robotic nomadism

m sc candidates course director studio master studio tutors consultants

Carmen Cristiana Matiz

Heather Brick McMenomy

Michael Weinstock

Dr. Elid Erdine

Dr. Lidia Badarnah

Antiopi Koronaki

Alican Sungur

Dr. George Jeronimidis

Mohammed Makki

[robotic]

n omadism

ARCHITECTURAL ASSOCIATION SCHOOL OF ARCHITECTURE

GRADUATE SCHOOL PROGRAMMES

COVERSHEET FOR SUBMISSION 2017-18

PROGRAMME: Emergent technologies and Design

STUDENT NAME(S): Carmen Cristiana Matiz Heather Brick McMenomy

DISSERTATION TITLE: Robotic Nomadism

COURSE TITLE MA/MSc Dissertation MSc Dissertation

COURSE TUTOR Michael Weinstock

DECLARATION:

“I certify that this piece of work is entirely my/our own and that any quotation or paraphrase from the published or unpublished work of others is duly acknowledged.”

Signature of students

Carmen Cristiana Matiz Heather Brick McMenomy

Date:

acknowledgements

We would like to express sincere gratitude to our Director Michael Weinstock, and our tutors, Dr. Elif Erdine, Antiopi Koronari and Alican Sungur, for their invaluable advice an for their support throughout the project. We would like also to thank Dr, George Jeronimidis and Mohammed Makki for their constructive comments and critiques throughout the course of the program, and Angel Moreira, Alvaro Rodriguez and Henry Cleaver, who supported us throughout the experimentation faze of the project with their fabrication and robotics expertise. Finally, we want to thank our families and friends for their encouragement and congratulate our colleagues, for the invaluable and unforgettable shared experience in the AA.

00. t able of c ontents

01. i ntrod U ction ...........................................10 02. domain ........................................................16 03. material s Y stem ......................................48 04. fabrication ..............................................84 05. com PU tational e XP eriments ..............120 06. desi G n P ro P osal ...................................164 06. o n-site fabrication ..............................161

01.intro

a bstract

Nomadic pastoralism is the most sustainable mode of existence in arid climates, and current housing solutions only utilize the most basic forms of building technology. Incipient desertification lends itself to the expansion of this lifestyle, but current housing proposals in west africa do not accommodate seasonal movement. Furthermore, vernacular african architecture provides a democratization of construction which is not considered. Incorporating additive manufacturing with transportable robots into existing vernacular techniques could catalyze modernization without losing cultural relevance.

Therefore, the focus of this research is to create a material system which can provide dwellings for nomadic pastoralists in sub-saharan Africa using existing construction techniques and additive manufacturing. Vernacular precedents are studied, including actively bent armature tents and earthen construction techniques. The proposed solution is a wattle and daub system, which combines actively bent wooden rods and extruded earth. Studies in gridshell systems and their structural performance under compressive loads are conducted, as well as studies in extrusion techniques and the thermal performance of resultant forms.

The resulting proposal can be assembled on-site, then disassembled and re-created. The rods are transported, and the earth is left behind and re-formed with each erection. As a result, this material system allows dwellings to maintain ephemerality of form.

Robotic Nomadism | iN t R o 012

0.0 i ntroduction

013

t raditionalism

Traditional building methods involve structures that are built and perodically edited by those who inhabit them, allowing for a democratized process of construction. The technology associated with traditionalism is associated with something that is of a time before modern construction techniques. A move towards more contemporary forms tends to leave behind the accessibility of traditional construction techniques; however, this does not have to be the case. Utilizing traditional methods of construction with modern geometry can help disenfranchised people attain more contemporary forms without sacrificing the useful methods of construction and social engagement traditional architecture affords them.

First, it will be beneficial to define what is meant by “traditionalism.” For the purposes of this research, it will be defined as “That which is handed down”1 in that it is a method of building which is inherited from generation to generation through practice, and revised slightly with each generation. Therefore, it is created by those who make do with what is there, rather than importing materials from elsewhere. Because of this, materials can be replaced easily and locally, and buildings can be repaired by people in the community.

Traditionalism exists in contrast with instructionalism, a characteristic of modern architectural design, dissociates the user from the designer and the constructor. With instructionalism, the architect and the creator are separate entities, and the user to design feedback loop that traditionalism allows for is lost. This does not mean that traditional architecture cannot be modern, or that its design must remain the same over centuries.

Maintaining traditional building practices while advancing building technology allows for design revisions, so long as the practice and the ability to alter one’s space is not lost. As Tuan states in her essay on traditionalism, “Perhaps what we seek to retain are not so much particular artifacts and buildings, but rather the skill to reproduce them. If we retain the skill, no human work is irrevocably lost.”2 Skills can be maintained while utilizing computer aided design to achieve more complex geometry. In this way, modernization can be created without losing the sustainability and accessibility of traditionalism.

In a case study of Botswanese housing, the government used federal aid money to build more “modern” homes for semi-nomadic people. Typically, Botwanese women construct homes, and it is considered her property, while all things purchased are within their husband’s domain. Switching from traditionally constructed earthen dwellings to modern dwellings resulted in a loss of control over the home, and a subsequent disruption of an existing gender dynamic The change in housing construction was referred to as the “domestication of women” because it repurposed women’s primary source of economic agency: construction. Even after moving in, many women opted to rent out the modern home, and build themselves traditional dwellings in the backyard. While there was interest in living in a wood framed home, this interest was derived from a desire to be a part of the times, and to incorporate contemporary building techniques. Unfortunately, contemporary building techniques tend to be

synonymous with instructionalism, importing materials, and a western concepts of building and home. The ephemerality, tradition, and a democratization of construction techniques which traditional earthen housing provides is lost in many attempts to appear modern. Therefore, incorporating advanced construction techniques into traditional building methods provides an opportunity to create contemporary designs without losing the benefits and cultural relevancy of traditional architecture.

Robotic Nomadism | iN t R o 014

“Our conception of modernity creates its own self-enclosed canons of traditionality. Traditions identified as the past is a modernist idea. The same holds true for the concept of vernacular as equated with low technology. In a context where the relation between traditional and modern has lost a fixed temporal reference, tradition seen as a settled body of knowledge that can be transferred, uncovered, mastered, and laid claim to is at best reactive and at worst mortuary.”

-Jean-Paul Bourdier

015

016 02. domain

017

mobilit Y in west a F rica 02.01

West Africa is one of the most mobile regions in the world, characterised with 90% intra-regional migratory flows 1

National pastoral mobility

Cross-border pastoral mobility Pastoral zone

Wet season Dry season

Caravan Marketing itineraries Border crossing point Water bodies

10% 43 million livestock in m ali

T ranshumant pastoralist (1 375 489)

Nomadic pastoralist (93 296) Agro-pastoralist (8 342 126)

o F m ali’s gd P is based on P astoralism

018 r obotic n omadism domain

Fig 02.01.01 - Mobility patterns in West Africa in relation to Mali’s position within the territory

Fig 02.01.02 - Statistics related to pastoralism in Mali, Africa

ALGERIA MALI

LIBYA

NIGERIA

Source

1. EU Support to Mobility and Migration within West Africa, Strategic Steering Committee, Factsheet, Brussels, 2015

2. OECD/SWAC, “The African Approach on Migration”, in West African Mobility and Migration Policies of OECD Countries, OECD Publishing, Paris,2008

3. Bendandi B, Venier M, Vulnerability and Resilience in West Africa: Understanding Human Mobility in the Context of Land Degradation, KNOMAD, 2017

4. ECOWAS, CSAO/OECD, Elevage et marché régional au Sahel et en Afrique de l’Ouest. Potentialités et défis, Editions Club du Sahel et de l’Afrique de l’Ouest/OCDE, 2008, 162 p

the necessit Y o F mobilit Y

Long distance movement between complementary agro-economic zones and areas of traditional cross-border movement are deeply rooted in West African history , which has always been characterised by a high degree of human mobility.

Mobility is the most important response by the inhabitants of arid environments in the Saharan and Sub-saharan region to climatic adversity. The climatic conditions in these areas are characterised by instability, irregular rainfall patterns and periods of draughts, having an important influence in the decision-making process that dictates the lifestyle patterns that people adopt. The mobility configuration is also highly diversified, with some countries serving as source, origin and transit routes for migrants2

Contemporary migratory flows arise as a result of environmental factors, but also socio-economic, political and historical-cultural factors which have had serious impacts on intra-regional migration of cross-border workers, mobility of traders and pastoralists.

Land use degradation and desertification is often a key driver of human mobility in the area. Land degradation might lead to increases in migration because of the need to diversify incomes, but it can also cause reduced mobility by eroding the assets and capital required to finance migration . When on-site adaptation is either impossible or undesirable, migration allows people to modify their exposure to climatic stress3. On one hand , temporary and circular labour migration are the most common strategy used throughout history and increasingly in the last decades to cope with increasingly hostile environments, while on the other hand, land abandonment and out-migration can lead to further isolation and marginalization of vulnerable rural populations.

Pastoralism is the main activity in arid and semi-arid regions of West Africa that involves sustainable use of irregular and fragile natural vegetation and scarce water resources, while enforcing growth in local communities.

mali

We chose Mali as the area of our analysis. Due to its climatic instabilities and political issues, Mali has been characterised with high degree of mobility, to such extent that even the sedentary image of farmers in central and south of the country transitioned to a mobile lifestyle. This leads to the increased need for change in the way of thinking about the geographical and political dimension when considering issues related to access to land, land use and conflict in West Africa and beyond, but also inquiries as to how can architecture, as a highly static industry, respond to the increased need of mobility in the area4

While the extreme draught in the previous years affected drastically the number of livestock at a national level, pastoralism is still an important part of the Malian society and an appropriate and sustainable way of lifestyle that responds to the increasingly arid environmental conditions.

019

Pastoral societ Y

“Pastoralism is mobility: mobility is pastoralism” A Borana proverb

Although there is no standard definition of pastoralism, it has often been described as a livelihood in which at least 50% of a household’s food and income is derived from livestock1 In addition, pastoralism is characterised by mobility and, in particular, the seasonal movement of livestock to access grazing resources and water. Pastoralists occupy vast arid and semi-arid zones with very high spatial and temporal variability of rainfall. In these dry areas, the strategic movement of livestock is a rational and productive response to uncertain availability of pasture and water, and includes substantial cross-border movements of animals. Typically, livestock herding produces milk for direct household consumption, as well as offspring for sale, or for exchange for cereals. These are the basic elements of pastoralism which, in general terms, have remained unchanged over hundreds of years. The common perceptions about pastoralist are that they represent a minority who practice an archaic and outdated lifestyle, but even if they often inhabit harsh remote regions, they are fully integrated with a wider global process. Pastoralism across the region not only has diverse forms, but is also robust and highly dynamic, responding to market opportunities and a range of other economic, social and environmental influences over time2

Pastoral mobility plays a critical role in the economic prosperity of Africa’s drylands. Across West Africa, an estimated number of 50 million pastoralist support their families and communities in an industry based solely on livestock, that depend on natural dryland pastures.

