• A Woman of All Trades

• Expand Emulsion Use

• Relational Leadership

• Street Smart with Bill Stanley

• 4th Annual Corporate Profiles

• A Woman of All Trades

• Expand Emulsion Use

• Relational Leadership

• Street Smart with Bill Stanley

• 4th Annual Corporate Profiles

Astec paves the way for sustainable, innovative asphalt plants. The new IntelliPac Moisture System is a revolutionary solution that integrates seamlessly with Astec control systems. This provides unparalleled, real-time visibility into virgin aggregate moisture content. IntelliPac empowers operators to optimize mix design, minimize energy consumption, and reduce environmental impact. With Astec, you get superior asphalt production – better for the environment, better for your business.

At Gencor®, we’ve led the industry with the most fuel-efficient, environmentally clean and lowest-maintenance design available to the hot mix industry. Gencor Industries remains focused on proactively serving and satisfying its customers from all aspects.

Through improved cost-effectiveness, and quality of its products and services, Gencor’s personnel are dedicated to the principle of providing the highest quality to the industry to maintain a sustainable competitive advantage for Gencor®.

Your Trusted Choice!

6 – That Wasn’t on Purpose

MANAGEMENT

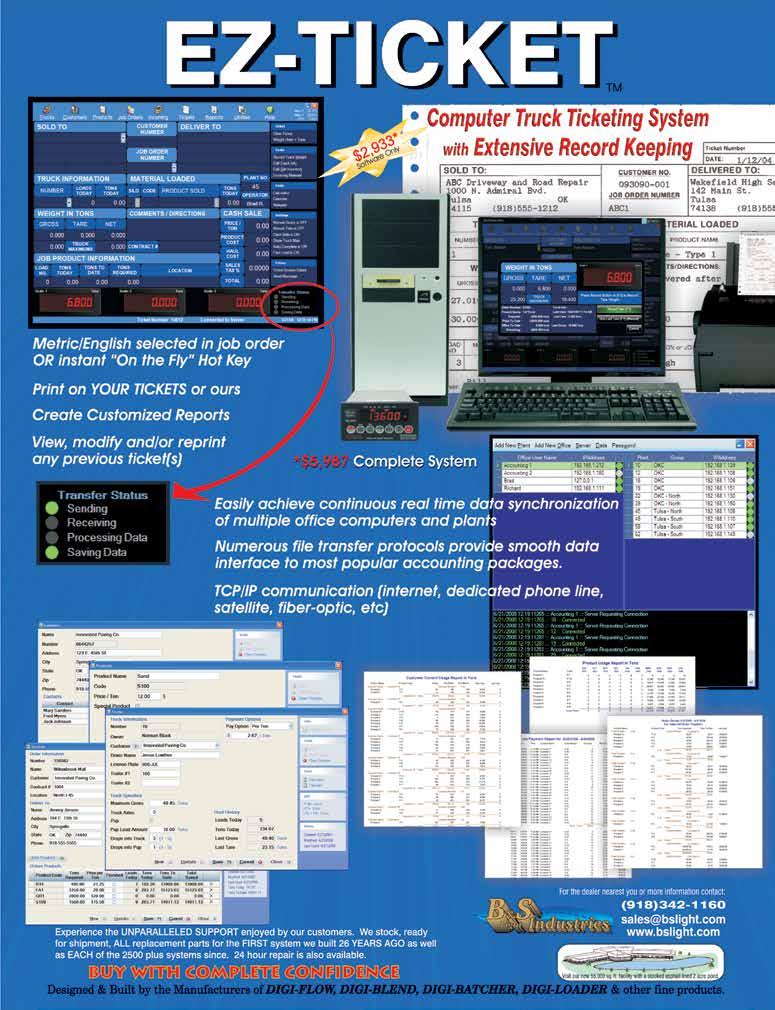

8 – How Software Consolidates, Simplifies Business, Operations By AsphaltPro Staff

12 – Know Your Worth to Get Paid Your Worth By Bill Stanley

OF ASPHALT

16 – Meet A Woman of Asphalt: Triple A Milling’s Amanda Harrington By Sandy Lender

44 – Increase Production From AsphaltPro Staff

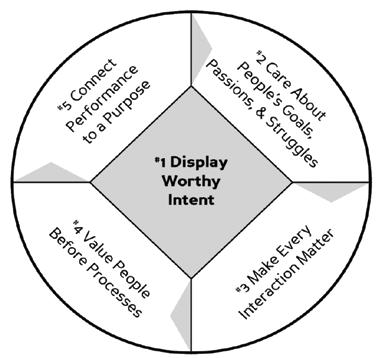

50 – A New Value Proposition for Leaders By Ed Wallace

24 – Race to Resurface F1 Track From Wirtgen Group

28 – Expand Into Production Emulsions 101 By Sarah

Redohl

32 – 2024 Corporate Profiles Supplement

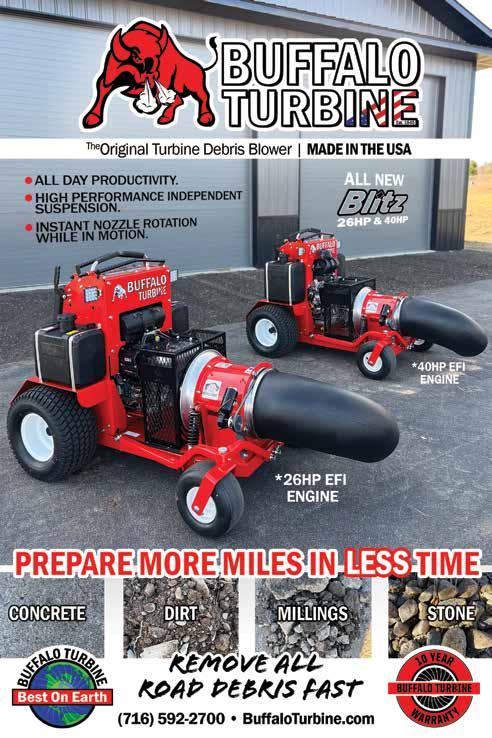

The fourth annual Corporate Profiles supplement gives our partners a chance to share their latest technologies with you. They’ve reached out to satisfied customers this year to share testimonials of how they’ve helped your peers enhance the bottom line and meet sustainability goals. Dive in to see how these OEMs and service providers can assist you, too.

Getting proper compaction on any lift should be a contractor’s goal, no matter the importance or profile of the project. From someone’s driveway to the Formula 1 racetrack in Miami, people notice the finished product and will talk about it. As members of the asphalt industry, we want their conversations to be positive and glowing for years to come.

We want the public to tout the benefits of the long-lasting asphalt road in front of their houses, in the church parking lot and on the highway they take for the daily commute.

It stuns me how many people try to tell me paving contractors build roads with flaws on purpose. These are people not in our industry, obviously. They tell me, usually with indignation, that our tax dollars are wasted because contractors will merely build something that crumbles a year or two from now so the contractor can be hired to go back and fix the road. When the person learns I’m a construction magazine editor, he or she usually pauses to listen to my explanation of why that assumption is incorrect.

I don’t think I’ve heard tell of a contractor who has the time or workforce to go back and redo a project on purpose. Your local department of public works (DPW) is probably begging contractors to bid its system maintenance contract for the season because even the city or county doesn’t have the time or staff to fix random problems in the network.

It would be ludicrous to purposely work “failures” into a pavement system in an effort to create more work for our backlog down the road. Or, to be fair, to create work for our competition.

Yes, that’s right. When a pavement system experiences a failure, the agency’s latest materials manager or engineer is likely to reassess and decide, “We better use a different method on this road.”

What this means is not only do we, as members of the asphalt industry, have a public relations message to get right in the public eye concerning our best practices, we also must get our best practices right to ensure pavements remain asphalt. This month’s issue includes the annual Corporate Profiles supplement where various original equipment manufacturers and service providers share how they’ve helped clients enhance the bottom line, and it includes information on getting good density. Best paving and compaction practices are included in every issue of AsphaltPro and that’s for your edification. The more we review and incorporate best compaction practices, the better results we get on every project and the better we’re poised to win the public relations battle.

