33 minute read

Welcome

Well, not the greatest start to a new decade of course as we sit again on the brink of an “Asian medical crisis” (the popular media’s way of looking at things) that is becoming a “global medical emergency”. Of course, it is tragic that already several hundred people have died from the dreaded “Corona” virus…but with global influenza deaths usually of the order of up to 500,000 every year, perhaps we shouldn’t quite hit the panic button just yet.

However, with China’s place so critical in the global

G L A S S M I D D L E E A S T SEE US AT:

Inside: Façade recycling Turkey: a country in focus Fenestration trends Cosmetic packaging PLUS! news, views, analysis and much, much more! GLASSM AN MIDDLE EAST See us at AG Covers_CURRENT.indd 1

13/12/2019 13:36

supply chain, any change of situation in the People’s Republic sends tremors throughout companies from Hong Kong to San Francisco, and all places in between. With factories returning after the (extended) Lunar New Year break as AG goes to press, it has been noticeable that many firms are expecting just 20% or so of employees to make it back to work, with many factories holding off re-starting production and manufacture until the end of the month instead. For some companies in glass – especially those that depend on China’s increasing dominance of the markets of ultrathin glass – this is problematic. Order books, filled to the brim are suddenly all going to be delayed. Instead, those that were far-sighted enough to support growing production bases in the likes of Vietnam, Indonesia and India are going to be well-placed to slip into some of these overdue product situations and fulfil orders that might otherwise go astray. Where there is an issue for one, there is opportunity for another.

For some companies – and goverments in fact – such a biological intervention, however, relatively minor (and I really stress that people should look at the FACTS not the hyperbole surrounding this virus) is heaven-sent. A chance to kick a combatant whilst its already weakened and struggling under onerous dumping duties and tariffs. The Chinese authorities are supremely aware of the potential here for the country to be rapidly usurped by an eager pack of surrounding nations, many of whom had industries suffer because of China in the past and are now in the position to turn the tables.

Will this go on for too long? We hope not. The “I can’t possibly go to China” approach of many European (in particular) companies borders on the ridiculous with the flames fanned by our 24 hour exaggerative media. This could indeed be the best time to strike the deals with the country; with partners eager to maintain trading and indeed not be pillioried for simply being “Chinese”.

Remember everyone; the sun will set and rise tonight and tomorrow; the world will keep spinning; the mountains will keep inching higher…and China is still going to be there with its manufacturing might at the end of this. Rather than victimise it, is this not the time to stand up, be counted and lend it some support? Happy reading!

Andy Skillen Publishing Director

Got a general enquiry? use enquiries@asianglass.com

EDITORIAL Publishing Director Andy Skillen Email: askillen@asianglass.com Direct line: + 44 (0) 208 123 0196

ADVERTISING AND DESIGN

Advertising Sales Valerie Adamson Email: vadamson@asianglass.com Direct line: + 44 (0) 208 133 5273

Paul Russell Email: prussell@asianglass.com Direct line: + 44 (0) 208 638 0619 Production and design Tim Mitchell Email: tim@bowheadmedia.com Direct line: + 44 (0) 208 123 0839

RESEARCH Research Manager Alex Murphy Email: amurphy@bowheadmedia.com Direct line: + 44 (0) 208 123 0839

EXHIBITIONS AND CONFERENCES

Contact the team on: Email: events@bowheadmedia.com Direct line: + 44 (0) 208 123 0839 Bowhead events

Creating Opportunities: Delivering Results OVERSEAS OFFICES

China Professor Wen Xin Email: 18980921123@163.com Tel: +86 28 8701 9077 Fax: +86 28 8701 9077 Bangladesh Jahir Ahmed jahir@asianglass.com

India Yogender Singh Malik yogender@asianglass.com

Sri Lanka Rohan Gunasekera rohan@asianglass.com

HEAD OFFICE

Bowhead Media Ltd, The Old Casino 28 Fourth Avenue Hove East Sussex, BN3 2PJ

Asian Glass (ISSN: 1475-6501), is published by Bowhead Media Ltd, registered in the UK no: 6127651

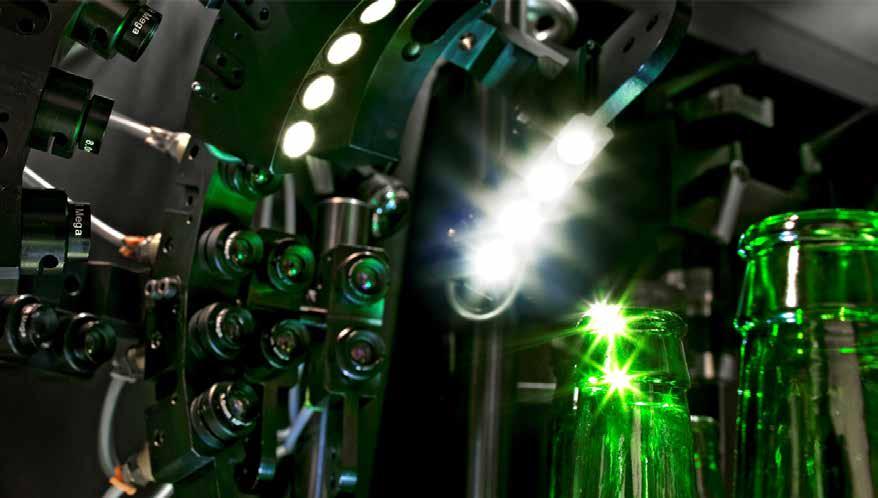

CAMERA CHECK DETECTION

THE ULTIMATE HIGH-SPEED AND HIGH-RESOLUTION CAMERA CHECK DETECTION SYSTEM

Fully modular scalable system for every budget Check inspection areas: horizontal, shoulder, vertical, bottom Easy and quick job change Intelligent Cloud Masking (ICM)

HEADLINE NEWS ASIA

Gujarat Borosil sets up a new furnace

India

Sole producer of flat glass for solar modules in India, Gujarat Borosil has commenced operations from its second float glass line at Bharuch in the state of Gujarat. With this expansion, Gujarat Borosil has an installed capacity of 460 tonnes per day of solar glass for domestic industry and exports.

