We were meant to fly.

Our engines power flight. A love of flight powers us.

DAY 2

Representing Boeing at the air show’s static display are a U.S. Navy P-8A Poseidon and a Qatari F-15QA Eagle.

JULY 23, 2024

We were meant to fly.

Our engines power flight. A love of flight powers us.

DAY 2

Representing Boeing at the air show’s static display are a U.S. Navy P-8A Poseidon and a Qatari F-15QA Eagle.

JULY 23, 2024

By Cathy Buyck

Boeing made a splash on the first day of the Farnborough Airshow with large and strategically important order announcements, demonstrating that airlines remain confident in the U.S. airframer’s ability to overcome its well-documented and highly publicized challenges.

Korean Air committed to buying up to 50 of Boeing’s widebody airplanes, including twenty 777-9s and twenty 787-10s with options for 10 more of the largest 787 Dreamliner variant. The new agreement comes on top of the expansion of the airline’s

firm backlog of 22 Boeing 737 Max jets and seventeen 787s.

Korean Air chairman and CEO Walter Cho told reporters he “trusts the 777-9s will be delivered to us on time.”

“I have complete confidence in Boeing,” he said. “If I was not assured [Boeing would deliver the 777Xs on time], I would not have ordered them.”

AINONLINE . COM

DEFENSE C-390 Millennium

The Netherlands and Austria jointly purchase Embraer C-390 military transport aircraft | 06

MRO demand forecast

Increasing demand for shop visits will outpace capacity growth by 17% this decade | 08

AIRCRAFT

Urban air mobility

Joby Aviation’s five-seat eVTOL air taxi makes its European airshow debut at Farnborough | 16

Competing for talent Aerospace and defense recruiters face stiff competition in talent search | 34

The first delivery slot of the 777-9 won’t open until 2028, Cho told AIN. He also said the carrier, which is in the process of merging with rival Asiana Airlines, could be interested in the 777X freighter at a later stage.

continues on page 38

The latest iteration of the GCAP consortium’s sixth-generation fighter graces the Farnborough Airshow’s exhibit halls.

By David Donald

The Anglo-Italian-Japanese consortium developing the Global Combat Air Program (GCAP) sixth-generation fighter has unveiled the latest iteration of the aircraft’s design. New models and graphics show a configuration with a large, near-delta shaped wing, broadly similar to that of other sixth-generation fighter projects taking shape in Europe and on the U.S.

That the configurations are similar is no great surprise, as operational requirements are similar, said Herman Claesen, BAE Systems’ managing director for future combat air systems. “They all need to go far, carry lots of stuff, and to do it with low observability,” he stressed.

Claesen, along with Italian and Japanese industry counterparts Guglielmo Maviglia (Leonardo) and Hitoshi Shiraishi (Mitsubishi Heavy Industries), reported that work continues at a rapid pace as the program nears its next major milestone, the full launch of a multi-year detailed design and development phase. The shape of the aircraft is beginning to crystallize as the team “homes in on the final outer mold line,” said Claesen—although what’s underneath the skin is more important.

Digital design and evaluation tools have permitted a much higher rate of development than previously possible, particularly in terms of reconfigurations of various elements. Making development easier is a joint set of

requirements, with Italian, Japanese and the UK governments having adapted national protocols to permit the levels of security access required to establish a detailed requirement.

The aircraft and its systems are designed to operate in a fully interoperable environment, both with other allied forces and other ownforce assets such as F-35 and Typhoon. In the case of the F-35, all three nations operate the type and see the GCAP as a complementary asset bringing considerable additional capability to the existing force mix.

Learning from past multi-national programs such as Tornado and Typhoon, the GCAP model will likely “look different.” The plan calls for completion next year. While the GCAP aircraft is intended for export sales, it remains feasible for additional nations to join the industrial effort, but not at the expense of the development timeline.

That timeline has seen rapid progress from the first announcement of the enterprise in December 2022, underlined in the following September by a collaboration agreement by the three national industrial leads (BAE Systems, Leonardo, MHI). The governments signed a treaty in December to deliver a combat aircraft by 2035.

The nature of what that “in-service date” comprises remains undefined, but many assume that it will be the date on which aircraft get handed over to the air forces. z

Pratt & Whitney has completed a preliminary design review of its Engine Core Upgrade (ECU) program for the F135 powerplant installed in all versions of the Lockheed Martin F-35 fighter. The review afrmed that the program is on track to introduce the upgrade to new and in-service engines in 2029.

The engine OEM developed the ECU to address two specific requirements. The first concerns the diminished service life of the F135 as a result of higher-than-anticipated demands on the engine in service, which in some cases have been more than double those in the original specification. The ECU can be retrofitted during routine depot maintenance.

In addition to restoring full service life to the engine, the ECU also ensures that the F135 can meet the future demands of the power and thermal management system—regardless of whether the PTMS is modified or replaced with a new one— as the aircraft prepares for its Block 4 capability enhancements. The system upgrade requires a power oftake requirement of up to 80 kilowatts.

Elements of the ECU technology have emerged from the hundreds of hours of running of Pratt & Whitney’s advanced technology demonstrator. The result also informs the design of the next-generation adaptive propulsion prototype that could power the U.S. Air Force’s Next Generation Air Dominance fighter. D.D.

The F-35 is set to get an engine-core upgrade in 2029.

By Peter Shaw-Smith

Leonardo launched the Block 20 iteration of the M-346 training and fighter aircraft at the Farnborough Airshow on Monday. The upgrade will mean a comprehensive capability enhancement for the aircraft.

The M-346 trainer has enjoyed a measure of market success. New features that will augment

the fighter’s combat potential to include new AI, digital video, navigation, weapon management, and flight management systems, plus upgraded identify-friend-or-foe equipment.

Leonardo has delivered more than 100 versions of earlier iterations of the technology to operators worldwide, and the company has logged more than 120,000 flight hours in operational service with customers and through

A resurging De Havilland Canada has secured an order seven Dash 8-400 turboprops and launched a refurbishment program for the global fleet. The announcements accompanied multiple sales confirmations, including one aircraft for Skyward Express, another to Tanzania’s Government Flight Agency, and a pair to Wideroe Airlines of Norway. Separately, DHC signed a deal to supply a quick-change freighter kit to Advantage Air.

In 2018, DHC (then Viking Air) launched a program to convert and upgrade previously used CL-215 aircraft into the CL-415 Enhanced Aerial Fighter. To date, nine of 11

aircraft have undergone the upgrades.

The DHC OEM Certified Refurbishment Program allows the company to acquire, upgrade and remarket the aircraft for specific customers’ needs. MRO work will take place at its Calgary, Alberta facility. Works ofered include aircraft configuration to match the customer’s fleet, completion of overdue MRO, integration of airworthiness directives, service bulletin upgrades, and freighter conversions—including the introduction of the new Dash 8-400 large cargo door and quick change between cargo and passenger missions.

Leonardo’s Block 20 iteration of the M-346 fighter landed at Farnborough Airport this weekend ahead of the Farnborough International Airshow. The OEM is showcasing the updated aircraft at the show’s static display.

the unique training abilities delivered by the International Flight Training School (IFTS) in collaboration with the Italian Air Force.

“The M-346 has established itself as the most complete training system for pilots and is meeting emerging needs for cost-effective combat operations,” the company said in a statement.

On the sidelines of a Leonardo press conference at the Farnborough Airshow on Monday, Dario Marfè, Leonardo’s director of commercial aircraft and customer service, told AIN that the fighter had yet to engage in combat, although he added that the current uncertain geopolitical climate has increased the chance of combat deployments in future. z

To date, DHC has acquired 28 Dash 8-400 aircraft for the program. For more than four decades, the Dash 8 family of aircraft has served as regional airliners, accumulating over 46 million flight cycles in global operations.

DHC has assembled a product strategy council and met in recent months with operators in North America, Oceania, Japan, Africa, and Europe to understand their requirements and expectations as their business objectives and passenger preferences evolve.

“It’s clear that the Dash 8 continues to be a highly valued fleet for operators around the world, whether in an airline’s network or performing a specialized mission,” said DHC v-p of sales and marketing Ryan DeBrusk. P.S.-S.

.

