Celebrating excellence in the glass, window and security screen industries

ISSUE 19 | AUTUMN 2024

ACCREDITATION

Priority audits for 2024: Onsite audits highlighted as a priority for this year

SAFETY

Sexual Harassment: A new postive duty from 12 December 2023 for all workplaces

TECHNICAL Statements of conformity: NCC evidence of suitability

Australia’s Architectural Glass Maker

make the brands you know and trust for the community we live in. oceaniaglass.com.au TM are trademarks of Oceania Glass Pty Ltd I BuiltView 2024

We

ISSUE 19 | AUTUMN 2024 THE INDUSTRY MAGAZINE OF AGWA ECONOMY 7 COMPANY PROFILES 18 MASTER GLAZIER 24 COLLABORATION OPINION PIECE 26 CEO WORDS 5 PEOPLE 9 TECHNICAL 20, 34 TRAINING 29 MEMBER PROFILES 10, 14 CASE STUDIES 12, 32 SAFETY 36 ACCREDITATION 40, 53 AGWA NEWS 30, 42, 47, 50, 54 MEMBER NEWS 45, 49, 52 PRODUCTS 46, 52, 53, 54 BUILTVIEW ISSUE 19 Autumn 2024 3

Siddarth Kumaran

GRADUATE ENGINEER, AGWA

Siddharth is an engineer with over 6 years of experience in the Structural and Civil Engineering field. Before joining AGWA, he worked for 5 years as a structural engineer, specialising in the design of commercial, residential, and industrial buildings, civil structures and wind and seismic resistant façade systems.

Since joining AGWA, Siddharth has been providing technical guidance and support to members. He spends much of his time developing technical resources and industry tools for members, as well as participating in the revision of Standards via the AGWA Technical Committee. He is currently completing a Master’s Degree in Structural Engineering.

EXECUTIVE OFFICER, BUILDING PRODUCTS INDUSTRY COUNCIL

EXECUTIVE OFFICER, BUILDING PRODUCTS INDUSTRY COUNCIL

Rodger Hills is currently the Executive Officer for the Building Products Industry Council (BPIC) and has held a number of senior roles in the building sector including as CEO of the Australian Building Sustainability Association. He has a wide background in building policy and regulation, industry advocacy, compliance and standards. Rodger is currently involved in liaising with jurisdictions on control mechanisms for nonconforming and non-complying building products, harmonised building product standards and embodied carbon methodologies.

Vivienne Munter

SYSTEMS ADMINISTRATION, AGWA

Vivienne began her employment with AGWA in mid-2017 assisting in the administrative duties in the Sydney office on a casual basis. Her role soon progressed to part time providing administrative assistance to the Training Manager including preparation of material for trainers and the annual AGWA Design Awards. Later she was offered a full-time position split between managing the administrative side of AGWA’s Accredited Companies Program (ACP) and Dispute Resolution Services.

Prior to AGWA, Vivienne worked as a high school teacher for twelve years teaching Business Studies, Commerce and Geography and marking HSC exams.

Angela Farrell

Angela is an advertising copywriter and business content writer with over 15 years, advertising agency experience. She loves the challenge of working across industries and genres; writing radio ads for snack brands, websites for SaaS, articles for AGWA, and everything in between!

Having represented Australia in the sport of sailing, Angela is passionate about the teamwork and hard work that goes into success — be it in sport or business.

Ingrid Pagura

Ingrid Pagura

INDUSTRY DEVELOPMENT COORDINATOR, AGWA

Ingrid began her role with AGWA in May 2021 looking after the training needs of members. Her role soon progressed to include working on Safety, BuiltView, the AGWA Design Awards, the website and other marketingrelated activities.

Prior to AGWA, Ingrid worked for a legal publishing company as an editor, a publishing manager and then an editorial trainer. Her time at Butterworths saw her work on their building and local government and environment suite of products and with the CSIRO and ABCB on other BCA projects. She also previously worked for many years as a part time teacher at TAFE teaching law, business, communications and work health and safety across multiple faculties.

Maurice graduated with a Bachelor of Economics from the University of Sydney in 2021, majoring in Financial Economics and Econometrics. He led two collaborative projects, one analysing of the effects of COVID on the stock prices of commercial property companies and the second, collaborating with ANZ Banking involving recommendations to improve their data analytics for the approval of home loans in disadvantaged postcodes. He joined the HIA in 2023, and his responsibilities involve contributing to HIA’s suite of publications and articles.

Deborah Deeth

MANAGING DIRECTOR,

GREATER GLASS

Deb has been in the glass industry for 20 years since the inception of Greater Glass, of which she is the proud founder and the driving force.

For the past decade, Deb has held prominent positions within the glass industry and currently serves as a Director on the AGWA Board, contributing to the advancement of the glass industry and glazing as a competitive and lucrative trade and profession. She actively campaigns to entice young apprentices into the field and to elevate safety, compliance, and quality standards.

A firm believer in the power of shared knowledge and learning, she is committed to advancing our industry through awareness programs around reduced energy consumption and emission targets.

BUILTVIEW ISSUE 19 Autumn 2024 4

ECONOMIST

Maurice Tapang

COPYWRITER, TRADE ADVERTISING AGENCY, AUSTRALIAN OLYMPIAN

CONTRIBUTORS

Mr Rodger Hills

EDITORS

Melissa Baker

Ingrid Pagura

SUB EDITOR

Helen Dawes

DESIGN

Webqem Pty Ltd

Ahmad Awick, AGWA

EDITORIAL & ADVERTISING ENQUIRIES

Helen Dawes

+61 2 9498 2768

marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208

Suite 101B, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073

+61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

COVER IMAGE & CONTENTS PAGE IMAGE

Darebin St, Mile End, SA

Builder: Exterior Dimensions

Fabricator: AA Windows & Doors

Photographer: Art Department Styling + Creative

Alspec products:

Carinya Classic Awning and Fixed

Carinya Classic Sliding Door

Carinya Select 125 Hinged door

CONTRIBUTORS

Clinton Skeoch, Ingrid Pagura, Russell Harris, Maurice Tapang, Deborah Deeth, Rodger Hills, Carver Broomhall, Steven Poole, Scott Phillips, Siddharth Kumaran, Vivienne Munter, Angela Bevitt-Parr, Angela Farrell, Mari Lehtinen, Elizabeth Dimabuyu, Emma Savage, Joanne Tao, Samara Davis, Kim Desler, Lido Russo, Helen Dawes, Melissa Baker, Kerrie Henderson, Ahmad Awick, Homa Sheikholeslami, Dominique Macartney, Lucy Kendall and Kellie Moore.

PRINTED BY SOUTHERN IMPACT

southernimpact.com.au

Our printer conforms to the ISO-14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY

D & D MAILING SERVICES

www.ddmail.com.au BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2024. All rights reserved. Reproduction in whole or part without written permission from AWA-AGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary seek professional advice.

Clinton Skeoch Executive Director and CEO, AGWA

Clinton Skeoch Executive Director and CEO, AGWA

Welcome to 2024. The year ahead promises to be filled with opportunities for growth, collaboration, and recognition within our community, and the whole AGWA Team is looking forward to continuing to serve our industry.

For those of you wanting to know what is new and likely to affect your business in the coming year, I look forward to seeing you at one of the upcoming state Member Forums, set to take place across the country. These gatherings serve as invaluable platforms for networking, knowledge sharing, and forging new connections within our industry.

In addition to our state Member Forums, I am thrilled to shine a spotlight on the prestigious 2024 AGWA Design and Industry Awards that are on the horizon, with Award Presentation Dinners booked for each state. These accolades celebrate the remarkable achievements of our members, showcasing groundbreaking projects and innovative solutions that push the boundaries of design excellence. I encourage all of you to submit your best work for consideration and join us in celebrating the remarkable talent within our community.

To highlight the ongoing additions to member value in 2024, I am delighted to announce a new agreement on member discounts with Australian Standards. Under the plan, active AGWA members will get a 10% discount off the Small Business Standard Set subscriptions. This initiative underscores a long journey of engagement with Standards Australia to ensure reliable and more cost-effective access to Standards for our members, helping to underpin capacity building and compliance within our industry. In delivering member value, I am also pleased to have locked in another year of free Creditor Watch medium plan access for our members. With more and more news stories around builder viability, now is the time to reach out to the AGWA team and understand how to take advantage of this opportunity.

