SOLUTIONS IN BUSINESS AVIATION

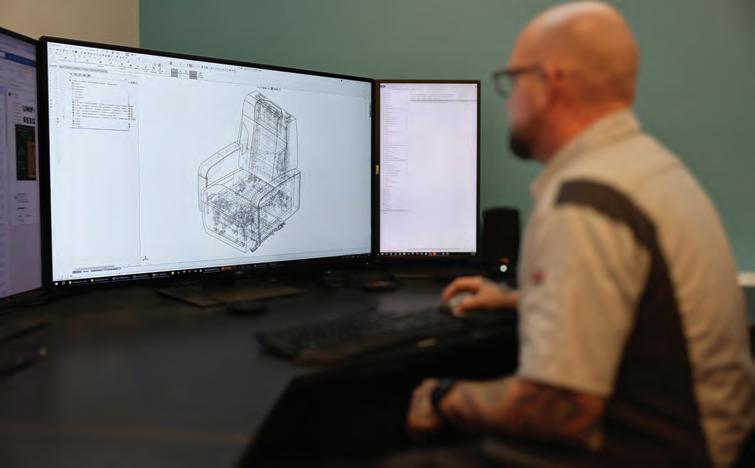

With decades of experience and thousands of installations, the avionics pros at Stevens Aerospace and Defense Systems know that the only way to deliver the performance their customers demand is to pay attention to every tiny detail.

Whether you’re flying a turboprop or large-cabin jet, sooner or later you’ll need to upgrade your avionics. The problem is that any shop can make the front of the panel look great. But it’s the attention to detail behind the installation that truly makes a difference in performance and reliability.

Prioritizing detail is what makes Stevens Aerospace and Defense Systems’ installations stand out from the rest.

As the company’s Director of Aircraft Modifications, Rob Reed, explains, “Over the years, we’ve developed several STCs to alleviate obsolescence issues on many types of aircraft. But no matter the goal, each job starts with our team ensuring every element is done to the highest level of quality and by paying attention to every detail behind the panel. That’s the only

way to guarantee that the systems will provide reliable performance for the life of the aircraft.”

One of the “smaller details” that sets Stevens Aerospace and Defense Systems installations apart is the quality of their wire terminations. It may not seem critical, but after a few hundred hours of vibration, a poorly terminated connector will fail, and so will the unit it’s connecting to.

“The quality supervisor in our Greenville (South Carolina) wiring harness shop has been certified as a trainer for the IPC/Wiring Harness Manufacturing Association A-620 standards,” Jim Williams, Stevens Aerospace and Defense Systems, VP Government Operations, adds. “It includes a robust quality

assurance system that approves every phase of our harness-making and connection termination processes.” This level of quality assurance and harness-building excellence is in place at Stevens’ wire harness facilities in both Greenville and Nashville.

Another detail that sets the company’s installations apart is the craftsmanship of its wiring harnesses. For example, both Stevens’ wire harness facilities have full-size mock-ups of King Air compartments to create pre-contoured harnesses for Garmin G1000 installations.

“Other shops build them on a flat table, and that means the wires and connectors can be strained during installation—which can lead to failures,” says Gary Brown, Stevens’ Nashville sales director. “We pre-contour the harnesses to eliminate all those stress points— and prevent problems.”

Reed adds that the company’s unmatched history of delivering high-end installations is one reason it does so much avionics upgrade work on various U.S. government agency aircraft.

“Our DoD contracts require extremely detailed processes, and we have incorporated many of them into our standard installation practices,” he says. “The result is that we’re bringing even higher quality, reliability, and safety to all of our customer aircraft.”

While the processes have evolved to keep up with changing technologies and customer needs, Williams stresses that it’s still the skills and attention to detail provided by Stevens Aerospace and Defense Systems technicians that makes the difference.

He added that the company is so proud of its technicians’ work behind the panel that it sends photos of the finished work to the aircraft’s owner. Not many shops do that today.

“It comes down to the technicians behind the connections,” Williams says. “They are the ones touching every part of the installation.

It’s their unwillingness to compromise that sets our installations apart.”

That level of quality enables Stevens Aerospace and Defense Systems to cover each of its avionics installations and stand behind the workmanship for “as long as they own the aircraft.”

