%

of annual carbon emissions come from the food sector!

Let’s work together to minimize carbon emissions at all stages of food system

Increase production of Eco-friendly agricultural and marine products

Reduce distribution steps and use green fuels

Prepare only the necessary amount of food and consume it without any leftover

Minimize waste in processing and handling

As a response to climate change, we support the declaration of a Global Low Carbon Diet Day to reduce carbon emissions from food, which accounts for 31% of global greenhouse gas emissions, and the formation of the Low Carbon Diet Forum, a movement for action that promises a healthy humanity, a healthy planet, and a sustainable future.

One. We recognize that a low carbon diet is essential for a healthy global environment, which is directly related to the future of humanity.

One. We will solidarise and cooperate in all projects and activities promoted by the international community to achieve food carbon neutrality.

One. We will work together to minimize carbon emissions at all stages of food production and consumption.

One. We will designate every Wednesday as Low Carbon Diet Day to promote and practice the importance of food carbon neutrality.

As a public institution in charge of food industry, aT has established a network of cooperation with more than 600 companies, institutions, and organizations at home and abroad to spread low-carbon diet movement.

Please scan the QR below, and show your support

Robo Arete Co., Ltd.

Pioneers Korea’s First Professional Cooking Robot System

Changchang Food Co., Ltd.: A Company Specializing in Traditional Korean Vegetable Oils

Trends in Traditional Korean Vegetable Oils

Korean Syrup, a Popular Product on Amazon in the U.S.

The Art of Slow Brewing: Seojung Cooking’s Sikhye and Sujeonggwa

Introduction of Korean Food Service at International Schools in Sao Paulo, Brazil

Korea’s Leader in Year-Round Apple Watermelon Production Using Smart Farming Technology eongil C ., Ltd.:

This issue focuses on the multifacets of Korean vegetable oils. The cover story provides an overview of the current status and statistics related to traditional Korean oils, namely, sesame oil and perilla oil. We shine a spotlight on Changchang Food, a leading producer of specialty oils. Perilla oil is a good source of omega-3 fatty acids, while sesame oil has excellent antioxidant properties. Both are indispensable ingredients in Korean cuisine and are receiving increased recognition. In July, watermelons are in season. We met with Seongil Farm, a smart farm that produces apple watermelons, which are smaller than 20% the size of regular watermelons, year-round. We also conducted an interview with Robo Arete, a specialist in robotic cooking systems and the operator of the fried chicken shop Lambert Chicken. In addition, we visited Seojung Cooking, which produces traditional Korean sikhye (sweet rice punch) and sujeonggwa (cinnamon punch), maintaining the tradition of slow food preparation. Other notable features of this issue include oligosaccharides produced from Korean rice, which are gaining traction on Amazon in the U.S., the operations of Korean peach farms, a recipe for budaejjigae (sausage stew), a dish with historical significance originating from the Korean War, and emerging trends in the food industry seeking distinctive flavors.

Kim, Eil Chul Chief Reporter

Founded in August, 1995, Published monthly by the

227, Munhwa-ro, Naju City, South Jeolla Province, Korea Tel: +82-61-931-0963 Fax: +82-61-804-4521

Government Registration Number: Ra-7210

Dated April 26, 1995

Copyright by the aT (Korea Agro-Fisheries & Food Trade Corp.) All rights reserved.

CEO Kim Choon-jin

EXECUTIVE VICE PRESIDENT Kwon O-yub (Food Industry & Trade Division)

EDITOR Hwang Doyoun

CHEIF REPORTER Kim Eil Chul

COORDINATOR Yoon Hyun-joo

CREATIVE DIRECTOR Chang Soobum

PHOTOGRAPHY DIRECTOR Hwang Donggun

TRANSLATORS Kivit Adrianus (ENGLISH), Shin Nakajima (JAPANESE), Bart Wu (CHINESE)

EDITORIAL BOARD

BEIJING John Dae-young (redsun@at.or.kr) 070-4617-5090

SHANGHAI Lee Jong-geun (jglee@at.or.kr) 070-7077-6197

DALIAN Lee Jeong-seok (rhee@at.or.kr) 070-4617-3278

HONGKONG Kim Hyun-hoo (max@at.or.kr) 070-4617-2696

QINGDAO Lee Sun-Woo (bird@at.or.kr) +86-532-5566-8873

QINGDAO aT LOGISTICS Han Seung-hee (shhan@at.or.kr) 070-7939-0863

HANOI Kim Kyoung-chul (yohang@at.or.kr) +84-24-6282-2987

HOCHIMIN Cho Sung-bae (chobae@at.or.kr) 070-8098-6514

BANGKOK Byun Kyung-yong (yong7619@at.or.kr) 070-4617-7227

JAKARTA Lee Seung-hoon (afmchoon@at.or.kr) +62-21-2995-9094

KUALALUMPUR Jang Jung-ho (lastjang@at.or.kr) 070-5223-4901

TOKYO Yoon Sang-young (foodkorea@at.or.kr) +81-3-5367-6656

OSAKA Kwon Hyun-ju (hyunjukun@at.or.kr) 070-7000-4138

NEW YORK Shim Hwa-Sop (sirshim@at.or.kr) +1-212-889-2561

LA Kim Min-Ho (mhkim@at.or.kr) +1-562-809-8810

SAO PAULO Jung You-sun (usuni@at.or.kr) +55-11-3283-0089

DUBAI Jeon Yong-pil (pioneer@at.or.kr) +971-4339-2213

PARIS Nam Sang-hui (mudpearl@at.or.kr) +33-1-4108-6095

MOSCOW Shin Jae-hun (chekov@at.or.kr) 070-4617-3277

Korean vegetable oils include sesame oil made from sesame seeds and perilla oil made from perilla seeds. Sesame oil is renowned for its excellent antioxidant properties, while perilla oil is rich in omega-3 fatty acids, which benefit digestion and boost metabolism. In particular, raw perilla oil has been shown to enhance gastrointestinal function and improve blood circulation. Perilla seeds are more sensitive to heat and have a nuttier flavor than sesame seeds under the same conditions. The value and functionality of these traditional Korean oils are being rediscovered, and products are being modernized and upgraded to meet contemporary tastes and needs. As a result, the number of export destinations for these oils is growing. Notable domestic sesame oil products include Ottogi’s “Sesame Oil,” Changchang Food’s “Friendly Park Seobang,” CJ CheilJedang’s “100% Whole Perilla Oil,” and Komega’s “Non-Roasted, Cold-Pressed Raw Perilla Oil.”

韓国の伝統油、 エゴマ油とゴマ油

韓国の伝統的な油には、胡麻から 作ったゴマ油とエゴマから作ったエゴ マ油がある。ゴマ油は抗酸化機能に優れ、エゴ マ油はオメガ3が豊富で胃腸にも良く、新陳代 謝を活発にしてくれる。特に生のエゴマ油は、油 そのものを摂取することで、胃腸機能の強化や 血液循環にも役立つ。同じ条件下では、エゴマ の方が胡麻よりも熱に敏感で、より香ばしい。

これら韓国の伝統油の価値と効能が再認識さ れ、新たに現代人の好みやニーズに合わせて製 品の現代化やプレミアム化が行われてきた結 果、海外輸出も増え続けている。韓国の主なゴ マ油製品としては、(株)オットゥギの「香ばしい ゴマ油」、農業会社法人である(株)チャンチャン フードの「やさしいパクソバン」が、エゴマ油とし てはCJ第一製糖の「100%エゴマ油」、(株)コメ ガの「炒らずに一度だけ圧搾した生エゴマ油」 などがある。

Komega is a market-leader that is revitalizing

(株)コメガは、韓国の伝統的な油である生エゴ マ油の価値と効能に改めて着目し、韓国のエゴ

and exporting domestic perilla oil by modernizing traditional raw perilla oilmaking. In April 2003, CEO Jeong Hoon-baek produced Korea’s first conventional cold-pressed raw perilla oil. This oil is produced by pressing perilla seeds in their natural form, without roasting, resulting in a soft and clear oil that retains the natural flavor of the seeds. From 2007 to 2009, CEO Jeong focused on establishing

standards for perilla oil as a traditional food product. In September 2012, it won a gold medal at the World Oil Test in France, opening the door for exports to Europe. In addition, it was awarded the iTQi Oil Taste Award for six consecutive years from 2016 to 2022.

CEO Jeong is dedicated to raising international awareness of Korean raw perilla oil and has participated continuously in the Taiwan Food Expo for the past ten years. These efforts have led to Korean raw perilla oil becoming the first Korean food product to be certified as a “functionally declared food” in Japan. The product received functional certification for its effectiveness in treating high blood pressure and was introduced in a pharmacy chain in Shizuoka, Japan. Komega’s raw perilla oil was first exported to Japan in 2008, followed by exports to Taiwan and Singapore in 2015. In 2022, the company expanded its export destinations to Hong Kong, Malaysia, and Russia. Approximately 40% of their total sales are exported to Japan, Taiwan, Russia, Malaysia, the United States, and Singapore. Changchang Food, established in 2020 and specializing in cold-pressed sesame and perilla oils, exported “Friendly Park Seobang” products to the United States in November 2022 and August 2023. Bangyudang Co., Ltd. is a famous producer and supplier of premium traditional oils. The parents of Son Min-jeong, the CEO of Bangyudang, established an oil restaurant in Jeonju Jungang Market in 1976, which Son subsequently assumed control of in 2012. The company is committed to developing flavorcentered oils that harmonize taste and nutrition.