In an area where other land use systems are failing in the face of climate change, mobile livestock keeping is producing national and regional economic benefits, determining specific lifestyle patterns. Mobility is a key way for pastoralist to make the best use of water and grazing resources in these dryland areas. Their strategies have evolved through time, being highly efficient and adaptive to the environment.

Pastoralism relies on unique production strategies, with the ability to move being the most crucial. Mobility is an essential component of the herd’s productivity in arid and semi-arid areas. It allows livestock to benefit from fodder resources which vary in quantity and quality in different areas during the year. As new policies and innovative practices for pastoral mobility are beginning to take root in many parts of dryland Africa, it encourages governments to develop informed, progressive policies that reflect the need of modern pastoralist.

Livestock mobility is a modern approach to poverty alleviation and accelerated development. While supporting mobility does not require substantial financial investment, it requires refreshed thinking and a clearer problem understanding. Transhumant livestock farming also contributes to the development of abandoned and isolated areas by ensuring a human presence in areas with significant security issues.

Source

1. Catley A, Scoones I, Lind J(ed.), Pastoralism and Development in Africa: Dynamic change at the margins, Routledge,2013

2.Idem

3. Bendandi B, Venier M, Vulnerability and Resilience in West Africa: Understanding Human Mobility in the Context of Land Degradation, KNOMAD, 2017

020 r obotic n omadism | domain

P astoral mobilit Y

021

Fig 02.01.03 - In an area where other land use systems are failing in the face of climate change, mobile livestock keeping is thriving

agro -P astoralism

Agro-pastoralism is a form of sedentary or semi-trashumant livestock farming that links crop-growing and livestock. Having a wider availability of resources in their surrounding area, or being pressured by socioeconomical factors, pastoralist choose to settle into permanent settlement. While the herd still needs to be mobile, it is of smaller dimensions at the groups are not dependent on them. The grazing areas are generally in the surroundings of the settlement and only designated members of the family follow their movement. It is generally a short-range mobility. Once the settlement prospers and agriculture lands expand, conflicts may arise between the two ways of food production, finding the balance being essential1

P astoral transhumance

Transhumance is an animal production practice characterised by regular seasonal movements between complementary ecological areas. The herds generally leave a disequilibrium environment, where pastures become scarce, and move towards areas with more abundant resources. The movement is mainly cyclical with a set trajectory, primarily a northsouth movement based on the dry and wet season variance. In this context, transhumance in West Africa may be considered as a form of adaptation to these arid environments, making good use of the existent ecological complementarity. While it implies long distance mobility or cross-border mobility, its degree of dependence on sedentary settlements is higher, as only part of the pastoral family follows the herd movement, while others remain sedimentary with a few animals that sustain their life until the herd returns. While their movement may vary, it explored a defined area named in specialised literature as a transhumance shed.2

P astoral nomadism

Pastoral nomadism is the simplest form of pastoralism. It is characterised by continual and unpredictable movements of all members of a family or a group. As the household is primarily dependent on the herd for survival, their movement is controlled by the movement of the livestock. While they pursue the general seasonal movement of transhumance, the length of stay of nomads at one place and the direction of movement a2re solely governed by the availability of water and natural forage. It is common in sparsely populated areas that are not suitable for the cultivation of crops. Nomadic herding is the only food production method adapted to these ecosystems and it is the most extensive land use system.

Source

1. Catley A, Scoones I, Lind J(ed.), Pastoralism and Development in Africa: Dynamic change at the margins, Routledge,2013

2. Alidou S M, Cross-border transhumance corridors in West Africa, CapEX Report, 2016

022 r obotic n omadism | d omain

Fig 02.01.03 - Pastoral transhumant in Mali.

tYP es o F P astoral mobilit Y

While mobility is an essential practice of pastoral society, different degrees of mobility can be identified based on the availability of climatic dependent resources.

Pastoral nomadism P astoral transhumance a gro P astoralism

Self-sufficient

No permanent structures

Locations and timing is determined by the livestock needs.

Cyclical movement

Regular encampments

Cyclical movement, set trajectory

Do not depend on animals

Family remains in permanent settlement

Reduced movement related to fixed settlement

Adaptable to existing conditions

and

023

Temporary camp 1 14 days 3 3 km 4-9 km/day 14-20 km/day 6 months 1+ years Seasonal camp Settlement Short distance travel Long distance travel Hearding loops Temporary camp 1 14 days 3 3 km 4-9 km/day 14-20 km/day 6 months 1+ years Seasonal camp Settlement Short distance travel Long distance travel Hearding loops

Fig 02.01.04 - Pastoral movement types in relation temporary

permanent settlements

Factors determining the degree o F mobilit Y

A delicate balance between environmental, socio-economical and political factors determine the degree of mobility a certain pastoral society adopts as a lifestyle.

Production

The major reason for mobility is to maximise livestock productivity levels. When on the move, pastoralists are not just searching for food for their animals, they are tracking the very best grazing and water sources. High quality nutrients in dry rangelands are short-lived and predictably patchy. In order to exploit them efficiently pastoralists need to move often and quickly

Trade

Livestock need to be bought and sold. The best markets where pastoralists can get good prices for their animals are often far from the best production areas. Trading can be local, national or international depending on the season and what is to be sold or purchased. Often trade involves extensive treks and the safe movement of animals is therefore key.

Survival

Livestock movement becomes absolutely essential to flee drought, disease or conflict. Prompt and often long-range mobility during these times is necessary for the survival of the herds and the pastoralists themselves.

The mobility patterns are not fixed, as a pastoral family or group can transit from semi-transhumant to nomadic due to the availability of resources, or nomadic pastorals can become mainly sedentary due to socio-economic and political pressure determined by land use and land availability.1

Source

024 r obotic n omadism | domain

1. Catley A, Scoones I, Lind J(ed.), Pastoralism and Development in Africa: Dynamic change at the margins, Routledge,2013

025

Fig 02.01.05 - Nomad herd engaged in long distance mobility

variation o F movement

Flexibility is crucial for the pastoral society. Increasing opportunities for mobility

When discussing adaptation to environment of pastoralist in nonequilibrium range ecologies as the Sub-Saharan area, flexibility is one of the key considerations. The high variability and low predictability of spatialtemporal distribution of pastoral resources (water and forage) is the major driving factor.

A pastoral corridor is a strip of land that is reserved for livestock passage to access pasture, water sources or other herd infrastructure suck as livestock markers, vaccination areas or holding areas. Access to water points, grazing areas and resting points are key elements in long distance and cross-border pastoral mobility. It ensures long-distance and cross-border mobility, connecting north and south dispersion zones2. Resting and settling points are chosen according to grazing areas. A grazing area is an area identified and specially reserved for grazing livestock. As it may or may not be developed, it must contain good quality and abundant pasture and be able to receive a large number of animals. The size should take into account not only the quality and quantity of pasture, but also the pasture carrying capacity.2 The annual herd movement is enclosed within an area termed pastoral shed. The movement remains seasonal within this area and a pastoral shed can spread over hundreds of kilometres. Provided enough resources, the pastors tend to remain within the same pastoral shed. On the other hand, the movement within the pastoral shed is flexible. While some parameters display a certain level of regularity, predictability at certain scales, dryland ecology is a continuum between equilibrium and non-equilibrium conditions that coexist within the same system.

To further understand the importance of variation, the figure displays results from a recent study that considered 4 pastoral sheds in Mali.3 Satellite images comparing green up periods and vegetation density on the same dates at subsequent years. The dryland locations where vegetation is available are seen to vary significantly over time, both within and between years.

Pastoralism is by definition flexible and dynamic. Pastoralists mobility responds to changing circumstances, so initiatives need to be equally flexible. This translates in providing formal services as well as building infrastructure aimed at reinforcing pastoral mobility. As paths traditionally change course from one year to the next according to local climatic and social conditions, policies for infrastructure and housing requirements has to be adaptable, having formalised agreements and rights that are not overly prescriptive and rigid.

A hybrid mechanism should be built for long-term management of mobility4, middle way between formal and informal representing the optimal approach for ensuring flexibility, involving the simultaneously the authorities and local pastoral communities.

Translating this to the built environment, temporary housing rights regarding land use can present a way for transitioning from informal housing to a more formalised and controlled building environment.

Sources

1. Jode H de (ed.), Modern and mobile: the future of livestock production in Africa’s drylands, London: IIED, 2009

2. Idem

3. OECD/SWAC, An Atlas of the Sahara-Sahel: Geography, Economics and Security, West African Studies, OECD Publishing, Paris,2014

4. De Haan C., Steinfeld H., Blackburn H., 1999. Elevage et Environnement. A la recherche d’un équilibre. FAO, 115 p.

Robotic Nomadism | iN t R o 026

r etaining F lexibilit Y r easons o F variation

Northern dispersion zone

north- s outh dis P ersion zones variation in vegetation green u P [variable speed of movement] [movement path are determined by available forage resources]

123 days multiple resting points

seasonal camps long distance movement short distance movement 165 days Southern dispersion zone

Pastoral corridor 28 days 44 days

Main harvest

Labor migrants depart

Pastors move southward

Dry season

Early start of pastoral and agricultural lean season Ramadan

Pastoral lean season Agricultural lean season

Land preparation Sowing Migrants return

Pastors return northward

Rainy season

027

Fig 02.01.08 - Mali Agricultural Timeline. Analysis regarding food security.

Fig 02.01.07 - Satellite image analysis of variability in vegetation green up within a pastoral shed at the same date across multiple years

Fig 02.01.06 - North-South dispersion zones. The variability of movement speed within a pastoral shed

Nov Oct 11 Dec Jan Feb Mar Apr May Jun Jul Aug Sept Oct 2

2003 2005 0 20 40 80 km 2003 2005 0 20 40 80 km 2003 2005 0 20 40 80 km

remote construction

Low dependency on permanent settlements applies certain limitations to the construction process and design

building in remote locations

The necessity of building in remote locations imposes certain important constraints on the design process. Modern building techniques imply the use of industrially processed material which is transported to the construction site, together with a skilled team of labourers. When discussing construction in remote locations, this process become extremely difficult as it involves transporting material, tool and human labour across extended distances. Careful planning needs to be done to ensure the success of the project, which has a high demand of resources.

As for the nomadic pastoral community, because the construction process reoccurs every few months, at locations that vary in distance from permanent settlements, the modern formal construction techniques become impossible to use.

New design and assessment criteria need to be developed in order to constrain the design process for achieving optimal solution that respond to the needs of a nomadic community. One of the most important criteria that dominates both design and construction is self-sufficiency because of the possibility of settling in secluded in remote locations is a recurrent condition.

The material systems should allow customization to respond to the changing needs of the community and also to the new conditions that the settling locations provide. It must adapt to the availability of resources and be economical from that point of view.

The construction sequence is entitled to careful planning and timing,

nomadic construction

Nomadic construction adds further limitations as it requires a carefully planned balance between the time needed for construction and the comfort that the design can provide. They require a different perspective when discussing sustainable and economic models of housing. One of the most important quality to be considered is the quality of being self-sufficient.

