CULTIVATING COMMONS

Designing Public-Common Partnerships to mobilise the biobased construction industry in the East Midlands through a landscape urbanism approach

Priyanka Awatramani (M.Arch)

Emily Bowerman (M.Arch)

LANDSCAPE URBANISM 2023- 2025

ARCHITECTURAL ASSOCIATION SCHOOL OF ARCHITECTURE

ACKNOWLEDGEMENTS

We would like to extend our heartfelt gratitude to our thesis adviser, Clara Olóriz Sanjuán, who made this project possible. This work reached its full potential under her invaluable guidance and unwavering support. Our deepest thanks go to our directors Jose Alfredo Ramirez and Eduardo Rico-Carranza as well as our tutors—Daniel, Elena, and William (Huang)—for their mentorship throughout the process.

We are sincerely grateful to Dr. Andrew Barkwith and the BGS for providing us with an opportunity to develop this project for their campus and for their consistent support throughout the process. We also deeply appreciate the contributions of our external jurors, interviewees, survey participants, and all other professionals who offered their insights and expertise through emails, calls, and other forms of communication. Your contributions have enriched our project immensely.

Special thanks to our friends and families, in London and back home in Canada and India, who supported us throughout the project.

Cultivating Commons was conceptualised in collaboration with Alejandra Iturrizaga Andrich in term 2 and 3 of the AALU programme. All work presented in this document was produced by the authors unless otherwise credited.

Thesis Supervisor

Clara Olóriz Sanjuán

Programme Directors

Jose Alfredo Ramirez

Eduardo Rico-Carranza

History & Theory Seminar Tutor

Clara Olóriz Sanjuán

Elena Luciano Suastegui

Technical Tutor

Daniel Kiss

Huang Sheng-Yang (William)

Printed at: F E Burman, 20 Crimscott St, London SE1 5TF

Bound at: Wyvern Bindery, 187 Hoxton St, London N1 6RA

92 Skegness

94 Sustainable Aquaculture principles

Reflections 107 OWNERSHIP

109 Network of Actors

Policy Engagement

Policy Memo

PCP Handbook

Basford 144 Prototype Site Model

Reflections

153 LABOUR

154 East Midlands Industrial History 158 A Just Transition 160 Transition Away from Extractive Industries 168 Transition Towards Biobased Industries 170 UK Just Transition

Reflections

175

CONCLUSION

176 Appendix I: Term 1, 2, & 3 Key Informant Interviews

176 Appendix II: Ethics Application Approval

177 Appendix III: Term 4 Survey

179 Appendix IV: Model Making

180 List of Maps

183 List of Illustrations

183 List of Figures

184 Figure Credits

CULTIVATING COMMONS

Landscape, Ownership and Labour

As we grapple with a climate and economic crises, political interest usually lies with carbon reduction—typically in the energy sector. Major corporations, exploiting natural assets such as land, resources and ecologies, often evade true accountability by simply purchasing carbon credits to offset their emissions. This practice, while promoted as a solution, has led to what is known as ‘greenwashing’—the use of environmental claims to mask ongoing exploitation.1 In the construction industry, sustainable building certifications that prioritise energy efficiency, environmental impact, and occupant wellbeing are similarly prone to this issue.

To what extent are these impacts assessed? Are developers genuinely held accountable for their environmental footprint, or do they simply externalise the costs elsewhere?

In this discourse, biobased materials are often heralded as the ultimate solution. Biobased materials are low impact, self-replenishing and have historically demonstrated excellent performance. And yet, focusing solely on the carbon benefits of biobased materials risks perpetuating greenwashing within the construction and materials industries. This narrow focus often obscures deeper, systemic issues tied to the production, processing, and distribution of these materials. For instance, the reliance on monoculture farming—a practice that depletes biodiversity and degrades soil health. Similarly, the entanglement of public-private enterprises often prioritises profit over sustainability, sidelining community welfare and equitable resource distribution.

Moreover, exploitative labour practices remain a significant blind spot in the sustainability narrative. Workers in the supply chain, particularly those involved in manual labour, frequently face unsafe conditions, unfair wages, and a lack of legal protections. These practices not only undermine the presumed

1 United Nations, “Greenwashing – The Deceptive Tactics Behind Environmental Claims,” UN Climate Change, accessed January 6, 2025, https://www.un.org/ en/climate change/science/climate-issues/greenwashing

environmental and social benefits of biobased materials but also reinforce the same capitalist structures responsible for environmental degradation and social inequity.

Cultivating Commons critiques these capitalist systems by challenging the processes, methods, and systems underpinning biobased materials. It calls for a reevaluation of how sustainability is defined and measured, advocating for a novel approach that considers the landscapes, labour and ownership within the biobased sector. The study also proposes a reformed policy for designing and planning landscapes of production to enhance regional ecologies and local economies.

We explore the role of agriculture in shaping landscapes and livelihoods, particularly as biobased materials are cultivated and harvested within these environments. We advocate for a shift from monoculture farming to regenerative practices, facilitating soil carbon sequestration and economic diversification. The project advocates for transforming the construction industry by transitioning from extractive materials to biobased alternatives such as straw insulation and kelp acoustic paneling. It explores opportunities for using biobased materials to not only decarbonise the UK construction industry but move beyond net zero targets to address landscape, labour and governance structures, and derive an architecture that is inextricably linked to the lands the materials from which it is derived.

Through Public-Common Partnerships, this project focuses on local community ownership, fair resource distribution, and collaborative decision-making. By engaging institutions, farmers, local businesses, designers, and community members, the project fosters a shared stewardship of productive landscapes. Cultivating Commons is a collective effort to cultivate landscapes of production that not only sustain people and nature but also contribute to building a surplus shared as commons

PROJECT STRUCTURE & METHODOLOGY

Project Structure

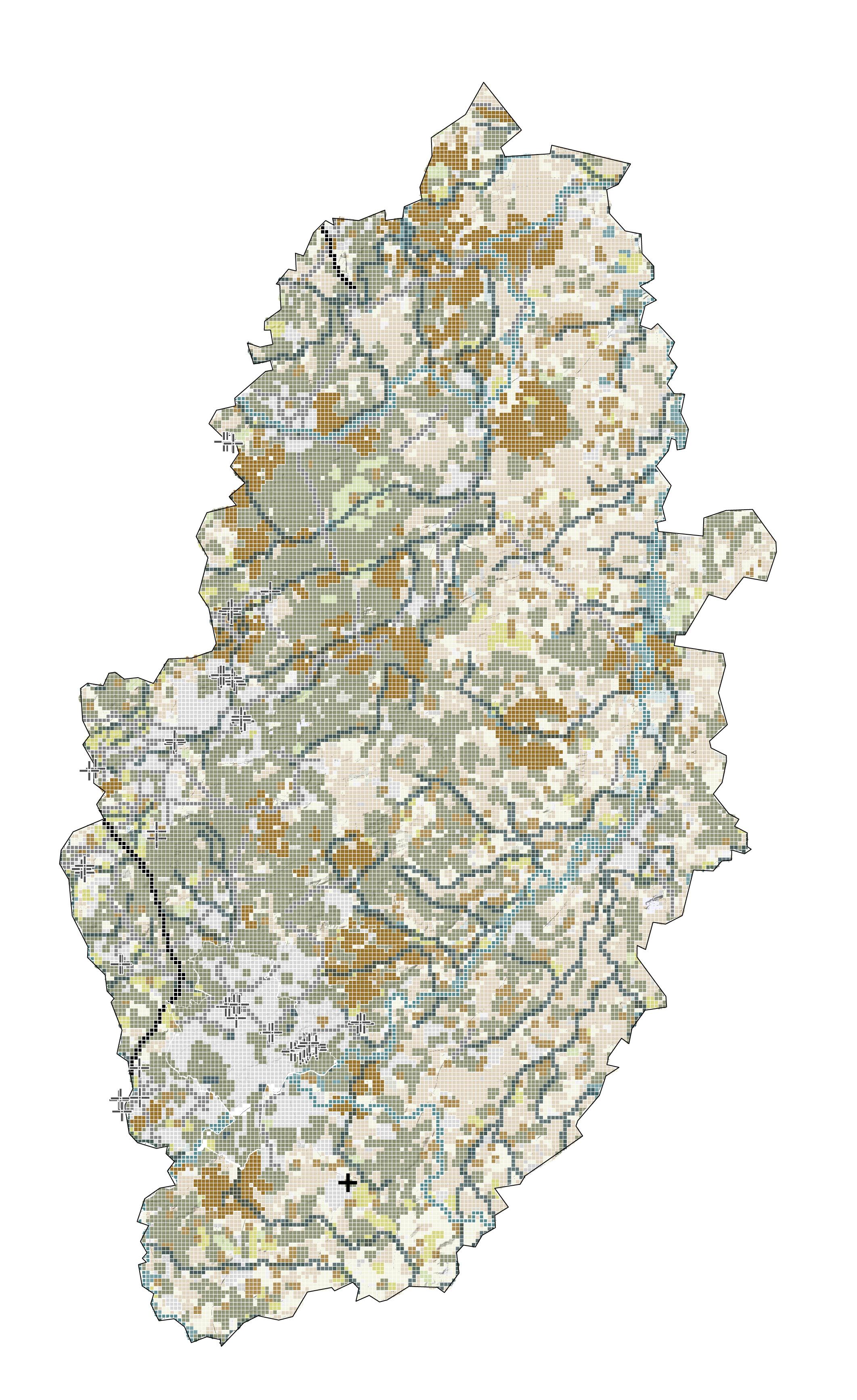

The project is structured into three main arguments: Landscapes, Ownership and Labour. Landscapes addresses: How can we produce biobased materials in ways that enhance local ecologies and improve biodiversity within the East Midlands bioregion? Ownership questions: who is responsible for funding, resources, and education to mobilise the industry? And who profits from the emergent biobased industry? Labour : For this, we have speculated the transition of workers from the mining industry in two parts; the transition away from extractive industries and the second part focuses on how the labour force can shift to the biobased sector.

