BA3 Technologies Part C

Technical Detail Study: Architectural Fragment

Alexandra Cristina Iordache

ID 20104134 [CPU]ai Atelier

Techologies Positions

Architectural Design Position + Technical Detail Study Purpose

Technologies Resolution Plan (HOW?) + Framing your Architectural Fragment (FOCUS)

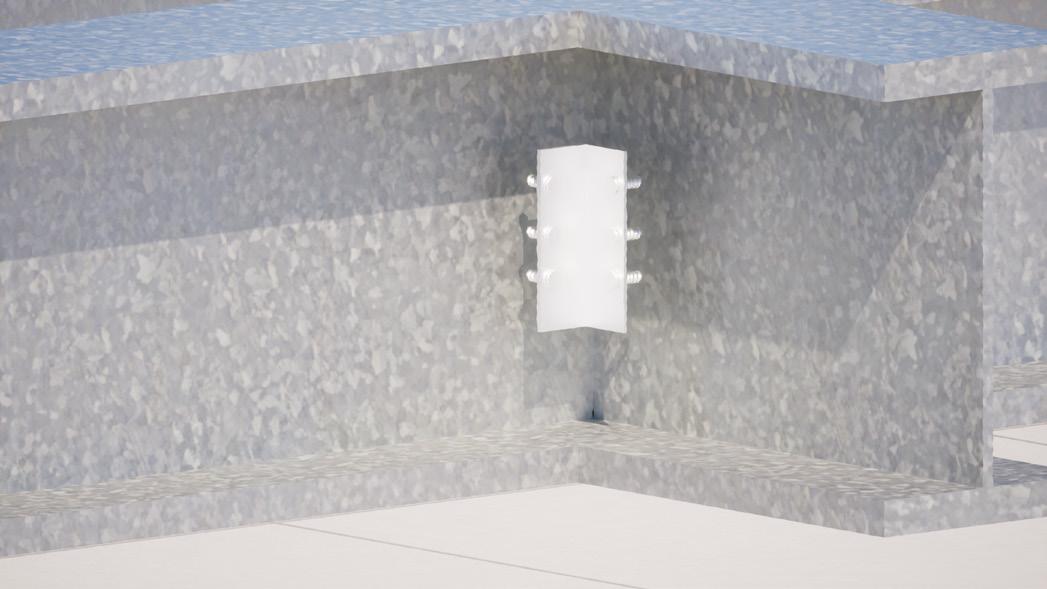

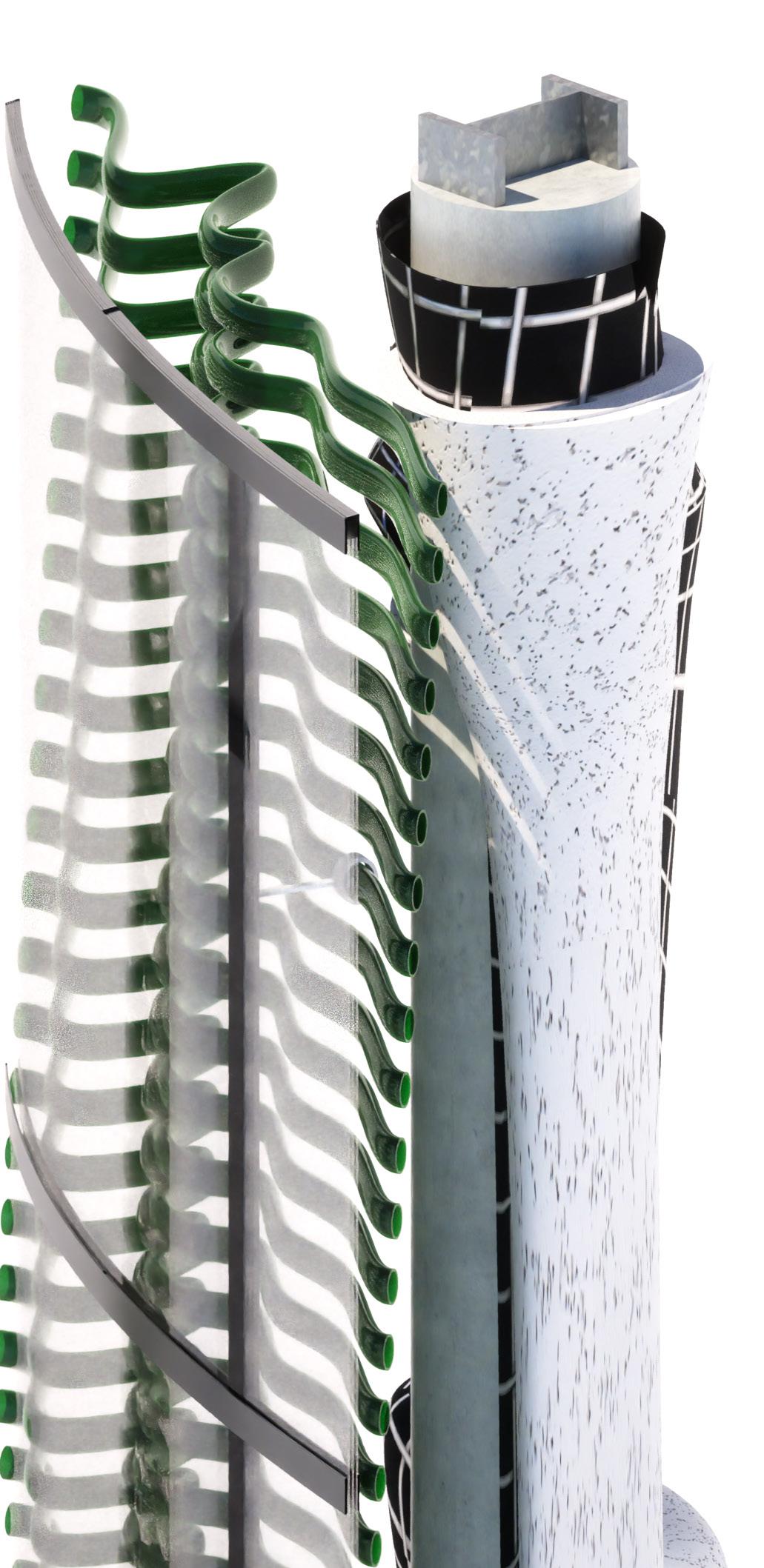

The chosen Architectural Fragment is an extract of the South-orientated façade of the building developed in [CPU]ai Atelier. It showcases the roof, façade system, mezzanine access bridges, ground floor, and basement interior wall. All these are significant technological features of the project, enclosed in a 300x300x400cm volume (total height of the ground floor facade is 1000cm, so the facade itself has been sectioned in the middle to accomodate the brief dimensions).

Aligned with the CPU[ai] Atelier position, the design reflects its two themes this year: ‘‘Zero Carbon Futures’’ and ‘‘Biophilic Design’’. This architectural fragment of the building addresses new possibilities for the future of the University campus, meant to transcend and engage beyond the boundaries of the traditional disciplinary domain. Encompassing spaces for the MMU Faculty of Health, MMU Faculty of Education, but also a physiotherapy clinic for the community, the project explores themes of Health and Wellbeing (both mental and physical healing environments), Design/Systems/Futures Thinking (referencing biophilic design, environmental strategies -wind & solar energy, rainwater harvesting, algae biofuel generator for lighting and electricity), Adaptability/Change-Over-Time (focus on recyclablity and modular/pre-cast construction), Growth of the Circular Economy (by integrating produce gardens and partnering with Hulme Community Garden Centre, Brooks Building, and the surrounding community), and Human-Centred-Design (Education, Medicine, Community- a powerful hub of interconnectivity).

One of the key aspects of the project is the use of biomaterials, especially mycelium With a focus on both edible and functional fungi, the project aspires to be a ‘‘living building’’, within a self-sustainable ecosystem. Mycelium is a network of fungal threads, like roots, from which mushrooms sprout; it’s an exposed sentient membrane that is aware and responsive to environmental changes. It’s the oldest and largest living organism, and can theoretically live on forever. Similar to human interconnectivity and neural networks in our brains, a ‘‘mycorrhizal network’’ connects multiple plants and trees together and transfers water, nitrogen, carbon and other minerals in need, essentially becoming an ecosystem’s way of communication. This ensures resilience and health for the organisms involved, meaning that trees, plants, and produce gardens can thrive with such a system, even if artificially introduced. In construction materials such as thermal and acoustic insulation, and even load-bearing panels and bricks mycelium is extremely resilient, and its self-healing properties can mend mechanical damage - which means the building’s lifespan increases with the use of mycelium, too.

