MOTION CONTROL

LINEAR MOTION

ROBOT REPORT:

ISO 5599

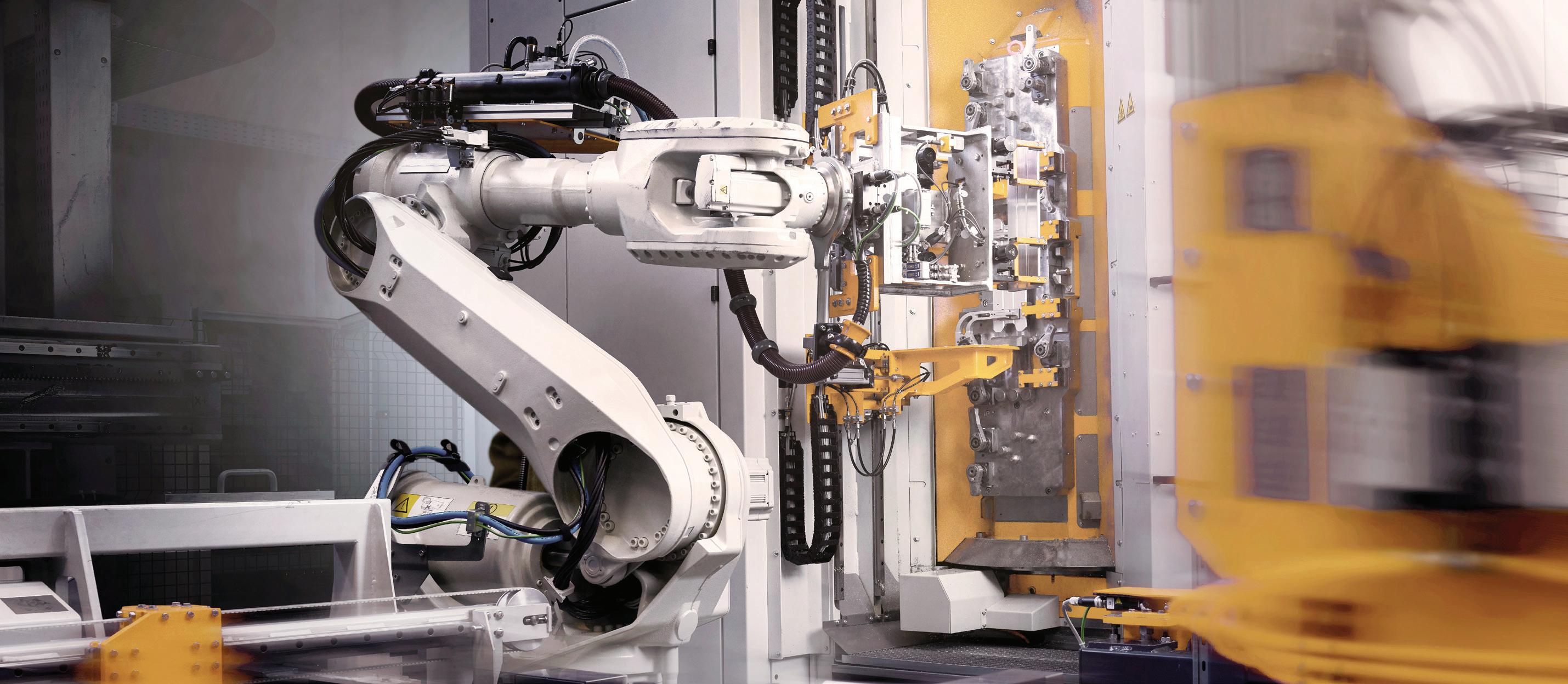

COVID-19 changed so much in the world, om losing loved ones to financial distress for individuals and businesses. It also changed a lot of things in industry — fostered innovation in pharmaceutical and vaccine science, made remote working the norm for many workers, and made Zoom meetings more of a reality for everyone. And its influence continues. At a recent NFPA conference, Donna Ritson of DDR Communications shared results om an industry survey done for the Packaging Machinery Manufacturers Institute looking at the future of robots and cobots for automation.

Ritson explained that COVID is still driving a lot of decisions and changes in manufacturing.

“In general, it’s driving more automation. In an independent study we conducted, about a third of the people participating had already implemented robots and cobots in new technology,” she said.

Robot experts are also looking for functional improvements needed for the greater adoption of pneumatics in robots and cobots, such as the ability to move heavier objects and more seamless integration of pneumatic controls.

“We’re talking about less programming and more teachable operations, and integration of those pneumatic controls into the cobot, the regulators and the valves, the feedback loops to achieve a more plug and play compatibility,” she said. “And plug and play is something that we definitely hear about; it is desirable because that decreases the need for programming. The industry is looking for a broader range of solutions om pneumatics and cobots and robots.”

From a spending perspective, Ritson’s data shows that more than half of the companies surveyed plan to spend more in the next decade on robots, cobots, and automation than they had in the past 10 years. The spending level is increasing — they know they need this type of automation, as labor will remain di cult to find.

“Companies are expecting their suppliers to provide a solid business case,” she said. “They’re saying, ‘Give us the reasons why robots and cobots will help us improve our operations.’ You may have to conduct a plant audit, go into their facilities, and help them find the applications that they need to improve. Where is labor lacking, and how can automation be part of that?”

The main challenge for integrating robots and cobots lies in the questions of where to put them, where can productivity be improved, and where can the best e ciency be added.

While COVID has helped push us faster in this direction, we need to actively think about these issues, whether we’re building the robots and cobots — or whether we’re going to be using them in our own manufacturing facilities. Either way, the future is coming, faster and faster. DW

Paul J. Heney Director

Director

There was a brouhaha a few months ago about a patent granted to Tupolev, a major Russian military aircra maker. The patent covers an aircra engine intake. The intake itself wasn’t all that interesting, but what got a lot of comments among aircra aficionados was the patent drawing of the aircra carrying the engine intake. Speculation is that the drawing was meant to be a Tupolev subsonic bomber called the PAK DA.

The PAK DA is said to be Russia’s answer to the B-21 Raider, a stealth bomber being developed to replace the Air Force’s aging B-1, B-2, and B-52 bomber fleet. Builder Northrop Grumman says the Raider will be able to penetrate enemy air defenses anywhere, hit targets, and return safely home, something 90% of the USAF’s current bomber fleet can’t do.

Surprisingly, Russia’s plans for the PAK DA have been public for quite a while. It’s development program started in 2007 and has progressed in fits and starts apparently because of wide swings in the price of oil, which Russia exports. Russian o cials have said the PAK DA would be a flying wing able to fly 9,300 miles without refueling. They’ve also said some of its weapons would be the same as those on the Tu-160 Blackjack, a Russian bomber in production since 1987.

Aircra industry watchers have been trying to divine additional details about the PAK DA om the

engine intake patent. The patent itself is available online in the original Russian. It’s only five pages long. Unlike most U.S. patents, it lacks a section that outlines the prior art behind the invention. It’s well known that stealth aircra use complex S-shaped intakes to hide the spinning jet engine blades om enemy radar.

Also known is that engine intakes must prevent slow-moving boundary layer air coming off the air ame om entering the jet engine and hampering performance. But there is no mention of any such factors in the Russian patent. So it isn’t clear what’s patentable in the air intake the Russians describe.

The ambiguous nature of the patent hasn’t stopped speculation about the bomber that will carry the intake. Some observers suggest the drawings depict an air ame design that’s less stealthy than the B-2, especially when viewed om the rear and below. Time will tell, but absent om the speculation is how any kind of stealth features will fare given the advances in radar technology now on the drawing board.

One such development om the Los Alamos National Lab recently won an R&D 100 award and involves launching electromagnetic waves via accelerated polarization currents. The polarization current is generated by applying an electric field to a dielectric so that negative and

positive charges in the material move small distances in opposite directions, creating electrical polarization. This polarization can be made to move through a series of dielectrics at faster than the speed of light—the sequentially moving patterns don’t possess mass so they are aren’t bound by the speedof-light limit. When this happens, a special kind of electromagnetic radiation is emitted. It is tightly focused and can contain information that is almost impossible to spoof.

Developers say the main application for this technique is likely to be in 5G communications, thanks to the high privacy implications. But it’s not hard to read between the lines of their proposal and realize that they may be outlining a new kind of radar that can’t be defeated or fooled by using conventional methods.

If polarization current radar comes to uition, it will be one less arrow in the quiver of stealth designers. DW

It’s no longer a question of if additive technology will be used within manufacturing processes. It’s now a question of how soon will additive equipment be a normal part of manufacturing? Already, additive technology is installed in a number of manufacturing facilities, working alongside and with more traditional manufacturing technologies.

In addition, additive technology is leading the shi into digital manufacturing. Because of the pandemic’s disruption of the supply chain, more decision makers saw how additive to help minimize that disruption. The ability to design a part through CAD, send the design into the cloud to be picked up by another system half-way around the world and produced there on additive equipment has helped accelerate the shi to digital manufacturing.

As the shi to digital proceeds, there are gaps in having a smooth production line om initial product to final shipped product. But the industry is focusing on those gaps and developing solutions. Thus, the next major area of focus within the additive industry is the development of an ecosystem to smooth production flow and deliver additive’s unique needs and capabilities to a manufacturing production line.

Much of this ecosystem will involve production flow so ware. Nearly all additive vendors either offer some type of so ware or are developing it.

Another major trend in the additive industry involves materials. From polymers to metals, additive companies are partnering with material developers to offer a wider range for additive manufacturing. One area of focus is developing materials that, through additive technology, achieve the quality and surface finish of injection molded parts. Another area of focus is developing a greater range of high-performance materials. You’ll find materials that offer a range of strengths, that can handle high temperatures beyond 100 C, for example, and that are less brittle at such high temperatures. You’ll also see more materials come out that compete with traditional injection molding materials. One drawback of a number of materials specifically for additive is their inability to handle the high temperatures that can be found in injection molding. Vendors are developing materials to accommodate those temperatures.

And, of course, more companies are quali ing materials for use on metal additive systems.

The ASTM International recently established a Consortium on Materials Data & Standardization. Contributing to this consortium will be a new U.S. National Science Foundation (NSF) research project to Southern University, Louisiana State University, and Auburn University. The newly funded $4 million NSF EPSCoR award is to conduct research on rapid qualification for additively manufactured (AM) critical components used in such industries as aviation, space, and medical.

Finally, mergers and partnerships will continue. These business deals are less about fierce competition and more about building the needed ecosystem to help additive take its place within manufacturing. DW

Paul J. Heney • VP, Editorial Director

Paul J. Heney • VP, Editorial Director

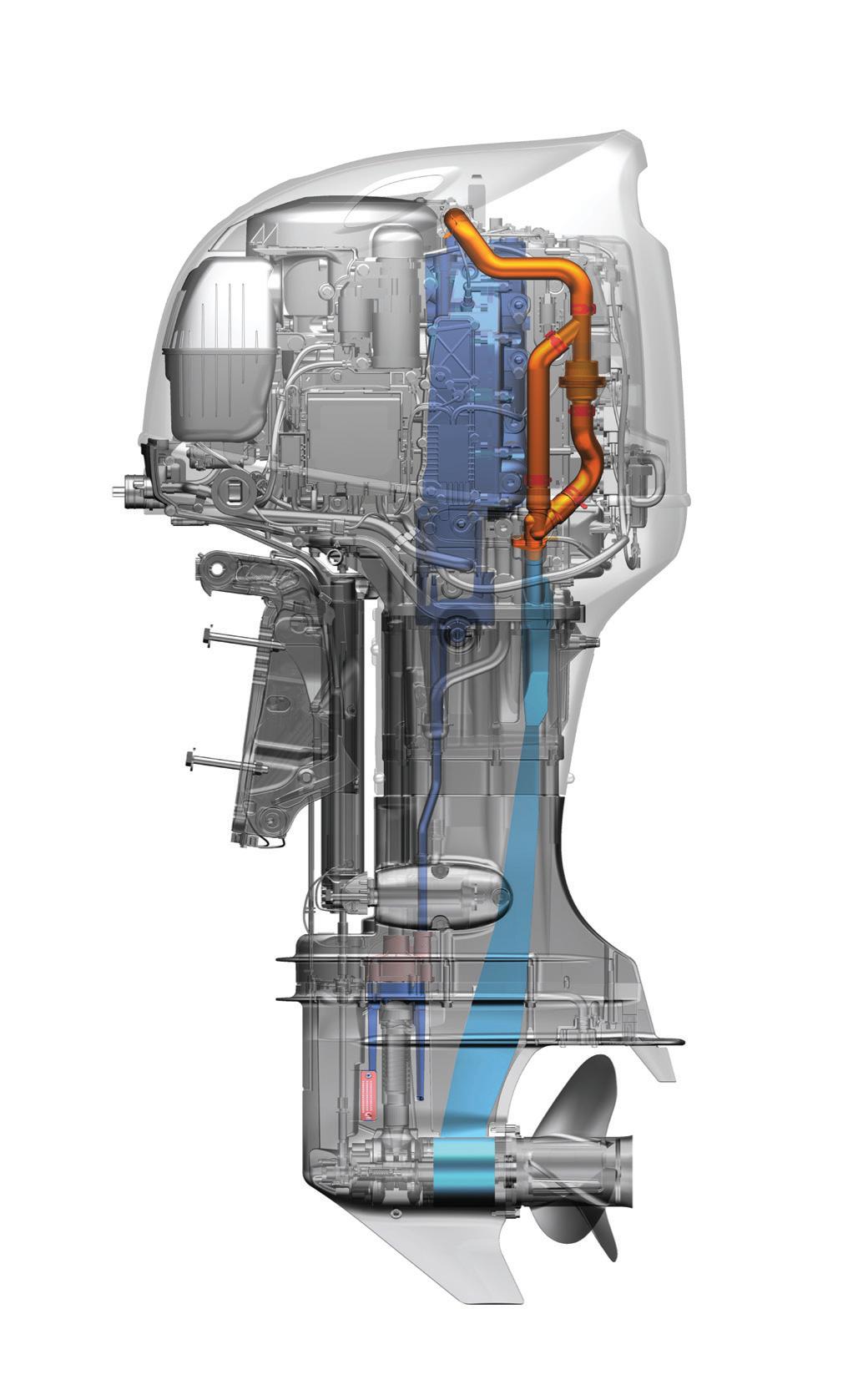

Suzuki Motor Corp. has started rolling out its innovative new microplasticcollecting device as a standard part in four of its midrange outboard motors. The DF115B, DF115BG, DF140B, and DF140BG motors will now feature the microplastic-collecting device and will be shipped worldwide — including to major markets such as North America and Europe.

The amount of plastic waste that flows into the oceans has become a significant environmental problem. Moreover, microplastics that are further crushed in the natural environment have a massive impact on ecosystems. To tackle these issues, Suzuki announced the development of a microplasticcollecting device in October 2020. By installing this device on outboard motors, microplastics near the water’s surface can be collected simply by running the engine.

A er the announcement, monitoring surveys were conducted in 14 countries around the world, including Japan, the United States, and Europe. As a direct result of these initial tests, improvements were made to prepare the device for the rollout.

The installation of this device on outboard motors is one of the three activities that form the “Suzuki Clean Ocean Project,” which is the company’s commitment to address the marine plastics issue:

This is a volunteer waterside clean-up campaign run by Suzuki Group employees and Partners that began in 2011. As of March 2022, 53 distributors and more than 10,000 people worldwide have participated — and the company plans to continue and expand this activity.

