ETIN

Quarterly Journal of The Association for Petroleum Acts Administration

OCTOBER, 1966 Volume 5 No. 4

•

THE ASSOCIATION FOR PETROLEUM ACTS ADMINISTRATION THE COUNCIL 1966-67

E. V. BEEBY (Chairman), c. R. PESKETT (Vice-Chairman), L. A. CAVE (Hon. Secretary/Treasurer),

Officers: Members: J. BEER, R. L. BLOOR, M. GEE, H. GRIFFITHS, D. HALL, G. H. HARVEY, J. W. HEWISON,

R. P. HOLDAWAY (Editor), G. N. DEAN (Liaison Officer), T. KERR, Surveyor, F. H. MELBOURNE, C. T. PEACOCK, R. E. J. RODEN, B. W. C. THACKER,

Hon. Electrical Adviser: J. A. SHARP,

Hon. Legal Adviser: P. D. WADSWORTH,

-··-·

OCTOBER, 1966

The Bulletin

Published quarterly by the Association for Petroleum Acts Administration

Opinions expressed in this journal are not necessarily the views of the Association

CONTENTS

Editor: R. P. HOLDAWAY WEIGHTS AND MEASURES DEPT GUILDHALL, SHREWSBURY

Subscription: 30s. per annum

TALKING POINT NOTES AND NEWS LETTERS .• A TTINGHAM, 1966 :

74 74 75

THE NATURE OF PETROLEUM SPIRIT AND ITS HAZARDS-W. M. LEWIS . • 77

THE INSTALLATION OF UNDERGROUND TANKS-K. SHERWOOD 80

THE LAW RELATING TO LICENCES FOR KEEPING PETROLEUM SPIR!TC. s. McDONALD 83

FUTURE TRENDS IN PETROLEUM SPIRIT DISPENSlNGG. M. STEER AND M. T. R. BOWEN 87 SENSITIVE, CURRENT OPERATED, EARTH LEAKAGE PROTECTION-L. C. EALES 89

IN PARLIAMENT • 93 FURTHER SELF-SERVICE CONCEPT-R. BILLINGS 94 MODERNISED TANKERS FOR Esso 95 THROUGH THE PIPELINE 96 PETROLEUM SAFETY AND THE FILLING STATION IN Los ANGELES, CALIFORNIAJ. H. B. HORNBY 97 BRANCH MEETINGS :

YoRKSHIRE-SCARBOROUGH-23RD MAY, 1966

TEES SIDE-MIDDLESBROUGH-2ND JUNE, 1966

WEST MIDLANDS-WALSALL-16TH JUNE, 1966

Chairman: E. V. BEEBY

Honorary Secretary/Treasurer: L. A. CAVE Liaison/Advertisement Officer: G. N. DEAN

98 100 101

....--

Volume 5 Number 4

Talking Point

CONSTRUCTION OF PETROLEUM TANKERS

We understand the Home Office proposes to amend the Petroleum Spirit (Conveyance by Road) Regulations, 1957, which at present place an upper limit of 4,000 gallons on the quantity of petroleum spirit which may be conveyed in a road tank vehicle, so as to permit the carriage of not more than 6,600 gallons in such a vehicle.

By way of background to this proposal, the Motor Vehicles (Construction and Use) Regulations, 1963, which limit the size of goods vehicles, were amended in August, 1964, to permit a maximum gross weight of 28 tons in the case of four axled rigid vehicles, and 32 tons for five axled articulated vehicles. These amendments would permit loading considerably in excess of the weight of 4,000 gallons of petroleum spirit, and it is not surprising that the oil companies have been pressing for the 1957 Regula- tions to be changed so as to permit larger tankers to be built and used in the interest of operational efficiency.

Most European countries have a higher limit than the United Kingdom and accidents involving petroleum tankers are fortunately rare as indeed they are in this country. In the unhappy event of an accident can it be said that 6,600 gallons rather than 4,000 gallons of petro- leum spirit at risk, materially affects the hazard ? It is a fact that by carrying 100,000 gallons in 15 journeys mstead of 25 the incidence of risk is lowered by 40 % and road congestion correspondingly reduced.

The present economic situation requires that every con- sideration be given to increasing efficiency and turnover. We do not feel this proposal will nullify the high standards of safety set by and enjoyed in an industry that in every aspect of its work is conscious of its heavy responsibility.

New Associate Members

H. Abrahan, Gunnes Pump Services, Scunthorpe.

L. B. Fentum, Assistant Chief Engineer, Gilbarco Ltd., Essex.

S. L. Hope-Gale, Maintenance Supervisor, Shell Mex & B.P. Ltd., Brighton.

R. J. Reeves, Construction Supervisor, Shell Mex & B.P., Ltd., Nottingham.

A. Vernon, Sales Manager, Gilbarco, Ltd., Essex.

Changes in Administration

Aldridge-Brownhills U.D.C., Staffs., now H. Swindon M.B.C., Wilts., now W.M.

Change of Address

Home Office Explosives Branch: "Horseferry House," Dean Ryle Street, London, S.W.I. (VICtoria 6655).

Reprinted

The Petroleum (Transfer of Licences) Act, 1936. 5d.

Secretary's Notes

It has come to the knowledge of members of the Council that the term "Officer Member" is not fully understood by some Officers whose Department administers the Petroleum Acts.

There is an impression, particularly in some Offices where more than one person is appointed to enforc.e the Petroleum Acts, that if the Head of the Department ts the Chief Petroleum Officer and receiving The Bulletin, there is no point in any other of his staff becoming a member.

Notes and News

Membership

Total membership of the Association now stands at 458.

New Members

R.D.C. Surrey S. Cl ailey R.D.C. East Sussex H. ydebank Burgh W.M. Farnham s K U DC Surrey . mgswood · · · Gl H L U.D.C. oucs. ewes H SI h M.B.C. East Sussex .. oug M WM S h .B.C. Bucks. outb C.B. Hants. W.M. Ton n ge R D c K S . . ent Wellingborough U.D.C. Northants. H.

K. M. Marsden, C.P.H.I., Watford M.B.C., Herts. P. Turner, C.I.W.M., Accrington M.B.C., Lanes.

This point of view appears to be a short-sighted and an unwise one, especially in the case of the young Petroleum Officer. Members of the Association receive a issue of The Bulletin individually and do not have t<? "'.a1t until it has "gone the rounds". Attendance at and Branch Meetings is an additional means of the knowledge and experience of others necessary Ill the proper performance of a Petroleum Officer's duties.

The first Object of the Association is "The advai:cement of scientific, technical and legal knowledge req':ured in the administration of the Petroleum Acts and associated legislation".

The advantages of membership are many and the use- fulness of the Association is known not only over the British Isles and Europe, but as far afield as the Malay States.

Any duly authorised Petroleum Officer is entitled to become a member and all non-member Petroleum Officers are invited to give serious consideration to this oppor- tunity of extending their knowledge of Petroleum Acts Administration.

74

The Hon. Secretary reports that he is constantly being asked for back numbers of The Bulletin which are now out of print.

These requests indicate that it might be possible to reprint the original duplicated issues, but this could only be done economically provided a sufficient number of back issues were required.

It has also been suggested that those members who possess the first duplicated Bulletins might like to take advantage of a reprint in the same format as at present, thus having the complete volumes in uniform size and design.

The duplicated issues are:

Vol. 1, Nos. 1, 2, 3 and 4, 1962.

Vol. 2, Nos. 1, 2, 3 and 4, 1963.

Vol. 3, Nos. 1, 2, 3 and 4, 1964.

Will those desirous of obtaining reprints of Bulletins, whether of the duplicated issues or later issues which they may have mislaid or missed please let the Secretary know as s?on possible, giving the number required of any particular issue. Ii

No engine modifications are necessary for the use of gelled fuels, and the American Petroleum Institute are now working on its application to the handling of petroleum spirit. In the years to come it is likely that petroleum spirit will be in this form.

Oxford J. H. HORNBY

PETROLEUM MIXTURES

Further to my letter in the last issue of The Bulletin, I should like to thank all those readers who have sent me information regarding this matter.

I think it would be of interest to members to have particulars of the information sent to me by Mr. L. A. Cave, who received it from a colleague in Germany.

This information included a copy of parts of the German regulations covering the labelling requirements regarding inflammable liquids from which it appears that all portable containers used for the storage or transporting of inflammable liquids of Group A, danger class I or of Acetaldehyde, Acetone, or acetone mixtures must be conspicuously marked with the appropriate symbol the highly inflammable nature of the contents (i.e. flame symbol). The colours to be used are black on a yellow base and the size of the label varies according to the volume of the container. It must be affixed both to the container and to any outer wrapping.

Portable containers used for the storage or transporting of inflammable liquids of group A, danger class II, or group B with the exception of Acetaldehyde, Acetone or acetone mixtures must be labelled "Highly Inflammable".

EMULSIFYING JET FUEL

I have been spending a short time with the American Institute in New Mr. R. Southers, Operand Engineering Co-ordmator at the Institute has devoted much time to discussion with me on pracall aspects of work, and I am completing articles on Cathodic Protection of underground storage tanks and fibreglass tanks, which I think will be of interest to readers of The Bulletin.

At Attingham school, I commented on the possibilities in the use of emulsifying jet fuel and I find this is now in an advanced stage of development over here. The idea is that _in using jellied fuel a fire risk is greatly reduced. earned at all times in the form of a gel, this fuel is injected into the engines. Pumping is no problem but difficulty is experienced in creating a flow from the wing tanks to the pump. On impact gelled fuel comes into its own. Instead of raging areas of fire when fuel tanks are spilt, all that occurs is a collection of burning blobs, which are much easier to control and cover only a fraction of the area that burning jet fuel will spread over.

Originally a system was developed whereby-literally at a touch of a button-any fuel carried by a crashing plane could be solidified, but pilots objected to this because once the button had been pressed the engmes could not be used again.

Labelling of individual small containers (under 10 c.cs.) is not required if enclosed in a bulk package properly labelled.

Products intended for human consumption or personal use, if in packages prepared for sale are exempt from these provisions.

I trust this information will be of interest and value to members.

J. W. HOBSON

Burgess Hill U.D.C.

With reference to the letter from Mr. J. W. Hobson published in the last edition of The Bulletin, I recently found a five gallon can of "Brunophen 70", which is used for the treatment of woodworm infestation, carrying two labels one label gave directions for use, precautions to be taken' on use, and states the flash point as 110°F. The other is a red label with the wording "Inflammable Liquid -Flashpoint 73°-141°F." in black.

