The 44th International WorkBoat Show.

The simplified solution.

Located in Northeast Florida, 2 nautical miles from the Atlantic Ocean, BAE Systems Jacksonville Ship Repair applies competence, efficiency, and integrity to your projects, keeping them within budget, and on schedule. With additional capacity and capabilities coming in early 2025, now is the time to consider BAE Systems. Contact us for more information and to subscribe to our Ship Repair announcements.

Jacksonville, Florida | USA +1-904-431-2227 | jaxshiprepair@baesystems.us

baesystems.com/commercialshiprepair

16 Focus: Ill Wind

Trump 2.0 reverses course on offshore turbines.

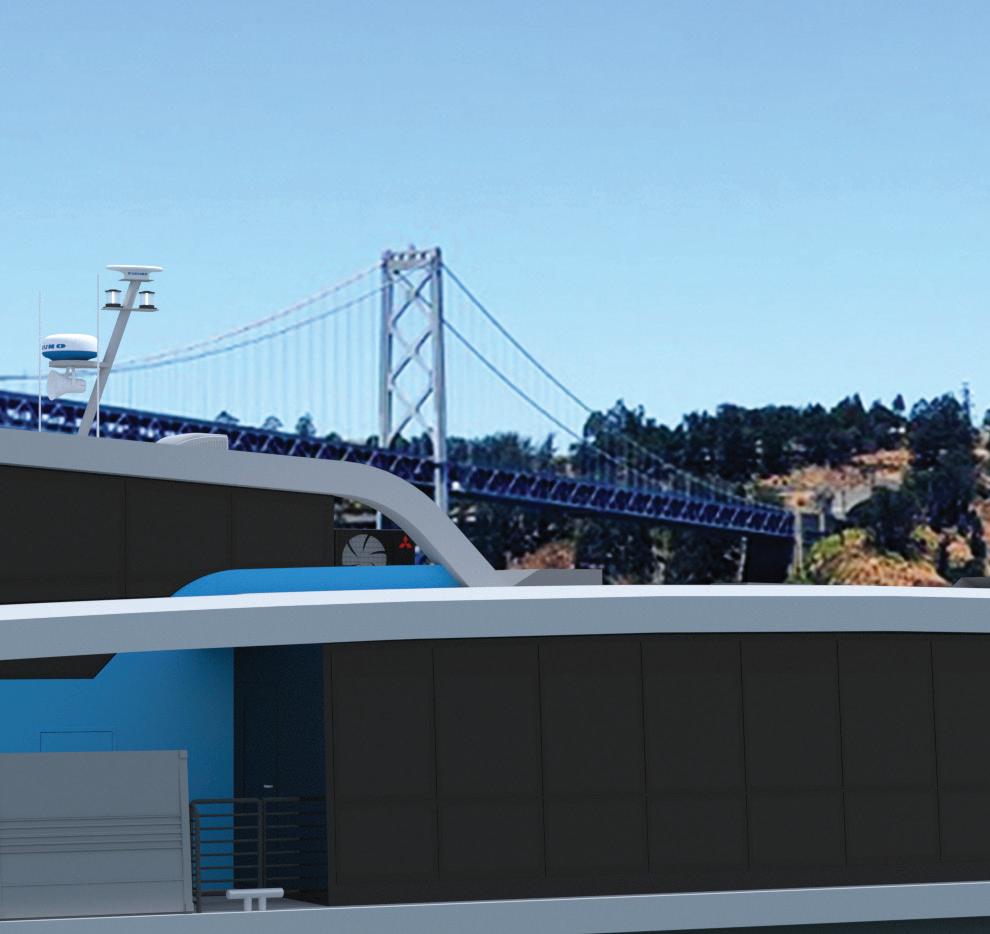

18 Vessel Report: Zero In San Francisco takes first step toward no-emissions ferry fleet.

24 Cover Story: Newsmakers

Coverage of the 44th International WorkBoat Show.

20 On the Ways

• Senesco launches sixth crew transfer vessel for WindServe Marine

• Photon Marine wants to build workboats powered by electric outboards • Blount Boats delivers 98' CTV to American Offshore Services • Multi Cat dredge support vessels voted WorkBoat's Boat of the Year • Derecktor Shipyards launches a pair of hybrid-electric ferries.

28 Deep Dive

Louisiana company is becoming a big player in diving services.

8 On the Water: Sleep deprivation can be deadly.

8 Captain’s Table: Build relationships that yield lasting dividends.

9 Energy Level: Heading for a lull is not the worst outcome.

9 Nor'easter: Can Trump kill offshore wind?

10 Inland Insider: Lower Miss dry-cargo imports fall 12.5%.

10 Credentialing Insights: Speed up your MMC applications.

11 Insurance Watch: Review insurance clauses before signing.

11 Legal Talk: Was my claim handled properly?

14 Coastal Virginia Offshore Wind project stands at 43% complete.

14 Inspection closes lock on Tennessee River.

14 Electric Boat evacuated after bomb threats.

14 Icebreaker Polar Star leaves for Antarctica.

tion while also embracing the evolving challenges of the present day.

The maritime industry is changing rapidly, driven by advancements in automation, fuel technologies, and digital systems. These innovations are not only transforming vessel operations but also reshaping how companies manage their eets, crews, and safety protocols. As we move forward, our goal is to

Eric Haun, Executive Editor ehaun@divcom.com

ensure that WorkBoat remains a reliable resource in this fast-paced, dynamic environment.

In the coming months, you can expect more in-depth reporting, expert commentary, and real-world stories that highlight both the triumphs and challenges of the maritime community. We’ll focus on critical issues like technological innovation, workforce development, regulatory changes, and environmental sustainability, among others.

I’m thrilled to begin this journey with you. Your continued engagement and feedback will be invaluable as we work together to keep WorkBoat relevant, impactful, and true to its mission as the go-to resource for the U.S. maritime industry.

Thank you for your trust and support.

EXECUTIVE EDITOR Eric Haun / ehaun@divcom.com

EDITOR EMERITUS David Krapf / dkrapf@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTENT EDITOR Benjamin Hayden / bhayden@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS

D CLOSE- 1/17 1 erries

Marine Propulsion

iesel En ines arine pril 2025 D CLOSE- 2/14 2

Capt. Alan Bernstein • Steve Blakely • Arnie Brennaman • G. Allen Brooks • Bruce Buls • Robin G. Coles • Michael Crowley • Jerry Fraser • Pamela Glass • Max Hardberger • Joel Milton

DIGITAL PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com

ADVERTISING ACCOUNT EXECUTIVE S

Mike Cohen 207-842-5439 / mcohen@divcom.com

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

Subsea Technology

atrol Boat - Militar utboards

ubsea ay 2025

D CLOSE - 3/7 3

Producers of The International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

VICE PRESIDENT Wes Doane / wdoane@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION

4/28 - 5/1 - Houston TX IPF - 5/5 - 5/8 - Virginia Beach, VA ffshore

esearch Vessels lectronics ONUS DISTRIBUTION

cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET) © 2025 Diversified Communications PRINTED IN U.S.A. IN

Your December issue of WorkBoat had a [Mail Bag entry] by B.W. Clare, Capt., U.S. Coast Guard, (page 6) regarding rejections of Merchant Marine Credential applications. When I got my rst MMC, which in those days was a wall-sized frameable certi cate, naming me as a “US Merchant Marine Of cer.”

At that time, applicants were required to be processed for and pay for a TWIC. Shortly thereafter someone at the National Maritime Center must have realized that not all of us holding an MMC work at secured port facilities. A vast number of us work out of public marinas, at yacht clubs, or even foreign facilities in my case. I did away with my TWIC.

I am at the point of my third re-

newal of my MMC and have no need for a TWIC. I contacted a nice lady at the Regional Exam Center regarding the renewal. She sent me an incredible pile of documents to ll out including a TWIC application.

My experience with the NMC on matters of vessel documentation is that their personnel are inclined to reject submittal packages without identifying what caused the rejection. Three times I submitted the documents to secure a USCG Form CG-1270 so as to U.S. ag a South African-built charter vessel. All were rejected by the same NMC person to whom I sent the material. I'm inclined to think that rejections of MMC renewals will be handled the same.

During my last 50 years of boat ownership, I’ve processed documents for changes of ownership for four other boats we purchased. One was a French- agged vessel, so we had to do a de ag/re ag to U.S. This was not a

problem in those days. Do you have any solutions?

