Twin Disc continues to advance hybrid electric propulsion, uniting mechanical and electrical components to reduce fuel use, cut emissions, and increase reliability. Our Marine Control Drive with PTI gearbox, which splits a tugboat’s main engine power to operate auxiliary equipment and enables the azimuth thrusters to be driven by an electric motor, was recently chosen for its first application.

ADVANTAGES

Don’t miss the boat on going green.

To find the right hybrid electric system for your application, contact applications@twindisc.com

20 Focus: Head Count

NOAA research ships struggle to retain ans hire mariners.

36 Cover Story: Top 10 News Stories

The 10 top workboat industry stories of 2024.

98 People Skills

The 44th Annual International WorkBoat Show.

99 IWBS Listings

WorkBoat Show schedule and exhibitors list.

28 On the Ways

• ACBL to christen new towboat at International WorkBoat Show

• Amogy takes delivery of ammonia-powered tug • Main Iron Works delivers new tractor tug to Bisso Towboat

60 In Business: New Leadership, Same Values

Virginia shipyard celebrates 150 years of operation.

68 2024 Boatbuilding Review

A look at the boats featured in WorkBoat from December 2023 to November 2024.

8 On the Water: Leave your troubles at the dock — Part I

8 Captain’s Table: Drills are an essential part of our professional lives.

9 Nor'easter: New supply, legal challenges to offshore wind.

10 Inland Insider: towing vessel fatalities were low in 2023

12 Energy Level: Where is the energy sheepdog?

14 Legal Talk: Sometimes King Neptune throws us a softball.

16 Credentialing Insights: MMC radar renewal tips.

LOG

18 Arkansas, Kentucky put millions into multiple port projects.

18 Oregon opponents block offshore wind auction.

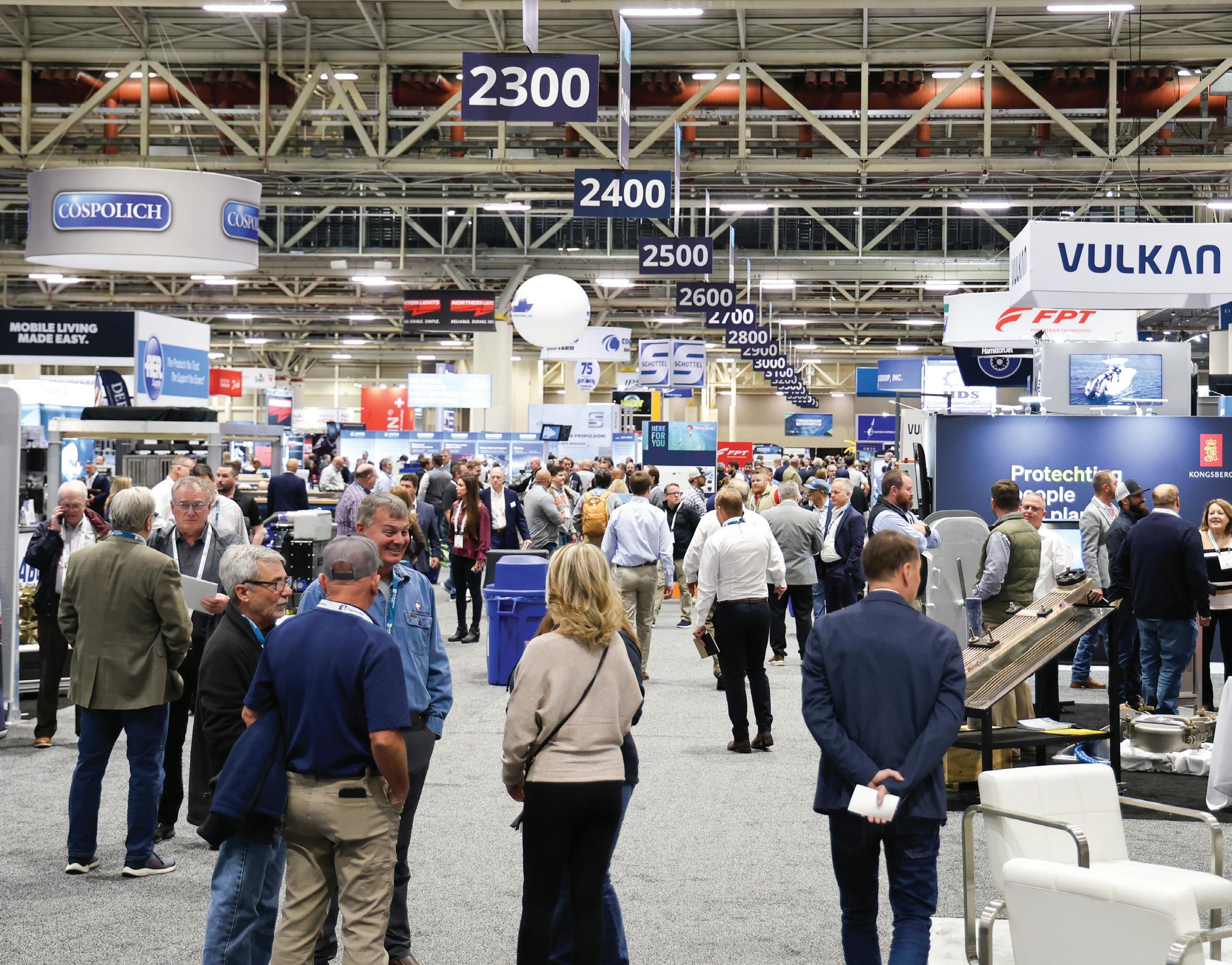

There is no answer to the question, “What came rst, the chicken or the egg?” What about this question, “What came rst, WorkBoat magazine or the International WorkBoat Show?” Well, there is an answer to that one.

Some people believe the magazine began its existence at the same time the WorkBoat Show began in 1979. Not quite. Sitting on my desk are bound copies of WorkBoat magazine from 1944. Yep, the magazine goes back to World War II.

As for this year’s show, it’s the 44th edition of the trade show, and it’s become more popular than ever, based on the number of booths sold and visitors expected at the Earnest N. Morial Convention Center Nov. 12-14 in New Orleans.

Ken Hocke, Senior Editor khocke@divcom.com

Atmospheric Administration (NOAA) will also make its wishes known to those in attendance.

•

•

•

•

•

•

For you math wizards, those numbers don’t jibe, I know. That’s because there was no WorkBoat Show in 2005 because of Hurricane Katrina. As far as the belief that there were two WorkBoat shows in one year somewhere along the way, my research shows that that is not true. From 1979 until 1987, the show was held in January. It moved to December in 1988. There was no show between January 1987 and December 1988.

In the back of this magazine, you will nd a list of exhibitors and a conference schedule. Note that representatives from the Navy, Army, and Coast Guard will again be part of the conference program. The reps will share with you what their boatbuilding and maintenance needs are going forward. This year, the National Oceanic and

Something new this year is the Women in Maritime Luncheon on Wednesday, Nov. 13, from noon until 2 p.m.

The luncheon will provide a platform for women professionals to network, share experiences, and discuss the opportunities and challenges they face in the maritime sector. Attendees will hear from female industry leaders and experts in the maritime industry who have navigated their maritime careers successfully, paving the way for future generations.

Headlining the luncheon will be Rear Adm. Ann C. Phillips, Maritime Administration (Marad), administrator.

This year at Pacific Marine Expo take some time to explore WorkBoat West; a brand new free educational program designed for shipyards, vessel owner operators and other commercial marine stakeholders. The International WorkBoat show propels the industry forward by bringing together the most important stakeholders in the commercial marine market together each fall in New Orleans. WorkBoat West will bring a piece of that best-in-class maritime tradition to Seattle.

Entry to WorkBoat west sessions is included in your Pacific Marine Expo pass. Please see schedule of events at pacificmarineexpo.com/ workboatwest

Use code “ ” to secure your free pass to Pacific Marine Expo and start planning today. pacificmarineexpo.com

© 2024 Diversified Communications PRINTED IN U.S.A. IN BUSINESS

EDITOR IN CHIEF David Krapf / dkrapf@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS Capt. Alan Bernstein • Steve Blakely • Arnie Brennaman • G. Allen Brooks • Bruce Buls • Robin G. Coles • Michael Crowley • Jerry Fraser • Pamela Glass • Max Hardberger • Joel Milton

CONTENT EDITOR Benjamin Hayden / bhayden@divcom.com

DIGITAL PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com

EDITORIAL DIRECTOR Jeremiah Karpowicz / jkarpowicz@divcom.com

ADVERTISING ACCOUNT EXECUTIVE S

Mike Cohen 207-842-5439 / mcohen@divcom.com

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

Producers of The International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

VICE PRESIDENT Wes Doane / wdoane@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION

cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET)

The author of this Mail Bag letter (“Check your math” WorkBoat, August 2024, page 6) may well understand his statement that "Germany is currently deriving 59.7% of its energy from renewable resources: wind, solar, biomass, and hydropower," but I believe the great majority of your readers will not!

