33 minute read

IX. APPENDICES

IX. APPENDICES

APPENDIX A: PV SIZING

To assess how much capacity is required to enable solarization of agri-feeders and grid-connected pumps, as well as the energy subsequently generated for use and sale, this report uses data on locationspecific agricultural loads and estimates of local solar generation potential to determine the average capacity utilization factor (CUF) of PV systems under local conditions and the yearly energy available for use/sale under both KUSUM A and KUSUM C. Results of this analysis are used to inform:

1) A financial analysis of costs and benefits to farmers and developers participating in KUSUM

2) An assessment of KUSUM’s financial impact on Discoms with irrigation pumping loads

3) Estimates of the currently specified KUSUM scheme’s technical potential to meet statewide irrigation electricity needs

Data and Methodology

Agricultural Loads

Data on agricultural loads at substations across the state were taken from the Jaipur, Ajmer, and Jodhpur Discoms tender documents for KUSUM A. The comparable documents for KUSUM C provide the state’s estimates of the number of agricultural pumps of a given size that could be solarized within each Discom under the scheme.

PV Systems

Estimates of hourly solar generation and resulting capacity factors for fixed array solar installations during typical meteorological year across the state relied on calculations using the National Renewable Energy Laboratory’s PVWatts tool.161

• Feeders: PVWatts assumes 14.8 percent losses due to soiling, shading, light-induced degradation, wiring, and age to account for local conditions of use. in addition, the analysis for solarized feeders assumes 10 percent losses from moving the electricity from panel to substation.162

• Solar Pumps: Only PVWatts-derived 14.8 percent losses were included in these calculations, as proximity of the PV array to the pump under this scheme reduces distribution losses.

Pump Use

Estimates of actual hourly demand for electricity at the individual pump or feeder-wide level depend on farmer behavior and are likely quite variable. Due to lack of this data, this analysis studies a range of possibilities by assuming: ● For the scenario of solar pumps without net-metering, the pumps run whenever PV supply is at least 50 percent of what the pump needs ● For all other scenarios, the pumps run for four, six, or eight hours a day (centered around midday) at full load ● Pump use is not needed during monsoon months of July and August

Based on the agricultural load data, PVWatts analysis, and with the assumptions above, the PV sizing and generation scenarios were built in MS Excel for feeders and pumps (Link).

Results: Capacity utilization factor

Sampling across sixteen sites showed that the variation in CUFs across the three Discom regions was not larger than 3 percent (Table 7: Capacity Utilization Factors Across Jaipur, Jodhpur, and Ajmer Discoms). KUSUM A arrays yielded a CUF of roughly 21 percent based on power delivered to the substation. KUSUM C pumps yielded a CUF of approximately 23 percent.

The difference between solar feeder and pump CUFs result from the fact that electricity for solar pumps is generated at point of use and does not need to account for system losses in transmission from the local substation, as feeders do. Both CUFs are slightly higher than the 20 percent figure reported by the RREC and attest to robust generation potential within the region.

Table 7: Capacity Utilization Factors Across Jaipur, Jodhpur, and Ajmer Discoms

Parameter Discom Substation

KUSUM A feeders Jaipur Hamidpur

KUSUM A feeders Jodhpur Bagora

KUSUM A feeders Ajmer Karkari

KUSUM C pumps Jaipur Jhalawar - 2

KUSUM C pumps Ajmer Banswara (III) CUF (%)

20

21

21

23

23

Results: KUSUM A Generation Potential

The current sizing guidelines for KUSUM constrain the size of the array to between 0.5 MW and 2 MW. Based on the KUSUM A array sizes tendered for pump use, Figure 10 shows the solar electricity generated as well as the residual grid electricity that farmers need to power their pumps for a range of four, six, and eight midday hours. Across all Discoms, even the four-hour irrigation scenarios show that KUSUM A generation (blue bars) meets less than half of pump electricity demand, indicating that under the scheme as currently specified there is relatively low solarization of agricultural load.

Figure 10: PV Generated and Purchased Under KUSUM A across each Discom for 4/6/8 midday hours each. For each Discom, this calculation assumes an installed PV capacity equal to the sum of PV capacity allowed across substations and an installed peak agricultural load equal to the sum of peak agricultural loads across substations, both as enumerated in the KUSUM A tender document for each Discom163,164,165. For Jaipur, Ajmer, and Jodhpur, respectively, the sum of allowed PV capacities are 1.730, 1.761, and 2.631 million kWAC. The sum of installed peak agricultural loads are 4.419 million hp (3.292 million kWAC), 4.510 million hp (3.360 kWAC), and 9.311 million hp (6.937 million kWAC.)

Results: Net-Metered KUSUM C Generation Potential

KUSUM C with net-metering permits farmers to sell excess electricity to the Discom. Figure 11 shows the portion of PV electricity used to run pumps for four, six, and eight hours per day relative to the portion sold back to the Discom under three different generation scenarios: with PV array size (in kWAC) equal to 1, 1.5, and 2.0 times the installed pump capacity (in hp).

