WE’RE MORE THAN UNIQUE, WE’RE AUSTRALIA’S LARGEST MANUFACTURER AND SUPPLIER OF WINDOW & DOOR HARDWARE

WE’RE MORE THAN UNIQUE, WE’RE AUSTRALIA’S LARGEST MANUFACTURER AND SUPPLIER OF WINDOW & DOOR HARDWARE

MAJOR EXHIBITION SPONSOR

CASUAL DINNER SPONSOR

WELCOME PARTY SPONSOR

GOLD SPONSOR

SILVER + LANYARD SPONSOR

MAJOR EXHIBITION SPONSOR

DAY 1: Exhibition Open 8.00 AM to 5.00 PM Norfolk Hall, Prince and Monarch Rooms

DAY 2: Exhibition Open 8.00 AM to 3.00 PM Norfolk Hall, Prince and Monarch Rooms

Find out more about the Genuine Hush™ range

Genuine Hush™ is Australia’s noise-reducing glass choice for homes, offices, and public buildings. Products include ComfortHush™ and QLam Hush™. Look for the label to identify your glass is Genuine Hush™ made by Oceania Glass.

oceaniaglass.com.au

Kommerling

Kommerling Cyncly

Cyncly

Overseas Glass Agencies

Overseas Glass Agencies

Overseas Glass Agencies

A+W Software

Fenestration Solutions Australia

Fenestration Solutions Australia

Elegant IG

Elegant IG

Glaston Finland OY

Klaes

Siegware

EnduroShield

Viridian

Quattrolifts

Quattrolifts

Aluflam Australia

Aluflam Australia

Proctor Group Australia

GRC Tooling

Aluplast Aluplast

Breezway Australia Deceuninck

Orgadata Biesse Group

Glassworks

Antas Sealants & Adhesives

Elite Security Screens & Doors

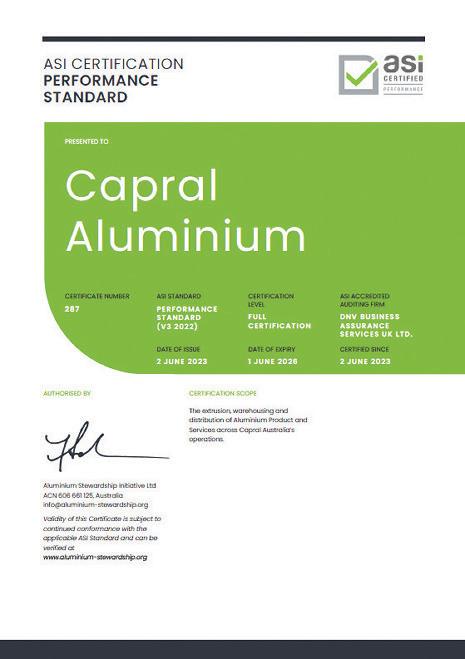

Capral

Interform Supplies

Techni Waterjet

Doric

Doric

Doric

Admil Sealants & Adhesives

Admil Sealants & Adhesives

Azuma Design

NFK Glazing & Industrial Supplies

LandGlass Technologies

Guru Corporation

CR Laurence

EBSA

EBSA

Oceania Glass

Lincoln Sentry Bostik

Oceania Glass EBSA EBSA

Modern Frameless Glass Systems

G.James

Parkwood Doors Doric - Coffee Cart Deco - Coffee Cart National Glass - Coffee Cart

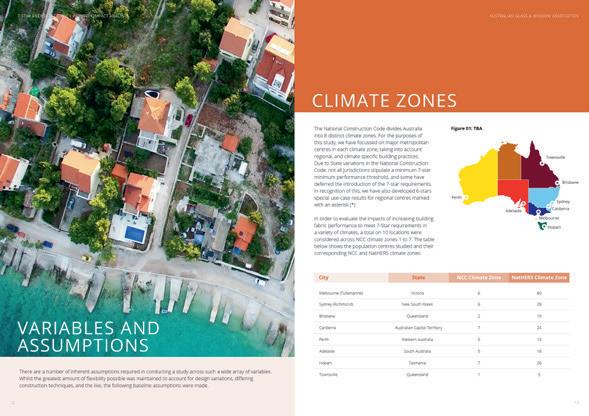

North, South or somewhere in between... Viridian has a solution to meet 7 Star compliance for every region in Australia.

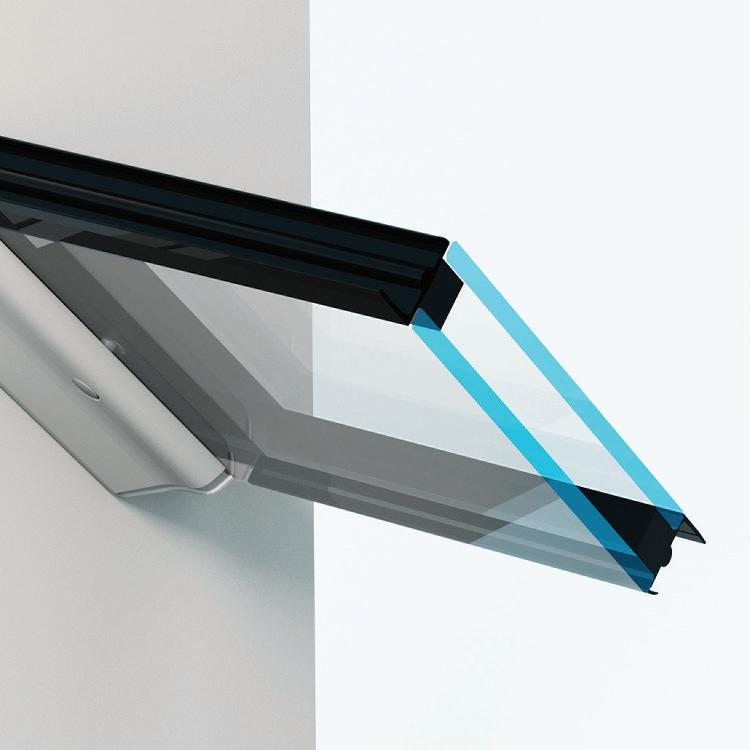

Double glazing will improve the comfort and liveability of your home, it is a simple and e ective way to reduce energy bills and cut carbon emissions. We have provided our key double glazing solutions that work towards better insulation and 7 Star compliance.

ThermoTech™

SUITABLE FOR WARMER CLIMATES

ClimaTech™

SUITABLE FOR MIXED CLIMATES

LightBridge™

SUITABLE FOR COOLER AND MIXED CLIMATES

Products in the ThermoTech™ range are ideal for keeping your space comfortable and naturally lit with energy e cient benefits.

ClimaTech™ is a great option for those wanting double glazing on a budget.

LightBridge™ o ers exceptional insulation, using a high performance Low E glass with a thermal spacer.

For more information visit viridianglass.com or call 1800 847 434

Laureate Professor Veena Sahajwalla (UNSW) | Sponsored by AWS

Enjoy a 2-course lunch while listening to an inspirational speaker and networking with your peers.

Where: RACV Royal Pines Resort - Videre Restaurant

Time: Wednesday 12:30 PM

Sponsored by Doric

Enjoy a delicious buffet dinner on on the Podium Lawns with entertainment and take the chance to catch up with colleagues and friends.

Where: RACV Royal Pines Resort - Podium Lawns

Time: Wednesday 6.30 PM to 9.30 PM

MC: Andrew Daddo | Band: The Filthy Animals

For our final night, join us in the Royal Benowa Ballroom for the 2023 AGWA National Design & Industry Awards Gala Dinner as we celebrate our amazing achievements in the industry. Includes a 3-course dinner, drinks (beer, wine and soft drinks) and entertainment.

