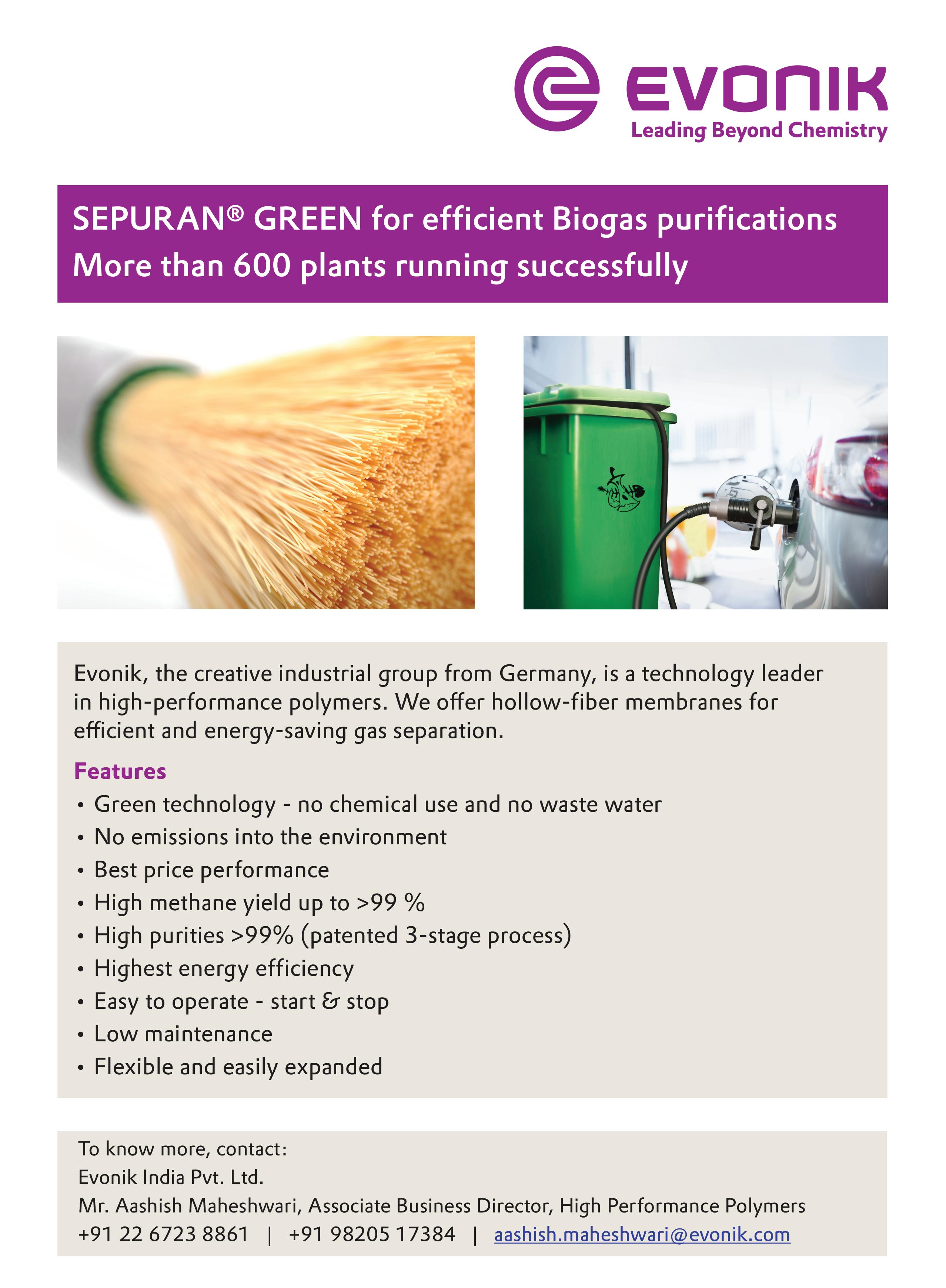

SEPUR AN® GR EEN - 1,000 reference plant for efficient biogas upgrading

TABLE OF CONTENTS

Harnessing Microbial Magic:

Transforming waste into a sustainable future 12

Transforming Anaerobic Digestate into Premium Compost and Biochaar++ Interview

In conversation with Dr. P. Shanmugam

Enhancing Crop Yield and Soil Health

Through Gobargas-Slurry and SuDhan Fertilisers:

Biogas:

Up-gradation & Quality analysis for Grid Injection

From Biogas to Bio-Slurry:

Organic and Bio-Fertilizers in Nutrient Economy of India

Biogas Magazine | Edition 27 | 4

16 31 36 22 40

“

Dear Readers and esteemed members,

Welcome to another edition of the Biogas Magazine, your one-stop resource for exploring the ever-evolving world of biogas and compressed biogas (CBG) and Fermented Organic Manure (FOM) technology. As we navigate an increasingly energy-conscious landscape, this edition dives deep into the transformative potential of these solutions, offering insights and advancements that pave the way for a more sustainable future.

Speaking of recent advancements, I am sure the readers are aware of India’s budget released at the beginning of February 2024, which came as a booster dose to the CBG sector, further strengthening the nation’s commitment to transition towards clean energy. The budget announced financial support for purchasing biomass collection equipment, which is a crucial step in the production of CBG and will surely boost the establishment of the agricultural biomass supply chain. The budget also proposed a phased blending of CBG and natural gas (CNG) for transportation and piped natural gas (PNG) for domestic use, which is aimed at increasing CBG adoption and accelerating its integration into the national energy mix.

In our latest edition of Biogas Magazine, you will be pleased to find the lead article, "Unlocking Sustainable Energy: The Transformative Potential of Bio-methane Liquefaction in Biogas Plants,", in which we delve into a transformative technology: Bio-methane liquefaction. We explore how this process unlocks the vast potential of biogas by making it easier to transport, store, and integrate into existing energy grids. By unlocking the door to a more versatile fuel source, Bio-methane liquefaction paves the way for a more accessible and impactful clean energy future.

We examine the role of organic and bio-fertilizers in India's nutrient economy, highlighting their potential to replenish vital soil health and contribute to a more sustainable agricultural landscape. Additionally, we explore innovative techniques for transforming anaerobic digestate – the leftover material from biogas production – into premium compost and biochar. This process recovers valuable nutrients and creates valuable soil amendments, further contributing to a circular economy and resource optimization.

As we strive to integrate biogas into existing infrastructure, ensuring its seamless compatibility becomes crucial. This edition explores this need in the article on biogas upgradation and quality analysis, wherein we uncover the pivotal role of quality analysis in ensuring the seamless integration of biogas into the grid. The article sheds light on the latest upgrade technologies that enhance biogas' purity, making it a viable and reliable component of the broader energy infrastructure. By understanding the intricacies of gas composition and upgrading processes, we can ensure the quality and consistency required for grid injection, enabling wider adoption of biogas as a mainstream energy source.

Within these pages, you will find a plethora of insightful articles, expert opinions, and industry updates that shed light on the dynamic world of biogas and CBG technology. We encourage you to delve into this edition and discover the transformative potential of these innovative solutions. Together, we can harness the power of biogas to build a cleaner, greener, and more sustainable future for all.

Happy digesting!

Dr. A. R. Shukla President Indian Biogas Association

Dr. A. R. Shukla President Indian Biogas Association

Editors

Savita Boral

Abhijeet Mukherjee

Designer

Komal Raghav

Jyoti Narang

Production Co-ordinator

Jyoti Malik About Us

The “Indian Biogas Association” (IBA) is the first nationwide and professional biogas association for operators, manufacturers and planners of biogas plants, and representatives from public policy, science and research in India.

The association was established in 2011 and revamped in 2015 to promote a greener future through biogas. The motto of the association is “propagating biogas in a sustainable way”.

/biogasindia

/indianBiogasAssociation

/indian-biogas -association

Biogas Magazine | Edition 27 | 5

GRUPPO PEVERONI Arka Brenstech Pvt Ltd Indian Distributor - +91 95010 24421 - +91 90046 89601 info@brenstech.com - product@brenstech.com www.brenstech.com More than 15 years of experience in gas-tight covers for biogas

Biogas Magazine | Edition 27 | 7

IBA'S commitment to advancing industry prospects for biogas/bio-CNG

- Period: Jan'24 - Mar'24

IBA’s budgetary recommendation on fiscal support needed for the CBG/Biogas Industry:

Before the commencement of the Union budget session, the Indian Biogas Association recommended that the Ministry increase financial allocation for CBG plants to support on the following lines:

a) Establishing a Fair and Remunerative price (FRP) for biomass and a minimum support price for output fertilizer

It is recommended to define a framework by the concerned Ministry for the procurement of biomass at a FRP [Fair and Remunerative Price], which needs to be worked out based on cost and markup.

To arrive at a rational pricing of the FOM (Fermented Organic Manure) or any organic fertil-

izer under consideration, it is suggested to holistically consider a nutrient-based (i.e. N, P, K, and organic Carbon) valuation approach to appropriately determine the market price of the FOM. To be a competitive option for end-use of the FOM by farmers, IBA suggests a ‘floor market price’ at par with the Urea Retail Prices (presently INR 242 per 45 kg bag), i.e. approx. INR 5.0-5.5 per kg (exclusive of taxes). The Market Development Assistance (MDA) of INR 1.5 per Kg shall be realized over and above the floor market price by the FOM producer. The floor market price should have additional leeway to accommodate additional transportation charges if incurred (suggested additional rate of approx. INR 50 per ton/km), and should also be indexed to the appropriate price basket to factor in inflation. The table below showcases our suggested

Biogas Magazine | Edition 27 | 8

floor pricing points for a variety of organic fertilizers purported to be covered under the MDA scheme:

Note:

1. The MDA of INR 1.5 per kg. is over and above the above-suggested prices.

2. * Includes loading and unloading charges as well.

b) CGD pipeline Infrastructure needs to be extended to incorporate CBG for a 5% blending possibility

The CGD entities, with the Ministry's support, should pave the way for the construction of the necessary gas grid infrastructure for such last-mile sourcing. The budgetary allocation (in the short term) for grid connectivity of the majority of the upcoming CBG plants (at least half of the 750 plants expected to be commissioned in three years) is roughly estimated to be INR 2500 crores (at INR 3500 per meter for approximately 10 km of laying per project).

c) Credit Guarantee MSME

There is currently a scheme called the Credit Guarantee Fund Trust for Micro and Small Enterprises (CGTMSE) that provides guarantees on credit or loans given to MSME borrowers by lending institutions (banks).

CBG developers can also avail the facility, although the scheme's coverage limit is set at INR 5 crores of borrowing, which

is way too little to meet the capital requirements of a typical CBG project. The requirement of such a credit enhancement facility dedicatedly earmarked for upcoming CBG projects (750 plants in the short term) is estimated at around INR 3000 crore. The government should earmark INR 3000 crore for the Credit Guarantee Scheme.

d) Manure MDA and market linkage

India's FOM potential is undeniable but needs a financial nudge. Thus, Market Development Assistance is necessary to lower entry costs and make FOM compete with chemical fertilizers. This fuels production, guaranteeing a constant supply. However, the allocated budget of INR 1450 crores would require a three-fold boost to ensure the smooth push to be given to the new 750 plants in the next three years.

e) Creating the ‘Biogas-Fertilizer Fund’

Indian Biogas Association pro-

poses to set up a new 'Sustainable Biogas Plant Fertilizer-Based Cultivation Programme' (SuBiCulP) with a dedicated INR 1.4 lakh crore fund for five years, which would also include the credit guarantee scheme and Generation Based Initiative (GBI). Based on a SATAT-like policy for organic manure, this all-encompassing initiative aims to secure organic fertilizers for improved soil and human health. It also incentivizes digestate use by fertilizer companies and cooperatives.

Hands-on training workshop on biogas for enthusiasts at SSS-NIBE, Kapurthala

SSS-NIBE, in collaboration with IBA, organized a hands-on training program on Biogas Technology and its implementation from February 19-23 at the SSS-NIBE campus in Kapurthala, Punjab. The Hands-on training program was attended by over 50 participants and proved immensely beneficial in upgrading their skills to meet the contemporary requirements.

Biogas Magazine | Edition 27 | 9

S. No. Organic Fertilizer Type Floor Market Price (excl. taxes in INR/kg) Logistics and Transport (INR/ton/km)* 1 Solid-FOM 5.0-5.5 50 2 Liquid-FOM 0.50-0.75 75 3 PROM (Phosphate Rich Organic Manure) 7.0-7.5 50 4 KROM (Potash Rich Organic Manure) 7.0-7.5 50 5 Bio-Fertilizer 10.0-12.0 75 6 Other Enriched Forms (bio-char, etc.) 7.0-7.5 50

This program aimed to impart training to SNDs/ SNAs/ BDTCs/ KVIC, Manufacturers of Biogas Plants, Purification Systems, Engines, Gas Flow Meters, Project Developers, Implementers, Consultants, Biogas Aspirants, and Start-ups, various aspects of biogas technology like biogas generation, enrichment, design, Operation & Maintenance, and Policy & Financing to familiarize them with the importance of biogas as a fuel the present status the biogas program, inter-alia details about how biogas is upgraded to CBG & bio-CNG. The program is also intended for field supervisory functionaries involved in the implementation of biogas programs.

IBA supported the workshop series on CBG organized by the Oil and Gas Marketing companies

The Ministry of Petroleum and Natural Gas (MoP&NG) is executing various pathways to accomplish the aim set by the Panchamrit plans, which were present globally at COP 26 to intensify India's climate action, including achieving Net Zero by 2070. In pursuit of this goal, the propagation of Compressed BioGas (CBG) has been launched under the ambitious scheme of SATAT (Sustainable Alternative Towards Affordable Transportation).