Guidelines for KUSUM C permit installations of capacity up to twice that of the connected pump, though recent analysis from the World Bank uses a more conservative 1.5 scale to account for the

financial constraints of farmers unable to purchase higher-capacity pumps, even using government subsidies. This analysis uses scales of 1, 1.5, and 2 to consider a range of financial capabilities.

Figure 11 illustrates that for four-hour scenarios across Discoms, a higher portion of electricity is sold back to the Discom than with six or eight hours/day of pumping. Figure 11 contrasts with Figure 10 in that a very high portion of the pumping load in the former is supplied by PV. Moreover, for KUSUM C pumps without net-metering, the only electricity available to pump is PV, so the entire pump load is met by PV. Changes to the KUSUM A feeder size limitations would therefore be needed to achieve the same level of solar PV input to the state’s agricultural electricity balance.

Figure 11: KUSUM C Net Metering Scenarios With a 5 HP Pump in Jaipur Discom For four-hour scenarios across Discoms, a higher portion of electricity is sold back to the Discom vs. the six and eight hour scenarios. Results look similar across other Discoms as well. KUSUM C guidelines stipulate that the allowable installed PV capacity in kWAC is up to 2 times the installed pump capacity in hP. Correspondingly, the installed PV capacity assumed for each of the three scale factor cases in this diagram are 5, 7.5, and 10 kWAC, respectively.

APPENDIX B: DISCOUNTED CASH FLOW ANALYSIS

METHODOLOGY

Net present value (NPV) is used to calculate the present value of cash flow over multiple years, by discounting future cash flows. Project specific discounted cashflow models were built in MS Excel for Feeders and for Solar Pumps (Link).

For Discoms, the discount rate is assumed to be 10 percent. For developers the discount rate was assumed to be 10.2%, and for farmers the discount rate is assumed to be 12.5 percent. In the latter two cases the discount rate was based on WACC (weighted average cost of capital) (Appendix C). The lifetime of the solar photovoltaic (PV) system is assumed to be 25 years. The NPV formula is shown below, where �� is the discount rate.

KUSUM A and C Tender Documents

Under the KUSUM scheme, each of the Discoms in Rajasthan have released tenders for KUSUM A and C. In the KUSUM A tenders, the Discoms list all available substations to which agricultural load (HP) is connected, identify solar capacity (MW) for KUSUM A as 70 percent of the agricultural load, and state the available transformer capacity at the substation (MVA). All specified capacity values are between 0.5-2 MW, consistent with the KUSUM A design constraints. A summary table of the identified sites in KUSUM A are shown in Table 8.

Table 8: Summary Table of KUSUM A Tenders

Discom Number of Identified 33 kV Substations

# Jaipur 1,324 Ajmer 1,384 Jodhpur 1,611

Total 4,319 Total Agricultural Load at Identified Substations

HP 4,419,046 4,510,170 9,311,013 18,240,229 Total KUSUM Agricultural Solar Capacity (Identified by Discoms) MW 1,730 1,761 2,631 6,121

Sources: RRECL Request for Selection (RfS) for KUSUM A Annexures166,167,168

Expected Deployment of KUSUM A

Based on the interest in bids under KUSUM A, the RRECL has increased the pilot deployment target until 2023 from the centrally allocated 325 MW to 725 MW.169 In addition, RRECL recently

announced that the State Budget for 2019-2020 had set the target for KUSUM A at 2,600 MW by 2023, and tenders will be forthcoming.170 This is compared to the total solar capacity of 6,121 MW as identified in the KUSUM A tenders.

Expected Deployment of KUSUM C

In the KUSUM C tenders, the Discoms identify lots where grid-connected pumps can be solarized. As shown in Table 9, the identified lots include 60,008 HP of grid-connected agricultural load. In terms of MW, this load amounts to 44.7 MW. For each lot, the Discom tenders identify the number of the grid-connected pumps by size (3 HP, 5 HP, and 7.5 HP) and the total estimated cost for solarizing the lot.

In Rajasthan, all grid-connected electric pumps within a lot must be solarized, for farmers in that lot to be eligible for KUSUM C. As such, the 44.7 MW of agricultural load identified in the tenders are interpreted to reflect the expected KUSUM C deployment under the pilot scheme.