Trusting CAE with pilot training allows airlines to focus more on customer centered and day-to-day operations. CAE’s training infrastructure, Instructor quality assurance, and dedicated Training Managers, ensures your training is executed fawlessly. Whether it’s for entry into service, or for mature operations, CAE instructor-led training makes it easier to keep your pilots fying.

Today and tomorrow, we make sure you’re ready for the moments that matter.

By Peter Shaw-Smith

The Dutch Ministry of Defense signed a contract for nine Embraer C-390 Millennium aircraft on Monday at the Farnborough Airshow. As part of their “Replacement of Tactical Airlift Capacity” project, the contract calls for a joint purchase in cooperation with Austria under which five aircraft go to the Royal Netherlands Air Force and four to the Austrian Air Force.

Embraer said the C-390’s enhanced tactical airlift capacity would increase operational flexibility, provide logistical support in various missions, and enable a range of humanitarian and medical operations.

Since entering service with the Brazilian Air Force in 2019 and the Portuguese Air Force in 2023, the aircraft has proven its reliability and performance, Embraer said. A total of seven air forces including those of

Hungary, South Korea, and the Czech Republic have selected the C-390.

Vice Admiral Jan Willem Hartman, national armaments director of the Netherlands, applauded the signature of the agreement on behalf of both nations. “This is a good example of collaboration in Europe between countries,” he said. “The constructive support of Embraer has played a crucial role in the successful realization of this agreement.”

The C-390 carries a payload of 26 tonnes and flies at a top speed of 470 knots. Its primary missions include dropping cargo and troops, medevac, search and rescue, firefighting, and humanitarian flights.

Bosco da Costa Jr, president of Embraer Defence and Security, called the aircraft “the best choice on the market, o ff ering an unbeatable combination of high performance, advanced technology, and low lifecycle costs.” z

Aircraft sales broker Global Sky has agreed to buy 15 of VoltAero’s Cassio hybrid-electric aircraft. The memorandum of understanding signed on Monday would make Singapore-based Global Sky the launch customer for the French startup’s vehicle.

VoltAero is developing three members of the Cassio family, with seating capacity for between five and 12 passengers. The aircraft could serve a variety of regional air services, freight deliveries, and emergency medical support.

The aircraft is powered by a combination of Safran’s EngineUs 100 electric motor mounted in the aft of the fuselage and an internal combustion engine. Operating in all-electric mode, the range would be limited to around 82 nm. However, its range would increase when the aircraft flies on engine power, which would also recharge batteries.

VoltAero is exhibiting the first example of the Cassio 330 model at the Farnborough Airshow this week. “Cassio is a perfect match for the regional air mobility ambitions of Southeast Asia, bringing together the aircraft’s flight range with the designed-in safety of our patented parallel electric-hybrid propulsion system,” said Jean Botti, the company’s CEO and chief technology ofcer. C.A.

By Peter Shaw-Smith

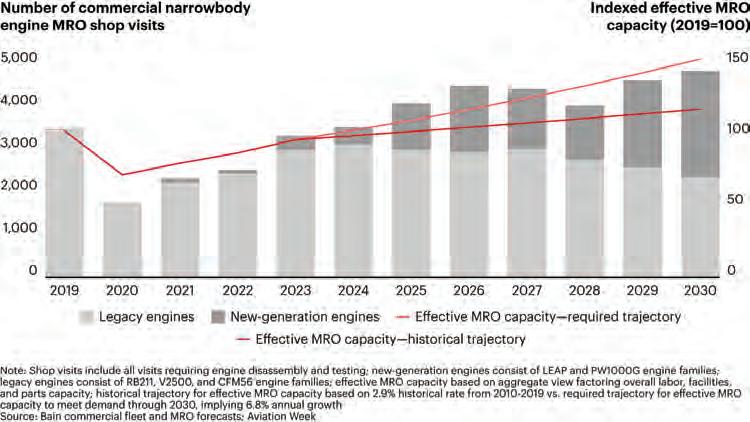

A new study has found that demand for maintenance, repair, and overhaul (MRO) shop visits at the end of the decade could exceed supply by over 17%, impeding air traffic growth by forcing operators to limit flights and routes.

U.S. management consultants Bain & Company said airlines already face “historically high” engine shop turnaround times, up by 35% or more for legacy engines and more than 150% for new generation engines, compared to pre-pandemic levels.

“Our analysis shows that aircraft engine MRO demand will likely experience a nearterm peak in 2026 and remain constrained through the end of the decade,” said Jim Harris, co-leader of Bain’s global aerospace and defense practice. “The next large surge in demand from new generation engines will begin towards the end of 2030.”

“Unless MRO companies act quickly to close this capacity gap, airlines will face higher costs to operate constrained fleets,” Harris added. “The financial burden, on top of growing costs to decarbonize air travel, is likely to slow passenger travel growth.”

Several factors account for the looming lack of MRO capacity, according to the Boston, Massachusetts-based outfit. Engine shop visit deferrals during the pandemic led to pent-up demand. An array of problems, including powder metal contamination, have meant repairs in much greater numbers than anticipated

to newer-generation CFM Leap and Pratt & Whitney GTF engines.

Supply chain constraints have led to insufficient delivery of new-generation aircraft. The defferals mean airlines rely on aging fleets, which also require servicing involving greater complexity and turnaround times. Meanwhile, a general lack of spare parts complicates shop visits.

Used serviceable materials (USM) play a critical role in providing access to life-limited parts. For some MRO shops, USM parts cover as much as 30% of total part demand. Delays to legacy aircraft retirements, especially the Boeing 737NG and Airbus A320ceo aircraft, further affect parts supply.

suggests three key planks to a successful MRO service providers’ strategy.

First, they should improve efficiency and productivity ahead of the next demand surge by accurately forecasting demand and increasing the use of AI and automation tools to boost productivity gains. Maintenance providers should make every effort to boost the supply of used and repaired parts, thereby relieving the overall demand for new OEM parts.

Constraints in MRO capacity will impede the ability to meet engine overhaul demand

To prevent MRO from becoming a more complex “choke point” for operators, Bain

Technology incubator Aerospace Xelerated (AX) is running a pitching contest for shortlisted startups competing for a £5,000 prize at the Farnborough Airshow this week.

The futuristic brainchild of several global aerospace brands is displaying 16 portfolio companies at the show, presenting their solutions in the Innovativation Zone. For the first

The decision by many airlines to delay the retirement of legacy aircraft amid uncertainty about new OEM deliveries has limited the supply of used parts (see Figure 3). Used serviceable material (USM) plays a critical role in providing operators with a cost-effective, low-risk option to access life-limited parts. For some MRO shops, USM parts cover as much as 30% of total part demand. In particular, airlines have put off the retirement of Boeing 737NG aircraft and Airbus A320ceo models. That trend is likely to continue for 7/18/24, 3:08 PM

Finally, MROs should build capabilities and scale the business. “New generation fleets will be far larger in size to accommodate growing travel demand. MRO providers plan for that will be able to capture a greater share of shop visits,” Bain said. “In addition to organic growth, M&A provides opportunities to build market share and improve return on sales.” z

time in its history, the show will also feature a dedicated start-up zone. The Aerospace Xelerated Innovation Zone includes a lounge area and a stage with panels, workshops, product demonstrations, and more.

Among the entities chosen to participate in the Wednesday competition are Dutch firm Eddytec, which identifies defects in carbon-

fiber composites; France’s Estuaire, a provider of data designed to reduce aviation’s environmental impact; and battery electric propulsion systems developer Flux Aviation.

Also included will be Lyneports, a Hungarian enabler of ground and airspace integration of eVTOL aircraft using geospatial software; food and beverage specialist Onegrab of Milan, Italy; and Sora Aviation, which is developing the S-1, a 30-passenger eVTOL aircraft. P.S.-S.

Hybrid-electric propulsion is key to sustainable flight, and we unlock new opportunities to advance it. By combining fuel-burning engines with electric motors and batteries, our solutions boost efficiency and help reduce fuel burn, maintenance costs and aircraft noise. It’s just one of the ways we work to create a more sustainable world.