Company’s expansion came after imposition of anti-dumping duties on solar glass imports from Malaysia. In Feb 2019, Indian government had imposed the long awaited anti-dumping duty on textured tempered coated and uncoated glass, originating in or exported from Malaysia for a period of 5 years. The duty amount is USD 114.58/ MT. The duty will be applied to products from all producers, except M/s Xinyi Solar Sdn. Bhd. Gujarat Borosil had filed a petition requesting imposition of anti-dumping duty of Malaysian solar glass, stating that the said goods imported by India were below their normal values and consequently, the domestic industry had suffered material injury.

Indian imports of toughened (tempered) glass from all nations more than quadrupled since FY14, to reach USD 75mn or 15.9 mn sqm in FY 2018- 19. Out of this, Malaysia’s share was USD 15.7 mn or 3.8 mn sqm.

After the imposition of this duty, Gujarat Borosil does not have to face competition from cheap imports of solar glass from Malaysia. In addition to this, various policy reforms by Indian government to increase usage of solar power will give a boost to Indian glass players, involved in manufacture of solar glass.

Emirates Glass sees profit and output surge

UAE

Emirates Glass, a subsidiary of Dubai Investments and one of the largest processors of flat architectural glass in the Middle East, announced that it has recorded manufacturing of more than 1.8 million sqm of glass products, valued at over Dh180 million during 2019.

Recording a 10 per cent rise in business as compared to the previous year, the company has confirmed more than 40 per cent of business being generated from the UAE.

Higher percentage of customer retention coupled with optimum delivery services have been instrumental in garnering new projects, the company has confirmed. Latest products like Emicool Solite and Emicool Sun T Series have been identified as products that facilitated the maximum volumes of sales.

"In line with the current demand for our glass products, it is extremely satisfying to know that our production lines are running in full capacity to meet the high demand. There has been substantial demand for our premium coated glass product range providing high efficiency and durability to meet the most stringent requirements for high performance window glass products. With Expo on close heels, the UAE's real estate sector has seen rampant projects and we have been active contributors with more than 40 per cent business generated from the UAE market", said Rizwanulla Khan, executive president of Emirates Glass.

Emirates Glass currently operates a 60,000 sqm production facility in Al Quoz and a 32,825 sqm post-temperable glass coating line in Dubai Investments Park since 2010.

Emirates Glass currently provides glass and glass solutions to GCC countries such as Saudi Arabia, Egypt, Oman, and Kuwait as well as to Azerbaijan, Australia, Kenya, Lebanon, Turkey, India, Sri Lanka, Pakistan, Bangladesh, East and South Africa, and Canada. The company is focused on enhancing its geographic footprint further.

Kyzylorda factory to begin flat glass production

Kazakhstan

During this year, Orda Glass Ltd plans to finally begin the output of flat glass in Kyzylorda.

As explained in the company, at the moment, construction and installation works are at the testing stage.

"At the same time, the installation of the technological equipment of the plant is ongoing. The heating of the melting furnace is scheduled for July 2020," the company said. It is noted that 70% of the finished products are planned to be sold in the domestic market, and 30% they want to export to the countries of Central Asia and Russia. At the same time, 226 jobs will be created during the operation of the enterprise.

It was expected that the construction of the plant for 42 billion tenge would have been completed in the IV quarter of 2019, but in early April 2019, it was reported that the plant had not yet been commissioned due to a conflict between the founders. According to the regional department of industrial and innovative development, the American company Stewart Engineers without any arguments decided against further participation in the project, thereby causing the main sponsor of the project, the Chinese company King Charm Development, to rethink its strategy.

However, as differences became resolved, according to reports, Stewart expressed a desire to return as long as Orda fulfilled its obligations under the contract.

ASIA... is one click away

Vedanta targets major investment programme

India

Vedanta Resources Chairman Anil Agarwal has said the company is planning to invest around Rs 60,000 crore in the next 2-3 years, with the glass sector potentially a major target. The company is also eyeing a top line of USD 30-40 billion and a bottom line of USD 10 million in 4-5 years, Agarwal said at the India Economic Conclave 2019. "I am committed to India. I have already invested USD 35 billion in India in the past 10 years. I have bought 13 companies so far including Hindustan Zinc, Balco, Sesa Goa and Cairn and all of them are doing well. I hope to invest Rs 60,000 crore in the next 2-3 years," he said.

However, he did not give further details on how the company plans to utilise the funds, but hinted at being keen on acquiring a few public sector companies. "We currently have the best in class assets and we are looking at many more nationalised companies. I want to tell the government that it should not depend on foreigners but depend on us. They (foreign investors) want to make money but we want to make the country. If government depends on us we will also bring in foreign investment," Agarwal added.

