AGGREGATIONS

GEOMORPHODYNAMIC

MICROCLIMATES

KAROLADIERICHS EMERGENTTECHNOLOGIESANDDESIGN/MARCH2009 TUTORS:MICHAELWEINSTOCK,MICHAELHENSELANDACHIMMENGES

12REFERENCES 12.01 BOOKS 12.02 ARTICLES 12.03 PATENTS 12.04 WEBSITES 11GLOSSAR 10Y APPENDIX 10.01 SOLIDIFICATION METHODS 10.02 SAMPLE FORMATIVE METHOD 10.03 AGGREGATES UNDER VIBRATION 09OUTLOOK 04H 03YPOTHESIS CASES 03.01 INTRODUCTION 03.02 DUNE MORPHOLOGY 03.03 SOFT ENGINEERING 03.04 PHILLIPS PAVILION 03.05 SANDSTONE 03.06 CONCLUSION 02CONTEXT 02.01 INTRODUCTION 02.02 GEOMIMETICS 02.03 GEOMORPHODYNAMICS 02.04 MICROCLIMATES 02.05 GEOMOPHODYNAMIC MICROCLIMATES 02.06 AGGREGATIONS AS EMERGENT SYSTEMS 01ABSTRACT P 09P 17P 27 P 163 P 167P 195P 199 P 05

AGGREGATIONS CONTENTS - GEOMORPHODYNAMIC MICROCLIMATES 13DVD14ACKNOWLEDGEMENTS15DISCLAIMER 05METHODS 05.01 INTRODUCTION 05.02 OVERVIEW 05.03 SCALE 05.04 LABORATORY MODELLING 05.05 CONCLUSION 07DESIGNAPPLICATION 07.01 INTRODUCTION 07.02 SITE ANALYSIS 07.03 DESIGN PROPOSAL 07.04 GEOMORPHODYNAMIC MICROCLIMATE 07.05 CONCLUSION 06DESIGNDEVELOPMENT 06.01 INTRODUCTION 06.02 SEDIMENTARY ENVIRONMENTS 06.03 ONSITE MODELS 06.04 LABORATORY MODELS 06.05 SOLIDIFCATION METHODS 06.06 OVERVIEW DESIGN DEVELOPMENT 06.07 CONCLUSION 08EVALUATION P 31 P 47P 115P 159 P 203 P 207P 211

P4

P5

01ABSTRACT

01ABSTRACT

Nature processes large amounts of potential construction material in the form of aggregates and assembles them into dynamic morphologies. The idea is to use these natural formative processes in order to actuate semi-natural dynamic microenvironments. These induce morphological and climatic transformations which are relevant both with regards to their human inhabitation and the original geology. The system can have loose and solid phases, the solid being often embedded in a loose aggregate and thus becoming a particle in itself. The morphologies continuously change over time through cycles of erosion and accretion, entering a cycle of continuous construction. Throughout this process the construction material and energy are in large parts provided by nature itself and the structures are thus formed by minimal energy input. The project investigates several case studies that relate to geomorphodynamic systems as well as natural and architectural methods of aggregate solidification. Coastal beaches are chosen as a sedimentary environment. The hypotheses are then being developed and tested for this specific environment via onsite and laboratory models. A proposal for a design application is made on the island of Sylt/North Germany, where several responses of the system are being investigated. Conclusively further areas of implementation of the thesis are indicated as well as an argument for an emphasis on empirical modeling is being made.

Keywords: Aggregates, Geomorphodynamics, Microclimates, Dune Morphology, Sedimentary Processes, Analogue Modelling

6 AGGREGATIONS 01 ABSTRACT

01

FIGURE

FIGURE01

WEATHERED SANDSTONE BOULDER

This massive lump of sandstone was once attached to the rock outcrop behind it. The processes of weathering caused it to become detached. It has since been smoothed and rounded by wind and water. Gradually it has weathered further and has split into three pieces. Weathering can occur by chemical or mechanical processes. Chemical weathering involves removal of part of the rock in solution by chemical reactions, for example with rainwater. Mechanical weathering causes rock to disintegrate due to physical processes such as extremes of cold or hot temperatures, or freezing and thawing of water. Photographed in Arizona, USA. (Source: George Steinmetz/Science Photo Library)

7 AGGREGATIONS 01 ABSTRACT

P8

02CONTEXT

02.01 INTRODUCTION

02.02 GEOMIMETICS

02.03 GEOMORPHODYNAMICS

02.04 MICROCLIMATES

02.05 GEOMOPHODYNAMIC MICROCLIMATES

02.06 AGGREGATIONS AS EMERGENT SYSTEMS

P9

02.01INTRODUCTION

The following introduces the paradigm this research has been conducted in and establishes the basic contextual concepts, i.e. geomorphodynamics and microclimates. A link between these two core aspects is established.

02.02 GEOMIMETICS

Processes mimicking and using geological phenomena for design purposes might be placed within the paradigm of Geomimetics. ‘Geomimetics is the term given to replicating the synthesis of minerals in the laboratory. It is analogous to biomimetics - i.e. chemists developing new organic compounds by copying and enhancing natural ones.’ (Source: IMG). The term is usually applied to the mimicking of minerals coming from geological processes on a very small scale. It would need to be redefined within this context to encompass a wider range of geological solidification and aggregation processes as well as larger scale ranges.

02.03 GEOMORPHODYNAMICS

Geomorphodynamics refers to the dynamic process of landscape formation. The term is used in relation to various landscapes such as dune fields or submarine landscapes. It studies the influences that establish the typical formation of such a landscape and how these as a consequence change over time. The basic processes are those of accretion, sedimentation and erosion, of accumulation, resting and vanishing material assemblies (Source: Siever, 1988). The inherent logic of these material assemblies is thus one of continuous construction, only temporary solidification rather than that of a finite optimized structure. To understand and utilize these processes might entail an architecture, that accepts these core principles of earth formation and rather than opposing utilizes them as an actuator of its designs.

10 FIGURE 02 AGGREGATIONS 02 CONTEXT

11 AGGREGATIONS 02 CONTEXT

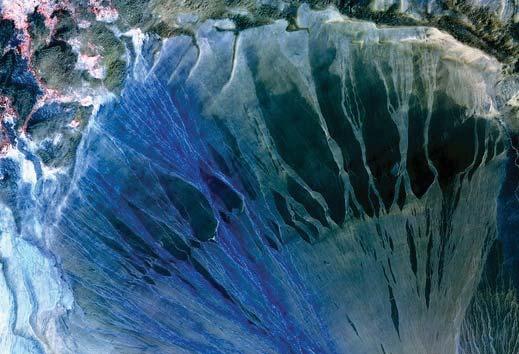

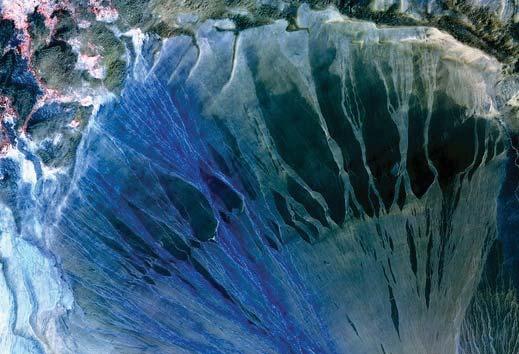

FIGURE02

QAIDAM BASIN, CHINA Twisted folds of eroded sedimentary rocks, and sand dunes, in the western part of the Qaidam Basin (also called the Chaidamu Basin), Qinghai, China. This is the western edge of the largest field of yardangs (wind-eroded rocks) in China. (Source: George Steinmetz/Science Photo Library)

02.04MICROCLIMATES

The second contextual concept is that of a microclimate. Climate generally refers to a variety of atmospheric processes, such as wind, rain, heat and solar radiation. Usually these are dealt with on the level of the globe or continents, spanning hundreds to thousands kilometres across. These ranges can be called macroclimates. These macroclimates however will be broken down into a medium range of climatic differentiations, which can be termed mesoclimates. These encompass the range between tens to hundreds of kilometres. Mesoclimates, in turn, can be resolved into numerous microclimates, which relate to scales of less than 0.1 km, as in the climatic differences between forests, crops, and bare soil, at various depths in a plant canopy, at different depths in the soil, on different sides of a building, and so forth (Sources: Oke, 1987, Climatic, 2008 and Microclimates, 2008). Architecture can on one level be understood as a conscious climatic modulation. In this paradigm any change in an environmental climatic condition can thought to be relevant on the level of human inhabitation. Architecture then becomes the modulation of climatic zones and the continuous adaptation of them.

12 FIGURE 03 AGGREGATIONS 02 CONTEXT

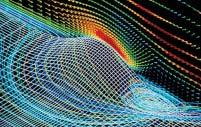

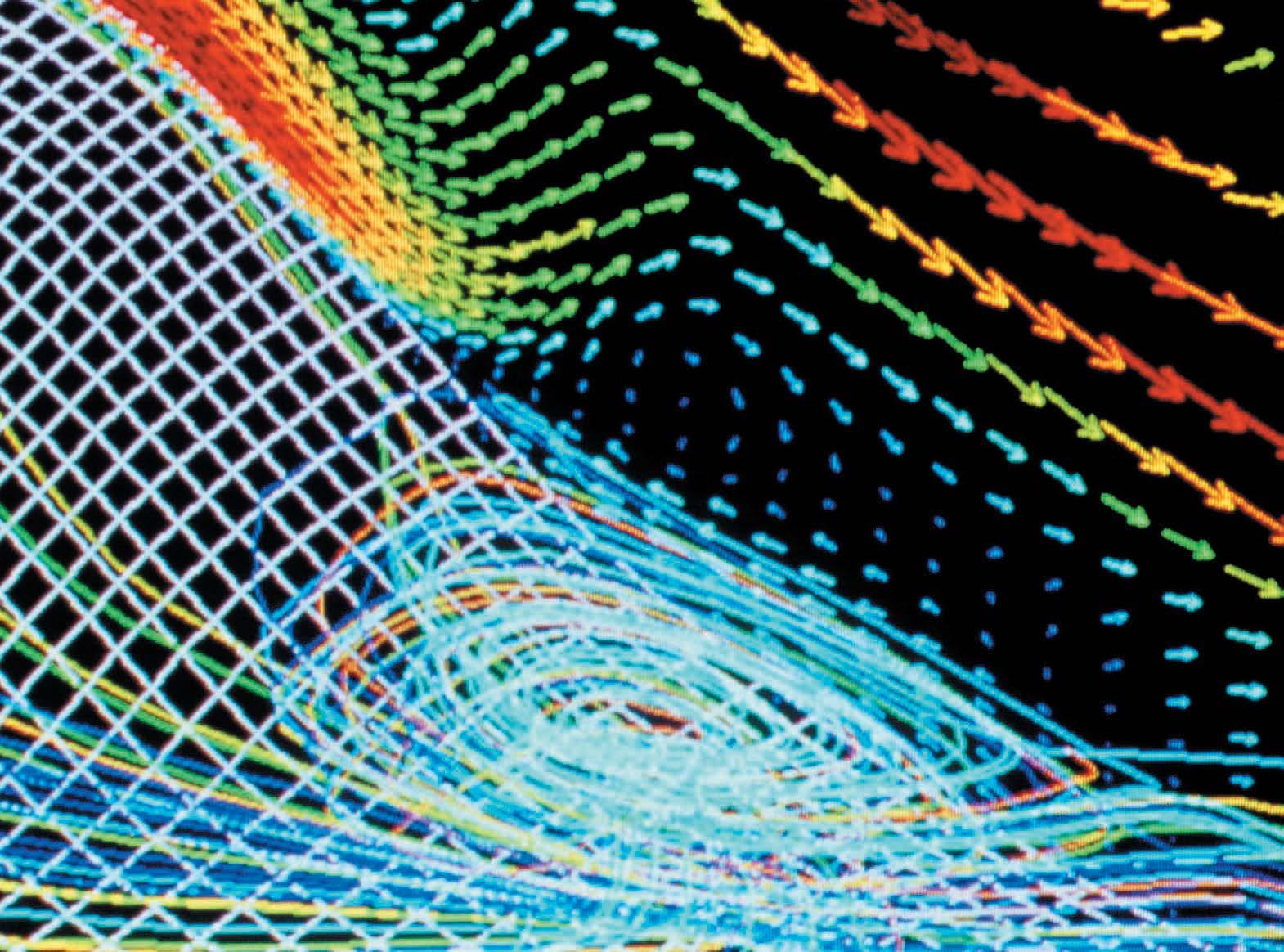

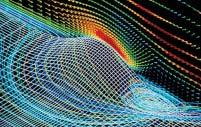

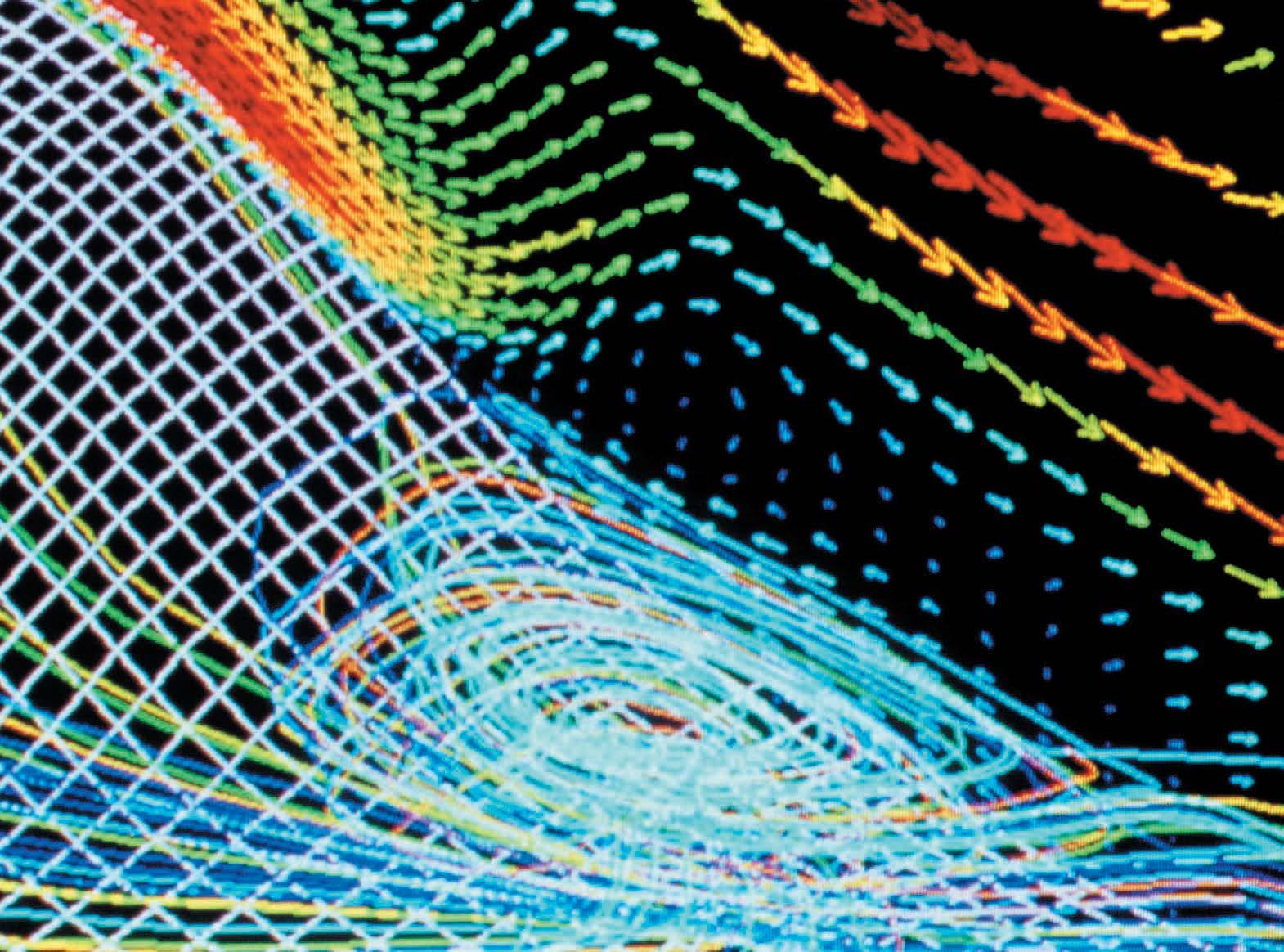

FIGURE03

WIND TUNNEL SIMULATION OF WIND EFFECTS ON A HILL

Computer simulation of the line contours of a hill (at centre) and the path of wind over it. Wind direction is arrowed. Wind speed and force is colour-coded: red is highest, blue is lowest. A circular eddy is seen beneath the hill (lower right). Wind erosion and snowdrift modelling are some applications of this computer study. This research is conducted at the wind tunnel Centre Scientifique et Technique des Batiments (CSTB), Nantes, France. The Centre can also accommodate in its wind tunnel scaled-down models of whole towns, bridges and rockets, to be tested in winds of more than 200 km per hour. Rain, snow, intense sunlight and heat can also be simulated.(Source: Ph. Plailly/Eurelios/Science Photo Library)

13 AGGREGATIONS 02 CONTEXT

02.05GEOMORPHODYNAMICMICROCLIMATES

The aim of this project is the conscious modulation of geomorphodynamic and microclimatic processes. These modulations result in geomorphodynamic microclimates, conscious modulations of both geology and climatic conditions. This will have an effect on two levels. On the one hand the geomorphology will be altered, inherently linked to this climatic processes will also be affected and this in turn will influence the actuating environment. If on the other hand habitable space is understood as the modulation of climatic processes, such as rain protection, heat provision and ventilation, these geomorphodynamic processes can also have immediate basic architectural effects.

02.06 AGGREGATIONS AS EMERGENT SYSTEMS

Emergent systems can be described as patterns that arise from a multiplicity of simple interactions. Common characteristics of these emergent systems are radical novelty, correlation of the parts, the existence of a global level, dynamic evolution of the system and the clear distinction of the phenomenon (Source: De Wolf/Holvoet, 2005). Aggregate systems are based on the interactions of very basic units, the granules. These form coherent recognizable morphologies, which can be identified as coherent wholes and evolve dynamically over time. They are thus emergent systems. Aggregations can in this far be called emergent as they use these properties of aggregates entirely or in parts.