602 W. Morrison, Box 6a Fayette, MO 65248 (573) 823-6297 • www.theasphaltpro.com

GROUP PUBLISHER

Chris Harrison chris@ theasphaltpro.com

PUBLISHER

Sally Shoemaker

sally@theasphaltpro.com (573) 823-6297

EDITOR

Sandy Lender

sandy@theasphaltpro.com (239) 272-8613

DIGITAL EDITOR

Sarah Redohl sarah@theasphaltpro.com (573) 355-9775

MEDIA SALES

Cara Owings

cara@theasphaltpro.com (660) 537-0778

ART DIRECTOR Kristin Branscom

BUSINESS MANAGER

Susan Campbell (660) 728-5007

Stay Safe, Sandy

Lender

AsphaltPro is published 11 times per year. Writers expressing views in AsphaltPro Magazine or on the AsphaltPro website are professionals with sound, professional advice. Views expressed herein are not necessarily the same as the views of AsphaltPro, thus producers/contractors are still encouraged to use best practices when implementing new advice.

SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the United Sates, Canada and Mexico to qualified individuals.

One year subscription to non-qualifying Individuals: United States $90, Canada and Mexico $125.00. For the international digital edition, visit theasphaltpro.com/subscribe/

The future is connected. That’s why we’ve designed the ALmix Insignia Control System (ICS) around the power of high-speed Ethernet communication. An ethernetconnected facility means our team of programmers have complete visibility into your plant equipment and motor control center for diagnostics and remote troubleshooting. View and control data from your asphalt plants like never before. The Insignia Cloud Platform provides access while you are at the plant, in the office, or on the go. Critical, real-time, plant information is at your fingertips when you need it.

DON’T LET YOUR EXISTING ASPHALT PLANT CONTROLS KEEP YOU GUESSING:

The Insignia Control System is available on all new ALmix Asphalt Plants and is also available for existing plant control upgrades.

SCAN HERE TO LEARN MORE OR TO SCHEDULE A DEMO

BY ASPHALTPRO STAFF

Construction software providers wish to offer both a simplified experience for contractors and smart systems that result in more business for the user. More tons is the mantra for the asphalt professional.

During his work zone stage presentation at the National Pavement Expo (NPE) 2024 in Tampa, Jared Hislop, co-founder of Bitumio, Garden City, Utah, shared facts and ideas for streamlining sales and operations in a construction company with software and automated responses. He shared with the audience on the tradeshow floor how to implement efficiencies in the back office through software and he started with how to close more sales.

Whether you’re a hot-mix producer servicing FOB customers or a striping contractor seeking schools and businesses with parking lots to stripe, you want to capture and respond to every lead that comes into your shop. Hislop shared some statistics that should make us all feel the pressure to hustle more.

In terms of conversion rates, he explained, when a lead comes in, you want to capture and respond to that lead within the first five minutes of its arrival. You’ll have an eight-time higher conversion rate if you respond within the first five minutes.

You can respond via an email, a phone call or a text message, but confirming with that lead to say, “Hey I saw you, and here’s the next step that you can expect,” is critical to closing the sale.

“Additionally, following up on the lead after 30 minutes is 21 times less effective than within that first 30 minutes,” Hislop said.

Hislop’s first key takeaway of the presentation was to set up a CRM or some process that not only captures and stores leads, but that can follow up with your leads and can notify the internal staff when a new lead has come in.

The next step after responding is to get a proposal to the potential customer. Hislop shared a statistic from a company that has collected data from sending tens of thousands of proposals: “We can see that after 12 hours of that proposal request coming in, your customers start to lose interest.”

What data showed, and logic confirms, is customers reach out to more than one source for work and they start to lose track of who they reached out to. The companies they’ve reached out to blend in their minds and they can easily confuse your brand or offered services with another.

“After two to three days, they’re about half as interested,” Hislop shared. This means it’s vital to have your process in place where you can quickly send out new proposals during that first 12-hour window, when the customer’s interest is the highest.

He shared the next step is to make the proposal easy to access and “close,” stating almost half of the Bitumio proposals can be opened on

The all-new Blaw-Knox PF-7110C tracked paver combines all-around visibility, ease of operation and a new powerful Cummins 235hp engine for the ultimate in dependability and efficiency. The turbocharged diesel engine provides more torque and less weight in a more compact package, letting you power through steep grades with confidence. Coupled with the proven Blaw-Knox durable track and automatic tensioning system, the 7110C ensures smooth and consistent paving power on any terrain.

With over 90 years of proven Blaw-Knox paving technology, the PF-7110C delivers all the power you need and more.

BLAW-KNOX, THE LEGACY LIVES ON.

mobile. “We saw that within 10 seconds of sending that proposal, the customer had opened it, viewed it and signed it.”

The key is making the process easy and painless for the customer, but don’t forget you’re incorporating processes that make it easier for your staff, as well. Hislop pointed out the need to follow up with leads who don’t respond right away or who might have questions. Building the follow-up reminders into the system is smart thinking for a company. “Almost half of salesmen give up after one contact, after one outreach.” How we improve our system is with one that follows up with the customer automatically to close more leads.

The goal for the software system you look to is to have a process that helps you quickly put together proposals, within that first 12-hour window—or at least the first two days. You want to make it extremely easy for your customers to access and open the proposal, and then you want to follow up with that prospect, at least five times after sending the proposal, “and I promise you, your close rates will thank you,” Hislop finished.

Once the proposal is signed and that new lead is closed, it’s time to get to work. Integrating software into your process can help on the operational side, as well. Hislop told the audience, 54% of customers have higher customer service expectations than they did a year ago. And 7% of them are willing to pay more to get it.

This comes into play not only when estimating and bidding, but also when you see repeat customers. You want to be the HMA plant all the FOB customers flock to. You want to be the sealcoating contractor all the residential property managers recommend to their BODs. You want to be the pavement maintenance contractor the DPW short-lists for the year’s PMS contract.

Hislop outlined how to be the contractor who gives the higher customer service experience—starting with communication both internally and externally. By having software that entrains all the aspects of the upcoming job, you don’t have your community operation team calling up the customer to ask basic questions about the contract or the parameters of the job. By having software that includes pre-job reminders, you can instead reach out to the customer to let them know exactly what to expect and when.

“Once the job is scheduled, or rescheduled, we’re going to be communicating that to the customer. Let them know we’re coming on this day to start the job and share more details as we’re getting closer.”

He recommended to the audience multiple pre-planning “touches” to confirm the customer’s obligations to minimize problems on the day of the project.

“Seven days, four days, one day before the job starts, you’re sending out communications to the customer and saying, ‘Hey, we’re coming on this day,’ just so they can help you.” You want to say, “Please make sure your sprinklers are turned off. Make sure your garbage isn’t running. Make sure the cars are out of the parking lot.”

This is so your arriving crews can get to work on the customer’s project and execute a good job. The last thing you want is to have the foreman call the boss at 5 a.m. saying, “Hey, we’re at the job but there are cars that need to be towed.”

This means you must call the customer, and suddenly the experience is no longer great. By using proactive communications to set expectations, Hislop shared, you eliminate some of those situations.

One of the aspects of the job Hislop reminded the audience to do better is the final step of asking for a review. After the job is done and closed, it’s time to ask the customer, “How did we do?” You can ask for recommendations to be posted on whatever platform you’ve selected, but using software for that task can automate the ask and free your staff for the next job.

Hislop explained to the audience, when building Bitumio, they wanted a user-friendly, smart system. He said they wished to place the daily repetitive tasks for contractors—such as calculating trucking, materials and travel times, and scheduling route planning—in one platform, freeing contractors to close more business on one side of the coin and streamline operations on the other. While his goal on the NPE stage was to talk about business processes and operations no matter what software platform a contractor uses, he shared a specific example from a Bitumio user that can illustrate the backup or double-checking of an app for readers.

When preparing a proposal, the staff have a detailed list of line items. When software is integrated, there are ways to work efficiency into cluster scheduling, traffic control, shared equipment, materials and so on. All team members can access the app to see what assets are available to what job and at what time. No longer should the paving foreman get 30 or 50 text messages the night before a project starts confirming start time, location and so on. All the crew members can see the details in the app.

Finally, management can double-check the margins and the parameters. The foreman can look at the app and recognize when something catastrophic is missing.

It may seem a silly example, but the line item of trucking was overlooked on an estimate before a client added the Bitumio software to help them. Hislop showed an example of estimating for a project that included a 3-inch lift of asphalt pavement. “We underbid our material costs, we underbid our equipment and for some reason, we didn’t even count for trucking in our proposal, right?” By using software to double-check the bid, the customer could narrow down their estimates, see their true margins and have improved oversight.