I am looking forward to your support in 2024 as we have a lot to deliver and, indeed, to celebrate.

Stay safe.

COVER AND CONTENTS:

Darebin St, Mile End – Carinya Project

Located just west of the Adelaide CBD in the suburb of Mile End, the home features high wall-length windows on both levels, which ensure natural light filters into every room. Created by award-winning firm Exterior Dimensions, this large family home utilised window and door framing solutions from Carinya’s residential products. Created by Alspec, and based on their experience in the commercial environment, Carinya products come in two ranges: Classic and Select.

To provide light without compromising privacy, a series of high awning and fixed Carinya Classic windows were used on both the lower and upper levels of the home. Carinya Classic Sliding Doors were used on the ground level of the home to enable the easy integration of the living areas when required. Unlike the exposed tracks which are found on most residential sliding doors, Carinya sliding doors include threshold and jamb in-fills, end caps to conceal all cavities and internally concealed weather flaps.

Clinton

Achieve Affordable 7-Star Performance

Thermally Improved Aluminium Windows & Doors

Features

Superior Uw & SHGC Values

Inline Reveal Technology

Tested For Australian Conditions

Unmatched Value For Money

Minimised Condensation

Discover the ultimate window and door solution for comfort, value, and energy efficiency with the Thermal Star™ Aluminium Window & Door Range.

With inline reveals, thermally improved frames, and unbeatable value, the Thermal Star™ range of aluminium windows and doors is designed to help you achieve affordable 7star performance.

Learn More

www.southernstarwindows.com.au

1300 733 599

info@southernstarwindows.com.au

P:

E:

STABLE AND RELIABLE SUPPLY CHAINS

Maurice Tapang Economist, HIA

The typical value of an approval to build a detached home in Australia was a little over $333,000 just before the COVID pandemic. In the decade to 2019, this value would usually see an annual growth rate of 3%. This was reflective of the growth rate in the prices of materials, which grew in the same period at a rate between 2%-3%.

During the pandemic, supply shocks saw the overall price of home construction materials increase by as much as 17% in the span of a year. Some materials surged in price by more than double that rate, with certain timber and steel products reaching annual price growth rates of around 40%.

Prices, in general, tend to be downwardly sticky and rarely move backwards, especially in the long term. An example of this is the price of timber windows, which are over 60% more expensive than pre-pandemic levels. The result is a sharp and sustained rise in home building costs. In the most recent quarter, the cost to build a typical detached home was over 40% higher than it was prior to the pandemic.

The COVID’s disruptions on supply chains not only made it more expensive to acquire construction materials, but also more difficult to get them onshore on time. To keep up with demand, domestic suppliers had to build both warehousing and production capacities. Suppliers in the construction industry needed to shift from a ‘Just-In-Time’ to a ‘Just-in-Case’ model. This buffer-building gave greater certainty on the availability of materials but was also costly.

An example of this response to the supply shock was an increase to domestic storage in the supply chain. Approvals for building transport facilities, factories and warehouses went up by 13% in 2021. The value of building domestic supply chain facilities was 72% in 2021 than the decade average.

Timber supply is another example of an increase in building onshore capacity during the pandemic. Domestic timber production amped up in mid-2021 by over 7% compared to the previous year. Despite this, it was not enough to satiate domestic demand. A return to stable timber supply and prices relied on a normalisation of imports and transport facilities.

In 2023, pandemic restrictions were unwound across the world and shipping container prices sustained a return to prepandemic levels. There are concerns though that the conflict in the Middle East will again markedly disrupt supply chains. This has seen container prices more than double within weeks as a result of shipping network diversions.

The escalation in shipping prices has yet to materialise in the prices of house construction materials. It would be likely to be immaterial for two main reasons: (1) signs that the current shipping constraints would be short-lived, and (2) the capacity built by suppliers during the pandemic.

As a result, the growth rate in the value of a typical house approval has plummeted from the sharp increases in 2021-22. There are positive signs that construction costs are set to return to stable annual growth rates of around 3%-5% in the long term. This will be largely driven, not only by a return to normal supply chains, but also because of more resilient networks and practices developed during the pandemic.

ECONOMY BUILTVIEW ISSUE 18 Autumn 2024 7

December quarter 2023 vs pre-Covid levels Concrete, cement and sand Taps and valves Shower screens Plaster products Aluminium windows and doors Cement products Paint and other coatings Electrical equipment Timber, board and joinery Waterproofing materials Mirrors and other glass Structural timber Insulation Reinforcing steel Timber windows 38.9% 29.9% 44.9% 25.3% 39.9% 31.6% 50.1% 64.1% 23.2% 39.8% 31.3% 45% 26.5% 40.5% 31.9%

HOUSE CONSTRUCTION MATERIALS PRICE GROWTH

Discover confidence in compliance

Viridian manufacture locally, with tightly regulated supply chains, ensuring full compliance to Australian Standards.

Our assurance to you

Indepently certified, Viridian delivers compliance to AS4666 and AS2208, meeting the highest industry standards and setting the benchmark for quality, energy e ciency, safety and performance.

Put your trust in Viridian

With 14 sites across Australia, our large geographical footprint provides customers with convenient access to Viridian’s products with more flexibility over lead times –and we’re able to deliver in full, on time to more places.

Compliance & Performance

v i r i d i an g l ass .com | 18 0 0 8 47 43 4

Australian Certified Australian Manufactured

CHANGES TO WORKPLACE LAWS

Ingrid Pagura Industry Development Coordinator, AGWA

On 1 January 2024, some changes took place under the Fair Work Act. This article will focus on superannuation now being included in the National Employment Standards Employers have an obligation to pay superannuation (super) contributions for eligible employees under superannuation guarantee laws, which have been in place since 1992. As a result of this change, superannuation is now an entitlement under the National Employment Standards as well.

What are the National Employment Standards? These are a list of minimum entitlements for Australian workers who fall under the Commonwealth Fair Work Act, which is most Australian workers, except for state and local government public sector workers in most states. This varies in some states and territories so if you’d like to find out if you are included under this legislation, please go to: Fair Work Australia. While the National Employment Standards (NES) set out minimums any employer can provide their employees more if they wish.

The NES include minimum standards for working hours, parental leave, annual leave, redundancy and now superannuation as well. For more detail on the NES and what each standard sets out please see Fair work Australia.

Small business redundancy exemption changes

A non-small business employer can become a small business employer due

Fair Work has also updated the Fair Work Information Standard. This is a document that must be given to every new worker before or soon after they start work with you. There is now a second one for casual workers. It covers all the NES and other essential information for workers. Download a copy and make sure you are up to date with the latest.

https://www.fairwork.gov.au/sites/default/files/migration/724/FairWork-Information-Statement.pdf

https://www.fairwork.gov.au/sites/default/files/migration/724/ casual-employment-information-statement.pdf

It is also important to note there were other changes that came into effect with the passing of the Fair Work’s Closing Loopholes Law. Some of this commenced in December 2023 but much of it will come into effect this year. Fair Work Australia has produced a PDF of the major changes and a timeline for their introduction. Please look out for more information in the next issue of BuiltView

conferences changes in protected action ballot matters

Protected action ballot orders can be made by the Fair Work Commission (the national workplace relations tribunal) in relation to industrial action over a proposed enterprise agreement.

Where an order for industrial action is made, the bargaining representatives must attend a conciliation conference.

The new laws confirm that for this industrial action to be protected, the conciliation conference must be attended by:

' the employee bargaining representatives who applied for the ballot order (not necessarily all employee bargaining representatives for the agreement) ' the employer and their bargaining representatives

New discrimination protections

There are stronger protections against discrimination for employees experiencing family and domestic violence.

Other workplace health and safety and workers compensation changes

The changes include:

' expanding the functions of the Asbestos Safety and Eradication Agency to include silica (15 December 2023)

' streamlining the Comcare workers compensation claims process for certain first responders who sustain post-traumatic stress disorder (PTSD) (15 December 2023)

' amending the Commonwealth Work Health and Safety Act to introduce a new criminal offence for industrial manslaughter and significantly increasing penalties for other offences (1 July 2024).