Where: RACV Royal Pines Resort - Prince and Monarch Rooms

Time: Thursday 6.30 PM to 11 PM | Dress Code: Formal

PROGRAM: TUESDAY 29

Sponsored by Viridian and Tomma

Sponsored by Southern Star Group of Companies

Royal Benowa FoyerMarquis Room

Welcome

Housekeeping and Opening Rob Carlton | Conference MC

Welcome Address

and Monarch Rooms Prince and Monarch Rooms

Keynote 1

Keynote 2

A Clear Future - Adapting to Change

Jason Clarke | Minds At Work | Sponsored by Capral

Change in the Regulation Space (2025 and beyond)

Russell Harris (AGWA) and Michael Reid (ABCB)

Morning Tea | Sponsored by GRC Tooling

The Changing Economic Outlook

Keynote 3

Keynote 4

Tom Devitt | HIA

Change or Be Changed - NZ Perspective

Brett Francis and Rob Campion | NZGGWA

12:30 | Ticketed Event - Women In Windows Lunch

12:35 PM | Lunch

Innovation in Construction

Prince and Monarch Rooms

Prince and Monarch Rooms

Prince and Monarch Rooms

Prince and Monarch Rooms

1.50 PM

Keynote 5

Keynote 6 Keynote 7

Professor Chris Knapp | Building 4.0 CRC

Energy and the Future of Buildings

Rob Murray-Leach | Energy Efficiency Council

Energy Sustainability Discussion Panel

Clinton Skeoch | AGWA CEO/Excecutive Director 9.15 AM 2.35 PM 3.20 PM

Clinton Skeoch, Russell Harris, Rob Murray-Leach, Professor Veena Sahajwalla and Professor Chris Knapp

Afternoon Tea

Exhibition Open 8.00 AM to 5.00 PM Royal Benowa Foyer and Marquis Room

Prince and Monarch Rooms

Prince and Monarch Rooms

Prince and Monarch Rooms

Breakout Session 1

Breakout Session 2

Breakout Session 3

Breakout Session 4

Smart Vision for a Sustainable Future

Laureate Professor Veena Sahajwalla | UNSW

Durability is the Key to Net Zero

Professor Michael Stacey | Bartlett School of Architecture London Sponsored by DECO

Managing Hazardous Manual Handling with an Ageing Workforce

Rick Carlei | Quattrolifts

Glass Innovations, Electrochromic Tinting Glass and Solar Facades

Anthony Breach | George Fethers

Energy Ratings in Australia

Prince Room

Monarch Room

Norfolk Hall

Prince Room

Breakout Session 5 Monarch Room

Andrew Wright | CSIRO

All Things IGU

Breakout Session 6

Adam Davies | AGWA

Morning Tea | Sponsored by AGC

Disputes and Non Compliance Investigations

Breakout Session 7

Breakout Session 8

Breakout Session 9

Breakout Session 10

Breakout Session 11

Breakout Session 12

Russell Harris , James Whitehouse and Adam Davies | AGWA

Tangible Benefits of Silicone Sealants vs Organic Solutions in the Facade Sealant Market

John Cook | Shin-Etsu | Sponsored by Admil Adhesives

Lessons Learnt in the Safety Space

Kate Wendt | Dragon Glass

WERSlink and Supporting Efficient Window Selection

Russell Harris | AGWA

Industry Training, Recruitment and Skill Development, Licensing

Melissa Baker and Clinton Skeoch | AGWA | Sponsored by Thermeco

Standards and Consumer Law

Atul Singh and Cameron Spanner | Adams and Partners Law Firm

Transforming Mindsets for Business Growth

Breakout Session 13

Breakout Session 14

PM

Final Keynote

*Please note, Program subject to change.

Leanne Luhrs | DLG | Sponsored by AWS

Laminated Glass – The Fit for Purpose Product for Today’s NCC Requirements

Geoff Rankin & Julia Schimmelpenningh | Eastman Chemical Company

Coming Together to Thrive Through Change

Rob Carlton | Conference MC | Sponsored by Viridian

Norfolk Hall Prince Room

Monarch Room

Norfolk Hall

Prince Room

Monarch Room

Norfolk Hall

Prince and Monarch Rooms

Norfolk Hall

Prince and Monarch Rooms

Rob Carlton is an Australian actor, best known for his Logie winning performance as Kerry Packer in ABC’s Paper Giants.

Rob is also a writer, winning an Australian Writers Guild Award (an AWGIE), for best narrative comedy, for the show he created; Chandon Pictures (STAN). Rob won Tropfest with Carmichael and shane, a short film about a father of twins who chooses a favourite. 2023 sees Rob appearing in Black Snow for Stan, Boy Swallows Universe for Netflix and North Shore for Paramount Plus.

A popular entertainer and true professional, Andrew Daddo is a regular face on Australian television, stage and film.

Andrew’s also carved out a niche as one of Australia’s favourite corporate MC’s and Conference Hosts. He has hosted high profile television events including the Logies, People’s Choice Awards, and the Australian Music Awards. Working across all industries, his clients have included Subway, Mc Donald’s, CBA, Westpac, BT, National Insurance Brokers, AusRail, Baker’s Delight, Engineering group SMEC, Holden, Travellers Choice and Arbonne. Having enjoyed a successful media career that began with Network Ten while an undergraduate at Monash University, then completed his studies majoring in politics/ history, it’s fair to say, there’s not much Andrew has not done or is unable to accomplish. With extensive experience, he believes the secret to a good event is communication with the people as much as the industry.

A Smart Vision for a Sustainable Future: SMaRT Technologies and MICROfactories™ Creating Sustainable Materials and Products from Waste | Women in Windows Lunch Speaker | Sustainability Panel

Professor Veena Sahajwalla is an internationally recognised materials scientist, engineer, and inventor revolutionising recycling science. She is renowned for pioneering the high temperature transformation of waste in the production of a new generation of ‘green materials’ at the UNSW Sustainable Materials Research and Technology (SMaRT) Centre, where she is Founding Director. Professor Veena is the inventor of polymer injection technology, known as green steel, an eco-friendly process for using recycled tyres in steel production.

Professor Veena is the director of the ARC Industrial Transformation Research Hub for ‘microrecycling’, a leading national research centre, where she launched the ARC Research Hub for Microrecycling of Battery and Consumer Wastes this year.

Tom joined HIA as an Economist in 2018. As Senior Economist, he assists in the research and analysis of housing market trends and manages the assumptions and statistical modelling behind HIA’s residential building forecasts. He has also authored many of HIA’s wide range of economics publications.

Before joining HIA, Tom worked as an Economist for private sector consultancies. During this time, he worked on projects engaging with and providing advice to all levels of government, as well as private sector clients and the community sector.

Jason is a Director of Minds at Work, a commercial collective of autonomous thinkers and problem solvers dedicated to supporting anyone interested in Making Things Better. He has worked across most industries and government sectors in Australia.

While establishing Minds at Work, Jason also worked as a lecturer teaching Innovation, Logic and Problem Solving at Melbourne Business School and as a Guest lecturer in Innovation at the Australian Graduate School of Entrepreneurship and for the Stern Business School of New York.

Brett is the CEO of the Window & Glass Association NZ. Five years ago, he helped combine the Window Association and Glass Association together with a common goal and agreed strategies. The Association is the recognised voice of the industry, supporting and education its membership community.

Rob has had a life-long involvement in the window and door industry and brings his experience to the table, working closely with MBIE, BRANZ and other industry bodies on window-related projects, aiding in the fulfilment of the Associations mantra ‘helping to create a better built environment for all New Zealanders’.

Professor Chris Knapp is an experienced leader, educator, design practitioner, researcher and maker and Research Director at Building 4.0 CRC. He previously served as Head of School at Bond University, where he helped establish the Abedian School of Architecture from 2011.

Dr Knapp’s research expertise is in the application of digital fabrication and digital design tools toward transforming the relationship between design and construction. Since 2015, Chris has co-directed Studio Workshop, a practice in Southeast Queensland creating innovative spatial and technical approaches to building-making through digitally-assisted means. His research, teaching, and practice work have been published widely and received national and international recognition.

Rob Murray-Leach, has a background in environmental policy, biology and behavioural sciences and has worked in climate and energy policy for 20 years. Rob founded the Energy Efficiency Council in 2009 as it’s CEO and is now the Council’s Head of Market Transformation.

Prior to the Energy Efficiency Council, Rob worked for industry, government and non-profits, including the Garnaut Climate Change Review, the South Australian Government and the Conservation Council of South Australia. He has contributed to award-winning books on sustainable transport and urban ecology.

