Introducing the new VHD

On the jobsite you need a truck that’s tough, safe, and smart. So, we built the new Volvo VHD to be the best-looking, most rugged vocational vehicle in the industry, packed with innovative ideas like Volvo Active Driver Assist and the revolutionary Volvo Dynamic Steering. Your toughest jobs just got easier. Learn more at volvotrucks.ca/en-ca/trucks/vhd/

FEATURE STORY

INVESTMENT IN TECHNOLOGY SETS UP B.C. CONTRACTOR FOR SUCCESS

SPEC GUIDE: DOZERS

COVER PHOTO: JOHN DEERE 700L

DOZER

Spec Guide: Dozers

Turn to page 18 . JULY/AUGUST 2024 | VOLUME 39 • NUMBER 5

WE’D LIKE TO HEAR FROM YOU

Do you have a job site story, innovation, or industry concern that our readers should know about? We’d like to hear from you.

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330

EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

EDITOR Lee Toop ltoop@baumpub.com 604-291-9900 ext. 315

ASSOCIATE PUBLISHER Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

ADVERTISING

PRODUCTION MANAGER Tina Anderson tanderson@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com

604-291-9900 ext. 325

PRESIDENT/PUBLISHER Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER

Melvin Date Chong mdatechong@baumpub.com

FOUNDER

Engelbert J. Baum

Published by: Baum Publications Ltd.

124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8

Tel: 604-291-9900

Toll-free: 1-888-286-3630

Fax: 604-291-1906 www.baumpub.com www.heavyequipmentguide.ca @HeavyEquipGuide

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227 email: heg@mysubscription.ca

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/

Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published eight times a year in January/ February, March, April, May/June, July/August, September, October, and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2024, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed on paper made of FSC®-certified and other controlled material. ISSN 1715-7013.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to:

Circulation Dept., 124-2323 Boundary Road, Vancouver, BC V5M 4V8 email: heg@mysubscription.ca Toll-free: 1-866-764-0227

BIG BROTHER IS NOT WATCHING – BUT DO YOUR EMPLOYEES KNOW THAT?

Irecently attended a technology-focused event where contractors were invited to share some of the roadblocks and concerns around adopting new technology for their businesses. The biggest concern was, unsurprisingly, price, and the significant up-front outlay that can be required to set up a digitally connected job site before the benefits and savings from that technology are realized.

But another concern that repeatedly came up was that employees would think that “Big Brother” was watching if management introduced camera systems or other operator behaviour tracking and intervention tools on the equipment.

This is a completely understandable concern, and organizations need to address it with employees before introducing something that looks like a surveillance tool into what is effectively their office.

When introducing any new technology on the job site, the first mistake that management can make is adding that technology without explaining how it benefits the workers using it. This problem can arise with the introduction of any new productivity boosting tool, but the point of introducing the new tool is defeated if workers don’t know how to use it effectively or understand the value. When the new technology involves cameras and data collection the additional risk is the erosion of trust between employee and employer. Employers already strapped for skilled labour can’t risk the degradation of those relationships.

It is essential to have transparent conversations with employees because camera-based safety alert systems, in particular, can save lives and protect assets. Obstacle detection systems on heavy equipment alert operators to the presence of people and objects within dangerous proximity of working machinery. Cameras in the cab on haul trucks alert operators if their attention is diverted from the road. Sensors and cameras on trucks can detect hard braking and speeding and record these incidents for review.

No one wants to admit that they have lapses in attention or make mistakes – but we all do. When operating heavy equipment or driving a truck the consequences of not seeing a pedestrian or falling asleep behind the wheel can be

When introducing any new technology on the job site, the first mistake that management can make is adding that technology without explaining how it benefits the workers using it.

catastrophic. The case for introducing camera technology on the job site has to start there. These are not tools used to judge or police every behaviour. They are teaching tools used to improve performance, and they prevent accidents when mistakes are made so that everyone can go home safely at the end of the day.

Before introducing this technology into your workplace, sit down with your employees and listen to their concerns. New technology needs buy-in at all levels of the organization to maintain morale and trust, but that can only happen once the operator in the cab understands that Big Brother is not watching. Once that trust is established, everyone in the organization can experience the benefits of a safer, more efficient job site.

Kaitlyn Till Editor In Chief

ktill@baumpub.com

heavyequipmentguide.ca

From the original compaction brand comes a full line of construction equipment designed to help you get the job done with efficiency, quality and comfort. Whether your challenge is to load, move or place material, compact soil and asphalt, or to provide light, heat, power or pumping on your job site, Wacker Neuson has the machines to get it done right. This includes zero-emission, battery-powered solutions to meet the demands of the construction environment today, as well as tomorrow.

Contact your local Wacker Neuson dealer today. All it takes for

HD Hyundai Construction Equipment North America has opened a parts distribution centre in Mississauga, Ontario. Representatives from HD Hyundai Construction Equipment North America and HD Hyundai Construction Equipment were in attendance for the opening event along with Maninder Sidhu, a Canadian Member of Parliament who serves as the Parliamentary Secretary to the Minister of Export Promotion, International Trade and Economic Development.

“This is an important first step toward establishing an HD Hyundai Construction Equipment corporate presence in Canada,” said Stan Park, president of HD Hyundai Construction Equipment North America. “Canada accounts for a significant share of our North American construction equipment business. This centre will provide important efficiencies and cost savings to further strengthen our Canadian presence.”

The new facility is located at 2450 Hogan Drive, Unit 3, Mississauga, Ontario. Mahmoud Jamii, Canada parts sales representative at HD Hyundai Construction Equipment North America, will lead the operation, with initial staffing through Expeditors Canada.

“Our first goal in adding this centre to our global integrated supply chain is to provide faster, more comprehensive parts availability to Hyundai customers and dealers across Canada,” said Park. “Working with an established partner like Expeditors allows us to grow our presence and infrastructure in Canada more quickly.”

HD Hyundai Construction Equipment North America currently serves its Canadian customers through its network of 17 dealers with 33 locations across Canada.

SMS Equipment has unveiled the expansion of its Timmins branch at a grand opening celebration. The $30M development bolsters the company’s support to Northern Ontario’s mining, construction, and forestry sectors.

“We’re thrilled to open our incredible new SMS Equipment Timmins branch and serve our customers with equipment, technology, service, and support right where it’s needed in Northern Ontario,” said Robin Heard, SMS Equipment president and CEO.

“The demand for heavy equipment has steadily increased alongside explosive growth of the province’s mining sector and its related service industries,” he continued. “We wanted to invest in a facility and the personnel that could fulfill that demand with a broad range of solutions to keep our customers’ operations running smoothly.”

Spanning 37,000 square feet, the Timmins branch houses the company’s new and used equipment sales. The expansion also increases its service and maintenance capabilities in the region. The new building is designed to hold large mining equipment. It includes two heavy-duty welding bays, five service bays, and a 100-ton heavy-lift capacity, which together accommodate new remanufacturing, welding, painting, and large equipment rebuilds in-house. Environmental sustainability was top-of-mind in its design. Among many water and energy-saving features, its solar generation system is expected to supply nearly 70 percent of the administrative offices’ power.

“With this expansion, we’re building on our 30-year foundation in the region,” added Heard. “SMS Equipment is proudly investing in Northern Ontario through our facility, local community initiatives, and job creation.”

Along with jobs created through the expansion, the branch employs a growing staff, including skilled heavy equipment technicians and apprentices.

“Timmins is the city with a heart of gold and having a worldclass supply and service company like SMS Equipment is important for our local economy,” said George Pirie, Member of Provincial Parliament for Timmins. “I want to congratulate SMS Equipment on this terrific expansion that will create over 100 good-paying jobs and benefit the people and businesses in our region. This brand-new facility will help mining operations get machines back up and running faster, while also ensuring Timmins will be the supply and service hub of the Northeast.”

STERLING CRANE NAMED ONE OF SAMSARA’S

ACanadian crane services company has been recognized for its leading use of technology in reducing costs and improving safety and efficiency with one of Samsara’s 2024 Connected Operations Awards.

Sterling Crane is a Marmon Crane Services/Berkshire Hathaway company that provides crane services across Canada, the U.S., and Australia. It has more than 16 branches and 650 employees in Canada, and has a reputation of trusted and reliable service for customers in infrastructure, industrial, power, and commercial sectors.

