CONSTRUC TION

Find out more about how Cordell Connect and Cordell Estimator Platinum can help your business grow

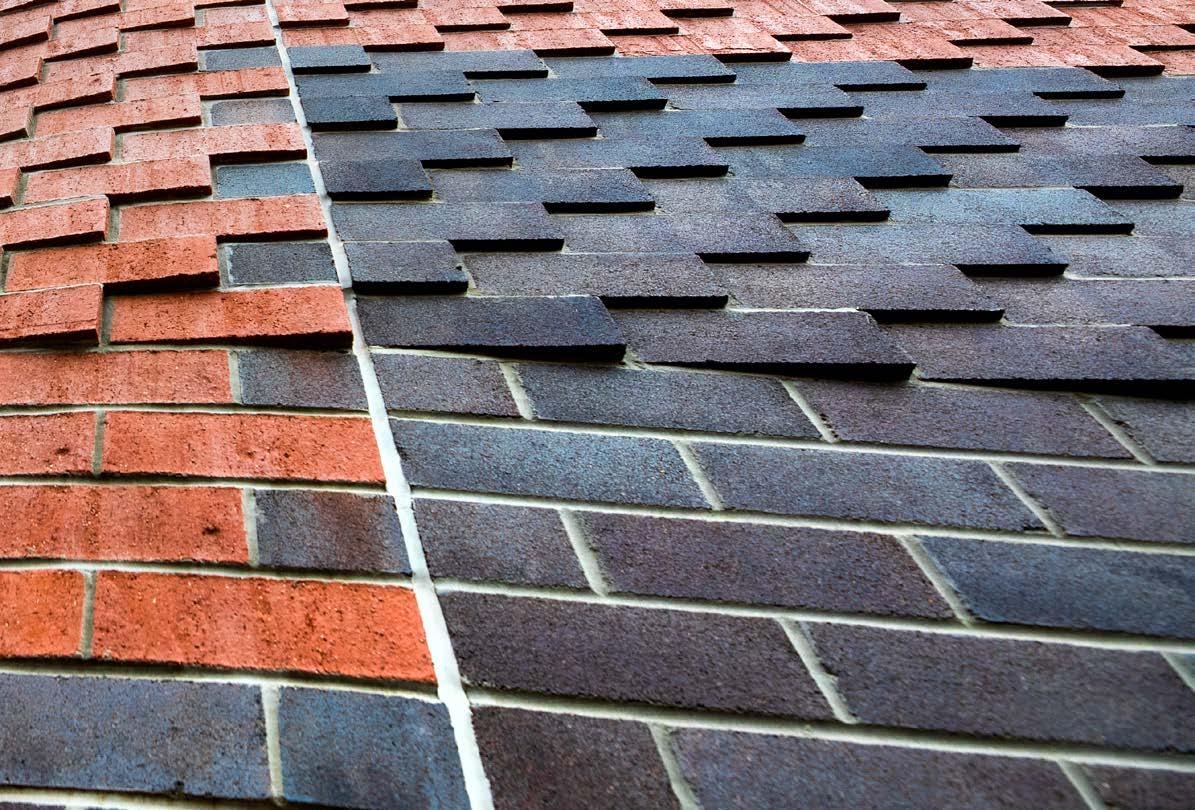

BORAL’S UPGRADED

CARBON-REDUCING TECHNOLOGY

AT ITS BERRIMA CEMENT WORKS

Boral Limited’s (Boral) upgraded carbonreducing technology at its Berrima Cement Works was officially opened, signifying a significant step in Boral’s move to net zero. Federal Minister for Climate Change and Energy, the Hon Chris Bowen MP was on-site to officially open the upgraded facility.

Located in the Southern Highlands region of New South Wales (NSW), Boral’s Berrima Cement Works is responsible for supplying 40% of cement in NSW and the Australian Capital Territory (ACT). The upgraded facility is a significant milestone in the company’s decarbonisation efforts and transition from its reliance on emissionsintensive fuels.

A key part of its upgraded facility, the Chlorine Bypass (which reduces the buildup of chlorides and other alternative fuel by-products), will enable alternative fuel usage to reach 60% over the next three years at the site. To date, Boral has already achieved 30 per cent coal substitution.

As part of Boral’s integrated operations in the NSW Southern Highlands, Berrima Cement Works is strategically significant for the company and to Australia’s manufacturing capability. It is also an important regional employer, with a workforce of around 115 people in operational and administrative roles, contributing to the approximately 350 people employed across integrated sites in the Southern Highlands.

The site also indirectly supports local jobs associated with logistics, contractors, and suppliers. To this end, it is one of the largest employers within the Wingecarribee Local Government Area.

On the opening, Vik Bansal, CEO of Boral, said: “From our Federal Highways to the Sydney Opera House and Parliament House in Canberra, for almost a century, the Berrima Cement Works have helped to build and shape Australia.

“We all understand that though cement is vital to construction and building our

nation, it is carbon-intensive. Boral takes its responsibility to decarbonise our operations and comply with the Safeguard Mechanism obligations seriously. The Chlorine Bypass Facility reaffirms this commitment and moves our vital cement manufacturing infrastructure and Southern Highlands operations into a new era - one with less impact on the planet.

“We thank both the Federal government and NSW Government for their respective investment in this facility and remain committed to decarbonising our operations, in line with our net zero commitment.”

SKYview

Boral’s Berrima Cement Works, photographer Paul Robbins

HEALTHY MINDS, SAFE SITES: NSW GOVERNMENT WORKING TO IMPROVE PSYCHOLOGICAL WELLBEING IN CONSTRUCTION

The Minns Labor Government is undertaking a campaign across New South Wales construction sites to improve psychological health and safety at work.

Known as the ‘Healthy Minds, Safer Sites’ campaign, inspectors are providing advice and resources to manage psychosocial hazards. These include aspects of work and situations that may cause a stress response, which in turn can lead to psychological, and sometimes physical harm.

The initiative forms part of the New South Wales Government’s Psychological Health and Safety Strategy 2024-2026 plan which is backed by $5.6 million over the next two years to deliver workplace mental health programs.

Some of the common psychosocial hazards in the construction industry are harassment (including sexual or racial), bullying, work pressure, exposure to a traumatic event and violence, and hazardous physical working environments.

Workplace mental ill health is estimated to cost Australian businesses up to $39 billion each year, due to lost participation and productivity. In addition, the rise in psychological injury is leading to an increase

in workers compensation claims which in turn is pushing up premiums. An investment in preventing psychological injury will also save money.

The NSW construction industry employs over 400,000 people. Data shows that psychosocial hazards are increasing, with the cost and time off work typically three times higher than that of physical claims. Between 2019 and 2024 there were almost 900 major workers compensation mental stress claims in construction, with work related harassment and/or bullying the most common reason.

SafeWork NSW Inspectors have found most employers are aware that poor mental health is an issue, with around half reporting that they have assisted a worker or colleague with mental health issues. They will continue their visits to construction sites until the end of March 2025.

One business working to achieve a psychologically healthy and safe workplace is Western Earthmoving Works Pty Ltd. They have a vision of mentally healthy workplaces by listening to their people and designing workplaces where people can thrive.

Preventing psychological harm, supporting

recovery, and promoting mental health are critical components of a mentally healthy workplace.

All employers can achieve psychologically healthy and safe workplaces by taking these steps:

• identify the things that could cause harm and consider the potential risks,

• consult with their workers on things that could cause harm and ways to manage risks,

• implement control measures to eliminate and minimise risks,

• monitor worker safety to ensure control measures are working, and

• review the controls regularly.

For more information on how to manage psychosocial risks and for further resources, visit the SafeWork NSW website

Need help? Reach out to your GP or access free help 24/7 by calling the following:

Lifeline Australia 13 11 14

Beyond Blue 1300 224 636

MensLine Australia 1300 789 978

Suicide Call Back Service 1300 659 467 Mates in Construction 1300 642 111

CHARTER HALL EXECUTES $3.35 BILLION GREEN LOAN TRANSACTION, ONE OF THE LARGEST IN THE SECTOR

Charter Hall Group (Charter Hall or the Group) has executed a fully underwritten $3.35 billion of Green Loan facilities on behalf of one of its funds, marking the completion of one of the largest Green Loan transactions in the Australian real estate sector.

Led by CBA, WBC, ANZ, HSBC and SMBC as Mandated Lead Arrangers, Underwriters and Bookrunners (MLAUBs), the transaction is part of a strategic capital management initiative for its $8.6 billion flagship office fund, Charter Hall Prime Office Fund (CPOF or the Fund).