To take this initiative forward, under the guidance of the Ministry of Petroleum & Natural Gas (MoP&NG), a series of aware-

ness dissemination workshops were organized in the final couple of weeks of February 2024 at Ahmedabad, Chandigarh, Guwahati, Bangalore, and Lucknow by IOCL, GAIL (INDIA), OIL (India), BPCL, and HPCL, respectively. The workshop deliberated upon the emerging ecosystem of CBG businesses nationwide and aimed to create awareness among stakeholders to aid in spreading the SATAT program. IBA shared its insights on "Financial Modelling of CBG project" throughout the workshop series. The workshop series saw the participation of officials from MoP&NG, the Department of Drinking Water and Sanitation

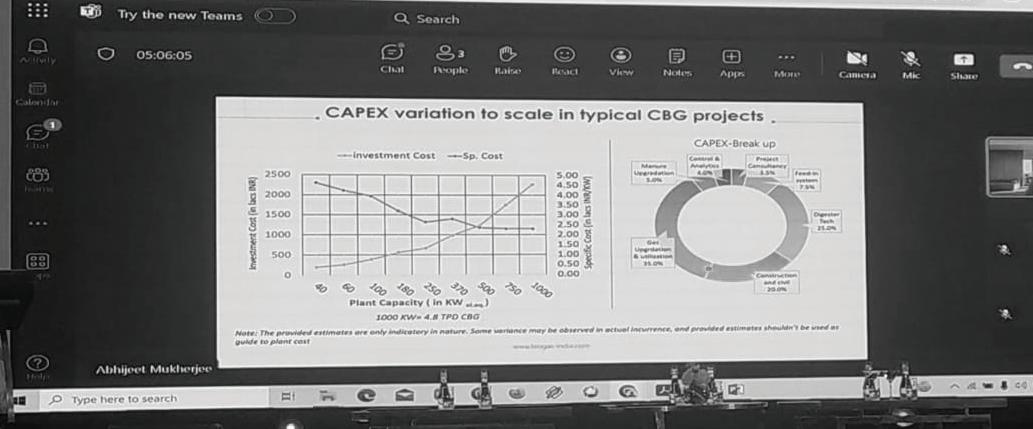

Abhijeet Mukherjee Director Operation Indian Biogas Association

(DDWS), the Ministry of New and Renewable Energy (MNRE), the Dept. of Financial Services, the Ministry of Finance, Dept. of Fertilizer, Ministry of Chemicals & Fertilizers, the Dept. of Agriculture and Farmers' Welfare (DA&FW), UPNEDA, World Bank, Indian Biogas Association (IBA), Technical experts, PSU & Private Banks, CBG LOI holders, OGMCs (Oil & Gas Marketing Co.), etc.

Biogas Magazine | Edition 27 | 10

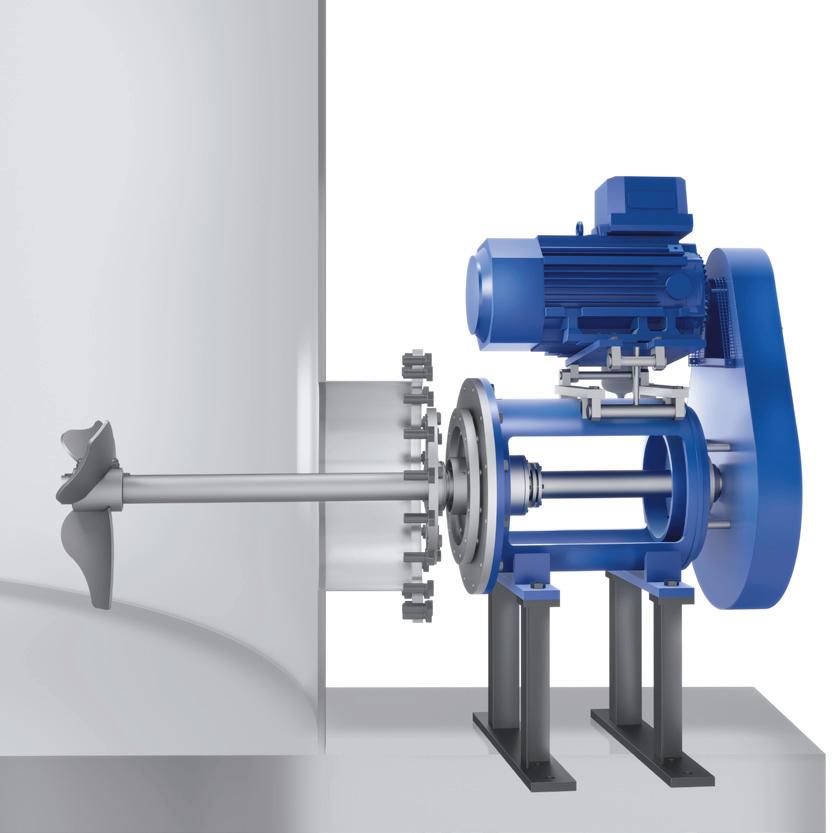

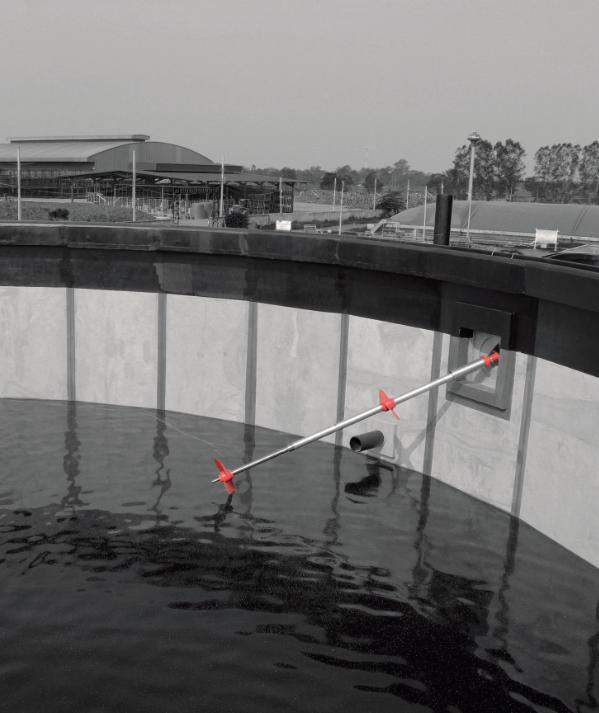

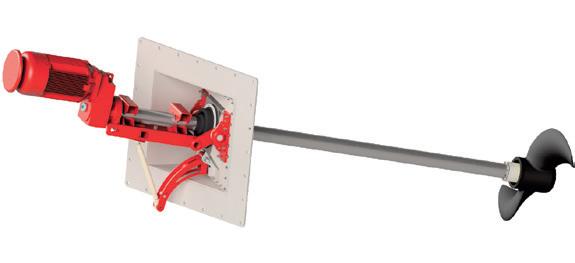

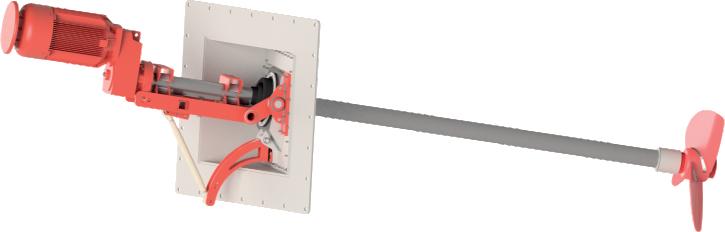

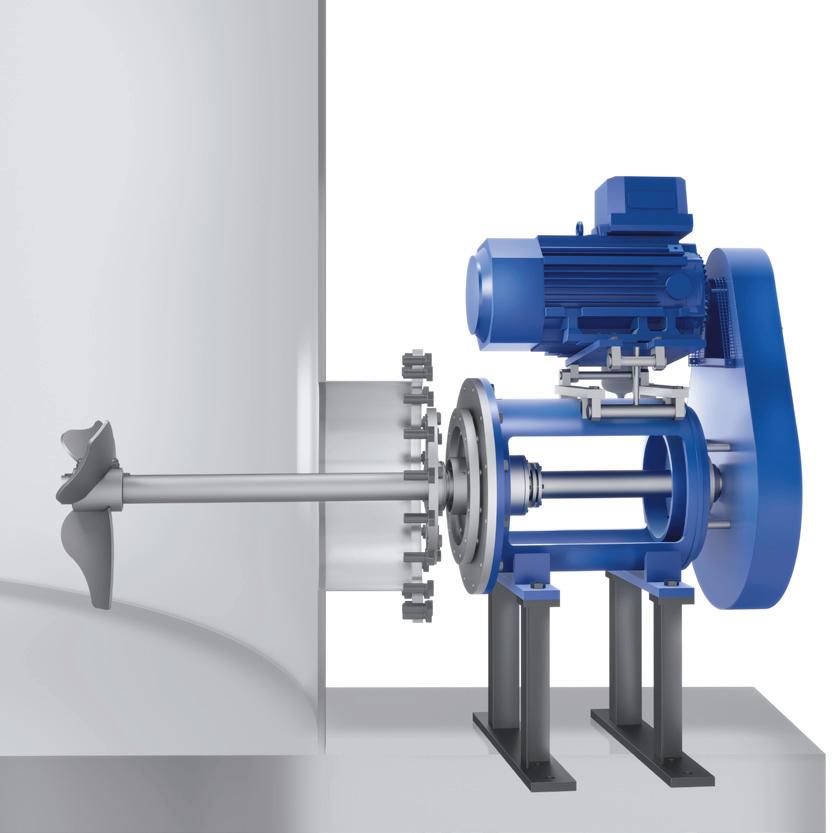

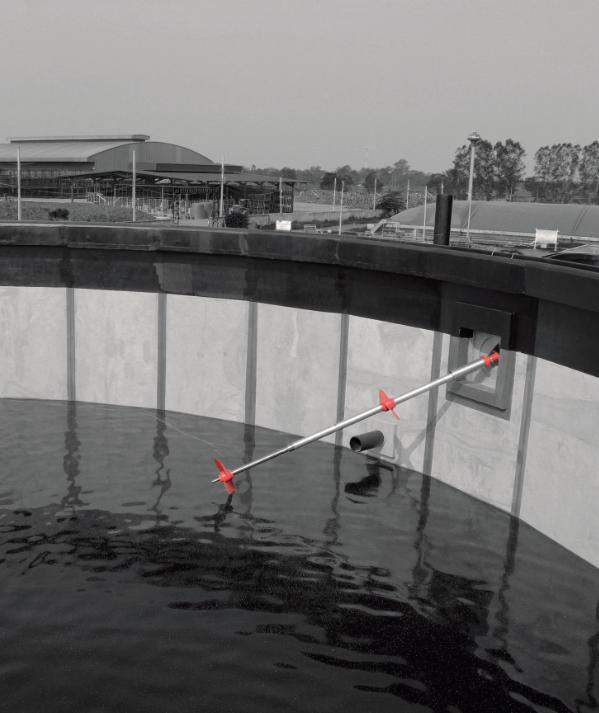

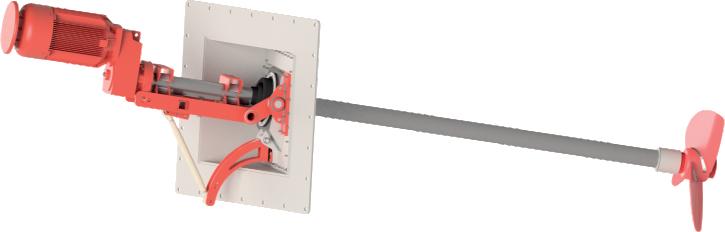

Agitator Technology from Germany – ‘Made In India’

PRG Agitators Pvt. Ltd., located in Vadodara, is a 100% subsidiary of a German Multinational. We have successfully installed agitators for 700+ biogas plants worldwide and boast over 20 years of experience in the biogas industry. We provide a diverse range of sophisticated agitator types that can be perfectly adapted to the respective task and system size – for optimum yields and maximum operational reliability right from the start. Contact us to find the perfect mix for you.

PRG Agitators Pvt. Ltd.

66 Alindra, Savli GIDC Manjusar Vadodara, 391 775 Gujarat, India

PRG Präzisions-Rührer GmbH

Phone: +91 90999 89907

Email: info@prgagitators.com

Email info@prg-gmbh.de

BIOGAS

Anton-Böhlen-Straße 13 34414 Warburg, Germany

Phone +49 (0) 5641 9006 – 0

WWW. PRG - AGITATo RS . C o M / PRG - I n DIA

Harnessing Microbial Magic:

Transforming Anaerobic Digestate into Premium Compost and Biochaar++

Introduction:

We were looking at the farm yard manure, and it was told that it could fix our soils, but the yields of onions/ chickpeas in Rabi, as well as soybeans in Kharif, did not improve on my farms. So we tested the farm yard manure and it was found that it has just 0.2% N, 0.5% P, and 0.3% K, whereas it was good on microbes and C: N ratio. So, we decided to move into the enrichment of the compost. Actually farmyard manure is collected for over six months, so it never reaches 70 degrees Celsius. Thus, the pathogens and weed seeds are never neutralised. So, we moved to the digestate from the Gobar gas plant in our village and tested its digestate.

Understanding Digestate Composition:

Cow Dung-Based Digestate:

Nitrogen (N): 1-2%

Phosphorus (P): 0.5-1.5%

Potassium (K): 1-2%

Organic Carbon: 20-25%

Paddy Straw-Based Digestate:

Nitrogen (N): 1-4%

Phosphorus (P): 0.5-2%

Potassium (K): 0.5-2.5%

Organic Carbon: 20-40%

Press-Mud-Based Digestate:

Nitrogen: 0.5-0.7%

Phosphorus: 1.5-1.6%

Potassium: 1.42%

Organic Carbon: 20-30%

Challenges in Digestate Composting: Common issues include nutrient imbalances, potential pathogens, weed seeds, and

Biogas Magazine | Edition 27 | 12

odor management. Achieving the correct carbon-to-nitrogen ratio and ensuring proper maturation is crucial. Appropriate monitoring and management practices can address these challenges.