To guarantee consistent quality, they introduced a dedicated roasting device and developed a savory scale (BGST) to accommodate the distinctive characteristics of each sesame and perilla oil. The BGST categorizes oils based on their roasting level: level 1 is for lightly roasted perilla oil, level 2 is for lightly roasted sesame oil, level 3 is for roasted perilla oil, and level 4 is for sesame oil. Bangyudang has enhanced and diversified the design and quality of these traditional oils to align with premium standards. Recently, they opened a new restaurant specializing in vegetable oils and a flagship store for their oil products.

マ産業の拡大と輸出に大きく貢献している代表的な企 業である。チョン・フンベク代表は2003年4月、韓国で初 めて、伝統的な方法で圧搾した生エゴマ油を生産した。 焙煎しないため、エゴマ本来の香ばしさが保たれ、まろ やかで透明な油が味わえる。また彼は2007年から2009 年にかけて、エゴマ油に関する伝統食品規格化基準を 設けることに力を注いだ。2012年9月、フランスで開かれ た世界オイルテストで金賞を受賞し、ヨーロッパ輸出の 道を開いた。2016年から2022年までiTQi Oil味覚賞を6 年連続受賞している。

熱心に韓国産エゴマ油の存在と価値を海外に発信して いるチョン・フンベク代表は、9年に渡って出展してきた

台湾の食品博覧会に今年も出展した。このような努力の 末、日本において、加工食品である生エゴマ油が高血圧に 効果があることから、韓国の食品として初めて「機能性表 示食品」の認証を取得し、静岡県の薬局チェーン店に納品 した。(株)コメガは、2008年の日本を皮切りに、2015年に は台湾とシンガポール、そして2022年には香港とマレーシ ア、ロシアへと生エゴマの輸出先を拡大してきた。現在は日 本、台湾、ロシア、マレーシア、米国、シンガポールなどへの 輸出が、売上高の約40%を占めている。また、2020年に設 立され、低温圧搾方式でゴマ油とエゴマ油を生産する(株) チャンチャンフードは、2022年11月と2023年8月、2度にわ たり自社製品「親切なパクソバン」を米国に輸出した。 (株)芳油堂(バンユダン)は、プレミアム伝統油を生産 ・販売する企業である。ソン・ミンジョン代表の両親が 1976年に全州(チョンジュ)の中央市場で油屋を開店

し、2012年にソン代表が後を継いだ。現在は、味ばか りが注目されがちな油に対して、栄養も伴った美味しさ を追求するために努力している。一貫した品質の油生産 に適した焙煎専用機械を導入し、ゴマ油とエゴマ油それ ぞれの特性を生かした香ばしさの尺度(BGST)を独自に 開発した。例えば、BGSTレベル1はから炒りしたエゴマ 油で、レベル3は焙煎したエゴマ油である。レベル2はか ら炒りしたゴマ油で、レベル4は焙煎したゴマ油である。 (株)芳油堂は、これらの伝統油をプレミアムの名に相応 しくデザインや製品のクオリティを高め、多様化した。ま た最近伝統油専門レストランを兼ねた伝統油の旗艦店 も新たにオープンした。

A Company Specializing in Traditional Korean Vegetable Oils

Changchang Food Co., Ltd. is a producer of traditional Korean vegetable oils, including sesame and perilla oil. The company employs low-temperature pressing techniques to manufacture its products, which are sold domestically and internationally. The company was established as an agricultural corporation in late January 2020 and launched its products at the Wanju Local Food offline store in 2021. Changchang Food was recognized at the 2022 International Fermented Food Expo (JIFFE) for its excellent products and achieved HACCP certification for both sesame and perilla oil that year. On April 30, 2024, the company filed a patent for its “Method for Manufacturing Perilla Oil Using Low-Temperature Roasting.” In 2023, Changchang Food sold 1,153 kg of perilla oil, 11,952 kg of raw perilla oil, and 2,139 kg of sesame oil in South Korea. In addition, the company exported 335 kg of oil to the United States in November 2022 and August 2023. The products are available for purchase on various e-commerce platforms, including SSG.COM, LOTTEON, Interpark, Coupang, and Kakaotalk Shopping. The company cultivates approximately 71,166 square feet of sesame and perilla seeds, supplementing any shortfall with local purchases.

Changchang Food’s products are sold under the brand name of “Friendly Park Seobang.” These products are made from 100% domestically produced perilla and sesame seeds, which are pressed only once

using a low-temperature pressing method. This method guarantees the production of pure oil through a secondary filtering process. The bottling process employs a semi-automatic system with a filter to prevent the contamination of foreign substances, with an output capacity of up to 200 bottles of 300ml per day. The product line includes bottles of sesame and perilla oil in 100ml, 180ml, and 300ml sizes, as well as 5ml raw perilla oil sticks in packs of 10. Additionally, the product line includes 180ml and 300ml “Chamdeul Set” packages containing both sesame and perilla oils. The 5ml “Perilla oil stick” is particularly convenient for consumption, with a recommended 1 to 2 sticks daily, directly or in salads, juices, and various dishes. Both sesame oil and perilla oil should be stored at cool room temperature, with a shelf life of one year from the date of manufacture.

Sesame and perilla oils are traditional Korean vegetable oils. They are free of sodium, sugar, trans fats, and cholesterol. Sesame oil contains 2% carbohydrates, 174% fat, 1% protein, and 98% saturated fat per 100ml (897 kcal), with 45% omega-6 fatty acids. It contains 40% monounsaturated fatty acids and lignans, an antioxidant that helps prevent cancer and inhibits aging. With 53% saturated fat per 100ml (867 kcal), perilla oil is rich in omega-3 fatty acids (60%), which effectively prevent cardiovascular disease, cancer, inflammatory diseases, and rheumatoid arthritis. It also has anti-inflammatory properties and helps prevent skin diseases.

Producing high-quality vegetable oil that retains the benefits of oils requires a significant investment of time and effort. Pressing the oil more than two or three times will significantly impair the quality of the product. Changchang Food guarantees that its products are pressed only once, impurities are removed using a fine filter, and bottling is done with infrared sterilization. The sesame and perilla seeds are sourced directly from farms and undergo intensive washing (4-5 times) before being roasted using a low-temperature technique to prevent the formation of benzopyrene, a carcinogenic compound produced when sesame seeds are excessively roasted and blackened. The company has successfully passed benzopyrene detection tests conducted by professional testing agencies, reflecting its commitment to strict hygiene and quality control.

(株)チャンチャンフードは、低温圧搾方式で韓国の伝統 油であるゴマ油とエゴマ油を生産して国内外に販売す る韓国伝統油専門企業である。2020年1月末、農業会 社法人として設立された。翌年の2021年、全羅北道の完 州(ワンジュ)ローカルフードオフライン店舗に出店し、国 際発酵食品エキスポ2022の「JIFFE優秀商品」に選定され た。2022年には、ゴマ油とエゴマ油のHACCP認証も取得 している。2024年4月30日、「低温焙煎を利用したエゴマ 油の製造方法」という特許を登録した。また販売において は、昨年2023年、エゴマ油1,153kg、生エゴマ油11,952kg とゴマ油2,139kgを韓国国内で販売し、2022年11月と 2023年8月の2度にわたり、総重量335kgの油を米国に 輸出した。SSG.COMとLOTTEON、interpark、coupang、 Kakaotalk shoppingなどにも出店している。原材料である

胡麻とエゴマを2千坪以上の規模で栽培し、不足分は地元 の農家から買い上げている。

(株)チャンチャンフードが生産する製品のブランド名は「親 切なパクソバン」である。100%国産のエゴマと胡麻を使っ て、低温圧搾方式で一度だけ搾油した後、2次フィルター 工程を経て澄んだ油を作る。それから半自動システムフィ ルターを使用し、異物を混入させることなく瓶に詰める。1 日に最大300ml入りの瓶を200本まで生産することができ る。100ml、180ml、300ml入りのゴマ油とエゴマ油、そし て生エゴマ油スティック5ml×10本入りの商品を揃えてい る。ゴマ油とエゴマ油が一緒に入っている「ゴマ油セット」 180mlと300mlのほか、摂取しやすい「エゴマ油スティッ ク」5mlも揃えている。スティックタイプは1日に1~2包が 目安である。直接摂取はもちろん、サラダやジュース、各種 料理にも使える。ゴマ油とエゴマ油はいずれも涼しい屋内 で保存し、賞味期限は製造日から1年となっている。