The manufacturers inform me that the red label is required to be attached by the carriers to any product that has a flash-point in _the of 73°F.-141°F. and they will not transport without it.

Felixtoll'e

H. W. RUNNACLES

Letters " ~~~--~

75

MIXED LOADS

Recently at a local garage, 500 gallons of petroleum spirit was discharged into an underground paraffin tank in which there was approximately 54 gallons of paraffin. The paraffin is delivered to customers through a pump. In spite of the paraffin tank being clearly marked and the nearby tanks clearly numbered, this error was made.

Fortunately, emergency action and publicity was immediately given and it appears that all but half a gallon of paraffin mixture has been recovered.

This dangerous practice I feel sure, could be prevented if it was required that delivery pipes serving paraffin tanks or diesel oil for that matter had different fittings from those serving petrol tanks.

Perhaps the Association could take up this matter with the powers to be.

Bognar Regis R. G. CoYsH

AN UNREPORTED ACCIDENT

I am writing concerning an accident which occurred recently in Worthing involving petroleum spirit, which I think may be of interest to members. The accident did not occur on licensed premises so no official report was called for, but the contractors concerned were kind enough to acquaint me of the circumstances.

On the 14th August, 1966, a large radio and television shop with associated workshops and garage was gutted by fire, and a small motor van was garaged in part of the premises which were completely burnt out. A Building Inspector with experience of petroleum administration who examined the premises for safety the day following was surprised to see the filler cap of the van still in place, but on examination he found that the rubber sleeve connecting the fill pipe to the tank had melted away as a result of the fire.

On the 31 st August an employee of the demolition contractors was cutting up the vehicle with an acetylene torch to free it from fallen girders and debris, and because the vehicle had been in the burnt out part of the premises and there had been reports that the petrol tank had expl_oded during the fire it was assumed that no petroleum sp1r!t could have remained in the tank; the filler spout hav11:1g blown out. Unfortunately, it would seem that the meltmg of the rubber connection merely vented the tank it from exploding at the time of the fire, and it sufficient petrol to explode later when the ?emohtion co':1tractors' employee's acetylene torch came mto contact with it, burning him about the face and arms. Fortunately the extent of the burns was no more than scorching the workman was only off work for seven days but I thmk we have here another example showing that where petroleum is concerned it is better to take all possible safety precautions and not rely on secondhand information.

Worthing F. A. SMITH

UNATTENDED SELF-SERVICE

The Bulletin reports that at the A.G.M. the general concensus of opinion was turning towards self-service coin operation on unattended sites, and I am wondering whether this is a sincere appraisal of the merits of the case, or simply acceptance of the fact that the coming of unattended self-service is inevitable.

I suggest that this "inevitability" is due in part to intensive "lobbying" by the industry, and the reluctance of local authorities to be thought backwards and reactionary-put in another way, the ambition of certain authorities and officers to be trend-setters and to be able to say that they were in the forefront in introducing self-service petrol.

Let us consider first the question of public demand. We hear harrowing tales of motorists stranded at night with no petrol, but just how widespread is this, and to what extent is it directly attributable to the absence of selfservice pumps ? Where are all the petitions from indignant motorists about this injustice, or is it possible that all the noise is being made by the industry ? Even if there a great public demand, local authorities concerned with safety regulations must still be more concerned with what is right than with what is wanted.

If the brewers were more powerful at lobbying, pre- sumably self-service of beer would be "inevitable", and the answer to the fact that this would contravene existing legislation would be that the legislation must be amended. After all, other countries have no restriction on drinking, and we cannot lag behind other countries, can we ?

If unattended self-service comes it will make a mockery of many of the standard conditions-good, worthwhile conditions. The case against self-service is simple. If licence conditions for safe-keeping are imposed, sorr.iebC?dY must see that those conditions are observed. F1ddhng about with special nozzles, magic eyes, and all the other gimmickry is no substitute.

With all this talk about keeping up with the times, I suggest that the truly progressive authority will be the one which says "We will pay due regard to public opinion (if any) and to the views of commercial interests, but in deciding what conditions to attach to our licences we will be guided solely by our responsibilities under the and will not be hurried into accepting something which we believe to be wrong".

The South Eastern Branch Committee considered this question earlier in the year, and recommended that selfservice should be limited to adequately supervised sites. I hope that this recommendation will stand, and that others will take the same view.

My own local authority is not a member of the Association. I write as an individual officer, and the views which I express are my own.

Greater London Council

J. H. DoMONEY

76

ATTINGHAM 1966

THE NATURE OF PETROLEUM SPIRIT AND ITS HAZARDS

W. M. Lewis, F.R.I.C., City Analyst, Coventry

Although this morning it is my duty to convey to you some understanding of the Nature of Petroleum Spirit and its Hazards I would be failing in my duty if at the commencement I did not signify that I am not an expert i!1 field. I, like the majority of you present, earn my ltvelthood as a Local Government Officer, concerned like yourselves with a variety of duties, one of which involves me in the testing of samples submitted for examination under the Petroleum (Consolidation) Act, 1928, and the (Mixtures) Order 1929. Basically, therefore, I am a mere chemist and it i; mainly as the result of the persuasive of your colleagues .that I find myself to-day in the mv1d10us position of standmg before you with this responsibility on my shoulders. Now that I have excused myself I can, with your forebearance, commence the task ahead.

I have already mentioned the pertinent Acts with which presumably both yo.u and I are concerned, it is perhaps a good starting pomt to my talk. The definition of the substance with which we are concerned is set forth in the 1928 Act and here 'petroleum ' as defined, 'includes crude petroleum oil made from petroleum or from coal shale, peat or ;ther bituminous substances and othe1'. products of petroleum'.

The definition as you will agree is to say the least. allembracing and upon critical appraisal perhaps a httle confusing.

Further 'petroleum spirit' means-according to the Act of 1928, 'such petroleum' as when tested in a defined manner-gives off an inflammable vapour at a temperature of less than 73 °F. Presumably therefore a physical of laboratory testing can evaluate the inflammab1ltty of a suspected sample .

To appreciate the nature of the however , requires a knowledge of its origin and particularly so me conception of the make-up of the article .

All present know the nature of the sta rting which basically in the Petroleum Industry 1s 011 ?r starting stock. Such material exhibits wide vartatwns m composition and also properties.

Analysis of the crude oil-:-wh?se the.ories of formation-makes fascmatmg readmg-sbows 1t to contain essentially the two elements carbon and hydrogen in the weight ratio of about 85 to We also know that other elements are also present m very much smaller quantities; these to name the most important are sulphur, nitrogen and oxygen.

The elements which I h a ve mentioned are o bviou sly present in chemical composition as highly compl ex orga ni c compounds, so we can generalise and say that the co nstituents of petroleum consist of hydrocarbons, sul1>hnr compounds, nitrogen compounds, oxygen compounds a nd some metallic derivatives.

We publish a selection of papers presented to students at the mid-week school held in May this year

77

Attingham Park, The Shropshire Adult Colleg e

The first group is the one which gives to petroleum its chief characteristics and is the group about which we as people interested in the subject, should have some basic knowledge.

Laboratory investigation-by a variety of tests-has shown that the hydrocarbon group is subdivided-it is a highly complex collection of individual C and H chemicals. which may be roughly classified as paraffinic, naphthenic and aromatic.

This classification you must appreciate at the outset is rather inadequate but it will suffice for basic knowledge in a further appreciation of the subject.

There would appear to be no acceptable standardised method used throughout the industry-for the full assay of crude oil.

If a sample of crude oil is subjected to a process of distillation-so arranging the process that the distilled materials can be collected in fractions-one is able to assess the yields of products covering the entire boiling range covering so-called light hydrocarbons, light and middle distillates, residual fuels, heavy distillate lubricants and bitumens.

The names will be familiar to you and the diversity of material recovered, again you will readily appreciate, differs not only in its visual appearance but also in its chemical and physical properties.

From your experience of the valuable assistance offered by the petroleum companies you will also know that in a modern refinery recovering a multitude of products from crude oil-straight distillation has long since been super- seded by alternative techniques. Essentially the introduction of these variations have been perhaps forced on the industry in an attempt to provide an adequate supply of the materials demanded. 'Straight run' petroleum spirit is perhaps therefore not the substance commercially sold but for the purpose of simplicity in this talk it fits the bill. The boiling range yielding the fraction called light hydrocarbons, i.e. the first run from the distillation typifies the material we wish to discuss and contains the previously mentioned group of hydrocarbons as its chief ingredient.

We now have to look more intimately at this main ingredient-this hydrocarbon group-this group whose members are composed of essentially C and H. By techniques peculiar to the laboratory it has been shown that whether petrol is produced as a straight run material or by the alternative process of cracking, etc., the hydrocarbon content consists of varying proportions of the chemical group known as paraffins, naphthenes, aromatics and olefines-all made up from C and H, and all therefore hydrocarbons. The ratio of any one of these groups to any other group in the petrol characterises its performance in the internal combustion engine.

What precisely do we understand when referring to the above groups? Perhaps to some they are mere names with no mental appreciation.

To a chemist the mere pronouncement of either of these named groups projects in his mind a class of material which enables him to prognosticate its properties and for you to realistically appreciate the material with which you daily come into contact, it is my job this morning to point out to you the elementary nature of these groups.

The group referred to as paraffins include substances whose names will be readily recognisable-methane, propane, butane, etc., to mention but three. A chemical 'looksee' into each of these substances shows that the combinations of carbon and hydrogen takes place with a systematic regularity and can be expressed by the simple formula C,.H 2,,+ 2

Thus the simplest of them all is methane, having but one carbon atom therefore the hydrogen atoms total 4; thus the formula is CH 4 • Ethane is the next and has two carbon atoms, propane has three carbon atoms, butane has four so the formula for butane is C4 H 10• The difference between two successive substances in the list is CH2 • Heptane, octane have 8, 9 carbons. The higher members include a material known as octocosane having 28 carbon atoms in the molecule.