14 FIGURE 04 AGGREGATIONS 02 CONTEXT

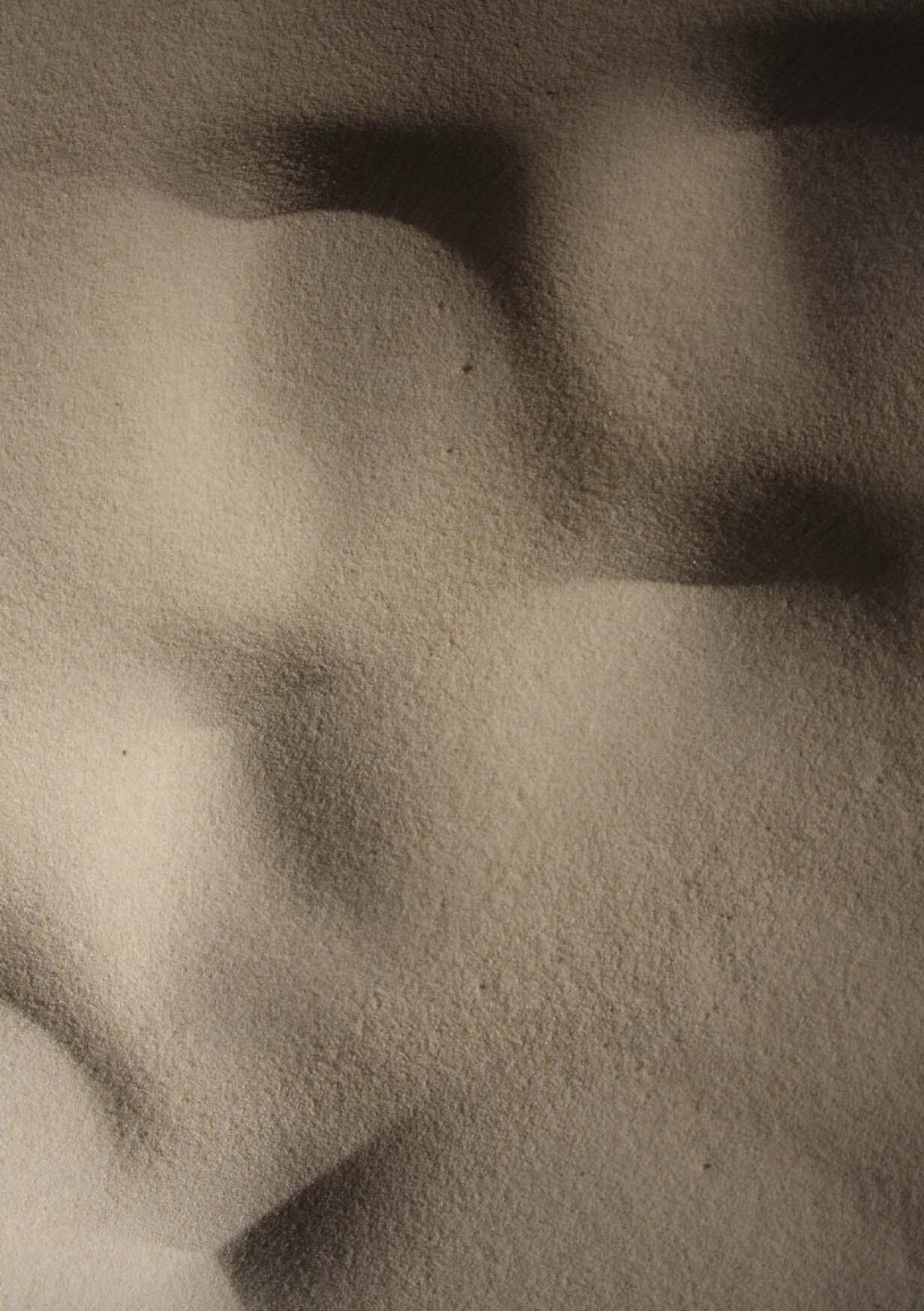

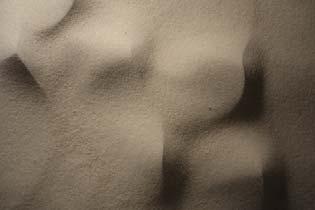

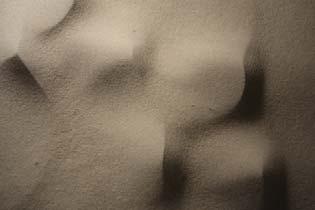

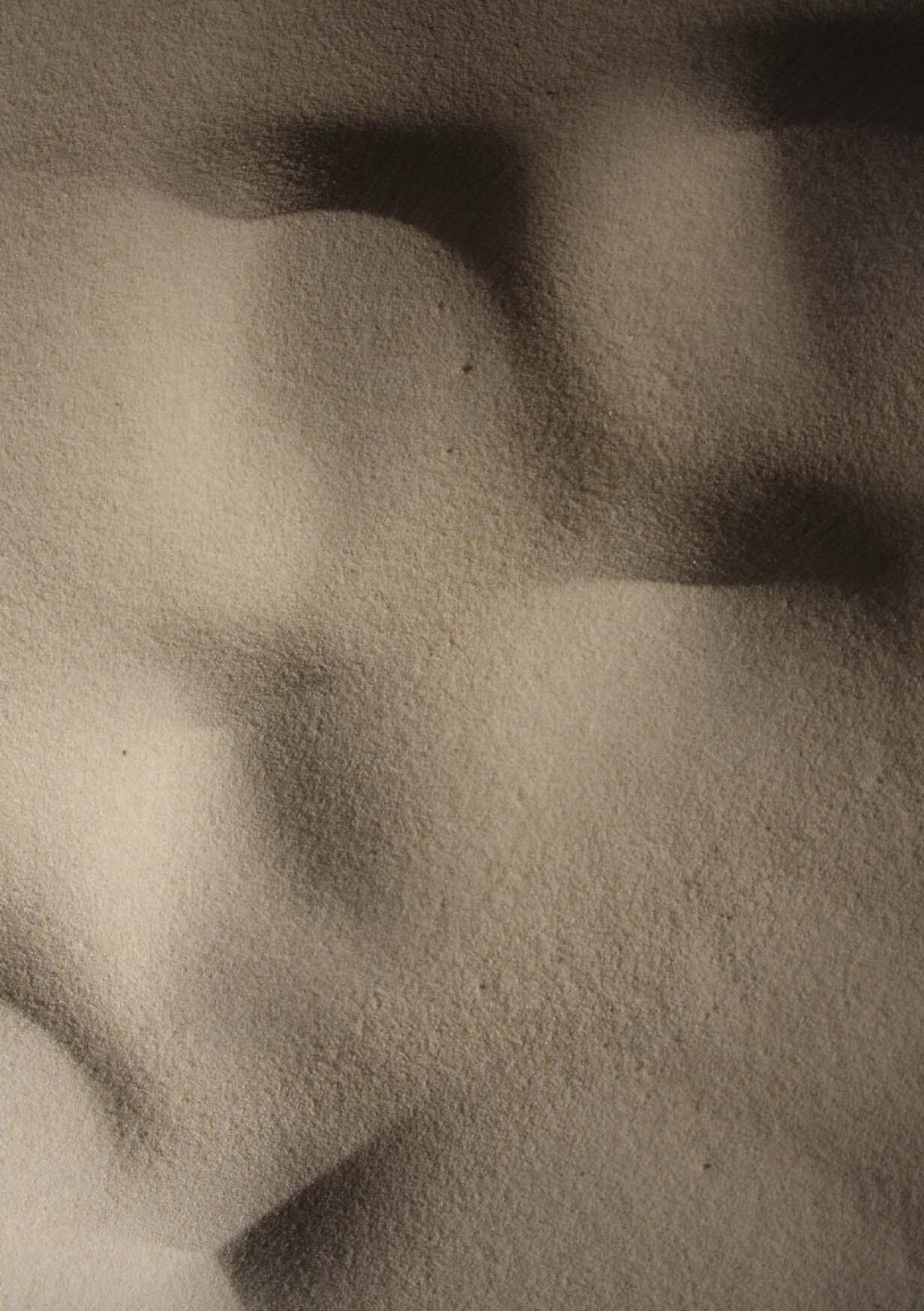

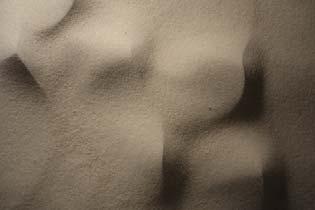

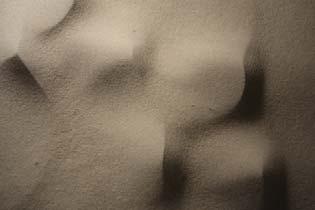

FIGURE04

GEOMORPHODYNAMIC MICROCLIMATE

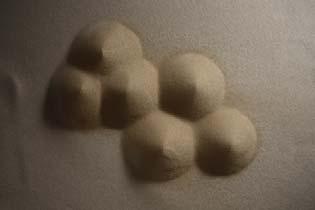

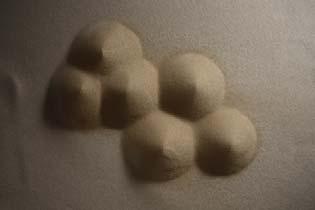

Seven piles of grey granite ballast, each 4 cm in diameter are exposed to a unidirectional airstream of 21 km/h. The piles deform, showing a low windward slope and a steep slip-face. The lee-faces are areas of wind-shadow, where there is little or no air-movement. The sand thus allows for the formation of a specific climatic modulation due to its ability to react to an impacting force, in this case the airstream. Adaptive modulation processes like this are typical of geomorphodynamic environments.

15 AGGREGATIONS 02 CONTEXT

P16

03CASESTUDIES

03.01 INTRODUCTION 03.02 DUNE MORPHOLOGY 03.03 SOFT ENGINEERING 03.04 PHILLIPS PAVILION 03.05 SANDSTONE 03.06 CONCLUSION

P17

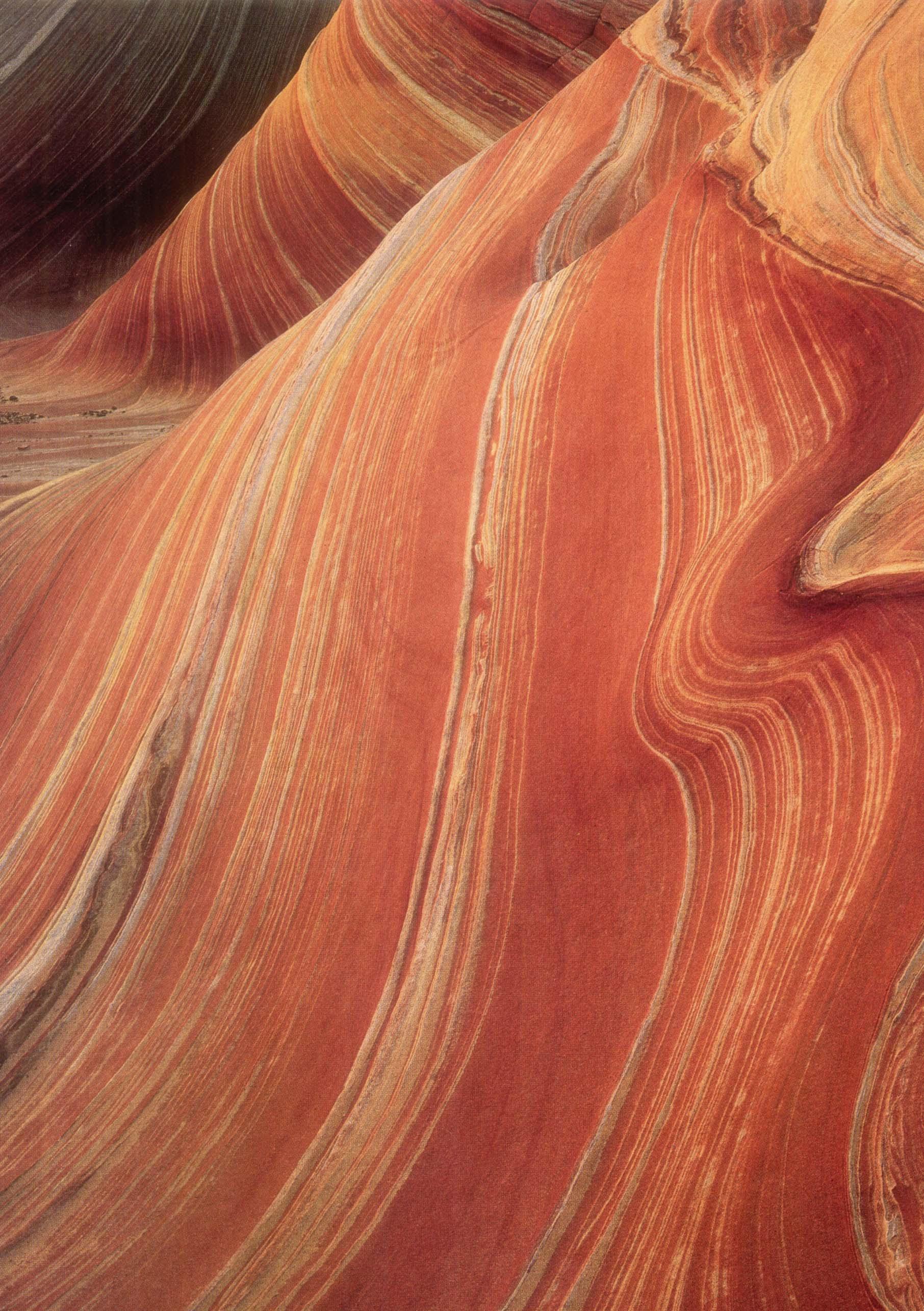

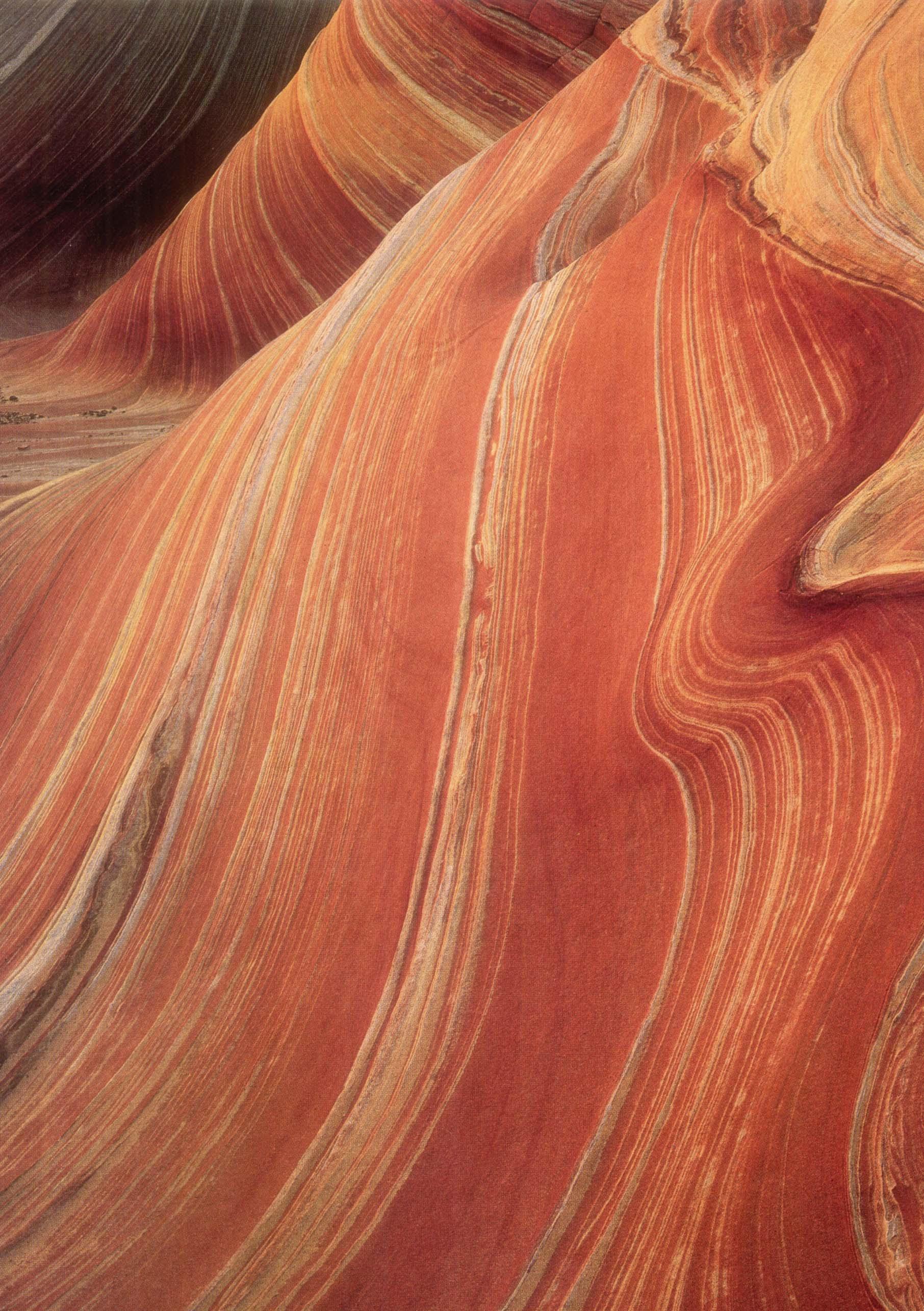

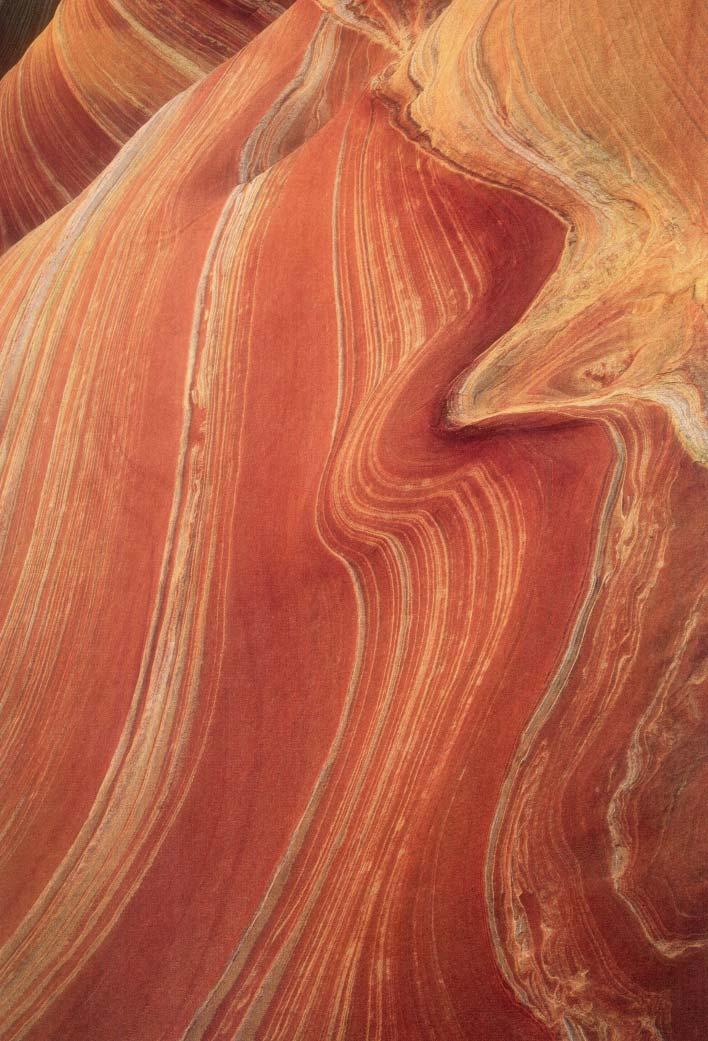

FIGURE 05

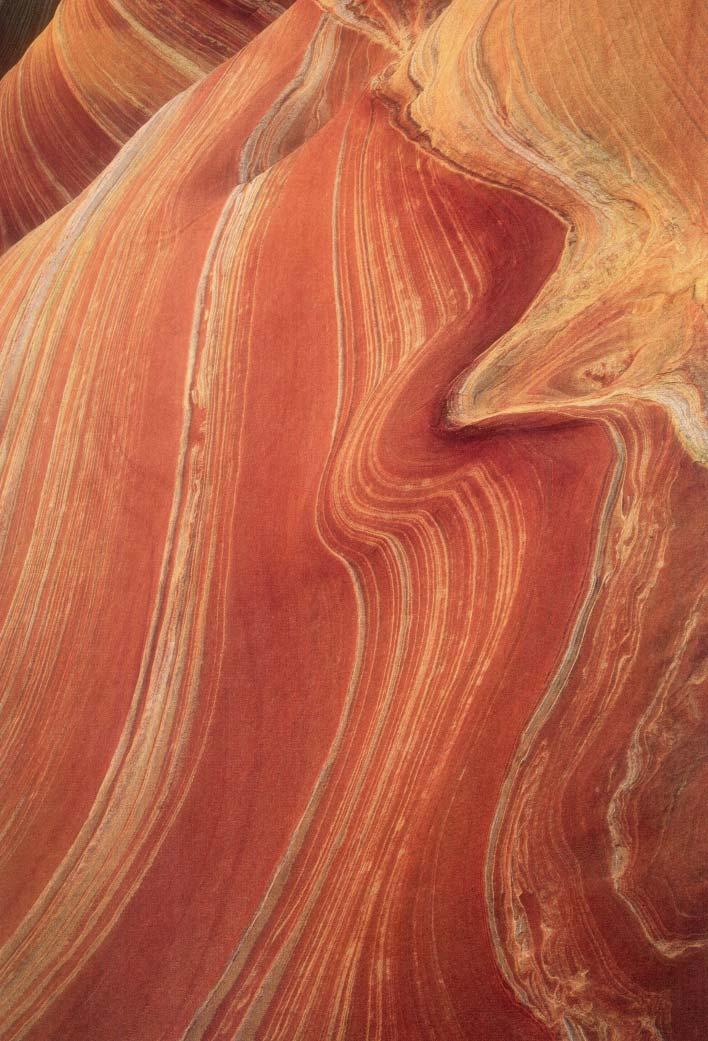

NAVAJO SANDSTONE, VERMILION CLIFFS, ARIZONA

This sedimentary rock has formed through the deposition of successive layers of sediment, later compressed into rock. The cross-bedding (narrow lines) was produced by changes in the direction of the depository water over time. (Sources: Science Photo Library and Siever, 1988, p. 01)

03.01INTRODUCTION-CASESTUDIES

Four case studies have been chosen to investigate several aspects relating to the main hypotheses of this research. Two of them, the dune morphology and soft engineering (case 01 and case 02) are being introduced to study the dynamic behaviour of aggregate systems on two scales as well as in the case of soft engineering to investigate already existing construction techniques in that field. The other two cases, the Philips Pavilion and the natural sandstone formations (case 03 and case 04) are being studied with regards to potential solidification methods. Both of them, even though one is an engineering project and the other a natural occurrence, use cementing techniques, where either a top layer or embedded layers of sand are solidified by a binding agent. The following introduces these four cases.