韓国の伝統油であるゴマ油とエゴマ油は、ナトリウム、糖 類、トランス脂肪酸、コレステロールがゼロである。ゴマ 油の栄養成分は、100ml(897kcal)当たり炭水化物2%、 脂肪174%、タンパク質1%、飽和脂肪酸98%となってお り、オメガ6脂肪酸を45%含んでいる。また、40%の一価 不飽和脂肪酸や抗酸化成分であるリグナンを含んでいる

ため、がん予防やアンチエイジングに役立つ。エゴマ油は 100ml(867kcal)の中に飽和脂肪酸が53%含まれていて、こ のうちオメガ3脂肪酸を60%含んでいるため、心血管疾患、 がん、炎症性疾患やリウマチ性関節炎などを予防する効 果があり、抗炎症作用と皮膚疾患の予防にも役立つ。 しかし、伝統油の様々な効能を発揮できるような良質の 油を生産するには、少なからぬ投資と努力が要る。仮に 油の生産量を重視して搾油を2~3回行うと、生産量が増 える反面、製品の質は著しく低下する。そのため(株)チャ ンチャンフードでは、1回だけ搾油した後、マイクロフィル ターで不純物を除去し、赤外線殺菌消毒済みの瓶に入れ て生産する。原材料である胡麻とエゴマは、農家で直接 目視検査を行ったものを買い上げる。これらの原材料を 4~5回集中的に洗浄した後、低温焙煎技法で焙煎してベ ンゾピレンの発生を根本から防ぐ。発がん性区分1の環境 ホルモンであるベンゾピレンは、胡麻を過度に炒って黒 く焦げてしまったときに発生する物質である。(株)チャン チャンフードはこのベンゾピレン検出検査において、専門 検査機関から不検出合格判定を得た。厳格な衛生・品質 管理を行った結果である。

CEO: Park Jung-kyou

E-MAIL: kind_mrpark@naver.com

WEBSITE: http://changchang.co.kr

TEL: +82-(0)63-242-6395

ADDRESS: 183, Sinjisonggwang-ro, Yongjin-eup, Wanju_gun, Jeonbuk-do, Republic of Korea

Changchang Food Co., Ltd. produces high-quality, coldpressed sesame and perilla oils using locally sourced seeds from North Jeolla Province, emphasizing clean and honest production.

(株)チャンチャンフードは、全羅北道産の地元の種子を使用

The domestic market for traditional vegetable oils has experienced a notable expansion since 2020, driven by the increased prevalence of home-cooked meals due to the impact of the COVID-19 pandemic. Furthermore, an increasing number of consumers are considering not only the taste of food but also its health benefits, which has contributed to this market growth. As of 2021, domestic sesame oil production reached 31,094 tons, an increase of 26.9% compared to 24,495 tons in 2017. Recently, companies specializing in traditional oils, such as sesame and perilla, have emerged. The increased interest and sales of these oils, which are used widely in Korean dishes as seasonings and dressings, have also seen a rise in sales and interest due to the increase in home cooking and the opening of specialized restaurants. As of the first half of 2022, Ottogi held the leading position in the traditional Korean vegetable oil market with a 45.4% market share, followed by CJ CheilJedang with 31.5%, Sajo Haepyo with 5.9%, and Daesang with 2.3%.

In 2021, the estimated market size for sesame oil was KRW 400 billion. The majority of consumers (59.5%) purchase sesame oil manufactured by large food companies, with products from markets and mills representing the next most popular choice. Approximately 30% of sales are made through distribution channels such as supermarkets, convenience stores, and online platforms, while stores that manufacture and sell their products account for 20%. Traditional sesame oil is primarily produced and distributed through channels such as oil houses and mills. When purchasing sesame oil, 20% of consumers consider whether the product is domestically produced, 11.9% look for reliability, and 9.7% prefer handmade products.

In 2021, the estimated market size for perilla oil was approximately KRW 100 billion, with major players including Ottogi, CJ, and Sajo. In contrast to sesame oil, 19.9% of consumers purchased perilla oil from supermarkets, while a higher percentage (48.8%)

bought it from local markets and mills. The country of origin is the most important factor for 21.3% of consumers when purchasing perilla oil, followed by homemade products (13.7%) and trustworthy products (12.4%). Consumer trends indicate that 41.2% of perilla oil products are sourced from family members and relatives, while 34.8% are produced by large food manufacturers. In 2022, consumers placed a high value on health benefits, such as the omega-3 content, in addition to enhancing the taste and enjoyment of cooking.

In 2018, the production of sesame oil reached 26,312 tons, with a total value of KRW 191.155 billion. This figure increased to 28,138 tons valued at KRW 202.796 billion in 2019 and 27,888 tons valued at KRW 239.039 billion in 2020. By 2021, production had reached 31,094 tons with a value of KRW 239.2 billion. In 2018, perilla oil production reached 5,421 tons, with a total value of KRW 38.87 billion. In 2019, production reached 4,395 tons with a value of KRW 41.196 billion, 4,187 tons valued at KRW 60.566 billion in 2020, and 4,661 tons valued at KRW 61.356 billion in 2021.

The cultivation area for sesame seeds for sesame oil-making saw a significant increase of 14.7% in 2022, reaching 22,039 hectares compared to 19,218 hectares in 2021. Sesame production increased by 15.7% to 11,697 tons in 2022 from 10,090 tons the previous year. In 2018, the sesame production was 12,727 tons, cultivated on 24,760 hectares. In 2019, production reached 12,986 tons on 25,159 hectares, followed by 6,795 tons on 22,930 hectares in 2020 and 10,090 tons on 19,218 hectares in 2021. In 2021, the perilla cultivation area reached 37,406 hectares, representing a 3.6% increase from the previous year. In 2018, perilla production reached 40,344 tons, representing a 20.5% decline from the previous year. In 2018, 40,344 tons were produced from 34,863 hectares. This increased to 42,341 tons from 37,377 hectares in 2019, 38,784 tons from 36,111 hectares in 2020, and 42,493 tons from 37,406 hectares in 2021.

韓国伝統油の現状と推移

韓国の伝統油市場は、新型コロナウイルス感染症をき っかけに家庭での食事が増えたことから、2020年以降、 その成長規模が増加し始めた。食品に対して味だけでな く健康も求める方向へと意識が変わったことも一つの 要因と考えられる。2021年の韓国のゴマ油生産量は3万 1,094トンで、2017年の2万4,495トンに比べて約26.9% 増加した。近年、高級化やニッチ化などで細分化し、伝 統油の専門業者も少しずつ増えている。たれやドレッシ ングとしてあらゆる韓国料理に活用されてきたゴマ油と エゴマ油も家庭で料理する機会が増えたことから売上 と関心度が共に高まり、専門レストランも誕生するなど 盛況ぶりを見せている。韓国伝統油の市場シェアは、 2022年上半期には(株)オットゥギが45.4%で1位を占め、 CJ第一製糖が31.5%で2位、サジョヘピョが5.9%で3 位、続いて大象(デサン)が2.3%で4位となっている。

2021年現在、業界が推定するゴマ油市場の規模は4 千億ウォン規模である。消費者が普段使用するゴマ油 は、大手食品メーカーが製造したゴマ油が59.5%で最も 多く、次いで市場や工房などで生産された製品となって いる。流通面では、大型量販店やコンビニエンスストア、 インターネットショッピングなどの流通チャネルを通じ た販売が30%台に達している。直接搾って販売する店も 20%に及ぶ。これは主に、昔ながらのゴマ油の販売チャ ネルである油屋や工房などを通じて生産・流通されてい るものと推定される。ゴマ油を購入する際に考慮する点 は、国産かが20.0%、信頼できる製品かが11.9%、直接 搾った製品であるかが9.7%だという。

2021年のエゴマ油の市場規模は約1千億ウォン前後と 推定される。オットゥギ、CJ、サジョなどが代表的な企 業である。エゴマ油はゴマ油とは異なり、大型量販店で 購入する割合が19.9%であるのに対し、知り合いや市 場の工房などから購入する割合が48.8%とはるかに高 い。エゴマ油を購入する際に考慮する点も、国産かどう

かが21.3%で最も高い。次いで、直接搾ったかどうかが 13.7%、信頼できるかが12.4%となっている。消費者の エゴマ油の使用傾向を見ると、家族や親戚が直接搾っ て提供したものを使用する場合が41.2%、大手食品メー カーの製品を使う場合が34.8%である。2022年、消費 者がゴマ油とエゴマ油に期待する価値は、味と料理の楽 しさをプラスすることに加え、オメガ3の効果などで健康 要素を重要視していることが分かった。

ゴマ油の2018年の生産量は26,312トンで、生産額は 1,911億5千500万ウォンであった。2019年の生産量 は2万8,138トンで生産額が2,027億9千600万ウォン、 2020年は生産量2万7,888トン、生産額2,390億3千 900万ウォンであった。2021年は生産量3万1,094トン に生産額2,392億2,100万ウォンを記録した。エゴマ油 の2018年の生産量は5,421トン、生産額は388億700万 ウォンで、2019年は生産量が4,395トン、生産額411億 9千600万ウォンを達成した。2020年には生産量4,187 トンに生産額が605億6千600万ウォンであった。2021 年には生産量4,661トン、生産額は613億5千600万ウォ ンを記録した。

ゴマ油の原材料となる胡麻の栽培面積は2022年に 22,039haで、2021年の19,218haに比べて14.7%増加し た。胡麻の生産量は2022年に1万1,697トンで、前年の 1万90トンから15.7%増加した。2018年の胡麻生産は、 生産面積24,760haに生産量が1万2,727トン。2019年は 25,159haに1万2,986トン、2020年は22,930haで6,795 トン、2021年は19,218haで1万90トンを生産した。エゴ マの栽培面積は2021年37,406haで、2020年に比べて 3.6%増加した。生産量は2018年が4万344トンで、対 前年比20.5%減少した。2018年は34,863haで4万344 トンを、2019年は37,377haで4万2,341トンを生産し た。2020年には36,111haで3万8,784トン、2021年には 37,406haで4万2,493トンを生産した。

Seongil Farm Co., Ltd. is the most prominent and best apple watermelon farm in Korea. The farm produces apple watermelons year-round using the latest high-set hydroponic cultivation techniques and environmentally controlled smart farm facilities. The farm was established in 2017 with the objective of producing and distributing apple watermelons. Seongil Farm initially focused on producing and distributing apple watermelons. In the first year, the company achieved KRW 100 million in sales. By 2018, the company had expanded to 25 farmers and achieved KRW 2.6 billion in sales.

