Career Course

Students learn from experience at maritime high schools.

Presentedby

FEATURES

16 Vessel Report: Versatility Afloat

The U.S. Navy is ordering RIBs by the hundreds.

22 Cover Story: Pathways to Waterways

Maritime high schools help prepare kids to fill industry needs.

BOATS & GEAR

18 On the Ways

• Steiner Shipyard delivers passenger/vehicle ferry to Maine • Eastern Shipbuilding launches Long Island ferry • General Dynamics delivers fleet replenishment oiler to U.S. Navy • Marinette Marine gets contract to build two more Navy Constellation-class frigates • Metal Shark and ReconCraft awarded IDIQ patrol boat contracts.

28 Power Guide

WorkBoat’s annual directory of marine diesel engines

44 Group Therapy

Keeping track of a fleet’s maintenance and scheduling needs has gotten easier

AT A GLANCE

8 On the Water: Ships do lose power without warning

8 Captain’s Table: Embracing our nation’s river roots.

9 Energy Level: FTC’s cynical view of oil industry unwarranted.

9 Inland Insider : Changes to tug-assist protocals could be coming.

10 The Hocke Net: Deadly bridge allisions.

11 Tech Watch: Imtra highlights KPM Marine pump as new tech product.

12 Legal Talk: Collision brings attention to maintaining lookout.

13 Insurance Watch: Look for marine insurance costs to climb.

NEWS LOG

14 Edison Chouest delivers first SOV constructed in the U.S. to Ǿrsted.

14 Barge tow narrowly misses N.O. steamboat.

14 Trump promises to use an executive order to block offshore wind use.

SAVE THE DATE

Getting schooled

Normally, during a discussion about marine training and education, we talk about prospects right out of high school or someone who has already been in the workforce in another industry but now wants to try maritime. But our cover story this month (see page 22) is about maritime high schools. That’s right — high schools. And I immediately learned something I didn’t know: The city of Des Moines is in Washington State. All this time, I thought it was in Iowa. Turns out that both Washington and Iowa have a Des Moines.

Des Moines, Wash., is located between Seattle and Tacoma and is the home of Maritime High School, an upstart educational facility that is scheduled to graduate it’s rst class in 2025.

The model for the new school is New York City’s Harbor School. It’s located in an old Coast Guard base on Governor’s Island. As our Editor-atLarge Bruce Buls writes, “The school was speci cally created to train future mariners, marine scientists and industry leaders. The current enrollment is about 500 students in ninth through 12th grades.”

NEW ORLEANS

Introducing kids to career opportunities in maritime is an important function for both schools, each actively reaching out to communities that have had little interaction with the industry. The Harbor School promotes its programs at various high school fairs around the city and hosts lots of middle-school students learning about the Billion Oyster Project.

Ken Hocke, Senior Editor khocke@divcom.com

The Maritime High School has access to the Admiral Jack, a 40' catamaran owned by the Northwest Marine Center, Port Townsend, Wash., and it uses the boat to help recruit middle school students. It’s also a training vessel during the school year, especially for ninth and 10th graders.

And Harbor School's Billion Oyster Project? You’ll de nitely want to read about that.

What jumped out at me while reading the story is that the educators are making learning about the maritime industry fun. The kids are going to high school and having a good time doing it. These schools have found a way to make the marine industry cool.

Produced by Presented by

Morial Convention Center, Halls B, C, D, E & F

David Clark Marine Headset Systems

Because they watch over us. Because they give so much. Give to the Coast Guard Foundation

To learn more, visit RescueTheRescuers.org

Krapf / dkrapf@divcom.com

Ken Hocke / khocke@divcom.com

Kirk Moore / kmoore@divcom.com

Capt. Alan Bernstein • Bruce Buls • Robin G. Coles • Pamela Glass • Stephen Blakely • Max Hardberger • Joel Milton

Hayden / bhayden@divcom.com

PROJECT MANAGER / ART DIRECTOR Doug Stewart / dstewart@divcom.com eremiah Karpowicz / jkarpowicz@divcom.com

ACCOUNT EXECUTIVE S 842-5439 / mcohen@divcom.com

207-842-5635 / kluke@divcom.com

207-842-5657 / krandall@divcom.com

207-842-5634 / dwalters@divcom.com

COORDINATOR

207-842-5616 / wjalbert@divcom.com

of The International WorkBoat Show and Pacific Marine Expo www.pacificmarineexpo.com

SALES DIRECTOR Christine Salmon salmon@divcom.com

PRESIDENT & CEO Theodore Wirth / twirth@divcom.com

GROUP VICE PRESIDENT Bob Callahan / bcallahan@divcom.com

PUBLISHING OFFICES

Main Office 121 Free St., P.O. Box 7438, Portland, ME 04112-7438 207-842-5608 • Fax: 207-842-5609

MAGAZINE SUBSCRIPTION INFORMATION

cs@e-circ.net • 978-671-0444 (Monday-Friday, 10 AM – 4 PM ET)

MARINE LUBRICANTS WITH THE POWER TO PROTECT YOUR VESSEL YOUR EQUIPMENT AND THE ENVIRONMENT

Lubriplate is committed to providing you with the right lubrication for your vessel and other equipment affected by (VGP) Vessel General Permit regulations. Designed specifically for use in harsh marine conditions, these high performance, Environmentally Acceptable Lubricants (EAL)s deliver all the performance and protection you need, while maintaining compliance with regulations protecting the environment.

ATB BIOBASED EP-2 GREASE

• This versatile grease meets U.S. EPA Vessel General Permit (VGP) requirements.

• Passes U.S. EPA Static Sheen Test 1617 and U.S. EPA Acute Toxicity Test LC-50.

• ECO-Friendly and Ultimately Biodegradable (Pw1) Base Fluid – 75.2%.

• Designed for use on Articulated Tug Barge (ATB) notch interface, coupler ram and drive screws, above deck equipment, rudder shafts, wire rope, port equipment, cranes, barges and oil platforms.

BIO-SYNXTREME HF SERIES HYDRAULIC FLUIDS

• These fluids meet U.S. EPA Vessel General Permit (VGP) requirements.

• High-performance, synthetic polyalkylene glycol (PAG)-based formula.

• Non-Sheening – Does not cause a sheen or discoloration on the surface of the water or adjoining shorelines.

• Provides long service life and operating reliability, lower maintenance costs, and reduced overall downtime.

• Excellent anti-wear performance - rated as anti-wear (AW) fluids according to ASTM D7043 testing and FZG testing.

• High flash and fire points provide safety in high temperature applications.

• All season performance – high viscosity indices and low pour points.

• ECO-Friendly and Readily biodegradable according to OECD 301F.

• “Practically Non-Toxic” to fish and other aquatic wildlife according to the U.S. Fish and Wildlife Service hazard classification.

COMPLIANCE STATEMENT LUBRIPLATE ATB BIOBASED EP-2

and BIO-SYNXTREME HF SERIES HYDRAULIC FLUIDS are Environmentally Acceptable Lubricants (EAL)s according to the definitions and requirements of the US EPA 2013 Vessel General Permit, as described in VGP Section 2.2.9

MARINE LUBRICANTS

Newark, NJ 07105 / Toledo, OH 43605 / 800-733-4755 To learn more visit us at: www.lubriplate.com

Don't blame marine engineers/architects for ships' steering failures

I’veenjoyed reading your articles for many years; today I must speak out. In closing your recent May 8th article [workboat.com] with re ection on the Baltimore [Francis Scott Key] bridge collapse [the 985' container ship Dali rammed the bridge on March 26, shutting down Baltimore’s port], you suggest the marine engineers and naval architects of 2024 must be able to build a more redundant steering system for our ships.

I am a long-time member of SNAME (Society of Naval Architects and Marine Engineers). You must know that the engineers and architects don’t establish the rules of this industry, rather we attempt to design and build complex ship systems that comply with rules and speci cations developed by

ship owners, Class societies, nance companies, politicians, operators, etc. First, it’s unlikely the ship was dead in the water. It’s more likely a system control problem developed, and the operator was unable to shut down the direct-coupled diesel engine and or operate the steering system that was probably still functional but uncontrollable. The ship probably powered into the bridge pier.

The design industry is well aware of the need for doubly redundant ship systems, and they were likely already installed. These kinds of problems generally originate from maintenance activities that are not carefully checked and tested thoroughly with a second set of eyes conducting QA (Quality Assurance) as is the custom in aircraft maintenance.

Speaking of QA, you probably have already noticed the spelling/grammar error in the closing of your recent May 8th article. Unfortunately, the news

media also makes their fair share of errors. Let’s hope all of us can get to the bottom of this most recent disaster and actually agree on the proper remedy.

Cyril Silberman, CEO Atlantic Marine Electric Miami Beach,

Fla.

First of all, it was never my intention to put any blame at the feet of naval architects and marine engineers. Quite the contrary. I was trying to say that the skill level of marine engineering across the world is such that no steering system should be at the mercy of an engine or electronics failure. Whatever is needed to make sure a ship does not face what happened in Baltimore is doable. Cost might be a deterrent for owners, but it's doable. People like you have the skill. As for my making mistakes, I'll try to do better next time.

