www.plantandcivilengineer.com PLANT & CIVIL CONSTRUCTION, QUARRY & RECYCLING MAGAZINE APR-MAY 2024 £4.95 €6.95 IN ASSOCIATION WITH & ISSN 2041-7829

FINLAY SHOWCASING THE FUTURE DIRECTION OF QUARRYING AT HILLHEAD www.terex.com/finlay

THE SMART POWERHOUSE FOR THE CONSTRUCTION SECTOR. THE AROCS RATED AT 18 TO 41 TONNES.

Regardless of whether it is a rigid ,tractor unit, cement mixer or heavy-duty tipper: the road and all-wheel-drive variants of the Arocs provide an especially robust, resilient vehicle that is optimally prepared for use for almost any construction haulage challenge.

To find out more visit mbtvni.co.uk or call 028 9034 2411

MBNI Truck & Van | 47-49 Mallusk Rd, Newtownabbey BT36 4PJ

Mercedes-Benz Trucks you can trust

TEREX® FINLAY TO SHOWCASE ELECTRIC MACHINES: ENGINEERED TO ELEVATE INDUSTRY STANDARDS AT

So, if you haven’t already put me on your circulation and contact list for your news and views, please do so now – my contact details are below. The truth is that I can only put your news in the magazine if I’ve got it! This is even more important now, as, after so many years editing numerous titles for 4SM, former PCE editor, David Stokes has taken well-earned semiretirement. This means that I am the first port of call for all your news. Thankfully, we’ve got lots of content for this issue. The PCE Awards 2024 are now open for entry so don’t forget to read through the categories and enter – you could win! Our cover story gives the inside story behind Terex Finlay’s first all-electric machines for quarrying and recycling, which are launching at Hillhead 2024, along with many more exciting launches from leading brands. We also preview the Balmoral Show and assess the view from the cab of the Takeuchi TB2150R compact excavator and the SANY SY215C LC. Finally, we’ve got the latest developments in highways and road maintenance plus local news, product reviews and more.

You can keep up to date every day with all the industry news 24/7 at www.plantandcivilengineer.com. Of course, you should also be getting our weekly newsletter which is emailed out every Tuesday; if not, do subscribe on our website so you don’t miss out. It’s free!

Emma Cowan

Editor: 07921 787686

3 PLANT & CIVIL ENGINEER contents

PLANT & CIVIL APR-MAY 2024 COPYRIGHT NOTICE: © Plant & Civil Engineer 2023. All material in this publication is copyright, including advertisements which have been prepared for advertisers. No part of it may be reproduced in any way whatever or stored in electronic retrieval systems without the written permission of the publishers. We are a completely independent voice and are not connected to any Institutes or Associations within the industry. Our aim is to publish accurate, specific and dedicated information, targeting each sector of the industry, throughout Ireland. The publishers cannot be held responsible for any inaccuracies supplied by the contributors. All rights reserved. Golda Burrows General Sales Manager Helen Beggs Chief Operating Officer Plant & Civil Engineer is Published by: 4 SM (NI) Ltd, The Old Coach House, 12 Main Street, Hillsborough BT26 6AE CONTACT Golda: 07724 192032 or Martin: 07985 887171 Email: golda@4squaremedia.net Email: martin@4squaremedia.net 4SM (NI) Ltd is part of the North West News Group As the Editor of Plant and Civil Engineer Magazine, I pride myself on providing straightforward commentary. Serving as THE voice of the industry in Ireland, I oversee the compilation of all content. While I'm still relatively new to

www.plantandcivilengineer.com

the role, having been on the job for a year, I'm thoroughly enjoying the experience and the opportunity to engage with industry experts who continuously enhance my understanding of the machinery I cover.

News 10 18 32 36 38 76 80 Trucks to Introduce Northern Ireland's First Fully Electric Skip Lift Vehicle

Email: pceeditor@4squaremedia.net comment

View From The Cab AG Wilson Civil SANY Excavators: A Testament to

45 ENTER NOW

HILLHEAD 2024

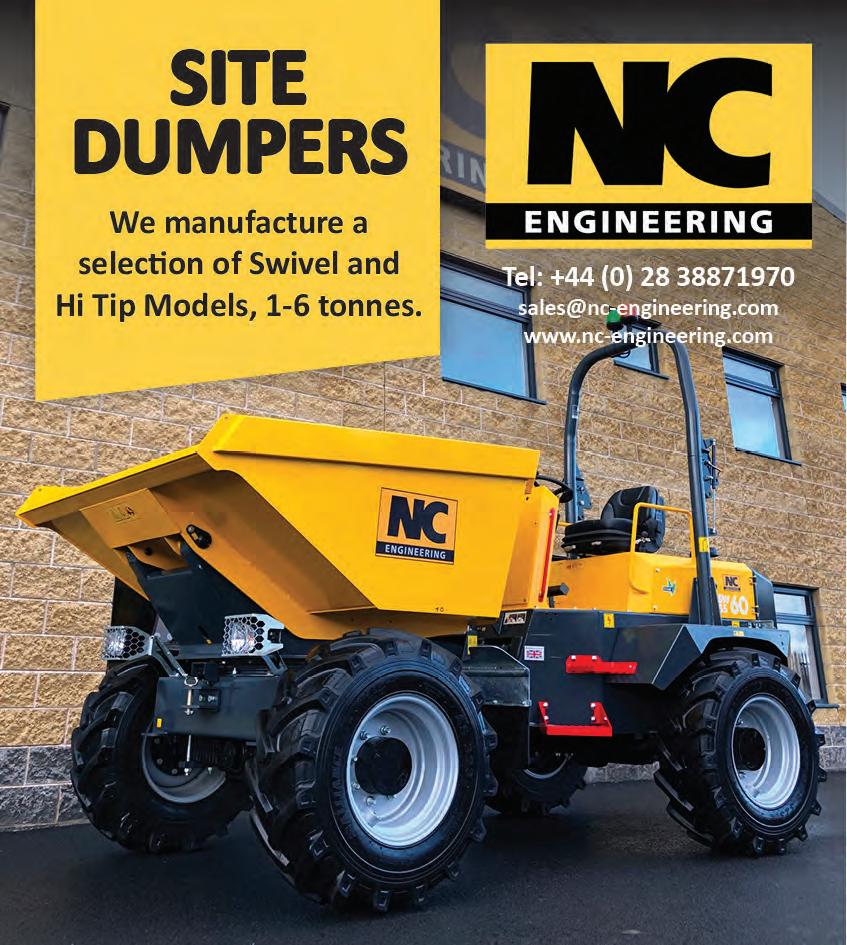

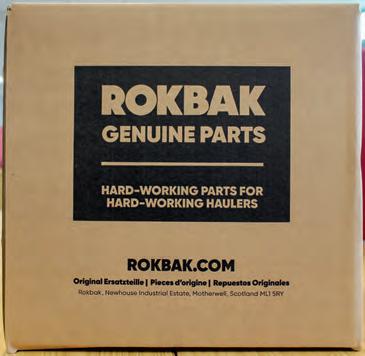

GENUINE PARTS ENSURE ARTICULATED HAULIER QUALITY AND UPTIME

Articulated haulers excel at navigating challenging terrain while transporting heavy loads, making them indispensable in construction, mining and infrastructure projects. However, the integrity of these machines can be compromised when fitted with alternative or substandard parts during maintenance or repairs, as Gary Bradburn, Rokbak Aftermarket Commercial Manager, explains.

The importance of good quality, reliable parts when maintaining articulated hauliers is paramount – especially with the increasing prevalence of lower-quality alternative components on the market.

While some ADT owners may view opting for non-factoryapproved components as a cost-saving measure, it often leads to a false economy. The hidden costs of alternative parts include higher parts usage, higher operating costs through lower efficiencies, greater risk of equipment failure and more frequent machine downtime.

AVOID SHORTCUTS

Rokbak trucks are dependable and durable, built to perform

on the toughest job sites and deliver maximum uptime with low total cost of ownership (TCO).

That’s why Rokbak factoryapproved parts provide unequalled levels of reassurance – they are built to the original design and material specifications to deliver peak performance, reliability and durability in combination with your Rokbak truck. The decision to use factoryapproved parts extends beyond individual component integrity – it safeguards the integrity of the entire truck.

We know that the poor fit and design of alternative parts can compromise overall safety and reliability, which can put both the equipment and operators at risk. When alternative parts costs are particularly low, it’s suggestive of the low-quality materials that have been used to make them. This means components of incorrect specification and greater risk of consequential damage, jeopardising site and operator safety and leading to an eventual increase in TCO – with a higher frequency of replacement components needed.

In contrast, genuine factoryapproved parts ensure compatibility, durability and optimal performance. Rigorously tested and meeting strict quality standards, official Rokbak components for the RA30 and RA40 articulated haulers offer peace of mind to customers and operators and prolong the equipment’s lifespan.

ROKBAK’S GUARANTEE

As part of the Volvo Group, Rokbak’s commitment to quality ensures that every part meets exceptional standards. At Rokbak, we stand by our products with one of the most comprehensive guarantees in the industry.

Our genuine replacement parts, designed and approved at our Motherwell factory in Scotland and supplied by an authorised Rokbak dealer, come with a 24-month or 6000-hour warranty.

By using Rokbak factory-approved parts for your Rokbak articulated hauler, you will extend your truck’s service life, protect uptime and TCO and optimise value for the long-term.

parts 4 PLANT & CIVIL ENGINEER

Gary Bradburn, Rokbak Aftermarket Commercial Manager.