To clearly define the parameters of development of housing concepts appropriate to a nomadic lifestyle, the following criteria of assessment needs to be considered:

028 r obotic n omadism | domain 02.03

design criteria

Remote settling locations determine the use of resources immediately available on-site.

local

Local construction techniques have evolved to respond to local material and local climate.

The design has to be able to incorporate the needs of each community

assesment criteria

The design must respond to the changing family dynamics and must be easily adaptable to new locations.

The nomad community needs to have be the main decision makes in the design and construction process and be in full control of the tools.

The tools involved in construction need to be easily transportable. If part of the structure travels with the community, weight and dimensions are key factors for design.

As it will be a recurrent process each time the community temporarily settles in a new location, time is an essential factor.

029

Fig 02.03.02 - Criteria considered for assessing design solutions in relation to the needs of a nomadic community

Fig 02.03.01 - Criteria that drive the design process for a nomad comumnity

techniques trans P ortabilit Y construction time F lexibilit Y /ada P tabilit Y local availabilit Y P artici P ator Y design sel F -su FF icienc Y

Numerous methods of surviving in climates with little rainfall have been developed across the centuries, and many of them involved structures whose location never changed. These structures held various forms of permanency and occupation to accommodate the transient nature of existing in extreme environments. Permanent structures existed, but they were not inhabited regularly by the same people year-round. One option was that inhabitants would cycle through, and the structure would act as a hotel to those crossing the desert. Another option for permanent structures was that they would be owned by a single family, but left alone for most of the year as dwellers found alternate sources of water. The third structure, and the most widely used today, are tent structures, which would travel with dwellers and are erected with each new settlement.

The aforementioned architectural solutions to extreme environments offer different degrees of architectural suitability. Customization refers to the ability of users to revise a space to meet their needs. If a structure can be edited throughout its life to accommodate different family sizes, then it is more likely to sustain continued use by the same inhabitants.

Autonomy refers to a housing solution’s ability to be maintained by those inhabiting it. In remote environments, maintenance from those not currently inhabiting the structure can be difficult to obtain. Tools and supplies not available on site are difficult to transport to remote locations, therefore, when structures are not supported by an external government source, they fall to ruin. As a result, housing solutions which don’t offer a high degree of autonomy tend to go into disrepair if they cannot be maintained solely by those inhabiting it.

Thermal refers to the amount of thermal comfort provided by a dwelling solution. Dry, hot environments are difficult to survive in, and material systems which can enclose space and absorb heat during the day are preferable to those which cannot. Having thick, heat-absorbing walls works to the detriment of autonomy and customization because of the long construction times that mud brick structures require, as well as the large amount of workforce needed in an environment with few people Security refers to the amount of protection from crime a building provides. The Sahel region of the Sahara desert is known to have large amounts of crime, and no acess to the protection of a government entity. Architectural solutions can help provide a temporary respute from the threat of theft and violence. Large, earthen structures can block incoming bullets, and enclose courtyard spaces can help prevent unwanted intruders from entering the space.

No singular architectural solution has met all of these needs equally, but stuctures have created differing amounts of suitability by adjusting their levels of occupation and permanance. Large, earthen structures can be inhabited infrequently and respond thermally, and tent structures can be inhabited constantly but do not provide thermal comfort. By adjusting levels of occupation and constructability, hitoric structues have been able to meet some of the requirements of living nomadically in harch environments.

Robotic Nomadism | iN t R o 030

tYP es o F d esert d welling

Permanent Structure, Constant Occupation

Caravanserai were trading posts placed a day’s journey apart along desert trading routes between the 14th and 17th century. They were constructed using mud brick formed from the surrounding soil, with the help of nearby governments. Because of their long construction time and the limited amount of time that travellers would occupy the space, the rooms were not tailored to the user’s needs, and the building required funding from outside sources to be maintained. Because of this, their use fell during the Ottoman Empire.

Programmatically, they served the same role as motels, in that traders who were passing through would stay in the space temporarily before moving on to a new location. Visitors could replenish their water supply, trade goods, and gain a night’s rest with the insurance that their precious cargo would be safe as they slept. To achieve this, the building was shaped like a square doughnut, with exterior walls comprised of sleeping and storage rooms, while the interior courtyard enclosed livestock. This prevented theft from bandits, as well as the possibility of livestock wandering off during the night. They included one guarded entryway, as well as sites of religious worship in the corners of the interior courtyard. Because they served as a site of constant cultural exchange, these sites offered both churches and mosques.

All spaces; however, lacked a sense of specificity to one particular culture in order to achieve suitability for all cultures. Therefore, once their economic purpose faded away, Caravanerai fell into ruin and disrepair. Because their form could not be tailored to meet future needs or provide for indigenous populations, they were no longer used.

031

Customization • a utonomy • t hermal ••• s e C urity •••

c aravanserai

Permanent Structure, Seasonal Occupation

Terraced Wadi were part of a system of desert dwelling which allowed for seasonal occupation of desert homes. Typically in the Negev Desert in Israel, these settlements were created to plant crops on a hill in a way that allowed them to be consistently irrigated without any labour present.

The three types of terraced wadi include a basic terrace, walled terrace, and irrigated terrace. I the basic terrace, water flows down a series of steps, irrigating the crops on top of the terraces. This system can support a small family, but is not suitable for larger settlements. On the walled terrace, each parcel of land is protected by a 2m wall, allowing the area to flood. This allows for larger settlements, but requires more labour to produce, as each wall must be water-tight. In the irrigated terrace, a large body of water is collected using a 3m wall, and redistributed to crops in a different area. This is the most difficult irrigation system to implement of the tree, provides the most amount of water storage, and allows for larger volumes of production as a result.

Made of mud brick, the dwellings adjacent to the wadis provided thermal comfort as needed, along with a degree of specificity and customization that many self-built houses provide. While valuables could not be left on site during seasonal abandonment, these structures provided more security then transportable dwellings, but less than what a walled enclosure of multiple families would provide.

Due to the upkeep of irrigation systems; however, these dwellings also fell into ruin due to a lack of use. While there was a degree of freedom in the design, requiring assistance from a nearby government for its maintenance led to its eventual state of ruin.

Robotic Nomadism | iN t R o 032 1m-2m 3m

Customization •• a utonomy • t hermal •• s e C urity ••

t erraced w adi

Ephemeral Structure, Constant Occupation t

The third and currently utilized method of dwelling in the desert are tent structures. These structures allow for maximum autonomy, as all the materials can be procured on site and carried by its users. They also allow the highest amount of customization, as their form can be varied by erecting the same materials in a different sequence. The Bedouin, for example, are able to create 27 different configurations with the same materials.

Black cloth weaved from goat hair in strips create thermal convection zones within the fabric, allowing for more ventilation than a cloth cover. This does not; however, provide nearly as much thermal comfort as a mud brick structure.

Security is a concern with tent structures, as the typical nomadic tribe must have a person on guard to alert others of a possible security concern. The tents do not provide protection from herding animals, or weapons in the are.

Despite these drawbacks, this is the main type of dwelling utilized by those who inhabit the Sahel area of the Sahara desert because it allows for a high degree of autonomy as well as a high degree of customization. There are many different types of tent structures currently in use by nomadic tribes, three of which will be studied in greater detail in the following chapter.

033

Customization ••• a utonomy ••• t hermal • s e C urity •

ents

tYP

es o F t ent s tructures

t ensile

Tensile structures enclose the most spce with the least amount of material, and are popular in the western region of the Sahara. Central poles are supported in tension by a fabirc layer, which is pinned to the ground. The potential for adding a thermal layer; however, is limited with this style of tent.

Customization •• t hermal • a utonomy ••• s e C urity •

Robotic Nomadism | iN t R o 034

a rmature

Armature tents enclose space with actively bent wooden members. They do not have a central pole, and are therefore more limited in their variety. These are more popular in the western and central Sahara, and Mali.

Customization •••

t hermal •

a utonomy •••

s e C urity •

035

The term self-build defines the practice of creating housing for oneself and can be done through a variety of methods. The self-builder’s involvement in the process of construction can range between doing the actual building work to actually designing and building it. This process can be extended to the scale of the community, having every individual contributing to the construction of the settlement. Many examples throughout history identify self-build communities in which each family had a specific role in the construction process. The role, in some cases, could be inherited across generations.

Self-sufficiency and rapid construction are the two main characteristics that define the nomadic community construction needs for housing, and these can be simultaneously met using self-build strategies.

sel F -building existing methods

The existing methods used by self-builders vary based on the degree of prefabrication that they involve. From the existing range of solutions, we selected the ones that were optimal for rapid and remote construction and could be deployed by nomadic pastoral communities.

Flat-packs are usually shipped to the site and can be rapidly assembled on site. The construction process is time efficient, but all the elements need to be pre-designed and prefabricated using industrial methods. Popular choice among self-builders as its structure can be deployed in a number of days. Lightweight compared to usual constructions, the elements can be voluminous. As it requires prefabrication and needs processed material, it does not represent a favourable solution for the criteria considered.

The kit-of-parts, and more precisely, the solution proposed by Foster and Partners for the Rwanda Drone ports is a balanced solution between prefabrication, predesign and on-site construction. The kit provides geometrically defined formwork and a brick pressing machine. The mud bricks are produced with local material and assembled using the formwork. This solution lacks the needed flexibility for nomadic construction, as the design is limited to the prefabricated formwork.

A third option would be providing design tools and construction tools that ensure that raw local material is used 100% and that the housing design can be customised to address the dynamic needs of the community. An on-site 3d printer can be an example of such construction tool, that can ensure on site fabrication and on-site assembly.

036 r obotic n omadism | domain

sel F- build strategies

F lat- P acks

(providing geometrical defined material )

Off-site fabrication

On site assembly

Open source

local material usage

Wiki house 2011

Wikihouse Foundation

kit o F P arts

( providing formwork )

Off-site fabrication of formwork/ scaffolding

On site assembly and construction

local material usage

Drone port proposal Rwanda

Foster and Partners 2015

tool kit

( providing Tools )

On-site fabrication

On site assembly

local material usage

3D printed house - Milan Design week 2018

Arup/ CLS Architecti

037

Fig 02.03.03 - Self-build techniques

SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY

DURABILITY

CONSTRUCTION TIME

SCALE

TRANSPORTABILITY ADAPTABILITY

AVAILABILITY

im P ortance o F using local materials

Due to the remote locations that seasonal nomadic settlements require for unrestrained access to forage resources and wide spread range lands, the communities usually lack access to infrastructure. This translates into the impossibility of having constant access to industry processed material or the possibility to transport large quantities of material. Making use of what is available in their proximity ensures not only a sustainable lifestyle, but is, in fact the only way a nomadic community can remain self-sufficient and survive in extreme conditions. Therefore, the use of local materials as a design strategy is critical, as it can allow the degree of independence needed, while also promoting local techniques and craftsmanship, creating a community responsibility towards engaging in participatory design and construction process.

l ocallY available materials in mali

Most commonly available material that is intensely used in construction is loam. Earthen constructions, built using traditional techniques, are currently often not perceived as a modern solution. While loam offers great thermal properties, the construction process requires a long period of time, being used for permanent settlements and being permanently improved and adjusted.

