Celebrating excellence in the glass, window and security screen industries

We make the brands you know and trust for the community we live in.

Celebrating excellence in the glass, window and security screen industries

We make the brands you know and trust for the community we live in.

Overall Winner National Commercial Project Over $750K

National Winner Commercial Project Over $750K

ARCHITECT: ACME | Cavcorp

BUILDER: Torre Developments, manager Jaron Schubert

FABRICATOR: iron works fabricator- Robert Everingham IRONFIST.

PHOTOGRAPHER: Greg Sullavan, Sunburst Studio

National Overall Highly Commended Residential Project Over $80K

National Winner Residential Project Over $80K

ARCHITECT: Tom Kanchanasinith, TKoncepts

BUILDER: Maxpan Constructions

PHOTOGRAPHER: Tom Kanchanasinith

National Highly Commended Commercial Project Over $750K

ARCHITECT: Baldwin O’Bryan Architects

BUILDER: Tristan Plevin, Plevin Building

GLASS SUPPLIER: Chevron

METAL SUPPLIER: Alspec

PHOTOGRAPHER: Robert Lang

Warrnambool Golf Club

National Highly Commended Commercial Project Under $750K

ARCHITECT: Matthew Morse Architect Pty Ltd

BUILDER: Lee Haberfield, Modus Constructions

ALUMINIUM EXTRUSIONS: Alspec

POWDER COATING: Dulux

GLAZING: Australian Glass Group

PHOTOGRAPHER: Matt Seebeck, Seebeck Photography

Clifton Hill Passive House Primary School

National Winner Commercial Project Under $750K

ARCHITECT: Jackson Clements Burrows Architects

BUILDER: Kapitol Group | Figurehead

GLAZING SUPPLIERS: Viridian

PHOTOGRAPHER: Peter Clarke Photography

National Winner Commercial Retrofit Project

BUILDER: Tanner Carpentry PHOTOGRAPHER: Adelaide Portrait Studios

National Highly Commended Residential Project Over $80K

ARCHITECT: Saaj Design

BUILDER: Brynor Constructions

PHOTOGRAPHER: Dave Kulesza

National Highly Commended Residential Project Under $80K

ARCHITECT: Archier

BUILDER: Sheringham Constructions

PHOTOGRAPHER: Rory Gardiner

National Winner Residential Project Under $80K

ARCHITECT: Archier

BUILDER: Bushblend Homes

PHOTOGRAPHER: Thurston Empson

Beach Retreat

National Winner Residential Retrofit Project

ARCHITECT: Ellen Whoolley, Woolley Architects

BUILDER: Tristan Davis, Davis Builders

GLAZING SUPPLIER: Australian Glass Group

PHOTOGRAPHER: Chosen Photography

ARCHITECT: Sebastian Kaintoch, KA Design Studio

BUILDER: Brianda Projects

FABRICATOR: Eastern Suburbs Steel

ENGINEER: Gilcon Structural Engineers

PHOTOGRAPHER: Berniek Media

National Winner Bespoke Design Project

ARCHITECT: Aspire Architecture

BUILDER: Bruce Lee Builder

PHOTOGRAPHER: Admedia

National Winner Shower Screen or Barrier Project

ARCHITECT: Lina Strati, Aesthetic Developments

BUILDER: Phillip Strati

ARCHITECT: Sketch Building Design

BUILDER: Rob Wandaller, Melbourne Home Builders

National Winner Small Showroom of the Year

ARCHITECT: Yemen Zeitoune

PHOTOGRAPHER: Melanie Makris

Because your home deserves the best

Embrace the spirit of each season in your home with Kömmerling‘s versatile windows. From the vibrant colors of autumn to the gentle breezes of spring, invite the beauty of nature to your doorstep. Allow your space to mirror the ever-changing world outside, turning every moment indoors into a celebration of the seasons.

The VOLTA Powered Roller V2

National Winner Most Innovative Component

Solar Vision IGU

National Highly Commended Most Innovative Product or Service

MP2 - Flush Louvre - Opposed Opening (MP2-FL-OP)

National Highly Commended Most Innovative Window System

PHOTOGRAPHER: Aeroshots

High performance double glazing.

The ideal residential solution for 7 Star compliance.

LightBridge™ o ers exceptional insulation, reduces energy consumption and limits heat conduction between inside and outside temperatures.

Locally stocked and manufactured for short lead times and reliable supply.

Thermal Comfort

Natural Light UV Protection

Australian Certified Compliance & Performance

Australian Manufactured

Windows & Doors

BUILDER: Zac White Building

PHOTOGRAPHER: Studio Door Orange

MOST INNOVATIVE COMPONENT

NSW Highly Commended

Ventora Group Ventora Group Hardware

SMALL SHOWROOM OF THE YEAR

NSW Highly Commended

DESIGNER: With the assistance of AWS

SMALL SHOWROOM OF THE YEAR

NSW Winner

MOST INNOVATIVE COMPONENT

NSW Winner

ARCHITECT:

Peter's journey began in the serene landscapes of Tasmania, where he pursued his passion for science, earning a PhD in Physics from the University of Tasmania in 1981. His groundbreaking research on ‘Atmospheric Effects on High Energy Cosmic Rays’ marked the beginning of a career that would leave an indelible mark on our industry. Between 1981 and 1997, Peter worked in Canberra for the university sector and the Australian Defence Force Academy, where he began his pioneering work in energy performance modelling of windows and building facades, laying the foundation for many of the innovations we see today in sustainable building design.

In 1995, he played a key role in developing the Window Energy Rating Scheme (WERS), and later, further enhancing this scheme by developing the WERS Star Rating procedure. He has been instrumental in bringing cuttingedge building energy simulation software to our shores. His collaboration with Ian Bennie to develop the WERS for Skylights Energy Rating Program, a scheme unique to Australia, further highlights his innovative spirit and dedication to sustainability.

In 2006 Peter took the bold step of starting his own consulting business, Peter Lyons & Associates, with his expertise sought after by industry and government alike. He has worked closely with CSIRO, NFRC and AFRC and served as a principal consultant to Sustainability Victoria.

Not content with merely contributing to research and industry, Peter has also played

a pivotal role in professional societies and regulatory bodies, serving in, among many others, the Australian and New Zealand Solar Energy Society, ASHRAE, the Australian Institute of Architects, and, of course, AGWA and its predecessor organisations.

In recognition of his unparalleled achievements, it is fitting that we acknowledge Peter's dedication, innovation, leadership and commitment to advancing the window and glass sector both in Australia and around the globe. His work has had a tangible impact on the sustainability of our built environment. AGWA congratulates Dr Peter Lyons on this well-deserved win.

Congratulations to the following winners of the State Industry Awards for 2024. AGWA thanks you for your generosity in giving back to your Industry with your time, knowledge and expertise.

Queensland

David Jones

Bradnam’s Windows and Doors

New South Wales

Andy Nguyen Alspec

Victoria

Stuart Khan AWS

South Australia

Stuart Bulmer

Chevron Glass

Western Australia

Royce Deere Pivotech

Debra Kaye Action Glass

Darryl Rector

Dowell Windows + Doors

Vicki West Glass Co

Ingrid Pagura

Industry Development Coordinator, AGWA

It is with great pleasure that AGWA announces that the winner of the 2024 AGWA National Safety Award is Festival Glass & Glazing (SA) with their ‘Connecteam’ App for the Delivery of WHS Materials. This is the second year in a row that Festival Glass & Glazing has taken out this Award and we commend them on their dedication to improve workplace health and safety.

This year’s entry, the ‘Connecteam’ App, is a simple, customisable and cost-effective platform for managing the delivery of WHS materials and training to site-based trade employees. AGWA asked Nicki Reeves, Human Resources Manager, to tell us a little more about this winning entry.

What was your entry for the 2024 AGWA Safety Awards? Our entry focused on the introduction of the ‘Connecteam’ App as a means of sharing safety documents, alerts, reporting, and training to our staff. With our most vulnerable staff generally working offsite, we looked for a way to deliver customised safety information to them in real time, with resources at their fingertips.

How did you come up with your safety idea? Did something happen that prompted you to change your safety procedures?

We were concerned that some of our trade staff were not engaging with safety materials in a timely manner. When discussing WHS issues, we had noticed an increasing number of ‘I didn’t know that’ type conversations, despite the information being provided. It was difficult for our office staff to monitor engagement with emails, printed materials and signage and we felt that our WHS resources were not effectively reaching staff most at risk of workplace injury ― our site-based glazing team. We began searching for an app-based solution that could be customised to our needs and we found ‘Connecteam’. It contained the basic features that we needed but was very customisable and the data that showed the engagement with each resource by each staff member, allowed for follow up if required.