These three arguments are organised in this document as six chapters. Chapter 1, Introduction, outlines how the UKRI’s BGS retrofit project challenges traditional decarbonisation approaches and presents an opportunity to mobilise a JUST transition towards biobased materials through PCP frameworks. Chapter 2, Beyond Extraction, discusses the issues with the BGS buildings. Chapter 3, Biobased Materials, explores how biobased materials could address these challenges by improving insulation and interior building conditions. Chapter 4, Landscapes, contextualises a phased approach for developing a strategy to supply biobased materials to the BGS, while also enhancing productive landscapes to benefit local and regional communities and ecologies. Chapter 5, Ownership, advocates for a systematic transformation of the ownership structures entrenched within conventional capitalist supply chains and suggests using PCPs to catalyse change within the industry. Chapter 6, Labour, proposes a just transition away from extractive industries towards biobased material production, ensuring that industrialised communities and the labour force benefit from this shift. Finally, Chapter 7, Conclusion, identifies gaps in the study and explores potential avenues for future research.

Methodology

This project undertakes qualitative research, guided by an understanding that architectural research can follow a rigorous research methodology that enables creativity whilst working within the bounds of contemporary research methods. 2

Approach

The research follows a case study approach to develop an in-depth analysis of the opportunities for retrofitting the British Geologic Survey campus in Keyworth, UK with biobased materials. The research involves a mixed-method approach3 and the research was conducted from February 2024 to January 2025 within the UK – our case being specifically within the bioregional boundaries of the East Midlands region. 4

Methods

Critical Discourse Analysis

Critical Discourse Analysis defined by Fairclough, was conducted to understand the status of knowledge and policies related to decarbonisation initiatives in the UK; biobased material research, development, and use; and existing evidence of Community Wealth Building initiatives in the UK.5 The document analysis contributed to initial literature reviews about decarbonisation, biobased materials, transition to bio-economies and community wealth building through Public-Common partnerships. The literature informed a policy map to document the current pathways for achieving net zero, using biobased materials in

2 Wang, David, and Linda N. Groat. Architectural Research Methods. Hoboken, NJ: John Wiley & Sons, 2002; Robert K. Yin, Case Study Research: Design and Methods (Thousand Oaks, CA: Sage Publications, 2013).

3 John W. Creswell and J. David Creswell, Research Design: Qualitative, Quantitative, and Mixed Methods Approaches, 5th ed. (Thousand Oaks, CA: SAGE Publications, 2018).

4 Robert E. Stake, The Art of Case Study Research (Thousand Oaks, CA: Sage Publications, 1995); Robert K. Yin, Case Study Research: Design and Methods (Thousand Oaks, CA: Sage Publications, 2013).

5 Fairclough, Critical Discourse Analysis: The Critical Study of Language (London: Longman, 1995).

practice, and opportunities for alternative economic models through community wealth building approach.

ENGAGEMENT

Key-Informant Interviews

To understand the status of A. the viability of using biobased construction materials and the availability in the UK, and B. understand the status of agricultural and aquaculture industry in the East Midlands, we needed to speak with experts in the field. We engaged 9 key informants in open-ended interviews. Through preliminary case building, we selected straw, seaweed and shellfish to focus our study. Key-informants were selected based on their expertise and their prior engagement in research projects or initiatives. Interviews were conducted intermittently throughout the project development phase (February 2024-June 2024), based on participant availability. We sought iterative feedback from key information, and additionally, benefited from multiple crit sessions from industry professionals throughout Term 4.

Site Visits

The study involved a preliminary site visit to the BGS and Norfolk Coast near Holkham at Wells-next-the-Sea in February 2024. Understanding the East Midlands landscapes was essential to make informed policy and design recommendations. We had a return visit to the BGS on October 3 rd, 2024, to assess site conditions, ground-truth our observations and speak with additional BGS employees.

Survey

Once the initial Public-Common Partnership policy was developed and illustrated, we devised a Survey using Google Forms, accompanied by a four-minute video explaining the policy proposal. We invited 13 industry professionals to participate via email. Of the 13 invitations, we received 8 responses. Responses were organised by question and coded according to theme.

VISUALISATION

Cartography /Mapping Cartography was a foundational visual representation technique and analysis tool for inventorying existing conditions to understand current contexts and cross-analysing datasets to devise a policy proposal based on existing social, cultural, economic, and environmental conditions. The creation of the maps was not a neutral process, however, a series of critical decisions that represent a particular worldview.6 Throughout the document we have disclosed the methodology and process for deriving the results represented within the maps. However, we acknowledge that our individual biases are present within the decision-making process and the maps could be interpreted differently depending on the audience. The accompanying text and methodological disclosures are essential to understand the intent behind the maps.

Data Analysis

Following the Critical Discourse Analysis, Key-Informant interviews, and Site Visits we triangulated the information to develop a policy proposal for procuring biobased materials for the BGS and mobilising the

biobased sector within the East Midlands.7 The preliminary proposal was then revised upon receiving feedback from the Survey. The policy proposal was also iteratively evaluated through conversations with the design tutors and revised accordingly.

Sampling

The Key-Informants were selected through purposive sample according to their expertise in the following topics: decarbonisation of the construction industry in the UK; biobased material use or research and development; biomass production and farming; and knowledge of Community Wealth Building and Public-Common Partnerships (PCP). KeyInformants were approached via email and were asked for their willingness to engage in a brief conversation regarding their expertise in a particular topic. Participation was entirely voluntary with no incentive or deception. Consent to participate in the open and semi-structured interviews, and survey, was acquired prior to participation in accordance with the Architectural Association’s Ethics Agreement.

Data Dissemination

The information is disseminated in two AA Landscape Urbanism Thesis documents. Firstly, the MSc in Landscape Urbanism by Alejandra Iturrizaga Andrich in September 2024, and by Priyanka Awatramani and Emily Bowerman, January 2025. If the information within the thesis were to be used for publication or for a conference, we would ask permission from the British Geologic Survey and the Key-Informants to ensure all information is represented as per their intent.

7 Michael Q. Patton, “Enhancing the Quality and Credibility of Qualitative Analysis,” Health Services Research 34 (1999): 1189-1208.

6 Denis Cosgrove, Mapping Meaning: A Cultural Critique of Cartography (1999), 3.

BIBLIOGRAPHY

Cosgrove, Denis. Mapping Meaning: A Cultural Critique of Cartography. 1999.

Creswell, John W., and J. David Creswell. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches. 5th ed. Thousand Oaks, CA: SAGE Publications, 2018.

Fairclough, Norman. Critical Discourse Analysis: The Critical Study of Language. London: Longman, 1995.

Patton, Michael Q. “Enhancing the Quality and Credibility of Qualitative Analysis.” Health Services Research 34

(1999): 1189–1208.

Stake, Robert E. The Art of Case Study Research. Thousand Oaks, CA: Sage Publications, 1995.

United Nations, “Greenwashing – The Deceptive Tactics Behind Environmental Claims,” UN Climate Change, accessed January 6, 2025, https://www.un.org/en/ climatechange/science/climate-issues/greenwashing

Wang, David, and Linda N. Groat. Architectural Research Methods. Hoboken, NJ: John Wiley & Sons, 2002.

Yin, Robert K. Case Study Research: Design and Methods. Thousand Oaks, CA: Sage Publications, 2013.

BEYOND EXTRACTION

In 2018, the UK emitted 1511 million tonnes of carbon dioxide equivalent (MtCO2e) Green House Gas (GHG), encompassing territorial, production, and footprint emissions as per the Office for National Statistics.1 With the Climate Change Act 2008 the UK government in 2019 set a target for achieving a 100% reduction in Greenhouse Gas emissions by 2050 known as the Net Zero Target. 2

The construction industry plays a significant role in these emissions, accounting for approximately 42% of the UK’s total carbon footprint, as estimated by the UK Green Building Council.3 However, most decarbonisation efforts within this sector have primarily focused on reducing operational carbon, which pertains to emissions from a building’s energy consumption for heating, cooling, and lighting. However, the clean energy transition is questionable. As cited by Dark Matter Labs in their New European Bauhaus lighthouse project, “solar and wind facilities require up to 15 times more concrete, 90 times more aluminum, and 50 times more iron, copper, and glass than fossil fuels or nuclear energy”.4 It is also estimated by the

1 “Emissions,” accessed April 16, 2024, https:// climate-change.data.gov.uk/dashboards/emissions

2 UK Green Building Council, Net Zero Whole Life Carbon Roadmap: A Pathway to Net Zer o, November 2021, https:// ukgbc.org/wp-content/uploads/2021/11/UKGBC-WholeLife-Carbon-Roadmap-A-Pathway-to-Net-Zero.pdf

3 UK Green Building Council, Net Zero Whole Life Carbon Roadmap 4 “New-European-Bauhaus-Economy_Digital-version_ DML.Pdf,” accessed February 18, 2024, https://www.irresistiblecircularsociety.eu/assets/ uploads/20230707-New-European-Bauhaus-Economy_ Digital-version_DML.pdf

Mining Watch Canada that approximately three billion tons of metals and minerals will have to be mined to facilitate the energy transition. Additionally, inefficiencies in insulation and design contribute to high energy consumption for heating and cooling in buildings, particularly in the UK.5

This emphasises the crucial need for reducing our energy consumption and adopting practices that make our buildings more resilient to the climate. This would entail critically addressing the contribution of the “embodied” carbon emissions in the construction industry. As stated by ACAN in the Briefing Note of Carbon Footprint Construction, embodied carbon emissions account for up to 75% of a building’s total emissions over its lifespan.6 These emissions are associated with materials and processes throughout the entire lifecycle of a building, including extraction, processing, and manufacture of materials; transportation; assembly and installation on-site; as well as replacement, refurbishment, maintenance, demolition, and disposal.