Snapshot of changes Key changes Timeline 15 December 2023 ' New rules and Fair Work Commission orders for labour hire workers. ' Small business redundancy exemption changes. ' New discrimination protections. ' Right of entry changes. ' New workplace delegates’ rights and protections. ' Compulsory conciliation conferences changes in protected action ballot matters. 1 November 2024 ' Labour hire orders made by the Fair Work Commission can come into effect. 1 January 2025 Unless an earlier day is announced ' Criminalising intentional wage underpayments. New rules for labour hire workers Employees, unions and host employers can now apply to the Fair Work Commission (the national workplace relations tribunal) for new types of orders relating to labour hire employees. When an order applies, labour hire employees working for a particular host employer must be paid the same rate of pay they would receive under that employer’s enterprise agreement (or other relevant workplace instrument). The orders are subject to certain rules too. Compulsory conciliation

to insolvency in the period leading up to (or after) becoming bankrupt or going into liquidation.

the new laws, employers that become a small business employer in these circumstances may still be required to pay their employees redundancy pay, even though small businesses are usually not required to pay redundancy pay.

small business employer is an employer with less than 15 employees at a particular time.

workplace delegates’ rights and protections Workplace delegates now have new rights and protections under the Fair Work Act. This includes the right to represent the industrial interests of union members and potential members. Right of entry changes The requirement for officials assisting a state or territory work health and safety representative to hold an entry permit under the Fair Work Act has been removed. Certain rules and safeguards that apply to permit holders will still apply to those officials Criminalising intentional wage underpayments Intentional underpayment of wages by employers will become a criminal offence. A Voluntary Small Business Wage Compliance Code (Voluntary Code) will be established. Compliance with the Voluntary Code means a small business won’t be criminally prosecuted if they underpay their employees. Last updated 24 January 2024 Please note this is only a summary snapshot of the Closing Loopholes changes. For more detailed information, read our news article: Closing Loopholes: Fair Work Act changes PEOPLE

Under

A

New

BUILTVIEW ISSUE 19 Autumn 2024 9

THE AUSSIE BALUSTRADE BIZ ON TOP OF THEIR GAME

Coming together from different industries, Railsafe Balustrades business owners Steven Poole and Andrew Walker found they had much more in common than just a desire to build a successful balustrading business.

‘We’re both committed to fostering a collaborative team culture, and that’s what we’re most proud of’, begins Steven, who co-founded the business in 2014. ‘Our team is from a diverse range of professional backgrounds and comes together at all stages throughout our projects to solve problems and deliver exceptional customer service. Not only does this make it a great place to work, but it’s also one of the key reasons our customers keep coming back to us.’

The Railsafe admin team (led by Operations Manager Wendy Fallow, Sales Manager Charles Barabas, and Head Technician Tony Casling) has been unchanged for some years now, which has helped steady the business while growing from 3 staff, to more than 15!

When we asked Steven what gives the company an edge in the competitive glass and aluminium market, he replied ‘Railsafe has always been at the cutting edge of balustrade product development. From designing, engineering and certifying high quality aluminium and glass balustrade systems for a range of

BUILTVIEW ISSUE 19 Autumn 2024 10

MEMBER PROFILE

residential and commercial use, to automating and systemising the manufacturing process, every Railsafe product is proudly designed, engineered and manufactured in Australia. Railsafe procures aluminium from Queensland, and glass from Sydney, Melbourne or Perth, so it really is a true Aussie business. The challenges we faced during covid cemented the fact Aussie-made is a robust long term business strategy, because we can rely on our suppliers and are proud to support them.’

Railsafe has an impressive track record of delivering secure and successful projects, including the timely completion of a high-rise complex on Liverpool St, Sydney, just before Christmas last year. Steven explains ‘the client faced a challenge whereby a 50 mm handrail on an existing aluminium and glass balustrade obstructed the breathtaking views from level 29, which overlooked Hyde Park and a 250-degree panorama of Sydney’. In response, Railsafe presented three distinct options, collaborating with their engineering company to devise a balustrade design that eliminated the need for a handrail, ensuring an unobstructed view. The solution involved the installation of 21.52 mm and 25.52 mm toughened laminated glass balustrades. Railsafe actively participated in the project from the tender stage to completion, ensuring the client achieved the desired outcome. ‘The customer was thrilled we could deliver this high-quality result for them just in time for the holidays’, ends Steven.

Railsafe’s highly skilled team faced another challenging project at a large apartment block in Redfern, Sydney. The job site was nicknamed ‘Death Valley’ by the installation team due to the tight and maze-like scaffolding surrounding it, which made moving around the site precarious. The team collaborated to devise ways to make the site safe, and they were able to move nearly 500 panels of glass throughout an 8-level building. ‘Ultimately,

the finished balustrades showcased our team’s resilience, and elevated Railsafe Balustrades’ reputation with remedial builders, which highlights the value of having such an experienced team’, says Steven.

For more information visit www.railsafe.com.au

BUILTVIEW ISSUE 19 Autumn 2024 11

PINE AVENUE, ELWOOD: WELL-POSITIONED OPENABLE WINDOWS AND SLIDING DOORS MAKE THIS SERIES OF MODERN TOWNHOUSES LIGHT, WELL-VENTILATED AND COMFORTABLE PLACES TO CALL HOME.

Building on narrow urban sites can create challenges when it comes to ensuring good natural light and airflow reach key living spaces. However, for this series of townhouses in Elwood, near Melbourne, Victoria, the challenge was ably overcome, thanks to well-positioned windows and doors across every level.

Due to a series of windows and doors chosen, from the Alspec’s Carinya Classic range, positioned on opposing sides of the properties, ample light effectively reached all three levels of the townhouses. A mixture of window and door styles were selected, including awning, sliding and sashless, depending on the location, function required and wall space available.

For example, the combination of awning windows with fixed louvres was selected for the smaller rooms on the ground floor where windows were nearest to a site boundary. The slightly recessed windows allowed for enough space for the awning windows to open, while the louvres filtered light and provide privacy.

Where more wall space was available on upper levels, windows in the sliding configuration (horizontal or sashless) were chosen, allowing for wider openings and a larger contribution to cross-ventilation. With access required to the ground level courtyards and upper-level balconies,

Carinya Classic Sliding doors were selected. These high-performance sliding doors are cost effective for the residential environment, despite coming with commercial grade credentials. The ability to open up the home on both sides is an easy way to take advantage of cool afternoon breezes and minimise the need for artificial cooling. When the doors are closed, their robust design and integrated rollers ensure a secure and weather-tight environment.

Finished in Black Matt, the panels of vertical glazing on each façade contrast effectively with the white curved brickwork of the house, delivering a series of contemporary homes, while referencing the history and character of the local neighbourhood.

Licensed Carinya Dealer :

Cera Stribley Architects

Builder : Cohen Building

Licensed Carinya Dealer :

Absolute Dynamic Windows Pty Ltd

Photography : Emily Bartlett

Alspec Products:

Carinya Classic Sliding Door

Carinya Classic Awning Window

92 mm Frame

Carinya Classic Sliding Window

50 mm Frame

BUILTVIEW ISSUE 19 Autumn 2024 12 CASE STUDY

MAXIMISE THE BENEFIT OF YOUR AGWA MEMBERSHIP IN 2024

Did you know you have access to all of this...

Technical Support

Industry Events and Design Awards

Technical Guides

BuiltView Magazine

Compliance Certificates and Labels

Members can call or email for assistance with any technical issue they may have. We aim to respond to any member enquiry within 24 hours.

Member events held multiple times a year to update you on industry happenings, allow you to network with industry colleagues and be recognised for state and national winner for outstanding projects.

Technical Fact Sheets and Industry Guides - over 80 information flyers and booklets created to assist with your technical issues.

Quarterly Industry magazine, created for the glass and window industry with advertising opportunities and the latest news on your industry.

Compliance Certificate Templates for members to create and store official numbered AGWA compliance certificates (AS 1288 and AS 2047) for all supplied products and projects as proof of compliance. Access to discounted prices for performance labels.

Safety Resources

Industry Training

Disputes and Non-compliance

Business Support

Safety Management Tools and Guidance resources (including templates) to help create your safety management system and the latest changes.

Industry Specific training with member discount prices for on demand and instructor led courses.

AGWA offers a Dispute Resolution Service and non-compliance investigation service to assist and advise members when a complaint is made against them or a dispute with a customer occurs.

HR advice line, job board and classifieds web site to support your business and employees. CreditorWatch access is included in membership to help your business reduce exposure to the risk of credit default.

Biannual industry conference and trade exhibition. Conference sessions and key note speakers covering topics crucial to our industry.