Sand is rarely used in construction as it requires large quantities and an appropriate binder to achieve structural capabilities.

Grasses and leaves are widely used in a bundled form for roofing in permanent settlements and for covering nomadic tents, being weaved into mats. Being lightweight, they can be easily transported.

Wood is not widely available in large quantities required for timber, but local trees provide long branches and roots which are used in formal and informal constructions in rural environments. This represents a sustainable use of local resources at it does not damage the source of raw material.

Stone is only available in selected regions. Rarely used in construction due to the difficulty of processing and transportation.

m aterial suitable to nomadic construction

Considering the needs of nomadic remote construction, wood in form of branches and roots together with vegetable fibres like grasses and leaves seem to be the best solution due to their wide availability and easy transportability. Earth, on the other hand, can provide the needed thermal properties for indoor comfort.

038 r obotic n omadism | domain

l ocallY sourced materials

earth sand grasses wood stone

039

Fig 02.03.04 - Locally sourced materials and their availability across Mali

l ocal a vailabilit Y SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY SCALE DURABILITY TRANSPORTABILITY ADAPTABILITY CONSTRUCTION TIME AVAILABILITY

c onstruction as a Practice

n ankani

Construction is not an event, nut a process in the Sahel region of Africa. The three case studies of housing studied in this paper are Nankani, Gabra, and Mugsum. The Nankani alter their housing to accommodate growing families, changing their earthen dwellings with every new birth to accommodate growth. Each person contributes to construction, and metaphors are used comparing the growth of a village to the growth of a living organism.

g abra

g abra

The Gabra are best known for their communal practices of building tents together, as construction is primarily done by women and childern in groups. Passing on of tents is an important aspect of mother-daughter bonding, and complex, actively bent gridshell structures are slowly revised through generations of tradition. this structure does not provide thermal protection from harsh winters, but is available for nomadic societies.

Mugsum huts are created by hand with patterns that minimize erosion and allow for continual repair. Their section is a caterenary arc, which allows for a thin profile. Huts are arranged in a circle to create a boundary, but one hut cannot physically meet with one another. Each structure takes 6-8 months of consistent work to construct. Due to its difficulty, these huts are a dying form of dwellings, and typically done for tourist attractions.

Robotic Nomadism | iN t R o 040

m ug s um

himba

himba

One of the very few nomadic societies in Africa which utilize earthen construction are the Himba in Namibia. Because the soil is suitable for sculpting, the Himba are able to create a wattle and daub system quickly and easily. They are limited in the forms they can create; however, this is one of the few nomadic housing forms which do respond to thermal comfort.

Robotic Nomadism | iN t R o 042

e xtension F or the c harcoal b urner’s h ut

A contemporary wattle and daub system was created in Chile, in which a wire mesh was used to create a charcoal dome. The wire mesh is reused after the charcoal is created, so the structure can be created elsewhere.

043

Pro P osed m aterial sY stem

c ontem P orar Y w attle & d uab

t extured e arth la Y er

Can add more thermal mass, protecting inhabitants from harsh weather

Flat e arth la Y er

Can be rapidly produced, and creates a heafty shell for additional extrusion

d ate Palm m esh

Readily available, and allows soil to be added to the form between gridshell members

a ctivelY bent gridshell

Easily portable, and uses existing building practices to drive the form of the structure.

