A PUBLICATION OF AICC, THE INDEPENDENT PACKAGING ASSOCIATION

May/June 2020 Volume 24, No. 3

REALITY SHOWS VR and AR technologies hold untapped potential for boxmakers and clients alike

ALSO INSIDE Focus on Security A Worldwide Whirlwind Members Meeting: E-Commerce Xperience

TABLE OF CONTENTS May/June 2020 • Volume 24, No. 3

COLUMNS

36 FEATURES

36

REALITY SHOWS VR and AR technologies hold untapped potential for boxmakers and clients alike

40

FOCUS ON SECURITY

40

Five critical areas toward fostering a strong safety culture at your facility

44

A WORLDWIDE WHIRLWIND Trade and pandemic concerns are among the greatest hindrances to the global supply chain

44

BoxScore is published bimonthly by AICC, The Independent Packaging Association, PO Box 25708, Alexandria, VA 22313, USA. Rates for reprints and permissions of articles printed are available upon request. The statements and opinions expressed herein are those of the individual authors and do not necessarily represent the views of AICC. The publisher reserves the right to accept or reject any editorial or advertising matter at its discretion. The publisher is not responsible for claims made by advertisers. POSTMASTER: Send change of address to BoxScore, AICC, PO Box 25708, Alexandria, VA 22313, USA. ©2020 AICC. All rights reserved.

3

CHAIRMAN’S MESSAGE

4

SCORING BOXES

6

LEGISLATIVE REPORT

10

MEMBERS MEETING

16

ASK RALPH

18

ASK TOM

20

SELLING TODAY

22

TACKLING TRENDS

24

ANDRAGOGY

26

LEADERSHIP

52

THE ASSOCIATE ADVANTAGE

54

WHAT THE TECH?

56

STRENGTH IN NUMBERS

64

THE FINAL SCORE

DEPARTMENTS

8

WELCOME, NEW & RETURNING MEMBERS

29

AICC INNOVATION

32

MEMBER PROFILE

60

ICPF UPDATE

Visit www.aiccboxscore.org for Member News and even more great columns. Scan the QR code to check them out! BOXSCORE www.aiccbox.org

1

OFFICERS Chairman: Jay Carman, StandFast Packaging Group, Carol Stream, Illinois First Vice Chairman: Gene Marino, Rusken Packaging Inc., Cullman, Alabama Vice Chairmen: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas Matt Davis, Packaging Express, Colorado Springs, Colorado Gary Brewer, Package Crafters, High Point, North Carolina Immediate Past Chairman: Joseph M. Palmeri, Jamestown Container Cos., Macedonia, Ohio Chairman, Past Chairmen’s Council: Al Hoodwin, Michigan City Paper Box, Michigan City, Indiana President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia Secretary/General Counsel: David P. Goch, Webster, Chamberlain & Bean, Washington, DC Counsel Emeritus: Paul H. Vishny, Esq., Chicago, Illinois AICC Canada Director: Rene Annis DIRECTORS West: David DeLine, DeLine Box Co., Denver, Colorado Southwest: Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma Southeast: Ben DeSollar, Sumter Packaging Corp., Sumter, South Carolina Midwest: Casey Shaw, Batavia Container Inc., Batavia, Illinois Great Lakes: Mike Schaefer,Tavens Packaging & Display, Bedford Heights, Ohio Northeast: Stuart Fenkel, McLean Packaging, Pennsauken, NJ AICC Canada: Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada AICC México: Pedro Aguirre Martinez, Tecnología de Cartón, Querétaro, México OVERSEAS DIRECTOR Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE Finn MacDonald, Independent II, Louisville, Kentucky Guy Ockerlund, OxBox, Addison, Illinois Kevin Ausburn, SMC Packaging Group, Springfield, Missouri Nelva Walz, Michigan City Paper Box, Michigan City, Indiana EMERGING LEADER DELEGATES Daniel Brettschneider, CST Systems, Kennesaw, Georgia Cassi Malone, Corrugated Supplies Co., LLC, Chicago, Illinois ASSOCIATE MEMBER DIRECTORS Chairman: Pat Szany, American Corrugated Machine Corp., Indian Trail, North Carolina Vice Chairman: Joseph Morelli, Huston Patterson Printers, Decatur, Illinois Secretary: Greg Jones, Sun Automation, Glen Arm, Maryland Associate Board Director: Tim Connell, A.G. Stacker Inc., Weyers Cave, Virginia Immediate Past Chairman, Associate Members: David Burgess, JB Machinery, Weston, Connecticut ADVISORS TO THE CHAIRMAN Greg Tucker, Bay Cities, Pico Rivera, California Jerry Frisch, Wasatch Container, North Salt Lake, Utah Pat Szany, American Corrugated Machine Corp., Indian Trail, North Carolina PUBLICATION STAFF Publisher: Michael D'Angelo, mdangelo@aiccbox.org Editor: Virginia Humphrey, vhumphrey@aiccbox.org

SUBMIT EDITORIAL IDEAS, NEWS & LETTERS TO: BoxScore@theYGSgroup.com CONTRIBUTORS Maria Frustaci, Director of Administration and Director of Latin America Cindy Huber, Director of Conventions & Meetings Chelsea May, Education and Training Manager Laura Mihalick, Senior Meeting Manager Patrick Moore, Member Relations Coordinator Taryn Pyle, Director of Training, Education & Professional Development Alyce Ryan, Marketing Manager Steve Young, Ambassador-at-Large Richard M. Flaherty, President, ICPF ADVERTISING Information: Virginia Humphrey, vhumphrey@aiccbox.org Opportunities: Taryn Pyle 703-535-1391 • tpyle@aiccbox.org AICC PO Box 25708 Alexandria, VA 22313 Phone 703-836-2422 Toll-free 877-836-2422 Fax 703-836-2795 www.aiccbox.org

EDITORIAL/DESIGN SERVICES The YGS Group • www.theYGSgroup.com Vice President: Serena L. Spiezio Content & Copy Director: Craig Lauer Managing Editor: Jessica Price Senior Managing Editor: Sam Hoffmeister Copy Editor: Steve Kennedy Art Director: Reynaldo Alvarado Account Manager: Max Lalwani

ABOUT AICC PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER PACKAGING INDUSTRY SINCE 1974 We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company and employees at all locations have access to member benefits. AICC offers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Chairman’s Message

Persevering Together

I

am so proud of my fellow boxmakers, our suppliers, and AICC, our Association. In the middle of March, events related to COVID-19 accelerated at an incredible rate. As we know, the virus itself grew exponentially both in the number of people afflicted and, sadly, in the number of people killed. Governments at all levels responded with varied and numerous orders, some following federal guidelines, others not, some even stretching the imagination if not the Constitution itself. Our boxmakers and suppliers were in most cases deemed “essential businesses,” although in some states, members had to fight for this designation. They did, and they were successful in keeping their doors open. It’s truly amazing how little politicians seem to understand about supply chains. Members responded to the demand to provide packaging products for food, produce, hygiene, medical, and pharmaceutical goods that must necessarily go to a now homebound populace. In the midst of the new realities brought on by the COVID-19 pandemic and the immediate demands to produce, members rose to the occasion, reassured their employees, took great lengths to ensure their safety, and created clever and flexible ways to accommodate the needs to produce with the needs of employees’ families and the changes wrought in their lives. The federal government responded with a number of programs meant to alleviate some of the uncertainty created by the situation, even for an essential business. I can tell you, it has not been easy to navigate through these programs—FFCRA, CARES Act, IRS changes, SBA PPP loans—but it is something that we have all done and continue to do as we don’t know yet what we don’t know about the coming months. There is so much uncertainty. Will increases in the above market sectors last? Will these increases offset decreases in orders from customers that have been deemed nonessential? Which direction will the economy go? Through all this tragedy, economic carnage, and uncertainty, we have all been there for each other. Many AICC members have produced personal protective equipment for their employees and for local care providers and have made these available to other members. We have shared best practices and helpful ideas with each other. We have provided emotional, mental, and humorous support to each other, because crisis leadership takes a toll, and we need to remain resilient. AICC, your Association, has been there for us as well. It has provided the forums necessary to facilitate so many of the exchanges among members, from a website page updated daily with the information members need to make decisions to a weekly video conference in which you, the members, are the educators. AICC has provided webinars on the relief legislation, HR issues, and business planning. It has created an online community board where members can exchange experiences, ask questions, and provide answers and guidance. AICC will continue to adapt and create—just as we all will. Stay well.