5 MiningWatch Canada and Environmental Justice Atlas, Mapping the Mining Impacts of the Energy Transition November 23, 2021, https://miningwatch.ca/ news/2021/11/23/new-report-maps-mining-impactsenergy-transition

6 On the other hand, in ACAN’s full report on The Carbon Footprint of the Construction, it estimates the embodied carbon emissions in the construction industry at around 10% of the UK’s total emission and 40% as the total emissions of the construction sector.

LANDSCAPES OF EXTRACTION

Mapping Conventional Building Material Sites and Industries

Most conventional building materials like cement and stone are non-recyclable materials, meaning that at the end of their life cycle they just go into the landfills, creating pressures on waste management. These extractive and disposal processes not only contribute to carbon emissions but have a detrimental impact on the environment including natural resource depletion and waste generation, harming ecosystems. The global resource extraction and processing currently accounts for more than 35% of global biodiversity loss and water stress.8 Despite their substantial contribution to overall emissions, strategies aimed at reducing embodied carbon have often been overlooked.

This stems from traditional linear approaches to building design and operation which overlook the interconnectedness of various systems within a building. Building materials and structures, often perceived as durable, are actually “designed for obsolescence”.9 Rapid urban development exacerbates these

8 United Nations Environment Programme, Global Resources Outlook 2019: Natural Resources for the Future We Want (UN, 2020), 5, https://doi.org/10.18356/689a1a17en

9 United Nations Environment Programme and Yale Center for Ecosystems +Architecture, “Building Materials and the Climate: Constructing a New Future” (United Nations Environment Programme, September 2023), https://wedocs.unep.org/xmlui/ handle/20.500.11822/43293

challenges, involving significant land use changes and extraction of natural resources, leading to habitat destruction and increased carbon emissions.

Through the lens of Jane Hutton’s Reciprocal Landscapes, we examined the material supply chains within the UK’s construction sector. In this framework, the construction sector’s reliance on material extraction sites as sites and the built environment as non-sites becomes apparent. UK’s construction sector is a critical component of the nation’s economy; the industry contributes significantly to carbon emissions and landscape degradation due to heavy reliance on fossil fuels and machinery.

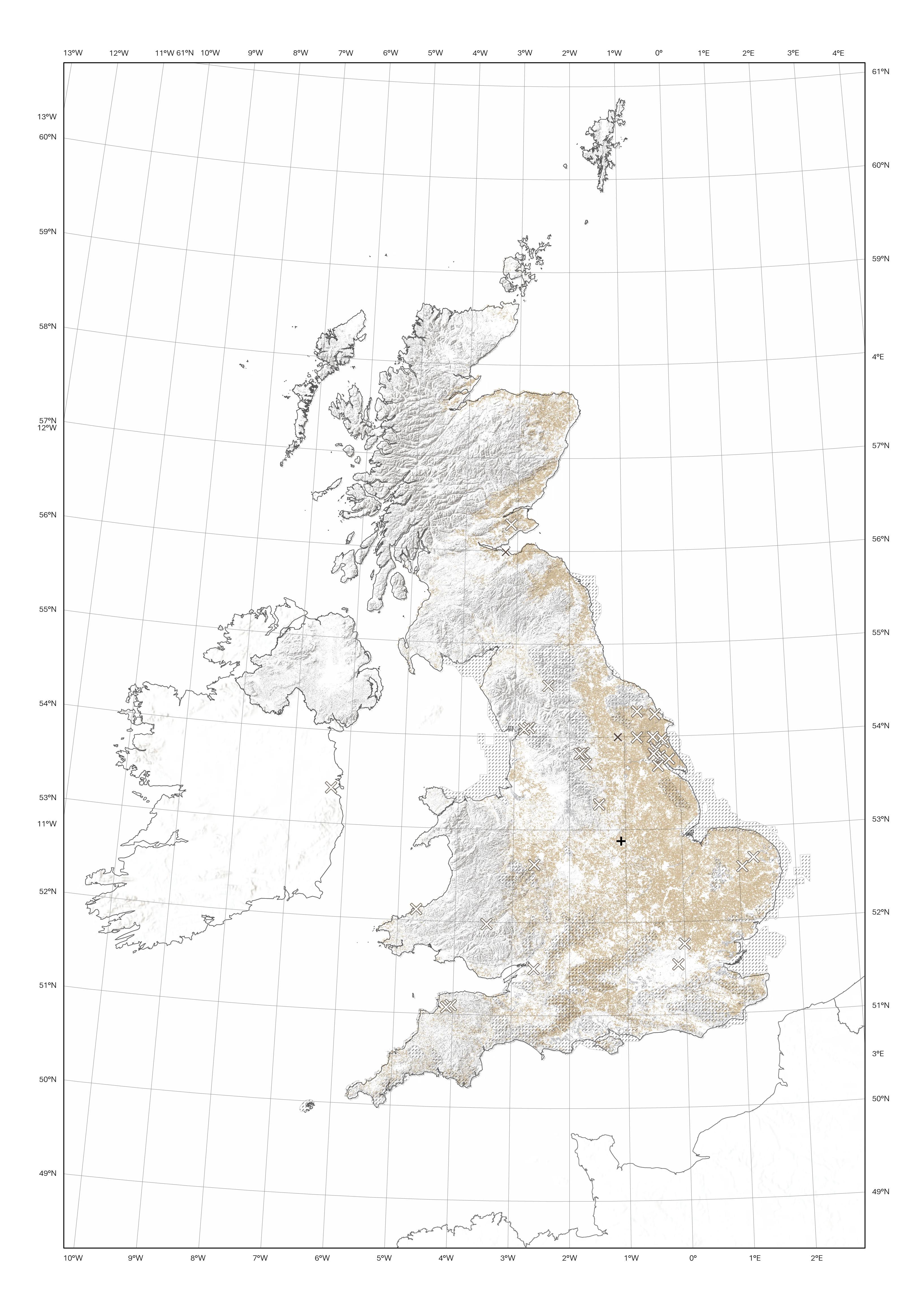

We mapped these extraction sites into two categories: geological reserves reflecting resources and stone quarries along with superficial deposits representing available aggregate resources. According to the Mineral Planning factsheet by BGS, there are 439 active building stone and slate quarries, with concentrations particularly evident in regions such as the Midlands, South-West, and Northern Ireland.10 The East Midlands hosts an abundance of limestone resources, with

10 Graham Lot, David Highley, Don Cameron, John Cowley, “Mineral planning factsheet : building and roofing stone. British Geological Survey” (2007) : 3. (Unpublished), accessed April 17, 2024, https://nora.nerc.ac.uk/id/ eprint/534424/1/mpf_buildingstone.pdf

“The sites and non-sites were linked by material displacement from one to the other, but also through their differences. Sites were peripheral, overlooked spaces that supplied materials for urban development, while non-sites were central concentrations of cultural capital”.7

7 Hutton, Jane. Reciprocal Landscapes: Stories of Material Movements. (Routledge, 2019): 1.

numerous cement factories spread around these resources.

Sand and gravel, essential components for construction, are sourced through various means, including crushing sandstone and extraction from superficial deposits. These aggregates, comprising approximately 85% of non-energy minerals extracted in the UK, are procured from over 1300 quarries across the UK, as well as through marine aggregate dredging.11 The heatmap reveals the highest concentration of quarries in regions like the South-East, Midlands, and East Scotland highlighting an abundance of reserves in these areas. Due to the scale of this industry, the production totaling approximately 260 million tonnes annually, remains labor-intensive, providing employment for an estimated 88,000 individuals, both directly and indirectly. 12

This insight into the scale and spatial dynamics of material extraction and production in the UK, within the framework of reciprocal landscapes, becomes crucial for informed decision-making regarding resource management and environmental sustainability.

11 “Aggregates | Mines & Quarries | MineralsUK,” accessed April 17, 2024, https://www2.bgs.ac.uk/ mineralsuk/mines/aggregates.html

12 “Aggregates | Mines & Quarries | MineralsUK.”

fig 2.2 1953 The site for the new McKechnie Brothers Ltd Engineering Works. Source: Historic England

fig 2.3 2005 Buddon Wood Quarry, Mountsorrel, Leicester.

Source: Historic England

BGS

OVERSEAS SUPPLY CHAINS

Construction Material Imports in the UK

Despite the significant extraction of construction materials within the UK, a substantial portion of the carbon footprint associated with the construction industry stems from the imports of materials. The UK is a net importer of crucial construction materials such as cement, iron, and stone from various regions worldwide.13 This reliance on imports introduces complexities into the carbon accounting of the construction sector, particularly as these materials traverse vast distances, often from disparate continents.

Iron ore, for instance, is sourced from five different continents, highlighting the global nature of material supply chains and the interconnectedness of the construction industry with international markets. This dependence on imported materials is visually represented through the depiction of emission rings surrounding the globe, illustrating the total emissions linked to the imports of these materials into the UK, map.05.