Ken Hocke

Photo credited to Snow & Company

BY JOEL MILTON

Joel Milton works on towing vessels. He can be reached at joelmilton@ yahoo.com.

On the Water

Ships do lose power without warning

The Port of Baltimore is inching closer to a full reopening of the Fort McHenry Channel. Current projections are that within a few more weeks the final clearance of the port’s only way in and out will be completed when the still-grounded M/V Dali is refloated and shifted to a berth within the port. A very, very expensive loss of commerce has ensued.

Immediately following the shocking collapse of the Francis Scott Key Bridge, a vital part of the I-695/Baltimore Beltway, both the investigation and crazy-talk began in earnest as the conspiracy wingnuts surged into action.

Everyone wants to know what specific failure(s) occurred within the power and propulsion systems on the Dali that ultimately led to the allision with and collapse of the Key Bridge. Which in turn killed six road workers and could easily have been far worse for loss of life.

I’m largely indifferent because it doesn’t really matter all that much. Why? Because we already

BY CAPT. ALAN BERNSTEIN

Alan Bernstein, owner of BB Riverboats in Cincinnati, is a licensed master and a former president of the Passenger Vessel Association. He can be reached at 859-292-2449 or abernstein@ bbriverboats.com.

Captain’s Table

Embracing our nation’s river roots

As mariners, we are continuously caught up in the day-to-day details that are unique to our operating environment. On the Inland Rivers we deal with low water, high water, ice flows, snags, and heavy traffic of all shapes and sizes in restricted spaces to name just a few of the operational challenges that test our skills and require our constant attention.

Whenever I have a quiet moment, and there are never many of these, I reflect on those who came before us on the rivers and the trials and tribulations that they overcame in their time. While technology has changed dramatically, many of the challenges put forth by Mother Nature are the same today as then.

As I ponder these things, I realize that my operational back yard, Cincinnati, was considered the Steamboat Capitol of our country in the 1870s. To ensure that this incredible distinction is not lost to the dust bin of history, many of us who locally appreciate our rich steamboat history have been working to resurrect a “Tall-Stacks-like” event in Cincin-

know the two most important things and knew them before this “unforeseeable accident” that blindsided Baltimore. One, no matter what we do, we will never eliminate ships losing power without warning. That’s a given. Reduce it? Maybe. But we will no more stop that from happening ever again than we’ll eliminate auto accidents. And two, that the bridge was functionally unprotected from ship strikes, and had been so since it opened for traffic in 1977.

It’s a fair argument to make that every piece of critical infrastructure nationwide, sometimes even really important infrastructure, can’t be given the maximum available protection using the best available technology (BAT) for reasons of cost. You have to analyze, rank and triage everything using a cost/benefit/likelihood calculation. It won’t be perfect, but it can surely prevent the worst outcomes that inflict the greatest damages. In Baltimore’s case, it’s really hard to understand the lapse of judgment that led to the existence of the only bridge over the main channel being left completely to continuing good fortune as its only real defense.

It’s not like we didn’t know it could happen. Sunshine Skyway in 1980, anyone?

nati to place the spotlight squarely on steamboating and river history. If you recall, Tall Stacks was held successfully in Cincinnati in the ’80s, ’90s and early 2000s, and it featured numerous steamboats from around the country for hundreds of steamboating and river history enthusiasts.

The event has aptly been renamed “River Roots” and on Oct. 8-12, 2025, in Cincinnati we will celebrate the historical development of our inland river transportation system, its contribution to our country’s early westward expansion, and its continuing maritime prominence.

River Roots will feature a dozen or more of the nation’s most historical and impressive steamboats including the Natchez, New Orleans; the General Jackson, Nashville, Tenn.; the Belle of Louisville, Louisville, Ky.; the Belle of Cincinnati and River Queen, Newport, Ky.; and The Colonel, Galveston, Texas. In addition, there will be a noteworthy exhibit that will feature a variety of towing industry vessels and equipment for the public to view.

River Roots will be a commemoration of the rich history of the Inland River Transportation System and the mariners, steamboats, towing vessels, and others that have made our country strong. I hope you will join me in Cincinnati in October 2025 to celebrate our rich inland river heritage.

Energy Level

FTC's cynical view of oil industry unwarranted

BY G. ALLEN BROOKS, CORRESPONDENT

Last October, Exxon Mobil Corp. agreed to acquire Pioneer Natural Resources in a $60 billion all-stock merger. The deal adds Pioneer’s 850,000 acres in the Midland Basin to ExxonMobil’s 570,000 acres in the Delaware and Midland Basins creating the industry’s leading high-quality undeveloped U.S. unconventional oil inventory. Much of the combined acreage is contiguous, which allows the drilling of four-mile-long lateral wells reducing the number of wells needed and their footprint, thus reducing the breakeven oil cost to $35 a barrel.

The company’s combined production this year will be 1.6 million barrels of oil equivalent, which is projected to

BY PAMELA GLASS

Pamela Glass is the Washington, D.C., correspondent for WorkBoat. She reports on the congressional committees and federal agencies that affect the maritime industry, including the Coast Guard, Marad and Army Corps of Engineers.

grow to 2 million BOE by 2027. Importantly, 40% of ExxonMobil’s 2027 production will be short-cycle barrels, enabling the company to quickly adjust production to meet demand fluctuations.

The Federal Trade Commission approved the deal at the beginning of May with one condition. ExxonMobil had to agree to not add Pioneer CEO Scott Sheffield to its board of directors as envisioned in the original merger agreement. This was an unusual condition. Moreover, it was based on “thin” evidence. It represented yet another Biden administration slam of the fossil fuel industry.

The eight-page complaint against Sheffield contained redacted text messages as well as public statements. The FTC believed Sheffield’s position on the ExxonMobil board would be a bigger platform for him to “pursue his anticompetitive schemes.” The FTC cites as evidence a statement Sheffield made to the Financial Times in the fall of 2021.

Inland Insider

Changes to tug-assist protocols could be coming

Federal safety investigators believe the cargo ship that hit the Baltimore bridge in March experienced multiple blackouts before the collision, and in a preliminary report also recommends a deeper look into many port operations, including the use of vessel-assist tugs.

Released in May, the National Transportation Safety Board’s preliminary report offers the first detailed examination of the crash that toppled the bridge, killed six construction workers and launched a broader examination of the safety of U.S. bridges from ship strikes and how they can be avoided. The report outlines a timeline of what happened before, during and after the Singaporeflagged Dali container ship lost power and drifted into the span, but investigators are still studying the cause of the crash. Another criminal investigation by the FBI is also underway.

The report says the Dali lost power twice the day before and had two more power outages that disabled key ship systems on the day of the ac-

He said, “Everybody’s going to be disciplined, regardless of whether it’s $75 Brent, $80 Brent, or $100 Brent. All the shareholders that I’ve talked to said that if anybody goes back to growth, they will punish those companies.”

Sheffield was reflecting on the views of oil investors who were warning that shale oil producers who ramped up production, which drives down oil prices, would have their stock prices punished. This sentiment was not a secret communication to OPEC or national oil companies. The sentiment was expressed openly and frequently on Wall Street and in energy investment conferences.

More frustrating for the domestic oil industry, of which Sheffield was acknowledged as a key player, was that the Biden administration had implemented policies hamstringing the industry from expanding. However, between 2019 and 2023, Pioneer’s daily production more than doubled, which suggests Sheffield wasn’t trying to collude with OPEC to restrict output.

cident.

Two McAllister Towing tugs guided the ship away from the dock and out of the port in the early morning hours of March 26 and were released from duty, according to protocol, before the ship headed under the Francis Scott Key Bridge and into the Chesapeake Bay on its voyage to Sri Lanka. The tugs headed back to port but within 15 minutes, electrical problems started onboard that cut power to key pumps, automatically shutting the Dali’s main engine. The crew was able to restore power, the tugboats were called back to help and a pilot onboard ordered that the anchor be dropped. Then a second blackout occurred, and the Dali drifted off course and struck the bridge.

Speculation began almost immediately that had the tugs stayed with the ship the entire time the collision could have been avoided, and it was suggested that the port of Baltimore — as well as other ports — expand their tug assist protocols to address broader safety risks. In Baltimore, tugs are required to guide vessels in and out of port but aren’t needed for extended escorts into the port’s channel or further. It’s up to harbor pilots, the Coast Guard or the shipping company to ask for extra services.

BY KEN HOCKE

The Hocke Net

Deadly bridge allisions

Coming on the heels of the deadly Francis Scott Key Bridge collapse in Baltimore was the allision in May of the 321' barge MMLP 321 with the Sea Wolf Parkway Bridge in Galveston, Texas.

Thankfully, there have been no reports of death or injury from the Galveston collision.

It certainly could have been worse.

For example, on Sept. 15, 2001, Brown Water Marine’s 52'x20' towboat Brownwater V, while pushing four barges owned by American Commercial Lines, struck the Queen Isabella Causeway bridge near Brownsville, Texas, causing two 80' sections of the bridge to collapse.