The strategic capital management initiative has enabled the Fund to leverage its market-leading sustainability credentials and implement a best-in-class finance platform

providing significant financial and operating flexibility. This will facilitate the delivery of CPOF’s premium grade development pipeline and strategic objective of providing long term outperformance for its investors.

This transaction grows Charter Hall’s platform-wide sustainable finance to more than $9.0 billion, 100% of which is in the Office sector, reflecting its continued progress toward integrating sustainability

into its operating assets. Further, the Green Loan facilities secured in this transaction have been certified by the Climate Bond Initiative and independently verified by DNV and KPMG, ensuring a thorough and transparent approach.

Do you have a project, media release, product or news item you would like to feature with the Australian National Construction Review?

Get in touch with our submissions team by scanning the code or at submissions@ancr.com.au to find out more.

Scan to read the full article.

ARDEX AUSTRALIA OFFICIALLY OPENS OCEANIA HQ AT THE YARDS ESTATE, NSW

ARDEX Australia has officially opened its Oceania HQ at The YARDS Estate in Kemps Creek, NSW, a joint venture between Frasers Property Industrial and Aware Real Estate.

The new $140 million facility is targeting a 6 Green Star rating from the GBCA. The new manufacturing regional headquarters features a world-class 35m-high powder manufacturing tower, a 20m silo tower, onsite production and manufacturing, research labs, warehouse storage, training rooms and has been built to enhance employee wellbeing with an onsite gym, multiple cafes areas for staff, a rooftop terrace and highend interior designed offices by IA spanning over 3,000m2

ARDEX Australia, a global company that specialises in the development and manufacturing of high-performance building materials, is expanding its footprint in NSW and created their state-of-art flagship facility in Australia.

Fabian Morgan, Regional Managing Director for ARDEX Oceania and Member of the Global Management Committee, said:

“ARDEX has built its reputation on quality performance and a relentless commitment to meeting the evolving needs of the building and construction industry.

Today, the facility enhances our ability to deliver on that commitment. We’re not just increasing production capacity, we’re embracing our future, we’re embracing innovation, sustainability and aspirational excellence. Thank you to Frasers Property Industrial and Aware Real Estate for your partnership in developing the site. The professionalism, vision and collaborative spirit across all teams has been critical in bringing this project to fruition.”

The new HQ location at The YARDS is strategic for an optimal national logistics network for the warehouse, located nearby the 24/7 Western Sydney International Airport and future Southern Link Road in

SUBSCRIBE NOW

Your Subscription to the Australian National Construction Review ensures you receive our premium hard copy publication, featuring stunning Project Showcases, Case Studies, Product Information and Commentary from within the industry and associated disciplines.

OR if digital is more your speed, subscribe to our e-newsletter, released monthly for a snapshot of new products, innovations and services that can benefit your next project. Scan the QR code to Subscribe

the Western Sydney Aerotropolis, close to the M4 and M7, and within Greater Western Sydney’s sought-after industrial zone.

The opening ceremony was attended by Mayor of Penrith, Councillor Todd Carney and Member for Badgerys Creek and Shadow Assistant Minister for Jobs and Small Business Tanya Davies MP, along with the teams at Frasers Property Industrial, Aware Real Estate, Barings and ARDEX Australia.

The YARDS, an expansive 77 ha estate in the Mamre Road Precinct, is undergoing significant construction with five additional buildings scheduled for completion in 2024. The estate is now 75 per cent leased, with a limited number of remaining available lots.

Currently available is Lot 6 and is planned for completion in early 2025.

SHORT-TERM PIPELINE UNCERTAINTY UNDERMINES LONG-TERM INFRASTRUCTURE DELIVERY

The release of Infrastructure Australia’s Infrastructure Market Capacity 2024 Report high-lights the urgent need for greater certainty and confidence to support Australia’s $213 billion five-year pipeline of major public infrastructure.

Consult Australia has welcomed the report’s insights while raising concerns about the shortterm volatility in the infrastructure pipeline, which continues to undermine business confidence, investment and workforce planning.

Jonathan Cartledge, Chief Executive of Consult Australia, says: “The report’s findings will come as no surprise to the industry. Businesses are grappling with a challenging environment where changes to previously committed projects are forcing firms to restructure and make redundancies. This volatility is particularly alarming in areas where we already face long-term skills and capability gaps, such as engineering and professional services.”

Now in its fourth year, the Infrastructure Market Capacity 2024 Report shows an 8% decline in the value of previously committed projects compared with projections from the same period last year.

Transport infrastructure remains the largest expenditure category, accounting for 59% of the major public infrastructure pipeline, but with a significant $32 billion reduction compared to the previous year’s forecast.

“The reduction in transport infrastructure investment, particularly in Victoria and New South Wales, is creating a ‘two-speed economy,’ with regional areas and northern Australia seeing greater growth while metropolitan areas bear the brunt of project delays and cost changes,” Mr Cart-ledge says.

Infrastructure Australia’s report notes that these delays and project reviews have shifted projected investment peaks further into the

future. While the report suggests the market may be struggling to deliver an overly ambitious pipeline, the issue lies with governments’ inability to deliver confidence and certainty, Mr Cartledge adds.

“Businesses need pipeline continuity to invest in capability, skills and workforce development. Without it, we risk further undermining Australia’s long-term capacity to deliver the infrastructure we need.”

The report also underscores the critical importance of improving construction productivity, pointing to the need for better risk allocation in contracts and a more collaborative approach to project delivery.

“We welcome Infrastructure Australia’s focus on construction productivity and look forward to working across government to support reforms through the National Construction Strategy.”

ALPHA HPA REACHES CONTRACTUAL CLOSE FOR $400 MILLION TO DELIVER AUSTRALIA'S FIRST LARGE-SCALE HIGH-PURITY

ALUMINA PLANT

Alpha HPA announced that it has reached Contractual Close with Export Finance Australia (EFA) and the Northern Australia Infrastructure Facility (NAIF), securing pivotal debt funding for Stage Two of its High Purity Alumina (HPA) First Project in Gladstone, Queensland.

The company has executed binding documentation for $400 million in senior debt financing which includes a $320 million construction facility, and an $80 million cost overrun facility, with competitive interest rates and an 11-year tenor from Financial Close.

Alpha HPA’s Managing Director Rimas Kairaitis, describes the milestone as a major achievement for the company.

“The Australian Government’s support underscores confidence in our innovative technology, sustainable production processes, and our role in the global critical minerals supply chain,” Mr Kairaitis said.

“This milestone consolidates the funding commitment and builds further on our

confidence in establishing the world’s largest, single site high purity aluminium materials facility manufacturing the high-tech materials essential for the global energy transition.”

EFA’s Managing Director and CEO, John Hopkins said today marks a key milestone with the Contractual Close of Alpha HPA’s Stage Two HPA First Project.

“We’re proud to support the delivery of Australia’s first high-purity alumina

processing facility in Gladstone, Queensland, reinforcing our commitment to the sector.” Mr Hopkins said.

Alpha HPA’s proprietary processing technology offers a low-carbon, near-zero waste solution to produce high-purity aluminium materials. Compared to traditional processes, Alpha HPA’s technology results in up to 70 percent lower carbon emissions, while recycling nearly 100 percent of its reagents. The facility will also operate on 100 percent renewable energy, further minimising its environmental impact.

These innovations place Alpha HPA at the forefront of sustainable manufacturing, supporting industries such as semiconductors, lithium-ion batteries, Direct Lithium Extraction (DLE) technology, synthetic sapphire and LED lighting.

This milestone cements Alpha HPA’s role as a cornerstone of Australia’s critical minerals strategy and showcases the transformative potential of innovative, sustainable manufacturing in supporting the global clean energy future.

© AlphaHPA

BREAKING GROUND AND BUILDING FUTURES:

2024 NAWIC NSW Awards Celebrate Excellence

Trailblazing leaders, innovative projects and transformative workplace policies have been rewarded at the 2024 NAWIC NSW Awards for Excellence.

Hosted by the National Association of Women in Construction (NAWIC) NSW Chapter, the event attracted a record 153 nominations across 13 categories, drawing 1,100-plus industry professionals to Sydney’s ICC Ballroom to celebrate.

“This is more than an awards night – it is a call to action,” said Georgia Coulston, NAWIC NSW Chapter President. “The NAWIC NSW Awards for Excellence spotlight exceptional leadership and challenge the status quo. Together, we have the power to dismantle barriers, lead with empathy and lay the foundations for a future where every contribution builds lasting impact.”