Response (WHY?) Technologies Artefacts (WHAT?)

Roof Type: INTENSIVE GREEN ROOF

1. Hydroscopic Soil, min. 150mm depth, as substrate for native, slow-growing, biodiverse flora with shallow roots. Water management system in place to resolve drainage, rainwater collection, and plant watering.

2. Geotextile Filter.

3. Drainage Board.

4. Waterproof Membrane.

5. Insulation: Mycelium insulation

6. Vapour Barrier Control.

7. Graphene-Infused Concrete (Concretene)

Pre-cast Slab. This type of concrete is more sustainable than the regular type, having a lifetime of 200 years, as opposed to 100 years for concrete. It delivers higher strength and durability, faster curing time, reduced water and cement usage, lower environmental impact, as well as cost savings. It also reduces shrinkage and cracking.

8. Aluminum Roof Deck.

Facade System: BIO-centric, Green Energy Generator

9. Triple Glazed Curtain Wall - three panels of glass separated by gaps filled with insulating gas. Triple glazing has more depth and higher installation cost than double glazing, but also offers more energy efficiency, noise reduction, and thermal comfort than double glazing. U value: 0.8-1 W/m^2K, lower than double glazing, and the life expectancy is approximately 20-35 years.

10. Algae Pulley System - Algae is strung on rope and harvested manually using a pulley-system, accessible through the mezzanine bridges. Pumped from a tank in the basement trough pipes, the nutrient medium solution in which the algae will grow is contained by the curtain walls. Algae biomass is then mechanically filtered and transformed into biofuel, which can be used for electrical and heating needs.

11. Steel I-Beams (UB 406 x 178 x 54) and Steel I-columns (UB 305 x 165 x 54). Chosen for their resilience, ease of disassembly and reuse, as well as spanning distances required by this project, structural steel elements are an environmentallly conscious solution for this project. Steel channels/spider clamps are the connectors between steel columns and curtain walls.

12. Aluminum frame for the triple-glazed windows, secondary structure. Chosen for durability and strenght over Vinyl / PVC (polyvinyl chloride) or wood frame, they have a longer lifespan, don’t require maintenance and are not so energy intensive in production.

13. Concealed ceiling, containing the electrical wiring, plumbing pipes, and the HVAC system, as well as acoustic panels for overall noise reduction. The services are concealed mainly for aesthetic reasons.