Nine vehicles that were crossing the 2.4-mile causeway at the time of the accident plunged into Laguna Madre Bay. (The bridge connects Port Isabel and South Padre Island.) In all, eight people

Joe Dedmon lost consciousness in the wheelhouse of the 104'x30' towboat Robert Y. Love. While he was unconscious, Dedmon’s towboat shoved one of the two 297'x54' asphalt barges it was pushing into the Interstate 40 bridge over the Arkansas River, collapsing a section of the span. Ten cars drove off the bridge and into the river, killing 14 people. Magnolia Marine Transport Inc. owned the towboat, while the barges belonged to Magnolia’s parent company, Ergon Inc.

Following the Texas accident, the captain of the Brownwater V, David Fowler, told U.S. Coast Guard investigators that he had hit some kind of bump as he approached the bridge and tried to steer back into the channel, but the head kept coming to port making it impossible to stop the tow.

“The apparent cause of the casualty was Captain David D. Fowler’s failure to exercise reasonable care according to the standards of the ordinary practice of good seamanship,” an April 2005 report from the USCG said.

In the Oklahoma incident, Dedmon was rushed to a hospital after the accident and later operated on for a heart condition that required the insertion of a de brillator.

Ken Hocke has been the senior editor of WorkBoat since 1999. He can be reached at khocke@divcom. com

BY BEN HAYDEN

Ben Hayden is a Maine resident who grew up in the shipyards of northern Massachusetts. His passion for storytelling came about on a freelance film that highlighted businesses, farmers, and fishermen while sailing up the coast of Maine.

Tech Watch

Imtra highlights KPM Marine pump as new tech product

Lastmonth, I went on a shipyard tour through New England, and I was able to visit Imtra, New Bedford, Mass., which offers products for the recreational and commercial marine markets, as well as the transportation and energy industries.

During the facility tour, I was introduced to a lot of new products that I hadn’t seen before, ranging from Isover’s thermal, acoustic and fire insulation solutions, to Norsap’s high quality helm, pilot and operator chairs. Given my monthly column, it’s fitting that wherever I go I inquire about any new technology in the maritime sector.

“This is one of our newer products and it’s pretty impressive,” said Eric Braitmayer, Imtra president and CEO, pointing to a KPM Marine Predator 350 S bilge pump that can fit in a bag the size of a briefcase. Imtra employees tested it in the warehouse. It took less than a minute to empty a 50-gal. trash barrel and it shot about 25' in the air.

The need for a powerful and compact pump was brought about through KPM’s customer requests. “We were asked to develop a light, high-capacity pumping system (that can) run at 16 amps but deliver maximum flow of 200 liters per minute. The result was the Predator range,” KPM’s website notes. Over a 10-year span, the company boasts a recorded failure rate of just 0.03% of the 4,000 Predator units operating globally.

Additional features of the Predator 350 S include a run-dry capacity of two weeks. The anticorrosion hard anodized aluminum pump is IP68 rated and fully waterproof up to 50'. Including the bracket, the pump weighs 17.5 lbs. and measures 4.5"x13.75". KPM also makes a Predator 700 S dual pump, capable of pushing 350 l/min. An Imtra employee noted the pump manufacturer is working on a smaller pump for recreational use.

“The KPM engineers are always receiving customers stories where the pump saved the vessel,” the Predator pamphlet states. “One customer continued on a two-week voyage when they sprung a leak rather that returning to port because they had total trust in the Predator, which ran for the whole voyage without any issues.”

Efficient power for your needs

Through high torque at low revs, prompt power response, and agile performance, Scania engines allow operators to utilize the appropriate amount of power at all times. Our job is to help you run a reliable and efficient operation. Today and tomorrow.

Scania Dealer Locator

BY TIM AKPINAR

Tim Akpinar is a Little Neck, N.Y.based maritime attorney and former marine engineer. He can be reached at 718-224-9824 or t.akpinar@verizon. net

Legal Talk

Collision

brings attention to maintaining lookout

Acollision in the waters of the Bahamas highlighted a fundamental element of the Collision Regs that appears with regularity in marine collision litigation, which is the requirement to maintain a “proper lookout.” The collision also brought another important rule center stage, which is the rule on overtaking vessels.

The accident took place on Dec. 23, 2021, some 20 miles northwest of Nassau, in the Northeast Providence Channel. The vessels involved were a 176' aluminum yacht named Utopia IV and a 159' steel product tanker named Tropic Breeze

The captain of Utopia IV was conning the vessel as the bosun handled navigation and the bridge log. The captain left the wheelhouse a couple of times to check on passengers. While alone in the wheelhouse, the bosun saw no radar or AIS targets.

On the bridge of Tropic Breeze, an able seafarer

(AB) and the master were on watch. The tanker’s AIS had a power issue and only worked intermittently. At around 10 p.m., the bow of the yacht struck the transom of the tanker. The relative speed of the impact was about 15 knots, given the yacht’s speed of 20 knots and the cargo ship’s speed of 5 knots.

The National Transportation Safety Board (NTSB) investigated the collision and made the following conclusions. Visibility was good, at around 10 miles, and the cargo vessel’s stern light should have been seen. The NTSB believed it was likely that neither vessel’s crews looked at the radar display for some 12 minutes prior to collision (based on time to cover three miles at a relative closing speed of 15 knots).

As the overtaking vessel, the yacht was required to give way to the cargo vessel. The NTSB concluded that the yacht had not maintained proper lookout by all available means. The NTSB also felt that if the tanker noticed the approaching yacht, it was likely it could signal the potential danger in some manner, using radio, whistle, or other means.

The NTSB identified the yacht’s actions as being the probable cause of the collision.

WHEN YOU PARTNER WITH US, IT’S

HANDS ON DECK.

OUR APPROACH

We have a customer-focused philosophy. Led by a seasoned management team averaging 25 years of experience, we specialize in innovative capital solutions for maritime asset owners and operators. With local decision-making, we can adapt quickly and give you certainty to close.

TYPES OF SERVICES WE PROVIDE

• Harbor services

• Inland and river coastal

• Coastwise transportation

•

• Manufacturing and repair

and infrastructure

• Offshore energy services

BY DAN BOOKHAM

Dan Bookham is a vice president with Allen Insurance & Financial. He specializes in longshore, offshore and shipyard risk. He can be reached at 1-800-236-4311 or dbookham@ allenif.com.

Insurance Watch

Look for marine insurance costs to climb

As I sit down to write this, I’m still shaking off the jet lag from a week of meetings at Lloyd’s of London. Lloyd’s was buzzing with a range of issues: the pending North Atlantic hurricane season, tensions in the South China Sea, the potential for increased interference with shipping off Iran, and the ongoing con icts in Ukraine and Gaza and the implications thereof for coverage in the Black and Red seas.

The number one topic was the Dali bridge accident and the signi cant rami cations that are already falling into place following the allision between the 9,971 TEU container ship and Baltimore’s Francis Scott Key Bridge.

Anyone with even a rudimentary grasp of how my industry works can guess the rst issue: this incident will result in substantial insurance claims. Experts estimate that insurers may face claims of up to $3 billion. This gure is double

the largest-ever protection & indemnity (P&I –liability relating to vessels) claim to date, which was the $1.5 billion collective loss from the 2012 Costa Concordia disaster. One excess P&I underwriter I met with put the potential loss in context by pointing out that $3 billion would wipe out 20 years of underwriting pro t across Lloyd’s.

Another big topic was the complex insurance structure around this incident. The marine insurance sector operates with a complex and layered structure of insurance and reinsurance designed to minimize, transfer, and offset nancial risk. While it’s too early to de nitively say whether this structure will be breached, the Dali incident has raised concerns about its limits.

Something else that cannot be ignored is the incident’s location and our well-deserved reputation for aggressive and expensive litigation here in the States.

In summary, the Dali bridge accident poses challenges to the marine insurance system, and its impact will reverberate for many years. And in what won’t be a surprise to anyone, marine insurance rates are likely to increase as a result.

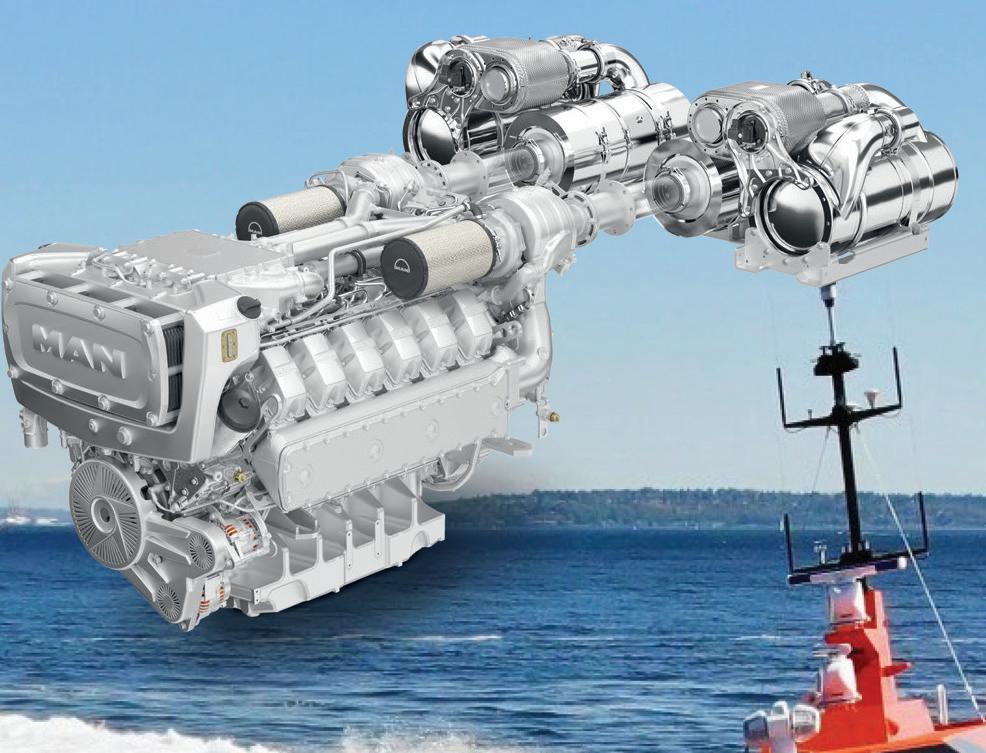

STACKING THE DECKS

WITH THE MOST TRUSTED POWER & PROPULSION SYSTEMS ON THE PLANET

Edison Chouest delivers first SOV constructed in the U.S.

to Ørsted

The rst U.S.-built service operations vessel for offshore wind was christened on May 11 by wind energy developer Ørsted and vessel builder Edison Chouest Offshore (ECO).

