Copper tops $5 a pound! What does it mean?

Düsseldorf WRAP-UP

& EQUIPMENT

Wire Link Scholar A European experience

Copper tops $5 a pound! What does it mean?

& EQUIPMENT

Wire Link Scholar A European experience

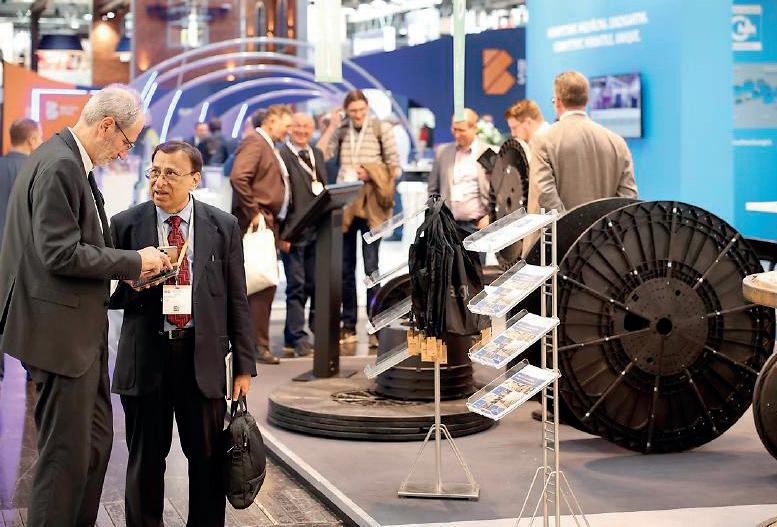

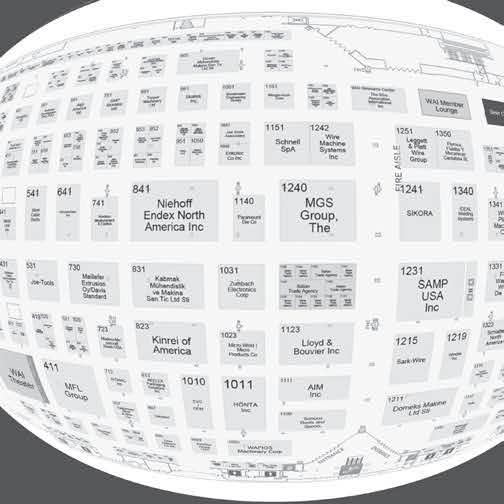

Some 2,700 wire and Tube exhibitors from more than 60 countries filled the halls April 15-19 at the Messe Fairgrounds. This wrap-up presents comments from the organizers as well as exhibitors, and a range of equipment presented at the event is shown in the equipment feature.

What a great trade fair season!

It’s hard to disagree with that official perspective from Messe Düsseldorf, which in its wrap-up of wire Düsseldorf pointed out that there were 1,500 exhibitors from 60 countries on 67,400 sq m. That made the 2024 staging at the Fairgrounds the largest ever in its nearly 40-year history. The sister event, Tube Düsseldorf, saw 1,200 exhibitors from 54 countries. Collectively, the week-long events presented the most comprehensive technology presentation ever for the fields.

“The world seems to turn faster and we turn with it,” said Daniel Ryfisch, director of wire, tube & flow technologies. “Every two years our industries get together here in Düsseldorf – the community stands by its location on the Rhine. We are very grateful for this and are working consistently to ensure that wire and Tube will also remain their industries’ No. 1 trade fairs in the future.”

The press release noted that while the exhibits continued to present the latest advances in technology and services, the event also included a solid educational program. “For

This feature presents some of the equipment that was shown at the Fairgrounds on April 15-19. Some companies chose to highlight their philosophy and/or focus, but either way, they provide a taste of the show floor. Other “new” entries are in the Products section, and more will follow in July.

Beta Sistemi’s MB24 is a powerful drawing machine’s platform up to 48-wires for high-speed operation and mass production of medium-sized wires. Up to 12-wires in one row of capstans. Drawing capstans onto two rows with separate haul-offs to provide a perfectly straight and aligned wire path. Solid frame in electro-welded and stress

relieved heavy steel plates. Reliable mechanical transmission with independent main power chain and largely oversized helical gears, suitable to sustain long term heavy working conditions. Enhance lubrication system for high-