With this software, the contractor is “not allowed” to send out a proposal with zero material unless he or she explicitly agrees to that parameter.

Soon, Bitumio is also adding a fleet management feature to the software and incorporating AI that helps use aerial imagery to enhance estimating. By using AI, the software will assist in calculating parking stalls to stripe, the length of a job to pave and so on.

At this time, software is a tool to assist contractors in performing tasks they might otherwise forget or might not get to in as timely a fashion as called for in today’s climate. With the knowledge that potential customers need a response before they forget who you are, you want to pounce on every lead you can.

“No matter what system you’re using, you can do any of these things,” Hilsop said. “You don’t need the software to say, ‘every time I send a proposal, I’m going to pick up the phone, and we’re going to call that prospect five times for five days.’ Follow up. You don’t need the software to get that. You need the process, right? Same thing with communicating with the customer before a job. You don’t need the software. But software can automate and remove a lot of these processes that you have to streamline and make sure that they’re actually getting done.”

Hard-won know-how for the next generation

Editor’s Note: Bill Stanley is not only a successful entrepreneur in the paving industry, building a successful company and raising the next generation to love and carry on the family business, but he’s also a willing educator. It’s a pleasure to share with you his wisdom, gained over decades of hard work and business acumen, in this new column in the pages of AsphaltPro magazine.

BY BILL STANLEY

If we want to attract the next generation of asphalt professionals and secure prosperity for paving companies in the future, we have to recognize the role perception plays in our profitability.

I was raised on blacktop. My dad owned a small driveway paving company in the ’60s, and as soon as my brother and I were out of diapers, we got to go with Dad in his truck. My first job was getting paid $2 a day to keep the job site and tools clean. By the time I was 13, I couldn’t wait to show the incredibly hard working men on our crew (my heroes) that I could also be a man.

When I met my wife, her dad wasn’t thrilled she was marrying a paver. As much as people tend to brag about their children’s accomplishments, I’ve never heard a parent brag that their kid was a paver (or married to one). In my case, as many of you have, I’ve proved that this industry can provide a good living.

But, that experience illustrates a valuable lesson. Because those same people who have that perception of what a paving contractor is worth? Those are often our customers. Clearly, they have a price point in their head of what our time is worth—and trust me, it’s different from mine.

This is a perception we need to change. It’s our responsibility to our families and to the future generations of hardworking men and women this industry desperately needs.

Have you ever been on a paving project and a neighbor comes up to your crew and offers them a case of beer to fix a pothole in his

SHOULD YOUR COMPANY BE MORE PROFITABLE? SHOULD YOUR EMPLOYEES BE MAKING MORE MONEY? MY ANSWER: YES AND YES.

driveway or parking lot? Nothing upsets me more! Can you name another industry where beer is offered as payment?

Our crews, like many other crews across the country, are hardworking and highly skilled professionals that we compensate fairly for their time, effort, and expertise. We show up to the job site in clean, well-maintained equipment to perform a technical task to perfection using the latest technology. We spend our days building the roads our country relies on. We do not work for beer.

In 1776, the United States had two maintained roads. One from Boston to New York, large enough for a horse and wagon. The other, from New York to Philadelphia, just wide enough for a horse. These roads played an important role during and after the founding of our country. In the 1800s, muddy roadways covered in animal feces began to be replaced with paved roads with a crown and gutter, improving sanitation and community health while also increasing trade and economic growth.

During WWII, the construction battalion (CBs) were among the first units in Europe, building the roads and airstrips that were so important to an Allied Victory. Dwight D. Eisenhower saw the importance of roads during the war and afterwards set in motion the construction of 41,000 miles of highways, saying that these roads were not only America’s arteries, but also its lifelines to prosperity.

Our industry has played a key role in the prosperity of our country. It’s important that we remember the role we continue to play and ensure we value ourselves well enough to share in that prosperity.

When American Pavement Specialists started sharing about our company online, we were quickly hit with questions from people who wanted to know our game. At first, I struggled with this because I grew up in an era when the mantra was “Don’t give the competition anything, not even a kind word.” It took stepping out of my comfort zone to realize the only way to increase profits for the future of my family was to bring the competition along with us. Hear me out.

Be sure to catch this article on AsphaltPro’s social media to share your thoughts about the column and suggestions for future topics you’d like Bill to cover!

I consider what we provide our customers to be a premium service— the Cadillac of asphalt paving. There are some customers who are willing to pay our prices, and there are others who won’t. Some people are willing to pay 20% more for a Cadillac rather than a Chevy, even though they’re made by the same company. But very few people would be willing to buy a Cadillac if it cost 70% more than a Chevy.

Even paving companies like mine that consider themselves the premium offering have to keep the low bid in mind, because if the difference becomes too great the price of that Chevy will be too attractive even for the folks on the market for a Cadillac.

That’s why it’s been important to bring our competition with us. That’s why it’s important to realize we are all in this together. Not only do we need to change the perception of our industry to attract the next generation, but also because it’s key to increasing our profit margins. I want to see the whole industry—from the Chevys to the Cadillacs— earning what they’re worth, so they can not only survive for another season but thrive for many years to come.

Bill Stanley owns American Pavement Specialists, Danbury, Connecticut, with his wife, Colleen. The family-owned asphalt paving company offers paving, milling, reclamation and grading services in Connecticut and New York. Bill has more than 50 years experience in the asphalt industry.

American Pavement Specialists is a family-owned asphalt paving company that offers paving, milling, reclamation and grading services in Connecticut and New York.

3 Actionable Steps to Show Your Worth

1. Answer your phone.

Your first interaction with a customer will often be by phone. When you pick up the phone, you are already being sized up and your worth calculated. Does your phone manner exemplify your value? Do you exhibit your knowledge and experience?

2. Sizing up is a two-way street.

It’s important to listen very carefully, especially when a client says “I want to pave my parking lot or driveway” versus “I need to pave.” The person who wants a new lot probably called you because you came recommended, they did their homework, or are familiar with your company. The person who needs a new lot (maybe because people are complaining or because their insurance company is requiring them to pave it) is likely looking for the cheapest price. Customers who need that lot are looking for someone to tell them what they want to hear and quote a price they like. That doesn’t mean you want to (or need to) be the person who gives it to them.

3. Don’t undermine your fellow contractors. Every day I hear customers say X Company said this and Y Company said that. Many contractors will immediately discount the expertise of their competitor. I never, ever do this. Not only does it undermine their expertise, but by extension, it undermines my own and our whole industry’s. When customers try to get my opinion on my competition, my answer is always, “I’m here to present to you my firm, my proposal and my quote. That’s it. It’s your decision to hire who you feel most comfortable with.”

BY SANDY LENDER

Since 2021, Amanda Harrington has worked as a float driver, skid steer operator and milling machine operator for Triple A Milling, headquartered in Concord, Ontario. She joined the construction industry in 2019 after a decade driving trucks, so her skills translated perfectly into the role of transporting machines from site to site. But Harrington had her eye on doing more and increasing her responsibilities. In 2023, when Triple A was short on operators—as most contractors can sympathize with—Owner Andrew Alfano gave her the opportunity to try her hand at learning to operate the mill. She enjoyed that and jumped at the chance to learn new skills. Triple A has five sizes of cold planers from the Wirtgen Group and Harrington has a comfort level with the W 150 mid-size machine specifically. She recently took some time to share her story and encourage others as a woman of asphalt.

AsphaltPro: You shared that you were a truck driver for 10 years before moving into the asphalt industry. Could you share with the readers what attracted you away from truck driving and into the asphalt/construction industry?

Amanda Harrington: I started out my truck driving career as most drivers do—hauling freight in a dry van or a reefer van. I quickly discovered that sitting behind the wheel all day staring out the windshield was not mentally or physically stimulating enough for me. I have always enjoyed learning new skills/roles and welcome challenges that push me out of my comfort zone. So when the longhaul gig became a lesson in what not to do, and what I did not want to do, I started looking for something else. Through the years I have driven a variety of different types of trucks with many applications. A good portion of my career was in the solid waste industry, and when I felt I had learned and experienced all that I could in that industry, I got a job at a road construction company. After the first few weeks of driving water trucks and dump trucks, my boss gave me the opportunity to learn how to drive the lowbed truck to transport our equipment to and from job sites. I absolutely loved learning how to run and load and unload the equipment, how to chain the different pieces, and to drive with an oversize load. I felt like I was getting to “play” every day at work, and after my nerves settled, felt very much at home in the construction industry.