Visit RTX at Pavilion C631

By Curt Epstein

The UK’s Farnborough Airport has always been associated with advancements in aviation and so is a fitting location for the biennial air show staged there. After being the site of the country’s first powered flight in October 1908, it became the headquarters of the Royal Flying Corps (RFC) during the First World War and the site of the Royal Aircraft Factory, which designed and built hundreds of airplanes during the war. In 1918 when the RFC was renamed the Royal Air Force (RAF), some found it too confusing to have two entities with the initials RAF, so the aircraft design and manufacturing facility was renamed as the Royal Aircraft Establishment, a name it held for much of the 20th century.

While several successful aircraft came out of the Farnborough facility during the 19141918 conflict—the first war in which aircraft played a major role—the British government decided it would change the RAE’s role. “They said you should leave the building of aircraft to the companies that had emerged to make them,” said Richard Gardner, chairman emeritus and former president of the Farnborough Air Sciences Trust Museum. “They had to make thousands of them, and the RAE would be concentrated on development, evaluation, and testing—all aspects of aviation basically.”

The successful designs would then be handed over to industry for mass production. “RAE did the initial build in parallel with industry because the RAE had its own designers and they had workshops and the facilities to actually put the engines and the airframes together and test them, and it was obvious with the needs of the first world war you had to get the wider industry involved,” explained Gardner. “That sort of set a pattern and established Farnborough as one of the, if not the leading aviation research center in the world.”

Among the early successes in material sciences developed at the RAE was the creation of anti-inflammatory dope and paint coatings

for the fabric that covered the early, flimsy airplanes that had previously been easy to set ablaze with incendiary ammunition. The RAE also developed new camera housings to enable easy removal and exchange of film canisters for battlefield intelligence and conducted pioneering work in aerial radio communications.

The facility grew with the addition of more sophisticated wind tunnels and eventually employed thousands, including many of the

Hendon as a gathering of RAF aircraft with a flight display. This continued into the 1930s as a combination of RAF flight demonstrations along with exhibits from the companies that produced the aircraft, showing off their latest designs and innovations.

Organized by the Society of British Aircraft Constructors, the event grew and inevitably changed venues several times, first to Hatfield and then to the Radlett Aerodrome in 1946. Initially meant as a showcase for British-built aircraft, it gradually expanded to include aircraft equipped with UK-built engines and avionics. After the war, SBAC began considering a permanent site for the annual show. With convenient access to London by road or rail, and with plenty of available space, the first

top scientists and engineers in the industry. “They were developing absolutely everything, from the evacuation of aircraft, survivability of aircraft in ditching, bombing equipment, radar, and electronic countermeasures. All of these pioneering things were tested there,” said Gardner.

That pioneering spirit included the first flights of Britain’s first single-engine and twin-engine jets.

The ancestor of today’s Farnborough International Airshow was the RAF Pageant in 1920. It was first held in the north London suburb of

Farnborough Airshow took place in 1948.

“Most of the UK industry had been geared up for wartime production, but by 1948 they realized there was a slowly growing civil market that could do with new designs,” Gardner told AIN. “There were some very radical aircraft for that time being considered, big airliners with the possibility of powering them with jet engines or turboprop engines, and SBAC was very keen to show them off.”

The formula of what became the typical Farnborough show solidified the following year. “You had an industry banquet to start it off and the SBAC had the list of VIPs to invite, which would be the chief executives of the major companies

More than 85,000 engines in service—and we’re just getting started. From the peerless PT6 to the legendary F135 to the groundbreaking GTF, we continue to take powered fight to new heights—increasing efficiency, developing the latest hybrid-electric technology and creating a future that is smarter, cleaner and greener.

Visit RTX at Pavilion C631

and invited foreign guests, and then they widened it out to include what were then the dominions of Australia and Canada, which also had sizable aircraft industries at the time,” Gardner explained. “In 1949 they decided to make more publicity about having a flying display at the end of this exhibition week, and 275,000 visitors came on the last two days.”

The 1950s saw the heyday of the UK aircraft industry with new aircraft of all categories emerging every year, and SBAC built a 67,000-sq-ft exhibition hall at Farnborough

“You were so close to the runway and you had such a good overall view of everything because you were on the hill, only a hundred yards from the runway,” explained Gardner, “whereas if you were down by the flight line, you were only just beyond the wing tips actually—incredibly close—which made it very popular on the public days.”

While safety rules have limited maneuvers demonstration pilots can perform, the displays were designed to amaze. The RAF’s Black Arrow team showed up one year with a

to house company stands. “There was more of a development of high technology from the late 1950s onwards, and although the aim of SBAC remained to sell British aircraft and equipment, the show was also [a] huge what we now call a networking opportunity,” Gardner said. In those pre-internet days, if your company produced a component to go on an airplane, you could just walk a few yards to speak with a key person from Boeing or de Havilland.

In addition to the stands, exhibitors would tow hospitality trailers up to the hill terraces above the runway where rows of corporate chalets stand today. It was that view that made the site an iconic airshow venue.

routine involving 22 Hawker Hunters, while the Royal Navy pilots performed a stunt where two Supermarine Scimitars landed and folded their wings as they taxied down the runway and a third Scimitar landed between them in the opposite direction. In another year nine Hawker Seahawks landed simultaneously in a diamond formation.

“That really reached a climax in the 1960s where you had a lot of competition between the navy and the airforce,” said Gardner. “The RAF and Navy had a whole series of staged mock attacks on the airfield, with multiple aircraft one year, where virtually everything the air force had they threw at it, and that sequence was about an hour of continuous flying.”

Yet, as airframers consolidated in the post-war years, the number of new aircraft

arriving on market slowed, diminishing the need to have an annual show—particularly when the rival Paris Air Show was taken into consideration.

“Farnborough was traditionally in September, and the Paris show was always late May or June, and it was very expensive for the exhibitors to basically repeat the show for Farnborough,” Gardner explained, adding Farnborough organizers in 1962 made a decision that they wouldn’t have a show the following year. “The next one would be in ’64, and it was established that it would be biennial thereafter and would alternate with Paris so they didn’t duplicate things.”

One of the most exciting moments at the show was always the first demonstration of a new aircraft, but Gardner noted that the most recent Farnborough debut on the civil aviation side was the Airbus A350 a decade ago, with Boeing’s 787 Dreamliner arriving on the scene in 2010. Given the current backlogs held by the two leading civil manufacturers stretching for years, he believes it might be a while until the next one.

“I suspect we won’t see all new serious aircraft emerging for at least another decade,” Gardner said. “If an airline wants to stay in business, it’s got to have aircraft that make money. As long as airlines want to buy sort of bulk standard A320s and 737s, [the airframers] will keep doing it.”

Yet Gardner still describes the show as a must-go event for the industry even as the focus shifts with the emerging emphasis on new technology such as 3D printing manufacturing, urban air mobility, and sustainability.

On the military side, he expects to see some changes among the exhibit stands due to the recent geopolitical situation and the development of future air combat systems. “We’ve had almost three decades where all the combat experience has been in anti-terrorism in the Middle East and Afghanistan, and now we’ve got what would have been unthinkable until a few years ago, that sort of state-onstate threats—China, North Korea, Iran, and Russia,” he said. “With the Ukrainian war underway, a lot of lessons are being learned with what you can and can’t do.” z

It starts with a spark. A moment of wonder. The kind that opens your eyes as a child and compels you forward as an adult. It’s what we nurture when we support education programs worldwide, and it’s what we look for when we grow our global team. Encouraging great minds to pursue great breakthroughs—it’s how we drive progress for generations to come.

Visit RTX at Pavilion C631

The full composite wing assembly and booms for the first S-A2 eVTOL technology demonstrator have arrived at Supernal’s engineering headquarters in Irvine, California.

By David Donald

GKN Aerospace has delivered the wing assembly for Supernal’s eVTOL technology demonstrator aircraft. It handed over the complete composite assembly in June and intends to deliver the vehicle’s booms before the end of this month. It builds the assemblies in the UK at facilities in Cowes and Bristol.

