A rtic r ecalibration

Resource driven fabrication system for the Artic in the near future [<2050]

Emergent Technologies and Design 2016 - 2018

M.Arch Candidates

Mithuna Murugesh | Elena Shilova

Director Michael Weinstock

Emeritus Professor Dr. George Jeronimidis

Studio Master Elif Erdine

Studio Tutors Antiopi Koronaki Alican Sungur Lidia Badarnah

A rtic r ecalibration

Resource driven fabrication system for the Artic in the near future [<2050]

Architectural Association School of Architecture

Master of Architecture, Emergent Technologies and Design 2017-2018

Architectural Association, 2018 36 Bedford Square, London WC1B 3ES

Architectural Association (Inc), Registered charity No 311083 Company limited by guarantee. Registered in England No 171402

M.Arch candidates: Mithuna Murugesh Elena Shilova

ii i Architectural Association Arctic Recalibration

Architectural Association School of Architecture

Graduate School Program

Coversheet for submission 2016-2018

Programme Emergent Technologies and Design

Term Dissertation

Student Name(s) : Mithuna Murugesh, Elena Shilova

Submission Title Arctic Recalibration

Title Emergent Technologies and Design Course

Tutor Michael Weinstock, George Jeronimidis

Submission Date 12.01.’18

Declaration :

“I certify that this piece of work is entirely my/our own and that any quotation or paraphrase from published or unpublished work of others is dully acknowledged.”

Signature of Student(s)

Mithuna Murugesh Elena Shilova

iv iii Architectural Association Arctic Recalibration

”Fall seven times, stand up eight.”- Japanese Proverb

I would first like to thank my thesis advisor Michael Weinstock, Director of the Emergent Technologies and Design program of the Architectural Association school of Architecture. The door to your office was always open whenever I ran into a trouble spot or had a question about my research or writing.

To George Jeronimidis, your feedback and always helpful advice and attitude are always appreciated. Your helpfulness will not be forgotten and I am very grateful for your positive influence at the AA.

I would also like to show gratitude to my tutors, including Elif Erdine, Evan Greenberg, Antiopi Koronaki, Alican Sungur and Lidia Badarnah for their insightful comments and encouragement, but also for the hard question which incented me to widen my research from various perspectives. I would also like to thank Mohammed Makki who’s input was highly valued. A special thanks to Angel Lara Moreira who’s ‘can do’ attitude was always a positive reinforcement.

I would like to sincerely thank and show my gratitude to my family for always believing in me, and for the continuously support to help me to pursue my ambitions. Special thanks to my mother for the unwavering encouragement and support through out.

I thank my fellow teammate, Elena Shilova, for the stimulating discussions, her thirst for knowledge and for the sleepless nights when working together without whom this research would be incomplete.

-Mithuna Murugesh

“In the middle of every difficulty lies opportunity” -Albert Einstein

I would like to express my sincere appreciation to my advisor, Michael Weinstock, for his impregnable belief in this project, as well as knowledge and guidance, both professional and personal. His sincere love and passion for architecture was contagious, encouraging us to challenge ourselves, be ambitious, adventurous and push our boundaries.

I also want to express my deep gratitude to prof. George Jeronimidis, whose expertise and patience supported this project at every step of its winding path. I am thankful to Elif Erdine, Evan Greenberg, Manja Van de Worp, Lidia Badarnah, Antiopi Koronaki and Alican Sungur for their highly professional attitude and for the warm, friendly atmosphere they created at Emergent Technologies and Design. Lastly, I would like to acknowledge the contribution AA staff, and Angel Lara-Moreira in particular for his help and good advice.

I would like to sincerely thank my beloved family, who always supported and believed in me, providing me this opportunity in the first place. I would like to express my gratitude and admiration to all of my colleagues in EmTech and in the AA, whose kaleidoscope of cultures, passions and characters inspired me along all the journey.

Last, but not the least, I would like to thank my amazing teammate, Mithuna Murugesh, whose unbelievable dedication, attitude and professionalism was an example for me and a powerful driver in the completion of this project.

-Elena Shilova

vi v Architectural Association Arctic Recalibration

Materials are not inert receptacles for a form imposed from the outside, but active participants in the genesis of form.

Neri Oxman MIT Media Lab

viii vii Architectural Association Arctic Recalibration

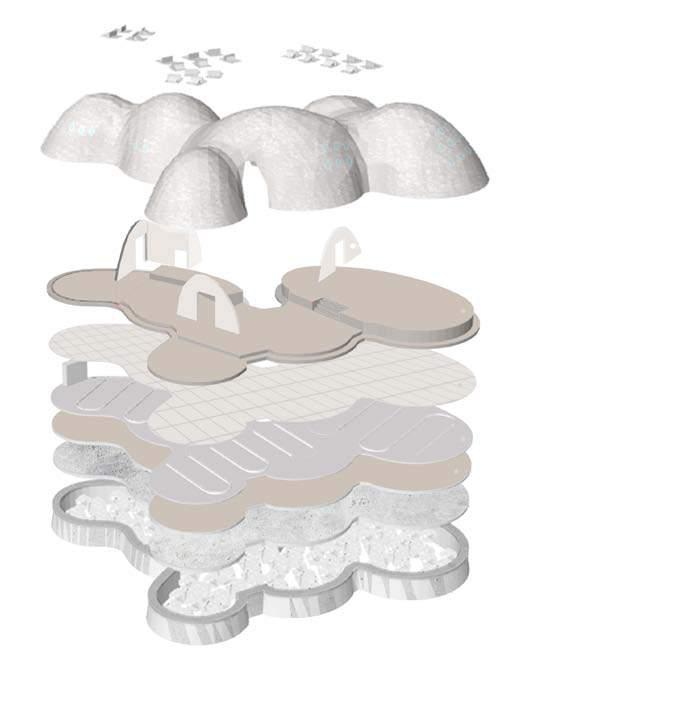

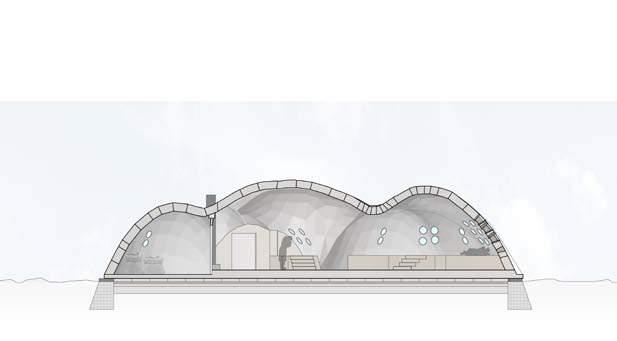

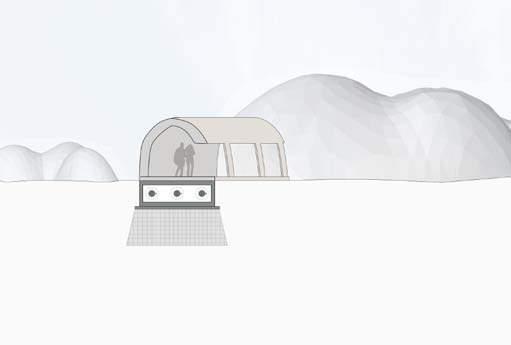

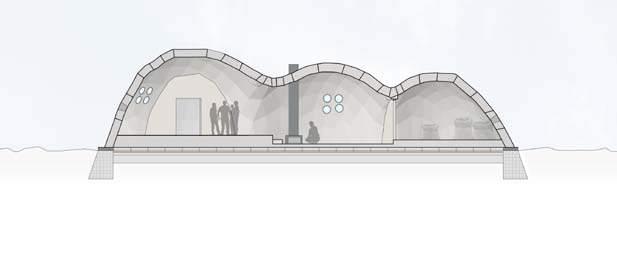

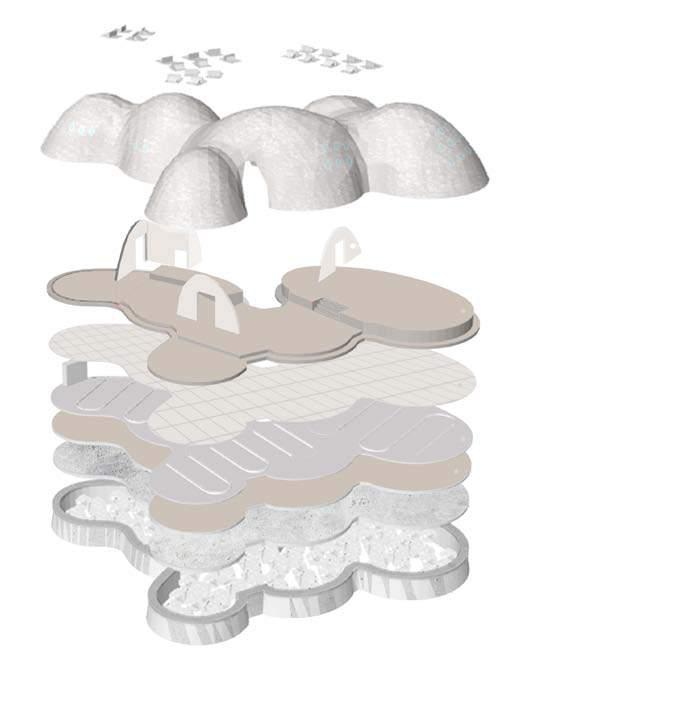

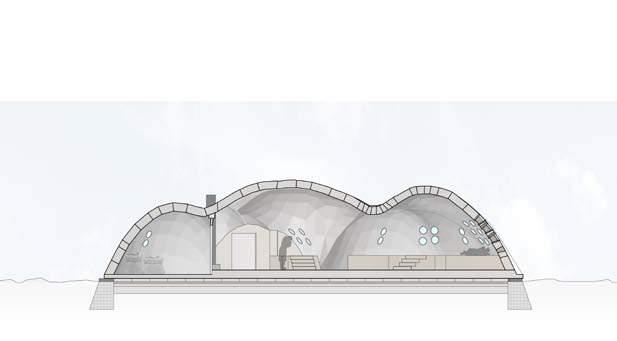

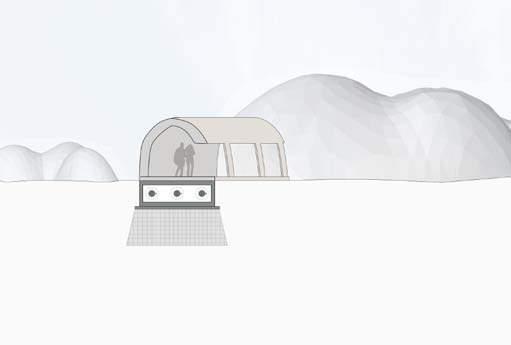

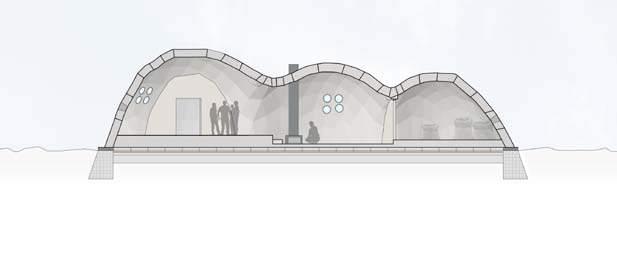

Arctic Recalibration is an investigation of resource-driven settlement strategies in Arctic environments. Traditional construction materials are scarce in the northern latitudes, and extreme environmental challenges to construction are notoriously common to the Arctic. As such, the majority of the built mass consists of imported panellised assemblies that borrow from modular military buildings or housing types better suited to lower latitudes. In light of global warming and economic interest in the Arctic, this project reconsiders current models of construction and importation.

Firstly, a material system fabrication system and building type was developed to address locally sourced materials. This material strategy has been explored at a variety of scales ranging from material properties to environmentally driven building arrangements. The aim of the investigation is the development of sustainable settlement types for pioneering what is often perceived to be the Earth’s final frontier.

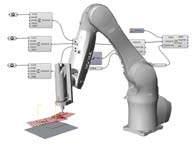

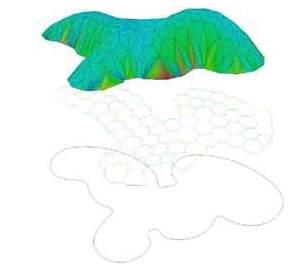

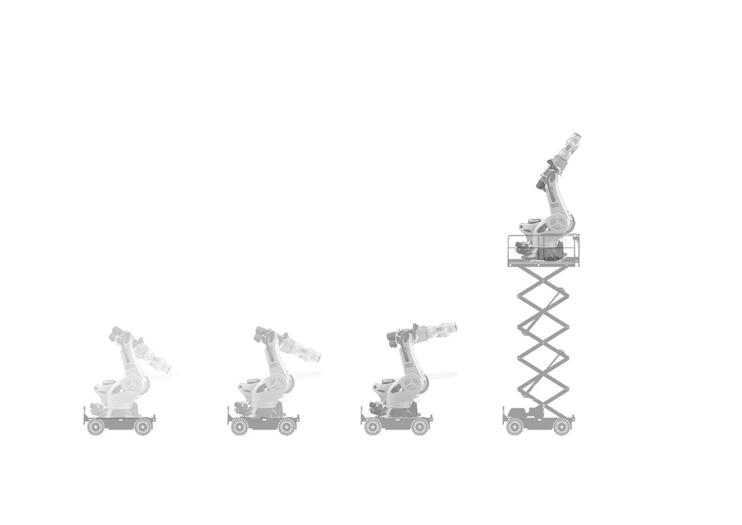

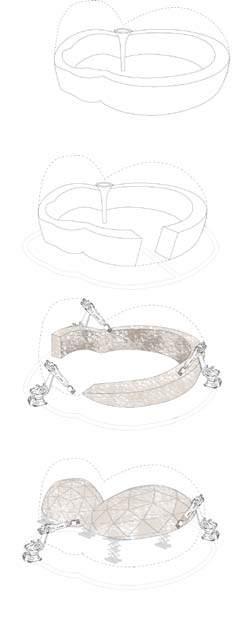

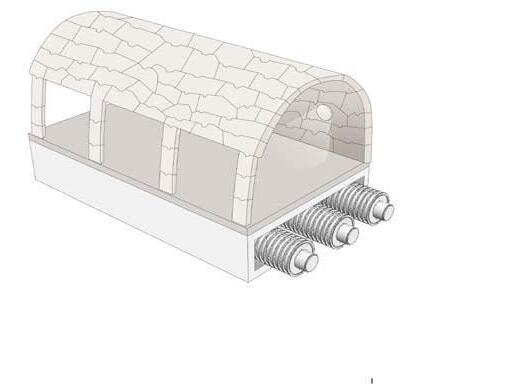

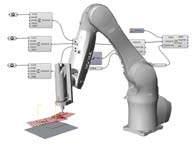

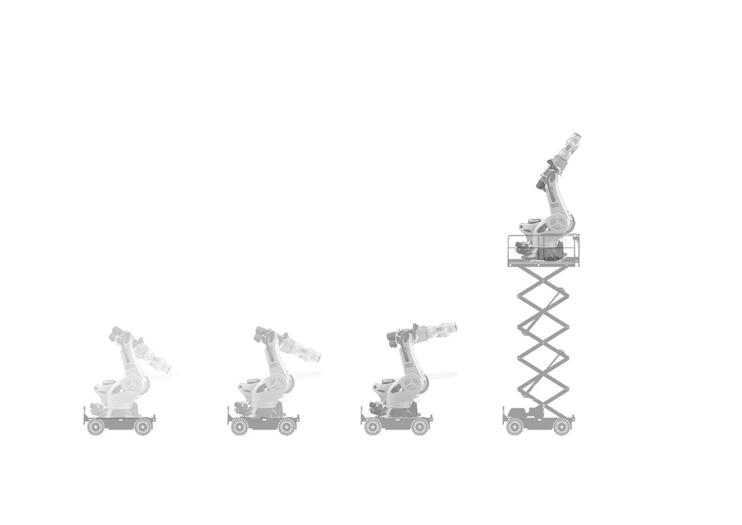

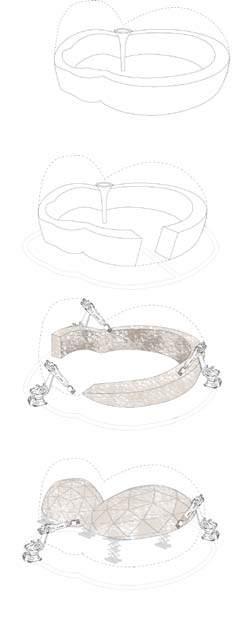

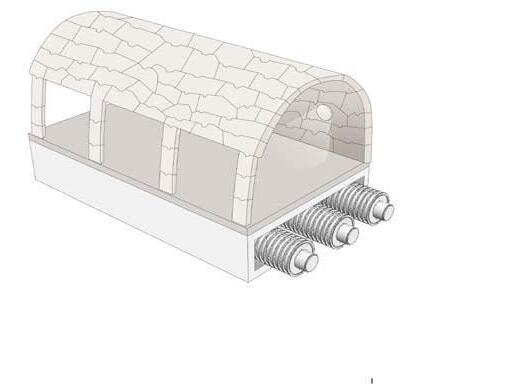

The work is contextualised in the Seward peninsula in Alaska, the site of abundant thermokarst drained lake basins as a part of a relocation strategy for local peoples. In response to the lack of conventional construction materials, this project has been developed to capitalise on a potentially abundant resource in the Arctic: peat, which, conveniently, also has positive thermal properties. Peat can easily be prepared for use in a one year period the proposed system. Contemporary construction techniques in the Arctic are slow [limited to the summer period], labor-intensive, dangerous, expensive, and constrained to primarily rectilinear forms, often resulting in homogenous structures built using materials sourced from centralized factories that are not contextualised to site. To begin to address these issues, we present the proposed fabrication system, an automated construction system capable of customized on-site fabrication of architectural-scale structures using real-time environmental data for process control. The system consists of a multi robot, composed six axis robotic arms carried on a tracked mobile platform.

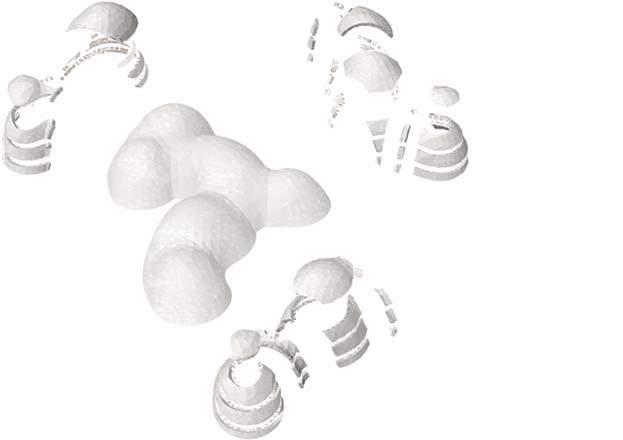

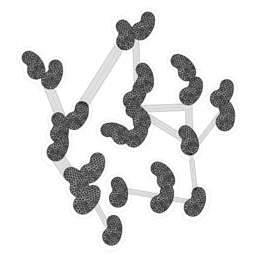

With this model as a proposed building type, various environmental, topological and strategic relationships have been used to develop a design model for autonomous building clusters.

The aim of this multi-scale investigation of a local [low technology] material strategy in conjunction with robotic fabrication [high technology] is to investigate the possibility of pioneering the New North in a way that is economically efficient and environmentally meaningful in the near future [< 2050].

x ix Architectural Association Arctic Recalibration a bstract

1. Introduction

xii xi Architectural Association Arctic Recalibration the arctic ..........................................................................................14 the new north ..........................................................................................16 inhabitating the arctic ..........................................................................................18

THE ARCTIC

Identifying the environmental, economical and social driver that will define the future of northern development

INTRODUCTION :

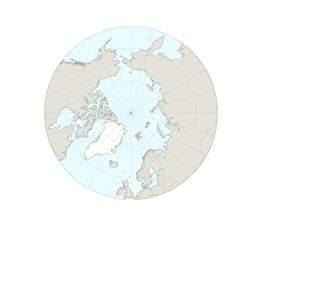

The region surrounding the North Pole consists of a large ocean surrounded by land. This ocean, called the Arctic Ocean, is like no other ocean on Earth; and because of its special location and climate, the lands that surround it are unique.

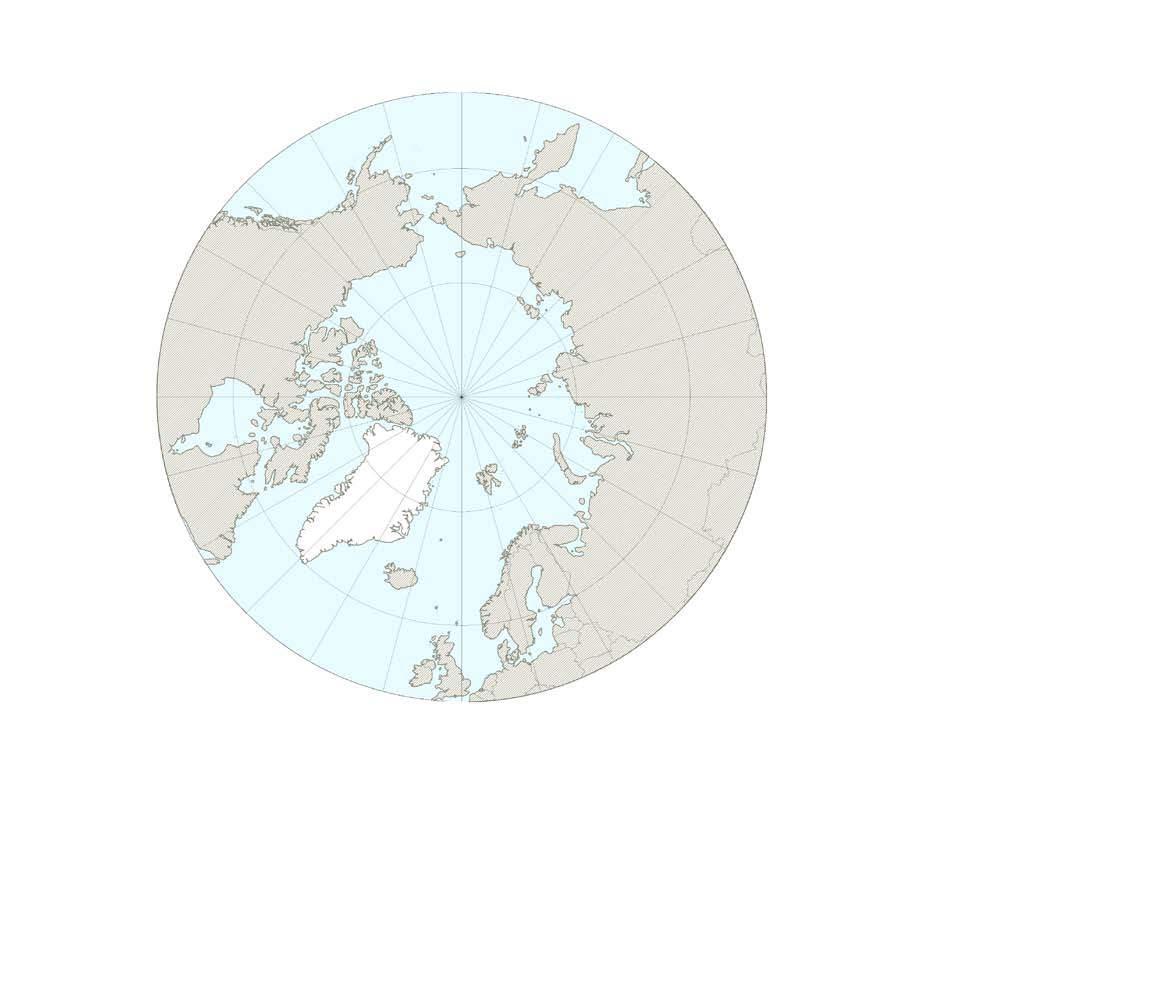

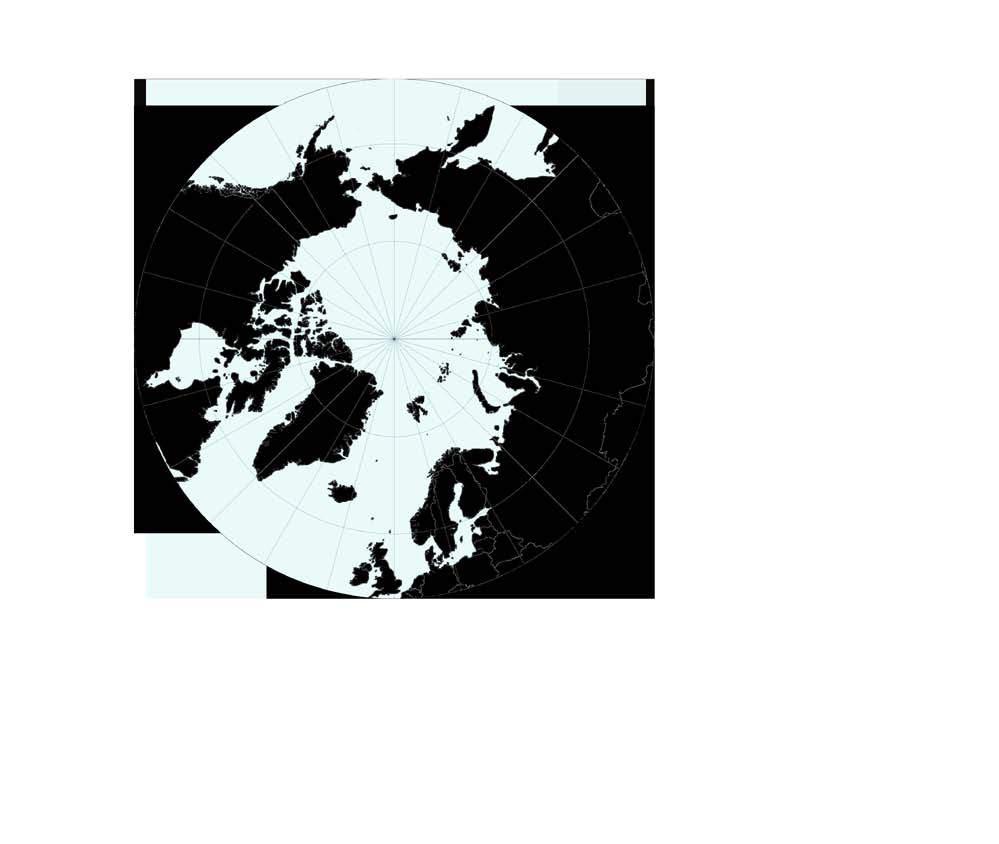

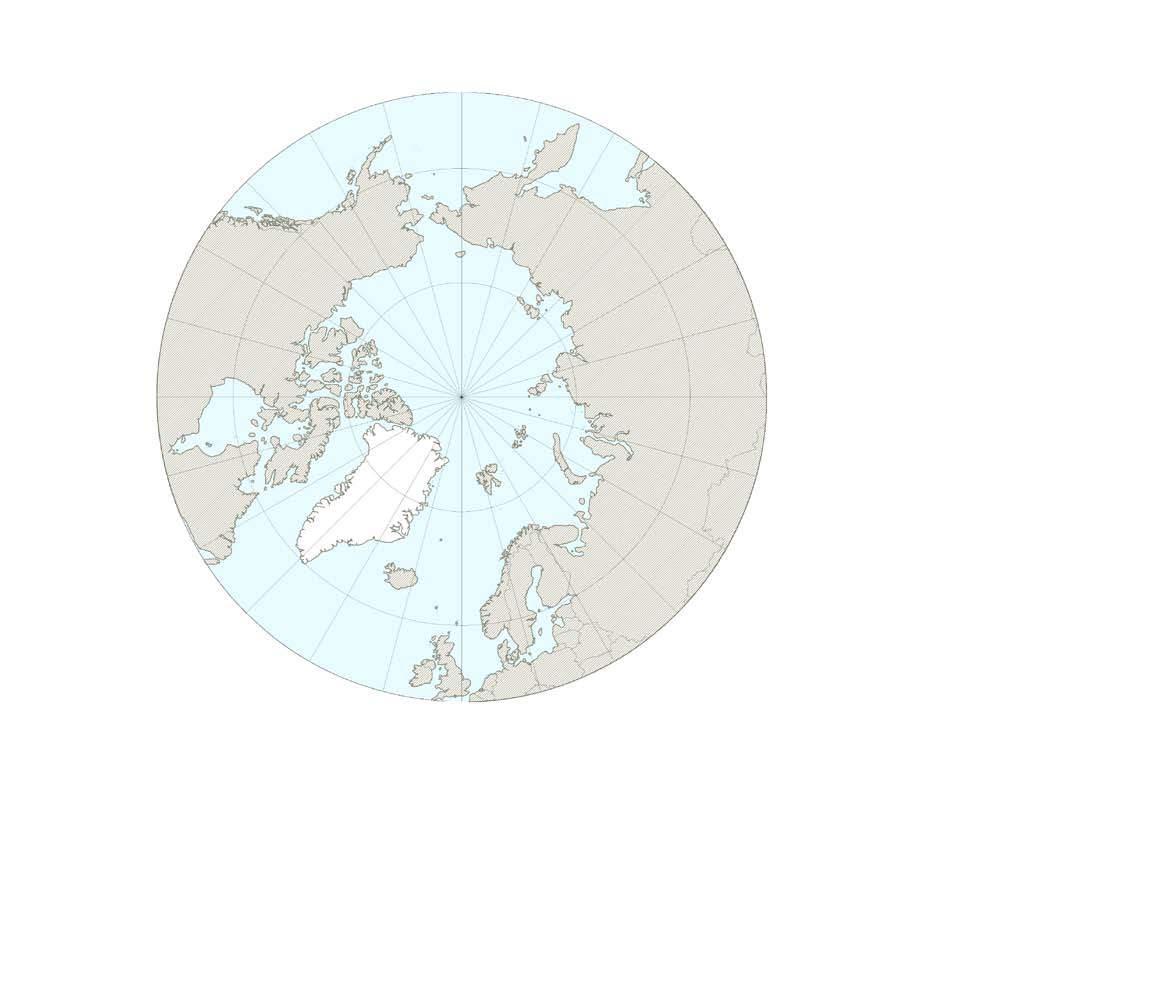

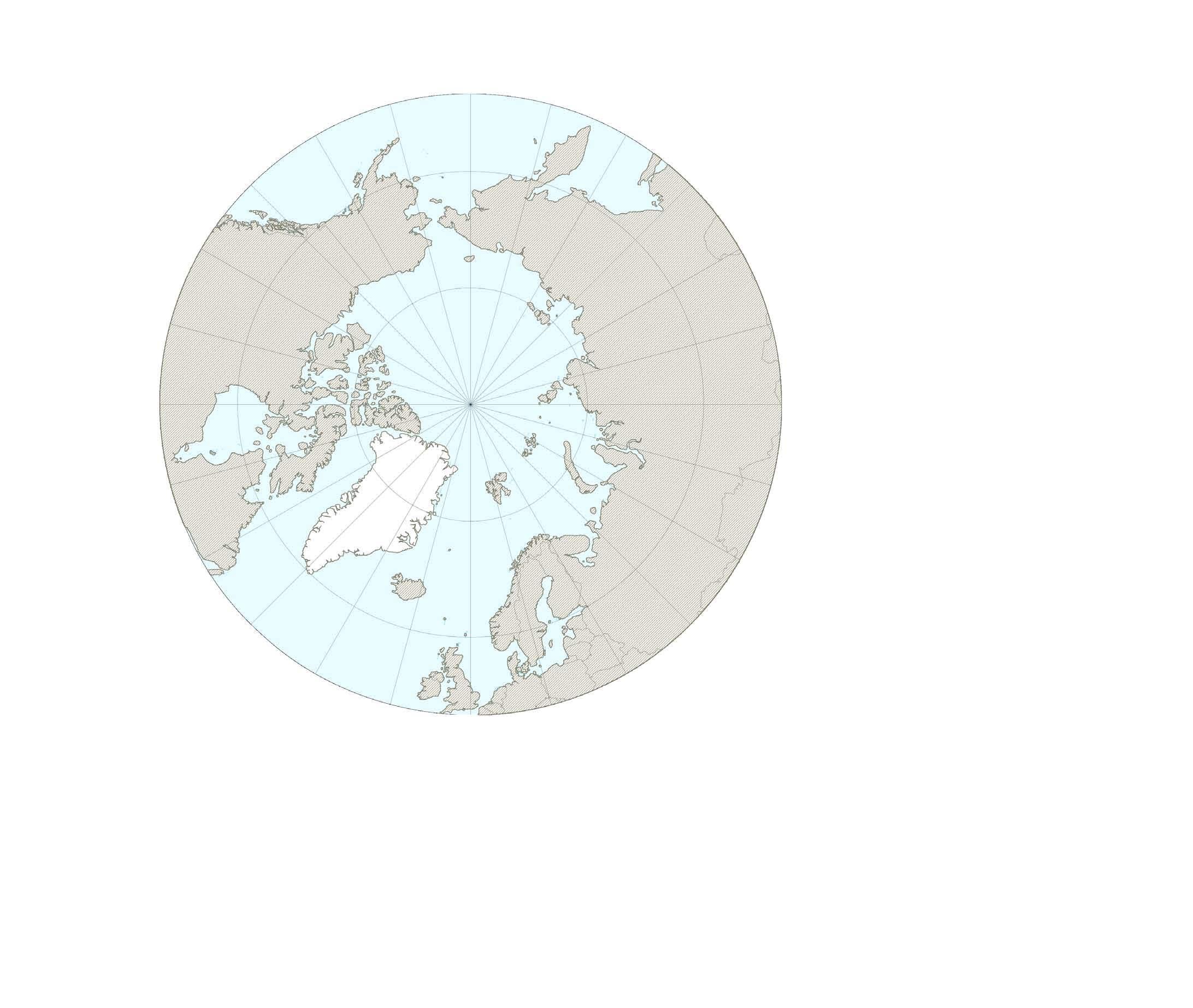

Most commonly, scientists define the Arctic as the region above the arctic circle, an imaginary line that circles the globe at approximately 66° 34’ N [dashed grey circle in the image at left]. Another definition of the Arctic is the region above the tree line [marked in green]. Arctic tundra is found across northern Alaska, Canada, and Siberia. This biome has long cold winters and short cool summers resulting in a complex and highly dynamic scenario of chemical and physical phenomena, including rapid cycles of freezing and thawing, evapouration and precipitation. The Arctic tundra has low precipitation [less than 10 inches per year] and dry winds with almost permanent ice and snow conditions. These conditions make the Arctic tundra a desert-like climate

The average Arctic winter temperature is -30° F [-34°C], while the average Arctic summer temperature is 37-54° F [3-12° C]. In general, Arctic winters are long and cold while summers are short and cool. The Arctic’s inhospitable weather and other environmental challenges have limited human activity and settlement.

