A PUBLICATION OF AICC, THE INDEPENDENT PACKAGING ASSOCIATION

New Administration, NEW POSSIBILITIES

March/April 2021 Volume 25, No. 2

What the new presidential regime may mean for independents

ALSO INSIDE HR Rundown Digital Download Member Profile: Columbia Container

TABLE OF CONTENTS March/April 2021 • Volume 25, No.2

COLUMNS

ON THE COVER New Administration, New Possibilities

38

NEW ADMINISTRATION, NEW POSSIBILITIES What the new presidential regime may mean for independents

44

HR RUNDOWN

44

Managing benefits- and nonbenefitsrelated issues in 2021

52

DIGITAL DOWNLOAD How boxmakers are leveraging social media channels to engage customers and prospects

CHAIRMAN’S MESSAGE

4

SCORING BOXES

10

LEGISLATIVE REPORT

12

MEMBERS MEETING

14

ASK RALPH

16

ASK TOM

18

SELLING TODAY

22

ANDRAGOGY

24

LEADERSHIP

58

THE ASSOCIATE ADVANTAGE

60

STRENGTH IN NUMBERS

68

THE FINAL SCORE

DEPARTMENTS

FEATURES

38

3

12

WELCOME, NEW MEMBERS

27

AICC INNOVATION

30

MEMBER PROFILE

64

FOUNDATION FOR PACKAGING EDUCATION

66

ICPF UPDATE

52

BoxScore is published bimonthly by AICC, The Independent Packaging Association, PO Box 25708, Alexandria, VA 22313, USA. Rates for reprints and permissions of articles printed are available upon request. The statements and opinions expressed herein are those of the individual authors and do not necessarily represent the views of AICC. The publisher reserves the right to accept or reject any editorial or advertising matter at its discretion. The publisher is not responsible for claims made by advertisers. POSTMASTER: Send change of address to BoxScore, AICC, PO Box 25708, Alexandria, VA 22313, USA. ©2021 AICC. All rights reserved.

Visit www.aiccboxscore.org for Member News and even more great columns. Scan the QR code to check them out! BOXSCORE www.aiccbox.org

1

OFFICERS Chairman: Jay Carman, StandFast Packaging Group, Carol Stream, Illinois First Vice Chairman: Gene Marino, Akers Packaging Service Group, Chicago, Illinois Vice Chairmen: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas Matt Davis, Packaging Express, Colorado Springs, Colorado Gary Brewer, Package Crafters, High Point, North Carolina Immediate Past Chairman: Joseph M. Palmeri, Jamestown Container Cos., Macedonia, Ohio Chairman, Past Chairmen’s Council: Al Hoodwin, Michigan City Paper Box, Michigan City, Indiana President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia Secretary/General Counsel: David P. Goch, Webster, Chamberlain & Bean, Washington, DC AICC Canada Director: Renee Annis DIRECTORS West: David DeLine, DeLine Box Co., Denver, Colorado Southwest: Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma Southeast: Ben DeSollar, Sumter Packaging Corp., Sumter, South Carolina Midwest: Casey Shaw, Batavia Container Inc., Batavia, Illinois Great Lakes: Mike Schaefer,Tavens Packaging & Display, Bedford Heights, Ohio Northeast: Stuart Fenkel, McLean Packaging, Pennsauken, NJ AICC Canada: Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada AICC México: Juan Javier Gonzalez, Cartró, S.A.P.I. de C.V. (CP), Tepotzotlán, Mexico OVERSEAS DIRECTOR Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE Finn MacDonald, Independent II, Louisville, Kentucky Guy Ockerlund, OxBox, Addison, Illinois Kevin Ausburn, SMC Packaging Group, Springfield, Missouri Nelva Walz EMERGING LEADER DELEGATES Daniel Brettschneider, CST Systems, Kennesaw, Georgia Cassi Malone, Corrugated Supplies Co. LLC, Chicago, Illinois Lauren Frisch, Wasatch Container, North Salt Lake, Utah ASSOCIATE MEMBER DIRECTORS Chairman: Pat Szany, American Corrugated Machine Corp., Indian Trail, North Carolina Vice Chairman: Joseph Morelli, Huston Patterson Printers, Decatur, Illinois Secretary: Greg Jones, Sun Automation, Glen Arm, Maryland Associate Board Director: Tim Connell, A.G. Stacker Inc., Weyers Cave, Virginia Immediate Past Chairman, Associate Members: David Burgess, JB Machinery, Weston, Connecticut ADVISORS TO THE CHAIRMAN Greg Tucker, Bay Cities, Pico Rivera, California Jerry Frisch, Wasatch Container, North Salt Lake, Utah Pat Szany, American Corrugated Machine Corp., Indian Trail, North Carolina PUBLICATION STAFF Publisher: Michael D’Angelo, mdangelo@aiccbox.org Editor: Virginia Humphrey, vhumphrey@aiccbox.org

SUBMIT EDITORIAL IDEAS, NEWS & LETTERS TO: BoxScore@theYGSgroup.com CONTRIBUTORS Maria Frustaci, Director of Administration and Director of Latin America Cindy Huber, Director of Conventions & Meetings Chelsea May, Education and Training Manager Laura Mihalick, Senior Meeting Manager Patrick Moore, Member Relations Coordinator Taryn Pyle, Director of Training, Education & Professional Development Alyce Ryan, Marketing Manager Steve Young, Ambassador-at-Large Richard M. Flaherty, President, ICPF ADVERTISING Information: Virginia Humphrey, vhumphrey@aiccbox.org Opportunities: Taryn Pyle 703-535-1391 • tpyle@aiccbox.org AICC PO Box 25708 Alexandria, VA 22313 Phone 703-836-2422 Toll-free 877-836-2422 Fax 703-836-2795 www.aiccbox.org

EDITORIAL/DESIGN SERVICES The YGS Group • www.theYGSgroup.com Vice President: Serena L. Spiezio Content & Copy Director: Craig Lauer Managing Editor: Jessica Price Senior Managing Editor: Sam Hoffmeister Copy Editor: Steve Kennedy Art Director: Alex Straughan Account Manager: Max Lalwani

ABOUT AICC PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974 We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company and employees at all locations have access to member benefits. AICC offers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Chairman’s Message

Our Constants

I

n the past year of disruption and dislocation, I’m sure that you have sought reassurances from the constants in your life. Family has certainly been one of those constants. Like many of you, for me and my company, StandFast Packaging Group, the family and the business, in the past and for the future, are closely related. That family feeling also extends to AICC. Our Association works well because of the family atmosphere of collegiality and caring. Because of the pandemic, we have been away from our AICC family for too long. Hopefully, this will change soon. My father, John Carman, and his business partner, John Morrice, founded StandFast in 1967. Today we have the third generation of the Carman family working in the business alongside my three brothers and me. The StandFast story is not so different from the stories of so many AICC members. There are many multigeneration AICC member companies. So many are celebrating historical anniversaries that AICC recognizes during the “Members Milestones” presentation during national meetings. Companies have shared with their fellow members their 40-, 50-, 75-, and 100-year anniversaries, and the celebrations always highlight the origin and the family. Sadly, my father passed away July 2 at age 90. Serving as your chairman since the fall of 2019 is a continuance of my father’s service to AICC. He was a founding member and served in various roles in the governance of AICC through the early years and beyond. But he left a legacy in his sons, in the company he created, and in the Association he helped found. These legacies come to mind when we turn our thoughts to other members of AICC’s “greatest generation” who have passed this year. Ross Ausburn, Jim Johnson Sr., and Marvin Grossbard all built companies that are outstanding printers and converters today and a far cry from their humble roots—great representatives of AICC and the independent spirit of entrepreneurship and customer focus. They, along with my father, were founders and builders. They passed a torch that is extremely important today, and given what we went through in 2020, perhaps more important than ever. We need to continue to grow, to learn, and to build our companies with the same spirit, fervor, and boldness that our predecessors showed. We have tremendous tools available to us: high technology for production and efficiency; the internet; unparalleled communication power; the most educated and capable workforce; AICC; our supplier partners; and each other. Our box plants have been operating at historically high levels in response to the changing dynamics of the supply chain, wrought by the pandemic. When we emerge from the pandemic, will our markets, will our customers, revert back to what we have been familiar with, or will there be a new landscape? Bet on the new landscape. As with the upheaval of the past year, the new can be as challenging as it is exciting. To navigate successfully, I suggest we rely on the constants that have kept us grounded and Jay Carman successful: our families and our famPresident, StandFast Packaging Group ily businesses. Chairman, AICC