As all should know, electricity is not a "source of energy" at all, but rather a "form of energy", produced by some

half of which is biomass, not a "fuel of the future" that anybody is pushing for). Source: Clean Energy Wire, AGEB, 2024.

The author's "59.7% by renewables" is only true for electricity production, which is only about 30% of energy consumed. All [of it] produced by some other true "source" of energy and experiencing the transmission losses which he did also reference. And all other associated environmental issues, which all forms of energy sources have.

I think it is highly misleading for anyone to use the terms "energy" or, as done in some circles, "power" when it is only produced electricity being included. It signi cantly understates the challenges replacing existing sources.

Don Nyborg Houston

According to the U.S. Energy Information Administration, forms of

energy include potential (chemical, mechanical, nuclear, and gravitational) and kinetic (radiant, thermal, motion, sound, and electrical).

Sources of energy are either renewable (solar, geothermal, wind, biomass, and hydropower) or nonrenewable (petroleum, hydrocarbon gas liquids, natural gas, coal, and nuclear).

"Renewable energy sources are naturally replenished. Day after day. the sun shines, plants grow, wind blows, and rivers ow."

Something on your mind?

WorkBoat encourages readers to write us about anything that appears in the magazine, on WorkBoat.com or pertains to the marine industry. To be published, letters must include the writer’s address and a daytime phone number. Email: khocke@divcom.com

The legendary RANCO controller, a

and contactors are all you need!

No expensive, prone to failure, printed circuit boards!!

Every chiller is "stand alone" no remote control boxes or integration with anything!

We design, build, and install electrical systems for new builds, retrofit and maintenance, ensuring reliability and smooth operations.

We design, build, uninstall, and install custom Switchboards and Control Panels, offering full-service solutions. We are a registered UL508A Control Panel shop.

www.uselectric.com

sales@uselectric.com

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@ yahoo.com.

Leave your troubles at the dock — Part I

On

Aug. 1 the NTSB released its casualty report on the allision between the towboat John 3:16 and an industrial pier on the Lower Mississippi River at St. Rose, La., on Sept. 12, 2023. Yet another example of fatigue causing or contributing to an accident.

This one was straight-up fatigue. No mixer, no ice. The pilot (mate) of a fleeting towboat nodded off at the sticks while transiting light-boat. Neither weather nor river current was a factor. He simply had accumulated an acute sleep deficit, and his body called in those chips just before 0641 that Tuesday morning. No one was hurt and the damage did not result in the loss of either the vessel or the pier, nor was there a petroleum spill. The crew was lucky.

The pilot was evidently having significant personal problems off the boat, which predictably leads to additional distractions and stress while on the boat, resulting in a serious lack of sleep.

BY CAPT. ALAN BERNSTEIN

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@ bbriverboats.com.

Thoseof us in the commercial maritime industry know that drills are an essential part of our professional lives. We conduct drills regularly so that in the unlikely event of an accident we can take decisive action.

Our first responsibility is safety and in order to achieve this we must plan and practice our responses to potential threats and accidents. We have learned that where safe practices are concerned, repetition eliminates guesswork and memorializes best practices. Conducting regular drills also allows mistakes to be reviewed and future actions to be fine-tuned.

Recently, BB Riverboats participated in a maritime-related drill on the Ohio River in Cincinnati. The drill involved a hypothetical active-shooter incident aboard the company’s riverboat Belle of Cincinnati while the vessel was underway.

While such an incident has never happened aboard one of my vessels in my 40-plus years of operating on our nation’s waterways, I believe it was necessary to take part to be prepared, nonetheless. Being prepared meant coordinating with

It’s common to hear people say that you have to “leave your home-problems at home” and not bring them to work with you, as if it were simply a matter of self-discipline. To say that this is an unrealistic view of human nature is a massive understatement.

Not only do people routinely bring their nonwork problems to work with them, those problems, undoubtedly, will to some degree affect their ability to stay adequately focused on their jobs. The more demanding the job (like steering) the more sustained focus is required, resulting in a heavier sustained stress load, and the more likely any distractions will have negative consequences. It’s a vicious feedback loop. It also affects how they behave towards their fellow crewmembers.

If the problem is with the captain, it’s even worse. There is nothing as miserable as being on a boat with a miserable captain, due to the inevitable trickle-down effect.

Anyway, pay attention. Watch out for your shipmates. Say or do something if you’re in a position to. It often doesn’t end this well.

all the government and law enforcement entities who should react to such an incident. In this drill, the local Area Maritime Security Committee scheduled the drill and the Coast Guard, state and local police, fire departments, and rescue assets participated.

In our hypothetical scenario, two armed individuals boarded the Belle of Cincinnati for its midday lunch cruise. As the vessel departed the dock and proceeded upriver, a crewmember noticed that these two individuals were carrying weapons and immediately notified the captain. The captain then contacted the Coast Guard. A SWAT team then approached the Belle of Cincinnati from the stern in a high-speed rigid inflatable. The riverboat slowed down but did not come to a full stop so the SWAT team could board while the vessel was still moving. The SWAT team, which was fully turned out in battle dress uniforms, personal protective armor, and assault-like weapons, searched the vessel with precision looking for the shooters.

Ultimately, the shooter threat was eliminated, and the drill was successfully concluded. There were valuable lessons learned and BB Riverboats, the Coast Guard, our local government, and law enforcement resources are now much better informed about what to do in the event of an active shooter scenario should such a terrible situation occur.

BY KIRK MOORE, CONTRIBUTING EDITOR

Economic and supply-chain warning signs are ashing again in the international wind energy sector.

Turbine manufacturer GE Vernova said Sept. 20 that it will downsize its offshore efforts, after a reported $300 million third-quarter loss in its wind business overshadowed the marketing push of its top-line Haliade-X machine.

A Haliade-X turbine lost a blade to fracture on the Vineyard Wind project off Massachusetts in July, following two other blade failures on projects in Europe.

GE Vernova officials said the blade breakages were not due to design faults; the Vineyard Wind breakup was blamed on a manufacturing defect at a plant in Quebec. But GE Vernova said its planned pullback now could cost 900 production jobs.

Days before, bp announced its plan to sell its onshore wind assets in seven U.S. states, following a pause in the company’s offshore wind plans. The moves under CEO Murray Auchincloss are a reversal of his predecessor Bernard Looney’s much-touted rebrand-

ing of bp as “Beyond Petroleum.” In June Reuters reported that shareholder discontent led to a return toward core oil and gas production.

Still, the unrelenting U.S. push to develop offshore wind plunged into deeper waters in late summer, with new lease sales announced off the Oregon coast and in the Gulf of Maine.

The leases are the first attempt by the Bureau of Ocean Energy Management (BOEM) to bring floating wind turbines into the U.S. market. The sales are opening a new front in legal challenges to BOEM’s permitting process, already under siege from East Coast beach resort communities and the commercial fishing industry.

“The New England Fishermen’s Stewardship Association [NEFSA] remains steadfast in its opposition to the industrialization of our oceans, despite the shrinking of the original proposed lease area,” said NEFSA’s founder and CEO Jerry Leeman, a New England trawler captain.

“The final eight lease areas encompass a total of 827,886 acres in the Gulf of Maine and pose an existential threat to all marine species, habitat, and to the livelihoods of current and future generations of sustainable fishermen upon whom their communities rely on for survival,” said Leeman. “The six lease

areas in the southern Gulf of Maine comprise a Great Wall of Windmills that threaten mariners and the marine environment.”

In Oregon the Confederated Tribes of the Coos, Lower Umpqua and Siuslaw Indians filed a lawsuit seeking to block the Coos Bay and Brookings lease sales that BOEM planned for October.

“Coastal tribes have repeatedly met with BOEM urging the agency to take its time to develop wind energy in a way that does not adversely impact Tribes and the resources which they depend on,” said Tribal Council Chair Brad Kneaper.

“BOEM has repeatedly disregarded these requests, telling the tribes that wind energy development is being driven by the White House.”

BOEM canceled the Oregon auction as September drew to a close.

Critics of East Coast wind power projects argue that building turbine arrays will harm marine mammals, especially the highly endangered North Atlantic right whale. One opposition group filed a new lawsuit, arguing the acoustic effects of construction will hurt people living on the beach.

Noise is another negative that has been cited by groups like New Jersey's Save Long Island Beach. Sound travels better over water than land.

