21 minute read

Hand Tools & Diagnositics: Keeping on top of technical nuances

KNIPEX PLIERS WRENCH XS

Offering 100 millimetres of pure gripping strength: small, handy and versatile

Tridon says the tried and tested Knipex Pliers Wrench is now also available as an XS version. Knipex’s Pliers Wrench XS (86 04 100) is the smallest pliers wrench in the product portfolio of the German based pliers manufacturer. With a length of only 100 millimetres, the versatile tool with a width across flats of up to 21 millimetres can tighten and loosen screws gently and much more. It has a continuous gripping capacity for all common widths, both metric and imperial.

The high lever transmission joint means that workpieces can be securely gripped, held, pressed or bent. Thanks to its compact design and very slim head, the Pliers Wrench XS is also perfect for working in the most confined spaces. The tool can be easily fine adjusted with one hand and has ten adjustment positions for different workpiece sizes by simply pushing. The sturdy slip joint offers great stability and long-term resilience, while a pinch stop prevents crush injuries. Small enough to fit in a pocket, the classically embossed and chrome-plated Pliers Wrench XS is extremely versatile: it can be used in precision engineering, plumbing applications or model making, and is also suitable as a compact onboard tool for cyclists or motorcyclists. It is a real “everyday carry tool” that is the perfect solution for many everyday tasks. The smallest pliers wrench is also highly suitable for delicate materials. Smooth jaws ensure absolutely gentle assembly of delicate fittings with surface finishes. This means you can work on the entire surface of a fitting without worrying about damaging the chrome. Tridon is the exclusive distributor of Knipex in Australia. For more information, call 1300 362 263 for your nearest distributor or visit www.tridon.com.au

SP TOOLS PREMIUM BATTERY ANALYSER

Tools.com says this analyser is essential for workshops

The SP Tools Premium battery analyser (SP61065) has a built-in printing functionality, providing instant hard copy test results ensuring you have all the details of your job when needed. Features for this workshop analyser include: • Capacity: 100-2000CCA. • Displays and prints time stamped reports: effective CCA, battery voltage, percentage of battery health and condition, charge system analysis and starter system analysis. • Auto-saving function ensures the latest test results are automatically saved for reviewing or to store digitally via USB cable. • Multi-function testing: accurately tests battery, alternator charge current, starter function and diode ripple • Easily adjustable date/time printing mode. • Extremely simple interface provides quick and easy battery analysis. • Circuit protection provides the analyser with reliable protection against short circuiting. • Reverse polarity connection protection ensures reverse connection will not damage the tester or affect the vehicle and battery. • No additional batteries required – unit is powered via test battery. The SP Tools Battery Analyser is available to purchase online from www.tools.com

AUTEL MAXISYS ULTRA

Those behind the product says it offers “unparalleled performance for all workshop types”

The MaxiSys Ultra is Autel’s most ambitious diagnostics tablet designed to maximise technician intelligence. It features a 12.9-inch touchscreen tablet with Android 7.0 OS powered by an Octa-core processor (2.3GHz Quad and 1.7GHz Quad) and substantial 256GB built-in memory, all powering the new split-screen multi-application navigation to provide diagnostic guidance and test components to confirm repairs. Combined with the dynamic topology module mapping, enhanced Autoscan features and Intelligent Diagnostics options, the Ultra offers the technicians step-by-step repair guidance. The new MaxiFlash VCMI functions as a fourchannel oscilloscope, waveform generator, multimeter, and CAN BUS tester. The convenient docking station ensures you always have power to scan. Those behind the product say it takes intelligent diagnostics to the next level with diagnostic trouble code symptom-based repair assistance with Technical Service Bulletins from OEM manufacturers for common vehicle issues. This allows technicians to compare TSBs with current issues, eliminating unnecessary stripping of components and improving efficiency. The topology module tree is a new, exclusive feature from Autel, in which the tool automatically displays all the modules on a single page and highlights the modules that have faults. Technicians can then see which modules are linked directly, for a better understanding of how faults are related, and which faults are a priority. For more information, contact your local Repco or NAPA store today. Visit www.repco.com.au or www.napaparts.com.au for your nearest branch.

