Rural WaterScapes

Sub - Saharan Africa

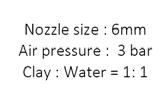

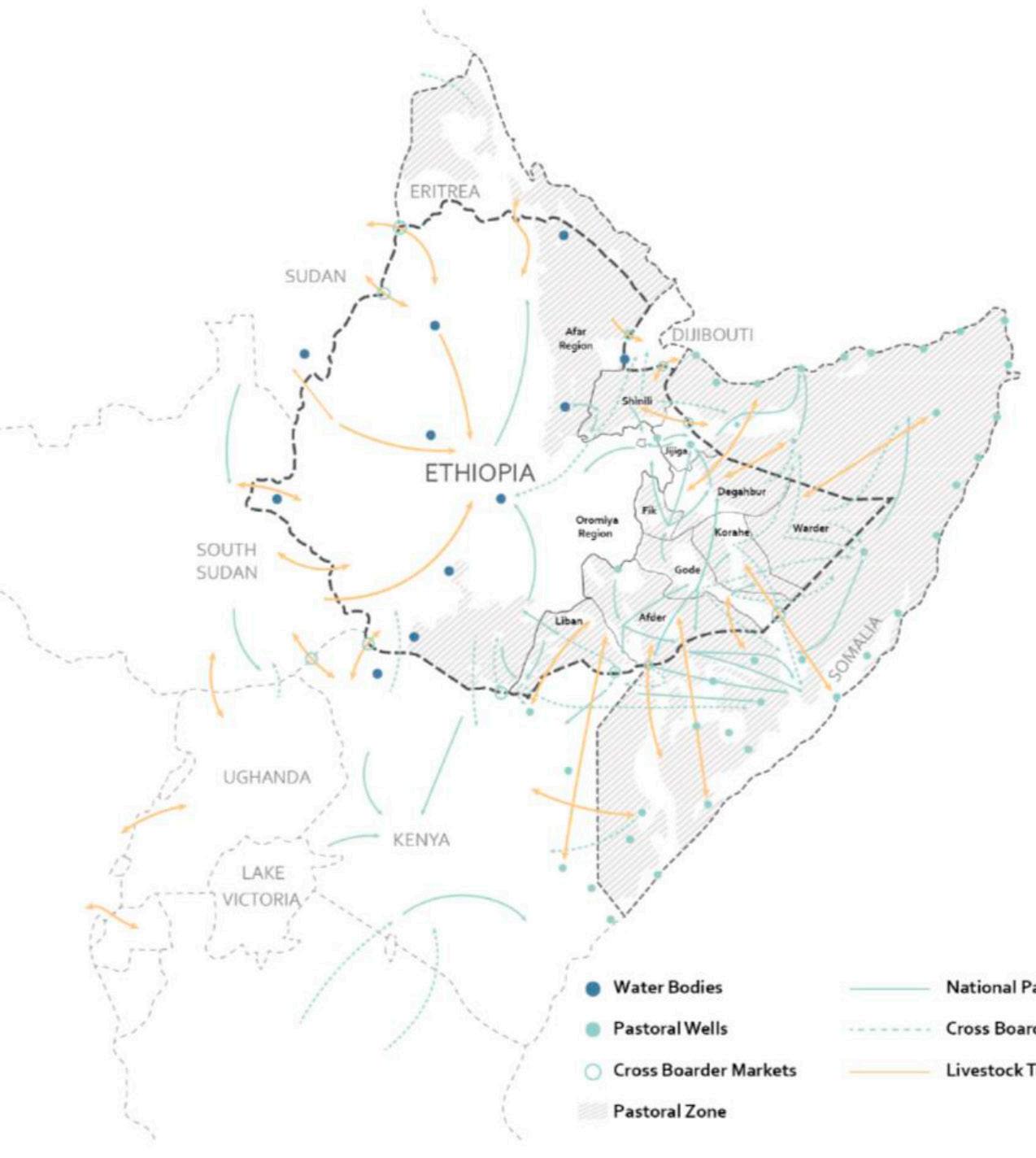

Construction, Agriculture and Water Management strategies for a resilient settlement in Ethiopia

M.Arch Candidates :

JongIn Choi

M.Sc Candidate :

Devaiah Ponnimada Ashok

Yousra Elshafeei

Felipe Oeyen

Rural WaterScapes

Sub - Saharan Africa

Construction, Agriculture and Water Management strategies for a resilient settlement in Ethiopia

M.Arch Candidates :

Devaiah Ponnimada Ashok

Felipe Oeyen

Jong In Choi

© Architectural Association, 2021 Architectural Association School of Architecture Emergent Technologies and Design 2019-2020 36 Bedford Square, London WC1B3ES Yousra Elshafeei M.Sc Candidate : 2 3 Rural WaterScapes Rural WaterScapes

ARCHITECTURAL ASSOCIATION SCHOOL OF ARCHITECTURE GRADUATE SCHOOL PROGRAMME

PROGRAMME : Emergent Technologies and Design [EmTech]

TERM :

COURSE TITLE :

COURSE TUTORS :

2019 - 2021

M.Sc Dissertation

Dr.Michael Weinstock, Dr. Elif Erdine

Abhinav Chaudhary, Alican Sungur

Eleana Polychronaki, Lorenzo Santelli Milad Showkatbakhsh.

SUBMISSION DATE :

SUBMISSION TITLE :

29th January, 2021

STUDENT NAMES :

Rural WaterScapes Devaiah Ponnimada Ashok

Felipe Oeyen

JongIn Choi

| M.Arch Candidate

| M.Arch Candidate

| M.Arch Candidate

STUDENT NAMES :

“We certify that this piece of work is entirely our own and that any quotation or paraphrase from the published or unpublished work of others is duly acknowledged.”

SIGNATURE OF STUDENTS :

Devaiah P. Ashok Felipe Oeyen JongIn Choi

SIGNATURE OF STUDENTS :

29th January 2021

4 5 Rural WaterScapes Rural WaterScapes

ACKNOWLEDGEMENT

We would like to express our sincere gratitude to Dr. Michael Weinstock and Dr. Elif Erdine for their invaluable support and guidance in this project. And for the valuable time we got to spend together at the Architectural Association.

We would like to thank George Jeronimidis for the timely advice given to us during the course of the project. We would also like to extend our gratitude to Abhinav Chaudhary, Alican Sungur, Eleana Polychronaki Lorenzo Santelli and Milad Showkatbakhsh for their constructive feedback and support.

We would also like to thank the Angel Lara Moreira and the AADPL for providing us access to use their facilities despite the constraints and giving us valuable feedback.

Lastly, we would like to acknowledge the support and encouragement of our family, friends and colleagues at the Emergent Technologies and Design Program.

6 7 Rural WaterScapes Rural WaterScapes

ABSTRACT

Construction, Agriculture and Water Management strategies for a resilient settlement in Ethiopia

The thesis investigates the potential for the generation and development of a resilient rural community capable of harvesting and managing rain and atmospheric water in the context of an arid/semi-arid environment located in the Somali region of Ethiopia, Eastern Africa. The current situation in the region was studied, quantifying water requirements and potential water collection, local materials available, vernacular construction techniques and traditional housing typologies.

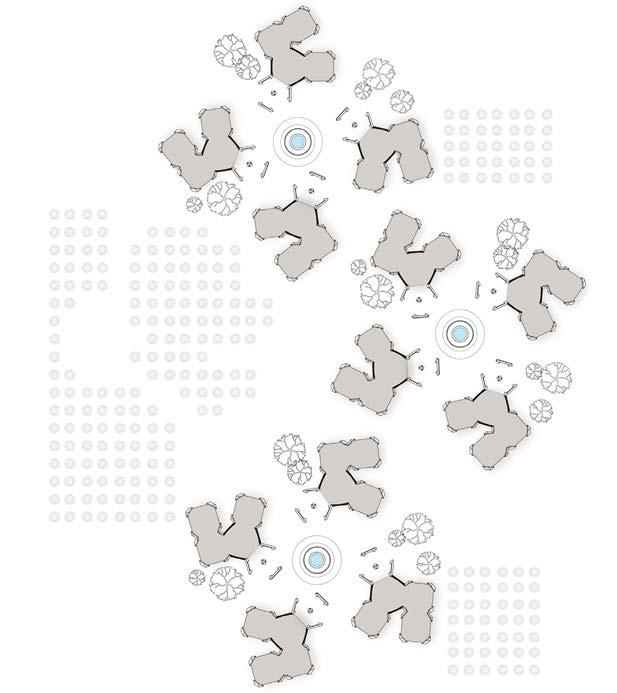

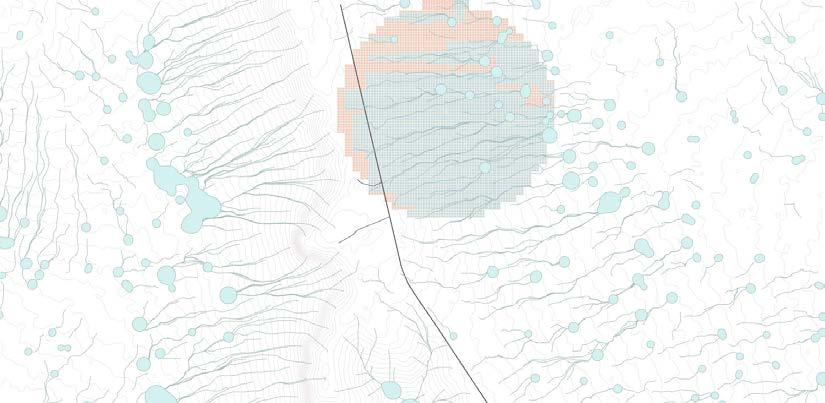

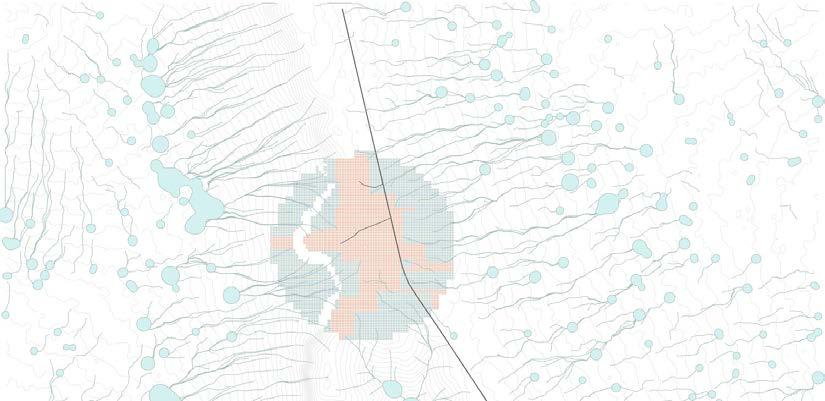

The research focuses on the design and fabrication strategy for a settlement that could permanently house and ensure the necessary water and productive land for the development of refugees, IDPs and rural settlers whilst also temporarily housing pastoral groups during the dry season. Environmental and site conditions, as well as indigenous agricultural strategies were considered for the design of a settlement network and distribution that can be adapted to the existing terrain hydrology.

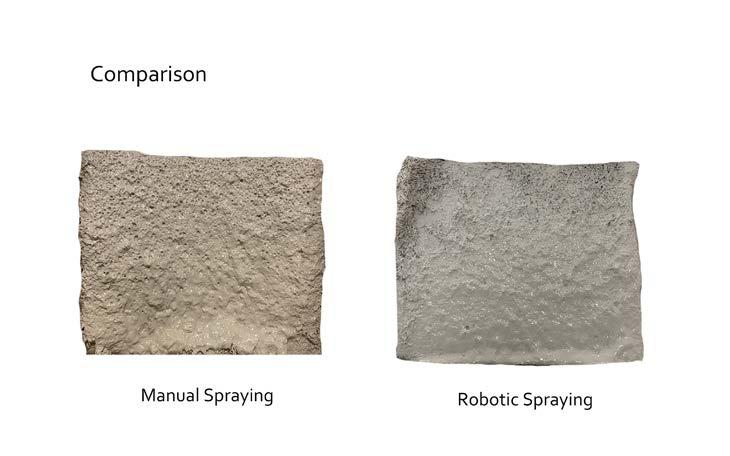

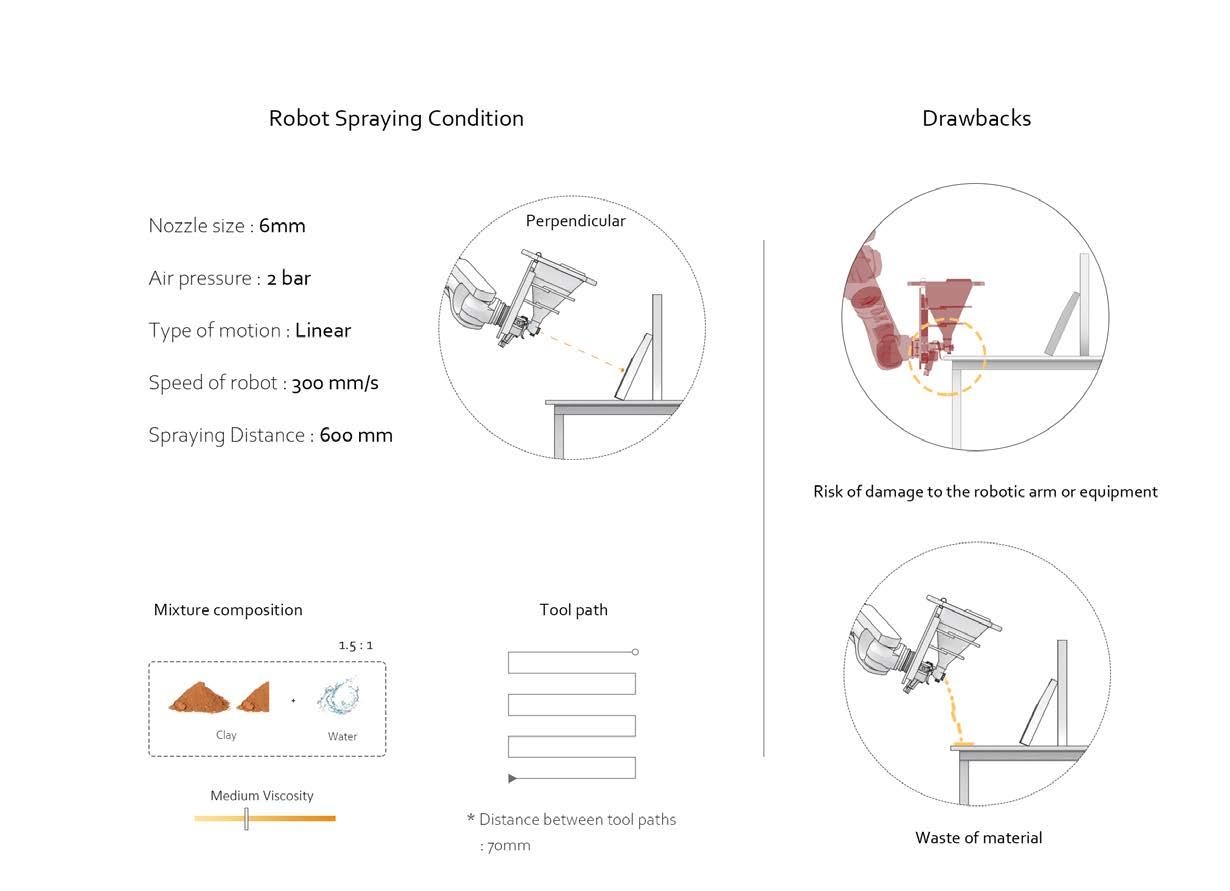

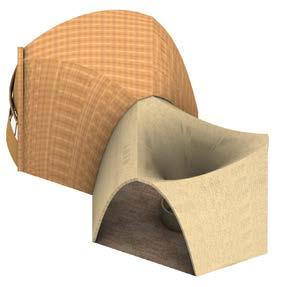

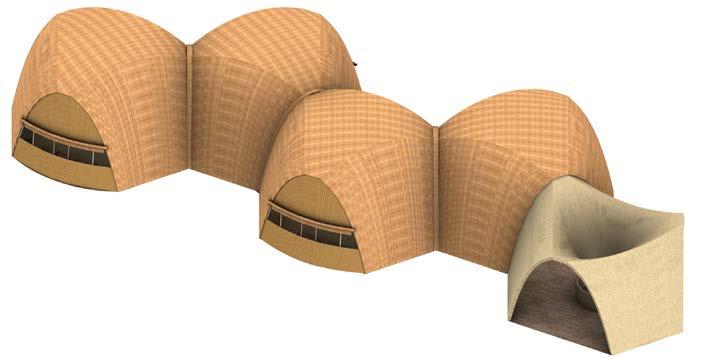

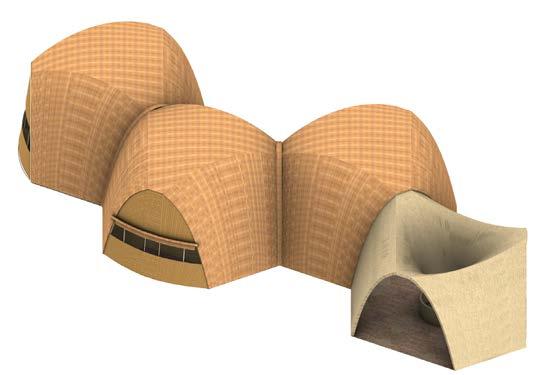

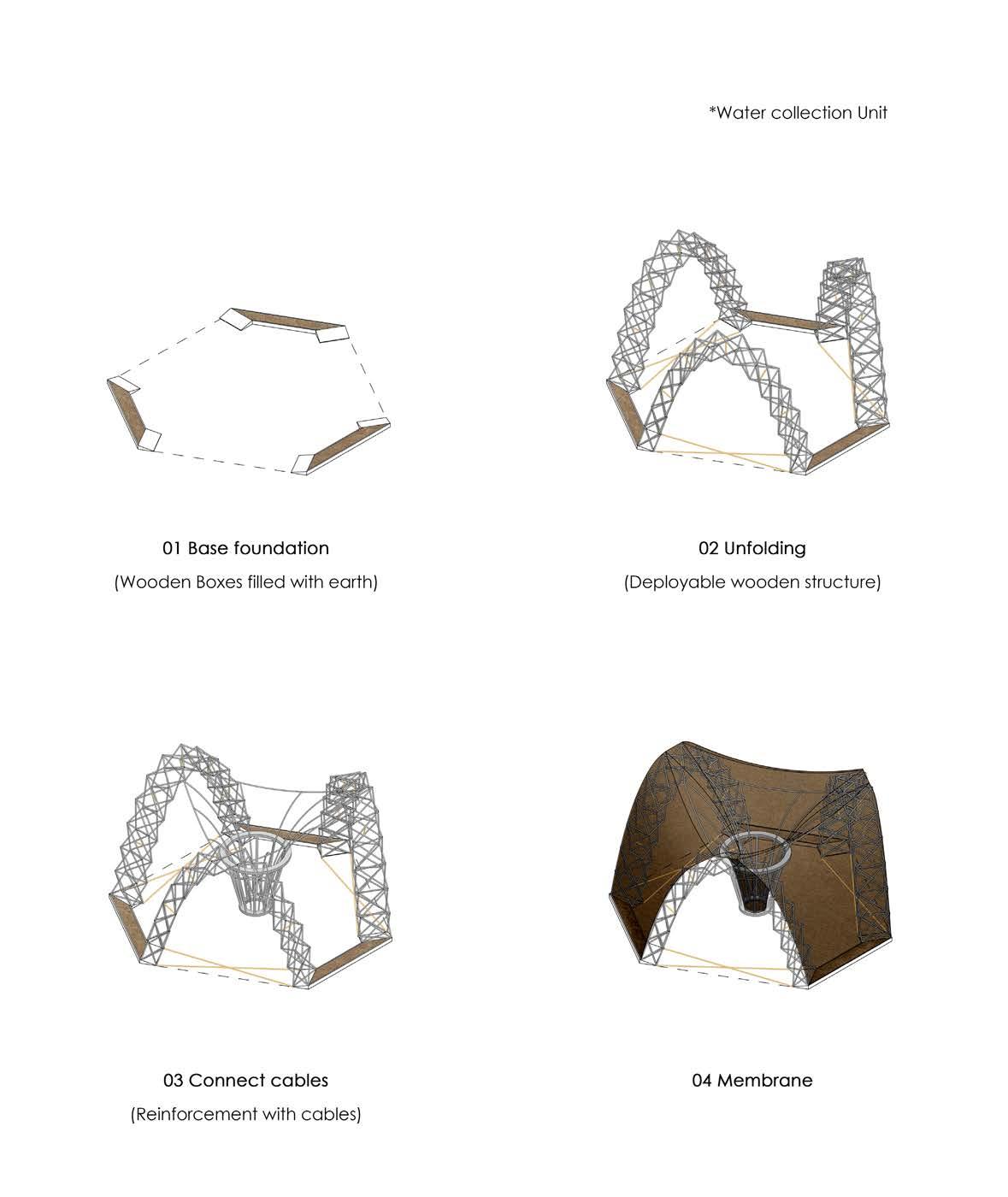

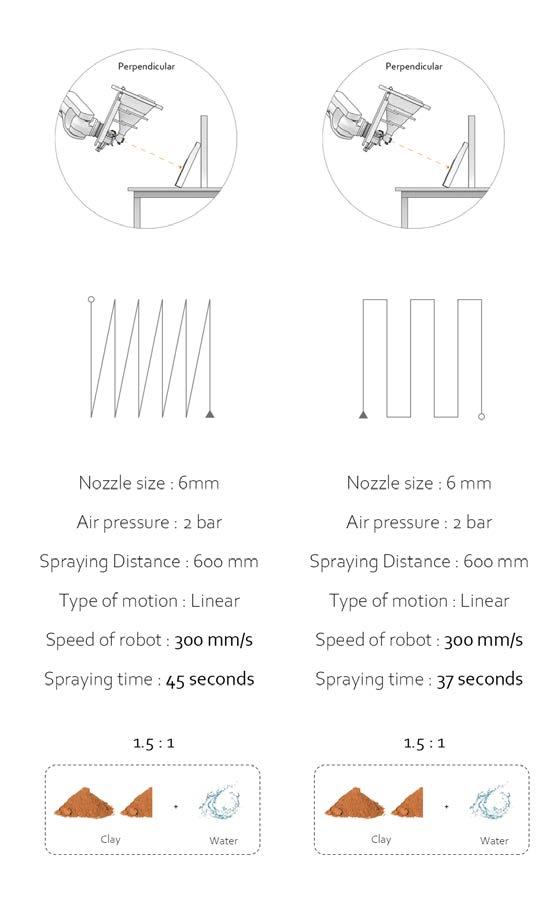

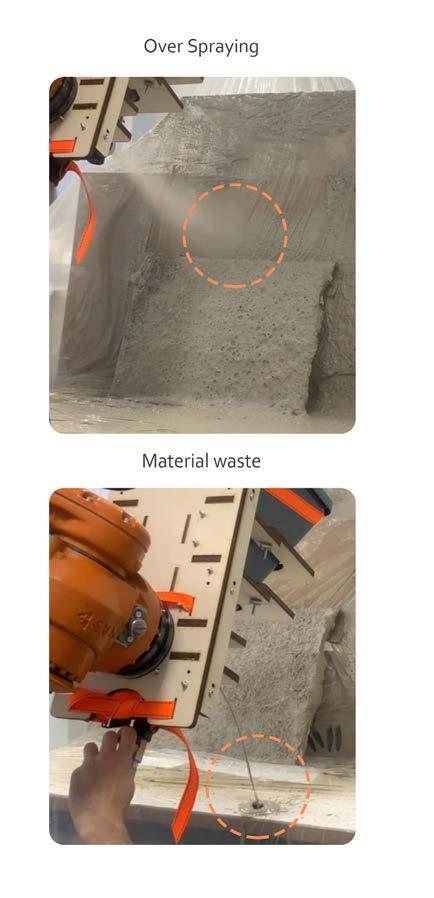

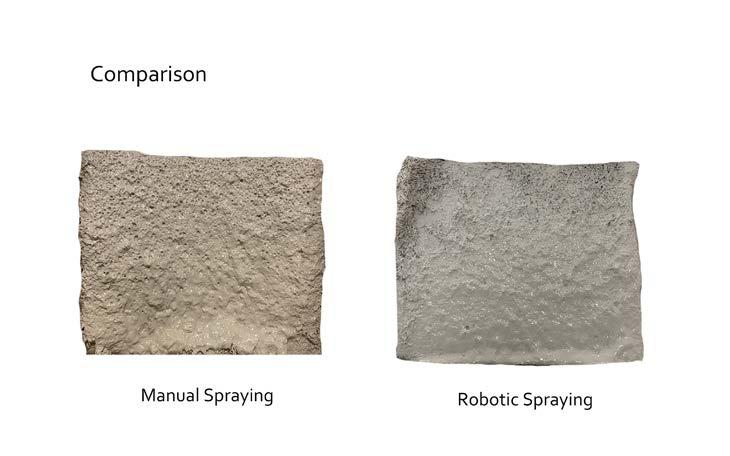

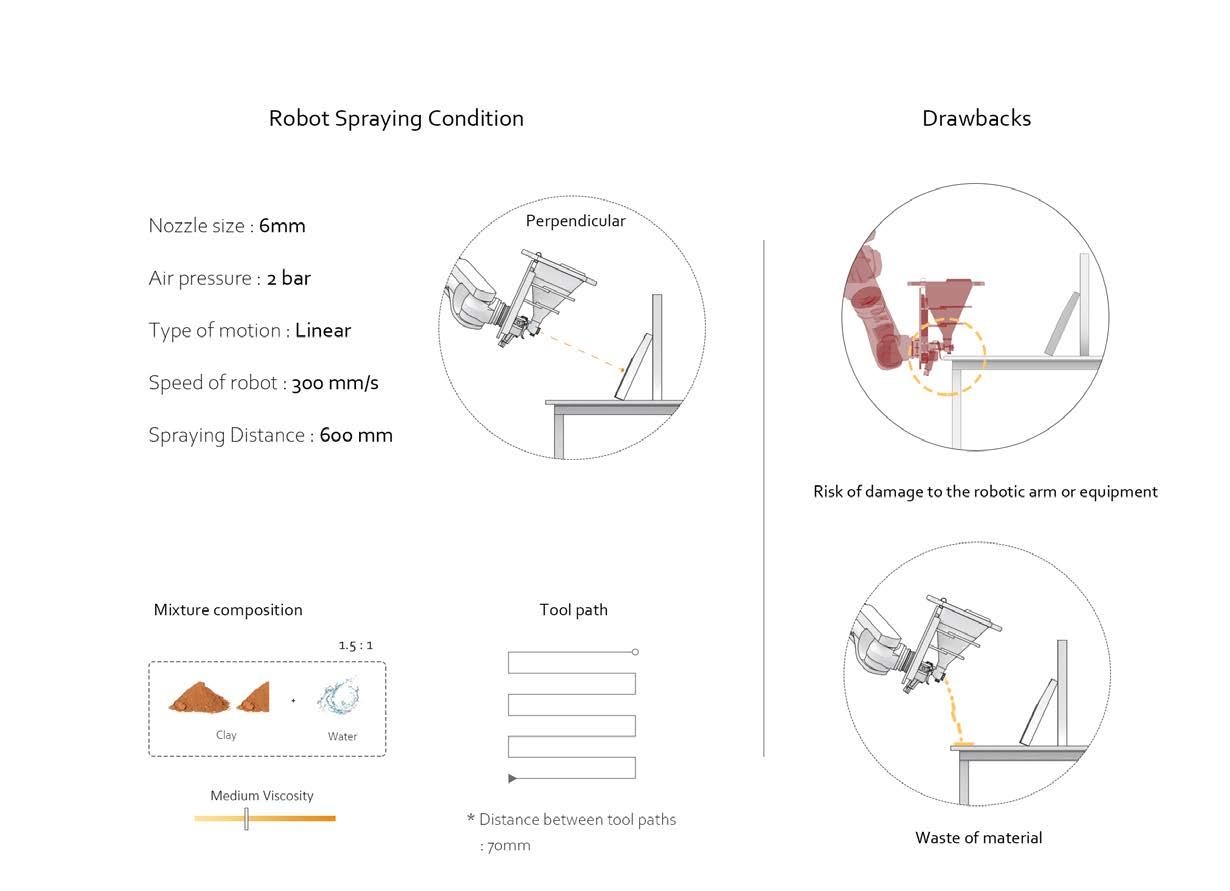

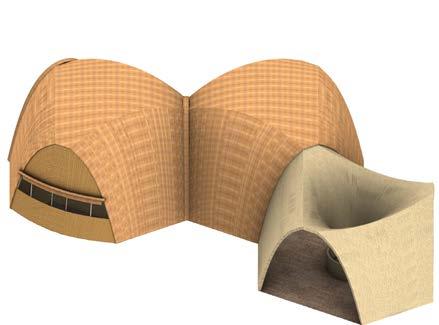

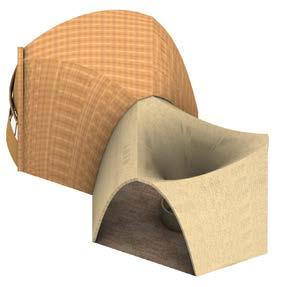

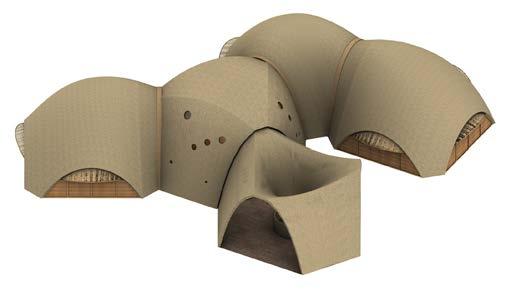

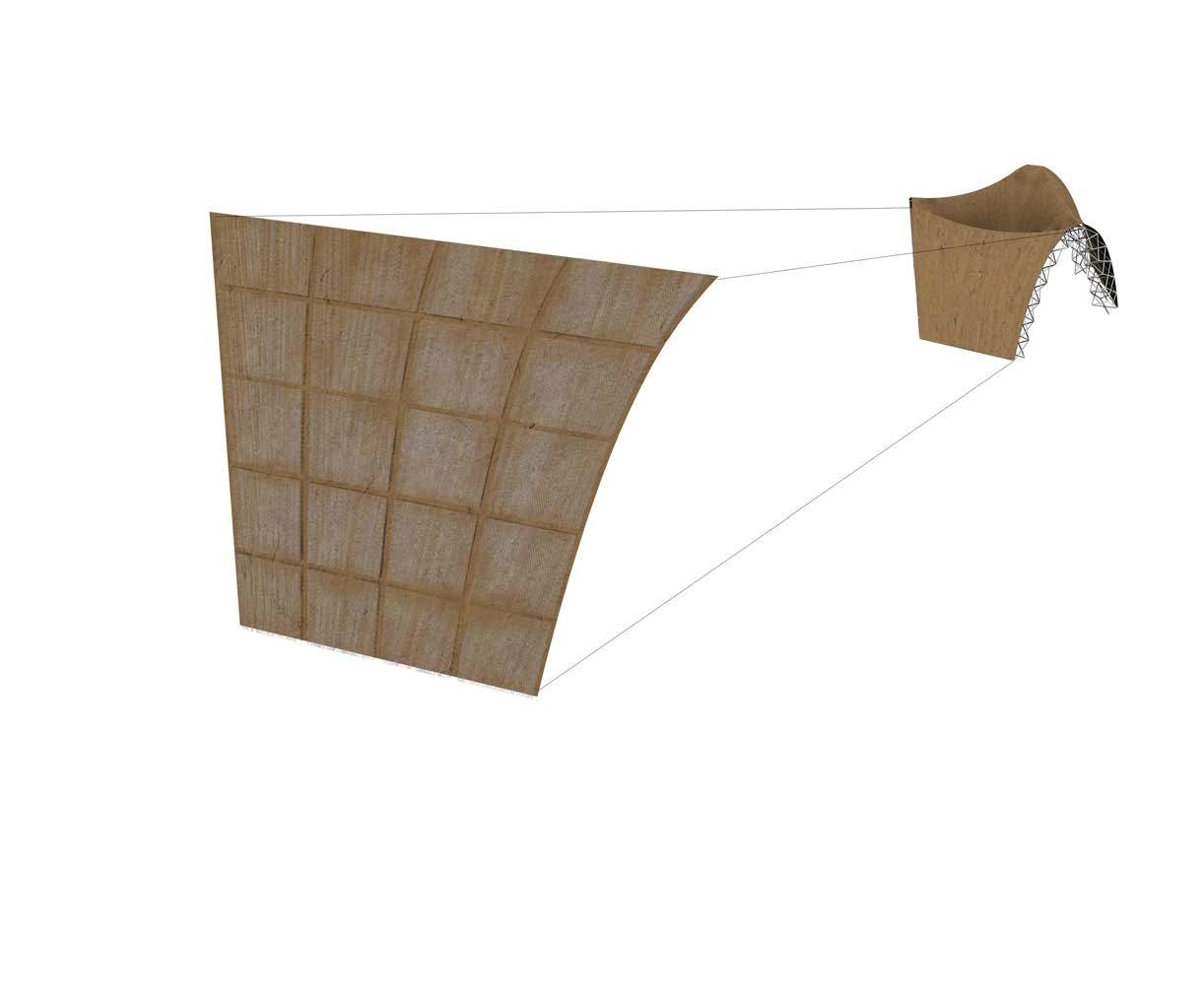

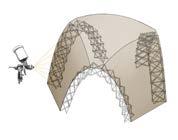

Material, fabrication and living conditions were examined to design the housing units. The chosen approach was to use local resources and manual labour to build deployable units, capable of becoming permanent shell structures via a bio-shotcreting process. Automation of a part of the construction process was evaluated through a set of spraying experiments both manual and robotic.

