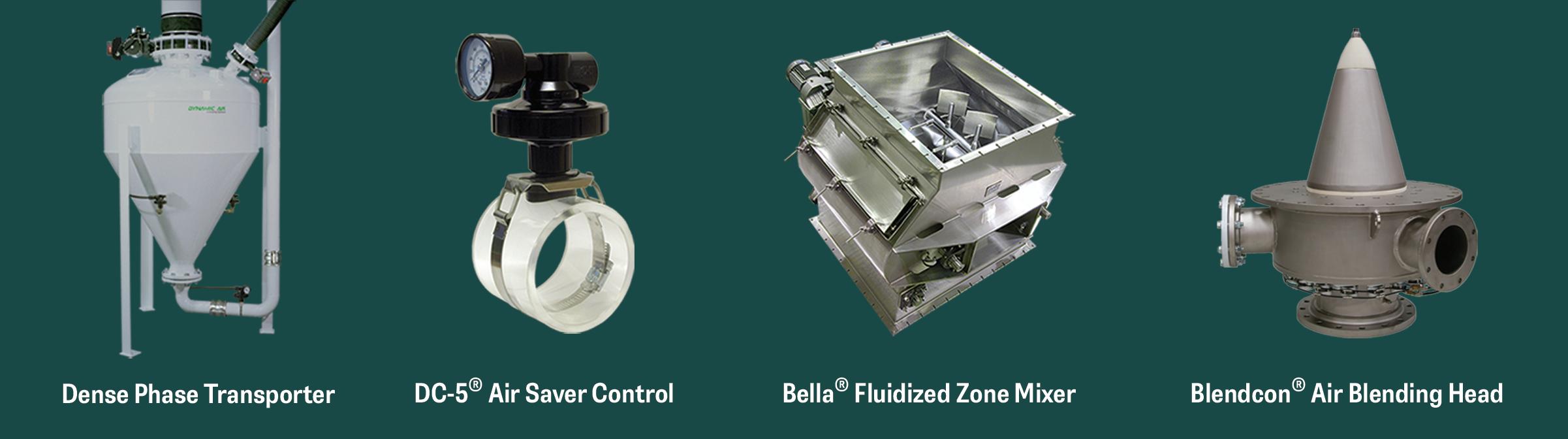

We are a leading provider of custom solutions for the handling of bulk materials for processing businesses across various industries. Dynamic Air has over five decades of expertise in designing and manufacturing pneumatic conveying systems and equipment for handling dry bulk solids.

At Dynamic Air, we set the standard for excellence in bulk solids handling. With a relentless focus on quality, reliability, and customer satisfaction, we deliver reliable, high-quality pneumatic conveying systems, equipment, and custom solutions that exceed expectations. BULKBUSTERTM

We never take a cookie-cutter approach just to cut costs up front; we know that the right solution will save you money in the many years to come. Our tailored solutions involve thoughtful planning, meticulous engineering and precise manufacturing that optimize efficiency and productivity.

Sales Director: James Scrivens

Production: Sarah Daviner

Accounts Manager: Avery Hudson

Office Manager: Katie Brehm

BULK SOLIDS TODAY is published 6 times a year by Abbey Publishing Ltd

ADVERTISING & EDITORIAL

Please contact us at:

Tel: 01933 316931

Email: editorial@bulksolidstoday.co.uk advertising@bulksolidstoday. co.uk

Web: www.bulksolidstoday.co.uk

Twitter: www.twitter.com/ BulkSolidsToday

CIRCULATION

To receive a copy free of charge, please send your details to subs@bulksolidstoday.co.uk

No part of this publication may be reproduced by any means without prior permission from the publishers. The publishers do not accept any responsibility for, or necessarily agree with, any views expressed in articles, letters or supplied advertisements.