Atul is a Director at Adams & Partners in charge of the Litigation Department, covering both Civil and Criminal Litigations.

He has over 17 years of experience in the legal industry in the public and the private sectors, successfully achieving great and practical results for businesses and individuals in New South Wales. His experience expands from extensive court work in litigation & appeals in criminal and civil matters, including contracts, building & construction, contracts, defects, property & development, extraditions and defence proceedings. Atul was also a recipient of the Minister’s Award during his time with the public sector.

Professor Michael Stacey is an award-winning architect, author and professor of architecture, and is a leading international expert in the field of aluminium sustainability. For the past 30 years, Prof Stacey has undertaken a wide range of research, which has focused on the benefits of aluminium in architecture and the built environment.

Stacey’s building designs have been recognised by national and international awards. Stacey’s passion and commitment to design excellence has also seen him develop prefabricated cladding and façade systems, which includes the system used by architect Philip Cox on the Melbourne Tennis Centre. Stacey’s new publication ‘Aluminium: A Studio Design Guide’ will be published in 2023.

Anthony Breach connects Australia’s glass fabricators, façade engineers, architects and building owners with world-leading, sustainable glass and solar solutions.

As National Sales Manager at George Fethers & Co, Anthony brings the latest glass technology to the Australian market, enabling projects that are both beautiful and sustainable.

With over 20 years’ industry experience Russell has a thorough understanding of fenestration, including compliance, product design, development, and testing. Russell’s background in R&D means he is familiar with many of the emerging technologies, innovations and market influences that are likely to impact the industry in the future.

Since joining the Association in 2016, Russell has been a noteworthy leader in the technical space, and an active contributor to the ongoing development of the Regulatory framework affecting the window industry.

John Cook has spent decades in the functional sealant market and is an expert in all aspects of high performance sealants within the Australian market including Structural Glazing, Insulating Glass, Cladding, etc.

John has had extensive involvement with new build and refurbishment projects, including glazing, curtain wall, stone and glass facades as well as knowledge and understanding of both structural and insulated glazing systems.

Julia Schimmelpenningh is the architectural technical engagement manager at Eastman Chemical Company, in Springfield, Massachusetts USA, a global specialty material and chemical company. Her work includes new product development, qualification and commercialisation of laminated glazing solutions, regulatory development and industry education and association support for Architectural Saflex and Vanceva interlayers.

Julia has been a very active and solid contributor in the glazing industry for 30+ years and served as president of the Glass Association of North America and as chair of several committees on ASTM International. She is currently on the ASTM Board of Directors and has been published in trade magazines and peer reviewed journals.

Kate Wendt is a highly skilled professional with expertise in the fields of glazing, joinery, construction, and project management. As a trade qualified glazier and joiner, licensed builder, and qualified project manager, Kate possesses a diverse set of skills that she has honed through her remarkable journey.

During her time in Europe, Kate dedicated three years to mastering the art of glass lamination, immersing herself in the intricacies of the craft. In her pursuit of excellence, Kate established her own lamination line. Despite her growing success, Kate remains committed to being hands-on and personally oversees every job within her businesses, Dragon Glass Lamination and Black Widow Australia.

Anthony leads the Building Energy Efficiency Team at CSIRO. In the last 5 years he has overseen the development of the Australian Housing Database, the redevelopment of AccuRate as a cloud tool, the implementation of new whole-of-house regulations under the NCC 2022, the development of the NatHERS benchmark tool for disclosure, development of the RapidRate artificial intelligence, and many other residential energy efficiency projects.

Prior to his current role, Anthony worked in State Government and in architecture practises as a building designer and project manager, always with a focus on energy efficient residential design.

Cameron was admitted to practice Law in New South Wales in early 2017. Cameron began at Adams & Partners Lawyers as a paralegal, then transitioned into the role of a junior lawyer. In late 2019, at the age of 25, Cameron became the youngest ever Director at the firm.

Cameron has a vast wealth of knowledge in multiple areas of practice including commercial and contractual law, building law, wills and estates and personal injury and workers compensation litigation. Cameron is a people person and enjoys problem solving, which is why he enjoys what he does.

Adam holds a degree in Materials Engineering from the University of NSW and started his glass career as a part-time employee at the Viridian Ingleburn float line in his final year of study. After graduation, he moved into a full-time role as a Process Engineer and later to Technical Manager at Viridian. Adam has seen most aspects of the industry.

Adam has brought a new structure and process development skills to the AGWA Accreditation Programs to support members, drawing on his experience in glass processing, warranty investigation and reporting, and product testing.

Rick graduated as a chiropractor 1987 and operated chiropractic clinics from 1987-2004. He is an OHS consultant specialising in hazardous manual handling for various companies including Pilkington Glass/ Viridian, A&L Windows, Amcor, Visy, Olex Cables and various councils around Victoria.

In 2006, Rick started Quattrolifts Glass Handling equipment, which manufactures and exports glass handling equipment to North America, Europe and Asia.

Melissa has worked in the training industry for more than 20 years, most recently in the VET sector at TAFE NSW. She has a wide range of training and management experience across a variety of sectors, including in a head teacher capacity.

At AGWA Melissa works with our industry subject matter experts to develop new and improve resources for our members. This has included training courses, both on demand and instructor led, safety resources, the new AGWA website, Events and AusFenEx23. Melissa is also the co-editor of BuiltView Magazine.

Leanne is a seasoned business owner with over 27 years of experience in the glazing industry and has honed her skills in decision-making and adapting to an ever-changing market. Leanne knows the importance of adapting to change and taking calculated risks to grow a business. Her hard work and dedication have not gone unnoticed, as she was the inaugural winner of the Women in Windows Award.

Despite her busy schedule, Leanne never loses her passion for work and always looks for new opportunities to grow and improve her business.

Michael Reid’s role involves oversight of technical projects which lead the development of changes to the National Construction Code. He also sits on various technical and standards committees and has a particular interest in structural performance, climate change resilience and adaptation of buildings, and external envelopes.

Prior to joining the ABCB, Michael was a building façade engineer working on national projects in Australia, the United Kingdom and the Middle East. He is a Chartered structural engineer and with his industry nous and a solid technical background, Michael is passionate about driving positive change in the built environment.

While there are increased minimum performances within the two key glazing factors (U-Value and SHGC), don’t ignore other key performance factors that impact aesthetic and comfort of homes:

U-VALUE:

Think of this as a measure of Insulation – how much internal heat escapes through the glazing, per m², when it is colder outside than inside, as heat wants to move from where it is hot to where it is not. The lower the U-Value, the better the Insulation.

SHGC:

Solar Heat Gain Coefficient. This is a measure of Solar Control –how much heat from the sun enters inside the building through the glazing. The higher the SHGC, the more passive heat from the sun enters inside while the lower the SHGC, the less sun heat enters in.

VLT:

Visible Light Transmittance is how much % of sunlight enters inside through the glass. The lower the VLT, the less light enters, and also affects the look and clarity of the glass. For Residential homes we generally want higher VLT to allow high levels of natural light inside.

SELECTIVITY:

This is a ratio that looks at the relationship of VLT and SHGC as we must be mindful of what impact lower SHGC has on the amount of natural light ingress. A ratio of 1.25 is considered great while a ratio over 2.0 is extremely high performing and even more beneficial. Also known as Light to Solar Gain ratio (LSG).

QUALITY:

The processing of glass opens up the potential for quality issues. The Heat Treating of glass for example (Toughening and Heat Strengthening) can see distortion affect the reflection on the glass. Reflections should be as close to a mirror-like reflection as possible.

COMPLIANCE:

Compliance to not only the NCC 2022 demand of Total System U-Value and SHGC, but also processing standards such as AS 2208 for safety glass and AS 4666 for Insulated Glass Units (IGU). All Australian Glass Group plants are certified to these standards.

Australian Glass Group also understands the vital importance of certification and compliance of glass products. Our products are manufactured and certified to Australian Standards by an international certification body and compliance is certified and available on request in key areas including;

See our Insulglass® Projects at www.agg.com.au/about/projects

Insulglass ® Double Glazed Units - available in a full range of options to suit your needs;

A full range of non-coated DGU options, surpassing any single glazed option in terms of insulation.