Highlighting the critical need for change, Ms Coulston noted that women comprise just

12% of the construction workforce and only 2% of trades – a figure stagnant for over four decades.

“This isn’t just a gender challenge; it’s an industry-wide opportunity. Elevating women’s participation is essential to solving labour shortages, boosting productivity and securing Australia’s future.”

Award highlights

Lendlease Crystal Vision Award: Natalie Haydon of Multiplex, affectionately known as ‘Hard Hat Nat,’ was recognised for creating the Jump Start Juniors – Multiplex | LEGO® Australia Learn to Build program. Through engaging workshops, Natalie inspires primary school students to explore careers in construction while championing female leadership.

Richard Crookes Business Woman of the Year Award: Sianne Bennett, Head of

Human Resources at Gamuda Australia, was recognised for her transformative leadership. Under her guidance, Gamuda grew from 10 employees to more than 750 in just five years. Sianne’s focus on diversity has driven a 30% female workforce and a 65% female graduate participation rate.

ADCO Champion of Change Award: Greg Anderson, Alliance Manager for the Mulgoa Road Upgrade Alliance, achieved 31% female representation on his project through a holistic approach to diversity and mentorship. “We encourage more men in the industry to take Greg’s lead to innovate, advocate and take risks to create change,” Ms. Coulston said.

All finalists show how a diverse construction industry can deliver profound benefits for Australia, Ms Coulston concludes. “Each of us holds the power to address the challenges ahead. But only by working together can we build an industry where everyone thrives.”

Photography © Nicholas Smith

AWARD RECIPIENTS

Lendlease Crystal Vision Award

Winner: Natalie Haydon

Affectionately known as ‘Hard Hat Nat,’ Natalie Haydon developed the Jump Start Juniors – Multiplex | LEGO Australia Learn to Build program, inspiring primary school students to explore careers in construction while promoting female leadership through LEGO© and role modelling. During her 13 years with Multiplex, Natalie has balanced site-based roles and parenting. As Design Manager on the $1.9 billion Western Sydney International Airport project, Natalie is committed to fostering an inclusive environment for women to thrive.

Richard Crookes Business Woman of the Year Award

Winner: Sianne Bennett

As Head of Human Resources at Gamuda Australia, Sianne Bennett has expanded the team from 10 to over 750 employees, achieving a remarkable $1.2 billion in revenue within five years. Her dedication to diversity and inclusion has resulted in a 30% female workforce and a 65% female graduate participation rate. Sianne played a key role in acquiring DT Infrastructure, diversifying the business and enhancing the company’s renewable energy capabilities.

MPA Award for Achievement in Construction, Refurbishment and Fitout

Winner: Brie Ranchhod

Design Manager with Kane Constructions, Brie Ranchhod led refurbishment works at the Children’s Hospital at Westmead. By managing multiple design

teams and concurrent milestones, Brie accelerated the program and minimised disruptions. Her meticulous safety and design management ensured timely issue resolution and seamless project execution within a live hospital environment. As a leader of NSW Kane’s Women in Construction team, Brie actively mentors female colleagues and champions diversity within the construction industry.

CPB Contractors Award for Contribution to Sustainability Winner: Robyn Simpson

As the National Manager – Environment and Sustainability at Coates, Robyn Simpson is spearheading strategies that minimise emissions and embodied carbon. Among Robyn’s achievements, she led the implementation of data visibility systems across 145 Coates branches, enabling trend analysis to pinpoint sustainability priorities. With this insight, solar panels were installed across 26 branches, and Coates uses almost 70% of the solar energy generated. Robyn’s hands-on leadership has inspired a movement towards sustainable practices at Coates.

Scentre Group Award for Team Innovation

Winner: Lendlease Workforce Participation Team

The Lendlease Female Apprentice Development and Peer Networking Program was developed to increase engagement and trade completion rates, and to build a robust network for future female tradespeople. Designed by apprentices for apprentices, the program offers coaching and professional development typically reserved leaders, alongside access to a growing peer network. Lendlease has expanded the initiative to industry

partners, and will soon include male apprentices, fostering allies and creating a more inclusive site culture.

Hassell Award for Innovation in Design Winner: Afrida Salma

To minimise disruption during construction of the Warringah Freeway Upgrade, CIMIC Group’s CPB Contractors Design Engineer Afrida Salma developed an innovative slotted drain system that improved drainage while reducing excavation and construction time. Collaborating with principal designers, the construction team and Transport for New South Wales, Afrida created a solution that lowered the project’s carbon footprint, improved performance and enhanced air quality, benefitting both workers and nearby residents.

Ferrovial Project Manager of the Year Award

Winner: Melanie Bowden

As Project Director of the Mindyarra Maintenance Centre project in Dubbo, CPB Contractors’ Melanie Bowden has fostered a welcoming workplace for women, surpassing the national average for female representation in construction and exceeding NSW Aboriginal Procurement Policy targets. Through effective communication and team restructuring, Melanie reduced turnover and significantly improved morale. Under her guidance, the project achieved a ‘Leading’ Design rating from the Infrastructure Sustainability Council, demonstrating the real-world impact of Melanie’s leadership.

Roberts Co Award for Contribution to a Project’s Development

Winner: Carinne Watson

Leveraging her clinical background, CPB Contractors’ Health Facility Planner Carinne

Watson proposed an alternative staging strategy for the Royal Prince Alfred hospital redevelopment. Carinne’s approach reduced clinical decants – where patients are temporarily moved during construction activities – from eight to one, saving 12 months on the program and $10 million in costs, while ensuring uninterrupted patient care. Carinne’s innovative approach also minimised concurrent work sites, enhancing safety and reducing staff fatigue.

Laing O’Rourke Future Leader Scholarship Winner: Lufeng Zhang

A chartered civil and environmental engineer, Lufeng Zhang has demonstrated ingenuity and technical acumen in her work for Laing O’Rourke on Sydney Metro projects. Lufeng also helped to redesign procurement processes to enable greater local supplier participation in bushfire recovery construction. A mentor and role model for young women in construction, particularly from culturally and linguistically diverse backgrounds, Lufeng has delivered engaging sessions on digital innovation and STEM to high school students.

Transport for NSW Tradesperson Scholarship Winner: Jordyn Allan

Her family’s construction business and a love of tools led her to a carpentry apprenticeship, but Jordyn Allan's career took a turn when she discovered Gamuda’s Tunnelling Pre-Employment Program. Relocating from Goulburn to Sydney, Jordyn was the youngest in her cohort. Inspired by the program’s personalised support, Jordyn is now pursuing a Certificate III in Electrotechnology, confidently paving her way in the electrical trade and inspiring other women to follow.

John Holland University Scholarship Winner: Imandee Jayawardena

Exemplifying determination and tenacity, Imandee Jayawardena overcame cultural and gender barriers in Sri Lanka and Australia to forge a rewarding construction career. After 45 unsuccessful job applications to Australian construction companies, Imandee boldly visited a potential employer’s head office to showcase her commitment. Her perseverance paid off, and Imandee is now an Assistant Quantity Surveyor with MBM while pursuing a Bachelor of Construction Management at Western Sydney University.

ADCO Champion of Change Winner: Greg Anderson

As Alliance Manager on the Mulgoa Road Upgrade Alliance, Greg Anderson achieved 31% female representation by embracing a holistic and authentic approach to diversity and inclusion. Greg piloted the Construction Industry Cultural Standard, prioritising flexibility, wellbeing and diversity, and created the ‘My Time’ flexible work program, now being embedded into all Seymour Whyte

About NAWIC

Established in 1995, the National Association of Women in Construction (NAWIC) champions and empowers women in the construction and related industries to reach their full potential. NAWIC’s vision is an equitable industry within which women fully participate, and it values are: Courage, In-clusion, Resilience, Integrity, Safety & Wellbeing. See: www.nawic.com.au

projects. Greg mentors women and actively engages high school students to inspire the next generation of female leaders and create lasting change.

NAWIC Regional Woman of the Year Award

Winner: Eliza Blight

As ADCO’s Project Engineer on the Griffith Base Hospital, Eliza Blight led the successful delivery of the façade package. Eliza expertly managed design clashes and material delays, ensuring the building was sealed and watertight so other trades could progress swiftly and recover lost time. Eliza’s expertise contributed to the building’s aesthetic appeal and long-term functionality. With an enduring commitment to her industry, Eliza also actively mentors other rising stars and inspires schoolgirls to embrace construction careers.

