Emissions KBB and Eminox combine forces Emissions control specialist Eminox and turbocharger maker Kompressorenbau Bannewitz (KBB) have announced a major collaboration to meet increasing emissions compliance requirements for marine diesel engines. By working together, the two companies will provide marine engine manufacturers and vessel operators with a fully integrated emissions control solution, from turbo to tailpipe, to deliver clean marine diesel engines. Aimed at medium speed engines over 1MW power, the new market-leading solution brings together KBB’s expertise in marine turbocharging and air handling with Eminox’s proven EMx exhaust after-treatment system (EATS) technology. Customers will benefit from a complete, integrated solution, refined to their specific needs for both existing (retrofit) and new engines. The end-to-end solution includes the design, manufacture, installation, certification and, the breadth of knowledge and expertise from KBB and Eminox will ensure customers are supported with service, maintenance and aftersales. This integrated project management and full in-house solution removes the need for engine manufacturers to assemble components from multiple suppliers or undertake their own costly testing and type/class approval certification. The KBB Eminox solution is optimised for specific engines which increases performance efficiency and the effectiveness of emissions reduction. As part of the maritime industry’s commitment to achieving a zero carbon future, diesel engines are subject to IMO Tier I and Tier II regulations. Additionally, every vessel entering specific emission control areas (ECAs), including the Baltic Sea, North Sea and North American ECAs must meet much stricter IMO Tier III targets, with tighter nitrogen oxide (NOx) emissions requirements. For vessels to be compliant when operating on European Inland Waterways Stage V regulations apply. Future legislation, including an update to the marine Stage V regulations and IMO IV are expected to set dramatically lower NOx emissions targets and introduce controls on particulates from the early 2030s. “Diesel engines are the backbone of the marine industry, making it vital to optimise their