BOXSCORE www.aiccbox.org

3

Scoring Boxes

Deteriorating Trade Erodes Paper Packaging Markets BY DICK STORAT

S

4

BOXSCORE March/April 2021

Real Consumer Spending for Nondurable Goods

250

4.0%

240

3.5%

Index (2009 = 100)

230

3.0%

220 210

2.5%

200

2.0%

190

1.5%

180

1.0%

170

0.5%

160 150

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 2018

2019

2020

0.0%

Percent Change Year-to-Date

Source: BEA

Industrial Production Nondurable Consumer Goods 106

1.0%

104

0.5% 0.0%

102

Index (2012 = 100)

hifting consumer patterns in response to the coronavirus pandemic have been at the center of strong paper packaging markets since the pandemic’s beginning. Consumption of packagingintensive nondurable goods has risen, providing packaging suppliers with expanding market opportunities. As the top chart at right depicts, inflation-adjusted consumer spending for nondurable goods surged as the pandemic led to travel lockdowns and recovered rapidly as the pandemic continued. Through November, spending for these goods had risen by 2.6%. Yet, while consumption of food and other fast-moving goods has grown, domestic production has not kept pace. Most of the initial surge of demand for pantry and paper goods came from existing stocks, and the subsequent recovery in domestic production of these goods was much more muted than the recovery of spending. As the middle chart at right shows, production sank during March and April and recovered only slowly thereafter. Domestic production of nondurable goods has yet to rise above prior year levels. And at the end of November, monthly production was declining, and production had declined by 2.8%. That left a spread of more than five percentage points between consumption and production. Imports supplied the additional nondurable goods that were consumed but not made in the United States. To get some perspective on the impact of international trade on paper packaging markets, we identified the commodities in international trade that required protective paper packaging. The table at right summarizes international trade

-0.5%

100

-1.0%

98

-1.5%

96

-2.0%

94

-2.5%

92

-3.0%

90

-3.5%

88

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 2018

2019

2020

-4.0%

Percent Change Year-to-Date

Source: U.S. Census

Packageable Goods Trade Deficit ($ Billions Over 11 Months, 2020) PACKAGEABLE COMMODITY Computers & Electronic Equipment Textiles & Apparel Pharmaceuticals & Medicines Appliances Food & Beverage Fruits, Vegetables & Tree Nuts Cleaning & Toilet Supplies Other Packageable Goods TOTAL LIABILITIES & NET ASSETS

EXPORTS $175 18 62 8 68 16 16 66 $429

IMPORTS TRADE DEFICIT $342 $167 136 118 154 92 31 23 91 23 29 13 13 (3) 131 65 $926 $497

Consistency gives you an edge Brands require consistent packaging. Our DiamondTopTM white linerboard grades deliver reliable performance in strength and visual appearance run after run. Produced with a focus on manufacturing excellence and adherence to strict quality standards, DiamondTopTM helps you increase your efficiency, produce high quality packaging and deliver exceptional graphics. Give yourself the competitive edge; choose DiamondTopTM for efficient converting and superior print across flexo and digital presses.

DiamondTopTM White linerboard solution © 2021 WestRock Company. All rights reserved.

Scoring Boxes

6

BOXSCORE March/April 2021

U.S. Packageable Exports

$50

-2.0%

$40

($ Billions/Month)

0.0% -1.0%

$45

-3.0%

$35

-4.0%

$30

-5.0%

$25

-6.0%

$20

-7.0% -8.0%

$15

-9.0%

$10

-10.0%

$5 $0

-11.0%

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 2018

2019

2020

-12.0%

Percent Change Year-to-Date

Source: Census Bureau, RSA, Inc.

$110

U.S. Packageable Imports

$100

0% -1%

$90

-2%

$80

($ Billions/Month)

for packageable goods during the first 11 months of 2020. During that time frame, exports of packageable goods amounted to $429 billion and provided demand for paper packaging. On the other hand, imports of packageable goods amounted to more than twice as much—$926 billion—and represented lost opportunities for U.S. producers of paper packaging. Foods, including fresh produce, do not have the largest trade deficits. The dubious honors of having the largest trade deficits go to electrical equipment, clothing, and pharmaceutical goods, not to foods, beverages, and fresh produce. However, the markets for these packaging-intensive edibles have still racked up a combined trade deficit of $36 billion through this past November. The top chart at right plots the monthly exports of these packageable goods. The three-month precipitous decline in exports reduced their value to 10% below the prior year’s shipments abroad. Although there has been some recovery from the initial decline, it has not been enough to get even close to prior year exports. At the end of November, packageable goods exports were down by 8.6%. Exports of these goods totaled $470 billion for the first 11 months in 2019, but they were only $430 billion in 11 months of 2020, a decline of $40 billion. That represents $40 billion of lost market opportunity for domestic producers of corrugated and other paper packaging. The situation with imports of packageable goods is equally distressing. The bottom chart at right shows the trend of imports of packageable goods since 2018. Imports suffered just as exports did when international trade patterns were initially disrupted by the pandemic. However, the recovery of imports has been substantially more robust than for exports. For the past three months, imports have exceeded prior year levels by a significant amount.

-3%

$70 $60

-4%

$50

-5%

$40

-6%

$30

-7%

$20

-8%

$10 $0

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 2018

2019

2020

-9%

Percent Change Year-to-Date

Source: Census Bureau, RSA, Inc.

Through the first 11 months of 2020, imports were off by only 0.7% from 2019’s shipments abroad. Through the first 11 months of 2020, imports of packageable goods amounted to $926 billion, close to their $933 billion at the end of November 2019. Both imports and exports impact U.S. packaging markets, and the most comprehensive way to look at their overall impact is to look at the trade deficit, which is the excess of imports over exports. The chart on page 8 shows what the trade deficit for packageable goods looks like since 2018.

Beginning in June 2020 and continuing for every month since then, the trade deficit has grown by leaps and bounds compared to its year-earlier level. By November, the trade deficit had expanded by 7.2%. In November 2019, the trade deficit amounted to $463 billion. But, by November 2020, the deficit had increased by $33 billion to a total of $496 billion. While the trends toward rapidly rising online purchases and more stay-at-home meals have provided opportunities for paper packaging producers, the increasing trade deficit for packageable goods has

Scoring Boxes

Dick Storat is president of Richard Storat & Associates. He can be reached at 610-282-6033 or storatre@aol.com.

8

BOXSCORE March/April 2021

$60

U.S. Packageable Goods Trade Deficit

$55 $50 $45

($ Billions/Month)

resulted in a significant share of that market growth being siphoned off to imports rather than to the packaging of domestically made goods. Dealing with the economic impact of the coronavirus pandemic may be garnering the headlines these days, but the impact of the country’s growing trade deficit for packageable products is being felt in the marketplace by corrugated and other paper packaging converters every day.

$40 $35 $30 $25 $20 $15 $10 $5 $0

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC 2018

Source: Census Bureau, RSA, Inc.