Jay Carman President, StandFast Packaging Group Chairman, AICC

BOXSCORE www.aiccbox.org

3

Scoring Boxes

Other Uses of Containerboard BY DICK STORAT

I

4

BOXSCORE May/June 2020

UID

400

Unidentified Uses of Containerboard

350 Three-year average = 150,000 tons/month

300 250 200 (000 Tons)

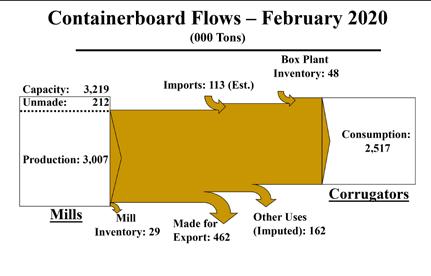

n this article, we will discuss domestic uses of containerboard other than that corrugated by America’s boxmakers. For orientation, the graphic at top right displays graphically the flows of containerboard for the month of February 2020. While the specific numbers will of course change from month to month, the overall pattern remains pretty much the same. The left side of the graphic shows mill production, which in February amounted to just over 3 million tons. Of the total production, some may go to inventory at mills, which amounted to 29,000 tons in February. A substantial fraction of production is made for export and shown as an outflow of 462,000 tons in the diagram. In February, that amounted to 15% of the total U.S. production, mainly unbleached kraft linerboard grades, some 20% of which is exported monthly. Imports, mostly from Canada, account for about 4%–5% of monthly consumption. Also, containerboard held in inventory at box plants can contribute to corrugated volume. In February, 48,000 tons of box plant inventory contributed 1.9% of the 2.517 million tons consumed by corrugators during the month. The remaining 2.356 million tons of February’s corrugated volume was supplied by domestic containerboard mills, amounting to 93.6% of February’s consumption and 78% of production. On top of containerboard that is converted in the U.S., there are uses of containerboard that do not involve corrugation. These are not reported but imputed as the remainder of board produced by mills after adjustment for inventory change and trade flows. It is labeled as “Other Uses” in the top graphic.

150 100 50 0 -50

-100 -150

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

Source: AF&PA, FBA, RSA

2018

2019

2020

In February, these other uses amounted Page 1accounted for in statistical reports. Over time, these other uses amount to about to 162,000 tons, or 5.4% of monthly 150,000 tons per month, and they track containerboard production. These can be with what some industry observers believe considered in several distinct categories. the actual other uses to be. The first and largest category is actual While these other uses have remained uses of linerboard or medium. The full fairly constant over multiyear periods, spectrum of uses for which linerboard the monthly swings can be quite volatile, and medium are needed is broad, if not

Scoring Boxes

as the bottom chart shows. It plots the monthly imputed other uses of containerboard for the past 26 months ending in February 2020. The bold line indicating 150,000 tons per year is the monthly other uses averaged over the past three years. This averaging eliminates the wide monthly swings. While some of the remaining variability is part of normal swings in short-term demand for containerboard to be used without corrugation, other factors are involved. Monthly inventory statistics supplied by mills and box plants do not include containerboard that is in transit on rail cars or trucks between the mills and box plants. If the volume in transit does not change significantly, there will be no effect on other uses. However, if the amount of board in transit rises or falls compared to the prior month, that change in in-transit

containerboard will be accounted for as an additional use or source of containerboard. Changes from the amount of containerboard initially reported by mills as being made for export will also impact the amount of other uses. If an amount of mill production is reported as made for export but is subsequently diverted to domestic usage at box plants, it will also show up as additional corrugator production and a reduction to other uses. Sometimes, inventories are more completely counted at the end of a fiscal quarter or year. When that additional inventory “reenters the statistical reporting system,” it will show up as a reduction of other uses. If the more exhaustive counting of inventory yields a sufficient increase of mill or containerboard stocks, the imputed other uses of containerboard

ROLLERLESS

SURFACE

Our mesh ball bundle conveyor is a must for load-forming operations, allowing transfer rates of 20+ bundles per minute. Call today; let us solve your toughest problem.

Leading supplier to the corrugated box industry

812-558-7960 • sales@cmconveyor.com www.cmconveyor.com

can become negative, providing another source of containerboard for corrugators. Understanding the behavior of the imputed other uses of containerboard can be helpful in assessing the relative market balance between supply and demand. For example, evaluating one month’s rise in other uses as future additional rollstock likely to show up in the box plants’ reporting would lead to an assessment that there is more unconverted containerboard supply than may be assessed from the mill and box plant inventory levels alone. Dick Storat is president of Richard Storat & Associates. He can be reached at 610-282-6033 or storatre@aol.com.

WIN THE WAR ON DUST

The Dust Wizard is an ambient air dust cleaner for the removal of dust contamination where direct source capture is difficult, such as converting equipment, baler or shredder. Creates a healthier, more productive work environment with clean air.

MORE THAN AIR SYSTEMS 216.681.7379 • sales@obpairsystems.com www.obpairsystems.com/dust-wizard/

BOXSCORE www.aiccbox.org

5

Legislative Report

Bring Manufacturing Back! BY ERIC ELGIN

I

’m writing this during the height of the COVID-19 pandemic when our economy, in the interest of preventing the spread of the outbreak, is in a state of suspended animation. Thankfully, most if not all of us in the corrugated and paperboard industries are considered to be part of the essential infrastructure feeding our supply chains for critical food, pharmaceutical, and medical stocks. We are fortunate to still be working, albeit with heightened sanitation and preventive measures in place. One of the messages I’ve heard through all the noise of the nonstop reporting is how we have jeopardized our ability to fight this pandemic by our overreliance on foreign suppliers—in this case, pharmaceutical suppliers overseas. President Donald Trump, in one of the press briefings for his Coronavirus Task Force, said that the coronavirus crisis has taught our country that “we can never again be dependent on a foreign country for our vital supplies.” The president, in this case, was referring to supplies of critical strategic materials. However, if we honestly consider this lesson, we can see how we in North America have become “addicted”—if I can use that term—to a ready supply of cheap imported nondurable goods, most of which are readily available through the many online e-commerce platforms that we have become used to using every day in our homes and businesses. In saying all this, I think that a silver lining of the coronavirus crisis could very well be a movement of key strategic manufacturing and material sourcing back to North American shores. Back in 2003, Jay Wertheimer, president of Wertheimer Box in Chicago, was chairman of AICC.

6

BOXSCORE May/June 2020

During his year as chairman, Wertheimer championed a theme for AICC and our industry: “Make it in America!” This battle cry was in response to what we were seeing then as the mass exodus of manufacturing to lower-cost manufacturing environments in Latin America and Asia. Our government affairs efforts were reborn in those days, when we began our annual Washington Fly-In to ask AICC members to come to Washington, D.C., to plead with their representatives in Congress to repair this exodus by embracing a pro-manufacturing economy that encourages manufacturers to remain and do business on our shores. Our success has been mixed at best, and only in recent years have tax and regulatory policies begun to favor the manufacturing sector

again. Our box business is dependent on a robust manufacturing base, so we have a vital interest in this message. I do not know what situation we will be in by the time this column arrives in your hands, but let us hope that once this COVID-19 crisis is behind us, we can soberly assess the importance of a strong, sustainable, and North American manufacturing economy and say, “Bring manufacturing back!” Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com.