Can you please talk us through the steps you undertook to implement the change and the timing? How do you now ensure that this new procedure/change is being followed?

After taking advantage of a 30-day free trial, we identified features in the App that could be customised for safety materials. We then revisited all our current safety

processes and identified and planned how they could be digitised, and approximately 2 months later we had fully adapted, customised and digitised all our safety resources and processes.

We wanted to have a full platform before launching the App, so it was important to have everything fit for purpose before the launch. A week before going live, we began promoting the App to staff with posters and emails, and links to the website featuring quick clips of the App’s features.

We then sent an invitation email to all staff which, once clicked on, gave them full access to their customised account on the App. We had already prepared several training courses, walking staff through the features that they would be using, and we were diligent in following up anyone who hadn’t yet gone through the full training process by the end of the first week.

Was your staff engaged from the outset? Please share some examples of how you got them on board. Our staff were very enthusiastic in accepting their invitation and exploring the App. Each day in the first week we sent them a new alert about a major feature of the App with some tips, advice and links to training materials.

Within the first week, we were able to see the resources that they had engaged with in our control panel, and were impressed with how the team had embraced the new platform. Almost from the first day, checklists, reporting forms and feedback posts began flooding through to our administrator for actioning. Instant messaging and staff alerts were embraced and engaged with, and training courses were completed. A huge improvement in communication between the office and site-based staff was evident almost immediately.

Have you seen a change since implementing your safety idea? Productivity? Safety culture? Other?

‘Connecteam’ has completely revolutionised the way we deliver WHS materials and training. The App has given our staff the resources they need to work safely at their

fingertips. The greatest improvement has been the timeliness of interaction with resources. Where previously a safety incident or potential hazard would be reported in a physical form after the staff member returned to the office, they are now able to report an incident or hazard immediately through the App, adding photos, videos and map locations to their report.

We’ve also been able to make our training and alert materials more interactive, incorporating multimedia resources including YouTube clips, infographics, quizzes and surveys, which has resonated with our staff and resulted in far greater engagement. Importantly, we are also able to see who has engaged with the resources and when they accessed it, providing peace of mind that staff is informed on safety matters. The App also allows for follow up of those who may be slow on the uptake.

What advice would you give your colleagues in the industry about making changes to the safety culture on their own workplaces?

Always look for new and innovative ways to deliver safety materials and training to your staff. There are some great platforms out there that can be customised to your own specific needs. Identify the shortfalls, and search for a platform that can be customised to deliver what you need in a more effective manner.

AGWA hopes that this award-winning entry has given you some ideas about how you can make safety in your workplace an everyday thing rather than a tick box on a form. We are committed to helping our industry improve its safety culture. If you have implemented something in your workplace that has improved safety and would like to share it with other members, please email training@agwa.com.au and we will happily share it on our safety platform and socials.

Congratulations to our finalists on their outstanding entries.

The Viridian Glass Health, Safety, and Wellbeing App was created to actively engage employees with an innovative tool offering convenient access to health and wellbeing resources, Viridian’s Workplace Safety System and safety news updates. Since its introduction, there has been significant engagement from employees and an increase in hazard and incident reports.

Having worked at TAFE for several years, Head Teacher (Glazing) Mike Hidderley noticed that they had to lift and move glass panels from an outdoor yard area inside for use, across uneven paving. The safety team purchased 8 glass A-frame racks requiring minimal manual handling because they can be moved with a forklift, leading to a significant reduction in the number of reported injuries.

‘I would also like to take the necessary steps to become a Master Glazier, to show people that I do care about quality and that the job has be done to the best standards available. Also, the title of Master Glazier sounds pretty cool!’

Zack studied at Holmesglen TAFE and is employed by Clark Glass. Zack states, ‘from my experience so far in the glazing industry, I am yet to find something that I find boring. I have a passion for intricate jobs’.

Lucas studied at TasTAFE and completed his apprenticeship at Glass Supplies in Launceston. Lucas says, ‘a very satisfying aspect of glazing is when ... you can stand back and see the difference it has made and how it all fits together’.

Representing WA, Caleb entered the 2024 Apprentice Awards competition in the Residential category. He studied at North Metropolitan TAFE and is employed by Cullen & Co Glass in Balcatta, where he is somewhere new and doing something different every day.

He always enjoyed working with his hands, learning new skills, undertaking challenges and overcoming them, so glazing was the ideal career for him. He gets immense satisfaction from showing up to a house with old windows and doors and leaving that afternoon, having removed the old and installed the new. In Caleb’s own words, ‘stepping back and seeing what I’ve accomplished, it truly is a great feeling seeing hard work pay off … that feeling of pride’.

Caleb’s career goal is to continue to grow and learn new skills and make himself a better tradesman, hopefully with his own business in 10 years.

Lochie studied with Gimbal Training and is employed by CHGA Windows and Doors in Caloundra. In Lochie’s own words, ‘there’s always something new to learn and being part of the glass industry is truly enjoyable’.

Johnson studied at TAFE NSW and works with GBI Contracting at Prestons. Johnson says, ‘I like to take a step back and look at what I did, especially when the task was big and daunting … when it’s all installed, level and plumb … that really keeps me going with every other job’.

2024 saw a record number of apprentices entering the various categories of the Apprentice Awards, making the judging task very difficult this year. AGWA is proud to congratulate all the entrants who have shown a passion for our industry. AGWA is particularly proud of our winners who have shown themselves to be excellent ambassadors for the future of our industry.

Thank you to our judges for all their dedication and hard work: Paul Land, Peter den Boer, Mark Nicholls and Adrian Grocott.

Thank you also to all the RTOs and employers who supported their entries.

Kyle McIntyre (QLD)

Gimbal Training, CHGA Windows and Doors

Brock Portelli (NSW)

TAFE NSW, Taylors Aluminium

Lachlan Clee (VIC)

Holmesglen TAFE, O’Brien Glass

Nathan Dinning (TAS)

TasTAFE, City Glass Tasmania

Mia Peace (TAS)

TasTAFE, Woodhouse Glass and Glazing

Sam Kovacic (SA)

TAFE SA, Construction Glazing

Lee Skewes (WA)

North Metro TAFE, Shelford Constructions

Riva Rann (WA)

North Metro TAFE, Glass Co WA

Glass Processor Award

Tyron Hill (QLD)

TAFE QLD, G.James Glass and Aluminium

Samuel Blackman (QLD)

TAFE QLD, G.James Glass and Aluminium

Cooper Harley (NSW)

TAFE NSW, A1 Glass and Showers

Kobyn Dewis (TAS) TasTAFE, GP Glass

Nathan Bruhn (SA)

TAFE SA, Barossa Glass

Phillip Sutton (WA)

North Metro TAFE, Glass Co Metro

Anthony Tandy (QLD)

TAFE QLD, G.James Glass and Aluminium

Jack Holt ( VIC )

Holmesglen TAFE, Waynes High Access

Shaun Avent (TAS)

TasTAFE, Cityline WIndows and Doors

Connor Smith (WA)

North Metro TAFE, Jason Windows

Thanks to our program Sponsors.

Designed with a consistent aesthetic to provide a modern, whole of house solution, Forge has an answer for every application.

With Austral Lock it’s secure, with Forge it’s a family.

BuiltView Magazine is a quarterly publication of the Australian Glass & Window Association.

EDITORS

Melissa Baker

Ingrid Pagura

SUB EDITOR

Helen Dawes

DESIGN

Webqem Pty Ltd

Sehar Maniar, AGWA

EDITORIAL & ADVERTISING ENQUIRIES

Helen Dawes

+61 2 9498 2768 marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208

Suite 101B, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073 +61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

COVER IMAGE & CONTENTS PAGE IMAGES

2024 National Design Award winner, Euroglass Australia Total Fusion Wellness Centre, Newstead, QLD

Architect: ACME and Cavcorp jointly

Builder: Torre Developments, Jaron Schubert

Photographer: Greg Sullavan, Sunburst Studio

CONTRIBUTORS

Clinton Skeoch, Tom Devitt, Rafaella Kavouras, Mike Ward, Nayan Das, Ben Webster, Ingrid Pagura, Tim Johnston, Kellie Moore, Nicki Reeves, Elizabeth Dimabuyu, Lido Russo, Mari Lehtinen, Samara Davis, Lousie Stewart, Roger Bishop, Vivienne Munter, Helen Dawes, Melissa Baker, Kerrie Henderson, Tyler Gonzales and Dominique Macartney.