8 9 Rural WaterScapes Rural WaterScapes

TABLE OF CONTENTS

1. INTRODUCTION

Climate change and Water Scarcity

Food Insecurity

Climate change and Displacement

2. DOMAIN

Water situation

Water access

Agriculture in Africa

Mobility

From Temporary to Permanent

Strategy

Design Requirements

3. METHODS

Overview

Design Analysis

Design Methods

Material Fabrication

4. RESEARCH DEVELOPMENT

Overview

Site Analysis

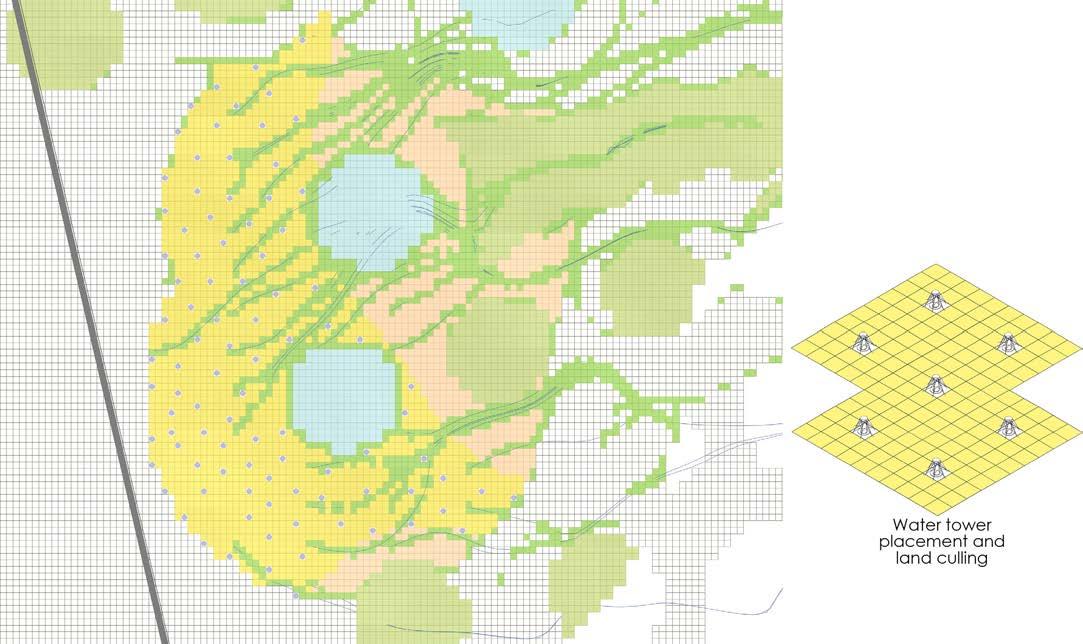

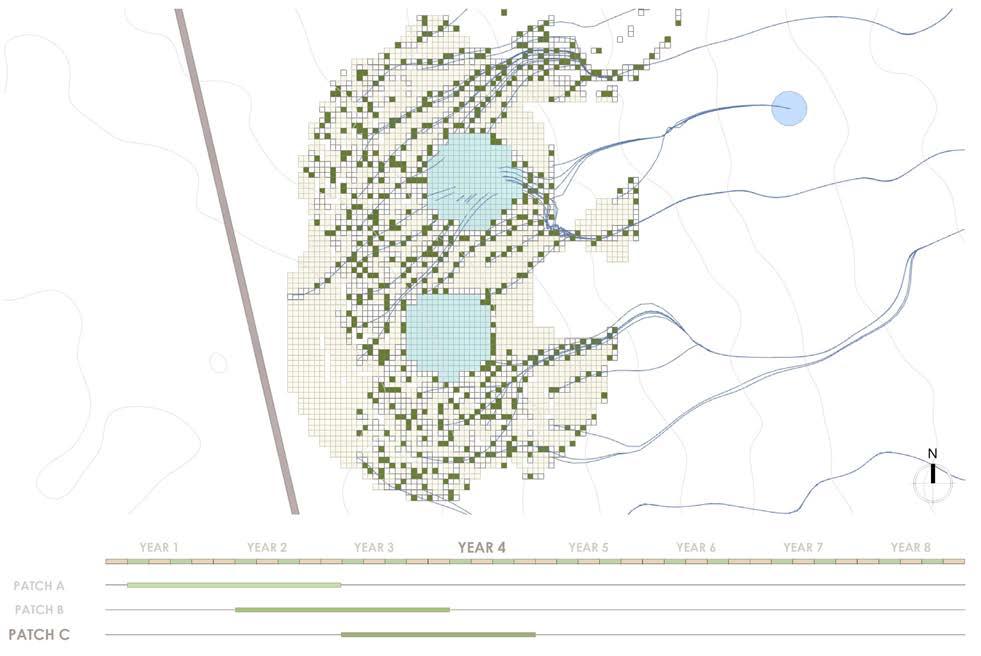

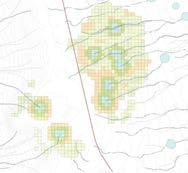

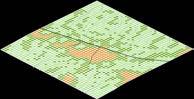

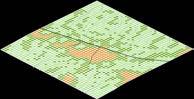

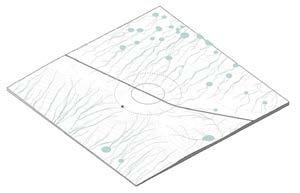

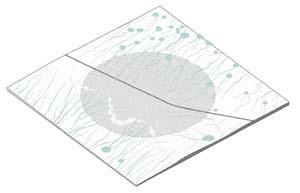

Settlement Planning

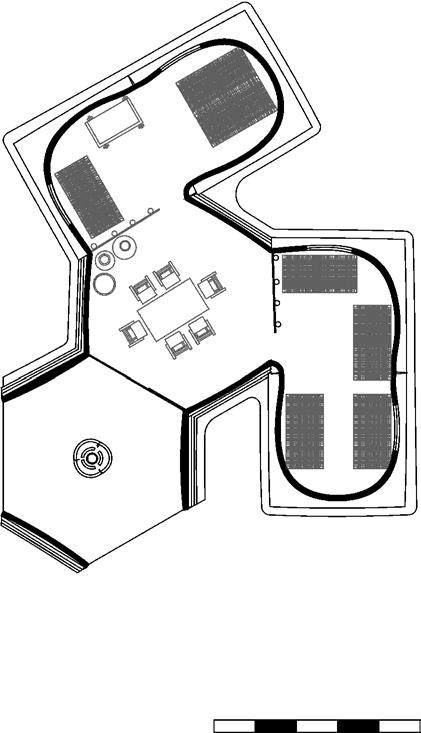

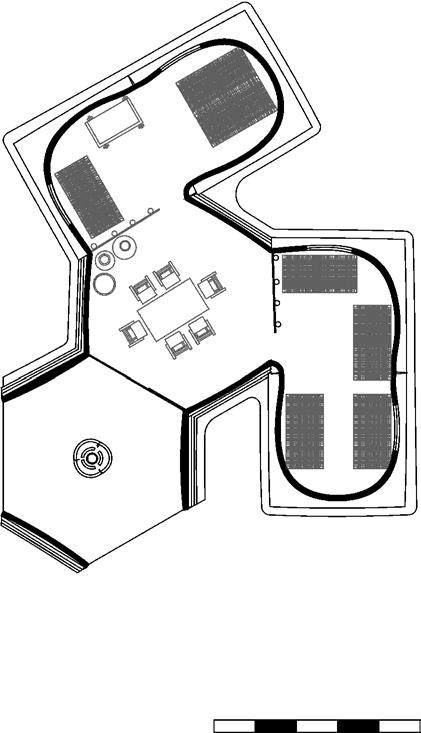

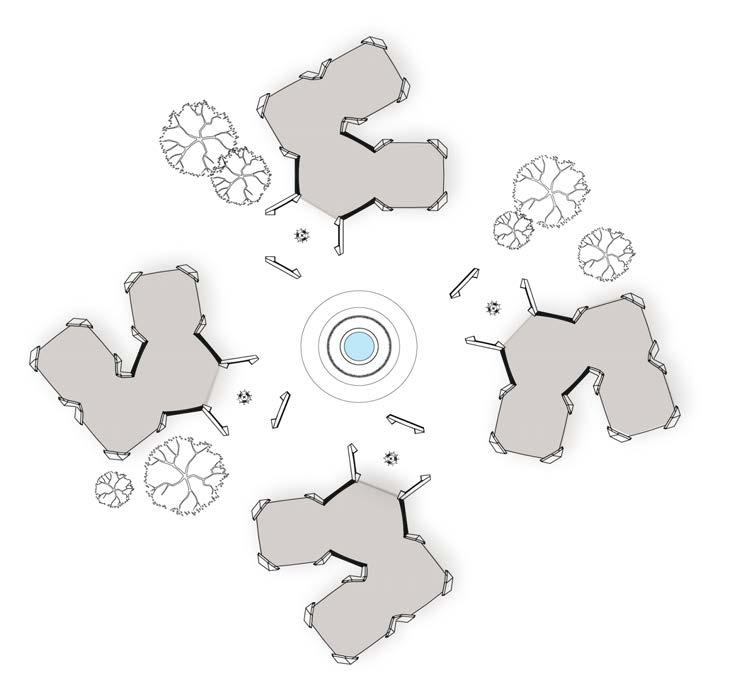

Block Planning

Agricultural Strategy

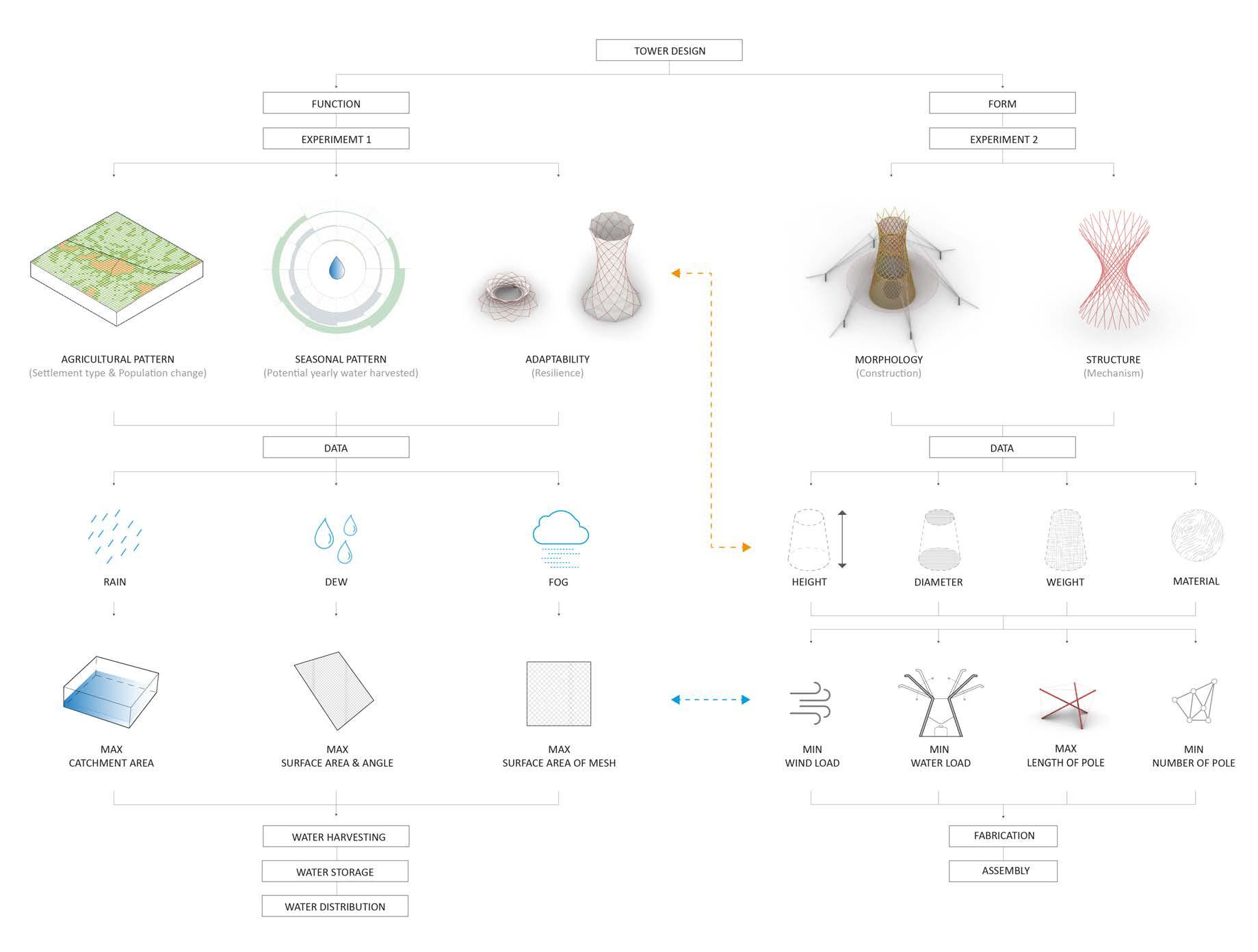

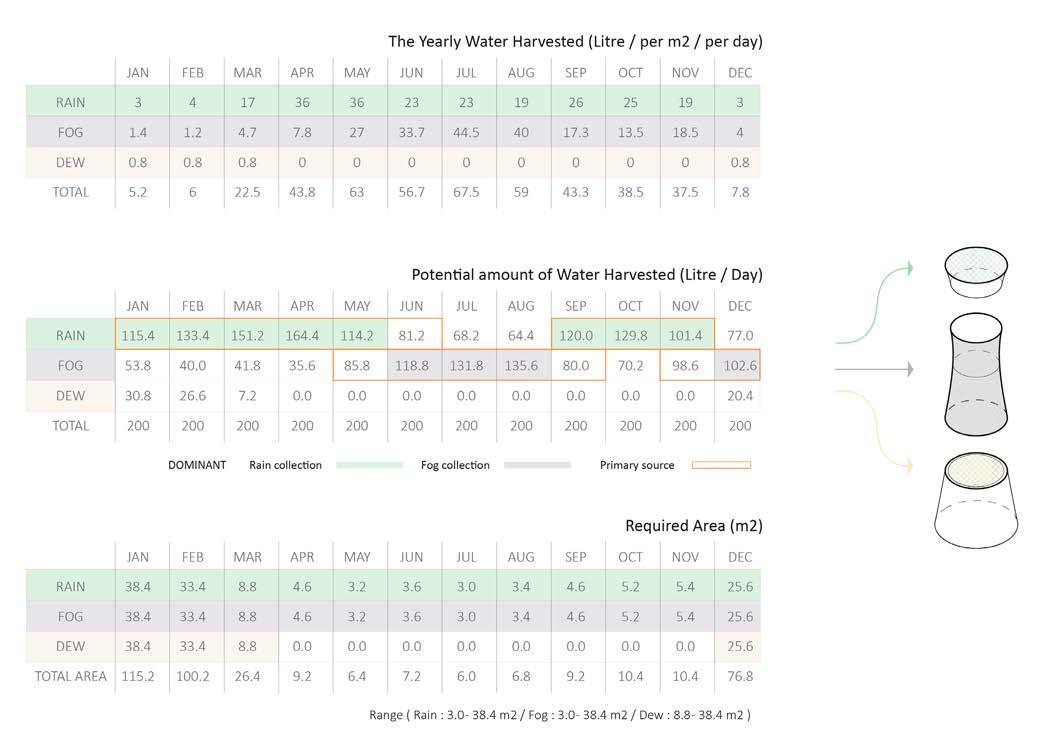

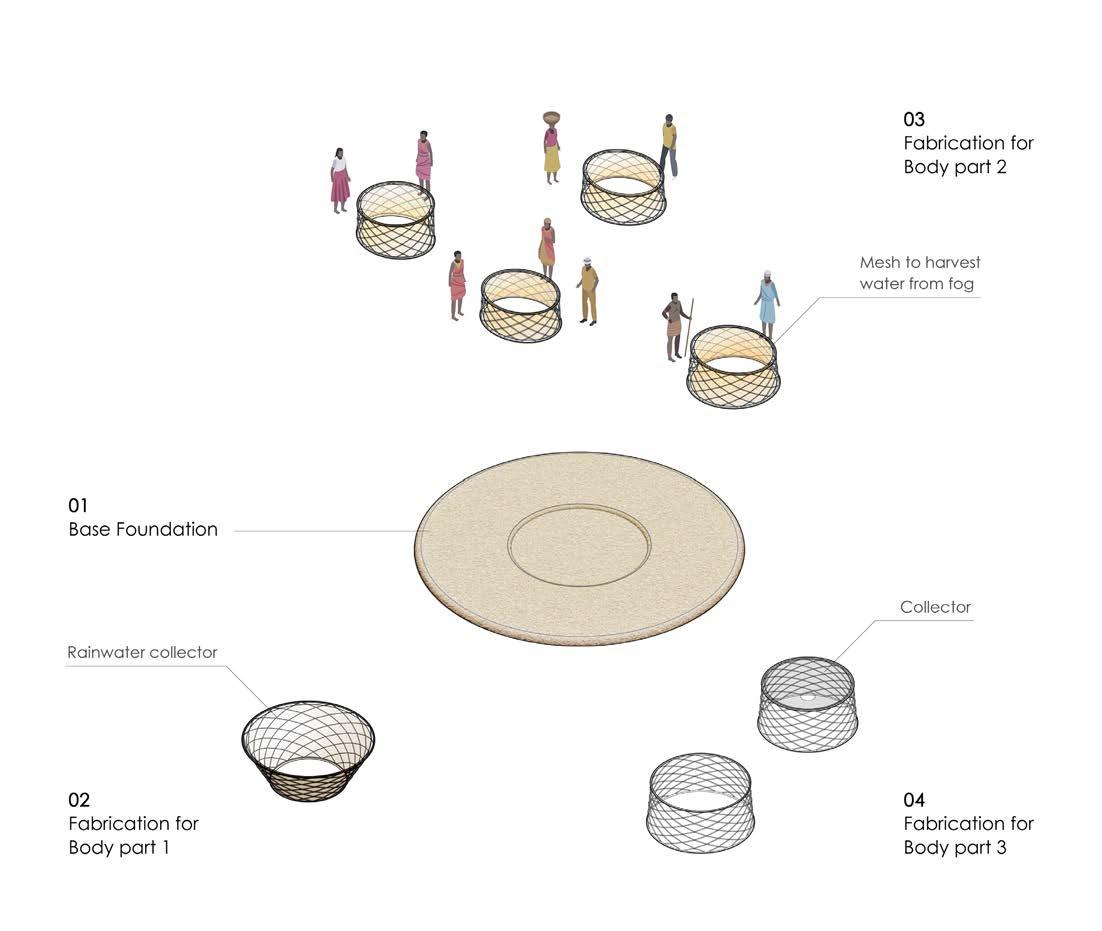

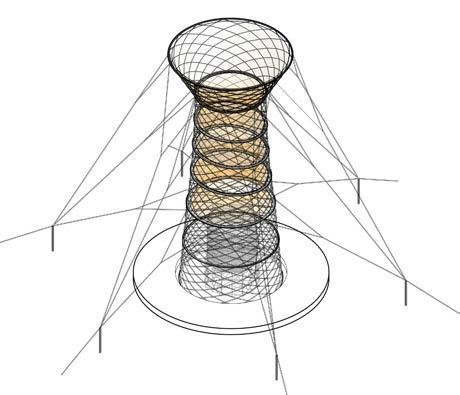

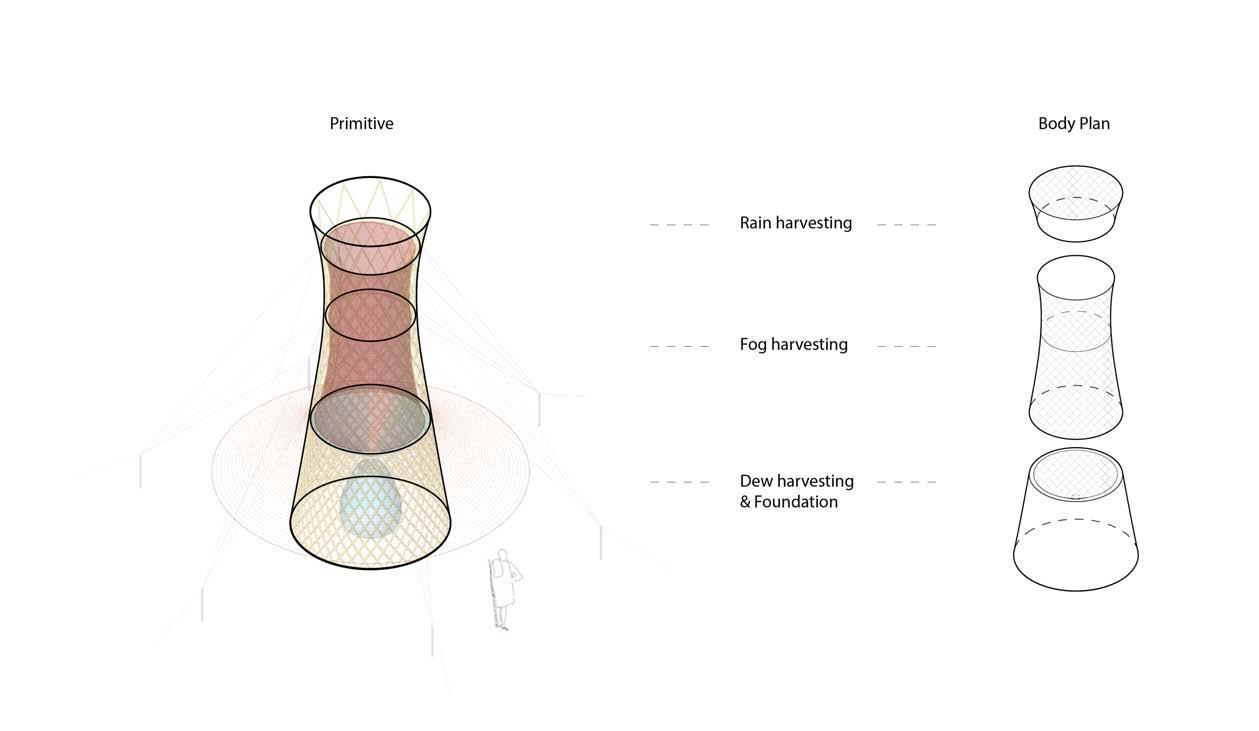

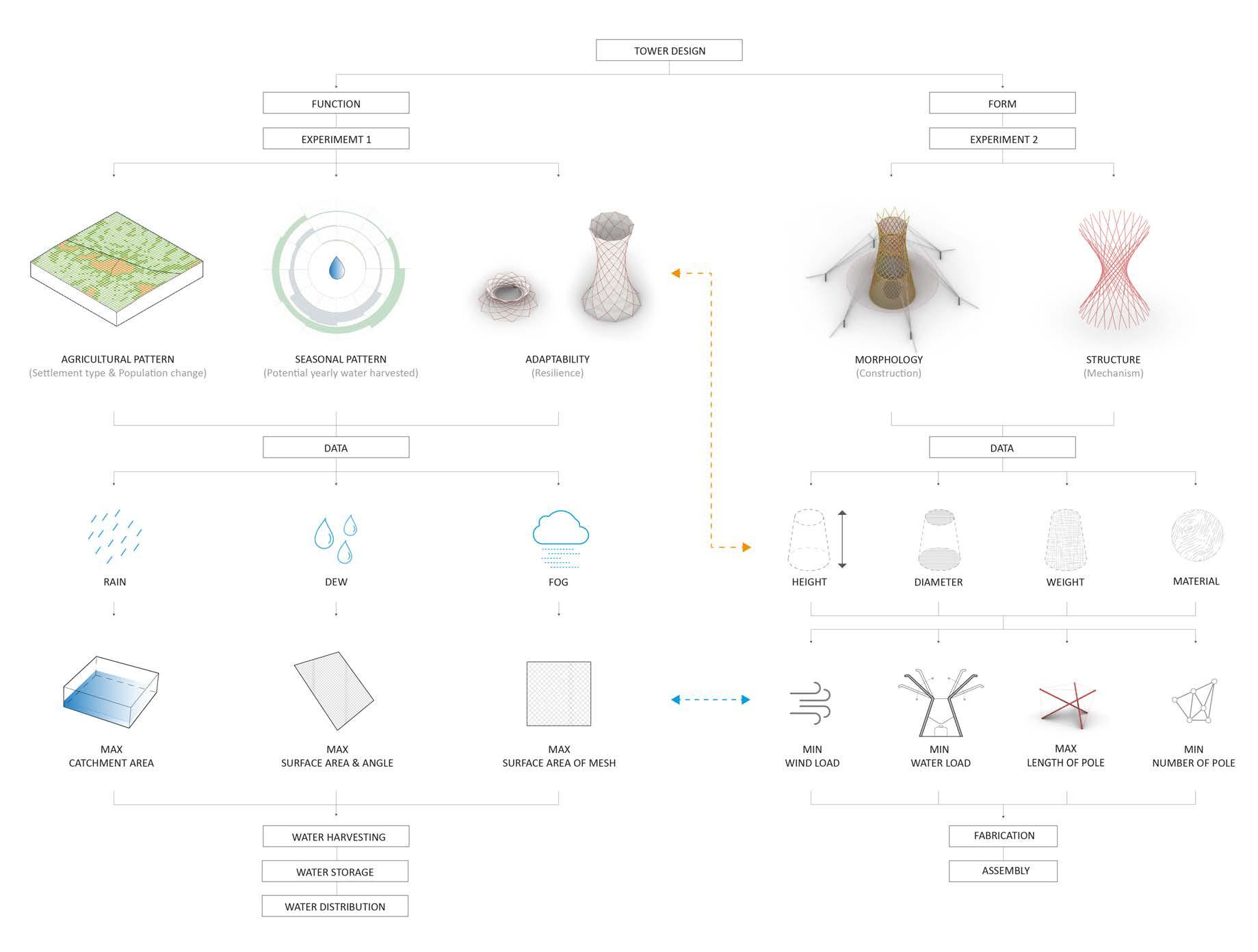

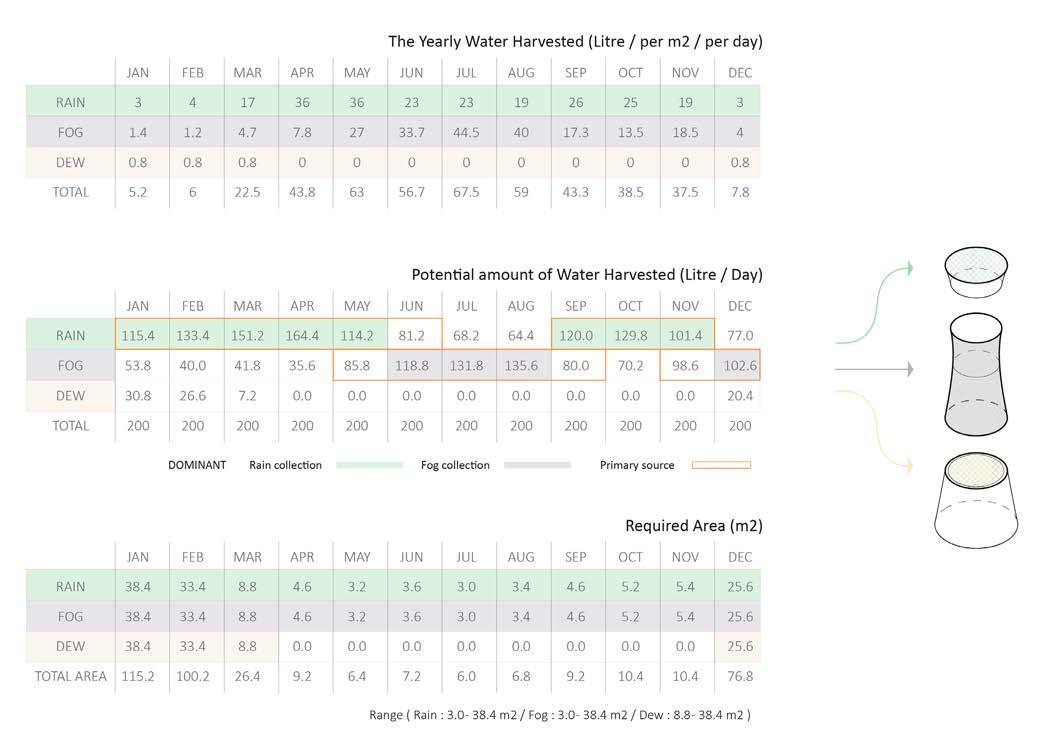

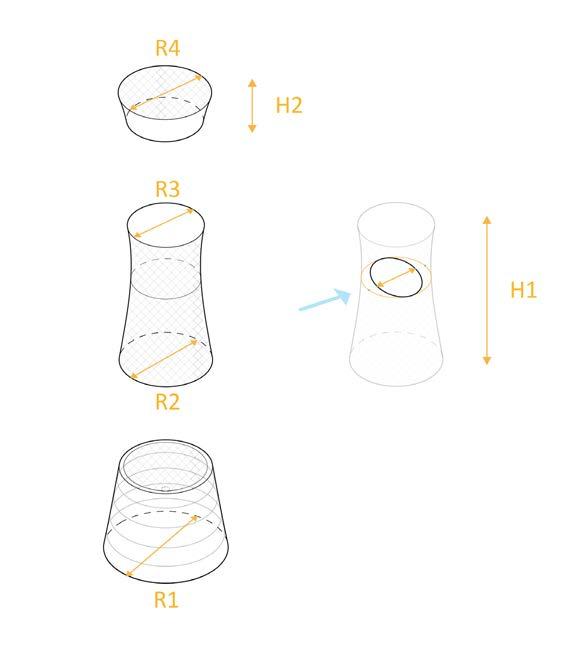

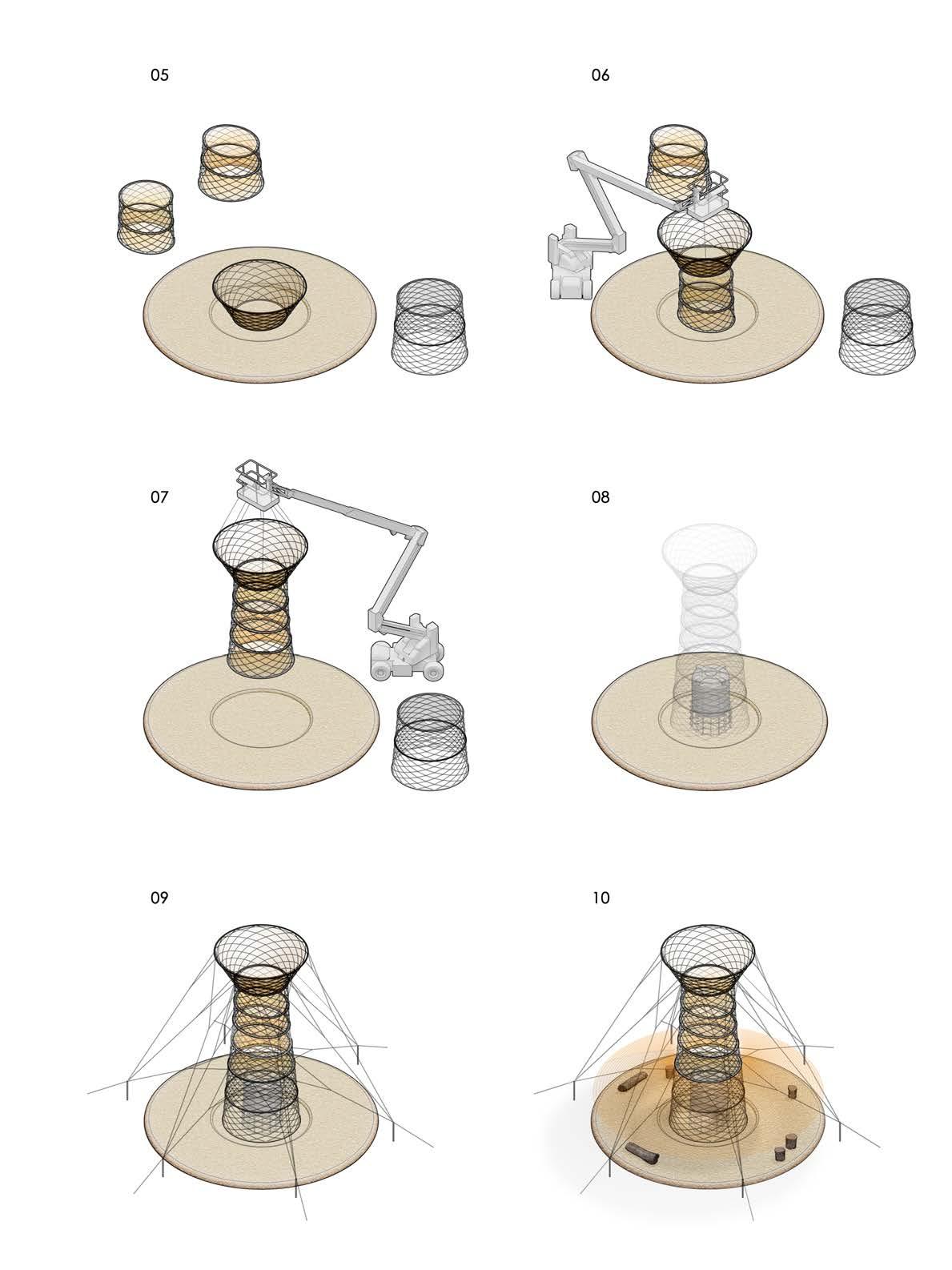

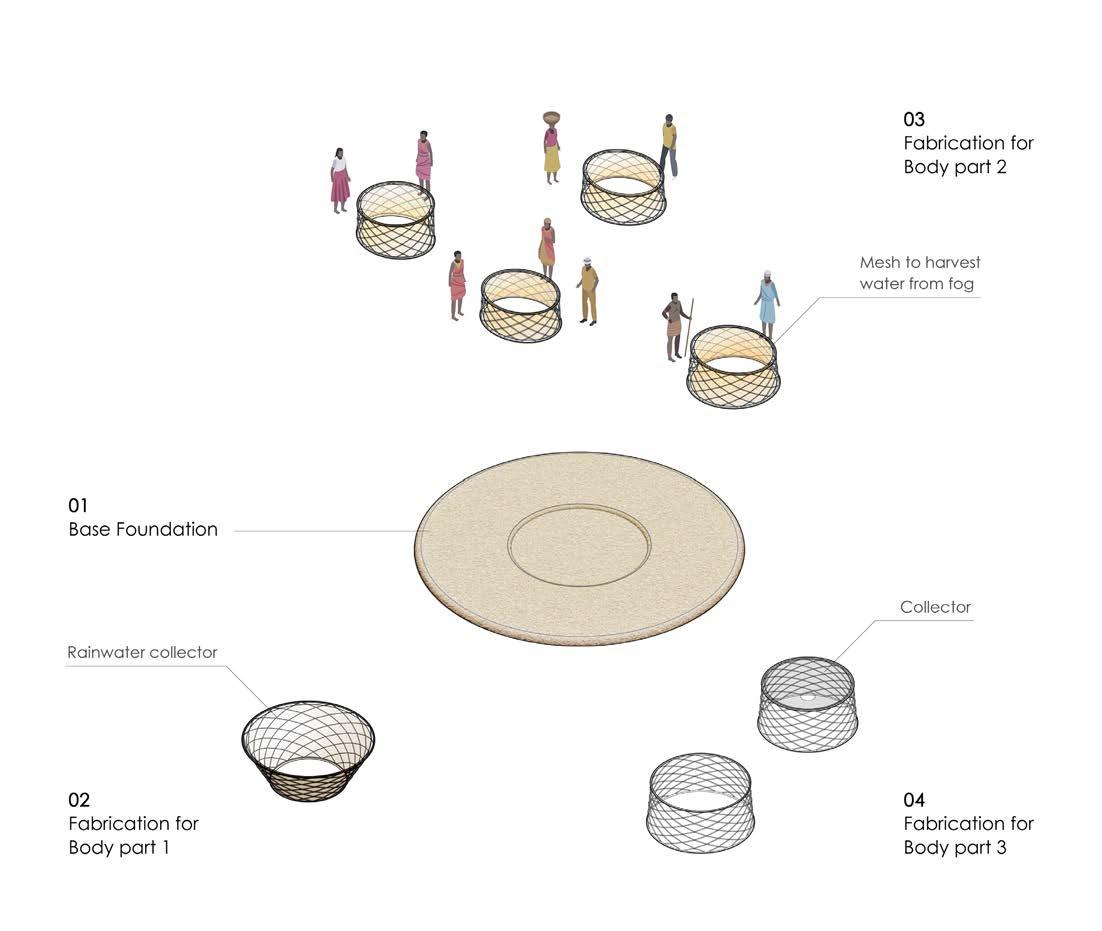

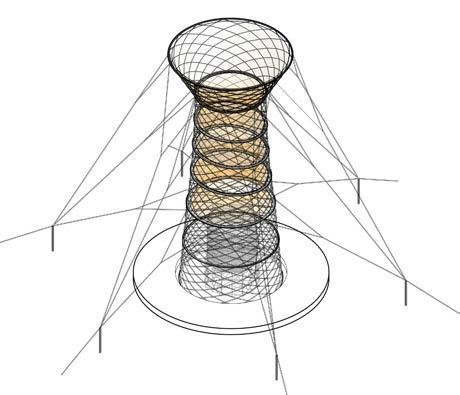

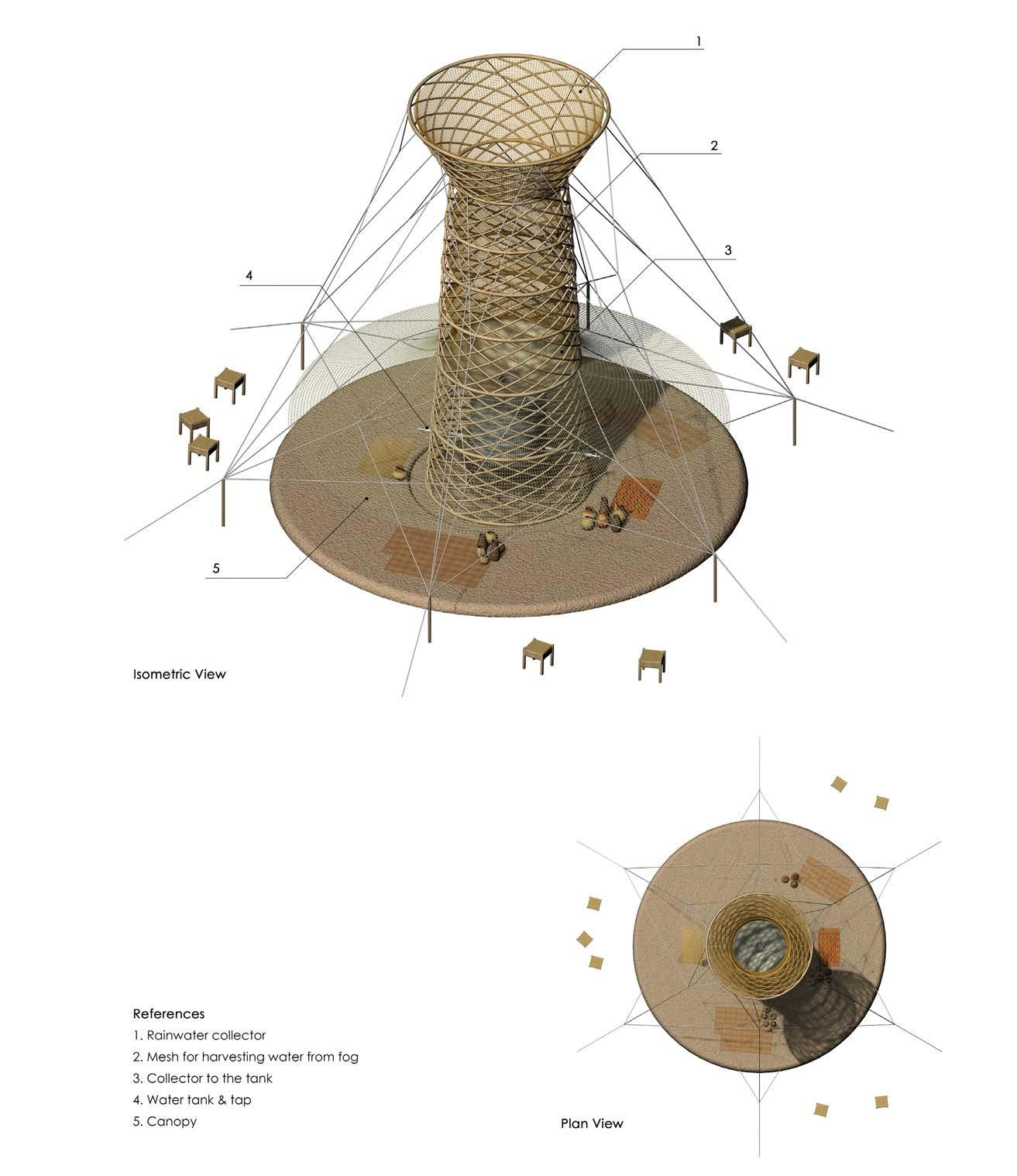

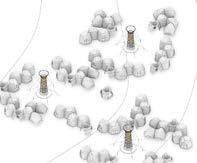

Water Harvesting Tower

Housing Units

Bio-Shotcrete Applications

Conclusions

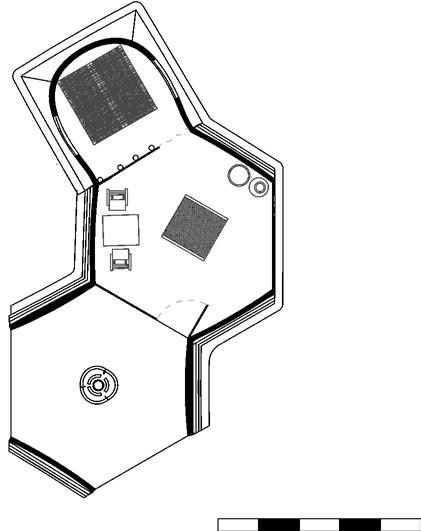

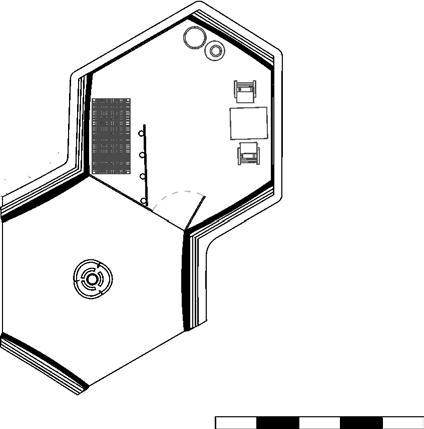

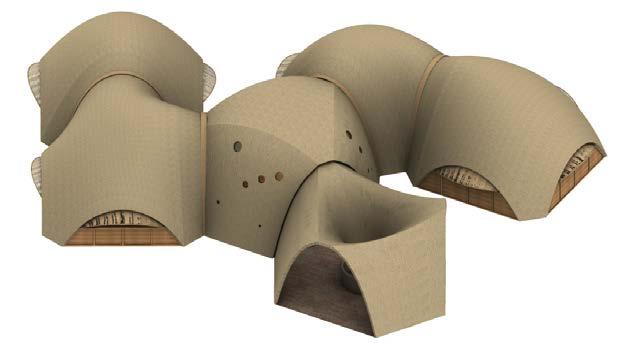

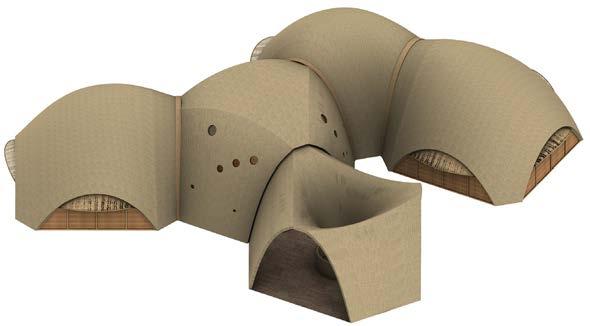

5. DESIGN DEVELOPMENT

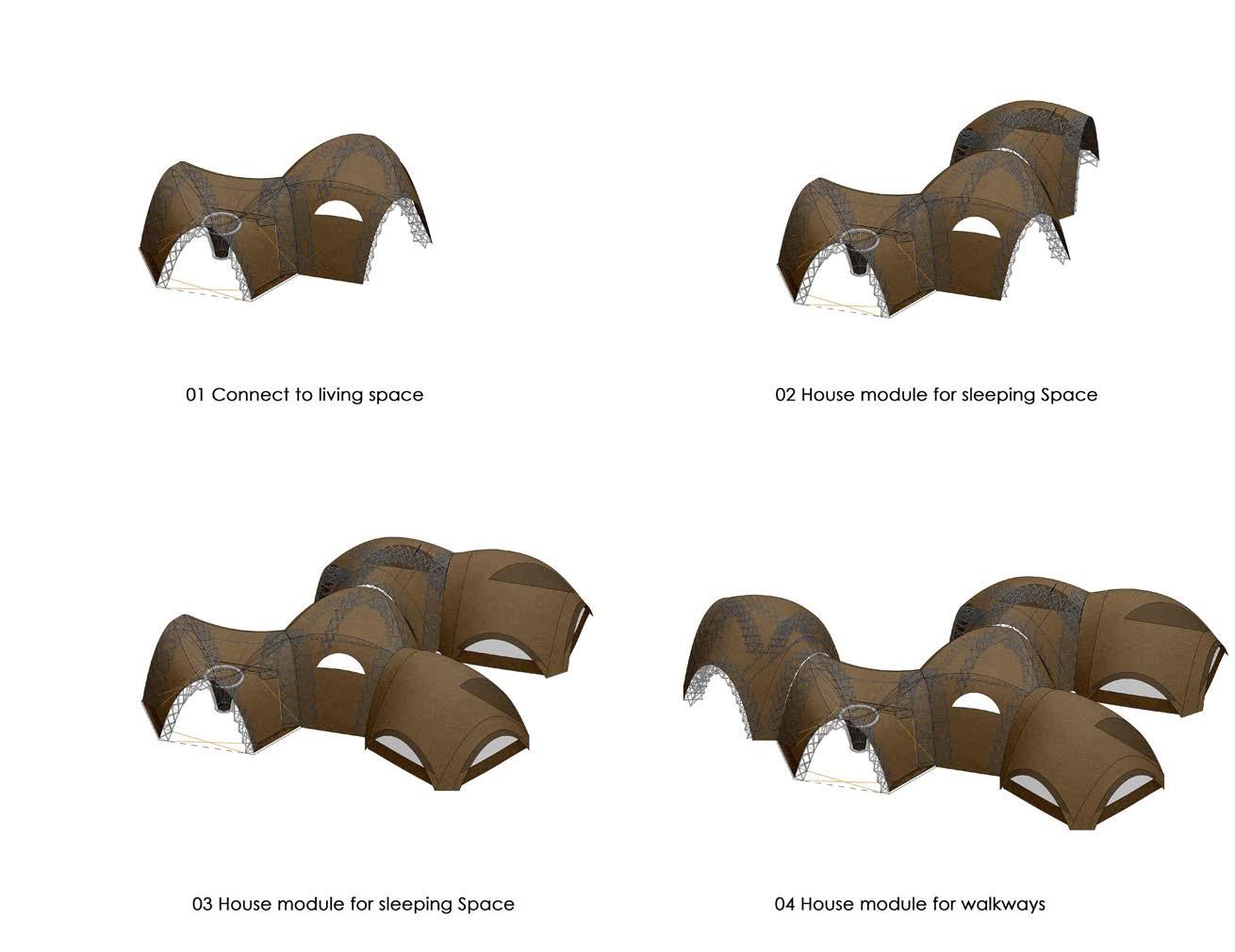

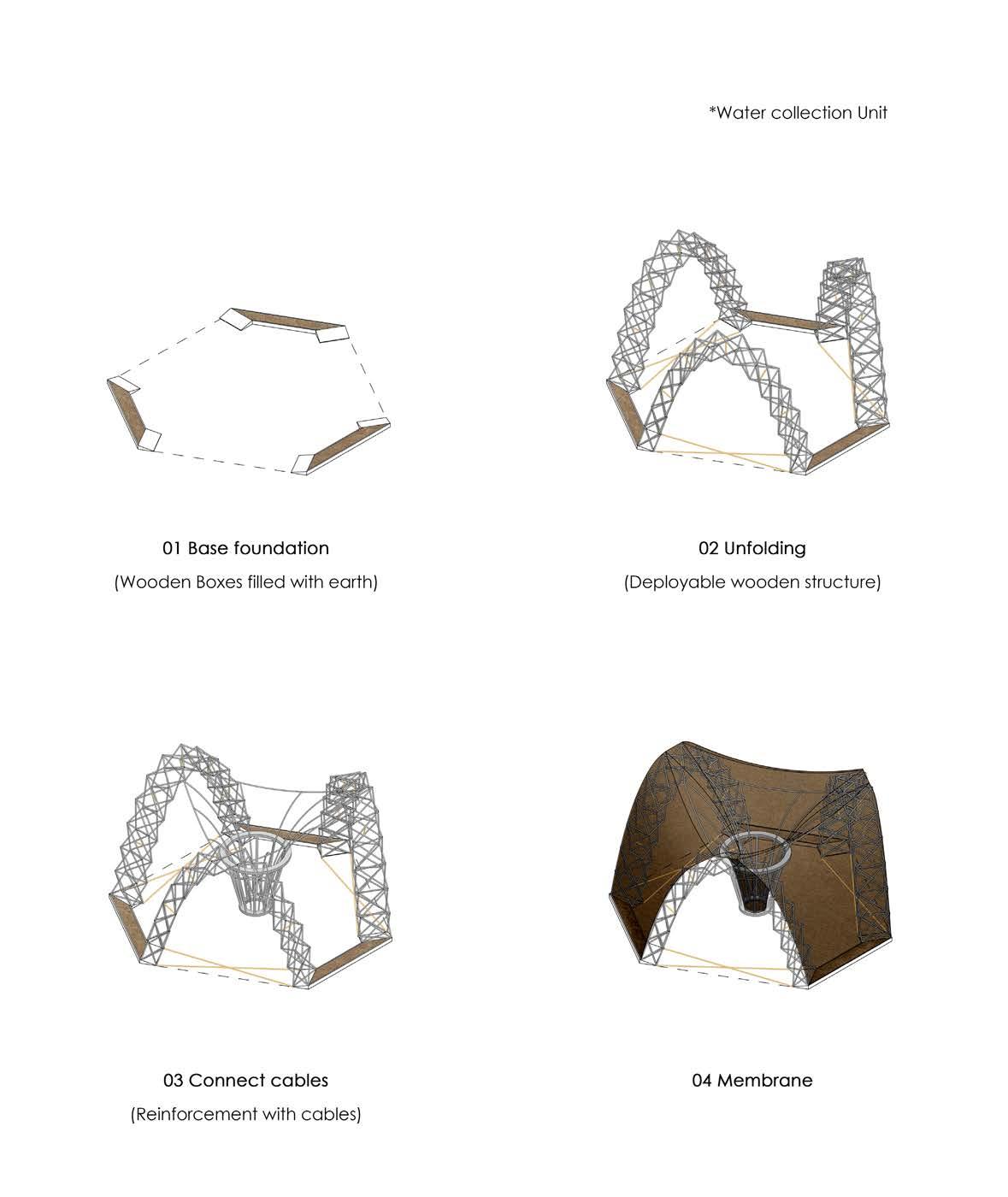

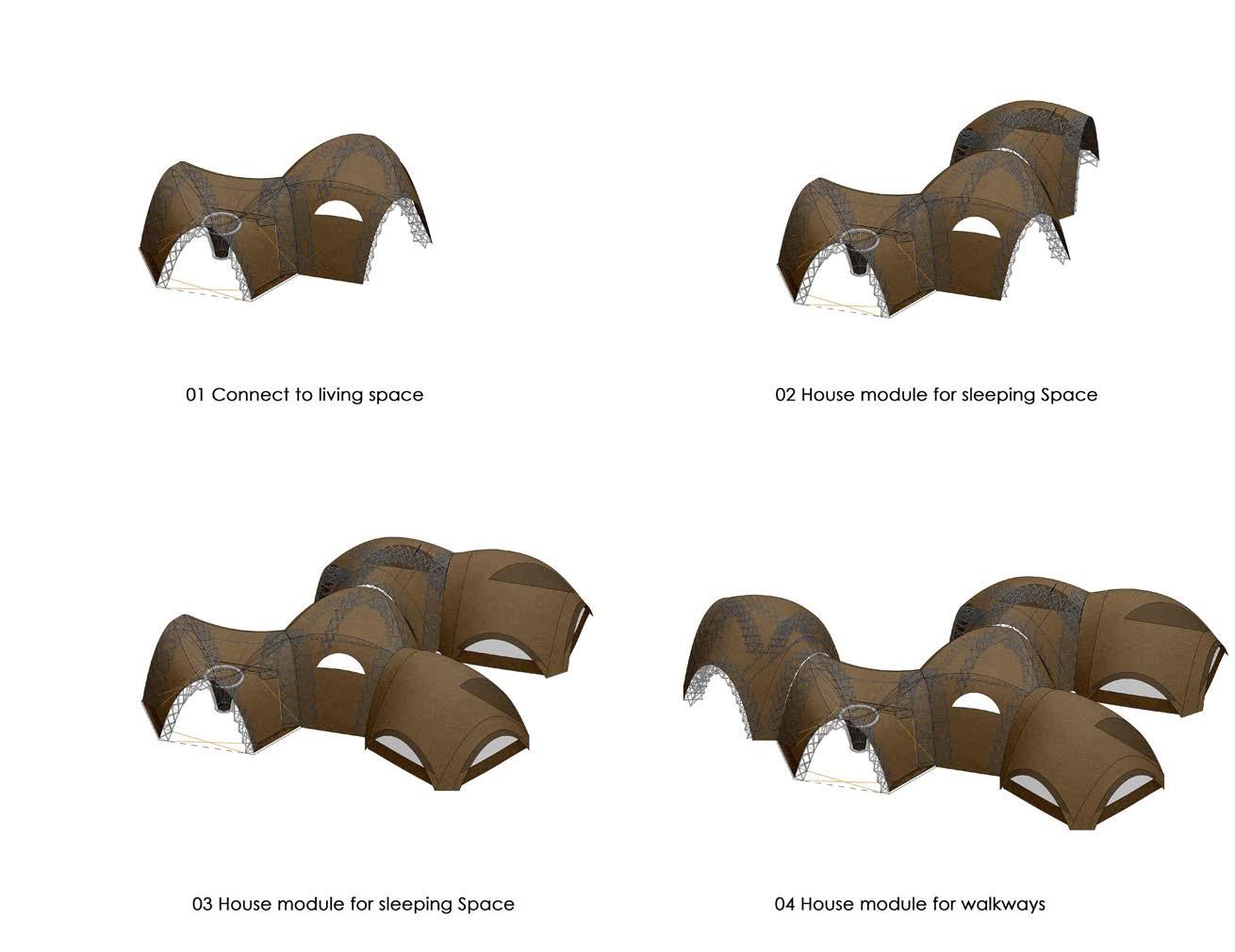

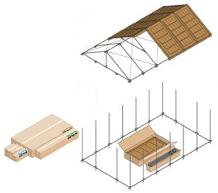

Housing Construction Sequence

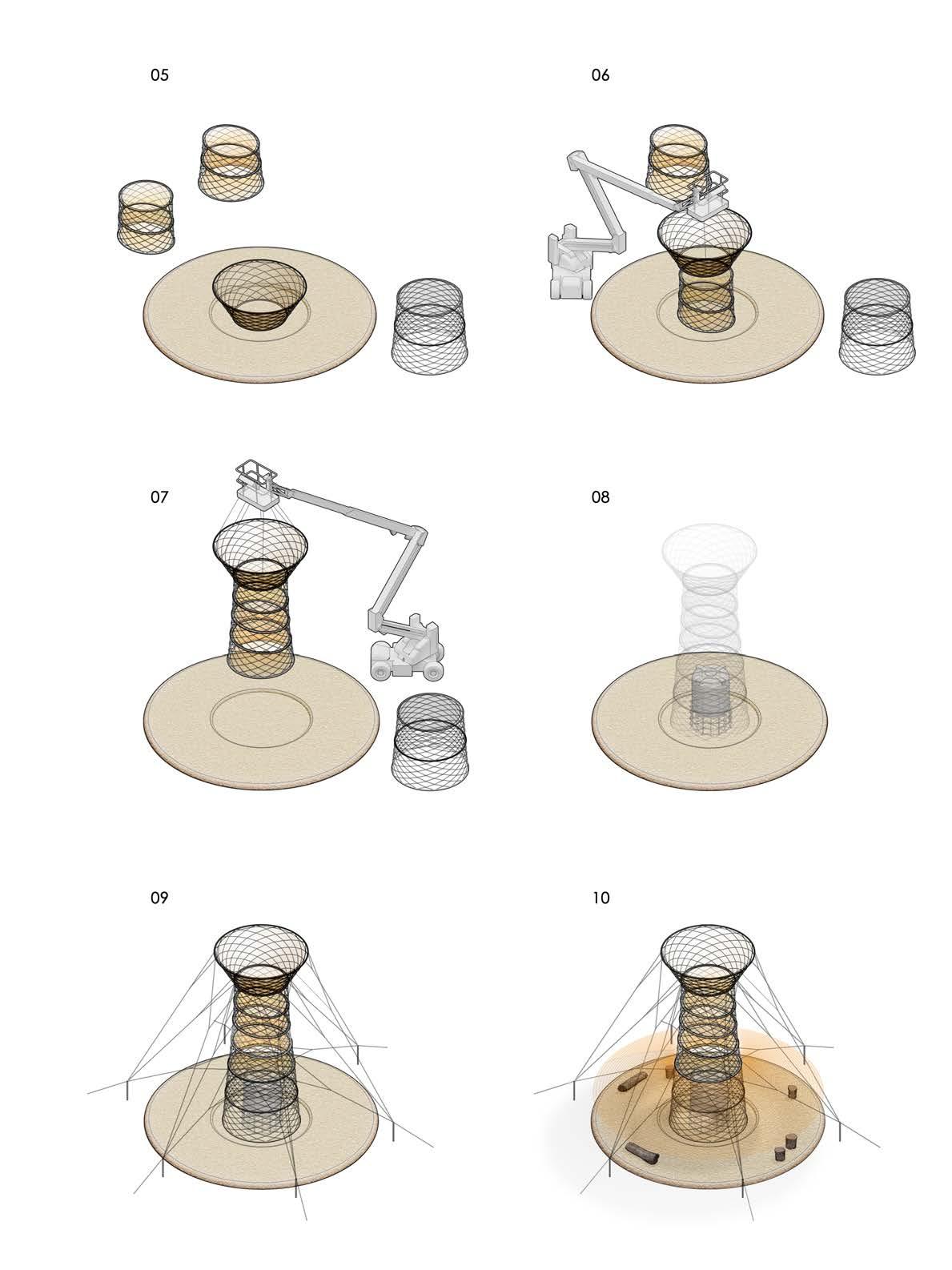

Tower Construction Sequence

6. DESIGN PROPOSAL

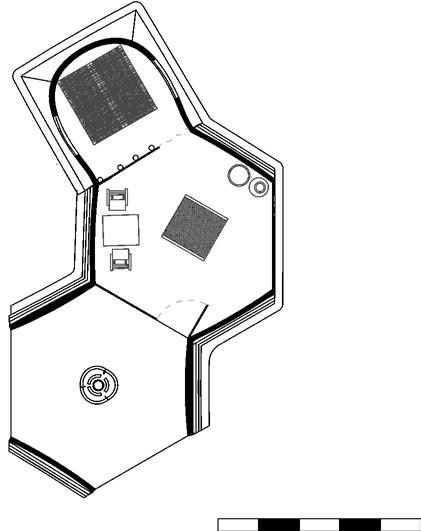

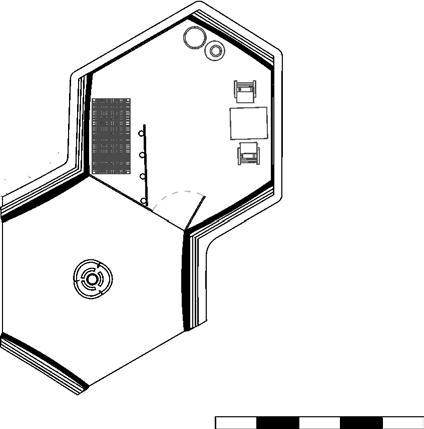

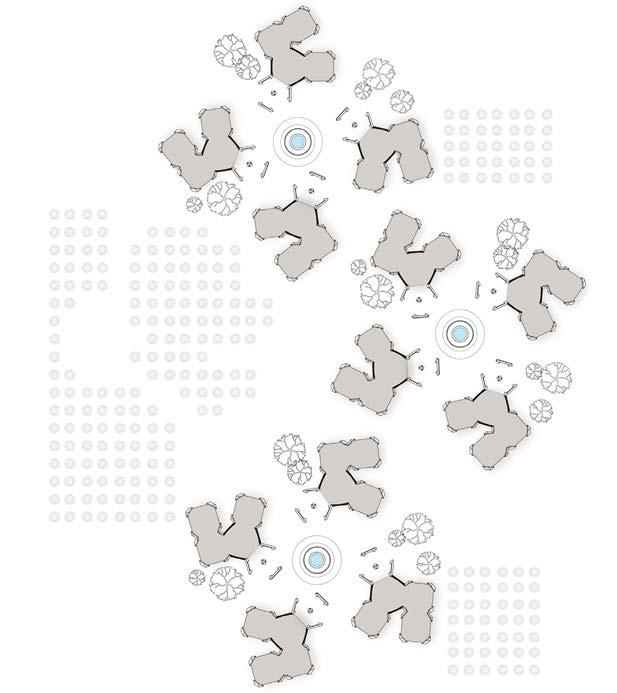

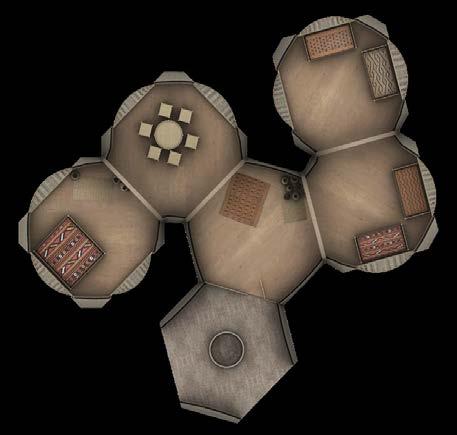

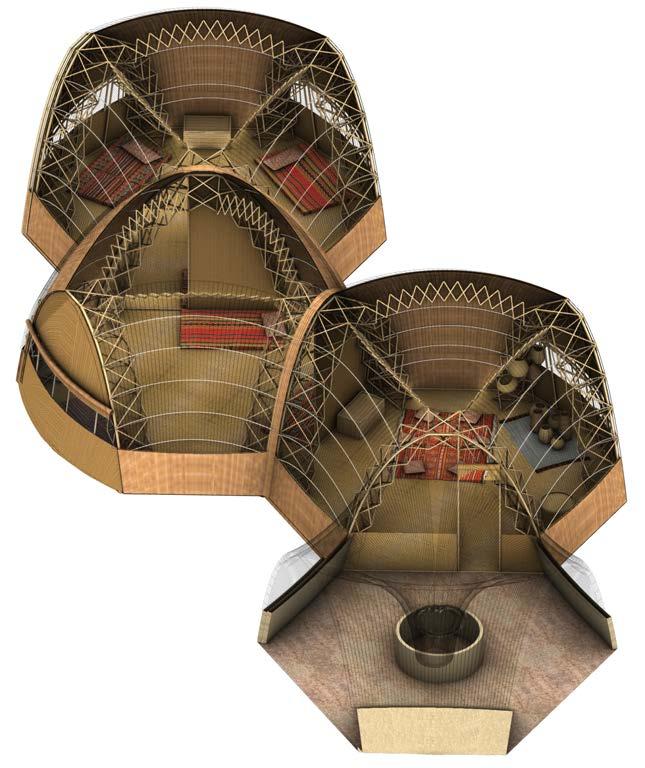

Housing Design Settlement Growth

Cluster Scale

Architectural Detailing

7. DESIGN EVALUATION

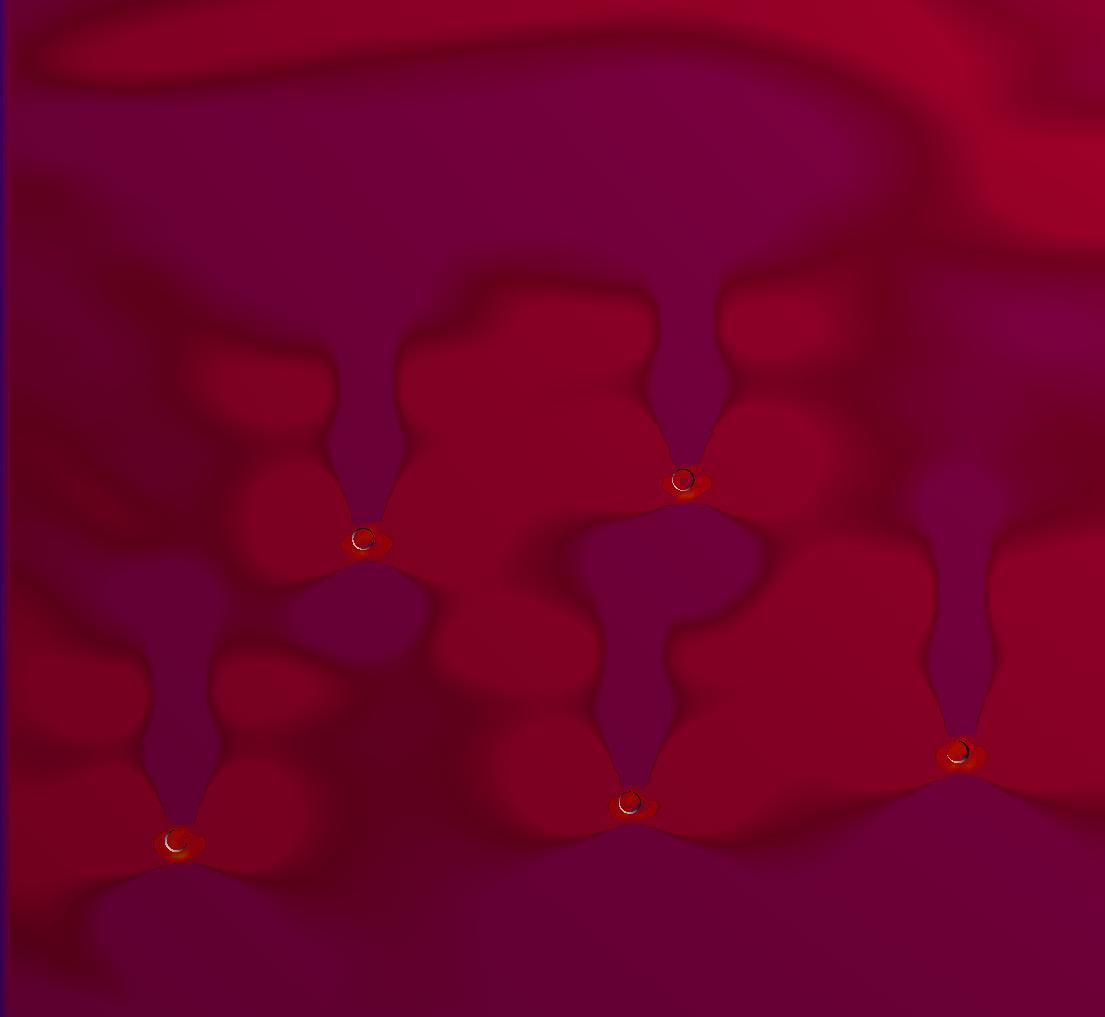

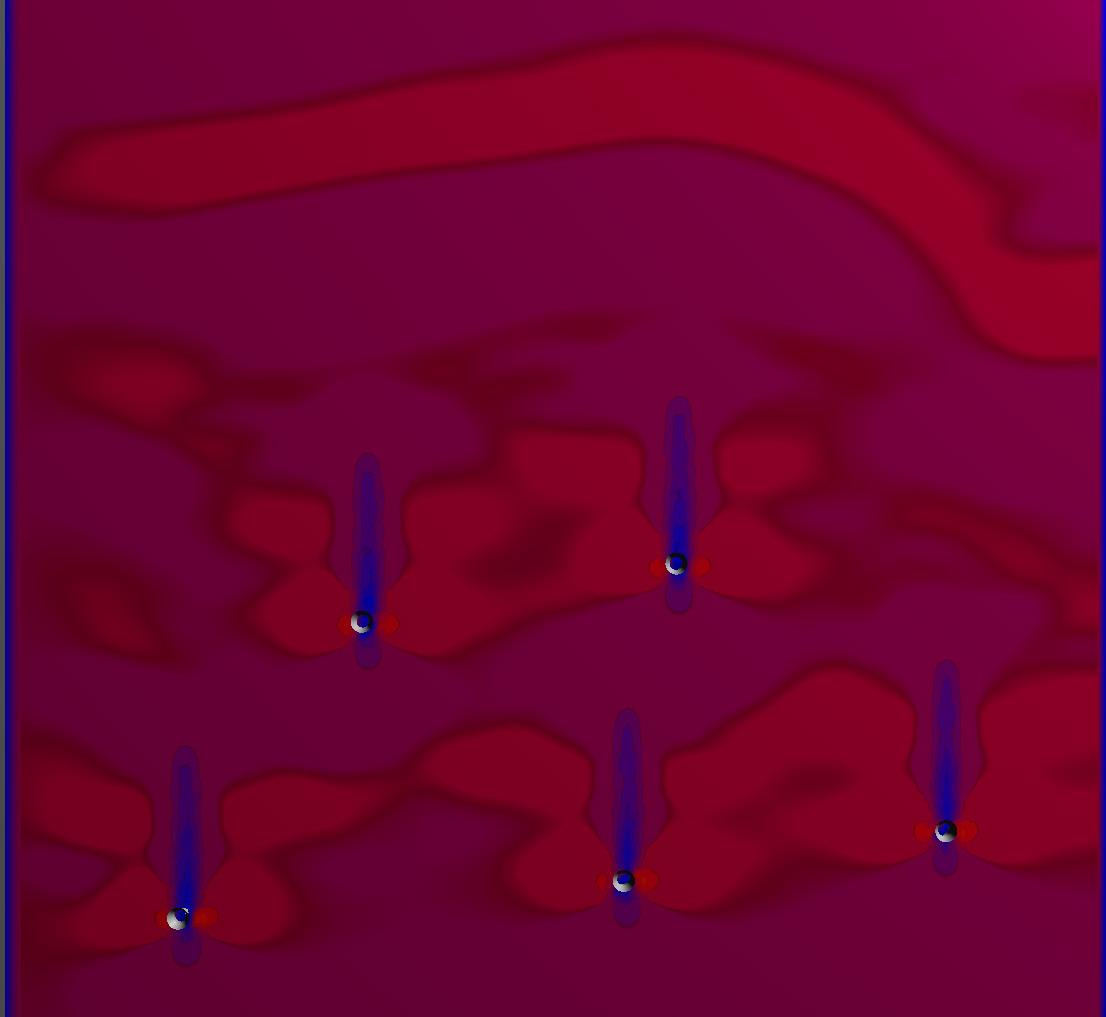

Tower Cluster Wind Analysis

Housing Structural Performance

8. CONCLUSIONS

Further Steps

Critical Review

9. REFERENCES

10 11 Rural WaterScapes Rural WaterScapes

CLIMATE CHANGE AND WATER SCARCITY 1-1 FOOD INSECURITY CLIMATE CHANGE AND DISPLACEMENT 1-2 1-3

01. INTRODUCTION

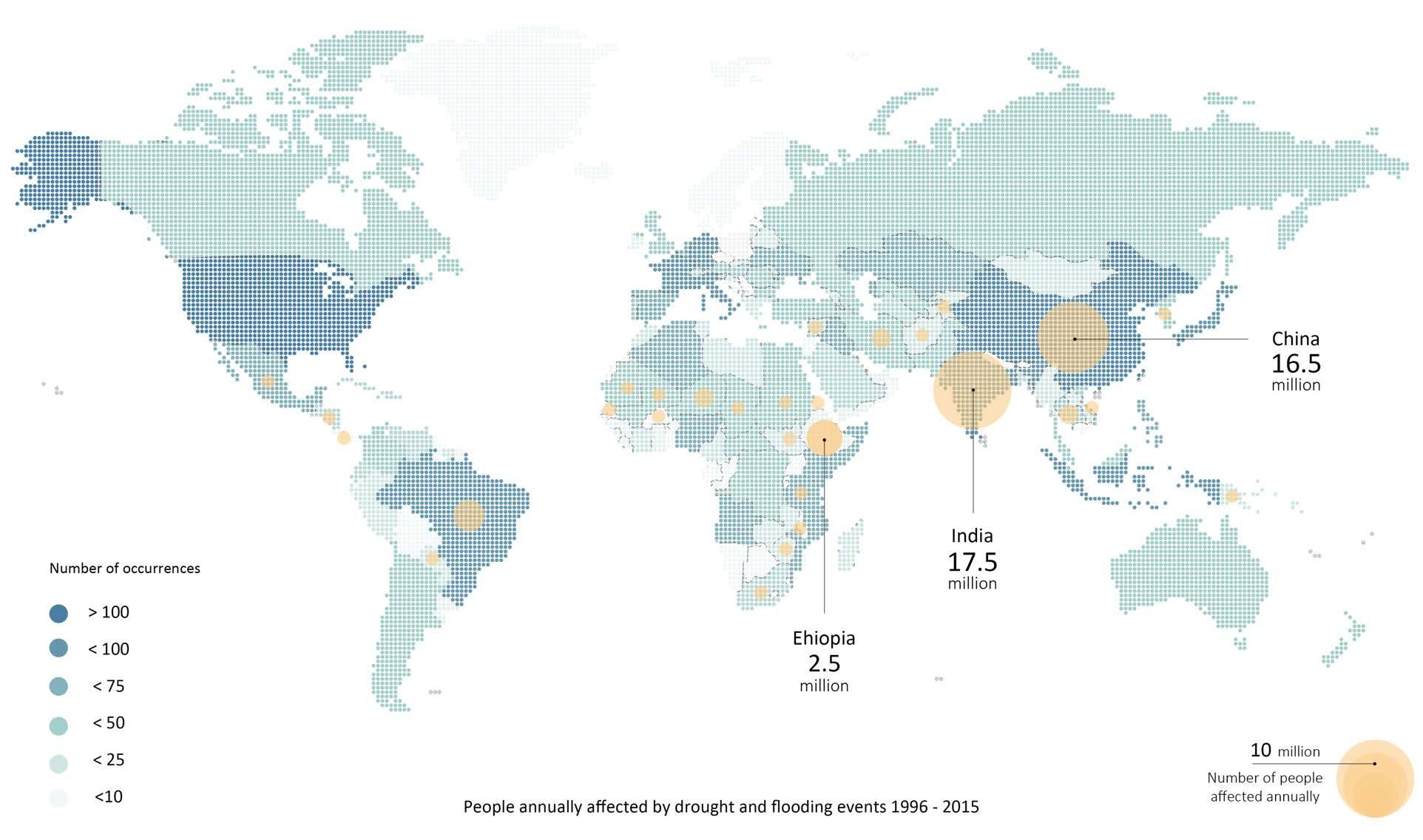

01 - 1 CLIMATE CHANGE AND WATER SCARCITY Droughts, Floods and Sanitation Problems