An ideal LowE for Warmer climates to minimise Glare and a balance of Solar Control and great Insulation.

An ideal LowE for Colder climates with maximum Visible Light, Passive Heat Gain and excellent Insulation.

Excellent performance to advance both Solar Control and Insulation without compromising Visible Light.

Superior performance to maximise both Solar Control and Insulation without compromising Visible Light.

Spadaccini Homes Cooling Brothers Glass Company

Birchgrove Residence Bent and Curved Glass

Cedarhill Tweed Coast Glass

Peninsula House Creative Windows

Alvie House European Window Co

Mangerton Residential Australian Glass Group

Spadaccini Homes Cooling Brothers Glass Company

Birchgrove Residence Bent and Curved Glass

Cedarhill Tweed Coast Glass

Peninsula House Creative Windows

Alvie House European Window Co

Mangerton Residential Australian Glass Group

Glass Co Metro Showroom Glass Co Metro

Emmerson Jason Windows

Altair IGLU Double Glazed Louvre System Breezway

Flush Drain Sill System

G.James Windows & Doors

Umbra Flush Mortice Lock Doric Products Pty Ltd

Bruce Rocksberg House Dowell Windows + Doors

Glass Co Metro Showroom Glass Co Metro

Emmerson Jason Windows

Altair IGLU Double Glazed Louvre System Breezway

Flush Drain Sill System

G.James Windows & Doors

Umbra Flush Mortice Lock Doric Products Pty Ltd

Bruce Rocksberg House Dowell Windows + Doors

BuiltView Magazine is a quarterly publication of the Australian Glass & Window Association.

EDITORS

Melissa Baker, Ingrid Pagura

SUB EDITOR

Helen Dawes

DESIGN

Webqem Pty Ltd

Ahmad Awick, AGWA

EDITORIAL & ADVERTISING

ENQUIRIES

Helen Dawes

+61 2 9498 2768 marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208

Suite 1, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073 +61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

COVER IMAGE & CONTENTS PAGE IMAGE

835 High Street, Armadale, VIC

Project by Thermeco

Architect: Carr Design

Builder: Flux Construction

Fabricator: European Window Co

Photograph: Rory Gardiner

CONTRIBUTORS

Clinton Skeoch, Atul Singh, Todd McInnis, Maurice Tapang, Craig Howard, Horst Mertes, Joost Bouten, Luca Mosca, Shane McDuff, Ingrid Pagura, Adam Davies, Mari Lehtinen, Roger Bishop, Joshua Ianni, Lido Russo, Kellie Moore, Emma Savage, Lee Thurbon, Helen Dawes, Melissa Baker, Vivienne Munter, Kerrie Henderson, Ahmad Awick and Dominique Macartney.

PRINTED BY

SOUTHERN IMPACT southernimpact.com.au

Our printer conforms to the ISO-14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY D & D MAILING SERVICES www.ddmail.com.au

BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2023. All rights reserved.

Reproduction in whole or part without written permission from AWAAGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary seek professional advice.

It is with great pleasure that I address you in this edition of BuiltView Magazine. While for many the NCC 2022 general provisions are in place, with the announcements and timelines a distant memory, the livable housing and energy-efficiency measures have not yet been adopted. However, in the rugged world of construction policy, not all is as it seems with several key sector groups pushing hard for up to a further two-year delay in the adoption of these important measures. As an industry we have invested well over $180 million in capacity, machinery, tools, training, product development and people to meet the new energy-efficiency measures. Our message to the various state and territory governments has been focused on ensuring they hold the line. Through numerous meetings and calls with departments, advisors and ministers we have emphasised the need to maintain the successful implementation of the National Construction Code 2022 (NCC 2022) with the previously announced time frames.

While it is true that we have experienced some minor slippages in the adoption time frames, they have not been of the size and quantum advocated by some builders and feared by many of them. AGWA has been unwavering in its focus on advancing energy efficiency in the built environment and the investments and support of our members has been pivotal in demonstrating the industries preparedness and future focus. I want to take a moment to thank those who have assisted us on this journey.

In parallel to this key advocacy journey, we have been working closely with the NSW Government to engage in the development of the draft trade licensing frameworks for the new NSW Building Act and we hope that these changes will form the foundation of further licensing improvements across the country. In support of this important agenda, I would like to extend my gratitude to the NSW Chapter for their invaluable support and feedback in this endeavour.

While ongoing consultations with the NSW Government are still underway, the latest guidance at the time of writing this, is that is that it is highly likely that a Glazing License will be mandatory for all building classes, including commercial structures, a large expansion of the current licensing framework in NSW. Furthermore, the value of monetary threshold for work is likely to be reduced with any glazing work exceeding $3,000 in value being likely to require a license. This development signifies a significant step forward in ensuring the highest standards of professionalism and expertise in the glazing industry. We remain committed to advocating for the best interests of our members and will continue to consult with the NSW Government to shape the final trade licensing frameworks and keep our members up to date with progress.

On a separate note, I would like to take this opportunity to express my sincere appreciation to Roy Loftus of Nu-Look Glass and Aluminium Windows in WA. After many years of dedicated service to AGWA and AWA, he has stepped down from the AGWA Board. His contributions have been invaluable, and the Board and I are grateful for his commitment, candour, perspective and engagement with the Association particularly during its formative stages.

With this change in WA and the recent passing of Liz North, the AGWA Board had vacancies for the WA and the NSW window board positions. Given this, I am pleased to announce the appointment of Daniel Gaunt from Glass Co Metro in WA and Chloe Luhrs from DLG Aluminium and Glazing from regional NSW as our new sector representatives. Both Daniel and Chloe bring strong industry experience and a fresh perspective to the Board. We look forward to their contributions in driving our Association's vision forward.

As we forge ahead, I encourage all members to remain engaged and to actively participate in our initiatives. We have a lot on and a lot to achieve. If you have any questions, I encourage you to reach out to me or the team.

I look forward to seeing you at the AusFenEx23 Conference and celebrating all that is great about our industry as we learn about the opportunities ahead.

Dean Haritos Chair

Clinton Skeoch Secretary

Deb Deeth Member

Greg Hunt Member

Corne Kritzinger Member

Chloe Luhrs Member

Peter den Boer Vice Chair

Tony Paarhammer Treasurer

Daniel Gaunt Member

Scott Kelly Member Perry Long Member

Dean Haritos Chair

Clinton Skeoch Secretary

Deb Deeth Member

Greg Hunt Member

Corne Kritzinger Member

Chloe Luhrs Member

Peter den Boer Vice Chair

Tony Paarhammer Treasurer

Daniel Gaunt Member

Scott Kelly Member Perry Long Member

COVER AND CONTENTS:

One of our design entries in the 2023 AGWA Design Awards

Welcome to 835 High St, Armadale. Featuring an architectural language of its own, the building of 835 High St is shaped by a distinctive grid pattern. Every horizontal and vertical frame aligns perfectly from the outside over five levels, one atop the other in a linear pattern. The façades to the east and south are highly refined and detailed, while those to the north and west gradually step back, wrapping around and dissolving the form with the use of the framing. The effect is calmness through consistency, balance through repetition. The minimal windows and glazing together with the colour palette, design and materials creates a humble and enjoyable site.

Atul is a Director at Adams & Partners in charge of the Litigation Department, covering both Civil and Criminal Litigations. He has over 17 years of experience in the legal industry in the public and the private sectors, successfully achieving great and practical results for businesses and individuals in New South Wales. His experience expands from extensive court work in litigation & appeals in criminal and civil matters, including contracts, building & construction, contracts, defects, property & development, extraditions and defence proceedings.

Atul was also a recipient of the Minister’s Award during his time with the public sector.

Ingrid Pagura Industry Development Coordinator, AGWAIngrid began her role with AGWA in May 2021 looking after the training needs of members. Her role soon progressed to include working on BuiltView, the AGWA Design Awards, the website and other marketingrelated activities.