PRINTED BY

SOUTHERN IMPACT southernimpact.com.au

Our printer conforms to the ISO-14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY

D & D MAILING SERVICES

www.ddmail.com.au BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2024. All rights reserved. Reproduction in whole or part without written permission from AWA-AGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary, seek professional advice.

Clinton Skeoch

Executive Director and CEO AGWA

As we approach the end of another remarkable year, I am proud to reflect on the incredible achievements and milestones we have reached together as an industry.

As always, this edition of our magazine showcases the very best of what we stand for, with the spotlight on the 2024 National Industry Design, Innovation and Service Awards winners. These Awards as always are a testament to the creativity, excellence, and commitment to innovation found so often in our member businesses. They highlight the inspiring efforts of our members, who continue to set new benchmarks for quality and service in all facets of the glass and window industry.

Throughout the year, we have focused on raising standards across the board, ensuring that our industry is built on solid foundations. As members interested in compliance and a level playing field, I encourage you to read the article, ‘Bigger is Not Always Better’ on p 56 of this edition. Our Association and Board play an active role in ensuring that all members know what is required and then do it. While at times this requires education and support, we are also not afraid to remove members who refuse to live up to our Code of Conduct and expectations for compliant work.

Finally, as the year comes to an end, it is hard to not continue to highlight the work being done to maintain the current NCC 2022 energy-efficiency requirements, (yes, I thought it was done and dusted as well), with the Federal Opposition’s recent announcement to halt further changes to the NCC for the next decade and review elements of NCC 2022. We have been work hard trying to argue for their retention. A key component of this work has been our 7-Star Costing Report. This Report has been instrumental in our public relation’s campaign to combat the misinformation surrounding the true costs of NCC 2022 energy compliance. Through focused advocacy and clear communication, we will continue to champion the long-term benefits of these energy standards for both consumers and our industry.

As we close out the year, I want to extend my heartfelt thanks to each of you for your hard work, dedication, and passion. Together, we are shaping a stronger, more sustainable future.

I would also like to take this opportunity to wish you all Happy Holidays and a Happy and Prosperous 2025 on behalf of the AGWA team.

Clinton

Executive Director and CEO

Ingrid began her role with AGWA in May 2021 looking after the training needs of members. Her role soon progressed to include working on BuiltView, safety, the AGWA Design Awards, the website and other marketing-related activities.

Prior to AGWA, Ingrid worked for a legal publishing company as an editor, a publishing manager and then an editorial trainer. Her time at Butterworths saw her work on their building and local government and environment suite of products and with the CSIRO and ABCB on other BCA projects. She also previously worked for many years as a part time teacher at TAFE teaching law, business, communications and work health and safety across multiple faculties.

Nayan has a background in Structural Engineering and is an AFRC Accredited Simulator.

He is currently responsible for overseeing product compliance, engineering, and testing at Dowell. He is passionate about bringing positive and sustainable changes to the fenestration industry. He is also actively involved on several technical committees and working groups organised by AGWA, further demonstrating his commitment to the industry. Prior to joining Dowell, Nayan gained invaluable experience working in various roles for the NSW Government and AGWA.

Melissa has worked in the training industry for more than 20 years, most recently in the VET sector at TAFE NSW. She has a wide range of training and management experience across a variety of sectors, including in a head teacher capacity.

Joining AGWA in 2019, Melissa works with our industry subject matter experts to develop new and improved resources for our members. This has included training courses, both On Demand and Instructor Led, safety resources, the AGWA website, Events and AusFenEx25. Melissa is also the co-editor of BuiltView Magazine.

Tom joined HIA as an Economist in 2018. As Senior Economist, he assists in the research and analysis of housing market trends and manages the assumptions and statistical modelling behind HIA’s residential building forecasts. He has also authored many of HIA’s wide range of economics publications. This provides him with the insight and expertise to advocate to all levels of government and media on behalf of the housing industry, for the purpose of informing policy debate. He has provided advice to both the private and public sectors across a range of areas.

Clinton has more than 20 years’ experience across building products, research and development and member services’ industries and with roles covering areas as diverse as supply chain management, sales, marketing, export market development, strategic management and planning, research and development, and industry advocacy. He is known for his passionate collaborative style when it comes to working with industry stakeholder groups and aligned partners. He is also the Chair of the Australian Fenestration Rating Council.

Tim joined AGWA in July 2023. With a degree in Architecture from the University of New South Wales, as well as postgraduate qualifications in environmental management and economics, Tim has more than 25 years’ experience working in the built and natural environment, not for profit industry associations, private and government sectors.

Tom Devitt Senior Economist, AGWA

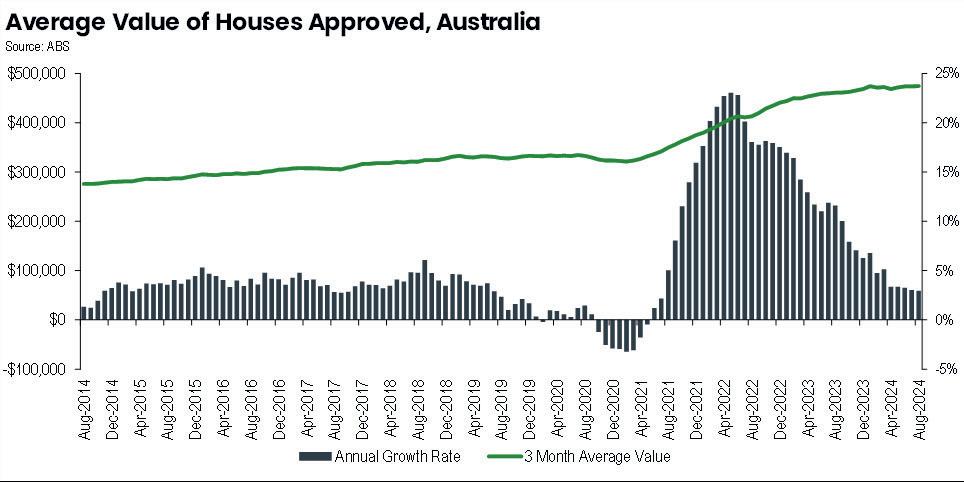

Recent building approvals data from the ABS confirm the improving outlook for home building across Australia, especially outside the largest markets.

While land costs and government impositions in Sydney and Melbourne are constraining these markets, more affordable capitals and regions have seen approvals numbers improve. Western Australia is leading the charge, with new house approvals in this state up by almost 50% on a year earlier.

This improvement reflects the slow return of confidence to the market. The Reserve Bank hasn’t increased interest rates since November 2023. Even in the absence of any cuts to the cash rate in the near term, underlying demand for housing continues to be supported by strong population growth, tight labour markets and acute shortages of rental accommodation.

As is typical, investors are able to see these macro-dynamics supporting longer term growth in demand and are leading the return to the market.

The other positive recent development helping to bring back confidence to the market has been a normalising of building costs. The cost of home building materials surged early in the pandemic, increasing by almost 30% in just 2 years. Some materials, like terracotta tiles and certain timber, steel and electrical products, saw 60%-70% increases on pre-pandemic levels. Since 2022, however, home building material costs have, on average, returned to pre-pandemic rates of increase, even slower in recent quarters.

Labour pressures have been more sustained. As at the middle of 2024, the price of skilled trades was up by a third since before the

pandemic. Just in the last year, trades prices increased by 5.5%, still almost 3 times the pre-pandemic rate.

The positive news is that recent ABS building approvals data suggests these costs may be normalising too. The average value of a newly-approved house in Australia increased by less than 3.0% in the year to August 2024, which is the smallest increase since the late-2021 Delta lockdowns and entirely consistent with the prepandemic decade average of 3.1%. In fact, the last 6 months are only up by an annualised 1.5%!

There could be several factors behind this trend. The recent ‘shrinkflation’ phenomenon has seen home buyers wind back some of their demands in terms of housing amenities, appliances, even settling for fewer bedrooms and bathrooms. Builders could also be sharpening their pencils and offering discounts to get new buyers across the line.

Home building is still facing ongoing uncertainties from the public policy space, including new taxes on the industry, the rate and magnitude of changes to the National Construction Code, and competition for labour and resources from public infrastructure projects. The elevated level of government expenditure will put upward pressure on employment and inflation, leaving interest rates structurally higher over the decade ahead, even in the face of weakening conditions for households and private sector businesses. All these factors threaten to constrain future home building volumes.

The return of confidence to the market and the broader normalisation of costs are, nonetheless, very welcome developments following the difficulties the industry has now faced for almost half a decade.