One unique characteristic of the Arctic tundra is permafrost-ground that is permanently frozen. Because the permafrost has no cracks or pores, nothing can penetrate it, neither plant roots nor water and it remains at a constant 0 degree celcius. However with the onset of global warming the arctic is one of the most rapidly changing environment.

S W E D E N F I N L A N D N O R W A Y UNITEDSTATES CANADA IC E L A N D GREE N L A N D RUSSIA 66 33N 2 00 PRO ECT ON P R E S E N T C E E X T END 10 C DEGREE ISOTERM 0 C J U L Y ISOTERM TREELINE xiv xiii Architectural Association Arctic Recalibration

NSIDC

National Snow and Ice Data Center

THE NEW NORTH

Identifying the environmental, economical and social driver that will define the future of northern development

DRIVERS OF DEVELOPMENT IN THE ARCTIC

The four major global forces influencing development in the New North can be identified in: the increase in global population and migr tion, the growing demand for natural resources, globalisation and climate change . Mineral resources [oil, gas, and mining], fisheries, shipping, and tourism the four main sectors for development. 2

Climate change is drastically changing the geography of the Arctic and its ecosystems. As sea ice thins and snow cover reduces, the Arctic absorbs more heat and reflects less light . Summers arrive earlier in the year and last longer. Younger ice breaks with less effort, making more of the Arctic navigable without icebreakers. Existing infrastructure built on permafrost will have issues to maintain. Winter roads, which many communities such as Tiksi, Russia, depend on for access to the outside world, have seen their seasons decline from over 200 days in the 1970s to 100 day 2.

Amidst this uncertainty, there is also economic opportunity. The Arctic Ocean has seen increased use in transport recent years. The Arctic shipping industry is currently a point-to—point operation but a diminishing of these barriers makes a trans- Arctic shipping route possible. And while new oil, gas, mineral reserves and construction materials are constantly being discovered, an increase in labour demand and economical opponunities is predicted to attract an increasing number of people in the years to come

O V Y R E N G O Y M K D 100,000 50,000 20,000 400,000 200,000 NSIDC , National Snow and Ice Data Center xvi xv Architectural Association Arctic Recalibration

INHABITING THE ARCTIC

Current design response the the climatic challenges and the role of responsive architectural designs

Any human intervention has an immediate and measurable effect on urbanisation and the soil tectonics below it. Thawing of permafrost causes unstable ground for the buildings and infrastructure supported on it. This serves as a precondition for architectural systems that demonstrate adaptability to site variability in the Arctic context. Thawing of permafrost not only causes unstable ground for established ecosystems, buildings and infrastructure but also releases methane (CH4) and carbon dioxide (CO2), due to the huge amount organic matter stored in the frozen soil, with heavy consequences on the environment.

Since the creation of permanent settlements in the 1950’s, these communities have been lacking of adequate buildings and infrastructure . Due to the inaccessibility of most Arctic communities, and a lack of building materials sourced locally, most buildings are designed to incorporate transportable components with low manufacturing costs, often yielding energy inefficiencies. Given the military and scientific nature of most of the buildings around which the first settlements were created, it is not uncommon to see houses in the shape of quonsets or hangars 5 This universal type of architecture based on economy rather than local climatic factors has produced buildings that for almost any function, from civic to residential, are usually rectilinear prefabricated envelopes, often called ‘matchbox’ houses for their lack of geometrical variation 6

With the dynamics of the future growth of northern settlements being unknown, there is an opportunity for a new paradigm in arctic architecture to be developed in response to the need for more regional designs

‘New North’ scenario Existing settlement strategy Discovery of reserves of resources Less extreme projected climate Potentially accessable routes Poor soil conditions for settlements due to climate change Poor living conditions Short periods of stay Increase in demand Migration of existing settlements Construction/housing materials Energy Transport infrastructure Migration from coastlines due to erosion and flooding into inland hotspots Integrated Strategy for Arctic Habitation xviii xvii Architectural Association Arctic Recalibration

CURRENT DESIGN RESPONSE TO THE CLIMATE CHALLENGES :

xx xix Architectural Association Arctic Recalibration

overview .........................................................................22 global warming in the arctic .........................................................................24 thermokarst DraineD lake basin .........................................................................30 Potenrial materials .........................................................................32 site selection .........................................................................34 PreDicteD PoPulation influx .........................................................................38 logistics .........................................................................42 arctic architecture .........................................................................50 arctic automation .........................................................................56 conclusions .........................................................................58

ii . D omain

OVERVIEW

Whoever wants to survive the extremes of the Arctic environment needs to adapt to it. During the centuries of Arctic occupation, humans, from the Thule to their Inuit descendants, have found different ways of responding to such challenges . Whether it is the materials they adopted for their dwellings, the strategic positioning and orientation of their settlements, or the seasonal migrations in search for food sources and milder climates.

The following sections explain what the potential change in climate is estimated and its effect and on the arctic, and how an originally dynamic and adaptive response approach has led way to a standardised, rapid and cost-effective one. The opportunity and limitations of the potential change in the arctic, on both the landscape and that of dwellings will be analysed in order to lay out the framework for what is intended to be a methodical approach encompassing several scales to improve construction in the North.

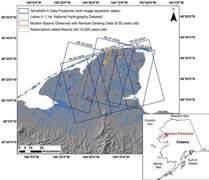

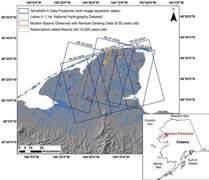

The scenario taken into consideration is that of Alaska. Although many of the challenges and indeed their possible responses can be valid for different Arctic contexts around the world such as the Siberian tundra and the Icelandic and Scandinavian regions, this area was chosen for the wide availability of data and information as well as the unique high frequency “Thermokarst basins” issue explained in depth in the following sections.

xxii xxi Architectural Association Arctic Recalibration

‘CONTINUOUS ADAPTING IS THE ARCTIC WAY OF LIFE’ :

The Arctic is warming at a rate of almost twice the global average.

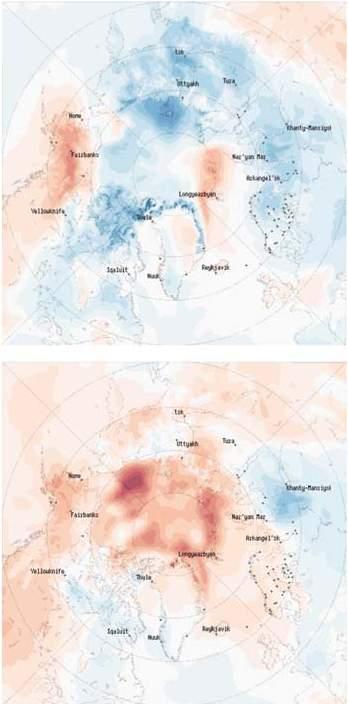

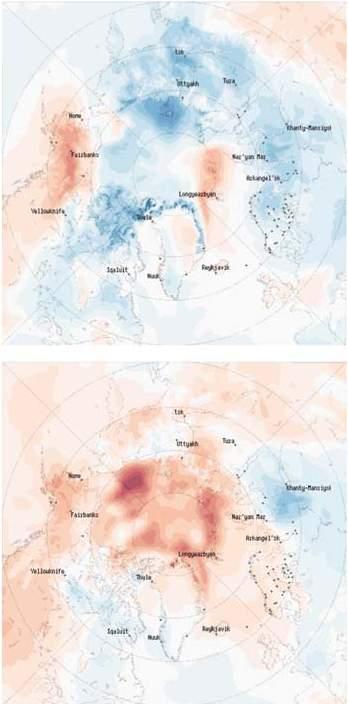

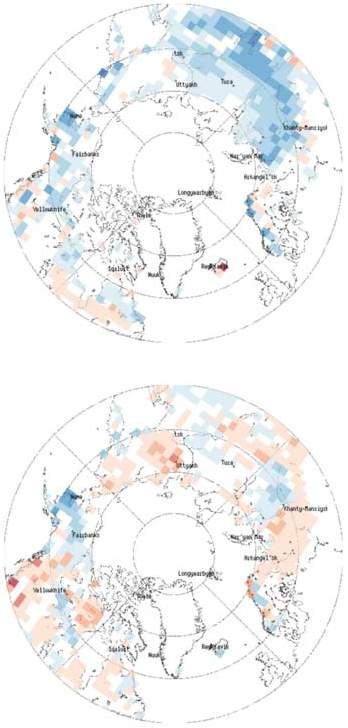

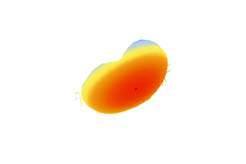

This sample image shows near- surface air temperature for October 1980.

NEAR SURFACE AIR TEMPERATURE

Surface air temperature change mapped in the Arctic

This sample image shows near- surface air temperature for October 2015.

A IR TEMPERATURE INCREASE IN RECENT YEARS :

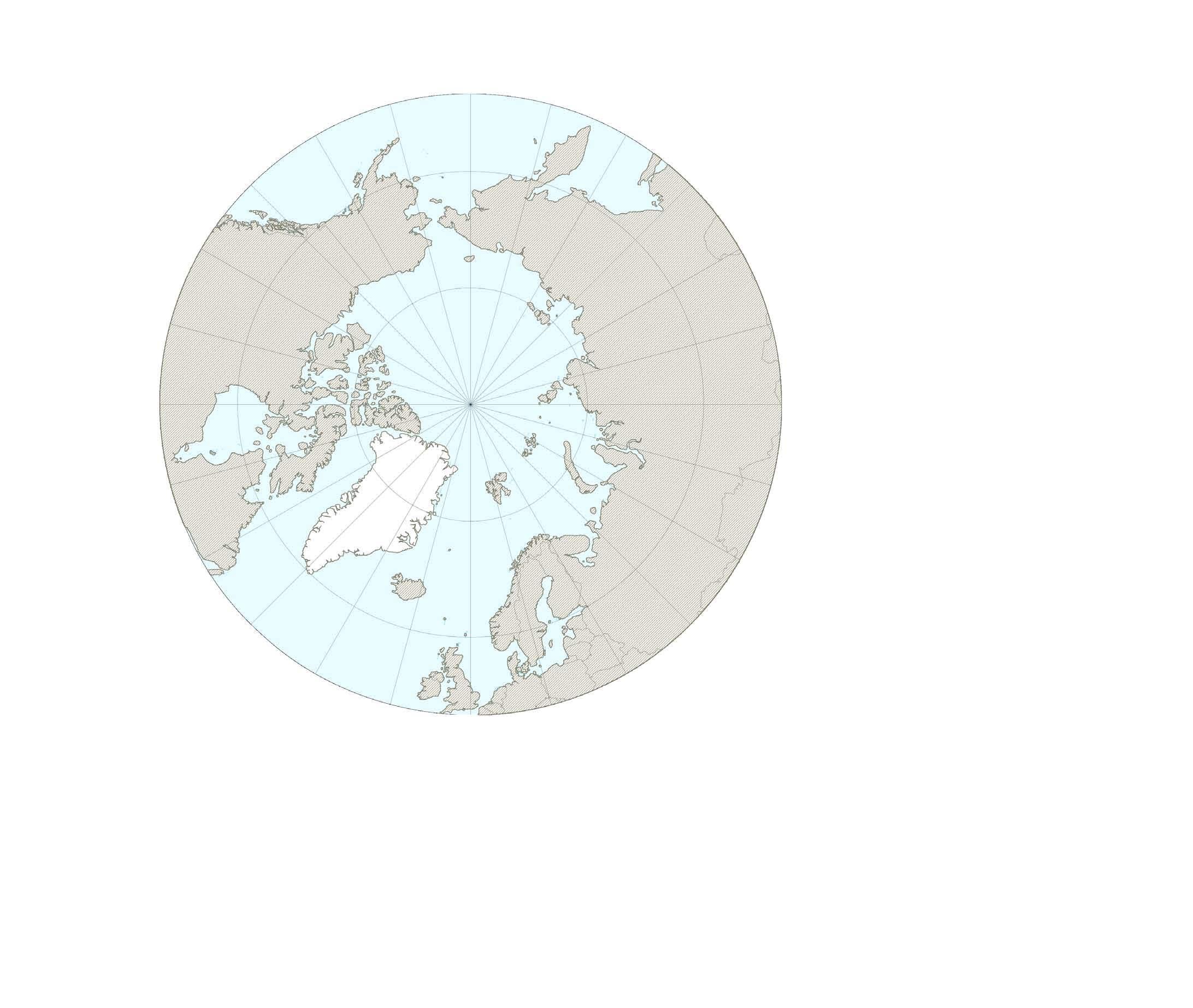

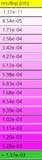

The maps show how air temperatures in the Arctic compare to averages from 1979 to 2015 . On the map, areas with higher than average temperatures for the selected month [Selected month being October onset of winter] and year are indicated in oranges and reds [positive anomalies], and areas with lower than average temperatures are shown in blues [negative anomalies]. The map of anomalies helps show where temperature change is strongest. These are temperatures two meters above the surface, similar to the temperatures given in weather reports and forecasts.

An interesting aspect of Arctic change seen in the temperature maps is the phenomenon of “Arctic amplification.” This refers to the outsized warming of the Arctic relative to the rest of the globe. While a number of mechanisms contribute to Arctic amplification, the loss of Arctic sea ice cover plays a dominant role. Basically, because there is so much more dark, open water than was the case even a decade ago, the ocean gains much more heat in summer than it used to. This in turn means that more heat is released back to the atmosphere in autumn as sunlight wanes. This warming climate allows for a milder climate resulting in an influx in population willing to settle in these areas which would previously not be the case.

xxiv xxiii Architectural Association Arctic Recalibration

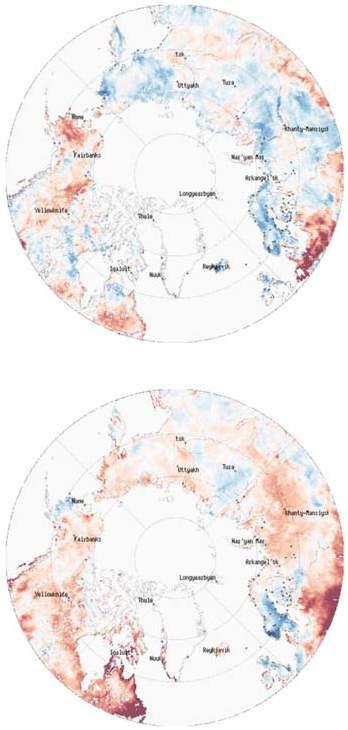

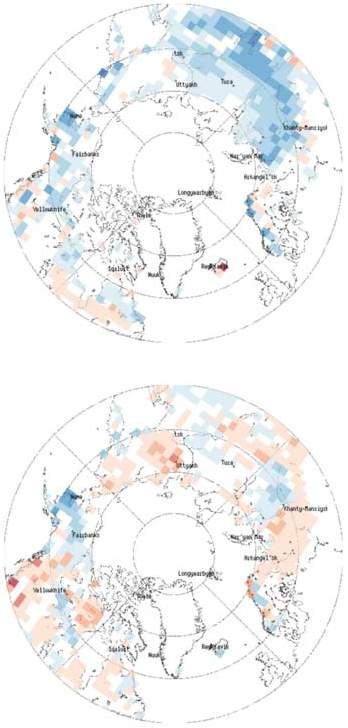

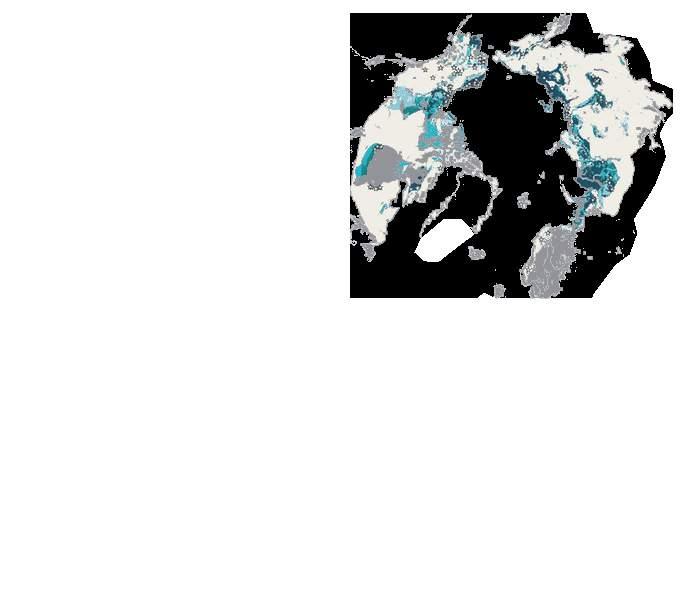

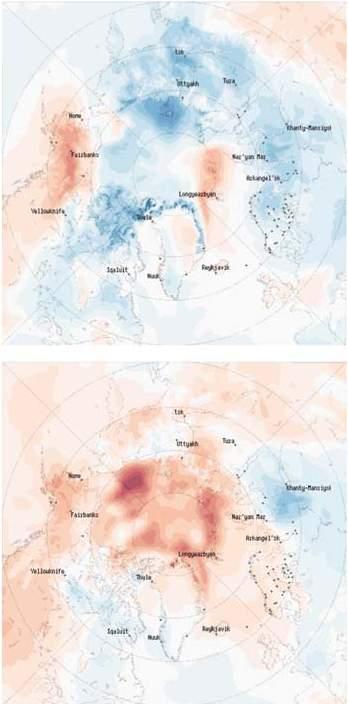

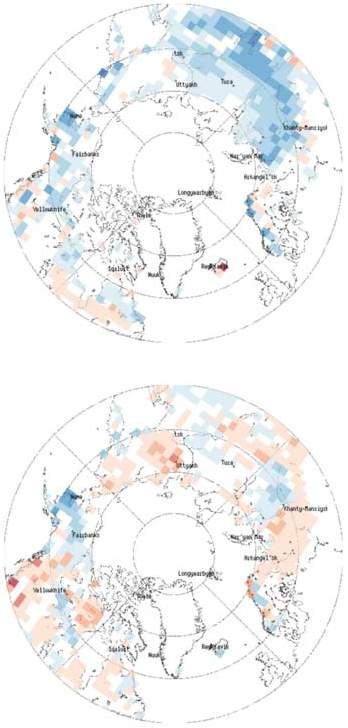

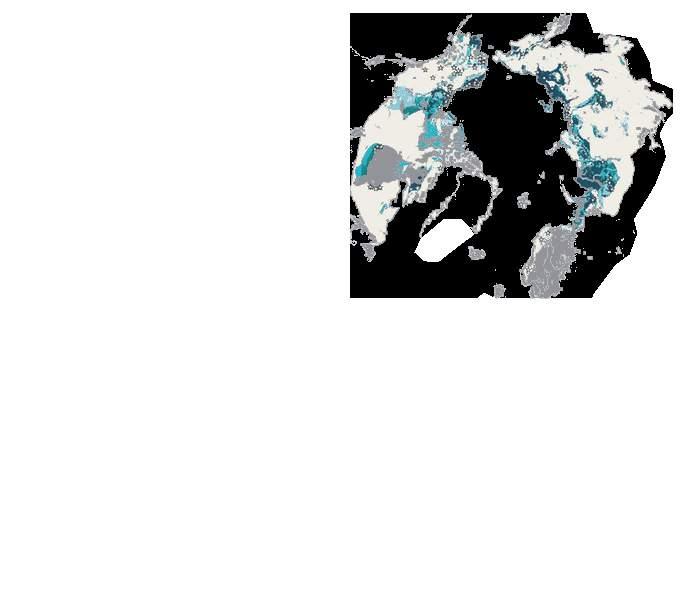

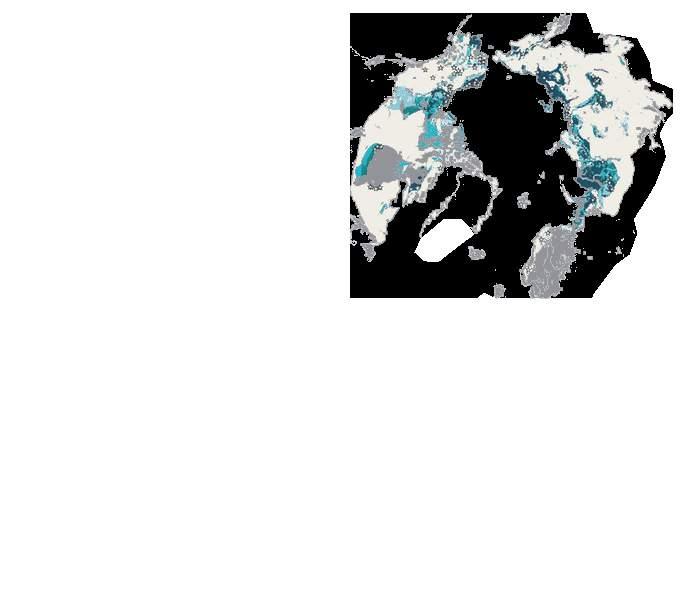

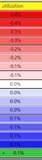

SOIL NON FROZEN ANOMALIES

Non-frozen soil change in the Arctic mapped

INCREASE IN NON FROZEN SOIL :

The map shows how the number of days in each year the soil surface is unfrozen compares to the average for the period 1979 to 2015 . On the map, areas where soil surfaces are unfrozen for more days than normal are shown by reds [positive anomalies]. Areas where soil surfaces are unfrozen for fewer days than normal are shown by blues[negative anomalies]3 The map of anomalies helps to show where changes the number of days with unfrozen soil are the strongest.

Much of Alaska and eastern Siberia exhibit increases in the non-frozen period in most years since 2005. However, central Siberia and northern Canada show more variability.

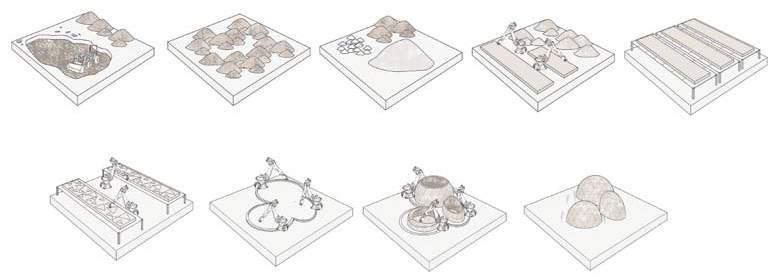

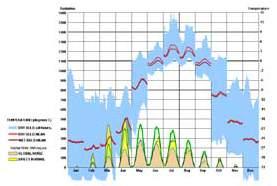

With an increase in unfrozen soil in the recent years, materials that were never before available in the arctic are now appearing. Materials such as peat, sand and potentially trees, due to the ability to now grow more than shrubs, are potential materials that could be used in the Arctic for construction purposes.

xxvi xxv Architectural Association Arctic Recalibration

This sample image shows soil non-frozen anomalies for October 1980.

This sample image shows soil non-frozen anomalies for October 2015.

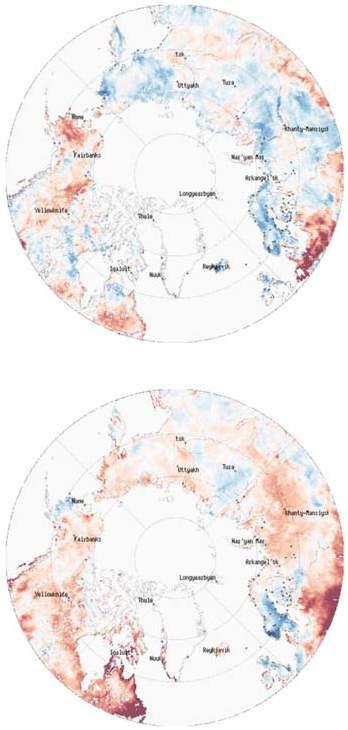

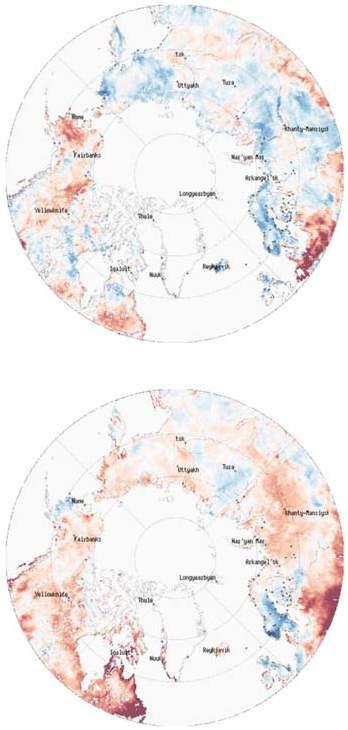

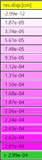

SNOW COVER DURATION

Snow cover anomolies mapped in the Arctic

CHANGE IN SNOW COVER DURATION :

The maps show how Northern Hemisphere snow cover for different years and months compares to averages for the period 1980 to 2015 9 The maps show snow cover duration, expressed as the number of days a grid cell is snow covered for each month for each year. On the maps, areas with longer than average snow cover duration are indicated in blue [positive anomalies]. Areas with shorter than average snow cover duration are indicated in red [negative anomalies]4 The maps of anomalies help show where changes in snow cover are strongest.

The maps show spatial patterns of anomalies of snow cover duration. There are no large anomalies in Arctic latitudes in winter months. Much of the Arctic at this time is so cold that precipitation is nearly always in the form of snow, and the snow, once fallen, rarely melts. Large anomalies in snow cover start to appear in the Arctic after May. Negative anomalies are prevalent over Alaska and Siberia after about 2005. In September and October, both positive and negative anomalies can be seen. An increase in the number of days with snow cover might indicate an increase in the frequency of early autumn snow events, which are related to a decrease of winter months leading to milder climate.

xxviii xxvii Architectural Association Arctic Recalibration

This image shows snow cover duration for October 1980.

This image shows snow cover duration for October 2015.

thermokarst D raine D basins

An overview of the formation of thermokarst drained lake basins

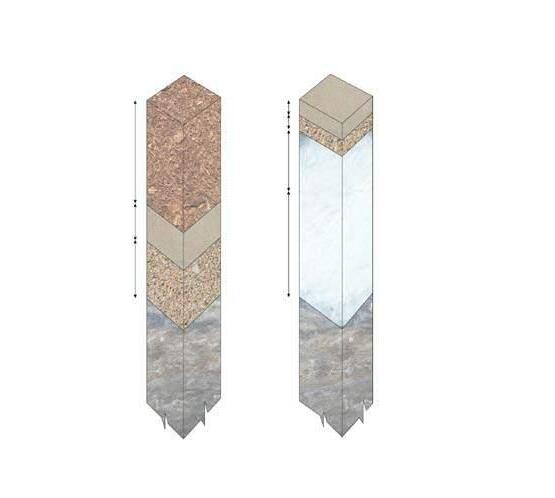

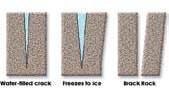

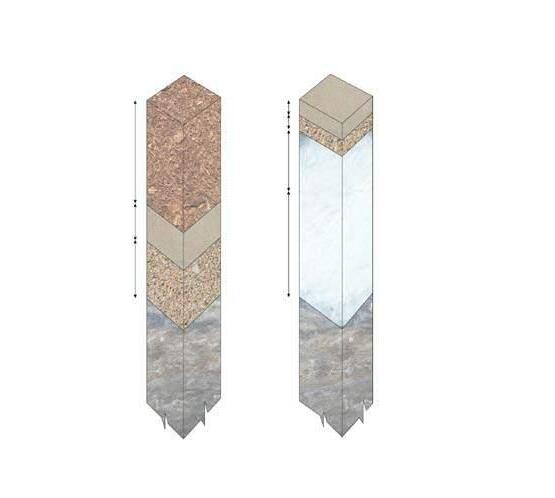

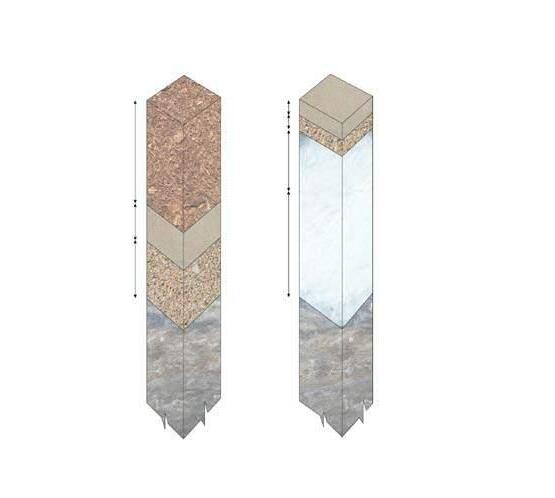

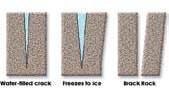

THERMOKARST DRAINED LAKE BASINS : Due to global warming with an increase in temperature in the arctic thawing of permafrost is now a common occurrence 10 The thawing of permafrost creates thermokarst topography, an uneven surface that contains mounds, sinkholes, tunnels, caverns, and steep-walled ravines caused by melting of ground ice.

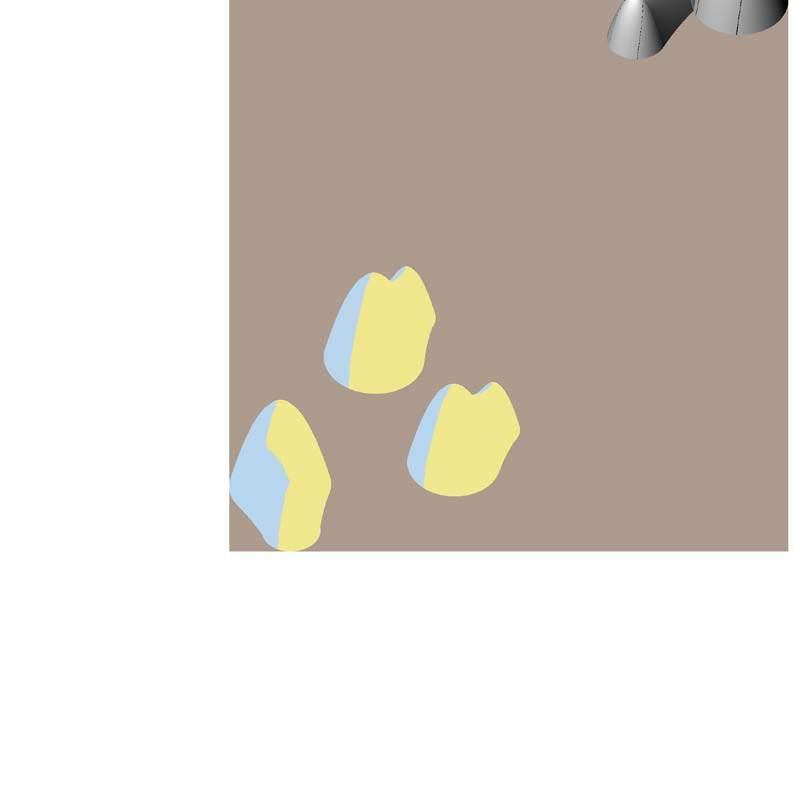

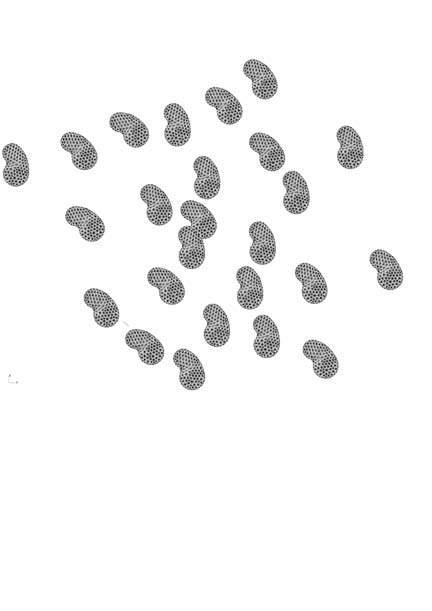

Thawed depressions filled with water (thaw lakes, thermokarst lakes, cave-in lakes) are widespread in permafrost areas, especially in those underlain with perennially frozen silt. Locally, deep thermokarst pits 6 metres deep and 9 metres across may form as ground ice melts. Some of these lakes drain away leaving behind large amounts of peat and sand. These two materials are explored as building materials.

Thermokarst lakes are an interesting phenomenon, who’s frequency of occurence is increasing with a rise in temperature due to global warming in the current scenario. Within the 30 year scenario there is an increase in the frequency of the next stage of thermokarst lakes, i.e. drained thermokarst lake basins 11 These basins leave behind materials that were previoudly unavailable in the arctic region.