Table 9: KUSUM C Agricultural Load and Cost by Discom

Number of Number of Pumps Total Agricultural Discom Identified 11 kV Substations 3 HP 5 HP 7.5 HP Load at Identified Substations # # # # HP Jaipur 119 270 4,057 2,040 36,395 Ajmer 92 4,616 1,093 165 20,551 Jodhpur 17 4 280 220 3,062

Total 228 4890 5,430 2,425 60,008

Pump Assumptions and Sensitivities

For both KUSUM A and C, the assumed average pump size is 5.0 HP, which is comparable to the weighted average pump size in the tenders for KUSUM C of 4.7 HP. To account for uncertainty in both the amount of daily pumping and hours of daily electricity availability, savings are estimated based on 4, 6, or 8 hours as the average daily hours of pumping. The annual hours of pumping per year are estimated assuming average daily operation, except for 62 monsoon days per year when it is assumed that pumping does not occur (for example, 8 average daily hours of pumping corresponds to 2,424 annual hours of pump consumption). The pump size and hours of pumping are used to calculate the electricity consumption per pump per year, as well as how many pumps would be able to be supported by the electricity generation. The current annual electricity consumption per pump per year is estimated by multiplying the average pump size (kW) by the assumed number of hours of pumping per year and assuming, in the absence of context-specific data on pump use characteristics, that the pumps run at their rated capacity during each hour of operation. For KUSUM A, the number of pumps supported is calculated by dividing the annual generation with the annual electricity

consumption per pump. For KUSUM C, the number of pumps supported by the pilot solar capacity is assumed directly from the KUSUM C tender documents.

Solar generation assumptions

The solar generation assumptions are based on the PV Sizing and Generation methodology (see Appendix A). The capacity utilization factor (CUF) is assumed to be 21 percent for solar feeders in KUSUM A and C, and 23 percent for solar pumps in KUSUM C. In addition, the solar age degradation factor is assumed to be 1 percent per year. Based on the CUF and solar degradation factor, the annual generation in GWh is calculated as shown in the following equation, where 8,760 is the number of hours in a year.

Current cost of supply for electricity

Under the KUSUM schemes, the Discom savings are the cost of supply under KUSUM compared to the current cost of supply. For this analysis, the current cost of supply is estimated based on average costs and losses as reported in the Discoms’ latest annual tariff order, RERC Petition No. 1541/19, 1542/19, 1543/19 (RERC Discom Tariff Order)171, transmission wheeling charges as reported in Rajya Vidyut Prasaran Nigam Limited‘s (RVPN) latest annual tariff order, RERC Petition No. 1587/2020 (RVPN Tariff Order).172

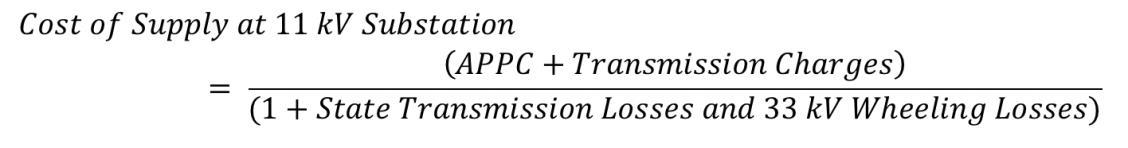

For comparison with the feeder level schemes, the cost of supply is calculated for delivery to the 11 kV substation level. When comparing with solar pumps, the cost of supply is calculated for delivery to the pump. The cost components of the cost of supply of electricity includes the average power purchase cost (APPC), transmission wheeling charges, transmission and distribution losses to the 33 kV and 11kV substations.

The assumed average power purchase cost (APPC) for Discoms is ₹4.02/kWh, obtained from Table 100 of the RERC Discom Tariff Order. The per unit transmission charges are ₹0.28/kWh, from Table 69 of the RVPN Tariff Order. The state transmission losses and 33 kV wheeling losses of 7.15 percent and the assumed distribution losses from 33/11 kV substation to pump of 12.6 percent are from Table 19 of the RERC Discom Tariff Order.173 The yearly escalation of the APPC is assumed to be 0.50 percent.

Based on these assumptions, the cost of existing grid supply at the 11 kV substation is calculated for the first year:

Based on these assumptions, the cost of existing grid supply at the pump is calculated:

Calculating Discom Savings

The savings to the Discoms associated with implementing KUSUM solar feeders is based on the difference between the cost of serving the agricultural load using grid electricity and cost of serving the agricultural load using solar generation. The per unit Discom savings are calculated for the first year, or t = 1, and the lifetime savings are estimated over 25 years of operation.

KUSUM A Solar Feeders

For KUSUM A, the per unit savings (₹/kWh) are calculated as shown:

The total annual savings represent the difference in cost between existing grid supply (₹4.63/kWh in Year 1) and the fixed price of solar power (₹3.14/kWh) for the total annual generation associated with 725 MW of solar capacity. The annual savings are estimated for each year of the 25-year lifetime, accounting for decreasing solar generation due to age-related degradation. A Performance-Based Incentive from the Government of India is estimated for the first five years of project operation. The PBI is valued at the lesser of either ₹6.6 Lakh/MW/year or ₹0.40/kWh/year. For Rajasthan, the ₹6.6 lakh/MW/year was estimated as being marginally lower and is applied for this analysis. It was assumed that one-third of the 725 MW capacity is deployed in each of the first three years for the purposes of adding the PBI estimate to the Discom savings. A NPV was calculated for the 25-year lifetime Discom savings and the PBI using a discount rate of 10 percent. The NPV estimates for Discom savings and PBI were divided by the number of pumps supported by 725 MW of solar capacity to estimate the per pump savings and required subsidy. In addition, the total savings and costs were divided by the total MW capacity to estimate per MW savings.