2. Reduce plastic packaging

Suzuki aims to reduce the plastic packaging for outboard motors and genuine parts under key considerations:

• Can we stop using it?

• Can we reduce the amount?

• Can we replace it with materials of less environmental impact?

Since October 2020, Suzuki has avoided using over 11 tons of plastic packaging — and the aim is to further reduce plastics by increasing the number of applicable products and genuine parts.

3. Collect marine-plastic waste

Suzuki aims to facilitate further improvement of the marine environment and therealization of a sustainable society by continuing the microplastic-collecting device rollout and promoting the Suzuki Clean Ocean Project, along with its customers all over the world.

“The rollout of the new microplastic-collecting device is another great step forward for Suzuki,” said Mark Beeley, Head of Marine and ATV. “We have been talking to boaters about this unique innovation at shows and events since it was announced as a concept — and it has been incredibly well received. We can’t wait to see the first outboards with it fitted as standard to be sold to customers in the U.K.”

Suzuki Motor Corp. www.suzuki.com

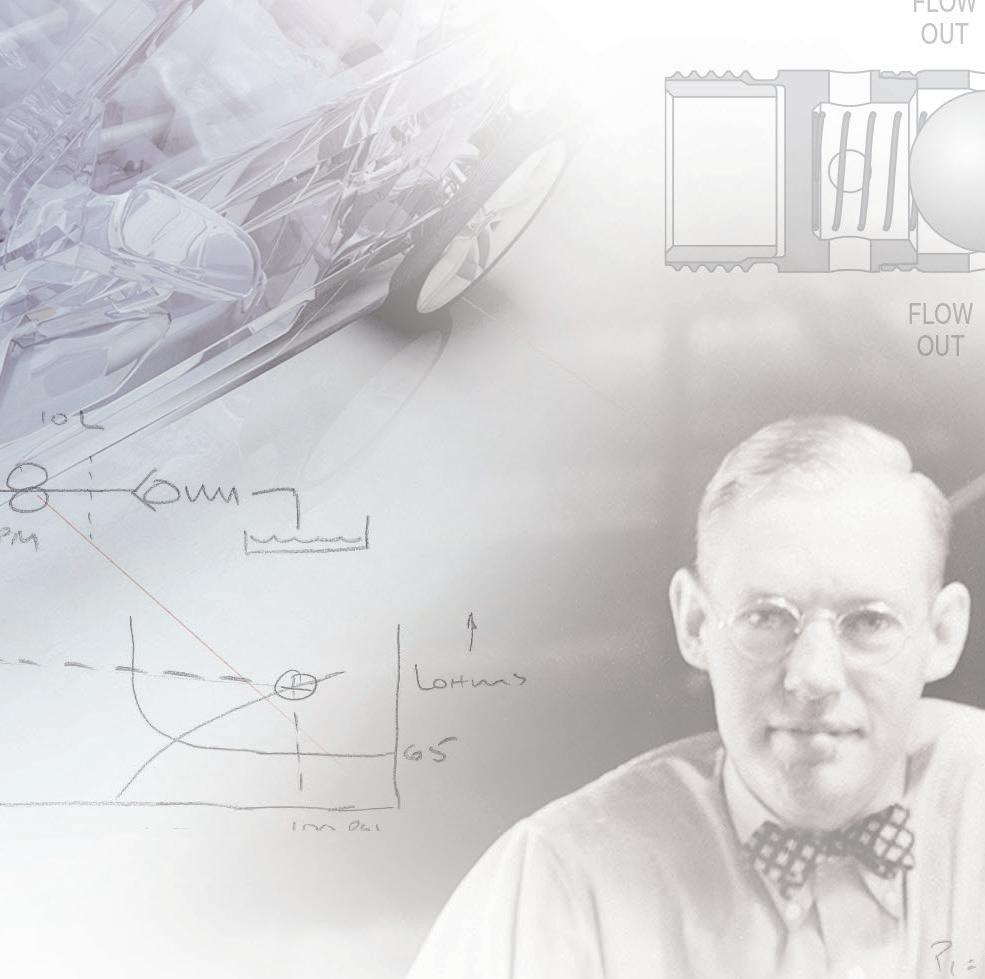

Imitation is easy. Innovation is hard work.

Leighton Lee II was an innovator. He founded our company on that spirit, and it’s how we solve tough problems today. Every product you see here—from miniature check and relief valves to shuttle valves, flow controls, precision orifices and plugs—was developed to solve a customer’s fluid control challenge. Since 1948, we’ve been delivering engineered solutions for a wide variety of demanding applications. We have the experience, product breadth, and technical know-how to provide engineered performance, with zero risk. Don’t let an imitator ruin your day—or your design. Contact us today to put our knowledge to work for

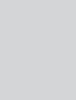

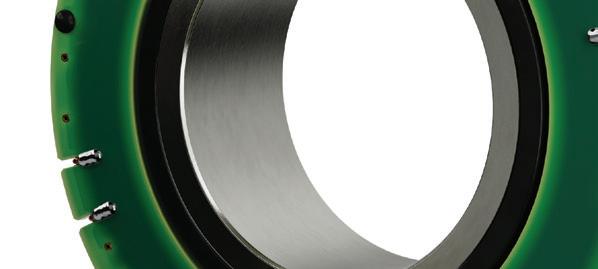

Focus on embedded motion control Di ering definitions of embedded motion control reveal how each term is typically used and what it means for motion control and machine designers.

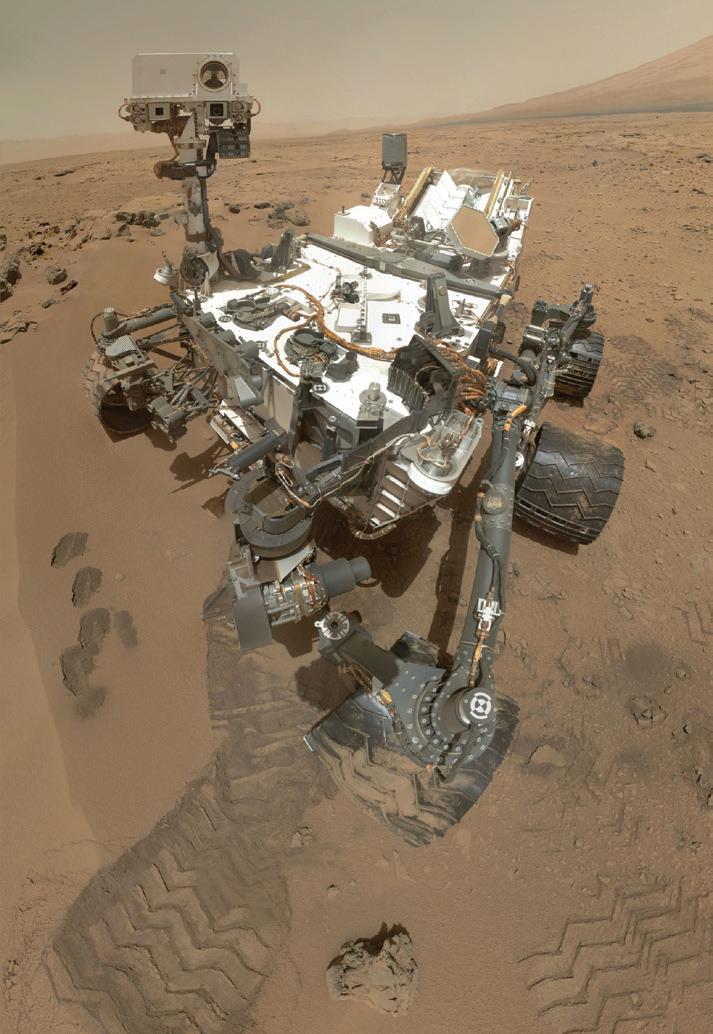

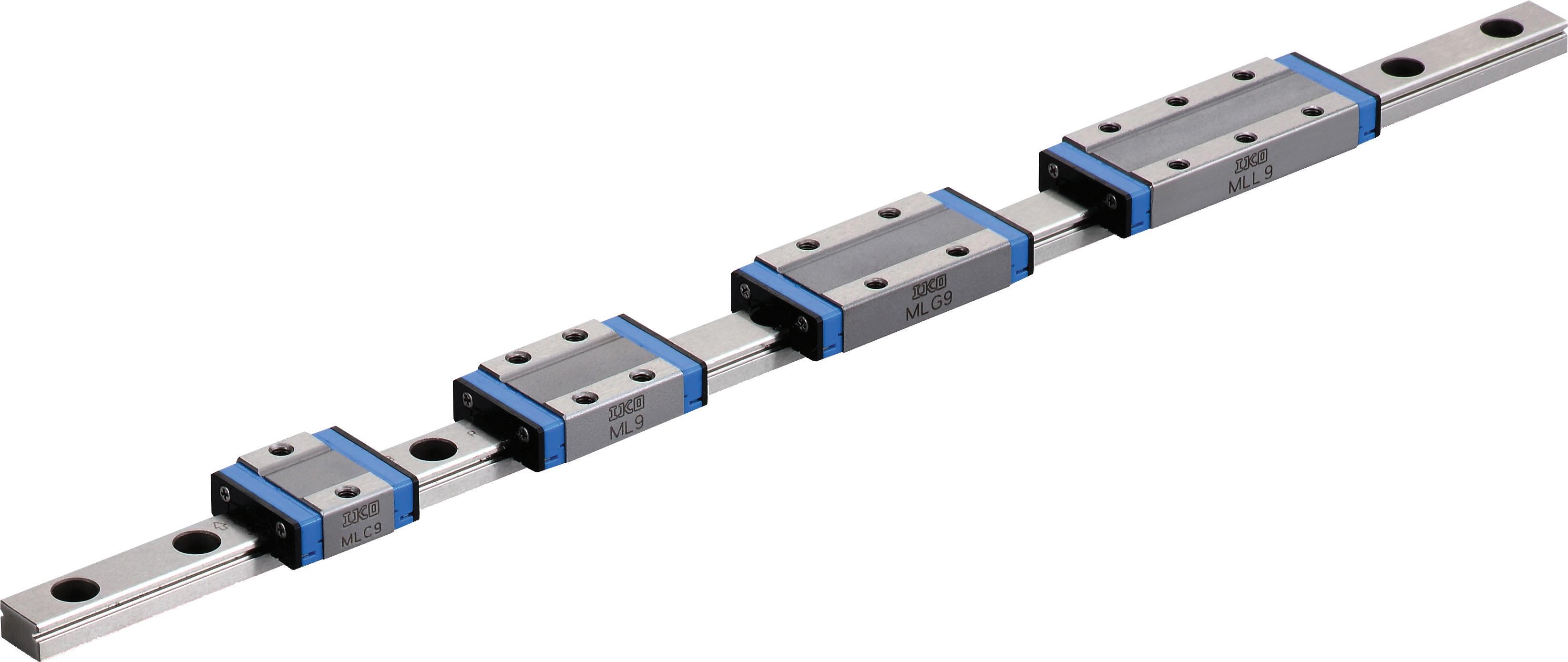

Linear guides, cam followers, and crossedroller bearings can satisfy the demanding requirements for space-flight hardware.

In the engineering world, 3D scanners were mainly used for reverse engineering. Now, researchers are putting the technique to use in new ways, such as creating objects with unusual shapes. Even your smartphone can act as a pretty good 3D scanner.

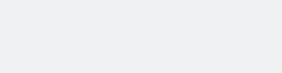

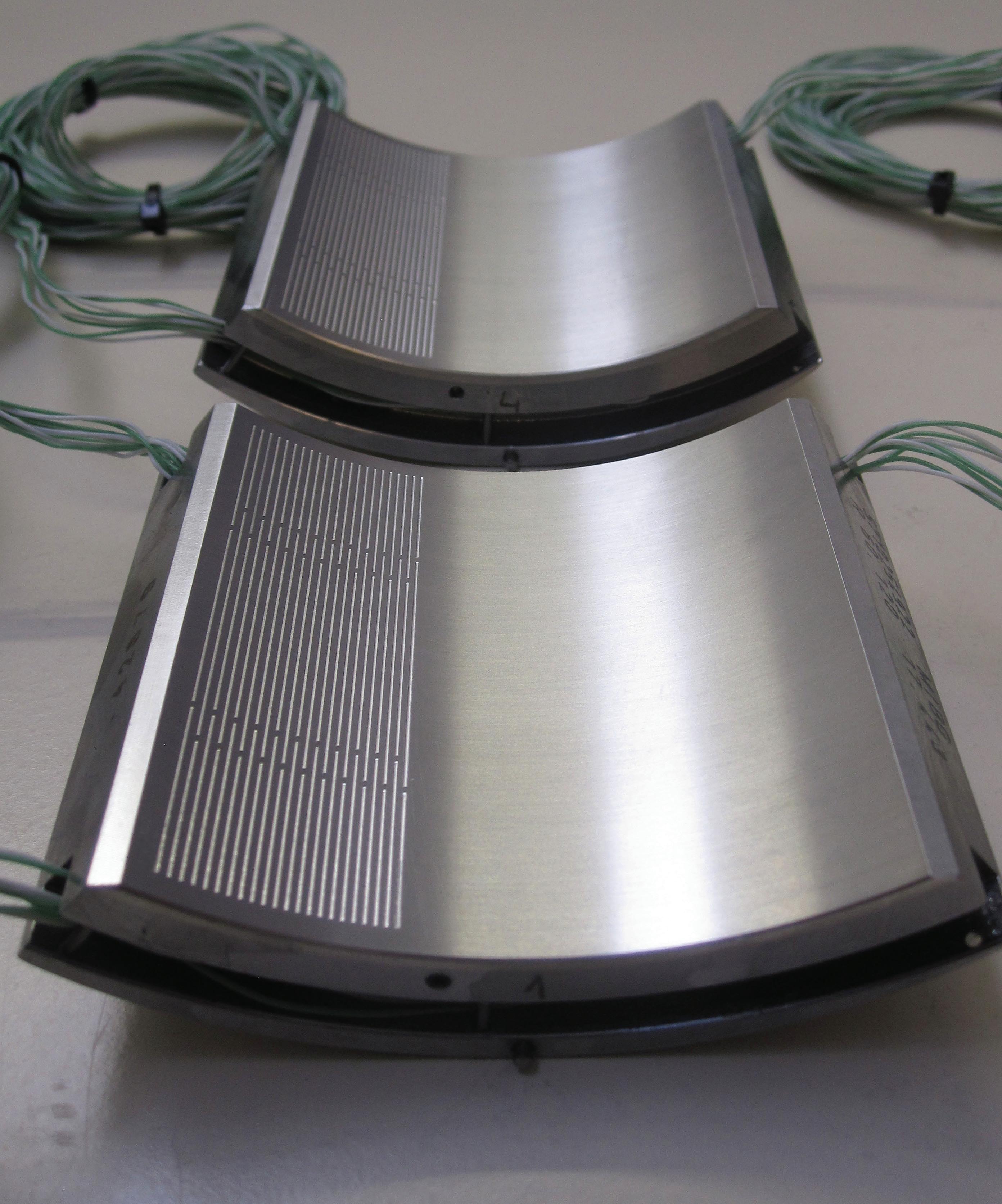

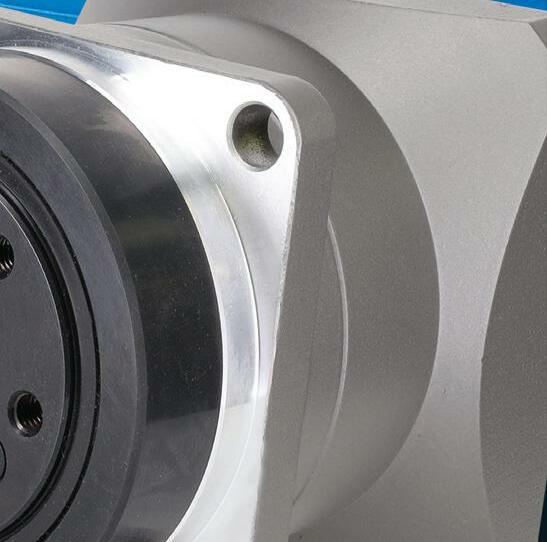

Tilting pad journal bearings are used in turbomachinery like turbo compressors, turbo gears, gas turbines, or steam turbines. Demand for bearings with increased load carrying capacity or power density is growing. Certainly, this goal must be achieved without an impairment of bearing functionality and operational reliability.

