimes you have to go slower to go fast,” said TE Chief Information Officer Joseph Eckroth. “Before implementing AI, leadership needs to ask a few important questions: What problem or question are we trying to solve? Do we have the necessary data to solve it and the talent to use what we build? What outcome or value do we expect to get from this effort?”

AI will be game-changing for companies that do it the right way and apply it to the right opportunities, Eckroth said. The organizations that do the hard upfront work in its implementation and maintain the agility to evolve with this rapidly changing technology will win.”

Ratings of company engineers/executives as to their investment priorities for the next three years. TE chart.

MAY 12-15, 2025

ABSTRACTS DUE: OCTOBER 2, 2024

ACCEPTANCE NOTIFICATION: NOVEMBER 7, 2024

MANUSCRIPTS DUE: FEBRUARY 13, 2025

CASTING FORUM IN CONJUNCTION WITH:

J. Markowski

Courtesy:

Photo

ATLANTA, GA, USA

You are invited to participate at the Wire Association International’s fourth Continuous Casting Forum as an author and speaker.

This conference provides a forum for academics, researchers, metallurgists, and professionals in the continuous casting arena to meet and exchange innovative ideas and information on all aspects of continuous casting.

Paper submissions can include the following or related copper/aluminum continuous casting topics:

Casting technologies

Electrical energy

Global copper & aluminum markets

Cost-saving opportunities

Filtration concepts

Molten metal

Combustion Systems

Furnaces

Degassing

Metal flow

Refractories

Aluminum & Copper Alloys

Sustainability

Submit your abstract now: bit.ly/WAIabstracts

QUESTIONS? CONTACT: education@wirenet.org