A publication of Bejo Zaden B.V. Postbus 50 1749 ZH Warmenhuizen

A publication of Bejo Zaden B.V. Postbus 50 1749 ZH Warmenhuizen

4 THE RISKS AND CHALLENGES IN BEET SEED PRODUCTION

6 SVZ: INNOVATION & SUSTAINABILITY IN THE FOOD INDUSTRY

8 MEET BEET GROWERS FROM ALL OVER THE WORLD

10 CONTINUOUSLY WORKING ON ROBUST, RELIABLE VARIETIES

12 BEJO’S BEET SEED JOURNEY

14 HAK’S AMBITION GOALS

Editors

Jelger van Weydom

Daniëlle Bruin

Jorien Smak

Kevin van Schaik

Robert Schilder

Ronald Loos

Esther Plevier

Copywriters

Jelger van Weydom

Daniëlle Bruin

Jorien Smak

Photography

Petra Tesselaar

Jurgen van Baar

Marissa Goussard

Jelger van Weydom

Design

Nathalie España

Layout

Nathalie España

Printing Company

Koopmans’ drukkerij BV, Zwaag

No rights can be derived from the information contained in this Bejo magazine.

Reproduction of articles or parts thereof is permitted only with permission of Bejo Entity and with acknowledgment of the source.

18 VARIETY INFORMATION

22 ‘IN A FIELD WITH 1,000 PLANTS WE HAVE TO LOOK AT EACH PLANT ONE BY ONE’

24 BEET AS CULTURAL HERITAGE?

26 THE POWER OF BEET

28 BEJO-PARTNER IN LATVIA: EZERKAULIŅI AGRO

30 WORLDWIDE ACREAGE

32 DISCOVER THE BEET REVOLUTION: BIET IT!

33 FROM TRAYS TO STAD-UP POUCH

Welcome to this first edition of our Beet Magazine. We are pleased to present you with this comprehensive guide to all things beet. This edition delves into the multifaceted world of this vibrant root vegetable, covering everything from the latest in seed production challenges to the cultural significance of beet in different corners of the world. Our aim is to celebrate beet as a powerhouse in the world of vegetables, offering insights and stories which inspire and engage beet professionals like yourselves.

Bejo has been successfully breeding beet varieties for decades and recent successful introductions have highlighted our commitment to this crop. All the time that Bejo breeders invest in this crop serve only one purpose: to develop even better, more reliable varieties.

Seed production is the cornerstone of successful beet cultivation, yet it is fraught with challenges. The professionals at Bejo are there to overcome these challenges and mitigate risks. With the long history of beet seed production, we ensure to have a stable supply of quality seeds for our customers.

Of course, we cannot avoid the topic of climate change in this magazine. As temperatures rise the lifecycle speed and spread of most pathogens in beet cultivation increase. This means that pests and diseases which were once contained are now thriving in new regions. Phytopathology research is an integral part of our efforts to breed reliable, disease-resistant varieties.

For many years Bejo has invested in seed technology research. Where chemical plant protection products have been a standard for many years, we are now moving towards a legislative landscape favoring a chemical-free world. Bejo is already capable to deliver clean and healthy seeds, but growers too have a role to entrust these seeds to healthy and balanced soils.

We invite you to explore articles featuring growers from around the world and various industries, offering unique perspectives and approaches to beet cultivation. Additionally, you will find overviews of storage techniques around the world. We also include a look at the health benefits of beet consumption and presentations of beet in various markets.

We trust that you will be inspired and wish you much success in your beet endeavours.

Please do not hesitate to contact your Bejo representative.

Kevin van Schaik, Robert Schilder, Ronald Loos

BEJO PRODUCES BEET SEED IN FRANCE, AUSTRALIA, AND NEW ZEALAND. WITH CULTIVATION IN BOTH THE NORTHERN AND SOUTHERN HEMISPHERES, WE SPREAD RISKS TO ENSURE THAT WE ALWAYS HAVE A CERTAIN AMOUNT OF HARVEST. EVEN STILL, PRODUCING BEET SEED REMAINS A CHALLENGE. IN A CONVERSATION WITH JOS DOODEMAN, GLOBAL SEED PRODUCTION SPECIALIST, AND JULIEN JOUANNEAU, PRODUCTION MANAGER IN FRANCE, WE ASKED WHAT RISKS AND CHALLENGES THEY ARE CURRENTLY FACING.

Climate changes

“Spreading risk is important. After all, we work with nature and are therefore dependent on weather conditions. And yes, we too are seeing climate change,” says Doodeman. He continues, “Until ten years ago New Zealand and Australia had the perfect climate for beet seed production, but we are now facing problems because of climate change. Heavy rainfalls are affecting the standard operations on the field, which is something you don’t want for beet seed production.” Jouanneau also sees this trend in France. “We are experiencing heavier rainfall more often. In addition, it freezes less or not at all in the winter months and we have more frequent heat waves in summer. Seed production has always been risky work, climate change makes the challenge even greater. We therefore have frequent contact with our breeders and researchers to develop robust varieties that are resistant to diseases.”

France as a production country

Despite the changing climate and associated risks to yield, Bejo has seed production in the Northern Hemisphere, but only in France. Doodeman explains why: “This has two main reasons. As Bejo, we work with growers who produce seed for us. For this, long-term relationships are essential. Through good cooperation with reliable partners, there is the trust to share

knowledge with each other. Sharing knowledge and experiences helps both parties to optimize productions. The second reason is that the French government has a strict legal system to ensure isolations between production fields. Wind can carry pollen from sugar beet, for example, into a red beet field. This can have enormous consequences for the quality of the seed, which can even lead to whole seed lots having to be destroyed.”

“Indeed, in France, we have a special system that ensures that isolation between production fields is regulated,” Jouanneau confirms. He continues, “This is managed and controlled by an organization called SEMAE. Agricultural companies are required to declare what they grow, where it is planted and when. This is how the distances between different fields are determined, which can vary between 5, 10 or sometimes even 20 kilometers, depending on the risk. This system ensures that we can grow in a controlled way and prevent pollination between different fields.” It is important to add, continued Doodeman, “That all production companies respect the restrictions of SEMAE. You can think of it as a kind of ‘gentlemen’s agreement,’ together we ensure that we keep all production fields sufficiently isolated.”

Monitoring and roguing Jouanneau continues, “In addition, our technical team has the important task of continuously monitoring and roguing our fields. From early March to mid-April, all production fields are checked at least two, sometimes even three times to investigate whether there are plants in the field which are not true to type. This takes a lot of time and with today’s labour shortages, it is difficult. Nevertheless, this is an essential process to keep our production fields clean. We are now investigating the possibility that AI powered drones can support us in the monitoring of fields and identifying plants which are not true to type. For the second year in a row, we are testing how a drone can help us with certain processes.”

Dealing well with all these challenges and risks ensures that we can keep the high quality of our production seed. Indeed, the goal is always to provide not only the highest quantity, but also the highest quality production seed. We continue to respond to changes in nature and prepare for the future. We do this by staying in close contact with breeders and researchers. For this reason, a ‘Beet Expert Team’ has been established with the aim of sharing knowledge and learning from each other. By joining forces, we stay informed of what is happening in the market, keeping an eye on climate developments, and discuss how we as Bejo can respond to them.

Strict laws and regulations have also brought additional challenges. Jos Doodeman explains, “Especially in Europe, the laws and regulations surrounding pesticides are becoming more stringent, while we still have to deal with diseases such as mildew, we have noticed these challenges in seed production.

Jouanneau adds: “We see it working to our advantage that Bejo has been investing in organic seed for years. All the knowledge we have gained we not only use for organic seed, but where possible we also apply it to the production of our conventional seed. In doing so, we try to minimize the use of pesticides. Doodeman summarizes, “A good motivation to invest in organic cultivation is the big challenge. If you can manage to produce enough high-quality organic seed then you should certainly succeed with conventional seed.”