“We are excited to support Supernal’s multi-year eVTOL testing program,” said John Pritchard, president of civil airframes at GKN. “Delivering these vital aerostructures is a testament to our wealth of experience in the design

The U.S. Department of Defense is showing a pair of Lockheed Martin F-16Cs in its outside display area. One of them, serialed 89-2137, carries three stars to signify the three Bosnian Serb J-21 Jastrebs it shot down near Banja Luka during a single mission on Feb. 28, 1994. The pilot was Captain Robert Gordon “Wilbur” Wright of the 526th Fighter Squadron “Black Knights.” Today the aircraft serves with the 31st Fighter Wing at Aviano in Italy.

and high-rate manufacturing of aerostructures.”

The two companies signed preliminary agreements in 2022 and 2023, and GKN serves as a key partner in Supernal’s vehicle development.

Supernal’s full-scale technology demonstrator is scheduled to fly before the end of the year. The company unveiled its S-A2 product concept in January and is displaying a full-scale mockup at the Farnborough Airshow this week.

The four-passenger urban transport vehicle features eight tilting rotors mounted on four wing-mounted booms. Supernal aims to have the aircraft certified and in service by 2028. z

GE Aerospace has chosen Triumph Group’s Geared Solutions business to provide the auxiliary gearbox for the F404 afterburning turbofan engine. Potential future use on multiple applications includes the Boeing T7-A Red Hawk, Korea Aerospace T-50 Golden Eagle, and Turkish Aerospace Hürjet platforms.

Triumph Geared Solutions president Pete Gibson described the sole-source award to supply F404 auxiliary gearboxes to the legacy fleet and new aircraft as the “latest chapter in a great legacy of our supporting GE Aerospace engine applications.”

Triumph will perform the work at its facility in Macomb, Michigan. Radnor, Pennsylvania-based Triumph has provided GE Aerospace with proprietary and build-to-print projects across multiple applications for decades. C.B.

By Peter Shaw-Smith

GKN Aerospace has officially opened an expansion to its facility in Chihuahua, Mexico, in what the company calls “significant advancement” for its manufacturing capabilities for the North American market.

With the 80,000-sq-ft expansion project, GKN has doubled the facility’s manufacturing capacity. The Chihuahua site will primarily assemble composite aerostructures and electrical wiring interconnection systems. According to GKN, the expansion will create more than 200 new jobs.

“The company’s expansion in Chihuahua is a testament to the trust and confidence placed in our state,” said Chihuahua governor Maria Eugenia Campos.

GKN expects the enhanced production capacity will strengthen partnerships with customers in the region, including HondaJet and Gulfstream, and will position the site for future growth.

“The expansion of our Chihuahua facility is an important milestone for us. It will supplement our already established aerostructures footprint in the region, embedding our industry-leading EWIS capabilities into North America for the first time,” said John Pritchard, president of civil airframes at GKN.

“Combined, lightweight structures and

An 80,000-sq-ft expansion of GKN Aerospace’s facility in Chihuaha, Mexico has doubled the company’s manufacturing capacity.

advanced EWIS systems are critical for both our customers’ platforms today, as well as to enable the future of sustainable flight. Having this multi-technology site in Chihuahua is an important step forward in enabling this.”

GKN has three facilities in Mexico that serve both civil and business aviation markets in the U.S. and Europe. The Chihuahua facility specializes in advanced composite and metal structures, specialized processes, and engineering services.

Meanwhile, manufacturing capability from China, India, Turkey, and Mexico complements GKN’s EWIS center of excellence in the Netherlands and extends to the company’s agreement with Airbus for A220 EWIS packages in a multi-year contract extension with the European OEM. z

By David Donald

Joby Aviation is displaying its electric vertical takeoff and landing (eVTOL) air taxi at the Farnborough Airshow this week, where it is making its first European appearance.

After more than a decade in development, the first production model of Joby’s four-passenger aircraft, which has six tilting rotors for lift and thrust, rolled out in June last year.

Joby has covered more than 33,000 miles in tests over the past decade, and it has conducted more than 100 flights with pilots on board.

According to Joby, the aircraft will fly to a range of at least 100 miles on a single charge and generate noise levels around 100 times

lower than those of a conventional helicopter.

The FAA accepted the certification plans for Joby’s aircraft, with full approval and service entry expected next year. Further local approvals are under discussion in the UK and Japan. In November Joby performed the first flight

by an eVTOL in New York City, and claimed the first delivery of an eVTOL to a customer— in this case the U.S. Air Force at Edwards Air Force Base in California.

Joby sees Europe as a potential major market for urban air mobility. In the UK, the London region is a natural target. The company also has mapped out a potential network for the north of England and the north Midlands that would link destinations such as Liverpool, Manchester, Leeds, Hull, Sheffield, Stoke, Derby, and Nottingham, providing a rapid air taxi service in a region with limited connectivity. A zero-emission journey from Manchester Airport to Leeds could be accomplished in 15 minutes, instead of the average of 90 minutes by road. z

The Bahrain International Airshow returns this November to continue its journey, providing an unrivalled platform for innovative and personalised commercial networking. A valuable and unmissable opportunity facilitating international trade and leveraging opportunities.

13-15 November 2024

Sakhir Airbase, Kingdom of Bahrain

Sakhir Airbase, Kingdom of Bahrain

By Charles Alcock

Not so long ago, the perceived wisdom suggested that demand for sub-50-seat regional airliners would remain limited for the foreseeable future. But the pressure to bring reduced or zero-carbon propulsion technology to market is changing the outlook and opening new possibilities to connect thousands of smaller communities with little or no scheduled airline service.

Cranfield Aerospace Solutions (CAeS) expects to close the first stage of its Series B funding round at the end of July, allowing it to accelerate plans to bring a hydrogenpowered regional airliner to market. Delays in raising funds meant the UK start-up had to defer purchases of hardware needed for its technology demonstrator. However, it remains intent on bringing the first converted nine-passenger Britten-Norman Islander into commercial service in 2027.

The plan calls for the replacement of the Islanders’ piston and turboprop engines with CAeS’s hydrogen fuel cell system, which would fully integrate into nacelles on the wing.

“We now have a very sophisticated hydrogen fuel cell system that we believe delivers the highest available energy density, which

means we can be sure of producing 100% or more of the energy of the engines it is replacing, not just 40% to 50% as is the case with other systems,” CAeS chief executive Paul Hutton told AIN. He added the company now aims to start flying a technology demonstrator by the end of July 2025, after completing ground tests.

In October 2023, Dronamics agreed to acquire 1,290 of the CAeS propulsion systems for integration with its in-development Black Swan uncrewed cargo aircraft. The Cranfield team will work with UK-based Dronamics to help bring an aircraft to market capable of carrying a payload of 350 kilograms (770 pounds) and a range of 2,500 kilometers (1,359 nm).

At the same time, CAeS held discussions with several airlines eager to replace APUs, which account for around 20% of ground emissions of carbon dioxide from aircraft and 10% of all airport emissions. It seeks to demonstrate how hydrogen propulsion units ranging in power output from 125 to 500 kilowatts could cover the APU needs of all current airliners with hardware that would conveniently fit in the space occupied by the increasingly unwelcome equipment.

Heart Aerospace plans to reveal a technology demonstrator for its ES-30

hybrid-electric regional airliner in the fall. The Sweden-based company has changed the architecture for the 30-seater’s propulsion system to an independent hybrid configuration it said will allow for more missions flown in all-electric mode.

Instead of the earlier series hybrid configuration, the aircraft will now use a pair of as-yet-unspecified turboprop engines installed on the outboard section of the wing and two electric motors inboard. The decision to drop the series hybrid configuration with a turbogenerator was confirmed in May and has prompted other design changes, including moving the battery bay from the lower fuselage and removing winglets and strut-braced wings.

Despite the extensive engineering work required by the program’s latest changes, Heart’s president and chief commercial officer Simon Newitt told AIN it still aims to achieve EASA type certification in 2028. In May, the Swedish start-up opened a research and development facility in California.

According to Newitt, the hybrid configuration will give airlines the option of flying all-electric missions without using the turboprops at all. “The turboprop [propellers] could be feathered so that they can take o ff using just the inboard motors and fly up to 200 kilometers [109 nm] from entry into service,” he explained. “The outboard engines will be sized to be turned on to allow for range extension [of up to 800 kilometers] and operators can have everything working at the same time for some improved takeoff performance.”