New Members

Welcome, New & Returning Members! FOSTER PRINTING KRIS BLACKBURN Vice President of Sales 700 E. Alton Ave. Santa Ana, CA 92705 Phone: 714-731-2000 www.fosterprint.com ROXCEL CORPORATION CARLA BUFORD Sales Operations Specialist 1326 Haywood Rd. Suite 201 Greenville, SC 29615 Phone: 864-434-7616 www.roxcel.com

MY PRESS NEEDS LLC ROBERT WEIDHAAS Founder 3001 N. Rocky Point Drive E. Suite 200 Tampa, FL 33607 Phone: 856-728-5090 www.mypressneeds.com PACKAGING SERVICES INDUSTRIES BECKY KLINE Human Resources Manager 16461 Elliott Parkway Williamsport, MD 21795 Phone: 301-223-6200 www.psimd.com

ST. WORTH CONTAINER INC. CHRISTOPHER CAMARENO Chief Operating Officer 727 S. Wannamaker Ave. Ontario, CA 91761 Phone: 909-390-4550 www.stworth.com BALDWIN TECHNOLOGY DANIEL GILMAN Account Manager 40 Glendale Ave. Hinsdale, IL 60521 Phone: 773-896-6060 www.baldwintech.com

MEASURE MANUFACTURER’S GAP FROM THE BUNDLE WITH

GAPCHEK

LEAD GAP

TRAIL GAP

GapChek™, the latest corrugated vision system from Valco Melton’s ClearVision division, moves the measurement point to the bundle so that the lead and trail gaps are measured on finished boxes. GapChek displays live measurements of each gap and per-bundle averages with statistical process control charts on-screen Users can look at per-job and per-box gap data and analyze historical trends for certain box designs or customers.

8

BOXSCORE May/June 2020

Adhesive Dispensing & Quality Inspection Systems World HQ: +1.513.874.6550 | ask@valcomelton.com For more information visit: www.valcomelton.com

Allies in

Productivity Automate your line and improve efficiency with robotic loadformers by Alliance. Raptor XR –High-speed flexos –Rotary die cutters –Specialty gluers Raven –Medium-speed, 50-inch flexos

Watch the video! alliancellc.com/raptor-diecut

alliancellc.com | 509-535-0356

Members Meeting

Opportunities and Challenges for Corrugated in the E-Commerce Economy BY STEVE YOUNG

E-Commerce: an Opportunity for Corrugated The sessions opened by offering a view of the total e-commerce economy and an outlook for its growth in the years ahead. Ron Sasine, a principal in the consulting firm of Hudson Windsor LLP, presented a positive picture of a corrugated industry that, although 2019 saw its growth slacken from the previous three years, will continue to benefit from the growth in online retail sales. The caveat, he said, was that this benefit will be reserved for those companies in the industry with the “best assets and best operations.” Every year, online sales capture a greater percentage of the $3.8 trillion U.S. retail sales market. According to Statista, in 2013, 6% of all retail sales were online; in 2019 the figure was 11%, or $546 billion, and by 2023 it is forecast to be nearly 14%, or $740 billion. Sasine reported that the e-commerce sales of major consumer packaged goods, or CPG, companies are growing at five times the rate of conventional retail sales and are expected to double by 2024. Sasine predicted that online grocery sales would be a major driver in the demand for corrugated packaging. He made the case for this by showing how

10

BOXSCORE May/June 2020

buying a book four times a year online from Amazon will result in the use of four five-panel corrugated folders. On the other hand, online grocery purchases made through Amazon’s Pantry unit or from retailers such as Walmart or Target require several boxes every week for 52 weeks. Grocery items, Sasine said, are “bulky, inexpensive, and low-margin” and are not suitable to Amazon’s ship-in-own-container (SIOC) guidelines. As a result, Sasine predicted that as e-commerce sales grow, consumption of corrugated packaging will increase. ‘The Future of Amazon’ Disclosed Brent Lindberg, CEO of Fuseneo, gave an insightful presentation on “The Future of Amazon.” Fuseneo’s focus is to help clients improve their packaging, minimize unnecessary material consumption, and thereby better conform to the new rigors of the online sales platforms. Amazon, the largest digitally native online sales platform, last year captured upward of 47% of all those online sales; its closest competitor, eBay, trailed at 6%. Because Amazon dominates this market, it exerts the lion’s share of influence in setting new packaging guidelines for brands wishing to sell through its platform. These standards, also known as “frustration-free packaging,” include new requirements on design and ease of use, both for the online fulfillment and distribution system and for the end-use customer. Lindberg explained that Amazon’s standards look at packaging in three tiers; all three tiers consider the level of handling that must be done in

Spring Meeting Supplier Innovations are located at aiccbox.org/SI2020

Photos courtesy of AICC

A

ICC’s E-Commerce Xperience, which took place February 18–20 in Irving, Texas, brought together brand owners, packaging designers, converters, and suppliers for a comprehensive look at the e-commerce economy and how it will affect the corrugated industry. More than 150 AICC members and industry experts attended.

Ron Sasine of Hudson Windsor presented “The Future of Corrugated: Everything Depends on It” at AICC’s E-Commerce Xperience.

Amazon’s distribution centers and on the customer’s doorstep. Tier one requires that packaging products arriving at the customer’s door be curbside-recyclable where those programs exist. The second tier requires vendor products to SIOC (ship in own container). Neither tier one nor tier two requires any additional packaging modification, or “overboxing,” by Amazon. Tier three products require some sort of preparation or overboxing to prevent damage or to allow oddsized items to ship more easily through the distribution system, and Amazon currently charges vendors up to $1.99 per

Members Meeting

Brent Lindberg of Fuseneo presented an overview of Amazon’s changing packaging requirements for products sold through their platform.

item for products that must be prepped for shipping in this way. Lindberg told the AICC audience that Amazon is putting increasing pressure on brands to conform to Amazon’s packaging protocols by requiring International Safe Transit Association-6 (ISTA-6) SIOC test certification for items shipping in their own container. For those items requiring additional product preparation, brands are simply paying the per-item penalty. “They consider paying the Amazon penalties a cost of doing business,” Lindberg said, adding that it’s more difficult to retool their own packaging lines to meet the Amazon standards than it is to pay the penalties. In the final analysis, Amazon is a data company, employing internal Amazon Serial Identification Numbers, or ASINs, to track every item through its fulfillment and distribution hubs. Through this data collection, the company is fine-tuning its packaging guidelines to ensure smoother flow

through its automatic sorting and labeling lines. Through a series of illustrations, Lindberg showed how Amazon determines whether an item meets overboxing or SIOC requirements by using dimensions and product weight. Amazon’s stated goal to become carbon neutral by 2030 means it continues to refine its packaging and shipping methods, utilizing lighter-weight flexible mailers and padded envelopes. While these moves will reduce the company’s corrugated consumption for many items, Lindberg said, corrugated packaging will continue to make up the largest portion of materials used in Amazon shipping. To blunt public criticism of “the box that’s too big,” Lindberg said, some brands are using the box as a way to “delight the customer.” He pointed to examples of brands that have used graphics to suggest that the box has utility beyond a shipping medium—a yoga mat or a child’s toy, for example—to shift consumer perception.

A Brand’s Perspective: What’s the E-Commerce Packaging Sweet Spot? Jared Butts is senior manager of e-commerce supply chain for The Hershey Company. Butts’ presentation, “Understanding Packaging in E-Commerce Process,” focused on how major brands such as The Hershey Company view the various channels through which their product is sold, from retail to e-commerce platforms, and how the differing characteristics of these channels affect their packaging decisions. Butts first defined e-commerce, saying that “e-commerce is the conversion of sales on online platforms,” distinguishing it from simply “digital,” meaning sales through online platforms, or “omnichannel,” meaning sales through direct and third-party online platforms and traditional retail stores. He further defined e-commerce as “an integral piece of the digital and omnichannel experience.” Major consumer brands such as Hershey’s Kisses rely on such

BOXSCORE www.aiccbox.org

11

Members Meeting

Jared Butts of The Hershey Company was one of several major brand owners talking about their packaging challenges in the e-commerce economy.

omnichannel sales, Butts said. The company has: its own website, hersheys. com, a business-to-consumer site; retail platforms in traditional retailers such as Target, Walmart, and Kroger; and thirdparty digitally native platforms such as Amazon and Candy.com. To meet packaging requirements of the major brands selling across e-commerce platforms, Butts set out four basic principles to govern e-commerce packaging: 1. Design: Keeping it simple, as most manufacturers are concerned first with cost. 2. Dimensions: Optimizing dimensions saves cost through the distribution and fulfillment system. 3. Dunnage: Don’t use plastic fill or foam peanuts, as the interim user may be in a fulfillment or distribution center. 4. Disposal: Is it easy for the consumer to break down and recycle?