He also said the company is keenly looking at the glass and optical fibre and cable industries. "Sterlite Tech is doing a good work in optical fibre. I am now keen on developing the glass industry which will be used in

Glasspro to get fourth outing

India

The 4th edition of glasspro India scheduled from 24 – 26 September at Aerocity ground, New Delhi, showcasing the latest and finest trends and innovation in flat and processed glass products and applications.

After successfully organising India’s major glass exhibition in Mumbai in 2019, the 4th edition of glasspro India scheduled from 24 – 26 September at Aerocity ground, New Delhi, showcasing the latest and finest trends and innovation in flat and processed glass products and applications. Also on display will be the latest glass processing solutions, tools, auxiliary products and services.

The growth in the flat glass industry is characterised by the increased use of processed and reflective glass as Indian customers have become more aware of the importance of glass in effectively addressing the concerns of safety and energy efficiency. Considering Government’s vision of smart cities, opportunities in flat glass industry tends to increase. As per the industry need, glasspro India is ready to set up a one stop destination for the industry professionals to unveil the latest technological advancements, products & application in the world of flat glass industry.

The show is supported by AIGMF- The All India Glass Manufacturers Federation Ltd, BAI - Builders Association of India. CCPS- Confederation of Construction Products and Services, Ludhiana glass dealers association, Noida glass and dealers association, The Madras glass & plywood merchant association, Rajkot glass merchant association, Glazing electronics. We are developing the glass used in mobiles, TV sets and computers in countries like Korea, Taiwan and Japan. If the atmosphere in India is conducive we will get to do that here as well. This will give a boost to the electronics industry," he added.

When asked about the growth the company foresees by 2024- 25 he said, "we are hoping to have a USD 30-40 billion of revenues and a profit of USD 10 million."

society of India. Helping glasspro India to bring together industry veterans under one roof.

The 2020 edition of glasspro India focusses on adding new & diverse product categories which also includes doors & windows segment with participation of more than 110 exhibitors, 6+ country participation with more than 6000 trade visitors. Glasspro India 2020 provides opportunity to interact & network with industry experts and will act as an experiencing centre for new technology, solutions & products.

CSG commences float glass operation

China/Nigeria

One of the, if not the, largest producers of float glass in China, China Southern Glass ( CSG) Holding has commenced operations from its new float glass plant in Nigeria in early January. Located in Ogun Guangdong Free Trade Zone, the newly inaugurated production line has a daily melting capacity of 500 tonnes of float glass per day.

The float glass line will contribute to the development of the local glass supply chain, sourcing 80% of its raw materials domestically, and further supporting the development of the local network of glass distributors and traders downstream. Some 80% of production is expected to be sold locally to meet rapidly rising domestic demand, while the balance will be exported to other countries in West Africa. Nigeria’s infrastructure development has led to high demand for float glass, however, currently, most of the supply is met through imports, and is insufficient to meet domestic needs.

News, views and analysis

Schott keeps the upward trend

World

SCHOTT AG has continued on its growth course again in fiscal year 2018/19. The key financial figures developed positively or remained at the solid level of the previous year.

“We were able to meet our forecasts from last year and continued the positive business development of previous years despite the difficult global economic situation. For this reason, we are satisfied with the past fiscal year,” said Dr. Frank Heinricht, chairman of the Board of Management, at the Annual Results Press Conference.

The international technology group managed to increase its sales by 5.1% to nearly €2.2 billion. The operating result (EBIT), which now stands at €275 million, also improved slightly. Consolidated net profit for the year amounted to €206 million. All three segments – Precision Materials, Optical Industries and Home Appliances – contributed to the successful fiscal year.

On the other hand, the difficult situation in the automotive industry also had an impact on SCHOTT. The Electronic Packaging division that supplies components to the automotive industry, in particular, suffered from this development. At the same time, future topics such as autonomous driving and electromobility offer new opportunities for specialpurpose glasses

Sales of more than €506 million were reported out of the North America region. In terms of overall sales, 87% were achieved outside of Germany. In total, 23% of global sales were attributable to North America.

“SCHOTT grew strongly in the North American market led by our Pharmaceutical Packaging business unit,” said Jim Gareau, president SCHOTT North America Inc. “Our investments in the North American region enable innovations to be brought to market particular-ly in the pharma industry where investments allowed for the production of the expanded adaptiQ portfolio.”

Investments in property, plant and equipment amounted to €257 million in the fiscal year, an increase of 38% over the previous year. The expansion of the production capacity of an existing plant in India and the construction of a new plant in China were the largest foreign investments.

After getting off to a good start in the first three months of its new fiscal year, SCHOTT expects sales to increase by between 3% and 6% for the year as a whole. The technology group expects impetus to come, among other areas, from a demand for specialty glass for pharmaceutical packaging and ultra-thin glass for the foldable mobile devices of the future.

In fiscal year 2019/2020, SCHOTT plans to invest €320 million, the highest amount in the company’s history. One main focus here will be on capacity expansions in the pharmaceutical packaging business in China and India. In Germany, SCHOTT plans to invest in its pharmaceutical packaging business in Müllheim, among other sites, as well as in its manufacturing capacities for specialty glass in Mainz and Jena.

HK recycling services to be resumed

China

Glass bottle recycling services will resume soon in Hong Kong, two months after collection was stopped because of antigovernment protests in the city.

Secretary for the Environment Wong Kam-sing revealed the decision during a Facebook live chat session on Friday, in which the minister took questions from the public about a range of issues including recycling, the city’s climate change strategy, and a long-delayed waste charging scheme.

