®

®

.

Discover why the best in the business trust Mack Granite ® as the tried-and-true partner to help their businesses grow.

Visit MackTrucks.com/BuildBest to learn more.

Mack Granite®

Mack Granite®

Find

EDITOR IN CHIEF Kaitlyn Till ktill@baumpub.com 604-291-9900 ext. 330

EDITORIAL DIRECTOR Arturo Santiago asantiago@baumpub.com 604-291-9900 ext. 310

EDITOR Lee Toop ltoop@baumpub.com 604-291-9900 ext. 315

ASSOCIATE PUBLISHER Sam Esmaili sam@baumpub.com 604-291-9900 ext. 110

FOUNDER Engelbert J. Baum

ADVERTISING

PRODUCTION MANAGER Tina Anderson tanderson@baumpub.com 604-291-9900 ext. 222

DESIGN & PRODUCTION

Morena Zanotto morena@baumpub.com 604-291-9900 ext. 325

PRESIDENT/PUBLISHER Ken Singer ksinger@baumpub.com 604-291-9900 ext. 226

VICE PRESIDENT/CONTROLLER Melvin Date Chong mdatechong@baumpub.com

Published by: Baum Publications Ltd. 124 - 2323 Boundary Road Vancouver, BC, Canada V5M 4V8 Tel: 604-291-9900 Toll-free: 1-888-286-3630 Fax: 604-291-1906 www.baumpub.com www.heavyequipmentguide.ca @HeavyEquipGuide

FOR ALL CIRCULATION INQUIRIES

Toll-free: 1-866-764-0227 email: heg@mysubscription.ca

Subscription: To subscribe, renew your subscription, or change your address or other information, go to: http://mysubscription.ca/heg/

Heavy Equipment Guide serves the Canadian engineered construction industry including: roadbuilding and maintenance; highways, bridges, tunnels; grading and excavating; earthmoving; crushing; trucking and hauling; underground utilities; trenching; concrete paving; asphalt paving; demolition; aggregates production; fleet maintenance; and asset security and management. The magazine is distributed to key industry personnel involved in these sectors.

Subscription Price: In Canada, CDN $91.00; Outside Canada, US$149. Heavy Equipment Guide is published ten times a year in January, February, March, April, May, June, July/August, September, October and November/December.

Heavy Equipment Guide accepts no responsibility or liability for reported claims made by manufacturers and/or distributors for products or services; the views and opinions expressed are those of the authors and not necessarily those of Baum Publications Ltd.

Copyright 2022, Baum Publications Ltd. No portion of this publication may be reproduced without permission of the publishers.

We acknowledge the financial support of the Government of Canada.

Printed in Canada on FSC®-certified paper by Mitchell Press Ltd. ISSN 1715-7013. PUBLICATIONS MAIL AGREEMENT NO. 40069270.

PUBLICATIONS MAIL AGREEMENT NO. 40069270

Return undeliverable Canadian addresses to: Circulation Dept., 124-2323 Boundary Road, Vancouver, BC V5M 4V8 email: heg@mysubscription.ca Toll-free: 1-866-764-0227

Contact: Editor in Chief Kaitlyn Till at ktill@baumpub.com or 604-291-9900 ext. 330

The L 586 XPower® is a part of the new generation of Liebherr’s large wheel loaders. XPower is an innovative machine concept that combines performance, robustness, operator comfort and outstanding fuel efficiency.

With Liebherr power-split travel drive as standard equipment, XPower wheel loaders work efficiently in all areas providing maximum performance even under the toughest of operating conditions. www.liebherr.ca

As we close out 2022 and look back at the heavy equipment introductions from the year, I am struck by the many different innovations and how they are moving the industry forward.

When you browse through Heavy Equipment Guide’s Top Introductions for 2022, I’m sure you will agree that this year has been a busy one for new equipment and advancement in technologies. Many manufacturers also focused on drastically reduced emissions and improved efficiency in new equipment, and every indication suggests that these trends will continue as we move forward.

For myself, the most impressive advance represented in these introductions is the growing number of machines powered by electricity. In 2022, Bobcat was central to the electric revolution, thanks to the launch of its T7X fully electric compact track loader, which stands out for its embrace of the battery-electric approach throughout, including the replacement of hydraulics. The result is a machine that is nearly fluid-free, reducing maintenance – and it performs just as well as its diesel fellows.

Volvo CE reached North America with its electric wheel loaders in 2022, and paired them with an electric fleet management app to help owners track and maintain their equipment efficiently. Volvo has been a leader in electric development, and we can expect more from them soon. Another electric standout this year is AUSA, which at bauma 2022 introduced an electric site dumper as well as a telehandler. Designed for urban environments, these machines are a great fit for battery-electric operation, and I expect to see even more equipment along these lines make its way to North America.

Beyond electric, we saw many other innovations in 2022. Case Construction Equipment brought its long-awaited Project Minotaur to market in the form of the DL550, a compact dozer loader. It is purpose-built to provide pushing power as well as lifting capacity in a small package that fits into plenty of roles on any job site. Doosan, which is preparing for some big branding changes come 2023, brought its first dozer to the market this year and updated a variety of other machines.

Technology has also made its mark on the industry. Take

Topcon’s MC-Mobile, for example, which brings affordable and portable machine control to compact equipment – that’s huge for smaller operations. Or, check out the various roadbuilding machines on our list, which are all benefitting from technology additions to make it easier for users to get the precision they need much faster.

As you can see, 2022 has been a busy year for heavy equipment, and we now have CONEXPO-CON/AGG 2023 on the horizon – which will drive even more activity. It’s a sure thing that 2023 will deliver even more exciting technology and introductions.

Lee Toop Editorltoop@baumpub.com heavyequipmentguide.ca

When you browse through Heavy Equipment Guide’s Top Introductions for 2022, I’m sure you will agree that this year has been a busy one for new equipment and advancement in technologies.

The 2022 bauma Innovation Awards have been presented in five different categories which include Climate Protection, Digitalisation, Mechanical Engineering, Building Innovation, and Research Innovation. The winners are: Climate Protection – Liebherr-France SAS for its R 9H2 hydrogen-powered crawler excavator: The H2 hydrogen drive in Liebherr’s concept R 9H2 crawler excavator does not require a permanent energy supply, and generates low NOx and CO2 emissions. Depending on how emissions are measured, and whether the entire life cycle of the machine is taken into account, the hydrogen combustion engine reduces CO2 emissions by almost 100 percent in day-to-day operations, or by 70 percent for the entire life cycle of the machine.

Digitalisation – MiC 4.0 Machines in Construction for its common digital language for construction sites: MiC 4.0’s aim is to create a universal, uniform, and manufacturerindependent data interface between construction equipment and attachments. Through the cooperation of over 25 users and machine and tool manufacturers, a data interface via the CAN bus internet protocol is defined under the name MiC 4.0 BUS.

Mechanical Engineering – Herrenkneckt AG for its continuous advance tunnelling process: Herrenknecht AG’s new continuous tunnelling process is for tunnel infrastructure in common soft ground formations with or without water-bearing layers. Using the latest technology, the continuous tunnelling process leads to a significant reduction in construction time for longer sections of tunnel as it eliminates the stop-and-go process of tunnelling.