Jack M. Schmidt, President Investors Management Services Inc. LLC Management and Registered Agent ProMaritime LLC

Capt. Schmidt, you do not need a TWIC to renew your USCG MMC. You either need a copy of a valid TWIC, a copy of the receipt from recently applying for a TWIC, or a TWIC exemption memo. — Nate Gilman

WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number. Email: khocke@divcom.com

Sleep deprivation can be deadly

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@yahoo.com.

Regardless of what watch schedule you use, it’s important to understand that the back watch (the middle-ofthe-night watch) always has it the hardest when it comes to sleep.

There are very few true “night owls” who appear to have no issues with being up all night, working through the normal low point of the human circadian rhythm in the wee hours. The older you get, the more your body tells you that the back-watch is not your friend. Sleep interruption and deprivation becomes less tolerable, and the negative effects on health become more pronounced.

One of the biggest gains you can make is very simple: set

MBY CAPT. ALAN BERNSTEIN

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@bbriverboats.com.

y father taught me that the key to succeeding in business is making customers happy and building professional relationships that stand the test of time. In my more than 40 years in running a family business, I have witnessed this philosophy play out successfully repeatedly and I have stressed the importance of this concept with my family members, employees, and crew.

Maintaining good relationships goes beyond just keeping customers happy. It extends to vendors, suppliers, local, state, and federal government entities, and many others. This is a balancing act that is getting increasingly complicated with changing technology and evolving regulation. While it is one thing for me to have a commitment to customer service and developing good relationships with my many publics, I must emphasize that this is a two-way street and sometimes these others do not demonstrate the same attitude toward me.

As a lifelong mariner who has operated Coast Guardinspected passenger vessels for many years, I have logged

your watch schedule, and adjust it seasonally as needed, to always make sure that the back watch gets inside and into their bunks well before the sun comes up. Specifically, before there is much more than just a trace of the approaching dawn in the sky, in fact. The lighter it gets, the more detrimental the effect. And if the sun breaks the horizon, assuming that skies aren’t sufficiently overcast, it’s game over.

When outside light levels begin to brighten, it sends a signal via your eyes to the pineal gland to gradually slow down production of the sleep-regulating hormone melatonin. When direct sunlight hits it’s like an all-stop order, and your body then shifts to wake-up mode. You can’t reverse it once it starts. No matter how tired you may be, it will now be more of a fight to get to sleep, and precious off-watch time will be wasted in the morning period where the back watch gets the vast majority of their daily rest. Rest quality is degraded as well. There is no advantage in it whatsoever.

This is a serious issue that affects the front watch too, though indirectly. While they sleep their lives are literally in the hands of the back-watch, which may be a dangerously tired back-watch. Fatigue never improves situational awareness and decision-making. It’s in every captain’s direct selfinterest to do anything reasonable to minimize it.

hundreds of vessel inspections by an ever-changing assortment of Coast Guard inspectors. Most of these Coast Guard inspectors have been knowledgeable and professional. From time to time I have interacted with an inspector who has been uninformed, arrogant, and had extremely poor customer service skills. Unfortunately, this person can cast a dark shadow upon all of the others who are doing a good job. No matter who your inspector is, good or bad, it is important to find common ground and understanding.

The Passenger Vessel Association (PVA) has long recognized the importance of involving Coast Guard personnel in its meetings, conventions, and events as a way of building relationships and greater understanding. During the PVA Annual Convention at MariTrends 2024 in Portland, Ore., I was impressed with the number of Coast Guard attendees, from Adm. Wayne Arguin, as well as a variety from Coast Guard headquarters in Washington D.C., to Coast Guard men and women from local and regional offices. These individuals made presentations, attended sessions, interacted with passenger vessel operators and vendors, and were generally immersed in all the convention had to offer. The communication established there was very valuable.

Experience tells me to work to find common ground with Coast Guard inspectors and to build professional relationships that promote mutual understanding and goodwill. You will find that this approach will deliver lasting dividends.

[This column first ran in the April 2024 issue. We think it’s worth another look.]

BY G. ALLEN BROOKS

G. Allen Brooks is an energy analyst with over 50 years of experience, having worked as an energy security analyst, oil service company manager, and served on several oilfield service company boards.

The combination of West Texas Intermediate oil below $70 a barrel, OPEC+ announcing an extension of its voluntary 2.2 million bpd “adjustment” (production cut) until March 2025 before feeding the supply into the market, and Chevron’s 2025 capital budget calling for a cut in spending next year increases the odds of a slowdown in oilfield activity.

Recent forecasts for drilling and the offshore industry call for a slowdown. For some, it is considered the worst outcome possible for the industry. But is it?

Supply and demand dynamics set global oil prices. Crude oil output continues to hum along. However, oil is a depleting resource requiring steady drilling to keep the supply from collapsing. Therefore, all eyes are focused on OPEC+ and the Permian Basin. Will the two deliver the supply needed or create either a glut or a shortage?

Demand is critical, too. China has disappointed market experts all year and is the most significant question mark. There are doubts that the latest Chinese financial stimulus is sufficient enough to drive a meaningful economic upturn. China’s steel production data for the first half of November showed an increase. The steel production increase has also lifted iron ore futures prices of iron ore.

OPEC+’s extension was anticipated. However, some experts suggest OPEC+ should disband as its supply management strategy is irrelevant in today’s global oil market. Realistically, OPEC has only exercised cartel power a few times in its 64-year history.

OPEC always gives itself cover: “This monthly increase can be paused or reversed subject to market conditions,” OPEC said. OPEC remembers that their effort to destroy the U.S. shale industry took years and was costly for everyone. OPEC’s leaders are no dummies. They understand that the product they sell will be in demand at some point, likely when we least expect it.

The most telling development reflecting oil’s uncertainty was Chevron’s 2025 capital budget announcement. The company’s $14 billion budget is $1 billion below this year’s spending. However, the key takeaway was the Permian Basin capex, slightly below this year’s $5 billion in spending. Chevron emphasized cutting capex spending “in favor of free cash flow.” This should please shareholders while permitting the company to boost activity to capitalize on higher oil prices. If global demand and supply conditions change, expect U.S. shale producers to increase their activity quickly.

BY KIRK MOORE

Contributing Editor Kirk Moore, with over 30 years of experience, joined WorkBoat in 2015. He has won multiple awards for his marine, environmental, and military reporting. Contact him at KMoore@divcom.

Invigorated by president-elect Donald Trump’s election, opponents of offshore wind power hope the new administration will sweep President Biden’s renewable energy plans aside.

“If Biden can cancel XL pipeline’s border crossing permit over climate concerns, why can’t @realDonaldTrump yank offshore wind permits over BOEM’s disregard of evidence showing harm to marine life?” wrote activist Lisa Linowes of the Save Right Whales Coalition on social media site X Dec. 9.

At a May campaign rally on a New Jersey beach, Trump famously promised to end wind projects “on day one” if he returns to the White House. In the final weeks of the campaign, Trump amped up his rhetoric, repeating offshore wind critics’ accusations of projects threatening marine life.

“It drives the whales freaking crazy...and the environmentalists, they don’t talk about it,” Trump said on podcaster Joe Rogans’s Oct. 26 show.

A new Trump administration could block new offshore wind leasing by the Bureau of Ocean Energy Management (BOEM), which pushed ahead future lease planning in the waning months of the Biden presidency. For developers with existing leases, Trump could interfere and slow-walk permitting — or even try to reverse it, as Department of Interior officials did to the Vineyard Wind project in late 2020 as Trump’s first administration was in its final weeks.

As a candidate, Trump slammed the Biden administration’s Inflation Recovery Act of 2022 and threatened to rescind spending and subsidies that promote wind and solar power development. But those technologies are now the fastest-growing energy sectors, the U.S. Department of Energy has reported. Even in Texas, still dominated by the fossil fuel industry, wind, solar and battery power have grown dramatically.

Market-driven transformations will be harder to derail, with bipartisan support built into Congress among members, including Republicans, whose home districts have benefited from those new energy investments.

Offshore wind advocates are hopeful some of that will hold true for their industry, with support from Louisiana Republicans whose offshore operators, shipbuilders and fabricators do business with wind developers.

“Wind projects take years to develop. Offshore wind especially has long lead times,” wrote Julia Pendleton, managing director of the Southeastern Wind Coalition, on the group’s website Nov. 11.