19 AGGREGATIONS 03 CASE STUDIES

FIGURE05

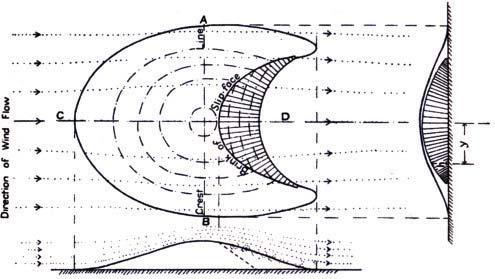

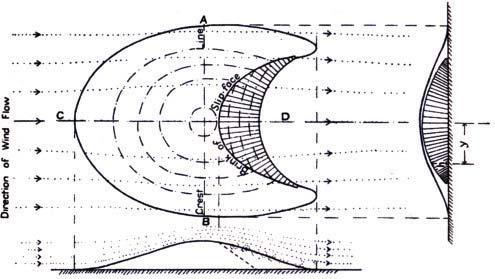

03.02CASE01-DUNEMORPHOLOGY

Dunes are repetitive structures that recur with wavelengths typically of around ten to several hundred metres and 1.00 metre to 100 metres height. Ripples form on them, with wavelengths of 0.5 cm to several metres and a height of 0.5 to 25 cm. Dunes are superimposed on ‘draas’ of 100 metres to several kilometres wavelength. The ‘draas’ are in turn part of the ‘erg’, of up to 500.000 square kilometres (Source: Siever, 1988, pp. 83-86). In order for a dune to form, there needs to be loose sediment, energy mostly in the form of wind, an obstacle to collect the loose sediment or an agglomeration of sand and a predominantly dry climate. Depending on the nature of the wind field, steady or varying in direction, fast or slow, and depending on the amount of sand, different dune morphologies appear. There are five basic types: crescentic, linear, star, dome and parabolic. Reversing dunes are varieties of any of the five basic shapes and appear wherever winds periodically reverse direction. All these dune shapes may appear in three forms: simple, compound, and complex. Simple dunes are basic forms with a minimum number of slip-faces that define the geometric type. Compound dunes are large dunes on which smaller dunes of similar type and slip-face orientation are superimposed, and complex dunes are combinations of two or more dune types. Simple dunes represent a wind regime that has not changed in intensity or direction since the formation of the dune, while compound and complex dunes suggest that the intensity and direction of the wind has changed. (Source: USGS, 1997)

The Barchan or Crescentic Dune can be considered the prototypical dune, as it reduces the mechanisms of dune formation to their essentials. A Barchan Dune forms under constant wind directions in very hot, dry climates, it is thus based on unidirectional wind and dry sand. In plan it has a crescentic shape, with the horns pointing downwind and advancing at a faster rate than the rest of the dune. Its windward side has a slope of ca. 11 degrees and usually shows ripple formation. Beyond the crest, its leeward side, the slip face, gradually forms. More and more sand is deposited on the top, the leeward side thus steepens and finally reaches its angle of repose around 35 degrees. Yet the wind cannot flow smoothly along the steep slip-face and abruptly breaks, thus forming a wind shadow with very little moving air. Only some grains tumble down into that shadow, occasionally setting off an avalanche, if the movement angle around 37 degrees is being reached (Source: Bagnold, 1954).

FIGURE06

FORCES ACTING ON A SAND GRAIN IN AN AEOLIAN ENVIRONMENT

The Lift Force (FL) results from an increase in velocity and a decrease in pressure due to airflow compressing above the grain. The drag force (FD) is the resistance to the flow coming from the sand bed. The resulting force is the Fluid Force (FF) that pivots the grain around its neighbour. (Drawn according to Siever, 1988. Illustration for Weinstock, 2009)

FIGURE07

SUSPENSION, SALTATION AND CREEP

Wind impacting on a sand grain can have three different effects. The grain can either be suspended like in a dust storm, it can saltate (Latin: salire, to jump) or it can creep. This depends on the grain size and density as well as the wind speed. Small light particles are most likely to be suspended, but a strong storm can lift even heavy objects from the ground. In saltation, the landing grain can hit other grains which in turn jump off the ground, the effect is thus proliferated across the sand field. (Drawn according to Bagnold, 1954. Illustration for Weinstock, 2009)

FIGURE08

FORMATION OF A SLIP FACE

Wind impacts on a pile of sand and gradually erodes its wind ward slope. This becomes lower in angle. The eroding grains are collected on the leeward side which becomes steeper and steeper, gradually reaching its angle of repose. Occasionally an avalanche is set off if the angle of movement is reached. (Source: Bagnold, 1954, p. 202)

FIGURE09

WIND DISTRIBUTION AROUND A DUNE

Approximate wind distribution and position of a slip face of a Barchan Dune, top view, side view and front view. The windward slope receives the main wind impact whereas the lee side gradually forms a wind shadow. (Source: Bagnold, 1954, p. 209)

DRAG FORCE, FD LIFT FORCE, F L FLUIDFORCE,FF PIVOT AXIS GRAVITY FORCE, F G SUSPENSION SALTATION CREEP 20 AGGREGATIONS 03 CASE STUDIES

FIGURE06 FIGURE07

FIGURE08

FIGURE09

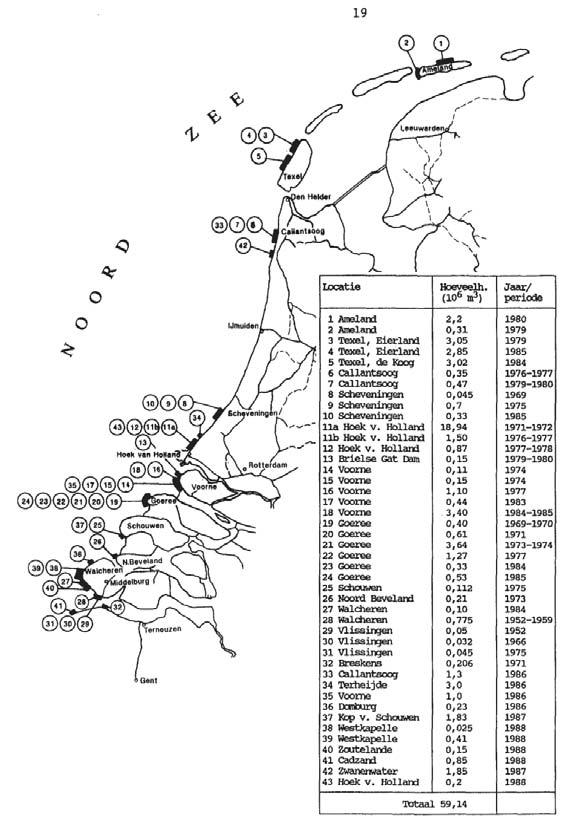

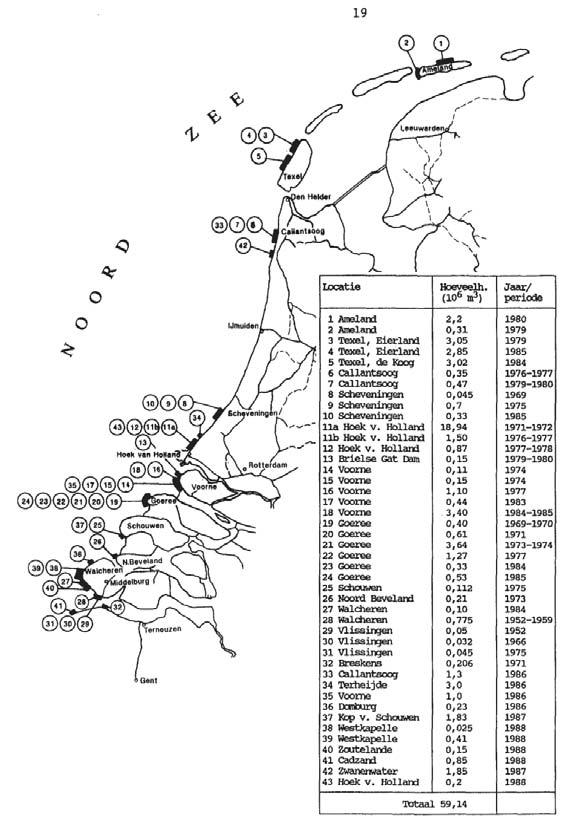

03.03CASE02-SOFTENGINEERING

Soft engineering techniques are considered to be the opposite of hard engineering techniques. Whereas hard engineering techniques seek to keep the status quo of a landscape by hardening it, soft engineering techniques use the principles already inherent in a natural system to achieve a specific effect. They deploy methods such as sand nourishment to restore beaches or certain planting strategies. All soft engineering methods have in common that they mimic the natural process and that they are left to perform on their own after and initial induction to the environment. This means that they work dynamically with the landscape morphology and as they are very akin to it only induce subtle modulations. The Dutch Rijkswaterstaat has made a series of such interventions, where sand was added to the coastline at specific locations and quantities. These sand supplements were initially thought to be only protective measures, but have now evolved into new coastal morphologies. These techniques however remain on a landscape engineering level and are not linked to architectural interventions (Sources: Trummer, 2008, MVW, 1989, 01 and MVW, 1989, 02).

FIGURE10

SAND SUPPLEMENTS

Overview map of the sand supplements in front of the Dutch coastline. The map specifies location (Dutch: Locatie), Amount (Dutch: Hoeveelheid) and Year/Period (Dutch: Jaar/Periode) of the sand supplements. Extensive studies have been conducted as to how these sand supplements have affected the makeup of the coast and the wind dynamics along the coastline.

(Source: Rijkwaterstaat, 2008)

21 AGGREGATIONS 03 CASE STUDIES

FIGURE10

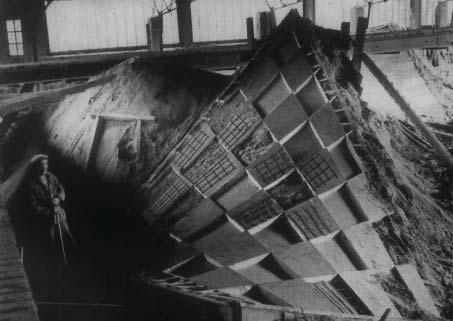

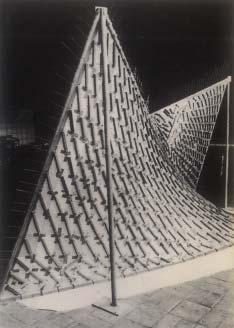

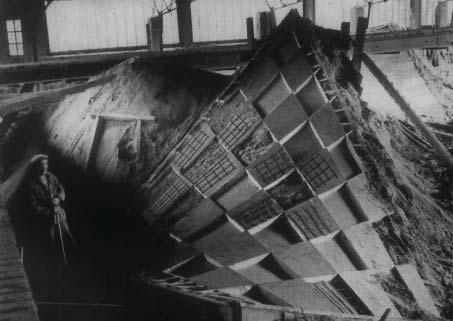

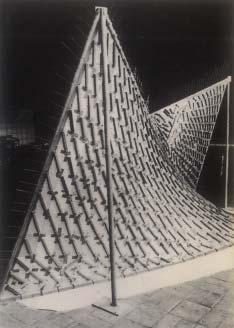

03.04CASE03-THEPHILIPSPAVILION

AUTHORS: IANNIS XENAKIS , LE CORBUSIER AND EDGAR VARESE

CLIENT: PHILLIPS / BRUSSELS WORLD FAIR YEAR: 1958

The Phillips Pavilion has been designed by Iannis Xenakis, Edgar Varese and Le Corbusier for the occasion of the Brussels World Fair. It is made from hyperbolic paraboloid shells derived from one of Xenakis scores. The shells are made from pretensioned concrete. In order to construct them, a new manufacturing technique was developed, that uses sand as a mould. This technique is quite primitive and is usually deployed to pour sidewalks. A sand bed is prepared in the form of the eventual shell. Then a wooden framework is placed onto the sand bed and the concrete is poured into alternating compartments for worker mobility. The individual segments are left to cure and then reassembled on site. (Source: Treib, 1996)

FIGURE11.01TO11.03

CASTING PROCESS

The components are being poured onto the sand, using a wooden grid. The sand mould is being laid out. Subsequently its profile is being built up. Should the required angle have been lower, vibration might have been needed to settle it, yet the actual angle of repose match the one required for the wooden mould. The wooden mould is subsequently being placed onto the sand bed and the individual concrete components are being cast using the tile-laying technique. (Source: Treib, 1996)

FIGURE12

CONSTRUCTION PROCESS

The wooden mould is applied onto the sand mould. This will serve as a grid for the casting of the concrete components on the sand bed. This sand-casting method has been specifically developed for the Philips Pavilion. (Source: Treib, 1996)

FIGURE13

HYPERBOLIC SHELL WOOD MODEL

A wooden mock-up model of the entire Phillips Pavilion has been developed and undergone physical load testings. This wood model then has been directly used as a mould for the concrete sand cast. (Source: Treib, 1996)

FIGURE14

TILE LAYING TECHNIQUE

The idea for the sand casting technique was derived from tile-laying. Here, a concrete slurry is applied on a sand bed. The concrete hardens and can be removed from its reusable sand mould. (Source: Treib, 1996)

22 AGGREGATIONS 03 CASE STUDIES

FIGURE 11.01

FIGURE 11.02

FIGURE 11.03

FIGURE 12

FIGURE 13

FIGURE 14

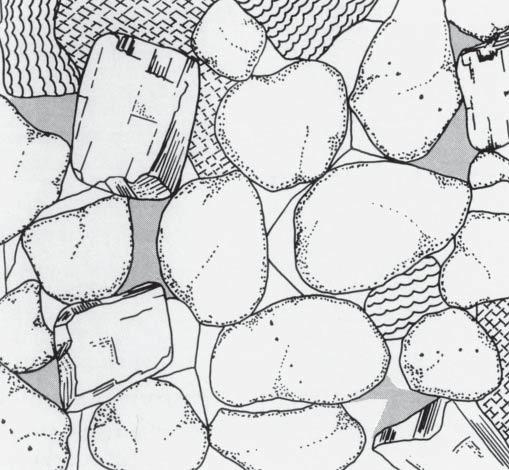

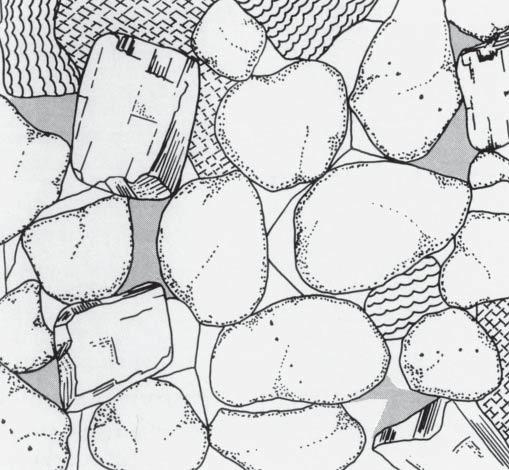

03.05CASE04-SANDSTONE

Sand stone originates from a natural sand cementing process. Genesis is the initial process of sedimentation, when a granulate stops moving around, diagenesis are the physical and chemical process which follow and which are responsible for the cementation of the grains into agglomerates of stones. Sand is deposited, i.e. it stops to move around on the ground or the seabed. Subsequently it is compacted by overlying deposits and then cemented mostly through embedding silica or calcium carbonate. Sandstones can be characterized by grain size, sorting and composition as well as rock geometry and sedimentary patterns. Sandstone from marine origins typically shows regular blocks when weathered, whereas deposits from dunes show wavy coloration lines and fluidly shaped patterns. Sandstone is used as a building material either as primary construction material or as a facing stone. As it also can carry other, fluid materials in its pores, such as gases and oils, it is exploited as a natural reservoir. Sandstone is subject to erosion, which can be brought forth by chemical processes, such as reaction with water, and mechanical processes, such as the effect of extreme temperatures or the exposure to windblown sand. It is thus embedded in a continuous cycle of accretion and erosion, which often leads to several sizes of grains and rocks being present together in a given sedimentary environment. Sand grains are often recycled in this process several times, being sedimented, cemented and eroded over and over again (Source: Siever, 1988, pp. 164-191).