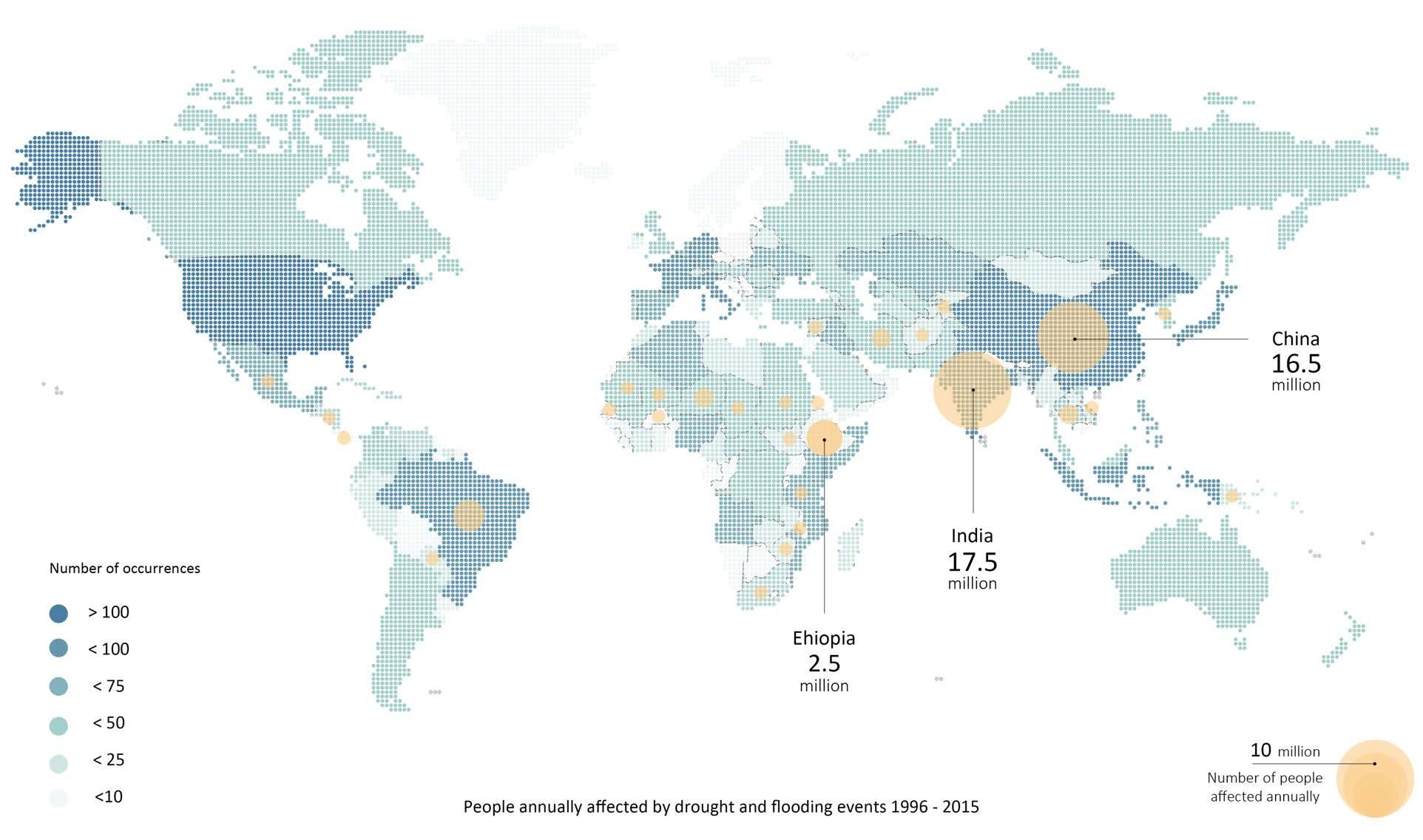

Over- exploitation of natural resources and uncontrolled human intervention are causing the disruption of numerous ecosystems worldwide and increasing the global temperature of the planet. This is resulting in severe Climate change, causing disorders in the historic rainfall patterns which manifest through drought and flooding events.

As stated in the United Nations World Water Report 20191, over 2 billion people worldwide live in waterstressed areas, 4 billion experience “severe water scarcity for at least one month of the year” and “three out of ten people do not have access to safe drinking water”.

14 Rural WaterScapes 1 Introduction

15 Rural WaterScapes

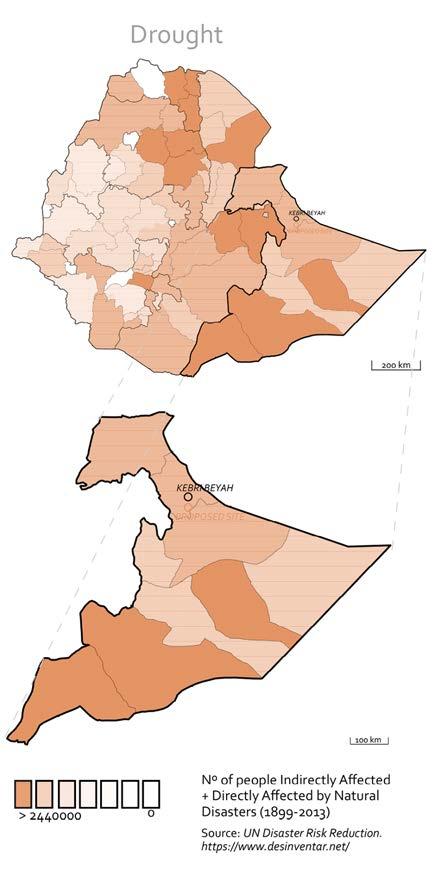

Map showing number of people affected by drought and flooding between 1996 and 2015

01 - 1 CLIMATE CHANGE AND WATER SCARCITY Droughts, Floods and Sanitation Problems

Africa is without a doubt one of the continents with the biggest pure water access deficit, where in 2015 about 10% of its population drank water from untreated surface water sources. Inside it, Sub-Saharan Africa is the region with the highest pressure on water sources, where less than 25% of the population has access to a safely managed water supply.

When it comes to rural Ethiopia, only 31.06% of the population have access to either safely managed or basic water, whereas the remaining 68.94% depend on limited, unimproved or surface water sources, and only 3.81 % of the population have access to safely managed sanitation services (2017)2 Poor sanitation conditions and water scarcity are responsible for the appearance of water borne diseases such as Cholera and Malaria, which could easily be avoided.

16 Rural WaterScapes 1 Introduction

17 Rural WaterScapes

Women carrying water canisters

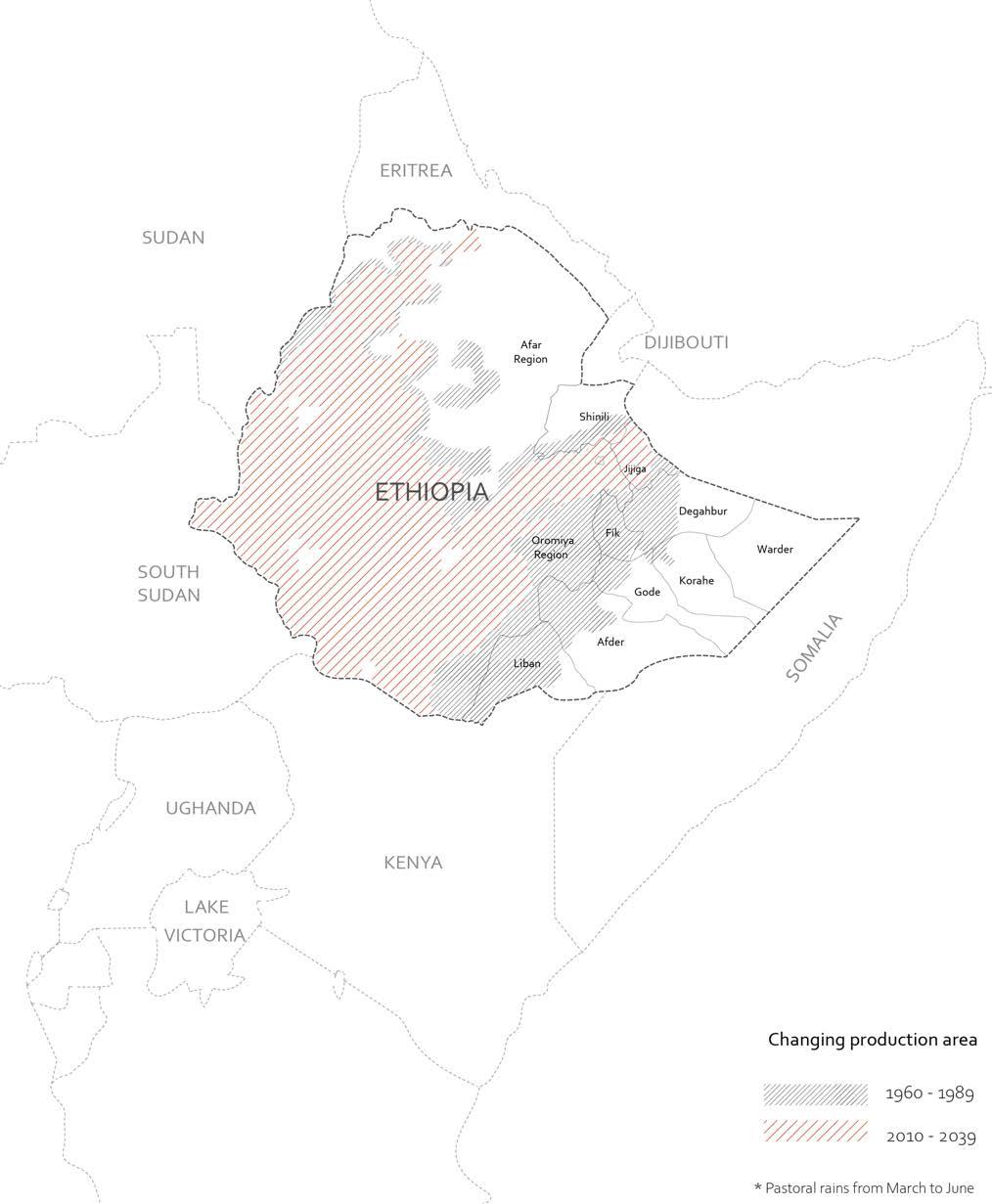

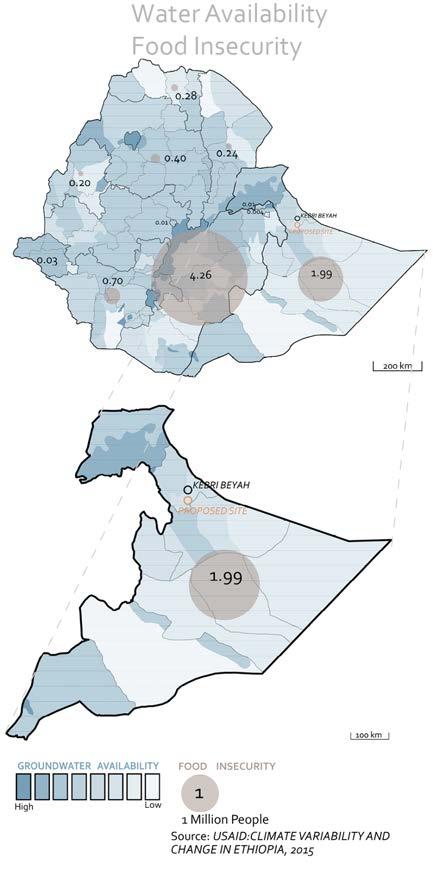

01 - 2 FOOD INSECURITY

Droughts, Floods and Sanitation Problems

Malnutrition has been present in Africa for decades, and even if the situation has improved in some aspects, in the year 2016 still 10.6% of the male adults and 8.4% of the female adults in the continent were underweight. The situation is even worse for the younger population, needing higher amounts of nutrients to develop correctly. According to the WHO, over 40% of the children under 5 years old in Ethiopia presented brain development problems caused by malnutrition.3

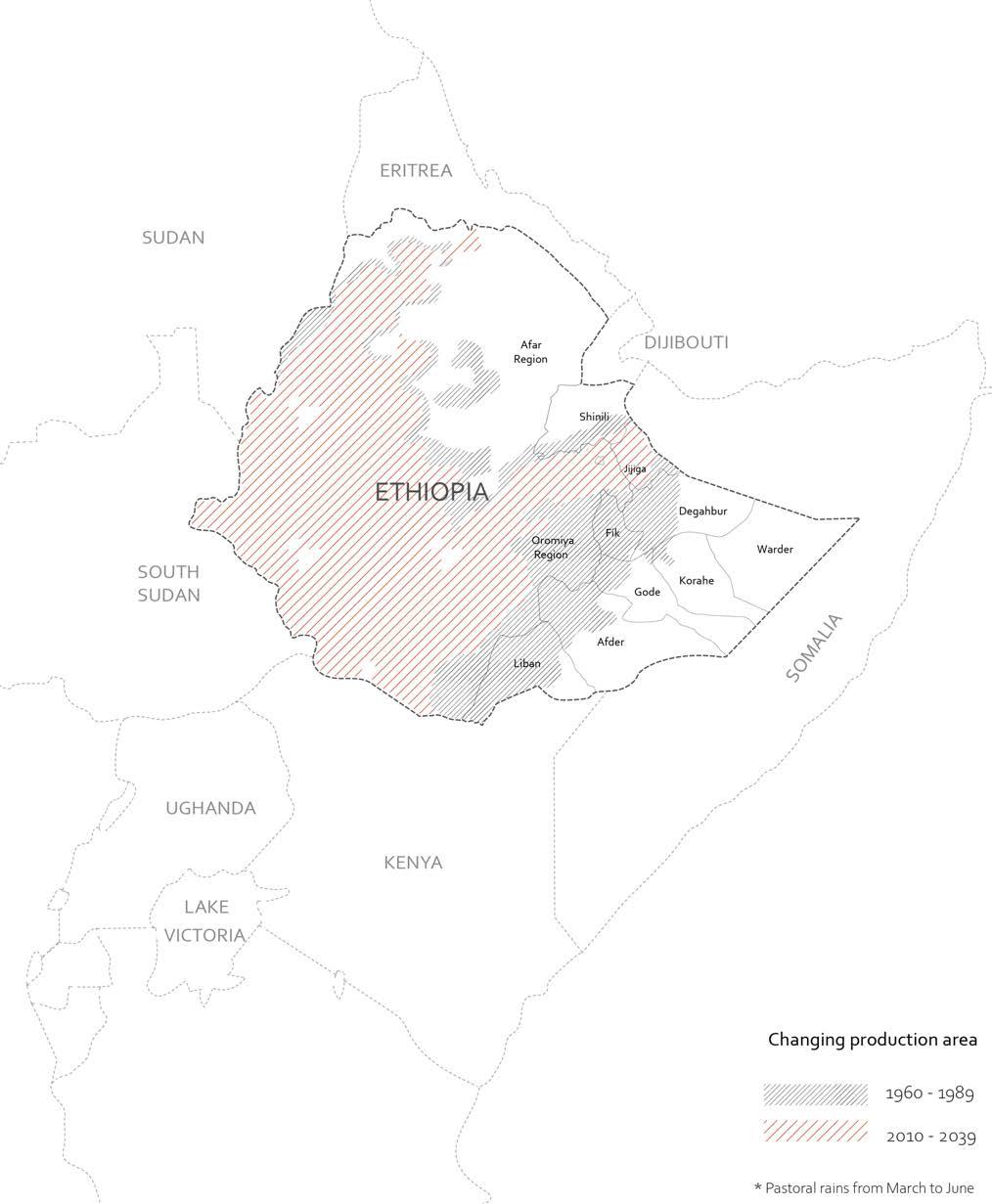

The country is highly dependent on rain fed agriculture and livestock production to ensure the well-being of its local communities, with around 78 % of its population living in rural areas in 20194. Recurring droughts affecting the food access since 1950, have been caused by changes in the rainfall patterns. Dry seasons are becoming longer and rainy seasons shorter with great floods which are washing the soil nutrients, making it harder for plants to grow. In the year 2017, a very important drought led to low water availability and resulted in high livestock death rates and crops losses.

18 Rural WaterScapes 1 Introduction

19 Rural WaterScapes

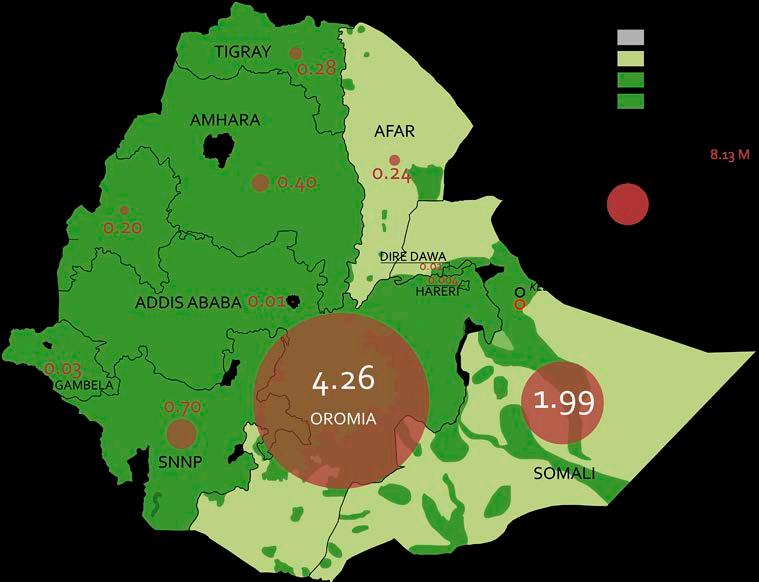

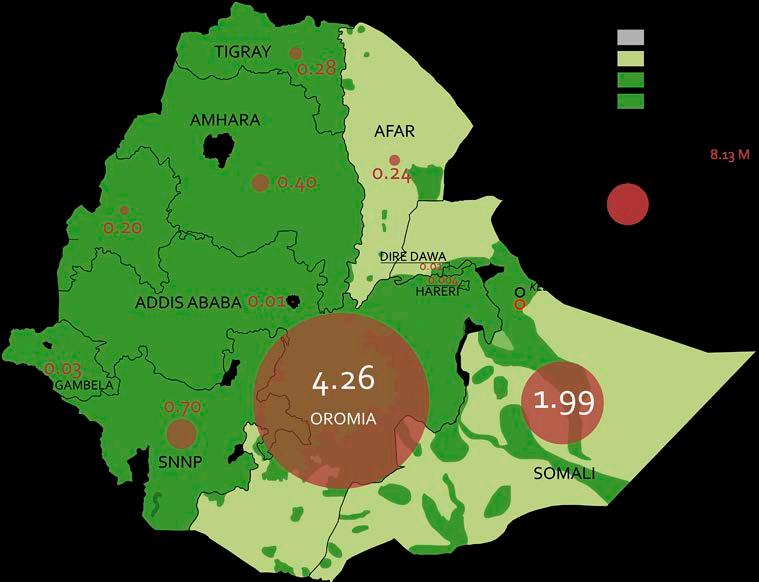

The Map shows changing production area in Ethiopia

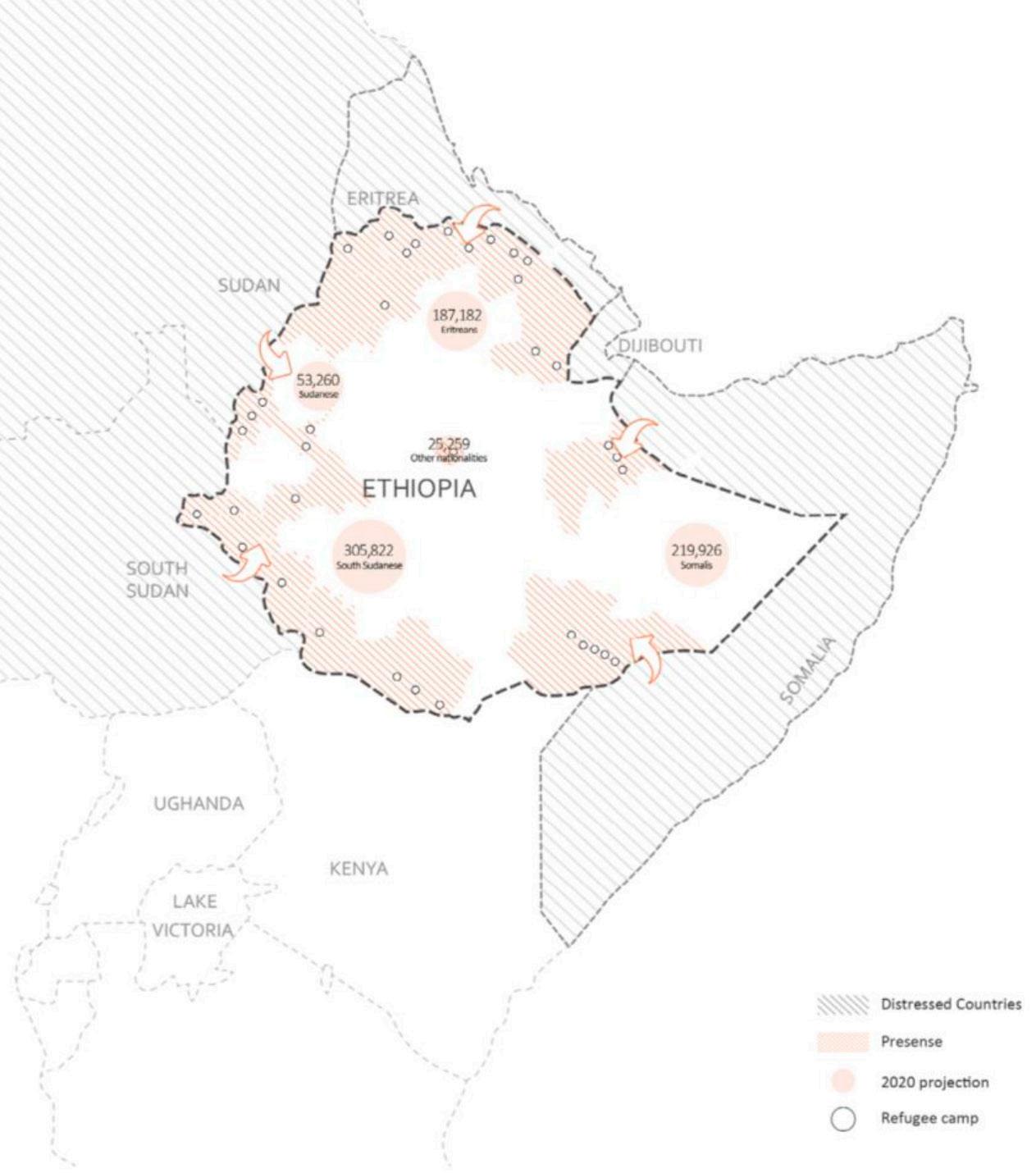

01 - 3 CLIMATE CHANGE AND DISPLACEMENT

Natural Disasters, Refugees, IDPs and Pastoral Nomads

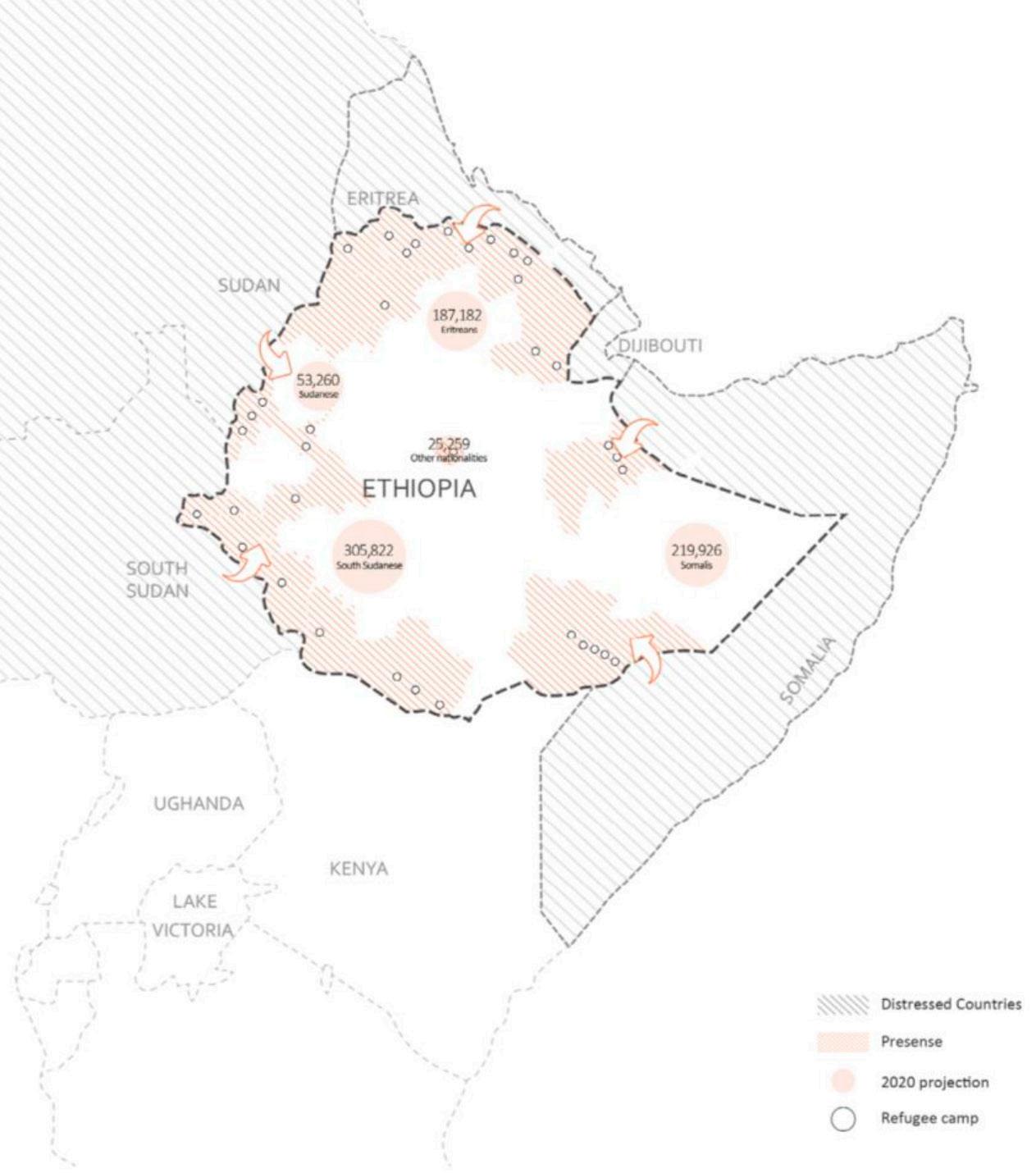

A big percentage of the world’s population is experiencing the negative effects that Climate change is having on the natural environment. In many cases people are forced to leave their houses and resettle in temporary shelters or refugee camps. According to the UNHCR, between 2008 and 2015, 203.4 million people were displaced by natural disasters, and the likelihood of being displaced by them has doubled since the 1970s5. On top of this, persons already displaced for other reasons are exposed to secondary displacement related to natural hazards caused by climate change.

Ethiopia is surrounded by countries with important religious and political conflicts which turn it into a natural destination for refugees escaping Somalia, Eritrea and South Sudan. The country has a prevailing history of hosting refugees in the region, due to the open-door policy that allows for refugee inflow and humanitarian access, whilst providing protection to those seeking asylum in its territory. On the 17th January 2019, the Ethiopian parliament adopted revisions to its existing national refugee law, which provides refugees with the right to work and reside out of camps, access social and financial services and register live events, including births and marriages. Thus, making it the most progressive refugee policies in Africa.

For these reasons, Ethiopia accounts for one of the 10 most important protracted refugee populations in the world. It is also home to one of the largest refugee camps to exist, the Kebri-Beyah refugee camp, which has been in its territory for more than 30 years now. According to the UNHCR around 860 thousand refugees were expected to be living in Ethiopia by the end of 20206, with a predicted refugee inflow to be majorly from South Sudan (450,000), Eritrea (150,000) and Somalia (170,000).7

20 Rural WaterScapes 1 Introduction

21 Rural WaterScapes

Map showing Refugees entering Ethiopia

01 - 3 CLIMATE CHANGE AND DISPLACEMENT

Natural Disasters, Refugees, IDPs and Pastoral Nomads

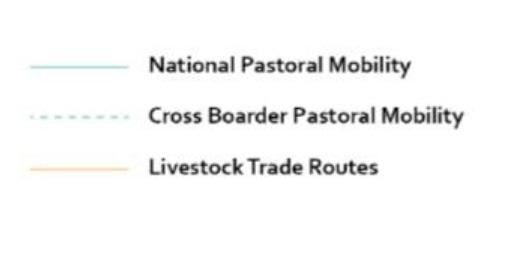

The country is also home to a big population of pastoral nomads wandering across its territories searching for water and grazing lands. The changes in the season’s duration and amount of water falling on the surface are driving a desertification process which is reducing the pastoral access to water and grass for their livestock. Furthermore, this process is amplified in some areas of Ethiopia by uncontrolled deforestation practices.

The reduction of the available natural resources triggers local conflicts over land control and eventually increases the Internally Displaced population. In the year 2018 IDPs reached around 950,000 people, 80 percent of which had an agro-pastoralist background.8

A balanced water management strategy combining alternative sources, with water recycling could help tackle the current water crisis and guarantee a proper water access for crops and livestock. The use of indigenous agricultural strategies and drought resistant crops would enhance the crops and fodder production, increasing the food security in the horn of Africa, reducing the conflicts over land control and resources and ensuring the survival of pastoral nomads’ groups. A settlement strategy and a material system that can adapt to population flows and be carried out using local materials could help address the displacement problem with a sustainable solution that empowers rural communities and generates a positive impact against deforestation and desertification.

22 Rural WaterScapes 1 Introduction

23 Rural WaterScapes

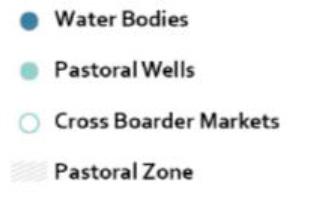

Map showing Pastoral Mobility inside Ethiopia

02. DOMAIN 11 12 13 14 WATER SITUATION IN SOMALI REGION.................................................................................... WATER CONTROL ..................................................................................................................... MOBILITY IN SOMALI REGION ................................................................................................ TEMPORAL ................................................................................................................................ 2-1 WATER ACCESS FROM TEMPORARY TO PERMANENT AGRICULTURE IN AFRICA STRATEGY MOBILITY 2-2 2-5 2-3 2-6 2-4

Drought and poor water access

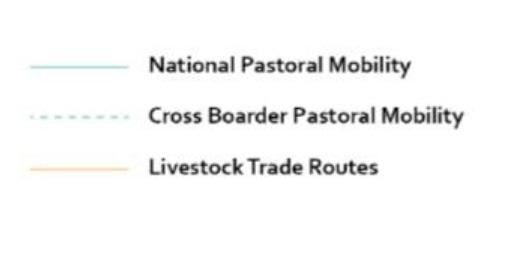

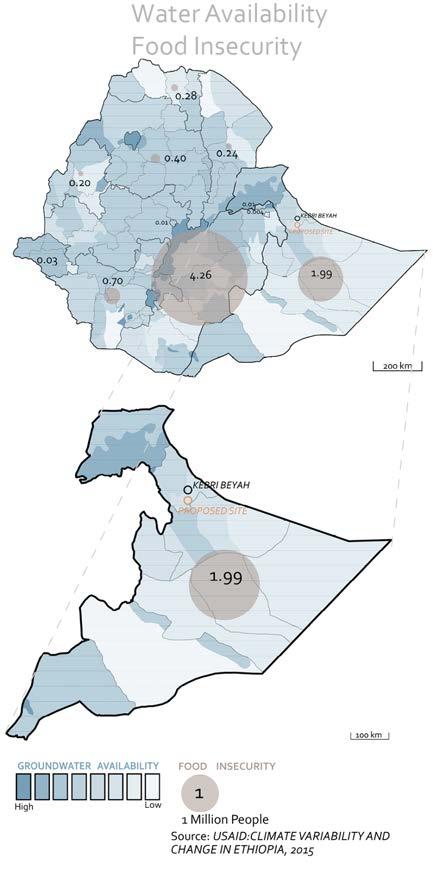

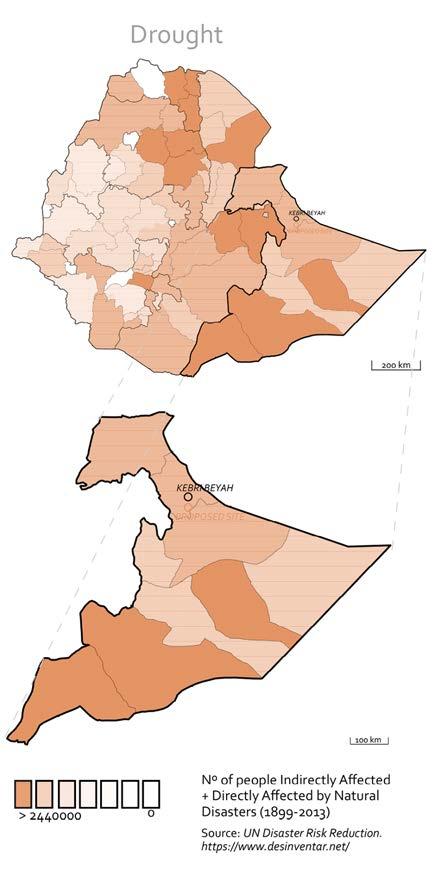

The impacts of climate change are amplified in the Somali region of Ethiopia, due to the combination of population pressure, environmental degradation and unreliable water supplies. This area has been severely affected by changing weather patterns for the past 70 years. According to the USAID 2015 technical report, since 1950 12 major drought-induced food security crises have occurred. The agricultural production here is highly dependent on rain to produce and the water points are scarce.

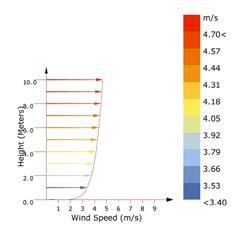

Climate change is resulting in temperature rising and the number of hot days increasing in this region. The mean annual temperature is supposed to grow between 1.1 to 3.1ºC and the number of hot days to occur on 19 to 40% of the year by 2060 (USAID, 2015)9. These rising temperatures and erratic rainfall are causing moisture loss on the land, reducing water infiltration and groundwater recharge. This is having a negative impact on the natural water sources’ availability and quality, and therefore also affecting the crop production and the livestock survival.

Ethiopia maps showing number of people affected by drought and groundwater availabilty with food insecurity

02 - 1

WATER SITUATION

2 Domain Water Situation 1. 26 Rural WaterScapes 27 Rural WaterScapes

Animals waiting to drink at the borehole in Lehey, Somali Region, Ethiopia. Source: Modern and Mobile, The future of livestock production in Africa’s drylands

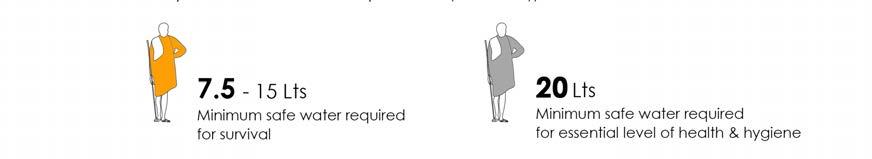

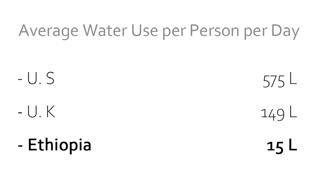

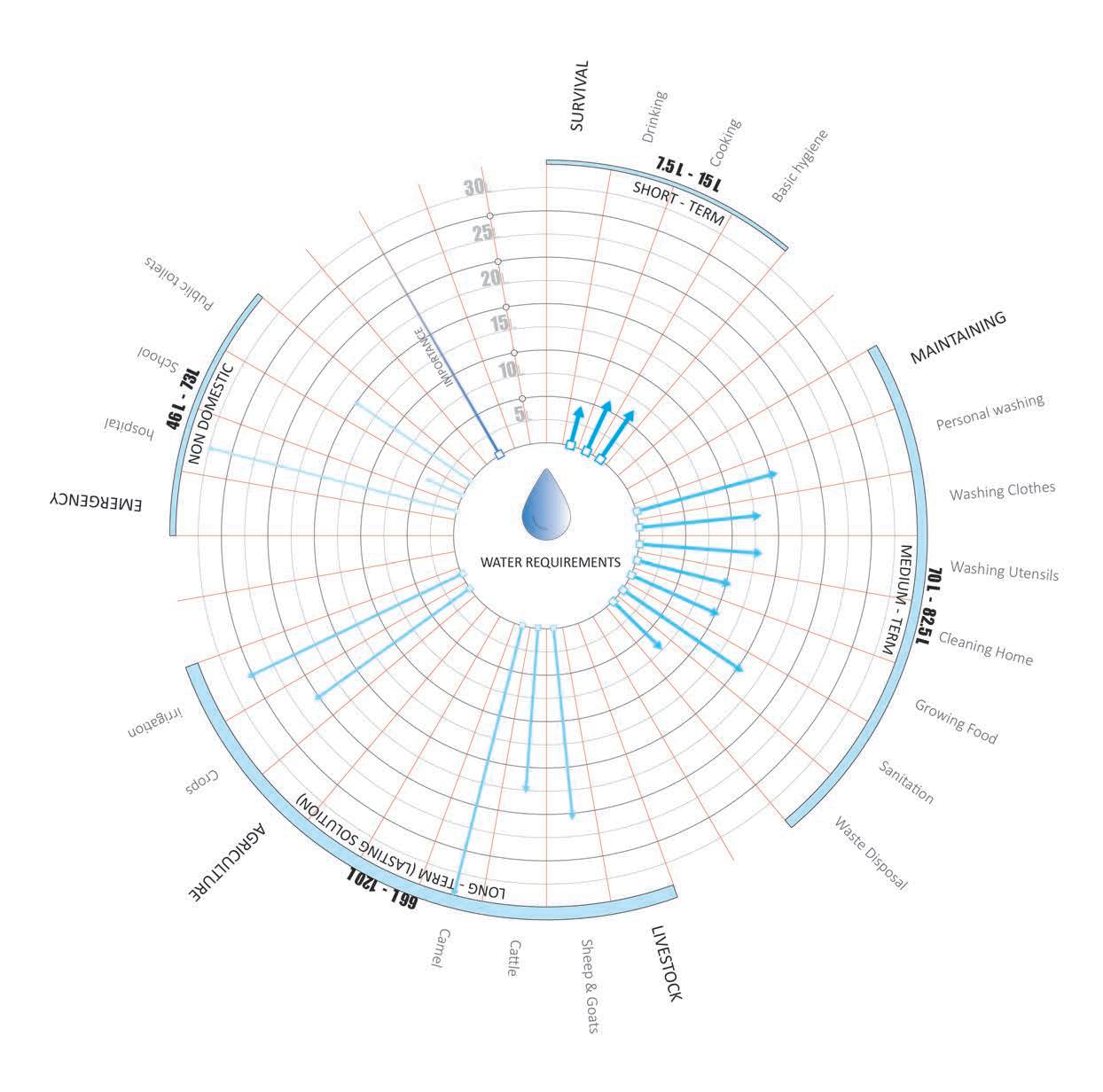

WATER AVAILABILITY The average water use per person a day ranges from 200 - 300 litres in most countries in Europe and up to 575 in the United States, while in Ethiopia, it is only about 15 litres. Even though the water requirement in Ethiopia is relatively low compared to first world countries, some areas like the Somali region still suffer from grave water shortage caused by severe droughts and other factors making it impossible to cover even their most basic needs.

Rural Ethiopians spend much time, trying to obtain water due to the fact that 42% of it comes from untreated wells or springs which are relatively difficult to access. Furthermore, the lack of sanitation accessibility is an even bigger problem than the lack of accessibility to water, especially in countries like Ethiopia. Due to the scarcity of water, poor sanitation, and hygiene, some of the pastoralist regions have experienced Acute Watery Diarrhoea (AWD), Water Washed Disease, and other hygiene-related diseases.

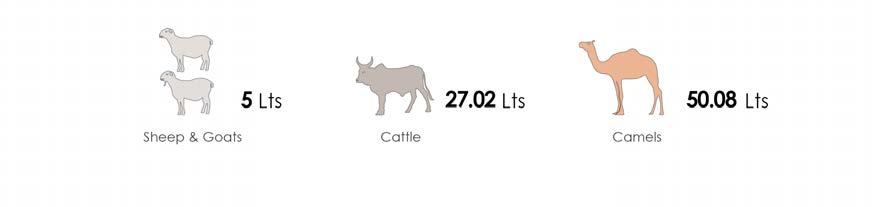

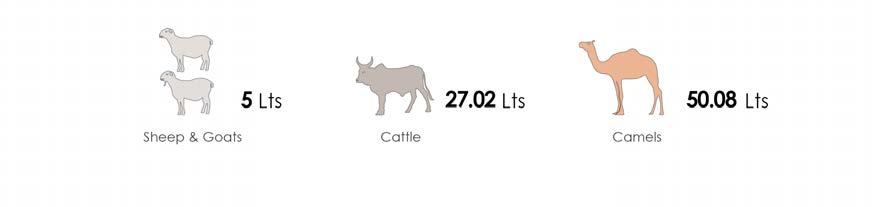

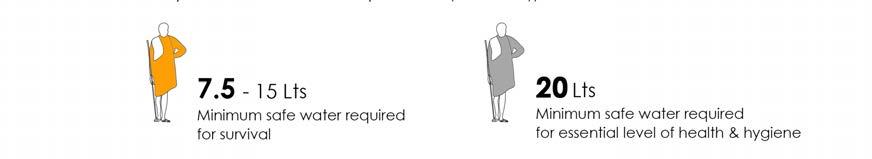

Inhabitant According to the World Health Organization Report 2013, minimum safe water required for survival is 7,5 to 15 litres a person a day to cover drinking, cooking, and basic hygiene necessities. In addition, people should secure at least 20 litres of water when considering the amount of water for essential level of health and hygiene.

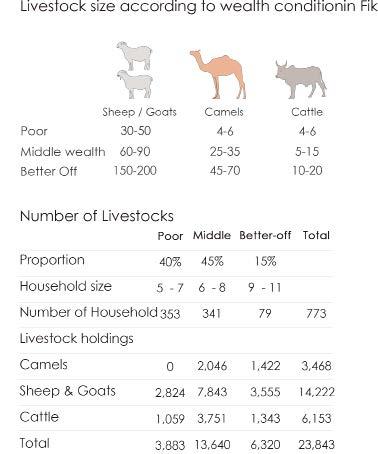

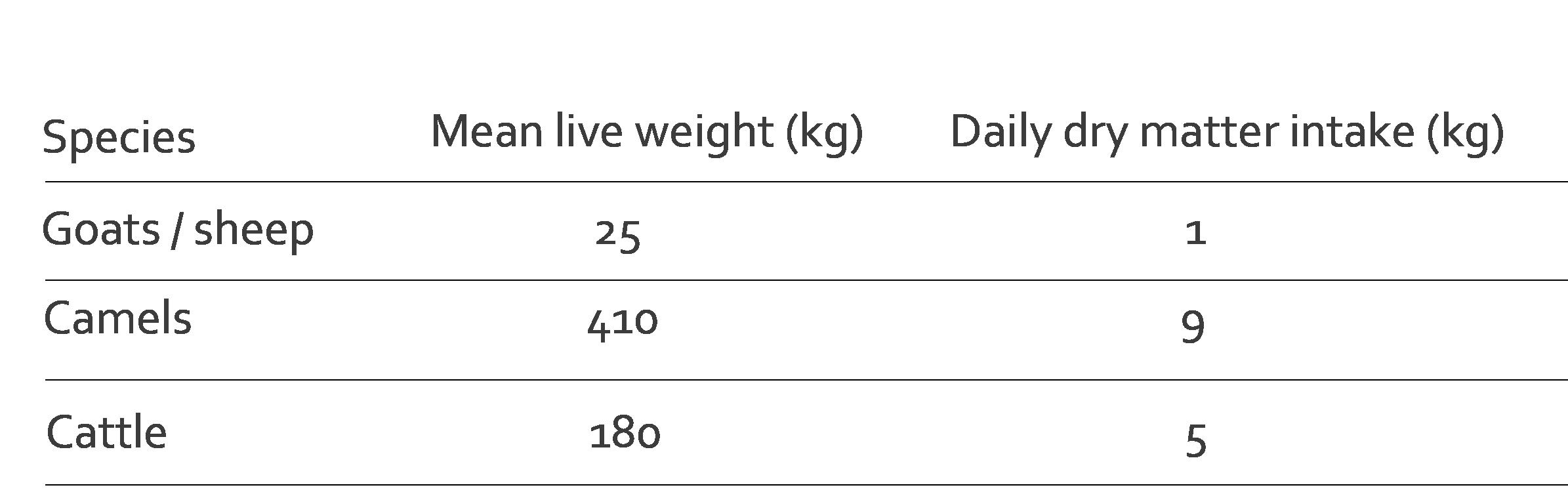

Livestock In addition to the minimum safe water required for humans, It is significant to consider water requirements for livestock. The animal population that pastoralists mainly depend on in the Somali region consists of Sheep, Goats, Camels, and Cattle. Sheep and goats have the lowest daily water requirements, with 5 litres per day, followed by cattle and Camel, around 50 litres and 27 litres, respectively. Pastoralists try to lower the risk of drought and diseases by having all types of animals.