In 2019, the company had 41 farmers and achieved KRW 3.9 billion in sales. However, sales declined to KRW 2.2 billion in 2020 due to the impact of the coronavirus pandemic. In 2021, the company rebounded to achieve KRW 4.8 billion in sales despite maintaining the same number of farms. Sales continued to grow, reaching KRW 6.7 billion in 2022 and KRW 5.8 billion in 2023. The company is targeting sales of KRW 6 billion in 2024 and KRW 12 billion in 2025.

Seongil Farm provides a comprehensive range of services, including smart farming, seed distribution, cultivation technology, and distribution. A smart

farm producing apple watermelons has been shown to yield five times more than a traditional farm of the same size. This equates to a 1.4 times higher product yield, a 1.25 times higher price point, and a seven times higher total sales figure. A smart farm can produce 640,000 apple watermelons annually, compared to 120,000 with conventional farming, due to the ability to grow five crops per year with 32 plants per pyeong (3.3 square meters). Over the past five years, Seongil Farm has refined its cultivation methods by consulting with 42 farms and developing a solution optimized explicitly for apple watermelons.

Kang Sang-hoon, CEO of Seongil Farm, hails from a farming family in Gochang, North Jeolla Province. He graduated from the Korea University of Agriculture and Fisheries in 2014 and was selected as a successor agricultural manager that year. In 2021, he was recognized as a prominent figure in the field of Korean agriculture. Kang has secured substantial greenhouse space for the company, including 747,246 square feet for house greenhouses, 533,747 square feet for agricultural greenhouses, 391,414 square feet of open space, and 177,915 square feet of cultivated open space. Furthermore, Seongil Farm boasts a 10,674-square-foot sorting logistics center, non-destructive sorting machines, mobile logistics equipment, and cold storage facilities. Apple watermelons from affiliated farms undergo initial appearance inspection and subsequent checks for quality and integrity at Seongil Farm’s sorting facility. Only the highest-quality watermelons are selected through a non-destructive sorting process that evaluates size, weight, appearance, and sweetness. Seongil Farm ensures consistent

marketability through rigorous quality control, employing a non-destructive sorter specifically designed for apple watermelons. The company has established solid domestic partnerships with leading suppliers such as SSG.COM and distributes to CU Convenience Store, SSG Dawn Delivery, and Lotte Mart. Their products are available for purchase at approximately 20 offline retail locations, including CU, GS25, Lotte Mart, Home Plus, E-Mart, Shinsegae Department Store, Hyundai Department Store, and E-Mart Traders. They are also available for purchase online at various e-commerce platforms, including Coupang, G Market, Tmon, Hello Nature, Auction, WeMakePrice, and SSG.COM. In the global market, Seongil Farm has achieved exports worth KRW 20 million in 2020 and 2021. Now the company is pursuing further global expansion by participating in the Paris SIAL food fair in 2022.

A regular watermelon is large and heavy, with an average weight of approximately 8 kg, and the rind constitutes over 20% of the total weight. The fruit is challenging to cut and consume, and the amount of waste generated is considerable. On the other hand, apple watermelons weigh only 1.5 kg, making them an ideal choice for smaller households and easily stored in a refrigerator. The efficient transportation of apple watermelons is also a significant advantage, with 4,000 to 5,000 units able to fit in a single vehicle, reducing logistics costs and shortening handling time. The peel of an apple watermelon accounts for only about 5% of its total weight and is slightly thicker than the chamoe (oriental melon) peel. Unlike traditional watermelons, which are typically cut and eaten, apple watermelons are small, easy to prepare, and versatile for various dishes, including apple watermelon hwachae (punch), wa-

Seongil Farm(株)凭借智慧农场 实现小西瓜全年不间断生产

农业法人Seongil Farm(株)是韩国规模最大最好的小西瓜

农场,在环境控制智慧农场设施的基础上采用最新高架床 水培方式,实现小西瓜一年365天全年不间断生产。公司 成立于2017年,致力于生产和销售小西瓜。成立第一年销 售额就达到1亿韩元,第二年2018年携手25家农户创下26

亿韩元销售额,2019年与41家农户创下39亿韩元销售额。

2020年受到新冠疫情的影响,销售额骤降到22亿韩元,但

2021年又和原有的41家农户一起达成了48亿韩元的销售 额。2022年和2023年销售额分别达到67亿韩元、58亿韩元。

2024年和2025年的销售额目标是60亿韩元和120亿韩元。

Seongil Farm(株)拥有智慧农场、优良种子的普及和栽 培技术、流通渠道等综合解决方案。假设在4千坪(1坪约 为3.3平方米)规模的小西瓜农场种植,智慧农场与常规

的农场相比,生产量高5倍、商品率高1.4倍、价格高1.25 倍,总销售额高7倍。常规农业方式生产12万个小西瓜,

Seongil Farm(株)的智慧农场就能生产64万个。因为智 慧农场每坪出产32个,一年可采收5次。不仅如此,最近5 年间,Seongil Farm(株)通过为42家农户提供咨询,获得

了耕种数据,掌握了小西瓜的最优栽培解决方案。

Seongil Farm(株)的姜湘焄代表理事出生于韩国全罗北 道高敞郡的农户家中,2014年毕业于韩国农水产大学。

2014年被选为农业经营接班人。2021年荣获农业单元的 韩国年度人物大奖。姜湘焄搭建的双层温室大棚规模为 21000坪、农作物温室大棚规模为15000坪。确保的露地 面积为11000坪、农作物露地为5000坪。此外,还有300 坪规模的筛选物流中心、无损筛选机、移动物流装备、低 温仓库等设施。Seongil Farm(株)的小西瓜种植农户分 散在韩国各地,这些农户出产的小西瓜都要在SEONGIL FARM(株)的筛选中心进行第一次外观检测和第二次糖度 无损检测。之后通过无损筛选机整体检测大小、重量、外 观和糖度,筛选出优质的西瓜。

Seongil Farm(株)通过小西瓜专用的无损筛选机进行 严格的质量管理,保障商品性,成为SSG.COM、CU便利 店、SSG凌晨配送、乐天玛特等韩国知名企业的供货商。

线下供货点主要有CU便利店、GS25便利店、乐天玛特、 Homeplus、易买得、新世界百货店、现代百货店、易买 得Traders等约20家店铺。线上有Coupang、Gmarket、 TMON、HelloNature、Auction、薇美铺、SSG.COM等20 家左右。此外,小西瓜还销往海外,2020年和2021年各 出口了2000万韩元,2022年还参加了巴黎食品博览会 (SIAL),旨在进一步扩大出口业务。

普通大西瓜通常又大又重,平均重量在8公斤左右,而且

西瓜皮占整个西瓜重量的20%以上。大西瓜通常需要切 片吃,不仅麻烦,而且吃完后西瓜皮也不好处理。但是小 西瓜的重量在1.5公斤左右。适合1~2人的家庭食用,可 轻松放进冰箱里保管。用汽车运输时,一台车可装载4~5 千个西瓜,不仅节省物流费,又缩短了工时。小西瓜的瓜 皮占据整个西瓜的5%左右,就比香瓜皮稍微厚一些。不 同于需要切片吃的大西瓜,小西瓜体积小,处理起来简 单,可轻松做成小西瓜甜茶、西瓜汁、沙拉等各种料理。

CEO: Kang Sang-hoon

TEL: +82 10 2544 7728

E-MAIL: sh7728@naver.com,

WEBTAGE: https://www.seongilfarm.kr

ADDRESS: 92, Donghaknongmingun-ro, Gongeum-myeon, Gochang-gun, Jeollabuk-do, Republic of Korea

Seongil Farm Co., Ltd. is the largest apple watermelon farm in Korea, producing apple watermelons year-round using advanced smart farm technology and recording annual sales growth. They actively enter domestic and international markets through excellent quality control and various distribution channels.