Obituary: Vincent Murphy, formerly of Readymix

The team at Plant and Civil Engineer was saddened to hear of the death of Vincent Murphy, who was widely known in the concrete and quarrying sector locally. Indeed at the Plant and Civil Engineer Awards in 2018, Vincent was the recipient of the ’special recognition’ award for his service and contribution to the industry. Vincent passed away peacefully in Downe Hospital on 19th February 2024.

Vincent Murphy was a man who dedicated his long career to the industry in a variety of roles within Northern Ireland and has been described as a gentleman of the highest order,

with a career that stretches back almost half a century and includes successful periods with RMC and subsequently Readymix plc. When he retired, Vincent was the General Manager at Readymix.

A father of two, he began his career as a sales representative with the concrete side of the business, progressing to be Sales Manager of the aggregates division before becoming joint General Manager with Readymix. He has been described by one of his former colleagues there as ‘an excellent individual’ who was conscientious and always had the best interests of those who worked alongside him.

Other former work associates describe him as ‘a decent, mannerly, dedicated, focused and diplomatic’ man who was also recognised as a good ‘deal maker.’ He always had an eye for a bargain.

A member of the Northern Ireland branch of the Quarry Products Association and a past president of the Institute of Quarrying, a role in which he served for two years between 1994 and 1996, Vincent continued to take a keen interest in the industry after his retirement. For some time after he retired from his General Manager role at Readymix, he

Breedon Group acquires Phoenix Surfacing

Breedon Group plc (Breedon), a leading vertically-integrated construction materials group in Great Britain, Ireland and the United States, has acquired Phoenix Surfacing, a leading independent, multi-disciplined, surfacing contractor based in the Midlands.

The acquisition of Phoenix Surfacing builds upon Breedon’s focus on expanding its Surfacing Solutions business and follows the successful integration of Minster Surfacing, an award-winning regional surfacing business based in Lincoln that Breedon acquired in 2023, as well as the 2022 acquisition of the regionally renowned Thomas Bow Ltd, a surfacing and civil engineering contractor based in the East Midlands.

Founded in 1991, Phoenix has over 30 years of experience in the design and delivery of successful highways and infrastructure projects for both public and private sector clients. The business has successfully grown into one of the

to welcome Phoenix to the Breedon team as we continue to focus on expanding our Surfacing Solutions business’ geographic footprint and offer for our clients.

Midlands’ leading independent surfacing contractors and merchanting businesses, with an annual turnover of £23m-£24m.

Phoenix’s services include all of the key activities needed to keep the UK’s roads in optimum condition. From rapid response pothole repair programming through to complete road resurfacing and civil construction projects, its teams have the experience, skills and expertise necessary to deliver individually planned projects from inception to completion.

James Haluch, Managing Director of Surfacing Solutions at Breedon, said: “We are delighted

continued to work part-time in sales and as a consultant. Vincent is survived by his wife Shelagh, son Colin, daughter Sharon, daughter-in-law Patricia, son-in-law Alan, and his grandchildren Owen, Callum, Hannah, Hugh and Patrick. Martin

“Phoenix Surfacing has built up a huge amount of experience over the course of its history and has an outstanding delivery team; the combination of our businesses will significantly enhance our offer in the Midlands, while also strengthening our regional surfacing, airfields and recycled asphalt capabilities across the Breedon group.”

Alistair Lauder, Managing Director of Phoenix Surfacing, commented: “This is a significant milestone in our company’s history, and we are excited about the opportunities the transaction will bring to our customers and colleagues. We look forward to leveraging the strengths of Phoenix and Breedon together, to enhance our overall capabilities and provide an excellent service for our customers.

“Since we founded Phoenix Surfacing in 1991, we have always focused on delivering the best customer service, supporting our people and growing our business, and Breedon is the perfect partner for us as we continue to deliver on these goals.”

news 6 PLANT & CIVIL ENGINEER

e. martin@4squaremedia.net m. 07985 887171 GET IN TOUCH

Elliman

Vincent Murphy.

Compact from 14 to 36 tonnes

The range of Liebherr compact crawler excavators offers a machine for every application. The R 914, R 920, R 926 and R 936 Compact range features a minimal turning radius, especially suitable for applications in restricted environments, without compromising on operator comfort. www.liebherr.com

Liebherr-Ireland Ltd. Unit 23 N • Greenogue Industrial Estate • Rathcoole, Co. Dublin • Phone +353 1 458 7650 LGBSalesLIR@liebherr.com • www.facebook.com/LiebherrConstruction • www.liebherr.com

Crawler excavators

DEVELON OPENS NEW EUROPEAN TRAINING CENTRE IN FRANCE

Develon, formerly Doosan Construction Equipment, has opened the company’s new European Training Centre at Allonnes close to Nantes in the west of France.

Among the aims of the new Training Centre is to provide dedicated conditions to update and develop the knowledge and skills of dealer personnel and the company’s service technicians and demonstrators, to enhance the Develon customer experience and satisfaction throughout the European market.

Sited in an easily accessed location close to the beautiful chateaux region of the Loire Valley, the new Training Centre is designed to provide a relaxing and attractive environment for all attending the new facility.

Patrice Pesnot, Head of Training at Develon in Europe, said: “The new Training Centre is intended to provide an environment to allow participants to concentrate on Develon products, allowing them to remove themselves from their daily work and focus entirely on the training activities.”

PROVIDING A SAFE AND SECURE AREA FOR TRAINING

The new Training Centre consists of a main building with several areas that can be set up for training. In addition to the classroom space, the facility also includes offices, workshops for service training and an impressive 3000 m² outdoor area which is devoted to hands-on try outs of machines from Develon and competitor machines.

Patrice Pesnot added: “Another aspect of the Training Centre is to provide a secure and safe environment with excellent conditions for training, in a fully equipped area that demonstrates the professionalism of Develon,

allowing testing of machines both in the workshop but also in the working conditions in the outside demonstration area.

“The new Develon Training Centre is dedicated to helping Develon dealers and company personnel to enhance their knowledge and skills in all possible ways, as we believe personal development is the foundation of further dealer performance growth. The new Training Centre also aims to greatly enhance Develon customer experience right across the European region.”

MORE THAN SIMPLY TRAINING

Activities at the new Training Centre include:

• Dealer Service Training

• Dealer Product Training

• Internal ‘Train The Trainer’ sessions to widen the training capabilities for the region

• Training development: including video tutorials and other tools

• Virtual Classrooms

• Future events to include promotion of Develon in schools (in France and Europe)

Patrice Pesnot concluded: “The Develon Training Centre aims to enhance dealer and staff performance with the right training, support and tools for enhanced customer experience. To achieve this, the Training Centre builds on our strong training foundations to also focus on the competition’s equipment with proactive sales materials, complemented by supporting dealers further with equipment demonstrations and other positive action.”

training centre

PLANT & CIVIL ENGINEER 8

When work gets tough Develon delivers more

enjoy a

5-year warranty with our DX17Z-7 & DX19-7 Mini-Excavators For more details and to find your nearest dealer please visit: eu.develon-ce.com Visit us at EXT5 F002

Now

unique

TAKEUCHI EXPANDS NEW 3-SERIES LINE-UP

Takeuchi has expanded the lineup of 3-Series excavators and expect to see the full line up at Balmoral and at Hillhead.

First up, the new 10-tonne wheeled excavator, the TB395W is now available with a fourwheel Steer with crab mode. The Takeuchi rubber ducks have always been a popular choice, you still see the early TB175W and TB295W operating across the region.

The latest 3-series model moves on with more in-cab automotive styling, larger cab size and easy service access. Overall, it is a compact wheeled option for its 10-tonne size with excellent ground

clearance and powerful breakout force.

The new generation 3-Series offers the very latest style with the TB325R, TB335R and TB350R, all with short tail swings for tight working spaces.

Unique to the Takeuchi 3-Series machines is the fact that many enhanced operating features come as standard, including an autostyled interior with jog dial control, all-round LED lighting, added auxiliaries, quick hitch factory-fitted steel pipework and check valves.

FIRST ELECTRIC TAKEUCHI

The brand-new Electric Takeuchi has been one of the most highly anticipated electric mini excavators for the UK.

The new 100% battery-powered TB20e is Takeuchi’s first electric mini excavator launched following extensive two-year field testing.

The new TB20e is a 100% batterypowered mini that delivers eight hours of continuous working time at 65% load. That is a significant output that matches the typical work

rate of its equivalent diesel TB216.

The TB20e also matches for dig depth, dump height, travel and slew speed.

It features electro-hydraulic controls, a 24.7kW lithium-ion battery and 3 charging options: onboard, offboard and tethered. The machine is available with a portable fast charger that securely rests on the blade when transporting.