There is clearly a lot to consider in beet seed production, as this conversation with Doodeman and Jouanneau has revealed. While it can be strenuous, both agree, “Above all, it is what makes our work very enjoyable. And we look to the future in good spirits; Bejo has prepared excellently.”

Background:

Van Boesschoten has a solid background in food technology with studies at at college and university level, followed by a rich career that has taken him from grain processing to the forefront of innovation in the food industry.

Career at SVZ:

THIS ARTICLE TAKES YOU INTO THE FASCINATING WORLD OF SVZ, A LEADING COMPANY IN THE FOOD AND BEVERAGE INDUSTRY. THEY HAVE A FOCUS ON THEIR INNOVATIVE AND SUSTAINABLE APPLICATIONS OF BEET. SVZ SUPPLIES HIGH-QUALITY INGREDIENTS TO THE GLOBAL FOOD INDUSTRY. MARCEL VAN BOESSCHOTEN, PROCESS AND PRODUCT TECHNOLOGIST, SHARES HIS INSIGHTS ON THE CRUCIAL ROLE THIS POWERFUL CROP PLAYS. BEET IS USED FOR A WIDE RANGE OF APPLICATIONS, INCLUDING AS A NATURAL COLOURING AGENT. WE EXPLORE HOW THE APPLICATIONS CONTRIBUTE TO THE INDUSTRY’S SUSTAINABILITY GOALS AND MAKE SVZ A MARKET LEADER BY ADDRESSING SUSTAINABLE AGRICULTURAL CHALLENGES AND INTRODUCING INNOVATIVE PRODUCTION METHODS.

Marcel van Boesschoten, employed at SVZ since 2008, explains how beet is not only crucial to their product range, but also plays a key role in their sustainability strategy. "Beet is versatile and offers huge benefits for our sustainability agenda," van Boesschoten says. SVZ uses advanced extraction techniques to extract natural pigments from beet. These serve as natural sustainable alternatives to synthetic additives in the food industry, resulting in healthier and colourful foods without chemical additives. The beet juice, juice concentrate or puree is used in numerous foods such as juices, dairy products, and bakery like tortillas.

At SVZ, the focus is on maintaining natural properties and quality during the processing process. "Here, the importance of good raw materials is essential; what is not in the raw material cannot get into our product,"

van Boesschoten points out. “The importance of sustainable growing practices and working with local farmers to ensure quality is also part of this, of course. The challenges in processing are significant, especially in maintaining nutritional values and colour during production”.

Van Boesschoten shares his insights on how SVZ meets these challenges: "From seed to finished product, it's a constant balance between nature and technology."

SVZ uses beet not only for their flavour and nutritional value, but also for their naturally occurring pigment, which are a natural alternative to artificial colours. "The extraction process of juice combined with the beet pigment is a fascinating combination of precision and innovation," says van Boesschoten. He explains that SVZ is constantly improving their methods to ensure the highest quality and sustainability.

"We aim to minimise our carbon footprint by using specific cultivation methods and reducing waste by using every component of the beet."

Furthermore SVZ is working within the Carte Blanche concept to develop 'colourless and flavourless' vegetable ingredients, a new field that it is exploring to preserve the colourfastness of the final product without changing the visual aspects of these food products. Instead, the nutritional value of the vegetables is exploited. This innovation responds to the demand for natural ingredients that maintain the integrity and aesthetics of the final product.

SVZ has production sites in Europe (Spain, Belgium, Poland) and America. The company works closely with local farmers to optimise the cultivation of beet and other fruits and vegetables, with sustainability and quality as top priorities. SVZ is also exploring future innovations such as the use of drone technology and advanced biotechnology to further improve the efficiency and sustainability of growing and processing beet. The company aims to save water and reduce the use of chemical pesticides in their cultivation processes.

The focus on beet is an excellent example of how traditional crops can be transformed into key components in modern, sustainable food products.

Van Boesschoten concludes with the importance of forward-thinking in the industry: "Every step we take towards more sustainable practices is a step towards a healthier planet."

Van Boesschoten started in 2008 as a product developer. In the following years, he broadened the scope of his work and, together with his colleagues in the R&D department, created a key linking role between agro, production and sales departments including customers. His focus is on the use of agricultural natural raw materials such as beet.

Personal drive:

Van Boessschoten is passionate about transforming natural ingredients into healthy and eco-friendly products. He strongly believes in sustainability and innovation.

u Age: 39 years old

u Location: Carandaí, Minas Gerais

u Company: EFFA Agribusiness

u Crops: Carrot, beet, corn and soy

u Number of hectares: 360 ha irrigated and more than 450 ha not irrigated.

What has been the main focus in your company?

The main focus is on beet and new milk products. Our company seeks to diversify investments while keeping them directly linked to the field.

Do you have a specialty or novelty?

Our latest investment is in dairy and beef cattle farming.

Which Bejo varieties do you have? Boro (180 ha) and carrot Natuna.

What will the future of your company look like?

We project a positive future for our company by always seeking to grow in a responsible and sustainable way. By investing in technology that can improve the productivity and quality of the products produced by us.

u Age: 42 years old

u Location: Mococa, São Paulo

u Crops: Beet, onions, soybean, corn and coffee

u Number of hectares: In total there are 170 hectares, of which 60 hectares are beet and 40 hectares are onion. Corn and soybeans are included in the rotation of these crops.

What has been the main focus in your company?

The main focus is on all crops I mentioned earlier.

Do you have a specialty or novelty?

We don’t have any specialties, as we only serve a niche market. Also due to the shortage of labour, it is unfeasible to diversify more crops beyond those that I already grow.

Which Bejo varieties do you have? Boro and some Bresko too. But my main market is Boro. Boro is a well-known material on the market. I've been planting Boro for a long time, it's a material that gives me a lot of security. Bresko is only for those markets that require beets with a rounder shape. Not that Boro doesn't have a good shape, but Bresko is slightly rounder.

What will the future of your company look like?

Our company follows the traditions of previous generations. Currently, we have advanced our technological level, for example, with a pivot irrigation system, cold beet storage chamber, solar energy, and the use of seeds with high productive potential. I believe that my son will continue in this tradition, as he is graduating in agronomy.

u Age: 43 years old

u Location: Brits, North West Province

u Crops: We have an irrigation farm and Beet is one of the four different crops that we cultivate. We also farm wheat, soybeans and corn.

u Number of hectares: 350 ha.

What has been the main focus in your company?

We try to give every crop the optimum care it needs, and don't have any favourites. It is important to be disciplined in every aspect of the specific crop's needs, from soil preparation until the day of harvest.

Which Bejo varieties do you have? I plant Boro.

What will the future of your company look like?

Hopefully we can keep up with the fast pace of agricultural innovation and development in technology. It is important to farm in such a way that will make it possible for the next generation to be able to continue putting their best foot forward, and for this generation to carry over their knowledge and love for farming.

I think you will be in a good place and enjoy farming when you realize it is a privilege to farm, and not a right. God gives us the opportunity to experience His magnificent creation, from planting, caring and through to harvesting the crops He created.

u Age: 32 years old

u Location: Cambridge, Cambridgeshire

u Company: Greens of Soham

u Crops: Beet, potatoes and onion

u Number of hectares: 800 ha.

What has been the main focus in your company?

The main focus has been growing beet on 800 ha, producing 40,000 tons per year. The product is sold directly to food factories and wholesale markets based off wash, size, and grade. We also grow potatoes and onion. Our focus is on providing a year-round beet supply to the UK and European markets, specializing in baby beet production.

Which Bejo varieties do you have? Pablo and Action.

What will the future of your company look like?

In the future, we plan to continue investing in new techniques, such as ‘Zero Wheeling’. This has helped our company develop future ways to optically sort the beet at the washing site.

u Age: 60 years old

u Location: Tashkent, Tashkent City

u Company: Top Agro seeds

u Crops: Boro

u Number of hectares: 650 ha.

What has been the main focus in your company?