Building Innovation – Holcim GmbH for carbon prestressed concrete (CPC): Instead of steel, the concrete of Holcim’s carbon prestressed concrete (CPC) panels is reinforced exclusively with prestressed carbon fibres. The thin concrete elements enable material savings of up to 80 percent, depending on the design, and reduce the component’s CO2 footprint by up to 75 percent.

Research Innovation – Freiberg University of Mining and Technology Mechanical Engineering Institute for deep sea sampling: The research project aims to electrify a compact trench cutter and transform it into a smart, semi-automated vertical mining unit for deep sea mining that can work through the pressure, darkness, and temperature challenges.

Common Ground Alliance (CGA), the national nonprofit trade association dedicated to protecting underground utility lines, people who dig near them, and their communities, has released the findings from its 2021 Damage Information Reporting Tool (DIRT) report. The annual DIRT Report provides a comprehensive accounting and analysis of damages to buried infrastructure in the U.S. and Canada to help stakeholders understand the current damage landscape and the factors contributing to underground facility damages.

The report analyzed all 2021 data submitted to DIRT by facility operators, utility locating companies, 811 centres, contractors, regulators, and other stakeholders from the U.S. and Canada. The report contextualized the data utilizing different models as part of a three-year trend analysis (2019 to 2021), which points to an overall plateau or slight increase in damages since 2019. At a time of increasing excavation activity and greater infrastructure funding from the Infrastructure Investment and Jobs Act of 2021, the report underscores the importance of addressing the ongoing causes of damages to critical facilities to drive these damage numbers down.

The analysis of 2021 data suggests that ongoing challenges in the damage prevention process – including no notification to the 811 centre, failure to pothole and/or maintain sufficient clearance, facilities not marked or marked inaccurately due to locator error, and other improper excavation practices – are consistently responsible for more than 76 percent of damages that occur, and addressing these challenges would significantly reduce instances of damages and near misses. The report recommends that stakeholders tailor damage prevention efforts and investments to address the specific leading root causes, most effectively lowering damages and improving the damage prevention process. Additional recommendations from the report include strengthening engagement with public works stakeholders, expanding damage prevention outreach to address increasing construction activity, and enhancing excavator education around the consistent and efficient use of 811 as well as safe excavation within the tolerance zone.

The full DIRT report can be found at commongroundalliance. com.

Tractor Bob’s, a Yanmar America Corporation dealer, has designed and fabricated a tractor conversion for an operator who uses a wheelchair. The Yanmar YT3 chair lift is the first chair lift on a compact Yanmar tractor. It allows a person to access the tractor and operate it by hand when in a wheelchair. The further addition of a Jiffy Hitch allows the operator to easily change tractor implements.

When Tractor Bob’s was approached with a request to retrofit a Yanmar YT3 tractor for easy access for an operator in a wheelchair the team fabricated a custom seat lift transfer system and fitted it to the tractor. The system allows the user to transfer from their wheelchair to the lift, be raised to the tractor cabin, and easily transfer across to the tractor seat. The seat lift comes with a wireless remote that controls the lifting operations of the chair. Once in the cabin, a hand throttle and a hand-operated braking mechanism enable the user to operate the Yanmar YT3 tractor entirely by hand.

Turn to page 18 for this year’s top equipment and technology introductions.

Sunbelt Rentals has received its first Bobcat T7X all-electric compact track loader in Sacramento, California. Sunbelt Rentals has an exclusive rental agreement for the Bobcat T7X, which is the world’s first all-electric compact track loader and joins a Sunbelt Rentals fleet that also includes all-electric scissor lifts and skid steers. The T7X offers zero emissions and nearly silent operation.

Kubota Canada has opened a new Canadian corporate headquarters and distribution facility in Pickering, Ontario. This new facility, which comprises 500,000 square feet of industrial warehouse space and 65,000 square feet of office, meeting, and training space on three floors, was built with an $80 million investment from Kubota, which continues to expand its presence in Canada since it was founded in 1975.

United Rentals, Inc. has entered into a definitive agreement to acquire the assets of family-owned Ahern Rentals, Inc. for approximately $2.0 billion in cash. The board of directors of United Rentals unanimously approved the agreement. The transaction is expected to close prior to yearend 2022, subject to customary conditions.

JAPA Machinery Group, which has offered equipment sales, rentals, and service in Alberta for five decades, is celebrating by adding a new location in Calgary – its first outside of the Edmonton area.

The facility in southeast Calgary is expected to open in early 2023, and will give the JAPA team a second location for sales of its line of XCMG equipment. JAPA specializes in earthmoving, compaction, and construction machinery from XCMG, the third largest equipment manufacturer in the world.

JAPA has been working with Alberta’s oil and gas, construction, and roadbuilding industries for 50 years, and is a family-owned company.

The ARA Show 2023 will be held at the Orange County Convention Center in Orlando, Florida, from February 12 to 15, 2023. The event provides an opportunity for those in the rental industry to meet with their peers for targeted education, networking, and a three-day trade show.

Converting waste products and virgin materials into high-quality aggregates, requires equipment that is engineered to perform. Unrivaled in performance, the Keestrack R6 mobile impact crushing plant is designed with state-of-the-art technologies, innovative controls, and a heavy-duty mobile design. This is where portability meets performance.

The past year has been filled with numerous challenges for the heavy equipment manufacturing industry including economic inflation, labour shortages, supply chain delays, and more. Since becoming president of the Association of Equipment Manufacturers (AEM) on January 1, 2022, Megan Tanel has steered the association and its members through these challenges, picking up a few victories along the way. She has clear priorities for 2023 and beyond when it comes to CONEXPO-CON/AGG, infrastructure, and technology.

Tanel knows full well AEM’s core mission of advancing the business goals of construction and agriculture equipment manufacturers in the global marketplace. She originally joined AEM in the mid-90s and has previously led AEM’s exhibitions and events initiatives, including the launch of World of Asphalt in 2001, and served as senior vice president, construction and utility sector before becoming president.

Tanel says the year has moved at a fast pace, and her transition into the role has been smooth. She was able to hit the ground running thanks in large part to the staff at AEM and an engaging and supportive membership. Her tenure as president began as the world was emerging from the pandemic, AEM was bringing staff back to the office, and the industry was dealing with numerous issues that were causing manufacturing and delivery delays.

Tanel says, “To be quite honest, the mood around here was pretty intense. Coming in, I didn’t need to continue to rock the boat as much as it’s been rocked lately. I just came in wanting to calm the waters a little bit, keep our momentum, and keep our focus where it needed to be.”

A significant challenge this year was chip and semiconductor availability for manufacturers. Tanel says one of the major legislative victories of the year has been the passage in the U.S. of the Creating Helpful Incentives for Production of Semiconductors for America Act (CHIPS). It aims to spur investments in domestic semiconductor manufacturing capacity.

Manufacturers also continue to struggle to attract a skilled workforce. According to Tanel, 78 percent of respondents to AEM’s CEO survey assert that a shortage of skilled labour is re-

sponsible for delaying production. While keeping track of labour shortage data and trends is important, Tanel also considers the bigger picture. “When it comes to workforce, every industry seems to be hurting to find workers, and I think a lot of that wraps around the perception of your industry. For us, it’s making sure that people understand what our industries provide: safe working environments, a working wage, and new technologies. We can start telling a better story about ourselves and what we offer to future employees. We need to blow that up beyond just high school students and make sure their parents understand how valuable it is to have a job in manufacturing.”