BY KEN HOCKE

Ken Hocke has been WorkBoat's senior editor since 1999, previously associate editor. An LSU graduate, he’s also written for The Times-Picayune and Daily Shipping Guide. Contact: khocke@divcom.com.

dry cargo commodities tracked by the U.S. Customs District in New Orleans dropped 12.5% during the third quarter, according to Criton Corp.’s River Transport News (RTN)

Aggregate imports of dry commodities totaled 4.675 million metric tons during 2024’s third quarter. “These volumes were down 12.5[%] from comparable year-ago imports of 5.345 million metric tons. Third quarter 2024 New Orleans Customs District imports also declined by 8.5[%] from the prior quarter, when import volume totaled 5.109 million metric tons,” the report said.

Here are some other highlights from the RTN report:

BY NATE GILMAN

Nate Gilman, president of MM-SEAS USCG Licensing Software, uses his hawsepiping experience to support mariners and workforce development. Connect on LinkedIn.

The Coast Guard has announced another improvement to its processes to reduce the time it takes to issue a Merchant Mariner Credential (MMC).

Now, only full and complete MMC applications will be accepted. This means that perfect applications without the common issues will be able to be issued their MMCs even more quickly by the Coast Guard National Maritime Center.

On Dec. 1, the Coast Guard National Maritime Center will begin rejecting any application with issues in the CG719B application form, oath, TWIC, drug test, evaluation fees, or previous convictions paperwork.

The Coast Guard will email mariners a “Notice of Rejected Incomplete Application” form with checkboxes next to issues and notes on what the issues found were.

Mariners must address the issues noted on the form and resubmit the entire, updated application to MMCApplications@uscg.mil.

• Aggregate imports of steel and steel sector raw materials totaled 1.856 million metric tons during the most recent quarter, down from about 2 million metric tons imported during the same year-ago period. Steel imports improved slightly from the 1.793 million metric tons imported during the prior quarter.

• Cement imports during the third quarter totaled about 500,000 metric tons. While volume was down slightly from the year-ago total of 527,700 metric tons, third quarter volumes were the highest yet so far in 2024.

• Imports of fertilizer fell to 1.421 million metric tons from 1.729 million metric tons imported during the comparable year-ago period.

Marad announced that $4.85 million in grants have been awarded to five marine highway projects across the U.S. via the U.S. Marine Highway Program.

One of the recipients, Tidewater Barge Line Inc., Vancouver, Wash., was awarded $454,000 to support expanded barge service between Tidewater’s terminal in Vancouver and the Port of Morrow, Ore. The award will be used to acquire a low-emission container handler.

The Coast Guard Regional Exam Center Initial Evaluation team will then do another evaluation and issue another Notice of Rejected Incomplete Application form if they find any issues. Mariners must continue this process and resubmit entire, updated applications each time to MMCApplications@uscg.mil.

The new Coast Guard policy should speed up the approval of perfect applications through the NMC. It is a step in the right direction to reduce the MMC application backlog and the total time for perfect applications submitted to be issued by the Coast Guard.

As of August, the NMC had an application backlog of 10,668 and an average wait time for MMC issuance of 51 business days. In 2023, there were almost 34,000 problems and issues on applications mainly related to drug test forms, Coast Guard approved course certificates, sea service forms, and simply filling out the Coast Guard CG-719B application form.

To prepare for the upcoming rule change, Coast Guard credentialing experts who work at MM-SEAS USCG Licensing Software listed their three top tips to avoid rejected applications.

• Tip 1: Always select “Merchant Mariner” as a mariner’s occupation in both locations on the online form during the TWIC application process.

• Tip 2: Always sign as the mariner and check the National Driver Registry (NDR) box on page 4 of the CG-719B form.

• Tip 3: Ensure drug test documentation meets the Coast Guard NMC requirements.

WeBY CHRIS RICHMOND

Chris Richmond is a licensed mariner and marine insurance agent with Allen Insurance and Financial. He can be reached at 800-439-4311 or crichmond@allenif.com.

are often asked by our insureds to review the insurance clause in contracts clients are asked to sign. Unfortunately, the contracts have often already been signed before we have a chance to review them. These contracts are often prepared by legal teams or pulled from the Internet. While it is important to have the legalities in a contract correct, it is equally as important to have the insurance aspects correct — which is why a conversation with your insurance agent is important before you sign on the dotted line.

A contract, when properly drawn and signed, can become an enforceable document. But for insurance purposes, just because you have signed the document does not mean that your insurance policy will react to it. Your insurance policy is also a legal contract, and the insurance company is only

Was my claim handled properly?

MBY TIM AKPINAR

Tim Akpinar is a Little Neck, N.Y.-based maritime attorney and former marine engineer. He can be reached at 718-224-9824 or t.akpinar@verizon.net.

ost people have a rough idea of what the term “bad faith” means. It brings to mind the notion of playing “dirty pool.” In maritime lawsuits, this can mean handling insurance claims in a manner that is not professional. I’ll provide a few examples, since this can cover a wide range of conduct. This issue of bad faith was raised in a recent case in Alabama.

The matter arose from the towing of a spud barge. The court said the barge owner was bringing a third-part claim against the towing company’s insurer, based on negligence. The barge owner argued that refusal to pay the claim and delays with the claim were “unreasonable, negligent, and/ or in bad faith.”

The court denied the spud barge owner’s bad faith claim. This was because the barge owner was bringing a thirdparty claim against the towing company’s insurer/under-

going to respond to the limits and conditions written out in your policy. It is important to make sure that the limits and conditions that you are insured for will meet the requirements in the contract you are signing.

In addition to limits there are often other stipulations that need to be verified with your agent before signing. Waiver of subrogation and hold-harmless clauses are often inserted. While these can be very beneficial to the party making the request, these types of requirements need to be approved by your insurance company beforehand.

Contracts often include the words “any and all” when referring to risks covered. However, your insurance policy most likely will not react to “any and all” claims made against it. Again, have these clauses reviewed beforehand.

If your contract only involves a vessel, any general liability and workers compensation limits that are required will most likely not apply. Your hull and protection and indemnity (P&I) policies will react to claims made against the boat. Getting the party who is requesting these limits to understand this can often be futile. This is when you should get your insurance agent involved to help sort out the wording and coverage issues.

Contracts are required for many reasons. A boilerplate contract most likely will not fit your unique situation. Contracts are also negotiable. It is wise to get your insurance agent involved in this process before signing any contract.

writer without first having obtained a judgment against them — something required under Alabama law (Alabama Code § 27- 23-2). I won’t go into the relationships between everyone in the case because I want this brief discussion to be something of practical value to readers.

So, let’s get into the nuts and bolts. Here are a few examples of the type of conduct that could result in a bad faith claim:

• failure to honor the terms of an insurance policy,

• unreasonable delaying of the claims process,

• unnecessarily burdensome requests for information,

• denial of straightforward claims without cause,

• extreme lowball offers,

• failure to properly investigate a claim,

• deceit, in terms of not being honest about the policy, and

• intimidation, such as threats of bringing legal action, filing formal complaints, or launching unjustified investigations.

It’s important to keep in mind that bad faith doesn’t mean insurance carriers can’t play hardball. They often do, which explains why disputes make their way into federal court. An insurance carrier doesn’t have to act like a friend, nor is there an obligation for it to be generous. In all fairness to the insurance industry, human nature being what it is, carriers must treat claims as suspect until all facts are verified. Bad faith means going beyond acceptable cautionary measures.

Dominion Energy’s Coastal Virginia Offshore Wind project passed a milestone in early November, with 78 of the planned 176 monopile foundations installed. With a total nameplate capacity of 2.6 gigawatts, the array will be the biggest project in U.S. waters.

Dominion of cials said the project was 43% complete, with work in the winter months turning to continued export cable lays and installation of an offshore power substation. At the end of November, the rst of three jacket foundations for the CVOW project had left Denmark’s Port Esbjerg, headed for the U.S. on the BigLift Baf n heavy carrier vessel.

At 197' tall and 2,445.6 tons, the jacket foundation will support one offshore power substation.

The foundation was fabricated at the port and moved with custom-built heavy-load vehicles over roads to the Netherlands- agged Baf n ro/ro carrier, and onto it 410'x138' ush deck, with a capacity up to 16,000 metric tons.

“Producing and transporting these foundations require both the right equipment and effective collaboration,” said Jesper Bank, chief commercial of cer of Port Esbjerg. “Our infrastructure and capacity to handle heavy and complex constructions are crucial for ensuring a smooth process, which demands careful planning and close cooperation between technicians, logisticians and operators.”

During the rst CVOW installation season contractors installed monopile foundations for turbines starting about 27 miles offshore. Transition pieces were placed onto monopiles, with construction scheduled to resume in May 2025 with the installation of Siemens Gamesa 14-megawatt turbines.

Dominion Energy said its construction schedule is on track, with the project to be completed in late 2026.