EDITORIAL

VP, Editorial Director

Paul J. Heney

pheney@wtwhmedia.com @wtwh_paulheney

Managing Editor

Mike Santora msantora@wtwhmedia.com @dw_mikesantora

Executive Editor

Leland Teschler

lteschler@wtwhmedia.com @dw_leeteschler

Executive Editor

Lisa Eitel

leitel@wtwhmedia.com @dw_lisaeitel

Senior Editor

Miles Budimir

mbudimir@wtwhmedia.com @dw_motion

Senior Editor

Mary Gannon mgannon@wtwhmedia.com @dw_marygannon

Senior Editor

Rachael Pasini rpasini@wtwhmedia.com

Associate Editor

Heather Hall hhall@wtwhmedia.com @wtwh_heathhall

Senior Contributing Editor

Leslie Langnau llangnau@wtwhmedia.com @dw_3dprinting

VP, Creative Services

Mark Rook

mrook@wtwhmedia.com @wtwh_graphics

Senior Art Director

Matthew Claney mclaney@wtwhmedia.com @wtwh_designer

Senior Graphic Designer

Allison Washko awashko@wtwhmedia.com

@wtwh_allison

Graphic Designer

Mariel Evans mevans@wtwhmedia.com @wtwh_mariel

Director, Audience Development

Bruce Sprague bsprague@wtwhmedia.com

WEB DEV / DIGITAL

OPERATIONS

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com @wtwh_webdave

Senior Digital Media Manager

Patrick Curran pcurran@wtwhmedia.com @wtwhseopatrick

Front End Developer

Melissa Annand mannand@wtwhmedia.com

Software Engineer

David Bozentka dbozentka@wtwhmedia.com

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com @wtwh_virginia

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com @WTWH_Taylor

Digital Marketing Coordinator

Jill Bresnahan jbresnahan@wtwhmedia.com @WTWH_Jill

Webinar Coordinator

Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator

Kim Dorsey kdorsey@wtwhmedia.com

EVENTS Events Manager

Jen Osborne josborne@wtwhmedia.com @wtwh_jen

Events Manager

Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist

Olivia Zemanek ozemanek@wtwhmedia.com

VIDEO SERVICES

Video Manager

Bradley Voyten

bvoyten@wtwhmedia.com @bv10wtwh

Garrett McCafferty gmccafferty@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative

Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager

Samantha King sking@wtwhmedia.com

Marketing Graphic Designer

Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

FINANCE Controller

Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist

Jamila Milton jmilton@wtwhmedia.com

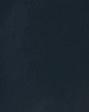

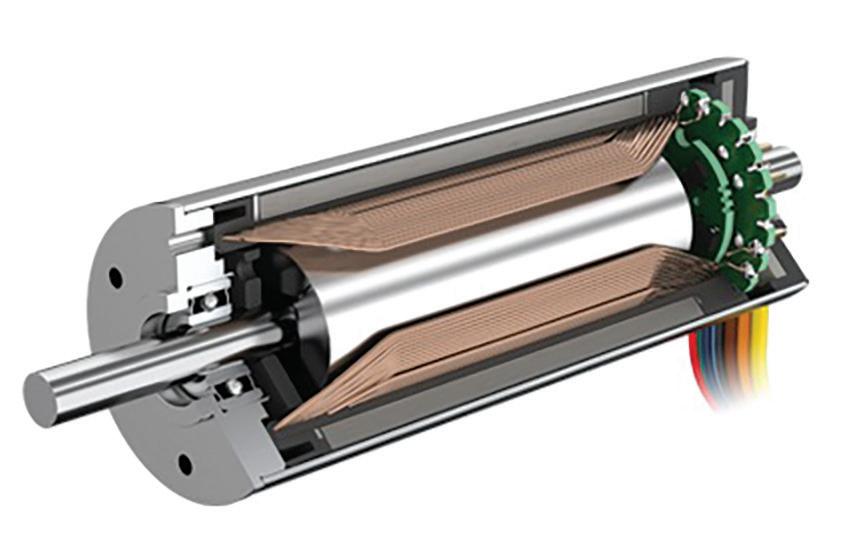

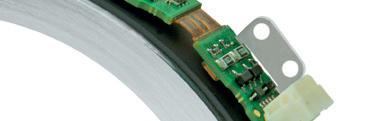

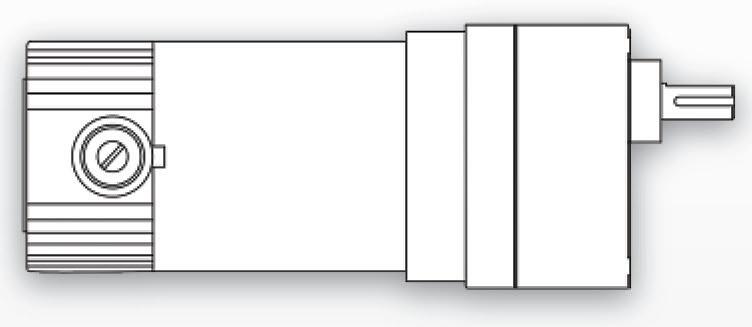

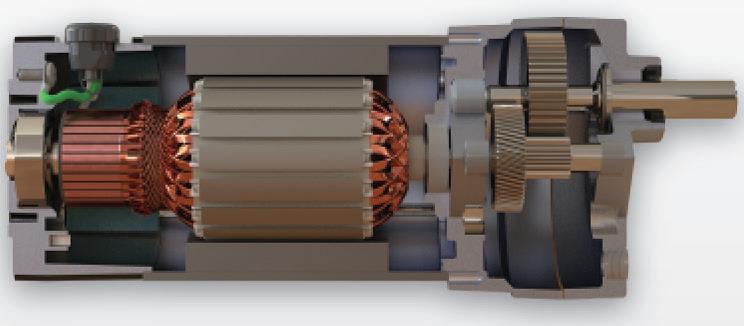

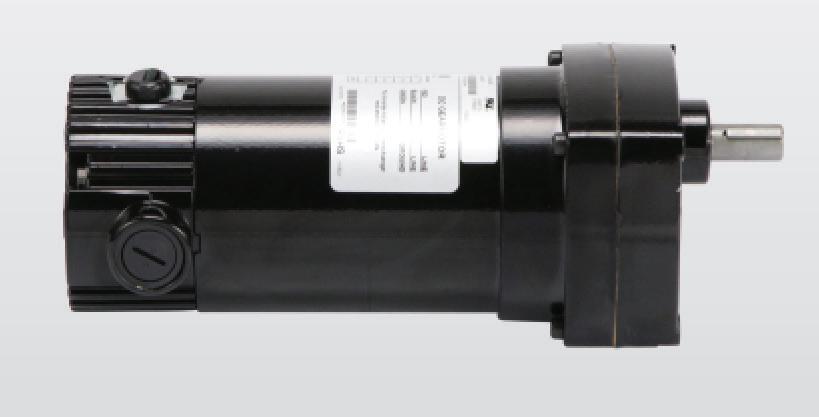

The exoskeleton, Autonomyo, helps people with certain neuromuscular disorders walk without crutches. Powering it are six micromotors with an all-in-one component motor with a torque sensor to facilitate a harmonious interaction between the exoskeleton and its user.

The exoskeleton, Autonomyo, helps people with certain neuromuscular disorders walk without crutches. The active walking aid supports the weakened muscles and enables an intuitive sequence of movements that mimics natural walking. Medical science distinguishes between more than 800 different neuromuscular disorders. Even though these disorders have different causes and develop in different ways, they all have one thing in common: muscle weakness (muscular dystrophy), which is progressive in many cases.

Powering this exoskeleton are six micromotors. To facilitate a harmonious interaction between the exoskeleton and its user, FAULHABER developed an all-in-one component motor with a torque sensor.

Notes Mohamed Bouri, Leader of the research group for Rehabilitation and Assistive Robotics (REHA Assist) at the Swiss technical university of Lausanne (EPFL), “The muscles are still functional but they cannot muster enough strength for the patients to stand stably or move their legs independently. Our aim was to overcome these limitations as much as possible using motorized support –– therefore, still taking advantage of the patient’s contribution to his own movements.”

Conventional exoskeletons already in use lean on humanoid inspired technology. These devices enable paraplegic people to walk without a crutch, but they weigh more than 40 kilograms. At 25 kilograms, the Autonomyo is much lighter, and it works with the patient’s weakened but still partially functioning musculoskeletal system.

The exoskeleton is fastened with a corset around a person’s midsection and cuffs around the legs. On each side, three motors enable movement by supplying the power that the muscles are lacking.

One motor is responsible for the flexion and extension of the hip and another motor does the same for the knee. The third motor supports abduction and adduction of the leg at the hip joint. Alltogether, the motors help the patient to maintain their balance and to walk upright.

It is absolutely crucial that the device assists gait according to the user’s intention. “The initial trigger to change position – that is, to start walking – is expressed as a small change in the lower limb position,” explains Bouri. “We detect it by combining the information from an inertial measurement unit, eight load sensors at the soles and the encoders of the motors that act as joint position sensors. All these data contribute to the assistance of balance.”

When walking, the interaction between the device and the user is crucial. Thus, a torque sensor senses this interaction and precisely implements the assistance strategy.

The conventional technology for torque detection uses expansion strips on components; these strips are deformed by the force exerted. The weak point of their construction is the adhesive bond they use to attach. The developers in the Advanced Engineering group have replaced these strips with a

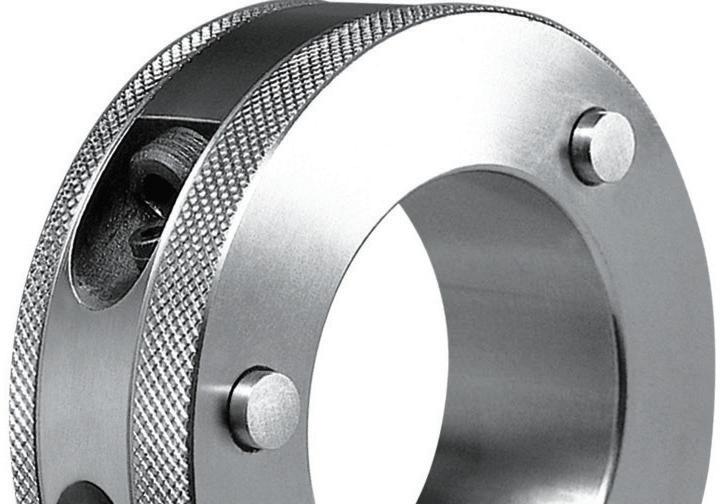

LEFT HANDED as well as RIGHT -HANDED

Materials of: CARBON,

WHITTET-HIGGINS manufactures quality oriented, stocks

delivers quickly the best quality and largest array

heavy

torque load carrying retaining

high-resolution measurement system. This achieves a deviation of less than 1.5% in the measurement range of plus/ minus 30 newton meters. The sensor therefore supplies a highly precise value for the response torque in the walking movement.

This value plays a vital role in controlling the Autonomyo exoskeleton. “Adjusting the device to the individual patients requires differentiated calibration of the entire system,” explains Bouri. “Using the various parameters and the feedback om the movement, the so ware calculates the control signals for the drives. The type and level of assistance om the motors are then determined based on the information.”

The six drive units in each device are supplied by FAULHABER. Their core

component is the 3274 BP4 brushless motor with a diameter of 32 millimeters. Its power is transmitted by a 42 GPT planetary gearhead with a sha produced especially for this application. A magnetic IE3 encoder supplies the position data to the controller. The torque sensor is integrated in the gearheads of the four motors for the flexion/extension movements.

For the time being, the component is not a series product and has so far been produced only for the EPFL in small quantities. However, high-resolution torque measurement can add significant value in all haptic applications. For example, for all types of robotic assistance in operating theaters where the surgeon guides the instrument and the machine controls the power and

precision. The sensor can also provide a protective function and be used to limit torque. DW

FAULHABER www.faulhaber.com

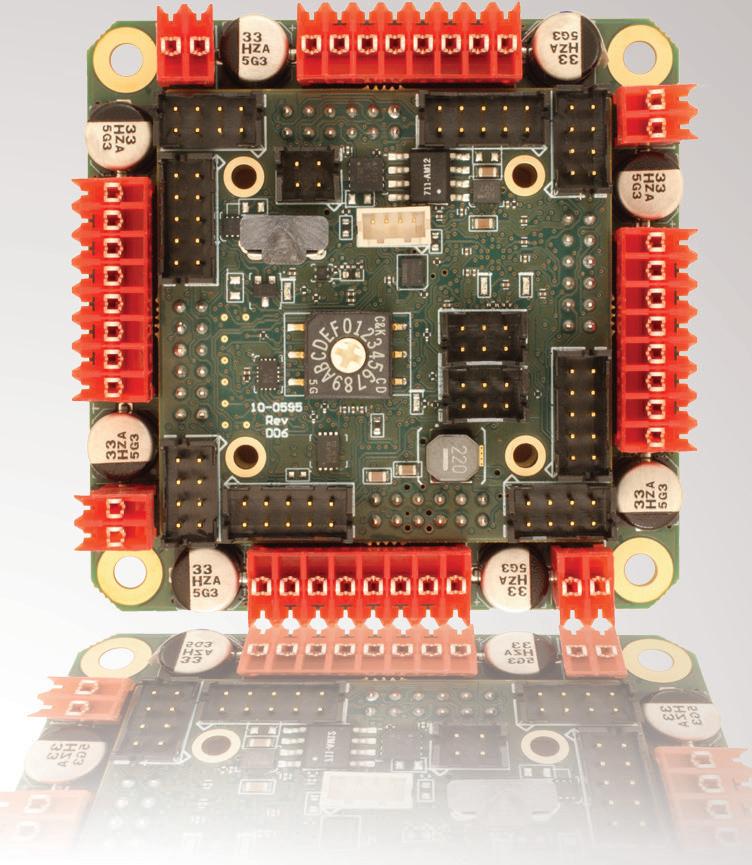

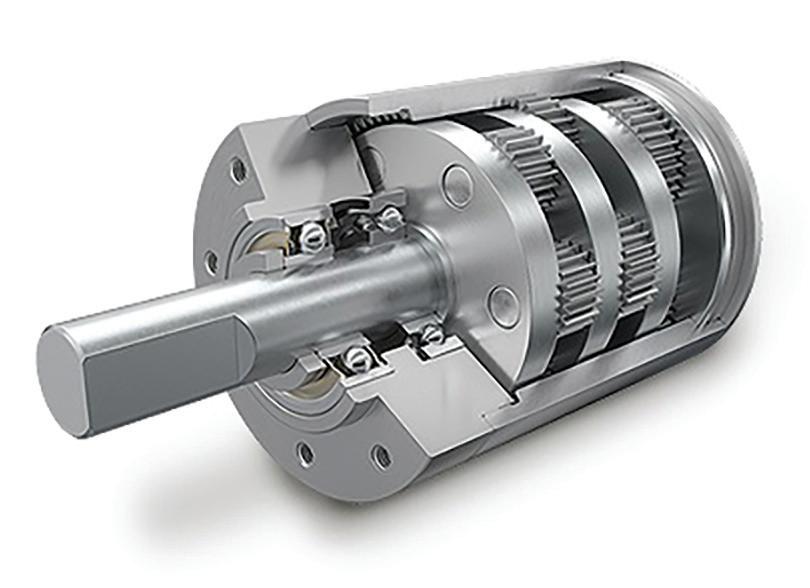

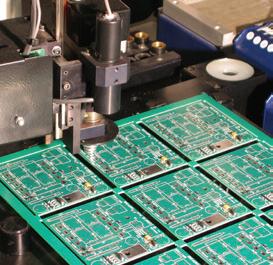

By integrating functions and the threedimensional routing of circuit tracks, the design space for the electronics of hearing aids can be optimally used.