Building and Life Safety

This architectural fragment aims to analyse part of the primary steel structure of the building, which is based on a long-spanning grid system of 8000x8000mm. Timber structure was ruled out on the basis of load-bearing capacities (the building has 7 levels), but also it’s incompatibility with Manchester’s climate - being a natural and cellular material, it moves with changes in climatic conditions. Wood also requires a lot of maintenance to look good over time, and it is predisposed to mold, pest, rot or being affected by fungi. Since the building uses different types of live mushroom mediums and mycelium insulation quite heavily throughout the building, it would be a risk to the building’s longevity. Also, the native and biodiverse fauna and flora that this project intends to attract can possibly harm the timber in time.

Additionally, by using steel columns and beams, the project ensures its recyclability properties -worldwide, around 90% of steel is recycled-, and expedites the process of construction.

Constructability

The design uses mostly pre-fabricated structural elements and pre-cast slabs. This is to ensure that the building’s carbon footprint is lowered and only concerns the emissions during transportation and on-site assembly processes.

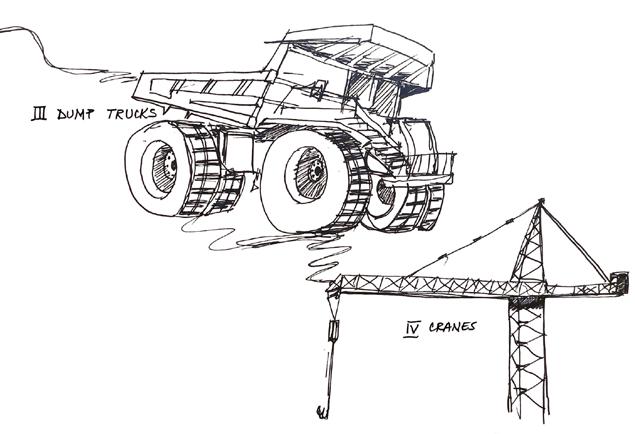

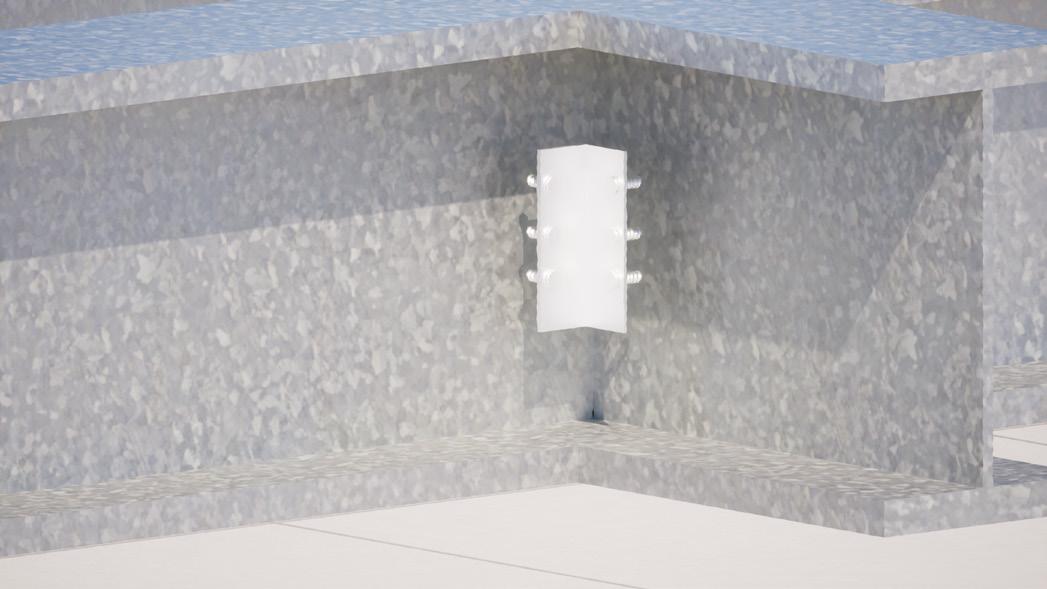

For example, the steel beams and columns are securely assembled together using steel brackets and nails. Below is shown an L-shaped bracket holding two structural beams, raised in position with the help of cranes, and manually secured with nails on-site.

15. Acoustic Insulation type: Mycelium

As acoustic insulation, mycelium outperforms petrochemical/plastic based construction elements, and is safer and healthier. It is made with agricultural by-products that would otherwise go to landfill, it’s a regenerative manufacturing process, and carbon-negative so it’s good for the environment. Mycelium provides excellent acoustic insulation, as it shows an acoustic absorption of at least 75% at 1000Hz (the typical frequency of road traffic noise).

16. Timber Floor Deck.

17. White-coated metal railing.

Ground Floor: INTERIOR

18. Timber flooring - native wood - Elm, Oak, or Ash.

19. Acoustic Insulation type: Mycelium.

20. Underfloor Heating (UFH) + Tacker Insulation Panel. Underfloor heating is more energy-efficient than typical radiators, as it spreads the heat evenly throughout the spaces. It provides a better visual and thermal experience for the building users, and requires little to no maintenance.

21. Damp-Proof Membrane.

22. Thermal Insulation Type: Mycelium

As thermal insulation, it does not contain the synthetic, resin-based compounds that can cause harmful toxic smoke and the quick spread of flames during a fire. Mycelium releases less heat and smoke when burned, and takes a longer time to flash over synthetic materials owing to its charring behaviour, inhibiting spread when exposed to fire. Mycelium outperforms most biomaterials in thermal performance, having a thermal conductivity as low as 0.03W/m.K.

23. Concretene Pre-cast Slab.

24. Aluminum Floor Deck. Unlike other decking options, it is really low maintenance, and resistant to mold and humidity. As such, there is no risk of potential live mycelium components in the building to be affecting it.