The Electric Takeuchi has been in the United Rentals fleet for two years in the USA and Takeuchi is confident of its performance credentials. It delivers a quieter zero-emission model that can get to work anywhere. For an update on all things new from Takeuchi contact your local Takeuchi dealer.

excavators 10 PLANT & CIVIL ENGINEER

Reliable and dependable, we set the standard for excavating excellence. Designed and manufactured in Japan, TAKEUCHI deliver precision engineered excavators that outperform year on year. TAKEUCHI offer an extensive range of proven high performance excavators with more than 20 models from 1 to 15-tonnes. Always the operator’s favourite, you can trust a Takeuchi to excel in every weight class. NEW 100% BATTERY POWERED DON’T SETTLE FOR ANYTHING LESS SUBSIDISED MACHINE DEALS AVAILABLE NOW VISIT US AT Reliable and dependable, we set the standard for excavating excellence. Designed and manufactured in Japan, TAKEUCHI deliver precision engineered excavators that outperform year on year. TAKEUCHI offer an extensive range of proven high performance excavators with more than 20 models from 1 to 15-tonnes. Always the operator’s favourite, you can trust a Takeuchi to excel in every weight class. ALAN MILNE TRACTORS / DIECI Newry T: 02830 821230 BREENS Cashel T: 062 61356 Ennis T: 065 684 1000 Naas T: 045 493 410 IMITATIONS DON’T COME CLOSE

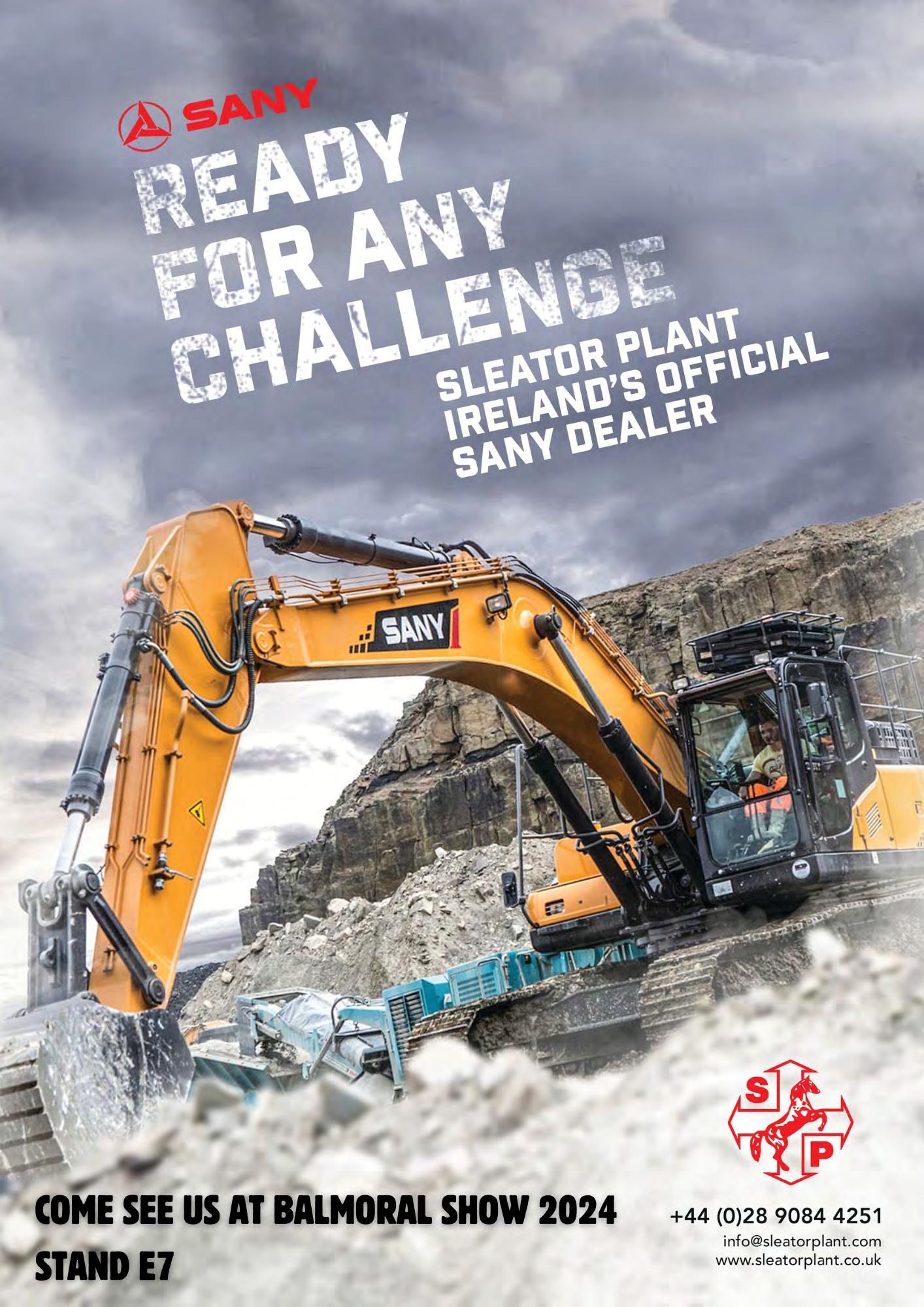

AG WILSON CIVIL ENGINEERING FLEET INVESTMENT INCLUDES THREE SANY SY215C LC EXCAVATORS

For some years, AG Wilson Civil Engineering has been on a business growth trajectory that requires continuous investment in upgrades and additions to its plant fleet to service current projects and a pipeline of contracts on the order books. Recently, the company has looked to SANY and its Northern Ireland dealer Sleator Plant to facilitate future plant acquisitions. The new equipment includes three SANY SY215C LC medium excavators, another two SANY SY75 small excavators and a SANY SY390 40t excavator. The current consignment on its way to the company offices outside Portadown follows on from the purchase, last year, of five SANY

SY80U short-tail-swing excavators; a SANY SY155U tracked, compact short-tail-swing excavator, and a SANY SY 155W ‘Rubber Duck’. The company is clearly familiar with the brand and finds it worth investing in.

PLANNED AND RESOURCED IN-HOUSE DELIVERY

Richard Chambers, one of the directors of AG Wilson Civil Engineering explained the company’s approach. “Our approach to delivering projects is that we use all of our own equipment and people on our job sites,” said Richard. “For us, it’s a model that works and has established our reputation for quality workmanship at every part of the job, from the design, costing and project-managing right through to all the work with plant on site.

We know we have every piece of equipment we need for a project in good working order and operated by our own experienced and committed team. We believe this approach gives us an edge and we wouldn’t consider hiring plant or self-employed operators using their own diggers.”

SANY AND SLEATOR: THE RIGHT PARTNERSHIP

The level of investment, both last year and this year, certainly attests to the market demand for AG Wilson’s business approach. This is not simply an exercise in replacing out-of-date plant, rather it is a continual and significant expansion of the fleet to prepare for new jobs that are booked in but haven’t commenced on-site yet. And this particular investment is entirely in partnership with Sleator Plant and SANY. “We do have a range of brands in our plant fleet, but our experience in dealing with Sleator Plant and with the SANY machines in action has led us to focus this tranche of investment on the SANY offering”, explained Richard. “ The products perform exceptionally well and we’ve enjoyed consistently good service, reliability and very good backup from both Sleator Plant and SANY.

Richard continued: “We have a rolling programme of continuous investment in plant and we have a range of different models. Going forward, however, it is very likely that we will stay with the SANY brand through Sleator Plant, driven by our experience of their products and customer service. I find Sleator excellent to work with.”

STRONG CUSTOMER RELATIONSHIP

Jonathan Campbell, Managing Director at Sleator Plant is as impressed with AG

12 view from the cab PLANT & CIVIL ENGINEER

L-R: Richard Chambers and Derek Wilson, two of the directors of AG Wilson Engineering.

view from the cab

“WE’RE LOOKING FORWARD TO PUTTING OUR THREE SANY SY215C LC EXCAVATORS STRAIGHT INTO WORK ON A WATER INFRASTRUCTURE PROJECT IN SCOTLAND. WE ARE CERTAIN THEY ARE THE RIGHT MACHINES FOR THE JOB, DELIVERING STABILITY ON SITE, LIFTING MORE AND DIGGING DEEPER” RICHARD CHAMBERS, AG WILSON

Wilson Civil Engineering as they are with his company’s product and service offering.

“Our working relationship with AG Wilson began in earnest in December 2021 when Richard [Chambers] and Derek [Wilson] bought their first SANY excavators from us”, said Jonathan. “They attended Bauma in Germany as our guest the next year, and they have been purchasing plant items every year since then. They invest in a planned schedule based on the plant fleet they need to deliver the projects they know they will be working on in the year ahead.

“I would have to say that AG Wilson’s planned approach stands out as marketleading in the civil engineering sector. It would be fair to say that many companies would take a much more reactive approach and I have come across few like AG Wilson, which meticulously plans continual investment to keep it at the forefront in delivering civil engineering excellence.”

SLEATOR OPENING IN DUBLIN

The big news from Sleator Plant is focused around its own expansion plans, as Jonathan Campbell outlines: “We are moving Sleator Plant to an all-Ireland level with the opening

of a Depot in Dublin, scheduled for late May or early June. We feel that now is the time to establish our credentials on an all-island basis, to serve the needs of the Irish market and its contractors and civil engineers. “We are already at an advanced stage of planning with core sales and service personnel recruited and building work underway at our new site close to Dublin airport. We will be hoping to bring new customers across Ireland into the SANY fold,” concluded Jonathan.

SANY SY215C LC – STANDING FIRM AND DIGGING DEEP

Sitting in the medium excavator category, the 23.5t SANY SY215C LC is a machine that can be trusted to take on big jobs on tough terrain. The LC variant of the SANY SY215C LC shares all the features of the standard and very popular SY215C but has a longer undercarriage. That is one change that makes a myriad of differences.