While the UK’s extraction sites contribute to domestic supply, the industry’s increased demands and globalisation have normalised the use of materials produced from across the world. This is driven by factors such as cost considerations, availability, quality standards and aesthetics in the design and construction industry. This trend has led to the establishment of complex networks of extraction, transportation, and distribution, amplifying the carbon footprint associated with the construction industry.

Moreover, the imports of construction materials affect additional environmental and social considerations beyond carbon emissions. Issues such as habitat destruction, land degradation, and labour exploitation are often linked to the extraction and production of materials in other countries, making it crucial to incorporate holistic assessments in construction material procurement. To demonstrate where these impacts might be most severe, the global cartography displays the domestic extraction of construction materials by each country along with locations of major extractive sites. It is therefore critical that addressing the carbon footprint of imported materials adopts a multifaceted approach that considers not only the direct emissions associated with extraction and transportation but also the broader environmental and social impacts throughout the supply chain.

13 Graham Lot, et al.,“Mineral planning factsheet,” 3.

Based on the Polar Orthographic Projection, with the UK at the center, this global cartography is designed to mimic the view of Earth from a distant vantage point. In this projection, all straight lines radiating from the center represent true directions (azimuths), providing an accurate depiction of relative positions and directions from the UK. The globa map illustrates the distribution of major non-metallic reserves, significant ports, and trade routes across the world, alongside the domestic extraction levels of each country. These elements establish the foundational understanding of the global impacts of construction material industries.

To illustrate the environmental footprint, the cartography uses rings to represent the emissions associated with material imports. These emissions were calculated by multiplying the quantity of imported material by the distance traveled (in nautical miles) and applying a benchmark emissions factor. A benchmark, developed by CarbonChain for global supply chains, provides insight into a ship’s carbon dioxide emissions per unit of nominal transport work known as the Annual EfficiencyW Ratio (AER) of cargo ships based on their deadweight capacity. For ships exceeding 10,000 gross tonnage, the emissions rate is 11.2 gCO₂/dwt.nm (grams of CO₂ per deadweight ton per nautical mile).14

14 Sinay, “How Much Does the Shipping Industry Contribute to Global CO₂ Emissions?” September 22, 2023, https://sinay.ai/en/how-much-does-the-shipping-industrycontribute-to-global-co2-emissions/

map.05 UK IMPORTS OF CONSTRUCTION MATERIALS IN2020

Emissions associated with import of construction materials by the UK in 2020 [t CO2]

UKRI INSTITUTIONS & BRITISH GEOLOGICAL SURVEY CAMPUS

Assessing campus retrofit requirements

The British Geological Survey (BGS) is one of the UK’s oldest scientific research institutes, celebrated for preparing the country’s first national survey of the geological landscape. Operating under the UK Research and Innovation (UKRI), BGS manages significant geoscientific data and research critical to the UK. 15 UKRI was established in 2018 to bring together nine distinct research councils, including the Natural Environment Research Council (NERC), which oversees BGS. As part of its commitment to the UK’s Net Zero 2050 goals, UKRI is encouraging its institutions— more than 80 research organizations and facilities across the UK—to lead by example in reducing carbon emissions. These institutions play a critical role in developing innovative solutions for climate change, energy transition, and sustainability.

Therefore, when BGS decided to retrofit their campus by 2040, and Pick Everard, a consultancy firm, was commissioned to conduct a thorough review of their campus. In response to BGS’s requirements for short and

15 British Geological Survey. “Our History.” British Geological Survey. Accessed March, 2024. https://www. bgs.ac.uk/about-bgs/our-work/our-history/

long-term maintenance, net zero aspirations, energy decarbonisation, and adaptable working methods, Pick Everard proposed five distinct options, ranging from Business as Usual to Partial Refurbishment to an entirely New Build. These options were analysed to address the need for phased strategies, storage solutions, and improvements to workspace design. With most of the existing building fabric requiring replacement within the next decade, Pick Everard’s assessment also considered the structural integrity and longevity of the facilities.16

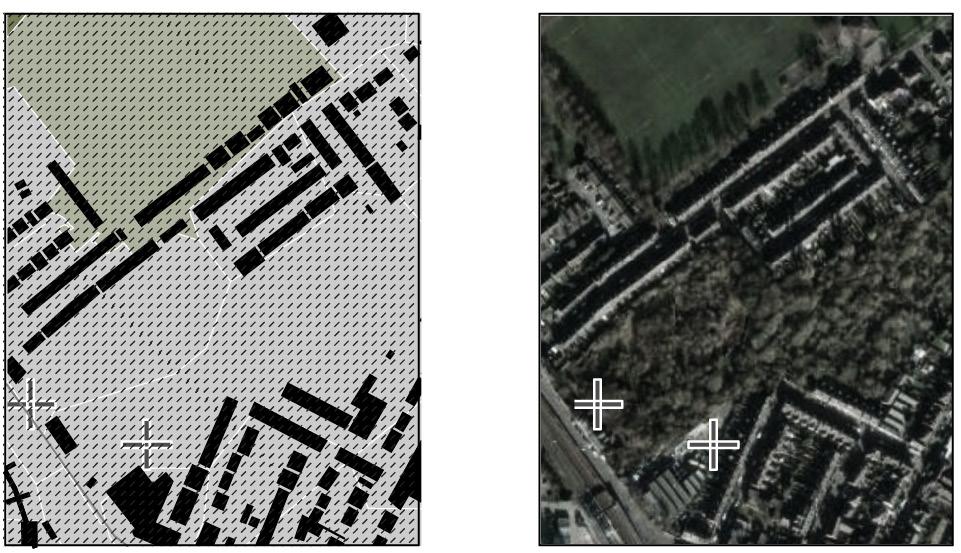

With support from BGS staff including Dr. Andrew Barkwith, we had the opportunity to visit their campus twice— in March and October 2024. We gained insights into the existing infrastructure and highlighted areas for potential improvement.

The BGS Keyworth campus, situated in the situated in the Rushcliffe borough of Nottinghamshire, hosts more than 500 employees including scientists, technicians,

16 Pick Everard, Feasibility Report, Natural Environmental Research Council, British Geological Survey Laboratories, Keyworth, issued March 6, 2024 (confidential).

fig 2.4 Aerial view of the Mary Ward College as it was offered for sale in 1975.

Source: BGS

Andrew Barkwith

Associate Director of Operations at British Geological Survey

1. Business as Usual

Pros: Maintains existing infrastructure. Minimal disruption to operations. Opportunities for workspace reconfiguration.

Cons: Long-term maintenance impacted. Limited flexibility. Limited improvement in workspaces.

2. Partial Refurbishment

Pros: Less schedule impact. Achieves degassing of site. Low impact on electrical capacity.

Cons: Limited long-term benefits. Disruptions during refurbishment. Limited scope for new science.

3. Full Refurbishment

Pros: Enhances BREEAM Energy Issue performance. Utilises existing space efficiently. Improves building fabric.

Cons: Requires ambitious BREEAM score commitment. Disruption to workspace during construction.

4. New Build / Relocation

Pros: Compliance with regulations. Potential for new science opportunities. Improved energy efficiency.

Cons: Challenges in achieving BREEAM Excellence. Disruption to workspace during construction. High negative impact on electrical capacity.

5. Hybrid

Pros: Flexibility of spaces. Position as world-class leaders. Positive impact on decarbonisation.

Cons: Relocation expenses. Risk to business continuity. Disruptions during construction.

analysts, among others. The campus has multiple facilities including research laboratories, technical workshops, archives, core stores, monitoring systems, and office spaces. Additionally, BGS maintains an open and collaborative presence, regularly welcoming school groups, university researchers, and government officials. Its presence has greatly influenced the socioeconomic development of Keyworth and the surrounding Rushcliffe borough.

The campus features a mix of older and newer buildings, with only two recent constructions. While materials like brick and concrete are durable, it was evident that the buildings lacked adequate insulation, as evidenced by the thin windows and the necessity to use curtains to minimise heat loss. It became evident that the older buildings, while having historical charm, require significant upgrades to meet contemporary standards of energy efficiency and functionality.

The laboratories, critical hubs for scientific research, were a focal point of the retrofitting

analysis. However, their configuration reflects outdated designs, limiting their functionality and usability. Two primary concerns emerged during our assessment of the laboratories: acoustics and thermal conditions. The presence of loud noises in some labs significantly detracted from the work environment, while inadequate insulation and outdated windows compromised thermal comfort and energy performance. Addressing these issues emerged as the top priorities for retrofitting, as they directly impacted their productivity and well-being.

During our exploration of the campus facilities, we encountered small, closed cubicles that were implemented during the COVID-19 pandemic for e-meetings. However, it was apparent that these spaces were not adequately ventilated, resulting in uncomfortably warm conditions. Given the shift towards remote collaboration, there is a clear need for designated, properly ventilated spaces to accommodate virtual meetings effectively.

Additionally, we were made aware of the requirements of additional storage space in the core stores to accommodate the growing volume of geological samples received on campus. Addressing this requirement is crucial to maintaining the integrity and accessibility of BGS’s extensive sample collection.

The campus also features interspersed green spaces and a unique Geological Walk, showcasing three billion years of Earth’s history. While these areas offer educational and recreational value, the overall landscape strategy feels outdated, with limited collaborative spaces for employees.

The BGS community demonstrates strong ecological awareness through independent recycling efforts and participation in habitat restoration programs, which is likely due to the diverse demographic of employees, with varied interests and passions. However, the campus’ sustainability initiatives could be better integrated into its retrofitting strategy to enhance environmental impact and employee well-being.

fig 2.5 BGS Campus Site Visit in October 2024. Photo by Priyanka Awatramani

fig 2.6 BGS Campus Site Visit in October 2024; looking into the courtyard. Photo by Priyanka Awatramani

ill 2.1 BGS Campus Plan highlighting the buildings designated for retrofitting

1

3

Noise from large machinery and ‘chillers’ causes an unpleasant working environment. *Acoustics are a primary issue.