Towing vessel fatalities were low in 2023

BY PAMELA GLASS

A new safety report on the towing industry shows that on-the-job crewmember fatalities continue to

remain low, with the industry recording its second lowest fatality rate per 100,000 employees in 2023.

The data is contained in the Coast Guard-American Waterways Operators (AWO) Annual Safety Report that was released in August. For the past 30 years, the safety report has used three main measures to track towing industry safety trends: crewmember

fatalities per 100,000 towing industry workers, gallons of oil spilled from tank barges per million gallons transported, and the number and severity of towing vessel casualties.

On fatalities, the report said a total of ve towing vessel crewmember deaths were reported last year, of which four were directly related to towing vessel operations and one was caused by a cardiac problem.

In one incident, a crewmember fell overboard while serving as a lookout on the head of the tow during eeting operations. The crewmember was wearing a man overboard transmitter, but it didn’t appear to work underwater.

A crewmember fell overboard while departing a lock and it is suspected that he was struck by a bumper that had come free as the barge passed through the lock, while in another incident, a pickup truck and trailer on a deck barge rolled off the stern into the water and the driver drowned.

Meanwhile, the operator of a towing vessel suffered a cardiac event related to a pre-existing condition which rendered him unconscious and caused the vessel to strike a submerged object and capsize, while the fth crewmember was found unconscious in the berthing area and an autopsy said the death was due to natural causes because of a history of substance abuse.

The report also notes that ve people were killed last year as a result of four collisions between towing vessels and recreational vessels, which AWO said underscores the importance of its new Recreational Boater Safety Working Group.

There were ve deaths in 2023 compared to nine reported in 2022 that were either directly related to towing vessel operations or were caused by pre-existing medical conditions.

The largest number of fatalities since 2000 have been from falls, while collisions with xed objects, line handling, being struck by moving objects and burns were also cited.

The report also evaluated the number of incidents in which tank barges spilled oil into the navigable waterways. In 2023, it said 5,799 gals. of oil were spilled from 36 operational tank barge pollution incidents. These included a tank over-pressurization which was attributed to an overheated boiler, improper valve alignment during ling operations, inattention of the person in charge during transfer operations, and the sinking of a tank barge.

The tank barge spill rate was 0.1 gallons of oil per million gallons transported, which is the fourth-lowest rate recorded since 1994, noted AWO.

Jennifer Carpenter, AWO president and CEO, said the safety report has been a 30-year partnership between the Coast Guard and the industry with the “mutual goal to advance safety in the tugboat, towboat and barge industry by taking a cooperative, non-regulatory data-driven approach to identifying safety issues.”

She said the report shows that the industry has reduced the rates of both towing vessel fatalities and tank barge spills, which is “a re ection of the depth of our shared commitment to safety and sustainability, the success of our collaboration and the enduring value of this safety partnership.”

BY G. ALLEN BROOKS, CORRESPONDENT

Sheepdogs are breeds that guard and keep sheep herds together. They keep strays from wandering away.

Today’s energy markets are like sheep herds with various energies heading off independently. A good energy sheepdog might help regulators and politicians create sound policies rather than the quilt-like assortment of today.

A case in point was the recent announcement of Microsoft’s deal with Constellation to restart Three Mile Island Unit 1, a nuclear power plant shuttered for five years. The software giant needs the carbon-free baseload power for a new data center to support its artificial intelligence work.

Three Mile Island was famous for the 1979 partial meltdown of its Unit 2 nuclear reactor which helped fuel the anti-nuclear power movement. Unit 1 operated continuously until 2019 when it was shut down by poor economics. The 837-megawatt unit operated 96.3% of the time, an attraction for Microsoft.

While nuclear power is experiencing a rebirth of interest, renewables continue to dominate the energy news with soaring new capacity additions reported worldwide. Generating capacity, however, doesn’t always equal increased power output.

On the fossil fuel front, the Environmental Protection

Agency is in court defending its latest air quality rule that would force early closure of coal and natural gas generating facilities. Four regional grid operators fi led amicus briefs supporting the plaintiff and warning about blackouts.

Across the Atlantic, Germany’s economy continues to de-industrialize due to high electricity prices. A Norwegian hydrogen energy plan has imploded over cost. The lack of higher subsidies is hurting renewable projects on the continent, especially offshore wind. Public protests against EV mandates and agricultural restrictions are plaguing numerous countries.

Schizophrenic China continues building record renewable generation and new coal plants. Its policy to

dominate green energy supply chains drives investment and sparks backlash from Western economies captive to Chinese supply chains.

The Chinese government just introduced significant fi nancial stimulus to re-ignite its economy’s growth which could lead to increased petroleum consumption. Weak Chinese oil demand has been the missing ingredient in higher oil prices. The stimulus could restart the long-term oil cycle.

The need for a dependable, clean, low-cost energy system has become apparent to politicians. The energy world has become more chaotic and needs a sheepdog to prevent national blackouts.

Craft Tampa, the city’s first dining river cruiser, is powered by twin Volvo Penta D4-175 engines, offering smooth and reliable performance. These engines deliver exceptional fuel efficiency, low emissions, and robust power, ensuring each journey is as eco-friendly as it is enjoyable.

Maintenance is made easy with Volvo Penta D4 engines, which feature long service intervals. When service is needed, Craft Tampa relies on the authorized Volvo Penta Dealer, Florida Detroit Diesel Allison (FDDA), located in Tampa, for genuine parts and expert support.

Scan the QR code to learn more about our D4 engines or visit volvopenta.com to learn about all of our products.

BY TIM AKPINAR

Whenever a vessel sinks, we typically look for lessons that could be learned to prevent future accidents. Sometimes we identify

areas for improvement with safety and training. Well, on Aug. 8, 2023, King Neptune threw us a softball in the sinking of the towboat Jacqueline A on a summer evening where the water temperature was a pleasant 85°F.

When the 60' towing vessel sank three miles off the coast of South Carolina at around 7 p.m., we learned a few lessons about the legal doctrine

of unseaworthiness — and mercifully, without anyone getting hurt. In investigating the sinking, the National Transportation Safety Board (NTSB) and U.S. Coast Guard identified factors that contributed to the vessel’s unseaworthiness.

According to the NTSB, the tug’s bulwarks had been modified by adding plating to the inboard side. This created small void spaces and was inconsistent with “Merchant Ship Construction” by D.A. Taylor, which recommends against, “…setting up of corrosion cells in places which cannot be reached, are poorly ventilated, or rarely protected or maintained.”

• Unmatched accuracy in monitoring and managing diesel fuel consumption

• Digital Sensors – no specialized wiring required

• Available in single and dual chamber models (flow rate requirements ranging from .2 to 1100 gallons/hour)

• Built-in battery keeps registering data to the internal memory

• Anti-tamper modes available with larger models

• Reduces installation time and footprint

• Cost savings on product, installation, and maintenance

• Extends the service life of the fuel system through preventative maintenance

Airmar DFMs connect to the award-winning Airmar SmartBoat Module (ASM) through a digital interface. The collected data is effortlessly accessible on the NMEA 2000® network, allowing integration with various devices, including NMEA 2000 multifunction displays (MFDs).

The NTSB also found gaskets missing from weathertight doors, and only a single bilge high-water level sensor. It reviewed a recent ultrasound survey showing metal wastage along various points in the hull, ranging from 25% to a maximum of 46% along the hull sides. The NTSB determined that the probable cause of the sinking was a lack of watertight integrity due to the poor material condition of the vessel’s bulwarks and main deck plating.

In the courtroom, the concept of “unseaworthiness” is often expressed in basic terms. It doesn’t usually require a naval architect’s understanding of centers of buoyancy or metacentric heights to see why it’s a bad idea to plop an additional deck on an already top-heavy ferry to increase passenger capacity.

In the federal court system, the U.S. Ninth Circuit is quite concise in its Manual of Model Civil Jury Instructions, “A vessel is unseaworthy if the vessel, or any of its parts or equipment, is not reasonably fit for its intended purpose.”

The sinking of Jacqueline A was a softball from King Neptune. It should remind us to look at hull surveys, survival suits, and other safety equipment closely. One doesn’t want to think about this situation confronting a crew at 7 p.m. in January, instead of August, off the coast of Chatham, Mass.

In the ever-changing landscape of offshore energy production and support, ABS remains committed to navigating the evolving industry with you.

At ABS, we deliver industry-leading classification, verification and certification services that ensure compliance at each phase of offshore projects. Join us as we lead the way towards a safer, efficient and more sustainable future offshore.

Scan the QR code or visit eagle.org/offshore to learn more.

BY NATE GILMAN

Anoften-overlooked rule change that went into effect in 2019 harmonized the renewal of radar observer endorsements and eliminated the need for mariners to take a radar observer refresher or recertification course as long as they can provide documentation for one year of sea time on a radarequipped vessel in the previous five years from the date their application is submitted for renewal.