GO CORDLESS

With the Lithium-Ion Soldering Iron

Tradeflame is home to an extensive range of soldering irons which it says have stood as an industry benchmark for many years. Tradeflame says its soldering irons have been designed in-house to be more versatile and ergonomic and are loaded with innovative features for improved function and ease of use. The range varies from 8W to 100W, fully portable to 240V, and has an iron to suit any level of user, project, or location. Portable Soldering options are the way to go for many tradies and caravanners, and the 4.2V 12W Rechargeable Lithium-Ion Soldering Iron is a new firm favourite. Powered by a 2900 mAh, 4.2V lithium-ion battery which recharges in two hours with the provided USB-C cable, Tradeflame says this little power iron reaches the maximum temperature of 480°C in a record time of three minutes and provides continuous use for up to 50 minutes per charge. Not only is this soldering iron a fast-charging powerhouse, Tradeflame says it has included the best features that every soldering enthusiast has always asked for. “We learned that many users worked for extended amounts of time on certain projects, and with a bad grip design comes tiredness and soreness in the hand. With this is mind, we gave it an ergonomic design for maximum comfort in every way, including safe anti-roll wings to stop it rolling off surfaces when placed down,” Tradeflame Category Manager, Scott Archibald, said. “We’ve also taken into consideration that certain portable areas can be quite dark to work in, so we’ve added an LED working light so you can always see what you’re soldering no matter how small or dark the space. “Some copper soldering iron tips can deteriorate quite quickly, but with our long-life conical tip, the tip is iron plated for anti-corrosion, the inner core is copper for good conduction of heat resulting in a longer lifetime for the tip if properly maintained, you’ll also get great value for money and a more cost-effective option for serious users.” Recently, Tradeflame sent the Lithium-Ion Soldering Iron on a road-test with avid caravanners Grant and Linda Bloffwitch on a trip around Australia. Upon their return, they were incredibly happy with their new iron. “No longer do we need an inverter and extension lead specifically for using the soldering iron. The LED illuminated the soldering tip for the times when we were working in dark areas such as under a vehicle’s dashboard, and the unit heats up in minimal time,” Linda said. Whether you’re on the go or just like the freedom of soldering without a cord, Tradeflame says the Lithium-Ion is ideal for any job faced by a mechanic, 4WDer or carvananner, electrician or DIY enthusiast. For more information, visit www.tradeflame.com

BOSCH OFFERS A UNIQUE DIAGNOSTIC SOLUTION

Cyber security measures may change how diagnostic testing is approached

The “Secure Gateway Module,” often called SGW, is a technology that has been developing in the aftermarket diagnostic repair arena. The SGW acts as a firewall between a vehicle’s multimedia system, diagnostic port, and other electronic systems to prevent unauthorised access. As the electronic systems in cars become more powerful, they also become more vulnerable to failures in cyber security. For example, in 2015 a pair of hackers demonstrated that they were able to access and gain control of a Jeep Cherokee’s electronic systems from a remote location. This was achieved by infiltrating the connected vehicle’s multimedia Wi-Fi connection. Chrysler quickly corrected this particular problem, but it brought awareness to the need for better cyber security for vehicles. This is where the SGW comes in, and it’s expected that all vehicles with integrated connected technology will have a form of SGW installed within the next five years. This will affect aftermarket workshops in a few different ways. It’s possible that the scan tools that many shops utilise now will have very limited access when it comes to vehicles fitted with the SGW. Something as simple as a service reset function may become impossible to complete. Users might not be able to access any Advanced Driver Assistance Systems (ADAS) to calibrate. It could be that a scanner could read fault codes but not clear them. Nobody knows for sure yet what will and will not be possible as this is still a developing technology. Bosch Diagnostics has created a solution to this looming problem with its Secure Diagnostics Access (SDA) technology, which is integrated into Bosch’s KTS 250, 350, 560, and 590 range of diagnostic tools with the latest ESI[tronic] 2.0 software. This software offers comprehensive vehicle coverage while also giving unrestricted access to vehicles with the SGW. The diagnostic tool will need to be connected to a stable Wi-Fi connection, and the user will need to register a Bosch ID and possess a valid and current ESI[tronic] software license. It offers an added advantage of eliminating the need to register employees and the business with each individual vehicle manufacturer and paying a subscription fee every time the diagnostic tool is used (which is currently the case with FCA vehicles). For a demonstration on the Bosch KTS250, KTS560 and KTS590 diagnostic tools, please contact your nearest CoolDrive Auto Parts branch. For more information, visit www.cooldrive.com.au