ISSN: 1365/7119 All

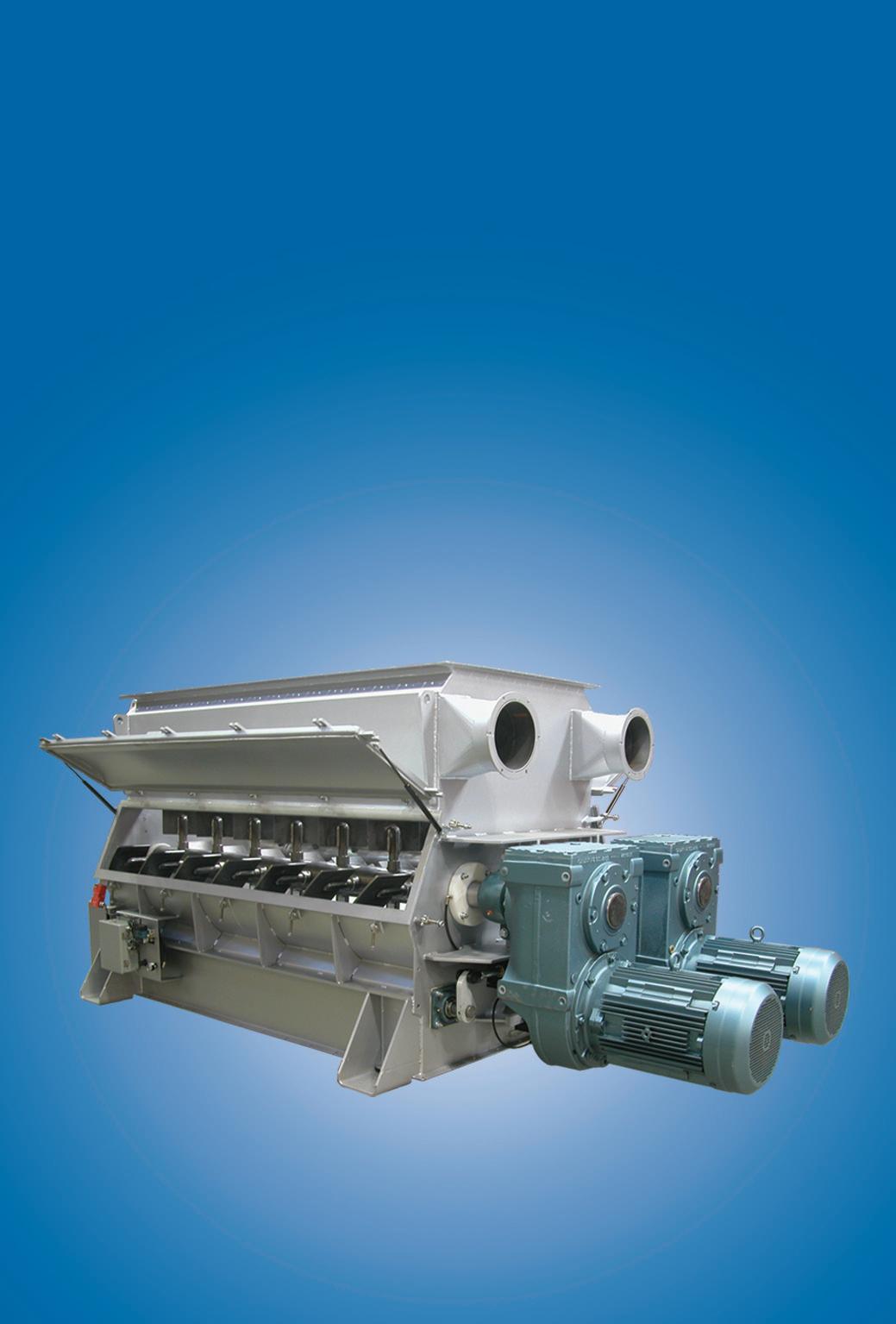

The HDP4000 dense phase pneumatic conveying system by Dynamic Air Inc. offers a clean, efficient and easy way to move bulk materials from production to bagging/packaging without compromising the location of either process. Often the best

place for a production process is not the ideal place for bagging and packaging so a compromise is made that puts both processes in a less than desirable location. Utilizing an HDP4000 conveying system allows each process to be located in its ideal space. The

system, which features “keep full” operation and an anti-segregation design, is custom designed to meet individual process requirements. https://www.dynamicair. com/system/hdp-4000-full-lineconcept-dense-phase-pressuresystem/

Rainbow Dynamics, the UK-based designer and manufacturer of robotic and automated materials handling solutions, has announced the appointment of Jens Mueller as its Managing Director.

Jens Mueller has broad experience of the logistics systems market having held senior management roles with several well-known companies in the sector, including storage products giant, SSI Schaeffer, and warehouse and industrial buildings developer, GLP.

He will be responsible for growing Rainbow Dynamics’ business in the UK and key

markets across mainland Europe.

Rainbow Dynamics’ founder and CEO, Alfred Chen, commented: “The appointment of Jens Mueller is a positive step in our plans for future growth and success. I have known Jens for many years, having worked with him before and his entrepreneurship and clientrelationship skills have always been impressive. He also has a wealth of knowledge and contacts in the industry, so I am delighted that he has agreed to take on this key role.”

Jens Mueller said: “It’s an honour to be appointed Managing Director of Rainbow

Dynamics. My objectives are very clear: we have a huge opportunity to create something very impressive and I intend to drive the company forward to realise its potential to become the number-one name in logistics automation and robotic material handling solutions.”

With its head office in Lancashire, Rainbow Dynamics designs and builds a suite of sustainable robotic load handing and automated parcel sortation solutions for logistics warehouses, post and parcel handling facilities, manufacturing sites and e-commerce fulfilment centres.

www.rainbow-dynamics.com

Flexicon’s PNEUMATI-CON® Pharmaceutical Grade Filter Receiver for medium- to highthroughput vacuum and positivepressure conveying of extrafine, difficult-to-handle and/ or contamination-sensitive bulk solid materials, features designs to readily change/inspect filter cartridges and sanitise the interior.

A gas-spring-operated lid provides access to a removable filter plate, allowing cartridge ilters to be removed and inspected or cleaned from the top, eliminating product hold up points and cleaning difficulty associated with side access doors and bolted-in filter plates. Tri-clamp fittings additionally allow rapid disconnection and

cleaning of all accessory parts and lines.

Constructed of #316L stainless steel to pharmaceutical standards, the receiver housing is devoid of interior ledges, cavities or recesses that could harbour contamination, and features three tapered filter cartridges that separate conveyed material from the air stream. Automatic reverse pulse-jet cleaning of the pleated filter media maintains separation efficiency, while the tapered filter design improves material release.

Available in 450 and 610 mm diameters, the design can accommodate level sensors, pressure monitors, and other accessories. Typical applications

PNEUMATI-CON® Pharmaceutical Grade Filter Receiver for vacuum and positivepressure systems offers total dust containment and tool-free interior access.

include separation of bulk pharmaceuticals, nutraceuticals, foods, and other contaminationsensitive materials being conveyed to tableting machines, packaging lines and other downstream processes.

Flexicon also manufacture complete pneumatic conveying systems, flexible screw conveyors, tubular cable conveyors, bulk bag dischargers, bulk bag conditioners, bulk bag fillers, bag dump stations, drum/ box/container tippers, weigh batching/blending stations and plant-wide bulk handling systems.

Contact Flexicon Europe Ltd, +44 (0)1227 374710, sales@flexicon.co.uk, www.flexicon.co.uk

Hinged lid allows rapid removal of tapered filter cartridges, and unobstructed interior access for sanitising and visual inspection of material contact surfaces.

Being Official Partner for material handling equipment at the Olympic and Paralympic Games Paris 2024, Toyota Material Handling Europe launches a new communication campaign that aims to raise public awareness of the role played by the logistics industry.

Under the tagline #WeDeliverForYou, the campaign focuses on the vast role logistics plays in supplying daily needs to over 750 million people across the continent – from food, clothing, and medicines through to the supply of raw materials for factories and, in today’s world, in responding to the ever-growing e-commerce enterprise.

One of the campaign messages is ‘every click makes something move’ – illustrating how advanced digital systems result in items being almost instantly selected for despatch as soon as consumers complete an on-line order.

automatically consolidated into a single delivery to households by autonomous vehicles, reducing road traffic and emissions.

The campaign also draws parallels between the preparation of Olympic athletes to ready themselves for sports events with the need for logistics operators to be prepared for and responsive to consumer demands - shown in a powerful film clip.