Carrying up to 60 technicians on board, the 262' ECO Edison will serve in operations and maintenance for Ørsted and Eversource’s South Fork Wind, Revolution Wind, and Sunrise Wind projects off southern New England and Long Island, N.Y.

The vessel was christened at the Port of New Orleans by Jennifer Scalise, wife of U.S. House Majority Leader Rep. Steve Scalise, R-La. Scalise, a booster of offshore wind opportunities for Louisiana’s shipbuilding and offshore services industry, celebrated the SOV launch — just hours before former president Donald Trump, the Republican party leader, explicitly threatened to shut down all offshore wind projects at his campaign rally in Wildwood, N.J.

The ECO Edison was built by more than 600 workers — across nearly 1 million work hours — at ECO in-house shipyards in Louisiana, Mississippi and Florida, with components of the vessel sourced from 34 states.

“The Gulf Coast region is playing a huge role in the growing U.S. offshore wind supply chain, using their decades of experience to deliver more homegrown American energy and serving as one example of Ørsted’s more than $20 billion of investments into the United States,” said David Hardy, group executive vice president and CEO Americas at Ørsted.

The new CTV is powered by two 3512E engines from Caterpillar Marine, Houston.

“Caterpillar Marine is committed to helping our customers reach their most challenging goals and is proud to provide the power for this first American-built offshore wind SOV. The U.S. EPA Tier 4 certified Cat 3512E engines are built with the highest durability and are ready to be dual-fuel methanol converted in the future, ensuring that Ørsted can always meet their needs, both today and long into the future,” said Caterpillar vice president and general manager Brad Johnson.

News Bitts

Port NOLA president, CEO Christian moves on

ThePort of New Orleans (Port NOLA) announced that its president and CEO, Brandy D. Christian, stepped down in midJune 2024 to pursue an opportunity in the private sector. Christian has served as the president and CEO of Port NOLA since Jan. 1, 2017, and as the CEO of the New Orleans Public Belt Railroad (NOPB) since its acquisition by Port NOLA on Feb. 1, 2018, during which time Port NOLA increased operating revenues by 70% and NOPB increased operating income by 300%.

Trump promises to use an executive order to block off shore wind use

Formerpresident Donald Trump said he would immediately block off shore wind power projects if elected in November. The former president made the remarks during a May 11 beachfront campaign rally on the New Jersey coast. Trump said he would use an executive order to stop off shore wind industry growth.

Barge tow narrowly misses N.O. steamboat

AMississippi

River tow with 24 barges came close to the Natchez riverboat at its New Orleans dock April 28, missing the iconic tourist attraction and the nearby Canal Street Ferry Landing. No damage, injuries, or pollution has been reported. There was a small craft advisory out due to high winds. The vessel had 24 empty hopper barges attached. The head barge touched the Ferry Landing, according to Coast Guard offi cials. The incident remains under investigation.

Ørsted

The 262' service operations vessel (SOV) was christened May 11 at the Port of New Orleans.

MITSUBISHI

MITSUBISHI

MECHANICAL ADVANTAGE

MECHANICAL ADVANTAGE

We designed our Tier 3 & Tier 4 engines: Simple, Reliable, & Mechanical controlled. A real advantage when operating in remote locations.

We designed our Tier 3 & Tier 4 engines: Simple, Reliable, & Mechanical controlled.

A real advantage when operating in remote locations.

FUEL ECONOMY

FUEL ECONOMY

Our mechanically controlled engines meet emissions while providing excellent fuel economy through engine design.

Our mechanically controlled engines meet emissions while providing excellent fuel economy through engine design.

PARTS/SERVICE SUPPORT

PARTS/SERVICE SUPPORT

Strategically positioned around the world. Our Americas HQ maintains a large inventory of parts, backed up with the support of our distributor and dealer networks.

CUSTOMER PARTNERSHIP

Strategically positioned around the world. Our Americas HQ maintains a large inventory of parts, backed up with the support of our distributor and dealer networks.

CUSTOMER PARTNERSHIP

Mitsubishi and its network of distributors and dealers focus on providing support for the right engine for your application.

Mitsubishi and its network of distributors and dealers focus on providing support for the right engine for your application.

LEARN MORE LEARN MORE

LEARN MORE

Versatility afl oat

The U.S. Navy is ordering RIBs by the hundreds.

By Ben Hayden, Content Specialist

Rigid Hull In atable Boat (RIBs) are versatile assets with applications across various domains, including military, USCG interdiction, law enforcement, recreation, and yacht servicing.

Mission-speci c RIBs can be tailored to the needs of endusers with an array of equipment such as cranes, unmanned underwater vehicles (UUV), launching platforms, or weaponry. Center consoles can be enclosed in cabins or exposed to the elements. These boats typically feature hulls constructed from berglass or aluminum, with the hull shape playing a crucial role in their operational capabilities. The RIBs themselves are commonly composed of foam or air- lled rubber tubes.

IN ACTION

A recent example of a RIBs utility was demonstrated in the suspenseful moments following the Francis Scott Key Bridge collapse in Baltimore. The rst boat on scene was an Ocean Craft Marine (OCM) 9.5 meter (31.1') berglass law enforcement interceptor, which played a pivotal role in the rescue of one of the two survivors pulled from the waters of Baltimore Harbor.

“We sold a RIB a couple years ago to the MBTA. The Maryland Department of Transportation Authority Marine Police,” said Ryan Salus, director of business development at

Annapolis, Md.-based OCM. “The guy who runs the boat is a huge champion of our brand,” Salus said. As it happened, he was stationed at the bridge and was the rst responder on the scene. “One of the two survivors, he was able to rescue by himself from one of our RIBs just because of the low freeboard and the diver notch,” Salus said. “He was able to pull one of the guys out.”

Although the rst responder, under a blanket gag order, could not provide direct statements for publication, it was emphasized that the unique features of the 9.5-meter OCM were instrumental in facilitating a successful solo rescue, an operation that other available assets were incapable of performing.

RIBCRAFT USA

Ribcraft USA is currently in the production phase of three of its contracts with the U.S. Navy, including its ve-year IDIQ (inde nite delivery inde nite quantity) $80-million contract to build the standard seven-meter (22.9') RIB. Under the multi-year contract, Ribcraft will build up to 278 of the seven-meter rigid hull in atable boats This is purported to be the largest single contract based on number of boats ever awarded by the Navy.

“Eighty to 85% of our business is commercial-government with the rest being recreational for use as yacht tenders for

Ocean Craft Marine’s 9.5-meter RIB was involved in the rescue of one of the survivors from the Francis Scott Key Bridge allision.

Incat Crowther

personal use,” Ribcraft’s vice president of sales, Matthew Velluto, said during a visit to the company’s Marblehead, Mass., facility in May. “We have three ve-year IDIQ contracts with the U.S. Navy right now to build an 11-meter (36') Expeditionary RIB for countermined measures, the seven-meter shipboard RIB, and the 11-meter shipboard RIB, all of which are built here at these facilities."

Ribcraft has had to expand its shipbuilding facilities to accommodate its military contracts. The new building expansion ts two 11-meter and three seven-meter boats to be worked on at one time. In addition to their military boats, the company is currently working on a number of law enforcement vessels.

“The standard seven-meter shipboard RIBs are primarily used as a ready service life boat for rescue; however, they're also used for crew transport, boartding parties, security, interdiction, you name it, anything that they need to use it for," said Valluto. "Two of these go on every Navy ship, and we have a ve-year contract for that."

Naval orders come in bunches, with different variants commissioned at different times. “There’s a standard variant, which is the typical gray boat that you would see that the government has on the ships and then we do a SOLAS variant (orange) as well,” said Velluto, referencing the International Convention for Safety of Life at Sea.

"To address the requirement, the government decided to use their seven-meter RIB and make a SOLAS variant, and so now we build that for them as well under this contract," said Valluto.