Tim Johnston Head of Policy and Advocacy, AGWA

AGWA has been working to increase the role and prominence of trade licensing around the country, notably by consulting with and providing meaningful feedback on changes to the Building Commission NSW (Commission). This includes consolidating building legislation into a single framework, removing regulatory duplication, modernising legislation and making it easier to understand as well as ensuring regulatory oversight of emerging trends.

The latest round of engagement centred on 3 Bills: Building Bill 2024 (NSW); Building Compliance and Enforcement Bill 2024 (NSW); and Building Insurance Bill 2024 (NSW).

As outlined in our recent Member Forum, the Building Ministers requested the Australian Building Codes Board (ABCB) to develop and design a new risk-based Building Product Registration Scheme (BPRS) for all building products. In early September, the ABCB released a Discussion Paper, along with regulatory options and a cost benefit analysis, seeking feedback on the proposed initial principles and scope of the Scheme for review and consideration by the Building Ministers in late 2024.

The consultation clearly outlined that Australia has seen significant problems caused by building products that do not conform or comply with the NCC and also that building product information in Australia is often inadequate.

As outlined in our member information sessions, the key themes for AGWA members include:

• ongoing competency assessments throughout a tradesperson’s career and for ongoing trade CPD;

• co-regulation model for trades;

• expansion of the glazing licence to all trade work (not just residential);

• clarification of who can and who can’t contract for glazing trade work; and

• the supervision requirements for nontrade certified employees.

Of particular interest to AGWA and its members is the proposed competency assessment and co-regulation model. This change could see industry bodies responsible for trade licensing assessments and significant changes proposed to the licensing framework. This would add an additional step in the licensing assessment process, strengthening the Commission’s confidence in licensing decisions and improving regulatory oversight of the industry.

Consumer protections for home building work were also in focus. This proposed change aims to ensure consumers are empowered to make informed decisions and that the rights and obligations of consumers and builders are clear and enforceable. The proposal included maintaining the existing monetary

The proposed national Scheme outlines a desire to improve confidence in building products and reduce unacceptable risks to Australians’ life and wellbeing, anchored by 3 key reforms:

1. product labelling, traceability and information;

2. national designated building product register; and

3. enhanced accountability for product suppliers.

Under the proposed Scheme, all building products would be required to have minimum information in a standardised format, including evidence that the product conforms to the NCC. Building products would be traceable through labelling, and high-risk products (including glass) being required to be on a national product register.

Thematically, AGWA supported improved building product traceability and conformity assurance and believes that existing Regulations should be enforced as a first step. Nonetheless, AGWA considers this is an important national discussion for the construction and building products

thresholds for major work contracts ($20,000) and minor work contracts ($5,000) and no contract (below $5,000). There are also proposals relating to progress payments, contract variations, preliminary service agreements, statutory warranties, incidental work, and dispute resolution.

Other proposed changes include the development of NSW Chain of Responsibility legislation, requiring all parties in the design, selection, supply and installation of building products to ensure they are compliant, leading to major improvement in accountability within the sector. A clearer definition of ‘prefabricated’ and ‘manufactured building’ is also proposed, allowing the Commission to improve building quality and provide better protection for homeowners and building owners.

These changes are, overall, positive for our industry and construction in general, and we hope they form the basis of potential licencing reforms in other states. While AGWA has submitted its response to the consultation, we are keen to receive your thoughts on this ongoing consultation. We will keep members informed and have a full briefing once the final framework is presented. In the meantime, for further information, please contact tim.johnston@agwa.com.au.

sectors, seeking to be involved in ongoing consultation and reform.

While supportive in principle, AGWA’s response focused on 7 key areas:

• the significant under-estimation of the size, scale and complexity of industry, and its product range;

• non-compliant and non-conforming products and outcomes and how site factors effect compliance;

• further clarification of the definition of ‘product’ and how risk is to be measured and managed;

• jurisdictional harmonisation and adoption certainty;

• the integration of the proposed Scheme with existing product information frameworks, certifications and reporting;

• scheme inter-operability; and

• and how to address additional conformity requirements.

While the engagement on this important issue is more complex than can be fully covered here, if AGWA members would like further information, do not hesitate to tim.johnston@agwa.com.au.

AGWA is excited to announce the release of the next 3 videos in its Safety Series.

The videos, produced in conjunction with SafeWork NSW and our member Dragon Glass, cover the following topics:

• Safe Manual Lifting and Moving of Glass, including lift preparation and PPE

• Assessing glass shape, weight and balance

• Manual Handing Fundamentals ― manual lifting, carrying, pushing and pulling and moving glass as a one person and 2-person lift.

These videos are made specifically for the glass and window industry and are available now on the AGWA website. They are designed for you to download and use in your workplace safety training and toolbox talks either as 1 video or as 3 separate ones.

For more information on the safety videos and other safety resources, please contact training@agwa.com.au.

The videos are also available on the SafeWork NSW website www.safework.nsw.gov.au.

We are seeking a Southern-based Product Trainer to join the supportive Licensee team. This is a diverse and challenging position, and you must be prepared to travel from time to time.

Your role will be responsible for the Product Training of our Licensed Fabricator network within the Southern Region of Australia. You will be required to prepare and present training on tooling, processing and manufacturing of the Bradnam’s product range.

Training will be provided to ensure that the successful candidate is prepared with the full resources of Bradnam’s product knowledge, fabrication and assembly ‘know how’ required for success in the role.

The position also consists of providing ongoing product & technical support for our customers as the need arises. This may include, but not limited to:

• Tooling Advice & Rectification

• Hardware Assembly & Use

• Fabrication Assistance

• Glazing Methods

• Factory Process Improvements

• Site Maintenance

Knowledge of industry window & door systems would be mandatory. The ability to communicate well and train effectively are vital for this role.

You will be an enthusiastic and highly customer focused person, proud of your ability to establish and maintain strong relationships. The ability to work autonomously, think outside the box and be a problem solver will also be highly regarded.

The Bradnam’s Licensee Team is continually growing and performing exceptionally! Opportunities for personal growth and development into a future Licensee Management role is available for the right person… Could this be you?

Salary is negotiable and a company vehicle will be supplied.

If you believe you meet these criteria please send a current resume and covering letter to Justin.medwin@bradnams.com.au

On the 12 September 2024, the best apprentice glazier selected from each state met at Holmesglen TAFE in Victoria to compete for the highly regarded title of AGWA National Apprentice of the Year. Lochie Turner (QLD), Caleb Gray (WA), Johnson Huynh (NSW), Lucas Brockman (TAS) and Zackary Bernardo (VIC) all fought hard, with Caleb from WA coming out with the title of National Apprentice of the Year 2024.

Apprentices are nominated by their RTOs and employers, and then must submit a portfolio of their work, as well as being interviewed by our Apprentice Interview Panel to determine the top apprentice in each state. The 5 finalists represented their states at the AGWA National Apprentice Competition and were put through a 7-hour Capstone Assessment, consisting of 7 tasks: IGU assembly, glass

cutting to a template, edge work, window hack out and reglaze, fan holes, silicone work and a commercial door reglaze as well as a theory assessment.

The apprentices, their employers and trainers then spent the day in Melbourne on Friday with a tour of the Oceania Glass Float Line and the Capral Aluminium Extrusion plant and testing laboratory before attending the National Gala Awards Dinner at Crown Melbourne.

Congratulations to all the finalists, and particularly Caleb, on all the hard work. A big thank you to our major sponsor Express Glass and materials and tools sponsors Alspec and NFK.

Catherine McAuley Catholic College in Medowie is the newest secondary school in the Newcastle (NSW) region, opening its doors to students in 2021. The College’s construction spanned 5 stages, with the most recent stage completed in 2023. PCW Commercial Windows was proud to be the selected supplier of commercial glazing solutions for all stages of the project, demonstrating its expertise in managing the complexities of modern educational architecture.

The project’s tight schedules and varied energy, acoustic and structural requirements demanded precision and careful coordination. PCW’s ability to provide value engineering throughout the project ensured that the client’s exacting standards were met while adhering to budget constraints.

PCW supplied and installed commercial windows, doors and security screens across all stages of the College’s construction. The fifth and latest stage involved 5 key buildings: A (Extension), E, F, G and H. Each building posed unique challenges, from varying energy and acoustic requirements to complex structural demands. The tight project timelines added further pressure, requiring meticulous design, documentation and management.

PCW’s success in navigating these challenges earned them the trust of clients, architects and builders. The company’s commitment to design and manufacturing excellence, coupled with effective value engineering solutions, ensured that the project was completed to a high standard, within budget and in full compliance with the client’s specifications.

