Jheny Nieto Ropero

Architectural Association School of Architecture

Emergent Technologies and Design Master/ Feb 2010

Tutors: Michael Weinstock, George Jerodimus and Toni Konik

London, UK

jhenyni@googlemail.com

Jheny Nieto Ropero

Architectural Association School of Architecture

Emergent Technologies and Design Master/ Feb 2010

Tutors: Michael Weinstock, George Jerodimus and Toni Konik

London, UK

jhenyni@googlemail.com

I thank my tutor Michael Weinstock for helping me in structuring my thousands ideas and for his wise advise on the way of this project.

I am deeply grateful to George Jerodimus who have reinforced this research and my own knowledge with his great dedication and involucration in the project.

I own a big thank to my friends and family for constantly supporting my work all the time.

Finally, I am thankful to Emtech as it has opened my mind in discovering parallel interests to architecture that I know one day will become real constructions.

Jheny Nieto Ropero Architectural Association School of Architecture Emergent Design and Technologies Master London, UK jhenyni@googlemail.com

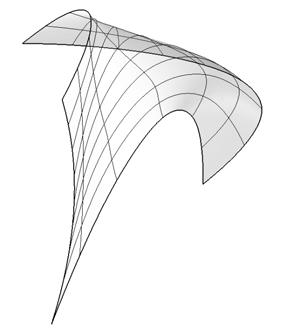

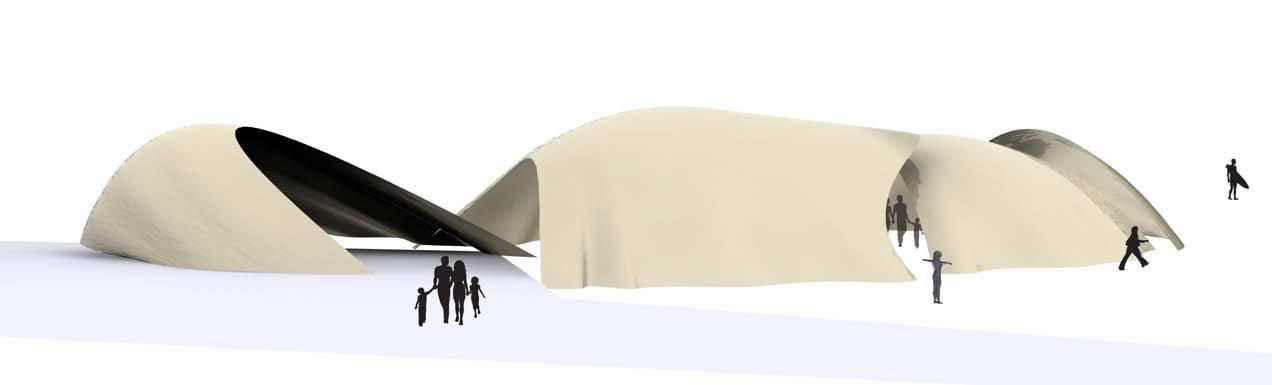

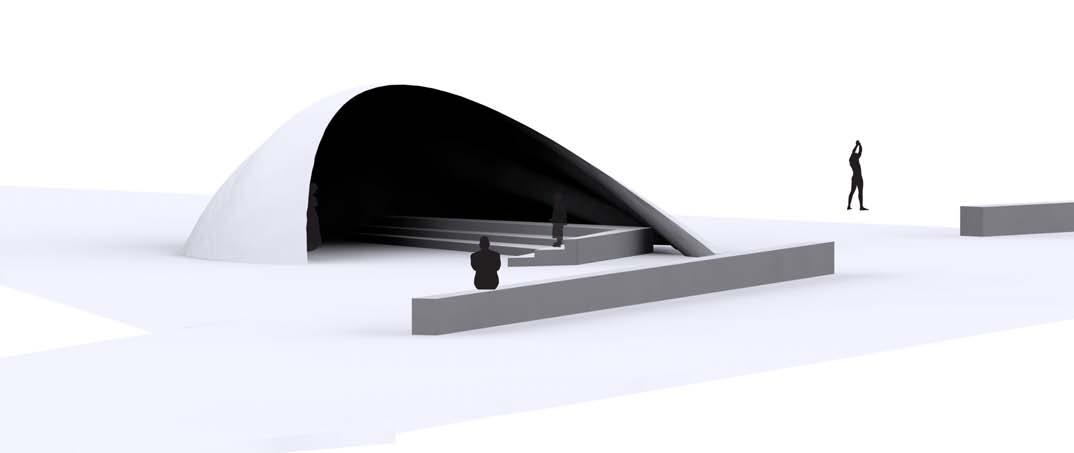

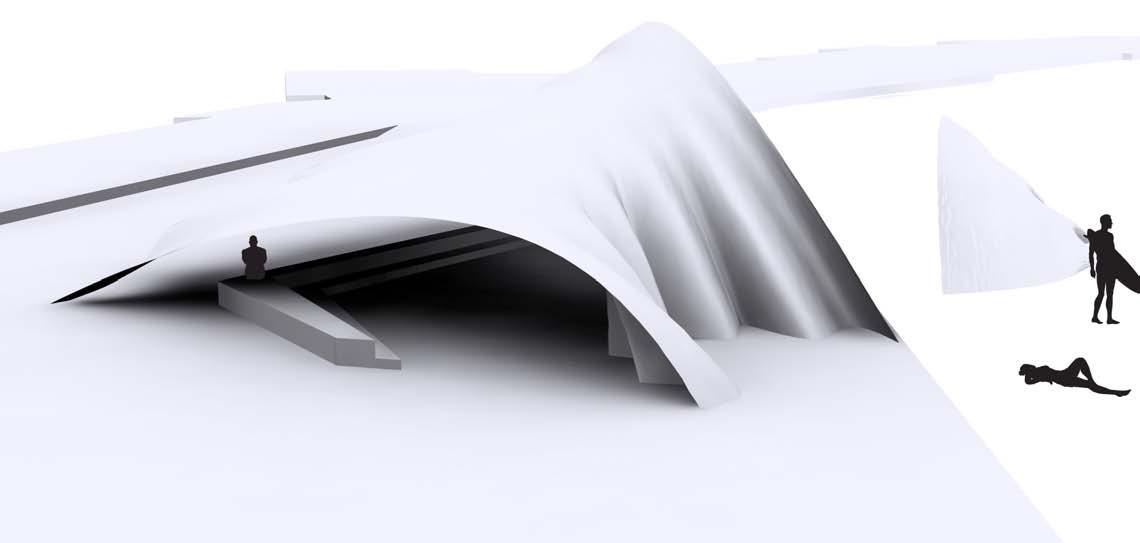

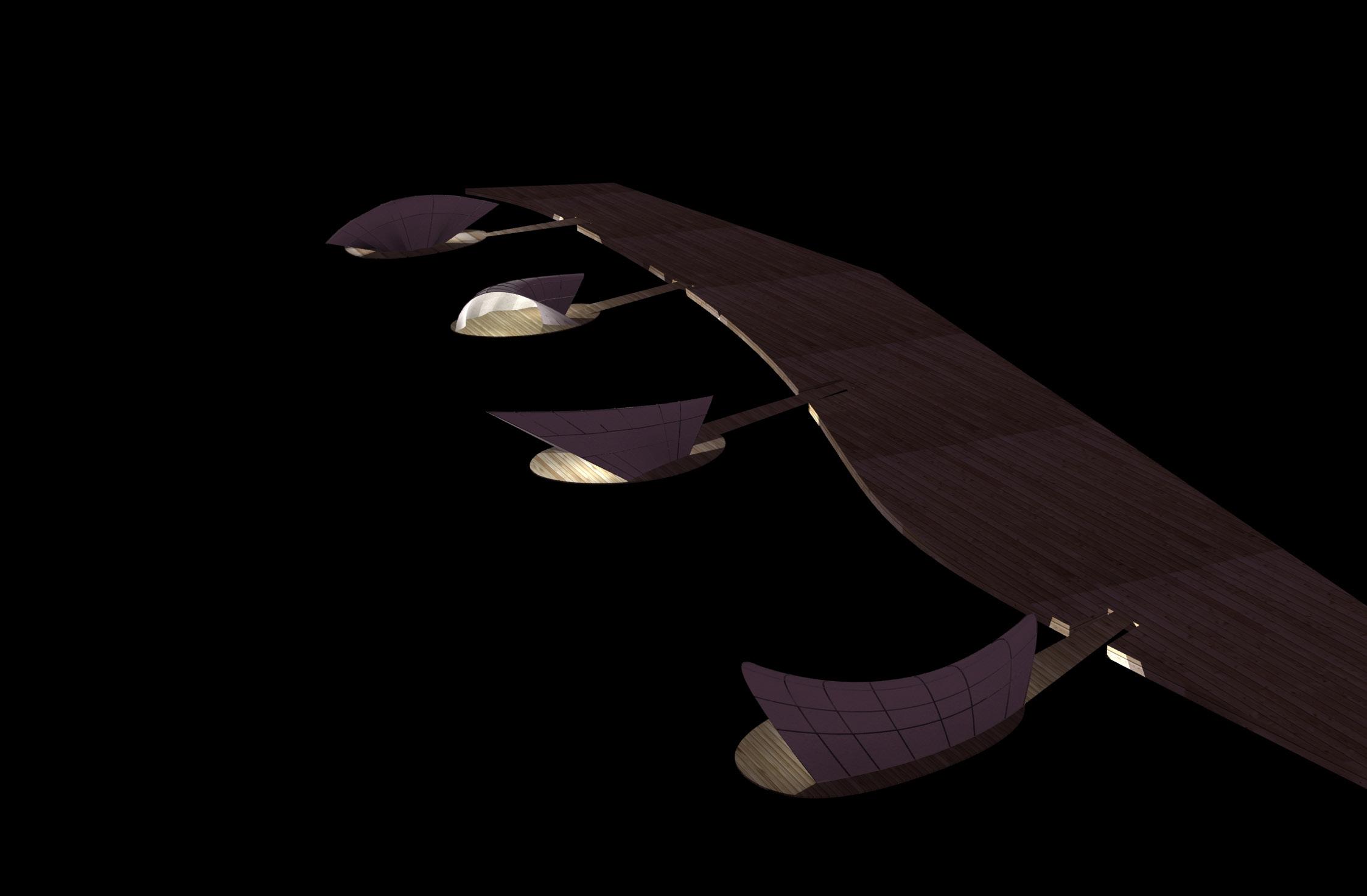

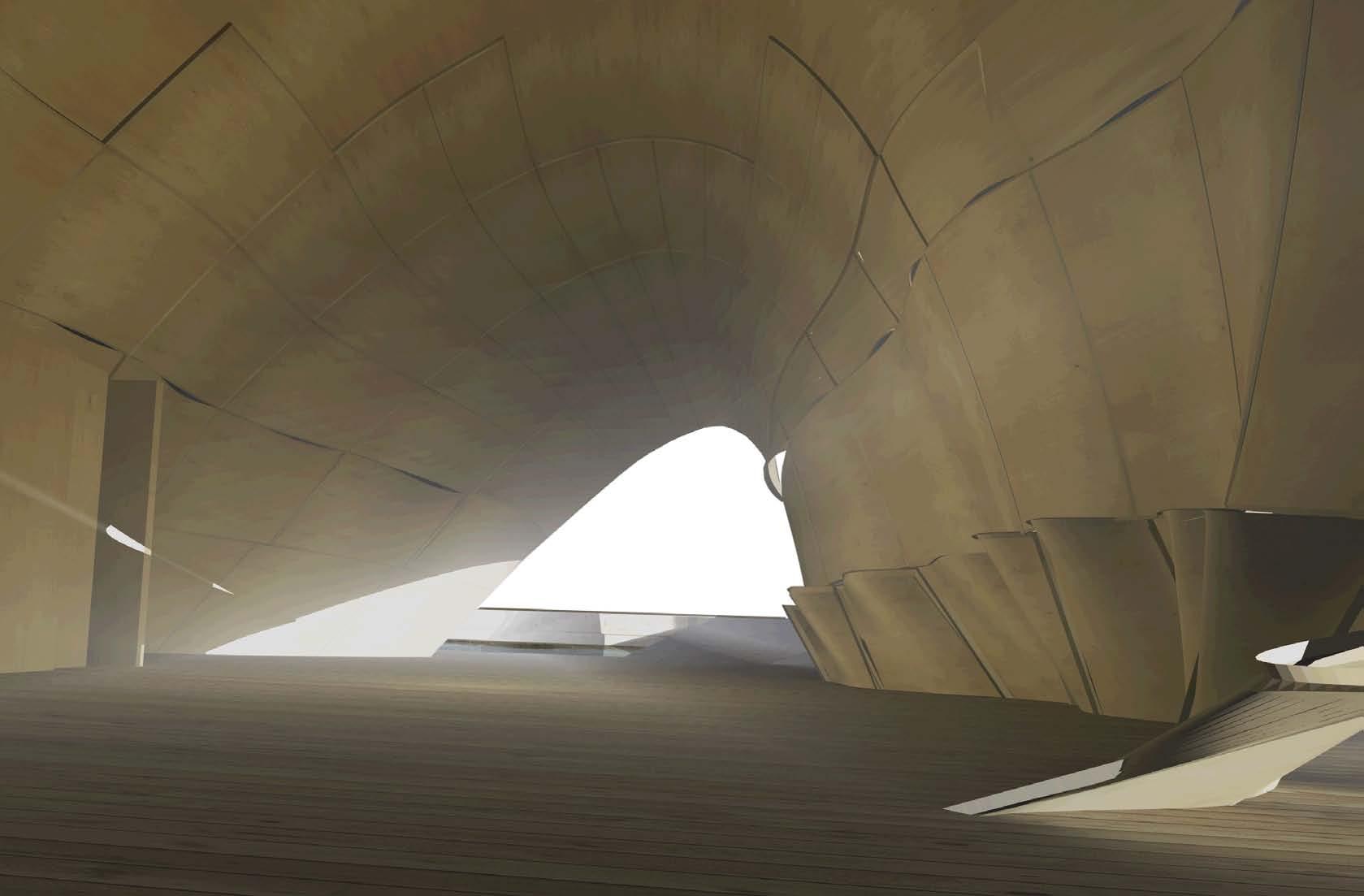

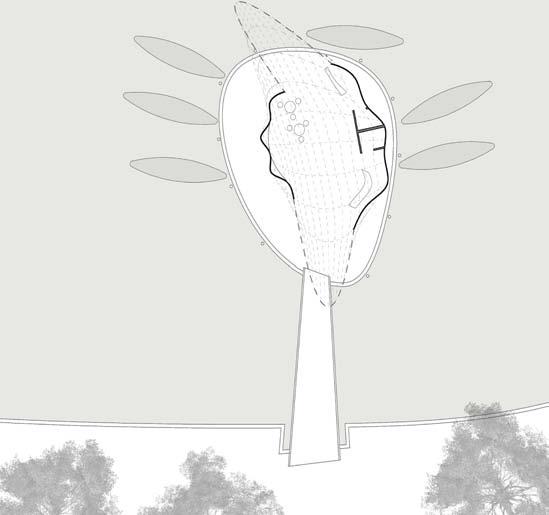

In this project, the aim is the experimentation and further development of a new composite material made out of plywood, fiber glass and resin. It proposes a fabrication logic to design large continuous double skin, self structural and performative surfaces.

The project introduces a step forward in the manipulation of plywood panels, pre-stressing them in a form finding process to achieve curvatures; thus, developing large structures. Through a reinforcing construction process necessity of big mandrels is avoided. Digital simulations and physical experiments were implemented in the research in order to achieve real possible geometries, to reduce weight and to simplify the structure.

The project gets the interest of producing one continuous surface based on the material behavior just as Dieste explored deeply in his research where he recognized that the surface offered a realm formal exploration that in turn, could solve structural problems.

The surface is the result of environmental, structural and architectural necessities. Its efficiency responds to the optimization process. Therefore form and expression, fabrication and structural efficiency led the development of a new language of building. The optimization process determines the final shape. The shells are the material with certain thickness, but the shape is still more fundamental as it contains the space and the quality of itself.

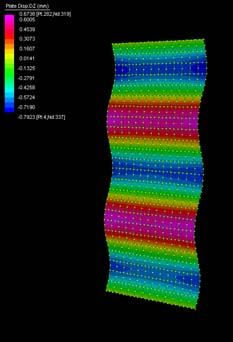

1.5

2.4

2.5

2.6

3.1.

3.2.1

LOAD CAPACITY IN INDIVIDUAL STRIPS pag 52

3.2.2 EVALUATION OF TORSION pag 56

3.2.3 LINEAR BUCKLING ANALYSIS COMPARISON ONE THE STRIP WITH DIFFERENT MATERIALS pag 60

3.3.1 PHYSICAL BUCKLING MODES IN A SHEET OF PLYWOOD pag 62

3.3.2 DIGITAL BUCKLING MODES IN A SHEET OF PLYWOOD pag 64

3.4.1. DIGITAL SIMULATIONS OF STITICHING BUCKLING AND BENDING PLYWOOD. pag 68

3.4.2. PHYSICAL SIMULATIONS OF STITCHING BUCKLING AND BENDING PLYWOODREINFORCING PROCES S pag 70

3.5.1. DEVELOPABLE SURFACES pag 72

3.5.2. DEVELOPABLE SURFACES pag 73

3.6.1. PHYSICAL BENDING OF PLYWOOD pag 74

3.6.2. SIMULATION OF A RESTRICTED SURFACE pag 76

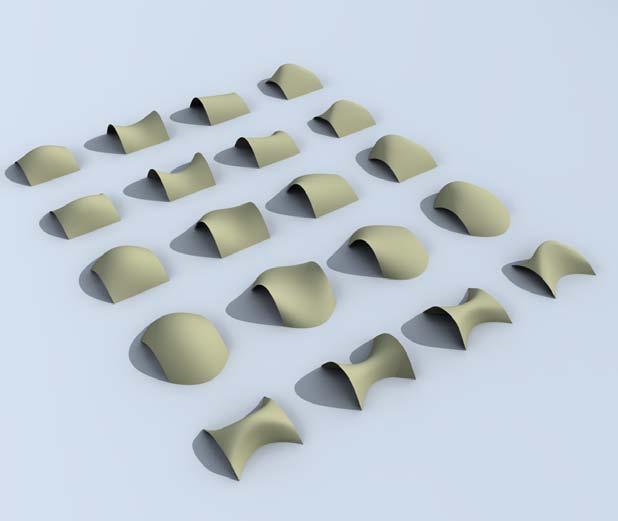

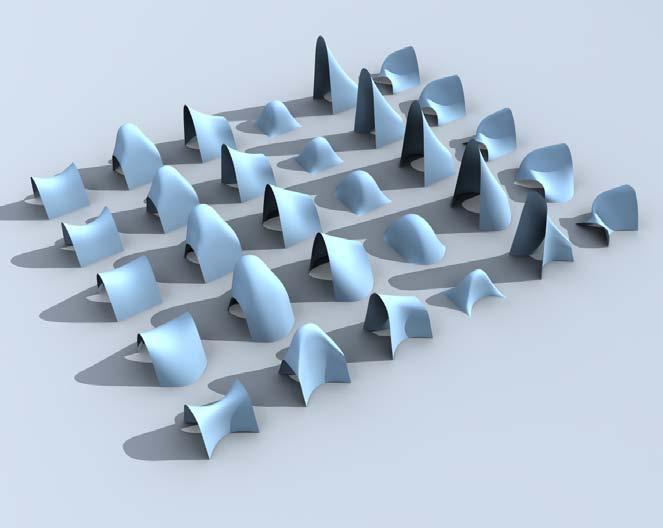

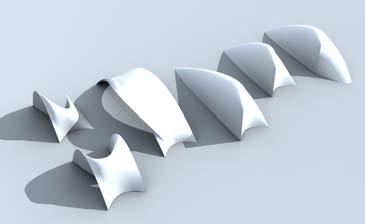

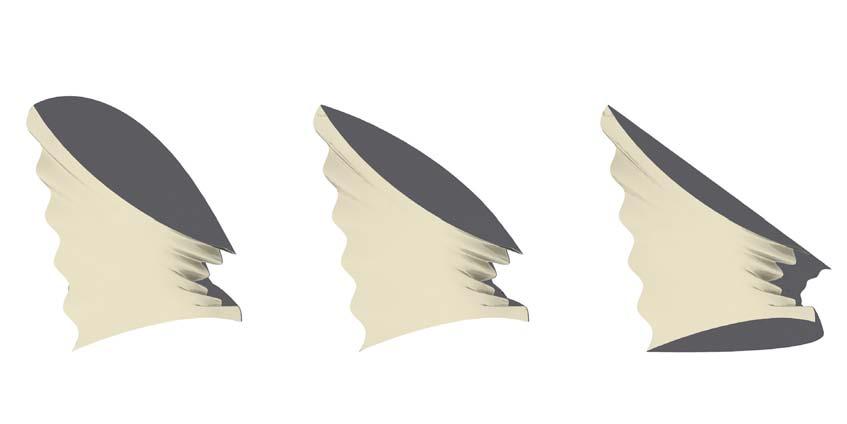

3.7. SET TING THE LOGIC FOR MY THEORETHICAL SHELLS IN TIMBER COMPOSITES pag 78

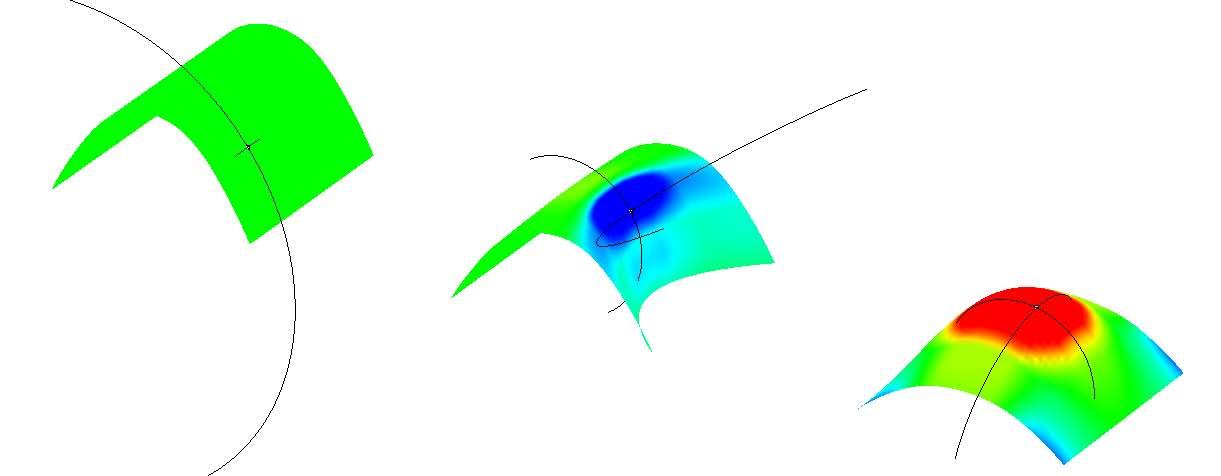

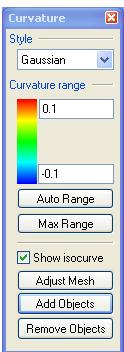

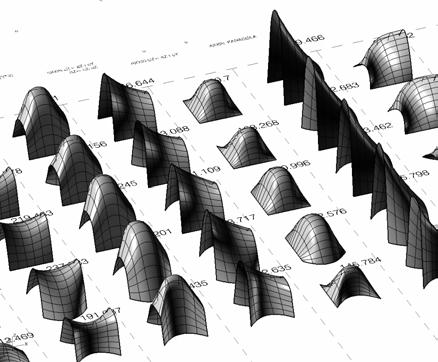

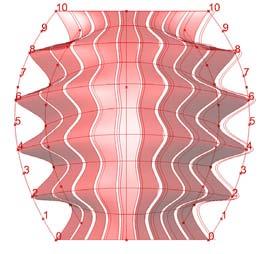

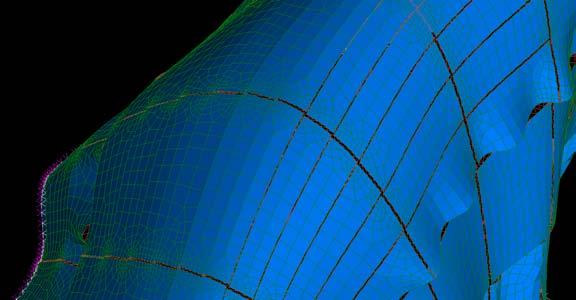

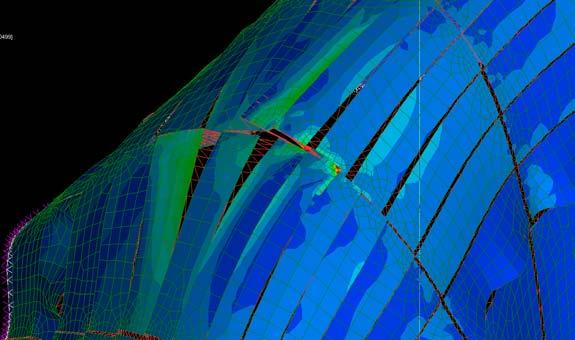

3.8. CURVATURE ANALYSIS pag 80

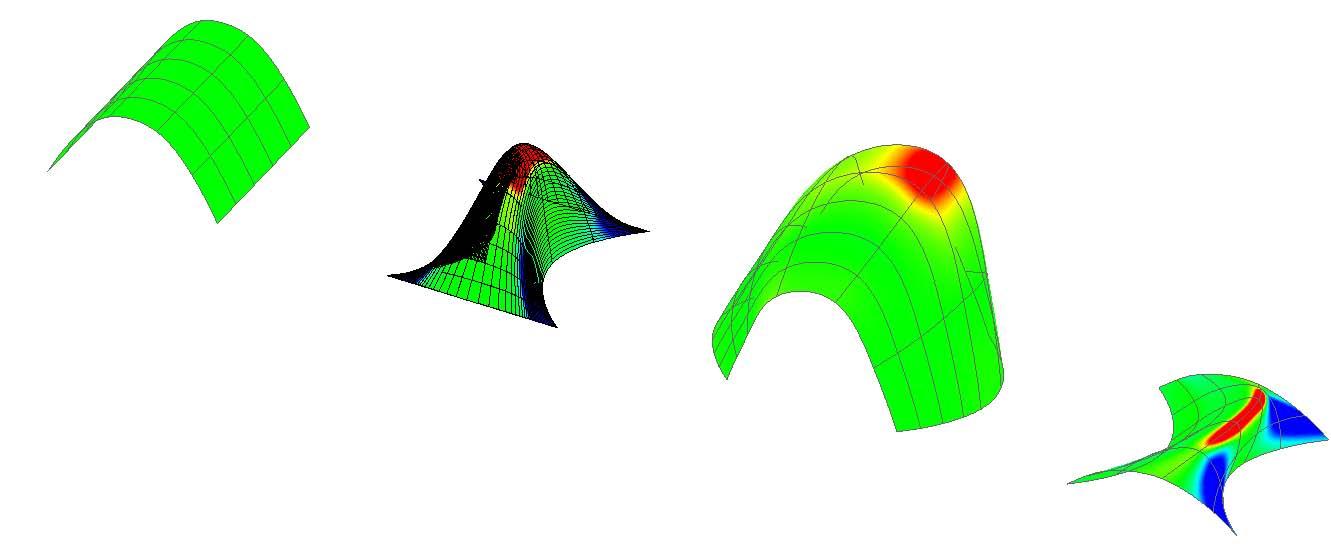

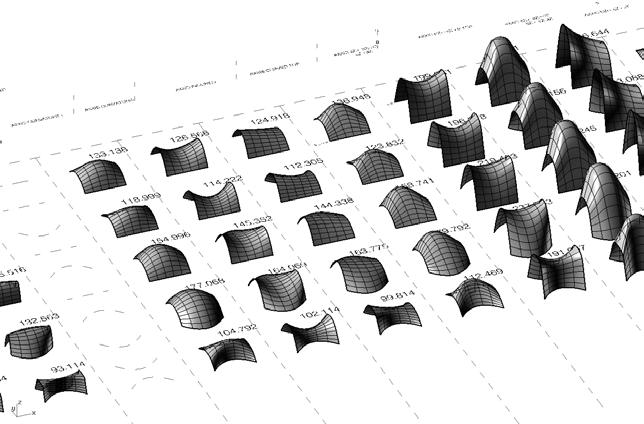

3.9. PANELIZATION pag 82

3.10. EVALUATION AND RANKING pag 86

CHAPTER

4.1 FABRICATION

4.2

4.3.1

4.3.2

4.4

5.1

5.2

CHAPTER ONE - MATERIAL PROPERTIES AND MANUFACTURING TECHNIQUES

Ancient composites, such as straw reinforced clay; structures of wood, hide bone sinew and horn, have been used and implemented according to necessity. The combination of different materials usually improves quality and the disadvantages of the individual disappear.

Composites combine high stiffness and strength with low density, their composition allows new designs such as the shape of the wings of airplanes with regard to air speed. Their capacity to display complex shapes sounds attractive for different fields like aerospace, the sports industry and civil engineers and designers, and in the past years in architecture.

The idea of turbo-fan engines, where flying faster is linked to flight at higher altitudes due to the low air density (lower friction) and where the resistance to moving mass could decrease, was one of the first reasons to implement fiber reinforced polymers. The transport systems started looking into reducing the resistance per unit weight as it changes according to the friction in water or air. The history of the aircraft is important in demonstrating the improvements in shape and material. Jack Northrop created in the late 40’s the flying wing, which blends the fuselage and the wing approaching an enclosed cross-section, which reduces fuel consumption, take off-weight, empty weight propulsion, and increases the aerodynamic efficiency.