2 Inadequate ventilation and noisy air circulation vents make it difficult for employees to concentrate and work without noise cancelling headsets. *Acoustics are one of the major considerations for employee comfort.

4

Some tests and machinery require staff to work directly in the labs for polonged periods to time to run tests and studies. Appropriate desks and workspaces are required.

Interior lab layouts should encourage collaboration. The BGS labs are currently spread apart, making it difficult for teams to meet, collaborate and share knowledge.

Labs are dated, isolated, and do not reflect the innovative research being undertaken by the BGS.

BGS management recognise the interconnection between employee well-being and design of physical space. They want to ensure the building architecture and spaces within the BGS promote employee well-being and research excellence.

Appropriate solar control is required to better regulate interior temperatures.

fig 2.7 NEIF Archaeological Radiocarbon Laboratory at BGS. Source: Geo-Biosciences Advanced E-Learning Academy

To address retrofitting of BGS, rockwool insulation is a viable option due to its excellent thermal and acoustic properties, as well as its fire-resistant characteristics. However, the production of rockwool presents significant environmental and waste management concerns. Rockwool is made from natural stone, primarily basalt, and recycled slag, which are melted at extremely high temperatures—around 1500°C17—to form fibers. This process is highly energy-intensive and heavily reliant on fossil fuels, leading to substantial carbon emissions during manufacturing. The carbon footprint of Rockwool can range between 1.12 and 1.8 kg CO₂-equivalent per kilogram of material produced, depending on the energy source

17 Anders Schmidt, Anders Ulf Clausen, Allan Astrup Jensen, and Ole Kamstrup, Comparative Life Cycle Assessment of Three Insulation Materials: Stone Wool, Flax, and Paper Wool (dk-TEKNIK Energy & Environment and Rockwool International, March 2003): 76.

and efficiency of the manufacturing process.18 To compare, the carbon footprint of Cork is around 0.19 kg CO₂-equivalent per kilogram.

Moreover, rockwool production involves a complex supply chain that depends on the extraction and transportation of raw materials, further increasing its environmental impact. The durability of rockwool, while beneficial for long-term use, becomes problematic at the end of its life cycle. Unlike biodegradable materials, rockwool does not break down naturally and often ends up in landfills. In the UK, construction and demolition waste accounts for 62% of total waste, and its disposal contributes to the growing landfill crisis. The UK faces a critical challenge, with

42% of its landfills already reaching capacity,19 emphasising the urgency for better waste management solutions. This waste not only occupies valuable landfill space but also poses risks to soil and water quality due to potential leaching of contaminants.

Efforts to recycle rockwool exist but are limited by economic and logistical challenges. The fibrous nature of the material and the contamination from mixed construction waste often make recycling inefficient or costly. Additionally, the energy required to recycle rockwool can offset its environmental benefits, perpetuating its reliance on energy-intensive processes.

18 Craig Jones and Geoffrey Hammond, The Inventory of Carbon and Energy (ICE) Database, Version 3.0, November 10, 2019, http://circularecology.com/embodied-carbonfootprint-database.html

19 Environment Agency, 2020. “Remaining Landfill Capacity.” Retrieved from https://www.data.gov.uk/ dataset/237825cb-dc10-4c53-8446-1bcd35614c12/ remaining-landfill-capacity ”

map.07 LANDFILLS AT CAPACITY

REFLECTIONS

The landscapes of extraction and architecture are intricately linked, since landscapes around the world are being shaped by extraction activities. Understanding this is crucial, especially considering that the typical lifespan of modern buildings is around 50 years. Mapping these sites of material extraction provides a critical perspective on the construction industry by revealing the sites where the material is derived from, the emissions associated with their transport and processing, and the broader environmental impacts of these activities. This spatial and process-oriented understanding highlights the inefficiencies and carbon-intensive nature of current supply chains. Decarbonisation efforts must extend beyond solely reducing carbon emissions to encompass broader environmental factors such as water usage, material sourcing, and waste generation. This prompts a need to reconnect design with landscape and agricultural practices. As proposed by Material Cultures, the initial drawings when designing a building should carefully consider the selection of materials and their potential impact on people, the

economy, and environmental factors such as climate and ecology. 20

In response to these challenges, we propose adoption of ethically produced, low-carbon, and regenerative biobased building materials that can significantly reduce dependence on conventional materials such as concrete, steel and aluminum. These materials not only have low embodied carbon but also reduce environmental degradation and simplify supply chains, making it easier to trace and manage emissions effectively. By prioritising materials with minimal ecological footprints and streamlined logistics, the construction sector can move towards more sustainable and transparent practices. As a prestigious research institution, BGS is well-positioned to lead innovative retrofitting solutions. They can integrate biobased materials and technologies into their operations, setting a benchmark for environmentally conscious practices. By doing so, they not only advance their commitment to Net Zero goals but also inspire broader industry adoption of ecologically conscious construction practices.

20 Material Cultures. Material Reform. London: Mack Books, 2023.

BIBLIOGRAPHY

“Climate Change Act 2008,” 2008.

“Measuring UK Greenhouse Gas Emissions - Office for National Statistics.” Accessed February 18, 2024. https://www.ons.gov.uk/economy/ environmentalaccounts/methodologies/ measuringukgreenhousegasemissions.

“New-European-Bauhaus-Economy_Digital-version_DML. Pdf.” Accessed February 18, 2024. https://www. irresistiblecircularsociety.eu/assets/ uploads/20230707-New-European-BauhausEconomy_Digital-version_DML.pdf.

“Our Waste, Our Resources: A Strategy for England,” n.d.

“Plants for a Future.” Accessed February 17, 2024. https:// pfaf.org/user/.

“Reducing Our Carbon Emissions.” Accessed January 27, 2024. https://www.barnsley.gov.uk/services/ our-council/our-environment/reducing-our-carbonemissions/

“UK Innovation Strategy,” n.d.

Anderson, Jane. “Embodied Carbon (Aka Embodied Energy) & EPDs.” Accessed January 21, 2024. http://www. greenspec.co.uk/building-design/embodied-energy/.

Bide, Compiled T P, P S Balson, E Campbell, and S Green. “United Kingdom Continental Shelf Marine Sand and Gravel Resources Scale 1:1 500 000,” n.d.

Bide, Thomas. “Thinking Big - Defining Resources for Major Coastal Defence Projects.” In 18th Extractive Industry Geology Conference, 14–20. EIG Conferences Ltd., 2014.

British Geological Survey. “Aggregates | Mines & Quarries | MineralsUK.” Accessed April 17, 2024. https://www2. bgs.ac.uk/mineralsuk/mines/aggregates.html.

Cameron, D G, E J Evans, N Idoine, J Mankelow, S F Parry, M A G Patton, and A Hill. “Directory of Mines and Quarries 2020,” no. 11th Edition (2020).

Casey, Diana. “Options for Switching UK Cement Production Sites to near Zero CO2 Emission Fuel: Technical and Financial Feasibility,” n.d.

Climate Change Data. “Emissions.” Accessed April 16, 2024. https://climate-change.data.gov.uk/dashboards/ emissions.

Dyson, Anna. Building Materials and the Climate: Constructing a New Future. Nairobi: United Nations Environment Programme, 2023. Environment Agency. “Remaining Landfill Capacity.” Accessed 2020. https://www.data.gov.uk/ dataset/237825cb-dc10-4c53-8446-1bcd35614c12/ remaining-landfill-capacity.

Hartwell, Rebecca, Graham Coult, and Mauro Overend. “Mapping the Flat Glass Value-Chain: A Material Flow Analysis and Energy Balance of UK Production.” Glass Structures & Engineering 8, no. 2 (September 1, 2023): 167–92. https://doi.org/10.1007/s40940-022-00195-9.

Hutton, Jane. Reciprocal Landscapes: Stories of Material Movements. Routledge, 2019.

Jones, Craig, and Geoffrey Hammond. The Inventory of Carbon and Energy (ICE) Database. Version 3.0, November 10, 2019. http://circularecology.com/ embodied-carbon-footprint-database.html

Lot, Graham, David Highley, Don Cameron, and John Cowley. “Mineral Planning Factsheet: Building and Roofing Stone.” British Geological Survey, 2007. Accessed April 17, 2024. https://nora.nerc.ac.uk/id/ eprint/534424/1/mpf_buildingstone.pdf.

Material Cultures. Material Reform. London: Mack Books, 2023.

MiningWatch Canada and Environmental Justice Atlas. Mapping the Mining Impacts of the Energy Transition. November 23, 2021. https://miningwatch.ca/ news/2021/11/23/new-report-maps-mining-impactsenergy-transition.

Pick Everard. Feasibility Report. Natural Environmental Research Council, British Geological Survey Laboratories, Keyworth, issued March 6, 2024 (confidential).

Schmidt, Anders, Anders Ulf Clausen, Allan Astrup Jensen, and Ole Kamstrup. Comparative Life Cycle Assessment of Three Insulation Materials: Stone Wool, Flax, and Paper Wool. dk-TEKNIK Energy & Environment and Rockwool International, March 2003.

Sinay. “How Much Does the Shipping Industry Contribute to Global CO₂ Emissions?” September 22, 2023. https:// sinay.ai/en/how-much-does-the-shipping-industrycontribute-to-global-co2-emissions/.

UK Green Building Council. Net Zero Whole Life Carbon Roadmap: A Pathway to Net Zero. November 2021. https://ukgbc.org/wp-content/uploads/2021/11/ UKGBC-Whole-Life-Carbon-Roadmap-A-Pathway-toNet-Zero.pdf.