Also of concern is global competition – especially when it

I just came in wanting to calm the waters a little bit, keep our momentum, and keep our focus where it needed to be.

Megan Tanel President, Association of Equipment Manufacturers

comes to doing business with China whether it is the sale of Chinese-made equipment in North America, or being able to sell domestic manufactured equipment in China. Tanel explains, “We just completed a CEO survey and of our CEOs that responded, 84 percent believe that China’s unfair trade and investment practices are preventing American companies from competing on a level playing field. I don’t see that being much different within Canada. Thirty-nine percent of those respondents said that the Chinese government and its trade practices, including intellectual property theft, forced technology transfer, and unfair subsidies continue to pose just enormous, long-term challenges for our companies.”

Repairing or replacing aging roads and bridges remains a top priority. “There are major safety concerns with a number of our roads and bridges, and we need to bring those up to the level that

they need to be,” Tanel says. The passage of the bipartisan infrastructure bill in the U.S. offers renewed enthusiasm in addressing not only crumbling roadways and bridges, but also connectivity and developing a robust rural broadband network.

CONEXPO-CON/AGG 2023 is on track to have the largest exhibit footprint of any CONEXPO. More than 1,800 exhibitors are expected to participate covering nearly 251,000 square metres of exhibit space at the Las Vegas Convention Center. More than 150 education sessions will be presented by industry experts and AEM staff.

A new awards program will debut at CONEXPO-CON/AGG 2023. The Next Level Award will recognize innovations that make a difference in the construction industry – companies that push the envelope to create next-level products, technologies, and services. The criteria for the award are products that:

• Address a common industry need in a unique and innovative way;

• Benefit the industry across multiple applications for industry-wide adoption; and

• Positively impact the safety, sustainability, and workforce of the industry.

Ten finalists will be chosen by a panel of Associated General Contractors of America (AGC) members based on innovation, application, engineering, scalability, and impact.

Show attendees will have the opportunity to visit the Next Level Award finalists’ booths and vote for the Contractor’s Choice Award.

There is no denying Tanel’s enthusiasm as she wraps up her first year as AEM president. She looks to the future saying, “I think the biggest thing is the resilience of our members that has really shone through with this pandemic. The last time many of us were together was at CONEXPO 2020, and the world literally shut down. We transitioned immediately to make sure that our industries and every aspect of our industries were deemed essential. I think that really helped to keep many people employed, kept manufacturing going, and kept the ability to maintain our roads and bridges to be as safe as possible. But we have a lot of work to continue to do and I’m looking forward to working with our membership and their customers and our staff to accomplish the strategic plan we’re in and not to slow down as we launch our next strategic plan.” HEG

MB Crusher’s MB-HDS220 padding bucket has a 1-tonne weight, 0.6-cubic-metre capacity. The bucket is designed for skid-steer and compact loaders ranging from 4.5 to 11 tons. Suited for gardening, landscaping, and urban construction sites, the padding bucket aerates packed topsoil for landscaping and can also be used to reclaim clean soil from demolition debris, stones, or roots. A 2.20-metre inlet mouth opening aids loading by ensuring that the carrier machine’s tracks or wheels remain clean. Greasing is centralized and done on-site. The coupling system is designed to aid maneuverability by increasing visibility of the material. The MB-HDS220’s rotors can be changed on-site by the operator.

John Deere has added three new P-tier excavator models to its large excavator lineup. The 470 P-tier, 670 P-tier, and 870 P-tier models deliver improved visibility features including right, rear, and left cameras with LED surround lighting. The lighting and cameras provide the operator with a 270-degree view of the area around the machine. All three excavators feature auto-idle technology which reduces engine speed when hydraulics are not in operation. The excavators use an auto-shutdown feature to preserve fuel, and a hydraulic reversing fan keeps the coolers clean in high debris environments. The 470 P-tier is available with optional grade management solutions, and may also be ordered with a hydraulic coupler-ready option.

The power needed to start motors usually dictates the size of the chosen generator. After the motor is started, the load on the machine drops. But running a generator at a low load is not recommended for Tier 4 Final engines and can lead to engine wet stacking. Doosan Portable Power’s 20kVA to 50kVA generators use upsized alternators to solve this issue. Large alternators give smaller generators more motor-starting capability. Operators can get the initial energy needed to start the motor and then continue to work with an ideal load. The 20kVA to 50kVA generators have a digital control panel that displays the tachometer, oil pressure, coolant temperature, and fuel level. A digital meter shows AC output, generator voltage, and current.

Caterpillar’s new Tilt Rotate System (TRS) models fit Cat mini excavators. The new TRS4 and TRS8 S45 plus updated TRS6 models enable work tools to rotate 360 degrees and tilt 40 degrees side-to-side. Interface connections for the TRS4, TRS6, and TRS8 include a choice between an S Type hydraulic coupler or pin-on, while bottom interface options include a pin grabber or an S Type coupler. The compact design of the tilt rotate systems allow the mini excavator to maintain ideal digging force. A TRS gearbox with a specially designed bearing ring distributes working forces to reduce stress on the TRS and the host machine, and a no-maintenance lubrication system for the rotation system effectively distributes heat.

Volvo has updated its first two electric compact wheel loaders with additional features including higher speeds and linkage options, as well as optimized charging. The L20 and L25 compact wheel loaders have a maximum speed increased to 12.4 mph (20 km/h), along with an option to add a parallel linkage, which offers high breakout torque in a number of applications. A new hydraulic pump and repositioning of the main control valve from the cab to the front frame reduces noise even further. Volvo has added a programmable cab heater option for programming which days to pre-warm the cab. Hill-hold functionality has been added thanks to a new electric parking brake, and the disc brake has been removed in favour of a spring-applied and hydraulic-released wet-disc brake, which reduces maintenance.

Volvo’s Electric Machine Management Application (EMMA), provides users with insights and information on one machine or several, ranging from charge status to location.

Focus on the operator experience and emissions reduction were dominant themes throughout 2022. As contractors adjust to a shrinking skilled workforce and the unfolding reality of emissions reduction regulations throughout the world, manufacturers stepped up with equipment and technology introductions to address these pain points – in an impressive way.

From Bobcat’s fully electric CTL, to monitoring technology for Volvo’s compact electric machines, to the rapid expansion of Liebherr’s Unplugged line, and a fuel-efficiency update to a classic Cat excavator, options for contractors to meet low- or no-emissions requirements are expanding.

Manufacturers also stepped up to deliver new technology and updates that provide an injection of confidence to novice operators and an uptick in productivity to experienced hands. Rototilt introduced new joysticks that make it easier for female operators with smaller hands to customize their setup for more comfortable operation, Komatsu reintroduced its machine control technology with new features, and Topcon’s MC-Mobile machine control system makes adding technology to compact machines easier than ever.

Turn the page to check out these top introductions – and the rest of our picks for 2022.

The T7X all-electric compact track loader, first previewed as a prototype at CONEXPO 2020, shipped to its first customer, Sunbelt Rentals, in 2022. As a world-first in its category, the T7X impresses with instant power and silent operation, but its innovation goes beyond swapping the diesel engine with a battery. All hydraulic functions of the T7X have been replaced with electric actuation, delivering a machine that is as impressive for what it does have, as what it does not – there are virtually no fluids. Bobcat is now rolling out its own line of electric attachments for the T7X, and all standard non-hydraulic attachments are compatible.

track loader with a blade on the front – this beast has been engineered from the ground up with a chassis-integrated C-frame to deliver true dozer performance in a CTL package providing multiple equipment solutions in a single compact machine. Like its mythical namesake, this combination of two creatures is designed to deliver the best of both – without compromise – to job sites.