The end properties of a composite part produced from these different materials is not only a function of the individual properties of the resin matrix and fiber (and in sandwich structures, the core as well), but is also a function of the way in which the materials themselves are designed into the part and also the way in which they are processed.

Geometries in architecture have been evolving parallel to the materials. For instance, shells have been explored in thin concrete skins as well as in glass reinforced polymers resulting in different space qualities and fabrication constraints. Grid shells have passed from steel beams to bamboo structures and tensile and membrane structures have passed from temporary to permanent.

The textile industry has explored in-depth the different fibers and different patterns while composite engineers have just started to explore these ideas. Typically, with a common hand lay-up process as widely used in the boat-building industry, a limit for Fiber Volume Fraction is approximately 30-40%. With the higher quality, more sophistication and precise processes used in the aerospace industry, Fiber Volume Fractions approaching 70% can be successfully obtained.

Architecture is a field that broadly has influenced societies and countries in several aspects, from art to economy. Evolving architecture means evolving other disciplines and vice versa and since primitive constructions in adobe or straw, man has been looking into techniques to build their own habitats. In this sense new materials have evolved demonstrating the intelligence in obtaining certain performance or requirements. Science keeps looking for “smart materials” that can offer multi-functionality at all scales.

The aim of this first chapter is to understand the properties of timber and fiber composites and their existent manufactured forms, which will be used in the timber composite as the proposal material.

The elasticity of fiber-glass allows the wood to be more elastic, increasing the yield stress of the final material. The composite allows a greater structural capacity, while leaving a thin material, in addition to the fact that the matrix (fiber glass) allows the adherence between plywood and resin.

The chemical and anatomical properties of wood define its technical qualities. This is the most anisotropy material, which means its characteristics depend on directionality. Along the grain, wood has one hundred times greater tensile strength and four times greater compressive strength than at the right angles to the grain. Its load capacities are higher than concrete structures, having the advantage of low dead weight. For example, wood’s strength and hardness will be different for the same sample if measured in different orientation. Cellulose, which is a high molecular weight polysaccharide, is the main constituent of wood and is directly responsible for stiffness and strength. Lignin is a heavily cross-linked phenolic resin which is very brittle. Wood is stronger in tension than in compression and has a breaking stress of about 100 to 140 MPa. “The compressive strength of wood is about a third of its tensile strength. The difference is attributed to local buckling of the cell walls under compression followed by a macroscopic crease” (Dinwoodie, J. M. 2000).

1.3 CURVED TIMBER SURFACES

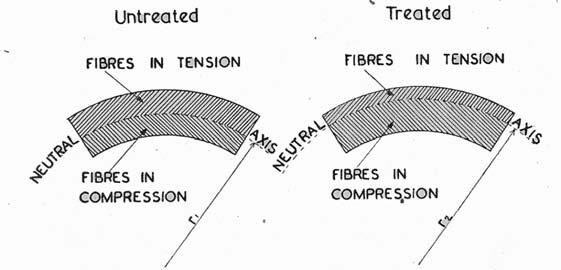

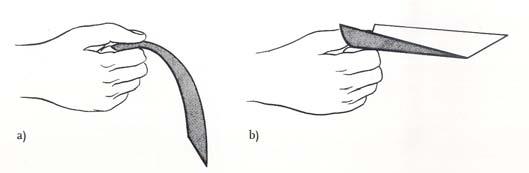

In the bending of wood or other elastic materials it is usual to assume that transverse plane sections remain plane and normal to the longitudinal fiber. The end sections initially square with the faces of the piece remain square during the process of bending. In the bent state, the lengths of the convex and concave faces are no longer equal, as they were when originally cut. The difference in these lengths on the concave faces to shorten, and induced tensile stresses causing fibers on the convex face to stretch. (fig. 1.3.1)

fig. 1.3.1

Common timbers cannot be bent in their natural state to small curvatures without fracturing, or retaining its elastic properties to cause them to spring back to approximate their original shape on removal of bending forces. However, some timbers when are subjected to heat in the presence of moisture, such as steaming or boiling, become semi-plastic. Therefore its compressibility is increased and comparatively small compressive stresses are capable of producing a very appreciable strain without fracturing the material.

Bending has a long history that goes from small devices made out of wood through proper steel machines that bend several pieces at the same time. The methods have improved along with the machines.

Solid bending requires soft treatments such as steaming, which, in order to render plasticity, and compression, provides heat and moisture. Studies have proven that if wood contains 25-30 percent moisture it is suitable to bend. The method most commonly used to obtain this condition is to subject the timber to saturated steam at atmospheric pressure in a steam chest. Other methods such as immersing the wood in heated wet sand or heating the appropriate portions in a naked gas flame shape the wood into the desired curvature without the application of moisture. What is remarkable is that the fibers from the compressed side of a bent piece show compression failures, shrinkage and expansions in the longitudinal direction (fig. 1.3.1).

Hand bending can be applied to some devices, but the bending will be performed manually. Cold bending refers to bending in untreated timber, in its natural or dried states such as in the curved planking of boats, which sometimes are cold, bent and secured to the ribs. Hot bending will vary the radius of curvatures according to the type of wood, but in general will be use for bends of smaller radius. For making steamed but unsupported material some of the following methods can be utilized: a. Clamp the piece to the suitable curve. b. Force the piece to a prepared wooden or metal curved and sequentially clamps it into to the right position (figure 1.3.3). Wood is very prone to fracture when subjected to tensile stress.

S/R = 0.02 Cold bending

S/R = 0.08 Hot bending

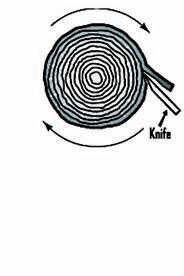

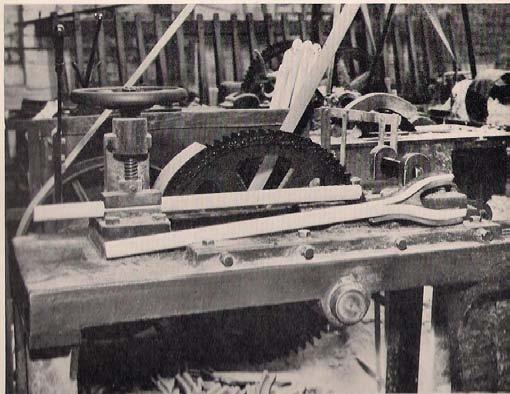

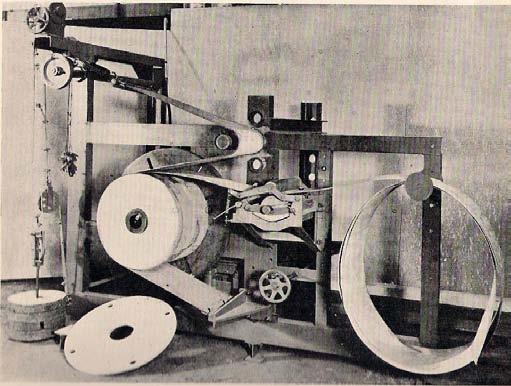

fig. 1.3.5 Spade handle bending machine

fig. 1.3.6 Bending machine for making split type spade handles

fig. 1.3.7 Lever arm bending machine operated by a rack and pinion mechanism

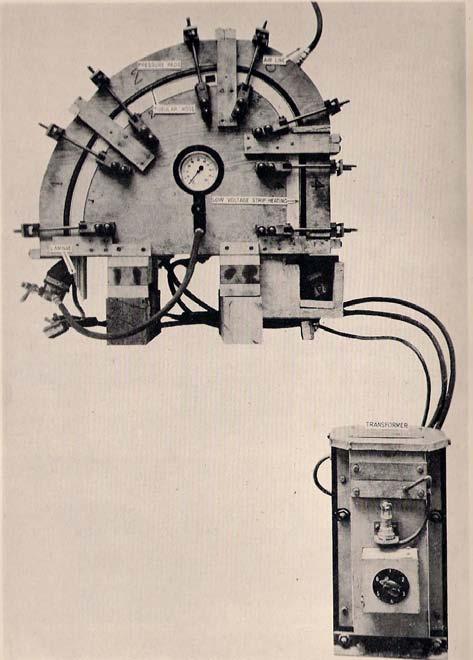

fig. 1.3.8 Air-inflated tubular hose and low voltage strip-heating used in the production of laminated bends

fig. 1.3.9 Pressure moulding bag

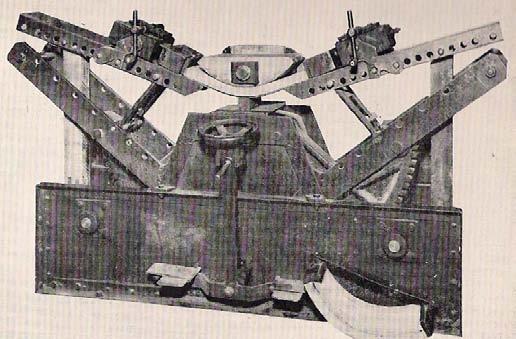

fig. 1.3.10 Hydraulic press and steam heated cauls

fig. 1.3.11 Laminated bending by the autoclave process (rubber bag re moved)

fig. 1.3.12 A commercial machine employed for production of laminated bends by the continuous strip method

The evolution of machines for bending is marvelous and of course its capacities to bend several pieces at the same time, plus the possibility to apply greater forces (fig. 1.3.8).

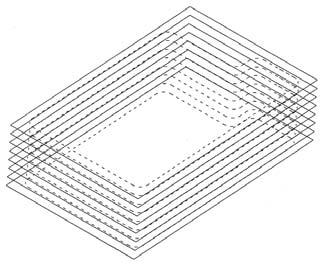

Laminated bending was introduced in timbers as pieces could be bent by cold or hot systems; however they will tend to resume their original shape upon removal of the bending forces. To avoid this, the pieces need to be secured to a rigid framework or secured to one another in a concentric manner that wouldn’t allow them to move. Laminate should be dried to a moisture content of less than 20 percent before they can be considered in a stage fit for gluing. They may be in the form of sawed, sliced or rotary cut veneers or plywood.

The following new methods were introduced to press and laminate: the metal tension band, the fluid pressure, the flexible rubber hose and metal strap, the inflated rubber bag and female mold, the deflated rubber bag. These methods are outdated and require a mold to shape the timber into a specific curvature and thickness.

Engineered timbers are composite constructions of wood and high strength adhesive. Wood particles, strands or veneers are locked into a laminated structure, which is dimensionally stable and durable. These materials are used in a variety of combinations to produce lightweight structures, engineered to precise requirements.

Some theoretical considerations suggest engineering timbers utilize the high strength and stability of laminated wood. The visual and mechanical properties are affected by the type of wood, adhesive and method of production. Laminated strand lumber (LSL), oriented strand board (OSB), medium density fiberboard (MDF), plywood and I-beams. It is possible to produce flame retardant and water resistant grades.

The basic element for composite wood products may be the fiber, as it is in paper, but it can also be larger wood particles composed of many fibers and varying in size and geometry. Properties of such material can be changed by combining, reorganizing, or stratifying these

elements.

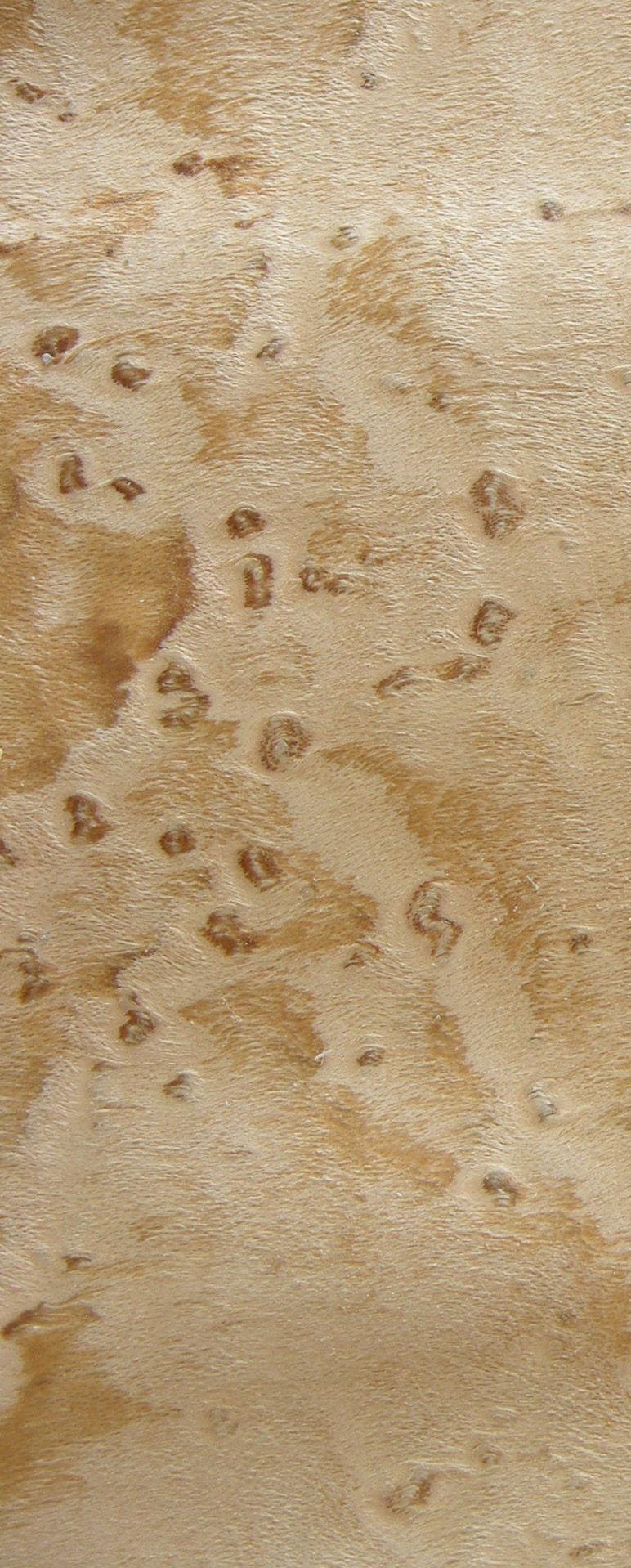

Plywood was invented in the 1850s as a combination of three or more layers of wood. Cheap and easily accessible, it has been an important medium for experimentation by modernist designers from the 1920s onward.

Many important examples of modernist furniture were made of plywood. Cheaper and more easily accessible than aluminium or steel, plywood was a key material for early 20th century designers such as Gerrit Rietveld, Marcel Breuer and Alvar Aalto, as well as midcentury modernists like Charles and Ray Eames, and contemporary figures including Jasper Morrison.

Plywood consists of at least three layers or veneers of wood which have been plied together with the grain running crosswise to add strength and resilience. The earliest examples of plywood furniture date back to the 18th century, but it was not until the 1850s that it was put into commercial production by John Henry Belter, a German émigré to the US. Furniture progressed as new fabrication techniques evolved. The case studies in the second chapter will show some of this evolution at both small and large scales.

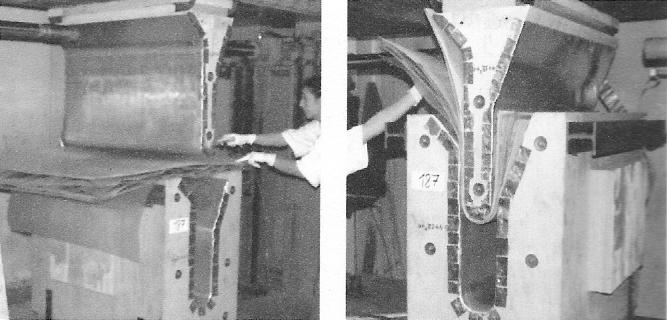

After the machines already had the control of the bending one of the bigger tasks was to pass from small scale to large scale . The timber has been used as molds for different materials, from traditional concrete structures that require it to frame the liquid to mold structures for airplanes.

“The Havilland Mosquito was a lightweight, fast British combat aircraft made mainly of wood using advanced construction methods. The fundamental considerations in the design was that the aircraft be as clean and aerodynamic as possible, that it get into the production phase as short a period of time as possible and that it be capable of being produced by as many firms as needed to meet mission requirements.”.

Crew: 2

Length: 44 ft 6 in

Wingspan: 54 ft 2 in

Height: 17 ft 5 in

Wing area: 454 ft²

Empty weight: 14,300 lb

Powerplant: 2× Rolls-Royce Merlin 76/77

Maximum speed: 361 knots

Range: 1,300 nm with weapons load

Pictures on the right correspond to the construction done in 2005 by The Fighter Factory.

fig. 1.3.13 Fuselage shell half construction

fig. 1.3.14 Fuselage shell half construction

fig. 1.3.15 Fuselage shell half construction

fig. 1.3.16 Fuselage with steel bands

fig. 1.3.17 Browning door, fitting catches

fig. 1.3.18 Browning doors Port open

fig. 1.3.19 Fuselage on assembly jig 2

fig. 1.3.20 Joining shell halves

fig. 1.3.21 Rear bulkhead with fittings

fig. 1.3.22 Nose browning doors off KA114

fig. 1.3.23 Port mould fitting interskin members

fig. 1.3.24 Fuse to wing front on 12 07

Source: http://www.fighterfactory.com/restoration/dehavilland-mosquito-aircraft.php

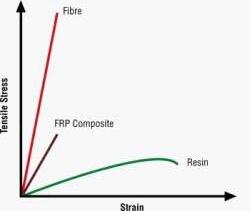

A fiber-reinforced polymer (FRP) composite is a combination of fibers within a matrix of a plastic or resin material. The fibers bring the strength to the composite, the matrix binds the fibers together, transfers the loads between them and the rest of the structure, and protects the fibers from the environment. Fibers are usually: glass (GRP), carbon, aramid (Kevlar or Twaron), and natural fibers.

The matrices are divided in two groups of polymers:

Thermosets are resins cured by heat or chemical reaction (polyesters, vinyl-esters, epoxies, phenolics).

Thermoplastics melt to form highly viscous liquids at elevated temperatures (200C and 300C) but solidify to glassy or crystalline substances as they cool. They can be softened again by reheating polyamides (nylon), thermoplastic polyesters (eg PET) polypropylene.

MANUFACTURING

Well manufactured composites structures display higher stiffness and strength as better resistance to fatigue and environmental degradation, and when big impacts on the structure occur the composite perform with a better energy absorption such as in formula cars. The manner of combining fibers and matrix into a composite material depends on the fiber/resin combination and on the scale and geometry of the structure to be manufactured. There are seven main methods for FRP. This study will present all of them briefly and focus on the molding methods.

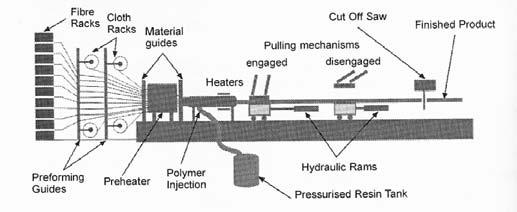

Pultrusion tightly packed tow of fibers, impregnated with catalyzed resin, are pulled through a shaped die to form highly aligned.

Due to the high fiber content and the high degree of fiber alignment resulting from the tensile force used to pull the fiber bundle through the die, extremely good mechanical properties can be obtained

Cylindrical symmetric structures can be made by winding fibers or tapes soaked into with precatalysed resin onto expendable or removable mandrels. After the resin has hardened, the mandrel (mold) is removed and if the size permits, the product may be post-cured at an elevated temperature. Uniformity is definitely one of the advantages of this method.

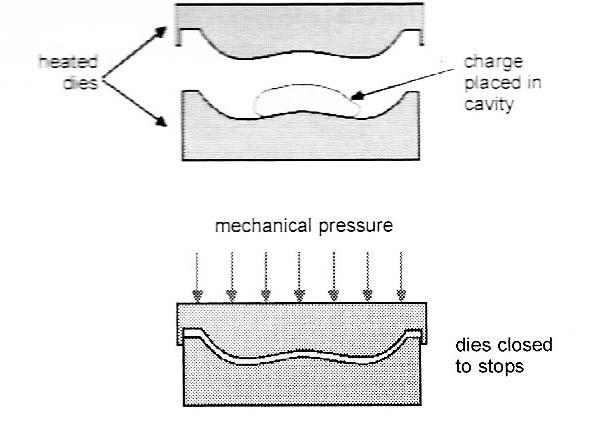

Compression and transfer molding SMC and DMC

If the fibers are short (1 cm or 2cm) a dough-molding compound (DMC) is created, known as bulk molding compound (BMC). When fibers are longer (5cm to 10cm) a pliable sheet molding compound (SMC) is produced. DMCs are produced by blending together the good combinations of resin, chopped fibers, fillers and pigments, and moldings aids in an industrial blender (or mixer) to form a thick doughy paste. These compounds can be fabricated to their final shape by compression molding - squeezing into shape between heated, shaped dies.

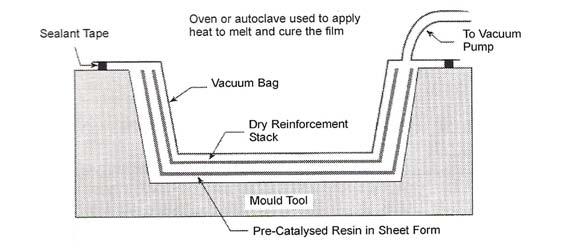

Matched-die molding and autoclaving

Hot-pressing sheets of pre-impregnated fibers or cloth between flat or shaped platens. Or by pressure autoclaving to consolidate a stack of prepreg sheets against a heated, shaped die. Double curvatures can be made by woven reinforcements.

A mold of a section of the fuselage is wrapped with carbon-fiber tape using a robotic tape-laying machine. The tape-wrapped mold is then placed into a large pressurized oven called an autoclave, where the composite is cured through a process of head and pressure. (Over 300C of temperature and pressures over 90psi).

After curing in the autoclave, the fuselage is separated from the fuselage mold. Openings are cut out if necessary.

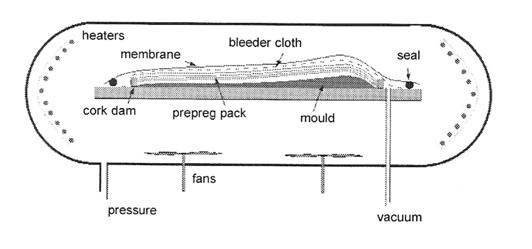

In autoclaves moldings, a single shape surface is used and consolidated and the pre-preg stack is achieved under heat and pressure in a chamber, which can be both evacuated to remove excess air and pressurized to compact the pre-preg and drive out excess resin.

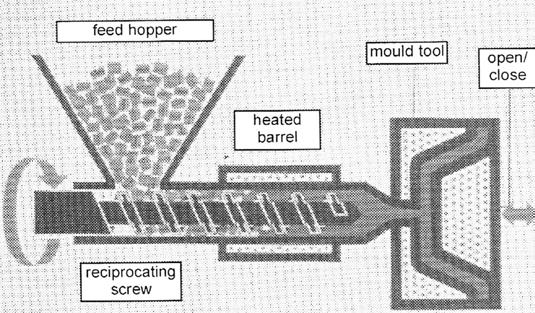

Injection- molding of reinforced thermoplastics

Thermoplastics-based materials such as Nylon, are made by the injection molding of granules of material, in which the chopped fibers and matrix have been pre-compounded. It is often used for repetitive manufacturing and the dyes and presses are very expensive.

Continuous sheet production

Continuous sheet production chopped strand mat or chopped strands are impregnated with resin and sandwiched between two layers of film on a moving belt. The sandwich passes through guides that form the corrugated or other desired profile as it enters a long oven section in which curing takes place.

fig. 1.4.1 Pultrusion method

fig. 1.4.2 Filament Winding

fig. 1.4.3 Compression and transfer molding SMC and DMC

fig. 1.4.4 Matched-die molding and autoclaving

fig. 1.4.5 Autoclaving

fig. 1.4.6 Injection molding of granules of material

fig. 1.4.7 Continuous sheet production

Source. Ann ALderson. 2002. Fibre-reinforced polymer composited in construction. London, CIRIA.

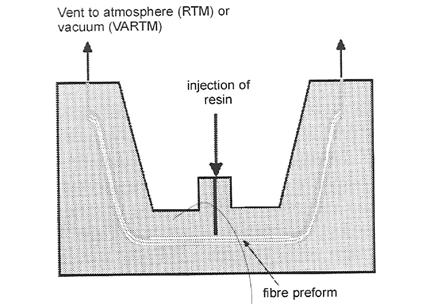

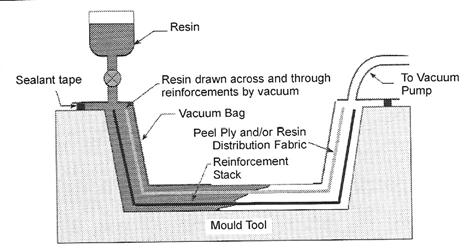

Resin-transfer molding (RTM) and vacuum- assisted resin-transfer molding (VARTM)

RTM is a low-pressure process, the equipment is not as expensive and the dies can be made from metal sheets, electro-formed nickel, cast or machined aluminium alloys, or even GRP. It produces high-quality mouldings of complex shape at much lower cost. Pre-catalysed is pumped under low pressure into a fiber pre-form in a heated space. Thick components containing foamed polymer cores can also be produced this way.

In Resin-infusion a pre-arranged fiber pack is laid against a single-sided shaped die and covered with a flexible sheet. The space is evacuated and atmospheric pressure consolidates the fiber pack, where pre-catalyzed resin is then bled into the fibers to form the desired component.

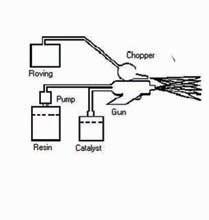

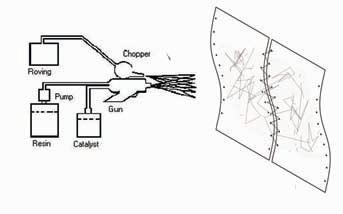

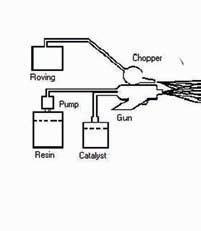

Open-mould processes: contact molding by hand layup or spray-up.

Composites reinforced with chopped-strand mat (CSM) or woven cloth are often laid up by hand methods, especially for irregularly shaped structures. A shaped former is coated with gel-coat and the required shape and thickness are then built up by rolling on layer upon layer of resin-impregnated cloth or mat. After the final flow coat, the structure is cured by the heat. The same process can be alternatively done by spraying short fiber bundles through a gun. The distribution and quality depends on the operators.

3d thermal laminating

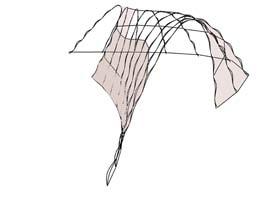

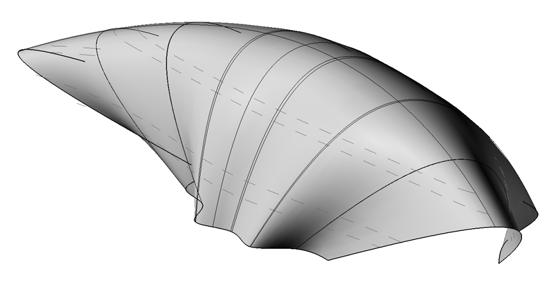

This technology is used to make ultra lightweight, seamless 3D sails. The fiber reinforcement is continuous over the entire surface of the sail, replacing traditional methods of cutting and gluing.

The process combines the benefits of composite laminating with filament winding. The 3D sheet geometries are formed over computer guided molds. The fiber reinforcements are laid down individually along pre-determined lines of stress.

They are sandwiched between thin sheets of polyethylene terephthaalte (PET) coated with a specially developed adhesive. Since the demand increased, 3D rotary laminating (3DR) was developed as a method of continuous production. Instead of the large 3D molds, 3DR is carried out on a single rotating drum.

The shape of the drum is manipulated as the sail is constructed over it.

1. The process starts with the digital design according to each specific sail boat.

There are a range of sizes from 10-500 sqm.

2. The PET film is laid across the mold and pulled tight with tensioning straps.

3. The 6-axis computer controlled gantry lays down the strands of carbon fiber (fig.1.4.13). Finally an operator checks for mistakes (fig.1.4.15). The PET and fiber are vacuum bagged and held under pressure.

A technician then moves over the sail applying heat to thermally form the composite over the mold surface (fig.1.4.14).

Due to the factors described above, there is a very large range of mechanical properties that can be achieved with composite materials. Even when considering one fiber type on its own, the composite properties can vary by a factor of 10 with the range of fiber contents and orientations that are commonly achieved.

The comparisons that follow therefore show a range of mechanical properties for the composite materials. The lowest properties for each material are associated with simple manufacturing processes and material forms (e.g. spray lay-up glass fiber), and the higher properties are associated with higher technology manufacture (e.g. autoclave molding of unidirectional glass fiber pre-preg), such that are found in the aerospace industry.