speed drawing and severe heat dissipation. The machine structure is monolithic, made of electro-welded normalized sheet metal, requiring no foundations. The drawing section is at the front, while the transmission system and auxiliary systems are at the back. It features a built-in coolant tank for efficient discharge flow and can connect to centralized or autonomous coolant systems. The drawing section includes ceramic capstans for wire alignment, with separate pulling rings and coil separation systems. Die holders are designed for easy cleaning and constant wire alignment. The transmission system uses hardened steel gears and includes a pneumatic disc brake for emergencies. The annealing section has four steps: pre-annealing, annealing, cooling, and drying, with precise control of annealing current. It includes multiple annealing axes with detachable flanges and automatic wear monitoring for brush replacement. Annealing occurs in a nitrogen-protected atmosphere, followed by efficient cooling and drying systems. For tinned wires, there’s a wetting system and automatic innovative cleaning device for each annealer’s contact cylinder. Transmission to each annealing ring is via servo-ventilated AC motors, ensuring precise alignment and speed control. Beta Sistemi Srl, www.betasistemi.it.

Eurodraw Wire Equipment displayed two interesting machines at wire Düsseldorf. The MTX wire drawing machine, the first truly “plug-and-play” dry drawing line that features an integrated electrical cabinet, water refriger-

ation system and air compressor, all installed on board the machine. Just one connection is required: electrical power. This type of machine is pre commissioned at the manufacturer factory, so, once it is positioned at the client factory, it is just necessary to connect power and it is ready to go. The MTX type machine features the well-known Eurodraw “Alucool” capstan cooling system that ensures optimum wire cooling and high production speeds. The second machine on display was a section of a low relaxation PC Strand line. The latest model of the CLR strander has been updated with smart wire break detection systems, improved wire tensioning control systems and extended enclosure of the spool. With such new systems, bow damage in case of wire break are extremely reduced, improving the overall efficiency of the line. The Eurodraw product line includes double twist stranders and closers for the production of wire ropes up to 12 mm in diameter. Low power consumption, high production speeds and large spool size loading capability without compromising speed, makes a double twist strander or closer the most efficient and eco-friendly choice for the factory of the future. Eurodraw Wire Equipment, www.eurowire.com.

Founded in 1987, Eurolls SpA is recognized for the design and production of steel rolls and accessories for tungsten carbide rolls, wire cassettes and a large range of machinery for the wire industry. Its four plants are located in Italy with subsidiaries and branches spread across the USA, Brazil, Mexico and China. The company’s Eurolls’s CA and CB rolling cassettes (CL25CB33 and CL30CA33) are mostly used to process low carbon wire for the construction industry. These cassettes are normally

mounted on one or more drafts machines, where the wire is reduced and/or deformed, used as a base for lattice girders, mesh, or generally reinforced concrete application. Each model can cover different ranges on entry and exit wires according to several parameters which will be evaluated from time to time. These rolls are provided with new surface coatings that increase their life and improve the quality of the final product. The sizing, forming and reducing rolls made of either tungsten carbide or steel are used to produce smooth or ribbed wire for use in the construction sector. Profiling rolls are tungsten carbide rolls that are demanded for wire ribbing or indenting, and roll holders are made of steel and hold the sizing, forming, reducing, and profiling rolls. Eurolls has produced and sold more than 10,000 cassettes all over the world. The company has also carried out new developments in this sector which consists of an implementation of the quality of rolls surface utilizing special coatings leading to improved life span. Eurolls SpA, www.eurolls.com.

When it comes to explaining its equipment, GEO Reinigungstechnik (GEO), represented in the U.S. by Cable Consultants Corporation, reports that a company must first know its objective when it comes to cleaning a surface. The solution (equipment) of course is essential, but the correct solution is far from a matter of selecting the latest equipment. Consider that the surface of deformed material is often far away from a smooth, “ideal” surface, and can be filled with residual drawing lubricating material. Particulate contamination also often causes problems in downstream processes. Cleaning usually aims to reduce or remove this contamination. Whether mechanical or aqueous, the individual cleaning methods have their respective strengths to achieve the desired result. Economical mechanical wire cleaning with brushes, textiles and microfibers remove trouble causing contamination from the visible surface by mechanical friction at

SAVE THE DATES: May 13-15, 2025 • Georgia World Congress Center

Everything points to INTERWIRE. It is the North American wire & cable conference & marketplace where you will find valuable new contacts.

Look for developing details: interwire25.com

It is the place to be in 2025, whether you are a visitor, exhibitor, speaker, or sponsor. And with 44 years of continuous improvement since the event began, thousands continue to choose INTERWIRE. Meet you there! official publication:

AESA Cortaillod

AGAPE Industrial, Inc.

AITMAC, Inc.

Ara Makina İmalat Sanayi ve Ticaret Ltd. Şti.

AT Wire GmbH & Co. KG

Automated Industrial Machinery Inc. (AIM, Inc.)

AWT Machinery Inc.

Aztech Lubricants

B&H Tool Co.