About NAWIC NSW Chapter

The NAWIC NSW Chapter is a passionate group of women who volunteer their time and expertise to host and deliver a range of events aimed at furthering women in the construction industry.

The committee and NAWIC members work in a variety of fields within the construction industry and the Chapter’s activities are designed to address the diversity of these

groups. NAWIC NSW’s goal is to celebrate the achievements of female colleagues in the construction industry as well as to inform, educate and provide networking opportunities.

Photography © Nicholas Smith

TOBY KENT

CHIEF EXECUTIVE OFFICER

Toby Kent, a renowned leader in sustainability and resilience, was recently appointed as the Chief Executive Officer of the Infrastructure Sustainability Council (ISC).

With over 25 years of experience across public and private sectors, Toby Kent brings a wealth of knowledge in sustainable development, energy transition, and infrastructure planning. Known for his innovative, collaborative approach, Toby is set to lead the Infrastructure Sustainability Council (ISC) toward a future of more sustainable and resilient infrastructure across Australia and New Zealand

What is your vision for the ISC?

My vision for the ISC is to be a critical part of every infrastructure decision across Australia, and New Zealand, and perhaps in coming years, the Asia-Pacific. Infrastructure is inherently multi-generational, and we need to transform our approach to ensure sustainable impacts for future generations.

This requires whole of sector change, not just those projects that are currently seeking to be certified ‘sustainable’.

What are the key priorities you plan to focus on during your tenure?

It’s still early in my tenure, but I’ve identified several priorities. First, our membership base is strong, but we need to connect more broadly outside of the current circle.

We also offer fantastic training programs that go beyond our membership, and there’s potential to expand these.

Our IS Ratings tools provide benchmarks for what sustainable infrastructure looks like, but we need to streamline some of the processes and make them easier to use, while retaining the rigour of our tools.

We also need to broaden the number of sectors that are using the tools. For example, we have some fabulous water and energy projects using IS ratings but we are not yet fully embedded across those sectors.

As demands for financiers to communicate the sustainability impacts of their lending and investments grows, we offer a clear solution to that and I expect us to be much more active in that space.

Some of this talks to the final point, which is that ISC has strong support among a core group of users. We need to expand this group, make it easier for people to engage with us.

Ultimately, the goal is to achieve greater transformation in how infrastructure is developed and to drive more significant sustainable impact.

How does your experience in resilience and sustainability shape your approach to leading the ISC?

In my role as Chief Resilience Officer for Melbourne, I often heard the question, ‘Isn’t resilience just another name for sustainability?’

There is lots of cross-over, but resilience thinking acknowledges that while pursuing sustainabile development, things will still go wrong along the way. The question becomes: ‘How do we plan for that?’

My experience has taught me to recognise the strengths of an organisation and amplify those to create real impact. Whether it’s for infrastructure or entire communities, it’s about preparing for the stresses and shocks that will inevitably come, and designing systems that can survive and ultimately thrive despite them.

Achieving Net Zero in construction is a major goal for the industry. How close are we, and what challenges do you see ahead?

We’re still quite far from achieving Net Zero, but national commitments in Australia and New Zealand provide a helpful framework. Collaboration across the private and public sectors is critical, and we’re seeing more of this now than ever.

Tools like IS Ratings are helping guide projects toward sustainability goals, both in terms of mitigation and adaptation. Over the past six years, projects certified under IS As Built Ratings have avoided more than 23 million tonnes of carbon emissions and in FY24 alone, projects diverted almost 35 million tonnes of resources from landfill. The challenge from a net zero perspective is that we’re moving forward with initiatives now that should have been implemented 20 years ago.

What role does innovation play in reaching sustainability targets within the infrastructure sector?

Innovation is essential. We’re seeing improvements in resource management, with

more materials being reused and recycled, reducing landfill waste. The use of renewable energy and energy-efficient practices is becoming more mainstream, which is encouraging. However, we still have work to do in preparing infrastructure that looks generations ahead, rather than focusing on short-term needs.

Integrating Internet of Things (IoT) technology, AI, and other smart infrastructure solutions will allow us to build systems that can evolve as technology does. We need to design infrastructure that isn’t just built for today but for decades into the future.

This means thinking about connected infrastructure – the aggregated opportunities that come from different infrastructure elements connecting effectively, as well as their interdependencies and consequent inter-vulnerabilities.

How does the ISC measure the impact of its work?

We’ve been fortunate to have an independent assessment that found for every dollar invested in IS Ratings, the return was $1.6$2.4 across the lifestyle of any given asset.

We’re also continuously refining how we articulate the financial and environmental benefits of our ratings tools. The numbers are clear—through IS Ratings last year alone projects have saved over half a million tonnes of asphalt.

Continues over page

We need to design infrastructure that isn’t just built for today but for decades into the future.

Toby

Kent,

CEO, Infrastructure Sustainability Council

Also, the ISC provided training to over 1,700 professionals in sustainability and leadership. We produce an annual impact report that captures all such information.

Again, we need to communicate these impacts ever more effectively to demonstrate the value we bring to the industry.

Looking forward, what initiatives or projects at the ISC excite you the most?

I’m particularly excited about the new IS Essentials Design & As Built tool, which is designed for projects between $5 million and $100 million. This allows smaller projects to benefit from sustainability standards without compromising on quality.

Additionally, IS 2.1 ratings, which are now fully in the market, are receiving good feedback and we have significant work program in

place to make the tool more effective for users, supporting better outcomes.

These tools are helping the industry not only meet immediate needs but also set the stage for long-term sustainable infrastructure development.

Our new Sustainability Academy and enhanced membership model, both to be rolled out this year, are both important developments that will see us offer more benefits to the market and improve sustainability practices.

What legacy do you hope to leave at the ISC, and what impact do you want to have on the infrastructure sector?

My goal is to ensure that the standards we develop become the norm for preparing for and achieving infrastructure outcomes across Australia and New Zealand and, potentially,

the Asia-Pacific.

I want the ISC to be a well-resourced organisation that can be an employer of choice and afford to invest in more inclusivity and innovation ourselves. I see us driving sustainability outcomes for decades to come.

Ultimately, I hope to leave a legacy where infrastructure is inherently sustainable, resilient, and prepared for the future, serving communities in the long term and not just in the immediate.

Scan to read the IS Council's Impact Report 2024

My goal is to ensure that the standards we develop become the norm for preparing for and achieving infrastructure outcomes.

Toby Kent, CEO, Infrastructure Sustainability Council

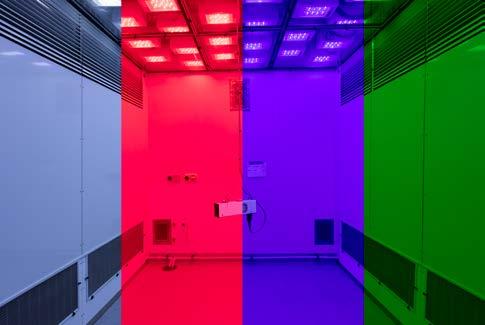

INNOVATIVE CLIMATE CONTROL SOLUTIONS POWERING LUXURY AT THE FELLOWSHIP

PROJECT : The Fellowship

LOCATION : Kew, VIC

COMPLETION DATE : October 2024

CONTRACTOR : DP Heating and Cooling

Nestled in the exclusive suburb of Kew, Victoria, The Fellowship redefines contemporary luxury living with its mid-century-inspired design, premium finishes, and seamless integration of modern amenities.

Comprised of 20 high-end residences designed by CHT Architects, Sora Interiors, and Jack Merlo Landscaping, this prestigious development required an advanced climate control solution that matched its aesthetic sophistication and operational demands.

Mitsubishi Heavy Industries Air-Conditioning Australia (MHIAA), in collaboration with DP Heating and Cooling, rose to the challenge with a tailored approach that exceeded expectations.

High-Performance Systems for a High-End Development

For a project of this calibre, the heating and cooling systems needed to blend functionality with elegance, providing comfort without disrupting the architectural integrity or tranquility of the residences.

MHIAA deployed a mix of state-of-the-art systems, including 96 FDUT**KX slimline ducted units, 41 compact VRF systems from

the KX Micro Series, and medium-static FDUM ducted units, all designed to deliver outstanding performance and energy efficiency.

“The KX Micro Series was a game-changer for this project,” said Nick Bennet from MHIAA. “These outdoor VRF units, with their compact size and long pipe run capabilities, are ideal for the constrained rooftop spaces while still delivering exceptional heating and cooling performance.”