Ground Floor: EXTERIOR - Extensive Green Roof

25. Hydroscopic Soil, min. 50mm depth, as substrate for native, slow-growing, biodiverse flora with shallow roots. Water management system in place to resolve drainage and plant watering.

26. Geotextile filter

27. Drainage Board

Basement: Interior Wall

Mezzanine Access Bridge 14. Timber flooring - native wood - Elm, Oak, or Ash. Using timber as a floor finish has a positive psychological impact on its users, and has a naturecentric aesthetic combined with the bio-composite materials used in this building, such as the mycelium and the algae elements.

28. Mycelium panels (1200x2400mm)acoustic/thermal insulation and educational exhibit on benefits of bio-materials in sustainable futures.

29. Timber framing for mycelium - Green Douglas Fir Beams -Douglas fir has the highest strength rating as a softwood and is a cost effective choice for timber framing. As a structural timber, it offers a cost effective wall frame material.

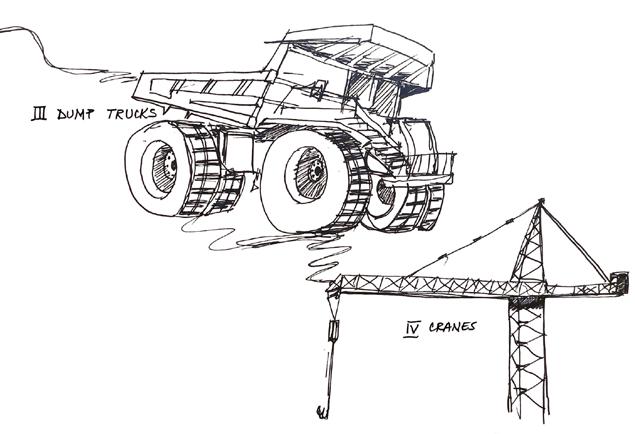

Tools

Sketch shows the vehicles necessary for the construction and assembly processes.

site, excavation of basement, laying the foundation, bringing the materials to the site and assemblying them.

Using structural steel elements, pre-fab slabs and finishes ensures a lower operational carbon footprint, faster construction and assembly processes and materials can be recycled and reused in construction.

Construction steps are:

1. demolition of pre-existent building on site.

2. excavation of basement.

3. laying the foundation

4. assembly of the steel structural columns and beams.

5. placement of pre-cast floor and roof slabs. [the image on right shows progress between the 5th and 6th step]

6. erecting the external walls, aluminum glazing frame, triple glazing and algae system.

7. erecting the internal walls, wall frames and mycelium panels.

8. placing the floor and roof finishes

9. add the service areas.

10. place the green roof layers, the soil and the plants.

Processes

MSA | BA3 Technologies Part C - Technologies Design Project | Alexandra Cristina Iordache - CPU[ai] -20104134 Technologies