“In the past four years alone, we’ve completed hundreds of cockpit and cabin avionics installations across our network of locations,” Williams explains. If there is ever a problem a problem with our workmanship, we will stand by it and get you flying quickly.”

“That kind of reliability is why our customers come to us,” he says. “In the end, system reliability is critical to their operational safety.”

» Authorized installer for Collins, Garmin, Gogo, Honeywell, STARLINK, Universal, and others

» From connectors to cut-outs, every detail is completed to the highest U.S. DoD standards

» Stevens’ world-class workmanship warranty - proven by 70-plus years of civilian and government installations and backed by decades of solid proven performance.

4

9 3

7 10

12 13 1

For over three decades, CAA’s independent contract fuel program has been the trusted choice for Part 91 turbine aircraft operators, offering not only guaranteed lower jet-A pricing but also discounts on other essential trip and aircraft handling services.

With the continued popularity of private aircraft travel, pilots and trip planners don’t need the added hassle of trying to find the lowest jet-A prices—and with CAA, they don’t have to.

“Whether they’re operating a fleet of longrange jets or a single aircraft, CAA’s independent contract fuel program guarantees members that they will pay lower prices than any other independent fuel program at participating FBOs,” stated a CAA representative. “We work hard every day to connect our loyal members with some of the best FBOs in the world who share our vision for fair and competitive fuel pricing.”

“We’ve partnered with leading independent and chain FBOs to ensure the price our members pay is at least ten cents a gallon lower than other programs,” they continued. Our members can easily access our pricing via maps on our website and mobile app. In addition, we also work with key fuel pricing locators, including ForeFlight, JetFuelX, and FuelerLinx, to make sure our pricing is easily accessible to our members.

CAA currently provides the guaranteed lowest contract fuel prices at over 260 domestic and international FBOs and handlers at con-

veniently located airports that business and private travelers want to fly to—no more landing at inconvenient airports to save on fuel.

The representative stated that, along with the lowest jet-A prices, CAA members also receive discounts on ramp fees, rental cars, hotel rooms, and even international trip planning through participating partner FBOs and providers.

“The strength of our program lies in our members. We currently have over 12,000 aircraft registered in our program, and we work hard to provide a great value to their operations every day,” they continued. “Our goal is to continue to grow our membership to drive more traffic to our CAA Preferred FBOs and ensure continued competitive pricing in the future.

To those ends, CAA is offering a FREE 90day trial membership to any Part 91 turbine aircraft operator. You can sign up at www. caa.org. After the trial period, operators may choose to join CAA and pay the yearly membership fee of $500 for each enrolled aircraft.

» Independent contract fuel program created specifically for Part 91 turbine aircraft operators

» Average 25% saving o ff retail prices

» Turbine aircraft operators can sign up for a FREE three-month trial at www.caa.org

“Since 1994, CAA has grown into the most trusted and respected name in competitively priced jet fuel in the business and private aviation user community,” the representative stated. “And all of our efforts then and now continue to be focused on encouraging the growth of Part 91 operations by bringing together operators and FBOs in a win-win arrangement.”

Duncan Aviation is acquiring the latest in digital design and automated material and foam-cutting tools to help its upholstery artisans continue to deliver the highest-quality cabin finishings while controlling costs and minimizing aircraft downtime.

Like any true art, hand-crafted upholstery takes time. Unfortunately, today’s MROs don’t have any to spare. Every minute counts when a customer brings their aircraft in for interior work.

How do you achieve consistent quality while minimizing downtime? Duncan Aviation’s answer: Upgrade its interior shops with the latest digital design and automated production equipment to help its team of experienced upholsterers continue to provide the extremely stylish and high-quality cabin completions they have been known for since 1981.

“In 2023 alone, we had over 460 interior work orders across our three facilities, and that means we have to strive for efficiency,” explains Duncan Aviation’s Lincoln, Neb., Interior Manager, Jared Stauffer. “Traditional upholstery work would mean significantly longer downtime for those aircraft. To help reduce that downtime, we’ve been upgrading our upholstery shop with automated tools to save time and maintain quality.”

Stauffer says that Duncan Aviation’s evolution to advanced upholstery automation started in the early 2000s when it installed its first CNC machine for leather cutting. The next big step was adding software to create custom seat and divan patterns.

