3 minute read

The World Market

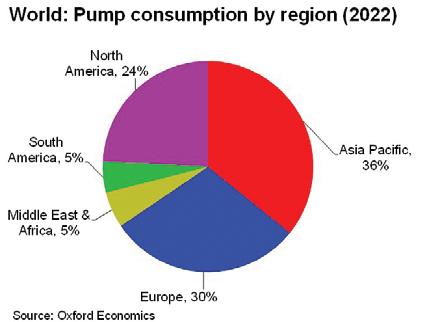

Economic data in recent months have proven to be stronger than anticipated. The warm European winter mitigated the effects of the Russia-Ukraine conflict in the region.

Additionally, strong labour markets in Europe and the US, the re-opening of China, and the decrease in commodity prices have all been positive contributors. However, these factors have not, for the most part, translated into a stronger industrial outcome or outlook at the global level.

The resilient activity in many regions, alongside stubbornly high inflation has prompted central banks to continue hiking interest rates. Inflation has, and we expect will, translate into weaker consumption, and the tighter monetary policies have already and should continue to lead to weak investment. Both the consumption and investment effects are negatively affecting industrial production prospects.

Activity in pump consuming sectors is set to slow down this year. Capex-sensitive segments such as industrial machinery are expected to suffer tight credit conditions, while consumerfacing ones such as food and beverage will face low global demand, particularly for goods. Within the construction sector, the residential component will heavily drag on growth in many economies. We also expect subdued growth in the chemical sector given its exposure to the energy crisis in Europe and a shrinking global trade in 2023.

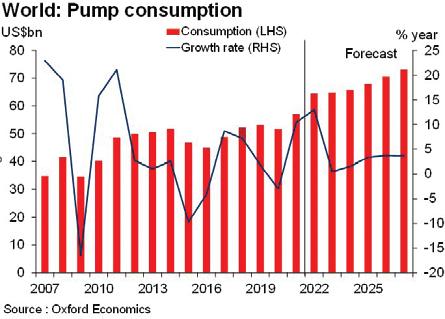

Overall, Oxford Economics sees global pump consumption (excluding parts) growing at 0.5% this year, and 1.6% in 2024.

Source: Oxford Economics

Solutions for systems of all types and sizes

→ Learn more about our products: visit www.reflex.de/en or contact sales@reflexuk.co.uk

Flux Pumps International (UK) Ltd

The award-nominated FLUX Viscopower is the World’s most advanced mobile progressive cavity pump for drums, IBC’s and tanks. Made in our dedicated facility near Stuttgart in Germany, Viscopower replaces our highly successful F500 series high viscosity pumps.

Viscopower has been designed to deliver better performance and be even easier to clean and maintain, with fewer moving parts. Flow rates up to 52 LPM and discharge pressures up to 15 bar are possible, depending on application. The pump can be dismantled without special tools in under a minute and the modular design ensures Viscopower can be configured to suit almost any application. Industrial, ATEX, food and pharmaceutical versions are available, plus trolley and baseplate mounted models for IBC transfer applications.

For more than 150 years, innovations have been our driving force – and we are proving this once again with a completely new KSB Eta!

The world’s best-selling standardised water pump, fully updated and perfectly equipped for the future thanks to optimised planning certainty and maximum sustainability.

G.M.Treble Ltd

Trebles Trident is a new approach to combined tank & booster pump systems which minimises footprint whilst maintaining serviceability.

Once installed, pumps can be isolated, drained and removed/replaced without having to access or drain the tank resulting in minimal down time and water wastage. Water cooled variable speed drives maximise efficiency and performance whilst being whisper quiet due to the lack of any fans. The pump chamber is finished with a clear door giving visibility of the unit status whilst protecting internal components.

The smallest Trident sizes will fit through most common standard UK doorways. Full range available.

KGN Pillinger

The KGN Pillinger CAT 5 Washdown Booster Set is designed to prevent backflow contamination of the mains water supply, while maintaining flow and pressure. The “Internal” unit is compact, lightweight and housed in a stainless steel cabinet for easy floor or wall mounting.

The “External” version is purposely designed for outdoor weather proofed installation, with its built in thermostatically controlled heater for frost protection all housed inside a GRP kiosk with easy access door.

Since 1999, it has been illegal for commercial organisations to put a hosepipe directly on to a tap to wash down machinery or a vehicle. It is essential to incorporate a backflow prevention device to ensure no back flow and syphonage leading to contamination of the potable water supply by bacteria returning up the hose pipe into the mains water supply.

NOV Process & Technologies UK Ltd

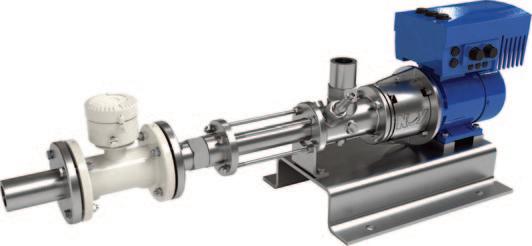

NOV Process & Flow Technologies introduce a New Low Flow Metering range of Progressive Cavity Pumps including enhanced element offerings with improved precision metering control technology, reduced break-out torque, and excellent slow-speed performance.

The elements help to expand the scope of metering applications for your customer, while still supplying each fluid with a smooth, pulsation-free flow.

Handles abrasives, corrosives, solids in suspension, and viscous fluids

• Works with pressures to 300 psi or 24 bar

• Self-priming, high suction lift capability

• Low shear pumping action

• Low power consumption and operating costs

• No valves to clog, stick, or vapor lock

• Pressure capability is independent of speed

• Compatible with Integral VFD/Motor Controls

Key performance details

• Capacity – 0 to 1.29m3/hr or 0 to 341 US gph

• Pressure – up to 348 psi or 24 bar

• Temperature – 100°C

• Highly repeatable accuracy

The use of different stator materials enables the pump to be used for a wide range of products.