2019

2020

Percent Change Year-to-Date

8% 7% 6% 5% 4% 3% 2% 1% 0% -1% -2% -3% -4% -5% -6% -7%

Legislative Report

Jobs, Taxes, and Minimum Wage: The Manufacturing Sector’s Looming Setback? BY ERIC ELGIN

T

he independent boxmaker doesn’t have a lot to cheer about given the news out of Washington, D.C., these past two months. While I like to be optimisitic about future prospects, the policy agenda of the Biden White House and Democraticcontrolled Congress are providing what I consider to be a challenging outlook for the business community in the months ahead. (See also “New Administration, New Possibilities,” page 38.) Already we saw on the president’s first day in office the pen-stroke cancellation of the XL Pipeline, resulting in the direct loss of more than 11,000 well-paying union jobs in pipeline construction and supporting industries. In addition to this executive order on the XL, the president has also put a moratorium on all new oil and gas leases on federal lands, a move that the American Petroleum Institute said will cost upward of 1 million unemployed. Those of you who may have attended our annual Washington Fly-Ins in the past might remember our industry’s collective advocacy of the XL Pipeline, specifically, and of greater energy independence generally in our visits with congressional representatives and senators. We argued then, and it’s just as true now, that a healthy manufacturing sector—and a healthy box business—cannot survive without abundant and reliable sources of competitively priced energy. Somehow, our president and his allies in Congress have missed the point that, as

10

BOXSCORE March/April 2021

we are able to transition toward alternative sources of energy, fossil fuels will still be necessary for the efficient propulsion of our economy. And even as our corrugated and paperboard industries applaud advances in sustainability, as we produce a renewable and sustainable packaging product, we also have to remain competitive as an industry. And competitive energy is essential to that goal. Another area of concern to us is the potential reversal of the tax cuts enacted in the 2017 Tax Cuts and Jobs Act. In 2018, when this legislation took effect, the stimulus effect of lower overall individual and corporate rates, plus the provisions for accelerated depreciation, boosted the overall economy generally and our box business in particular. For example, in August 2018, box shipments reached 35.5 billion square feet, the highest permonth level since the Great Recession of 2008–2009. Containerboard mills ran at 97% capacity, and the Institute for Supply Management’s monthly purchasing index topped 60 for two months in a row, according to the September 2018 edition of Scoring Boxes. Thus, we see the effects that lower tax rates can help achieve. Now, the Biden administration has floated an overhaul of the 2017 law, which will increase corporate rates to 28% from their previous low of 21%. In addition to these corporate rate changes, the administration’s proposals will also raise marginal tax rates for high-income individuals. Mitch Klingher, CPA, of

Klingher-Nadler breaks this down in his excellent article on page 60 of this issue. Added to these new burdens on business is the likelihood of a national minimum wage of $15 per hour. Now I know that our industry in general pays starting wages in excess of this figure. According to AICC’s 2020 Salary, Hourly Wage & Benefit Survey, the average probationary rate for a forklift driver in a sheet plant is $17.62; for a flexo folder gluer operator, it’s $19.55. But there are many other positions, those requiring far fewer skills, that are paying in the $11–$12 range. Depending on the part of the country you’re in, your pay scales may be within the proposed minimum or dramatically below. If that’s the case, every business owner is forced to make the decisions that are likely to result in fewer jobs, not more. As I told writer Robert Bittner in our cover story, overall, I’m an optimistic person, and I do hope for the best. If the Biden administration can stay in the middle, I think that’ll be best for everyone. Yet a new administration cutting jobs right out of the blocks, raising taxes, and increasing the minimum wage does not bode well for a booming economy or the continued robustness of our business. Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com.

The next time your customer asks for recycled white top linerboard, the answer is:

Of course!

Contact us for Leipa trials or to learn about our inventory programs. Contact Sharp Internat ional Group www.sharpinternat ionalgroup.com Phone: (757) 410-3601 rbanks@sharp-internat ional.com

Leipa linerboards are manufactured from 100% recycled waste paper for a more environmentally responsible packaging..

New Members

Welcome, New Members! JAMEL CONTAINERS LLC J. PERRY MORRIS President 333 W. 45th St. Chattanooga, TN 37410 423-509-8200 www.jamelcontainers.com

Members Meeting

Dusobox Virtual Plant Tour

M

ore than 360 registrants clicked into AICC’s first virtual plant tour—a walkthrough of Dusobox, with President John Kelley. Attendees watched a video tour of Dusobox’s 250,000-squarefoot facility in Orlando, Florida, and asked questions of Kelley as well as featured suppliers. After a brief company history highlighting the achievements of Dusobox during their nearly 70 years of operation, the tour brought attendees through the company’s administrative office, highlighting their data analytics team before moving on to showcase several of their design successes for displays and industrial packaging. After explaining their facility’s layout and the increased collaboration they have seen with their open floor plan, the tour then moved on to the

12

BOXSCORE March/April 2021

plant floor. When Dusobox moved to their current facility in 2016, they focused on material flow and workflow. In the maintenance department, Kelley espoused the importance of maintenance, especially on the hightech machinery. They have achieved an uptime of 95%. Their system uses artificial intelligence to bring predictability to their maintenance plan. All parts data, electrical schematics, and machine drawings have been digitized, so their team of five maintenance technicians can access the information wherever they are in the plant. Kelley then walked attendees through the ink kitchen and around the floor to see their five-color Göpfert, laminating section, Autoplaten cutting and creasing area, specialty folder gluers, then ending in their digital space.

Following the tour, breakout rooms were open to allow participants to ask Kelley questions and get more information from the suppliers highlighted in the video, which included Bobst, JB Machinery, Bahmüller, Göpfert, Poteet Printing Systems, HP, Esko, and Kiwiplan. The tour was sponsored by Dusobox, HP, Kiwiplan, Poteet Printing Systems, and JB Machinery. By the time this issue has gone to press, hundreds of AICC members will have also participated in virtual tours of Wasatch Container & The BoxMaker. AICC will host several more virtual tours in the coming months. Registration for AICC members is free. For more information on upcoming virtual plant tours and to register, visit www.aiccbox.org/virtualtour.

printing better together

Our Teamwork Brings It All Together

Connect With Us

Each department works hard to ensure Quality, Precision, and Expertise in every Anilox Roll that leaves our facilities.

www.pamarco.com Shon Cornwell shon.cornwell@pamarco.com | 404-691-1700

Ask Ralph

Plastics: A Primer BY RALPH YOUNG

T

he corrugated and paper industries, both domestically and internationally, have rallied to sing our praises and use hard analytical approaches to assert that organic fiber-based packaging solutions are more environmentally friendly than plastic alternatives. One such case was the life cycle analysis of comparing corrugated shipping containers to returnable plastic crates for fresh fruit and produce. On a personal basis, my wine club in California switched from Styrofoam primary bottle protection to molded pulp. Yeah! In the 1950s, ’60s, and ’70s, there was a Dupont advertising slogan one would often hear on TV or read in the news magazines: “Better Things for Better Living ... Through Chemistry.” They are known for their research and innovation. In those old days, most single-use and, often, returnable or truly recyclable single-use food-grade products came in glass or metal containers. Paperboard for juice and milk cartons and food packaging was just starting to be introduced. Then came plastic food jars. Single-use plastic has always been an issue, especially in the area of food service. A few countries, states, and cities have even banned plastic straws recently. Check out www.bio-agave.com. They have discovered additional uses for agave beyond liquid tequila. At the time of this writing, a group called Break Free From Plastic reported research from their collection from 55 countries and found that for three years running, Coca-Cola, PepsiCo, and Nestlé were the top three plastic polluters globally. And 5,000 other brands were also categorized from the waste stream. Plastics do not disintegrate or disappear, but instead break up into microplastics that often get consumed by the tiniest organisms. These toxins bioaccumulate and move their way

14

BOXSCORE March/April 2021

up the food chain and into our air, food, and water. Now the research is focused on the even smaller nanoparticles. Maybe a Yeti cup is the pollution solution! Amazon reports that it used about 116 million pounds of plastic packaging in 2019. Oceana disagrees and reports Amazon’s volume is 465 million pounds of plastic waste. Maybe 22 million tons of that end up in our water ecosystems. I wonder what it is in the COVID year, considering those two-ply bubble wrap plastic envelopes. A recycled-pulp bulk liner seems a better substitute. Recycling rates for plastic are generally around 10%, with No. 1 and 2 rates at nearly 30%. These have sufficient market demand and domestic recycling and reprocessing capacity. Corrugated has been at the 90% level for many years, but it may have been a little lower in 2020, as collections from institutional facilities have fallen and as residential curbside collection has never been stellar. Europeans are ahead of us on the replacement of plastics with corrugated and paperboard. Mondi, as recently announced in the media, is providing reductions in both plastic and carbon dioxide emissions. Their solution was a paper-based bag that was fully recyclable in existing paper streams and was able to be filled and sealed on existing machines. Other innovative paper-based packaging options do come along, like the collaborative venture of Fishbone and Atlantic Packaging with a recyclable fourand six-pack can carrier system. And there are compostable paper-based mulches available to replace plastic sheets in farming, which are used to conserve moisture, control weeds, and boost soil temperatures. So-called biodegradable plastics are not like cellulose-based or fiber-based

packaging. They require special industrial facilities and still get comingled with recyclable and compostable materials. At the present time, biodegradable plastics are not the solution. A recent press release said that DuPont and Kemira have partnered to bring about bio-based and inherently biodegradable product lines derived from simple sugars. The process is commercial and will be rolled out shortly. The product will provide strength and barrier properties to fiberbased packaging. The United States, China, and India appear to be the leading plastic waste generators. Taken collectively, European Union nations would come next. It had been reported at a 2018 Bank of America materials conference that the 10 worst river-to-ocean plastic waste streams come from eight rivers in China and two in Africa. In total, it has been estimated that 8.8 million tons of plastic waste flow from the world’s coastal regions each year. Some estimates report that the total count of micro- and nanoparticles in the oceans’ surfaces is between 12.5 trillion and 125 trillion. In conclusion, stay informed, and look even more intentionally at replacing plastic with corrugated and paperboard and recyclable coatings. Act before your customers ask. We are here to support you and are always working on your behalf. Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@aiccbox.org.