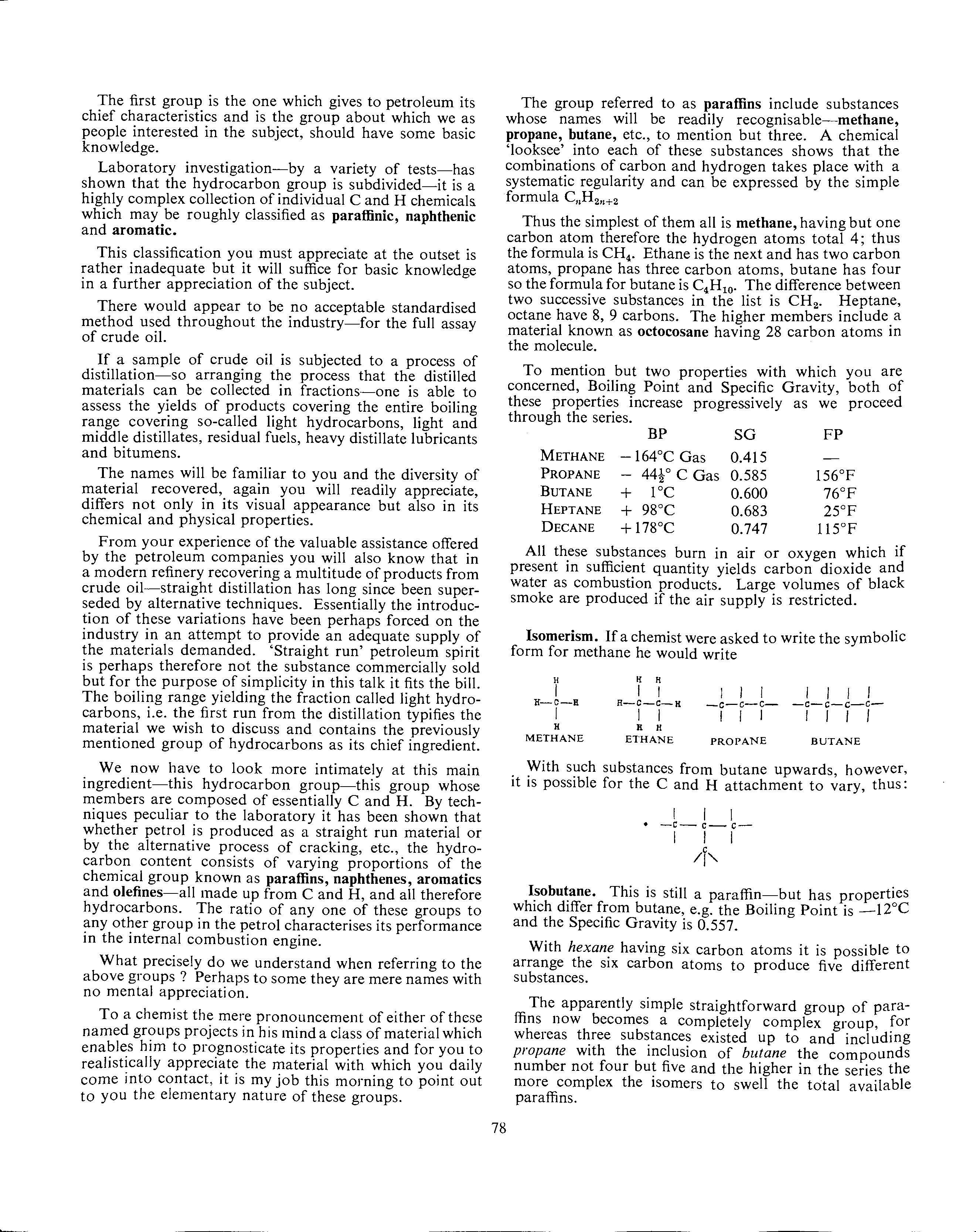

To mention but two properties with which you are concerned, Boiling Point and Specific Gravity, both of these properties increase progressively as we proceed through the series.

BP SG FP

METHANE -164°C Gas 0.415 PROPANE 44!° C Gas 0.585 156°F BUTANE + l°C 0.600 76°F HEPTANE + 98°C 0.683 25°F DECANE + 178°C 0.747 l 15°F

All these substances burn in air or oxygen which if present in sufficient quantity yields carbon dioxide and water as combustion products. Large volumes of black smoke are produced if the air supply is restricted.

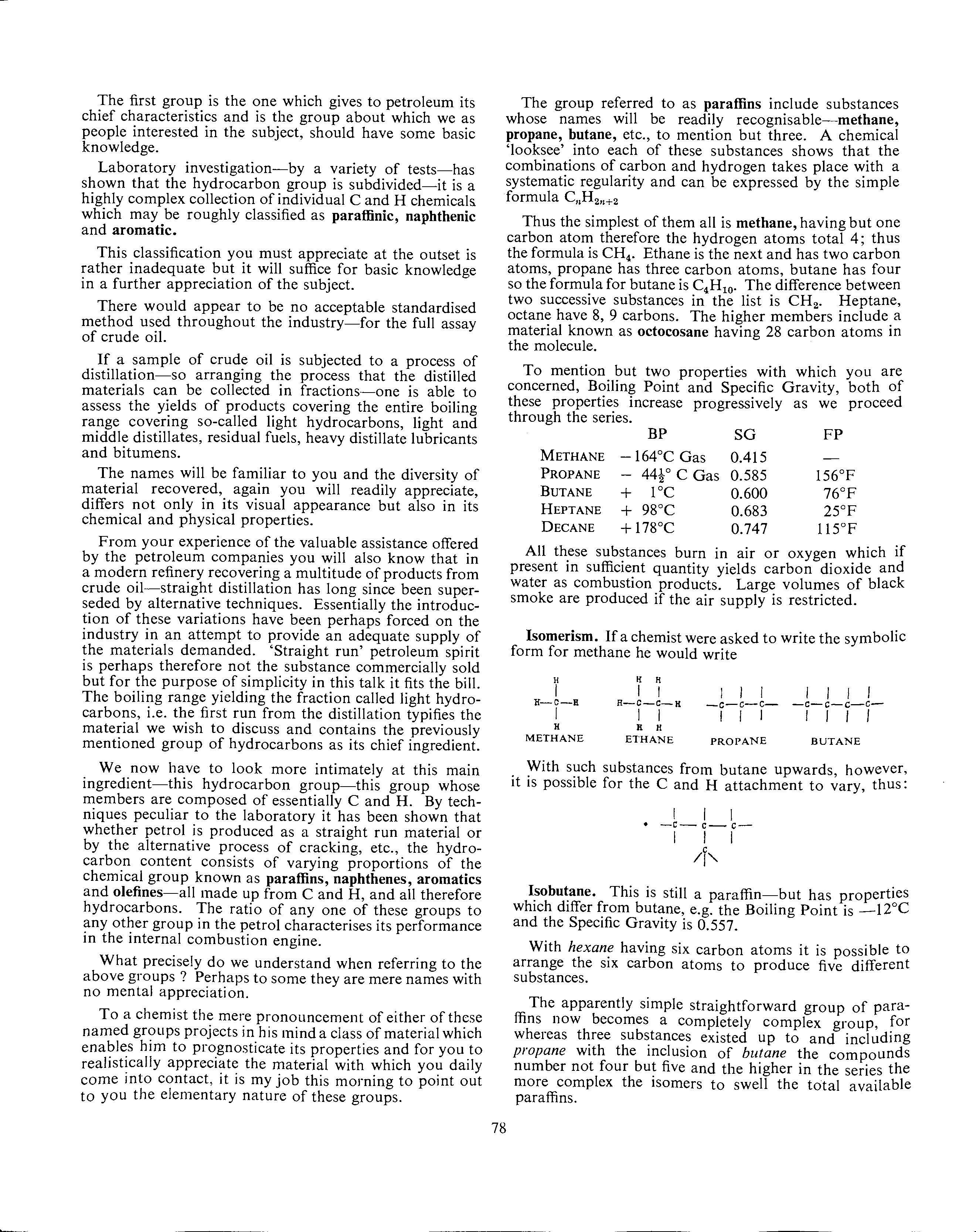

Isomerism. If a chemist were asked to write the symbolic form for methane he would write H H H I I I I I I I I lf-0-B H-C-C-H -c-c-c- -c-c-c-cI I I I I I I I I I H R H

METHANE ETHANE PROPANE BUTANE

With such substances from butane upwards, however, it is possible for the C and H attachment to vary, thus: I I I • -c-c-c1 I I

/J'-

This is still a paraffin-but has properties which differ from butane, e.g. the Boiling Point is -12°C and the Specific Gravity is 0.557.

With having six carbon atoms it is possible to arrange the six carbon atoms to produce five different substances.

The apparently simple straightforward group of paraffins now becomes a completely complex group, for whereas three substances existed up to and including propane with the inclusion of butane the compounds number not four but five and the higher in the series the more complex the isomers to swell the total available paraffins.

78

Excepting for the lower members of the series which chemically readily react with such elements as chlorine etc., the higher members are rather chemically inert. '

To summarise, the paraffins are open chain hydrocarbons of the general formula C,,H 2,,+2 and range from the gas methane through a series of liquids to solids.

The so-called 'naphthene' compounds found in the petroleum fraction of petroleum are again hydrocarbons and .differ from the paraffins which are open chain compounds m that the naphthenes are closed rings.

In other words the carbon atoms are joined cyclically. The lowest member of the group contains three carbon atoms and is given the name Subsequent compounds of the group are agam by the addition of a carbon atom and are named tetremethylene-pentrahexa, etc.