“There are over 5 million people working in the logistics industry across Europe - whether they are in warehouses, driving lorries, delivering parcels or running sophisticated IT systems – and we want to put a spotlight on the vital role that they play in society,” explains Mark Peters, Marketing Director at Toyota Material Handling Europe, “and we realised that we have a great opportunity to do this as a result of our involvement at Paris 2024.”

“Another dimension of the role played by the logistics industry is the pioneering work done in the area of sustainability,” continues Peters. “We are already seeing moves towards electric delivery vehicles on our roads, but behind the scenes we have been working with electric vehicles in enclosed environments like warehouses for decades. We are also already working with hydrogen solutions, and we see many customers generating their own renewable energy on-site. We are also extensively working with automation to improve efficiency, accuracy and safety, and to reduce damages. All of this means our industry is making a substantial contribution towards future technology development.”

Additionally to the We Deliver For You campaign is a concept film recently released by Toyota Material Handling Europe called ‘A.I.TeamDelivery’, which imagines a new approach for home deliveries where different items from different suppliers are

Details of the We Deliver For You campaign can be found under ‘Paris 2024’ at toyota-forklifts.eu.

We Designed it

Unlike other valves that seal with friction, Posi-flate’s unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower cost. Plus, the seat automatically compensates for wear, providing longer life. Some users have reported over six million cycles and the valves are still going strong.

• Less friction • Low torque

Low maintenance

Lower actuator costs

Longer valve life

More reliable

OMRON, a global leader in automation technology, has launched the VT-X850, a 3D Computed Tomography Automatic X-ray Inspection (3D CT AXI) solution engineered to meet critical inspection needs in the electric vehicle (EV) and electronics manufacturing sectors.

The VT-X850 addresses the complexities of inspecting large, intricate, and dense materials, joining innovative design with the latest technology. With the integration of a high-voltage X-ray tube and Artificial Intelligence (AI), the VT-X850 delivers on speed, accuracy, and ease of use. The new VTX850 Xray solution enhances the inspection process of assembly modules, primarily focusing on the barrel fill of connectors, and power devices, with an emphasis on detecting voids or insufficient solder.

“Our focus was to create a solution that not only addresses the technical challenges but also empowers professionals of all expertise levels to conduct efficient and effective inspections,” said Kevin Youngs, Sales Manager EMEA - Inspection Systems Division at OMRON Europe. “The VTX850 underlines OMRON’s commitment to driving innovation that combines technological sophistication with user accessibility.”

Key Features of the VT-X850: Higher speed & higher repeatability: Employing a highvoltage X-ray tube up to 160kV ensures stable, clear images in shorter time spans, even for intricate materials like heat sinks or aluminium die casts.

Handling of large and heavy modules: The design accommodates modules up to 335mm in height and 40kg in weight, ensuring broad applicability and versatility.

AI-Powered inspection: AI binarization ensures superior image processing, making the VT-X850 a user-friendly solution for individuals with varied technical expertise.

Automated solder and void detection: The innovative design eliminates dependency on manual settings, offering precise and efficient inspections without the need for specialized skills.

Enhancing user experience

The VT-X850’s pullout structure ensures ease of maintenance and the

replacement of the X-ray tube using a hand lifter. The unit is specifically designed to meet the escalating demands of inspecting complex and hard materials, particularly in the burgeoning EV market.

“As the EV market continues to grow, the need for precise, efficient, and user-friendly inspection solutions becomes key,” added Kevin Youngs.

“The VT-X850 is ideal for manufacturers aiming for impeccable quality control while navigating the complexities of varied materials and components.”

For more information, please visit http://inspection.omron.eu

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our website - www.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk

Hillhead 2024 is providing the perfect platform to both display and demonstrate for the first time at the show the latest products for the quarrying and construction industries from Develon, formerly known as Doosan Construction Equipment. The static display on Develon‘s Stand Z4 includes the DX530LC-7 53 tonne crawler excavator, the DL420-7 wheel loader and the DA45-7 articulated dump truck (ADT). In the demonstration area, further products for the quarry face showing their paces include the DX420LC-7 43.5 tonne crawler excavator, the DL550-7 wheel loader and the DA30-7 ADT.

Among new products being shown for the first time at Hillhead on the Develon stand is the new DD130-7 dozer. Compact equipment is another strong aspect, with the DX27Z-7 and DX55R-7 mini-excavators on show. The stand display is completed by Develon‘s DX235LCR-7 24.3 tonne crawler excavator.

The DX-7 Range of Crawler and Wheeled Excavators from Develon

The DX420LC-7 and DX530LC-7 are part of the range of large crawler excavators from Develon

that also includes the DX800LC-7 80 tonne and DX1000LC-7 100 tonne machines. Overall, all the models in the DX-7 range of crawler and wheeled excavators from 14 to 100 tonne combine enhanced comfort with the latest features to boost fuel efficiency, uptime and return on investment, with a focus on increased power, robustness and agility.

Increased Productivity and Versatility

The DL420-7 and DL550-7 are two of the four biggest standard models in the DL-7 range of wheel loaders from Develon, that also includes the DL4807 and DL580-7 models. With redesigned buckets offering up to 7% more capacity, these DL-7 wheel loaders provide easier and faster loading with maximum bucket capacities from 4.5 to 6.4 m3. Altogether, the eleven DL-7 wheel loaders in the Develon range with bucket capacities starting at 2.0 m3 provide increased productivity for a very wide range of material-handling applications.

Best-in-Class Rough and Soft Terrain Performance

The market-leading DA30-7 and DA45-7 ADTs offer payloads of 28 tonne and 41 tonne, respectively.

These models feature an articulation hinge positioned behind the turning ring to provide equal weight distribution to the front axle even during maximum steer articulation. This combined with a free-swinging rear tandem bogie ensures equal distribution of weight to each wheel and guarantees permanent 6-wheel contact and drive for equal power distribution and excellent performance particularly on difficult terrains such as soft ground, uneven surfaces, very steep slopes, tight turns or a combination of all of these difficult conditions.