Hierarchy of water requirements (after Maslow’s hierarchy of needs)

Water Situation in Ethiopia

28 Rural WaterScapes 2 Domain

02 - 1.1

Water situation 1 29 Rural WaterScapes

Daily minimum safe water requirements for survival (Litre / Head) Daily

water requirements for survival (Person

minimum safe

/ Day)

WATER COLLECTION Even if the Somali region is partially occupied by the Wabi Shebelle Basin, with an estimated 558Mm3 of water that could be used, groundwater exploitation is not very common in the area. This is due to the fact that the aquifer lies at an average depth of 250 meters and under several layers of hard rock, making it too expensive for the local context to use (Kebede, 2015) 14.

Rain water harvesting remains the main water source in here, where it is collected and stored by the construction and use of run-off harvesting ponds, also known as Birkas. This practice is very common in Ethiopia’s rural areas, where around 15 to 20% of the human and over 80% of the livestock consumption is covered with water coming from either rivers, streams or ponds. (Binyam & Desale, 2015) 15. According to them, these Birkas hold about 60 m3 of water in average. Even so, rainfall patterns are becoming increasingly irregular and harder to predict. Rainfall in the Somali region ranges between 200 mm/year in the south to 800 mm/year in the Jijiga plains, with between 50 and 85% of the annual precipitation falling during the rainy season known as the Kiremt (Fazzini et al., 2015)16.

This combination of water falling in a short period of time and being stored in open ponds often results in stagnant pools which contribute to the proliferation of waterborne and water related diseases such as malaria or cholera. On top of that, the fact that water is coming from surface run-off increases the risk of pollutants flushing into the ponds, creating other health issues when it is used for drinking (Kassa, 2018)17.

30 31 Rural WaterScapes Rural WaterScapes

02 - 1.2

Birka in the Somali Region

2 Domain Water situation 1

Typical birka Diagram with dimensions

Even if some improvements have been made globally, pure water access in Sub-Saharan Africa has worsened in the past two decades. According to the WHO-Unicef Joint Monitoring Program Report (2019)18, 85 million people depend on surface water, 180 million people rely on unimproved sources and 135 million have access to a limited water supply to cover their basic needs. When it comes to rural Ethiopia, only 31.06% of the population have access to either safely managed or basic water, whereas the remaining 68.94% depend on limited, unimproved or surface water sources, and only 3.81 % of the population have access to safely managed sanitation services (2017)17.

New strategies combining different sources with greywater recycling have to be developed in order to tackle the increasing pollution of surface water sources and the water scarcity projected for the coming years.

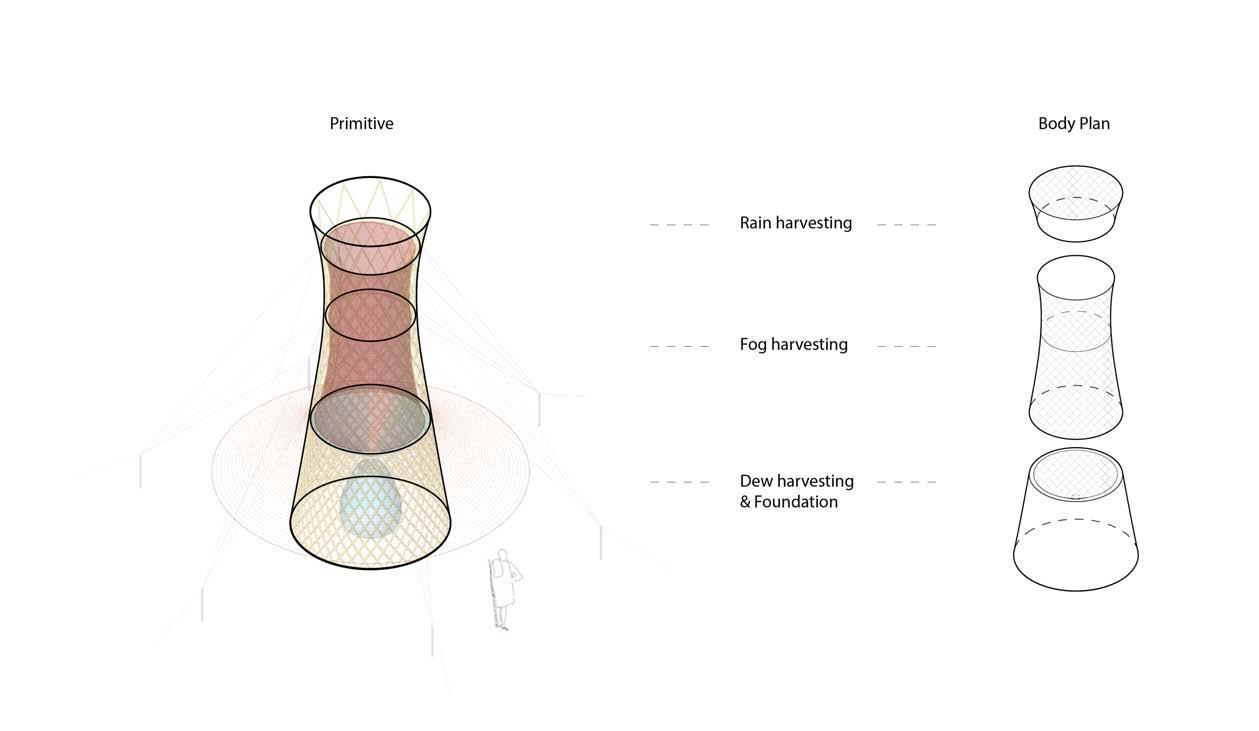

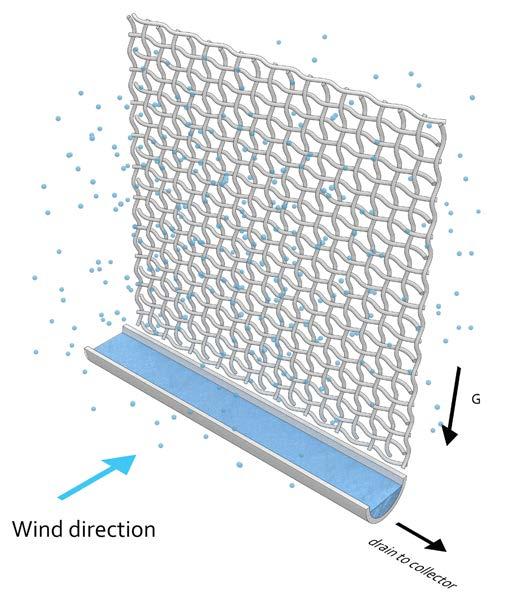

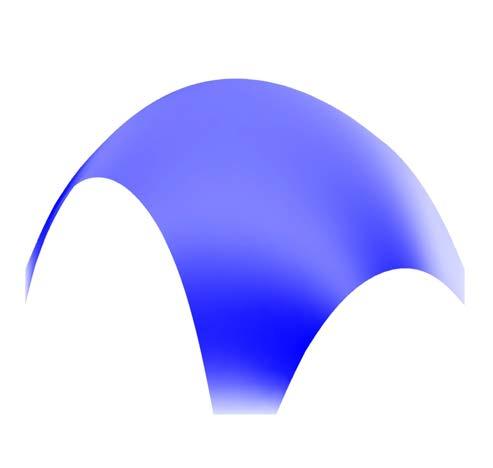

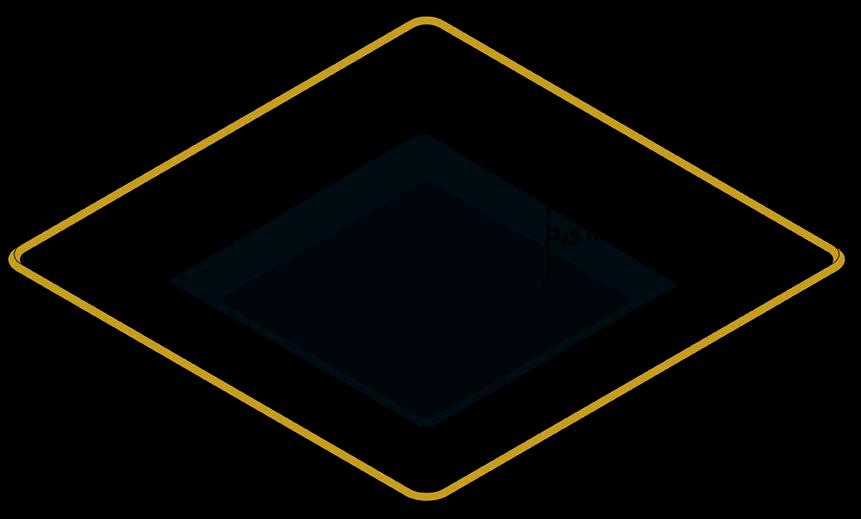

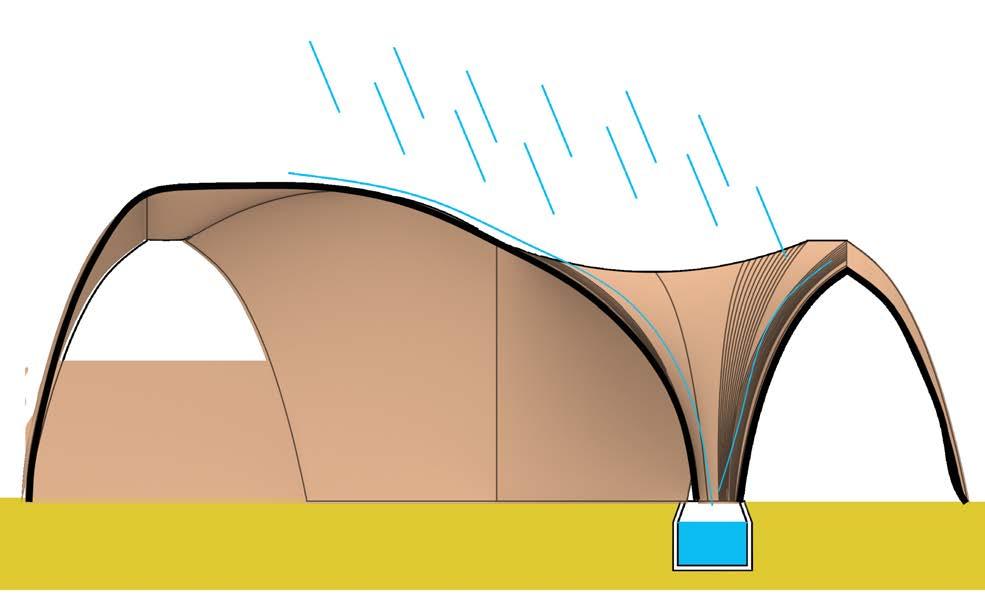

FOG COLLECTION Fog water is an alternative source in contexts where rain is scarce. The appearance of Fog clouds is the result of the saturation of air with water vapour. Whenever this micrometric droplets encounter a cold surface they condense into water that can be collected via a system of gutters and pipes (Salehi et

al., 2020)19. Fog events can occur throughout arid zones close to the ocean, where clouds are regularly formed above water and carried inland by prevailing winds, turning into fog once they reach higher ground (Rivera, 2011)20. Fog currents allow for the use of passive water collection devices, using different meshes to enable harvesting as the fog passes through them.

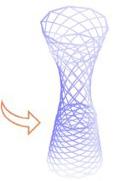

These fog water collectors (FWC), can be divided into 3D and 2D FWCs according to their geometry. 3D devices are not subjected to a particular wind direction, their shape is most commonly a cylinder or two cross-intersecting perpendicular panels. Whereas 2D FWCs are made out of flat vertical structures fixed facing the main wind direction (Regalado & Ritter, 2019)21.

According to Regalado and Ritter, the potential water to be harvested from fog events is difficult to estimate due to the high number of variables present, both climatic, device related, and those appearing in the interaction between these two. Just to name a few, we find droplet size distribution, liquid water content of the cloud, wind regime, collector efficiency, aerodynamics, turbulence, mesh clogging, droplet

32 33 Rural WaterScapes Rural WaterScapes 02 - 2 WATER ACCESS

Potential sources and management

People collecting water from a water point

02 - 2.1

2 Domain Water Access 2

Fog collector concept diagram

attachment/detachment and filament impaction mechanics. This is why, the best way to determine potential fog water collection is physical on-site experimentation.

Even so, we know the chosen mesh pattern will determine its efficiency. As Rivera20 states, with a shade coefficient too small, a minor percentage of the fog droplets will hit the mesh, but if it is too large, most of the fog will go around it. He also introduces the following formula for the theoretical estimation of the collection efficiency:

ηcoll = ηAC.ηcapt.ηdr

Where ηAC corresponds to the aerodynamic collection efficiency, or the maximum amount of fog that could be captured by the FWC, ηcapt stands for capture efficiency, meaning the fraction of droplets that are actually captured by the mesh, and ηdr represents the proportion of water that reaches the gutter, out of the amount that is captured by the mesh.

Dew is defined as the condensation of water vapour into liquid, when in contact with a substrate. For this to happen, the temperature of the substrate has to be lower than that of the surrounding atmosphere. According to Beysens, an ideal dew condenser should be a light sheet thermally isolated from massive parts and from the ground. Without becoming too light, as it could easily be warmed by the surrounding air. These condensers should be placed in open areas where the wind velocity is low, the humidity is high and with a clear view of the sky. This allows for the surface to emit more energy than the one received and absorbed, enabling it to steadily cool down during night-time (Sharan, 2011)22.

Having higher wind velocities and lower humidity in our site, Dew does not seem to be a significant water source for our strategy.

34 35 Rural WaterScapes Rural WaterScapes

02 - 2.2 DEW

Dew condenser concept diagram

2 Domain Water Access 2

Pastoralist with a flock of goats, Ethiopia. photo by Ibrahim Abdhi Hussein©

GREYWATER

Greywater is the wastewater containing no input from toilets, this groups the wastewater generated in bathing, hand washing, laundering and kitchen sinks. Its volume has been estimated at around 75% of the residential sewage (Eriksson et al., 2002)23, and its use can therefore be very important in water scarcity contexts. Nevertheless, a few parameters such as pH, bacterial presence, turbidity and the presence of inorganic chemicals should be evaluated in order to determine the best way to use it. Different multistage treatment units have been developed containing chambers for suspended solid settling, anaerobic degradation and sand filtering to improve its quality for irrigation. In the past decades a few guidelines have been introduced for GW use, which recommend using it only on trees, forage crops, or on vegetables with low water content, considering a minimum number of days between irrigation, harvest and consumption (Leas et al. 2014)24.

02 - 2.4

WATER STORAGE Water storage has to be done correctly to avoid the pollution of the water supply and the spread of water borne diseases. Storage tanks significantly contribute to the reduction of microbial presence through sedimentation processes. A very important aspect to consider in a water tank is its capacity, smaller tanks can present higher levels of bacterial contamination, due to the fact that the sediment in the bottom is more likely to become agitated and mixed with standing water (Meera & Ahammed, 2006)25. According to Meera and Ahammed, the tank’s material is also important in the quality of stored water, potentially causing water alkalization if it is made out of ferrocement.

36 37 Rural WaterScapes Rural WaterScapes

Camels at water surface, Ethiopia.

photo by Genady Shkiar ©

02 - 2.3

2 Domain Water Access 2

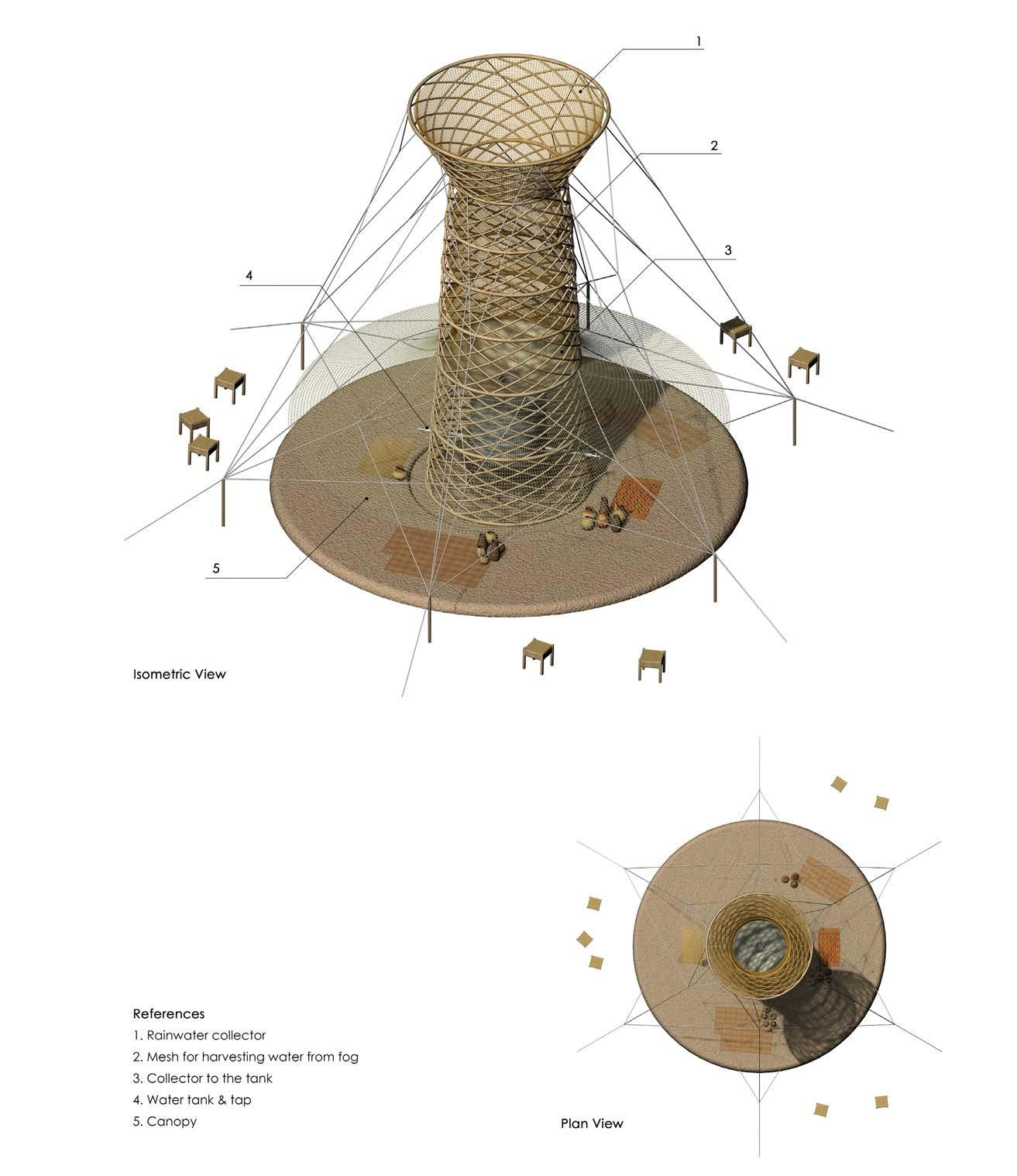

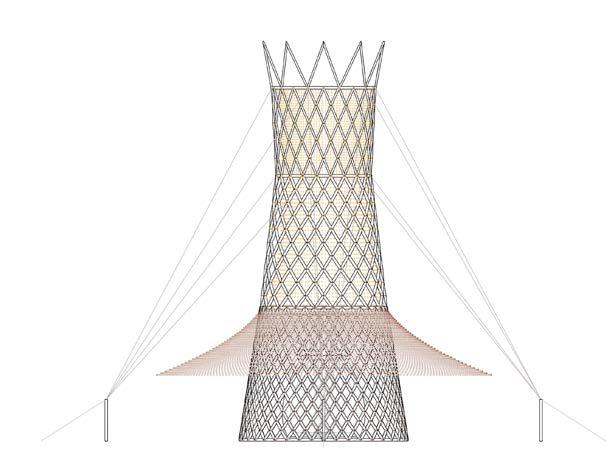

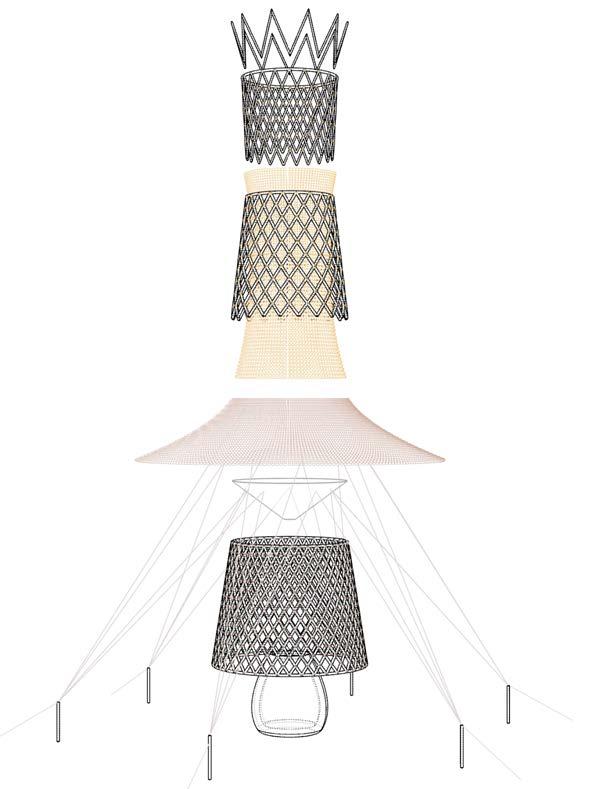

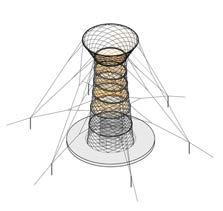

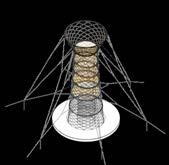

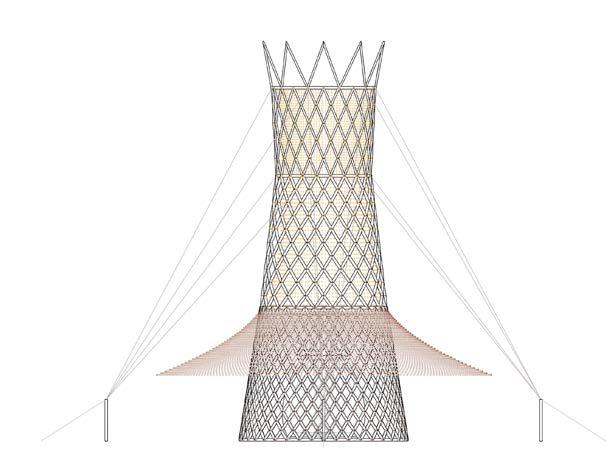

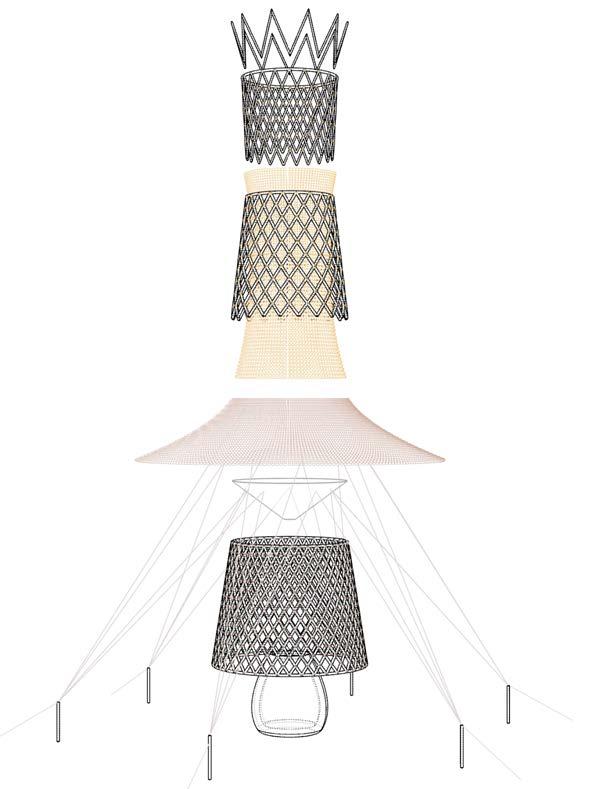

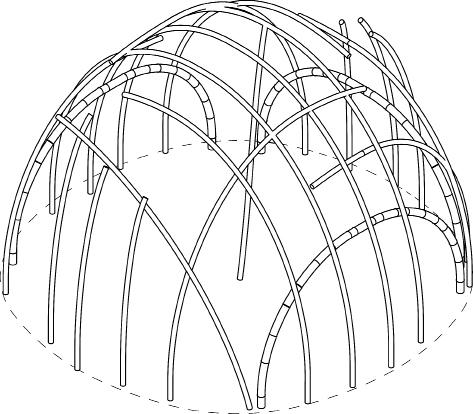

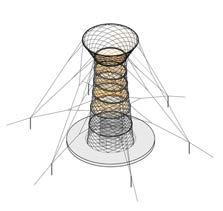

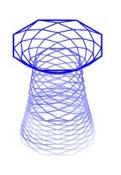

CASE STUDY: WARKA TOWER

02 - 2.5

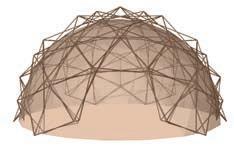

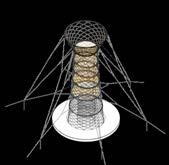

Warka Tower is a water harvesting device designed by Architecture and Vision, which is aimed at providing an alternative source of clean water for rural populations that have a reduced access to it. The tower has been designed to be built in regions that lack infrastructure.26 It is inexpensive, can collect rainwater and harvest water from fog and dew. The first pilot tower was installed in 2015, in the Dorze region of Ethiopia.

The tower consists of 6 parts which can easily be assembled within a day incorporating traditional construction techniques. The framework of the tower comprises of lightweight bamboo stalks interwoven in a pattern that offers stability in the face of strong wind whilst still allowing air flow27. Natural fiber ropes are used to tie the overlapping sections of the bamboo stalks in place. Within the bamboo framework is 30 m2 of polyester mesh which collects droplets of dew. As the droplets begin to accumulate, they trickle down into a storage container at the bottom. The water then passes through a distribution network transporting it to the collection points28.

Warka Tower is designed to be operated by the villagers, providing a sense of ownership. It also has a canopy which provides shade, creating a social space for the community. Each tower is supposed to collect up to 100 litres of water a day. This claim is supported by a tower which was constructed in a semi-arid region in India.29

The Warka Tower was selected as a precedent project as it was installed successfully in a different region of Ethiopia.

38 39 Rural WaterScapes Rural WaterScapes

Warka Tower axonometric diagram

6 5 4 3 2 1 Bamboo

Natural

Mesh

Ropes

Polyester Cables Bamboo Hemp

8Kg

Polyester Mesh 30

3m 9.5m 3m 4m 4m 4m Warka

1 day 50 to 70 % 500 - 1000 USD Upto 40 c 2 Domain Water Access 2

Framework

Fibre Ropes

Canopy Collector

Antenna

Ropes

- Approx 200 units - 1.5m tall

sqm

Tower section diagram

02 - 3 AGRICULTURE IN AFRICA

Indigenous Strategies and growth potential

According to the New partnership for African Development, the demographic growth in Africa over the last 30 years has caused an increase in food insecurity, even if the agricultural production in the continent has almost tripled during that period (NEPAD, 2013)30. This growth in production is mainly generated by an increase in cultivable area and not by a real improvement in the methods used to do agriculture. This has a negative impact on the native forests which are being logged to increase the amount of agricultural land. The deforestation and loss of natural flora and fauna triggers a change in the natural and climatic cycles associated to rainforests that may lead to extinction of numerous species and desertification. According to FAO’s world forests report, the rate of net loss has been increasing in Africa driven by agricultural expansion since 1990, showing the highest net loss of forest area in the last decade with around 3.94 million hectares lost per year (FAO, 2020)31.

It is therefore very important to develop strategies combining water conservation techniques with droughtresistant plants, which enable an increase in yield per hectare for semi-arid lands. This would result in a production surplus that could help reduce malnutrition, and in an expansion of cultivable land

WATER CONSERVATION INDIGENOUS STRATEGIES

02 - 3.1

that would not generate deforestation and natural ecosystems loss, but an increase in soil moisture and nutrients. Enhancing semi-arid land agriculture could therefore help stop the current desertification process.

To do that, we looked into soil and water conservation techniques being implemented in Ethiopia and in other sub-Saharan countries, to choose the most suitable one for our site. We also studied drought resistant plants that could grow in contexts where water is scarce or unevenly distributed throughout the year.

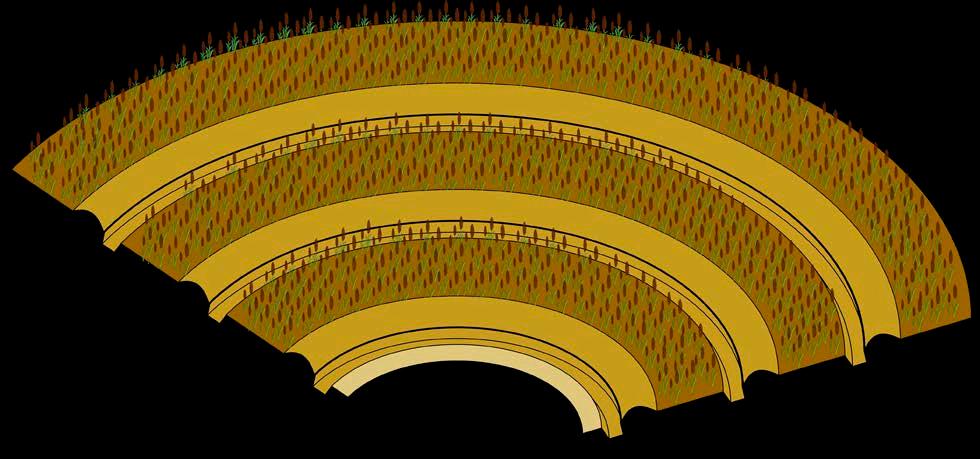

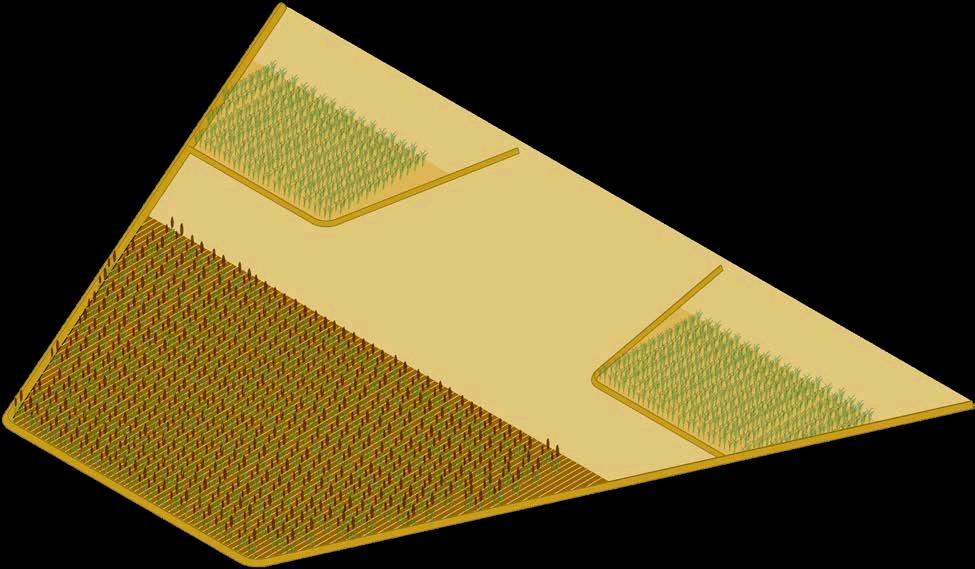

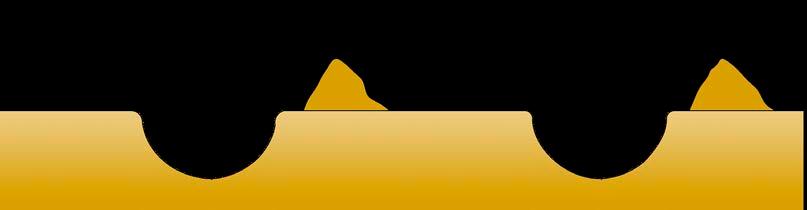

Our study of African water conservation techniques was particularly focused on Ethiopian Fanya Juu, Sudanese Teras and Burkina Faso´s Zai pits. Extracting the way the technique works, where it is being carried out, potential yield gain and limitations.

40 41 Rural WaterScapes Rural WaterScapes

Ethiopian farmers harvesting teff. Photo by : Eva-Lotta, Oxfam America

2 Domain Agriculture in Africa 3

Map of Ethiopia relating Livelihood zone types and food insecurity

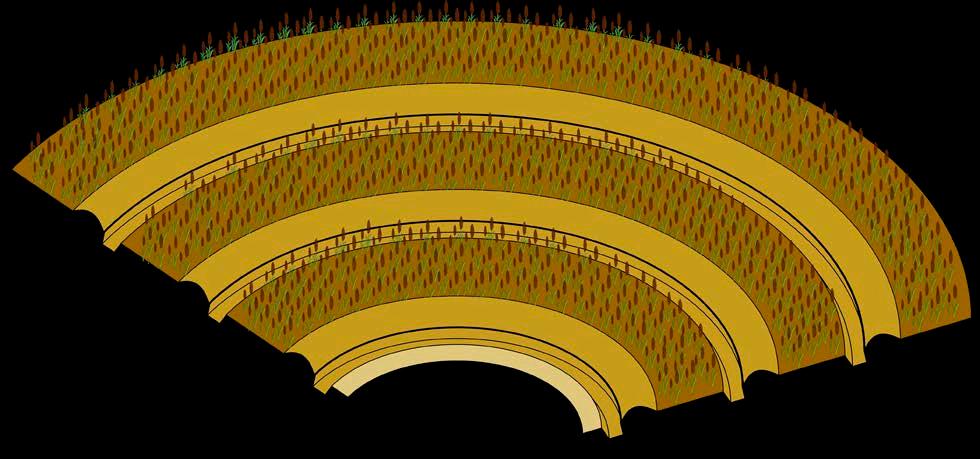

Fanya Juu

Fanya Juu, meaning “throw uphill” in Swahili language is an embankment along the contour made of soil and/or stones, with a basin at its lower side. These embankments are spaced every 1 meter decrease in the terrain level. The technique reduces the velocity of overland flow, therefore diminishing surface runoff for a slope range between 3 and 50%. After a few years, enough material has been deposited as to generate a Bench Terrace structure (MoA Ethiopia, 2016)32.

Limitations

This technique is effective in wetter areas, where rainfall is 700 mm/year or more. It is a very labourintensive technology, requiring between 150 to 350 person labour days/ha. On top of that, bunds that have not been planted with grass are easily eroded by water. (UNEP, 1998)33.

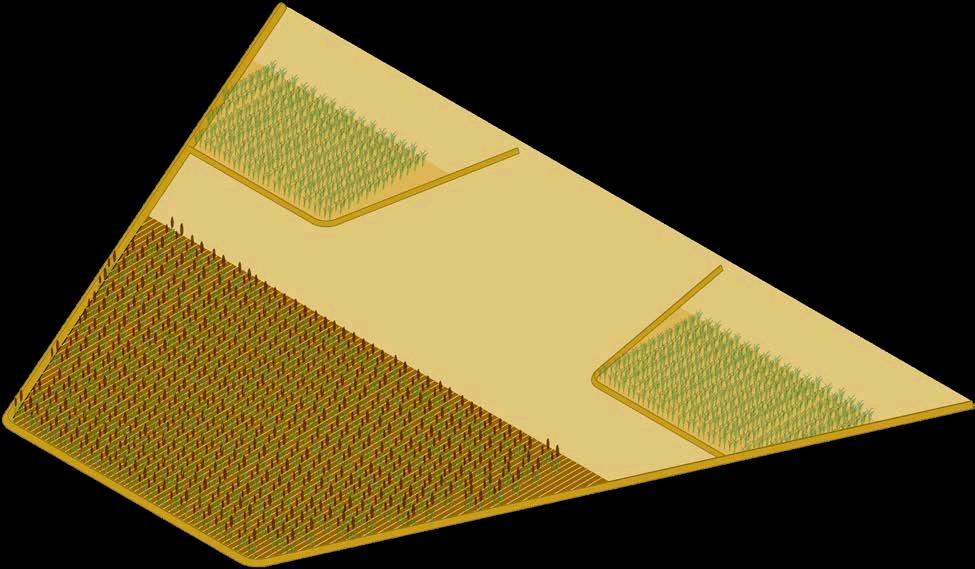

Teras is a form of water harvesting used extensively in the clay plains of Sudan, where an earthen bund contours three sides of each agricultural plot, holding back water and mud flowing from the plains (Chris Reij, 1990)34. The system aims at increasing soil moisture for agriculture by keeping part of the land for the catchment and diversion of rainwater to the arable land, before it reaches seasonal streams. The enclosed land is further divided into smaller units by shorter arms, which make it possible to benefit from small run-off volumes coming from small rain events as well as to decrease flow velocities when rain is abundant (VanDijk, Hassan Ahmed, 1993)35. The usual dimension of the bund is 0.5m for the height, 2m for the width and between 50 and 300 m for the length. The usual slopes for this system are under 1%.

Traditional construction of the ridges is done by hand using simple tools and needing an approximate time of 60-110 person hours/ha. Heavy earth work is postponed until the first rains have softened the soil (VanDijk, Hassan Ahmed, 1993)6.

Limitations

For the system to work, the land has to be in proximity to flood plains, where water is available to catch. The system largely benefits from soils with a high proportion of clay, which allow for water to run over the surface. In sandy soils, where infiltration is higher, this system does not work, since it impossible for the water to run.

42 43 Rural WaterScapes Rural WaterScapes

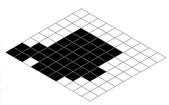

Fanya Juu axonometric diagram

2 Domain Agriculture in Africa 3

Teras axonometric diagram

Trench Bund

Teras

Main cultivated area Subsiduary cultivated area

Cultivation area

DROUGHT

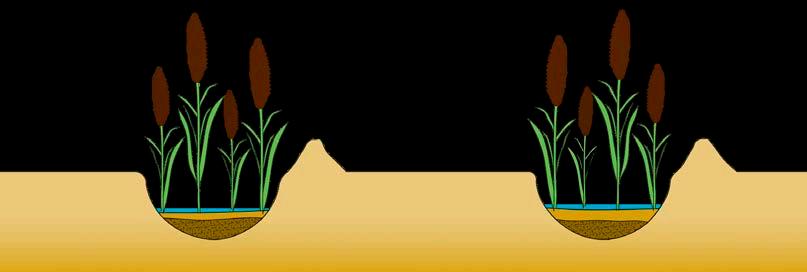

Zai pits

Zai is a term that farmers in Burkina Faso use to refer to small planting pits. This technique is particularly useful to rehabilitate degraded soils in semi-arid environments, as it improves water infiltration and restores soil fertility for slopes below 5%. For its application, 20-30 cm wide and 10-20 cm deep holes are dug into the ground, spacing them 60-80 cm apart (Danjuma and Mohammed, 2015)36. The dimensions may change according to the type of soil reaching between 12,000 and 25,000 pits per hectare. The earth coming out of the excavation is used to form a demi circle ridge on the lower edge of each hole, contributing to water catchment and moisture retention. Organic matter coming from crop residues and/or animal manure is added to each pit at a recommended rate of 0.6 kg/pit, increasing the amount of nutrients in the soil and increasing production up to 500% (World Bank, 2005)37. This important potential increase in production turns it into a very attractive strategy for our site, as it would allow for a maximization of the crop and fodder production along with a regeneration of the soil fertility and moisture storage.

Limitations

The digging of the holes is done during the dry season when the temperatures are at its highest. It can be very labour-intensive, requiring around 300 person hours/ha (Clavel et al. 2008)38. It is therefore advisable for the task to be undertaken by groups of farmers instead of individuals (Motis et al., 2013)39.

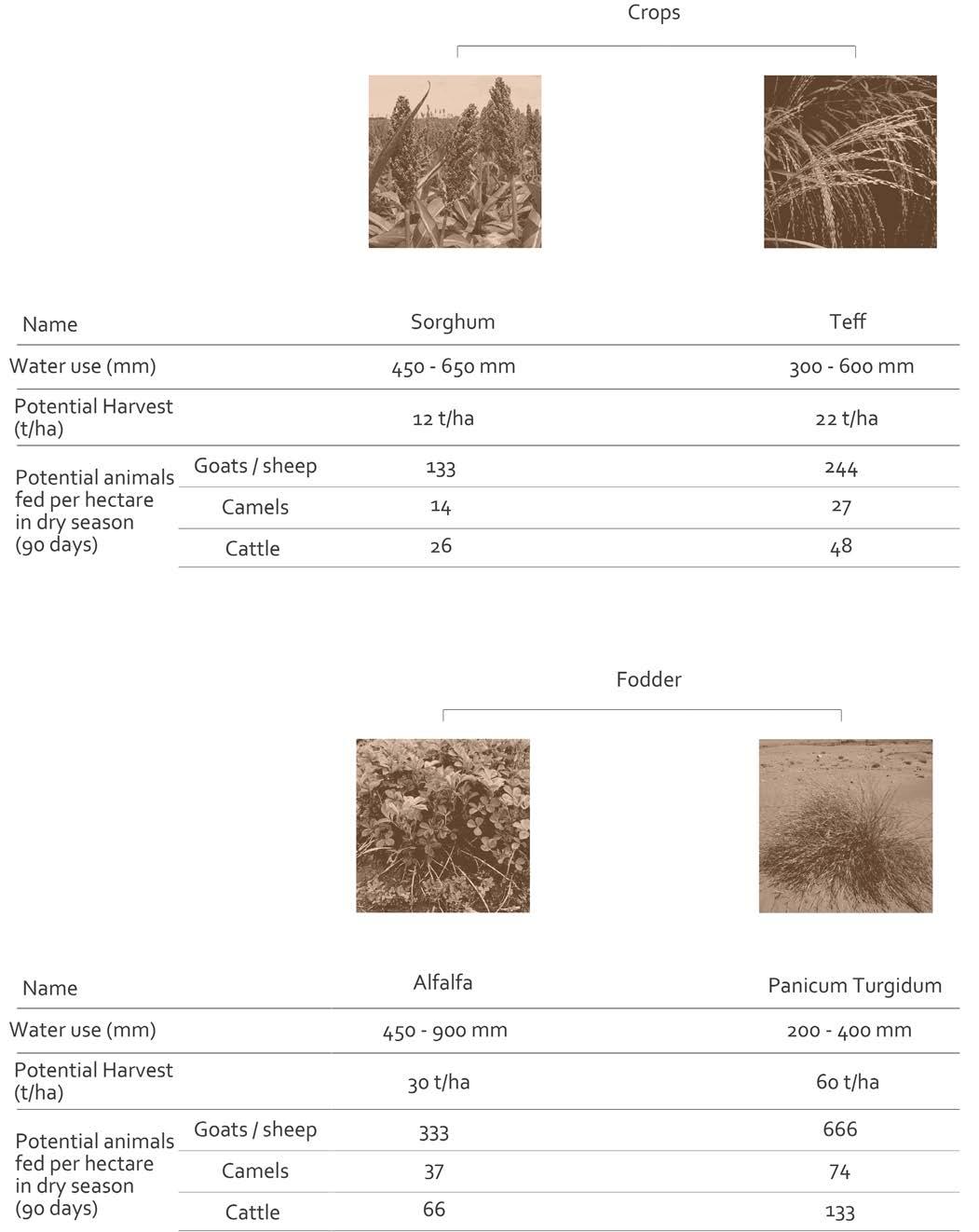

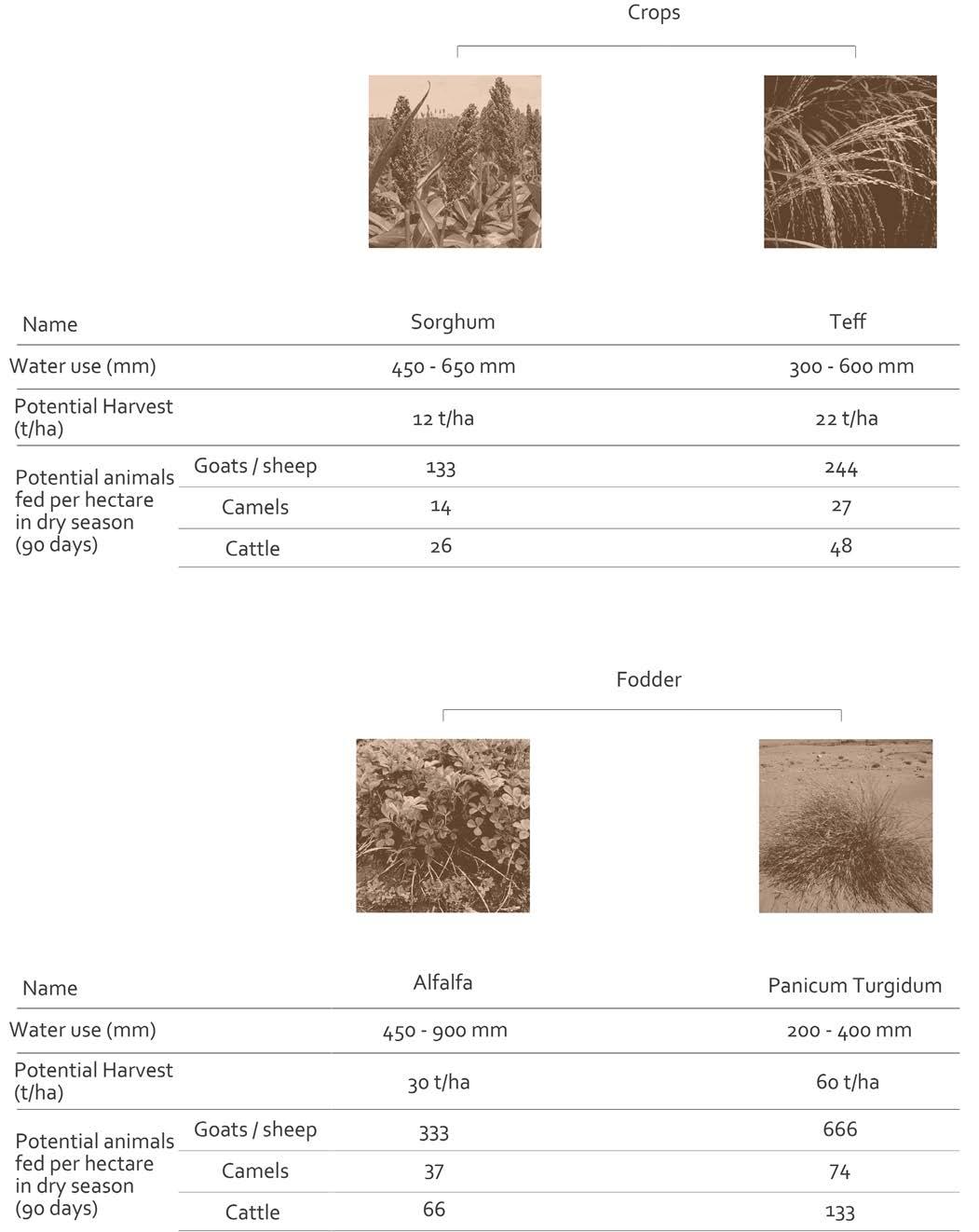

The second step to guarantee a successful agricultural strategy, after introducing water conservation techniques, is choosing crops and fodder which tolerate water stress and/or have low water requirements.

To do so we studied Sorghum, Alfalfa, Panicum Turgidum and Teff, trying to quantify their water requirements and their possible yield per hectare. With the objective of also estimating the number of animals that could be fed with their production. All of these plants are already being grown locally or in environments with similar conditions to the Somali Region.

44 45 Rural WaterScapes Rural WaterScapes

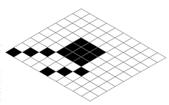

Zai pits construction sequence

2 Domain Agriculture in Africa 3

Zai pits axonometric diagram

02 - 3.2

RESISTANT CROPS AND FODDER

1: Hole digging

2: Organic matter addition

3: Seeding and harvesting

Sorghum

According to the FAO, Sorghum domestication is believed to have started in Ethiopia 5000 years ago (FAO, 2021)40, and it was the second most important cereal in terms of tons produced in that continent in 2003, with around 20 million tonnes per year. Out of which Ethiopia produced more than 1.5 million tonnes per year (Taylor, 2003)41. These figures show that it is a cereal that has been chosen by producers all over Africa and particularly in Ethiopia, due to its high drought resistance.

For high yields, a sorghum planted field requires around 450 to 650 mm of water during its growing cycle of 120 days, with a maximum water requirement of 10 mm/day appearing 60 days after planting (Assefa et al., 2010)42. The plant’s grain yield will vary according to the water availability and soil salinity. Assefa et al. state that the yield for dryland sorghum is around 4 t/ha, approximately half of that of irrigated sorghum, and FAO states that the plant is moderately tolerant to high soil salinity, decreasing its yield up to 50% in soils with 11 mmhos/cm (FAO, 2021)11.

Teff is a native crop of Ethiopia and Eritrea, constituting around two thirds of the daily protein intake in the Ethiopian diet, where the grain is used for making bread, porridge and alcohol, and the stem is used for livestock feed and for reinforcing mud for plastering (FAO, 2021)43.This gluten-free food crop has a high market value, which makes it very popular amongst Ethiopian farmers (Araya et al., 2011)44. Its fibrous root system makes it suitable for erosion control.

The expected yield under proper water conditions for Teff is between 2 to 4 tons/ha per cut every 50 days (Teff Grass Production guide)45. It has a total growing period of 80-85 days, where it uses around 300 mm of water. This crop is moderately resistant to water stress decreasing its yield by 50% under limited water supply conditions (Araya et al., 2011)15.

46 47 Rural WaterScapes Rural WaterScapes

Ethiopian farmer in a Sorghum field.

Source: Allafrica.com

Ethiopian Farmers harvesting Teff.