BUILTVIEW ISSUE 19 Autumn 2024 13

For more information go to the web site www.agwa.com.au/members

AusFenEx

FIN WINDOWS AND DOORS LEADING THE WAY IN RESPONSIBLY SOURCED

AND MANUFACTURED RESIDENTIAL

WINDOWS

Kellie Moore Corporate Marketing Communications Manager, Capral

Kellie Moore Corporate Marketing Communications Manager, Capral

Step into a sustainable future with Newcastle-based residential window manufacturer Fin Windows and Doors, a leading advocate for responsibly sourced lower-carbon aluminium windows and doors.

As the demand for eco-friendly building solutions increases, Fin Windows and Doors is at the forefront of providing innovative products that cater to both the environment and the demands for high-quality residential building projects. With a solid commitment to sustainability, Fin Windows and Doors has consciously shifted to sourcing lower-carbon aluminium from Capral and manufactures a comprehensive range of high-performance residential windows and doors, the ideal choice for environmentally conscious homeowners.

Established in 1968, Fin Windows and Doors, led by Jeff Picton, is a long-standing supplier of aluminium windows and doors in the NSW Newcastle and Hunter regions.

‘We specialise in providing high-quality residential windows and doors into the domestic construction market’, comments Jeff.

Recently, the business has also seen a growing demand for more efficient and more sustainable building products.

‘For a long time, customers have asked about efficient glazing options, double glazing and WERS ratings; now they are asking about sustainability, recyclability and where our products come from; it’s a definite shift in the conversation ― sustainability has become a genuine priority for our customers’, continues Jeff.

BUILTVIEW ISSUE 19 Autumn 2024 14

MEMBER STORY

In 2022, Capral introduced LocAl ® lower-carbon aluminium, offering LocAl ® as standard on all Capral proprietary window and door systems it supplies, including the Urban and Urban Plus ranges typically used by Fin Windows.

‘It’s a game changer’, says Jeff. ‘Now we have a unique offer for our residential builders and homeowners; we can supply aluminium window and door systems that meet and exceed their expectations around compliance, energy efficiency and performance. At the same time, offering them a product with excellent sustainability credentials.’

One key aspect of sustainable construction is the choice of materials. Traditional aluminium production is energy-intensive and emits large amounts of greenhouse gases. By opting for lower-carbon aluminium, used in high-performance, thermally efficient window systems, such as those provided by Fin Windows and Doors, homeowners can significantly reduce the carbon footprint of their buildings. This helps combat climate change and saves on energy consumption and costs.

The carbon emissions in primary aluminium production range from under 4 kg CO2e/kg Al to over 20 kg CO2e/kg Al, largely dependent upon the energy sources used. The current global average carbon emission for primary aluminium is approximately 13.9 kg CO2e/kg Al.*

Capral’s LocAl ® offer includes two lower-carbon aluminium options: LocAl ® Green with carbon emissions of 8 kg CO2e/kg Al* and LocAl ® Super Green at 4 kg CO2e/kg Al*, among the lowest carbon aluminium available globally.

Using lower carbon aluminium in windows and doors is a crucial step towards reducing the carbon footprint of Australian homes.

‘We are proud to partner with an aluminium supplier leading the way in this area. Capral is prioritising sustainability and making it possible for small, independent businesses like ours to make a responsible choice around the aluminium products we supply’, adds Jeff.

In addition to making LocAl lower in carbon standard for its window systems, Capral has also been accredited under the Aluminium Stewardship Initiatives (ASI) performance and chain of custody standards and is currently the only aluminium extruder within Australia to hold these credentials.

Marketing Manager Kellie Moore comments, ‘ASI Accreditation is essential and will continue to become increasingly relevant in

our industry as businesses focus on the responsible sourcing and procurement of aluminium. Like everything, consumers are becoming more interested in understanding the origins of their products, be it coffee beans, leather shoes or building products. Being able to stand hand on heart and say I know where the aluminium I’m supplying comes from and that it has been sourced responsibly is essential for Australian window fabrication businesses’.

Capral was also recognised at the 2023 Sustainability Awards as the Green Building Product category winner for its marketleading lower-carbon Aluminium offer LocAl ® . By embracing innovative technologies and responsible sourcing practices, Fin Windows is paving the way for a greener, more sustainable future, making a positive impact on the environment, one window at a time.

For more information, contact Kellie Moore at kellie.moore@capral.com.au

BUILTVIEW ISSUE 19 Autumn 2024 15

The Block 2023

The 19th season of The Block showcased what is possible when using High Performance Glazing and ended with a record sell price and the highest profit in Block history.

The Block 2023 witnessed a fascinating transformation of five neighbouring 1950s brick homes located in the colder climate of Hampton East, Victoria One of the key glazing focuses was bringing these renovated homes into the world of high performance, energy efficiency, sustainability, and lower operating embodied carbon.

From a glass and window perspective, the show highlighted the importance of using innovative technologies such as Insulglass LowE Plus® clear double glazing, partnered with aluplast uPVC systems to enhance insulation, design aesthetics and energy efficiency. The contestants, with the help of the Nine in Six builders, faced numerous challenges and drama as they worked on these ambitious retrofits. The end results were nothing short of phenomenal. The houses underwent five dramatic transformations, each with its unique presentation features. These impressive renovations not only captured the viewers’ attention but also led to record sell prices and profits. The Block 2023 showcased how strategic thinking, cutting-edge glazing technology, and a commitment to sustainability can lead to remarkable outcomes in the world of home renovation.

House 1

“Winplex was proud to be part of the team for House 1, The Block 2023. We worked seamlessly with AGG, aluplast and the team at Nine in Six. The final results speak for themselves. Kyle and Leslie were awesome!”

Couple: Kyle & Leslie

Fabricator: Winplex Double Glazing

House 2

“Living Design Double Glazing were thrilled to be working alongside the contestants and be a part of The Block 2023, supplying advanced windows systems to compliment the contemporary design of House 2. It’s been a great experience, allowing us the opportunity to demonstrate the skills and experience of our team, and our capabilities.”

Couple: Leah & Ash

Fabricator: Living Design Double Glazing

Proudly manufactured, stocked and supported in Australia by Australian Glass Group

Insulglass LowE Plus® was the ideal glass choice. A high performance Softcoat LowE coated glass, protected within a double glazed unit. An ideal LowE for colder climates with maximum Visible Light, Passive Heat Gain & excellent Insulation. Multiple make-ups were used ranging from 4mm to 8mm thick Toughened glass on both sides of the double glazed units. Argon gas is used in the air gap also to enhance Insulation properties further.

Partnered with German-engineered aluplast systems and fabricated by five different experienced window companies, the homes enjoy the form and function that the frame types offer – fixed and tilt-turn windows, vario-slide and smart-slide, single and French doors. The Total System U-Values enjoyed achieved as low as 1.6, while a range of SHGC was covered.

“EuroTech Windows has been a proud installer and manufacturer of aluplast uPVC, double glazed windows and doors, using AGG LowE Plus for House 4 at The Block 2023, and it’s been a fantastic experience from start to finish!”

Couple: Steph & Gian Fabricator: EuroTech Windows

House 3

“Glad to have been given the chance to work on the 2023 season of The Block and be part of the team at House 3. It was exceptionally rewarding for our team and certainly tested all of our skills.”

Couple: Kristy & Brett

Fabricator: Weatherall Windows

House 4 House 5

“Astellite take great pride in its contribution to ‘The Block’ House 5, creating more than just windows, but a dedicated commitment to revolutionizing Australian living. Our windows not only enhance your living experience but also seamlessly integrate with a sustainable and energy-efficient lifestyle, thanks to our cutting-edge aluplast profiles and glazing solutions.”

