• Networking cocktail hour

Viakable is fully committed to this event, just as it was in 2016 when Sergio Valdés Ramírez delivered the keynote.

• Welcome dinner

• Facility tours to be announced

Learn more and register: waimonterrey.com

• Networking cocktail hour

Viakable is fully committed to this event, just as it was in 2016 when Sergio Valdés Ramírez delivered the keynote.

• Welcome dinner

• Facility tours to be announced

Learn more and register: waimonterrey.com

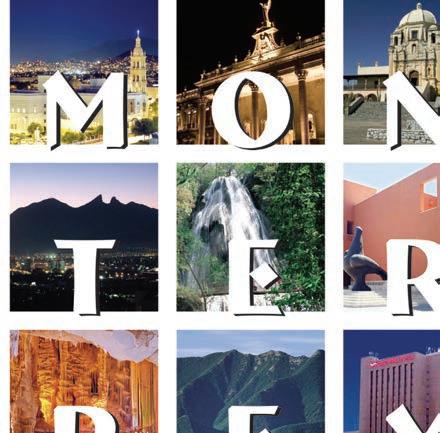

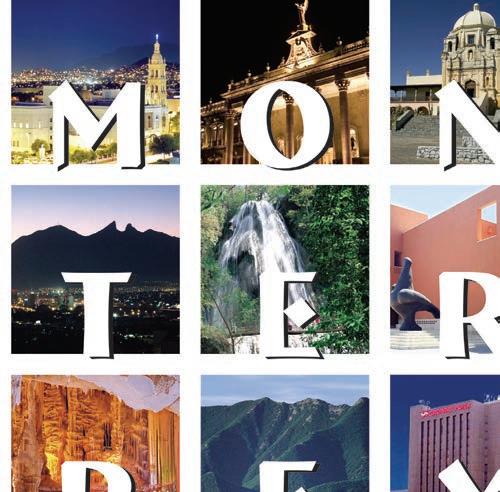

CONFERENCE: CROWNE PLAZA MONTERREY

13-15 NOVEMBER 2023

WAI has shifted into high gear for its return to Monterrey for staging what will be its fourth International Technical Conference (ITC). The energy, program quality and strong participation levels that were seen in 2008, 2010 and 2016 are expected to be matched, if not topped, when the Association returns to the same city, and the same location—the Crown Plaza Hotel—Nov. 13-15.

The 2023 program looks to follow the same general format as the 2016 event, which drew 190 participants. The educational forum included 20 technical presentations, tabletops, a keynote speaker from the Asociación Nacional de Transformadores de Acero AC (ANTAAC), and presentations from companies that included Viakable, a leading Mexican manufacturer. It has 15 elements (including two panel discussions). More presentations were still being considered, so visit the event website to see the latest list.

The presentations that start at 10 am on Monday, Nov. 13, include: a panel discussion with electrical wire and cable executives; transmission line congestion in Mexico, MTY; trends in compounding for the cable industry, Dynext; and design and installation of high performance OH lines, Viakable. Following lunch, there will be a presentation by Prysmian, followed by one from Condumex on topics to be finalized; then HVDC transmission lines, Borealis; and efficient sustainability: copper’s role in the new economy, SDI LaFarga COPPERWORKS.

On Tuesday, Nov. 14, the presentations include: wiredrawing best practices, (Niehoff); cabling best practices, (SKET); standards for insulated transmission lines, CFE/ LAPEM; high efficiency extrusion for cable applications,

Troester; manufacturing process for automotive harnesses, Yazaki; a technical paper, Quimica Iberoamericana; a panel discussion, steel wire and cable industry executives; and the steel cable industry, DeAcero.

The Suppliers Market will be open on Monday, Nov. 13, from 9 am to 1 pm, and from 2 pm to 5 pm. That night there will be a reception and dinner. On Tuesday, Nov. 14, it will be open from 9 am to 1 pm, and from 2 pm to 4 pm.

On Wednesday, Nov. 15, there will be a tour of a Viakable plant that leaves at 9:30 am and returns at 1 pm.