“We’ve eliminated the time and cost of shipping the seats to Lincoln,” he explains. “All we need is a couple of measurements from the seats, and we can start the production process before the aircraft even arrives in our hangar. Or we can cut the leather here and send it to our Provo or Battle Creek facilities for final fitting. That saves a tremendous amount of time.”

Another recent automation addition is a new leather quilting machine, significantly increasing Duncan Aviation’s ability to create unique designs for its discerning customers.

“We were using outside vendors for this work, but that limited our control of the process both from a design and delivery standpoint,” Stauffer said. “Being able to work inhouse is a big plus for us.”

Another big time-and waste-saving technology adopted by Duncan Aviation is the addition of a five-axis CNC machine to cut seat foam to the most exacting design specifications.

“These technologies make it much easier for our technicians to produce top-notch quality and consistency in less time,” he continues.

“That leaves more time to concentrate on the finer points like uniform stitching, consistent panel gapping, and the overall high level of final finishing that sets our interiors apart.”

Like so many MROs, Duncan Aviation is faced with the fact that many of its talented uphol-

sterers are approaching retirement. In the past, it would take years to train an apprentice with the skills necessary to maintain the company’s legendary quality. Today’s automation is helping to dramatically shorten that learning curve.

“With routine tasks like material and foam cutting now being done by the CNC machines, we can concentrate on having our experienced craftsmen mentor our less tenured technicians, reducing their training time,” Stauffer explains. “By bringing the new hires up to speed quicker, we will be able to continue to deliver the exceptional quality our customers expect from us.”

While it may seem that advanced automation and digital technologies will replace experience and craftsmanship, Stauffer stresses that this is not the case—not at Duncan Aviation, anyway.

“Just to be clear, there’s nothing the machines can do that our craftsmen can’t. We have a lot of talent and experience under our roof,” he says. The main thing is that the automation enables us to better support our customers’ needs for high finish quality and low aircraft downtime.”

“It’s just one more way for current and future Duncan Aviation customers to see that we are constantly innovating to improve our services and meet their goals,” Stauffer adds. “We are taking steps to continue to do what we’ve done well since 1956: delivering the services our customers want.”

» Over 43 years of experience with high-quality aircraft cabin upholstery and refurbishing

» Talented upholsterers use advanced automation to create unique cabin finishes

» Automation enables new upholsterers to learn skills faster and with greater consistency

“Just to be clear, there’s nothing the machines can do that our craftsmen can’t. We have a lot of talent and experience under our roof... ”

JAMES HOLAHAN (1921-2015), FOUNDING EDITOR

WILSON S. LEACH, FOUNDER & CHAIR EMERITUS

EXECUTIVE CHAIR

Dave Leach

PRESIDENT

Ruben Kempeneer

HEAD OF PEOPLE AND BRAND

Jennifer Leach English

SENIOR DIRECTOR, INDUSTRY AFFAIRS AND EVENTS

Nancy O’Brien

ADVERTISING SALES

SALES TEAM LEAD - Victoria Tod – Northeastern U.S./Eastern Canada/ United Kingdom, +1 (203) 733-4184

Michelle James – Western U.S./Western Canada, +1 (520) 343-0236

Susan Joyce – Midwestern U.S., Southeastern U.S./Caribbean/Brazil, +1 (303) 641-5505

Diana Scogna – Europe/Middle East, +33 6 62 52 25 47

DIRECTOR OF MARKETING AND CLIENT SERVICES – Lisa Valladares

AUDIENCE DEVELOPMENT DIRECTOR – Eileen Silberfeld

MARKETING SPECIALIST – Alyssa Barry

SOCIAL MEDIA MARKETING – Zach O’Brien

SALES ADMINISTRATOR – Cindy Nesline

MANAGER OF FINANCE & HUMAN RESOURCES

Tracy Britton

ACCOUNTS PAYABLE

Mary Avella

ACCOUNTS RECEIVABLE Bobbie Bing

PRODUCTION MANAGER

Martha Jercinovich

GRAPHIC DESIGNER

Gzegorz Rzekos WRITER

Dale Smith

U.S. HEADQUARTERS

214 Franklin Ave., Midland Park, NJ 07432, +1 (201) 444-5075

Advertising Inquiries: +1 (201) 345-0085, adsales@ainonline.com

Circulation Inquiries: +1 (201) 345-0085, subscriptions@ainonline.com

This year’s edition of Solutions in Business Aviation marks its sixth anniversary and will have a different look, originally appearing as an exclusive sponsored content section within the pages of AIN’s August issue.