In 2022, CASE didn’t stop with the Minotaur – it also relaunched its full-size excavator line with the E Series. As part of a trend we saw throughout 2022, CASE focused on the operator experience at a time when attracting and retaining skilled operators is vital. The E Series consists of seven machines including two in new size classes for CASE. Its largest model is the all-new 78,600-pound CX365E SR – a short radius machine with minimum tail swing. The other new model, the CX190E, falls into the 41,000-pound range.

Rotating telehandlers, historically more popular in Europe, have become a machine to watch out for in North America. JLG’s entry into the North American market with three rotating telehandler models in 2022 is indicative of the growing interest from a range of industries, particularly in urban working environments where repositioning a machine is difficult. With the R11100, JLG has delivered its highest reaching telehandler ever, and the 3-in-1 capability of all three models – as a traditional telehandler, a mobile elevating work platform, and a rough-terrain crane –makes the rotating telehandler an appealing option for tight job sites that require big reach.

John Deere’s performance tiering strategy for wheel loaders and excavators is a way for contractors to easily identify the machine that best suits their needs – from simple, reliable machines in the G-tier that can work hard but don’t have advanced features, all the way to the most technologically tricked out equipment in the X-tier. The middle option P-tier machines that John Deere introduced in 2022 are indicative of what many end users ultimately want in today’s environment – a machine designed for reliable, high production with some additional technology and comfort features that improve operator confidence, whether it’s situational awareness technology, or optional grade control features. John Deere introduced several large wheel loaders and excavators under the P-tier umbrella this year and will continue to roll out the line into 2023.

Big changes are on the horizon for Doosan Infracore North America in 2023 with an anticipated rebrand coming early in the year. Ahead of this rebranding, Doosan entered a new product category in 2022 with the introduction of the DD100 dozer – a 10-metric-ton machine that sits in the 140-hp and under category. Doosan has focused on delivering a power-to-weight ratio that maximizes power to the ground and tractive effort. The dozer is the first in what will be a Doosan dozer line for North America – a 13-metric-ton machine is coming in 2023.

In 2022, Doosan also completely relaunched its mini excavators delivering an all-new Doosan design with its -7 lineup covering 2.7 metric tons up to approximately 9 metric tons. This new lineup now features common controls with large Doosan crawlers and wheeled excavators and includes models with zero and reduced tail swing.

While “don’t mess with the classics” might be a rule of thumb in some arenas, when it comes to construction equipment, updates to classic models give operators the machine they know with the benefit of the latest features and capability. In 2022, Caterpillar updated two classic excavator models. With its new 350, Cat focused on reducing fuel consumption and CO2 emissions while still delivering the powerful digging that operators expect from the 350.

With the updated 336, Caterpillar has delivered rugged reliability for operators working in extreme hot and cold conditions, from 52 degrees C down to -18, in addition to high elevations, while reducing maintenance costs. This machine is designed to get straight to work with standard technologies that include Cat Payload on-board weighing, Grade Assist for maintaining grade, and 2D Grade with depth and slope indication.

With the new BM 2200/65, BOMAG delivers a large milling machine with a compact design to boost capability in tight-radius applications. The company also zeroed in on operators’ needs with this milling machine by simplifying control with technology, such as BOMAG Easy Cut to automatically regulate the height of the rear drive, and BOMAG Easy Level which clearly displays grade and slope settings and provides operators with the ability to quickly change settings. The stepless platform side-shift of up to 7.8 inches gives the operator visibility to the right cutting edge and side plate allowing them to hold the milling line.

Liebherr has grown its Unplugged line with six new machines across multiple categories, including two piling rigs, two drill rigs, and two crawler cranes. The zero-emissions technology has already been proven on job sites in London, Paris, and Oslo and is a game changer for city operations delivering low noise levels enabling it to work at night in urban environments.

Liebherr’s new generation of wheel loaders pushes power and performance to a new level over the previous models with up to 20 percent greater power and breakout force. A new lift arm design has optimized z-bar kinematics, and improved working hydraulics are ready to deliver performance in earthmoving, recycling, and log handling applications.

SBM’s new plug-in hybrid REMAX 600 mobile crushing plant was hard to miss at bauma 2022. With this 600 tph plant, SBM focused on delivering multiple power options, connectivity, and a sharp new

Operating a tiltrotator can be a handful – particularly for female operators who typically have smaller hands. With that in mind, Rototilt has introduced all-new multi-way adjustable joysticks as part of its larger Rototilt Control launch, putting more comfortable control in the hands of operators with this inclusive new design. With Rototilt Control, the company has also added greater connectivity and management through a new app, and has increased fuel efficiency of its tiltrotators.

Volvo upped the capability of its L20 and L25 wheel loaders with greater travel speed, a new linkage option, and a new electric fleet management app in 2022, continuing its commitment to delivering a full zero-emission compact lineup.

Volvo made a big update to its L350H wheel loader in 2022 giving the machine a more responsive hydraulics system, new lift and tilt cylinders, and an increased hydraulic working pressure that delivers faster work cycles and higher productivity. The upgraded driveline features new Volvo axles and an all-new Volvo transmission.

Kleemann’s MOBICAT MC 110(i) EVO2 jaw crusher and MOBICONE MCO 90(i) EVO2 cone crusher now feature direct drive provided via a reliable fluid coupling for high fuel efficiency.

With this new drive concept, the speed of the cooler fan and cooling capacity are controlled automatically, reducing noise and dust penetration with the reduction in moved cooler air.

GOMACO has upped the technology on its pavers with a new vibrator monitoring system, new self-programming valves, and Navigator display with wi-fi capability. The paver can now communicate with other machines via the Navigator display. Machine-to-machine communication enables the equipment to fine-tune its operation to match the real-time conditions on the job site. For example, if the concrete placed in front of the paver is too low, the paver can tell the placer/spreader to raise its strike-off and allow more concrete to be placed.

Grades of up to 45 degrees, rough terrain, and sensitive ground conditions are no challenge for Prinoth’s Raptor 100 remote-controlled compact carrier. With this cabless machine, Prinoth puts control in the hands of the operator, up to 100 feet from the working area – delivering a safe solution for mulching, green space maintenance, forestry work, and steep ground applications.

Hitachi opened a new chapter in its North American business in 2022. After the end of its licensing and manufacturing agreement with John Deere it introduced three new excavator models including the ZX210LC-6 HP full-size excavator and the ZX26U-5N and ZX50U-5N mini excavators. The mini excavators are simple to operate and have a durable design, and the ZX210LC-6 HP full-size excavator delivers strength in lifting operations with its heavy boom and counterweight, while also managing delicate bucket maneuvering.

Komatsu has advanced its iMC platform for mid- to large-size excavators

Site dumpers are already an ideal machine for urban working environments, delivering maneuverability and a small footprint – so electrifying these machines is a natural fit. AUSA’s first electric site dumper, the D151AEG, has a 1,500 kg payload capacity. AUSA has also introduced its first electric telehandler, the T164E, which has a 1,600 kg payload capacity and maximum lifting height of four metres.