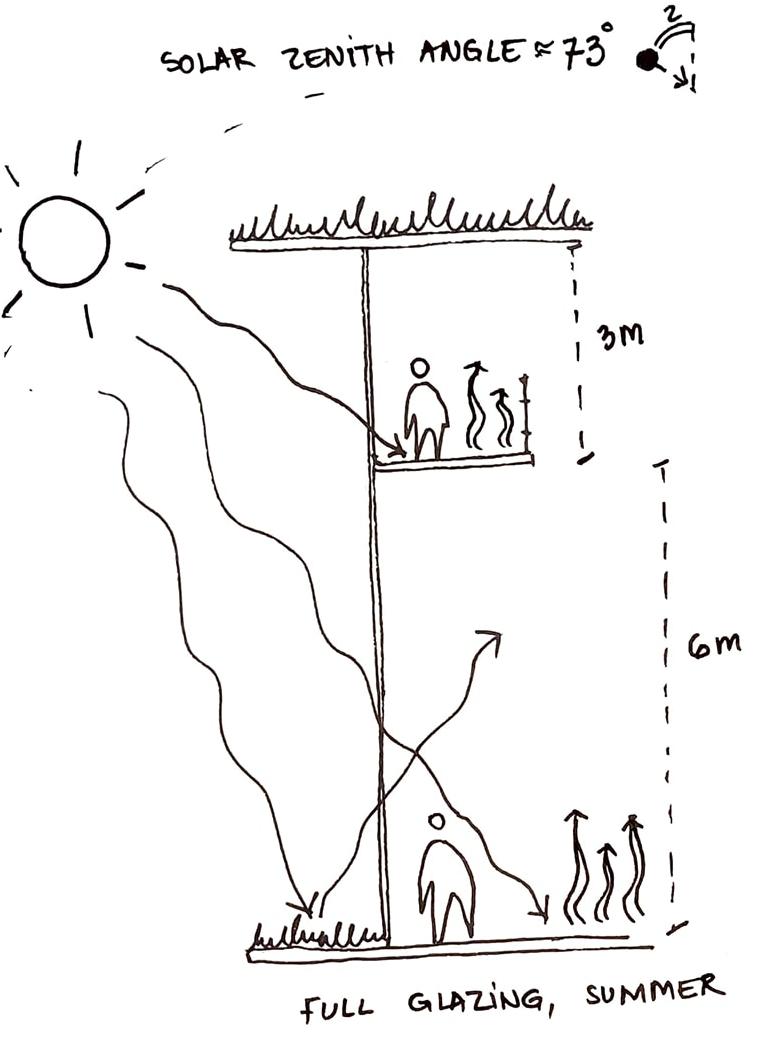

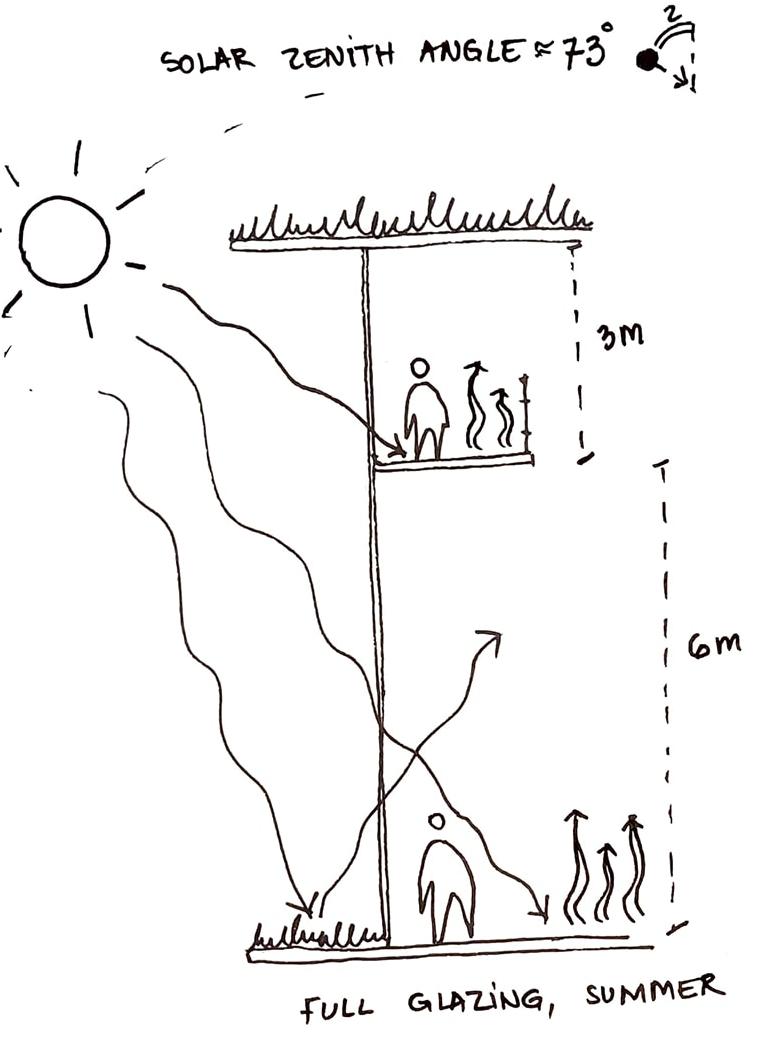

Materials Climate Change In terms of environment and interior climate, the façade performance is a critical point in the design process. Being a fragment of the South-facing area of the building, full glazing requires further strategies to optimise the project’s thermal performance. Therefore, the elected strategy for the façade system involves a seawed wall, meant to control the solar and thermal gain of the building. The sunlight is filtered through the algae medium and partially absorbed by it, which offers user-comfort during the day. Besides solar shading, the algae biomass is then transformed into biofuel - to be used in the building’s energy requirements. During winter, when the sun is lower, the algae medium can be filtered in a thinner medium, to ensure natural light enters through the façade, thus lowering the amount of artificial lightning needed. During summer the façade aims to lower the amount of solar gain also with the instalation of mezzanine bridges, which block the higher sun angles but also ensure maintenance access, as well as connectivity throughout the building’s open spaces.

01

construction process requires demolition of pre-existent structure on

The

1. 2. 3. 4. 5. 6. 7. 8. 11. 11. 11. 9. 10. 13. 14. 17. 15. 16. 11. 12. 18. 19. 20. 21. 22. 23. 24. 11. 29. 28. 11. 25. 26. 27.

This exploded axonometric of the architectural fragment analysed in the Technology Detail Study, exposing the layers making up the South-facing part of the building. It showcases the roof, façade system, mezzanine access bridges, ground floor, and basement interior wall.

Prototyping Constructability Iterative Testing + Record of Process

The focus of the prototyping is generating different facades from a constructability point of view, concerning the materials used, the connectors, and the environmental strategies employed within the building, as well as thermal comfort and solar gain throughout the year, and building and life safety.

: 3D modelling of the facade using Rhino, and Grasshopper plug-in for the parametric design of the algae pipes in the latter stages of testing - there are four iterative stages in the process.