The design of medical devices increasingly involves the use of mechatronic design tools to meet the need for ever smaller devices. In one example, integrating functions and the three-dimensional routing of circuit tracks can help to optimize the electronics of hearing aids.

The Mechatronic Integrated Devices (3D-MID) technology allows higher density integration of electronic components into the smallest possible space. As medical devices such as hearing aids and dental instruments become smaller and smaller, the manufacture of their most important elements, traditionally printed circuit boards, require more delicacy and precision. High-end miniaturization is facilitated by 3D-Circuits: a combination of mechanical and electronic integration.

Here’s a closer look at 3D-MID technology.

HARTING’s 3D-Circuits technology, for example, makes it possible to combine mechanical and electronic functions into a single component to fit into the smallest

spaces. The electronic circuit can be built into the device itself, making it more compact and functionally dense. By using injection-molded circuit boards, the number of process steps, assembly times, and parts can be reduced.

Device designers can go above and beyond the limits of traditional manufacturing with the help of 3D-Circuits by helping designers uni electrical and mechanical functions in a single three-dimensional component. These components are constructed using malleable bits of plastic through injection molding. This process makes it possible to create anything with precise measurements according to the requirements laid down by final customer usage.

Injection molding is used for mass production of products with complex geometries and in miniature sizes, such as the components of high-end medical devices. A process called laser direct structuring (LDS), developed by LPKF Laser & Electronics, can then draw the needed electrical trace layout to

A microphone carrier in 3D-MID design precisely aligns the microphones of the hearing aid and at the same time integrates the electrical contact.

these components, which will be made conductive in a subsequent chemical plating process.

Mechatronics allows for the extreme downsizing or miniaturizing of medical applications, enabling examination, sensing, and monitoring om within the

patient. With such technology, medical devices can be designed to be much less invasive, improving patient care.

Taking large medical machines and devices and putting them into a more compact package is a big part of what 3D-Circuits brings to the table. It helps change how medical devices are used today.

Implementing a 3D-MID ring switch in the dental instrument improved the ergonomics and weight of the instrument while simultaneously reducing the assembly effort.

INDIANA

The micro actuators and miniature sensors also propel the development of small mechatronics systems for the following applications:

• Handheld diagnostics for use at the point of care, including ultrasound and blood testing

• Scientific instruments for flow cytometry, DNA identification, pathogen detection, and DNA sequencing

• Medical imaging using small, precise modules for lens control and laser tuning

• Implantable devices that can be dynamically adjusted in-place

• Mobile miniature robots

• Micropumps and auto-injectors for drug delivery products

Some of the value-added benefits that medical organizations can gain om using mechatronics in place of more conventional manufacturing methods:

• The miniaturization of medical devices

• Development of low-cost disposable gadgets, which has become a pressing requirement

• Device portability

• High levels of accuracy and precision

• Improved performance in all aspects

• Design eedom

• Weight reduction

• Simplification of products

The most important developments in mechatronics lead to new technologies that will shape the healthcare of the future so that devices are safer, more portable, and, most importantly, painless.

HARTING | www.3D-Circuits.com

This is a substitution for an endoscope. You basically swallow it like a pill which makes way more comfortable than an endoscope.

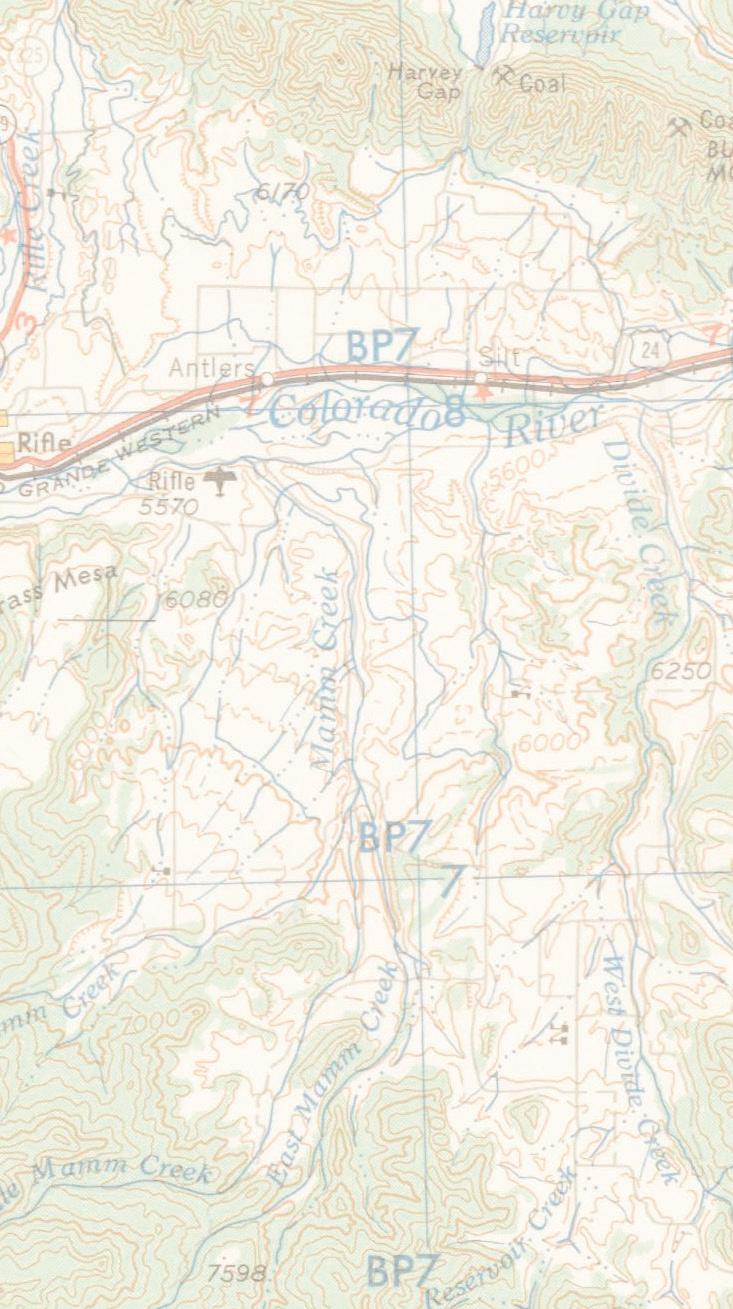

wear

positioning accuracy

Products Inc., www.siko-global.com

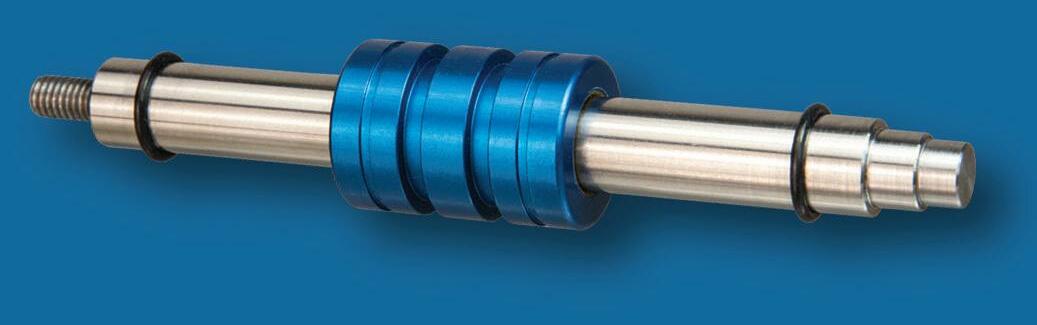

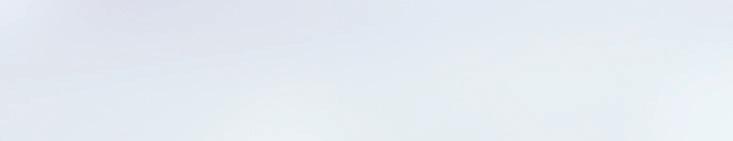

Bearings in motors controlled by VFDs can face harsh operating conditions which can shorten the life of the motors. The CERAMICSPEED radial bearings will last in such conditions up to 8 times longer than traditional radial bearings.

Custom made for electrical motors CERAMICSPEED Insulate Radial Bearings protect against damage to the race, balls and retainers resulting om high voltage arcing, especially, when Variable Frequency Drives are controlling the motors as speeds constantly changing exacerbates arcing. Insulate’s (SiN3) Silicon Nitride ceramic balls are 400% smoother, 128% harder, and feature an insulation rating of 15 kV per mm compared to 1 kV per mm of steel balls. Because ceramic balls are harder and smoother, they have a lower coe cient of iction, run

at 10 to 20 degrees C lower temperatures extending life of the lubrication. This allows for up to 50% higher speeds, and consumes less energy.

These bearings are FDA and USDA compliant and have been approved for food and beverage, and pharmaceutical applications. They also tolerate extreme operating conditions such as: Abrasive slurries and powders, caustic and high-pressure wash downs, corrosive atmospheres, shock and vibration, and there is no spalling under extremely high loads.

These bearings are available in several different sealed and open configurations in sizes for small motors operating at speed to 70,000 rpm, and for offshore wind turbines operating at 20 rpm. Additionally, there are a variety of seals and lubricants that can be recommended depending on loads and equencies so that they can be configured to the exact needs of a customer.

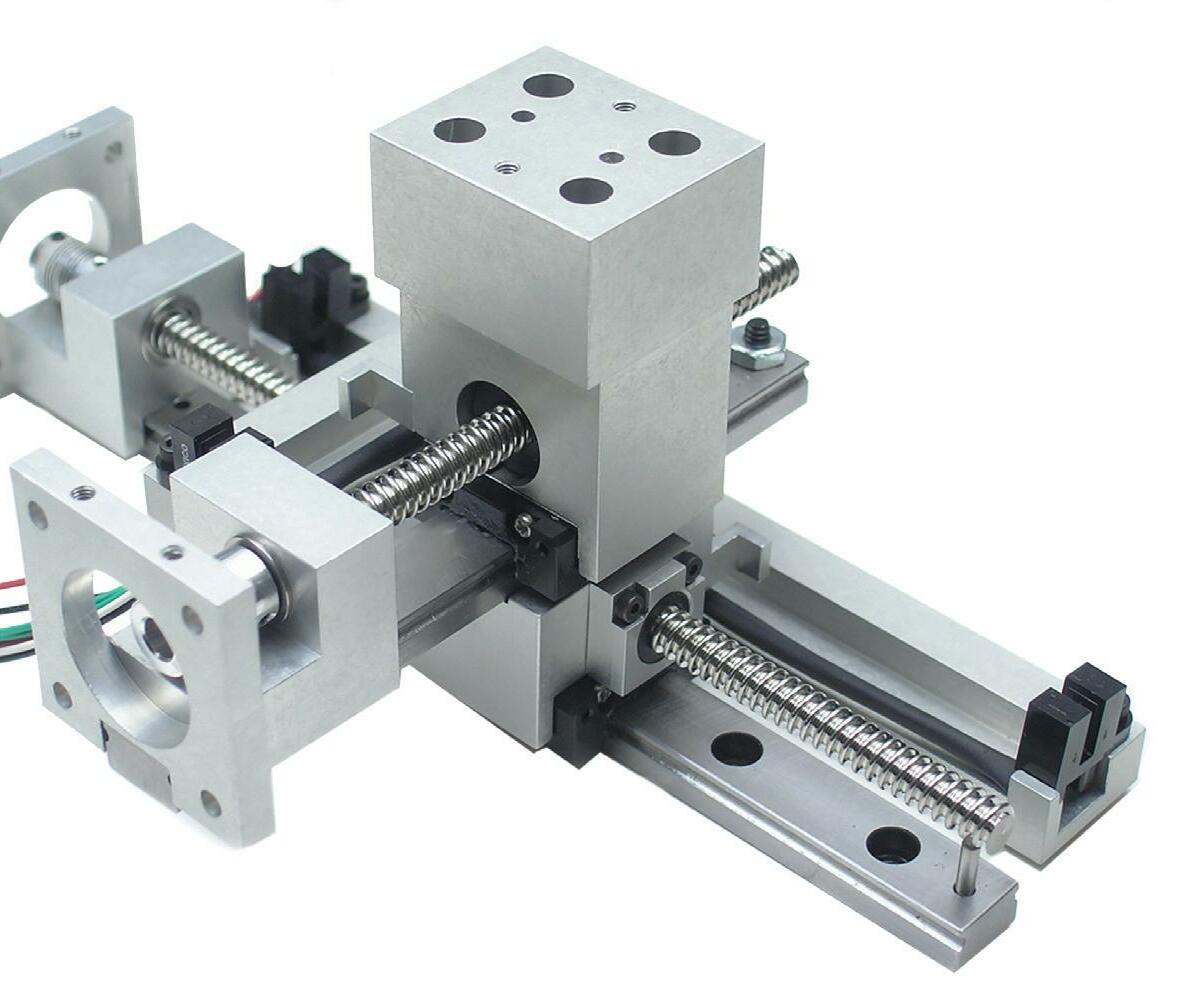

A number of applications, such as medical, need stages with micron accuracy. The XYR-300-400 Alignment Stage offers +/- 3 micron accuracy for industrial, medical, semiconductor, production, research, and laboratory applications. It features +/- 15 mm of travel in the X and Y axes and +/- 5 degrees of rotation (theta). It moves in XYplane and rotates around the center of the XY-plane.