Prior to AGWA, Ingrid worked for a legal publishing company as an editor, a publishing manager and then an editorial trainer. Her time at Butterworths saw her work on their building and local government and environment suite of products and with the CSIRO and ABCB on other BCA projects. She also previously worked for many years as a part time teacher at TAFE teaching law, business, communications and work health and safety across multiple faculties.

Horst has been working in the software industry for glass and window processing for more than 37 years. He speaks seven languages fluently and has been working world-wide promoting and developing integrated and modern software solutions to the marketplace. In 2007, Horst joined US-based software specialist FeneTech as VP of Sales & Marketing. Today FeneTech is part of the Cyncly group of companies who employ more than 2400 talented software specialists. FeneTech offers a leading completely integrated and modern software ERP solution which has been installed in more than 220 companies world-wide, including Australia. Horst has spoken at various other conferences worldwide including GPD, GPAD or other industry events.

Luca Mosca Sales Area Manager, Monticelli

Luca's role at Monticelli is to provide companies with assembling solutions useful to improve both quality and production of their Aluminium Systems. Luca oversees the Northern European, Eastern European and Oceania markets. Monticelli is the only company specialised exclusively in corner joints, from their design and development to the manufacture of the finished piece, which is fully carried out in Italy. Monticelli’s purpose is to ensure that each profile is perfectly connected and aligned, combining quality, speed and affordability. This attention to detail translates into top quality corner joints, with a vast range of over 4000 products.

Joost Bouten Sales Director, Orgadata AustraliaJoost Bouten started in the window and door industry assembling and installing. After graduating as a Mechanical Engineer and working for several years as Facade Engineer, he graduated in Business Management and started as first employee for the software company Orgadata Benelux. After making Orgadata Benelux market leader, Joost moved to Australia to setup the Australian department.

Craig Howard is the Managing Director of EnduroShield and with over 20 years’ industry experience, he has a deep understanding of the challenges involving glass faced by processors, architects, designers, building owners, installers and end users and is dedicated to finding solutions to these challenges. Under his leadership, EnduroShield has become a leading provider of glass protection solutions, helping to enhance the durability and longevity of glass surfaces. With Craig's commitment to excellence and his technical expertise, EnduroShield continues to deliver impressive results and make a positive impact on the industry.

Todd McInnis Senior Economist, HIATodd is an economist with over 15 years' experience in a broad range of fields. Prior to joining HIA, he spent two years as an independent contractor with the government and private sectors. He is currently completing a Masters degree in Applied Economics with Macquarie University.

Adam Davies Accreditation/IGMA Manager, AGWA

Adam Davies Accreditation/IGMA Manager, AGWA

Maurice graduated with a Bachelor of Economics from the University of Sydney in 2021, majoring in Financial Economics and Econometrics. Maurice comes from a construction background, with his family involved in the quarrying, hauling, earthmoving, and waste business in the Philippines.

Adam holds a degree in Materials Engineering from the University of NSW and started his glass career as a parttime employee at the Viridian Ingleburn float line in his final year of study. After graduation, he moved into a full-time role as a Process Engineer and later to Technical Manager at Viridian. Adam has seen most aspects of the industry. Adam has brought new structure and process development skills to the AGWA Accreditation Programs to support members, drawing on his experience in glass processing, warranty investigation and reporting, and product testing.

Can award entitlements such as penalty rates, allowances, and loadings be included within an employee’s salary or wage? One of our goals is efficiency in record keeping and calculating payroll.

It is common practice to include award entitlements within a salary or rate of pay, which is usually fine so long as:

• an employee's total remuneration is no less than their award/enterprise agreement requires;

• there is a written agreement acknowledging that certain award entitlements are included within an employee’s remuneration; and

• employers keep adequate records of hours worked and duties performed.

In the case of any employees who have a guarantee of earnings in place and who are paid above the high-income threshold (HIT), this becomes a moot point as Modern Awards do not apply to them because their income is deemed adequate compensation for all Award entitlements. The high-income threshold as of now (April 2023) is $162,000 per annum.

For employees below the HIT (or above the HIT without a guarantee of earnings), the employee’s specific Award/Enterprise Agreement is very important as many have clauses that will describe exactly how certain entitlements can be included within the salary or rate of pay.

For instance, a small number of Modern Awards incorporate a similar concept as they have a ‘salary absorption’ clause that exempts managerial staff from specific award entitlements above a certain salary threshold.

Many Modern Awards now incorporate an ‘Annualised Wage Arrangements’

model clause which details the minimum requirements for such an arrangement:

1. The clause first lists those penalty rates, allowances and loadings that can be included within an annualised wage.

2. It requires that a written agreement be made specifying:

• which of the provisions of the award will be satisfied by payment of the annualised wage;

• the method by which the annualised wage has been calculated, including specification of each separate component of the annualised wage and any overtime or penalty assumptions used in the calculation; and

• the maximum limit on what the annualised wage will cover whereby any hours worked beyond that limit would earn additional pay in accordance with the award.

3. At least once every 12 months employers must calculate the total remuneration an employee would have earned if paid according to the award ie, earning the award minimum rate plus all other applicable award entitlements (eg, penalty rates, allowances, loadings etc) for the exact hours they worked. If their annualised wages fall short of the award, and the shortfall wasn’t made up in the relevant pay cycle when it occurred, then employers must backpay that shortfall in the annual review.

4. The employer must keep a record of the starting and finishing times of work, and any unpaid breaks taken, by each employee for the purpose of undertaking the 12 months’ comparison mentioned above. This record must be signed by the employee each pay period or roster cycle.

Many employers question that fourth point as they hope to avoid such onerous time and record-keeping requirements. The good news here is that in practical terms employers only really need to keep records of hours worked and duties performed outside of those that the annualised wage has been calculated to cover. For example, let’s say an annualised wage was calculated to compensate for an average of 45 hours work per week (inclusive of applicable overtime and shift penalties under their award), and presumed no weekends or

public holidays would be required. Then employers only need to record hours outside those parameters ie, hours beyond 45 per week, and any weekend or public holiday hours, or when the employee was filling for another on higher duties. Then these extras would have to be paid for separately within each pay cycle, to comply with the annualised wage clause.

Another way to incorporate award entitlements into a higher salary or rate of pay is through a written Individual Flexibility Agreement (IFA). However, the two major drawbacks to an IFA are that first they cannot be made a condition of employment (ie, they can only be made with an existing employee, not a new candidate) and second, either party can unilaterally cancel the agreement with 13 weeks’ notice.

Thus, the approach that is generally the most recommended when wanting to incorporate award entitlements into an employee’s remuneration while ensuring that they are not underpaid, and minimising the record-keeping burden, is to use a compensation for legal entitlements clause or offset clause in an employee’s common law contract. Such a clause should make clear that both parties agree that the remuneration specified in the employment contract compensates the employee for any award entitlements (such as wages, overtime, allowances, penalties, and loadings) that may arise for any hours worked in the course of employment.

Of course, the remuneration provided must meet or exceed what the award requires for the same hours and duties performed. It is highly recommended that employers seek legal advice on the drafting of such clauses and ensure the correct award that covers the employee (if any) is identified as well as the relevant classification.

The bottom line: Employers can incorporate award entitlements into a higher remuneration, so long as a written agreement is in place, specifying what entitlements are compensated for and employers ensure an employee’s remuneration does not fall below what the award requires. Employers must maintain adequate records of work performed because the onus of proof is always on employers in answering any underpayment claim.

Having a worker who has been off on leave due to an injury or illness can be stressful for everyone involved. Having that worker return to work can also be stressful for everyone involved. Your injured worked doesn’t need to be fully recovered or finished their medical treatment for them to return to work. Often complete recovery doesn’t happen until they are back at work. Generally, returning to work post-injury isn’t always easy but long-term absences from work have negative health impacts, including the reduced likelihood of ever returning to work.

Returning to work has benefits for all involved. For injured workers returning to work can:

• Enhance the recovery process

• Increase social participation and confidence

• Decrease the physical, psychological, social and economic effects of being absent from work.

For employers, playing an active role in the return to work can:

• Help your worker recover faster

• Keep the skills and knowledge of the worker in the business

• Reduce costs associated with finding and training new staff

• Build morale within the workplace.