Since implementing Samsara, Sterling Crane has achieved an estimated annual savings of $2.5 million from major maintenance costs for its on-road and off-road fleet by using Samsara to inform its proactive maintenance program. Samsara has also helped improve driver productivity, saving more than $1.2 million, and technician time and maintenance costs have been reduced by saving more than $500,000.

“At Samsara, we understand the pivotal role that physical operations play in running our world’s economy. Technology is a critical component to ensure that operations run smoothly, efficiently, and safely,” said Lara Caimi, president of worldwide field operations at Samsara. “Our Connected Operations Award winners are leading the way in transforming their organizations and industries with a combination of technology, strategy, and creativity. We are honoured to be part of their story and celebrate their impact on the world’s foundational industries.”

Samsara recognized 16 companies in all from North America and Europe. They represent a broad range of segments including infrastructure, logistics, specialty contracting, communications, and more.

United Group’s investment in technology sets the company up for success in B.C.

Turn to page 28.

EPIROC ACQUIRES CANADIAN

DIGITAL GEOTECHNICAL

INSTRUMENT MANUFACTURER

YIELDPOINT

Epiroc has agreed to acquire Yieldpoint Inc., a Canadian company that provides ground support solutions that strengthen safety for mining and civil engineering applications. Yieldpoint is based in Kingston, Ontario, and has about 10 employees. The company designs, manufactures, and sells digital geotechnical instruments worldwide. The products, which include ground movement sensors and telemetry solutions, are primarily used for underground mining, tunnelling, and civil construction applications. Yieldpoint’s solutions help digitalize ground support and create a safer working environment.

K-TEC TO BECOME FIRST SCRAPER MANUFACTURER TO BUILD ITS MACHINES USING FOSSIL-FREE STEEL

K-Tec has partnered with SSAB to source pilot deliveries of its fossil-free steel for manufacturing heavy-duty scrapers. The collaboration will reduce emissions and improve sustainability for scraper customers. K-Tec currently designs and manufactures earthmoving equipment using SSAB’s Hardox and Strenx performance steel. Pilot deliveries of SSAB Fossil-free steel use HYBRIT technology. It replaces the coking coal traditionally used for iron ore-based steelmaking with fossil-free electricity and green hydrogen. The byproduct remaining is water, rather than carbon dioxide emissions.

Manitou North America has named Quebec’s J.-Rene Lafond as its first Canadian partner dealer. Partner dealer is a designation given to Manitou dealers who exhibit quantifiable excellence in product sales, parts support, and service in its territory. This includes commitments to training, parts inventory, brand support, and overall sales of Manitou equipment.

“Our first partner dealers represent both American and Canadian excellence in serving their customers with the right mix of products, service and support to succeed,” said Ilmars Nartish, vice president of Manitou North America. “Both Ste-

venson Crane and J.-Rene Lafond have demonstrated excellence in listening to the needs of their markets and building their businesses intelligently – and representing Manitou to the industry with great pride and customer service proven to make a difference.”

Bird Construction Inc. will acquire Jacob Bros Construction for an estimated $135 million. Headquartered in Surrey, British Columbia, Jacob Bros is a privately owned civil infrastructure construction business with a workforce of over 350 personnel. Scott Jacob, CEO of Jacob Bros, and Todd Jacob, COO of Jacob Bros, will join Bird to lead the combination of Bird’s western infrastructure business and their existing business. Jacob Bros specializes in civil infrastructure construction across a wide array of projects, such as airports, seaports, railways, bridges and structures, earthworks, energy projects, and utilities.

Get the best of both worlds with the TCi 920 dozer.

Power and durability for tough applications. Finesse and response for fine grading.

H Series rough-terrain forklifts handle heavy loads off-road and now available with the option of a factory-installed, enclosed cab to provide a more comfortable operating environment. These forklifts can travel at up to 24 mph, and have mast options that lift up to 8,000 pounds as high as 22 feet. Cabs include heat and air conditioning, Bluetooth radio, and USB charging ports, giving operators the ability to work in any temperature and weather conditions. Wide doors secure completely open for easy communication with crew on the ground as well as increased air flow. An overhead roof window gives visibility to overhead loads.

The Woodcracker tree saw with grapple is available for three Manitou rotating telehandlers, the MRT 2260, MRT 2660, and MRT 3060 Vision+. Designed for tree and limb removal work, the saw paired with a rotating telehandler can reach up to 98 feet in height and more than 84 feet out, depending on the model. The saw rotates into position to cut, hold, and deliver each limb. Maximum lifting capacity with the tree saw attachment is 8,000 pounds. Telehandlers equipped with the tree saw are fitted with a specialized forestry package including a windshield guard, boom covers and guards, hydraulic and electrical system covers, and a second return-to-tank line.

The SUPER 1800-5(i) is a compact machine capable of paving widths between 2.55 and 10 metres on city streets and highways. Vögele Dash 5 technologies feature the ErgoPlus 5 operating design that provides more visibility and comfort, an ergonomic design, and simplified use of individual functions for operators. Fine-tuning can be accomplished easier using a smartwheel. A new four-cylinder motor uses less fuel than previous models while maintaining output with its the EcoPlus low-emissions package. The auger and conveyors communicate to ensure material feed is consistent and coordinated, which reduces load peaks and saves more fuel while ensuring an optimum head of mix.

operator comfort, ergonomics, and visibility. The ZB21 bolter has intuitive operator controls and integrated patented screen handling. An optional pumpable resin system allows resin to be pumped into the hole prior to bolt installation. The ZJ21 jumbo drill is a single-boom development drill with innovative drilling feeds and advanced pilot hydraulics. Both feature Montabert drifters. Battery-electric versions are available for both machines, fusing Komatsu’s on-board charging system which offers compatibility with mine infrastructure.

hydrostatic transmission, advanced controls, electric-over-hydraulic joystick are highlights of the SkyTrak 8042 telehandler. The machine has a maximum lift height of 42 feet 4 inches, a maximum reach of 29 feet 6 inches, and a 21,200-pound operating weight. The enclosed cab has optional air conditioning and a larger LCD display plus single-page load charts. The hydrostatic transmission provides greater comfort, ease of operation, and inching – running the boom at high speeds without shifting into neutral – for faster material delivery. A 74-hp Deutz diesel engine does not require diesel exhaust fluid, reducing maintenance costs.

Dozers are a perennial favourite among equipment enthusiasts young and old. The simple raw pushing power of these earthmoving elder statesmen holds an appeal for both kids in the sandbox and operators in the field. Dozers, however, have evolved beyond the simplicity of merely pushing material with the level of precision totally reliant on the skill and experience of the operator in the cab. Today’s dozers can no longer be separated from the technology that now often comes standard. These technologies make it easier and faster for novice operating talent to run the machine with the finesse of a grizzled veteran. Turn the page for our 2024 spec guide, and explore dozers up to 100,000 pounds for earthmoving applications.

The Liebherr PR 726 XL and LGP crawler dozers offer excellent efficiency and versatility, making them ideal for medium-duty tasks such as site preparation, road construction, and moderate earthmoving. Both versions of the PR 726 have advanced Liebherr diesel engines that deliver high performance and low fuel consumption. Equipped with operator assistance systems such as Free Grade and Definition Grade, along with an innovative hydrostatic drive, these dozers ensure precision and ease of use. The PR 726 XL handles demanding tasks, while the LGP model’s low ground pressure undercarriage is perfect for soft, sensitive terrain.

Liebherr Crawler Dozers ensure that full power is on-call at all times, regardless of weather conditions or material grades. Designed for heavy dozing and precision grading, the hydrostatic drive system provides optimal pushing speed, ensuring consistent power and efficiency. Operator Assistance Systems enhance grading quality and operational efficiency, maximizing productivity on the job site. Whether tackling tough terrain or intricate grading tasks, Liebherr Crawler Dozers are designed to meet high standards with robust performance and innovative technology.

*Models available in XL and LGP configurations.

John Deere currently offers eight dozer models – three small P-Tier dozers, three midsize dozers, and two large P-Tier dozers. Enhancing operator performance and safety, the P-Tier small dozers feature a variety of strategic design choices aimed to increase visibility and comfort. The mid-size dozer models offer exceptional performance, reliability, and ease of operation in a mid-size design. Lastly, the 950 P-Tier and 1050 P-Tier large dozer models have been upgraded with versatility and efficiency in mind, equipped to optimize productivity and fuel savings.