Leveraging Microbial Magic: By understanding microbial composition, maintaining optimal temperatures, and comprehending microbial processes, we can convert anaerobic digestate into premium compost. These factors play a pivotal role in enhancing the composting process and ensuring optimal pH levels for decomposition.

Our Enrichment Process:

Enrichment of SMS (Mushroom Substrates):

Utilizing waste spent mushroom substrate (SMS) in conjunction with microbes to produce high-quality compost has been successful. We are able to elevate its temperature to 70 degrees Celsius within 45 days, resulting in compost readiness within 65 days. We have also enriched biochar with this compost in micronutrients and adjusted the pH of biochar as it is generally north of 8.5. Now, we have successfully got a production facility ready in Maharashtra with around 3,000 tons of SMS-based compost.

Mushroom Substrates Composition:

●Organic materials (straw, hay, corn)

●Nitrogen sources (soybean meal, wheat bran)

●Minerals (gypsum, limestone)

●Water (60-70% moisture content)

●Microorganisms, supplements, and additives

pH Adjustment of Biochar and Compost: Biochar is initially alkaline, with a pH range of 8 to 10. Incorporating biochar into composting processes helps neutralize its pH over time, with compost microorganisms aiding in the breakdown of organic matter. This is very important as most of India's soils are alkaline except in two southern states and North East India. Even for acidic soils of North East India, Kerala, and Tamil Nādu, it needs to suit the requirement; otherwise it attracts heat and may cause crop failure.

Our Enrichment Process: for the AD from press-mud based digestate

Enrichment of AD press-mud CBG (Mushroom Substrates): Utilizing AD from the press−mud based Compressed Biogas (CBG unit) has a few additional challenges; it does not look good to the farmers as vermicompost and SMS-based compost. Its organic carbon is lower than that of other composts. It has lower N but moderate P and K; there are enough micronutrients and we need to enhance the NPK to 1.5-2.5% through NPK enrichment as it is already there.

We also need to add microbes that raise temperatures to 70 degrees Celsius to neutralize pathogens and weed seeds.

Press-mud CBG digestate Composition:

●Organic materials (Sugarcane Feedstock)

●Nitrogen sources (Sugarcane Feedstock)

●Volatile Solid (20%)

●Water (70-80% moisture content)

●Microorganisms, supplements, and additives

pH Adjustment of Biochar and Compost: Biochar used was alkaline with a pH of 8.9. The NH4-OH volatilization affects the N in the AD compost, and we managed it well through our inhouse techniques. Cations in the biochar help the compost manage its acidity as well as alkaline nature by bringing them towards neutral. After these microbial treatments, we brought down the pH of the biochar and compost combination to 6.5 level. We branded this as Biochaar++.

Customized Biochaar++ for Sustainable Growth

With the help of a press-mud CBG plant in the Pune district, we enriched the AD digestate into a compost upto 1.5%, N, 3.5% P and 1.6% K. Raising the temperature through thermophilic bacteria took time and larger quantity, but it worked in combination with our other microbes.

Biogas Magazine | Edition 27 | 13

Customized Biochaar++ is a mixture of Biochar and Compost in such a proportion which understands the specific soil requirements.

Biochaar++ Experiment:

We used this Biochaar++ for the nursery experiment and we are happy to share the results with our readers.

Nursery Experiments - Unveiling the Power of Biochaar++ : Our study took place at Sufalam Nursery, located at 247, Wakad Rd, Kaspate Wasti, Wakad, Pimpri-Chinchwad, Maharashtra, 411057. Here are the noteworthy outcomes:

Results and Discussion:

a. Plant Growth:

●Increased Height: Biochar-treated plants exhibited significant height growth compared to the control group.

●Enhanced Biomass: Biochar positively influenced plant biomass accumulation, fostering healthier and more vigorous plants.

●Improved Leaf Area: Treated plants showcased a larger leaf area, indicative of heightened photosynthetic activity.

b. Root Development:

●Longer Root Length: Biochar presence in nursery soil promoted extensive root development, enhancing nutrient and water uptake.

●Enhanced Root Architecture: Treated plants displayed a more branched and robust root sys-

tem, ensuring superior anchorage and stability.

c. Overall Plant Health:

●Increased Nutrient Availability: Acting as a nutrient reservoir, biochar gradually released nutrients, improving overall nutrient availability.

●Enhanced Water Retention: Biochar addition increased soil water-holding capacity, reducing water stress and enhancing plant resilience.

●Reduced Disease Incidence: Biochar-treated plants exhibited a lower incidence of diseases, suggesting a positive impact on disease resistance.

Customized Biochaar++ from AD from Indian CBG plants:

GK 91 Digital Pvt Ltd introduces a cutting-edge solution to compost making through its experiment at the lab level, then nursery, and finally on 10 acres of the plots in significant crops. The enrichment of the AD is as good as making the compost from any other feedstock. We need to make customized compost for every application, and that’s why enrichment takes time. pH and soil organic carbon of the biochar not only help in N2O emissions but also reduce the NH3 volatilization by 6080%. This is the most important factor for blending the biochar with the compost made from

anaerobic digestate. Today, GK 91 Digital Pvt Ltd, listed as the most innovative agritech startup in G-20 in September 2023 in the G-20 communique, is working on the customization of Biochaar++, designed to meet the unique soil characteristics of each taluka. Key benefits of Biochaar++ include:

● Overall Plant Health Improvement: Formulated to enhance plant health, promoting better growth, increased disease resistance, and improved nutrient absorption.

●Increased Water Holding Capacity: Aims to boost soil's water retention capabilities, crucial for plant support in regions with limited water availability.

●Stable Organic Carbon: Biochaar++ provides stable organic carbon, persisting in the soil for an extended period, contributing to long-term soil health and fertility.

●Long-lasting Impact: With organic carbon claimed to remain in the soil for over 300 years, this product promises sustained benefits for agricultural productivity.

Biogas Magazine | Edition 27 | 14

Prasad Dahapute Chief Executive Officer GK 91 Digital Pvt. Ltd.

Ghaziabad (NCR) Factory “Deepmala”Plot No: A-16/26, Sahibabad Industrial Area, Site –IV, Ghaziabad-201010, (UP) (India) (India)

In conversation with Dr. P. Shanmugam

Dr. P. Shanmugam

Chief Scientist & Commonwealth Fellow

Head, Enviromental Sciences Department

CSIR-Central Leather Research Institute

Dr. Shanmugam Palaniyandi working as Chief Scientist and HoD in The Environmental Dept of CSIR-CENTRAL LEATHER RESEARCH INSTITUTE, Chennai. He did both his Masters and PhD thesis from IIT Madras and Leeds University England UK on Biogas and Biohydrogen technology that has brought him as an international expert on BioCNG with enriched biomanure and advanced gas separations. He has been Senior level Scientist in CSIR for the past 31 years and contributed in developing and dessiminating innovative Biorefinary Technology for the sequential production of Bio-diesel bio-ethanol, bio-hydrogen and bio-methane using urban and industrial organic solid wastes.

1. You are one of the most prominent and experienced biogas experts. How do you see future energy production connected to anaerobic microbes?

Perhaps this will be one of the unique energy alternatives for India, particularly the biogas sector, which will boom like anything for the next 10 to 15 years. The major achievement will be through microbes specific to enhanced biogas production because people have done wonderful research worldwide on which microbes can give the maximum biogas production. So,we have been well aware of

what microbes the anaerobic digester needs to be acclimatized to enhance biogas production. It will indeed be the best boom in this era of biogas, using specific microbes for a specific substrate. This means some people use Napier grass, mixed vegetable market complex waste, biomass, leather solid waste, tannery solid waste, slaughterhouse waste, and paper and pulp. All this waste material needs specific microbes based on what is the substrate composed of. So the future is going to be bright because we have been able to develop microbes based on various substrates. For each type

of waste, you need separate microbes, so it is going to be fetching the Indian Biogas Market based on the specificity of the microbes to the specificity of the substrate.

2. What have been the key drivers of growth for the bioenergy segment?

●Source segregation of waste: For the key drivers for the bioenergy sector in the future, the primary driver is going to be source segregation of the waste. The organic waste needs to be segregated at the source, not only in household dwellers but also in the market areas where the veg-

Biogas Magazine | Edition 27 | 16

etable market complex waste needs to be segregated into biodegradable and non-biodegradable waste. So, according to me, the per capita solid waste generation in major metropolitan cities is approximately 400 grams per person per day, out of which 200 grams is the organic fraction of municipal solid waste. So 400 grams is the general municipal solid waste which contains plastic, rags, clothes, and many other materials, out of which 200 grams is the average organic fraction of municipal solid waste that is potentially available for producing biogas. So in a nutshell, there are 200 grams per person per day of the organic fraction of municipal solid waste which could be available for the production of biogas.

●Opting for a decentralized biogas plant or a centralized biogas plant: That is one of the significant decisions that we need to make; wherever it is not possible to go for a centralized biogas plant, we can have community digesters in a small community biogas plant we can have a domestic biogas plant because every household people who are located very remotely have got lot of organic waste being generated every day like a small household reverse osmosis plant for purifying the water. There could be a small domestic biogas digester for converting the household organic fraction of municipal solid waste into biogas, and this will enhance or boost the biogas industry in a decentralized way.

●Selecting an appropriate engineering design of the technology: In a centralized concept, in all cities like Indore, Bathinda, or Chennai, there are 100 tons

per day bio CNG plants available. All these biogas digesters were set up by people who feel biogas digesters came from the Gobar gas plant, but there has been adequate technology, and maturity has been attained. Still people are not using the matured technologies. People need to gain adequate knowledge of what kind of engineering design technology needs to be implemented. Because the gobar gas plant is a primitive technology. It produces around 20 m3/30 m3/40 m3 per ton of waste. But what the Indian entrepreneurs of the biogas industry feel if my digester produces around 30 m3/40 m3 per ton, the biogas is produced but not at the efficiency of what it's supposed to produce. Hence, the appropriate engineering design comes into the picture.

● Promoting “Make in India” for enhanced design engineering: Upon visiting several European countries and the Biogas Associations in Europe, I realized they also have an engineering design. Still, there are a lot of digesters branded with their name. BIMA Digester is from Austria, Linde Digester is from Germany, and the Slambi digester is from the UK. In India, we should have our Indian-branded digesters and thus promote the make-in-India concept to further develop the biogas industry. This needs to be prioritized as there are still a lot of Indian entrepreneurs looking for the European biogas industry, German or many other countries’ biogas technology which we don't need to opt for.

India has achieved excellence for the past 7 to 8 years. India has gone well ahead of the technology revolution, particularly bio-

gas technology. So, I have been coordinating with the MNRE and with the BIS. Recently, we have developed Indian biogas standards for the Bureau of Indian Standards. I have been one of the core members of that. Hence, we need to adopt better design. It needs to be based on what substrate we are going to select. If there is a very high fatrich waste, particularly slaughterhouse waste and tannery waste, it will be different, and if there is only carbohydrate-rich waste, like sugarcane waste, molasses, distilleries, or breweries, the design has to be different.

●Technology Selection and Adoption: In India, the PPP (Polluters Pay Principle) was primitive long back. From the PPP we came to Public Private Partnership. All the solid and liquid waste was managed through the Polluters Pay Principle, further, the second stage of achievement for the biogas sector was the Public Private Partnership.

The biogas industry came forward to invest money in themselves. In doing so, they realized it had a payback period of 2/3/4 years. Thus Polluters Pay Principle evolved as Public Private Partnership. Most of the municipalities and corporations could not deliver the designed capacity of the feedstock because of overestimated designs and Pre-feasibility studies at the beginning which became a bottleneck. But the third stage of PPP is Profitability Preventing Pollution. Hence, all the solid and liquid waste people are in a dilemma whether to go for briquetting, composting, landfilling, micro composting, mechanical biological treatment, windrow composting, or to

Biogas Magazine | Edition 27 | 17

come and fetch revenue from a biogas plant.

Most of the municipalities and corporations in India have adopted microcomposting technology for organic solid waste. If we look at the European hierarchy of solid waste management, initially, Europe came forward for landfill diversification, where all the organic waste was discouraged from going into the landfill as the landfill emits a lot of CO2 and other pollutants. The second act they enacted was the Landfill Tax Escalation Act. If any waste was to go into the landfill, they started taxing people on a per Kg basis. The third strategy Europe went into was the Bioenergy Strategy. The fourth strategy was the “White Energy Strategy”.

The fifth strategy was the Renewable Obligation Certificate. This is the recent strategy the European Government has gone into. The Indian Government should formulate similar strategies. Currently, we are in Bharat Stage VI in controlling air pollution. All these Bharat Stages came from European norms of Euro IV, Euro V, Euro VI, and so on. We did not adopt 100% of the Euro norms but adopted partially and modified them according to the Indian context for controlling air pollution. Likewise, we should also develop a strategic plan for the GOI on what should be the roadmap for the next ten years for white energy, green energy, and renewable energy obligation certificates.

● CO2 Mitigation Potential by Implementing Biogas and Carbon Credit-Based Biogas Tech Enhancement: How we will

tackle the biogas industry in managing the waste as we all have a determined quantity of CO2 to be emitted. COP-28 could partially fix a determined quantity of CO2 to be emitted for every country. If we go for landfill technology, micro composting, or if we go for anything else other than biogas technology, we will not be able to achieve the determined quantity of CO2 mitigation potential.

Therefore, the biogas industry needs to be projected so that it has a great potential to control CO2. It has a good potential of determining and achieving the determined quantity of CO2 mitigation, particularly that can be claimed in the Conference of Parties, going to be in 2028. So there has to be a national mandate. We all have to get to the national mandate on the CO2 mitigation potential of implementing Biogas. Way back in 2009, there was the first plant that we implemented, and at that time, a nature journal stated that the biogas plant is not only implemented to produce power or only to produce bio CNG, but the major mandate of implementation of the biogas plant is to mitigate the CO2 emission, and to mitigate the global warming potential, also to mitigate the groundwater contamination upon open dumping.