Captains, mates and deckhands working on vessels where they are routinely using radar need to have the exact language required under 46 CFR

10.227, 10.232, 11.480 and Policy Letter 03-19 on their sea service letters provided to the USCG for their renewal.

If a mariner routinely uses radar as part of his or her bridge watch-keeping duties, their sea service letters must include the statement, “carried out Bridge Watch duties in a position that routinely uses radar for navigation and collision avoidance purposes.”

Mariner sea service letters that accidentally leave this statement off, commonly received an awaiting information (AI) letter from the Coast Guard that states: Radar certificate — To qualify for renewal of radar observer, you must submit the following:

• Approved original, refresher, or recertification radar certificate dated within the last five years; or,

• proof of employment as a qualified instructor who has taught an approved

or accepted radar course at least twice within the last five years; or,

• service of 360 days in a position that routinely uses radar for navigation and collision avoidance within the last five years.

Please provide an approved radar course as listed above.

If you do not want Radar Observer endorsed on your credential, please submit a statement to change your application. (Reference(s): 46 CFR 11.480(d); Policy Letter 03-19)

If mariners have enough sea days for renewal but receive an AI letter with a statement similar to the one above, they just need to have their letter updated by the company to include the radar statement.

Incorporating this sentence in your company’s sea service letters for captains, mates and deckhands who use radar saves companies money.

Earlier this year, the Arkansas Waterways Commission (AWC) awarded nearly $3.5 million to six Arkansas ports. The grants were based on safety improvements and areas of greatest need, according to the commission.

Among those to receive funds was the Little Rock Port Authority. It was awarded $500,000 for a mooring upgrade project to restore and expand barge eeting capacity at the Port of Little Rock on the McClellan-Kerr Arkansas River Navigation System. That project’s total cost is $4.6 million with $1 million needed to complete it.

A $1 million award went to the Osceola Port Authority for construction of a 420' retaining wall along the west bank at the center barge loading dock to prevent further bank caving and operations disruptions at the Port of Osceola on the Mississippi River.

Meanwhile, Kentucky Gov. Andy Beshear announced $5.5 million in state funding for 16 Kentucky public riverport projects. Beshear's of ce said that all projects are designed to enhance the ports’ economic activity and support future expansion. The grants will fund dredging, mooring and warehouse repairs, port equipment purchases and other needs.

At the beginning of 2024, the Kentucky General Assembly allocated, and Beshear approved $15 million for the next two years to the newly created Kentucky Public Riverport Construction and Maintenance (KPRCM) grant. To date, more than $5 million has been awarded for eight projects. Additionally, $500,000 was awarded through the Kentucky Riverport Improvement (KRI) grant for eight projects. The grant will provide funding to maintain current operations and improve current facilities and infrastructure.

Approved grants must be used to improve riverfront facilities and infrastructure for new construction and major replacement or repair projects. Eligible projects do not include routine operations, maintenance or repair activities. Projects were reviewed by the state's Water Transportation Advisory Board. Kentucky has 10 public riverports.

Fairbanks Morse Defense (FMD), Beloit, Wis., has entered into an agreement with Rolls-Royce to acquire its naval propulsors and handling business. The acquisition will include a range of propellers and waterjets for naval applications, as well as marine handling systems, which enable the deployment and recovery of manned and unmanned craft, and other cargo, from naval vessels. No fi nancial details were released.

Korean defense conglomerate Hanwha has offi cially abandoned its bid to acquire Australian shipbuilder Austal , following a year of contentious negotiations that highlighted signifi cant regulatory obstacles. The proposed merger, which aimed to strengthen defense ties between Australia and South Korea, was fi rst announced in September 2023 but faced skepticism from Austal's board regarding regulatory approvals. In a letter dated Sept. 25, Hanwha CEO Hyek Woong Kwon cited Austal’s unexpected demands and lack of cooperation as key reasons for terminating discussions.

auction of Oregon offshore wind leases was postponed Sept. 27 after Gov. Tina Kotek withdrew the state from an agreement with the federal Bureau of Ocean Energy Management. In a rare victory for wind power critics, BOEM abruptly announced it was “delaying the offshore wind energy auction planned for potential lease areas offshore Oregon due to insufficient bidder interest at this time.”

Imtra curates an exclusive line of bestin- in class products from innovative global leaders known for the highest quality and performance. Discover the difference in our family of brands.

Imtra’s team of experienced marine industry professionals is here to help you find the ideal solution for your unique needs. Our product experts are invested in your success.

Imtra is a 100% Employee-Owned company committed to providing the kind of customer focused service and support that will win your loyalty for a lifetime.

For those who qualify, a $10,000 hiring bonus is being offered to professional mariners who commit to two years of service.

By Pamela Glass, Washington Correspondent

Aglobal worker shortage that has hit the U.S. maritime industry hard is also causing recruiting challenges to the National Oceanic and Atmospheric Administration (NOAA). NOAA is a federal agency that runs a eet of research and survey ships that collect data used for nautical

charts and climate, ocean and sheries research.

The 15 research vessels are operated by a mix of of cers with the NOAA Commissioned Of cer Corps and civilian professional mariners.

The ships range from large oceanographic research vessels

involved in deep ocean exploration around the world, and smaller ships responsible for charting shallow U.S. bays and inlets.

NOAA says in its hiring literature that professional mariners “play a key role in improving our understanding of the ocean and atmosphere and also bring a mariner’s know-how to NOAA’s scienti c research.”

Professional mariners make up most of NOAA’s mariners, and they serve in various crew positions such as credentialed licensed engineering of cers, unlicensed engineers, licensed mates, electronics technicians (who operate and maintain the ship’s communications and navigation equipment), able and ordinary seamen, cooks and survey technicians.

As of last year, there were 270

plan is now underway to add four more research ships and offer some fresh initiatives to grow the workforce, especially improving work-life balance.

NOAA Corps mariners and 350 professional mariners. Credentialed mariners work exclusively on ships and don’t ro-

tate between sea and shore assignments like commissioned of cers do.

NOAA data shows that hiring has not

kept pace with the number of departing Corps members and professional mariners, especially last year due to the postponement of retirements during the Covid pandemic.

This has hurt the agency’s ability to ful ll many of its scienti c missions, according to of cials of the NOAA Ofce of Marine and Aviation Operations (OMAO), which runs the programs. Over the past few years, OMAO has

only been able to complete half of the days at sea needed to meet its research mandates due to workforce shortages and the limited size of its eet of ships.

The biggest factors affecting recruitment and retention have been mariner unhappiness over work-life balance, the limited knowledge of opportunities at NOAA compared to those in the Navy or Coast Guard, extended sea time, less time off and lower pay than other mari-

time jobs, and the high rate of disqualication of applicants (60%) during the medical screening process, which does not permit medical waivers.

On the other hand, mariners gave high marks for participating in NOAA’s scienti c and research work.

A plan is now underway to add four more research ships and offer some fresh initiatives to grow the workforce, especially improving work-life balance.

For the NOAA Corps of cers, NOAA is experimenting with rotational schedules so that instead of spending two years aboard during a sea tour, of cers rotated between 12 weeks aboard the ship and six weeks in shoreside positions during a three-year period.

For professional mariners, NOAA is planning to transition to a rotational schedule in which mariners will spend two months (60 days) at sea followed by one month (30 days) on leave. Ofcials said this 60/30 rotation is comparable to what is offered by many private maritime employers.

“This is a phased approach, and we aim to include all ships by the end of 2026,” said Kelley Belva, a NOAA spokeswoman. “Additionally, all of our ships have reliable internet services,

which helps everyone stay connected during extended missions.”

NOAA is actively recruiting more mariners — especially licensed engineers, oilers, able seamen (including shermen) and cooks, and has been holding recruiting sessions around the country.

For those who qualify, a $10,000 hiring bonus is being offered to professional mariners who commit to two

years of service. Last year, a 10% salary increase paid biweekly was offered to current mariners as a retention bonus. NOAA also offers on-the-job training as well as formal training programs.

Asked why a mariner would choose NOAA over a private industry job, Belva said a big reason is the allure of the agency’s mission. “We think NOAA is a great place to work,” she said. “As a science organization, NOAA research

and ordinary seamen, cooks and survey technicians.

ship missions explore the deepest parts of the ocean, conduct sheries surveys and ocean and climate studies and chart the shallow bays and inlets of the United States.”

She also cited the advantages of being a federal employee, such as competitive salaries, “unmatched” job security, health and life insurance, retirement plans, access to military base commissaries and exchanges, and shore leave.

“Our salaries are competitive, especially when federal bene ts and overtime pay are considered,” Belva said. An average annual salary for an ordinary seaman, for example, is $63,167.