Slimline FDUT ducted units were strategically installed in areas with limited ceiling space, ensuring a seamless fit into the design without compromising functionality. For larger, more open areas, FDUM units offered robust air distribution, paired with sleek metal linear grilles to maintain the luxurious aesthetic.

Overcoming Challenges with Tailored Solutions

Space constraints on the rooftops posed a significant challenge, requiring compact outdoor units that could operate efficiently without overcrowding the area. MHIAA's solutions, including the adaptable KX Micro VRF systems, turned these challenges into opportunities for innovation.

Another hurdle was the evolving project design, with adjustments being made even during construction. “The project demanded flexibility, and our collaboration with DP Heating and Cooling allowed us to adapt quickly,” Bennet said. “This ensured the system

met the changing needs of the residences without delaying the project timeline.”

Modern, Sustainable Living with User-Centric Design

MHIAA systems prioritise user convenience and efficiency. All ducted systems are equipped with intuitive RC-EZX3A wallmounted controllers, offering streamlined operation for each resident. These systems allow for centralised management, ensuring optimal comfort while minimising energy consumption.

By addressing both technical challenges and design requirements, MHIAA delivered a comprehensive climate control solution that perfectly complemented the high-end nature of The Fellowship.

Beyond aesthetics and performance, sustainability was a guiding principle throughout the design and system selection process. Every choice was made with an emphasis on reducing environmental impact while maintaining exceptional efficiency. The KX Micro VRF systems were carefully selected for their superior energy efficiency thanks to the use of R32 refrigerant.

These innovative systems reflect MHIAA’s unwavering commitment to sustainable solutions by delivering outstanding heating and

cooling capabilities with minimal energy consumption and ultra-quiet operation. This ensures not only comfort and performance but also a responsible approach to preserving the planet for future generations.

Setting a Benchmark for Excellence

The Fellowship stands as a testament to MHIAA’s ability to deliver bespoke climate control solutions for complex and high-profile projects. From innovative system design to seamless integration, the partnership with DP Heating and Cooling and The Fellowship’s design team has set a new benchmark for residential luxury in Melbourne.

As urban developments continue to raise the bar for comfort, sustainability, and design, MHIAA remains at the forefront, delivering solutions that enhance the living experience while maintaining environmental responsibility.

Understanding Acoustic Glazing

Specifying the best glass for noise reduction

The ability to control external sounds in our homes, workplaces, hospitals and schools has gained importance due to modern lifestyles and the close proximity of these buildings to highways, airports, construction sites and industry. Among the many building materials and products that make up a structure, windows and doors have a big impact on how well the home or building is insulated from outside noise. With the wide range of glazing solutions available, understanding the differences between singleglazing, multi-layered glazing, laminated glass and high-performance acoustic glazing is essential.

Understanding Acoustic Glazing: Specifying the best glass for noise reduction explores the role of glazing in acoustic design and how different types of glazing products compare in terms of sound reduction performance. We highlight what makes acoustic glass a high-performance solution distinct from other forms of glazing. We also look at common misconceptions surrounding acoustic glass.

Australia’s leading brand of acoustic glass, Genuine Hush™ is highly specified and made exclusively by Oceania Glass™ Genuine Hush™ offers a range of quality performance acoustic glass that has been tested and certified. The Genuine Hush™ acoustic performance range comprises of QLam Hush™ and ComfortHush™ –two distinct yet complementary products suited to a wide range of applications and available in a choice of colours.

Download this whitepaper and learn why acoustic glass stands above the rest when it comes to sound reduction.

www.oceaniaglass.com.au/resources/white-papers/

Our Range of Acoustic Glass is Made In Australia by Oceania Glass

A COOL SOLUTION FOR THE AUBURN MOSQUE PLAYGROUND

Sydney Shade Sails recently completed an innovative shade sail installation at the Auburn Gallipoli Mosque, enhancing the children’s playground with a functional yet aesthetically pleasing design. The project, spearheaded by Managing Director Leonard Collins, is a testament to the company’s commitment to quality, customer service, and creating community-oriented solutions.

“The client needed to revamp the playground but didn’t have a clear vision of what they wanted,” Collins explained. “Our team designed a layered sail structure that not only provides vital shade but also complements the surrounding palm trees and environment.”

The playground, used daily by children, presented unique challenges. Softfall areas could reach over 50 degrees on hot days, posing safety risks. The solution involved strategically placed sails to ensure full coverage and UV protection, keeping the area cool and safe. “We considered design, height, and aesthetics to ensure the structure blended seamlessly with the mosque’s architecture,” Collins said, highlighting the pale eucalypt columns and cream sails chosen to harmonise with the outdoor aesthetic of the mosque.

The installation process was equally complex, requiring meticulous planning. “Accessing the site was a challenge,” Collins noted. “We had to lift columns over fences and navigate between palm trees without damaging tiles or other works. Safety and minimising disruption were

paramount, especially in this community space where prayer times and WHS risks had to be carefully managed.”

One standout feature was Sydney Shade Sails’ dedication to ensuring a complete process for the client. Although repair after cutting through existing softfall wasn’t part of their standard service, they coordinated with specialists to seamlessly restore the playground surface.

With this project, Sydney Shade Sails showcased its 25 years of industry expertise, delivering a durable, visually striking shade structure that serves the mosque’s vibrant community while embodying the company’s ethos of excellence and care.

For more information contact Sydney Shade Sails (NSW) Pty Ltd, 23 – 25 Norman Street, Peakhurst, NSW 2210, phone 02 9592 0401, email enquiries@shadesailsydney.net.au, website shadesailsydney.net.au

SETTING NEW STANDARDS IN CIVIL & CONSTRUCTION REINFORCEMENT SERVICES

Goldenlight Pty Ltd has firmly established itself as an innovator in Canberra’s construction industry, renowned for its mastery in reinforcement installation and dedication to sustainable practices. Among its standout achievements is the Woden Green development – a transformative project redefining urban living in the Woden Town Centre.

Hindmarsh Woden Green encompasses three architecturally stunning residential towers, housing 419 meticulously designed apartments, all harmonised with 3,000m² of lush green communal spaces.

The project exemplifies Goldenlight's unwavering commitment to quality, innovation, and environmental stewardship, setting a new standard for excellence in the region.

Goldenlight was responsible for overseeing reinforcement installation for critical structural components, including lift pits, footings, slabs, walls, columns, and stair cores. Their meticulous approach combined advanced techniques and a skilled workforce to ensure high-quality outcomes.

“We used specialised equipment and tools to tie, cut and bend reinforcement bars with precision, adhering strictly to engineering specifications,” said Alex Tumurbaatar, Goldenlight Director.

Regular inspections throughout the project allowed for immediate resolution of any discrepancies, maintaining the highest quality standards. This level of care not only secured the safety and durability of the structures but also elevated the overall execution of the Woden Green project,

setting a benchmark for future developments in Canberra.

One of the standout achievements of Goldenlight’s involvement was the completion of their scope of work two months ahead of schedule. This remarkable milestone was attributed to efficient planning, task sequencing, and strong communication with subcontractors.

“By adopting lean construction principles and maximising productivity through concurrent tasks, we streamlined operations and minimised delays,” said Alex. “Our experienced team, led by skilled supervisors, ensured that the project progressed smoothly and met its deadlines.”

The early completion not only underscored Goldenlight’s reputation for reliability but also provided significant cost savings and allowed other project phases to advance ahead of time.

“Reinforcement installation remains primarily a labor-intensive task, we are committed to leveraging technological advancements and continuous skill development to optimise efficiency and quality,” said Alex. “By incorporating innovative tools and techniques, we aim to improve worker safety, and increase productivity.”

This ongoing focus on training and development ensures that their workforce stays updated with the latest industry practices, empowering them to deliver exceptional results.

Goldenlight focuses on minimising construction waste, including integrating accessory provisions into their services, such as bar caps, tie wires and spacers, to eliminate inefficiencies. Materials were carefully managed, and any spoil was repurposed for beneficial reuse, aligning with the company’s commitment to a circular economy.

Their new package services, which supply and install their accessories, save lots of money and eliminate accessory wastage for their clients. Build369 Heather apartment project has already liked their packages.

Goldenlight consistently stays ahead of industry standards by incorporating cuttingedge tools and techniques. For the Woden Green project, they employed data-driven decision-making to track performance and optimise resource allocation. Additionally, their focus on workforce training ensures that team members remain well-versed in the latest industry practices.