To date, 17 companies have signed up for a tabletop, and more are expected (at the 2016 event there were 42 tabletops). Those signed up so far include: Balloffet Die Corporation, Calmec Precision Limited, Cemanco LC, Esteves Group, Interequip SA de CV, LaserLinc, Madem Carretes de Mexico, S de RL de CV, Metalube Ltd.; Niehoff Endex North America Inc., Pan Chemicals Americas, Quimica Iberomericana (Blachford Distributor), Rainbow Rubber and Plastic, RichardsApex Inc., Roteq Machinery, Taymer International Inc.. Thermoplastics Engineering Corp and Troester GmbH & Co. KG.

For accommodations, the Crowne Plaza Hotel is the host event. It is located at Avenida Constitucion Oriente 300, Monterrey. To make a reservation, call tel. 52-800-8399300. Parking is free for guests. The standard room rate is $125, superior room rate is $135 and the executive room is $145. To receive the discounted rate, mention Grupo Wire Association or visit the below-listed event website.

Registration details are on the next page. The latest details can be seen at www.waimonterrey.com. n

11:15 am

12:00 pm

MONDAY, NOVEMBER 13

TUESDAY, NOVEMBER 14

Viakable, Condumex Group, and Kobrex: Executive Panel – Electrical Sector

Tecnológico de Monterrey: Analysis for alternatives to reduce congestion in electrical network

R&D innovAction: Wire and Cable Opportunities Through Materials Innovation

Niehoff: Stranding Power Cable

SKET: Cabling technology throughout the years

CARSO Research and Development Center, Condumex Group: AC electrical resistance measurement method for high and extra high voltage cables in Mexico

Viakable Technology & Research Center: Technical considerations for the transmission lines design using ACCC® high thermal performance conductor 1:00

12:00 pm

Prysmian Group: E3X Robot System 2:45 pm

pm

3:30 pm

pm

CARSO Research and Development Center, Condumex Group: Superconductor cable for up to 7,200 amp is a reality for generation plants in Mexico

Borealis: HVDC Technology and Market Trend

Troester: High Efficiency Extrusion for Cable Applications

Yazaki: Manufacturing process for automotive harnesses

Química Iberoamericana: Technical paper, Rogelio Sanchez

Panel Discussion: Steel wire and cable industry executives

DeAcero: Steel cable industry

4:15 pm

pm

SDI LaFarga COPPERWORKS: Efficient Sustainability: Copper’s Role in the New Economy 5:30 pm

9:30 am

WEDNESDAY , NOVEMBER 15

Viakable

Note: schedule is subject to change. Go to www.waimonterrey.com for latest schedule.

This section asks OEMs to explain why what they have to offer for customers is “the best of.” That claim could be for a wire drawing system that either offers the lowest operating cost or the newest advanced technology, but part of the equation has to be what else a company has to offer customers. What makes it a good potential partner. Also, some companies present more technical details in entries in the Products section.

Since 1900, FENN has been a trusted global supplier of rugged, stateof-the-art, metal forming machinery. With equipment options for all aspects of wire drawing and metal forming, backed by a dedicated team of experts, we can assure you will get the right machine for your needs. We understand that machinery doesn’t fall into “one size fits all,” so we work with our customers to design a custom solution for their specific requirements, which makes every machine we offer unique.

For wire drawing equipment, FENN manufactures drawbenches (see p. 64), draw blocks, and swagers. We also recently expanded our machinery product portfolio by introducing additional drawing equipment through the acquisition of MACBEE, which includes dead blocks, de-scalers, multi-pass draw machines, pointers, spoolers, spooler payoffs and take-ups, wire and rod payoffs and ancillary wire drawing equipment. FENN can build and support MACBEE machinery with OEM spare parts, rebuilds, and service.