2 Domain Agriculture in Africa 3

Source: Farm Radio International

Teff

Alfalfa

Alfalfa, as FAO states it, is a forage crop thought to be native from the Mediterranean region. Its growth cycle is around 3 months, with an expected yield of approximately 2 to 2.5 tons/ha per cut every 30 days (FAO, 2021)46. This turns it into a good nourishment for livestock to eat directly from the ground or to make hay that can be stored for the drier seasons. On top of that, this crop is very good at improving soil structure and minimizing erosion thanks to its perennial root system and capacity to fix nitrogen (Platt, 2021)47.

According to Bauder (Bauder 2021)48 Alfalfa’s water requirements are approximately between 450 and 900 mm per season, but it can withstand drought for extended periods of time. The expected yield varies according to climatic conditions and soil salinity, presenting yield differences between fully irrigated and deficit irrigated Alfalfa ranging from 0.9 to 6 tons/ha approximately (Hanson et al., 2008)49 and decreasing its yield up to 50% in soils with a salinity content of 8.8 mmhos/cm (FAO, 2021)46.

Panicum Turgidum is a perennial desert grass, present all over Northern Africa above parallel 4°N, the Middle East and Central India. It is used as a sand binder, a fodder grass, its grains are consumed by some nomad tribes in Western Sahara and its stems are used to build woven mats (Williams & Farias, 1972)50. It is appreciated for its high drought resistance and high soil salinity tolerance, presenting grains with a nutritive value comparable to those of corn, wheat and barley, which can be grinded into flour and used to make porridge or bread (Heneidy & Halmy, 2009)51. This grass also has a high potential for use as animal feed, as it can reach a height of 1m in 30 days in summer with temperatures of up to 35°, taking 35-40 days to reach the same height in winter (Khan et al., 2009)52.

Panicum Turgidum needs around 200-400 mm of water per year, tolerating 100-600 mm (PFAF, 2021)53, presenting a yield of 60 t/ha/year grown in a saline soil using brackish water (Khan et al.,2009)52.

Panicum Turgidum

Source: http://www. ville-ge.ch/

48 49 Rural WaterScapes Rural WaterScapes

Farmers in a field of alfalfa in the Tigray region, Ethiopia.

Source: Lives Ethiopia

2 Domain Agriculture in Africa 3

Panicum Turgidum

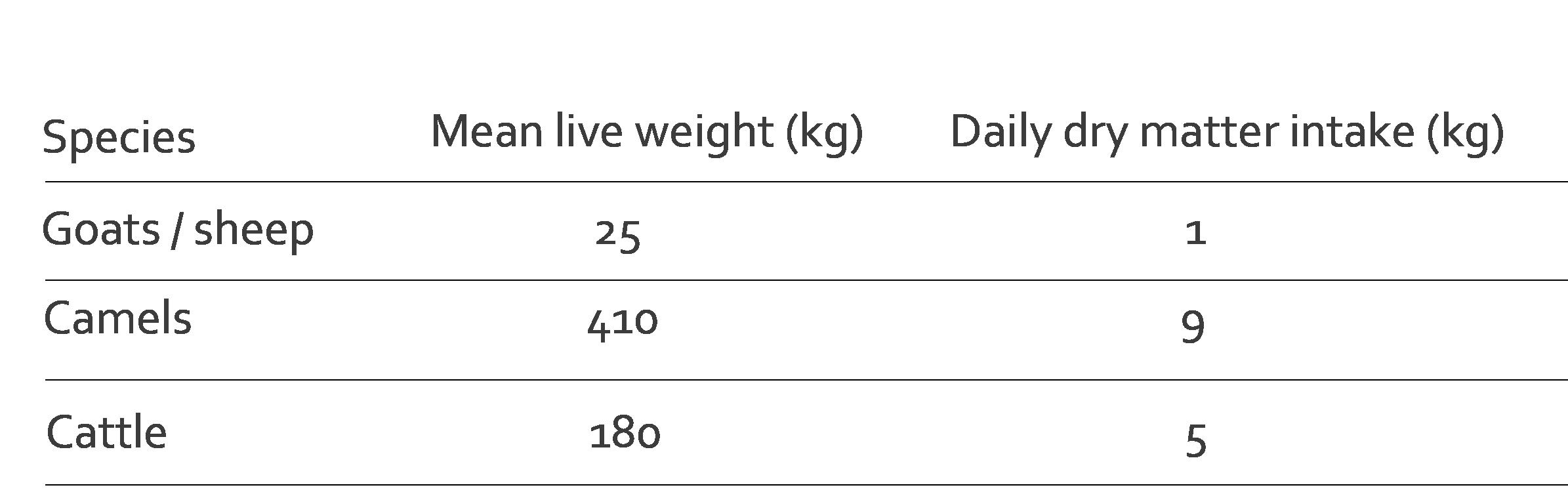

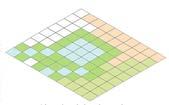

PLANTS YIELD AND ANIMAL FED ESTIMATION

02 - 3.3

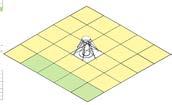

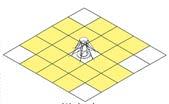

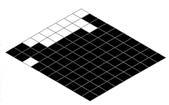

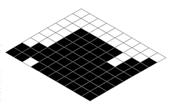

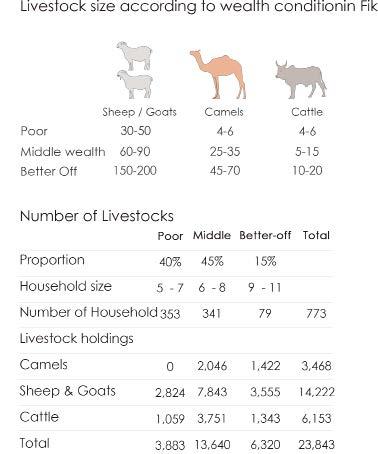

In order to reach an approximation of the agricultural land needed to feed the animals coming to our settlement, we extracted the potential harvest data from the literature for Sorghum, Teff, Alfalfa and Panicum Turgidum and made an annual estimation. We then extracted the daily dry matter intake values for Goats/sheep, Camels and cattle (Peden et.al, 2003)54 and multiplied those daily kg ingested by animal by 90 days, which would cover for 3 months of the dry season. Finally, we divided the annual yield per hectare of each plant by the kilograms ingested by each type of animal for 90 days. The result was a table showing the annual water consumption of the plants, along with their annual yield and how many animals of each type could be fed for 90 days with a hectare of that plant. We would later use these numbers for our urban experiments.

50 51 Rural WaterScapes Rural WaterScapes 2 Domain Agriculture in Africa 3

Mean animal wieght and Daily dry matter intake.

Source : Peden et al.

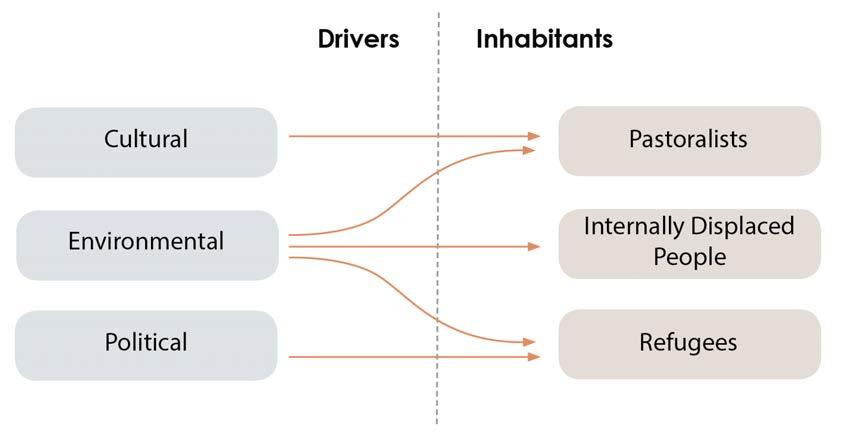

Pastoralists, IDPs and Refugees

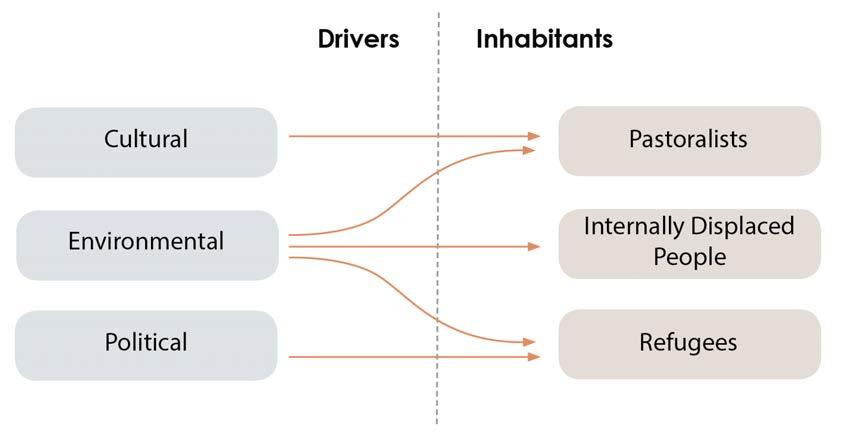

Mobility is a key aspect to understand the current situation in Eastern Africa in general and in the Somali region in particular. There are several drivers for it, some of which are cultural, other are political and most of them have an environmental aspect playing an important role.

Pastoralists have historically seen mobility as a resource for survival and continue to do so. One of the main reasons for this is that they live in remote areas where fodder and water availability are scarce and their existence varies seasonally and yearly. This resulted in a tribal organization that moves collectively from one place to the other and considers every new settlement to be temporary until conditions change and they will have to move elsewhere in search for better resources. Another aspect explaining their mobility is that they get a better price for their animals in markets distant from where the best pastures are.

Nevertheless, changes in land management policies in the recent years favouring permanently settled farmers over moving pastoralists, along with changing climate conditions, are going against pastoral mobility, since grazing lands and water sources are becoming harder to access. This is leading to conflict between different groups and to death of a high number of animals due to insufficient water and grass. Along with their livestock, pastoralists are losing their main source of survival and end up changing their status to Internally Displaced People.

On top of that climate change is reducing the available natural resources all over Sub-Saharan Africa, causing more conflicts over land-control, leading to civil war in many countries with pre-existing tribal disputes. This is the case in South Sudan and Somalia, having 1.6 million55 and 750.000 nationals56 living in neighbouring countries respectively, many of them currently settled in Ethiopian refugee camps and centres, where they hope to temporarily move until conflict is over and they can return. But such moment can take several years and sometimes it may never arrive at all.

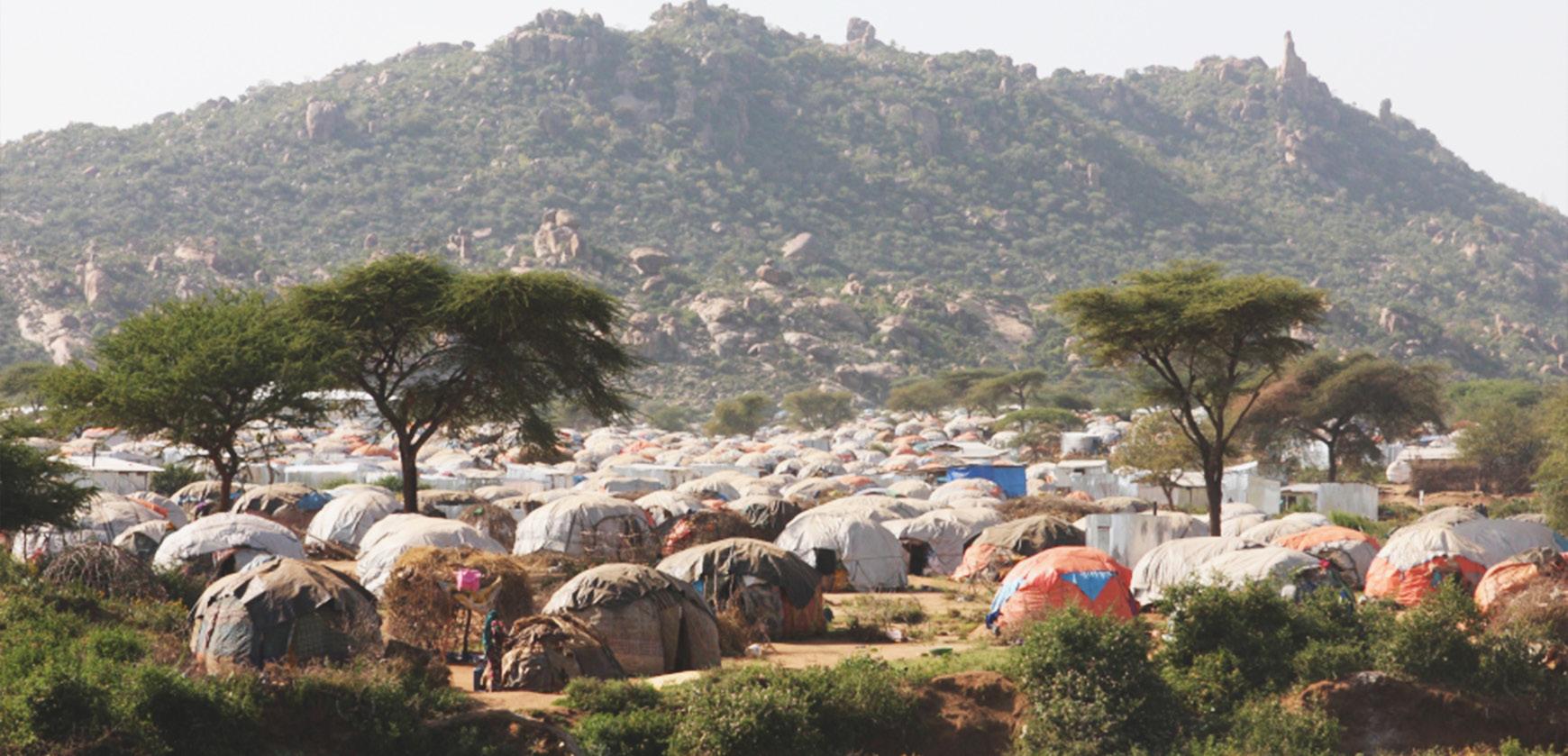

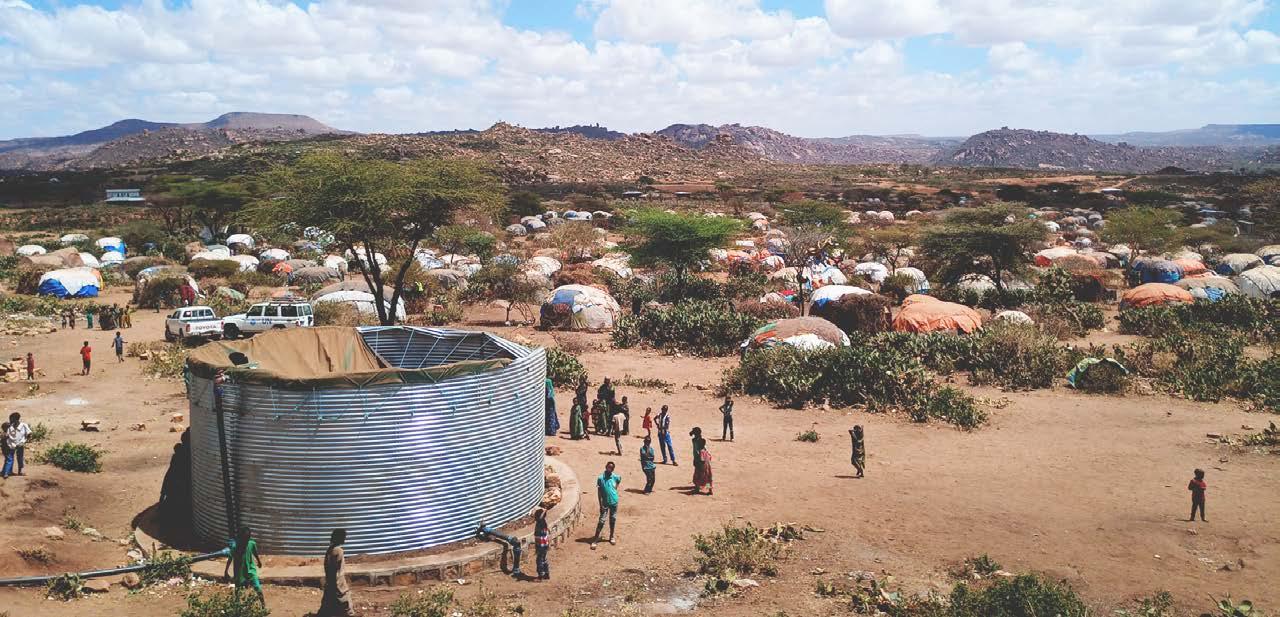

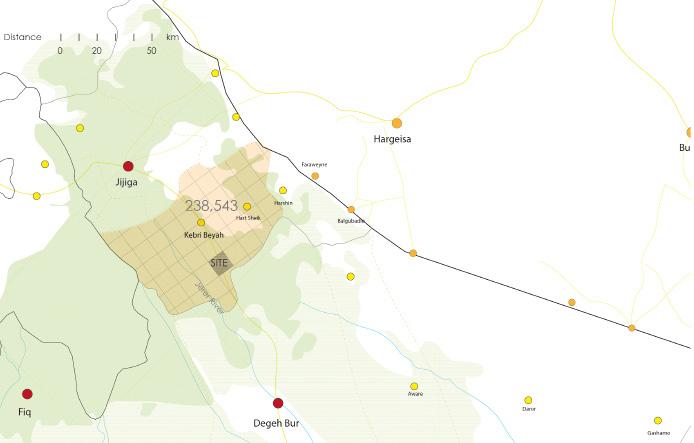

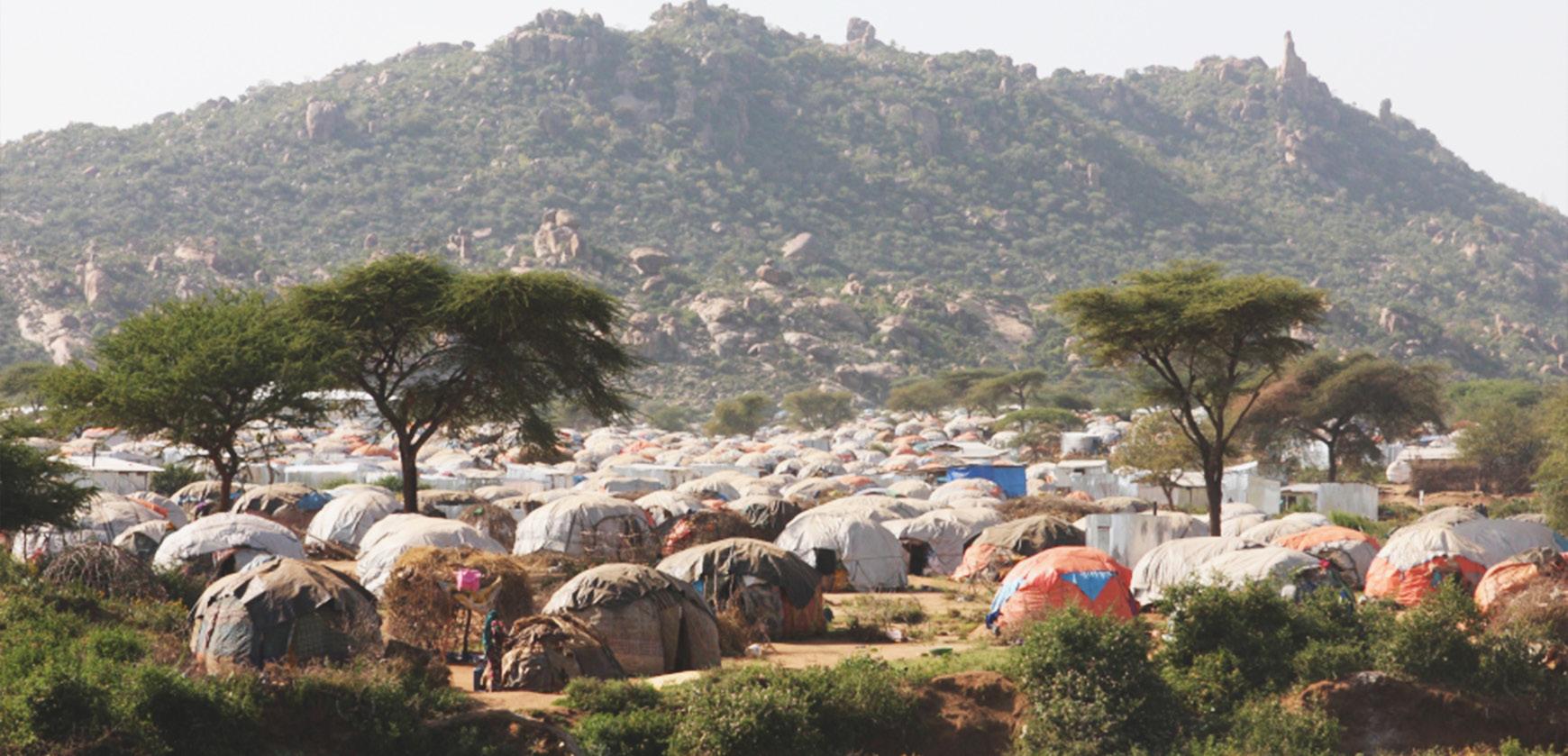

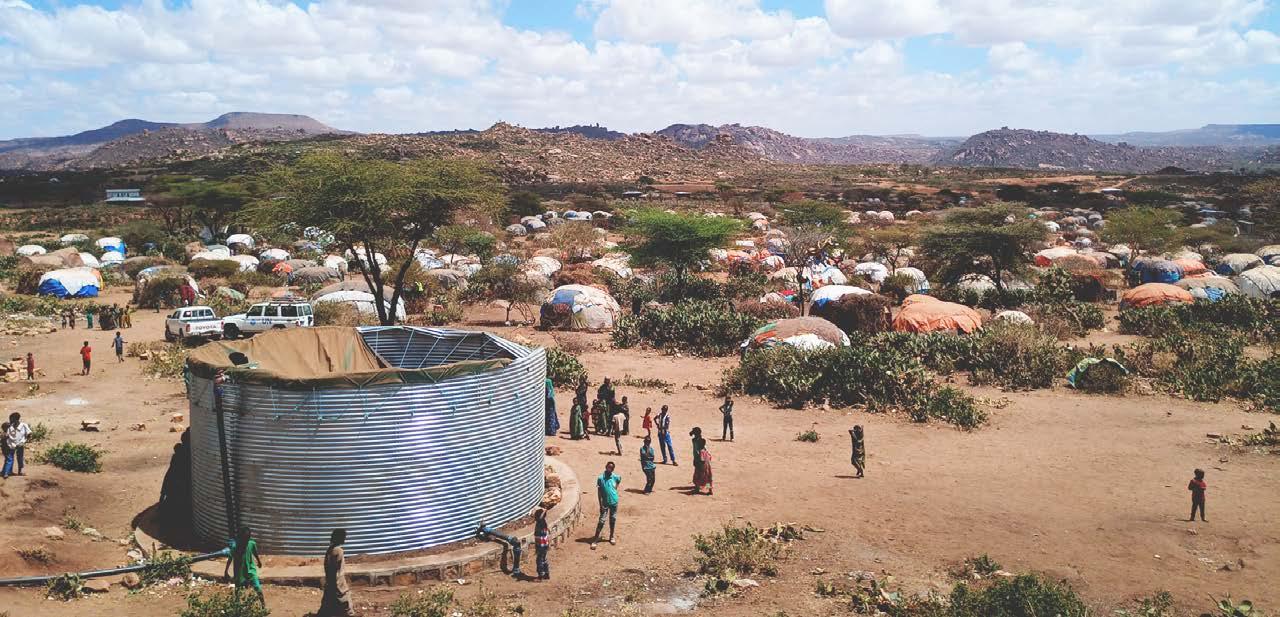

The Somali Region of Ethiopia clearly shows how these mobility patterns are affecting the landscape. A number of Refugee camps and informal settlements have appeared here, especially in proximity to the Somalian border. They act as a quick response to the current crisis, with different degrees of planning, but there is no long-term idea as to what to do with them. In the meantime, camps such as the one in Kebri-beyah have existed in a very precarious condition for more than 30 years now.

This is why we think the situation should be handled in a more sustainable manner, addressing the humanitarian crisis while also considering the pastoralist lifestyle and the coexistence of all this people within a settlement built using local materials.

52 53 Rural WaterScapes Rural WaterScapes 02 - 4 MOBILITY

2 Domain Mobility 4

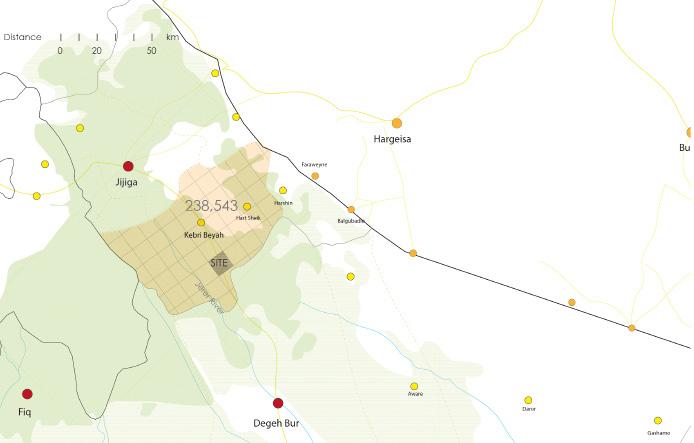

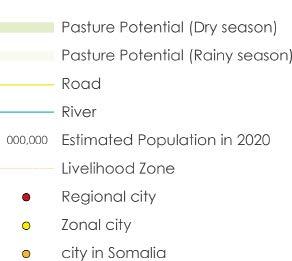

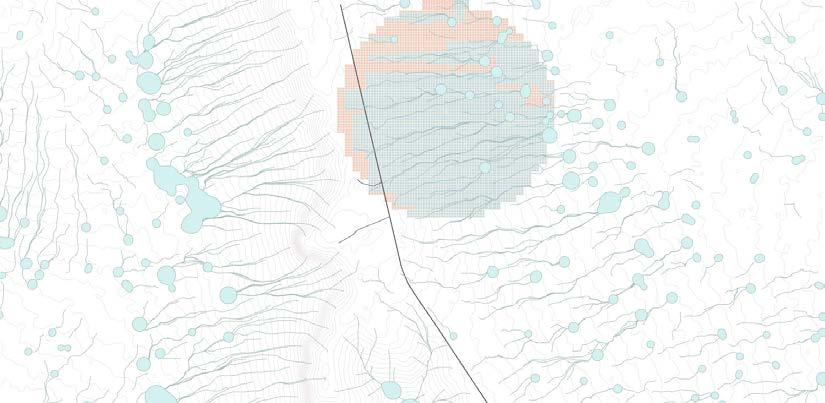

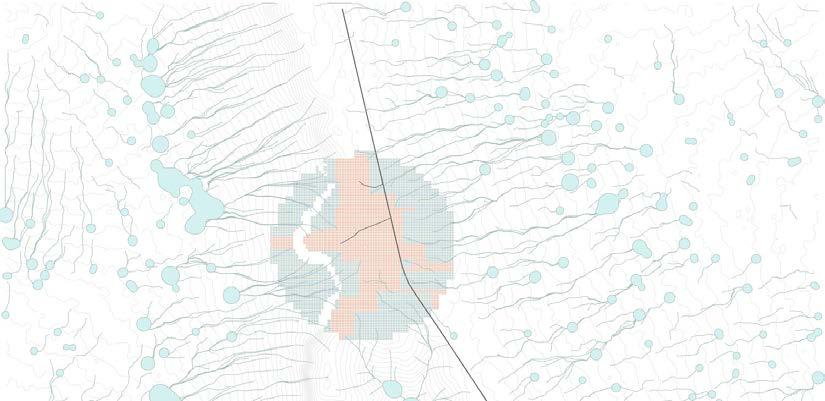

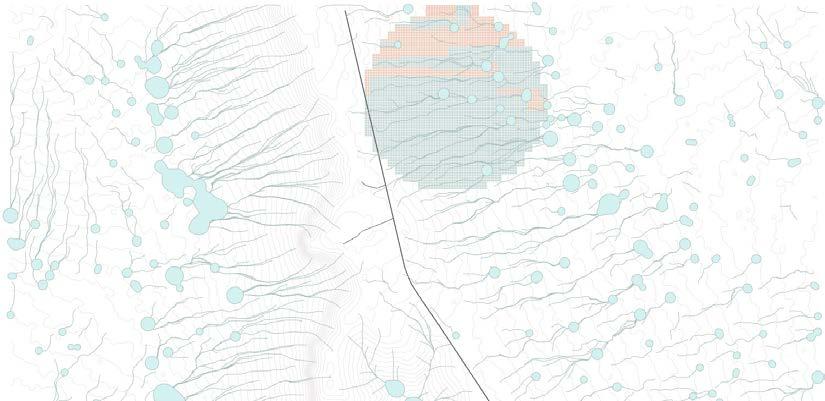

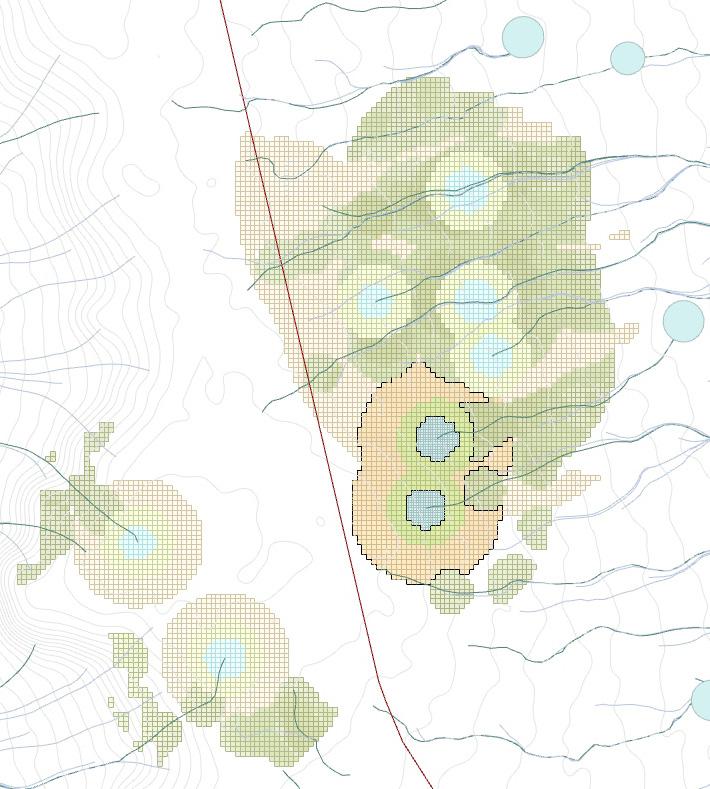

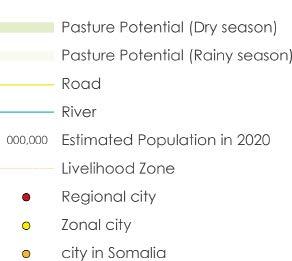

Top Left: Map showing the relationship between our site and the surrounding pasture potential in both dry and rainy seasons

PASTORALISTS Pastoralism is a land use system and a way of life for people who derive most of their income from keeping domestic livestock reared in conditions where most of the feed is natural rather than cultivated.57 Their activities make up an essential contribution to local and national economies and their cultural lifestyle is deriving their mobility. Pastoralists keep moving around their territories and sometimes cross borders to ensure the survival of livestock and sell it in local and foreign markets.

Eastern Africa is home to one of the world’s biggest populations of pastoralists, with an estimated number of around 22 million pastoralists wandering around for more than 3000 years now.58 They depend on clean water and grazing lands to survive in arid and semi-arid biomes, which account for 60 percent of the total area in the Horn of Africa. 59 In the Somali region, around 60% of the rural population are estimated to be pastoral nomads, while another 25% of them are Agro-pastoralists. The number of livestock however varies according to three different wealth conditions.

Climate Change is turning the arid and semi-arid lands they inhabit into deserts, affecting the lifestyle of these pastoralists. Dry seasons are becoming longer and rainy seasons shorter with great floods washing the soil nutrients and making it harder for plants to grow. This is causing the death of livestock due to lack of water and grass, forcing a large proportion of pastoralists to resettle in refugee and IDP camps relying on aids for survival.60

54 55 Rural WaterScapes Rural WaterScapes 2 Domain Mobility 4

02 - 4.1

Estimated Number of rural population (per 100 km2 60 % Pastoralists 25 % Agro - Pastoralists 15 % Sedentary Farmers Total population 3,180 1,325 795 5,300 INDEX

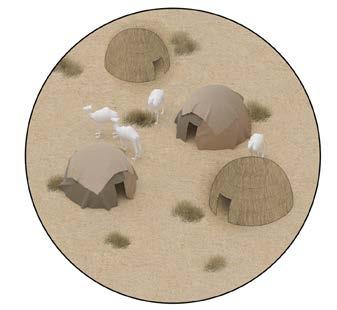

PASTORAL NOMADS

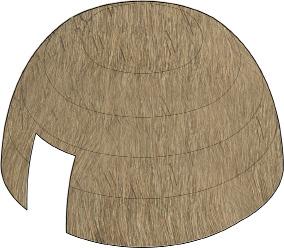

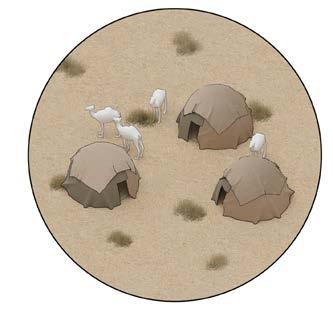

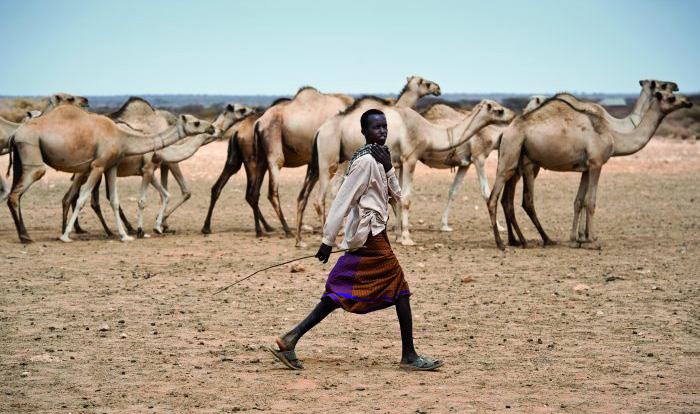

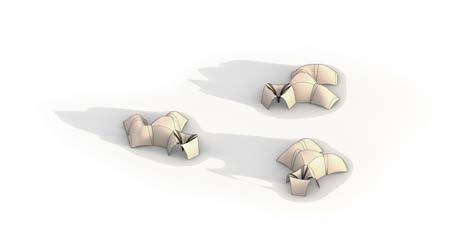

Pastoral nomads move with their herds in irregular patterns following seasonal showers, trying to escape the dry season. They perfected their housing forms for their nomadic way of life in which settlements are demountable making them easy to be assembled and disassembled temporarily throughout their journey. Although the availability of demographic and statistical data on mobile pastoralists is not easy to keep track of, it was clear that the proportion of nomads has declined over the past few decades due to climate change. 61

Housing Typologies and Settlements

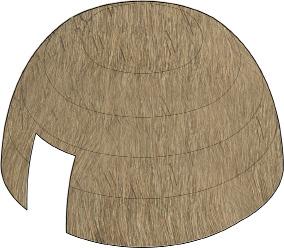

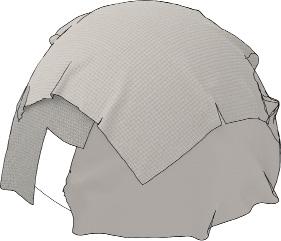

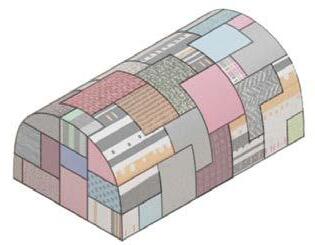

The nomadic shelter in Somali is called Aqal; it represents a simple form of an armature tent optimized for the nomadic life and harsh environmental circumstances.62 It is separated into two areas: one at the back, which holds the sleeping area, and one at the front, which is used as a living area. There might also be an outer uncovered veranda for cooking and gathering activities.

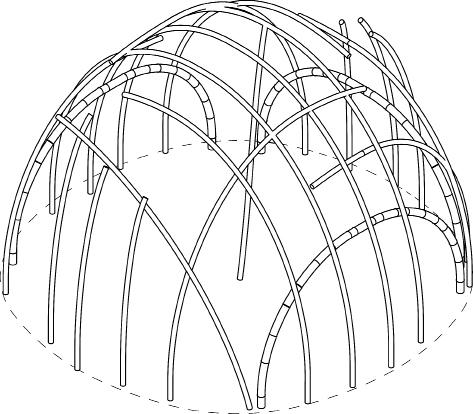

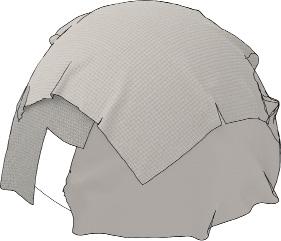

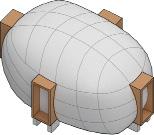

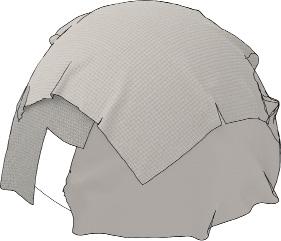

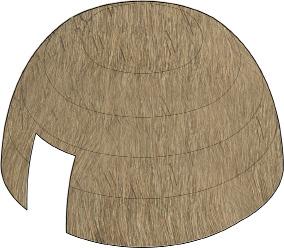

The Aqal is a hemispherical dome, 1.5-2.13 m in height with an elliptic base, constructed of 3 parts: semicircular shaped poles that give it its strength and form, vertical poles for reinforcement, and layers of woven mats for covering and decoration. This portable hut is mainly of female construction as they are responsible of gathering wood, mounting and dismounting the house, carrying it on camel backs and maintaining its components.63

This mobile house takes its shape from the curved poles known as dhigo, which can be divided into two categories. Qabax, the thicker curved poles, are the main structural supports obtained from the acacia tree roots and expected to last from ten to twenty years. It is worth mentioning that nomads never touch the trunk or the foundation root as its removal would destroy the tree itself, but they use instead its lesser roots of 12 meters. Lool are the thinner curved poles made from flexible reed-like rods that help implement the shape and hold the coverings in place. The second vital component is the tall vertical poles (udubs) which are used to support the framework of the house and partition it.64

56 57 Rural WaterScapes Rural WaterScapes 2 Domain Mobility 4

3.1.1

02 -

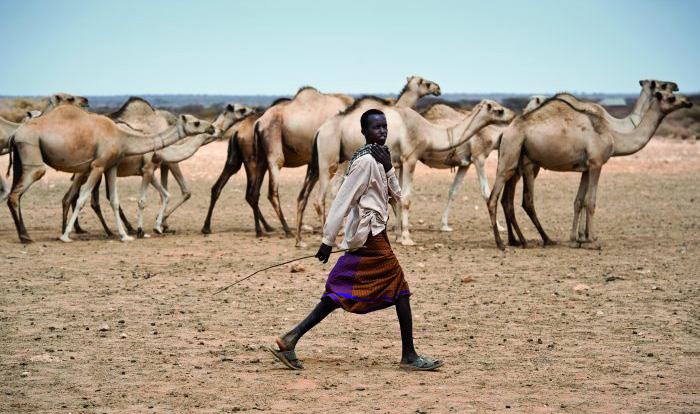

FIG 2 A typical pastoralist herding camels in search of pasture in the Somali region

Structural diagram of the construction of a Somali Aqal

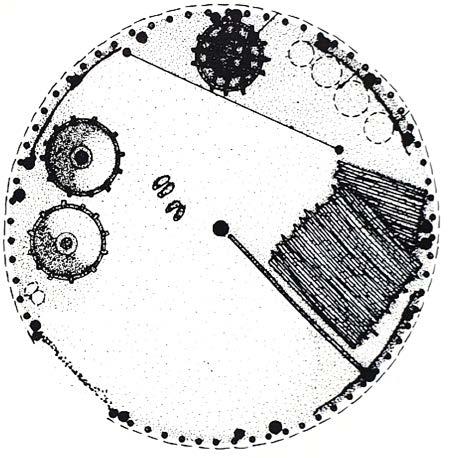

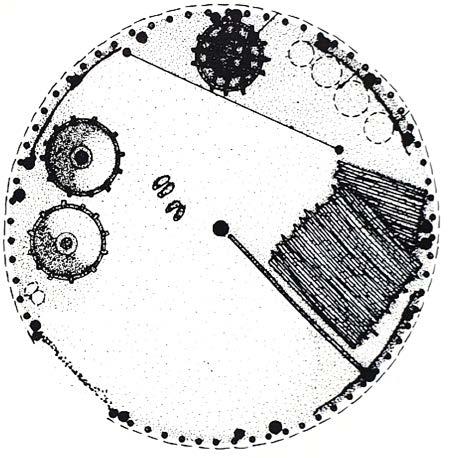

Floor plan showing various mats and storage containers

As Soon As the frame of the house is completed, it is covered usually by animal skin or woven mats made of local grass; These mats are handmade for which specific types of grass are gathered from woodland after days of scouting. When the grass is collected, it is assembled and interlaced, and followingly a single long sheet of mat is made. Hundreds of single plaits are then interweaved to form a large mat covering the hut.65 Once finished, the huts are fastened to the ground diagonally and horizontally not to be blown away by storms. During rainy seasons waterproof plastic sheets called shiraac are used to protect the huts on top of the mats.66

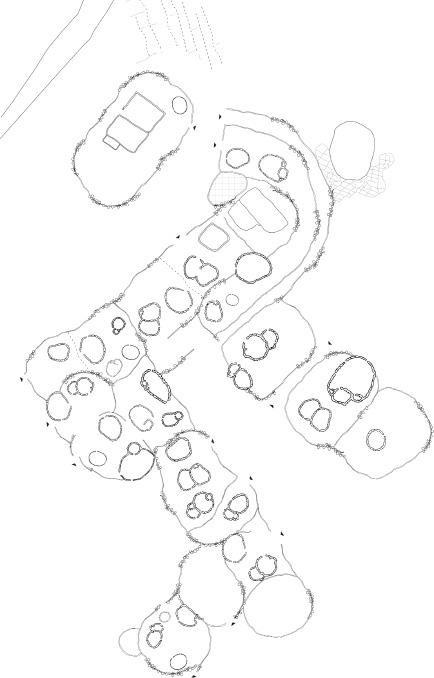

A Somali nomadic moving camp consists of an average of 20 huts in which each group of huts is surrounded by a hedge for the protection of both residents and livestock from predators. The structural framework, the mat cover and the entire household items of the mobile hut are tied to the back of a camel and taken along when moving to new pastures.

ae animal enclosures ae

ae

Limitations ae n 50 20m

Schemtaic of a typical moving pastoralist nomads camp with tree branches separating the different families.

58 59 Rural WaterScapes Rural WaterScapes 2 Domain Mobility 4

FIG 5 Left the initial phase of the interweaving process of a nomadic grass mat done by a somali nomad

FIG 5 Right A mobile nomadic hut (Aqal) after assembling the different grass mats near Kebri-Beyah

While the domed Aqal has a stiff and aerodynamic shape which withstands the strong desert storms, it is only of restricted suitability for long-lasting settlements. It is limited in size due to its structural grid and cannot satisfy the rising demand for larger living spaces and the development of new building types (schools, shops etc.) which require extended structures. Moreover, the construction materials are not suitable for building large scale settlements as they depend on the acacia roots which can be hardly available in large quantities with the desired specifications. animal enclosures naabo of stones

Temporary Shelter

Construction Time: 1 day

Dwellers: 2-3 people

Duration: Months

Two neighbouing permanent and temporary shelters owned by a transhumant pastoralist family in Afar region near Somali

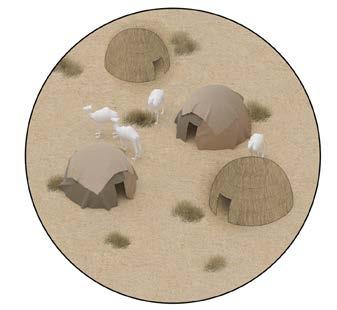

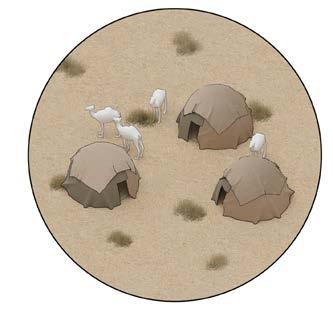

TRANSHUMANT PASTORALISTS

Transhumant Pastoralists move seasonally, aiming to guarantee their livestock’s survival during the dry season by moving to higher lands. They are part of an agricultural system that combines permanent arable agriculture with cyclical movement of livestock; 67 If a village has no access to nearby pastures, part of the camp organizes transhumance to a distant place where forage and water can be found for their livestock. On the other hand, the other part stays permanently with a small number of animals providing their daily feed. These permanent settlers are responsible for cultivating the land.

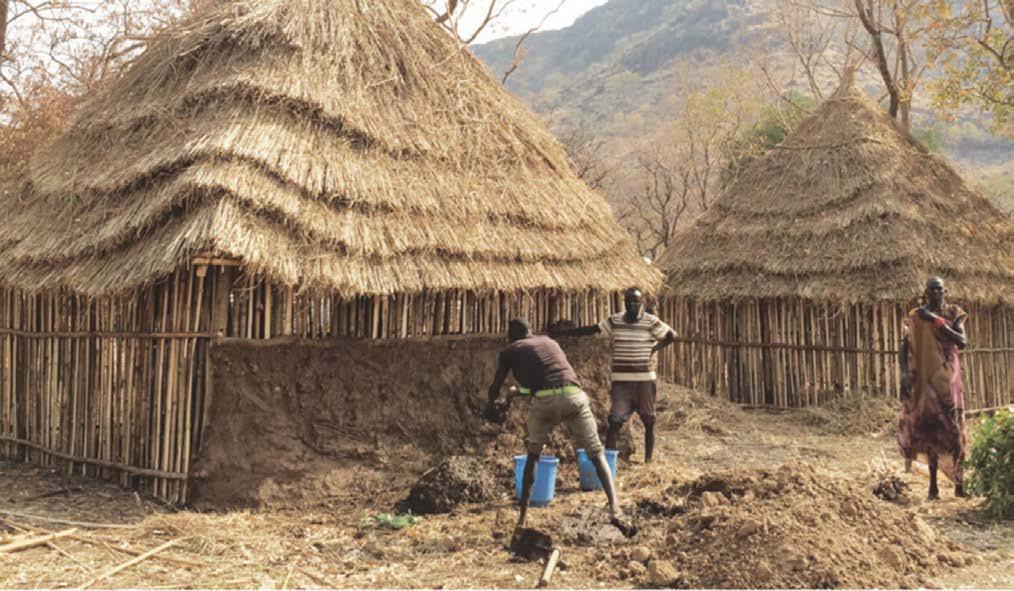

Transhumant pastoralist settlements are a combination of coexisting temporary and permanent structures accommodating the two described different lifestyles.

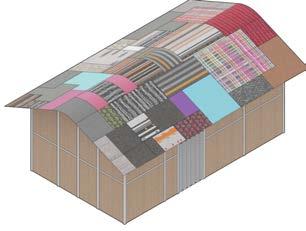

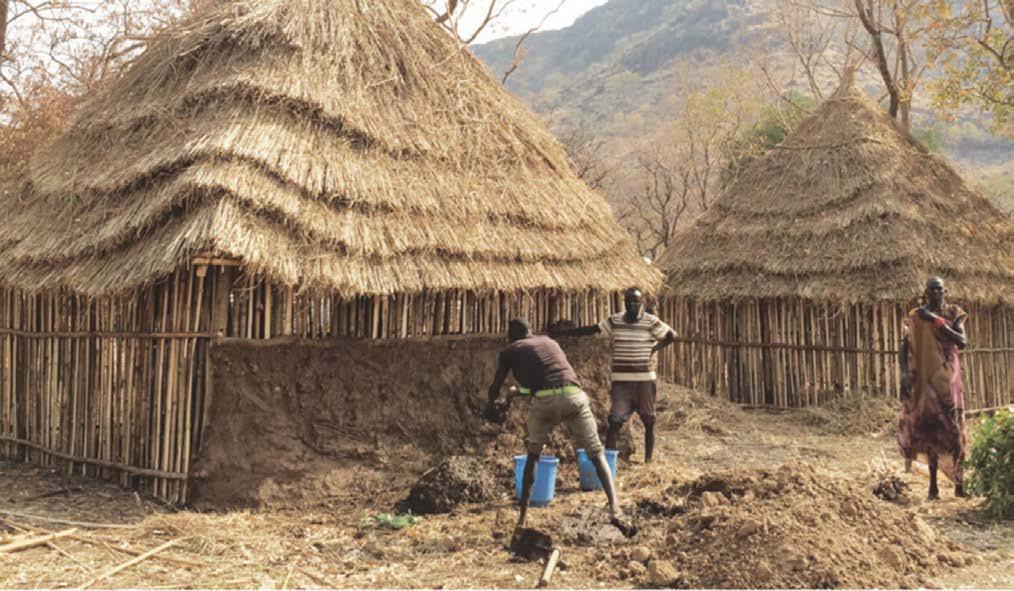

Housing Typologies and Settlements

Along with the previously described Aqal shelter used for the temporary housing of pastoralists, a new type of a permanent dwelling is developed in the Transhumant settlement adapting to different conditions; This house is constructed with a similar structure to this found in the Aqal, but it has a different covering approach mainly consisting of several layers of grass.

M2 M2

Area: 5 m2

Coverings: Grass mat

Permanent Shelter

Construction Time: 2-5 days

Dwellers: 2-5 people

Duration: Years

Area: 5-8 m2

Coverings: Grass bundles

Compared to the mobile Aqal, the poles of the primary structure of theses permanent dwellings are denser, arranged more irregularly and less systematically; They are also dug deeper into the ground, resulting more stable structures. While the thatched structures remain in the settlement, the mobile mat huts are taken along when moving to new grazing grounds.68

60 61 Rural WaterScapes Rural WaterScapes

02 - 4.1.2

2 Domain Mobility 4

FIG 6 A transhumant pastoralist camp with multiple family clusters comprising of both permanent and temporary structures

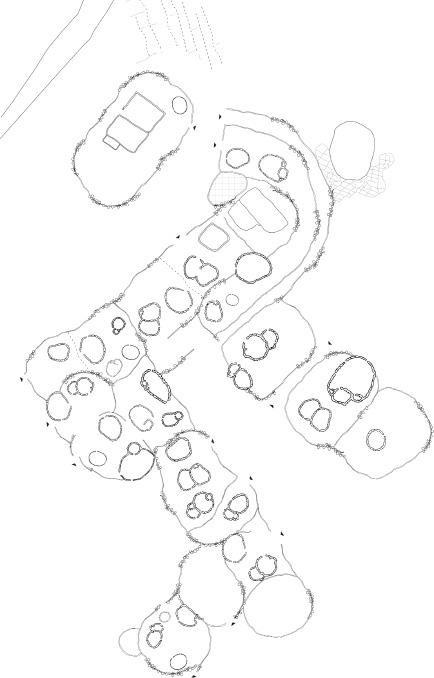

Floor plan for a transhumant pastoralist camp near Somali Region with different animal enclosures and one open tank for water storage

At a settlement scale, the property of one household consists of a fenced area with several huts and animal enclosures. The fencing strengthens the ownership of the structures; Moreover, it protects the inhabitants and their animals. The cattle enclosures on the other hand consist of simple fences made of branches. Their construction is very similar to that of the Aqal with straight rods open at the top rather than bent poles. This social unit is integrated with other units comprising a settlement of the extended family which includes up to sixty households.69

Limitations

Although the new shelter is providing a sense of permanence to the settlement, its material represented in grass needs to be constantly renewed when mobile pastoralists return. Moreover, the interior of these dwelling is of a poor quality as using bundles of grass makes it hard to have ventilated openings; additionally, it attracts different desert insects.