Couple: Eliza & Liberty

Fabricator: Astellite

agg.com.au | info@agg.com.au ph: 1300 768 024 NSW | VIC | TAS See our Case Studies for each House at theblock.agg.com.au

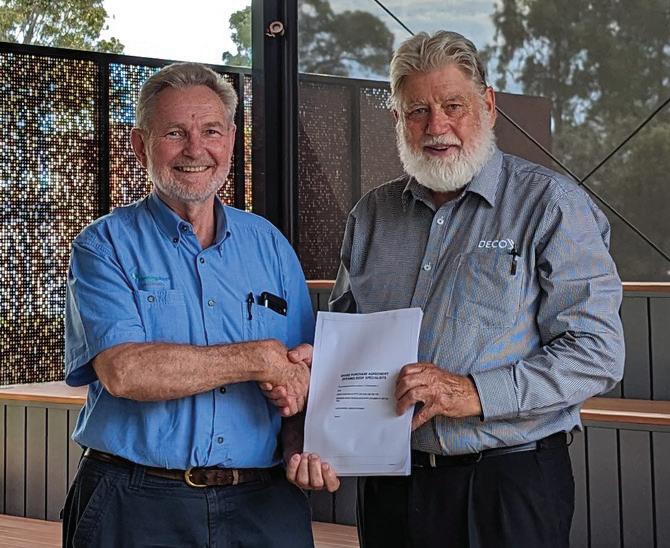

THREE GENERATIONS OF PARKWOOD OPENS DOORS TO AUSTRALIA

Growing up building homes around Auckland New Zealand, Steve Parkes saw how people’s houses were at the very centre of family life, and a special place to come together. Familyfirst values and putting care into every single product became the foundations of what is now a thriving multinational door business for Steve, his sons, and now a third generation, Steve’s grandsons.

In 1992, Steve and his wife Rachel purchased an old joinery workshop in the town of Wanganui (NZ) with a desire to make custom stairs and doors, while supporting the local community with jobs. Business was tough at first, until the workload grew enough to employ staff. Steve reflects on Parkwood’s very first big job. ‘We secured the job of replacing the stairs and solid doors in the large Parliament buildings in the capital of Wellington, which thankfully led to much more work.’

In 1993 their eldest son Dean joined the business, and they continued expanding over the next few years, sending doors all over New Zealand. By the time their younger son Simon joined Parkwood in 2002, the company had built a solid reputation in the New Zealand door-making industry.

As the second generation of Parkwood Doors, Dean and Simon identified that the market was looking for door options that were more durable and less maintenance than timber. ‘In 2007 we developed our first thermally broken aluminium front door’, says Dean. ‘Window fabricators soon began approaching us to supply Parkwood front doors alongside their aluminium windows, which is a simpler process for homeowners and specifiers. Window fabricators now supply over 90% of Parkwood’s front doors in New Zealand today, and Parkwood is now one of the key businesses providing employment in the city of Wanganui’, he adds with great satisfaction.

In 2014, after researching the market in Australia, the same issue was apparent; timber doors twisted and warped over time, with no safe or stylish alternative. Starting out in Victoria, Parkwood expanded into Australia and now supplies aluminium powder coated architectural front doors nationwide through a network of window fabricators. ‘We have continued our tradition of supporting regional towns, with our facilities based in the Southern Highlands outside Sydney’ says Steve.

COMPANY STORY

When we asked Steve what it means to run a family business, he explained that ‘it gives us an inner drive to succeed as we cannot rely on a large corporate presence to carry us. Everyone has to work together to keep innovating and improving to retain product leadership. Serving customers, staying focused on them, and making them completely satisfied is the blood that keeps Parkwood pumping – there is no other way to go’. Steve is proud to report that Parkwood’s ‘third generation has officially started on the factory floor and is working through the various departments (of which there are a lot!) which will give them an excellent overview of the company’.

Parkwood Doors has big plans for the Australian market. ‘Now that we have spent 10 years building our foundation and facilities in Australia, we are ready to take it to the next level. We are currently building partnerships with some statewide and nationwide window dye holders and fabricators. Our vision is that home builders anywhere in Australia can easily have an architectural aluminium front door on their home, seamlessly supplied along with their windows’, says Dean.

Providing a low maintenance solution for front doors is clearly Parkwood’s superpower niche, because there are a limited

number of high-end quality architectural aluminium doors on the market. They are constantly innovating to maintain their market-leading position, evident in their Thermtek patented technology, allowing for large architectural doors in dark colours, impossible in timber, with high BAL, thermal and sound ratings. ‘These doors are designed to fit into existing window fabricator’s frames, so they can be provided as a seamless part of the overall window package’, adds Dean.

‘Putting people first is always our priority. Whether that be our team, our customers, or our suppliers, we’re focused on fostering a culture that’s sensitive, not only to the needs of our community, but to their dreams and goals for the future’, ends Parkwood’s founder and family man Steve Parkes.

For more information on Parkwood Doors please visit www.parkwooddoors.com.au

BUILTVIEW ISSUE 19 Autumn 2024 19

STATEMENTS OF CONFORMITY: PRINCIPLES OF NCC EVIDENCE OF SUITABILITY

Rodger Hills Executive Officer, Building Products Indudtry Council (BPIC)

Evidence of Suitability (EoS) claims are used by decision-makers in the construction supply chain to decide what products to specify and procure, and how to meet building regulatory requirements. However, EoS claims are only useful when they are true, accurate, in easy-to-understand language and appropriately verified. False, misleading or incomplete claims of product conformity also unfairly disadvantage businesses that are making genuine claims.

When making EoS claims, you can use the following five principles to help you comply with your building regulatory obligations and ensure that any claims you make create trust in your business and allow construction decision-makers to make informed decisions.

Principle 1: Make accurate and truthful claims

Any product conformity claims you make must be accurate, true and factually correct. If products are provided to you by a third party (eg, components for a more complex product, or where products manufactured by others are marketed by you as ‘own brand’), you should ensure that any product conformity claims you make about those products are accurate and truthful. This may involve undertaking reasonable steps to verify supporting information provided to you by your suppliers.

TECHNICAL

Quantify the level of NCC or Standards compliance

Product conformity statements are often incorrectly made as blanket claims of compliance with the NCC and/or a Standard but the performance level not quantified. For example, a statement of conformity for a window claiming compliance to AS 2047, without declaring the specific wind loads or water penetration resistance rating, would be incomplete and potentially misleading.

Where any claim is made the use of a product or system is fit for its intended purpose to achieve a Performance Requirement (be it a Deemed to Satisfy Provision, a Standard, or a Performance Solution), the relevant quantified performance level(s) or attribute(s) must be specified on all evidence. This includes test reports, Product Technical Statements and Certificates of Conformity.

Be clear about what is being certified

Products tested in isolation, as individual components and not as part of systems or assemblies constructed on site, should be clearly stated in any claims of conformity. While testing materials in isolation provides a logical and level comparison between products, it does not allow for dynamic effects, or build tolerances when different products are fixed together into systems.

When testing products to an Australian or International Standard, a clear distinction needs to be made and communicated to construction decision-makers, between the physical tests performed on a product, and results that are simply extrapolated mathematically from those or other physical tests.

Principle 2: Make sure your evidence backs up your claims You must be able to substantiate any product conformity claim you make ― whether the claim is made as EoS on your packaging, in your advertising, through your employees, or in other ways ― with clear evidence.

When choosing evidence to support your claims, keep the following in mind:

• Your evidence may come from third parties (such as suppliers). When making product conformity claims, however, do not rely solely on claims made by your suppliers or other third parties. Instead, take reasonable steps to verify any information you want to rely on.

• If you have conducted laboratory testing to support your claim, make sure the laboratory test regime reflects the conditions that would normally be experienced by building practitioners using your product as well as any limitations that might apply regarding the use of the product (refer to Principle 4).

• Compliance tests may not directly relate to a current batch of specified or supplied material, product or form of construction, so in such cases, there should be a verifiable means linking the relevance of a compliance test report to the product or system of interest. While typically this can be achieved through a process of formal product certification, in the absence of such certification, or in addition to it, other approaches might be appropriate, proportionate to the risk associated with the product or system. Where considered necessary, these might include ongoing surveillance testing (consistent with AS ISO/IEC 17020 or AS ISO/IEC 17065 requirements) of certain product attributes, production monitoring or other controls.

Always ensure that continuous and ongoing product compliance is backed up by evidence that is demonstrably reflective of the currently supplied product and not simply a one-off achievement.

Principle 3: Do not hide important information

In many cases, giving consumers incomplete information is also misleading. This can occur if you provide some information but leave out important details which might contradict or qualify the product conformity claim.

BUILTVIEW ISSUE 19 Autumn 2024 21

For example, highlighting the positive aspects of your product, service, or business while omitting information about the negative aspects, can give construction decision-makers the impression that your business, product, or service has better performance than it really does.

It is good practice to be transparent about your product conformity claims and policies, and the information you are relying on to support them. In doing so, it can be helpful to consider the information that construction decision-makers and, potentially consumers, need to form their own conclusions about the performance of your product.