The stage features linear resolutions of the X and Y axis of 1 micron resolution with a 10 micro-steps per step motor driver and static parallelism of less than 0.05 mm. Two-phase stepper motors are standard; however, servo motors with quadrature optical encoders are also available as an option for greater resolution and repeatability. The 8 mm diameter and 2 mm per-turn precision ball screws and preloaded V-groove and crossed roller bearings add to the high precision and stiffness of this compact alignment stage.

The table of the stage is 300 x 300 mm and has threaded holes and a 110 x 110 mm opening for optics, cables, etc.; a solid top is available. The base plate is 400 x 400 mm and the height of the alignment stage is just 98 mm.

The XYR-300-400 Alignment Stage is black anodized aluminum, and is easy to integrate into new or existing systems. Compatible Motion Controllers are available om OES and the XYR-300-400 Alignment Stage can also be ordered as a complete plugand-play system. DW

Semiconductor vendors are always looking to improve yield. This ultrahighpurity (UHP) diaphragm valve delivers the consistency and long service life necessary for semiconductor fabricators to achieve better chip yields.

The ALD7 valve provides better flow consistency, flow capacity, and actuator speed. It also offers the performance at high temperatures necessary to allow chip fabricators to overcome limitations in current production processes and keep up with demand.

ALD7 valves can be integrated into either new tools or legacy equipment to improve flow capacity (up to 0.7 Cv) in the same 1.5-in. (38.1 mm) footprint as existing valves, helping fabricators keep up with the strong global demand for chips. The valves deliver precise dosing over tens of millions of ALD (atomic layer deposition) production cycles by actuating quickly and consistently. The actuator’s open and close response time can be less than 5 ms. The actuator is immersible to 150°C (302°F) and the valve body is rated to 200°C (392°F), allowing the valve to better support low-vapor-pressure precursors that require high temperature delivery. This gives fabricators the control needed to maximize throughput and yield.

ALD7 valves feature a compact design with an integrated thermal isolator, allowing system designers to maximize limited space near the reaction chamber of chip production tools. The valves are also resistant to corrosive gases used in ALD processes, with valve bodies comprised of proprietary ultrahigh-purity 316L VIM-VAR stainless steel.

The ALD7 is available in a modular surfacemount configuration with a high-flow C-seal or in straight configurations with a tube butt weld, and VCR face seal fitting end connections. High-temperature electronic position sensors, optical position sensors, or solenoid pilot valve configurations are also available as add-on components.

For off-highway applications, online ordering and configuring of ball screws can be easier with an online tool. Thomson Industries, Inc., offers an online ball screw selection tool that includes online configurability options as well as expert guidance. Design engineers using the tool will have access to more capabilities and expert guidance in configuring end machining, end fixity, thread lengths, nuts and related assembly preferences. An interactive reference table is updated, providing one-click access to information on the safety factors for each available option. A real-time diagram displays the status of their assembly, and built-in prompts guide them through optimal design sequences.

The following are some of the new ball screw configuration capabilities that design engineers can perform online:

• Select cut ends or standard machined ends, with or without end supports.

• Speci whether end supports should be assembled or shipped separately.

• Define overall screw lengths and threading.

• Configure the right product more quickly and easily with an enhanced user interface.

• See all available nut options instantly.

• See safety factors for each configuration with a single click.

Faster processing and data loading capabilities accelerate all such operations and enable design engineers to download a CAD diagram of their configuration more quickly. DW

Thomson Industries, Inc. www.thomsonlinear.com

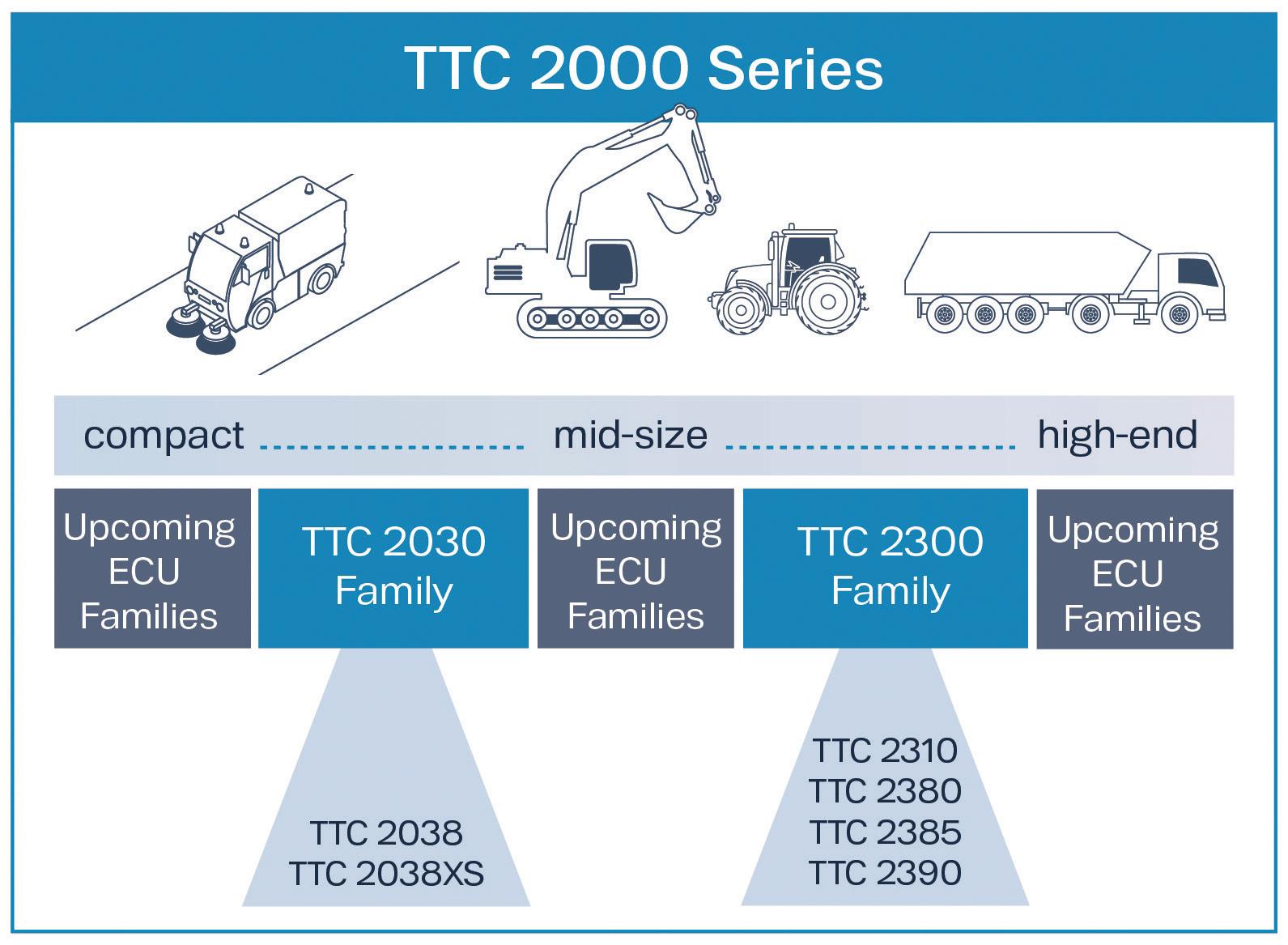

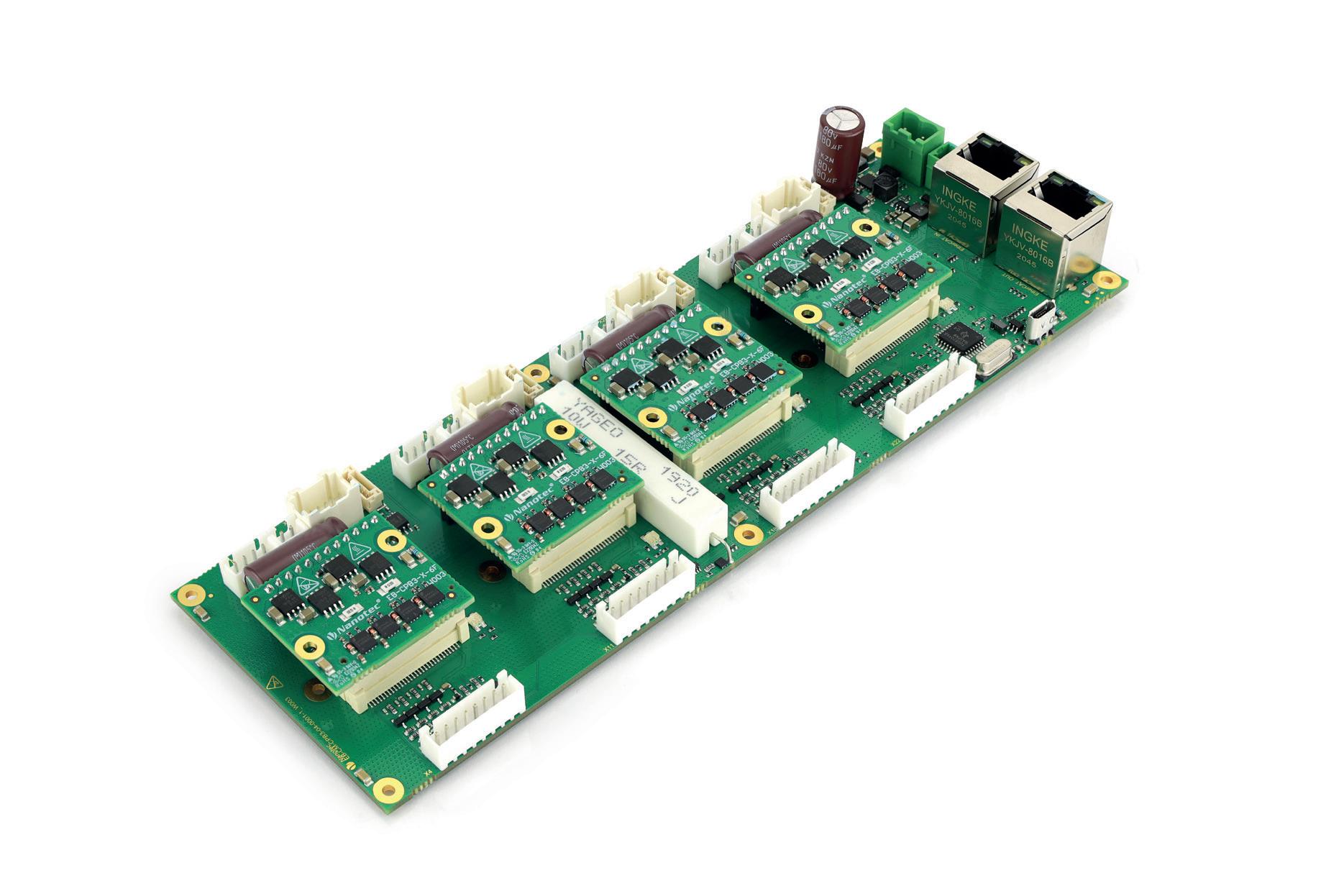

As technology advances, one way to help off-highway equipment manufacturers is through control units. The TTC 2030 is part of the TTC 2000 ECU series, which consists of compatible Electronic Control Unit (ECU) families of different sizes, but with the same modular building blocks. This ensures that the right number of interfaces and the right amount of processing power is available for each mobile machine application, while significantly reducing time-tomarket and maintenance for the vehicle manufacturer.

The two now available members of the TTC 2000 ECU series, the new compact TTC 2030 family and the TTC 2300 family, enable machine manufacturers to future-proof their machines. Operators of construction machinery in rugged operating environments on construction sites around the globe can fully rely on the functionality of the control units. This is due to their robustness, high ingress protection rating and resistance to

extreme temperatures (full output current om -40 to +85 °C).

Future automation and operator assistance systems are supported by the large internal memory and the transmission of smart sensor data through various communication interfaces such as CAN, Ethernet and SENT (Single Edge Nibble Transmission). This enables operators of construction machinery, for example, to define operating areas for excavators or limit the reach and load moment of cranes.

Both the TTC 2030 and TTC 2300 ECU families fulfill safety standards in the construction, agricultural and automotive industries and help reduce certification costs for vehicle manufacturers. The mixed criticality approach allows safety-critical and non-safety-critical code to run on

the same CPU without reducing the overall safety level. The real-time operating system

PXROS enables full use of the CPU multicore architecture and ensures a high level of safety through eedom of interference and a significantly reduced development effort.

Both ECU families are equipped with Infineon’s latest high-performance processor, the second-generation AurixTM TriCore, to ensure the right computing power for future mobile machines.

The mid-sized TTC 2300 features the Aurix with up to six cores and with two high-speed data ports (HSD) for standard Ethernet and BroadR-Reach Ethernet communications. It is equipped with application-configurable status LEDs, support for an emergency stop button, and an H-Bridge mode for controlling electric motors.

The TTC 2030 includes the compact ECU TTC 2038 variant with a two-core Aurix CPU and the I/O module TTC 2038XS, all of which share modularity and synergy potential with the TTC 2000 series.

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

The KHS Innofill Glass DRS filler that can process up to 60,000 bottles per hour is part of the glass line in Mannheim.

Within just three years, Coca-Cola in Germany has invested around 50 million euros in one of its biggest plants in Mannheim. KHS has contributed a returnable glass line to the project — one that also manages highly complex sorting tasks.

In July 1950, beverage retailer Wilhelm Müller procured the bottling rights for CocaCola in Germany. He established the entrepreneurial basis for the production site that can still be found in Mannheim. Initially, many tasks like sorting and quality assurance were performed manually until 1965, when the first fully automatic setup went into operation.

Today, the production plant is part of Coca-Cola Europacific Partners Germany (CCEP DE), the biggest beverage producer in the Federal Republic. “Among our older employees, there are still plenty who fondly look back to what’s known as the Cola Müller era,” said

Christopher Bee. The 39-year-old has worked in Mannheim for seven years and was made plant manager in September 2021. The extensive company premises still belong to the Wilhelm Müller Foundation, with the lease extended for another 30 years just two years ago.

“There’s nothing old-fashioned about our technical equipment, however,” he said.

“In 2018 and 2019, we invested around 50 million euros in two new filling lines. These were the biggest investments ever to be made in the history of our production site. This makes us here in Mannheim one of the most technically advanced Coca-Cola plants in Germany and Europe.”

One of the two new production lines is a returnable glass system om Dortmund systems supplier KHS. “We fill a total of six different bottles on this line: four in 200-milliliter and two in 330-milliliter format. The smaller sizes are primarily destined for the hospitality trade, where the packaging must be a bit more impressive than for retail. Therefore, the Coca-Cola, Fanta, Sprite, and mezzo mix brands on this line have their own respective bottle designs. We process two formats for the bigger containers that are also sold in the retail trade. What’s known as the contour bottle for products in the Coca-Cola family and our green multibottle for Fanta, Sprite and mezzo mix.”

One outstanding KHS line feature is the sorting system that feeds the empty bottles by type to the washing and filling process automatically. “In principle, the sorting and filling processes take place on two separate systems. We use a segment to combine both sections specifically for

our main product types, the 200- and 330-milliliter Coca-Cola bottles. Here, the containers that are largely returned om the market by type are sent straight om sorting to production. They no longer have to take a detour through the empties warehouse. This reduces the amount of effort needed for handling.” The other five product types om the sorting process are first packed into beverage crates and then onto pallets before being temporarily stored until they are filled.