FIGURE15

COMPOSITION OF SANDSTONE

A typical sandstone shows, in this magnified image, more or less rounded grains of quartz, feldspar, and rock fragments, cemented by diagenetic, or postdepositional, precipitates of quartz and calcium carbonate. A small amount of open pore space remains. (Source: Siever, 1988, p. 166)

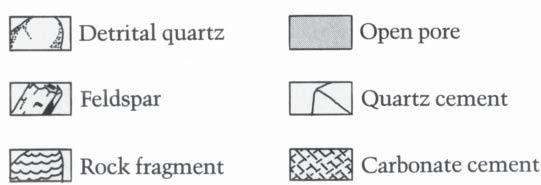

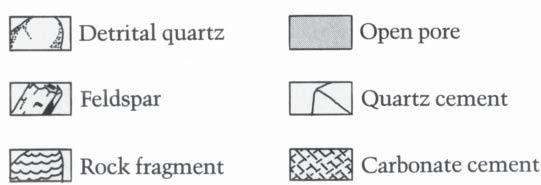

FIGURE16

THIN SECTION OF SANDSTONE IN THE PROCESS OF LITHIFICATION

This light micrograph is an example of diagenesis, the process by which rocks are reformed from weathered fragments close to the Earth’s surface at low pressures and temperatures. The sandstone consists of quartz fragments of 3 types, each with a different history, one above the other. The green is epoxy resin, injected into the rock to enable the thin section to be prepared. This picture is one of a pair, showing the same specimen in unpolarised and polarised light. Magnification: x50 at 35mm size, x112 at 6x9cm size. (Source: Mike Mc Namee/Science Photo Library)

FIGURE17

NAVAJO SANDSTONE, VERMILION CLIFFS, ARIZONA

This sedimentary rock has formed through the deposition of successive layers of sediment, later compressed into rock. The cross-bedding (narrow lines) was produced by changes in the direction of the depository water over time. (Sources: Science Photo Library and Siever, 1988, p. 01)

23 AGGREGATIONS 03 CASE STUDIES

FIGURE 17

FIGURE 15

FIGURE 16

03.06CONCLUSION-CASESTUDIES

The four case studies give an initial approach to some of the concepts developed in the hypothesis. Dunes are in a cycle of continuous construction and adaptation. They reconfigure until they fully erode, only to be reconstructed elsewhere. They are also able to modulate climatic conditions through their specific granular makeup which responds to impacting winds. Soft engineering techniques are using the intelligence hidden in natural aggregates systems to develop strategies for coastal protection. These are however not deployed on an architectural level but only as an engineering strategy. With regards to solidification methods, the Philips Pavilion manufacturing process gives a rare example of how sand can be used as a mould, it does apply cementation techniques similar to that of sandstone, but the cement is applied as a wet slurry, so that a careful hardening of individual layers is not possible. Sandstone itself offers a good insight in natural processes of cementation, where binders are filtering into the aggregate as powders or grains and are hardened by water afterwards. This concept will be taken further. Sandstone also gives a good insight into the concept of using onsite material for construction, as it is formed solely of materials that are immediately available in its surroundings. It is like the dunes subject to continuous cycles of construction, being accreted, sedimented, cemented and subsequently eroded.

FIGURE18

DUNES, EMPTY QUARTER, OMAN

These sand dunes, blown by the wind, are moving across drill holes (round, some at centre) made by oil exploration crews in the 1960s. While small dunes (5 or 10 metres high) move from year to year, the larger dunes mostly remain stationary, as shown by the maps made by the oil prospectors some 40 years earlier. The Empty Quarter (Rub’ al Khali) is a vast sand sea in the south of the Arabian Peninsula, and one of the largest deserts in the world, covering an area hundreds of kilometres across. These sand dunes are in Oman’s section of the Empty Quarter. Photographed in 2004. (Source: George Steinmetz / Science Photo Library)

24 AGGREGATIONS 03 CASE STUDIES

FIGURE 18

P26

04HYPOTHESIS

P27

04HYPOTHESIS

Nature processes large amounts of potential construction material in the form of aggregates and assembles them into dynamic morphologies. The idea is to use these natural formative processes in order to actuate semi-natural dynamic microenvironments. These might induce morphological and climatic transformations which are relevant both with regards to their human inhabitation and the original geology. The main hypothesis is thus to investigate, if natural formative aggregate processes can be deployed to induce new morphologies and then how these new morphologies can perform on an architectural as well as on a geomorphological scale. This main hypothesis might be broken down into the following sub-hypotheses, which will be dealt with throughout the course of the research.

(01) How can these microenvironments induce morphological and climatic transformations which are relevant both with regards to their human inhabitation and the actuating geology.

(02) How can the system have loose and solid phases, the solid being embedded in a loose aggregate and thus becoming loose in itself.

(03) How are these morphologies continuously changing over time through cycles of erosion and accretion, entering a cycle of continuous construction.

(04) How throughout this process can the construction material and energy in large parts be provided by nature itself, the structures thus being formed by minimal energy input.

28 AGGREGATIONS 04 HYPOTHESIS

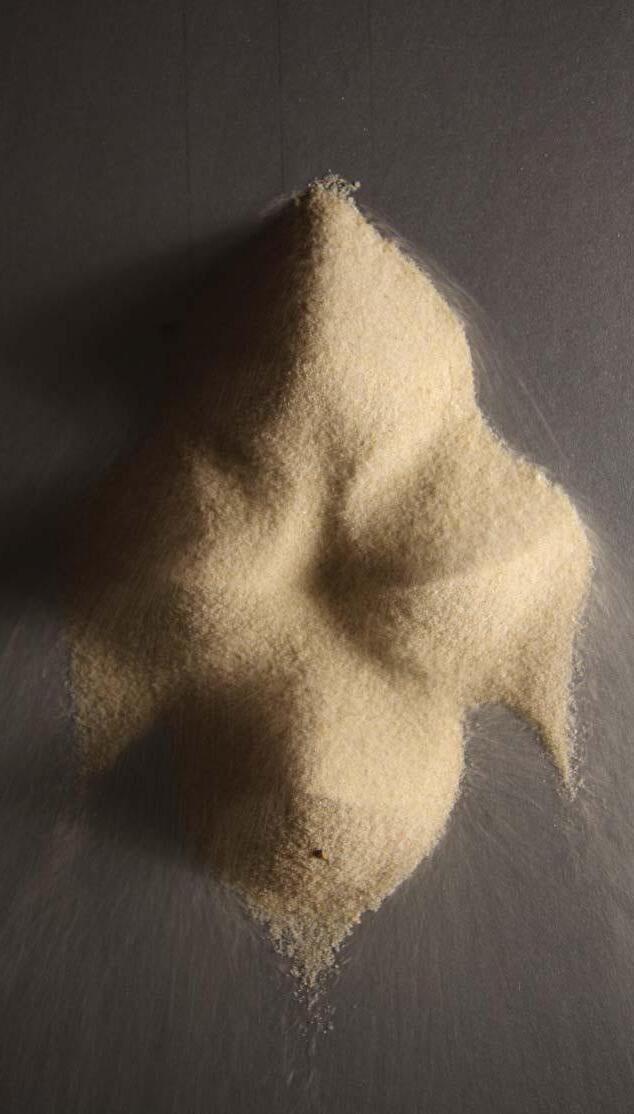

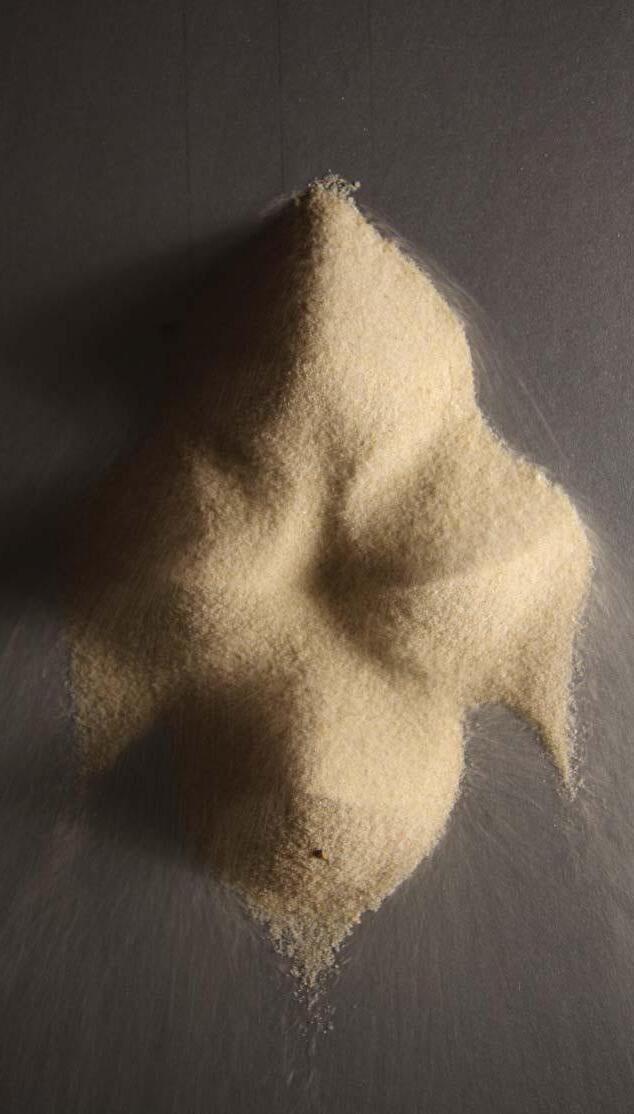

FIGURE 19

COARSE SAND PILE UNDER STRONG WIND IMPACT

Two piles of coarse sand, 25 cm diameter each, have been built up on the beach in List/Sylt/ Germany. The very strong impacting wind of 45 km/h to 65 km/h almost immediately forms them into a morphology resembling that of a dune, showing a windward low slope and a steep slip face. Smaller and lighter grains are transported across the crest, tumble down in the still air on the leeward side and come to rest in the wind shadow. Coarser grains remain on the windward slope and crest.

29 AGGREGATIONS 04 HYPOTHESIS

FIGURE19

P30

05METHODS

05.01 INTRODUCTION 05.02 OVERVIEW 05.03 SCALE 05.04 LABORATORY MODELLING 05.05 CONCLUSION

P31

FIGURE 20

FIGURE20 LAYERED AGGREGATE MODEL

Two sand types of the same grain size but different colour are built up in layers. The darker one is piled up first, the lighter one is sieved on top. The field is exposed to an airstream. The impact of the air takes off the light-coloured sand, exposing areas in dark, where impact is high and leaving areas in light sand, where there is little or no impact.

05.01INTRODUCTION-METHODS

The following chapter describes the methods that have been chosen to develop the research. Several sources have been consulted on available aggregate modelling methods (Sources: Cambou, 1998, Duran, 2000 and Pöschel/Schwager 2005). There are essentially two main groups, digital and analogue models, which will be introduced in the following. Analogue models are chosen as the main method of research and subsequently the analogue modeling methods applied in this research will be described in terms of their setup and the basic measurements and principles used. Scale issues will be discussed with regards to their qualitative and quantitative accuracy. Conclusively an outlook of required methodological developments will be given.

33 AGGREGATIONS 05 METHODS

ANALOGUE MODELS

ONSITE MODEL

LAB MODEL

FORMATIVE TOOLS

DIGITAL MODELS

DEM - FORMATIVE FEA

05.02OVERVIEWOFMETHODS

The following chapter is an introduction into possible aggregate modelling methods and the description of the models used in the context of this research. The models can be distinguished between formative and analytical ones, as well as between analogue and digital tools. Aggregates are most easily and efficiently modelled by analogue methods and since some of the physics governing aggregates are not yet fully understood, analogue models are also as of yet the most reliable aggregate method. However simulations exist and can be useful in some occasions, even though they have not been used in this context. Analytical tools can equally be devised in an analogue method, and where possible complemented by digital tools.

ANALOGUE MODELLING

Analogue modelling uses physical aggregates like sand or gravel and exposes them to the boundary conditions they would experience in a real situation. The models are very rapid and can yield useful and easily repeatable results. The high number of quick repetitions that are possible makes this method the most accessible one.

ANALOGUE ANALYSIS

In order to complement analogue models, analytical analogue tools can be developed. These are very common in aggregate modelling. Tracer particles that have a different colouring than the main aggregate body are frequently used.

DISCRETE ELEMENT MODELLING (DEM)

Digital simulations of particle systems are based on Discrete Element Methods (DEM). These model the local behaviour between particles using so-called event driven algorithms. As these models tend to be very heavy computationally, cells are grouped into clusters which are repeated periodically. The digital modelling of particle systems is still relatively young. It offers advantages in studying particle motions in great detail and simulations are accurate. However the computational

power needed is very high and simulations are mainly limited to spherical particles (Sources: Duran, 2000 and Pöschel/Schwager, 2005). DEM models are frequently combined with Finite Element Analysis (FEA) to model boundary conditions of the aggregate system.

DISCRETE ELEMENT MODELLING (DEM) ANALYSIS

DEM models can also be used to analyze particle behaviour through the colour coding of digital tracer particles (Source: Pöschel/Schwager, 2005).

34 AGGREGATIONS 05 METHODS FIGURE21

ANALYSIS TOOLS

ONSITE ANALYSIS

LAB ANALYSIS

DEM - ANALYSIS

APPLIED METHOD

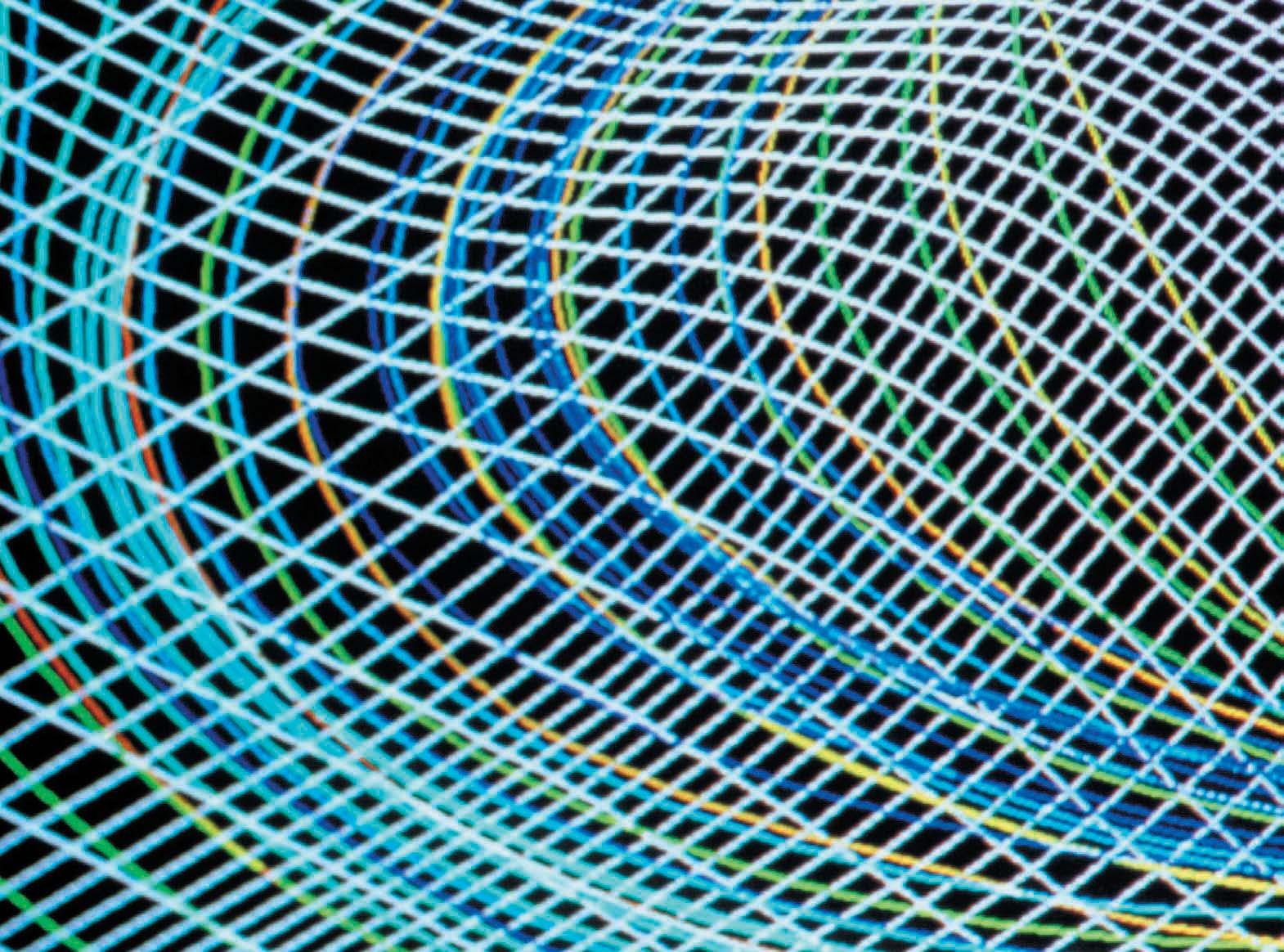

FIGURE21

OVERVIEW OF FORMATIVE AND ANALYTICAL ANALOGUE AND DIGITAL TOOLS

This chart gives an overview of the formative and analytical tools available for aggregate modelling. Both digital and analogue modelling methods were investigated. Digital methods rely on Discrete Element Modelling (DEM), which uses event-based algorithms. Yet even the physics of aggregates are not entirely understood, which makes digital models potentially inaccurate. Analogue modelling on the other hand offers a very direct and quick access to aggregate behaviour, which is why it has been chosen as the main methodological basis.

35 AGGREGATIONS 05 METHODS

05.03SCALE

‘The physical laws governing the behavior of granular media actually apply to objects whose dimensions cover several orders of magnitude. From grains, a few hundred microns each, to ice floes drifting across the polar seas (over distances of 1000 km), not forgetting Saturn’s rings (made of icy particles about 1 cm wide distributed in a band roughly 1 km thick), the science of granular materials covers at least twelve decades of sizes.’ (Source: Duran, 2000, p.3)

Essentially aggregate models can thus be scaled up or scaled down. Crucial to consider is that all relevant forces need to be scaled accordingly. However, dunes, which are the core morphology of this investigation, have mainly been studied one to one in field conditions. Their morphology has been thought to be scale-dependent, being reduced to the scale order of at least one meter, which does not allow for smaller laboratory experiments. Yet field research is often incomplete and difficult to perform, and experimental laboratory models are increasingly needed to closely understand the dynamics at hand. (Source: GIT, 2005)

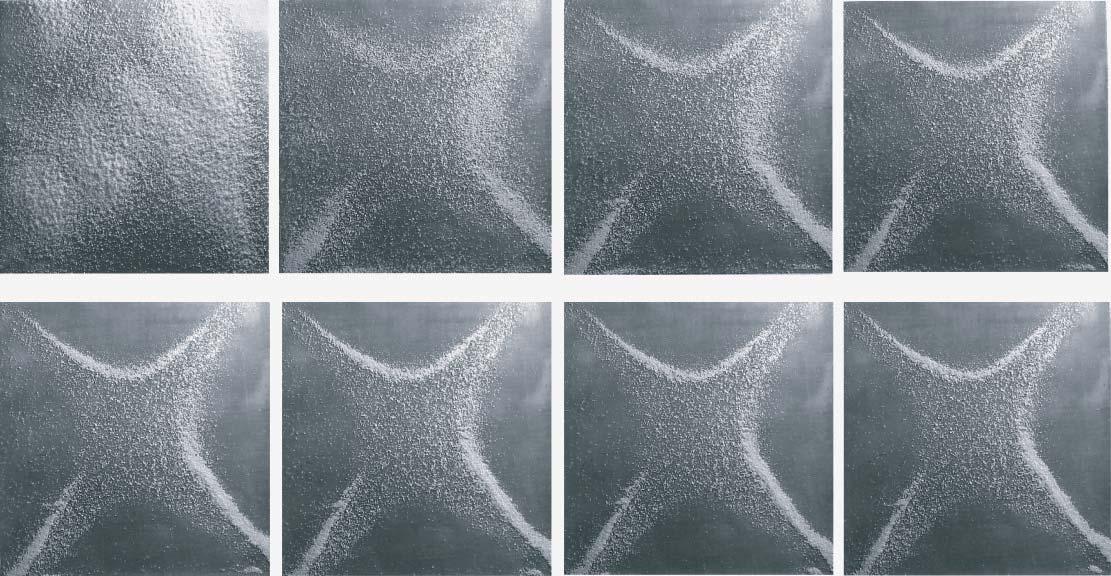

In the course of this dissertation, it has been found that a pile of a diameter as small as 4 cm transforms into the basic morphology of a Barchan Dune under a constant airstream. A Barchan Dune shows a windward slope of ca. 11 degrees, a slip face of ca. 35 degrees and has two horns pointing in the windward direction. The scaled laboratory model developed shows all these features on a much smaller scale. This finding has been consolidated by similar models of other research groups (Sources: ITP, GIT, 2005 and DLGD, 2002). As the development of laboratory models for dunes is extremely recent, it is not yet possible to supply exact quantitative methods for the relative scaling of each factor affecting the model, such as relative wind speeds and grain sizes. This will need a far greater collection of empirical data relating one to one dunes and their laboratory models. It is however possible to give an indicative qualitative assessment of the laboratory and onsite models versus their one to one counterparts. The above study shows the development of a pile under an airstream. Its basic morphology is consistent with that of a Barchan Dune, however the duration of formation is vastly reduced. Natural dunes take years to form, laboratory

ones are made within seconds, which allows to study them in very condensed time spans. This reduction of timescale also allows the observation of the morphological behaviour of dunes in continuous formation one by one, which is very hard to achieve in a natural setting. The main morphological difference between a laboratory and a one to one natural dune is related to the saltation length of the particles. This length remains more or less the same and where in a natural dune, grains are collected on the slip face, in a laboratory dune they are propelled far beyond, leading to a very quick erosion of the formation (Source: DLGD, 2002).