NEW ZENITH Z5 AUTOMOTIVE DIAGNOSTIC SCAN TOOL

Locally designed and engineered for the Australian/New Zealand and Oceania markets

G-Scan Oceania would like to introduce the exciting new Zenith Z5 which continues on the highly successful G-Scan professional scan tool series. The Zenith Z5 is described by G-Scan Oceania as a world class, premium quality, compact, ruggedised eight-inch industrial tablet made in Korea, which features an enhanced user interface designed to seamlessly integrate with new Australian fair to share legislation. It features EZDS’ “unparalleled” diagnostic software program familiar to the Australian/ New Zealand market since 2009 and is driven by a powerful octa-core processor for optimum performance and efficiency in the workshop. The first model of the new Z series is a result of demand from tech savvy automotive professionals in various world markets including Japan and South Korea. EZDS has opted for an ergonomic, light weight, workshop friendly ruggedized tablet with an eightinch Eyellumicate crystal clear display. It says the premium field optimised full high-definition display offers higher resolution and is clearly seen in bright sunlight conditions. Featuring the Android 9 operating system for fast and easy menu selection, quick boot up, multitasking, fast networking and enhanced security, the Zenith Z5 offers advanced graphing, recording and logging of vehicle data analysis and momentary glitches can be monitored, saved and reviewed very simply. The Zenith Z5 supports 12 and 24v light and heavy vehicles with Bi-Directional functionality to perform functions such as key programming, DPF regeneration, injector pilot learning, steering angle calibration, electronic park brake service mode, automatic transmission learn functions, module coding and programming, ADAS calibrations, J2534 pass thru programming (internal), hybrid and electric special functions, battery registrations and more. The Smart update system allows the user to remain up to date easily using Wifi and files can be printed or shared via Wifi and Bluetooth. The professional Pre and Post scan diagnostic report function provides an intuitively designed diagnostic report created quickly and easily, including business logo, workshop and customer details, diagnostic trouble codes, saved image files, camera images, personalised notes and more. The Z5 offers diagnostic software programmed by engineers with technicians in mind, including fast access to Service functions menu and Auto selections, all backed by a professional, local technical support team to assist. The Zenith Z5 is available to purchase throughout Oceania from the same reseller network. For more information or to order, call 02 9905 8055 or email sales@zenithdiag.com.au for an upgrade option available in your location.