“Our dedication to continuous improvement allows us to adapt to the unique challenges of each project,” Alex explained.

“By blending traditional methods with innovative approaches, we deliver solutions that are both practical and forward-thinking.” Goldenlight’s work on the Woden Green project is a testament to their expertise

and vision. As they continue to contribute to projects like the Heather Apartments in Dickson, they remain focused on quality, sustainability, and efficiency. Their innovative reinforcement services and eco-conscious practices position them as a trusted partner for contractors and developers across Canberra and beyond.

Through projects like Woden Green, Goldenlight Pty Ltd is shaping the future of Canberra’s construction landscape, delivering structural excellence while supporting a greener, more sustainable environment.

For more information contact Goldenlight, 490 Northbourne Avenue, Dickson ACT 2602, phone 0421 548 469, email alex@goldenlightcivil.com.au, website www.goldenlight.com.au.

PAKENHAM’S TRANSFORMATION TO SMARTER TRANSPORT

The Pakenham Level Crossing Removal Project features a modernised Pakenham Station and the newly built East Pakenham Station, complemented by a 2.5km rail bridge. The upgrade includes an enhanced station forecourt, a bus interchange, dedicated pick-up and drop-off zones, street-level lifts, and a climate-controlled waiting room. Additional improvements expanded walking and cycling paths along the rail line, creating a seamless and sustainable transport experience.

The Pakenham Level Crossing Removal Project (LXRP) marked a significant achievement in improving transport infrastructure and safety in Victoria. As part of a broader initiative removing 110 level crossings by 2030, with 84 already gone, the Pakenham LXRP transformed the local community by reducing travel times and enhancing safety for pedestrians and drivers.

The $864 million project delivered a modernised Pakenham Station and a brand-new East Pakenham Station. It also involved the construction of a 2.5km rail bridge, an upgraded station forecourt, a bus interchange, and additional pick-up and drop-off zones. Alongside these improvements, the project created 450 new car parking spaces, secure bike storage, and new walking and cycling paths, providing a comprehensive upgrade to the area’s transport network.

“The rail bridge design and new stations improve safety, reduce road congestion, and create more than six MCGs of new open space for the Pakenham community to enjoy,” said an LXRP spokesperson.

“The Pakenham LXRP was about more than just removing level crossings; it was about future-proofing the community by enhancing accessibility and safety,” said an LXRP spokesperson. “By upgrading the stations and improving infrastructure, we ensured that the area could support growth and provide a better commuting experience for everyone.”

The construction phase of the Pakenham LXRP focused on minimising disruption to commuters and residents. The centrepiece of the project was the 2.5km rail bridge, which elevated train tracks, allowing traffic to move freely underneath. This was complemented by the modernised Pakenham Station, which had been redesigned to accommodate growing passenger numbers and provide a more pleasant and accessible experience.

“One of our main goals was to ensure that the local community could continue with their daily routines with minimal impact during the construction period,” a LXRP spokesperson said. “We implemented

detailed planning and careful coordination with local authorities to manage traffic flow and ensure safety around the work sites.”

The community was invited to engage with the project throughout the construction period with opportunities to attend site tours, participate in information and online sessions, so residents could be involved at every stage.

Sustainability was a cornerstone of the Pakenham LXRP. The iconic roof of Pakenham Station exemplifies industry-leading innovation, integrating digital fabrication technology to reduce raw material use and incorporating an energy-efficient 27.6 kWh solar panel system. These panels save 37 tonnes of carbon emissions annually.

“At East Pakenham, we went a step further by using recycled-rubber kerbs in the station car park, capturing rainwater for reuse, and planting over 330,000 trees and shrubs across the project site,” said a LXRP spokesperson.

Like many large infrastructure projects, the Pakenham LXRP faced challenges, particularly in terms of coordinating the removal of multiple level crossings while ensuring that train services and road traffic could continue to operate smoothly.

The team worked closely with local businesses, residents, and other stakeholders to address concerns and keep the community informed

throughout the process. “Coordinating such a large project, especially in an area as busy as Pakenham, required us to be adaptable and responsive to changes,” a LXRP spokesperson noted. “The feedback from the community was invaluable, and it helped us make adjustments that kept the project on track.”

Now that the Pakenham LXRP is complete, the community is already reaping the rewards of this extensive upgrade. The removal of level crossings has significantly reduced congestion, cut travel times, and improved safety for pedestrians and drivers. The new and modernised stations, along with the added infrastructure, serve as a transport hub, supporting the area’s future growth and development.

The Pakenham LXRP was just one part of a wider effort to improve Melbourne’s transport network, but it stood out as a shining example of what could be achieved through thoughtful planning, innovation, and strong community collaboration.

“We’re proud of what’s been accomplished here,” said a LXRP spokesperson. “The Pakenham project left a lasting legacy that will benefit the local area for years to come.”

For more information contact Level Crossing Removal Project, website www.levelcrossings.vic.gov.au

CIRCULAR ECONOMY LEADERSHIP: SUSTAINABLE SOLUTIONS FOR

PAKENHAM LXRP

Lantrak, a leader in material management and plant hire, served as John Holland’s primary subcontractor on the Pakenham Level Crossing Removal Project (LXRP) for material disposal and truck hire. With decades of experience and a strong commitment to sustainability, Lantrak’s expertise was essential to the project’s success.

“Our goal was to ensure that every aspect of the bulk earthworks scope was handled efficiently, on schedule, and with minimal environmental impact,” said Rhys Tomlins, Lantrak’s Sales Manager.

Lantrak’s contributions included a comprehensive range of services essential to the project’s earthworks scope. These included onsite truck hire, haulage and disposal services, and material supply sourced from local quarries.

“Our involvement in this project speaks to the core of what Lantrak does best,” said Rhys. “By providing reliable and sustainable material and transport solutions, we were able to meet the project’s needs while upholding our environmental commitments.”

One of the primary challenges for Lantrak was providing a reliable disposal solution that could withstand Melbourne’s unpredictable weather. Lantrak leveraged its partnership with Barro Group, utilising their Nyora Quarry site as an all-weather disposal location. “This site was essential for maintaining the project’s timeline,” Rhys explains.

“The all-weather capabilities at Nyora ensured that material disposal could continue uninterrupted, even after heavy rainfall.”

Lantrak successfully navigated the challenge of the industry-wide truck shortage, which arose due to multiple large-scale infrastructure projects happening across Victoria.

“We made a conscious decision to avoid overextending our commitments to ensure that our fleet could meet the demands of the Pakenham project,” says Rhys. “This meant we were able to provide reliable, daily support without compromising quality or delivery.”

The scale of Lantrak’s involvement was significant, particularly during peak periods of the project. The company utilised a fleet of fully compliant rail-specified Tandem Tippers, alongside 3- and 4-axle PBS Truck and Trailer combinations. At peak, Lantrak supplied over 40 truck and trailer units, along with 25 tandems, each day.

“This level of deployment was crucial to maintaining the pace of the project,” said Rhys.

Lantrak’s role in the Pakenham LXRP aligns with its broader commitment to sustainability and material reuse. Through its Circular Economy initiative, Lantrak diverts materials from landfills, repurposing them for beneficial projects.

“We’re leaders in the reuse of raw materials, and we repurpose spoil from various infrastructure projects across Melbourne,” explained Rhys. The spoil from the Pakenham project, for example, contributed to the rehabilitation of an exhausted quarry hole at Nyora Quarry.

“Our disposal solution at Nyora serves a dual purpose. It enables us to assist in large-scale infrastructure while also supporting land rehabilitation, which is a key component of our sustainability efforts.”

Lantrak’s dedication to innovation is further exemplified by its Lantrak 360 initiative, launched at the Lysterfield Transfer Station during the Pakenham LXRP. This facility accepts mixed fill and inert waste materials, which are then sorted, screened, and recycled. This approach not only minimises waste but also contributes to a more sustainable model of material management, aligning with the company’s commitment to environmental responsibility.

Since its establishment as a transport cooperative in 1959, Lantrak has supported some of Australia’s most iconic infrastructure projects, including the Snowy Mountain Scheme, Homebush Bay Olympic Stadium, and the New Royal Children’s Hospital. With a history that spans more than six decades, Lantrak has grown into one of Australia’s largest material management and plant hire businesses, annually moving over 20 million cubic metres of clean and structural fill.