I’m a distributor of Bejo in Uzbekistan, working with Bejo for 26 years. Our beet growers in Uzbekistan grow on average between 1-3 ha of red beet with 400,000-500,000 seeds per hectare and grown on ridges. Irrigation is mostly done by furrow irrigation, but drip irrigation has been increasing in popularity since its introduction.

Do you have a specialty or novelty?

The market is primarily focused on beet for fresh market because beet is a popular crop in Uzbek cuisine. It's consumed mostly in salads, soups, or salted and combined with other vegetables. In the early spring we are able to export beet early from Uzbekistan to neighbouring countries. Those beet are grown under plastic tunnels.

Which Bejo varieties do you have?

We sell mainly Pablo and Boro, which are both popular brands in the market of beet. Mainly the second rotation of Boro is popular, sowing begins in July-August and harvesting starts the second half of October. Last year we started with the introduction of Bresko and Manolo. Storage is done in the field, in holes in the soil and in store houses.

What will the future of your company look like?

With our rapidly growing population and the possibilities for export, we are positive about the future.

u Age: 40 years old

u Location: Zeewolde, Flevoland

u Company: BioBeta B.V.

u Crops: Beet and onion (organic)

u Number of hectares: 350 ha.

What has been the main focus in your company?

We grow, process, and package mainly organic beet and onion. We also grow in our cropping plan; pumpkin, carrot, parsnip, potatoes, broccoli, peas, beans, potatoes, grains and grass/clover. The focus within our company is on growing organic products requested by customers, with the right quality requirements.

Do you have a specialty or novelty?

The novelties that contribute to the main focus of our company is the weeding robot, which helps to remove weeds, along with a new camera sorting system.

Which Bejo varieties do you have? Boro (organic), Subeto, Manzu, Bazzu, Rhizu , Pablo, Alto.

What will the future of your company look like?

We want to further develop organic farming in cooperation with our customers. Through our cultivation and processing activities, we would like to grow with them to make the organic product accessible to a broad target group.

BEJO HAS BEEN SUCCESSFULLY BREEDING BEET FOR DECADES. VARIETIES SUCH AS PABLO AND BORO HAVE BEEN HOUSEHOLD NAMES SINCE THE 1990S AND MORE RECENTLY THE COMPANY HAS ALSO HAD SUCCESSFUL INTRODUCTIONS. MORE WILL FOLLOW, EXPECT BREEDERS JACK VAN DORP AND KATERINA KONTIDOU. THEY DISCUSS VARIOUS TOPICS AT PLAY WITHIN BREEDING AND ALSO LOOK AHEAD: "THANKS TO NEW BREEDING TECHNIQUES, WE CAN SAVE TIME."

Van Dorp is Breeding Manager of the beet team, which is also responsible for celery, celeriac and rooted parsley. Kontidou is a Junior Breeder on that team. When you sit at the table with two breeders, an obvious question is: why do you actually breed? In other words, what traits do you ultimately want to see reflected in the varieties?

"Reliability, robustness, health, mainly that," lists Van Dorp. "We want to develop varieties of good quality: with a good shape and a nice internal and external colour. And of course we have to take into account resistances and the challenges posed by climate change. In addition, the market is also asking more and more about contents, such as brix."

The fact that global temperatures are slowly but surely rising means that there is also extra work for breeding. For example, diseases such as viruses and fungal diseases can spread faster, something breeders are trying to guard against by adding resistances to varieties. Breeders are paying particular attention to resistance to Rhizomania virus, which leads to yellow discoloured leaves and root deterioration, among other things.

"Once it is in the ground, this virus is virtually impossible to get rid of," Van Dorp explains. "It's an increasing problem, with hot summers accelerating its spread. We also spend a lot of time developing resistance to Cercospora, a fungus that infects leaves."

The process of crossing parental lines, doing trials and incrossing resistances can take five to six years with traditional breeding methods. With marker technology, breeders can research DNA and make an early choice. DNA testing allows us to see immediately which plantlets are interesting for a follow-up step, Van Dorp explains: "Because we can skip a whole cycle of tests, the time savings are enormous. It can give us the same result in half the time."

Bejo's global success with beet is also because it is a "relatively strong crop".

It is resilient and thrives well in different climates. The latter in particular appeals to Kontidou. "We work for an area so much wider than just Europe, the whole world is part of our market. And as breeders, we face many challenges, which we tackle together with our colleagues."

As the biggest challenge in her work, she mentions, "When we introduce a variety that becomes a global success and guarantees growers a reliable yield."

Classic examples of such successful introductions are varieties like Pablo, from the early 1990s: a nice uniform beet, which added value in the market. Boro, dating from 1995, was an even stronger grower that did better in difficult climate conditions.

These two names name the varieties with which Bejo gained a good position in the market. In recent years, breeders have faced additional challenges, especially the fight against Rhizomania. Manzu was the first variety to have high resistance to this: a beet with similar characteristics to Boro, with that resistance as an important additional feature. Rhizu, in turn, can be seen more as a successor to Pablo.

In their activities, Bejo's breeders work closely with representatives within Bejo, but also listen to insights from the industry, Van Dorp and Kontidou indicate. "That is most interesting for all parties involved. Sales and Processing often visit trials around the world together. The wishes and insights from Sales and the upcoming developments from Breeding can thus be optimally aligned."

The slogan "Exploring nature never stops" can be found on all Bejo's communications. It refers to the sustainable use of scarce natural resources. Beet is a crop that fits perfectly within this sustainable ambition. It is strong, easy to grow organically and needs relatively little fertiliser and chemicals.

"Because Bejo varieties are grown over large parts of the world, they include areas with higher disease pressure," Kontidou points out. "In addition, our trials are also in various countries; all this information together is very interesting for us and helps us make decisions."

Of course, all the time invested in beet at Bejo ultimately serves only one purpose for the grower: to deploy even better, more reliable varieties. Van Dorp, about this: "It is a challenge to put all the strong characteristics into one variety, but we always strive to breed robust varieties that can be used in many areas and on which the grower can rely. The crop should not be good one year and not the next, that is of no use to him. A good crop should be the standard."

The breeders conclude with a useful tip: looking for a variety that is resistant to Rhizomania? That trait is already hidden in the variety's name. In fact, all varieties ending in a 'u' possess this resistance.