Also, it is to mitigate the diseases spread across the country through open dumping and rain, and the spread of diseases biogas is one of the major sources of revenue that we could achieve from there. But at the same time, there can be zero carbon emission and a carbon neutral technology. There can be a huge carbon footprint can

be achieved Through carbon banking because, in today's era, every industry and every municipality has been asked to make a Carbon Stock Exchange, a carbon stock assessment of how much the carbon stock as of today and what is the possibility of exchanging carbon credits with other. The biogas industry has a high potential for high-carbon banking and carbon credits, so this should be encouraged.

3. Do you have a favorite ‘pet’ microbe?

We do have the best microbes for leather solid waste, municipal solid waste, and vegetable market complex waste. So for all these three, we have specific bugs which are multi-consortia bugs, it's multi-organisms, it's a consortium of bugs. If the biogas needs to be produced exorbitantly very high, the seed sludge needs to be very good at the beginning of the digested planning, trial run, and commissioning and at that stage itself, there is less possibility of failure of the digester. Because the initial seed inoculum that is being fed into the digester is multiplied, the organism become very predominant in the entire digester. It does not allow the harmful organisms to grow there.

Therefore, for the long-term achievement of the biogas industry, the major bottleneck is identifying the microbial predominance demand for each solid waste because we have our protocol to choose the seed sludge. Because this is what in my past 32 years of biogas industry experience, we gained. If you give us the waste, I'll give you which microbes are suitable because I have a protocol to un-

Biogas Magazine | Edition 27 | 18

dertake in the laboratory a series of studies in which microbes have survived to produce more biogas. I have a protocol, and the protocol is called biochemical Methane Potential evaluation at various substrate ratios and mixing ratios. Then finally, I find out what is the quantity of the microbes. Which types of microbes are essential to maximize the biogas yield? You provide me with the waste, and I shall develop and suggest which microbes would be the best and develop it in a seed inoculum for ensured gas production based on the microbes that I am going to identify, inoculate, develop, and increase the culture and population and that will be the best for your waste material.

Failing to do this is the major cause of the failure of the digesters, because they do not put the right microbial consortia at the beginning, and they do not study intensively, at least for a period of two to three months. Considering the primary composition of vegetable waste, the eating bacteria needs to be promoted and enhanced. Hence, instead of looking at the very accurate chemical composition of the waste, what we look into, is the protein content of the waste, fat content of the waste, and carbohydrate content of the waste.

Hydrolysis is the major bottleneck to achieving efficient methanogenesis in the biogas industry. So how can abreast hydrolysis be achieved? Nowadays, so many instruments are used to bring down the size of the solid waste into a bacterial-eatable size. Suppose we develop a lot of enzymes, the enzyme can take care of the hydrolysis

process of converting the solid waste into volatile fatty acid, which becomes a soluble substrate for the bacteria. Based on the protein, carbohydrate, and fat composition, if the waste is slaughterhouse industry waste, it will have 90% fat content. And in there, if there are carbohydrate-eating bacteria because the waste is a fat, it doesn't have carbohydrates. How do carbohydrate-eating bacteria survive in slaughterhouse waste? Hence, this needs to be adequately addressed to the biogas entrepreneurs.

4. How can the industry-institute interface (triple I) play a big role in India?

The biogas industry needs to be promoted, and the institute could be an academic, Research Institute, or private enterprising institute. However, it should be exclusively an expertise institute on biogas for patent interests. Because you have a lot of institute industry interactions and institute industry collaboration, if you can promote in the regional side of the East, West, North, and South and develop a consortium of industries and have a partnership in institute, Because that was recently I mentioned to one of the government officers and said that we need to make biogas training centers in North, South, East, and West that can be connected to institutes like academic institutes, Research Institute. Because most of the analysis, process evaluation, and microbial analysis may not be available to the biogas entrepreneurs. They can partner with the government institute, and that partnership can have a memorandum of understanding and a demo. This institute will have a

biogas industry partnership and help the biogas industry with design, commission, execution, or whatever their expertise is. So if they want exclusively biogas purification some other institute can have a partnership with the biogas industry. Therefore, we need to promote the industry institute partnership for the growth of biogas particularly in all four regions we need to develop.

5. You are vocal about ancient Indian science and its relevance today. Please let our readers also know something about it.

There is Vedic science and Vedic mantras. India is traditionally the hub of the herbal pharmacy. I would like to reiterate this particular statement. Because India is the world's pioneer in the biogas industry. Also, the biogas industry was invented in 1938 at Nasik. For the world, the biogas industry was given by India. Afterward, it was adopted and was practiced very successfully elsewhere.

My purpose in saying the computer was invented in America, and India has excelled well in computers. Cricket was invented in the UK, but India has excelled in cricket. Biogas was invented in India, but European countries have also excelled in biogas. The inventors need to be the followers and practitioners. But why do I emphasize this particular thing? Biogas also reasonably prevents a lot of diseases in the human system. In the olden times, people used cow dung to produce biogas and utilize it in their own homes. Because all the other gases and fuels have sulfur and lead in them. But in biogas, there is no sulfur and

Biogas Magazine | Edition 27 | 19

lead, which can produce sulfur dioxide and create a lot of respiratory diseases. In ancient times, biogas was one of the healthiest gases for cooking for every purpose. At that time microbes were not talked about. But as scientists what I would like to emphasize here, particularly on the biogas, is whatever practice we are reinventing on this biogas technology, the ancestors have done excellent in that during those days. The ancestors have made an excellent practice of this biogas technology. We are only reinventing, and we are just resizing and reinventing the entire technology. So the ancient practice of this is naturally nature dependent.

For a biogas plant to thrive, we need anaerobic conditions. In anaerobic conditions where there is no air, it can only be beneath the earth in those days because that is where the concept of biogas emerged. They just dig out and put all these waste material and create the kind of a digester and develop piping from the digester, and that is what the gas comes into the houses and they were cooking, when there was no LPG, no diesel, or no petrol.

Biogas was used as one of the best fuel in those days. That is why we have failed to practice those a little bit, and now it has come in a very sophisticated way. But I feel all the rural sectors have understood the ancient way of practicing this.

Biogas is also going to protect their health from sulfur dioxide, lead pollutants, and other other concepts. Therefore the ancient practice will be practiced as early as possible because our

country performed so well in the world on giving yoga as the practice for good health management. In the same way, biogas is also going to make it for domestic health management in the future. That is why the ancient practice is always a golden practice, which is going to be practiced very soon by our government because the government’s vision also matches the ancient practice and brings the modern practice together, making it a best practice in the country.

6. What estimations do you have for 2047 if we consider biogas in the whole energy basket?

You would have seen India Energy Week happened in Goa in First week of February and we had Bangalore Energy Week inaugurated by our honorable Prime Minister because the Energy Week itself predicted a huge potential for the biogas. Our government has a determined target for what is to be achieved in 2030, 2025, and 2047. The mandate of the government is planned so nicely to achieve 31 million tons of biogas per day in the year 2047 only from managing the municipal organic solid waste. Beyond that, there is industrial organic solid waste.

There are pharmaceutical, leather, slaughterhouse, food, hotel, market, and vegetable complex waste industries. Likewise, there is tenfold more municipal solid waste than this municipal solid waste, which is something like 300 million tonnes of biogas/ bio CNG potential we will be able to achieve in the year 2047. Therefore that will be our Golden Jubilee celebration period to

make it a minimum of 300 million tonnes of biogas/Bio CNG considering the industry waste, hotel and food waste and all organic wastes put together as of today.

Biogas Magazine | Edition 27 | 20

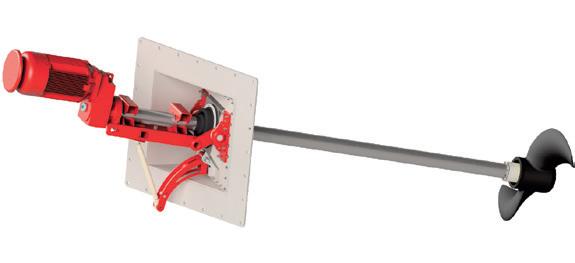

Agriculture,biogas,sewageandwastewater,andindustrialapplications

ArmaMixTWIN

Theultimateinceiling installation

Slowspeeds,highcirculation capacityandlongservicelife STIRRING-PUMPING-MOVING-ANDMORE

ArmaMixEVO+ Slow-runninglong-shaft agitatorfordrysubstrate contentsofupto15%. ArmaMixEVO

Differentcomponentsforyoursystem

ARMATEC-INDIAPVTLTD

G1,Sairesidency, Plotnumber45, srinivasnagarcolony, Nizampet, Hyderabad-500090

Agricultural,biogas,sewageandwaste waterandindustrialapplications

VijaykumarLanka

Mob:00918919532349

vijayklanka@armatec-fts.de www.armatec-fts.com

Biogas Magazine | Edition 27 | 21

ARMATEC-FTS.COM/EN Designed, developed and made in Germany

Enhancing Crop Yield and Soil Health

Through Gobargas-Slurry and SuDhan Fertilisers:

Introduction

NDDB Mrida Ltd., a wholly owned subsidiary of NDDB works to scale up and establishing a commercially sustainable ‘Manure Value Chain’ across the country. Under which Gobargas digested slurry is separated into solid and liquid form to make fertiliser and growth promoters. From solid, organic fertiliser PROM (Phosphate Rich Organic Manure) and liquid growth promoter products i.e. Root Guard, MRL (Micro Nutrient Rich Liquid) and GroMax are made and sold to the farmers under the brand name “SuDhan”. While promoting the direct use of slurry in the field, there was a need to demonstrate the combined benefits of slurry and SuDhan fertilisers to farmers. Keeping this in view a comprehensive study was conducted with the support of Sustain Plus Energy Foundation- an organization established by TATA Trust to determine the combined effects of gobargas-slurry and gobargas slurry-based “SuDhan” organic fertilisers on the yield of different crops.

Objectives:

•To examine the combined effects of Gobargas-slurry and SuDhan fertilisers on crop yield and cultivation costs at farmers' fields.

•To evaluate the impact of the slurry application on soil, followed by the application of recommended slurry-based fertilisers.

•To demonstrate the use of Go-

bargas-slurry and Slurry Applicator in the field.

Methodology

The study was initiated in the Rabi season of 2022-23, starting in November 2022 and continuing until March 2023. Gobargas-slurry (ranging from 3000-4000 litres/bigha, 1 Bigha = 2200 m2 depending on the crop; and SuDhan products were applied in the land of 100 farmers (70 plots in Anand and 30 plots in Ranchi), covering a total land area of 84.4 Bighas. Control plots were identified for comparison, where farmers followed their practices without applying gobargas-slurry or SuDhan products. The impact was assessed based on the total crop yield and changes in soil parameters, including EC, pH, total organic carbon, available nitrogen, available phosphorus, and available potassium, measured before slurry application and after har-

vesting.

Disclaimer: The application of organic materials to soil has both immediate (1 crop cycle) and long-term (3-4 crop cycles) effects, particularly on soils lacking sufficient organic carbon and available nutrients. High-quality organics like "SuDhan" fertilisers, made from gobargas slurry, not only provide essential nutrients but also improve soil properties, facilitating rapid nutrient uptake by plants and reducing nutrients losses.

The present study also utilized various organic inputs, such as PROM, biogas slurry, enriched bio-liquid, seaweed extract, and micronutrients besides gobargas slurry, to promote root and plant growth and supplement micronutrients through foliar application. "SuDhan" organic fertilisers showed immediate benefits on crops.

With prolonged use of these fertilisers, it is expected to further enhance crop growth, yield, and soil quality.

Results and Discussion

The yield of different crops with inputs of Gobargas-slurry and SuDhan products was compared to the average yield of control plots where general farm practices with conventional chemical fertilisers were followed and no Gobargas-slurry or SuDhan products were applied.

Biogas Magazine | Edition 27 | 22

Data on crop yield were grouped into categories such as cereals, vegetables, pulses, fruits and other crops. Crop yield data were measured in metric tons (MT), and the area was measured in Bighas.

The data presented in the below table revealed an increase in yield ranging from 13.49% to 39.27% for cereals, 8.04% to 37.50% for pulses, 9.05% to 19.35% for cash crops, 14.17% to 43.33% for fruits, and 0.79%

to 50.42% for vegetables. These results encouraged farmers at both locations to adopt gobargas-slurry and SuDhan fertilisers, paving the way for establishing the 'Gobargas-slurry Application as a Service (BAAS)' model.

Biogas Magazine | Edition 27 | 23

SN Crop Yield (MT/Bigha) Increase in yield over without Gobargas slurry & SuDhan (%) General farm practices (without Gobargas-slurry & SuDhan) With Gobargas-slurry & SuDhan Organic Fertilisers

1 Sorghum (Fodder) 1.76 2.89 39.27 2 Wheat 0.98 1.12 16.49 3 Maize (Cob) 1.06 1.66 23.33 4 Bajra 1.09 1.28 14.94 5 Sweet Corn 2.33 3.00 13.49 Vegetables 6 Cabbage 6.34 7.61 16.36 7 Chilli 1.46 1.81 20.55 8 Cucumber 3.95 7.96 50.42 9 Coriander 2.46 2.58 0.05 10 Potato 12.64 12.74 0.79 11 Okra 0.93 1.08 13.51 12 Brinjal 2.63 3.06 15.47 13 Capsicum 0.96 1.42 32.57 Pulses 14 French Bean 1.55 1.69 8.04 15 Mung Bean 0.54 0.70 17.58 16 Pea 0.54 0.87 37.50 Fruits 17 Water melon 7.0 8.16 14.22 18 Mango 0.92 1.63 43.33 Others 19 Tobacco 0.25 0.31 19.35 20 Napier Grass 395.49 434.85 9.05

Cereals

Table 1 Impact of Gobargas-slurry and SuDhan Fertilisers on different crops

Soil Characteristics

The findings for soil samples from different tehsils of Anand district presented in Table 2 demonstrate enhancements in soil attributes, specifically the

increased presence of important nutrients, such as nitrogen (N) and phosphorus (P2O5) and potash (K2O) due to slurry application. Additionally, there was a rise in soil organic carbon content at post-harvest. More-

over, the application of gobar gas slurry was observed to have a favorable impact on soil pH, while also effectively mitigating the buildup of soluble salts (EC).