Rigid Hull Inflatable Boat (RIBs)

Roughly a year ago, Ribcraft won a third contract to build the Navy 11 meter (36') shipboard RIB. Velluto talked about the process of getting those built at scale. “Some contracts require that we build an initial production boat that the government tests for a year. We then incorporate any feedback into the design and out t and begin producing the boats at production rates," said Valluto. We're at that production stage with the seven meters, where we're getting into the steady progression of production. The Expeditionary RIB has been going now for about three years, and the new 11meter shipboard one is just coming on now."

SILVER SHIPS

Last June, Silver Ships, Theodore, Ala., was awarded a $6 million contract to build and deliver up to 246 high-speed maneuvering surface target (HSMST) custom vessels for the Navy. The contract is the largest and most lucrative in Silver Ships’ history and includes options that, if exercised, would bring the total value of the contract to $48.25 million.

The aluminum boats are based on the shipyard’s AM800 RIB series. As target vessels, the 27'x9'6" boats are subsequently destroyed by the Navy after delivery.

Since 1994, Silver Ships has delivered more than 800 RIBs to the U.S. military. Many are used by the Navy to support ship, aviation training and operational needs.

The shipyard also completed the rst deliveries under Naval Sea Systems Command of seven 36' open center-con-

sole (OCC) vessels and two 26' OCCs, under the Naval Special Warfare Surface Support Craft (NSWSSC) contract.

The contract entails construction of ve different vessel variants of the Ambar series RIBs. The NSW surface support craft (SSC) are 26' and 36' aluminum deep-V hulled boats with a protective collar. Both boat series have a multipurpose deck for carrying various payloads or mission gear. Variants of the SSC include both open center console (OCC) and cabin versions.

METALCRAFT MARINE

MetalCraft Marine, Watertown, N.Y. and Kingston, Ontario, has a long track record of building for the Navy, but its current order from the Navy for 67 RIBs — 22 measuring 39'x11'6" and 45 measuring 27'x8'6" — represents a rst — all of the RIBs will come with MetalCraft’s push knees built into the bow.

The rubber push knees protect the collar, and when engaged with a seawall they stick to it. A RIB’s stern might be moving up and down but the bow “is stuck to that wall and not moving,” said Bob Clark, MetalCraft’s contracts manager. “Everybody is blown away by how they work.” He compares it to how a crew transfer vessel works when up against an offshore wind tower

Two special features built into a pair of MetalCraft Marine Interceptor RIBs — an eight-meter (26'6"×8'5") and 10-meter (34'×9'19") — for the Ohio Department of Natural Resources are a fold-down bow and a pair of Porta Products transom brackets with 425hp Yamaha outboards.

Ribcraft USA’s 11-meter RIB on sea trials off Winter Island, Salem, Mass.

The military sealift vessels are now held to commercial standards and require a SOLAS boat on them.

Ribcraft

RIBCraft

CONSTRUCTION ACTIVITY AT WORKBOAT YARDS

Steiner Shipyard delivers passenger/vehicle ferry to Maine

Steiner Shipyard, Bayou La Batre, Ala., delivered the new steelhulled 104'x28'x11', passenger/ vehicle ferry Charles Norman Shay to Maine’s Department of Transportation in Portland in May.

“We’ve been working with the Coast Guard to get some last-minute details covered,” Gregory Marshal Jr., Steiner’s project manager/purchasing assistant, said prior to leaving for Maine aboard the new ferry.

“The vessel plans did change from a Thursday, May 23rd departure to a Thursday, May 30th departure while awaiting the stability letter. Currently waiting on the Coast Guard to give us the go-ahead on picking up one of their [department of transportation’s] employees somewhere in Maine.”

Designed by Gilbert Associates, Braintree, Mass., with a 7' draft, the new 149-passenger ferry will run between Rockland, Maine, and Matinicus Island. In addition to its passengers, the boat has room for a single tractor trailer and four small, light trucks or eight cars or light trucks and no tractor trailer.

Main propulsion comes from twin

Caterpillar C18 diesel engines hooked up to Sound 4-bladed 52" diameter wheels through Twin Disc MGX-516 close-coupled vertical offset gears with 4.04:1 reduction ratios. The propulsion package gives the Charles Norman Shay a running speed of 13 knots.

For additional maneuverability, the ferry is fitted with a Veth VT-50 64kW tunnel bow thruster.

Twin Disc supplied the ec6000 controls, EMI the steering system, and Simrad the electronics suite. Ship’s service power is the responsibility of two Caterpillar 99-kW gensets.

Capacities include 3,200 gals. of fuel oil; 1,900 gals. potable water; and 300 gals. lube oil.

The Coast Guard classification is Subchapter T and the delivery date, June 2024. — Ken Hocke

Eastern Shipbuilding launches Long Island ferry

Eastern Shipbuilding Group Inc. (ESG) launched the ferry Long Island (ESG Hull 228) at its Allanton Shipyard in Panama City, Fla., for

McAllister Towing’s Bridgeport and Port Jefferson Steamboat Co., New York.

The new passenger and auto ferry is scheduled to operate between Bridgeport, Conn., and Port Jefferson, N.Y., traversing Long Island Sound.

“This launch is a testament to the dedication and expertise of our team at Eastern Shipbuilding Group,” Joey D’Isernia, CEO and chairman of ESG, said during launching ceremonies. “We are honored to partner with our friends at McAllister Towing and contribute to enhancing the transportation infrastructure for the residents and tourists of Long Island. This ferry will not only serve as a vital link between communities but also exemplify our commitment to delivering excellence to our valued customers.”

The 302' ferry is designed to accommodate both vehicles and passengers and is designed with several enhancements, including Tier 4 main engines, increased crew capacity, and an upgraded furniture package.

“The Bridgeport and Port Jefferson Steamboat Company is proud to provide safe, scenic, and relaxing transit Across Long Island Sound for hundreds of thousands of passengers and cars every year,” Buck McAllister, the ferry company's president said in a prepared statement. "We are thankful to Eastern Shipbuilding and the D'Isernia family for the happiness this new vessel will bring."

Eastern also recently was awarded a contract to construct the newest Fisher Island Ferry for the Fisher Island Community Association Inc. (FICA) in Miami. The 152'x52'x12' vessel will be constructed at ESG’s Allanton and Port St. Joe facilities

Steiner Shipyard

The new ferry made a 10-day trip from Alabama to Maine.

and is expected for delivery in 2026.

“Eastern Shipbuilding Group delivered the vehicle passenger ferry Heron to the Fisher Island Community Association over 20 years ago, and we understand that she has been the most reliable ferry in their fleet,” Joey D’Isernia, chairman and CEO of ESG, said in a prepared statement. “We look forward to delivering another robust and reliable ESG-built ferry that will serve the residents of Fisher Island for decades to come.”

In collaboration with FICA and Elliott Bay Design Group (EBDG), Seattle, the ferry will be built with yacht-style finishes and will be designed to provide safe and comfortable transportation for the residents of the Fisher Island community.

The new passenger/vehicle ferry will have an 8' draft and deck space for 150 passengers and 30 vehicles.

“The Heron is probably the most reliable ferry in our eet,” said

Roberto Sosa, FICA's president and CEO. “The quality and design of this speci c ferry, along with their reputations in the industry, are the main reasons we chose Eastern Shipbuilding Group and Elliott Bay Design Group. We look forward to continuing our relationship with them throughout the construction of this ferry.”

The ferry will boast 1,200 total horsepower.

“Elliott Bay Design Group is excited to continue our longstanding relationship with the Fisher Island Community Association and collaborate on another exceptional ferry project,” said John Waterhouse, principal in charge at EBDG. “Partnering once more with Eastern Shipbuilding Group emphasizes our commitment to designing and delivering top-tier vessels while maintaining strong client relationships.”

Shipbuilding Group

The Long Island will join a fleet that includes two other Eastern-built

ON THE WAYS

BOATBUILDING BITTS

The Department of Defense announced that Fincantieri Marinette Marine (FMM) has been awarded a contract worth over $1 billion to build the fifth and sixth 496'x64.6' Constellation-class frigates for the U.S. Navy. The frigates, which will have 18' drafts, feature RollsRoyce naval generator sets for phase one of the U.S. Navy’s Constellation (FFG-62) class frigate program, previously known as the FFG(X) program. The FFG-62 is a multi-mission warship designed for operation in littoral and bluewater environments to conduct air, antisubmarine, surface and electronic warfare, in addition to information operations. The generator sets are based on the MTU 20V 4000 M53B engine and will provide a total power output of 12 MW for propulsion and onboard power supply.

Main propulsion comes from four Colt-Pielstick diesel engines generating a total of 40,000 hp.

Louisiana-based boatbuilder Metal Shark and ReconCraft , Clackamas, Ore., have been awarded seven-year U.S. Navy indefinite delivery/indefinite quantity (IDIQ) contracts worth up to $290 million to produce up to 73 40-foot patrol boats for Naval Expeditionary Combat Command. Designed by Metal Shark’s in-house engineering team specifically for the Navy, the 40 PB has been built by Metal Shark since award of the 40 PB Flight 1 contract in 2017. With the Flight 2 award, 40 PB production will continue in force at Metal Shark’s South Louisiana production facilities, with ReconCraft also building at its Clackamas, Ore., facility.