12

BOXSCORE May/June 2020

Ultimately, Butts said, it’s important for suppliers of packaging to end users whose products are being sold through e-commerce channels to understand the product—is it premium or not?—to understand the channel through which it’s sold, and to understand the nature of the distribution and fulfillment environment—whether the item requires special handling on the part of the e-commerce platform. Understand the Stakeholders in Your Customer’s E-Commerce World Joe Fernandez is the senior packaging engineer for handbag maker Vera Bradley. In this capacity, he manages the brand’s catalog of e-commerce and retail packaging, which deals with movement of the company’s goods in all stages of manufacturing and distribution. In his presentation to the E-Commerce Xperience audience, he addressed the packaging challenges brands

face and the kinds of design solutions that will appeal to internal stakeholders. According to Fernandez, there are three principal stakeholders in major brands such as Vera Bradley: procurement, operations, and marketing. He described the procurement department as the “bridge to other stakeholders.” While they are primarily cost-driven, they also are the receiving point for the stated needs of operations and marketing departments. As a result, Fernandez said, bringing cost-savings solutions—ones that reduce packaging materials or weight or can consolidate the number of various designs—is the best approach. A brand’s operations department is the next stakeholder that packaging manufacturers need to reach. He focused on the new norms of online buying, such as two-day shipping and the rise of highly automated distribution centers. These new norms present opportunities for

In times of uncertainty, you need to know you have suppliers you can rely on. ND Paper is your supplier of choice for all your pulp, paper, and now packaging needs. Our proud heritage in papermaking spans more than 100 years in resource-rich Maine, Wisconsin and West Virginia. Our paper products boast a well-earned reputation for durability, dependability and consistent performance for a wide variety of applications. Our newly rebuilt paper machine is ready to meet your containerboard needs. It joins our renowned printing and specialty papers to provide a variety of optimal product solutions for your evolving business needs – ensuring your operations perform at maximum efficiency. ND Paper offers a full range of liner and medium products to fit a variety of corrugated board combinations. We are investing in our mills to ensure we can continue serving as your supplier of choice, now and for the next 100 years.

Sustainable paper for everyday life. Learn more about ND Paper products and our 100-year outlook at us.ndpaper.com.

Members Meeting

well-designed packaging to “save seconds” in the fulfillment of each order. He also said that user-friendly box designs are important to workers in distribution and fulfillment centers. “A happy employee is part of your solution,” he said. Finally, he touched on the brand’s marketing department and spelled out what keeps them up at night. First, “What do customers think of our brand?” Second, “Is our design consistent?” And third, “How do we communicate the sustainability of our brand?” In answering these questions, Fernandez said that packaging that fits the brand in terms of shape, color, and quality are the principal design solutions that brands will look for. He said that social media presented special challenges in the rise of so-called “unboxing” videos in which brands are highlighted. Fernandez caused a bit of controversy among the attendees at the E-Commerce Xperience by saying that Vera Bradley had done away with much of graphics associated with their e-commerce packaging, adding that the product itself is the focal point and that the company found no change in consumer buying habits when it reduced graphics and shipped the product in a plain box. After a spirited exchange on this question, he allowed that they may be open in the future to considering a change. AICC’s E-Commerce Xperience is part of AICC’s annual “Xperience” series, which focuses on industry-specific issues and trends. Watch for more articles from AICC’s E-Commerce Xperience and other Xperience events in future issues of BoxScore. Steve Young is AICC’s ambassador-at-large. He can be reached at 202-297-0583 or syoung@ aiccbox.org.

14

BOXSCORE May/June 2020

Joe Fernandez of Vera Bradley told AICC’s audience that graphics are not a priority in their e-commerce packaging.

OTHER SPEAKERS, TOPICS AT AICC’S E-COMMERCE XPERIENCE AICC’s E-Commerce Xperience featured many more speakers and topics than those highlighted in this article. We will feature some of these in future editions of BoxScore and as new developments emerge in the e-commerce economy. Thanks to the following members and guest speakers:

• Mark Mathes, Vanguard Packaging • Sarah Meiburg, Paper & Packaging Board • Tania Montesi, H.B. Fuller • Michael Pelletier, Scaling Operations LLC • George Perreira, Whitebird

• Miriam Brafman, Packlane

• Olivia Pietersen, The Packaging Co.

• Richard Brown, The Boxmaker

• Stephen Shannon, HP

• Abby Byland, Dusobox

• Robert Stabler, Koenig & Bauer Durst

• Paul Chambers, Subscription Trade Association • Lauren Frisch, Wasatch Container and Box Essentials

We are grateful to our sponsors & supporters: • Koenig & Bauer | Durst

• Jesse Genet, Lumi

• Poteet Printing Systems

• R. Andrew Hurley, Ph.D., Clemson University

• HP

• Lawrence Ingrassia, Henry Holt & Co.

• Huston Patterson

• Paul Jarrett, Bulu Box

• American Carton Company

• Richard Kelley, Dusobox

• Harris Packaging

• Liz Logue, EFI

• SUBTA, Subscription Trade Association

• Tilia Labs

Ask Ralph

Updating Educational Resources BY RALPH YOUNG

Y

our Association never fails to bring new, relevant, and updated materials to help you be more successful. We also see this responsibility as speed to market, as we often have a heightened sense of urgency to keep the most pertinent information before you as soon as possible. This is our No. 1 priority.

Sources While the AICC staff offers many news feeds across a broad range of subjects and international markets for the AICC InBox newsletter, another resource you may want to pull up is www.aiccbox.org/ rules, which houses a list that summarizes the organizations and government entities that currently or in the future may have an impact upon your business. If you have anything to add, we would like to hear back from you. Not that I am the gatekeeper, but with more than 100,000 hits and more than 350 followers, also look to the Ask Ralph blog resource as a key to open the network of fellow career experts on your behalf. For example, we frequently receive inquiries about warp. The blog community is there to help you determine whether the warp issues you are experiencing are related to moisture, improper starch, starch application, stresses introduced into the liners during the corrugating process by the pulling sections, or cross-direction and machine-direction tensile strength differences induced in the liners at the paper mill. During our Corrugated Packaging Essentials seminars, there is a short investigation segment into how to select the most cost-effective combinations of containerboards to engineer a 44 ECT.

16

BOXSCORE May/June 2020

While we do not know how you currently choose the linerboards and mediums to produce this combined board grade, the margin gap from a more historical method to a more “balanced” method can be a difference of 25% in cost. Lately, we have seen that the most cost-effective method of constructing a 32# ECT minimum can be with a 29/26C/29 structure fibered with 100% OCC. What’s New? We have released the third edition of Understanding the Key Characteristics of Linerboard, avaialble at www.aiccbox. org/store, which focuses on obtaining the highest-quality linerboard and corrugating medium for the purchasing dollar. At the end is your opportunity to download a template page to use with your suppliers to compare characteristics of the containerboards in the marketplace. You now have the option to evaluate your internal or external sheet and containerboard suppliers. American Forest and Paper Association and TAPPI have been very cooperative at providing selective data for us for each of the three editions. We would labor in vain without their assistance. In this revised third edition, the characteristics of 23# and below are delineated. These grades and characteristics are from my personal resources, as the AF&PA does not collect data on these emerging elements of linerboard and medium production. However, these grades are available and are being used. Our goal is that this brochure will become a valuable resource to AICC Emerging Leaders and Leadership Development Groups. Looking at e-commerce and digital printing, one may need to investigate

both the strength characteristics and the surface properties of these individual substrates. While digital ink transfer is relatively indifferent to surface smoothness, roughness, and hardness, nanotechnology is even more forgiving than today’s digital. We have two installations in North America, and more are expected. Sustainability has entered fiber-based packaging, and we are well equipped with options in choosing a variety of different containerboard combinations at different cost points to meet known packaging needs. While not part of this particular document, we can usually answer your questions about greenhouse gases, ocean plastics, carbon sequestering, carbon footprint, and life cycle analysis. Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@aiccbox.org.