“Lantrak has an unrivalled reputation for delivering material and plant hire solutions that prioritise sustainability and efficiency,” says Rhys. “We’re proud to continue that legacy with projects like the Pakenham LXRP.”

For more information contact Lantrak, 18 Dansu Court, Hallam VIC, phone 13 9666, email info@lantrak.com.au, website www.lantrak.com.au

Below Lantrak a trusted material management and plant hire expert, delivering sustainable solutions for Pakenham LXRP bulk earthworks success.

Below Daly’s Constructions provides expert design, civil works, cable installation, jointing, and terminating services for energy infrastructure projects.

WATT IT TAKES: FROM DEISGN TO DELIVERY

Daly’s Constructions, a family-owned and operated business with a 52-year legacy in the energy infrastructure industry. Daly’s expertise proved invaluable in navigating the complexities of the Pakenham Level Crossing Removal Project (LXRP)

“We provide specialist design, civil works, cable installation, jointing and terminating services to the energy infrastructure industry across Australia and New Zealand, specialising in major sub-transmission and transmission design and construct underground projects,”

said Alex Anderson, Operations Manager at Daly’s Constructions.

The Pakenham LXRP demanded meticulous planning and execution to ensure minimal disruption to existing infrastructure and services. Daly’s Constructions rose to the occasion, contributing a team of 20 skilled professionals from their overall workforce of 100.

Their specific tasks included the crucial relocation of electrical assets.

“We relocated high voltage and low voltage AusNet Services electrical assets to enable the LXRP and corresponding rail works to proceed,” Alex said.

Further demonstrating their comprehensive capabilities, Daly’s Constructions also undertook an upgrade of the rail corridor’s high-voltage underground cables. This involved not only replacing outdated infrastructure but ensuring its seamless integration with the broader LXRP network. “Multiple crews had to be coordinated across various work fronts in close cooperation with NWPA and AusNet Services,” Alex said, emphasising the collaborative nature of the undertaking.

While Daly’s Constructions didn’t deploy any entirely new products on this project, their success lay in their adept application of existing technologies and their commitment to safety and quality. Their long-standing reputation is built upon a strong value system prioritising these element.

“Our company has a strong value system based on principles that include commitment to safety, quality of service, integrity in our relationships and client satisfaction,” Alex said. This commitment has translated into a record of consistent, high-quality workmanship.

The Pakenham LXRP is just one example of Daly’s Constructions’ broad portfolio of significant projects across Australia and New Zealand. Their expertise is currently contributing to a wide range of initiatives, reflecting their leading position in the industry.

“We’re currently working on the North East Link (NEL), Suburban Rail Loop (SRL), West Gate Tunnel Project (WGTP), other LXRP projects, the Melton Renewable Energy Hub, and design and construction of sub-transmission supplies to power new Data Centres,” Alex said, highlighting the scope and diversity of their involvement in shaping critical infrastructure across the country.

Daly’s Constructions’ contribution to the Pakenham LXRP showcases their ability to successfully manage complex, large-scale projects. Their expertise in underground electrical infrastructure, combined with their unwavering commitment to safety, quality, and client satisfaction, solidifies their reputation as a reliable and capable partner for future major infrastructure projects.

For more information contact Daly’s Constructions, 20-26 Cyanamid Street, Laverton North VIC 3026, phone 03 9360 9485, email cable@daly.net.au, website www.dalysconstructions.com.au

BREAKING GROUND, NOT PIPES: NDD IS A GAME-CHANGER FOR COMPLEX PROJECTS

Enhancing project efficiency and safety, Ontrack Excavation Group has become a vital partner in the Pakenham Level Crossing Removal Project (LXRP) through its expertise in Non-Destructive Digging (NDD) and excavation services.

The family-owned, company has over three years of industry experience and is known for delivering customer-focused solutions using cutting-edge technology, reliability and safety. Ontrack Excavation Group’s commitment to excellence makes them a top choice for complex infrastructure projects across Australia

For Ontrack Excavation Group, one of the primary tasks was navigating the complex network of underground utilities while ensuring that all services were preserved during excavation. Their use of NDD was pivotal in overcoming these challenges, enabling them to carry out the work without the need for extensive manual digging, thus reducing the risk of accidental damage and project delays.

“With our state-of-the-art vacuum trucks, we were able to carry out the job without disturbing the critical services already in place. It’s what makes NDD such a game-changer for projects like Pakenham,” said Hasan Yalcin, Director of Ontrack Excavation Group.

The efficiency of their operations also contributed to the overall project timeline, allowing other contractors to proceed with construction activities promptly. By providing clear service identification and drain cleaning, Ontrack Excavation Group helped streamline the integration of new installations, including utilities, transport infrastructure, and public amenities.

“Working on a project like Pakenham requires precision and teamwork. We knew that every day our efficiency was helping to keep the project moving forward,” added Hasan.

With a team of 15 skilled professionals, including 12 who were directly involved in the Pakenham project, Ontrack Excavation Group successfully delivered services that met the project’s stringent safety and operational standards. “Our team’s expertise, paired with the best equipment, allows us to tackle complex projects with confidence. We’ve always been committed to investing in the latest technology to ensure the job gets done right,” explained Hasan.

Safety and efficiency are at the core of Ontrack Excavation Group’s operations. Throughout the Pakenham project, the team adhered to strict safety protocols, ensuring that all work was performed with

minimal risk to the public, their workers, and the environment. Their specialised fleet of vacuum trucks enabled precise, clean excavations, which was critical in maintaining the safety and cleanliness of the site, especially in areas with high foot and vehicle traffic.

The success of Ontrack Excavation Group’s involvement in the Pakenham LXRP underscores their capabilities in managing large infrastructure projects. Their recent projects, including the Tram Maintenance Facility (TMF) in Maidstone and the Suburban Rail Loop (SRL), demonstrate a continued expansion in scope and capability, reinforcing their position as a leader in the industrial services sector.

“We’re proud of the work we’ve done at Pakenham, and we look forward to bringing our expertise to future projects. Our mission is to keep pushing boundaries, always striving to deliver the best,” said Hasan.

For more information contact Ontrack Excavation Group Pty Ltd, phone 0499 654 865, email info@ontrackexc.com.au, website www.ontrackexc.com.au

Below Ontrack Excavation Group excels in NonDestructive Digging, enhancing safety and efficiency in Australian infrastructure projects.

A FRESH PERSPECTIVE ON RETIREMENT LIVING

The Bert Newton Retirement Village in Highett, Victoria, offers luxurious living for 250 residents. With independent apartments, assisted living, and a care center, it provides seamless aged care. Amenities include a café, bar, pool, and cinema. Developed by Ryman Healthcare, it reflects innovation, quality, and a holistic approach to care.

Ryman Healthcare, a leader in retirement living and aged care, has successfully completed construction of its prestigious Bert Newton Retirement Village in Highett, Victoria.

This luxurious development showcases Ryman’s commitment to innovative design, exceptional resident services, and a holistic approach to aged care, offering a continuum of care within a single, vibrant community. The project highlights not only Ryman’s dedication to quality but also its resilience in navigating unforeseen challenges.

The Bert Newton Village provides a diverse range of accommodation options, catering to individual needs and preferences. From fully independent apartments to serviced apartments offering assisted living, and a 79-bed care centre providing low care, high care, and specialist dementia care, residents can seamlessly transition within the village as their needs evolve. This ‘continuum of care’ model is a cornerstone of Ryman’s philosophy, ensuring residents can age in place with dignity and support.

“From assisted living services and specialist care to fully independent apartments and resort-style amenities, the Ryman model empowers residents to design their own retirement experience and ensures no one is left behind,” said Andrew Moulding, Design Practice Lead Australia.

This philosophy is reflected in the village’s extensive amenities, creating a self-contained hub for recreation, relaxation, and social interaction. Residents enjoy access to a café, bar, shop, hair and beauty salon, workshop, craft room, billiard room, library, swimming pool, spa, and gym.

For aged care residents, dedicated lounge and dining areas and tranquil outdoor spaces provide comfortable and supportive environments. The inclusion of specialised dementia care further underscores Ryman’s commitment to providing comprehensive, tailored services.

Commencing in mid-2020, the onset of the COVID-19 pandemic introduced unforeseen logistical hurdles. Ryman and its construction

teams swiftly adapted by implementing rigorous safety protocols and revising project timelines to address labor shortages and evolving trade contractor availability. Adding to the complexity, Ryman also had to navigate unpredictable weather conditions.