Initial stage (pre-thawing)

Thermokarst lake inception (ice-rich permafrost thawing)

ice wedge

peat

water

ice-rich permafrost

Mature stage (maximum lake depth)

Drained stage (no water in the basin)

Thermokarst drained lake formation

xxx xxix Architectural Association Arctic Recalibration

P otential materials

Site selection

OVERVIEW :

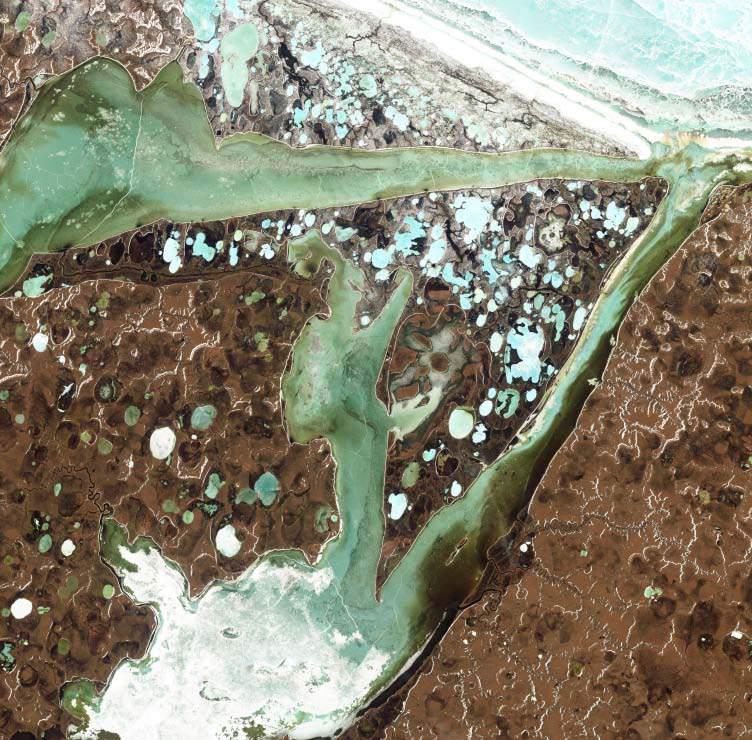

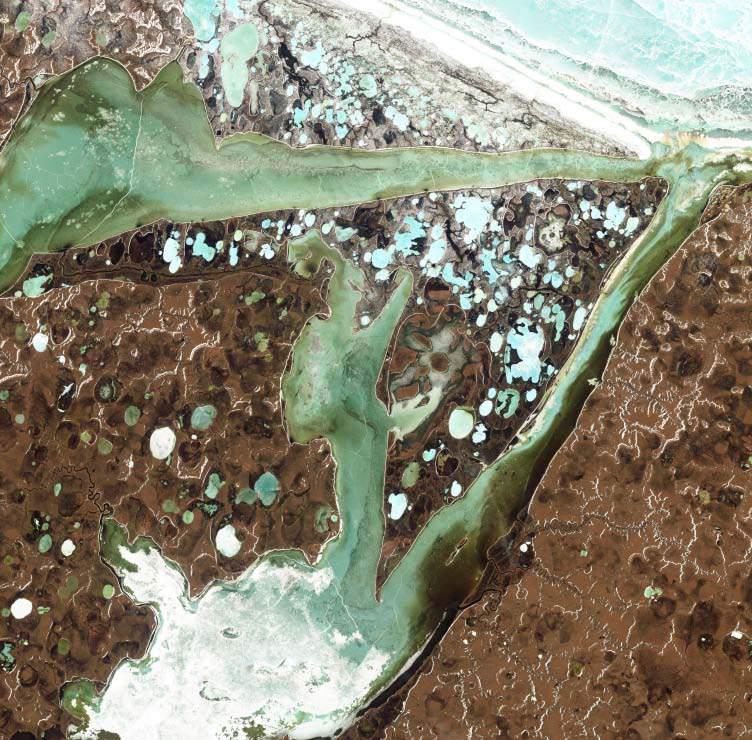

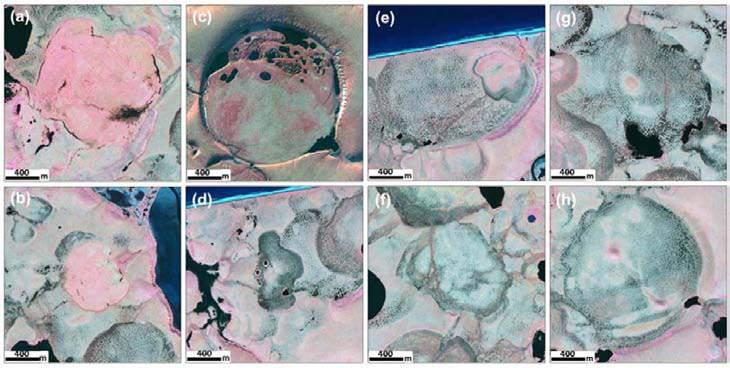

Drained lake basins are widespread in Arctic lowlands affected by thermokarst and, in tundra areas, the topography of these basins typically constitutes a wet, depressed margin surrounding a slightly elevated, better drained centre. This low grade geomorphological feature is widespread in Arctic lowlands (see satellite images to the right), yet the genesis of this topography is poorly understood.

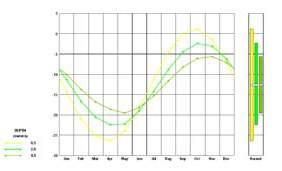

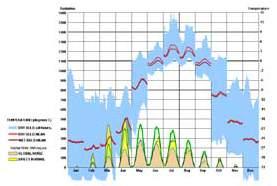

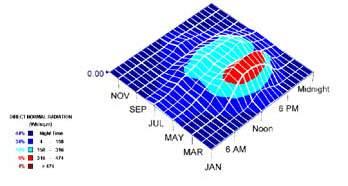

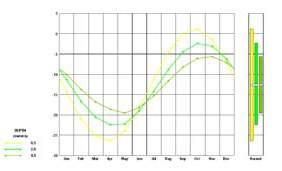

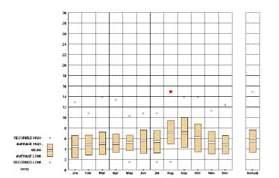

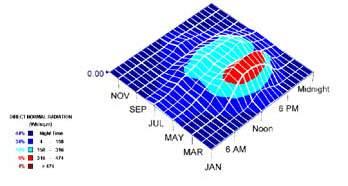

The seward peninsula in Alaska has a high frequency of existing thermokarst lakes which in the 30 year scenario many would become drained thermokarst lake basins due to their old age. Climate in the Sweard peninsula is characterized by long cold winters and short growing seasons [May to September]. The mean annual air temperature of the region is −6.1 °C, and the mean annual precipitation is 255 mm, with roughly 125 mm falling in the form of snow based on historical summaries for the period 1971–2000 recorded at Barrow, Alaska which is located 60 km to the northeast, but has a similar mainland position as the northern Seward Peninsula.

xxxii xxxi Architectural Association Arctic Recalibration

Basin Out- Out0 1000 600 800 400 200 Sandy Basin Volumetric water 12 10 8 80 20 40 60 2 100

Sphagnum peat Fine sand Bedrock Gravel sand

sewar D P eninsula , alaska

Site selection

OVERVIEW :

Drained lake basins are widespread in Arctic lowlands affected by thermokarst and, in tundra areas, the topography of these basins typically constitutes a wet, depressed margin surrounding a slightly elevated, better drained centre. This low grade geomorphological feature is widespread in Arctic lowlands (see satellite images to the right), yet the genesis of this topography is poorly understood.

The seward peninsula in Alaska has a high frequency of existing thermokarst lakes which in the 30 year scenario many would become drained thermokarst lake basins due to their old age. Climate in the Sweard peninsula is characterized by long cold winters and short growing seasons [May to September]. The mean annual air temperature of the region is −6.1 °C, and the mean annual precipitation is 255 mm, with roughly 125 mm falling in the form of snow based on historical summaries for the period 1971–2000 recorded at Barrow, Alaska which is located 60 km to the northeast, but has a similar mainland position as the northern Seward Peninsula 12

Digital Elevation Model (DEM) base map of the Seward Peninsula showing the location of lakes (>1 ha) mapped the DTLBs that drained (>90% of surface area loss) 0–50 years ago

xxxiv xxxiii Architectural Association Arctic Recalibration

Number of lakes, thousands Latitiude, N 73 71 69 67 65 63 0 80 20 40 60 61 Surface area, thousands Latitiude, N 71 69 67 65 63 0 80 20 40 60 61

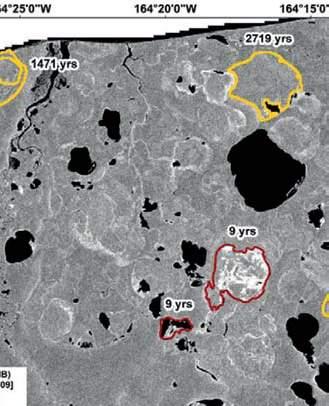

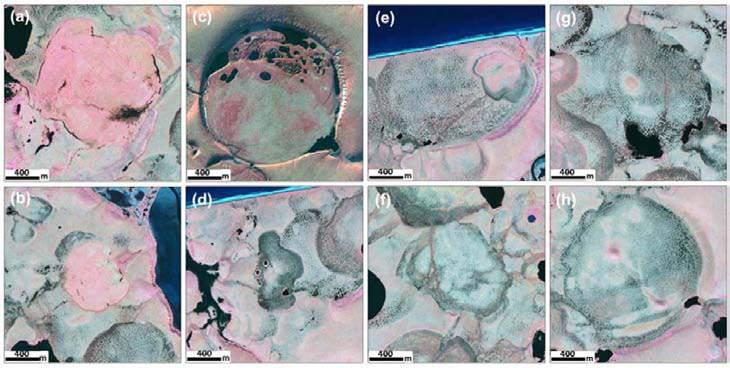

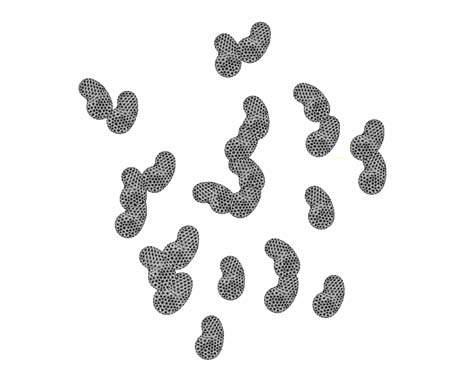

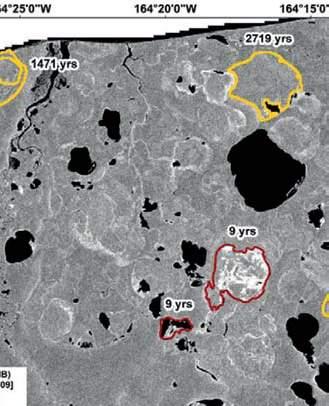

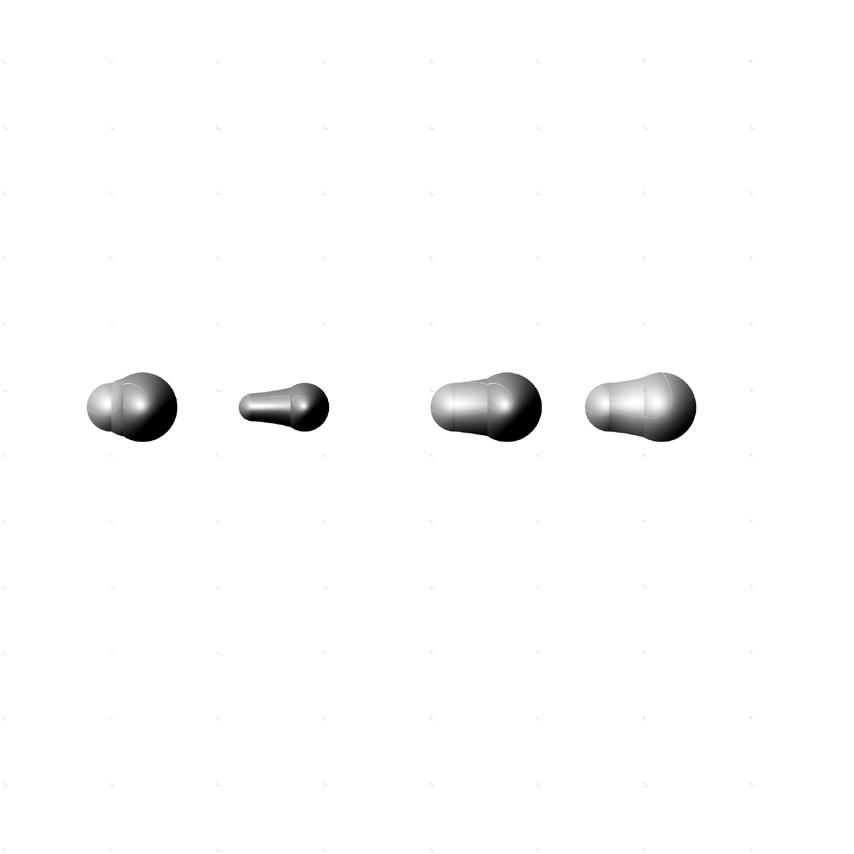

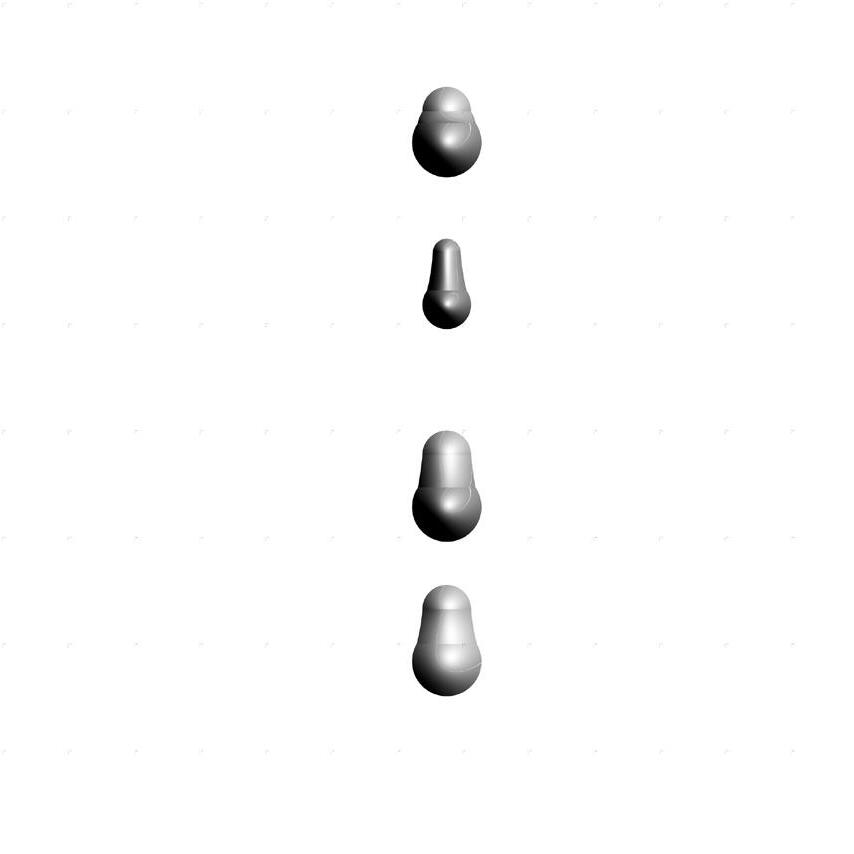

DTLB of different age classes located in the northern Seward Peninsula (Modern: (a) 9 yrs old, (b) 29 yrs old; Young: (c) 403 ± 55 cal·yr·BP, (d) 294 ± 15 cal·yr·BP; Medium: (e) 1471 ± 60 cal·yr·BP, (f) 770 ± 35 cal·yr·BP; Old: (g) 2719 ± 40 cal·yr·BP, (h) 2567

xxxvi xxxv Architectural Association Arctic Recalibration

basins and new DTLB and old DTLB

Landscape at the Seward peninsula - varying lake

NEAR TERM (<2050) P HANGE IN THE ARCTIC

An overview of population change due to climate change in the Arctic

OVERVIEW OF POPULATION GROWTH IN ARCTIC

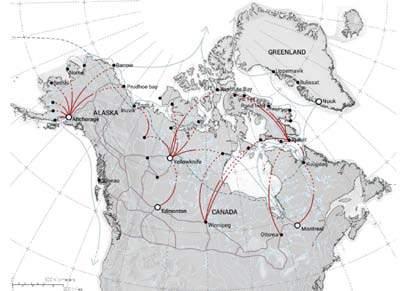

The population of the Arctic remained about the same in 2010 as in 2000, through a combination of growing and declining Arctic regions balancing each other out 13 Indicating that while the overall population remained around the same, the population per area changed drastically due to erosion and flooding of coastlines of the arctic with population influx into certain areas of the Arctic that are now safe to inhabit.

Among Arctic regions, Alaska’s population increased at a faster rate than the U.S. average 14. The regions of the Canadian Arctic also increased at a faster rate than Canada as a whole. Population growth in Iceland was 14 percent, similar to the North American Arctic. In all Arctic regions of Fennoscandia, population growth in the northern or Arctic regions was considerably less than the countries as a whole. The population of the Russian Arctic declined by 6%,, much less than the decline during the 1990s, but twice that of the Russian Federation rate. Growth in the oil and gas producing regions Nenets & Yamal-Nenets Okrugs] was outweighed by decline in all other Arctic regions of Russia.

The main factor driving trends in population change in the Artic is migration. The major trend in most Arctic regions is migration losses to the southern regions of their respective countries and migration gains from abroad 15 Nearly all of the Arctic regions are experiencing considerable international migration of people seeking work in resource extraction and the service sectors. These migration flows are having a considerable impact on the social composition of the Arctic regions.

xxxviii Arctic Recalibration

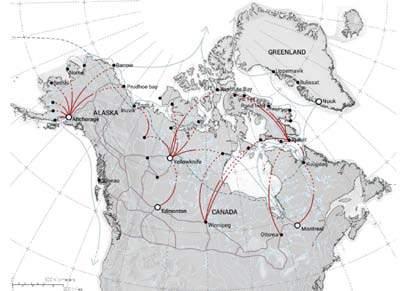

ooding and erosion at the coast POPULATION Migration from global regions due to milder climates and new potential resources NEED FOR NEW SETTLEMENTS CURRENT PREDICTED S W E D E N F I N L A N D N O R W A Y UNITEDSTATES CANADA IC E L A N D GREE N L A N D RUSSIA 66 33N 100 ROJ CT ON P R E N T C E X T END C DEGREE ISOTERM 10 C J U L Y ISOTERM TREEL NE Current treeline Projected treeline >1 No change <1 40,000 10,000 1000

arctic econom Y

An overview of the current and potential economy of the arctic which causes population influx

HIGH POTENTIAL :

Alaska GDP was 0.9% of the GDP of Arctic nations (Canada, Denmark, Finland, Iceland, Norway, Russia, Sweden, US) 16

Measured by real GDP the Arctic economy grew over 31% between 2000 and 2009, faster than the rate of growth for the Arctic nations (2.1%). GDP grew much faster than population in the Arctic, which meant real per capita GDP grew 30%, more than twice the rate of per capita GDP growth for the Arctic nations as a whole and approximately 10% more than growth of per capita GDP for the world economy.

Arctic nations are currently optimistic about the prospects for Arctic resource development. Various resource development projects are proposed for Greenland, Nunavut, Russian and Alaskan arctic seas.

Optimism about the future of the arctic economy is based on 3 observations:

NATURAL

RESOURCES EASE

The Arctic is a storehouse of natural resources, holding almost 22% of the world’s undiscovered conventional oil and gas.

Global warming in the Arctic will likely allow ice free travel in arctic seas and lower the cost of access to and development of the Arctic’s resources, while access by sea will lower cost delivery of supplies and of shipment of the resources to markets.

xl xxxix Architectural Association Arctic Recalibration

OF ACCESS

The potential for accessing resources has increased with the current rapid rise in commodity prices. Increasing demand from emerging nations is driving prices increases of commodities, most of which have risen sharply since 2001. :

: DEMAND

Oil drilling in Alaska

LOGISTICS

Evaluation of the modes of transport and limitations of construction in the Actic region

BY LAND

Terrestrial transportation happens prevalently by truck on paved or more commonly gravel-surfaced roads. For just a few months during the winter freeze up, ice bridges are formed and what are called ‘ice-roads’ which allow circulation of heavy goods vehicles (HGV’s) can function as the only way to reach certain settlements by land.

MAIN USE- Large tanks, medium sized crates, barrels and oversized shipments.

BY SEA

Marine transportation is rapidly expanding as it is becoming easier to sail the Arctic Ocean as perennial icestarts retreating. Since port facilities and wharf in arctic destinations are almost non existent, shipments loaded on container ships are usually unloaded onto landing barges which can run up onto the beaches.

MAIN USE- Large crates

RESOURCE TRANSPORT

Due to the lack of local suppliers, building material, including steel, wood and concrete must be imported. In some communities even gravel or coarse aggregates for foundation backfill is scarce. Construction equipment might also not be readily available and forklifts and cranes- when required- might have to travel a long way to reach the site. It has been estimated that marshalling and shipping charges for transporting material to the Arctic may take up to 20% of the total cost of construction17. Transporting material on site in the Arctic usually takes place in three ways: by truck, ship or air cargo. It is important to point out that the availability and cost of these modes of transport highly depend on the location of the settlement and the time of the year.

BY AIR

Due to its high costs, aerial transportation is more commonly reserved to high priority or perishable goods such as medicines or the movement of people. Almost every major arctic settlement is provided with short landing strips for small charter planes to land.

MAIN USE- Perishable goods, medicines.

xlii xli Architectural Association Arctic Recalibration

ARCTIC CONSTRUCTION

Analysis of past and present building types with specific focus on Alaska.

PERMANENT ARCHITECTURE IN ALASKA :

Government post-WWII housing typologies have created a template for arctic shelters which is in use still today. Development of Alaskan Arctic did not start until the 1950’s when the government started using the small ports and whaling stations built in the early twentieth century as a basis to form communities for indigenous people 18

Permanent settlement was encouraged by providing health care, education and social amenities to the lnuit. Installing permanent architecture in these zones can be seen as a Canadian and American attempt to assert arctic sovereignty during the Cold War when the arctic started having greater strategic importance19 The resulting architectural designs are the proof of this fact, as they appear more “frontier” designs than family houses.

xliv xliii Architectural Association Arctic Recalibration Aerial view of the settlement of Inuvik

CONTEMPORARY ARCTHITECTURE

Current building forms, methods and materials

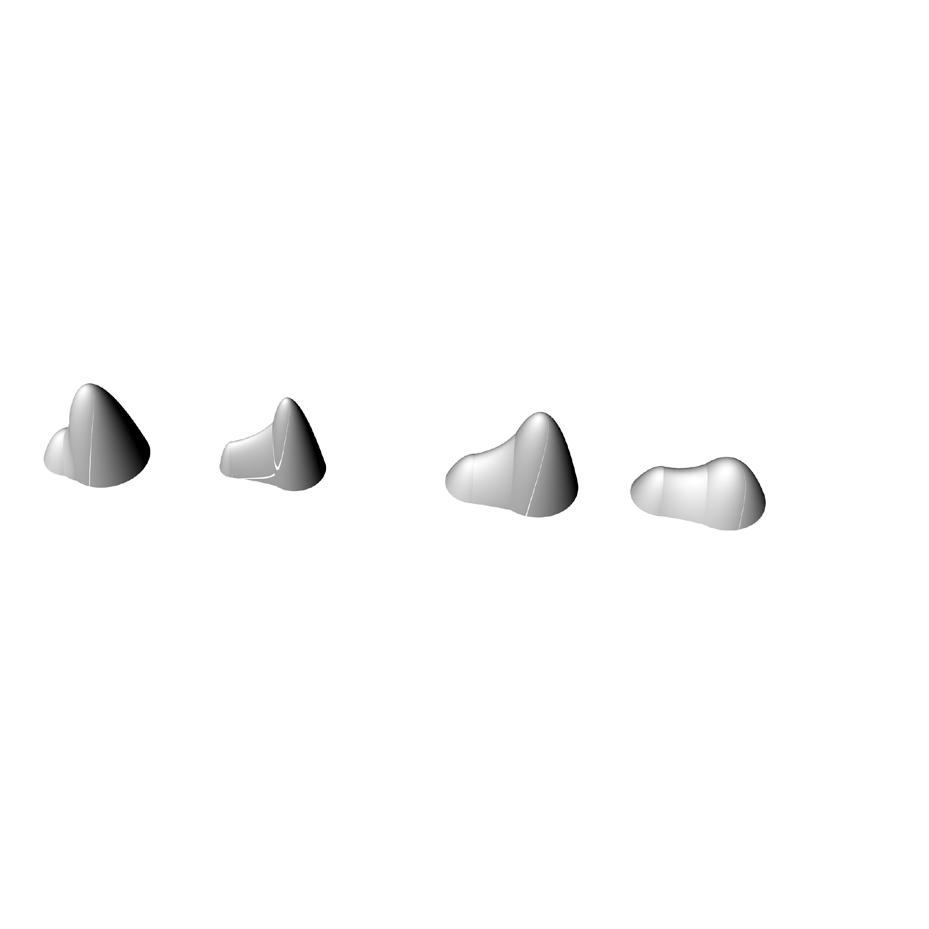

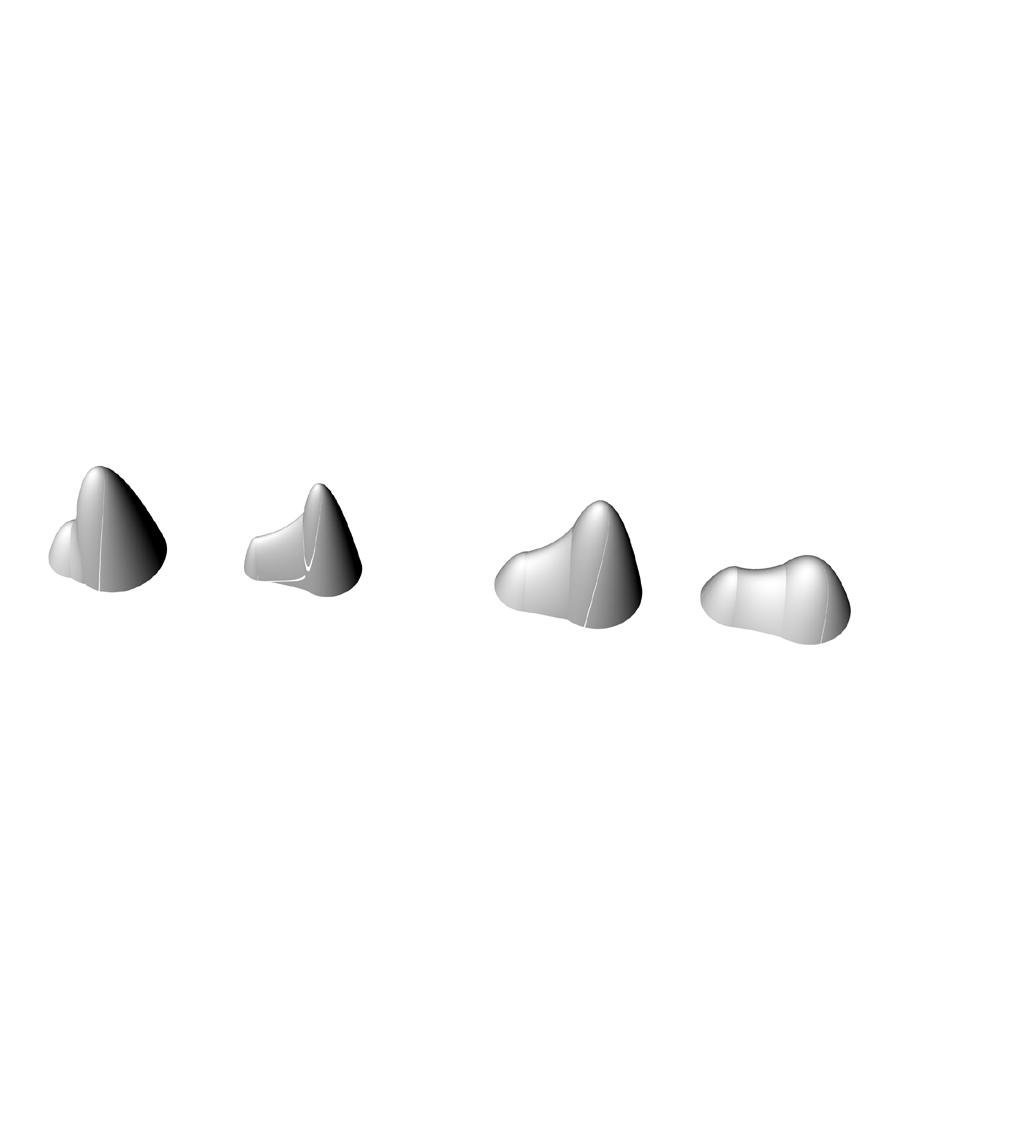

TYPE A

Irregular body, roof pitch >30

EXISTING DWELLING

Despite promoting the new notions of comfort and durability, the housing stock provided by the Canadian government in the last five decades completely disregards the traditional Inuit lifestyle and the cultural and sustainable intelligence of their existing dwellings. ln fact, the local model of dwelling, articulated around a common living room and several individual sleeping quarters, often took the form of an hermetic container. Several Canadian anthropologists, like Peter Dawson in 2002 19 recorded how the activities of Inuit families [e.g. food preparation, crafting, storage, etc.] were often ill-accommodated by the spatial configuration of the new homes.

MATERIAL

These so called ‘Euro—Canadian’ dwelling types applied the post-war modernist ideal of regularity to ‘universalise’ the design process and cut down design and fabrication costs. The result is the choice of aluminium as primary structural and exterior surface material, as is was inexpensive to import it from the southern regions. The poor thermal insulation of such material, and its rapid deterioration in the arctic environment however often caused expensive maintenance.

TYPE B

Straight body, roof pitch >30

TYPE C

Other [quonsets]

xlvi xlv Architectural Association Arctic Recalibration

VERNACULAR ARCTHITECTURE

vernacular building forms, methods and materials

MATERIAL

Historic evidence suggests that Arctic indigenous architecture often featured semisubterranean house floors, passageways, cold-trap tunnels, raised sleeping platforms and a variety of construction materials that differed according to seasonal needs and availability. In the generally treeless tundra environment they commonly used materials such as sod, turf and animal skins as a building envelope, and driftwood, whalebones, caribou antlers and even narwhal tusks for the main structure.