As a secondary analysis, the total annual savings were also estimated assuming that less than 100 percent of solar generation displaces grid electricity. From the solar generation analysis in Appendix A, it was assumed that 46 percent, 64 percent, and 76 percent of generated electricity is utilized by pumps operating for 4, 6, and 8 hours per day, respectively. The solar generation analysis for solar

feeders assumes that pumps will utilize generated solar within the specified daytime hours up until the pump capacity is reached. While the main analysis assumes that all generated solar displaces grid power, this secondary analysis assumes that the remaining portion of generated electricity is assumed to be curtailed, reducing the overall savings for the Discom.

KUSUM C Solar Pumps

The KUSUM C solar pump analysis is calculated for both modalities of the scheme: no net metering where the farmer cannot withdraw grid electricity, and net metering where the farmer is able to withdraw grid electricity. The excess generation and grid electricity used in each of the modalities is from the PV Generation and Sizing analysis in Appendix A. Based on the 6,000 7.5 HP of agricultural load identified in the Discom tenders for KUSUM C solar pumps, and sizing for double the load and converting to kW (1.5 kW/HP), the total estimated MW capacity for KUSUM C is 90 MW. The estimated system cost is ₹13.90 crore/MW as calculated in the farmer section above.

For KUSUM C solar pumps, the per unit savings (₹/kWh) for Discoms is calculated as shown:

As mentioned, the amount of grid electricity used with KUSUM C solar pumps is 0 in the no net metering case.

The total annual savings represent the difference between the cost of existing grid supply to the pump (₹5.36/kWh in Year 1) and the cost of purchasing excess solar generation from farmers at the fixed feed-in-tariff (₹3.44/kWh). As with the KUSUM A analysis, the annual savings are estimated for each year in the pump’s 25-year lifetime, accounting for the yearly solar degradation. The total subsidy cost associated with KUSUM C solar pumps include 30 percent capital subsidy from GoR and 30 percent capital subsidy from GoI. A NPV was calculated for the 25-year lifetime Discom savings for the total estimated capacity of 90 MW using a discount rate of 10 percent. In addition, the NPV estimates of the total subsidy costs were calculated for the 25-year lifetime. The total savings and costs were divided by the number of pumps supported by the total capacity at each given hourly consumption level to estimate the per pump savings and subsidy costs. Finally, the total savings and costs were divided by the total MW capacity to estimate per MW savings.

As a secondary analysis, the total annual savings were also estimated assuming that the excess generation purchased by the Discom can be used to displace grid electricity for non-agricultural loads. The additional cost savings are estimated based on whether the load served by the solar generation is located at the same feeder, or if the load is located further away. Similar to the analysis in KUSUM A, the additional cost savings represent the difference between the cost of existing grid supply to the pump and the cost of solar generation at the feed-in-tariff.

KUSUM C Solar Feeders

The total annual savings represent the difference in cost between existing grid supply (₹4.63/kWh in Year 1) and the break-even cost for solar feeders from the developer discounted cash flow analysis (₹2.72/kWh). The break-even cost represents the costs to the Discom under the CAPEX option where Discoms themselves are the RPG.

For KUSUM C feeders, the per unit savings (₹/kWh) are calculated by the same method as for KUSUM A feeders. The per pump savings were estimated using the same method as with the previous analyses. Finally, the total savings and costs were divided by the total MW capacity to estimate per MW savings.

GoR Benefit-cost Analysis for KUSUM A and C Solar Feeders

For solar feeders under KUSUM A or C, any change to GoR’s agricultural tariff subsidy burden is highly uncertain. Potential savings for GoR would be modulated by the RERC tariff setting process. Thus, no savings are estimated in this analysis.

GoR Benefit-cost Analysis for KUSUM C Solar Pumps

Compared to KUSUM A and C feeder schemes, the impact of the KUSUM C solar pumps on the state subsidy burden can be estimated based on current tariff level. The subsidy level of agricultural electricity is ₹4.65/kWh, considering the agricultural tariff (₹5.55/kWh) and the portion of the tariff that the farmer pays (₹0.90/kWh). Assuming that the amount that the farmer pays does not change due to the political difficulty of raising tariff payments for farmers, the per-unit subsidy increases yearly as the assumed cost of supply escalates per year. The subsidy savings is the amount of subsidy burden avoided due to the displacement of grid electricity with farmers’ self-generation. GoR cost for KUSUM C solar pumps is 30 percent of the capital cost. Based on the annual subsidy savings and upfront capital cost, the NPV savings and NPV GoR cost are calculated for the 25-year lifetime of a pump.