Small print shouldn’t hide the truth

You cannot rely on disclaimers, disclosures or clarifications buried in small print, or otherwise not displayed prominently enough compared to your headline claim, as an excuse for making misleading product conformity claims. Any information that you provide in small print or qualifications should not conflict with the overall message of your claims. Courts and Regulators pay little attention to the font size used but more to the information conveyed.

When making product conformity claims, it is good practice to only use small print to provide supporting information. If you do need to make a disclaimer or qualification, you can reduce the risk of giving an overall impression that is misleading by prominently displaying this near the headline statement.

Principle 4: Explain any limitations or qualifications on your claims

Some product conformity claims may only be true under certain conditions. Other claims may only be realised if certain steps are carried out, such as installation/paring with some products but not others. For example, tests conducted on a balustrade fixed to a concrete structure may not be directly applicable to one that is intended to be fixed to a timber balcony requiring additional fixings or different supporting brackets.

These types of claims can be misleading if the conditions or required steps are not clearly stated or are unlikely to be realised during ordinary construction use.

Therefore, you should consider:

• How building practitioners normally use the product or system.

• The normal conditions where the product or system is usually sold.

• Any access to infrastructure, technology and resources that are required for the product conformity benefits to be realised.

• If certain actions, facilities or resources are required for the product to be conforming, you should clearly and prominently explain to construction decision-makers what needs to happen to achieve this. If possible, you should incorporate this as part of the claim.

Principle 5: Visual elements should not give the wrong impression

The visual elements of your marketing, products and packaging can also convey certain things to construction decision-makers. Images and visual elements should be used with care, as construction decision-makers may interpret them as making a broad claim of a product conformity benefit that does not actually exist or over-emphasise one that does.

Third-party labels and certifications

Having your product conformity benefits verified or certified by an independent, robust third-party scheme can build construction decision-maker trust in your brand. However, construction decision-makers may also be unfamiliar with local or international product certification schemes. When using a logo from such a scheme, consider the overall impression created and whether any further information or explanation is required to ensure consumer construction decision-makers are not misled.

For example, you should not use a certification logo in a way that implies that:

• You have been certified for an aspect of your product, service, or business which you have not.

• Your product certification covers all aspects of a related Standards or NCC Performance Requirements, when in fact it only meets one or a limited number of aspects.

• Your product has been independently certified if this is not the case.

• The certification means certain product conformity benefits have been certified as having been achieved when it does not.

BUILTVIEW ISSUE 19 Autumn 2024 22

AGWA UPCOMING EVENTS

NATIONAL

National Apprentice Competition: Thursday 12 September, Holmesglen TAFE (VIC)

National Awards (Melbourne): Friday 13 September, Crown Melbourne

NSW/ACT

Member Forum: ACT/NSW Wed 13 March, Royal Hotel Queanbeyan

Member Forum: Sydney Thursday 14 March, Parkroyal Hotel Parramatta

Golf Day: Friday 22 March, Bankstown Golf Club

State Awards Gala Dinner: Friday 23 August, Fullerton Hotel Sydney

QLD

Member Forum: Brisbane Wednesday 10 April, View Hotel Brisbane

Member Forum: Cairns Thursday 11 April, Pullman International, Cairns

Golf Day: Friday 17 May, Nudgee Golf Club

State Awards Gala Dinner: Friday 26 July, Rydges South Bank, Brisbane

SA

Member Forum: Wednesday 3 April, Rydges South Park, Adelaide

State Awards Gala Dinner: Friday 9 August, National Wine Centre of Australia, Adelaide

TAS

Member Forum: Wednesday 27 March, The Grange Funtion Centre, Campbell Town

State Awards Gala Dinner: Friday 30 August, Wrest Point, Hobart

VIC

Member Forum: Tuesday 26 March, Parkroyal Monash

VIC & National Awards Gala Dinner: Friday 13 September, Crown Melbourne

Golf Day: Thursday 12 September, Holmesglen TAFE

WA

Member Forum: Thursday 4 April, Royal Perth Yacht Club

State Awards Gala Dinner: Saturday 10 August, Novotel Perth Langley

Golf Day: Friday 11 October, Maylands Golf Club

For further information, please scan the QR Code:

MASTER GLAZIER

GOLDEN ANNIVERSARY AND RETIREMENT FOR AGWA’S FIRST MASTER GLAZIER

Campbell Pudney, AGWA’s first Certified/ Master Glazier recently retired after nearly 50 years in the industry. BuiltView took the opportunity to talk to him about those 50 years.

Campbell started his glass apprenticeship in about 1972 with a company called Yencken Glass in Coburg, Victoria. It was called Flat Glass Working on his trade papers and they were members of the furniture trade union.

Campbell’s first job was cutting, by hand, wired louvre blades by the hundreds for the sides of factories, then digging through the offcut racks and taking them to the bevelling shop to give them a rough arris. This was done with a horizontal carborundum stone wheel (an abrasive composed of silicon carbide crystals), which was shovelled into the centre of a stone wheel and had a water drip feed. As the water rose it picked up the crystals and washed them onto the stone wheel where you ran the edge of the glass then soaking them in a wooden tub to rinse them.

In the bevelling shop everything was done by hand as well. A polished arris was done on a stone wheel then onto the pumice wheel for polishing and blind bevelling where a mirror was held face down onto a flat wheel without being able to see the edge of the bevel until afterwards. All very time consuming and physical.

After finishing his apprenticeship in 1977, Campbell moved to WA, and we fast forward a few years and where a negative in Campbell’s life turned into a positive.

In the later part of the 1980s Campbell was involved in a serious workplace accident. During the unloading process of getting an endcap of laminated glass off a semitrailer, the full end cap came off, pinning him just above the knees onto his chest.

In Campbell’s own words ‘I can only thank my workmates (MY SUPER HEROES) for lifting 30 sheets of glass in an endcap, one on each corner, by hand in one move, somehow, they lifted over a ton of glass and the fifth dragging me out from under it, without exaggeration saving my life’. This terrible accident put Campbell in the intensive care unit and hospital for months and he was unable to walk properly for about 2 years. Overtime he eventually eased back into work, but not glazing right

away, with the help of his employer which was bought and became Pilkington Glass.

In the late 1980s computer operators were in massive demand and with his glazing experience, Campbell retrained and started doing computer programming, while learning the administration side of the glass business, eventually becoming a branch manager.

When Campbell eventually started his own small business, Woodvale Glass, he also became interested in Glass Association and was elected to the committee of the GWAWA. During this time, GWAWA were receiving concerns nationally from members about non-tradespeople entering the industry. People were asking for something to be done, so the Master and Certified Glaziers and Accredited and Compliance Company programs were started through AGGA.

As he was a qualified glazier on the committee, he was asked to complete the requirements for the Certified Glazier before the system went live and was rolled out throughout Australia. About a month later, he was notified that he was the First Glazier in Australia to go through the certification process. About 2 years later, the Association asked him to upgrade to a Master Glazier and as he was a sole trader, to become an Accredited Company. The rationale for Campbell doing so was an incentive for others to do the same and it worked.

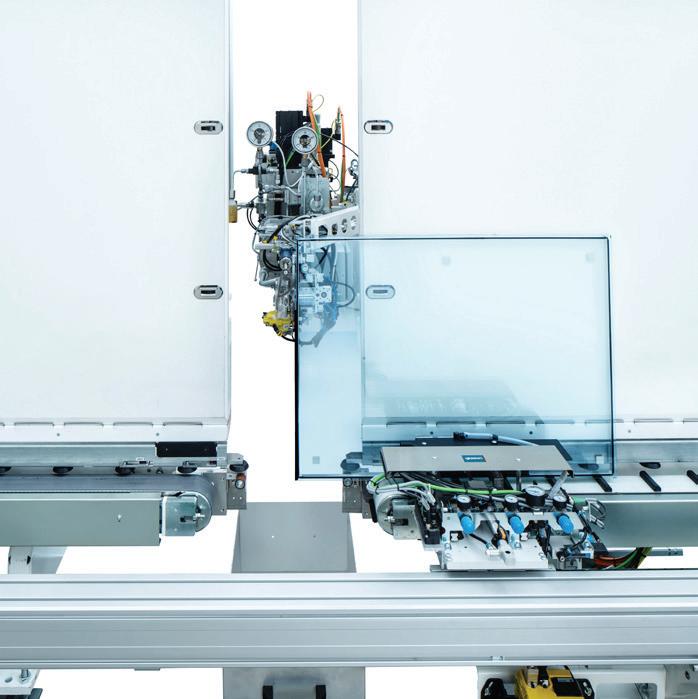

Campbell remembers laughing when it was mentioned that we would one day be able to cut and process a piece of glass without touching it. Now, it is just a normal day, and it makes him wonder what the industry will be like 50 years from now!