Steel I-Columns

Steel Spider Clamps

Algae Pulley System

Algae nutrient solution

Triple-Glazed Curtain walls

Aluminum Window Frame Grid

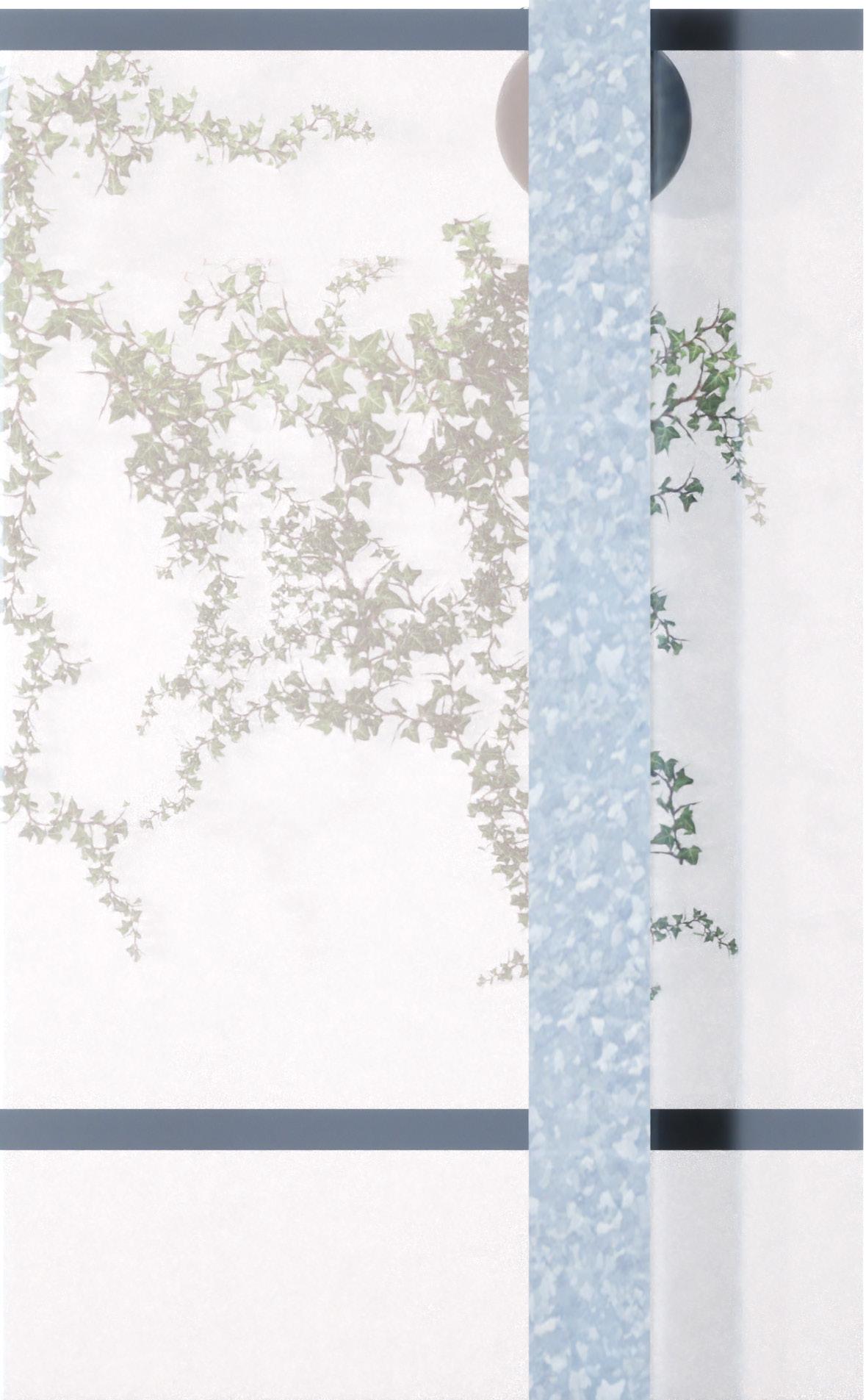

The aspect of the architectural fragment tested is the ease of constructability of the facade, especially concerning the algae bioreactror system and its connections to the structure. This first iteration shows the initial considerations, a strategy regarding seaweed on a pulley system, that would be grown in a medium of water and nutrients enclosed by two curtain walls. As structural integrity, the triple-glazed curtain walls were to be supported by an aluminum frame split into a grid of 3000x3000mm and 3000x4000mm. Steel spider clamps would be the connectors between the aluminum frame and the steel columns (UB 305 x 165 x 54). The algae biomass would be manually harvested from the access bridges, and then mechanically processed into biofuel in the basement of the building, from where energy would be generated. However, the downside of this strategy would be the high-maintenance and supervision needed to harvest, as well as maintaining the nutrient solution ermetically contained within the glass walls, and the proper growing temperatures.

Steel Circular Hollow Seection (CHS)

Graphite-Infused Concrete Filling

Steel Spider Clamps

Algae Tubular Bioreactor, Vertical Pipes

Triple-Glazed Curtain walls

Aluminum Window Frame Grid

The secondary iteration of the facade buildup shows the replacement of the algae pulley system and sealed nutrient solution. A tubular algae bioreactor, vertically orientated, ensures that the culture is in continuous motion, as to prevent matter from stagnating. The algae is not seaweed-sized anymore, it’s microalgae sized. Low-maintenance mechanical process in producing biofuel would be installed in the basement - a feeding vessel and a media recyrculating tank, powered with a pump, inserts CO2 and a solution of microalgae, water and nutrients into the pipes of the bioreactor. When exposed to sunlight, the matter decants and is collected via pipes into a filter system with cooling attachment, from where biomass is harvested and then transformed into biofuel. The whole production process is simple and easily manageable on site grounds, and provides energy that can be used in the building, achieving the ‘‘building as an ecosystem’’ agenda for this project. There is no more need for two adjacent steel columns, so they’ve been replaced by a CHS column.

Algae Tubular Bioreactor, Parametric Design Generated

Steel I-column UB 457 x 191 x 98

Steel Spider Clamps

Mycelium Insulation

Triple-Glazed Curtain walls

Aluminum Window Frame Grid

Further documentation determined a third iteration in which there is only one curtain wall. The reason is that the ideal temperature parameters for the algae bioreactor are between 15-30 degrees Celsius, temperatures which the interior environment will be within at all times, year-round. This decision also eliminates the carbon footprint of the second triple-glazed curtain wall. Additionally, the algae tubular bioreactor has the pipees generated parametrically, and orientated horizontally. This greatly improves the aspect of the facade, and provides better solar shading. The structural column is back to I-shape, due to the use of less concrete than the CHS steel column filled with concrete. Mycelium insulation bricks clad the steel column in an interlocking attachment connection, and secured with natural adhesives if more support is needed. Using mycelium not only provides thermal and acoustic insulation, but also explores the very core of the building’s purpose: showcasing the use of biomaterials in the architectural world for a sustainable future, especially mycelium.