Austal USA celebrated the christening of the company’s 19th Independence-variant 421'6"x103.7' littoral combat ship (LCS) in May — the future USS Pierre (LCS 38). Each aluminum trimaran LCS has a displacement of 3,200 MT, a 15.1' draft, and is powered by a pair of 12,200-hp Rolls-Royce 20V8000 diesel engines and two 29,500-hp GE LM2500 gas turbines. The Pierre (LCS 38) is the last Independence-variant LCS scheduled to be built at Austal USA.

Silver Ships , Theodore, Ala., has completed the construction and delivery of the first four coastal fast

response boats (CFRB) under a contract award worth $6.12 million from the Naval Sea Systems Command. The vessels were designed and constructed as a part of the U.S. Navy Foreign Military Sale (FMS) program and will benefit a NATO Navy, while the other three boats will support a Central American Navy upon delivery. Each CFRB was inspected in Alabama and accepted by the Navy. The seven custom-designed military CRFBs feature specialized communication and navigation equipment. The 46', deep-V hull vessels feature a cabin and Wing collar system. Main propulsion comes from twin Caterpillar C7 500-hp inboard diesel engines hooked up to HamiltonJet HJX-29 waterjets. The waterjets enable the vessels to continuously operate in shallow and coastal areas where outboards would typically be less effective.

The United Launch Alliance (ULA) announced in May that it has signed agreements with Bollinger Shipyards, Lockport, La. and Bristol Harbor Group Inc. (BHGI), Bristol, R.I., to design, oversee and build a new ship to transport Vulcan rockets from the factory in Decatur, Ala., to the launch sites at Cape Canaveral Space Force Station in Florida and Vandenberg Space Force Base in California. ULA awarded Bollinger Shipyards a contract to build a second roll-on/roll-off vessel classed for both oceangoing and river service. Construction has just begun on the 356' vessel — Spaceship — at Bollinger’s shipyard located in Amelia, La. Delivery to ULA is expected in January 2026.

Fincantieri's FFG-62 is a multimission warship.

New patrol boats will be built in Louisiana and Oregon. Metal

Austal USA christened the USS Pierre in May.

GD NASSCO delivers fleet replenishment oiler to U.S. Navy

OnMay 7, the U.S. Navy accepted the delivery of the 746'x106'x33.5' John Lewis-class eet replenishment oiler, the USNS Earl Warren (T-AO 207). Delivery follows the successful completion of integrated sea trials to test the readiness and capability of the ship and to validate requirements. The vessel was built at General Dynamics National Steel and Shipbuilding Co. (GD-NASSCO). The keel laying ceremony took place on April 30, 2022.

“Delivery of the third ship in the class will bring more refueling capability directly to the fleet, including replenishment-underway capacity,” John Lighthammer, program manager of the auxiliary and special mission shipbuilding program office, said in a statement announcing the delivery. “The civilian mariners who crew this ship will have the tools they need to operate in often rapidly changing environments.”

The John Lewis-class ships are based on commercial design standards and will recapitalize the current T-AO 187-class fleet replenishment oilers to provide underway replenishment of fuel and lubricating oil, small quantities of fresh and frozen provisions, stores, and potable water to Navy carrier strike group ships operating at sea, including fuel for embarked aircraft.

The ships are part of the Navy’s Combat Logistics Force, and they have the capacity to carry 162,000 bbls. of fuel oil or aviation fuel; 55,662 cu. ft. dry cargo storage; and 40,099 cu. ft. refrigerated cargo. The ship has ve refueling stations and two dry cargo transfer rigs.

Earl Warren will carry a crew of 125, 99 of whom are civilians.

Main propulsion comes from two Fairbanks Morse Engine MAN 12V48/60CR diesels that feature common-rail technology, which the engine manufacturer says provides an advanced control system to deliver precise amounts of fuel throughout all

engine operations. The Earl Warren can reach speeds up to 20 knots.

GD-NASSCO is also in production on future T-AOs Robert F. Kennedy (TAO 208), Lucy Stone (T-AO 209), and Sojourner Truth (T-AO 210). Future TAOs Thurgood Marshall (T-AO 211), Ruth Bader Ginsburg (T-AO 212), and Harriet Tubman (T-AO 213) are under

contract.

As one of the Defense Department’s largest acquisition organizations, Program Executive Of ce Ships is responsible for executing the development and procurement of all destroyers, amphibious ships and craft, auxiliary ships, special mission ships, sealift ships, and support ships. — Ben Hayden

PURPOSE-BUILT ENGINES ALWAYS UP FOR THE JOB

General Dynamics NASSCO christened the USNS Earl Warren in January 2023.

Pathways to Waterways

Maritime high schools help prepare kids to fill industry needs.

By Bruce Buls, Editor at Large

It’s well known that the maritime industry, like many others, faces what’s being called a “silver tsunami” of older men and women who are aging out of the workforce. But finding replacements is often frustratingly difficult because much of the work usually requires extensive training and documented time at sea.

One approach to refilling the ranks is early recruitment into secondary school programs that will set young people on the path to full-time careers, either on the water or on the beach in support positions.

MARITIME HIGH SCHOOL (DES MOINES, WASH.)

One such program, now in its third year in the Puget Sound area, is the Maritime High School in Des Moines, Wash. (between Seattle and Tacoma). The school is part of Highline Public Schools, but students from outside the district are welcome and even recruited.

The recently stood-up school has two direct antecedents. One is the Raisbeck Aviation High School in Tukwila, Wash. Located next to Boeing Field and the Museum of Flight, that school is an aviation- and aerospace-themed school, with an emphasis on science, technology, engineering and math (STEM). It, too, flies under the wing of the Highline School District, even though the school itself is in the Seattle District. Because the location is ideal, being in Seattle also reserves a set number of seats for students from the Seattle district.

Not long after being elected to the Port of Seattle Commission in 2019, Ryan Calkins was invited to the Raisbeck school to help judge student projects.

“Each year the tenth graders do a project in which they take a real-world scenario, and in groups, do a creative proposal on how to address the problem,” said Calkins. “I was just so extraordinarily impressed with what these tenth graders were doing, with these real-world case studies within the aviation context where they were applying things like math and science and civics to actual work that they were doing in school.”

It was in the parking lot at the end of the day that Calkins had an epiphany: “I just turned to a Port of Seattle staff person with me and said, ‘Why don’t we have something like this for maritime?’”

And now they do, thanks to Commissioner Calkins and three other influential individuals, including the superintendent of Highline Public Schools (Susan Enfield), the CEO of the Northwest Maritime Center (NWMC) in Port Townsend (Jake Beattie) and the executive director of the Duwamish River Community Coalition (Paulina Lopez).

New York Harbor School

Students at New York City's Harbor School get hands-on experience.

MARITIME HIGH SCHOOLS

After many meetings with stakeholders, industry leaders, education professionals, philanthropists, government entities and elected of cials, the “core four” coalesced around the concept of a small school of about 400 students in ninth through 12th grades. “The focus would be on recruiting kids who wouldn’t have historically been a part of the maritime industry,” said Calkins. “We wanted to make sure that we were well represented with girls and also students of color and to try to address some of the lack of representation in a lot of these maritime trades, which was an industry concern.” On top of that, there was an interest in sustainability. “That came from the community participants and also from educators. They saw a real desire among their students for education that focused on climate action.”

New York City’s Harbor School

In many ways, the model for the new Maritime High School is the Urban Assembly Harbor School in New York City. Created in the early 2000s as part of a city-wide, secondaryschool overhaul, the Harbor School initially was landlocked in Brooklyn but in 2010 moved to Governor’s Island, a short ferry ride from the southern end of Manhattan. The old Coast Guard base was available for renovation and revitalization and has reemerged as the campus for a high school speci cally created to train future mariners, marine scientists and industry leaders. The current enrollment is about 500 students in ninth through 12th grades.

New York City’s secondary schools now include a wide variety of education/vocational options that middle school kids can choose from. Students rank their choice from one to 12. Harbor School is so popular that it gets many more numberones from prospective students than it can accommodate. The school is currently expanding, however, and hopes to double its year-class size as a result.

Along with renovation of existing buildings, there will also be more labs, a new gym and a deep pool. Michael Cohen, the

school’s partnerships manager, said the pool will save students a lot of time spent commuting to a pool in Brooklyn.

“We have been trying for years to get an on-site pool,” he said. “So it’s very exciting that we’re having a customdesigned pool with a ten-foot-deep end so they can actually do their open water dive training and certi cation.” Cohen is

The Maritime High School uses this 40' catamaran as a training vessel.

Northwest Maritime Center

Maritime high schools in New York City and Des Moines, Wash., teach vessel operations.

MARITIME HIGH SCHOOLS

talking about the school’s professional diving course, the only one of its kind in the U.S. “The goal is to get them that rst certi cation as early as possible, and then that quali es them to grow and to actually dive, professionally.”

The divers also participate in the school’s number-one project, the Billion Oyster Project. Created by a past aquaculture teacher at the Harbor School, the Billion Oyster Project is in the process

of planting that many oysters in New York Harbor by 2035. The count to date is about 127 million, according to Cohen. None of these bivalves are meant to be eaten; they’re there to naturally lter the water. Aneal Helms, the Harbor School’s interim acting principal, said that a single oyster can lter 50 gallons of water per day. With a billion oysters, said Cohen, all the water in New York Harbor will be oyster- ltered every three days.