“Now that the situation is relatively calm, we have asked our contractors to resume collection in safe areas such as housing estates and at government community green stations,” Wong said.

“Throughout the social unrest, many glass recycling bins were damaged. If the bins filled with glass were poured out into public spaces, it would have posed a danger to both residents and protesters.”

Glass bottles, mainly for beer and other alcoholic drinks, were used by protesters to make petrol bombs to throw at police. The unrest was triggered by a now-withdrawn extradition bill, but later morphed into a wider anti-government movement.

Rubbish and recycling bins have been regularly used to block roads during the more than seven months of protests.

Wong added the government was working to ensure there were enough uses for recycled glass, such as in eco-pavements and construction. Over the past two to three years, its efforts had improved the recycling rate for glass bottles from one out of every 10 bottles, to three out of 10, and Wong urged residents to continue to recycle glass.

Edwin Lau Che-feng, executive director of The Green Earth, hoped the government could speed up the resumption of glass collection. The group has previously criticised the glass recycling ban, and said it would have caused tonnes of bottles to be dumped in landfills.

“Taking away the collection bins was never going to stop people who wanted to use glass bottles for any illegal activities in the first place. People could just go to any back alley behind a bar and collect the bottles there,” Lau said.

The removal of the bins would have just deterred residents’ will to recycle glass, while at the same time businesses that had already trained employees to separate glass from other waste would have to relearn how to handle glass without recycling services, he said.

Wong’s live chat session, which he promoted on Facebook as “conversation is better than opposition”, has since been viewed almost 5,000 times.

While Wong mostly took questions related to environmental policies, many commenters demanded to know how tear gas, which has been heavily used by police to disperse protesters, had affected the environment.

Others simply commented, “five demands, not one less”, the main rallying cry of the protest movement. Only the first demand, the withdrawal of the extradition bill, has been met. Protesters have also called for universal suffrage in the city, and an inquiry into police use of force.

“While Wong is a relatively low profile in terms of politics, it would be difficult to shift people’s focus away from what they consider the most pressing matters, namely police brutality and the government’s inaction throughout the protests,” said Chung Kim-wah, assistant professor at Polytechnic University’s department of applied social sciences.

News, views and analysis

We see a world designed with smarter, safer and more energy-efficient glass. We’re innovating the technology for you to make this a reality.

All about glass processing: www.glastory.net

Meet us at CHINA GLASS 2020 Shanghai, China Apr 14-17, 2020 Hall E1, Booth 419

Tecglass confirms printer installation

UAE

Based on a deal signed with Technical Glass and Aluminium Company LLC last year, the innovative Vitro Jet FS24 digital printer with Side Kinetix technology developed in the company’s Lalìn plant, has now been confirmed as an imminent installation in the United Arab Emirates.

Measuring 3,300 x 12,000 mm, the Vitro Jet FS24 is designed to optimize printing on super-sized glass. Thanks to the special movement of the print head parallel to the support table, Side Kinetix technology is specifically engineered to always print along the long edge of the glass, making the Tecglass digital printer an effective tool for on-demand client customization of glass 12 meters in length, in the shortest time possible. This patented technology makes for increasingly efficient printing and production processes.

But the many advantages of this model do not end here. It has 1440 dpi print resolution, 12 always- available color channels at maximum speed, 48 individual heads (with 1000 nozzles each) for maximum power and 7 different ink drop sizes to make the best use of Tecglass ceramic inks. This positions the Vitro Jet FS24 among the best tools for maximizing architectural glass use in the most sophisticated decorative design projects.

The agreement signed last year formalizes a new partnership between Tecglass and Technical Glass and Aluminium Company LLC, a steadily growing business known for the extremely high quality of its products and one of the leading glass manufacturers in the United Arab Emirates market area. An especially beneficial choice for a company that since day-one has carried out some of the most complex and exciting projects in the entire region, consistently focusing on innovative, cutting- edge jobs for the local market, paving the way to the most optimistic expectations for the year ahead.

Dagestan container glass to create new jobs

Russia

The implementation of the investment project to expand the production of glass containers in the city of Dagestan will create about 200 jobs. The total budget of the investment project will be more than 1.8 billion rubles, Zarema Urazaeva, the head of the press service of the Ministry of Economy and Territorial Development of Dagestan, has released.

"In 2020, in Dagestan, on the basis of the plant of DagestanStekloTara OJSC in the city of Dagestan Lights, it is planned to start an investment project to modernize and expand the existing production of glass containers that meets European standards. The total budget of the project is over 1.8 billion rubles," said Urazaeva.

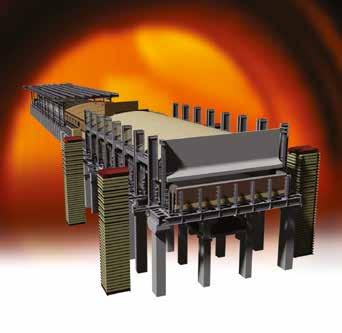

According to her, thanks to the implementation of this project, it is planned to create 192 new jobs. "The project involves the construction of a new furnace with a capacity of 240 tons per day and the installation of production equipment for the production of glass containers in the amount of 216 million pieces per year in 0.5 liter terms, with a capacity of 0.1 to 5 liters of lightweight glass containers with a neck of any type and diameter," said the agency.

She added that the goal of this investment project is to increase the volume of production of the enterprise. "The completion of the project and its commissioning is scheduled for 2021," concluded the Ministry of Economic Development of the region. Earlier, sources reported that in 2019, the export of glass containers produced in Dagestan almost doubled: from 129 to 245 million rubles. The volume of sales of these products in the domestic market amounted to 700 million rubles.