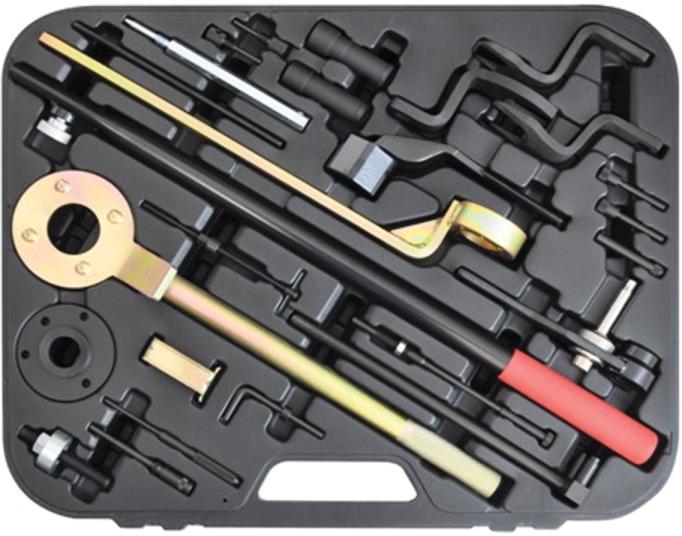

TIMING TOOLS

Specialist Tools Australia has an extensive range of timing tools

The relationship between the moving parts of an engine is kept in check by the very precise timing of the engine components. Specialist Tools has a wide array of tools for the job. The engine timing and supply pump removal tool for the Ford/Mazda Duratorq 2.0L/ 2.2L/ 2.4L and 3.2 litre engines combination kit (SA-8033 and SA-8033A) can assist with the positioning of gears, retaining of the timing belt and holding of the supply pump gear. The SA-8366 timing belt replacement set is said to be very comprehensive and versatile, suiting many Honda, Mazda, Hyundai and Daewoo (diesel and petrol) vehicles. This kit contains 25 different components that will lock and align the camshafts, crankshaft, tensioner etc during the removal and installation of the engine timing belt, chain and other engine servicing and repairs while removing components. It also contains a comprehensive range pulley holding and pulling tools suitable for popular Australian, Japanese and Korean applications. When an engine is fitted with a VE type rotary fuel pump the setting is expressed as plunger lift measurement in mm at a specified point, usually ATDC (At Top Dead Centre). It is often difficult to ascertain “Top Dead Centre” before the engine or casing needs to be dismantled as this position will be critical for all other timing operations – Specialist Tools Australia’s Top Dead Centre tool (SA-5193) is a pneumatic indicator for finding top dead centre. Measurements can be checked and set with dedicated tooling containing a dial indicator and specific adaptors like those found in Specialist Tools’ Diesel Fuel Pump Timing Set (SA-8214A) which is designed for many vehicles in Australia such as Toyota, Nissan, Mitsubishi, Mazda, VW, Audi and Ford. This kit contains the dial indicator, DTI bracket and probe with adaptors, Injection pump locking pin and camshaft alignment pin and locking bracket. In the Specialised Govoni range is a number of tools for European vehicles including kits for the removal of fuel pumps, injection Fuel Pump and engine timing tools. Amongst the range is the Audi/VW Kit with specialised components for locking the camshaft, crankshaft and fixing the chain tensioner (G310215000), while the Govoni Timing Tool Set for Fiat, Ford, Volvo, Peugeot and Citroen vehicles includes special tools for the flywheel and locking pin for the camshaft/crankshaft. There are also many other timing tools available on Specialist Tools’ website. For more information or assistance in finding the right tool, visit www.specialisttools.com.au or call 02 6280 4334.

CENTURY YU-FIT BATTERY CONFIGURATOR TOOL

Proper battery configuration matters now more than ever

Today’s vehicles are becoming increasingly complex, with a variety of technologies now being employed by manufacturers to improve fuel efficiency and reduce carbon emissions. With the introduction of C02 production control systems including Idle Stop Start, it is essential that vehicles have a battery of the correct type and specification installed. More importantly, several automotive manufacturers have introduced active energy management systems that require the replacement battery to be correctly configured to the vehicle following installation. This configuration is required because a brandnew replacement battery requires a very different charging strategy compared to the battery which has reached the end of its serviceable life. Applying the old charging strategy to a new battery could result in a loss of Stop Start system functionality, loss of vehicle system functionality, plus increased fuel usage and C02 emissions. Luckily, the configuration of these vehicle energy management systems can now be carried out simply and easily using the Century Yu-Fit battery configurator tool. The Yu-Fit tool can be used to configure the replacement battery to the vehicle’s active energy management system – informing the vehicle that a new battery of the correct type and performance has been installed. It will also inform the charging system of the new battery characteristics and ensure the correct charging strategy is applied right from the start. Century says configuring a vehicle with the YuFit tool following battery replacement will ensure the vehicle’s charging, energy management and system functionalities will perform as intended, and ensure that your customer will receive the best possible performance from their battery purchase. The Century Yu-Fit tool comes pre-loaded with profiles for all common vehicle manufacturer makes and models and receives regular updates to help keep pace with the latest changes to the Australian new car market – all by simply connecting the tool to your PC. Don’t leave your customers stranded - test every battery

Research has proven the correlation between the more batteries you test, the more you sell. In Australia, approximately 750,000 vehicles per year require a roadside battery replacement – and over 70 percent of these vehicles would have been in a service bay or retail outlet within the last six months. Century says proactive battery testing using