Biogas Magazine | Edition 27 | 24

Soil properties OC % N (kg/ha) P2O5(kg/ha) K2O (kg/ha) pH (1:2.5) EC (dSm-1) B.C A.C B.C A.C B.C A.C B.C A.C B.C A.C B.C A.C Wheat 0.61 0.61 217.3 204.3 26.4 73.3 173 309 7.77 7.88 0.16 0.20 Tobacco 0.58 0.54 137.0 137.0 29.0 62.0 255 417 7.62 7.38 0.12 0.16 Sorghum (F) 0.53 0.63 226.0 213.0 71.5 86.5 439 509 7.86 7.75 0.18 0.10 Potato 0.61 0.54 225.0 238.0 68.3 125.0 562 638 7.60 7.78 0.20 0.19 Okra 0.59 0.76 188.5 181.5 31.5 69.5 416 708 7.93 7.33 0.10 0.11 Napier Grass 0.72 0.62 225.3 219.0 81.3 65.0 300 381 7.67 8.03 0.16 0.17 Mustard 0.72 0.76 213.2 188.0 52.0 55.0 336 320 7.79 7.08 0.11 0.25 Maize 0.34 0.53 269.5 257.0 46.0 53.0 339 421 8.19 7.84 0.23 0.28 Mung 0.30 0.54 301.0 301.0 58.0 63.0 451 565 8.04 7.76 0.27 0.12 Ivy Gourd 0.58 0.87 200.7 200.0 29.2 26.0 168 297 8.19 8.47 0.12 0.18 Fenugreek 0.69 0.79 175.6 200.0 67.3 43.0 255 383 8.14 7.62 0.11 0.19 Cabbage 0.67 0.81 163.0 150.0 65.7 28.0 339 266 8.02 7.19 0.09 0.09 Coriander 0.57 0.62 207.0 232.6 83.2 91.2 466 674 8.05 7.86 0.23 0.16 Bajra 0.48 0.54 252.1 256.5 69.0 71.4 488 595 7.92 7.91 0.29 0.25 Average 0.5 0.6 238.4 237.9 68.1 70.4 356 463 7.90 7.80 0.30 0.20 B.C= Before Crop A.C= After Crop pH is measured using 1:2.5 soil to water dilution ratio

Table 2 Effect of Gobargas Slurry Application on Changes in Important Soil Properties in Different Crops (Anand District)

Likewise in Ranchi district the findings demonstrate some increase in soil attributes, specifically the nutrient, such as phosphorus (P2O5) beside OC at post-harvest. The meager re-

duction in available nitrogen and potassium could be attributed to the luxury consumption of these nutrients especially by vegetables. Moreover, the application of gobargas slurry was observed

to have a somewhat favorable impact on soil pH.

These overall results indicated about the beneficial effect of use of the gobargas slurry and SuDhan products on soil health.

Biogas Magazine | Edition 27 | 26

Table 3 Effect of Gobargas Slurry Application on Changes in Important Soil Properties in Different Crops (Ranchi District)

Soil properties OC % N (kg/ha) P2O5 (kg/ha) K2O (kg/ha) pH (1:2.5) EC(dSm-1) Crop B.C A.C B.C A.C B.C A.C B.C A.C B.C A.C B.C A.C Cabbage 0.92 0.78 220 187 88 156 425 313 3.48 3.84 0.11 0.17 Capsicum 0.95 0.78 213 225 35 40 369 400 4.12 3.93 0.05 0.05 Chilli 0.63 0.73 192 220 119 112 306 411 4.26 4.14 0.11 0.15 Bitter Gourd 0.96 0.83 176 137 64 86 381 276 4.18 4.16 0.16 0.13 Sweet Corn 0.69 0.68 192 196 111 87 424 351 4.39 4.02 0.08 0.11 Watermelon 0.63 0.81 188 150 133 162 299 255 4.32 3.92 0.1 0.13 Cucumber 0.63 0.63 183 179 90 120 327 369 4.73 4.47 0.18 0.13 French Bean 0.54 0.57 188 225 32 99 343 370 4.06 4.09 0.05 0.06 Peas 0.67 0.81 175 200 195 96 333 295 4.06 4.07 0.16 0.13 Brinjal 0.59 0.81 238 182 94 97 267 380 4.29 4.73 0.16 0.19 Mango 0.46 0.82 163 188 93 119 249 279 4.31 5.57 0.06 0.09 Cauliflower 0.43 0.69 200 187 150 145 270 239 4.17 4.22 0.09 0.13 Average 0.68 0.75 194 190 100 110 333 328 4.20 4.26 0.11 0.12

B.C=Before Crop A.C= After Crop pH is measured using 1:2.5 soil to water dilution ratio

Economics

Anand District

The findings in Table 4 demonstrated an average yield improvement of approximately 14% compared to traditional farming practices when farmers employed organic materials such as FYM and chemical fertilisers like urea and DAP for crop production.

On average, the monetary benefits resulting from increased crop yield and reduced fertiliser expenses, as compared to not using gobargas-slurry and SuDhan products, were Rs 6644 and Rs 1890 per bigha, respectively. The average overall monetary gain per bigha was Rs 8534. The data also highlighted that mung crops yielded the highest mon-

etary benefit at Rs 16975 per bigha, while tobacco had the lowest at Rs 3885 per bigha, as detailed in Table 9.

Note: The data on yield and input cost due to fertilisers are considered for the complete information under different treatments.

Biogas Magazine | Edition 27 | 27

Crop Yield w/o organics (kg) Yield with organics (kg) Increase over w/o organics (kg) Increase over w/o organics (%) Price (Rs./ qtl) Benefit in yield increase over w/o organics (Rs.) Fert Cost with organics (Rs.) Fert Cost w/o organics (Rs.) Benefit in Fert Cost over w/o organics (Rs.) Total monetary Benefit over w/o organics (Rs.) Potato 12640 12740 100 0.79 1500 1500 6705 9320 2615 4115 Coriander (leaves) 2460 2580 120 0.05 8000 9600 5779 6870 1091 10691 Tobacco 250 310 60 19.35 6250 3750 7145 7280 135 3885 Wheat 980 1120 140 16.49 2125 2975 5742 8527 2785 5760 Maize 1060 1660 600 23.33 2090 12540 5190 6320 1130 13670 Okra 930 1080 150 13.51 4000 6000 8070 9960 1890 7890 Mung 540 700 160 17.58 8000 12800 4545 8720 4175 16975 Bajra 1090 1280 190 14.94 2100 3990 5211 6507 1296 5286 Average 2494 2684 190 13.26 4258 6644 6048 7938 1890 8534

Table 4 Effect of gobargas-slurry and SuDhan products application on yield and economics of different crops (per bigha)

Ranchi District

The data presented in Table 5 demonstrated an average yield improvement of approximately 24 percent compared to traditional farming practices. On average, the monetary benefits resulting from increased crop yield and reduced fertiliser expenses,

as compared to not using gobargas-slurry and SuDhan products, were Rs 16022 and Rs 7678 per bigha, respectively. The average overall monetary gain per bigha was Rs 17070. The data also highlighted that cucumber crops yielded the highest monetary benefit at Rs 51338 per bigha, while French bean had the low-

est at Rs 3615 per bigha, as detailed in Table 5.

In summary, the economic analysis favoured the use of gobargas-slurry and SuDhan organic products over chemical fertilisers in farmers' fields.

Biogas Magazine | Edition 27 | 28 Crop Yield w/o organics (kg) Yield with organics (kg) Increase over w/o organics (kg) Increase over w/o organics (%) Price (Rs/qtl) Benefit in yield increase over w/o organics (Rs.) Fert Cost with organics (Rs.) Fert Cost w/o organics (Rs.) Benefit in Fert Cost over w/o organics (Rs.) Total monetary Benefit over w/o organics (Rs.) Brinjal 2630 3060 430 15.47 4500 19350 6148 5001 -1147 18203 Cabbage 6340 7610 1270 16.36 800 10160 7326 14208 6882 17042 Capsicum 960 1420 460 32.57 3500 16100 10515 16374 5859 21959 Chilli 1460 1810 350 20.55 5000 17500 9582 9549 -33 17467 Cucumber 3950 7960 4010 50.42 1300 52130 5141 4349 -792 51338 Frenchbean 1550 1690 140 8.04 4000 5600 9432 7447 -1985 3615 Peas 540 870 330 37.50 3500 11550 8486 10356 1870 13420 Sweet corn 2330 3000 670 21.64 1400 9380 7574 7274 -300 9080 Water melon 7000 8155 1155 14.22 1050 12128 4898 3982 -916 11212 Average 2973 3953 979 24.09 2783 17100 7678 8727 1049 18148

Table 5 Effect of gobargas-slurry and SuDhan products application on yield and economics of different crops (per bigha)

Conclusion

The findings highlight the significant positive impact of gobargas-slurry and SuDhan fertilisers on crop yield and soil health in farmer's fields. With yield increases ranging from 8% to 50%

across different crop categories, and improvements in soil parameters such as nitrogen, phosphorus, potassium, and pH, the study emphasizes the importance of adopting slurry based organic inputs for sustainable agriculture. These results en-

courage farmers to consider the use of gobargas-slurry and SuDhan fertilisers, paving the way for enhanced productivity and soil sustainability in agricultural landscapes.

Biogas Magazine | Edition 27 | 29

Figure 1: Effect of Bio-slurry and SuDhan fertilisers on French bean crop and economics of different crops (per bigha)

Figure 2: Effect of Bio-slurry and SuDhan fertilisers on Sweet corn crop

Dr. K. P. Patel Advisor NDDB Ms. Jinny Macwan Project Executive NDDB Dr. Chandrashekhar Dakhole Chief Marketing Officer NDDB Mrida Ltd. Dharmendra Kumar Program Manager Sustain Plus Energy Foundation