OJSC "DagestanStekloTara" (the city of Dagestan Lights) is the only manufacturer in the republic of glass containers. Export of goods is carried out to Azerbaijan, Georgia and Armenia.

Solar glass float furnace starts operation

Vietnam

Nippon Sheet Glass (NSG) Group has started commercial production from its Vietnam based solar glass line in the third week of January. This line was previously a float glass line, which was upgraded as part of the plan announced in May 2018 to expand production capacity of solar glass to support the growing solar market in the country and region.

The restarted float furnace is one of the two lines at NSG Vietnam Glass Industries Ltd. (VGI) located near Ho Chi Minh City. Solar glass production at VGI has been positioned to support a long-term supply agreement with First Solar, the world’s leading provider of comprehensive photovoltaic (PV) solar system. Manufactured with the online coating technology, in which a conductive oxide on the glass surface is formed during its passage through the float line, NSG’s TCO glass is very durable with a wide range of applications. Online coating also enables cost effective production of coated glass in high volume. With the expanded supply capability for VA products, such as solar glass and other products, NSG Group intends to drive its growth strategy while supporting the expansion of renewable energy.

ASIA... is one click away

Tomorrow , s Technology Today

Are you interested in CO 2 reduction?

l Innovative allelectric furnace designs l Electric boost for extra tonnage and reduced emissions l Versatile bubbler systems to eliminate floor wear l All-electric forehearths reducing energy consumption by up to 80% l Mathematical modelling l Proven technical innovations

www.fic-uk.com +44 (0) 1736 366 962

The World , s Number One in Furnace Technology

FIC (UK) Limited Long RockIndustrial Estate, Penzance, Cornwall, TR20 8HX, United Kingdom

ADivision of Glass Service

Since 1947, Henry F. Teichmann, Inc. has grown and progressed on the theme: “Satisfied clients are our most important asset.” Our employees are practical, conscientious, and experienced in every phase of the glass industry. As a result of our clients’ successes, we have become recognized worldwide as one of the largest independent – Engineers and Contractors to the Glass Industry.

• Engineering • Procurement Services • Construction Services • Project Management • Annealing Lehrs The key to the success in turnkey projects is to seamlessly integrate ...

Engineers and Contractors to the Glass Industry

3009 Washington Road • McMurray, PA 15317-3202 • USA

+1 724 941 9550

Fax: +1 724 941 3479 info@hft.com www.hft.com

Solar glass plant gets green light

Malaysia

The $483 million fab will be built by an unnamed ‘multinational glass manufacturer’ at the Kota Kinabalu Industrial Park, in the Sabah region. Rumours had abounded that the project would get the go-ahead, but in a tweet at the turn of the year, the Malaysian Industrial Development Authority seemed to confirm the likelihood:

“The National Committee on Investment, co-chaired by YB Datuk @DarellLeiking & YB Tuan @guanenglim approved another 4 projects in the manufacturing sector worth RM5.4 bil on 12/12/2019. The projects will be located in Sabah, Johor, Selangor and Pulau Pinang”

Indeed, it transpired soon after that one of the manufacturing projects announced by Malaysia’s international trade and industry minister Datuk Darell Leiking with that tweet is an MYR2 billion ($483 million) glass factory which will manufacture PV as well as float glass.

The identity of the “multinational glass manufacturer” referred to in a press release issued by the minister on his facebook account to publicize the move was not released but it was confirmed the facility will be built at the Kota Kinabalu Industrial Park, in the Sabah region.

In February, Malaysian newspaper the Daily Express had reported a Chinese silica-sandbased glass manufacturer was planning to build a factory at the industrial park, and that the producer already owned and operated a solar glass factory in Malaysia’s Malacca.

The company in question could be Chinese manufacturer Xinyi Solar, which has operated a 900-ton annual production capacity factory in Malacca through subsidiary Xinyi Solar (Malaysia) Sdn Bhd since 2016. The company has not responded

Piramal enjoys domestic boost

Sri Lanka

Piramal Glass Ceylon PLC, Sri Lanka’s only glass bottle manufacturer, saw its December quarter (3Q20) earnings surging amid higher domestic sales, stoked by festive season.

According to the interim financial accounts released to the Colombo bourse, the firm reported revenue of Rs.2.3 billion for the quarter under review, up from Rs.1.9 billion reported for the corresponding period, last year.

The improved top line boosted the firm’s earnings per share for the quarter to 25 cents or Rs.235.8 million compared to earnings of 12 cents or Rs.115.4 million reported for the same period, last year.

Piramal Glass in an earnings review said domestic sales grew 24 percent year-on-year (YoY) to Rs.1.5 billion while exports grew 10 percent YoY to Rs.804 million. “The investment of over Rs.1 billion made on a sixth production line during the first quarter of this financial year has started paying dividends. This line helped the production to maximise its capacity utilisation and in turn to increase the overall production tonnage.

This additional capacity together with deferring of some export orders helped create space for the increased domestic demand to be catered during the festive season and also to yield maximum results,” the firm said. During the quarter under review, Piramal Glass introduced several new products to its export market, which included a 750ml flint water bottle for the UK market and 1lt juice bottle for Mauritius market.

