Spotlight BY MATT THOMPSON

NLB: Celebrating 50 Years of Innovation, Safety Solutions This year marks the 50th year of business for NLB Corp., the largest manufacturer of high-pressure water equipment and accessories. Rick Sloan, sales manager at NLB, says that during that time—and particularly in the last 10 years—the industry has evolved tremendously, with a focus on automated systems. “The biggest drive behind the move towards automated, or as we term it, hands-free equipment, is really safety,” Sloan says. “What we’re trying to do is get that high-pressure hose out of the operators’ hands.” He adds that many of the largest industrial cleaning contractors in the country have a goal of being fully automated. Many of them, he adds, are at 90% or 95% automation. Those changes have resulted in a safer environment for cleaning, but also bring some advantages for asset owners, including ethanol plants, Sloan says. Manual cleaning might not clean evaporators as well as automatic cleaning does, according to Sloan. Because the operator doesn’t want to pull the cleaning lance out of the tube while it’s under pressure, the end of the tube may not get cleaned as thoroughly, as the operator will turn off the water as the lance reaches the end of the tube. That’s not the case with automated cleaning, Sloan says. “If my tube is cleaner, my heat transfer is going to be better,” Sloan says, which may allow ethanol plants to go longer in between cleanings or see energy cost savings. “Our focus of the last few months has been

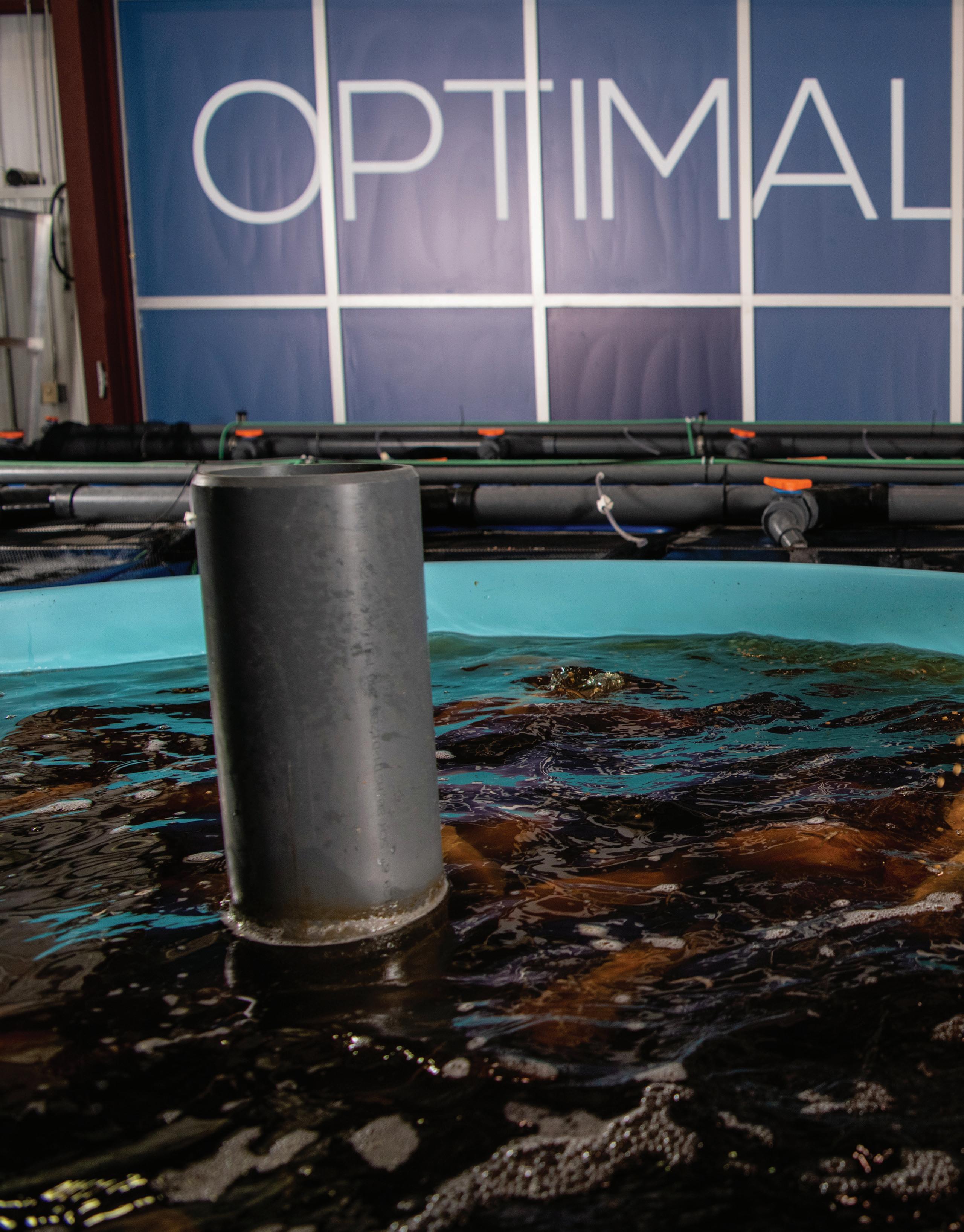

NLB 225 Series Diesel Unit PHOTO: NLB CORP.

trying to garner that information so that we can present it to the asset owners,” he adds. Ethanol plants can benefit from automated systems in other ways, too. The systems collect data on the plant itself and the cleaning process—how many tubes were cleaned, what tubes were blocked, how much water was used, etc.—which can benefit both the cleaning contractor and the plant, Sloan says. “I think having that data is important to both the asset owner and the contractor.” NLB’s partnerships with Peinmann, which supplies automatic feeders for cleaning, and with Terydon, which offers a means of controlling those automatic feeders through a tablet, as well as a feature called smart indexing, which allows the system to map the tubes, allows NLB to offer high-tech cleaning solutions to the ethanol industry and industrial cleaning contractors. “We are known for having the highest-quality, longest-lasting equipment on the market,” and the innovation that brings to the industry, Sloan says.

NLB WATER JETTING SYSTEMS.

BEST, MOST CONSISTENT

S

uperior cleaning of evaporation towers and processing systems makes a difference – namely, better heat transfer and longer mean time between cleanings. NLB high pressure water jetting systems feature legendary long-running pumps, coupled with industry-leading Peinemann cleaning systems and wireless control technology from Terydon. The result is high-quality cleaning of ethanol processing componentry and safer cleaning operation without anyone needed inside the dome. NLB cleaning systems are also excellent for removing scale build up in process lines and boiler washdowns, all with the power of clean water. Sales, service and rentals available at any of our eight North American branch locations.

34 | ETHANOL PRODUCER MAGAZINE | MAY 2021

NLBCORP.COM

© Copyright 2021 NLB Corp. | PSaleBund_21_001_v4

CLEANING SYSTEM IN THE INDUSTRY.