SEASONAL SHIFT

A crucial element of the Inuit settlement pattern is its seasonal shift between concentration in winter and dispersion in summer 20 This major demographic shift is heavily coupled with the surrounding life: summer was the season for exploring, and kayak hunting; while winter was a time for visiting, storytelling, ritual ceremonies and regenerating the cooperation vital to the

xlviii xlvii Architectural Association Arctic Recalibration

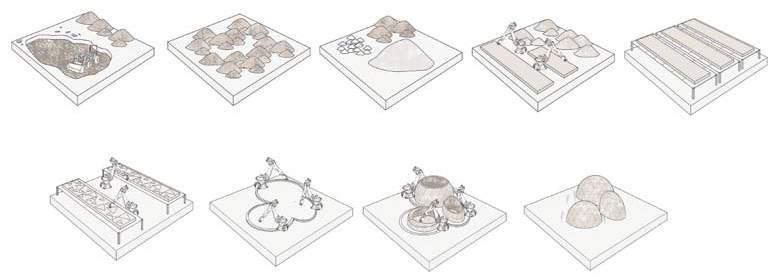

1-4 InhabitantsConstruction materia- Ice blocks

1-4 InhabitantsConstruction materia- Driftwood,

IGLU

6-8 InhabitantsConstruction materia- Sod, rocks

NAPAQTAQ IGLUYUARVK

1-4 InhabitantsConstruction materia- Saplings

4-6 InhabitantsConstruction materia- Sealskin

4-6 InhabitantsConstruction materia- Bones

TUPIQ ARCHED TUPIQ

WINTER DWELLINGS SUMMER DWELLINGS QUALURVIK

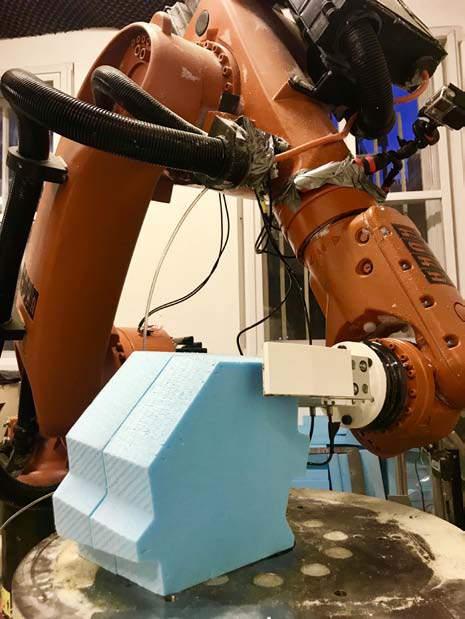

AUTOMATED CONSTRUCTION

Introduction to robotic construction processes

INTRODUCTION

Construction shapes our modern world. With global annual output in excess of $8.5 trillion, construction is an integral part of the global economy’s backbone, yet it relies on traditional fabrication technologies that are dangerous, slow, and energy-intensive. Common labor-intensive processes including bricklaying, wood framing, and concrete casting have, for decades of design construction, put workers at risk. The International Labour Organization estimated in 2005 that more than 50,000 people die globally in the construction industry per year, accounting for 17% of workplace accident fatalities 21

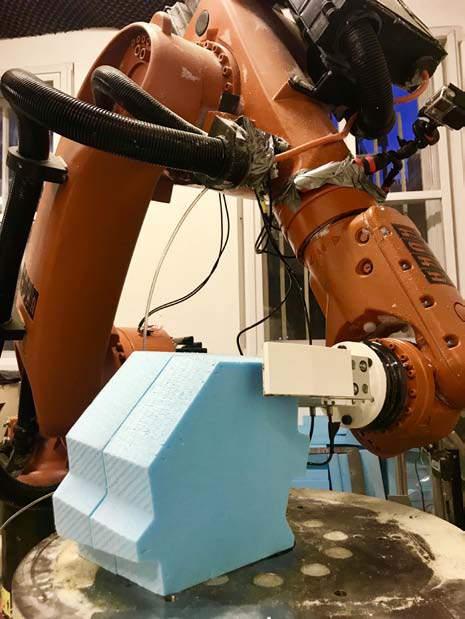

To improve safety, speed, and quality and to facilitate complex integrative fabrication operations, other manufacturing sectors such as automotive and consumer electronics have adopted the use of automated fabrication. Automated construction systems promise to yield similar benefits to the construction industry and, moreover, make newer digital fabrication techniques available at large scale. In combination with layer-based and freeform additive manufacturing techniques, automated construction systems could produce geometries that would be economically, if not physically, impossible to realize with conventional construction techniques. Structures produced by automated construction systems could be adapted on the fly to site-specific environmental conditions and constraints, using data collected in real time during fabrication. This capacity for data collection could also support more direct, detailed quantification of the building process, generating valuable data sets and describing a structure’s construction in high detail. Last, automated construction systems that could operate autonomously would find ideal applications performing construction tasks in inhospitable [such as after natural disasters] or extreme [such as Arctic] environments.

xlix Architectural Association Arctic Recalibration

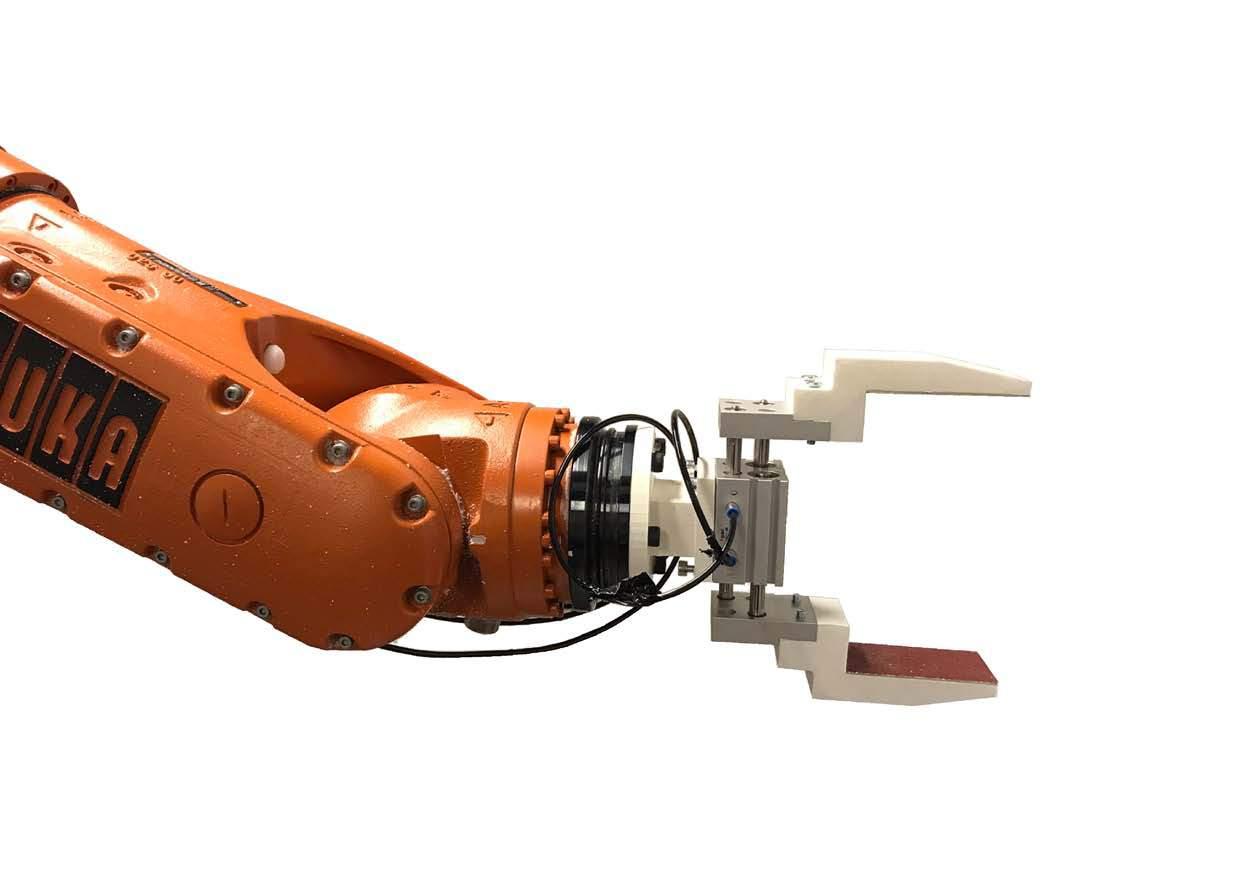

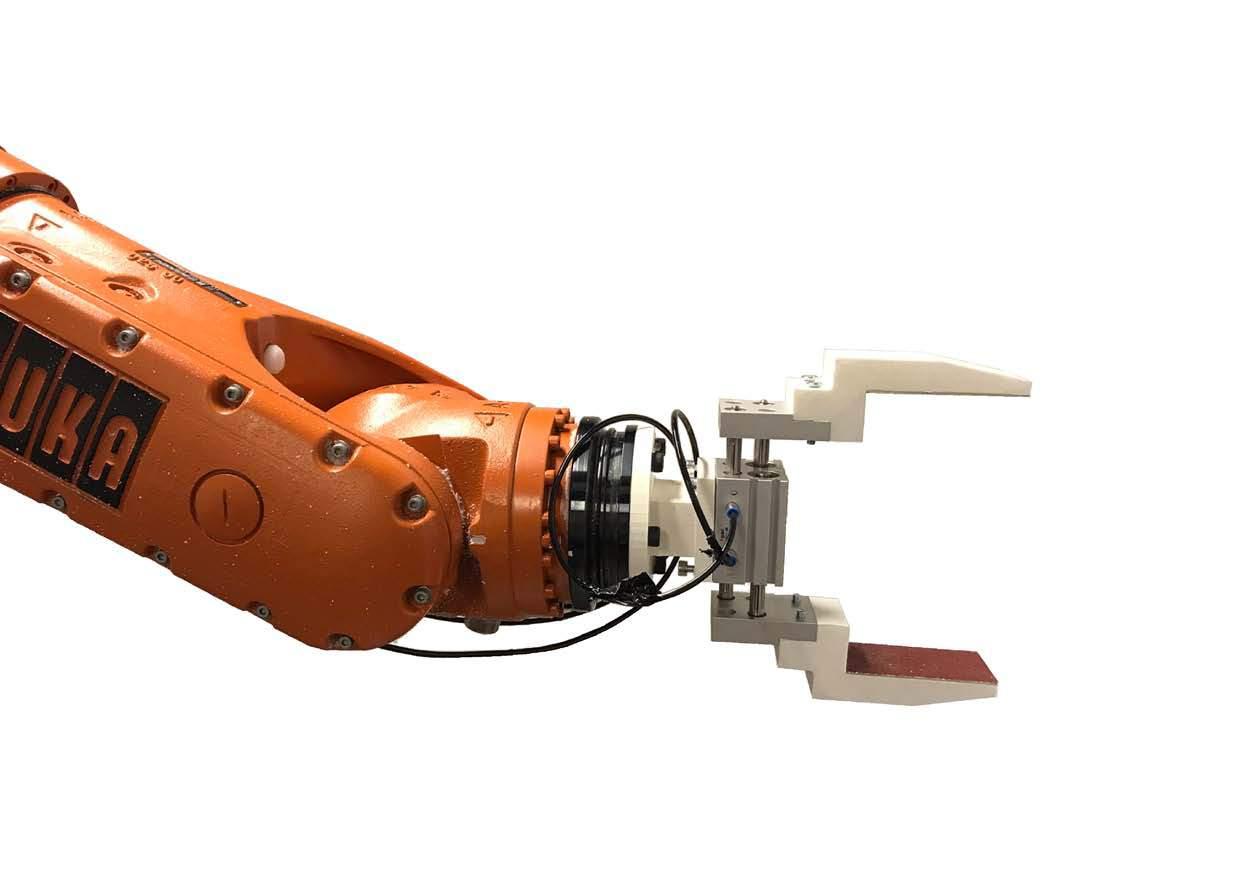

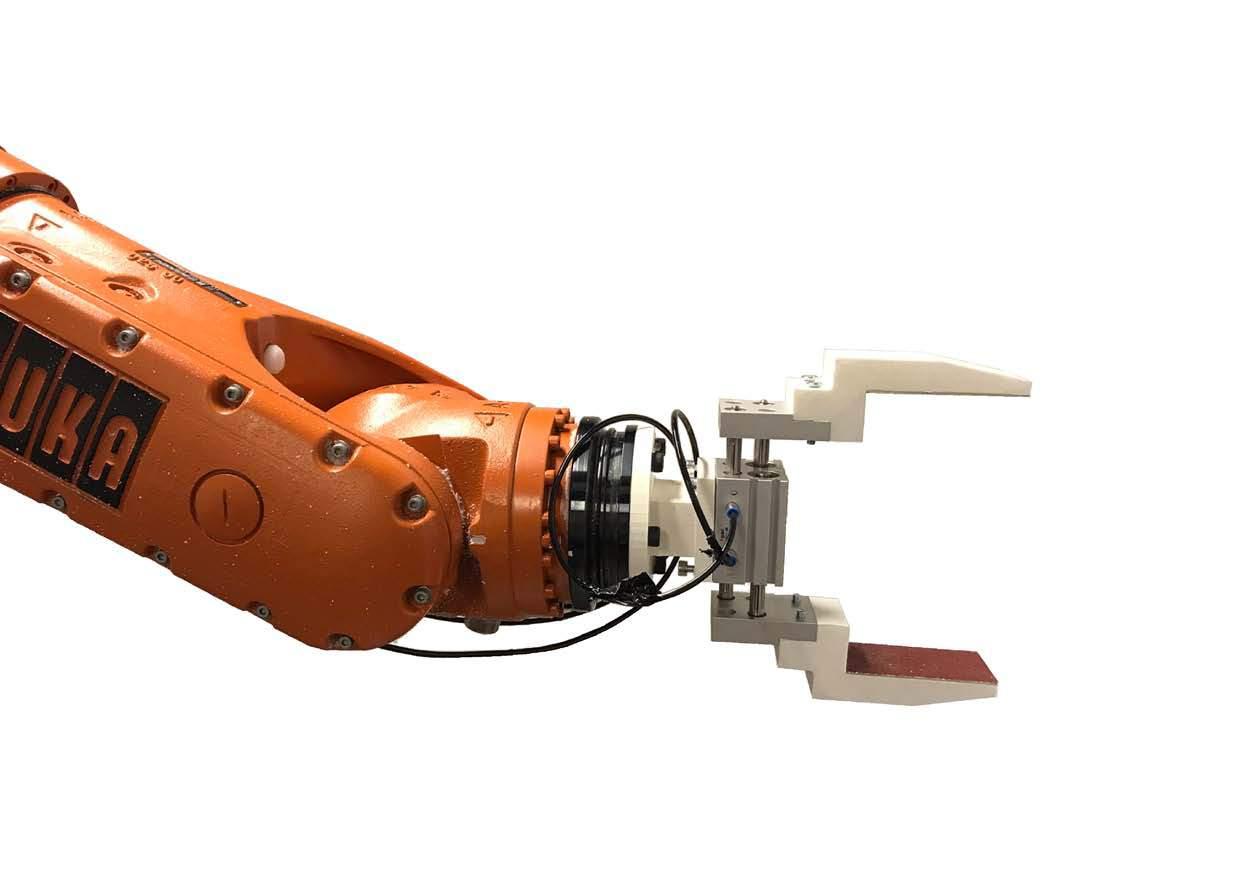

ROBOTIC FABRICATION

Parameters in robotic fabrication

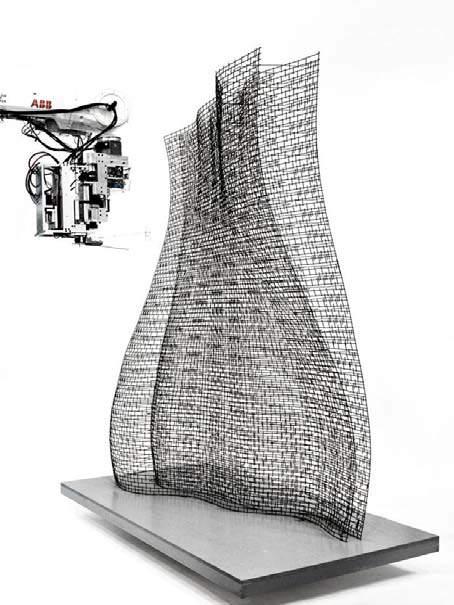

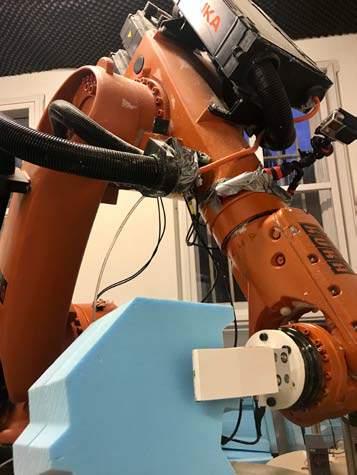

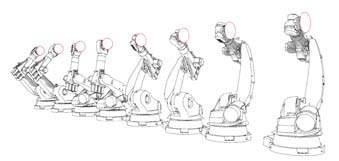

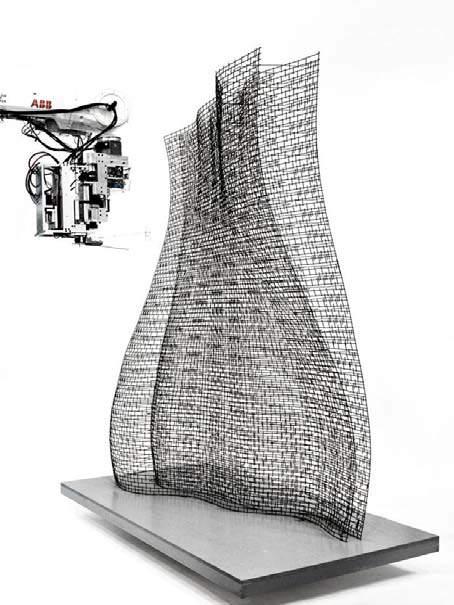

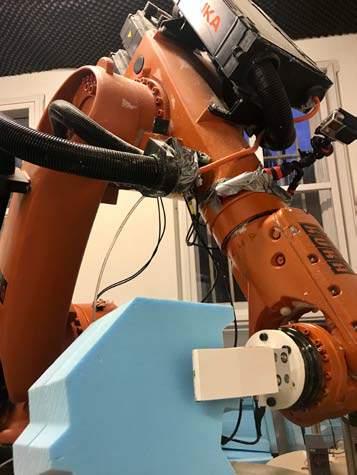

ROBOTIC FABRICATION

Robotic design and fabrication technology have brought a big impact in architectural design as well as in construction process in terms of new material exploration, high resolution production, and automation. The ability to be applied with different tools and tasks such as extrusion, brick layering, filament winding etc. opens up a wide range of fabrication possibilities and a new novel of techniques.

It’s ease of construction and shortening of construction time is a huge asset to the harsh conditions of the Arctic.

POTENTIAL FOR DESIGN :

Recent researches in these fields offer the opportunity towards digital fabrication in scale of construction. Furthermore, such construction of large scale systems push the researcher and architect to transform design traditions to a more complex, yet more detailed resolution output.

Some main variables of this fabrication technique are:

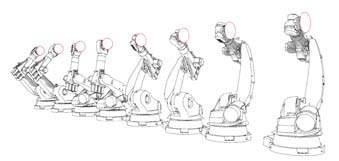

a) The robot

b) The end effector

c) Robotic movements and

d) Collaboration

lii li Architectural Association Arctic Recalibration

PARAMETERS OF ROBOTIC FABRICATION

The systems that define the robotic fabrication process

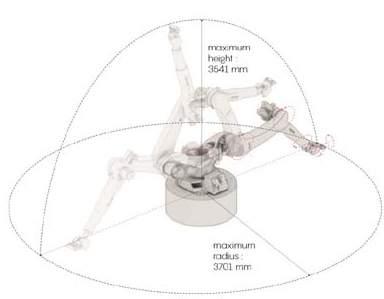

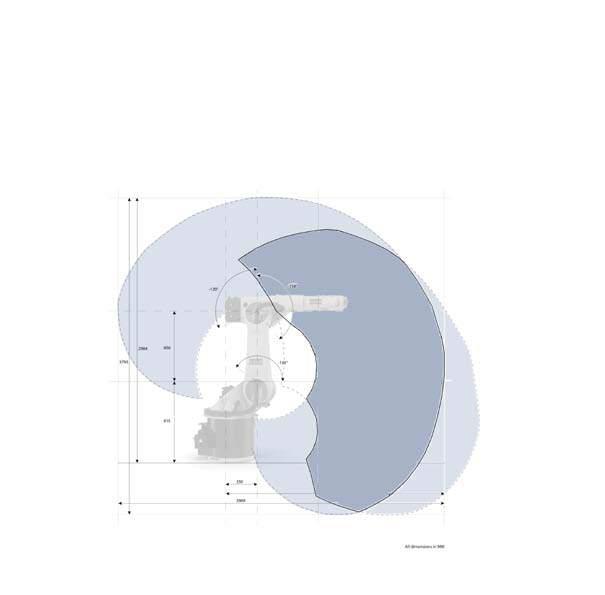

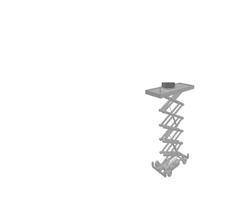

ROBOTIC PLATFORM

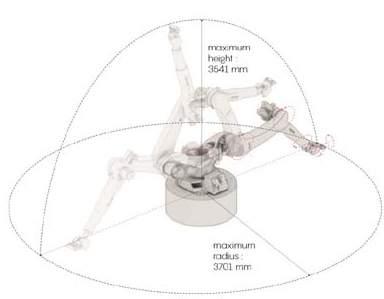

There are robots capable of doing various tasks or specific fabrication approaches, such as additive fabrication, subtractive fabrication, assembly, layering, stitching etc. depending on the needs. Robots can also be classified into two types based on their mobility which are in place robots or movable robots.

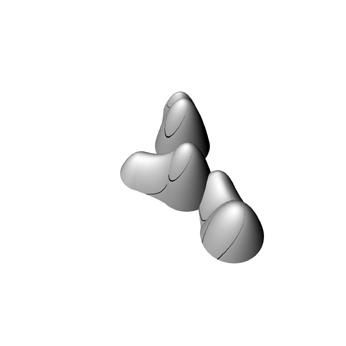

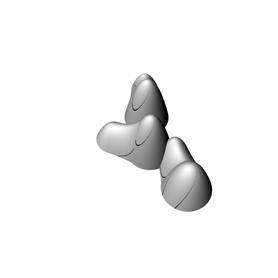

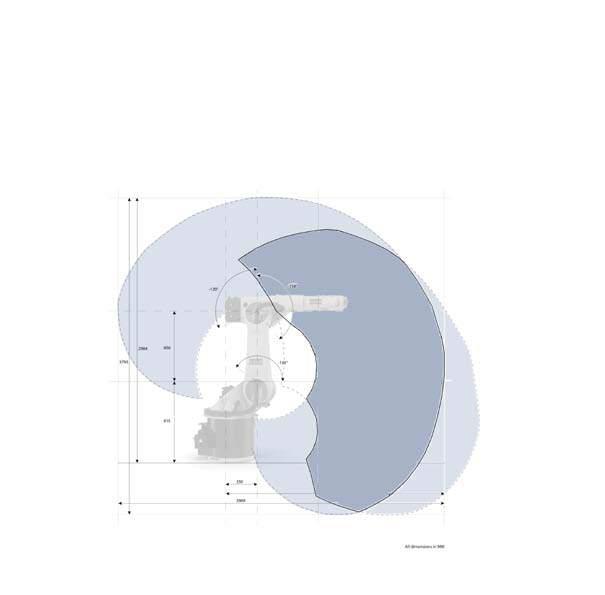

However, the most used robots in researches and some architectural practices are the six axis robotic arms. Their capability to be equipped with almost any tool implies that this robot can almost do anything if programmed to.

CONTROL SYSTEMS

The control system is designed to get the high accuracy in robotic fabrication process. Some parameters such as speed, gripper size, curing time, and material friction are the main factors that can affect the output especially in an continuous system.

In such an advanced fabrication systems, integrating sensor devices can be used to enable a real-time and even in-situ fabrication process. A multi robotic system for a continuous system would be ideal.

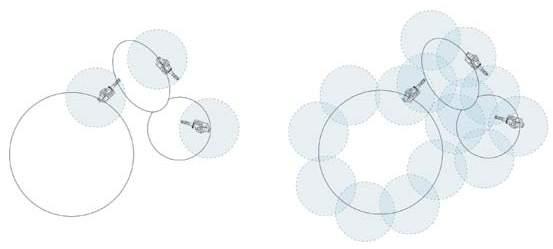

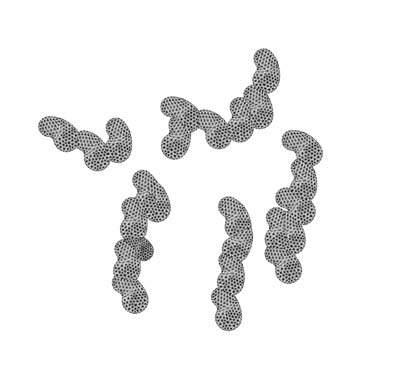

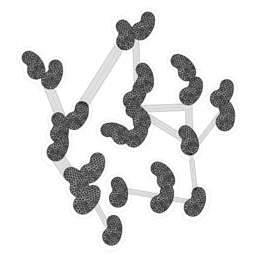

MULTI-ROBOTICS

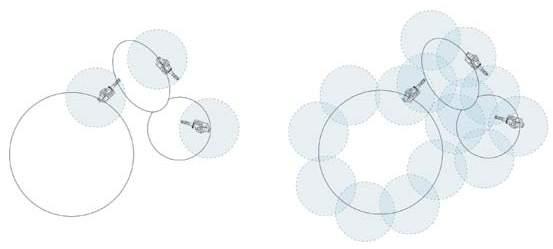

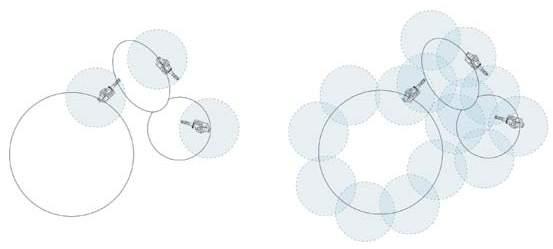

Multi-robotic fabrication methods can improve significantly the potential of robotic fabrication in architecture and construction techniques through an integration of assembly task in higher complex fabrications.

There are several challenges facing these methods when multi robotic works are used for building complex constructions. An example is the robot path and the necessity for collision avoidance. In the end, these challenges will become robot constraints when it is combined with the working area of a robot and its kinematic behaviour.

liv liii Architectural Association Arctic Recalibration

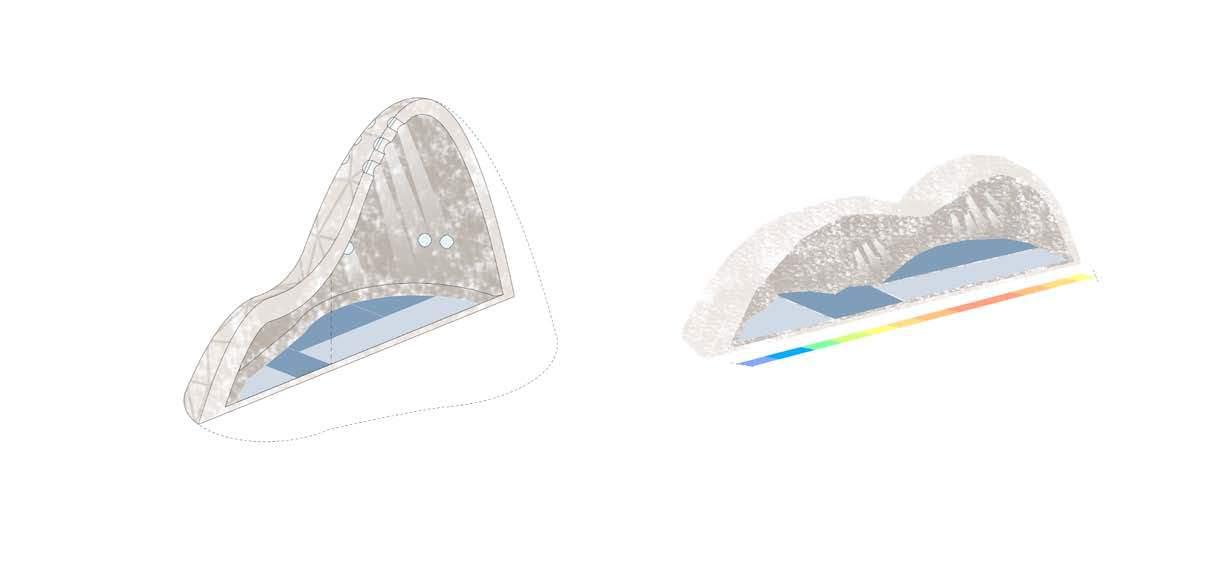

on site | off site construction

The pros and cons of automated onsite and offsite construction are discussed

OVERVIEW :

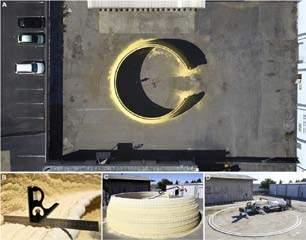

The design of buildings is strongly linked to the environmental conditions of their sites. Ground stability, the presence of extreme winds, or other environmental and social factors will determine the construction techniques and materials that are necessary to build safe, usable structures. These, in turn, dictate the capabilities required of the construction system itself.

The first point of classification is thus systems that manufacture prefabricated components in an off-site factory environment, systems that perform fabrication tasks directly on site, and systems that perform a combination of both. Prefabrication has been widely used in the construction industry, with a major example being the prefabricated aluminium flat packs outsourced to the Arctic 21

However, this prefabrication is limited by a range of costs and constraints associated with transportation and assembly and by poor customizability of structures, which can pose particular challenges when information about build sites is limited or inaccurate. Raw materials need to be transported to a centralized factory, processed, and then shipped to the site. For large structures, such as buildings and civil infrastructure, transportation can be constraining due to volumetric limitations and the absence of roads [both relevant to the conditions of the Arctic]. For structures being built in remote or extreme locations, sufficient information about the environment can be challenging to obtain and hence affect the ability to plan a structure.

Therefore autonomous on-site construction can offer improved worker safety, improved process control and quantification, and last-minute adaptability to local conditions. Although prefabrication is a convenient stepping stone for the field, on-site fabrication will rapidly displace it as automated construction systems take a

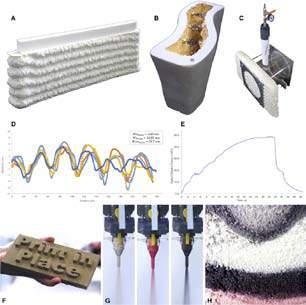

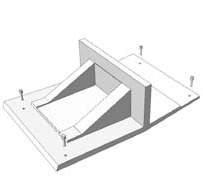

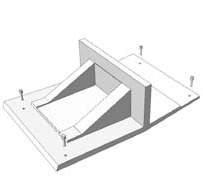

PiP wall section, with milled portion to geometric accuracy milled offsite and then assembled

lvi lv Architectural Association Arctic Recalibration

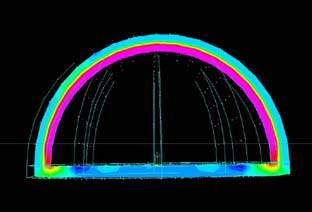

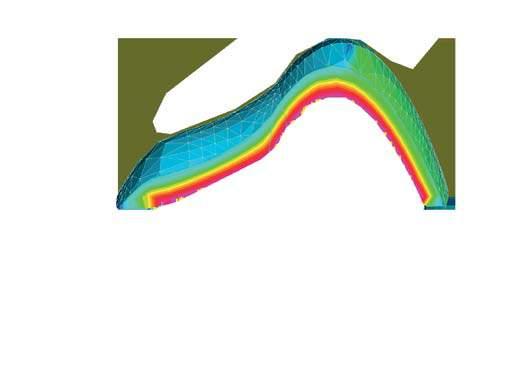

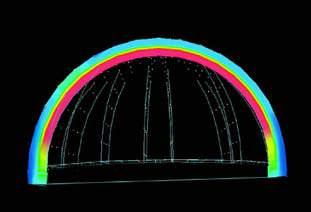

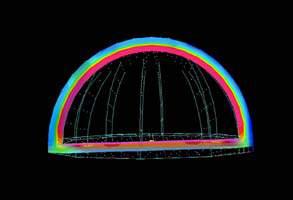

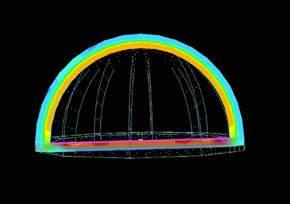

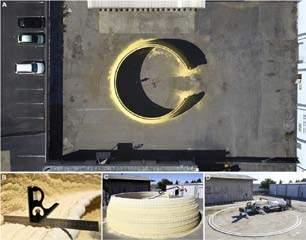

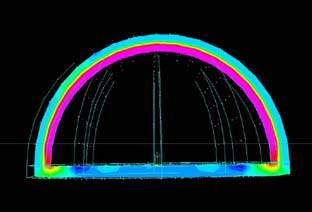

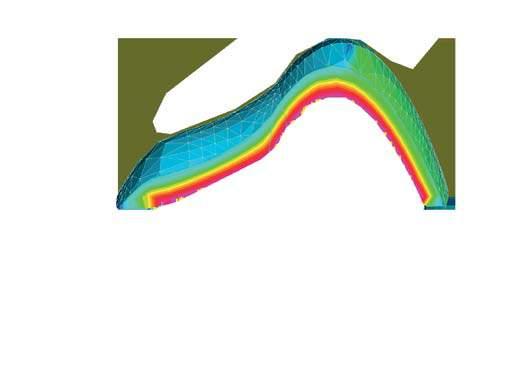

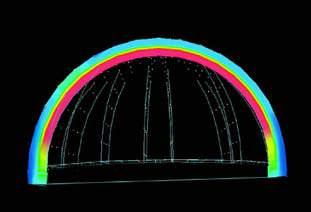

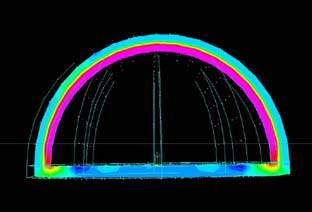

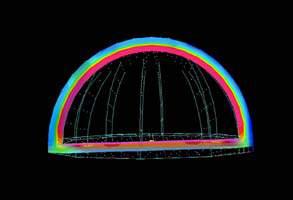

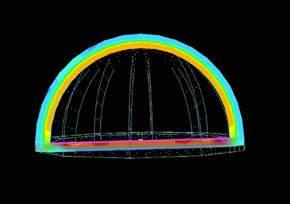

Architectural-scale hemiellipsoidal 3D printed on site

research project by Gramazio

Kohler Research at ETH Zurich

titled ‘Mesh Mould’

static or mobile s Y stems

A historical over of static or mobile robot systems

OVERVIEW :

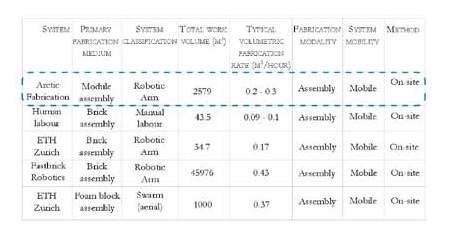

Historically, most of the automated construction systems explored have been functionally static, either because they are too large and unwieldy to safely move even if they operate on site or because they are intended to operate as prefabrication systems in factory conditions, as with most gantry-style systems 21. Static systems generally benefit from simpler construction, design, and operation.

The most common static platforms are gantry-style systems, which generally have 3 degrees of freedom (DOFs) and are unable to handle complex geometries and overhangs. Even small arms mounted on gantry systems rapidly encounter issues with collision with the structure when attempting to fabricate overhang-like structures. Static systems also require assistance from either a human-operated device or another autonomous system for transportation to and set up at a work site.

MOBILE SYSTEMS :

More recent work has begun to explore mobile platforms for construction. Mobility rapidly becomes imperative as researchers seek to develop systems with much larger build volumes, to enable fully autonomous on-site fabrication, and to effectively deploy automated construction systems in swarm configurations.