Ask Tom

Blister Packaging, Part 1 BY TOM WEBER

G

o into any department store, grocery store, or convenience store across the globe—staying six feet apart and wearing a mask, of course— and one of the first things that will draw your eye is the products on display in blister packaging. You’re no doubt familiar with them: thin plastic bubbles mounted to highly decorated paperboard, designed to showcase the products they contain. There are many reasons blister packaging is so popular. It is unparalleled

18

BOXSCORE May/June 2020

at highlighting the enclosed product, often augmenting its contents with attention-grabbing design and colorful graphics. Blister packages put the actual product the consumer will buy in clear view at the point of purchase, helping to generate or confirm buying interest. For manufacturers, blister packaging can be a relatively simple and economical way to get products in front of consumers. They can also help protect the product when it’s on display and when

it’s in transit. Consumer product manufacturers considering using blister packaging for their products should take into account a number of factors that can impact how effective the packaging will be, both from a marketing and an economic standpoint. Here are a few considerations you’ll want to keep in mind when determining what kind of blister packaging and blister card composition may be right for your products.

Ask Tom

What Are the Main Types of Blister Packaging? Blister packages encompass a wide range of packaging options for a host of products found in consumer goods, pharmaceuticals, and food-service applications, to name just a few. When it comes to consumer goods, there are four primary types of packaging: top-of-card or face seal, card-to-card (two pieces), fold-over card (one piece), and hinged blisters, commonly called “clamshells.” For our purposes, we’ll focus on the two types that feature polyvinyl chloride (more commonly known as PVC), polyethylene terephthalate (PET), and recycled PET plastic blisters mounted to blister card stock: • Top-of-card. The card is printed and top-coated with a heat-seal adhesive, and the plastic blister is sealed to the print surface. This type of card is the original blister package configuration and has been used in many high-volume small-part packages. The problem with this kind of blister card is the amount of manufacturing steps that may be required to coat the preprinted sheets. • Card-to-card. Also known as frontand-back cards, these are blister packs that consist of two separate cards that are bonded together to sandwich the plastic blister flange between them. In

this process, the heat seal is applied to the paperboard on the paperboard’s backside, most of the time requiring a C2S type of blister stock to control the blister coating holdout to ensure adequate adhesion is maintained. • Fold-over card. Fold-over card packages consist of a single longer card that is folded over at the midpoint to trap the plastic blister between the two sections. In this process, the heatseal blister coating is again applied to the backside using a C2S grade of blister paperboard. • Hinged blisters. Hinged blisters are completely plastic and typically consist of one plastic blister folded over and are often heat-fused at the edge. They can be difficult to open, usually requiring a knife or a pair of scissors. While this resistance to opening may help reduce shoplifting at the point of purchase, it tends to also result in frustration as we consumers struggle to get them open. (There’s even a name for this frustration: “wrap rage.”) For What Products Are Blister Packages Best Suited? The versatility of blister packages makes them an appealing option for a very diverse array of products. They are particularly well suited to small higher-value

consumer goods, products that consumers want to visually examine. Blister packages are also a great option for products that may have an unusual shape and thus are not good candidates for a folding carton package; plastic blisters can be formed into almost any shape, and blister cards allow them to be hung with a point-of-purchase display or racked for high-visibility display anywhere in the retail establishment, regardless of how asymmetrical the product may be. The rack or hanger holes are easily movable to determine the exact center of gravity of almost any product configuration, which also lends itself to an ease of use and display at the retail level. As important as choosing the right blister package for the right product is choosing the best materials and coatings for blister packaging. In the next issue of BoxScore, I’ll break down these factors and even offer insight into recyclability and testing procedures associated with blister packaging, all to ensure the best possible utilization of this viable packaging option. Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@aiccbox.org.

BOXSCORE www.aiccbox.org

19

Selling Today

Understanding the Length of Your Sales Cycle BY TODD M. ZIELINSKI AND LISA BENSON

T

he sales cycle is undoubtedly one of the most critical metrics a company can measure. Without a clear picture of your sales cycle, accurately forecasting sales and growth becomes nearly impossible. Many factors can impact the length of your sales cycle. Some impacts may be seen right away, such as those created by the current economy or new and competing technologies and products, while others occur over time, such as changes in the way people buy. It goes without saying that the length of the sales cycle can be fluid, and monitoring and measuring your sales cycle must be an active and ongoing process.

Process Is Imperative Even beyond the fluidity of it, the sales cycle is a complex creature. The first step to understanding your sales cycle is to have a clear process that your organization follows consistently. What are the steps in your sales cycle? How do you define the beginning of the sales cycle? Is it when you first enter it into your CRM, at first touch, or at some other point? Consider how your company treats potential leads. If you are dumping trade show leads or purchased lists into your CRM but you’re not doing anything with them, using “entry into CRM” as a starting point will skew your data. A side note on using a CRM: You will find tracking your sales cycle becomes effortless when it is used consistently by the entire sales staff. Implementing a process that dictates that leads are entered into the CRM and followed through the sales pipeline will make tracking your

20

BOXSCORE May/June 2020

sales cycle much easier. It will provide transparency and efficiency and allow salespeople to prioritize opportunities, potentially shortening the sales cycle. Accurate Data and Expectations Many companies have an inaccurate perception of their sales cycles because they are not analyzing the data in a way that creates appropriate expectations. If your sales goals include closing large sales, make sure you’re looking at data from large sales. Orders from current customers are typically the fastest to close. You’ve built relationships, they are familiar with you, and they are in your systems already. If included, these can make your new-business sales cycle appear artificially compressed. Smaller and one-off sales will typically close faster than larger sales. However, if you are looking for six- or seven-figure repetitive deals, you will need to have patience and understand the process can be lengthy. Make sure you are comparing apples to apples.

If you are trying to understand how long your sales cycle is for new business that fits your target-market profile, look at those types of deals independently of others to get a true sense. Sometimes a really large deal will come out of nowhere and close quickly because the company had an immediate critical need. Those don’t happen regularly and should be considered anomalies. Closing the Whales Takes Time Most companies are fishing for whales— those big six- or seven-figure accounts that repeat annually. Not only do these types of deals take time, but they also take work. If you are new to an industry or territory, it will take time to educate the market. You will need to have a plan for doing this, which may include content creation, social media, inbound marketing, SEO efforts, outbound marketing, etc. If you have been tracking data, you should have a good idea of how many touches it will take to convert a lead.

nilox If you are trying to wedge out an existing vendor, you will have to do some digging to find cracks in the relationship. What issues are they having with the current vendor? Is there an opportunity for you to relieve this pain? Even if you lose the first quote, keep trying. Sometimes, you may get a small job as a test, and you will have to prove yourself before you get the full opportunity. From our experience, it takes an average of six to 12-plus months to convert new prospects for large brown-box orders and six to 18-plus for point-of-purchase display orders. One key point is that there is a need for constant communication and scheduling of the next steps before ending a meeting with a prospect. For our packaging clients, it takes 15–20 touches (calls, emails, voicemails, direct mail) to get the first appointment, and it can easily take that long to get to the next step of the sales cycle if the next steps are not identified and scheduled before ending the initial meeting. The key to accurately forecasting your sales and achieving the growth your company desires lies in understanding your sales cycle by having a process in place for it, ensuring your organization is consistent with using it, measuring key metrics, and most of all, having patience. Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com.