PCW’s efficient local fabrication and transport processes were integral to the timely completion of the project. Products were fabricated at PCW’s Somersby factory and carefully transported to the site, with the team constantly monitoring timelines to anticipate and mitigate potential delays.

The windows were manufactured using Capral AGS Commercial systems, including the 400, 419-100 Flushline, 950, and 225 Series, chosen for their compliance with rigorous testing, technical support, and sustainability features such as LocAl® Green aluminium. Amplimesh® screens were installed for enhanced security, ensuring the safety of the school environment.

The complexity of the project, with window frames exceeding 6 m in height, required meticulous design and documentation, including steel, precast and shop drawings. This thorough documentation enabled early manufacturing, reducing lead times and pre-empting price increases. Stringent pre-manufacture inspections minimised defects, while careful transport protection was able to maintain frame integrity. Onsite, regular toolbox talks ensured personnel safety amid changing conditions. PCW’s integrated approach, from fabrication to site management, ensured the project was completed on time, meeting all quality and safety standards.

The project’s technical demands were significant, with each window having to meet specific energy, acoustic, and structural requirements. This complexity was compounded by the variety of building types within the project, including both single and doublestorey structures, and the use of internal and external window frames, subheads, subsills, and angle trimmings.

For Building A, PCW utilised Capral’s 419-100 Flushline, 400, 950, and 225 Series systems, all finished in Dulux Duratec Zeus Matt Black. The frames, some of which were over 6200 mm tall, were bracketed back to the steelwork to ensure structural integrity. The glazing solutions included 10.38 mm translucent, 12.38 mm clear laminated, 6.38 mm clear laminated glass, and 6 mm toughened louvres, complemented by Breezway® power louvres. Amplimesh® screens were installed for added security.

Building E required a combination of Capral’s 400 and 225 Series, along with 619 Flushline Acoustic Framing, all finished in the same durable Dulux Duratec Zeus Matt Black. The acoustic demands were met with DGU glass, 10.5 mm hush glass and 6.38 mm clear laminated glass. Breezway® power louvres and manual louvres were integrated into the design, with Amplimesh® screens providing security.

Buildings F and G featured similar configurations with Capral’s 400, 225, and EN4023 Series systems. The use of DGU glass, 10.5 mm hush glass, 6.38 mm translucent and clear laminated glass ensured the buildings met both acoustic and energy-efficiency standards. Breezway® power and manual louvres were again utilised, and the structures were secured with Amplimesh® screens.

For Building H, Capral’s 400 and 225 Series systems were used, along with DGU glass, 10.5 mm hush glass, 6.38 mm translucent glass and clear laminated glass. Breezway® power and manual

louvres enhanced the building’s ventilation and Amplimesh® screens ensured security.

PCW conducted stringent inspections and testing procedures throughout the project to ensure compliance with Australian Standards. This included meticulous documentation of Inspection and Test Plans (ITPs) for all products installed, ensuring that each component met the project’s specific requirements.

Catherine McAuley Catholic College in Medowie is a shining example of how careful planning, precise execution and innovative solutions can create a state-of-the-art educational facility. PCW’s involvement in this project, utilising Capral’s advanced aluminium systems and its own rigorous quality control processes, ensured that each stage was completed to the highest standards.

The success of this project highlights PCW’s capability to manage complex, large-scale projects, from initial design through to final installation. PCW’s ability to meet the diverse energy, acoustic, and structural requirements, while staying within budget and on schedule, has established PCW as a trusted partner in constructing high-quality educational facilities.

For more information on this project or products used, please contact Kellie Moore, Capral Corporate Marketing Communications Manager at kellie.moore@capral.com.au.

I remember being offered some words of wisdom when I was younger that went along the lines of ‘the bigger they are, the harder they fall’. Being 6 foot 6, these words resonated with me more frequently than I care to remember on the rugby field and left a lasting legacy of being very wary of small, determined halfbacks.

While in a slightly different context, these words have resonated with me more and more lately as the AGWA team is seeing bigger and bigger windows installed on jobs that are non-conforming, non-compliant and, increasingly, where windows are failing under wind load.

While our member audit reviews show high levels of compliant, tested systems and product manufacture, at the same time we are seeing a growing trend of large-span windows driven by customer, architect and builder requirements.

Understanding AS 2047 and its importance

AS 2047 is the mandatory Standard for windows and doors in Australia, specifying the testing protocols for a variety of performance attributes. It encompasses air infiltration, water penetration, structural integrity, and deflection under load, ensuring that windows can withstand Australia’s diverse climate conditions.

The trend to bigger windows

The current trend among homeowners, particularly in renovation projects, and second and third home builds, is to incorporate large, expansive windows offering stunning views and enhancing the aesthetic appeal of the home. The allure

of large windows in a home is easy to understand. These windows provide more natural light, create a seamless connection between indoor and outdoor spaces, and make rooms appear larger and more open.

Luxury homes and architectural magazines feature such designs prominently, setting trends that many homeowners wish to follow. However, these high-end homes often have the resources to invest in engineering, materials, and precise installation techniques that ensure compliance with AS 2047. In contrast, many renovation projects do not take these steps, either due to budget constraints or a lack of understanding about the compliance requirements.

Builders and contractors face pressure to meet the aesthetic demands of homeowners. In the pursuit of creating luxurious spaces with wide, uninterrupted views, many homeowners, designers, and even builders, are not considering (or overlooking) the critical role that proper product selection, design and installation plays in meeting compliance expectations and ensuring human safety and property protection.

Large-span windows have a unique set of challenges making them more susceptible to non-compliance. These windows are typically heavier, more prone to deflection, and more difficult to seal properly against weather conditions. Wind loads, for instance, increase significantly with larger window spans, making the correct structural support crucial. Water

penetration, operating force and air infiltration can also become greater issues if the frames, seals, and glass units are not selected, fabricated, and installed with precise care and attention to the product’s tested size allowances.

While there are provisions that allow for extrapolation of windows from their test report, we are finding, with increasing regularity, that these rules are not well understood. This lack of understanding can sometimes lead to a false sense of confidence, as the windows may initially appear functional despite being noncompliant with AS 2047 and ultimately breach the NCC. This non-conformance will, in many cases, lead to poor outcomes, including the potential for catastrophic structural failure in extreme weather conditions.

In an average year, AGWA undertakes around 140 non-compliance investigations, as well as over 500 member audits. Some of the stand-out issues we found, across at least 5 different states, in the last few years have been:

• A 5-panel stacking door 2.8 m high x 16 m wide. Investigations showed that while there were test reports available for the door system, the product on-site was well outside its design limitations at around 200% what was tested.

• A commercial shopfront in a cyclonic region that was not manufactured to the technical literature (span-load tables) and nearly 6 m high, which was about 70% of the design strength required.

• A large window wall in a Sydney residence which was over height, and outside design limitations. This window was showing signs of decoupling and is, even at the time of writing this article, at high risk of imminent failure.

• A 3 m high sliding door, in a newly constructed house, with 6.8 m2 panels fitted with IGUs which were 5 mm toughened glass (well outside limitations in Table 5.1).

• A 180-degree silicone butt-jointed window facing the Southern Ocean that spanned 2.4 m with no fins or mechanical support in a high windload situation.

• Several large curtain wall and shop front installations that have failed under wind load, with more than one actually having blown out of the building.

While it is AGWA’s wish that noncompliance and non-conformance did not occur, it is sadly alive and well, often driven by a lack of knowledge and understanding rather than deliberate non-compliance. While I wish I had a dollar for every time I heard the response ‘the software let me do it’, this doesn’t fix the situation and is not an excuse for noncompliance.

In each instance where concerns have been raised, we have engaged and sought to make all parties aware of the issues of concern and worked with them to validate compliance. Where a member has made a window that is not supported by Standards, testing or engineering, we have worked with them to find a compliant outcome.

While in the majority of the time, this is resolved by working with the member to support the delivery of a compliant outcome, this has not always the case. Despite the best endeavours of the Technical and Accreditation teams, occasionally the business is unable or unwilling to correct the issue as expected by our Member Code of Conduct.

So far this year, we have had a couple of projects, where bigger was not better, let alone conforming. Despite following due process and providing support to the member over a considerable period of time, they were unable to demonstrate compliance or rectify the product compliance issues to the satisfaction of the AGWA Board. This led to them having had their Association membership terminated and referrals, where appropriate, made with the relevant authorities.

Similarly, our investigations often involve products supplied by non-member companies. In these cases, our approach has been a little less forgiving, with several projects referred to the appropriate Regulator and in, at least a few cases, leading to company closure and/or bankruptcy.