The Measure of Quality.

Clean up your act.

AD

Washboarding, warping & delaminating:

the

dirty laundry of corrugators everywhere. But top-quality, consistently-printable board is within your reach: Accora.

APEX

The Accora Advantages HARDENED STAINLESS STEEL APPLICATOR ROLL

CONSISTENT, CONTROLLED GAP

MIRROR-FINISH 1300 VICKERS RATED CERAMIC DOCTOR ROLL

You’re busier than ever. So if you’re getting bent out of shape over warped or washboarded corrugated runs — or if you’re resigned to overgluing as the norm, don’t put off looking at Apex Accora glue sets. Unlike chrome-plated applicator rolls, Accora’s hardened AST stainless steel rolls never flake or corrode. We take extra quality-control steps in our applicator roll engraving process to ensure equivalent cell volume throughout. Accora doctor rolls feature super-dense, lowporosity ceramic that maximizes resistance to scoring and corrosion. Accora is certified and approved by all major OEMs. But because we use premium materials and methods on our rolls and journals, Accora exceeds OEM standards for T.I.R. tolerances. We minimize T.I.R. down to 0.0005” for the tightest controlled gap. Results? How about faster speeds and easier clean-up? Longer roll life. Job repeatability. Flatter board and fewer rejections. And potential starch/energy savings. Discover what the leading box manufacturers already know: Accora makes quality board easier. Request a quote today for your new or refurbished set.

L E A R N M O R E AT

apex-groupofcompanies.com

Ask Tom

Why You May Want a Data-Driven Manufacturing Culture BY TOM WEBER

C

onnected devices are everywhere today. The manufacturing community may not have transformed as quickly as others, but it is one more place you can find connected and smart devices. The key to thriving, though, is creating a data-driven manufacturing culture that takes full advantage of all available data. Here are some reasons and benefits. In a data-driven manufacturing culture, the firm leverages the breadth of data available from new technologies such as the Industrial Internet of Things (IIoT), automation, artificial intelligence, or other digitization tools. There are many advantages to a data-driven culture. First, decisions are made based on fact. Rather than relying on hunches or “how things have always been done,” a firm can use real-time information—often in conjunction with predictive forecasting and historical data. With data driving decisions, a firm can efficiently identify potential risks and new opportunities and achieve better results. Added benefits include: • Reduced machine downtime from enabling predictive maintenance;

• Increased production capacity; • Lower material consumption; • Greater receptiveness to consumer demand; and • Improved ability to customize products. The challenge can be in creating the data-driven manufacturing culture. How to Create a Data-Driven Manufacturing Culture 1. Identify Assets In digital manufacturing, there are more assets available. On top of the factories or buildings and machinery and equipment, along with intangible assets such as patents, copyright, and licenses, there are now digital assets from industrial applications, digitally optimized processes (such as ERP, CRM), and edge and cloud computing. To achieve the productivity and profitability gains possible in a data-driven manufacturing culture, the firm needs to clearly define all of its assets and put plans and processes into place to identify and dispense with data bottlenecks.

2. Break Down Silos Sharing data across the manufacturing organization streamlines processes and helps ensure that every team at the firm is pulling in the same direction—and able to understand why. Develop your capabilities (software and human) to gather, merge, manage, and analyze the big data stored throughout the manufacturing firm. If procurement and production, for instance, aren’t sharing data, you can’t improve their decision-making. Don’t expect your humans to be able to get the most out of big data without the aid of advanced analytics. For instance, with artificial intelligence and analytics doing the heavy data lifting, a company might analyze profit-per-hour factoring in as many as 1,000 variables and 10,000 constraints to help manufacturers figure out what to buy, what to make, and how they should make it, to yield the most profit in each period. Fun fact: The digital universe is doubling in size every two years. By this year, the data we create and copy annually was expected to reach 44 trillion gigabytes, according to IDC. 3. Train Humans Better When a manufacturing firm adds more technology and demands greater interoperability, it creates a more complicated ecosystem. The humans already need to understand how to operate, troubleshoot, and monitor machines and the related technology. Now they also need to be trained on the process of data sharing and learn how the entire plant can

16

BOXSCORE March/April 2021

Ask Tom

Tom recently hosted a four-part data managment webinar series to help companies leverage the breadth of data available from new technologies such as the industrial Internet of Things, automation, artificial intelligence, or other digitization tools. Panelists included Kiwiplan, Amtech, EFI, Advantzware, and OMP. Recordings of these webinars are available to members with the All Access Pass.

function better by embracing this new interconnectedness. For example, valve manufacturer Richards Industrials achieved a 40% increase in productivity within six months of integrating its shop-floor management software.

By showing employees how to test and measure data, and helping them to understand its importance, you help get them invested in the datadriven culture. 4. Lead Intelligently While demonstrating empathy for those who find change challenging and are nostalgic for the “old ways,” leadership needs to prioritize developing an understanding around the value of smart devices, data analysis, and digital transformation. Leaders must know that the results are only as good as the decision-makers themselves. This also can’t be an IT-team-only initiative. Heads of every business unit need to understand the use of big data and educate their teams about the importance of effective data security and data management.

5. Encourage Experimentation Data analysis should be directed at problem-solving, process improvement, and profit generation. Yet it can help to encourage people throughout the firm to experiment with the data. You may get a fresh perspective on processes or business challenges. Establishing a data-driven culture as a priority can improve buy-in to the initiative while also leading to improved production rates, lower costs, reduced downtime, and greater employee satisfaction along the way. Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@aiccbox.org.

BOXSCORE www.aiccbox.org

17

Selling Today

Flexibility, Ingenuity, and Persistence Remain Key to Managing Sales Pipeline BY TODD M. ZIELINSKI AND LISA BENSON

A

year ago, we couldn’t have imagined the tumultuous ride ahead of us when, without warning, the COVID-19 pandemic took “business as usual” and turned it on its head. Corrugated box, folding carton, and rigid box manufacturers needed to adapt quickly. Flexibility, ingenuity, and persistence helped many not only survive but prosper. We are looking back on the past year to see how some manufacturers adapted their selling techniques to the uncertainty they were facing. Selling Challenges During the Pandemic Before the pandemic, the phrases “essential business” and “nonessential business” were not part of our everyday vernacular. As governments scrambled to define them, manufacturers saw orders plummet in nonessential business sectors as well as

18

BOXSCORE March/April 2021

retail display work. Those fortunate to service essential businesses saw orders skyrocket. The first challenge for sales was to shift focus onto industries showing growth, such as food and beverage, medical and pharmaceuticals, do-it-yourself, and cleaning supplies. Manufacturers looking to grow in new industries or increase their customer base were faced with the challenge of reaching their prospects. Trade shows and in-person networking and meetings were no longer options. Many decision-makers who were not involved with operations directly, such as procurement and engineering, worked from home. For some, this made them harder to reach. In the first months of the pandemic, salespeople found that even those in essential businesses were reluctant to talk because they were overwhelmed with

keeping up, and the timing wasn’t right to switch suppliers. Large companies and specific demanding industries, such as medical, became even more challenging to crack. Since in-person meetings couldn’t happen, an uptick was seen in prospects requesting quotes and focusing on price, which could put independents at a disadvantage. Flexibility in Trying Times It became clear right away, for better or worse, that virtual selling would need to be embraced. For many, it was a massive paradigm shift from the traditional selling techniques they were used to. Through baptism by fire, some learned new technologies to adapt. Virtual meetings, webinars, and virtual plant tours began to replace traditional selling methods.