A gradual return to work can help as it can help minimise the risk of being injured again or making the original injury worse. As an

employer you are required to provide modified or gradual return to work options

This is a complex situation and varies from person to person, however a successful return to work is more likely if done gradually. Often, even starting these conversations can be daunting. Safe Work Australia has put together a guide for supervisors in small and medium businesses to help with this. It is called Managingthe RelationshipwithanInjuredorIllWorkerDuringReturntoWork. This Guide covers the process from the injury to the return to work, including conversation starters. That first step is often the hardest. It includes suggestions as to what to include in conversations, checklists and even how to talk to the rest of the team. It is really an invaluable tool that can help take the awkwardness out of a difficult situation.

If you would like a copy of the Guide, please see safeworkaustralia.gov.au or contact AGWA at training@agwa.com.au.

It is with great pleasure that I announce that the 2023 AGWA Safety Award finalists are:

1.Lucidity Rollout by Glass Co Metro (WA)

The system provides a ‘single source of truth’ and clear visibility as well as integrated and automated reporting including safety goal tracking, task completion status on actions from audits or inspections, and incident management. It gets rid of the standard paper types of systems used traditionally by businesses of our size and makes reporting easier. We would be able to demonstrate due diligence and sound record keeping should a serious incident occur.

2.Heavy Lifting Safety Solution by Festival Glass (SA)

This Festival Glass & Glazing safety improvement program identified the need to eliminate soft tissue and back injuries by investigating and then implementing factory and onsite mobile mechanical lifting equipment, to ensure a safer and more productive workplace. This fundamental program has been an exciting and valuable WHS benefit to our team now and into the future, and our team continue

to see the benefits by working and staying safe. We believe that the results speak for themselves – the complete elimination of all soft tissue injuries in the 3 years since the implementation of the solution is an award-winning achievement for our team and an outstanding example of continuous WHS improvement that can benefit the glazing industry.

3.No Injury November by AGG (NSW)

The AGG NSW ‘No Injury November’ initiative was designed to find practical ways to have safety ‘top of mind’ during the busiest time of the year. A heavy focus in one month with activities, prizes, training and guest speakers and designed to kick start a more intense focus on safety that continues throughout the year. Also hoping it can be embraced by other companies to improve the safety of all industry participants.

Engagement was pleasantly encompassing with all team members being active and contributing. We continue to witness validated effectiveness as it is still referred to today (5 months later) and we are especially proud of the team.

4.Partnership with University of SA to host final-year Physiotherapy students by Aussie Aluminium (SA)

The work performed to manufacture aluminium windows and doors is very labour intensive, with an ageing experienced workforce, combined with architects designing bigger and bigger doors and windows the importance of working safely i s now at the forefront of our core responsibility as an employer. The partnership between Aussie Aluminium and the University of South Australia has enabled business owners, Davis and Tiffany Perin to implement and provide their staff with a much safer, compliant workplace for their employees. The reports presented by the students have assisted in the strategic planning for preventing workplace injuries and many of the recommendations given have been implemented. We currently have students researching an industry-specific manual handling training package that we will use as part of our staff training.

The main driver of Australia’s housing shortage is population growth — more people needing more houses. In the year to September 2022, Australia’s population grew by 1.63%, up on its 10-year average of 1.36%. So, not only do we need more houses, but we actually need more than previously thought.

Adding to that pressure is the fact that the average household size has been consistently falling over the past few decades — or in other words, the same number of people need more houses today than they did in, say, the early 1990s. These pressures are not likely to change anytime soon as people these days have fewer kids and are more likely to live by themselves. So, we don’t have enough houses to cater for our existing population, let alone one that’s growing at around 400,000 people per year. And, given that the shortage is nothing new, there’s already an accumulated shortfall. Fortunately, the Federal Government is beginning to recognise this. In its most recent forecasts, the National Housing Finance and Investment Corporation (NHFIC) estimated that by 2028 we’ll have 100,000 fewer homes than we need. This is an under-estimate because it assumed a population growth of around half what we’re currently seeing, and it also didn’t consider an existing shortfall — but that’s another story.

Todd McInnis, HIA Senior Economist Maurice Tapang, HIA Economist.

Todd McInnis, HIA Senior Economist Maurice Tapang, HIA Economist.

The Government’s target of building a million homes over five years from 2024 is similarly a positive development. While it won’t be enough to address the housing shortage, it at least provides a bit of certainty for all those sectors that depend on a strong housing market.

One of the simplest and most obvious ways to boost our housing stock is to attract more foreign investment. The argument that foreign investment takes away from Australians’ housing options does not stack up. Foreign investors have been restricted to only investing in building new apartments across Australia and, therefore, do not compete in the established home market. They can only build new homes. Their exit from the market is a key reason apartment supply is contracting.

The reasons why Australia has under-supplied homes for decades revolve around a systemic failure of government. Here we consider what are probably the two main failures of government: taxes and Regulations.

There are few items in our economy that are more heavily taxed than new homes. There is a long list of taxes, fees and charges imposed on new home building from Stamp Duty through to a ‘temporary levy’ imposed to recover the cost of the HIH collapse in 2001. Governments tax tobacco to impede its consumption, and by t axing new homes, they achieve the outcome of building fewer homes.

The effect is even more pronounced for foreign investors. Attracting more foreign investment to the housing market is one clear way of alleviating the housing shortage. Unfortunately, both state and federal governments have implemented a raft of Regulations and taxes in recent years aimed at precisely the opposite.

All this adds up. HIA estimates that an overseas investor looking to purchase an average property in Sydney — by far the largest market — must pay $150,000 in stamp duty, land tax and FIRB fees, around three-quarters of which is solely through foreign surcharges. Altogether, stamp duty, land tax and FIRB fees account for between 15-20% of the median dwelling price in major housing markets.

There are also proposals to tax domestic investors, or restrict short-term rentals, all of which would restrict the supply of housing. Apartment construction remains the cheapest, fastest option to increase the stock of housing in locations

where there are stable and reliable employment opportunities.

For this reason, given the acute shortage of housing stock, the advice to policy makers at all tiers of government, is stop making new homes more expensive. It only makes the problem worse.

Australia ranked at number 80 out of 140 countries in overall burden of government regulation, according to the World Economic Forum’s 2019 Global Competitiveness Report. That’s just behind Vietnam (ranked 79) and well behind China (ranked 19). The housing sector is arguably one of the most heavily regulated sectors in Australia. To be one of the most heavily regulated sectors in one of the most heavily regulated countries does not do much to encourage more housing supply.

Some regulation is necessary, just as overregulation can discourage investment, so too does under-regulation. But Australia is far too heavily swayed toward the former. For example, owner occupiers, especially first home buyers, have been forced away from ownership by increasingly restrictive lending Regulations. These restrictions have been ramped up over the past 15 years, largely because of the Global Financial Crisis in 2008, despite a lack of evidence that there is a problem with mortgage delinquency in Australia. This has resulted in reduced competition for lending to first home buyers and those with less than a 20% deposit. This further reduces the pool of investment for new home building.

Different states and territories also have a raft of different Regulations, which adds an additional challenge for those who operate across borders — which is most. What suffices for one state may not suffice for another, which adds to the overall cost of regulation. One element of this that is often not fully appreciated is the extent to which a heavily regulated society actually generates more self-regulation. Or to put it another way, the more burdensome government Regulations are, the more internal process procedures that private businesses will put in place to ensure they’re compliant with the government’s Regulations.

There are some promising signs ahead for the housing market and all the sub-sectors that depend on it, but government taxes, at both the state and federal level, and Regulations need to be amended if the sector is to work at maximal capacity.

Azuma has installed two new large chambers that are designed for testing up to 20 kPa positive and negative pressures. Highly trained testing technicians will be with you every step of the way to provide all the equipment & guidance that you may require.

These new chambers are capable of testing to the requirements of:

AS2047 - “Windows and External Glazed Doors in Buildings”

AS4040 - Parts 2 and 3 “Method for testing Roof sheet and Cladding”

AS4284 - Testing of building Facades (Cyclic Water).