Dynapac is delivering new pavers and screeds with a focus on reduced learning time and simplified operation with features such as FeedAssist, CleanAssist, ImpactAssist, DiveStop, and LightAssist. Dynapac’s new highway-class pavers and screeds for North America include 8- and 10-foot tracked and wheeled pavers, plus 8- to 16-foot and 10- to 20-foot screeds.

Topcon’s MC-Mobile grade control solution for compact earthmoving equipment combines surveying and machine control technology to increase efficiency and is packed with fullsize machine control performance. The displays and components can be moved between pieces of equipment and from the grade checking/layout rover pole to the machine and back, upping the value proposition for adding advanced technology to smaller equipment.

Superior’s massive new TeleStacker conveyor extends 210 feet and is capable of building 425,000-ton stockpiles. PilePro automation automatically controls the stacker while building partially or fully desegregated stockpiles. Delivering pile volume reporting, maintenance triggers, and diagnostics makes this telescoping stacking conveyor easy to

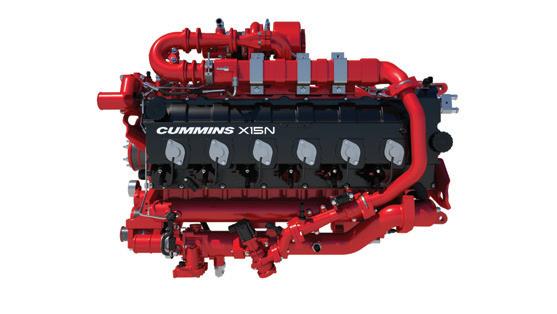

Cummins is pushing forward the transition to alternative fuel options with its new fuel-agnostic platforming program where its B, L, and X Series will be available in options powered by diesel, hydrogen, or natural gas. Whichever fuel option end users adopt, these engines will all have common bases and parts with optimization above the head gasket for each fuel type. This will allow the end-user to pick the fuel option that makes the most sense for each application without sacrificing the convenience of parts commonality –and simplifying training for technicians.

McCloskey has delivered an update for its big J4 jaw crusher which is designed to excel in hard rock work. The J4 offers oversize recirculation for a higher end-product specification and is easily moved between job sites with remote control tracks. End users can choose between either a two-deck or one-and-ahalf deck system. The two-deck option delivers an extra product spec over the mid-size product conveyor.

In a complete update of its excavator line, CASE Construction Equipment has launched seven models, including a pair that slot into size classes previously untouched in the CASE portfolio.

The E Series includes updated and enhanced hydraulic performance and precision, greater engine power and responsiveness, extended service intervals, and greater connectivity for streamlined fleet management and service. It also features a range of 2D and 3D machine control options, all OEM-fit to make it easier for buyers to take advantage of precision excavation solutions.

E Series machines have updated and enhanced hydraulic performance and precision, greater engine power and responsiveness, extended service intervals, and greater connectivity.

Seven models span an operating weight range from 28,900 to 78,600 pounds and include the CX190E and CX365E SR, which are all-new in key size classes. The other five models replace existing D Series machines, though Case states that some D Series models will remain in the CASE product offering until next-generation versions are introduced later.

“The CX190E is a 41,000-pound machine that fits a very

important area of demand for contractors throughout North America, and the CX365E SR represents something that our partners have made clear they want – a minimum swing radius excavator in that 3.5 metric ton or larger class,” said Brad Stemper, head of construction equipment product management in North America for CASE. “The size, power, and performance of that machine in a tighter footprint will transform the workflow and productivity on job sites with space restrictions.”

New FPT Industrial engines are featured throughout the line, offering a variety of improvements over previous powerplants in CASE excavators. The new engines bring greater displacement, horsepower, and torque compared to previous CASE models, providing more power and responsiveness. They have four work modes – SP (Super Power), P (Power), E (Eco), and L (Lifting) that can be set within a range of 10 throttle settings. This allows operators to dial in performance as needed. Eco mode can lower fuel consumption by up to 18 percent compared to previous machines, CASE says.

FPT Industrial engines feature innovative emissions solutions; they use a combination of diesel oxidation catalyst (DOC), selective catalytic reduction (SCR), and particulate matter catalyst technologies that provide further fuel efficiency and reliability, while not requiring lifetime aftertreatment replacement or mechanical service.

CASE Hydraulic Flow Control Balance adds new hydraulic priority capabilities which allows operators to set performance and responsiveness as they prefer. Arm in, boom up, and swinging flow can be adjusted, improving the way the machine responds to the operator’s control inputs.

Extended service intervals on engine oil and fuel filters are one step to improve uptime on the E Series machines. Telematics updates using the CASE SiteConnect Module and SiteManager app allow operators to use their phone or device to enable remote access. CASE technicians can diagnose the health of connected machines remotely and assess whether a service call is needed. Owners can opt to share real-time data with their dealer and CASE to allow for greater analysis and optimization. SiteConnect Module can be used to improve the flow of data to the SiteWatch telematics platform as well.

Greater control is a key part of the redesign, according to CASE, and the interface between operator and machine has been updated. In the cab, the E Series has a 10-inch LCD display which provides easy access to cameras, machine data, and controls. Controls can be custom-set to the operator’s preferences through the system, offering access to machine information, fuel consumption, hydraulics, emissions controls, the new Hydraulic Flow Control Balance, and new attachment controls.

Rear- and side-view cameras can be displayed at all times while accessing machine data and controls, improving visibility and job site awareness. CASE offers an optional Max View display which provides 270 degrees of visibility around the machine.

Ergonomics have been improved as well, with a new suspended operator station that locks the seat and console together and ensures that all sizes of operator can get comfortable and work efficiently in the cab.

The availability of OEM-fit 2D, 3D, and semi-automatic machine control solutions has been expanded across more excavator models, ensuring that the optimal combination of machine and solution is installed and tested by CASE professionals. This also allows buyers to bundle the technology into the purchase of the machine.

Supply chain shortages are causing significant deck mounted air compressor delays. We have a solution: H40 & H60 hydraulic air compressors are available today.

Learn more at: VMACAIR.com/hydraulic

NEW FPT INDUSTRIAL ENGINES PAIR WITH UPDATED HYDRAULICS TO PROVIDE MORE POWER AND RESPONSE.

Tproviding the most power of any compact machines the compa ny has ever produced.

been designed with a system that delivers three hydraulic flow options in one machine, adding performance and improving the machines’ versatility with attachments. They also feature Premium Power Performance, Bobcat’s power management sys tem which, on loaders with high-flow and super-flow hydraulics, helps distribute power more efficiently.

To ensure that hydraulic performance is right for each user and every job, three flow options are available on these loaders. Standard flow, designed for operating attachments that require lower hydraulic horsepower, delivers 23.0 gpm and 3,500 psi. High flow, which delivers 36.6 gpm and 3,500 psi, offers added hydraulic power for attachments like trenchers, planers, stump grinders, and more. At the top of the range, the optional Super Flow offers 42 gpm and 4,061 psi and is aimed at users running milling attachments and land and brush clearing tools, among others.

Bobcat has designed these machines and attachments to match up ideally in electronics, hydraulics, and geometry. A small, seven-pin attachment harness activates power and fingertip control functions while taking out mechanical relays

traditional fans, which is more energy efficient and generates less noise.