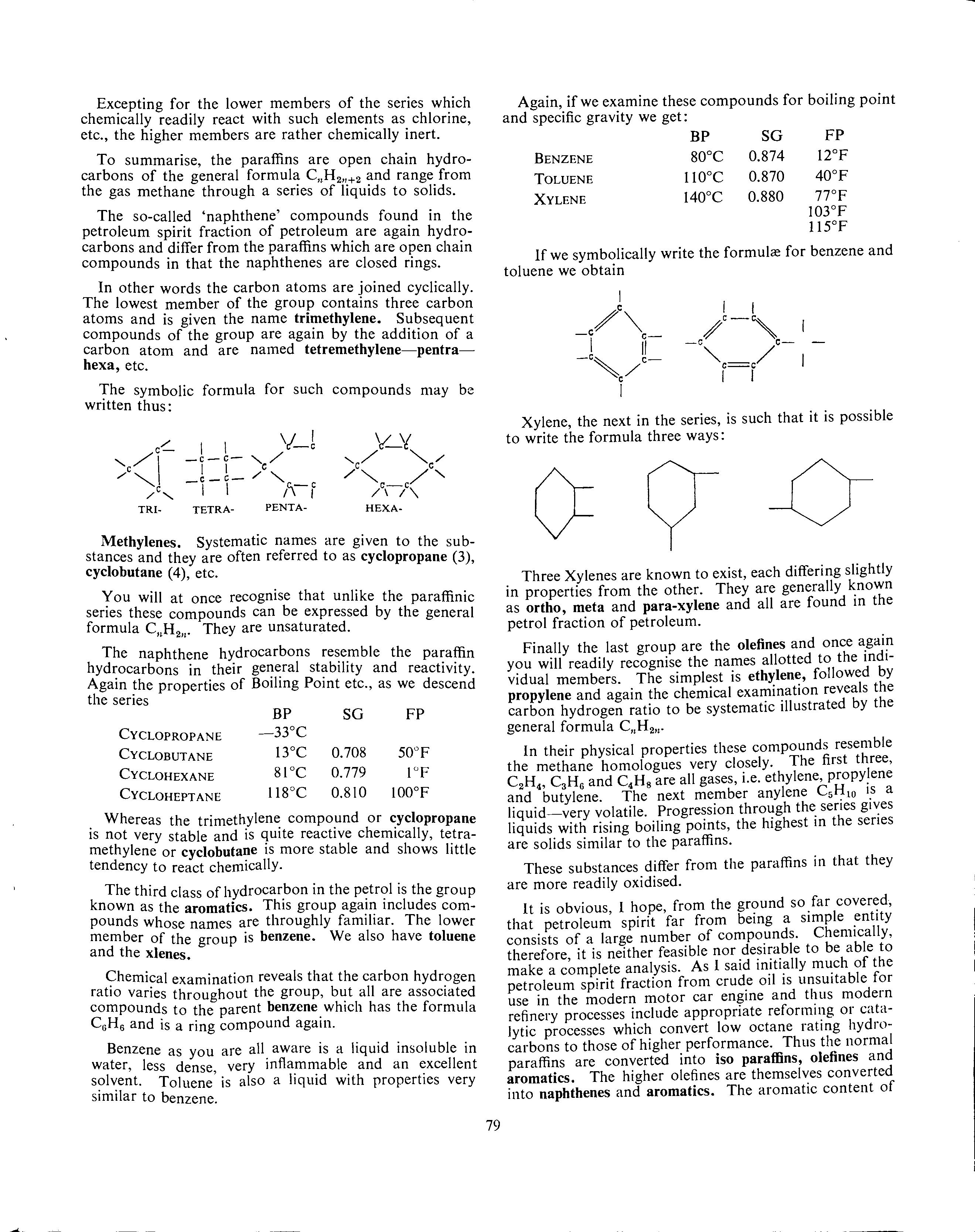

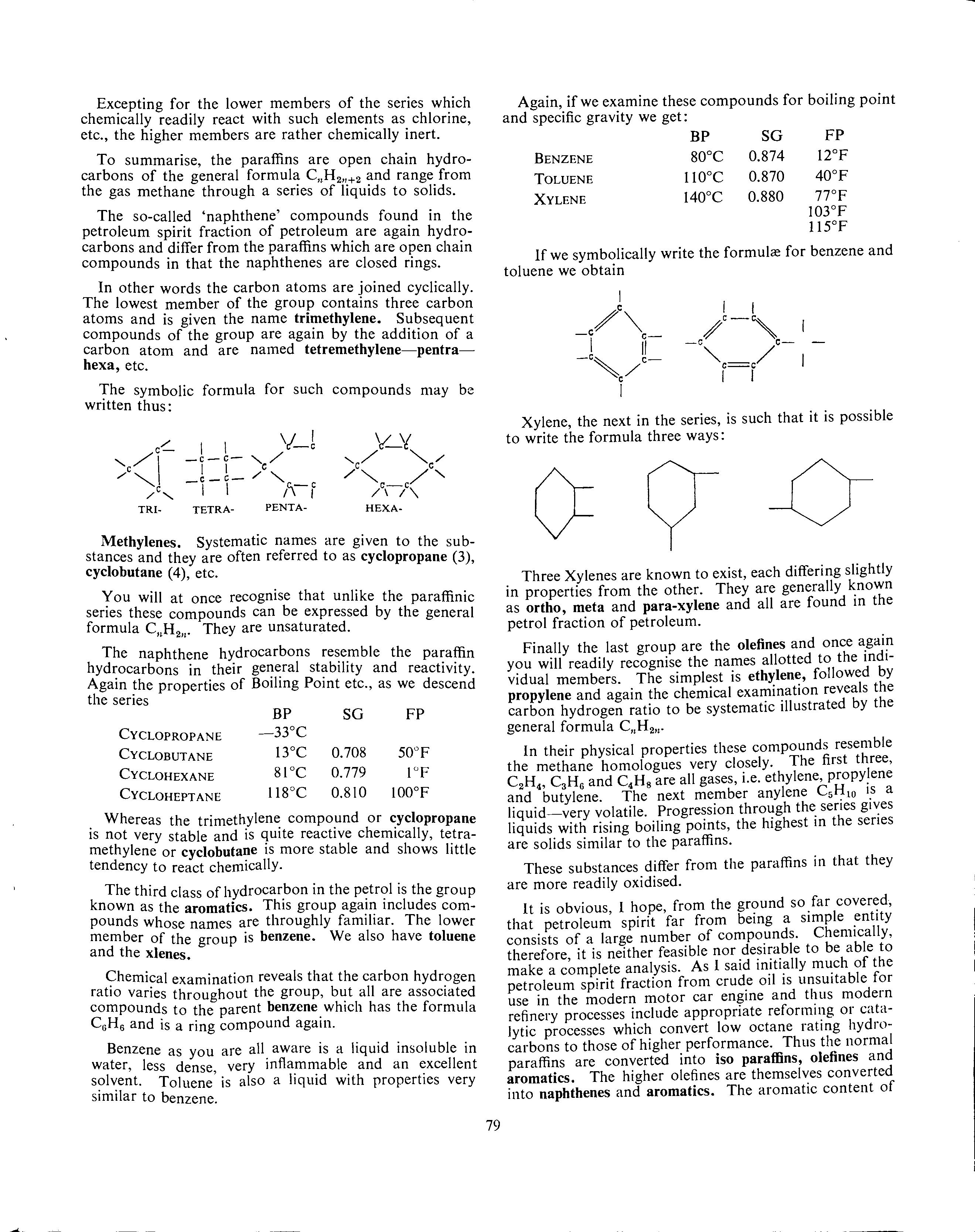

The symbolic formula for such compounds may be written thus:

Again, if we examine these compounds for boiling point and specific gravity we get:

BP SG FP

BENZENE 80°C 0.874 12°F

TOLUENE I 10°c 0.870 40°F

XYLENE 140°C 0.880 77°F 103°F 115°F

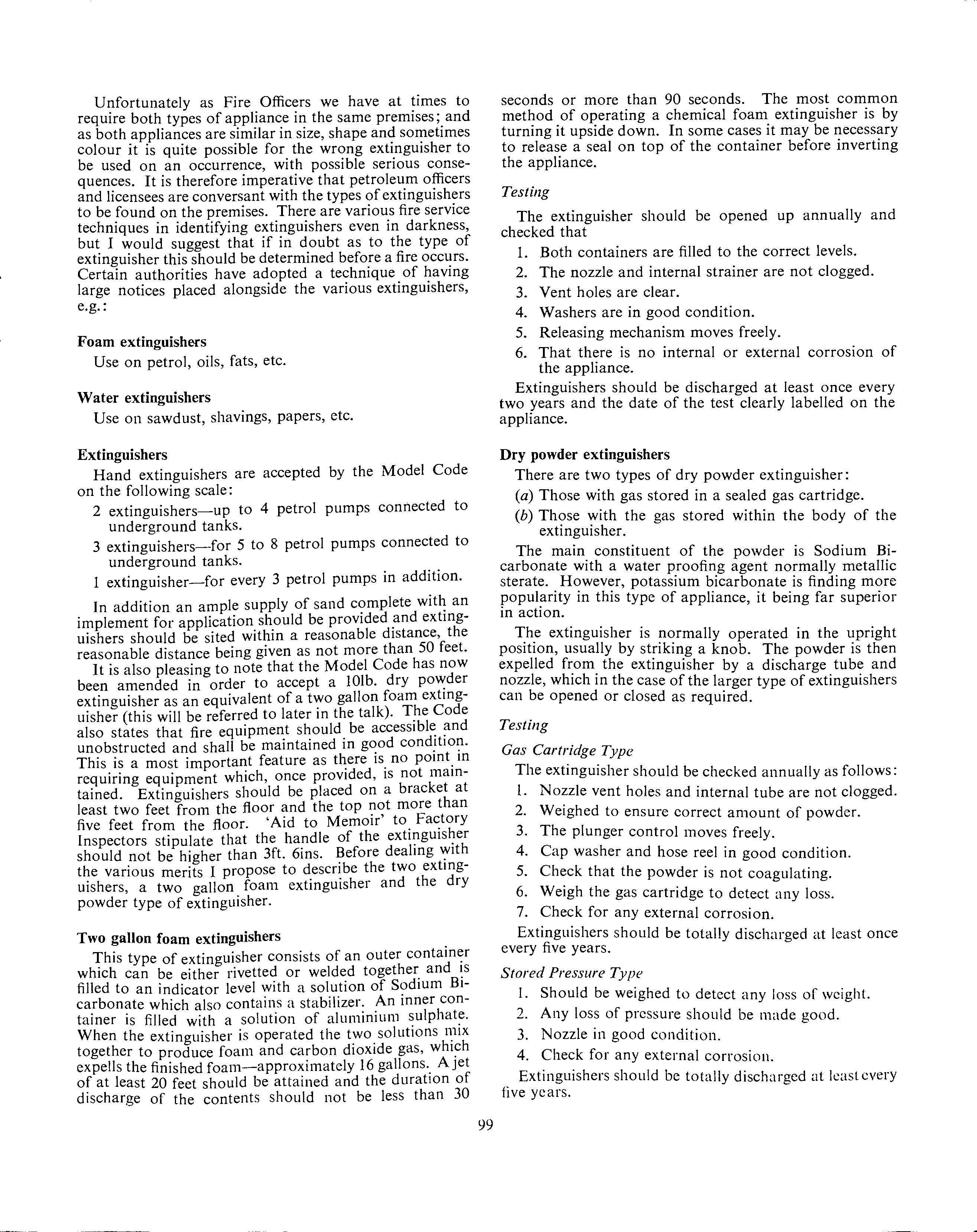

If we symbolically write the formulre for benzene and toluene we obtain

Methylenes. Systematic names are given to the substances and they are often referred to as cyclopropane (3), cyclobutane (4), etc.

ou will at once recognise that unlike the paraffinic senes these compounds can be expressed by the general formula C,.H 211 • They are unsaturated.