REACH, DIG, LIFT, AND REPEAT

The SY125C LC model’s long carriage might give the standard C model a bit of an advantage in terms of manoeuvrability but that extra length brings significant advantages in increased stability and performance. Let’s put some figures on that! On digging reach, the SANY SY215C LC has a maximum digging reach of 13,307mm (half a metre further than the standard model) The SANY SY125C LC excavator’s arm digging force is 115 kn (versus 103kN), the bucket capacity is 1.2 m³ (versus 0.93 m³) and the bucket digging force is 143 kN (versus 138kN).

13

PLANT & CIVIL ENGINEER CONTINUES ON NEXT PAGE

Sleator Plant Managing Director Jonathan Campbell.

view from the cab

CONTINUED

This is not a machine designed to work on restricted sites but it certainly packs a punch for the type of infrastructure projects AG Wilson Civil Engineering has bought them for.

The SANY SY215C LC is powered by a fuel-efficient Cummins QSB6.7 172hp engine, with 125/1900kW/rpm power force. Precision is paired with power through the advanced, position-controlled hydraulic system, which adjusts the required pressure and oil quantity according to requirements. The fact that the variable piston pumps reach a flow rate of 2 x 241 l/min, the SY215C LC achieve a very high level of efficiency at a low engine speed.

SANY-STYLE CAB COMFORT

Of course, whilst the stand-out performance features are the right fit for AG Wilson’s infrastructure project needs, The SY215C LC is SANY ‘all the way’ in terms of operator comfort, safety, durability and maintenance. Designed to provide the operator with higher levels of comfort, this SANY model comes with an improved driver’s cab which includes an upgraded air suspension, heated, seat with console adjustment. The 10” LCD touchscreen display enhances control and functionality, giving the operator greater command over the set-up of the machine.

Intended to reduce fatigue, the cabin also features an intelligent climate control function with in-cab sensors, helping to automatically adjust the temperature for the operator. Finally, the operator cab features a fast-charge USB point, providing reduced charge times for mobile phones and electronic devices. The new Stage 5 model comes with fully proportional controls as standard, allowing

operators to perform grab and rotation functions at the same time, increasing machine performance and functionality.

BIRD’S-EYE VIEW

The cab is also designed to maximise visibility, even in poor lighting conditions. The operating area is illuminated by two LED roof headlights, two LED headlights on the boom, one in the superstructure and an LED headlight facing backwards. This lighting system provides particularly good illumination, but low power consumption durability, being virtually maintenance-free. Built with high-quality materials and precision engineering, like all SANY machines, the SY215C LC boasts exceptional durability and reliability. Its rugged construction and minimal maintenance requirements minimise downtime and ensure long-term performance, making it a cost-effective investment, particularly when sourced from Sleator Plant, who provide service and backup!

In conclusion, the SANY SY215C LC excavator epitomises power, precision, and reliability. With its advanced features, operator-friendly design, and exceptional performance, it stands as a testament to SANY’s commitment to delivering high-quality machinery that meets the evolving needs of modern engineering and construction projects.

www.sleatorplant.co.uk

SANY SY75C: COMFORT MEETS EFFICIENCY

The new SANY SY75C – powerful and with a large excavation depth, completes all tasks efficiently and with a reliable performance.

The excavator’s sophisticated structure allows it to tackle very high loads with exemplary stability. In addition, the cab’s comfortable and ergonomic design is precisely tailored to the requirements for safe and concentrated work.

– Stage V YANMAR engine and efficient load-sensing hydraulic system

– Comfortable ROPS/FOPS certified operators’ cab

– 5-year warranty for complete peace of mind

RATED POWER: 42.4 kW / 1,900 rpm

OPERATING WEIGHT: 7,280 kg

DIG DEPTH: 4,400 mm

SANY SY390H: MOVE MORE WITH LESS EFFORT

The SANY SY390H works powerfully wherever maximum performance is required for excavation work and in civil engineering.

The machine‘s high-quality technology and robust components form the basis for reliable and quick operation.

– Powerful Stage V CUMMINS engine and efficient Kawasaki hydraulic system

– Comfortable operator cab with optimal visibility

– 5-year warranty for complete peace of mind

RATED POWER: 252 kW / 1,800 rpm

OPERATING WEIGHT: 40,000 kg

DIG DEPTH: 7,125 mm

A demolition specification option (SY390H-XD) is also available.

See the SANY SY390H on the Sleator Plant stand at Balmoral Show.

PLANT & CIVIL ENGINEER 14

BUILT TO LAST:

POWERSCREEN UNVEILS NEW GLOBAL HEADQUARTERS

Powerscreen®, leading provider of mobile crushing, screening, and conveying equipment, has unveiled its new global headquarters in Dungannon, Co. Tyrone.

Under the theme ‘Built to Last’, the revitalised facility was revealed to local stakeholders including First Minister Michelle O’Neill at an official ribbon cutting ceremony and celebration.

Speaking following a tour of the new facility, First Minister of Northern Ireland Michelle O’Neill said: “Your new headquarters are really impressive. It’s a physical demonstration of your success, and a welcome statement of your future ambition. Your growth on this site since the original Powerscreen days is a testament to entrepreneurial spirit and resilience.

“You have been instrumental in growing an engineering cluster here. You have set the standard in terms of quality and product development, and you have been pioneers in research, development and innovation.”

Sean Loughran, Powerscreen Business Line Director and General Manager said: “As pioneers in mobile crushing and screening, we’ve always believed in building not just equipment, but legacies. As Powerscreen

approaches 60 years of operating, we understand the value of durability and innovation. Our new headquarters isn’t just bricks and mortar; it’s a testament to our commitment to lasting excellence.

“Built to Last isn’t just a strapline for us; it’s a promise to our team members, our customers, and our community - a promise of enduring quality, reliability, and progress.”

The new headquarters on Coalisland Road includes a new 8,500 sq ft state-of-theart office space, a modern wellness centre to promote team member wellbeing, and several energy saving enhancements

aimed at reducing carbon emissions. The unveiling also represents the latest in a series of strategic investments by Terex to modernise its operations and bring its facilities into the digital age, such as the integration of robotic welding and automation systems to enhance efficiency and precision in manufacturing processes.

Additionally, the implementation of job tracking and digital shop floor information systems has streamlined workflow management, while data capture technologies leverage valuable insights for continuous improvement and material management

systems to optimise inventory levels and reduce waste.

Peter Doherty, Maintenance and Facilities Manager at Terex Dungannon said: “The main building has been reimagined to create a state-of-the-art office space that reflects Powerscreen’s standing as a global market leader. As well as extending the footprint, the traditional cellular office accommodation has been replaced with open-plan spaces that have been carefully arranged around modern working arrangements and informal collaboration areas.

“Additionally, the building fabric has been upgraded to improve thermal efficiency, along with the use of low energy fittings and products - reducing overall energy consumption in line with global Terex policy and targets to implement sustainable practices that minimise the environmental impact of our operations.”

Concluding, the First Minister, Michelle O’Neill, said: “It is companies like Terex that put us [Northern Ireland] on the map and we are fortunate that you are located here. Your employment of thousands of people across the region is vital and we are proud to have you as a key part of the community.”

news

PLANT & CIVIL ENGINEER 16

Sean Loughran, Powerscreen and First Minister Michelle O'Neill, MLA at the official ribbon cutting ceremony.

Sean Loughran, Powerscreen with First Minister Michelle O’Neill, MLA along with local dignitaries at Powerscreen’s new headquarters official ribbon cutting ceremony.

DISCOVER YOUR DIAMOND www.renault-trucks.co.uk THE RENAULT TRUCKS CONSTRUCTION RANGE For details of our dealer network and to book a demo call 02890 837171 Commercial Way, Mallusk, Newtownabbey BT36 4UB TRUCKS TO BE PROUD OF www.diamondtrucks.co.uk THE RENAULT TRUCKS CONSTRUCTION RANGE To discover more about our full range of products call 02890 837171 Commercial Way, Mallusk, Newtownabbey BT36 4UB

VINCI AIRPORTS LAUNCHES MAJOR INVESTMENT AT BELFAST INTERNATIONAL AIRPORT

• A £100m five-year investment programme to enhance operational and environmental efficiency

• New security terminal and improved departure and border force areas

• New 26MWp solar farm to be created on site

Nicolas Notebaert, CEO of VINCI Concessions and President of VINCI Airports, has announced the launch of a £100 million five-year investment plan that will increase the airport’s operational efficiency, improve

passenger experience and environmental performance.

Phase one of the program is currently underway, with the construction of a new security building adjacent to the current terminal building. This ultramodern £25m facility will transform the passenger security

experience by implementing the required Standard 3 Xray screening equipment, meaning passengers will no longer have to remove liquids or electronics from their luggage. The new building will be operational by Summer 2024.

VINCI Airports’ investment plan will also revamp existing facilities, improve airside departure area with additional departure gates and extra seating. Shopping offering will include new catering and retail outlets and the

immigration area will also be extended over the next five years.

These investments will improve operational efficiency and quality of service. They will support Belfast International Airport as a key gateway for passengers, as traffic reached 5.9m passengers in 2023.

The initiative will also have a direct positive impact for the entire region, creating an estimated 400 jobs with local construction firms for the duration of the build.

VINCI Airports has also announced the launch of a 26 MWp new solar farm on the airport site which will generate 22.4 GWh of electricity and save 12,500 tonnes of CO2 emissions per year.

investment 18 PLANT & CIVIL ENGINEER

The farm will be developed, financed, built, and operated by VINCI Concessions’ photovoltaic subsidiary SunMind. This initiative forms part of VINCI Airports’ global environmental action plan, which aims to reach 50% emission reductions by 2030 and net zero by 2050. A member of VINCI Airports network since 2018, Belfast International Airport has already decreased by 44 % its emissions (scope 1 and 2) by applying VINCI Airports’ environmental solutions.