An attractive Cobalt blue of 330ml capacity was launched for Beer, whilst a whiskey bottle range in varied sizes of 180ml, 375ml and 750ml was launched in both flint and emerald green for the

Gas price reduction to aid glass sector

Indonesia

Indonesia’s largest gas distributor aims to lower industrial gas prices to US$6 per million British thermal unit (mmbtu) by April, from around $8 mmbtu as AG goes to press – a price point that has been considered burdensome for manufacturing industries.

PGN president director Gigih Prakoso said on Monday that the company was engaged in talks with gas companies and the government to meet the $6 price mark, as stipulated by Presidential Regulation (Perpres) No. 40/2016. The regulation promises cheap gas for the rubber gloves, ceramics, glass, steel, fertilizer, petrochemical and oleochemical industries, which consume 70 percent of Indonesia’s industrial gas.

“Hopefully, with all these discussions, there will be a way out such that on April 1 we can implement Perpres No. 40/2016,” he told lawmakers in Jakarta.

Four years have passed since the regulation’s issuance yet gas prices still hover around $8 per mmbtu, hurting manufacturing industry growth, at a time when Indonesia is trying to break free from the middle-income trap.

In response, President Joko “Jokowi” Widodo announced last month three possible solutions to reduce prices: domestic market obligation (DMO), fiscal incentive or import relaxation. Jokowi is set to make a decision on the matter by March.

PGN has made clear that it favored the DMO option but Gigih, speaking on Monday, said to pv magazine’s request to confirm if the newly announced factory is part of its expansion plans for Malaysia.

Hong Kong-based glass manufacturer Sun Bear Solar Ltd had announced plans for a facility at the Kota Kinabalu park in 2010 but nothing has been heard of that proposed fab since. The Indian government has imposed a trade penalty on textured, toughened (tempered) solar glass from Malaysia since February. The five-year duty of $114.58/metric ton is applicable on solar glass from all Malaysian producers except Xinyi Solar.

Indian market.

For the nine months ended December 31, 2019, Piramal Glass reported earnings of 35 cents or Rs.330.2 million compared to earnings of Rs.16 cents or Rs.153.8 million reported for the same period, last year.

The sales rose to Rs.5.8 billion from Rs.5.4 billion a year ago.

For 3Q20 gross profit margin increased to 23 percent from 21 percent YoY while for the nine months gross profit margin rose 20 percent from 16 percent YoY.

Piramal Glass Private Ltd holds 56.45 percent stake in Piramal Glass Ceylon as the controlling shareholder. Employee’s Provident Fund has 9.51 percent stake in the company being the second largest shareholder.

the company also wanted tax cuts to reduce operational costs. Specifically, PGN wanted the government to eliminate value added taxes (PPN) for when the company purchased gas and do away with a gas distribution tax “that we will use to build infrastructure instead.”

PGN expects the slashing of the two taxes to reduce transmission and distribution costs, which respectively comprise 13 percent and 17 percent of its final selling price. The remaining 70 percent comes from purchasing the gas, a price that the government does not want to cut as it would hurt oil and gas producers.