The company’s future plans also include two additional leases it obtained from the Bureau of Ocean Energy Management: 176,506 acres about 35 miles from the mouth of Chesapeake Bay, and 40,000 acres off the North Carolina Outer Banks. The company estimates those tracts could produce power of up to four gigawatts and 800 megawatts respectively.

The main chamber of Wilson Lock on the Tennessee River near Florence, Ala., will be closed for several months after engineers discovered extensive damage to the lock’s infrastructure. The Army Corps of Engineers Nashville District and the Tennessee Valley Authority shut the lock’s main chamber this fall following a dive inspection that revealed cracks in the lock gates on both the land and river sides.

December, General Dynamics Electric Boat evacuated its Quonset Point, R.I., facility twice following two separate bomb threats. The written threats were discovered less than 10 hours apart, leading to emergency response by local, state, and federal authorities. No injuries occurred and the facility resumed normal operations.

The Coast Guard’s heavy icebreaking cutter Polar Star and crew departed Seattle Nov. 22 on their annual deployment to support U.S. scientific stations in the Antarctic. Commissioned in 1976, the 399'x84' Polar Star is now the Coast Guard’s sole operational heavy icebreaker, as the service works to recapitalize its fleet. The Antarctic voyage supports Operation Deep Freeze, an annual joint military mission to resupply the U.S. Antarctic stations in support of the National Science Foundation, the lead agency for the United States Antarctic Program. Each year, a joint and total force team works together to complete a successful Operation Deep Freeze season. Polar Star completed the fourth of five phases of a service life extention project this year.

The cutting-edge of commercial marine meets a 45-year maritime industry tradition at The International WorkBoat Show. As the maritime industry embraces innovation, The WorkBoat Show remains at the forefront, driving progress and propelling the industry forward.

Join us in December alongside Underwater Intervention to experience the dynamic synergy between the commercial marine and subsea industries.

By Kirk Moore, Contributing Editor

Facing the existential threat of a new Trump administration, offshore wind power advocates are mounting their own post-election campaign to win critical support from Republican and Democratic lawmakers and governors.

President-elect Donald Trump’s campaign promise to make sure offshore wind development “ends on day one” of his new administration has cast a pall over the fledgling U.S. wind industry – raising the prospect of the incoming administration cutting off environmental and construction permits and blocking any future offshore wind

lease sales by the Bureau of Offshore Energy Management (BOEM).

Wind industry advocates are scrambling to make their case that offshore wind is good for Trump’s stated goals of rebuilding U.S. industry and jobs. Since 2016, wind power companies have invested in purpose-built, U.S.-flagged vessels and have helped promote the use of hybrid power over traditional diesel propulsion – a shift that is being adopted by ferry and passenger vessel operators too.

Pitching U.S. offshore wind power as a bipartisan success story, Liz Burdock, president and CEO of the industry group Oceantic Network, credits Trump’s first administration

for helping to get the industry off the ground.

“When President-elect Donald Trump takes office, he will re-inherit an industry he kickstarted. Eight years ago, the first Trump administration began implementing the fundamental framework for our modern offshore wind industry and oversaw three federal lease sales that netted $456 million for the federal treasury,” Burdock wrote in the Nov. 22 issue of Recharge.

“Those actions led to the first wave of investments in supply chain facilities for the industry, which are now creating jobs in places like Texas and South Carolina and enabled the substantial level of investment we’ve seen since 2020,” wrote Burdock.

Anticipating opposition from the impending Trump presidency, offshore wind developer TotalEnergies SE, said Nov. 26 it is suspending work on its Attentive Energy project planned off New York and New Jersey.

The 3,000-megawatt array south of New York Harbor could be operational in the 2030s, according to developers. Nonetheless, “I have decided to put the project on pause” with Trump’s return, Patrick Pouyanne, CEO of the France-based TotalEnergies multinational, said at an energy industry conference in London, Bloomberg reported.

The Attentive Energy project is still in the early stages of permitting with BOEM, although developers have obtained offshore leasing rights from the federal agency. Pouyanne indicated TotalEnergies may wait for political winds to shift again.

“I said to my team, the project in New York, we’ll see that in four years,” he said, Bloomberg reported. “But the advantage is it’s only for four

years.”

Although wind power was supported early in Trump’s rst administration, his top Department of Interior of cials turned sharply against the industry in the last months of 2020, trying to cancel permits for the Vineyard Wind project off southern New England.

In early 2021, President Biden’s new administration swiftly restarted Vineyard Wind permitting. A new Trump administration can upend the process again, by blocking permits and new lease sales.

The move by TotalEnergies could foreshadow dif cult decisions by other offshore wind companies – and for domestic U.S. companies who have mobilized to provide the supply chain to offshore wind power. Despite Trump’s change of heart, existing leases, long lead times for permitting and growing demand for power give the wind industry hope to outlast opposition.

Burdock stresses how many U.S. companies are already deeply invested: “Our message to policymakers is clear: the U.S. offshore wind industry has become an economic powerhouse,”

she said. “It’s driving local and state economies and positioning the U.S. as an energy leader. It has the potential to accelerate this progress and even enhance our national security by diversifying our energy sources and increasing domestic energy production.

“It would also advance the incoming administration’s goals, supporting the domestic production of steel and

shipyard expansion while rebuilding our nation’s port infrastructure.”

New Jersey opponents of offshore wind projects, including commercial shermen, seaside homeowners, and tourism interests, are heartened by Trump’s electoral win. Trump made

his pledge to end wind projects at a May campaign rally on the beach at Wildwood, N.J., before a crowd that included many local activists.

“The national election results may portend a change in federal policy regarding offshore wind projects,” the opposition group Save Long Beach Island wrote on its social media page a day after the Nov. 5 election. “However, the wind company for the project

off LBI has stated its intention to proceed under prior federal approvals if it receives approval from the state. Save LBI remains committed to fight the construction of the country’s largest offshore wind project just 8 miles from our pristine shore. There will be no letting up in our efforts in this battle.”

New Jersey’s Democratic Gov. Phil Murphy, who made renewable energy and offshore wind a central policy of his administration, is fighting to maintain support. The state energy plan took a major blow in fall 2023 with developer Ørsted’s sudden decision to cancel its Ocean Wind 1 project in the face of escalating costs.

In a Nov. 13 interview with Newark, N.J., radio station WBGO, Murphy insisted renewable energy will boost the economy and criticized Trump and Republican efforts to make offshore wind another front in the political culture wars.

“It’s gotten this ‘woke’ label, which is ridiculous,” said Murphy.

New Jersey’s official goal of 100% renewable energy by 2035 far surpasses a 2006 study that envisioned a pilot project of up to 80 turbines using then-available designs around 400' tall – compared with current plans by Atlantic Shores, a venture by Shell New Energies and EDF, to build up to 195 turbines more than 1,000' tall off Long Beach Island.

Environmental groups, wanting to move away from fossil fuels, supported the state’s planning from the beginning. But even then, activists focused on New Jersey coastal waters were more skeptical, as were fishermen, fearing future conflicts.

“Even if the site isn’t that important to us, it could have an impact on commercial fishing. It might be clam beds, it might be scallop beds, it might be grounds where the flounder guys drag,” Tony Bogan, a party fishing boat captain and president of the industry group United Boatmen of NJ/NY, told the Asbury Park Press in May 2006.

Regardless of how the political battle unfolds for future wind projects, developers with established leases and construction plans are driving activity – and innovation – among designers and shipbuilders supplying the new wind energy fleet.

In late 2024, American Offshore Services (A-O-S), Providence, R.I., took delivery of the newbuild crew transfer vessel (CTV) Guarder from shipbuilder Blount Boats, Warren, R.I.

Blount was an early entrant in the U.S. CTV market, in 2016 delivering the Atlantic Pioneer, a 70'6"x24'x4' aluminum catamaran and the first U.S-flagged CTV. A-O-S’s Guarder is a 98' Jones Act-compliant aluminum catamaran purpose-built to transfer technicians and equipment in support of the offshore wind industry on the U.S. East Coast. It has capacity to accommodate 24 passengers.

The boat is the third G-class series CTV delivered to A-O-S, a partnership between Swedish CTV operator Northern Offshore Services (N-O-S) and U.S.-based investment firm Orion Infrastructure Capital (OIC). A-O-S’ G-class vessels are being built according to ABS and

U.S. Coast Guard standards. Each features quad Volvo Penta IPS propulsion. Guarder is “hybridready”, meaning it has been built with extra space on board to enable a conversion to hybrid power in the future.