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com.

BOXSCORE www.aiccbox.org

21

Tackling Trends

Things Change BY JOHN CLARK

M

any new cars now come equipped with satellite GPS dashboards that show you the best route from point A to point B. For most of us, it is rarely necessary to turn it on, as we mostly drive the same routes all the time—to work, to school, to the store—normal places we go to again and again. Sometime for fun, punch in a destination and a route you have driven hundreds of times, and see the results. Most times the optimum route selected by the navigation system takes you the way you always go. But every now and then, you find out there was a better route that you never knew about. Usually the time-savings would be minor and hardly worth noting. Occasionally, the new route is a real time-saver, but if you are like most people, you stay with what you know and avoid the change. We prefer what is familiar over change. Today, everything has changed with the advent of the coronavirus. Nothing is familiar. Our lives are off-kilter. Most everyone was caught flat-footed. Few companies had contingency plans for a pandemic with no remedy in sight. Schools are closed, businesses are shuttered, travel is disrupted or abandoned, and the phrase “social distancing” is now actually part of our lexicon. World War II did not stop baseball. This year, there is a very strong possibility that the full season may be called off. Restaurants are closed, airplanes are nearly empty, colleges have dismissed early, and the American lifestyle has been altered beyond recognition.

Rethinking Your Business The packaging industry was granted a waiver by the federal government

22

BOXSCORE May/June 2020

to continue operating its plants and producing products. It was deemed critical to the economy for the packaging companies to keep running for fear the entire economy would collapse without shipping containers. The plants are producing, goods are flowing, but for how long? What happens if someone on your staff becomes infected? Working from home is a viable solution for many information workers, but there is no such option for the machine operators, mechanics, drivers, and dozens of other positions in a converting plant. You can’t take your rotary die cutter and work from home. Those of us who have spent time in the plants and understand how things really work may have a different view of priorities as opposed to those who have to manage the bottom line. If the president of a company does not show up to work, his absence has minimal impact on the daily production. If his baler operator walks out of the plant, the company is paralyzed in a matter of hours. We have to reexamine and rethink the enterprise. Cross-training, continuing education, seminars, and documentation are helpful in this regard, but there is no substitute for hands-on experience in every aspect of the business. Every Marine a Rifleman The U.S. Marines are the pointed end of the sword when bad things happen. They are the among the most respected military services in the world. Every Marine, ranking from private to general is, at their core, a rifleman. They pride themselves on that capability. Regardless of rank or station, a Marine will do what is required.

If you work in the packaging industry, regardless of your position or job title, at your core, you are a boxmaker—and if you are not, you should learn. Every member of the staff should know exactly what each machine’s purpose is and how it works. Each person in the office should spend time in the plant— working, not watching—to understand how the business and machinery work and how all the pieces come together. Plant staff should spend time in the office to understand all the work that is done upfront, so that when the order hits the machines, everything is carefully defined and measured to ensure that every order runs perfectly. And it sure would not hurt if some of the executives learned how to drive a forklift and work a second or third shift sometimes to hone their skills. Keep the Troops Engaged Though modern machines are amazingly automated, your staff is not. They need to know they are important; they need to know that they are valued and respected. They need to know the sacrifice is shared among all members on the staff equally. We all hope this pandemic ends soon. But the values of shared sacrifice, cross-department training, and management engagement on the factory floor should be values that continue far past our current challenges. John Clark is director of analytics at Amtech Software. He can be reached at jclark@ amtechsoftware.com.

Andragogy

Investing in Your Future Is Wise BY JULIE RICE SUGGS, PH.D.

From left: Kristy Marques, client services representative; Alain Mayhew, account manager; Tim Burgess, structural designer; Caroline Scholz, client services representative; Connie Murray, graphic designer; and Keith Rae, structural designer, pose in front of Moore Packaging’s Core Values Wall with their Packaging School certificates.

“I

am confident much will come from Julie, and investing in her future is wise.” This is one of the best endorsements I’ve seen for a student in a recommendation letter. R. Andrew Hurley, Ph.D., packaging science professor at Clemson University, co-founder of The Packaging School, and incidentally, my mentor, once used this in a reference for me. I have since copied the sentence in every recommendation letter I write for others. Now working in the field of packaging education, I’ve often pondered the meaning of “investing in their future” from a company viewpoint. Of course, it means giving an applicant the chance to work at said company, but I think there’s a lot more to it than that. Getting the job is obviously the first step, but what about keeping the job and growing into the role? “Tell me, and I forget. Teach me, and I may remember. Involve me, and I learn,” Benjamin Franklin once said. Involving an employee in learning stems from a company’s desire to invest in their

24

BOXSCORE May/June 2020

future—both the employee’s and the company’s. Employee training and development becomes the path for investing in that future. Let’s look at some of the ways this plays out. Education is critical to growth, and online learning beyond traditional brick-and-mortar school walls is a great way to receive education in today’s world. Research has shown that employee education can increase development and self-esteem. When employees feel like they are contributing to their company, they have a profound sense of value, which in turn boosts their confidence in the workplace. Likewise, it increases their productivity, adding vast benefits to a company. And education can help foster productivity by allowing employees to acquire a wider range of skills. If people learn best when they feel challenged and pushed out of their comfort zone to learn something new, don’t you think it’s a good idea to further their education? Another benefit to investing in an employee’s ongoing education is a lower

turnover rate within the company. Deloitte, a multinational professional services network, has done extensive research on this topic. They found that employees feel more empowered and appreciated when companies invest in them, thus increasing their loyalty to the company. Not to mention the fact that hiring new employees is often more expensive than maintaining existing employees, even when investing in their training. This type of putting-out-what-you-hopeto-get-back investment also helps stimulate opportunities for internal promotion.

Employees at AICC member companies can take advantage of more than 80 free online courses. As your human resources and training managers look at strategic planning initiatives for 2020 and beyond, have them visit www. aiccbox.org/packagingschool to start registering employees for any online course. Remember, training time counts for employee PPP hours.

Andragogy

Well-trained employees have a larger arsenal of knowledge, allowing them to efficiently cover more areas within the company. The value of internal promotion cannot be overstated—these emerging leaders are already familiar with the mission and culture of the company, so they get the ball rolling more quickly in their new role. When Stephen Moore, director of corporate strategy at Moore Packaging in Ontario, Canada, received multiple requests for education at his company, he embraced the opportunity to invest in his employees. Moore understood that by working to educate his employees, he would be making them better fit to climb the company ladder and take on more leadership roles. Fortunately, as a member of AICC, education for Moore Packaging was right at their fingertips. AICC’s partnership with The Packaging School allows for member companies and all their respective employees the value-add of training programs for free. This program offers more than 80 online courses in both English and Spanish, all related to the packaging industry and the manufacturing environment. Among these offerings is the Certificate of Packaging Science (CPS), a 12-course online curriculum that teaches the materials, processes, and influences shaping the advancement of the packaging industry. The capstone course brings the previous 11 courses together to create a holistic perspective with Packaging Design Workflow—a key process that requires empathy for all the preceding courses. After completing all 12 CPS courses, AICC members are eligible for the CPS final exam, coordinated through The Packaging School. The resulting credential is registered, and framed certificates are sent to each earning graduate. This e-learning program provides relevant and comprehensive education on the global role of packaging in business and society. For these online courses, a technique called microlearning is utilized to break

up difficult topics (corrugated board grades can get pretty tedious) and arrange them into bite-sized lessons for the learner to engage with on any device. Lessons take the form of infographics, quick readings, videos, animations, discussions, and interactive slides. These unique delivery methods empower employees to complete courses on their schedule, at their own pace. Short, focused sessions can help avoid mental burnout and cater to adult learning styles. All of it paves the way for the successful implementation of employee education and development—leading to the many benefits we’ve discussed here. “Professional development is one of the core values of the company,” states Moore. Moore Packaging now has six CPS

graduates and is looking to build up its class of 2020. Moore Packaging thought it wise to invest in the future of its employees—will you be next? Julie Rice Suggs, Ph.D., is academic director at The Packaging School. She can be reached at 330-7748542 or julie@ packagingschool.com.