Results Summary

As noted above, the primary results for solar feeders assumes that 100 percent of generated solar displaces grid electricity, whereas the primary results for solar pumps are estimated assuming that only agricultural electricity is displaced. Solar feeders under KUSUM A are either appropriately sized or undersized compared to load, so less overgeneration is expected for those systems (proportionate to load). Thus, it is reasonable to assume that all generated electricity displaces higher-cost grid power. On the other hand, solar pumps under KUSUM C are oversized compared to load, and it is less certain whether a larger proportion of excess generation can be absorbed by non-agricultural load during hours of high solar generation.

Table 10: Summary of Primary Analysis Results

Parameter Hours KUSUM A KUSUM C

Feeder Pump – No Net Metering Pump – With Net Metering Feeder

₹/Pump

₹ crore /MW ₹/Pump ₹ crore /MW ₹/Pump ₹ crore /MW ₹/Pump

₹ crore /MW

NPV Discom Savings NPV Total Subsidy Costs

NPV GoR Subsidy Savings

BenefitCost Ratio 4 7.57 15.04 0.19 0.22 0.19 0.19 1.84 3.69 6 11.36 15.04 0.63 0.64 0.61 0.62 2.76 3.69 8 15.15 15.04 1.00 0.99 0.88 0.94 3.69 3.69

4 ₹97,030 ₹3.46 -₹71,094 -₹0.75 -₹73,028 -₹1.03 ₹108,652 ₹3.87 6 ₹145,545 ₹3.46 ₹95,710 ₹1.43 ₹90,876 ₹1.29 ₹162,977 ₹3.87 8 ₹194,060 ₹3.46 ₹245,837 ₹3.42 ₹208,885 ₹2.96 ₹217,303 ₹3.87 4 ₹12,812 ₹0.23 ₹589,010 ₹8.34 ₹589,010 ₹8.34 ₹58,968 ₹1.05 6 ₹12,812 ₹0.23 ₹589,010 ₹8.34 ₹589,010 ₹8.34 ₹58,968 ₹1.05 8 ₹12,812 ₹0.23 ₹589,010 ₹8.34 ₹589,010 ₹8.34 ₹58,968 ₹1.05 4 ₹0 ₹0 ₹185,231 ₹2.62 ₹182,958 ₹2.62 ₹0 ₹0 6 ₹0 ₹0 ₹276,288 ₹3.91 ₹271,061 ₹3.91 ₹0 ₹0 8 ₹0 ₹0 ₹341,774 ₹4.84 ₹308,140 ₹4.84 ₹0 ₹0

Table 11: Analysis for KUSUM A – Less Grid Electricity Displaced

Parameter Hours KUSUM A Feeder

NPV Discom Savings ₹/Pump

₹ crore/MW 4 -₹33,573 -₹1.20 6 ₹5,281 ₹0.13 8 ₹56,501 ₹1.01

Table 12: Analysis for KUSUM C – Solar Pumps, Savings from Excess Solar Generation Sold

Parameter Hours No Net Metering Generation sold within the feeder Generation sold to farther load Net Metering

Generation sold within the feeder Generation sold to farther load

NPV Discom Savings ₹/Pump ₹/Pump ₹/Pump ₹/Pump 4 ₹349,424 ₹291,015 ₹347,491 ₹289,082 6 ₹428,894 ₹382,616 ₹424,060 ₹377,782 8 ₹516,213 ₹478,659 ₹479,261 ₹441,706

Table 13: GoR Costs and Savings for KUSUM C – Solar Pumps

Parameter Hours No Net Metering ₹/Pump ₹/Pump

NPV GoR Savings 4 ₹185,231 6 ₹276,288 8 ₹341,774 ₹ 2.62 ₹ 3.91 ₹ 4.84 Net Metering ₹/Pump ₹/Pump

₹182,958 ₹2.62

₹271,061 ₹3.91

₹308,140 ₹4.84

NPV GoR Cost

Benefit-Cost Ratio 4 0.63 0.31 0.62 0.31 6 0.94 0.47 0.92 0.47 8 1.16 0.58 1.05 0.58

4 ₹294,505 6 ₹294,505 ₹ 8.34 ₹ 8.34 ₹294,505 ₹294,505 ₹8.34 ₹8.34

8 ₹294,505 ₹ 8.34 ₹294,505 ₹8.34

APPENDIX C: SENSITIVITIES AND PRIMARY UNCERTAINTIES

AFFECTING THE VALUE PROPOSITION FOR SOLAR

FEEDERS AND SOLAR PUMPS

Solar Feeders under KUSUM A and KUSUM C

The primary factors contributing to uncertainty around the NPV of solar feeders under KUSUM A and KUSUM C are: (i) the capital cost (CAPEX) of solar modules, (ii) the operational and maintenance cost (OPEX) of solar modules, (iii) the cost of land for construction, and (iv) the panels’ capacity utilization factor (CUF). Variability within any of these four factors could substantially alter the NPV of solar feeders from those figures presented in Table 10. The sensitivity of NPV to each uncertainty factor studied is shown below in Figure 12. Various sensitivities are displayed horizontally, while the height of the bars represents the uncertainty’s capacity to change the NPV of a feeder project (with gray being the maximum overperformance above best estimates and orange the maximum underperformance). The range for each uncertainty is based on research into the range of existing cost estimates.