AsphaltPro: What physical and soft skills from the truck driving experience did you find yourself transferring to your role in the construction industry early on?

Harrington shared one of her best practices for career advancement: “I made a point to be present on the job site, available to help in any way that I could when needed.” She asked questions and showed interest in the various roles available at Triple A Milling, Concord, Ontario; she turned a shortage of mill operators into an opportunity to learn and grow.

Amanda Harrington: You definitely have to have a certain amount of stamina to work in seasonal road construction. As anybody who works in it knows, the days are long and the summer heat can be unbearable, so it takes a lot, mentally and physically, to keep going and push through. My friends often ask me how I do it, and I reply, “I have no idea!”

Communication is crucial—it can make or break your day. Time management, work ethic, prioritization, multi-tasking, attention to detail, adaptability, problem solving, being able to work as part of a team—they all matter.

AsphaltPro: Could you tell the readers what you found most valuable about your first job as a lowbed driver in the asphalt industry?

Amanda Harrington: Being a lowbed driver gave me additional skills and showcased that I was capable of being a versatile and valuable employee. It also gave me a great confidence boost and proved to me that I am quite capable of doing this type of work and doing it well. It ultimately led me to where I am now and opened the door for me to become an operator.

AsphaltPro: Could you share with the readers what your different roles as a lowbed driver, skid steer operator, and milling machine operator generally require of you for the Triple A Milling team?

Amanda Harrington: It requires that I am consistent and reliable and to give my best effort to show up ready to complete the job—some days this is more challenging than others. I would also say that this is where those soft skills that I previously mentioned come into play.

AsphaltPro: Then what are some of your daily responsibilities when it comes to operating the milling machine specifically?

Amanda Harrington: The majority of the time I am responsible for transporting our mill to the jobsite. While on the jobsite my role is to operate, which entails completing a daily inspection and report, moving and steering the machine, controlling the conveyor belt to load the dump trucks, signaling and directing the dump truck driver, controlling the speed of the machine’s travel, staying in constant communication (verbal, eye contact, hand signals) with my gradesman, assisting with checking/replacing teeth in the drum, watching for/marking manholes, catchbasins or any other items we need to avoid in the asphalt or concrete, washing the machine down at the end of the day, and refilling the water tank and other fluids when necessary. Also, communicating with the mechanics regarding any necessary repairs and maintenance.

AsphaltPro: You mentioned the opportunity to run the mill came about due to the shortage of workers at your company. Could you share with the readers a little more about how that opportunity presented itself and how you approached Andrew Alfano to volunteer for the job?

Amanda Harrington: In my second season working at Triple A Milling, I learned how to load and unload our larger milling machines by myself, and once I was comfortable doing that, I voiced my desire to learn how to operate. I was told I had to learn how to operate the skid steer and sweep behind the machine first to understand what the finished outcome was supposed to look like. So I spent the better part of my second season in a skid steer as well as transporting our equipment. At the beginning of my third season, unfortunately (but fortunately for me) we were short a handful of mill operators, so my boss took me under his wing and gave me the opportunity to start learning how to operate.

AsphaltPro: What training/experience did you have prior to taking on operating the mill?

Amanda Harrington: The only prior experience with the mills was from loading/unloading them on and off my trailer and moving them around in the yard or at the jobsite. Also, my experience driving various trucks and machines from my 14 years as a truck driver.

AsphaltPro: What training did Triple A offer once you showed interest?

Amanda Harrington: It has all been on the job training. There are different techniques and approaches for different types of jobs, for example, a parking lot with a lot of curbs and islands versus mainline work on highways. So, I would watch the operators to see how they did things when I was on site with them as a driver or while in the skid steer, paying attention to things they did and when they did them. I made a point to be present on the job site, available to help in any way that I could when needed, asked questions, showed interest.

AsphaltPro: What about operating the milling machine is “most cool” to you?

Amanda Harrington: So many things come to mind! Being able to maneuver a large machine safely and accurately, when you get into a zone and everything is going as it is supposed to, milling a next to perfectly straight pass (not easy to do!), when you look back at the pattern left behind and it’s clean and consistent, when you and your gradesman become in tune and you can pull off some pretty technical and complicated maneuvers without stopping and with minimal discussion. The machine itself is incredibly impressive. And this is pure

ego, but I think being one of only four women (that I know of) in North America that operate a milling machine is pretty cool.

AsphaltPro: You mentioned the W 150 is the machine you had the chance to operate most often. Could you share with readers what is most comfortable about that equipment for you compared to other models that Triple A has in its fleet?

Amanda Harrington: The W 150 is what I have had the most time on, which is why I feel most comfortable on it. There is far more visibility around the W 150 compared to the larger models like the W 220. The conveyor is narrower, which allows you to easily see into the back of the dump truck, whereas the conveyor on the W 220 is much wider and obstructs most of your view. The conveyors have cameras, which helps, but I definitely still find it challenging to load a dump truck “nicely” with a W 220.

My approach to learning is to hold my breath and just do it. I try different techniques and see what works the best for me, take my time until I get the hang of something new, watch what other operators do and ask questions.

AsphaltPro: As a subcontractor with a variety of mill sizes, Triple A gets to work on a variety of projects. You mentioned government jobs for the Ministry of Transportation of Ontario (MTO), bridge decks, parking lots, as a few. What is your favorite type of project to work on and what makes that intriguing to you?

Amanda Harrington: I do enjoy the jobs that are not so straight forward, that require more thought and more attention. For me, these jobs are usually gas stations, which are a great type of job to learn on, but they can also be frustrating. There are a few of us that I would say have a love/hate sentiment for gas stations!

But so far my favorite job was when we worked on the Canadian side of the Blue Water Bridge between Sarnia, Ontario and Port Huron, Michigan. Besides having a beautiful view all day, we managed to mill 7,800 square meters (84,000 square feet) in one day. It was also a memorable job for me because it was on this bridge where I felt my confidence grew substantially.

AsphaltPro: What do you think is the most important skill you’ve brought to your position as an equipment operator in the asphalt industry? And how would you encourage other women entering the industry to hone a similar skill?

Amanda Harrington: My attention to detail and ability to learn and take direction. You have to learn what the machine is supposed to sound like, feel like, look like and sometimes even smell (or not smell) like in whatever function it is performing. These are large, complicated and expensive toys, so the more in tune with it you are, the better it is for everyone, and I believe that is one of my strong suits. If anyone is interested in becoming an operator, you just have to have the drive and interest to learn. It comes naturally to some people, others need a little extra practice, but that does not mean it cannot be achieved. There are courses you can take for many types of equipment. If it’s specifically related to road construction, just get your foot in the door with a paving company as a laborer and work your way up. Be vocal from the beginning about your goals (the squeaky wheel gets the grease). I got my foot in the door as a truck driver. If you are always trying to better yourself and learn new skills, you will be successful and get noticed by the right people. It may take some time, but you have to be willing to prove yourself and to put in the work. This is not an industry for anyone who is not willing to break a sweat and get dirty.

AsphaltPro: What would you say was the most challenging “obstacle” you, as a female on a subcontractor’s crew, had to overcome in the past, and how DID you overcome that obstacle?

Amanda Harrington: “Imposter Syndrome” has been my biggest obstacle. I am harder on myself than anyone else is. Having to convince myself that when I excel at my job, it is because I have put the effort in, I have learned from my mistakes, I have developed the skills—it is not a fluke or a coincidence. I will honestly say that I have not overcome this—it is an ongoing struggle. The way I deal with it is to remind myself that I work hard, I try my best, I believe I am good at my job and that I am valued in my workplace. I have a wonderful support system within my friends and community of other women that work in the trades to lean on.

The other obstacle is finding a clean washroom close to the job site when we are working out in the middle of nowhere!

The best advice I can give is to find a community of other women who can relate to the challenges we as women face in a male-dominated field. If possible, find a mentor or an ally at your workplace or in the same industry as you to encourage you and to be a witness to your achievements.

BY BECOMING A MEMBER of Women of Asphalt, you are joining an organization which strives to advance and support women in the asphalt industry.

THERE IS NO COST TO JOIN and invaluable benefits to be had, including connecting with women around the country working in various positions within the asphalt community, mentoring programs, networking events within your state and at World of Asphalt, and employment leads.