The naphthene hydrocarbons resemble the paraffin in their stability and reactivity. Agam the properties of Bo1lmg Point etc., as we descend the series

BP SG FP

CYCLOPROPANE -33°C

CYCLOBUT ANE 13°C 0.708 50°F

CYCLOHEXANE 81°C 0.779 I °F

CYCLOHEPT ANE I l8°C 0.810 100°F

Whereas the trimethylene compound or cyclopropane is not very stable and is quite reactive chemically, tetramethylene or cyclobutane 1s more stable and shows little tendency to react chemically.

The third class of hydrocar.bon in the is the group known as the aromatics. This group agam mcludes compounds whose names are throughly familiar. The lower member of the group is benzene. We also have toluene and the xlenes.

examination reveals that the carbon hydrogen ratio vanes throughout the group, but all are associated compounds to the parent benzene which has the formula CGH6 and is a ring compound again.

Benzene as you are all aware is a liquid insoluble in water, less dense, very inflammable and an excellent Toluene is also a liquid with properties very s1m1lar to benzene.

Xylene, the next in the series, is such that it is possible to write the formula three ways:

Three Xylenes are known to exist, each differing slightly in properties from the other. They are generally known as ortho, meta and para-xylene and all are found in the petrol fraction of petroleum.

Finally the last group are the olefines and once you will readily recognise the names allotted to the md1vidual members. The simplest is ethylene, followed by propylene and again the chemical examination reveals the carbon hydrogen ratio to be systematic illustrated by the general formula C,,H 2,..

In their physical properties these compounds resemble the methane homologues very closely. The first three, C 2 H 4 , C 3 H 6 and C4 H 8 are all gases, i.e. ethylene, propy!ene and butylene. The next member anylene CsI-;110 1.s a liquid-very volatile. Progression through senes liquids with rising boiling points, the highest m the senes are solids similar to the paraffins.

These substances differ from the paraffins in that they are more readily oxidised.

It is obvious I hope, from the ground so far covered, that petroleurr{ spirit far from being a simple .entity consists of a large number of compounds. Chemically, therefore, it is neither feasible nor desirable to be able to make a complete analysis. As I said initially much of the petroleum spirit fraction from crude oil is unsuitable for use in the modern motor car engine and thus modern refinery processes include appropriate reforming or catalytic processes which convert low octane rating hydrocarbons to those of higher performance. Thus the normal paraffins are converted into iso paraffins, olefines and aromatics. The higher olefines are themselves converted into naphthenes and aromatics. The aromatic content of

79

a motor car fuel is of importance in respect to the solvent effect on rubber joints, pump diaphragms and because the freezing point of benzene is about 5°C. it may crystallise out during periods of cold weather.

Obviously the primary requirement of a motor fuel is that its vapour should burn efficiently under the conditions existing in the cylinder to liberate the maximum amount of useful energy. Other properties must also be of imporance--it must not attack the various components, i.e. rubber-nor must it deposit sticky gum residues to clog pipes or stick valves. The volatility must whilst being adequate not be so great that excessive losses from storage vessels occur or vapour lock in the engine.

The volatility of a fuel is assessed by determining the boiling range, which normally ranges between 3°C and 200°C. To ensure a reasonable flexibility in the engine during warming up stage the maximum temperature at which 10 % is boiled off is important; 55/60°C is the value usually employed. Nearly half the fuel should boil off below I00°C and the temperature at which 90 % has evaporated (180°C) should not be excessive, otherwise incomplete combustion occurs with consequent dilution of the crankcase oil and fouling of the plugs.

Petroleum spirit containing as it does the variety of compounds enumerated-and also many others-gives rise to certain hazards. Vapours from the fluid are given off which may be described as both flammable and toxic. Petrols which contain benzene in particular may give rise to a toxicity hazard at concentration well below the lower limit of flammability.

The flammability range of petrol vapour will obviously depend on the blend of hydrocarbons used but is generally taken at ranging between 1 % and 6 % petrol vapour in air. A fact which is not always appreciated, especially by those people whose work constantly brings them in contact with such fluid is that petrol will produce an appreciable quantity of vapour even at temperatures as low as 0°F. Thus such material presents an explosive hazard under almost all conditions of storage and the utmost care in handling must be exercised.

Obviously it is frequently necessary for repair work either on motor vehicels or empty storage tanks to take place necessitating the use of welding techniques.

Iron rust which is obiquitous in nature is an excellent storage place for petrol and may lead, in an apparently empty vessel, to sufficient vapour to reach the minimum explosion hazard I %.

To safeguard against such levels a device is available known as an 'explosimeter', which is capable of recording hydrocarbon vapour concentrations in air above about 140 parts per million, i.e. well below the maximum permissible concentration, re: explosion.

Petroleum spirit containing benzene produces a vapour which on inhalation is considerably more toxic than a hydrocarbon vapour. In order for poisoning to occur the benzene vapour must be absorbed into the body via the air in the lungs and distributed through the body by means of the blood stream. Ordinarily, poisoning does not occur without absorbtion-on the other hand absorbti on does not necessarily or always result in poisoning. The human body is provided with an elaborate system of

protective mechanisms and is able to tolerate to an amazing degree the presence of many toxic materials. Some are excreted via the urine, some exhaled with expired air, some are metabolised and excreted in an altered form. Benzene poisoning is revealed clinically by an alteration in the red blood cells and severe poisoning causes bleeding into the urinary tract. Benzene has a definite cumulative effect and daily exposure to a concentration of 100 parts per million or less will usually cause damage if continued over a protracted period of time.

Fatigue, headache, dizzyness, nausea and loss of appetite are the vague symptoms associated with chronic poisoning as the result of daily inhalation.

Because of its high toxicity rating the maximum allowable concentration where benzene vapour is present is only 25 parts per million in air for eight hour exposure periods, i.e. well below the explosimeter sensitivity.

The toxicity hazards from benzene are in general associated mainly with problems involving entry into tanks containing vapour and when breathing apparatus is not available.

Vapour density is a measure of the density of the vapour of a substance compared with the density of air. The vapours of most flammable liquids are heavier than air, thus they can readily flow into low areas-excavations, etc. Vapour density: benzene 2.77; Hexane 2.97. The vapour density varies between 3.0 and 4.0 depending upon its composition. As you gentlemen are aware it three factors to produce a fire, (a) fuel, (b) oxygen or alf and (c) heat. If either of these are not present in the proper proportions or degree no fire will occur. The air and thus the oxygen is abundant and fortunately for us who depend upon it for our existence-ubiquitous. The other t.wo factors are controllable. Correct sitings and ventilation with adequate precautions against the collection of vapour pockets reduces the potential fuel supply.

The sources of igintion (I) open flames, (2) electrical sources-motors, switches, relays, fuses, circuit (3) overheating, (4) hot surfaces, (5) materials potent!al agents for spontaneous ignition-wiping rags, waste o.IIY residues, (6) sparks, (7) static electricity-belt dnve machinery and relatively low humidity, (8) friction-overheated fans are some of the sources of the third and perhaps most essential of the three requisites. This latter factor is the one over which you, gentlemen, have to ensure the minimum of hazard to the commumty generally.

THE INSTALLATION OF UNDERGROUND TANKS

K. Sherwood, A.F.I.P., Esso Petroleum Co., Ltd.

All gasoline tankage installations at service stations are governed by Licensing Conditions and the reasons for these conditions is to ensure safety.

The Petroleum Industry is extremely aware of the need for maximum safety precautions for the storage and handling of Petroleum products and often introduce thelf own requirements to supplement the licensing conditions.

80

I. Tanks

The safety considerations commence with the design and manufacture of the storage tanks. At present these tanks are invariably made of !in. thick M.S. plate welded to B.S.S. 2594. Prior to leaving the manufacturers' works tanks are tested to a pressure of lO p.s.i. They are also given a protective external coating of Bitumastic paint or similar.

The majority of Licensing Authorities require the tanks to be fitted with a manhole and cover. Several European countries will not permit tanks with manholes. There are arguments for and against manholes which can usually lead to lively discussion.

A major consideration could be that the elimination of tank manholes could result in the elimination of ground manhole chambers which without doubt are natural collecting pockets for gasoline vapours.

Each is supplied with a calibrated brass dipstick for measurmg the tank contents. It should be appreciated that these dipsticks are not accurate measuring apparatus but only approximate the tank contents. Most tankage manufacturers batch process the tanks and it is not unusual for the dipsticks to show errors of 2 %-3 %.

2. Siting

All Licensing Authorities demand that minimum· distances are observed between the tank manhole chambers and public highways and buildings. Normally 20ft. is the acceptable distance.

Bearing these requirements in mind the marketing company must consider operational aspects such as length of suction lines, road tank vehicle access and standing area for product deliveries.

3. Installation of Tanks

The Home Office Model Code (1957) suggests that tanks be encased in a minimum of 9in. thick mass concrete or alternatively installed in a brick vault, with the voids to be filled with clean dry sand after the tank has been positioned.

There are so many disadvantages to the brick vault and sand method that it is difficult to understand why a number of Petroleum Officers still insist on this method.

The following are a few of these disadvantages:

(a) Longer construction time.

(b) Poor quality porous bricks often used.

(c) The sand is invariably wet when backfilling occurs leading to accelerated corrosion of the external surface of the tank.

(d) More expensive due to high labour costs.

(e) Movement of the tank has been known to occur within the vault resulting in sprung pipelines.

(f) Takes up more space.

The m.ass concrete also has some disadvantages, but, until new matenals and methods are developed it must be considered the best method available where site circumstances necessitate an encased tank.

Contrary to popular belief there is plenty of evidence to prove that the concrete encasement does not provide a

secondary barrier to the possible escape of product to the surrounding ground.

Prior to commencing the excavation for the tank it is necessary for an employee of the marketing company to determine by calculation the required depth of the tank below ground level. Factors affecting this are the length of suction line and any gradients at ground level. It is generally accepted that the tank manhole should be no less than 2ft. below ground level. On the other hand the vertical distance between the base of the dispensing unit and the bottom of the tank should not exceed 13ft.

It is normal to position the tank at the minimum depth by calculation between these limits.

Most excavations are carried out by mechanical means with the bottom of the dig being trimmed by hand.

In many instances water is present in the excavation; this can usually be dealt with by means of a bottoming pump installed in a corner sump of the excavation.

The next operation is to provide a base of approximately 9ins. thick reinforced concrete. The length and width of this base normally exceeds the length and diameter of the tank by 9ins.-12ins.