These initiatives are helpful, but the Government Accountability Of ce, the investigative arm of Congress, recommended in a recent report that NOAA initiate comprehensive workforce plans that would guide the expansion of both the Corps and the professional mariner workforce. Of cials said these plans are being developed and are expected to be nalized at the end of next year.

For more information and to apply for a position, go to: www.omao.noaa. gov.

very Exp

“With the delivery of the Chugach Express, we’re thrilled to embark on this new chapter for our business. We’re beyond impressed by how well the vessel performs. The best-in-class design and construction of this vessel, paired with the top-notch performance of the MJP waterjets has surpassed our wildest dreams. This vessel will ensure the sustainability andtantly, provide a superior experience for our customers.”

-Casey Neumann, Managing Partner, Phillips Cruises

and Tours

C&C Marine and Repair, Belle Chasse, La., has delivered a new twin-screw 198'x50'x12'6" towboat to American Commercial Barge Line, Jeffersonville, Ind. Designed by CT Marine with an 11'6" draft, the Mariner is the largest towboat “on the planet,” according to Christian Townsend, CT Marine’s owner.

“We have spent four years and probably 24,000-plus hours of engineering on this project. She is the largest twin screw ever built for the rivers,” Townsend said.

Main propulsion will come from twin Caterpillar C280-12 diesel engines connected to Hung Shin 5-bladed wheels through Reintjes WAF 6755 marine gears supplied by Karl Senner

Steering and controls will be the responsibility of CT Marine’s TwinDIFF system.

Capacities will include 117,192 gals. of fuel oil; 17,250 gals. consumable potable water; 161,585 non-consumable

water; 506 gals. hydraulic oil; 2,300 gals. coolant; and 513 gals. genset day tank. In addition, Mariner will have accommodations for a 12-person crew and is tted with a single guest room.

The new towboat will be ABS certied and USCG classed, Subchapter M.

— Ken Hocke

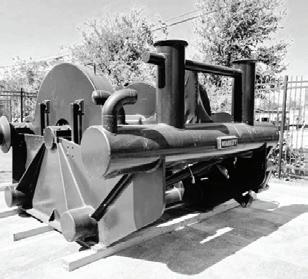

InSeptember, Amogy Inc., an ammonia-to-power solution company, took delivery of the 105'x27'x13' tug NH3 Kraken. The steel-hulled tug was retro tted with Amogy’s ammoniato-electrical power system and had its successful inaugural run on a tributary of the Hudson River, upstream from New York City.

Getting the rst ammonia-powered vessel on the water signals a milestone in Amogy’s journey to zero-emissions shipping, as ammonia is predicted to become the leading fuel source for the world’s giant cargo ships by 2050, according to the International Energy Agency.

The retro tting took place at Feeney Shipyard, Kingston, N.Y. SEAM was the electrical integrator. The tug was originally built in 1957 at Brooklynbased Jakobson Shipyard and uses diesel generators and electric motors with its ammonia-to-power system. The original tug was built for Virginia Railway Co.

Designed by Amogy and C-Job Naval Architects, Woodlands, Texas, the tug, which has a 13' draft, was not retro tted for commercial use, but rather

as a demonstration of the company’s ammonia-to-electric power system. The tug is now, technically, a recreational vessel.

Amogy of cials said the demonstration is a step towards reducing global carbon emissions and moving the maritime industry closer to the International Maritime Organization’s (IMO) target of net-zero emissions by 2050. It proves both the viability of Amogy’s technology and the potential of ammonia as a carbon-free maritime fuel.

“Amogy’s NH3 Kraken is the world’s rst successful demonstration of a carbon-free, ammonia-powered vessel,” Seonghoon Woo, CEO and co-founder of Amogy, told WorkBoat in an email following the demonstration. “This is a signi cant step towards reducing global carbon emissions and proves the viability of Amogy’s technology and ammonia’s potential as a carbon-free maritime fuel. I’m proud to be part of the team that has set out to help the world solve a massive problem.”

Amogy’s patented ammonia-toelectrical power system splits, or “cracks,” liquid ammonia into its base elements of hydrogen and nitrogen. The hydrogen is then funneled into a fuel cell, generating high-performance power with zero carbon emissions. The technology offers a sustainable, clean energy solution, tailored for hard-toabate sectors like maritime shipping, as well as stationary power generation applications. During the demonstration, the NH3 Kraken was fueled with green ammonia — produced entirely with renewable energy, the company said.

Main propulsion for the 259 gt-tug comes from a single RAMME Electric Machines’ SW860_M_750_B electric motor producing 750-kW of electrical power. The SW860 connects to a 2-bladed xed propeller through a Farrel marine gear with a 4.13:1 reduction ratio, giving NH3 Kraken a running speed of 12 knots.

The controls are by SEAM and the steering system a WEG 02509ET3E326T-W22. The tug can accommodate up to 20 people.

Amogy plans to release a case study

providing additional technical details in the coming months. — K. Hocke

Bisso Towboat Co. Inc., Luling, La., took delivery of its newest lowemission ship-assist tug, the 5,000-hp azimuth stern drive (ASD) tractor tug Mr. Brian. The Mr. Brian is the sixth

ASD tractor tug built for Bisso Towboat in the past nine years by Main Iron Works LLC, Houma, La. The new tug is named in honor of Bisso’s longtime vice president, operations, Brian Cyprowski.

“With the addition of the Mr. Brian, Bisso Towboat is the only ship-assist company on the river with a daily operating eet of 100% ASD tractor tugs,” said Bisso’s president, Scott Slatten.

The 100'x38'x13'6" Mr. Brian is

For commercial marine applications, gearbox failure isn’t an option either. Philadelphia Gear created Onsite Technical Services™ (OTS) to support all our marine customers, including the U.S. Navy and Coast Guard, to install, rebuild, and maintain critical rotating equipment anywhere they go.

Get Navy-trusted OTS for your commercial marine vessels: Visit PhilaGear.com/Marine today.

powered by Caterpillar 3516E Tier 4F main engines generating 2,500 hp each at 1,600 rpm. and drive two Kongsberg US205S Z-drives. The Z-drives feature 2,400-millimeter diameter, 4-bladed stainless-steel propellers in stainless steel nozzles. Estimated bollard pull is 68 tons.

Electrical service is provided by two 118 kW Caterpillar generators powered by Caterpillar C4.4 engines. The tug is equipped with a JonRie series 240 escort winch featuring 500' of 2-3/4" diameter Saturn 12 line.

Other features include USCGapproved engine room monitoring and re/smoke alarm systems, xed CO2 re extinguishing system, Simrad navigation and electronics systems, soundproof insulation throughout the engine room and crew quarters, stainless steel bitts and bow staple, and four bunk rooms with seven berths.

Tankage includes capacities for 30,162 gals. of diesel, 11,000 gals. potable water, 1,825 gals. each of lube and hydraulic oil and 2,000 gals. of

All American Marine (AAM), Bellingham, Wash., delivered the 74'x27'6" aluminum hydrofoil catamaran patrol boat Barracuda to the California Department of Fish and Wildlife (CDFW). Barracuda was designed and built to enhance CDFW’s capabilities in coastal and marine enforcement, and to play a crucial role in safeguarding California’s marine resources for its Law Enforcement Division. The vessel is equipped to handle a wide range of near coastal and offshore missions, including multiday patrols, commercial gear inspection and recovery, fishery enforcement, and marine protected area patrols. The new boat uses Teknicraft’s dynamic hydrofoil system, which is designed to minimize drag, enhance fuel efficiency, and provide superior stability and passenger comfort. Powered by twin Caterpillar C-18 diesel engines, each producing

800-hp, the boat has a cruising speed of 24.5 knots, with a top speed of 27 knots. Fuel capacity for the vessel is 2,000 gals.

Metal Shark delivered the firstof-two new welded-aluminum 50' fireboats to the Anne Arundel County Fire Department, Annapolis, Md., in mid-September. The vessels will operate across Chesapeake Bay and will be tasked with protecting over 500 miles of shoreline. The boats are being built to enhance the department’s ability to respond to emergencies on the water for residents of

Meets 2 mile requirement for marking of dredge pipelines

Navigation

1 to 3 mile visibility for aids to navigation and applications such as buoys, docks, barges, and temporary lighting

Permanent mount LED lighting for bridges, docks, and barges

For vessels greater or less than 50 meters Certified to meet UL 1104 and Subchapter M Platform Marker Lights

Solar or battery powered barge navigation lights for unmanned barges per UL1104 Regulatory Buoys

Available for all applications

*Available with or without lighting*

The new tug is the sixth ASD tractor tug built for Bisso Towboat by Main Iron Works in the past nine years.

diesel exhaust uid (DEF).