Alli Keigley, who assisted with writing this article, is production coordinator at The Packaging School. She can be reached at alli@ packagingschool.com.

BOXSCORE www.aiccbox.org

25

Leadership

Situation Critical: Keep Your Head BY SCOTT ELLIS, ED.D.

T

his is the first time, in my recollection, that the world has been at war against a common enemy in the form of a pandemic. Most people are quietly doing reasonable things and working for the health of family and community. There is also a noisier group investing in toilet tissue and losing their heads. My grandfather had hours of adventurous poetry committed to memory, and one that he often recited has come to mind this week. It is a verse by Rudyard Kipling that begins: If you can keep your head when all about you Are losing theirs and blaming it on you … The poet went on to describe multiple situations in which presence of mind would win the day. He closed with these lines: If you can fill the unforgiving minute With sixty seconds’ worth of distance run, Yours is the Earth and everything that’s in it, And—which is more—you’ ll be a Man, my son! Recalling those words, I am encouraged to keep my head, to plan for the worst

26

BOXSCORE May/June 2020

and hope for the best. Most important is to keep the long view and our core values. We know that, at this point, doing the right thing to curb the spread of the virus will be detrimental to the economy. And we need to do those things anyway, because we value family and community over prosperity. Confident that this is true, I trust that most remain committed to exiting this crisis stronger than we entered it. The mixed blessing of busy-ness is that it can be an excuse for delaying focused improvement efforts and raising team members’ capabilities. At this writing, backlogs are full, but it is likely that our essential industry will be faced with idle time before this crisis runs its course. Some will send workers home to reduce labor costs. In doing so, they may risk losing their hard-won employees to e-commerce fulfillment centers that are hiring workers to respond to increased demand. Others will speculatively pack warehouses to keep workers busy. Those who take the long view will redeem the idle time to do some things they have aspired to all along: They will grow their team’s effectiveness. Here are a

few activities that will help teams come back stronger. 1. Grow problem-solving capability. Though many may be working from home, they can convene via online platforms for problem-solving and prevention. This may be the time to grow the quality process or get that food-safety certification. Assign cross-functional groups to develop solutions for your top five problems. If possible, include your expert vendors (they’re lonely). 2. Map the order-entry process to get accurate information to manufacturing more quickly, and shorten the timeline from sales order (design request or estimate) to the production handoff. There is a Value Stream Mapping course on AICC’s Packaging School that will guide the team to map the current state of this process. Then, they can create a desired future state and an action plan to remove delays, extra steps, and redundancies. 3. Practice changeovers. As any team drills on fundamentals, crews can

Leadership

be assigned to practice changeovers. An e-learning from the Packaging School called Setup Reduction will show the way. 4. Implement cross-training. While others are reducing head count, make employees even more valuable and adaptive through cross-training. Create a matrix for essential duties, and use those trained in multiple processes to reduce overtime and the negative impact of illness, vacations, training, and other absences. Consider a continuous run schedule even if shifts are consolidated. 5. Organize for success. Use the principles of 5S to make any administrative or production work center more effective. Make it easy to keep clean, orderly, and

safe. Make expectations and measures of productivity clear and visible. Remove obstacles, and be certain that the tools needed for the job are prepared and easily accessible. The Packaging School course for this is titled Create a Visual Workplace. 6. Assign an individual training plan for team members. Even those working from home can access e-learning in English and Spanish on a wide variety of packaging topics, including manufacturing, safety, leadership, process improvement, sales, and customer service. Contact me for a custom training form and suggested courses. Keep your head when those around you are losing theirs. Your presence of

mind is a safeguard against short-term gains and resulting pains. As Packaging School faculty, I am happy to work with you and the AICC staff to provide you with resources to come out of this crisis even stronger. Scott Ellis, Ed.D., of Working Well provides the brutal facts with a kind and actionable delivery when a leader, a team, or a company needs an objective, data-based assessment of the current state of operations and culture. Training, coaching, and resources develop the ability to eliminate obstacles and sustain more effective and profitable results. Working Well exists to get you unstuck and accelerate effective work. Scott can be reached at 425-985-8508 or scott@workingwell.bz.

BOXSCORE www.aiccbox.org

27

AD Name of Ad

Randy Banks Sharp International

757 650 9905 rbanks@sharp-international.com www. friese-rockwelle.de

INNOVATION Education and Development

No Travel Doesn’t Mean No Training

A

ICC began offering free online education to member companies through a partnership with The Packaging School in April 2017. During today’s unprecedented times, virtual training is more important than ever. As of this writing, employees of AICC member companies have completed 2,876 courses and started an additional 1,646 courses. These courses represent 1,492 better-trained employees, $274,520 saved in training costs, and more than 1½ years of cumulative training time. “Having the ability to continue training programs at a time of ‘social distancing’ through AICC’s online Packaging School is very powerful for member companies,” says AICC President Mike D’Angelo. “So much discussion today is about business continuity planning—education is another way to ensure the resiliency of your business, certainly in a prolonged crisis and as a matter of good practice.” Nearly 80 courses are currently online, with more being released each

quarter. There are courses available for every department. Brian Strauss, human resource specialist at Michigan City Paper Box Co., says, “Whether it’s requiring a new hire to watch—and pass—the Safety Basics course or asking management and office staff to enhance their skills by taking courses from leadership and production to finance and sales, Michigan City Paper Box Co. uses AICC’s Packaging School as a fundamental piece of our training.” Several of the newest and soon-to-bereleased courses are through the support of AICC Education Investors—Fosber, BCM Inks, Sun Automation Group, Pamarco, JB Machinery, Printron, Absolute, Kruger, EFI, HP, Bobst, and Stafford Corrugated—that offer their time and expertise along with a financial commitment to create an online course in partnership with AICC and The Packaging School. AICC, with the support of sponsors—EAM-Mosca of Mexico, Cartró S.A., Cajas de Cartón Sultana S.A. de

C.V., and Michigan City Paper Box—is continuing the process of translating more online courses into Spanish. Learn more about online education at www.aiccbox.org/packagingschool.

BOXSCORE www.aiccbox.org

29

AICC Innovation

Relationship-Building

The Importance of Feeling Important BY TOM MURPHY

W

encouraging. It’s why they announce each graduate’s name at commencement. Who is more likely to close the account they’ve been calling on, the salesperson who stubbornly insists to see the buyer or the one who greets the gatekeeper by name with a warm smile? Birthdays and work anniversaries are also ripe opportunities to give your colleagues some unexpected recognition. Whether they’ve been employed for two years or 20, to take the time to appreciate loyalty will have a resounding effect on morale, not to mention decrease turnover.

ho would have thought a self-help book published in 1936 would be on the Amazon bestseller list in 2020? The timeless classic, How to Win Friends and Influence People, by Dale Carnegie should be required reading for anyone with a pulse. Despite being written well before the presence of baby boomers, Generation X, and millennials, its anecdotes and quirky tips outlining how to navigate personal relations are profound and shockingly relevant. Throughout the book, Carnegie tactfully educates the reader on key Listen and Be Interested principles to deal with people, creating “Good listener” should be a sought-after a how-to guide for becoming likeable, skill on résumés. People love to talk about agreeable, and a proficient motivator. themselves, and to listen intently is one of This ageless wisdom proves that even the highest forms of respect you can show. though the characteristics of generations Those in any type of sales understand the fundamentally change over time, there importance of maintaining relationships. are universal, unchanged elements to our Providing a quality product or service human nature: the desire to be important at a competitive price will put you and the craving to be appreciated. through the door, but the foundation of You don’t need to have a specific pera relationship starts when you can show sonality type or decades of experience to a genuine interest in the other person win someone’s affection. If great leaders, and their company. This applies outside motivators, and salespeople share one of the workplace as well. If you want to common trait, it’s their astute awareness be a great conversationalist, focus less of how they interact with others. I want on trying to be interesting and more on to share a few key principles from How being interested. Lend an ear whenever to Win Friends and Influence People you the opportunity presents itself, and wrap can work into your daily routine to your attention around the speaker. If make those you encounter feel important you can frequently give your undivided and appreciated. attention, you will quickly make yourself an invaluable business partner and friend. Remember Names and Dates A simple and obvious way to build rapport is the ability to remember a name. Be Hearty in Your Approbation and Lavish in Your Praise A name is one of the few intangibles This is perhaps the most recognizable someone can truly claim ownership theme of Carnegie’s book. The following of. To hear your name is pleasant and