Figure 12: Potential Change in NPV of 1 MW PV Feeder under KUSUM A The sensitivity analysis for feeders under KUSUM A demonstrates the change in NPV given the best and worst-case estimated parameters for relevant inputs.

Another key uncertainty for KUSUM developers is the weighted average cost of capital, which is a measure of the return on equity and cost of debt. Figure 13 illustrates the change in the tariff required by developers as a function of their weighted average cost of capital with other inputs constant. If risk profiles change or the banking sector becomes constrained, the cost of equity or debt financing for developers could become higher or lower than current best estimates.

In addition to the uncertainty in capital cost estimates, there is also potential for KUSUM’s domestic manufacturing requirements to increase the cost of PV panels. Thus, the viability of the scheme may depend on GoR’s willingness to adjust tariff ceilings as needed to allow developers to place profitable bids in the face of increased capital costs. In the event of severe supply chain constrictions, a flexible tariff cap could help developers continue to bid on feeder projects that would otherwise have been unprofitable at the ₹3.14/kWh ceiling. In order to deter potential abuse of a flexible cap by developers, regulators could ensure that the price rises only if certain unfavorable economic conditions exist and developers are not bidding at or below the current rate.

Figure 13: Required Tariff Feeder for Given Cost of PV Modules (NPV = 0) The sensitivity analysis for feeders under KUSUM A demonstrate the impact of weighted average cost of capital values on break-even tariff level. The current ₹3.14/kWh rate is denoted by the horizontal line, and its intersection with the center 10.2 percent WACC line indicates the assumed module cost of ₹3.6 crore/1 MW.

Solar Pumps under KUSUM C (with Net Metering)

The primary factors contributing to uncertainty around the NPV of solar pumps under KUSUM C are: (i) the capital cost of pumps, (ii) the price of avoided electricity purchases, and (iii) the ratio of installed PV capacity to pump power. We found evidence of considerable variability in several factors which makes increases the uncertainty associated with the value proposition of pump solarization, as

compared with feeders. For example, a 50 percent increase in capital cost would require an additional subsidy of ₹6.45 crore/MW. Alternatively, pumps that are only 2/3rds as expensive would reduce the required subsidy by ₹4.27 crore/MW. The scale of each uncertainty factor studied is shown below in Figure 14 for the modality with net metering.

Figure 14: Potential Change in NPV of 1 MW PV Net Metered Pumps for Given Uncertainties The sensitivity analysis for pumps under KUSUM C demonstrates the change in NPV given the best and worst-case estimated parameters for relevant inputs.

Finally, differences in the weighted average cost of capital do not substantially alter the total subsidy required for pump owners to achieve close to their required rate of return. The WACC is not as consequential for KUSUM C pump solarization because farmers’ total investment in equity and debt accounts for well under half of the necessary capital outlay, dampening the effects of a higher or lower WACC.

APPENDIX D: PREVIOUS SOLARIZATION PROGRAMS, THEIR

SUCCESSES AND CHALLENGES

KUSUM is not the first solarization scheme attempted in India, nor is it the only ongoing scheme. Thus, before turning to KUSUM itself, it is useful to analyze its predecessors and peers. This section reviews three such programs: (1) Dhundi Solar Pump Irrigators’ Cooperative Enterprise (Dhundi scheme; SPICE), (2) Suryashakti Kishan Yojana (SKY) Initiative, and (3) Mukhyamantri Kisan Aay Bodhotri Solar Yojana (Delhi scheme; MKABSY).

Dhundi SPICE.

SPICE was formed in 2016 between six farmers in Dhundi, a village in Anand, Gujarat, under the aegis of the International Water Management Institute (IWMI) and CGIAR’s Research Program on Climate Change, Agriculture and Food Security (CCAFS). At the time of its founding, SPICE was the first solar cooperative of its kind in India and managed 56.4 kW of solar generation capacity.174

SPICE’s design is fairly straightforward, especially for those familiar with the KUSUM C component it inspired. Under the scheme, diesel pump owners (i) set up solar systems on their own premises to solarize their pumps and (ii) entered 25-year PPAs with the local Discom who would purchase any electricity the farmer wishes to sell. The program received generous outside funding—so generous, in fact, that participants were required to front just 12 percent of the total project cost. What’s more, the program offered participating farmers the highly attractive FiT of ₹7.13 per kWh, ₹4.63 of which comprised the contracted PPA rate. The difference, ₹2.50, comprised ‘Green Energy’ and ‘Water Conservation’ bonuses that were paid out by IWMI and CCAFS. In exchange for this right to sell power, the Dhundi farmers surrendered their right to apply for a subsidized grid connection over the PPA period.175 SPICE’s highly-subsidized financing and above-market FiT mean that the program may serve as proof of technical concept for KUSUM C, but not proof of commercial concept.