Another change he has seen since he started his apprenticeship is the focus on safety. In the 70s, people hardly spoke about safety and glaziers had to ‘improvise’ with things like cutting up an old inner tyre tube to make hand grips. Whenever an accident happened it was always the employees’ fault and if they got cut it was because they were not paying attention. The industry progressed to gauntlets and gloves and so on to where we are today, where we have training and find ways to eliminate accidents before they happen.

To finish off in Campbell’s own words, ‘for me I can see the trade only getting stronger and I hope that one day glaziers get the recognition they deserve’.

‘Finally, I would like to thank all the hundreds of wonderful people I have met along the way, and as we move into retirement, I must also pay tribute to my gorgeous wife Paula who has been on this crazy journey with me pushing (shoving) and guiding me through the, sometimes, difficult times as we celebrate being together this year for 45 years’.

Campbell, we wish you well for your retirement and all the adventures you have planned. Thank you for contributing so much to the industry over all the years and for taking the time

BUILTVIEW ISSUE 19 Autumn 2024 24

COLLABORATING STARTS WITH CONNECTING. IS THIS THE ANSWER TO WELLBEING?

Deborah Deeth Managing Director, Greater Glass; AGWA Board of Directors

On New Year’s Eve, I found myself on a cattle station in outback Northern Territory. It was a completely new experience for our family. The invitation came from a friend I’d met in recent years via a business mentoring program. Like most Aussie BBQs the men and women were at opposite sides of the room. In this case, the men were out back in the incredibly large shed and the women were in the homestead with the air conditioning. I quickly realised that I was among the most interesting, down-to-earth, intelligent group of women, ranging from an Aboriginal doctor, a senior NT government official to a pastoral fire mapper! I was in awe of their connection considering the remoteness and vast distances they lived from one another. Collaborating was not only key to their successful lives but, quite literally, part of their survival. Collaboration was evident in every aspect of their lives.

I started thinking about the parallels between this remote lifestyle and mine. The similarities between life and business. Tapping into this feeling of connection and collaborating with like-minded people, I realised this is my jam.

Sharing ideas and involving oneself in deep conversations may not be everyone’s favourite past time, but when you take a close look at a thriving business and the people behind them, you will usually find a mentor, an advisory board; a collaboration of sorts. The key point being meaningful human connection.

My favourite recent example is the book called Ikigai: The Japanese Secret to a Long and Happy Life. This book, by Héctor

García and Francesc Miralles, explores the connection between human longevity and being connected. The authors delve into the concept of ikigai, a Japanese term that translates to ‘a reason for being’ or ‘a reason to wake up in the morning’. The book discusses how finding one’s purpose, cultivating meaningful relationships, and staying connected can contribute to a longer and more fulfilling life.

Another similar work exploring the link between longevity and social connections includes The Blue Zones: Lessons for Living Longer From the People Who’ve Lived the Longest by Dan Buettner. This book provides insights into the habits and lifestyles of communities with high life expectancies and emphasises the importance of social bonds in promoting longevity.

The glass industry for me is one of the best examples of great connection and collaboration . The perfect example of collaboration, business and social connection at its best was the recent AusFenEx23 Conference. Glass people do come together and collaborate well. Their walls come down and friendships are forged and strengthened. The sharing of information is key to the growth of our industry. The success of this last conference, no doubt, was in part to being the first post-COVID event, again proving human longing to connect and collaborate.

When I first joined the NSW Glass & Glazing Association, my eyes were opened to the possibility of support, with people just like me trying to make a living out of glass. What I found was exactly what I was looking for: A sense of belonging, these are my people, they are not just accountants

or business coaches, but glass people who have so much to offer.

It so common to hear people say, ‘this level of collaboration wouldn’t have happened in my last industry’. The reply is always the same ‘Yeah, that’s just the glass industry’. Are we unique? Are we just more niche than the Master Builders Association or others like the Concrete Institute of Australia?

The Australian Glass & Window Association (AGWA) by definition is an amalgamation of glass and window manufacturers, fabricators, glass processors, glaziers, merchants, suppliers, educators, regulators and professional stakeholders and bodies, focused on ensuring a professional and sustainable industry.

The word ‘stronger’ became overused during COVID. At the time it felt cringy but today ‘stronger together’ sounds valid, almost comforting to me.

Our industry is full of great collaborative examples. For me, personally, it’s the sharing of skills, such as a fair value exchange and the win-win that exists when lending a staff member to a local subcontractor for the day when they need a hand. It is the advice around the latest hardware used, or where to find some obscure product. There are so many examples of the way fellow glazing companies support each other. Within the glass world, we feel that these examples aren’t as commonplace in other industries.

Yes, we are still competitors but there is a sense that we are a rarer breed, a special kind, the forgotten trade. Maybe we should unite around this fact and start celebrating it. Can we do more? Are we doing enough collaborating? Where does collaboration start, and collusion begin?

Construction remains in the top 5 employers in the country. Glass can make up a third of a building’s envelope, yet the profile of glazing, as a trade, has a real identity issue, some might even say a crisis. Yet, our Association, AGWA, is larger by numbers than many others. Is it because we love a beer and a chat

BUILTVIEW ISSUE 19 Autumn 2024 26

or do, we truly love collaborating? The confidence, the kinship and the tangible results are evident. We have a connection, a strong and sustainable peak industry body. Yes, it’s not perfect but what is?

I’ve no doubt collaboration is not only good for business but good for our wellbeing. In 2024, being connected and collaborating will present itself in many forms. Regardless of your opinion of social media, good, bad, or indifferent, the Glaziers Australia Facebook page is just one example of collaboration. While not censored or fact checked, there are thousands of individuals on this platform seeking guidance, validation or just that sense of community via social media, though they may also benefit from

If you google collaboration, it says that it is ‘a partnership, union; the act of producing or making something together. Collaboration can take place between two people, many people, strangers or best friends. To collaborate is to commit to the possibility of producing an outcome greater than one that would be developed in a silo’.

For those of us looking to grow our business, personal profile or seeking a purpose bigger than ourselves, leaving a legacy for our families and or the industry, there is no doubt in my mind that collaboration is required to tackle the big issues facing our industry today and into the future. These are:

• Compliance

• Profitability of Australian-made products

• Energy

There are numerous successful case studies across all industries showing that by tapping into the power of collaboration, through good old-fashioned networking, businesses can unlock unprecedented growth opportunities without any breach of the Australian Consumer Law.

Collaboration is key to making anything more productive, positive and innovative!

So, let’s increase collaboration in our workplaces and in our industry for our own wellbeing and the greater good of the glass and window industry.

2024 AGWA DESIGN AWARDS Entries close 26 April 2024 agwa.awardsplatform.com

TRAINING NEWS AND CHANGES

Training is in full swing for 2024. Our Instructor Led course are back for 2024, kicking off with AS 1288 Human Impact and Wind Loadings in late February.

Following on from our changes to several On Demand courses last year, I have a few more changes to announce for 2024.

First, our popular Intermediate Fenestration course is undergoing a face lift. Following on from a revamp to all the content over the course of 2023, including expanding the sections on framing materials, hardware, the Standards and WERS, it is getting a new name as well: Fenestration Essentials. This reflects the changes we have been making and better describes the course. It is still the same excellent course over 5 afternoons but with a fresh name. If you’d like any information about the course content, please email me at training@agwa.com.au

The next major change I’d like to announce is a refresh of the Fenestration Diploma Program. The name of the program will change to the AGWA Fabricator Program , and the program has been revised to include additional On Demand Courses that now include WHS.

The AGWA Fabricator Program is an industry-based certificate that has been developed by AGWA to provide recognition of individuals with a higher level of both knowledge and industry involvement. The program provides training in all aspects of the industry and covers a wide range of topics. Graduating from the AGWA Fabricator Program will enhance a person’s career prospects and provide a platform for deeper involvement in the industry.

For more information on the AGWA Fabricator Program, including upgrading your Diploma, please contact training@agwa.com.au.