Mobile systems can be classified as terrestrial or aerial. Terrestrial systems remain on the ground and primarily increase lateral work volumes. Aerial drone-based systems provide theoretically unlimited work volume across all dimensions and tremendous operational flexibility. However, they are typically restricted to assembly tasks and also suffer from major constraints associated with flight, such as high energy costs, limited load capacity, fabrication time limitations due to battery/fuel consumption, complex control requirements, and substantial hazard associated with system failure. Environmental factors, such as wind, rain, and wildlife, are also important challenges. Thus, terrestrial systems can provide increased work volumes and swarm capabilities without incurring heavy costs on complexity of the system itself.

lviii lvii Architectural Association Arctic Recalibration

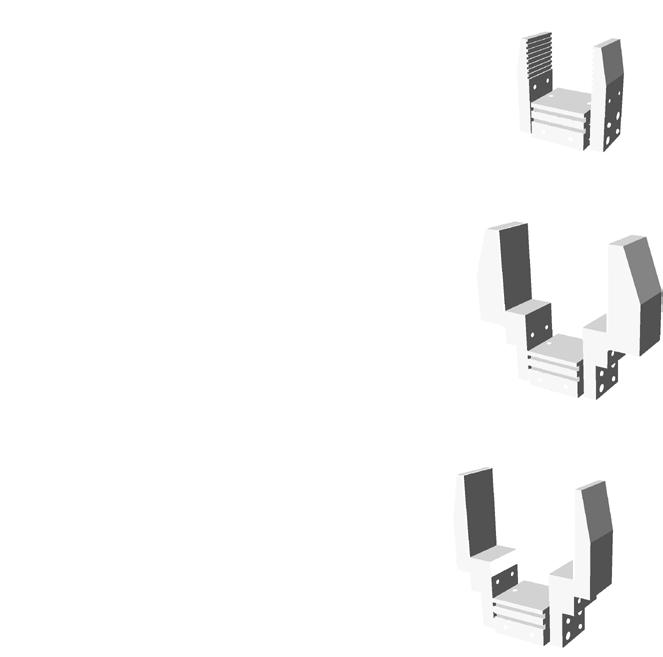

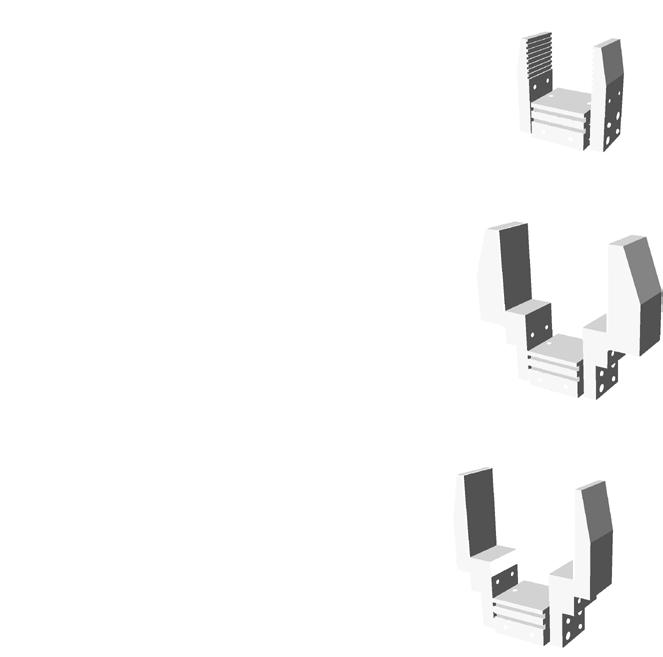

A SSEMBLY L OGIC

The assembly logics that the proposed construction system must consider

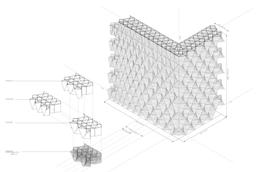

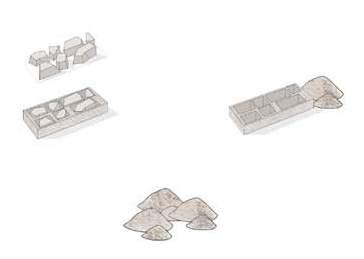

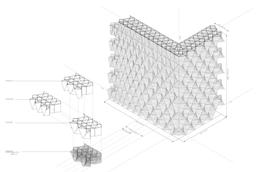

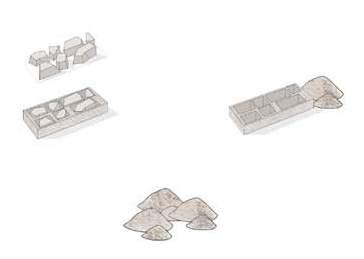

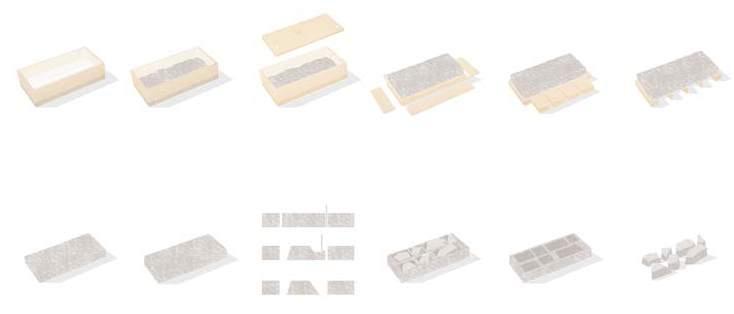

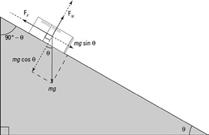

D iscrete a ssembl Y l ogic :

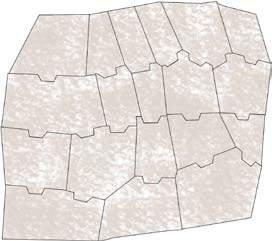

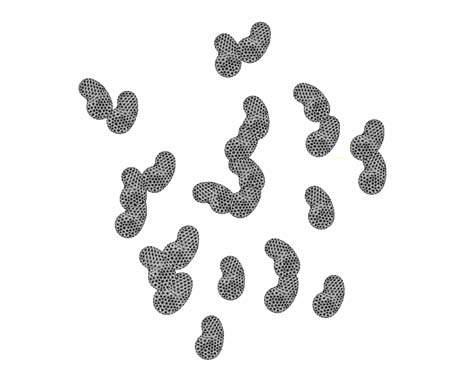

A discrete system is a system with a countable number of states. A discrete assembly logic is divided into two steps. The first step is the fabrication of discrete elements bricks, panels, frames, etc. which can all be identical, composed by family variations, or all unique and can be fabricated either off site or on site. Identical elements are better suited for bottom-up approaches since they are less restrictive. The second step consists of the on-site assembly of the elements.

The main limitation of employing a discrete assembly logic for a robotic construction method is the added complexity gained by separating fabrication and assembly, although in some cases the assembly process can become relativey simple since it consists only on the correct positioning of prefabricated elements.

n on -D iscrete a ssembl Y l ogic

A non-discrete [continuous system] is one in which the state variables change continuously over time. Non-discrete assembly logics are those in which fabrication and assembly are replaced by a single material deposition process. Although the process might be considerably more complex than the assembly of pre-made elements, by eliminating the fabrication process it becomes considerably easier to intergrate the entire construction process into an automated system.

The devices used for non-discrete assembly strategies should be designed specifically for the selected material and deposition strategy.

lx lix Architectural Association Arctic Recalibration

Discrete sYstem TerraPerforma - 3D Printed Performative Wall

sYstem Mnibuilders

robotic continuous system

Assembly Logic Assembly Logic Assembly Logic

non-Discrete

multi

C ONCLUSIONS

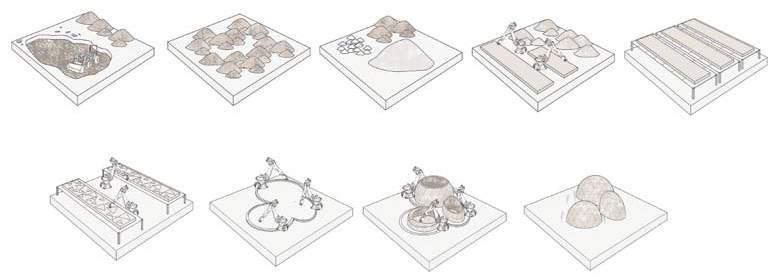

PEAT AS A MATERIAL FOR CONSTRUCTION :

Understanding the nature, availability, value and properties of peat in the drained thermokarst lakes and taking into consideration the material(soil) precedents, where forms of soil is used as a material for construction and research at various scales, using various techniques inspires the selection of this material for further research. The aim is to understand the innate properties of the material and use it advantageously for construction in arctic regions.

PROTOTYPYING TECHNIQUE

Analysing the various methods of construction and research using peat as a building material, the methods can be simply classified into Rapid prototyping techniques and Slow Prototyping techniques. Considering the local climatic conditions and material properties; a preference is placed towards slow prototyping formation techniques with a rapid assembly logic. The aim is to select suitable prototyping techniques based on the properties of the material determined through physical experiments and possibly integrate various techniques to form an architectural system that responds to external factors.

SITE SELECTION :

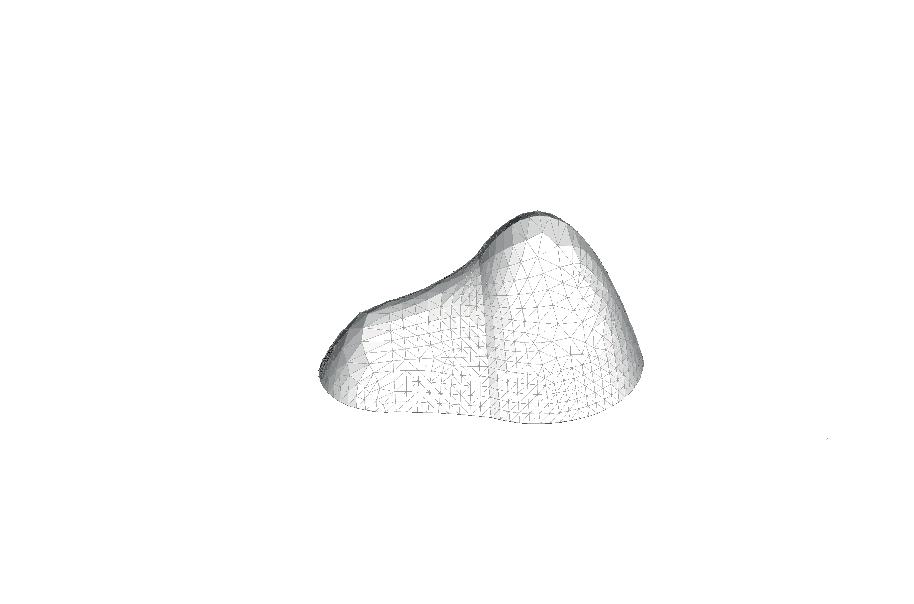

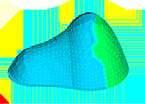

An area of approximately 3,800 km2 on the northern Seward Peninsula, Alaska [66.5°N, 164.5°W] is selected as the site. The study area is situated in an ice-rich permafrost region and is largely covered by thermokarst-affected terrain with a large number of thermokarst lakes and DTLBs and erosional remnants of uplands. The northern Seward Peninsula is identified as one of the major lake districts of Alaska, where 7% of the 6,418 km2 coastal lowland area is covered with lakes larger than 1 hectare. Thermokarst lakes in the lowland plain of the region mainly formed as a result of permafrost degradation due to warming throughout the Holocene

Currently, the mean annual ground temperature is recorded as −3 °C . This allows for current formation of permafrost following drainage of thermokarst lakes in the region . The depth of permafrost exceeds 90 M and the active layer is 0.3–0.6 M thick The permafrost thickness very likely varies due to the distribution and thermal impact of thermokarst lakes however, is confirmed to be abundant currently and only grow in its availibility with increasing temperatures.

FURTHER RESEARCH :

Further research aims on understanding in depth the properties and performance of the material in various states. This is aimed to be done through rigorous physical experiments through which the properties of the material may be determined and digitized for further computational processes. Various prototyping techniques will be investigated and weighed based on the advantages they offer both to the site and to the material while pushing towards innovative construction strategies.

lxii lxi Architectural Association Arctic Recalibration

iii . m aterial s Y stem

lxiv lxiii Architectural Association Arctic Recalibration

material science ...........................................................................65 case stuDies ...........................................................................68 binDer exPeriment ...........................................................................77 comPaction exPeriment ...........................................................................79 volume reDuction exPeriment ...........................................................................81 surface area exPeriment ...........................................................................83 freezing exPeriment ..........................................................................85 water resistance ...........................................................................87 self insulating material ..........................................................................89 material comParison ...........................................................................91

Physical and chemical properties of peat

Sphagnum Peat, is dead fibrous material that forms when mosses and other living material decompose in peat.

MATERIAL PROPERTIES

Peat is a type of soft soil composed of high contents of fibrous organic matters and is produced by the partial decomposition and disintegration of mosses, sedges, trees, and other plants that grow in marshes and other wet place in the condition of lack of oxygen.

Peat also contains high organic content, often more than 75%. The organic contents present in peat are the remains of partially decomposed and disintegrated plant. These take place in conditions where the rate of accumulation is more than the rate of decay. Peat is accumulated if the rate of decay is slower than the rate of addition 22

It accumulates whenever the conditions are suitable, that is, in areas where there is the ground is fully undrained, irrespective of latitude or attitude. Generally, the deposit is found in thick layers on limited areas. However, due to climate change and the creation of DTLB peat is found in abundance as the top soil. Since the main component is organic matter, peat is very spongy and highly compressible in characteristic (Roy, 2004

lxvi lxv Architectural Association Arctic Recalibration

m aterial s cience

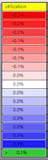

C,H,O,N,S Dark brown 0.61 um 1121 kg/m3 5.5 ph 37 % 12% 0.4-1.2 Material Element composition Colour Particle size Density Acidity Water Holding Capacity Air Capacity Friction

P eat c om P ressibilit Y f actors

The dominant factors controlling the compressibility characteristics of peat

FIBRE CONTENT

INITIAL PERMEABILITY

NATURAL WATER CONTENT

VOID RATIO

NATURAL ARRANGEMENT OF SOIL PARTICLES

The percentage of organic matter in peat [sphagnum moss peat] is 70 - 95%

600 barrier

12 - 50% .This water is available in the form of free water molecules.

0.5 - 25 %

Non alligned fibres distributed uniformly

lxviii lxvii Architectural Association Arctic Recalibration

PEAT [LOAM] SILT LOAM SILTY CLAY SANDY CLAY LOAMY SAND SAND SANDY LOAM SANDY CLAY LOAM CLAY SILTY CLAY LOAM CLAY LOAM CLAY% SILT% SAND %

r icola k räuterzentrum

Rammed earth block construction

OVERVIEW TECHNIQUE

Architects: Herzog & de Meuron

Location: Laufen, Switzerland

Year: 2014

Time of construction: 18 month

Size: 50x50 meters

Cost - unknown

The prefabricated earth elements are manufactured in a nearby factory out of ingredients extracted from local quarries and mines. Clay, marl and material excavated on site are mixed and compacted in a formwork and then layered in blocks to build the walls. To arrest erosion caused by wind and rain, a trass mortar achieved mixing volcanic tuff (trass) with lime, is compacted every 8 layers of earth directly in the formwork.

ADVANTAGES

-Locally sourced earch from the construction site

-Earth based mortar composition

-Large-scale blocks

-Short-time walls assembly

DISADVANTAGES

-Human labour compaction - additional time

-Logistics: Blocks are prefabricated on a factory 10 km from a site

-Heavy blocks are lifted by the heavy machinery

-Framework is required for the blocks fabrication

-Steel framework as a building framework

lxx lxix Architectural Association Arctic Recalibration

Earth tube construction

OVERVIEW

Architects: Nader Khalili

Location: Canada, Mexico, Brazil, Belize, Costa Rica, Chile, Iran, India, Siberia, Mali, and Thailand, U.S.

Year: 1995-present

Time of construction: 1-30 days

Size: D up to 10 m, h up to 6 meters, S up to 2,000 sq. ft

Cost - unknown

TECHNIQUE

Long or short sandbags are filled with moistened earth and arranged in layers or long coils. Strands of barbed wire are placed between each layer of sandbag to act as both mortar and reinforcement. Stabilizers such as cement, lime, or asphalt emulsion may be added. The SuperAdobe building system can be used for structural arches, domes and vaults, or conventional rectilinear shapes.

ADVANTAGES

-No mortar

-Continuous discrete process

-Short-time construction

-No need to lift heavy blocks

-No framework

-Additional tensile strength due to barbed wire

DISADVANTAGES

-Human labour required

-Polyethilene bags are required

-Spatial limitations to small compression-only structures

lxxii lxxi Architectural Association Arctic Recalibration

s u P era D obe

e D en P roject

Layered rammed earth construction

OVERVIEW

Architects: Grimshaw Architects

earth construction: Rammed Earth Consulting

Location: Cornwall, England.

Year: 2001

Time of construction: 8 weeks

Size: 2 walls 45 meters each

Cost: £70 per metre square

TECHNIQUE ADVANTAGES

The walls are built from a 3m deep subsoil - well graded material with clay, sand and stones in the mix, .extracted by the main contractor as part of their landscaping works. It is rolled into a ‘bund’, a pile of soil which was tracked over by a digger to seal the top surface. The formwork is the old ‘acrow’ type, from 15mm ply. In all about 270 tonnes of soil are used, placed into the formwork in 150mm deep fills and rammed. Clay plaster is used as a mortar.

-Showed resistance to flash flood

-Short period of construction

-No framework

DISADVANTAGES

-labor-intensive compaction

-Complex geometries not possible

lxxiv lxxiii Architectural Association Arctic Recalibration

lxxvi lxxv Architectural Association Arctic Recalibration

Physical material tests conducted to analyse material potentials

a DD itives

Introduction to the additives proposed, the types and the selection criteria of the additives

OVERVIEW

Peat requires a binder to hold the particles together and solidify the result to retain structural integrity. By definition, a binder is any material or substance that holds or draws other materials together to form a cohesive whole mechanically, chemically, or as an adhesive. A binder may be interchangeably used with adhesives, cements or glues and resists separation with the base material in use.

MECHANISM OF BINDERS

For a binder to perform efficiently and effectively with sphagnum peat, it is required to possess certain properties. It must be mixable, it should be able to harden either naturally or through induced processes and it must be able to transfer loads Adhesion, the connection between the binder and the base material may occur either mechanically or chemically. The strength achieved through adhesion depends on several factors including the means through which it occurs. In some cases, an actual chemical bond occurs between adhesive and substrate. In others, electrostatic forces, as in static electricity, hold the substances together. A third mechanism involves the van der Waals forces that develop between molecules. A fourth means involves the moisture-aided diffusion of the binder into the substrate, followed by hardening.

TYPES OF BINDERS :

Binders can be classified into two distinct types – Natural or Synthetic

Natural binders are produced from organic sources such as resins from tree barks, starches from vegetables or protein based glues form animals. They are natural polymeric materials and are often referred to as bio-adhesives. They are of commercial interest and tend to be bio-compatible

Synthetic binders are based on polymers such as plastics, elastomers and thermosets. Some of the commonly used commercial synthetic binders are epoxy, polyurethane and acrylic polymers. Though proven to be very effective they have a limited shelf life when compared to natural binders and may have reduced performance through prolonged storage.

SELECTION CRITERIA OF BINDERS :

The binder to be used in creating a stable material for construction need to based on certain selection criteria. As Peat is the base material used in this research, an appropriate binder that works well with its particles is to be used.

The selection will be based on Drying time, Compressive strength, Dimension after compaction, Sustainability, Recyclability or reusability, Strength achievable and properties imparted to the material as a whole.

FIRE RETARDANT ADDITIVE :

Peat inherently is a highly flammable material. Peat is partially decomposed plant matter formed in wetlands that can be harvested as fuel. It can be the first step in the formation of coal, a process that takes millions of years and is therefore, used as fuel in many parts fo the world.

To prevent peat from being inflammable a fire retardant is added to the mixture in a powder form [not in liquid form to prevent the increase of volume of liquid in the peat which could potentially absorb the proposed binders]

Phos-Chek fire retardants are manufactured as dry powders. Some of the main components of Phos-Chek retardants include ammonium polyphosphate, diammonium phosphate, diammonium sulfate, monoammonium phosphate, attapulgus clay, guar gum. The phosphate and sulfate salts act as fire retardants and prevent combustion of cellulosic materials which is highly available in peat.

lxxviii lxxvii Architectural Association Arctic Recalibration

Free water molecules

Material Peat Binder Fire retardant

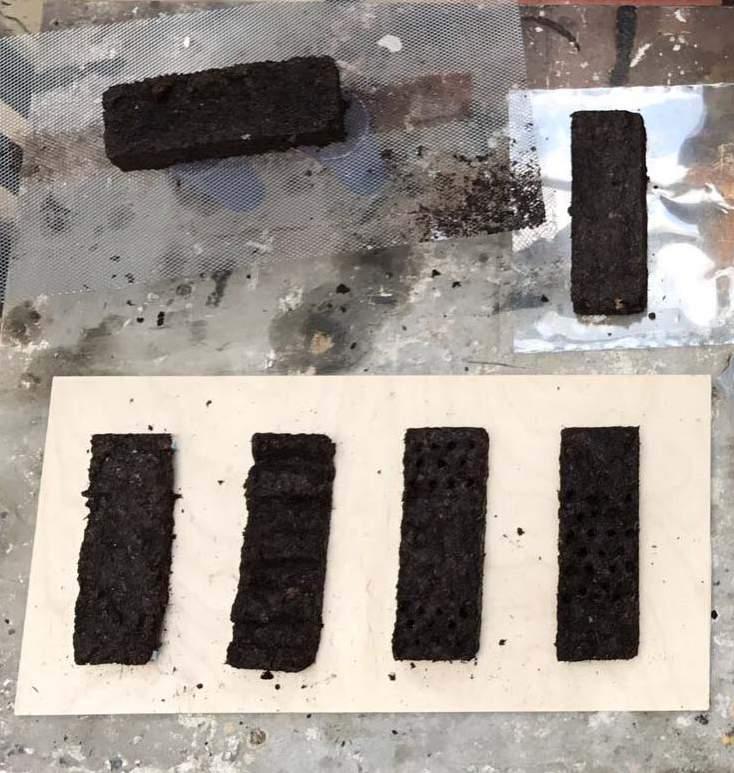

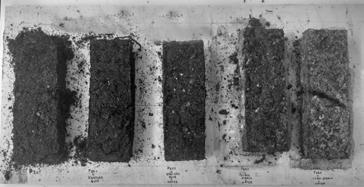

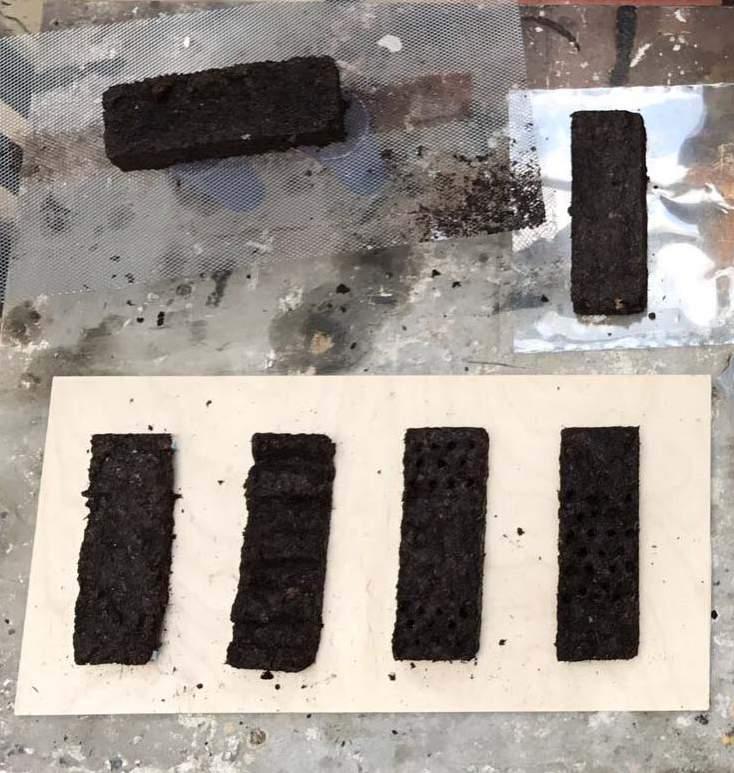

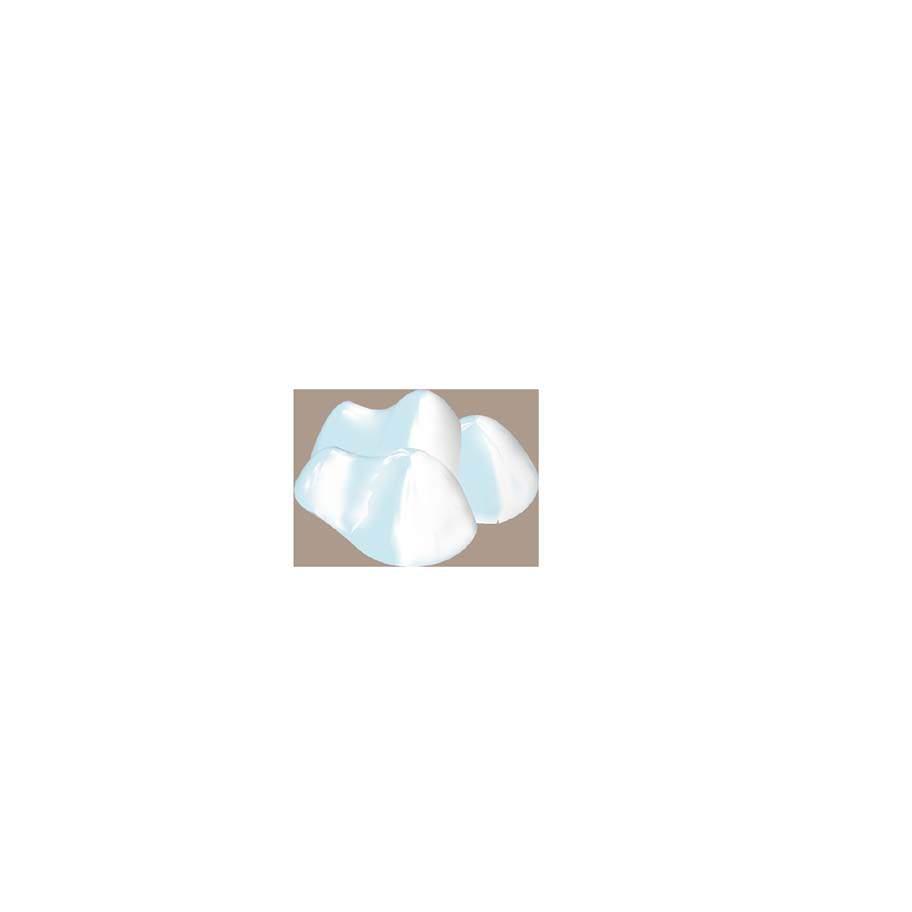

bin D er | ex P eriment i

Experiment to test suitable binder for the base material

APPARATUS

Peat+Additive+water mix

4-sided formwork.

Cap with the size of the hole in the formwork

Weights

TECHNIQUE STEPS

1. Mixing the composite: peat+additive+water.

2. Placing the mix into the 4-sided formwork

3. Compacting the mix from the top with the force

4. Removing the weight and waiting for the brick to dry.

INITIAL PARAMETERS

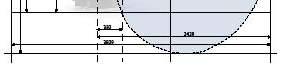

Size: 70x200x50 mm

Volume: 700000 mm

Force applied 30 kg with step of 2 kg;

OBJECTIVE :

the first physical experiments conducted was a simple compaction experiment, where the material is brought together to a homogenous mix and compacted using moulds and left to dry yielding bricks which are then examined for further studies and research.

As preliminary investigation, a series of different naturally and synthetically ocurring binbers combined with peat have been tested. The drying time, change in volume, color compressive shear strength, weight are used to rank the series. The aim of the experiment is to understand the results that different compositions of peat, additive, water combined with certain drying time and temperature can provide.

ConC Peat + xanthan gum

lusions Peat + Potato starch + Water

I. The block without binder does not perform structurally

Peat + xanthan gum + Water

Peat + corn starch + Water

II. Best type of binder is xanthan gum in composition without water, which performs better in regards to both hardening time and compression strength.

III. Potato starch sample has the least amount of compressive strength and can not be considered as an approppriate option.

lxxx lxxix Architectural Association Arctic Recalibration Step 1-2 Step 3 Step 4

Xanthan gum,a powerful thickening agent, that is also used as a stabilizer to prevent ingredients from separating is the binder selected for further experiments as it was found to have the highest compressive strength, lowest drying time and it not require additional water as it combined with the existing free water molecules in the peat thus, utilising less resources [additional water] keeping with objective of resource autonomy. Peat

