Cutting-edge subsea technology helps locate long-lost wreck

Located in Northeast Florida, two nautical miles from the Atlantic Ocean, BAE Systems Jacksonville Ship Repair applies competence, efficiency, and integrity to your projects. With additional capacity and capabilities coming in early 2025, now is the time to consider BAE Systems. Contact us for more information and to subscribe to our Ship Repair announcements. Jacksonville, Florida | USA +1-904-431-2227 | jaxshiprepair@baesystems.us

baesystems.com/commercialshiprepair

12 Focus: Maritime Vulnerabilities

Coast Guard focusing on cybersecurity threats.

16 Vessel Report: 24-hour Protection

There’s no downtime for the vessels that defend against bad actors.

24 Cover Story: 10,000' Under Ice

The subsea operations that found the HMS Endurance

20 On the Ways

• Dawn Services restoring 8,200-hp tug • North River Boats building

15 charter fishing boats for B.C. • Colonial christens new push tug from Eymard Marine • American Cruise Lines riverboat christened • First U.S.-built WTIV starts sea trials • Artemis Technologies, Delta Marine partner • Brix Marine delivers crew vessel for Bridgemans • Rocket Lab converting deck barge for at-sea landings.

28 On Board with Outboards

Manufacturers are pushing engine capabilities to new heights.

LOG

7 Lightning strikes Vineyard Wind turbine

7 SS United States limps into Mobile, Ala., under tow

7 Tidewater reports 2024 revenue growth.

7 Hawaiian distillery has a problem with the Jones Act

8 On the Water: Do-it-all towing.

8 Capital Corridors: Coast Guard needs a service secretary.

9 Energy Level: Trump's arrival stimulates maritime activity.

9 Nor’easter: As offshore wind stalls, what fills the gap?

10 Inland Insider: ACBL applies for barge fleeting permits.

10 Credentialing Insight: Time-and-a-half credit for MMC.

11 Legal Talk: Defining seaworthiness in a digital age.

12 Health, Safety, & Environment: The value of building port partnerships.

You may be asking yourself, why is a South African icebreaker on the cover of this month’s issue? It’s a good question, and I’m going to answer it.

The April cover story goes behind the scenes of a mission to locate and document one of history’s most wellknown shipwrecks: Ernest Shackleton’s HMS Endurance, which became trapped in Antarctic ice and was swallowed into the deep, frigid waters at the bottom of the world more than a century ago. The harrowing tales of Shackleton and his crew have been documented extensively, but the exact whereabouts of the long-lost ship had remained a mystery – until recently.

In 2022, teams of leading explorers, scientists, and technology experts aboard the S.A. Agulhas II did what many thought to be impossible. They found the Endurance resting on the sea oor some 10,000' below the icy surface of the Weddell Sea – a truly impressive technological feat that relied on some of the world’s most cuttingedge subsea tools.

Underwater vehicles like the one used to nd the Endurance wreck are unlocking new possibilities across many sectors, from subsea exploration, defense and science to underwater inspection, maintenance, and repair in the oil patch.

How do shipwreck hunters and deepsea drillers deploy this equipment? From workboats.

Vessels like the one on the cover of this edition transport and deploy the subsea equipment that enables more precise data collection, real-time moni-

Eric Haun, Executive Editor ehaun@divcom.com

toring, and autonomous underwater capabilities. These innovations reduce costs, extend operational reach, and support more sustainable and effective resource management in defense, scienti c research, and offshore energy. And, in case you haven’t heard, icebreakers are en vogue. President Donald Trump said in January that he plans for the United States to order 40 of them — “big ones,” he said. I welcome the idea. The U.S. desperately needs to expand its icebreaking capabilities, particularly as adversaries like Russia and China bolster their presence in the Arctic.

But I consider myself a realist. Forty new icebreakers? I’m not holding my breath.

EXECUTIVE EDITOR Eric Haun / ehaun@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTENT EDITOR Benjamin Hayden / bhayden@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS

Tim Akpinar • Jonathan Barnes • Capt. Alan Bernstein • Stephen Blakely

Dan Bookham • G. Allen Brooks • Bruce Buls • Michael Crowley

Jerry Fraser • Nate Gilman • Pamela Glass • Arnie Hammerman

Craig Hooper • Joel Milton • Richard Paine, Jr. • Chris Richmond

DIGITAL PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com

ADVERTISING ACCOUNT EXECUTIVE S

owboat ats & Bar r es ecruitment/Retention/ raining ONUS DIS RIBU ION

Marine Expo - May 28-30

Mike Cohen 207-842-5439 / mcohen@divcom.com

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

DISTRIBU ION iesel Director

Producers of The International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

VICE PRESIDENT Wes Doane / wdoane@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET)

David Clark Company is proud to be a part of “Project Perfect Storm ” - selected as the boat crew communications provider for the new 11.5-meter, high-tech RHIB Offshore Interceptor from Ocean Craft Marine.

David Clark Marine Headset Systems are transforming the way crews communicate on board high speed patrol boats and interceptors. Noise attenuating headsets and system components provide outstanding reliability and comfort, while reducing crew fatigue from prolonged exposure to wind and engine noise. Call 800-900-3434 (508-751-5800 Outside the USA) to arrange a system demo or visit www.davidclark.com for more information.

“ The {David Clark} wireless headset system has been a game-changer... enhancing crew coordination and overall communication capabilities, while increasing crew situational awareness and effectiveness, making it a must-have for professional boat operations. “

Todd Salus, VP of Operations, Ocean Craft Marine

Neil Maunu, executive director of the Paci c Northwest Waterways Association (PNWA), wrote a letter to members of Congress in the Paci c Northwest to oppose federal employee cuts proposed by the newly established Department of Government Ef ciency (DOGE), particularly those targeting employees of the U.S. Army Corps of Engineers (USACE).

DOGE intends to re over 2,000 USACE employees nationwide, including more than 600 in the Northwestern Division. In his letter dated Feb. 24, Maunu contended that the cuts would be detrimental to regional infrastructure and safety, causing harm to PNWA members, including ports, barge companies, agricultural companies, cruise lines, union labor, and others throughout Oregon, Washing-

ton, and Idaho.

“USACE is unlike any other federal agency — they recruit, train, and retain the nation’s best engineers, program managers, operators, maintainers, environmental scientists, conservationists and more. It can take years, and sometimes decades, for a USACE employee to gain the experience necessary to be successful in their eld. Losing these employees will dramatically affect the Corps’ ability to execute their mission safely and effectively,” Maunu wrote.

Maunu emphasized the Corps’ role in enabling commercial navigation on the Columbia-Snake River system, “the nation’s number one wheat export gateway.” USACE maintains critical locks and dams and dredges the Lower Columbia River channel, “which supports nearly 1,500 vessel movements a year, and over 140,000 jobs,” he said.

“It is absolutely critical this supply chain link remain open and unrestricted. If not, it jeopardizes the thousands

of farmers across the country who rely on it — this is a national issue of extreme importance,” Maunu wrote.

“Billions of dollars in economic impact are at stake if we do not ensure our partners at USACE have the resources and people they need to carry out this important mission.”

“PNWA strongly urges that the federal ring of USACE employees, and other federal employees critical to the safety and operation of a wide range of infrastructure in our region, be halted immediately.”

Something on your mind?

WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number. Email: ehaun@divcom.com

SS United States limps into Mobile, Ala., under tow

After12 days and 1,800 miles at sea, the historic ocean liner SS United States arrived in Mobile, Ala., for a year’s worth of preparation before being sunk off Florida as an artifi cial reef. Once the pride of the U.S. maritime fl eet, the 992'x101' ship shattered speed records for trans-Atlantic passenger vessels during its 1952 maiden voyage, averaging 36 knots.

ATVineyard Wind turbine located south of Nantucket, Mass., compromised by a blade failure last summer, was struck by lightning in February, according to the U.S. Coast Guard.

The incident raises further questions about the structural resilience of offshore wind infrastructure and its implications for maritime industries, including commercial shing.

The turbine, identi ed as AW38, had sustained signi cant damage when a blade snapped during routine testing on July 13, 2024. Vineyard Wind con rmed that the lightning strike further impacted the splintered nub of the broken blade.

“Based on visual inspection of the damaged blade, preliminary evidence indicates that a lightning strike may have impacted the blade, though we continue to assess in coordination with GE Vernova,” Vineyard Wind said in a statement carried by The New Bedford Light

Despite the strike, the company claimed there was “no indication of debris” from the incident, and the current assessments show no damage to the nacelle covering, the turbine generator, or the tower. They also deployed aerial resources and at least one shing vessel to monitor the area, to ensure no debris had fallen into the water. Fishing vessels had also assisted in collecting debris after the initial blade failure last summer.

The Coast Guard con rmed that there were no reported navigational hazards and that they had no active involvement in response efforts. However, The New Bedford Light said it obtained an email from a Coast Guard of cer stating that the blade nub “caught re and detached.” That email had not been veri ed with the Coast Guard as WorkBoat went to press. The turbine is scheduled for replacement in May.

idewater Inc., Houston, reported revenue of $345.1 million for the fourth quarter of 2024, marking an increase from $302.7 million in the same period the previous year. Tidewater generated $331 million in free cash fl ow for 2024, which company offi cials said is a substantial increase from the previous year. Some $103 million of that total helped pay down required amortization on outstanding debt, and $119.4 million reduced the number of shares outstanding through repurchases and tax payments related to equity compensation, the company said.

distillery has fi led a federal lawsuit challenging the Jones Act, arguing that the 1920 law violates a clause in the Constitution that prohibits Congress from favoring ports of one state over anoth er. The Kōloa Rum Company, founded in 2009 on the island of Kauai, argues that the Jones A ct violates the Port Protection Clause – a line in Article 1 of the Constitution – and “infl ates costs, stifl es competition, and severely disadvantages American businesses in Hawaii and Alaska.”