If holding down wires or straps are necessary, to prevent flotation which might occur prior to pouring the casting, the fixing bolts should be cast into the base.

At this stage most Authorities require an inspection by the Petroleum Officer.

It would be interesting to know what many of the Petroleum Officers are looking for, as this establishes little except that a base exists, and this could be established when the officer witnesses the pressure test.

This pressure test is carried out after the tank h_as been lowered onto the raft and after the internal fill pipe and suction pipe have been installed in the tank.

The fill/dip pipe should be carried down to within lJins. of the tank bottom. The suction pipe should .ternynate not less than tin. above the bottom of the fill/d1p pipe so as to maintain a liquid seal.

A small minority of authorities require a. .test before and after the tank has been lowered mto pos1t1011.

The pressure test on new tanks comprises an air test at lO p.s.i. held for 24 hours with suitable allowances made for temperature variation.

Most Engineers are satisfied that. a _10 p.s.i. air test "."ill establish the presence of a leak w1th111 a shorter penod than this.

After a satisfactory test the mass concrete casing can be poured. lt is advisable to use a sulphate resisting concrete.

In some areas sulphate concentrations are present in the surrounding ground and these sulphates can cause severe damage to ordinary Portland cement.

Shuttering should have been positioned in the excavation to ensure that the minimum thickness of 9ins. concrete is attained.

lt is advisable to hand agitate during pouring to ensure that air pockets and voids are eliminated.

81

4. Pipelines

After the tank has been encased the suction and vent lines can be installed.

The pipes and fittings be to B.S.S. _1387, for gasoline being galvamsed and those for diesel fuel in black iron.

The following recommendations are made in respect of vent pipes:

(a) Each tank or compartment should have a vent pipe not less than liins. in diameter.

(b) The upper end of the pipe should discharge upwards in the open air, out of reach, be at least 12ft. above ground level and should not be located within 5ft. of opening windows or other openings. On new installations 180° return bend vent heads which deflect vapours downwards should be discouraged.

(c) There should be no entry to basements or below ground areas within 5ft. of a point vertically below the vent discharge point.

(d) Electrical fittings within 5ft. of the vent discharge point should be to I within 5ft. of the vent nser pipe Division 2 fittings should be used.

(e) Vent pipes should be installed no closer than 5ft. to a boundary except where this is a solid wall extending for 5ft. beyond the vent discharge point and down to ground level.

Suction lines up to approximately 80ft. in length should normally be run in 1!ins. pipe, unless it is intended to connect two pumps to the same suction in which case the pipe should be 2ins. bore.

The sizes of the external fill pipes vary from 2ins.-4ins., dependent upon the operational policy of the marketing company concerned. The majority are 3ins. bore.

Many authorities have an aversion to offset fill pipes and yet if correctly installed they can be as safe, if not safer than the conventional ground chambers. Some that offset fills facilitate the possibility of a spillage at the underground tank, but if a hydrostatic contents gauge is used instead of a dipstick and all other openings sealed then a spillage at the tank is impossible.

When the installation is complete each tank should be numbered and its dipstick should be stamped with the same number.

Mention was made earlier that concrete encasement for tankage installation must be considered the best method until new materials and methods have been developed.

Over the past two years there has been international interest in storing gasoline in tanks made of plastic materials and fibreglass reinforced polyester tanks have been tested and installed in U.S.A., Canada and probably other countries. Similar road vehicle tanks have been used in Belgium for several years.

In J965 Esso Petroleum Company Limited obtained a plastic tank of the following dimensions:

Length I 3ft. I OMns. Diameter 7ft. Oins.

Wall thickness i (nominal). Nominal capacity 3,000 imperial gallons.

Moulding was by hand lay up of glass reinforcement in the form of a mat, on top of the resin gel coat on a mould. The second resin was then applied to the reinforcement. The tank was manufactured in three cylindrical sections, joined together at stiffener rings, fitted with dished ends. At the stiffener rings the sections were butted together overlaid with glass mat and resin. Stiffener rings were formed with paper rope and overlaid with more glass m_at and resin. The inside of the finished tank is smooth while the outside is a close grained "patchwork of resin impreg- nated glass strands".

Tests

The following tests were carried out:

(1) Hydraulic pressure test for 24 hours at 10 p.s.i. A vertical pipe was fitted on the tank vent and the water level was steadily increased in this pipe to allow the behaviour of the tank to be examined at 2.5, 5, 7.5 and 10 p.s.i. The tank successfully withstood this test and no detectable changes in diameter and circumference occurred. The average hoop tensile stress in this case is about 2,000 lbs. per sq. in.

(2) Torque test on fittings. Each of the pipe connection entries was made by using flanges on the outside and inside of the tank.

Any torque applied to the piping was therefore transferred to the tank via a set of fixing studs or bolts, arranged on a substantial pitch circle diameter. This test was therefore limited to testing whether individual bolts set in the plastic material resist the normal torque associated with tightening nuts with spanners.

These fittings resisted a steady torque of 50lbs. ft. applied through a torque wrench.

(3) Handling Test. The tank weighs 850lbs. when empty. It was lifted by a single hook on a crane using two rope slings. It was also lifted by a fork lift truck. It was pushed along on a trolley 2ft. x 4ft. on four small wheels and prevented from t1ppmg by the men who were handling it.

(4) Material test:

(a) Resistance to product: Pieces approximately 4ins. x 2ins. were immerse? at room temperature in various aliphatic/aromatic hydrocarbon mixtures at a W/V ratio of 1/10.

After 76 days in benzene large amounts of plastic were flaking off the surface. The resins contained chlorinated wax and antimoxy oxide mixture as fire retardant additives. With these omitted further tests were successfully carried out.

(b) Physical: Laboratory tests were carried out to determine the ultimate tensile strength and Young's Modulus of the materials from which the tank is made.

82

37 specimens were tested to destruction in the U.T.S. test on the "lnstron" machine. The average value was 16,200 p.s.i. A flexural test on a specimen, to pure bending was carried out. Strams were measured by means of electrical resistance strain gauges (a direct tensile test was then carried out on this specimen). An average value of Young's Modulus of 1.02 x JOG p.s.i. was obtained.

Poi ss on's Ratio was found to be 0.330.

(5) Tank tests:

(a) Above ground:

A series of above ground tests in a testing frame was performed to investigate the behaviour of the tank under controlled known loads. In all cases the loads were applied through three hydraulic rams connected to a single hand operated pump.

Electrical resistance strain gauges were attached to the tank with epoxy resin and used to determine strains and hence stresses.

Results indicated th a t due to st iffener rings and, to a much greater extent, the end dishings, the stresses were far lower than the calculated theoretical stresses in an open tube of the same dimensions.

(b) Underground:

These tests were designed to meas ure the stra ins and hence stresses actually occurring in the inner and outer surfaces of the walls of the tank when a vehicle was sta nding on the earth backfilling

over it. A spreader slab was provided at ground level. It consisted of 4ins. bitumen macadam on 9ins. of hardcore. Over 50 strain gauges were attached to the tank and connected to measuring apparatus at ground level.

It was possible to measure vertical deformations of the tank by means of a cathetometer. The test tank, thus buried, with 3ft. of earth cover on it, was loaded by means of a 4,000 gallon articulated road vehicle parked over it. Later a 10 ton roller was parked on the spreader slab. No stresses in excess of 450 p.s.i. were recorded, even with a 10 ton roller standing over a full tank. It follows that the earth cover must protect the tank from severe loading by arching.

It is apparent that the present system of encasing tanks in concrete is intended to:

(i) Contain liquid should a leak occur.

(ii) Prevent ingress of ground water to the outside of the tank which would cause metal corrosion.

(iii) Prevent uplift of empty or partially filled tank in high water table conditions.

A plastic tank as described in the foregoing, which cannot corrode should eliminate the necessity for protection against (i) and (ii). Condition (iii) can be prevented by earth anchors. It can be anticipated that within the next few years it will be common practice to install plastic tanks for gasoline with nothing more complicated than a simple sand backfill to the excavation.

THE LAW RELATING TO LICENCES FOR KEEPING PETROLEUM SPIRIT

By C. S. McDonald, M.A. (Oxon.), D.M.A., Senior Assistant Solicitor, Solihull County Borough Council

"For pity is the virtue of the law, and none but tyrants use it cruelly"-Shakespeare. "Nothing is certain in law, except the expense"Samuel Butler.

1. Grandi and Another v. Milburn 1

This case was a rare event; it is very infrequently that the High Court is requested to interpret provisions of the Petroleum (Regulation) Acts, 1928 and 1936, and regulations made under them In view of the frequency with which counsel are consulted by local authorities on such questions of interpretation , I find this rather surprising. This lack of litigation must constitute to some extent a tribute to the diplomacy and ingenuity of th e officers

83

enforcing the Acts, and to the forbearance and understanding of the general public and the petroleum companies. Personally, I find the ambiguity and uncertainty of some of the provisions somewhat disturbing.

This is not to imply that I regard the decision in Grandi v. Milburn as an unmixed blessing. In effect, Mr. Justice James delivered the Judgement, which resolved into interpretations of the words "kept", "premises" and "conveyance", none of which is defined in the relevant legislation.

I think it vital that there should be a definitive, if not exhaustive, interpretation of the word "kept' 7 , as used in the Acts and regulations. The "Concise Oxford Dictionary alone gives 18 different meanings of the verb "to keep". Moreover, as Mr. Justice James said,2 " ••• there is a real danger to be met when one seeks to construe a word in one statute by reference to the construction given to the same word in a different statute dealing with a wholly different subject-matter". It is surprising that the learned judge then immediately proceeded to adopt a course similar to that he warned against, by referring to Lord MacNaghten's observations on the meaning of the words "stored or kept" in Thompson v. Equity Fire Insurance Co. 3 ·

In fact, Mr; Justice James decided that petrol in a tanker parked on the forecourt of a shop for four hours, in order that petrol might be sold to the public directly from it, was "kept" there. Choosing to be guided by Lord MacNaghten, he came to this decision because he thought the three essential elements of "keeping" were present in this case. There was an element of considerable quantity -2,500 gallons; an element of duration-four hours, and an element of trade.

It is difficult to see the relevance of the 2,500 gallon capacity of the tanker to this question. Section 1(1) of the Petroleum (Consolidation) Act, 1928, clearly contemplates the "keeping" of petroleum-spirit in small quantities, an exception from the requirement of the subsection is made for particularly small quantities kept in vessels with a maximum capacity of a pint and in an aggregate amount of not more than three gallons. Are we to assume that quantities of spirit of more than three gallons may not be regarded as "kept" within the meaning of the subsection because they are not "of considerable quantity" ?