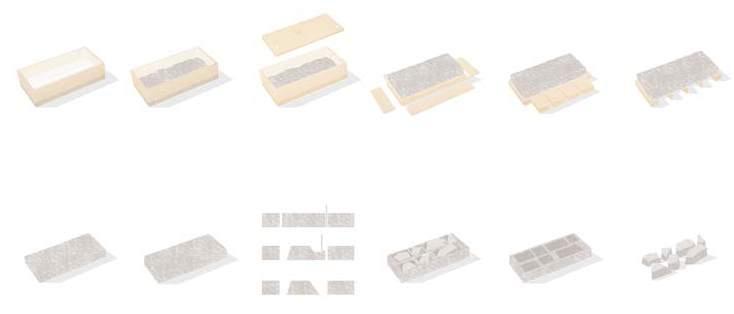

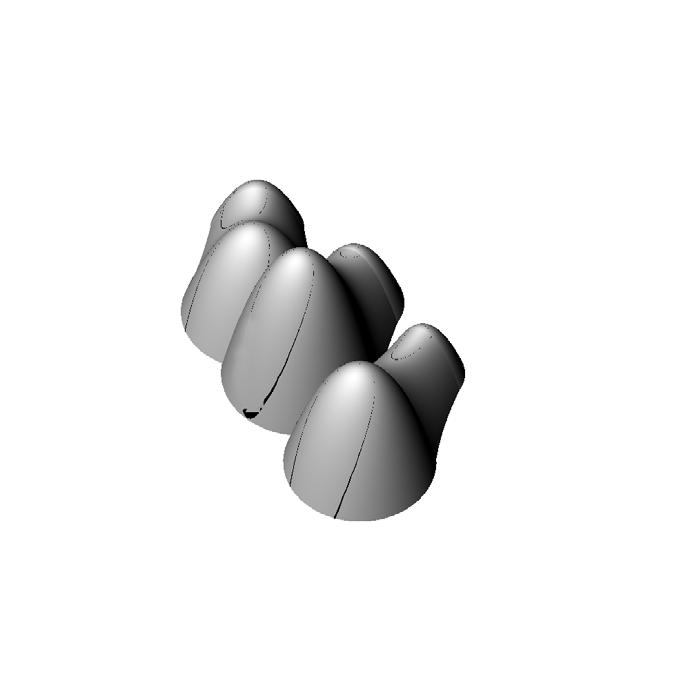

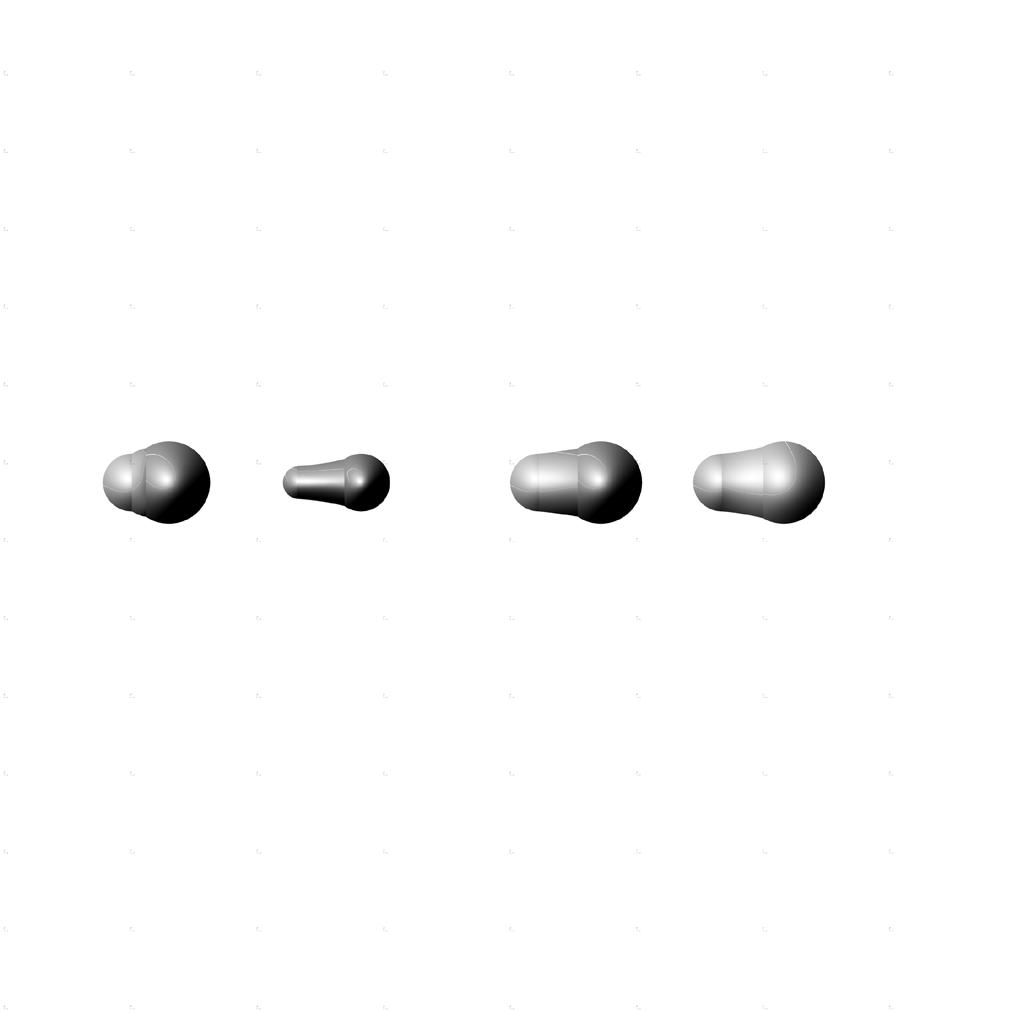

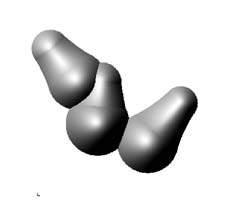

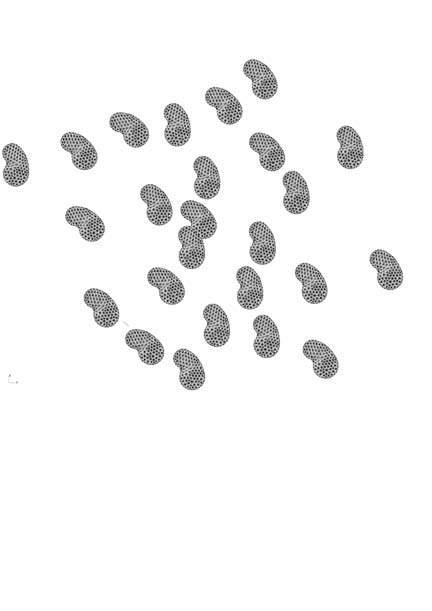

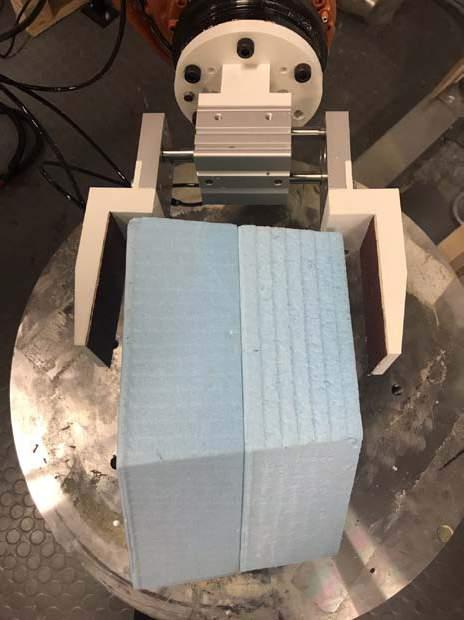

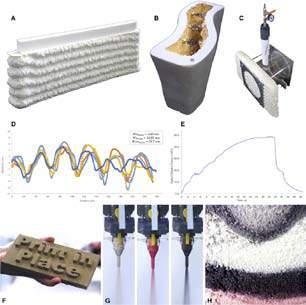

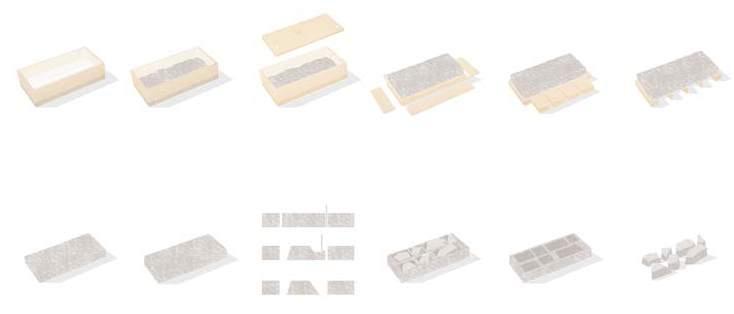

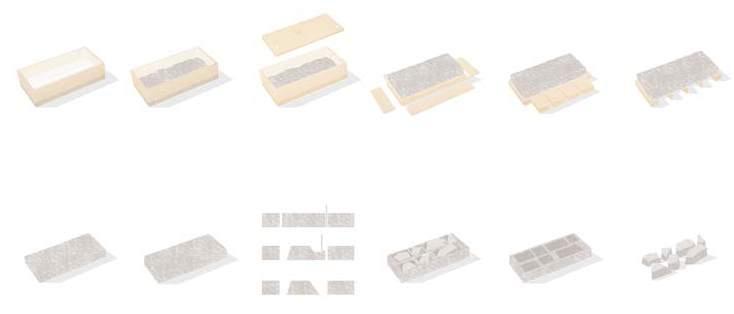

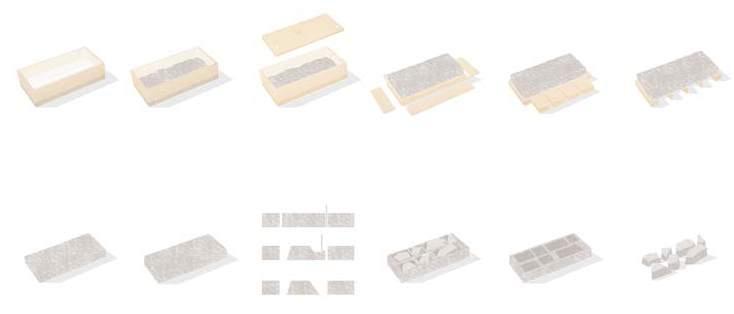

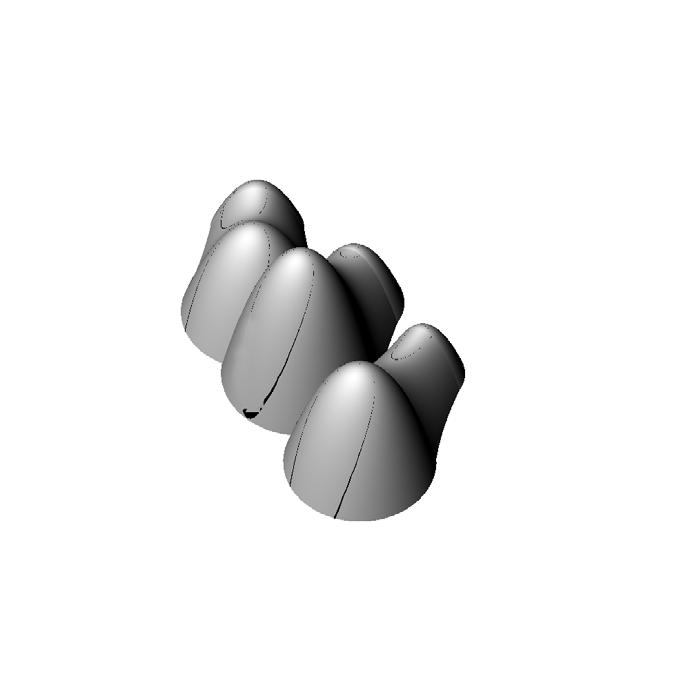

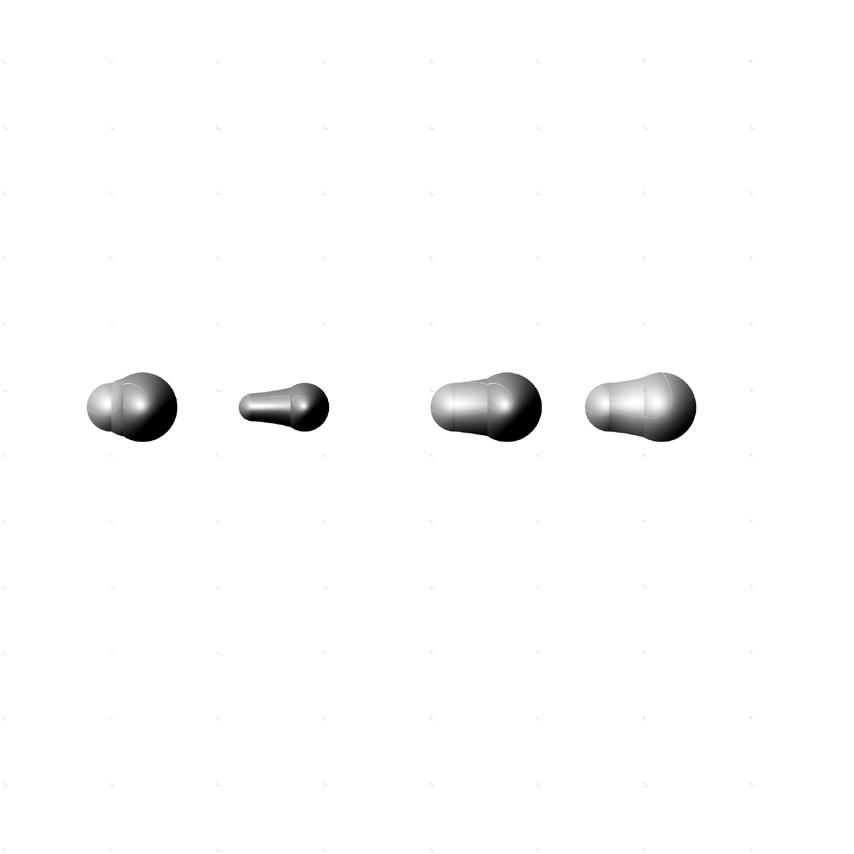

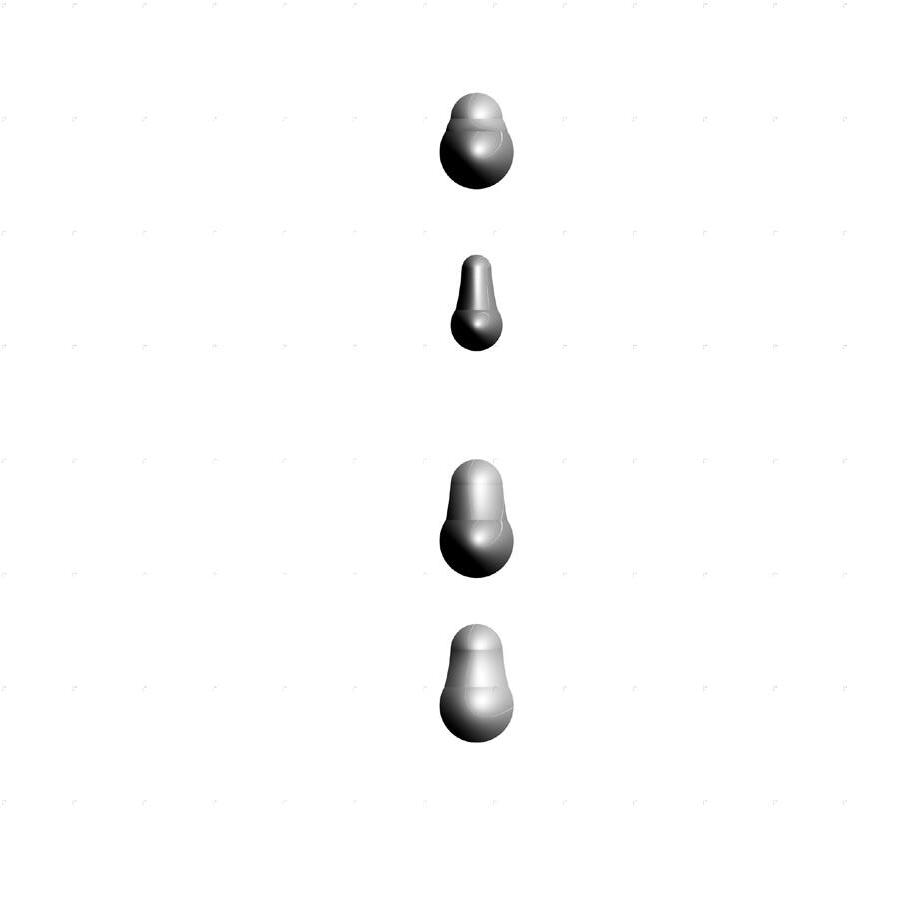

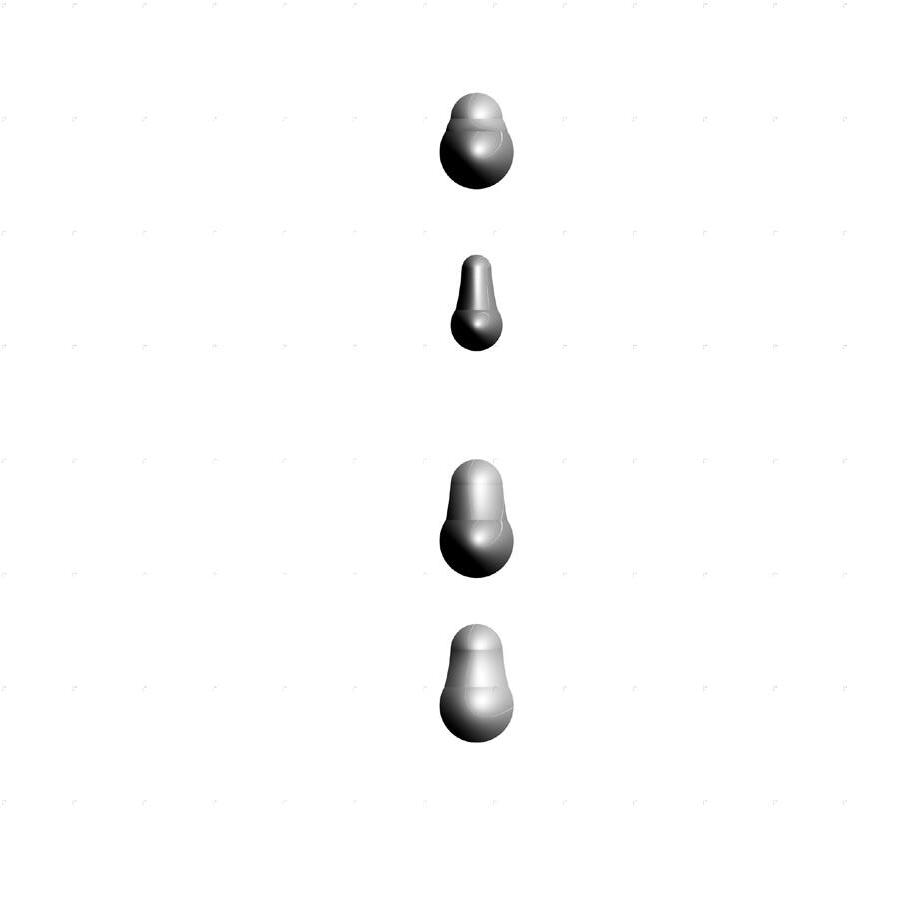

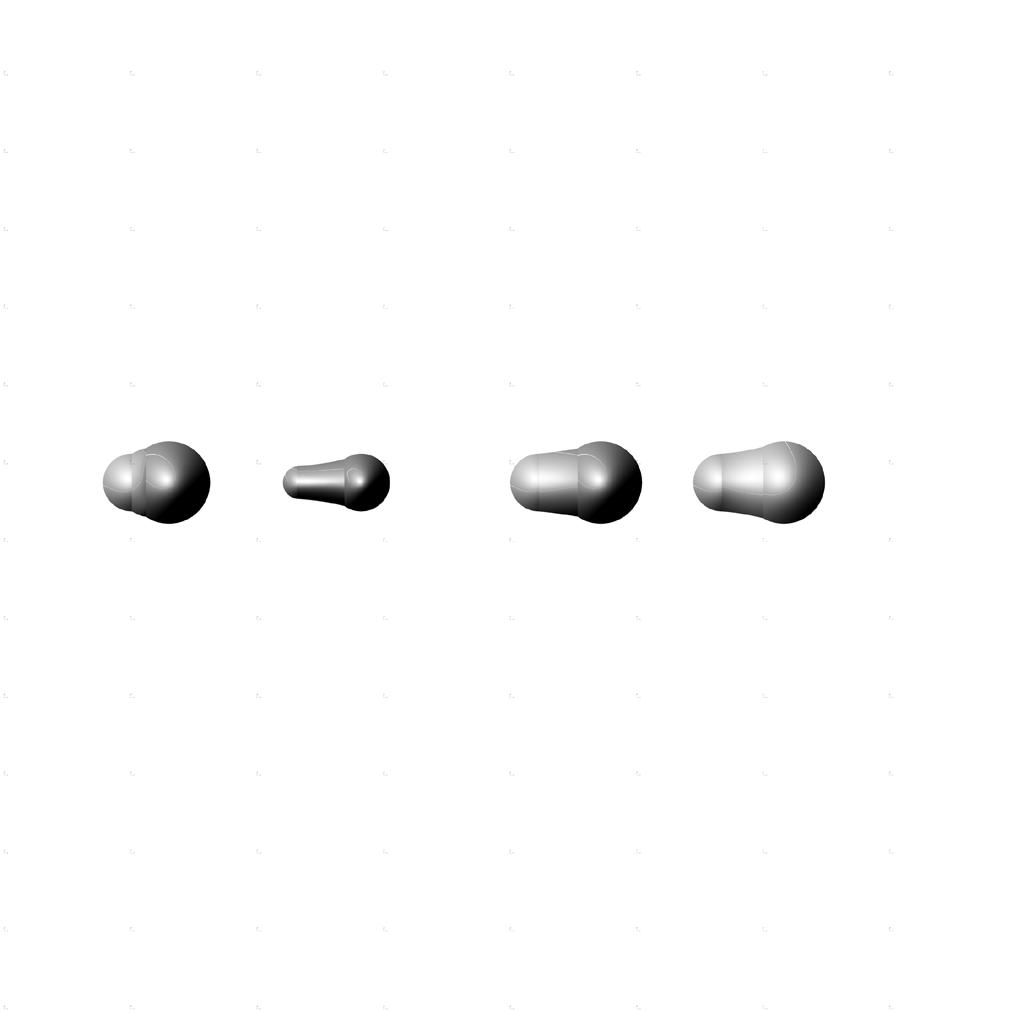

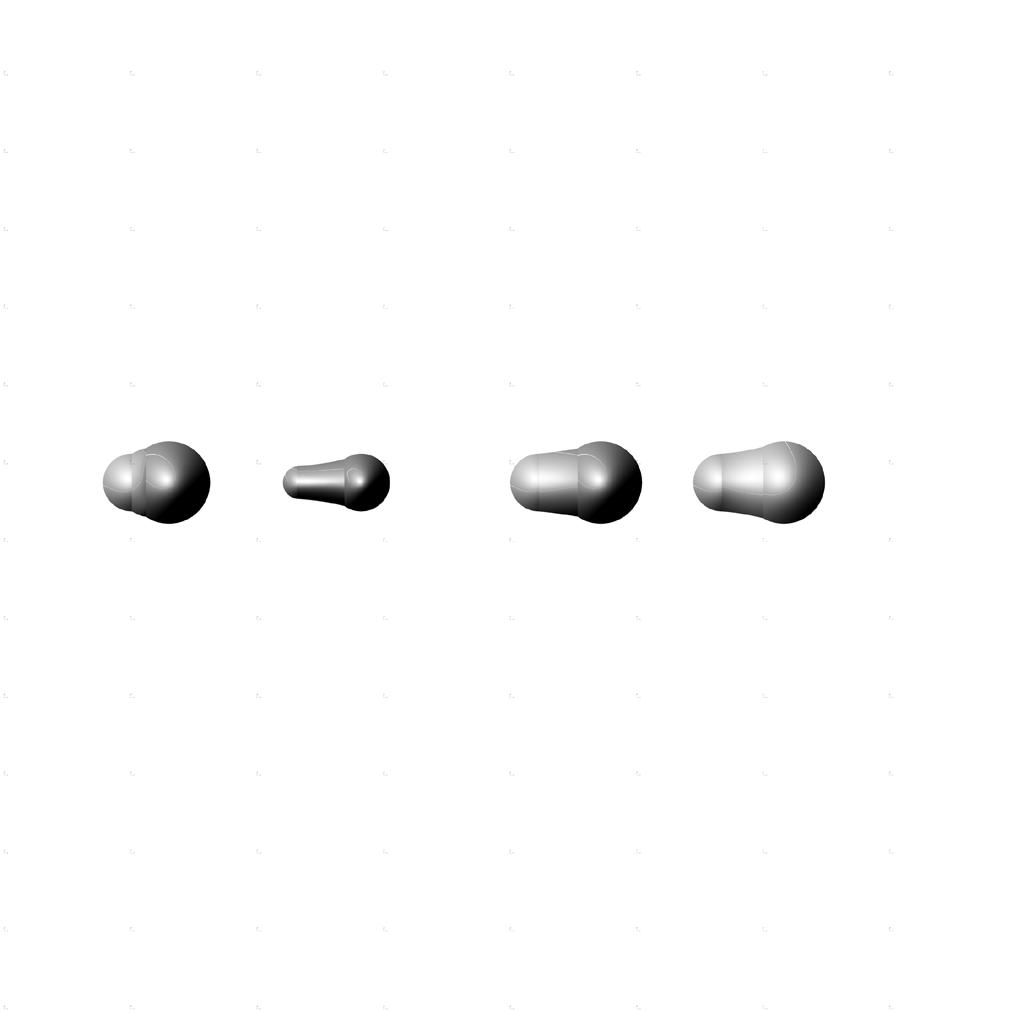

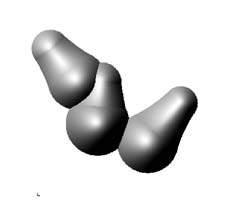

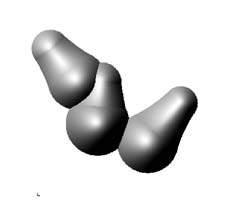

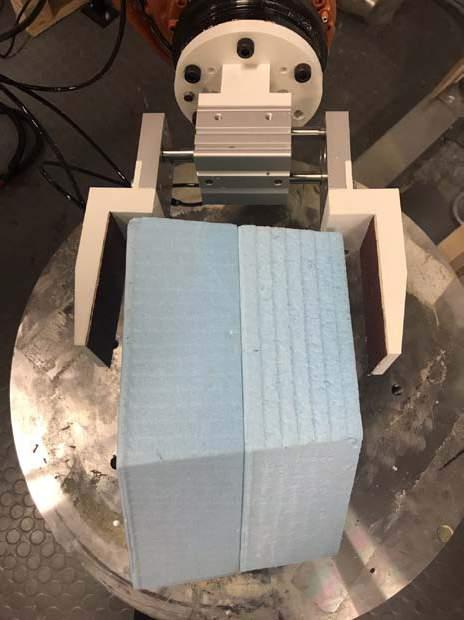

com Paction | ex P eriment ii

Experiment to test compaction methods

OBJECTIVE

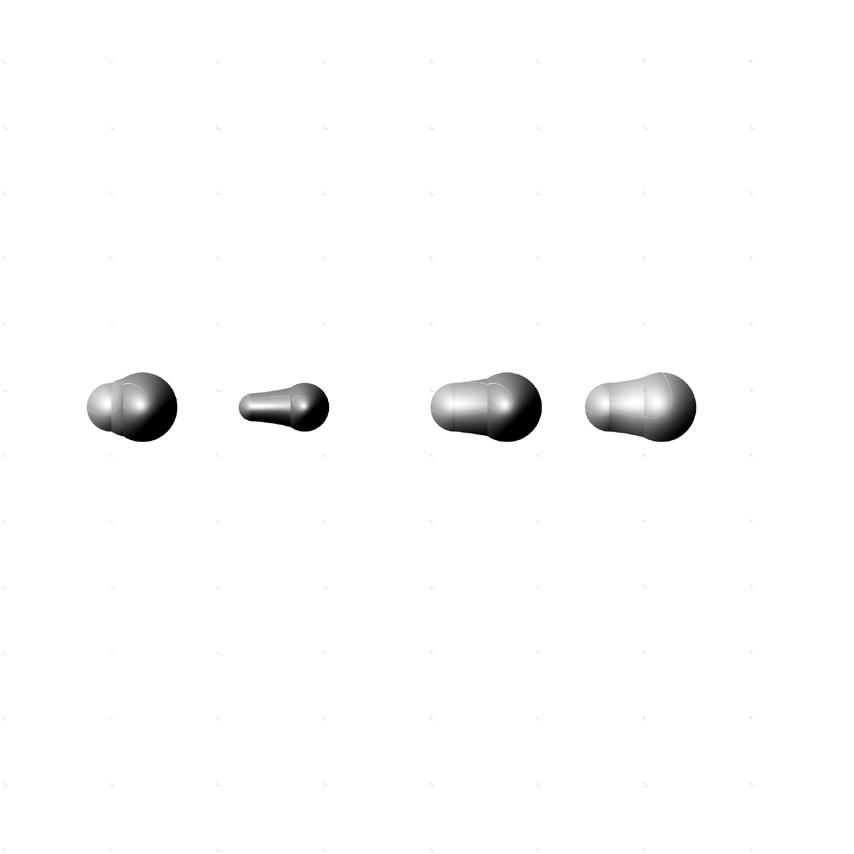

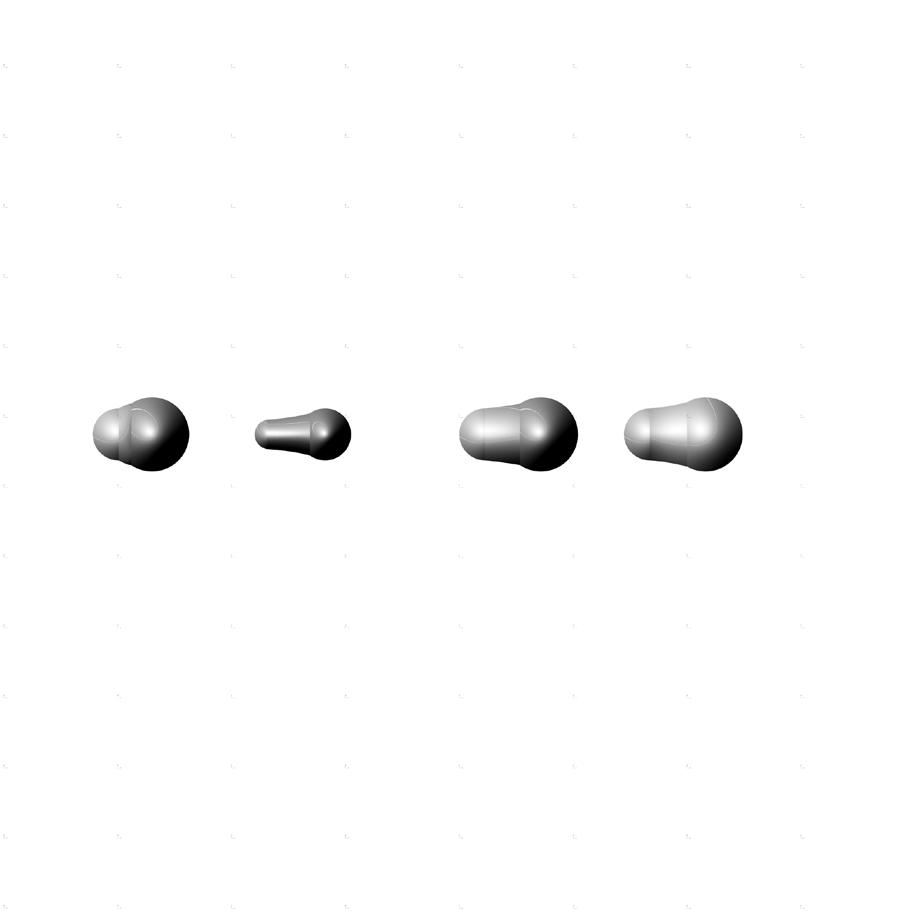

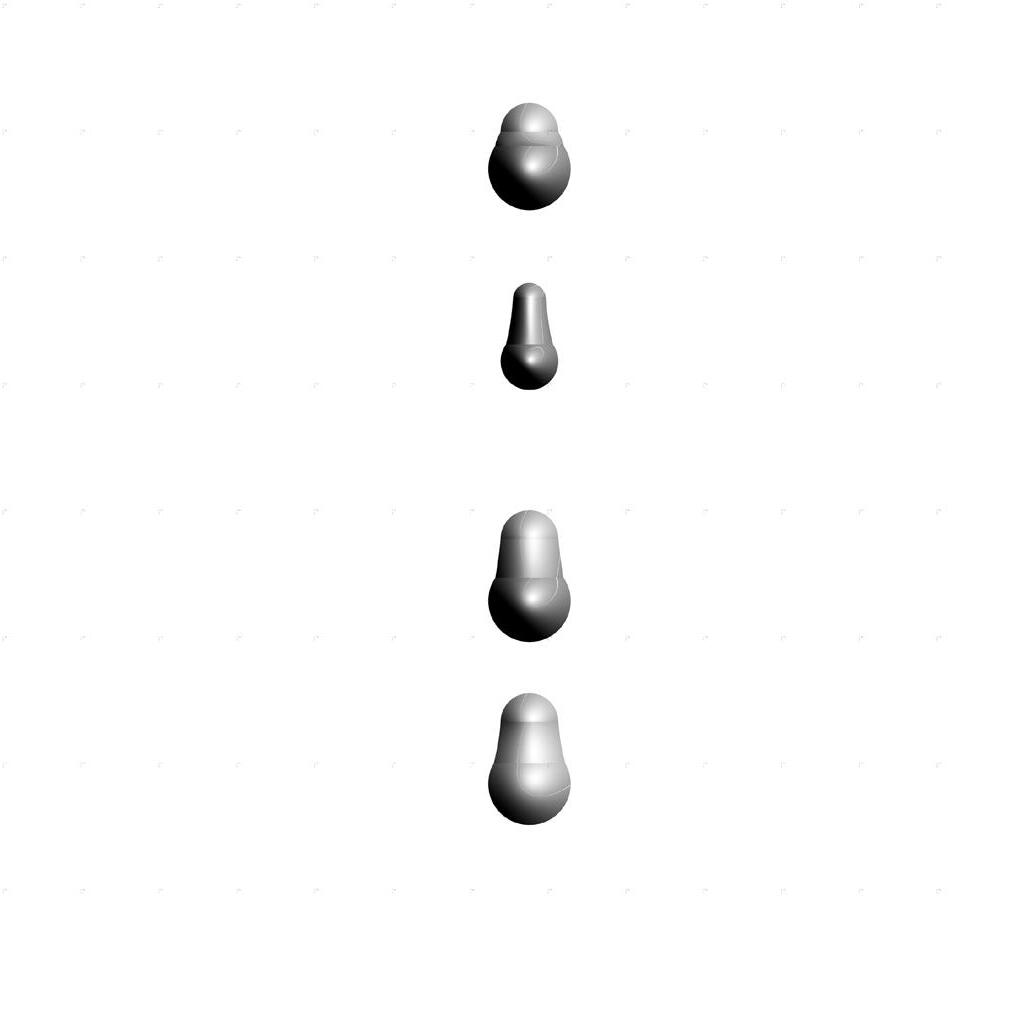

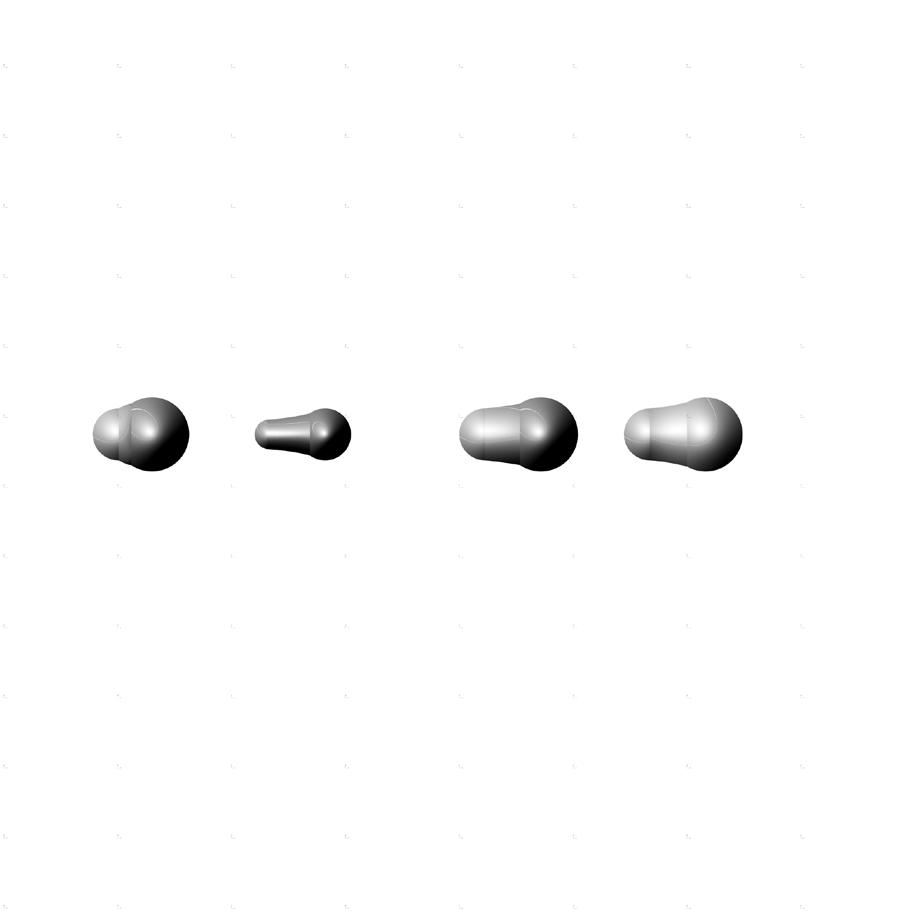

The fundamental mechanical property characterization of peat is in its compressive strength which develops once the material is compacted. Aiming to understand the material properties, two methods of compaction- ‘one step compaction’ and ‘layered compaction’ is tested.

One step compaction - peat is placed in the mold and compacted at the end once. Layered compaction - peat is placed in multiple layers with each placement intercepted with a compaction step.

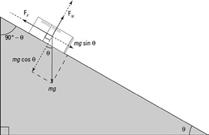

A classical experiment in mechanics is performed on material samples of varying compacted methods to decide the method utilised during fabrication.