Nicolas Notebaert, CEO of VINCI Concessions & President of VINCI Airports declared: “VINCI Airports’ investment will support Belfast international airport’s positive dynamic by strongly improving the passenger experience. The airport plays a pivotal role for aviation, tourism and the wider local economy. As a longterm partner, VINCI Airports is committed to sustainably develop the airport and increase its environmental performance”.

PREMIUM CAR PARK

Perfect for business trips and shortterm parking. Conveniently situated, 2 - 3 minute walk from the terminal building, it provides customers with wider spaces and full LED lighting. Pre-book only, space guaranteed.

Book now at belfastairport.com

investment 19 PLANT & CIVIL ENGINEER

FROM THE DESK OF: GORDON BEST, REGIONAL DIRECTOR, MPANI

WELCOME POSITIVITY FROM A RESTORED STORMONT MEANS THERE IS MUCH WORK TO DO

The restoration of our local Executive and Assembly is very welcome and long overdue. I have been up on the “hill” a few times since its restoration and you sense the determination to get to work on what are the many challenges facing our community and economy. However, we will judge the success of the Executive on the difficult and unpopular decisions they make, not the easy and popular ones. What is required now is urgent decisions, some difficult and that will be unpopular, to fundamentally reform many of our key economic enablers which have been subject to years of drift and delay. We can achieve our goals and overcome these significant challenges if our Executive works collaboratively with NI Business and our community sector to catch up and repair two years of lost opportunity costs and take advantage of the unique trading position that we now enjoy with access to both EU and UK markets.

MPANI has written to the Economy, Infrastructure and DAERA Ministers and the Assembly Committees briefing and updating them on the work we do with their Departments and Agencies highlighting our concerns and offering possible solutions to the many current and future challenges facing us as a society and economy. We are pleased to report that a number of Ministers and Committees have responded positively to our requests for meetings creating the opportunity to brief them on our Industry opportunities and challenges ahead.

NEW BITUMEN INDEX

On another positive note I am pleased to report that after 15 months of discussions with BCIS, MPA, Eurobitume and other stakeholders we have reached agreement on developing a new bitumen index that is much more reflective of monthly price movements of bitumen. This should certainly create a much more stable Highway Maintenance Industry going forward but also importantly facilitate recompense being

made to contractors for the divergence between the then measurement of Heavy Fuel Oil as a proxy and the bitumen index that occurred in December 20222.

AGM AT DUNSILLY

On March 7th we held our AGM in the Dunsilly Hotel Antrim at which that outgoing Chair, Paul Brogan, passed the baton of Chairmanship on to Paddy Mohan of Mannok at yesterday evening’s AGM.

Paul Brogan was thanked for his considerable leadership, support and guidance over his two-year tenure and I Had the pleasure of welcoming Paddy Mohan, noting that he is the last member of the original Executive Committee which welcomed me back in 2000. In his opening address, Paddy commented that it was an honour for both himself and Mannok to take on the role of Chair and he would endeavour to live up to those who have come before.

William Doherty of Creagh Concrete was also welcomed as Vice Chair and the Regional

essential materials sustainable solutions

20 PLANT & CIVIL ENGINEER

Gordon Best, MPANI

L-R: Incoming Vice Chair, William Doherty, Creagh Concrete; Incoming Chair, Paddy Mohan, Mannok; Regional Director, Gordon Best; Outgoing Chair, Paul Brogan, McQuillan Cos.

L-R: Stephen Kelly, CEO Manufacturing NI; Gordon Best, MPANI Regional Director; Kirsty McManus, National Director IoD Northern Ireland and Wales; Aileen Lawson, Senior Policy Officer, Ulster Farmers Union; Mark Spence, CEO, Construction Employers Federation.

Director commented that he is looking forward to working with such an experienced and valued Executive Management Group. Thanks to our guest panel, who helped make the Question Time event an interesting and frank discussion. Many thanks also to our sponsors, Breedon Group; McQuillan Companies and Northstone Materials for supporting the event.

It was great to see so many members attending and with over 70 guests, the level of chat certainly suggested there was plenty of networking being done and as the incoming Chair reminded us all, the strength of the Association is embedded in the commitment and support of its members.

SAFEQUARRY AND VISION ZERO

As many of you know, particularly MPANI Members, we are fortunate to have arguably the best Health and Safety Information Hub in SafeQuarry!! The frustrating thing however is the low uptake, registration and use of this excellent and unrivalled resource. That is why MPA and MPANI have recently been focusing on making members more aware of the benefits of Safequarry. The site has recently been updated and made even more userfriendly. To more about how you can keep up to date with key health & safety information, industry guidance and access toolbox talks watch the new 90-second promotional video. MPA collects health and safety data from all of our Members to help progress to Vison Zero and the reduction/elimination of harm. This includes, but is not exclusively, reporting progress against the ‘Hard Targets’ and ‘Leading Indicators’ agreed by the Members and as a means of informing public affairs. Good quality data and consistent reporting is essential if risks and causes of injury and ill health are to be identified and eliminated. Industry data can also be used to help to secure fair and proportionate regulation by relevant authorities.

In recognition of some confusion and lack of alignment in members understanding of what they are required to report and when, the MPA Health and Safety committee has developed a new Reporting Protocol, which

has been approved by the MPA Board. The revised protocol took full effect on 1st January 2024 and sets out definitions, scope and expectations for reporting data and can be downloaded from the main MPA website Health & Safety (mineralproducts.org)

CALL FOR VIDEO CONTENT FROM YOUNG LEADERS

At our most recent Young Leaders Group visit to CEMCOR in Cookstown we had a very useful discussion on how we can deliver a positive message to young people about the exciting career opportunities that are available within our mineral products sector. We would welcome assistance from all members to help us put together a collection of short, sharp interviews with young people from within your business, who of course are willing to go in front of the camera, that we can share widely through social media, Tik Tok, Instagram and You Tube.

So have a chat with some of the younger members of your team, ask them would they be happy to do a short talk in front of a mobile phone as set out below. We would envisage clips of no more than two minutes covering:

1. Who I am

2. What my qualifications are

3. How did I find out about the industry and get interested in a possible career

4. What training I did

5. The role I have within my company and why it is so interesting. i.e. diverse, responsibility, being part of a team etc.

6. What my ambitions are for future career development within the industry

We would welcome your support for this initiative and would encourage each member to use the information we put together to promote the industry in your area so that we as an Association can help address the age profile and diversity gap so prevalent in our sectors.

So, if you can send us two-minute clips (maximum) taken on the mobile phone that would be brilliant!!

CELEBRATE HABITAT RENEWAL EFFORTS

In the last few weeks, I have visited several members and have been impressed with the amount of work being done in relation to restoration and habitat creation around sites. Could I ask all of you to send me through, by email to gbest@mpani.org, the following information so that I can collate it and highlight to a wider audience the excellent work and stewardship of the environment our members carry out.

How many trees have you planted in the last 10 years up to the end of 2023?

Acreage of land planted

How many trees do you plan to plant as part of future restoration plans and what acreage will they cover?

MAY MEMBER FORUM

We look forward to seeing as many members as possible at our May Local Member Forum on Thursday 23rd May in the Killyhevlin Hotel Enniskillen, the 19th September in the Elk Toomebridge and the 5th December in the Glenavon House Hotel Cookstown.

If you’re interested in becoming a full or affiliate member of MPANI and get access to up to date Industry news and guidance don’t hesitate to give me a call on 07876 136929. It would be great to have you on board.

Take care and stay safe!!

essential materials sustainable solutions 21 PLANT & CIVIL ENGINEER

FINLAY TO SHOWCASE ELECTRIC MACHINES ENGINEERED TO ELEVATE INDUSTRY STANDARDS AT HILLHEAD 2024

Finlay will be showcasing the future direction of crushing, screening and recycling machinery on Stand: L3 Hillhead 2024, taking place from 25-27 June and the Hillhead Quarry, near Buxton in Derbyshire. Emma Cowan talked to Brian Pauley, Marketing Manager and Alan Witherow, Product and Applications Manager at Finlay about the strategy behind the company’s innovation and development programme.

The global manufacturer of mobile crushing, screening and conveying equipment will be introducing its electric I-120RS impact crusher and 883+ scalping screen at the event. The models on display feature electric technology permitting the flexibility to run the plant from the mains electric power supply or from a secondary power source such as a genset.

These new models will join the J-1175 jaw crusher and C-1540 cone crusher in the Finlay range of electric machines as Finlay moves forward in its commitment to innovation and environmental responsibility.

The Finlay stand will incorporate both static display and demos, giving visitors the chance to see their electric-powered performance capabilities, which deliver all the power of conventional machines. The machines will be in operation in the working demonstration area at the show in front of the Finlay booth.

Brian Pauley, who is looking forward to the Hillhead spectacle, says, “The development of the Finlay electric machine portfolio reinforces our commitment to excellence and unveils a new era of efficiency, reliability and sustainability.

The innovative features of these electric machines are poised to redefine how the

crushing and screening industry operates, setting new benchmarks for site efficiency and environmental responsibility.

“The adoption and integration of Finlay electric-powered machines can help operators reduce their carbon footprint on the planet while increasing efficiency, sustainability, and overall operational effectiveness.”