The John Deere 1050 P-Tier Dozer offers extreme durability to tackle even the most rough and rugged job sites. Customers looking to move large amounts of material efficiently will benefit from the standard 168-inch semi-U blade. Along with a wider blade, the 1050 P-Tier is now configured with a redesigned blade linkage which moves the blade rearward and reduces the overall length of the machine, improving balance and grading performance. Also, several changes have been made to enhance visibility to the blade corners, ensuring operators have optimum visibility on the job. Lastly, the redesigned suspended double-bogie undercarriage reduces vibrations throughout the machine, improving ride quality and component durability.

The D71PXi-24 is Komatsu’s largest and most powerful hydrostatic transmission (HST) dozer. This voice-ofcustomer-designed dozer performs in all grass to grade applications. From stripping, rough dozing, and spreading to finish grading, the D71PXi-24 utilizes iMC 2.0 automatics to maximize efficiency and productivity throughout the entire process. It is equipped with a power angle tilt (PAT) blade and 36-inch shoes providing a 5-psi ground pressure for maximum flotation and pushing ability. Komatsu’s super-slant nose cabforward design on HST dozers helps provide outstanding visibility to the cutting edges while enhancing operator comfort for a balanced ride and increased field of view.

Komatsu offers a diverse lineup of dozers ranging from small to large models designed for various applications and available in AX standard track; EX extended track for flat, rocky, or high-impact work; and PX for lowest ground pressure. Configurations can be tailored to meet specific applications, providing operators with performance, efficiency, and durability. Komatsu dozers are equipped with Komatsu’s Parallel Link Undercarriage System (PLUS), which offers a unique rotating bushing design, durable longer-wearing links, and self-adjusting idler support with recoil spring. iMC 2.0, offered on Komatsu dozers, gives inexperienced operators the ability to run a dozer like a pro. iMC 2.0 allows operators to use automatics nearly 100 percent of the time with proactive dozing, lift layer control, and tilt steering.

The DEVELON DD100 dozer competes in the 140-hp and under category. Standard premium features for the DD100 include MY DEVELON Fleet Management telematics for remote monitoring, ECO mode for reduced fuel consumption, rearview camera for enhanced visibility, blade shake for removing material stuck to the blade, and an easy-to-read, user-friendly touchscreen display for access to the dozer’s functions and machine settings.

DEVELON introduced its first dozer in 2022 and currently offers two models: the DD100 and DD130. Both dozers provide exceptional visibility from the cab to the front and sides of the machine. A standard rear-view (backup) camera enhances operator visibility. A sixway power-tilt angle blade moves and grades dirt, clay, and other materials. Operators can activate the blade float function for back grading or fine finishing. A blade shake button is available to quickly remove stuck-on materials. Operators can reduce the dozer’s fuel consumption using an ECO mode, saving up to 5 percent without sacrificing grading performance when working in lower tractive conditions. Additional fuel-saving technologies include auto idle and auto engine shutdown. Optional features available for DEVELON dozers include 2D blade assist and 3D machine guidance and 3D machine control.

*Operating weight is for low ground pressure dozer blade configurations.

CASE Construction Equipment’s M Series dozers deliver contractors more precision, reliability, and control than ever before. Electro-hydraulic blade control, which reduces overall operator fatigue while increasing productivity, comes as a standard feature on most models, along with customizable blade, shuttle, and steering controls.

When equipped with CASE Universal Machine Control, the M Series dozers can be outfitted with machine control solutions from any of the three major suppliers of precision construction technology. Each dozer also features maintenance-free, Tier 4 Final emission solutions, excellent serviceability access, spacious floor-to-ceiling glass, and positive-pressure cabs that offer ample elbow room while keeping dirt out.

CASE Construction Equipment’s 850M dozer offers drawbar pull of 41,010 pounds and features a 120-hp (90 kW) engine. A hydrostatic transmission ensures constant power transfer under load and allows for on-the-spot counter rotation, while electro-hydraulic blade and customizable steering and shuttle sensitivity controls, along with a load management system that adjusts the track speed based on the amount of dirt being moved, enable ease of use. The electrical and hydraulic routings enhance serviceability and durability while LED lights, Bluetooth radio, a rear-view camera, and undercarriage spade holder provide convenience and accessibility.

The D6 XE is the world’s first high-drive electricdrive dozer. The electric drive makes this the most fuel efficient dozer in Caterpillar’s lineup and with fewer moving parts and longer service intervals, there is opportunity to save on maintenance time and money as well. The D6 XE powertrain provides up to 45 percent steering radius reduction compared to the D6. The D6 XE offers ingear counter rotation for increased maneuverability. Cat dozers are designed with grouped service points and easy-to-access fluids and filters for an easy owning and operating experience. The cab features integrated ROPS (rollover protective structure) that provides more visibility to the work and comfortable seats with adjustments to personalize the work environment.

Caterpillar’s D4 to D8 dozers offer a range of technology features to help operators of varied experience levels get work done quickly and accurately. Cat Assist with ARO (attachment ready option) is a suite of features that is standard on every model. This technology package includes the following features: ARO Sensors (IMUs) on machine for GPS capability; Cat Grade with Slope Assist which holds blade angles with no GPS; Steer Assist which automatically keeps dozing straight; and Stable Blade, which makes finish dozing easier, as well as Slope Indicate, Blade Load Monitor, Traction Control, and AutoCarry. AutoRip, on the D7 and D8 only, automates ripper raise/lower and shank in/out.

*D4 shares more common features with D1–D3, and D5–D8 (high-drive machines) are more similar to each other. †The D6 is also available with XE Electric Drive (D6 XE). ‡Transmission with Lock Up Clutch (LUC) torque divider.

Cardinal Scale’s ARMOR® digital truck scale with included free iSite remote monitoring means you can say goodbye to downtime with high-tech Cloud-based diagnostics.

BY MACK PLOVIE

United Group has an extensive history of helping build British Columbia over the past 80+ years, working on key infrastructure projects like the original Sea to Sky Highway. With recent investment in Topcon technology and John Deere equipment, the company is primed for growth into new regions and is well-equipped to tackle larger construction projects.

United Group’s history is deeply rooted in British Columbia, dating back to November 1939 when A.B. (Tony) Cicozzi incorporated ‘United Cartage Co Ltd’, a hauling and trucking company servicing the region with a fleet of tandem axle dump trucks. United Cartage Co continued to grow with the acquisition of Hassell Bros Contracting in 1954, later renamed to United Contractors Ltd. United Contractors worked on numerous infrastructure projects throughout B.C., including the original construction of the Sea to Sky Highway in the 1960s – a challenging thread of highway skirting steep rocky terrain alongside the ocean, connecting North Vancouver to Whistler and beyond. The company also became actively involved in the BC Road Builders Association with founder Cicozzi, as the first President of the association and on the Board of Directors from 1966 to 1968.

Technology is an up-front investment. A lot of companies don’t see the benefit of it right away, but we have a long-term focus. It has given us an advantage and ability to tackle projects at a rapid pace.

Dave Kleszewski President, United Group

The company continued to work on projects throughout British Columbia’s lower mainland, and when Cicozzi passed in the 1990s his brother and son took over the company, changing the name in July 1998 to United Earth Contractors Corp. In 2023, the name was updated to United Group, a change that reflects the company’s growth in service offerings.

Today, United Group is a full-service company and has grown to over 100 employees with 200 pieces of equipment across three main divisions: United Earth, United Civil, and United Equipment, which specialize in earthworks, civil construction, and equipment rentals respectively. The company has done residential development, commercial development, major highway infrastructure, landfill closure and reclamation, land clearing, and grading.

“Construction of Highway 17 was when we really grew as a company,” says Dave Kleszewski, president of United Group. The four-year highway construction project involved building a 34km four-lane highway between Surrey and Delta.

In 2023, Corporate Vision named United Group the Best Com-

Development & Landfill Restoration Company – British Columbia, highlighting its accomplishment in reclaiming and closing a portion of a landfill in Richmond.