Heart Aerospace recently implemented some design changes to its ES-30 hybrid-electric regional airliner and intends to reveal a technology demonstrator later this year.

Deutsche Aircraft has shifted its projection for service entry for its D328eco regional airliner until the end of 2027. The German manufacturer has been working to modernize the 1990s-era twin turboprop and has aimed to achieve EASA type certification in 2026, after first flight of the program’s prototype scheduled for the third quarter of 2025.

In a statement issued on July 5, Deutsche Aircraft said it decided to delay the program after a detailed internal review and discussions with prospective customers. The company added that unspecified regulatory changes led to the shift in program timeline.

t or 60+ opratrs fo th trus yo plac in CFM –

in or popl and in or proucts – eery singl day.

We have an amazing hitry tgthr; a lot ha hapend

in th pat 50 years. Our promie t yo fo th nxt

and inoation that ha earnd that trus.

50 i that CFM wil aways deliver th l vel o supot

Gaël Méhus

P resident & CEO, CFM Intrnationa

By David Donald

With Brazil’s first air force squadron already gaining initial operating experience and Sweden well advanced in its plans to introduce the type next year, the Saab JAS 39E/Gripen E fighter program is rapidly gaining momentum as it closes in on full-service entry. The two-seat Gripen F model also is nearing its first flight.

At the same time, the Swedish aircraft— and its Gripen C/D predecessor—remain the subject of considerable interest in the export market, despite having lost out to Lockheed Martin’s F-35 in several competitions. Saab is pursuing the sale of four more Gripen Cs to Hungary and remains in talks concerning the supply of a second squadron, possibly of Gripen Es. Thailand, too, is interested in taking more Gripens. Other opportunities have arisen in Austria, Colombia, India, and the Philippines.

While Saab continues to support and develop the C/D warplane—including technology drawn in from the Gripen E—the second-generation model has become the focus of development. That work has been undertaken rapidly thanks to the desegregated nature of the aircraft’s core architecture, which permits upgrades to the mission software without affecting flightcritical functions. That, in turn, negates the need for time-consuming requalification of the overall system following an update.

“We code in the morning and fly in the afternoon,” explained Johan Segertoft, head of the Gripen business. “In software, there are no generations, only speed.”

Highlighting the rapidity of development, Segertoft reported that Saab generates up to 10 system configurations every week with the current high work rate. Developers produced 12 iterations in eight weeks for the ground proximity warning system alone, and more than 800 such “apps” hosted in the mission computers.

Of course, engineers can test developments and ideas in the system on the ground, but they still need validation in the air. However, the

nature of flight testing has changed, according to Segertoft. “[In] flight tests it is now more of the production team that answers questions,” he said. “We aim to fly an idea in four weeks. It’s better to fail early and we learn.”

Current Gripen E functions and capabilities are grouped into the Mission System 21 software load. As noted, though, engineers continually develop the software, but the “MS” approach remains in use to identify major program goals and government funding procedures.

MS22 has undergone development for some time. While MS21 primarily gave the Gripen E an air defense capability, the new software will greatly expand the aircraft’s air-to-ground repertoire. Electronic warfare (EW) is another area being enhanced to give the aircraft a wideband electronic attack capability. This, combined with capabilities such as the proposed MBDA Spear missile, will allow it to undertake defense suppression missions at long range without the need for a dedicated platform.

Developers have instituted one significant hardware change to the aircraft since its first flight in 2017, driven by an emerging requirement regarding the carriage of heavy external stores such as stand-off missiles. That prompted Saab to add considerable area to the wing trailing edges and move the canard foreplanes forward slightly as a balance.

Most of the test fleet now flies with the modification, and it is fully incorporated into the production line. Another change involved the addition of strakes aft of the cockpit to

optimize airflow into the cooling intake at the base of the fin.

The test fleet, including one aircraft in Brazil, has performed more than 2,000 sorties, and many of the main trials have been completed. Hot and humid tests were recently completed in Brazil.

Shortly to join the test fleet, the first Gripen F two-seater has just completed final assembly and fit-out in the factory at Linköping, including specialist instrumentation for its role as the two-seat testbed. The second is also well advanced in the final assembly process.

The schedule has slipped to a later time than originally planned due to a change of priority by the customer, Brazil, which revised the production plan to get its single-seaters into service as quickly as possible. The revised plan will also see all eight Gripen Fs on order built and assembled in Sweden, rather than in Brazil as originally planned.

Saab’s Linköping assembly line can produce up to 24 aircraft per year, but it holds the capacity to meet additional demand. The first aircraft from the Brazilian final assembly line at Gavião Peixoto is in the works and scheduled for delivery next year. Brazilian-made components have entered production and will be fed into both assembly lines.

The Gripen E entered service with the Força Aérea Brasileira (FAB) and Flygvapnet (Swedish air force) in 2019 and received its military type

certification in November 2022. By early June, the FAB had received seven aircraft—locally designated F-39E—for service with the “Jaguar” Squadron (1° GDA) of Ala (wing) 2 at Anápolis in Brazil. A second squadron within the wing, 1°/4° GAv “Pacau,” is scheduled to stand up later this month. The growing fleet is undergoing preparation for participation in its first major Latin American exercise, Cruzex 24. A single F-39E continues to fly in Brazil on test duties, operated by the joint Saab/Embraer test team.

Sweden plans to begin operations with the JAS 39E next year at the F7 wing at Såtenäs, where the country plans to base the training unit (as it is for the Gripen C/D). To prepare for its defense material administration (FMV) test and evaluation (T&E) unit at Malmen, on the opposite side of Linköping to Saab’s factory airfield, an integrated test fleet will concurrently conduct developmental and operational tests and evaluation.

Facing the unstable military menace posed by Vladimir Putin’s Russia, Sweden—NATO’s newest member—has begun the search for its future airpower. Although the nation appeared eager to partner in the UK/Italian/ Japanese Global Combat Air Program (GCAP), it has elected not to join.

For now, Sweden is evaluating airpower options and intends to make a decision in 2030. The Scandinavian state could choose the GCAP, or its Franco/German/Spanish Future Combat Air System (FCAS) equivalent, or it may pursue a new fighter program independently.

Work known as the Koncept för Framtida Stridsflyg (KFS, or future fighter concept) began in July 2023, with Saab’s informal “Building X” technology hub taking a leading role. On November 1, Saab formalized its status to establish the Advanced Programs business unit led by Peter Nilsson.

Saab has undertaken KFS in close collaboration with the FMV (Sweden’s defense mate-

The T&E unit received its first Gripen E in November and had three by the end of May. By the third quarter it expects to have five or six aircraft. It also has access to up to six JAS 39C/ Ds that can serve a variety of sensor tests and as chase aircraft and radar targets. The numbers permit the simulation of most air defense scenarios, including four-versus-four combats.

While the FMV is primarily concerned with developmental testing, including that of the aircraft’s sensitive electronic warfare capabilities, the air force’s operational test team is evaluating the aircraft’s combat potential and forging possible tactics for its employment. Combining both development T&E and operational T&E in a single unit maximizes the benefits of each sortie.

The combined unit is also building a training syllabus for the type’s forthcoming service entry. Conversion to the JAS 39E from the C/D for an experienced test pilot typically takes 10 sorties in the simulator and eight in the air,

but that would require a few more for regular squadron pilots.

Sweden plans to buy 60 JAS 39E fighters and equip Gripen E squadrons at its three current C/D bases—F21 Luleå, F7 Såtenäs, and F17 Ronneby—but it also wants to bring fighter aviation back to F16 at Uppsala, which will be the base for the air force’s new S 106 GlobalEye airborne early warning aircraft.

In response to growing tensions with Russia, Sweden has decided to keep a number of JAS 39C/Ds operational until at least 2035 and to upgrade them to maintain their relevance. The country uses a Block upgrade approach, with three more iterations likely beyond the current Block 2. That could include an electronically scanned radar based on the current PS-05/A mechanically scanned sensor. Saab also recognizes that other air arms might keep the Gripen C/D flying long after the Swedish aircraft have retired. z

rial administration), the FOI (defense research agency), the Swedish armed forces, and other industry players such GKN Aerospace, which provides the engine for the Gripen fighter. The initial phase focuses on concept exploration contracted and funded through 2025.