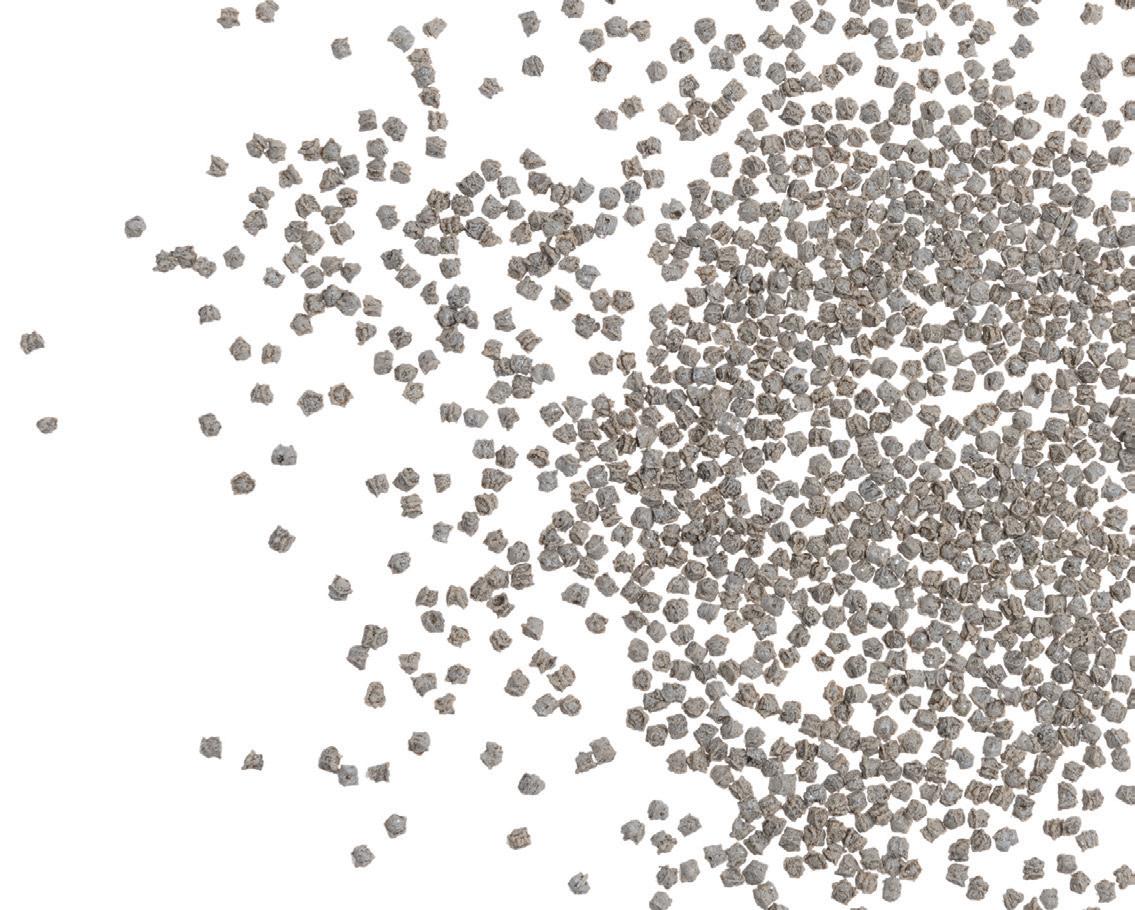

BEET SEED IS GROWN IN FRANCE, NEW ZEALAND AND AUSTRALIA. Seed production from New Zealand is sent to France for cleaning and upgrading.

WE REMOVE IMPURITIES FROM THE BATCH AND SORT BY SHAPE, WEIGHT, SIZE AND COLOUR.

This way we only select the best seeds.

Using steam, hot water and hot air, we disinfect the seeds to remove pathogenic FUNGI.

OF THE SEED TO BEJO WARMENHUIZEN (NL).

BEJO IS NAL-AUTHORIZED.

Naktuinbouw Authorized Laboratories (NAL) authorizes corporate labs for sampling and seed testing.

CLIMATE-CONTROLLED STORAGE

Optimal constant temperature (12°C) and humidity (30%).

At customer’s request, we treat the seed for even better results. COATING: FOR IMPROVED SOWABILITY AND VITALITY.

PACKAGING UNITS RANGE FROM 10,000 TO 500,000 SEEDS.

WE TAKE A SAMPLE OF EACH SEED BATCH.

Throughout the entire process, we perform tests on: HEALTH: presence of bacteria, viruses or fungi. QUALITY: germination, purity and other seed determination. GENETIC PURITY: all seed lots are checked.

ORDER PACKING & SHIPMENT

WE SHIP BEJO SEEDS TO MORE THAN 100 COUNTRIES IN THE WORLD.

VEGETABLE AND LEGUME MANUFACTURER HAK HAS BEEN A HOUSEHOLD NAME IN THE NETHERLANDS FOR NEARLY 75 YEARS. THE NOORD-BRABANT-BASED COMPANY ASPIRES TO BE A FAIR AND SUSTAINABLE FUTURE FOR LOCAL ARABLE FARMING AND HAS SET FIRM GOALS IN THIS REGARD. FOR EXAMPLE, HAK WANTS TO SWITCH TO ORGANIC CULTIVATION FOR ALL VEGETABLES AND LEGUMES FROM THE NETHERLANDS BY 2027. JOACHIM NIEUWHOFF, DIRECTOR OF PURCHASING AND AGRICULTURE, PROVIDES AN ADDITIONAL EXPLANATION OF THIS PLAN.

Within three years only organic cultivation from the Netherlands; why this sharp deadline?

HAK wants to continue to invest in sustainability. In recent years, we have already certified our local cultivation 'On the way to PlanetProof', and this is the next step. We believe in not only the long-term benefits of organic farming, but also that it will contribute significantly to the future sustainability of our company. We envision improved Dutch cultivation practices as well as a better living environment that includes healthy soil, good water quality, and overall healthier food.

And are you on track?

We have started growing organic beet and the first ones are now in the supermarket. It is emphatically not a separate line, but a replacement for the current beets. Beet is a robust crop that lends itself well to organic cultivation due to its relatively short cultivation time, which gives less opportunity for weeds, pests, and fungi to damage the crop.

In addition, the crop fits well into the schedules of organic growers. Beet will be followed by green beans, kale and white cabbage (sauerkraut) from Dutch soil this year.

What challenges do you have to overcome to achieve your goals?

In terms of cultivation, the biggest challenge lies in controlling weeds. By sowing the crops later, we shorten the growing season and reduce the risk of weeds. This does create a challenge on the planning and production side, in which choices will have to be made. In the future, robotisation will become an important tool in weed control.

What specific requirements do you have for organic cultivation?

For us, this means that we do not use chemical crop protection or fertilizers. Green agents under the SKAL certificate are allowed.

How important is the beet crop to HAK?

Our beets are a beloved product for many consumers in the Netherlands. It is a product with a specific and unique recipe with which HAK distinguishes itself from other manufacturers. Therefore, beet must meet certain conditions: we only process round, beets in different grades. The beets are delivered washed and sorted and must be free of foreign bodies, healthy and unblemished, i.e. (virtually) no blemishes or black spots.

As a seed company, what role can Bejo play in achieving your goals?

Keeping readily available, high-quality varieties that produce stable yields under varying climatic conditions is one-way Bejo can help us achieve our goal. The inbreeding of different resistances (such as against Rhizomania) remains a very important tool in this respect. So, continuing to breed in search of improvements to existing varieties is also a prerequisite for this. It is important to continue discussing new opportunities in the market together. As Bejo is good at breeding new varieties, if HAK can use these crops, then we must seize the opportunity to work together.

HAK is a Dutch vegetable and legume manufacturer based in the North Brabant town of Giessen. Founded in 1952, the company produces summer and winter vegetables such as green beans, carrot, red cabbage and beet, as well as legumes, such as brown beans and marrowfat peas. With its vegetables, HAK aims to promote a plant-based and healthy diet. At least 85 percent of the products are grown within 125 kilometers of Giessen, creating the lowest possible negative impact on the planet. HAK believes in honest and sustainable farming practices for the future of local arable farming, as well as for our food. One essential condition to achieving this is presenting an attractive earnings model for the grower. u Commit to sustainability and full organic local cultivation by 2027

THE AGRICULTURAL SECTOR NEVER STANDS STILL, DRIVEN BY THE NEED FOR SUSTAINABLE DEVELOPMENT AND ENSURING FOOD SECURITY. SEED TECHNOLOGY PLAYS A KEY ROLE. THIS IS TRUE FOR MANY CROPS, AND NOT THE LEAST FOR THE CULTIVATION OF BEET. ON THIS TOPIC, WE GIVE THE FLOOR TO THREE BIOLOGICAL SEED TREATMENT SPECIALISTS AT BEJO. LIESBETH VAN DER HEIJDEN, SENIOR RESEARCHER, GERTJAN VAN WESTEN, RESEARCHER, AND KELLY VAN KOOPEREN, RESEARCHER, ALL FROM SEED PATHOLOGY RESEARCH, EXPLAIN THE LATEST DEVELOPMENTS AND FUTURE DIRECTION OF SEED TECHNOLOGY IN BEET.

The need for innovation in the cultivation of beet is becoming increasingly evident. Growers face challenges such as changing regulations, climate change and the ongoing threat of diseases. Bejo is at the forefront in developing advanced seed treatment techniques. Not only to improve plant health, but also to contribute to a more sustainable crop.