“The Jones Act doesn’t just hurt our business — it hurts all Hawaii residents,” Bob Gunter, CEO of Kōloa Rum Co., said in a prepared statement announcing the federal lawsuit.

Carli Stewart

“It makes sense that it was the same turbine that was damaged in July 2024, because it is not operational and does not have the same grounding and lightning strike protection systems designed to protect these turbines from lightning strikes,” said Sen. Julian Cyr, who represents Nantucket and Martha’s Vineyard. (Lightening strikes remain the largest source of blade failures.) —

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@yahoo.com.

This month, we return to the theme of mental flexibility and adaptability being not just desirable but essential traits for developing the broad skill set required to successfully work and endure in the towing industry.

In 1990, at the beginning of my career on tugs, the economy was tough. Companies were struggling to survive, which meant that tug crews wound up doing whatever additional work could be found outside of their company’s core business. My New York Harbor-based company was a semi-specialist in oil that also did general towing. For the most part, everyone else did too, whether they were more of a ship-docking outfit, a petroleum-mover, or something else.

ABY CRAIG HOOPER

Dr. Craig Hooper is the founder and CEO of the Themistocles Advisory Group, a consulting firm specializing in maritime and national security strategy. He has been a keen observer of navies and coast guards for over two decades.

s an increasingly uneasy marriage between national security, law enforcement, and regulatory authorities, the U.S. Coast Guard needs to consider adopting a service secretary. The military service is the only in the U.S. run exclusively by its own admiralty, and, outside of distant guidance by an often overworked and distracted secretary of homeland security, the service lacks a dedicated political appointee.

At the Pentagon, service secretaries fill this void. They have the flexibility to engage in political advocacy and work within the Department of Defense to help adjudicate interservice funding and jurisdictional squabbles. Often serving longer than the admirals they support, service secretaries can afford to take a long-term, strategic view of their service.

The Coast Guard, tucked away in the Department of Homeland Security (DHS), doesn’t have this type of powerful political advocate. Right now, there’s nobody available outside of the commandant who can help the Coast Guard hold its own among the other 15 operational and support components at DHS. That’s a problem.

There was sand and stone (aggregate) work, ship-assists, derrick barges for construction projects, dredging projects, container barges, cement barges, garbage barges, scrap metals, etc. One-off jobs like dead-ship tows and fireworks displays from barges could come up. It was whatever, whenever, wherever, however, and it was never boring. These jobs proved invaluable.

The circumstances rewarded mariners in all positions who possessed (or were able to rapidly develop) a diverse skill set. Operators needed broad but detailed geographic knowledge. These necessities quickly weeded out overly rigid, unadaptable people.

In the decades since, technology has advanced in all sectors, and most companies are now more specialized than ever before. Even with conventional tugs, operations have generally narrowed as articulated tug barges have come to dominate petroleum transportation, and there’s less of everything else to go around.

To sum it up, over-specialization, whether at a company or at the individual level, leaves mariners vulnerable to changes in the business environment that render their expertise much less in demand. Highly competent generalists will easily and gracefully adapt, get the job done right, and find work even when work is scarce.

A Coast Guard secretary offers the service a fighting chance at DHS. Coast Guard leaders are military officers at the tail end of a multi-decade career. Other DHS components are run by political appointees, with the full backing of the president. It can be tough for a Coast Guard commandant — an officer who has been trained to be deferential to civilian authorities — to politely wave off a brash, newly-appointed U.S. Customs and Border Control commissioner who is eager to encroach on traditional funding lines or authorities.

As a civilian, a Coast Guard secretary can help the commandant, allowing the Coast Guard to engage other DHS components on a more equal footing.

In today’s heated political environment, it is also perilous for Coast Guard officers to mix mission execution with political advocacy. This is why the White House ignominiously fired commandant Adm. Linda Fagan, who, had she been simply carrying out directives from a Coast Guard secretary — and not been seen as the Coast Guard’s de facto political leader — would likely still be on the job.

A service secretary would help insulate Coast Guard leadership from political entanglements. The appointee would also likely handle tasks traditionally handed to other DOD service secretaries, like recruiting, equipping, training, maintaining and building infrastructure, freeing the commandant to focus on execution, rather than on political maneuvering.

The Coast Guard’s mission portfolio is enormous, and the always-stressed district and sector commanders need all the help they can get. A Coast Guard secretary, brought in to help support America’s iconic, low-budget team of maritime law enforcers, is overdue.

Trump’s arrival stimulates maritime activity

BY G. ALLEN BROOKS

G. Allen Brooks is an energy analyst. In his over-50year career in energy and investment, he has served as an energy security analyst, oil service company manager, and a member of the board of directors for several oilfield service companies.

Speculation about U.S. policy changes started after Donald Trump’s November election. Although many of Trump’s ideas have evolved over the past few months, many mysteries remain. We see some linked ideas. Several will impact the maritime industry.

Take Greenland. Why is Trump interested? It goes back to World War II. Greenland is strategically located between the U.S. and Europe. When Germany overran Greenland’s owner Denmark, the Nazis installed weather stations on Greenland to help plan their attack on the U.K. President Roosevelt sent U.S. troops to establish weather stations, destroy the Nazi stations, provide refueling facilities for warplanes shuttling to the U.K., and base Navy vessels protecting ships crossing the Atlantic with war and humanitarian supplies for Europe. Greenland was never more strategic for world peace. The melting of Arctic ice is opening sea routes for Russian and potentially Chinese vessels to reach the Atlantic Ocean, where they could threaten our shipping and national security. The control of Greenland could provide security for both the U.S. and Europe.

Additionally, Greenland has rare earth and critical mineral deposits that technology and green energy companies in the West need. Developing these resources will require new icebreakers to keep shipping lanes open. Canada’s Davie Shipbuilding seeks to acquire an American shipyard to complement its Finland shipyard acquisition and enable it to better compete for North American icebreaker orders. Canada also possesses mineral resources. These could boost North America’s self-sufficiency and reduce its dependency on China and Russia. Developing them as well as Greenland’s mineral volumes necessary for the energy transition will require more cargo ships. North America hardly participates in the global shipbuilding industry, which China dominates. It secured 70% of global new ship orders in 2024. Late last year, the Biden administration accused China of using unfair practices to gain its shipbuilding dominance. Securing Canada’s shipbuilding industry support would help the U.S. build icebreakers, expand and upgrade the U.S. Navy fleet, and grow North America’s commercial shipping fleet. This will boost national security. It will allow the U.S. to increase its maritime capacity and manpower, which are significant developments for our long-term future. It will take more than a deal with Canada to achieve these goals, but Trump’s ideas show a possible roadmap.

As offshore wind stalls, what fills the gap?

BY KIRK MOORE

Contributing Editor Kirk Moore, with over 30 years of experience, joined WorkBoat in 2015. He has won multiple awards for his marine, environmental, and military reporting.

New Jersey’s quest to build offshore wind energy was placed into a coma Feb. 3, when state energy planners decided against seeking new solicitations from developers. Shell had already withdrawn from its Atlantic Shores joint project with EDF Renewables. Combined with the new Trump administration’s unrelenting hostility to wind energy, that appears to put New Jersey’s hopes on ice — and severely constrain projects offshore from New York State.

Offshore wind opponents hailed the retreat by New Jersey Gov. Phil Murphy’s administration, contending that wind projects would drive up electricity costs for households.

Then, little more than a week later, state utility officials delivered more news: the average New Jersey monthly bill is projected to increase between 17.23% and 20.2% after June 1. The state Board of Public Utilities’ (BPU) annual Basic Generation System (BGS) auction set prices for four New Jersey power companies, reflecting costs from the Pennsylvania-New Jersey-Maryland (PJM) power grid, a wholesale electricity compact that includes utilities in all or part of 13 states and the District of Columbia.

“This week’s BGS auction results are the culmination of several issues: rapidly increasing demand for electricity, coupled with limited supply growth due to lagging new generation interconnection, and flawed market dynamics in the PJM region,” said BPU president Christine Guhl-Sadovy.

“PJM’s recent capacity auction results are the main driver of these increases. The Murphy administration will continue to aggressively push and hold PJM accountable to address rising costs by expediting interconnection and implementing additional market reforms, all of which will help drive down costs for ratepayers which is a priority for the BPU.”

The auction results brought a new broadside from Rep. Jeff Van Drew, R-NJ, a Jersey Shore congressman who encouraged the Trump administration’s offensive against wind power. The BPU “has failed the people of New Jersey,” he said in a statement demanding the board’s resignation. “For years, they knew these rate hikes were coming, yet instead of working to protect consumers, they wasted time pushing their Green New Deal agenda.”

“They have ignored real solutions like nuclear, solar, and natural gas while shutting down projects that could have helped like the BL England Power Plant and the South Jersey natural gas pipeline,” Van Drew added, harkening back to a failed attempt to repower a shuttered coal-fired generator.