In the cab, the T86 and S86 are comfortable and designed to give operators a good working experience all day. Design features throughout the machine help improve operator comfort – for example, the machines feature a one-piece sealed cab that blocks noise more efficiently, while a triple-flange rear idler and optional 5-link torsion suspension undercarriage cut down on vibration for easier operation through long days. Workgroup response settings give the operator an opportunity to adjust joystick sensitivity to their preference and desired level of precision.

The operator also has access to an easy-to-read cab display that allows for interaction and monitoring. A rear-view camera is standard on both machines. Bobcat’s Machine IQ allows for remote monitoring and management, and MaxControl adds the opportunity for remote operation and geofencing for object avoidance during semi-autonomous operation.

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

For info:

Western Canada 604-701-9098

Eastern Canada 514-792-9220

P Paul Basiuk 780-991-4606

Construction is a way of life for Karine Roy. Her grandfather Armand T. Roy specialized in excavation and road construction. Her father, Daniel Roy, started a trucking company in 1979, grew the business doing general contracting jobs’ and eventually pivoted to a quarry in the 1980s.

Now it’s Karine’s turn. She is the executive director of Roy’s Trucking and Landscaping, Ltd, in Nigadoo, New Brunswick. The company operates a quarry in nearby Belledune, a small, predominantly French-speaking Canadian coastal village.

“We’re focused on rock production: armourstone, filter stone, and aggregates,” Karine says. “We produce the quarry materials and export them.”

Like with other small businesses, employees wear many hats. Karine spends her days administrating tender submissions, estimating for selling of the rock, and managing cost of production. Meanwhile, Daniel oversees and operates heavy construction equipment in the quarry, including wheel loaders and excavators. Karine’s mother, Rachel, handles the administrative side of the business, and the newest family member to join the company, Karine’s husband, Mathieu Poirier, helps Daniel at the quarry and Karine in the office.

“Daniel and I sometimes have to help each other,” Karine says. “He comes to the office to close big tenders, and I go on site managing jobs, and transport and operate heavy equipment.”

Karine indicates there’s plenty of work to keep the family members busy for a long time.

“We are halfway on the first floor of the quarry and there are two floors underneath that,” she says. “Probably my children’s children would still shovel rock.”

In the last 30-plus years, customers have turned to the Roy family business for their large rock needs. Customers buy armourstone, from 1-ton to 20-ton rocks, for their shoring projects. These include breakwaters, bank protection, and the reconstruction of wharfs and roads.

Roughly 20 years ago, the company fulfilled a customer order and sent a barge to Magdalen Island, Quebec, loaded with armourstone. That shipment started a trend that led to larger projects for other

islands, such as Miquelon Island – south of Newfoundland – and St. Pierre.

“We still ship rock to Magdalen Island pretty much every year,” Karine says. “We’re presently in a project of shipping 150,000 tonnes this year.”

The company utilizes its trucks to transport rocks to the Port of Belledune. From there, the company has shipped the quarry materials as far away as the island of Barbados in the eastern Caribbean.

“We are about five to six kilometers from the Port of Belledune,” Karine says. “That’s a big port that’s exporting pretty much everywhere, and we get access to big ships. We do a lot of work there. We transport the rocks from our quarry to the port and load them on boats or barges. We are lucky to have that not far from our quarry.”

Like at other quarries, extracting rock starts with drilling and blasting.

“We try to aim for as much armourstone as possible,” Karine says. “We divide all the big rocks one by one, depending on how much the rock weighs. In the last couple of years, we’ve exported around 500,000 to 600,000 tons each year.”

Heavy equipment operators sort the rocks into piles based on their weight, down to the smallest rock – known as filter stone. Karine says the operators separate the filter stone into sizes from 8 to 30 inches. From there it goes through a crushing, screening, and

washing process.

“To produce the smallest rock, we put that rock in a crusher and then we do a 3-inch stone or a one-and-a-quarter-inch stone for asphalt projects,” she says.

Demand for the stone is highest in summer and fall, and employees at the company work through winter to ensure that the product is ready come spring. Karine works on bids in late winter and early spring so the company has the correct rock sizes and weights needed for the busy season.

Working on the “front row,” as Karine calls it, is heavy construction equipment, including a Doosan DX800LC-7 crawler excavator – the first 80-metric-ton Doosan excavator sold in Canada. The machine is equipped with a heavy-duty bucket and a thumb for handling the rock after it’s blasted or drilled.

“The DX800LC-7 likes the big rocks,” Karine explains. “Sometimes I have 100-ton rocks that the excavator has to push down, and then we re-drill or reblast. Other times the excavator moves the 20-ton rocks and divides them.”

It’s not uncommon for the DX800LC-7 to work as many as 10 to 12 hours a day. Once the excavator does the heavy lifting, wheel loaders equipped with scales pick up the rocks with a bucket or pallet fork. Each rock is weighed

before it moves on to the next step in the process.

One reason the company selected the DX800LC-7 is the machine’s boom and arm configuration.

“When you work in rock as we do, you don’t want long booms or sticks because it’s hard on it,” she says. “We have the shortest boom that was available for the DX800LC-7.”

Doosan offers the DX800LC-7 with a mass excavation arm for quarry applications like this one. A heavy-duty excavator front design offers additional reinforcement on key stress points to minimize machine downtime. It’s also more fuel-efficient than previous excavators in the same size class, and with high diesel prices, every little savings helps businesses like Roy’s Trucking and Landscaping.

Another significant reason for selecting the new machine was exceptional service from the local dealer: Paul Equipment & Sons. The dealer is not far from the quarry, and the parts and maintenance support provided by the dealer after the sale was vital in the decision process. Also, two previous equipment purchases from the dealer had proven to be wise decisions. A Doosan wheel loader purchased from the dealer is still in the company’s fleet and contributes to the day-to-day operation. In 2022, the company upgraded its DX225LC crawler excavator to a new DX300LC-5.

RoyThe DX800LC-7 likes the big rocks. Sometimes I have 100-ton rocks that the excavator has to push down, and then we re-drill or re-blast. Other times the excavator moves the 20-ton rocks and divides them.

Karine

Executive Director, Roy’s Trucking and Landscaping, Ltd

Industry knowledge and a dependable fleet of construction equipment are a good foundation for success. But that will only carry a company so far. Success also requires dedicated employees, proper

equipment maintenance, following safety protocols, and providing exceptional customer service. Roy’s Trucking and Landscaping checks these boxes each day.

“What sets our company apart from others is our experience and working

hard for many years,” Karine says. “Doing armourstone is not easy, and we’ve put lots of effort into understanding the process of extracting it.

“And the secret part of getting more production at fewer costs. Also, we have good employees that we can rely on. They are always there to ensure our needs are met.”

Safety is another cornerstone of the company’s success. Karine says each day there is a mandatory safety meeting with employees. She says they make sure everyone knows the dangers of working in the quarry. Another priority is providing the correct protective equipment and ensuring that employees are wearing it. The company’s DX800LC-7 excavator is outfitted with an all-around view monitoring (AVM) camera system for enhanced safety.

“When working near a rock face, the camera system is something we really need; to have eyes everywhere,” she says.

Looking ahead, Karine indicates there’s plenty more drilling and blasting to come – enough for at least another three generations at Roy’s Trucking and Landscaping.

JOHNSON is manager, strategic communications, at Two Rivers Marketing.