Innovation in seed technology

Van der Heijden, Van Westen, and Van Kooperen share their knowledge and commitment to innovation. They explain how Bejo focuses on developing techniques that enhance the germination and resilience of beet seeds.

A key focus is the 'steam vacuum treatment', a unique method developed by Bejo to eliminate harmful pathogens on the seed without using chemicals. "This treatment is a gamechanger in seed technology and is the result of our commitment to sustainability and innovation," Van der Heijden stresses.

Van Kooperen adds: "The beet seeds are disinfected by alterations of vacuum and steam. The alterations with vacuum help with even distribution of hot steam in the seed batch. The development of seed disinfection equipment and the design of targeted crop pathogen protocols is time consuming and continuous improvement is an important part of the research.

The load of infection dictates the intensity required for treatment. Tailor-made prescription could be desirable."

Research is also being conducted on natural seed treatments, which are environmentally friendly and add essential nutrients to the seed. These seed treatments are designed to optimise the interaction between the seed and its microenvironment, giving the plants a better start.

The future of beet seed

Looking to the future, experts underline the importance of resilience in beet cultivation. With the restriction chemicals, the search for alternatives is more intense than ever.

Bejo is involved in several research projects for development of alternatives, in terms of (seed) treatments and 'biofungicides'. Beet has been an interesting model for our research into alternative treatments because we have already supplied beet seed without chemicals for two seasons in the European Union. This is due to the fact that approval of Maxim for beet only came in 2022.

"The direction is clear: we are moving towards a future where chemical protection is replaced by natural resilience", explains Van Westen. "The ban on chemical plant protection products and the need to grow sustainably requires integrated crop protection. We are capable to deliver clean and healthy seed and innovations to

strenghten seed resilience in the form of a rich microbiome or biofungicides. Growers have a role in preventing diseases in the field by taking good care of their soil health for example through crop rotation and accurate monitoring. After all, healthy seed and soil are the start of a good crop."

There is an increasing focus in research on the seed microbiome - the community of microorganisms that live naturally on and in seeds. Bejo is investigating how this microbiome can be optimised to improve plant health and disease resistance.

Bejo's work in seed technology and beet marks an important transition in agriculture: away from chemical dependency towards more sustainable, organic methods. For growers and chain partners, this innovative approach offers prospects not only for healthier crops, but also for a future in which agriculture and ecological responsibility go hand in hand. Bejo remains committed to developing technologies that address today's challenges, looking towards a more sustainable future.

SENIOR RESEARCHER (LEAD)SEED PATHOLOGY RESEARCH

u Background: Van der Heijden has been with Bejo for almost a quarter of a century, where she started as a researcher and has grown into a leading specialist in the field of seed technology. With a rich background in biology and a PhD in mycorrhiza ecology (cohabitation of fungi and plants via roots) from Wageningen University & Research, Van der Heijden has in-depth expertise in the biological treatment of seeds and the development of technologies that promote plant resilience and health.

u Vision: “Innovation in seed technology is crucial for overcoming today’s challenges in agriculture. Our goal is to provide growers with seeds that are not only resilient to diseases, but also contribute to a more sustainable future.”

RESEARCHERSEED PATHOLOGY RESEARCH

u Background: Van Westen, with a background in biology from the University of Nijmegen, joined Bejo almost a decade ago. His work focuses on researching and testing biological crop protection products and exploring the role of the seed microbiome for improved plant health.

u Vision: “We are in the midst of a major shift in agriculture, where biologicals will play an increasingly important role as part of integrated crop protection and natural resilience. It is essential that we continue to innovate and work together to meet the challenges of the future.”

RESEARCHERSEED PATHOLOGY RESEARCH

u Background: Van Kooperen has worked at Bejo for eight years and studied biology in Leiden. She is mainly engaged in research in the field of steam vacuum treatment. She also delves into disease transmission in both field and controlled conditions. This research demonstrates the risk of seed pathogen infection for plant establishment, for example beet.

u Vision: “Physical disinfection is a proven method and remains highly relevant, especially as chemical agents fall away. Collaboration between physical disinfection (removing pathogens) and biological alternatives (adding resilience) is key.”

Wodan is an early, bolt-resistant red beet hybrid variety ideal for diverse climates. It produces uniform, round, smooth beets with a rich internal and external colour quickly, making it perfect for fresh markets and bunching. Its strong leaves support versatile planting schedules, and it’s suited for both processing and pigment extraction.

Bresko is a medium-late beet with smooth, round roots and intense colour both internal and external. Its strong, disease-resistant foliage and compact leaf attachment enhance root usability, making it ideal for fresh consumption, processing, and storage. Noted for its excellent flavour and uniformity, Bresko is well-suited for diverse climates and has a high yield potential.

Rhizu, with its intermediate resistance to rhizomania, yields consistent round beets featuring a vibrant, deep red colour and smooth skin. Optimized for high-density planting, it boasts a minimal leaf attachment and taproot, enhancing its suitability for efficient cultivation and processing.

Bazzu is suitable for more continental climates, but also suitable for the climates with Rhizomania infected areas due to its intermediate resistance. Bazzu is a robust beet variety with uniform yield, uniformly round, smooth beets and a strikingly deep red colour. With strong, healthy foliage and excellent taste, Bazzu is versatile for fresh markets, industry, and storage, offering a small leaf attachment for ease of harvest.

Pablo is a smooth, round main red beet variety that excels in high-density plantings. With its uniform shape, smooth skin and superb colour, it leads the market for its adaptability to early, main, and late production cycles. Resistant to bolting and drought resistant, it guarantees a high yield of top-quality beets, making it ideal for fresh consumption, processing, and storage.

Boro is a high-yield red beet variety, suited for varied climates and soils, ideal for fresh market. It produces round, dark red beets with robust, healthy foliage. Recognized for its excellent sweet flavour and smooth, ringless beet, Boro is also preferred for its nutritional juice benefits. Its strong foliage support all-year planting and adapt well to warm, humid regions, with great storage quality.

also organic seed available.

Manolo is a highly productive, early red beet variety with a smooth, round shape and an attractive reddish-purple colour. This beet boasts robust foliage and resistance to bolting, without zoning and excellent adaptability to adverse weather conditions. It’s ideal for high-density planting and has good storage potential.

Manzu is a premium red beet variety with intermediate resistance to Rhizomania, known for its smooth, round beets and intense deep red colour. It offers a robust, erect foliage, making it ideal for spring-summer planting. Suited for fresh markets, industrial use, and storage, Manzu combines excellent flavour with good sugar content and disease resistance.

also organic seed available.

Bohan is a robust, heat-tolerant beet variety known for its large, smooth, round roots with intense internal and external red colour without zoning. It features strong, disease-resistant foliage, making it suitable for fresh consumption and industrial processing, as well as bunching. This variety is adaptable to various planting seasons and conditions, ensuring high yield and long storage potential.

Taunus is a cylindrical red beet known for its high sugar content and uniform slicing qualities, making it perfect for the food industry. This variety boasts a deep red internal and external colour without zoning and has smooth roots ideal for processing. Taunus offers robust foliage, excellent yield potential, and strong resistance to bolting, adapting well to various growing conditions.

A yellow hybrid beet with beautiful intense internal and external colour. Excellent uniform shape with fresh green and healthy leaves. Amarelly keeps its uniform colour even under more stressful conditions meaning it is well suited for diverse climates.

u IR = Intermediate Resistance

u BNYVV = Beet Necrotic Yellow Vein Virus (Rhizomania)

i For detailed information, ask your local Bejo representative or check the country website.

IN ONE OF THE BEJO RESEARCH GREENHOUSES, DORA COELHO AND BERBER DE WOLFF SHOW ROWS OF POTTED BEETS ON TABLES. OR AT LEAST WHAT IS LEFT OF THOSE BEETS. OF SOME, THE LEAVES AND ROOT ARE AFFECTED, OTHERS ARE COMPLETELY GONE. "LOST BY THE RHIZOCTONIA FUNGUS," DE WOLFF POINTS OUT. IT SHOWS WHAT BOTH PHYTOPATHOLOGISTS ARE DEALING WITH: THE BATTLE AGAINST PATHOGENS (PLANT DISEASES) THAT HAS BECOME INCREASINGLY CHALLENGING OVER THE YEARS.