ACBL applies for barge fleeting permits

ABY KEN HOCKE

Ken Hocke has been WorkBoat's senior editor since 1999, previously associate editor. An LSU graduate, he’s also written for The Times-Picayune and Daily Shipping Guide. Contact: khocke@divcom.com.

M/NS Calvert, Calvert, Ala., is a steel manufacturer that primarily sells its products to the auto and pipe/tube steel processing industries. The facility can produce 5.3 million tons of hot-rolled steel annually. Right now, all that steel tonnage is processed onsite and consists of semifinished steel slabs imported from Mexico and Brazil that land in the U.S. at the Port of Mobile, Ala., which operates a dedicated steel slab terminal for AM/NS Calvert. The slabs are then barged about 35 miles to the Calvert facility.

American Commercial Barge Line (ACBL), Jeffersonville, Ind., recently filed permit applications with the Corps of Engineers’ Mobile District to create a fleeting operation on the left descending bank of the Tombigbee River that would accommodate up to 128 hopper barges close to the

ManyBY NATE GILMAN

Nate Gilman, president of MM-SEAS USCG Licensing Software, uses his hawsepiping experience to support mariners and workforce development. Connect on LinkedIn.

mariners work extended hours while underway. A typical workday may involve watchkeeping plus additional duties, but time-and-a-half sea service credit is regulated by the Coast Guard. This credit can accelerate career progression but is only granted under specific conditions.

To qualify, vessel operations must comply with 46 U.S.C. § 8104 and 46 CFR § 15.705. Time-and-a-half credit applies only to vessels operating on a six-on, six-off schedule or an equivalent system authorized by the Coast Guard. Per 46 CFR § 10.107(b), a “day” for sea service is defined as eight hours of watchstanding or day-working, excluding overtime.

The vessel must fit within an approved category. Eligible vessels include: Towing vessels (may operate on a two-watch system with Coast Guard authorization), offshore supply

steel manufacturer, according to River Transport News — Criton Corp.’s semimonthly newsletter.

If approved, the operation would consist of five individual fleeting blocks of varying sizes. The smallest, which would accommodate 12 barges in a three-long by four-wide configuration, would be located at the upstream end of the fleeting site. Immediately downstream from that block, a second block is planned that would accommodate 16 barges in a four-by-four configuration.

Moving downstream, the next block would accommodate 32 barges in an eight-long by four-wide configuration, while the following block would accommodate 20 barges in a fivelong by four-wide configuration, RTN reported.

The largest block would be located at the downstream end of the fleeting site, according to RTN, and would accommodate 48 barges in a 12-long by four-wide configuration.

The project’s public notice indicates that the fleeting site will be located along 8,500 linear feet of the bank of the Tombigbee River. ACBL plans to armor the shoreline adjacent to the proposed fleeting site with 7,440 linear feet of riprap from the mean low water level to eight feet above the top of the bank. The bank armoring will require 12,226 cu. yds. of riprap that will be placed on top of a geotextile fabric to a thickness of two feet. The fleet’s barge moorings will consist of 37 24" diameter pipe mooring piles, RTN reported.

vessels (must meet tonnage and geographic requirements), fish-processing vessels (eligibility varies based on vessel size and crew), and cadets (eligibile under separate regulatory authority)

A properly written Sea Service Letter on company letterhead, signed by an authorized official, is required to claim credit. Employers must document actual days worked and not divide total hours by eight or 12. A mariner must work at least eight hours for a sea day and 12 hours for 1.5 sea days. The letter must not include fractions of a day.

For vessels with three watches or day boats exceeding eight-hour shifts, the letter must state: “The listed sea service consists of eight-hour days.”

For vessels authorized for a two-watch system where mariners work six-on/six-off or equivalent, the letter must state: “The listed sea service consists of a two-watch system for a 12-hour working day. By documenting 12-hour day service, I am attesting that a two-watch system has been authorized by the United States Coast Guard, per each vessel’s manning requirements in accordance with 46 CFR 15.705.”

Sea Service Letters should specify actual days served and state eligibility for enhanced credit to prevent confusion or double-counting. If the vessel type is not on the authorized list but the certificate of inspection (COI) confirms a twowatch system, including a COI copy in the Merchant Mariner Credential Application package is optional but may assist in verification.

BY TIM AKPINAR

Tim Akpinar is a Little Neck, N.Y.-based maritime attorney and former marine engineer. He can be reached at 718-224-9824 or t.akpinar@verizon.net.

Imagine that one of your shipmates has decided to strike out on their own in the workboat business and finds a 65' Army tug from the 1950s for $200,000. Compared with the $3 million tugs on the brokerage site, the outdated tug was a steal.

Your friend asks you to help inspect the tug to meet an insurance company’s seaworthiness requirements. Eager to help, you arrive at the shipyard with flashlight and clipboard. You plan to inspect everything related to the tug’s seaworthiness: steel thickness, corrosion, dried-out gaskets on watertight doors, shaft seals, and safety equipment.

You might not direct your focus on the tug’s pilothouse. Electronic charts can wait for another day. This inspection is about seaworthiness, not navigation. Seaworthiness is about punching through nasty seas, not pinpointing your position

The value of building port partnerships

BY RICHARD PAINE, JR.

Richard Paine, Jr. is a licensed mariner and certified TSMS, ISM & ISO lead auditor with over 25 years of maritime industry experience. He is currently a senior VP at the Hornblower Group and can be reached at rjpainejr@gmail.com.

Isit on the board of directors for the New York-New Jersey

Area Maritime Security Committee with representatives from all sectors of the maritime industry and law enforcement. Recently, I was invited by a local U.S. Coast Guard official to co-chair a dormant sub-committee specifically related to passenger vessel safety and security.

This initiative was set to emphasize the importance of port partners strategically working together. As we went through the stages of planning, it reminded me of how important and valuable it is to forge port partnerships with both regulators, such as the Coast Guard and law enforcement, but also with private and public operators in our shared waterways.

I believe that making our waterways the safest for every-

with an electronic chart display.

But this view of seaworthiness might need updating as much as the software in this old tug’s electronic charts. In a recent case from the U.S. Court of Appeals for the First Circuit, a Massachusetts court dealt with this very issue. Here, a carrier argued that a vessel failed to satisfy the seaworthiness conditions of its insurance policy because of its charts.

The owner had planned to pick up the vessel in Grenada and sail to Aruba, and ultimately Sint Maarten. Unfortunately, the vessel ran aground off the Dominican Republic on a breakwater. The vessel’s insurance policy provided $365,000 in first-party property damage coverage for the waters of Florida, the Bahamas, and the Caribbean.

At the start of the voyage, the vessel had navigational charts for the Aruba-to-Sint Maarten route, which covered the Leeward Islands, Windward Islands, and Aruba. It also had a GPS and electronic charts for the Dominican Republic. However, the charts were outdated and did not show the breakwater.

The vessel owner argued that the charts it carried were adequate for its intended voyage. The insurance carrier argued that the vessel lacked up-to-date charts for the waters that the policy covered. The court ruled for the vessel owner. The case shows that seaworthiness isn’t merely about bow flare to deflect heavy seas. Seaworthiness can cover things like updates to navigational electronics.

one requires shared responsibilities and relationships built on strong communication and a reliable network of resources. These types of network resources provide unequivocal value to any vessel or operation in any port.

However, there still lives the contrary opinion held by some owners and operators across the industry. Usually, resistance comes down to a handful of similar concerns.

Instead of forging best practices and shared intel, they focus on their business interests or trade secrets. They prefer not to participate in joint opportunities to foil their competition or to remain under the radar to keep regulators away.

In a discussion about building relationships with the Coast Guard, a brownwater operator once told me, “You don’t bring the fox into the henhouse.”

I disagree with that mindset. In my experience, I have found that the positives of strong port partnerships always outweigh the negatives. I have seen these relationships prove valuable to me and to others, and often in the most critical moments, such as responding to severe weather events, evacuations, mutual aid in emergencies, or building an intelligence network that helps prevent potential terror attacks. Not to mention the unexpected challenges that included operating a critical service during the Covid-19 pandemic.

My final piece of advice is this: if you’re invited to join a port partnership committee or have the chance to help form one, say yes. It’s always better to prepare now than to pay the price later.

A new Coast Guard rule for cybersecurity in the U.S. marine transportation system will go into effect in July.

By Kirk Moore, Contributing Editor

When video of the 984' containership Dali slamming into Baltimore’s Francis Scott Key Bridge burst onto television screens, many mariners and shipping executives had a common first reaction: Was it a cyberattack?

The March 26, 2024 allision at 1:28 a.m. was preceded by the ship’s lights flickering and going out twice before the impact, recorded on Vessel Traffic Service cameras. Then came the urgent warnings from pilots and police stopping traffic on the span. Too late to save six construction workers repairing potholes on the bridge deck, the flashing yellow lights on their trucks descending into the Patapsco River were captured on the video.

Amid a $100 million cleanup and recovery effort, National Transportation Safety Board investigators came to focus on a low-tech culprit in the disaster: A loose cable in the Dali’s electrical system that contributed to a total power failure as the ship approached the bridge.

The 11-week shutdown of Baltimore’s main ship channel was a stunning illustration of port vulnerabilities. Cybersecurity had already been demanding the attention of port operators and the Coast Guard. The idea of hackers remotely commandeering a ship to use it as a weapon is now considered a threat.