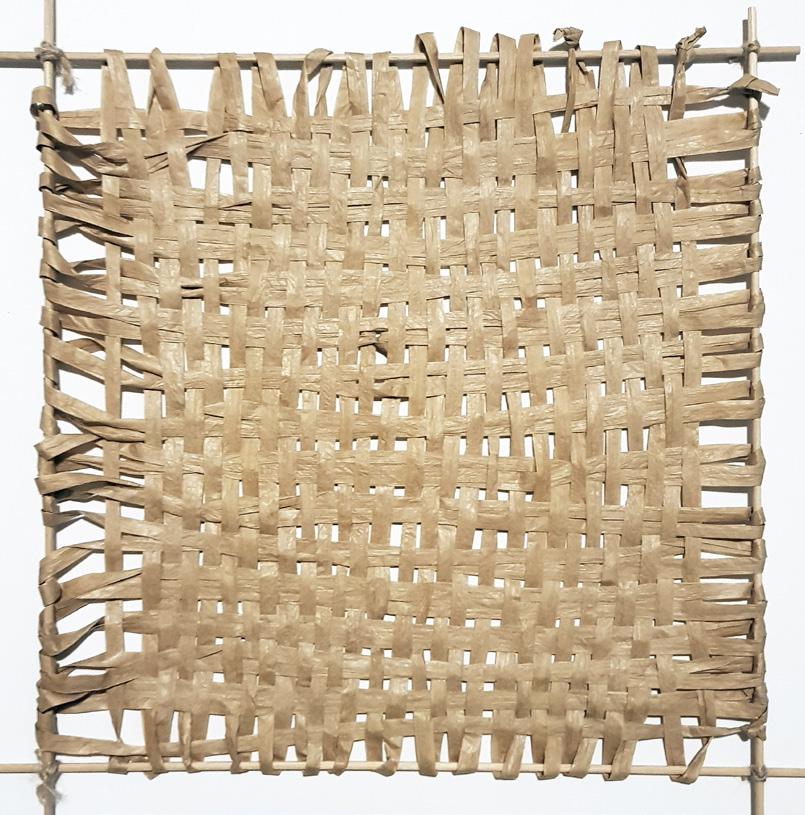

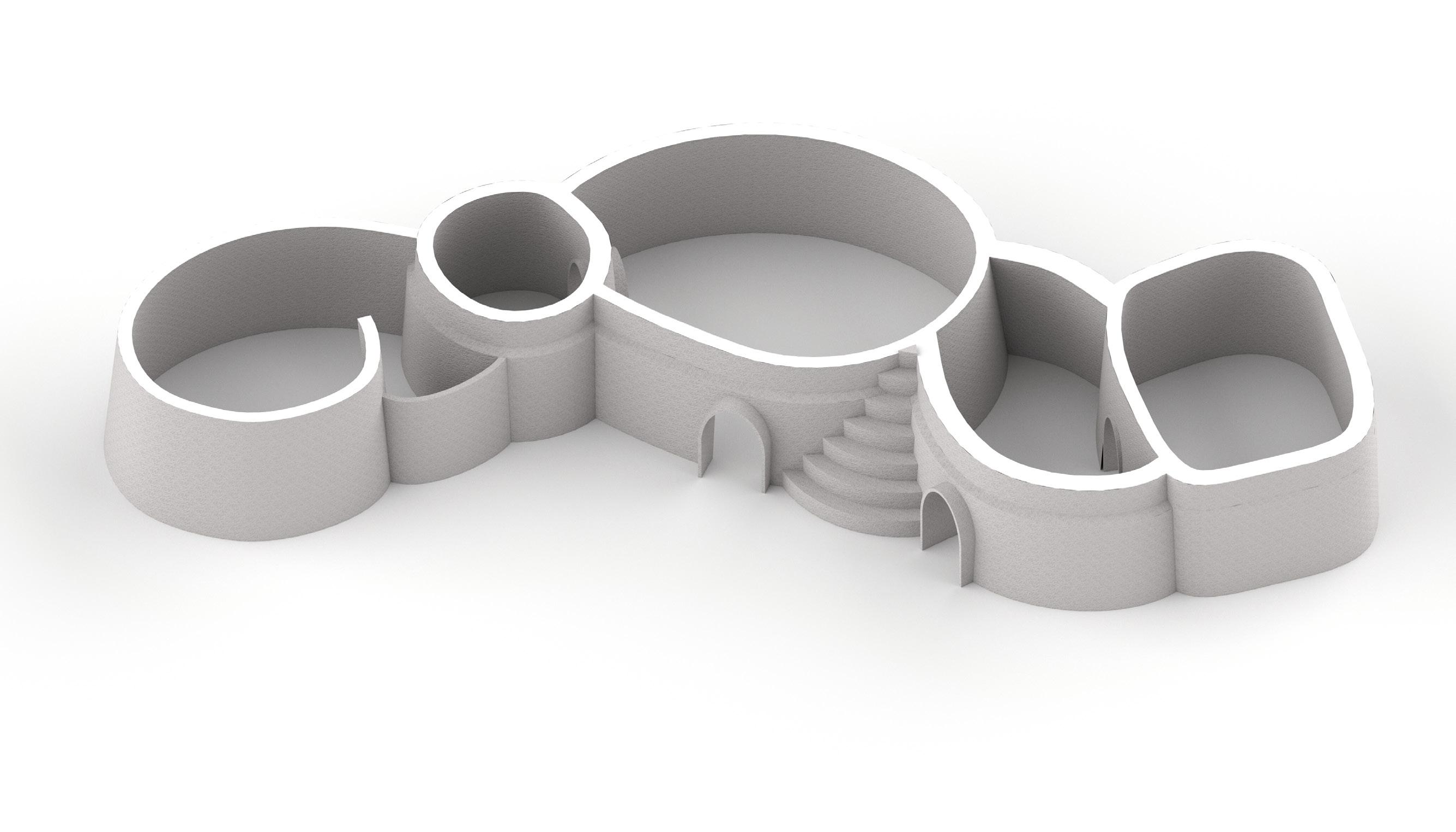

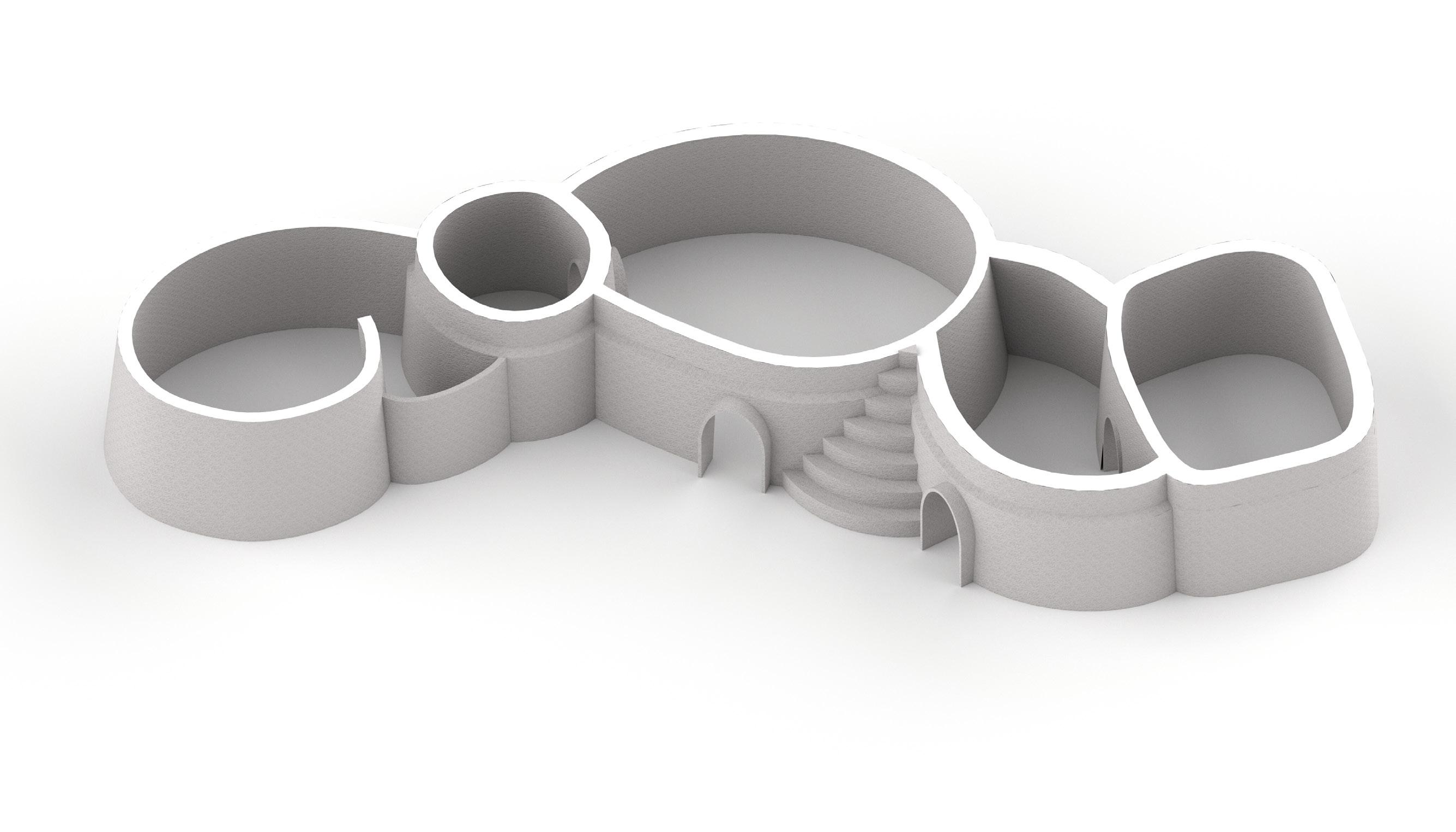

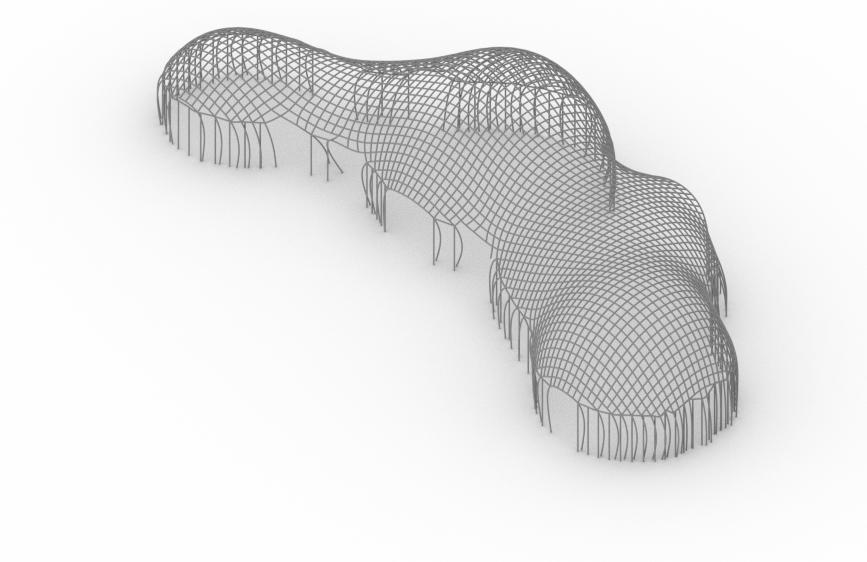

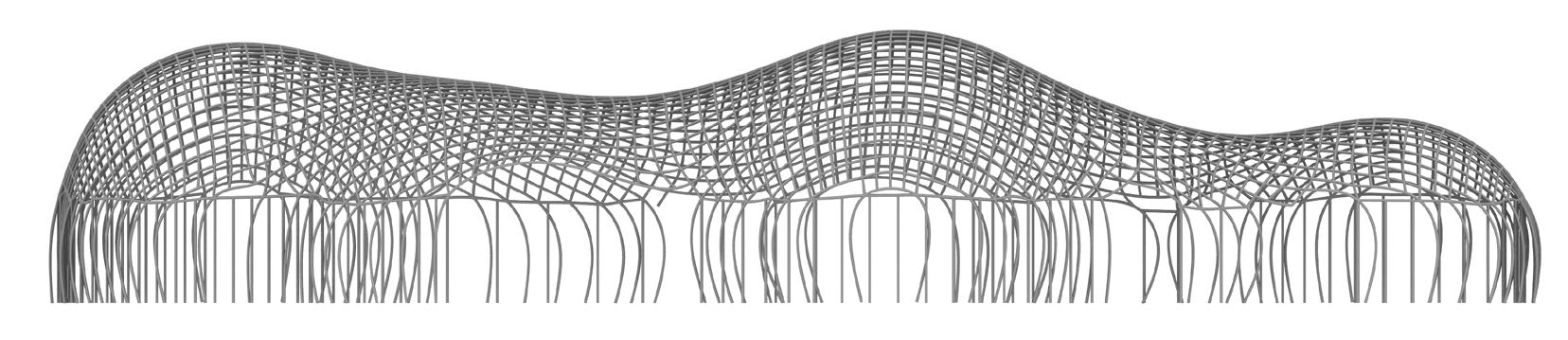

The proposed material system incorporates robotic fabrication with a wattle and daub technique, merging traditional building practices with contemporary construction technology. The bottom layer is an actively bent acacia gridshell, similar to the gridshells constructed by the Tuareg and Gabra. This layer encloses large amounts of space with relatively little material, allowing for a light load when the settlement must move again. Joints are tied with leather ties, and poles can be replaced by other acacia trees found on site. Its existing forms; however, will have to be adjusted to accommodate the upper layers. A date palm mesh will then be created between actively bent poles. Date palm is readily available, and the creation of mats from it is an actively practiced fabrication technique. This allows earth to be added on top of the gridshell without having to space acacia tightly enough to hold a soil mixture. This reduces the amount of poles needed in the system, and subsequently, the amount of joints and construction time needed. Above the date palm mesh is a layer of extruded earth which an be constructed quickly. The top flat layer allows the form to be enclosed as a thicker top layer is added over a longer period of time.

Robotic Nomadism | iN t R 044

Although population ratios are consistently in flux, certain parameters were set to help define the scope of this research. The depicted ratios are based on population dynamics of the Gabra nomads, although they are similar to dynamics displayed by Tuareg and Rendille. We will consider that there will be a camel to person ratio of 5:1, meaning that the animal enclosure space far exceeds the human enclosure space, although this can vary based on economic conditions. In addition, we will consider that there is roughly one truck per 20 people. This assumes that even in the smallest groups, there will be at least one transit vehicle. These are typically used to scout out new areas before alerting the rest of the caravan of the next move, and can also be used to carry heavy equipment, such as a robot. The minimum settlement size for a nomadic group is typically 25 people, and can grow to up to 250 people. These groups can change in scale regularly, as more groups join together to form larger settlements throughout the stationary seasons. In the urban scale section, growth and development of groups over time will be discussed in more detail. The lifespan of the structure will be for 3-4 months, between December and March, and June and September. These are the times when nomadic pastoralists settle, and are also the times of year with the most extreme temperatures. These two time periods will have separate camp-site processes, and one would not relate to another. This rebuilting allows for traditional revisions to take place during the building process, so long as changes are then written into the robot’s tool path.

045 s tructure l i F es P an maximum Po P ulation size m inimum Po P ulation s ize Person : t ruck r atio Person : c amel r atio 25 200 25 200 1 person 5 camels 20 people 1 truck 25 people 200 people t arget Program d ec. Jan. Feb. m ar. aP ril m a Y June JulY a ug. s e P o ct. n ov.

t ravels w ith Po P ulation

cell phone with acacia assembly instructions

truck to transport robot robot livestock with acacia sticks

r emains in Place

soil to extrude

In the proposed material system, the only physical addition to the nomadic travel load is a robot. The elastically bent gridshell can be constructed using wood that is currently used for armature tents. The robotic arm can be transported using trucks that are currently avaliable and used. Mobile phones are already avaliable to nomads, and instructions for alternate gridshell assemblies can be downloaded and applied to the sticks in the area. Files for robotic tool paths can be sent digitally through a phone, and implemented through a robot.

In this system, the heaviest load, which is the earthen layer that is applied to the gridshell, is left behind at the end of a 3-4 month settlement period. The wooden poles can be reuses for the next iteration, and also used in different forms if needed.

Robotic Nomadism | iN t R o 046

047

03. material s Y stem

[understanding the material contribution to the system]

048

049

The experiment process for this research melds multiple layers of consideration, combining the acacia and wood mechanical properties with cultural context to make a material proposal.

The preceding chapter highlights how available materials, environmental considerations, and programmatic needs lend themselves into a two-part wattle and daub system, utilizing acacia and extruded earth. From here, mechanical constraints for both materials are considered initially to obtain a first approximation of composition and form. Then, computational and robotic experiments are conducted, revised, and re-conducted until suitable conclusions can be drawn. Within the second round of experiments, cultural considerations are analysed and incorporated into the setup, allowing us to tailor the experiment to ensure they can produce solutions which are suitable for the target program.

Robotic Nomadism | iN t R o 050

e x P eriment Process

Fig 2.02 - Interesting image withrobofromuhfiushfsnkhkztjfzuhgisjgln nsunfusngk

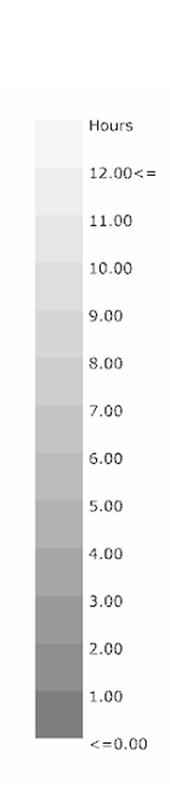

TEST EXTRUSION COMPUTATIONALLY [solar analysis]

IDEAL COMPOSITION IDEAL PROFILE

AVAILABLE MATERIALS [sand, wood, clay]

ENVIRONMENTAL CINSIDERATIONS [thermally responsive]

2 PART SYSTEM [wood & extruded earth]

EXTRUDED EARTH

TEST EXTRUSION MANUALLY [plastic nozels]

PROGRAMMATIC NEEDS [rapid production]

WOODEN GRIDSHELL

TEST GRIDSHELL PATTERNS [kiwi3D]