United Nations Environment Programme, and Yale Center for Ecosystems +Architecture. “Building Materials and the Climate: Constructing a New Future.” United Nations Environment Programme, September 2023. https://wedocs.unep.org/xmlui/ handle/20.500.11822/43293.

United Nations Environment Programme. G lobal Resources Outlook 2019: Natural Resources for the Future We Want. United Nations, 2020. https://doi. org/10.18356/689a1a17-en.

BIOBASED MATERIALS

Biobased construction materials are derived from natural resources, including earth, plants, animals, fungi, and microorganisms. These materials typically have low embodied carbon, with some offering carbon sequestration potential. They are renewable, biodegradable (when produced without synthetic additives), and contain fewer toxic chemicals and pollutants.1 Biobased materials can be considered regenerative if produced in a nonexploitative and tempered way. Regenerative materials are, “extracted at a rate and in such a way that allows the ecosystems they are harvested from to fully regenerate, either remaining healthy or as a part of a managed recovery towards a more resilient state”. 2 In an architectural context, local biobased materials lend identity to the design of buildings, connecting architecture with the unique ecological and cultural characteristics of the region. This chapter explores the availability of biobased materials in the UK and the benefits and limitations of biobased materials for construction.

What biobased materials are available in the UK for use in construction? What opportunities do they provide?

For this study, we explored six living biobased materials with significant potential for retrofitting: Clay, Hemp, Mycelium, Timber, Aquaculture and Straw. We acknowledge that the viability of these materials varies across the regions in the UK; therefore, to begin, we mapped the industries and opportunities of these materials for all regions of the UK since material sourcing is landscape specific and industries are at varied statuses and levels of development. This helped to assess the ease of scalability for production and manufacturing. We further cross-analysed their building suitability and code compliance to identify areas requiring further research. Simultaneously, we conducted open-ended

1 Material Cultures, Material Reform (London: Material Cultures, 2022), 111.

2 Material Cultures, 2024 Building Skills Report, 17, accessed January 4, 2025, https://materialcultures. org/2024-building-skills-report/

interviews with industry professionals involved in fields such as seaweed farming, marine rewilding, straw construction, and biobased architecture. The insights gathered informed recommendations for UKRI institutions, highlighting the biobased materials most viable for specific regions. For the East Midlands, straw and seaweed emerged as the most promising materials for retrofitting projects. Straw is readily available as for use as insulation, and Seaweed (kelp), and shellfish with further R&D could be a long-term solution. These materials also provide opportunities to strengthen local economies and enhance landscapes with their localised production and building material supply chains.

Despite its potentials, the biobased construction sector faces significant barriers, including a lack of awareness and understanding of biobased materials and their benefits, and limited standardised testing and certifications hindering their widespread adoption. Similarly, there are ongoing debates around material certification for construction purposes. Biobased materials also have underdeveloped supply chains and a lack of key actors leading to slow industry growth. Finally, there are regulatory challenges associated with approvals for farms and production sites due to the lack of standardisation.

Biobased industries are in their nascency in the UK, however, there are a few architectural practices including London-based nonprofit Material Cultures, who are raising awareness for the applicability of biobased materials in construction through built projects, community engaged workshops and research. Their work has served as a point of departure for this study. In this chapter, we review their report to speculate how Cultivating Commons contributes to professional discourse within the biobased research field. 3

3 Material Cultures, Circular Biobased Construction in the Northeast and Yorkshire. Energy Hub / York & North Yorkshire Local Enterprise Partnership, 2021, accessed January 4, 2025, https://materialcultures.org/cbconstruction/

3 tonnes of clay/shale are used in the manufacture of 1000 bricks

CLAYCLAY

Industries and Opportunities

Kimmeridge and Ampthill Clay Kellaways, Oxford Clay and Osgodby Formation

Lias

Marros Group

Bowland and Cravem Groups

Upper Cambrian Shales

POLICIES AND STAKEHOLDERS

Environment Agency

Natural England

Mineral Planning Authority

Local Planning Authorities like Ministry of Housing, Communities & Local Government in England

Brick clay comprises clay—a topsoil, shale and mudstone.4 It holds significant importance in various industries, including construction. Its limited availability makes it a valuable resource, particularly for its regenerative properties and ecological benefits. Clay deposits are alive with microorganisms and ecosystems, contributing to soil health and biodiversity. In our exploration of the UK’s clay industry, we mapped the spatial distribution of clay reserves across the country along with extraction sites and brick manufacturing facilities. These are mainly concentrated around the Midlands and southern England. In 2021, approximately 4 million tonnes of clay and shale were extracted, highlighting its indispensability as a construction material.5

Clay finds versatile applications in construction, serving as the foundation for bricks, tiles, and raw materials for cement and plasters. Its structural integrity and insulating properties make it invaluable, ensuring that buildings remain thermally comfortable by absorbing and storing heat, then gradually releasing it as temperatures fluctuate. While

4 “Brick Clay Mineral Planning Factsheet” BGS, 2022. accessed April 17, 2024, https://nora.nerc.ac.uk/id/ eprint/532490/1/Brick%20Clay%20Mineral%20 Planning%20Factsheet.pdf

5 “Brick Clay Mineral Planning Factsheet” BGS.

most conventional bricks are fired, rendering them non-biodegradable, more ecological alternatives like adobe bricks and compressed earth blocks need to be prioritised. These alternatives typically incorporate additives or stabilisers like cement, fly ash, lime, or agricultural waste, which vary based on local practices, the intended performance of the bricks, and the available resources. For example, a study in Egypt found that clay bricks mixed with sludge and sugarcane bagasse reduced heat flow through wall systems by an average of 64% compared to conventional fired bricks.6 Clay plaster, often stabilised with lime, is another sustainable application for covering biobased materials. It is commonly used to render external facades, offering weather resistance while maintaining breathability to regulate humidity.

While clay offers immense potential for sustainable construction, it is crucial to recognise its limitations. Unlike renewable resources, clay cannot be rapidly replenished, and large-scale extraction can lead to significant landscape degradation.

6 Ahmed M. Seddik Hassan et al., “Thermal Performance Analysis of Clay Brick Mixed with Sludge and Agriculture Waste,” Construction and Building Materials 344 (2022): 128267, https://doi.org/10.1016/j. conbuildmat.2022.128267

fig 3.2 Clay Extraction Site

HEMP

Industries and Opportunities

2022

110 licenses issued for a validity period of three growing seasons

AREA UNDER HEMP CULTIVATION

UK: 810 ha

Europe: 33,000 ha

EU UK

£500 for one tonne of Hemp seeds before processing

7.5 tonnes

Potential yield of Hemp fibre per hectare

4 metres Growth per 100 days

SPECIES IN THE UK

Finola

Finola 2

Henola

Finola

Finola 2

Henola Fedora 17

Kompolti

POLICIES AND STAKEHOLDERS

Hemp, a variety of cannabis with less than 0.2% THC, is regulated as a controlled substance in the UK. Cultivation requires an industrial hemp license, permitting the production of non-controlled hemp products derived exclusively from fiber and seed. To ensure compliance and avoid undue attention, hemp crops must be located away from schools, public rights of way, and vehicular access. 7 While the licenses are valid for up to three growing seasons (three years), the number of hemp licenses issued has increased significantly, from six in 2013 to 136 in 2023, reflecting growing interest in hemp cultivation.8

As an alternative to non-loadbearing concrete, hempcrete is made from a mixture of hemp shiv and lime serving as a low-carbon building material. It offers great insulation and breathability; it reduces the energy required to heat buildings while preventing issues such as dampness, condensation, and mould. It allegedly has the capacity to absorb approximately 110-160 kg of CO2 per cubic meter of wall, contributing to carbon sequestration. 9 Hemp’s rapid growth cycle, low water requirement, and ability to prevent soil erosion offer this as a viable biobased material.

The practical applications of hempcrete have demonstrated its potential as a viable building material. For example, the British Science Museum in Wiltshire opted for a hempcrete

7 Home Office, “Industrial Hemp Licensing: Factsheet,” last updated December 18, 2024, https://www.gov.uk/ government/publications/industrial-hemp-licensingguidance/industrial-hemp-licensing-factsheet

8 Home Office, “Hemp Licensing Changes Will Help Grow UK Economy,” last modified April 9, 2024, https:// www.gov.uk/government/news/hemp-licensing-changeswill-help-grow-uk-economy

9 “UK Hempcrete,” UK Hempcrete, accessed March 2024, https://www.ukhempcrete.com/

storage building to reduce relative humidity fluctuations and protect historic artifacts. It was noted that while construction costs were 10% higher, primarily due to design expenses, operational costs were two-thirds lower than traditional store buildings on-site. However, participants mentioned challenges such as a lack of contractors familiar with hempcrete in the UK, reflecting limited industry knowledge and adoption.10

Therefore, from an industrial perspective, we mapped the potential for hemp cultivation for its integration into biobased construction practices in the UK. First, we identified regions with suitable soil compositions, focusing on areas with Grade 1 to Grade 3 soil, which are optimal for hemp growth. Hemp can easily replace cereal crops like wheat, barley, and rapeseed, so we mapped farms growing these crops to assess the potential for replacing or integrating hemp cultivation. While cocultivation is theoretically possible, crop rotation is the more effective approach, as hemp’s deep root system improves soil structure and health. Beyond the potential cultivation avenues, we mapped existing hemp farms based on publicly available data to understand the current landscape of hemp cultivation in the UK. This mapping also included identifying hemp producers and pharmaceutical distributors to identify key stakeholders in the industry. However, it is important to note that due to restricted policies surrounding hemp cultivation, detailed information about hemp farms is not publicly available. This lack of transparency presents a significant barrier to scaling up the hempbased industry in the UK.