Since its beginnings in 1939 with a fleet of tandem axle dump trucks, United Group’s fleet has grown drastically to over 200 pieces of equipment today. The modern fleet primarily consists of John Deere equipment, including rock trucks, excavators, dozers, backhoes, skid steers, wheel loaders, and more, all supplied by Brandt Tractor Ltd.

“We are big on relationships here at United Group, and have built a great relationship with Brandt over the years to where we are now their biggest buyer in the lower mainland. They have always been able to get us equipment when we need it,” says Kleszewski. Although United didn’t start with all John

“TECHNOLOGY HAS REALLY SPED UP THE GRADING PROCESS TO WHERE EVERY PASS I MAKE IS ACCURATE TO A FEW MM,” SAYS KARL TASCHNER, HEAVY EQUIPMENT OPERATOR WITH UNITED GROUP.

UNITED GROUP RECENTLY USED MC-MOBILE ON A WAREHOUSE GRADING PROJECT IN SURREY TO INSTALL UNDERGROUND UTILITIES AND COMPLETE FINAL GRADING FOR CONCRETE SLAB TO MM ACCURACY INSIDE THE BUILDING.

Deere equipment, the company has focused on investing in the John Deere product in recent years, including an investment in K and L series dozers to modernize the fleet and streamline maintenance, operator training, and dealer support.

United Group remains focused on staying at the leading edge of its business, constantly updating the fleet with newer equipment once machines reach roughly the 5,000 hour mark. Not only does new equipment appeal to and attract operators, but the technology offerings, fuel savings, and performance offers United Group a competitive edge in a market saturated with contractors competing for work.

Early adoption of Topcon Positioning Systems technology for both heavy equipment and surveying has underpinned United Group’s growth. The contractor bought its first piece of Topcon technology in 2015, an indicate-only system for a Caterpillar D6T dozer. Today over 50 percent of United Group’s large equipment is outfitted with Topcon machine control.

UNITED GROUP’S FLEET HAS GROWN TO OVER 200 PIECES OF EQUIPMENT, INCLUDING JOHN DEERE ROCK TRUCKS, EXCAVATORS, DOZERS, BACKHOES, SKID STEERS, WHEEL LOADERS, AND MORE.

United Group’s fleet of Topcon-equipped machines now includes two 850 Deere dozers, two 700 dozers, and two each of the 245, 345, and 470 John Deere excavator models all equipped with 3D MC-Max machine control systems. The 245 size excavator and up is where United Group really notices production gains from 3D MC-Max grade control technology. In addition, United Group recently acquired the first MC-Mobile system installed on a Level Best box blade in Canada, which is currently fitted to a 333G John Deere skid steer. Alongside machine control, United Group invested heavily in base and rover kits for its in-house survey team. Multiple base stations allow for strategic setup of permanent bases to reduce any errors from daily setup. While rover kits enable accurate regular surveying for project take offs, design builds, and survey pickups on the job.

“Technology is an up-front investment. A lot of companies don’t see the benefit of it right away, but we have a long-term focus. It has given us an advantage and ability to tackle projects at a rapid pace,” explains Kleszewski.

United Group has also invested in drone surveying technology including Propellor software. This technology unlocks potential for their survey team to perform design builds, and more importantly enables quantity tracking in a marketplace where being accountable for materials on a project is important.

“We used to send out surveyors to get quantities on projects. With drone surveying, we get cost accountability with materials and accuracy on projects,” says Kevin Jones, operations manager.

With an industry-wide workforce shortage, experienced operators are hard to find, resulting in a pool of less experienced operators entering the industry. Technology is helping address this issue by enabling operators with little experience to achieve a baseline of productivity on machines equipped with Topcon machine control. United Group’s 3D MC-Max–equipped John Deere dozer fleet is a fine example.

“It’s very user friendly, we can honestly put anyone in the machine. If they know how to operate a machine, they can be taught how to operate GPS,” explains Rusty Hodge, site superintendent.

[Kleszewski] has been a great supporter of Brandt and has become one of our biggest customers in the span of about a year and a half. They’ve been really good to deal with,” says Jake Buskell, sales manager for Brandt Tractor’s Positioning Technology Division.

Brandt supports United Group from start to end, including acquisition and delivery of heavy equipment, performing installations of Topcon machine control on their fleet, supplying parts, and repairs. They are a full-service dealer for all United Group’s needs and have grown alongside United Group, adding more field technicians to the team.

“We started adding all machines to the remote support desk within Sitelink. Our technicians can dial into machines to diagnose problems, view error codes, and determine what parts are needed before we even send them out into the field,” explains Joseph Bradley, regional service manager with Brandt Tractor’s Positioning Technology Division.

“We really haven’t had to call Brandt much, and if we have, they have been great with warranty,” notes Hodge.

Now

we are putting experienced operators in machines equipped with machine control and getting two to three times the production. We have since changed our opinion of ‘it’s expensive’ to ‘everything needs it.’

Dave Kleszewski

“Now we are putting experienced operators in machines equipped with machine control and getting two to three times the production. We have since changed our opinion of ‘it’s expensive’ to ‘everything needs it,’” says Kleszewski.

United Group’s landfill closure and reclamation project proved that point during construction of a mechanically stabilized earth (MSE) wall using Topcon-equipped dozers. Operators of all skill levels were achieving tight tolerances on fills, minimizing rework and reducing waste of materials, all of which translates to a healthier bottom line for United Group and the client.

From United Group’s first purchase of John Deere equipment and Topcon technology to the numerous pieces of equipment and technology in their fleet today, Brandt Tractor has been right alongside supporting the company’s growth. “Dave

United Group certainly isn’t afraid of technology. In early 2024 they again took initiative and added a new Topcon product: MC-Mobile. Currently fitted on a Deere 333G skid steer, MC-Mobile functions as both a rover kit and machine control package, with the ability to create designs as a rover kit, then use the same design in Pocket 3D software on an Android tablet for grading. The system really gives one operator the ability to be self-sufficient, creating designs on the fly and then using them in the machine to build to.

United Group recently used MC-Mobile on a warehouse grading project in Surrey when partnering with a builder from Alberta. This project was different because the builder constructed the walls and roof before installing underground utilities and grading for a concrete slab – an approach that has proven successful in Alberta’s harsh weather conditions.

The United Group team had to install underground utilities and complete final grading for concrete slab to mm accuracy inside the building. Using a Local Positioning System (LPS) comprised of Total Station, MC-Mobile system, and Prism in place of GR-I3 GNSS receivers, United Group deployed a John Deere 700L dozer and the 333G skid steer to complete the final slab prep.

“We are ahead of schedule on this project thanks to our team, the machines, and the technology. That total station has mm accuracy, moving the dozer blade up to 100 times per second,” says Ryan Morrison, general superintendent. Having the ability to complete precise grading for a concrete slab indoors where conventional GNSS from a base station or network may not have proven reliable was a real advantage on this project.

“Technology has really sped up the grading process to where every pass I make is accurate to a few mm,” says Karl Taschner, heavy equipment operator with United Group. Once complete indoors, both the skid steer with Level Best box blade and dozer can easily convert back to using GNSS receivers operating off a local base station or Brandtnet, a service developed by Brandt Tractor’s Positioning Technology Division. This RTK GNSS network service allows contractors using Topcon technology on their machines to connect and start receiving GPS corrections without the need for base station setups.

United Group certainly isn’t done growing yet, and plans to expand in the Lower Mainland. The company also aims to add four more locations within the next five years, expanding into Edmonton, Squamish, Vancouver Island, and the Interior of B.C.

“Dave [Kleszewski] sets goals for the year, and we make it our goal to beat those goals,” says Terry Traynor, project manager with United Group.

United Group’s ambitious growth is underpinned by quality work and its track record of infrastructure projects in the Lower Mainland. The team is tuned into replicating that success in new regions.

“We are one giant team here at United Group. Nothing gets done without each other – I really have to applaud everyone’s effort,” says Kleszewski. With ambitions to be one of the top 5 construction companies in the region, United Group plans to purchase more John Deere equipment and Topcon technology. “We are already looking at more Deere 245 and 345 zero-swing machines with technology,” says Morrison. The zero-swing machines really shine on road work projects where space is limited and work is often conducted adjacent to live traffic.