“We have taken delivery of three vessels in three quarters. The industry is growing and the demand for CTVs is steady,” said Michael Burbelo, managing director at A-O-S. “As I said earlier this year, we are just getting started.”

Meanwhile, across Narragansett Bay, Senesco Marine, North Kingstown, R.I., launched a new Jones Act-compliant CTV for its sister company, WindServe Marine. The new vessel, WindServe Spartan , is servicing the emerging offshore wind industry on the U.S. East Coast. Both Senesco Marine and WindServe Marine operate under the Reinauer Group.

The delivery of the WindServe Spartan marks the final boat of a sixvessel contract that Senesco has with WindServe. The aluminum catamaran was designed by naval architects BMT, Houston, and measures 95'x30' with a 5'6" draft.

Compared with the rst four CTVs, the WindServe Spartan has an extended engine control room (ECR) to allow for hybrid-ready capabilities.

Ted Williams, Senesco’s president, spoke about the 6' ECR extension, which was also incorporated into WindServe’s fth delivered vessel, WindServe Frontier

“We’re not supplying the hybrid system at this time, but in the event a customer in the future wants that, there’s enough room in the back of the engine room to go hybrid if there’s the desire to do that,” Williams said.

On the West Coast, new moves toward hybrid low-emission transport include Washington State Ferries’(WSF) announcement on Oct. 3 that three shipbuilders have expressed interest in constructing ve 160'x53'x7.5' hybrid-electric ferries. The selected shipbuild-

ers include Nichols Brothers Boat Builders, Freeland, Wash., Eastern Shipbuilding Group, Panama City, Fla., and Philly Shipyard, Philadelphia.

WSF invited shipbuilders nationwide to submit pre-quali cation packages, a move made possible by 2023 state legislation enabling the agency’s capacity to source shipbuilding talent across the country and build vessels at multiple sites concurrently.

The planned ferries will each

accommodate 160 vehicles and are expected to enhance services on the Mukilteo-Clinton and SeattleBremerton routes. The rst two vessels are anticipated to be completed by 2028, with an additional two by 2029 and the nal vessel by 2030.

The WSF hybrid-electric ferries are part of WSF’s $3.98 billion Ferry System Electri cation plan. The plan aims to reduce greenhouse gas emissions by 76% by 2040 and achieve zero emissions by 2050.

By Michael Crowley, Correspondent

Ferries have come a long way in the San Francisco Bay transportation system since John Reed, an Irish immigrant, established a ferry service in 1826. Reed’s vessel of choice was a sailboat he sailed in the Oakland estuary. Over the years, that sailboat would be followed by a variety of vessels, many of which had originated elsewhere but ultimately served to transport people across San Francisco Bay.

Passenger ferry service began operating between Oakland, Calif., and San Francisco in 1851 with the sternwheel Sacramento River packet General Sutter. Two years later, the Clinton was California’s rst steam ferry, a 120'x24' side-wheel steamer, powered by a 125-hp low-pressure engine and built for trans-bay service. In 1909, the Melrose was launched as the rst San Francisco Bay ferry built with an unobstructed lower deck speci cally intended for automobiles and an upper deck for passengers.

The latest in the lineup of breakthrough designs will be a 92'3"x26'x5'7", 155-passenger, battery-electric powered, aluminum catamaran ferry for San Francisco’s Water Emergency Transportation Authority, the operator of the San Francisco Bay Ferry System. All American Marine, Bellingham, Wash., has been contracted to build three 155-passenger ferries for a

San Francisco takes first step toward no-emissions ferry fleet.

total of $46 million. There is an option for a fourth. Aurora Marine Design (AMD), based in San Diego, led the conceptual design, and New Zealand-based Teknicraft Design will work with AAM as the naval architect.

As of mid-December, no designer or builder had been selected for the larger, 400-passenger, ferries. Though Seattle’s Elliott Bay Design Group will be the construction manager, the actual design will be left up to the shipyard building the boat. The only stipulation is that “it should look something similar to the smaller boat,” said Green.

The 155-passenger and 400-passenger ferries will be the U.S.’s first high-speed, battery-electric ferries. Delivery of the first ferry — an Aurora 92-footer — is expected in mid-2026.

“The impetus for the design,” said Green, “is that San Francisco Bay Ferry is committed to zero emissions in its whole fleet by 2035.” San Francisco Mayor London Breed said in a Nov. 1 press release that the city was receiving a $55 million grant from the Environmental Protection Agency for completing “the nation’s first-ever, high-speed, zero-emission ferry network connecting critical transportation hubs.”

Ferries emerging from the designers’ boards to fulfill this vision will be vastly different from ferries available today. To

start with, the battery-electric ferries will be “sort of a unique experience. They are quieter and you hear other things,” noted Green.

The source of that “quiet” for the three 92' catamaran ferries will be a propulsion package provided by Wärtsilä that includes a pair of 219-kW battery packs, one in each hull, each matched up to a 625-kW electric motor that powers a 360°, high-speed Hydromaster azimuthing stern thruster.

Besides being quieter than the conventional propulsion package, “It will decrease docking time and greatly decrease the amount of energy used,” said Green. “Theoretically, fully loaded, it should be capable of 26 knots but will probably run in the 23-knot range.”

The closest thing in Europe, said Green, is the fully electric, 147' passenger ferry Medstraum, which was delivered to operator Kolumbus in 2022 and is said to be reducing emissions by up to 1,500 tons per year on the commuter route between Stavanger and Hommersåk on the west coast of Norway. San Francisco’s new 92' ferries should produce “93.3% less emissions. That’s the savings over the renewable diesel that ferries are currently using,” said Green.

The batteries for the San Francisco Bay 92-footers were selected by Wärtsilä after what Green said was “a big evaluation of all the batteries out there.”

Sweden-based Echandia announced in August that it will supply the battery systems from its new production facility in Marysville, Wash., targeting delivery in 2025.

“The battery vendor we selected has a battery chemistry you can really abuse,” Green said, noting a quick charging turnaround time. Green estimates the turnaround time to be six to seven minutes for the entire boat, and “the batteries’ lifespan is two to three times that of equivalent batteries.”

The ability to quickly recharge a battery “allows you to have a much smaller battery on board and be a lot safer,” added Green. It also means a lighter boat. The batteries going into each 92-footer should have a total weight of 15,400 lbs. That’s compared to 22,000 lbs., which

Green said is about what “normal batteries would weigh.”

All boats in San Francisco’s WETA eet will have the same propulsion system. Smaller boats will have one propulsion unit per hull. The 400-passenger ferries get the same propulsion, just two units per hull. “Standardization was one of the big, big highlights of the thing,” said Green. “We spent a lot of time making sure we could make that happen.”

Standardization cuts down on the number of spare parts that need to be stored. If a thruster needs to be replaced in the 155-passenger ferry, a spare from one of the 400-passenger ferries can be used. “It has the same gear ratio, the same everything,” said Green.

If the propulsion system for San Francisco’s new ferries makes them vastly different from what powers the current ferries, so, too, does the interior design, which Green said is derived from shoreside industrial designs, as opposed to standard ferry layouts. “We spent time with WETA asking how we can improve the passenger’s experience on board and save weight at the same time,” said Green. “They were looking for a different feel on board — more of an enhanced passenger experience, more lounge-like, less school-bus-feeling. They wanted something that was new, exciting and interesting.”

Thus the 92-footers will have what Green said is a more “lounge-style seating [arrangement], more like you see in

a bar,” as opposed to “three to four in a row seating.” In fact, the design calls for “a lot of barstool-type seating.”

When you look at the main deck layout, there’s a lot of barstools drawn in. “Passengers come aboard and literally plunk themselves down on a barstool and look out through really large windows, almost oor-to-ceiling windows. You’ll be more connected to the outside world and the water outside,” said Green.

Green said the interior design works especially well on shorter runs. “People don’t want to take the time to squeeze between other people and nd a middle seat,” he said.

The oat where the Aurora Marinedesigned 92-footers will tie up is different from the usual ferry tie-up. The oat contains a full electrical power management system.

“It takes like 12,000 volts from shore in the trunk of the oat and converts [it] into DC for charging the ferry and AC for running all re ghting and pumps and 1.3 MW of batteries in the oat,” said Green. "We designed and made the oat that contains all the equipment on the inside, so visually it's not impactful." That was important because San Francisco didn't want 40' containers packed with electronic equipment along it's downtown docks, creating a public eyesore.