CUTTING DIE STRIPPING DIE BLANKING DIE CUTTING PLATES MAKE READY SAFELY IN CASSETTES

Manual or Fully Automatic Flat Die Storage Systems by BCM

Rack up more space, productivity and efficency WhyAgonize.com Info@AskHitek.com 262-842-1700

Selling Today

Part of the virtual selling strategy included connecting through social media channels, such as LinkedIn, creating virtual connections with decision-makers and centers of influence. The connections provided contact information for follow-up. Mobile applications made connecting and direct messaging even easier. Many manufacturers, for the first time, evaluated the virtual first impression they were making. We saw many update their sales presentations, websites, and messaging. Inbound marketing tactics, combined with outbound and sales follow-up, have helped many manufacturers reach new prospects and build their sales funnels. Messaging is key. Understanding where their prospects are in the buying cycle is critical. Educational messaging demonstrates proficiency and leadership to those not ready to buy. In the early months of the pandemic, this included everyone that was struggling to find their footing as selling-based messaging wasn’t resonating. Initial communications, however, were focused on putting customers at ease and included information on how they were dealing with the upheaval, such as special cleaning protocols, employee staffing, and social distancing practices. As their prospects’ needs become evident, successful manufacturers adapt messaging, and sometimes services, to reach them. For example, the pandemic impacted the paper packaging industry as the demand for paper products and e-commerce packaging spiked, leaving some companies facing extremely long lead times, which further disrupted their supply chains. Various state governments restricted employee capacity on the production floor, reducing production. Savvy independent corrugators with excess capacity, understanding that many weren’t ready to change vendors, offered to be a secondary supplier and pick up the work overflow. To take it further, some offered vendor-managed inventory services, which helped their customers

20

BOXSCORE March/April 2021

manage box inventory while giving them a deeper understanding of the customer’s needs and the ability to provide additional solutions to them. In some cases, cold calling is more difficult during the pandemic. When business phones are not set up to transfer calls to cellphones, emails sent to those prospects will often be answered with outof-office messages that provide additional contact information for the prospect or additional decision-makers who can be reached out to. With the viable prospects pool shrinking during the pandemic, structured and repetitive follow-up is even more critical. Promptly following up on meetings, RFQs, and quotes can be the difference between making a sale and losing a sale to another supplier. If prospects don’t have an immediate need, ask when you can call back, and then make sure you do. Also, ask if you can send information to them periodically through a lead nurture email campaign. To contend with prospects focused only on receiving quotes, some manufacturers require a meeting to discuss the quote. They may also request samples and set a meeting to discuss them. The idea is to engage as much as possible while learning more about the prospect’s needs. The key is to pivot the conversation to learn as much as you can about the pains the prospect faces. In addition to changing the way they communicated with prospects, some manufacturers have expanded their solutions to meet customers’ needs. This included purchasing new equipment or going the extra mile for customers, like providing pack-out and fulfillment services. Lessons Learned There is still much uncertainty as we move forward and settle into a new way of selling. The No. 1 lesson learned is that flexibility is and will continue to be a primary factor in success, whether that means learning new technologies, adapting virtual selling

strategies, moving into new industries, or providing new services. Another lesson by many during the pandemic is the importance of having a process for managing your prospecting activities. That may sound counterintuitive to flexibility, but an important part of a process is looking at your data to determine what is and isn’t working and then taking necessary corrective actions. Having a process also ensures that follow-up activities are carried out. When a quote is drawn up, make it part of your process to virtually meet with the prospect to discuss it or, at the very least, follow up after a specified time. If it isn’t accepted, ask why. You might not get an answer, but if you do, it may provide valuable information about what is happening in that industry, especially if you are hearing the same reasons time and time again. Moving forward, we are still facing uncertainty. Although several vaccines have been introduced, and companies have instituted social distancing and other rules to keep employees and visitors safe, new strains of the virus have also been showing up. Some areas have resumed face-to-face meetings, but trade shows are still being postponed or done virtually. One thing that is certain is that flexibility, ingenuity, and persistence will continue to be essential characteristics of top performers. Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com.

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com.

People | Knowledge | Software | Services

So you want to reduce material cost and waste, reduce converting waste and downtime, reduce labor and overtime costs and reduce shipping costs...

Improve production efficiency, quality and automation

The smart solution? ... smart software Drive improvements and reduce shipping costs by integrating your shipping and production processes with our TSS.

Reduce costs

Increase visibility and communication throughout your business

TRUCK SCHEDULING SYSTEM (TSS) Provide premier customer service

Connecting you to smart software solutions

www.kiwiplan.com

@KiwiplanGlobal #followkiwiplan

Andragogy

Spring Refresh With Continuing Education BY JULIE RICE SUGGS, PH.D., AND ALLI KEIGLEY

S

pring is heralded for a host of reasons: the blooming flowers, heaps of sunshine, ideal temperatures, warm breezes, the emergence of new life. And with those changes comes a sense of renewal we feel all around us—a time for fresh beginnings. For many, we’re spurred into a flurry of activity in our homes. Windows are flung open, baseboards scrubbed, closets emptied and reorganized, and multiple trips to the local Goodwill ensue. But this year, let’s push ourselves to focus on more than just the cobwebs along the ceiling—let’s do something with the cobwebs in our minds. There has been much to fill our minds in the past year, and a lot of it may have bogged us down. Maybe now, during this season of hope, we can turn our thoughts to curated learning and personal growth in our education. You might have already reflected on this year, tested out some new ideas, made some plans—a list of things you want to start or improve on. That list may include exercising more frequently, cultivating a meditation practice, drinking more water, going to bed earlier, or making yourself smile before you even get out of bed. Adding continuing education would help round out that list. And while we may not be able to help you reach a state of enlightenment, we can most certainly help you learn more in the realm of packaging. Just like the relationships on display everywhere in the springtime (bees and flowers, gentle rains, sunshine, and plants), AICC and The Packaging School work together to offer member companies and all respective employees the value-add of free training programs.

22

BOXSCORE March/April 2021

Among these programs are more than 80 online courses in both English and Spanish, all related to the packaging industry and the manufacturing environment. With over 500 learning videos and some 250 educational documents and resources available, there’s plenty of opportunity for you to learn something new. The Certificate of Packaging Science (CPS), a 12-course online curriculum that teaches the materials, processes, and influences shaping the advancement of the packaging industry, should be on your list of achievements to undertake this year. After completing all 12 CPS courses, AICC members are eligible for the CPS final exam coordinated through The Packaging School—the resulting credential is a registered and framed certificate that is sent to each earning graduate. This e-learning program provides relevant and comprehensive education on the global role of packaging in business and society. What makes our online courses special? For starters, we use a technique called microlearning. If you aren’t familiar with the term, it just means we take difficult topics, break them up, and arrange them into bite-sized lessons learners can engage with on any device. We might use infographics, quick readings, videos, animations, discussions, or interactive slides as the vehicle to deliver information. This unique method empowers you to learn and complete courses on your schedule, at your own pace. We believe these short focused sessions help avoid mental burnout and cater to adult learning styles.

The benefits of continuing education throughout your career are numerous— an enhanced understanding of the world, newly opened doors to opportunities, improved quality of life, to name a few. Broadening your knowledge base will keep your brain active and sharp—and also improve your memory (anyone else desperate for help in that area?). Research shows a strong link between reading and overall health. Overall, learning is a form of mental exercise that can keep your mind robust and strong. The promise of hope seems more prevalent and longed-for this spring. We’ve collectively been through many challenging circumstances since the spring of 2020. As we look around our natural world to watch the green buds burst forth into life during this change of season, our hope for you is that you overcome whatever difficulties you may be facing. Keep striving, take advantage of our programs, and continue learning, growing, and bettering yourself. Julie Rice Suggs, Ph.D., is academic director at The Packaging School. She can be reached at 330-774-8542 or julie@packagingschool.com.