With an early and continued investment in Topcon technology, United Group has gotten ahead of the curve and plans to stay there.

MACK PLOVIE is the president and chief dirt enthusiast of Earthmovers Media Group.

A LOCAL POSITIONING SYSTEM (LPS) COMPRISED OF TOTAL STATION, MC-MOBILE SYSTEM, AND PRISM IN PLACE OF GR-I3 GNSS RECEIVERS WAS USED TO COMPLETE THE FINAL SLAB PREP INDOORS.

Volvo has begun the rollout of a complete reintroduc tion of its crawler excavator line starting with multiple medium and large models: the ECR145 short swing, EC210, EC230, EC370, EC400, and EC500. More models will be announced in the coming months.

“This new excavator series is the realization of our commit ment to our customers. Every design change, innovation, and weld were made with our customers’ needs top of mind,” says Scott Young, head of Region North America, Volvo CE. ”All together, these updates will substantially impact their produc tivity, uptime, employee satisfaction, and, ultimately, their success.”

Volvo has optimized the electro-hydraulic system and in troduced a smart cooling system and engine speed regulation at higher engine RPM to increase fuel efficiency by up to 15 percent compared to the previous generation – all while outper forming those models.

These excavators now have 10 work modes, including two specific to power and four specific to automatic ECO modes.

According to Volvo, enhanced hydraulics enable better machine control and the smooth, precise movement of the boom, bucket, and other hydraulic components. These excavators now have 10 work modes, including two specific to power and four specific to automatic ECO modes. A new creep travel mode combined with boom and arm shock reduction reduces spillage.

“Our customers are looking for ways to increase productivity and reduce expenses, and we deliver on that with these new excavators,” says Sejong Ko, product manager – large excavators at Volvo CE. “Fuel in particular is a major expense, and the improved fuel efficiency will reduce costs with the added benefit of lowering the environmental impact.”

job site.

Volvo Smart View with Obstacle Detection gives operators 360-degree visibility of the machine’s surroundings by combining cameras with radar detection to distinguish between objects and humans on the job site. Volvo has also added more lights to the cab, boom, and arm.

Hiring and retaining skilled operators is essential in a tight labour market, and Volvo has made the new excavators an attractive work environment for the operators who make them their office. Volvo has improved the human–machine interface and the automation of boom and bucket movement with the Volvo Active Machine Control system, and an advanced electric control joystick also helps operators increase productivity.

Other new and upgraded features include: updated seat design, improved ventilation, new footrest support for working on slopes, keyless engine start with ability to store multiple operator preference settings, larger cab side mirror with heater, in-cab wireless phone charger, built-in cooler/ heater compartment for food or drinks, more sunscreens and storage areas, additional safety railings and relocated steps, and new DEF sight gauges and splash guard.

Volvo has included the newest generation Co-Pilot in these excavators. The in-cab tablet’s larger, high-resolution screen will display Dig Assist applications, such as on-board weighing, in-field design, and more.

Volvo Smart View with Obstacle Detection gives operators a 360-degree view of the machine’s surroundings by using the camera and the new radar detection system.

Smart View with Obstacle Detection can identify obstacles as either an object or a human being, allowing the operator to take appropriate action.

Volvo used deep learning technology to develop Smart View with Obstacle Detection – a person crouching, moving, or leaning can be detected. Every human is visible to the system, no matter what colour of clothes they’re wearing.

The operator can set how far they want the radar to reach. For example, when working in a confined space the operator can set a smaller radar area. The operator can also customize which sectors they want to see via the touchscreen.

When it comes to your work, having the right features is a BIG advantage. It’s nice to have an ace up your sleeve when taking on the toughest tasks on the jobsite. From accessible technology and rear view visibility to a quiet and comfortable cab, plus roll-up front door and easy maintenance - all these features and more come together in the Kubota SVL75-3.

CANADA.

#1 in overall satisfaction in product quality in parts availability and parts quality in manufacturer response to dealer needs and concerns Kubota Canada was recently named the top full line manufacturer in multiple categories by the North American Equipment Dealers Association*, including: EXPERIENCE THE DIFFERENCE WITH KUBOTA

*2023 Dealer-Manufacturer Relations Survey, North American Equipment Dealers Association.

Purchasing your first piece of equipment is a big investment when you run your own small business and Jason Rottier was intent on getting it right.

“It was a giant, and I mean giant, step for a small company less than three years old,” explains the owner of Rottier Excavating in Wallaceburg, Ontario. “I looked at used and new machines, I looked at horsepower, hydraulic output, high flow capability, user comfort, I looked at everything.”

Jason’s exhaustive research led him 45 minutes up the road to nearby Wyoming, ON, where he met Eric Vanderlinde, a sales representative at SouthPoint Equipment, an official full line Kubota dealer.

“Once I talked to Eric, it was seamless - he kind of put me at ease,” says Rottier. “He said, “We’ll figure it out. We’ll get you in the machine you want to be in.”

That machine was the Kubota SVL65-2 compact track loader. Rottier made the purchase in early 2022 but with his company rapidly expanding, he found himself back at SouthPoint less than two years later ready to purchase the new SVL75-3.

“Jason was very confident in the Kubota brand,” explains Vanderlinde. “After experiencing zero issues and minimal downtime with the SVL65-2, and excellent support from our service department, he knew the SVL75-3 would prove to be just as reliable and durable for his business.”

“I wanted to upgrade to something with a little more horsepower and ergonomics,” says Rottier, who measures in at over six feet tall. “When you have big boots, you need a big area and there’s a lot of leg room in the SVL75-3. The Air Ride seat is nice. I have lower-back issues and I can sit in that thing for 10 hours a day.”

“Jason is a bigger guy, so having a roll-up door and the widest cab in the market is huge,” says Vanderlinde. “Getting in and out of the machine is very easy for him now.”

“I use it for everything - landscaping, bush removal, loading dump trucks, cutting wood, and I’m not easy on things, says Rottier. “If it lasts for what I do, then it’s a solid piece of equipment.”

“The pushing power of the SVL75-3 is great - it’s like a small dozer. Now I have the horsepower and weight to run a forestry mulcher and do more kinds of jobs.”

Thanks to its compatibility with all types of attachments, Rottier says his new machine has opened the door to additional opportunities.

“The SVL75-3 is a Swiss Army Knife for my business. I have a grapple bucket. I do a lot of brushing and moving material. I have a trencher for putting in hydro, gas and waterline trenching. I have a soil conditioner. I have a Kubota land plane, which is one of the most useful things I own. Forks, buckets, an HLA SnowBlade, you name it!”

“It’s nice when you can get your arms in and see the hydraulics and not have to dismantle everything and take all the panels off,” explains Rottier. “With the SVL75-3, you open the door and flip the hatch up and the whole thing’s open.”

“I had to change my hydraulic filter at 50 hours. It was the first service thing that popped up and I was dreading it. But when I pulled the cab up, it was two bolts and I lifted it by hand. I got my partner to put a lock on the hydraulic and I crawled into the belly of that machine and grabbed the filter, gave it a wrench, and we had it done in like ten minutes.”

“One thing that is very big, not only for our dealership but also for Kubota Canada, is training,” explains Vanderlinde. “We invest a lot of money into getting to know our products and competitor products, and Kubota has dedicated field product specialists to teach both our salesmen and our customers about the equipment.”

“Everybody at SouthPoint has extensive knowledge of the machines and the equipment,” says Rottier. “Parts are always in stock and I’m never shutdown or left waiting for service. When I call, someone answers the phone, and if Eric’s busy with a customer, he always calls me right back.”

“The Kubota KX080-5 series is a beautiful machine - it’s next on my wish list,” says Rottier. “I really want one bad, but I have to convince my wife and business partner, Sarah, that we need it and it’s going to pay for itself. Kubota machines always do.”

“ I USE IT FOR EVERYTHINGLANDSCAPING, BUSH REMOVAL, LOADING DUMP TRUCKS, CUTTING WOOD... ”

TRACK DESIGN – What an upgrade, I love it! It doesn’t plug up. It floats beautifully across the ground. In terms of comfort, it makes a 10-hour day a lot nicer.

VERTICAL LIFT – I think I gained eight-to-ten inches in reach height. That doesn’t sound like a lot until you’re loading over the side of a dump truck all day.