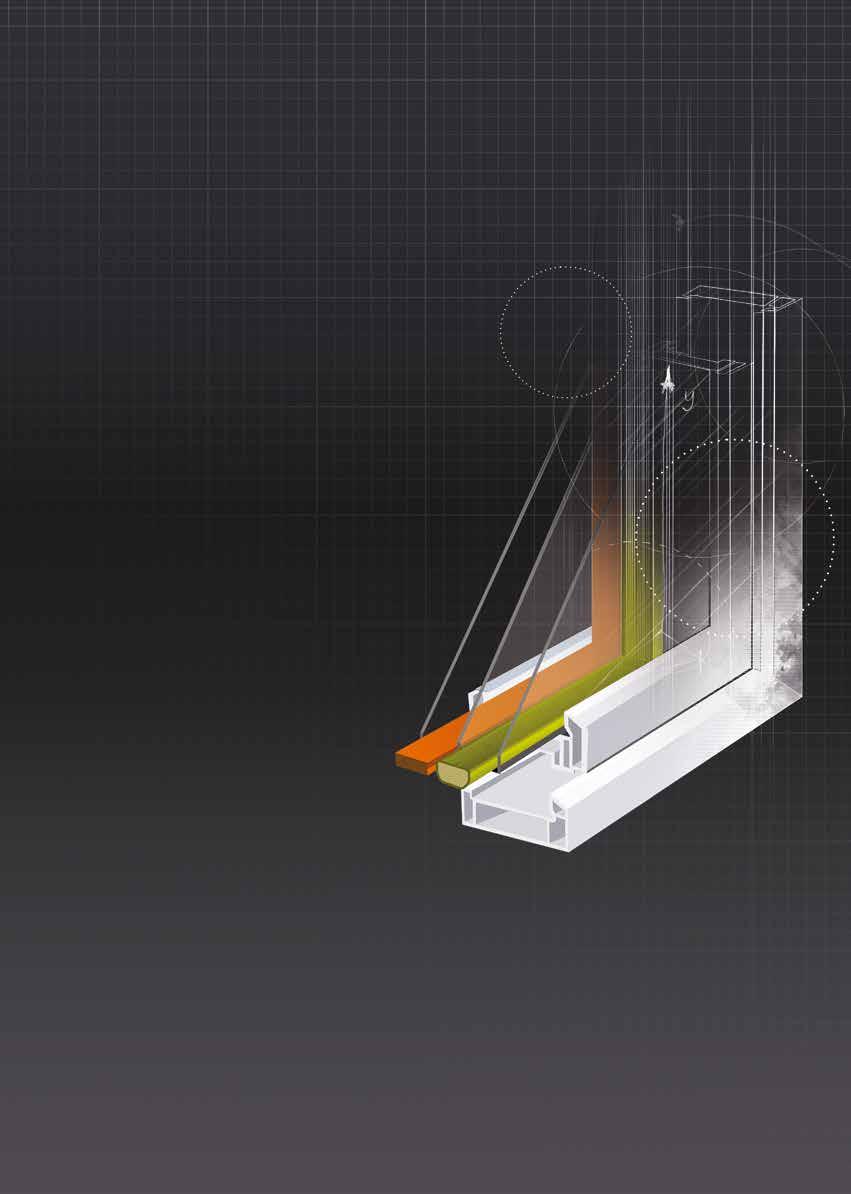

D e d i c a t e d t o I nsul a t e d G las s

From inception, to perfection

The leading UK manufacturer of highest performance warm edge spacers.

From initial design and compounding of raw materials, through the manufacturing process to delivery to the customer, our multiple award-winning team of specialists continue to enhance and develop new products for the window industry. We now supply over 2,500 insulated glass components.

Our 2020 show dates:

14 – 17 April China Glass, Shanghai Stand No. E1-553

3 – 6 June Glass South America, Brazil Stand No. A079

20 – 21 Sept Passive House Conference, Berlin Stand No.35

20 – 23 Oct Glasstec Dusseldorf, Germany Stand No. TBC

17 – 19 Nov Glasstech Asia, Bangkok Hall 5, Stand No. J12

We're always looking for Distributors in Export Markets. Contact us now for further information.

News EXHIBITION PREVIEW China Glass 2020 Promotes High-Quality Development of the Glass Industry

China

The 31st China International Glass Industrial Technical Exhibition (China Glass 2020) organized by the Chinese Ceramic Society and contracted by Beijing Zhonggui Exhibition Co., Ltd., will make a strong return at Shanghai New International Expo Centre from April 14 to 17, 2020. China Glass 2020 will cover the entire value chain of the glass industry, including flat glass manufacturing, glass production and application, technical glass, processing technology and equipment, raw and auxiliary materials, and refractory materials. China Glass 2020 is committed to providing an excellent market expansion and technology exchange platform for global glass manufacturers and providers of processing equipment.

In-depth processing The National total output of flat glass from January to November 2019 was 848.43 million weight cases, up 6.9 percent year-on-year. There was a slight increase in the output of processed glass sector, including tempered glass, insulating glass and laminated glass. The overall production and operation of China’s glass industry was stable in 2019. The growth in output was accompanied by a fall in average ex-factory price, showing greater downward pressure on the economic benefit of the industry. As the most notable event in the global glass industry in 2020, China Glass will focus on the industry restructuring and promotion of high-quality development. It will provide more innovative perspectives for the entire value chain from the areas of intelligent manufacturing, low-carbon and low energy consumption, and high efficient production. This event will set up 5 theme exhibition areas, including Hall E1 for international brands, Hall E2 for glass production and application, Hall E3 for tempering furnace & refractory materials, Hall E4 - E7 for deep processing equipment & domestic glass, hall E8 - E9 for refractory, raw and auxiliary materials, glass windows & doors, as well as art glass. As a professional exhibition, China Glass 2020 will provide more products and solutions for the construction, automotive, consumer electronics, household, photovoltaic and other industries.

Big brands arrive… In terms of size, professionalism and internationalization, China Glass 2020 is a leading exhibition and wind vane of the glass industry. It attracted many mainstream brands from home and abroad. By the end of 2019, 920 manufacturers (including 204 overseas companies) from 28 countries and regions confirmed their participation in this event, including China, Germany, Italy, the United States, the United Kingdom, South Korea, Japan, etc. The total exhibition area exceeds 90,000 m2. Domestic exhibitors include: China Building Materials Academy, Triumph Group, Anhui Huaguang, Xinfuxing Glass, Ruitai Materials Technology, Qinhuangdao Glass Industry Research & Design Institute, China New Building Materials Design & Research Institute, Sinoma Advanced Materials, China Yaohua Glass, Luoyang Float Glass, China Glass Holdings, Taiwan Glass, JING YOW Enterprise, Xinyi Glass, CSG Holding, Jinjing, Shanghai SYP, Kibing, Flat Glass, Shanxi Lihu, Hubei Yijun, Shandong Guangyao, Hebei Yingxin, Shahe Glass, North Glass, Mountain Glass, Land Glass, South Glass Technology, Tenon, Yinrui, Fangding, MGM Glass, EI, GOLIVE, Fushan Glass, BOZA, Weili, Liaoning North Glass, Lewei, Dinganda Glass, Guilin Champion Union, Dardi Water Cutter, Sanjin Glass, Mr. Glass, HIHO Glass, Sanjiang, Zibo GT Industrial Ceramics, ZIBO ASAHI, etc.

Foreign exhibitors include: Lisec, Glaston, Vonardenne, Vesuvius, Sefpro, Dip-tech, Benteler, Henry F. Teichmann, Buhler Leybold, Grenzebach, Five Stein, Precision, Hegla, Zippe, Bottero, Fenzi, Intermac, Ocmi, Horn, Koemmerling, Technoform, Teka, Viprotron, Glasstech, Teco, Honeywell, etc. Some of them are Global 500 companies, such as Schneider, Tüv, Honeywell, AGC, Carl Zeiss, Air Liquide, Sandvik, Heraeus, Air Products, etc.