CULTURAL PRECEDENTS

IDEAL GRIDSHELL PATTERN ARCHITECTURAL BODY PLAN

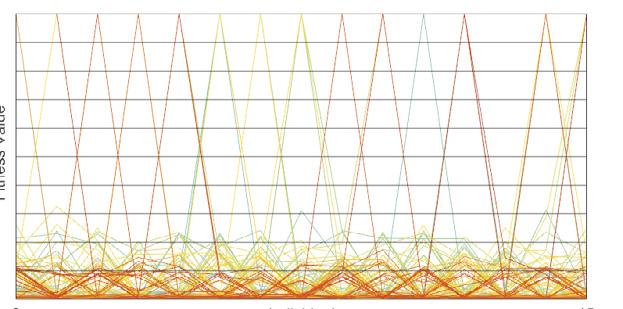

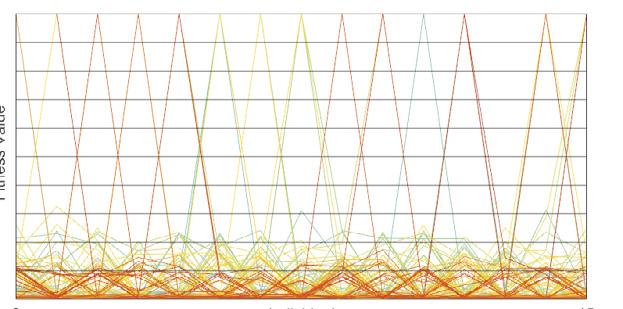

RUN GENETIC ALGORITHM

SYNTHESIZE OBJECTIVES ANALYZE CONSTRAINTS

CONCLUDING FORMS

TEST EXTRUSION ROBOTICALLY [air compressed extruder]

CONCLUDING PATHWAYS

PROPOSAL

ANALYZE RESULTS REVISE SIMULATION

051

03.01 acacia wood

Species: Acacia Tortilis / Vachellia Tortilis

Common names: Umbrella Thorn, Acacia Thorn

Acacia tortilis is known to tolerate high alkalinity, drought, high temperatures, sandy and stony soils, strongly sloped rooting surfaces, and sand blasting. It occurs from sand dunes to rocky scarps. A tough resistant species, the umbrella thorn grows in areas of annual rainfall as low as 40 mm and dry seasons of 1-12 months1. The wood is heavy and hard, and its strength values are considerably higher than those of oak. It is difficult to split, it is also tough and elastic.

Distribution and description

Acacia tortilis is commonly found in the north, north-west, east and south east of Africa. It is prevalent in the Saharan and Sub-Saharan and Sahelian belt. It reaches heights of between 5 and 20 m in nature. It is fairly slowgrowing and in cultivation reaches a final height of between 3 and 5 m with a spread of 8-13 m. In extremely arid conditions, it may occur as a small, wiry bush. Branches range between 40 mm and 10 mm2

General Uses

One of its uses is sand dune stabilization, for which it is particularly suitable. It is also one of the major dry season fodder trees for the SaharaSahelian belt. The thorny branches are used to erect temporary cages and pens, while the flexible roots and branches are used by African nomad societies to create frameworks of their temporary shelters.

Source

1. http://www.worldagroforestry.org

2.https://hort.purdue.edu/newcrop/duke_energy/Acacia_tortilis.html

052 r obotic n omadism | material s Y stem

m echanical P ro P erties

Property Specific gravity Weight Fibre stress at elastic limit Static bending Modulus of rupture Modulus of elasticity Work to elastic limit 0.66 1164 kg/m3 335 kg/m3 608 kg/cm2 0.133 kg/cm2 0.69 769 kg/m3 461 kg/m3 Impact bending - value of work absorbed 160 kg/cm2 105 kg/cm2 806 kg/cm2 58000 kg/cm2 71900 kg/cm2 0.199 kg/cm2 Green Dry Compression Parallel to grain Perpendicular to grain 344 kg/cm2 416 kg/cm2 90 kg/cm2 70 kg/cm2 Surface hardness Radial Tangential 615 kg/cm2 638 kg/cm2 614 kg/cm2 578 kg/cm2 Shear parallel to grain Radial Tangential 114,2 kg/cm2 160 kg/cm2 133.1 kg/cm2 122 kg/cm2

c haracteristics

[Oak] 86200 kg/cm2 12300 kg/cm2 245 kg/cm2 483 kg/cm2

053

Fig 03.01.01 - Acacia trees in the Sahel region, Africa

methods o F using wooden elements as structure

The aim of this analysis is to identify the optimal method of using wood elements that ensures a fast fabrication and assembly time and corresponds to the available material in a sustainable way.

timber F rame active bending P rebending [using straight elements] [bending straight elements] [using curved elements]

The material has to be industrially processed to achieve appropriate sections

Active bent elastic grid shells can be easily assembled using unprocessed local material

Prebending enable the structure to resist a higher load

F abrication time

m aterial used

a ssemblY time ada P tabilit Y

F abrication time

m aterial used

a ssemblY time

ada P tabilit Y

054 r obotic n omadism | material s Y stem

Fig 03.01.02 - Assessing ways of using wood as structural load bearing elements in construction

a ssemblY time ada P tabilit Y m aterial used

F abrication time

straight elements

Timber frames, also known as post and beam constructions are traditional methods of construction using heavy timbers. Straight elements are statically determined and present less reactions under temporary external load. They perform better in time and are suited for permanent structures. The elements cross section is larger and use ore have to be processed from tree logs to standard dimensions by industrial processes. These types of structures require a higher material volume and mass and are not easily transportable.

active bent elements

Active bending is well known for the low assembly time it requires and its fast erection methods. As it uses only thin and long elements for the fabrication of a structure, branches and root can be used, not compromising the entire tree. This is important to take into consideration, as Acacia trees are heavily used to combat desertification. The main characteristics of acacia wood are its flexibility and durability. This translates into a good structural behaviour during bending. The end design is usually typically a lightweight frame that can be easily disassembled and transported. The fore-mentioned information together with precedents of using active bending as a construction method in several nomadic tribes reinforces the observation that active-bending is a method worth further exploration.

P rebent elements

Prebending has most of the characteristics of active-bending, ensuring a lightweight structure that performs even better under load. The main disadvantage is that it requires constraining the elements in different bend positions prior assembly. It often requires special moulds, increasing wood moisture content and letting it dry in the desired position, which increases the fabrication time exponentially. The assembly becomes more difficult and the design solution less adaptable. Prebending may be a desired solution for special load carrying edge conditions, were the active bent elements cannot perform.

055

active bending

A form defining strategy based on systemized elastic deformation – bending

s tructural behaviour and geometr Y a ctive bending

Bending-active structures are structural systems that include curved beam or shell elements which base their geometry on the elastic deformation from an initially straight or planar configuration.1

The term was initially introduced by J. Knippers 2 to describe structures that base their geometry on the elastic deformation of elemets that were initially straight or planar ( curved beams and surfaces).

It is a form defining strategy based on bending, or in more technical terms, systemized elastic deformation.They can be understood as a subcategory of surface-active structures as they load bearing capabilities include a combination of bending and normal forces, in their final deformed state having the capacity to develop real arch or shell properties.

As grid shells are concerned, this study will focus on the elastically deformation of initially straight elements, more exactly the active bending of beam elements.

From a structural point of view, they can be classified as “constrained statically indeterminate structures”3

Taking into account the material properties, the induced deformation must always remain in the elastic range, making sure that the bending stress applied does not surpass the elastic limit of the material. This ensures that plastic deformations do not ocure and allow the use of linear material analysis methods.

From a geometrical point of view, due to the large deformations of bending-active structures, the calculations generally must be performed geometrically non-linear.

Source

1. Knippers et al 2011: 134

2. Knippers et al 2011: 80

056 r obotic n omadism | material s Y stem

Fig 03.01.03 - Erection process of an active bent gridshell

1 2 3 4 5 6

e lastica curves

Comparative study between geometrical defined curves

com P arison e lastica geometr Y

The geometry of bending focuses its study around a certain type of curve named Elastica.

From the perspective of ease of use and integration in the design process, there are many well known definitions of curves that offer simpler geometric and structural definitions.

An elastica curve is the shape a long, thin flexible rod creates when it is elastically bent. It is geometrically defined as a plane curve that has at all points a curvature that is proportional to the distance to a fixed line, called the directrix1. It is an analytical model.

Understanding the elastica curve is fundamental to understanding the structural behaviour of bent elements and for establishing the appropriate form-finding method in clarifying the design intentions.

Source

1. https://www.mathcurve.com/courbes2d.gb/linteaire/linteaire.shtml

In order to further understand the geometry and structural performance of the elastica curve, a comparison has been set up between it, the catenary curve and the circular curve. Using the same span and height over span ratio, it can clearly eb seen that until a 0.3 height/span ratio, the curve perform approximately similar. Increasing this span, the curves start to achieve very different curvatures along the length of their curve.

From a structural point of view, the elastica situates itself between the catenary, which exhibits minimum displacement under vertical load, and the circular curve .

057

Fig03.01.04 - Geometrical comparison between the elastica, catenary and circular curve

Elastica curve Heigth Span Span Legend Catenary curve Circular curve 4 0.90 0.60 0.30 0.10 0 3 2 1

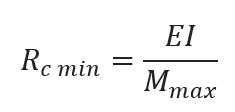

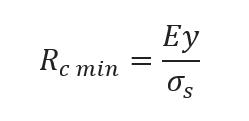

bending moment

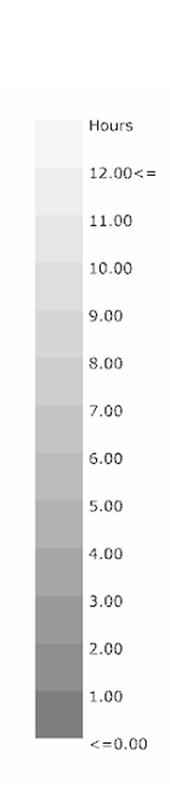

Identifying the bending moment associated with rupture

One essential thing to be considered when working with form-active structures achieved through bending, from a structural point of view, is the bending moment, as it is the most important value that can be related to moment of rupture. Given the fact that, as most wood materials, the mechanical properties of acacia reveal a compressive strength far lower that the tensile strength, Euler-Bernoulli beam theory will be used to identify the maximum bending moment associated to compression that an element can undertake while being bent1

This will lead to identifying the range of forms and curvatures available to the designer in the design process, allowing to impose certain limitation of the form finding method.

Initial studies were made on a 600 mm dowel with the cross section of 3mm. Using an iso geometric finite element analysis solver, the element was bent into multiple states. The bending moments associated to the different states of the element were extracted and compared with the maximum allowed bending moment in compression, using a visualization method. As can be observed in the figure, the orange colour marks sections of the element that are under more stress than the material can physically allow. From the 10 states that were achieved computationally, only 4 states can be achieved physically. The experiment was cross checked with physical experiments3

where σ

s - acacia compressive strength

y - distance from centreline to surface ( cross section)

I - second moment of area

M max - maximum moment at rupture

Associated to a chosen cross section of elements, knowing the compressive strength and material elasticity, a maximum bend before rupture can be identified using the resulted bending moment values.