THE DRIVE TO ELECTRIC POWER

Both Brian and Alan are clear that the impetus for innovation in power sources is a commitment to lowering global warming, however, that commitment translates to faster action if there is a legislative framework that drives it.

“You can see that the countries with the most stringent regulations are the first adopters of technologies and practices

cover story PLANT & CIVIL ENGINEER 22

that lower emissions,” says Alan. “The Scandinavian countries, particularly Norway and Denmark, are leading the way in adopting electric and hybrid machinery in the transportation industry due to stringent regulations coupled with incentives.

“At the moment, operators in the UK are facing increased costs due to the shift away from red diesel and towards road fuel, which has doubled fuel costs overnight, leading to a shift in focus towards reducing operating costs through lower maintenance and rolling costs.”

Alan continued: “Developing a suitable non-fossil-based energy source that can power large machinery is a challenge in itself. That challenge is even greater in the crushing and screening sectors, where operational locations are often distant from the power grid.”

ELECTRIC SOLUTION

A complete move away from diesel engines is the ultimate goal, and it is one that heavy machinery manufacturers are working toward globally but, at this point, the process is one of evolution through continual innovation. The Finlay I-120RS impact crusher and 883+ scalping screen are fully electric in their operational modes.

Brian explains: “During the development phase, the feedback we got from our dealer network and their customers was that they still wanted the familiarity and flexibility of mobile machines that can be easily transferred around sites and moved with ease to different locations. So, there is an on-board engine to retain these characteristics but the engine itself

is only used for tracking the machine. When it comes to the full operation of the machine; the feeders, crushers, and conveyors are all powered by electric.” “This is a new concept for us. There are two ways that operators can source operating power. They can plug the machine into electricity sourced from the main grid to power the machine. The second option is if they’re on a site where there is no access to the power grid infrastructure, they can use a generator, such as our Finlay TG500 tracked gen set, where that machine creates the electricity that then powers the machine. As a company we’re embracing the opportunity of electric power to drive sustainable progress, for a cleaner future where efficiency and productivity meets environmental stewardship.”

REAPING THE BENEFIT OF ELECTRIC POWER

The advantages of using electric-powered crushing and screening equipment machines encompass environmental, financial, and operational benefits, making them a forward-thinking and responsible choice for operators.

Environmental sustainability benefits include reduced emissions and achieving a lower carbon footprint. Electric powered machines reduce on-site emissions, contributing to a cleaner and healthier working environment. This is crucial for quarries located near urban and populated areas or regions with strict environmental regulations.

PLANT & CIVIL ENGINEER 23 cover story FINLAY SHOWCASING THE FUTURE DIRECTION OF QUARRYING AT HILLHEAD

CONTINUES ON NEXT PAGE

As the energy sector adopts more renewable sources, the overall carbon footprint of electric powered machines decreases, making them a greener alternative compared to traditional fossil fuel-powered equipment. Operational cost and maintenance savings include energy efficiency and maintenance savings. Electric motors are generally more energy-efficient and this translates to lower energy consumption and reduced operational costs over the long term. Electric machines also have fewer moving parts, resulting in reduced maintenance requirements and downtime. This can lead to lower maintenance costs and increased overall equipment reliability. Electric machines are typically quieter than their diesel counterparts which is particularly advantageous in areas with noise restrictions and close to urban or residential areas. Electric machines help operators comply with increasingly stringent emission standards. The transition to electric power brings future-proofing benefits. As the world shifts towards more sustainable practices, adopting electric-powered machines positions quarries for the long-term.

THE FINLAY 883+ ELECTRIC SCALPER

The Finlay 883+ scalper is renowned for its efficient screening capabilities, versatility, high production capacity and durability making it the global leader in quarrying, mining, construction and demolition debris, topsoil, recycling, sand, gravel, coal and aggregate applications. This aggressive forward-facing inclined modular configuration screenbox has a 4.8m x 1.5m top deck and a 4.8m x 1.5m bottom deck giving a total screening area of 14.4 m2 (155 ft2). Hydraulic adjustment can be used to vary the angle of the screen box between 13 – 19°, depending on the working application of the machine. The top deck of screenbox can be fitted with a variety of screening media including tines, bofor bars, punched plate and mesh. The bottom deck can be fitted with mesh or cascade fingers. A high torque drive steel pan apron feeder is fitted to the machine as standard and has proven performance and versatility in demanding and varied working environments. The hopper has a 7m³ capacity as standard with a drop rear door for use in conjunction with a mobile crusher. The machine, which benefits from rapid set up and tear down times, comes equipped with three hydraulically folding discharge conveyors allowing for maximum stockpiling capacity/ Additional features of the machine include:

• Galvanised access ladders and catwalks fitted as standard to both sides of the screen box.

• Hydraulic raising of the screenbox discharge end provides additional clearance for screenbox and fines transfer conveyor maintenance.

• Each onboard discharge conveyor is powered by a separate hydraulic circuit as standard.

• The width of the fines conveyor is now 900mm (36”) as standard.

• The banana profile and increased area of the new bottom deck maximise the screening of fines material.

• The screenbox discharge end can be hydraulically raised 500mm to facilitate efficient and easy media access and changing.

• Fully reversible side conveyors as standard, which offers ultimate flexibility to the customer depending on their specific requirements.

THE FINLAY I-120RS ELECTRIC IMPACT CRUSHER

The industry leading Finlay I-120RS impact crusher has an outstanding reputation in the materials processing industry for its proven performance and reliability in quarrying, mining, demolition and recycling applications. The heartbeat of the machine is the proven and robust direct drive Terex® CR038 impact crusher that provides operators with high material reduction ratios and produces a consistent product shape. A key component of the machine is the onboard, innovative quick detach 3.66m x 1.53m (12’ x 5’) two-deck screen and recirculating conveyor that ensures that only material meeting the desired specification is deposited from the machine. A key new feature of the onboard recirculating system is the ability to rotate the conveyor from a closed loop configuration to side discharge for stockpiling oversized material. For applications not requiring the recirculation of materials for further processing, the complete screening and recirculating system can be quickly and easily detached from the machine. The high productivity, ease of maintenance and operation make this machine an ideal solution for large-scale producers and contract crushing operators.

KEY FEATURES FINLAY 1-120RS IMPACT CRUSHER AT A GLANCE

• The ease of material flow through the machine has greatly improved with each component of the machine increasing in width as the material moves through the machine.

• Fully hydraulic apron setting assist provides convenient and efficient adjustment of the aprons

• The heavy-duty vibrating feeder (VGF) with integrated prescreen removes dirt fines and sizes bypass material for reprocessing.

• A quick onboard detachable recirculating system including a large 3.66m x 1.53m (12’ x 5’) two-deck screen.

• The recirculating conveyor can be rotated from a closed loop configuration or utilised for stockpiling making an additional oversized product.

CONTINUED cover story PLANT & CIVIL ENGINEER 24

www.terex.com/finlay

Merlo Group set to appoint a dealer network in Ireland

Merlo Group the leader in telescopic handler innovation is pleased to announce a new distribution model for their extensive & proven product range in the Republic of Ireland.

Following more than 10 years with current distributor McHale Plant Sales the Italian manufacturer will strike out on its own dealing directly with a carefully selected group of dealers.

The new arrangements will see a new nationwide network of dealers for both Merlo agricultural and construction product ranges. This follows a model that Merlo has already established in several European countries and is designed to advance Merlo’s market share objectives in key territories.

“The Irish telescopic handler market continues to grow year on year, which is very encouraging” comments Paolo Merlo, CEO & President of Merlo Group. “As a family-owned and progressive business, we are committed to increasing our presence globally and Ireland is a key part of our future plans”.

McHale Plant Sales partnership with Merlo Group will conclude in the coming

months and Merlo will take control of distribution of products, parts, services across the Republic of Ireland thereafter.

“The successful relationship between Merlo & McHale began more than ten years ago, and we wish to thank McHale Plant Sales for

the excellent work in those years. It has for sure set the right foundation to empower Merlo’s products to carry forward the strongest of reputations in the Irish market and we wish the team at McHale all the very best for the future” concludes Mr Merlo.

news 25 PLANT & CIVIL ENGINEER

SHREDDING | SCREENING | HANDLING | COMPOSTING | CONVEYING CBI GRINDERS RECYCLING SCREENS TROMMEL SCREENS info@qrs.ie 10 Coolmaghry Road, Donaghmore, Dungannon BT70 3 HJ +442887767120 SALES/SERVICE/HIRE SHREDDING | SCREENING | HANDLING | COMPOSTING | CONVEYING WASTE HANDLERS MEDIUM SPEED SHREDDER CBI GRINDERS RECYCLING SCREENS TROMMEL SCREENS SLOW SPEED SHREDDER TWIN SHAFT SHREDDER info@qrs.ie 10 Coolmaghry Road, Donaghmore, Dungannon BT70 3 HJ +442887767120 SALES/SERVICE/HIRE PLANT & CIVIL FOLLOW US ON

Karen McShane

Karen McShane

President, The Chartered Institution of Highways and Transportation

HOW BELFAST IS SPEARHEADING SUSTAINABLE PUBLIC TRANSPORT

My Presidential Role this month took me to my home in Northern Ireland to celebrate the Region’s 60th Anniversary. As part of my year in office, I have been highlighting Climate Action and what we need to do to decarbonise the transport industry and achieve an Attitudinal Change in how we travel. I have seen some innovative technology and learned new ideas from my colleagues around the different Regions. But this month it was an opportunity to showcase Northern Ireland’s strengths and I was fortunate to have two exceptional visits. The first was a trip to Belfast Harbour Estate to meet the team at Artemis Technologies, trailblazers in clean maritime technology. Born out of a heritage of excellence from the America’s Cup team - Artemis Racing - the company has leveraged their expertise in high-performance sailing

to develop pioneering electric foiling technology for marine transport. This zero-emission technology is used to power Artemis Technologies’ diverse range of vessels, including an eco-friendly passenger ferry - the Artemis EF-24 Passenger.