62 63 Rural WaterScapes Rural WaterScapes

2 Domain Mobility 4

Water Storage

INTERNALLY DISLACED PERSONS (IDPs)

02 - 4.2

According to the Displacement Tracking Matrix (DTM) conducted by the International Organization for Migration (IOM) in Somali region and published in August 2019, more than a million displaced individuals comprising around 175 thousand households are identified in around 400 displacement sites in the Somali region70; Most of whom are originally pastoralists. over 25% of these households are living in shelters below regional and cultural standards and 2550% in 56 sites are living in overcrowded shelters. Moreover, the shelters of 51-75% of IDPs are fully destroyed in their place of origin.71

While a percentage of these displacements are conflict-induced related to competition for land and resources, the vast majority is climate-induced mainly caused by the prolonged droughts Eastern Ethiopia has been facing since 2015 which forced people to flee their original habitat and settle elsewhere.

Once people are displaced, they are temporarily housed in different settlement options including host families, rural self-settlements, self-settled camps, and planned camps. Their shelters are often built informally near their places of origin in self-settlements, and at times they receive emergency shelters from international organizations in planned camps. IOM has been managing and monitoring planned camps by doing a bimonthly site assessment and generating a DTM to evaluate conditions and needs in Camps.

We focused on IDP camps within Fafan zone as it is our potential area of intervention and especially Kebri-Beyah Region. “Iswad Camp” is where most IDPs live in the region; their number has been slightly fluctuating since 2017, when DTM reports started, with a fixed number of 1,374 households 72(Fig.1).

64 65 Rural WaterScapes Rural WaterScapes

FIG 7 (Top Left) Damaged water tank in an internally displaced persons site in the Fafan zone. Photo taken by IOM officials

2000 0 4000 6000 8000 10,000 IDPs Feb-17 Jun-17 Oct-17 Feb-18 Jun-18 Oct-18 Feb-19 Jun-19 Oct-19 Feb-20 2 Domain Mobility 4

FIG 10 (Bottom Left) Iswad IDPs camp in Fafan zone with several plastic and cloth temporary shelters. Photo taken by IOM officials

Tybe A Specificstions

Construction Time: 1-7 days

Dwellers: 5-6 people

Duration: 6-9 months

An internally displaced person in front of his worn out shelter in a photo illustrating the general bad living conditions of IDPs in the Somali Region.

Photo taken by UNHCR officials

02 - 4.2.1

ISWAD CAMP IDP households are mainly pastoralists out of which only 12% still own livestock; They collect an average of two 20-litre water jerrycans/buckets per day and their latrines are mostly non-functioning. The main water distribution point is on-site and within a 30-minute walk for a one-way journey. Once at the water distribution point, they queue for an average of 16-30 minutes for drinking water, which they complain to be of a bad quality.73

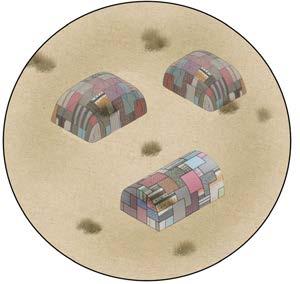

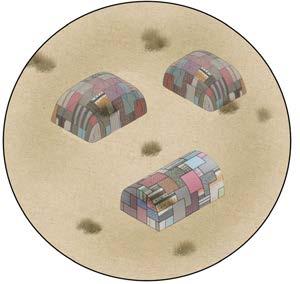

Housing Typologies and Settlements

IDP shelters are inspired by the nomadic hut ‘Aqal’ as they have a similar dome shape in addition to some elongated hemispherical forms. Their makeshift shelters are of a poor quality built of locally available thin wooden poles, tree branches, reeds, and twigs tied together with ropes forming the skeleton of the shelter.74 The wooden formwork is then covered with cloth, plastics (by IOM) and sometimes with animal skin. The area of these shelters is usually around 12 m2 accommodating 5-6 people. Small fences made of bush branches are sometimes built around shelters for privacy and security purposes.

M2 M2

Area: 12 m2

Coverings: CGI- cloth- Plastics

Tybe B Specifications

Construction Time: 1-7 days

Dwellers: 5-7 people

Duration: 6-9 months

Area: 15 m2

Coverings: CGI- cloth- Plastics

Limitations

IDP shelters are not durable as they last about six to nine months, and after that, they become damaged and unusable. Additionally, the option for expanding is very limited, which does not adapt to the changing configuration of a household overtime and its needs to reorganize its living space. In Conclusion, these dwellings are built to be temporary, but they are not; they stay in use for years and even decades.

66 67 Rural WaterScapes Rural WaterScapes

2 Domain Mobility 4

A schematic diagram of a typical IDPs camp in Ethiopia showing the different overcrowded housing enclosures.

REFUGEES The Refugee situation is another face of displacement that Ethiopia, especially the Somali region, has been facing for decades. According to the UNHCR refugee operational portal, the Somali region is currently hosting about 200 thousand refugees originally from Somaliland in 8 different sites75; Most of whom have fled civil war in their home country seeking protection and aid in Ethiopia. Though repatriation initiatives were taken to return these people back to their homes, none were of a total success. Coming back to their countries, these refugees find themselves in a desperate situation in which armed conflict restricts opportunities, drought severely affects livelihoods and aid is the only reliance for survival.76

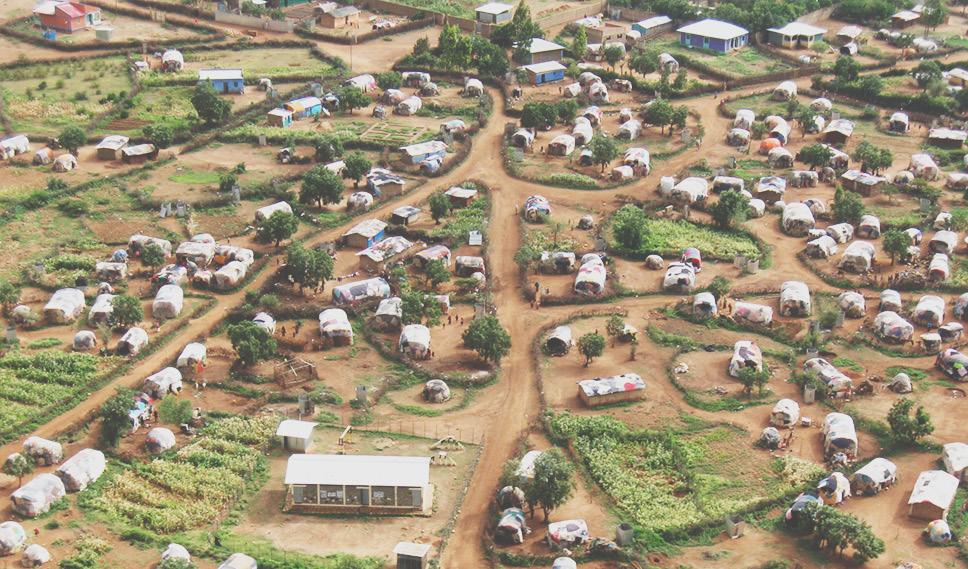

Kebri-Beyah region has been the site of a refugee camp since 1991 as it lies only 70 km away from the borders. The camp originally housed about 10,000 refugees and returnees from Somaliland77 and it was the only camp to remain open while UNHCR managed to close down other camps in the region between 1997 and 2005; This is related to the influx of more refugees from south-central Somalia escaping the lethal combination of conflict and drought. Currently, the camp occupies an area of around 1.55 km2, and it houses around 14,600 refugees.78This number has been changing over the past years due to the growth of Somali refugees and the relocation of some to either nearby camps in the region79, or to the USA.80

68 69 Rural WaterScapes Rural WaterScapes

FIG 21 (Bottom Right) A Somali refugee family in front of their new transitinal shelter provided by IOM

02 - 4.3

FIG 20 (Top Left)

Refugees 2013 2014 2015 2016 2017 2018 2019 2020 2 Domain Mobility 4

A Somali refugee sitting infront of her shelter that is covered in blankets in Kebri-Beyah refugee camp. This photo was shared by the UNHCR.

14,000 12,000 16,000 18,000

KEBRIBEYAH CAMP

Kebri-Beyah camp refugees are mainly rural pastoralists who faced similar circumstances in their home country as IDPS causing them to abandon their background and work mainly in either farming or smallscale trading in different shops scattered around the camp. They rely on poor water facilities as the whole camp is provided by only 33 water taps; out of which 5 are only operating. Thus, they resort to harvesting rainwater in self-built rain collectors and storing it in big tanks, which leads to weak hygiene conditions. Moreover, latrines and showers are public and shared between several households; They are mostly defective, of a bad condition and not sufficient for their number.81

Housing Typologies and Settlements

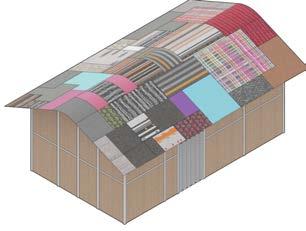

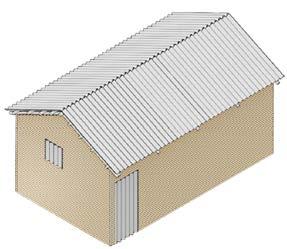

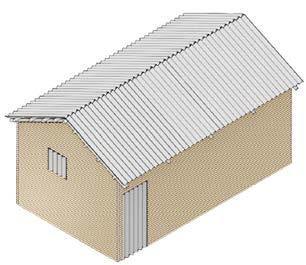

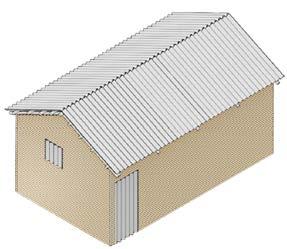

Refugees live in shelters similar to those of IDPs mainly made of poor-quality locally sourced wood branches covered with fabric and corrugated iron. Occasionally UNHCR provides refugees with more formal shelter solutions known as the transitional shelter; its design consists of a wooden wattle support structure, bamboo slices walling as plaster, and a roof covered by either durable corrugated iron (CGI) or fabrics. These shelters can be constructed in one week and they have an area of 21 m² that can house 3-4 people.

Transitional Shelter

Construction Time: 7 days

Dwellers: 3-6 people

Duration: 2-4 Years

Area: 21 m2 M2

Coverings: Bamboo- CGI/ Cloth

Limitations

In addition to the limitations described for the IDP shelters, the transitional shelter provided by the UNHCR is no satisfactory alternative. Not only does it require significantly larger quantities of wood for construction (one to two trees per m2), but also bamboo cannot be sourced locally in this region and it must be transported from further locations. In addition to that, it uses CGI which is not a sustainable solution due to long distance transports, high cost and low quality of processing.

70 71 Rural WaterScapes Rural WaterScapes

02 - 4.3.1

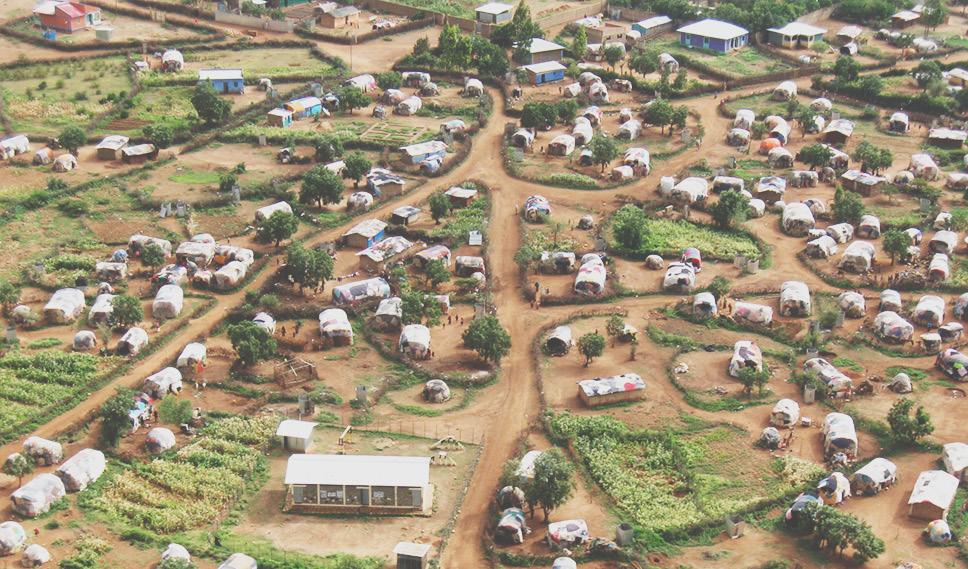

FIG 22 An aerial view of Kebri-Beyah camp showing the poor shelters people are inhabiting and the different facility buildings made out of clay, conctete and CGI roofs.(Google Earth Images)

2 Domain Mobility 4

Water Distribution Points: 33 operating only Rainwater collection (self-built): Water storage tanks:

Kebri-Beyah camp site map showing the distribution of main water points provided for refugees and the different self-built rainwater collectores and water storage tanks

Latrine: 1009, Public- Mostly defective (One Latrine for 9 shelters)

Showers: 321,Public- Mostly defective (One Shower for 23 shelters)

Sanitation facilities are mapped on the site to show its distribution and the hygiene conditions

72 Rural WaterScapes Rural WaterScapes

FIG 23 An aerial view of Kebri-Beyah camp showing an empty water storage tank and the different farming plots cultivated by the refugees( Google Earth Images)

2 Domain Mobility 4

Internally Displaced Persons

Pastoral Nomads Shelter

Adaptiveness

Quality

Duration

Sustainability

Transhumant Pastoralists Shelter

Adaptiveness

Quality

Duration

Sustainability

IDPs Shelter

Adaptability

Quality

02 - 3.4

CONCLUSION By Investigating the situation of the vulnerable groups in the Somali Region, especially the Fafan zone, and having a closer look into their living conditions and humanitarian needs, we were driven towards adopting a strategy that can host these exposed groups of people in a hybrid settlement system where inhabitants can be gradually relocated from the IDP and refugee camps existing in the region, in order to offer them humane more stable conditions. In addition, the proposed settlement can temporarily house the severely climate affected pastoral nomads and transhumant pastoralist during the dry season to ensure their survival along with their livestock.

The design of the new dwellings is to be abstracted from the traditional building practices which were clearly suitable for a temporary lifestyle with the potential to transform into long-lasting ones when needed. Furthermore, available natural materials are to be further investigated allowing for an implementation of a self-sufficient system for a rural settlement.

Finally, consideration of the previously explained limitations exerted by the different settlement types is to be thoroughly taken into the design.

Duration

Sustainability

Refugees Shelter

Adaptiveness

Quality

Duration

Sustainability

74 75 Rural WaterScapes Rural WaterScapes

Pastoral Nomads

Transhumant Pastoralists

Refugees

2 Domain Mobility 4

40 Refugees plastering the walls of a transitional shelter with mud, made from soil, sourced by the refugees themselves in areas agreed with authorities and host communities in southern Ethiopia. Photo tshared by UNHCR officials.

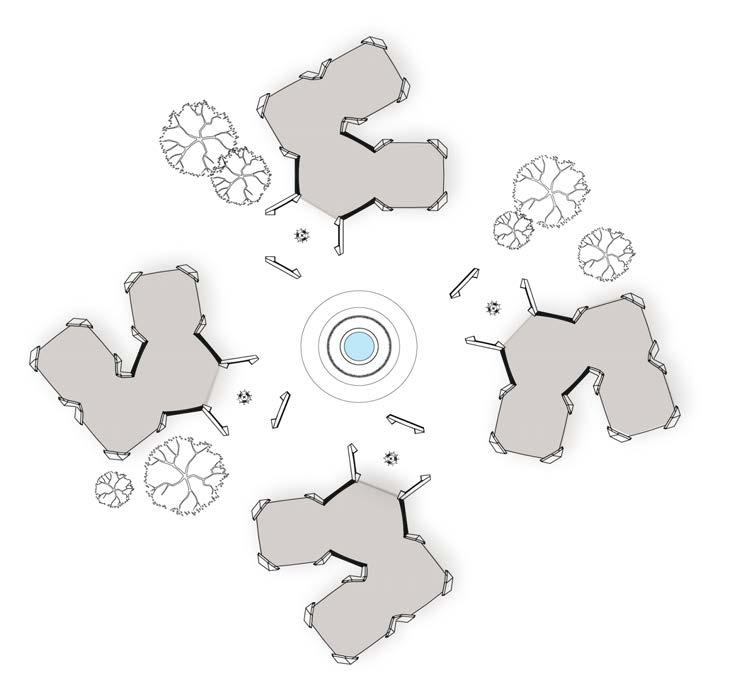

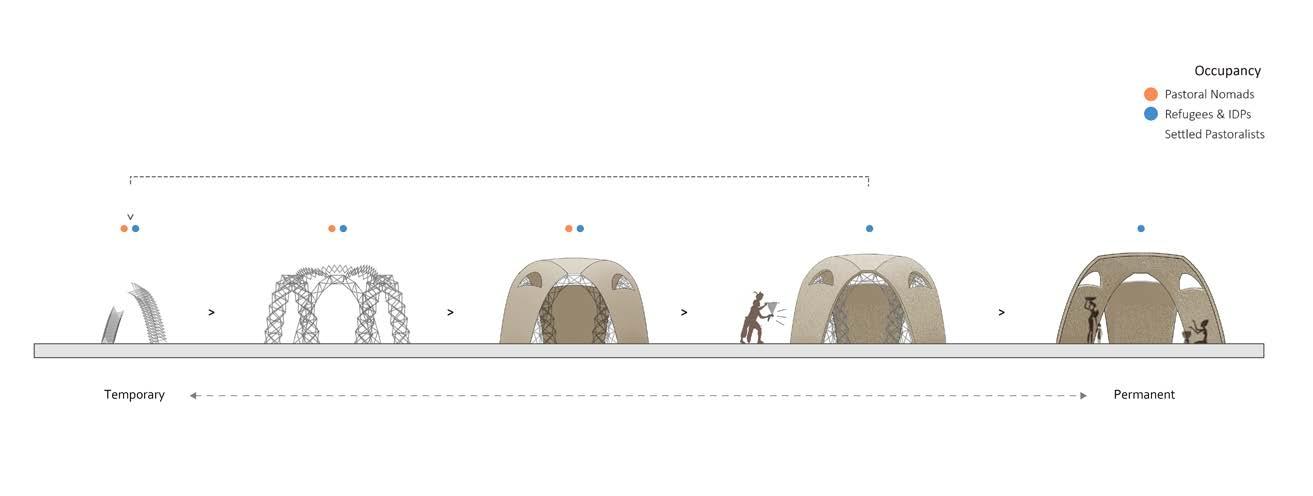

TEMPORARY TO PERMANENT Towards A Hybrid Logic

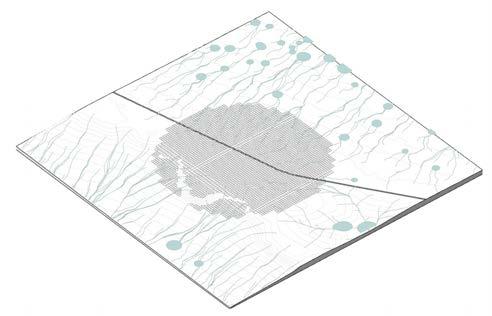

To design a settlement strategy that can fit the varying vulnerable groups in the Somali region, we must consider the patterns in their population change along with their preferences and the projected future changes to their situation.

The number of internally displaced persons has been increasing throughout the past years and is expected to continue rising within the next years with subsequent growth in emergency shelter needs.83 At the same time, 90% of the IDPs already existing in the Somali region prefer local integration as a more durable solution to permanently settle within local communities.84

Also, by analysing the situation in Kebri-Beyah refugee camp and its increasing inhabitants, it was found that 56.8 % of the population is under the age of 18 85, meaning that more than half of the residents were born in the camp and have lived there all their lives; Furthermore, it is unexpected for them to return to their country anytime soon due to the ongoing political and climate issues; These refugees end up living most of their life in a camp with poor shelters meant to be used for only a few months and don’t have the qualities for permanent usage.

Here to say, the Somali pastoralist situation is no different from either IDPs or refugees in terms of vulnerability and the need for a proper shelter where they could settle down if contextual circumstances forced them to. While a proportion of them are ending up in IDP and refugee camps due to the changing environmental and economic conditions, more and more are getting settled down along the trading routes; This is causing new settlements to emerge where pastoralists are turning into permanent Agropastoralist settlers.86 The dominant construction method of the newly settlements is the so-called chikka (wattle and daub) which is built out of timber pole walls plastered with clay and thatched roofs 87; This technique is considered a highly unsustainable building technology especially in such arid region with scarce vegetation where every tree is extremely valuable, and yet trees are being uprooted on a big scale.

All of that together has encouraged us to propose a settlement strategy with architecture adapting to the emergent and changing living conditions. Our aim is to provide a framework for the design of a transitional shelter that can work as an emergency housing solution once newly displaced persons arrive, and would also have the ability to transform into a permanent one after a certain amount of time has passed. This design is also intended to help pastoralists maintain their cultural lifestyle by hosting them temporarily during harsh seasons, and finally offering them an alternative sustainable solution if they decided to permanently settle down, one that adapts with their former lifestyle and more importantly, with their ecological environment. For that, we are investigating locally available materials and different emergency solutions that can both fit the local lifestyles and have the potential transform into permanent dwellings.

76 77 Rural WaterScapes Rural WaterScapes 02

- 5 FROM

FIG

2 Domain From Temporary to Permanent 5

FIG 20 an Aerial view of the land surrounding our propsed site showing soil texture and the scattered vegetation available in the area. (Google Earth Images)

LOCAL MATERIALS

02 - 5.1

Earth

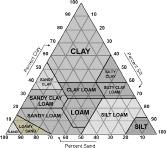

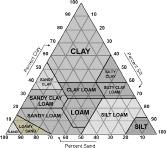

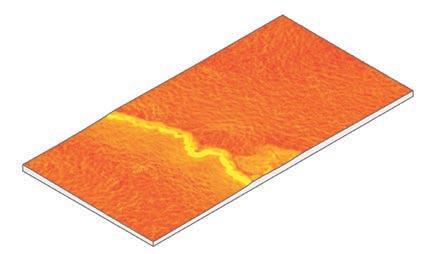

Earth is the only building material sufficiently available directly in the Somali region with varying soil types and textures. According to the soil geo-database of Ethiopia presented by (Berhanu et al), the soil type of our site is called Petric Calcisols, and the textural class is Loamy Sand.88 This soil type consists of a 1 meter thickness of Loamy sand which has a 70-90 percentage of sand, 10-15% clay and a remainder percentage of silt. This layer lies upon a much deeper layer of indurated or cemented layer of sandstone.89

The soil textural classification triangle shown illustrates precisely where our soil class stands amongst all earthern soils.

Somalis depend mainly on wood for construction in their different housing typologies. However, the supply of wood for building is running short and good quality timber is becoming scarce due to deforestation.90 Interestingly, Somali pastoralist nomads use wood in a very sustainable way as only branches or roots that quickly regrow are used for construction, thus the tree itself is not harmed. On the other hand, agro-pastoralists use trunks of trees in unsustainable manners.91

To further define the local tree species used around our area of intervention, it was important to understand the vegetation classification type of our site. According to the atlas of vegetation in Ethiopia presented by (Friis et al), it was found that our site lies within the Acacia-Commiphora woodland and bushland proper type.92 This class is known for its drought-resistant trees and shrubs where the most common trees used for construction are Acacia trees.93

Based on H.N. Le Houerou’s research on browse plants of Ethiopia, specifically in the Fafan region, it was concluded that the most common species, used by pastoralist and Agro-pastoralists, available around our site are by order: Acacia nolitica, Acacia tortilis, Acacia bussei, Ziziphus muritania, Acacias grow slowly with a final height of 3 to 5 m, and a spread of 8-13 m. Their branches range between 10 mm and 40 mm2 in thickness with varying length ranging from 20 to just over 150 cm.

78 79 Rural WaterScapes Rural WaterScapes

2 Domain From Temporary to Permanent 5

Wood

FIG 50 Acacia nolitica tree in the semi dry region of Ethiopia surrounded by short shrubs (Google Earth Images)

Loamy Sand

Sand Stone

Acacia nolitica

Acacia tortilis

Acacia bussei

The specific use of these trees was further detailed by Prussin94, where he illustrated the following:

Acacia nilotica: branches used for tent pickets and lateral bars; roots are used as thick curved poles.

Acacia tortilis: roots and bark are made into rope; roots are also used as house poles.

Acacia bussei: roots are used for bent armatures; bark is braided into ropes.

Ziziphus Muritania: branches are used for tent pickets and bent into arches for barrel-vaulted tents

Ziziphus muritania

Andropogon greenwayi

Panicum atrosanguineum

Grass

Grass is abundant in that semi-arid area of somali where the most common species are the Andropogon greenwayi and panicum turgidum 95; these are mainly used in weaving the mats used for tent sidewalls and also, for making ropes.96

80 81 Rural WaterScapes Rural WaterScapes

T r e e s / S h u r b s LOCAL AVAILABILITY G r a s s E a r t h 2 Domain From Temporary to Permanent 5

TRANSITIONAL SHELTERS

02 -

A Transitional shelter is often comparable in quality to that of the emergency shelter; however, its main advantage is that, with affordable upgrades, its quality can be improved. The design of our shelter is intended to reflect on the vernacular construction forms and materials and develop a transformation process informed by the habitual and emergent patterns of action.

Emergency shelters are then explored, assessed, and compared to further develop the concept based on the different results.

Fabrics

Construction time

Local Material Usage

Durability

Transformation

Modularity

Vernacular Adaptation

Deployable Structures

Construction time

Local Material Usage

Durability

Transformation

Modularity

Vernacular Adaptation

Inflatables

Construction time

Local Material Usage

Durability

Transformation

Modularity

Vernacular Adaptation

Kit of Parts

Construction time

Local Material Usage

Durability

Transformation

Modularity

02 -

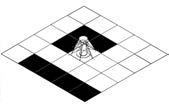

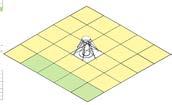

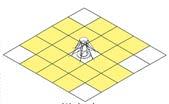

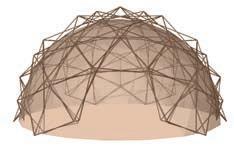

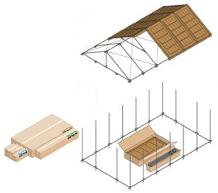

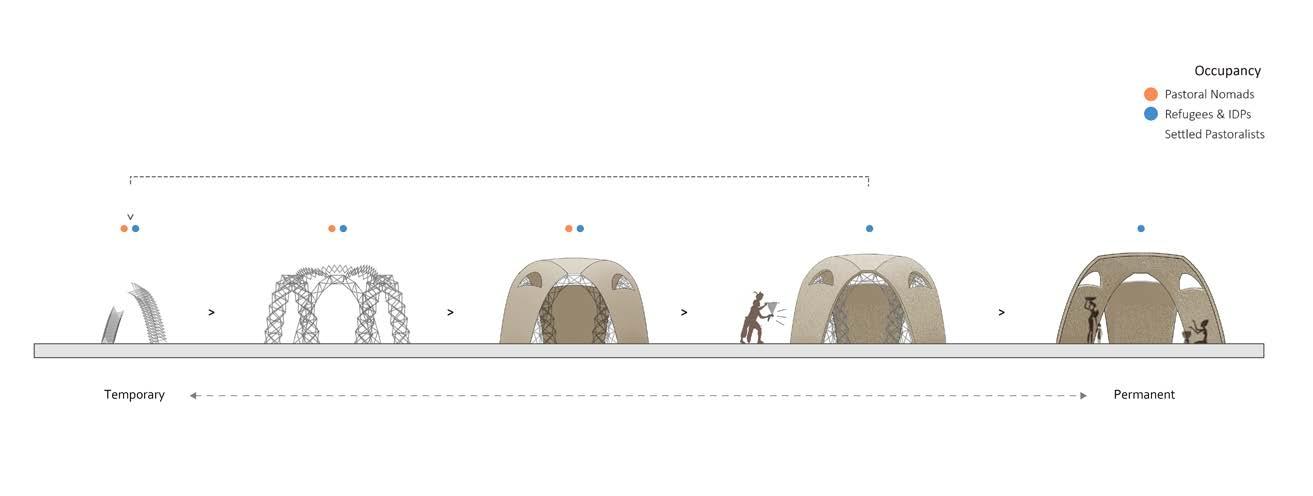

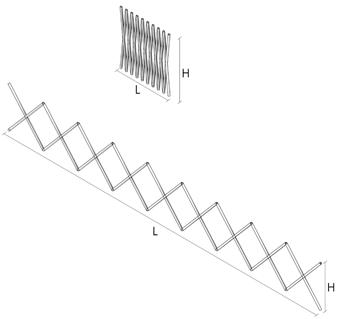

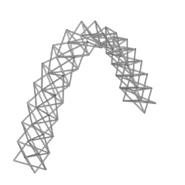

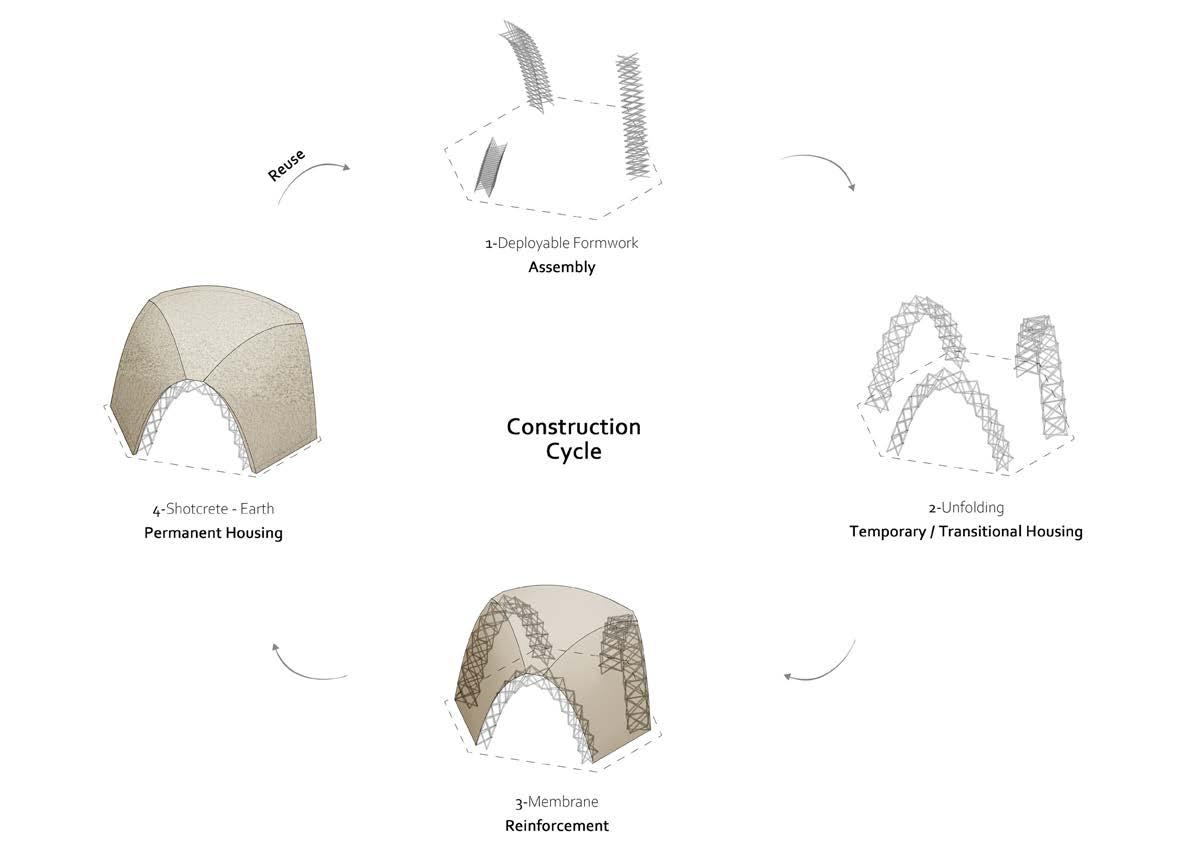

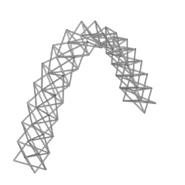

EMERGENCY SHELTERS According to assessment findings, deployable structures have showed the potential to be used for emergency shelters’ purposes. Their main advantage is the ability to be constructed out of small wooden elements that could be easily harvested within the region. Combined with different natural fibres, their ability to adapt and transform could be further enhanced.

Vernacular Adaptation

82 83 Rural WaterScapes Rural WaterScapes

5.2

5.2.1

Low-tech Balloon System UNHCR

Family Tent UNHCR

Refugee Family House, UNHCR

2 Domain From Temporary to Permanent 5

Deployabe Dome, SMIA

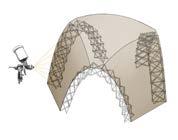

Spraying of concrete (shotcrete) over a mesh formwork in a construction site using a pipe connected to air compressor

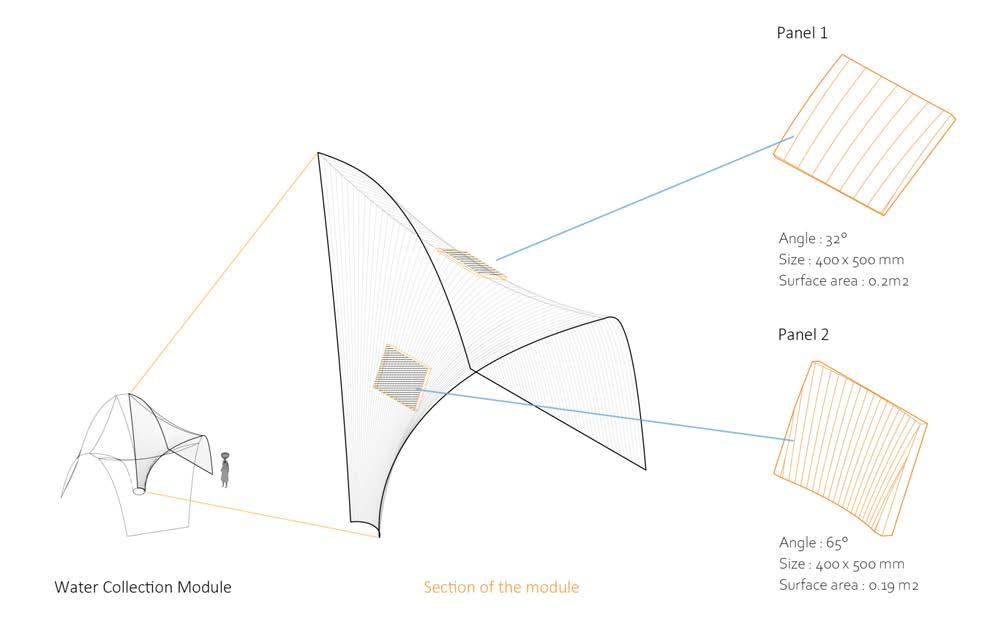

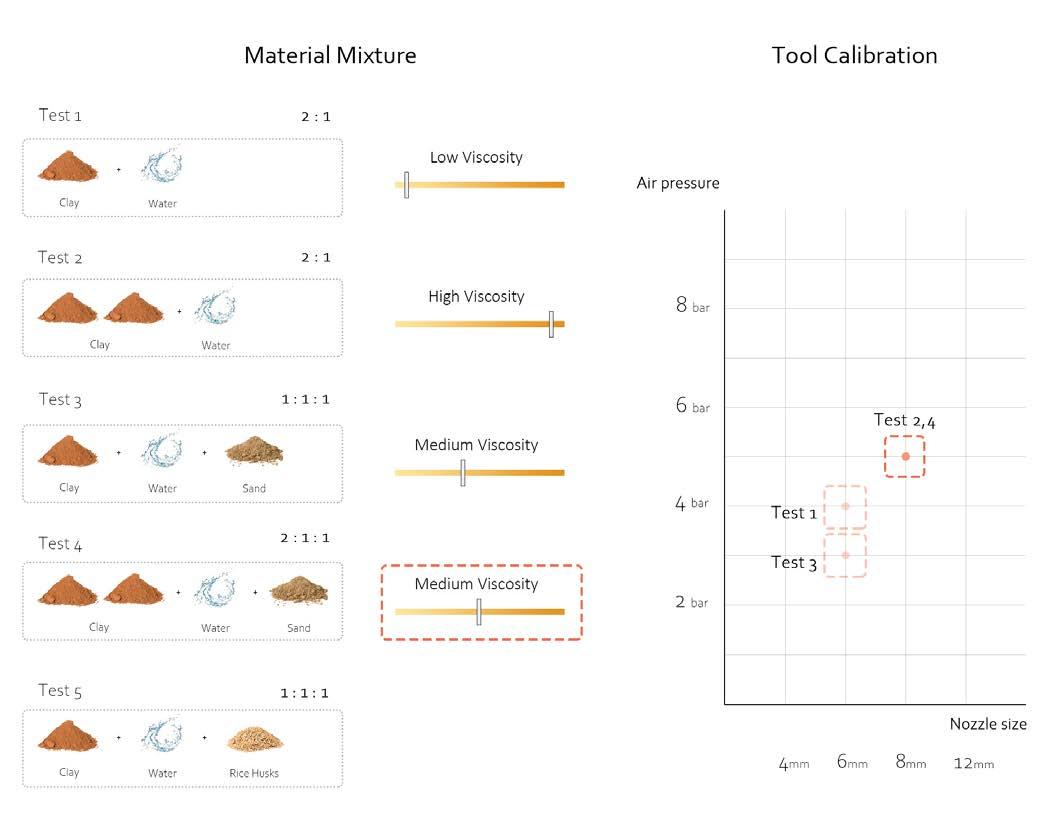

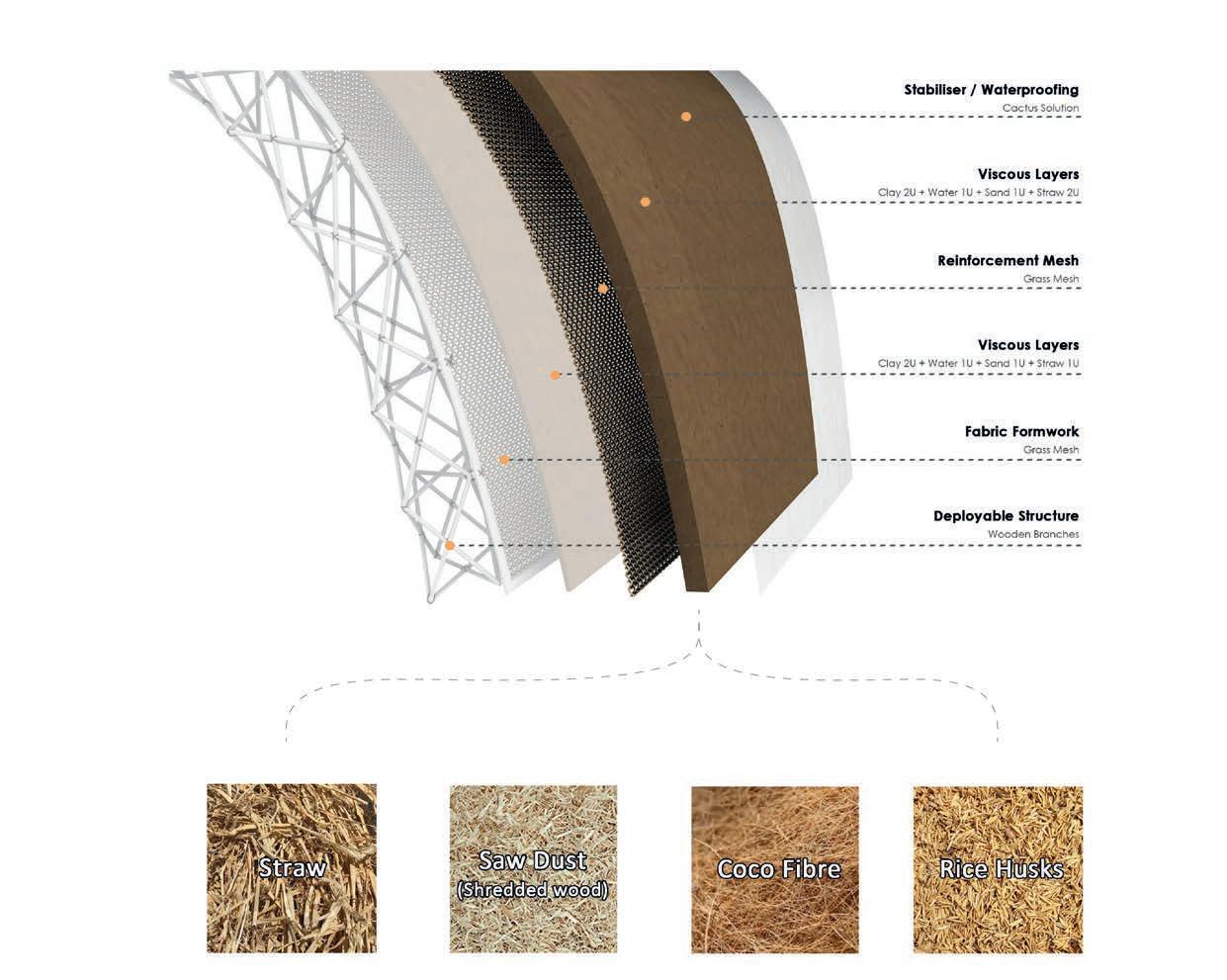

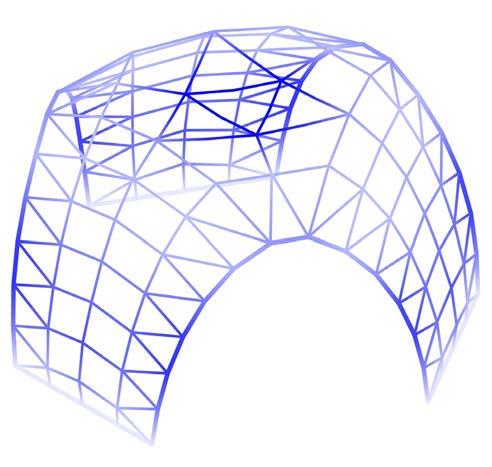

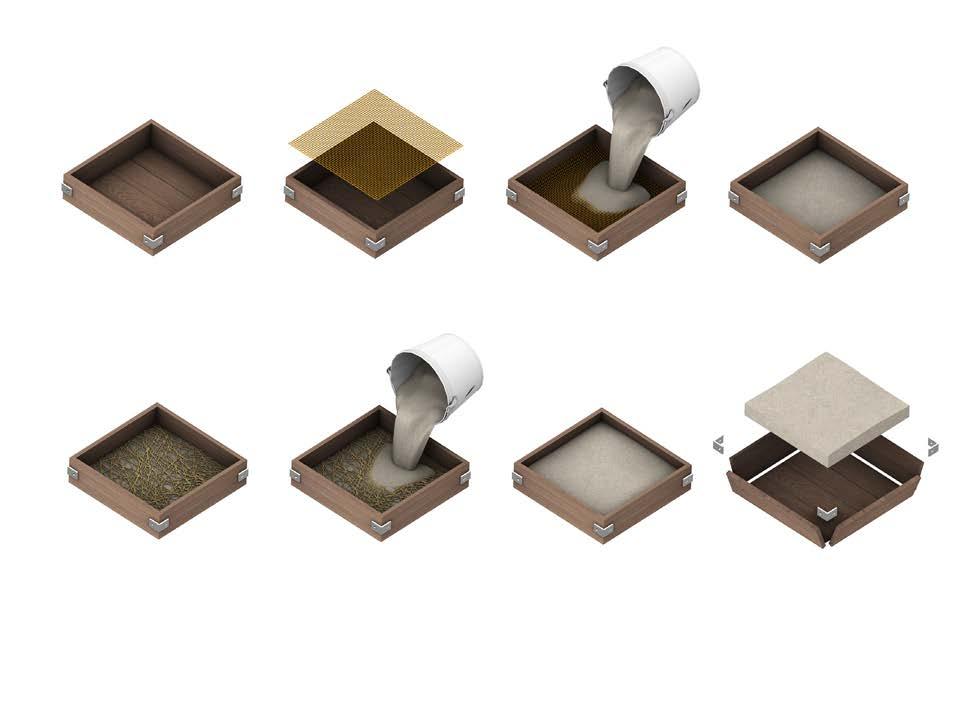

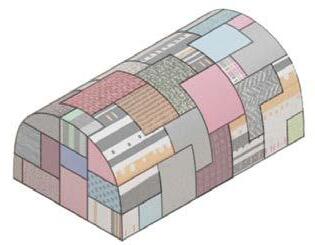

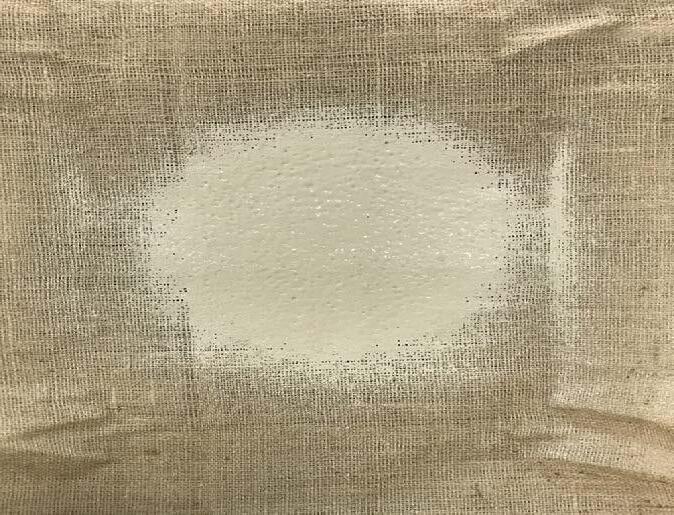

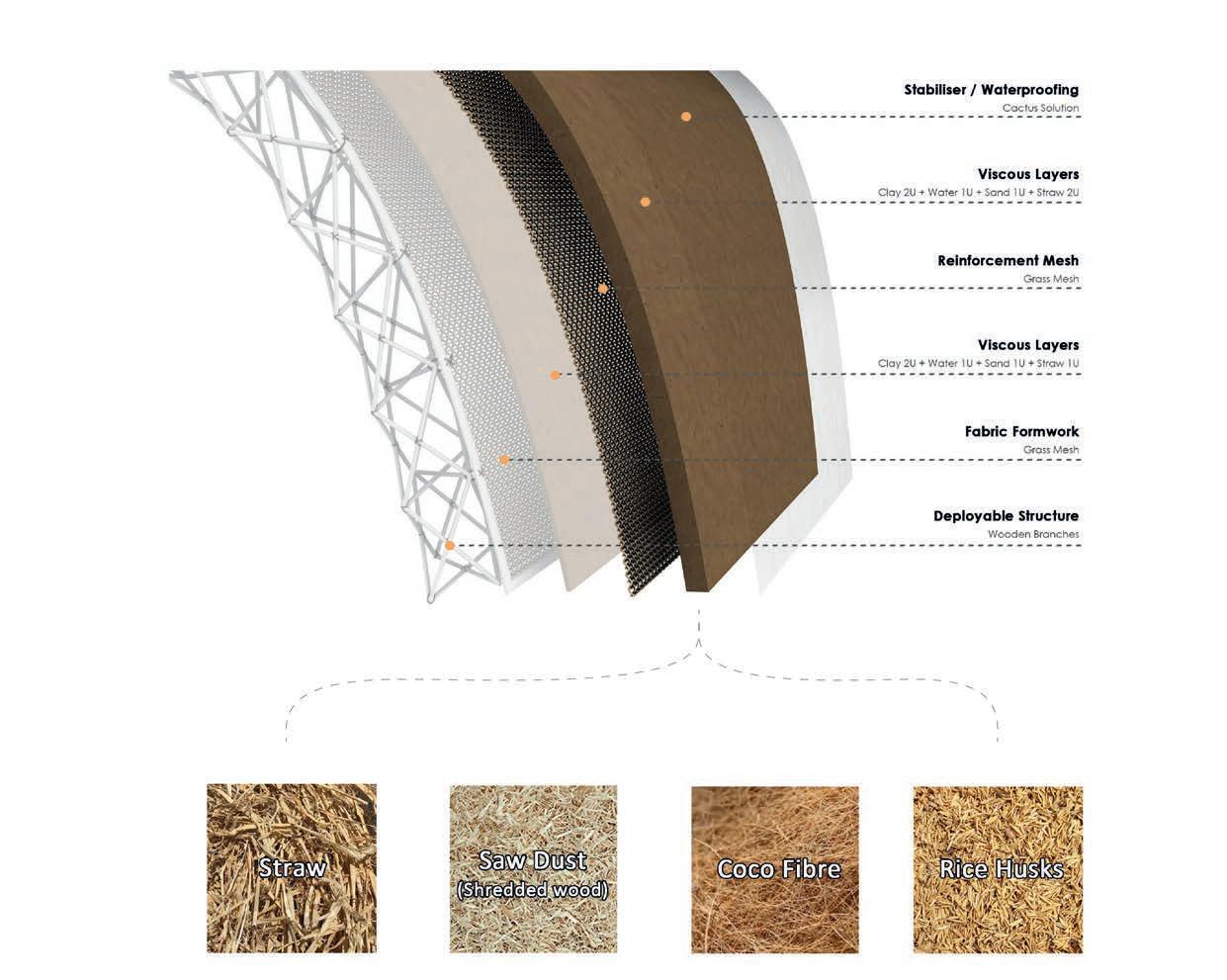

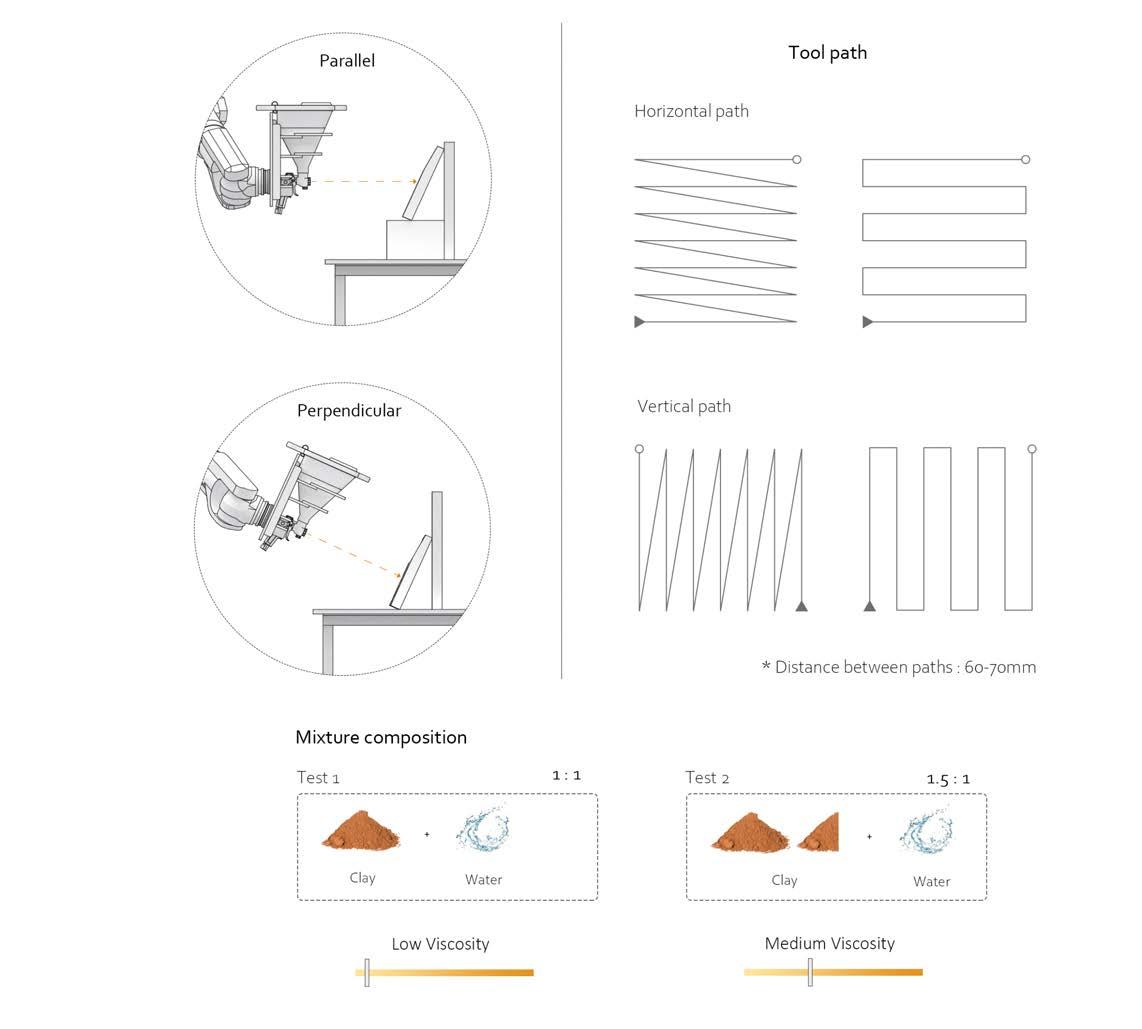

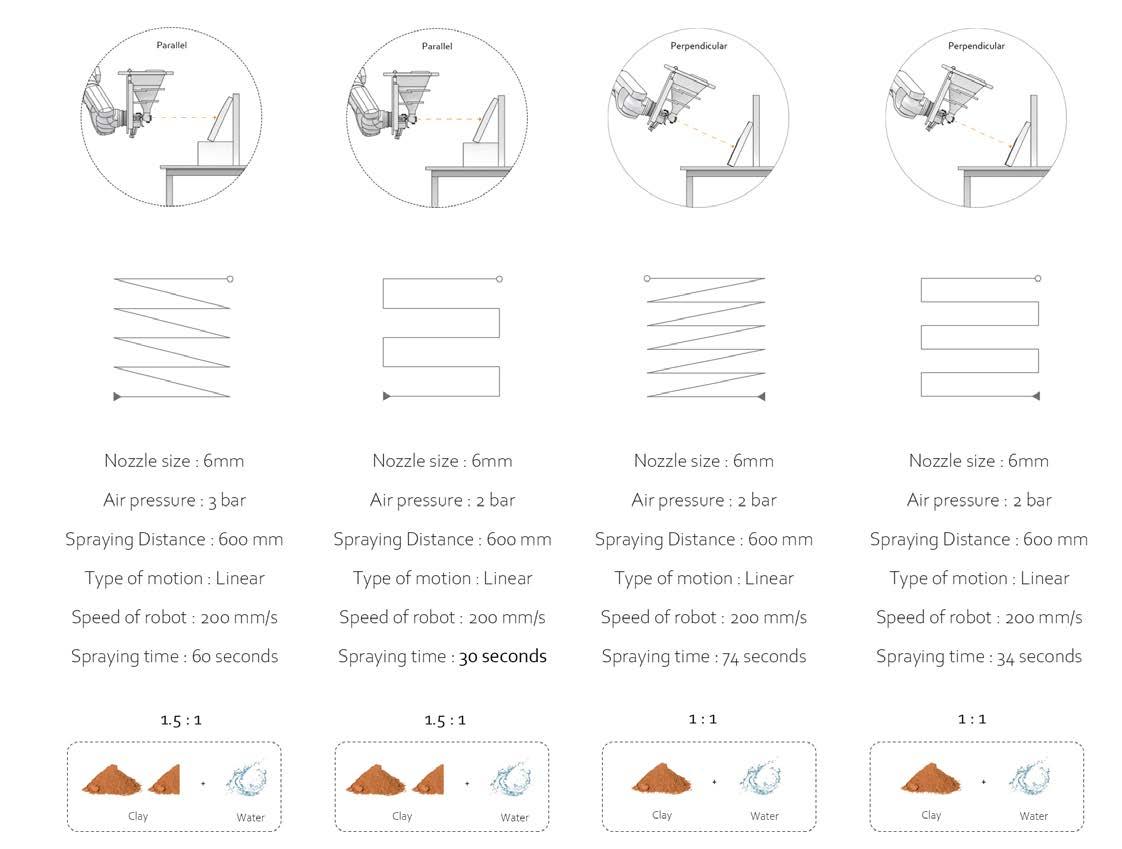

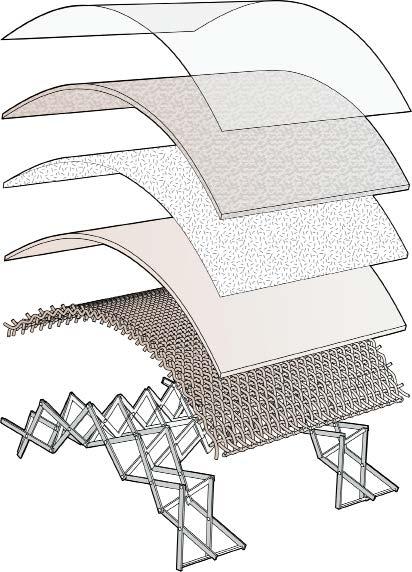

TRANSFORMATION Inspired by the wattle and daub technique developed by Agro-pastoralists, in which they use earth as a coating and plastering material to add more permanence to their different structures, we propose a potential transformation strategy using earth coating over a fabric formwork, as it is the most abundant building material sufficiently available in the region. In this traditional practice, different clay mix layers are sequentially coated by hand on a light wooden formwork resulting in wall panels used for either discrete construction or building monolithic shells. This led us to lean towards revisiting this technique to adapt it to our project conditions.