FIBRE CONTENT ORIENTATION FIBRE LENGTH APPLICATIONS MANUFACTURING PROCESS

CONTROL

Vf(%) (%) L(mm)

0 short fibers Small detailed parts Thermosets

Lcrt<L<10 Housing and brackets Thermoplastics Injection moulding

pressing

25 discontinous fibers beams and shell injection moulding

10<L<100 structures (S)RIM Resin infusion

car body parts pressing

BMC/SMC GMT

40 100 endless fibers large plate and laminating L->& shell structures

aerospace tapelaying

packaging/ filament winding pressure vessels

ship building/ civil engineering resin infusion

small plate and shell structures pressing aerospace

diagram forming

70 profile beams pultrusion

civil engineering

fig. 1.4.13 The 6-axis computer controlled gantry lays down the strands of carbon fiber

fig. 1.4.14 A technician then moves over the sail applying heat

fig. 1.4.15 Operator checks for mistakes

fig. 1.4.16 Fiber manufacturing specifications (from Flying LightnessPromises for structural elegance)

fig. 1.4.16

Corrosion Resistance

Superior resistance to a broad range of chemicals. Unaffected by moisture or immersion in water if ends are properly sealed.

Surfacing veil and UV additives create excellent weatherability

Insect Resistance

Unaffected by insects.

Strength

Stiffness

Electrical Conductivity

Pultruded fiberglass is stronger, and has higher flexural strength than timber. Ultimate flexural strength (Fu) LW = 30,000 psi, CW = 10,000 psi.

Pultruded fiberglass is approximately 1-1/2 times as rigid as wood. Modulus of elasticity LW = 2.5 x 106 psi, CW = .8 x 106 psi.

Non-conductive - high dielectric capability

Weight Specific gravity = 1.7

Pultruded fiberglass has significantly higher strength-to-weight ratio.

Finishing & Color Pigments added to the resin provide color throughout the part. Special colors available. Composite design can be customized for required finishes.

Cost

Lower maintenance, longer product life often equals lower overall costs.

Anisotropy Isotropic when it is bounded with the resin

TIMBER

Can warp, rot and decay from exposure to moisture, water and chemicals.

Coatings or preservatives required to increase corrosion or rot resistance can create hazardous waste and/or high maintenance.

Susceptible to insect attack (marine borers, termites, etc.). Coatings to increase resistance to insects can be environmentally hazardous.

Extreme fiber bending = up to 2800 psi.* Compression parallel to grain = up to 1800 psi.*

Modulus of elasticity = up to 1.8 x 106 psi.*

Timber can be conductive when it is wet.

Specific gravity = .51 (oven dried).*

Must be primed and painted for colors. To maintain color, repainting may be required.

Lower initial cost.

Is the anisotropy material by excellence.

fig. 1.4.17

CHARACTERISTIC S

WOOD 1. Anisotropic

2. Moisture

3. Electrical conductivity

4. Weight

5. Strength

6 Stiffness

GLASS 1. Isotropic REINFORCED

2. Unstiff and Unstrog across the axxis GLASS 3. Stiff and Strong (tension and compression) along the axis

RESIN 1. Bond

2. Adherence

3. Good longevity

4. Fair UV resistance

5. Good resistance to water

Bending one direction

Prestressed the fibers

fig. 1.4.17 Comparison chart fiber glass with resin and timber fig. 1.4.18 The manipulation of individual materials in the manufacturing steps.

Timing in the application

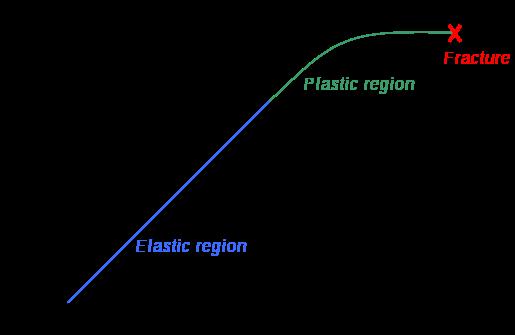

Young modulus (E) is a measure of the stiffness of an isotropic elastic material.

Young’s modulus is the ratio of stress, which has units of pressure, to strain, which is dimensionless; therefore Young’s modulus itself has units of pressure. MPa or N/ mm2.

Wood being an anisotropic material requires a minimum of 2 values of Young modulus: one along the grain (E1 ) and the other perpendicular to it (E2).

Glass fiber is a matrix molded by the resin or vice versa, according to the density of the GF more or less resin is required. The ratio of glass fiber or resin is measure in the Volume fraction. In general, since the mechanical properties of fibers are much higher than those of resins, the higher the fiber volume fraction, the higher the mechanical properties of the resultant composite will be.

Young module Glass Fibre Ef= 70000 N/mm2

Young module Resin E r = 1500 N/mm2

Volume fraction Glass Fibre Vf

Volume fraction Resin V r

E2 =1000 N/mm2 E1 = 10000 N/mm2 lay 1 thickness (t)=0.5 mm lay 2 0.5 mm t=0.5 mm lay 3 0.5 mm t=0.5 mm

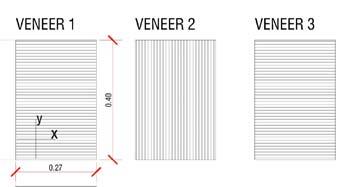

A sheet of plywood of 1.5mm (3 veneer layers of 0.5mm each one) is required to analyze the elasticity separately.

= E

+ E r

r = 70000*0.5 + 1500 *0.5 = 35000 + 750 = 35750 N/mm2

= E r

= 70000 * 0.4 + 1500 *0.6 = 28000 + 900 = 28900 N/mm2

E2 = E r E1 = 1/2 *28900 = 14450 N/mm2 E2 = 1/2 *28900 = 14450 N/mm2

= 70000 * 0.3 + 1500 *0.7 = 21000 + 1050 = 22050 N/mm2

= E r

= 1/3 * 22050 = 7000 N/mm2

Young modulus’s Yield Stress (N/mm2) (N/mm2) glass fiber unidirectional 35750 80000 glass fiber orthogonal 28900 40000 glass fiber random 7000 20000

(main direction horizontal) Ex

(main direction vertical) Ex

The weight of plywood depends on the number of veneer on it and on the amount of glue 3 pounds per square foot per inch of thickness.

¼ inch 0.71 pounds per square foot

3/8 inch 1.06 pounds per square foot

½ inch 1.42 pounds per square foot

5/8 inch 1.77 pounds per square foot

¾ inch 2.13 pounds per square foot

The common advantages of fiber composites are as follows: Time saving, durability, repair, lightweight, blast/fire, low maintenance, thermal insulation, high strength and dimensional stability; in addition to appearance and design flexibility.

The structural efficiency of the fibers varies according to manufacturing, fiber orientation and density. Fiberglass can be tailored to meet the specifications by building up layers oriented with stress while removing unnecessary material from areas with little stress. The timber composite, being quasi-isotropic could be assumed to be as strong in the x-y directions.

The uniformity in strength of composite panel. One of the big advantages of composites is that buckling is avoided, which is one of the main reason to be used in airplanes.

The curvature is directly related to the wood treatment and of course to the fiber state, which can make wood more or less flexible. The ratio of thickness and curvature are directly related.

The optimization of a shell structure, “monocoque shells” refers to optimization of geometry and therefore to reduction of weight.

Thin shell structures are lightweight constructions, which usually are assembled into large surfaces. Some examples are in airplanes, boat hulls, and roof structures. The shell structure has curvature as opposed to plate’s structures which are flat. Where a flat plate acts similar to a beam with bending and shear stresses, shells are analogous to a cable, which resists loads through tensile stresses. Therefore, the ideal thin shell must be capable of developing both tension and compression.

For instance the grid shell derives its strength from its double curvature, just as a fabric.

Fiber Reinforced Polymer (FRP) and Glass reinforced Polymer (GRP) initial architectural applications were focused in on pieces or parts of the building such as windows, and roofs. Nowadays there are a few examples at a bigger scale compared to the FRP applications but not as many as expected considering that one laminate of glass fiber reinforced is stronger than one laminate of steel. In some cases FRP has been used to produce self-supporting large structures such as curved domes for mosques, which would be

difficult and more expensive to build in conventional materials.

The geometric optimization is being an important task to reduce weight and eliminate a secondary structure, and it can be implemented in the efficient drainage strategy as well.

It is important to understand that most efficient FRP structures are fundamentally different in both geometric and structural form to conventional building structures. Therefore it is necessary to change the methodology of building design to enable FRP to provide more efficient solutions than currently available with conventional building materials.

The reduction of supporting structures for larger spans is one of the most challenging aspects of FRP, the material reduces assembly issues and filtrations. As will be shown in this chapter, complex surfaces have been made usually by plywood molds just adjusting the size of the sheets to be laid out.

Some interesting alternatives for the complements of these types of projects have been worked on by Frei Otto, particularly on the foundations of shell structures.

CHAPTER TWO - CASE STUDIES (Current Methods and Techniques implemented for composites and timber)

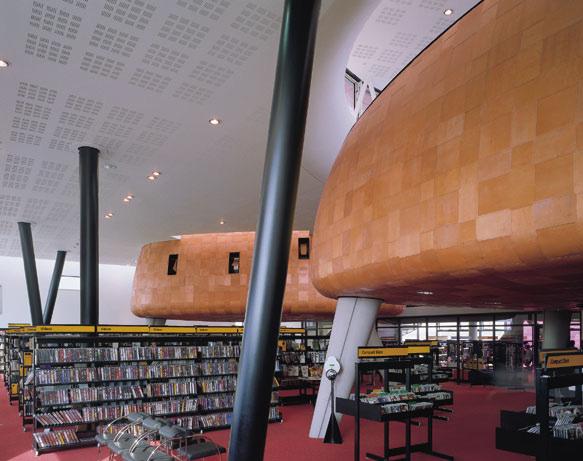

This is one of the meeting room pods designed by Alsop architects; it is located at the Victoria House courtyard, Bloomsbury Square, London.

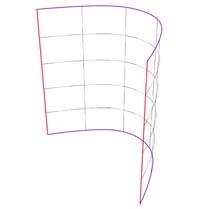

This project, developed from 2000 to 2003, had the task of locating the meeting rooms inside the covered courtyard of the building. As some other projects done by Alsop, GRP was the chosen material to create the entire surface. During the design and manufacturing stage the geometry was simplified to straight lines and arches at the corners. The section could be simplified in radius curves (arch) of 1.30m at the top corners and radius curves of 3m at the bottom corners, this rationalization had the goal to work with regular lines and avoid splines curves which are more difficult to achieve in real materials(fig. 2.1.3)

A set of ribs were made in MDF with the curvature that GRP pieces required, they were placed every 0.50cm (fig. 2.1.5) and subsequently some wood beams were placed in between to make enough support for the plywood (fig. 2.1.6). The strips of plywood [6] of approximately 0.40m were cut and laid out with the grain along its large dimension though directionality looked for adaptation to the curves at the corners (fig. 2.1.7). The glass fiber reinforced plastic was laid up with mats of random direction. The pod was built in 6 pieces which were assembled inside the building. The top two pieces didn’t require any additional structure, as it was selfstructural and didn’t have to bear extra load, contrary to the two intermediate, which had some metallic columns to support the mezzanine (fig. 2.1.10).

The complexity in the curvatures of the shell can be simplified into single curvature at the vertical corners, double curvatures at the 6 extreme corners and planar surfaces in the rest of the surface. As is expected, the plywood mold crosses the curves according to its bending possibilities.

fig. 2.1.1 Geometry abstraction

fig. 2.1.2 Top view

fig. 2.1.3 Transversal section

fig. 2.1.4 Geometry abstraction

fig. 2.1.5 MDF ribs

fig. 2.1.6 Wood beams placed in between MDF

fig. 2.1.7 Plywood strips

fig. 2.1.8 Temporary assembly of 4 pieces

fig. 2.1.9 Pod placement through the ceiling

fig. 2.1.10 Metallic mezzanine structure

fig. 2.1.11 GRP pod at the courtyard Victoria Housebury

fig. 2.1.3

fig. 2.1.5

fig. 2.1.4

fig. 2.1.6

fig. 2.1.7

fig. 2.1.8

fig. 2.1.11

fig. 2.1.10

fig. 2.1.9

fig. 2.1.3

fig. 2.1.5

fig. 2.1.4

fig. 2.1.6

fig. 2.1.7

fig. 2.1.8

fig. 2.1.11

fig. 2.1.10

fig. 2.1.9

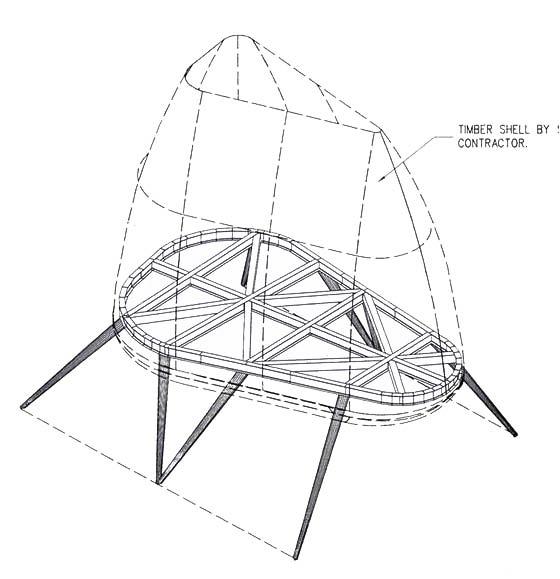

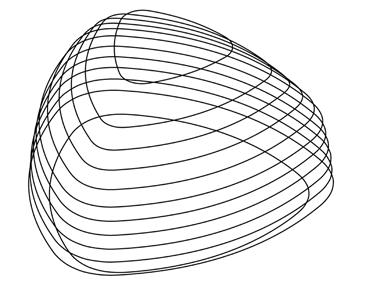

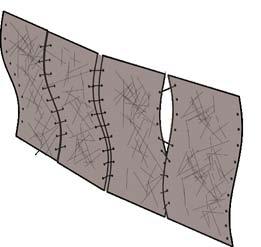

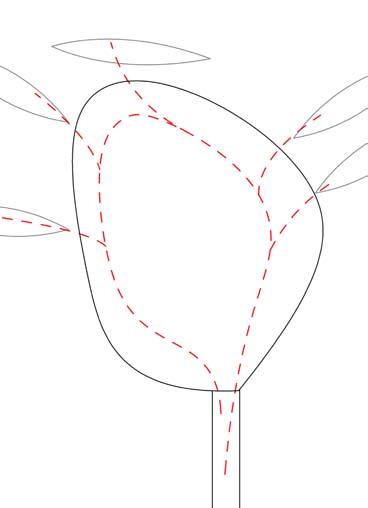

Three “organic” reading rooms located inside the new Peckham Library were created using shell forms from curved timber ribs with structural plywood inner and outer skins. These structures were designed by Alsop architects.

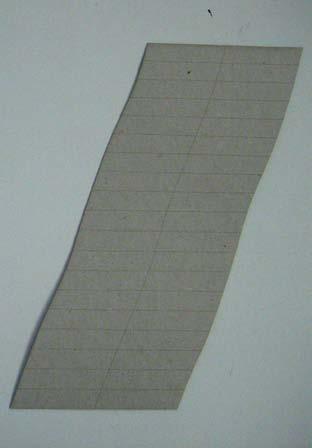

Drawing the objects was an important task for the team as the accurate definition of the geometry would allow unrolling the flat plywood sheets.

The timber ribs were set as a frame in a stand up structure. The initial idea was to create a smooth surface that was going to be covered with leather. The laminates (LVL laminated veneer lumber) were stapled to the ribs. Subsequently the pieces of 0.40 x 0.60m were laid out over the timber structure adopting small curvatures. The skin was placed on both sides, inside and outside, to encourage stress skin action. The pods have a very thin 3mm layer of the same timber tiles stapled to the frame. The pods have an insulating material inside.

The smooth curvature through the surface plus the decision of having short dimension laminates allowed the project to succeed.

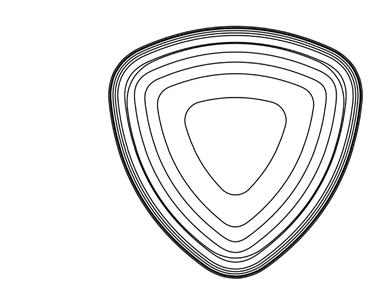

fig. 2.2.1 Geometry abstraction

fig. 2.2.2 Definition of the pod geometry

fig. 2.2.3 TImber ribs as the frame

fig. 2.2.4 Staple of LVL to the ribs

fig. 2.2.5 Interior of Peckam Library

fig. 2.2.6 Interior of Peckam Library

fig. 2.2.2

fig. 2.2.3

fig. 2.2.4

fig. 2.2.5

fig. 2.2.6

fig. 2.2.2

fig. 2.2.3

fig. 2.2.4

fig. 2.2.5

fig. 2.2.6

Material preparation

Wood veneer : About 1.2mm–1.6mm

Resins: UF and PF

Reinforcement: Chopped Strand Mat (CSM 200)

Binders: Polyester resin (PE)

Source: Development Of Fiberglass Reinforced Veneer Products article

The Forest Research Institute Malaysia (FRIM) carried out research looking for an alternative timber product, as timber has a large demand in architectural applications but is becoming gradually more expensive. This study presents an alternative product to minimize the usage of timber while still retaining the timber qualities. It aims to produce a thin, light and yet strong panel.

The limited timber resources in Malaysia has affected the supply of veneer that caters to the panel and furniture industry. Because of this the less popular or lesser-known species, as well as incorporating oil palm and coconut veneer as cores in plywood are used.

Methods

Board configuration

Flat fiberglass reinforced veneer panel (6 and 7 layers) were developed based on two design configurations: 1. CSM placed at the center of the panel between the veneers

Panel A: Veneer + CSM + Veneer

CSM : Three layers

Resin: UF (PA1) and PF (PA2)

2. CSM reinforced after the second and fourth layer respectively of the panel.

Panel B : Veneer + CSM + Veneer + CSM + Veneer ‘

CSM : Two layers

Resin: UF (PB1)

3. Control : Same configuration without CSM

Contact angle and formaldehyde test

“The veneer and panel were tested to determine the contact angle. This is done by determining the wetability of the veneer and the panel using contact angle calculation on the samples selected. The FRIM’s in-house method of testing and evaluation is used.ii) The panels were also sent for formaldehyde emission test based on JAS standard. Other parameters such as press time, temperature and veneer thickness were also considered and determined during the preliminary study. The optimum option was selected for subsequent panel production” (H. Hamdan)

Result and Evaluation

In this study, the veneers were arranged following the orientation of plywood. This orientation was preferred because the panel produced using the laminated veneer lumber (LVL) method tends to warp and be dimensionally unstable when thin layers are required. Contact angle is the mean value of contact angle of

the veneer was 80o before it gets penetrated after 2 to 4 seconds. Although the contact angle of the panels was about 82o, it took more that one minute before it penetrated. This shows that the latter is more difficult to be penetrated by the liquid adhesive which indicates that the board is dimensionally stable.

*Formaldehyde emission analysis. The panel was tested to determine the level of formaldehyde emission released by using the JAS standard for plywood. The panel tested was PA1 and PB1 using UF supplied by a collaborating agency. The result showed that it only achieved F** level. 47

In order to allow the Japanese market to use it for interiors, the panel should meet the F**** standard requirement. The classification obtained for panels in this study would qualify for exterior usage only. However, for interior usage, it is recommended that a certain percentage of catcher® be added into the resin to minimize the emission of formaldehyde, thus meeting the standard requirement. Physical and mechanical properties. Generally, the panels were quite heavy compared with the control. It is interesting to note that in panel PA1 and PA2, the MOE and MOR were much higher lengthwise than widthwise. For resins used, the panel PA2 that used PF had much higher physical and mechanical properties. For panel PB1 where the configuration of CSM was at 2 alternate layers, it is interesting to note that the mechanical properties were almost similar in both lengthwise and widthwise directions. This shows that the composite has become quasi-orthotropic (x-y) in nature. When the panels were tested for its mechanical strength, the veneer used in the panel prevented the panel from showing a ductile type failure characteristic that is often seen with fiberglass.

Generally, the fiberglass reinforced veneer panel shows great potential in being developed and utilized by the industry. The uniformity in strength of the panel at both x-y direction shows that it is more stable to be used as membrane for wider area. The results from this study are now being employed in the making of fiberglass reinforced molded products. The superior strength of this engineered composite panel product suggests that buildings can now be designed by incorporating this thin panel. In addition, this product contributes to less construction site waste because it can be ordered to specification. The thin and lightweight material also has potential for use in the development of some furniture designs.

2.4

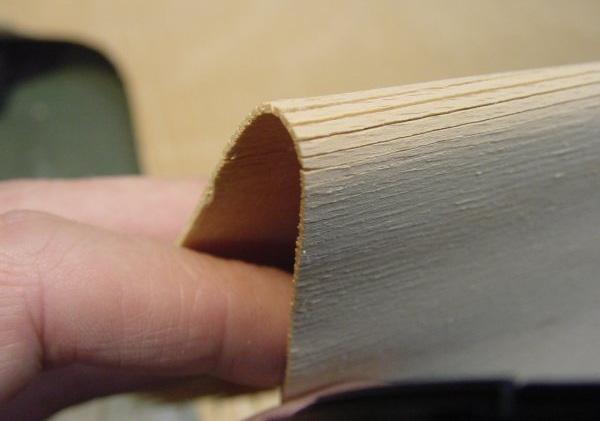

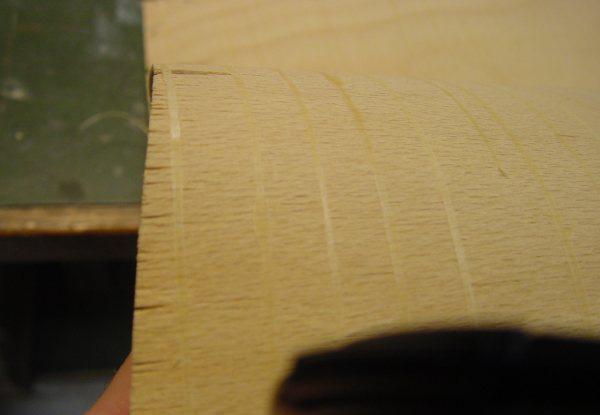

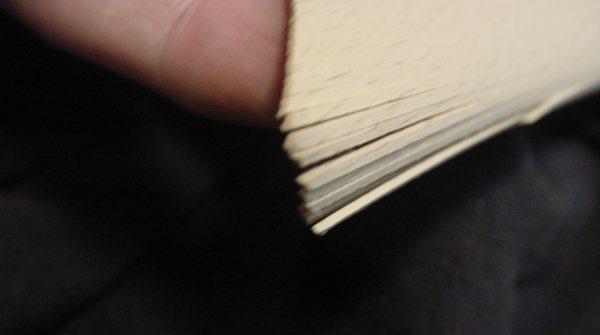

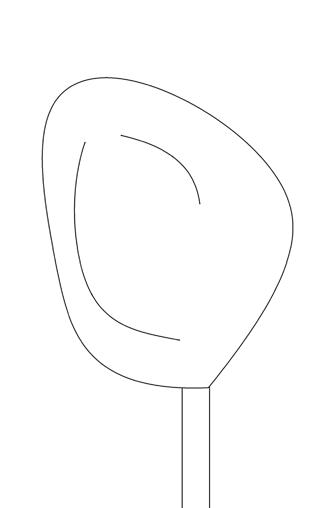

The 3D veneer is produced by the company Reholz especially for furniture (chairs weight could be 1.880g). The veneer is sliced (from the backside, not completely through) and “cracked” towards the upper/outside surface (fig. 2.4.1). This makes the slicing much less visible. The “individual sticks” are held together from the backside with glue-strings going in perpendicular direction.

The slices blend seaming less together after pressing the veneer together. The sliced veneer works similar to a textile and this is what allows the entire structure to get doubly curved (fig. 2.4.2). The individual sticks can slide a little according to each other; this is what the whole trick is about. Pressing tools are used to make the plywood with cold, glued layers with different directionalities.

With this technique the material thickness is reduced and high stiffness and strength is achieved due to the superposition of veneer in different directions. For prototypes die, stamp and sometimes a forming ring is necessary. For serial production pressing made of aluminium, heated (2- oder 3- parts, that means swage, stamp and if necessary a forming ring).

Glue for plywood manufacturing: Hot gluing: Kaurit 390 powder + hardener 70 + extender Bonit. cold gluing: Kaurit 234 (100 T) + hardener 30 (10 T) + extender Bonit (20T)

Processing: The surface layer does not required it to be moisten or glued and is the last process step to the veneer package. The 3D veneer should not be positioned back side together, in other words, the glue stripes of 3D-veneer shouldn’t be added together in the first join under the surface veneer.

Specifications: Amount of glue is approx. 130 g/m². Open time of the layer before last: 10…15 Min. depending on the climate.

Press temperature: approx. 100°C. press pressure spec.: approx. 2,5 Mpa (it´s a precondition for successful mechanical treatment).

Processing of the 3D-veneer with wood moisture approx. u=8%.

Mechanical treatment of 3D-plywood molding:

Clamping of the moldings without vibrations (especially for thin moldings important) of the pieces with holohedral vacuum, which have reached to the edges of the molding, is necessary. The best way is milling in parallel feed with an end mill, 90° to the surface of the molding

1,15 mm ± 0,05 mm size: length: max. 1300 (2100)mm witdth: max. 980 mm

Surface layer: Beech-rotary cut knife cut veneers (Beech, Am. Walnut, Euro Walnut, Am.White Oak, Euro Oak, Black Cherry, Euro Cherry, Vinterioveneers and others)

Inside layer: Beech rotary cut Ilomba/Kapokier rotary cut

Source: REHOLZ® GmbH. 2009

fig. 2.4.1 Sliced veneer fig. 2.4.2 Glue lines on the back fig. 2.4.4 The individual sticks slide a little according to each other

fig. 2.4.1

fig. 2.4.2

fig. 2.4.4

fig. 2.4.1

fig. 2.4.2

fig. 2.4.4

1859-2002

The next list shows the evolution of technique through designed chairs:

Bent, massive Chair, Thonet, 1859

Bent plywood Seat, AAlto, 1932

Slightly Molded ArmChair, Eames, 1945

Bent Chair, Prouve, 1950

Slightly Moled Chair, Jacobsen, 1950

Twisted plywood Chair, Gehry, 1990

Multiple Bent 2D plywood chair, Claesson, 2001

Molded

3d Plywood chair, Karpf, 2002

Plywood furniture construction

Lounge Chair, Charles and ray Eames, 1941

After a series of experiments, the Eames made a prototype chair seat produced by a laborious method of gluing together and heat bonding thin plies in a plaster formwork, located at the base of the machine. An inflatable machine membrane, enclosed in the wooden box, covered the layers of wood. After the device was securely bolted together, the membrane was inflated with a bicycle pump to keep the wood plies pressed against a plaster form. During the four to six hours molding process, heating elements embedded in the plaster form cured the glue. Air was pumped into the membrane regularly to maintain the required level of pressure. Heating elements embedded in the plaster form cured the glue. Air was pumped into the membrane regularly to maintain the required level of pressure. Once the glue had set, the pressure was released and the formed seat was removed from the mold. The edges were trimmed with hand say to the desired finished shape and hand sanded.

This first Bent Ply product for furniture application was made from three rather thick veneers, with all the grains laid out in the same direction. Where the radius was too small, so that bending would have broken veneers, cuts were introduced into the initial veneers. The here with separated parts of the sample where than later re-

joined with bolts to stiffen the overall structure.”

Used wood material : Veneer

Number of Plies: 3

Thickness of Plies: 003mm

Thickness of Composite (plywood): 009mm

Grain Direction: Parallel

Deformation Mode: Molded

Pre-treatment: Structural Edge cut veneers

Joints:

Leg Splint, Charles and Ray Eames, 1941

The famous Eames leg-splints were made from a relatively large number of very thin veneers, which all were pre-cut to size and therefore had to be laid upon each other very carefully before molding. These pre-cut forms match the load bearing character of the splint, in highly stressed parts the number of veneers increased; in others the number is reduced. Small bending radius were achieved by bending two, previously cut and separate edges towards each other and later joining them. The result offered a complex form with partly tight curvatures, structurally (by number of veneer in cross section) specifically designed according to its loading.

Used wood material: Veneer

Number of Plies: 6

Thickness of Plies: 001mm

Thickness of Composite (plywood): 006mm

Grain Direction: Perpendicular

Deformation Mode: Molded

Pre-treatment: Entirely pre-cut veneers

Joints: Glued

http://www.loc.gov/exhibits/Eames/Furniture.html

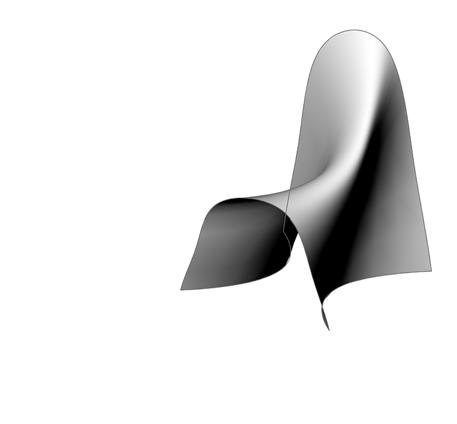

82us chair, Peter Karpf, 2002

This example employs abilities of high pressure molded plywood, which results in extreme structural performance. A plywood sheet is molded into a three dimensional shape with small curvatures and complex shell shapes and then cur and finished by hand. The chair, made out of this one single bolded plywood piece, takes advantage of the tensions appearing during the molding process- the upper plies get tensioned, while the lower plies in cross section get jolted, so that the performance is quiet similar to pre-tensioned concrete, where two parts with different load bearing characters complement each other , this shell principles allows a coherent and non-joints chair uniquely made form plywood.