FULL-COLOUR REAR-VIEW CAMERA – The clarity of the integrated backup camera is phenomenal. I can maneuver it to see in those blind spots, which from a safety standpoint, is huge for me.

BY KEN SINGER, PUBLISHER

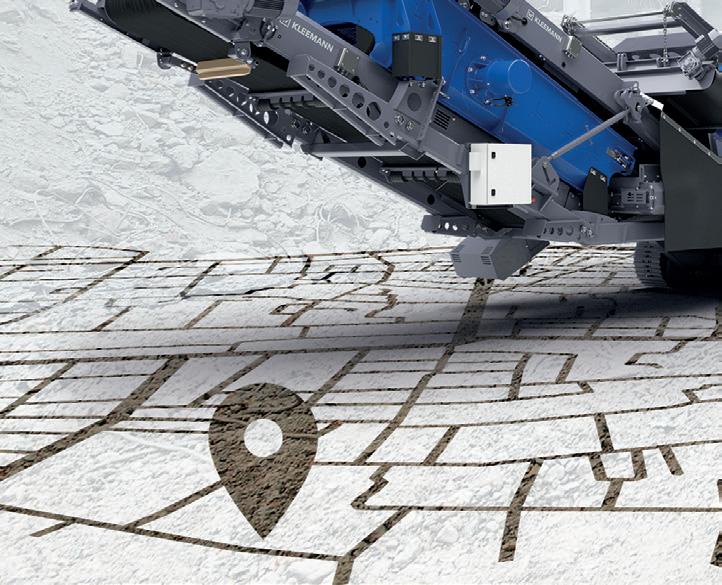

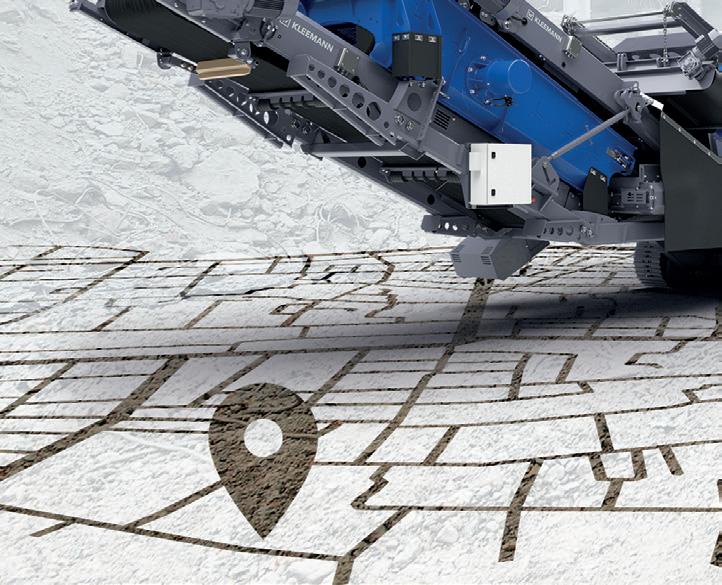

This April, 2,700 guests from more than 100 countries attended Wirtgen Group Technology Days 2024 in Göppingen, Germany. The overarching themes of the two-day event at the headquarters site of Kleemann were digitalization and sustainability, inspired by the motto “Smarter. Safer. More Sustainable.” At Göppingen, the Wirtgen Group demonstrated machines and technologies developed to enable maximum versatility and productivity to meet today’s changing, demanding expectations.

The Wirtgen Group impressed the attendees with numerous innovative systems and solutions, including 11 new machine world premieres and a clear vision for the future of road construction.

“Innovation is in our genes. As we are aware from the feedback we receive from our customers, there is increasing demand for smarter, safer, and more sustainable solutions in markets around the globe. We have concentrated our efforts on this and can now present state-of-the-art machine technologies and digital systems with which we provide support and assistance to our customers in all aspects of the digital transformation. At the same time, we attach great importance to holistic solutions for their construction projects – from the planning phase through to documentation and statistical analysis,” says Dr. Volker Knickel, CEO of the Wirtgen Group.

With around 70 exhibits for a range of different application scenarios, Wirtgen, Vögele, Hamm, and Kleemann, as well as the Benninghoven and Ciber brands not currently offered in North America, showed the solutions which will propel the industry to more integrated digitalization and automation in road construction and materials processing.

Interest in the world premieres was particularly strong. These included a SUPER 1800-5(i) “Dash 5” generation asphalt paver from Vögele, which offers smart automatic functions, improved comfort, and an optimized drive system. The SUPER 1800 is considered Vögele’s most popular paver, and attendees were impressed by the updated ergoPlus 5 operating system and the optional “Premium Touch” display screen which allows users to easily monitor and control existing and future digital solutions. Hamm presented a total of four new machines, including an HC series compactor with the innovative VA (variable amplitude) drum. The Smart Compact compaction assistant enables automatic compaction to a specified target value with VA-compactors. With its satellite-based AutoTrac system, the latest addition to the portfolio of wheeled soil stabilizers from Wirtgen, the Rock Crusher WRC 240i, demonstrated how preparation of the ground for road and highway construction can be realized

more quickly and with fewer resources.

For the materials processing sector, Kleemann, the host of the event, presented the new MSS 502(i) EVO scalping screen with an alternative, fully electric drive option. With its compactness, the MSS 502(i) EVO is optimized for the lower feed capacity range of up to 350 tph. A generously dimensioned feed hopper, a screening surface of 5.4 square metres, and a wide main discharge conveyor guarantee excellent material guidance. For high flexibility in the application, the speed of all conveyor belts is steplessly adjustable and a simple conversion from two to three final grain sizes is possible.

Asphalt production offers the greatest potential for reducing CO₂ emissions. In response to this, the Wirtgen Group also presented the new generation of burners from Benninghoven, which supports the simultaneous use of up to four different fuels. This means, for example, that an asphalt mixing plant can be flexibly operated with the most appropriate energy source –including, for the first time, exclusively with green hydrogen.

Internationally recognized experts and specialists from the Wirtgen Group provided first-hand insights into the technologies of the future. On the subject of sustainability, they shared

THE WIRTGEN GROUP IMPRESSED THE ATTENDEES WITH NUMEROUS INNOVATIVE SYSTEMS AND SOLUTIONS, INCLUDING 11 NEW MACHINE WORLD PREMIERES AND A CLEAR VISION FOR THE FUTURE OF ROAD CONSTRUCTION.

their experiences and knowledge of sustainable construction, the potential for CO2 reduction offered by the recycling of hotmixed asphalt and cold recycling, and new electrically powered drive solutions for crushers and screening plants.

In the thematic complex of digitalization, presentations by specialists from the Wirtgen Group showed how the company can support and assist its customers in the course of the digital transformation. The John Deere Operations Center for construction equipment will become the central platform for providing digital solutions for the management of entire construction sites – at any time and from anywhere, including planning, monitoring, analysis, and maintenance. The Operations Center will act here as an interface between operators and machines on the construction site, the offices of site and resource managers, and the workshop manager.

But what does this mean in practical terms? Thanks to plannable machine availability, customers will, for instance, enjoy the benefits of reliable equipment utilization. The immediate availability of comprehensive information will enable project managers and machine operators to make the right decisions. A higher degree of process automation and the use of machine assistance systems will not only lead to higher productivity due to operators being able to concentrate fully on the work in progress, but also to a more efficient and effective deployment of human resources. The precision and, consequently, the quality of the work will

also increase, which will in turn avoid the necessity of reworking and will help reduce material and operating costs.

The broad spectrum and informational depth of the presentations underscored a clear road map that lays out how customers can be fully supported on today’s evolving job site. Wirtgen Group Production Systems provides end-to-end process solutions that address a wide range of project requirements aiming to decisively accelerate the digital transformation and connectivity of the industry with the ultimate goal of increasing profitability and maintaining the highest machine utilization rate

The greatest ecological and economic potential lies in the totality of the construction process. Various live demonstrations showed how the Production System solutions from the Wirtgen Group play a role in this – for instance the use of low-temperature asphalt, concrete and asphalt recycling, or soil stabilization – and illustrated how the target-oriented utilization of technologies leads to greater precision, higher quality of results, and the consumption of fewer resources. Or, in other words: how to “Do More with Less” – and be “Smarter, Safer, and More Sustainable.”