FENESTRATION DIPLOMA PROGRAM GRADUATES

The end of 2023 saw quite a few people complete AGWA’s Fenestration Diploma Program. All these graduates must be congratulated on this achievement as it requires a lot of hard work and commitment to complete 8 On Demand Courses, Intermediate Fenestration and then successfully pass a final exam.

Congratulations to the following people and well done from AGWA, their companies and colleagues:

Lee-Anne McLean, Bradnams, NSW

John Nguyen, Bradnams, NSW

Stuart Neilsen, Windoor Joinery, NSW

Katrina Swiatczak, Architectural Window Systems, SA

Keith Golding, Architectural Window Systems, SA

BUILTVIEW ISSUE 19 Autumn 2024 29

TRAINING

WA Golf Day 2023

Our 2023 Western Australian Golf Day was held on Friday 13 October at the Wembley Golf Club. Over 100 golfers joined us for a great day on the greens. Thanks to our sponsors Glass Co Metro, Tough Glass, NFK, Glasspower, Breezway, Glasscorp, Cooling Bros, Zone Group, Jason Windows, Glass Australia, Pivotech, Westec, Walshs Glass, AWS, Alchin Long Group, and WA Glass for supporting the event. We look forward to seeing you on the next day on the greens.

BUILTVIEW ISSUE 19 Autumn 2024 30

BUILTVIEW ISSUE 19 Autumn 2024 31

WILYABRUP FARMHOUSE: SUSTAINABLE CRAFTSMANSHIP

The Wilyabrup Farmhouse, located in the scenic Margaret River region of Western Australia’s southwest, is an example of contemporary rural architecture. The region renowned for its contrasting seasons — warm, dry summers and cool, wet winters — demanded an energy-efficient, off-grid home capable of year-round comfort. The property owners commissioned Holst Design + Build for the project, wanting a modern farmhouse that would gracefully meld with its natural surroundings.

Constructed using local granite and Shou Sugi Ban jarrah, the residence elegantly integrates holistic design practices, sustainability and craftsmanship. The efforts did not go unnoticed as the home clinched six awards at the MBA’s 2023 Housing Excellence Awards, including Best Country Home in the Southwest Region and Best Contract Home in the $2.5 million$3.5 million bracket.

Builder Jarrod Holst, and his in-house architect, took advantage of the property’s generous footprint to optimise orientation, capturing views, sunlight and natural ventilation throughout the year. ‘Our clients sought to leverage the northern sun for heating and cooling, while also mitigating the harsh lateafternoon sun from the west’, explained Holst. The design thoughtfully navigates these environmental factors, offering oceanic vistas to the West and dam and bush views towards the Northeast and North. To offset the impact of the intense summer sun, a spotted gum batten system was integrated into the western gable.

The residence relies on 74 solar panels coupled with battery storage, highly efficient insulation and ventilation, and hydronic underfloor heating to meet the owners’ offgrid, year-round living requirements.

Of pivotal interest is the inclusion of Capral Aluminium window and door joinery, particularly the 425, 50 Series Awning, 225 Door, and 900 Series door systems, all finished in Monument Matt GL229A powder coat. This strategic selection has multiple advantages:

• The double-glazed windows and doors significantly contribute to the home’s 7-star energy rating. ‘Once heating is activated, it’s crucial to keep it within the structure. Double glazing was paramount’, affirmed Holst.

• Capral’s engineering expertise ensures ease of operation, aligning with the homeowners’ desires for daily comfort by harnessing natural environmental conditions.

• The Monument Matt finish complements the home’s metal cladding and roofing, creating a visually cohesive design. ‘Capral seamlessly integrates into our designs, delivering both aesthetic and functional value’, Holst noted.

BUILTVIEW ISSUE 19 Autumn 2024 32 CASE STUDY

Fabricated by Busselton Aluminium Windows & Doors, these specialised windows and glazing systems reflect Holst’s commitment to quality and sustainability. ‘Capral produces proven window sections’, Holst added, highlighting the long-standing, trust-based relationship between his firm and their fabricator.

The home’s 450 sqm footprint incorporates a material palette that deftly blends traditional and modern farmhouse elements. The living area showcases century-old, salvaged timber beams and a doublesided stone fireplace made from regional granite. In a first for the firm, Holst employed Shou Sugi Ban timber for the facade, praising its low-maintenance qualities. The charred jarrah was supplied by Mortlock Timber, a West Australian specialist and is something Holst intends to use in future projects.

The Wilyabrup Farmhouse is more than a residence; it is an integrated ecosystem where each component, from locally sourced stone to Capral Aluminium joinery, fulfills a unique yet interconnected role. This architectural home underscores Holst’s relentless commitment to design and sustainability, attributes that have garnered welldeserved industry recognition.

As the building industry endeavours to reconcile built environments with natural landscapes, the Wilyabrup Farmhouse serves as an archetype, championing sustainability without compromising aesthetic finesse or functional utility.

For more information, please contact Kellie Moore at kellie.moore@capral.com.au

BUILTVIEW ISSUE 19 Autumn 2024 33

SUMMARY OF THE KEY CHANGES IN AS 2208: 2023 SAFETY GLAZING MATERIALS IN BUILDINGS

Siddharth Kumaran Graduate Engineer, AGWA

In the ever-evolving landscape of the glass industry, ensuring the safety of the occupants interacting with glass is paramount. This is the key reason the Australian Standard AS 2208: 1996 has been superseded with AS 2208: 2023, which brings forth significant changes that redefine the regulatory parameters for safety glass in Australia. These changes came into operation on 15 December 2023.

Let’s delve into the key changes:

AS/NZS 2208 becomes AS 2208

The Standard was prepared by the Joint Standards Australia/Standards New Zealand Committee BD-007, to supersede AS/NZS 2208: 1996. However, after consultation with stakeholders in both countries, Standards Australia and Standards New Zealand decided to develop this document as an Australian Standard rather than a joint Standard.

New Normative Appendix for Curved Glass Impact Test

A noteworthy addition is the incorporation of a new normative Appendix J in the Standard which provides guidance on the impact test of curved glass.

Bid Farewell to Wired Glass and Plastic Material Glass

One of the major changes is the removal of the category Grade B Safety glass from the Standard which had consisted of Wired Glass and Plastic Material Glass.

Upgrade on Fragmentation Test

The revised Standard nominates the minimum particle count for additional glass thicknesses for fragmentation testing, which now extends to 15 mm, 19 mm, 22 mm, and 25 mm glass under AS 2208 Table 3.2 for Grade A Safety Glass.

Expansion of Laminated Glass Thickness

Laminated glass sees an expansion with the inclusion of two new nominal thicknesses: 20.38 mm and 24.38 mm.

New Thickness Limit Defined for Patterned Glass

The thickness for patterned glass should be measured from the lowest indentation. Also, for 6 mm patterned glass, the upper thickness limit of acceptance has been lowered from 7 mm to 6.5 mm

Please note that the thickness of patterned glass advertised by the supplier might differ from its actual nominal thickness. Furthermore, some patterned glass in general may not be able to satisfy the tolerance limits provided in AS 1288 Table 2.1. In this case the minimum thickness of the glass must be used to determine the nominal thickness of the glass.

BUILTVIEW ISSUE 19 Autumn 2024 34 TECHNICAL

MINIMUM THICKNESS OF GLASS

ComfortEDGE™ double glazed windows and doors, are for architects and building designers who don’t want to compromise on performance, style and affordability. Fabricator: Coastline Architectural Windows For more information: specifyaws.com.au ComfortEDGE TM 7 star solutions Give your project the Uw From 1.9

SAFETY

SEXUAL HARASSMENT: A NEW POSITIVE DUTY CHANGES TO AUSTRALIAN WORKPLACE LAWS

Ingrid Pagura Industry Development Coordinator, AGWA

In late 2022, the Anti-Discrimination and Human Rights Legislation Amendment (Respect at Work) Act 2022 (Cth) came into force. While most of us did not take much notice at the time, you will now need to pay close attention because parts of those amendments will impact your daily life in the workplace. From 12 December 2023 , major changes came into operation. The main impacts on workplaces will be the following:

• Introducing a positive duty on employers and PCBUs (Business owner/ Directors/Self Employed) to eliminate workplace sexual harassment.

• Introducing a positive duty on employers and PCBUs (Business owner/ Directors/Self Employed) to eliminate sex-based harassment and subjecting a person to a hostile work environment on the grounds of sex (both new).

• The positive duty relates to all workers but also anyone else visiting the worksite such as customers and contractors.