Each state or territory implements the NCC through its regulatory framework covering building and plumbing work. These changes place additional responsibilities on all builders, developers, and tradies. When entering into a contract (or subcontract), each party must be aware of their obligations and responsibilities under NCC 2022 and the contract that they are taking on board.

This will have a follow-on effect on the materials that you contract to supply/receive. Builders will need to ensure that all documentation they receive from other contractors or subcontractors, including designs and test certificates, is aligned with the NCC 2022. It is important to carry out a ‘health check’ of all your compliance documentation to ensure it meets the new requirements. In some cases, they may require amending to be valid.

Among the new obligations is included a push for more energy-efficient homes. As such, you will need to turn your mind to, and accommodate, better insulation in your contractual documents and consider the performance of windows and solar panels where needed. The minimum level of thermal performance of new homes is to be raised to the equivalent of 7-stars under the National House Energy Rating Scheme. Your contract documents will now need to reflect this depending on the site or location of the build, in order to comply with the energy requirements.

NCC 2022 also places emphasis on improving accessibility and provides specific measurements for constructions of hallways and doors. Standard size hallways and doors previously relied on by builders will no longer be compliant under the new regime. Have you checked whether these obligations have been passed on to you under the contract that you have entered into?

Where, as part of a contract, an owner is to select particular materials or products, you must ensure they comply with NCC 2022. Where a builder engages a subcontractor to install particular product the onus is on the builder to ensure that the materials, products, and method of installation are in line

with NCC 2022 and its objectives. These extra requirements will no doubt reflect on the costs of any contract.

Where an owner wishes to construct a hallway or door in a particular way, they must consider the expressed provisions of the NCC 2022 and its objective of improving accessibility.

Such legal obligations will almost without a doubt be passed onto the installer/ supplier. The question is, are you reading and understanding what contractual (and therefore legal) obligations have been placed on you?

Ensure that in any contract that you enter into you:

• Understand what your obligations are;

• Are clear on which relevant Standard and/or Code is relied upon;

• Have sufficient details in all respects.

If you are unclear, obtain formal verification prior to signing and confirm that all works required of you in the contract are within your expertise.

If you require any legal advice or assistance for personal and/or commercial matters, get in touch with Adams & Partners, Lawyers at multiple locations on (02) 4721 6200 or visit www.adamslawyers.com.au

In light of the new National Construction Code 2022 (NCC 2022), parts of which came into effect from 1 May 2023, are you ensuring that you are aware of what your contractual obligations are?

In the increasingly competitive world of flat glass processing, industry players are not just grappling with the need to automate their machinery and robotics, but also the pressing challenge of outdated and disjointed administrative processes. With a significant portion of businesses still relying on bespoke software solutions or dated packages designed for the industry, they are left confronting issues such as inconsistent data across different databases and subpar system response times — issues that are further exacerbated for companies operating multiple branches nationwide.

This highlights the importance of moving towards a modern, fully integrated ERP (Enterprise Resource Planning) solution that unifies all essential functions within a single central database, from quotation management and production scheduling to invoicing. Such a shift can significantly mitigate these challenges, ensuring smoother operations, better efficiency, and a stronger competitive stance.

An ERP software system is an IT-based system of software solutions helping management to keep track of existing resources and business processes. With the help of an ERP system, management can optimally design, influence and manage all processes effectively. ERP systems are integrated programs and modules based on central data management. Part of the claim of an ERP system is that it is integrative and maps the company, both in the cross-divisional basic functions and in the specialist departments or functional areas of a company.

The efficient storage of large amounts of data, its collection and analysis represent a serious challenge for ERP systems in larger companies and enterprises. Although an ERP system can consist of numerous software modules, it can only fulfill its task across all industries if the data is unique throughout the company and only available once. Information is derived from

data and represents the most valuable asset in companies. That is why clean and valuable data is so important.

The data management itself is one of the most important aspects of modern software ERP solutions. The key is to decide whether to use centralised or decentralised data management. Centralised data management has several advantages over the use of decentralised systems. One key advantage of using centralised data, for example, is the need for a single and central database system. This simplifies the maintenance of collected data, as all data is stored in a uniform structure. This can simplify searching for specific information in the database, as all data is located in the same place. In addition, centralised management will also reduce maintenance costs since there is only a single database system.

An additional advantage of centralised management is improved data security. In a centralised database, permissions can be set for each user so that only authorised individuals have access to specific data. This improved security feature makes it easier to build an overall secure network.

Another important benefit is the streamlining of data access. By using a central database system, users can access the same data even if they are located at different sites. This allows the company to ensure that information is managed quickly and efficiently. In the flat glass processing industry, this is even more important for larger companies and enterprises who operate different branches across the country, but only one server and database is accessed via modern and fast WAN connections. All branches can be created and managed in this central database with their own settings and variations. This includes branch-specific data, such as delivery route information, machinery and capacity variations and restrictions, etc.

The advantage of this concept is that certain database tables such as customer tables, credit limits or pricing data can be maintained centrally for all branches. This facilitates data maintenance a great deal in the case of price increases, for example and eliminates the duplication of customer data in the case of end customers dealing with various branches of the enterprise. A centralised database offers some significant advantages over decentralised management. By implementing a central database system, a company can store its data securely and manage it more efficiently, quickly and cost-effectively.

The term ERP as a Service (analogous to SaaS — Software as a Service) emerged as early as the 2000s. It stands for a new generation of ERP systems — ERP in the Cloud . Soon, these systems will replace today's traditional solutions. The systems will then be Internet-based and platformindependent (Cloud). In addition, they are easily scalable. ERP as a Service is particularly suitable for small and mediumsized companies due to its scalability. Furthermore, adjustments and changes can be made even faster due to the webbased, functional and open architecture. The term ERP as a Service has now been replaced by ERP in the Cloud or Cloud ERP.

One of the most important aspects in today’s challenging and competitive glass industry is the full integration of the different functions in one central system. A key function is a comprehensive, dynamic and flexible capacity planning tool, not only to balance machinery capacities, but also to ensure on-time deliveries and perfect customer service. Many existing software solutions in our industry do offer such tools but unfortunately, due to the system architecture using multiple databases, capacity planning usually resides on the production side of the system.

kept as short as possible. At the same time, maintenance work is necessary to ensure that the production flow runs without interruption as much as possible. If maintenance on machinery is necessary, it needs to be planned ahead of time, so that time slots can be reserved for these maintenance cycles meaning that production capacity is planned dynamically around these slots.

Why is capacity planning so important in the glass processing industry?

Inadequate capacity planning results in, among other things, an increase in the so-called idle capacity costs in a glass processing company, as excess capacity then becomes a cost factor. For example, staff members who are not needed at a certain point in time must still be paid. Idle costs can also arise from the downtime of machines and systems. In production, low machinery utilisation drives up unit costs due to the high proportion of fixed overheads. When capacity utilisation is high, on the other hand, the fixed costs are spread over a higher number of produced units, so that the proportion of idle costs is

reduced. This approach can also be applied to other areas — for example, the service sector or larger projects: over-capacities are always cost-relevant. The same applies to under-capacities, which can bring the entire process of delivery to a standstill. However, many companies consciously accept over-capacities to maintain their flexibility for new orders. This can only be achieved in an optimal way with integrated and powerful capacity planning software. Other important advantages of capacity planning are as follows:

• Planning deviations and bottlenecks are mitigated by resource planning at strategic, tactical and operational levels. In this way, companies ensure that sufficient resources are available for all activities (machinery time and staff).

• Continuous capacity planning secures the flexibility of glass processing companies better than the automatic provision of excess capacities. Resource requirements and resource supply — including a buffer for unforeseen events — are better coordinated.

It is essential, however, that capacity planning is done right at the point of order entry, completely interactive and in real-time as order items are entered into the system. This ensures that eventual capacity bottlenecks or other technical problems (physical restrictions of existing machinery, for example) are detected right at the beginning and that an accurate delivery time can be confirmed to the final customer. Because of that reason, it is so important that the capacity planning function resides as an integral tool in order processing. In production, while machines are usually available around the clock, the employees can usually only work eight hours a day or a shift. To keep downtime to a minimum, set-up times, which are used for setting up machines or preparing production batches, for example, as well as times spent on maintenance, must be Fig.2 Detailed drawings for both customer and production using integrated CAD

• The results of a functioning resource planning system also include a valid and constantly updated database. The data generated in this way makes an important contribution to forecasts, to the optimisation of processes, to the planning and implementation of new projects or as a basis for change management in the company or to adjust capacity parameters for the future.