While AGWA is doing its part, ultimately, we need industry participants to have a greater awareness and understanding of compliance. All parties involved in the building process need to understand that the Standards, and system testing limitations, are in place to ensure the structural integrity of our buildings and to protect the public. They must be complied with, no ifs, buts or maybes.

Despite many industry participants articulating how long they have been glazing or making windows, the awareness of system and fabrication limitations is not well understood in some cases by business owners, but increasingly more so by their staff.

If you or your staff members are unsure or unclear of what limitations apply to windows, I would encourage you to sign up for some of our training as soon as possible.

At a minimum please:

• Only use windows that have a AS 2047 compliant test report and make the windows within the limitations of the testing.

• Seek advice from appropriately qualified engineers, or the system supplier, before agreeing to supply over-sized products.

• If a larger window is required either request or undertake further testing or understand that in line with AS 2047, you can extrapolate the size of the window by no more than 10 % in height or width or up to 15 % in total area (this applies equally to sashes and door panels within the window assembly).

• Naturally, ensure that all glazing complies with AS 1288 regardless of size.

AGWA stands for a level playing field and compliance and expects all members to support this. If you are aware of projects of concern, please reach out to the technical team to raise your concerns.

Nestled among the peaceful Nattai National Park, the Woodlands House is a sublime dwelling where architectural ingenuity, environmental responsibility and the serenity of nature converge to celebrate the gentle juxtaposition of past and present.

Conceived by AO Design Studio as a spacious, light-filled retreat for a family transitioning from the bustling, sun-soaked beach-side Bondi, this modern home embodies the occupants’ newfound love for Southern Highlands.

Building on the heritage of the 1970s brick homestead, the architect created an enduring home that seamlessly fused the existing structure with a contemporary addition. This was achieved through a harmonious interplay of simple forms and refined lines that maximised the beautiful northern outlook and established an unimposing dialogue with its surroundings.

Tony O’Meara, the architect behind the project, was committed to a sustainable approach that favoured transformation over demolition. ‘There was so much embodied energy in the existing house’, Tony explains. ‘To just knock it down and build something new wouldn’t be a very sustainable way to build. It’s so much better to work with what’s already there, and really transform how the house performs.’

Additionally, the design needed to embrace the surrounding landscape, while ensuring the clients, accustomed to a milder climate, would remain comfortable throughout the colder highland winters. The site’s location in a high bushfire risk area also posed a challenge, necessitating the careful selection of materials to ensure the safety and resilience of the home.

Tony’s solution was a masterpiece of passive solar design. A thoughtfully angled skillion roof, with carefully placed overhangs and blade walls, maximised winter sun exposure while mitigating the summer heat. ‘The winter sun actually comes about 7 m into the space and almost hits the back wall’, explains Tony, ‘so, it’s hitting the entire slab, heating it up through the day, and then that just radiates throughout the evening.’

To amplify this design, AWS Series 424 Double Glazed CentreGLAZE™ Fixed Highlights, were incorporated throughout. AWS’s high-performance products not only helped flood the interior with natural light, but also played a crucial role in maintaining the home’s thermal comfort.

In addition, the striking Vantage Series 618 MAGNUM™ Sliding Doors offered an uninterrupted 180-degree view from the open plan living, dining and kitchen, providing a smooth transition between indoor and outdoor spaces. Used in place of a window, the expansive doors not only framed the awe-inspiring views, but also offered the flexibility to use the concrete plinth, from the fireplace, as overflow seating and an extra side table in the dining space, as well as extra terrace seating when open.

Throughout the home, the flush thresholds of AWS windows and doors, combined with their innovative FlowTHRU™ draining system, ensured a seamless flow between spaces, while the consistent double glazing contributed to the overall energy efficiency of the dwelling. ‘It was a core part of the design and material palette’, Tony explains, ’plus we knew they’re Australian designed and manufactured and built to stand the test of time.’

Tony adds that AWS’s specification portal was invaluable, too. ‘It provided detailed drawings that allowed us to refine every element’, he says. ‘In a house like this, where the sizes and sections were so critical, consistency was key. It was reassuring to see that across AWS’s different ranges.’ Importantly, the AWS range has been designed and tested to meet stringent Australian Standards for bushfire resistance, adding the much-needed layer of safety to the home’s design.

The result is a dwelling that not only captivates with its striking, simple aesthetic but also delivered on its promise of sustainability and comfort. ‘The clients loved the house’, Tony enthuses. ‘They were amazed by how warm it was in winter without needing artificial heating ― the house simply performs.’

The Woodlands House stands as an embodiment of thoughtful design that respects the site and environmental impact, while meeting the needs of its occupants and yielding an authentic aesthetic that harmonises with the surrounding landscape. By embracing the existing structure, harnessing the power of passive solar design and opting for high-performing, enduring building materials and products, AO Design Studio has created a modern family home, that not only respects the plot’s past, but is bound to enhance the lives of its occupants well into the future.

For more information on this project or products used, please contact AWS Marketing on marketing@awsaustralia.com.au.

ARCHITECTURE AND DESIGN: AO Design Studio

BUILDER: Burlace Construction (Main House) + Quay3 Constructions (Pool Pavilion)

AWS fabricator: Millennium Windows and Doors

PHOTOGRAPHER: AO Design Studio + AJ Moran

PRODUCT: Elevate Series 424 Double Glazed CentreGLAZE™ Fixed Highlights and Vantage Series 618 MAGNUM™ Sliding Doors

Forty years ago, two families started what would eventually become the Australian Glass Group (AGG). Moen Glass was founded in 1984 by Gary and Mona Moen in Melbourne, operating as a small, suburban glazing business. From their home in Glen Iris, they handled residential glazing projects, with Gary often arranging after-hours deliveries of materials. By 1989, Moen Glass invested in a LiSEC double glazing line, marking the beginning of a long affiliation with double glazing technology.

Meanwhile, in Sydney, Dennis and Lesley Loudoun purchased Bevelite Glass, a small lead lighting business, in the same year. With just one polisher and a hand bevelling wheel, they built their business through hard work, despite Dennis having suffered a career-altering injury. Both families nurtured their businesses, growing steadily and embracing challenges with a passion for quality craftsmanship and a strong commitment to family values.

In 2008, the Moen and Loudoun families merged their businesses to form the Australian Glass Group. The merger brought together two industry pioneers with complementary strengths. Moen Glass, with its expertise in double glazing, and Bevelite, known for its quality toughened processing and innovative custom lamination, became one of the most respected glass suppliers in the country. Today, AGG continues to uphold the same family values, innovation, and resilience that have been central to their growth over the last four decades. Moen trucks delivering double glazing

In 1984, two family-owned glass businesses were born - Bevelite Glass in Sydney and Moen Glass in Melbourne. By 2008, these companies merged to create the Australian Glass Group (AGG). Now, in 2024, AGG is celebrating 40 years of passionate involvement in the Australian glass industry.

Both families played pivotal roles in shaping the glass industry in Australia. Dennis Loudoun became a prominent figure, serving as President of the Australian Glass and Glazing Association (AGGA) and advocating for technical training at TAFE institutions. His commitment to the next generation of glass professionals was evident in his involvement in gifting new processing equipment to TAFE campuses to ensure apprentices could develop real-world skills.

Similarly, Vic Moen took on industry leadership, serving on the Victorian Glass Merchants Association (VGMA) committee and the AGGA

Growth often meant outgrowing their facilities. Moen Glass moved from Glen Iris to Boronia, then Montrose, and eventually to Knoxfield. Bevelite Glass followed a similar path, expanding from Seven Hills to Girraween. With each move, both businesses increased capacity, allowing them to serve their customers more efficiently and expand their product offerings.

national board. He was also a key contributor to the creation of the double glazing manufacturing standard AS 4666 and founding member of IGMA. Under his leadership, the annual glass industry awards dinners became a tradition, uniting hundreds of glass professionals from across the state.

This dedication to industry advancement ensured that both Moen Glass and Bevelite stayed at the forefront of innovation. Their early adoption of new technologies, including cutting-edge equipment and IT systems, drove quality improvements and kept their businesses competitive.

The Moen and Loudoun influence continues with Vic Moen (General Manager NSW) and Karen Loudoun (Production Manager NSW) working together in the AGG NSW site. The 3rd generation is coming through as well, with Chelsea Moen, joining AGG in 2022.

In 2024, the Australian Glass Group stands as a leading provider of glass solutions across Australia, offering high-performance products that meet the evolving needs of the market. With facilities in Sydney, Melbourne, and Hobart.