Senesco Marine, North Kingstown, R.I., late last year launched a new Jones Act-compliant crew transfer vessel (CTV) for its sister company, WindServe Marine. The new vessel, WindServe Spartan, was built to serve the emerging offshore wind industry on the U.S. East Coast. Both Senesco Marine and WindServe Marine are part of the Reinauer Group.

The delivery of the WindServe Spartan marks the final boat of a six-vessel contract with WindServe. The aluminum catamaran was designed by BMT, Houston, and measures 95'x30' with a 5'6" draft.

Compared with the first four CTVs, the WindServe Spartan has an extended engine control room (ECR) to allow for hybrid-ready capabilities.

Ted Williams, Senesco’s president, discussed the six-foot ECR extension,

which was also incorporated into WindServe’s fifth delivered vessel, WindServe Frontier

“We’re not supplying the hybrid system at this time, but in the event a customer in the future wants that, there’s enough room in the back of the engine room to go hybrid,” Williams said.

The new CTV is equipped with quad Volvo Penta D13 main engines, each rated at 690 hp at 2,300 rpm, and connected to a Volvo Penta IPS 900 propulsion system. The vessel has Volvo joystick controls, including a dynamic positioning system feature that allows the vessel to maintain its position and heading despite strong winds and current.

The WindServe Spartan can achieve a service speed of 24 knots, with top speed capability of 27 knots, carrying up to six crewmembers and 24

offshore technicians. Crew amenities include Starlink internet, DirecTV satellite television, and KPM suspension seating.

Also onboard are a pair of Rehlko generators, a Toimil T-12505M/2 forward deck crane, a portable high-pressure washer on the bow, Hercules AAW-150 anchor windlass, First Electric automation system, and a Reygar BAREFleet vessel monitoring system.

Capacities include 9,715 gals. of fuel, and 792 gals. fresh water. The 540 sq. ft. forward cargo deck can handle up to 20 tons of freight.

WindServe Spartan is built to U.S. Coast Guard, Subchapter L certification and ABS classification.

Senesco uses Pierce Aluminum, Franklin, Mass., and Yarde Metals, Southington, Conn., for its aluminum parts, and Kloeckner Metals, Middletown, Conn., for its steel.

“We get all of the aluminum pre-cut, because we don’t want to contaminate steel and aluminum,” Williams said. “Aluminum is really fickle. And if you get any steel dust in it, it will degrade the welds significantly.”

Senesco separates its aluminum builds from its steel builds in buildings that originally served as World War II aircraft maintenance hangars.

The WindServe Marine fleet is made up of the 64'6" WindServe Odyssey (2020), the 88'6" WindServe Genesis and WindServe Journey (2023), the WindServe Explorer (2023), and the 95' WindsServe Frontier (2024).

— Ben Hayden

What will the workboats of the future look like? Photon Marine, a Portland, Ore.based developer of electric propulsion systems, believes that its technology will be sought out by vessel owners and operators that are seeking ways to improve efficiency, environmental performance, and their bottom line.

It’s widely recognized that hybrid and electric vessels typically cost more initially than diesel-powered boats, with fully electric propulsion systems sometimes costing up to three times more. However, despite these higher initial costs, there are still nancial incentives to adopt these cleaner technologies, according to Charles Steinback, cofounder and vice president of business development at Photon Marine.

“People understand that there is a signi cant potential cost savings with the rising cost of fuel,” Steinback said, also pointing out the reduced maintenance costs associated with electric propulsion systems. “It’s obvious that [this technology] is good for the environment, but [the cost savings over the total lifespan of the vessel] will ultimately drive the uptake.”

Steinback founded Photon in 2021 alongside Marcelino Alvarez, CEO, and Nick Schoeps, CTO. Since then, the team has developed and re ned

their product, which is scheduled to enter commercial production from Portland in 2025.

At peak, Photon Marine’s agship P300 electric outboard offers up to

300 hp and 500 newton meters (Nm) torque. Notably, it operates silently without any vibration or emissions.

At Paci c Marine Expo in Seattle in November, Photon conducted on-water

demonstrations, giving attendees the chance to experience its electric outboards installed on a Silverback Marine-built Grizzly aluminum workboat. The 24' vessel, which features dual motors, and a pair of 63-kilowatt-hour (kW) battery packs, has an estimated range of about 30 nautical miles, cruises easily at 25 knots (at roughly 65% power) and can reach a top speed of 40 knots. It can be charged overnight on Level 2 (240 V) or in 45 minutes using DC fast charge.

Steinback acknowledged that electric outboards, like any technology, have their limitations, but he emphasized that the technology will continue to improve, especially as battery systems advance. “We’re not for everybody,” he said. “But there are many applications where our technology is a great fit.”

Photon Marine sees opportunities across several segments and vessel

types, such as research and survey, mariculture, dredge and marine construction support, harbor patrol, ecotourism and water taxis, crew transport, and ports and utilities, among others.

“Our focus is completely on the commercial market because that’s where the [charging] infrastructure is going to be established first,” Steinback said. The company has focused on developing partnerships with ports and utilities to help accelerate the adoption of its technology.

Photon’s electric outboards are currently being put to the test on the U.S. East Coast under a two-year lease agreement with the New York Power Authority, with additional projects planned in other locations. “We have about 20 units that are scheduled,” Steinback said.

On the West Coast, Photon Marine is

Dayone of the International WorkBoat Show concluded with the annual Significant Boat of the Year event.

This year’s nominees consisted of a dinner cruise vessel, a passenger/vehicle ferry, an electric harbor tug, a crew transfer vessel, towboat, excursion and research vessels, dredge support vessels, and a cutter suction hopper dredge. The 2024 honor was claimed by a pair of Great Lakes Dredge & Dock Corp.’s (GLDD) 99'x41'x12' Multi Cat dredge support vessels, Cape Hatteras, and Cape Canaveral, marking the second year in a row that sisterships have won the award. The two Damen 3013 Multi Cats were built by Conrad Shipyard, Morgan City, La. Main propulsion for the boats comes from three Caterpillar 3412D TTA diesel engines producing a total of 2,500 hp at 1,800 rpm. The mains connect to Promarin fixedpitch wheels in Optima nozzles through Reintjes WAF 464 marine gears with 5.591:1 ratios from Karl Senner, Kenner, La.

supporting the Port of Friday Harbor, which was recently awarded $7 million as part of the Washington State Department of Transportation’s Port Electrification Grant Program. The initiative will see the port deploy up to five electric vessels, including a 24' pump-out vessel, a 24' workboat and a 28' passenger transport boat.

Ultimately, electric workboats are part of a wider push toward sustainability, Steinback said. “This is more than just electric boats. This is about energy independence and resilience and creating opportunities for coastal communities and working waterfronts to start to transition into the future,” he explained. “We understand that this is a tool, and we’re just trying to make it a better tool — one that is going to cost less and is better for the world,” he said.

— Eric Haun

Derecktor Shipyards, Mamaroneck, N.Y., has launched a pair of new hybrid-electric ferries for Savannah, Ga., operator Chatham Area Transit (CAT). The 65' aluminum catamarans, Juliette Gordon Low II and Susie King Taylor II, were launched on Nov. 6, 2024, and Dec. 4, 2024. The ferries are designed to transport up to 149 passengers at a top speed of 11 knots using BAE Systems HybriGen Power and Marine Jet Power (MJP) Ultrajet 305 dual waterjets. A pair of Cummins 6.7L marine diesel generators will charge the 308- kW XALT lithium-ion battery systems.

Elliott Bay Design Group (EBDG) and Diversified Marine, Inc ., chose the WorkBoat Show to unveil plans for the industry’s first and only electrified truckable tug. The tug, 26'x3.6', features twin permanent magnet motors producing 800-plus total horsepower and dual rudders for steering. While the battery range and duration will vary depending on the application, EBDG director of sales Joe Hudspeth told WorkBoat that the charge “can last a full working day.” Construction is tentatively scheduled for 2025.

Blount Boats, Warren, R.I., delivered the 98.4'x36.08' crew transfer vessel Guarder to American Offshore Services (A-O-S), Providence, R.I., at the end of November. (Blount delivered the Atlantic Pioneer for Atlantic Wind Transfers in 2016, the rst CTV for the U.S. market.)

The Jones Act-compliant aluminum catamaran is purpose-built to transfer technicians and equipment in support of the offshore wind industry on the U.S. East Coast. It has capacity to accommodate 24 passengers.

The newbuild is the third G-class series CTV delivered to A-O-S in 2024. The company is a partnership between Swedish CTV operator Northern Offshore Services (N-O-S) and U.S.-based investment firm Orion Infrastructure Capital (OIC).