The project team leveraged the versatility of precast concrete, incorporating textured form liners to introduced intricate patterns and visual depth to the surfaces, while satin finishes provided a sleek and refined aesthetic, without the need of additional materials or trades. The result is a visually striking and cost-effective solution.

The final development comprises 209 residential units: 85 independent apartments, 45 serviced apartments, and a 79-bed care centre. The design seamlessly blends luxury with practicality, providing residents with spacious, comfortable accommodations and access to a full range of amenities within a beautifully landscaped setting.

Ryman’s origins are rooted in a commitment to raising the standards of aged care. In 1983, co-founder Kevin Hickman envisioned a different model of care. His experience, coupled with his business partnership

with John Ryder, led to the creation of Ryman Healthcare, built upon the philosophy of providing ‘single rooms with ensuites’, and a higher standard of living.

The Ryman recipe, established decades ago, remains effective: prime locations, meticulous design and construction, and an unwavering dedication to excellence. Today, Ryman Healthcare operates 49 retirement villages across Australia and New Zealand, providing exceptional care and support to over 14,000 residents.

The Bert Newton Retirement Village stands as a testament to this legacy, exemplifying the company’s commitment to creating thriving communities where residents can enjoy a fulfilling lifestyle, complete with peace of mind and security.

Construction of additional apartment blocks continues, further expanding the village's capacity and solidifying Ryman Healthcare’s position as a leader in the aged care sector.

For more information contact Ryman Healthcare, phone 1800 288 299, website www.rymanhealthcare.com.au

A LEGACY OF EXCELLENCE IN THE CONSTRUCTION INDUSTRY

SMB Windows, a fourth-generation family business, has been a cornerstone of the glass and window industry. With roots deeply embedded in craftsmanship and innovation, the company began its Melbourne operations in 2016. Since then, SMB Windows has successfully delivered over 500 projects across Australia’s commercial and residential construction sectors.

Notable projects include the Quarantine Centers in Melbourne, Brisbane, and Perth for Multiplex, Modscape, and Ausco for the Health Sector, Melbourne University’s B63 refurbishment with Shape for the Education Sector, and the Munro Library upgrades with Buildcorp, also the for the Education Sector. Additional highlights include AOD Rehabilitation Centers across regional Victoria and the prestigious Bert Newton Retirement Village for Ryman Healthcare.

Specialising in:

• Aluminium thermally broken and non-thermally broken windows and doors

• Skylights

• Glass and aluminium louvers

• Glass balustrades

• Aluminium and metal shrouds

• Frameless glass shower screens

A recent milestone, the Bert Newton Retirement Village, exemplifies SMB Windows’ commitment to enhancing Australian communities with cutting-edge and sustainable living solutions.

The Bert Newton Retirement Village is a large-scale project consisting of a commercial building and three residential buildings. With over 230 apartments and more than 1,000 windows and doors, SMB Windows’ involvement spanned two years, during which they provided a high degree of customisation to meet specific design, environmental and energy standards.

SMB prides itself on using innovative designs to meet project needs. For the Bert Newton Retirement Village, they provided AWS (Architectural Window Systems) thermally broken windows and doors equipped with double-glazed LowE glass (AGG Insulglass LowE Plus® - Grey), ensuring excellent thermal performance and energy efficiency. The doors also included automatic sliding systems, enhancing accessibility and ease of use for residents.

“Our windows and doors are fabricated locally, which not only supports the local economy but also ensures quality control and sustainability,” said Dawoodjee.

The use of LowE glass in combination with thermally broken frames allows for reduced heat transfer, maintaining comfortable indoor temperatures without excessive energy use.

“Our highly efficient 100mm Residential suite has one of the best thermal values on the market for standard windows and doors. It’s perfectly suited to ensure that residents enjoy optimal indoor temperatures while reducing energy costs,” explained Juzer Dawoodjee, Sales and Project Director at SMB Windows.

In the commercial building, the company installed thermally broken windows, chosen to enhance energy efficiency and align with the architect’s design intent, and accommodating diverse wall cladding types.

“To ensure that the installation of windows and doors aligned perfectly with the architectural plans, we engaged in regular design meetings with the project architect and Ryman’s design team,” said Juzer. This close collaboration helped prevent delays, allowing SMB Windows to integrate their products smoothly.

One of the unique design challenges for SMB Windows, was the installation of a glass sky light that connects two of the buildings.

“The glass canopy not only gives the building a distinctive look but also allows ample natural light to reach pedestrians underneath, providing shelter from the rain and other elements,” said Juzer. SMB’s design incorporated these functional requirements without sacrificing

aesthetic appeal, ensuring the canopy contributed to both the form and function of the development.

Through careful design, collaboration, and an emphasis on highquality, energy-efficient materials, SMB Windows has made a substantial contribution to the Bert Newton Retirement Village. Their expertise in creating tailored window and door solutions has helped ensure that residents will enjoy a comfortable, energy-efficient living environment.

“This development truly showcases our commitment to quality, sustainability, and innovation. We’re proud to have contributed to such a meaningful project,” said Juzer.

For more information contact SMB Windows, 21-23 Zilla Court, Dandenong South VIC 3175, phone 03 9703 3106, email admin@smbwindows.com.au, website www.smbwindows.com.au

Right: Juzer Dawoodjee Commercial Sales & Project Director SMB Glass Windows & Doors

Vamp Cranes made a significant impact on the Bert Newton Retirement Village project, providing specialised crane and rigging services that ensured efficient and safe operations. Vamp Cranes handled mobile cranage, tower crane crew labour and rigging for the project.

“Our practice spans from general lifts to environmental retrofits of existing buildings and beyond,” said Valerie Patragoulas, Business Development Manager. “With our extensive range of mobile crane hire and highly trained staff, we strive to achieve continued excellence in quality.”

With a fleet that ranges from a 2.85-tonne to a 450-tonne mobile crane, Vamp Cranes has built a strong reputation for versatility. Their expertise spans precast erection, civil work, steel erection, and general crane hire. “No job is too big or too small,” said Patragoulas. “Taking on jobs of all sizes throughout Melbourne and its extended regions, our team is ready to tackle any challenge with over 50 years of combined experience.”

Vamp Cranes, based in Coburg North, Melbourne, employs a team of 115 professionals, who have earned a reputation for reliability

and safety. “Our goal is to be established as an industry leader in the delivery of crane and rigging services to Victorian construction and industrial sectors,” Patragoulas said. Their current projects include the Footscray Hospital, along with a growing portfolio of tier-one projects across Victoria.

Looking forward, Vamp Cranes has expanded beyond Victoria, entering the South Australian market and aspiring to enter the Queensland market. “We’re committed to building strong partnerships with businesses and communities,” Patragoulas said. With a dedication to innovation, safety, and quality, Vamp Cranes is poised to become a leader in crane and rigging services across Australia, ready to take on both large-scale and community-driven projects.

For more information contact Vamp Cranes, 14-22 Gaffney Street, Coburg North VIC 3058, phone 03 8652 8635, email operations@ vampcranes.com.au, website www.vampcranes.com

Below Vamp Cranes enhanced the Bert Newton Retirement Village project with specialised crane services, prioritising efficiency and safety.

Below Contract Air Conditioning transformed comfort at Bert Newton Retirement Village with efficient, specialised air conditioning solutions.

Contract Air Conditioning made a significant impact on comfort and energy efficiency at the Bert Newton Retirement Village by installing advanced, state-of-the-art Mitsubishi Electric air conditioning systems across the entire facility. Their expert team designed and implemented solutions tailored to meet the needs of residents, ensuring reliable temperature control, energy savings, and a comfortable living environment year-round.

Established in 2010, Contract Air Conditioning has built a strong reputation across Melbourne for delivering high-quality commercial air conditioning and mechanical services, making them the perfect choice for this project.

“Our approach was to design a system that not only provided reliable comfort for residents but was also energy-efficient and easy to maintain,” said Robert Baker, Project Manager Contract Air Conditioning. “We understand how important it is for a facility like this to have a system that works seamlessly, especially given the diverse needs of residents.”

The project required careful planning, from initial design to final installation, ensuring the air conditioning systems were integrated effectively with the architectural layout of the village. Contract

Air’s skilled team, based in Keysborough, Melbourne, brought their extensive expertise to ensure the systems were installed on time and within budget.

“We focused on selecting solutions that offered long-term performance without compromising on energy efficiency. Sustainability was a key consideration for us,” Robert noted. “With the assistance of Mitsubishi Electric Design Team, the systems we installed are designed to reduce energy consumption while ensuring the comfort of residents year-round.”