NEW CSC-DIGITAL CALIBRATION TOOL

HELLA GUTMANN invites you to join the digital revolution

It is common knowledge that more and more vehicle models are being equipped with modern safety assistant systems such as Autonomous Emergency Braking, Adaptive Cruise Control, Lane Keeping Assist or Lane Change Assist. As quickly as ADAS – now a feature in most new vehicles – change and evolve so too does the equipment that services these systems. HELLA GUTMANN says it holds a strong sense of innovation and forward thinking in all products it has developed and the latest CSC-Tool Digital calibration solution is testament to this. Designed with workshop technicians, HELLA GUTMANN says the CSC-Tool Digital is efficient, easy to use and provides even more flexibility than ever before. Australian workshops service a wide range of vehicle makes and models, each with unique calibration requirements. As a result, the versatility necessary from calibration and diagnostic tools is even more important. HELLA GUTMANN states that with its CSC-Tool Digital app technicians now have access to more than 20 calibration targets across multiple makes and models. It explains that these targets are easily interchanged at the touch of a button, greatly reducing set-up time in comparison to conventional systems while there is no need to physically store multiple panels. Targets are projected in high resolution onto a 200cm screen, using a state-of-the-art ultra-short throw projector – reportedly the largest of any ADAS calibration tool currently available. In addition, patented green line laser technology makes it quicker and easier to ensure absolute alignment of the vehicle’s camera or radar sensor using its rear axle. With HELLA GUTMANN’s flexible licensing options users can choose between purchasing and renting target images based on their needs, allowing workshops to easily service a wider range of vehicles. a handheld tester like the DHC BT521A from Century Yuasa provides an accurate on the spot test result in minutes. It can help identify suspect batteries before they fail and highlight problems with the vehicle’s starting and charging system. But more importantly, it helps your customers avoid the financial and emotional costs associated with a flat or faulty battery. For more information, please contact your Century Yuasa representative on 1300 362 287 or visit www.centurybatteries.com.au

In addition, when used in conjunction with the HELLA GUTMANN mega macs series of diagnostic tools, a calibration report can be generated as a permanent record that calibration has been carried out. HELLA GUTMANN calibration and diagnostic solutions will be on display at AAAExpo with live demos also available throughout the duration of the show – visit the HELLA stand (J2) to find out more. For a no obligation discussion with one of HELLA GUTMANN’s specialists, call 1800 061 729 or email hgscustomersupport@hella.com