In March, Saab received an order from the FMV for conceptual studies of crewed and uncrewed solutions. It has rapidly expanded the number of people working on KFS-related activities from 120 to 270 and coordinates more than 150 relevant research and technology projects across the company.

Schedules call for the KFS to move into its second phase in 2026. An imminent concept evaluation review will identify technologies

Sweden’s Koncept för Framtida Stridsflyg program mainly evaluates future air combat options.

that Saab should demonstrate during the second phase.

A range of concepts remain under evaluation. While new technology demonstrators appear likely, new systems can operate on modified aircraft such as the Gripen. Meanwhile, Saab would use uncrewed demonstrators to fly technologies destined for a crewed fighter. Swedish experience with dispersed operations will feature prominently in any new system, along with the ability to provide robust, wear-resistant low observability.

KFS is due to conclude in 2030, at which time it should be able to fully inform a decision on which path Sweden should choose for its airpower requirements. D.D.

By Cathy Buyck

Aerospace manufacturers have a critical role to play in helping airlines achieve their goal of climate-neutral flying. Increasingly, their efforts toward net-zero carbon dioxide (CO₂) emissions by 2050 extend beyond the development of low-carbon aircraft, ultra-efficient engines, and hybrid-electric technology to include greener production processes.

In June, for example, Safran Aircraft Engines inaugurated a new CFM International Leap engine repair shop at Brussels Airport in Belgium that it said generates netzero carbon with energy-positive operations. The maintenance facility features a sustainable, carbon-neutral design created with 100% renewable energy, including solar panels on the roof and circular heating systems.

“This new site is a vital link in our global maintenance, repair, and overhaul network, helping to support the growing fleet of Leap engines around the world while reducing our environmental footprint,” said Safran Aircraft Engines CEO Jean-Paul Alary.

Back in 2018, Safran instituted a plan to reduce greenhouse gas emissions generated by its production processes across all sites.

The aircraft equipment manufacturer has committed to reducing scope 1 (direct) and scope 2 (indirect) CO2 emissions by 30% by 2025 and 50% by 2030.

Initiatives include lowering energy consumption, increasing renewable energy use at industrial and office sites, developing an internal carbon price to assign a monetary value to harmful emissions, and using sustainable fuels for engine testing.

Fellow French aerospace group Thales says it has fully embedded sustainability in its corporate strategy. The company plans to roll out a new sustainability strategy for 2024 through 2030, during which it aims to build on “standout performance” in the prior five-year period and a “record-setting” 2023 in terms of its carbon footprint.

Production of scope 1 and 2 CO2 emissions decreased 59.9% from the 2018 baseline. Renewables now account for 90% of its energy mix, and 127 Thales sites have contracts in place for the supply of electricity from renewable sources.

As part of its green manufacturing drive, Thales applies eco-design principles to each stage of the engineering process. It meets green manufacturing standards throughout

its production supply chain. By the end of last year, the group instituted 183 action plans with suppliers on methods to reduce their emissions.

Like Safran and Thales, regional airliner maker ATR also claims a commitment to strengthening responsible supply chain management. The joint venture between Airbus and Leonardo collaborates with more than 150 direct and 800 indirect suppliers on environmental and social responsibility in its procurement and overall strategy.

“Stringent requirements toward our suppliers are listed in a code of conduct,”ATR corporate social responsibility and environment manager Mathilde Raymond told AIN. “Since October 2023, we also assess the maturity of our suppliers’ commitments towards sustainability via a third-party agency (EcoVadis).”

The airframer has set ambitious goals to limit its environmental footprint, Raymond said. They include decreasing gas and electricity consumption and increasing renewable energy sources. Today, renewable energy fully powers its headquarters and flight test sites, and the company has set a target to cut waste production by 20% by 2025.

Toulouse-based ATR’s commitment to addressing climate change extends to its circular economy model, Raymond added. Through a partnership with Tarmac Aerosave, ATR started recycling its aircraft. It dismantled three aircraft in 2023 and salvaged 85.5% of their parts for reuse or recycling.

Embraer established a dedicated management team named DIPAS (Integrated Development of Environmentally Sustainable Products) to ensure product sustainability for customers in different countries, and occupational and environmental integrity throughout the aircraft’s operation, maintenance, and end-of-life. The Brazilian airframer told AIN it aims for a 50% reduction in net carbon emissions by 2040 from a 2018 baseline and 100% energy from renewable sources by 2030. To that end, it signed an agreement in 2022 that ensures 100% of the electricity its purchases in Brazil will come from renewable sources this year, bringing forward its public commitment set initially for 2025. z

By Charles Alcock

Rolls-Royce is preparing to introduce an upgraded version of its Trent XWB-84 turbofan that it expects to deliver a 1% improvement in fuel burn efficiency for the Airbus A350-900 airliner. The company aims to achieve certification later this year for the first production example of a modified engine now undergoing assembly.

The upgrade, which Airbus flight-tested on an A350, centers on aerodynamic improvements that have resulted in efficiency gains in the XWB-84’s compressor system. By redistributing the flow of air through the high-pressure turbine (HPT), Rolls-Royce engineers have reduced operating temperatures.

“The engine runs much cooler now and so it’s more durable,” Rolls-Royce group director of engineering, technology, and safety Simon Burr told reporters at a briefing ahead of the Farnborough International Airshow. “We took the engine and instrumented it [to assess] 2,500 parameters, which resulted in a lot of change to the turbine system and upgrades to the fans for better cruise altitude performance.”

Rolls-Royce will make available the new XWB-84 as an option for operators of new A350900s. In addition to flight tests, engineers have subjected the engine to endurance testing at the company’s ground test facility at Derby in the UK, where it ran a 2,800-hour hot-cycle test.

The fuel efficiency boost to the XWB-84 benefits from part of a £1 billion ($1.3 billion) investment in improvements to the Trent family, which has been in service since the 1990s. Rolls-Royce expects the changes to boost the durability of the turbofans on the wing.

The upgrades include a disc alloy to both the XWB-84 and the Trent XWB-97 engine, which powers the larger A350-1000. Burr explained that the RR173 super alloy introduces an improved safety margin that gives operators the option of running engines at least 50 kelvins hotter or extending service life.

With the XWB-97, the company’s objective

centers on doubling the permitted time on wing in challenging operating environments, such as in the Middle East, where extreme heat and sand can pose endurance issues. Rolls-Royce already has increased the temperature margin and enhanced turbine case cooling to support longer in-service times.

The company has added a new coating for HPT seal segments resistant to calcia-magnesia-alumino silicates, which can damage engine components. Rolls expects to make the upgrade available for HPT blades later this year. The third phase of the work, scheduled for rollout in 2028, will include a modified HPT and combustor to reduce metal temperatures with a new ceramic matric composite seal.

“The interface between the engine blade and the case has been running hotter than we’d modeled,” Burr explained. Efforts to resolve the problem have involved extensive rig testing at the Rolls-Royce Testbed 80 facility in Derby, where exercises have included blasting sand into an engine to replicate desert conditions. The manufacturer consulted with PhD-level geologists to ensure that the sand mix used directly mirrored the composition of sand found in the Middle East.

Well-documented reliability issues with the Trent 1000 turbofans that power Boeing’s

787 widebody airliner have prompted RollsRoyce to introduce a new HPT blade already in service with the Trent 7000 on the A330neo aircraft since September 2022. “We lost market share because it simply wasn’t durable enough,” Burr acknowledged.

Rolls-Royce’s engineering team now plans to start flight testing the new Trent 1000 blade in August using its 747 testbed aircraft. Following initial certification by EASA, the company expects to deliver the first of the new design in early 2025.

Applied on the Trent 7000, the design’s increased cooling airflow has reduced blade metal temperatures by 45 degrees C (113 degrees F). Changes include additional midchord holes and widening of existing holes, improvements the company plans to make retrofittable across the Trent 1000 fleet.

On the commercial front, Rolls-Royce predicts this year will show a return to pre-2019 market conditions, with increased engine deliveries and growing flight activity driving demand for product support. Recent new orders have included Trent XWB purchases by Turkish Airlines, Delta Air Lines, and Japan Airlines, as well as a Trent 7000 order from Vietjet. Newcomers to the cohort of Trent operators include Asian operators IndiGo, EVA Air, and Korean Air.