圣日农场有限公司是韩国最大的苹果西瓜农场,利用先 进的智能农场技术全年生产苹果西瓜,并且每年实现销 售增长。通过卓越的质量管理和多样化的分销渠道,他

Robo Arete Co., Ltd. was established in 2018 as a food tech company with a focus on developing specialized cooking robot systems for food and beverage establishments. The company also runs fried chicken restaurants. In May 2019, Robo Arete filed a patent for an “automatic frying cooking device and cooking method.” By February 2020, Robo Arete had opened its first directly operated fried chicken restaurant, Robert Chicken, which specializes in utilizing fried chicken robots. As of 2024, the company has expanded to ten domestic locations, offering eleven chicken varieties, including the popular “Basak basak basak basak” (basak means “crispy” in Korean). In the international market, the company opened its first franchise in Singapore in June 2023, followed by a temporary store in Mexico in July 2024. This August, the company plans to launch a flagship store in Manhattan, New

York, with additional franchises opening in Long Island in August and the Philippines in September.

In February 2022, Robo Arete and GS Retail entered into a memorandum of understanding for the supply of robots, which led to the installation of the

“ROBERT-E” frying robot at the GS25 Busan Dongrae flagship store in April. In January 2023, they made their first overseas B2B robot sale to Nuri Chicken’s Columbus store in Ohio. In November 2023, they secured a master franchise agreement for Robert Chicken in the Philippines. This year, they have exported cooking robots to Greenbea Food Ltd. in London, England in January, 365 Holdings and No Brand F&B in the United States in February, and The Hansik Express in Mexico in March. In the domestic market, robot sales were made to Sinbihan Brothers in April 2023 and to Hangry Joe’s Hot Chicken in May. The cost of installing the robot in Korea is KRW 1.6 million per month over three years, while the

overseas price is approximately USD 49,000 per unit. Robo Arete has consistently refined its cooking robot system based on insights gained from directly managing “Robert Chicken.” Their robot operation solution, installed on hardware from domestic robotics specialists Doosan Robotics and Rainbow Robotics, has created a robot operating system optimized for specific kitchen environments and recipes. This system is designed to integrate with a variety of ordering systems, including kiosks, ordering apps, table orders, and point-of-sale (POS) terminals. It automates the cooking process with a single start cooking button. The cloud-based operating system also allows Robo Arete’s R&D headquarters in Seoul to monitor and control robot systems globally. Software updates and menu additions are handled remotely, ensuring timely solutions to operational needs.

The Robo Arete robot system, designed as a collaborative tool to work alongside humans, is available in two models: the ROBERT-E-F-4 and the

ROBERT-E-F-6. The ROBERT-E-F-4 has the capacity to fry up to 33 baskets per hour and features four fryers within a compact footprint of 1,500mm. Robo Arete’s cooking robot systems have been installed in approximately 30 locations across the globe. In July 2023, the entire system, including the frying robot arm ‘ROBERT-E’ and all its components, received NSF certification, guaranteeing hygiene and safety compliance. This makes the ROBERT-E the first cooking robot in Korea to achieve this level of accreditation for its hardware.

Remarkably, the Robo Arete robot requires only 17.7 square feet of space and is versatile enough to cook a wide range of fried foods, including chicken, French fries, pork cutlets, donuts and hot dogs, depending on the operational settings. In addition to frying, Robo Arete has also developed robots for bartending and cooking various dishes such as noodles, churros, donuts, pork cutlets and patties. In Korea, their robots are used to cook items such as pork cutlets and French fries, while in the UK, they are used to fry fish and chips.

韓国で初めて調理専門ロボットシス

2018年に設立された(株)ロボアルテは、飲食店に最 適化された調理ロボットシステムを開発するフード テック企業でありながらフライドチキン店も運営し ている。2019年5月、「自動揚げ物調理装置とこれ を利用した揚げ物調理方法」に関する特許を出願し た。2020年2月、(株)ロボアルテのフライドチキンロ ボット専門直営店「ロバートチキン」1号店をオープ ンし、2024年現在、韓国国内の店舗を10店舗にまで 拡大した。「カリカリカリカリ」など11種類の様々な チキンを調理・販売している。海外では、2023年6月 にオープンしたシンガポール加盟店を皮切りに、2024 年7月7日に仮オープンしたメキシコ店など2店舗を運 営している。8月にはニューヨークのマンハッタンに直 営の旗艦店を、そして同じくニューヨークのロングア イランドに加盟店をオープンし、続いて9月にはフィリ ピンでも加盟店をオープンする予定である。

(株)ロボアルテは2022年2月、GSリテールとロボ ット供給MOUを締結し、同年4月、GS25プサン

(釜山)ドンレ(東来)の旗艦店に揚げ物ロボット 「ROBERT-E」を設置した。2023年1月、「ヌリチキ ン」のオハイオ州コロンバス店に、海外市場として は初めてB2Bロボットを販売した。同年11月にはフ

ィリピンにて「ロバートチキン」マスターフランチャイズ 契約を締結し、今年1月には英国ロンドンの「Greenbea Food Ltd.」に、2月には米国の「365 Holdings」と「No brand F&B」に、そして3月にはメキシコの「The Hansik Express」に調理ロボットを輸出した。韓国国内でも 2023年4月に「神秘的な兄弟たち」、5月には「ハングリ ー・ジョー・ホットチキン」にロボットを販売した。ロボ ットの設置費用は、韓国国内の場合、月額レンタル料 160万ウォンを3年間支払う仕組みとなっている。海外販 売価格は1台あたり約49,000USドル水準である。 (株)ロボアルテは、これまで「ロバートチキン」の直営 を通じ、調理現場のニーズを継続的にロボットシステム の構築に反映してきた。韓国のロボット専門企業である 「斗山(ドゥサン)ロボティクス」と「レインボーロボテ ィクス」のハードウェアに、自社製作のロボット運営ソリ ューションを搭載した結果、特定の厨房環境やレシピに 最適化されたロボット運営システムが実現できた。ロボ ットシステムと、注文システムのキオスク(タッチパネル)

や注文アプリ、テーブルオーダー、POSなどを連動させ ることで、「調理開始」ボタンさえ押せば自動的に調理 が行われる。また、クラウドベースの運営システムによ って、韓国国内外にあるロボットシステムの状態をソウ ルのR&D本部から制御することができる。ソフトウェア のアップデートやメニュー追加などの要求が発生した時 は、遠隔制御によって対応できる。

(株)ロボアルテのロボットシステムは、人と一緒に働く協 働ロボットである。ROBERT-E-F-4とROBERT-E-F-6の 2つの仕様があり、ROBERT-E-F-4は、時間当たりバス ケット33個分の揚げ物を調理することができる。フライ ヤーが4口あるROBERT-E-F-4のサイズは1,500mm× 930mm×1,850mmで、フライヤーが6口あるROBERTE-F-6はもう少し幅が広く、1,770mm×930mm× 1,850mmである。これまでに、韓国国内外の約30カ所 に調理ロボットシステムを納入している。2023年7月に は、揚げ物調理ロボット「ROBERT-E」のロボットアーム とシステムを構成する設備全体の衛生性と安全性を確 保し、衛生及び安全面において厳しい基準を設けてい る米国NSFの認証も取得した。韓国の調理ロボットとし ては初めて、ハードウェアを含む全製品の安全性が認め られたのである。

(株)ロボアルテのロボットは、0.5坪の空間さえあれば 設置できる。同一のロボットを運営条件の変更に応じ てチキン、フライドポテト、トンカツ、ドーナツ、ホットド ッグなど様々な揚げ物調理に使用することができる。 カクテルを作るバーテンディングロボットや、麺、チュ ロス、ドーナツ、トンカツ、パティなどを作れる調理ロ ボットも開発し、韓国国内ではトンカツやフライドポテ トなどの調理にも使用され、英国ではフィッシュ&チッ プスを揚げるロボットとしても使われた。

TEAM LEADER/MARKETING TEAM: Namkoong Eun-young

TEL: +82-6929-0557

E-MAIL: eynk@robertchicken.com, contact@robertchicken.com

WEBSITE: https://roboarete.com

ADDRESS: 4F, 401, Arc Valley Knowledge Industry Center, 37, Seongsui-ro 22-gil, Seongdong-gu, Seoul, Republic of Korea

Robo Arete Co., Ltd. is a food tech company specializing in automated cooking robots, including the NSF-certified ROBERT-E models for frying foods. Founded in 2018, the company operates “Robert Chicken” restaurants and has expanded globally, offering robotic solutions for diverse culinary applications. They provide cloud-based system management, enabling remote monitoring and updates.