Thanks to the system’s high degree of automation, the only manual task required takes place right at the start of sorting. When the crates arrive, they’re scanned om above. If they contain foreign objects such as paper cups or film, the crates can’t be identified. The obstacle must then be removed by hand before the crate can be fed back into the automatic process. “The decrater is so intelligent that it places the biggest bottle type on one conveyor,” explained Bee. “The smaller bottles are set down on a different conveyor where they’re separated and guided to different lanes with the help of camera systems and pushers. Here, we aim to manipulate the containers as little as possible: in other words, to ensure that they have minimal contact with the machine. In this way, we can keep the risk of something falling over at such high speed to a minimum.”

With an output of up to 66,000 bottles per hour, the sorting system has a greater capacity than the returnable glass line that can fill a maximum of 60,000 bottles every 60 minutes. This means that CCEP in Mannheim seldom suffers any downtime with its empties — even during the peak season.

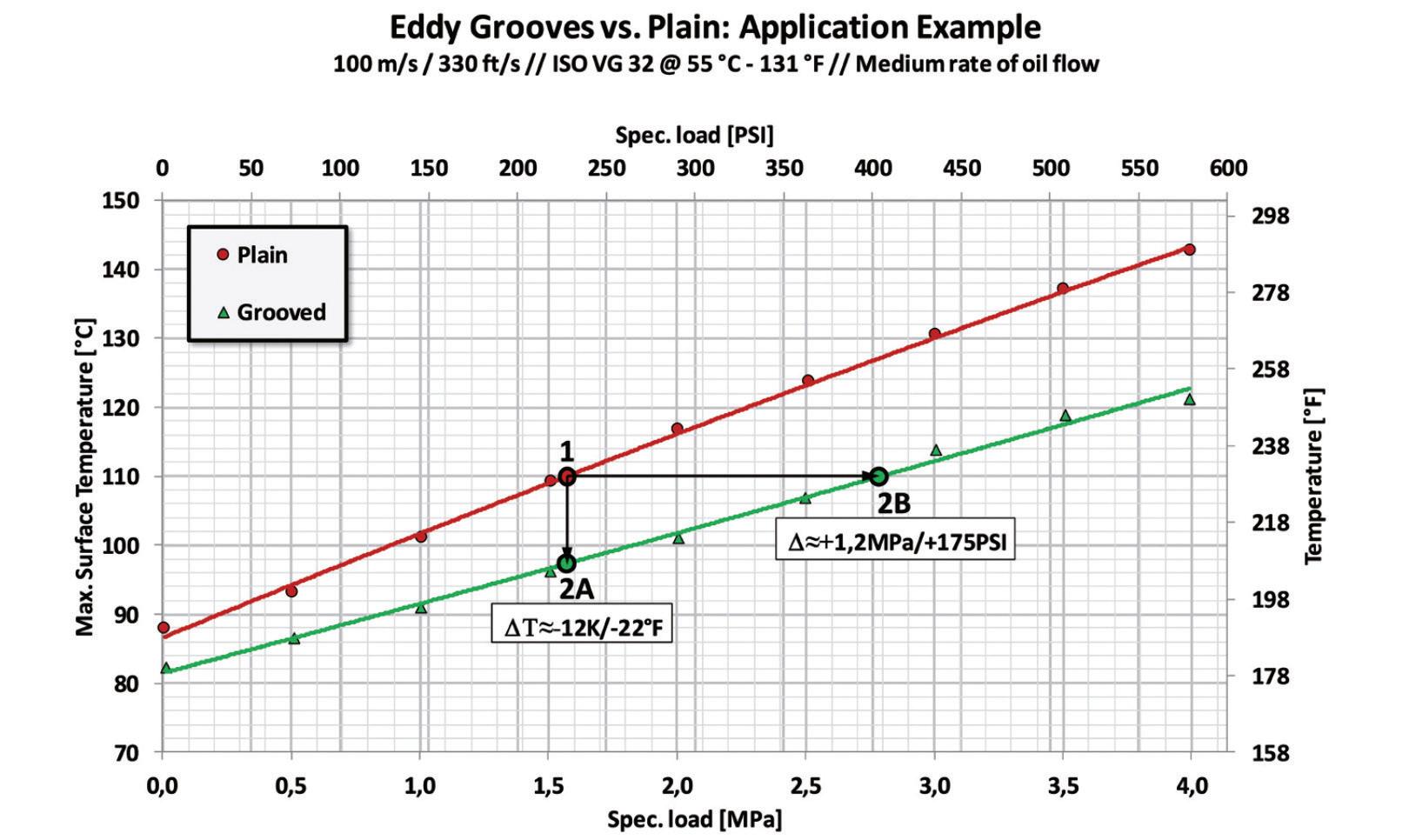

American-made North American and international cord sets provide correct country-specific amperages and voltages ensuring end users have access to their local mains power—for every world time zone. Are your cords dry-docked or stuck in a warehouse awaiting transport? Interpower in-stock cords, cord sets, and components ship the same day!

Interpower manufactures state-of-the-art electrical cord sets for global markets with no minimum order requirements. All Interpower cords and components are manufactured in accordance with Interpower’s product quality plan: hipot testing, continuity testing, and ground testing with multiple inspections. Interpower offers value-added options: lengths, colors, packaging and labeling!

®

®

The irregular return of empties o en results in peaks, says Bee. One good example is music festivals, at the end of which more empty glass bottles are to be expected than usual. “What’s special about this system is that it can individually react to these peaks,” he states. “To facilitate this, during commissioning, we ran a live simulation with an external service provider. Based on the results, in close cooperation with KHS, we were able to make several optimizations and fine adjustments.”

For Christopher Bee, one highlight of the new returnable glass line om KHS is the Innoclean DM double-end bottle washer. This is enabled by the eshwater control that’s automatically adjusted to the current machine capacity by a control valve. The new ECO carriers are also good for the energy balance: they weigh about a quarter less than the previous bottle pockets and have side openings that permit better rinsing. This reduces the amount of caustic and heat carryover and, thus, the cooling requirement within the machine. If at any point no empties are available, the bottle washer switches to an energy-saving idle state: its new standby mode. The Liquid E ciency Spraying System (LESS) lowers the pressure of the spray pumps to 0.3 bar during downtime and cuts electricity consumption by up to 80%.

CO-LOCATED WITH CONEXPO-CON/AGG (two shows, one price)

The International Fluid Power Exposition (IFPE) is the place where engineers meet to:

Spark new ideas with in-depth technical conversations with other engineers.

Discover solutions current suppliers can offer to your unique challenges.

Find new partners among suppliers pushing the envelope on what fluid power can do.

Danfoss Power Solutions

Including Bosch Rexroth

Parker Hannifin

Hawe Hydraulik

Poclain

IFM Efector

Husco , and 375+ more!

Join your peers from these OEMs:

Caterpillar Inc

Volvo Construction Equipment

Liebherr

CASE Construction Equipment

Komatsu

John Deere Construction

Doosan Bobcat

KOBELCO Construction Machinery USA

LBX Company

There’s no other show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.”

See why IFPE is the can’t-miss fluid power event of 2023! Learn more at IFPE.com

14-18, 2023

USA

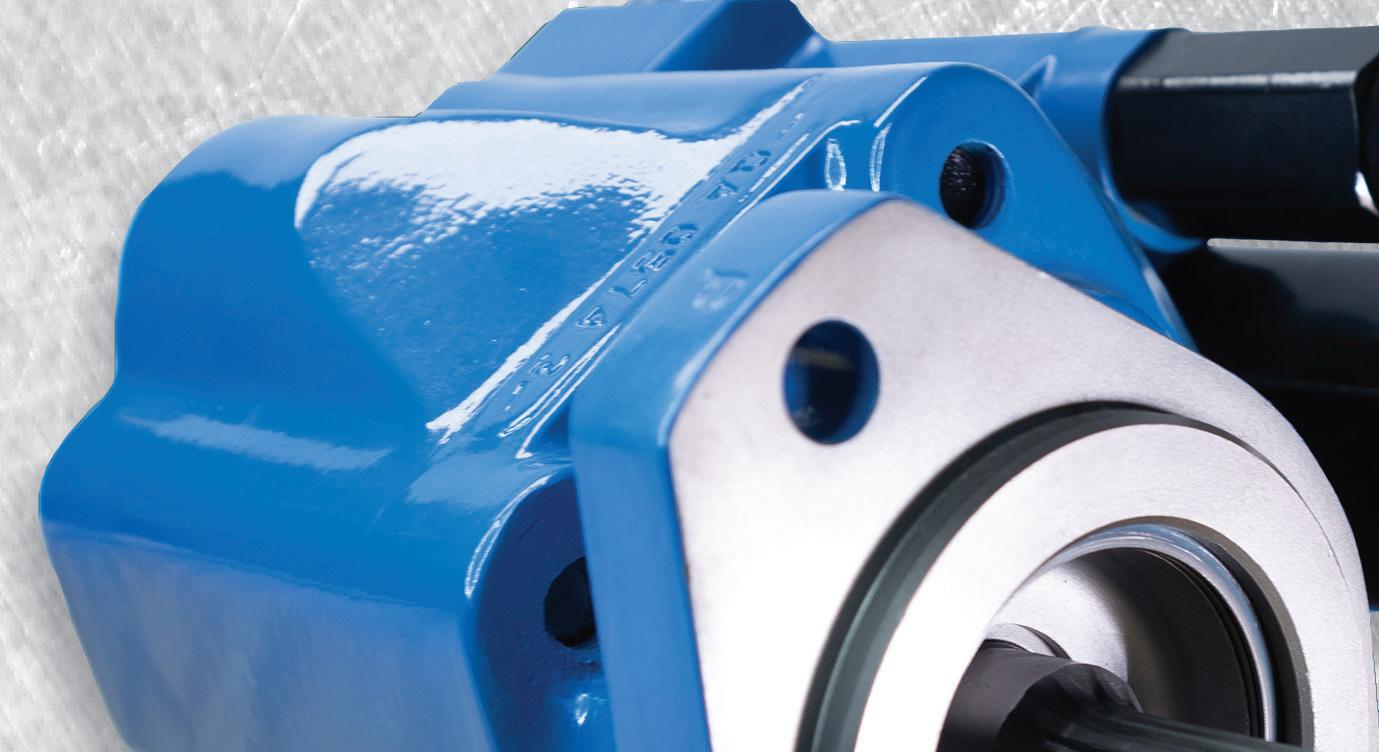

CLINCHER parallel shaft gear units provide strong e ciency while o ering an economical option for many applications.

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

The steel industry is known for having some of the toughest environmental conditions, including the high temperatures of continuous casting applications, heavy loads, and irregular operating modes of hot roller systems. NORD’s gear units, motors, and control products ensure constant performance and are engineered to handle the most demanding loads and environmental hazards. These drive systems can be configured to fit specific application needs and installation spaces. Many of these gear units for the steel industry include a robust mechanical housing for shock absorption, heavy-duty bearings and sha s, double Viton sha seals, synthetic lubricants for higher heat tolerance, and heavyduty surface protection options. Motor options include high acceleration rates, reverse operation, unventilated designs, heavy-duty encoders and brakes, Class ISO H insulation to handle higher temperatures, and can be designed to provide su cient torque to withstand heavy shocks om reversing operation and material jams.

UNICASE helical inline gear units are a flexible, reliable solution with a wide power range of 0.16 - 215 HP. Their one-piece housing ensures a long lifespan,

requires minimal maintenance, and the compact design can fit in tight installation spaces. These units also deliver high axial and radial load capacities, enabling safe operation in heavy-duty applications such as furnaces, roller tables, and logistics applications.

CLINCHER parallel sha gear units provide ultimate e ciency while offering an economical option for various applications. They are equently used in applications such as shearing lines because they ensure the highest cycle and acceleration rates as well as high shock loads. CLINCHERs supply up to 268 HP, produce up to 885,075 lb-in of torque, and their robust housing enables them to function for years without

maintenance, even under extremely harsh conditions. With 15 case sizes and flexible mounting options, these gear units are highly adaptable to fit precise application needs.

Continuous casting applications o en involve high temperatures and confined installation space. UNICASE helical bevel right-angle gear units are most o en used for these applications due to their compact design and mounting versatility. These units can be configured with various bearing options, ensuring high axial and radial load capabilities and shock absorption. Class ISO H insulation is also recommended to protect against harsh environmental factors.

Built to handle the toughest loads, MAXXDRIVE industrial gear units offer high output torques of up to 2,495,900 lb-in. Their large roller bearings and center distances increase the load capacity and service life of internal components. At the same time, an advanced cooling system effectively manages heat dissipation and extends the life of lubricants. Special input and output sha s are available to fit specific application needs and provide operation in either direction.

Many applications in the steel industry equip various drives into one system solution. Variable equency drives such as the NORDAC FLEX and NORDAC PRO SK 500P deliver scalable functionality to effectively manage individual units and optimize synchronization across multiple drives. The NORDAC FLEX is NORD’s most flexible VFD and has easy parameter transfer, a compact design capable of motor or wall mounting, and optional integrated functional safety options such as STO, SS1, and PROFIsafe. The NORDAC PRO SK 500P series includes 5 ame sizes with multiple interface options for easy connectivity, integrated PLC functionality, and POSICON-integrated positioning for intelligent control. Their small footprint saves space in installation cabinets, where space is o en limited.

With over 1,400 standard products to choose from, you can count on the engineers at Bodine to help you find a gearmotor with the right torque, power and speed for your application. We’ll get your design moving. Contact us today!

Ball bearings are used in countless precision agriculture applications and in conveyors, mixers, and picking and weighing machinery.

Edited by Mike Santora • Managing Editor

Edited by Mike Santora • Managing Editor

From the London Beer Flood of 1814 to the Tapioca Tanker Disaster of 1972, there has been many high-profile food and beverage disasters at all stages of the food processing chain. While innovative new technologies have been vital in continuing to improve safety of modern operations, one small mechanical component is indispensable across the whole food and beverage supply chain.

Despite consistent challenges over the past two years, the food processing industry is projected to reach USD 235.67 billion by 2028, demonstrating healthy growth om its USD 143.51 billion market size in 2020.

Ball bearings are used in countless precision agriculture applications and in conveyors, mixers, and picking and weighing machinery. If any piece of food processing machinery rotates, it will use bearings to ensure smooth travel. So, let’s take a closer look at the importance of choosing the right bearings at three key stages of the food processing supply chain.

The food cycle begins at the production stage. In the face of greater demand, farmers are increasingly employing automation to augment their operations.

In this setting, bearings are used in various machinery such as agricultural scanners, combine harvesters, balers, and seeders. Due to the severe mechanical strain and abrasive particles in this environment, bearings for agriculture must be durable and reliable, with a long service life.

Heavy duty bearings are a popular choice for precision farming technology as they are o en subjected to heavy loads, shock loads, and vibration. Due to the high risk of contamination, bearings fitted with labyrinth contact seals are o en specified along with extreme pressure (EP) greases. Many agricultural bearings have a “hex bore” and are designed to fit onto a hexagonal sha for easy assembly.

Next, the product passes to the manufacturing stage. From continuous high speeds to extreme temperature, excessive moisture, and chemical exposure — bearings in food processing lines face numerous challenges.