30

BOXSCORE May/June 2020

quote illustrates the concept well: “Once I did bad, and that I heard ever. Twice I did good, but that I heard never.” Constant criticism is great if you need to stymie ambition and hurt someone’s pride. Of course, this wouldn’t make you many friends and certainly wouldn’t earn you much respect among your employees. Rather, sincerely praise any and every improvement. If a machine crew did a great job on a complicated order, let them know! Passing out gift cards or a gesture as simple as a handshake is a great way to show appreciation. A positive work attitude can be contagious, and nothing motivates more than having pride in one’s work. The principles laid out in How to Win Friends and Influence People transcend generations, race, and sex. Whether you are a salesperson who struggles to move past the gatekeeper, are a millennial recently thrust into a leadership role, or want to reap the value from a networking event, if you incorporate some of the tried and true methods I presented, you will be on the path to winning friends and influencing people. If you haven’t read Dale Carnegie’s book, I highly suggest you do—then pass it along to a friend for their next birthday. Tom Murphy is director of marketing at Reliable Container Inc. He can be reached at 630-543-6131 or tom.murphy@ relcontainer.com.

Only 2 Hours of Training and You’re Flat Out Running Marumatsu Automatic Flat Bed Die Cutter by Mikawa

Advantages Quick Easy Training 3 Minute Set-ups One Die Operation No Stripping Dies Required Chaseless Cutting Die Mounting System Available in 40”x55”, 47”x67” and 51”x78”

AskHitek.com Info@AskHitek.com 262-842-1700

Member Profile

Washington Box BY VIRGINIA HUMPHREY

COMPANY: Washington Box ESTABLISHED: April 1998 JOINED AICC: April 1999 PHONE: +52 81-1184-8231 WEBSITE: wabox.mx LOCATIONS: Monterrey, Mexico OWNERS: Humberto Trevino

H

umberto Trevino, president of Washington Box, a sheet plant in the industrial city of Monterrey, Mexico, had been under COVID-19 shelter-in-place orders for 13 days at the time of this writing. It was fitting in terms of timing, because it was during a time of turmoil 25 years ago that Trevino started in the paper industry and, soon after, his business.

From Banking to Boxes The boxmaking business was not a venture he ever imagined undertaking. Trevino worked in his family’s thriving financial services business straight out of college. His path had been laid out for him, and he had no intention of straying from it. But fate saw a different future for him. On December 20, 1995, a day Trevino remembers well, newly inaugurated Mexican President Ernesto Zedillo announced the Mexican central bank’s devaluation of the peso. Soon after, the

32

BOXSCORE May/June 2020

Mexican economy experienced 52% inflation, and several large Mexican banks collapsed amid widespread mortgage defaults. In short, it was not a good time to be in the financial services business. Trevino soon found himself looking for a new job in the middle of a recession. “In some places, they told me I was overqualified, and in others, there were hundreds of applications for one seat. It was like a nightmare,” Trevino says. Finally, his perseverance paid off, and he was offered a position with General Electric. The job came with perks, including managing the company’s skybox at Texas Stadium, home of Trevino’s beloved Dallas Cowboys. But the entrepreneurial blood ran strong through Trevino’s veins, as he had also been considering starting his own business. “I had the opportunity to be a very important executive with a large company, or I could start making boxes,” Trevino says. “I chose to make boxes.”

Humble Beginnings With just US$700 in capital, Trevino got to work. His first customer was Soriana, a popular Mexican grocery and department store chain. They needed a box that wasn’t available in Mexico, but in such a low quantity that importing them from the United States was not cost-effective. Trevino told them what would become the company’s motto: “We can make it.” Soriana approved the prototype, and after some tough negotiation with three of the Soriana sharks, Trevino had his first order for 700 custom-made boxes to be delivered each month. He just needed someone to help him make his boxes and a place in which to do it. Trevino signed a lease on a tiny workspace—about the size of a small bedroom—and built some tables and bought a few knives, a lot of glue, and corrugated sheets. Then he hired a ragtag crew to work for him.

Planning for the future is one of your most important jobs. Selling your business, succession planning, equipment decisions and expansions require the best advice and strategy. We’ve been providing Business Planning Services to the independent converter for over 30 years. Need to make a big decision? Call us now.

STILL the Industry Experts 580 Sylvan Avenue, Suite M-A Englewood Cliffs, NJ 07632 (201) 731-3025 • Fax: (201) 731-3026 info@klinghernadler.com

Member Profile

“There were, at that time, 17 young guys and one ancient guy—85 years old,” Trevino says. “No one knew who brought him, but he arrived for work every day.” Trevino grew his business solving problems as they came at him. One problem was trying to get the corrugated they needed. Because they required such small quantities, they had to piggyback on someone else’s order. That was too unreliable, so Trevino and his crew built their own first die-cutting machine. As business increased, so did their need for more equipment. Trevino traveled through the U.S. Midwest, looking for a bargain on used equipment. Their first purchase was an old S&S letterpress built in the 1950s. “I had no idea how these machines worked or about inks,” Trevino says. “I had zero experience.” Their customer just happened to stop by for a visit as they were taking their first box off their new machine, and the customer exclaimed, “Hey, is this the first time you were making a box or what?” Trevino laughed and said that while he didn’t own up to it at the time, he did tell him many years later that yes, it was their first time—their first box ever made. On Expansion Trevino’s son Patricio joined the business about 2½ years ago. He now leads operations, and Humberto has been reassigned to do what he does best—talking to the customers, coming up with innovative

ideas, and developing additional services to offer customers. “It was pretty tough letting the young guys do things in a different way than how I had been doing them,” Trevino says. “But I finally understood that we need to do things differently if we want different results.” And so far, those new ways of doing things are working out well for Washington Box. They have four factory buildings, a distribution center on the southernmost border with the U.S. in Matamoros, Mexico, and another distribution center in north central Mexico opening soon. Trevino had hoped to announce the building of a new plant to consolidate all its operations. However, that plan has been put on hold while he concentrates on getting his business through the COVID-19 pandemic. As of late March, his plant was still operating, taking all the precautions to keep workers safe, but Trevino doesn’t know how much longer that will last. But Trevino has not let up despite the shelter-in-place orders. He jokes he is working only a bit more than half days now—from 8 a.m. until 9 p.m. So, what keeps him going during this time of crisis? “I guess it’s in the blood,” he says. “I learned from my father. He worked every single day until the day he passed.” For now, Trevino is focused on building the business for his family,

much as his father did. He hopes that sooner or later, the rest of his family will join the company. The doors are always open to them if they can add value to the business, help it grow, and make it stronger. Investing in the Industry and the Future Besides running Washington Box, Trevino is on the board of directors of AICC and is a founding member of AICC México. He is also a frequent speaker at different international forums in countries such as China, the U.S., Brazil, and Mexico, among others, on topics related to the box business and commercial trade among the nations. But Trevino is not just focused on growing the business. He is also investing in the future by leading two foundations. One is a scholarship program that provides a dedicated mentor, funds for brilliant low-income students, and funds for those students to attend school. The other foundation supports a school for high-achieving students in a low-income town. That school is rated one of the top-10 schools in the country. Virginia Humphrey is director of membership and marketing at AICC. She can be reached at 703-535-1383 or vhumphrey@aiccbox.org.