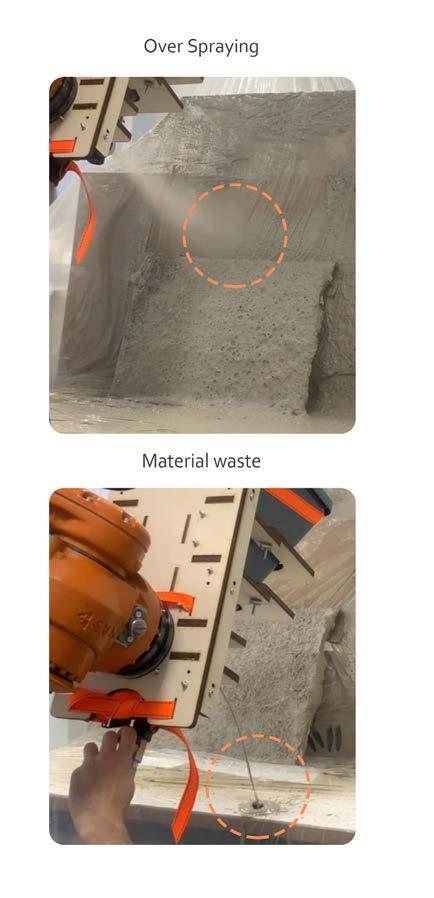

unexperienced builders. However, the process requires important human resources to spread out the material at an even rate. It is a time and energy consuming process which provides an uneven finishing to the outer layer.

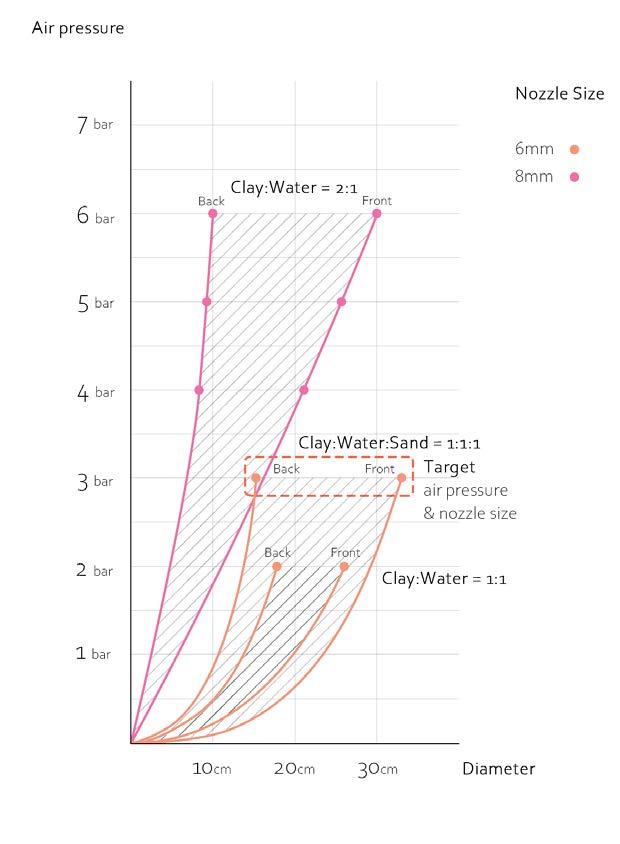

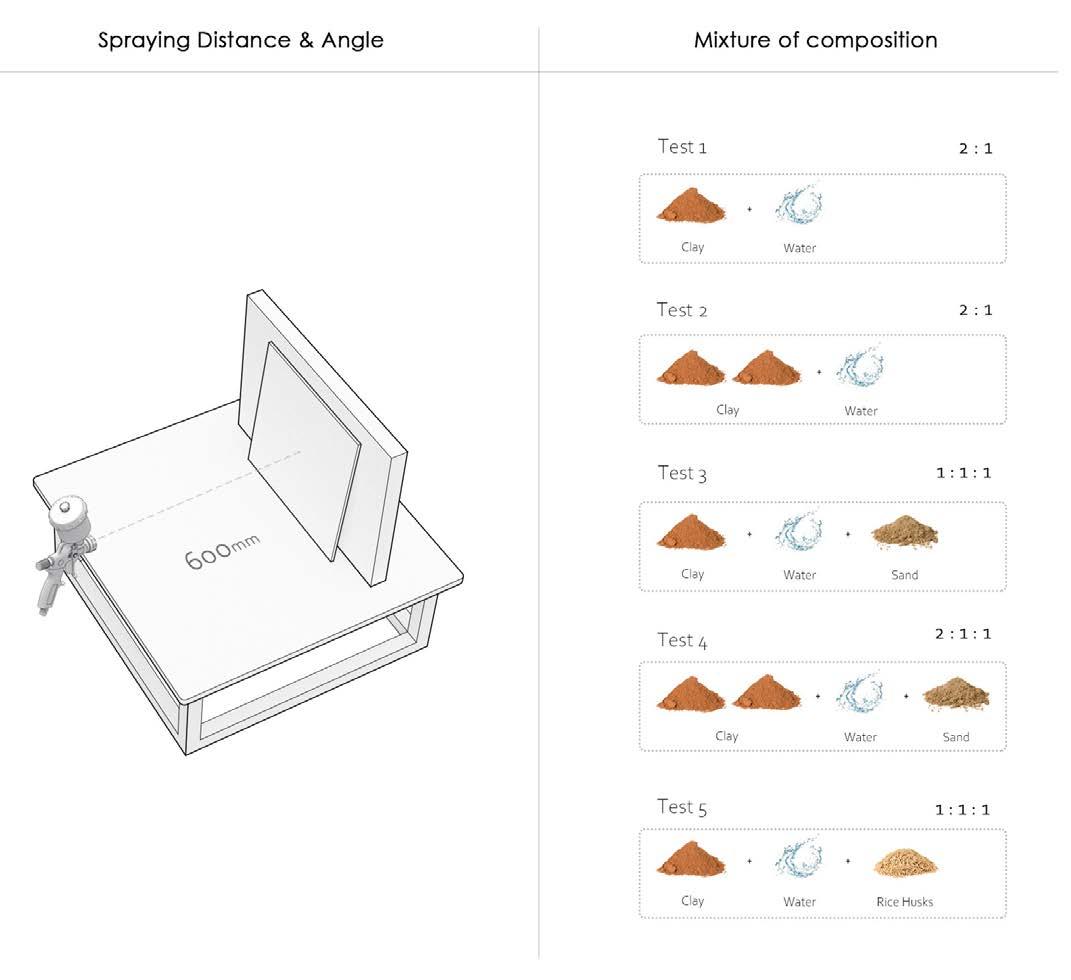

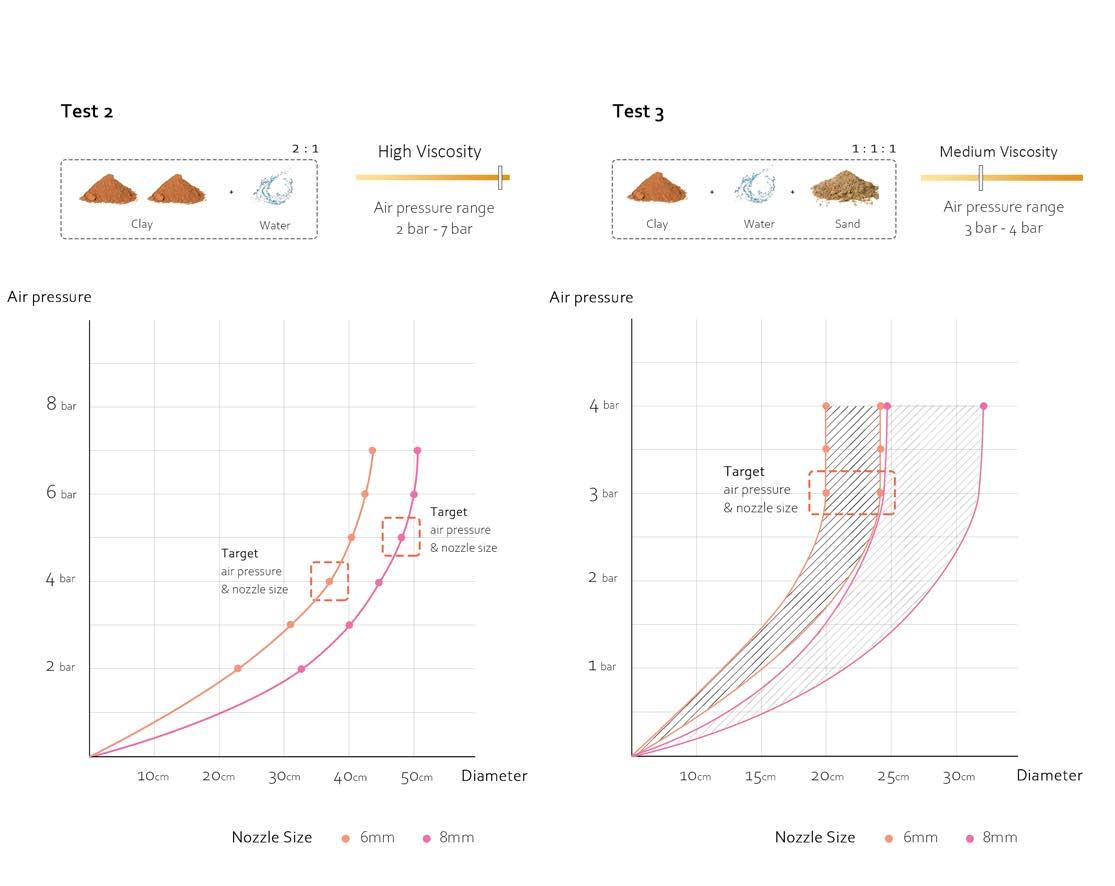

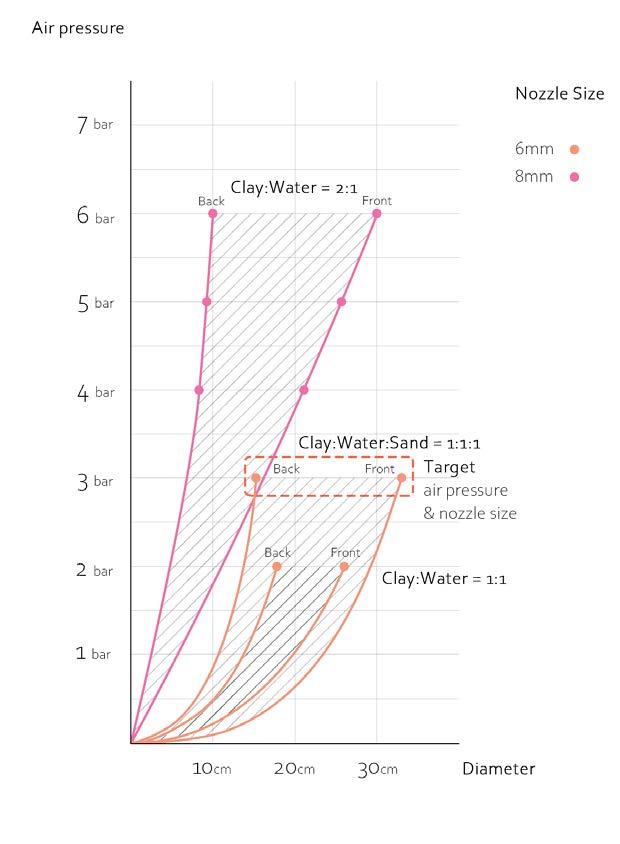

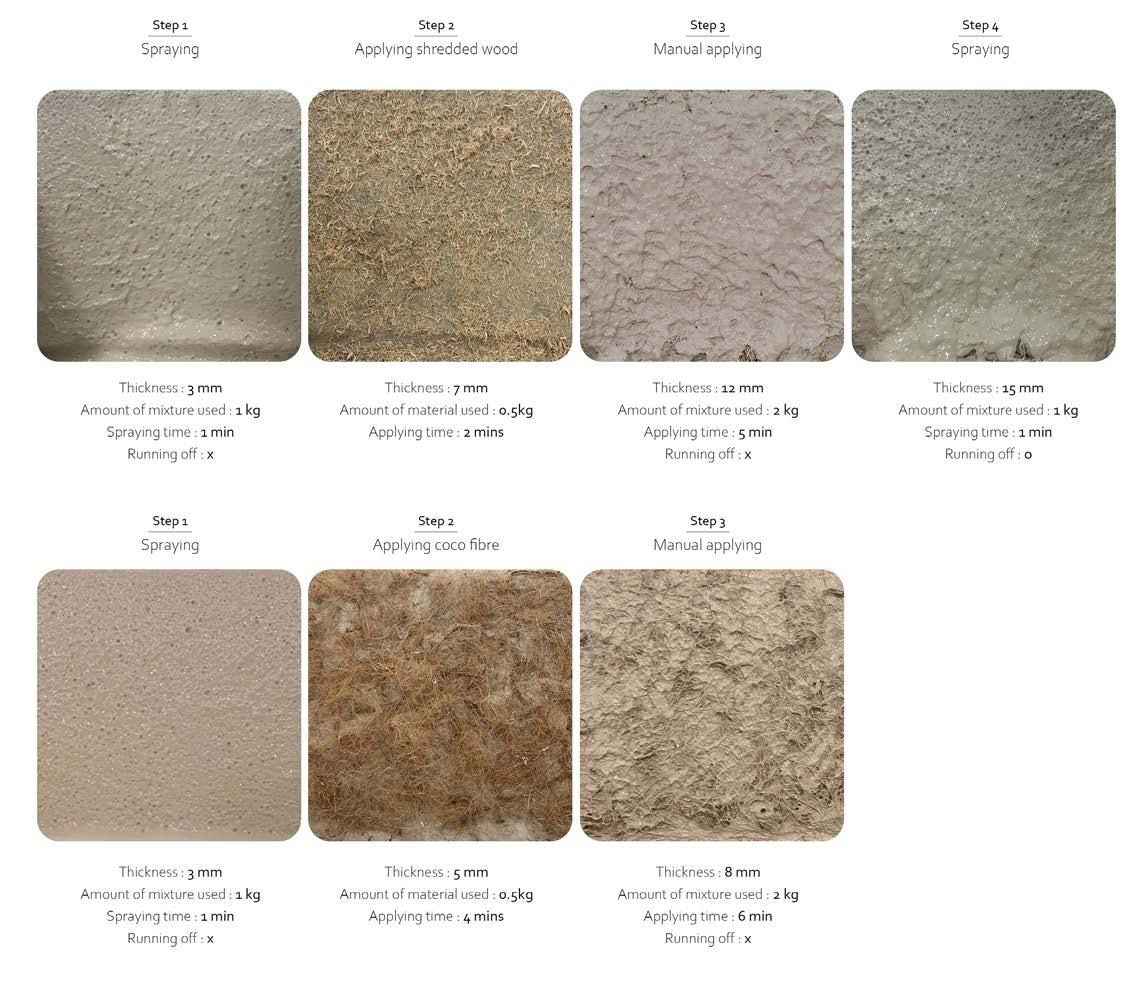

Spray Gun

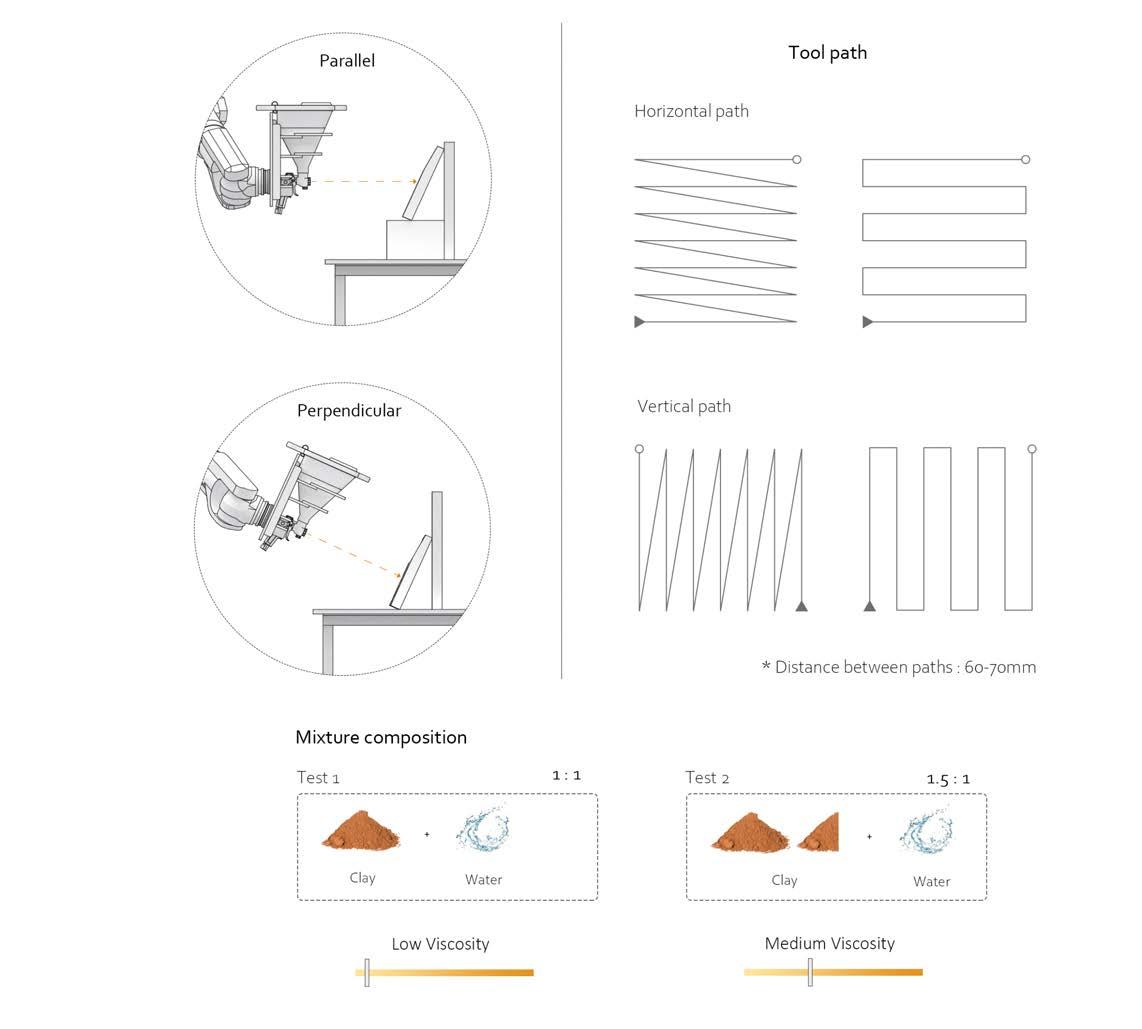

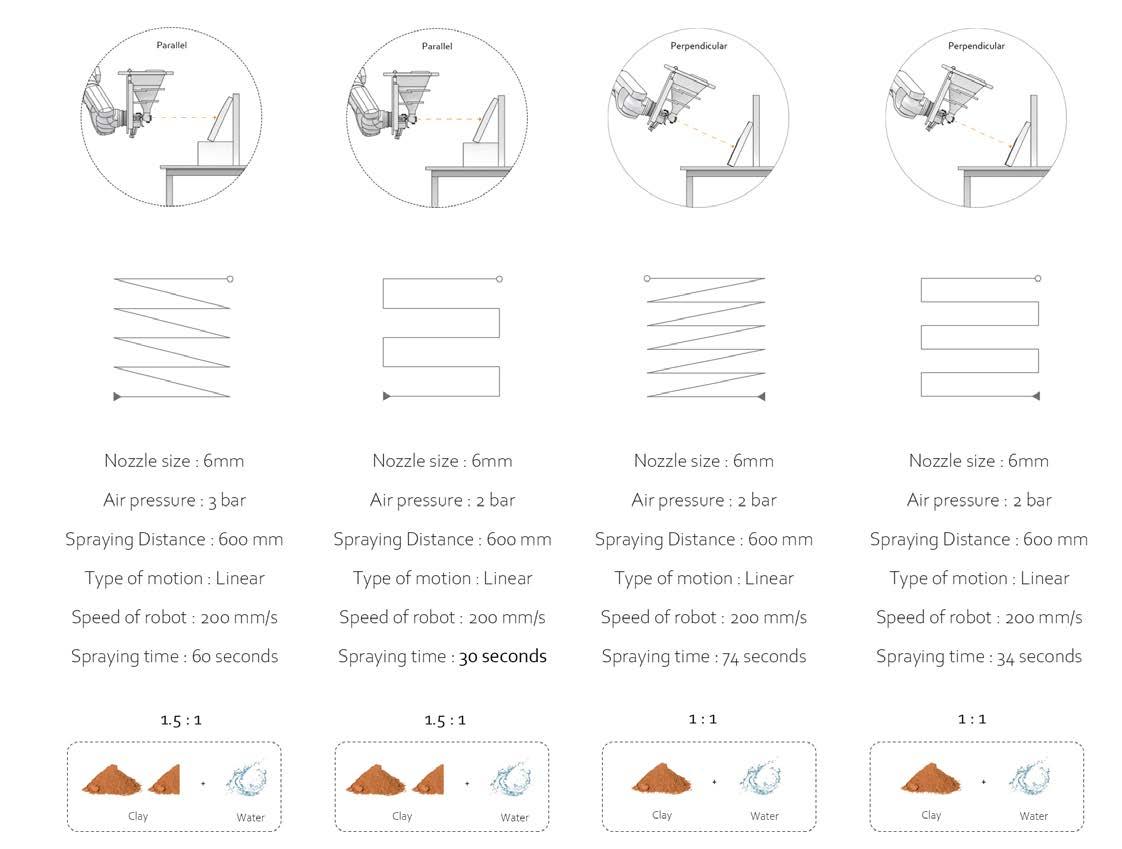

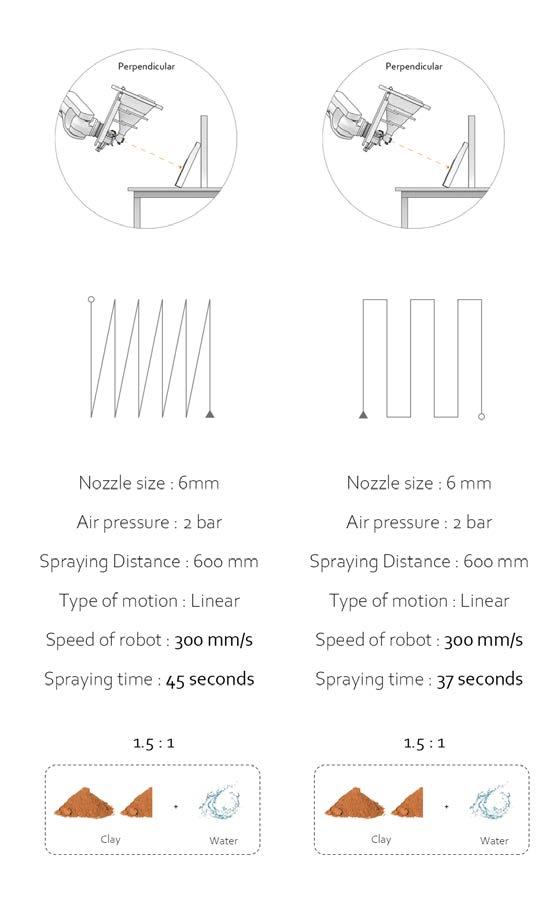

The use of a spray gun can improve certain aspects of the material application, while allowing for rural inhabitants with little construction technological knowledge to conduct the process without further complications. Through the use of simple and cheap equipment, it is possible to increase work efficiency with a minimum number of people. Besides, it allows for the material to be applied evenly over the target surface. Different finishing results can be obtained according to the given material conditions and by using different nozzle sizes and air pressures.

Shotcreting automated process

Several experiments carried out mostly in academic environments in recent years propose to revisit clay as a traditional building material and to study possible formulations and applications using different technologies. These experiments feature additive manufacturing through spraying, which already has a long history in the concrete industry.97

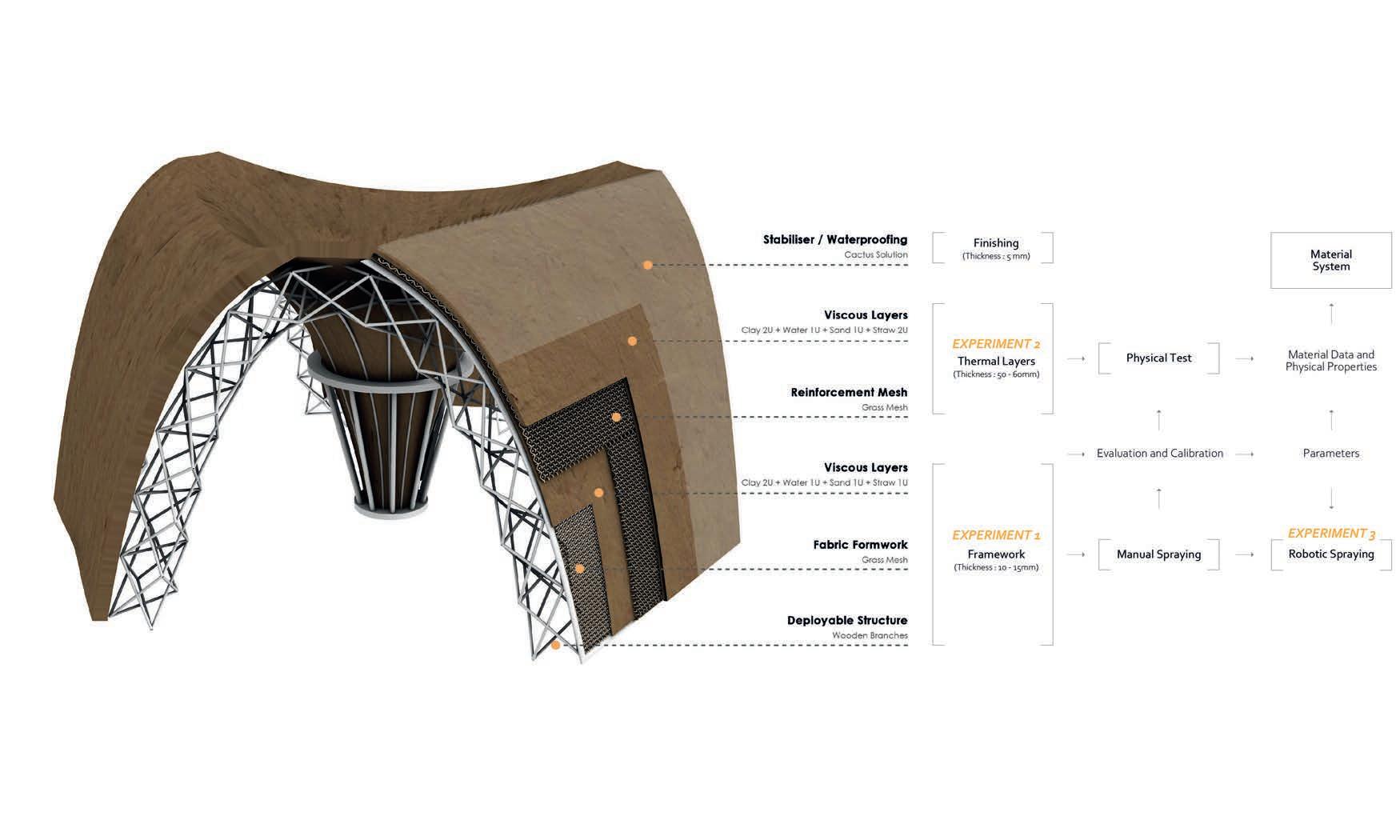

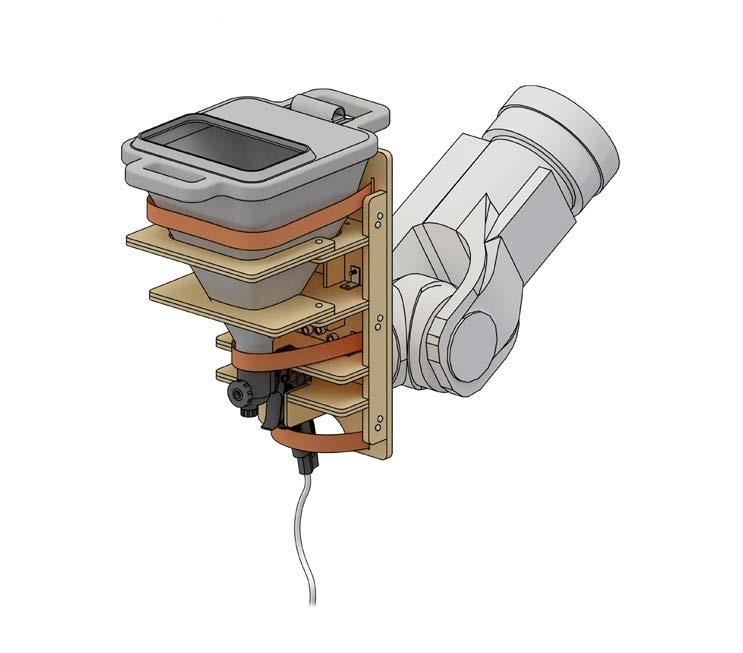

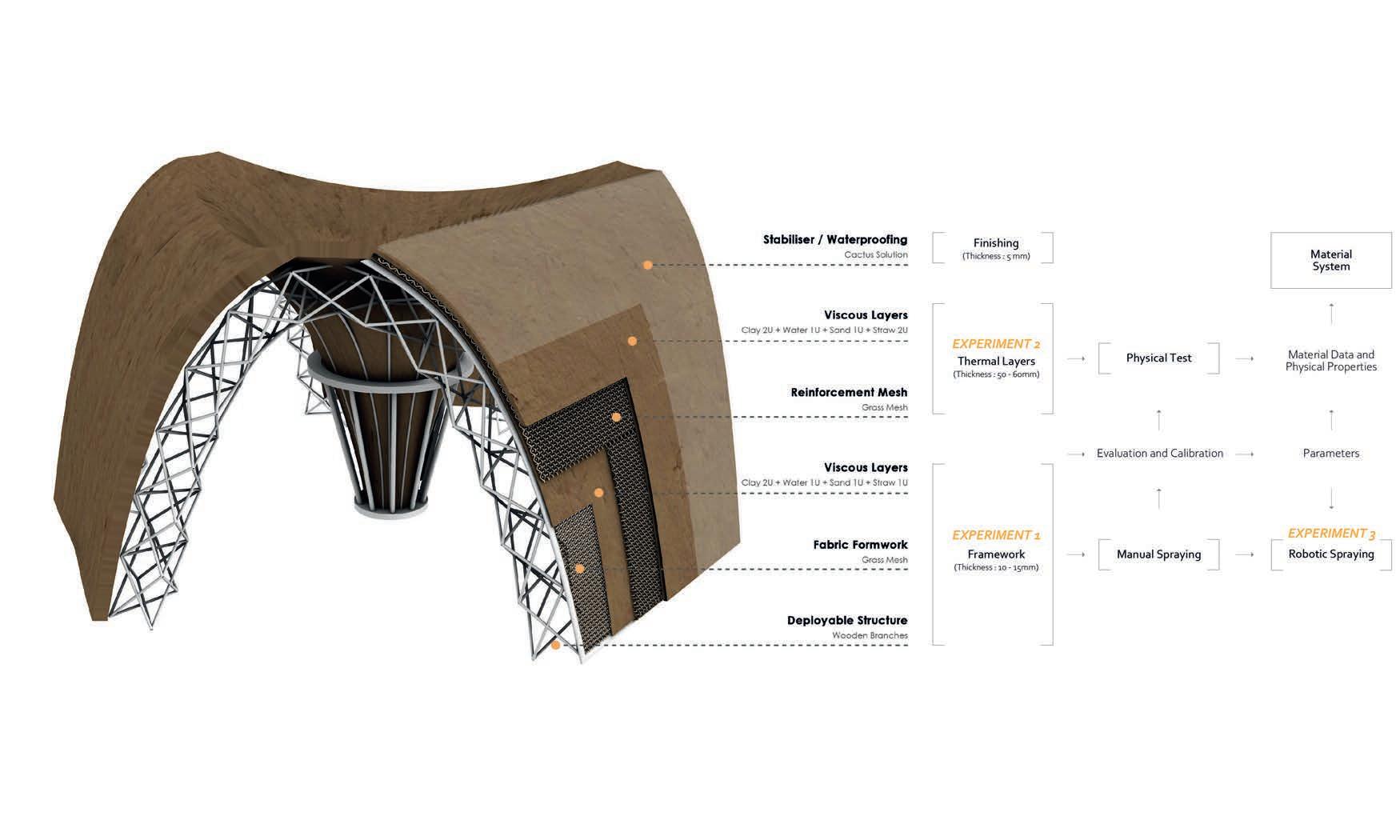

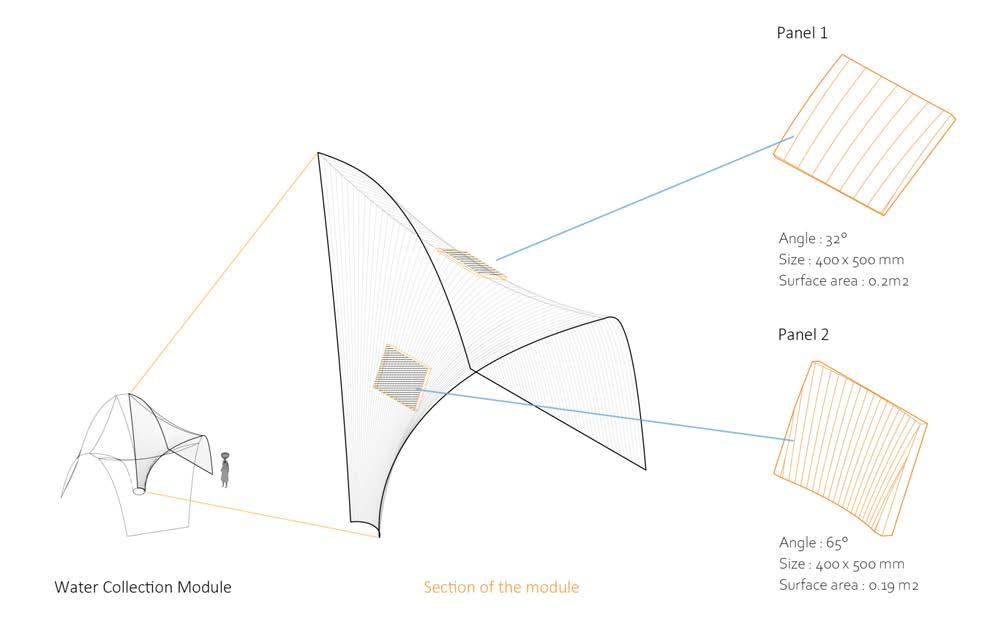

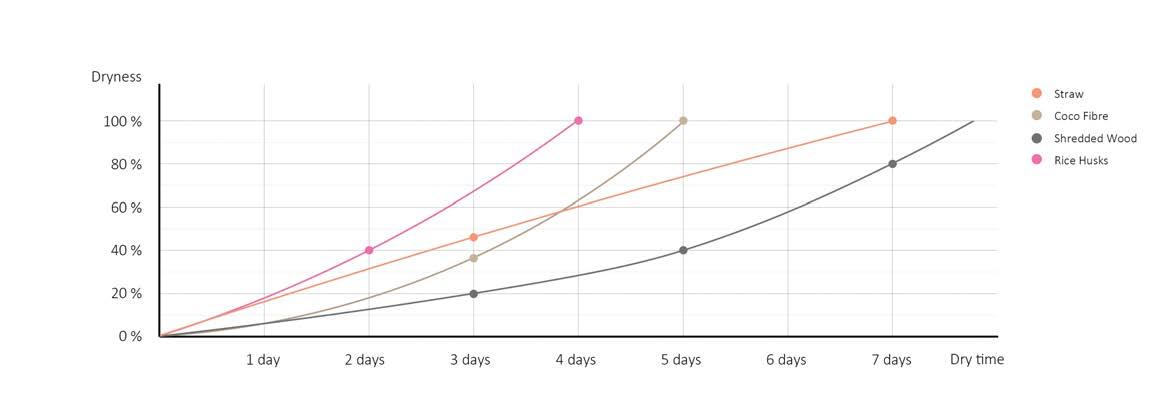

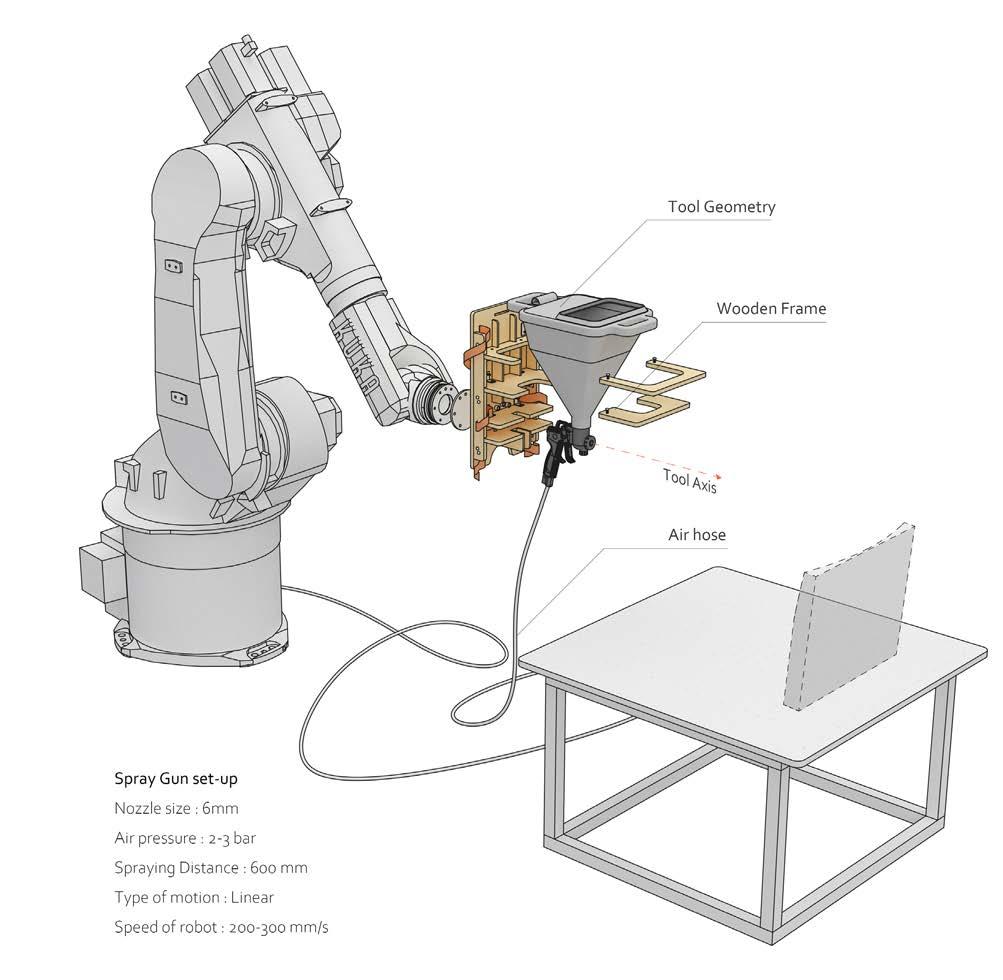

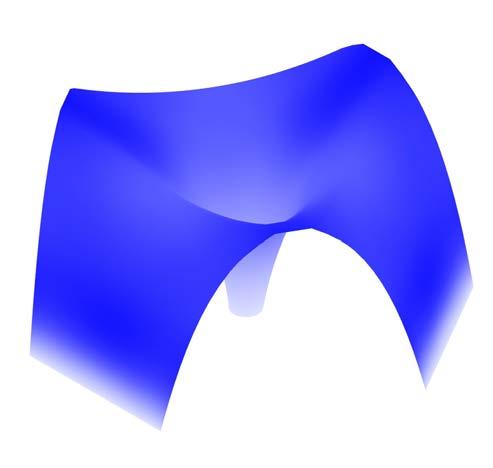

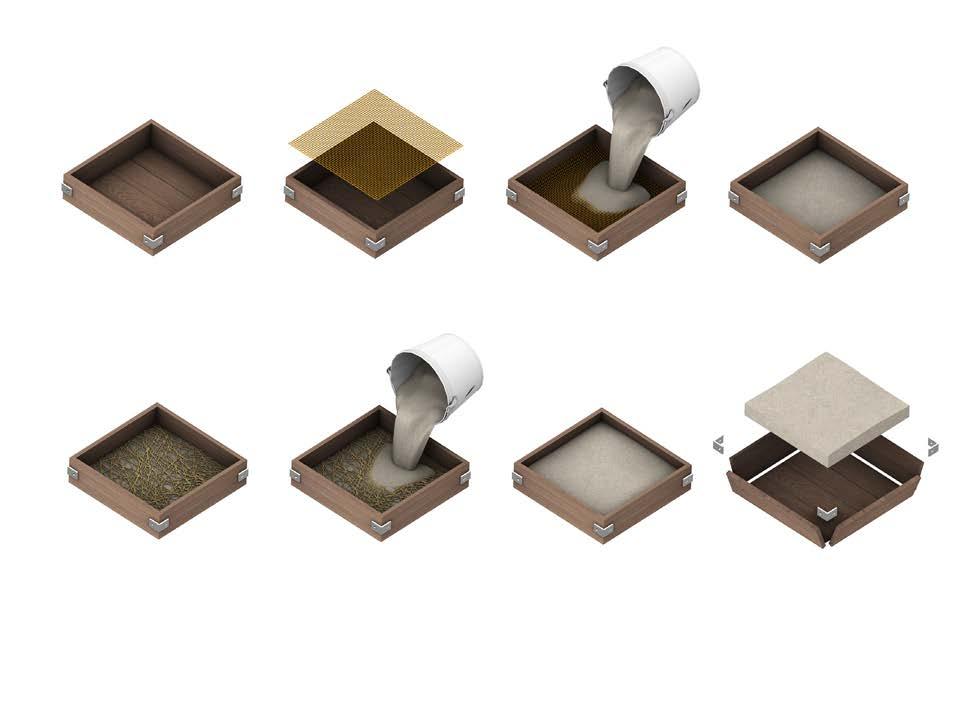

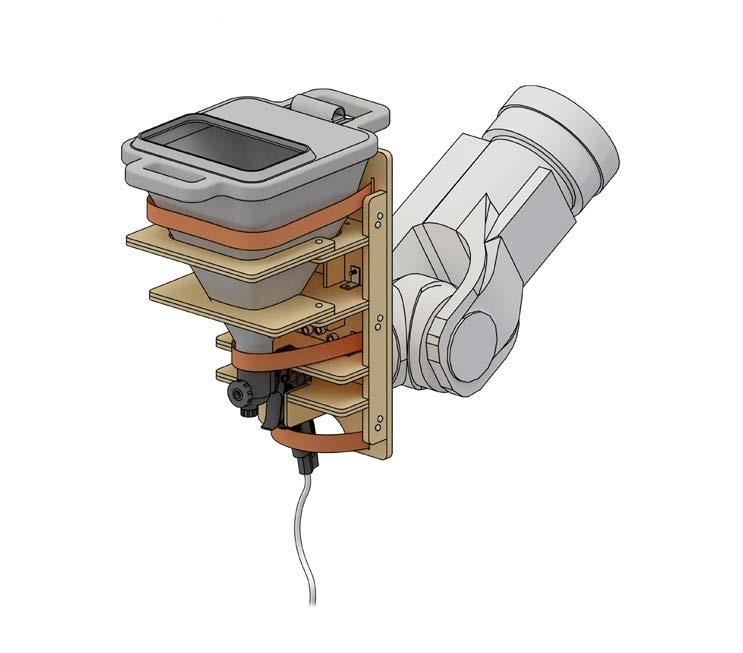

We believe the use of semi-autonomous machinery for conducting the shotcrete process could significantly reduce the construction time, minimizing the human resources required for construction. This could become even more beneficial if the operations are repeated in building the same house typology.