Contact: Annelise Mackiewicz, marketing & sales coordinator

Tel: 860-259-6600

sales@fenn-torin.com

www.fenn-torin.com

Headquartered in East Berlin, Connecticut, FENN is proud to design and build every machine at that location. We have agents across the globe to provide world-class sales and service to support your projects and goals. We pride ourselves on manufacturing “built-to-last” machinery. Our relationship with customers doesn’t stop once machines leave our doors. We are there for the lifetime of their machine and are quick to respond with our aftermarket service and support. All FENN customers can get OEM spare parts, operator and maintenance training, and be cared for by OEM certified service technicians. For improved efficiency and quality, greater throughput, and increased safety, we also offer rebuilds, retrofits and upgrades when the time comes.

Italy’s Gimax, represented in the U.S. by Cable Consultants Corp. and best known for having 44 years of experience in welding wire machinery, has a team of well-versed engineers highly experienced in production of wire and the entire process of wire manufacturing.

Gimax has introduced a range of “TRD” dry drawing equipment (pictured), available with vertically or horizontally mounted, non-slip capstans. These models have independently driven capstans, tilted horizontal capstans, rotating dies, water-cooled capstans, etc. The capstan diameter can vary from 300 mm up to 800 mm (inquire for other diameters) depending on the application and diameter of wire, and can reach a line speed of 35 meters/second.

For nonferrous applications (aluminum), the drawbenches are often used in combination with shaving or other equipment.

The Gimax drawbench with vertical capstan (horizontal shaft) has added further benefits to the features of the more traditional line that has the horizontal capstan (vertical shaft).

U.S. Contact: Mason McClaugherty, vice president of sales and technical services Cable Consultants Corp.

Tel. 914-240-6033

mmcclaugherty@cableconsultantscorp.com

Gimax Srl, tel. +39-0444-55790

info@gimaxgroup.com

www.gimaxgroup.com

In the newly designed machine, the weight of the wire that accumulates on the capstan doesn’t weigh down the lower wraps of wire on the capstan. Subsequently, that means it does not affect the pull required from the wire on the bottom to higher wraps on the capstan.

The vertical capstans have also improved ergonomics during maintenance and string up of the line. The result is that the machine is far more accessible, especially for the rear of the line where key elements—such as the motors, gearboxes, piping and cabling—are housed.

Gimax also manufactures fully automatic and semi-automatic respooling machines and a full range of no-twist after packing units.

Flexibility is key for Swedish wire machinery manufacturer Lämneå Bruk. With nearly two centuries of expertise in manufacturing machines solely for the wire industry, they design, develop and produce all machine components in-house, employing state-of-the-art systems technology. Their extensive product range includes wire drawing machines, a top-selling category with three variations: straight line, loop and control line. These drawing machines offer unmatched flexibility for diverse production requirements.

Contact: Jonas Hagstedt, president

Tel: +46-122-232-00

info@lamnea.se

www.lamnea.se

All drawing lines have an extremely flexible machine setup. It is possible to start on, bypass, and finish on any block depending on the customers’ production requirements. They are equipped with a double cooling system for effective prevention of block overheating. The v-grooves with their special shape create a bigger surface, supporting the cooling mechanism effectively. In addition to that, each block is coated with zinc on the inside and tungsten carbide coating on the outside, enabling superior cooling capabilities. The adjustable tilted table design adds flexibility and can be regulated in height and degree. For increased efficiency, the block wire height is automatically filled to a preset level, which can be easily adjusted in the operator control for constant wire filling.

Lämneå Bruk’s drawing machines cater to various wire types, including low to high-carbon, welding, and stainless-steel wires. The control system brand is customizable, allowing buyers to choose from leading brands like Siemens, Mitsubishi, and Allens Bradley. For detailed information on Lämneå Bruk’s wire drawing machines and equipment, visit our website at www.lamnea.se. Experience Swedish precision and innovation with Lämneå Bruk.

the wire association international presents its:

Welcome to Monterrey where you’ll hear the latest wire and cable manufacturing information at the 2023 Wire Association International Technical Conference.

Both ferrous and nonferrous topics will be covered.

Simultaneous translation to English is offered.

Highlights include:

• 50 tabletop exhibits

• Lunch buffet

• Networking cocktail hour

• Welcome dinner

• Facility tours to be announced

Learn

CONFERENCE: CROWNE PLAZA MONTERREY

13-15 NOVEMBER 2023