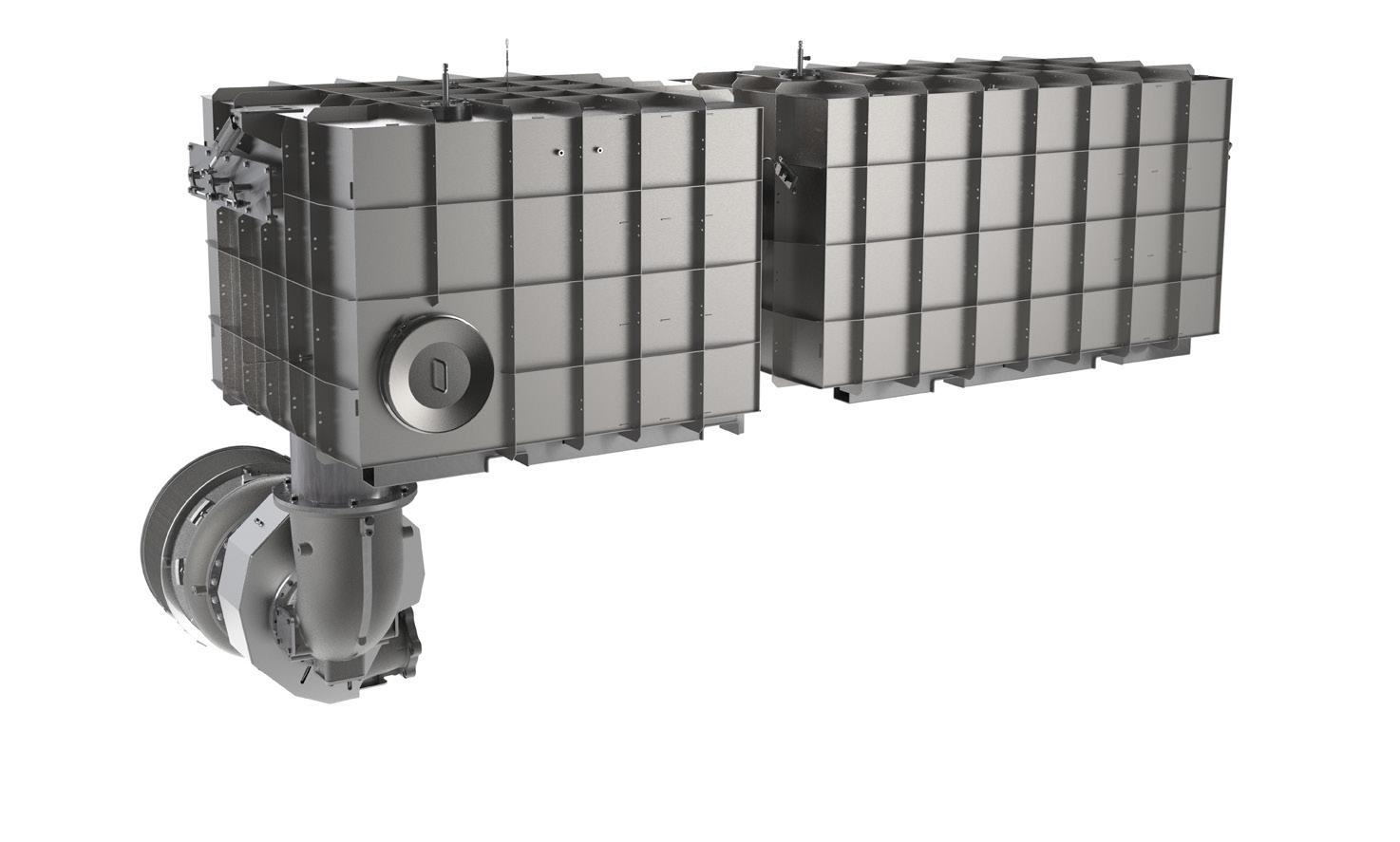

The KBB EMx-powered marine and power generation exhaust

performance to lower emissions as we move to a zero carbon future,” said David Phillips, Engineering Director, Eminox. “Working with KBB, we’re committed to helping achieve this. We’ve developed a complete, integrated solution for the maritime industry that builds on the proven strengths of diesel while reducing harmful emissions, preserving investment in existing engines. Given the need to plan for the long-term, now is the time for marine operators and engine manufacturers to accelerate their emissions reduction journey by working with partners that can provide an in-house solution for all their needs.” Built to meet the demands of marine environments, the Eminox/KBB solution is designed for over 20 years of service, lowering operational costs, and positively supporting the resale value of engines and vessels. It is future-proofed and upgradeable as and when legislation changes. A fully serviceable solution, replacement parts are available through KBB’s global service network. “Operators and engine manufacturers understand the need to meet more stringent marine emissions requirements, but achieving compliance has previously been complex and costly,” said Dr. Roman Drozdowski, Managing Director, KBB. “Our combined solution brings together two trusted, experienced suppliers to the industry and is built to fully address all emissions requirements, now and in the future. Together, we look forward to helping customers around the world meet maritime standards while reducing the total cost of ownership of their diesel engines.” KBB turbochargers are on-board many

ships owned by large and traditional owners, such as Maersk and Evergreen. Some 2,000 ST-EP single stage units are now in operations. Roman Drozdowski re-iterated his commitment to GHG emissions reduction at an interview with SORJ at the recent Europort exhibition, “KBB turbochargers are proven technology and can be utilised on engines as the maritime world moves into non-diesel propulsion systems. These new forms of fuel include LNG, hydrogen, methanol and ammonia.”

Emission projects at Wärtsilä Finland’s Wärtsilä has received marine sector commercial certification for compliance with the EU’s Stage V standards. The Stage V legislation, which came into force in 2020, tightens restrictions on non-road engines and equipment, and sets stricter limits on emissions, especially particulate matter (PM) and nitrogen oxide (NOx) emissions. The certification applies to the total solution, including the Wärtsilä 14 engine and exhausts after-treatment system. Stage V certification is required for engines powering the European inland waterways vessels, which together comprise a fleet of approximately 17,500 ships. The first deliveries of the certified Wärtsilä 14 engine will be for two new passenger ferries being built for the Switzerland’s General Navigation Company (CGN) by Shiptec AG. The ferries will operate between Switzerland and France across Lake Geneva, with the first vessel expected to

Volume 19 Issue 5 – Page 31