In February, the Government Accountability Office (GAO) issued a report on Coast Guard efforts, titled “Additional Efforts Needed to Address Cybersecurity Risks to the Maritime

Transportation System.”

GAO auditors found the “greatest cyber threats” to the U.S. maritime transportation system are posed by China, Iran, North Korea, Russia, and international criminal groups. Those adversaries can target port facilities and vessels that increasingly rely on technology and systems that are vulnerable to cyberattacks.

Cyber incidents have already affected U.S. port operations, according to federal officials and other sources interviewed by GAO auditors, “and the potential impacts of future incidents could be severe.”

The GAO report cited U.S. cybersecurity incidents that Coast Guard officials say disrupted operations at port facilities.

In a June 2017 incident, Russian military intelligence conducted worldwide attacks using NotPetya malware, which included international containership operator A.P. MøllerMaersk among the targets.

“Once NotPetya infected a machine, it was capable of automatically spreading through a network and infecting other machines,” according to the GAO. “The attack began in Ukraine and spread and infected organizations across the globe — including Maersk. As a result of the attack, computers throughout Maersk were shut down, bringing port operations (including U.S. operations) to a halt and leaving ships idle at sea. According to Maersk, the incident cost the company approximately $250 to $300 million.”

In December 2019, the Coast Guard reported a ransomware attack on an unnamed port facility’s network, believed to have

started when a perpetrator gained access through a phishing email containing a malicious link.

When clicked by the recipient, the link delivered ransomware into the facility network, which encrypted critical les and disrupted “the entire corporate IT network,” the report noted. “Additionally, the malware compromised OT” — operational technology — “systems that monitor and control cargo transfer and disrupted camera and physical access control systems, which led to a 30-hour shutdown of primary operations.”

Since those incidents, many more ransomware assaults have targeted port operators. In August 2024 the Port of Seattle was hit by the Rhysida ransomware group, which gained access to numerous systems including those for the SeattleTacoma International Airport.

Despite the disruption, port of cials said most ights stayed on schedule, and cruise ship operations were not affected.

In time, systems were restored.

“The Port of Seattle has no intent of paying the perpetrators behind the cyberattack on our network,” Steve Metruck,

the port’s executive director, said after the attack. “Paying the criminal organization would not re ect port values or our pledge to be a good steward of

taxpayer dollars.”

The Department of Homeland Security warned in November 2022 that cyberattacks are one of the most signi cant threats to the 900 U.S. ports. Ports are considered particularly vulnerable to cyberattacks due to the extensive outsourcing of their workforces.

A 2022 survey by Jones Walker LLP on ports and terminals cybersecurity revealed that cybersecurity remains a top concern within the maritime industry. The survey showed a signi cant increase

in reported cyberattacks, from 43% in 2018 to 74% in 2022, despite 90% of respondents claiming they were prepared to withstand such threats.

Security concerns have been raised over cranes used at U.S. container ports. Some 80% of those cranes are built by Shanghai Zhenhua Heavy Industries Company (ZPMC), a Chinese stateowned company with military links.

A 2024 congressional investigation reported that the semiautomated cranes could be monitored or even controlled

remotely, suggesting that an adversary could do so to shut down port operations.

ZPMC and Chinese government of cials dismissed the concerns as “paranoid.”

Coast Guard teams evaluated more than 90 cranes, but found no “unique vulnerabilities or exploitations speci c to foreign ship-to-shore cranes,” the GAO report said. They did see the same potential vulnerabilities found across operating systems.

In February 2024, the Coast Guard issued a directive requiring owners and operators of Chinese-built cranes to take cybersecurity precautions, including eliminating connections to the internet. The Coast Guard followed up with more risk management requirements in November.

In 2018, the federal Maritime Transportation Security Act was amended to require that port owners and operators assess and address cybersecurity risks. “However, implementing regulations for this requirement were not issued until January 2025,” the report noted. “As such, there were no speci c cybersecurity controls or measures that [Marine Transportation System] owners and operators were required to include in their security plans at the time of our review.”

That nal rule, titled “Cybersecurity in the Marine Transportation System,” will become effective on July 16. Some new requirements are to go into effect immediately, while owners and operators can have six to 24 months to implement other requirements.

The GAO found that the Coast Guard lacks procedures for cataloging cyber incidents. “Implementing procedures to identify and track accurate cybersecurity incident information would help strengthen the Coast Guard’s ability to prevent or mitigate disruptions that could jeopardize billions in critical commerce,” the report concluded.

Updating its case management system would help the Coast Guard to better understand the scope and type of cybersecurity risks maritime transport owners and operators have found, the GAO report said.

There’s no downtime for the vessels that defend against bad actors.

By Ken Hocke, Senior Editor

The words patrol boat are straightforward in their meaning. Military patrol boats do exactly what the name says. They look out for the entities and interests of the countries who own them, protecting them from those who wish to do them harm. They are normally used for border security, coastal defense, and law enforcement.

“We define patrol boats by their application by the end user. Typically, patrol boats are designed for longer missions and often have additional features to enhance habitability and crew comfort,” said Rob Goley, director, business development and strategy, SAFE Boats International, Bremerton, Wash. “In the United

States, patrol boats are often 40' to 120' in length. However, our international customers may use boats as small as 25' or 30' for extended patrol missions.”

There are shipyards in the U.S. like SAFE Boats that build patrol boats for the U.S. Department of Defense and for foreign governments through the U.S. Foreign Military Sales (FMS) program. FMS is a form of security assistance authorized by the Arms Export Control Act (AECA) and a tool of U.S. foreign policy. Under Section 3 of the AECA, the U.S. may sell defense articles and services to foreign countries and international organizations when the president of the United States formally finds that to do so will strengthen the security of the U.S. and promote world peace.

Under FMS, the U.S. government and a foreign government enter into a government-to-government agreement called a Letter of Offer and Acceptance. The secretary of state determines which countries can participate, and the secretary of defense executes the program through the Defense Security Cooperation Agency (DSCA).

DSCA’s mission is “advancing U.S. defense and foreign policy interests by building the capacity of foreign partners in order to encourage and enable allies and partners to respond to shared challenges,” according to its website.

The program has been a financial boon for some Tier II U.S. shipyards. Between 2024 and 2026, for example, SAFE Boats has 113 aluminum patrol boats ranging in size from 25' to 45' under contract, under construction, or delivered. Approximately 45% of those boats are contracted via FMS. The shipyard designs and builds all its vessels.

Four of those boats are SAFE’s 45'7.5"x13'11" full cabin inboard patrol interdiction and search-and-rescue design for the Lebanese Armed Forces. SAFE, which is an acronym for secure around flotation equipped, delivered four of the 45s to Lebanon in 2022 and 2023. Of the current lot of four, one was delivered in November 2024, another in February and the other two are scheduled for delivery in May and August.

“The Lebanon Armed Forces boats are part of a foreign military sales package to support security cooperation in the region,” said Goley. “Four boats have already been delivered, and another four boats are currently under construction. The total contract value is approximately $10 million, which includes the boats, spare parts, and incountry maintenance support.”

With a 3'3.5" draft, the boats are powered by dual Caterpillar C12 diesels, each producing 705 hp at 2,300 rpm. The Cats hook up to HamiltonJet HTX 30 waterjets. The propulsion package gives the boats a running speed of 42-plus knots.

Ship’s service power is the responsi-

bility of a 24VDC house battery system with a Cat C1.5 50-hz, 10-kW onboard generator.

The boats carry 476 gals. of fuel, giving them a maximum range of 420 nm. Maximum payload including personnel — up to 52 with 16 seated positions — gear, and other customer-speci c equipment, but minus fuel, is 6,000 lbs. There is also approximately 100 sq. ft. of cargo space on the aft deck.

The electronics suite consists of Furuno transducer, heading sensor, AIS transponder, doppler radar, and multiple 12" displays. There is also a FLIR M364 thermal camera.

Ancillary equipment and systems include chemical, biological, radiological nuclear detection equipment; 250-gpm Darley marinized portable re pump, stored on the aft deck; Cushman three-piece davit; 600' tow spool; reinforced push knees; Whelen LE strobes and loudhailer system; dual Cruisair 27,000 BTU A/C units; aft deck bimini top; custom galley with sink, refrigerator, microwave, coffee maker, and two-

burner cooktop; and head with toilet and shower.

“Our customers see value in the products and services we provide. This is the key to our success,” said Goley. “We are committed to providing high-quality,

rugged, dependable patrol boats to our customers worldwide.”

Goley said those qualities have been the shipyard’s focus for almost 30 years and are deeply engrained in everything they do. “Everyone on our team is

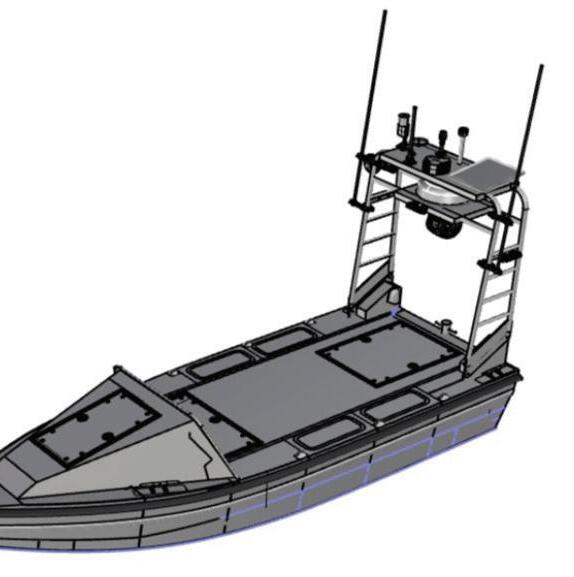

Saronic Technologies, Austin, Texas, announced the closure of a $600 million Series C expansion financing round, bringing its valuation to $4 billion — quadrupling its worth in just seven months.