Alli Keigley is production coordinator at The Packaging School. She can be reached at alli@packagingschool.com.

Leadership

Brain Space

7S WORKPLACE 7S WORKPLACE PLAN PLAN FISHBONE DIAGRAM FISHBONE DIAGRAM LESSON

BY SCOTT ELLIS, ED.D.

7S WORKPLACE PLAN

FISHBONE DIAG

P

eople often want to borrow your brain. Our Matthew used to ask me why boys of his age and stature were required to take out the garbage. I would promise to discuss it when he came back from taking out the garbage. Come to think of it, it has been 30 years, and we still have not discussed it. I think I will text him about this, while I talk to you about developing critical thinking in your team. In recent articles, I have described some of the tools used to solve proximate problems and to teach team members to solve the problems they face tomorrow. We have discussed tools to plan, problem-solve, and measure progress. They are used in the moment to improve work processes, to reduce waste, and to foster a healthier and more profitable company. Over time, they have the added benefit of providing much-needed experience with concepts of judgment. Working with people with a wide range of capacities, I have found that the willing ones can learn habits of critical thinking. This will improve the work and the culture, but it will also enhance the individual’s career and the community. I have limited brain space and a number of projects that fill it. Self-serving as I am, I have noticed that I spend a good deal less time solving problems for others. Folks often ask questions for spurious reasons. Sometimes, they want to delegate the problem back to me; other times, they are just avoiding an onerous task. When those who have participated in the use of these tools ask me to think for them, I try to resist the temptation. Instead, I ask what they learned when they looked at the data, prioritized, or completed an A3 report. Then they leave—annoyed—and I work on more value-added tasks. When

24

BOXSCORE March/April 2021

BRAIN BRAIS BRM MA

they return, they have pride in having done the work, and their solutions are usually superior to those I would have suggested. Most often, people learn these concepts best using low-tech tools like

whiteboards. I am well acquainted with the various software tools available for meeting management, problem-solving, planning, and measurement reporting. In fact, I use many of them, but not in a group setting. This has absolutely

Leadership FISHBONEDIAGRAM DIAGRAM FISHBONE LESSONS LEARNED

ESSONS LEARNED

LESSONSLEARNED LEARNED LESSONS AGENDA

AGENDA

IN SPACE BRAIN SPACE SPACE BRAIN MAP

N SPACE MAP MAP MAP nothing to do with me being a boomer. It does, however, have a good deal to do with learning theory. People learn best when they are involved. If our education system were modeled on the schools developed by Maria Montessori, then

all subject matter would be integrated and interactive. For example, in today’s kindergarten class, we might play with frogs, learn about the color green, write the letter F, and sing along with Kermit. This would use all the associations

AGENDA AGENDA involved to embed the lessons. However, economics’ influence on public education has devolved to students sitting quietly while they are shown things and talked to. Some folks adapt to learning well in this environment, but everyone learns faster and better when they interact with the subject and with one another. Consequently, utilizing a lowtech interactive tool keeps all engaged and learning. Some of the most intentional learning companies adorn the walls of their meeting room with planning and problem-solving tools. If you enjoy Toyota Production System nomenclature, you can dub it the Obeya Room. I think that would be dumb, because it just means “big room,” but you can do it. I prefer the Improvement Center, or War Room, or maybe even the Brain Space. No matter what you name it, the value is found in the fact that the tools are right there to help reinforce critical thinking. In the midst of a busy day, we can take a moment to explore an error and try to make it very difficult to repeat. We could also celebrate a success by making it easy to replicate. There have been many times when I was just about to think for a questioner, but the fact that the tool was right there on the wall reminded me that we could find a better solution together. Matthew just texted me back. He says he doesn’t want to talk about it. Go figure. Scott Ellis, Ed.D., delivers training, coaching, and resources that develop the ability to eliminate obstacles and sustain more effective and profitable results. He recently published Dammit, Learning Judgment Through Experience. His books and process improvement resources are available at WorkingWell.bz. AICC members enjoy a 20% discount code: AICC21.

BOXSCORE www.aiccbox.org

25

Planning for the future is one of your most important jobs. Selling your business, succession planning, equipment decisions and expansions require the best advice and strategy. We’ve been providing Business Planning Services to the independent converter for over 30 years. Need to make a big decision? Call us now.

STILL the Industry Experts 580 Sylvan Avenue, Suite M-A Englewood Cliffs, NJ 07632 (201) 731-3025 • Fax: (201) 731-3026 info@klinghernadler.com

INNOVATION Awards

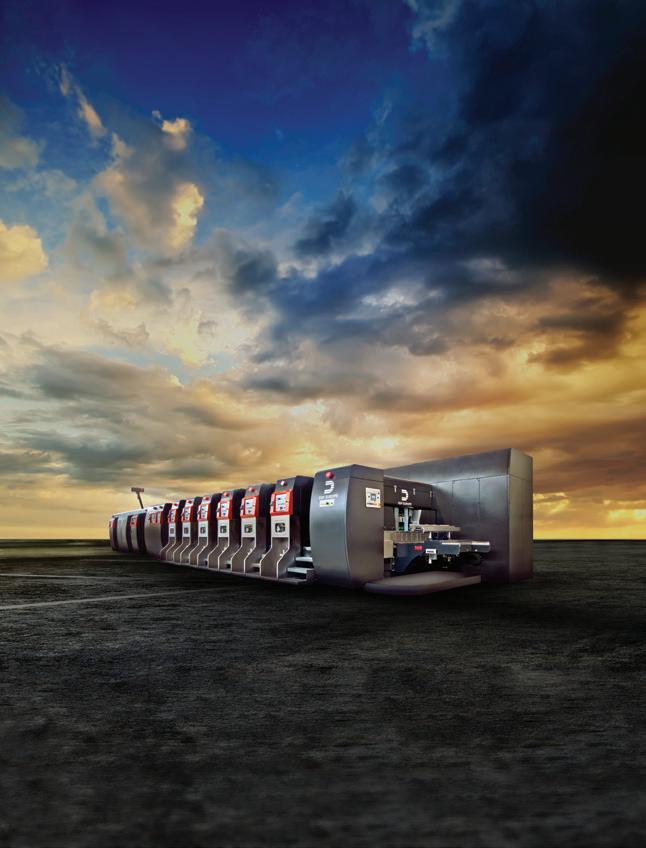

Calling All Machinery Innovators: 2021 IOY Call for Entries

A

ICC, Board Converting News, and Corrugated Today have issued a call for entries in the 2021 Innovator of the Year (IOY) competition. This year’s category is machinery. The Innovator of the Year competition, held in conjunction with the AICC/TAPPI 2021 SuperCorrExpo, August 8–12, at the Orange County Convention Center in Orlando, Florida, will highlight the best that AICC Associate members have to offer. Developed more than two decades ago as a forum for AICC members to share their best ideas, IOY has evolved into a highly competitive arena that showcases solutions that AICC members have developed. The entries submitted into the IOY competition are first judged by a panel of industry experts on the AICC Plant Innovations Committee, who select the finalists. Finalists are featured at SuperCorrExpo, and meeting attendees vote by ballot to name the winner. The machinery category, open to

AICC Associate (supplier) members, focuses on innovations of equipment, products, or services that are directly related to the mechanical converting process. Innovations should benefit the paperboard packaging industry through enhanced efficiency, quality, productivity, and/or safety of converting plants. The mechanical converting process covers all operations that involve direct contact with corrugated, folding carton, or rigid box substrates (i.e., printing, cutting, creasing, scoring, stitching, gluing, material handling, etc.). Entries must be received by Friday, June 4. More information and the entry form can be found at www.aiccbox.org/innovator. Questions about the IOY competition, SuperCorrExpo, and the value a well-connected workforce brings to a company can be directed to Cindy Huber, director of conventions and meetings, at 703-836-2422 or chuber@aiccbox.org, or to Laura Mihalick, senior meeting manager, at lmihalick@aiccbox.org.