2 CM 2 CM T01: 00 secT02: 02 secT03: 04 sec T01: 00 secT02: 02 secT03: 04 sec T01: 00 SEC T02: 02 SEC T03: 04 SEC 36 AGGREGATIONS 05 METHODS FIGURE22

TRANSFORMATION OF A PILE UNDER A MONODIRECTIONAL AIRSTREAM

A sand pile of 4 cm diameter deforms under a mono-directional airstream into a dynamic morphology that is very closely related to that of a typical Barchan (Crescentic) Dune. Under airflow, two horns gradually form, the windward slopes becomes lower through erosion, whereas the leeward side steepens. This process takes about ten seconds. The top row shows a digital model in plan, the second row the same model in perspective view, the third row shows the top view of the physical experiment and the bottom row the same experiment in side view.

T04: 06 secT05: 08 secT06: 10 sec T04: 06 secT05: 08 secT06: 10 sec T04: 06 SEC T05: 08 SEC T06: 10 SEC 37 AGGREGATIONS 05 METHODS

FIGURE22

WINDSPEED 01

WINDSPEED 02

WINDSPEED 03

WINDSPEED 04

WINDSPEED 05

WINDSPEED 06

WINDSPEED 07

WINDSPEED 08

WINDSPEED 09

WINDSPEED 10

05.04LABORATORYMODELLING

A wind-table is constructed in order to model the natural behaviour of the aggregates as closely as possible. The table measures 2.00 m by 0.80 m by 0.34 m and the wind is simulated by two different size ventilators.

WINDTABLE PARTS

01 VENTILATING FANS

Two ventilators of different size have been used for the experiments. The smaller one measures 6.0 cm width and allows to model piles or dunes of up to 4.0 cm width. It allwos to adjust two speed regimes. The larger ventilator of the type Cyclone VAF 250 measures 35 cm width and allows to model a width of 33 cm.

02 HORIZONTAL BOARD

The horizontal board is the base that the dry aggregate is filtered onto and where the dune-field forms under the influence of the ventilating fans.

CAMERA POSITION AND LENS ANGLE

A horizontal camera of the type Canon EOS 40 D can be adjusted to different positions on top of the table using a 17 mm to 85 mm lens and time lapse mechanism (PCLIX TM).

WINDTABLE SPECIFICATIONS

WIDTH OF AIRSTREAM

The width of the airstream defines how big a dune field can be modelled. The airstream needs to be slightly bigger than the modelled field.

DISTANCE FROM SOURCE/AIRSTREAM SPEED

The distance from the airstream defines the speed that can be investigated. The speed decreases with an increasing distance from the airstream.

HORIZONTAL DIRECTION OF AIRSTREAM

The air source can be rotated horizontally to model different wind directions. Increments of ten degrees are marked on the table.

VERTICAL DIRECTION OF AIRSTREAM

The air source can be rotated vertically to model different wind directions. Increments of ten degrees can be achieved by tilting the air source.

REYNOLDS NUMBER OF THE AIRSTREAM

‘Most streams, the surface layers of the ocean stirred by the winds, and the winds close to the ground are turbulent. We can see laminar flows in small rills with thin flows of a few millimetres but rarely elsewhere on the natural surface of this planet. The prevalence of turbulent flows accounts for the sediment-transporting capability of the many different sorts of natural currents found in the environments of the Earth’s surface.’ (Source: Siever, 1988, pp. 40-42). A low Reynolds Number means that there is laminar flow. A high Reynolds Number indicates that there is turbulent flow. In the context of this research only turbulent flow is relevant, as this is the regime that most sedimentary environments are found in. For a more detailed discussion of the Reynolds number see chapter 11.

MAIN AXIS OF AIRSTREAM C01 C02 C03 C04 C05 C06 C07 C08 C09 C10 38 AGGREGATIONS 05 METHODS FIGURE23

FIGURE23

PERSPECTIVE VIEW OF THE WINDTABLE Perspective view of the 2.00 m x 0.80 m wind table. The airstream can be rotated in two axes allowing to simulate varying wind directions. Along the table, the wind speed decreases, so that each zone allows to test a different wind speed, altogether there are ten different zones.

FIGURE24

SIDE VIEW OF THE WINDTABLE

A camera (Canon EOS 40D) is adjusted on top of the wind table at right angle. It is connected to a time lapse device (PCLIX TM), that allows to take digital images at 1 second intervals. The camera can be adjusted along the table in ten different positions and uses a 17mm to 85 mm lens.

WINDSPEED 01 WINDSPEED 02 WINDSPEED 03 WINDSPEED 04 WINDSPEED 05 WINDSPEED 06 WINDSPEED 07 WINDSPEED 08 WINDSPEED 09 WINDSPEED 10 CAMERA 01 CAMERA 02 CAMERA 03 CAMERA 04 CAMERA 05 CAMERA 06 CAMERA 07 CAMERA 08 CAMERA 09 CAMERA 10 MAIN AXIS OF AIRSTREAM 10 20 30 40 50 60 70 80 90 39 AGGREGATIONS 05 METHODS

FIGURE24

MEASUREMENT01 SPEED 01: 40.4 km/h SPEED 02: 26.7 km/h

MEASUREMENT02

01: 33.0 km/h

02: 21.0 km/h

MEASUREMENT03

01: 24.6 km/h

km/h

MEASUREMENT04

01: 20.0 km/h SPEED 02: 14.3 km/h

MEASUREMENT05 SPEED 01: 16.5 km/h SPEED 02: 10.5 km/h

MEASUREMENT01 SPEED 01: 35.0 km/h

MEASUREMENT02

01: 33.1 km/h

MEASUREMENT03

km/h

05.04WINDSPEEDMEASUREMENTS

In order to be able to construct the wind-table as closely to on site conditions as possible, some preparatory measurements are needed, such as the wind speed generated by a regular hairdryer and a large ventilating fan of the type Cyclone 250 VAF, which are used as sources of airflow. Measurements are carried out at 15 cm intervals moving away from the air source. As the hairdryer has two speed levels, two sets of speeds are taken. As a measuring device, a digital hand-held wind speed meter is used.

40 AGGREGATIONS 05 METHODS

MEASUREMENT 010.15 M MEASUREMENT 020.30 M MEASUREMENT 030.45 M MEASUREMENT 040.60 M MEASUREMENT 050.75 M

FIGURE25

SPEED

SPEED

SPEED

SPEED 02: 17.1

SPEED

SPEED

SPEED

FAN01 FAN02

01: 28.6 km/h MEASUREMENT04 SPEED 01: 27.0 km/h MEASUREMENT05 SPEED 01: 25.5

MEASUREMENT06 SPEED 01: 14.0 km/h SPEED 02: 8.9 km/h

MEASUREMENT07 SPEED 01: 11.3 km/h SPEED 02: 7.3 km/h

MEASUREMENT08 SPEED 01: 9.7 km/h SPEED 02: 6.3 km/h

MEASUREMENT09 SPEED 01: 8.8 km/h SPEED 02: 5.2 km/h

MEASUREMENT10 SPEED 01: 7.7 km/h SPEED 02: 4.7 km/h

MEASUREMENT06 SPEED 01: 22.3 km/h

FIGURE25 WINDSPEED MEASUREMENTS ALONG THE WIND TABLE Two fans of different size have been used for the experiments. The top row of wind speed measurements is for a 6 cm wide fan. The bottom row shows speeds for a 36 cm wide fan of the type Cyclone VAF 250. Speeds have been measured using a hand held digital wind speed meter.

41 MEASUREMENT 060.90 M MEASUREMENT 071.05 M MEASUREMENT 081.20 M MEASUREMENT 091.35 M MEASUREMENT 10 -

M

1.50

MEASUREMENT07 SPEED 01: 21.4 km/h

MEASUREMENT08 SPEED 01: 19.0 km/h

METHODS

MEASUREMENT09 SPEED 01: 18.1 km/h MEASUREMENT10 SPEED 01:16.5 km/h AGGREGATIONS 05

ANALYTICAL METHOD

05.04LAYEREDAGGREGATEMODELS

A specific formative and analytical method is being developed in order to study the wind distribution in a modulated aggregate field. Two aggregates of the same grain size yet different colour are layered on top of each other. If an impacting airstream or wind impacts on the modulation, the lighter colour grains are taken off in the areas that are affected by the impact, leaving a clear distribution of areas that are affected by the impacting stream and those that are in a wind shadow. Techniques like these that use so-called marker aggregates are very common in aggregate modelling.

42 AGGREGATIONS 05 METHODS FIGURE26

FORMATIVE METHOD

00sec02sec04sec06sec08sec 00sec02sec04sec06sec08sec

FIGURE26

FORMATIVE AND ANALYTICAL LABORATORY METHOD

The top row shows the formation of seven sand piles under an airstream of 21 km/h. Windward faces and leeward sides form within seconds. This process can be analyzed by using a lighter coloured sand of the same grade that is taken off at the leeward sides, giving a clear distribution of wind sheltered areas across the entire formation.

43 AGGREGATIONS 05 METHODS 10sec12sec14sec16sec18sec 10sec12sec14sec16sec18sec

05.05CONCLUSION-METHODS

Several approaches to aggregate modelling have been introduced and a detailed description of the analogue setup developed for this research has been given. Deploying these methods has brought up several issues for further development, that will also be described in parts in the overall evaluation, but which will be introduced at this point. Firstly, there is a strong need for accurate aggregate laboratory models, that allow to scale down processes in terms of size or scale. A basic setup has been introduced, but much more empirical tests need to be conducted to arrive at an accurate scaling model. One to one tests preferably on site also become indispensable. It has also become apparent that photographic and image processing methods might be a good way into aggregate research, as they offer to analyze behaviours using time lapse photography (See also: Duran 2000).

Two sand types of the same grain size but different colour are built up in layers. The darker one is piled up first, the lighter one is sieved on top. The field is exposed to an airstream. The impact of the air takes off the light-coloured sand, exposing areas in dark, where impact is high and leaving areas in light sand, where there is little or no impact. Local modulations can be achieved by the impact of a singular airstream.

44 AGGREGATIONS 05 METHODS

FIGURE27

LOCAL BLOWOUTS

FIGURE 27

P46

06DESIGNDEVELOPMENT

06.01 INTRODUCTION

06.02 SEDIMENTARY ENVIRONMENTS

06.03 ONSITE MODELS

06.04 LABORATORY MODELS

06.05 SOLIDIFCATION METHODS

06.06 OVERVIEW DESIGN DEVELOPMENT

06.07 CONCLUSION

P47

FIGURE 28

FIGURE28

SEVEN PILES UNDER AN AIRSTREAM

Seven piles of kiln dried sand are exposed to an airstream at 21 km/h. They quickly form windward slopes and a lee-face. Time lapse photography allows to see grain movement in motion around the formation and deduce possible airflow patterns.

06.01INTRODUCTION-DESIGNDEVELOPMENT

The aim of this research is to develop a system that uses natural aggregates and their dynamic behaviours in order to actuate semi-natural dynamic morphologies. In order to develop such a system, several phases of design development are being conducted. Initially, all sedimentary environments are being studied in order to get an overview of their specifics and make a clear distinction between them. Common general strategies are being outlined. One specific sedimentary environment, the coastal beaches and dunes, is chosen and analyzed in greater detail. Subsequently, a specific formative material method is developed through onsite and laboratory studies. It is based on the fact that a simple aggregate pile transforms into a morphology resembling that if a dune if exposed to an airstream. This basic setup is developed and expanded. Solidification methods are being introduced. Conclusively an overview of the system is being given.

49 AGGREGATIONS 06 DESIGN DEVELOPMENT

P50

06.02SEDIMENTARYENVIRONMENTS

P51

SEDIMENTARY ENVIRONMENT: Continental. Alluvial fan

DESCRIPTION: Aprons of river-laid sediment at the edges of valleys bordering mountains

SEDIMENTARY PROCESSES: River transport

SEDIMENT TYPES: Alluvium

SEDIMENTARY ENVIRONMENT: Continental. Glacial

DESCRIPTION: Till and outwash plains of continental and valley glaciers

SEDIMENTARY PROCESSES: Weathering (Mechanical/Chemical)

SEDIMENT TYPES: Intermontane basin fills

06.02SEDIMENTARYENVIRONMENTS

A sedimentary environment shows a consistent sediment facies. It is understood as a group of sediment-forming processes with a corresponding recognizable sediment facies that can be mapped. There are subfacies to the main facies, but the sedimentary environment defines the overall character of the aggregation. Ten different sedimentary environments can be distinguished ranging from glacial moraine fields to abyssal plains under the ocean surface. Within the context of this design investigation only those environments are considered which are above sea level (Source: Siever, 1988, pp. 72 to 77).

SEDIMENTARY ENVIRONMENT: Continental. Alluvial plain

DESCRIPTION: Channel and floodplain deposits of braided- and meandering river-valleys

SEDIMENTARY PROCESSES: River transport

SEDIMENT TYPES: Alluvium (Channel/Floodplain)

SEDIMENTARY ENVIRONMENT: Coastal. Delta

DESCRIPTION: Shoreline deposits by rivers at their mouths, modified by waves and tides

SEDIMENTARY PROCESSES: Hydraulic sorting and abrasion

SEDIMENT TYPES: Moderate to well-sorted deltaic sediments

52 FIGURE 29 AGGREGATIONS 06 DESIGN DEVELOPMENT

05 06 01 02

SEDIMENTARY ENVIRONMENT: Continental. Desert or Eolian

DESCRIPTION: Dune fields of deserts; semi-arid, broad, sandy river-valleys; coastal dunes

SEDIMENTARY PROCESSES: Eolian transport

SEDIMENT TYPES: Dunes

SEDIMENTARY ENVIRONMENT: Continental. Lake

DESCRIPTION: Similar to shoreline deposits of deltas, but smaller in scale

SEDIMENTARY PROCESSES: Hydraulic sorting and abrasion

SEDIMENT TYPES: Deltaic sediments

SEDIMENTARY ENVIRONMENT: Coastal. Beach and bar

DESCRIPTION: Sand distributed parallel to the shoreline by waves and tides

SEDIMENTARY PROCESSES: Hydraulic sorting and abrasion

SEDIMENT TYPES: Moderate to well-sorted littoral sediments

SEDIMENTARY ENVIRONMENT: Continental border. Continental shelf

DESCRIPTION: Sand ribbons, sheets and dunes on shallow, broad continental margins

SEDIMENTARY PROCESSES: Hydraulic sorting and abrasion

SEDIMENT TYPES: Fine-grained and residual shelf-sediments

FIGURE29

OVERVIEW OF SEDIMENTARY ENVIRONMENTS

Eight sedimentary environments are considered relevant with regard to this research. Beyond the Continental Shelf, there are two more submarine sedimentary environments, the continental slope and rise as well as the abyssal plain. These have been left out as they are not relevant as areas of implementation. (Source: Siever, 1988, pp. 74 and 76)

IMAGE CREDITS

01 Alluvial Fan: NASA/Science Photo Library

02 Alluvial Plain: Bernhard Edmaier/Science Photo Library

03 Desert/Aeolian: George Steinmetz/Science Photo Library

04 Lake: Bernhard Edmaier/Science Photo Library

05 Glacial: George Steinmetz/Science Photo Library

06 Delta: George Steinmetz/Science Photo Library

07 Beach/Bar: George Steinmetz/Science Photo Library

08 Continental Shelf: NASA/Science Photo Library

53 AGGREGATIONS 06 DESIGN DEVELOPMENT

07 08 03 04

FORMATIVE PRINCIPLE 01

DYNAMICS: Vibration ENVIRONMENT: Seismic Locations

FORMATIVE PRINCIPLE 02

DYNAMICS: Gravity ENVIRONMENT: Glaciers/Mountains

FORMATIVE PRINCIPLE 03

DYNAMICS: Wind ENVIRONMENT: Desert/Dunes

FORMATIVE PRINCIPLE 04

DYNAMICS: Water ENVIRONMENT: Alluvial

06.02OVERVIEWFORMATIVESTRATEGIES

The intervention in these environments can happen on two scales. On the one scale different formative strategies for the overall aggregate modulation can be devised, depending on the sedimentary environment. They will be determined by the dynamics at hand in a given sedimentary environment, such as branching, wind-driven formation or aggregate piling. Special effects can be used in environments with seismic conditions, where aggregates can form very specific formations under the impact of vibrations. Each of these strategies can also be used in combination, if the environment requires it.