AGG continues to push boundaries in double glazing, energy efficiency, and sustainability. The group’s commitment to quality and innovation remains unwavering, as it invests in state-of-the-art equipment and processes.

AGG’s team of skilled professionals, many of whom have been with the company for decades, embody the family values that underpin the business. Their expertise, combined with AGG’s customer-first approach, ensures the group remains a trusted partner for builders, architects, and homeowners across the country.

The old Bevelite site refocused in 2019 and changed to a sole focus on Insulated Glass Units (IGU). Adding a second furnace and IGU line in 2023, NSW offers the full range of Insulglass® products.

The old Moen Glass site remains a 24 hour IGU processor of the full range of Insulglass® products. The National warehouse for AGG is also located in Melbourne where regular logistics support all three facilities.

A greenfield addition to the group in 2018, AGG TAS offers all product ranges including support to the group with Oversize IGU at 5000mm, custom made AGGLam®, and the full range of Pyroglass® specialised fire rated products.

Insulglass® Insulated Glass Units (IGU) can be either Double Glazed Units (DGU) or Triple Glazed Units (TGU) manufactured as one unit with a trapped air gaps separated by a desiccant filled spacer bar and sealed with a primary and secondary seal for structure and guaranteed performance.

Argon gas filled air space as standard to add further insulation benefits and a comprehensive range of glass options to suit multiple performance needs, including a full range of High Performance Softcoat LowE coated glass options to supercharge your Insulation and cover the full spectrum of Solar Heat Gain levels.

All Insulglass® products are manufactured in Australia by AGG and to AS 4666 –Insulating Glass Units, by all three of our independently certified manufacturing plants.

AGGLam® is a full range of Laminated Safety Glass and consist of 2 or more pieces of glass that are held together by an interlayer that hold the glass together if in the event of breakage. AGGLam® is Safe, Secure, Quiet and Protects with specific performance seen in multiple categories.

Laminated glass can add extra performance and can also be incorporated into an Insulglass® unit. From stockstandard annealed glass laminates (regular clear, privacy, LowE, Audioshield® Acoustic) to custom-made laminates (heat treated, fire rated, flooring, barrier, overhead), including our advanced Security IntrudaShield® and handrail-free SkyGlass® brands.

All AGGLam® custom made products are manufactured in Australia by AGG and to AS 2208 – Safety glazing materials in buildings.

As AGG looks ahead, the future is bright. The company is committed to staying at the forefront of the glass industry by continuing to invest in new technologies and sustainable solutions. With a strong foundation built over four decades, AGG plans to expand its offerings, enhance product efficiency, and strengthen relationships with key partners.

Celebrating 40 years of innovation and dedication, AGG honours its roots and embraces its future in the ever-changing glass industry.

Pyroglass® is a range of certified Fire Rated Glass with Fire Resistance Level (FRL) for up to 120 minutes in both Integrity (FRL -/120/-) and Insulating (FRL -/120/120) performance. Suitable also for the highest Bushfire Attack Level – Flame Zone (BAL-FZ) and Fire Boundary Glass.

Specialised fire rated glass that offers different performances from Robax® in fireplaces to Pyran® S for Boundary glass up to FRL -/120/- to Pyranova® for BAL-FZ glass up to FRL -/120/120 performance, all available to be incorporated into an Insulglass® unit for non-fire rated performances.

All Pyroglass® products are manufactured in Australia by AGG and to AS 2208 –Safety glazing materials in buildings (except Robax®) and AS 4666 – Insulating Glass Units when incorporated into an IGU.

Our WA golfers had a fantastic day at Maylands Golf Course in Perth on Friday 11 October. As always, there were plenty of tall tales and cold beverages both on and off the course.

Thanks to our sponsors who made the day possible:

Hole sponsors: Westec Doors & Windows, Alspec, Cooling Bros, Glass Co Metro, Waglass, AWS, Walshs Glass, Tough Glass, GlassCorp, Breezway and Jason Windows

Ball Sponsor:

Prizes Sponsor:

Shirt Sponsors:

Smartech Door Systems has consistently led the industry with its innovative, precision-engineered motorised door, wall, and window systems. Renowned for blending stylish design with cutting-edge technology, the company offers a comprehensive range of products that serve an extensive array of residential and commercial applications. Smartech’s unwavering commitment to innovation and quality is evident in every project, ensuring that its solutions not only meet but often exceed customer expectations in both functionality and aesthetics.

Smartech Queensland: Strengthening Regional Presence

Reflecting its long-term commitment to supporting the region’s rapid growth, Smartech has established Smartech Queensland, a dedicated business unit specifically meeting the needs of its growing customer base in Queensland. Queensland’s booming construction and real estate sectors demand innovative, highquality solutions, and Smartech is now positioned to meet that demand more effectively. This will allow Smartech to offer localised services while maintaining the same high standards that have earned the company its reputation for excellence.

Smartech Queensland is fully licensed under the Queensland Building and Construction Commission (QBCC), ensuring that all installations adhere to the stringent state and national Building Codes and Regulations. This certification underscores Smartech’s commitment to compliance, safety, and quality, giving clients confidence that their projects will meet both legal standards and the company’s own rigorous quality benchmarks.

At the core of Smartech’s success is a continuous investment in research and development. It is committed to staying ahead of industry trends and exploring new technologies to improve existing product offerings and develop innovative solutions. Smartech’s R&D team focuses on enhancing the performance, durability, and energy efficiency of their motorised systems, responding to evolving customer needs and regulatory requirements for sustainability. Smartech is ensuring its products, not only meet current demands, but are future proofed for tomorrow’s challenges by keeping Smartech at the cutting edge of architectural design.

Quality is a non-negotiable factor at Smartech, and its quality control measures are second to none. Every product undergoes rigorous testing to ensure it meets the highest standards of reliability, durability, and performance. For example, Smartech products used in high-humidity environments, such as swimming pools, are marine-grade powder coated and constructed with stainless steel components to prevent corrosion and ensure longevity. Additionally, double glazing is available as an option, offering not only aesthetic value but also improved energy efficiency and thermal insulation, which are critical factors in both residential and commercial applications.

The company follows a strict quality control protocol during the manufacturing process. Each unit is carefully inspected before it leaves the factory, ensuring that only the best products make their way to customers. By focusing on quality at every step, from design and engineering to production and installation, Smartech ensures the long-lasting performance of their products.

Smartech caters to a diverse clientele, with projects spanning both commercial and residential sectors. On the commercial side, Smartech works with a wide range of industries including public schools, automotive dealerships, warehouses, hospitality venues, retail spaces, and even surf clubs. Its ability to deliver large-scale, custom-motorised door, wall and window solutions makes Smartech a trusted partner for businesses looking to enhance the functionality and aesthetics of their spaces.

Smartech also serves a broad range of residential clients, from individual homeowners to high-end luxury developers. Its bespoke designs cater to clients looking to transform their homes with solutions that merge indoor and outdoor living, creating expansive, adaptable spaces.

Smartech’s influence extends far beyond Australia’s borders, with projects in strategic locations such as United Arab Emirates, Malaysia, and Singapore. Showcasing its adaptability to meet diverse architectural and regulatory demands, Smartech has provided solutions across European countries such as France and Belgium as well as North America.

Tested for Strength, Safety, and Performance

Smartech is dedicated to ensuring the highest standards of safety, durability, and innovative design across its product range.

The Smartech Tilt Façade Garage Door has been rigorously tested to meet stringent Australian Standards, including AS 1170, AS 4055, and AS 4505, particularly for cyclonic conditions. This product successfully endured cyclonic testing for 50,000 cycles, wind pressure assessments in high-wind regions, and wind-borne debris impact evaluations. These tests, along with durability checks on major components and clear safety labelling, confirm the door’s robustness and compliance for both residential and commercial use.

Similarly, the Smartech Tilt Window has been rigorously tested under AS 2047 and AS/NZS 4284 having been verified for its exceptional ability to withstand structural stress, water ingress, air leakage, and wind forces. This comprehensive evaluation has proven that the Smartech product not only offers structural integrity, but also excels in insulation, weather proofing, and energy efficiency. Perfectly suited for a variety of settings — from the sunny coasts of Melbourne to the tropical climate of Darwin — the Smartech Tilt Window has been recognised as the premier choice for dependable and enduring performance in any Australian environment.

Empower Your Projects with the Smartech Trade Portal Smartech has developed the Trade Portal to provide its valued trade clients with easy access to vital resources, including technical documentation, design drawings, the technical design catalogue, brochures, and other key materials. Once registered, architects, builders, and distributors can quickly retrieve the documents they need to efficiently specify, design, and install Smartech solutions.