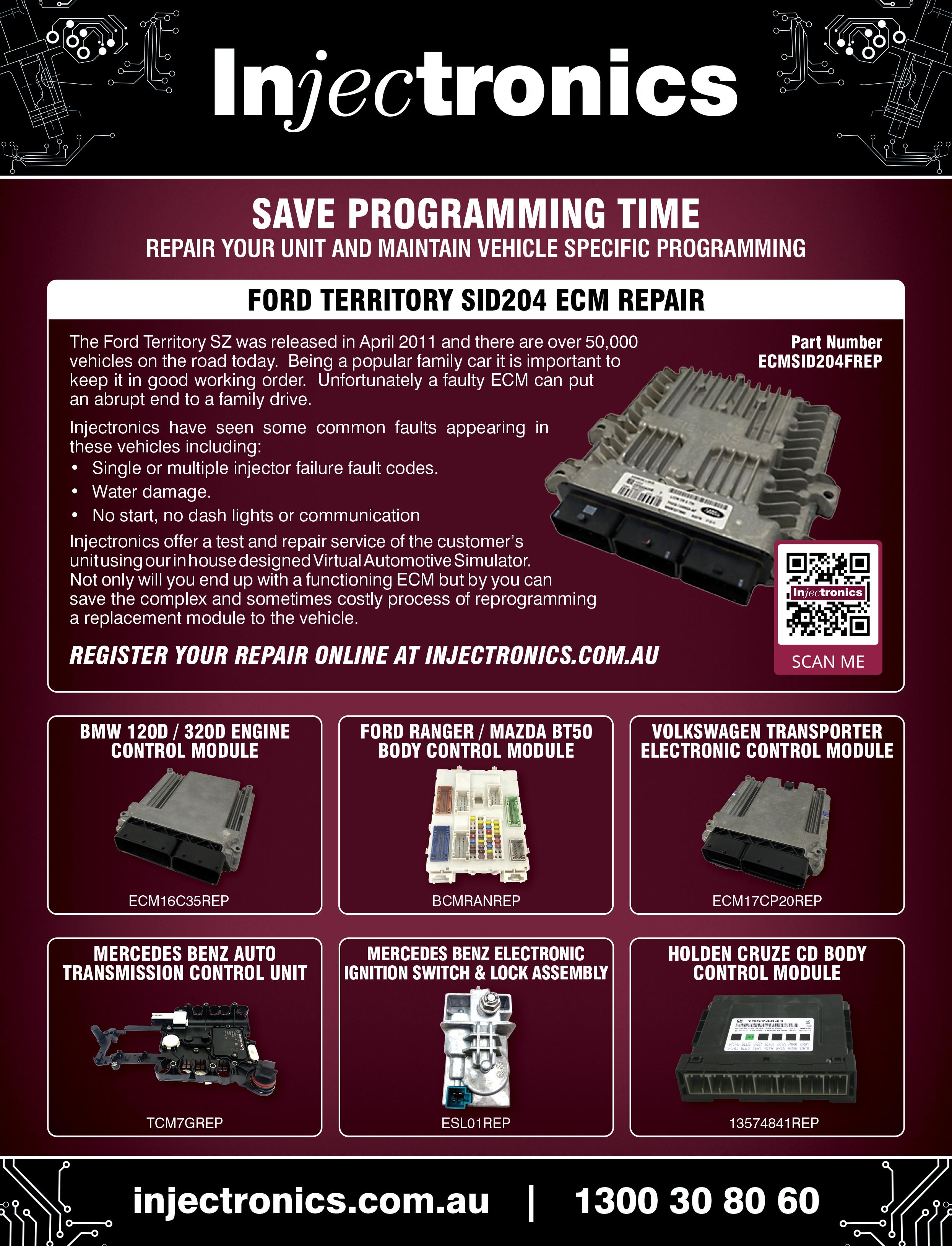

REPLACE OR REPAIR?

It all started with simple ignition modules, closely followed by the enigmatic ECM

Since then, the OEMs have taken electronic control to the extreme. Modern vehicles commonly feature a slew of complex, electronic modules controlling the driveline, braking/stability systems, security systems, climate control – there’s even controllers working the wipers (auto rain detect) and automatic headlight levelling. As we all know, these control modules are prone to failure – with correct diagnosis and rectification anything but straightforward. Injectronics launched in 1984 and says it has become the industry leader in the remanufacturing and repair of automotive electronic modules. It states the service is not only cost effective, it is also fast and worry free thanks to its 12-month warranty, making it the most viable option for many workshops. Why new modules need programming

Control module programming is and will surely be the topic of conversation for the next decade or so, as many more electronic modules require specific programming. They are programed with unique, VIN-specific data relating to the vehicle’s individual engine, transmission, driveline, safety, security, instrumentation, infotainment and comfort systems. Brand new modules have none of this information and require programming, often completed by an OEM diagnostic tool using a process called PassThru Programming. And it gets worse. When a new module is introduced to a vehicle, if the components it operates, along with the other modules it links to do not all communicate correctly, completely new issues can emerge within seemingly unrelated systems. Plug ‘n’ Play convenience

Few shops have the specialist diagnostic equipment to carry out the necessary reprograming. After replacing a faulty module, the vehicle still has to go to the dealer on the back of a truck. So, Injectronics asks, is replacing a control module the only option? In most cases, Injectronics says it is able to repair electronic control modules, without losing any VIN-specific or functional programming data and return it ready for re-installation. It explains this means there is little to no additional programing required, no need for specialised programing equipment, no need to download software from the internet and no need to send the customer’s vehicle off to the dealership. When repair is not possible, Injectronics says it can typically ‘Clone’ the original VIN-specific data and move it across to the replacement module. The age problem