Past IOY Competition Machinery Winners 2016: Gemini North America – Barberán high-speed, high-quality digital printer 2012: JB Machinery – KleenPlate® plate wash eliminator 2008: HIDE-Pack – Inline R.F.I.D. embedding system for flexo folder gluers 2004: Alliance Machine Systems International – ALF-MAX robotic palletizer system 2001: Curioni USA Inc. – Extend-O-Slot 1998: Pamarco Inc. – Fiberlyte anilox roll 1995: Langston Corp. – Rotofold folding system

BOXSCORE www.aiccbox.org

27

AICC Innovation

Leadership and Management

Leading Remote Teams – One Year On BY BEN BAKER

W

e all remember that day in our company’s life when we sent our teams home in the spring of 2020. Most of us assumed, hoped, and planned for this to be a short-term exercise. “A couple of weeks of inconvenience,” and therefore, not much thought went into things beyond making sure people took their laptops and cellphones home with them. Weeks turned into months, and for many of us, bringing everyone back to the office full time may never happen again. Teams have grown accustomed to working remotely, leaders have adjusted—some well, some not—and in the vast majority of cases, this has not been as horrible an exercise as we have thought it would be. Or has it? The challenge is, we sent our teams home with Band-Aid and duct tape solutions. There were no new policies, very few procedures, and leadership teams who had never managed remote workers before. Some innovative companies have realized this and have taken the time, made the effort, and invested capital in making sure that this shift has happened not only efficiently but effectively; but unfortunately, many have not. Many companies are stuck relying on antiquated ways of doing business and leading their people, hoping that things will eventually go back to the way they were; but they might not! The ways we work and how we lead people have evolved and must continue to change. If we do not, we will be left behind as businesses. We will become inefficient

28

BOXSCORE March/April 2021

and ineffective, and we will lose our best people and possibly our livelihoods. Every company must evaluate how they are communicating with, setting expectations for, and supporting remote teams. This is vital to ongoing success. If we are not communicating with our teams effectively, we have failed right off the bat. When people are remote, we do not have the same opportunity to check in as frequently, and therefore clear and concise communication is critical in isolated situations. The more you can get people to acknowledge, communicate back, and verify, the more effective you will be. It is imperative to have people listen, understand what is expected of them, and know why those expectations exist—to have them engage and be productive members of the team. Expectations are critical. People need to understand what is required, when, by whom, and why, in order to prioritize tasks efficiently. We are no longer in the Henry Ford assembly line mentality world. We live in a world where our goal is to have our people solve problems and help the company and its clients achieve their objectives. Leaders must focus expectations on results and not time-based activity. The more we micromanage, the more we focus on time spent instead of outcomes, the more frustrated our teams will become, the less engaged and productive they will become. Supporting teams requires different thinking and active leadership. Command-and-control management styles need no longer apply. We need

to realize that, for every worker, working from home is unique and has different needs and challenges. Do they have a quiet, well-lit space where they can work effectively? Do they have the technology they need to be effective and efficient? Do they have a desk and a chair that enable them to be comfortable? Are they safe from physical or mental harm working from home? Are they a single parent juggling three kids while trying to live up to work expectations? All of these could be realities for your teams. It is up to each leader to assess what individual workers require to be effective and to coach, lead, and mentor them accordingly. The goal must be to work with members, both individually and collectively, to communicate objectives, motivate them, and be successful and productive team members. None of this is easy. All of this takes effort, but the long-term return is well worth the investment. Ben Baker is president and CEO of Your Brand Marketing, an employee engagement consultancy designed to help you communicate the value of your brand effectively. He is the author of two books: Powerful Personal Brands: A Hands-On Guide to Understanding Yours and Leading Beyond a Crisis: A Conversation About What’s Next. Ben also hosts the iHeart- and Spotify-syndicated YourLIVINGBrand.live show, with more than 180 episodes.

VISIT OUR WEBSITE LPCINK.COM OR CALL 800.559.1526

Member Profile

Columbia Container: ‘The Right Box at the Right Time’ BY STEVE YOUNG

COMPANY: Columbia Container ESTABLISHED: 1998 JOINED AICC: 2014

Photos courtesy of Columbia Container Corp.

PHONE: 410-467-1400 WEBSITE: www.columbiacontainer.net LOCATIONS: Baltimore, Maryland CEO: Brendan Moynihan In the Columbia Container lobby, from left: Columbia Chief Financial Officer Jim Swope; AICC President Michael D’Angelo; and Columbia CEO Brendan Moynihan.

T

he term “elevator speech” has gained some traction in the business world of late, based on the supposition that you had better be able to articulate the value proposition of your enterprise in the short span of an elevator ride. Visit the website of Columbia Container in Baltimore, and you’ll see a model of succinct clarity: “The Columbia Advantage: The right box at the right time.” Brendan Moynihan, CEO, expands: “Columbia Container focuses on providing the cost efficiencies of a manufacturer with the high level of customer service typically found with a distributor.” Moynihan, who started his career in 1986 as a sales representative for Oxford Container in New Oxford,

30

BOXSCORE March/April 2021

Pennsylvania, explained that in his years at Oxford, he noticed there were many corrugated manufacturers that focused on high-volume, cost-efficient production runs and distributors who focused on customer service. “We saw a market opportunity for a company that could combine both these characteristics, and that has been our operating philosophy here at Columbia Container,” he says. Rich History in a Rich Market Feeling the tug of entrepreneurship, Moynihan left Oxford Container in 1998 and, with his partner, Jim Swope, purchased Columbia Container. Swope, now chief financial officer of Columbia, was a lifelong banker who left the

financial world to start a career in the corrugated industry. Columbia emerged on the partners’ radar screen when Don Sturtz, who had been in the corrugated business locally for more than three decades, was looking to sell the company. As Moynihan tells it, Sturtz named the company Columbia Container because that was the name of the first corrugated box company he worked at—one with an interesting connection to local Baltimore lore. “The original Columbia Container had been destroyed in a fire but had employed both Don and legendary Baltimore Colts Quarterback Johnny Unitas as salesmen,” Moynihan explains. “As we’ve heard the story told, Johnny worked at Columbia in his early years

Member Profile

with the Colts, because the pay in professional football in those days was not enough to support his growing family; boy, how times have changed!” Moynihan says Sturtz had no children interested in taking over the business, and like many good business owners, he didn’t want to sell without giving the people he employed a chance to continue working at Columbia. Says Moynihan proudly, “We still have one employee, Gerald Helmick, who worked for Don.” Moynihan and Swope recognized the potential of the Baltimore market. Baltimore, as the major seaport between New York and Norfolk, is a major manufacturing and distribution hub. According to the Baltimore County economic development authority, manufacturing accounts for more than 56,000 jobs in 1,800 employing companies. Industries such as machine tools, defense, food and beverage, consumer products, and building supplies take advantage of the city’s extensive and accessible rail, road, and shipping networks, making Baltimore the locus of an extensive box market area encompassing Maryland, Pennsylvania, Delaware, and Northern and Central Virginia. Moynihan says that most of Columbia’s customers are located within 60 miles of the plant in Baltimore. “Our market is comprised of food and beverage, pharmaceutical, distribution, and industrial companies,” he says. “Our largest concentration is in the food and beverage segment.” Sales Manager Chris Saumell, who joined Columbia in 2004 after a 14-year stint in sales at Oxford Container, concurs: “We are heavily involved in food and beverage,” he says. “We sell brown boxes with one- or two-color print to a number of meat companies, spice companies, bakeries, food distributors, and retail food manufacturers, with customers also