Used wood material: Plywood

Number of Plies: 7

Thickness of Plies: 000,8mm

Thickness of Composite (plywood): 005,6mm

Grain Direction: Perpendicular

Deformation Mode: Molded

Pre-treatment: None

Joints: None

fig. 2.5.1 Lounge Chair

fig. 2.5.2 Leg Splint

fig. 2.5.3 Mold for Wave Desk

fig. 2.5.4 Cut pattern on veneers for Lounge Chair

fig. 2.5.5 Cut pattern on veneers for Leg Splint

fig. 2.5.6 Cut pattern on veneers for 82us

fig. 2.5.7 Cut pattern on veneers Plywood Chair 50642

fig. 2.5.8 Cut pattern on veneers for Wave Desk

Plywood Chair 50642, Erich Menzel, German Workshops

Hellerau, 1950

Used wood material: Veneer

Number of Plies: 8

Thickness of Plies: 001mm

Thickness of Composite (plywood): 008mm

Grain Direction: Parallel

Deformation Mode: Bent

Pre-treatment: -

Joints: Glued

Source: “Mythos Hellrau” /Exhibition catalogue , Deutsche Werkstatten, 2002

Wave Desk, Eric Pfeiffer, 2002

This wave desk is still made from numerous veneers, which get stacked and then pressed into a mold. The pressed sample is then automatically cut, sanded and finished, so that the usual work distribution of industrial production, followed by a manufactured finish is inverted.

Used wood material: Veneer

Number of Plies: 8

Thickness of Plies: 001mm

Thickness of Composite (plywood): 008mm

Grain Direction: Perpendicular

Deformation Mode: Molded/Bent

Pre-treatment: None

Joints: Glued

Source “Bent Plky, Ngo, Pefeiffer, Princeton architectural, press, new york, 2003)

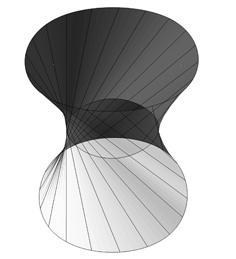

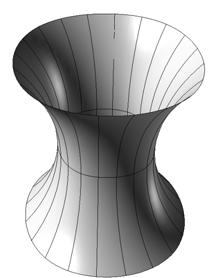

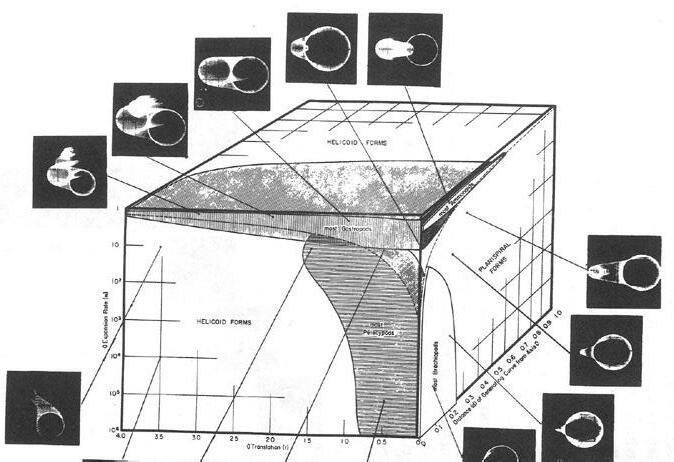

Eladio Dieste is an Uruguayan engineer who developed the technique of reinforced masonry vaults, technique that has genuinely provided advances in the use of brick in complex geometries and its construction process. The first technique refers to self-weighted vaults, which are always catenaries curves, the most efficient structural form. The vaults are pre-stressed to take bending forces and thus act like beams. What the main interest is for this research is the ingenuity of combining the aesthetic and the structural capacity to its maximum in the surface. For instance, in the storage of the Massaro there are groups of vaults supported in distant columns, having 16.5 m cantilevers. The vaults are also perforated for light in middle areas but also overlap to have indirect light.

The second vault type used by Dieste solves the problem of buckling in the Gaussian vaults through the shape, giving strength in the center of this span with the changing S-section. “The simple catenary curve of a reinforced self-supporting vault allowed it to perform as a beam” (Nordenson, G. 2008). Dieste’s work is outstanding architecturally and in engineering as he combines through one surface the concepts of proportion, space, light, surface, texture, structure and rapid construction.

fig. 2.6.1 Wood strips nailed to formwork to position the bricks

fig. 2.6.2 Small self-carrying vaults

fig. 2.6.3 Timber trusses for the formwork

fig. 2.6.4 Pre-stressing the looped steel rods with a manual jack

fig. 2.6.5 Looped pre-stressing steel, absorbs negative bending moments

fig. 2.6.6 S-shape on Gaussian vaults

fig. 2.6.7 Corrugation effect on a sheet paper

fig. 2.6.8

fig. 2.6.9 Cadyl Horizontal Silo

fig. 2.6.10 Lonja de la Seda de Valencia, 15th century

fig. 2.6.11 The method of timbrel vault

fig. 2.6.12 Oyster Bar in Grand Central Terminal

fig. 2.6.13 Adhesion of several layers of overlap ping tiles

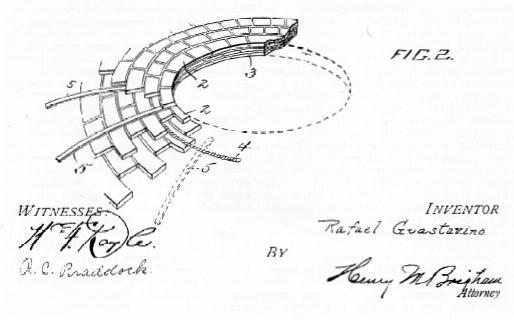

The Catalan vaulting system is a masonry technique perfected in Catalonia, Spain. Rafael Guastavino took it to United States where the system was used in many large scale buildings. This technique as this research proposes, does not require formwork and is capable of spanning large open spaces and constructing robust, self-supporting arches and architectural vaults.

The Catalan system is effective at covering large areas gracefully and economically. The key of the system is a fast-setting mortar on two edges of a tile, which allows it to hold itself after being tapped into place. Once the first course is laid, the second course of single tiles is progressed, breaking the joints of the previous layer with rich Portland cement mortar. After the second course is set, the worker can stand on the tile ring and lean to progress erecting the first course of the second row. The process continues until the dome is closed at the apex. One of the most remarkable aspects of Guastavino’s vaults is that they hold their own weight the day after the tiles are set. Due to this inherent selfsupporting nature of the construction, the vaults can be built without centering and scaffolding – unless it is necessary to elevate the workers.

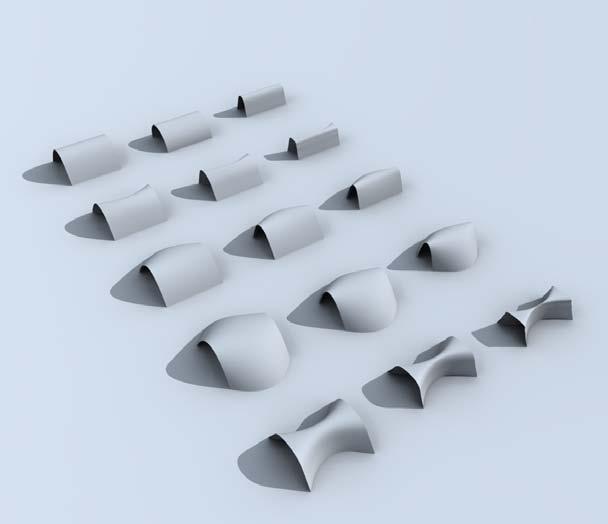

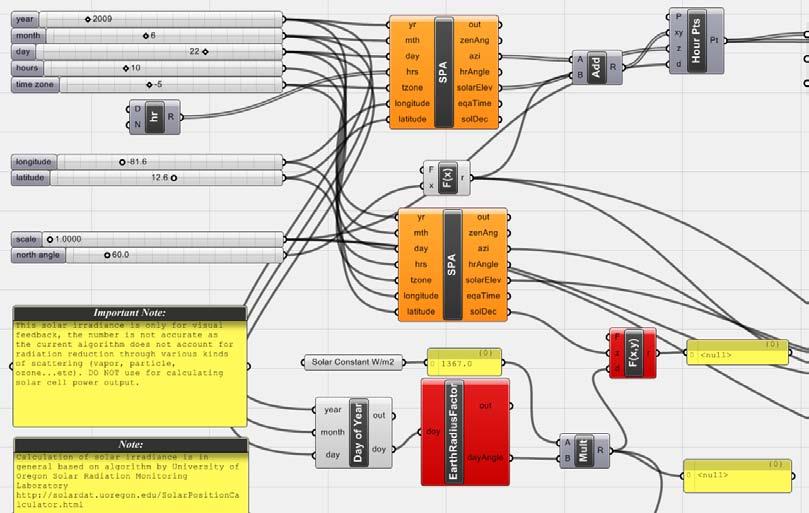

A wide range of fabrication techniques were explored in the next chapter in order to achieve different geometries in wood and plywood and to keep the resulting curvatures on the final shape. Some experiments have focused their efforts in transferring the geometry from physical to digital experiments, in order to provide precision and viability in the fabrication. The research looks for different methodologies in the simulation of the plywood deformed geometries using Rhino*, Rhinoscript*, Grasshopper* and Strand7*. The material behavior of the composite is understood through the simulations, as well as the structural capabilities.

* Rhino is 3D design software

* RhinoScript is a scripting language based on Microsoft’s VBScript language

* Grasshopper is a graphical algorithm editor tightly integrated with Rhino’s * 3-D modeling tools * Strand7 is a Finite Element

DESIGN PROCESS

Geometry

FABRICATION METHOD (no mould)

-Theoretical shells - Form finding for panels (buckling method)

- Panelization - Form finding on the assemblies (stitching)

- Light filters

System to create shells

- Reinforcing construction method

CHAPTER THREE - EXPERIIMENTS

Plywood + Fiber glass + Resindesign process

CFD Analysis wind rain

Structure

Parametric model

geometry

fabrication

Bending material CNC milling

Construction Sequence

fig. 3.1.0 Close capture of the overlaping

fig. 3.1.1 Options for matching the strips

fig. 3.1.2 Inclination of assembly for drainage

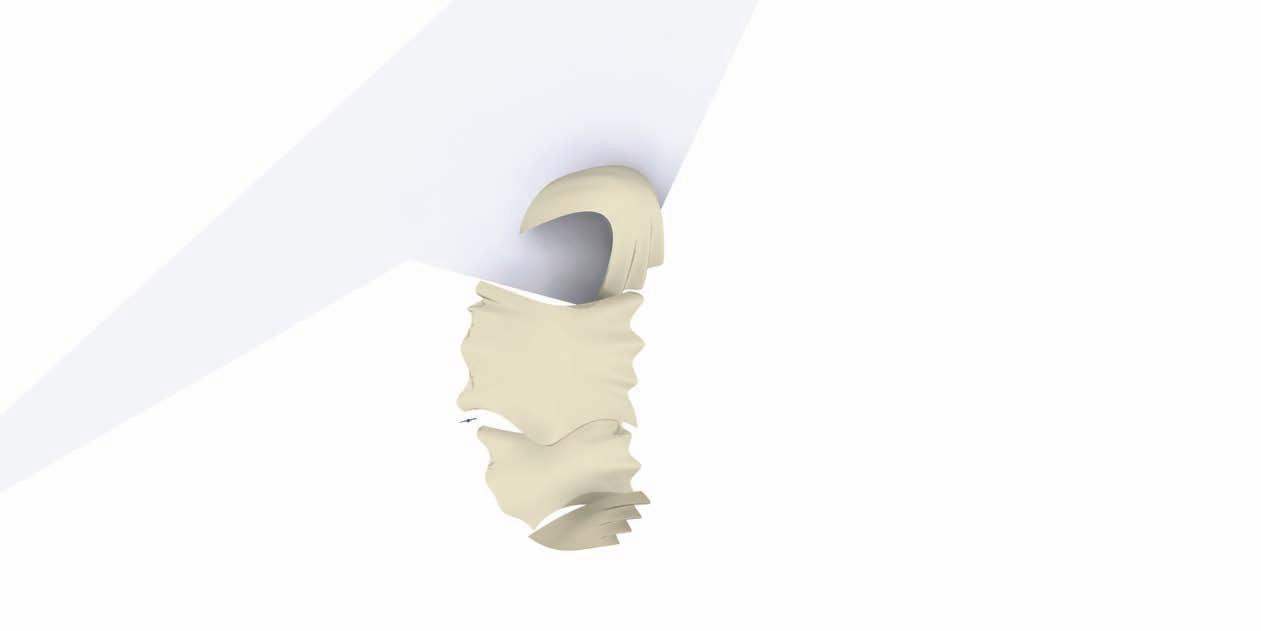

fig. 3.1.3 Fin section

fig. 3.1.4 Variation in the openings by Grasshopper definition

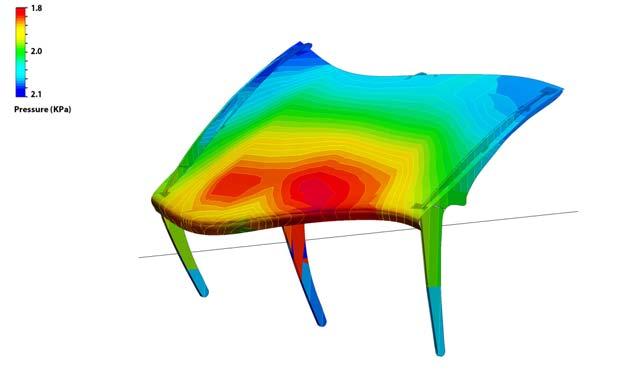

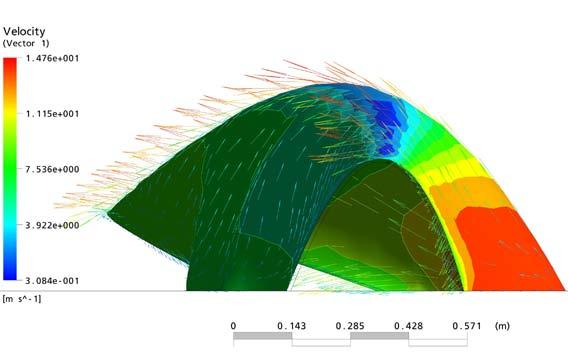

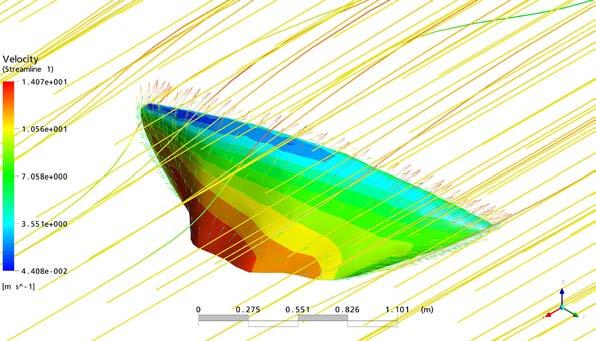

fig. 3.1.5 CFD (Computational Fluid Dynamics) analysis

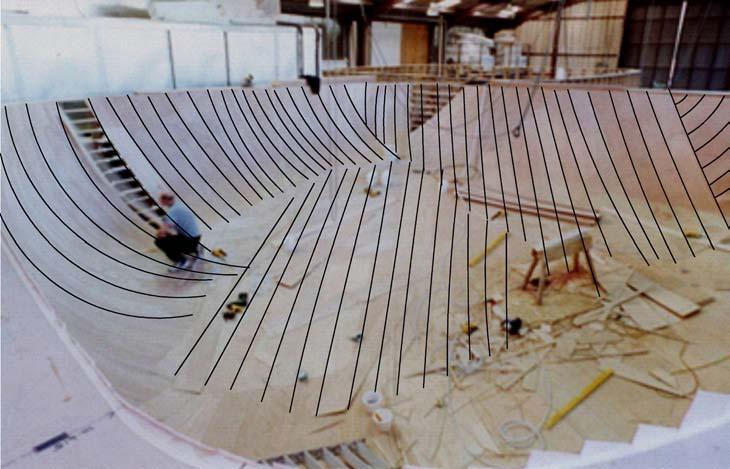

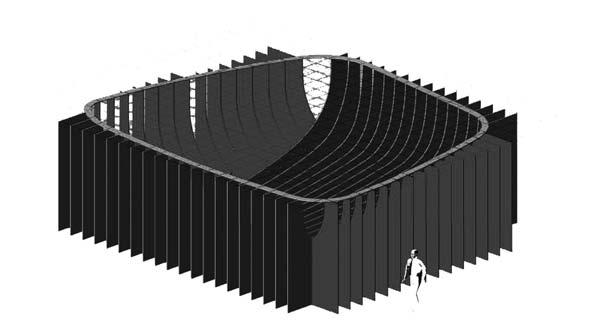

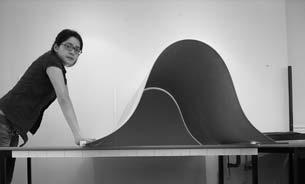

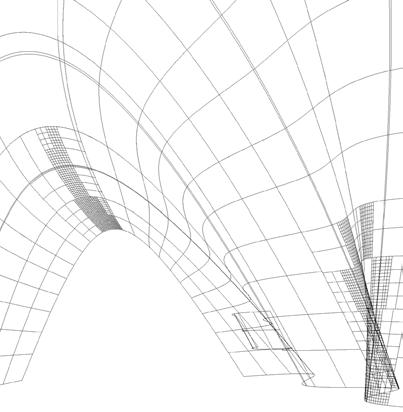

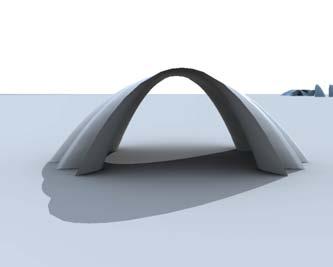

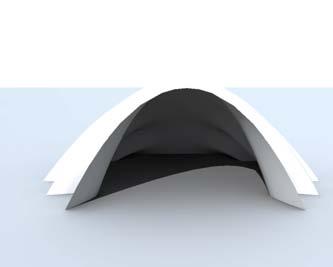

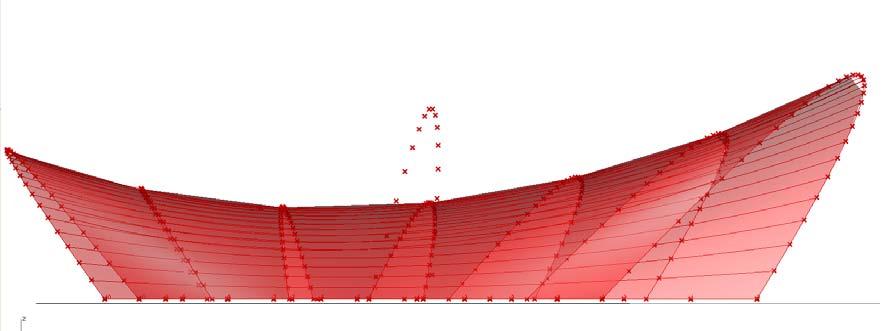

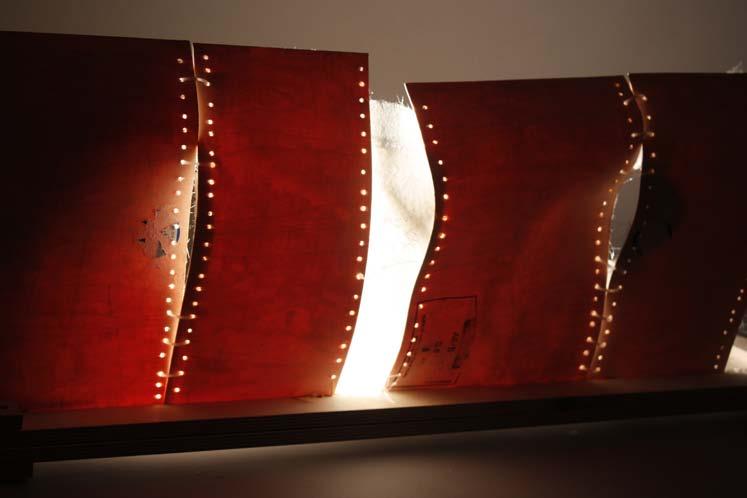

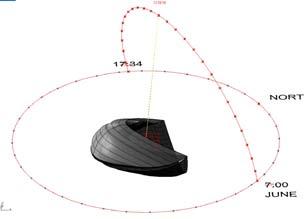

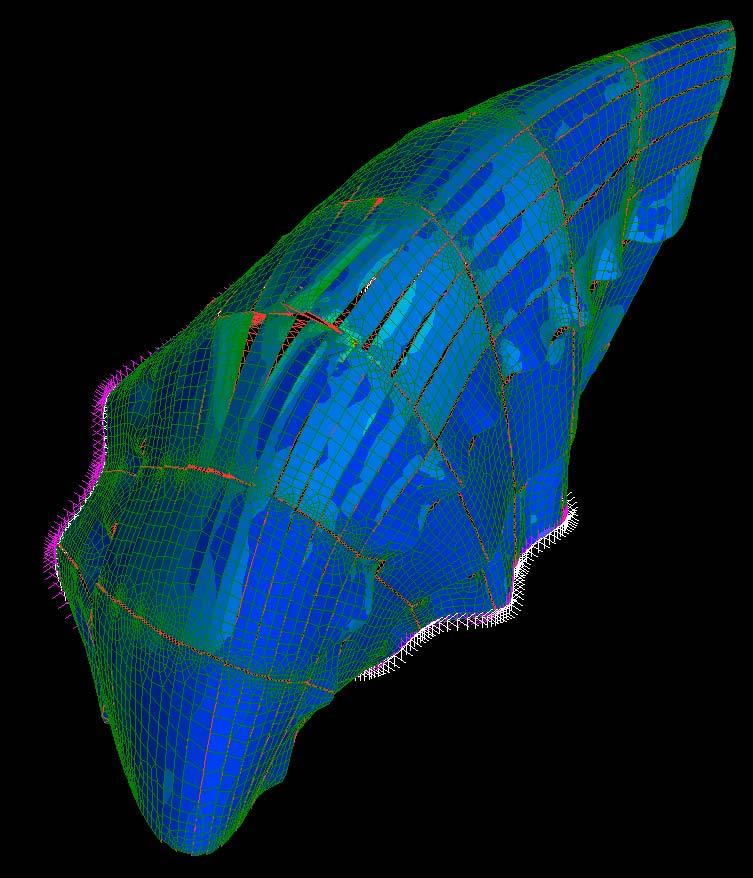

Design and Fabrication of “EmTech” Canopy at the Architectural Association

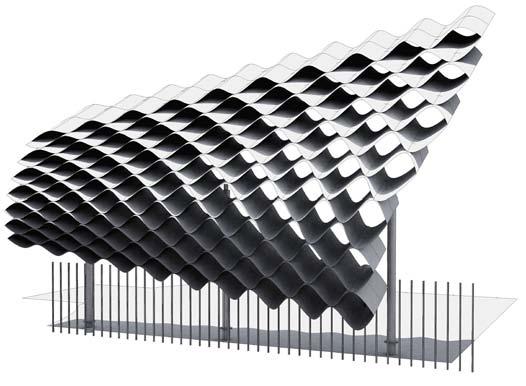

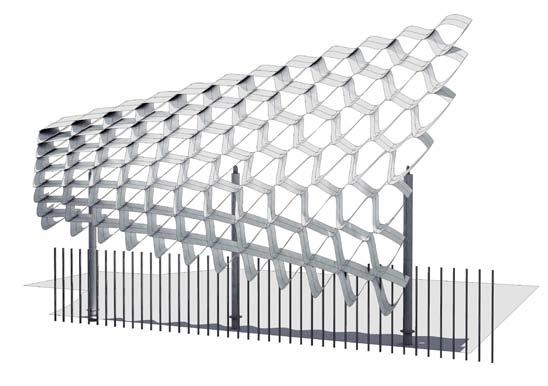

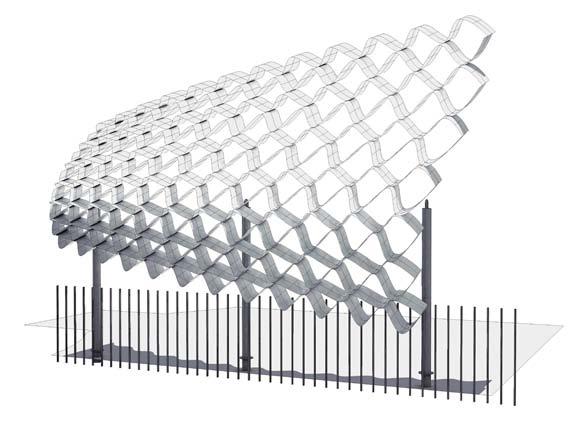

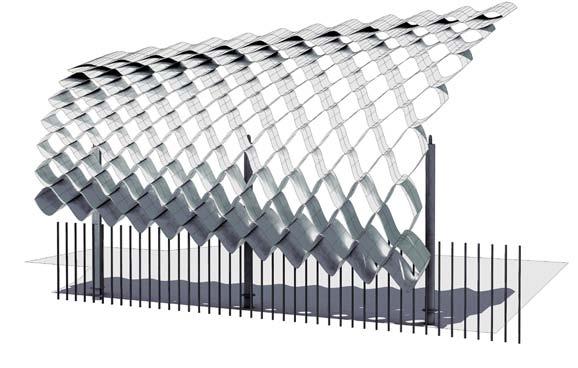

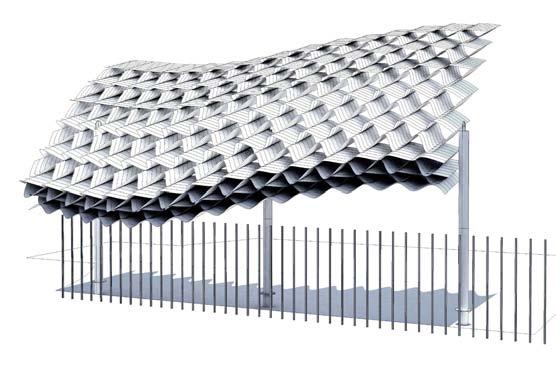

The Canopy project was developed by the master course Emergent Technologies and Design 2008-2009, and consultant from Buro Happold Engineers for the structural design.

The project utilized the timber composite as a result of previous experiments run in Core Studio at the beginning of the year. These initial explorations of the material are presented on the experiment 2.1.

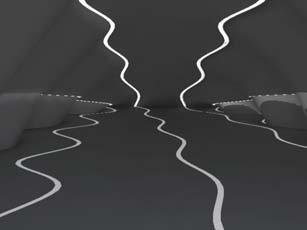

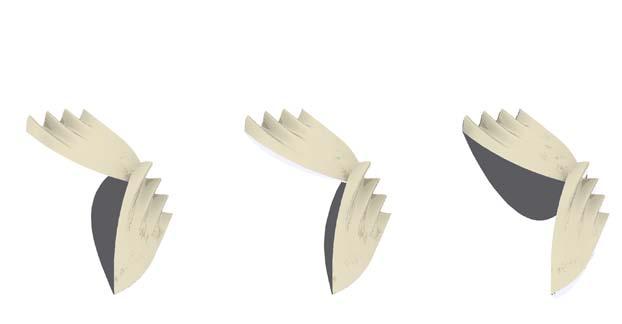

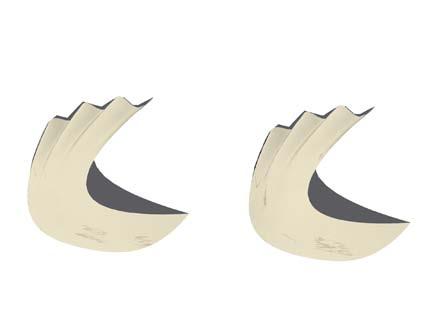

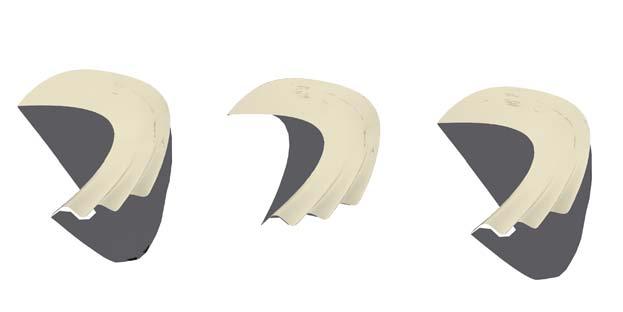

The design had to respond to wind conditions, drainage facility and structure capacity at the AA terrace. After deciding the wood as the main material and corrugated strips as the strategy for the overall form, the goal was to stand up the canopy making the strips work as struts when transferring the load to the ground. Sadly the wood wasn’t enough to create the 3D struts required (Figure XX). Plus, due to its thickness and overall geometry it would continuously creating fatigued moments which were not appropriate to the only three columns available to transfer loads to the beam located within the terrace floor.

In the initial prototypes steel struts were placed as compression elements in between the strips, however, one of the final decisions before starting the fabrication stage was to remove them and as a solution transfer loads to the existent rounded columns and to guaranty the stability of the structure through high wind channels. The struts were eliminated and three fins were placed to support the canopy.

Structure

The curved morphology distributes vertical loads laterally. The component made use of the elastic bendable properties of plywood.