China Glass 2020 Highlights

Energy saving The strong development of urbanization in China has pushed up people’s demand for energy saving and living comfort, and put forward higher technical requirements for new glass products. With the development of green building, energy-efficient insulating glass, coated glass, electrochromic glass and tempered vacuum glass are penetrating into tier 2 and tier 3 cities, which will greatly expand the deep processing glass market. More domestic and foreign manufacturers at China Glass 2020 will focus on environmental performance, design novelty, processing precision and high quality of glass products, as well as introduce more new products.

Ultra-thin As one of the raw materials for panels used in photovoltaic power generation and electronic products such as smart phones, televisions and computers, ultra-white and ultra-thin glass have a huge demand in China, and show an increasing trend year by year. Domestic enterprises represented by China Building Materials Academy and Triumph Group will launch innovative products in this field.

Product innovation Innovation and development of glass industry have been focusing on the direction of thinness, high transparency, large size and multi-function. Some leading glass companies including CSG Holding, Shanghai SYP, Kibing, Mountain Glass, Land Glass, Jinjing, Glaston, and Dip-tech will bring more innovative products and equipment, such as: float glass manufacturing technology, pretreatment and large-scale processing equipment, tempering equipment, insulating glass production line, glass digital printing equipment, etc.

Art glass display The art glass display area at China Glass 2019 attracted a large number of visitors. Exquisite glass crafts added vivid humanistic and artistic ambience to this technical exhibition. China Glass 2020 will continue to set up an exclusive area for art glass, gathering works of famous domestic glass artists. Chic and unique design of glass crafts will reveal the special charm of glass in the changes of light and shadow.

Industry evolution In the context of uncertain global economic growth, reduction of excessive capacity, and shift in driving forces for development, the glass industry will benefit from industrial restructuring and policy of stimulating domestic demand. Driven by the requirements of environmental protection and high-quality development, the glass industry shows great demand in the areas of improving processing equipment, investing in environmental facilities, and upgrading in the field of deep processing. China Glass is still the preferred development platform for both domestic and foreign glass enterprises. China Glass 2020 will, as always, maintain close cooperation with domestic and foreign industry institutes and professional media, integrate superior service resources, actively use the Internet and social network to carry out in-depth online and offline promotion, and invite more high-quality professional buyers for exhibitors.

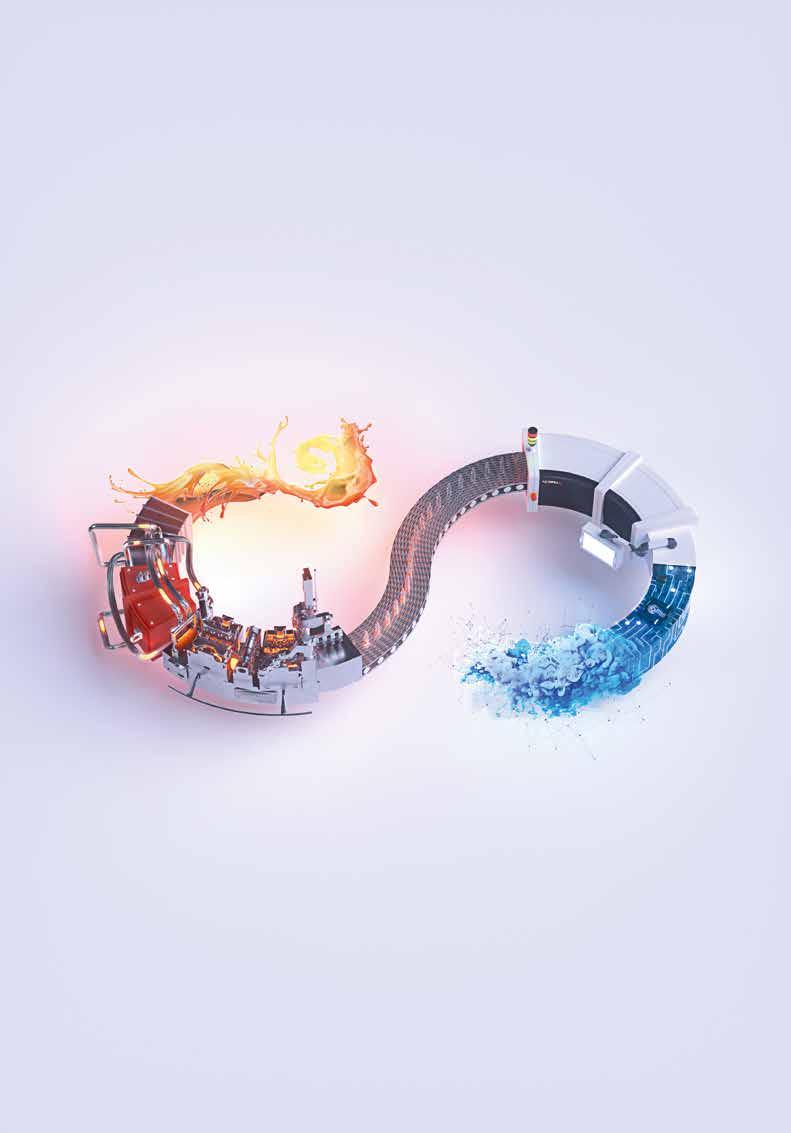

Discover the building blocks behind End to End.

These are the building blocks behind End to End; they are the technology behind the process. Future-proof machines and control systems. Enhanced process stabilization and insight. From data collection and analysis, to container traceability and tracking, End to End is here to help you increase your efficiency.