The funding aims to accelerate the development of Saronic’s autonomous maritime systems and is a step in advancing the U.S. military’s push for a hybrid fl eet of crewed and uncrewed vessels. With a focus on naval and maritime autonomy, the company plans to establish Port Alpha, a next-generation shipyard designed to rapidly scale the production of autonomous surface vessels (ASVs).

“We are actively searching for the right location for Port Alpha and are moving as fast as possible to ensure we can support our customers’ needs,” a spokesperson for Saronic told WorkBoat Saronic’s new shipyard will produce small ASVs, including the company's 24’ fl agship model, Cor-

sair, launched in 2024, as well as the 14' Cutlass and the 6' Spyglass. With its new facility and robust investment, Saronic aims to expand its fl eet of autonomous ships and address growing demand from U.S. government customers, including military and defense organizations.

“Each of our platforms leverage diff erent materials, from aluminum to fiberglass to advanced composites. We focus on what is best for the mission and what enables rapid delivery at scale,” the spokesperson said.

The company said it plans to build boats that support a range of launch and recovery options.

“We are focused on delivering critical capabilities to U.S. and allied naval and maritime forces. As the business continues to grow, we plan to explore additional use cases and industries,” the spokesperson said. “We see applications for our vessels in non-defense federal and commercial markets, including off shore energy, law enforcement, marine services, and others.” — K. Hocke

Today’s Force Protection boats purposely have less horsepower than their predecessors.

laser-focused on building boats that our customers can rely on to do the mission safely and effectively and ultimately supporting the boats throughout their service life,” he said.

MetalCraft Marine US Inc., Watertown, N.Y., is working on a ve-year, $47 million contract to deliver 67 of its Force Protection Small (FPS) and Force Protection Large (FPL) Interceptor BD series patrol boats to the U.S. Navy.

The FPS measures 28'x8'6", has a draft of 24", and a loaded vessel weight of 11,860 lbs. The FPL shakes out at 39'x11'11", has a draft of 23", and a loaded vessel weight of 15,944 lbs.

“The Force Protection Small and Large patrol boats are MetalCraft Marine US Inc’s fourth or fth time building for the Force Protection program,” said Bob Clark, MetalCraft’s contracts manager. “The FP program started back in 2000 subsequent to the (USS) Cole bombing.”

(In October 2000, the USS Cole was refueling in Yemen’s Aden Harbor when suicide bombers detonated a boat

lled with explosives next to the Navy ship. When the smoke cleared, 12 sailors were dead, and 39 others suffered various injuries.)

MetalCraft built FP Mediums for the Navy from 2001-2004. The Navy tested the rst FP Smalls starting in 2016-2018. “These boats were tested at many bases worldwide and offered very pleasing creature comforts that the crews much enjoyed such as suspension seating, bathrooms, air conditioning and diesel heaters as well as exterior and interior decks with shock-mitigating,

long-lasting ooring,” said Clark. “MetalCraft has argued that when crews have long shifts, they need heating, cooling and shock mitigation to prevent fatigue, which can result in accidents.”

Clark said propulsion for these boats are a mix of Honda, Mercury, and Yamaha outboards but gave no details beyond naming the manufacturers.

Under this contract, MetalCraft has delivered 14 of 47 FPS boats and ve of 20 FPL vessels to date. “The FP program is a worldwide program to provide security for ships in foreign and

in-country ports,” said Clark. “Typically, two boats are stationed at each ship’s dock. They are well-armed and wellmanned with two fore and aft machine gun stations.”

The FP program large is used for ports that are not well protected from sea swell, where a larger platform can handle the sea state motion better than a small platform. The FP program large has four-gun stations. “In both size boats the cabins are identical for con guration management and crew training purposes,” said Clark

It’s been a long and winding journey for the latest tug to join the eet of Dawn Services LLC, Harvey, La. The 22-year-old vessel is being refurbished after spending ve years laid up in Pascagoula, Miss.

The tug was built in 2003, but its story dates to the early 1980s when a group of keels were laid for new tugs designed to tow barges between Seattle and Alaska. Market challenges derailed the builds, and the un nished hulls changed hands and shipyards several times before the tug that would become Foss Maritime Co.’s Corbin Foss was completed at Marine Power & Equipment Co., Seattle, in 2003.

Removed from operational duty and laid up in 2021, the tug is now being given another chance after being recently acquired by Dawn Services, which is in the process of restoring the vessel for reentry into service under full ABS class.

Notably, the 150'x40' tug packs a lot of power, which Dawn Services found

attractive as it looks to expand its presence in the larger tug market.

The 16,000-hp class tug — renamed the Capt. John J. Charpentier in honor of Dawn Services’ founder — will be the company’s largest and most powerful tug, offering 108 tons of bollard pull. It is equipped with two Fairbanks Morse ALCO 16-251F diesel engines that turn twin 144"x127" 4-bladed, xed-pitch propellers in Kort nozzles through a pair of Haley GMC 4228 reduction gears. It also features a pair of 170-kW Cummins N-14-TA generators and a 500-hp bowthruster.

“When it comes to tugs that have 100 tons of bollard pull or more, there’s not a huge market,” said Kevin Hopel, business development manager at Dawn Services. “We felt like we wanted to transition into the larger tug market. The last six tugs that we’ve added over the last ve years have been 4,000 hp or more.”

As Dawn Services’ offerings have expanded, its eet has grown too, in-

creasing from eight tugs ve years ago to 15 today. The eet now includes three tugs with 2,200 hp or less and 12 tugs rated at 3,200 hp and above, including vessels with 4,000 hp, 4,100 hp, 5,800 hp and 8,200 hp. The company has been deploying its larger tugs to tow ships and to support offshore decommissioning work — “pretty much anything and everything,” said Hopel. “We’re hoping that in the future, as the oil eld picks up, the bigger boats will get even busier.”

Topside refurbishment work on the Capt. John J. Charpentier has started at a dock rented by Dawn Services in Port Fourchon, La. The vessel will move to Bollinger Fourchon for more extensive repair work to be carried out in the coming months.

“The boat, steel-wise, is in great shape. Other than handrails and some smaller items on the deck that are being cut off and replaced, there’s nothing major. All the tanks look good. The engine room is in really good shape,” said Hopel. “The engines are probably going to be top-end rebuilds, turbo rebuilds, injectors, things like that. The boat runs.”

Most of the required refurbishment work will be focused on mechanical components, said Hopel. The tug’s Intercon DD 225 tow winch, for example, has some rust and will be totally broken down and rebuilt along with the winch engine. The tow pins are frozen and need to be restored.

“We’ll pull the shafts and wheels, we’ll have to go through the bowthruster, blast and paint the hull,” said Hopel. “But the boat is in really great shape.”

Hopel said he expects Capt. John J. Charpentier to be fully refurbished and “ready to go” by June. — Eric Haun

Roseburg, Ore., can be identi ed by its proximity to Portland (three hours north on I-5) and the California border (two hours south on I-5). One

hundred miles inland from the Paci c Coast, and surrounded by forests, Roseburg has been called the timber Capital of the world.

The largest employer in town has long been Roseburg Timber Products. Roseburg is also home to North River Boats, which employs about 300 people who collectively build about 300 aluminum boats a year. Sizes range from a 21' fishing boat with a 150-hp outboard to a 32'x16' Bristol Bay commercial gillnetter with twin waterjets to a 52'x16' crew transport boat with a wide variety of power options and cabin configurations.

It’s a broad spectrum with many different models, almost all of which are powered by outboard engines. Many, maybe most, North River boats are used for fishing, both recreationally and commercially by charter operators. One such operator is Nootka Marine Adventures, which owns three upscale resorts on Vancouver Island, British Columbia.

This summer, Nootka Marine will be getting eight new North River 3100SXL models followed by seven more next year. The 31-footers will be delivered from Port Boat House in Alberni, British Columbia, also on Vancouver Island. Port Boat House is a dealer for North River and Yamaha and does all the final outfitting.

“We do motors, controls, electronics,” said Dan Redland at Port Boat House. “We assemble the seats. We usually do the anchor systems. They usually come to us basically wired and plumbed for toilets, sinks and showers and things like that. And then we pretty much do the rest.”

Nootka Marine already has 10 other North River boats, all 32-footers. The new 31s are powered by twin Yamaha F250 outboards, which are mounted on a stern platform extension. Inside the cabin there is seating for five passengers and one operator. All seats are S5s from ShockWave, Sidney, British Columbia. The house also provides a stand-up head and a small sink. There is no galley equipment. These are getout-there-and-fish boats, but comfort-

American Cruise Lines, Guilford, Conn., has christened the 241'x56' American Legend, the newest small ship in the company’s Project Blue series. Built at Chesapeake Shipbuilding Corp., Salisbury, Md., American Legend was visiting Key West along one of the company’s eight-day Florida Gulf Coast & Keys cruises, which sail roundtrip from St. Petersburg, Fla. American Legend accommodates 100 guests, features four decks, and a catamaran bow. Like its sisterships, it also offers private balcony accommodations, a top deck for viewing the surroundings, lounges inside and out, a main restaurant and casual café, plus a walking track and fitness center.