㈱ロボアルテは、NSF認証を受けたフライ調理用ロボット 「ROBERT-E」モデルを含む自動調理ロボットを専門とす

料理のロボットソリューションを提供しています。クラウド ベースのシステム管理により、遠隔監視とアップデートが可 能です。

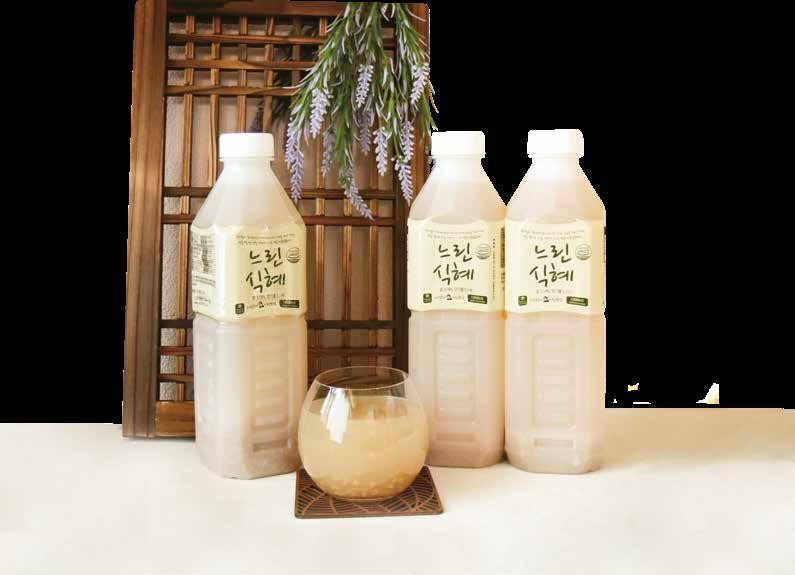

Seojung Cooking’s Sikhye and Sujeonggwa

“There is no better drink in the world than this,” asserts Seo Jeong-ok, CEO of Seojung Cooking Co., Ltd. She takes pride in her company’s products, “Slowbrewed Sikhye” and “Slow Sujeonggwa.” These slowbrewed and homemade products offer a superior quality and taste compared to factory-produced alternatives. Seojung Cooking’s unique approach has made its sikhye and sujeonggwa the best traditional beverages representing Korea. Despite being nearly twice as expensive as other products in the market, consumers who prioritize health and authentic taste consistently choose “Slow-brewed Sikhye” and “Slow-brewed Sujeonggwa.”

Seojung Cooking’s beverages are crafted using traditional methods. Instead of the conventional enzyme breakdown method, they use malt in a fivehour saccharification process, allowing them to produce just one bottle in the same time it takes others to produce ten. The products are free from preservatives and chemical additives. Therefore, they must be refrigerated. These are the only sikhye and sujeonggwa in Korea that require refrigeration and are made with unique skills and know-how. That’s why they are the real sikhye and sujeonggwa, not a sikhye-style or sujeonggwa-inspired drink. The company also offers “Slow-brewed Pumpkin Sikhye,” a health drink made with sweet squash and pumpkin. Slow-brewed Sujeonggwa is boiled in a sot (traditional Korean cauldron) and enriched with persimmon extract to give it a deep, elegant flavor and aroma. Both beverages have a shelf life of 180 days and should be stored in the refrigerator (0-10°C).

“Slow-brewed Sikhye” and “Slow-brewed Sujeonggwa” are Seojung Cooking’s flagship brands, representing traditional Korean beverages. Seojung Cooking has been growing steadily since 2018. The company achieved sales of KRW 3.7 billion in 2018, KRW 4.6 billion in 2019, KRW 5.6 billion in 2020, KRW 6.6 billion in 2021, KRW 8.2 billion in 2022, and KRW 9.4 billion in 2023, with an annual growth rate of over 120%. The company expects sales to reach KRW 12 billion this year. Seojung Cooking supplies sikhye and sujeonggwa to major domestic markets and well-known cooperatives such as Costco, Coupang, Sangha Farm, Mamacook,

Dure-coop, and Hansalim, and exports to the United States, Australia, and Canada. They strive to provide consumers with products made from fresh ingredients with no additives, and respecting the necessary time for each process. Their products are crafted by hand, not mass-produced. CEO Seo Jeong-ok holds a Bachelor’s degree and a Master’s degree in culinary arts and food science, as well as a culinary degree from a UK institution, completed between 1981 and 1985. She also holds a Food Studies License from Harrow on the Hill College. Upon returning to Korea, she dedicated herself to promoting Korean cuisine globally and teaching recipes, leading her to develop her unique methods for making slow sikhye and sujeonggwa.

The “Slow-brewed Sikhye” is rich in enzymes produced through a slow, five-hour saccharification process using malt enzymes, which replicates the homemade method. The “Slow-brewed Sujeonggwa” retains its unique characteristics, made by boiling ginger and cinnamon for a long time before adding dried persimmon. The entire process from production to taste differs significantly from conventional sikhye and sujeonggwa. By embracing the five-hour “Slow Food” method, Seojung Cooking has differentiated itself from competitors, finding success through a method that is not feasible in mass production. This differentiation has been the key to the company’s success.

外,还有“慢南瓜甜米露”产品,这是使用甜南瓜和老南瓜 瓜肉制作的健康饮料。“慢水正果”在大锅中熬制而成,风 味浓郁。其中还会加入柿饼浓缩液,增添了浓郁高级的口 感和香气。甜米露和水正果的保质期均为180天,需冷藏 保存(0~10℃)。

“慢甜米露”和“慢水正果”是代表韩国传统饮料的甜米露 和水正果品牌。凭借这些产品,Seojung Cooking(株)自 2018年以来持续发展。2018年销售额为37亿韩元,2019 年为46亿韩元,2020年为56亿韩元,2021年为66亿韩 元,2022年为82亿韩元,2023年达到94亿韩元。每年同 比增长率超过120%,预计今年的销售额有望达到120亿 韩元。出口到美国、澳大利亚和加拿大的甜米露和水正 果,以及在韩国本土的大型超市和著名生活合作社—— 开市客、Coupang、上下农园、Mama Cook、Dure shop、

The food market has seen a significant shift in consumer preferences since the start of COVID-19, particularly a growing desire for new and unique tastes. The increased amount of time spent at home as a result of telecommuting and online education has driven the demand for new food products that can be enjoyed at home. In addition, the growing interest in health has boosted the popularity of healthy foods with new flavors. With the growing spending power of Millennials and Generation Z, a culture has emerged where people seek to experience brands through unique flavors and dynamic marketing that align with their new consumption patterns.

In the context of the pandemic, strict social distancing was in effect and the influence of convenience stores in the distribution industry increased. The convenience of purchasing various products close to home led to increased usage among consumers, prompting the development of products that attract them with diverse and unique offerings. CU convenience stores launched Jjajang Ramyeon in collaboration with the global beer brand Guinness. The

食品市場において,新しくてユニークな味を求める 消費者のニーズは、コロナ禍以降、より強くなった。 これは、在宅勤務やオンライン授業などにより自宅 で過ごす時間が増え、お家で楽しめる新しい料理に 対するニーズが高まったからである。また、健康への 関心が高まるにつれ、新しい味を追求しながらも、 身体に良い食品の人気も高まっている。MZ世代の 消費力が強くなり、彼らの新しい消費パターンに合 わせて、様々なブランドとのコラボレーション、ユニ ークな味、多彩なマーケティングを活用して、美味し さだけではなくブランドを体験できる文化として根 を下ろしている。

新型コロナウイルス感染症対策として、ソーシャル ディスタンスが徹底されていた頃、流通業界ではコ ンビニの影響力が大きくなった。家からも近く、いろ んな商品を購入できるというメリットのため、利用す る消費者が増え、これが、多彩で目新しく、消費者を

product received a positive response in the market, with sales of alcoholic beverages with distinctive flavors such as energy drink-flavored highballs, herb-flavored highballs, and subtle pine-flavored highballs. GS also collaborated with the famous tteokbokki franchise “Young Dabang” to launch “Young Dabang Chadol Tteokbokki.”

In response to the identified preferences of Millennial and Generation Z consumers, numerous brands are proactively engaging in collaborations to meet their needs. This strategic approach ensures that they remain relevant and appealing. For example, Shake Shack, a popular American burger brand, has introduced a new product in collaboration with Haechang, a well-known Korean makgeolli brand. Simi-

惹きつける商品の開発に拍車をかけることになった。大 手コンビニチェーンのCUでは、グローバルビールブランド のギネス(Guinness)と提携してジャージャーラーメンを発 売したり、栄養ドリンク味のハーブ風味ハイボール、ほのか な松葉風味のハイボールなど、ユニークな酒類を発売し、 消費者から好評を得ている。また、同じくコンビニチェーン のGSは、有名なトッポッキフランチャイズ「青年茶房」との コラボで、「青年茶房薄切り牛トッポッキ」を発売した。

MZ世代の消費パターンに合わせて、様々なブランドと のコラボ作業も活発に進められている。アメリカの有 名ハンバーガーブランドの「シェイクシャックバーガー」 は、韓国の有名マッコリブランドの「ヘチャン」とコラボし て新商品を発売した。「アワーホーム」は、プレミアム和

larly, Our Home plans to launch a ready meal (RMR) called “Buckwheat Soba” in collaboration with the premium Japanese restaurant Saboten. Even within the same food industry, brands are collaborating with each other to develop new products. Samyang and Hite Jinro have teamed up to launch “Jinro Original x Original Buldak Fried Noodles.” Ottogi has joined forces with Binggrae to launch “Crab-Shaped Snack Noodles,” a ramyeon version of Binggrae’s signature snack, “Crab-Shaped Snack.” Samyang Foods has also introduced a triangular gimbap with red chicken fried noodle sauce, which has been well-received by consumers who enjoy spicy flavors.