OBSERVATION

I. Compacting layer by layer drastically increases the compressive strength of the unit.

II. However, layer by layer compacting increases the time of fabrication.

III. Layer by layer compaction has an increased drying time when compared to one step compaction.

CONCLUSION

Layer by layer compaction is the selected method of compaction for the units. The compressive strength of the layered compaction for this specific dimension is 1.19 MPa. This experiment further reinforced the logic to be used during the construction process.

one step compaction layer by layer compaction one step compaction layer by layer compaction

-Compaction methods proposed

- Image of comapction proposed

- Table of properties of two proposed compaction methods

lxxxii lxxxi Architectural Association Arctic Recalibration

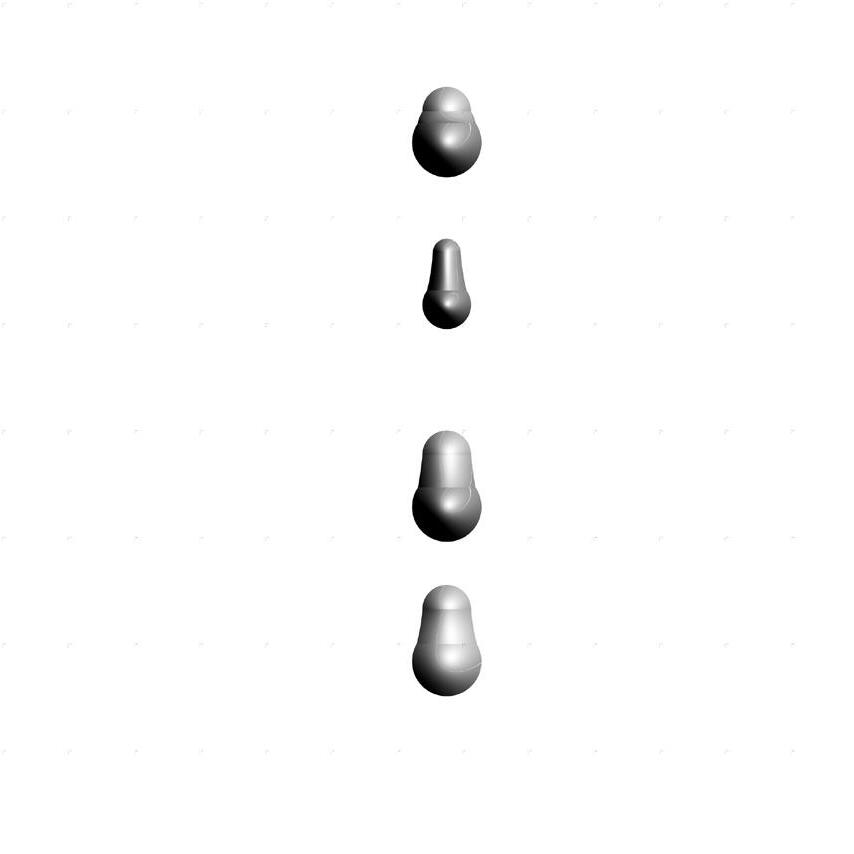

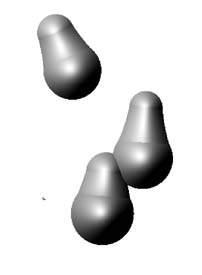

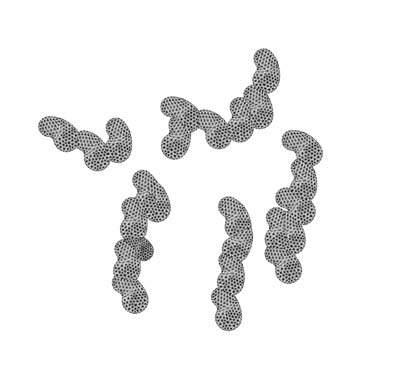

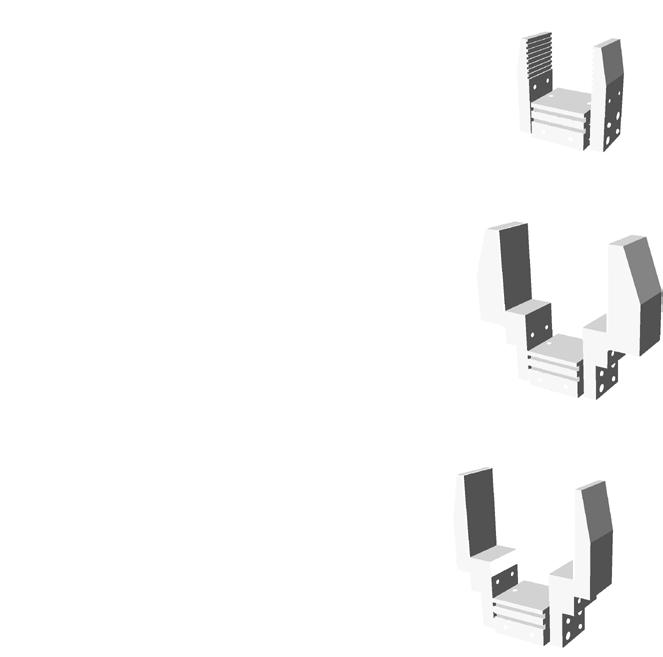

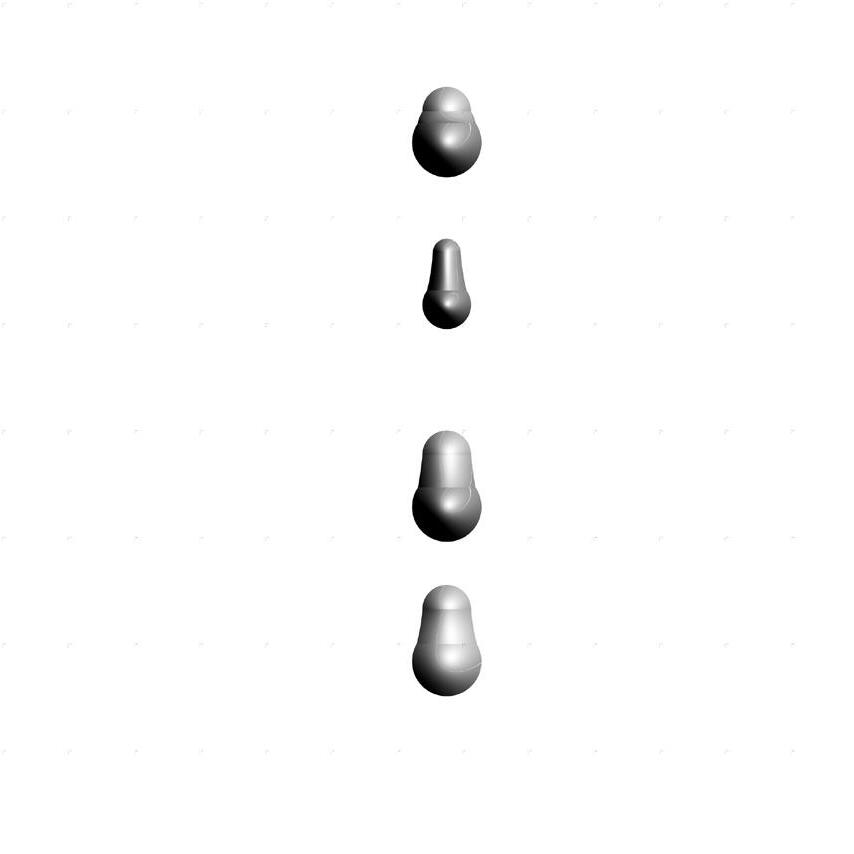

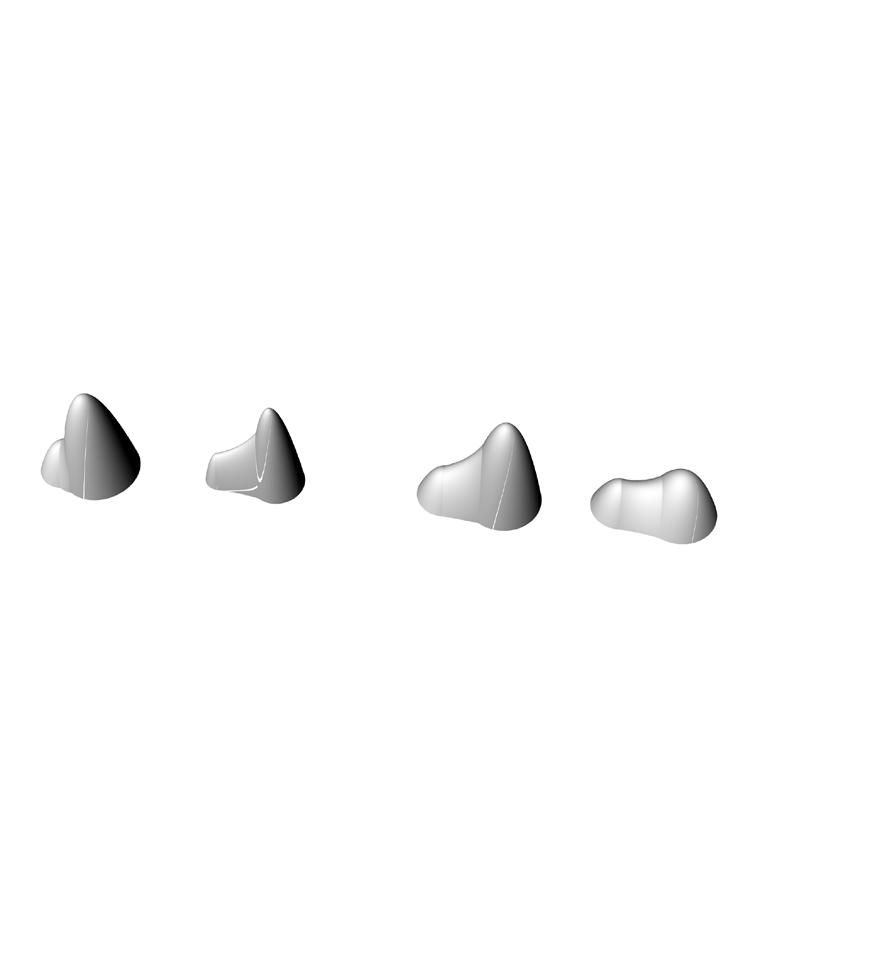

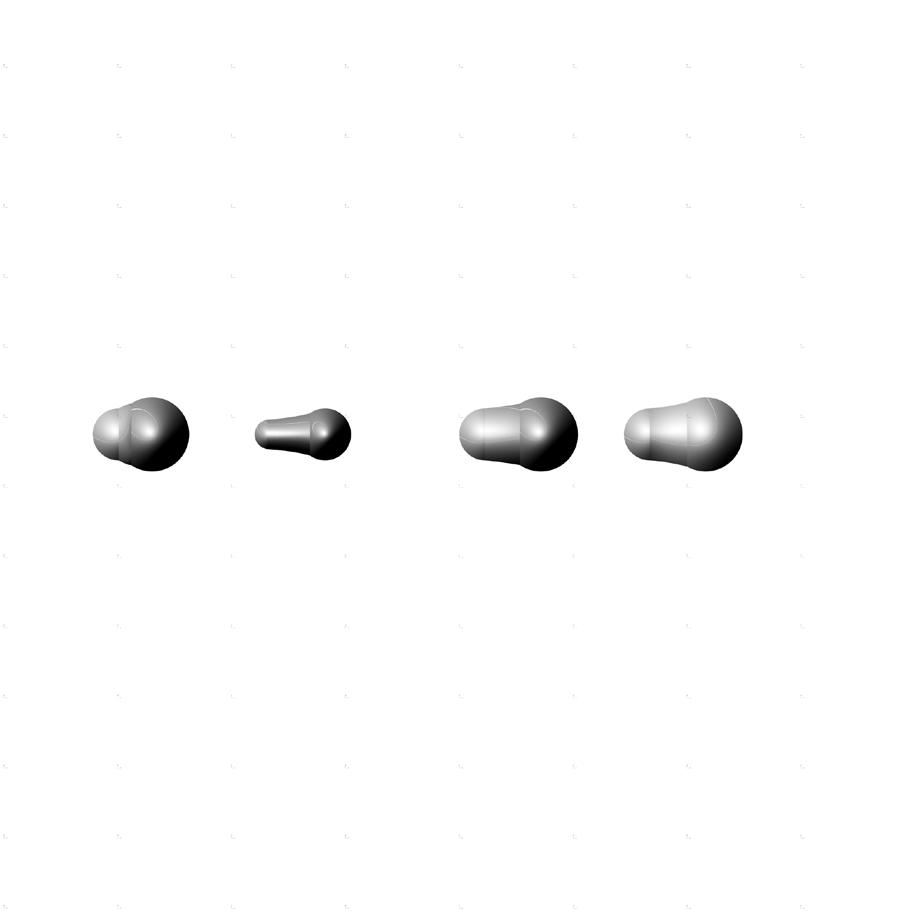

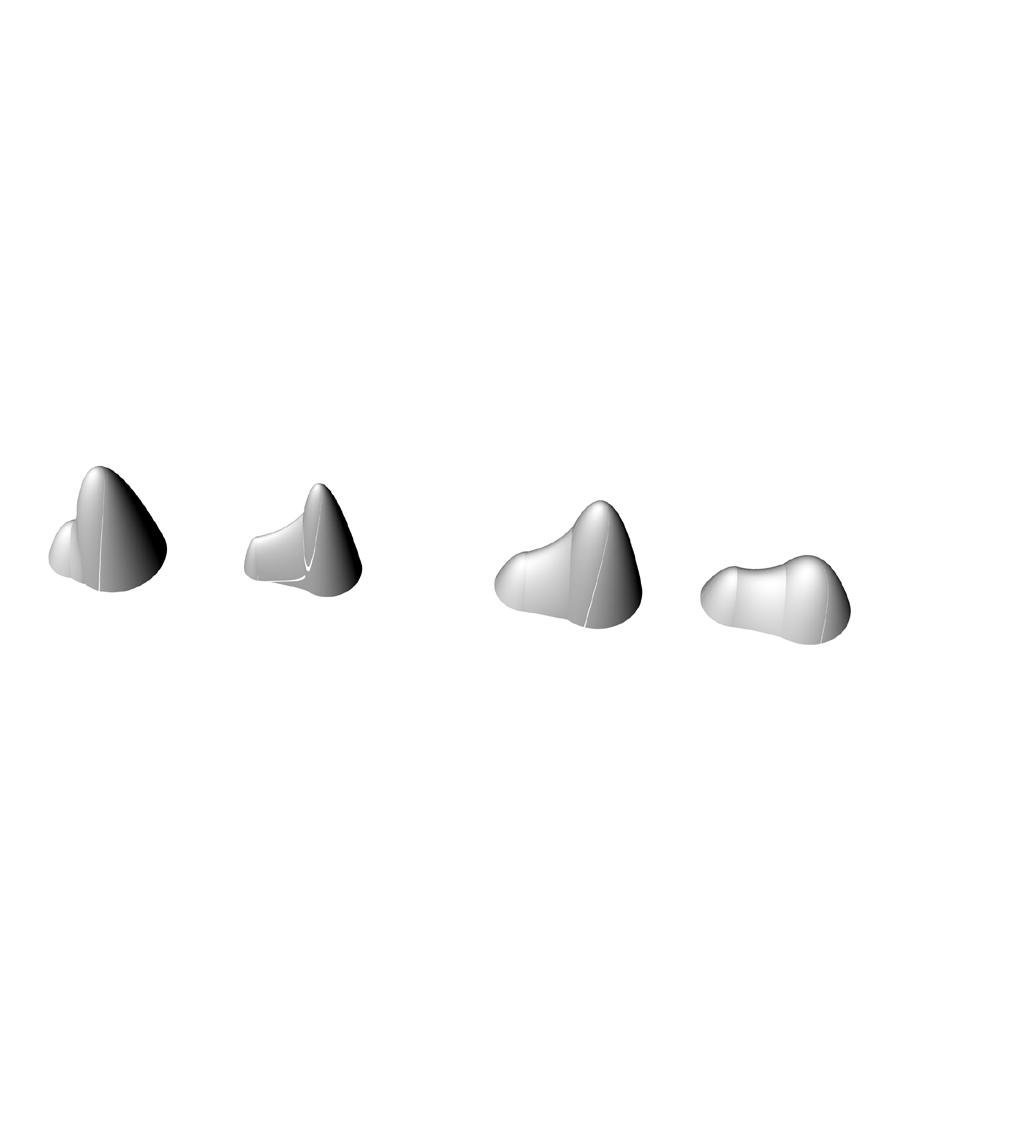

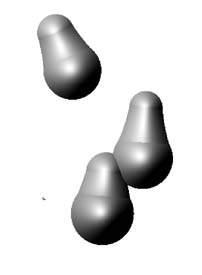

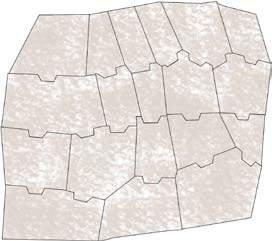

VOLUME REDUCTION | ex P eriment iii

Experiment to test amount of material that would create an optimum block

5 cm height block

V

5 cm height frame

V1 = V/2

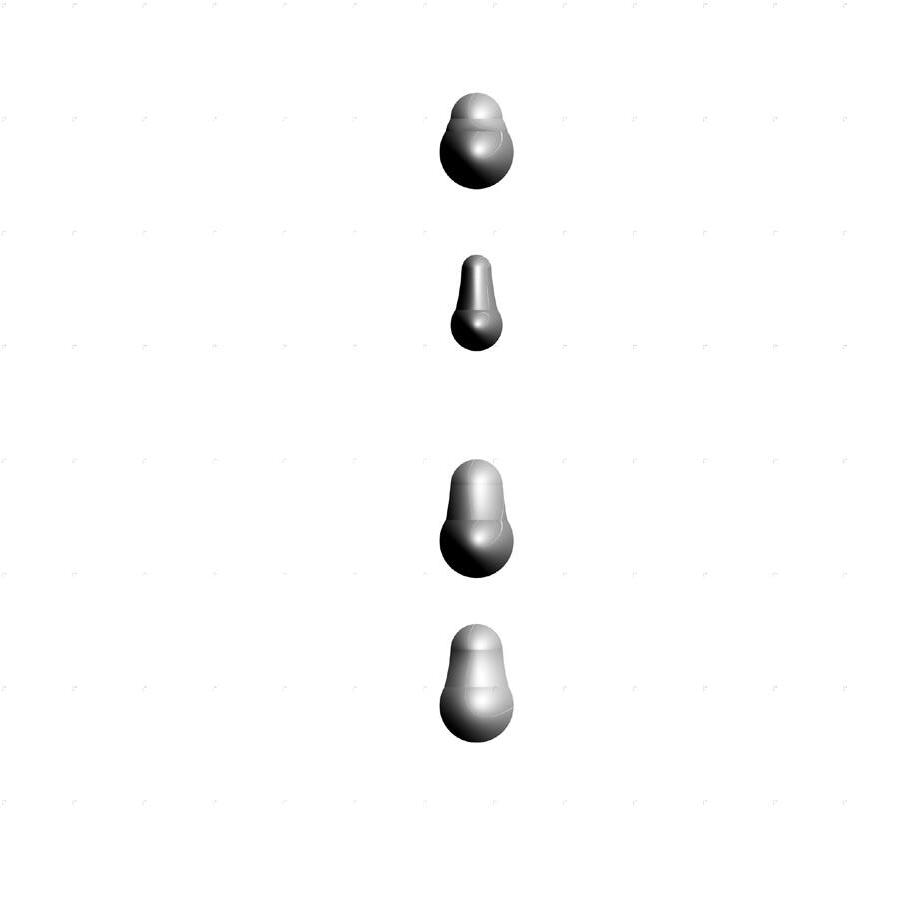

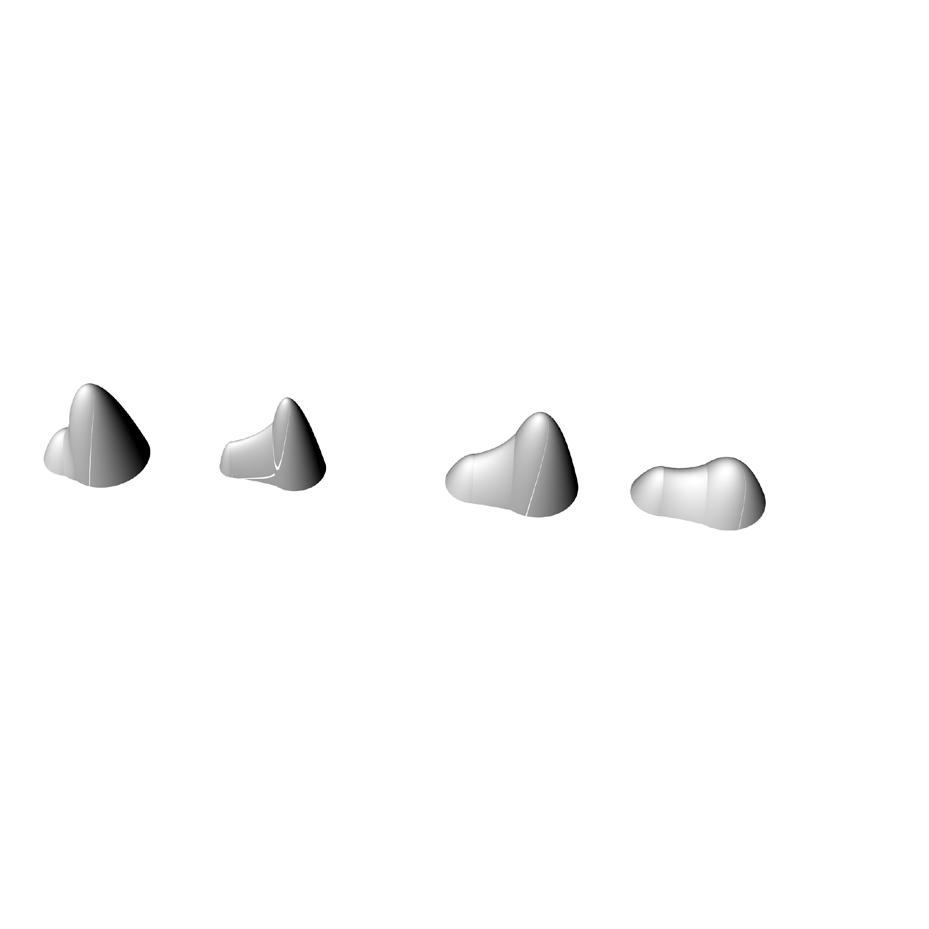

OBJECTIVE

The aim of this experiment is to analyse and quantify the compressive strengths of material samples to understand the different types of geometries possible; hollow, thin shells or thick blocks.

OBSERVATION

I.Extraction of the material from the middle of the component drastically decrease the compressive strength. In fact, this “frame” component does not perform structurally.

II. Decreased thickness of the unit decrease the hardening time,but potentially increase the assembly and construction time.

CONCLUSION

The usage of hollow blocks and thin sections of modules is rejected due to the observed low compressive strength. A module with high thickness will have to be produced.

2.5 cm height block

V1 = V/2

5 cm height block V

5 cm height frame

V1 = V/2

2.5 cm height block

V1 = V/2

-Geometries tested

- Image of tested geometries

- Table of properties of various volumes and geometries

lxxxiv lxxxiii Architectural Association Arctic Recalibration

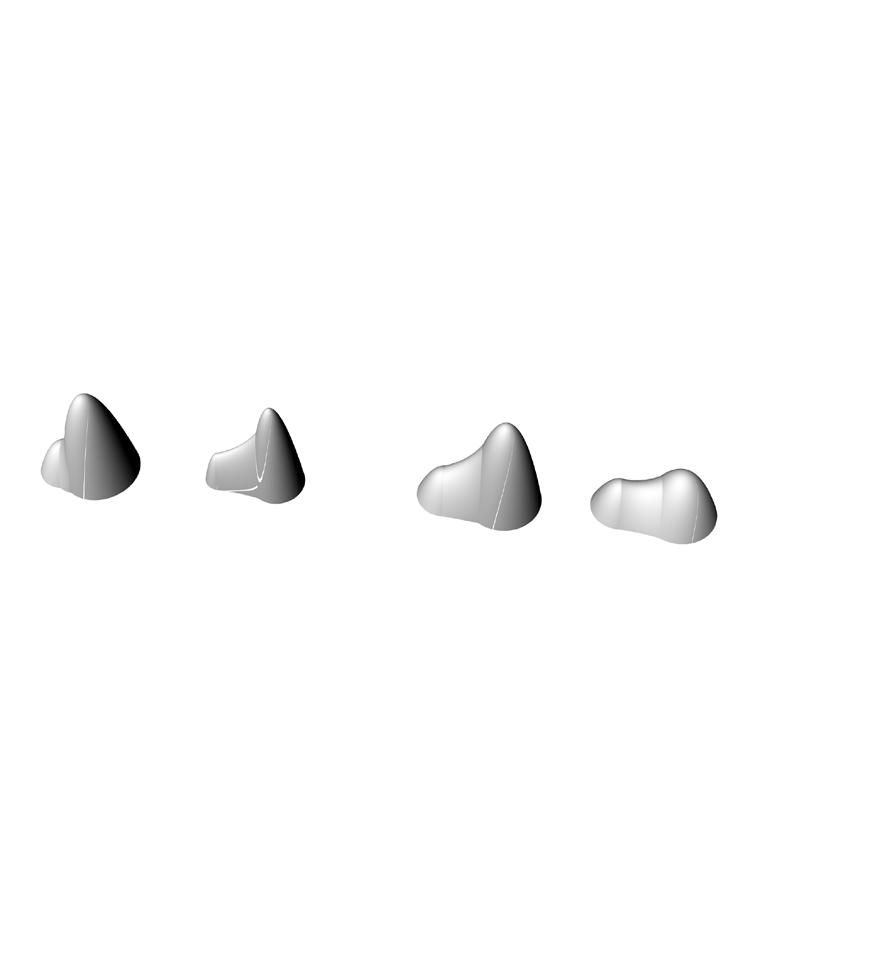

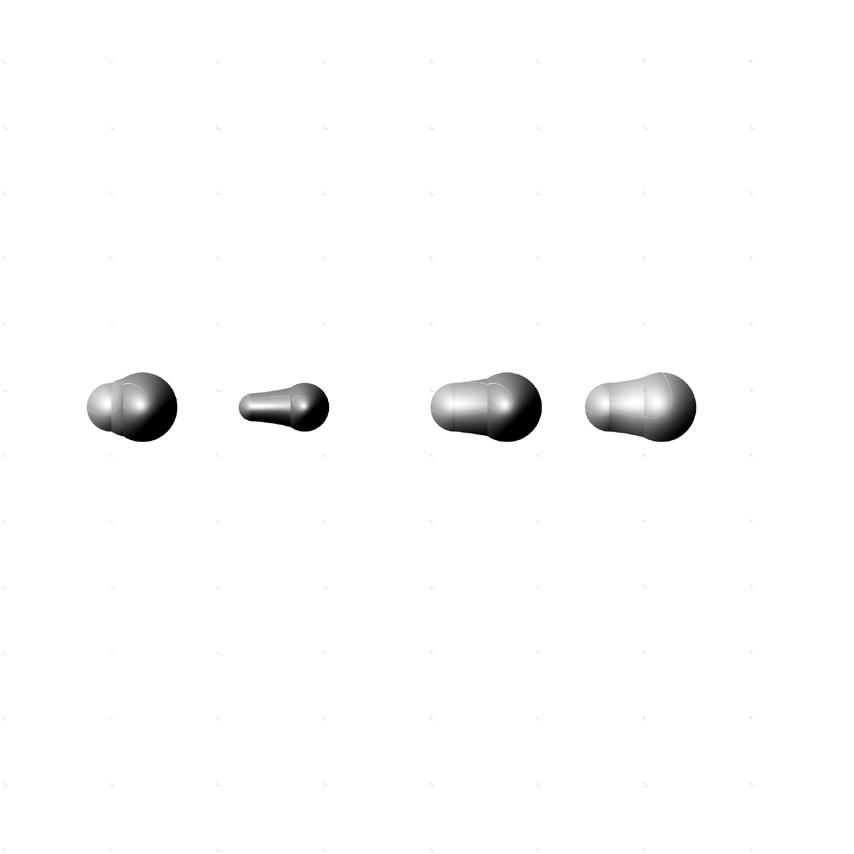

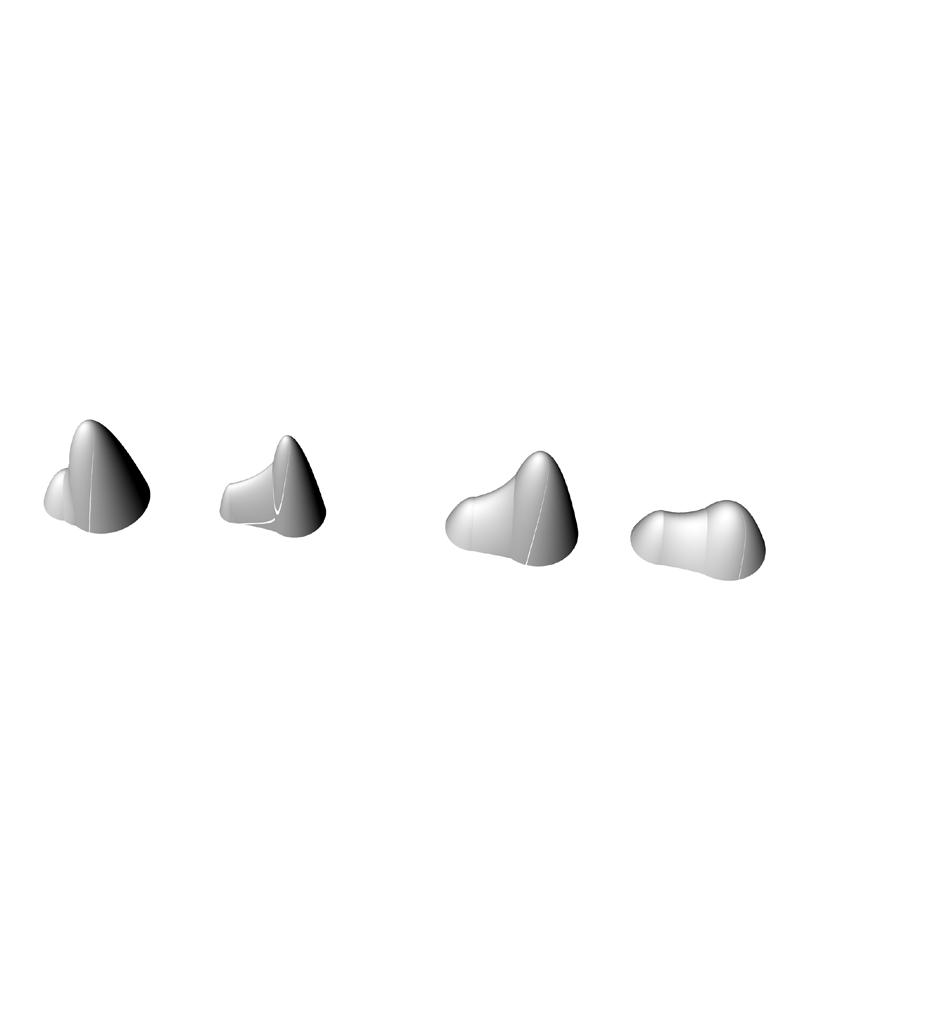

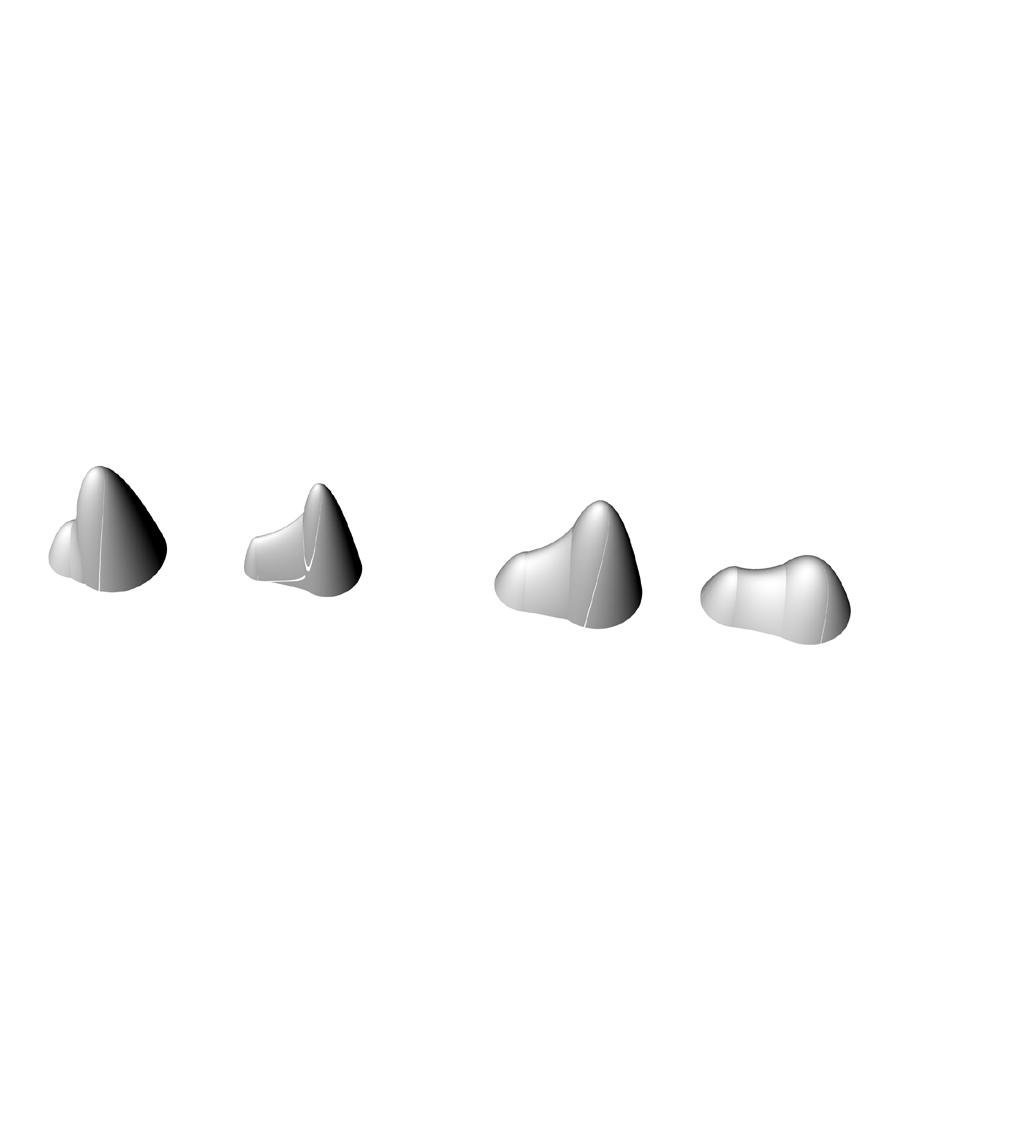

SURFACE ARE| ex P eriment iii

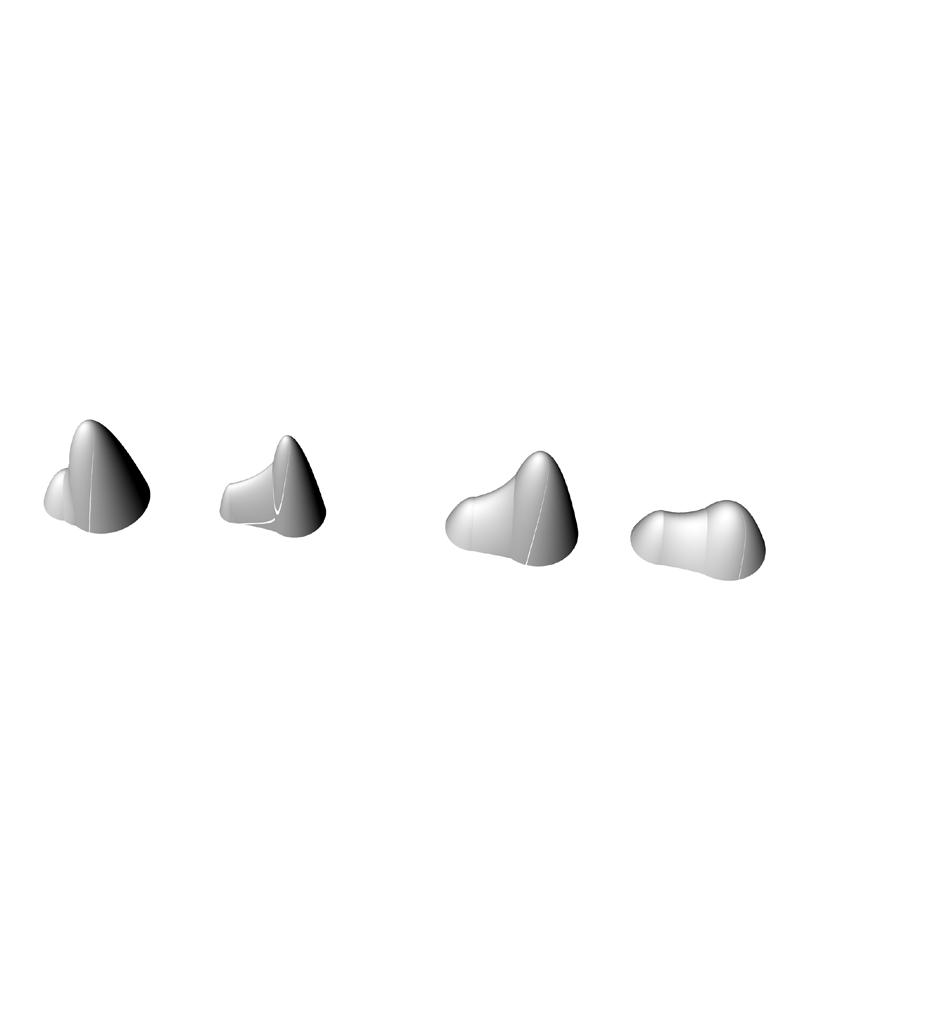

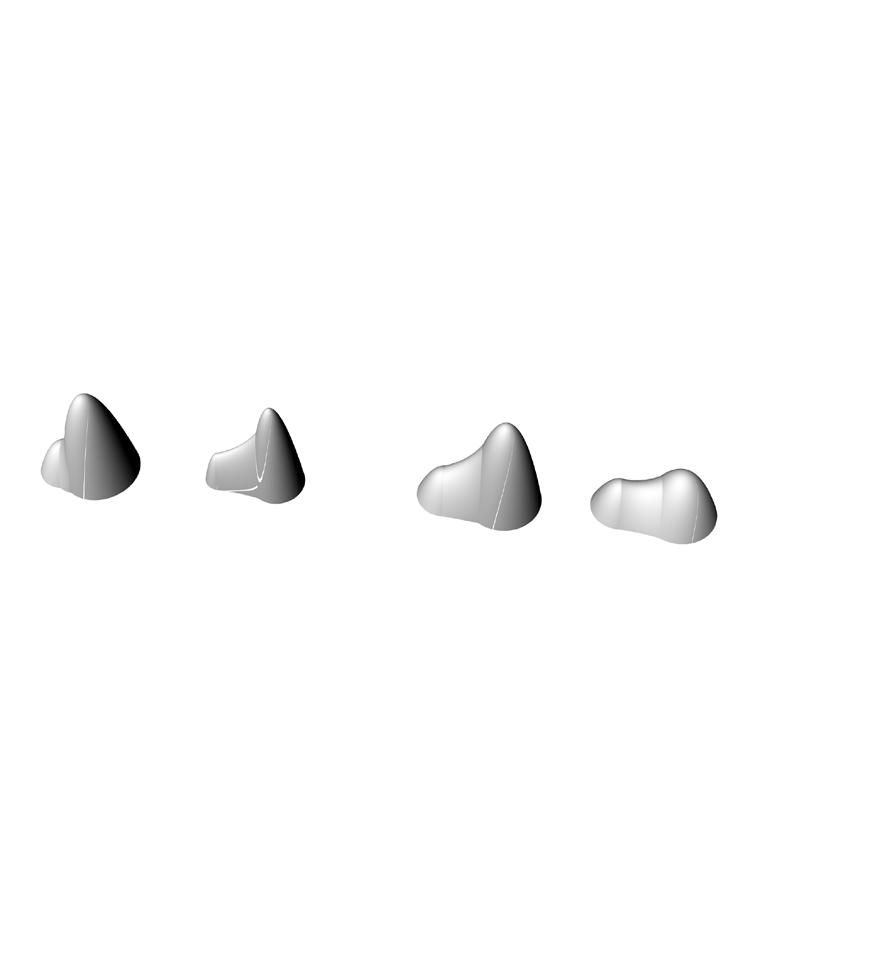

Geometry

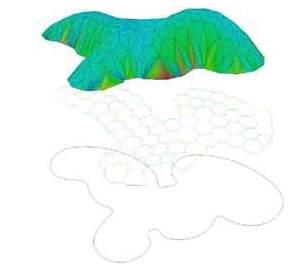

oBJECTiVE : The objective is to find the relation between increasing the surface area while keeping volume constant to the drying time of these units.