Algae Tubular Bioreactor, Parametric Design Generated

Steel I-column UB 457 x 191 x 98

Vapour Control Barrier + Insulation

Aluminum mesh, clamped/bolted on the I-column

Mycelium Panels, with external waterproof coating, glued to the mesh with natural resin

Triple-Glazed Curtain walls

Aluminum Window Frame Grid

In the fourth and last iteration, the buildup of the column was reconsidered for a safer and more resilient mycelium cladding. The mycelium panels are to be attached to a metal mesh withnatural resin, and externally coated with a waterproof layer. Clamps or bolts will connect the mesh to the I-column, and extra vapour control barrier and insulation layers have been added to ensure no interference of the mycelium with the steel, just as a precaution for steel’s longevity. As the mesh is flexible and lightweight, it will not be an impediment in the structural capabilities of the primary steel structure; moreover, it improves the columns stability. Both the mycelium panels (grown in custom molds) and the mesh are maleable in terms of shape, so the column will apear as organically formed mycelium structures to the outside eye. Additionally, the aluminum window frame will be attached directly to the beams, which ensures a continuity in the parametrical algae tubes, hence the aesthetic impression of a continuous facade, uninterupted visually by the steel structural columns.

The external view of the facade would expose the medium and the algae in the solution, providing a green, biophilic aesthetic to the users. However, due to the extemnsive spacing between the curtain walls, the sunlight would barely be able to penetrate the facade, which would increase the need of artificial lighting in the interior spaces, especially during winter or just cloudy days. Even if the medium and concentration of the solution could be manually controlled, due to the unpredictable climate of Manchester, UK, it would require permanent maintenance and adjusting to reach the optimal levels of illumination needed in the spaces.

Reflections on Climate

On the second iteration, the facade allows for natural light penetration while also offering solar shading and solar gain control. However, the vertical orientation of the tubes require more energy from the pump to continuously circulate the matter up and down, which indicated that the horizontal orientation of the tubes can solve this dilemma. Additionally, the aesthetic of the facade seems a bit rigid in communication, and although it indicates an environmental strategy to its users, the shadows and overall vertical tubular bioreactor pipes elude to a confining type of space, restrictive in terms of accessability.

Regarding performance in terms of daylight, thermal comfort, and energy demand, the question of whether to combine the algae bioreactor facade with regular, triple-glazing or photovoltaic glass depended on the goals of the project. For the primary goal of producing algae for use as a renewable energy source, it would be more beneficial to use photovoltaic glass in combination with the bioreactor facade. The photovoltaic glass can generate electricity from sunlight, helping to offset the energy used in the bioreactor system and providing additional renewable energy for the building. However, the PV glass is generally darker in shade, so it would restrict the daylight levels on top of the shading provided by the algae tubes.

On the other hand, for the goal of creating a visually striking and biophilic facade that integrates living organisms into the building design, the choice would have to be regular, triple-glazing. This would allow more natural light into the building and provide a clearer view of the algae growing within the bioreactor system.

To reduce thermal bridging in the aluminum frames for the curtain walls, the windows will be fitted with timber components, as thermal breakers, to reduce heat loss through the metal.

As for the third iteration, the horizontal orientation of the algae tubes provides a more serene aesthetic, and better solar shading properties. The use of mycelium as cladding for the column showcase biophilic design throughout the building, and the elimination of the second, internal curtain wall provides more transparency in the facade. This openness from the inside spaces allows free exploration of the algae bioreactor system by the users, and the parametrically generated design achieves a modern, organic, natural visual. The interruption in the facade is provided by the attachment of the secondary aluminum frame structure to the steel columns.

The final iteration achieves the wanted narrative of the design. As the system is now fully resolved, this iterative testing’s results are to be integrated into the architectural fragment studied. The constructability parameter by which the prototyping was done has offered a design that is easy to construct from a technical point of view, and has optimised material needs (components can be efficiently produced off-site and installed on-site, lowering the operational carbon footprint of the project), as well as connectors that are suitable for the systems involved (and that yield a shorted time of assembly process).

Reflections on Building and Life Safety

In terms of Fire Resistance and preventing Fire Spread, the properties of mycelium ensure that in case of a fire inside the building, the flames will take a long time to burn though this biomaterial, since it tends to char and not spread the fire. Mycelium doesn’t realease much heat and smoke when burned, and is similar to timber in terms of burning time.

Using mycelium on a mesh or netting allows the creation of more organic and irregular shapes for the column cladding, which could be designed to resemble mycelium root connections, trees, or other natural forms. Mesh or netting can be flexible and adaptable, which allows it to conform to the contours of the columns and support irregular shapes. This makes it possible to create a more fluid and natural appearance for the mycelium cladding, rather than being limited to the rigid and angular shape of the steel I-shaped column.

The mesh with the mycelium cladding offers an interesting and visually appealing design option, and the structure is safe, durable, and functional over time.

MSA | BA3 Technologies Part C - Technologies Design Project | Alexandra Cristina Iordache - CPU[ai] -20104134 02

1. 2. 3. 4.

Annotated

axonometric render of the South-facing facade buildup, 1st iteration

1st iteration Elevation render of the South-facing facade buildup, 2nd iteration Elevation render of the South-facing facade buildup, 3rd iteration Elevation render of the South-facing facade buildup, 4th iteration

Methodology

Annotated

axonometric render of the South-facing facade buildup, 2nd iteration Annotated axonometric render of the South-facing facade buildup, 3rd iteration Annotated axonometric render of the South-facing facade buildup, 4th iteration

Elevation render of the South-facing facade buildup,

Image courtesy [Photovoltaic Glass for Buildings - Onyx Solar. Available at: https://onyxsolar.com/ (Accessed: May 1, 2023).] Image courtesy [Mavrik European Windows. Available at: https://www.mavrik.build/ (Accessed: May 1, 2023).] Image courtesy [Critical Concrete. Available at: https://criticalconcrete.com/ (Accessed: May 1, 2023).]