“This contract to build four new CTVs is an important milestone for our company and validates our position as a pioneer and major supplier of CTVs to meet the growing demand for these specialized support craft for the burgeoning American offshore wind industry,” Marcia Blount, president of Blount Boats, said when the contract was rst signed in late 2021.

Main propulsion comes from a combination of Volvo Penta D13 diesels and four Volvo Penta IPS 1050 propulsion drives, two in each hull. The fully integrated system includes Volvo Penta’s GPS-based dynamic positioning system and integrated joystick controls, designed for convenient and easy maneuverability even in conditions of strong currents and high waves. All subsystems are connected by Volvo Penta’s Electronic Vessel Control (EVC) data network.

Guarder is “hybrid-ready”, meaning it has been built with extra space on board to enable a conversion to hybrid in the future.

The G-class CTVs are equipped with the N-O-S fender design, which has been proven on windfarms throughout

Crew transfer vessel for American Offshore Services from Blount Boats in support of the offshore wind industry on the U.S. East Coast.

Europe, and has shown “unparalleled gripping qualities, which increases transfer performance,” according to A-O-S.

“We have taken delivery of three vessels in three quarters. The industry is growing and the demand for CTVs is

steady,” said Michael Burbelo, managing director at A-O-S. “As I said earlier this year, we are just getting started.”

The G-class CTVs are ABS classed, and U.S. Coast Guard certi ed, Subchapter L.

The 2024 edition of the International WorkBoat Show (IWBS) was a success. So much so that the 2025 show is expanding.

The show hosted over 1,000 exhibitors and 14,000 attendees.

“The WorkBoat Show continues to expand the horizons of maritime innovation,” said Liz Plizga, president, Diversi ed Communications, the show’s owner. “That innovation has been taken to the next level this year with over 200 companies that are new to the show, a revitalized conference program, and an exhibit oor with tools and technologies that highlight the true breadth of this sector. The event has become a catalyst for personal and professional development and really shows the transformative power of a trade show to push the boundaries of an entire industry.”

Two new events this year — the Women in Maritime Luncheon and the Jones Act Breakfast — both sold out.

The 44th International WorkBoat Show was by any measure a success, with 14,000 attendees and 1,000 exhibitors flooding into New Orleans for the annual event.

The Conference Program drew large crowds to sessions on the Baltimore Key Bridge allision, the future of shipbuilding, vessel electri cation, vessels of the future, and the U.S. dredging boom, among others.

Again, this year, sessions involving the vessel needs of the Coast Guard, Navy, and Army were among the most popular. And this year the National Oceanic and Atmospheric Administration (NOAA) got in on the act and attracted a big crowd.

IWBS will return to its traditional

rst week of December time slot on the calendar next year. The 2025 International WorkBoat Show is scheduled for Dec. 3-5 at the Morial Convention Center in New Orleans.

Meanwhile, here’s some of what was making news at this year’s IWBS.

The March 26 ship allision and catastrophic collapse of the Francis Scott Key Bridge in Baltimore was a stark revelation of U.S. port vulnerability.

When the 8,600' continuous-truss span came down, killing six workers, it was the end to a “sequence of poor decisions that are just about the hallmark of all disasters,” said Morgan Fanberg, CEO of Glosten, during a panel discussion.

But the weeks that followed were “a testament to all involved who got the Baltimore Harbor back up and running,” said Fanberg, whose Providence, R.I., marine architecture and engineering firm was involved in the recovery operation that had the main channel fully reopened by mid-June.

Outbound from Baltimore for Sri Lanka, the 948' containership Dali experienced electrical failures that triggered an automatic engine shutdown as it approached the bridge over the Patapsco River. The allision left the Dali pinned under the collapsed span and resulted in approximately 50,000 tons of steel debris in the water. The six men who were killed had been working on the bridge when it collapsed.

Two years before, the same kind of unified command response was brought into play after the containership Ever Forward grounded near the Chesapeake Bay bridge, recalled another panelist, William Doyle, a past CEO of the Port of Baltimore and now executive director and CEO of the Dredging Contractors of America.

“That kind of coordination on command and control is critical,” said Doyle.

While the National Transportation Safety Board determined the Dali had experienced power problems before its early morning departure and the bridge allision around 1:30 a.m., the agency has yet to reach conclusions about the accident. An FBI investigation is likewise continuing.

The interim report pointed to maintenance problems and operating conditions of the ship as possibly having affected its electrical systems.

“I don’t doubt that vibration was an issue,” a typical problem in older vessels, said Glosten’s Fanberg.

— Kirk Moore

feature a 360° hydraulically driven, 310-hp bowthruster.

Each year, WorkBoat magazine names its 10 Significant Boats. To be nominated, the newbuild vessels must adhere to a few mandates that include an appearance in WorkBoat ’s On the Ways section or as a stand-alone story between December of the previous year to November of the current year.

Then the editors open up the naming of the Boat of the Year to the public via a website created specifically for the occasion.

This year’s winners were Great Lakes Dredge & Dock Corp.’s (GLDD) 99'x41'x12' Multi Cat dredge support vessels, Cape Hatteras and Cape Canaveral, marking the second year in a row that sisterships won the award. The twin Damen 3013 Multi Cats were built by Conrad Shipyard, Morgan City, La.

Main propulsion comes from three Caterpillar 3412D TTA diesel engines, producing a total of 2,500 hp at 1,800 rpm. The mains connect to Promarin fixed-pitch wheels in Optima nozzles through Reintjes WAF 464 marine gears with 5.591:1 ratios.

The propulsion package gives the new Damen Multi Cats a speed of 9.6 knots and a bollard pull of 35 metric tons. For added maneuverability, the multipurpose dredge support vessels

Ship’s service power comes from two Caterpillar C 04.4 gensets, sparking 107.5 KVA (one KVA is equal to 1,000-volt amps) each. Hydraulic power comes from a Caterpillar 3412D TTA engine producing 632 kW of electrical power.

Cape Hatteras and Cape Canaveral are the first Damen Multi Cats to be built in the U.S. and are fully compliant with Coast Guard and Corps of Engineers stability criteria.

— Ben Hayden ***

The commercial marine industry, like nearly every other sector across the globe, is grappling with its contributions to climate change and the regulations that have recently been developed to try to curb carbon emissions. According to the Department of Energy, the maritime industry is responsible for roughly 3% of total greenhouse gas emissions globally every year.

The idea of embracing further sustainability within the commercial marine industry was the topic of a session entitled “Paving the Way to Sustainable Shipyard and Port Operations.” The panel discussion included professionals who are working on

these problems daily. Moderated by Brittney Blokker, program manager, Green Marine, the panel featured Jan Allman, vice present and general manager, Fincantieri Bay Shipbuilding; Emily Federer, sustainability manager, Port of New Orleans; and Jeri Shull, vice president, corporate environmental, Arcosa.

In this mission to bring more sustainable efforts to the industry, Blokker pointed out in the session’s opening remarks that shipyards and ports are target areas for meeting these goals.

“Ports and shipyards are uniquely positioned to combat climate change due to their strategic role in global trade, while also being deeply ingrained in their local community,” she said. “Their capacity to develop infrastructure, adopt cleaner technologies, and engage multiple stakeholders will allow them to drive sustainable initiatives that have both local and global impacts.”

One of the topics discussed was how organizations can begin their journey toward sustainability, an area where Shull has focused due to Arcosa’s relative youth in the industry. The company is still finding its footing, she said, emphasizing that its environmental, social, and governance committees are leading the push to sustainable decision-making, leaning heavily on committees specifically formed to address these issues.

“Our ESG committees, which are built from our executives, our leadership, and our champions across our enterprises,” she said, “are the ones that drive the knowledge throughout our enterprise, understanding what our initiatives are, what we’re trying to do, and build up the knowledge of our personnel.”

For her part, Federer spoke from the perspective of a significantly older organization, with the Port of New Orleans celebrating over 130 years as a recognized marine entity in Louisiana. Even so, Federer said, her company feels relatively new in this area with its ESG program having been established in 2013. — Matt Collins

draft by up to 18" to navigate shallow waters during low-river levels.

American Commercial Barge Line (ACBL), Jeffersonville, Ind., christened its new 200'x50'x12'6" towboat Mariner on the Mississippi River in an out-of-the-ordinary nighttime ceremony. ACBL officials said Mariner is the largest towboat built in the U.S. in 50 years.