This change was made to ensure we keep delivering the superior content that you have come to expect from AIN. This feature is filled with compelling solutions from some of the top companies in the industry.

In addition, our industry continues to face issues regarding the management of generational differences as new graduates enter the market. This topic has been among the most popular roundtables at our Corporate Aviation Leadership Summit events.

To further stimulate this discussion, we asked market leaders how their organization is preparing for the retirement of highly experienced employees and transferring that knowledge to the next generation. Their responses are included in this edition of Solutions in Business Aviation.

Please enjoy.

Warm Regards

Lisa Valladares Director of Marketing & Client Services

Engine Assurance Program has amassed a $41M inventory of rental engines and replacement LRUs and complemented that with a large network of dedicated AOG technicians to meet one goal: Ensuring its customers enjoy 99.9% aircraft availability.

Whether you’re talking about Sam Walton’s two-seat Ercoupe 145c or a global conglomerate’s longrange jet, all aircraft owners have one thing in common: When they need to take off, they want their airborne assets ready to fly.

Unfortunately, engine-related AOGs do happen. When they occur, the Engine Assurance Program (EAP) team has the parts and the technical expertise to get its customers’ aircraft airborne as quickly as possible.

“We are totally focused on supporting our customers and their aircraft,” explains Sean Lynch, EAP’s founder and managing director. “That’s why we’ve invested over $41 million in our inventory of rental engines, replacement oil pumps, fuel controllers, and the like.

“I can’t tell you the last time a customer has been AOG because we could not get them an oil pump,” he continues. “And as of today, we still have a flawless track record of getting rental engines on customer aircraft quickly. I think only Honeywell has a larger stock of TFE731-series engines than EAP.”

Parts are just pieces of the solution.

Of course, any business jet MRO would give their “eyeteeth” to have access to EAP’s extensive parts pool, but Lynch knows that parts

aren’t worth much if highly experienced technicians aren’t available to install them.

“We’ve negotiated an exclusive arrangement that gives us priority access to a team of top field service technicians,” he says. “These technicians are basically on ‘standby,’ so when a customer has an AOG situation, the expertise they need will arrive as quickly as possible.

“In my opinion no one else in the business is going to the extent that we are,” Lynch continues. “It’s a huge investment, but it actually saves us time while assuring the high quality of the work. And because the parts and engines come from our inventory (as often as possible), we get the parts faster and at lower overall costs.”

As you might expect, solving AOGs is just one service EAP delivers to its customers. The dedicated field-support relationships can also provide routine inspections and maintenance along with more in-depth services like R&Rs, performance runs, fan balancing, vibration surveys, engine borescoping, and more. “It sounds like a cliché, but everything we do is to benefit our customers,” Lynch stresses. “Other MROs might not see it today, but ours is a customer-focused business, and our customers care about dispatch reliability.

“We are investing in the parts and people

to help ensure that our customers can use their airplanes when they need to fly,” he says. “We take great pride in helping them do that, and that commitment is the reason we are in business.”

See the list of engines we cover. Visit eap.aero or call +1 (214) 350-0877 for a quote.

» An exclusive network of engine AOG specialists helps achieve a 99.9% aircraft dispatch rate

» Supporting 26 models of legacy CFM, Honeywell, Pratt & Whitney, and Rolls-Royce engines

» Also offering rental engines for MPIs

How is your organization preparing for the retirement of highly experienced employees and transferring that knowledge to the next generation?

We strive to hire the best and brightest at CAA. In our customer surveys, we get excellent feedback on our customers’ interactions with our team. In fact, 99% of our customers say they plan to renew their membership—an extraordinary number. We continue to grow our employees and expand their responsibilities to ensure we continue to provide great services and customer experiences in the future. We also provide our team with an education reimbursement program to continue expanding their skills for today’s competitive marketplace. I absolutely love working with this amazing team!

David Scobey, President & CEO

Duncan Aviation has developed excellent partnerships with technical trade schools and high schools with aviation programs. We are also active in the DOD SkillBridge program, which provides opportunities for separating service members. In addition, we have a Department of Labor-certified A&P Apprentice Program to help team members attain the necessary skills for engine and airframe maintenance certification.