As Knickel explains, “This enables our customers to realize more construction projects with fewer resources, build and rehabilitate more infrastructure, and simultaneously increase their profitability.”

At the same time, he emphasizes that digital assistance systems and process automation also contribute to offsetting the shortage of qualified personnel throughout the industry. “This also means that less experienced machine operators will be in a position to deliver qualitatively identical results to those a skilled specialist would achieve,” he says.

On top of this, telematics solutions will deliver greater transparency about the operational status of customers’ fleets and enable them to carry out proactive and even more precisely targeted servicing and maintenance of their machines.

On a guided tour through the Kleemann production facilities, the host of the event gave the professional audience fascinat-

ing insights into the manufacturing process. Since the opening of the new plant in 2009, the highly specialized facility has been successively extended and, like all other Wirtgen Group factories, has been constantly upgraded for sustainable operation in line with the Group’s sustainability strategy. Today, the Kleemann plant is one of the world’s most modern facilities for the production of crushers and screening plants. Many of the visitors were particularly impressed, not least by the highly complex prefabrication centres in which the core components of the Kleemann plants are produced with exceptional precision.

“In past years, we concentrated our efforts on target-oriented expansion of our product portfolio and now offer suitable solutions for every application, no matter whether for recycling or natural stone processing. To achieve this, we invested in areas such as expanding our production capacities and improving our assembly or logistics processes,” says Kleemann CEO Alexander Knam, describing the development of the company’s headquarters site in Göppingen. He believes that the specialist for materials processing equipment is ideally positioned for the future. “With these investments, we have laid the foundation for the ongoing production of our products and technologies under ideal conditions, sustainably and efficiently.” HEG

MILLS, PAVERS, MACHINE CONTROL & MORE

Three cold planers in the Caterpillar PM300 series have been updated with new designs and features that improve peak torque, gross power, and the operating environment. The PM310, PM312, and PM313 are compact and maneuverable, good for smaller or mid-sized road repairs where high capacity is needed.

New models are fitted with the Cat C9.3B engine generating an increased 343 hp along with increased torque. Performance upgrades on the PM300 series include a redesign of transition flashing between the primary and loading conveyors, which improves material containment and cuts down buildup on the front of the machine. The right-hand side plate, chamber-to-conveyor sealing, and loading conveyor belt sealing have all been enhanced as well. Front track deflectors in front of the drive motors also provide more debris

protection for increased service life.

An adjustable on-screen guidance line added to the left-hand camera now gives operators the ability to track the cutting edge from either side of the machine.

Ground personnel can also control the obstacle jump capability from rear ground controls. LED lighting options provide better visibility and safety around the machines.

FAE road planers use cold planer technology to turn skid-steer and compact track loaders into road maintenance machines capable of resurfacing in preparation for new asphalt or concrete, or simplifying excavation work.

The RPL/SSL is compatible with loaders from 60 to 120 hp. It can mill up to 7 inches deep in three widths – 18, 24, or 30 inches. The RPM/SSL, for loaders between 75 and 120 hp, mills up to 10 inches deep and up to 24 inches wide. Both heads have self-levelling skids and tilt to ensure good results on uneven surfaces. A hydraulic drive system helps the attachments mill precisely. A high-visibility design makes these planers easy to view from the cab. Attachments are plug-and-play with most SSLs and CTLs.

The 8-ton CC2200 VI tandem asphalt roller is part of a new series of rollers ranging from 8 to 10 tons with drum widths of 59 to 66 inches. Dynapac says it has taken cues from larger rollers to improve paving results and operating efficiency on the CC2200 VI, such as 180-degree seat rotation, an efficient eccentric system that combines with ECO mode to cut down on fuel use and emissions, and full backup sprinkler water systems.

A new operator interface is part of the roller’s ergonomic interior and includes

a full-colour 7-inch touch display along with easy access to all controls. An optional 360-degree pedestrian detection camera is available and provides a continuous bird’s-eye view around the machine while working.

Dynapac’s SEISMIC asphalt technology is standard on the CC2200 VI. It automatically determines the optimal frequency for any compacted material, monitoring the variations of the asphalt layer and automatically adjusting to temperature conditions. The optional Dyn@Lyzer is a

compaction control and documentation system that records and maps stiffness and compaction progress of the compacted asphalt layer in real time. It also tracks asphalt temperature and the number of completed passes and can be used as a quality control and assurance device.

Five roller models will be available in the range, with three articulated machines, including the CC2200 VI, joined by two fixed-frame pivot-steer split-drum models. Combination versions of select models will also be available.

BOMAG is taking on segregation to improve mat quality with its updated CR 1030 10-foot paver. Available in 2025, the CR 1030 Series includes new interface features, multiple control options, and a new independent auger/conveyor system. Also new is the versatile Versa 20 front-mount screed.

The independent auger/conveyor system has an outboard auger drive system and a design that lets the conveyors and auger run independently with a two- or optional four-sensor control system. A raisable or fixed outboard-driven auger system allows better visibility into the conveyor discharge area, and eliminates segregation in that area for better mat quality.

New interface features grouped on the tractor console, and a new screed control system with integrated automation features, help operators run their machines more efficiently. On the console, similar functions are grouped together for quick identification and adjustment. A 7-inch multifunction colour screen display has multiple configurable detailed screens that accommodate multiple operators and working conditions. With both a touchscreen and remote dial control, operators are able to navigate and adjust settings in whichever way is more convenient. A new sloped hood improves visibility into the hopper.

The Versa 20 front-mount electric screed offers variable paving widths from 10 to 19 feet at paving thicknesses to 12 inches. Bolt-on left- and right-hand extensions add more width up to 23 feet. Quick connections provide heat and vibration for increased mat quality.

A 10-foot catwalk and foldable walkway extensions for the operator are standard.

The 11-inch-deep hydraulic extensions, with manually adjustable angle of attack, allow for better density and mat quality, and the hydraulically powered crown can be adjusted from 3-inch positive to 1-inch negative. New controls and remotes allow for a better operator experience and accommodate special features like integrated MOBA automation.

Modular, simplified configurations and advanced features are highlights of the MC-Max Asphalt Paving and MC-Max Milling solutions from Topcon Positioning Systems. Made up of GNSS receivers, total stations, displays, and other high-precision sensors, these solutions are built on the MC-X machine control platform which includes highly customized systems and upgradeability for growth.

Choices range from entry-level 2D systems that follow a

Apair of new highway-class pavers provide versatility and choice for contractors who want efficient asphalt machines.

The PF-5170C paver is powered by a 188-hp Cummins Tier 4 Final engine with DPF and active, semi-automatic regeneration, reducing engine emissions while increasing fuel efficiency. On the larger PF-7110C paver, a 225hp Cummins Tier 4 Final engine provides the power.

A four-sensor feed system matches proper delivery and flow of material to the speed of these pavers for smooth and even paving. Both the driver and the screed operator have a button on the control panel to hydraulically extend two-stage tunnels that give better material control and a consistent head in front of the screed. Flow gates can also be used.

reference, such as a curb or string, to automated solutions that track the paver or mill in 3D. Users can pave and mill at variable depths to meet smoothness requirements. Solutions also include MC-X licensing options that provide users with further flexibility to meet project and budget requirements.

expands on Topcon’s SmoothRide road resurfacing solution to create 3D models of existing road surfaces.

Operators have 360-degree visibility from Blaw-Knox’s single-level platform. Dual rotating, tiltable consoles make the machines more versatile – the operator can work from either side. An adjustable seat extends beyond the edge of the paver for even more visibility.

The SmokEater fume extraction system removes fumes at 83 percent efficiency without blocking the view into the auger channel.

The newest member of the Wirtgen milling machine lineup is the W 150 XFi. A compact unit that mills up to 6 feet wide, the machine is a good choice for use on construction projects taking place in tight spaces, such as downtown cores. New engine technology from John Deere is environmentally friendly and fuel efficient, and performance is boosted by digital assistance and levelling systems.

The front loading design delivers high performance on restricted job sites.

The Level Pro Plus levelling system combines with an intuitive operating system to ensure the machine can be run by a single person while achieving precise results.

Wirtgen’s Flexible Cutter System permits the use of different milling drums offering maximum working widths of up to 6 feet, making the compact milling machine flexible and allowing it to be used on more contracts.