32

BOXSCORE March/April 2021

in industrial, bio-tech, and consumer products industries. “We manufacture RSCs mostly—a lot of kraft single-wall but also a lot of oyster white double-wall. Recently,” he adds, “we have been converting a lot of D flute.” D flute has a caliper lying between C and E flutes and has as its major advantage a high strength-toMoynihan shows off Columbia’s recent acquisition, a Post volume ratio. In other specialty gluer. words, it’s a space saver for customers. are supported by the Langston, where Saumell, who worked as a salesman standard setups are done in 14 minutes, under Moynihan at Oxford, oversees and on the EMBA, where similar setups a team of four sales reps: Kevin Parks, take all of seven minutes. Colin Moynihan, Shawn Yakscoe, and The most recent addition to this roster Ron Milhimes. He says they get a lot of is the 74-inch Post. Acquired in 2019, it opportunities because of referrals from was completely rebuilt in early 2020 by existing customers. “We are seizing on Tom Torosian of Torosian Tech Services our ability for quick-turn, reliable serin Racine, Wisconsin. According to vice and competitive pricing,” Saumell Moynihan, the Post will lead the comsays. “We do what we say we are going pany’s push into value-added packaging, to do; if we fall short, we communicate particularly the addition of auto-bottoms, proactively. We give outstanding service small RSCs, and glued trays in demand at a competitive price. We have forged in the market. long-term relationships with many of Will Cole, in his role as plant manager, our customers, and as they have grown, oversees the manufacturing floor. He’s so have we. We rarely lose a customer.” a 26-year veteran of the corrugated Last year, he adds, despite the COVID industry with an extensive résumé of slowdown in May and June, sales were production responsibilities. “I’ve served “up dramatically.” in various capacities, including machine operation, supervision, superintendent, Equipped for the Job quality manager, and safety manager,” he Columbia’s equipment mix supports its explains. He has been at Columbia for business model. The company has a 43" x four years. 94" EMBA two-color flexo folder gluer, Columbia, like many independents a 50" x 113" Langston Saturn III flexo in North America, relies on a well-oiled folder gluer with die-cut section, a 60" x maintenance plan to keep their older 80" Staley two-color rotary die cutter, a machines running efficiently. “We just 74-inch Post folder gluer, and a 50" x 112" use common sense,” Cole says. “We Serenco two-color flexo printer slotter get feedback daily from our machine with lead edge feeder. Moynihan explains operators on the operational aspects that their quick turnaround capabilities of each piece of equipment. We track

A new level of PERFORMANCE...

...the next level of QUALITY

the highest IR Drying safety and performance standards

KleenPlate 3.0 ®

print defect eliminator with auto plate washing

print defect eliminator

with auto plate washing

the highest UV curing safety and performance standards

precise ink temperature control

optimizing productivity and quality

®

®

JB MACHINERY

(+)1-203-544-0101 | Fax (+)1-203-544-0202 | 33 Riverside Ave, 4th floor | Westport, CT 06880 USA | jbmachinery.com

Member Profile

preventive maintenance using a simple Outlook task manager.” Touring Columbia’s orderly plant floor, the emphasis on good housekeeping is evident. “We employ lean manufacturing principles, particularly 5S,” Cole says. “We are constantly looking at process improvement, especially setup times.” The effort has paid off in supporting Columbia’s quick-turn-around customer satisfaction. Cole says his past experience has taught him what can be done with a dedicated and focused approach to process improvement. “I came from a three-shift integrated operation to a one-shift sheet plant,” he says. “I was asking myself, ‘How much could they be doing?’ ” Now, of his experience at Columbia he says, “It’s amazing how much we are putting through this plant and what we are getting done, day in and day out. I am proud to be a part of this team.” Christine Lee is Columbia’s customer service manager. She tells us she’s been with the company 13 years, adding, “with many more to come.” Lee is the linchpin in Columbia’s promise of quick turnaround and on-time delivery, a promise that starts with understanding and getting to know each account personally. “It’s all about knowing the story,” she says. “I sit down with our sales reps to help understand the ‘story’ on each account.” Lee says that this data collection process is the key to acquiring and keeping loyal customers. “A simple rule is that the more you know about the account and their specific needs, the better your chances of figuring out what will work for them and winning,” she says. “I ask a lot of questions: What are the issues? Where are their needs not being met? What are the three things they would change if they could?” Lee’s enthusiasm for the business is contagious: “It has been a joy working for a family-owned company and learning

34

BOXSCORE March/April 2021

about boxes,” she says. And acknowledging what industry veterans have long known, she adds, “Who knew boxes could be that interesting?” Lee and her three colleagues in Columbia’s customer service department, Cliff Mangle, Ashley Fama, and Shakara Alston, also profess what she calls one of their “core beliefs” of continuous improvement. “We never stop improving what we are doing and how we are doing it at each of our accounts,” she says. “We constructively challenge our production team, tooling vendors, sheet suppliers, and even our customers to improve our understanding so On the plant floor, Moynihan notes the daily setup we can improve our approach.” time numbers for Columbia’s 43" x 94" Emba two-color These practices inevitably lead to flexo folder gluer. what she says is “a happy ending for each story.” No member interview in the year “tremendous core” of talent with 2020 can ignore the effect of the keeping up with demand and keeping COVID health crisis. Corrugated customers satisfied. Yet Columbia, industry data in the fall of 2020 shows like many independents in the industry, a year-to-date increase in corrugated is struggling to find workers who are shipments of 2% or more over 2019, a willing to commit to the rigors of figure driven by online shopping and working in a fast-paced, ever-changing government stimulus actions to dampen environment like an independent the negative effects of various economic sheet plant. shutdowns. AICC members have with Moynihan and Cole rely on referrals near uniformity reported robust order to fill the gaps, offering monetary backlogs but also tightness of material incentives to employees, dependent on supply and increasing challenges in how long their new recruits remain recruiting and retaining workers. successfully on the job. They say they Columbia’s experience mirrors the had their best success recruiting from industry’s. “We’ve had a dramatic commercial printers and binderies, increase in sales in this year alone,” says which have similar job-shop processes Moynihan. “Our lead times are three or and order procedures. Cole believes four days, and we are four weeks into the key to finding and retaining good the addition of a second shift to keep up people, while challenging in today’s with the COVID demand. The second environment, is really very simple. shift has really helped keep our lead “Simply do what you say and say what times down.” you do,” he says. “Treat everyone with The company employs 53 people, dignity and respect. Word-of-mouth has and Moynihan credits what he calls a been huge for us. We have an employee

Serving AICC Members Serving AICC Members Since Since

2003 2003

AD

Da ttaa--Dri vven Solut utions ions Da Dri en,, Holis Holist tic ic Energ Energy Sol

Why y APPI APPI Energ Energy? Wh

APPI Energy

APPIEnergy EnergyisisAICC's AICC'sendorsed endorsed APPI energyconsultant, consultant,providing providingAICC AICC energy memberswith withaacomprehensive comprehensiveway way members reduceenergy energyexpenses expensesand and totoreduce minimizebudgetary budgetaryrisks. risks.Through Through minimize ourdata-driven data-drivenprocurement procurement our services,we wenegotiate negotiatewith withsuppliers suppliers services, ensureyou youare areprovided providedwith withideal ideal totoensure pricingand andcontract contractterms termsto tofit fityour your pricing services needs.Our Ourholistic holisticenergy energyservices needs. provide financially and functionally provide financially and functionally vetted solutions to decrease energy vetted solutions to decrease energy costs, reduce demand, and improve costs, reduce demand, and improve resiliency and sustainability. We are resiliency and sustainability. We are here as a true extension of your team. here as a true extension of your team.

800-520-6685 800-520-6685 appienerg y. com appienerg y. com

Decrease Energy Energy Costs Costs Minimize Budgetary Budgetary Risk Risk Increase Sustainability Increase Sustainability& & Efficiency Efficiency Contact Contact AICC's AICC's Dedicated DedicatedEnergy Energy Consultant, Carolyn Consultant, Carolyn Johnson, for your Johnson, for your complimentary complimentary assessment. assessment.

Member Profile “We do what we say we are going to do; if we fall short, we communicate proactively. We give outstanding service at a competitive price. We have forged long-term relationships with many of our customers, and as they have grown, so have we.” —Chris Saumell, sales manager, Columbia Container

incentive program where it pays to bring in good people, and this has been working very well for us.” As Moynihan sees it, recruiting and maintaining a high-quality workforce is one of the biggest challenges facing the industry today. “We feel our people are our biggest resource and that our employees have significantly contributed to our growth,” he says. Vision Ahead When we ask Moynihan and Swope about their future plans for Columbia, both agree that technology will drive the company forward while keeping their focus on maintaining short lead times. “As technology continues to impact our industry, choosing the right equipment is critical,” says Moynihan. Adds Swope, “We look at the direction the industry is going and look for strategic investment after our current machines are filled.” Like so many independent sheet plant owners, Moynihan and Swope have established their success on well-maintained used equipment selected to support the mission. “We are a brown box plant focused on expanding our offering and pushing into new markets,” says Moynihan. “Our investment in new equipment will never stop so we can ensure our ability

36

BOXSCORE March/April 2021