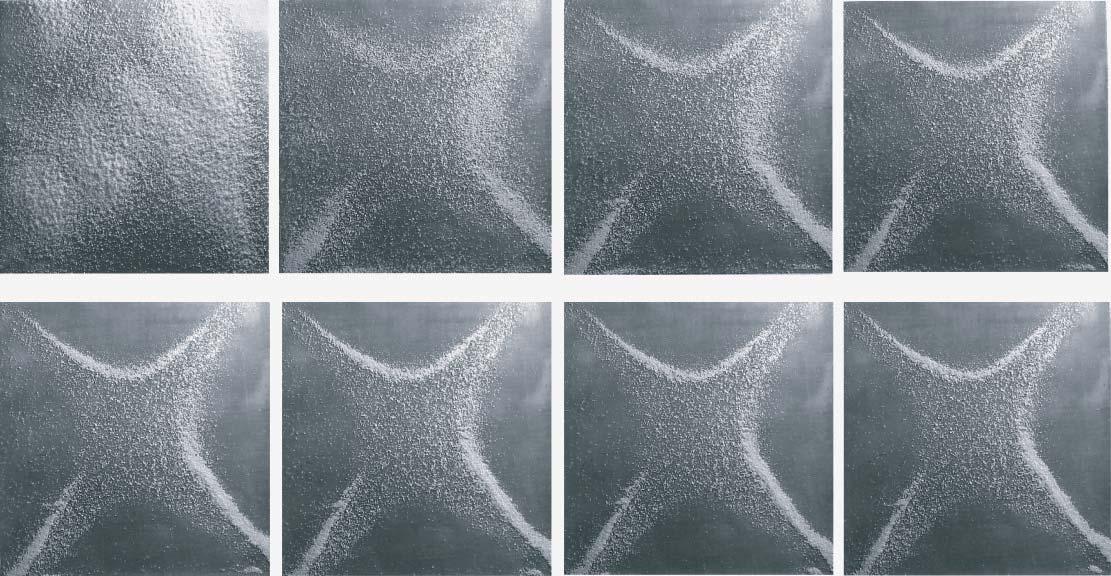

FIGURE30.01

AGGREGATE FORMATIONS UNDER VIBRATION

Sand on a metal plate is collected at the nodal lines under resonant frequencies of the plate. These aggregate effects might be used in seismic environments. (For a more specific experimental setup see the Appendix)

FIGURE30.02

AGGREGATE FORMATION UNDER GRAVITY ONLY

Aggregates under gravity only form piles. Their outline is convex, whereas that of funnels is concave. If the angle of movement is reached, an avalanche occurs until the aggregate again settles at its angle of repose.

FIGURE30.03

AGGREGATE FORMATION UNDER AIRSTREAM IMPACT

A sand pile under the impact of an airstream takes on the morphology of a dune. It develops a low windward slope and a steep slip-face, as well as downwind pointing horns. This strategy might be used in an aeolian environment.

FIGURE30.04

AGGREGATE FORMATION WITH WATER

If an aggregate is built up in a slope and saturated with water, a branching system with inlet, branches and a lake forms. Strategies involving these dynamics might be deployed in alluvial environments.

54 AGGREGATIONS 06 DESIGN DEVELOPMENT

30.01FIGURE 30.02FIGURE 30.03FIGURE 30.04

FIGURE

GRANULAR MODULATION 01

PRINCIPLE: Aggregate Grade EFFECT: Structural/Dynamic Behaviour

GRANULAR MODULATION 02

PRINCIPLE: Fibres EFFECT: Structural

GRANULAR MODULATION 03

PRINCIPLE: Climatic Additives EFFECT: Climatic

GRANULAR MODULATION 04

PRINCIPLE: Textural Grains EFFECT: Surface Articulation

06.02OVERVIEWGRANULARMODULATIONS

The other scale of intervention can be the granular level itself. Strategies can be the grading of an aggregate assembly by using different grade aggregates available on site. Additives can be used, either available or brought onto site. These might modulate climatic conditions, surface textures or structural performance of the modulations.

FIGURE31.01

AGGREGATE GRADING

Aggregates are frequently appearing in different grade on site. These might be used to achieve several effects, such as additional structural strength or a specific performance under wind and humidity as will be seen in the following chapter.

FIGURE31.02

FIBRE ADDITIVES

Fibres can be included in solidifications to add structural strength. They might be found onsite, as in this case algae, or manufactured and brought onto site.

FIGURE31.03

CLIMATIC ADDITIVES

There are several climatic additives used in materials such as concrete to give specific performative characteristics to the material. Wax pellets for example are used to extract heat from the material and adjacent spaces by melting thus dispersing the heat energy.

FIGURE31.04

TEXTURAL ADDITIVES

Local textural variations such as holes or indentations can be introduced into an aggregation by scattering a coarser aggregate, that spares and thus textures certain areas.

55 AGGREGATIONS 06 DESIGN DEVELOPMENT

31.01FIGURE 31.02FIGURE 31.03FIGURE 31.04

FIGURE

06.02COASTALDUNEBELTS

Coastal dune belts are chosen as a testing bed for the implementation of seminatural dynamic morphologies. They are a sub-group of deserts and eolian sedimentary environments and are related to the sedimentary activity along shorelines. Their morphology is due to typical processes of formation. The basic processes are driven by wind speed and direction as well as the gradation of the sand. A small obstacle, such as a group of pebbles can be the start of sand piling up in the sheltered region behind the pebbles, eventually forming a small dune. Typically the windward slope is relatively hard due to the accretion of saltating sand grains, whereas the lee side is rather soft due to the loose packing caused by cascades of sand forming slip faces. Small ripples form on the windward slope of a dune in transverse direction to the wind. The dune itself can be either transverse or longitudinal to the wind, with a tendency to be transverse under constant wind direction. Dunes can be between 1.00 metre and 100.00 metres high. (Source: Siever, 1988, pp. 84-85)

56 AGGREGATIONS 06 DESIGN DEVELOPMENT

LOCATION: Fraser Island. Australia

DESCRIPTION: Wind-formed ripples on coastal sand dunes IMAGE CREDITS: Bill Bachman/Science Photo Library

LOCATION: Scotland. United Kingdom

DESCRIPTION: Frost covered sand dunes Ythan estuary, Newburgh, Aberdeenshire

IMAGE CREDITS: Duncan Shaw /Science Photo Library

LOCATION: Namibia. Africa

DESCRIPTION: Sand dunes in the Namib Desert, Namibia, as they meet the Atlantic Ocean IMAGE CREDITS: Bernhard Edmaier/Science Photo Library

LOCATION: Dyfi Estuary Wales. United Kingdom

DESCRIPTION: Sand dunes patterned with ripples from wind, and vegetated by grasses

05 06 02 01 FIGURE 32

IMAGE CREDITS: Janet Baxter/Science Photo Library

DESCRIPTION: Barchan sand dunes, which are migratory coastal sand dunes

COASTAL DUNEBELTS

Even though displaying a basic morphology of foreshore, backshore and dunes, coastal dune belts across the world vary widely in their appearance. This is on the one hand due to different sedimentary compositions, on the other hand different aerodynamic and hydraulic conditions result in a wide variety of morphologies, ranging for example from linear to crescentic dune formations.

57 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE32

LOCATION: Baja California Sur. Mexico

IMAGE CREDITS: George Steinmetz/Science Photo Library

LOCATION: Georgia. USA

DESCRIPTION: Sand dunes with sea oats on Cumberland Island National Seashore IMAGE CREDITS: Kenneth Murray/Science Photo Library

LOCATION: Scotland. United Kingdom

DESCRIPTION: Formation of sand dunes along the seashore at Achnahaird

04 03 07 08

IMAGE CREDITS: Simon Fraser/Science Photo Library

LOCATION: Isla Magadalena. Mexico

DESCRIPTION: The dunes are oriented in the direction of the prevailing wind IMAGE CREDITS: George Steinmetz/Science Photo Library

SWELL OR SUMMER PROFILE

NEARSHORE ZONE

06.02STANDARDSHOREPROFILE

The diagram shows the standard profile of a shoreline. A beach has a winter (dotted line) and a summer profile (full line), the winter profile being lower than that during summer months. In the foreshore area, the dynamics are mainly dominated by waves and thus hydraulic accretion and erosion. In the backshore area and dune belt aeolian, wind-driven processes dominate, showing ripple formation and gradually the building up of dunes. The backshore area with ripple formation and little or no dunes is the main area of intervention.

58 FIGURE33 AGGREGATIONS 06 DESIGN DEVELOPMENT

INSHORE

OFFSHORE

BARBAR TROUGH LOW

WATER

SUBAERIAL BEACH (SWELL)

SUBAERIAL BEACH (STORM)

BACKSHORE FORESHORE

BEACH FACE

STORM OR WINTER PROFILE

SEA

CLIFF OR DUNE

FIGURE33

TERMINOLOGY OF A SHORE PROFILE

This diagram shows the terminology for a shore along a shore normal profile. The dotted line shows the storm or winter profile, the full line the summer profile. The backshore beach is the main area of focus. It is frequently considered as a fore dune in itself, but not yet a full dune.

(Source: Schwartz, 2005, p.162)

59 AGGREGATIONS 06 DESIGN DEVELOPMENT

BERM

P60

06.03ONSITEMODELS

P61

06.03MODULATION01-TWOHUMIDPILES

The onsite models have been conducted in November/December 2008 on the island of Sylt in the German North Sea. After an initial investigation of the beach morphology, which is shown in greater detail in chapter 07, experiments were carried out in the backshore area at the edge of the dune belt. They are all using the same principle, namely that of a pile transforming into a morphology similar to that of a dune under wind impact. All three experiments conducted on site test different aspects of this basic principle. The initial one (modulation 01) is set up to test the behaviour of relatively humid sand and how it affects the formative process.

62 FIGURE 34 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE34

TWO HUMID SAND PILES AFTER WIND IMPACT

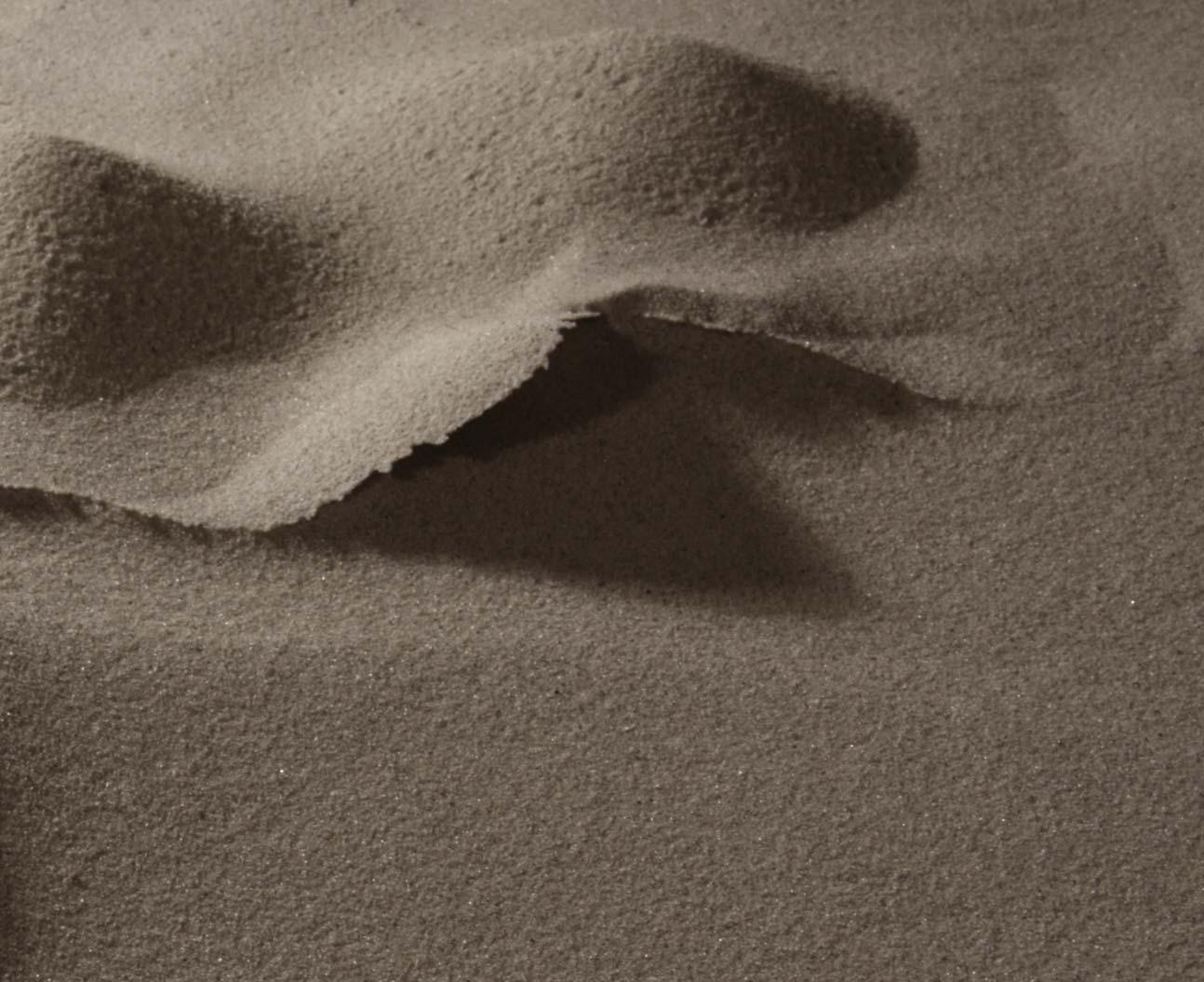

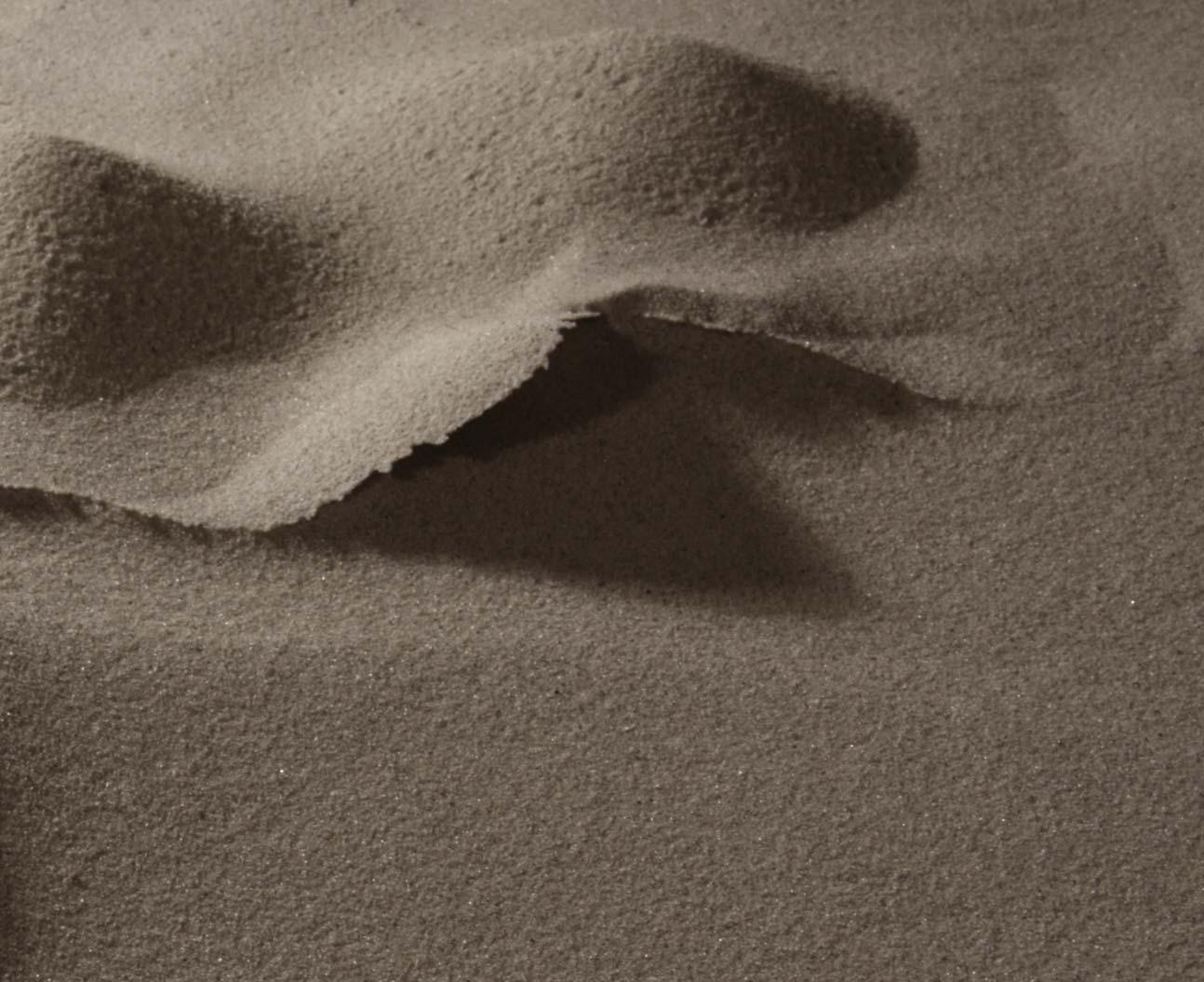

Two piles of humid sand, 35 cm diameter each, have been left to deform on a beach in List/Sylt/ Germany. After three days of impacting winds of around 30 km/h they have formed a windward slope and a slip face.

FIGURE35

EDGE CONDITION OF WINDWARD FACE AND LEEWARD SLOPE

The edge of one of the piles clearly shows two common aspects observed in dune formation. On the one hand only the windward side becomes humid during an impacting rainfall, this clearly shows that the leeward side is wind protected. On the other hand, the windward edge has slightly coarser grains than the leeward one. This is due to the fact that the lighter grains are transported across the ridge and tumble down through the still air at the leeward side, where they remain.

63 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 35

06.03

MODULATION01-TWOHUMIDSANDPILES

EXPERIMENTAL SPECIFICATIONS

MODEL SIZE: two piles, 35 cm diameter each

CREST CREST DISTANCE: 2 x radius

GRAIN SIZE: 0.1 to 0.2 mm

WIND SPEED: between 25 km/h and 35 km/h

WIND DIRECTION: west/west north to west/west south

RAINFALL: 60%

HUMIDITY: 90%

DURATION: 3 days

PERIOD: 13.11.2008 to 16.11.2008

MODELLING PROCESS

The two piles are being set up at the edge of the dune belt. Relatively humid fine sand is chosen. The piles are covered in darker grain aggregate and left on the beach for three days. Records of their development are taken on a daily basis.

OBSERVATIONS

Humid fine sand was chosen in order to test how humidity which is held mainly in very fine aggregates, affects the process of formation. On day two, windward slopes become discernible, where the marker aggregates is eroding. The lee sides of the piles remain dry under an impacting rainfall. On day three, low windward slopes have formed as well as a steep slip-face. The ridge shows that coarse grains are remaining on the windward side and finer ones are tumbling across the brink and coming to rest in the wind shadow. The windward side is exposed to rain impact, whereas the leeward side remains dry. The wind analysis shows that winds have come mainly from west/west north and west/west south directions.

64

FIGURE 36.01

FIGURE 36.02

FIGURE 36.03

DAY02 DAY03 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 37 DAY01

FIGURE36.01TO36.03

MODULATION OF TWO HUMID PILES BY IMPACTING WIND

Two piles of humid sand, 35 cm diameter each, have been left to deform on a beach in List/Sylt/ Germany. On Day 01 they are irregular, on Day 02 they start to show a windward and leeward side, also made visible by marker sand. On Day 03 windward face and slip face are clearly discernible.

FIGURE37 TOPVIEW OF ONE MODULATED PILE

The top view allows for a clear distinction of wind exposed and wind sheltered areas. This especially as an impacting rainfall has marked the zones that are exposed to wind versus those that are left both wind protected and dry.

FIGURE38 CONTRAST ANALYSIS OF TOPVIEW

As light conditions are frequently very shallow on the North Sea image contrasting techniques are used to analyze the image results. The contrast is set to 65%, which allows to more clearly see wind protected areas in lighter tones versus wind exposed areas in darker tones.

FIGURE39 WIND DIRECTION ANALYSIS OF TOPVIEW

The contrast analysis image is used to do a wind direction analysis. A wind rose is placed over the image and the areas that cover the windward side are marked. In this case the wind has come mainly from west/west north to west/west south directions.