Coelho and De Wolff are part of the extensive team of Bejo phytopathologists, scientists working on research into ingredients and diseases in crops (and how to minimise their impact). An example of their work in the field of content matter: a few years ago, in a large research on taste, they concluded, among other things, that the beet sugar content (brix) does not fully predict sweetness or general impression of the beet in a taste panel and that several compounds are involved in the powerful aroma. Company-wide, Bejo employs several phytopathologists and the team of Coelho, specialized in the beet crop (among others), comprises besides De Wolff, also of Marja Seignette as research assistant.

When developing varieties, cooperation between the various departments at Bejo is crucial. The breeders work on varieties the grower can rely on (more on this in the article on page 10), the sales team advises customers and identifies problems they encounter. Often these are pathogens that threaten a crop's yield. The phytopathologists are closely involved in all these processes.

Coelho and De Wolff talk enthusiastically about their work and developments in their field.

In a nutshell: the phytopathologist investigates in the laboratory which pathogens are responsible for the field problems and gives advice on identification and control. And also develops the protocols for testing different pathogens (fungi, viruses, bacteria, insects, etc.) on plants. By looking at the symptoms, or further analysis on specific ingredients, the best plants are selected as part of the process to develop varieties with disease resistance and improved quality. This can be time-consuming, especially when we test a population of plants that are all different genetically, De Wolff explains: "For example if we have a field of 1,000 plants, we have to look at them one by one to draw reliable conclusions about the trait we are evaluating. From the results, breeders then benefit in their work."

The researchers' work has intensified in recent years due to stricter regulations on the use of chemicals and - we cannot ignore - climate change. "Higher temperatures, will increase the life cycle speed and spread of most pathogens

and insects (which can transmit diseases)," Coelho explains. "And with milder winters, they also survive during these periods into the next season." And, she continues, "As a result, we also have to deal with mutating pathogens, evolution of new ones and resistances that break through more often. That’s why it is important to test variants of pathogens from different regions that could have an impact on the local production, also because, due to the increase of global trading and travelling, the diseases tend to spread faster to new areas. This means we have to keep up to date with the newest developments in the field and adapt our programs accordingly.”

Well-known pathogens for beet are Rhizomania (soilborne root rot disease), Cercospora (leaf spot disease), Rhizoctonia (root and crown rot), Nematodes (root parasites) and Phoma (seedling or root storage disease). But there are more like these, and new variants are also developing all the time. Can your group with the expertise in this field keep up with all these developments?

Coelho, laughing: "Expansion of the team is always welcome, but I think we're especially going to benefit a lot from the latest advances in rapid diagnostics and from the new technologies in automation of certain steps in disease trials. And of course from the possibilities that artificial intelligence offers us" This can be used in high-throughput phenotyping systems, for example, adds De Wolff: "You can develop an automated system that takes pictures of diseased plants (phenotyping) and immediately gives them a score by training a model to recognise the symptoms. This can be done for instance in the greenhouse with high-tech cameras or in the field with drones."

Do both recognise in Bejo an employer that sees the importance of investing in these modern technologies? "Absolutely," thinks Coelho. "Bejo always strives to be progressive and acts accordingly. It has to be in order to achieve our company's mission of producing sustainable varieties of the highest quality. Resistance to pathogens is essential in this respect. But with a team of dedicated people and dedicated researchers per crop, complemented by the capabilities of modern technology, all the conditions are in place to realise that mission."

IT IS A GLOBAL TREND: PROTECTING UNIQUE REGIONAL PRODUCTS FROM COMPETITION BY DESIGNATING THEM 'CULTURAL HERITAGE'. CHAMPAGNE CAN ONLY BE CALLED CHAMPAGNE IF IT IS ACTUALLY PRODUCED IN THE CHAMPAGNE REGION. THAT MANY WINES AND CHEESES ARE ALSO PROTECTED SHOULD COME AS NO SURPRISE. BUT BEET AS CULTURAL HERITAGE? THAT SEEMS LESS OBVIOUS. IT IS CURRENTLY PLAYING OUT IN AUSTRALIA.

A group of growers there invoked the unique role beet play in the Australian hamburger variety, 'The burger with the lot', in order to protect the local cultivation of beet.

What exactly is that, such a 'burger with the lot?'. The full recipe is as follows; spread a little mayonnaise on the bun, top with the cheese covered burger, bacon, pineapple and a slice of beet. Add tomato and egg, squirt some barbecue sauce on top and put the top on the bun. Done is 'the burger with the lot'.

This is also known as the 'Aussie burger'. As far as we know, nowhere else in the world is a slice of beet used on burgers, but there isn't an Australian to be found who doesn't know what an 'Aussie burger' is.

A combination of factors caused a temporary shortage of sliced beet. A group of growers took that opportunity to highlight the importance of beet to Australia's 'burger culture'.

Due to economies of scale, many small factories that processed beet worldwide have closed or been taken over by larger companies. Australia, too, has not escaped this trend. In the last 10 years, factories here too have closed down and part of production has moved to New Zealand. Obviously, local growers were not happy about this.

In 2023, cyclone Gabriella overtook New Zealand, causing severe flooding in the Hawke's Bay region. This is precisely the area where much of the beet crop is grown. The damage to the crop caused shortages in the supply of beet. So grist to the mill for Australian growers who want their lost beet crop back.

For growers, it is unfathomable that such an important part of Australian culture is being put at risk by outsourcing it to foreign countries. "Beets are grown in our immense country from Tasmania to Queensland, and then we move cultivation to an area the size of a postage stamp," is the general thought. Growers wonder how the country could have made itself so vulnerable.

The fact that the crop has been moved to New Zealand makes the situation extra incomprehensible to growers. The rivalry that still plays out in some areas between the two countries means that the story has also generated a lot of media attention.

Good news for Aussies: the new harvest has already been released, solving the temporary shortage. After all, Australians really can't do without their 'burger with the lot'.

Not even if 'the lot' is from New Zealand.

BEET IS A TRUE SUPERFOOD, PACKED WITH NUTRIENTS THAT CONTRIBUTE TO A HEALTHY LIFESTYLE. FROM THE COLOURFUL BETANIN TO A HOST OF VITAMINS; THIS VEGETABLE OFFERS COUNTLESS BENEFITS TO THE HUMAN BODY.

Betanin: the purple power

The intense purple-red colour of beet is due to betanin, an antioxidant (among others) that helps protect cells from harmful free radicals. Betanin also has anti-inflammatory properties, which can help reduce inflammation in the body.

Folic acid and vitamin C

Beet is high in folate, which is important for red blood cell formation and nervous system health. It is also rich in vitamin C, a powerful antioxidant that supports the immune system and contributes to iron absorption.

Nitrates: the key to better blood flow

Beet contains significant amounts of nitrates. These improve blood flow and lower blood pressure. The nitrate is converted to nitrite by enzymes in the mouth. This causes the veins to open up properly and increases blood flow to the muscles. Your muscles are thus oxygenated faster and more easily, delaying acidification. It also helps drain waste products faster and promotes recovery. Several studies also show that the nitrates from concentrated beet juice improve athletic performance in endurance athletes.

Fiber and brix: good for digestion

Beet is rich in fiber, good for healthy digestion and regulating cholesterol and blood sugar. The high brix value means that the crop is high in natural sugars, which contributes to a sweeter taste.

Additional benefits and contents

Beet also contains potassium, manganese, iron, magnesium and vitamin B6. It reduces oxidative stress, improves cognitive functions and supports liver detoxification.

Beet products

There are several ways to benefit from the health advantages of beet. Freshly squeezed beet juice is a powerful source of antioxidants such as betanin and vitamin C. Fermented products contain probiotics and nitrates. Dried beet powders and supplements concentrate nutrients. Beet hummus is a healthy spread rich in fiber, protein and betanin.