10 Thérèse Dams et al., “Crossing Boundaries Conference 2021 Full Paper,” (paper presented at the Crossing Boundaries Conference, University of Bath, 2021).

fig 3.3 Hemp Farm

MYCELIUM

MYCELIUM

Industries and Opportunities

MYKOFOAM

40%

less electricity than polystyrene

90%

less water than polystyrene

YIELD

10-30 days cultivation time for complete colonisation

2-4kg of fresh mycelium per 1 kg of dry substrate

SPECIES IN THE UK

Trametes versicolor

Fistulina hepatica

Laetiporus sulphureus

Grifola frondosa

Fomes fomentarius

Daedalea quercina

Fomitopsis betulina

Ganoderma australe

Daedaleopsis confragosa

Polyporus squamosus

POLICIES AND STAKEHOLDERS

British Mycological Society (BMS)

Office for Product Safety and Standards (OPSS)

Biorenewables Development Centre

DEFRA

UK Innovate

Mycelium is the vegetative part of fungi, consisting of a network of fine white filaments, that spread from a single spore throughout a substrate. When combined with organic matter derived from agricultural and industrial waste, mycelium forms a bio-composite suitable for a range of applications. These include low-value uses such as gap filling and packaging, as well as high-value composite materials for structural purposes. 11 Using agricultural by-products like sugarcane bagasse, rice husks, cotton stalks, and straw as growth substrates, mycelium-based products convert waste into continuous composites without excessive energy or water input or additional waste generation compared to conventional alternatives. 12

Mycelium is lightweight and versatile in nature, making it useful as a building material as an insulation. It provides both acoustic and thermal performance alongside significant fire resistance and moisture regulation properties.13 Mycelium-based products can repurpose waste from the paper industry to manufacture building materials. Mycelium composites are resistant to pests and mould, ensuring longevity and structural integrity in construction. Notable projects such as the

11 Libin Yang, Daekwon Park, and Zhao Qin, “Material Function of Mycelium-Based Bio-Composite: A Review,” Frontiers in Materials 8 (September 30, 2021): 737377, https://doi.org/10.3389/fmats.2021.737377

12 “Mycelium Insulation,” UK Green Building Council accessed March 2024, https://ukgbc.org/resources/ mycelium-insulation/

13 Mykor Limited, “Mycelium Materials: Fantastic Fungal Innovations & Will Fungal Composites Take Over the World?” Mykor, accessed March 2024, https://www.mykor. co.uk/news/mycelium-materials-fantastic-fungalinnovations-will-fungal-composites-take-over-the-world

HY-Fi Installation in New York and the Mycelium Hayes Pavilion at the Glastonbury Festival showcase its architectural potential and aesthetic appeal. Mycelium biobased material research has been funded by Innovate UK14 and the EU15 which proves interest in this material and acceleration in certification processes.

To understand the potentials of the mycelium industry for its production we mapped urban areas as mycelium can grow in relatively small spaces. Focusing on urban environments complements the shift toward sustainable, high-density living, creating opportunities for repurposing under-utilised spaces for mycelium cultivation. Additionally, we mapped paper factories in the proximity since paper waste is a key substrate for mycelium insulation production. Locating mycelium production facilities near paper factories can minimise transportation distances and associated carbon emissions. We further mapped existing mushroom farms and dedicated mycelium producers to identify regions which have established infrastructure and expertise in fungal cultivation. However, it is important to acknowledge the possible presence of laboratories and other facilities cultivating mycelium for research or niche applications, for which comprehensive information was not readily available.

14 Mykor Limited, “New UKRI Funding Aims to Enhance UK Sustainable Biomanufacturing,” Mykor, accessed March 2024, https://www.mykor.co.uk/news/new-ukri-fundingaims-to-enhance-uk-sustainable-biomanufacturing

15 Mykor Limited, “Mykor Secures a £825k Pre-Seed Funding Round” Mykor, accessed March 2024, https:// www.mykor.co.uk/news/dj5kgcutix4gq9oi14v0xhj1h15151

fig 3.4 Urban Mycelium Farm All

MYCELIUM

CONDITIONS

PROCESS AND LABOUR

Cut Mushroom spores

Add substrate to bags

Add spores to substrate

Mycelium growth

map.10 MYCELIUM INDUSTRY

TIMBER

TIMBER

Industries and Opportunities

2046

2.5% increase in Softwood availability in the UK

12.3% increase in Hardwood availability in the UK

YIELD

40-150 years to reach mature stage and ready to be cut down

4-15m of growth in the first 5 years

86 tonne per acre average volume of natural pine clearcut

SPECIES IN THE UK

Sessile Oak

Pedunculate Oak

Ash

Beech

Silver or White Birch

Common or Down Birch

Sweet Chestnut

Sycamore

Black Poplar

Balsam Poplar

Hybrid Black Poplar

English Elm

Wych Elm Wild Cherry

Common Walnut

Black Walnut

Scots Pine

Cosican Pine

Sitka Spruce

Norway Spruce

European Larch

Japanese Larch

Douglas Fir Western Red Cedar

POLICIES AND STAKEHOLDERS

Natural England

Forestry Commission

Forestry Act

Landscape Recovery

Environment Agency

The timber industry plays a significant role in the UK’s environmental strategy. According to estimates from the Forestry Commission, approximately 10.9 million tonnes of roundwood was harvested from the UK forests in 2020, with softwood accounting for the majority (92%) of these removals.16 Softwood, known for its faster growth rates in the UK, comprises the bulk of timber harvested, with hardwood making up the remaining portion. However, the reliance on softwood presents challenges, as UK-grown softwood is typically graded as C16, necessitating the imports of higher-grade timber from Europe.17

While mapping the timber industries in the UK, it was difficult to obtain precise data on active woodlands in the UK complicating efforts to assess the industry’s spatial distribution. However, spatial datasets indicating possible harvested areas—such as coppice or ground preparation sites were mapped—suggested high concentrations in regions like Scotland and Wales. Additionally, mapping privately and publicly managed woodlands and timber

16 “Forestry Statistics 2021 Chapter 2: UK-Grown Timber,” Forest Research, 2021. Accessed April 17, 2024, https://cdn.forestresearch.gov.uk/2022/02/ch2_timber_ fs2021_mlulwth-1.pdf

17 Exova Trada, “Specifying British-Grown Timbers,” 2017.

processing facilities provided further insights into the industry’s infrastructure and distribution across the country. It is important to note that the data for Northern Ireland is lacking hence the insights might be more applicable for Britain scale.

Despite these challenges, the UK’s abundant timber resources offer opportunities for utilising timber as a biobased material. Biobased materials such as hempcrete blocks or mycelium blocks, which require supports at frequent intervals, can complement traditional timber usage. Leveraging timber as a biobased material therefore has the potential to align with the net zero strategy, offering environmentally sustainable alternatives to conventional construction materials. Furthermore, as the UK aims to increase tree canopy and woodland cover to 16.5% by 2050, opportunities arise for expanding the timber industry sustainably.18 Sustainable forestry practices, including selective logging and reforestation, are vital in enhancing woodlands’ capacity as carbon sinks, aiding in greenhouse gas mitigation.

18 “Timber in Construction Roadmap,” GOV.UK, accessed April 17, 2024, https://www.gov.uk/government/ publications/timber-in-construction-roadmap/timber-inconstruction-roadmap

fig.3.5 Timber Harvesting Site

AQUACULTURE

SEAWEED

Industries and Opportunities

£1

cost per kg of dried seaweed in the UK

13 marine licences issued for commercial seaweed farming in the UK 2023

15,000 tonnes

(wet weight) of seaweed was harvested in the UK by some estimates

YIELD

Autumn Spring seeding harvesting

1500 kg per 100m line of wet seaweed is produced

1-2m of kelp is grown in 7-8 months along each line

Seaweed farming is an emergent industry in the UK have more than doubled since 2016.19 Kelp is gaining popularity for producers since it requires no arable land or freshwater, absorbs significant amounts of carbon dioxide, acting as a carbon sink to mitigate climate change, and thrives in nutrient-rich marine environments without the need for fertilisers or pesticides.

SPECIES IN THE UK

Chondrus crispus

Laminaria digitata

Saccharina

Sugar kelp

Ascophyllum nodosum

Sea Spaghetti

Saccorhiza

Polyschides

Channelled wrack

Bladder wrack

Himanthalia elongata

Serrated Wrack

Ulva Lactuca

Fucus Vesiculosus

Fucus Spiralis

Pelvetia Canaliculata

Corallina Officinalis

Sea Lettuce

Ulva intestinalis Gutweed

POLICIES AND STAKEHOLDERS

Scottish Association for Marine Science (SAMS)

Centre for Environment, Fisheries and Aquaculture Science (CEFAS)

Marine Management Organisation

DEFRA

Sustainable Inshore Fisheries Trust (SIFT)

20 Seaweed is mainly used in food, cosmetics, pharmaceuticals, and agriculture, with future potential in biofuels and construction, 21 and presently, the UK has 97 seaweed-related businesses, mostly in England and Scotland, relying on wild harvesting. 22 According to the Cefas registry of aquaculture producers, there are also 101 active shellfish farming businesses in England and Wales and 103 in Scotland (2023). 23 Many UK companies are currently using seaweed sourced from other countries in their products due to availability and cost. According to the Scottish Shellfish Farm Production Survey 2023, producers would be interested in sourcing materials locally if the biomass were available in the UK. 24

19 Elisa Capuzzo, “The Developing UK Seaweed Industry,” Centre for Environment, Fisheries and Aquaculture Science Blog, May 5, 2022, https://www.cefas. co.uk/News/the-developing-uk-seaweed-industry

20 World Bank Group, Global Seaweed - New and Emerging Markets, Report 2023, commissioned and published by the World Bank Group.