The Mr. Brian will have a crew complement of four and carry an ABS International Load Line in addition to being built to Subchapter M certi cation and receiving a USCG certi cate of inspection. — K. Hocke

Anne Arundel County, Baltimore City, Baltimore County, Calvert County, City of Annapolis, Prince George’s County, Queens Anne County on the Eastern Shore, and the United States Naval Academy. Metal Shark’s engineering team designed the vessels in-house, and vessel construction took place at the company’s Franklin, La., shipyard. The new 50 Defiant NXT monohull pilothouse fireboats are built to offer faster speeds enabling shorter response times, greater pumping volume, and a next-generation design.

Silver Ships Inc., Theodore, Ala., recently delivered a Catamaran 26 model to the U.S. Army Corps of Engineers (USACE) Mobile District. The design was focused on stability and maneuverability, crucial for navigating challenging waterways.

The 26'x 9'6" vessel is equipped with twin 200-hp Yamaha outboards and a Honda EU3000IS generator. The shipyard said the design ensures optimal performance under various environmental conditions. Additionally, the vessel includes a Garmin electronics suite, enhancing its survey and navigation capabilities. The Catamaran 26 model offered by Silver Ships lists mission-specific outfitting options, such as a full climate-

We are establishing a new division focused on deck and crane barges, tailored to meet customer specifications, and will be offered for sale or charter.

Senesco aims to develop a fleet comprising 12 barges of diverse sizes and capacities, contributing to the modernization of aging barges in the construction sector

today or visit us at: www.senescomarine.com

Yank Marine, Inc. has built and repaired thousands of boats: private yachts, commercial and fishing craft, military vessels, and a large array of USCG-certified passenger vessels.

control package, dive door, bow gate, stainless steel davits, and a retractable hydrographic sonar mount.

Gulf LNG Tugs of Port Arthur LLC (Gulf LNG Tugs) has ordered four RApport 2800 tugboats specifically designed to serve the Port Arthur LNG export facility. Two will be constructed by Master Boat Builders Inc., Coden, Ala., and two by Sterling Shipyard LLC, Port Neches, Texas. The 92'x40' RApport 2800 tugs, designed by naval architect Robert Allan Ltd., feature a compact design providing increased maneuverability in ship handling and escorting through waterways while including the latest in environmental and safety technologies, tug organization officials said. Gulf LNG Tugs members each currently operate tugs of a similar hull design within their commercial fleets,

with an additional four under construction. Each vessel is being designed and built to stringent safety and environmental standards, to U.S. Coast Guard Sub-M regulations and ABS classification. The eco-designed tugs will feature EPA Tier-4 emission standard Caterpillar 3516 E main propulsion engines connected to Kongsberg US-255 FP-Z drives. The tugs will be outfitted with a Markey DESF-48-100 Electric Class III hawser winch, including a render-recover feature for full bollard pull capacity.

Austal USA, Mobile, Ala., has been awarded a $450 million contract by General Dynamics Electric Boat, Groton, Conn., for the expansion of production capacity in support of the U.S. Navy submarine industrial base (SIB). The award will enable Austal USA to expand infrastructure in its Mobile, Ala. shipyard.

he crash of the container ship MV Dali into the Francis Scott Key Bridge in March of this year was by any measure a disaster. It resulted in the loss of innocent life and virtually incalculable expense. It shut down a U.S. port where 2,000 people work as well as a transportation artery that carries 30,000 vehicles (including trucks carrying hazardous materials prohibited in metropolitan tunnels) a day. Litigation will entail untold millions of dollars and may well employ as many attorneys as there were boxes on the nearly 10,000 TEU Neo-Panamax containership.

The crash — more precisely, the allision — occurred in the early hours of March 26, when the ship lost power

on its way out of Baltimore, sending it drifting down on the 8,600' continuous truss bridge.

In the 90 seconds or so they had to react, police stopped traf c in both directions, but they were unable to contact the seven maintenance workers and an inspector who were on the bridge. The inspector, who had been walking the length of the bridge, made it to the nearest intact span. The seven workers were in their vehicles and fell with the bridge: one survived.

In its preliminary report, the National Transportation Safety Board said a primary electrical circuit breaker aboard the Dali tripped, shutting down generator-driven electrical pumps that fed the main engine cooling water and lubricating oil, triggering the automatic shutdown of the engine itself.

Engineers were able to start the emergency generator. This would have restored electricity and emergency steering. The NTSB pointed out, how-

ever, that the rudder would have turned at a slower than normal rate, and without the ship’s propeller turning, “would have been less effective.”

Meanwhile, the pilots called for tug assist. The Eric McAllister, one of two tugs that earlier had escorted the Dali, was three miles away and immediately headed in the container ship’s direction, but it did not reach the ship in time to prevent or minimize damage from the allision — had it been able to do so.

Aboard the Dali, the senior pilot ordered the anchor dropped, and the pilot’s dispatcher called the Coast Guard to say the ship had lost power.

With the Dali within 0.2 miles of the bridge, a second electrical blackout occurred, the NTSB said. The emergency generator continued to power emergency equipment, and the pilot ordered the rudder hard to port.

The ship broadcast a warning via VHF radio to all waterborne traf c. The crew was able to restore electrical

power, but the main engine remained shut down.

A little more than a minute later, the Dali struck the bridge.

Mark Twain famously observed that “History does not repeat itself, but it does rhyme.”

In January 1975, 12 people died in what has become known as the Tasman Bridge disaster. In this episode, the 459' bulk carrier Lake Illawarra, traveling up the River Derwent, in Tasmania, Australia, struck two piers, resulting in the collapse of a 416' section of the bridge.

Instead of passing through the bridge’s center span, the Lake Illawarra, in the grip of the tide, attempted to navigate a narrower span.

A portion of the collapsed span landed on the vessel’s deck, and in minutes the Lake Illawarra sank. Seven crewmen were trapped and drowned. Four cars ran off the edge of the bridge, claiming the lives of their occupants, while the passengers in two vehicles whose front wheels overhung the breach miraculously scrambled to safety.

The Tasman Bridge disaster is also noteworthy for the social and logistical impacts it imposed. Without the bridge, the city of Hobart was split in two.

In February 1977, the SS Marine Floridian, a 523’ tanker, was downbound on the James River bound for Newport News, Va., when its steering system malfunctioned. The vessel veered to port, away from the raised center span of the Benjamin Harrison drawbridge and struck a support pier. The adjacent deck slab fell into the river, taking with it the two vehicles that had been holding at the lift gate.

Fortunately, the vehicles’ occupants had seen t to ee the span prior to impact.

Nor were there injuries aboard the ship, on whose deck the northern end of the truss span landed.

Thirty- ve people who were crossing the Sunshine Skyway Bridge over Florida’s Tampa Bay were not as fortunate three years later when the 609’ bulk carrier Summit Venture struck the

bridge during a squall. A Greyhound bus was among the eight vehicles on the 1,300' section of the bridge that collapsed.

The NTSB determined that the probable cause of the accident was “the Summit Venture’s unexpected encounter with severe weather involving high winds and heavy rain associated with a line of intense thunderstorms….” The ship strayed just far enough off course to clean out two support piers.

Whether Twain’s dictum improved on the New Testament’s admonition that “there is no new thing under the sun,” this much seems certain: as long as there are bridges within reach of ships, ships will try to run into them.

Still, there is no such thing as a sure thing. Lose power, the Dali made clear, and all bets are off. — Jerry Fraser

he U.S. offshore wind industry saw another year of changing fortunes. While the Biden administration pressed onward with planning new wind lease sales — including the rst deepwater ventures — developers faced new supply chain challenges.

New York State of cials on April 19 canceled three provisional contracts with developers holding federal leases in the New York Bight, after turbine manufacturer GE Vernova decided to cancel its plans for supersized 18-megawatt turbines the developers had planned to use.

GE Vernova’s troubles came into public view after a blade fractured July 13 on a turbine in the Vineyard Wind array off southern Massachusetts. One month after the fracture, the federal Bureau of Safety and Environmental Enforcement (BSEE) issued an “updated suspension order” to allow some work to resume on the planned 62-turbine, 806-megawatt rated array. The order continued to block new blade installation or power production at the 24 turbines installed

before the break.

Reports of broken blade pieces drifting across southern New England waters were cited by opponents off the Atlantic Shores project off New Jersey as proof of their fears that building turbine arrays starting just 8.7 miles off their beaches will endanger their own tourism industry.

“We saw what happened in Nantucket. God only knows what would happen when we get a cat [category] 3 or any hurricane,” said Rep. Jeff Van Drew, R-N.J., a erce critic of the Bureau of Ocean Energy Management (BOEM) and the wind industry. He predicted “a blizzard of berglass” if turbine blades break apart in a severe hurricane.