Bearings used in these settings must meet several non-standard criteria. The first consideration is the need for continuous high speeds. Contamination is also a concern in many forms. For the highly regulated food and beverage sector, contamination can lead to costly production loss. Excessive moisture due to washdown cycles can also flush lubricants out of the component.

Similarly, chemical exposure om detergents and sanitizers can cause corrosion and accelerate component wear. Acetal resin bearings offer a low-cost, corrosion-resistant option. Suitable for low-load and low-speed use. For greater corrosion resistance and extreme temperatures, alternative ring or cage materials can be used, such as polyether ether ketone (PEEK), polytetrafluoroethylene (PTFE), or polyvinylidene fluoride (PVDF).

Following production, the product passes to the packaging stage. By investing in a high-speed robotic pick and place cell, operational e ciency can be increased substantially.

For processes such as heating, boiling, and baking, bearings must be suited to extreme temperatures. Stainless steel ball bearings can be supplied with non-toxic lubricants approved to NSF H1 or H2 standards. Bearings with a choice of food-grade lubricants can withstand the ingress of water or cleaning chemicals and can cope with regular steam cleaning.

Following production, the product passes to the packaging stage. By investing in a highspeed robotic pick and place cell, operational e ciency can be increased substantially. For robotics applications, thin section bearings deliver high speeds, improve e ciency, and offer design flexibility. With the minimal difference in size between the internal and external ring, these bearings also reduce the weight on the application and the space requirements. However, because they are so thin, you

must pay particular attention to the roundness of the ring itself. As a result, the manufacturing process must be precise to ensure the highest possible degree of roundness in both rings, as well as good noise levels in the bearing itself. This will typically call for fine grinding and machining, complemented by high quality in both the process and the raw materials. If the rings are not perfectly formed, even a minute discrepancy will stop the bearing om running as smoothly, producing excess noise, and

For the highly regulated food and beverage sector, contamination can lead to costly production loss. Excessive moisture due to washdown cycles can also result in lubricants being flushed out of the component.

disrupting the food packaging line. In efforts to enhance supply chain e ciency, even the smallest components can make a big difference. It’s important that food and beverage plant managers consider component suitability at all stages of the food cycle to ensure they can meet the production needs of tomorrow.

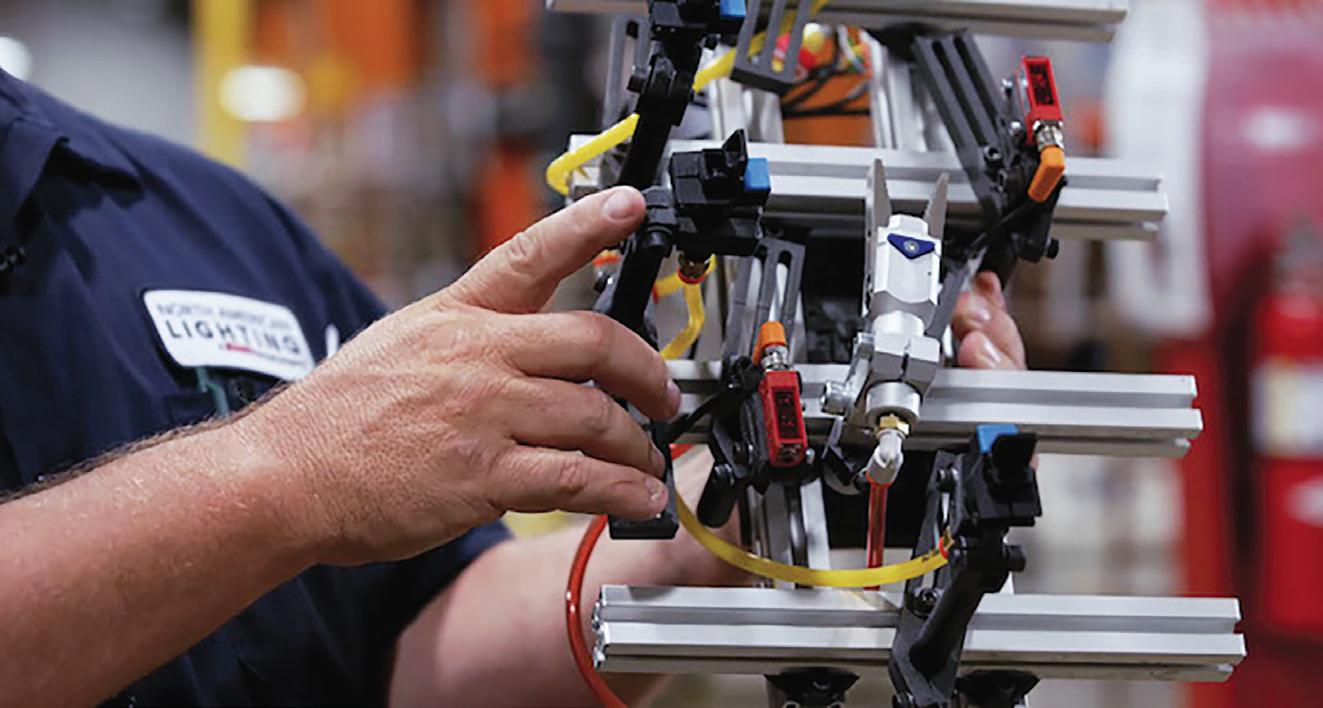

orth American Lighting (NAL), a Koito Group Company, has been manufacturing automotive lighting systems for vehicle manufacturers since 1983. With eight facilities across the U.S., NAL provides advanced lighting technology, engineering design expertise, and state-of-the-art production capabilities.

North American Lighting manufactures automotive lighting systems for vehicle manufacturers. Assembly production tools are essential to ensure that production continues smoothly.

NAL works with some of the largest automotive OEMs in America like Ford and GMC, so speed and precision are critical. To that end, assembly production tools are essential to ensure that production continues smoothly. If a part breaks, that could mean extended lead times and added costs.

Joey Carpenter, production engineering technician, began using 3D printing to bring tooling production in-house and reduce potential disruptions. Carpenter was new to 3D printing when he was introduced to the MakerBot METHOD X series in early 2022. Since then, Carpenter, who handles robotic builds and cycles in new end of arm tools for production runs on new launches, has become the resident expert.

Before 3D printing, Carpenter and his team relied on external vendors to design, produce, and send back parts that they would need. Receiving a new part could take several weeks. This was less than ideal since orders were equently late, forcing them to readjust their timelines.

“Now with a METHOD X in-house, there is minimal wait time,” said Carpenter. “In 12 hours, we have what we need to build an end of arm tool. Not only does this drastically reduce our wait times, but we are also seeing a massive cost reduction. The cost to 3D print a part in nylon carbon fiber is one-third the price of what we were paying for outsourced aluminum parts.”

“In addition, since we started 3D printing, our overhead costs decreased by half because we don’t have to stock up on excess parts,” he continued. “We have reduced part inventory by 50%. Now all of our tool designs are digital so they’re easier and quicker for us to access, iterate, and print as we need. Instead of waiting weeks, we can turn parts around in five days, from design to assembly.”

In the Flora factory, the robots use around 200 end of arm tools a year, which are built in-house. Bringing tooling production in-house allows the team to significantly reduce costs while also saving them tremendous amounts of time.

While Carpenter mainly prints end of arm tool parts, he has also found new applications where he can utilize the versatility of METHOD X. “We’ve also used in-house mockups and prototypes for water fittings and parts like that for future use. We prototyped with carbon fiber in house within a matter of three days, rather than outsourcing it which could take a month to get back,” he said.

“We’re finding that it’s very easy to replace aluminum with carbon fiber parts. With weight reduction and durability, carbon fiber is comparable to aluminum,” Carpenter noted. “With the LABS extruder, MakerBot and Jabil materials offered on the METHOD X, the tolerances and the consistency of your prints are far better than you can imagine.”

Carpenter’s team isn’t the only ones using METHOD X at the Flora facility. The Assembly and Lighting team at NAL also began using the printer to produce

nest blocks for the assembly line. The nest blocks go into the tooling on the assembly line and are used to keep parts in place while the machine is working on them. Before METHOD X, the team would have to bring in one of their tool shop vendors to access their needs. They would have to then wait for the vendor to design the part and build it as well as wait for a quote for the part to be approved, before receiving the final product.

“There would be a four-to-six-week lead time before getting a part back,” said Dee Jay Griffith, manufacturing engineering technician. “And the cost would be pretty high— With METHOD X, we’re able to print a full nest for less than 10% of the cost and we’re able to do that faster.”

“The METHOD X and 3D printing helped my workflow by enabling faster lead times and cost savings that comes with being able to print my own things,” Griffith noted. “We’re now able to accomplish what we need to on these assembly lines faster and without having to rely on vendors’ timelines.”

Primarily printed in carbon fiber and

PolyMax PC, the nest blocks are lightweight and durable. Since printing them months ago, Griffith has not yet seen any wear on them. He is also experimenting with different materials, constantly finding things they would like to print. For example, camera mounts, grease tips, leak test seals, and more.

While the teams at NAL are experiencing a significant savings in cost and time when using 3D printing, those are not the only factors for their use of METHOD X. Its ease of use and seamless ability to print carbon fiber as well as other industrial-grade materials with the MakerBot LABS Experimental Extruder have made METHOD X a must-have in their facility.

“We’ve already ROI’d this machine and we’ve only had it for a few months. Just in the savings of what we’ve already printed, not to mention the time we’ve saved doing it ourselves as opposed to waiting for a shop to come in to get it done,” said Griffith.

“I work for a multi-billion-dollar company and can afford any 3D printer out there but yet we have five MakerBots in house right now and there’s a reason for that,” Carpenter concluded. DW

esktop Metal announced two upgrade packages on its Shop System, offering new flexibility, functionality, and value for this metal binder jet system. The Shop System+ and Shop System Pro offer new options for materials and controls.

The Shop System+ package enables users to access Desktop Metal-engineered powders and binders at a discount to MSRP, reducing the running costs of their additive manufacturing operations and improving their part costs to drive a faster return on investment.

The Shop System Pro package is for high-production users with powder metallurgy expertise who seek not only to optimize

their running costs, but also to enable specific applications or cost structures by leveraging proprietary or third-party powders. This Shop System Pro package includes all the benefits of the Shop System+ package as well as additional process flexibility through new features, such as custom printing and spreading parameters and bi-directional printing for the Shop System Printer and custom sintering profiles for the Desktop Metal Furnace.

Featuring the highest resolution and most advanced single pass print engine in the binder jetting market, the Shop System is a complete end-to-end solution for producing complex, end-use metal parts that includes:

• a binder jetting printer with 1600 native dpi resolution and 5x nozzle redundancy,

• a drying oven for hardening green parts prior to depowdering,

• a powder station for depowdering parts with built-in powder recycling,

• a furnace designed for accessible, industrial-strength sintering,

• integrated powder handling accessories and workflow,

• Desktop Metal-engineered binders and powders, and

• Desktop Metal so ware for build preparation and sintering simulation.

This turnkey solution, designed with the modern machine shop in mind, seamlessly integrates with existing shop operations and makes it easy for businesses to get up and running with binder jetting in days instead of weeks or months. DW

aterialise has acquired Identi 3D, a company that develops so ware to encrypt, distribute and trace the flow of digital parts across complex supply chains. Data security and integrity have become top of mind for companies that want to retain control over their design and production data, as they transition om a centralized production model to multiple digital production sites, closer to their customers. The acquisition of Identi 3D makes Materialise’s CO-AM platform the most secure platform for distributed manufacturing.

The Identi 3D product suite encrypts, distributes and traces the flow of digital parts, preventing counterfeits and ensuring that maliciously or inadvertently modified, substandard or uncertified parts cannot enter the physical supply chain. It also allows designers and manufacturing engineers to couple designs with specific production criteria, such as a designated user, a type of machine or material to control the production process and to meet the original manufacturing specifications.

The Materialise CO-AM so ware platform gives manufacturers cloud-based access to a full range of so ware tools that allow them to plan, manage and optimize every step of the 3D printing process. At the heart of the CO-AM platform is a data lake that connects to all production tools and keeps track of what is happening on the production floor. Moving forward, CO-AM will offer the most robust and secure so ware platform to manufacturers that are concerned about protecting their design data, such as prototypes, and their unique production expertise.

The acquisition of Identi 3D allows Materialise to add an additional security layer to CO-AM, making it the most robust and secure so ware platform for manufacturers that are looking to scale

up their 3D printing operations as part of a digital and distributed production environment.

“We believe that the factory of the future will not be a single, central location”, says Fried Vancraen, CEO of Materialise. “Instead, future manufacturing, enabled by smart technologies like 3D printing, will take place at multiple digital production sites, distributed around the world, closer to customers. But this will only be possible when companies are sure that their design and production data remains secure. This acquisition allows manufacturers to secure the flow of digital parts and maintain a competitive advantage.” DW

arbon announced the acquisition of ParaMatters, a software provider for additive manufacturing. This acquisition expands Carbon’s current software capabilities to include topology optimization. Carbon’s technology platform now broadens to enable product design and development teams to create better products in less time using a wide variety of materials and production systems.

The lack of modern design software that can quickly iterate and take advantage of the benefits of additive manufacturing continues to constrain the product development lifecycle. This acquisition addresses this gap and expands Carbon’s generative design software capabilities to enable increased automation and the creation of more complex, higher performance part designs. These benefits build on Carbon’s introduction of Design Engine™ earlier this year which is used by global brands to automate the process of developing latticed parts for production.

“We recognize the critical role software design tools play in our customers’ digital transformation. For far too long, designers have settled for software design tools that adhere to the limitations of traditional manufacturing,” said Phil DeSimone, co-founder and member of the Office of the CEO. “Many design tools of yesterday are not optimized to take advantage of industry innovations, including advanced 3D printing materials and manufacturing processes. Both Carbon and ParaMatters have shared the same vision to provide modern tools to ensure product development teams can create better products in less time.”

Drone-based multispectral cameras can take less than half an hour to scan a 100-acre field.

| Coptrz

Agriculture 4.0 is emerging and requires an expended sensor suite. Agriculture 4.0 refers to systems that employ drones, robotics, the Internet of Things (IoT), vertical farms, artificial intelligence (AI), renewable energy, and advanced sensor methodologies. Agriculture 4.0 is similar to Industry 4.0 in some ways: Where Industry 4.0 is designed to support automation and mass customization of production processes, Agriculture 4.0 is expected to support autonomous operations and mass customization of farming practices across microenvironments. Integrating digital technologies into farming, agricultural operations can target resources needed to increase yields, reduce costs, and minimize crop damage, water, fuel, and fertilizer usage. This FAQ looks at sensor technologies under development for Agriculture 4.0, including wearables for plants and hyperspectral imaging, the EU’s Agricultural Interoperability and Analysis System program, and the security challenges related to wireless sensor networks and the Internet of Things in Agriculture 4.0.

Graphene and fiber optics are two technologies used to develop wearable sensors for plants. Graphene sensors can measure the time it takes for different crops to move water om the roots to the lower and upper leaves. Initially, researchers are using these sensors to help develop plants that use water more e ciently. In the longer term, these graphene sensors on tape (also referred to as “plant tattoos”) are expected to support the design of inexpensive, high-performance sensors for Agriculture 4.0 applications (Figure 1) and help improve the e ciency of irrigation

systems. The process used to make the sensors can produce devices that are several millimeters across with features as small as 5 µm. The small feature sizes increase the sensitivity of the sensors. The conductivity of the graphene oxide in these sensors changes in the presence of water vapor, enabling the measurement of transpiration (the release of water vapor) om a leaf.