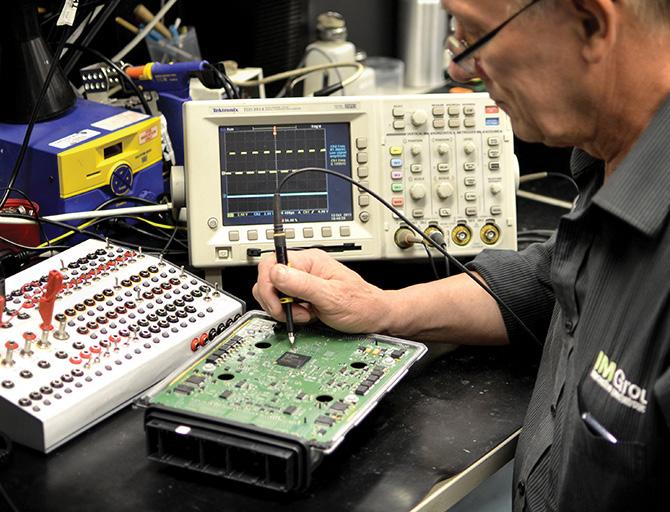

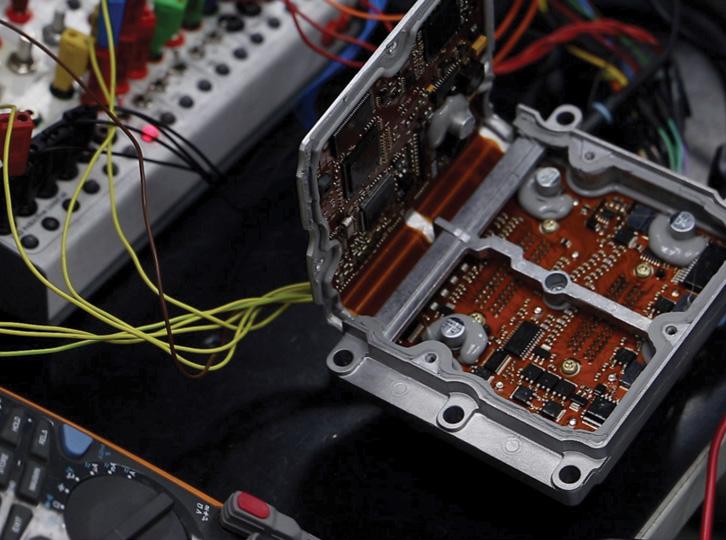

As vehicles get to the age where new, replacement modules are no longer available – or the dealer no longer caters to a vehicle, the ability to make these repairs and maintain original programming is vital – otherwise the vehicle essentially becomes a throw-away proposition. This was a prime motivation for Injectronics to heavily invest in developing the specialised equipment and expertise necessary to assess, repair and reprogram a myriad of automotive electronic modules. Injectronics states that it utilises its very own designed and built Virtual Automotive Simulator (VAS). With this sophisticated computerised testing station, there is no probing of wiring looms or circuit boards, rather the VAS is able to run and verify a module’s every function. Which in turn enables repair technicians to quickly and confidently identify any operational faults, plus ensure the completed repair is ready to plug and play. Intermittent faults are the worst

With its VAS machine, Injectronics states it is able to repeatedly cycle a suspect module to induce the intermittent fault to reveal itself. It is also not uncommon for intermittent faults to only occur under certain temperature conditions. The engineers place modules in Hot and Cold conditions, while using the Virtual Automotive Simulator, to replicate both real-world operating conditions but also extreme temperatures. 800 and counting

Currently Injectronics lists over 800 different electronic control modules with an identified and proven repair procedure. As impressive as this number is, Injectronics says it is particularly proud of its ‘First Unit’ department which is constantly evaluating, decrypting and problem-solving new units to add to Injectronics’ database, which is why Injectronics encourages enquiries regarding units not listed on the website. The diagnosis dilemma

Injectronics says that yes, the recent passing of the Australian Data Sharing Legislation is going to prompt more opportunity for independent repairers and the replacement of new electronic control modules. It states that diagnostic and reprogramming equipment will still be required – along with specialised, in-depth training to complete the tasks. It encourages you to keep in mind that Injectronics provides a dedicated technical support hotline to discuss issues and asses the best direction for repair – a service which is offered for free to customers. Both light and heavy

It is not all about passenger vehicles for Injectronics. The widespread use of electronic control modules in heavy vehicles (trucks) and plant equipment has made servicing this industry a major area of growth and resource allocation for the company. With its strong focus on research, development and innovation, combined with its extensive experience – Injectronics says it is the perfect workshop partner, stating that it can take the headache out of dealing with the myriad of unfathomable electronic control modules fitted to modern vehicles. Visit www.injectronics.com.au for a full listing of services, or to book a repair and speak with the technical team call 1300 308 060.