The DA30-7 and DA45-7 6x6 ADTs are now complemented by a new 4x4 version of the DA457 ADT intended to compete with rigid dump trucks (RDTs) in the 40-tonne class. In the new 4x4 ADT, the front truck and cab unit is the same as in the original 6x6 model, with modifications being made on the rear dumper unit only.

With the launch of the new DD130-7, Develon has entered the European dozer market. The wide range of features on the DD130-7 provides a productive finegrading solution for residential and light commercial construction projects. One of the biggest differences between the DD130-7 and other brands is the visibility it provides of the machine’s dozer blade. To facilitate this, the front engine compartment offers a narrower design and is combined with other features that make it easier for operators to see their work.

For further visibility and safety, a standard rearview camera provides operators with an additional view of the dozer’s surroundings. The full-colour, 8-inch Smart Touch display shows the feed from the rearview camera. Also standard are high-illumination LED lights and four premium wiper blades. The DD130-7 offers

a high level of comfort with a premium high-quality seat. The seat and joysticks move together via the air suspension system, to absorb all vibrations.

Develon Mini-Excavators

The DX27Z-7 2.8 tonne and DX55R-7 5.7 tonne Stage V compliant models are typical of the new Develon range of mini-excavators from 1 to 10 tonne. The zero tail swing design of the DX27Z-7 and the reduced radius design of the DX55R-7 models make them ideal for confined space work.

The DX27Z-7 is powered by the D17 Stage V compliant diesel engine providing 18.4 kW (24.7 HP) of power at 2400 RPM. The DX55R-7 is powered by the D18 Stage V compliant diesel engine providing 36.4 kW (48.8 HP) of power at 2200 RPM. As a result, these models offer the highest power and torque in their respective classes and cover a wide range of applications including heavy duty work.

For more on Develon, please visit the website: https://eu.develon-ce.com/en/

Trelleborg to showcase latest tyre innovations at Hillhead 2024, the UK’s largest quarrying, construction & recycling exhibition, in Stand #M3 from June 25th to 27th

From EMR series to Brawler range: Trelleborg tyres feature more cut-resistant compounds and wider treads, delivering greater stability, performance and fuel efficiency while reducing downtime

In the ever-changing world of construction, the need for advanced tyre solutions is critical. Tyres are key to maintaining safety and efficiency in construction operations. Trelleborg Tyres understands the shifting challenges builders face, from optimizing operations and reducing fuel use to improving operator safety and comfort, and allowing for significant cost savings for construction projects of all sizes. Trelleborg Tyres has taken the lead in engineering tyre solutions tailored to these unique demands, focusing on durability, performance, and enhanced productivity.

operators.

At Hillhead 2024 (June 25th to June 27th), the UK’s largest quarrying, construction & recycling exhibition, Trelleborg Tyres, a global leader in the tyre industry, will bring at its stand #M3 a selection of its latest tyre innovations from EMR series including the EMR1030, EMR1031, EMR1042, EMR1050, EMR1051 as well as Brawler tyres: tyres designed to meet the needs demands of construction professionals operating in such demanding environments.

EMR SERIES: PERFORMANCE AND RELIABILITY

Trelleborg’s EMR series will be a major highlight at Hillhead 2024. These tyres feature a multisurface tread design, providing exceptional grip and control across various terrains—from sand to rock, gravel, and soil. Their radial all-steel construction and reinforced carcass offer long-term durability and equal load distribution, ensuring a comfortable drive and reduced fuel consumption for

The EMR1030 offers excellent self-cleaning and versatility, while the EMR1031 features a wide tread contact area for superior control and tight grip. The EMR1042 is designed with a multisurface tread pattern for excellent ride comfort, and the EMR1050 is built for very hard conditions with a deep tread. Particularly noteworthy is the EMR1051, which provides optimal traction and enhanced damage protection, making it ideal for loaders in intensive applications.

BRAWLER TYRES: DURABILITY REDEFINED

For the waste and recycling industry, Trelleborg’s Brawler High Performance Solid (HPS) line is engineered to withstand severe operational stress, minimizing downtime caused by tyre changes or failures. The Brawler HPS Soft Ride, with 40% greater deflection compared to standard solid tyres, features unique elliptical sidewall construction for greater shock absorption and 30% less vibration, maximizing operator comfort.

The Brawler tyres on display will include a model offering the ride comfort of a filled pneumatic tyre with unique elliptical sidewall apertures, and another model designed for excellent ride comfort with a deep lug tread pattern.

To find out more about Trelleborg high performance tyres for construction go to: www. trelleborg-tires.com/en/products-and-solutions/ construction

If you would like to subscribe to receive a regular copy of the digital edition of Bulk Solids Today magazine, you can subscribe on our websitewww.bulksolidstoday.co.uk

If you are interested in advertising within Bulk Solids Today magazine or supplying editorial content, please feel free to get in touch using the details on our website or below.

Bulk Solids Today is sent to our digital readership of over 9,000 Chief Engineers, Operations Managers and Technical Managers from within sectors including Chemicals, Food & Drink, Mining, Quarrying, Transport/ Distribution, Recycling & Waste Management and more.

www.bulksolidstoday.co.uk bst@abbeypublishing.co.uk

Tuf-Lok ring grip pipe and tube couplings are rugged, heavy duty, self-aligning and self-grounded couplings with a high end pull. They can be used for almost any application where pipe or tube ends need to be connected. The Tuf-Lok self-aligning couplings install quickly and easily with little effort.

Features

• Self-aligning

• Self-grounding

• High pressure rated

• Full vacuum rated

• Stainless or mild steel

• Usable on thin or thick wall pipe or tube

• Low cost

• Reusable

• Absorbs vibration

• Externally leakproof

A start-up low access and material lifting rental specialist is confident of impressing clients after placing an order with Access Platform Sales for new ToughLift material lifts.

Prime Hire Solutions has taken delivery of 20 of the machines, designed to set new standards for simple yet tough push-around manual material lifts, and plans to order more.

Tom Wade, Managing Director of the South London rental specialist, viewed a ToughLift material lift on the APS stand at the Executive Hire Show and liked its quality plus its additional safety features.