According to Rolls-Royce’s chief customer officer, Ewen McDonald, a boom in express delivery demand continues to underpin growth in the air freight sector, reinforcing the engine maker’s position on both the new A350F model and conversions of A330 passenger airliners. z

Rolls-Royce is implementing a series of upgrades to its Trent XWB family of turbofan engines that power airliners including the Airbus A350 and the Boeing 787. The A350-900’s upgraded Trent XWB-84 turbofans offer a 1% reduction in fuel burn.

By Peter Shaw-Smith

United Airlines has selected Honeywell Aerospace Technologies to provide a range of avionics for 737 Max jets slated to enter service over the next decade. The new cockpit equipment includes advancements such as the industry’s only 3D weather radar, new 25-hour flight data recorders, and advanced traffic avoidance systems.

United first chose a similar suite of Honeywell avionics in 2018 to equip 161 of its 737 Max aircraft. Honeywell said the latest agreement builds on its reliability in delivering world-class aerospace technology.

“We are proud to continue our long-standing relationship with United Airlines to provide advanced avionics for its growing 737 Max

fleet,” said Heath Patrick, president of Honeywell Aerospace’s Americas aftermarket division. “Our technology reduces pilot workload, improves situational awareness, and supports dispatch reliability.”

The IntuVue RDR-4000 3D Weather Radar System is the first automatic commercial radar to accurately depict weather in the flight path of an airplane, according to Honeywell. “IntuVue automatically scans the sky at 17 tilt angles—the most in the industry—and delivers a 3D view of the weather through an intuitive display that pilots can quickly and easily reference,” the company said.

The Honeywell Connected Recorder-25 allows commercial aircraft to accommodate

Honeywell Aerospace offers avionics solutions for aircraft of all sizes, ranging from airliners to eVTOL air taxis.

mandatory flight data and cockpit voice recording requirements. It could potentially result in better maintenance predictability and operational insight through data analytics, the OEM said.

Honeywell’s TPA 100B Traffic Alert and Collision Avoidance System and TRA 100B Transponders identify the airplane to surrounding aircraft via an airborne collision avoidance system.

Meanwhile, in June, Honeywell demonstrated a new ground control station for eVTOL aircraft in an agreement with Frequentis, an Austrian supplier of communication and information systems for control centers. The ground control station allows remote piloting beyond the visual line of sight. z

Aerospace solutions provider GA Telesis and artificial intelligence (AI) specialist Alitheon are collaborating to integrate Alitheon’s FeaturePrint optical AI technology with Wilbur, GA Telesis’s Web3-enabled parts provenance and records platform.

According to Alitheon, Wilbur will generate a “revolution” in aircraft and parts authenticity while improving data security within the aviation sector.

“This collaboration will empower stakeholders to meet the highest standards for product documentation and verification set by all global regulatory bodies,” Alitheon said.

The firm claims that the integration will ensure the irrefutable verification of

products. It designed Wilbur and FeaturePrint to enhance traceability and identification of aircraft parts throughout the entire aircraft lifecycle.

The combined technology addresses aircraft parts already manufactured and serves as a forward-looking provenance and verification system for the transfer of assets within the supply chain.

Counterfeit and gray market goods, untraceable items, and misidentification of physical products have all recently bedeviled the industry. Using standard industrial cameras or mobile phones, FeaturePrint algorithms create unique digital fingerprints based on the minute surface details of each physical item.

Similar to human fingerprints, the digital “FeaturePrints” are inherently unique and persistent. “The technology eliminates reliance on removable tags, QR codes, data plates, labels, and paperwork, which are susceptible to damage, loss, manipulation, and fraud,” Alitheon said.

Longstanding risks in the aerospace sector were recently exposed via fraudulent events involving false paperwork and counterfeit parts and materials entering the aviation supply chain.

“FeaturePrint was developed to establish transparency, traceability, and trust using nothing more than a photo,” said Alitheon CEO Roei Ganzarski.

P.S.-S.

By Peter Shaw-Smith

Electric aircraft manufacturer and regional air mobility pioneer Lilium is expanding its “Power-On” aftermarket services portfolio, the German eVTOL aircraft manufacturer said at the Farnborough Airshow this week. Power-On provides a suite of digital solutions to ensure efficient and seamless operations of the Lilium Jet eVTOL.

In partnership with several digital providers, Lilium intends to deliver a full gamut of offerings for all aspects of the daily operation of the aircraft, including flight planning, flight

data monitoring, ground operations, and MRO services.

Initial partners already contribute to Lilium’s flight test campaign as part of the first phase. In a briefing at the Farnborough Airshow on Sunday, chief operating officer Sebastien Borel told reporters that testing and certification would involve around 1,000 flight hours before the aircraft gains regulatory approval from EASA and other watchdogs.

Microsoft’s Azure cloud solution will monitor the health of the aircraft to streamline its path to flight test clearance. As development continues, the offering will expand to integrate additional capabilities for efficient flight planning, using

The Cameroon Civil Aviation Authority (CCAA) has signed a memorandum of understanding with Luxembourg-based Vallair Group to cooperate on aeronautical training, maintenance, and workforce development.

The African country contracted with Vallair to transfer its maintenance know-how and to help it develop a comprehensive aircraft and engine tear-down and recycling ecosystem, including training a specialized workforce.

“The CCAA operates several domestic airports which provide a fertile ground for establishing economically beneficial and sustainable aircraft maintenance and disassembly operations,” said CCAA director general Paule Avomo Assoumou epse Koki.

“This partnership is an important opportunity to jointly study and implement a range of skills development activities.”

“CCAA has a world-class training facility for the development of skills, and it is accredited by ICAO, ACI and IATA,” added Vallair Group president Grégoire Lebigot.

“We have come together to combine Vallair’s worldwide reputation for aircraft maintenance and disassembly that maximizes the life and value of aircraft, engines, and components. Together we will impart knowledge and embark upon a far-reaching and innovative program that will also see Vallair’s expertise being replicated in Cameroon.” C.B.

Lilium’s Power On delivers a full gamut of offerings for flight planning, data monitoring, ground operations, and MRO services.

proprietary algorithms for Lilium’s energy and propulsion systems, and ground operations and vertiport management systems suitable for various types of landing sites.

Power-On will also work with travel technology company Amadeus on passenger check-in and biometric vertiport security screening and plans to use Amadeus’s global reservation system for eVTOL operations.

GE Aerospace’s event management system will supply flight data monitoring to improve safety management and training. Customers will also be able to access technical documents and request engineering support through a dedicated customer portal, which will integrate artificial intelligence functions for more efficient workflows.

“Our goal is to ensure that every aspect of operating the Lilium Jet is efficient, safe, and as seamless as possible,” said Borel.

Separately, in a representative survey conducted in the UK, Lilium found that almost three-quarters (71%) of the UK population want to see cleaner forms of air travel. More than 60% of respondents said they were concerned by aviation’s impact on environmental noise, traffic, congestion near large airports, and damage to rural environments.

Last week Lilium announced a firm order from the Saudia Group for 50 Lilium Jets and options on 50 more on July 18. It expects the aircraft to become commercially operational in 2026.

In a July 2024 SEC filing on the Saudia announcement, Lilium said its order book consists of 106 firm orders and reservations, 76 options, and roughly 600 aircraft under MOU. z

by David Donald

Bombardier has opened a new line maintenance station at Farnborough Airport, expanding the company’s customer service network in Europe and adding its ninth such station globally. The UK facility provides light scheduled and unscheduled maintenance for all Bombardier Learjets, Challengers, and Globals

“The addition of the Farnborough line maintenance station is an integral part of our

A new line maintenance station at Farnborough Airport will augment and support Bombardier’s heavy maintenance operation at Biggin Hill.

overall mission to provide easy and enhanced OEM support for our customers in this very important region,” said Paul Sislian, executive v-p of aftermarket service and strategy at Bombardier.