Sea trials got underway in February for the Charybdis, the first U.S.built wind turbine installation vessel, now 96% complete at the Seatrium AmFELS shipyard in Brownsville,

Texas, Dominion Energy reported in an update on its Coastal Virginia Offshore Wind project. The 472'x184' Charybdis was launched in mid-April 2024. Scheduled for delivery later this year, the installation vessel will support the CVOW project with its planned 176 turbines rated up to 2.6 GW. Dominion’s investment was also aimed at the global shortage of wind installation vessels. Charybdis is designed to handle current and next-generation wind turbines up to 12 megawatts or larger. It is equipped with a 426' crane capable of lifting 2,200 metric tons and has accommodation capacity for up to 119 people.

Electric foiling vessel developers Artemis Technologies has entered a partnership with Delta Marine, Seattle, to use the patented eFoiler design for building new ferry and water taxi vessels expressly for Washington State’s Puget Sound. Based in the U.K. with a U.S. division in Brooklyn, N.Y., Artemis has invested more than $100 million in research and development since its founding in 2017. The company reached a milestone in 2022 when it deployed the 37.7' Pioneer of Belfast, billed as the world’s first commercial workboat electric foiling vessel.

able get-out-there-and-fish boats with shock-mitigating seats, Seakeeper 2 roll-stoppers, and Espar G4 diesel heaters.

Seakeeper gyro stabilizers have

The 78.7'x36' Artemis EF-24 passenger ferry carries up to 150 passengers at a cruising speed of 32 knots and has a range of 115 nautical miles, according to a company spec sheet. The 39' Artemis EF-12 Escape is advertised as a water taxi “designed for commuters and luxury travel” and debuted at the America’s Cup races in Barcelona.

Brix Marine, Port Angeles, Wash., has delivered a new workforce transportation vessel, the Bridge Cat 49, to Bridgemans Services Group, Vancouver, British Columbia. The 44'x18'6" personnel transfer vessel accommodates up to 45 passengers and three crew and is built to meet Transport Canada’s TP 11717 passenger vessel requirements for operations in British Columbia. The aluminum Bridge Cat 49 is powered by twin Cummins QSL9 405-hp diesel inboard engines paired with ZF marine transmissions. The vessel has a 500-gal. fuel capacity and a lightship weight of approximately 43,000 lbs., according to Brix. The boat’s navigation and electronics suite includes Garmin GPSMAP multi-function displays, radar, and VHF radios. Bridge Cat 49 is equipped with an Espar/Eberspacher heating

been around since the first prototype was developed in 2006. The concept is basic physics: a heavy flywheel is spun to a very fast rpm (8,000-9,000) while positioned on a vertical shaft. The

Artemis Technologies’ EF-24 foiling ferry is designed to carry up to 150 passengers.

system, Fireboy-Xintex fire suppression system, and Delta T ventilation.

Rocket Lab USA, Inc., Long Beach, Calif., is converting a deck barge for use as a specialized platform to catch at-sea rocket landings. The company said it acquired the 2010-built, 400'x105'x25' barge Oceanus from Canal Barge Inc., New Orleans, and renamed it Return On Investment. Conversion work will be performed throughout 2025, with the barge expected to be ready for service in 2026. Modifications will include the addition of autonomous ground support equipment to capture and secure the landed rocket, blast shielding to protect equipment during landings, and station-keeping thrusters for precise positioning, Rocket Lab said in a prepared statement.

spinning gyroscopic action counteracts the rolling of the boat. It doesn’t eliminate rolling, but it diminishes it to just a few degrees. Most boats, like the 3100SXL, have the gyroscope under the deck and on the centerline, but off-center and on-deck locations can also work. The Seakeeper flywheel is housed inside a vacuum-sealed, spherical steel cover. Sensors inform the unit of the boat’s motion, and the gyro is adjusted as necessary by hydraulic arms powered by electric motors.

On the new boats, the Seakeeper 2 model runs on 12-volt battery power, as opposed to 120-volt systems on larger models. The 31-footer’s Seakeeper 2 battery bank has three AGM (absorbed glass mat) batteries. Alternators on the Yamahas provide the power for recharging these batteries as well as powering the boats’ other batteries, starters, helm electronics, lights and pumps.

The North River 32s have a walkthrough cabin that opens to the bow and seating for nine, including the operator. The 31s will have a cuddy across the front and the house is pulled forward to provide more room on the back deck for fishing — and a larger aft overhang — while limiting seating to six, including one operator. “We’ve definitely increased the back section of the dance floor, as we like to call it,” said Luke MacLaurin, Nootka Marine’s marketing specialist.

Like the 32s, the 31s will also carry all necessary fishing gear such as downriggers, cannon balls, rod holders, and iced fish boxes.

With twin 150s, MacLaurin said the boats could run faster but speeds are generally held to about 30 mph at 3,800 rpm. “We have maybe 10 boats a day out fishing, so we need to manage our costs for fuel,” said MacLaurin. The boats will have tankage for 255 gals. of gasoline, five gals. diesel and 10 gals. fresh water.

All three Nootka Marine resorts are located on ocean inlets on the west side of Vancouver Island. Fishing trips are often taken to the outside for ocean trolling.

On average, each resort is about 30-40 minutes from the outside running at about 30 mph. The 31'x9.5' deep-V hull has a 24° deadrise at the transom and a 55° entry at the bow. “It’s a very stable boat,” said Mike Blocher, sales director at North River Boats. “It has a nice wide step chine and a full self-bailing deck. It’s the most popular charter fishing boat in Alaska and becoming that in British Columbia.”

— Bruce Buls

Eymard Marine Construction & Repair, Harvey, La., delivered the steel-hulled 67'6"x28'x9'6" push tug Soaring Eagle to Colonial Oil Industries Inc., Savannah, Ga., at the end of last year.

Soaring Eagle left New Orleans shortly after Christmas and headed east on the Gulf Intracoastal Waterway. With a lock on the Okeechobee Waterway closed to navigation, the crew aboard the push tug had to go through the Florida Keys and up the east coast of Florida, with a diversion through Miami due to weather. The push tug arrived in Savannah on Jan. 8.

Soaring Eagle and its tank barge, CTOW 320, mark a signi cant step forward in enhancing Colonial’s marine capabilities and a strategic investment in the future of the company’s marine fueling and towing capabilities.

The tug and barge were both christened at Colonial Terminals on the Savannah River on Jan. 31. The event welcomed key stakeholders.

CTOW 320 has a 32,000 bbls. capacity, 12 compartments, four segregations and the ability to carry various fuels and cargoes. The vessel also represents the company’s continued commitment to reducing environmental impact.

“This new addition to our eet symbolizes our vision for the future — one where technology, ef ciency and sustainability go hand in hand,” Bob Kenyon, president at Colonial Oil Industries and chief operating of cer at Colonial Group, said during the christening ceremony. “As we continue to grow, this tug and barge will play a crucial role in expanding our marine capabilities and delivering exceptional service to our customers.”

The Entech-designed, twin-screw Soaring Eagle’s main propulsion comes from two Caterpillar C32 diesel engines each producing 800 hp at 1,800 rpm. The Cats connect to Sound Propeller stainless steel, 4-bladed 68"x57" wheels through Twin Disc MGX-5321 marine gears with 5.96:1 reduction ratios. The tug draws 8' fully loaded. The propulsion package gives the tug a running speed of 10 knots.

Soaring Eagle will primarily work between Charleston, S.C., and Jacksonville Fla., pushing the new CTOW 320 tank barge.

According to Kenyon, Colonial Oil Industries’ marine division is a cornerstone of company operations as it ensures the seamless transportation of fuel products across strategic

locations from Norfolk, Va., to Tampa, Fla. “The christening event underscored the signi cance of a milestone in Colonial Oil Industries’ ongoing mission to innovate and lead in the oil and maritime industries,” he said.

Soaring Eagle’s tankage includes 18,512 gals. of fuel; 4,500 gals. water; and 453 gals. lube oil.