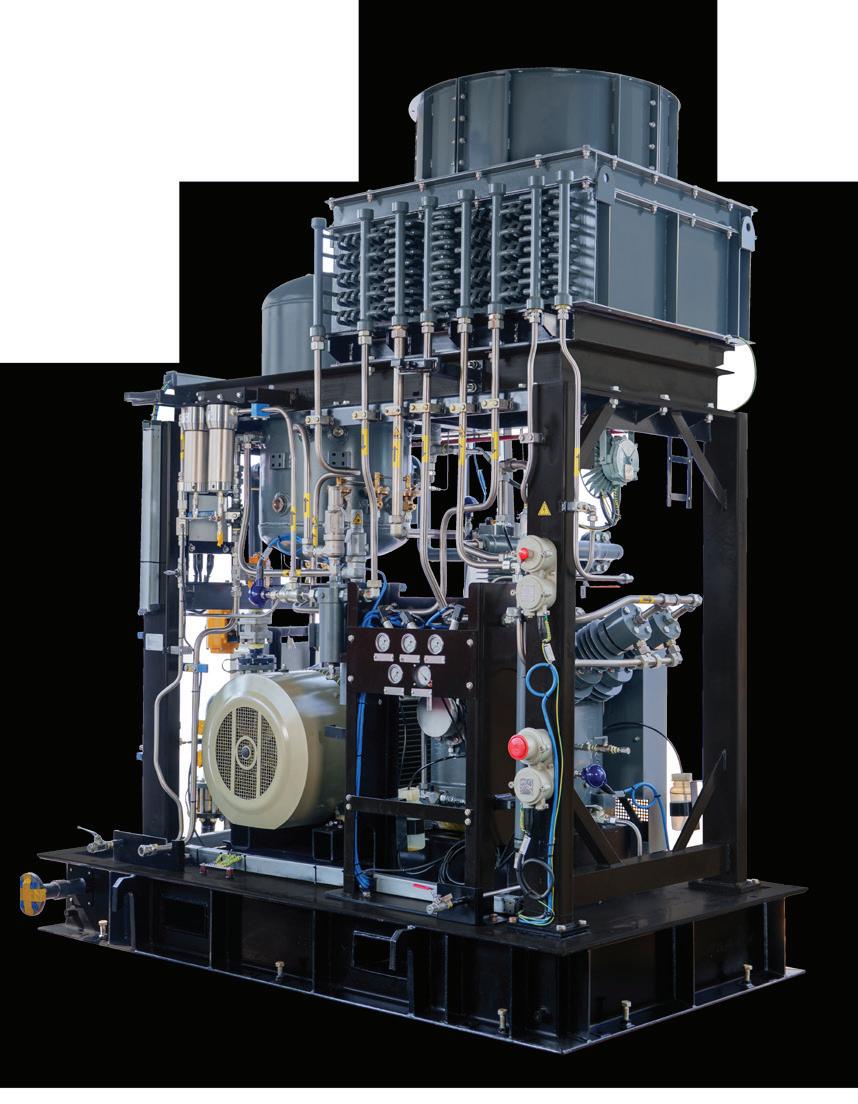

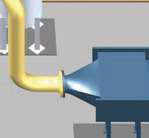

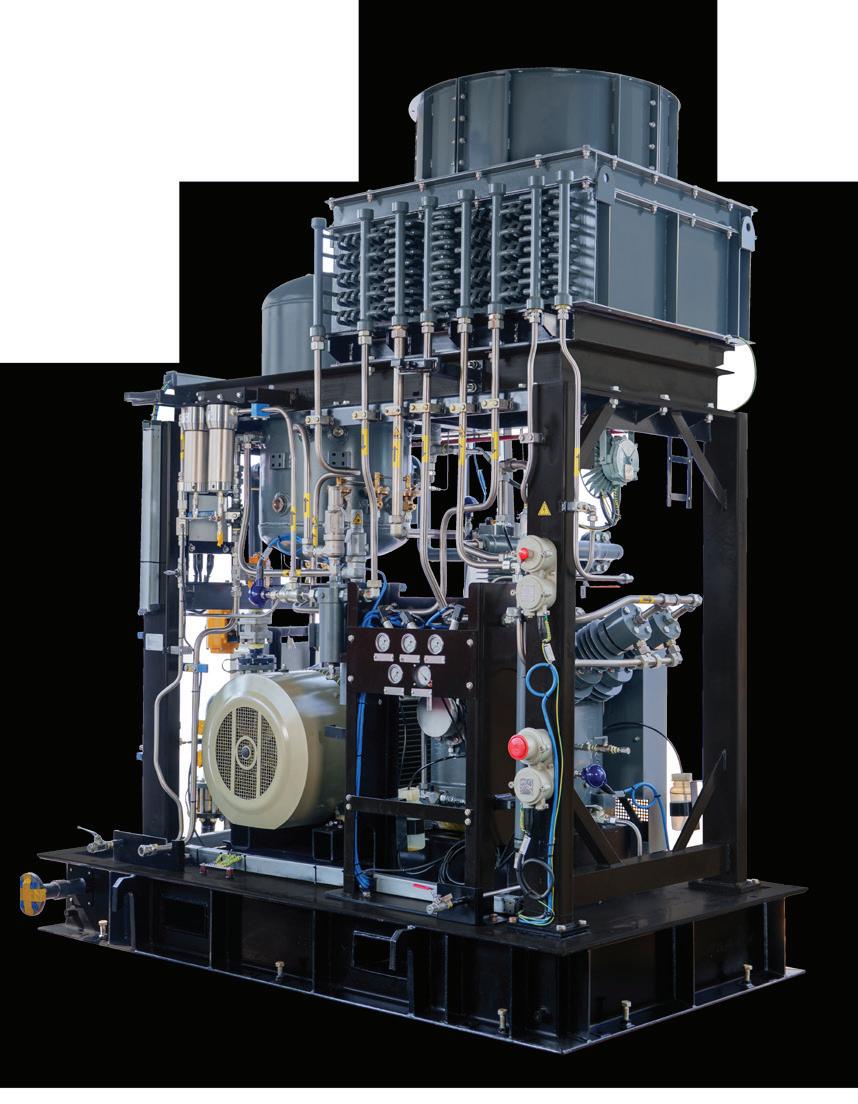

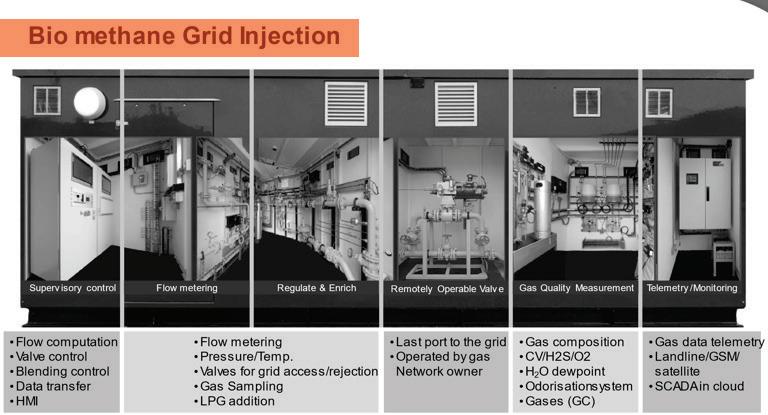

Biogas:

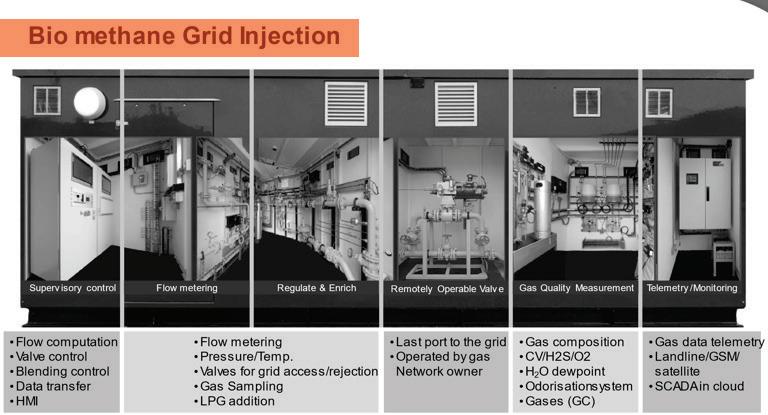

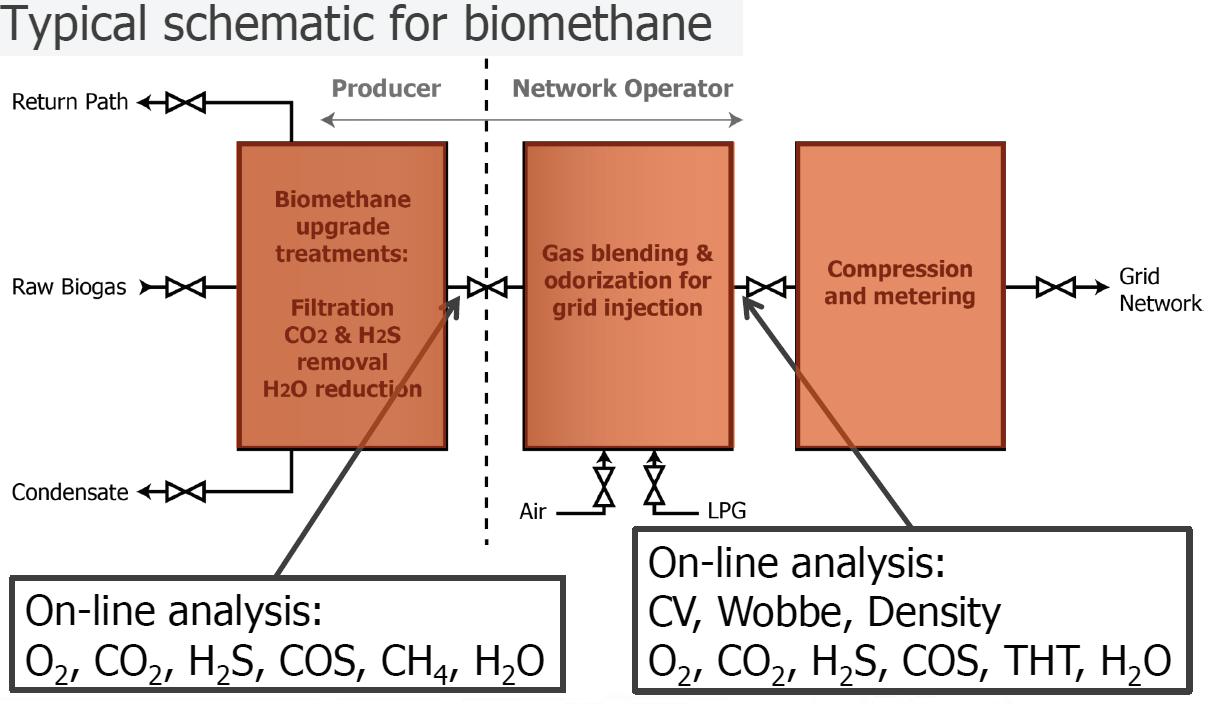

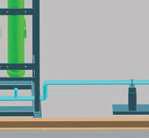

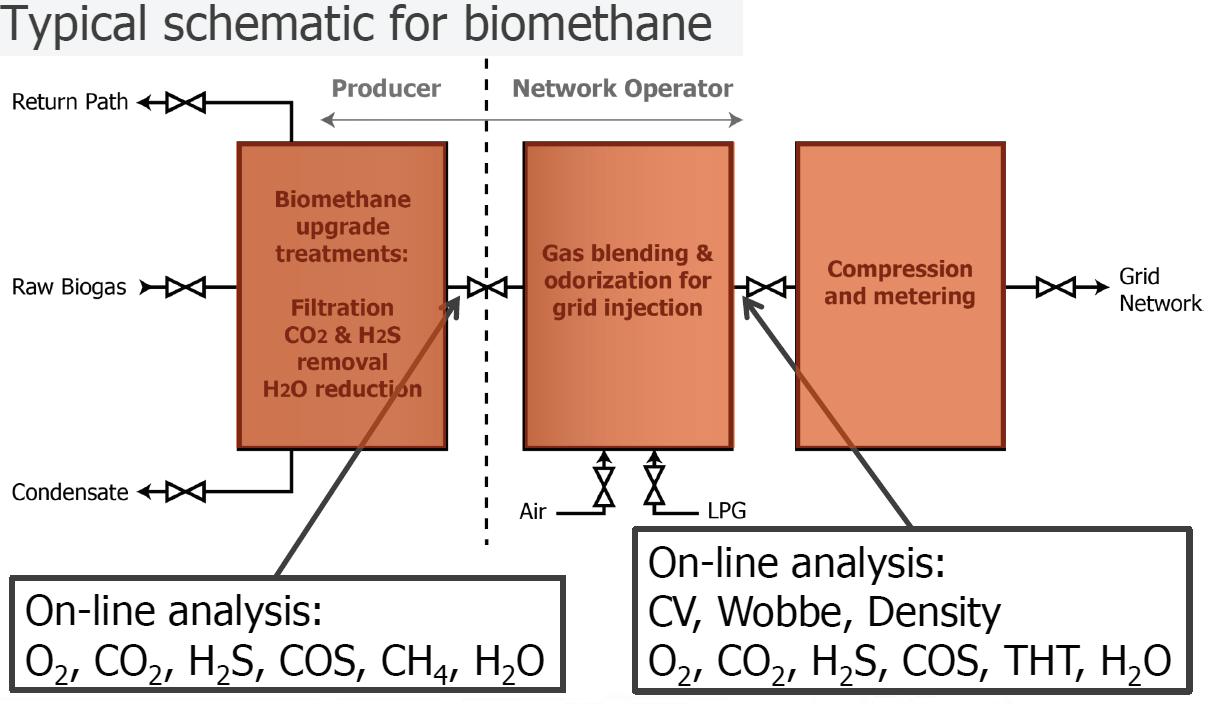

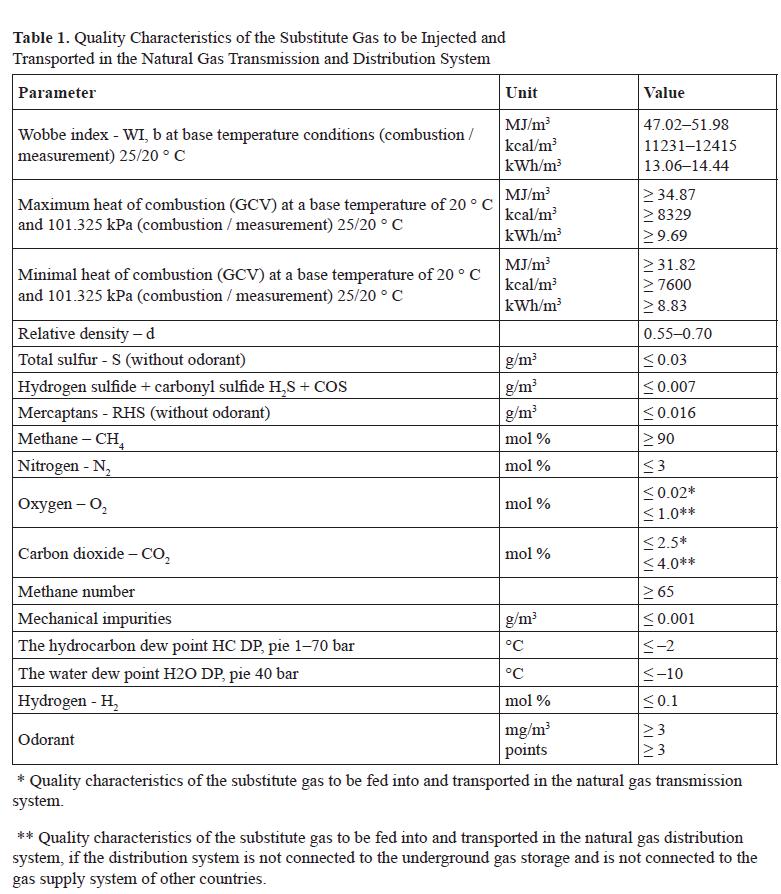

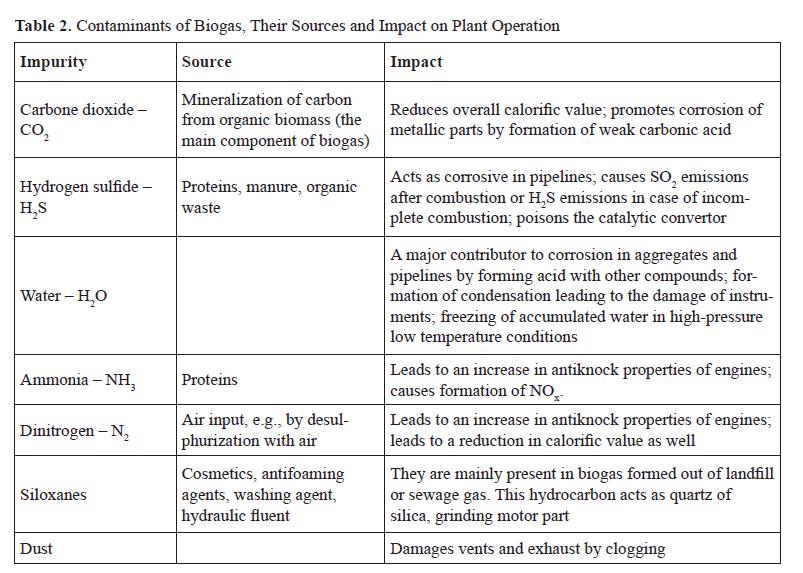

Up-gradation & Quality analysis for Grid Injection

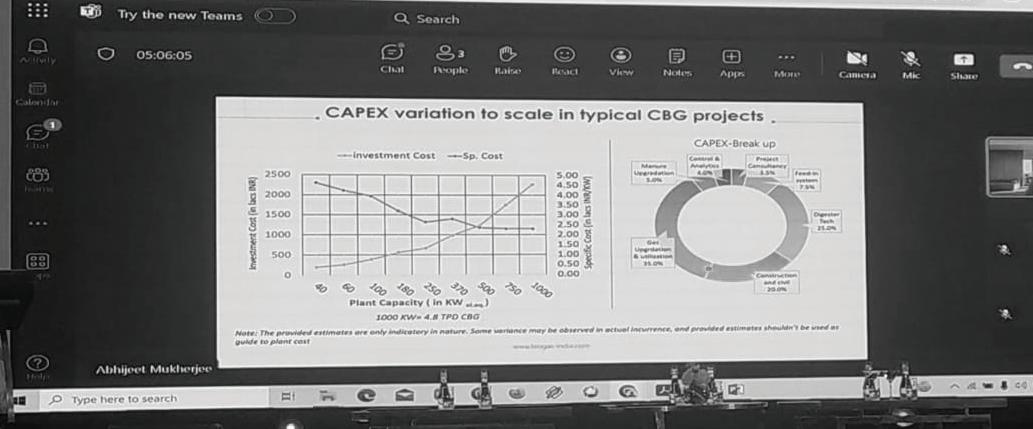

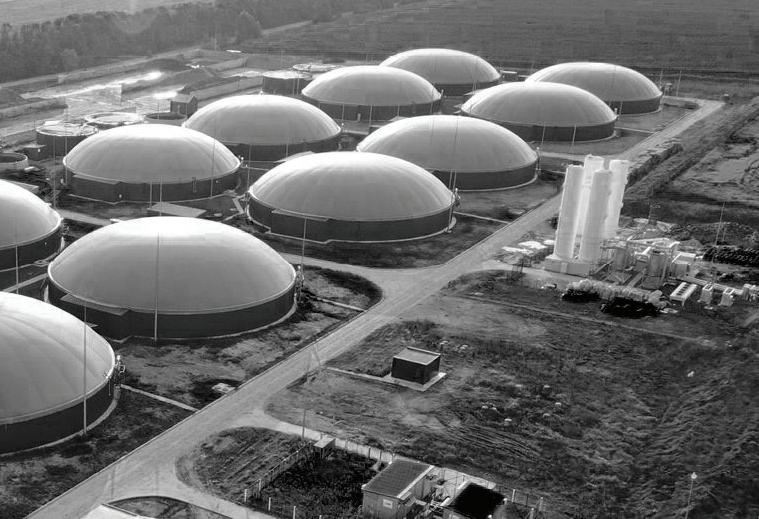

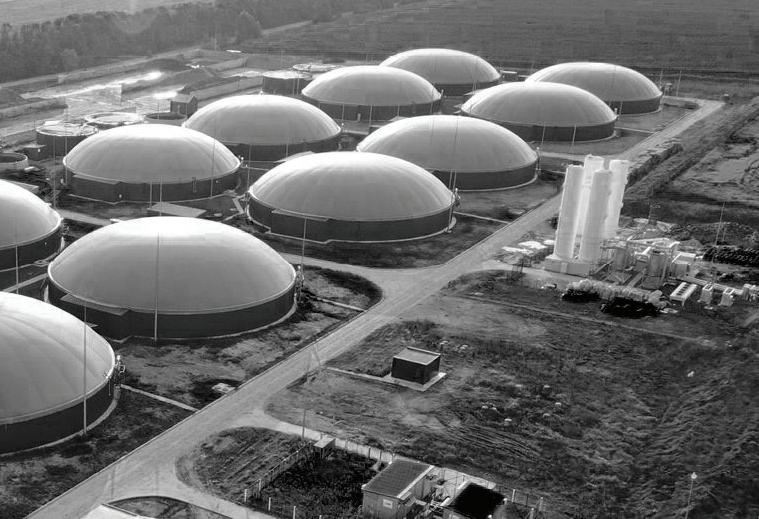

The Indian government has set an ambitious target to achieve 100% fossil independence across all energy sectors, which demands optimum utilization of renewable energy sources, such as wind and biogas, by 2050. Biogas production has increased, and upgrading biogas offers a broad range of applications, such as transportation and gas grid injection for downstream utilization. The biogas has to meet natural gas quality prior to injection into the gas grid system. The investment costs of the gas grid, upgrading costs, and gas compression costs are the major challenges for integrating the biogas into the existing gas infrastructure. In this investigation, GCV, Quality of raw biogas, and upgraded biogas was measured to evaluate the scenario for biogas injection into

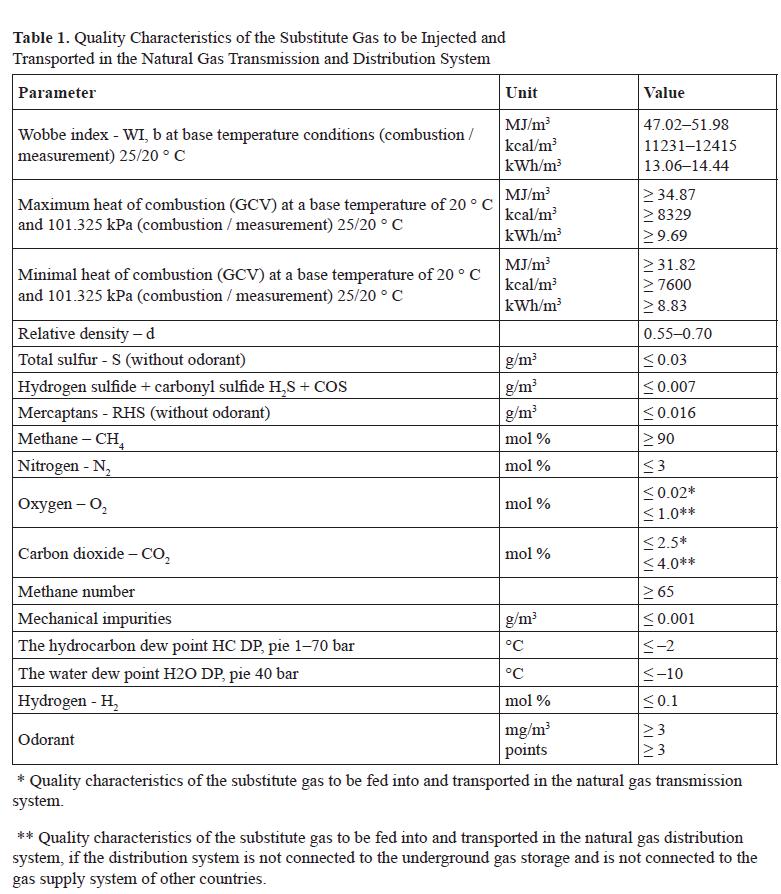

the gas grid system. It was found that raw biogas has to improve its GCV from 4713.208kCal/ SCM to 8126.222KCal/SCM, NCV from 4243.415kCal/SCM to 7316.234 KCal/SCM, & Density from 1.25kg/SCM to 0.758 Kg/ SCM as per ISO16087:2016 via upgrading along with Quality as per Table 1 before compressing and injecting into the grid.

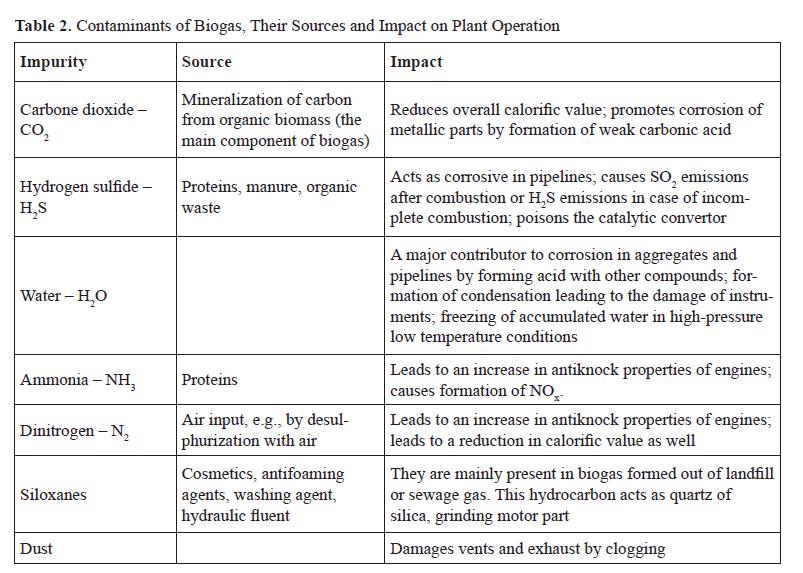

Biogas is produced by anaerobic biodegradation of waste, e.g., municipal solid waste, landfills, sludge from wastewater treatment plants, industrial waste, agricultural waste, manure, and energy crops. It is mainly composed of a large proportion of CH4 and carbon dioxide (CO2), followed by other contaminants like hydrogen sulfide (H2S), carbonyl Sulfide(COS), nitrogen (N2), oxygen (O2), ammonia

Biogas Magazine | Edition 27 | 31

(NH3), and siloxanes as per Table 2, depending on the feedstock. It is used for various energy utilization, such as heat production by direct combustion, electricity production by fuel cells or microturbines, combined heat and power (CHP) generation, or transportation fuel. Nevertheless, low calorific value (CV) due to the existence of carbon dioxide and other impurities is one of the foremost bottlenecks for injection in gas grid systems.

Several biogas upgrading technologies are available to enhance methane, such as water scrubbing and/or physical absorption, pressure swing adsorption, chemical absorption, membrane separation, and cryogenic and biological technologies. Water scrubber and (V)PSA is a worldwide-applied common technology for biogas upgrading; nevertheless, aminebased technology & membranes

are also gaining much traction. Proper Upgrading system significantly reduces methane slippage, which adds to revenue and reduces the greenhouse effect.

Since the biogas is being injected into the pipeline network, it must be measured with metrologically approved analyzers to determine the gas properties like heating value and density as per ISO6976 (and latest AGA , the American Gas Association guidelines, https://www.iso.org/ standard/13531.html).

Gas chromatograph has been adapted to measure all essential components present in biogas. Components like H2, O2, and H2S usually are not measured in natural gas heating value determination. These components are measured in the Chromatograph and the Physikalisch-Technische Bundesanstalt PTB has approved the application in metrologically approved meter-

ing systems. The H2S and COS concentrations in the biogas are essential to monitor since these components may negatively affect the pipeline integrity and could damage instrumentation downstream, especially in the presence of water. These sulfur-containing components in biogas need be measured with a detection limit as per the Grid operator's requirement.

Injection of bio-methane into the natural gas grids can bring a valid option for decarbonization of the natural gas supply chain and provide local, renewable resources with wider market accessibility. The most promising connections can be built with the biogas plants located within a 10 km radius; thus, costs of the pipeline connections tend to grow significantly compared to biomethane injection facility costs when biogas plants are located further than 10 km around

Biogas Magazine | Edition 27 | 32

the natural gas grid. At the same time, centralized biomethane injection can be a viable solution for regionally clustered biogas plants where owners are not willing to subsidize separate biomethane upgrading and injec-

tion projects.

The fiscal incentives or other support schemes should be developed in order to trigger biomethane production with its subsequent injection into the

natural gas grid. This is one of the most viable ways to ensure the gas synergy for a sustainable future of the existing natural gas infrastructure in India

Source: https://www.iea-amf.org/content/fuel_information/methane

Biogas Magazine | Edition 27 | 33

Biogas Magazine | Edition 27 | 34

Source: dena.de

Sharad Garg Manager – Biogas & Green Hydrogen Emecon Controls Private Ltd.

NDIR sensors for CH4, CO2 and electrochemical for H2S & O2

Up to 10 sites sample gas switching & monitoring on time sharing basis

Integrated Dew Point measurement

Calculated GCV, NCV, MMBTU values

Programmable Auto calibration for data validation

Real Time Monitoring with Remote Access, data transfer & report generation facility.

Actuation of solenoid valve for closure, as per user settable limits

Alarm Generation on deviation from standard composition with message to concerned personnel / control room

Tamper Proof Password protection

Ex Proof Models also available

Internal data storage for about 20,000 readings. SD card, Mini-USB & Bluetooth for data transfer to Smartphone, Tablet or PC

Long-life rechargeable battery with standard USB charger

GERMAN PRODUCTS INDIAN PRICE TECHMARK ENGINEERS & CONSULTANTS 1020, Ansal Tower 38 Nehru Place New Delhi - 110019 Tel. 011 46570392 - 94 Mobile : 7011389878 sales@techmark.co.in www.techmark.co.in CONTACT US FOR DEMONSTRATION S W G 1 0 0 B i o g a s Handheld Analyser O P T I M A B i o g a s

German technology with proven performance Over 2000 anlaysers sold worldwide Preferred choice of Indian OEMs, Project developers & owners All India Service & Calibration support by trained team Experience of over 26 years in handling gas analysers

ANALYSERS

Continuous Stationary Analyser

BIOGAS

From Biogas to Bio-Slurry: Transforming waste into a sustainable future

According to the Budget Announcement 2023 and on the recommendations of the EFC, the CCEA, in its meeting held on 28th June 2023, has approved Market Development Assistance of ₹1,500/MT to promote organic fertilizers produced at plants under the umbrella of the Galvanizing Organic Bio-Agro Resources Dhan (GOBARdhan) initiative covering different Biogas/ CBG support schemes/programs of stakeholder ministries and departments such as the Sustainable Alternative Towards Affordable Transportation (SATAT) scheme of the Ministry of Petroleum & Natural Gas (MoP&NG), ‘Waste to Energy’ programme of Ministry of New & Renewable Energy (MNRE) and the Swachh Bharat Mission (Grameen) of

the Department of Drinking Water & Sanitation (DDWS), etc., with a total outlay of ₹1451.84 crore (FY 2023-24 to 2025-26), which includes a corpus of ₹360 crore for research gap funding, etc.