Go to womenofasphalt.org for more information and to register to become a member

25 branches and counting

Striving to advance and support women in the asphalt industry. Membership is FREE and open to all.

womenofasphalt.org

AsphaltPro: You mentioned the regional community “Women On Site” as a positive and encouraging group you’re a part of. Tell our readers about the group.

Amanda Harrington: Women On Site has grown into a national community, and has already crossed the border into the United States. It was started by four women that work in male dominated fields as they identified a need for a community like this. It can be very lonely and isolating as the only woman on a jobsite or crew. Even the most empathetic man cannot truly understand what that is like. I have been fortunate that I have felt welcomed and comfortable in the majority of companies I have worked for, but not all women are as fortunate and have to face a lot of adversity and harassment. Having a community of like women to lean on and share stories with is so valuable.

Women On Site has chapters across Canada and one in the United States. They host a few large events throughout the year, as well as local monthly meetups. The group originated on Instagram (@women.on.site), they also have a website (www.womenonsite.ca), and I would highly recommend that women get involved with this organization. I have met some amazing, bad ass ladies through this community, and I am so grateful that I have.

AsphaltPro: How has Women On Site been a help to you in your career or in your day-to-day role as a woman in the construction industry?

Amanda Harrington: It may seem trivial, but just knowing how many women are actually out there working in the trades and construction makes a difference. It sounds cliché, but it really does show you that you are not alone.

AsphaltPro: How can other women, maybe those who aren’t in the Toronto area, be involved in Women On Site?

Amanda Harrington: Follow them on Instagram and go to one of the monthly meetups! The meetups are on the first Wednesday of every month in most major cities in Canada. The website will have a list of local chapters. @women.on.site www.womenonsite.ca

AsphaltPro: Let’s talk about Teamwork. What is the most challenging project you’ve been a part of and how did you and the Triple A Milling crew overcome the challenge?

Amanda Harrington: One job does not really stand out more than any other to me as far as being more challenging - each job presents its own set of challenges. Overcoming any challenge as a crew of more than one person will always require communicating— discussing different approaches and techniques, possible outcomes, etc. You cannot accomplish anything without communicating with your crew on ANY job. You have to work together as a team to get the job done.

AsphaltPro: Let’s talk about Perceptions. What do you think is an incorrect perception that we, as an industry, can re-educate young people about to encourage more women to consider a career in the asphalt business?

Amanda Harrington: An incorrect perception of people in construction is that we are unintelligent, uneducated, unsavory dregs of society who barely pass for humans. I have met so many intelligent, caring, hilarious, decent people that are just trying to make a nice living for themselves and their family. Of course, there are always a few bad apples, but that is true of any industry. I follow a great account on Instagram that touches on this subject of misconceptions and perceptions of people in construction. I recommend checking it out. @humansideofconstruction

AsphaltPro: What is something you would tell a young lady to encourage her in this industry?

Amanda Harrington: I would tell her that there is a place for her in this industry, and it is absolutely possible for her to have a successful career, that she can make a comfortable living for herself. I would also tell her that it will instill a sense of confidence and resiliency in her that she may not get from an industry that is female dominated.

AsphaltPro: What is the most rewarding aspect for you of being in the asphalt business?

Amanda Harrington: My sense of accomplishment, the confidence, strength and resiliency that I have gained over the years. The ability to financially take care of myself and not want for anything. Job security too—the roads will always need to be maintained.

AsphaltPro: Will you tell us about a person who served as a mentor for you? Is there a piece of advice from this person that you would share with other women in the industry/other operators?

Amanda Harrington: I would have to say my boss, Andrew Alfano. He encouraged me by giving me the opportunity to operate, by not limiting me and making assumptions about my abilities based on me being a woman. He is patient in his instruction, takes the time to explain to me what we are doing and why we are doing it, answers all of my questions, pushes me when I need to be pushed, and creates an environment that allows me to learn and grow.

This is more of a reminder/encouragement than advice: I was operating one of the bigger machines (W 220), having a rough day, feeling very overwhelmed with trying to operate faster, but also load the dump truck without “spilling” the grindings over the edge of the box, but also trying to keep the machine in a straight line, and trying to remember where all the controls are by feel (the control panel on a W 220 is much different than the one on the W 150) and I felt like a complete disaster. It must have been quite obvious to my boss that I was struggling, so he told me to come down off the machine. He said many encouraging things to me, but what he said that stuck with me the most was, “If this was easy, everyone would do it.” So, I took a deep breath and got back up on the machine and kept going. I try to remind myself of this when I am having a difficult day.

Customize any ADM plant to your specific production needs with our standard components.

“Owning our ADM asphalt plant has been a real game changer. ADM focuses as much on service as on the sale of the plant, and the payoff has been well worth it.”

Trent Nielsen, President & Owner-Operator, Nielsen Blacktopping & Concrete

To address racecar drivers’ concerns about pavement grip, the Miami International Autodrome’s Formula 1 Miami Grand Prix track was milled and resurfaced ahead of the 2023 big event. All photos courtesy of C2C Visuals

IIn the Formula 1 world, millimeters matter in both racing and paving. Management at Sunland Asphalt & Construction, Littleton, Colorado, knew they would need their A team on hand to handle the 2023 resurfacing project at the Miami International Autodrome, home of the Formula 1 Miami Grand Prix. They mobilized 75 internal employees, 15 technical specialists and 40 pieces of heavy equipment from around the country on 35 separate transport loads.

The project’s scope consisted of milling 2 inches of the existing track and repaving it with a highly specialized asphalt mix designed

to Formula 1 standards. Crews were to repave the track at 2 inches thick for a total of 9,500 tons over an eight-day period.

Construction scheduling for the 3.36-mile anticlockwise circuit, which winds around the Hard Rock Stadium in Miami Gardens, had to be choreographed around the stadium’s other events, including the end of the National Football League season, a jazz music festival and the Miami Open tennis tournament. The International Automobile Federation also required Sunland to have the mix put down 60 days before its big event for the material to properly cure.

Needless to say, it took a lot of coordination for Sunland to make this happen and the Wirtgen Group was just one of the many partners in place to help.

In 2022, Miami held its first Grand Prix event on the track. When drivers expressed concerns with the grip on the pavement, track owners decided to lay fresh asphalt ahead of the 2023 race. The track management hired Tilke Engineers & Architects, headquartered in Aachen, Germany, to oversee track resurfacing, which they said would ultimately improve the “spectacle” of the 2023 race.

Sunland was hired to complete the mill-and-resurface of the track and began work to remove the existing surface in the early spring of 2023.

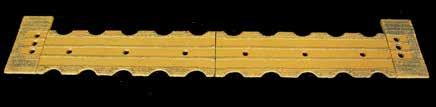

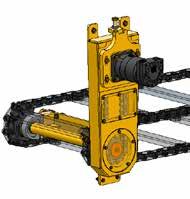

• Three Wirtgen W 210 Fi mills

• Universal total station (UTS) machine control

• Smaller milling teeth than standard to achieve millimeter accuracy

• Slow and steady pace of 38-40 feet per minute (fpm)

• About 17,000 square yards of material per day

• Completed all removal of material in five days

Sunland Asphalt trucked all their equipment in to ensure crews were familiar and comfortable with their equipment and processes. They used three pavers working in echelon to prevent cold joints along the 50-foot-wide track. The pavers were also moving at a very efficient pace of only 6 fpm to ensure paving smoothness.

The mix design for the track included 60% US-mined granite from Georgia with the remainder of the aggregates being locally sourced lime rock from Southern Florida. These aggregates ensured the grip needed on the course.

In addition to the three Wirtgen mills, Sunland used three HAMM HD+ 80i rollers and two VOGELE Super 2000-3i asphalt pavers. The Wirtgen Group technology on these machines is “plug and

play,” which allowed the team at Sunland to get up and running with these machines easily.

“The plug and play feature on all these machines has been a huge advantage to us as a Topcon provider, making the installs quick and easy,” Tony Carden, intelligent paving product manager at RDO Equipment said. “We’re also able to provide serviceability for them both on the dealer side and from the manufacturer side. It’s a win-win.”

The pavers on the job were equipped with a temperature monitoring system. Thermal cameras were mounted to the pavers and used to find any temperature differences that could indicate potential segregation in the mat as it was being laid.