Then news broke Sept. 20 that GE Vernova could lay off 900 workers as part of readjusting its offshore wind sector. CEO Scott Strazik told the Wall Street Journal that the industry’s supply chain problems still require a reset.

Meanwhile, BOEM pressed on with opening future wind development areas. Two wind energy leases offshore of the Mid-Atlantic’s Delmarva region brought in nearly $93 million in an Aug. 14 auction from Equinor Wind US LLC and Virginia Electric and Power Co.

BOEM moved to advance oating offshore wind development in the Gulf of Maine and off Oregon. But a planned Oct. 15 Oregon lease sale was cancelled by the agency, amid opposition from Gov. Tina Kotek, shing groups, and Oregon tribes. Updated regulations for offshore wind development announced by U.S. Secretary of the Interior Deb Haaland in April include a ve-year planning framework that could bring 12 new offshore wind lease sales by 2028, according to Interior of cials.

“By modernizing and updating these regulations, we are paving the way for the safe and ef cient deployment of offshore wind projects, providing clarity for developers while continuing to protect important natural and cultural resources,” said Haaland, speaking at the International Partnering Forum offshore wind conference in New Orleans in April.

Offshore operators and shipbuilders

continued slowly building the U.S.-flag Jones Act fleet. The first U.S.-built service operations vessel for offshore wind was christened on May 11 in New Orleans by wind energy developer Ørsted and vessel builder Edison Chouest Offshore (ECO).

Carrying up to 60 technicians on board, the 262' ECO Edison will serve in operations and maintenance for Ørsted and Eversource’s South Fork Wind, Revolution Wind, and Sunrise Wind projects off southern New England and Long Island, N.Y.

— Kirk Moore

abMar Inland, New Orleans, began marketing towing and pushboat operations to the inland marine market on July 15. The inland company is the newest affiliate of New Orleans-based Laborde Marine Management. With a fleet of 23 vessels, Laborde has been providing OSV and crewboat services for the offshore Gulf of Mexico market since 1995. Laborde Marine’s new inland waterway venture has been some time in the making.

The idea to diversify its towing and

pushboat operations began in about 2015, said Ashton Laborde, president of Laborde Marine Management, during what he refers to as “the last downtime.” It was a period of “lower utilization and day rates for vessels in the offshore sector, beginning in late 2014 and running through the covid pandemic,” Laborde said.

The first venture into diversity was LabMar Ferry Services. A ferry service for the New Orleans area began in 2019, with the Margaret Lab, a 162' crewboat retrofitted as a passenger ferry. Today LabMar Ferry Services is made up of two 105', 149-passenger-only, high-speed aluminum catamaran ferries and one car ferry that carries 30 vehicles and 600 passengers.

“We were leaning on our core competences and lessons learned on the offshore side” to launch the ferry business, said Laborde, “bringing kind of the same culture into that operation.” At the same time, Laborde Marine had been monitoring the inland towboat and pushboat market for a few years. “We were in a position now with the offshore business in an uptick to commit some cash to exploring that market. That’s kind of where we are now,” said Laborde.

LabMar Inland’s first inland pushboat is the Ivy Steiner, a bareboat chartered

Sophisticated designs, complete solutions and specialized services are goals that we at PALFINGER MARINE live and breathe every day. We guarantee reliability and safety in every aspect, especially in search, rescue, and o shore operations.

Visit our partner Donovan Marine at stand 2219 during this year’s International WorkBoat Show to explore our impressive portfolio of boats, davits, and more.

78'x34'x10', 2,000-hp pushboat built by Steiner Construction, Bayou La Batre, Ala. Going the bareboat charter route “allowed us to take delivery of a new vessel immediately and to best respond to the demands of our customers,” said Laborde.

Powered by a pair of Caterpillar C32 diesel engines turning stainless steel props through Reintjes WAF reversereduction gearboxes, the Ivy Steiner has a running speed of about 8 knots. On deck are two 40-ton Nabrico DF-1-40H winches.

The Ivy Steiner was launched this past July. “It went straight out of the yard onto a charter,” Laborde said. “We are running crude oil from Rio Honda, Texas, to Nederland, Texas,” he said.

Typically, that means pushing two 30,000-bbl. barges along the Gulf Intracoastal Waterway. “It’s a tough route,” Laborde said. “You are dealing with shoaling, heavy traffic, heavy winds. The consensus we get is if you can do this job on that route, you guys can do it anywhere.”

LabMar Inland’s solution for the crewing issue was reaching “into our other operations for mariners that have experience and the proper licenses to come back to the inland market,” said Laborde. If there’s been any question, potential crew candidates are carried as extra crew “on the Ivy Steiner, so we

Today’s modern vessels are highly sophisticated and represent a much higher risk profile for a ship owner when it comes to selecting the right shipyard. Eastern’s proven track record of successfully engineering and building these large and complex ships on time and on budget dramatically reduces that risk. As one of the top tier-two shipyards in the United States, Eastern Shipbuilding Group is the reliable partner you can trust to deliver your next vessel on time, every time.

can put them through our vetting process and have our existing vessel managers sign off on these guys. We are at a point now where we are comfortable bringing an additional vessel on with guys we feel will be a good t for our company.”

Looking further into the future, expect LabMar Inland to increase its towing and pushboat presence on the inland waterways even further. “We have additional boats lined up,” said Laborde, “and are looking at additional bareboat opportunities, as well as potential purchasing of existing vessels. We are also exploring the barge market through those same avenues.”

Laborde admits that he would like to “have contracts in hand” before acquiring additional vessels, “but depending on the timing, we’re exploring potentially taking a vessel on spec and marketing it or taking a bareboat without a charter in place,” he said.

— Michael Crowley

mall shipyards have always played an essential role in the U.S. maritime industry, often providing specialized services and craftsmanship that larger shipyards do not offer. However, staying competitive has become increasingly challenging. Yards must contend with regulatory pressures, in ation, supply chain issues, and a shrinking skilled workforce.

Yet, for these smaller shipyards, a crucial lifeline remains — the Small Shipyard Grant Program.

Administered by the U.S. Maritime Administration (Marad), small shipyard grants have been a reliable resource for many shipyards across the U.S., helping them modernize their facilities, purchase new equipment, and invest in

workforce training. The program has proved to be critical in maintaining the competitiveness of these smaller shipyards.

Given that, the survival and success of this program hasn’t always been guaranteed, and much of its continued relevance can be attributed to the efforts of the Small Shipyard Grant Coalition — a group formed to advocate for the program’s funding and support.

Now underfunded and under threat, the Small Shipyard Grant Program nds itself at a crossroads. For the past six years, the program had a budget of around $20 million. For example, in scal year 2023, 27 different shipyards across 20 states split a purse of $20.4 million to improve their facilities and upgrade their equipment.

But 2024 saw a steep cut to $8.75 million. With the reduced funding, there are fewer grants and smaller awards,

leading to a signi cant decrease in transformative projects like marine boat lifts and drydocks — essential elements for shipyard operations. This year, only one drydock was funded, and no boat lifts, a sharp contrast to last year’s provision of four each.

Coalition founder Dave Matsuda, notes that the shortfall is most telling in the absence of haul-out equipment, the backbone of any shipyard’s functionality, but he remains positive. “This is a critical year,” he told WorkBoat recently. “If Congress comes back and gives us the 8.75 number again, we

might be stuck at that for a while. And if they come back at 20, then it just kind of shows that [20]24 was an aberration, and that was just a one-time thing.”

The take home message from coalition-to-industry is that this is a critical time for the program. “If you care about this program, if you want to see it continue, you’ve got to be engaging with us, with your members of Congress, to let them know how important this is, and that we want to see the funding restored,” Matsuda said.

As the program continues to evolve, the success stories of shipyards that

have bene ted from the grants are powerful testaments to its impact.

Last year, Senesco Marine, North Kingstown, R.I., was awarded $738,000 through the Small Shipyard Grant Program to support the purchase and installation of a one-sided submerged arc welding system that consists of three integrated digital systems to load, t, and weld multiple-plate panels, upgraded network servers and software, an all-terrain lift with variable reach, and a Tier 4 compressor.

“This machine runs a bead and can weld two (40'x40') plates together in about an hour and a half,” Ted Williams, Senesco Marine’s president, said in describing the bene ts of that grant and the sub arc welder as an asset to the yard. “It would take a human about three-to-four days to do it,” he said.

Mike Foster, Senesco’s general manager, mentioned the increased capabilities that the new welding head will provide.

“This one’s capable of welding up to ve-eighths of an inch thick,” he said. “Whereas the new machine’s threequarters to one-inch, so it allows us to weld thicker materials with less distortion.”