Constructed by C&C Marine and Repair, Belle Chasse, La., and designed by CT Marine, Edgecomb, Maine, the 11,000-hp boat has an operating draft of 11'6", eight 65-ton winches, dual steering and flanking rudders, and can adjust its operating

The baptism began about 6 p.m. after the close of the first day of the WorkBoat Show. The ceremony took place at Mardi Gras World and featured the traditional breaking of the bottle on the boat’s bow, a lavish fireworks show, and a mini parade, followed by a party to rival an upscale wedding reception.

“Mariner represents all mariners, from the deckhand to our most experienced captain,” ACBL’s CEO Mike Ellis told the crowd. “This boat is not just a vessel. It’s a home” to the mariners who operate it.

Ellis said the contract to build the

boat was signed in 2022 with the boat scheduled for delivery in 2025. But during Mariner’s construction, Ellis got a call from Tony Cibilich, C&C Marine’s owner, asking him if ACBL would host a christening party during this year’s WorkBoat Show if C&C Marine delivered the boat in time. There would be no additional cost to ACBL except that Cibilich wanted a big christening party to mark the occasion. Cibilich delivered the boat, and Ellis delivered on the party.

Main propulsion for the Mariner comes from twin Caterpillar C28012 diesel engines connected to Hung Shin 5-bladed wheels through Reintjes WAF 6755 marine gears supplied by Karl Senner. Steering and controls are the responsibility of CT Marine’s TwinDIFF system.

Within days of the christening, Peter Coxon was named ACBL’s CEO, succeeding Ellis, who had held the position since 2020. — Ken Hocke

ing valuable insights into how the industry can build a sustainable, skilled workforce.

A recurring theme throughout the session was the need for stronger collaboration between maritime schools, industry leaders, and local communities. “We’re not going to do the thing that we’re trying to accomplish without partners,” said Capt. Elizabeth Simmons, vice president of external affairs at Massachusetts Maritime Academy.

Simmons pointed out that the collective efforts of maritime academies, community colleges, and private companies can create a powerful network to attract, train, and retain talent.

In Houston, this kind of partnership is already showing results. John Stauffer, associate vice chancellor of maritime at San Jacinto College, shared the efforts made to enhance maritime education with cutting-edge technology.

industry players are getting involved at the grassroots level.

Another topic that sparked discussion was the role of social media and digital marketing in attracting younger workers. As more students turn to platforms like Instagram, YouTube, and TikTok to discover new career opportunities, maritime institutions are adapting to meet them where they are.

“Our admissions office is using social media to create short video clips about current students talking about why they came, how they found out about maritime, and what they’re looking to do with their careers,” said Simmons .

The approach, which focuses on sharing real student experiences, is proving to be an effective tool in reaching potential recruits, especially those who may not have considered a maritime career previously.

Col. Michael E. Fossum, COO and vice president at Texas A&M Galveston, touched on the importance of using digital tools to not only reach students but also to engage their families. Geo-tracking technology, for example, facilitates monitoring or recording the physical location of individuals in real time. “We’re able to see what the students are interested in as well as where they are located,” Fossum said. The panelists also shared that geotracking helps them understand the students’ parents as well. He emphasized that many students first learn about the maritime industry through their parents, making it essential to engage families in the process.

Industry leaders gathered for a session to discuss workforce development, one of the most pressing challenges facing the maritime sector. The conversation, which addressed recruitment shortages and explored innovative partnerships, was both forward-thinking and practical, offer-

“The Houston Pilots purchased three bridge simulators for us and put them in the college,” he said. “Chevron just adopted nine high schools with maritime programs to go ahead and build up their simulation capabilities.” The simulators are part of a broader initiative to modernize training facilities and give students handson experience with the latest equipment. Stauffer emphasized how major

While digital marketing strategies are becoming essential, funding for such initiatives remains a key challenge. Capt. Jeff Spillane, dean of the school of maritime education training at SUNY Maritime, acknowledged the difficulty many schools face when it comes to securing the resources necessary for outreach. “That’s usually our limiting factor — how do we pay for it?” Spillane asked. “We’re trying to figure out how."

— Carli Stewart

By Ben Hayden, Content Editor

Founded nearly seven years ago in Houma, La., Leviathan Offshore has made a name for itself in offshore and inland diving services. With a leadership team boasting over 100 years of combined oil and gas industry experience across regions from Canada to Venezuela, from the bayou to the shelf, the company attributes its success to a focus on expertise, professionalism, safety culture, and customer satisfaction.

WorkBoat spoke with Brady Teasley, Leviathan’s project and safety manager, and Todd Godeaux, of ce and human resource manager, to learn more about the company’s operations, challenges, and growth plans.

Godeaux said that Timothy Clements, Leviathan’s founder, CEO, and president, envisioned a company that offered a unique, client-focused approach to diving services. “He just decided to start his own. He wanted to bring a dif-

ferent type of personalized service to the industry, focusing on expertise and professionalism, safety, good work, and satisfying the customer’s needs,” said Godeaux.

To meet the diverse needs of its customers, Leviathan maintains a wide range of assets and equipment, as re ected in its project portfolio. The company is actively engaged in pipeline recovery and abandonment, platform removals, reverse lay-type operations, project partnerships with NASA, and environmental work, like installing arti cial reefs in the Gulf for the Coastal Conservation Association.

The company operates three vessels, each designed to handle speci c projects, enabling it to adapt to various industry needs.

The rst vessel to join the company’s eet, the Leviathan I, is a 110' diving support vessel (DSV) that was retro t as a three-point anchor vessel that can accommodate 18 people, with a maximum capacity of 31. The vessel’s smaller size makes it suitable for setting spreads, working in shallow

waters, and on smaller projects.

In 2020, the company expanded its fleet with the acquisition of the 240'x53' Leviathan , a vessel that has been pivotal for the company’s offshore operations.

“We made it the largest four-point vessel in the Gulf,” Godeaux explained. “It’s got a 50-ton crane which allows us to be able to pull up massive pipe lifts,” he said. Additionally, a set of shears are mounted on the boat's stern.

“It’s a two-shear mechanism,” said Teasley. “One shear holds a pipe, the other shear cuts it, and this is actually a faster method and more economical than using some of our competitors with their barges.”

“We’ve got such a large deck space and a clear deck space that we can store all this pipe on it without having to have two or three material barges, or a pipe-lay barge having to come out with dozens of people on it to work. And we can do this very quickly and very efficiently.”

In a 2023 project, Leviathan recovered over 1,000 metric tons of pipeline from the Gulf of Mexico. The pipelines were in water depths from 8' to 214', pipe diameters ranged from 3" to 12", and some were concrete coated. Leviathan recovered over 165,000' of pipe during the project, with recovery speeds averaging 4,500' per day and reaching a peak of 6,000' in a single day.

While inland projects historically helped fill gaps during slower seasons, the introduction of the Leviathan has made year-round offshore work possible. “Now that we have the larger vessel, our inland work has slowed because we’re much busier offshore, because this vessel can handle a lot more weather, a lot more seas, so we’re staying busier year-round,” Godeaux added.

Those sentiments were echoed by Rich McKeown, one of Leviathan’s commercial divers, who, at the time of this writing, had just pulled anchor and was returning to port after 170 consecutive days at sea, deeming it

one “hell of a season”.

Beyond the offshore work, Leviathan has undertaken unique projects, including a collaboration with NASA at the Johnson Space Center’s Neutral Buoyancy Laboratory. The partnership has allowed Leviathan to establish service capabilities outside the oil and gas industry, opening the door for future work with the agency.

“It was a good experience,” Godeaux said. “We had to go through lots of background checks and certifica-

tions to be able to be certified to go and do the work there. So that was a big positive and plus for us, knowing that we were able to get clear for that type of work and possibly any future work that they may have coming up.”

The company looks forward to expanding its offerings across various marine industry markets, supported by a diverse range of equipment that enables it to assist with third-party assets on projects that are not suited for its own vessels.

Recently, the company purchased its newest vessel, the 220'x46' Kraken from Hornbeck Offshore Services. Leviathan is allowing industry trends and customer demands to dictate its setup, with options including a potential retro t for saturation diving.

“We kind of held off this year to do anything with it. We’re just starting to do a little work on the inside and see where next year is going to bring us, and what we may be geared toward and where we want to move. We’ve positioned ourselves economically and nancially to move forward in whichever avenue we decide,” Godeaux said.

Teasley emphasized that safety remains a top priority for Leviathan.

“We’ve had zero major incidents or injuries since the company started,” he said. The company attributes its safety record to rigorous project planning, hazard identi cation, and training.

“Observation cards and hazard hunts are done weekly on the vessels,” he added, highlighting the proactive culture instilled within the team.

Leviathan has worked hard to build