It is equally difficult to see the relevance of an element of trade. Again, Section 1(1) of the Act of 1928 refers to "petroleum spirit kept either for private use or for sale"; and Regulation 1(1) of the Petroleum-Spirit (Motor Vehicles, etc.) Regulations, 1929, refers to the "keeping and use of petroleum spirit ... not either wholly or partly for the purpose of sale".

The element of duration is a different matter. It appears to be a commonly-held view that a degree of permanence is essential to the notion of "keeping" in this context. In this light the acceptance of a period of four hours may be regarded as a somewhat liberal or illiberal interpretation of "duration" or "permanence", depending on one's side of the fence. Certainly, those who advocate the licensing of commercial spraying booths and the like may still derive some comfort.

I think the element of duration should be of minor significance. It seems to me that there is a logical approach to the problem. The verb "to keep" has at least 18 different meanings; it is reasonable to suppose that Parliament

cannot have intended them all to apply in this case; which meaning or meanings, having regard to the clear purpose of the legislation, seem the most appropriate ? I believe that the most appropriate meaning is to "have possession, control or charge of".

The Court in Grandi v. Milburn 4 became involved in the question whether spirit could be "kept" and "conveyed" at the same time. It ruled in the affirmative. In my experience, enforcement officers sometimes pose the questioncan spirit be "kept" and "used" at the same time ?-and, in my opinion, once again, the answer should be in the affirmative. In the sense I have put forward, "to keep" is a different kind of verb from "to use" or "to convey"; the two latter describe an operation or activity, the former describes the relationship between the object and the external world. In other words, "kept" does not mean "stored" in this context. I cannot see why, if Parliament had meant "stored", it should not have said so.

The interpretation of the word "premises" is a simpler problem. In everyday language "premises" means "buildings", or, at least, "buildings and surrounding land". In legal language, it means "any land, whether built upon or not, capable of being conveyed or transferred at law". Which meaning should be applied in Section 1 of the Act of 1928 ? I incline to the latter meaning, atlhough this tends to be contrary to the accepted rule of statutory interpretation. I dislike the prospect of a person being entitled to keep many gallons of spirit on an open site in a built-up area with impunity, simply because there are no buildings on his land.

At the moment, the reports of the judgements in Grandi v. Milburn are not helpful on this point. The Times reports Mr. Justice James as saying that "premises" connotes buildings, or buildings on land; the All England Law Reports as saying it connotes land or buildings on land ! In any event, we are now clear that a petrol tanker is not "premises". Were we not always? Not quite, apparently, because in Coleman v. Goldsmith 5 a petrol monger's barrow had been regarded as a "place".

In a discussion of the licensing system, it is not really relevant to comment in detail on that part of the judgement concerning the word "conveyance". I agree that, in principle, spirit can be both "kept" and "conveyed" at the same time. I sympathise with the argument of the appellant: for a tanker to be "conveying by road" it must be on a journey. Thus an overnight stop may still be part of the "conveyance"; but is a four-hour stop to sell petrol part of a journey '!

2. The Petroleum Spirit (Motor Vehicles, etc.) Regulations 1929

As, I suspect, do many others I find difficulty in construing these Regulations to my My attention was first really drawn to them by the curious fact that many licensing authorities (a) issue licences for car parks in buildings and (b) apply the Regulations to garages in private dwellinghouses, although several counsel have advised against both.

Before turning to the Regulations, I think it is useful to attempt to determine whether the licensing system applies to premises in which are situated vehicles or engines containing spirit in their fuel-tanks. Certainly a

84

vehicle parked in premises is "kept" there, and certainly the spirit is "kept" in the vehicles. If vehicles are "kept" on premises, and spirit is "kept" in the vehicles, does it follow that the spirit is "kept" on the premises ? Or is the better argument that it is only the vehicles which are "kept", and not their contents ? I think it is consistent with my view that "kept" is used in the Act in a statusdefining rather than an activity-defining meaning to support the former argument.

Thus, in my view, unless the fuel tank holds less than one pint of spirit, the premises where a vehicle is parked require a licence, unless the Regulations grant exemption. Regulation 1(1) grants an exemption where spirit is kept "by persons intending to use it for the purpose of any motor vehicle, motor boat or aircraft", or of any specified class of engine, "and not wholly or partly for the purpose of sale".

The first point to appreciate is that exemption is only granted where it is the same person who is both keeping the spirit and intending to use it. Clearly, this would normally cover spirit kept in a private garage, but what about a car park ? In that case, clearly the driver of the car intends to use the spirit, but who "keeps" the spirit whilst the car is in the car park, the driver or the proprietor of the car park ? In the usual case, I incline to the view that the driver "keeps" the spirit. He who "keeps" the car, "keeps" the spirit in the tank. One would normally talk of the driver the car in the park, not the proprietor. Therefore I thmk that the ordinary car park is exempt from licensing. In unusual cases, for example long-term airport car parks, it might be proper to talk of the proprietor "keeping" the car, and so I think that in these cases there would be no exemption.

What about cars kept for sale in a showroom with spirit in their tanks ? If the dealer intends to charge the purchaser for the spirit, then there will be no exemption, as the spirit will be kept for the purpose of sale. If he intends to give the the spirit, there will again be no exemption unless he mtcnds to use the spirit, for example, to move the car around the showroom, before sale of the car.

An exemption is usually thought of as conferring a privilege, but it should be appreciated that this is not always the result. Two consequences flow from an exemption under Regulation 1(1): The first is the spirit must be kept in accordance with the Regulat10ns, and it is conceivable that these may be more burdensome than imposed on licence; second is that 1t 1s only persons intendmg to use spmt who may apply for a licence which will exempt them for the exemption !6 This has important consequences. For, if a car park, for is exempted from the system, only the dnvers who intend to use the spmt m the cars can apply for a licence, and not the proprietor. In other words, the proprietor of an ordinary car park cannot obtain a licence, and must see that the Regulations are complied with.

I realise that the foregoing is rank heresy so far as modern practice is concerned, but I would urge readers to read Regulation 1 carefully before passing judgement ! l anticipate that another objection at this stage may be based on a reference to Regulation 6, in particular, which prohibits the keeping of more than 60 gallons of spirit at the same time in any one storage place, including spirit

contained in fuel tanks. It may be alleged that, if one adopts the usual practice of assuming that the fuel tank of a car contains, on average, three gallons, and if one accepts my argument that a car park cannot be licensed by the proprietor, this means that no car park must contain more than twenty cars.

But this presupposes that a car park is a storage place. Regulation 14(2) defines "storage place" as including "any room building or place of any kind whatsoever, whether or not in the open air, used or proposed to be used for keeping therein petroleum-spirit for the purposes of any motor vehicle, motor boat, aircraft or engine". This is an inclusive, not an exhaustive, definition. Therefore, one first of all takes the ordinary meaning of the phrase. In the context of the keeping and use of spirit for motor vehicles and the like, I would submit that this ordinary meaning would not include car parks, garages or showrooms. These are storage places for vehicles, not for the spirit which powers them.

Secondly, one attempts to determine how far the definition extends the ordinary meaning. I think the key phrase is, "used or proposed to be used for keeping therein petroleum-spirit". Is an ordinary car park, garage, or showroom used or proposed to be used for keeping spirit therein ? My answer is yes, if spirit is kept or proposed to be kept therein in drums or other containers; no, if spirit will only be kept there in the fuel tanks of vehicles. I contend that a thing can be incidentally "kept" in a place, without that place being "used or proposed to be used keeping" it there. A car park, garage or showroom 1s ordinarily used only for keeping vehicles, not spirit.

Taking this view, I think it is incumbent on me to attempt to explain away the decision in Appleyard v. Bangham. 7 In this case, an old stable had been converted into a garage for three motor cars with dwelling over it. There was no spirit in the garage except m the fuel tanks of the cars, and in a container on one of the cars. It was held that the garage was a "storehouse" within the definition contained in the Regulations made _by the Secretary of State in 1907 under on Highways Act, 1846. The Regulat10ns said _the expression 'storehouse' shall mean any room, bu1ldmg, coachhouse, lean-to or other place in spirit for the purposes of light locomotives motor cars) is kept in pursuance of these regulat10ns

It should be noted that this definition was exhaustive, and not inclusive as in the 1929 Regulations. Mr. Justice Scrutton pointed'out that the 1907 Regulations do. the 1929 Regulations) clearly contemplated that SJ?mt might be kept in a storehouse in the fuel tank of a vehicle as well as in separate containers He adduced the argument that a motorist "keeps" his can m the garage, and so also "keeps" the contents of his car in the garage. Therefore, spirit in the tank of the car was "kept" in the garage for the purpose of the car and the garage was a "storehouse".

If I may respectfully say so, I agree with the decision. But the vital distinction between the two sets of Regulations is that for a garage to be a "storehouse" it was necessary for spirit to be "kept" there, whereas for it to be a storage place" it must "be used or proposed to be used for keeping" spirit. The 1929 Regulations replace the 1907 Regulations, and, in accordance with the ordinary rules of interpretation, some significance should be

85

if possible to the added words in the new Regulat10ns. It may be argued that the only true distinction is that the new Regulations were framed to deal with future use as well as present use. I cannot accept this. In the first place, a simpler elaboration of the original phraseology have been "is kept or proposed to be kept". Secondly, rt only makes sense to cover future use if an element of intention or design is to be included; otherwise covering existing situations is quite sufficient. The keeping of the cars themselves, or of spirit in separate containers is intentional or voluntary, but the keeping of spirit in fuel tanks is unintentional, involuntary, or of necessity only.

I think it is pertinent to note the comments of Mr. Justice Ridley in Appleyard v. Bangham on the 1907 Regulations: "I do not think that anyone who framed and drew up these regulations ever thought that they would be applied to the state of circumstances we find here, or intended them to be so " Although Mr. Justice Scrutton did not agree with these sentiments, was this a lesson which had been learned by 1929 ?

3. The operation and enforcement of the licensing system

Once again, it is surprising how little decided law there is on this topic. The lawyer is obliged to resort to analogies drawn from established principles of law in similar but more fruitful fields of legal activity, for instance, planning law. However, this is a legitimate pastime for lawyers as it is often indulged in by the courts themselves, as in Grandi v. Milburn.