“The thermal profiling that we’re using on the pavers gives a rundown of where the pavers were, where they’re going, at what speed they are running and at what temperature,” Greg Hughes, project engineer at Sunland said. “If one isn’t getting to a high enough temperature, we can go back and look at it and see what happened and fix it and that’s a great tool for us.”

“The intelligent compaction on all the rollers shows us our roller patterns throughout the day,” Hughes said. “It provides us real-time documentation of the areas we are hitting and if we’re hitting any areas more than we should. We’re also able to know if we should be vibrating more or less as well.”

With the HAMM Intelligent Compaction system, users can set a designated number of passes ahead of paving. The system shows the operator, on the in-cab display, how many passes have been completed.

Sunland management says they also use the intelligent compaction system as a training tool.

“We use it in the office to see where we could be more effective,” Hughes said. “We sit with our roller operators, and we can show them where we might be able to improve on future jobs.”

The crews finished paving the 19 turns of the course on the Autodrome’s schedule, and the 2023 Miami Grand Prix was a success thanks to the hard work and dedication of the people behind the machines.

Editor’s Note: For 2024, AsphaltPro Magazine allows experts in the industry to share how to expand your operations to the next phase of business. Let’s turn to some professionals who have equipment, services, software and tenure to help you expand to mix design, production, hauling and more. This month’s installment looks at the use of emulsions at the terminal, hot-mix plant and beyond to enhance your asphalt mix design and pavement structures.

PProper storing, handling and transport of asphalt emulsion are critical aspects of ensuring the quality and effectiveness of this versatile material in construction projects. From maintaining the stability of the emulsion during storage to safeguarding its integrity during transportation and handling, adherence to best practices is paramount for maximizing performance and longevity.

At World of Asphalt 2024, Bob McGennis, technical manager at HF Sinclair, Dallas, which has seven refineries and four asphalt terminals throughout the United States, presented an education session on these best practices based on 25 years of experience.

Although emulsions are commonly used in pavement maintenance and rehabilitation applications, McGennis said that’s

changing. “There are a number of factors that are probably going to give emulsions a higher profile in our industry,” he said. “We are on the precipice of a surge in asphalt emulsion technology because there will be an advantage to using it when we’re concerned about EPDs, global warming and life cycle analysis.”

Emulsions offer an environmentally friendly additive because they’re made workable through the mere use of water.

“When asphalt is milled into microscopic particles and dispersed in water with the aid of a chemical emulsifier, it becomes an asphalt emulsion,” McGennis said.

An asphalt emulsion usually contains 50 to 70% asphalt by weight. The rest is a combination of water and emulsifying agent (together, called the ‘soap solution’). “A run-of-the-mill asphalt emulsion concentrate is somewhere around 65% asphalt and 35% soap,” McGennis said. “Then there’s all kinds of other stuff that can be thrown in, such as polymers, adhesion promoters, rejuvenators.”

The asphalt and soap run through a colloid mill where the rotor grinds the asphalt into tiny droplets anywhere from one to 10 microns in size. “These particles are so fine, they would completely pass through a #200 sieve,” McGennis said.

What keeps the droplets separated is the emulsifying agent coating each asphalt particle. The emulsifying agent is either positively charged (cationic) or negatively charged (anionic). “We know like charges repel one another,” McGennis said. “That’s what keeps the emulsion droplets stable in the system.” On rare occasions, an emulsifier may be non-ionic, which works a bit differently. “They actually have a coating that keeps those droplets separated,” McGennis said.

“In my view, there’s no advantage of [anionic vs. cationic]. I think a lot of times why agencies choose one is because it’s what they’ve always done. From a supplier standpoint, it only matters in terms of hauling the emulsion to the project. I don’t want to have to switch trailers back and forth.”

McGennis said anionic agents are typically fatty acids, historically products of the wood processing industry. “Because they’re an acid, you mix them with some kind of base, typically sodium hydroxide or caustic,” he said.

Cationic emulsifiers are typically fatty amines, originally almost completely animal-derived such as tallow. “We actually mix these fatty amines with some type of acid, typically hydrochloric acid,” he said.

The goal of the emulsifier is to keep the emulsion stable enough to survive manufacturing and use, but unstable enough for the desired setting behavior. “You’ll hear people say, for example, in the case of chip sealing, that you want to get the aggregate on that film before the emulsion breaks,” McGennis said. “What’s happening [when it breaks] is the droplets [of asphalt] are coalescing as the water leaves the system. How fast that occurs indicates the [emulsion] classification.”

The volume of the emulsifier depends on the application for the product. For example, a spray application such as a chip seal would require less emulsifying agent as this instability of the emulsion reduces setting time, while a mixing application such as through a pugmill would require more emulsifying agent to remain stable through mixing, hauling and paving.

“Sometimes, [the emulsifier] left behind [when the emulsion breaks] can actually influence properties of the asphalt,” McGennis said. For example, high float emulsions where the emulsifier, tallow oil, gels the asphalt. “The gel structure left behind creates better high-temperature properties and there are some who think they’re more resistant to aging.”

However, McGennis’s top advantage to high float emulsions, at least in chip seal applications, is that it allows for use of slightly more dusty aggregate. “In the southwest where most of my activity is, there’s not a lot of washing of aggregates, so they tend to be a little dustier.”

IF YOU DON’T KNOW WHAT’S BEEN IN THAT TRAILER, MCGENNIS SAID THE TRAILER SHOULD BE THOROUGHLY CLEANED.

Emulsions must be viscous enough to spray and cover a surface without running off the road. They must also be able to hold aggregate without raveling, nor bleeding under traffic. “There are a lot of different expectations that we have of emulsions,” McGennis said. “That’s why there are so many different grades, in order to fulfill the needs of each application.”

A few years ago, McGennis set out to count the classifications of emulsions and discovered more than 300 classifications in 25 different use categories (most in roadwork). Let’s take a closer look at various features of emulsion classification:

• Charge: The first letter (or lack thereof) in an emulsion classification denotes if the mix is cationic or anionic. If cationic, the classification will contain a C. An anionic emulsion, however, will not have an A—there will be no letter at all. There’s also high float emulsions, a special category of anionic emulsions denoted with an HF.

• Setting speed: Rapid set emulsions break quickly and are denoted with an RS. Slow set emulsions are denoted with an SS. In between slow and rapid are medium set (MS) and quick set (QS).

• Viscosity: A number 1 in the classification means the emulsion itself has a low viscosity while a 2 indicates higher viscosity. The viscosity of the base asphalt may be designated in the classification of the emulsion with a H at the end to indicate a harder base asphalt. So, a CSS1H would be a cationic slow set with low viscosity with a harder base asphalt, while a CRS2 (the most common chip seal grade) would be a cationic rapid set with high viscosity. However, classifications don’t stop there.

For example, a CRS2P is the most common polymer modified chip seal grade, denoted with P at the end, while CRS2L denotes injection of latex. “There’s a whole raft of products out there that have been developed which use rubber, recycling agents or rejuvenating agents,” McGennis said.

There’s polymer-modified rejuvenating emulsion (PMRE) and emulsified rejuvenating agent (ERA1). There’s CIREE (cold inplace recycled engineered emulsion) and CREE (cold recycled engineered emulsion).

Despite decades of experience, McGennis said there are some classifications that still stump him. “It can be a bit of alphabet soup,” he said. “You have to look at the spec to really figure out what it is they’re wanting to use those for.”

“You have to be careful when you load transports to make sure that the emulsion that you’re loading into the transport is compatible with what was previously in the transport,” McGennis said. For example, if the trailer you’re loading cationic emulsion into was last used for hot asphalt, “you absolutely don’t want to load the emulsion because that asphalt could be hotter than the boiling point of water and you could, well, it’s like a volcano exploding.”

If it’s been hauling crude oil or heavy fuel oils, McGennis suggests emptying to no measurable quantity. “If you look down into the trailer with a flashlight, you might see a thin ribbon of oil down at the bottom, and that would probably be okay, but you’d prefer to have it as empty as possible.”

“If they’ve just been hauling another load of cationic emulsion, then you’re good to load,” McGennis said. If the trailer’s been hauling an anionic emulsion, it must be emptied to no measurable quantity or preferably flushed out.

“If you load cationic and anionic together, instead of those particles pushing each other apart, they come together and you could end up with basically clabbered milk,” McGennis said. Many suppliers will either avoid handling both anionic and cationic emulsions or use separate, dedicated trailers for each type. “If you’re going to use a distributor to spray tack and to do a chip seal, if you’re using cationic to chipseal, use cationic to tack.”