Freightliner recently launched its new Plus Series vocational trucks in Detroit, Michigan, and detailed the improvements and features of the line. I had the opportunity to get behind the wheel and drive the trucks on a simulated highway loop and off-road course at the nearby American Center for Mobility’s 3.7-km test track in Ypsilanti, Michigan.

Daimler Truck North America Product Marketing Manager Greg Treinen says, “With the Plus Series, based on customer feedback, we knew we needed to update the driver environment inside the cab and then also make a significant upgrade to the electrical system to enable some of the groundbreaking technologies that we are able to offer.”

The Plus Series includes enhanced versions of Freightliner’s M2 medium-duty trucks and SD severe-duty trucks, including the M2 106 Plus, M2 112 Plus, 108SD Plus, and 114SD Plus models. The improvements targeted safety, comfort, and connectivity.

Significant upgrades to the electrical system enable new technologies for safety, connectivity, and upfit efficiency. The reconfigured electrical architecture allows access to the Detroit Assurance 5.0 suite of safety systems which include active brake assist, lane departure warning, optional side guard assist, and adaptive cruise control which adjusts to maintain a safe following distance down to 10 miles per hour. A camera system and radar system mounted in the bumper provide the signals. I made full use of the lane departure feature setting off the alert a few times and took advantage of the adaptive cruise control as I drove behind another truck.

Treinen comments, “It takes one or two of those events to really understand how powerful that technology is and how it can help increase that level of safety for their employee and the truck – and also the public around them.”

The effectiveness of active brake assist was demonstrated by a product manager. He drove straight toward a dummy vehicle in the middle of the road, the system detected the obstacle, and the truck slowed then came to a full stop just a couple of feet short of hitting it. This safety system can detect moving vehicles, stationary vehicles, and even moving pedestrians.

Inside the cab, Freightliner has improved the materials for the trim using updated plastics and insulation. This reduces squeaks and rattles as well as exterior road noise. The quality and structure of the foam in the ergonomic seats has also been upgraded for better comfort. These features were most noticeable as I drove on the off-road course over a variety of bumps and ruts.

Other enhancements include a driver-centric dash with a driver information centre, a customizable switch layout, and a transmission control stalk that allows automated manual and automatic shifting and engine braking functions from the column.

Treinen adds, “The cab is designed for more robustness and improving the fit and finish of the operator’s environment. There is less physical stress on a driver who’s spending all that time in the cab throughout the day, whether it’s in the street or on a job site.”

Plus Series fleets will be outfitted with the Detroit Connect suite of connectivity systems. This provides information on vehicle performance with a remote diagnostic service. Remote updates for engine parameters are made with secure, over-the-air programming capabilities. Analytics provide users with on-demand automated analysis to identify driving behaviours and trends as well as data on fuel consumption and safety performance. A Safety Event Viewer notifies fleet managers of collision mitigation events, showing the time, date, location, and vehicle speed.

The Plus Series also introduces the QuickFit electrical system. It is a multiplexed architecture designed to make it easier to integrate truck equipment into the vehicle. Critical connection points, more power sources, programmable switches, customizable parameters, and interlock features are more accessible to upfit the vehicle. The Daimler Truck North America CHEC Tool provides a user-friendly interface to view and modify electrical configurations and change parameters. In the Plus Series, a number of key electrical components have been relocated to better isolate them from various hazards.

Treinen explains, “We relocated the power distribution module [PDM] from the top part of the fender to the firewall, and we’ve put it in a box that is IP69K waterproof rated. It’s really designed to keep that PDM safe from shakes and rattles, road debris, chemicals, anything that might cause downtime with our customers. We took great care to make sure we relocated those components in areas where we’re maximizing our customers’ uptime and maximizing the reliability of our vehicles.”

The Freightliner 114SD Plus sports the DD13 Gen 5 diesel engine, the latest in Detroit’s heavy-duty engine lineup. It has a rapid torque feature to get payloads moving quickly. ThermoCoasting in the DD13 Gen 5 prevents aftertreatment cooldown during a driving regen to keep the system at its optimum temperature and reduces the need for parked regens. The engine is paired with the Detroit DT12-V transmission. This transmission has an

off-road mode for aggressive shifting on any terrain, a hill start aid to prevent rollback on steep grades, and a rock-free mode to help avoid wheel-stuck situations. There is also a paver mode in which a dump truck can shift from neutral to drive without pressing the brake pedal allowing for a steady flow to the paver.

Depending on the truck model, the Plus series lineup will also feature the Cummins B6.7, L9, and X12 diesel engine options as well as L9N and ISX12N natural gas engines. Eaton manual and automated manual transmissions and Allison automatic transmissions are also available.

According to Treinen, “The SD Series has always been tied with a Detroit engine. But we have a lot of customers that run Cummins B6.7 and L9 engines. Now we’re able to offer assurance, active brake assist, lane departure warning, side guard assist, and adaptive cruise control down to 10 miles per hour in that truck. We are continuing to expand our coverage with the Detroit Assurance 5.0 suite of safety systems.”

Many of the key features of the SD and M2 models that operators have enjoyed in the past will remain the same, Treinen says. “The maneuverability, the visibility, the ease of ingress and egress, all of those types of things that have driven its success in the past, all of those things that our customers have come to know and love about the M2 and SD over time – now we’ve made that product even better with the Plus Series.”

The Freightliner Plus Series goes into full production in the third quarter of 2023. HEG

Carriers prefer demolition attachments made by Okada America, Inc. Okada’s demolition attachments expand the versatility of the excavator, mini-excavator, loader/backhoe, skid-steer and track loader carriers. Okada has a wide variety of attachments. Breakers. Demolition Shears. Compactors. Pulverizers. Processors. Grapples. Crushers. Screening Buckets. These attachments are precision-engineered, productive and dependable.

For the name of the Okada Distributor nearest you, call 1-800-270-0600.

Okada. On the job. Doing the job. www.okadaamerica.com

12950 SE Highway 212 Clackamas, Oregon 97015 904 Medina Road Medina, Ohio 44256 3701 Windmill Road Joshua, Texas 76058

BY ARTURO SANTIAGO, EDITORIAL DIRECTOR

BY ARTURO SANTIAGO, EDITORIAL DIRECTOR

Even in the most ideal road conditions, driving a truck all day can be exhausting. I recently had the opportunity to test Mack Command Steer, the active steering system designed to reduce driver fatigue. The demonstration area at H&K Easton Quarry in Easton, Pennsylvania, featured a variety of terrains, grades, and gravel mounds as well as obstacle courses. I drove two Mack Granites, one equipped with Command Steer and one without, so that I could experience the difference.

“Driving a heavy-duty construction truck is physically demanding on the body,” says Mack Construction Product Manager Tim Wrinkle. “Job sites have uneven road conditions which contribute to wear and tear on the driver. Mack Command Steer has been shown to reduce driver effort by 85 percent, improving job site safety and driver productivity.”

Once I got behind the wheel, the experience wasn’t as dramatic as transition ing from manual steering to power steering in a car, but the difference in the effort required to guide the trucks through an obstacle course was significant. It was considerably easier for me to steer the truck equipped with Command Steer than the truck that did not have the technology.

This is accomplished by combining an electric motor with the truck’s existing hydraulic steering. The terrain, driver inputs, and environmental conditions are monitored throughout the truck using multiple sensors that gather data more than 2,000 times per second. The system takes the information and uses it to provide variable steering effort and applies additional torque through the electric motor as needed. Command Steer can also suppress the feel of

potholes, dips, and ruts. It reacts to the uneven terrain by countering the steer force, smoothing the steering feedback, and reducing steering

steering wheel to the centre position (in forward and reverse), helping to simplify tight maneuvers.