The connections between the oyster project and the school illustrate the integration of academic and practical, real-world courses called CTEs (career and technical education classes). Helms can recite them succinctly: “So the Aquaculture students grow the oysters,” she said. “The Welding and Fabrication students assemble the oyster cages, the Vessel Operations students drive the oyster cages out into the harbor to place them at the oyster reef stations. Our Marine Systems Technology students monitor and maintain those boats, our Ocean Engineering students create underwater vehicles to help monitor those oyster stations, our Marine Biology Research students collect and analyze data around those research stations, and our Marine Policy and Advocacy students are there to deal with all the red tape and bureaucracy.”

Of the eight CTE pathways Helms oversees, she only forgot one: Professional Diving, the students who help place and secure the cages.

Although the partnership between the school and the oyster project is very important and very visible, it’s not exclusive for either organization. Cohen said the school has “well over 100 organizations that we are partnered with.”

Everything from the U.S. Coast Guard to a lot of post-secondary academic institutions to many industry groups like the tug companies and Staten Island Ferry. “We’re currently working with McAllister Towing here in the harbor on getting students to obtain their Merchant Mariner Credential before leaving school,” he said. The tug company has been helping the kids secure TWIC cards, get physicals and guide them through the process.

In addition to diving certi cation and Merchant Maritime Credentials (MMCs), Harbor School students also get Red Cross certi cation for CPR and First Aid, FCC marine radio operator permits and New York State Safe Boating certi cates. Students in the Welding & Fabrication CTE are being trained for OSHA30 certi cation, too.

The Maritime High School in Des Moines doesn’t have a Billion Oys-

Someday these Harbor School students may ship out on the teaching vessel Empire State, across New York harbor.

ter Project to help build its program, but it does have commercial support.

“We have a lot of industry partners,” said Robin Mills, program director at Northwest Maritime Center, one of the high school’s “core four.” “Before the

school even opened, we initiated working groups with industry input to help us understand what industry wanted from students who would be graduating and coming into their various operations.”

While the Harbor School has eight

YOUR PARTNER

THE WATER.

CTE pathways, initially the Maritime High School has only a few. There’s a Vessel Operations focus and a Marine Resources and Research focus. Marine Construction and Engineering is also being established as a student pathway. “We’ve had industry experts helping guide and develop the curriculum and they continue to be involved,” she said. “It spans from Washington State Ferries (WSF) to Vigor to the whole Saltchuk Consortium to Paci c Pile & Marine, Glosten, NOAA and Washington’s Dept. of Fish & Wildlife.”

Washington State Ferries has been especially active in its support for the new high school. It has paid for a group of Maritime High students to take classes at the Seattle Maritime Academy, which is part of Seattle Central Community College, where they recently completed applications for their Merchant Mariner Credentials as part of the Vessel Operations pathway. “We paid for them to get their credentials,” said Steve Nevey, the

Whether you’re powering an offshore service vessel, a passenger vessel, or an inland pushboat, Louisiana Cat has the right engine for your hard working fleet. We focus on you, the customer, and the reliability, safety and profitability of your business. Let us help you navigate every waterway. Visit us online to request an engine quote for your next project: www.LouisianaCat.com/Marine.

MARITIME HIGH SCHOOLS

state’s newly appointed Assistant Secretary of Transportation for Ferries. “It’s on us as an industry to build out that base of young people coming in,” he added. “Whether they work at your company or another company. We need to build a robust base so that we can continue to have a robust industry with a robust pool of people that we can pull from in the future. I’ve got no guarantee that those kids are going to work for WSF, but if

they work in the industry somewhere I think that’s a bene t for all of us.”

WSF is also working on setting up a summer school program for middle school students who are interested in attending the Maritime High School. “We would have kids spend a week on a ferry as a sort of classroom at sea where they could work on a project and see if they wanted to go further with the maritime program,” said Nevey.

Washington State Ferries has also initiated a scholarship program that underwrites a three-year professional course at MITAG’s Seattle facility that will develop licensed deck of cers. Graduates will come out as second mates making over $100,000 a year. “I see the kids in this high school program as the ideal candidates to get those scholarships when they graduate,” said Nevey. “The kids would be in a prime position to carry on with their career with WSF and on up to the pilothouse to become a captain one day.”

The Maritime High School partnership with Seattle Maritime Academy will also generate more marine engineers. Along with their basic MMC, the students in this program will graduate with Qualied Member of the Engineering Department certi cation (QMED). With that, they will be eligible for internships at WSF and other industry partners.

En mAnAging and FuEL COnsumpTiOn

FLEET COSTS, AcCuraCy MaTTErS

Airmar SmartFlex™ Diesel Flow Meters (DFMs)

• Unmatched accuracy in monitoring and managing diesel fuel consumption

• Digital Sensors – no specialized wiring required

• Available in single and dual chamber models (flow rate requirements ranging from 1 to 4000 liters/hour)

• Built-in battery keeps registering data to the internal memory

• Anti-tamper modes available with larger models

• Reduces installation time and footprint

• Cost savings on product, installation, and maintenance

• Extends the service life of the fuel system through preventative maintenance

Airmar DFMs connect to the award-winning Airmar SmartBoat Module (ASM) through a digital interface. The collected data is effortlessly accessible on the NMEA 2000® network, allowing integration with various devices, including NMEA 2000 multifunction displays (MFDs).

Both Harbor School and Maritime High School offer a blend of instruction that is both college prep and vocational. Students can move on to college or even maritime academies. Or they can go straight to a good job. “How often can you go to a high school, get college credit and certi cations so you can go out at 19 years old and make $50,000 a year,” said Jamilla Gordon, the Maritime High School principal. “That’s unheard of, right? I want to ensure that kids know about it.”

Introducing kids to career opportunities in maritime is an important function for both schools, each actively reaching out to communities that have had little interaction with the industry. The Harbor School promotes its programs at various high school fairs around the city and hosts lots of middle-school students learning about the Billion Oyster Project. The Maritime High School has access to the Admiral Jack, a 40' catamaran owned by NWMC, and it uses the boat to help recruit middle school students. It’s also a training vessel during the school year, especially for ninth and 10th graders.

While New York’s Harbor School is expanding its campus with an eye to increasing its enrollment, the Maritime

High School in Puget Sound is looking to graduate its rst class in 2025 and move into a permanent space, ideally on or close to the water. Right now, it’s situated in temporary facilities. “Getting a permanent home is our next big focus for the Maritime High School,” said Commissioner Calkins. “We've looked at a lot of options like the idea of a decommissioned vessel that's permanently moored. Where the kids could not only go to class but also work on a ship. We've also considered waterfront locations where they would be able to transition from classroom to eld experience immediately.

“The kids are learning as much outside the classroom as they are inside,” said Calkins. “As Jake Beattie, executive di-

Return of the Legend

rector of the Northwest Maritime Center, puts it, “There’s no greater teacher than the sea.”

New York Harbor School

New York Harbor School students work closely with the Coast Guard.

2024 POWER GUIDE

By Ben Hayden, Content Specialist

Here is our annual presentation of the diesel engine power guide — WorkBoat’s Diesel Directory.

Consistent with last year, an increasing number of engine companies are offering hybrid systems. These typically feature popular engines integrated with advanced components designed to reduce emissions.

Dave Brown, director of marine diesel sales at Volvo Penta, spoke to the fuel savings that come with their hybrid IPS propulsion system in crew transfer vessels (CTVs).

“The developers of offshore wind, since they pay the fuel bill, they are also

extremely interested in having IPS because there is a signi cant fuel savings when you're running with IPS, typically, somewhere in the 30 percent range,” said Brown.

Additional efforts to reduce emissions are championed by companies like Sea Change Fuels. The company states that its patented biofuel blends can reduce carbon emissions up to 60% from comparable quantities of traditional diesel in existing diesel engines. Under grants from the U.S. Department of Transportation and the National Science Foundation, Sea Change Fuels is working with scientists and engineers at Maine Maritime Academy to demonstrate a reduction in energy density offset by anticipated improvements to engine life.

MAN D2862 LE 438 1,200-hp US EPA Tier 4 engines drive the vessel Golden Gate to 30 knots using Twin Disc MGX-6599 SC gearboxes and Hamilton HTX52 waterjets. Onboard power is supplied by twin Northern Lights M944T3F 38kW generators. www.workboat.com

A big story on the West Coast involves the California Air Resources Board's (CARB) plan to extend the Commercial Harbor Craft (CHC) emissions rule to include all marine vessels, such as tugboats, towboats, and ferries. These amendments “will require zeroemission options where feasible, and cleaner combustion Tier 3 and 4 engines on all other vessels. In addition, they will require the use of diesel particulate lters (DPFs),” a statement from the board said.

Both the Coast Guard and maritime industry have concerns with this mandate, speci cally regarding the feasibility of vessels transitioning to Tier 4 engines and DPFs. It will take time to sort this out.

Snow & C0.

CATERPILLAR MARINE

Ph: 985-674-5163

2270 7th St., Mandeville, LA 70471 www.cat.com/en_US/ • E-mail: info-usa@catpropulsion.com

2024 POWER GUIDE

OPTIONS, CHECK YOUR LOCAL DEALER.