Its mission is to assist the customer throughout the entire project lifecycle, from initial concept to completion and handover, ensuring a smooth and exceptional customer experience.

In a rapidly evolving market, Smartech remains at the forefront of innovation. Its commitment to rigorous testing, high performance, and unparalleled quality ensures that it provides solutions that can be relied on for years to come. As it continues to push the boundaries of design and engineering, Smartech invites you to experience the Smartech difference — products built for strength, safety, and performance, backed by a team dedicated to supporting your success in every project.

For more details on Smartech products, visit Smartech Door Systems or contact the Sales Department at (03) 9747 9233, or via email at sales@smartechdoorsystems.com.au.

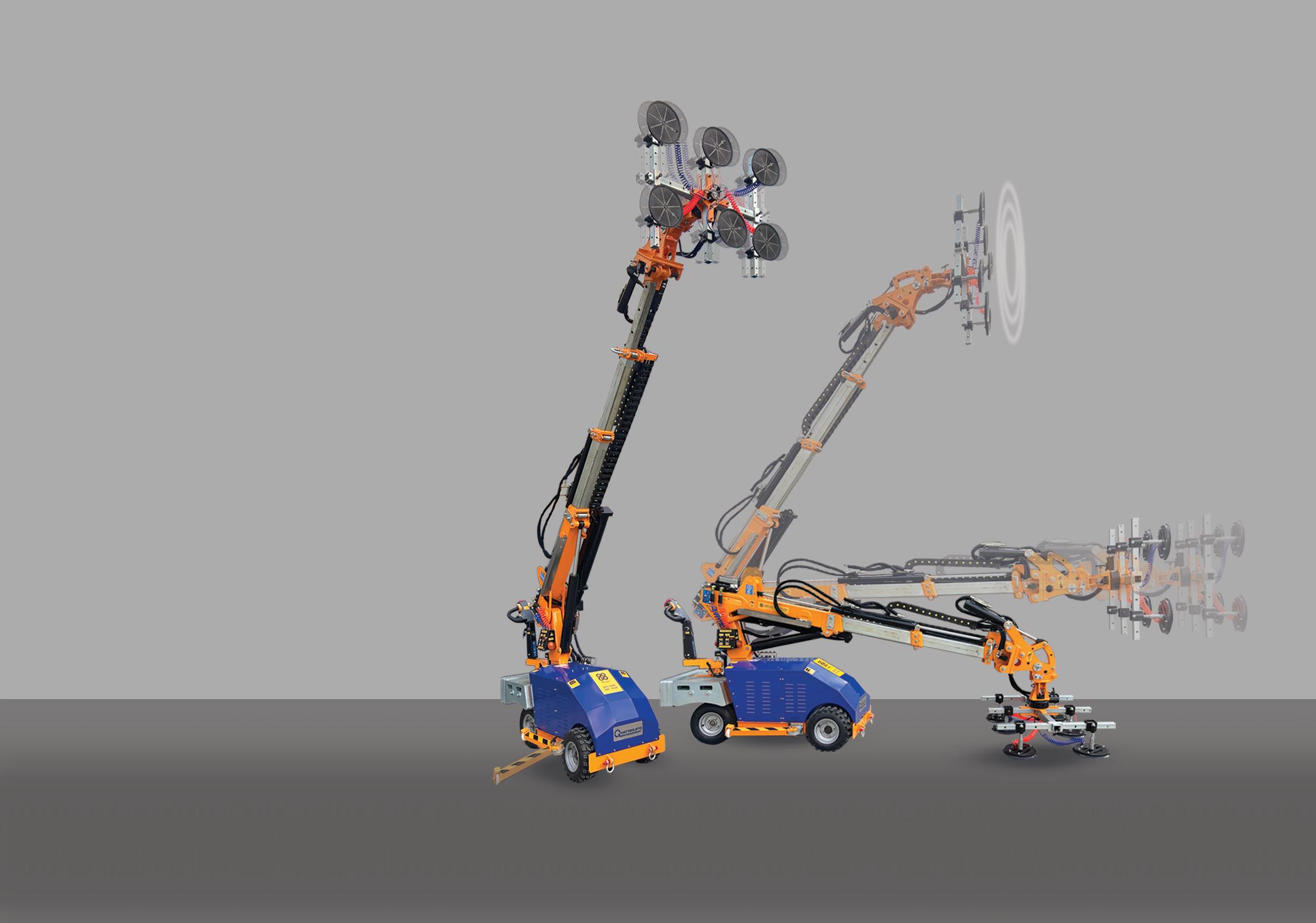

The Vector 800 Crawler is an extremely useful machine, whether glazing or craning up to 800 kg. With its tracks that can widen, the Vector 800 Crawler can successfully traverse soft, muddy terrain without getting bogged. Narrowing the tracks, allows the Vector 800 Crawler to pass though narrow doorways of 800 mm.

The multistage boom with fly-jib can reach 5 m, together with the capacity to slew left and right 25 degrees. The Vector 800 Crawler has safety features built in to prevent overloading and traversing grounds that are too steep. All functions and speed are controlled by wireless remote control with the backup manual levers on the machine if required.

The Vector 800 Crawler can be used both for craning and as a pick and carry crane for loads up to 800 kg. The central platform allows the load to be placed on the chassis, while driving, to prevent the load swinging during transport. The tracks extended laterally to the side to provide extra stability during transport.

The Vector 800 Crawler comes standard with 2 motors: gasoline for outdoor use and 240 V AC for emission-free indoor use.

The Vector 800 Crawler also has the option to fit an hydraulic winch with 100 m cable so loads can be lifted from below ground level.

For more information on this product, please see www. quattrolifts.com.au.

Sales Superstars: Expressions of Interest

Walshs Glass is Western Australia’s largest glass processor, a solid family-owned business and AGWA 2024 WA Supplier of the Year.

We’re keenly moving forward in the adoption of new products and technologies, under-pinned by our expert knowledge of flat glass processing and its applications.

Due to growth and progress, we have a range of account management, sales operations and intermediate sales team roles becoming available in metro and regional areas into 2025. So, if you’ve got experience in glass, an eye for detail and a passion for providing great customer service, we want to hear from you.

Applications are welcomed from East Coast and New Zealand candidates – Western Australia is calling you!

To express your interest in these roles or to find out more, please contact our HR Manager Katie Kemp on 08 9366 6666 or email hr@walshsglass.com.au

6mm LoE-452® #2 | 12mm Argon | 6mm LoE-i89® #4

• a quad silver low-E glass

• significantly reduces heat, glare and fading

• won’t darken the room like tinted glass

• blocks 99% of harmful UV rays

• lowest double-glazed U-value available

• features Neat® technology that helps keep the glass clean

For nearly 40 years, JG King Homes has been a leader in innovative construction of project homes, offering Victorian families quality homes with unrivalled structural warranties. As a family-owned business, JG King has earned the trust of its customers, delivering a 50-year structural warranty on all homes — an industry-leading assurance of their commitment to quality. As the only volume home builder in Victoria to provide steel frames as standard, JG King differentiates itself with TRUECORE® steel, ensuring strength, durability, and peace of mind for homeowners.

A key to JG King’s success is its vertical integration. The company not only manufactures its own steel framing, but also operates Project Windows and Doors, a window fabricating business supplying all of JG King’s new home builds, as well as other smaller builders and renovators across the region. This control over materials and processes enables JG King to maintain high standards of quality while innovating ahead of industry trends.

After the Federal Government first proposed increasing the minimum energy efficiency standard for new homes from 6-star to 7-star, JG King Homes responded swiftly. Already committed to sustainability and energy efficiency, the company saw this as an opportunity to enhance its offerings. ‘We’ve always been ahead of the curve in adopting better building practices’, says John King, Executive Director of JG King Homes. ‘When the government signalled the shift to a 7-star energy rating, we began testing our materials and designs to meet the new standards well before they became mandatory. We have never been scared to take a risk and choose what we believe are better building elements for our homes’, King says.

Following extensive research, JG King turned to uPVC, realising that double-glazed aluminium windows couldn’t achieve the necessary thermal performance. ‘I looked at what was happening in Europe and the USA, where uPVC dominates the market’, says King, ‘the systems, machinery and processes around uPVC were far more advanced than aluminium. It was a clear decision to move forward with uPVC.’

Selecting the right supplier was crucial. ‘We needed a partner who could meet our high demands for volume, consistency and quality’, King notes. After a thorough investigation, aluplast was