— Ken Hocke

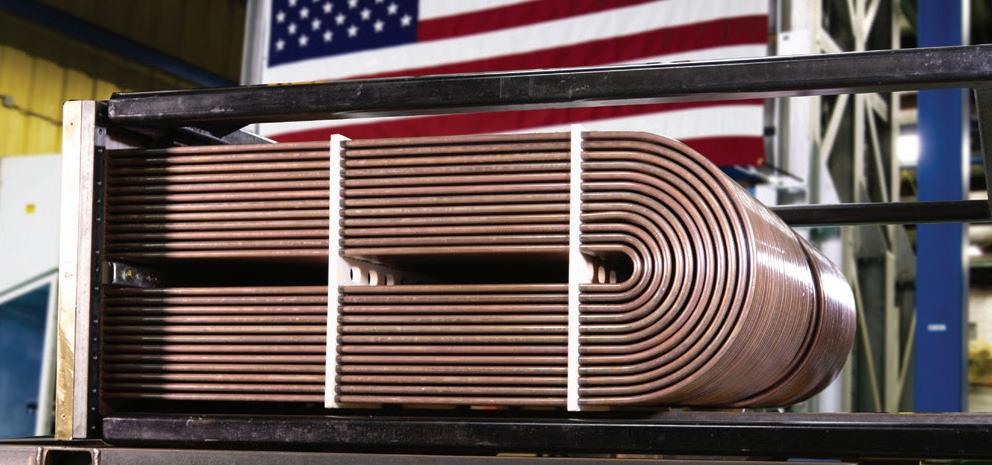

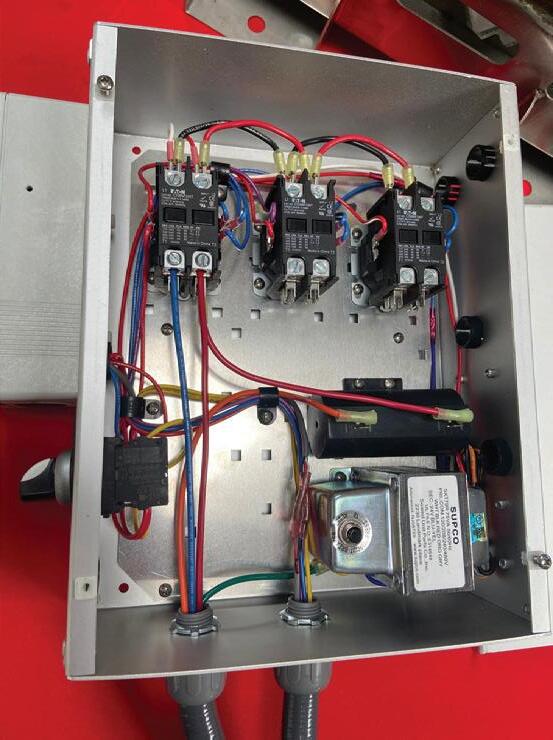

The legendary RANCO controller, a transformer, and contactors are all you need!

No expensive, prone to failure, printed circuit boards!!

Every chiller is "stand alone" no remote control boxes or integration with anything!

By Ben Hayden, Content Editor

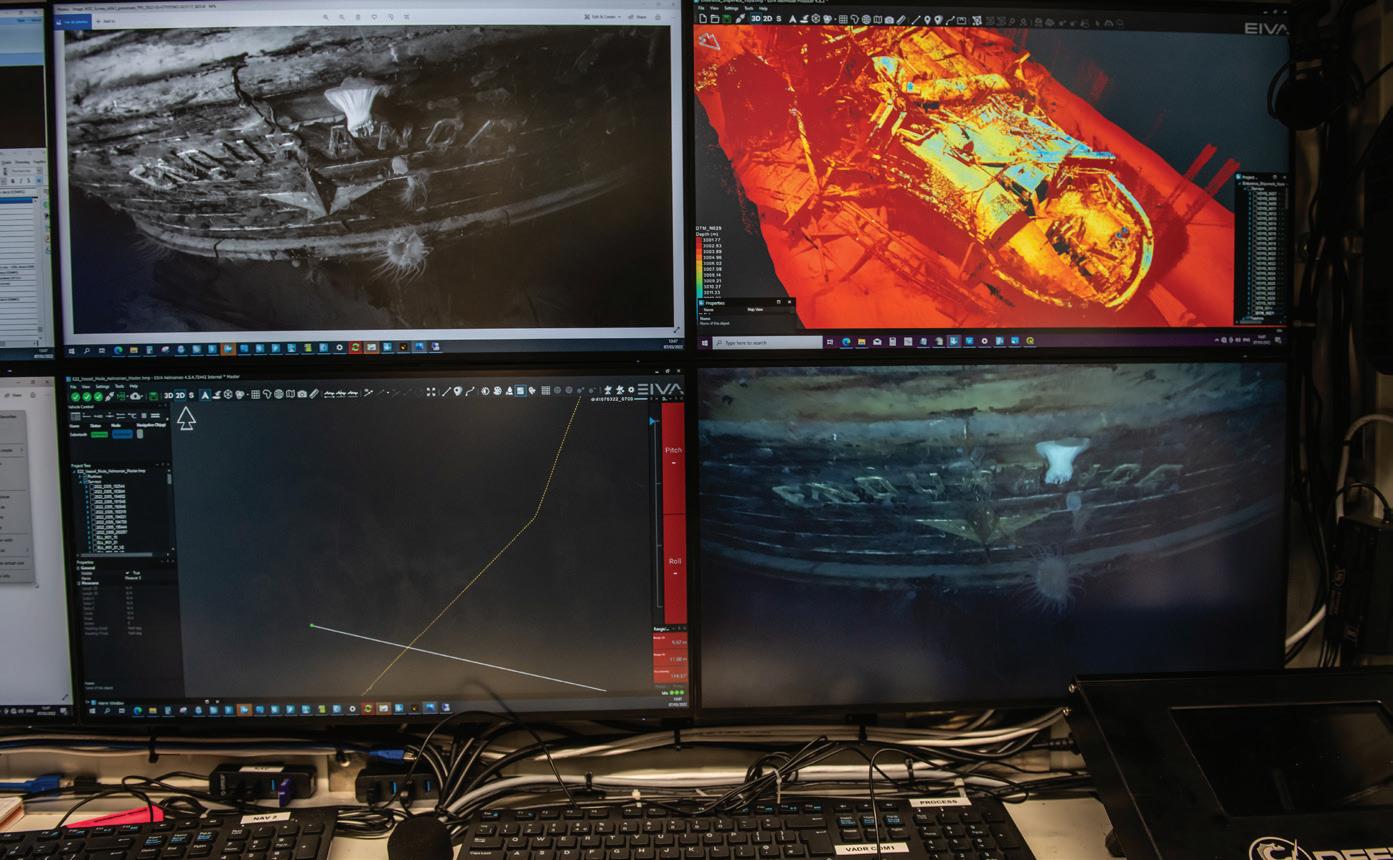

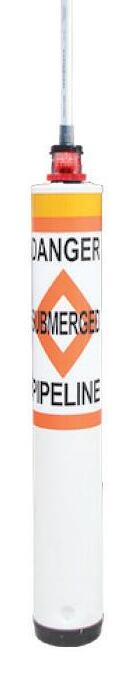

In March 2022, international teams embarked on an expedition to locate and document the wreck of HMS Endurance, the famed ship used by Sir Ernest Shackleton in his failed 1914-1917 Imperial Trans-Antarctic Expedition. The vessel had been lost to the Antarctic waters of the Weddell Sea for over a century. Using advanced subsea technology, the team, led by Nico Vincent of Deep Ocean Search (DOS) and John Shears of Shears Polar, found the ship resting on the ocean floor, 10,000' below the ice.

The Imperial Trans-Antarctic Expedition aimed to cross the Antarctic continent from coast to coast via the South Pole, but the expedition was thwarted when Shackleton’s threemasted barquentine, the Endurance, became trapped in ice, leading to a dramatic survival story as the AngloIrish explorer and his crew endured extreme conditions. All men were ultimately rescued, but the Endurance was crushed and sank, not to be seen again for more than 100 years.

The Endurance22 project, funded by the Falklands Maritime Heritage Trust (FMHT), aimed to locate the wreck and conduct a non-invasive study. The teams based their search on a 1915 journal entry by Capt. Frank Worsley, who, on the day of the sinking, had to delay taking sextant read-

ings due to overcast skies. The 24-hour pause meant his calculations provided an estimate rather than precise coordinates of the ship’s final position.

“This project was a decade in the making, beginning in 2012 when the project’s anonymous benefactor met with Trustee Mensun Bound in a London coffee shop,” an FMHT spokesperson told WorkBoat. “The initial plan was to launch the search in December 2013, but securing a suitable icebreaker proved impossible. Over the years, numerous experts advised on how to proceed, refining plans for both the first and second expeditions until the conditions were finally right in 2022,” they said.

Jérémie Morizet, subsea engineer at DOS, detailed the company’s mission preparation to WorkBoat.

“The project involved three years of management and planning led by Nico Vincent. Then, we had a period of, let’s say, six months of onshore prep,” Morizet said. “During this time, we had to go to the factory of Saab’s Sabertooths to oversee the [autonomous underwater vehicle (AUV)] survey payload integration and assist with configuration. We then conducted trials before transferring the vehicle to the south of France, where we tested it at depths of 3,000 meters (9,843').

“After the onshore phase, we mo -

bilized in South Africa, which took about two weeks to gather all the equipment that was air freighted from different parts of the world to fit everything on board, to connect everything, and then after … we finished overall integration as we were sailing underway,” he said.

The Endurance22 mission called on the S.A. Agulhas II, an icebreaker owned by South Africa’s Department of Environment, Forestry, and Fisheries that served as a central operations hub for eight teams on board.

The 440'x71'x35' ship carried a full South African crew of 65 managed by African Marine Solutions Ltd., along with an expedition team of 45 archaeologists, oceanographers, meteorologists, drift prediction experts, and ice scientists. Additionally, a subsea operations team of 17, including 10 subsea experts from DOS, was on board. While the Endurance22 mission focused on locating the wreck, other teams aboard the vessel conducted separate research efforts.

“Picking the right ship for the expedition was not just about finding an icebreaker — it had to be one of the very few in the world that could handle the extreme conditions of the Weddell Sea,” FMHT said “Only a handful of vessels are tough enough to operate there. The S.A. Agulhas II is a Polar Class 5 icebreaker, meaning it can smash through ice up to a meter (3.3') thick while still cruising at five knots. What was key for the Trust was the quality of the research facilities on board. On top of that, the ship had already proven itself in Antarctic missions, including reaching the Endurance’s last known location back in 2019,” the Trust said.

