Repairs Good 2021 for Astican The activity at Astilleros Canrios (Astican), Las Palmas, during this year has been quite regular with most months being busy. February ended up being a very busy month, with a diversity of customers, vessel types, sizes, and repairs. The yard reports a total of 101 repair projects were completed during 2021, 61 on the yard’s Syncrolift shiplift system. In the first and second quarter, Astican carried out a variety of work such as the replacement of the 35 tonne SNL crane onboard the non-self-propelled vessel Luft-1 and the first installation of a CMC on-board a drillship in the Canary Islands. It was also busy few months in the offshore market. There were also major repairs on-board Fred Olsen’s 6,348 gt fast ferry Bentago Express and the yard was fortunate to drydock, for the first time, the world’s fastest and most modern trimaran, the 7,915 gt Bajamar Express, the longest vessel ever drydocked at Astican, with a clearance of only 80 cm on the shiplift. During the autumn, Astican completed two important repairs, Mercy Ships’ 16,572 gt specialised hospital ship Africa Mercy and Odfjell Asia’s 9,999 dwt LPG tanker Bow Guardian. This latter ship is managed by Singapore’s Anglo Eastern. For Astican, the Africa Mercy has been one of the most important projects this year. Extensive work has been completed to cover the hull and bulkheads plates, the frames, all structural members, internal piping, as well as hull treatment, steel work, and tank coating (blasting and painting). Repairs to the ship required more than 70 tonnes of steel to make it as good as new. 80 access points in the hull had to be opened to accommodate the blasting equipment and tank work to ensure safety throughout the project. A lot of work was also carried out on the ship’s exterior, such as the deck cranes and funnel, which was structurally renovated. A total of 120 windows were replaced and up to 49 tonnes of paint was used to make the ship as good as new again. Thanks to the 450 people involved in the project, Africa Mercy has gained 15 more years of service life to be able to continue her missionary work in Africa and provide medical and surgical care to people in need as it has been doing for more than 40 years. After grounding the ship had several areas of steel damage from the bow to Frame 72. The steel in the flat bottom was cropped off and

The African Vision on Astican’s Syncrolift

renewed as required by the owner and Class, this included, the two cargo holds and four water ballast tanks a total of some 97 tonnes of steel was renewed. Due to the grounding, the insulation of the cargo tank was affected, and it was renewed. Astican also recently worked on-board Marine Platforms’ 4,845 gt OSV African Vision. Her length overall is 93.6 m, and her width is 19.7 m. The main work carried out were removal of stern azimuths thruster, box cooler cleaning, accommodation work, moonpool treatment and renewal of frames.

Ever Given enters Qingdao Beihei shipyard The Shoei Kisen-owned 20,124 teu capacity 2018-built container vessel Ever Given, famous for blocking the Suez Canal in March last year, arrived at Qingdao Beihei Shipbuilding & Heavy Industries (BSIC) during October last year for three weeks of repair work, which included significant repairs to the vessel damaged bulbous bow. BSIC, part of China Shipbuilding Industry Corporation (CSIC), has more than 330 hectares of land, 9 kms of coastline, nearly 6 kms of wharf length, two shipbuilding dry docks (500,000 dwt and 300,000 dwt), two shiprepairing dry docks (300,000 dwt and 150,000 dwt), and one floating dock for ship-repairing (100,000 dwt).