Jeff Lake, President

With the entire industry struggling to maintain a qualified workforce today, preparing for tomorrow is a daunting challenge. Along with mentoring the younger members of our team, we collaborate with organizations such as the Love Field Pilots Association and the Independent Falcon Aircraft Operators Association to engage and inspire the next generation of aviation professionals.

Sean Lynch, Managing Director

The Naples Airport Authority strategically addresses succession throughout the year. Employees are offered career path planning, robust training, industry engagement, and professional development opportunities. We are committed to retention by striving to be a best-in-class employer and maintain a formal succession plan.

Chris Rozansky, Executive Director

Covering 99% of the globe, Intelsat’s FlexExec and FlexAir are the only high-speed connectivity solutions “purposebuilt” to meet the rapidly increasing bi-directional throughput needs of today’s data-hungry business, personal, and governmental aviation passengers.

According to a report by Euroconsult Prospects, the connectivity capacity demand for business aviation will increase up to 60 Gbps by 2030. That’s a tenfold jump from today’s usage.

While that number may seem extraordinary, consider that a business aircraft’s data usage is expanding to not only meet increasing passenger needs but also include a growing array of high-demand applications that manage the critical aircraft and engine health monitoring information flowing to and from the airplane.

“Not long ago, higher-down load speeds were the end goal, but today, there’s a greater need for much higher upload speeds,” explains Tuomo Rutanen, Intelsat’s director of business and government aviation. “Video conferencing alone requires much higher bi-directional throughput speeds. Passengers won’t settle for poor network performance just because they’re in an airplane.”

Rutanen says that Intelsat has created its dedicated business aviation network “from the ground up” to deliver the high-quality user experience its customers expect.

“We’ve ‘purpose-built’ our network of satellites and ground stations to accommodate that fact that we’re connecting to jets traveling at

600 miles-per-hour,” he explains. “The jet is going from beam to beam very quickly, so our network anticipates the aircraft’s track to make sure the beam capacity is ready to pick it up.”

“We own and operate the largest constellation of Ku-band satellites, which means we have plenty of capacity worldwide,” Rutanen continues. “And because we have multiple layers of satellites in key locations, we can turn up the number of beams to add capacity in high-demand areas to ensure the data fow doesn’t get slowed down.”

“That’s unique in our industry. Some of our competitors try to do it with a single-layer of satellites, but in times of high usage, they don’t have access to the added capacity to meet the needs quickly,” he adds. “That fexibility is one of the big benefts of our FlexExec and FlexAir solutions. We deliver when others can’t.”

Rutanen says that today, Intelsat’s network consistently delivers speeds of 25 Mbps download and two Mbps upload speeds, but there’s more to come.

“By the end of this year, we’re going to double our bi-directional speeds to 50 Mbps on and three Mbps off the airplane,” he explains. “We have a roadmap that will take us to 100 Mbps and beyond in terms of the capacity we will deliver to the aircraft.”

“Our fexibility extends to giving us the ability to offer our providers and their customers a range of service options,” Rutanen concludes. “No matter what they want in a connectivity solution, we can deliver what customers want.”

» Global, enterprise-grade connectivity solution purpose-built for business aviation

» Multi-orbit satellite network delivers consistent performance in high-usage situations

» High-capacity, bi-directional throughput provides seamless global voice and video streaming