Agulhas II is powered by four Wärtsilä medium-speed diesel engines and a diesel-electric propulsion system. Two Converteam 6,000-hp motors drive 14.8' Kongsberg controllablepitch propellers, while Rolls-Royce bow and stern thrusters enhance maneuverability; useful features when operating in extreme weather conditions. The vessel’s 16-knot maximum

speed and 15,000-nautical-mile range ensured operational flexibility for the 50-day expedition.

After departing Cape Town, South Africa, on Feb. 5, 2022, it took the Agulhas II 13 days to arrive on site.

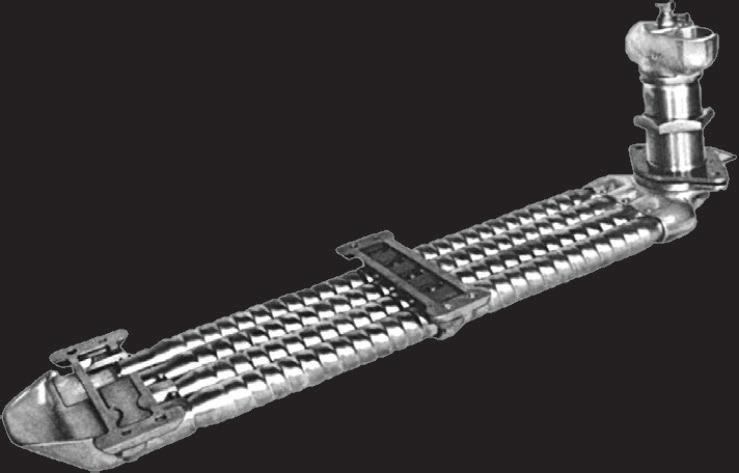

Central to the mission was the Sabertooth drone, which Morizet described as a hybrid system that can behave as a classic remotely operated underwater vehicle (ROV) or like an AUV. “You can switch between the two modes pretty instantly, which makes it the perfect tool to make object search, or in this case, wreck search,” he said.

The Sabertooth’s ability to transition between surveying and inspection streamlined operations that typically require separate vehicles. “With the Sabertooth, you can go from one mode to the other,” Morizet explained. “In standard subsea operations, you first make your survey with a towed vehicle or an AUV, and then only after, you can come back with the ship to deploy an ROV to check what is the target that you’ve picked up. So, it’s much more time-consuming. It’s much more expensive,” he said.

The Sabertooth was equipped with an R2Sonic Sonic 2024-V multibeam echosounder for high-resolution bathymetric mapping and a Sonardyne Gyro USBL LMF for acoustic tracking and positioning. Navigation, speed, direction, and motion data were provided by the Sonardyne Sprint NAV system, and the Voyis Imagery Insight Pro conducted photogrammetry, generating 3D models of the wreck using underwater laser scanners and imagery. An EdgeTech 2205 system collected side-scan sonar imagery, sub-bottom profiles, and bathymetric data to aid in the survey.

Operating in Antarctic waters posed unique challenges, especially in the presence of shifting sea ice. According to Morizet, once the icebreaker stopped to deploy the Sabertooth AUV, the surrounding ice began to carry the Agulhas II away at speeds of

up to one knot or more. “As soon as you stop the surface vessel to deploy the vehicle, the ice just captures you, like the Endurance, and takes you away,” he explained. His remarks parallel those from Shackleton crewmember Thomas Orde-Lees, who described the ice-trapped Endurance “frozen like an almond in the middle of a chocolate bar.”

As the icebreaker drifted, the AUV continued its survey within a designated search box, creating a complex situation where the surface ship and the subsea vehicle moved independently, requiring continuous adjustments to the survey pattern.

Morizet credited ice drift specialists from the German-based Drift+Noise Polar Services, who utilized a drift-prediction model to anticipate pack ice drift directions, allowing the team to draw the best survey line pattern in real time.

“It is a model, so it’s not always true,” he said. “The final survey pattern we had on seabed went from nice and clean parallel survey lines to a kind of weird patchwork with survey lines going in different directions and different shapes; S-shapes, U-shapes. So, it means that we had on bottom to adapt our survey pattern, depending on the direction of the surface vessel. It was a complex, complex game.”

Speaking to the AUV deployment and operations, Morizet said, “You preprogram your mission. It’s a very versatile vehicle, offering different modes of operation … A fantastic feature of this AUV, I would say, is that it can fly in any position, like a fighter aircraft … So you can … roll it 45 degrees and stabilize the position and run it like that, or you can even run it upside down if you want to scan under the ice.”

To prevent excessive tension on the fiber-optic tether, the team had to constantly pay out cable, up to five miles at one time. “You don’t want to maintain a strong traction on the vehicle, because otherwise it will go away from the search box,” Morizet noted. However, as more cable was deployed, drag from ocean currents increased.

“At some point, even though the fiber-optic tether is very thin, it creates a drag … and you start to feel on the Sabertooth that you have another consumption of battery, and the progression slows down,” he said. “It’s a trade-off between the current, the battery, etc. Sometimes the battery life forces you to recover the vehicle because there is no more battery. And sometimes, the drag is becoming so, so strong that it’s hardly workable,” he said.

The fiber-optic cable is a two-way data street between the control room and Sabertooth, carrying commands

from the ship to the AUV and returning information, including from its side-scan sonar, described by Morizet as the primary tool for detecting shipwrecks due to its ability to cover a large search area. To effectively monitor this incoming data, the control room aboard the Agulhas II was divided into two desks: one for the pilots and another for the survey team.

The AUV’s navigation relied on an inertial navigation system integrated with an ultra-short baseline acoustic positioning system. “The surface vessel sends an acoustic interrogation to the vehicle, which then replies. From this two-way travel, we determine the position of the subsea vehicle,” Morizet said. This data was transmitted through the bi-directional beroptic tether, however, in cases where the ber was lost, the team used an acoustic telemetry system for emergency recovery.

When the tether breaks, which happened a few times during the expedition, “the vehicle is still alive because it still relies on its batteries, but we don’t have the command, neither the feedback,” Morizet said. “And so, in that case, we could take control of the vehicle using what we call a subsea telemetry system. It’s a very slow communication system through water, but it allows at least to bring the ve-

hicle back home,” he said. By sending acoustic commands and receiving acknowledgments, the team could regain control and guide the vehicle back to the surface vessel.

To help mitigate ber breaks caused by sea ice, DOS designed a “ sh oat” that allowed the ber-optic cable to move with the ow, rolling around ice blocks rather than being crushed by them. “We were surprised we had so few breaks, because in such an environment where there is so much ice around that wants to crush the ber-optic through the water interface, we were just expecting to have much more damage than that,” he said.

After 20 days of navigating strong currents and overcoming operational

constraints, the Sabertooth’s side-scan sonar detected a reading from the ocean oor. The control room erupted in shouts as the team con rmed the identi cation of the shipwreck they had been searching for.

The team then switched the Sabertooth to inspection mode to survey the wreck, and using photogrammetry from the Voyis Insight Pro, they captured high-resolution images of the Endurance’s transom, hull, and deck, which contained preserved crew boots, intact tile patterns, blocks, pulleys, and other artifacts left on the vessel. The Sabertooth’s enhanced maneuverability also allowed for scans of the lower hull sections that a standard, at-positioned vehicle would have missed.

FMHT spoke to the mission’s success. “We are incredibly proud of what was achieved — not just in nding Endurance, but in sparking curiosity and interest in the story of Shackleton, the wonders of deep-sea exploration and the challenges of working in one of the most extreme places on Earth.”

Re ecting on the experience, Morizet said, “Meeting Antarctica is already something that changes every man and woman on board. You hear about it in the storytelling of Shackleton and everything, but when you really experience it, you truly understand what they endured. You really want to come back one day. So that was just fantastic.”

By Michael Crowley, Correspondent & Eric Haun, Executive Editor

Talk to some individuals who hang out on local waterfront docks and love to focus on fast, outboard-powered boats, and when the conversation turns to fuels other than gasoline, a few might project a look of disbelief, even disgust, with remarks like “Who uses that stuff?” and “Boats with other fuels can barely leave their own wake.”

Well, they don’t pay much attention to modern outboards if they haven’t heard about Cox Marine, Shoreham-by-Sea, England, and its 300-hp diesel outboard, the 300 V8. The engine, rst introduced as the CXO300, has been in production since 2020, and in 2022 it set the diesel outboard world speed record in Cumbria, England, from a ying start along a one-kilometer course.

The engine wasn’t optimized for racing but came straight off the production line. The fuel? Not diesel but hydronated vegetable oil (HVO).

Cox’s latest outboard model, the 350 V8, was introduced in 2024. It’s a 350-hp diesel with twin turbochargers that also can run on HVO. Cox describes the 350 V8 “as the world’s most powerful diesel outboard.” Cox 350 V8 production was due to start in March 2025 with deliveries beginning shortly after that. Cox Marine has a long list of fuels that the 300 and the 350 outboards operate on, including jet fuel for a military boat, “so you don’t have to carry two types of fuel,” said Patrick Bucci, vice president at Ring Power Corp., St. Augustine, Fla., the Cox Marine diesel outboard distributor for Florida, Georgia, the Carolinas, and Bermuda. “We have validated the largest brand of fuels of any diesel outboard.”

Worldwide, Cox has a list of 22 approved fuels for Europe, North America, Asia, Oceania, Africa, and the military.