“Bio-shotcrete” is a novel technique developed by multi-disciplinary group of designers and engineers aimed at formulating a more sustainable version of the current shotcrete industry by using clay as the matter instead of concrete, smaller equipment, and a temporary light formwork of natural fibre textiles.

The term is used to refer to clay spraying which lies at the intersection between shotcrete and wattle and daub. A precise construction process must be followed for its implementation, consisting in the precise formulation of different clay layers and in the correct deposition phasing, all aimed at achieving matter/surface adhesion and added control in the final thicknesses necessary for the construction of large-scale earthen shells in a matter of days.98

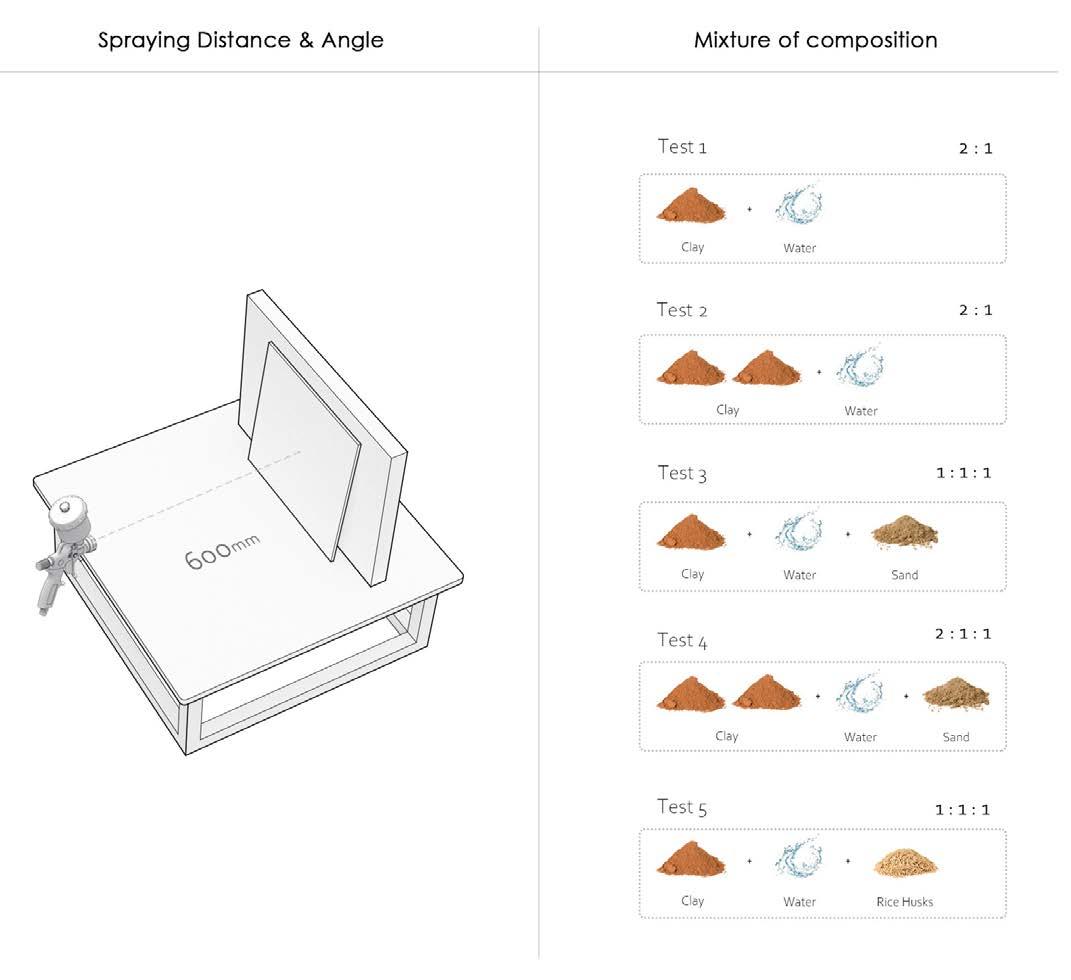

02 - 5.2.3

SPRAYING TECHNOLOGY When it comes to transforming a temporary house into a more permanent dwelling, there are three possible ways to apply clay layers onto the given surface. The methods perform differently in relation to the material composition used, and are analysed with respect to the needs and limitations of construction conditions.

Manual hand application

One of the easiest ways of applying the material is to cover the surface by hand the same way it is done by pastoralists in the wattle and daub technique. This method does not require highly skilled labour or industrial equipment, making it easy to access for

Past experiments explored automation technologies using robotic arms for bio-shotcrete. The use of robotic arms shows certain limitations such as the arm’s reaching capacity, the cost and size of the equipment, and the difficulty of transporting these heavy apparatuses to remote sites. Forefront experimentation is also being conducted using drones, which solve some of the problems observed in robotic arm’s experiments, but pose new challenges for automation such as the impact of environmental conditions in the drones’ performance, battery life autonomy and the need of a qualified professional to fly them.99

84 85 Rural WaterScapes Rural WaterScapes

02 - 5.2.2

Bio-Shootcrete

2 Domain From Temporary to Permanent 5

A satellite view of our site and its context.Our site has a soil containing of only 10-15% clay, however, we can see it lies just a few kms away from clay plains (3 km) formed by seasonal rivers, which we are planning to also use. (Google Earth Images)

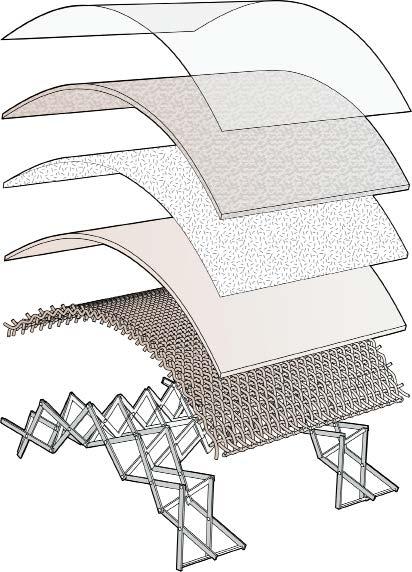

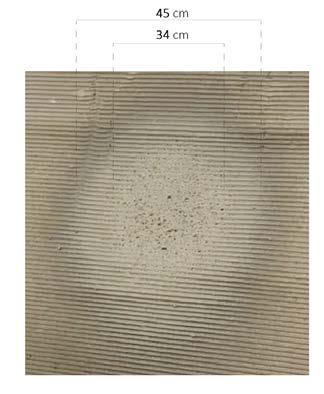

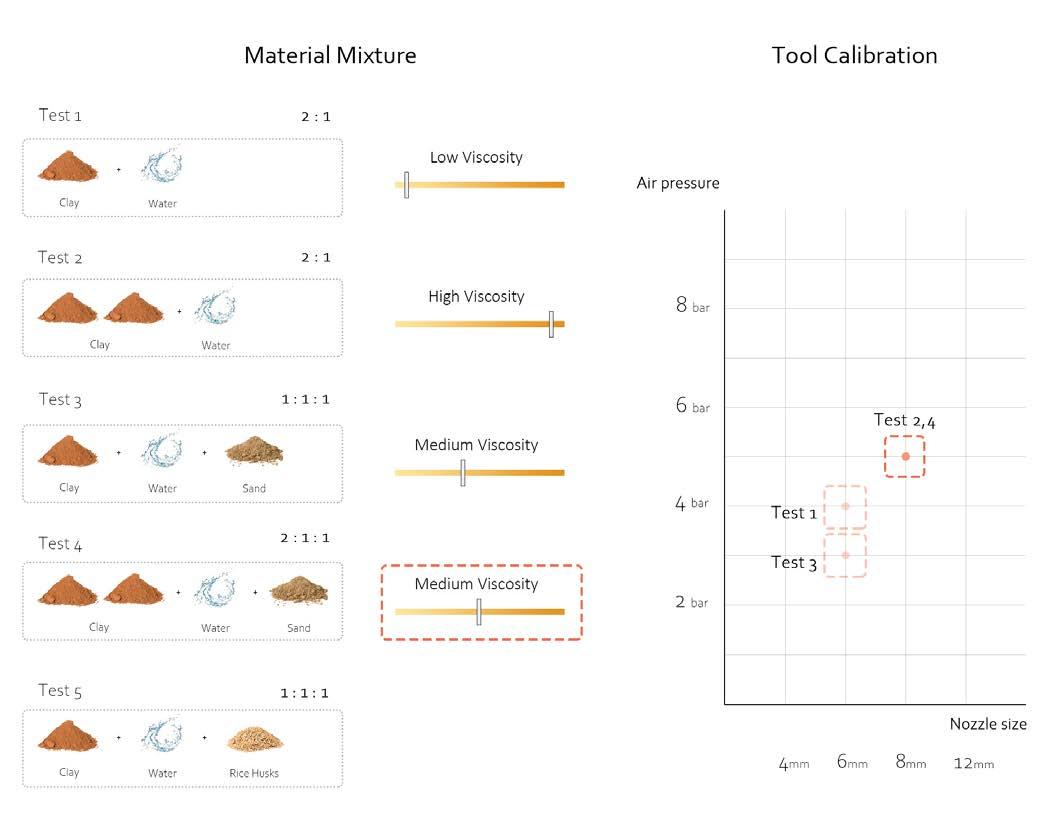

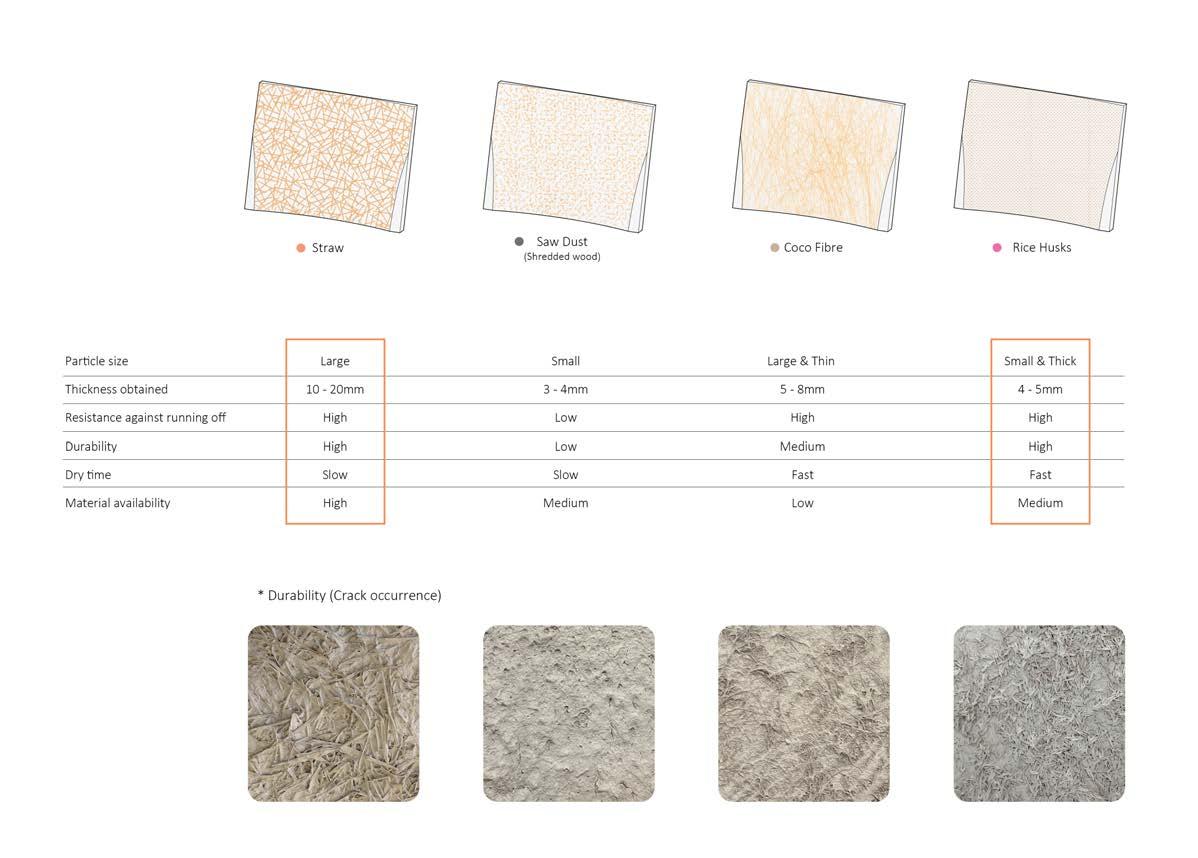

Bio-shotcrete requires the careful formulation of mixtures to achieve a desired performance in terms of solid crust adhering well to the previous layer or initial surface. Therefore, each deposition layer has a different composition in which grains, fibres, density, and the proportion of clay which acts as a binding agent and water can considerably differ. Three main types of clay mixtures are essential for successful results.100

1. The liquid layer for the initial spray called “barbotine” which forms a homogeneous solid thin crust replacing the initial light formwork. This layer increases adhesion for the following layers.

2. Middle layers containing fibres, clay, water, and sands are helping to give thickness without overloading the delicate formwork, and to absorb excess moisture.

3. The upper coating contains stabilizing agents.

The latest research indicates that separating wet from dry matter would be the most efficient technique for bio-shotcrete. The process is achieved through the spraying or blowing of 3 subsequent phases: liquid, dry and viscous layers.101 Accordingly, we decided to explore the showed mixture consisting of only natural materials since it is predictably the most suitable for our site conditions. In order to stabilize and waterproof the earth layers for the prospect of rainwater collection, a final layer of cactus solution is proposed .102

Although our site has a clay soil content of only 10-15%, it lies at a 3 kms distance from local clay plains formed by seasonal rivers, which we are planning to use as a main clay source.

86 87 Rural WaterScapes Rural WaterScapes

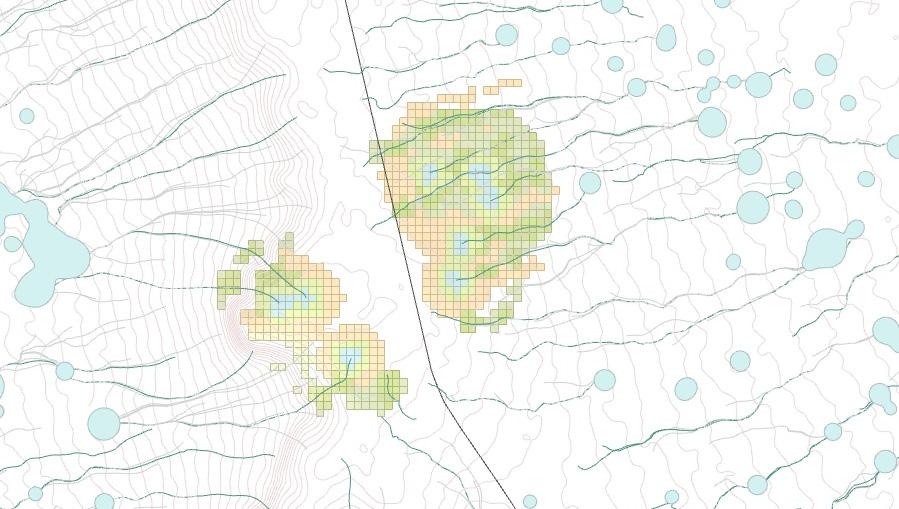

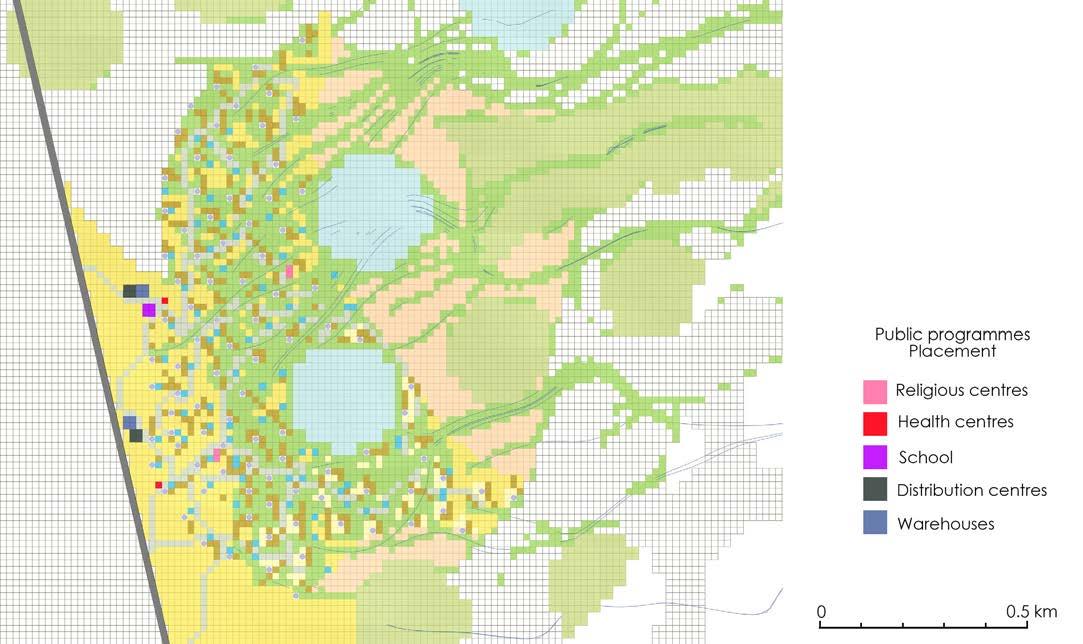

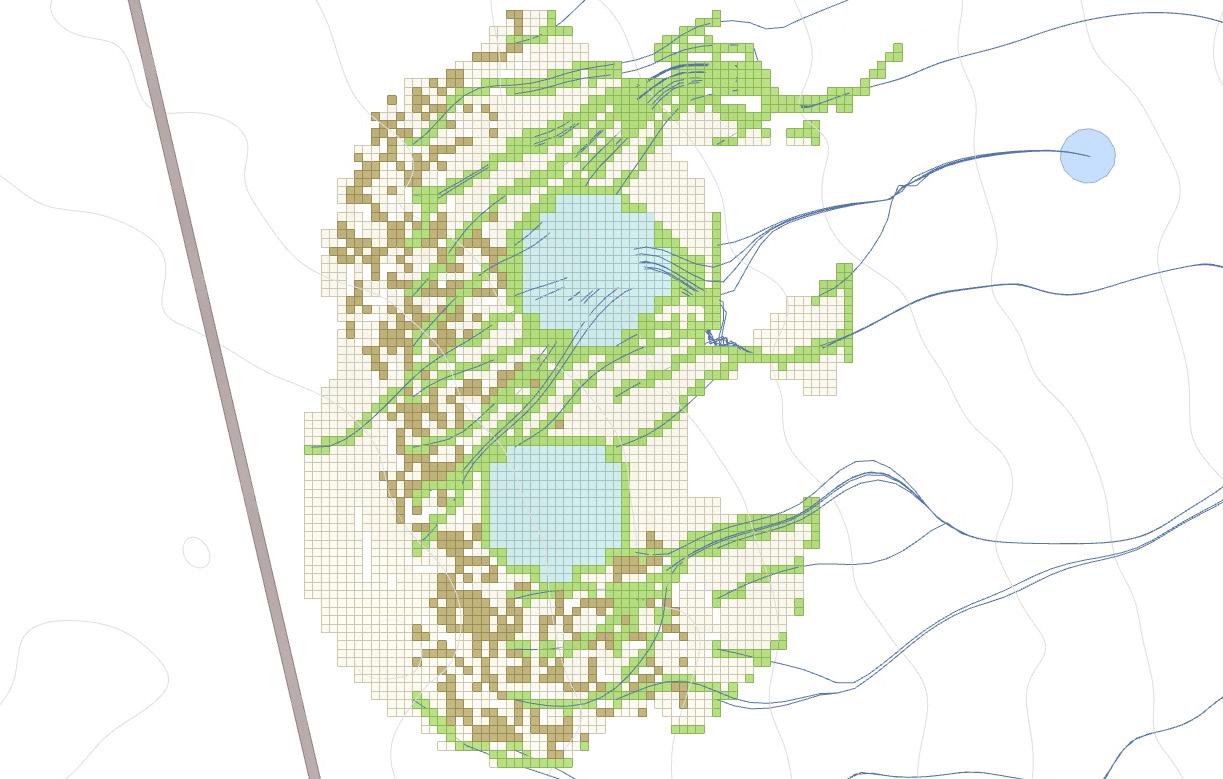

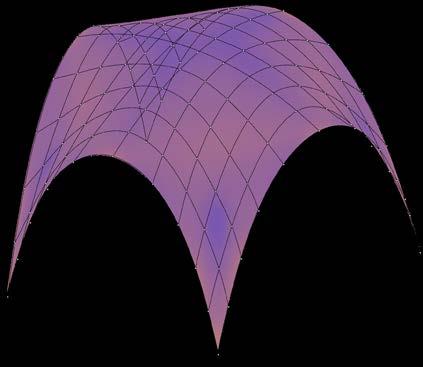

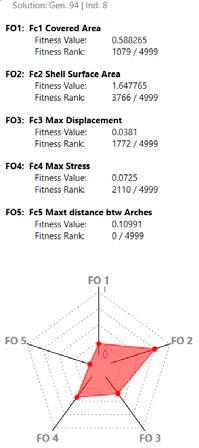

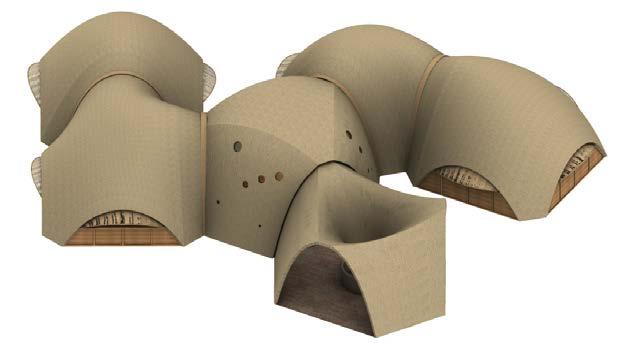

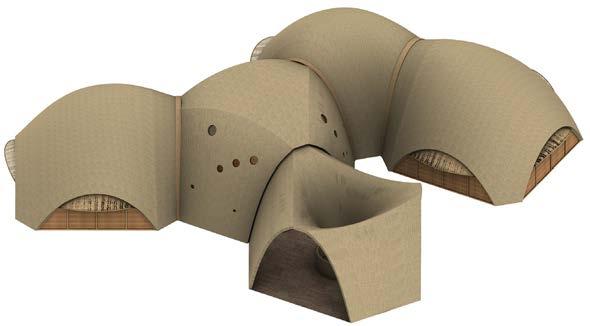

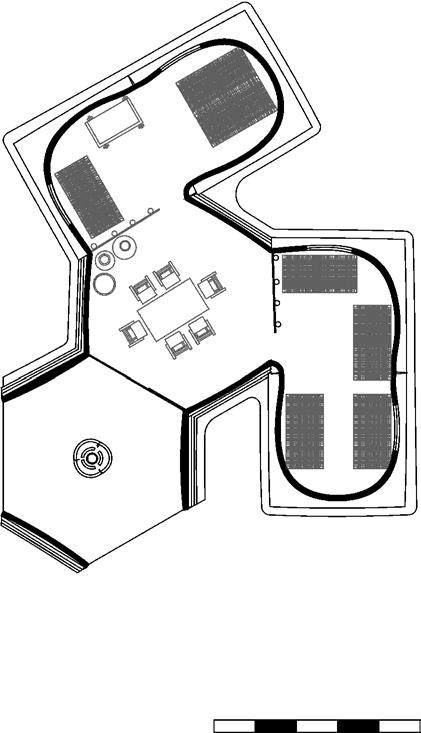

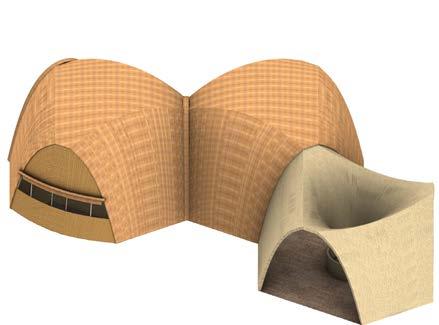

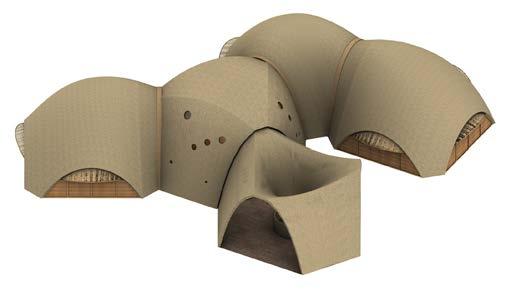

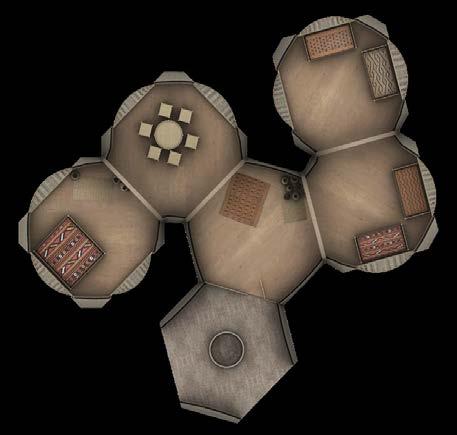

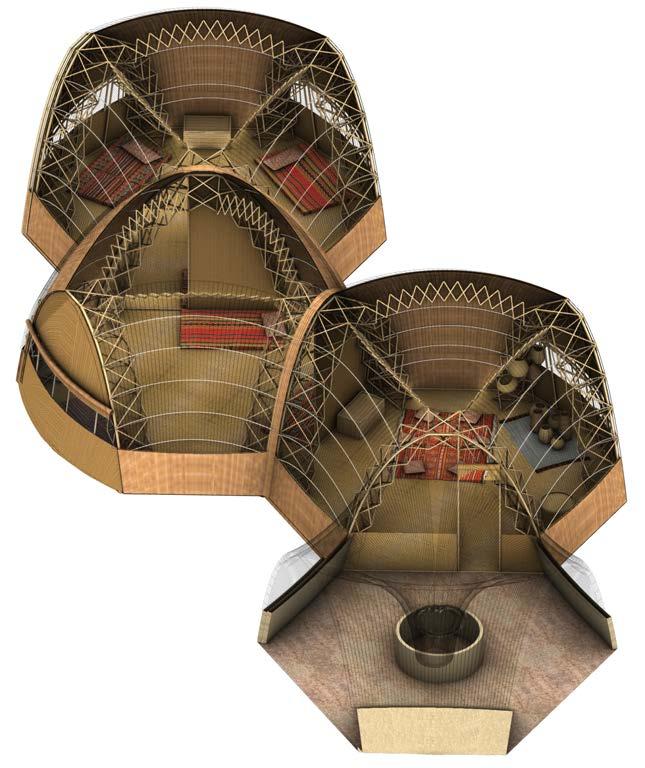

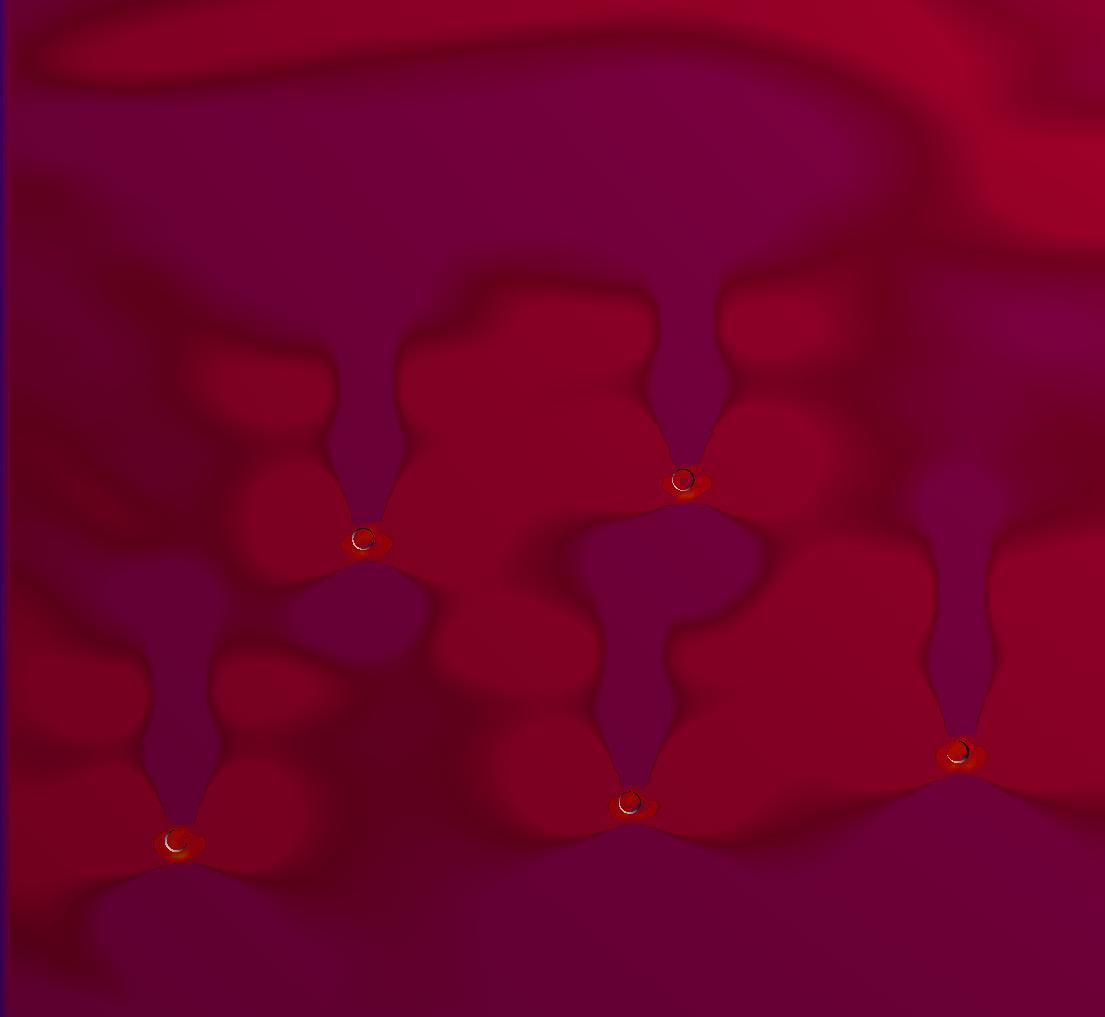

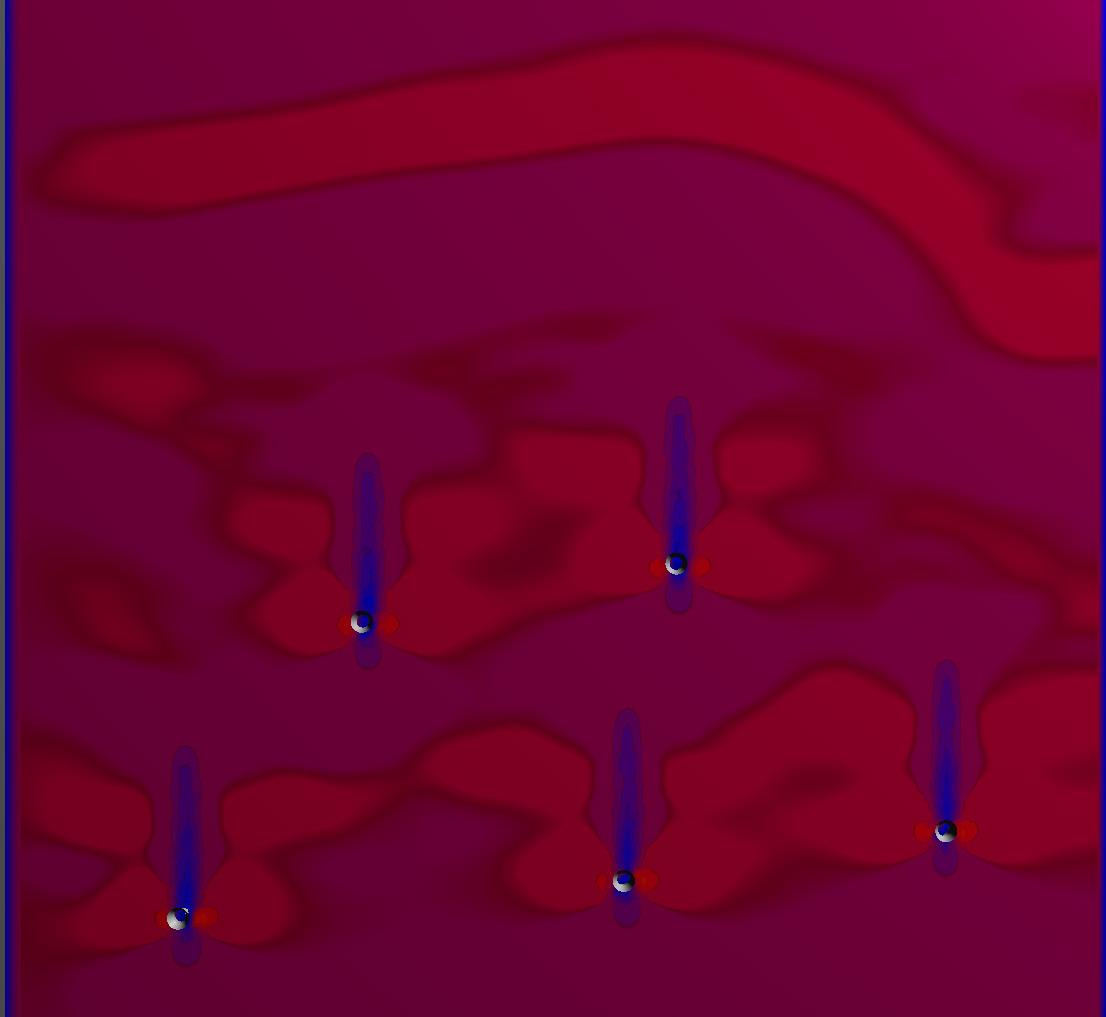

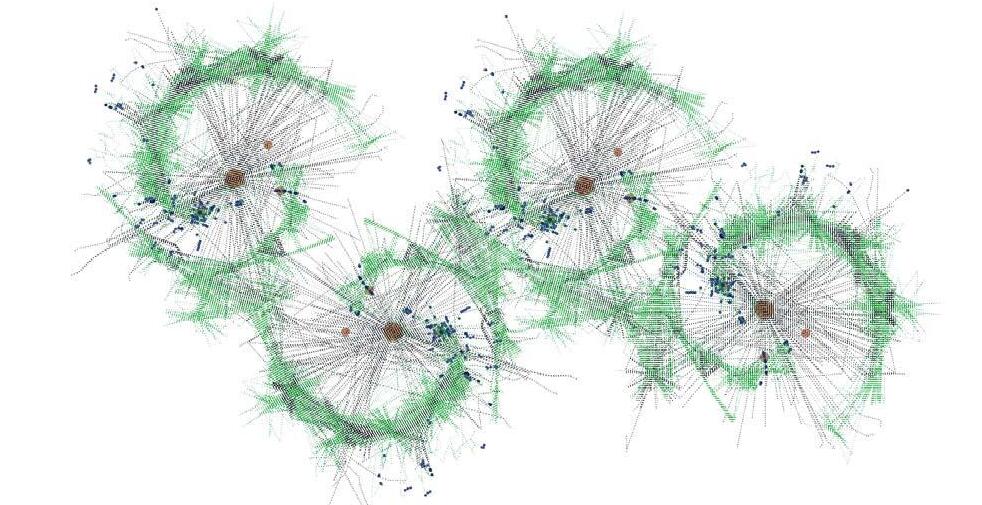

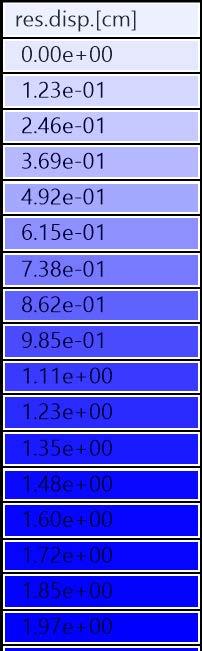

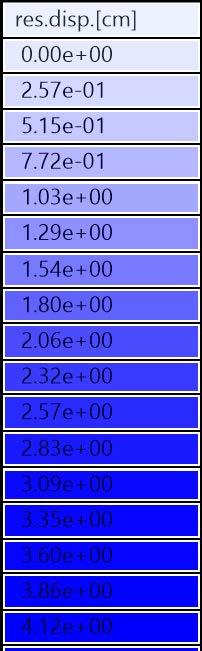

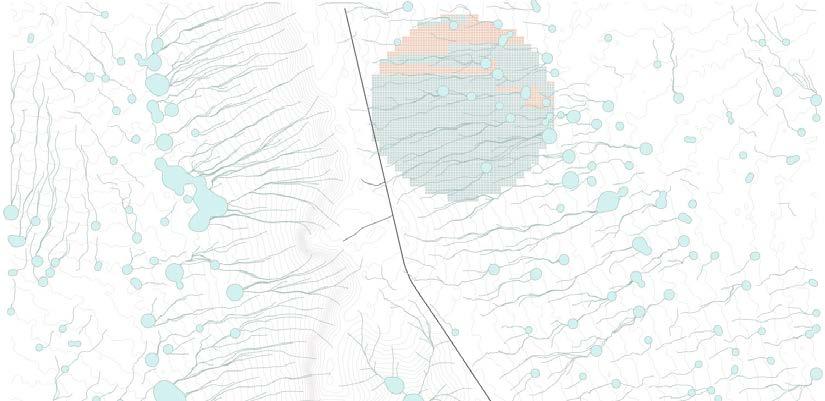

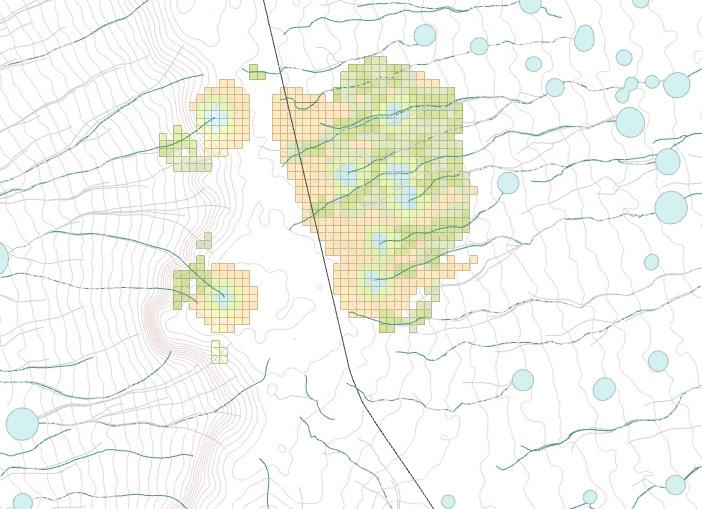

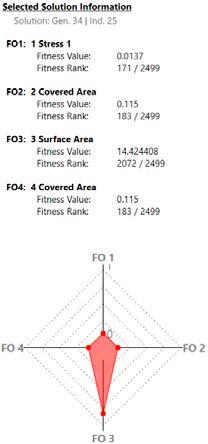

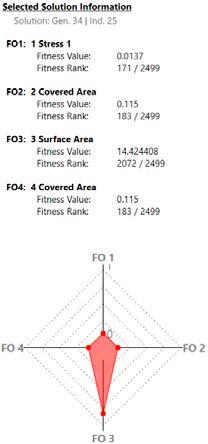

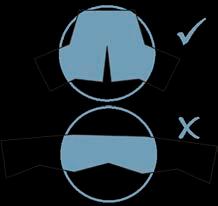

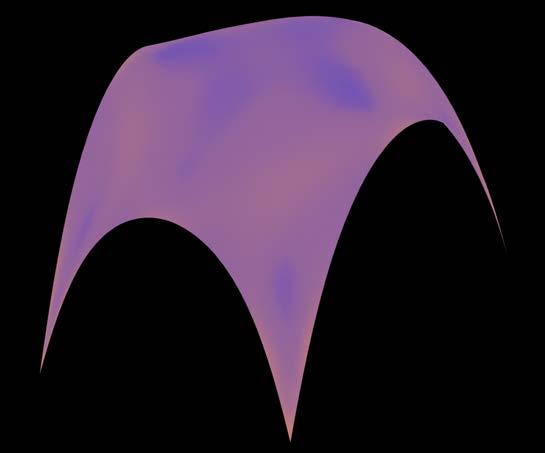

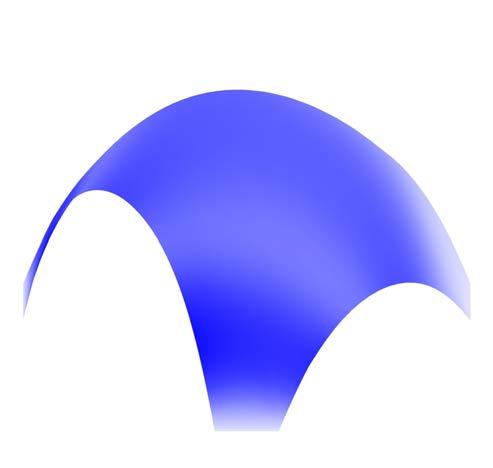

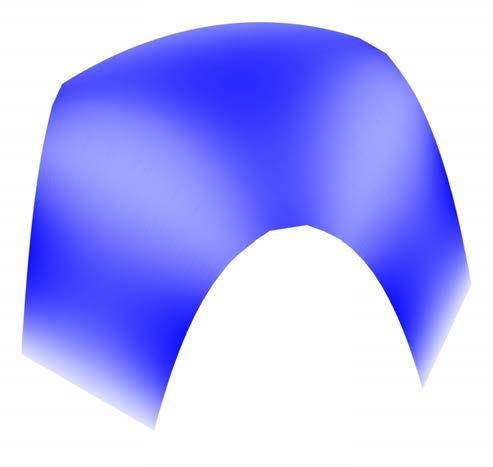

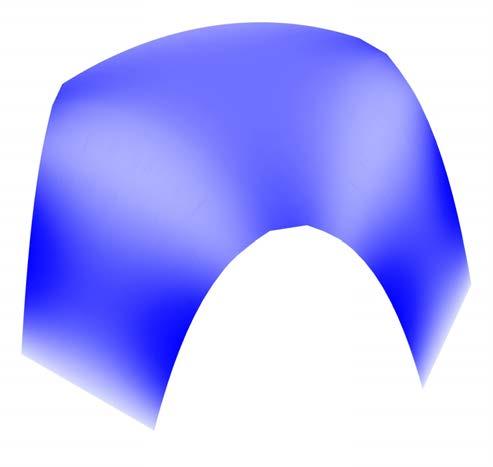

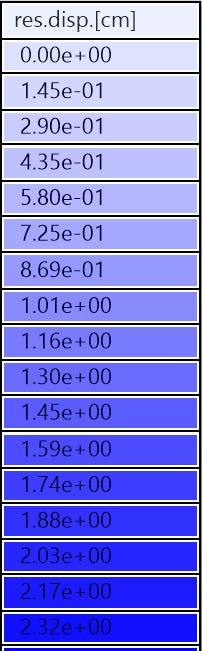

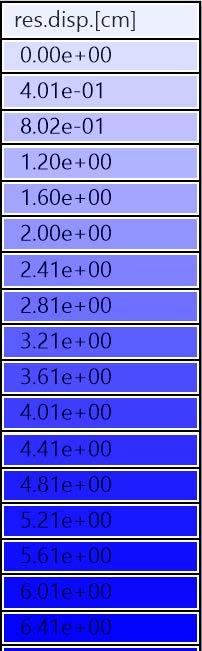

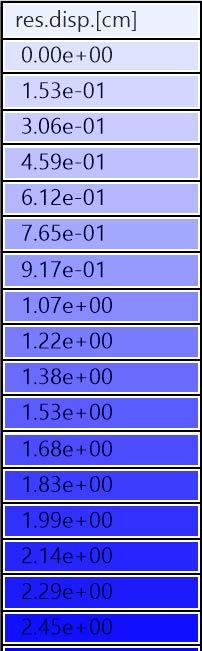

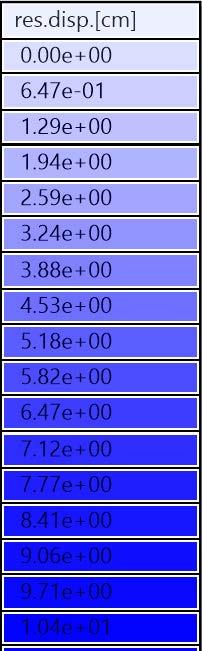

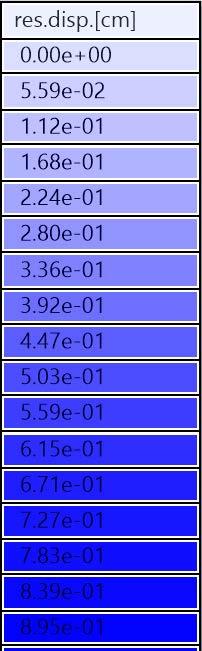

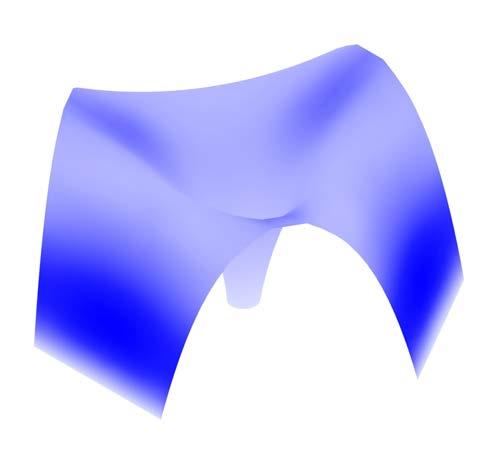

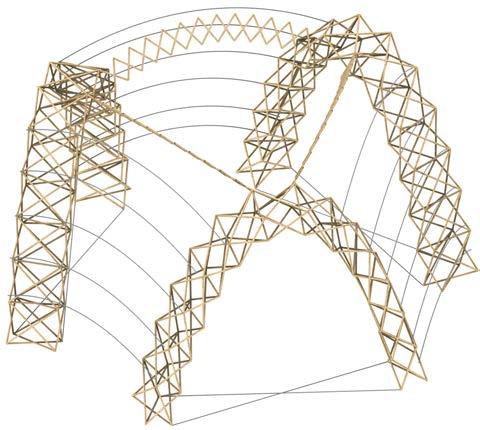

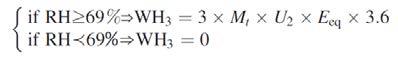

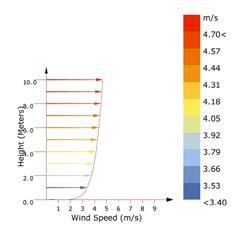

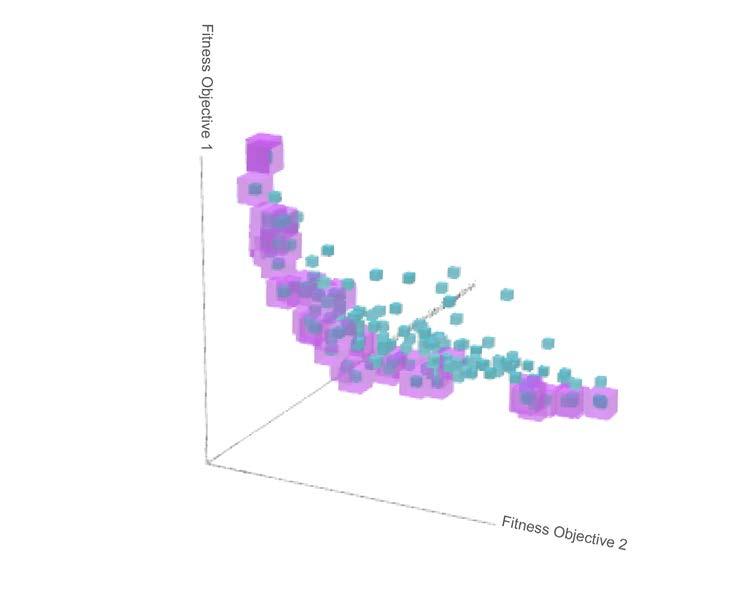

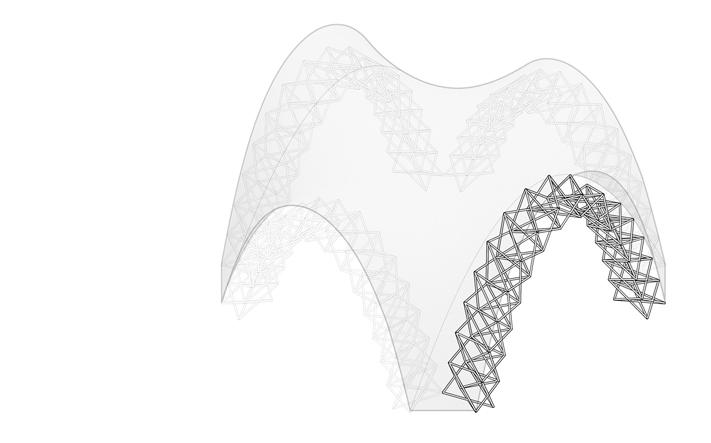

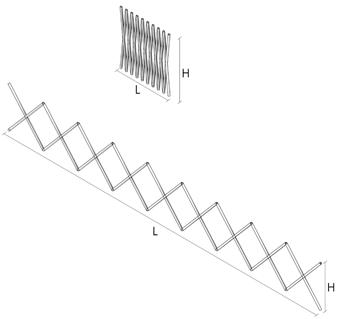

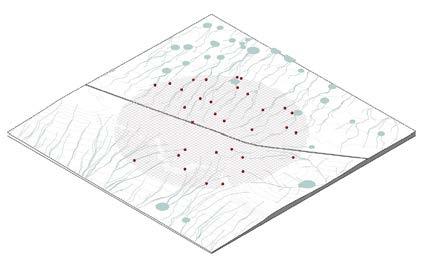

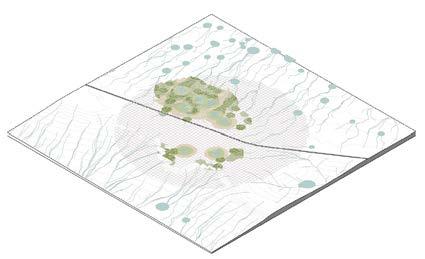

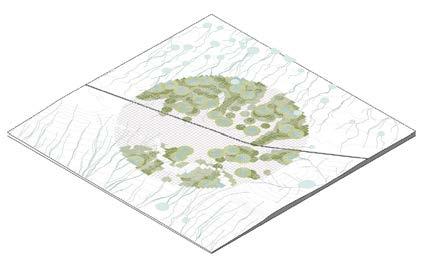

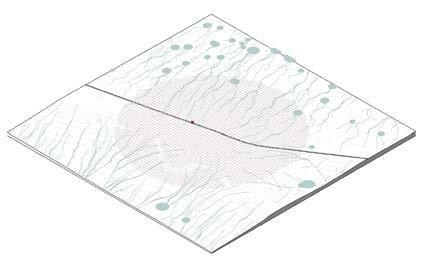

Material Mix