» Offered through Intelsat’s partner Satcom Direct

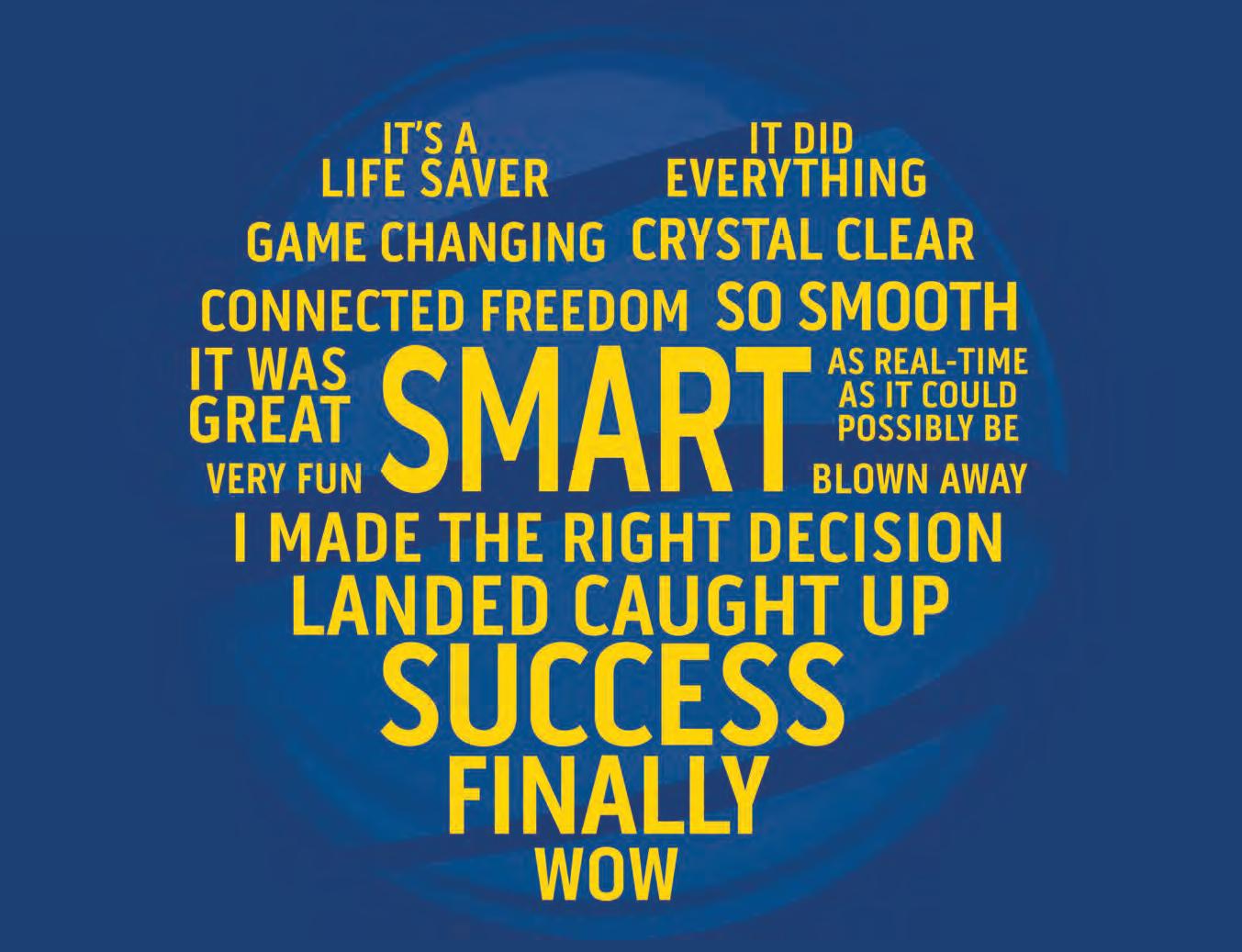

Created for business aviation, SmartSky’s patented ATG connectivity solution has been built from the ground up to provide the seamless connectivity capacity, speed, reliability, and security that today’s pilots and passengers really love.

When you think about it, we all have a love/tolerate relationship with our technology. Sure, we love what it can do, but we also need considerable tolerance for when it’s not performing up to par—like when you’re struggling with dial-up data speeds while flying on the company jet.

What you wouldn’t give to have your aircraft’s connectivity provider show you a little

love. Thankfully, that love/love in-flight Wi-Fi experience is closer than you think.

SmartSky® offers the only next-generation air-to-ground (ATG) connectivity solution that is fully tested, certified, and operating today. It reliably delivers the same online experiences in flight that you enjoy everywhere else. What’s not to love about that?

“Our network has been specifically built

to meet business aviation’s unique airborne connectivity needs,” explains SmartSky CEO David Helfgott. “Providing a reliable, two-way, real-time connection to an airplane flying at high speeds, at varying altitudes, that frequently changes directions, is very difficult. It’s connectivity in three dimensions, and it’s not easy.