He said: “The ToughLift machine shown to us by APS was clearly superior to the standard material lifts in use in the UK market, so we’re very confident our customers will also be impressed.

“We’re looking to build an equipment hire fleet focussed on serving clean trades, like HVAC and electrical installation and facilities maintenance, and ToughLift material lifts will be ideal for these clients.

“They’re robust, easy to use, with new safety features and design standards for this equipment that make lifting and manoeuvring easier and safer.”

The ToughLift range carries CE certification which is required by many large contractors and their Tier 1 clients, which was another key advantage compared with some other lifts on the market, he added.

APS is the UK and Ireland distributor for ToughLift material lifts.

Its Key Accounts Director Linda Betts said: “We’re very pleased Tom and his team at Prime Hire Solutions, could see the advantages built into every ToughLift machine.

“They want to offer a new standard in material lifting and that’s just what ToughLift achieves. We’re excited by the potential this product has and what it can do for ambitious businesses like Prime Hire Solutions.”

Prime Hire Solutions supplies low-level access, MEWPs, access towers and steps, site security and storage boxes, plus material lifting handling equipment, and plans to have more than 1,000 pieces of equipment in its fleet by the end of 2024.

• The ToughLift material lifts delivered by APS includes three of the four models in the current range.

• The ToughLift ML-10 has a maximum safe working load (SWL) of 454kg and can lift loads from or to a maximum height of 3.49m.

• The ToughLift ML-15 has a maximum SWL of 363kg and can lift loads to a height of 4.98m. The ToughLift ML-25 has a maximum

SWL of 295kg and can lift loads to a height of 7.94m.

Also available is the ToughLift ML-20. It has a SWL of 363kg and can lift loads at a maximum height of 6.46m.

All material lifts in the range are fitted with standard forks, with other lifting accessories available. These are pipe cradles, a load platform, extension forks, and a boom.

There is also a rough terrain wheel kit that can be attached to the material lifts to aid its movement across uneven or unstable ground.

A series of smart performance and safety features set APS’s ToughLift range apart from rivals.

The material lifts are quick and easy to set up, with no tools needed. A mast safety braking system holds the carriage and lifting columns in place if the cable becomes loose or breaks.

An extra-wide first pulley wheel improves laying of the cable on the winch drum, reducing the risk of tangling. A cable guard on the telescopic mast prevents finger trapping. There is also a hoisting and winching anchor.

Advanced swivel castors, with non-marking tyres, have a straight line lock to support loading and unloading and moving across sites. Also, a spirit level helps the operator level the chassis before raising the mast.

Each ToughLift material lift has an A5 document holder and a QR code that opens an operator manual on a smart mobile device.

www.accessplatforms.co.uk

Process Control specialist Promtek has developed a new smart motor control technique to maximise production at an animal feed mill. The ultramodern system, installed at Saracen Horse Feeds in Kent, allows manufacturers to access data on the materials, energy and time used per batch, using a unique combination of technology.

Looking to optimise production processes and bring the mill up to the 21st century, operations managers at Saracen turned to Promtek for its expertise in the integration of software and hardware.

Working in collaboration with Schneider Electric, engineers at Promtek have developed a solution where the mill’s machinery is controlled via a network connection. Previously, in order to gain such production insights, motors in the mill would have to be controlled with contactors and a costly PLC would have had to be installed, involving a complicated setup of cables and multiple measurement devices.

Engineers at Promtek installed a tailored StoraWeigh process control system to connect with Schneider Electric’s Tesys Island, a smart motor control platform that allows machinery to connect to the motor without a conventional digital IO. Tesys Island retrieves valuable production information which is then validated by Promtek’s StoraWeigh system, then shared and analysed using Promtek’s web based Condor platform.

The real time control and analysis enabled by the system has allowed Saracen to optimise output without the need for an expensive array of interconnected systems. Any hiccups during processing are also quickly dealt with, since the new system identifies and reports back the cause of any anomalies such as jammed or overheated equipment.

Being able to accurately monitor energy use during production is proving a major benefit to Saracen, especially given the rising energy costs currently being faced by manufacturers. Staff are able to see exactly how much energy has been used to make a product, helping to inform profit margins on a continual basis. It also aids in an accurate assessment of the return on investment of the new equipment, since the Condor programme can compare the efficiency of the previous setup with the new one.

Commenting on the new system, Saracen Operations Manager Joe Lydiate said: “To remain competitive in a challenging market we knew we

had to update the system. From the get-go, it was clear that Promtek understood our business and what was needed to bring it up to date. Using the analysis on the Condor, we’ve been able to see an increase in tonnes per hour, with many batches going through at faster speeds than before.”

Carbon footprint can also be measured using the equipment – increasingly important to manufacturers as they seek to prepare for coming green mandates and meet the sustainability expectations of their customers.

Promtek head of Projects, Liam Barks, added: “It’s been a really rewarding project to work on at Saracen. Supplying the whole package as one has given Saracen a complete solution, optimising their production in a fuss-free way. It’s a unique solution and, we believe, the first of its kind in the UK.”

For more information visit: https://www.promtek. com/

The highest wear part on an Overband Magnet is the belt that transfers the separated metal away from the conveyor and into a collection area. In order to reduce such wear, Bunting developed a special lightweight armouring for the rubber belt. This type of excessive belt wear occurs in heavy-duty applications seen in mining, recycling, and biomass power plants.

Bunting is one of the world’s leading designers and manufacturers of magnetic separators, eddy current separators, metal detectors and electrostatic separators, with globally located manufacturing facilities.

In operation, an Overband Magnet sits over a conveyor transporting materials such as aggregate, waste, shredded wood or mined ore. The magnetic field of the Overband Magnet, generated by either a

permanent magnet or an electromagnetic block, attracts ferrous metal from the conveyed material up and onto the revolving self-cleaning belt. Rubber upstands on the belt catch the lifted metal, transporting it away from the conveyed material into a separate collection area.

The force of the ferrous metal striking against the self-cleaning rubber belt is significant due to the magnetic attractive energy of the permanent or electromagnetic block increasing as the metal moves closer to the face. This means that the metal is accelerating into the belt. The moving belt becomes sandwiched between the lifted metal and the magnetic block momentarily, until the upstand catches and drags the item away and out of the magnetic field.