Most importantly, Foster said, Senesco was awarded about $500,000 out of that grant to get a new head, that yellow head right there,” he said, pointing to the arc welder. “We’re going to replace that in a few months as that comes in. That’s an old analog system. We’re go-

ing to get a new digital system, which will make it even better, more accurate, and more re ned,” he said.

Williams emphasized the impact the Marad program has had since its inception. “That’s a great thing for shipyards to be able to tap into something like that and get that support.” — Ben Hayden

Advocates for the U.S. offshore services industry kept up their pressure for Congress to pass the American Offshore Worker Fairness Act, legislation they say will ensure parity and job opportunity for American maritime workers and U.S.- ag vessels.

Bill S-3038 was introduced last October by Sen. Bill Cassidy, R-La., and referred to the Committee on Commerce, Science, and Transportation. This

summer more than 100 organizations signed onto a July 31 letter written by the Offshore Marine Services Association (OMSA) calling for Congress to enact the measure.

The legislation “will provide parity between U.S.- agged and foreignagged vessels operating in U.S. offshore energy activities and ensure that U.S. offshore energy creation means jobs for U.S. mariners,” the letter stated. “By requiring foreign vessels to utilize mariners from their ag state, or U.S. mariners, when working in U.S. waters, the American Offshore Worker Fairness Act creates a fair and level playing eld on which foreign vessels comply with the same rules that U.S. vessels comply with for domestic offshore energy operations.”

In August OMSA President Aaron Smith said that broad support from across the offshore sector underscores the importance of the legislation.

“This bill is crucial for ensuring safe

Secure. Professional.

Quality. On schedule.

Located in Northeast Florida, just two nautical miles from the Atlantic Ocean, BAE Systems Jacksonville Ship Repair offers professional ship repair and refit services to yacht customers.

Quality service, on schedule, within budget and without difficulty. Upfront and honest.

Jacksonville, Florida | USA +1-904-431-2227 | jaxyachtrefit@baesystems.com

baesystems.com/commercialshiprepair

and reliable domestic energy production at a time when the stakes are incredibly high,” said Smith. “Without AOWFA and the parity it provides, foreign vessels and crews will continue to take jobs away from American mariners and jeopardize the nation’s economic stability and national security.”

In letters to U.S. lawmakers since 2022, OMSA has stressed the need to update the law.

“Understanding this point, existing law (43 U.S.C. Section 1356) requires that all vessels, rigs, platforms, or other structures on the U.S. Outer Continental Shelf (OCS) be manned by U.S. citizens or lawful permanent residents,” according to OMSA’s position papers.

“The law also provides that vessels, rigs, platforms, or other structures that are more than 50 percent foreign owned are exempt from the requirement that they be manned by U.S. citizens. This exemption was enacted by Congress to ‘reconcile dual concerns of providing

fullest possible employment for Americans in [OCS] activities and eliminating to the fullest extent…retaliation by foreign nations against American workers in foreign offshore activities.’”

Pushing from the other direction, the International Marine Contractors Association in November 2023 warned that the American Offshore Worker Fairness Act “would make it harder to develop U.S. offshore energy projects by limiting the availability of vessels and crews.

“This proposed legislation ignores the reality for offshore delivery in wind markets around the globe,” association CEO Iain Grainger said then. “There is a worldwide shortage of specialist vessels, a limited talent pool with the skills, knowledge and experience required to operate them safely, and huge demands driven by the move to net zero and energy security concerns.”

The association said that “with the U.S. facing a shortage of mariners, American companies are struggling to

man existing eets.”

OMSA has campaigned since at least 2022 to show offshore wind developers are using foreign- ag vessels when U.S. boats are available.

In March, Vineyard Wind announced the Belgium-based DEME Offshore US would team with Foss Maritime, Seattle, to construct the 800-megawatt Vineyard Wind 1 offshore energy project, using the “feeder” concept of a foreign- ag wind turbine installation vessel (WTIV) supplied onsite by Jones Act-compliant U.S. vessels.

The American Offshore Worker Fairness Act “would require foreign vessels to utilize either U.S. mariners or citizens of the vessel’s home country while operating in offshore energy activities in U.S. waters,” according to OMSA. “This would change the current practice where foreign vessels utilize crewmembers from low-wage countries at day rates no American would or should accept. This unfair practice gives foreign vessels a

Whether you’re powering an offshore service vessel, a passenger vessel, or an inland pushboat, Louisiana Cat has the right engine for your hard working fleet. We focus on you, the customer, and the reliability, safety and profitability of your business. Let us help you navigate every waterway. Visit us online to request an engine quote for your next project: www.LouisianaCat.com/Marine

competitive advantage over U.S. vessels and takes jobs away from American mariners.”

The legislation still making its way through Congress is hotly disputed in the offshore wind industry. Renewable energy advocates warn it will hobble U.S. offshore wind development still in its early stages, when some foreign- ag vessels are needed for specialized tasks.

— K. Moore

n Jan. 2024, Master Boat Builders, Coden, Ala., delivered the 82'x40'x17'9" eWolf, the rst all-electric, ship-assist harbor tugboat in the U.S., to Jacksonville, Fla.-based Crowley

The eWolf was designed by Crowley’s engineering services team with a 16'5"

draft. Crowley said the vessel operates with zero emissions while providing the complete performance capabilities of a traditional tug.

The company also said it is committed to improving air quality through battery energy for the vessel and port technology, including a shoreside, microgrid charging and storage station at the Port of San Diego.

The industry had been anticipating the new tug’s delivery for over two years. During a visit to Master Boat Builders last year, Garrett Rice, the shipyard’s president, explained that the delay was a result of the Coast Guard never having had to sign off on this kind of tug before. There has never been a similar tug up for certi cation in the past. “Our industry has to be pushed to build toward innovation,” he said. “Our government doesn’t work fast.”

Main propulsion comes from a 6.2-MWh Orca battery energy storage system provided by Corvus Energy and

two 2,100-kW RAMME electric motors spinning two Schottel rudder propellers type SRP 430 LE azimuth thrusters. There are two switchboards — a DC grid and AC switchboard. For longer transits, the new tug has twin 300-kW John Deere generators.

The tug has a running speed of 12 knots.

“The eWolf will provide services through its advanced vessel control technology and first-in-class energy features, while providing the safety, quality and reliability that Crowley and our mariners are known for,” James Fowler, senior vice president and general manager of Crowley Shipping, said in a statement. “We are thrilled to reach this important achievement for our company and the U.S. maritime industry through the collaboration with our partners.”

According to EPA calculations, the tug will generate 178 fewer tons of nitrogen oxide (NOx), 2.5 tons less diesel

particulate matter and 3,100 metric tons less carbon dioxide (CO2) over the rst 10 years of its operations versus a conventional tug — the equivalent of removing 350,000 gals. of gas from use. The vessel uses ABB’s integrated electrical propulsion system.

Keegan Plaskon, director of business development at the American Bureau of Shipping (ABS), said during a conference session at last year’s International WorkBoat Show that the eWolf complies with U.S. shipping industry standards and will be the first Jones Act-compliant all-electric tug.

So, what is in the future? Batterydriven electric motors cannot be retro tted and placed in existing tugs, but alternative fuel engines can be retro tted.

Master Boat’s Rice said during the eWolf session that “it’s costly to retro t an already existing vessel fully. Federal and state grants can help fund new fully electric vessels.”

On deck is a Markey Machin-

ery DEPC-48-50-hp electric render/ recover winch.

“The eWolf demonstrates where the maritime industry can go, in terms of both innovation and sustainability, with solid partnerships between owners, designers, suppliers and shipyards,” said Rice. “We are proud to have partnered with Crowley in the construction of the eWolf.”

The 200-gt all-electric tug has an estimated bollard pull of 70 short tons. Tankage includes 9,800 gals. of fuel and 750 gals. fresh water. — B. Hayden

Twenty years ago, the U.S. Navy awarded contracts to two teams of defense contractors to build one or two prototypes each for what would become the littoral combat ship

(LCS), an agile, mission-focused platform designed to operate in near-shore environments.

One of those teams was a joint venture between General Dynamics and Australian shipbuilder Austal. Once it had secured a contract, the team planned to build its version of the LCS at Austal USA, a small shipyard in Mobile, Ala.

In response to the Navy’s goals, the contractor based its original ship design partly on high-speed ferries. The new design produced a 421'6"x103.7' trimaran aluminum LCS with a displacement of 3,200 MT, a 15.1' draft, and powered by a pair of 12,200-hp RollsRoyce 20V8000 diesel engines and two 29,500-hp GE LM2500 gas turbines.

Two decades later in August 2024 Austal USA successfully launched the Pierre (LCS 38), the last ship of the Navy’s Independence-variant LCS program.