Bombardier’s Farnborough station follows that of its similar facility at Paris Le Bourget Airport. The two stations augment the major heavy maintenance service center at London Biggin Hill. At approximately 250,000sq-ft facility, the Biggin Hill facility features

By Cathy Buyck

Patria Aviation has received EASA supplemental type certificate (STC) approval for the installation of Astronautics’ AFI4700 RoadRunner electronic flight instrument (EFI) for Bell 212/412EP helicopters.

The Finland-based company is doing its first installation of the RoadRunner EFI on a Bell 412EP search-and-rescue (SAR) helicopter for the Finnish Border Guard (FBG). The work is part of an ongoing modification program to upgrade the helicopter’s avionics, communication, and navigation capabilities.

“Congratulations to our dealer Patria for receiving the first EASA STC for Astronautics’

RoadRunner EFI on Bell 212/412EP rotorcraft,” said Aymeric Larose, Astronautics’ director of business development. “Not only will the RoadRunner modernize and extend the service life of the FBG Bell 412 SAR helicopter and others to follow, it will also add needed capabilities that will decrease pilot workload and increase situational awareness.”

The retrofit has received approval for singlepilot IFR operations and enables localizer performance with vertical guidance (LPV) approaches and RNAV with GPS while interfacing with multiple aircraft sensors.

“Helicopter operators in Europe and worldwide are facing issues with avionics obsolescence, evolving airspace

22 service bays and offers a diverse range of services, including modifications, avionics updates, and interior enhancements. The shop can accommodate up to 14 Global 7500s simultaneously. Bombardier also runs a service center at Berlin-Brandenburg, a 160,000sq-ft facility in operation since 1997.

Its Farnborough line station joins a global network coordinated by a 24/7 customer response center and includes 35 mobile response team members. z

requirements, and new navigation options based on global navigation satellite systems, all of which require upgrading the pilot avionics,” explained Tuomo Jokisalo, head of airworthiness for Patria. “Patria’s EASA-approved design organization is working with several customers to solve these problems, and it is our opinion that the most costeffective way to answer the full scope of these requirements is with the Astronautics RoadRunner display system.”

Astronautics is showcasing the RoadRunner EFI at the Farnborough Airshow, along with the company’s other display, systems, cybersecurity, and connectivity products.

This week Astronautics announced that Airbus selected the AeroSync Max wireless airborne communication system as the line-fit connectivity solution for its new H160M helicopter. The airframer has also chosen Astronautics’ airborne communication server system as the cyber-secured maintenance server for its Tiger MkIII helicopter upgrade. z

By Hanneke Weitering

Artificial intelligence (AI) has begun to permeate just about every aspect of GE Aerospace’s business as the engine and aircraft systems manufacturer looks to boost efficiencies while continually improving its products.

Over the past decade, the U.S.-based group has established one of the largest portfolios of AI-related patents in the aviation industry, and it employs more than 100 specialists focused on AI and data science, according to David Burns, the company’s chief information officer.

“We’re also very humble to the fact that we’ve got a lot that we will continue to learn,” Burns told reporters during a briefing at the company’s Cincinnati headquarters in June. “We’ve got to make sure that our pace of learning keeps up with the pace that technology is evolving.”

GE has already incorporated AI into inspection processes and maintenance services. However, generative AI “is an area where we don’t have as much experience,” said Burns, “so we’re really looking to build out some of those capabilities.”

Generative AI models like Chat GPT use existing data to create new and original content such as text and images. Some have suggested that generative AI could someday design entire aircraft. For now, GE Aerospace concentrates using generative AI for more pragmatic, shortterm solutions, like helping software developers generate code, explained Dinakar Deshmukh, v-p of data and analytics at GE Aerospace.

Deshmukh said his team of software developers is experimenting with a generative AI application that has shown promising results, with individual productivity increasing and software development life cycles accelerating.

On the customer service side, GE Aerospace uses AI for predictive maintenance, applying data to aniticipate maintenance issues before

they become problematic. The company operates remote monitoring diagnostics centers in Cincinnati and Shanghai, where engineers monitor engine data around the clock to detect potential issues.

GE collects data from all 44,000 of its inservice engines during every flight. It combines that data with physical models and environmental details to inform its predictive maintenance algorithms, said Jayesh Shanbhag, the company’s v-p of customer experience.

“[For example], we are able to detect through analytics and through AI models an anomaly on an oil filter sensor [if] the signal that we are getting back is not in the normal parameters, said Shanbhag. “We run those models automatically and are able to generate an alert for the maintenance team of an airline,” he explained.

This engine-by-engine, analytics-based maintenance system helps operators to reduce the lifecycle cost of ownership and keep their assets flying with high utilization, Shanbhag said. GE provides the feature as a basic support service for all of its airline customers at no additional cost.

GE Aerospace is also implementing AI in its engine inspections for manufacturing as well as maintenance, repair, and overhaul (MRO) activities. The company already uses robotics to automate inspection processes and capture standard images. Now it feeds those images to machine-learning models to train the AI algorithms that power GE’s analytics-based maintenance program.

“Digital inspection [and] standard image collection allows us to apply advanced machine learning and AI models to really drive a better outcome for our customers,” said GE Aerospace chief MRO engineer Nicole Jenkins.

“We like to support our customers throughout the lifecycle of the engine,” she explained. “That means not only applying AI when the

GE’s STAC facility features a robotic inspection tool that uses X-ray fluorescence spectroscopy.

asset is with the customer and in service, but all the way down to the piece-part or repair level once the engine is in the shop and fully disassembled.”

To further advance its inspection and repair processes, GE Aerospace is opening a dedicated facility in Cincinnati called the Services Technology Acceleration Center (STAC).

Scheduled to open in September, the STAC facility will feature an inspection tool that uses nondestructive X-ray fluorescence spectroscopy (XRF) to detect structural variations inside metal parts. The XRF device, which GE developed in partnership with Bruker, uses the same technology that art collectors use to identify forgeries.

XRF inspection can also help to alleviate ongoing supply chain constraints, as it can more clearly delineate airworthy repaired parts that might otherwise be replaced.

Burns explained that GE’s approach to AI centers around three core principles: using trustworthy data, making models transparent, and keeping humans involved in the process.

“We’ve got to ensure that everything we’re putting through artificial intelligence is built on a foundation of solid data,” he said. “AI is great to bring decision recommendations [and] insights forward, but we’re really focused on making sure we’ve got humans in the loop on everything we’re doing with AI.”z

By Arie Egozi

A wave of GPS jamming and spoofing has sent commercial airliners and business aircraft offcourse while flying over the Middle East and northern Europe, raising concerns about the safety of air travel worldwide. Intelligence analysts widely believe the interference originates from hostile states including Iran and Russia and their surrogates.

In airspace where jamming occurs, aircraft operators experience a degradation of their Global Navigation Satellite Systems (GNSS) as receivers cannot latch onto satellite signals. Spoofing involves sending out bogus satellite signals to deceive GNSS receivers into computing erroneous position, navigation, and timing information.

Jamming and spoofing have become common in military conflict zones, such as in the Middle East and over the Black Sea. Israel first suffered from GNSS service denial when the Russian forces in Syria operated some powerful jamming systems. The war in Ukraine also created a wide area of airspace where operators cannot trust GNSS signals.

The capability of armed forces to deny access to the GNSS service prompted some countries to invest in technologies aimed at enabling their military forces to continue their reliance on GNSS-based navigation. The U.S. operates the GPS navigation system, which uses a dedicated constellation of medium Earth orbit (MEO) satellites.

GPS anti-jamming systems protect against deliberate jamming and interference for GPS receivers. When the GPS signal gets to the surface of the Earth, stronger radio frequency (RF) energy can overpower it. A tiny jammer with a power of around 10 watts for up to 30 kilometers (19 miles) of line of sight can interfere with an unprotected code receiver.

Until recently, primarily armed forces used anti-jamming systems, but increasingly the civil aviation sector has realized it needs

protection from GPS service denial.

In early 2024, the frequent disturbances to GPS systems in the Middle East and Ukraine prompted an effort of the civil aviation regulatory bodies to address possible solutions to the worsening problem. In January, the International Air Transport Association and European regulator EASA hosted a meeting at the latter’s Cologne, Germany, headquarters. Multiple aerospace and defense groups have risen to the challenge of applying technology that generally has originated in the military sector to protect civil aircraft.