• The workload of employees is more balanced. This effectively prevents excessive demands and underdemands on individual employees or groups of employees. Through their human resources capacity planning, companies create important prerequisites for a high level of commitment, motivation and employee satisfaction. In this dimension, too, capacity planning is an important productivity factor in the company.

The abbreviation CAD stands for ‘computer-aided design’. In concrete terms, working with CAD software means that individual steps in the design process are no longer carried out manually, but are taken over by the computer software. With the help of CAD software functions, all steps from concept development to handover to the production department can be completed directly on the computer and transported in an electronical data format, such as DXF.

In the flat glass processing industry, CAD is extremely important and needs to be an integral part within the complete ERP system. Many existing glass-specific software solutions on the market use standard CAD solutions, such as AUTOcad and try to interface those to their main systems. Most times these solutions do not offer the necessary integration and flexibility and drawings need to be done in a separate system. Furthermore, such standard CAD solutions are very complex and require extensive training, as they were developed for a wide range of applications.

Therefore, a completely integrated software ERP solution for the glass industry needs to have a completely integrated CAD, but tailored to the glass industry to efficiently create complexshaped units, including edge processing, drill holes, cut-outs, surface processing, such as screen printing, edge printing, special tempering stamps, etc. Such a system needs to be flexible and userfriendly, so that users can be trained in minimal time. As with the capacity planning function, the CAD function needs to reside right at the point of quoting and order entry, as the final customer requires a detailed drawing of the ordered unit with their quote or order confirmation document.

One of the other advantages of such an integrated CAD solution is that the

system can automatically drive pricing of all processes through CAD entry — no separate entry of processing codes (drill hole categories, cut-out categories, processing articles, etc) is necessary to have the system calculate prices and costs based on processing edge lengths, etc. Furthermore, using such an integrated solution will eliminate the so-called CADdepartment in a glass processing company, where staff members usually need to create drawings for all shapes, for each CNC machine separately, all day long as many manufacturers of CNC machinery supply their own CAD solution with their specific own format. Using an integrated tailor-made CAD solution as part of the ERP will create all necessary generic DXF files in the background, ready to be imported by all CNC processing equipment available on the market offering the DXF file standard. In that case, sometimes only tool setting is necessary for some of the CNC processing lines, depending on the brand and the technology offered.

Optimising racks for delivery, such as A-Racks, L-Racks or others becomes as important as optimising glass to ensure that delivery lorries are used to the fullest capacity, while ensuring that weight restrictions and unit sequences are respected. This function should also be part of a modern integrated state-of-the-art software ERP solution for the glass processing industry. On many occasions, final customers, such as window manufacturers require their glass units to be delivered in a certain sequence, streamlined with their own production of window units or sashes to eliminate unnecessary sorting with the risk of breakage or scratches. This process will offer the same advantages to the DGU producer as to the final customer

because production, on both sides, will be completely streamlined and manual glass sorting (on both sides) can be eliminated. The window manufacturer can schedule their own production and then can transmit the scheduling sequence as an order to their DGU supplier, even in electronical data format (EDI). The glass manufacturer on the other hand, using their integrated packing optimisation as part of their own software ERP solution, can schedule their glass unit production using the requested sequence of the final customer. This efficient method saves time and increases productivity, while eliminating sorting and eventual breakage or scratching, especially in the case of soft coated glass types.

One of the key benefits of a completely integrated ERP system tailored to the glass processing industry is that it allows glass companies to streamline processes, eliminate redundant tasks or activities, and reduce the manual effort required to manage resources. There are different software solutions for glass processing on the market, some of them being supplied by machinery manufacturers. An efficient software ERP solution should be based on one single central database, for the reasons stated above and such a solution should be machinery-independent, yet able to control all glass specific production lines available on the market.

The doors for future machinery purchase decisions remain completely open for the company — a great advantage!

The Birchgrove Residence Project encompasses a contemporary addition to the rear of a heritage dwelling that reaches out to, flows down towards and embraces it’s dazzling harbourside location.

The unique curvilinear forms of the architecture create a dynamic interplay of positive and negative space interpreted and defined by an almost liquid flow of the facade glazing system.

The combination of applying a range of traditional glass craft skills with deployment of the latest glass manufacturing technologies has allowed Bent and Curved Glass to provide glazing solutions that meet the challenges presented by this unique architectural design vision.

The project is testament to what can be achieved by local curved glass manufacturer Bent and Curved Glass working with a collaborative approach combining with Architect, Builder and Window fabricator in a collective commitment to achieve the highest level of finish.

Bent and Curved Glass is dedicated to creating the most exciting and successful outcomes for all its’ customers.

Since the start of manufacturing windows and doors in Australia, the automation process has made significant steps. Just think about the introduction of the pneumatic punches, the phone, the fax, the computer, and the mobile phone.

Change is not always easy to come to terms with. Where some struggle with change, others thrive with it. The speed of technical change has rapidly gathered pace, transforming window, door and façade manufacturing beyond recognition. We are now amid the fourth industrial revolution (industry 4.0). Where some of our fellow window and door manufacturers have been able to adapt their productions lines with automated control systems, software, paperless manufacturing and CNC machines, some are still at a position where there is lots to gain.

It's important to understand the full scope of benefits that automation can bring to your company. This is especially so now that we have seen that being reliant on the international supply chain of cost-efficient window and door manufacturing is not always the best strategy. It’s worth taking stock of why automation is something to be welcomed, not feared.

Automating your company can massively increase the productivity of tasks, processes and manufacturing lead times on the shop floor and in the office. Processes that once took a significant amount of skilled labour and time, nowadays can now rely on a standardised work process with information being available to staff at the right time and at the right moment. Just think about it. If you could save between 10%-30% of the time it took to manufacture your projects, this could also increase your productivity, making you more flexible and most importantly, manufacturing a project gets more cost efficient.

The goal is to remove any manual handling within your processes if possible. There are great ERP and Estimation software packages

Automating your company can massively increase the productivity of tasks, processes and manufacturing lead times on the shop floor and in the office. Processes that once took a significant amount of skilled labour and time, nowadays can now rely on a standardised work process with information being available to staff at the right time and at the right moment.

available that can help you to achieve this. For example, if you have multiple software packages, trying to reduce them within your business would be a great place to start. When you order products from multiple suppliers, try to avoid your staff having to adapt to different work processes each time. The fewer software packages your staff need to work with the better as this increases their efficiency, reduces software maintenance, and reduces fail cost because of constant change. Be critical about how you do things and invite your suppliers and partners over to discuss this, as they have the opportunity to share with you methods that work with other businesses.

Did you know that if you improve your company processes it increase your project profit margin? When productivity increases, the cost to process a project automatically reduces. You might think, how does investing all this time and capital into new software, training and machines be financially the best choice? Let’s look at machinery for your factory, as an example. Considering that the total cost of investing in a startup package for CNC machinery equipment equals 2-3 staff members’ annual salary and equally reduces the workload of 2-3 staff members, after just one year, you have organised a massive reduction in cost to manufacture projects.

According to the Society of Manufacturing Engineers 89% of manufacturers have reported difficulty finding skilled workers. Software can help to aid the skilled labour shortage by reducing reliance on it. In the past, manufacturers that purchased a CNC machine needed to train their staff on an engineer-level of programmer, taking weeks or even months to code the new machines with macros. This process also created a dependence on a staff member who was then hard to replace. With software though, there is no need to have an engineer working on the machine. You simply quote a job in your office software which then automatically generates all the codes for all your machines in the factory. Not only do you not need a highly trained engineer, but

you also reduce fail cost because you are not depending on staff to copy that information into your machines as a standard process. In addition, it also saves approximately 30% of the time for the machine operator.

4.