The corrugation

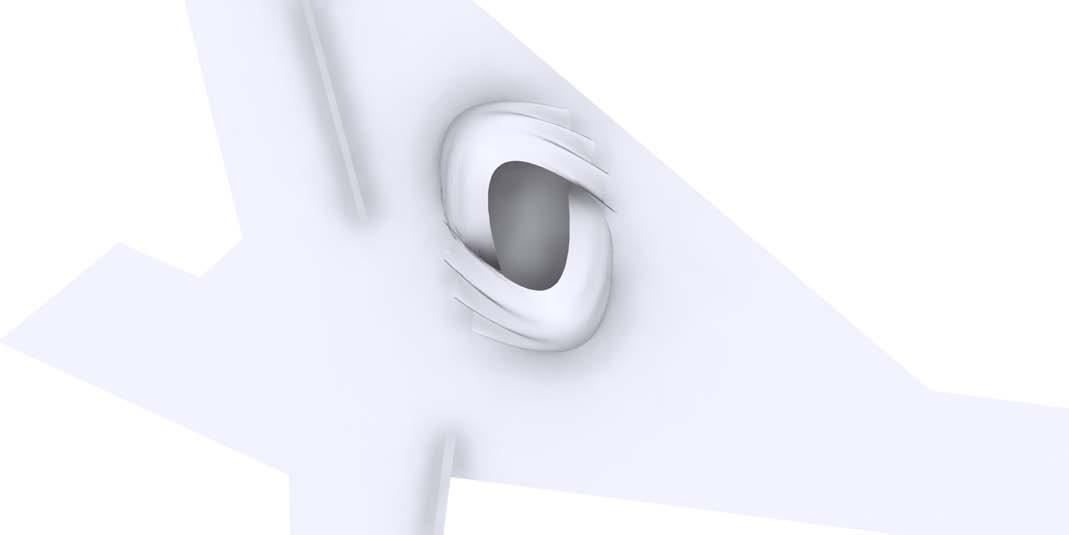

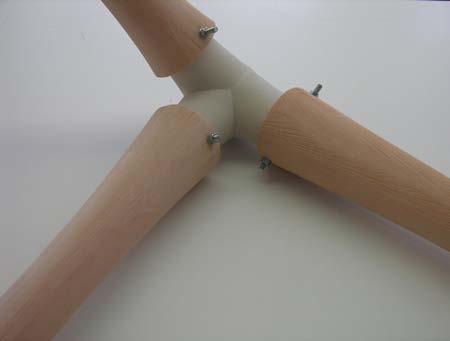

The fins - The structure has a total of three fins -one per column; each fin consists of three layers of plywood: 12mm in the outer layers and 18mm for the inner one. Plywood sheets with these thicknesses are only provided in 1.2 x 2.4m rectangular panels. This required each fin to be divided further into two parts: top and bottom. The upper fin is connected to the top plate of the existing columns through a pin connection (20mm dia.). The existing column plate is reinforced with a steel flitch plate screwed to the inner layer. The lower fin connects to the existing columns at the bottom using a ring clamp around the columns.

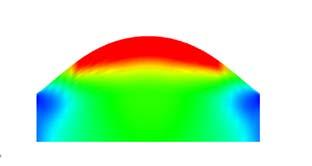

Wind and drainage

The wind is channeled through but the shape of the component creates local turbulence that separates the airflow from the rain. Rainwater is channeled down in the direction of the drainage points defined by the slope of the overall surface. A flow analysis of the final structure was necessary to determine how big the voids should be to help to reduce the wind pressure indicated in the specifications.

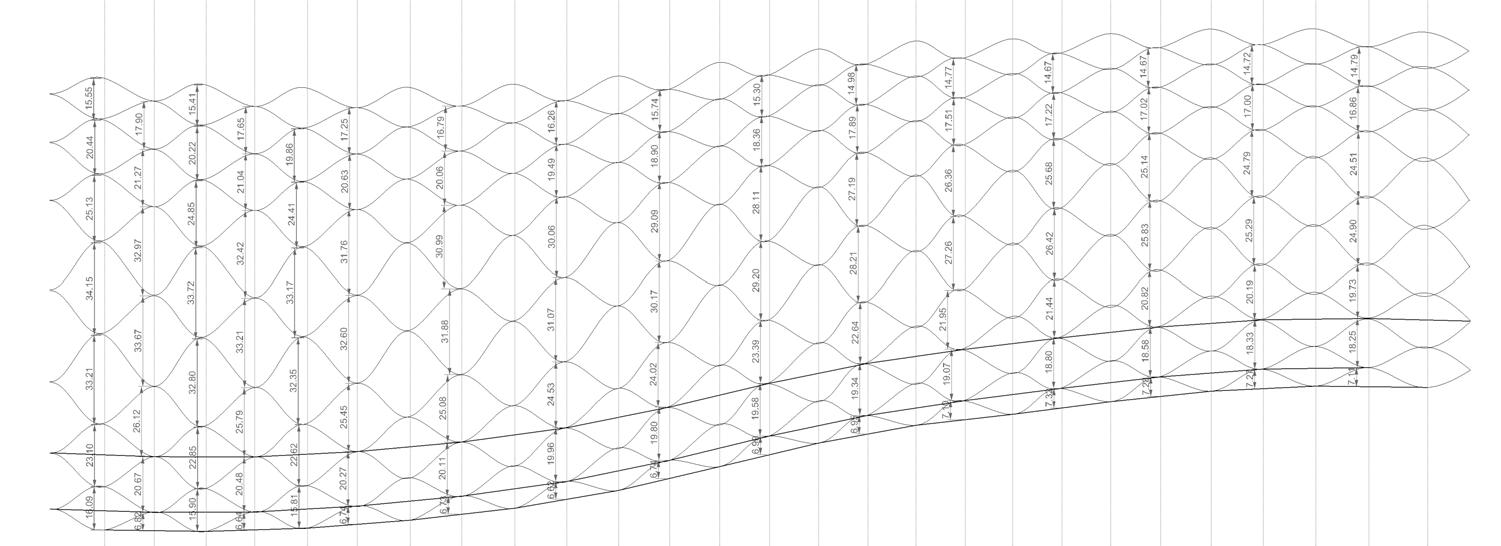

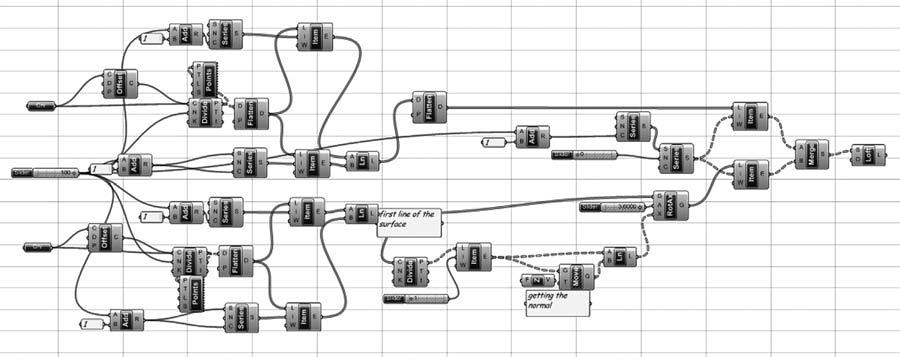

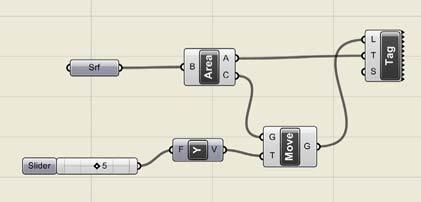

Variation

An associative digital model was developed so that it can input the changes and readapt to specific structural requirements. Transferring this associative model to the real structure was one of the major challenges as plywood had certain constraints in the bending according to the curvature required.

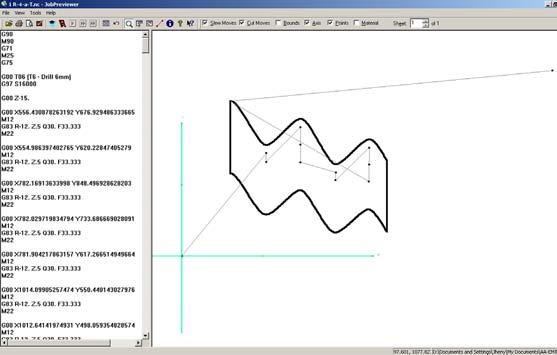

Option Explicit‘Script written by <insert name>‘Script copyrighted by <insert company name>‘Script version Friday, February 27, 2009 10:59:26 PMCall Main()Sub Main() Dim strCurve Dim blnCreate Dim arrPts, arrPoint Dim l Dim strtext1, strtext2, strtext3, strtext4 ‘l = blnSegments strCurve = Rhino.GetObject (“select curve to cut”,7) If isnull(strcurve) Then Exit Sub ‘points = Rhino.Getobjects (“select holes ‘points’...to drill”,1) l = Rhino.GetInteger (“number of segments”,750) arrPts = Rhino.DivideCurve (strCurve, l, 1) ‘1 it’s because it’ s boolean function Dim m , strfilter, strfilename, strpoint, objFSO, objStream strfilter= “*.txt” strfilename=rhino.SaveFileName(“points file”,”strfilter”,”c:\ Works”,”file”,”nc”) Set objFSO = CreateObject(“Scripting. FileSystemObject”) Set objStream = objFSO.CreateText File(strFileName) ‘’ starting part of the file Dim stt0 : stt0 = “G90” Dim stt1 : stt1 = “M90” Dim stt2 : stt2 = “G71” Dim stt3 : stt3 = “M25” Dim stt4 : stt4 = “G75” Dim stt5 : stt5 = “G00 T06 (T6 - Drill 6mm)” Dim stt6 : stt6 = “G97 S16000” Dim stt7 : stt7 = “G00 Z-15.” Dim stt8 : stt8 = “ “ objStream.WriteLine(stt0) objStream.WriteLine(stt1) objStream.WriteLine(stt2) objStream.WriteLine(stt3) objStream.WriteLine(stt4) objStream.WriteLine(stt8) objStream. WriteLine(stt5) objStream.WriteLine(stt6) objStream. WriteLine(stt8) objStream.WriteLine(stt7) objStream. WriteLine(stt8) ‘Dim temppt ‘’ generating points ‘For m = 0 To Ubound (points) Step 1 ‘temppt = rhino.pointcoordinat es(points(m)) ‘strpoint = (“G00” & “ X” & temppt(0) & “ “ & “Y” & temppt(1)) strtext1 = “M12” strtext2 = “G83 R-12. Z.5 Q30. F33.333” strtext3 = “M22” strtext4 = “ “ objStream. WriteLine(strPoint) objStream.WriteLine(strtext1) objStream. WriteLine(strtext2) objStream.WriteLine(strtext3) objStream. WriteLine(strtext4) ‘Next ‘’ generating curves.....starting part Dim str0 : str0 = “ “ Dim str1 : str1 = “Z-15.” Dim str2 : str2 = “G00 T21 (T21 - 9.52 mm Compression)” Dim str3 : str3 = “G97 S18000” Dim str4 : str4 = “G00 Z-6.” objStream. WriteLine(str0) objStream.WriteLine(str1) objStream. WriteLine(str2) objStream.WriteLine(str3) objStream. WriteLine(str4) Dim str5 : str5 = “M12” ‘’ generating curves For m = 0 To Ubound (arrPts) Step 1 If m=0 Then strpoint= (“G00”&” X”&arrPts (m) (0)&” “&”Y”&arrPts (m) (1)) objStream.WriteLine(strPoint) objStream.WriteLine(str5) End If If m<>0 Then strpoint= (“G01”&” X”&arrPts (m) (0)&” “&”Y”&arrPts (m) (1)&” “ & “Z.1 F166.667”) objStream. WriteLine(strPoint)End If Next ‘’ last bit Dim sq1 : sq1=”G00 Z-6.” Dim sq2 : sq2=”M22” Dim sq3 : sq3=”G00 Z-15.” Dim sq4 : sq4=”M22” Dim sq5 : sq5=”(End)” Dim sq6 : sq6=”G00 X2440 Y1220 Z-200” Dim sq7 : sq7=”M02” objStream.WriteLine(sq1) objStream.WriteLine(sq2) objStream.WriteLine(sq3) objStream.WriteLine(sq4) objStream. WriteLine(sq5) objStream.WriteLine(sq6) objStream. WriteLine(sq7) objStream.CloseEnd Sub

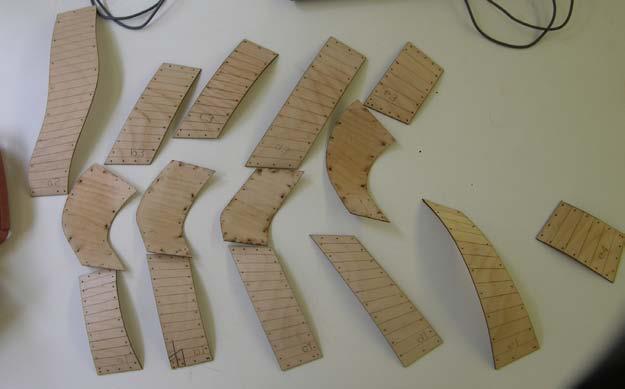

Fabrication

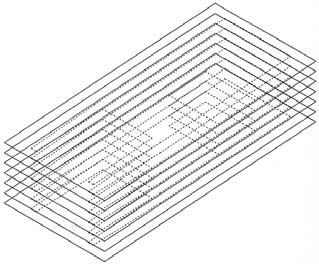

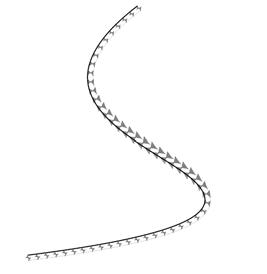

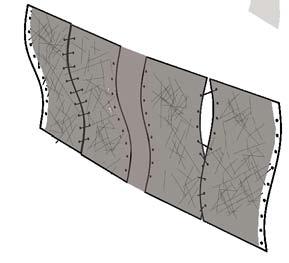

Before beginning the construction, the flat pieces were nested in Rhino files so that the top and bottom lines of the waves were along the grain to facilitate the manual bending process(fig. 3.1.8).

General construction Sequence

Phase 01: CNC milling of sheets (fig. 3.1.9). fig. 3.1.9

Phase 02: Sealing process on the outer side of the cut pieces plywood

Phase 03: Lamination of strips

Phase 04: Sealing the other side of the assembled strips /sanding of the borders

Phase 05: Assembly of the top and bottom fins

Phase 06: Placement of the 5m long strips from top to bottom

Phase 07: Rotation of the complete fin and strips structure to its final position and fixing of bolted joint at lower part of column

Phase 08: Lifting and securing of fins and boltconnection at top of column

Different tests were done at the beginning of the lamination process to decide the assembly method. Finally, the overlapping method was selected and the forming of a single strip a total of twelve pieces where required (six top and six bottom).

CNC milling

200 sheets of 1.5 mm thickness plywood were necessary to fabricate the 14 strips constituting the new canopy(fig. 3.1.11). Each sheet measured 1525x1525 mm. The bed of CNC machine used was 1220 mm width and thus, we had to re- cut the plywood sheets to 1525x1220 mm. A script was written in order to work with the Multi-CAM software used by the CNC where two drillers were used, 6mm for the cutting of the edges and 9mm for the cutting of holes for future bolting (fig. 3.1.9, fig. 3.1.10)

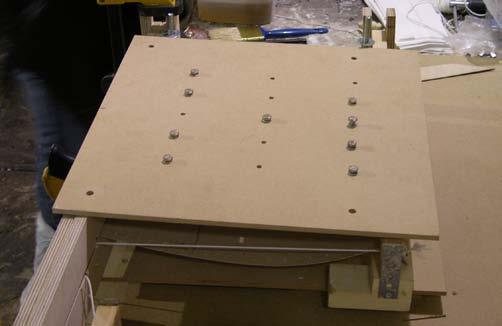

The precision of the entire canopy relied on fabricating the strips as precise as possible (fig. 3.1.14). In addition to the curvature of the individual waves, each strip was also curved overall. The curvature of the waves was governed by the height and length of each wave. In order to achieve the global curvature on each strip, a curved jig was carefully designed and built. The lamination process takes place on the jig. The process is a continuous iteration of the next steps: laminating, clamping, and bolting (fig. 3.1.15, fig. 3.1.16)

fig. 3.1.8 Rhino file

fig. 3.1.9 CNC milling machine

fig. 3.1.10 G-Code in Multicam software

fig. 3.1.11 Cut sheets of plywood

fig. 3.1.12 Cutting fiber glass pieces

fig. 3.1.13 Bolting strips

fig. 3.1.14 Jig under construction

fig. 3.1.15 Third strip curing

Significant knowledge was gained in the process of transferring the material capabilities into grasshopper model as parameters and of course vice versa. A ratio between strip height to the zigzag shape (from top view) was establish to allow the plywood get its bending without creating so much perpendicular force to the grain.

Each strip is laminated with fiber glass and resin in a sandwich and directly curved, bolted and held in position with clamps for at least one hour until the resin is dry. Subsequent strips are constructed on top of the previous, securing the relative position of the two strips with bolts (fig. 3.1.17 ).

The plywood is varnished before and after the lamination in order to protect the wood from humidity. Assembly - Placement of the 5m long strips from top to bottom

The assembly of the entire canopy was done by groups of strips in situ.

The fins were disposed on the terrace in order to assemble the groups of strips to the slots previously cut on them. In order to test the lifting process some attempts of the rotation of the fins were done with only one group of strips on it. Afterwards, the entire lower fins are positioned on the outer side of the balustrade, while only a small section of the upper fins goes over the terrace fencing. The connection between the top and bottom fins was first thought to be pinned similarly to the one at the top of the column. However, providing a momentary connection at this position helped with distributing the vertical load in between (fig. 3.1.18)

3.1.16 Close capture of voids differentiation

3.1.17 Laminating-Clamping-Bolting Process

3.1.18 Fixing the group of strip to fins

3.2.1

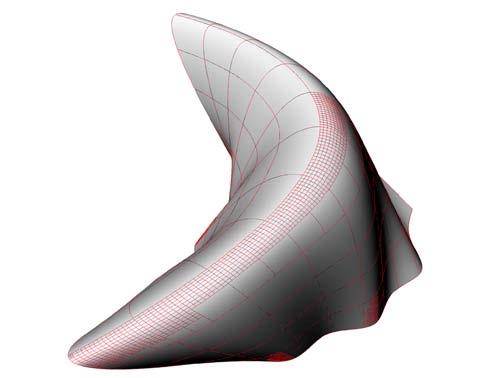

Having as a hypothesis that torsion pre-stress the wood fibers and avoids the buckling of each piece in order to support more load. The experiments were run with the expectation that the fiber glass with resin increases the properties of the wood and allow the performance of a light structure bearing larger loads.

The next 4 processes were taken in order to run the physical experiments, a torsion machine was built and a testing loading machine

When the torsion is given on the central axis the pieces that had 90degrees of torsion remained at 45 degrees of torsion, this is called spring back which is the property of the materials to change back. In this case, according to the original torsion and according to the ratio of the reinforcement process.

When the torsion is not given on the central axis it remains at 90 degrees as the pre-stress is not that high. The pieces get a predetermined trend to bend towards the displaced axis.

The reinforced process was initially done with different parameters in order to determine the output of each procedure. Resin on one side of the wood, fiber glass perpendicular to the wood fibers + resin, fiber glass parallel to the wood fibers+ resin, fiber glass around the knots + resin.

A priori to disassembling from the torsion machine the pieces were subjected to dry less than 23 degrees.

As the piece of wood has been in torsion and apriori reinforced, each one was tested under an increasing load in the same direction of the wood fibers.

The tests showed that a thin piece of wood under certain procedures can support considerable loads and confirm the knots as the weak area of any piece of wood.

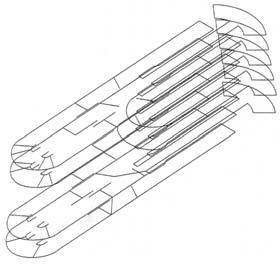

The variation in the torsion degree gave a change of direction to the assemblies which are remarkably efficient for geometries to avoid buckling; this means the “triangle” form increases the inertia on the structure (fig. 3.2.1.9)

Timber is a material with big variation on its internal structure. Each piece can display a different behavior according to its growth conditions; the reinforced material can give continuity to the wood fibers through glass fibers around the knots.

The pieces had a potential in carrying loads along the fibers and the torsion increase the section of the piece keeping it light (thickness of 3mm) but strength. The torsion is like a virtual bounding box. In testing, the results showed the reinforced pieces has a tendency to lose the torsion and start bending when the load applied is over 20 kg.

BENDING

TP TORSION PROCESS

TP TORSION PROCESS

before after

before after

RP REINFORCED PROCESS

RP REINFORCED PROCESS

RESIN

RESIN

TE TESTING EXPERIMENTS

TE TESTING EXPERIMENTS

UNRETURNABLE

UNRETURNABLE

BENDING

BENDING

RESIN + FIBRES

RESIN + FIBRES

PERPENDICULAR 1 LAYER

PERPENDICULAR 1 LAYER

RANDOM 3 LAYERS

RANDOM 3 LAYERS

RANDOM 5 LAYERS

RANDOM 5 LAYERS

AROUND KNOTS

AROUND KNOTS

fig. 3.2.1.1 Knot in strip wood

fig. 3.2.1.2 Torsion machine

fig. 3.2.1.3 Reinforced strip with fiber glass-one direction

fig. 3.2.1.4 Reinforced strip with 3 layer of fiber glass - random direction

fig. 3.2.1.5 Reinforced strip with fiber glass around the knot

fig. 3.2.1.6 Twisted pieces reinforced

fig. 3.2.1.7 Cracked pieces under load

fig. 3.2.1.8 Assembly of twsted pieces

fig. 3.2.1.9 Test aproximately 50kg on strips without displacing from its original position