Bartell Machinery Systems LLC

Bechem Lubrication Technology, LLC

Bergandi Marchinery

Blachford Corp.

Cable Components

Cable Consultants Corp.

Calmec Precision Ltd.

Carris Reels Inc.

Cemanco LC

Clinton Instrument Co.

CM Furnaces Inc.

CN Wire Corp.

Condat Corp.

Confex Technology Ltd.

Conneaut Industries

Custom Wire Products

Die Quip Corp.

DijitalPort Istanbul Dan. Loj.

Amb. San. ve Tic. Ltd. Sti

Domeks Makine A.S.

Dynamex Corp.

E-BEAM Services, Inc.

EBNER Furnaces, Inc.

Electronic Drives & Controls, Inc.

Enercon Industries

ERA Wire Inc.

Esteves Group

Fabritex Inc.

Fenn-Torin

Fil-Tec, Inc.

Filtertech, Inc.

FMS USA Inc.

Fort Wayne Wire Die, Inc.

Frekans Makina San ve Tic A.S.

FUHR Rolling Mills

Gem Gravure Co. Inc.

GMM USA LLC

Guill Tool & Engineering

HONTA Inc.

Howar Equipment Inc.

Huestis Industrial

IDEAL Welding Systems, L.P.

InnoVites B.V.

International Wire Group, Inc.

Jiangsu Kemaite Technology Development Co.., Ltd.

Jiangsu Singcheer Intelligent Equipment Co., Ltd.

Joe Snee Associates, Inc.

Joe Tools, Inc.

Kabmak Muhendislik ve Makina

San. Tic. Ltd. Sti.

Kalmark Integrated Systems Ltd.

KEIR Manufacturing, Inc.

Kinrei of America, LLC

KMG Wires Pvt. Ltd.

Lämneå Bruk AB

Laserlinc Inc.

Leggett & Platt

Leibinger Inc.

LLFLEX

Lloyd & Bouvier Inc.

M. Holland Company

Madem-Moorecraft Reels USA, Inc.

Magnetic Analysis Corp.

Magnetic Technologies

Maillefer Extrusion Oy

Mega Metal

Metal Link Inc.

MFL S.A.

The MGS Group

Microdia SA

Mid South Wire

Mikrotek Machines Ltd.

Mill Masters, Inc.

MSS Cable Machinery GmbH

Nano-Dies P/L

Nevatia Steel & Alloys Pvt. Ltd.

Niagara Composites International Inc.

Niehoff Endex North America Inc.

Nordson Measurement & Control

P & R Specialty Inc.

P/A Industries Inc.

Paramount Die

Parkway-Kew Corp.

Phifer Inc.

Precision Die Technologies Process Control Corp.

Properzi International, Inc. / Continuus-Properzi, SpA

Proton Products Inc.

Q8Oils

QED Wire Lines Inc.

Quaker Houghton

Rainbow Rubber & Plastics

Rautomead Ltd.

Reel Options by Vandor Corp.

REELEX Packaging Solutions, Inc.

RichardsApex, Inc.

Ridgway Machines Ltd.

Rockford Manufacturing Group Inc.

Rosendahl Nextrom

Roteq Machinery

SACO AEI Polymers

SAMP USA, Inc.

Sark Wire Corp.

Schlatter North America

Setic S.A.S - Pourtier

Shanghai Kechen Wire & Cable Machinery Co., Ltd.

SIKORA

Simpacks / Pioneer

Sivaco Quebec Division

Sjogren Industries Inc.

Sonoco

Star Materials Co. Ltd.

Steel Cable Reels

SWEED Machinery

TapeFormers Ltd.

Taubensee Steel & Wire

Taymer International

Teknikor

Teknor Apex

Tektapes

Tensor Machinery Ltd.

Thermoplastics Engineering Corp.

Traxit North America LLC

TROESTER GmbH & Co. KG

United Wire Co.

Universal Wires LLC

UPCAST OY

UYGAR Makina San. ve Tic. Ltd. Sti.

Vikas Spool Private Ltd.

WAFIOS Machinery Corp.

Wardwell Braiding Co.

Webster and Horsfall

Weilly Diamond Industrial Co., Ltd.

Windak Inc.

Wire & Cable Technology

International (WCTI)

Wire and Plastic Machinery Corp.

Wire Association International, Inc.

Wire Journal International, Inc.

Wire Lab Co.

Wire Machine Systems Inc.

WiTechs B.V.

Witels-Albert USA

Woodburn Diamond Die, Inc.

Yagmura Ajans Mak. Mob. San. ve Tic. Ltd. Sti

Zumbach Electronics Corp.

List as of 5/21/24