Source

1. https://www.engineeringtoolbox.com/area-moment-inertia-d_1328.html

058 r obotic n omadism | material s Y stem

Same initial length Same cross-section Different curvatures 0.60 m 3 mm Different initial lengths Same cross-section Same curvatures 0.25 m 4.00 m 9 mm Same initial length Different cross-sections Different curvatures 2.00 m 3 mm 40 mm

059

Fig 03.01.07 - Associated geometrical and structural analysis values

Fig 03.01.06 - Physically achievable bend states

Horizontal displacement (m) Horizontal span (m) Vertical displacement (m) Heigth span ratio Maximim bending moment (kNm) Minimum radius of curvature (m) Tangent angle at anchor points (degree) 0.157 0.32 0.212 0,000101 0,000132 0,000157 0,000181 0,000203 0,000225 0,000245 0,000278 0,000312 51.3 0.189 0.45 0.165 65.2 0.209 0.61 0.139 75.9 0.223 0.74 0.121 85.6 0.233 0.96 0.108 94.6 0.238 1.2 0.098 102.9 0.241 1.6 0.09 109.9 0.240 3.4 0.079 120.7 0.234 0.485 0.418 0.339 0.30 0.242 0.19 0.143 0.069 00.07 130.7 1 2 3 4 5 6 7 8 9 10 20% 30% 40% 50% 60% 70% 80% 90% 100% 0.115 0.21 0,000069 0.305 36.1 0.541 10% breaking point 0.6 100% 0 0 0.11 0.15 0.19 0.22 0.21 0.23 0.24 20% 30% 40% 50% 60% 70% 80% 90% 10% 0% 0 0.485 0.418 0.339 0.30 0.242 0.19 0.143 0.069 0.541 Rupture occures before reaching the curvature Curvature not achievable Curvatures achievable within the elastic range of the material behaviour 0.000164 kNm M max 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Fig 03.01.05 - Iso Geometric Finite Element Analysis - Legend includes maximum bending moment as limitation for form finding

moment and curvature relationshi P

In order to describe curvature, the term radius of curvature is used. The radius of curvature R is the reciprocal of the curvature. For a 2D element, like a curve, it represents the radius of a circular arc that has the property of best approximating the curvature at that specific point.2

Numerical analysis

The local radius of curvature of an elastica curve can be calculated knowing the bending moment at a specific point across the bent element using the relation:

is the point at which the value of the bending moment is the highest:

This lead to the observation that the minimum radius of curvature is a property of the curve that not related to the initial length of the bent element, but to the material properties. The minimum radius of curvature is a value that for a certain cross section, remains constant across length variation.

Structural analysis

From this we can understand that the minimum radius of curvature, which defines the point at which the curve present the most accentuated curvature

Using the same element cross section, elements with different lengths were tested in order to understand the relationship between the bending moment and the resulted curvature in the computational environment. FEA analysis revealed a small deviation between the values of the local minimum radius of curvature exhibited at the point of maximum bending moment. This was a result of small variation of the bending moment as the simulation was stopped on load case before the maximum bending moment value.

Robotic Nomadism | iN t R o 060

Same initial length Same cross-section Different curvatures 0.60 m 3 mm Different initial lengths Same cross-section Same curvatures 0.25 m 4.00 m 9 mm Same initial length Different cross-sections Different curvatures 2.00 m 3 mm 40 mm

061

Fig 03.01.09 - Associated geometrical and structural analysis values

Length(m) Horizontal displacement (m) Vertical displacement (m) Heigth span ratio Maximim bending moment (kNm) Minimum radius of curvature (m) Tangent angle at anchor points (degree) 0.472 0.076 0.004127 0.16 0.21 0.28 0.38 0.45 0.55 0.70 0.83 1.13 1.70 2.15 3.50 13.7 0.344 28.07 0.676 0.146 0.004241 0.384 36.5 0.844 0.239 0.0043 0.398 46.02 0.943 0.363 0.004418 0.39 58.43 1.045 0.473 0.004312 0.408 65.22 1.079 0.601 0.004364 0.414 74.09 1.045 0.737 0.004331 0.415 83.65 1.028 0.858 0.00424 0.428 90 0.87 Loadcase 6 10 15 22 26 31 36 39 43 0.989 0.00432 0.420 99.9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 0.50 m 0.75 m 1.00 m 1.25 m 1.50 m 1.75 m 2.00 m 2.25m 2.50 m 0.650 46 1.107 0.00437 0.412 109.9 2.75 m 0.560 47 1.209 0.004228 0.427 114.42 3.00 m 0.372 48 1.304 0.004204 0.430 120.7 3.25 m 0.000154 49 1.370 0.004383 0.4130 130.7 Force (kN) 0.00284 0.00129 0.000755 0.000508 0.000366 0.000283 0.000231 0.000192 0.000169 0.000154 0.000136 0.000125 0.000124 3.50 m 0.241 0.036 0.15 0.004400 0.196 26.07 4 0.25 m 0.011 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 0.033 0.074 0.143 0.236 0.361 0.599 0.856 0.987 1.366 0.471 0.734 1.205 0 0 0.033 0.074 0.143 0.236 0.361 0.471 0.599 0.734 0.856 0.987 1.104 1.205 1.300 0.004437 kNm 1.366 M max

Fig 03.01.08- FEA Analisys- Minimum radius of curvature in relation to length

m inimum radius o F curvature

The minimum radius of curvature of a certain element cross section can be related to the maximum bending moment, but in the same time it can be calculated using the equation, independent of it:

considering complex structures. In the same time it can be a way of structural optimisation, as the appropriate cross section can be calculated for a desired curvature.

The bending moment can also be numerically calculated if considered necessary in the further form finding procedure.

This translates in the possibility of geometrically finding the minimum radius of curvature that a cross section can perform in relation to mechanical material properties (elastic modulus and compressive strength). This eliminates the initial need of FEA analysis for determining the eligible forms that can be produced physically.

Geometrically constraining the form finding process with a minimum curvature analysis can substantially reduce the analysis time when

The locally available acacia branch and root cross sections have been analysed to determine a minimum radius of curvature data base that can prove useful in the form finding process. The results are cross checked with FEA analysis to exclude errors.

062 r obotic n omadism | material s Y stem

Same initial length Same cross-section Different curvatures 0.60 m 3 mm Different initial lengths Same cross-section Same curvatures 0.25 m 4.00 m 9 mm Same initial length Different cross-sections Different curvatures 2.00 m 3 mm 40 mm

063

Fig 03.01.11 - FEA Analysis- Minimum radius of curvature in relation to cross section

Section diametre (mm) Horizontal displacement- Span (m) Vertical displacement (m) Heigth span ratio Maximim bending moment (kNm) Max moment before rupture (kNm) Minimum radius of curvature (m) Tangent angle at anchor points (degree) 0.373 0.806 0.001315 2.1 0.7 0.45 0.33 0.24 0.18 0.15 0.12 0.12 0.001253 0.284 1.045 0.737 0.004437 0.004331 0.415 1.394 0.631 0.010518 0.010366 0.545 1.589 0.538 0.020543 0.02023 0.679 1.759 0.424 0.048695 0.047482 0.906 1.847 0.343 0.095107 0.090353 1.150 1.889 0.295 0.164345 0.157444 1.357 1.928 0.237 0.260973 0.228435 1.707 1.928 Loadcase 47 36 26 19 12 8 6 4 4 0.237 0.389557 0.389081 1.709 1 2 3 4 5 6 7 8 9 10 6 mm 9 mm 12 mm 15 mm 20 mm 25 mm 30 mm 35 mm 40 mm Force (kN) 114.4 83.6 65.2 53 40.2 31.9 27.1 21.7 21.7 0 0.7830.000164 0.000094 0.236 50/no break 3 mm 130.7 0.0049 0.018 0.0522 0.121 0.366 0.872 1.790 3.284 5.6033 0.00038 1 2 3 4 5 6 7 8 9 10 0 1.92 1.88 1.84 1.75 1.58 1.39 1.04 2.00 0.37 0 0 0.23 0.29 0.34 0.42 0.53 0.73 0.63 0.78 breaking point for each section Same initial length Different cross-sections Different Minimum radius of curvature 2.00 m 3 mm 40 mm 0.80 M ma