This trend of pursuing unique tastes reflects consumers’ diverse preferences and provides opportunities to pioneer new markets. Companies are creating new trends in the food industry by launching products with innovative flavors that meet consumer needs and establishing new values through brand collaborations.

食レストランの「さぼてん」とのコラボで、レトルト食品 (RMR、Restaurant Meal Replacement)の「蕎麦」を発売 する予定である。同じ食品業界の中でもブランド同士のコ ラボが行われており、「サムヤン」と「ハイト眞露」がコラボ した「眞露元祖×元祖ブルダック炒め麺」を発売した。ま た、「オットゥギ」は「ビングレ」と協業し、「ビングレ」の代表 スナック「コッケラン」をラーメンにした「コッケラーメン」 という商品を発売した。「サムヤン食品」は、「ブルダック炒 め麺」のソースを使ったおにぎりを発売し、辛いもの好き の消費者から好評を得ている。

このように異色的な味を追求するトレンドは、消費者の多 様な好みを反映し、新たな市場の開拓につながるような 企画を生み出すこともある。各企業は消費者のニーズに 応えられる新しい味の商品を発売したり、他ブランドとの コラボレによって新たな価値を生み出せるように取り組む など、食品業界に新たなトレンドを創り出している。

Tteokbokki

Home cooking is an integral aspect of American culture, with each family having their own unique recipes. Many enjoy preparing cookies and bread with their children and sharing them with neighbors. Snack bars are a highly popular snack in the U.S. They are readily available for purchase, and they can also be homemade by using your favorite ingredients. To create snack bars, simply combine cereal, granola, chocolate chips, nuts, dried fruits, and other desired ingredients with syrup to form bars with a crunchy texture. Commonly used syrups include corn syrup, brown rice syrup, sweeteners, and honey.

American home cooks use various syrups and sweeteners to bind ingredients together. Korean syrup (oligosaccharides) is emerging as a new favorite among them. Oligosaccharides are saccharides composed of 2 to 8 monosaccharides. They are sweet and highly digestible, and they promote the growth of beneficial bacteria in the gut. They are absorbed slowly into the body and do not rapidly raise blood sugar levels, making them a preferred sweetener for health-conscious individuals.

Amazon offers a comprehensive selection of Korean syrup products with distinctive flavors in the United States. From oligosaccharides to rice syrup and grain syrup, Korean products are readily available. Oligosaccharides, made from Korean rice, are popular for their rich and savory taste, using 100% Korean rice. Products that have been particularly well-received include Ottogi’s “Korean Rice Syrup,” Cheongjeongwon’s “Oligo Rice Syrup,” and Master Kang Bong-seok’s “Master Rice Syrup.”

Amazon customers who have purchased rice-based oligosaccharides in the U.S. have provided positive reviews. One customer stated, “It has a different flavor from the brown rice syrup available in the U.S. I bought it to make Korean food, and it adds just the right amount of sweetness and enhances the dishes.”

Another reviewer commented, “When I attempted to make snack bars in the U.S., I was unable to achieve the desired crispy texture with corn syrup and honey. However, with Korean rice oligosaccharides, the texture was significantly better. I intend to repurchase this product.” Another customer also noted, “It’s not as sweet as brown rice syrup or other syrups, making it a versatile ingredient for various dishes.”

美国亚马逊商城热销商品:低聚糖 (Korean Syrup)

美国的家庭烹饪文化非常发达,每个家庭都有自己独特 的食谱。他们喜欢和孩子一起做饼干或面包,并与邻居分 享。其中,能量棒虽然随处可买,但也可以根据个人喜好 加入喜欢的食材自己制作。能量棒通常会添加谷物、格兰 诺拉麦片、巧克力碎片、坚果、水果干等,并用糖浆搅拌后 使其凝固变硬,这样吃起来口感酥脆。制作能量棒时常用 的糖浆有玉米糖浆、糙米糖浆、甜味剂、蜂蜜等。

为了让不同材料更好地凝固在一起,美国的消费者通常会 使用各种糖浆和甜味剂。但是,最近来自韩国的低聚糖产 品逐渐替代了糖浆和甜味剂,走红美国。低聚糖是由2到8个 单糖结合而成的糖类,不仅味道甜,还易于消化,有助于促 进肠道内有益菌的增殖。低聚糖在人体内会被慢慢吸收, 不会使血糖突然升高,因此很多人将其用作健康甜味剂。

在美国的亚马逊(Amazon)商城里,可以找到各种韩国 的低聚糖产品。从低聚糖到谷物类糖浆“大米糖稀”,种 类繁多,可轻松购买到各种韩国产品。其中,最受欢迎的 是用韩国大米制成的低聚糖产品,原料是100%的韩国大 米,味道浓郁香醇。热销产品包括奥多吉的“Korean Rice Syrup”、清净园的“Oligo Rice Syrup”、Kang Bongseok大师的“Master Rice Syrup”等。

在美国亚马逊购买大米低聚糖产品的消费者纷纷留下了 好评,比如“风味和美国常见的糙米糖浆不同,我是买来 制作韩式料理的,甜度适中,可以为食物增添色泽”、“在 美国制作能量棒的时候,用玉米糖浆或蜂蜜也无法做出 酥脆的口感,但是韩国的大米低聚糖可以让口感变得更 好,我下次还会购买”、“相比糙米糖浆或其他糖浆,不是 很甜,很适合用于各种料理”等。

The Korea Agro-Fisheries and Food Trade Corporation (aT) is working with its Sao Paulo branch in Brazil on a campaign to provide Korean meals in three international schools in Brazil: Graded School, St. Nicholas School, and Stance Dual School. The objective of this school meal project is to foster long-term popularity and familiarity with Korean cuisine in Brazil, a country where Korean culture is gaining increasing recognition.

In line with this initiative, aT has introduced a series of Korean food experience programs, designed to facilitate familiarity with the taste and style of Korean cuisine among the Brazilian audience. Furthermore, we have plans to provide ongoing assistance by linking distributors of Korean food ingredients, such as gochujang (red chili paste) and sauces, with catering services. From March through November, we will introduce Korean cuisine to students and teachers at

international schools in Sao Paulo. We have selected ten Korean dishes for school meal services, purchased the ingredients for these meals (soy sauce, gochujang, glass noodles, etc.), and are selling Korean fruit drinks and snacks at school cafeterias to promote Korean food culture to Brazilians. Furthermore, we will be offering Korean cooking classes for international school parents with substantial purchasing power to introduce them to Korean ingredients and food products.

The schools and the Sao Paulo branch have signed a memorandum of understanding (MOU) to formalize their collaboration and introduce Korean food as part of the school meal service. This agreement involves a gradual and systematic approach to sharing information and introducing Korean food to their school meals by November 2024. Our objective is to familiarize local communities with Korean cuisine through preparatory workshops, organize Korean cooking programs, and provide on-site inspections and guidance by experts following the initial launch, ensuring a seamless and comfortable transition to Korean food culture.

The introduction of Korean food services will contribute to the growing popularity of Korean cuisine. To achieve this, we plan to develop new menus that feature Korean ingredients and identify significant consumer demand. By consistently providing Korean food experiences, we aim to increase sales of K-food by expanding its exposure to consumers with high purchasing potential.

Duration March - November, 2024 Location 3 International Schools in São Paulo (Graded School, St. Nicholas School, Stance Dual School)

Promotional items Korean food ingredients (soy sauce, gochujang, glass noodles, etc.), snacks, beverages, etc.

Peaches are a popular summer fruit in Korea, offering a sweet taste and aroma that are ideal for satisfying appetites during the hot summer months. There are several types of peaches, including white, yellow, and shaved. White peaches are distinguished by their white flesh and soft texture, while yellow peaches have yellow flesh and a sweet taste. Shaved peaches are known for their lack of fuzz and firm texture. Notable peach-producing regions in Korea include Yeongcheon-si in North Gyeongsang Province, Eumseong-gun in North Chungcheong Province, and Icheon-si in Gyeonggi Province. These areas are renowned for their high-quality peaches, which are cultivated in an optimal climate and soil conditions. Peaches are a rich source of vitamin C and fiber, which support immune system and prevent constipation. Peaches are also high in potassium, which aids in the elimination of sodium from the body. In addition, peaches contain aspartic acid, which can help relieve hangovers. In Korea, you can also enjoy an experiential program at a peach production farm where you can harvest and taste fresh peaches.