Beet is a powerhouse in the world of vegetables, with an abundance of nutrients that contribute to a healthy lifestyle. By including this colourful vegetable in your diet, you will enjoy its numerous benefits for your overall health and well-being. So, if you want to boost your vitality, make sure beet is on the menu every week!

IN LATVIA, BEJO SUPPLIES PRODUCTS TO EZERKAULIŅI AGRO, A MAJOR PLAYER IN THE EASTERN EUROPEAN VEGETABLE PROCESSING MARKET. AND NOT ONLY IN PROCESSING; THE COMPANY HAS ALSO TAKEN IN-HOUSE THE CULTIVATION OF FIELD VEGETABLES SUCH AS BEET, CARROT, PARSNIP, RADISH AND ONION. IN TOTAL, EZERKAULIŅI AGRO PRODUCES MORE THAN 5,000 TONNES OF PROCESSED PRODUCT ON AN ANNUAL BASIS. WE PUT SOME QUESTIONS TO OWNER KRISTĪNE BRUNOVSKA.

The combination of cultivation and processing within the same farm, how did it come about?

Ezerkauliņi farm was established in 1997. Initially, we did everything, about 40 different crops, by hand. Over the years, we started expanding: we bought, land, greenhouses and new machinery to process the produce. To expand further, we partnered with farms and acquired businesses. We also set up biogas plants in 2011 and 2012 to grow sustainably. All these developments ensure that we can produce the necessary volumes and offer a wide assortment. In our greenhouses, we now grow cucumbers, tomatoes, lettuce and green onion leaves on 9 hectares.

What does the market in Latvia look like?

The consumption of vegetables is increasing. People are opting for a healthier diet and are also increasingly choosing locally grown products. In doing so, they choose fresh vegetables that are available at the time.

And speaking specifically about beet?

Beet is a common vegetable in cooking, in both sweet and savoury dishes. Beverages with beet in them are also popular. Of our fresh beets, most are for domestic consumption: we export about 40 percent. For precooked beet, the percentage is even slightly lower, 30 percent of which is for export.

What are popular products?

We sell both fresh and processed vegetables, under the Ezerkauliņi and Mārupes Siltumnīcas brands. Ezerkauliņi includes processed greens such as sauerkraut with beet, as well as marinated beet and Korean-style beet. Our most popular product is a pack of 500 grams of cooked beet.

How long have you been working with Bejo?

We have been buying varieties from Bejo for about 25 years. At the moment, we use Manolo, Bresco, Manzu and Wodan, among others. It's important to us that beets have a high sugar content, which ensures a pleasant flavour. Also, the beet should have a distinct round shape, which prevents loss during peeling. Manolo is an exceptionally good beet in this respect.

What developments do you see in the future?

Besides our existing offer, we are interested in coloured (yellow) beets and chiogga beets with a stable colour. This is important because the colour sometimes wants to disappear during cooking. We ourselves will continue to profile ourselves as a provider of healthy products, with an emphasis on freshness and local origin. To complement this, we also offer simple and tasty recipes to inspire consumers.

u Based in Riga, Latvia

u 304 employees

u 2,500 ha of agricultural land

u Turnover 26.5 million euro

u Specialisation: beet, carrot, radish, parsnip and onion.

EUROPE

30,000 HA 35,000 HA

TOTAL HA

194,000

'DID YOU KNOW... THAT IN THE NETHERLANDS, BEETS MAKE IT TO THE TABLE IN JUST A THIRD OF HOUSEHOLDS, AND ONLY FOUR TIMES A YEAR?'. IT’S TIME TO GENERATE ATTENTION FOR THIS DELICIOUS HEALTHY AND VERSATILE PRODUCT! THAT IS WHY THE BEET CLUB WAS CREATED IN 2023, CONSISTING OF GROWERS, VEGETABLE BREEDERS AND PROCESSORS OF BEET.

This partnership was established to make beet top of the shopping list among Dutch consumers. In addition, the Beet Club wants to give a practical and concrete answers to the sustainability factors and health benefits of eating more beet. This will be done with the campaign: biet it!

With this campaign, we will motivate people to add beet to their favourite meals. Do what you already do, but make it a beet(er) version. In other words: biet it! Beet is not only very delicious, but offers numerous benefits: helping your wallet, your body and the planet. If you want to know more about the beet club or get some inspiration, check out www.bietenclub.nl!

Biet it! Give your dish a beet twist.

Impression of one of the actions: pop-up restaurant 'Bar Bietstro'.

Beetz, a Dutch processor of organic beet, is switching to new packaging in September. Namely, they are moving from trays to a stand-up pouch. This new packaging is for grated red beet, red beet cubes and marinated baby beets - which will be sold in Dutch retail.

This change extends shelf life by 21 days, reducing in-store wastage. In addition, the amount of plastic per pack is reduced by 50%. Because the product comes in an upright pouch, it is also more visible on the shop shelf.

At Beetz, they are happy with this progress. Beet is a hugely important vegetable for them and they hope that with this move, beet will be seen at the table in more Dutch households.

TO SUPPLY BEETS THROUGHOUT THE YEAR, SOME OF IT IS STORED AFTER HARVEST. THERE ARE DIFFERENT PRESERVATION METHODS FOR THIS, DEPENDING ON THE CLIMATIC CONDITIONS IN THE AREA AND THE COST OF THE METHOD. PAULO CHRISTIANS, GENERAL MANAGER BEJO BRAZIL, EXPLAINS WHICH OF THESE METHODS ARE USED IN BRAZIL. THEN RONALD LOOS, AREA CROP MANAGER EASTERN EUROPE AT BEJO, EXPLAINS HOW BEETS ARE STORED IN EUROPE.

In Brazil, beets are consumed year round, because they must be constantly available. "You would say that in such a big country like Brazil, you can plant beets all year round," begins Christians. "That is true, but warm and wet periods make it a challenge for growers. As a result, beets must be sprayed more often, which in turn causes a drop in quality, resulting in lower yields." He continues: "Growers can look for a better climate, but then distribution costs increase. For this reason, beets are also put into storage in Brazil."

In most growing areas, the dry season lasts from March to September. This is the main sowing season. The last beets are sown in July and, with a cycle of 90 growing days, there is fresh produce from June to October. If the supply of fresh beets in the dry season is high, prices are automatically low. Therefore, in September, depending on the price, the beets go to the fresh market or to storage waiting for a better price. Indeed, in January and February, prices tend to be higher due to lower supply.