Wrinkle tells me that

wheel kicks.

When I drove a slalom course in the Mack Granite with Command Steer, all I needed was a light touch on the wheel to steer my way through the turns. On the rough-terrain portion of the obstacle course, the wheel didn’t jerk out of my hands as I navigated over deep ruts and bumps. But my favourite feature was the system’s return-to-zero capability. It automatically returns the

Command Steer decreases driver fatigue by 30 percent, “Drivers no longer need to fight the wheel when driving on severe terrain or during difficult weather conditions requiring a lot of steer effort. Mack Command Steer helps the driver maintain greater control of both on-highway and off-road applications at low speeds and high speeds.”

The system is now available in Mack Granite models. HEG

Drivers no longer need to fight the wheel when driving on severe terrain or during difficult weather conditions requiring a lot of steer effort.

Tim Wrinkle Construction Product Manager, Mack TrucksTHE MACK GRANITE EQUIPPED WITH COMMAND STEER.

Many different factors are contributing to the compact equipment market’s growth, including increased spending on residential building and construction overall. Out of all the different compact equipment categories, compact track loaders (CTLs) have become the most popular. Their high traction, low ground pressure, and significant pushing power have made them indispensable on many construction sites. And, when the machines are outfitted with the proper hydraulic systems, they can use an ever-growing number of attachments.

Hydraulic systems have become increasingly sophisticated over the past few years while also offering better lifting capacity and breakout forces thanks to larger pumps and higher pressures. These systems can help CTLs and other carrier machines perform tougher jobs without requiring more horsepower, which keeps both emissions and costs down. While that fact is certainly important, it’s the hydraulic system’s ability to connect the CTL to multiple attachments that sells these machines to prospective buyers.

“Today’s hydraulic systems make so many tasks possible,” said Joseph Huling, national service and training manager for Takeuchi-US. “In the past, you couldn’t use a CTL to remove snow, clear land quickly and efficiently, or handle large quantities of materials, for example. Advanced hydraulics make CTLs into little powerhouses that can do so much more than lift and place materials. When potential buyers see how much CTLs can do, they realize that they’ll be able to get a really good return on their machine investment.”

Before these advanced hydraulic systems were available, CTLs could only use a limited number of attachments for shorter periods of time.

“Because today’s hydraulic components and cooling systems are so efficient, operators can outfit their carrier machines with hydraulic attachments and use those attachments longer,” Huling

said. “As a result, CTLs are now more productive in various ways. You can get so much more done with just a single machine. Thanks to hydraulic systems and attachments, you may not need to own or rent multiple machines.”

Because machine owners and operators often rely heavily on the hydraulic systems on their CTL, it’s imperative to keep them in top working condition – and that starts with pairing these systems with the right attachments.

Attachments that exceed the carrier unit’s pressure specifications and hydraulic flow, or max out the carrier unit’s settings, will cause increased wear and tear on the machine. Furthermore, using attachments that are undersized relative to the machine’s minimum flow and pressure settings can overburden the system. This could damage the attachment, seals, components, and hoses. Other than using the right attachments, keeping hydraulic systems in good condition comes down to proper maintenance.

“Proactively performing regular, routine maintenance on your CTL’s hydraulic system is essential to protect it from even the smallest contaminants,” Huling said. “You simply can’t wait until there’s a problem before you take action. Advanced hydraulic systems are more refined, making them extremely sensitive to contamination. If you don’t keep the system clean, you could drastically shorten its life. Or, if the situation is severe enough, you could even destroy its components.”

According to Huling, Takeuchi recommends the following hydraulic system maintenance schedule for CTLs:

Daily – Check fluid levels, then drain any fuel/water separators. Look around the machine for damaged lines, cylinders, and hydraulic leaks. Clean hydraulic attachment couplers before connecting to the machine. Check hydraulic oil temperatures, particularly when running high-flow attachments like mulching heads. Remove any potentially flammable debris from the machine’s belly.

Monthly – Clear any debris from the machine. Clean the radiator and cooling package fins to ensure sufficient airflow, then inspect and replace engine air filters.

Annually – Take fluid samples to ensure hydraulic oil and vital components are at acceptable particle levels. Always replenish fluids according to the manufacturer’s recommendations. Check and replace the fan belt if needed. Inspect the machine’s undercarriage.

At other intervals – Most manufacturers have a new machine “break-in” period, typically after the first 50 hours of operation, and they recommend checking hydraulic components at that time. Follow scheduled (hourly) maintenance when replacing hydraulic oil and filters.

“Inspecting and draining the fuel/water separator each day is very critical with today’s common rail diesel engines, as well as checking the machine’s fluid levels,” Huling said. “If you do that and remove debris from the CTL’s belly pan, loader arm towers, and hydraulic cooler as needed, you’ll get more consistent performance and less downtime.”

While routine maintenance is critical for the life of your CTL’s hydraulic system, so is cleanliness. Keep dirt and other contaminants from entering the machine’s hydraulic system when swapping out attachments on the job site by cleaning the attachment’s fittings, both on the machine and the attachment itself, before connecting it. When removing a hydraulic attachment from the CTL, clean the automatic fittings and protect them from debris during storage and usage intervals. If the carrier unit is low on hydraulic fluid, clean the refill cap and surrounding area before replenishing it.

“It’s also very important to connect only attachments that are new, inspected, or known to be in good working condition,” Huling

added. “Otherwise, you may introduce contaminated oil into your machine from a used attachment. Or, even worse, you could connect a failing attachment to your CTL and damage the carrier unit’s hydraulic components. For this very reason, before buying a hydraulic attachment from an unfamiliar source, it’s a good idea to have a reputable dealer or hydraulic specialist inspect it.”

There are also operational best practices that can help ensure CTL hydraulic systems aren’t subjected to unnecessary wear and tear. When applicable, ensure the attachment’s cutting teeth are sharp, remove any material build-up from the attachment housing and allow attachments to do their jobs without requiring additional force from the machine itself. Plan for adequate cooling intervals between operational cycles to ensure you’re not operating the machine outside of normal operating temperatures and straining the hydraulic system.

“All in all, if you take care of a CTL’s hydraulic system, it will take care of you,” Huling said. “Follow the manufacturer’s maintenance recommendations and timing. That’s the most important thing you can do to keep your hydraulic system running smoothly and avoid a breakdown while on the job. Yes, it takes more time and effort to perform daily, weekly, monthly, and annual services, but it will pay off with greater machine productivity and longer machine life.”

LYNETTE VON MINDEN is a public relations manager with Swanson Russell.

LYNETTE VON MINDEN is a public relations manager with Swanson Russell.

Other shows may talk a big game, but only World of Concrete speaks concrete and masonry. We know that a solid foundation isn’t just part of the structures you build — it’s also the key to a more profitable business. That’s why you’ll find everything you need to strengthen your operation here, from new products, innovative solutions, and new technologies to help you capitalize on emerging opportunities. We Speak Your Language: www.worldofconcrete.com

Central Hall -- C5176

Las Vegas Convention Center January 17-19, 2023

Central Hall -- C30280

Las Vegas Convention Center March 14-18, 2023