ARTEMIS TECHNOLOGIES ON BELFAST LOUGH

The Artemis EF-24 Passenger is the world’s first 100% electric foiling passenger ferry with a commercially viable range and speed and is set to embark on a demonstration route between Belfast and Bangor, Northern Ireland later this year. The global interest is palpable, with places like USA, Australia, and the Middle East keeping a close eye on progress - signalling a growing appetite for sustainable maritime solutions worldwide.

So, why Belfast? Rachel Edwards, Head of PR and Communications at Artemis, sheds some light:

“With Belfast’s rich maritime heritage and track record of pioneering maritime transport innovations, the city provides an ideal backdrop for our transformative technology. “We want to revolutionise people’s perceptions and behaviours towards travel. Throughout history, Belfast has demonstrated a remarkable ability to embrace change and reinvent itself - so it is an ideal location to showcase how innovative thinking can unlock opportunities for people, the planet, and prosperity.”

The idea of passenger ferries is well tested in these islands with operations at Rathlin and Strangford as well as across Lough Foyle. London has already started an Uber Boat along the Thames with a high-speed connection between the O2 Arena, London Bridge and beyond. If this technology can be mastered, it will offer a real sustainable alternative to fossil fuel ferries and reduce our carbon footprint.

from the desk of 26 PLANT & CIVIL ENGINEER

from the desk of

BOATS THAT ‘FLY’

Artemis Technologies’ vessels, inspired by their sailing heritage, use foiling technology to effectively ‘fly’ above the water, enhancing passenger comfort with the added advantage of protecting the shoreline. The minimal wake created sets these vessels apart from their traditional counterparts, as is clearly demonstrated in side-by-side comparisons. This not only offers a smoother ride but also holds the potential to ease congestion and support community connectivity.

Looking ahead, the company wants to engage with governments and developers to support the installation of standardised electrical chargers in marina schemes and upgrades, encouraging future-focused designs that support these types of vessels. With a diverse workforce boasting 19 nationalities based in Belfast, Artemis is not only driving technological advancements but also investing significantly in Northern Ireland’s workforce development. One of my goals as President of CIHT is to promote STEM careers, so I was delighted to also learn about their commitment to STEM and the tailored apprenticeship scheme they have developed with Belfast Met – underscoring their dedication to nurturing local talent.

As the world watches, I am excited to say that I believe Belfast is standing at the forefront of a maritime revolution - led by the visionary team at Artemis Technologies.

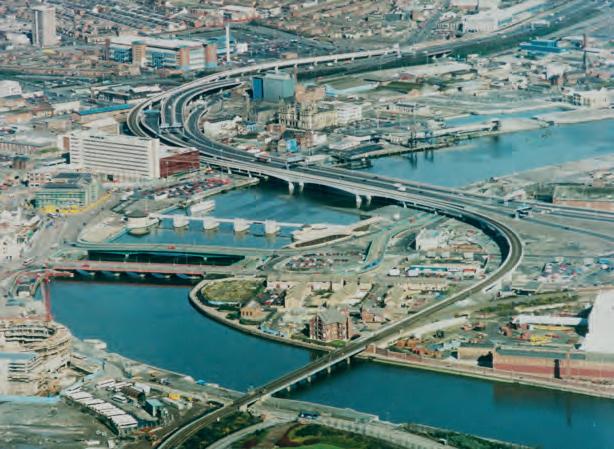

GRAND CENTRAL STATION

The second visit to showcase sustainable travel was facilitated by Translink with a visit to their new Belfast Grand Central Station at Weavers Cross, which is Belfast’s new integrated transport hub. Translink which maintains and operates Northern Ireland’s public transport sees this proposal as its flagship development, delivered through a blended team of enabling works by GRAHAM, the main construction works by the Farrans Sacyr Joint Venture, Translink, Babcock and a mixture of a client lead team. To help Northern Ireland achieve its Climate goals by 2040, Translink sees this as a key enabler. It will deliver 26 new bus stands replacing the existing 18 and will add four new platforms to the train hub. This allows the creation of cross-border services, relocating the Enterprise European cross-border service from Lanyon Station to the new Hub, delivering a more integrated service linking with local bus, glider, taxi, cycling and walking. Translink has already acted towards decarbonisation of the fleet and DerryLondonderry is the first UK city to have a full all-electric bus fleet. Belfast also has a zero-emission fleet of electric and hydrogenpowered buses with more electric to come. The organisation is also looking at the commercialisation of hydrogen production. This aligns Translink’s strategy with the DfI and programme for government, with a proposed 50% reduction in emissions by 2030. Working with Early Contractor Involvement the team has de-risked many items in

the programme achieved by two years’ work ahead of the main contract. The 2.5 years of enabling works by Graham and Babcock International have already changed some services and signal isolation allowing for more frequent services and more efficient use on the existing lines.

Translink described this as a transport-led regeneration project sandwiched between two of Northern Ireland’s lowest socio-economic groups. It considered support through social value clauses, education, extensive public consultation and outlined how Translink is delivering a project with the community and not to the community. They acknowledged the support of the community and elected representatives in approving planning permission for 1.4 million sq. ft. of residential and commercial development. People from all sides of the community could see the benefit. Translink appreciates that as an employer the scheme will generate a rise in economy as well as delivering the commercial aspect of Weavers Cross to drive investment into the city in the same way that Birmingham New Street and Liverpool One delivered.

TEAMWORK, BIM AND TRANSPARENCY TO BUILD BETTER

Duncan McAlister said that “In today’s market a lot of projects have been crippled with procurement challenges. The Executive team listened and gave authority to recruit expertise so that the client was well informed

of the risks involved”. Louise Doyle was appointed early as the station manager and led a very driven process. Partners were encouraged to develop along with the Translink team so that the experience and lessons learned are retained.”

Duncan continued, “the team shares an office together, enabling decisions to be made quickly”, and he added that “the NEC clauses are linked to collaboration. Projects like this don’t happen every day, but the integrated team has a can-do attitude.”

Looking to the future this project will link to the All-Island Strategic rail review in which the Irish government has potential for further future major investment. Already there has been an investment in excess of £300m, and no other transport provider in the UK has this level of investment.

Patrick Finnegan is part of the Project Management team, and he outlined how BIM played an important role, with a digital twin of the scheme developed to highlight clashes by bringing all disciplines into one model. When complete there will be an ‘as-built’ model with a laser scan of the constructed development.

Jason Wylie, also from the project management team, outlined how transparency of data had saved time and the project has 46 key milestones of which 94% have already been delivered early or on time. As the scheme has been delivered with public sector money it is noted that 91% of the funds have gone to local contractors and suppliers. The scheme reinforces that we cannot build ourselves out of congestion in ways of adding more capacity as we did in the past. We can no longer design for ‘predict and provide’. There is a need to refocus on moving people and goods rather than metal on our networks. With a constrained environment in city centres public transport needs to be reliable to provide that sustainable travel alternative. As President I am proud that these two schemes show how we can make a difference if we give serious consideration to achieving the Climate Change targets.

27 PLANT & CIVIL ENGINEER

NORTHERN IRELAND TRANSPORT INFRASTRUCTURE: PROUD OF THE PAST, AMBITIOUS FOR THE FUTURE

BY MICHAEL BELL, CHAIR, CIHT NORTHERN IRELAND

This year marks the 60th anniversary of CIHT in Northern Ireland, with the inaugural meeting of what was then the Institution of Highway Engineers taking place on 11th November 1964, and we continue to serve our members and play a role in representing the broad range of views on transportation in the region.

As a Region, we have always ‘punched above our weight’ within CIHT with the current President, Karen McShane, being the fifth from the Northern Ireland Region – following on from Harold Scott, Billy McCoubrey, Ronnie Porter and Geoff Allister.

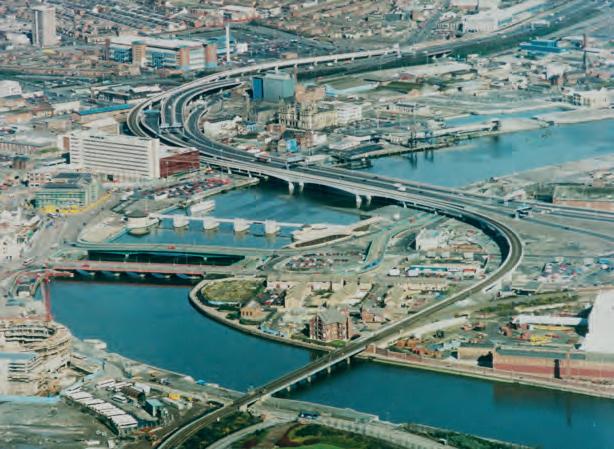

At our recent Annual Gala Dinner held in Belfast City Hall, we were delighted to be able to display some footage of the many schemes delivered by local Northern Ireland companies, interspersed with some old footage from the BBC archives – reminding us just how much progress has been made in transport and infrastructure over the last 60 years. Over the 60 years that CIHT has been active in Northern Ireland, there have been more than 200 major road, rail and bridge projects delivered across the province.