TORSION PROCESS

REINFORCEMENT PROCESS

fpa=fibers paralell

fpe=fibers perpendicular fr= fibers random

fk=fibers around knots

lay=layers of fiber

TEST EXPERIMENTS

s1= side 1

s2= side2 s1/s2

0.60m 0.60m 0.60m 0.90m 0.60m

0.05m 0.05m 0.05m 0.05m 0.05m

0.003m 0.003m 0.003m 0.003m 0.003m 1 0 1 1 0

fig. 3.2.1.10 Chart of parameters and craking results

fig. 3.2.1.11 Alternatives of assemblies

fig. 3.2.1.12 Stable Pair pieces assemblies

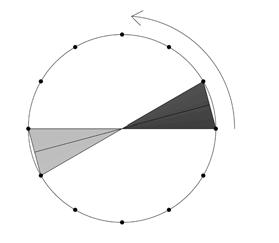

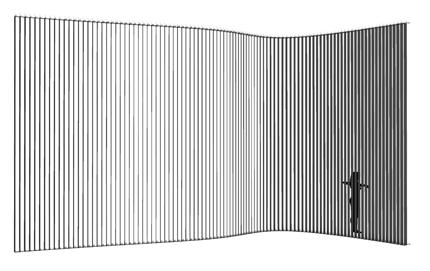

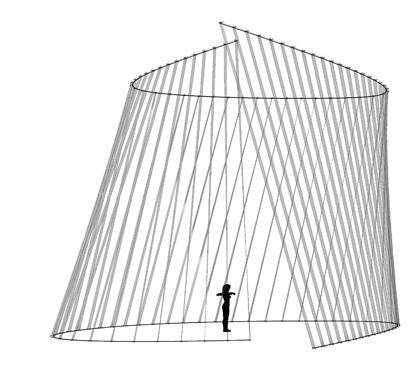

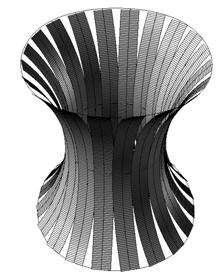

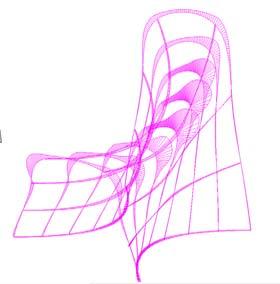

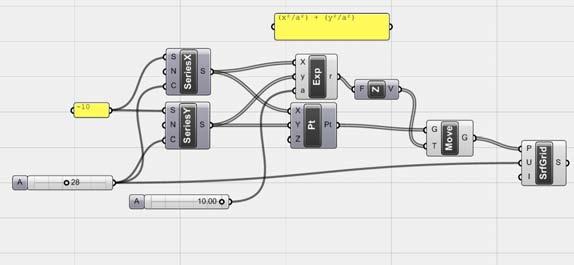

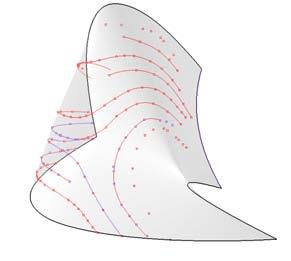

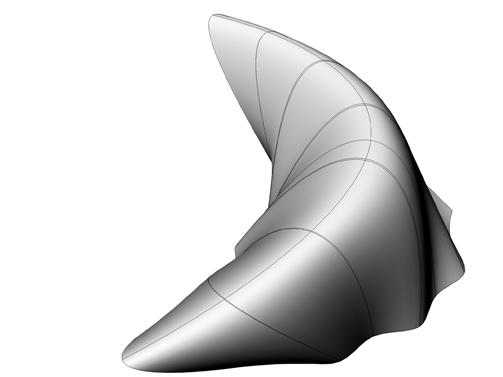

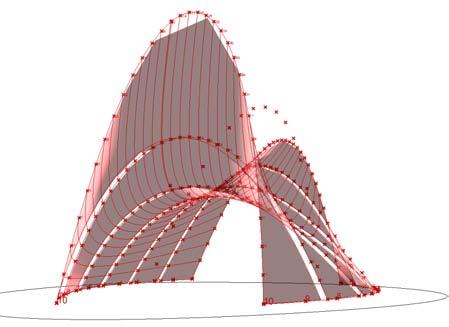

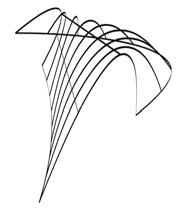

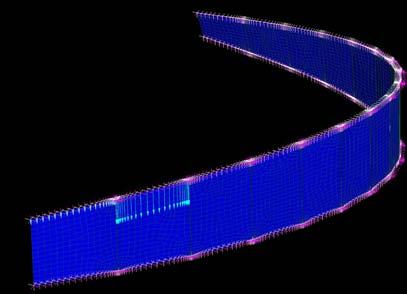

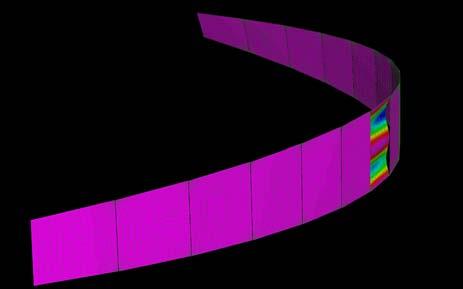

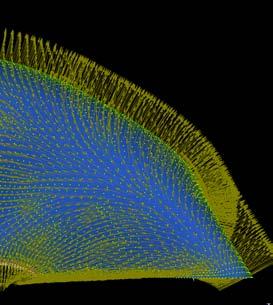

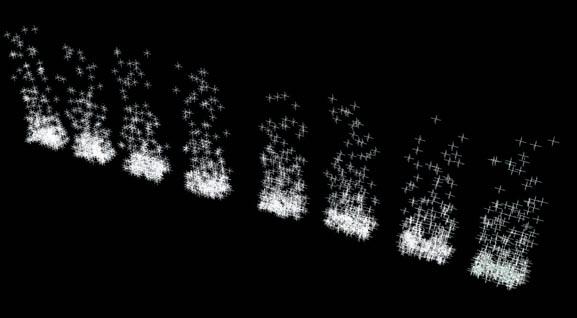

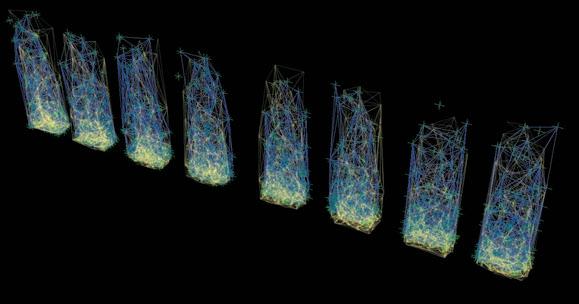

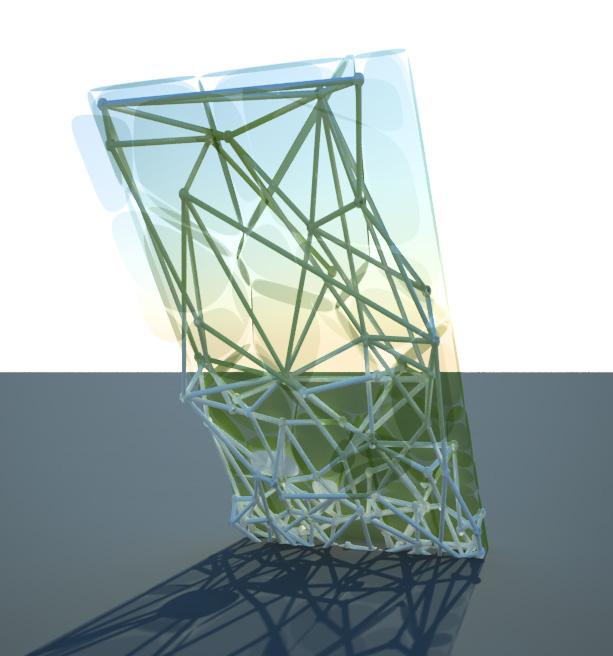

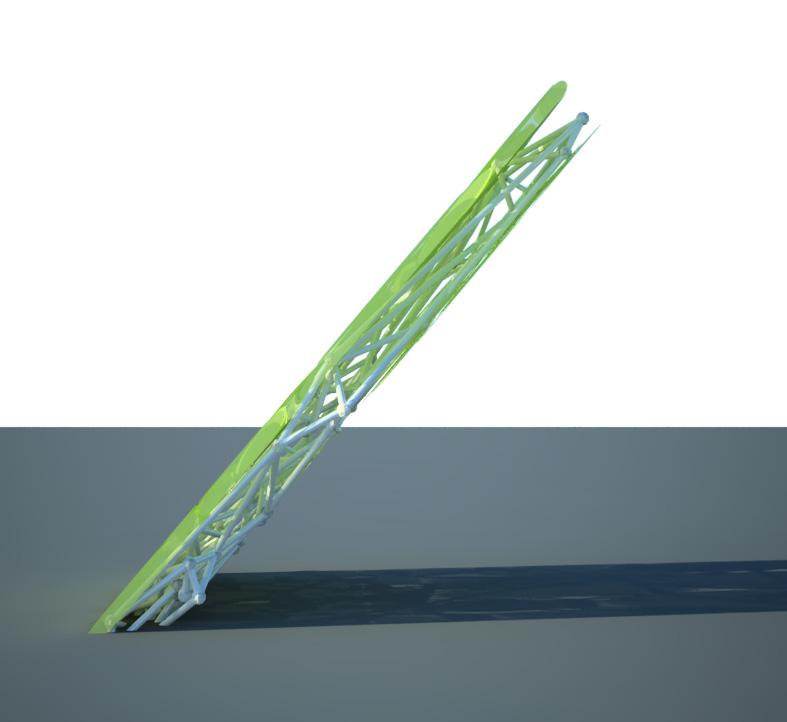

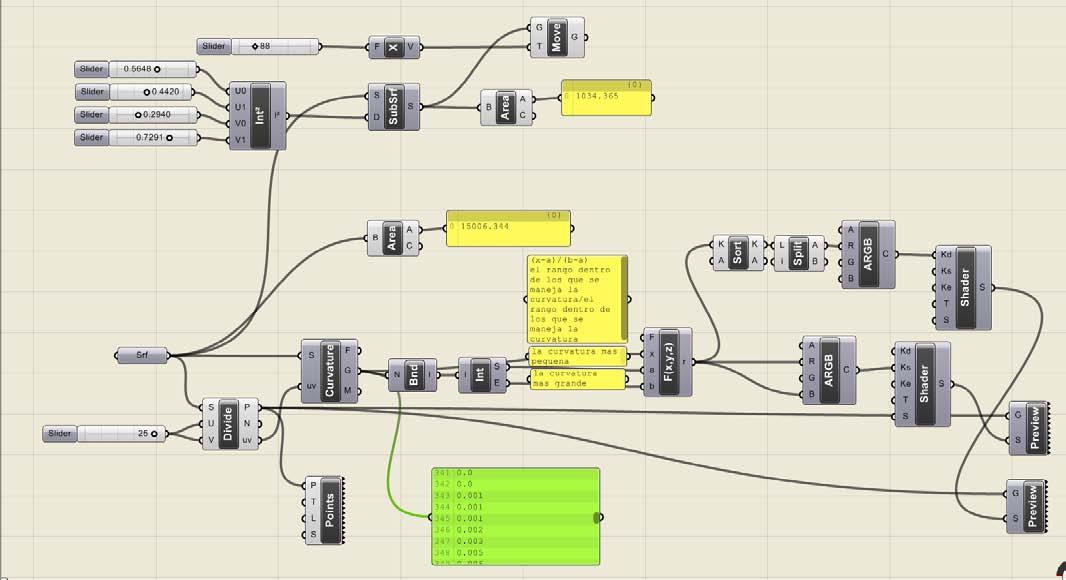

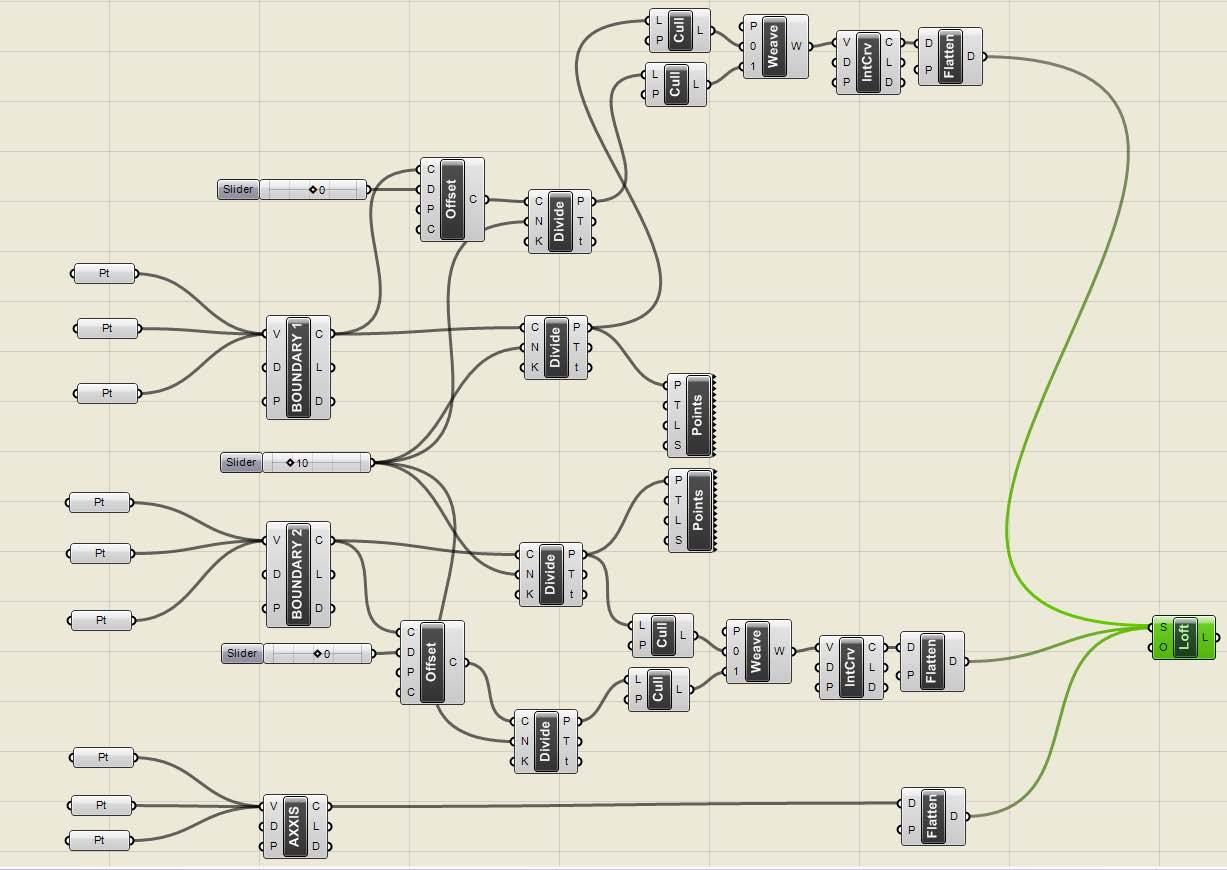

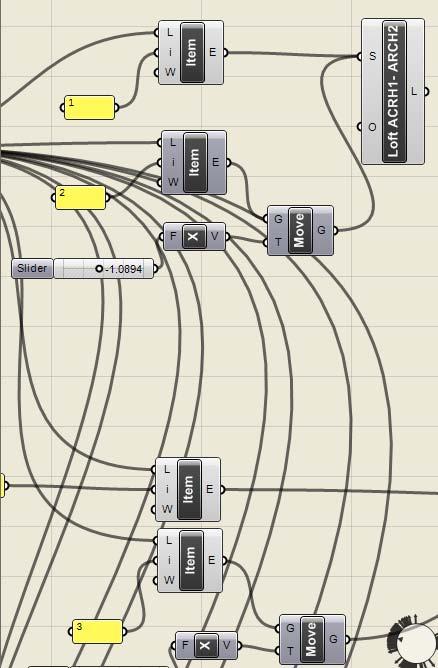

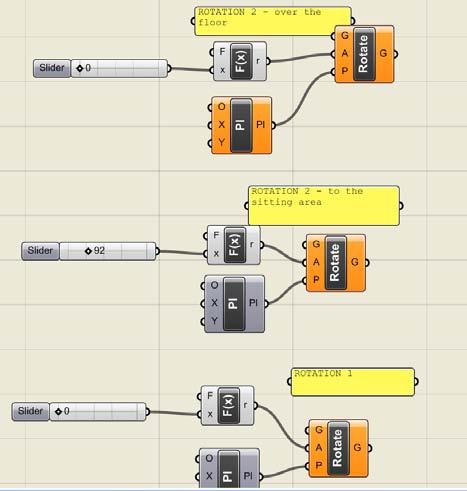

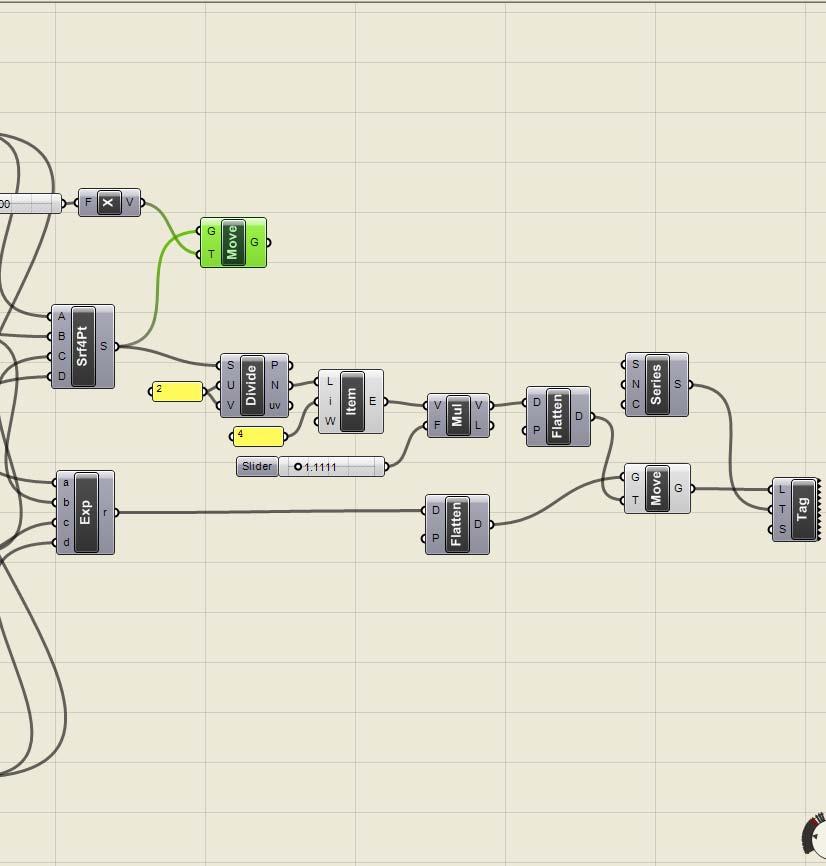

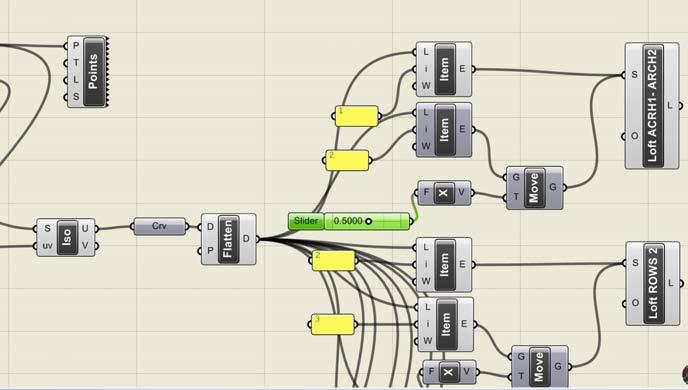

As a further exploration of the experiments done in Hooke Park, a Grasshopper logic* was developed to observe the advantages of controlling torsion individually and rotation in the overall form.

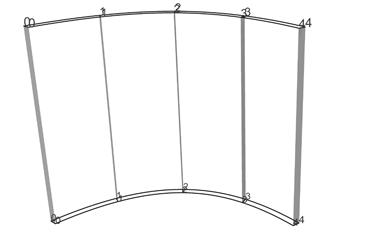

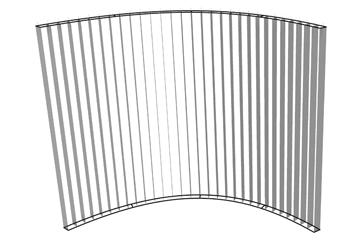

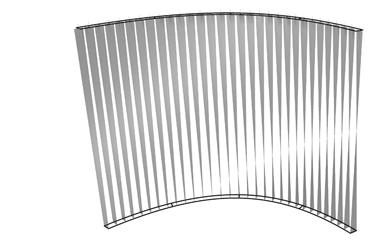

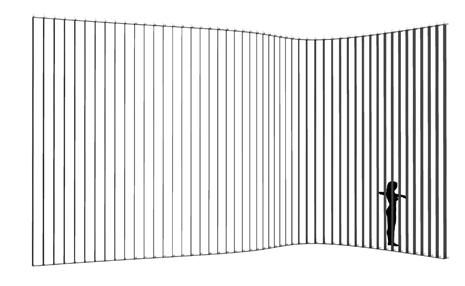

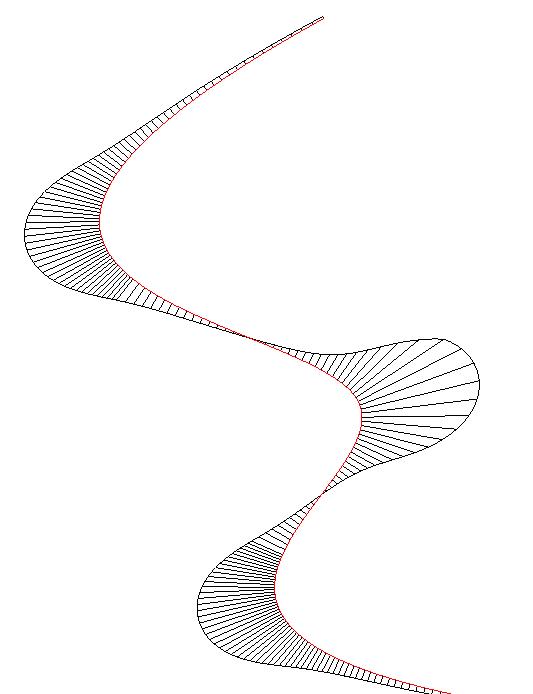

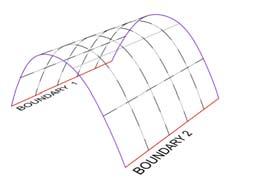

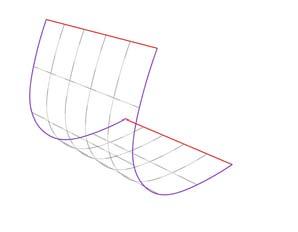

Two boundaries were defined and subsequently divided into equal segments; one line was located into each division point at the center and perpendicular to the boundary curve. As the number of segments from top and bottom are the same, the lines from the top are lofted with their correspondent lines at the bottom to create the strips. The torsion of each strip can be controlled by rotating the top lines, each on its own axis center.

Based on the strips density and torsion, visibility and transparency can be tested by changing the parameters.

These patterns are shown in the wall display. If this geometrical digital test could be done in phys ical experiments again, the torsion as it was studied in previous experiments added stiffness to each piece and in this case to the entire wall expects the geometry driven by the boundaries curves would define the strength in the total structure.

[See appendix]

Boundary 1

Boundary 1

Boundary 2

Boundary 1

Boundary 2

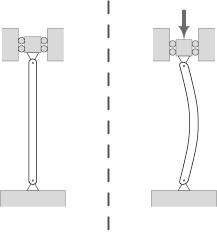

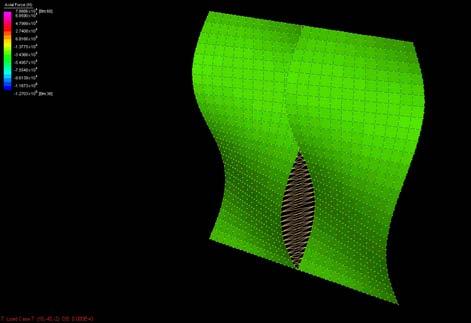

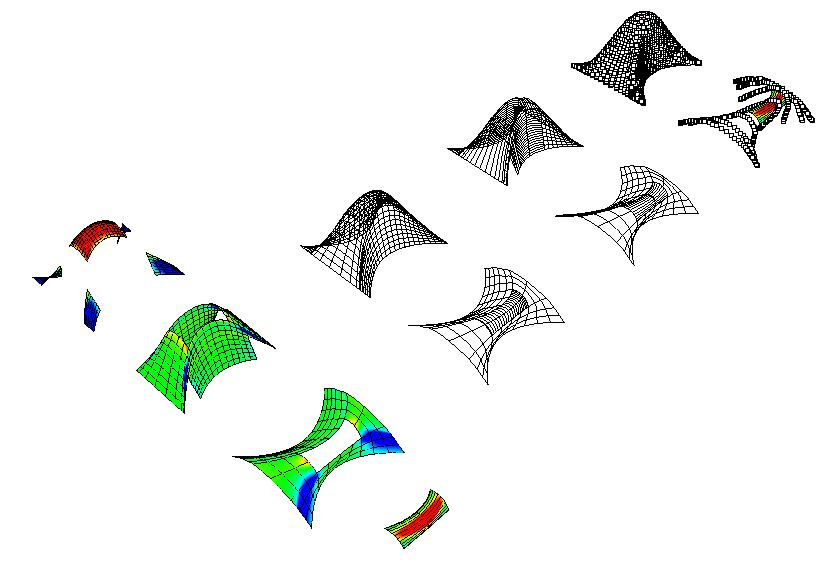

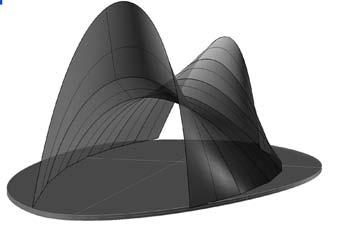

In engineering, buckling is defined as “a failure mode characterized by a sudden failure of a structural member subjected to high compressive stresses. This mode of failure is also described as failure due to elastic instability. Mathematical analysis of buckling makes use of an axial load eccentricity that introduces a moment, which does not form part of the primary forces to which the member is subjected.”(Wikipedia)

In order to obtain stabled buckles the form needs to be working according to the material, reason why for instance composites which have high yield stress values are known and utilized to avoid buckling in wing aircrafts.

However, buckling will be utilized on this research as a manufacturing process thus, it won’t be consider a failure as in the Timber Composite the load will be transfer through the GRP material.

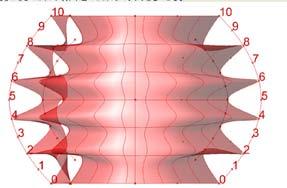

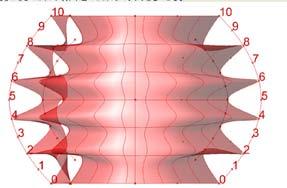

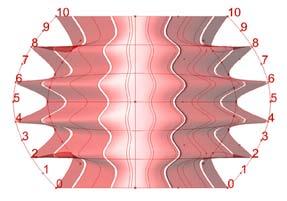

The graphs below show why the buckling modes on the plywood do not affect or decrease the plywood capabilities as they are still in the elasticity region.

Besides it will be seen in this chapter that the plywood won’t bear load when working on the final structure but it is important to state that the followings procedures won’t make the plywood weaker as the buckling modes stay in the elasticity region.

The load capacity of a material is determined by the Young Modulus, the Inertia area and the length of itself. The project will combine the three factors in order to increase structural capabilities on the final structure.

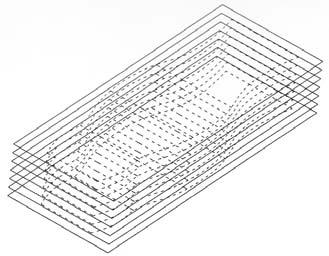

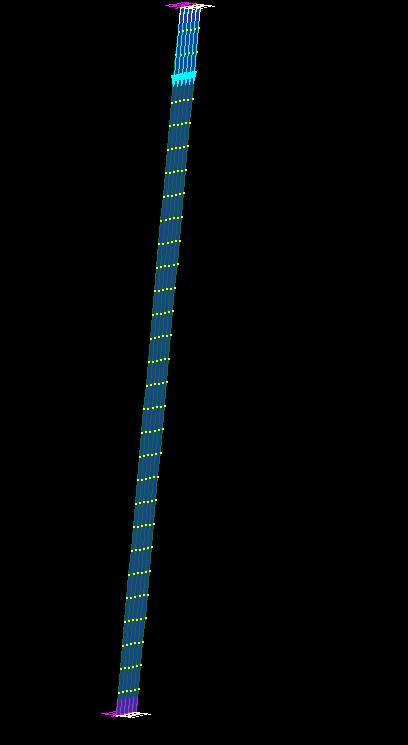

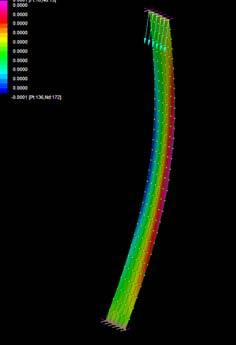

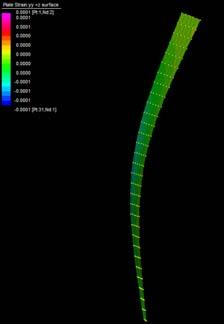

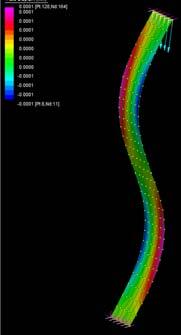

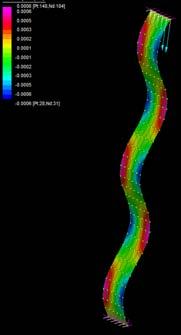

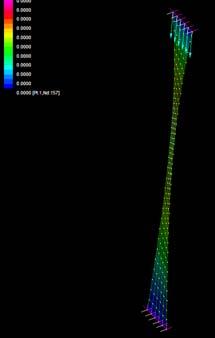

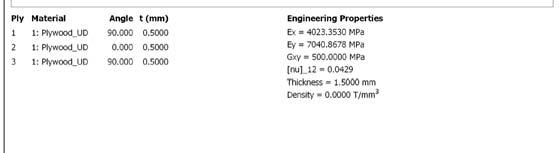

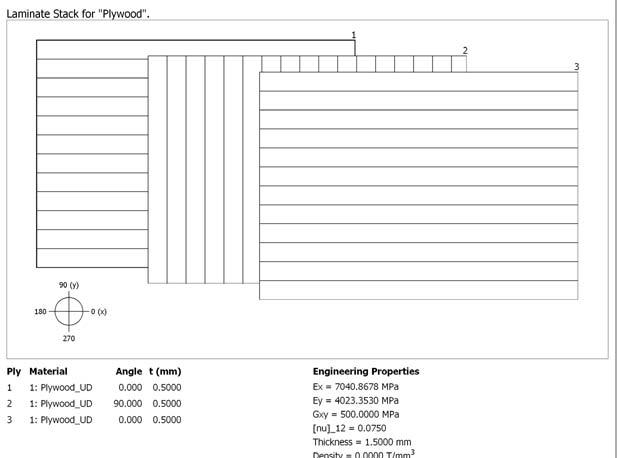

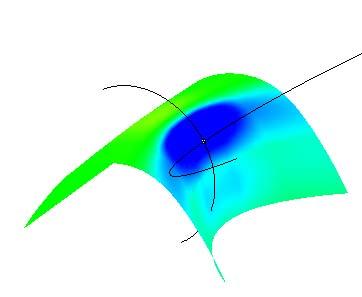

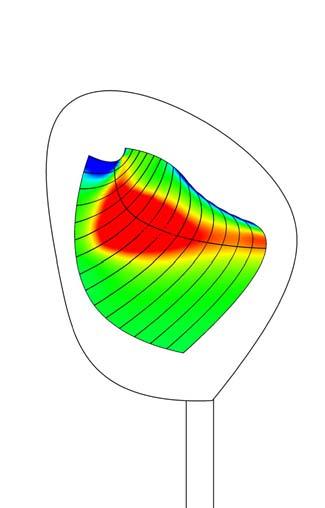

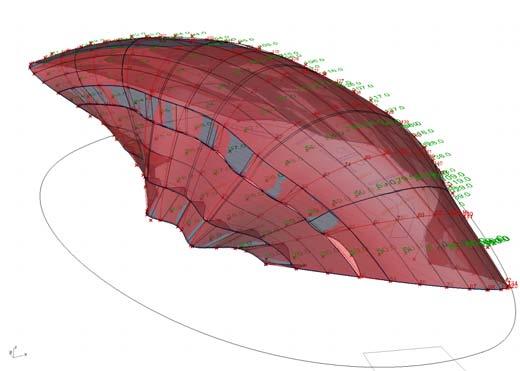

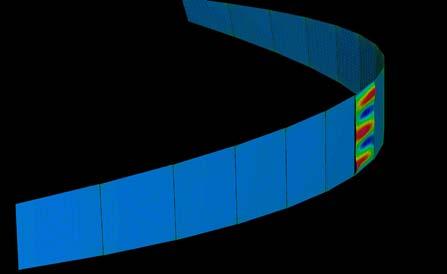

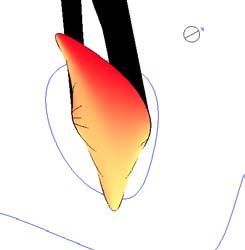

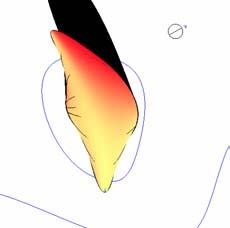

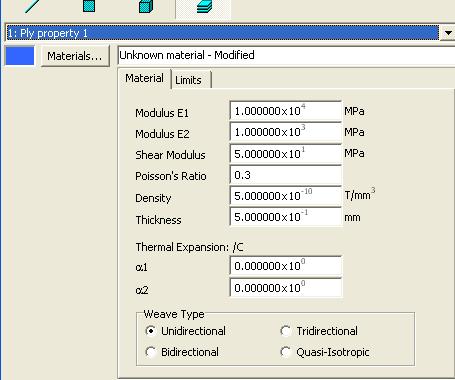

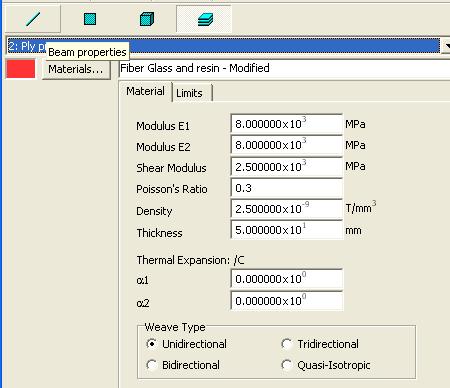

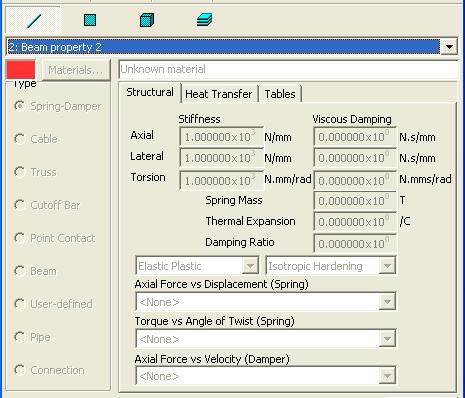

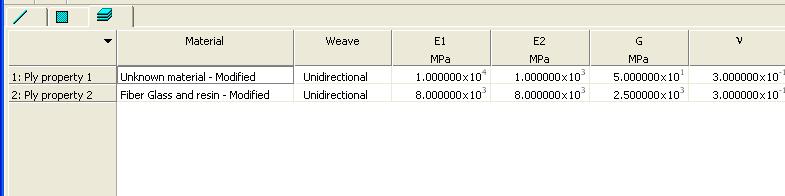

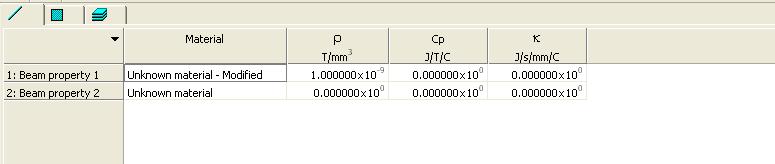

These sets of digital simulations were done in pieces with the same dimensions as the previous physical strips experiments (3mm, 50mm, and 600mm). The purpose was to test load capacity in strips of the same size but with different material composition.