“It requires a totally different network ar-

chitecture optimized for the unique needs of aviation,” he continues. “Any provider using a commonly-shared resource like a satellite— that bandwidth, by definition, is not optimized for aviation because it’s shared with all the other primary users, including thousands of users on the ground within the same footprint.”

Not only has SmartSky’s entire “pure-play” ATG network been created specifically for aviation, it delivers inflight connectivity in a new way.

“I would say that we haven’t just introduced a new network; we have invented a new kind of ATG network,” adds SmartSky Networks’ President Ryan Stone. “Our architecture has one ‘beam’ dedicated to each connection. Effectively, you have a private nationwide network following your aircraft.” And then, only aircraft are using the network and, instead of flying through a broad signal that is shared with other planes, your individual connection to each tower is handed off seamlessly as you travel across the coverage area.

“Our patented beamforming technology enables us to provide high-speed, low-latency, symmetrical data flow specific to a single aircraft,” he continues. “That sets the stage for what we alone can deliver—seamless,

real-time streaming capabilities.”

But what does that mean to SmartSky users? As Barry Blackwood, a veteran pilot flying a SmartSky-equipped Pilatus PC-12, says, “It’s a total game-changer. Having the SmartSky system on board is immensely valuable in aiding aviators with communications and access to real-time flight information.”

“A high-capacity datalink connection can augment flight operations and the safety of flight,” Stone says. “We are seeing a lot of interest from pilots because our network delivers what others can’t.”

“Connectivity use has moved aggressively downstream from large-cabin jets to single-engine turboprops,” Helfgott says. “But with that has come the expectation that the smaller aircraft will have the same online experience you have on big aircraft. That’s what SmartSky was created to deliver.

“Our hardware requirements are very compact, so we are able to get streaming-level, symmetrical datalink performance in aircraft where it has never been available before,” he continues. “Right now, we’re obtaining new STCs quickly, and by the end of the year, we’ll have 14,000 tails covered for SmartSky installations.”

» Low latency, 20x capacity of other ATG, equal bandwidth moving data to and from the aircraft delivers seamless real-time streaming and unprecedented performance

» Patented beamforming means no signal sharing, plus highly stable and secure connections

» Flagship and LITE systems deliver seamless connectivity to turbine singles through VVIP jets

That’s great news for the growing numbers of MROs and dealers that sell and install SmartSky because, in a word, customers love it.

“What’s different and so much easier about SmartSky is there is no pre-set limit to the number of devices connected, unlike the legacy ATG systems. We can have watches, cell phones, and computers connected as if you were in your office,” explains Eric Legvold, CEO of Davinci Jets. “Plus, customers can use their cellphones to make calls without any special app and stream on any device, all without paying additional fees or subscriptions.”

“We talk to our customers all the time, and it’s pretty common to hear them say how dissatisfied they were with their legacy connectivity provider and how much they love what SmartSky lets them do,” Helfgott adds. “These are people who expect high quality and consistency. There’s no tolerance for anything less.”

Whether it’s providing a first-class travel experience for its guests or implementing industry-leading environmental and sustainability programs, the Naples Airport Authority is working hard to live up to its promise of being the gateway to the Paradise Coast.

From the moderate winter temperatures to the relaxing Gulf breezes to the plethora of sporting and recreational activities, it’s no wonder Naples has earned its title as Florida’s “Paradise Coast.”

But as we all know, paradise is a fragile thing. That’s why, since its inception, the Naples Airport Authority (NAA) has been committed to taking whatever steps it can to ensure the airport safely handles the 122,000-plus movements it sees annually while actively protecting and enhancing the area’s sensitive natural environments.

“Naples attracts people because of its quality of life and breathtaking natural beauty,” says Christopher Rozansky, Naples Airport Authority’s Executive Director. “We aim to take every step we can to protect and enhance both environments.”

In fact, the NAA is a recent recipient of the Florida Airports Council (FAC) J. Bryan Cooper Environmental Award for its Com-

prehensive Wildlife Management Program, which included stormwater drainage system enhancements that improve water quality exiting the airport grounds and removing invasive slash pine trees near the approach end of runway 05. That effort not only enhanced aircraft operational safety but also eliminated popular nesting locations for bald eagles.

The NAA took another significant step forward in mitigating GA’s environmental impact by becoming one of the first public airports in Florida to offer UL94, unleaded avgas, at its FBO.