E S W N 65 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 38

FIGURE 39

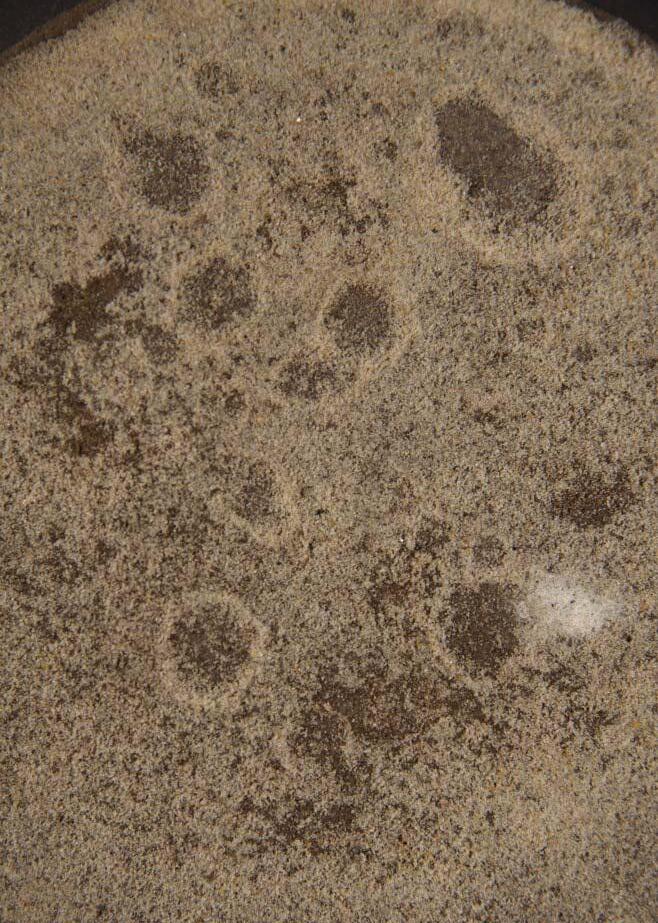

06.03MODULATION02-TWOCOARSEPILES01

Along the beach the grading of the sand varies. There are coarser stretches as well in the dunes as in the foreshore areas where there is wave impact. This availability of different aggregate composure, which is already sorted by grade through the energies available on site can obviously be used for different applications within the system, such as the temporary solidification of fine sand by a layer of very coarse one on top, which does not saltate as readily. In this case coarse sand has been used as a means to cope with humidity as water drains off more easily than from fine sand. However, heavier grains are not transported by wind as easily. Two tests using this coarse sand (modulation 02 and 03) have been conducted.

66 FIGURE 40 AGGREGATIONS 06 DESIGN DEVELOPMENT

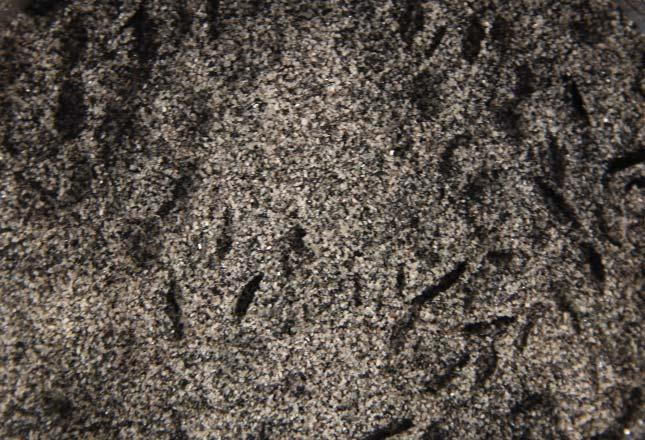

GRAVEL SAND CLOSE UP VIEW

Sand of coarser grain can be found in stretches along the beach. The granules are between 0.80 mm and 1.00 mm. These can be used in extremely wet conditions, as water drains off them more quickly and thus wind modulation can still happen during humid phases.

FIGURE41

MODULATED GRAVEL PILE

Two piles using gravel sand of 10 cm diameter each are left on the beach. After a period of two days and winds of around 31 km/h, they form a windward face and a lee face. The windward side is more humid due to impacting rain and shows coarser sand, whereas the lee face is dry and collects finer sand in its wind shadow.

67 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 41

FIGURE40

06.03

MODULATION02-TWOCOARSEPILES01

EXPERIMENTAL SPECIFICATIONS

MODEL SIZE: two piles, 10 cm diameter each

CREST CREST DISTANCE: 2 x radius

GRAIN SIZE: 0.5 to 1.0 mm

WIND SPEED: between 25 km/h and 35 km/h

WIND DIRECTION: south west

RAINFALL: 50%

HUMIDITY: 85%

DURATION: 3 days

PERIOD: 12.11.2008 to 15.11.2008

MODELING PROCESS

Slightly coarser sand is collected from coarse aggregate fields in the foreshore zone. The two piles are being set up at the border between foreshore and backshore. The piles are left on the beach for three days. Records of their development are taken on a daily basis.

OBSERVATIONS

Gravel has been chosen as it drains off water more quickly and can potentially balance effects of humidity has on the formation of sand. It is however heavier than regular dune sand and thus requires slightly higher threshold winds. After a period of three days, a slightly steeper windward side has formed and a wind protected and dry air is discernible. Effects however are not as clear as in Modulation 01-Two Humid Sand Piles, this is probably due to threshold winds, that have been too low for gravel. The wind direction analysis shows that winds have come mainly from south west directions.

68

43 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE

FIGURE 42

FIGURE42

TOPVIEW OF TWO MODULATED PILES

The top view shows the two piles after three days of impacting winds between 25 km/h and 35 km/h. Even though a windward and leeward side are discernible, their morphology has not changed as significantly as was seen in the two humid piles in modulation 01, which were observed during almost the same period.

FIGURE43

TOPVIEW OF ONE MODULATED PILE

The top view allows for a clear distinction of wind exposed and wind sheltered areas. This especially as an impacting rainfall has marked the zones that are exposed to wind versus those that are left both wind protected and dry.

FIGURE44 CONTRAST ANALYSIS OF TOPVIEW

As light conditions are frequently very shallow on the North Sea, image contrasting techniques are used to analyze the image results. The contrast is set to 70%, which allows to more clearly see wind protected areas in lighter tones versus wind exposed areas in darker tones.

FIGURE45 WIND DIRECTION ANALYSIS OF TOPVIEW

The contrast analysis image is used to do a wind direction analysis. A wind rose is placed over the image and the areas that cover the windward side are marked. In this case the wind has come mainly from southwest directions.

E S W N 69 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 44

FIGURE 45

06.03MODULATION03-TWOCOARSEPILES02

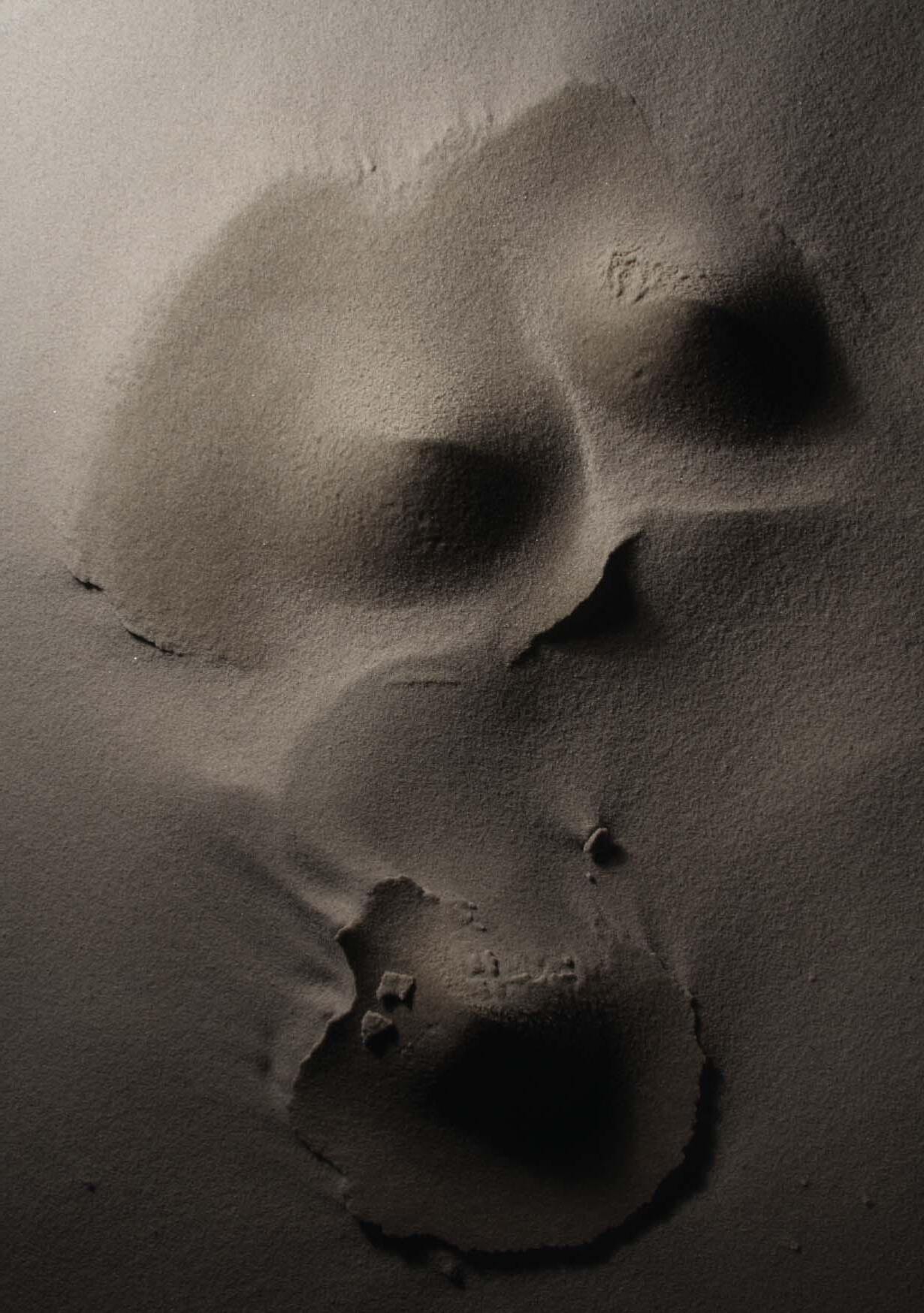

Coarse sand was gain tested, but this time in different boundary conditions of strong winds ranging from 45 km/h to 65 km/h. In this setting, the coarse sand performs extremely well. It does not cluster into larger assemblies as water and humidity drain off and evaporate easily, and the winds are strong enough to transport the grains. They are reaching the so-called threshold strengths. The piles almost immediately settle into a morphology resembling that of a dune with a low windward slope and steep slip-face, where saltating sand grains come to rest.

70 FIGURE 46 AGGREGATIONS 06 DESIGN DEVELOPMENT

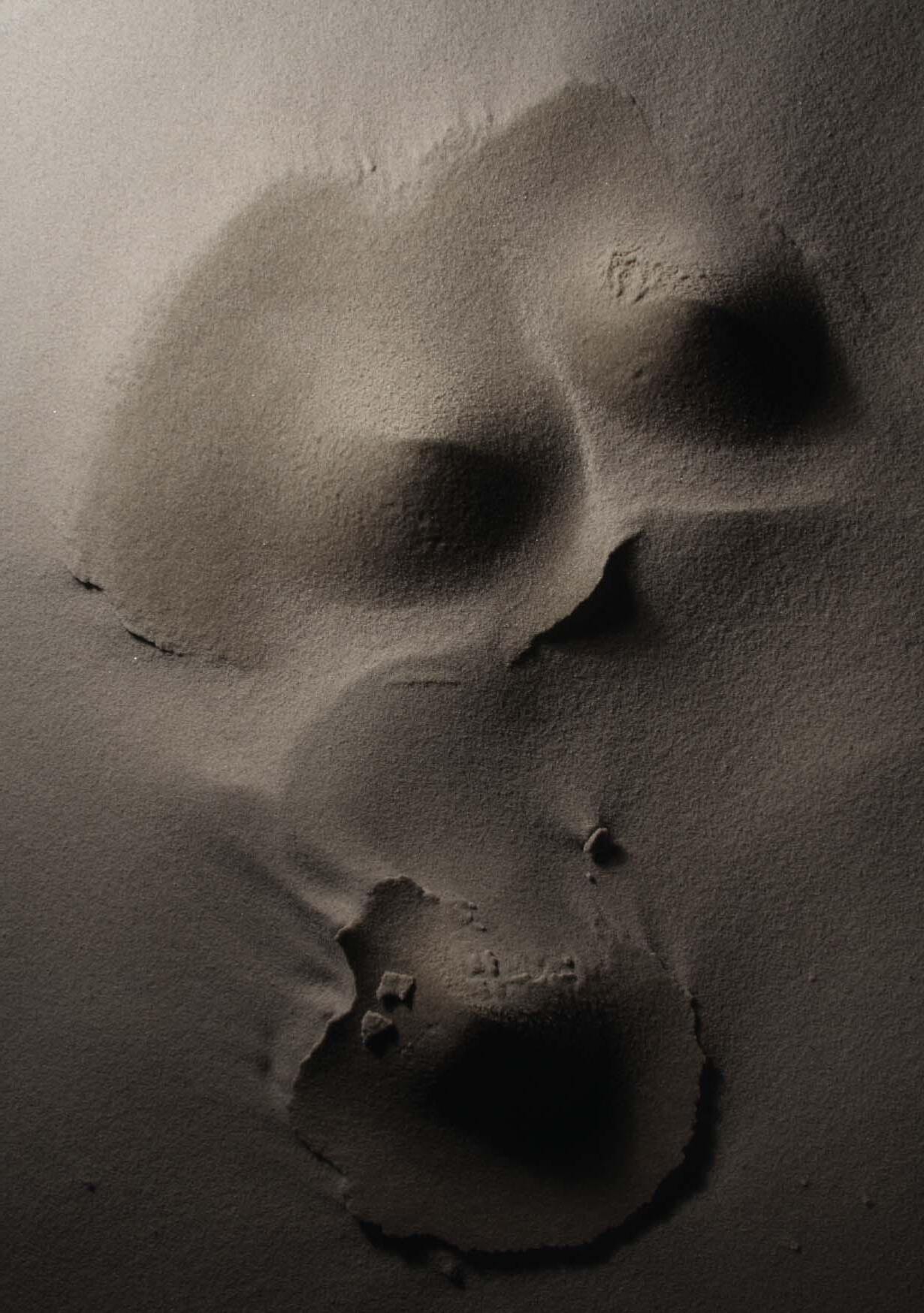

VIEW OF TWO MODULATED PILES

Two gravel piles are modulated under a strong wind of 65 km/h. They form a windward side and slip face within one minute, showing a very clear profile similar to that of a dune. The leeward side collects granules of lighter grain that come to rest in the wind protected zone.

FIGURE47

VIEW OF ONE MODULATED PILE

The closer view of one of the two piles again shows the extremely clear geometry that the two piles took during a relatively strong wind. The crest is clearly discernible, the lee face very steep showing the collection of finer sand grains. The wind has been almost unidirectional, which can be seen by the ridge running along the windward slope.

71 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 47

FIGURE46

06.03

MODULATION03-TWOCOARSEPILES02

EXPERIMENTAL SPECIFICATIONS

MODEL SIZE: two piles, 25 cm diameter each

CREST CREST DISTANCE: 2 x radius

GRAIN SIZE: 0.5 to 1.0 mm

WIND SPEED: between 45 km/h and 65 km/h

WIND DIRECTION: west

RAINFALL: 30%

HUMIDITY: 75%

DURATION: 1 minute

PERIOD: 21.11.2008

MODELING PROCESS

Slightly coarser sand is collected from coarse aggregate fields in the foreshore zone. The two piles are being set up at the border of the dune belt. The piles are left to form under the impact of an extremely string wind. Records of their development are taken minute by minute.

OBSERVATIONS

Gravel has been chosen as it drains off water more quickly and can potentially balance effects of humidity has on the formation of sand. It is however heavier than regular dune sand and thus requires slightly higher threshold winds. As in this experiment wind speeds are very high, the gravel almost immediately takes on a low windward slope and a steep slip face. Lighter grains collect in the wind protected areas on the lee side, whereas coarse grains remain on the crest and windward slope. The minute by minute record shows that the morphology of the formation remains, but gets eroded relatively fast.

72

48 00sec 15sec 40sec

FIGURE

49 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE

FIGURE48 VIEW OF TWO MODULATED PILES

Two gravel piles are modulated under a strong wind of 65 km/h. They form a windward side and slip face within one minute, showing a very clear profile similar to that of a dune. The crest is clearly discernible, the lee-face very steep showing the collection of finer sand grains. The wind has been almost unidirectional, which can be seen by the ridge running along the windward slope.

FIGURE49 SEQUENCE OF FORMATION OF TWO PILES

As this formation has been forming very quickly, a time lapse observation was possible. The piles almost immediately took on the formation of a windward side and a slip face. This configuration eroded during the time of observation, but its basic configuration remained the same.

73 AGGREGATIONS 06 DESIGN DEVELOPMENT 05sec10sec 30sec35sec 45sec50sec

P74

06.04LABORATORYMODELS

P75

06.04LABORATORYMODELS

Having observed how a pile transforms into the basic morphology of a dune onsite, this principle is developed in laboratory models using the setup described in chapter 05. The following sequence tests the behaviour of single piles, pile groups, varying crest to crest distances and that of piles on a loose sand bed. All laboratory models show very similar results to the onsite tests, yet they are conducted at a vastly accelerated speed, due to their small scale and continuously high airstream speeds. Onsite models of course will be subject to a change in wind directions, whereas in this series of laboratory models only mono-directional airstreams have been used. This will be further developed in chapter 07, where multi-directional winds are introduced.

76 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE 50

SAND SALTATING AROUND MODULATED PILES 01

Time-lapse photography allows to observe how sand grains are moving around a pile modulation under the impact of an airstream. They flow around the pile at both sides and as crests form are hopping over the edge, leaving the leeward side almost still.

FIGURE51

SAND SALTATING AROUND MODULATED PILES 02

The same process as in the previous figure can be observed, yet this pile configuration is slightly bigger so that features, such as downwind horns, become more distinct.