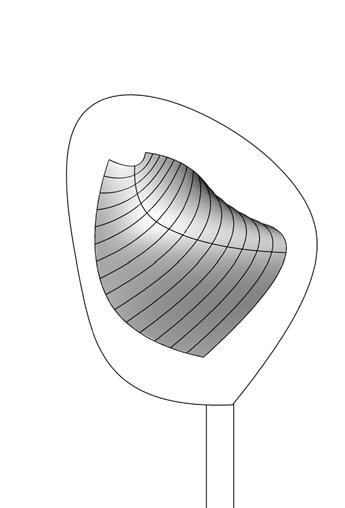

The simulations were run into Strand7* where the wood properties and the Glass Fiber composite properties were set. Linear Static Analysis was run previous to the Linear Buckling Analysis. First at all, the strip was meshed in a set of 6*60 nodes. The 6 nodes at the bottom boundary were fixed in translational (x,y,z) and rotational, the 6 nodes at the top were fixed in translational (x,y) and rotational. This set was in order to constraint the strip from displacing from its own central axis.

By applying 100N on the top boundary the Linear Buckling Analysis would give us several modes which are the result of increasing the load not gradually, but removing the load and applying it again; the last buckling mode is usually when the piece lose its own axis, and this is the reason why it shows a twisting piece. Observing the buckling modes of the four strips we could easily deduce they display the same pattern even when the bearing load is different from one to another.

Two main evaluations were deduced from these simulations. The strip 2 and 3 have very similar load capacity through the first 6 buckling modes, however the strip 3 (wood, fiber glass and resin) took more than the double of the force. Therefore, thickness is an important parameter to take into account at the time of defining a proportion of one or another material. Definitely the pre-twisted piece (strip 4) could take more than double of the force by replacing one laminate of wood for one laminate of GRP.

* Strand7 is a Finite Element Analysis (FEA) Software

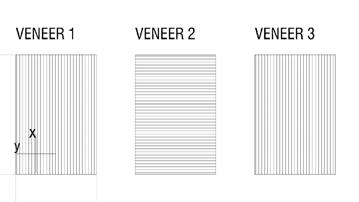

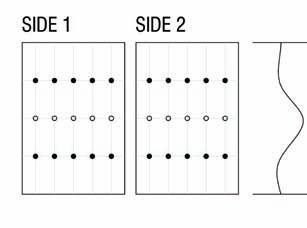

3.3.1.1 Grain direction of veneers

Outer layers horizontal grain direction

fig. 3.3.1.2 Outer layers vertical grain direction

Fixing the top boundary

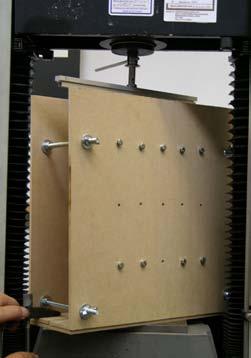

fig. 3.3.1.3 Loading machine

fig. 3.3.1.4 Constraint machine

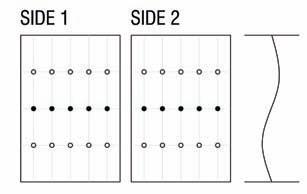

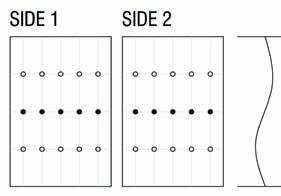

fig. 3.3.1.5 Horizontal grain direction-constraints

fig. 3.3.1.6 Vertical grain direction-constraints

fig. 3.3.1.7 Horizontal grain direction-constraints

fig. 3.3.1.8 Vertical grain direction-constraints

fig. 3.3.1.9 Horizontal grain direction-constraints

fig. 3.3.1.10 Adjustment of the experiment

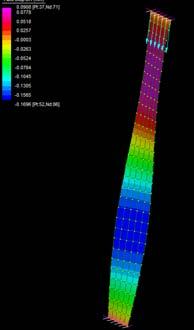

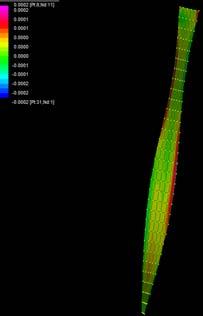

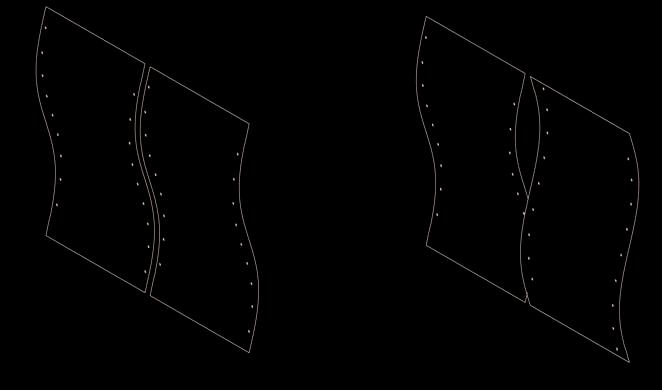

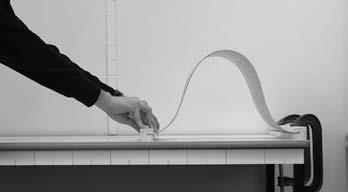

The next experiments were run at University of Reading, pre-stressing the plywood in a form finding process to obtain extreme curvatures. The exploration of these experiments looks towards deformations on the plywood as well as the implementation of a robotic machine that can produce and control the curvatures in the plywood piece by constraining some areas of the surface.

As it is already shown in previous experiments when applying load on the border of any piece (boundary), precision is required. As it is so sensitive, the horizontal displacement of the boundary or the none even force application could result in significant none acquires results. Therefore, the plywood piece was fixed at the top boundary and at the bottom and the force was applied for every sample buckling individually. The forces were checked on the computer as well as the z-displacement.

The results

Sample 1 has the outer veneers with horizontal grain direction which makes the piece bend quickly taking only 20N before breaking the piece. Sample 2 has the outer veneers with vertical grain direction which makes the piece take more than 4 times the load than the Sample1. This situation leaving the surface free of constraints, while holding the Samples at the center the comparison was 40N to 400N.

Same set of constraints were set for Samples 3 and 4, 5 and 6 respectively and with large differences between the horizontal grain plywood to the vertical. By digital experiments and the experience with the material buckles, forms are predictable at certain points, what is not predictable is which side of the plywood will deform, as it can be either side. By constraining only one side of the surface the robot tells the surface (gives a clue) which side will buckle. The constraints can reduce or increment the load that one piece requires to get certain deformation and this is where the control of the machine happens on the surface.

The machine could be used in a manufacturing technique to reinforce plywood as the surface area can be free (none having a pressing mold at any side). Ideally the constraints can be adjusted, the load could be applied and therefore the buckling would appear. As this process happens the constraints could be removed and the reinforcement process could take place with any

of the placing fiber methods already studied (most likely spraying the chopped fiber glass).

Another interesting method to develop would be to make the constraints in pneumatic system and probably controlled by Arduino program, which can establish the connection between the physical robot and the software.