Page 4 – www.shipandoffshorerepair.com

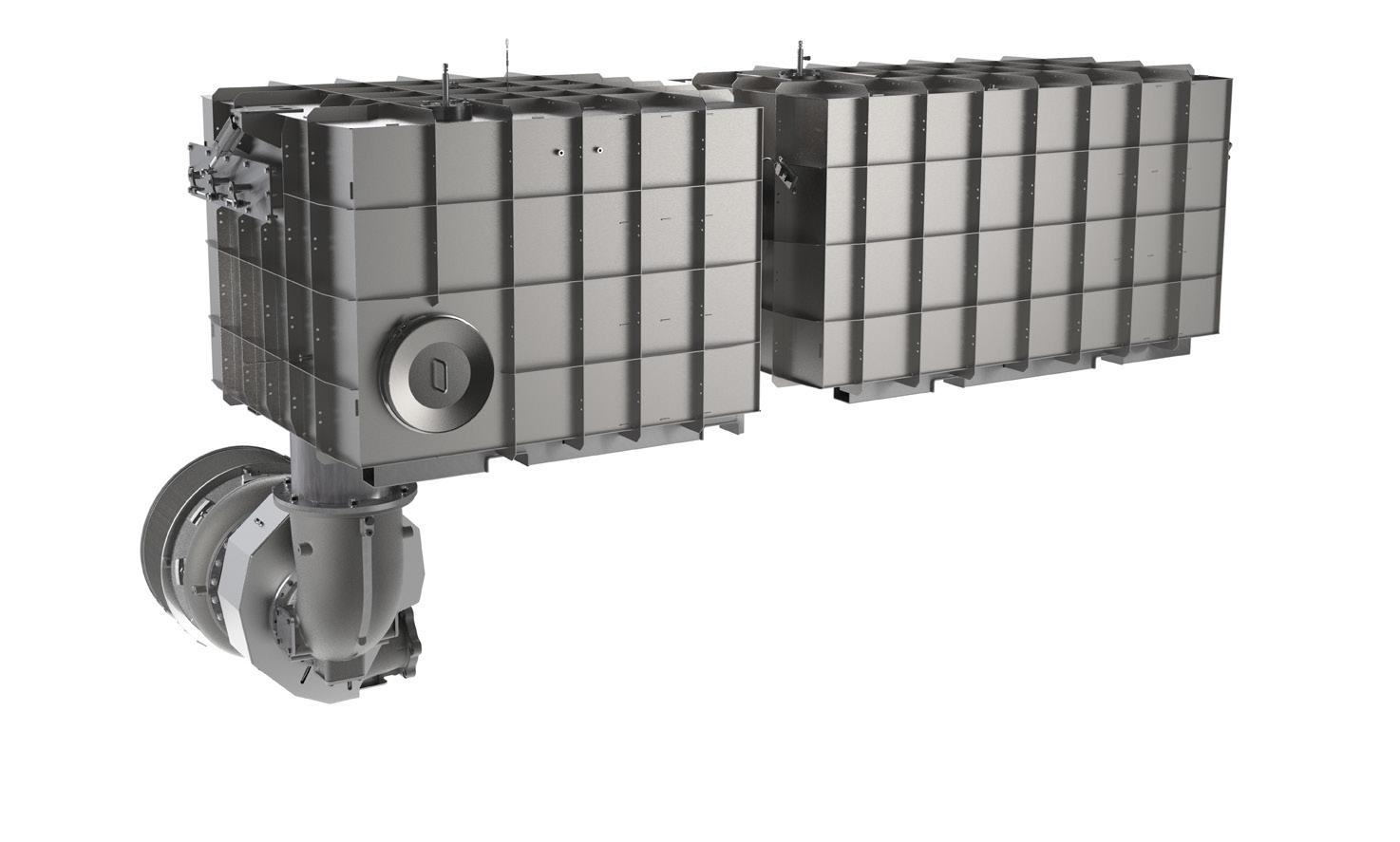

Offshore projects at Sembcorp Marine From the offshore market (FPSOs and FPUs), Sembcorp Marine currently has six projects underway. During October last year, the Tuas Boulevard Yard (TBY) carried out the load-out and tandem lift of the Vito Host mega-topside structure for the Vito FPU Project – both mark notable firsts for Sembcorp Marine’s newbuild track record. Following the load-out, the mega-topside structure was transported via the yard’s heavylift vessel Elite Prosperity and lifted onto the FPU hull using a pair of goliath cranes with a combined 30,000-tonne lifting capacity and 100 m hook height. Sembcorp Marine is working expediently at the request of Norway’s Equinor, to plan the remaining scope of work for the Johan Castberg FPSO to accommodate the available transportation window for the towing operations to Norway. The construction of the topside modules, module integration and final completion, which are not part of the Sembcorp Marine’s scope of work, will be performed in Norway. Recently, Sembcorp Marine entered into an exclusive Front-End Engineering and Design (FEED) contract with Siccar Point Energy E&P to deliver a FPSO design solution for the Cambo field in the UK Continental Shelf. The solution is based on Sembcorp Marine’s proprietary Sevan