Budaejjigae (sausage stew) is a Korean dish that originated after the Korean War. It is a spicy stew that combines traditional Korean ingredients such as kimchi, gochujang (red chili paste), and doenjang (soybean paste). The dish is characterized by its savory and spicy flavor. The rich flavors and aromas of the various ingredients work in harmony to create a delicious dish that tastes even better when eaten with rice. Recently, it has gained popularity on social media and is now considered one of the must-try dishes for international visitors to Korea. Uijeongbu, Songtan, and Itaewon in Korea, where US military bases were located, are particularly famous for their Budaejjigae. When visiting Seoul, we would be delighted to welcome you to experience the distinctive Budaejjigae of these areas.

Ingredients

200 g sausage

200 g ham

1/2 cup baked beans

150 g bean curd

60 g green onions

1 onion (200 g)

60 g carrots

100 g ramyeon

100 g pork (pork belly) water (1.5 L)

salt Instructions

2 Tbsp chili powder

1. First, mix the sauce ingredients to make the sauce.

2. Cut the pork belly into bite-sized pieces and add a spoonful of the sauce. Mix well.

3. Cut the sausage, ham, vegetables, and all other ingredients into bite-sized pieces.

4. Place the prepared belly, sausage and vegetables in a saucepan. Add the baked beans. Add the sauce.

5. Add water (or broth). Bring to a boil. When boiling, season with salt. Add the ramyeon noodles.

Nick Name

Nadim Khan (nk8247313@gmail.com)

Nationality

Pakistani

Age

31 Year

Favorite food Bulgogi (Halal food)

Korea Agrafood magazine stands a comprehensive guide and authoritative voice on Korean agriculture and cuisine. Each issue offers a deep dive into the country’s agricultural advancements, culinary traditions, and the dynamic intersection of the two. As a publication, it combines informative articles, interviews with industry experts, and visually stunning photography, making it a valuable resource for professionals and enthusiasts.

One of the most striking features of Korea Agrafood is its in-depth coverage of Korea’s agricultural sector. The magazine consistently highlights the latest innovations and developments, such as advancements in smart farming technologies, sustainable agricultural practices, and government policies to boost the sector. For instance, a recent issue explored the application of artificial intelligence and the Internet of Things in agriculture, showcasing how these technologies are transforming traditional practices. Articles like these inform and inspire readers to think about the future of agriculture and the potential for technology integration.

Moreover, Korea Agrafood magazine excels in presenting the rich tapestry of Korean culinary heritage. Each issue typically includes sections dedicated to traditional Korean foods, their history and cultural significance. Readers can expect in-depth explorations of iconic dishes such as kimchi, bibimbap and bulgogi, as well as lesser-known regional specialties. The magazine often includes step-by-step recipes, making it accessible to readers who want to recreate these dishes at home.

Visually, Korea Agrafood is a feast for the eyes. The magazine’s layout is clean and inviting, with high-quality photography that captures the essence of agricultural landscapes and culinary creations. These images not only complement the written content, but also stand alone as artistic representations of Korea’s agrifood culture.

Qingdao Branch Office

Room 705, Yuanxiongguojiguangchang

Beijing Branch Office 603 Room, Block A, Fairmont Tower No.33 Guangshun North Street, Chaoyang District, Beijing, 100102, China

(100102 中國 北京市 朝阳區 广顺北大街

33号院 1号楼 1单元 6层 603室)

E-Mail: beijingat@at.or.kr

TEL: 86-10-6410-6120~1

070-4617-5090~1, 7377

FAX: 86-10-6410-6122

Shanghai Branch Office Room 3201, New Hongqiao Central Plaza No.83, LouShanGuan Rd., Changning District, Shanghai, 200336, China

(200336 中國 上海市 長寧區 婁山關路 83 號 新虹橋中心大厦 3201室)

E-Mail: shanghaiat@at.or.kr

TEL: 86-21-3256-6325

070-7077-6197, 6199, 6205 FAX: 86-21-3256-6328

Dalian Branch Office

Room 1302, Xiwang Building,NO136 Zhongshan Road,Zhongshan District,Dalian 116001

(大连市中山区中山路136号希望大厦 1302号)

E-Mail: dalianat@at.or.kr TEL: 86-411-3960-3361~3 070-4617-3278

FAX: 86-411-3960-3362

Hongkong Branch Office Room 1003, 10F Jubilee Centre, 18 Fenwick Street, 46 Gloucester Rd, Wanchai, Hong Kong

E-Mail: hkatcenter@at.or.kr

TEL: 852-2588-1614~6 070-4617-2696, 7116 FAX: 852-2588-1919

Building, No.26, Hongkong Middle Road, Qingdao, 266071, China (中國 山東省 靑島市 市南區 香港中路 26 号 远雄国际广场 705户)

E-Mail: qingdao@at.or.kr

TEL: 86-532-5566-8870~3, 5 FAX: 86-532-5566-8873

Qingdao aT logistics Co., Ltd

266108, Qingdao aT logistics Co., Ltd

3 Baishawan Rd., Liuting Street, Chengyang, Qingdao, China (青岛市 城阳区 流亭街道 白沙湾路3号

青岛爱特物流有限公司)

E-Mail: qingdao_logistics@at.or.kr

TEL: 86-532-6696-2229

070-7938-0863~4

FAX: 86-532-6696-2181

Ha Noi Branch Office

#1213, 12th floor., Keangnam Hanoi Landmark 72 Tower, Plot E6, Pham Hung Str., South Tu Liem Dist., Ha Noi., Viet Nam

E-Mail: hanoi@at.or.kr

TEL: 84-24-6282-2987

070-4617-7101~2, 7256~7258 FAX: 84-4-6282-2989

Ho Chi Minh Branch Office

CJ Building, Floor 3, 2 Bis 4-6 Le Thanh Ton Street Ben Nghe Ward, District 1, Ho Chi Minh City

E-Mail: atcenterhcmc@at.or.kr

TEL: 84-28-3822-7504

070-4617-3276, 070-8098-6514 FAX: 02-838-227-503

Bangkok Branch Office

#2102 Level 21, Interchange 21, 399 Sukhumvit Road, North Klongtoey, Wattana, Bangkok 10110 Thailand

E-Mail: bangkok@at.or.kr

TEL: 66-2-611-2627

070-4617-7226~7

FAX: 66-2611-2626

Jakarta Branch Office

The Energy Building 20th FL, Zone F, SCBD Lot.11A

JL.Jenderal Sudirman Kav 52-53, Jakarta 12190 Indonesia

E-Mail: jakarta@at.or.kr

TEL: 62-21-2995-9032~3, 9035, 9094

070-4617-2695

FAX: 62-21-2995-9034

Kuala Lumpur Branch Office

Suite 6-04, 6th Floor, Menara Hap Seng, Jalan P. Ramlee, 50250 Kuala Lumpur

E-Mail: atcenterkl@at.or.kr

TEL: 60-3-2706-4299

070-5223-4901, 070-4617-7238 FAX: 60-3-2706-4301

Singapore Branch Office

1 Wallich Street #14-01 Guoco Tower, Singapore 078881 TEL: 65-9855-8277

Tokyo Branch Office

Korea Agro-Trade Center, Tokyo Korea Center 5F, 4-4-10 Yotsuya, Shinjuku-ku, Tokyo, 160-0004, Japan

(東京都新宿区四谷4-4-10 KOREA CENTER5F)

E-Mail: tokyo@at.or.kr TEL: 81-3-5367-6656 070-4617-7061~2, 070-8287-3060 FAX: 81-3-5367-6657

Osaka Branch Office

8F, Nomura Fudousan Osaka Bldg. 1-8-15, Azuchimachi, Chuou-Ku, Osaka, 541-0052, Japan

(大阪市 中央區 安土町 1-8-15, 野村不動 産大阪B/D 8F)

E-Mail: osaka@at.or.kr

TEL: 81-6-6260-7661 070-7000-4138 FAX: 81-6-6260-7663

Dubai Branch Office 57528 Office #48, Sunset Mall, Jumeirah Beach Rd, Jumeira 3, Dubai, UAE

E-Mail: dubai@at.or.kr

TEL: 971-4-339-2213 FAX: 971-4-456-1155

New York Branch Office

15 East 40th Street Suite 701 New york NY 10016, USA

E-Mail: newyork@at.or.kr

TEL: 1-212-889-2561

FAX: 1-212-889-2560

Los Angeles Branch Office

12750 Center Court Drive South, #255, Cerritos, CA 90703, USA

E-Mail: losangeles@at.or.kr TEL: 1-562-809-8810

FAX: 1-562-809-1191

São Paulo Branch Office

Av Paulista 1636, 10andar, #1008 –

São Paulo CEP 01310-000

E-Mail: saopaulo@at.or.kr TEL: 55-11-3283-0089, 55-11-3286-0059

Paris Branch Office

Korea Agro-Trade Center, 89 Rue du Gouverneur Général Eboué (1er etage), 92130, Issy-les-moulineaux, France

E-Mail: paris@at.or.kr

TEL: 33-1-4108-6076~8, 6095~6 FAX: 33-1-4108-2016

Moscow Branch Office

123610, Moscow, Krasnopresnenskaya naberezhnaya 12, 6th floor, 608 office

E-Mail: atmoscow@at.or.kr TEL: 7-924-007-1528 070-4617-3277