21 Hethel Innovation Ltd., University of East Anglia, and the Centre for Environment, Fisheries and Aquaculture Science, A Roadmap for the Seaweed Economy in Norfolk & the East of England (Norfolk, 2024), 3; World Bank Group, Global Seaweed - New and Emerging Markets, Report 2023.

22 Elisa Capuzzo, The Developing UK Seaweed Industry 2022.

23 Marine Directorate. Scottish Shellfish Farm Production Survey 2023. Cabinet Secretary for Rural Affairs, Land Reform and Islands, 26 June 2024.

24 Hethel Innovation Ltd. et al., A Roadmap for the Seaweed Economy, 4.

Pairing the production of shellfish and seaweed could improve habitats for fish species, and potentially enhance fish stocks. Similarly, producing seaweed and shellfish together provides opportunities for farmers to diversify production and harvest across multiple seasons. In addition, introducing marine rewilding efforts alongside kelp production could help restore marine habitats, dissipate wave energy, and stabilise sediment reducing coastal erosion. Research has shown an increase in fish abundance diversify in areas producing kelp. 25 However, a major barrier to scaling kelp production is licencing and high startup costs. One avenue to increasing kelp farms could be co-location of farms with offshore wind farm sites. 26 As production expands in the UK, it will become increasingly important to address the social aspects of scaling aquaculture on the coast.

27

To better understand the opportunities for kelp and aquaculture sites in the UK, we inventoried existing aquaculture and seaweed sites, coastal communities and infrastructure such as ports, planned windfarms and vessel traffic routes. We also overlaid environmental factors that would inhibit or encourage production such as water turbidity, currents, wave height, and bathymetry. Cross-analysing these conditions provide insights to the potential for increasing and scaling kelp and shellfish production for construction materials.

25 Corrigan, S., Brown, A. R., Tyler, C. R., Wilding, C., Daniels, C., Ashton, I. G. C., and Smale, D. A. “Development and Diversity of Epibiont Assemblages on Cultivated Sugar Kelp (Saccharina latissima) in Relation to Farming Schedules and Harvesting Techniques.” Life 13, no. 1 (2023): 2. https://doi.org/10.3390/life13010209.

26 Ibid.

27 Hethel Innovation Ltd., University of East Anglia, and the Centre for Environment, Fisheries and Aquaculture Science, A Roadmap for the Seaweed Economy in Norfolk & the East of England (Norfolk, 2024), 3.

fig.3.6 Seaweed farming

CONDITIONS

Mid-intertidal zone

Ascophyllum Nodosum thrives in the mid-intertidal zone, enduring fluctuating tides, while Laminaria Hyperborea inhabits the sub-littoral zone, anchoring to rocky seabeds in depths of up to 20 meters or more.

PROCESS AND LABOUR

Preparation of seedstock

Anchoring seedstock to support lines

Harvesting

Shred seaweed

Spreading on drying platform

Packing dried seaweed

For a farm size of 25m x 25m 3 people to manage

fig.3.7 Dried seaweed biomass

fig.3.8 SeaWood Acoustic Panel

fig.3.9 Shellfish rendering explorations by Alejandra iturrizaga

Why Seaweed and Shellfish for BGS?

Seaweed and shellfish for construction is considered a long-term goal for the UK industry. There are global examples of seaweed used in building materials such as bricks by Sargablocks, Mexico28 and as fibreboards and acoustic panels by Blue Blocks, Netherlands. 29 Several practitioners across Europe experimenting with eelgrass (zoster sp.) for construction.30 Similarly, there is potential for shellfish biproducts be used as rendering.31 It is important to note that this project distinguishes seagrass from macroalgae species as they are vastly different in terms of physical properties, growing conditions, and viability as construction materials. 32 Seaweed refers to macroalgae species including: Saccharina latissima, Laminaria digitata and Laminaria Hyperborea.

In the nearby region of Norfolk, Cefas, Hethel Innovation and the University of East Anglia have developed the Seaweed in East Anglia (SEA) project to explore a path forward for the seaweed industry. They devised a set of short and longterm goals for mobilising the industry. Short-term efforts include, “product development, establishing a local biorefinery and seaweed nursery, create testbeds for seaweed cultivation and longer-term goals such as exploring the potential for seaweed in energy production and formalising an end-toend supply chain”. 33

Aligning with predictions for Norfolk, there are opportunities for a seaweed industry to emerge a bioregional economy that supports underserved coastal community and diversify rural economies. As stated in the report, A Roadmap for the Seaweed Economy, by Hethel

28 Ana M. López-Contreras, Paulina Núñez, M.P. Gurrola, Rigoberto Rosas-Luis, and 6 others, “Sargassum in Mexico: From Environmental Problem to Valuable Resource,” Technical Report, August 2022, https://doi. org/10.18174/574423.

29 Rianne Reijnder, Sealutions: Looking at SeaweedBased Sustainable Building Materials in the Netherlands (Master’s thesis, TU Delft, 2022).

30 Studio Kathryn Larsen, “About,” accessed January 5, 2025, https://kathrynlarsen.com/about.

31 Katya Bryskina and Nataly Nemkova, interview by Priyanka Awatramani, Alejandra Iturrizaga Andrich, Clara Olóriz Sanjuán, and Emily Bowerman, May 9, 2024.

32 Kathryn Larsen, email message to author, March 1, 2024.

33 Hethel Innovation Ltd. et al., A Roadmap for the Seaweed Economy, 23.

Innovation, “This can be achieved by offering an additional income for fishers, harvesting and processing jobs and by using the products made to benefit the region, such as using seaweed fertilisers in agriculture settings to improve soil health and reduce overall carbon footprints”. 34 We envision the BGS retrofitting project as an opportunity to intersect the Hethel Innovation development timeline.

For example, the emergence of the biorefinery in the Norfolk region would be an immediate asset for facilitating the reuse of biproducts from energy production or fertilisers for use as acoustic panels. BGS could therefore serve as a testing ground for shellfish and seaweed construction materials and contribute to material development. Procuring biobased materials for the BGS retrofit could incite funding for the initiative within the Hethel Innovation project or comparable initiatives, and therefore the industry at large.

Furthermore, BGS is an organisation dedicated to geological and subsurface research. BGS is currently devoted to climate change adaptation research including decarbonisation research, taking form primarily as subterranean storage of CO2 and coastal modelling. Bridging this work, they may be interested in the climate benefits of kelp farms. Moreover, the BGS considers itself impartial to contributing to marine extractive industries such offshore oil and sand extraction but looking to history, it may be of interest for the BGS to engage in marine rewilding efforts. We will discuss how these efforts can be undertaken consciously, to support the emergent aquaculture industry, marine workers, and communities in the coming chapters.

34 Hethel Innovation Ltd. et al., A Roadmap for the Seaweed Economy, 4.

fig.3.10 Site Visit: Visiting Allie Wharf from Norfolk Seaweed at Wells-next-the-sea, Norfolk on February 23, 2024. Photo by Alejandra Iturrizaga.

Industries and Opportunities

STRAW

8.1-8.3 tonnes / ha average winter wheat growth in 2021 in GB

5.8-6.2 tonnes / ha average spring barley growth in 2021 in GB

4 months

Average time for growth for wheat

SPECIES

Straw has been used in construction for thousands of years for thatching, insulation, waddle and daub and structures. Straw as a building material provides many benefits including reduces operational carbon, sequesters carbon, can be easily deconstructed, reused or disposed as compost, mulch or biomass fuel. Straw has low embodied carbon that exceeds current UK building standards for thermal efficiency. According to Material Cultures, cereals store C02 as they grow, and therefore straw holds approximately 40% of its dry weight in atmospheric carbon.35 Similarly, straw can improve interior air quality since it emits no toxins and contains zero or low volatile organic compounds (VOCs) and formaldehyde emissions compared to conventional building practices.36 Moreover, a common misconception is that straw has low fire retardancy, however, strawbale construction and compressed panels provide a nearly airless environment to comply with fire ratings.

37 Lastly, straw buildings have high breathability that helps managed moisture through its ability to absorb (natural fibres), adsorb (if concealed with a lime plaster) and desorb and because it has a vapour open structure.38 These natural systems are commonly called ‘breathable’. 39 In the coming

35 Material Cultures. Material Reform. London: Mack Books, 2023, 107.

36 Julia Bennett, John Butler, Barbara Jones, and Eileen Sutherland, Straw Construction in the UK: Technical Guide 1st ed. (School of Natural Building, January 31, 2022), 11.

37 Bennett et al., Straw Construction in the UK, 34.

38 Ibid.

39 Cíaran Malik, interview

chapter we will explore the potential replacements for lime plaster, including shellfish.

Straw takes different forms depending on its desired use. The most used straw bale in the UK area rectangular bales – small, Flat 8s or Field bales, otherwise straw can be used as compressed straw in panels or blown-in chopped straw.40 Construction grade straw must be, “dry with a moisture content below 20%, well compacted with tight strings, be of a uniform size and shape, and contain virtually no seed heads. Straws should be at least 150mm. There should be no sign of mould, or of vermin having nested during storage”. 41 The size and density, and tightness of the bales may vary and is determined by the type of baler used. Architects should therefore consider the type of baler and how that could alter the building design if using straw bale construction.42