77 AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE50

FIGURE 51

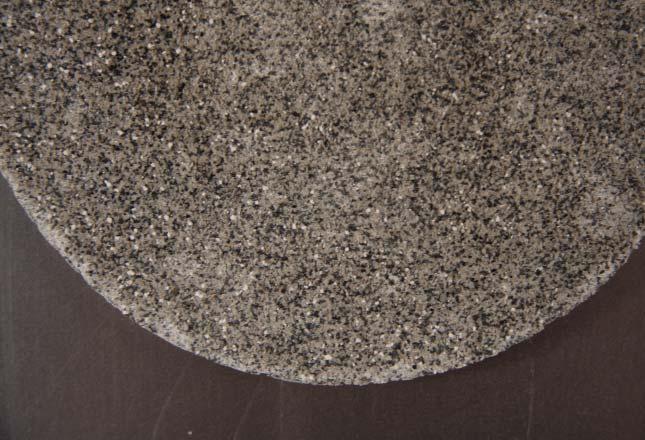

06.04MODULATION01-SINGLEPILE

EXPERIMENTAL SPECIFICATIONS

DIAMETER AIRSTREAM: 5.0 cm

DIAMETER SAND-PILE: 4.0 cm

DISTANCE AIR-SOURCE/SAND-PILE CENTRE: 36.0 cm

AIRSTREAM SPEED: 21 km/h

AIRSTREAM DIRECTION: 0 degrees

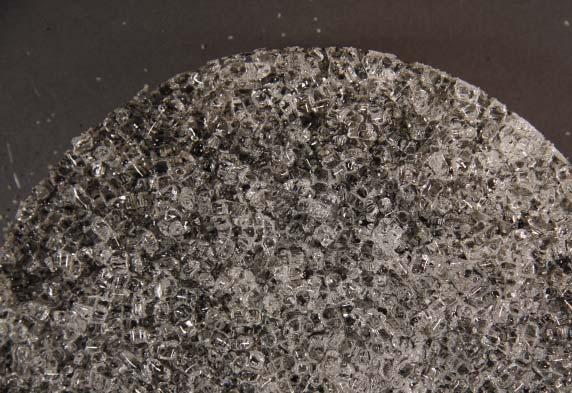

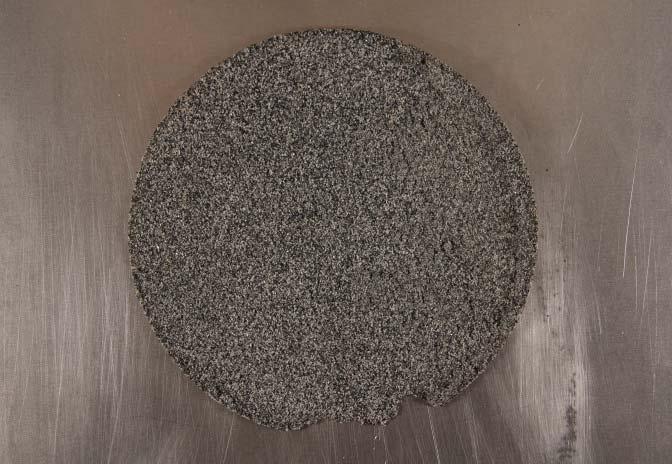

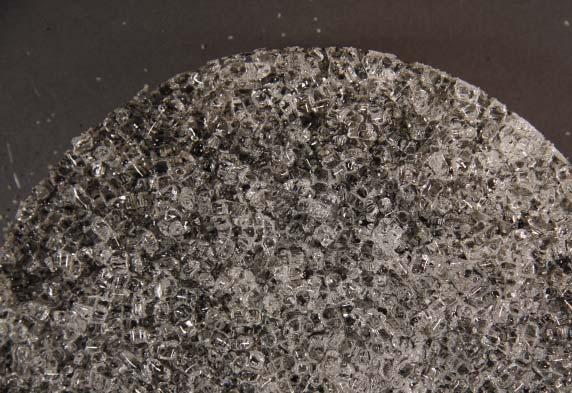

GRAIN TYPE: granite ballast

GRAIN SIZE: 0.5 to 1.0 mm

MODELLING PROCESS

In order to establish the basic ratios of the air source in relationship to the possible scale of the dune, a basic test is carried out. A pile with a diameter a little bit smaller than that of the air source is placed on a flat board. The wind source is placed at a fixed distance from the pile and switched to the lowest possible speed. This test is carried out three times in order to verify the results.

OBSERVATIONS

The piles take on the typical dune formation in all three tests. The windward slope has a relatively low angle the slip face remains the angle of repose. A crest forms and the dune takes on a triangular shape with the two horns progressing quicker in the windward direction. At 28 seconds, this morphology is fully discernible afterwards it remains the same, yet erodes very fast. Only in one of the tests does the artificial dune reach a stable state under continuing airflow.

78

52 FIGURE 53 28sec00sec02sec 12sec14sec 24sec26sec 36sec38sec

AGGREGATIONS 06 DESIGN DEVELOPMENT

FIGURE

48sec50sec

FIGURE52

SINGLE PILE UNDER AN AIRSTREAM

This time lapse image at 28 seconds shows the pile having completely transformed into a morphology resembling a dune. The windward face is low the slip-face is steep, showing two downwind horns. A ridge on the windward face is forming, indicating that the airstream has been unidirectional. The time lapse photo also allows to see the air movement around the formation by tracing the particles in motion.

FIGURE53

SEQUENCE OF FORMATION OF A SINGLE PILE UNDER AN AIRSTREAM

The time lapse photography allows to study the entire development of the pile under an airstream. A clear morphology resembling that of a dune is discernible after 32 seconds. After that point, the formation only erodes, but the basic morphology remains the same.

79 AGGREGATIONS 06 DESIGN DEVELOPMENT 04sec06sec10sec 08sec 16sec18sec22sec 20sec 28sec30sec34sec 32sec 40sec42sec46sec 44sec 52sec54sec58sec 56sec

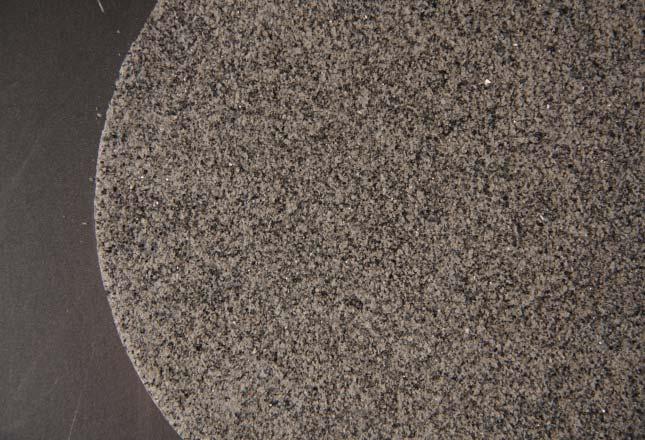

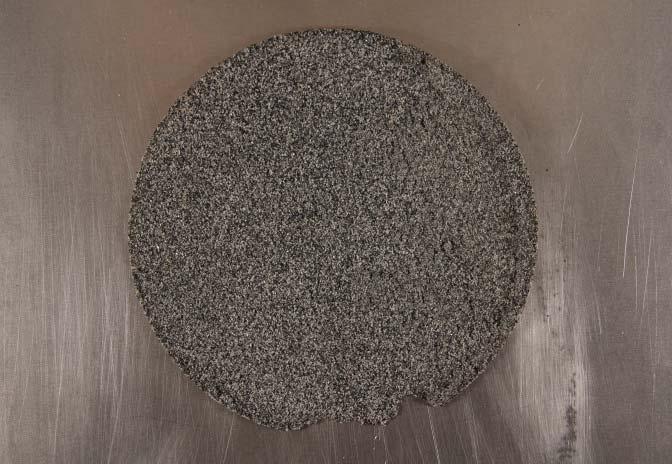

06.04MODULATION02-SEVENPILES01

EXPERIMENTAL SPECIFICATIONS

DIAMETER AIRSTREAM: 5.0 cm

DIAMETER SAND-PILES: 4.0 cm

AMOUNT SAND PILES: 7

DISTANCE AIR-SOURCE/SAND-PILE CENTRE: 36.0 cm

AIRSTREAM SPEED: 21 km/h

AIRSTREAM DIRECTION: 0 degrees

GRAIN TYPE: granite ballast

GRAIN SIZE: 0.5 to 1.0 mm

MODELLING PROCESS

Seven piles, 4.0 cm diameter each are built up in a regular pattern on a flat smooth surface. They are exposed to an airstream of 21 km/h at zero degrees. Records of their development are taken second by second.

OBSERVATIONS

The piles as a group take on the typical dune formation even though they are slightly wider than the impacting airstream. The windward slopes develop relatively low angles and the slip faces remain at the angle of repose. Crests form and the model dunes take on a triangular shape with the two horns becoming transitory ridges between them. At 14 seconds, this morphology is fully discernible afterwards it remains the same, yet erodes very fast.

80 FIGURE 54 FIGURE 55 12sec00sec01sec 06sec07sec 12sec13sec 18sec19sec

AGGREGATIONS 06 DESIGN DEVELOPMENT

24sec25sec

FIGURE54

SEVEN PILES UNDER AN AIRSTREAM

This time lapse image at 12 seconds shows the group of piles having completely transformed into a morphology resembling a dune. The windward faces are low the slip-face is steep. The downwind horns typical of single dunes now become transitional ridges between piles. A ridge on the windward face is forming on each pile, indicating that the airstream has been unidirectional. The time lapse photo also allows to see the air movement around the formation by tracing the particles in motion as they hop over the crests.

FIGURE55

SEQUENCE OF FORMATION OF SEVEN PILES UNDER AN AIRSTREAM

The time lapse photography allows to study the entire development of the piles under an airstream. A clear morphology resembling that of a dune is discernible after 14 seconds. After that point, the formation only erodes, but the basic morphology remains the same.

81 02sec03sec05sec 04sec 08sec09sec11sec 10sec 14sec15sec17sec

20sec21sec23sec

26sec27sec29sec

AGGREGATIONS 06 DESIGN DEVELOPMENT

16sec

22sec

28sec

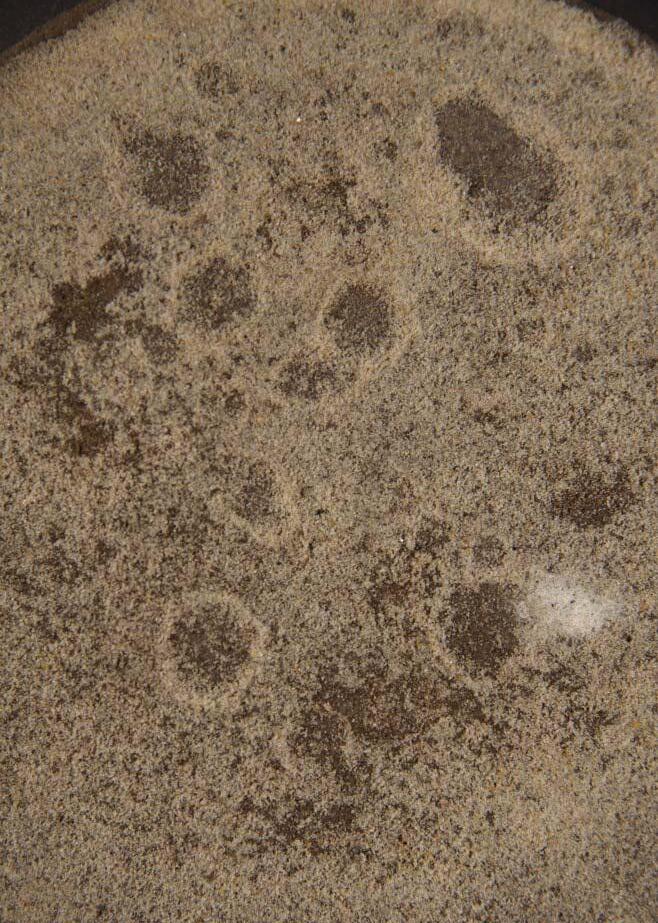

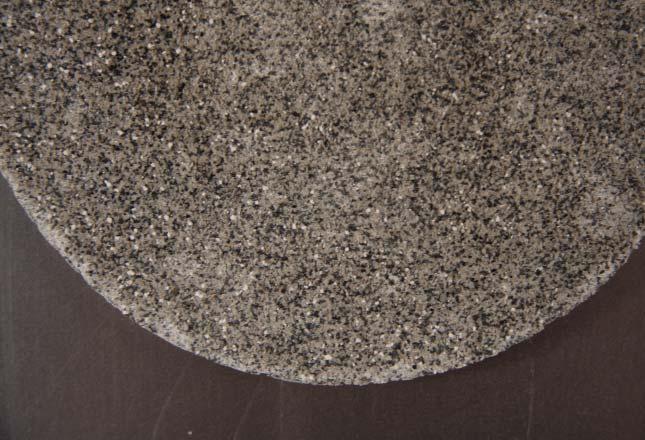

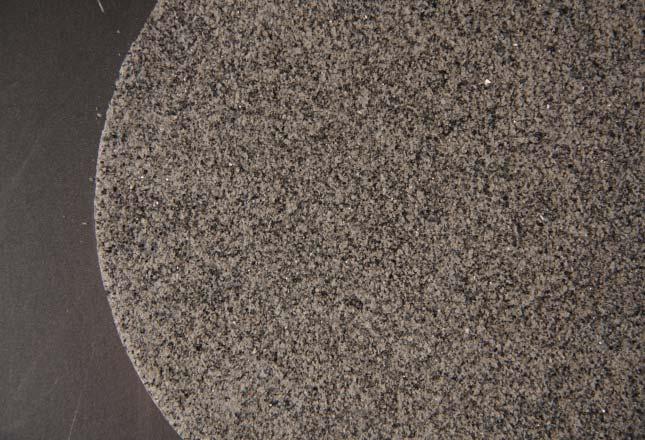

06.04MODULATION03-SEVENPILES02

EXPERIMENTAL SPECIFICATIONS

DIAMETER AIRSTREAM: 5.0 cm

DIAMETER SAND-PILES: 4.0 cm

AMOUNT SAND PILES: 7

DISTANCE AIR-SOURCE/SAND-PILE CENTRE: 36.0 cm

AIRSTREAM SPEED: 21 km/h

AIRSTREAM DIRECTION: 0 degrees

GRAIN TYPE 01: granite ballast

GRAIN SIZE 01: 0.5 to 1.0 mm

GRAIN TYPE 02: silver sand

GRAIN SIZE 02: 0.3 to 0.8 mm

MODELLING PROCESS

Seven piles, 4.0 cm diameter each are built up in a regular pattern on a flat smooth surface. They are exposed to an airstream of 21 km/h at zero degrees. Records of their development are taken second by second. The field is subsequently covered in a lighter sand for easier distinction. The field is again exposed to an air-flow until the windward sides are exposed.

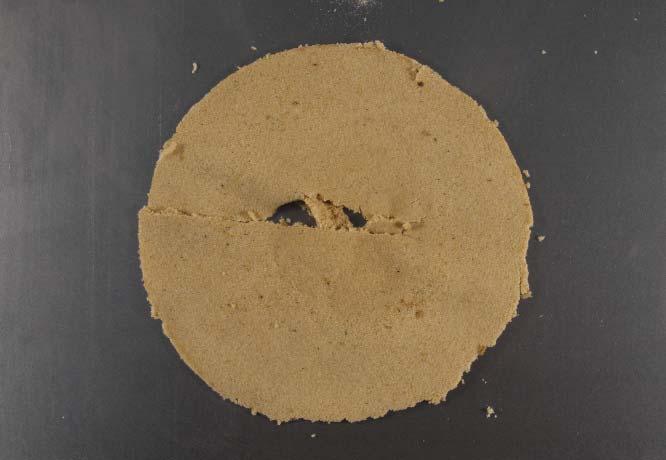

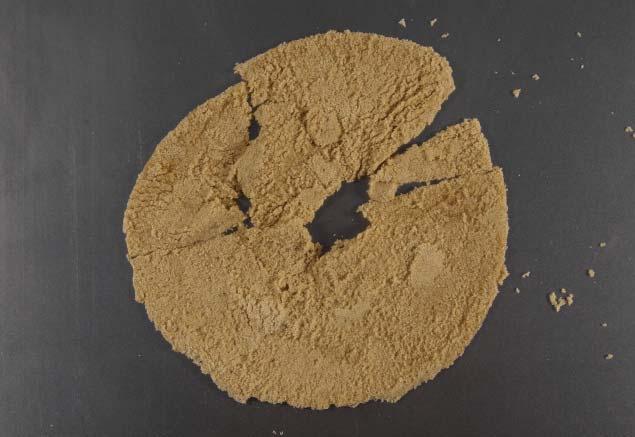

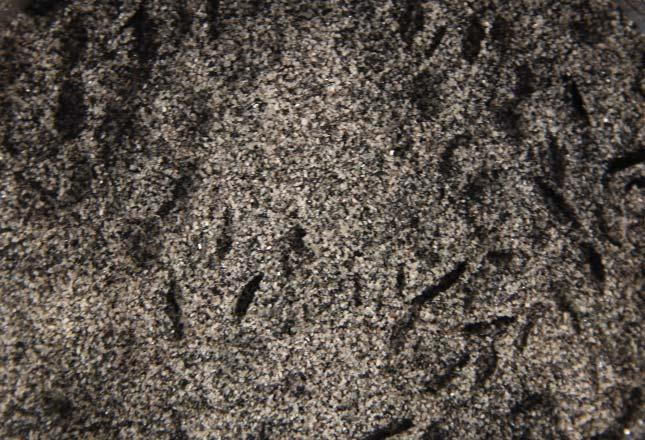

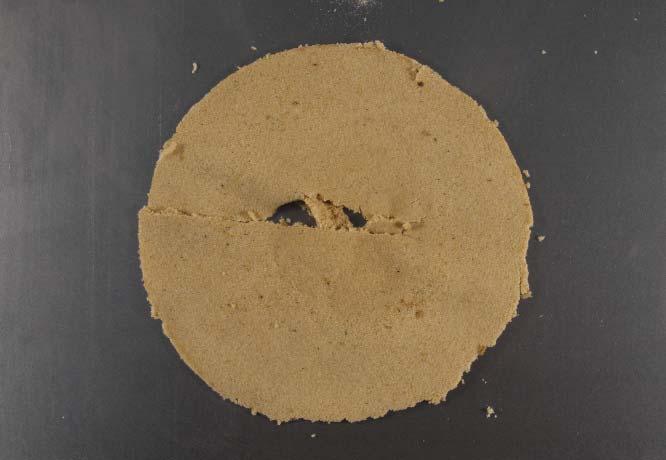

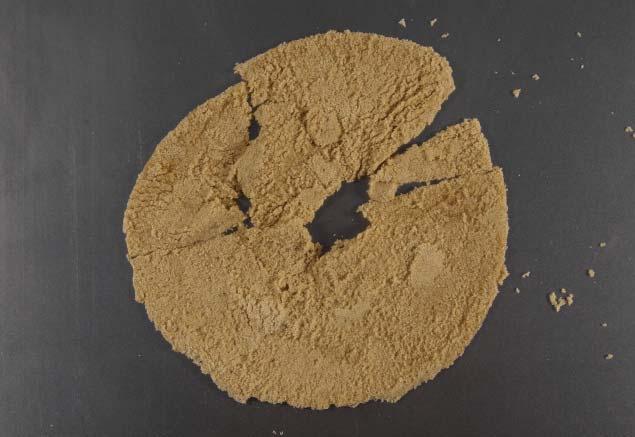

OBSERVATIONS

The piles as a group take on the typical dune formation even though they are slightly wider than the impacting airstream. The windward slopes develop relatively low angles and the slip faces remain at the angle of repose. Crests form and the model dunes take on a triangular shape with the two horns becoming transitory ridges between them. At 14 seconds, this morphology is fully discernible afterwards it remains the same, yet erodes very fast. The lighter sand is carried off the wind-ward slopes relatively quickly. It remains stable on the lee-sides and a clear pattern forms. From the one by one study of the time lapse analysis it can be seen, that sand in the back field is eroding from top to bottom as the tips are exposed first and grains gradually are taken off until the foot of the model dune is reached. In the front field, this process is inverted and erosion takes place from bottom to top.

82 AGGREGATIONS 06 DESIGN DEVELOPMENT 29sec00sec01sec 06sec07sec 12sec13sec 18sec19sec 24sec25sec

FIGURE 56

FIGURE 57

FIGURE56 WIND DISTRIBUTION IN A MODULATED SAND FIELD