Applications in which self-cleaning belts experience high levels of wear include:

• When there are high amounts of ferrous metal present in the conveyed material;

• When the ferrous metal is large and heavy;

• When there are nails or thin and sharp ferrous metals;

• When the magnetic block has additional magnetic force, as with the ElectroMax and ElectroMax-Plus models;

To combat the excessive wear and extend the life of a self-cleaning belt, Bunting’s engineers

designed a lightweight but heavy-duty armouring for the belt. There were other options, including special wear-resistant belt coatings and other types of rubber belt. However, the armouring provided unrivalled protection, significantly lengthening belt life.

The armouring on the rubber belt is comprised of high-density polyethylene (HDPE) slats. Each slat is 100mm wide and 10mm thick, with a length to suit the model of overband magnet. The slats are fastened to the belt using special 304 stainless steel elevator bucket bolts and nyloc nuts.

“The introduction of this design of armoured belt has proven very popular,” explained Adrian Coleman, Bunting’s Technical Director. “Other types of belt armouring have proven unsuccessful, but the HDPE has worked exceptionally well.”

For further information, please contact us on press@buntingmagnetics.com or visit our website:

Bunting-Redditch – www.bunting-redditch.com

The global leader of belt conveyor accessories has announced the next generation of secondary conveyor belt cleaners engineered to reduce dusty carryback and lower maintenance time. Designed to withstand the stress of heavier loads carried on wider, thicker belts at higher speeds, the Martin® SQC2S™ Orion Secondary Cleaner features individually cushioned tungsten carbide blade cartridges for effective cleaning without risk to the belt or splices. A two-tiered tensioning system means minimal adjustments and monitoring throughout the life of the blade. The heavy-duty blades are mounted on a slide-in/slide-out assembly for faster and safer oneworker external servicing. The result is improved belt cleaning with less dust and maintenance for greater workplace safety at a lower cost of operation.

“We field tested the Orion over several months side-by-side with competitor designs in punishing mining environments and found that the new design significantly outperformed the competition,” said Dave Mueller, Conveyor Products Manager for Martin Engineering. “At the end of the testing period, customer participants started the process of replacing all their heavy-duty secondary cleaners with the Orion. We now view this design as the future of our

secondary cleaner line moving forward.”

Secondary cleaners play an essential role in the belt cleaning process by significantly reducing the volume of dust and fines dropped as carryback on the belt return. Primary cleaners release most of the abrasive material remaining on the belt after discharge. Located below the head pully just behind the primary, secondary cleaners scrape off the fines and dust that hide in cracks and divots in the belt. Carryback is attributed to many environmental and operational issues such as air quality violations, fouling of rolling components and machinery, and increased labor for cleanup and maintenance.

The Martin® SQC2S™ Orion Secondary Cleaner is appropriate for all bulk handling material applications. The unit is made up of individual 6 in. (152.5 mm) blades mounted on a square steel tube assembly. Not designed for reversing belts, it is suitable for 18 – 96 in. (457 - 2438.5 mm) belt widths, belt speeds up to 1200 fpm (6 mps), and temperatures up to 250º F (121º C).

“What sets this unit apart from others on the

market is the innovative, dual tensioning system with independent heavy-duty tungsten blades which are game-changing design features,” Mueller explained. “The first level of tensioning is supplied to the entire assembly using the heavy-duty SQC2S™ Tensioner which applies light upward torque evenly across the belt profile for less friction and no wear on splices.”

The second level of tensioning is on the individual blade assembly. Each Orion blade assembly is attached to a steel square tube assembly which is secured a mounting plate. The square tube houses a rubber tensioner with a torsion arm bolted to each side. A specialized tungsten blade is attached to the arm. The whole system is mounted at a 90-degree angle then tensioned so each blade is vertical and perpendicular to the belt. As the belt runs, each blade assembly adjusts independently to precisely match the belt’s profile, permitting them to compensate for camber, flaws/blemishes, and stubborn material stuck to the belt’s face. To accommodate belt cupping and other uneven surfaces, the blade assemblies can be individually adjusted to match the belt profile.

The blades are specially designed for heavyduty abrasive applications in both dry and wet environments. Tested on hard rock and slurry belts, the Orion blades offered superior cleaning results with a longer equipment life. This is due to the rugged tungsten carbide core surrounded by mild

steel. Blades are also available in stainless-steel for specific corrosive materials.

The blade design features an attached deflector shield made from polypropene or rugged nylon for high temperature applications. Mounted directly to the blade in an outward scoop design, the shield ushers loosened material away from the mainframe and toward the discharge chute. This mitigates buildup on the assembly, extending the blade’s effectiveness and reducing the amount of maintenance.

Safety and ease of maintenance is a key feature and a core priority for all Martin Engineering designs. The slide-in/slide-out design allows a single worker to perform maintenance with easy access outside of the conveyor structure, eliminating the need to crawl underneath or awkwardly reach inside. This greatly improves workplace safety and reduces the amount of time and labor required for maintenance, significantly lowering the cost of operation.

“Every bulk handling operation is unique and requires equipment that is versatile and adaptable, and I think we’ve achieved that with the Orion,” said Mueller. “Martin Engineering products are developed to improve efficiency and safety, without compromising belt health. This design gives customers more options and superior results, regardless of the material or the process.”

Dynamic Air dense phase pneumatic conveying systems have been proven in over 15,000 installations worldwide. They handle a wide range of materials and bulk densities at rates from a few hundred pounds to 400 tons per hour, over distances exceeding 5,000 feet. The HDP 4000 Full-Line Concept dense phase pneumatic conveying system has many advantages over more traditional dense phase concepts with regard to abrasion, particle degradation and energy consumption. The system utilizes the DC-5 Air Saver technology to achieve an optimum pressure balance while counteracting forces of friction to enable low conveying velocities. The FullLine Concept system conveys materials at low velocity and high density while utilizing very low air consumption. The enclosed system is clean and can be fully automated to convey to packaging or process bins. Very few moving parts are utilized, as the prime mover is standard plant compressed air at 100 PSIG. Dynamic Air Full Line Concept systems have proven to be very low in maintenance and are very flexible with regard to space and various custom plant situations. https://www.dynamicair. com/system/hdp-4000-full-lineconcept-dense-phase-pressuresystem

Dynamic Air Ltd.