In section 2 of the Act of 1928, a distinction is made between provisions for duration and renewal (subsection 2) and conditions which may be attached (subsection 3). As section 3(1) refers specifically to conditions, it seems to me that no appeal lies to the Horne Secretary if an applicant is dissatisfied with the provisions for duration and renewal. If, for example, he thinks that the period of the licence is too short, his only remedy would appear to be to fail to apply for a new one, and to hope that the magistrates will sympathise and give him a discharge if prosecuted for keeping without a licence.

Nevertheless, authorities should take care in framing provisions for renewal. I have known such a provision to be so framed that it has at least been arguable that, when the old licence expired, if the applicant had observed the old conditions, the authority had no option but to issue him a fresh licence with the same conditions, even though they wished to impose fresh conditions.

Conditions must relate to the storage, premises, facilities for testing, or safe-keeping of the spirit. On general principles, it may be that a condition which does not relate to one of these items, or which does so relate but is unreasonable, may be legally invalid and unenforceable although there has been no appeal to the Home Secretary. For instance, magistrates may rule that a condition is invalid if there is a prosecution before them. It may be that a condition would be regarded as unreasonable and therefore invalid if, although it related to one of the matters mentioned above, it referred to premises other than those occupied by the applicant. If an authority felt

the regulation of such other premises were required, the only proper course might be for it to defer or refuse the application.

If a condition is invalid, does this render the licence invalid ? In planning law, there has been an attempt to say that it depends on whether the authority would have granted the permission if it had known at that time that it could not impose the invalid condition. This involves the body pronouncing upon validity trying to put itself in the place of the authority. I think the law should be that the licence is invalid in all cases, and the authority should be compelled, if necessary, to re-consider the application.

As the right of appeal to the Home Secretary against the refusal of, or the conditions contained in a licence is in very general terms, it seems clear th;t appeals to T?ay be on matters of fact, law or policy or any combmat10n of the three. This is not to say that the Horne Secretary need necessarily be the final arbiter in law. dissatisfied applicant has only ten days (or such further t!me as the Secretary may allow) after receipt of the cerof the grounds of the authority's decision within wh!ch to but I have already mentioned the way in which magistrates may become involved, and moreover the Act does not state that the decision of the Home Secret_ary shall be. final and binding. It seems likely that the High Court might become involved in one of the three ways-by a_n appeal from a decision of the magistrates; by apphcat10n. for a declaration, injunction or prerogative order against the local authority by a dissatisfied applicant who ignores his right of appeal to the Home Secretary; or by a similar action against the Home Secretary as a result of his conduct of an appeal.

_that the. local authority is not at fault, the remedies available to rt against breakers of the law are not excessive. There is no power to revoke a licence; but there should always be a provision in a licence that the right is reseryed to refuse to renew it if a condition is broken by the licensee: To the best of my knowledge, it has never been established whether "mens rea" is essential to an offence 1;1n?er Section 1(2) of the Act-in other words, whether 1t is necessary to prove that the occupier knew or to have known spirit was being kept on his or.th.at a condition was being broken. On general pnnc1ples, 1t 1s probable that it is so necessary.

This leads to difficulty, which is that it may not be the occupier who is morally responsbile for, in particular, a breach of some condition in the licence. An employee who contravenes a condition set out in a notice in acc_ordance .with section 2(4) can be prosecuted m his own nght, as rt were, but otherwise the culpable can only be prosecuted, if at all, for aiding and abet!mg an by occupier or employee. To obtam a conv1ct10n. for aiding and abetting, it is necessary to prove that the aider and abetter knew all the circumof the including the fact that he was a cond1t1on 1n_ the occupier's licence. The occupier may have been entirely ignorant of the circumstances of the breach, and the law is now in a state of some conas to when the knowledge of an employee can be imputed to the master. It is also doubtful whether an aider and abetter can be convicted without an offence by the

86

occupier having been first proved. Thus it is conceivable that, for example, a petrol pump attendant can connive at a serious breach of a condition by a customer without the authority being able to prosecute anybody.

The problem is not the same for a breach of Regulations made under the Act, for the Act provides that anyone who contravenes the Regulations commits an offence.

It is interesting to speculate on what might happen if a local authority were guilty of an offence under the Act or Regulations, for, on general principles, it is quite clear that local authorities are bound by the Act, and thus many authorities are obliged to issue licences to themselves. It seems to be a common practice for such licences to be issued in the name of an officer of the authority. In addition to its seeming invidious to place personal responsibility on an officer, this practice would appear to be strictly incorrect. It is the authority who owns or leases the land, and is therefore the occupier, and not the officer. The act does not apply to the Crown.

I have not so far referred to the Transfer of Licenses Act of 1936. It should be noted that there is no right of appeal against a refusal to transfer a licence. It may be that the High Court would no.t an authority to refuse to transfer a licence for capnc10us reasons, although this is not free from doubt. In any e':'ent, it would appear to be quite legitimate for an authonty to refuse to transfer a licence on the ground, for that the transfer would tend to perpetuate the existence of an old-fashioned site which cannot conform with modern safety standards.

1"The Times", 20th May, 1966, (1966) 2 All.E.R. 816.

2(1966) 2 All.E.R. at p. 820, paragraph C.

3(1910) A.C. at p. 596.

'At p. 821, paragraph D. 0 (1879) 43 JP 718.

6Regulation 1(2).

7(1914) 1 KB 258, 11 LGR 1220.

FUTURE TRENDS IN PETROLEUM SPIRIT DISPENSING

G. M. Steer (Shell Mex and B.P. Ltd.) and M. T. R. Bowen (B.P. Trading Ltd.)

The changes which have taken place in the structure of our retail petrol market over the decade or so, together with the tremendous expans10n of Britain's vehi.cle population, are now creating new problems for retailers in this country. Whereas pre-war some 35,000 garages were each selling an average of 24,000 gallons of petrol per year to about 1.9 million motor cars, there are now approximately 9.2 million cars to be served by only 39,000 retail outlets.

Within the motor trade the old multi-representation stations have almost disappeared and solus sites, selling one oil company's grades, have emerged. The once stable

market has now become highly competitive, with new companies selling at full or discounted prices in competition with the older established ones for a share of the country's business.

This picture is a fairly general one in Western Europe, where the restrictions on the creation of new outlets has made it essential for retailers to expand existing stations in order to dispense ever increasing annual throughputs. This situation has also been seriously aggravated by such well known characteristics of our modern socio-economic development as the gradual decrease in qualified forecourt labour, increasing distribution costs, fixed profit margins and the trend towards shorter working weeks and greater leisure time.

What then are the specific problems which are confronting the petrol retailers ? In the first place, an ever increasing load will be placed on his refuelling facilities by the vast expansion of the number of consumers. By 1970 it is estimated that there will be 13.6 million motor cars on the roads of this country, all requiring fuel and service from the motor trade.

What solutions are there for the filling station operator ? He can extend his forecourt and install extra facilities, but land is often very costly or just not available. For this reason we have turned to the re-organisation of existing forecourt layout and refuelling as a sol11:tion. For example, at a small station with pump island offering two refuelling pos1t!ons, 1t be possible to introduce a triangular shaped eqmpped with a central blending pump incorporatmg a rotatable boom arm and computer, to serve all grades to all. three re-fuelling positions. The blending system used first of these completely new dispensers, of is installed at a BP station in Datchet, Buckmghamshire, mixes a high and low octane petrol drawn from tw? separate tanks and by altering the proportion of the high and low fuels, a number or grades as well as the two basic ones. The dispenser mcorporates tl!e latched automatic cut-off nozzle, which when hooked m the open position in the car's fill pipe, can free the to carry out the cash transaction, attend to other services on the car, and if required serve two at the sa!ne time. The combination of improvements .111 refuelhng speeds and savings in labour costs are mcorporated in this unit are completed by a device on the end of the boom arm which allows the attendant to preset the tities to be delivered by value or b)'. full tank. A bu_ilt-m cash register and air and water are also The result of such a development is that the traffic handlmg capacity of the forecourt can be in?reased an of 30 cars per hour for a conventional one. LS!and stat10n with one salesman to 48 cars per hour. This is compared to an average of only 50 cars per hour for a two island station with two salesmen.

Land consuming pump islands, which are in fact forecourt obstacles, have been done away with entirely at some stations in Japan. Dispensing systems consisting of overhead hose reels, submersible pumps and remote read outs are improving the vehicle handling capacity ?f the smaller forecourts by 30 % or more. The reach afforded by the longer pump hoses permitted in many countries abroad does of course afford far greater flexibility to such a system.

87

Another of the retailer's problems is the rise in unit merchandising costs, mainly caused by increased labour rates. As in other trades, self service is providing a solution since it enables the retailer to achieve a reduction in bis expenses by a saving in labour. Few of us have not used cafeterias, vending machines or grocery supermarkets, and this technique has become so popular that it is already part of the modern way of life. There is no waiting for service, one bas freedom of selection, there are no sales pressures, an d in the majority of cases an attractive financial benefit.

The cashjer controlled or post-pay ment type of self service, which was fos tered in Sweden where labour is sho rt, tbe forecourt salesman's job un a ttractive in cold climatic conditions, and the people used to the benefits of serving themselves, is perhaps the mo st popular form of this technique in use in motor spirit ret a iling tod ay. It is not, however, the universal answer, since it is essential th at petrol throughputs should be big enou gh to justi fy the price reduc ti ons given. Nor is it a " tin shed" de velopment, for the equipment itse lf is expensive and one has to consider such additional on-cos t s as canopies and ancillary self service equipment . The introduction of the new Selective Employment Tax, a long with other social and economic pressures may serve to populari se thi s form of mar keting an d increase the demand for it from the motor trade .

The number of closed filling statio n s which show up in t he beam of the motorists' headlamps at night is ano th er cau se for concern More and more motorists are travelling during t hi s time and many have just ca u se to glance anx ious ly at their fuel gauge as mi le after mile they pass t he darkened fo reco ur ts.

One solution would be to convert "Closed for Petrol" signs to "Open for Coin Operated Self Service". Two systems are available here. The first is a simple single unit accepting two half crowns giving just under one gallon of petrol. This only really provides an emergency service which is often insufficient since the motorist frequently requires more petrol and the dealer loses the opportunity of a bigger sale. The second device , which BP bas developed so successfully in Germany, can accept and accumulate three denominations of coins. This takes night operation out of the realms of emergency service , especially in countries with high value coinage In both cases the pump itself can be used norm a lly during the day Applications have been successfully made to a number of Local Petroleum Officers in Britain for permission to install such units, and we are convinced as our German experience has shown, that the risks in the operation of these machines are no greater than with manned stations.