SPICE faced a number of ‘growing pains’ at the outset, including, among other things, (a) identifying willing participants, (b) clearing the land records of interested farmers, (c) registering the cooperative, and (d) preparing its bylaws. Despite these obstacles, in its first two years SPICE proved an unqualified boon to its members, whose incomes increased dramatically176 and who were able to repay their loans in full over just a 24-month period.177 It also proved surprising. Though the program was designed to provide participants with an alternative, market and climate risk-free source of income—namely, the FiT—the Dhundi farmers found they could sell solar-pumped water to their neighbors and earn more than twice the amount they would by selling power to the grid.178 Admittedly this result may be particular to Dhundi, where solar-pumped water replaced more expensive, diesel-pumped water, a substitution that is unlikely to be possible in most of Rajasthan. Even so, the experience of Dhundi supports this report’s argument that farmers may respond in unpredictable ways to the opportunities created by solarization schemes.

SKY Initiative.

Seeking to replicate SPICE’s success, the Government of Gujarat launched the SKY Initiative, a Dhundi analogue scheme that blends elements of both KUSUM A and KUSUM C. In its pilot stage, SKY Initiative sought to solarize 137 feeders which between them covered more than 12,000 farmers and 177 MW of solar power generation.179 SKY featured less generous financing than SPICE in two ways. First, it required that farmers shoulder 40 percent of the total program cost, five percent up front and the remaining 35 percent via a subsidized loan.180 Second, it only offered participants a FiT of ₹7.00/kWh for the first seven years of the PPA term, after which time the FiT would fall to ₹3.50/kWh. Perhaps as a result, the initiative floundered at the pilot stage. From its original goal of 137 feeders and 12,400 farmers, the pilot was scaled down to just five feeders and 2,000 farmers.181 While several explanations have been floated, the most frequently cited is that farmers are simply not interested in the project—unable to make the down payment and unwilling to forfeit their right to subsidized power.182

Delhi MKABSY Scheme.

The Government of Delhi has an alternative vision for solarization. While similar to KUSUM A in that it involves installation of solar panels on farmland, the new program does away with farmer cooperatives entirely. Instead, MKABSY compensates farmers for leasing up to one-third of their land to private developers, who erect solar panels on the land and take on all the associated risks therein.183 This point warrants emphasis. Unlike SPICE and SKY, the Delhi scheme neither requires a financial contribution from farmers nor imposes on them additional risks in the form of securing and maintaining panels in exchange for increasing their income. Farmers who participate in the scheme simply earn ₹8,333 per acre per month in the first year and receive increases of six percent per annum thereafter.184 This means that by the 25th and final year of the contract term, participating farmers will make ₹33,741 per acre per month. Since farmers earn roughly ₹20,000 per acre per annum, this fixed, stable income amounts to a 20-fold increase in annual income. 185 However, as a new program, it has yet to be seen what uptake will be like or whether unforeseen barriers may limit its implementation.

Lessons from Dhundi SPICE, SKY Initiative, and Delhi MKABSY Scheme

Farmers may require proof of concept at the local level before they agree to participate in a

solarization scheme. As SPICE illustrates, even highly attractive financing wasn’t enough to attract farmers unfamiliar with or unconvinced by the promise of solar panels to the scheme. It was only after farmers in Dhundi saw the benefits accruing to the cooperative’s six original members that they came around to the idea. This experience suggests that educating farmers about the solar scheme and its benefits, while perhaps necessary, may not be sufficient. Risk-averse farmers may have to ‘see it with their own eyes.’

Farmers are extremely sensitive to the specific FiT and financing arrangement. At a 12 percent capital requirement and with a FiT of ₹7.13 per kWh, farmers lined up to participate in SPICE. At a

40 percent capital requirement and a less favorable FiT, the SKY Initiative floundered. This stark contrast highlights the sensitivity of solarization schemes to the exact financial arrangement. Because KUSUM’s financing arrangement is even less generous than that of SKY and because farmers are unlikely to negotiate PPAs featuring FiTs as high as Dhundi’s, farmers may be less interested in KUSUM projects than many believe.

Farmers may be unwilling to trade certain subsidies for increased income, especially when that income is perceived as uncertain or variable. As the challenges in rolling out the SKY pilot demonstrate, farmers are loath to give up subsidized grid power for solar power. To make this trade-off attractive, a solarization scheme may need to provide (a) more reliable electricity supply than the grid, (b) with the option to sell excess power generated to the grid at a remunerative FiT (minimum five rupees per kWh, according to one estimate).186 While a successful solar pump scheme may include additional methods of incentivizing farmers to participate, proponents of solar pump schemes tend to emphasize these two.