Milton Keynes, United Kingdom

+44 (0)1908 622344

e-mail: sales@dynamicair.co.uk www.dynamicair.com

Schenck Process will be presenting the CS+ loss-in-weight feeder system at the Battery Show in Stuttgart from 18th to 20th June (Booth B73, Hall 8). The modularly configurable system is specially designed to meet the requirements of electrode production and is suitable for both continuous and batch processes. It fulfils the highest standards of safety, cleanliness and dosing accuracy.

The production of lithium-ion batteries is complex. To ensure a high-performance, highquality product, contamination of the slurry by metallic abrasion and the ingress of air and moisture must be avoided. At the same time, maximum feeding accuracy under challenging pressure conditions and a reliable containment concept are required. The new CS+ loss-inweight feeder system from Schenck Process perfectly meets these different requirements.

Practical design for individual requirements CS+ can be customized to meet individual

customer requirements. The modular design makes it possible to cover a large feeding range with just one feeder type: CS+ is suitable for small quantities from 30 litres per hour as well as for high feeding capacities of up to 3,000 litres per hour.

Schenck Process has placed particular emphasis on avoiding product contamination in the new development. To prevent metal-to-metal contact, components can be optionally coated. Smooth surfaces and limited relative speeds of the agitator and screw minimize metal abrasion. The patented design of the CS+ combines this with a quick-acting flap that prevents material from trickling out during the batch process.

The CS+ loss-in-weight feeder system also offers the user permanently high accuracy for consistently high product quality. Intelligent pressure management prevents the ingress of ambient air and moisture. This prevents pressure fluctuations from having a negative impact on the dosing accuracy. At the same time, the system impresses with its simple and practical design, which also allows several dosing units to be installed in the smallest of spaces. Last but not least, CS+ fits seamlessly into system concepts that rely on a consistent containment concept to limit dust emissions. The system complies with OEB class 4 and therefore minimizes the risk for users during production.

Trade fair visitors can see the new CS+ loss-in-weight feeder system at the Battery Show in Stuttgart from 18th to 20th June.

Schenck Process will be presenting the new system exclusively at Booth B73 in Hall 8.

Williams Transport has been in the haulage business for over 50 years and was an early adopter of the IVECO S-Way at its initial launch back in 2020. However, Managing Director of R.D. Williams & Sons Andy Williams’ relationship with IVECO tractor units goes back to the 80s when as a child his favourite toy was a TurboStar diecast model. Wind the clocks forward by 40 years and his company has taken delivery of the modern-day incarnation of the most celebrated trucks in IVECO history, the legendary TurboStar.

The 1 of 180 left-hand-drive IVECO S-Way 4x2 features various styling enhancements that pay homage to the classic truck including its 1980s-inspired red colour-scheme and retro graphics. A stylish yet functional lightbar, polished air horns, and contrasting body elements further bolster its visual presence.

In the cab the throwbacks to the original TurboStar continue with contrasting trim, a unique seat design,

leather dashboard and the iconic TurboStar logo proudly on display. Based on the IVECO S-Way, the interior retains its impressive levels of space, storage, and comfort with modern-day comforts such as a fridge, freezer, microwave, TV and even a coffee maker mean this cab is a welcoming space for drivers.

When not at shows and grabbing attention on social media, this truck will be a functioning member of Williams Transport’s 50-strong fleet. Powered by a 570hp Cursor 13 engine, the TurboStar will be paired with an innovative Knapen moving floor trailer, which will be responsible for transporting wastepaper and recycling materials.

The IVECO TurboStar was originally launched back in 1984 and instantly became a cult classic amongst enthusiasts. A nine-year production run saw divers love the model for its strong performance of up to 420hp and spacious cab.

Andy Williams, Managing Director of R.D. Williams & Sons, said “Ever since I was a kid, I loved the

TurboStar. That 1984 truck was an instant icon, and as soon as I heard a new TurboStar was hitting the road, I had to have one! It was the passion and enthusiasm of IVECO UK & ROI Business Director Vincenzo Nicolò and Guest Truck’s Bal Singh that made it happen and I have ended up with one of just two vehicles that have come to the UK.”

Expected to cover around 110,000km each year, this IVECO S-Way TurboStar is covered by IVECO’s 3XL Repair and Maintenance contract for five years, helping supply peace of mind, providing key operational services at fixed prices.

This IVECO S-Way is also fitted with a Connectivity Box, giving Williams Transport access to Smart Reporting where vehicle efficiency and health can be monitored. It also enables over-the-air updates, something that delivers software enhancements without the need to visit the dealer.

Mike Cutts, IVECO Business Line Director Full Range UK & ROI commented: “The TurboStar name is a legendary piece of IVECO history, one that decades on, resonates with the industry and enthusiasts alike. The IVECO S-Way TurboStar is an impressive homage and an incredibly rare sight on UK roads. While this truck will no doubt draw crowds at events, it’s great to see that this will also be a working vehicle, providing the same strong attributes customers expect of an IVECO S-Way.”

The Bella dryer/cooler offers thermal efficiencies to 80 percent or better because air flows around material while it is suspended in the weightless zone. The result is a more consistent material.