“We are striving to be at the forefront of making aviation more sustainable while ensuring the safe operation of all aircraft that use Naples Airport,” Rozansky states. “Offering the option of UL94 is a significant step in that direction.”

He also explained that the NAA, under the direction of its Board of Commissioners, is offering subsidies to its tenants that will cut the cost of UL94, selling at, or below, the price of 100LL. In addition, the NAA is offering tenant aircraft a one-time $250 credit to offset the required FAA certification.

“I am so excited about the Naples Airport Authority’s commitment to GA and the envi-

ronment by offering UL94 as an option,” states aircraft owner and Naples resident Linda Sollars. “I am exceptionally grateful for the ability to purchase unleaded fuel here in Naples.”

In addition to the introduction of UL94, the NAA is upping its sustainability game by phasing in a zero-emissions fleet to replace its fuel-powered ground support equipment and field vehicles.

Whether through encouraging the use of lead-free fuels, its voluntary “Quite Hours Curfew,” or a long list of ecological and environmental enhancements, the Naples Airport Authority is committed to protecting the local environment while ensuring the safe operation of every aircraft that uses the airport.

“As aviation continues to progress into new and exciting directions, including preparation for Sustainable Aviation Fuel and the eventual introduction of electric aircraft,” Rozansky continues, “the Naples Airport Authority aims to be an industry leader in environmentally sustainable and responsible technologies and programs.”

643-0733

» Recently remodeled terminal with on-site Customs office ranked among the “Top 10 FBOs”

» NAA recently received multiple awards for sustainability and environmental protection efforts

» First airport in southwest Florida to sell UL94 no-lead avgas

» Custom-tailored loan packages created by pilots who understand the turbine aircraft world

» Funding available for all types of new and pre-owned piston, turbine, and jet aircraft

» Refinancing options available that can save owners thousands per month

For over 10 years, owners of all classes and categories of aircraft have been trusting AOPA Finance’s experience and expertise to help them obtain the best financing package available while avoiding any transactional turbulence.

Congratulations—you’ve decided now’s the time to move up to a turboprop. While there are plenty of decisions still to be made, one of the biggest is who will handle your financing package.

“But wait,” you say. “I’m nowhere close to financing. I haven’t even found the right airplane.” Ah, but waiting is one of a buyer’s biggest mistakes. And the reasons go well beyond just being “pre-qualified.”

As AOPA Finance Director of Credit & Sales Brian Macbean explained, there are a lot of factors that impact the loan rate available to a borrower, especially when it comes to turbine-powered aircraft. The aircraft’s age, loan amount, down payment, term length, usage and even the borrower’s previous experience with turbine aircraft operations all play a role. If it sounds complicated, it’s because aircraft financing is different than what most people are used to. That’s why you need to start the financing process early and should have a turbine aircraft financing expert on your side.

“We’ve handled thousands of aircraft loan transactions, so we have a lot of experience and insights into which lenders are going to be the best match for a particular buyer,”

he said. “There are some lenders who prefer particular aircraft and will offer better terms on those models. That means faster approvals and lower interest for borrowers.”

Macbean stressed that this doesn’t mean that the airplane models that lenders find less desirable are unsafe or inefficient; it means that they are looking for qualities such as an aircraft’s utility and resale value. For example, right now, the Pilatus PC-12 and Cessna CJ3 are two examples of aircraft that lenders like.

“There is so much utilitarian value in these aircraft that lenders are eager to finance them,” he continued. “Some lenders also prefer to finance aircraft that are more expensive. With a larger purchase price, you’ll likely have slightly better terms available because these lenders have more interest given the dollar amount of the loan.”

Macbean also shared other insights into how lenders look at turbine aircraft differently than piston models.

“Buyers don’t know that most lenders require turbine aircraft to be on some type of

engine program to get a loan,” he said. “They also want to know if the aircraft will be operated under Part 91 or a Part 135 certificate. All that impacts the length and type of financing available.”

“Our only business is aircraft financing, so our experience allows us to put transactions together in the most beneficial ways .” Macbean continued, “AOPA has a strong reputation for helping our members with their aircraft and aviation needs, because of this reputation AOPA Finance is able to provide our members with access to the best lenders and the best possible financing options. Working with AOPA Finance means you have a team dedicated to the success of your aircraft purchase.”