Fiber Bragg grating (FBG) sensing technology is also being developed for agricultural applications. An FBG acts as a notch filter that reflects a narrow portion of light centered around the Bragg wavelength (λB) when illuminated by a broad light spectrum. It’s fabricated as a microstructure inscribed into the core of an optical fiber. Unlike graphene sensors, which are an emerging technology, FBG sensors are already in use in several areas, including aerospace, civil

engineering, and human health monitoring.

FBG sensors can be fabricated with high sensitivities, small size, and lightweight. In the case of agricultural sensors, the intrinsic sensitivity to strain (ε), and temperature variations (∆T) of FBG technology are being combined with a moisture-activated polymer to detect relative humidity changes (∆RH) in the surrounding air. In addition, FBG sensors can be multiplexed to support monitoring of both plant growth and environmental conditions in a single device. The FBG designed for agricultural applications consists of three segments, one for ε sensing, one for ∆RH monitoring, and a third optimized for ∆T measurements. It was fabricated using a commercial FBG with a grating length of 10 mm, λB of 1533 nm with a stretchable acrylate coating. The coating protects the FBG and improves its adherence to the plant’s stem.

Multispectral imaging is an established agricultural sensing technology. It can detect subtle changes in plant health before visible symptoms are apparent. For example, a drop in a plant’s chlorophyll content can be detected before the leaves are visibly yellow. Multispectral sensors use the 712 to 722 nm wavelengths (the red edge band) where indications of stress are most easily identified. Multispectral imaging can be implemented using fixed installations where the sensors travel back and forth on a track system in a greenhouse or across an open field. They are also well suited to be carried alo on a drone. For example, in one configuration, a drone-based multispectral imaging system can scan a 100-acre field (at 400- above the found with a 70% overlap) in less than 30 minutes. Some of the benefits of multispectral imaging include:

Early disease detection

Improved irrigation and water management

Quicker and more accurate plant counting to optimize fertilizer application

pest control

Cost reductions om the automation

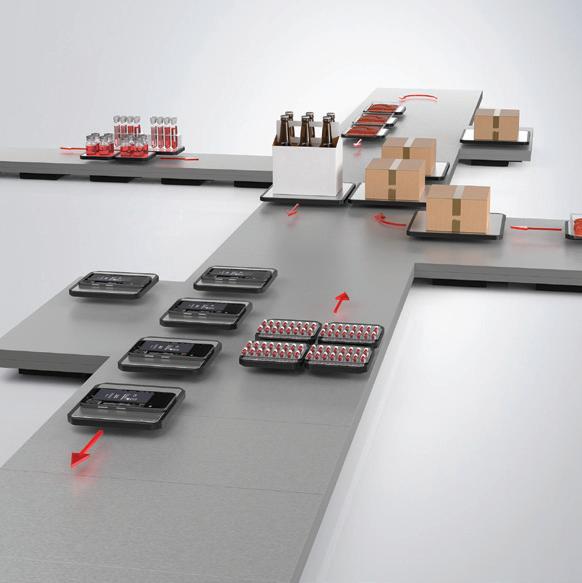

provide the ideal conveying platform for a variety

them to be carried, located and rotated all

The primary difference between today’s multispectral sensors and emerging hyperspectral sensors is the bandwidth (the number of bands and how narrow the bands are) used to represent the data of the electromagnetic spectrum. Multispectral imagery generally uses 3 to 10 bands to cover the relevant spectrum. Hyperspectral imagery consists of hundreds or thousands of narrower bands (10 to 20 nm), providing greater resolution, and covering a broader spectrum range. Spectral resolution, the ability to capture a large number of narrow spectral bands, is an important feature of hyperspectral imaging compared with multispectral imaging. Other advantages of hyperspectral imaging include:

• Higher spatial resolution and the ability to discriminate smaller features,

• Higher temporal resolution and the ability to more quickly sense importantcenvironmental changes such as the need for irrigation

• Higher radiometric sensitivity and the ability to discern small differences in radiated energy

Hyperspectral imaging sensors provide a highly detailed electromagnetic spectrum of agricultural fields, making it a useful tool for detecting smaller and more localized variations in important soil attributes and degradation, as well as changes in crop health and fitness. The

increasing use of sensors in Agriculture 4.0 and the addition of higher resolution sensors such as hyperspectral imaging is driving the use of big data and raising concerns related to data security, data integrity, and privacy. Addressing those concerns is a major emphasis for the EU’s ATLAS program.

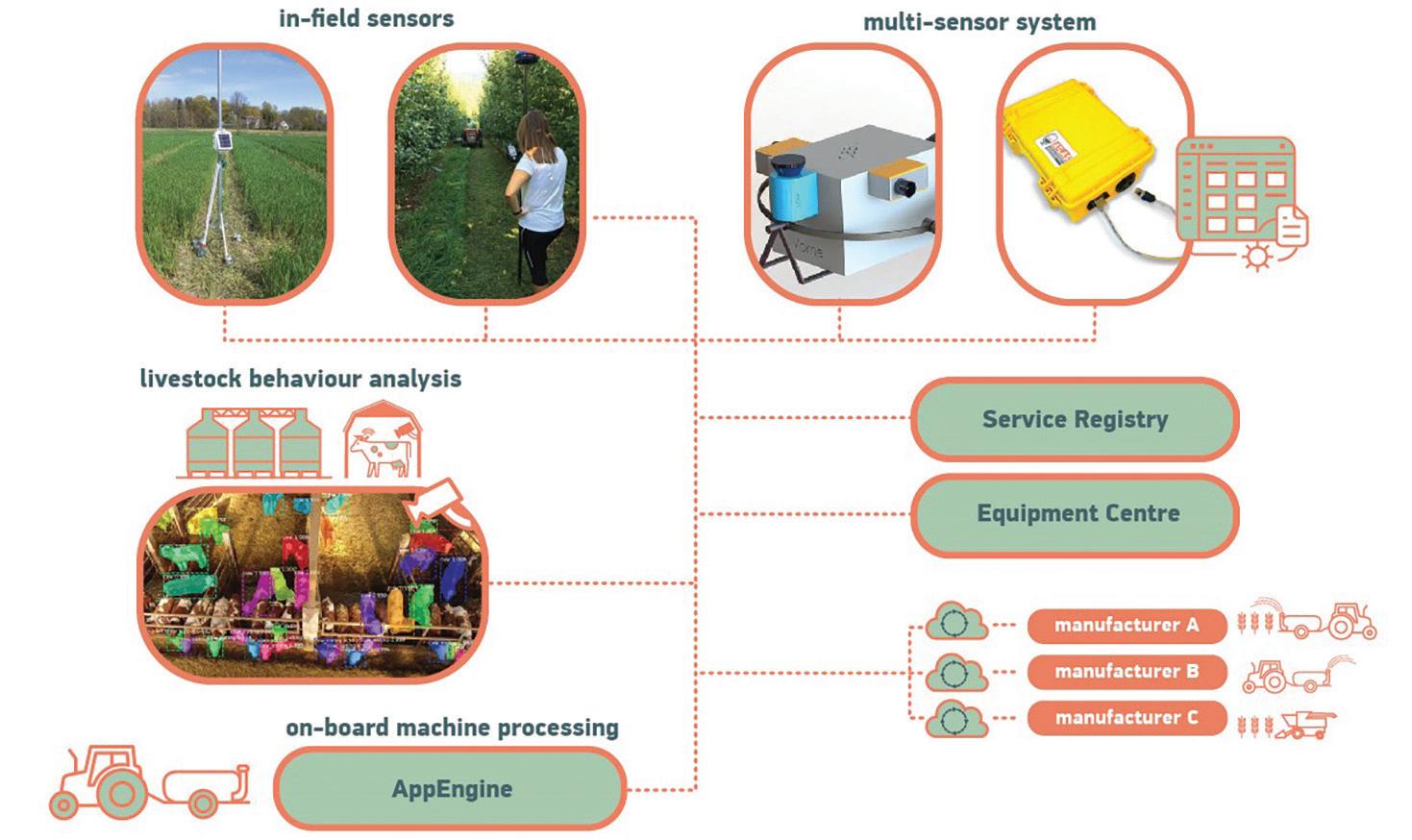

The EU-funded Agricultural Interoperability and Analysis System (ATLAS) project aims to develop an open platform to support innovation and Agriculture 4.0. ATLAS is one of the EU’s Horizon 2020 research and innovation programs. The Fraunhofer Society is managing the project. It addresses the current lack of data interoperability in agriculture by combining agricultural equipment with sensor systems and data analysis. The resulting platform is expected to support the integration of hardware and so ware interoperability om various sensor systems and ampli the benefits of digital agriculture. ATLAS aims to develop an open interoperability network for agricultural applications and build a sustainable ecosystem for innovative data-driven agriculture (Figure 2). ATLAS is building on networks of in-the-field sensors and multi-sensor systems to provide the big data needed to realize Agriculture 4.0.

The ATLAS platform is expected to support the flexible combination of agricultural machinery, sensor systems, and data analysis tools to overcome the current lack of interoperability and enable farmers to increase their productivity sustainably by using the most advanced digital technology and data. ATLAS will also define layers of hardware and so ware to allow the acquisition and sharing of data om a multitude of sensors and the analysis of this data using a variety of dedicated analysis approaches. The program will demonstrate the benefits of Agriculture 4.0 through a series of pilot studies across the agricultural value chain and end by defining the next generation of standards needed to continue the growing adoption of data-driven architecture.

Wireless sensor networks and security Wireless Sensor Networks (WSNs) and Internet of Things (IoT) solutions are extensively used in Agriculture 4.0, providing numerous benefits to the farmers. However, the interconnection among diverse sensors and network devices, which can contain unpatched or outdated firmware or so ware, creates opportunities for network insecurities and opens various attack vectors, including device attacks, data attacks, privacy attacks, network attacks, and so on.

The increasing use of automation and even autonomous operations to improve yields also raises safety concerns. In addition to ATLAS, the European Union’s Horizon 2020 research and innovation programs focus on developing network tra c monitoring and classification tools for use in Agriculture 4.0 systems. Effective tra c monitoring is expected to play an essential role in protecting assistants and users om the impacts of network attacks. Network tra c analysis and classification tools are being developed for Agriculture 4.0 based on Machine Learning (ML) methodologies to help mitigate the threats to WSNs and other IoT-connected assets.

The deployment of Agriculture 4.0 relies on the increasing use of WSNs to improve yields and reduce costs for farmers. It also requires the development of new sensor modalities, such as plant wearables using graphene-based and FBG sensors, and the expansion of existing sensor modalities, such as the move om multispectral to hyperspectral imaging. The EU’s ATLAS program is designed to improve interoperability and realize the maximum benefit om the growing diversity of sensor and data analysis technologies. Improvements in network security will also be essential to ensure data security, integrity, and privacy in Agriculture 4.0. DW

References:

5 Ways to Use Multispectral Imagery in Agriculture, Coptrz

Advances in hyperspectral sensing in agriculture, Special Agriculture 4.0 Agriculture 4.0 and Smart Sensors.

The Scientific Evolution of Digital Agriculture: Challenges and Opportunities, MDPI sensors

ATLAS, Agricultural Interoperability and

Figure 2: EU-funded ATLAS project is developing an open platform to support innovation, automation, and data-driven Agriculture 4.0

Analysis System, ATLAS Engineers make wearable sensors for plants, enabling measurements of water use in crops, Iowa State University

Plant Wearable Sensors Based on FBG Technology for Growth and Microclimate Monitoring, MDPI sensors Precision Agriculture Technologies and Factors A ecting Their Adoption, US Department of Agriculture

Global supply chains are buckling under the strain of demand and constricted logistics capacity. Adding inflationary forces to these issues, it’s no wonder an increasing number of OEMs are embracing Industry 4.0 to make their manufacturing processes more aware, predictive, and autonomous.

The shi om Industry 3.0 to Industry 4.0 involves a convergence between information technology (IT) and operational technology (OT). Connecting OT systems to an IT network allows a more detailed view of individual equipment and creates a comprehensive view of the entire ecosystem, simpli ing management, and operation. Besides allowing machines to be largely operated autonomously without human supervision, Industry 4.0 creates higher value when data collected om intelligent sensors and actuators connected to equipment leads to better decision making, as well as to the “learning” that’s now possible with artificial intelligence (AI) and machine learning (ML). These benefits explain the explosion of interest in Industry 4.0.

The Industry 4.0 is being applied across industrial sectors. Here are three ways to embrace this exciting paradigm shi :

• Artificial Intelligence

• Network Connectivity

• Device Cybersecurity

AI is all around us. Industry 4.0 uses AI to analyze sensor data to track equipment usage, improve workflows, streamline logistics, increase safety, and achieve higher overall e ciency across OT and IT operations.

One promising category for AI is providing intelligence for autonomous robotics. Autonomous robots are increasingly finding their way into warehousing, manufacturing, agricultural operations, and civil engineering. AIdriven cobots reduce labor costs and increase productivity by continuously working around the clock without fatigue or breaks. In addition, safety is improved in hazardous environments, and insurance and injury leave costs are reduced significantly.

As AI continues to advance, problem solving and learning analytics will enable autonomous robots to be responsive to their environment with minimal or no human feedback. For example, think of the thousands of manned forkli s operating in warehouses and port terminals. Forkli s are labor-intensive, expensive to maintain, and dangerous. As an alternative to a forkli , AI can be applied to an automated guided vehicle (AGV). Freight is picked using a barcode reader. The AGV then automatically reroutes itself with the eight on-board to the best path through the warehouse using wireless routers and industrial switches. Sensors assure no collisions occur with obstacles or employees.

The potential for autonomous robots using these devices is virtually endless. In the agricultural market, for example, industrial Ethernet switches are being deployed in robotic uit picking devices that can delicately grasp a single strawberry without bruising. The switches are also connecting and transmitting data in robots capable of

automatically targeting and eliminating weeds using thermal energy while rolling through agricultural fields. Also, industrial managed Ethernet switches are incorporated in an upgrade kit that transforms trench excavation equipment om the likes of Caterpillar, Volvo, Hitachi, John Deere, and Komatsu into autonomous robots operated remotely on a laptop.

With the growth of Industry 4.0 technologies, operational networks are continually going through expansion processes, requiring the same type of bandwidth allocations and in astructure support as the enterprise network counterparts. Furthermore, as Industry 4.0 is trending towards an increased focus on AI for big data analytics and cloud computing for process and control information collection, connectivity and connection points have become a critical piece in the industry 4.0 puzzle.

Ethernet is the technology of choice for operational networks, thanks to its standardization, versatility, and low cost. Ethernet thru TCP/IP-based communications now range om AI cloud-based processes to legacy bus systems that can interconnect the smallest application using just one twisted wire pair. In a recent development, the IEEE published a standard for 10 Mbit/s (IEEE 802.3cg) important to Industry 4.0 that allows transmission distances up to 1000 meters (3280- ), therefore holding the potential to replace virtually all fieldbuses currently in use.

One of the main components underpinning Ethernet connectivity is the Ethernet switch. Managed and unmanaged Ethernet switches are staples of Industry 4.0 architectures able to transmit data between connected