Private developers may be disinclined to work with individual farmers or farmer cooperatives.

There is some evidence to suggest that private developers are reluctant to work with farmers.187 Developers may not find the benefits of one-off agreements with farmers worth the transaction costs of negotiating them. This should be especially true of communities where farmers are unable to form cooperatives and where developers would therefore have to negotiate small agreements with individual farmers. Alternatively, developers may simply prefer to deal with either Discoms and business customers for utility scale solar generation, or urban, residential consumers in the solar rooftop space, shifting attention and investment away from agricultural solar initiatives like KUSUM.

APPENDIX E: LEGAL REGIME GOVERNING GROUNDWATER

IN RAJASTHAN

Indian common law gives landowners ‘absolute dominion’ over groundwater resources.

Groundwater is considered “part and parcel of the land” at common law,188 with the result that owners of property enjoy “the right… to collect and dispose within [their] own limits of all water under the land.”189 In other words, access to and control of groundwater is the exclusive prerogative of landowners on whose property the water is found.190 At common law, landowners may legally draw as much water as they please from below their land, even if they cause damage to the water resources of their neighbors as a result.191 These long-standing legal principles, which date from the British Colonial era, are one reason Rajasthan has suffered from depletion of its groundwater resources.

Though states may legislate out of this regrettable state of affairs, Rajasthan continues to adhere to the traditional common law framework. The Indian Constitution vests states with the power to make laws related to water,192 laws which would supersede the underlying common law regime. GoI, recognizing that the colonial regime is no longer up to the task of ensuring the long-term supply of groundwater, has encouraged states to pass water reform laws since 1970, even drafting a ‘Model Act’ to aid in the effort.193 Some states have heeded the call. West Bengal and Andhra Pradesh, for example, have followed the Model Act’s approach of issuing well permits and imposing extraction charges.194 Gujarat has passed similar legislation, but only for water used in irrigation.195 By contrast, to date GoR has passed no such legislation. Thus, the traditional common law approach permitting unrestrained groundwater extraction still prevails in Rajasthan.

The persistence of the common law regime in Rajasthan is not for lack of attempts at reform.

To the contrary, as recently as 2005 GR considered adopting the Rajasthan Groundwater (Rational Use and Management) Act. The bill, which was functionally equivalent to parts of the Model Act, would have, among other things, (a) established a Water Authority tasked with regulating groundwater extraction; (b) required registration of existing wells, (c) instituted an application process for construction of new wells, and (d) imposed user charges for water pumped beyond a certain threshold determined by the legislature.196 While some scholars fault this regulatory approach for focusing on individual extraction units (i.e., wells) instead of hydrological units (i.e., aquifers),197 the bill, if passed, would likely have improved upon the status quo.

APPENDIX F: PREVIOUS DISTRIBUTION SECTOR REFORM

EFFORTS

Previous reform efforts addressed root issues by improving revenue recovery, reducing transmission and distribution losses, enhancing metering infrastructure, and upgrading the grid. Recognizing the challenge of providing rural electricity, GoI approved Deendayal Upadhyaya Gram Jyoti Yojana (DDUGJY) in 2015, a scheme to fund rural feeder separation, improve distribution, reduce line theft, and improve metering of agricultural load. Rural feeder separation enables Discoms to schedule agricultural load while keeping domestic electricity available 24 hours a day, improving line visibility and reducing potential line theft. The following year, Rajasthan approved the Mukhya Mantri Vidhyut Sudhar Abhiyan (MMVSA) program to upgrade its agricultural power supply. Demand-side policies have also been proposed to manage agricultural electricity consumption. The Agricultural Demand Side Management Program (Ag-DSM) approved by GoI has prompted states like Rajasthan to replace over 10 percent of existing agricultural pumps with efficient alternatives.198, 199

Table 14: Government Schemes to Improve Distribution Network200

Year Central or State

2001 Central

2008 Central

2014 Central

2015 Central Policy

Accelerated Power Development Programme (APDP), later named Accelerated Power Development and Reform Programme (APDRP) Restructured Accelerated Power Development & Reforms Programme (RAPDRP) Renamed from R-APDRP, Integrated Power Development Scheme (IPDS)

Deendayal Upadhyaya Gram Jyoti Yojana (DDUGJY)

2016 State Mukhya Mantri Vidhyut Sudhar Abhiyan (MMVSA) Description

Central finance mechanism for upgrading sub-transmission and distribution network, improving generation projects

Central finance mechanism for AT&C loss reduction, focusing on measuring performance

Central finance mechanism for strengthening sub-transmission network, metering, IT application, customer care services Central finance mechanism for rural feeder separation, strengthening distribution network and metering in rural areas State program to improve rural and agricultural electricity supply, improve consumer services, and reduce AT&C losses to below 15%.