Fig 03.01.10- Associated geometrical and structural analysis values

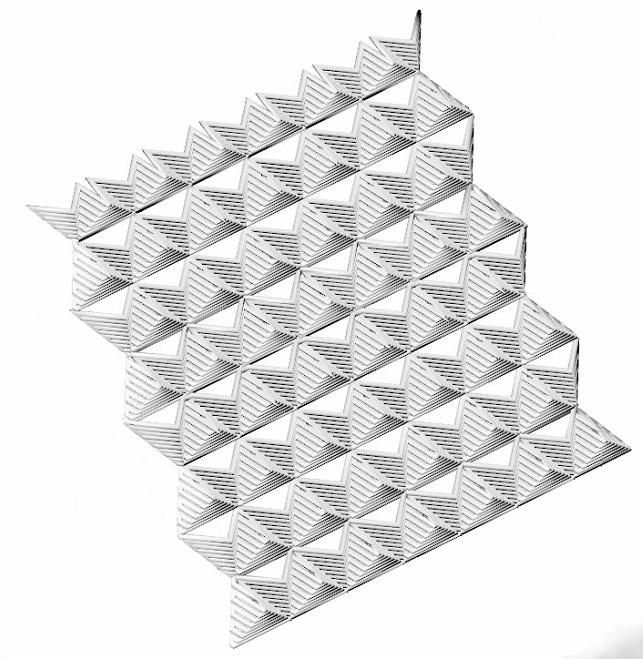

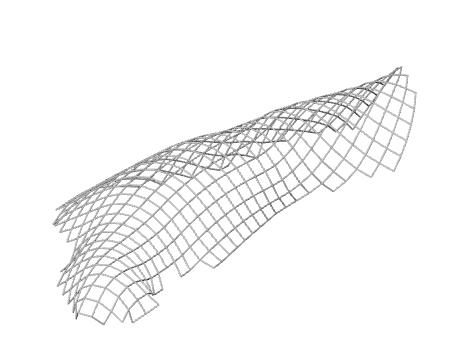

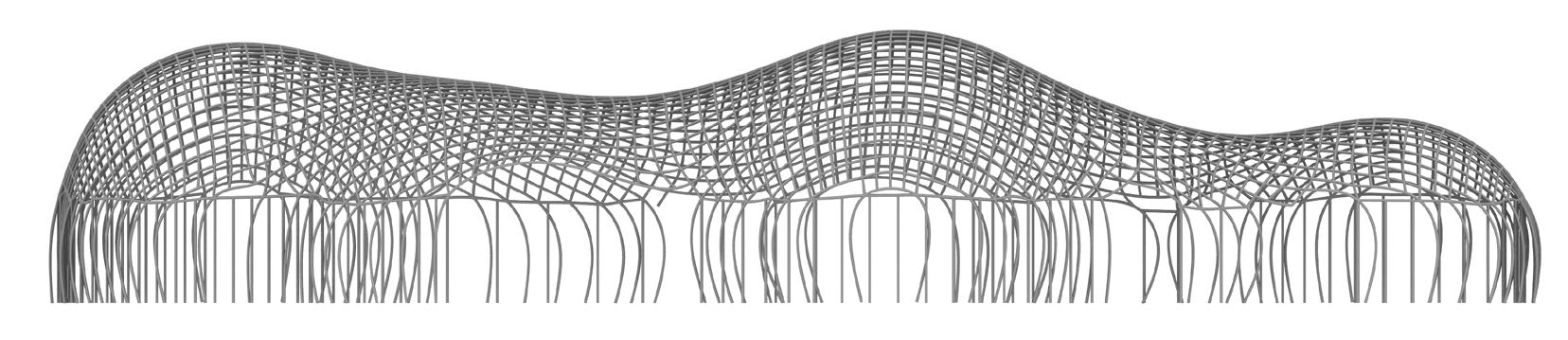

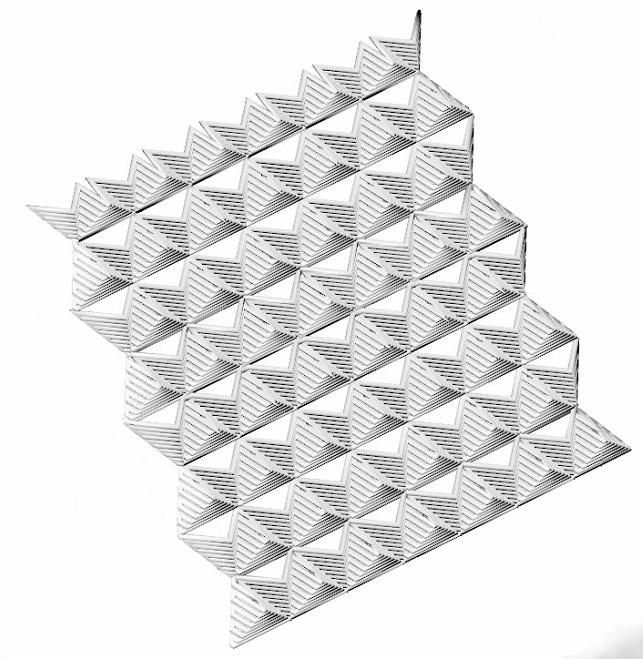

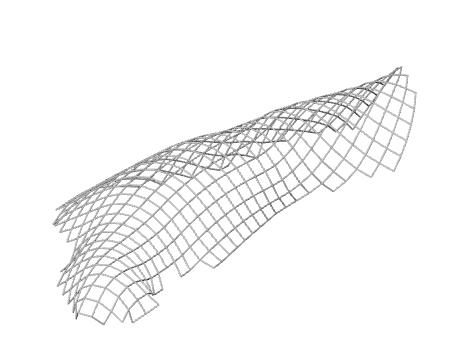

i nitial g ridshell s tudies

Because curves behave differently in an active bent structure than they do in a cantenary simulation, simple hanging chain methods of predicting behaviour would not suffice. Simply creating elastica curves mathematically would also lose accuracy, as the forces of neighbouring elastica curves change its form. Therefore, an initial study on how actively bent gridshells actuate, enclose space, and hold weight was conducted to determine the ideal pattern for gridshell optimisation.

Robotic Nomadism | iN t R o 064

a ctivelY b ent g ridshell

d e F ormed c urve

065 4m 1-3 cm of soil

point c om P ressive l oad a ctuation Force a nchor Point Freedom

until breaking

Breaking Point

t riangulation 1 1 cm soil

• Joints: 89

• Volume: 6.09 m3

• Cum. Length: 119.40 m

t riangulation 2 1 cm soil

• Joints: 4

• Volume: 4.94 m3

• Cum. Length: 85.55 m

Moment Calculation

t riangulation 3 2 cm soil

• Joints: 81

• Volume: 3.88 m3

• Cum. Length: 116.67 m

Robotic Nomadism | iN t R o 066

s tandard q uads 0 cm soil

• Joints: 45

• Volume: 6.62 m3

• Cum. Length: 54.74 m

d iagrid 3 cm soil

• Joints: 81

• Volume: 6.64 m3

• Cum. Length: 66.02 m

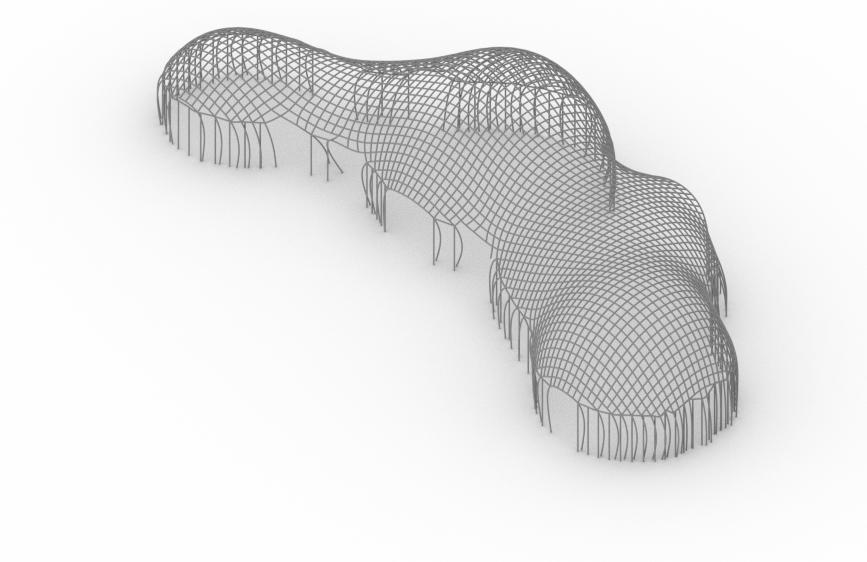

The diagrid structure was the most usable pattern in out initial studies because of its ability to hole 3cm of wet soil mixture. However, none of the forms were able to reach a height above 2m without breaking, so alternate methods of enclosing usable space would need to be performed.

s kewed q uads 0 cm soil

• Joints: 47

• Volume: 6.97m3

• Cum. Length: 65.58 m

067

l ocal material: date P alm F iber

lea F lets a vailabilit Y and P ro P erties

Fibrous and soft, the date palm trunk is not suitable as a structural material in construction. Its cellular structure makes flat sawing not a good option, and as a result, palm trunks are never used in the building environment. On the other hand, its leaves and fronds come as a well exploited regenerable resource. Often exploited for woven products, date palm leaves are a commodity due to their fibrous qualities1 .

Usually women into basketry and mats, the date palm leaves are intensely utilised by nomads for weaving their tent mats as they are strong in tension and due not lose their qualities with drying.

Every year under a normal growth rate is average conditions, a date palm produces between 12 and 15 new leaves, and consequently the same number of leaves can be harvested. Considering these quantities over thousand of trees, this can lead to a large available resource.

The leaves can be used in different ways according to the part that is used, but for weaving purposes leaflets are generally used. They can vary in length from 15 to 100 cm, being 1-6 cm wide. On the midrib of each leaf, the number of leaflets varies between 120 and 240.2

They are an accessible resource that does not necessitate intense labour, and can be easily collected and manipulated by hand, not needing additional tools.

Source

1. T. Odeyale and T. Adekunle, “Innovative and sustainable local material in traditional African architecture,” 2008

2. http://www.iranicaonline.org/articles/date-palm

068 r obotic n omadism | material s Y stem

Date palms can be easily found across Mali, especially is the proximity of oases.

069

Fig 03.02.01 - Gabra nomad carrying date palm mats

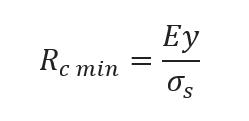

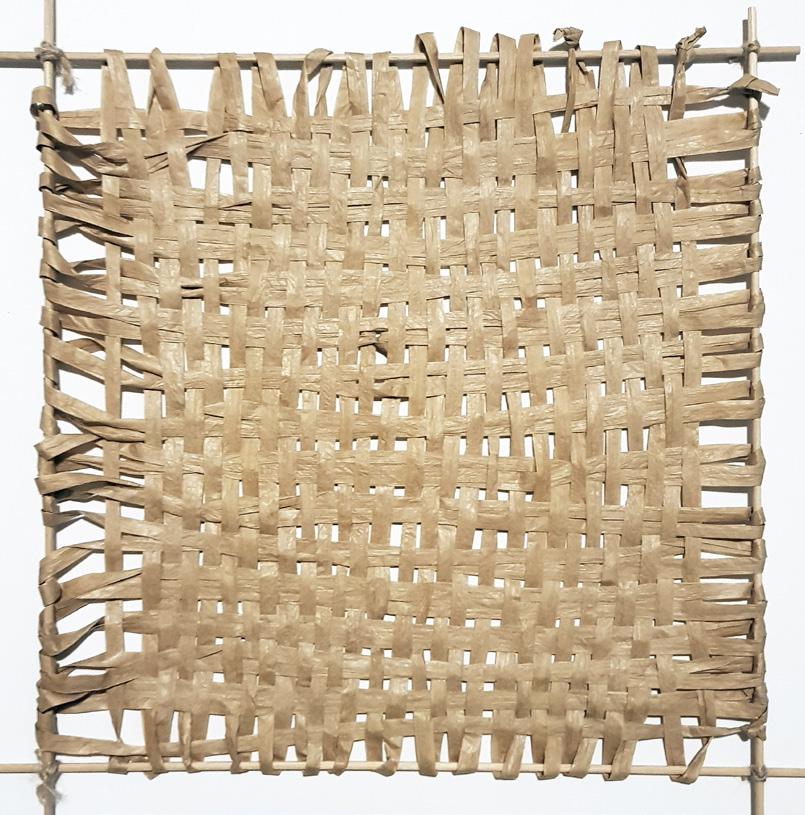

Two parameters are important to define the mesh properties: orientation and density

Taking into consideration that the material system uses a diagrid configuration, the mesh weaving orientation is discussed in relation to the pole orientation as well as the gravitational pull.

The mesh has two roles as an intermediary layer: it acts as cross bracing for the grid shell, conferring stability and rigidity to the structure, as well as acting as formwork for the following loam layers. The weaving orientation is important for both criteria. For the following layers, the horizontal weaving does not provide enough support.

For both criteria, the bidirectional weaving is the optimal solution as it offers enough strength hold earthen layers, and acts uniformly in both pulling directions, ensuring stability.

The mesh density affects proportionally the fabrication time and material quantity, in relation the strength it adds to the gridshell. The denser the mesh, the more material it requires, which result in a higher fabrication time, but in the same time more strength for crossbracing and a better defined formwork. The aim of this study is to identify a balanced solution between fabrication time and necessary stiffness. A 50% dense weave results in a sufficiently tense mesh as well as improved stability for the poles.

The mesh density has to also respond to the material viscosity and method of application on the mesh. Taking into consideration a viscous paste similar to plaster, the 50% mesh would provide enough support to ensure the continuity of an initial layer, as well as a good behaviour in supporting its weight.

070 r obotic n omadism | material s Y stem

grid bracing laY er su PP ort m aterial used F abrication time grid bracing laY er su PP ort m aterial used F abrication time grid bracing laY er su PP ort m aterial used F abrication time

weaving densit Y weaving orientation d

P

bidirectional weave vertical weave horizontal weave

Fig 03.02.02 - Physical experiments that test the mesh weaving orientation

ate

alm mesh

25 % densit Y

A less dense mesh provides the advantage of being time efficient in relation to the construction process

F abrication time