If you don’t know what’s been in that trailer, McGennis said the trailer should be thoroughly cleaned.

McGennis recommends storing emulsions in vertical tanks versus horizontal tanks. “If you go to an emulsion supplier, that’s what you’ll see because it exposes the least amount of surface area,” he said. “If you go look at the top of the emulsion in that tank, you might see it a bit broken on top, and that’s okay. That actually protects what’s underneath.” Just don’t pull that material for samples, he said.

In many maintenance yards, McGennis sees horizontal tanks. “It’s okay, because typically the emulsions they’re using in those types of applications are tack oil and other more forgiving applications,” he said. “But, the vertical tanks are best practice.”

Of course, tanks should be insulated and have sample valves. McGennis said it’s best practice to avoid agitators. “You don’t want vigorous agitation,” he said, opting instead for “a rod going uniaxially down the tank, with a couple of propellers gently circulating [the emulsion].”

In order to achieve accurate samples, McGennis recommends applying the following best practices.

A wide variety of grades are used for chip seals, McGennis said, “anything from the very common CRS2 to a high float, medium set, polymer modified emulsion.”

SS1, SS1H, CSS1 and CSS1H can be used for fog seals, tack coats, scrub seals and even some mixing applications, while CSS1P can be used for all of the above. “But it’s actually more common as a micro surfacing grade in our market and for fog seals,” McGennis said. “QS or CQS are emulsions that were almost 100% developed around the slurry seal or in some cases micro surfacing application.”

AEP and PEP are priming grade emulsions, and when tack coating in hot climates, McGennis recommends an H grade for better bond strength between layers.

“When you take the sample, allow about a gallon to run out so that you’re not testing the stuff that’s been left in the sample valve from the previous time that somebody took a sample,” he said.

Samples should not be collected in metal cans, as the extreme pH levels of emulsion (anionic is usually 10 to 12, and cationic is usually 1.5 to 2.5) can react with the metal. “It can actually break the emulsion or it’ll make it seem like the emulsion is out of spec when it’s really not,” McGennis said, suggesting the use of plastic cans.

Once the material is in the container, allow the emulsion to cool before putting on the lid. “As the emulsion cools, it shrinks and sucks in the can, and you run the risk the emulsion will escape,” McGennis said.

HF Sinclair uses triple containment for its samples: a plastic container, in a plastic bag, in a box. “There’s even an absorbent in there in case the box gets squished,” he said.

Although taking samples in the field makes sense because that’s where the emulsion is being used, McGennis warns that these emulsions are designed to be unstable for optimal setting. “All the specification requirements are written around tank samples,” he said. “In other words, undisturbed samples.”

McGennis strongly cautions against taking samples from the spray bar. “By then, the emulsion has been run through at least one pump, if not two,” he said. “It might be contaminated with [cleaning product] that they back flushed their pump with from the day before, and that [product] would make the base asphalt look too soft.”

The second issue with sampling from the spray bar, especially if the emulsion has been in the spray bar for a while, is that it can come out already broken. “It could be like clabbered milk,” McGennis said. “It would not pass the sieve test.”

“That’s why distributors as they come from the manufacturer all have a sample valve where you can get a tank sample that is more representative for determining specification compliance,” McGennis said. Once the samples are taken, proper handling is also important. “Everyone’s heard the urban legend of the DOT inspector grabbing the sample and throwing it in the back of a pickup truck for a week before taking it to the lab to be tested,” McGennis said. “The last thing you want to do is not take care of that sample. These emulsions are designed to be somewhat unstable. You want to handle them with care.”

Emulsions were developed in the early part of the 20th century. “Dust palliative was probably the first use of asphalt emulsions,” McGennis said. “In most cases, they took some kind of refinery left-behind— maybe asphalt mixed with fuel oil—and sprayed that on a road to kill the dust.” However, a lack of knowledge of chemical engineering meant there were few grades with limited use cases. Then, after WWII with the advent of the Interstate Highway program, “there was a groundswell of research and product development,” McGennis said, “so there are now dozens and dozens of different kinds of emulsions.”

BY ASPHALTPROSTAFF

Editor’s Note: The staff of AsphaltPro magazine is not responsible for the opinions expressed in the Corporate Profiles supplement. Statements made have not been verified thus producers/contractors are still encouraged to use best practices when implementing new advice or making purchasing decisions.

Since 2021, the staff at AsphaltPro magazine has brought this annual overview of original equipment manufacturers (OEMs) to the asphalt audience. This year, it’s a little different. We’ve still offered OEMs and service providers a chance to put their information in front of you, but this time, you get to hear from selected customers who have implemented the technology in their businesses.

We posed specific questions to the partners who support us, thus your operations, about how they have helped a specific producer or contractor enhance its business or achieve its sustainability goals. In last year’s supplement, we acknowledged OEMs are invested in helping contractors and producers reach the net zero goals the National Asphalt Pavement Association (NAPA) had enunciated in its The Road Forward initiative.

What we as an industry need to remember is we’ve been moving toward clean air goals long before legislators, associations and environmental justice warriors dreamed them up. And OEMs have been walking hand in hand with producers (and contractors)

Asphalt Lane is an activity book, available at theasphaltpro.com/asphalt-lane/, for children in preschool through elementary school, designed to give a basic overview of how an asphalt road is made. This booklet shares a great message about the community partners right down the road.

for decades to make a long-lasting asphalt pavement that represents a sustainable system. Perpetual pavements exist because responsible mix designers, producers and laydown specialists have paved the way toward an environmentally responsible pavement system. In the pages to follow, advertising partners who took the time to participate in this year’s Corporate Profiles supplement

show how they’re still walking hand-in-hand with you toward that goal.

Alongside the production zone, our industry looks toward sustaining its workforce. This is an area where AsphaltPro magazine is your direct partner. We’re not only bringing how-to, technical information to you 11 times a year in print and digital format, but we’re also offering tips and guidance for your workforce development and training goals. Check out our back-to-basics online training course, Asphalt Paving 101, designed to help you onboard new workers and give refresher training to veteran workers coming back after the down-season. This course is the first of a series we intend to offer to help paving contractors build up their employees for more excellent performance in the field.

Also, look at the activity book, Asphalt Lane, we prepared to engage the next generation’s imagination. If your company hosts field trips or provides materials for the local library, this activity book makes a great addition to the marketing kit. Don’t forget about career day at middle and high school programs. It’s up to us to remind the communities where we operate that a career in asphalt roadbuilding is lucrative, rewarding and part of the sustainability movement.

ADM manufactures high-quality, portable, skid-mounted, and relocatable asphalt plants and components (60-425 TPH), built to meet strict federal and state emissions standards and specifications, while handling 25 to 50% RAP. Our goal is to provide long-lasting solutions to meet the exact requirements of every job while exceeding industry standards. Our team takes pride in delivering service before, during, and long after the sale, ensuring producers have everything they need to operate at peak capacity.

ADM has worked with Nielsen Blacktopping & Concrete since 2021; Nielsen purchased a new, complete ADM EX 7636 counterflow asphalt plant.

According to Trent Nielsen—third generation of the family business—with the purchase of their ADM EX 7636 asphalt plant, Nielsen Blacktopping & Concrete’s products and services have been enhanced in many ways, along with the company’s ability as a paving contractor to win more bids and improve their company’s return on investment (ROI).

Trent explained, “Now that we produce our own asphalt, our trucks are no longer waiting in line for asphalt supply or unable to work on projects because we’re cut off at 5:30 p.m. With our own asphalt, we can work through the weekend like we did recently for a local hospital parking lot, producing 2,400 tons in a two-day period to get the job done to the customer’s schedule for a better service offering.”

He continued, “When it comes to ROI, our labor efficiency has been improved. We don’t have an outside asphalt bill. We have better cash flow because we can produce as we go, rather than making up-front product purchases.”

Trent remarked, “Now that we produce our own asphalt, our pricing is more efficient and competitive. Having our own asphalt plant has enabled our business to expand from a mostly residential and commercial paving company to a major player in municipal/public projects by completely changing the bidding process so we are winning more bids. We also have control over product availability, scheduling, mix qualities and mix specs which makes a big difference in the number of jobs we can handle.”

“Setting up your own asphalt plant is not for the weak of heart,” Trent stated, “But with the right asphalt-plant manufacturer, one that focuses as much on service as on the sale of the plant, the payoff is worth it. Owning our ADM asphalt plant has been a real game changer.”