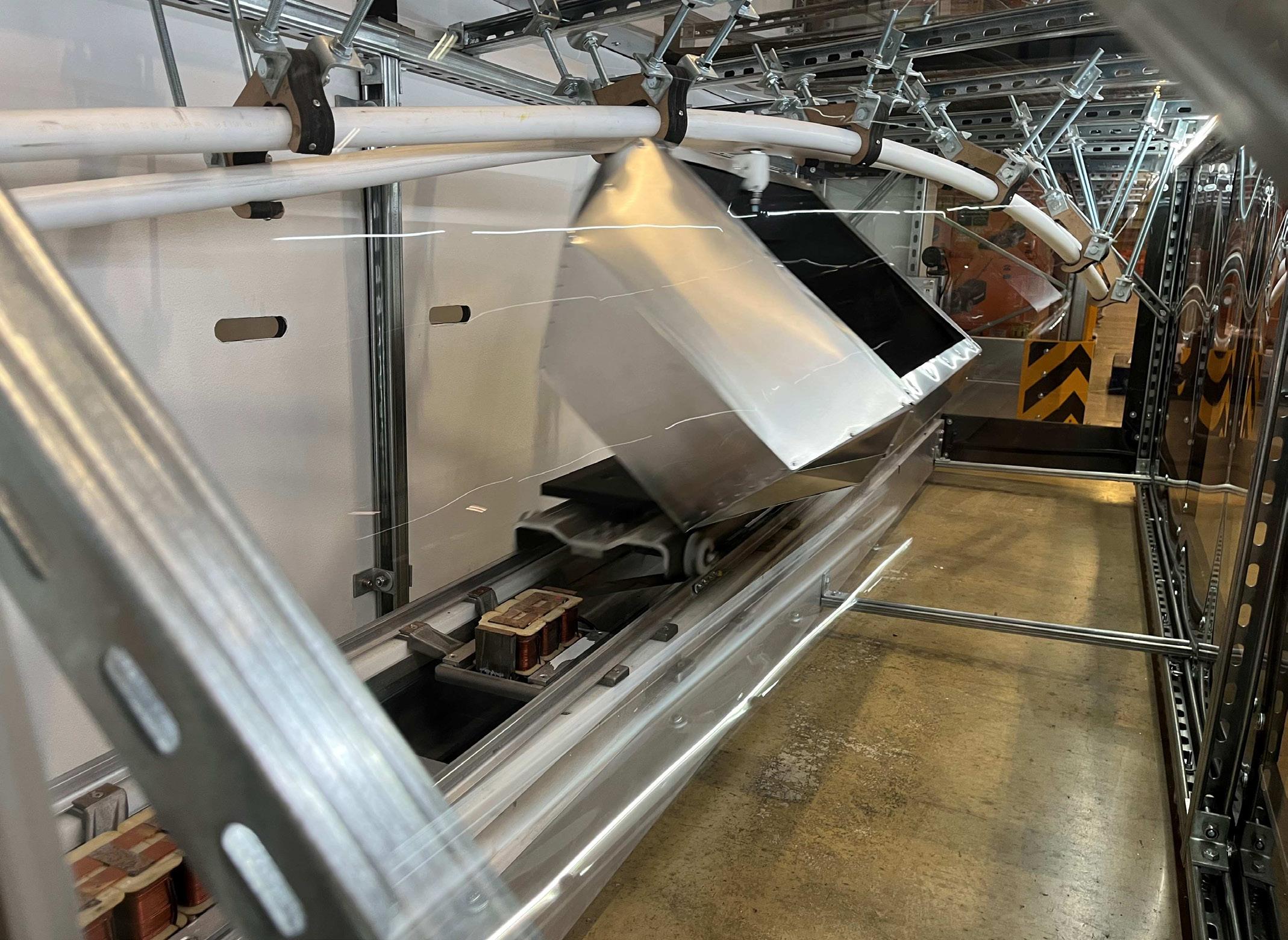

Northamptonshire, UK: Magway Limited, a pioneering developer of zero-emission goods transport systems, is set to showcase its innovative magnetic propulsion bulk material handling technology at Wincanton’s W² Innovation Centre.

Magway’s cutting-edge technology, designed to enhance the sustainability and efficiency of bulk material transport, will be showcased at logistics giant Wincanton’s state-of-the-art Innovation Centre in Rockingham, Northamptonshire. This centre, adjacent to The WEB – Wincanton’s automated shared user facility for high volume fulfilment, is a hub for the latest in supply chain innovation which benefits Britain’s businesses.

For six years, Magway has been at the forefront of magnetic propulsion, continuously pushing boundaries and refining its system. Magway’s technology enables precise control over the horizontal and vertical movement of loads up to 250kg, with a throughput capacity of 1,000 tonnes per hour. Remarkably, the system operates at less than 20% of the energy and operating costs of traditional solutions, while producing zero emissions.

Phill Davies, CEO of Magway, stated:

“Every year, over 100 billion tonnes of bulk materials—equivalent to two-thirds the mass of Mount Everest—are transported globally using traditional conveyors and trucks. In order to achieve net zero, businesses need to innovate in their supply chain processes and embrace new technologies. Our system offers a compelling alternative, providing unparalleled efficiency and sustainability.

“This is the first Magway demonstrator outside of our own controlled test environment, and we’re extremely excited to showcase our technology and vision for sustainable, efficient bulk material movement. Working with these leading organizations, we can ‘Move Mountains Together’.”

Magway’s initiative is supported by industry leaders including construction materials supplier GRS Group, Warwick Manufacturing Group, Mackley Engineering, KPMG and NatWest.

Paul Durkin, Chief Customer and Innovation Officer, at Wincanton commented:

“We are delighted to welcome Magway and its cutting-edge magnetic propulsion technology to our Innovation Centre. Innovation is at the heart of everything we do for our customers, and we are committed to collaborating with global innovators like Magway to drive emerging technology and sustainability in supply chain and logistics. Since its opening in 2021, our Innovation Centre has

welcomed over 5,000 visitors, and we look forward to many more experiencing this new technology.”

Gary Coles, Integrated Solutions Director at GRS Group, said:

“As a supplier of essential bulk materials for UK construction, we’re always looking for innovations to improve efficiency and support our journey to net zero. As soon as we heard about Magway, we were keen to get involved. We’re excited to see how this remarkable technology could improve material movement at a GRS site that’s one of London’s busiest processing plants.”

NatWest’s Clean Transport Accelerator, in partnership with WMG, recently welcomed Magway into its fold. This fully funded program provides specialised support to businesses developing clean transport solutions, facilitating the rapid deployment of innovative ideas into the market.

Richard Hill, Head of Mobility and Logistics at NatWest, remarked:

“Magway’s transformation from concept to a sustainable business model has the potential to revolutionise the bulk goods movement. The accelerator is dedicated to nurturing ventures like Magway, ensuring swift market entry and maximizing the benefits of groundbreaking innovations for the UK.”