Fire simulation render on the mycelium-clad column, Twinmotion

Technical Detail

Integrative Systems + Design Conclusions

The key features represented on the technical detail are the green roof, façade system, mezzanine access bridges, ground floor, and basement interior wall.

Roof Type: INTENSIVE GREEN ROOF - designed to respond to Constructability, through the use of a typical buildup of intensive green roofs, with integration of a soil substrate for native, slowgrowing, biodiverse flora with shallow roots. Water management system in place to resolve drainage, rainwater collection, and plant watering.

- designed to respond to Climate, the green roof reduces the urban island effect, cools the building, and enhances the building’s thermal performance.

Facade System: BIO-centric, Green Energy Generator

- designed to respond to Constructability, through the previous iterative testing of 3D digital model. - designed to respond to Climate, the triple-glazing increases heat retention and is more efficient than double-glazing; the aluminum frame fitted with timber components to reduce termal bridging; the algae bioreactor provides shading and provides renewable energy for the building. - designed to respond to Building and Life Safety, the mycelium does not spread fire.

Mezzanine Access Bridge + Ground Floor: INTERIOR

- designed to respond to Constructability, decking is pre-fab and mounted on site on the steel beams.

- designed to respond to Climate, the mezzanine acess bridges provide additional shading to the interior spaces, especially during the summer, when the sun is higher.

- designed to respond to Building and Life Safety, the mycelium insulation does not catch fire like synthetic insulation would do.

Basement: INTERIOR WALL

- designed to respond to Constructability, the buildup only consists of Green Douglas fir timber frame and mycelium panelling, attached to the main steel structure through the steel beams. - designed to respond to Climate, the mycelium responds to both thermal & acoustic insulation needs. - designed to respond to Building and Life Safety, the mycelium panels do not pose a fire safety risk.

Reflections of my Techologies Position + Design Insighs

The constructability tactical experiments on stage 2 advanced the design of the South-facing facade in a way that’s easy to construct and assemble, efficient in terms of algae bioreactor system as renewable energy generator, and aesthetic purposes. The facade is the driver of the building’s visual journey into a biophilic and biomimetic design, powered by environmentally-conscious materials and renewable energy production. Therefore, the project has also advanced on the climate and building and life safety aspects of this technical detail.

This design project encapsulates the essence of the CPU[ai] Atelier’s vision, showcasing the architectural fragment of a building that embodies the themes of “Zero Carbon Futures” and “Biophilic Design.” By addressing the future possibilities of the University campus, this project explores various aspects such as Health and Wellbeing, Design/Systems/Futures Thinking, Adaptability/Change-Over-Time, Growth of the Circular Economy, and Human-CentredDesign. With its focus on sustainable technologies, environmental strategies, community engagement, and interconnectivity, this architectural fragment represents a powerful glimpse into a building that not only benefits the university but also fosters collaboration and enhances the surrounding community. Through this design, one can envision a harmonious blend of functionality, aesthetics, and sustainability, paving the way for a brighter and more inclusive future.

In conclusion, this project stands as a testament to the power of sustainable design and its potential to shape a better future. By seamlessly integrating the RIBA Sustainable Outcomes into every facet of the design, this architectural fragment not only reduces operational and embodied carbon but also sets new standards for environmental responsibility. Through the careful selection of materials, from mycelium insulation to locally sourced timber, the design commits to responsible sourcing, ethical practices, and a circular economy. By optimizing energy efficiency through features like triple-glazed windows and efficient mechanical systems, the project achieves a net-zero operational carbon impact, making this building not only environmentally friendly but also economically viable in the long run. Moreover, the emphasis on longevity and resilience embraces a holistic approach to design that considers the well-being of both people and the planet.

RIBA Sustainable Outcomes of the developed design:

Net Zero Operational Carbon:

(2) focusing on reducing the building’s heat loss, achieving a low carbon, sustainable project that’s affordable to heat (mycelium insulation, timber thermal bridging, triple-glazed windows)

(3) fine tune internal environment with efficient mechanical systems – the façade plays a key role of the internal environment control throughout the summer and the HVAC mechanical ventilation system further improves the interior thermal comfort.

(5) Specify ultra-low energy sufficient appliances – low energy appliances for generating artificial light, they buildings permits natural lightning throughout the whole year thus artificial lightning is minimum and utilised in certain situations

(10) design building with ease of disassembly and the circular economy in mind – using standard prefabricated steel materials for the primary structure, the materials proposed could be recycled and further used for other purposes.

Net Zero Embodied Carbon:

(3) prioritizing responsible and ethical sourcing of materials - mycelium uses agricultural bi-products, and can be locally moulded.

(6) targets zero construction waste diverted to landfill – the project predominately uses materials prefabricated off-site.

(7) using the soil excavated in the creation of the landscape. using locally sourced timber such as Oak, Ash & Elm.

(9) building long lifespan and resilience – materials chosen for the design have long life spans, and mycelium is a renewable material.

MSA | BA3 Technologies Part C - Technologies Design Project | Alexandra Cristina Iordache - CPU[ai] -20104134 03

Concealed services: plumbing pipe, and HVAC system with airflow direction

Aluminum window frame to steel beam connector steel plate with screws detail

Aluminum window frame to algae tubular bioreactor parametric pipes steel connector detail

Mycelium on timber frame internal wall detail

3D digital model axonometric composition of the Architectural Fragment