ROAD AND RAIL

In the 1950s and 1960s the development of the road network, particularly motorways and trunk roads was buoyant with over

60% of the current motorway network being delivered between 1962 and 1969. Although road building projects slowed from the 1970s, we have still seen significant

highways 28 PLANT & CIVIL ENGINEER

Cross Harbour Road and Rail Bridges, 1995, courtesy of Farrans Construction.

Dungannon Public Realm, 2017, courtesy of McQuillan Companies.

Surfacing in Portrush, courtesy of P Keenan Quarries.

infrastructure projects such as the A12 Westlink, Cross Harbour Road and Rail Bridges and improvements to the strategic road network including the A1 to Newry, A4 to Ballygawley and A6 to Derry-Londonderry.

We have also had improvements to our public transport services, with the introduction of the CIHT award-winning Glider in Belfast providing a continuous link between East and West Belfast and out to Titanic Quarter with plans for Phase 2 to include a North-South route. On the railways there have been major track renewal projects, upgrades to signalling and extensions to platforms. The ambitious and multi-award-winning North West Hub in Derry-Londonderry involved the restoration of an 1873 building to make it suitable for use as a 21st-century transport facility and of course the ongoing construction of Belfast Grand Central Station.

This project will deliver a world-class integrated transport hub, the largest transport facility on the island of Ireland, and along with the associated regeneration of the surrounding area is set to bring

economic, social and environmental well-being benefits for everyone.

SIGNIFICANT CHALLENGES REMAIN

However, there are still significant challenges and improvements which are required to be delivered in the future to support and encourage the economic growth and prosperity of the region and to provide a safer and more sustainable environment for everyone who lives here.

Our industry urgently needs to take steps to address the decarbonisation of transport, particularly with climate scientists increasingly indicating we are not moving fast enough to meet the climate action targets that have been set.

CIHT NI welcomes the development of a new suite of transport plans for Northern Ireland by the Department for Infrastructure, which targets a more sustainable future for all of us. Having our local government and Executive Ministers back in place is a real positive and while budgets remain

challenging, hopefully we can really kick on and achieve some great things in the future.

EMBEDDING DECARBONISATION THROUGH CPD

CIHT has made its own Climate Change Pledge, with a number of commitments aimed at supporting members to adapt and respond. Updated continuing professional development (CPD) guidance, includes an expectation that all CIHT members should include some of their annual CPD on developing skills and knowledge they need to contribute to the decarbonisation of highways and transportation.

The launch of the Transport Decarbonisation Pathway, which is available to CIHT members free of charge through the CIHT Learn platform (and non-CIHT members for a small fee), aims to provide a structured framework fulfilling climate action-related CPD goals. This includes an introductory online course on Transport Decarbonisation and some more advanced material around skills and topics relevant to different job roles.

highways 29 PLANT & CIVIL ENGINEER

A1 Beech Hill to Cloghogue, 2010. Courtesy of AECOM

BRT Colin Connect Transport Hub, 2019. Courtesy of Amey

J & S MCKEE AND GROUNDFORCE “DIG DEEP” ON NELSON STREET

Building and engineering contractors J&S McKee Ltd, who have completed substructure package of works on a prominent new twelvestory student accommodation development in Belfast, appointed Groundforce to provide a ground retention solution during the substructure phases.

Called ‘Nelson Street’ and located on Belfast’s Westlink road corridor, the project required several large, deep excavations, in very poor ground and adjacent to one to one of the busiest road networks in Belfast and Groundforce was appointed to help achieve a solution for ground retention during the sub-structure phases. Working closely with Groundforce’s local operations and technical teams, J&S McKee was able to install a ground support system to

allow excavation to the depths required while maintaining access for heavy site traffic during the construction phase.

STAIRWELL AND LIFE CORE BASES

There were two stairwell/ lift core bases expanding to 16m x 13m at a depth of 3.5m, two tower crane bases at 12m x 12m and 4.0m deep and a 14m x 12m

base for an NIE substation at a depth of 2.5m with the 260m perimeter of the site also needing full retention for construction of the ground beams. The ground conditions consisted of 1.5m of made ground overlaying 2-3m of watersaturated sand, with a robust temporary works design and shoring system required to keep

other site operations running smoothly and unhindered. Due to the poor ground conditions, the sheet-piled perimeter of each excavation had to be supported by a heavyduty hydraulic framing system.

NO-TOE SOLUTION

“In reasonable ground conditions, a sheet pile toe can help reduce the load on the internal support system, however, due to the poor ground conditions in these locations, a sheet toe-in would have added load to the system. This occurs during the excavation phase, when the level of soft material tries to equalise, creating a moment at the end of the sheet and transferring loading into the support system” comments Groundforce director, Joe Lenihan. Therefore a “no-toe” solution was required but with no less than three levels of frames required to withstand the high loading from the saturated sand layer.

As part of our commitment to reaching net zero by 2050, we’re including embodied carbon estimates on all temporary works designs.

30 highways PLANT & CIVIL ENGINEER

COMMITMENT TO REACH NET ZERO BY 2050 SCAN THE QR CODE TO VIEW THE TECHNICAL GUIDE CO2 POSITIVE STEP TO SUSTAINABLE IMPROVEMENT CARBON REPORTING ON TEMPORARY DESIGNS Mountmellick Hire Desk 1800 883 364 Lisburn Hire Desk 0800 783 2055 www.vpgroundforce.ie

TEMPORARY WORKS MAKING A PERMANENT IMPACT

builds the future

Dynapac builds the future

Dynapac builds the future

At Dynapac Road Construction Equipment we strive to find new ways and better solutions. Productivity, performance, ergonomics and environmental care are our priorities. However, our most important priorities are customer satisfaction and success. That’s why we ensure our efforts and resources are focused on development and knowledge transfer. Still, after more than 75 years, the ability to take advantage of change helps us to remain pioneers.

W.A.C McCandless (Engineers) Ltd

95-99 Limestone Rd Belfast

Contact W.A.C McCandless today or visit www.dynapac.com for more information.

At Atlas Copco Road Construction Equipment we strive to find new ways and better solutions. Productivity, performance, ergonomics and environmental care are our priorities. However, our most important priorities are customer satisfaction and success. That’s why we ensure our efforts and resources are focused on development and knowledge transfer. Still, after more than 75 years, the ability to take advantage of change helps us to remain pioneers.

Contact W.A.C McCandless today or visit www.atlascopco.co.uk for more information.

At Atlas Copco Road Construction Equipment we strive to find new ways and better solutions. Productivity, performance, ergonomics and environmental care are our priorities. However, our most important priorities are customer satisfaction and success. That’s why we ensure our efforts and resources are focused on development and knowledge transfer. Still, after more than 75 years, the ability to take advantage of change helps us to remain pioneers.

Contact W.A.C McCandless today or visit www.atlascopco.co.uk for more information.

Tel: 028 9035 1811

Fax: 028 9074 6015

Email: sales@wacmccandless.com

www.wacmccandless.com

W.A.C McCandless (Engineers) Ltd

95-99 Limestone Rd Belfast

Tel: 028 9035 1811

Fax: 028 9074 6015

Email: sales@wacmccandless.com

www.wacmccandless.com

CHARTERED INSTITUTION OF HIGHWAYS AND TRANSPORTATION 60th ANNIVERSARY GALA DINNER

The Chartered Institution of Highways and Transportation celebrated its sixtieth anniversary in Northern Ireland at a gala dinner in the elegant surroundings of Belfast City Hall on the 2tth March.

The reception allowed the opportunity for guests to look at some of the many schemes delivered by local Northern Ireland companies, interspersed with some old footage from the BBC archives, highlighting the progress over 60 years.

Proceedings were opened by Michael Bell, Cahir of the CIHT Northern Ireland region. Karen McShane, CIHT President delivered the opening address, to which Denis McMahon, Permanent Secretary at the Department for Infrastructure, responded. The guest speaker for the evening was retired rugby union referee and television personality, Nigel Owens MDB. Widely considered to be one of the greatest rugby referees of all time., he is also passionate about his Mairwen Hereford herd, bred on his farm in his home village of Mynyddcerrig. Whilst Nigel is a fluent Welsh speaker and presenter of Welsh language chat shows, he regaled a captivated audience in English!

60th anniversary 32 PLANT & CIVIL ENGINEER

Tara Mills, Roisin Wilson, Hon Sec CIHT NI, Karen McShane, President CIHT, Michael Bell, Chair CIHT NI Region, Nigel Owen and Louise Dougan.

Karen McShane, President CIHT, Michael Bell, Chair CIHT NI Region, Nigel Owen, Frank Given, Chair Engineers Ireland, Martin O’Kane, President CEF and David Fletcher, Chair IStructE NI.

Jack Chapman, Katrina Wilson, Rachel McKeag and Neil Cooke.

Andrew Murray, Jenny Murray, Rona McRobert and John McRobert.

33 PLANT & CIVIL ENGINEER

60th anniversary

Matt Steele, Chair CIHT ROI, Paul Brogan, MD McQuillan Companies and Ronnie Porter, Past President IHT.

Karen McShane, President CIHT, Peter McParland, DFI, Stephen Bradshaw Hon Tres CIHT NI, Nigel Owen, Sue Percy CEO CIHT and Michael Bell, Chair CIHT NI Region.

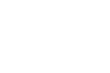

Martin O’Kane, President CEF, David Fletcher, Chair IStructE NI, Frank Given, Chair Engineers Ireland and Peter Morrow, Chair TPS NI.