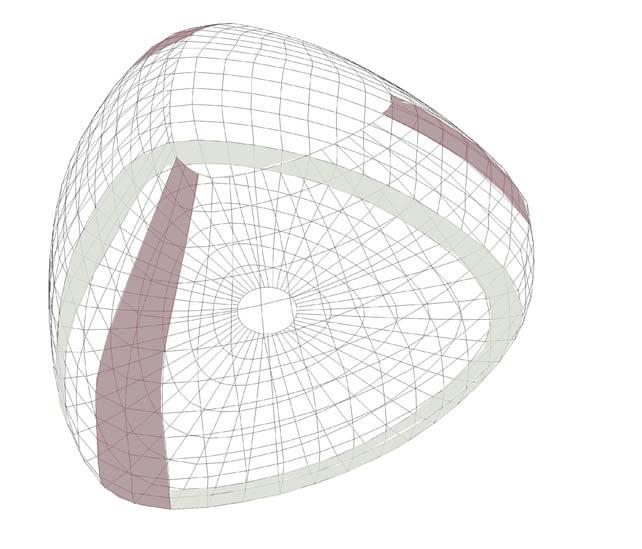

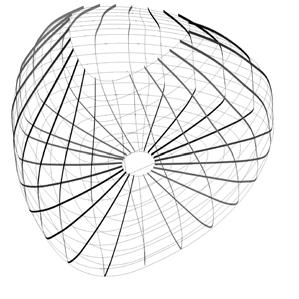

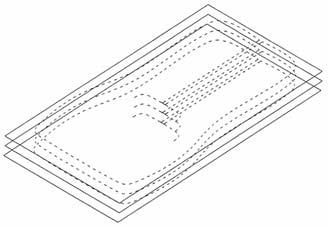

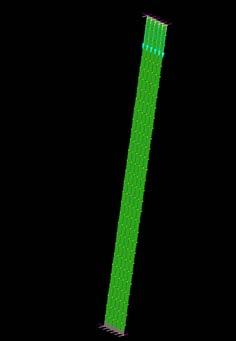

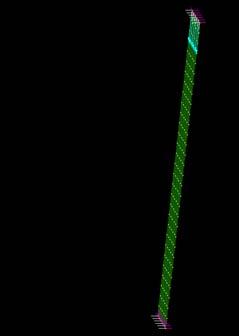

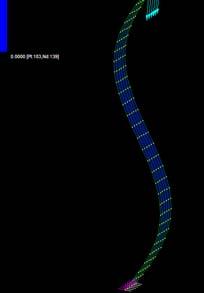

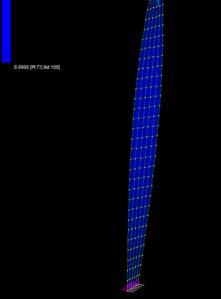

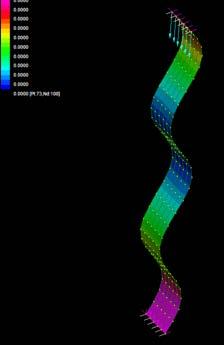

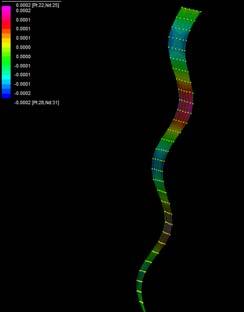

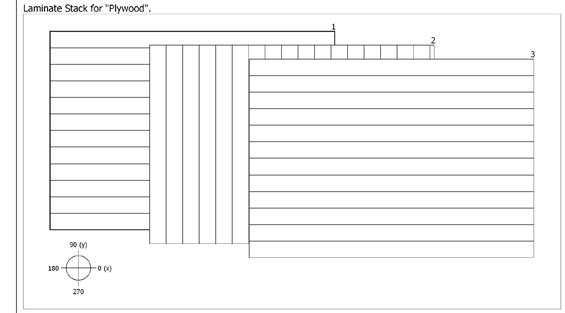

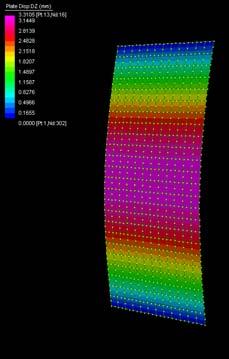

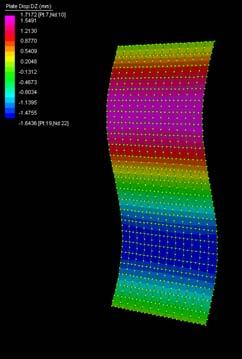

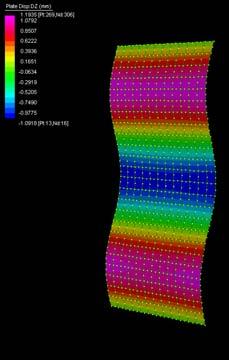

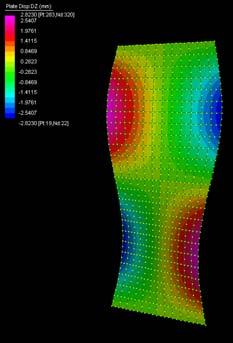

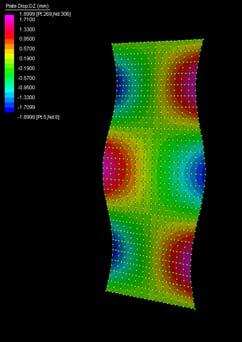

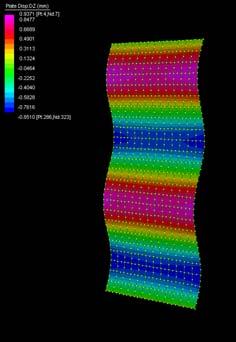

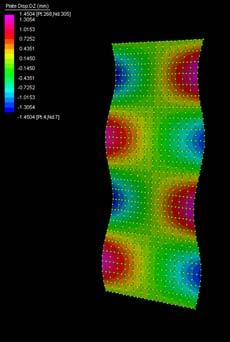

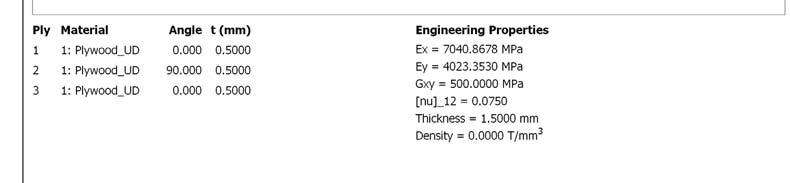

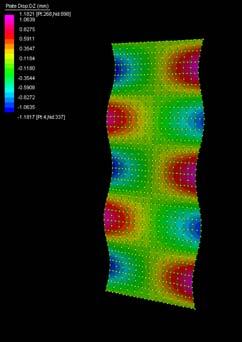

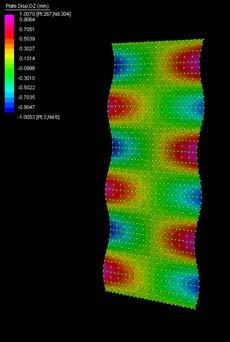

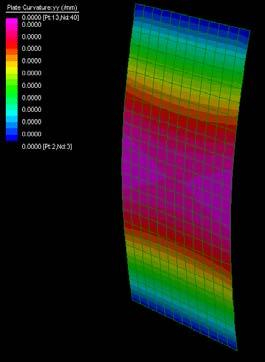

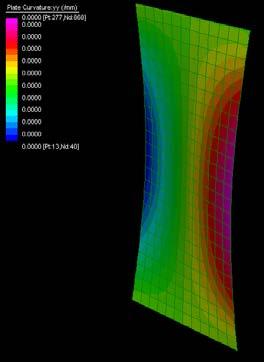

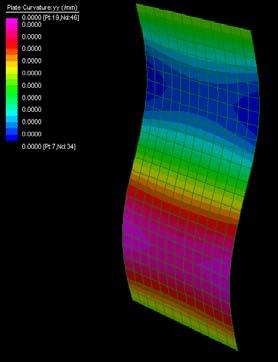

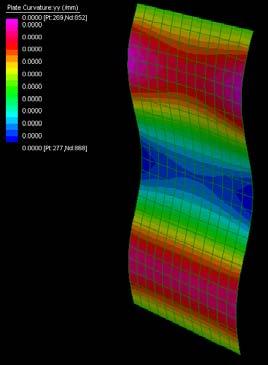

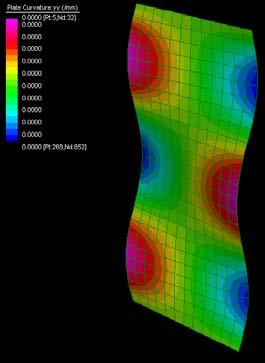

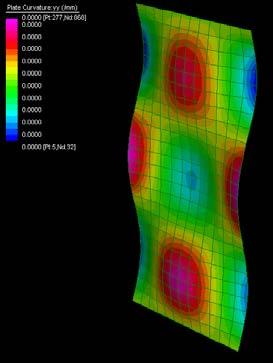

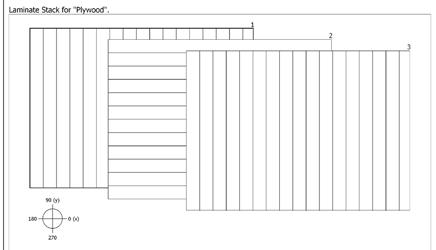

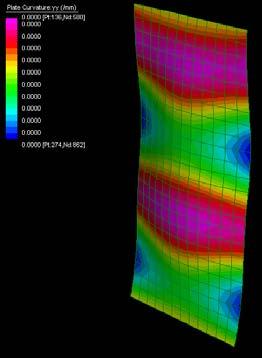

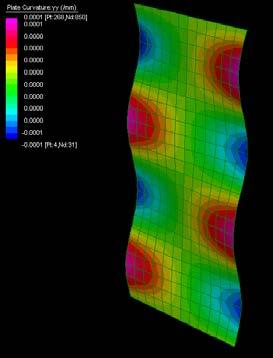

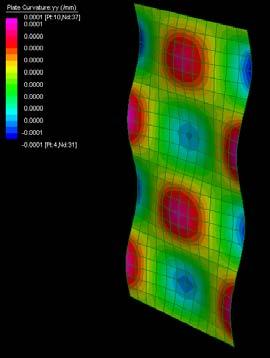

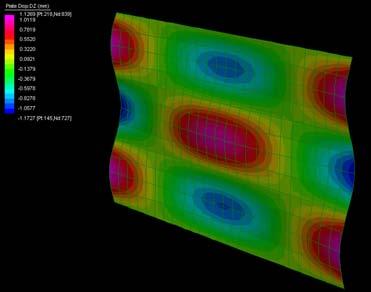

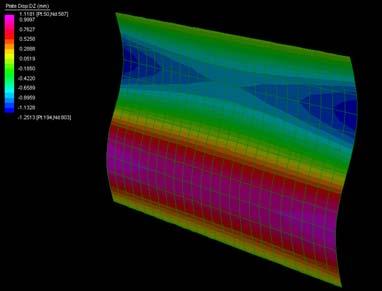

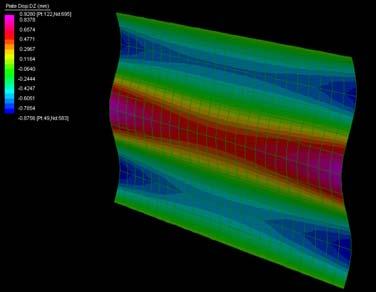

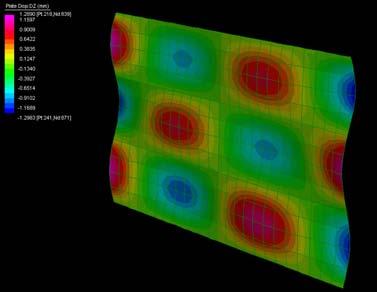

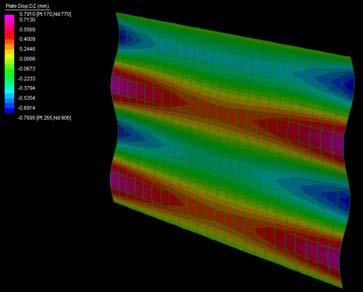

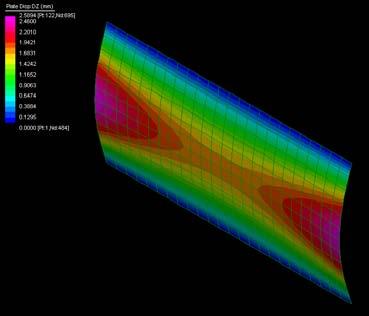

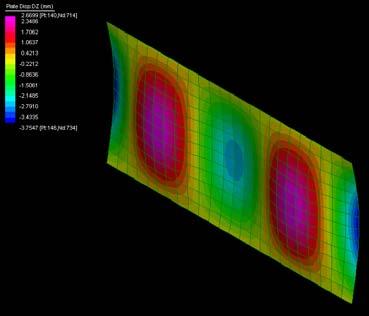

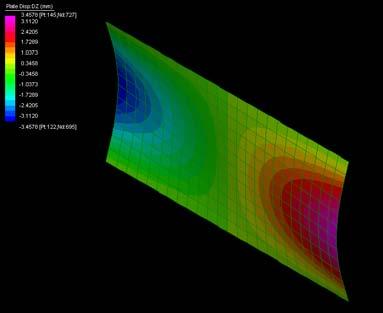

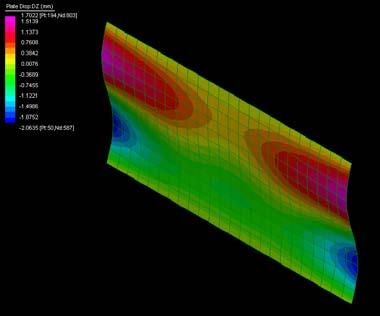

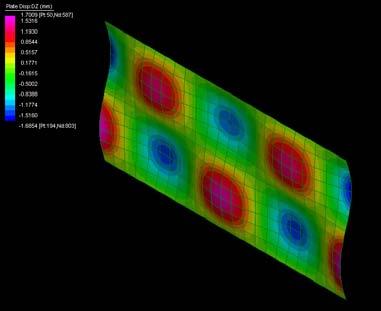

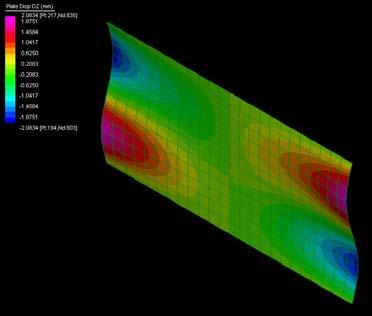

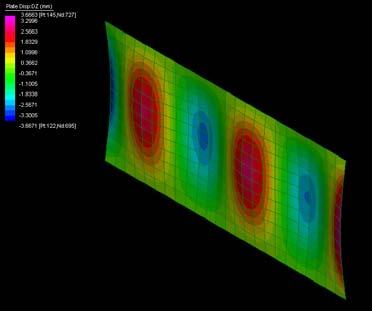

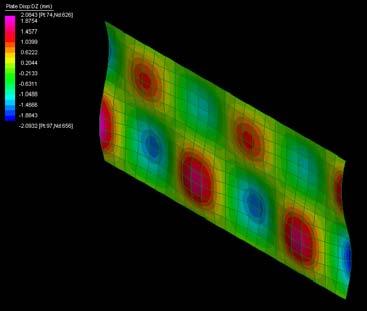

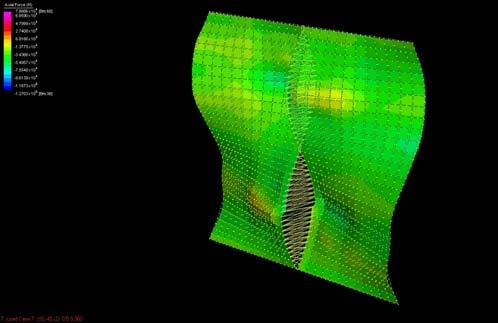

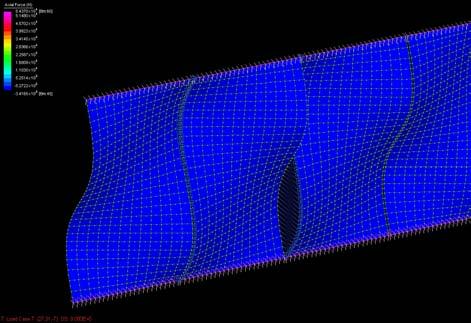

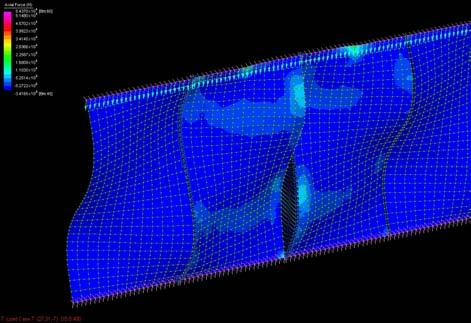

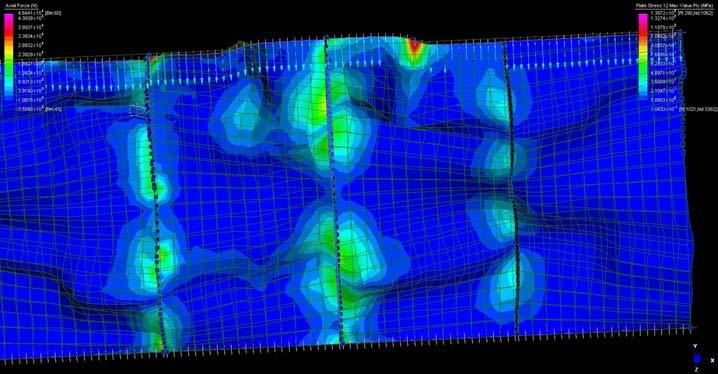

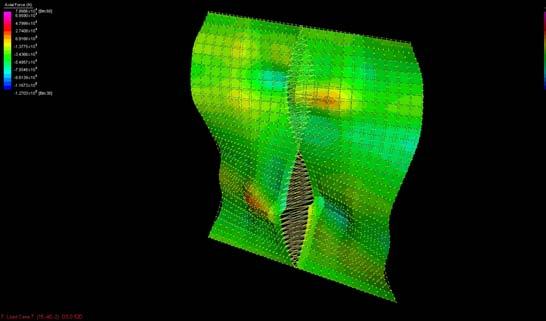

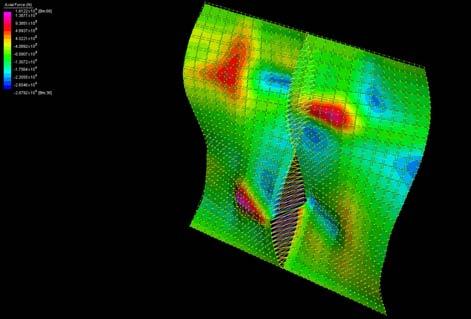

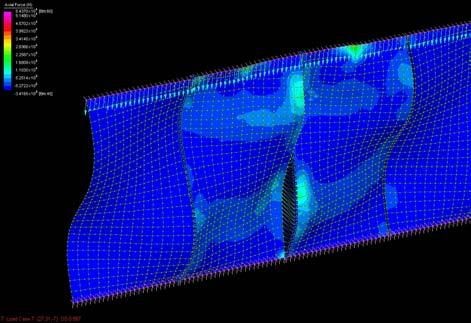

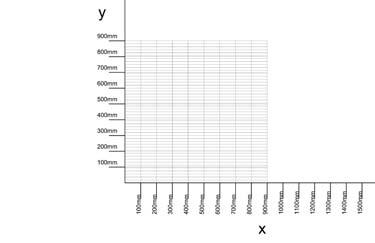

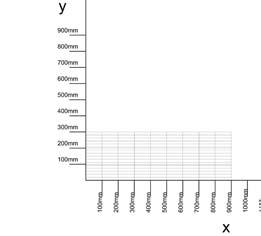

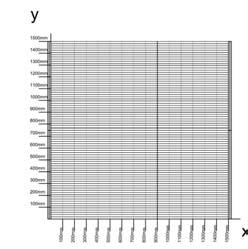

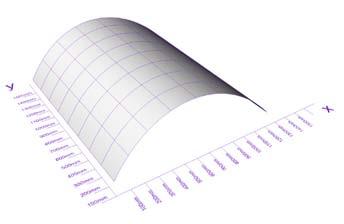

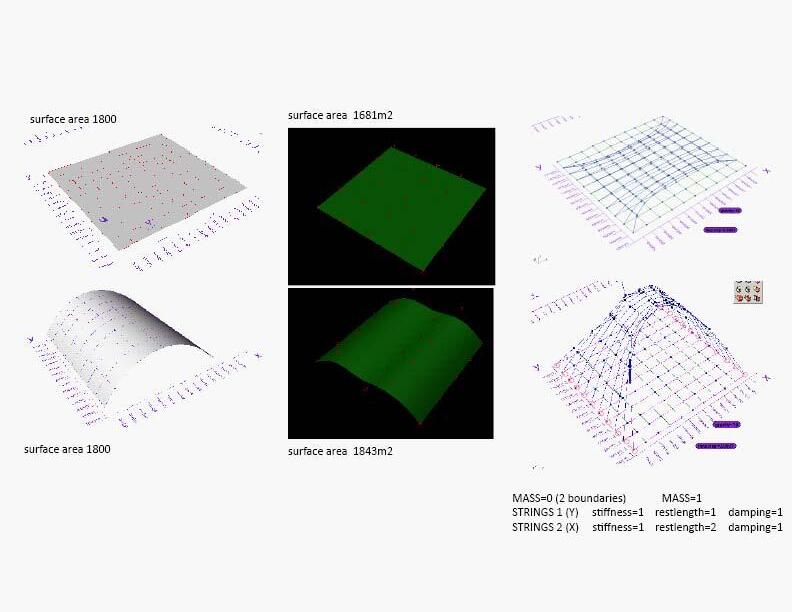

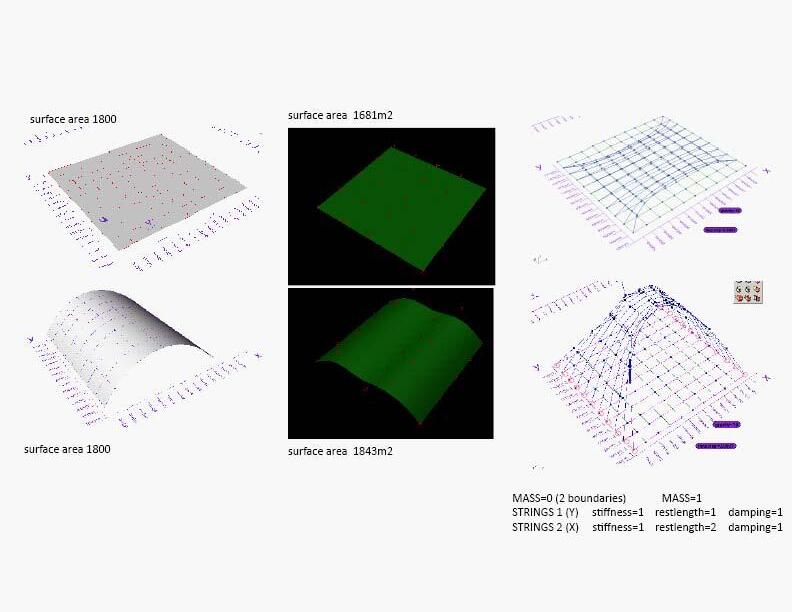

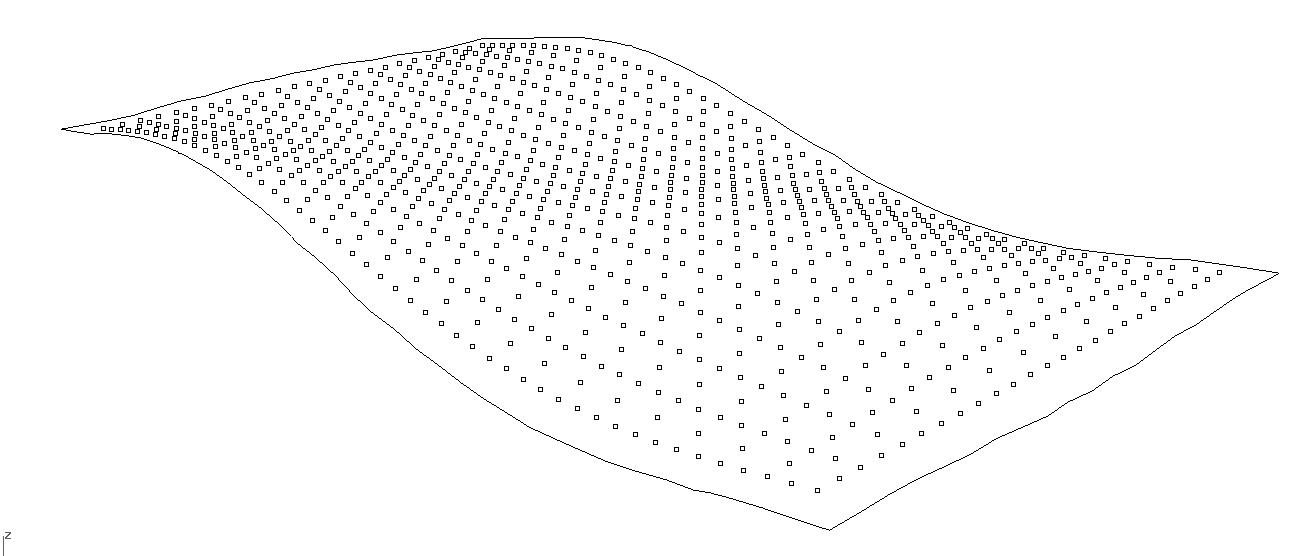

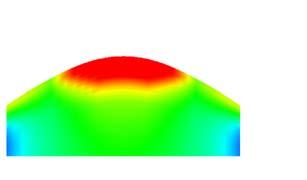

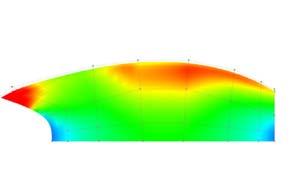

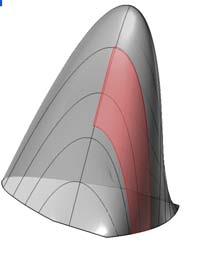

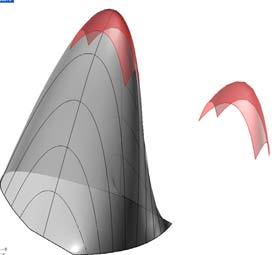

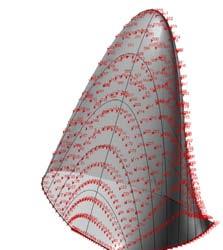

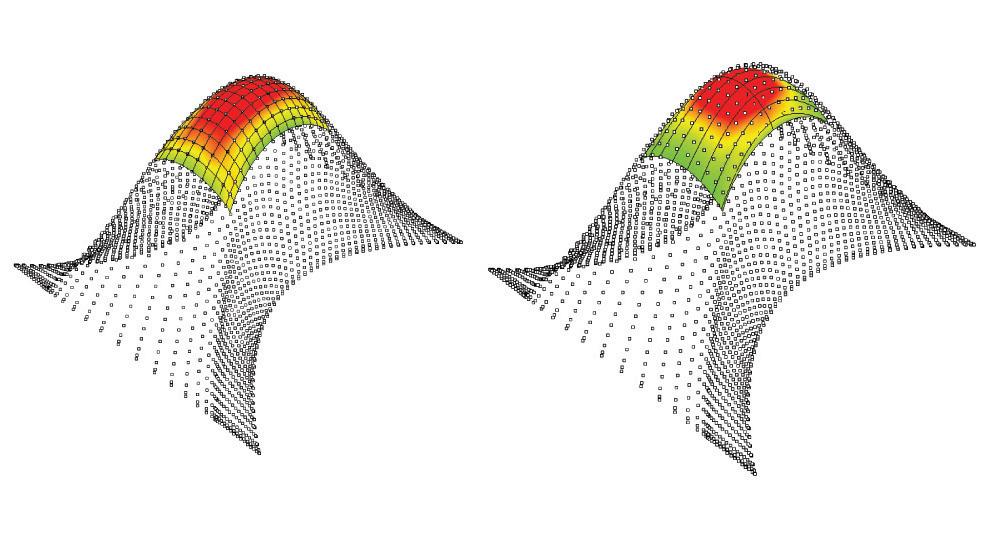

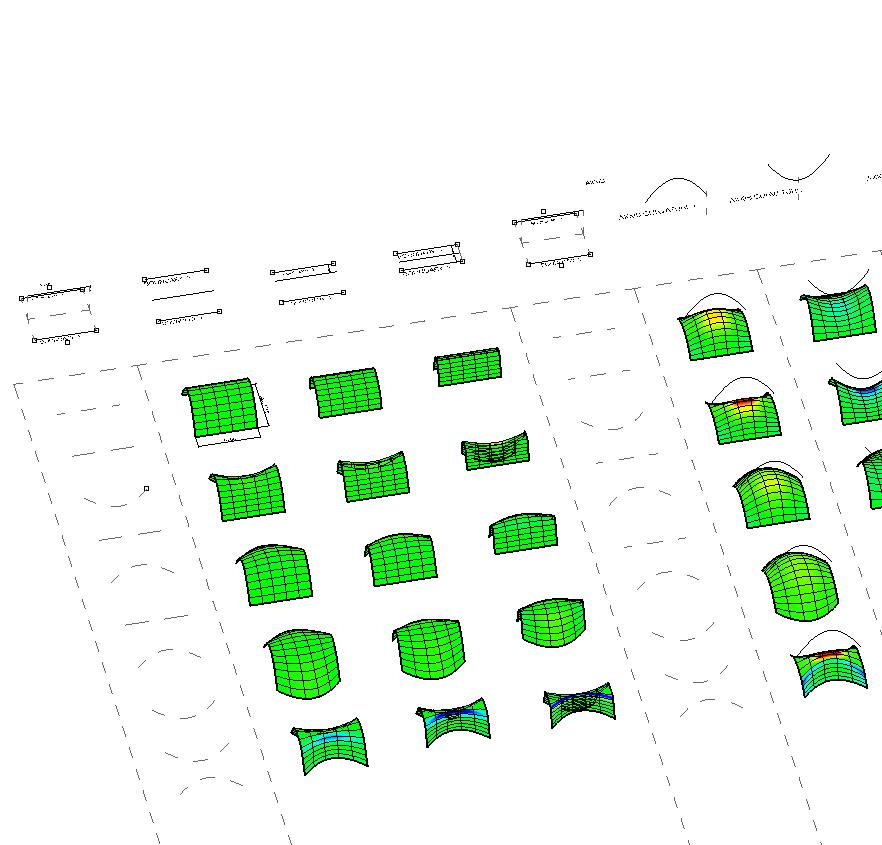

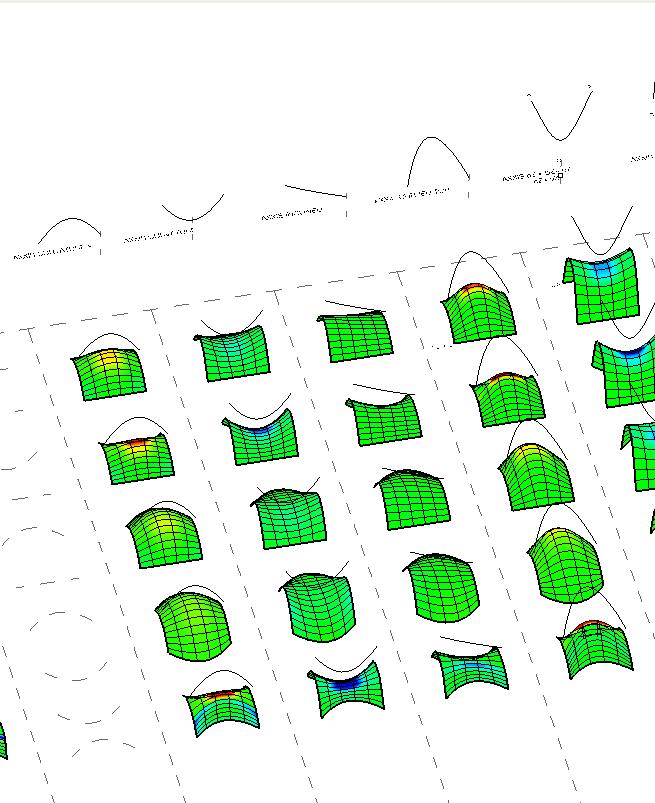

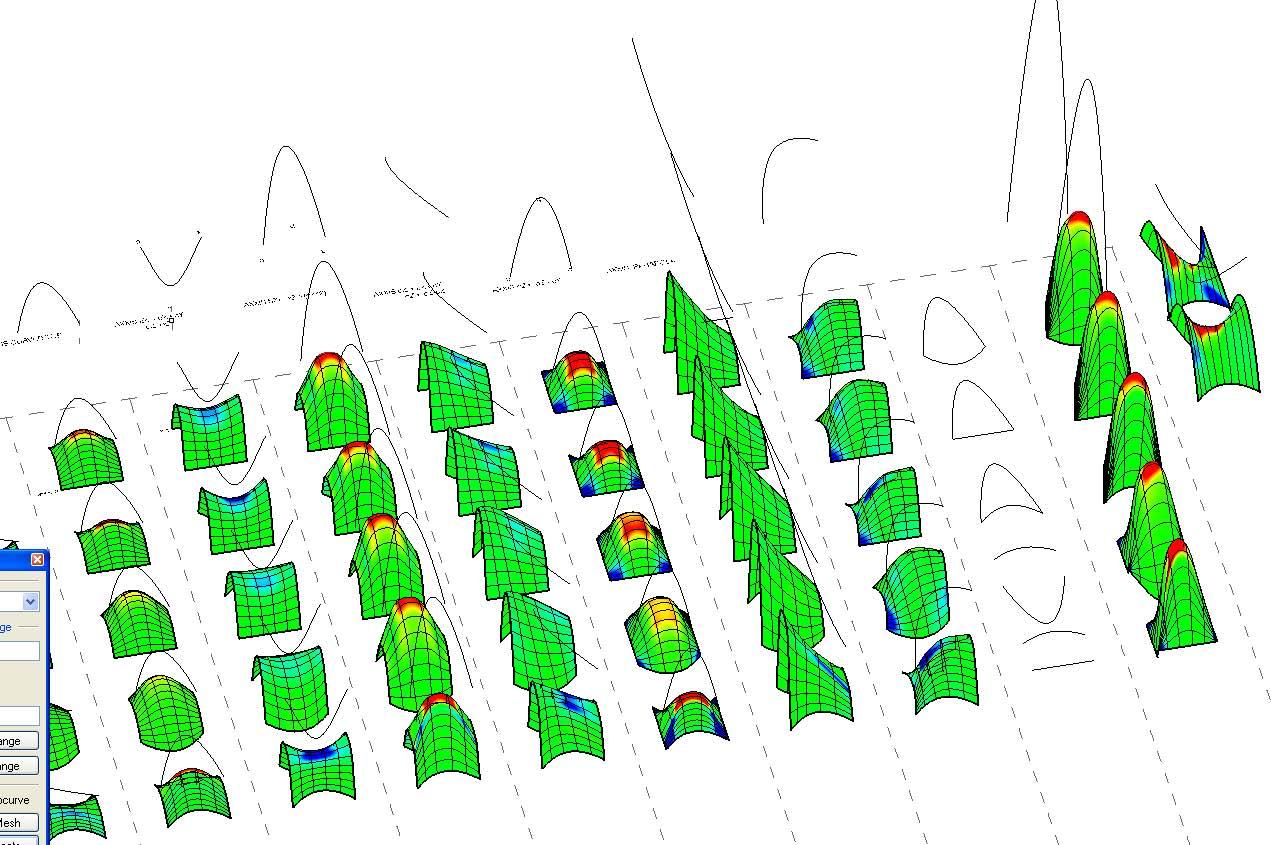

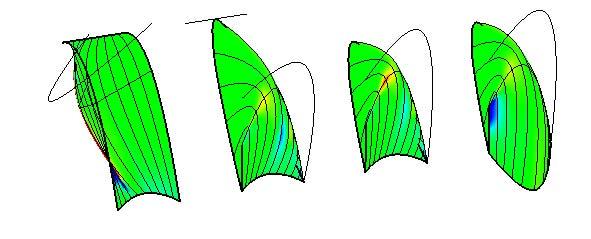

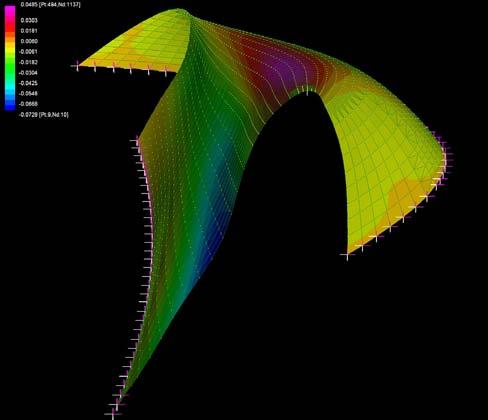

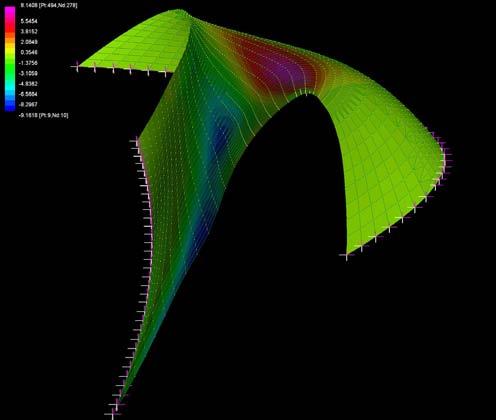

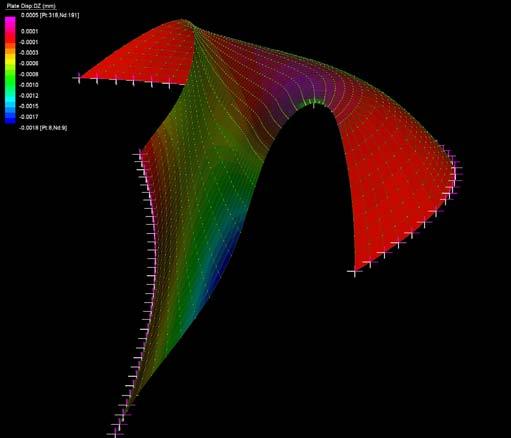

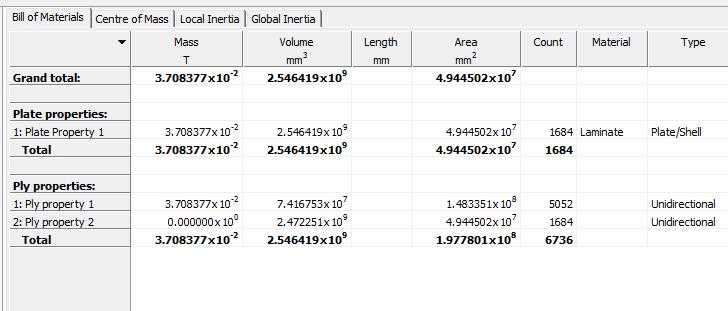

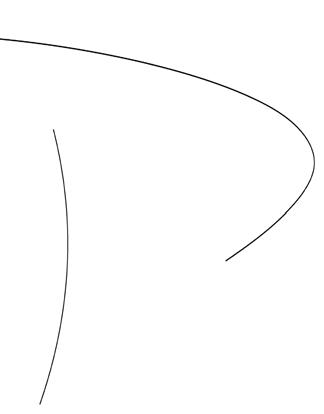

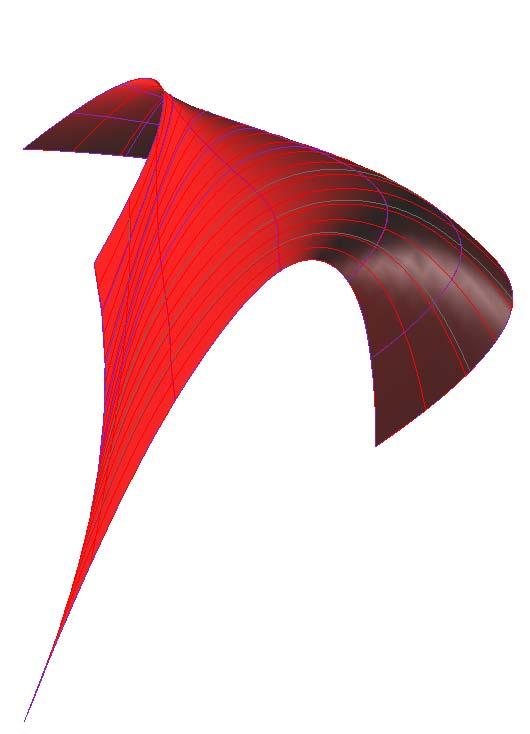

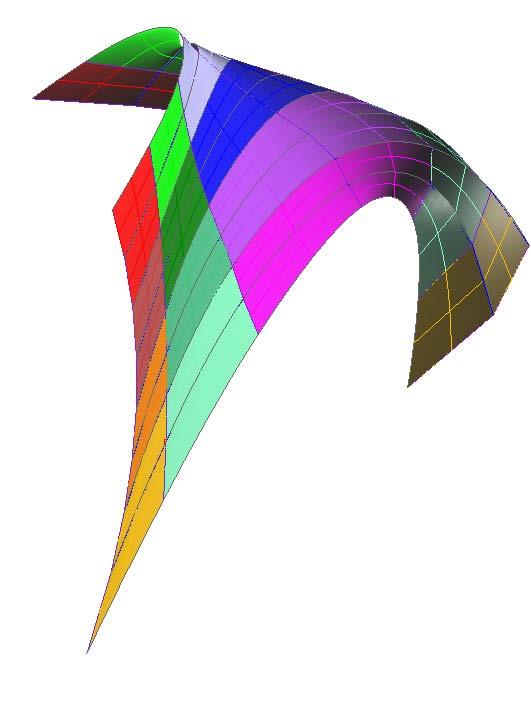

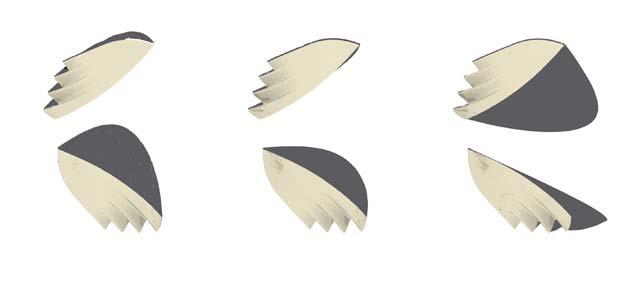

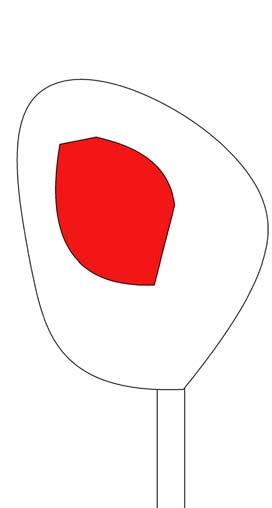

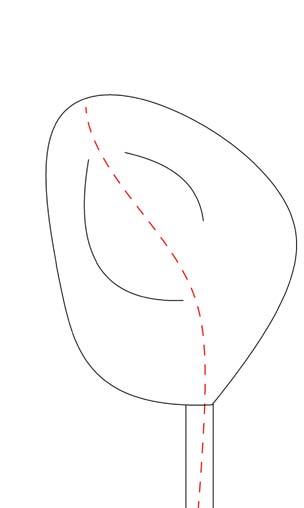

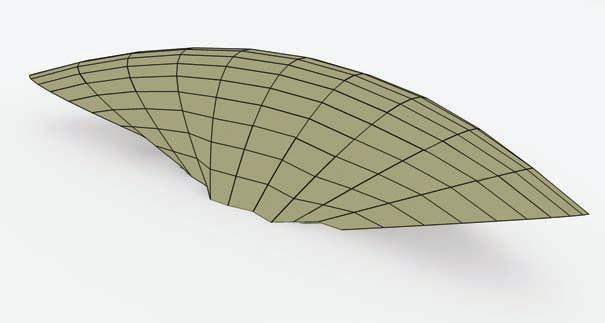

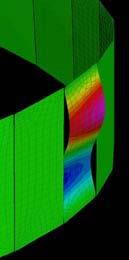

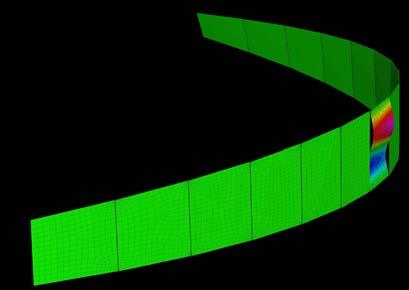

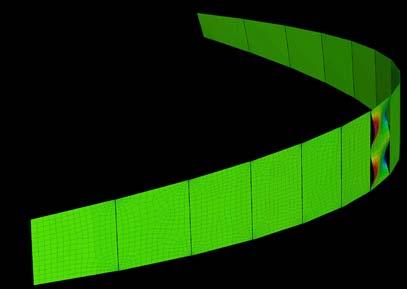

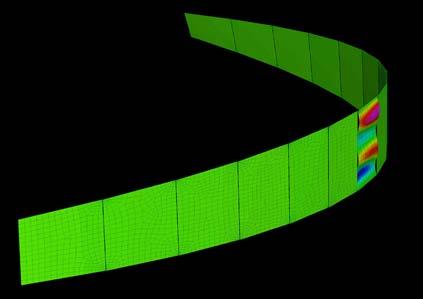

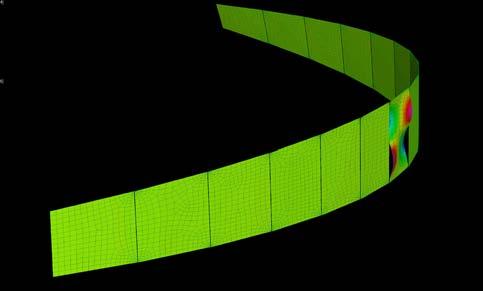

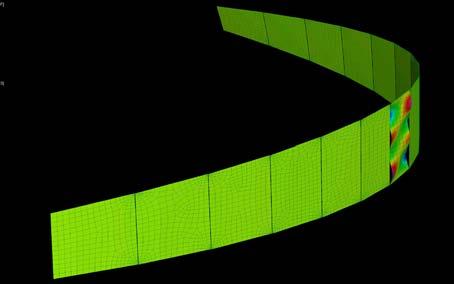

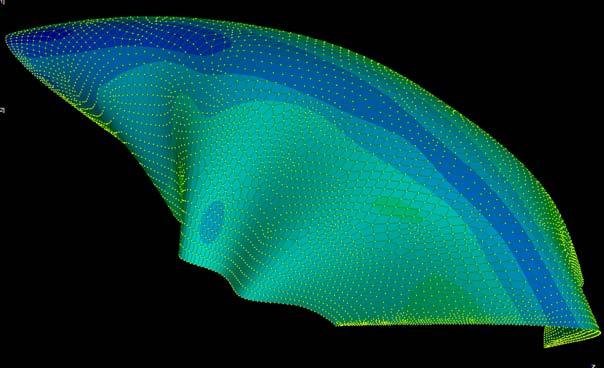

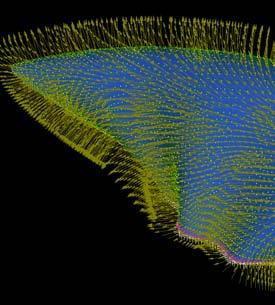

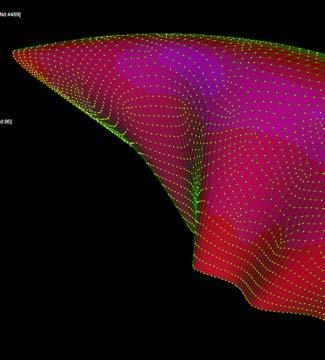

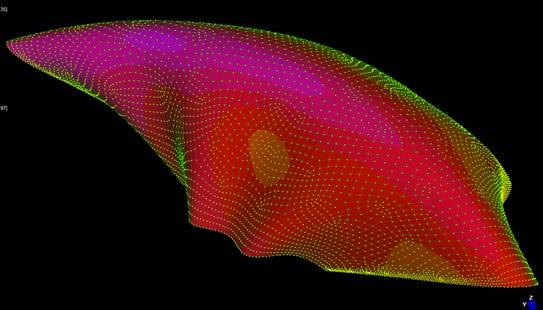

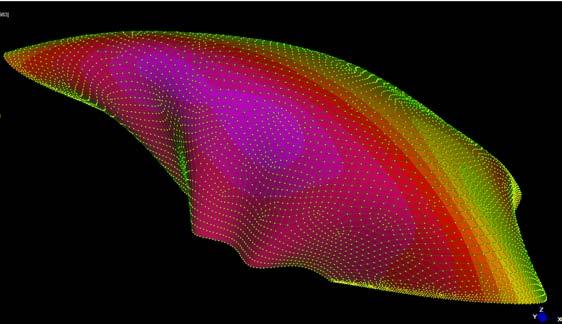

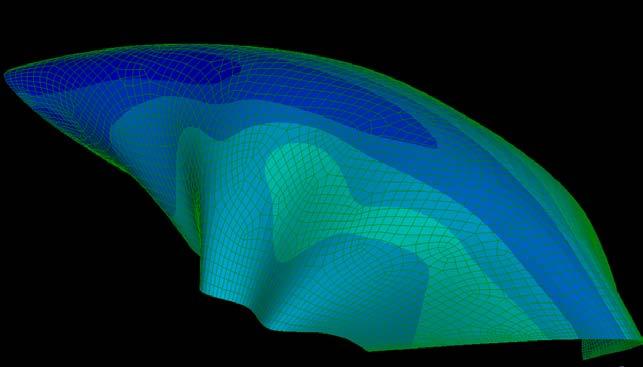

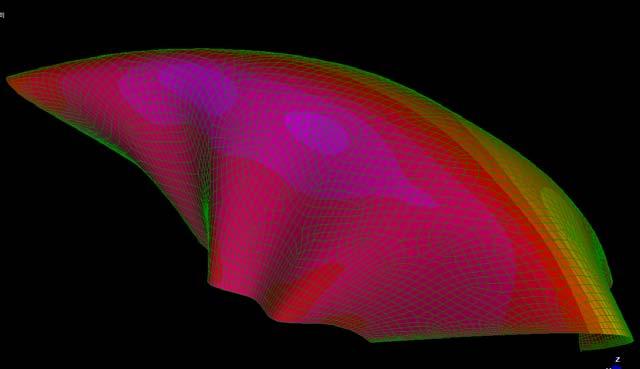

The next experiments were run into Strand7* in 4 sample sets changing the orientation of the rectangular sheet (1mx2m) and changing the grain orientation. First Static Analysis was run and then Linear Buckling Analysis.

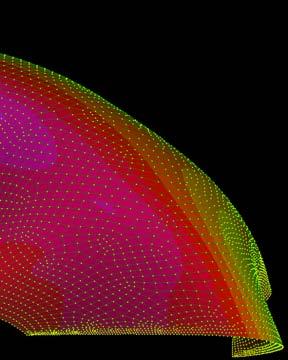

Please take into account that the results are showing color patterns of the displacement in z, in this case z is the axis perpendicular to the plate. As in previous experiments the top and bottom boundaries were fixed and aligned vertically. Next, an initial vertical force of 100N is applied on the pieces on the top boundary so 12 buckling modes are displayed in analysis before the piece could break. Each mode adds the load incrementally in small ratios.