When it comes to enhanced sustainability, T.J. Reed weighs in on his company’s ADM EX 7636 asphalt plant. Along with parents Donnie and Regina Reed, T.J. is an owner-operator of French

Broad Paving, in business for 26 years. They have been an ADM customer since 2020 when they formed Madison Asphalt, French Broad Paving’s asphalt production company.

T.J. stated, “If you're doing infrastructure city jobs, you can add RAP (reclaimed asphalt pavement) percentages to your mix, not only to save money on your mix but to help save the environment and its natural resources, too. With the ADM EX 7636, it’s great, because we can use up to 50% RAP.”

T.J. further remarked, “As we were choosing an asphalt plant, we knew we didn’t really have accessibility to natural gas so we chose a highly fuel-efficient ADM plant that was efficient for the fuel that we use in the plant and for our product. This fuel efficiency allows us to be more sustainable in a time when carbon footprints are really important to consumers.” According to ADM, maximum heat transfer and fuel efficiency is achieved with the ADM EX Series of plants through separate drying and mixing zones with the single-drum counterflow-system technology.

Also according to ADM, via this counterflow technology, their EX Series of asphalt plants captures residual gases and reintroduces them back to the plant’s combustion zone. T.J. said, “The technology enables us to all but eliminate hydrocarbon emissions to meet state and federal environmental regulations and to eliminate these emissions for the planet, as well. This is a real plus for our business and really helped in getting our asphalt plant permit.” admasphaltplants.com (260) 637-5729

We manufacture the most durably built and detail-oriented line of asphalt plants and asphalt equipment on the market as well as a fleet of robust automation solutions for a variety of different asphalt plants, burners, hot oil heaters, tank farms, and more.

One of the producers ALmix works with is GMI Asphalt, Belmont, New Hampshire.

Neil Arruda, general manager of GMI Asphalt’s materials division shares: “In 2021, our company (GMI Asphalt) made perhaps the most significant investment at our plant: a 300-ton silo, 500 TPH drag conveyor, and custom flop chute from ALmix, Fort Wayne, Indiana. We made those investments so we could produce more mix at the plant and also increase our production and trucking efficiencies.

“The silo allows the plant to run continuously and enables us to fill the silo in the morning or the night before. We’ve also noticed a number of cost savings related to GMI’s latest investments. First and foremost, in terms of trucking.

“We went from an average time for a truck in the yard of 35 minutes to less than 10 minutes. Just loading the truck used to take 7 minutes from the batch plant. With the silo, we’re at 1 minute, 5 seconds to fully load a truck. That has been particularly beneficial during the current truck shortage because it enables us to run with fewer trucks. A line at the plant to get loaded is just wasted money.”

We also estimate that GMI has saved 5% on its total fuel and electric bills by reducing startups and shutdowns. Being able to continue to produce mix even if there’s not a truck in the yard also allows us to produce a more consistent mix.

672-3004

Who We Are

Astec Industries has been a global leader in providing innovative Rock to Road™ solutions since 1972, specializing in equipment for asphalt road building and aggregate processing. Guided by the vision statement, "To build industry-changing solutions that create lifechanging opportunities," Astec is committed to customer-driven innovation, placing both customers and employees at the forefront. Rooted in its purpose of "Built to Connect", the company continues to shape communities through cutting-edge solutions for road construction, materials processing, and asphalt mixing.

An Example

Astec is a leading manufacturer of equipment for both hot and warm-mix asphalt production. Astec offers a wide range of asphalt mixing plants, including portable, relocatable and stationary models, to fit your specific needs. Whether you need a continuous-mix plant for high-volume production or a batch plant for smaller projects, Astec has the right solution for you.

More Than Just Paving: Complete Road Building Solutions

Road construction isn’t just about laying asphalt. Astec understands this and provides a full suite of equipment for all stages of the process, including:

• Road preparation: Equipment for reclamation, soil stabilization, and milling to get the surface ready for paving.

• Paving: Pavers to lay down the asphalt smoothly and efficiently.

• Finishing touches: Asphalt brooms for cleaning and smoothing the paved surface.

• Recycling: Equipment to reclaim and reuse old asphalt, saving costs and reducing waste.

Astec Industries builds quality into every product.

Astec embodies a standard of quality and reliability. Astec equipment for asphalt mixing is designed with a goal to produce high-quality mix.

Astec occupies a unique position for the industries we serve. With decades of proven experience as a premier manufacturer with a reputation for building high-quality equipment, supported by world-class service, Astec is the ideal partner to the asphalt mixing and road construction markets.

Astec maintains large parts inventories and has capabilities to manufacture custom parts when needed.

Astec’s road building equipment is designed with heavy-duty components to withstand demanding conditions and maximize uptime. They offer options suitable for various applications and job sizes, from large interstate projects to smaller parking lots.

We Enhance Sustainability

Astec Industries is committed to continually strengthening global sustainability as we lead in the innovation of everything we do from Rock to Road.

For our customers, we will continue to be the most innovative company in our industry, offering the world most advanced, productive, durable, and environmentally friendly products. Our team is constantly working to find ways for our customers to reduce their environmental impact in user-friendly and budget-conscious ways.

Astec has showcased a number of recent innovations with a sustainability focused benefit including the ReMix® CCPR system and the IntelliPac® moisture system. Several of our legacy products also contribute to sustainability efforts and initiatives including the Double Barrel XHR high RAP plant.

astecindustries.com (423) 867-4210

AsphaltPro magazine is the leading “how-to” magazine for asphalt producers, highway pavers and publicworks specifiers, but we’re more than just a magazine!

Get your AsphaltPro fix between issues by connecting with us online.

Visit our website at theasphaltpro. com for exclusive content, including videos demonstrating equipment or showcasing various projects and blog posts covering the latest industry news. theasphaltpro.com

Join us on Facebook, Instagram, X and LinkedIn for daily tips to improve performance, asphalt industry history and trivia, construction humor, and news and happenings. facebook.com/AsphaltPro instagram.com/theasphaltpro @AsphaltPro linkedin.com/company/ asphalt-pro-magazine

Sign up for our weekly Toolbox Tip emails to inspire your daily toolbox talks. Toolbox Tips: bit.ly/toolbox-tips

are! Scan to Sign Up for the Toolbox Tips!

Our patented, proven Blue Smoke Control system captures and filters 99.9% of blue smoke from plant emission points. Our X-VOCS system eliminates 99% of VOCs and odors from asphalt tanks. Together, these systems help producers to meet regulatory requirements and appease neighbors.

Butler-Justice has worked with BoDean Company since 2010. We provided BoDean with two blue smoke collection units, coupled with a ducting system installed throughout the plant. We installed ducting at the top of the silos, at drag slat conveyor transfer points and at truck loadout areas. These are the key points required to ensure only clean air leaves the plant. The ducting feeds two collectors that process the air until it is virtually 100% clean of blue smoke haze.

Bo and Dean Soiland, owners of BoDean, shared: “We researched every means possible to achieve the lowest emissions attainable. No blue smoke. No odors, no VOCs. That was nearly impossible, but we achieved 99%, exceeding our expectations with the technologies from Blue Smoke Control Division of Butler-Justice Inc.

“We’ve gone from the proverbial ‘ugly duckling’ to an accepted and contributing member of our community by reducing our environmental footprint to nearly zero. Blue smoke control helped us become invisible—environmentally. That’s good for us, good for the community.

“The experts at Blue Smoke Control made it possible, and it’s made us a model neighbor in the minds of the community. Our neighbors appreciate us.”

The Blue Smoke Control system from Butler-Justice, Inc., captures and filters blue smoke from emission points in your plant — with 99.9% overall efficiency. We can incorporate this system into new plants or retrofit your existing plant with minimal modification.

714-696-7599

www.bluesmokecontrol.com

mikeb@butlerjustice.com

CWMF Corp, a proud family-owned business, delivers unparalleled asphalt plant solutions with American craftsmanship. Our small yet dedicated team custom designs hot-mix asphalt plant equipment, emphasizing flexibility, integrity and excellence. From initial consultation to in-house manufacturing, we provide efficient, tailor-made solutions, covering AC tanks, baghouses, drum mixers, and entire asphalt plants. With a commitment to personal service, our family legacy fuels enduring relationships, ensuring peak efficiency for our customers’ operations.