A simple set up is designed for performing multiple experiments with precision. It consists of two panels joined parallelly to each other, one acting as a base and the other acting as the ‘compactor’ over which a weight is placed and then the drying time is recorded.

oBsERVATion :

I. The geometry of the component keeps changing while drying due to unequal water loss on the surface

II. Precision of the dried components is low, which can potentially have an impact to the stability of the final unit-composed geometry.

ConClusion :

I. Sine shape performs in the bast way, decreasing drying time by 30%.

II. Thickness of the component needs to be increased as this dimension [5 MM] easily deflects.

III. Decrease of a thickness increases the compressive strength, however increases the construction time.

A definite relation between drying time and surface area can not be conlusively drawn from this experiment due to varying results. While this experiment provided preliminary insights into the relation between uniform surfaces and drying time the potential idea of utilising ruled blocks that are molded into form is rejected due to the low precision of the material once hardened.

lxxxvi lxxxv Architectural Association Arctic Recalibration foam framework P vc firm P eat mix P vc firm foam framework 3 cm 3 cm 3 cm 15 cm 15 cm s ine c - sha P e w ave sha P e P lane

alteration to increase the surface area

c - sha P e s ine sha P e w awe sha P e

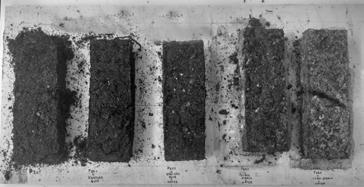

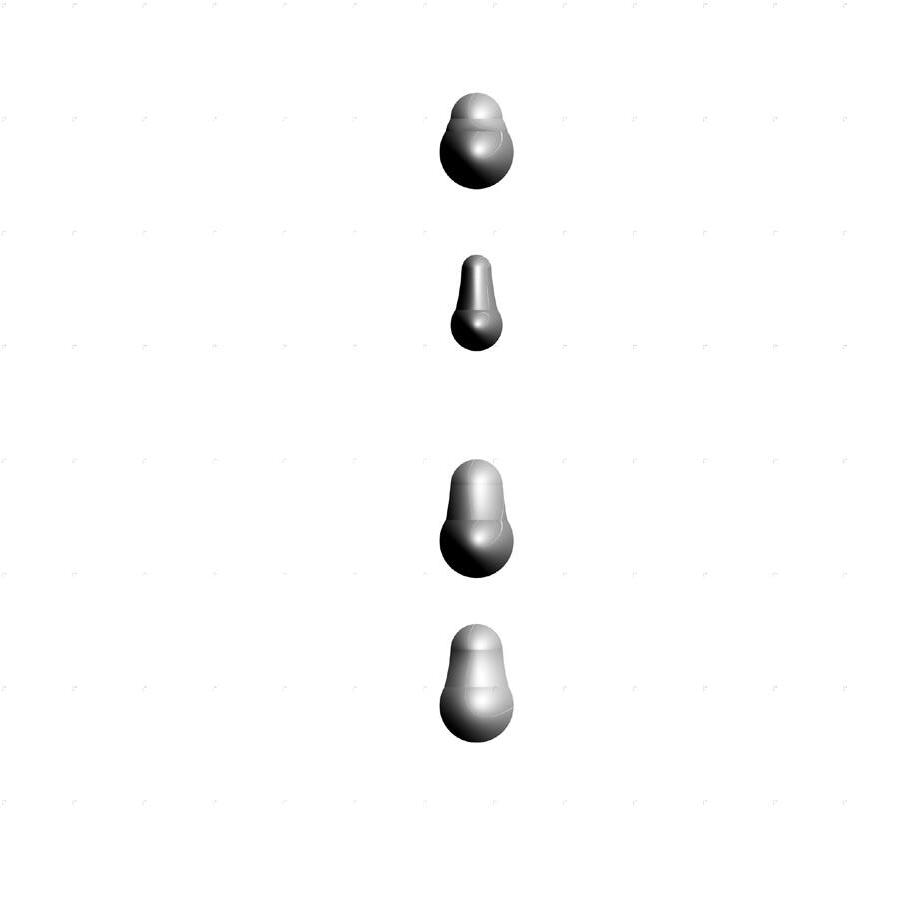

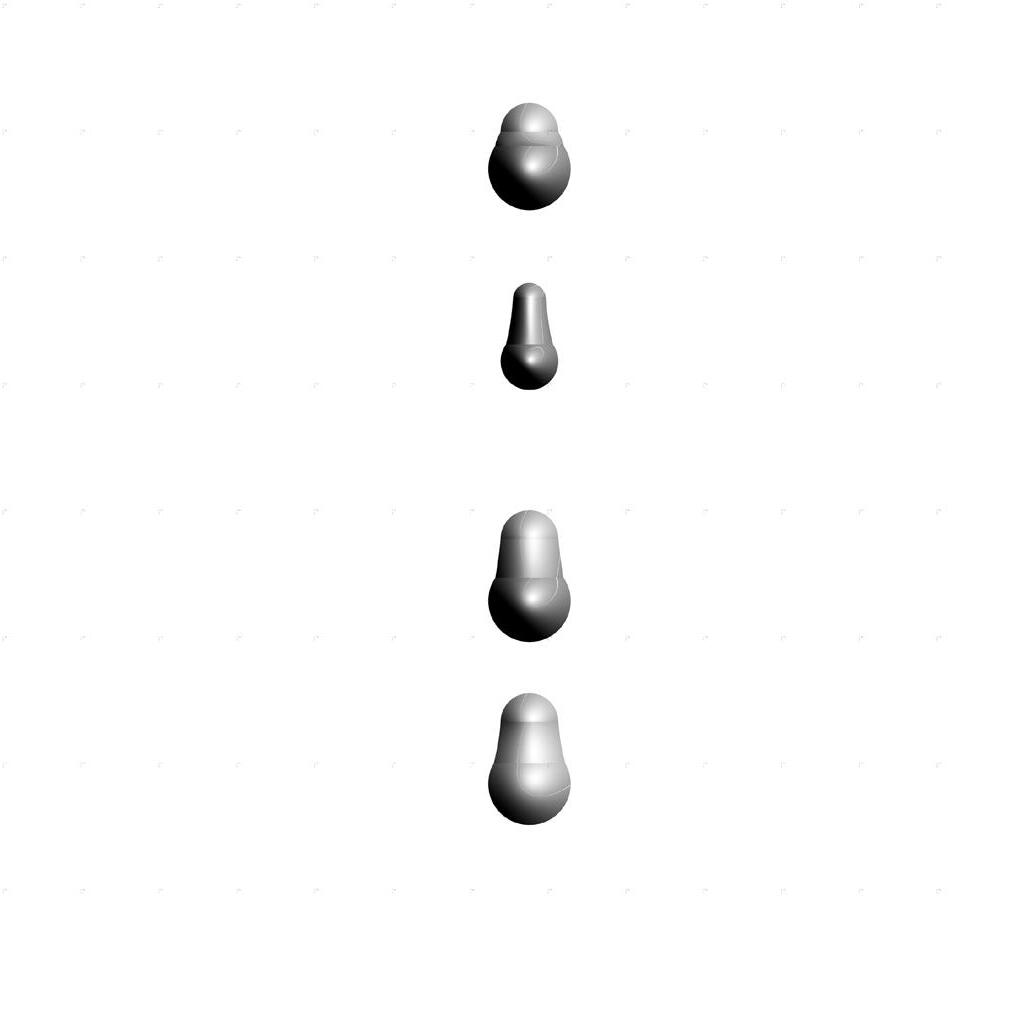

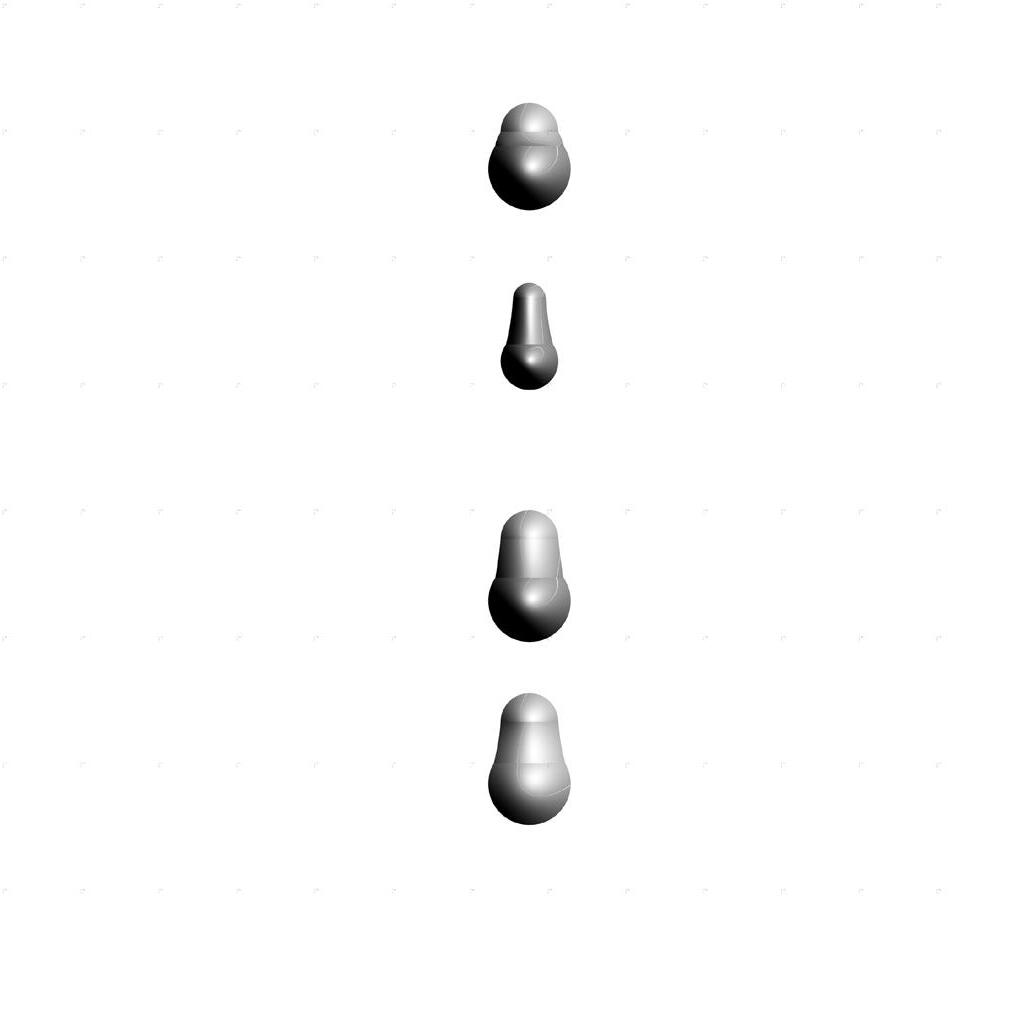

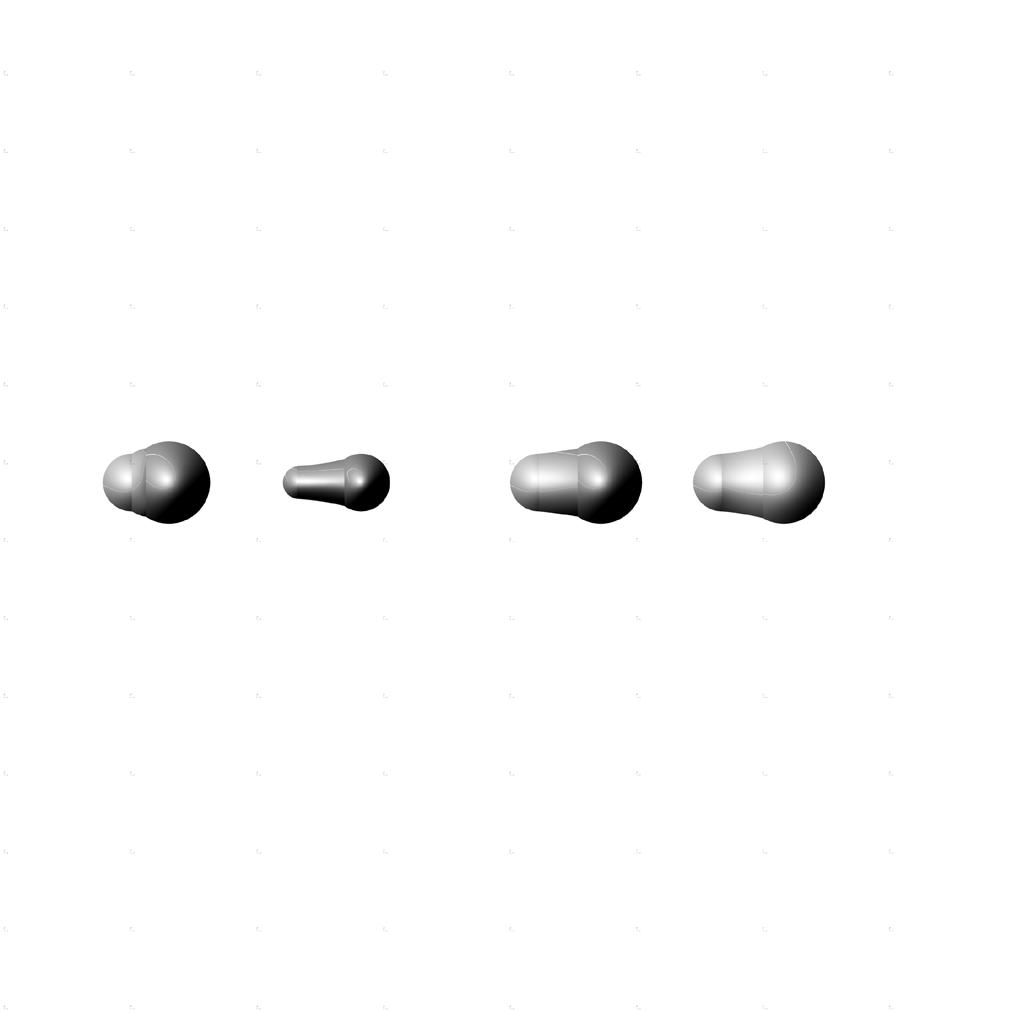

freeze & thaw c Y cle | EXPERIMENT IV

Geometry alteration to increase the surface area

+ Xanthan gum

+ Xanthan gum + water

OBJECTIVE

Peat + Salt + water

SET UP Three samples are tested

- Peat + Xanthan gum

Peat + Xanthan gum

+ Xanthan gum + water

Peat + Salt + water

OBSERVATIONS :

F reezing time :

P eat + X anthan gum - 4 hours

P eat + water + X anthan gum - 14 hours

P at + salt + water - more then 72 hours

i The sample with xanthan gum froze in 4 hours, the sample with xanthan gum and additional water froze in 14 hours while the sample with salt and water took over 72 hours to freeze.

ii. Salt addition to the mixture drastically increases the freezing time and/or the freezing temperature.

III. The sample without additional water freezes the fastest, and during the thawing creates less amount of cracks in a unit.

IV. The unit resists the freezing cycle regardless the mixture. However, the unit expands during the freezing causing a change in dimension.

V. The compression strength after freezing increases marginally.

CONCLUSION :

The results of the sample indicate that there is a change in dimension of the unit once frozen of %. There is a negligible increase in the compressive strength of samples once frozen and therefore the original compressive strength measured is taken into account for further experiments.

- Peat + Xanthan gum + water

- Peat + Salt + water [The presence of salt makes it harder for water molecules to bond to the ice structure, because ice naturally repels salt molecules]

The samples are placed in a freezing environment of a consistent - 17 ° c which is comparable the average temperatures during an Alaska winter.

lxxxviii lxxxvii Architectural Association Arctic Recalibration -17 ° c

0 ° c

Peat

Peat

Peat

water resistance | EXPERIMENT V

Understand water resistance of a dry sample

resource reusabilit Y

Reusability of the material

OBJECTIVE :

The aim of this experiment is to understand the behaviour of water absorption a completely dry sample as the proposed site has heavy precipitation in the form of snow.

OBSERVATION : It is observed that the material does not easily absorb the water once completely dry. After 6 hours there is minial dissolving of the external surface of the material with the water. After 24 hours the sample shows slight signs of dissolving however, the top surface which is not submerged by water remains completely dry. Post 48 hours along with the aid of manually crushing the sample into small particles water begins to be absorbed by the sample and requires constant stirring to fully break down and absorb the water.

CONCLUSION : While the material shows a strong resistance to water when completely dry it is not water proof. Therefore, a water proof coating will potentially be required. This experiment reinforces the idea that the material is potentially reusable and further pushes the concept of material autonomy.

RESOURCE AUTONOMY :

The dearth of resources and the demand to reduce environmental impacts both in the procurement and processing of materials and products in construction places great significance on the construction method in this remote site. This requires appreciable improvements in resource efficiency. Resource efficiency means using the Earth’s limited resources in a sustainable manner while minimizing impacts on the environment.

In this research, the material developed is mainly peat naturally occurring and derived from nature providing alternate methods of building and living. This material further has a high potential of being reused or recycled. The set material can be pulverized [as discussed in the ‘water resistance’ experiment] and mixed with determined quantities of water to produce the initial form of the material which is used to create compacted units.

The re-use of the material involves little processing and offers greater value than recycling as there are no additional tools or environmental impacts here associated with reprocessing. Therefore allowing to create more with less.

xc lxxxix Architectural Association Arctic Recalibration 6 Hours 24 Hours 48 Hours + crushing sample

Material mix

Pulverised unused material Panels created

self insulating

Understand of the inherent insulating nature of peat and its potentials in the Arctic

HEAT TRANSFER :

Thermal conductivity is a measure of resistance to heat flow through a given thickness of material. The principles of heat transfer help to understand how insulation works. Heat flows from warm to colder surfaces until the temperature of both is equal.

C ONDUCTION

Conduction is the direct transfer of heat between adjoining molecules. A warmer molecule transfers some of its energy to colder neighbours. A good example is when one sits down on a cold metal chair, one can feel the cold from the chair as heat from the warmer body is quickly transferred by conduction to the chair.

C ONVECTION

Convection is the transfer of heat through liquids and gases. An example is warm air rising from a hot surface and being replaced by cooler and denser air that sinks. Heat is carried away from the surface by the warm air.

Peat has been studied in its natural and artificial forms to understand its potential as a self insulating material.

R (Thermal conductivity) 0.33 W/m °C

PEAT IN NATURE :

Peat is inherently an insulating material. In nature when found in areas with snow as precipitation it works as a great insular to keep the ecosystem going. The peat which exists in the permafrost layer in the Artic protects plant life by freezing in extreme cold conditions, this causes the plants to freeze too. Once, the weather warms the peat thaws out and the plants in the permafrost also thaw out. Peat in nature in inherently self insulating.

CURRENT INSULATING

USES :

Peat is traditional insulating materials used in log construction. Peat fibres are lightweight, porous and mostly hollow, which gives them a good natural heat insulation capacity.

Combined with the modern manufacturing techniques used to produce insulating materials, peat fibre can be refined into easy-to-handle insulating sheets whose dimensions match construction standards. They do not cause itching during installation and they do not sag.

It is not uncommon to discover old peat-insulated wood roofs and base floors in good condition during building renovations. With peat preventing the growth of bacteria and fungi, the wood structures remain healthy from one decade to the next as long as they have not been exposed to rainwater or capillary water. Peat fibre is hydrophobic, which makes the insulating material breathable and quick-drying.

CONCLUSION :

The utilisation of peat allows for increased energy efficiency as the material itself is inherently insulating against the harsh climatic conditions. Utilising peat leads to securing energy efficiency.

xcii xci Architectural Association Arctic Recalibration

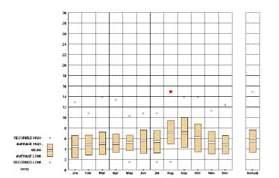

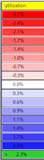

MATERIAL COMPARISON

Comparison of the compacted peat created to other commonly used building materials

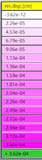

xciv xciii Architectural Association Arctic Recalibration Bricks hard Granite Limestone Portland concrete month Sandstone Slate Peat + Xanthan gum 10 20 30 40 50 60 70 80 90 100 110 120 130 0 Granite Limestone Sandstone Slate Peat + Xanthan gum 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 0 Bricks light Bricks common Portland concrete year Bricks hard Portland concrete 1 month Bricks light Bricks common Portland concrete year Bricks hard Granite Limestone Portland concrete month Sandstone Slate Peat + Xanthan gum 10 20 30 40 50 60 70 80 90 100 110 120 130 0 Granite Limestone Sandstone Slate Peat + Xanthan gum 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 0 Bricks light Bricks common Portland concrete year Bricks hard Portland concrete month Bricks light Bricks common Portland concrete year Bricks hard Granite Limestone Portland concrete 1 month Sandstone Slate Peat + Xanthan gum 10 20 30 40 50 60 70 0 Bricks light Bricks common Portland concrete year Compressive strength comparison Tensile strength comparison Elastic Modulus comparison N/mm N/mm GPa

xcvi xcv Architectural Association Arctic Recalibration iv. m etho D s overview ........................................................................................97 Data collection .........................................................................................99 Design methoDs .......................................................................................101 Design analYsis ......................................................................................103

Integrating several design strategies in the design process

oVERViEW

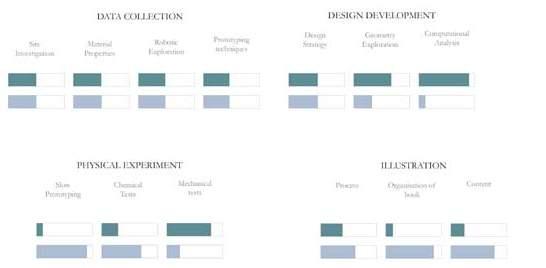

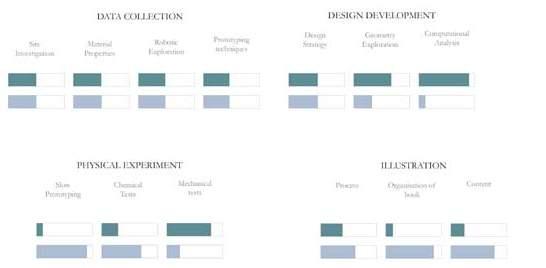

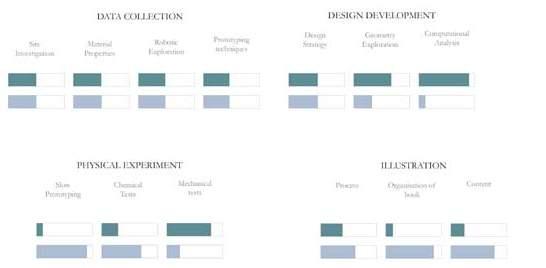

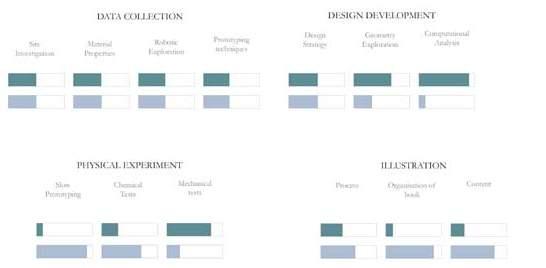

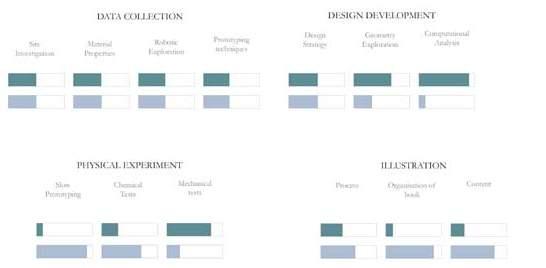

As part of the process of exploring the nature and uses of peat as a sustainable building material, this chapter illustrates in detail the methodologies and tools used for research, system exploration and for the design process. The methods defined in this chapter are described in three categories; Data Collection, Design exploration, Analysis and Evolutionary processes. The categories described in this chapter provide a sequence of work flow. Furthermore, each technique is described so as to provide specific knowledge and reasoning for its selection and its contribution to the system exploration. Each method provides precedence to the following method employed and are interdependent.

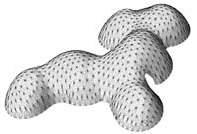

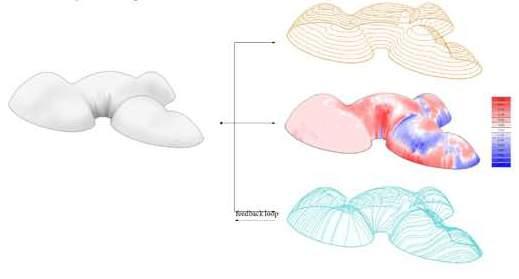

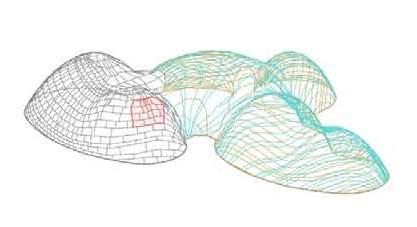

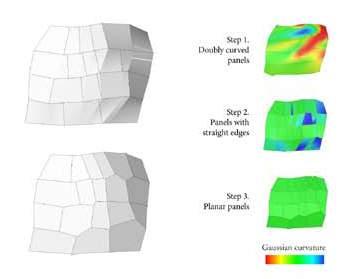

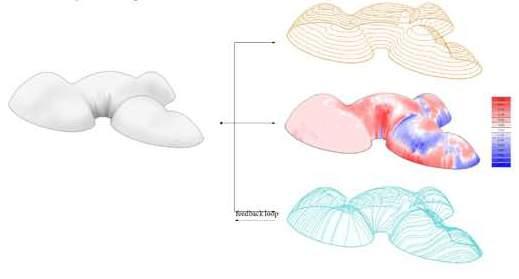

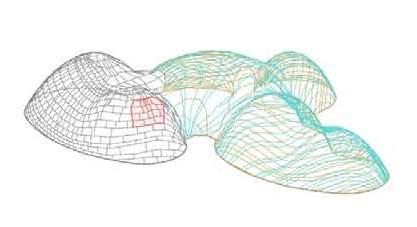

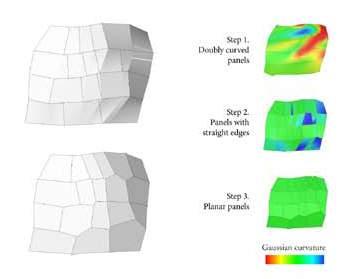

The complex system in this project require the integration of several design and analysis tools at various scales and stages of work. Early physical experiments with the material system were carried out in the design studio which informed the design process of compaction prototypes. From there on digital simulations at at various scales provide information feedback loops and workflows within Grasshopper.

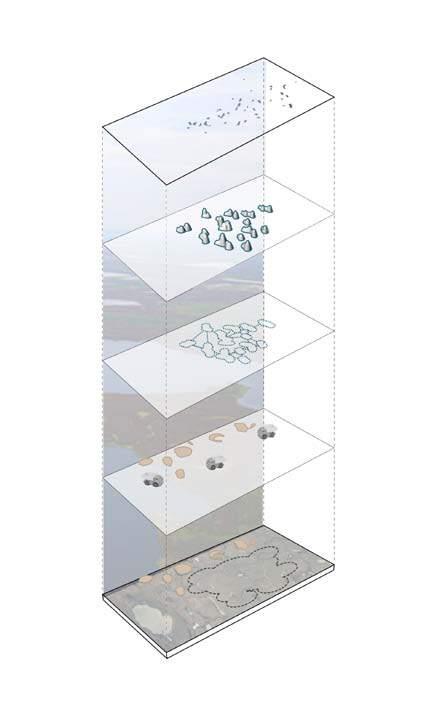

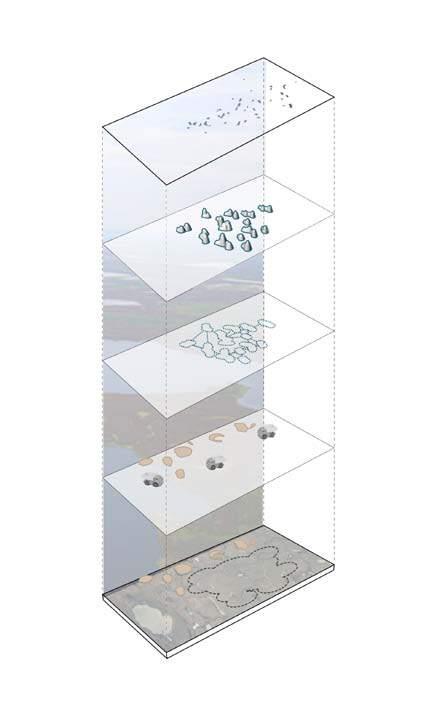

Models were produced at various scales to verify various assumptions about resource driven settlements in the Alaskan Arctic. Data mining techniques were elaborated to sample information published by the NASA Carbon Cycle Observatory to quantitatively evaluate potential available resources within the Arctic in the 30 year timeline within the Seward Peninsula of Alaska. Thermokarst drained basins were simulated to understand the viability of sustainably extracting peat for use in the proposed building type. As such data was sampled from various experiments from 1994 to 2015, to make statistical models of thermokarst drained basins within the site based on the basins age.

This chapter provides also an overview of the processes and explorations described and implemented in the chapters to follow

MATERIAL SITE

- Population in ux

PHYSICAL EXPERIMENTS

- Binding additives

- Compaction method

ROBOTIC FABRICATION

SOLAR ANALYSIS

EVOLUTIONARY PROCESS

MATERIAL RESEARCH

Material research: properties

Case studies

Physical Experiments: extrusion compaction

- Frequency of drained lakes

- Soli uction

- Thermokast depression