The low weight and milling drum unit mounted in the centre of the milling machine provide ideal weight distribution.

Flexible adjustment of the extra-large slewing angles and speed of the front-loading conveyor ensure efficient material loading.

include small milling jobs, such as spot road repairs, up to the removal of complete road surfaces.

BY LEE TOOP, EDITOR

Roadbuilding job sites are busy places, with workers and machinery moving constantly to ensure trucks, pavers, and rollers work together effectively. This can lead to increased risk of machines colliding with workers or other equipment. New technology and design features on tandem rollers are intended to reduce the risk of collisions.

Roller operators need to keep an eye on everyone around them when working, but that is easier said than done, explains Brad Belvin, sales and marketing manager with Sakai America.

“There are so many people on that job site, from dump truck operators to the people on the paving crew, to the rake people, people with a shovel, inspectors coming through – everyone has to be aware of everyone else at all points and times,” he says. “From a roller standpoint, you’re out there for eight hours a day going forward and backward – you have to pay attention. Awareness has to be the number one concern.”

Visibility is the top safety concern for roller design, Belvin says. It is important that workers on the ground and the roller operator can see one another clearly while the machine is working, no matter the angle the operator’s seat is at.

To determine the quality of visibility, Sakai uses what Belvin describes as a one-by-one system – if a one-metre by one-metre cube is placed against the machine on the front, side, or rear, the operator should be able to see it from their station. If not, the design must be adjusted.

Operator comfort is a close second to visibility for safety-focused design. If the operator is comfortable on the machine, they will be more vigilant throughout the day.

Operators of large Sakai double-drum

asphalt rollers are provided with a 180-degree swivel seat that has a number of different locking points. A lever the operator can control with their heel unlocks the seat for rotation, removing the need to bend over which reduces another stress point.

“If it’s easier to move with less obstruction and less torquing on your body, it’s going to be less stress on the person,” Belvin says. “If you are more stressed and more tired . . . you’re less aware because you’re focused on other things. Taking out that uncomfortable element and making it as easy to operate as possible increases overall awareness.”

A third area to consider is ease of control – the easier it is to understand and use the roller controls, the better for operator awareness. If a machine is difficult to run, the operator is going to spend more time focused on the controls and less on the surroundings. Sakai’s controls are kept very simple to reduce the operator’s stress, Belvin says.

QUICKLY BUT SMOOTHLY

The ability to brake quickly and smoothly is important for a machine as large as a roller.

“On our 79- or 84-inch double-drum rollers, you’re talking about 30,000-pound machines going at a general operating speed of around four and a half miles per hour. Stopping 30,000 pounds at that speed is not something you can immediately do,” Belvin says.

Sakai Guardman is integrated into the machine hydraulics to slow and stop the machine if an obstruction is detected.

“It’s essentially a rear proximity detection system but takes it a step further, where it actually brakes the machine before making contact with someone or something,” Belvin explains.

Guardman is available on a number of Sakai rollers, including the SW884ND, the first roller models to be produced

in and specifically for North America. It uses either a millimetre-Hertz wave radar system or 3D LIDAR depending on the machine, which detects objects behind the roller and moves through three stages of response.

When an obstacle is first detected, the system sounds an audio alert to the operator. If the machine moves closer, the audio alerts become more aggressive. Within a certain distance, the system engages through the hydraulics and brings the roller to a safe and smooth stop.

“If you’re going full speed, the machine does not come to a shaky, abrupt stop . . . it will slow the machine down just enough so it doesn’t skid,” Belvin says. “Obviously, the last thing you care about is the asphalt at that point in time, but if it can still protect that job, that is a nice thing.”

In addition to protecting those around the machine, Guardman also collects data about incidents that activate the system, providing greater awareness for owners and operators about the job site safety culture.

Operator comfort is a close second to visibility for safetyfocused design. If the operator is comfortable on the machine, they will be more vigilant throughout the day.

“Calculating near misses or stopping a general injury – it’s anything you can do to protect your workers. Did it go off and engage? How many times does that happen?” Belvin says. “Any time it does go off completely, you now have a time where you can sit down before a shift and say ‘maybe we need to do more coaching here, and raise more awareness of the people that are on our job site.’” HEG

SAFETY SUITE STANDARD ON ALL DRIVETRAINS OF ITS VOCATIONAL TRUCKS

BY LEE TOOP, EDITOR

More than any other type of truck, vocational trucks are at risk of accidents involving vehicles and pedestrians – on the road, around the job site, or at the terminal. Drivers must constantly watch for people, equipment, and other vehicles around them as they do their work.

Daimler Truck North America (DTNA), the parent company of Western Star, has developed the Detroit Assurance suite of active safety tools to promote more road and job site safety. Detroit Assurance was previously only available on Western Star trucks with Detroit Diesel powertrains, but is now standard on all X-Series vocational trucks.

Detroit Assurance helps drivers respond to potential accidents more quickly and, in some cases, provides direct action to mitigate or lessen the severity of collisions. Assurance includes features like Active Brake Assist (ABA5), Side Guard Assist (SGA), Lane Departure Warning, Intelligent High-Beam, and Automatic Wipers and Headlamps.

All X-Series trucks can also now be fitted with a factory-installed backup alert system.

Heavy Equipment Guide caught up to Aaron Scates, vice president, Vocational & Medium Duty Market Development with DTNA, to talk about Western Star’s expanded safety options for vocational trucks.

“The operator is the person who creates the safety of a truck or job site, so we want systems that make that operator better at being safe,” says Scates. “Safety is embedded everywhere in the design of the truck, and then we look at technologies that enhance the operator’s ability to get their job done efficiently and safely.”

Owners of truck fleets of different sizes and makeups have different approaches to technology, especially when it comes to active safety systems. On-highway fleet owners have come to recognize the benefits of such systems over time, but vocational owners tend to be more conservative, Scates explains.

Larger fleets are frequently driven by corporate values to emphasize safe operation as much as possible. For them, the cost of active safety is often non-negotiable. The adoption rate among smaller fleets tends to be slower – they want to see the value before they spend money on technology.

Broader availability of technology on new trucks helps improve that uptake rate and can also improve driver hiring and retention, especially with the ongoing skills shortage.

Scates points out that driving a truck has

always been a difficult job, but technology has consistently made it easier by allowing the driver to focus more on the road. For example, the shift from manual to automatic transmissions has made it easier for drivers with less experience, and newer safety tools will have the same effect.

“Drivers can focus on the road and their equipment, and they have a system there that helps them be better at what they do – it’s not taking their place, but it’s making them better,” Scates says.

DTNA has previously offered Detroit Assurance on Detroit Diesel–powered Western Star trucks, and has now expanded that availability to units with third-party powertrains.

“Our customers know that if they have a mixed fleet of vehicles, they can get that feature with similar functionality –there will be no difference in terms of

how they operate,” Scates says.

A combination of radar and camera technology makes up the Active Brake Assist feature (ABA 5), which provides a series of supports to the driver in the case of a potential collision. It calculates the truck’s speed and determines distance to obstacles such as pedestrians or vehicles, and if a collision is possible, begins to issue warnings in a four-stage process. A visual and audible alert is first, followed by a more insistent alert tone and partial automated braking. If there is no driver input, stage 3 initiates full braking along with alerts. Stage 4 is after the full braking event has completed, with the brakes held at a full stop.

Scates says ABA 5 is intended to provide safety as needed, without being too intrusive for drivers who may be uncomfortable with automation.

“Operators need to have control of the vehicle at all times, and unexpected intervention is something that some folks would say they don’t want. We heard a similar sentiment a few years ago when we were going from manual transmissions to AMTs and automatics,” he relates. “Once an operator experiences it and sees the

value, there’s a shift in mindset. I think the first time you have an active brake event that helps keep you out of trouble, it’s like ‘oh my gosh, I really want that.’”

In addition to the expansion of Detroit Assurance, Western Star’s X-Series trucks can now be fitted with a factory-installed backup alert system, adding a camera, reverse proximity sensor, and 7-inch touchscreen display. Cameras are used on most trucks today, and factory fit makes more sense for buyers than having an upfitter tear apart the dash, run wiring, and work other camera needs in around the body.