The National Biogas Programme, spearheaded by the Ministry of New and Renewable Energy (MNRE), isn't just about producing clean fuel. It recognizes the hidden gem within - bio-slurry. This nutrient-rich organic manure, often seen as a mere byproduct, holds immense potential for sustainable agriculture. By unlocking its power, we can create a virtuous cycle where clean energy production fuels responsible farming practices, benefiting both the environment and farmers' livelihoods.

Biogas Magazine | Edition 27 | 36

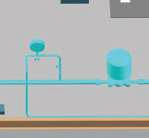

Biogas plants transform organic waste into two valuable resources:

Clean biogas and nutrient-rich bio-slurry. The animal and other organic waste-based biogas plant effluent, when fully fermented over 6-7 weeks, can be directly mixed with irrigation water and applied to crops and soil. This method ensures that the partially digested material degrades slowly, providing residual effects of Farm Yard Manure (FYM) for about 6-10 months, making the entire spectrum of nutrients in the slurry available to the soil and crops. Anaerobically digested cattle dung slurry, containing about 8-10% solids, offers a nutrient-rich composition. The slurry is rich in nitrogen, phosphate, potash, and other essential minerals, providing the same nutrients as dung. The manure produced through a biogas unit has a comparative advantage over ordinary manure, conserving approximately 70-75% of the original weight of cattle dung.

In a 2-cubic-meter biogas plant, daily input of 50 kg of cattle dung and 50 kg of water results in a total slurry output of 27 tons. Approximately 25% of the fed slurry is converted into biogas, with the remaining 75% returned as digested slurry. A total of 9 tons of slurry is converted into gas. After the drying process, the final dried form of manure contains 10.8 tons, preserving essential nutrients while

undergoing a slight loss in nitrogen, phosphorus, and potassium content.

Capitalizing on this valuable resource, MNRE actively champions the utilization of bio-slurry through various initiatives. Their recent program incentivizes the installation of Biogas Slurry Filters developed by organizations like BAIF. These filters efficiently separate solid and liquid manure, facilitating more accessible storage, transportation, and field application. Technology transfer partnerships ensure readily available and proven filtration methods empower farmers to harness the full potential of bio-slurry.

While small-scale biogas plants offer multiple benefits, including clean fuel and organic fertilizer, there's always room for optimization. While small-scale biogas plants provide multiple benefits, including clean fuel and organic fertilizer, there's always room for optimization. Moreover, focusing on operational improvements, such as regular maintenance and optimizing digester conditions, maximizes biogas production and ensures high-quality bio-slurry.

Scaling up production through large-scale biogas plants can significantly increase bio-slurry availability, but also introduce new challenges. Strategic planning is crucial, considering feedstock availability, logistics, and market demand. Operational

efficiency becomes paramount, with advanced fermentation technologies and proper manure management practices play a critical role in maximizing output and quality.

However, even with these optimizations, challenges remain on the path to widespread adoption. Transportation costs become a hurdle when production sites are far from farmlands. Implementing local processing facilities or creating bio-slurry markets closer to agricultural areas can be effective solutions. Storage and regular usage also pose challenges. Encouraging farmers to build proper storage facilities and integrate bio-slurry into their agrarian practices ensures optimal utilization and maximizes its benefits.

The biggest hurdle lies in awareness. Educating farmers about the advantages of bio-slurry, both environmental and economic, is crucial for broader adoption and unlocking its full potential. To promote wider adoption of fermented organic manure among farmers, the Ministry of Chemicals and Fertilizers incentivises by providing MDA (Market Development Assistance) at Rs. 1500 per MT on the sale of Fermented Organic Manure (FOM)/Liquid Fermented Organic Manure (LFOM) and Phosphate Rich Organic Manure (PROM) produced at Biogas/Compressed Biogas plants are established under GOBARdhan initiative only. Manufac-

Biogas Magazine | Edition 27 | 37

turing units registered under the Unified GOBARdhan portal will have the option to market through fertilizer marketing companies in packed form, or they can market themselves either in packed form or in bulk.

Quality testing at government laboratories/NABL accredited private laboratories is to be validated by the State Agriculture Department or State Energy Development Agency. Marketing of Fermented Organic Manure (FOM)/Liquid Fermented Organic Manure (LFOM), and Phosphate Rich Organic Manure (PROM) has been initiated by 45 CBG plants under the MDA programme. Recently, the ICAR, New Delhi, has brought out a package of practices for the application of FOM in major crops, which emphasizes a significant

impact on soil fertility and productivity.

The journey from biogas to bio-slurry is a transformative step towards a circular economy within the renewable energy sector. By addressing challenges, raising awareness, and exploring innovative solutions, we can unlock the vast potential of bio-slurry. This transformation promises a greener future for Indian agriculture, empowering farmers with a sustainable and cost-effective solution while enriching the soil and ensuring food security for future genera-

tions. Recently, the interim Budget 2024 announced the CBG blinding obligation, which will boost the biogas sector, leading diverse waste utilization towards sustainable growth of the agriculture sector.

Biogas Magazine | Edition 27 | 38

S. R. Meena Scientist D (Biogas Program) Ministry of New and Renewable Energy, GoI, New Delhi

CNG / CBG

CNG / CBG

Organic and Bio-Fertilizers in Nutrient

Economy of India

Preamble

Organic biomass generated from farming activities and soil microorganisms have been the key contributors to soil health and crop productivity for ages. The importance of such organic and biological inputs in conventional management systems, primarily based on chemical fertilizers, has also been realized, and stress is being given to using both sources in an integrated manner not only to keep the soil healthy but also to ensure the better use efficiency of applied inputs.

As per estimates of FAO worldwide, mineral fertilizer nutrient use is expected to increase from 142 million MT in 2002/03 to 199 million MT in 2030. In India, the requirement of total fertilizer nutrients is estimated to be around 60 million MT for the

year 2050 (comprising of 45 million MT from chemical fertilizers and 15 million MT from organic and biofertilizers) as against the current nutrient consumption of 36 million MT (containing 29 million MT from chemical fertilizers and 7 million MT from organic and bio-fertilizers). At the crop production level of 201718, crops removed around 35.49 million MT of NPK, whereas fertilizer consumption was around 26.59 million MT, which leave a gap of 8.90 million MT. Organic and biological interventions need to compensate for this gap to keep soils fertile and healthy. Although the country has vast potential for harnessing the vital nutrients from the pool of organic wastes and bringing in live macro and microorganism’s natural processes for managing soil health, because of the wide

disparity in prices and absence of a level playing field between chemical fertilizers and organic/ biofertilizers, farmers generally use chemical fertilizers. With the decreasing soil fertility, the dosages of chemical fertilizers are increasing, leading to nutrient imbalances, distortion of soil pH, and soil compaction. Therefore, to encourage farmers to use more organic and biofertilizers and use chemicals only as supplementary sources to fill the nutrient supply gap, the organic and biofertilizer inputs assume greater importance and call for innovative approaches for harvesting their full potential.

Let's Keep in mind

Soil’s productivity depends on its organic carbon and soil’s biological life. To keep the soil healthy and fertile, it must be

Biogas Magazine | Edition 27 | 40

enriched with biomass regularly. As a basic rule, the amount of generated biomass should be returned to the soil in one form or another. Biofertilizers and organic fertilizers are ideal inputs that can replenish the soil with organic carbon and beneficial microorganisms. Biofertilizers and organic fertilizers are not the replacement of chemical fertilizers, but they are essential to keep the soil healthy, live, and productive. The soil must be healthy even to get the best results from chemical fertilizer use. The use efficiency of chemical inputs also largely depends on soil organic matter and soil microbial life.

Growing inclination for organic and natural farming systems

In last two decades, the number of farmers adopting natural and organic farming systems has been growing. For nutrient and pest management, such farmers rely on recycling onfarm biomass and commercially available organic manures/ composts. Such organic and natural

farming systems now account for more than 4.5% of the total net sown area. They are not only contributing to soil health and sustainability but also helping reduce chemical inputs usage and, in turn, the need for subsidy on such chemicals.

Types of Bio and Organic Fertilizers

a.) Biofertilizers and their nutrient mobilizing potential

Biofertilizers are live microbial preparations, which on application to seed and soil, multiply rapidly around emerging crop roots and fix/ mobilize nutrients from air and soil, from unavailable form to available form. Nitrogen fixers absorb atmospheric nitrogen and fix it into usable form, which, in turn, is made available to plants. Similarly, nutrient solubilizers (such as P, K, or Zn solubilizers) transform insoluble nutrients present in soil into soluble form for easy uptake by crop plants. The application of N, P, and K biofertilizers contributes 25-30 kg of chemical fertilizer equivalent nutrients per ha to the crop.

Potential, Installed Production capacity

b.) Organic fertilizers and their nutrient status

Organic fertilizers are composted/ fermented products made from organic wastes (city waste, agro waste, crop residue, cattle waste, food processing industry waste, etc). The following three categories of organic fertilizers are being produced:

i. Category 1 - Having NPK nutrient potential up to 1.5%

a) Farmyard Manure (FYM)

b) City waste compost

c) Fermented biogas slurry compost from CBG plants

d) Fermented liquid manure from CBG plants

ii. Category 2 - Having nutrient potential from 1.6 to 3%

a) Vermicompost

b) Enriched compost and Press mud compost

c) Organic Manure

iii. Category 3 - Value added organic fertilizers having nutrient potential above 3%, including mineral fortified.

a) Phosphate Rich Organic Manure

b) Phospho-sulfo compost

c) Phospho-sulfo-potassic compost

d) De-oiled cakes

*Biofertilizer – keeping average dose at 10 kg/ha/season, *Organic fertilizer – keeping average dose at 4.0 tons/ha/season

**As per the data compiled by the National Centre of Organic and Natural Farming (NCONF), GoI for the year 2021-22

Biogas Magazine | Edition 27 | 41

and actual production in India Harvestable Potential area to be covered Potential for biofertilizer use (in MT) Installed production capacity (in MT) Actual production (2021-22)** Biofertilizers 141 million ha with 160% cropping intensity (226 m ha) 22.60 lakh MT/year* 10.0 lakh tons** 5.00 lakh tons Organic Fertilizers

with 160%

9000 lakh

lakh tons/year 722 lakh tons

141 million ha

cropping intensity (226 m ha)

MT/year But limited to 3500 lakh ton in view of limited raw material availability)* 750-900

Potential, production, and availability of different kinds of organic fertilizers

Note – The actual production figures may be much more than what reported, as many small producers do not provide production data

Saving of chemical fertilizer nutrients through Bio and organic fertilizers

a.) By biofertilizers usage

At the current usage level of 5 lakh MT, the expected area coverage is 45 million ha and nutrient contribution at 9.0 lakh tons (considering a minimum contribution of nutrients at 20 kg per ha). Even if we take 20-25kg nutrients as minimum contribution by biofertilizers, 22.60 lakh tons of biofertilizer application on entire net sown area with 160% cropping intensity can replace:

●If 100% area is covered for two crop seasons, quantity of nutrients released will be – 45.20

lakh tons (in terms of NPK nutrients) and

●If 50% area is covered, quantity of nutrients released will be –22.60 lakh tons

b.) By Organic fertilizers

At the current usage level of 722 lakh MT the nutrient contribution by organic fertilizers is

...to be continued in next edition of Biogas magazine

10.82 lakh tons of NPK (considering a minimum contribution of nutrients at 1.5% or 15 kg per ton of manure). Keeping because of the raw material availability, there is potential for the production of 3500 lakh tons of organic manure. Applying 3500 lakh tons of organic fertilizer can contribute 52.50 lakh tons as NPK nutrients.

Dr A.K. Yadav Former Director National Centre of Organic Farming

Biogas Magazine | Edition 27 | 42

Type of organic fertilizer Expected production potential* (in lakh MT) Installed production capacity for manures (in lakh MT) Actual production as manure (2019-20) (in lakh MT) 1City Compost 45 10.00 4.08 Rural compost and Farmyard Manure 1000 Household activity 543.00 2Fermented Biogas slurry compost/ compost 400 190 115.00 Compost from crop residue (rice and sugarcane) (Currently burnt or diverted to other non-agri usage) – 200 million tons raw material 800 NA NA Enriched compost/ organic manures 150 50.00 31.40 Press mud compost and distillery waste 150 50.00 NA Vermicompost 200 50.00 27.00 PROM 100 5.00 1.00 De-oiled cake (tree oilseeds and castor) 85 27 1.30 Other industrial and miscellaneous sources 570 NA NA Total 3500 722.78

ICL IS YOUR RIGHT PARTNER ! 80 Years Of Years Of Years Of Excellence! Excellence! Excellence! Air & Water Cooled Versions "Mini - lubricated" design for lowest oil contamination 275 bar, 2000 Designed in Italy H i g h P r e s s u r e B i o - C N G C o m p r e s s o r s Non - Lubricated Design For 24*7 continuous Process Duty Handles Raw Biogas L o W P r e s s u r e C o m p r e s s o r s Over 1800 Natural Gas/CNG Compressors Working Across India Dedicated Service Network in Every Indian City Serving All major CGD & Biogas Companies I N D I A N C O M P R E S S O R S L T D Sales@Didwania.com | www.Didwania.com Sm3/h BIOGAS COMPRESSORS

Dr. A. R. Shukla President Indian Biogas Association

Dr. A. R. Shukla President Indian Biogas Association

CNG / CBG

CNG / CBG