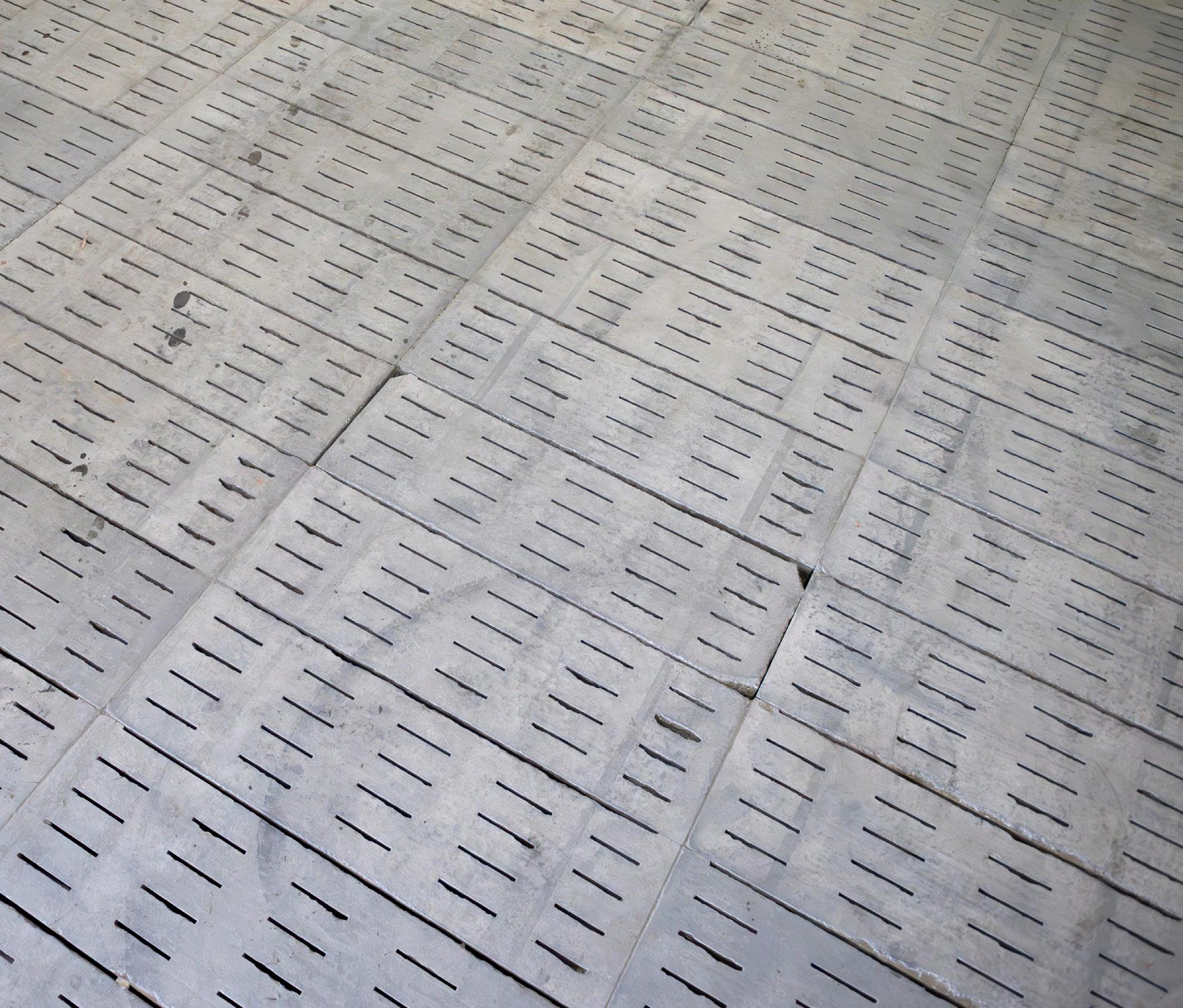

Most Brazilian growers store beets in wooden or plastic boxes, stacked on pallets. It is important that beets remain moist during storage. The pallets are therefore stored in conditioned cold stores. These have a floor that retains water. Sprinklers are used to keep the beet moist. It is necessary to keep the humidity between 85% and 100%, with temperatures between 2 and 5 degrees Celsius (35.6 to 41 degrees Fahrenheit). On small-scale farms, you sometimes see beets being stored in 20- to 25-kilo (44-55 pounds) bags. Some growers dislike the abundance of water on the floor and the mud that comes along with it, so they use heavy woven bags. These bags are then sealed tightly so that all the moisture stays in the bag. The room is made extra humid by the sprinklers in the cold cells.

"So even in a country like Brazil, it is important to have a beet variety that is good for storage. Our widely used variety Boro can be stored well for six months, even a little longer if necessary. We did try other varieties for storage at times, but at the moment Boro is still a favorite with the Brazilian grower," concludes Christians.

In Europe, many beets are stored under fully controlled conditions, such as with a mechanical cooling system. This allows growers to store their beets, in most cases, for a longer period. Unlike what is common in Brazil, growers from Europe try to store beets under drier conditions. Beets are stored in crates or loose bulks. Through a controlled ventilation system, the air is refreshed regularly without the beet suffering. A mechanical cooling system is a good way to store beets. However, this method is expensive, especially with the high energy prices in recent years. Where the climate allows, you therefore see some countries within Europe storing beets outside, under straw.

For proper storage under a deck of straw, a uniform mound of beets is made up to four meters (13 feet) high and a maximum width of five meters (16 feet) on a well-drained surface. As long as no frost is predicted, the heap can be covered with straw (sometimes combined with a small amount of soil so that the straw does not shift). The straw ensures that the heap is equally ventilated. For extra ventilation, a ventilation channel can also be placed.

In case of frost, it is essential to cover the beets with plastic to ensure quality. In this case, it is advisable to remove the plastic as soon as the temperature rises above freezing again, as it hinders ventilation.

"If you want to put beets into storage, I recommend not harvesting them in hot and dry weather. This is because beets then go into storage hot and this can negatively affect the climate in the heap," says Loos. "If you have no other choice, under these weather conditions you can moisten the beets in the heap after harvesting. This ensures favorable humidity, and that the temperature of those beets drops." Loos continues, "I recommend harvesting with a toplifting harvester. This machine significantly reduces the percentage of damaged beets. It is essential that beets enter storage damage-free. In addition, ventilation is important, so use a conveyor belt to make the heap. This way, you can sort out soil and small beets so that they do not block the ventilation channels between the big beets."

Although beets are stored in "uncontrolled conditions", modern techniques with smart sensors do give us increasing insight into the conditions in the heap. As a result, better choices can be made. Depending on the variety and storage conditions, beets can be stored under straw up to six months.

Of course, the best way to store beets varies depending on the situation. For advice, you can always contact the Bejo representative in your area.

BEETS ARE KNOWN FOR THEIR DEEP RED COLOUR AND EARTHY FLAVOUR. THEY ARE NOT ONLY A NUTRITIOUS ADDITION TO OUR MEALS, BUT ALSO A VERSATILE INGREDIENT THAT TRAVELS THE WORLD. FROM GROWER'S FIELDS TO SUPERMARKET SHELVES, BEETS HAVE FOUND A WAY INTO THE HEARTS AND KITCHENS OF CONSUMERS AROUND THE WORLD. BEETS ARE INNOVATIVELY MARKETED AND USED IN TRADITIONAL DISHES AS WELL AS MODERN SUPERFOODS AND COSMETICS.

Europe: traditional and trendy

In Europe, beets are traditionally consumed as part of salads or cooked as a side dish. With the rise of health trends, we see them more often in juices and smoothies. In the Netherlands, beets are used in baby food, indicating their nutritional value and versatility. In Spain, beet is used in "Salmorejo", a refreshing dish that shows the versatility of beets in Mediterranean cuisine. In Eastern Europe, the emphasis is on the traditional ways in which this crop is valued, such as borsjt.

North America: snack and supplement

In North America, beets have become a popular ingredient in healthy snacks. Dried and crunchy beet crisps are a favourite for those looking for a healthier alternative to traditional crisps. In addition, powdered beets are sold as a superfood supplement, often added to smoothies or used as a natural food colouring.

Latin America: colourful and creative

Beets are widespread in Latin America, especially in Brazil and Mexico. They are used in a variety of products, from fresh juice and baby and pet food to cosmetics such as creams, lipstick and blush. Beets not only add colour and flavour to tortillas, but are also incorporated into enchiladas, noodles for salads and even ice cream, highlighting the creative culinary uses of this vegetable.

Asia: traditional and innovative

In Asian countries, beets are often used in traditional dishes, but there is also a growing trend of innovative uses. In India, for example, beets are used in a variety of curries and pickles. While in Japan, beets are used as a natural colouring agent in confectionery and pastries.

Colour on your plate

Besides red beets, there are also colourful varieties such as yellow, white and chioggia beets. Yellow beets are a favourite with children because of their sweeter taste. Chioggia beets stand out for their pinkish-white rings, perfect for salads. White beets offer a subtle flavour that refines dishes. They add extra colour and flavour to any meal.

The marketing of beets shows their versatility. They are not only marketed fresh, but also pre-cooked and processed into cubes, slices and julienne. From health foods to cosmetics, beets continue to surprise us with their versatile uses and enduring popularity.