CATERPILLAR MARINE POWER SYSTEMS (MAK)

Ph: +49 (0) 40 2380-3000 • Fax: +49 (0) 40 2380-3535 Neumuehlen 9 • 22763 Hamburg, Germany www.mak-global.com • E-mail: ju_marketing@CAT.com

2024 POWER GUIDE

CUMMINS INC.

Ph: 800-DIESELS

4500 Leeds Ave. • Suite 301 • Charleston, SC 29405 www.cumminsengines.com • E-mail: marine.communications@cummins.com

ALL

RANGES ARE NOT LISTED. FOR MORE OPTIONS, CHECK YOUR LOCAL DEALER. CUMMINS RECON

Ph: 800-DIESELS

PRODUCT LINE

4500 Leeds Ave., Suite 301 • Charleston, SC 29405 www.cumminsengines.com • e-mail: marine.communications@cummins.com

2024 POWER GUIDE

• ALL HORSEPOWER RANGES ARE NOT LISTED. FOR MORE OPTIONS, CHECK YOUR LOCAL DEALER. DAIHATSU

DIESEL (AMERICA) INC.

Ph: 516-822-3483/3484 • Fax: 516-822-3485 350 Broadway, Suite 302. • Jericho, NY 11753 www.dhtd.co.jp

JOHN DEERE POWER SYSTEMS

Ph: 800-JDENGINE • Fax: 319-292-5075 3801 W. Ridgeway Ave. • Waterloo, IA 50704 www.deere.com/marine

ELECTRO-MOTIVE DIESEL INC.

Ph: 708-387-6398 • Fax: 708-387-5845

9301 W. 55th St. • La Grange, IL 60525 progressrail.com/powerproducts • E-mail: grwest@progressrail.com

EMD 710 Series

EPA Tier 4 Final/IMO III — check with EMD for details/ ALL HORSEPOWER RANGES ARE NOT LISTED. FOR MORE OPTIONS, CHECK YOUR

FNM MARINE DIESEL ENGINES

Ph: 800-856-9639 • Fax: 586-268-9320 35418 Mound Road • Sterling Heights, MI 48310 www.fnmmarinenorthamerica.com

Most Ratings Available EPA Tier 3 ALL

Manufactured in Italy

FPT INDUSTRIAL NORTH AMERICA MSHS INC.

2024 POWER GUIDE

Ph: 954-960-6744 • Fax: 954-946-9098

591 S.W. 13th Terrace • Pompano Beach, FL 33069-3520 www.man-mec.com • E-mail: jmilbert@man-mec.com

D2862 LE499

Engines fulfill latest EPA emissions standard, unless otherwise indicated

• IMO Tier II •• IMO Tier III R (Repower or Amendment only) ALL HORSEPOWER RANGES ARE NOT LISTED. FOR MORE OPTIONS, CHECK YOUR LOCAL DEALER.

MITSUBISHI TURBOCHARGER AND ENGINE AMERICA INC.

Ph: 630-268-0750 • Fax: 630-268-9293

Two Pierce Place • 11th Floor • Itasca, IL 60143 www.mitsubishi-engine.com

* Engines listed under High Output are actually Light Duty. ALL HORSEPOWER RANGES ARE NOT LISTED. FOR MORE OPTIONS, CHECK YOUR LOCAL DEALER.

MOTEURS BAUDOUIN

Société Internationale des Moteurs Baudouin Technoparc du Brégadan 13260 Cassis, France +33 488 688 500 • www.baudouin.com

ROLLS-ROYCE SOLUTIONS AMERICA INC.

Ph: 248-560-8000 • Fax: 248-560-8001 39525 Mackenzie Drive • Novi, MI 48377 www.mtu-solutions.com • Email: jeff.sherman@ps.rolls-royce.com

2024 POWER GUIDE

SCANIA USA INC.

Ph: 210-403-0007 • Fax: 210-403-0211 121 Interpark Blvd. • Suite 1002 • San Antonio, TX 78216 www.scaniausa.com • E-mail: na.contact@scaniausainc.com

2024 POWER GUIDE

STEYR MOTORS GMBH

Ph: 850-784-7933

2310 S. Hwy. 77, Ste. 110, #338 • Lynn Haven, FL 32444 www.steyr-motors.com

USA/NORTH AMERICA DISTRIBUTORS

Laborde Products, Covington, LA, Phone: 985-892-0107 Boatswain’s Locker, Costa Mesa, CA, Phone: 949-642-6800

* Waterjet Only. ALL

VOLVO PENTA

Ph: 757-436-2800 • Fax: 757-436-5150 |1300 Volvo Penta Dr. • Chesapeake, VA 23320

Phone: 757-436-2800 • Fax: 757-436-5150 www.volvopenta.com

AQUAMATIC

WABTEC CORP.

Contact: Patrick Webb • Ph: 251-222-0020 • Email: patrick.webb@wabtec.com 30 Isabella Street • Pittsburgh, PA 15212-USA

2024 POWER GUIDE

YANMAR MARINE

Ph: 770-877-9894 • Fax: 770-877-9009

101 International Parkway • Adairsville, GA 30103 www.yanmarmarine.com

*Due to space constraints, not all engine models are included. See your local dealers for complete lineups of all their engines.

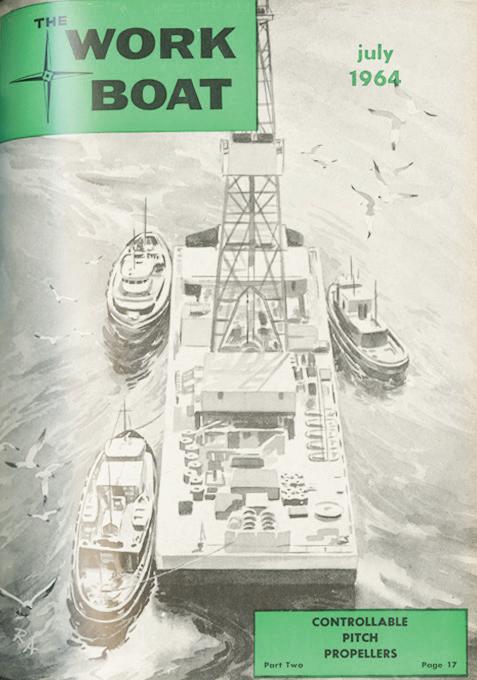

LOOKS BACK

JULY 1964

• The American Waterways Operators, in its quarterly tabulation of construction of waterside plants and installations, showed a downturn in such work for the rst quarter of the current year, as compared with the same period of 1963. However, the 1964 rstquarter total (95) was up slightly over the nal quarter of 1963, when 87 such projects were tabulated.

• The San Juan Number 1, the rst vessel to be built at Avondale's Bayou Black Division near Morgan City, La., was launched recently at Avondale's shipyard. Measuring 280'x60'x23', the massive bulk oil barge is being built for the San Juan Barge Co. The vessel was designed by the naval architect rm of George B. Drake and is consturcted in accordance with special sur-

vey of the American Bureau of Shipping to Class A-1 for Grade "B" petroleum products.

JULY 1984

JULY 1974

• Ingram Corp., New Orleans, has acquired Breit Engineering Inc.'s interests in Tug Barge Systems Inc. (TBSI), also New Orleans based, which previously was equally owned by Ingram and Breit.

• The latest of a proud family of pilot boats built by Gladding-Hearn Shipbuilding Corp., Somerset, Mass., for various pilot associations along the East Coast and the Caribbean area is the 48' U.S. Orca, recently accepted by the Panama Canal Co. after an extensive

on-the-scene evaluation.

• Blount Marine Corp., Warren, R.I., has been awarded an $8 million contract by National Boat Corp., Wilmington, Del., and Houston, to build six 190'x38' support ships for use in the offshore oil industry. Designed to carry 600 tons of drilling pipe, 850 tons of drilling mud and cargo, or 6,000 gals. of water, each boat will be powered by two 1,200-hp diesel engines.

• Construction continues at Eastern Marine Inc., Panama City, Fla., on a passenger/auto ferry for the Lake Champlain Transportation Co., Burlington, Vt. The 180'x43.5'x12' Pittsburgh will be powered by two Caterpillar 700-hp diesels, located at both ends of the drive-on, drive-off vessel.

• Bender Shipbuilding & Repair Co., Mobile, Ala., has signed a contract with Coastwise Cruise Line for the

construction of a 192'x40' cruise ship, Pilgram Belle. Designed by John W. Gilbert, Boston, the boat is slated for delivery this fall.

• New York City of cials have come up with a novel idea for sheltering the estimated 30,000 homeless living in the Big Apple: the proposed use of mothballed military ships or old ferryboats as oating dormitories, which would come from the federal government.

Group Therapy

Keeping track of a fleet’s maintenance and scheduling needs has gotten easier.

By Michael Crowley, Correspondent

For the uninitiated there’s something terribly misleading about working watercraft. A welldesigned ferry, passenger boat, even a tugboat, with pleasing hull lines, nice paint colors and an artful matching of the hull and its superstructure can be visually very pleasing.

But beneath the watercraft’s visually enjoyable lines are a laundry list of things that might go wrong: fuses that go dead, engine bearings that wear out, gear boxes that give out, and so on.

Failure of electrical or mechanical features, may mean serious trouble for the vessel owner, passengers and crew.